Technology and equipment for preparation of synthetic gas by two-stage high temperature biomass gasification

A biomass and synthesis gas technology, applied in the chemical industry, sustainable manufacturing/processing, granular/powdered fuel gasification, etc., can solve the problems of many impurities in the gas, high tar content, and low calorific value of the gas, and achieve Improve gasification intensity and production capacity, improve tar cracking, and improve thermal energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

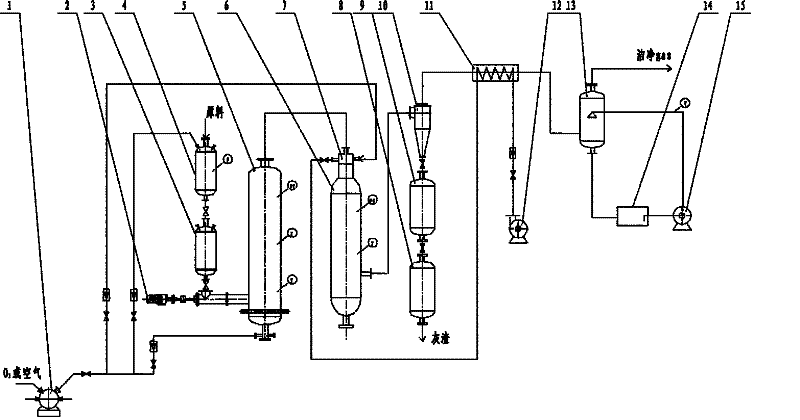

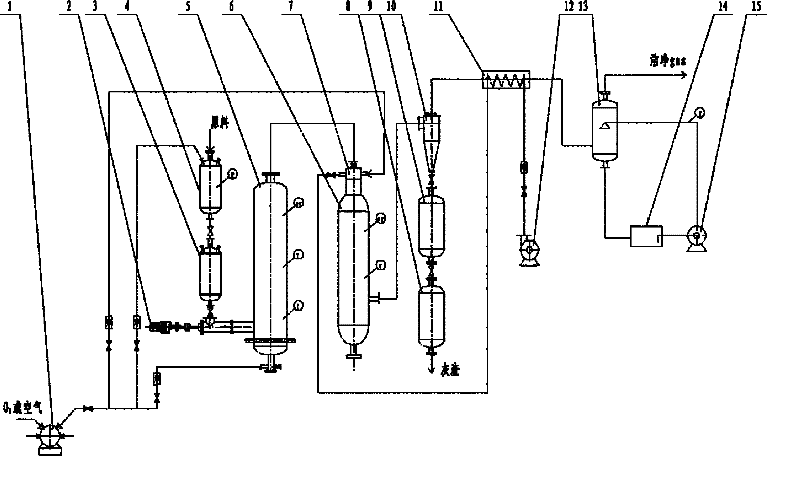

[0019] The present invention will be further described below in conjunction with accompanying drawing.

[0020] The invention provides a two-stage biomass high-temperature gasification process for preparing synthesis gas. The method includes the following steps:

[0021] The rice husk, straw, sawdust and other biomass raw materials are crushed into powder, and two storage bins I and II connected in series are used for feeding, so as to realize continuous feeding and ensure the sealing of the system at the same time. A valve is arranged between the two sealed storage bins; the storage bin is connected to the air compressor 1 through pipelines to provide balance gas. Then feed the raw materials into the gasification furnace I through the screw feeder 2 to carry out the primary gasification reaction, and the feed rate is controlled and adjusted by the rotation speed of the screw feeder 2;

[0022] The gasification reaction is carried out in two stages. The raw material first ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com