Method and apparatus for catalytic preparation of hydrogen by biomass down-draft gasifying stove

A gasification furnace and biomass technology, applied in chemical instruments and methods, hydrogen production, solid waste removal, etc., to achieve sustainable utilization, improve biomass conversion rate and energy utilization efficiency, and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

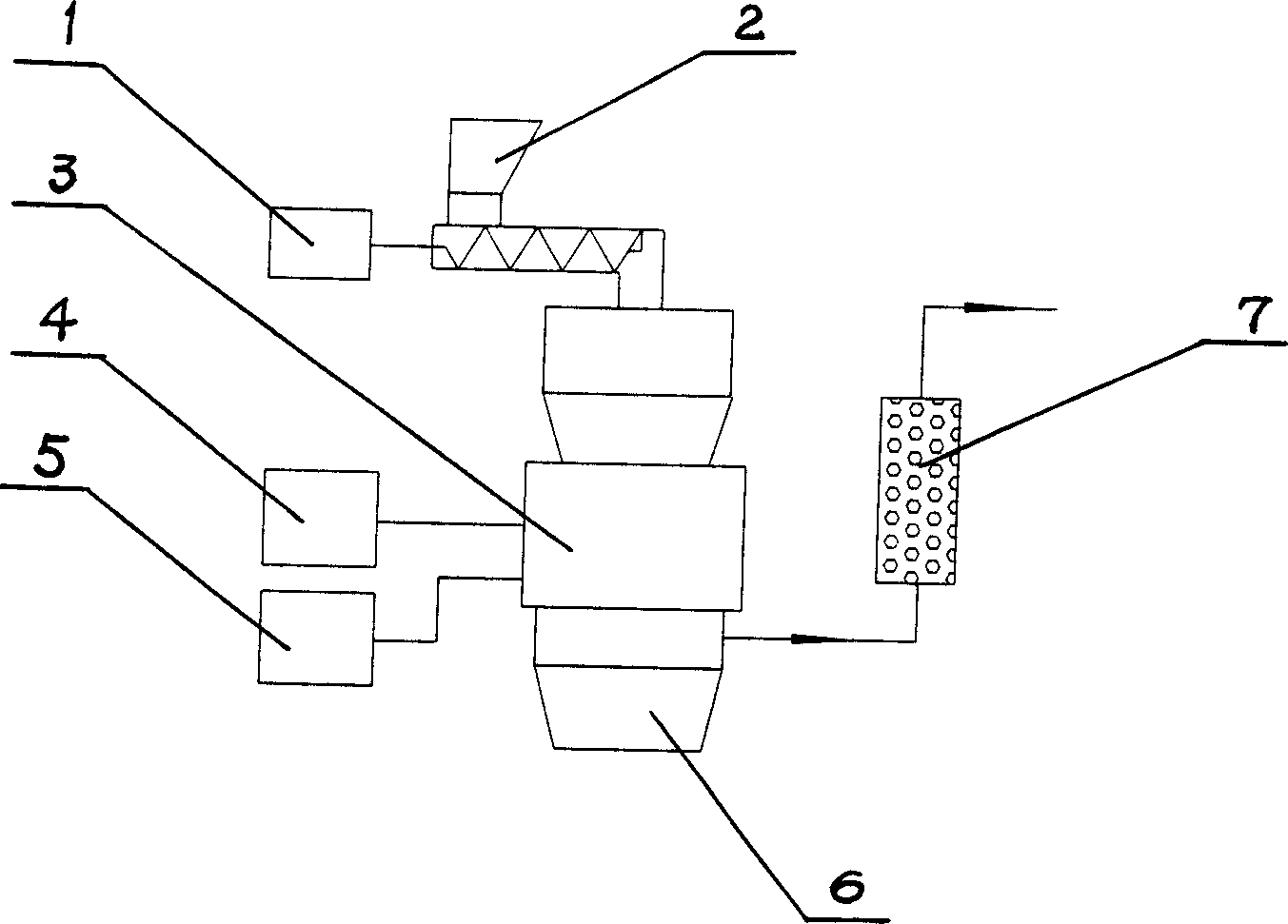

[0025] Such as figure 1 As shown, the biomass (such as pine powder) in the silo 2 enters the gasifier from the top of the downdraft gasifier reactor 3 through the screw feeder 1, passes through the drying zone and the pyrolysis zone, and is combined with the gasifier from the gasifier. Partial combustion reaction occurs with the enriched oxygen fed into the throat of the gasifier, and the enriched oxygen is supplied by the oxygen generator 4 connected to the gasifier 3; the water vapor generated in the steam generator 5 enters the reduction zone of the gasifier 3, mainly producing Tar cracking reaction, coke gasification reaction and steam reforming reaction of biomass gasification gas, wherein the catalyst for tar cracking reaction is natural ore dolomite, and the catalyst for steam reforming reaction is nickel-based catalyst; from the bottom of gasifier 3 The gas that comes out is deashed, and the dust accumulated in the ash hopper 6 is discharged regularly. After deashing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com