Environment-friendly automatic-temperature-control quartz tube furnace device for pyrolysis of high polymer

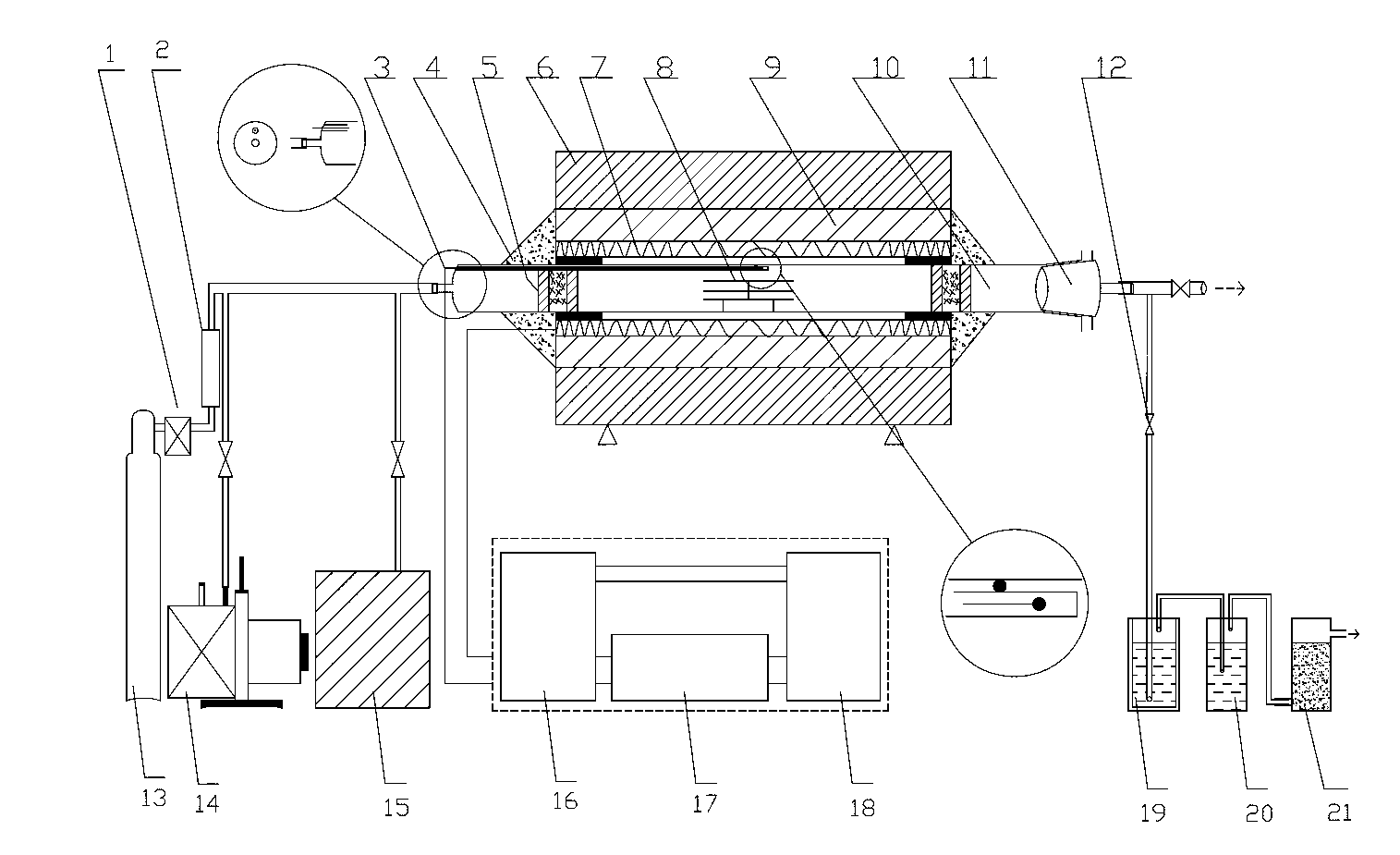

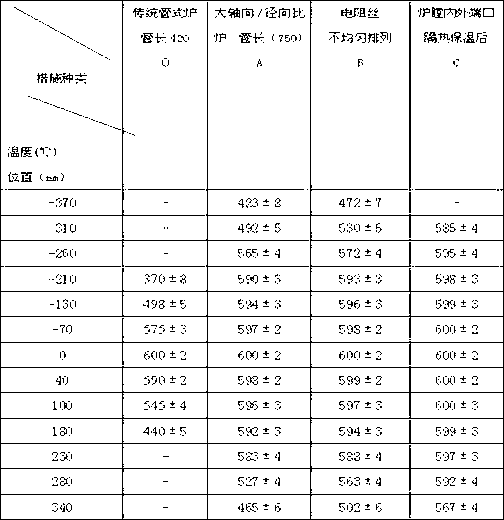

A high-temperature pyrolysis and polymer technology, which can be used in furnaces, furnace types, chemical/physical processes, etc., and can solve problems such as inaccurate temperature control and uneven temperature in the furnace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1: Preparation of fiber composite polyacene electrode material

[0055] Preparation of pyrolyzed samples: add carbon fiber to thermosetting phenol-formaldehyde resin, bake part of the solvent at 70°C to 80°C, put it in a flat mold, put it into a press head with heating function, and heat up to 90°C at 180°C / hr. Start to pressurize, the pressure is the natural head pressure; continue to rise to 150°C at 120°C / hr, decompress and deflate, and then pressurize to 50kg / cm 2 , solidified at constant temperature for 30 minutes, cooled naturally, and taken out as a cracked sample.

[0056] Pyrolysis process: put the sample prepared in the previous step on the quartz material sample holder 8, and put it into the central pyrolysis constant temperature zone in the middle of the quartz tube furnace 10. As described in the detailed description, after the device is evacuated and filled with nitrogen, the nitrogen flow rate is 0.3 L / min, and the temperature starts to rise. Wh...

Embodiment 2

[0057] Embodiment 2: Preparation of porous polyacene electrode material

[0058] Mix thermosetting phenol-formaldehyde resin (30% by weight), pore forming agent (64% zinc chloride, 6% ammonium chloride) and appropriate amount of ethanol to form a viscous liquid. The remaining steps of sample preparation are the same as in Example 1. The cracking process is also the same as in Example 1, except that the heating process is different. When it is less than 150°C, the heating rate is 160°C / hr; when it is 150°C-300°C, it is 60°C / hr; when it is greater than 300°C, it is 30°C / hr; when it reaches 500°C, keep the constant temperature for 2 hours.

Embodiment 3

[0059] Example 3: Preparation of doped porous polyacene electrode material

[0060] Thermosetting phenol formaldehyde resin (50%), pore forming agent (zinc chloride 50%), and appropriate amount of dopant iron powder and ethanol were made into a viscous liquid, and the rest of the steps of cracking sample preparation were the same as in Example 1. The cracking process is the same as in Example 2, except that a metal sample holder is used, and the temperature is maintained at 600° C. for 3 hours.

[0061] Compared with the cracked material prepared by other methods, the material prepared by this method has the following advantages:

[0062] 1. A very high content of pore-forming agent can be used, and compared with general electrode materials, the prepared material has a much higher specific surface area and a much smaller specific gravity; after doping, the conductivity is improved, so the battery assembled with the prepared electrode has Large specific capacity, specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com