Method for recycling papermaking waste residues

A technology for papermaking waste residue and oil and gas, which is used in the papermaking industry to use recycled waste paper as a raw material for recycling, can solve problems such as water pollution, waste gas, incineration environment, emissions, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

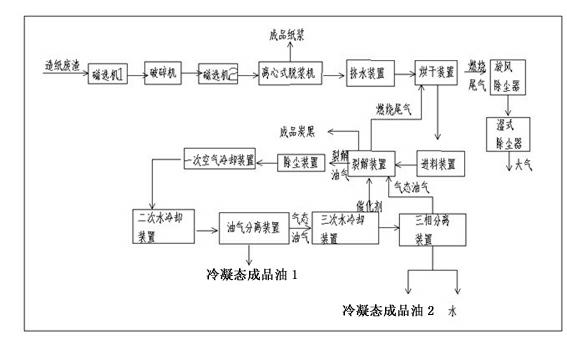

[0030] The present invention will be further described below in conjunction with the accompanying drawings, and the devices used in the present invention are all existing devices.

[0031] The paper mill samples a batch of papermaking waste residues. Generally, the composition of papermaking waste residues is 40% wet waste plastics, 50% wet pulp, 3% iron and 7% other components. The moisture content of wet waste plastics is generally 60%, the moisture content of wet pulp is 70%, the moisture content of iron and other components is low, and the overall moisture content of papermaking waste residue is about 60%, and the above ratio values are the weight percentages of each component. The invention is suitable for treating papermaking waste residues produced by papermaking in various paper mills. The following are the specific processing steps:

[0032] 1. The paper-making waste slag passes through the magnetic separation device to separate the hard iron from it, and 95% of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com