Catalytic cracking method and system for producing propylene and high-octane gasoline

A high-octane gasoline, catalytic cracking technology, applied in catalytic cracking, only multi-stage series cracking process treatment, bulk chemical production, etc., can solve the problem of increased dry gas and coke yield, complex product structure, Solve problems such as low propylene yield of inferior heavy oil, achieve the effect of increasing yield and gasoline octane number, improving product distribution and product quality, and reducing the formation of dry gas and coke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

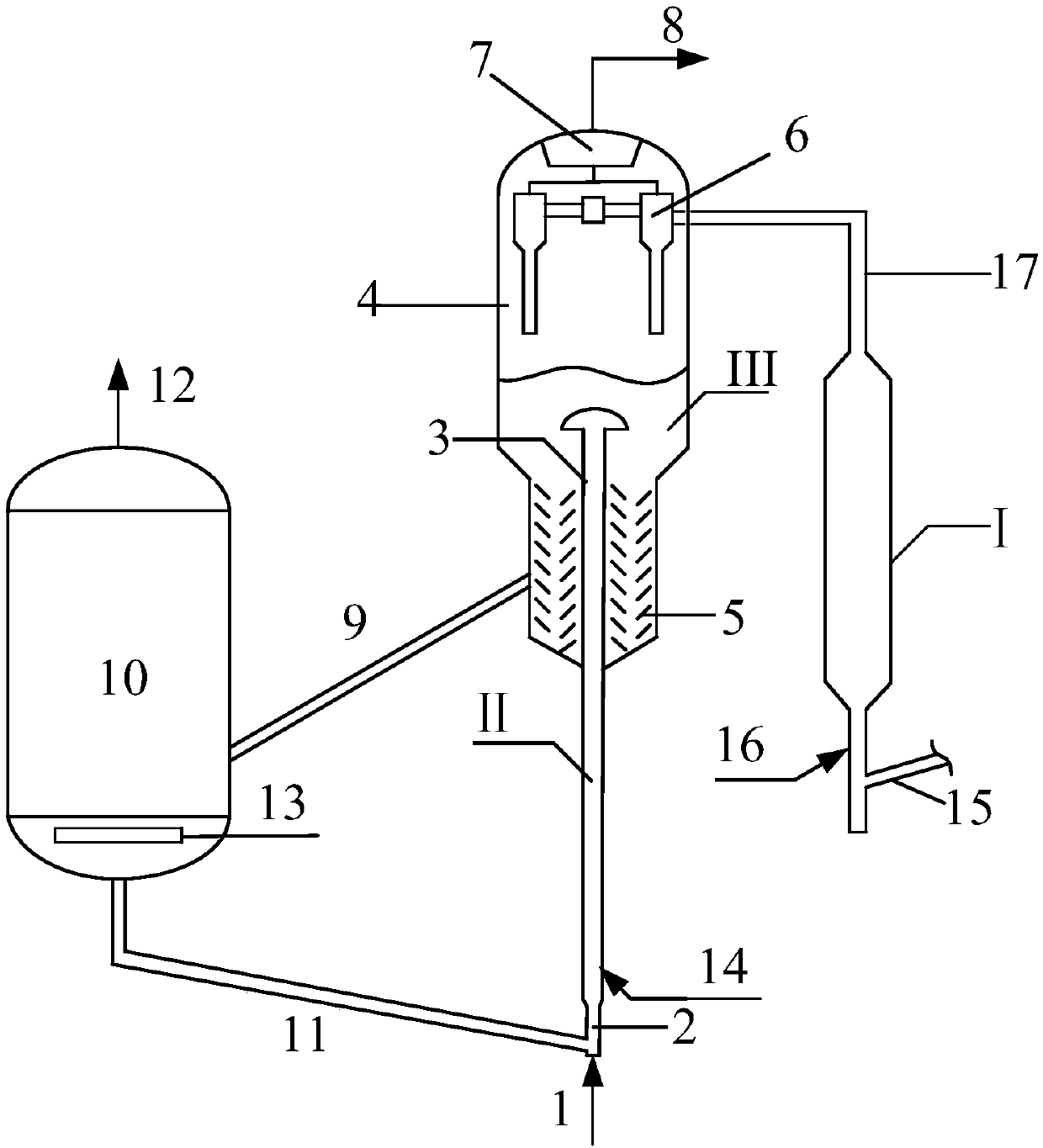

[0091] according to figure 1 The high-quality raw material oil is hydrogenated wax oil, and the inferior raw material oil is hydrogenated residual oil. The feed amount of the two raw materials in different reactors is the same. Using DMMC-2 catalyst, the test is carried out on a medium-sized device, and a combined reactor is used. The first reactor is a dense-phase fluidized bed reactor with a dilute-phase transport bed connected in series, and the second reactor is a fast fluidized bed reactor. . During the test, the preheated high-quality raw material oil enters the lower part of the dilute-phase conveying bed of the first reactor to carry out the first catalytic cracking reaction, and after the reaction, the first reaction product and half-spent catalyst enter the dense-phase fluidized bed to continue the second catalytic cracking reaction. cleavage reaction. The preheated inferior raw material oil enters the lower part of the fast fluidized bed and contacts with the rege...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com