Patents

Literature

49results about How to "Reduce equipment manufacturing costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

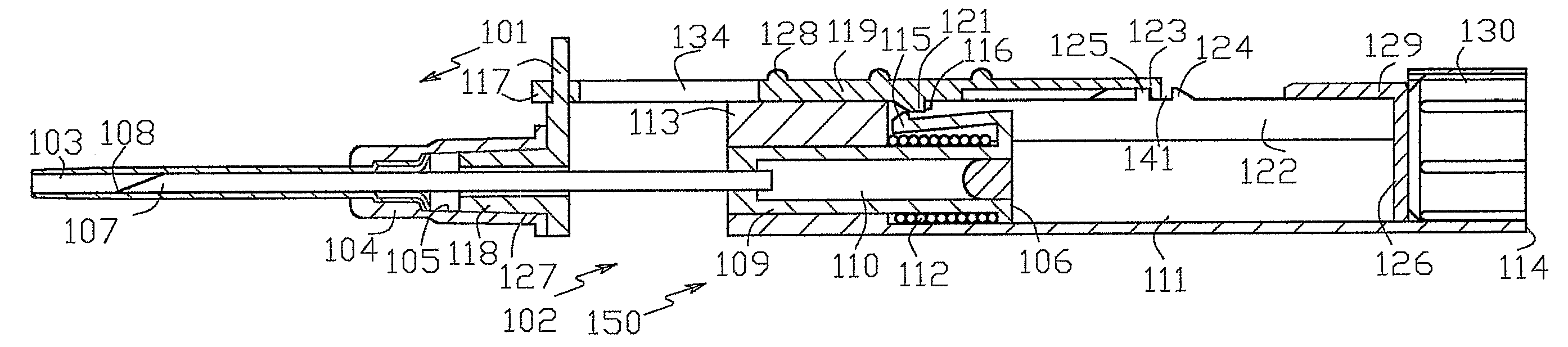

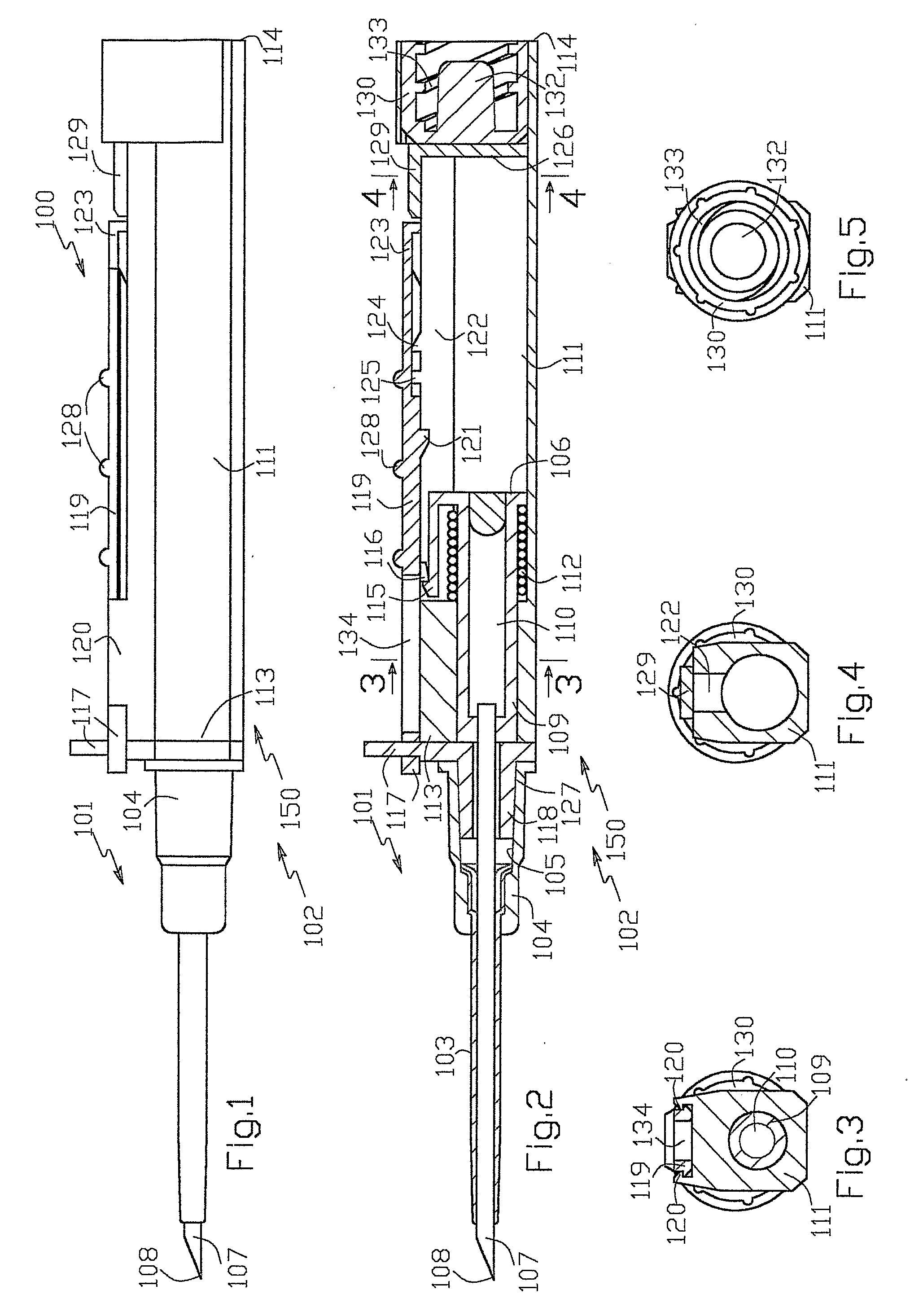

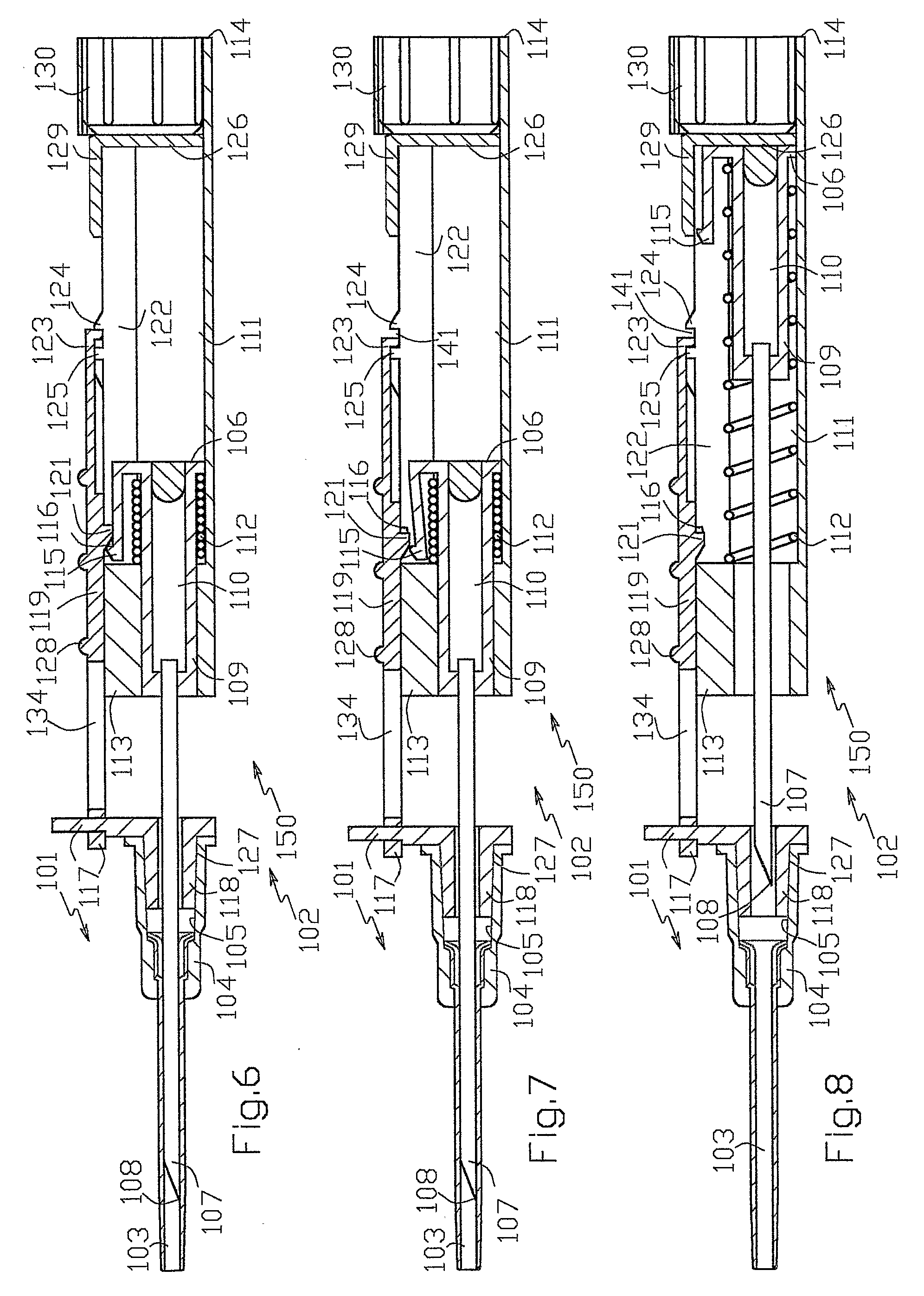

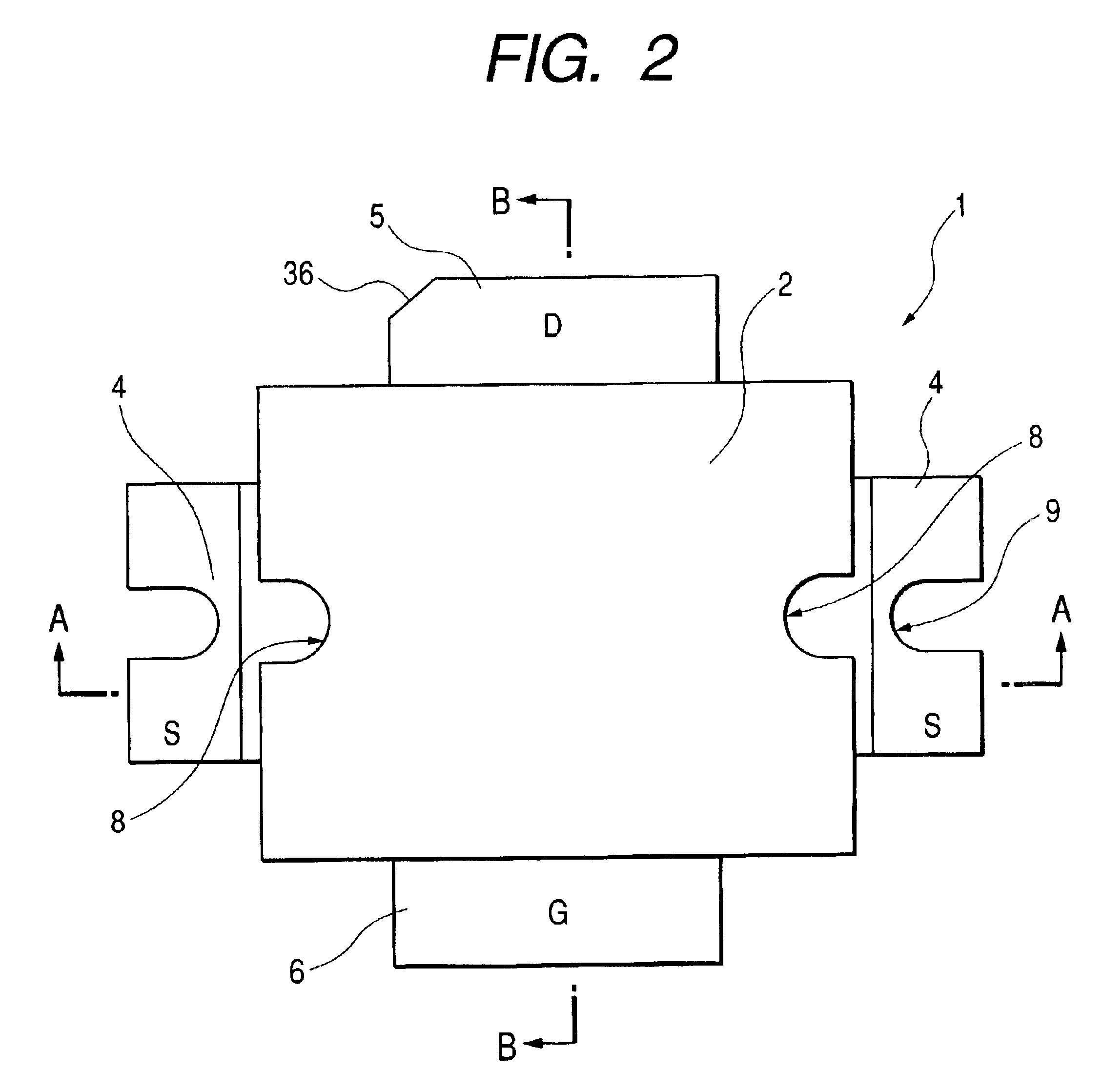

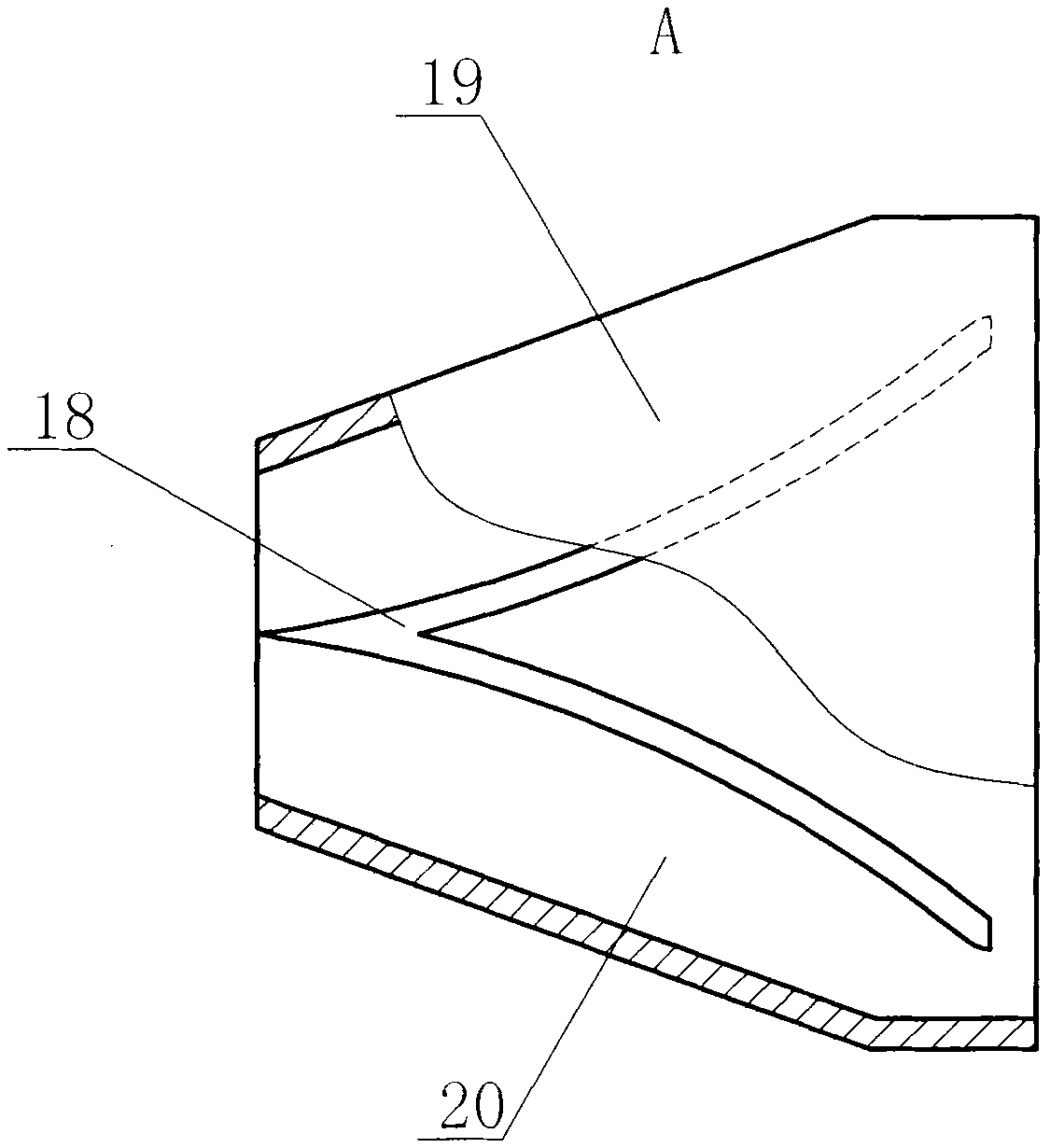

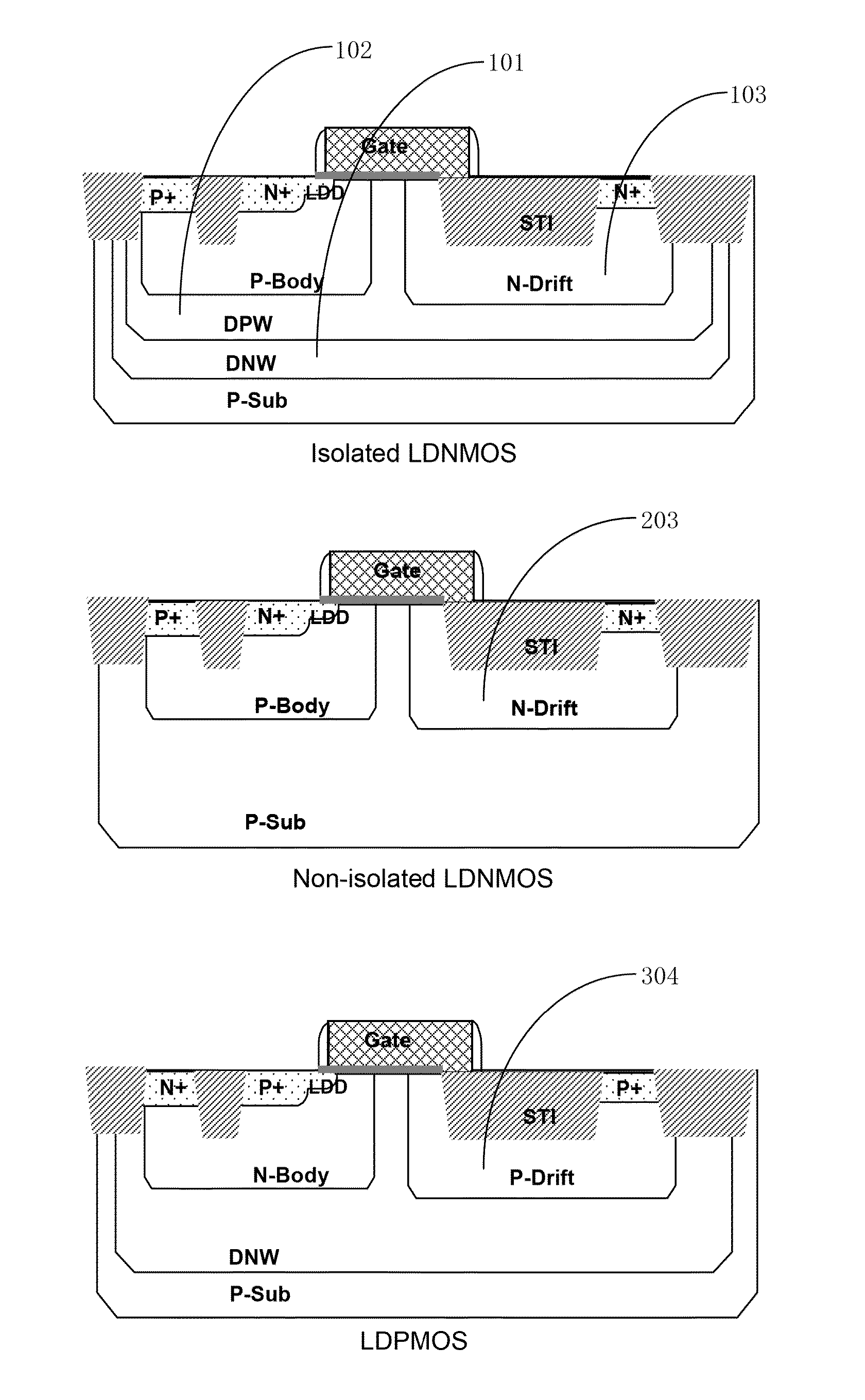

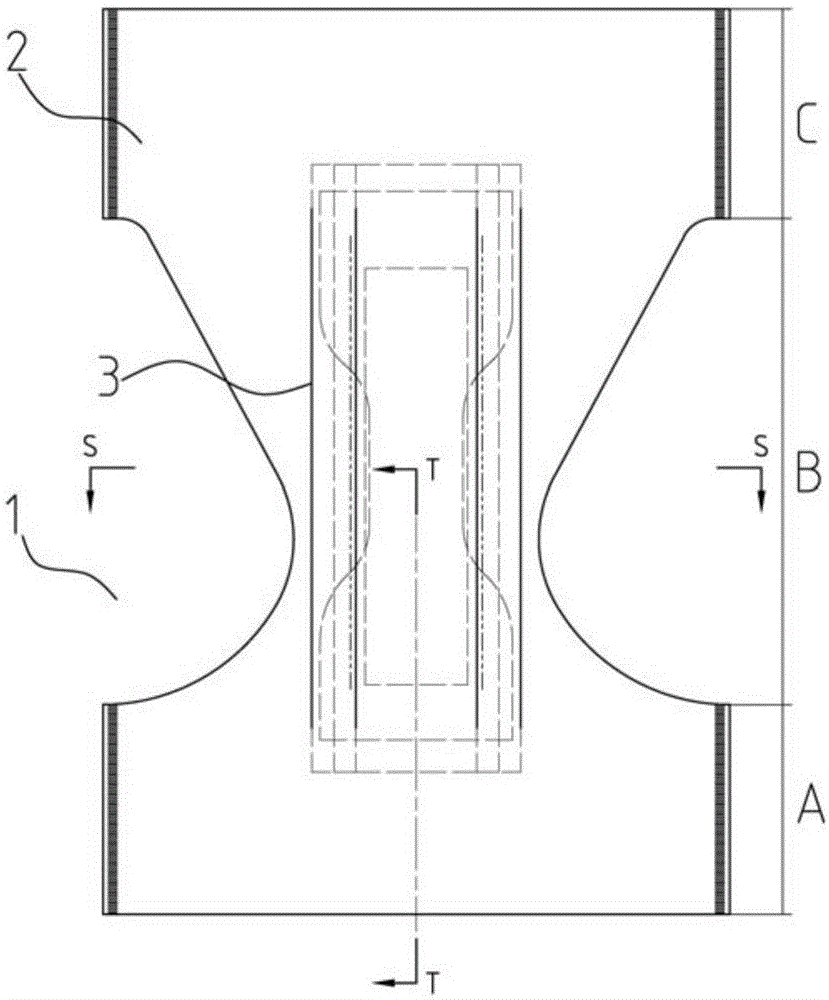

Catheter placement device

InactiveUS20090131872A1Avoiding catheter bleedingGood for observationGuide needlesInfusion syringesVeinCam

Abstract A catheter placement device (see FIG. 2) includes a needle unit, which in an initial position is releasably engaged with a housing distal end and has a sharp needle passing through a catheter and protruding distally of it. There is also a telescopic protector including guard unit, which is sliding in a housing guide. After inserting the needle into patient's vein, operator one-handedly pushes the guard unit distally, thereby emplacing the catheter, displacing the protector into a full length position and locking therein, and passively disengaging the needle unit from the hosing by a trigger cam located on the guard unit. As a result, a retracting spring moves a needle into retracted position, wherein it is protected from any contact with personal. Then, operator disconnects the guard from the catheter, turns the housing and occludes the catheter entrance with a cap, which was detachably mounted on the housing.

Owner:POPOV

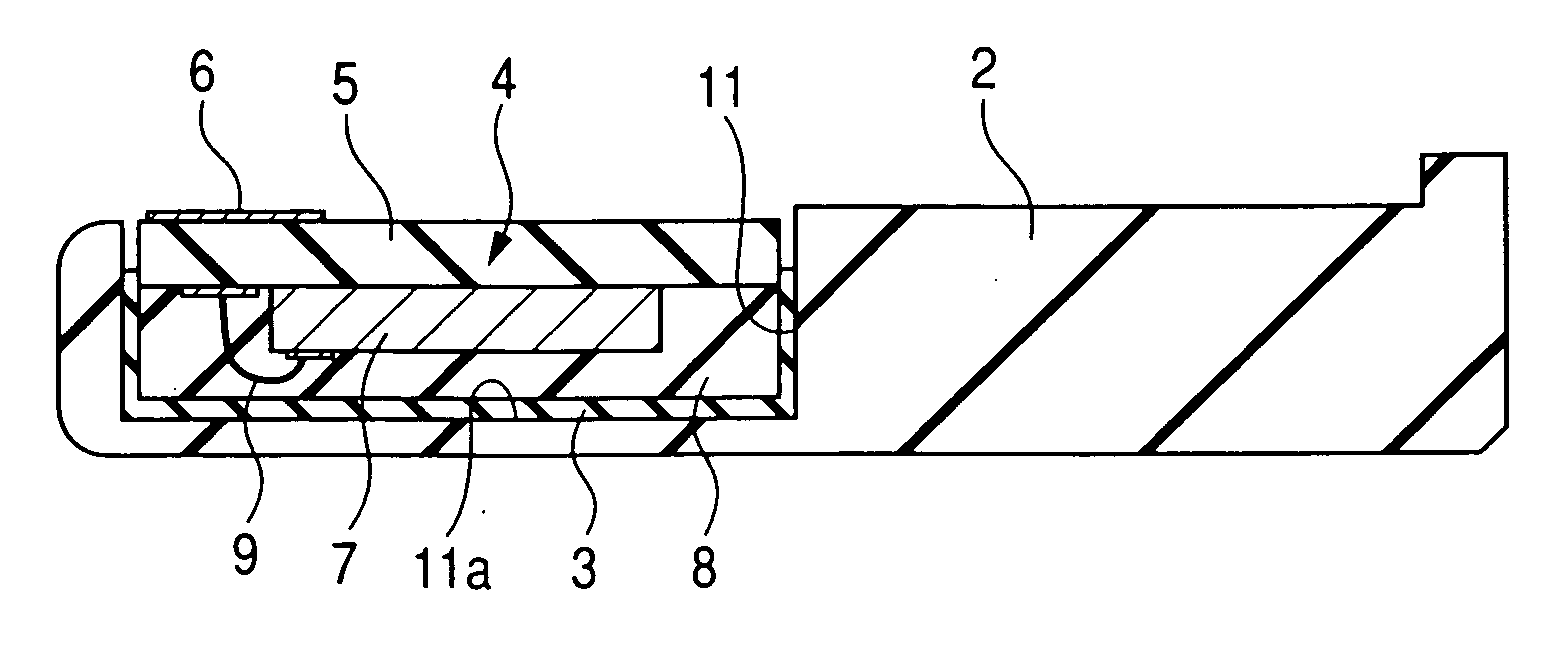

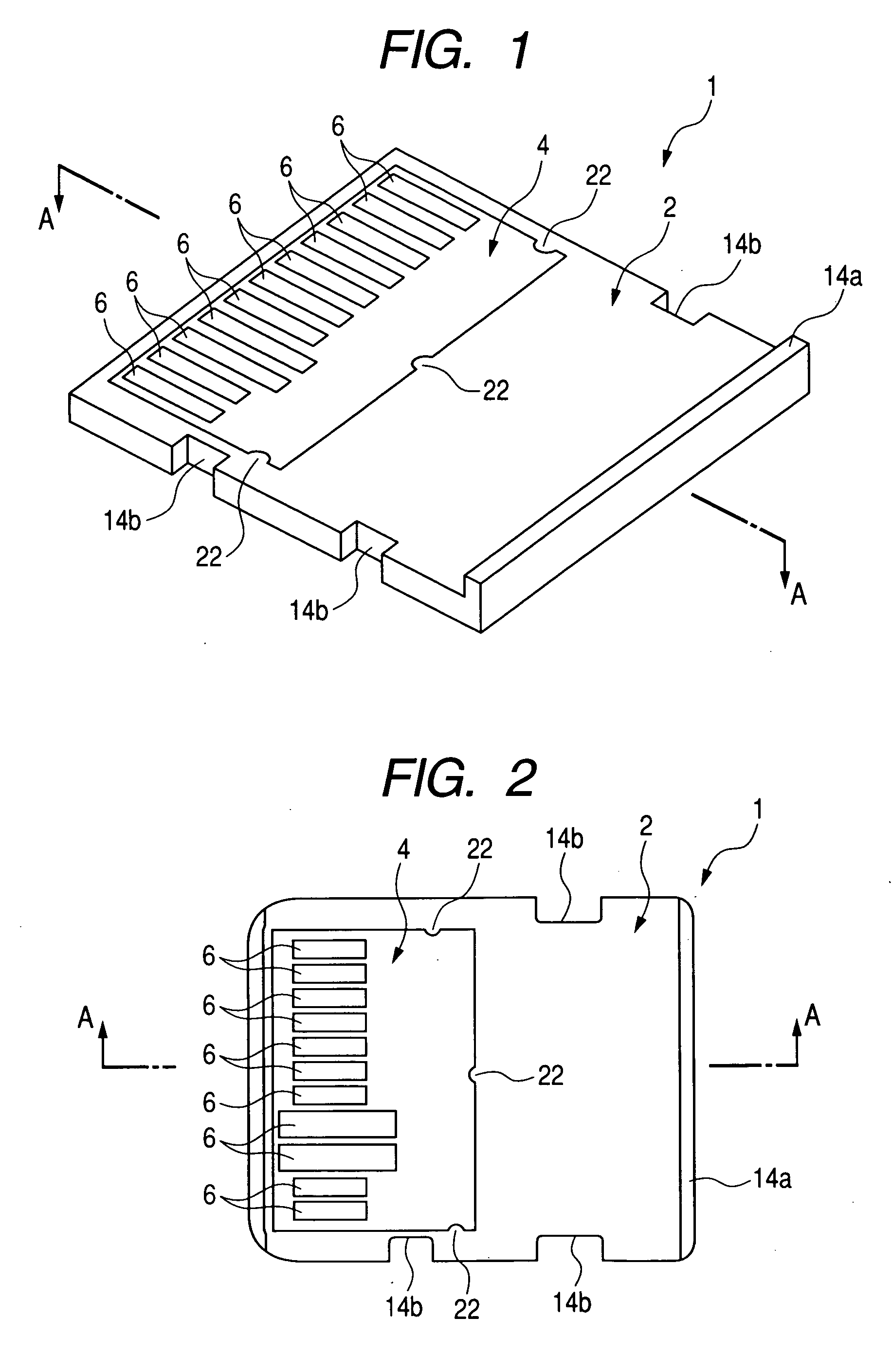

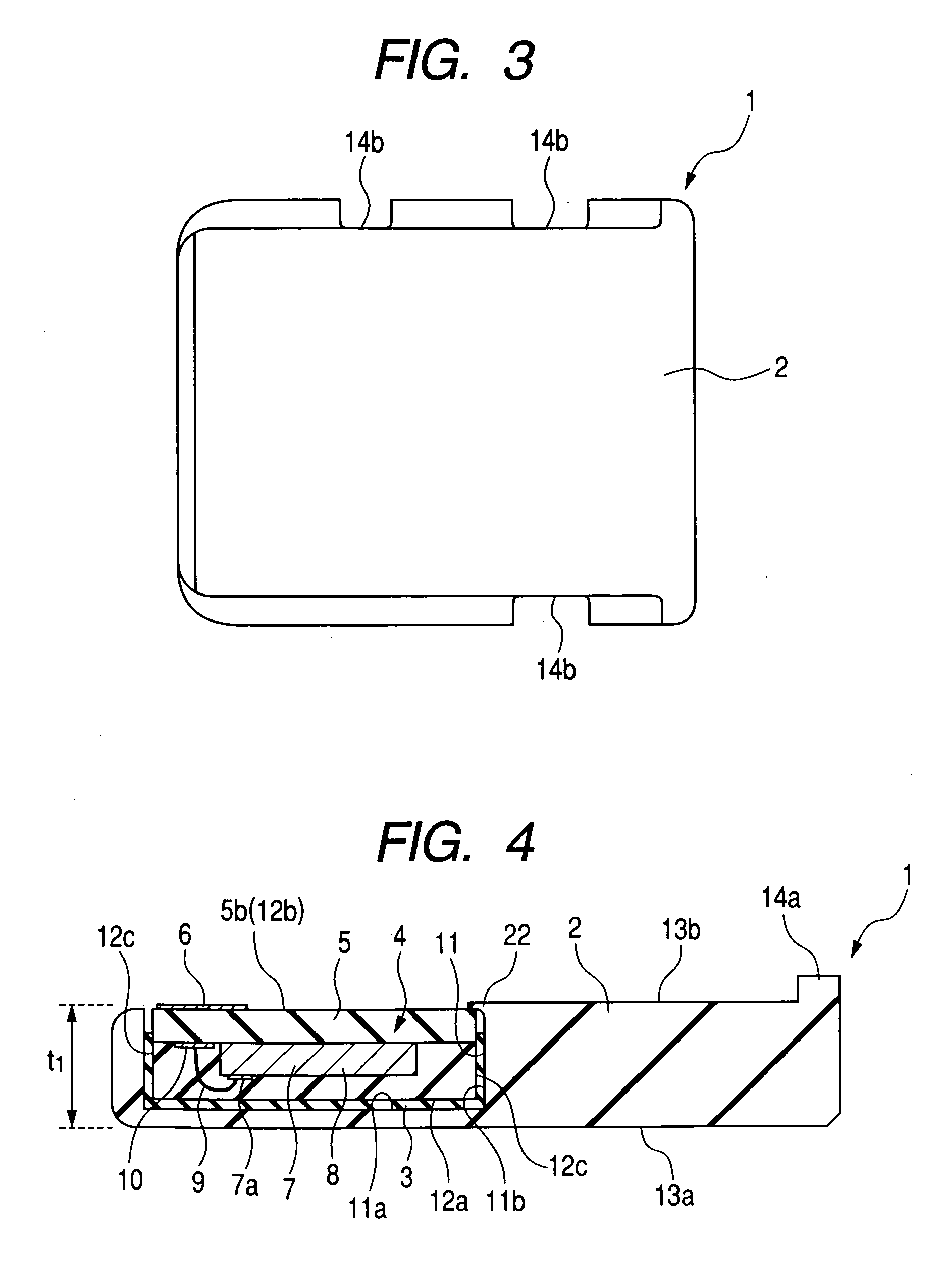

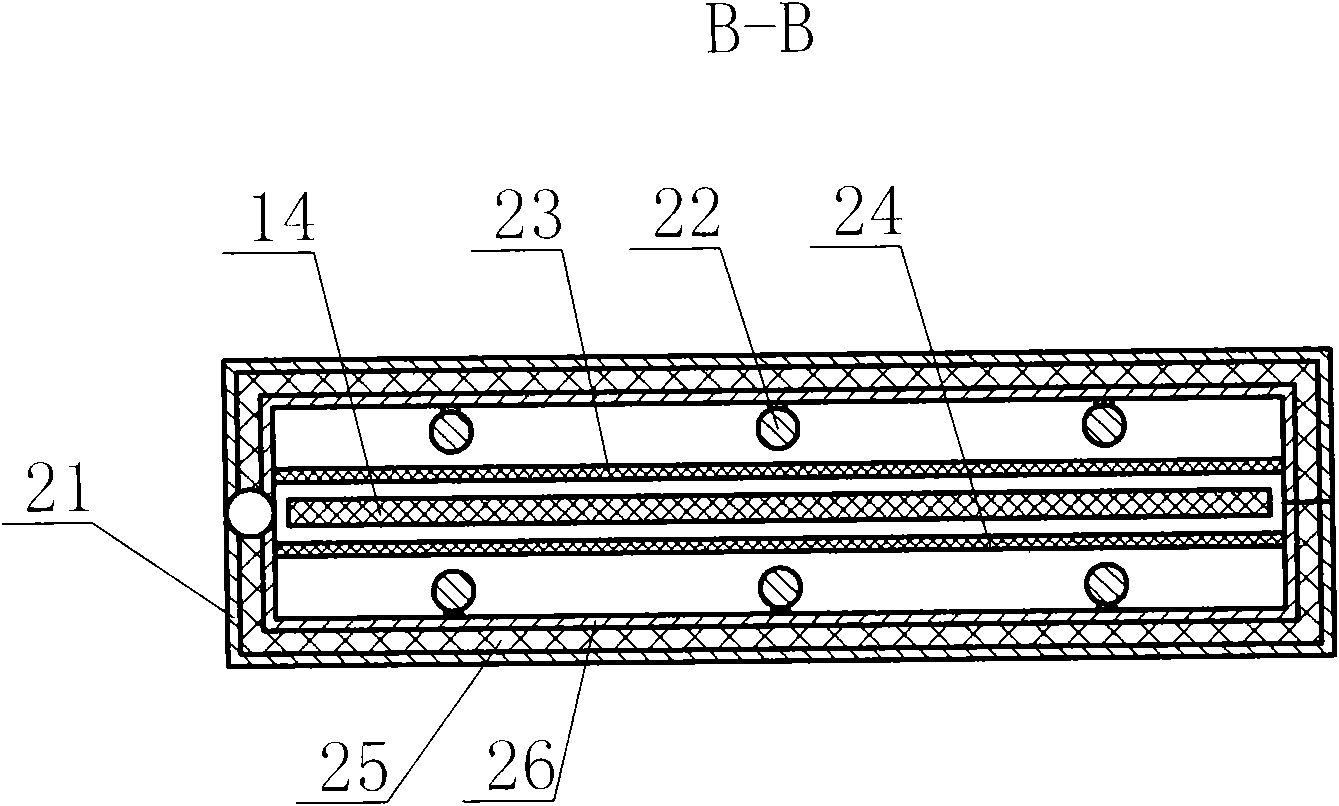

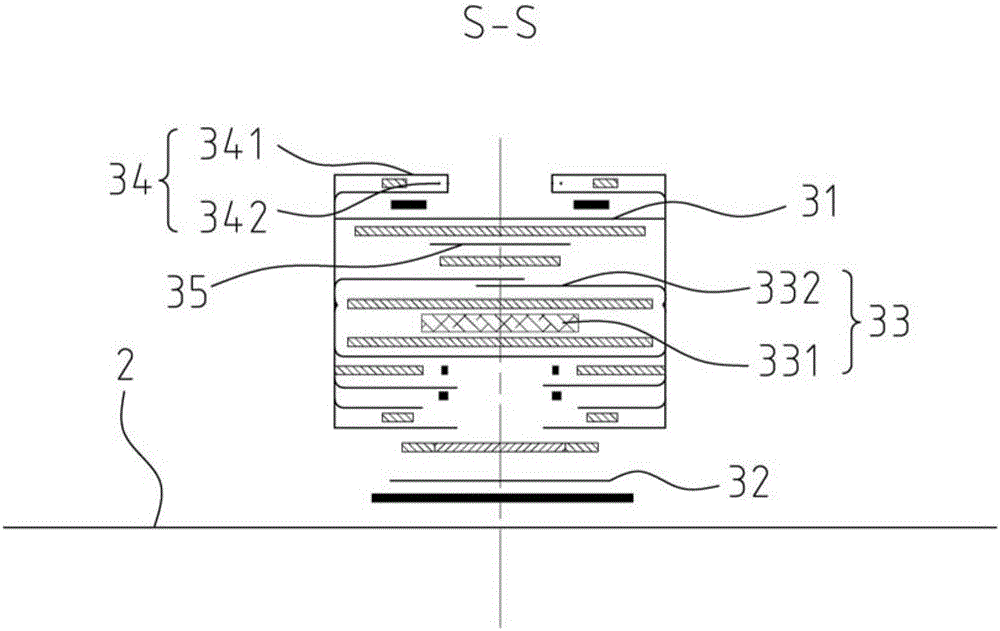

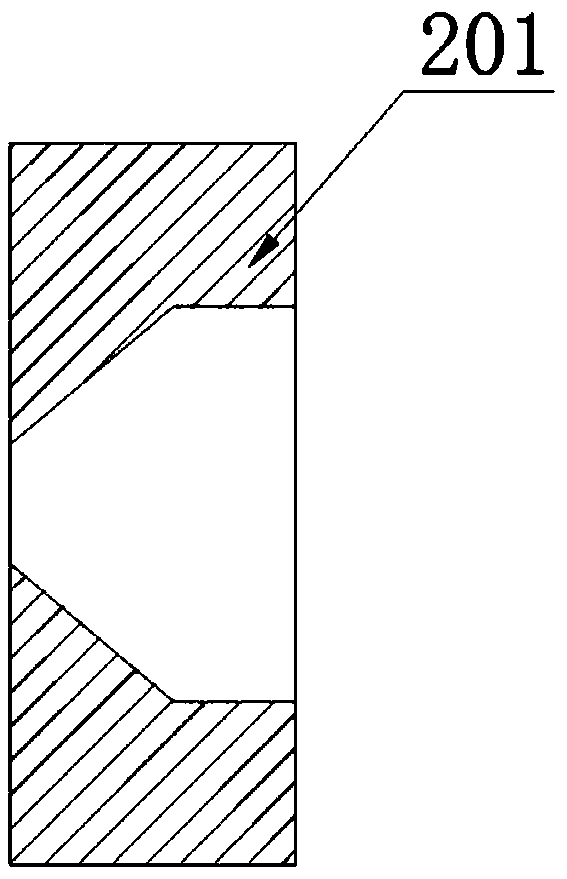

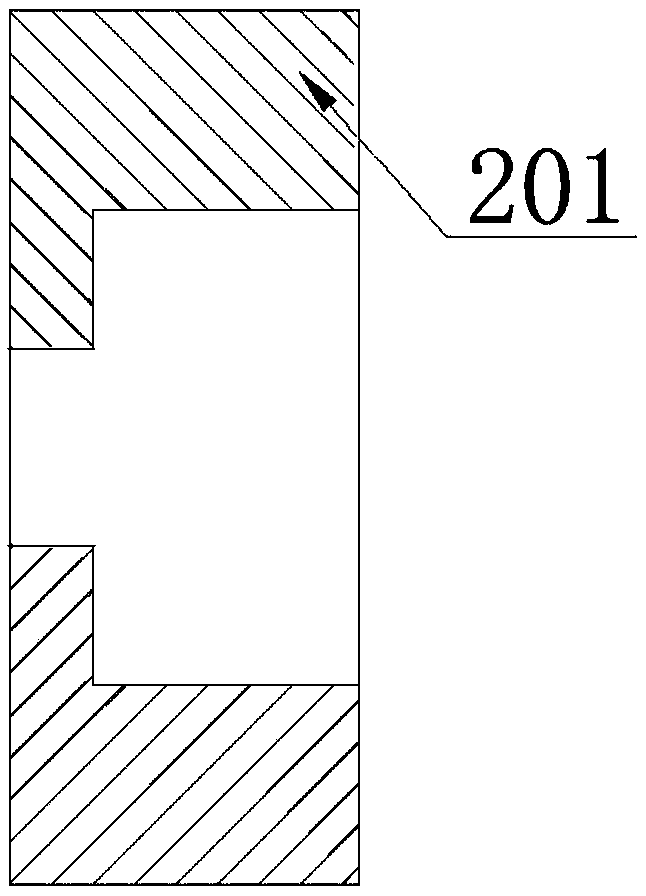

Integrated circuit card and a method for manufacturing the same

InactiveUS20060202041A1Increase the number ofInexpensively formedSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A semiconductor chip is mounted onto a wiring substrate having external connecting terminals, electrodes on the semiconductor chip and wiring lines on the wiring substrate are connected together electrically through bonding wires, and a sealing portion is formed by resin molding, to form an IC body. Further, a case formed of a thermoplastic resin is provided. The IC body is mounted into a recess of the case through a bonding material. Thereafter, a region near the recess of the case is deformed plastically to fix the IC body to the case and then the bonding material is cured. In this way there is fabricated an IC card comprising the case and the IC body whose stability is improved by being bonded to the case through the bonding material. The production yield of the IC card can be improved.

Owner:RENESAS TECH CORP

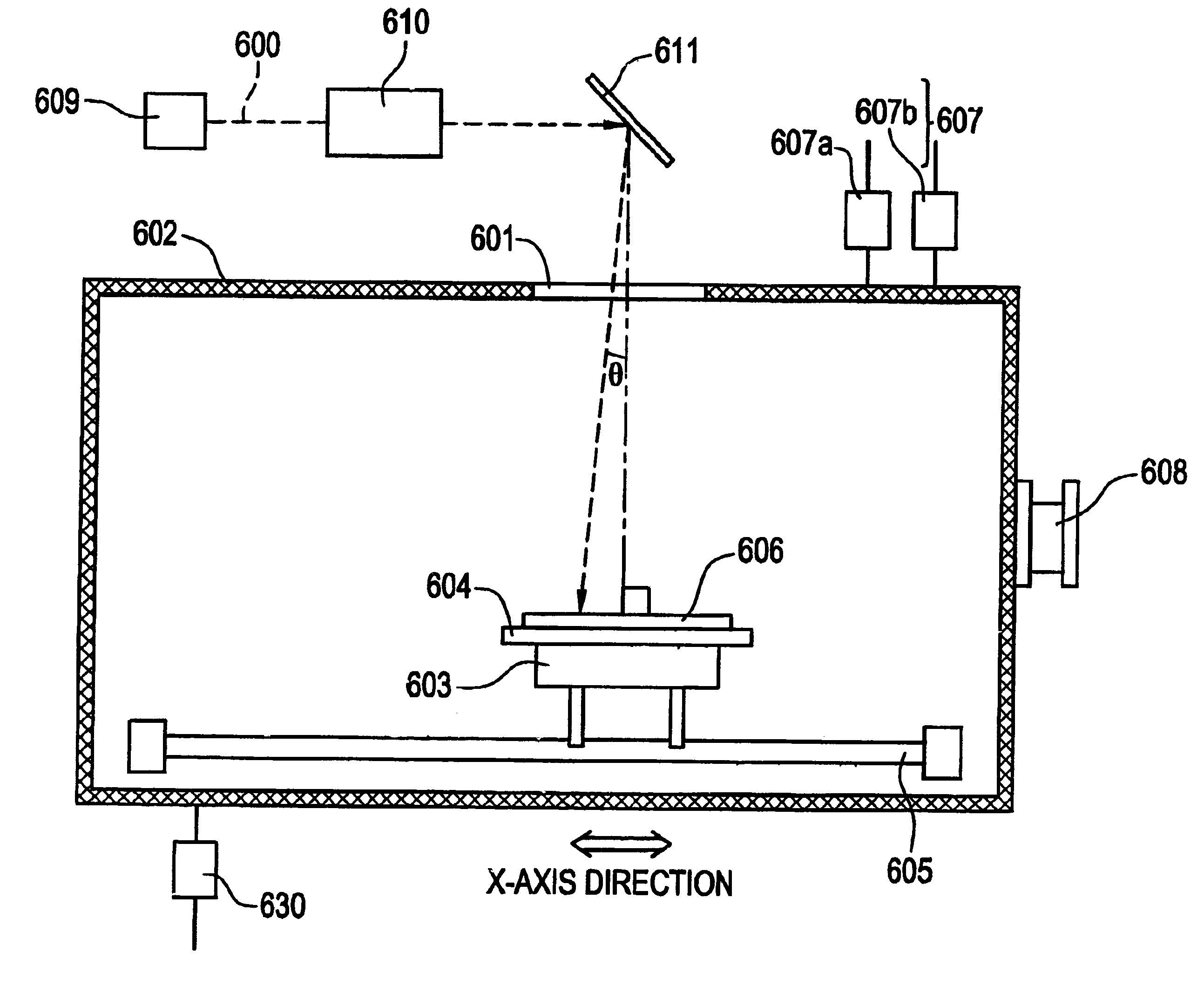

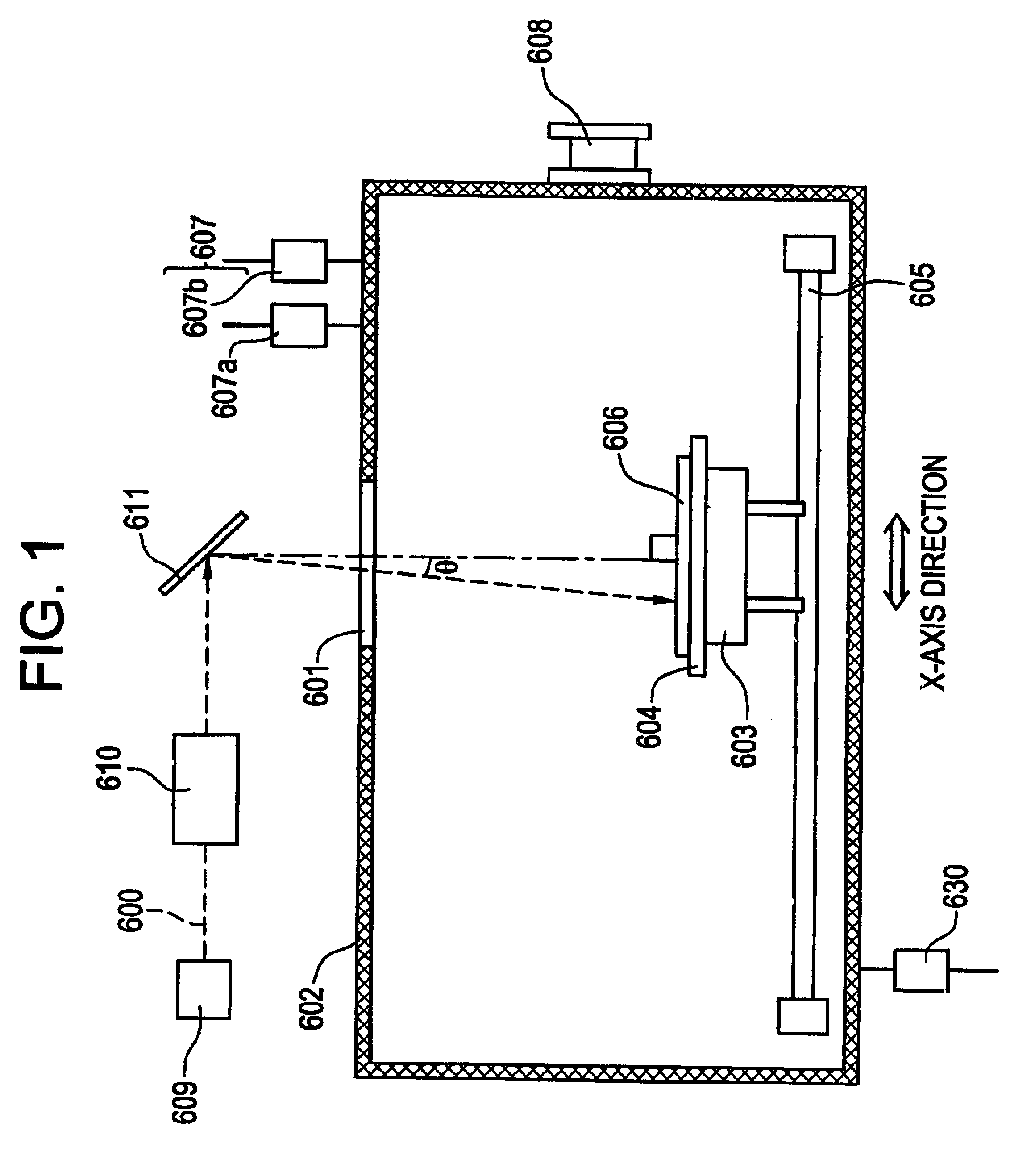

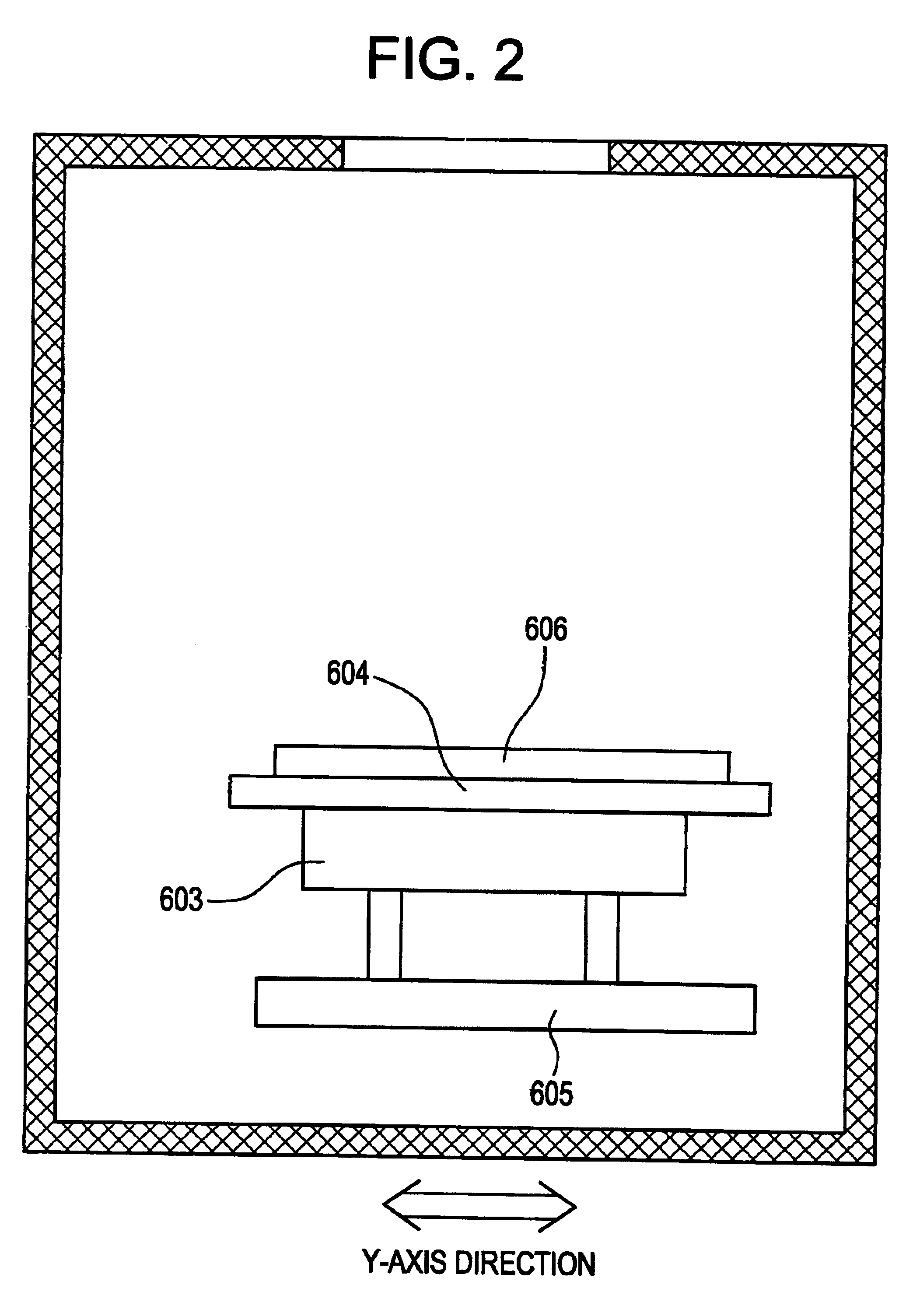

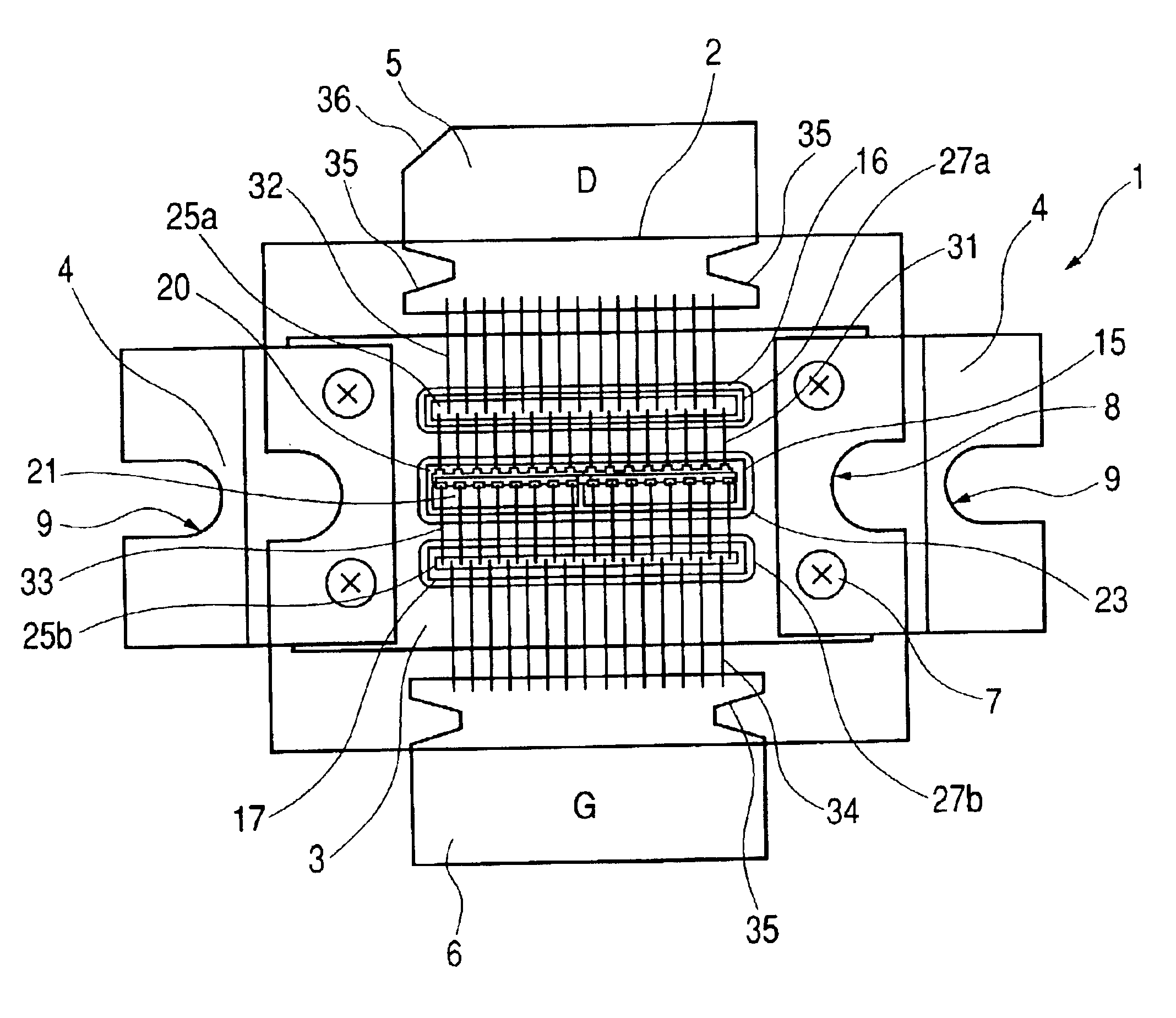

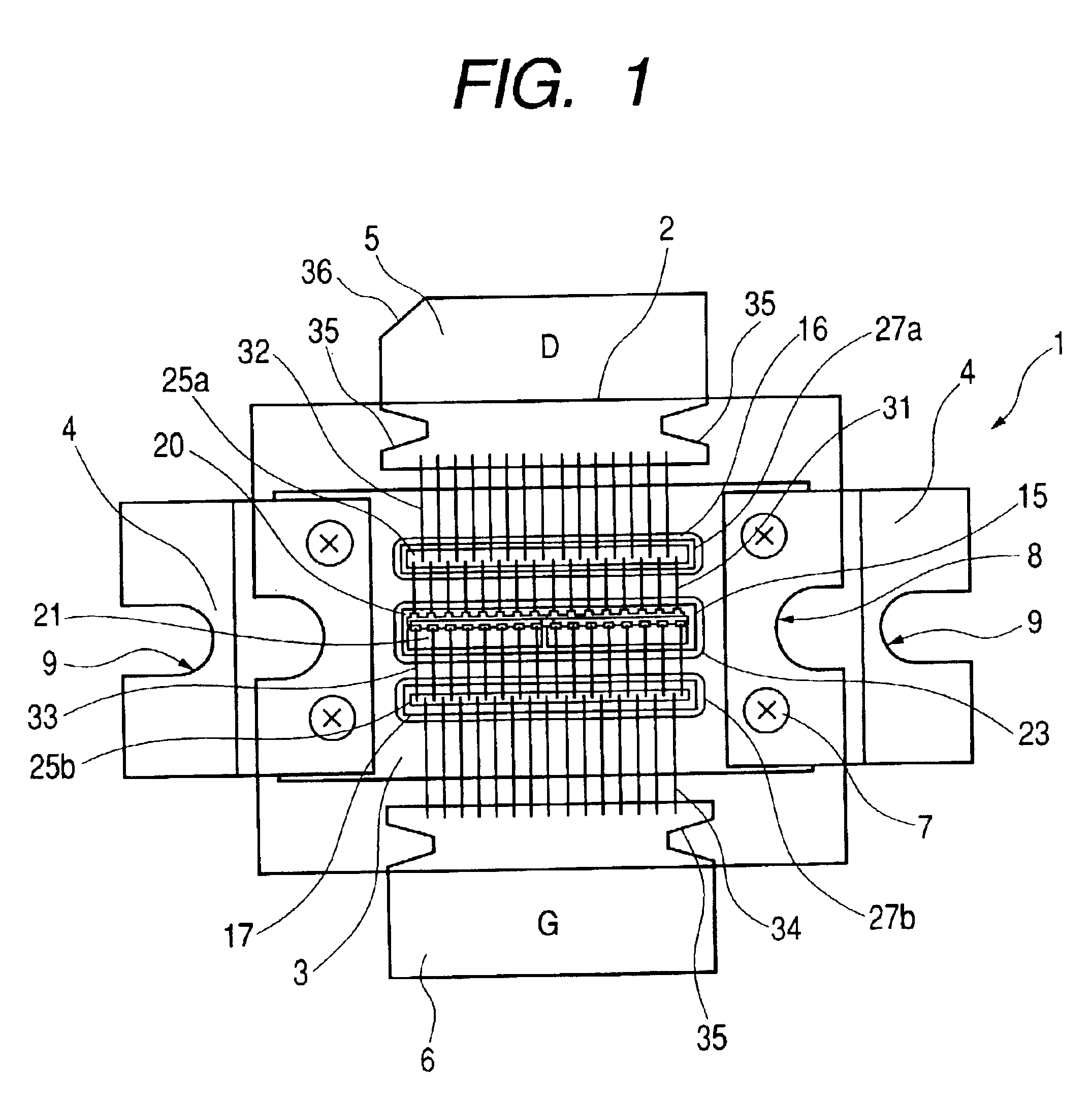

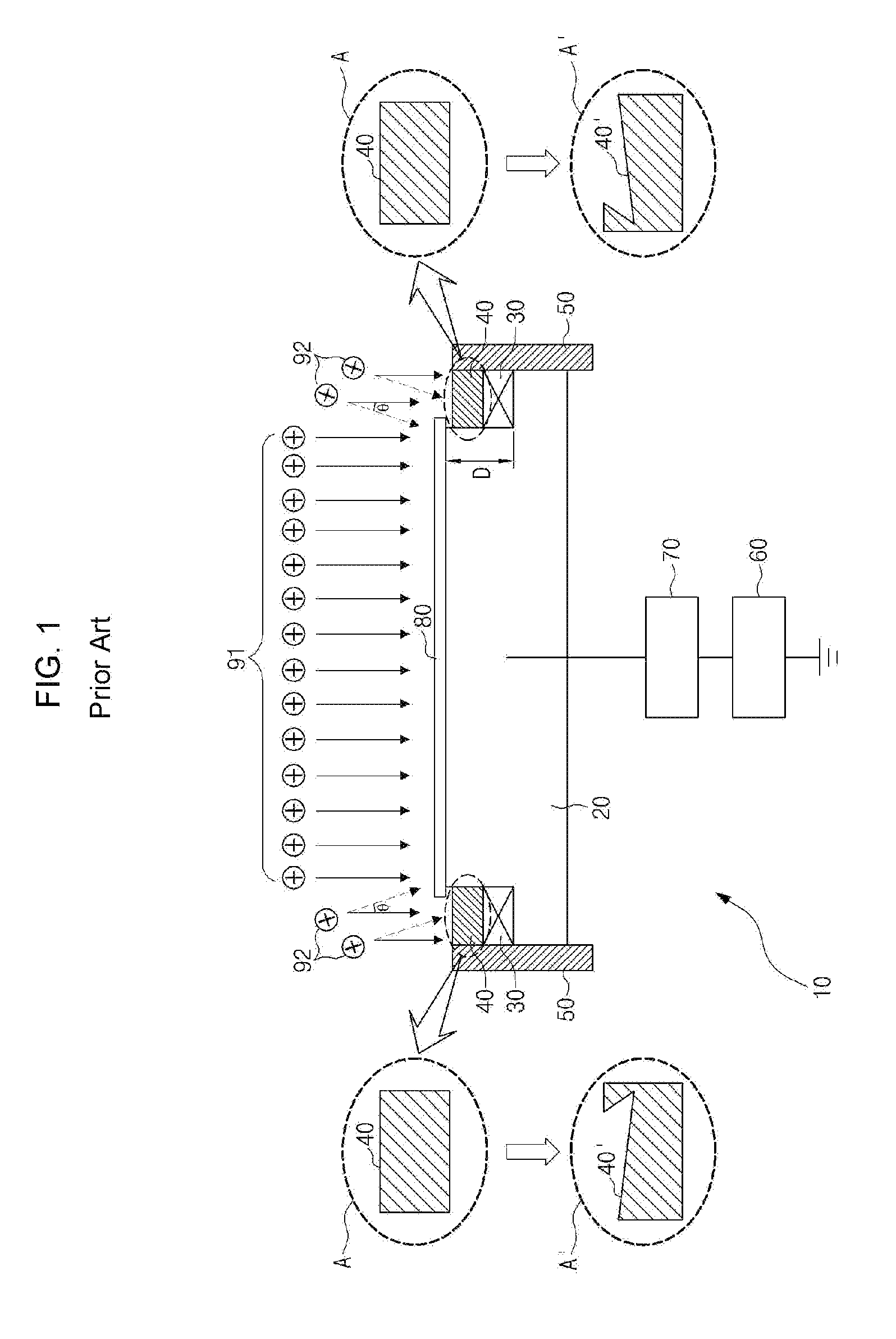

Laser annealing apparatus and semiconductor device manufacturing method

InactiveUS6847006B2Low running costReduce formationSemiconductor/solid-state device manufacturingCable carsLight beamLaser beams

This invention is intended to provide a laser annealing method by employing a laser annealer lower in running cost so as to deal with a large-sized substrate, for preventing or decreasing the generation of a concentric pattern and to provide a semiconductor device manufacturing method including a step using the laser annealing method. While moving a substrate at a constant rate between 20 and 200 cm / s, a laser beam is radiated aslant to a semiconductor film on a surface of the semiconductor substrate. Therefore, it is possible to radiate a uniform laser beam to even a semiconductor film on a large-sized substrate and to thereby manufacture a semiconductor device for which the generation of a concentric pattern is prevented or decreased. By condensing a plurality of laser beams into one flux, it is possible to prevent or decrease the generation of a concentric pattern and to thereby improve the reliability of the semiconductor device.

Owner:SEMICON ENERGY LAB CO LTD

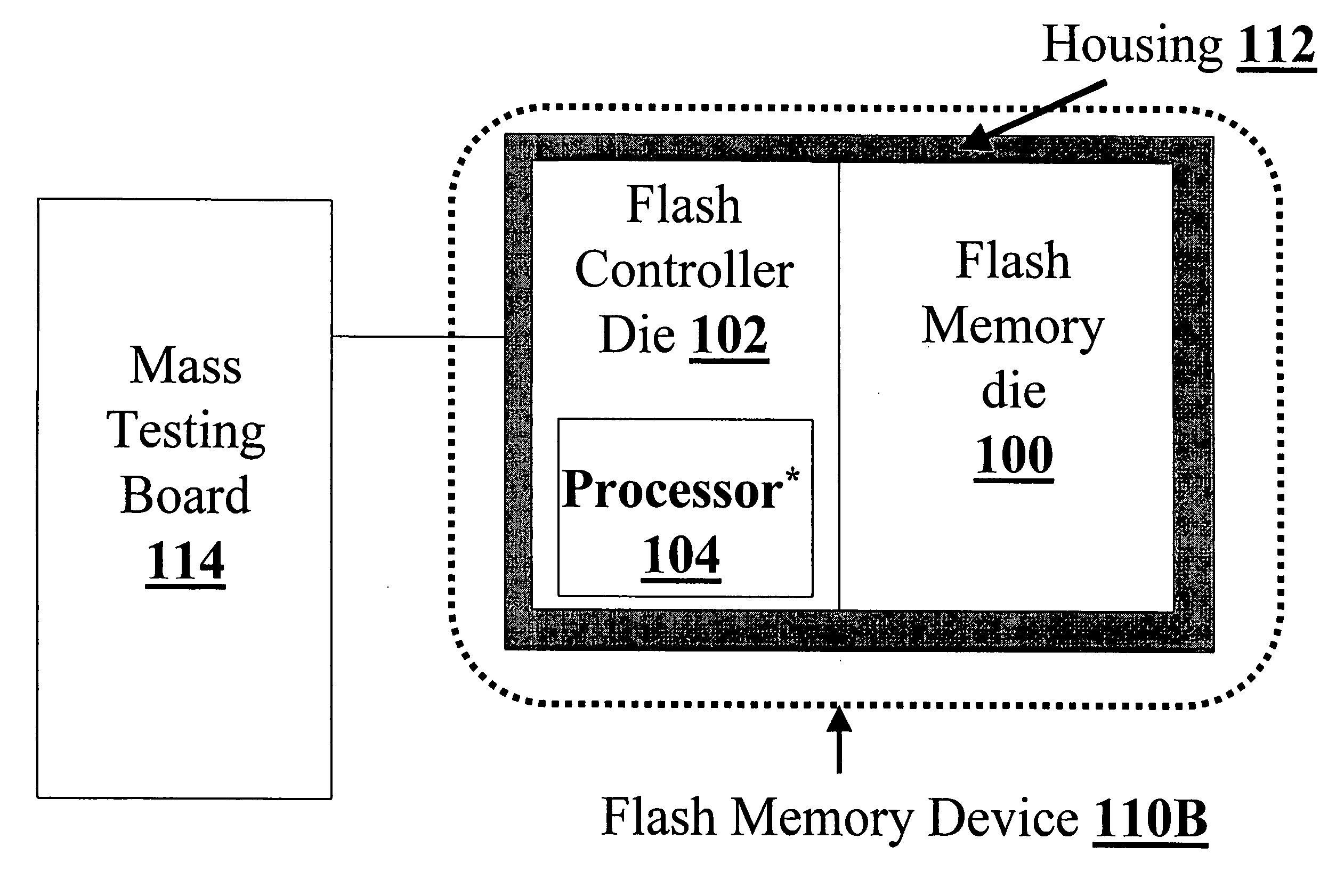

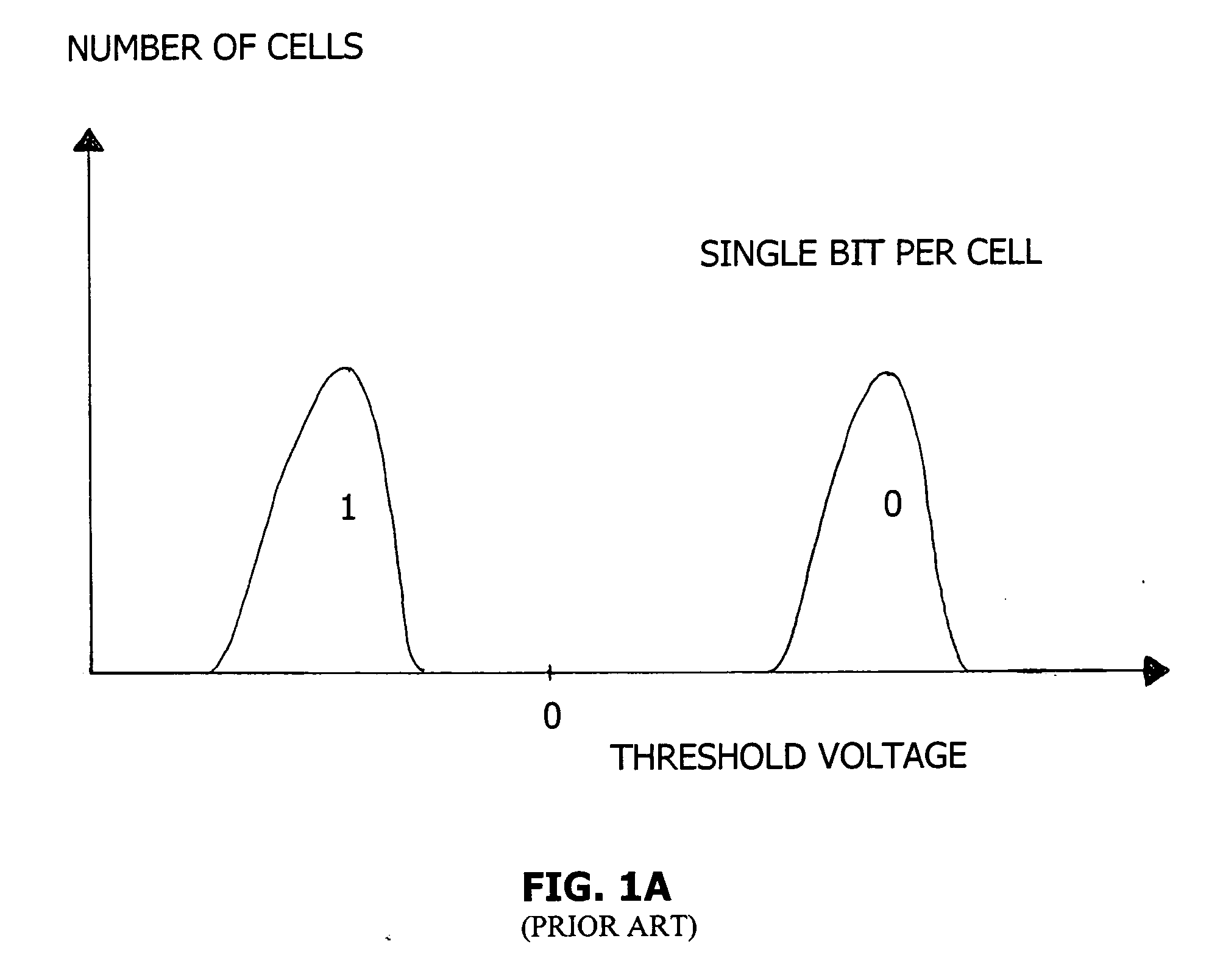

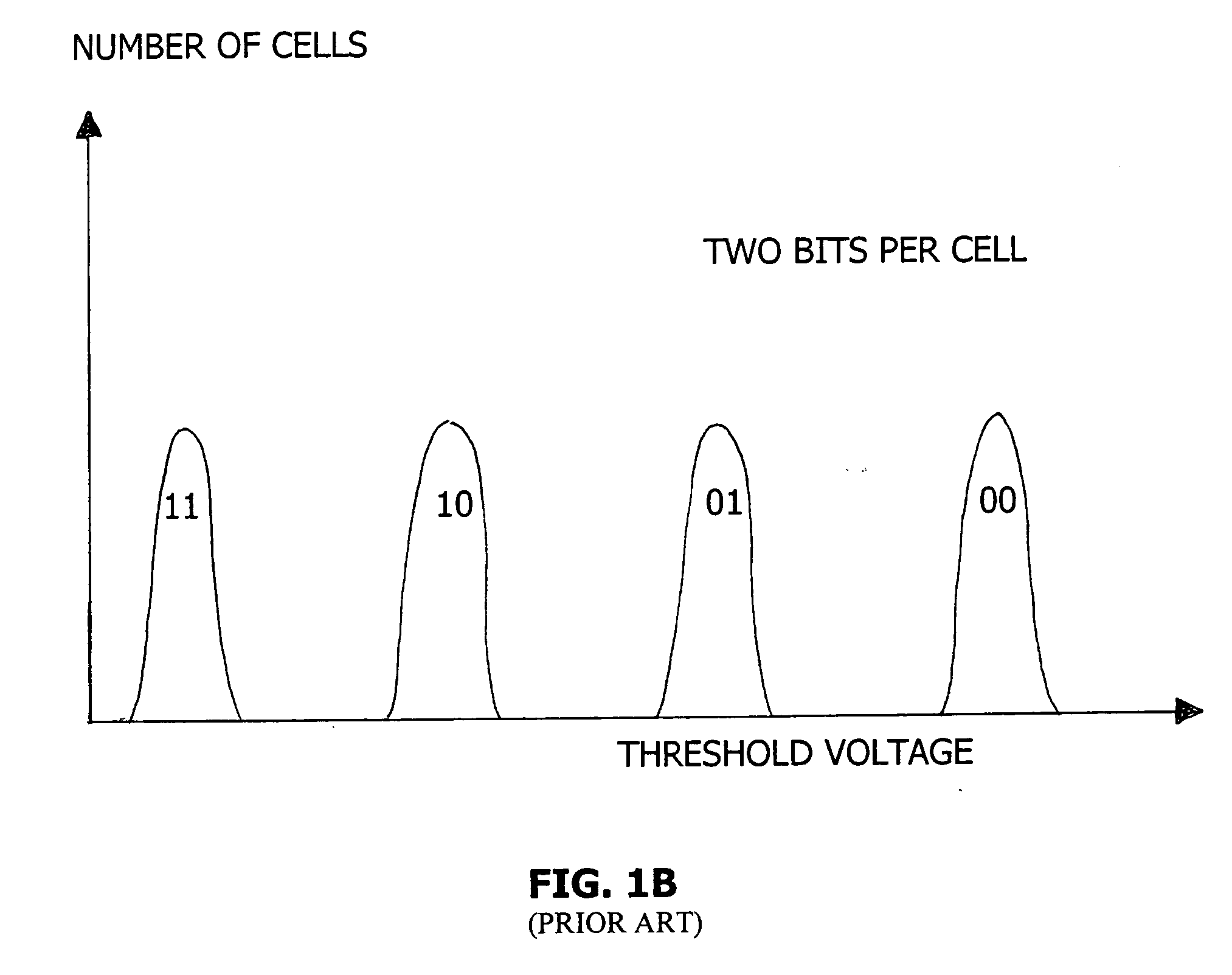

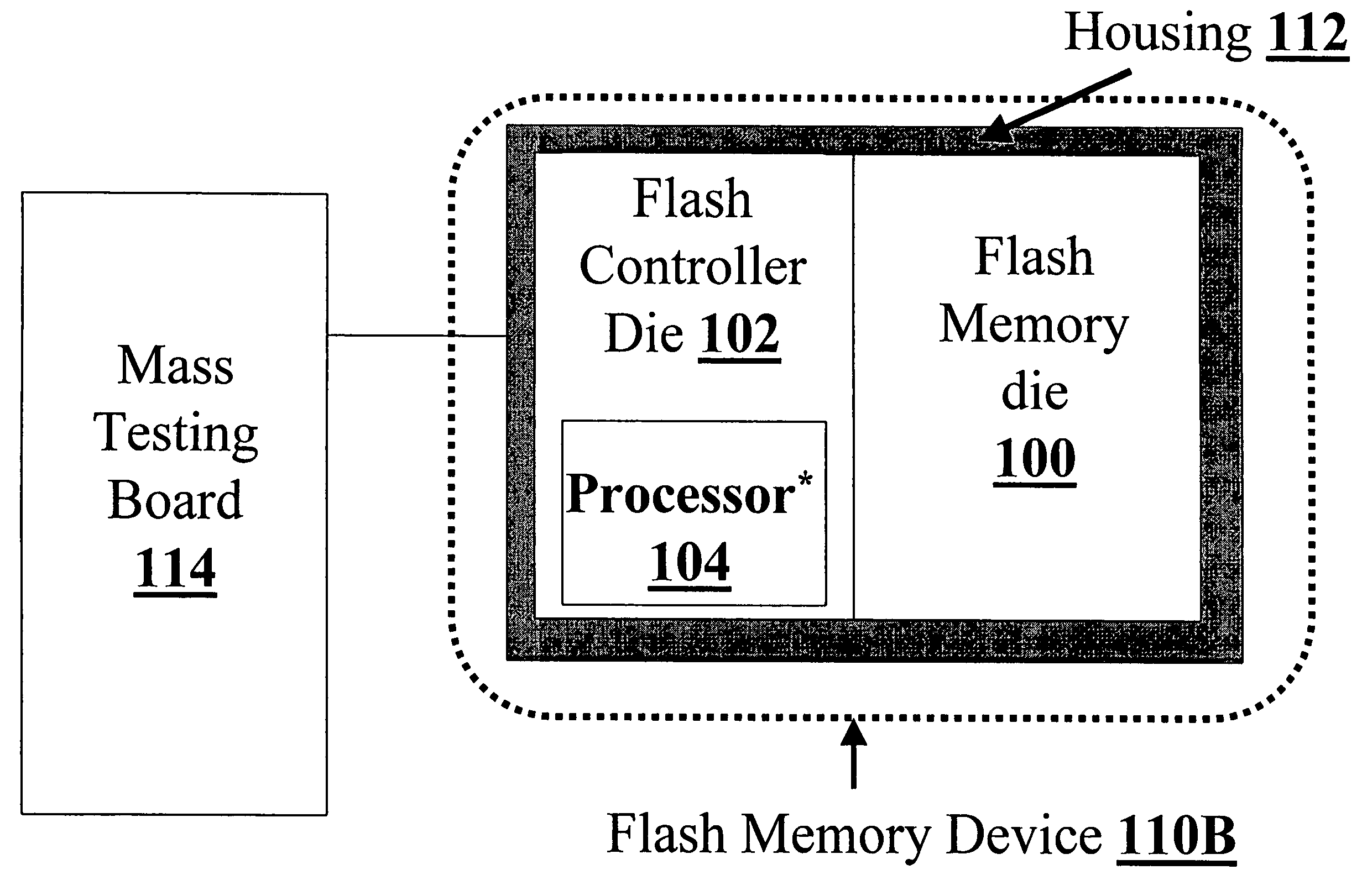

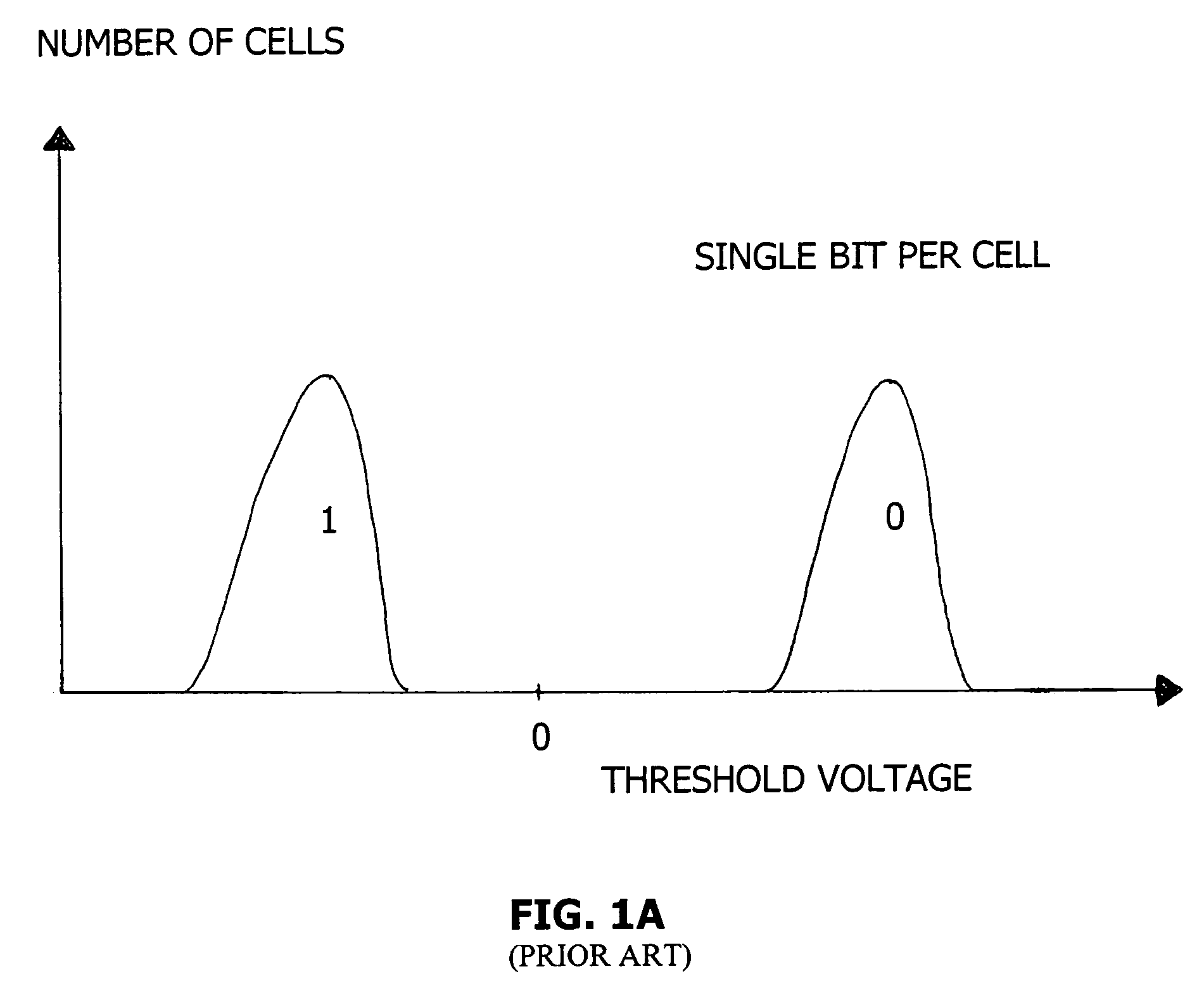

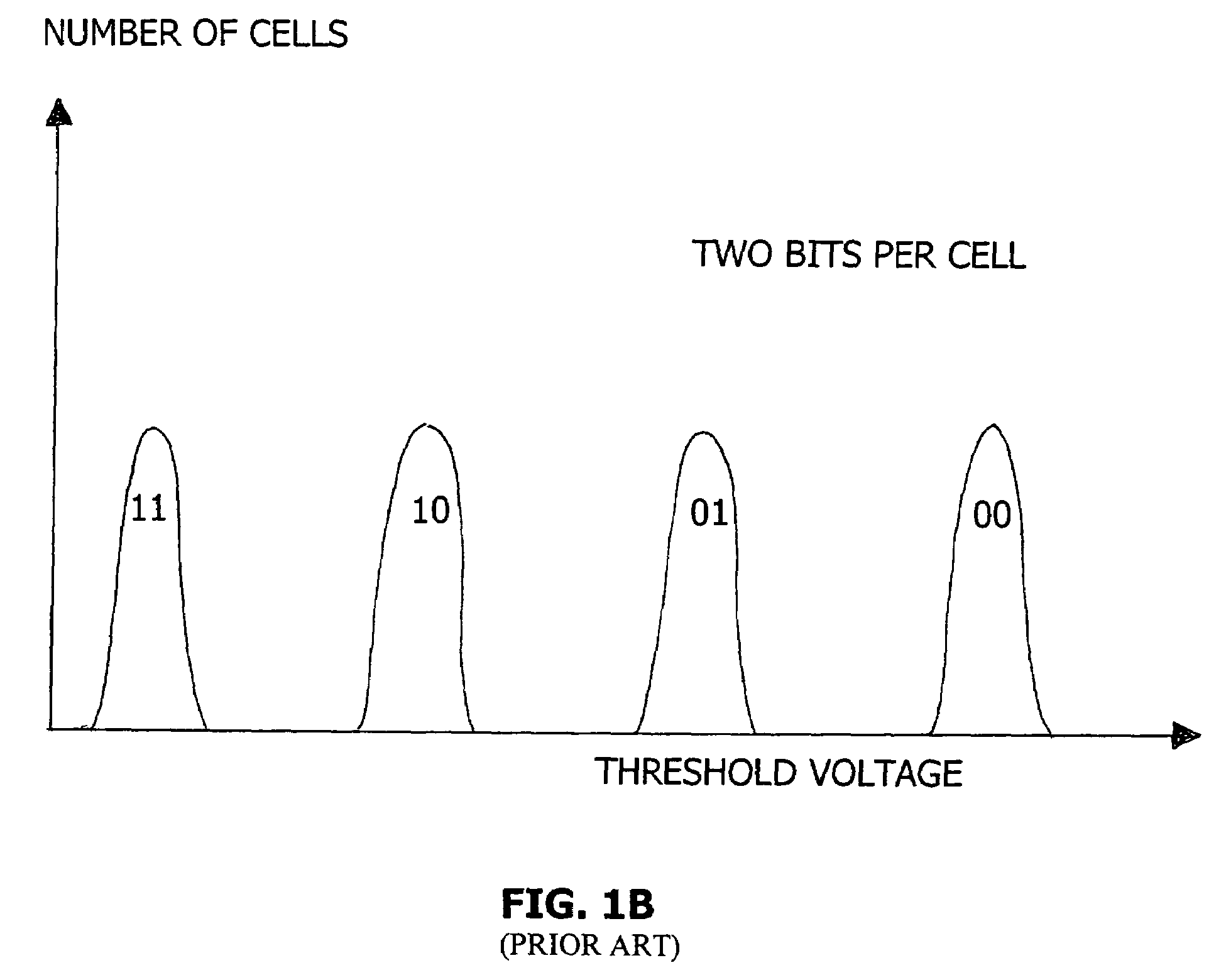

Method, system and computer-readable code for testing of flash memory

InactiveUS20060216841A1Avoid testingReduce equipment manufacturing costsSemiconductor/solid-state device testing/measurementRead-only memoriesFlash memory controllerProcfs

Methods, systems and devices for testing flash memory dies are disclosed. According to some embodiments, during the post-wafer sort stage of device manufacture, a plurality of flash memory devices, each of which includes a flash controller die and at least one flash memory die associated with a common housing, are subjected to a testing process, for examples, a batch testing process or a mass testing process. During testing, a respective flash controller residing on a respective flash controller die executes at least one test program to test one or more respective flash memory dies of the respective flash device. A testing system including at least 100 of the flash memory devices and a mass-testing board is disclosed. Furthermore, flash memory devices where the flash controller is operative to test one or more of the flash memory dies are disclosed. Exemplary testing includes but is not limited to bad block testing.

Owner:WODEN TECH INC

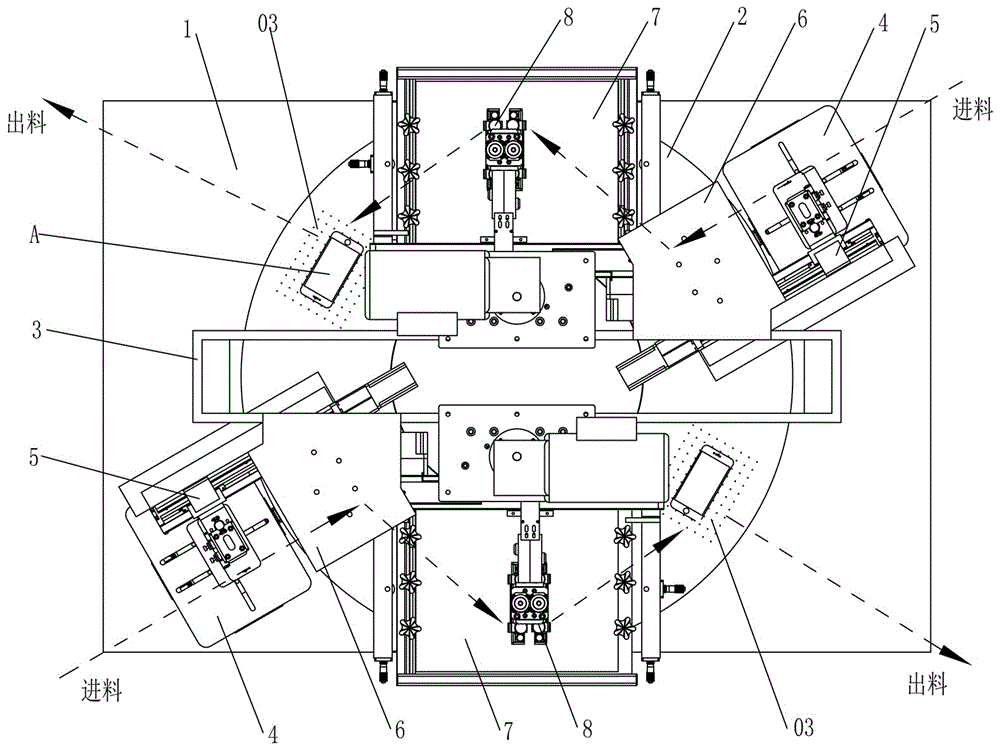

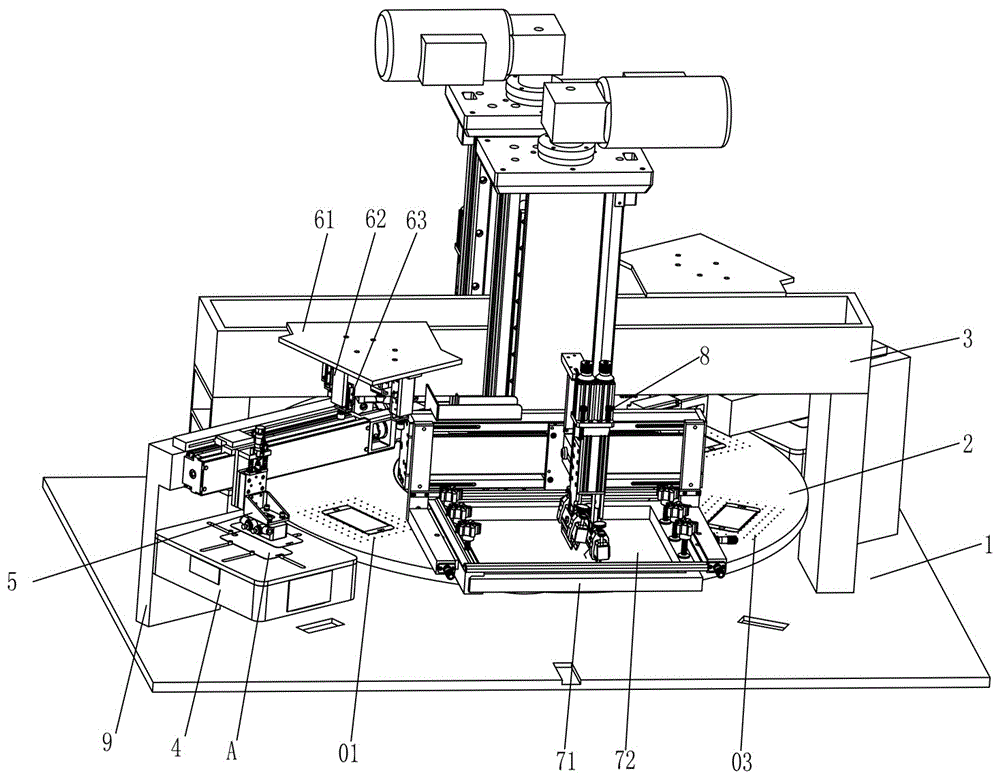

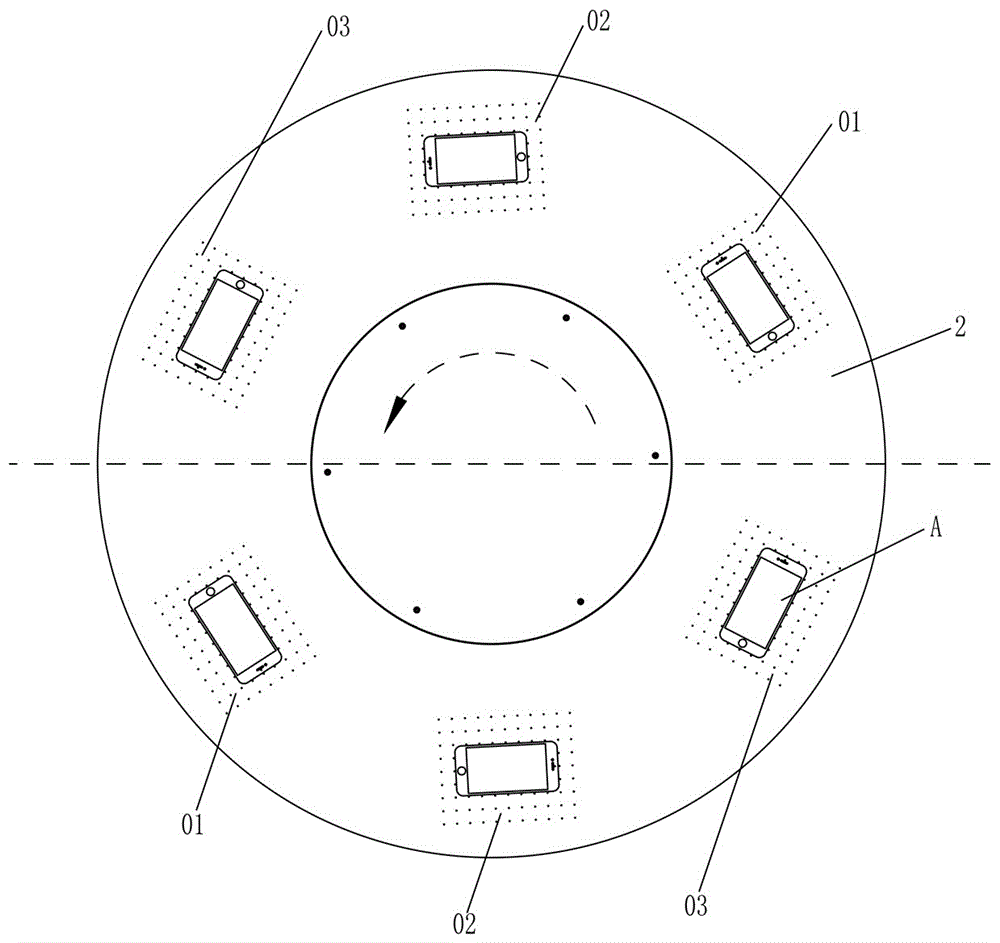

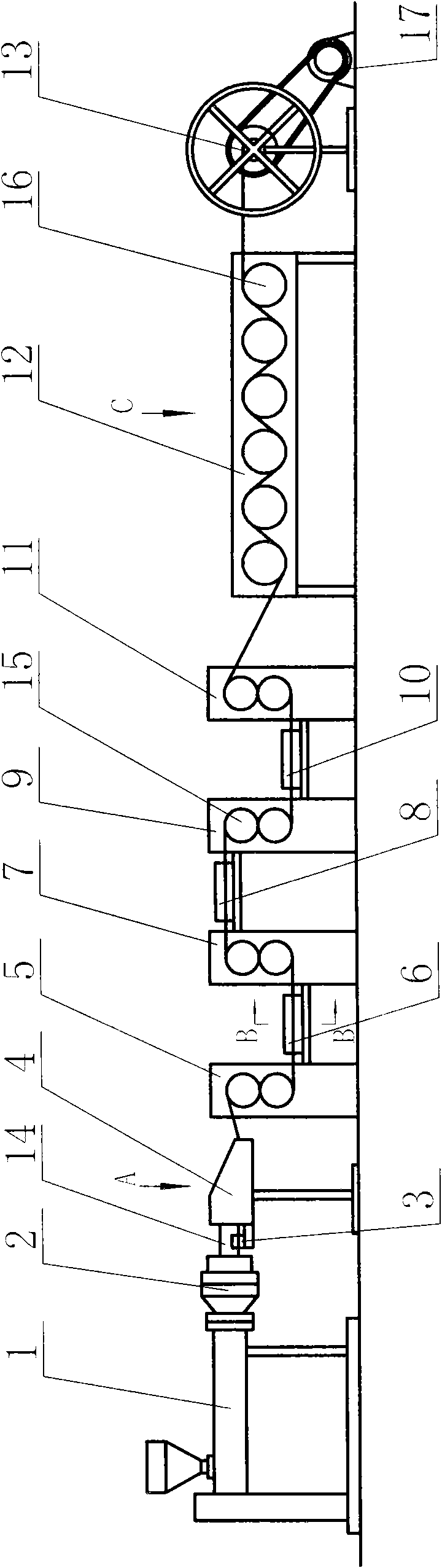

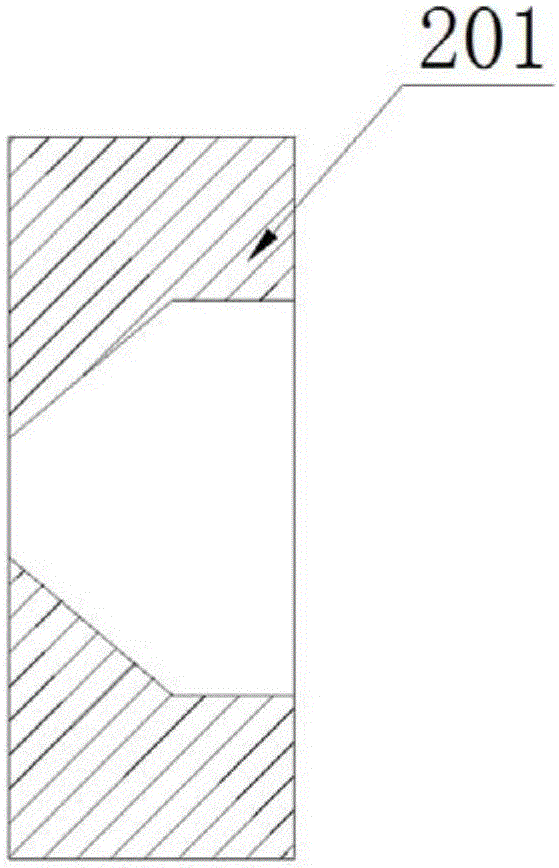

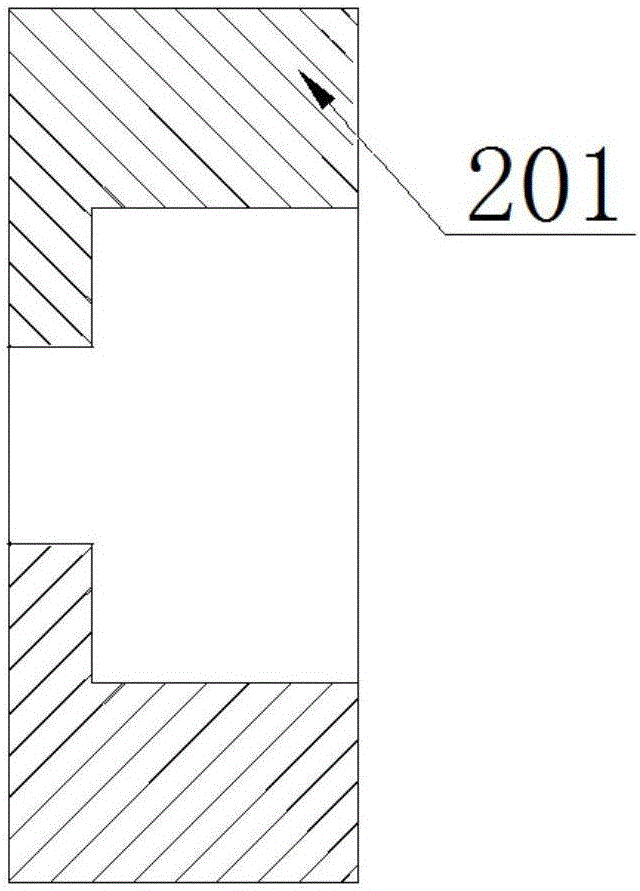

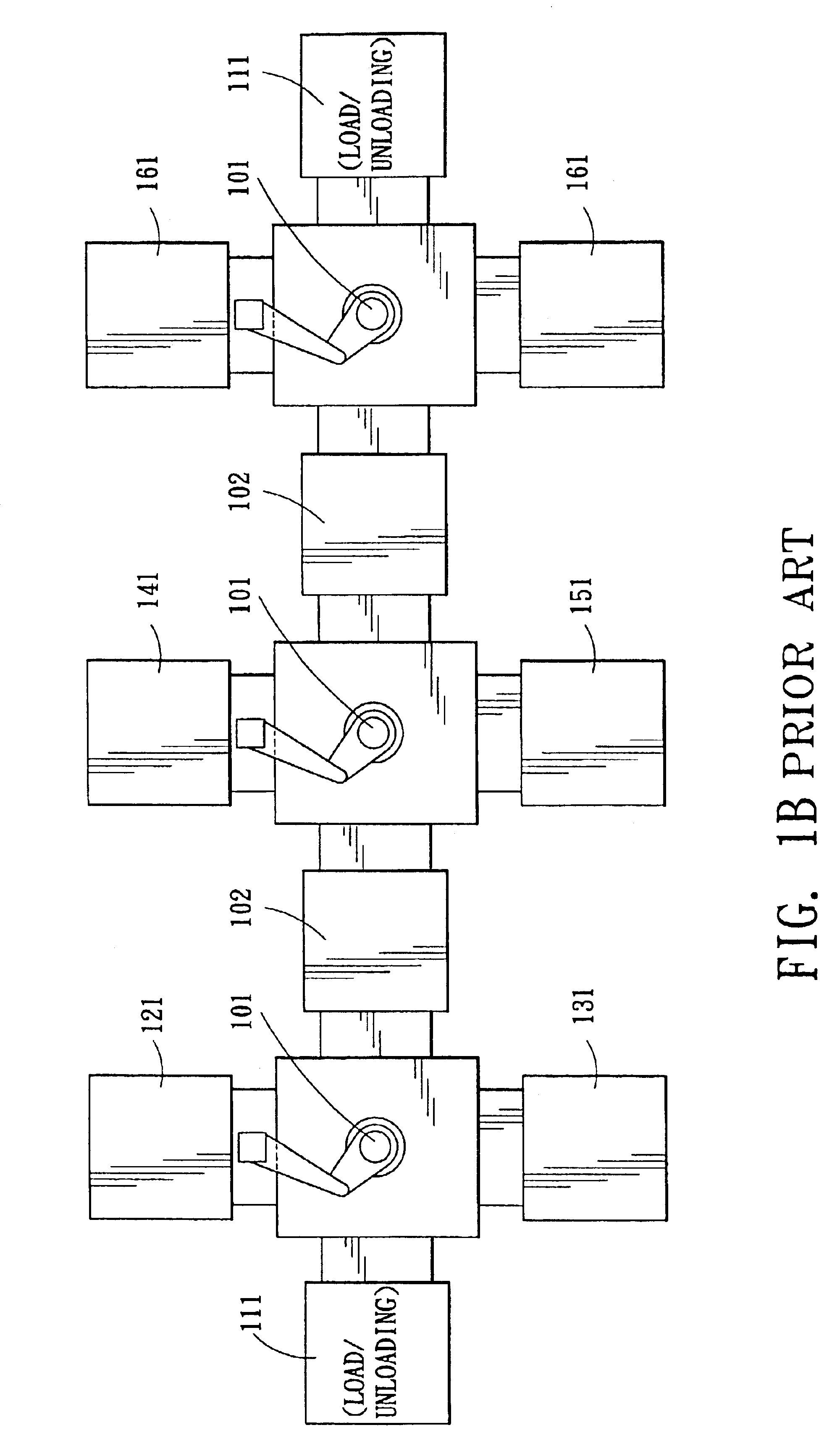

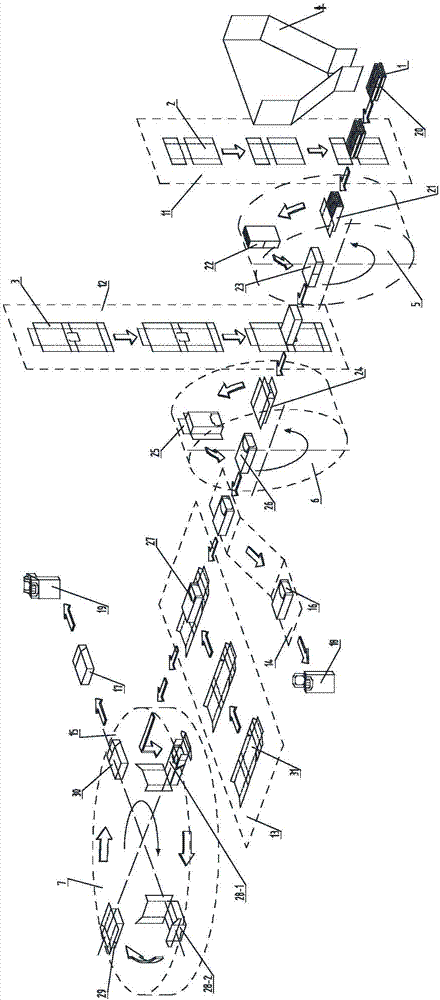

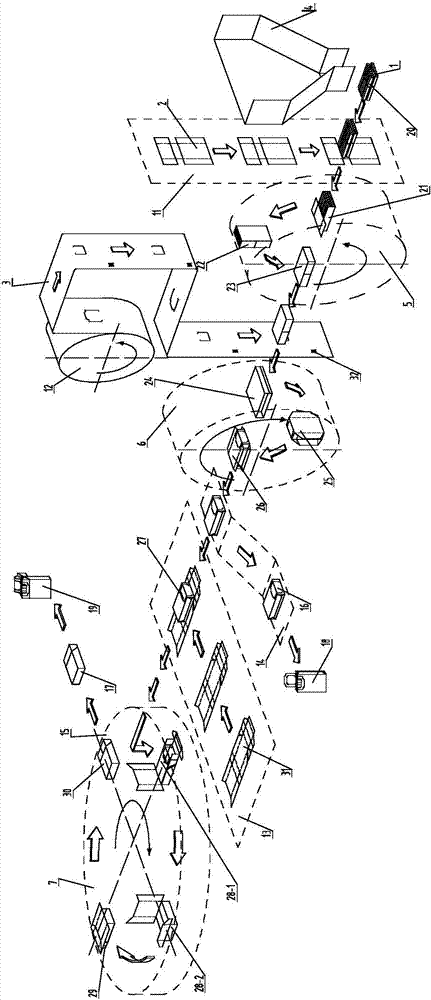

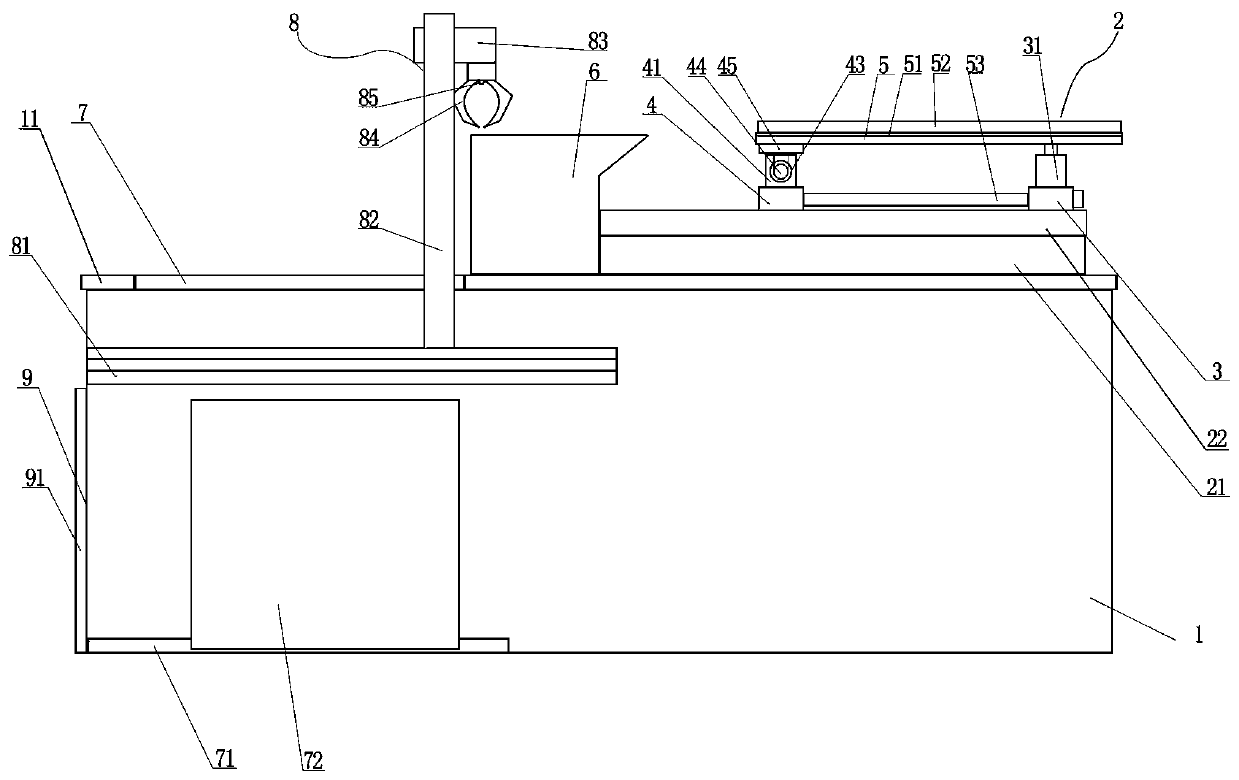

Full-automatic silk screen processing platform and silk screen technology thereof

ActiveCN105882121AReduce equipment manufacturing costsGuaranteed screen printing accuracyScreen printersTransfer mechanismEngineering

The invention discloses a full-automatic silk screen processing platform and a silk screen technology thereof. The full-automatic silk screen processing platform comprises a working platform, a turntable, an alignment platform, a material precise transfer mechanism, a material detection mechanism, a silk screen platform and a silk screen mechanism, wherein the turntable is rotatably arranged on the working platform; two or single or more than two silk screen processing production lines are arranged in the front and back of the turntable; each silk screen processing production line comprises a loading station, a silk screen station and an unloading station; the loading stations, the silk screen stations and the unloading stations of two silk screen processing production lines are gradually arranged; and the actions of material off-line precise positioning, material carrying, material position detection, station switch, silk screen, unloading and feedback are finished gradually. In the invention, by adopting the 6-station turntable structure design, integrating double silk screen processing lines and adopting the first-positioning and later-detection technology design, the steps of the silk screen technology are effectively simplified, and the silk screen efficiency and yield are increased; and by adopting the structural design of expandable material positioning and silk screen processing, the platform adaptability and universality are strong.

Owner:JIANGSU MEIJIA PACKAGE

Method, system and computer-readable code for testing of flash memory

InactiveUS7730368B2Reduce equipment manufacturing costsSemiconductor/solid-state device testing/measurementRead-only memoriesFlash memory controllerTest board

Owner:WODEN TECH INC

Semiconductor device and manufacturing the same

InactiveUS6847112B2Low costReduce material costsSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A semiconductor device is designed to resist warpage of a heat sink with an inexpensive construction. The device comprises a heat sink, a pair of screwing pieces having inner end portions connected to ends of the heat sink and outer end portions formed with through spaces for screwing, a semiconductor chip fixed to a main surface of the heat sink, a seal covering a back side of the heat sink and partially covering the paired screwing pieces, first and second leads having outer end portions projecting from the seal member and inner end portions within the seal member near respective side faces of the heat sink, and conductive wires electrically connecting the leads and predetermined electrodes of a semiconductor chip.

Owner:RENESAS ELECTRONICS CORP

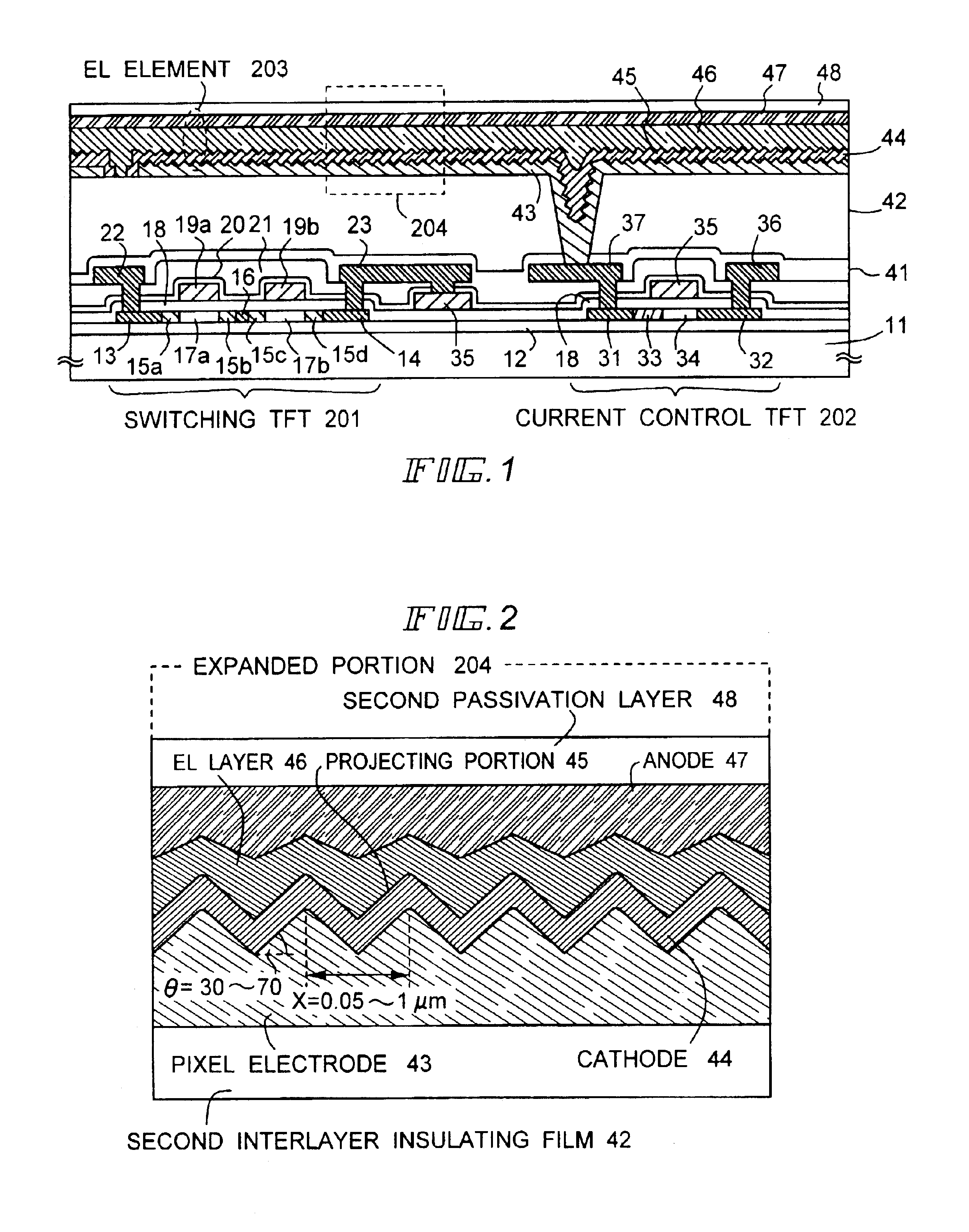

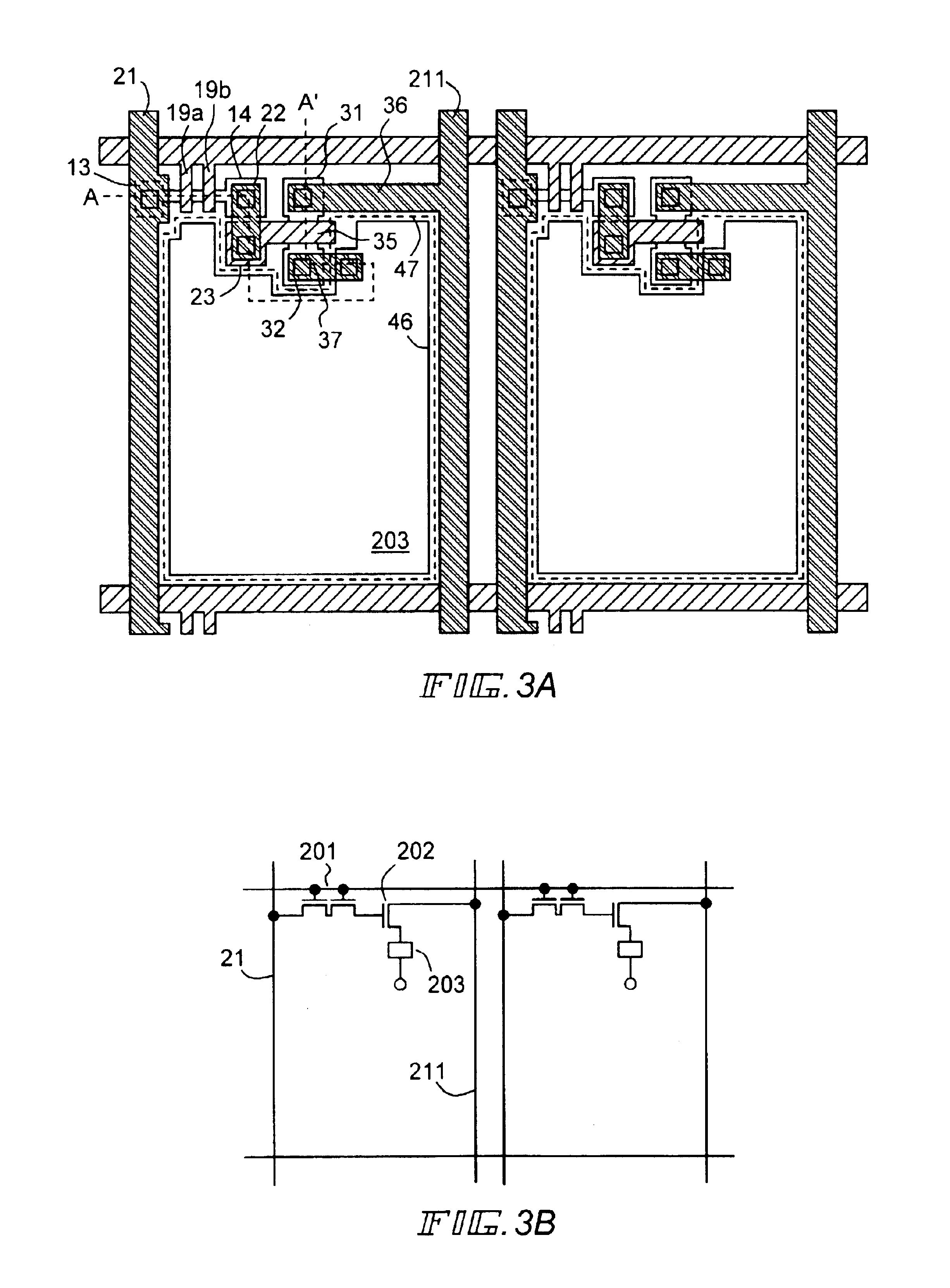

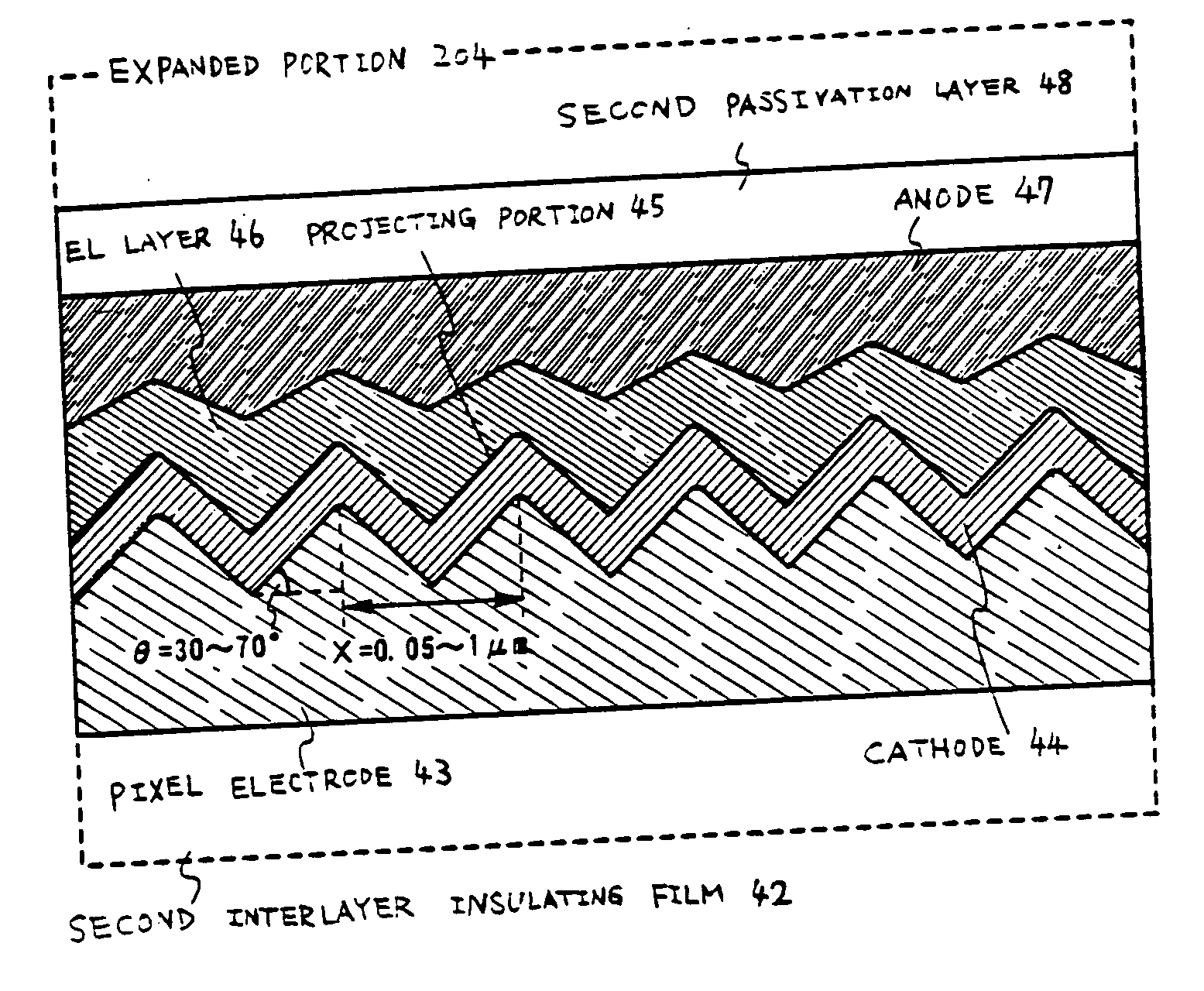

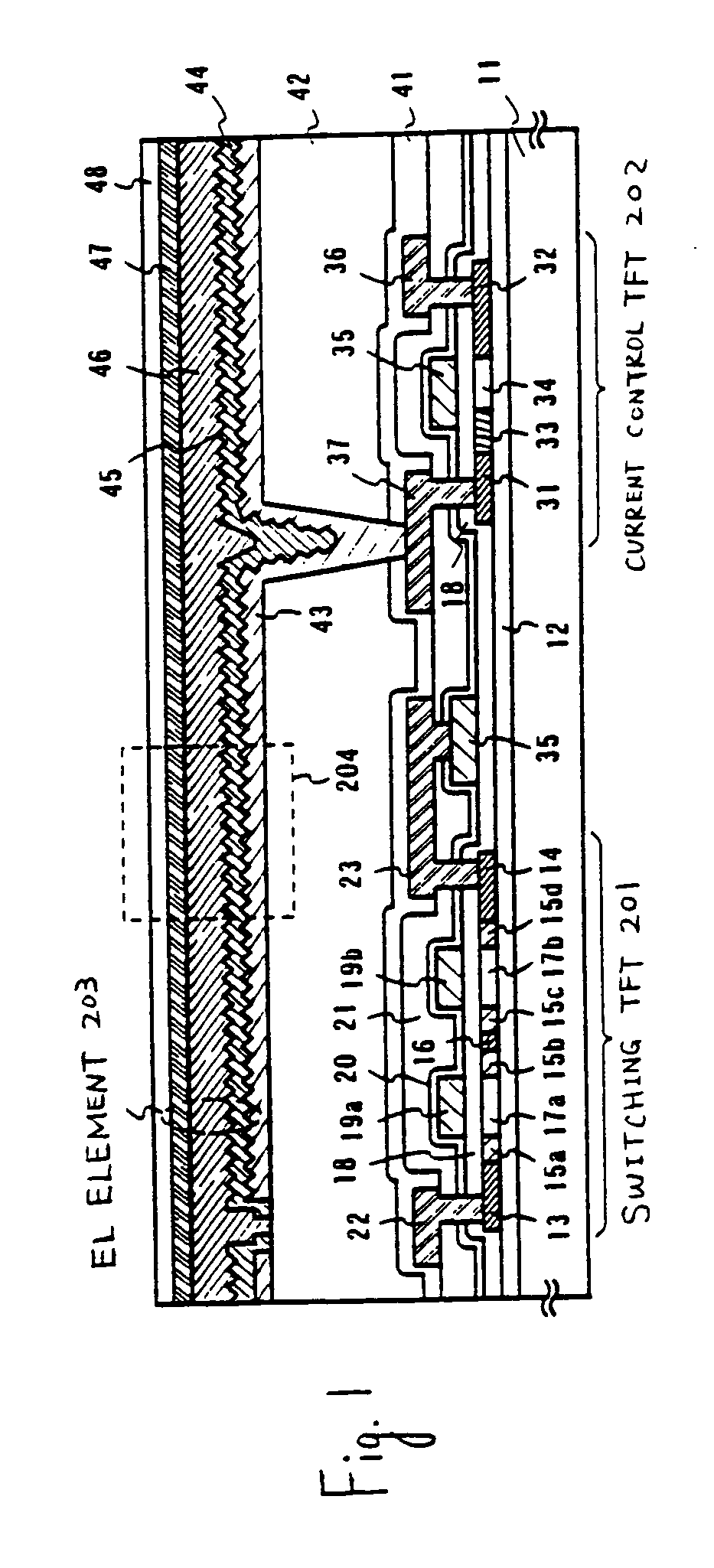

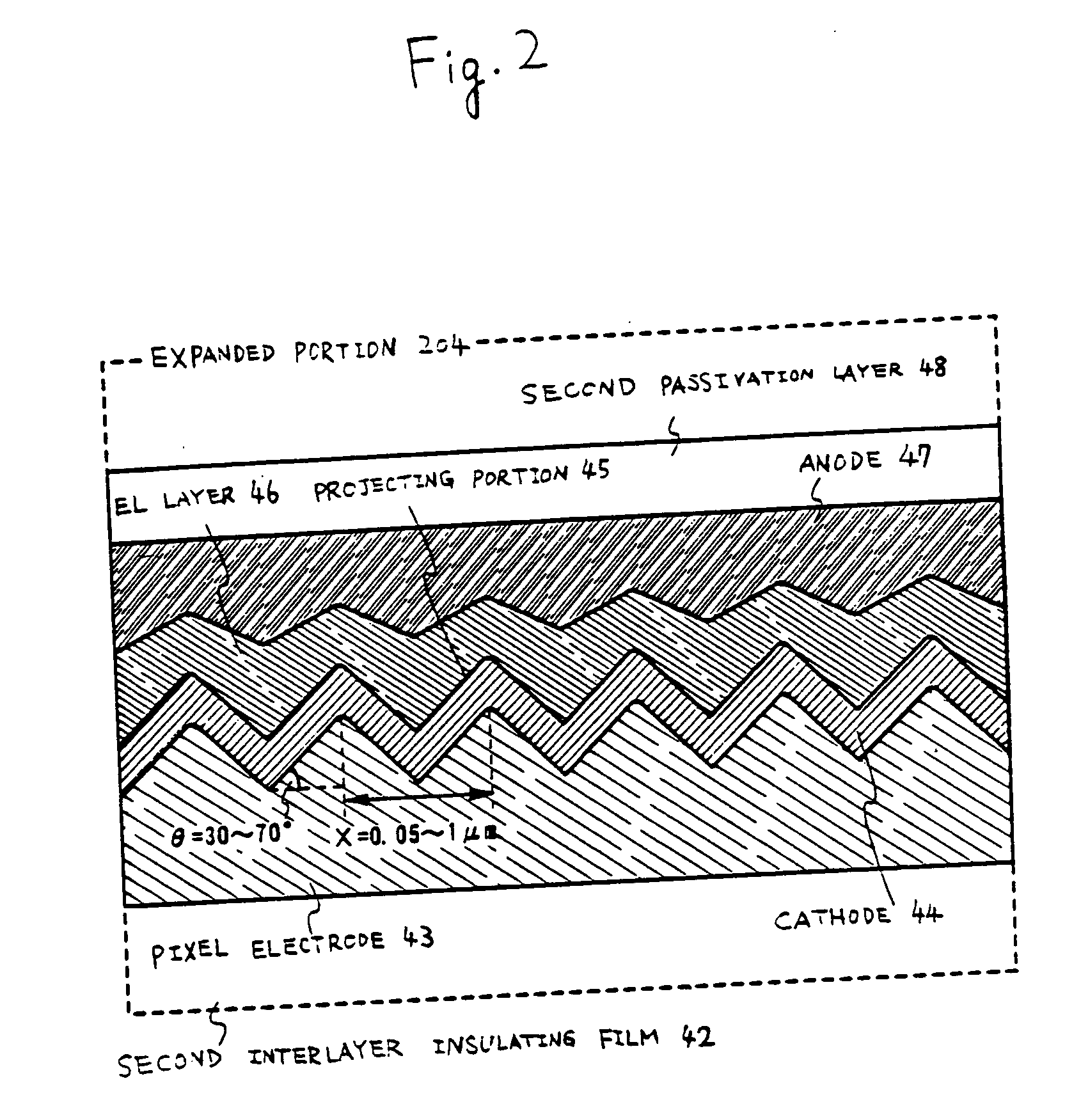

EL display device and manufacturing method thereof

InactiveUS7012300B2Low costReduce equipment manufacturing costsDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceEngineering

Owner:SEMICON ENERGY LAB CO LTD

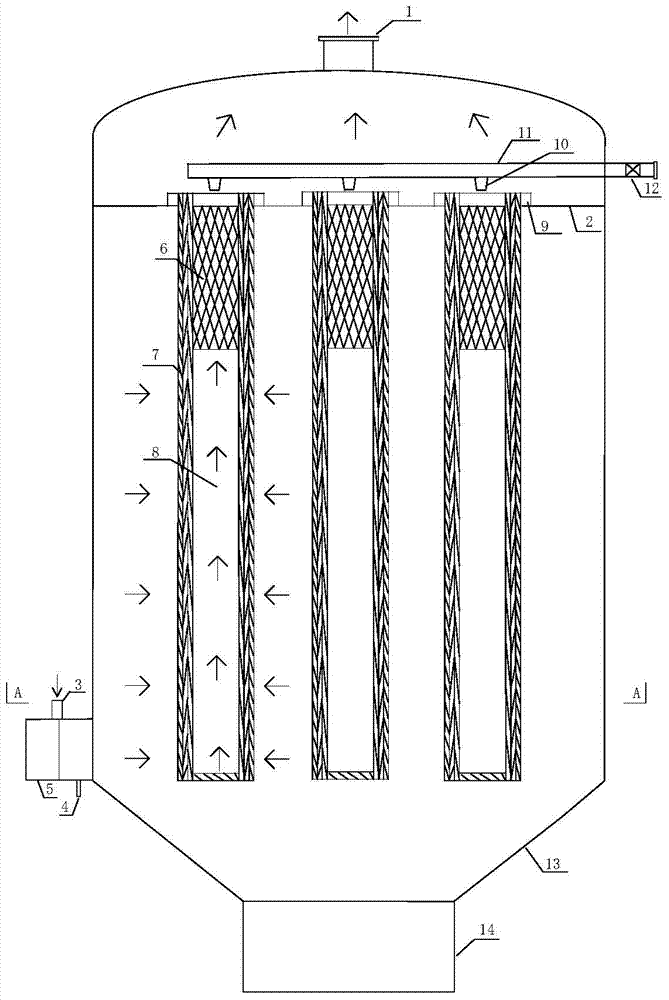

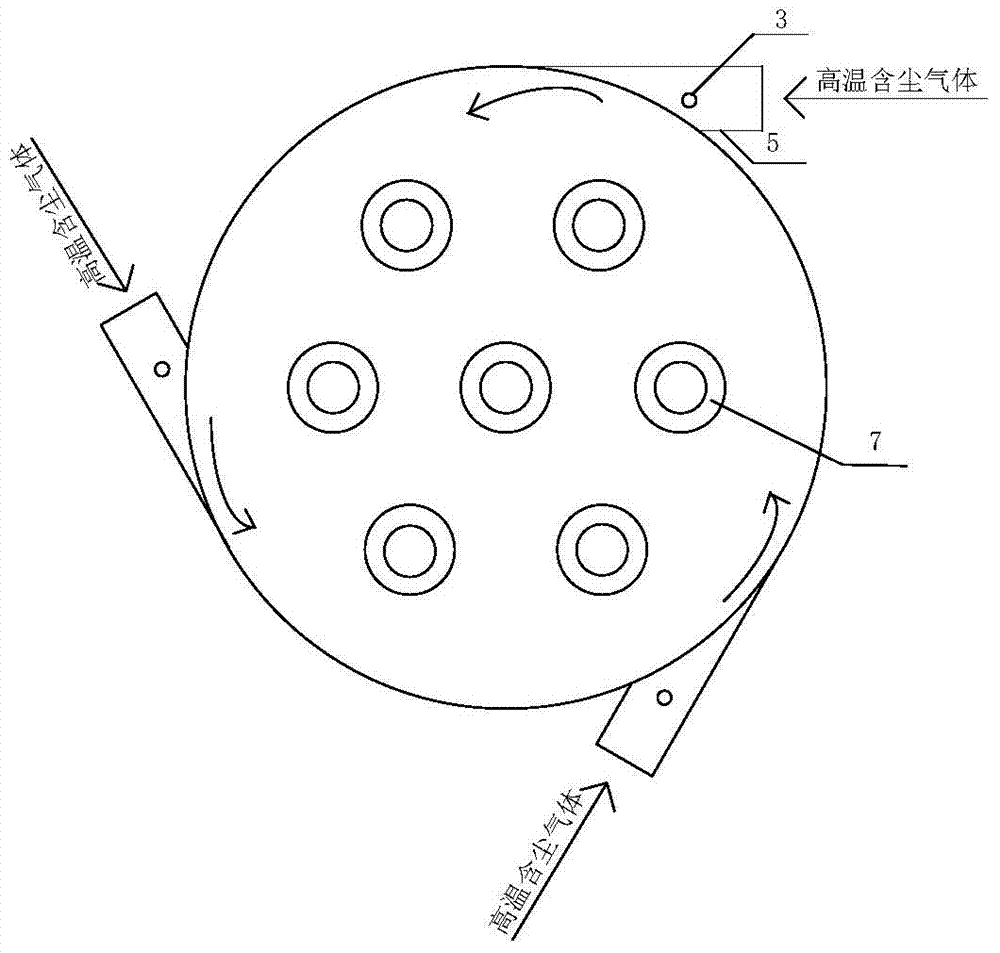

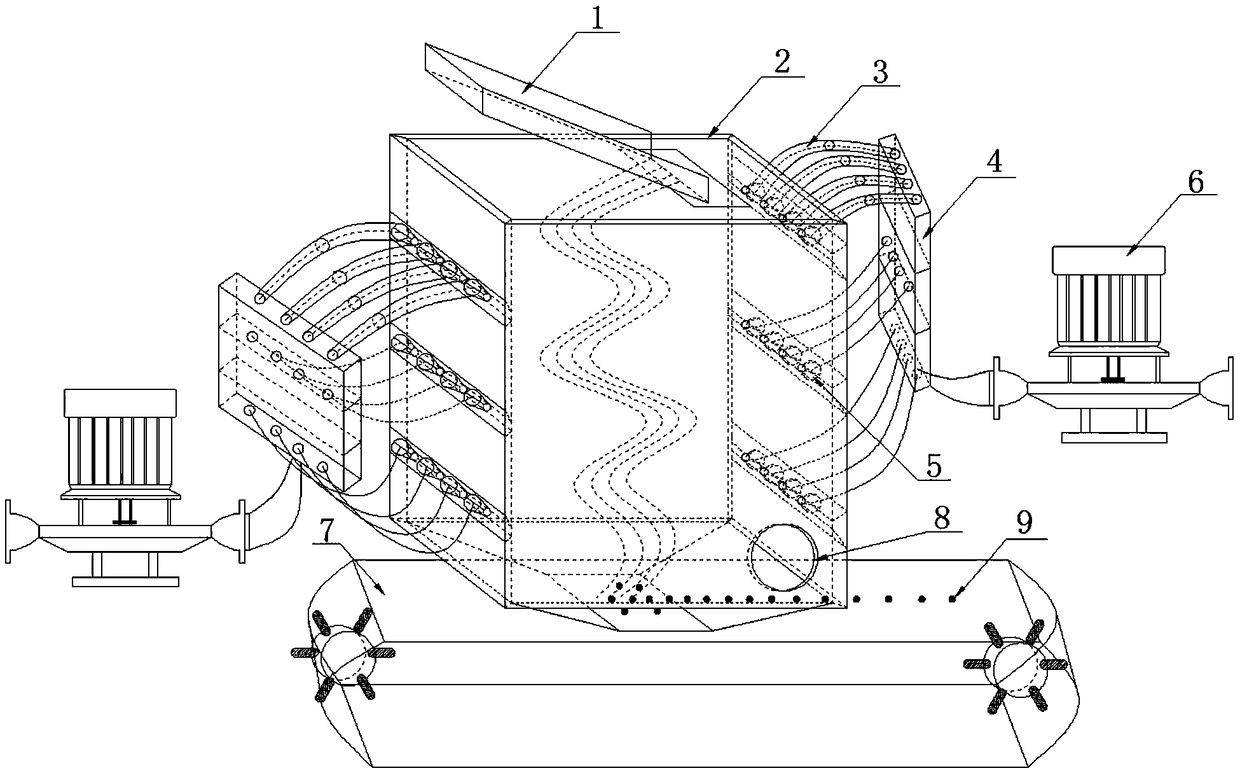

Dust removing and catalyzing integrated device

ActiveCN104275063AImprove gas handling capacityReduce equipment manufacturing costsCombination devicesProduct gasIntegrated devices

The invention discloses a dust removing and catalyzing integrated device. The device is mainly composed of a gas outlet, a ceramic membrane pipe pore plate, a gas supplying device, an ignition device, gas inlets, catalytic ceramic bodies, ceramic membrane pipes, ceramic membrane pipe cavities, back-blowing gas nozzles, a back-blowing gas air distribution pipe, a back-blowing gas control valve, an ash bucket, an ash discarding valve and a ceramic membrane pipe fixing plate. High-temperature dust-containing gas enters the system in a rotational flow manner and is mixed with oxygen, air and water vapor provided by the gas supplying device or a mixture of the gas; and then the mixed gas is reacted by the ignition device. The reacted gas passes through the ceramic membrane pipe to enter the ceramic membrane pipe cavities and is subjected to a catalytic reaction with a catalyst when passing through the catalytic ceramic bodies; and finally, the gas is collected and discharged by the gas outlet. The honeycomb ceramic or foam ceramic bodies loaded with the catalyst are located at the upper parts of the ceramic membrane pipe cavities. The device integrates dust removal and catalysis so that the high-temperature dust-containing gas can be effectively treated and the environment-friendly and economical effects are realized.

Owner:DALIAN UNIV OF TECH

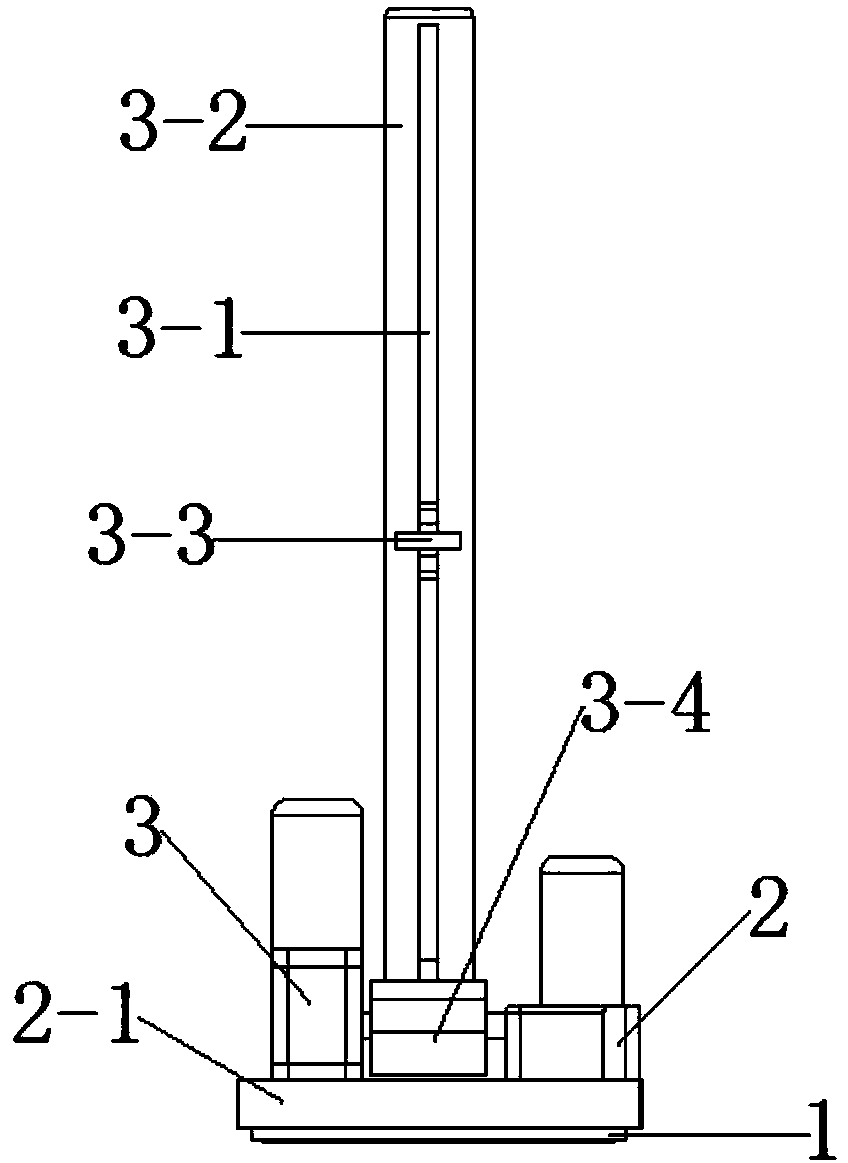

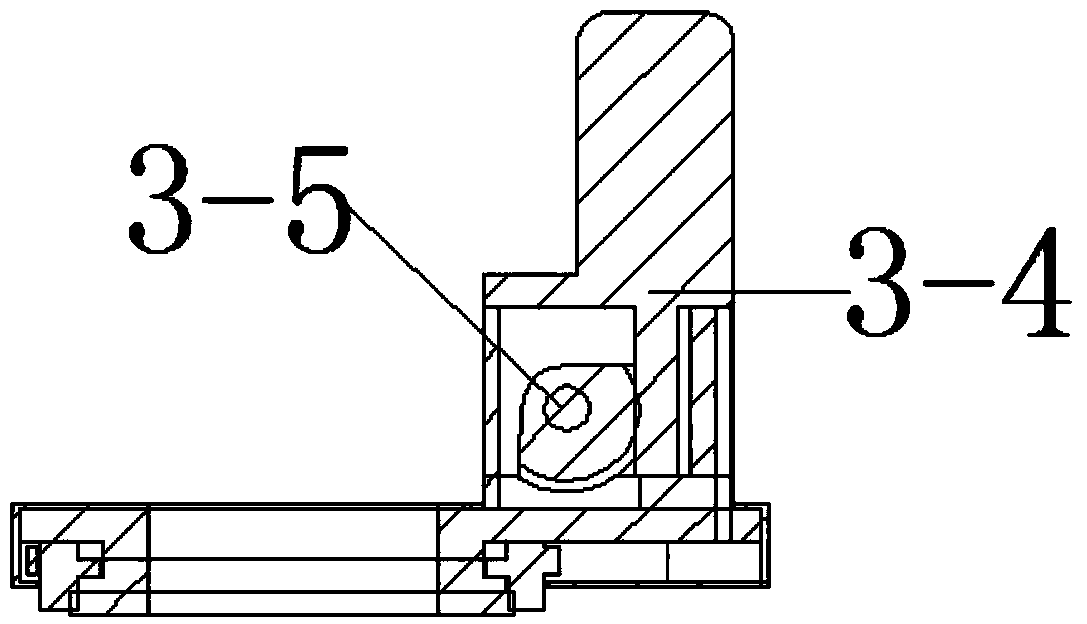

Portable mechanical endoscope fixture

ActiveCN104188613AProtection against sudden fall hazardsAvoid changing the position of the speculumSuture equipmentsInternal osteosythesisThree degrees of freedomEndoscope

The invention provides a portable mechanical endoscope fixture comprising a base, a horizontal rotating mechanism and a lifting pitching mechanism. Through adjustment of three degrees of freedom, an endoscope being fixed can be horizontally rotated, lifted up and down and pitched. The portable mechanical endoscope fixture has the advantages that manual fixing of the endoscope is completely replaced; the lifting pitching mechanism and a vertical lifting mechanism are arranged at the edge of the horizontal rotating mechanism, more operating space is saved, and more medical instruments can be used in surgery; in addition, a sound-operated or foot-operated control device can be added to the portable mechanical endoscope fixture, and medical labor cost is saved.

Owner:TIANJIN BOLANG SCI TECH DEV

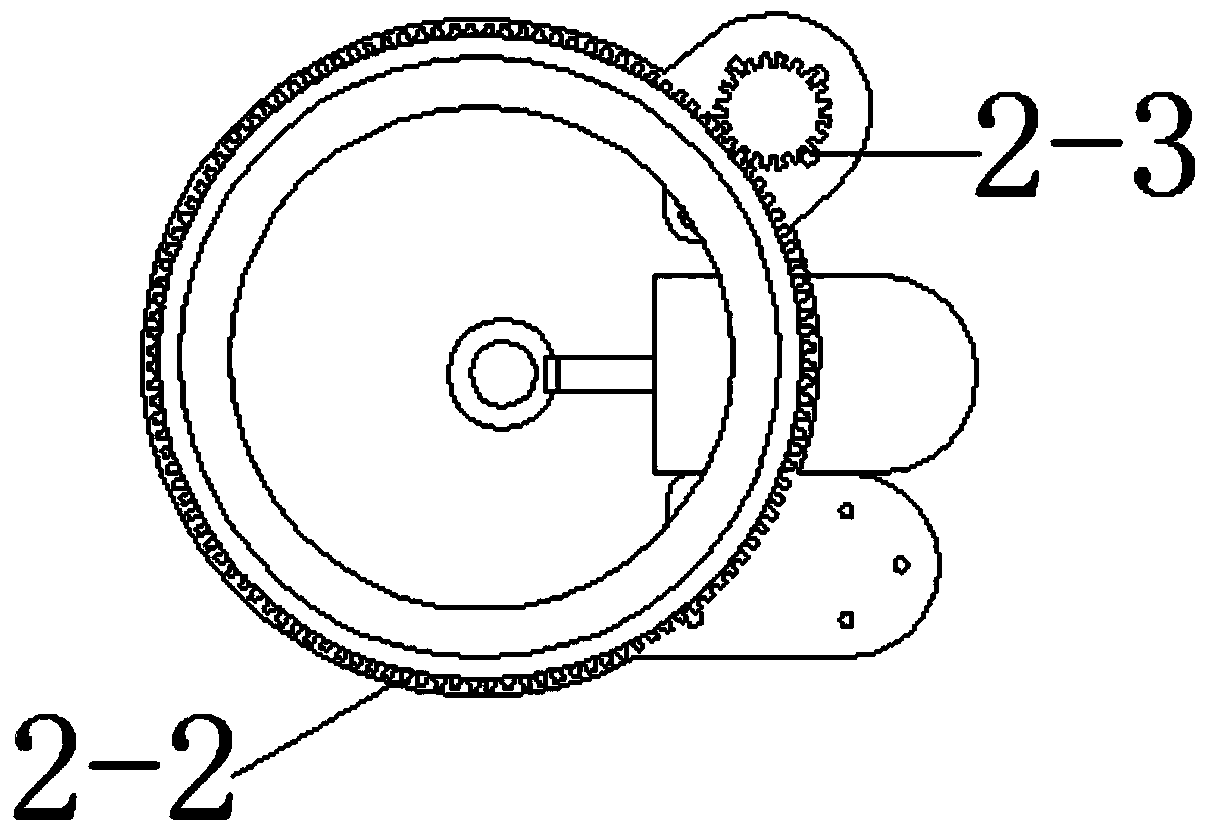

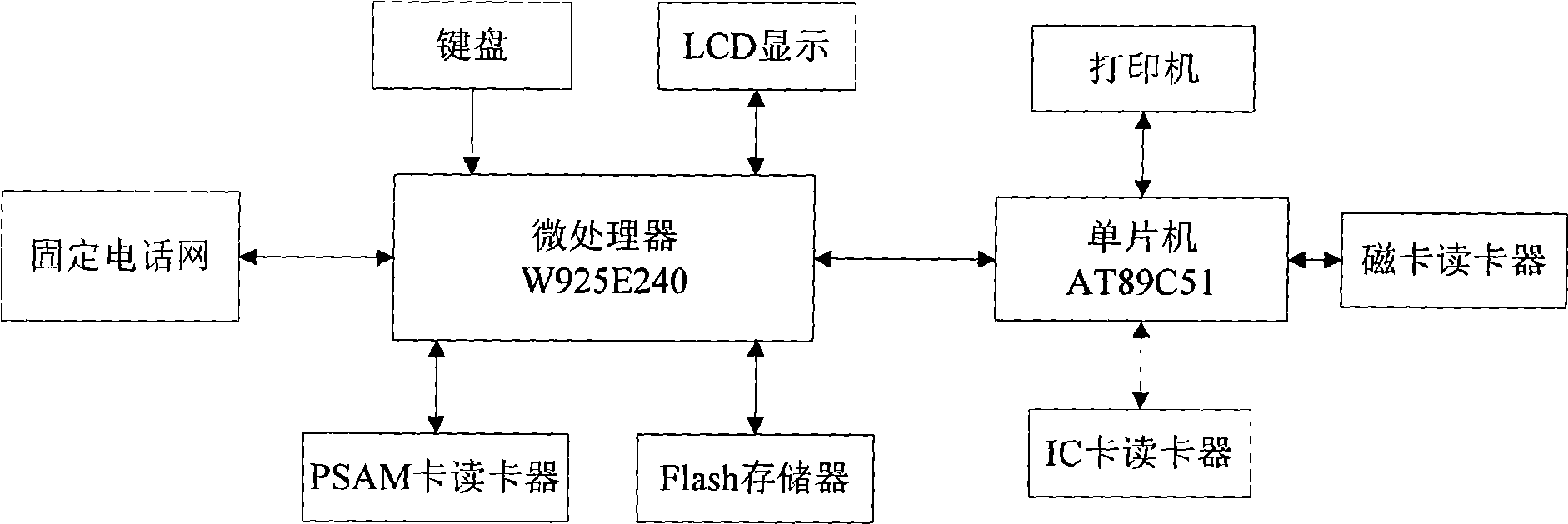

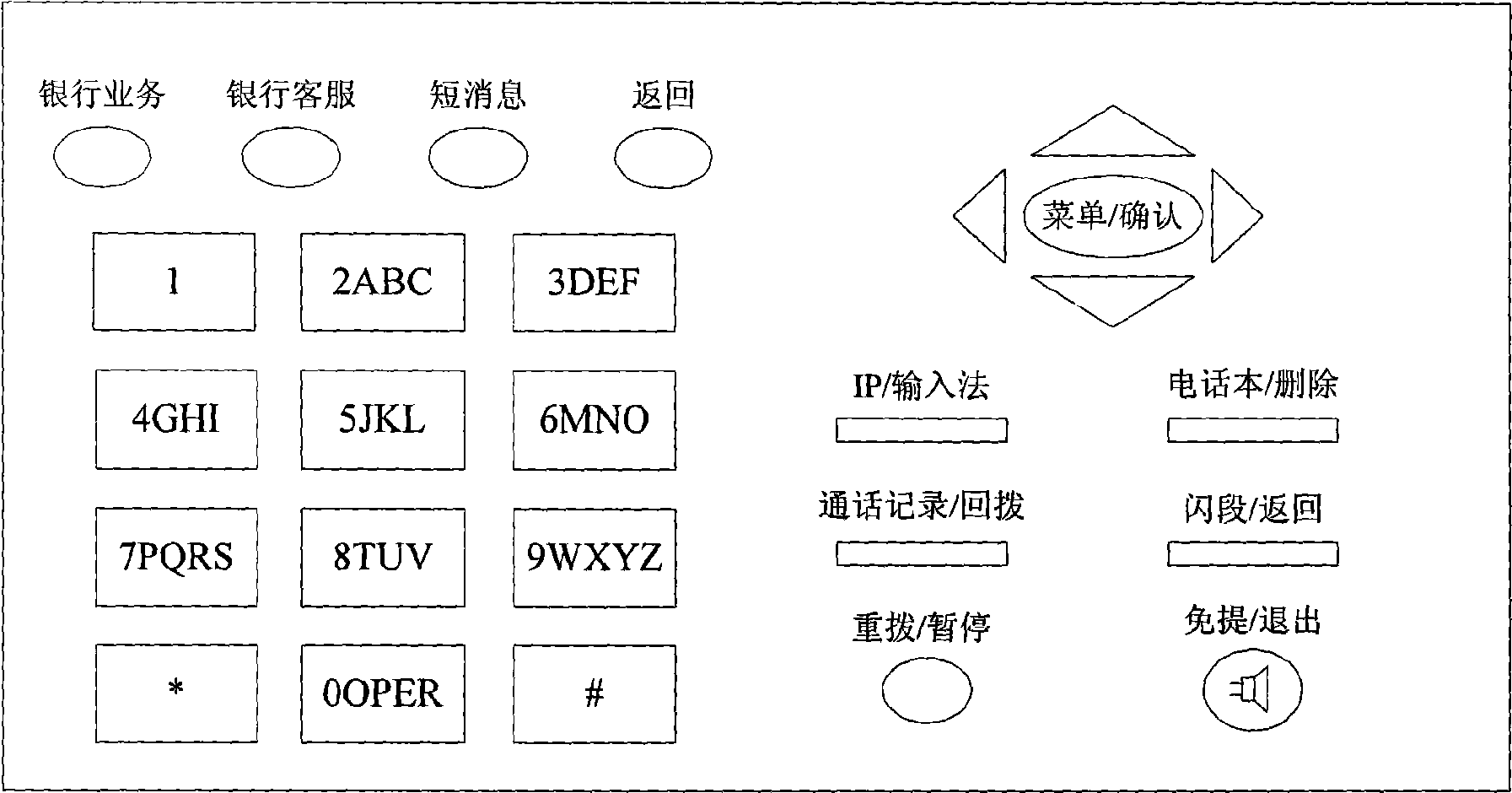

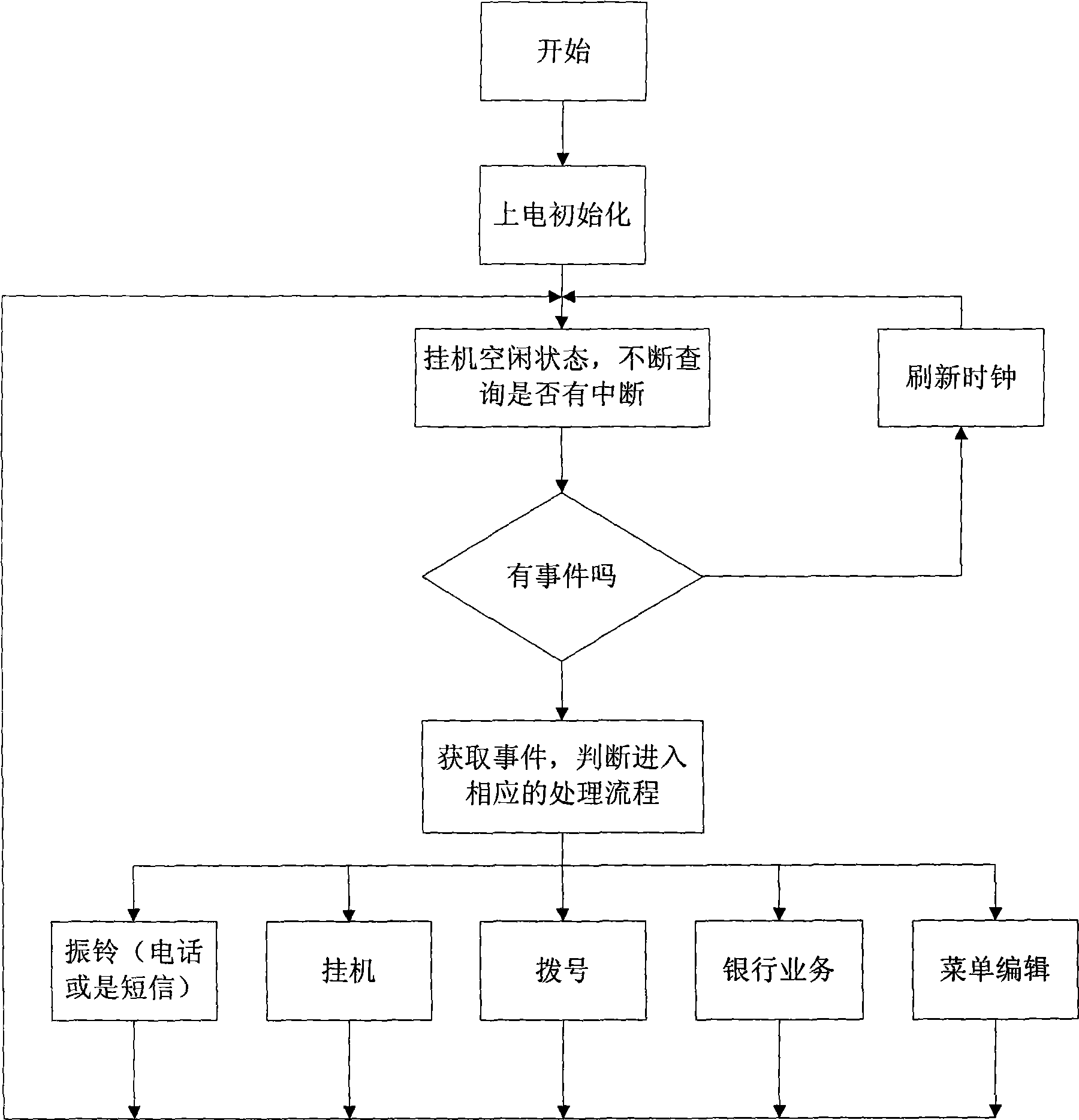

Fixed network payment terminal and operation method thereof

InactiveCN101520928AReduce equipment manufacturing costsCost-effectiveTelephonic communicationCash registersPayment terminalElectricity

The invention discloses a fixed network payment terminal and an operation method thereof. The fixed network payment terminal consists of a microprocessor, a singlechip, a keyboard, an LCD display screen, a Flash memory, a printer, an IC card reader, a magnetic card reader and a PSAM card reader, wherein the singlechip, the keyboard, the LCD display screen and the Flash memory are connected with the microprocessor and used for dialing a telephone, editing short messages, inputting bank services and editing menus; and the printer, the IC card reader, the magnetic card reader and the PSAM card reader are connected with the singlechip. The operation method thereof comprises that: after a system is powered and initialized, the system enters an idle state, and a main function of the system is continually searched whether to be interrupted; and when the interruption happens, the type of the event is judged by interrupting a vector table, and a corresponding event processing function is entered. A fixed line terminal and a POS terminal are integrally inosculated, so the fixed network payment terminal and the operation method thereof save the manufacturing cost of equipment, have high cost performance, and have the functions of receiving and transmitting short messages and reading bank IC cards.

Owner:SHANDONG UNIV

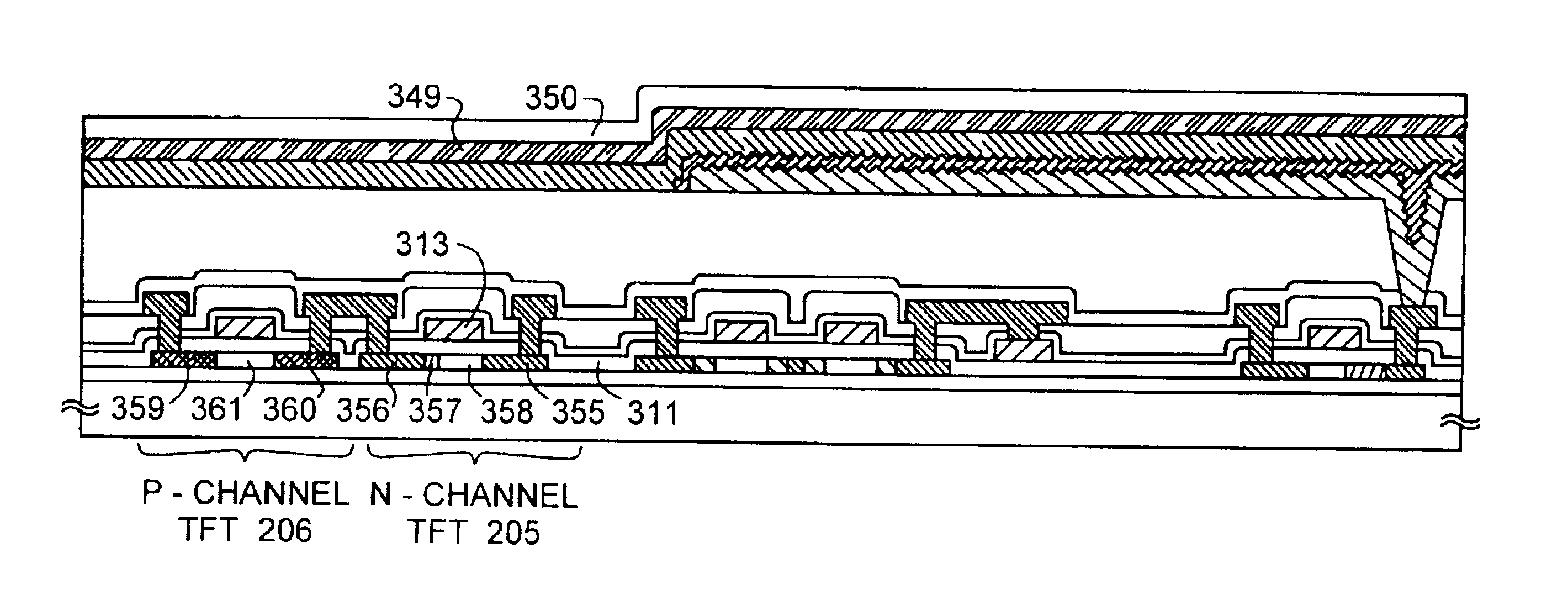

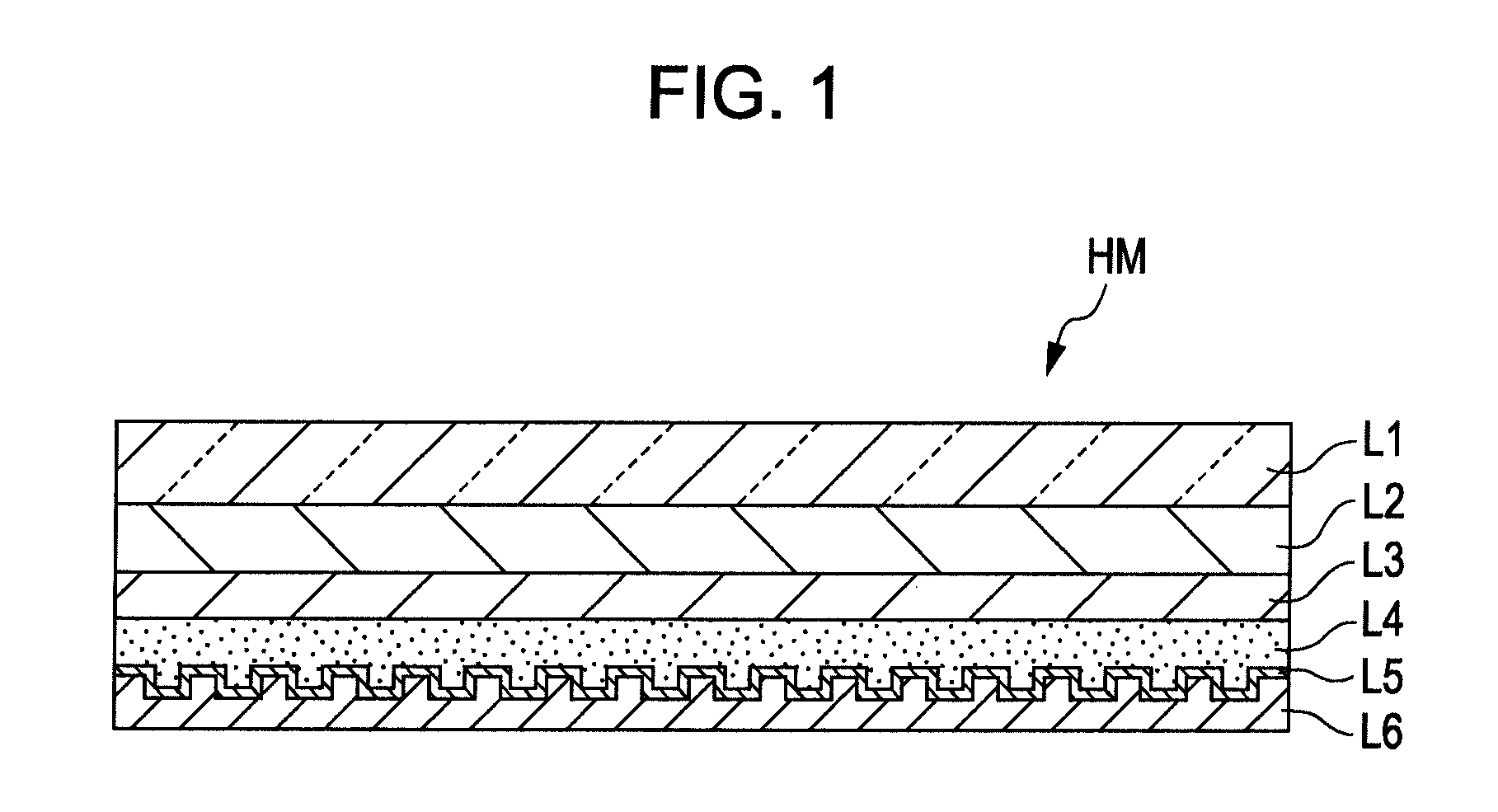

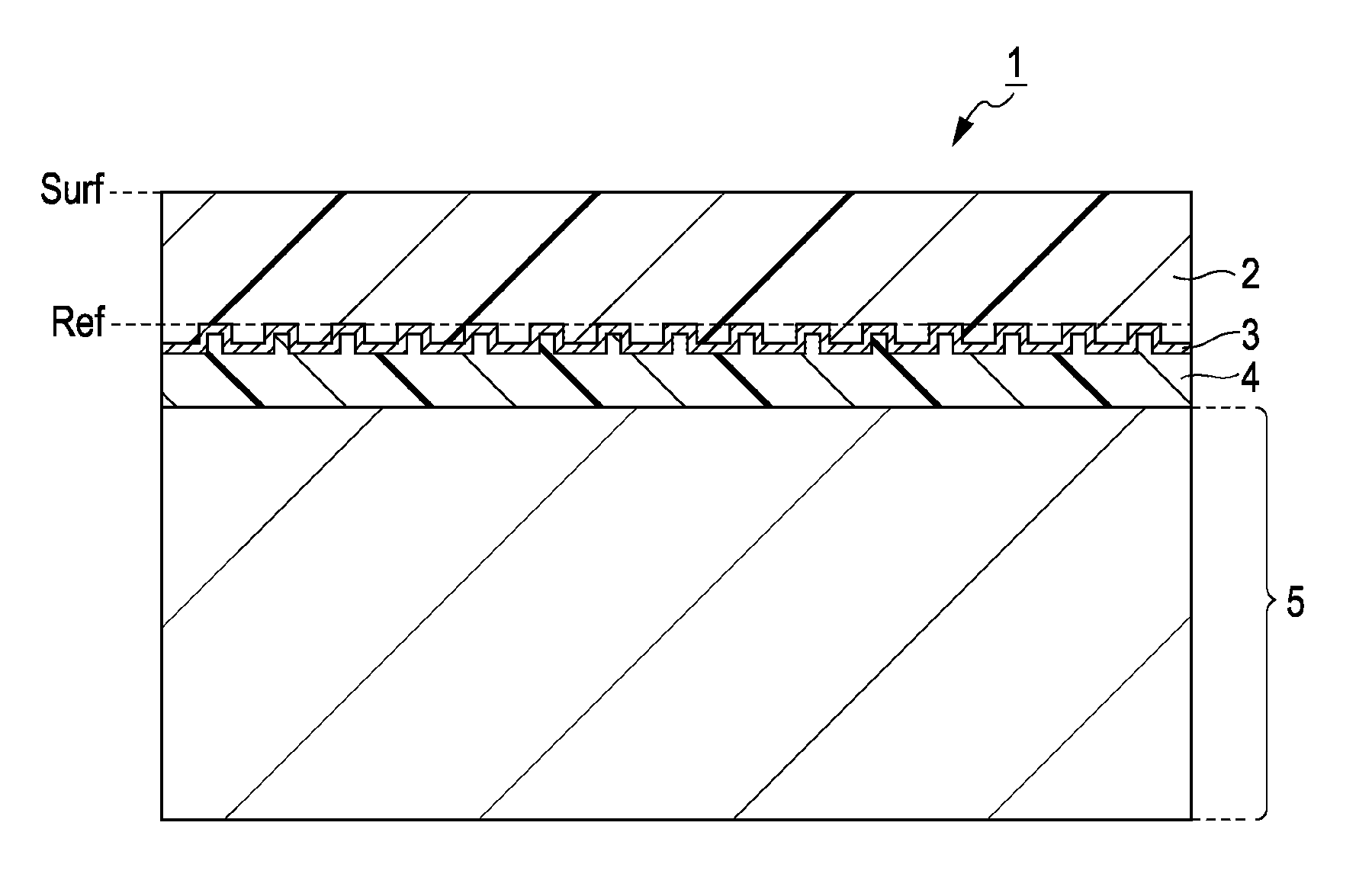

EL display device and manufacturing method thereof

InactiveUS20050029930A1Low costReduce equipment manufacturing costsVacuum tubesDischarge tube luminescnet screensDisplay deviceEngineering

Reducing the manufacturing cost of an EL display device and an electronic device furnished with the EL display device is taken as an objective. A textured structure in which projecting portions are formed on the surface of a cathode is used. External stray light is diffusely (irregularly) reflected by the action of the projecting portions when reflected by the surface of the cathode, and therefore a defect in which the face of an observer or the surrounding scenery is reflected in the surface of the cathode can be prevented. This can be completed without using a conventionally necessary high price circular polarizing film, and therefore it is possible to reduce the cost of manufacturing the EL display device.

Owner:SEMICON ENERGY LAB CO LTD

Thermal stretch processing method of ultra-high molecular weight polyethylene diaphragm

The invention discloses a thermal stretch processing method of an ultra-high molecular weight polyethylene diaphragm, comprising the following steps of: (1) taking raw materials of ultra-high molecular weight polyethylene resin, polyethlene wax, a plasticizer and an antioxidant for backup according to the following proportion by weight; (2) after mixing the mixture, putting the mixture into a single screw extruder to extrude a tube; (3) arranging a cutting tool on the lower part of an outlet of a tube mould of the single screw extruder to longitudinally cut the tube; (4) putting the cut tube into a wedge mould, spreading the tube into a plate material; (5) rolling the plate material into a diaphragm blank; (6) stretching the diaphragm blank when passing through a first heating channel; (7) guiding the rolled and stretched diaphragm blank into a second heating channel to heat; (8) guiding the heated diaphragm blank into a fourth calendar to roll and stretch the diaphragm blank rolled by the fourth calendar into a diaphragm product; and (9) forming the diaphragm product by a forming machine, and winding the diaphragm product. The finished product processed by the thermal stretch processing method has low cost and high efficiency, the tensile strength of the finished product can reach above 300MPa, the elasticity modulus can reach above 100g / d, and the like.

Owner:SHANDONG DIHAO WEAR RESISTING PIPE

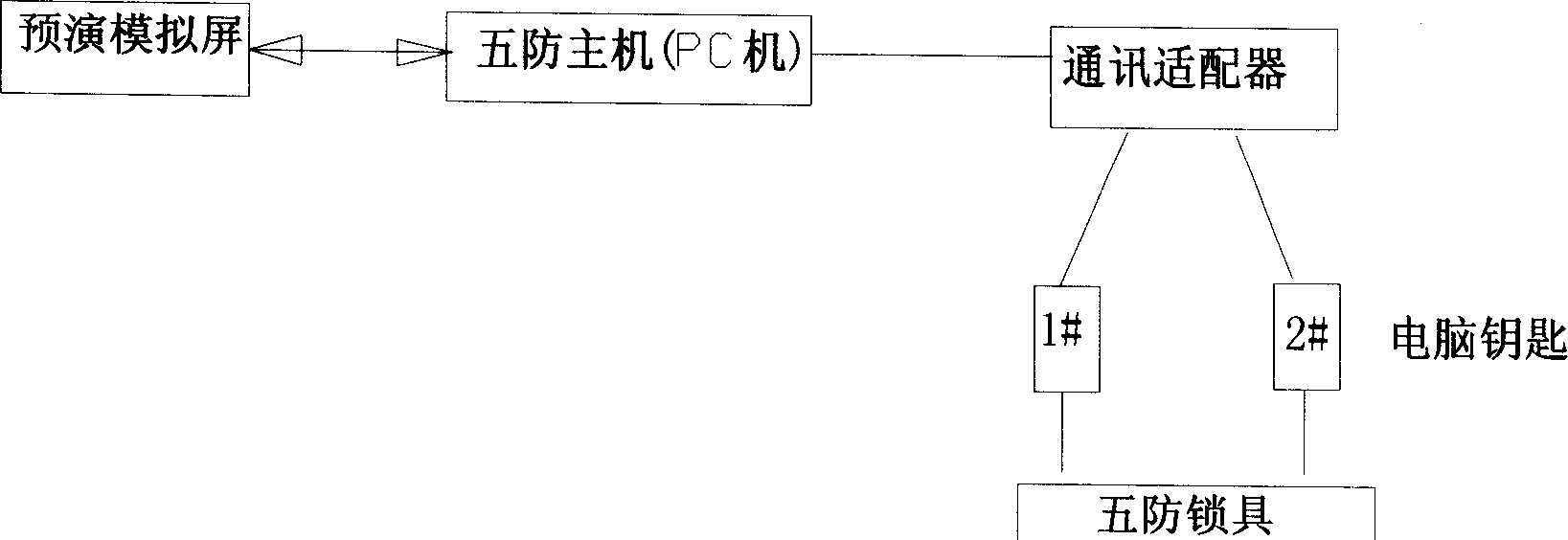

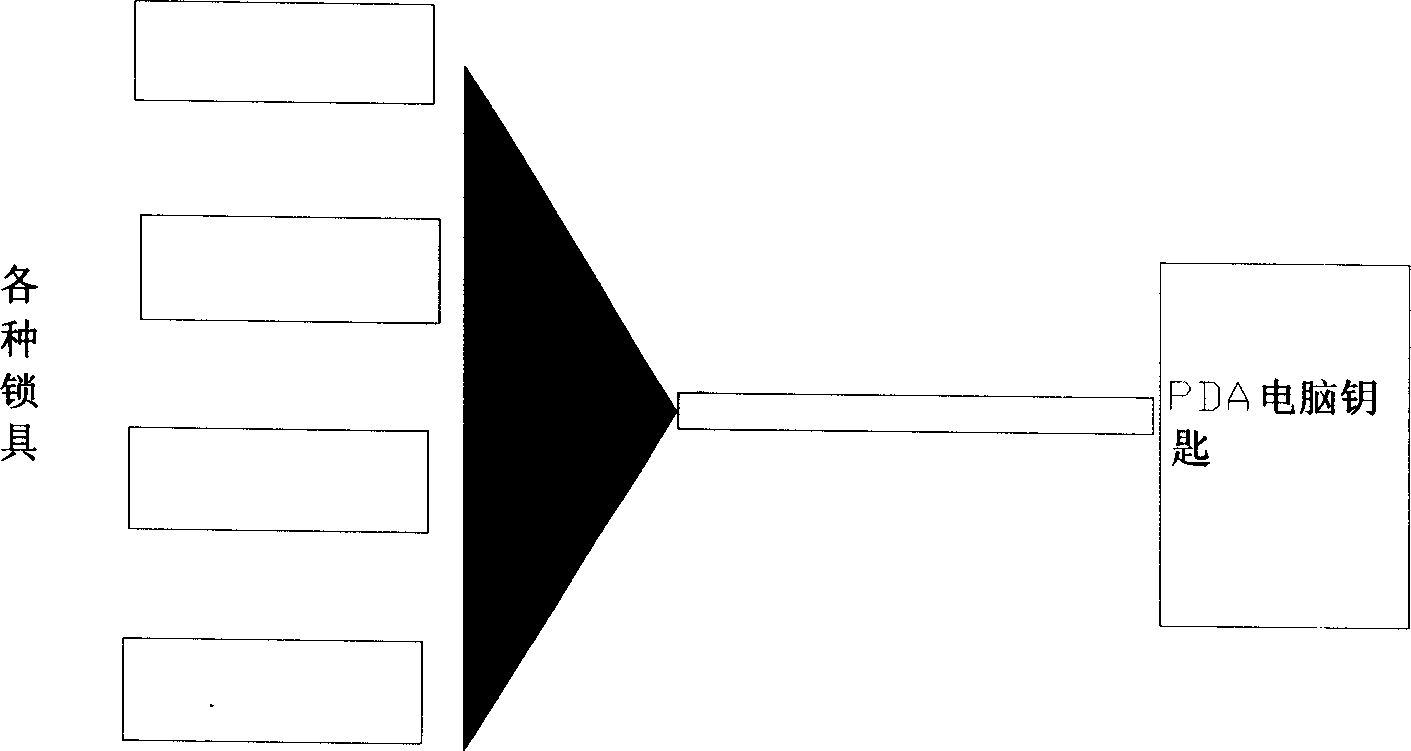

Error proof locking system of palm microcomputer

InactiveCN1835145ASimple system configurationReduce equipment manufacturing costsInput/output for user-computer interactionData processing applicationsTransformerGraphics

The invention is related to the blocking device for guiding against error operation applicable to preventing error operation to plant and station for power distribution and delivery. A block system for guiding against error operation of palmtop microcomputer includes a piece of computer key, software of graphics operation system (GOS), operation and display device. Characters are that the palmtop microcomputer also includes a PDA module of containing platform of bit processor, and operation system (OS) embedded to the said platform. Running on the OS, the software of GOS generates plate of paradigm, and preview plate for simulating equipment based on wiring diagram of primary system in transformer station compiled in advance, and operating rules of all facilities. Using PDA technique combined with computer key, the invention substitutes host for guiding against five operations and simulation screen.

Owner:CYG CONTRON

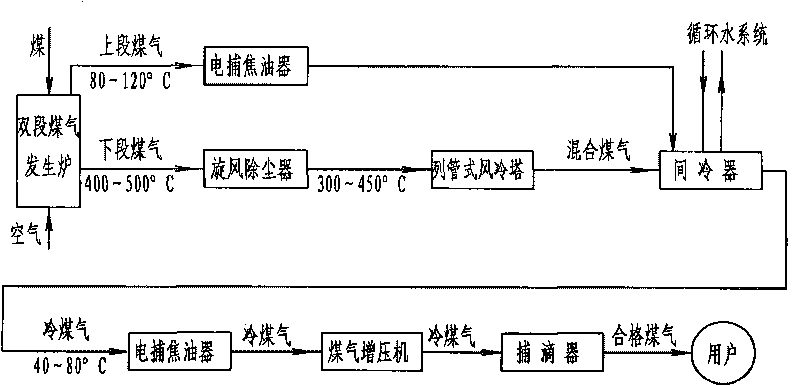

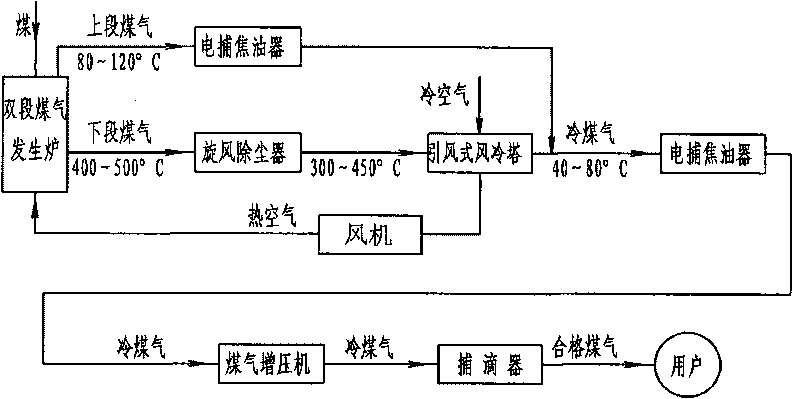

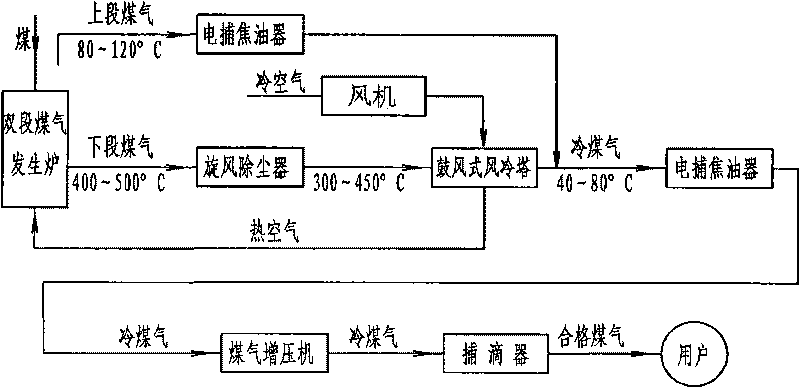

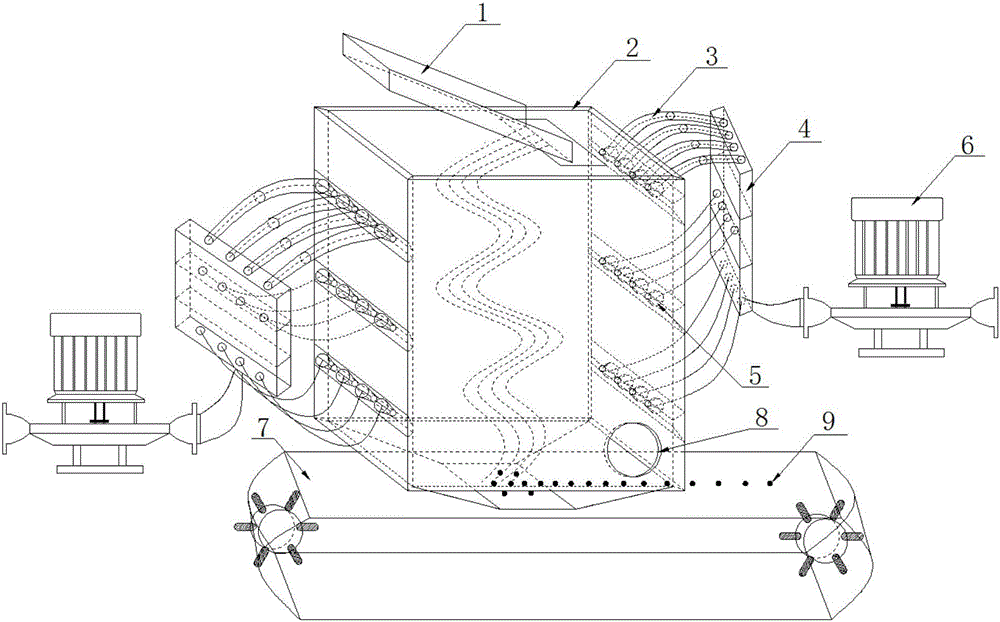

Gas purifying and cooling process and equipment of two-section furnace

InactiveCN101696362AIncrease productionEnhanced gasification processEnergy inputCombustible gas productionProcess systemsCooling tower

The invention relates to gas purifying and cooling process and equipment, in particular to gas purifying and cooling process and equipment of a two-section furnace. The gas is cooled by an induced air or blast type air cooling tower instead of a tube air cooling tower and an intercooler in the traditional gas cooling and purifying process, and the preheated air enters a gas furnace. Because the intercooler and a softened water supplying, returning and cooling system thereof are eliminated, the equipment manufacture cost and the maintenance cost of the whole process system are greatly reduced; the preheated air enters the gas furnace, thereby strengthening the gasification process of coal, improving the output of the coal and reducing energy loss; the induced air or blast type air cooling tower has a large heat transfer coefficient, reinforced convection heat transfer and good cooling effect; meanwhile, the volume and the weight of the induced air or blast type air cooling tower are reduced, and the equipment investment is lowered.

Owner:祁举 +1

Blast furnace molten slag dry method treatment device based on high-temperature slag waste heat recovery

ActiveCN106435068ASimple structureReduce consumptionRecycling and recovery technologiesProcess efficiency improvementSpray nozzleMolten slag

The invention discloses a blast furnace molten slag dry method treatment device based on high-temperature slag waste heat recovery. The blast furnace molten slag dry method treatment device comprises a furnace slag treatment box and a cooling unit, wherein blast furnace slag falls from the top of the furnace slag treatment box; and the cooling unit comprises a mechanism used for forming water columns in the furnace slag treatment box to impact and cool the fallen blast furnace slag. The cooling unit comprises spray nozzles. The spray nozzles comprise a plurality of layers of water column spray nozzle bodies used for spraying out the water columns. The multiple layers of water column spray nozzle bodies are arranged on the two opposite side faces of the inside of the furnace slag treatment box up and down in a staggered mode, so that the blast furnace slag falling in the corresponding positions can fall in a Z-shaped path. The blast furnace molten slag dry method treatment device based on high-temperature slag waste heat recovery is relatively simplified, water consumption is reduced, and particularly, solid-state furnace slag particles maintained in a high-temperature state can be provided; and the temperature of the furnace slag particles are controllable, so that a high-quality heat source is provided for waste heat recovery.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

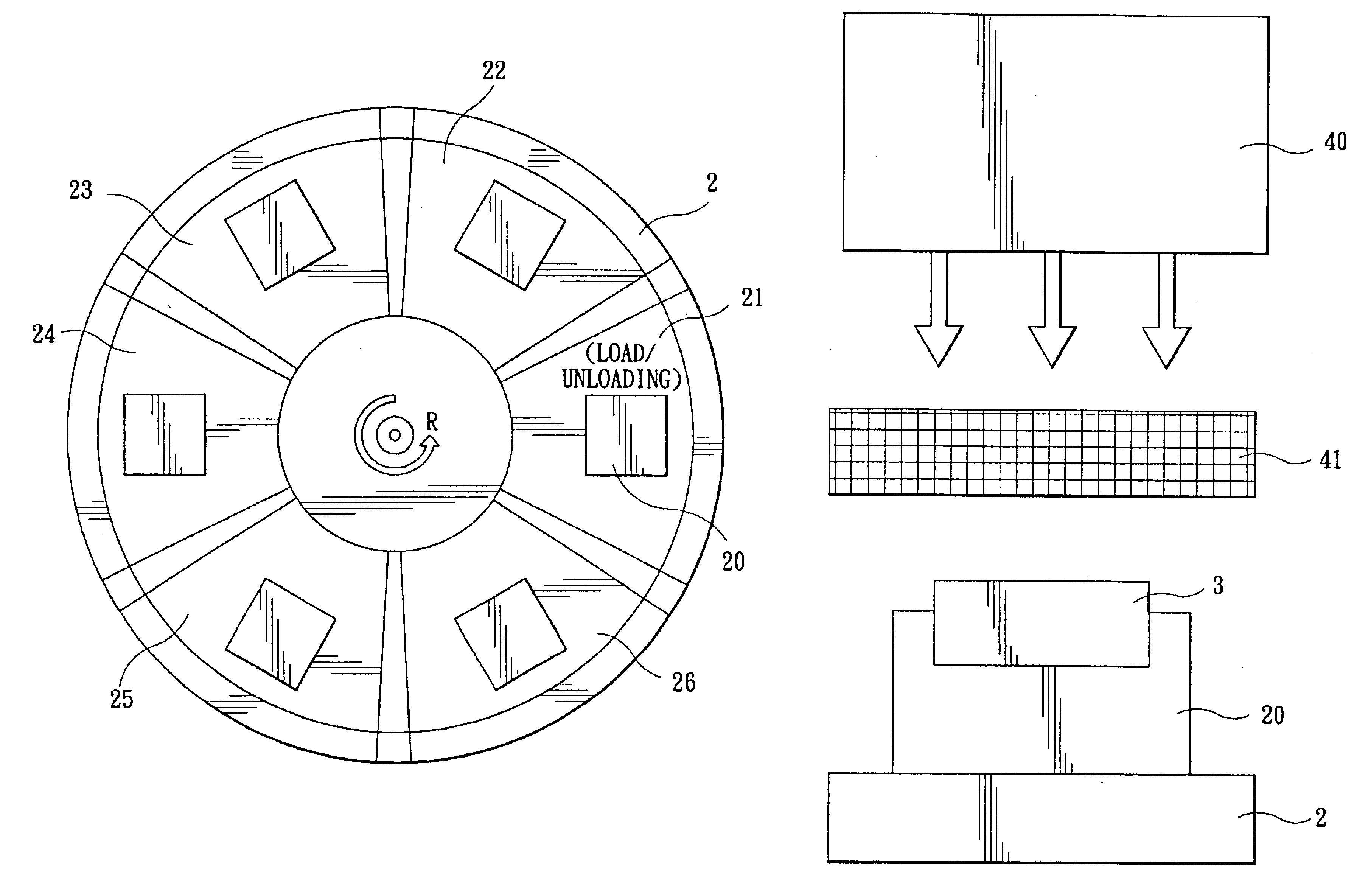

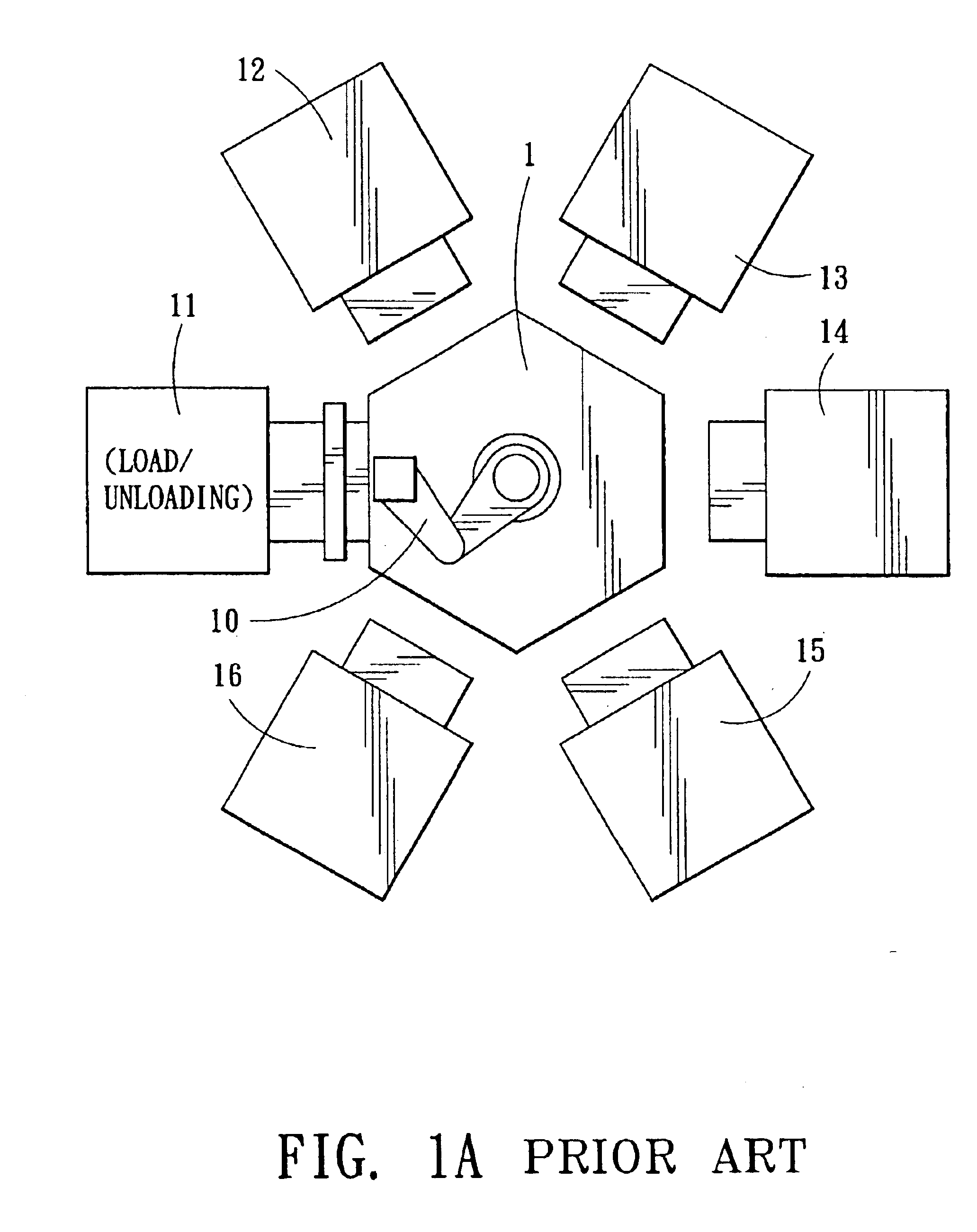

Deposition apparatus for organic light-emitting devices

InactiveUS6884299B2Reduce transfer timeReduce time lossCellsVacuum evaporation coatingOrganic light emitting deviceEngineering

A deposition apparatus for organic light emitting devices. The deposition apparatus includes a substrate conveying system and at least a chamber. In this case, the substrate conveying system is a circular turntable shape. The chambers are provided around the substrate conveying system in a specific order. While the substrate conveying system rotates in a circular direction, at least a substrate is transferred into the chambers for deposition. The substrate carrier, a shadow mask and a shadow mask alignment system, are positioned on the substrate carrier. After the deposition, at least a layer is deposited on each of the substrates, so as to manufacture at least an organic light-emitting device.

Owner:RITDISPLAY

Liquid light hydrocarbon bump formatting carburettor

InactiveCN101363632ASimple structureReduce equipment manufacturing costsLiquid fuel feeder/distributionMixed fuelVapor phase

A liquid light hydrocarbon bubble vaporizer comprises a horizontal tank body. Two baffle plates are fixedly arranged in the horizontal tank body to separate the inside of the horizontal tank body into three cavities which are respectively a raw material cavity, a vaporizing cavity and a residual liquid cavity, wherein, the raw material cavity is fixedly provided with a vapor phase tube, an oil inlet tube and an oil outlet tube; the vaporizing chamber is fixedly provided with an air tube, an oil supply tube and a temperature measuring connection tube, the lower part of the vaporizing cavity is fixedly provided with a laminated air disk distributed with a plurality of through holes, the end tube mouth of the air tube is arranged under the air disk; the residual liquid cavity is fixedly provided with an oil pumping tube and an overflow tube, the vaporizing cavity is communicated with the upper part of the residual liquid cavity, and the vaporizing cavity or the residual liquid cavity is fixedly provided with a fuel gas outlet tube. The bubble vaporizer is one of the main devices in a light hydrocarbon mixed fuel gas supply system which takes liquid light hydrocarbon as a raw material to produce the light hydrocarbon mixed fuel gas.

Owner:张路

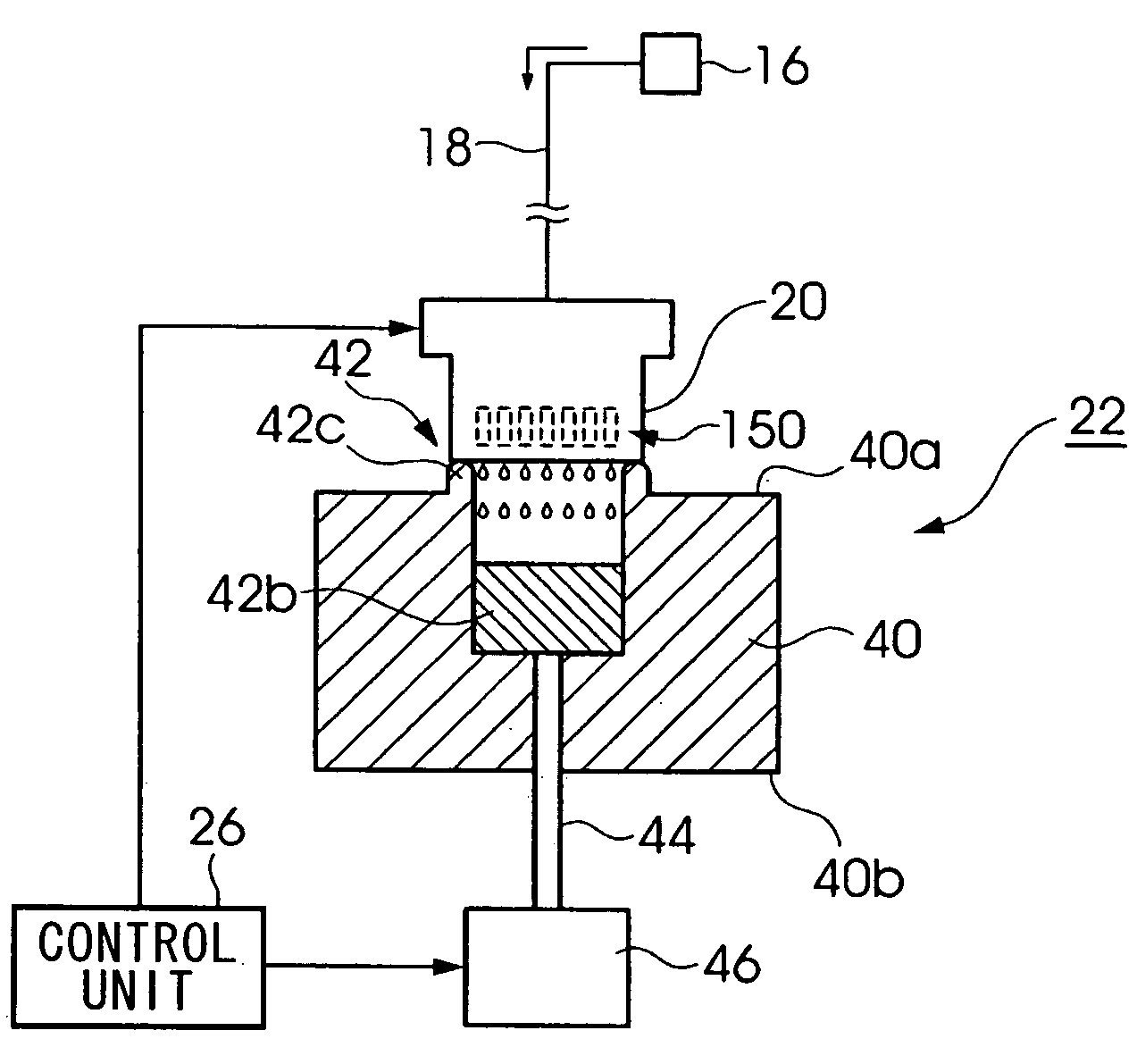

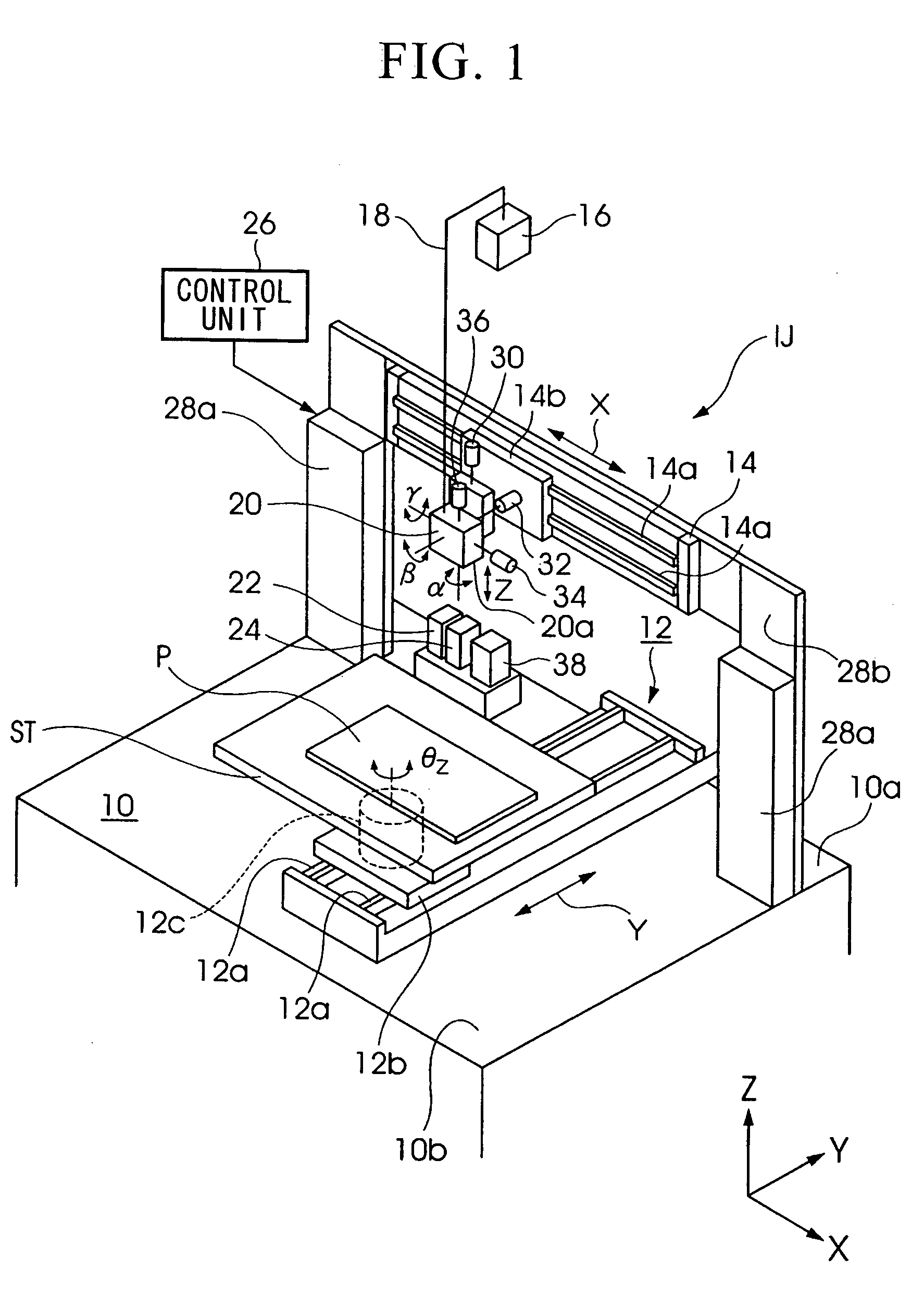

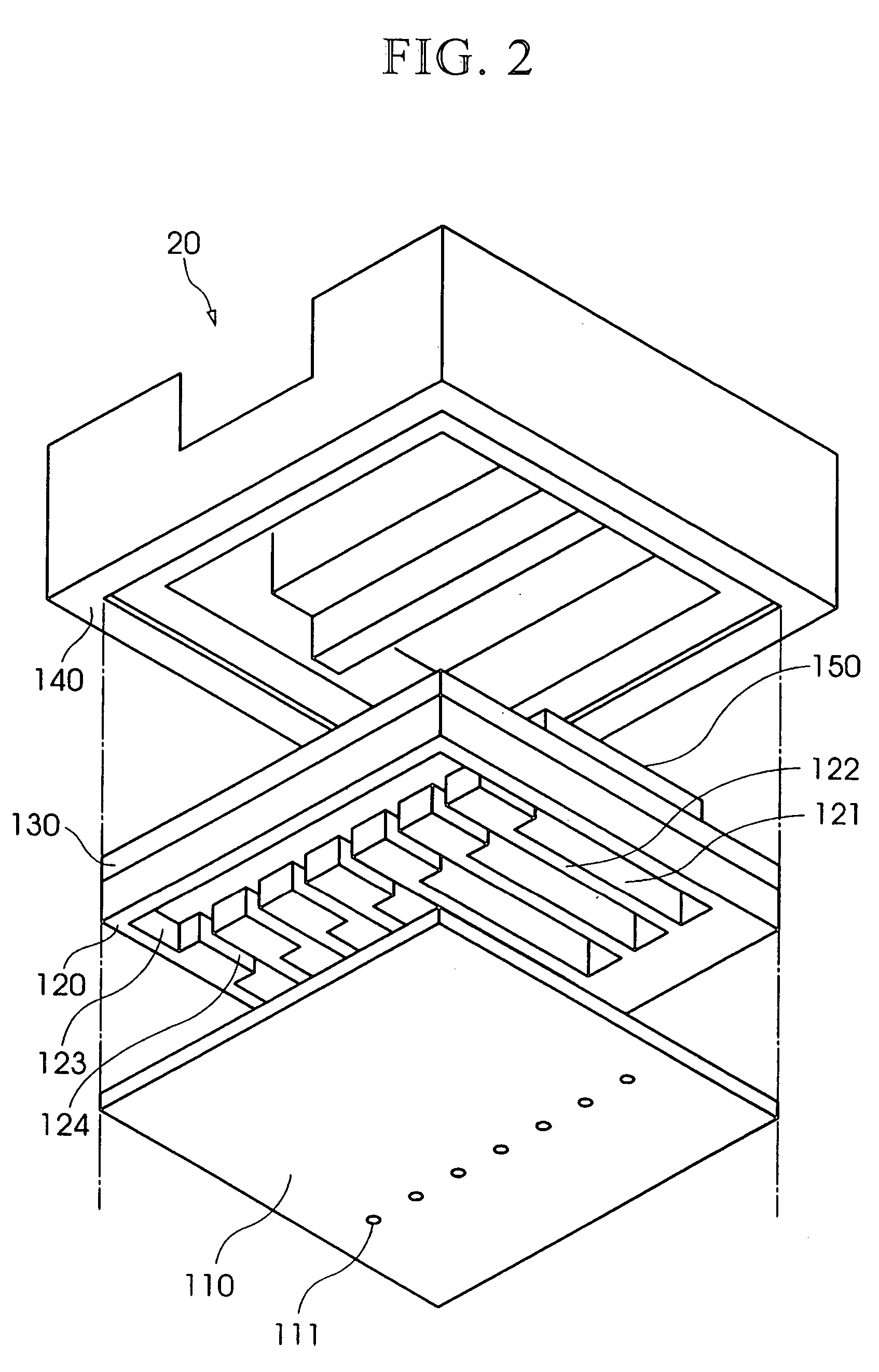

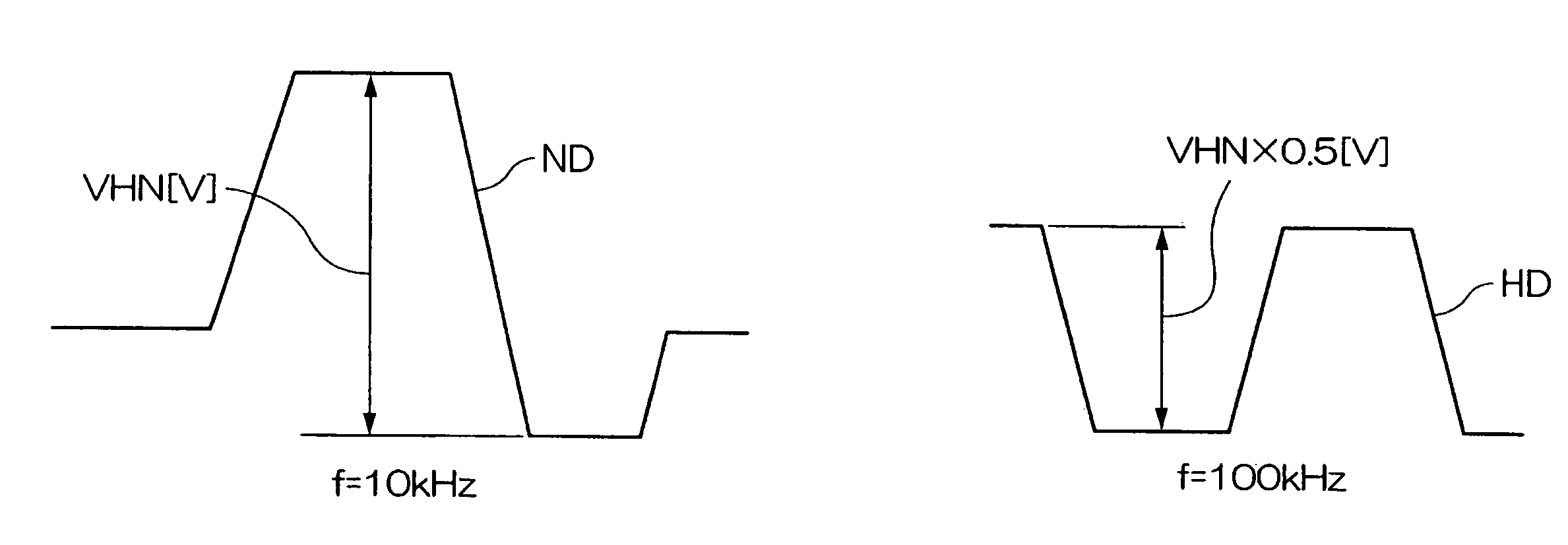

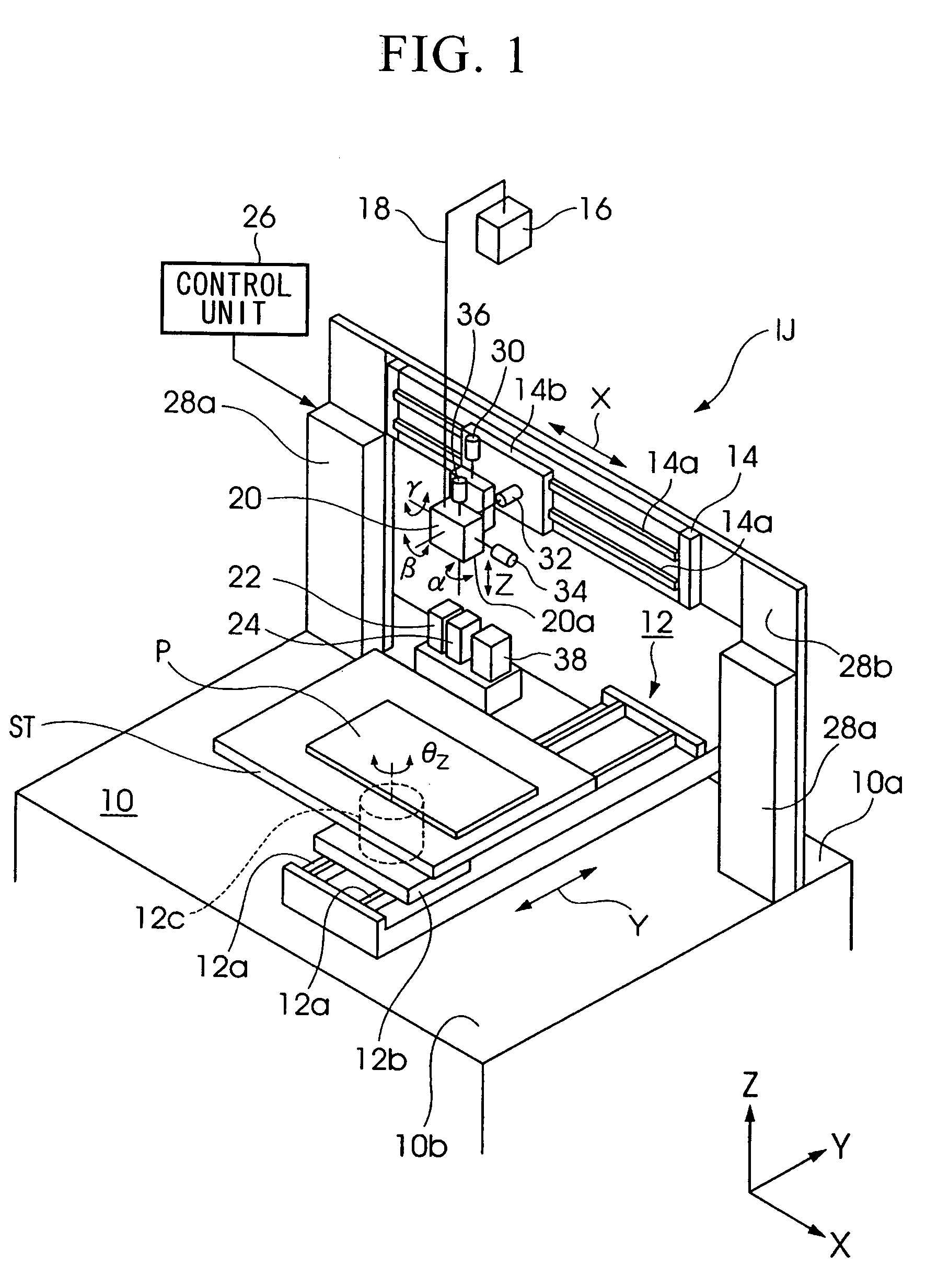

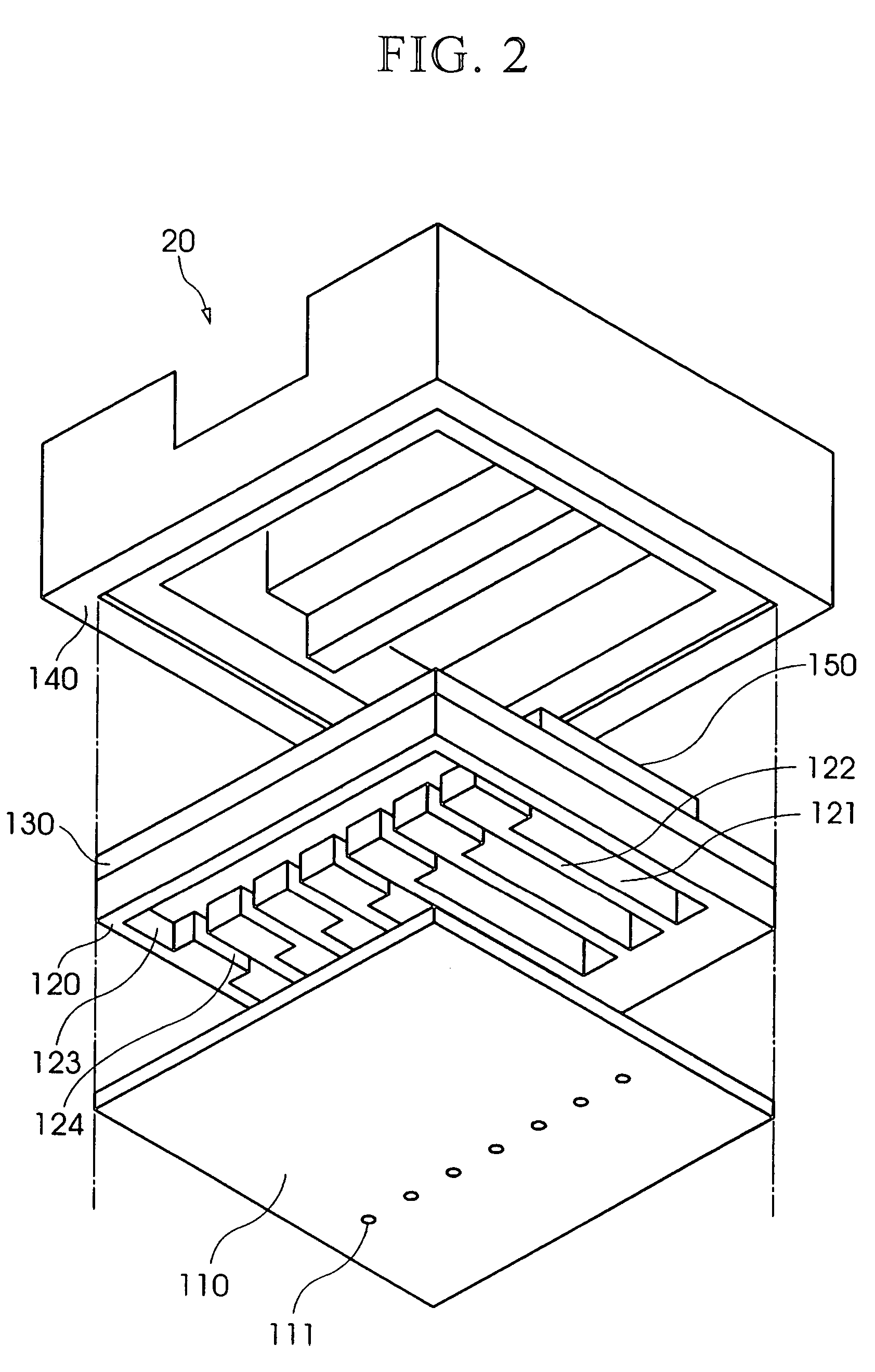

Capping unit and control method for same, liquid droplet ejection apparatus and device manufacturing method

ActiveUS20050140718A1Avoid unnecessary consumptionExtend liquid droplet ejection timePretreated surfacesCoatingsEngineeringHead parts

A capping apparatus including: a sealing unit that seals at least nozzle apertures of a liquid droplet ejection head that ejects liquid droplets; a heating unit that heats at least a vicinity of the nozzle apertures; and a negative pressure supplying unit that supplies an interior of the sealing unit with negative pressure that causes liquid droplets to be ejected from the nozzle apertures.

Owner:KATEEVA

Capping unit and control method for same, liquid droplet ejection apparatus and device manufacturing method

A capping apparatus including: a sealing unit that seals at least nozzle apertures of a liquid droplet ejection head that ejects liquid droplets; a heating unit that heats at least a vicinity of the nozzle apertures; and a negative pressure supplying unit that supplies an interior of the sealing unit with negative pressure that causes liquid droplets to be ejected from the nozzle apertures.

Owner:KATEEVA

Machining method and machining device for mechanical forming production of integral type moisture retaining cigarette case

ActiveCN106904308AFunction increaseIncrease productivityPackaging cigaretteMachiningIndustrial engineering

The invention discloses a machining method for mechanical forming production of an integral type moisture retaining cigarette case. Covering of inclusions with a paper inner framework and a composite covering material and forming of a case body, adhering or hot sealing are realized through mechanical action of equipment. The machining method specifically comprises the following steps: A1, restraining a cigarette group for later use; A2, covering the cigarette group with the paper inner framework, then carrying out folding and forming, and sealing an opening through or not through an adhesive application mode for later use; A3, covering the paper inner framework with the composite covering material, then carrying out folding and forming, and sealing the opening through the adhesive application or heating mode for later use; and A4, respectively preparing two or more complete moisture retaining cigarette cases by matching or not matching with conventional hard flip type cigarette cases. The machining method has the beneficial effects that the production mode is upgraded, the production efficiency and the production quality are improved, and the manufacturing cost of the equipment is controlled; and furthermore, by the matching or not matching with the conventional hard flip type cigarette cases, cigarette case products with various styles and rich functions are manufactured, thus realizing flexible production switching capacity.

Owner:CHINA TOBACCO YUNNAN IND

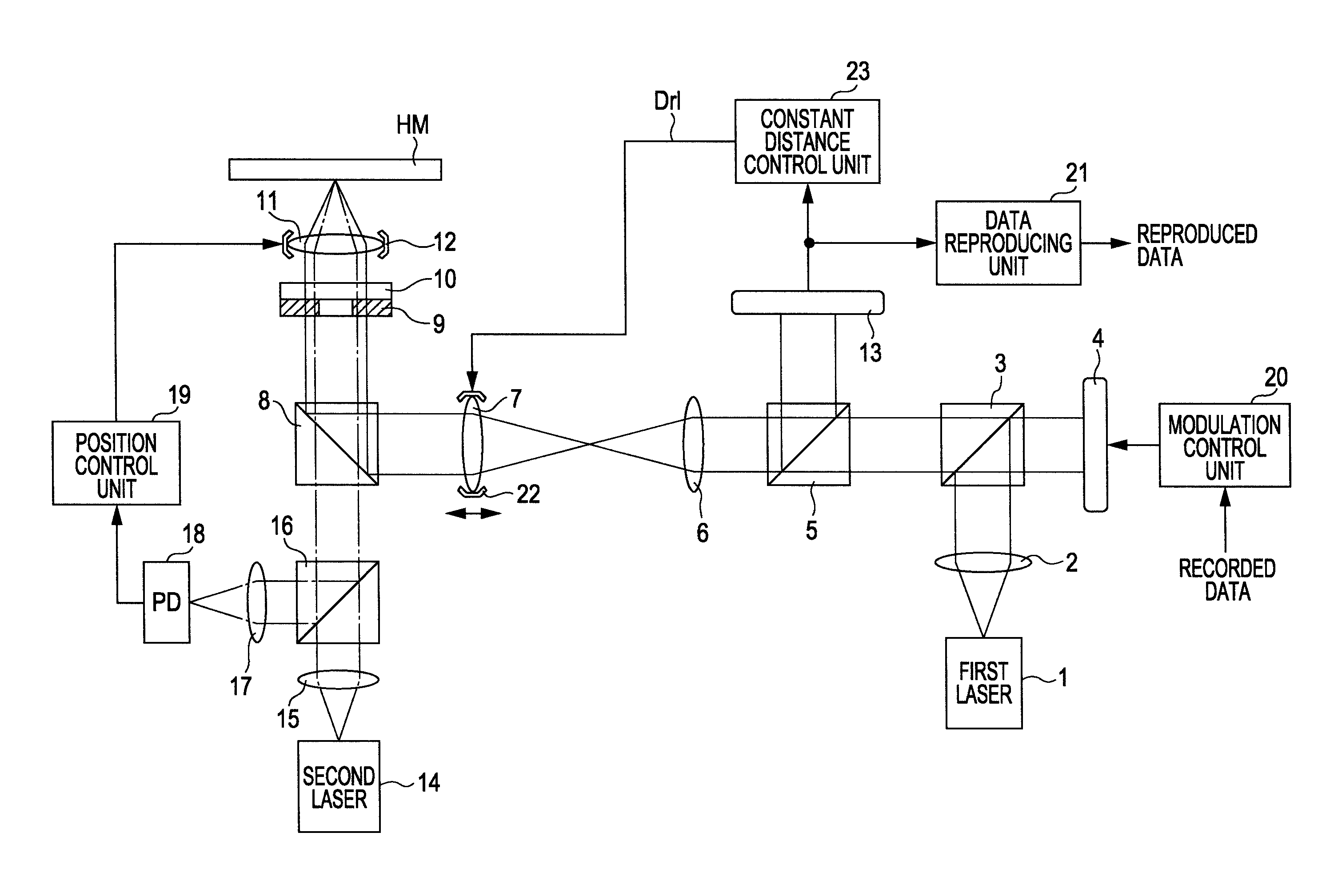

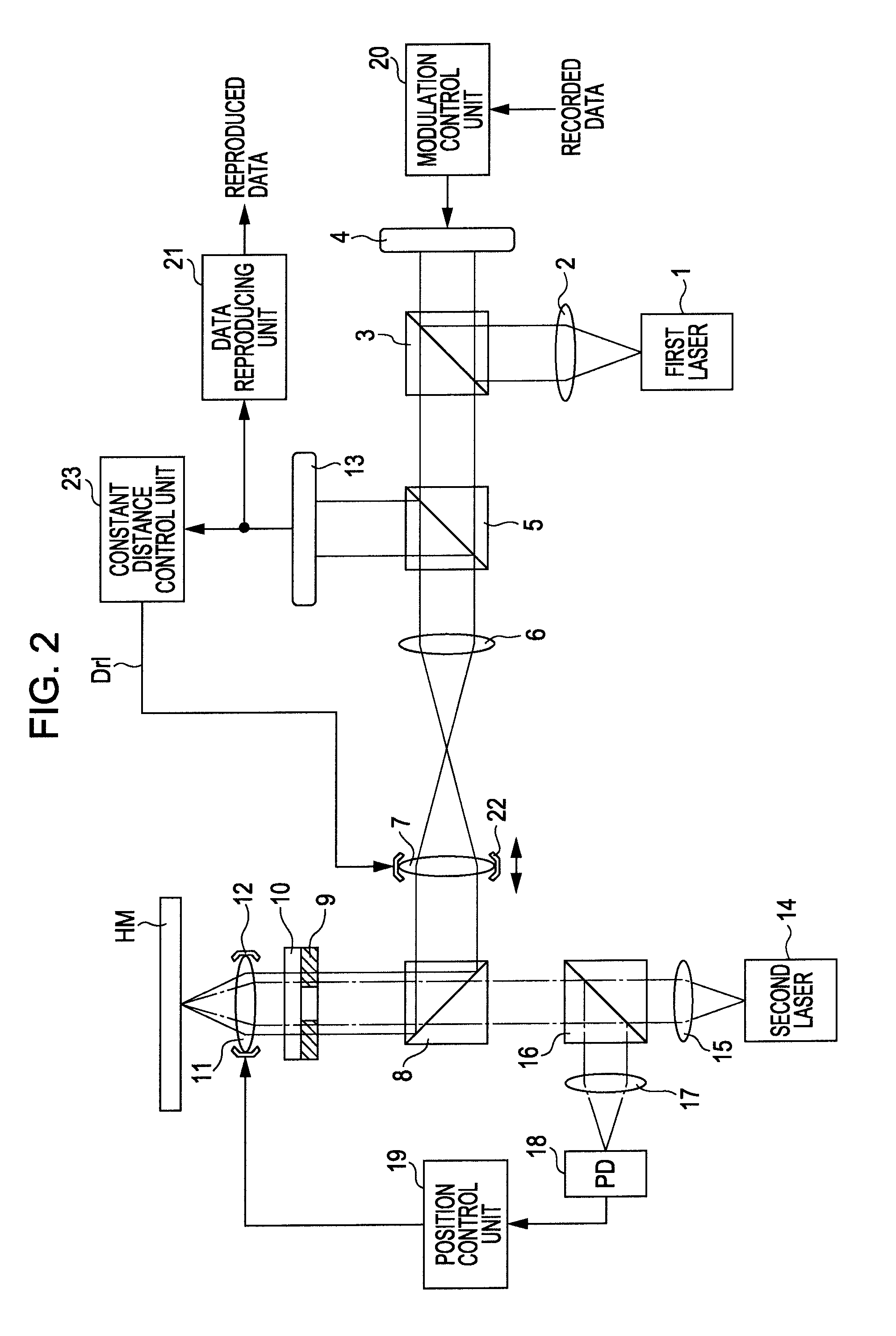

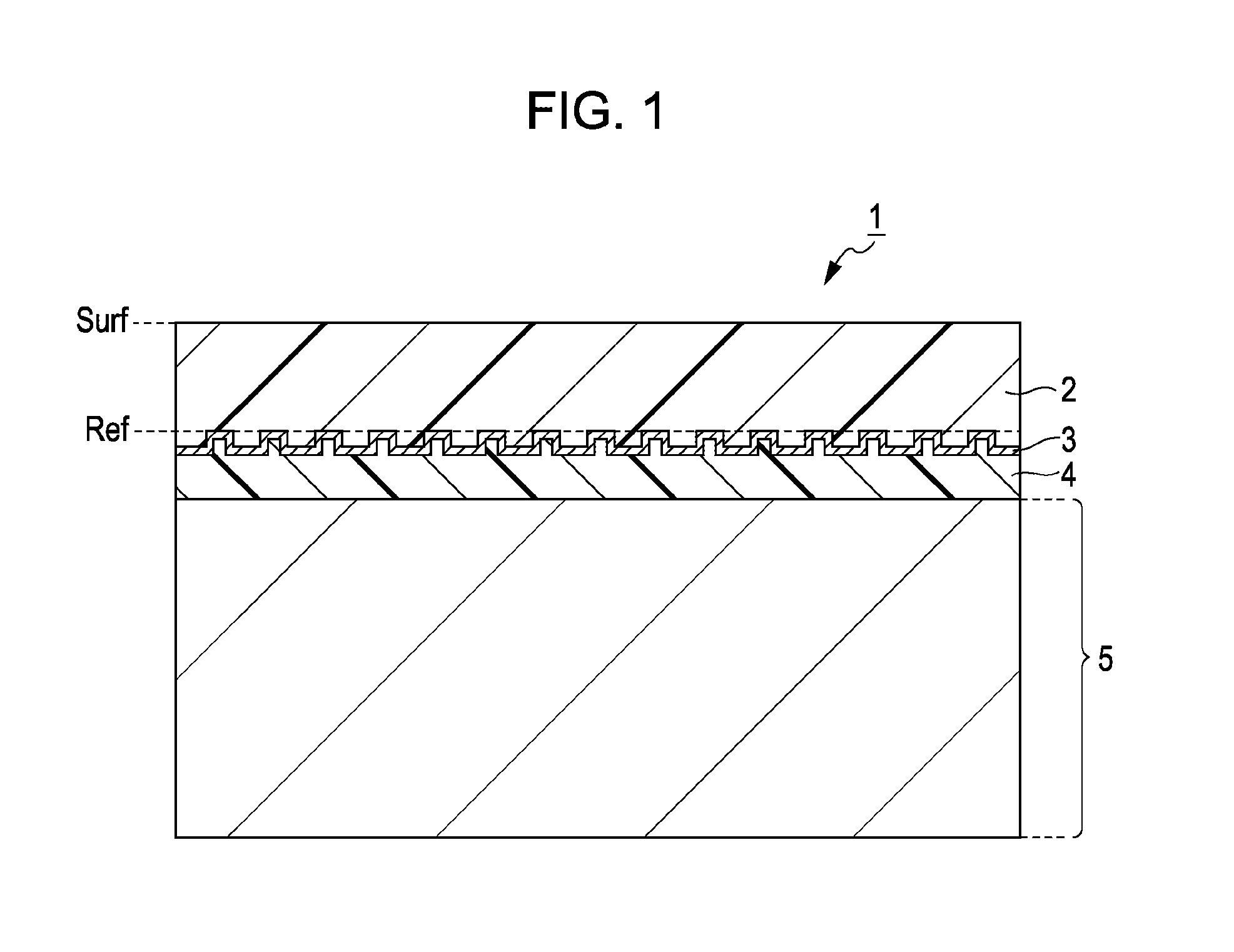

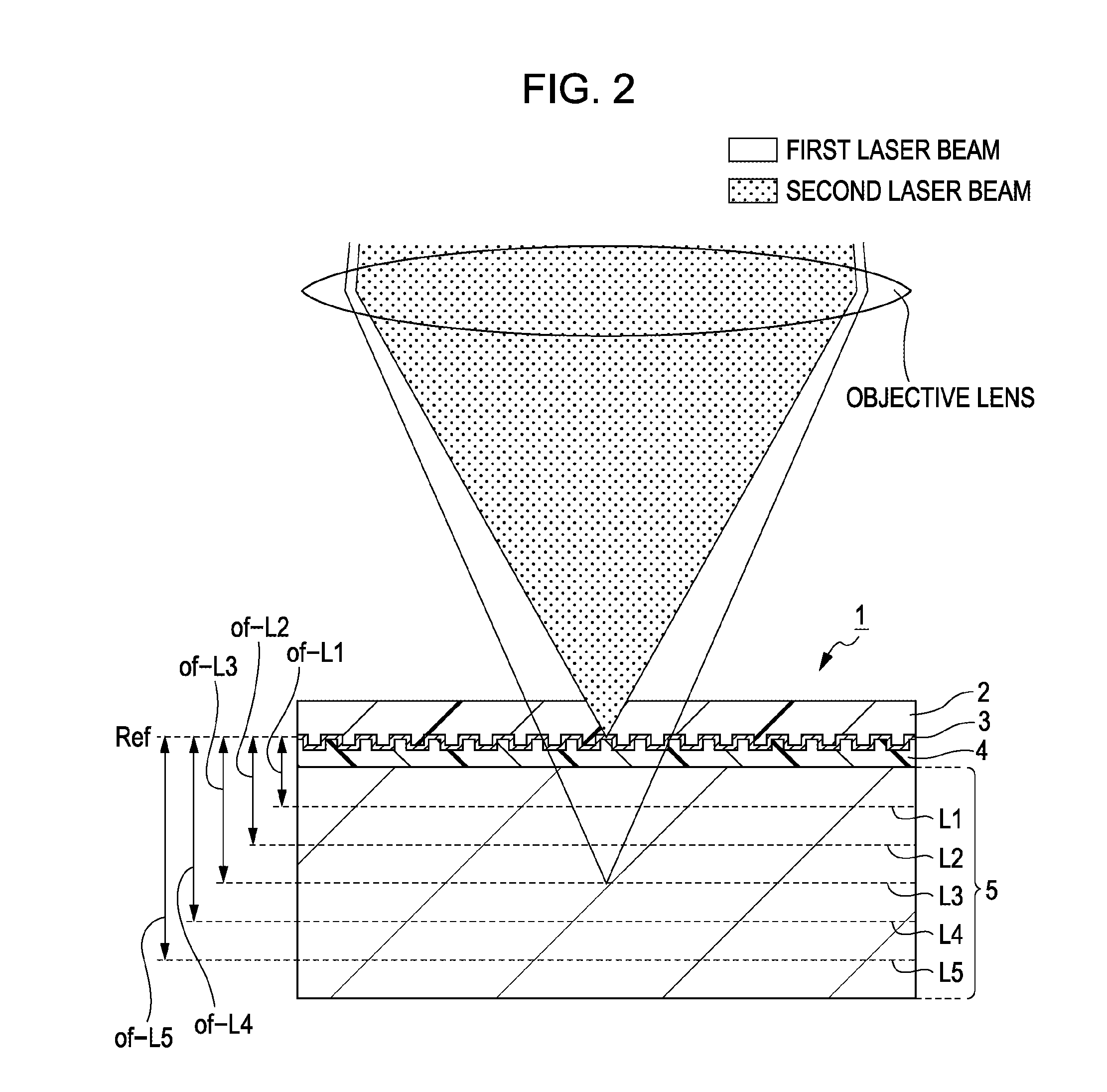

Light irradiation device for recording information in a hologram recording medium

InactiveUS8432591B2Reduce equipment manufacturing costsOptical beam sourcesRecord information storageLight irradiationFocal position

A light irradiation device includes: a focus servo control unit including a light source, a spatial light modulating unit, and a light irradiating unit, for focus servo control so that the ideal focal position of light via an objective lens is such that distance between an ideal focal position and a hologram recording medium surface is smaller than distance from the surface to the lower layer side face of the recording layer, and the focal position of light via the objective lens is constant at the ideal focal position; an objective-lens / relay-lens distance adjusting unit to adjust distance between the objective lens and a relay lens close to the objective lens; a light reception unit to receive marker light; and a constant distance control unit to control the objective-lens / relay-lens distance adjusting unit based on error between the ideal position of the marker light, and the actual position of the marker light.

Owner:SONY CORP

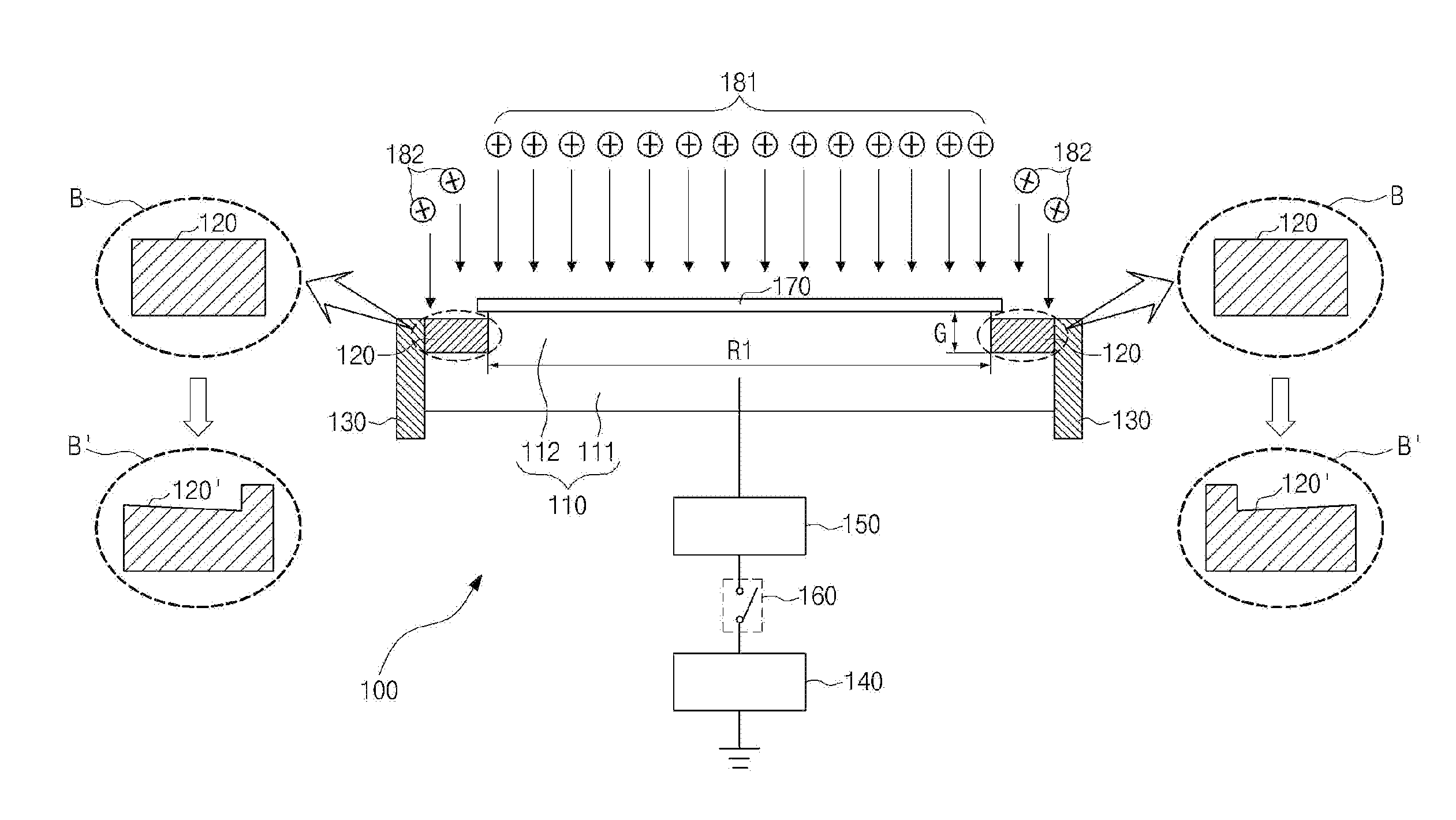

Electrostatic chuck assembly for plasma reactor

InactiveUS20100110605A1Extended service lifeSimple structureElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma reactorBiomedical engineering

Provided is an electrostatic chuck assembly for a plasma reactor. The assembly includes an electrostatic chuck, an electrostatic chuck cover ring, and a cathode assembly cover ring. The electrostatic chuck includes a body part and a protrusion part. The body part has a disk shape of a first diameter. The protrusion part is formed integrally with the body part and protrudes from the body part, and has a disk shape of a second diameter less than the first diameter. The electrostatic chuck cover ring is disposed to surround an outer circumference of the protrusion part. The cathode assembly cover ring is disposed at an upper part of the cathode assembly to surround an outer circumference of the electrostatic chuck cover ring and an outer circumference of the body part.

Owner:DMS CO LTD

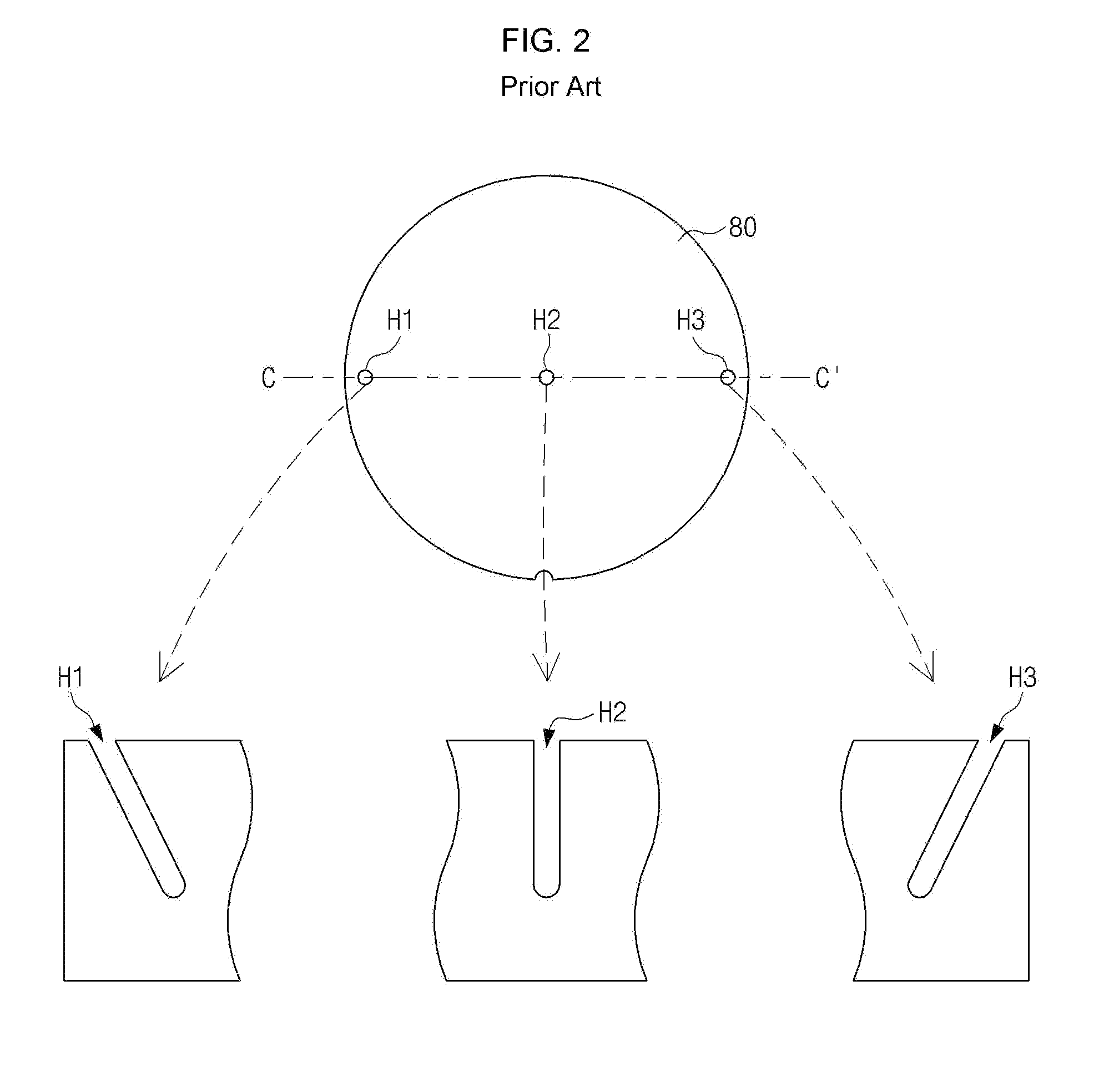

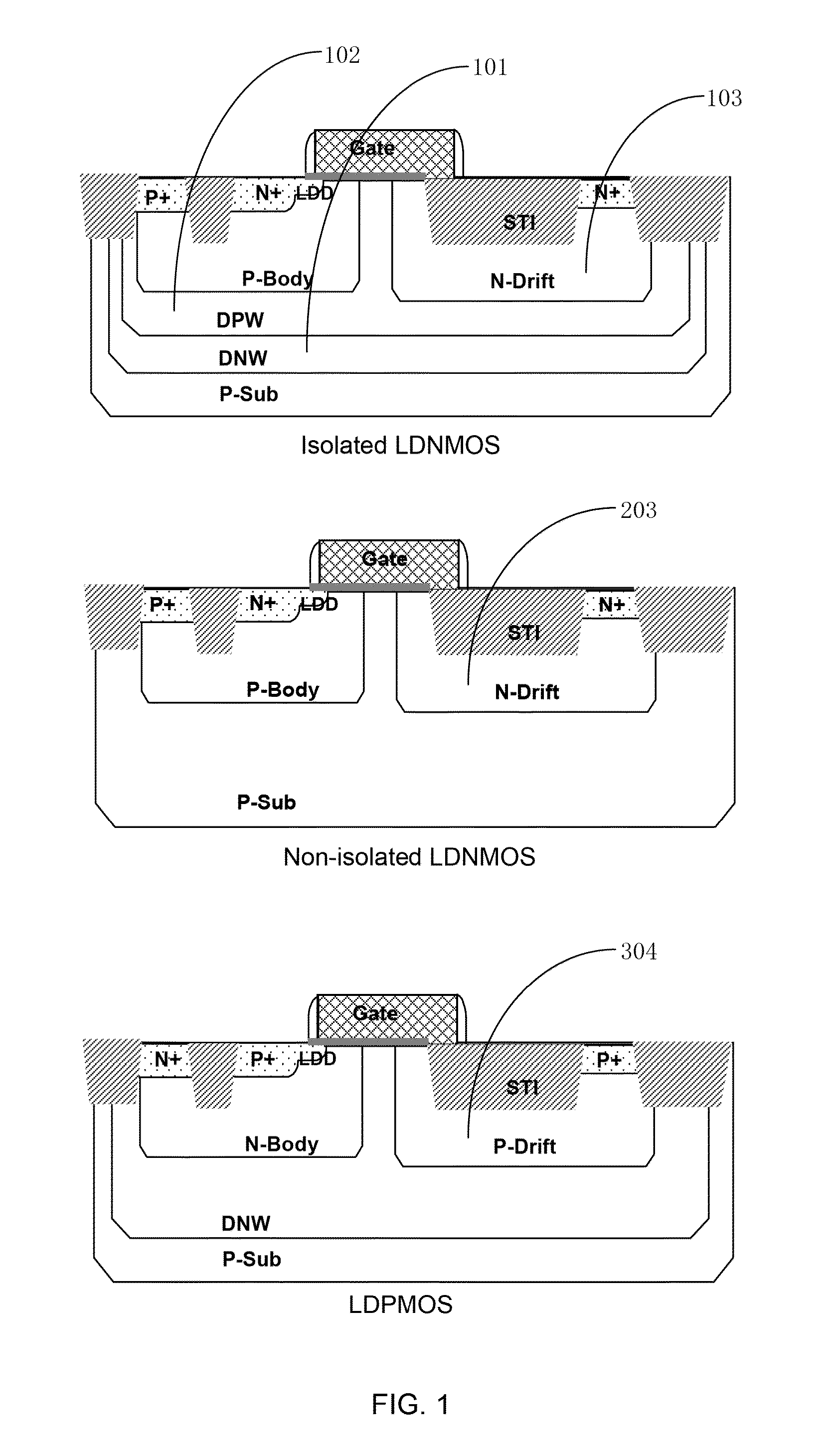

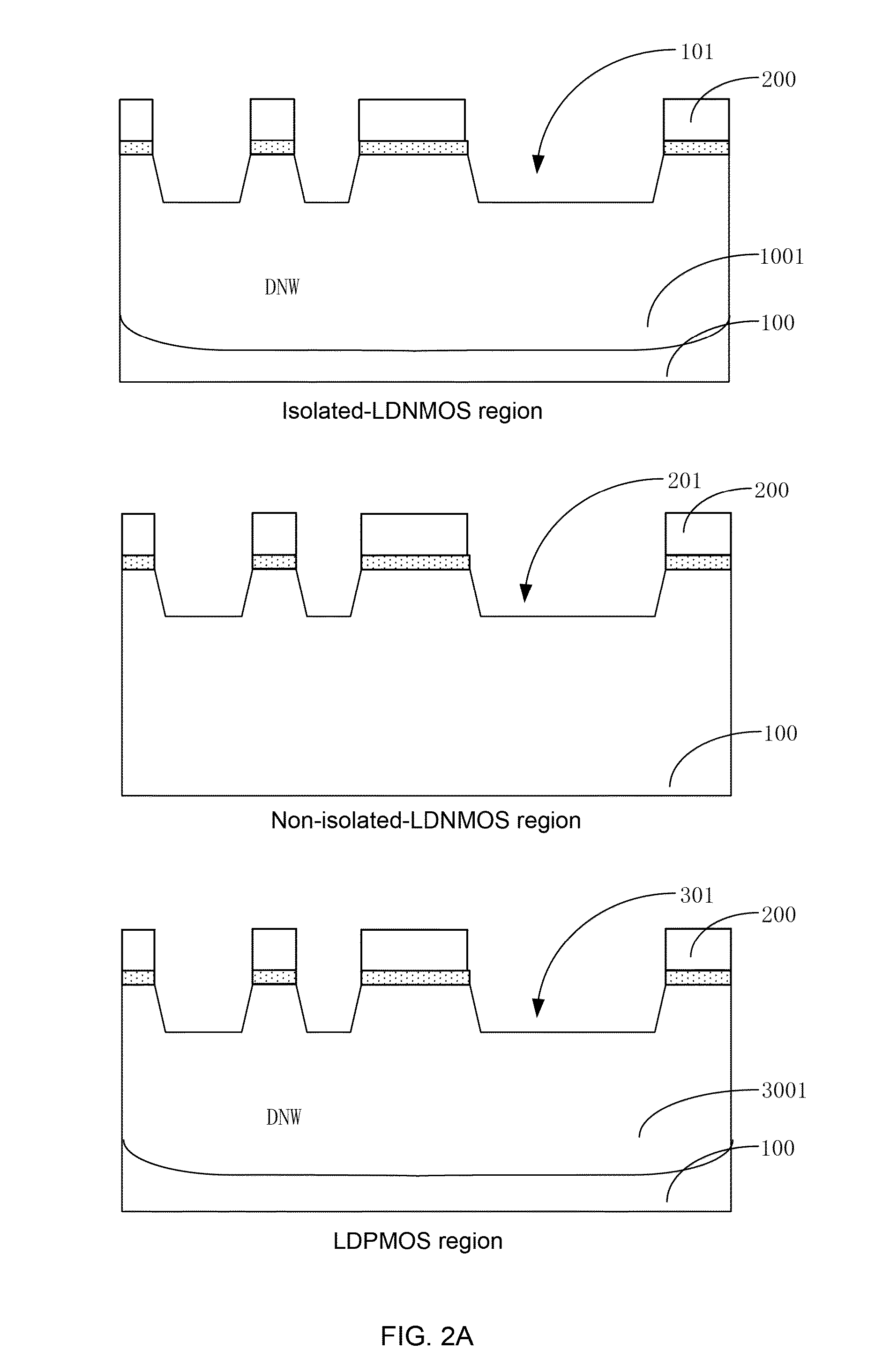

Method for manufacturing semiconductor device

ActiveUS20150262820A1Simplify semiconductor device manufacturing processReduce semiconductor device manufacturing costSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSemiconductor

A method for manufacturing a semiconductor device may include the following steps: preparing a semiconductor substrate that includes a first substrate region, a second substrate region, and a third substrate region; providing a first mask that overlaps the semiconductor substrate; etching, using the first mask, the first semiconductor substrate to form a trench in each of the substrate regions; providing a second mask that overlaps the semiconductor substrate and includes three openings corresponding to the substrate regions; performing first ion implantation through the three openings to form a P-doped region in each of the substrate regions; performing second ion implantation through the three openings to form an N-doped region in each of the substrate regions; and performing third ion implantation through the three openings to form another N-doped region in each of the substrate regions; and forming an isolation member in each of the trenches.

Owner:SEMICON MFG INT (SHANGHAI) CORP

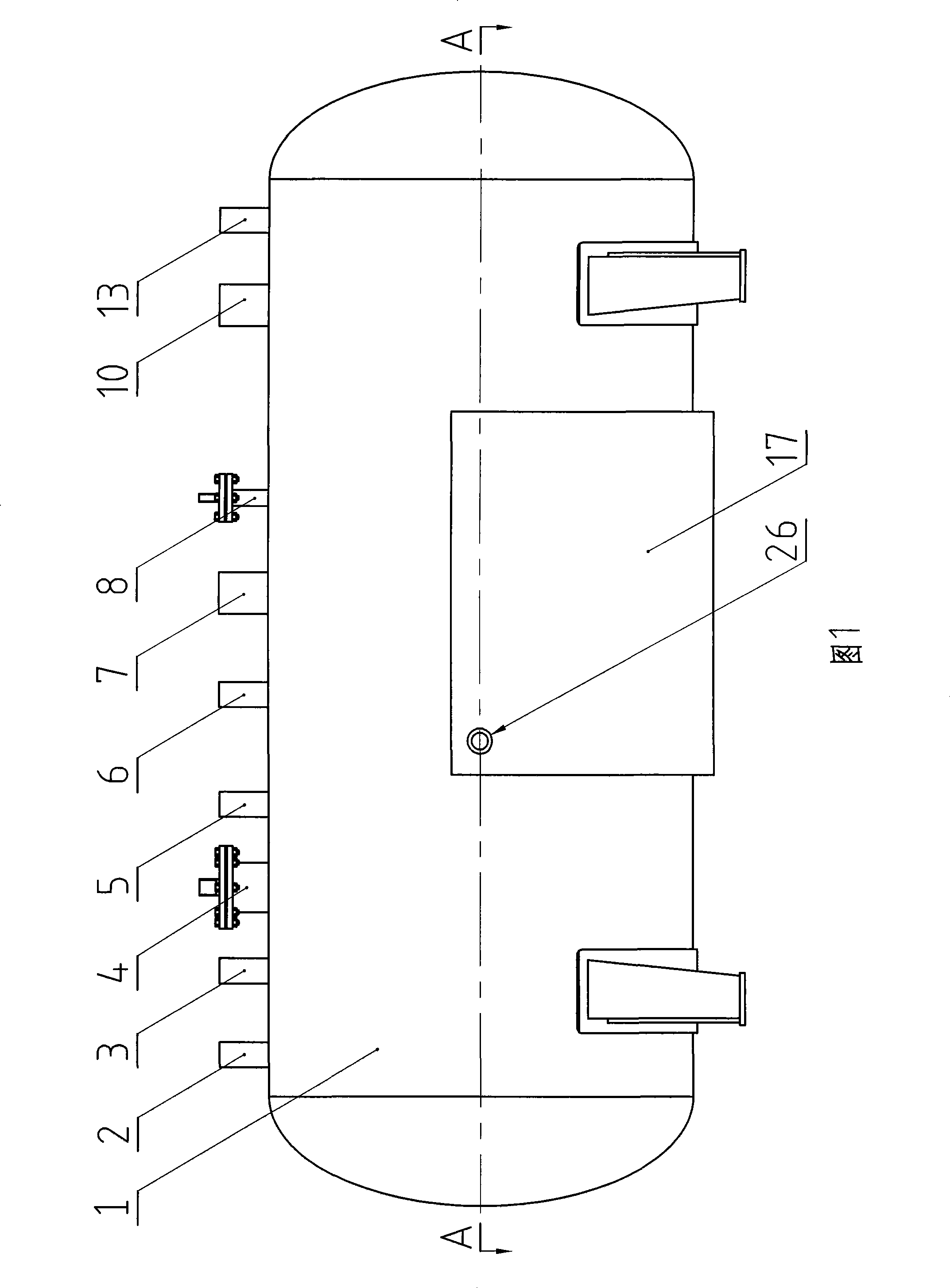

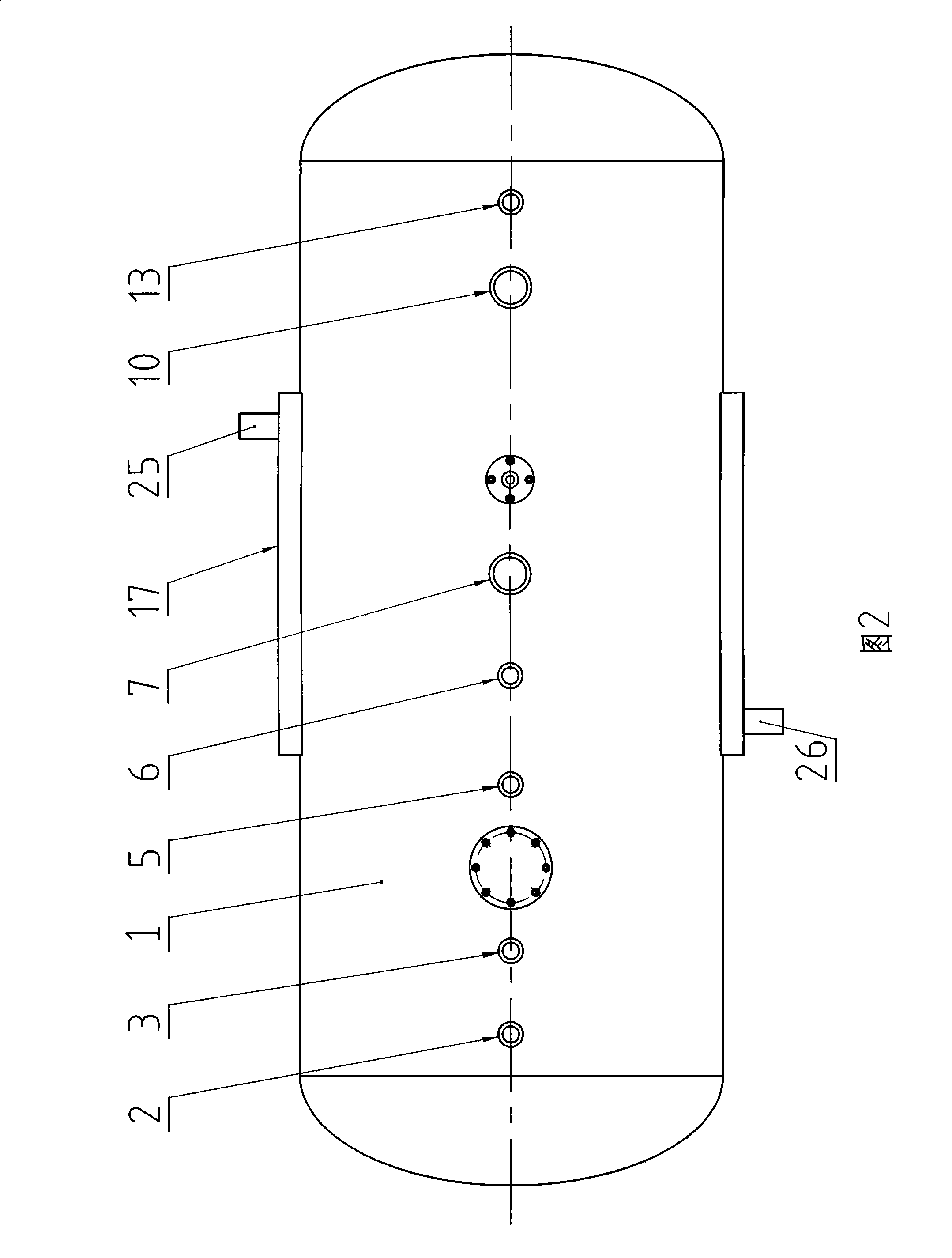

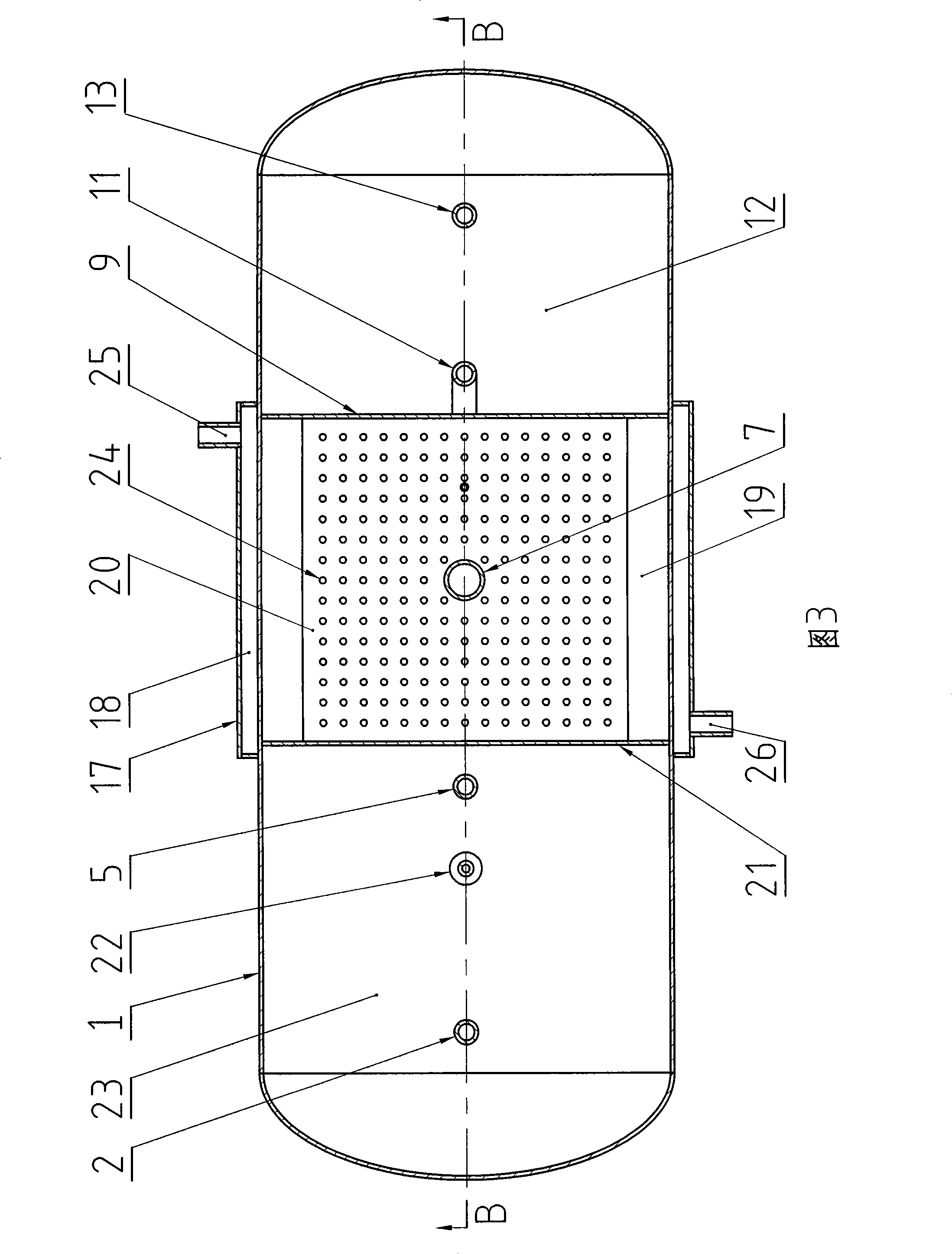

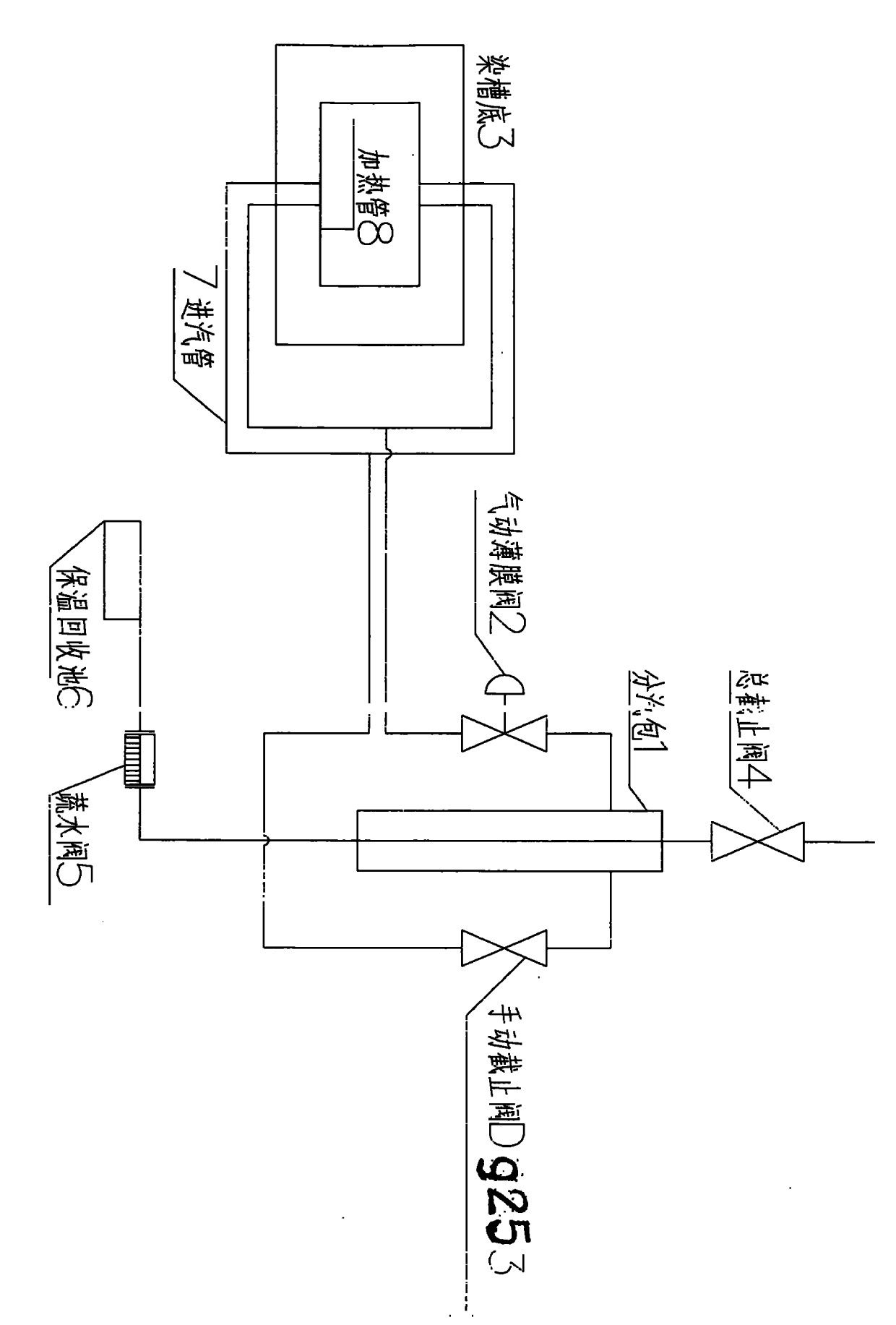

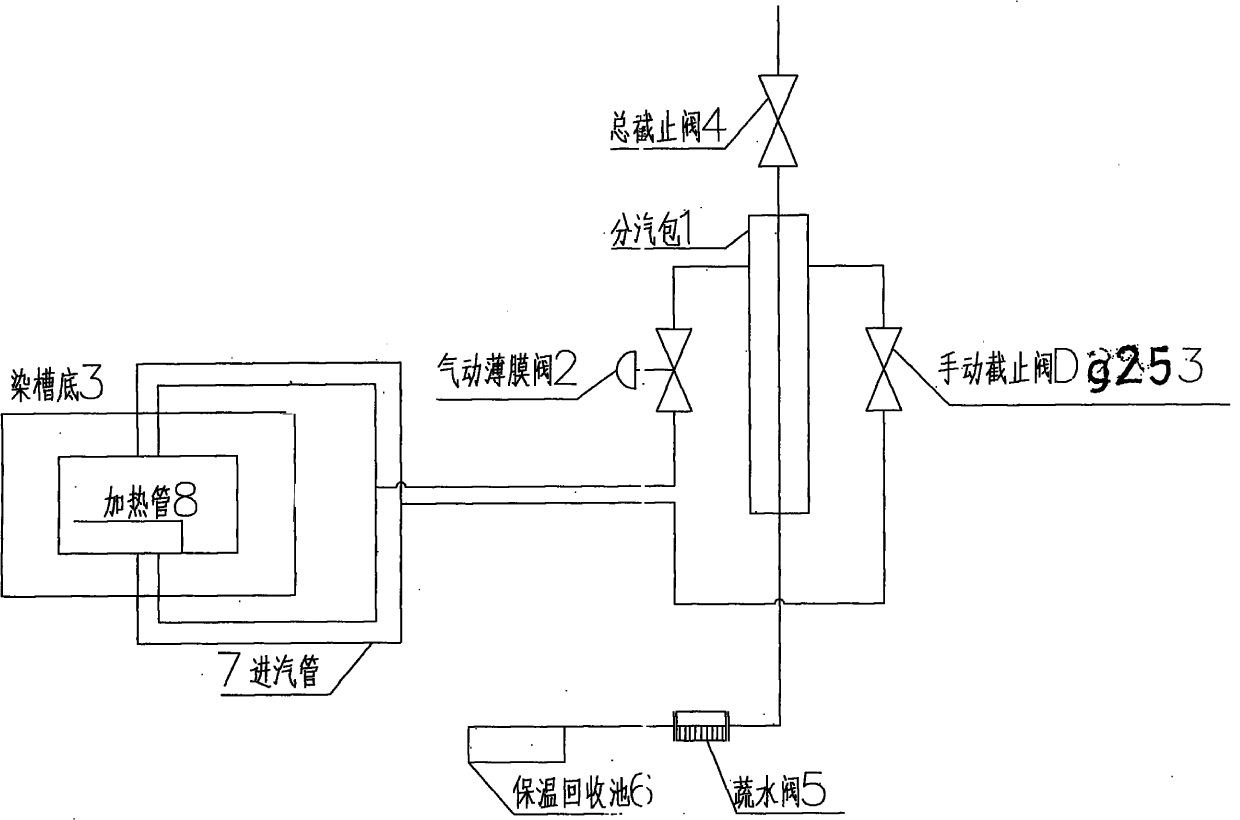

Water vapor separator and uniform heating pipe of jig dyeing machine heating system

InactiveCN101988246ASave steamReduce equipment manufacturing costsLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsHeating systemDyeing

The invention relates to a jig dyeing machine heating system in the technical field of printing and dyeing machinery. A direct heating pipe, a heat insulation pipe, a heat insulation layer and the like are adopted in the current heating system to cause the defects that: because the steam contains water during heating, the dye solution absorbs moisture, the process parameter is not accurate, the dyeing is not uniform, the steam water is seriously wasted, and the heating system is not favorable for energy conservation and consumption reduction. By adopting the principle that the water is on the lower part and the steam is on the upper part in a vertical steam pocket 1, the water is downwards drained through a drain valve 5 for recycle 6; the steam is upwards heated from a steam inlet pipe 7 and a heating pipe 8 by a pneumatic film valve 2 or a manual stop valve 3; the steam returned to a dye jar is pure steam so as not to affect dyeing; the temperature should be preserved during dyeing; a temperature control valve 2 automatically supplies and stops the steam so as to solve the problems of water carried in heating and moisture absorption of the dyeing solution and ensure the dyeing effect; if the heat insulation pipe or the heat insulation layer is adopted, the steam is wasted, and the manufacturing cost is increased; and the heating system has simple structure, reduces the maintenance, lowers the manufacturing cost, and saves the steam and the water.

Owner:新建特阔漂整(南通)有限公司

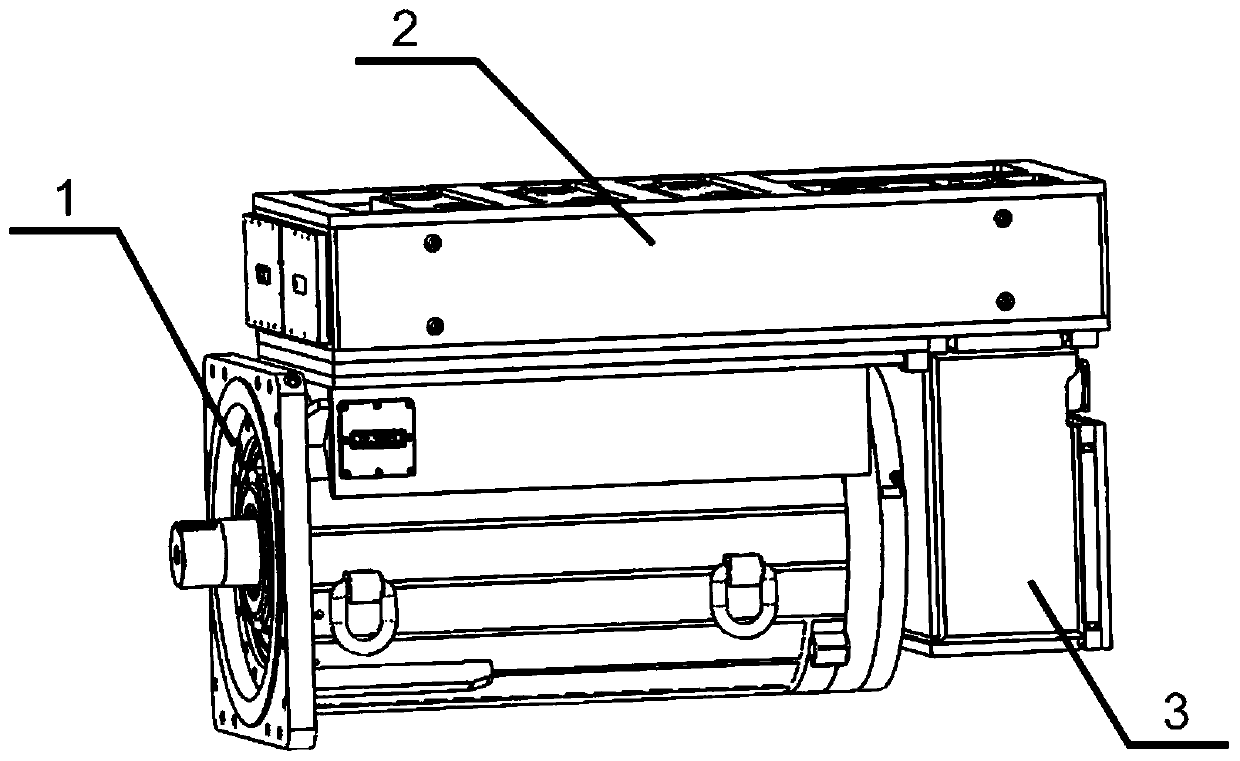

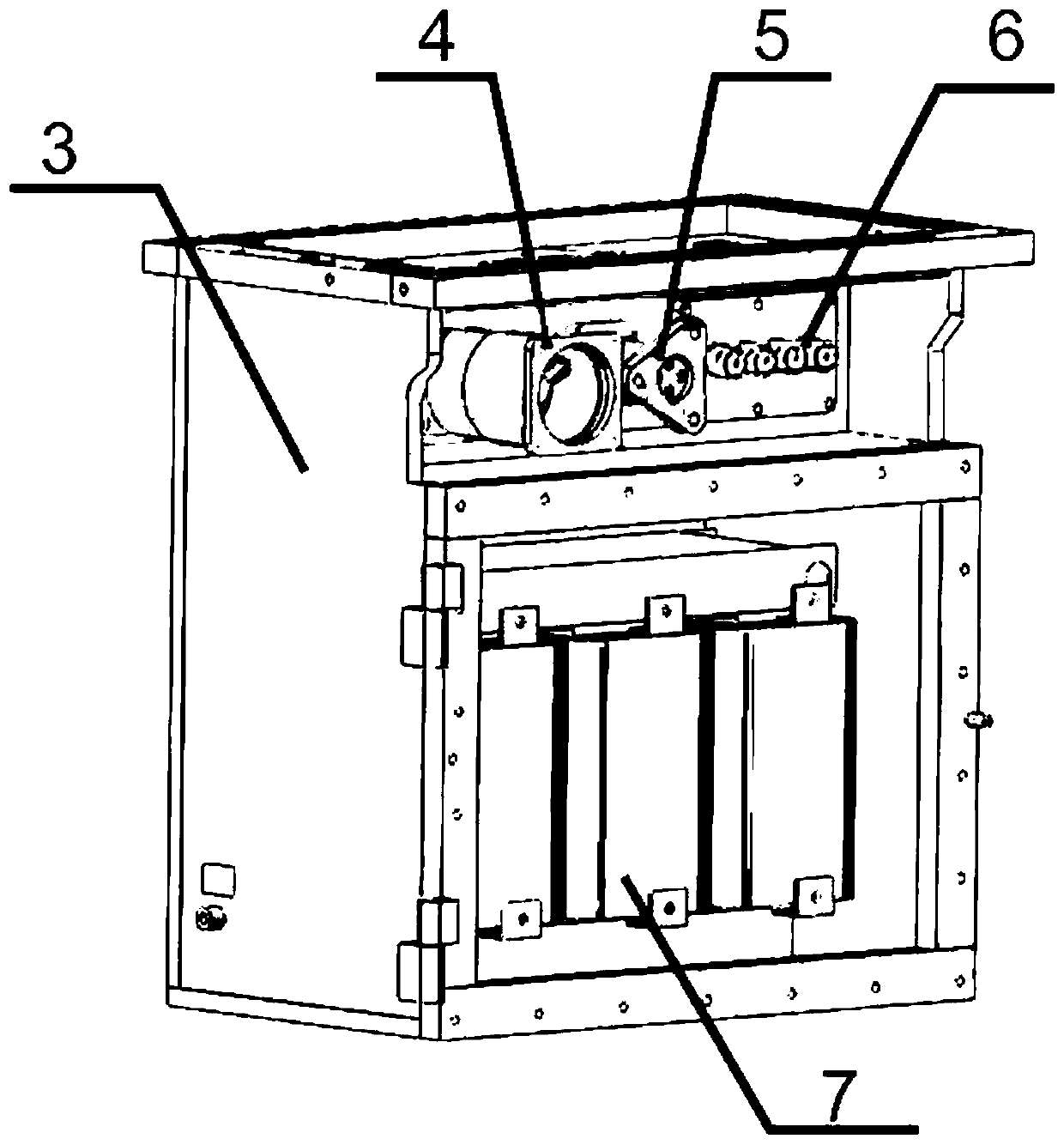

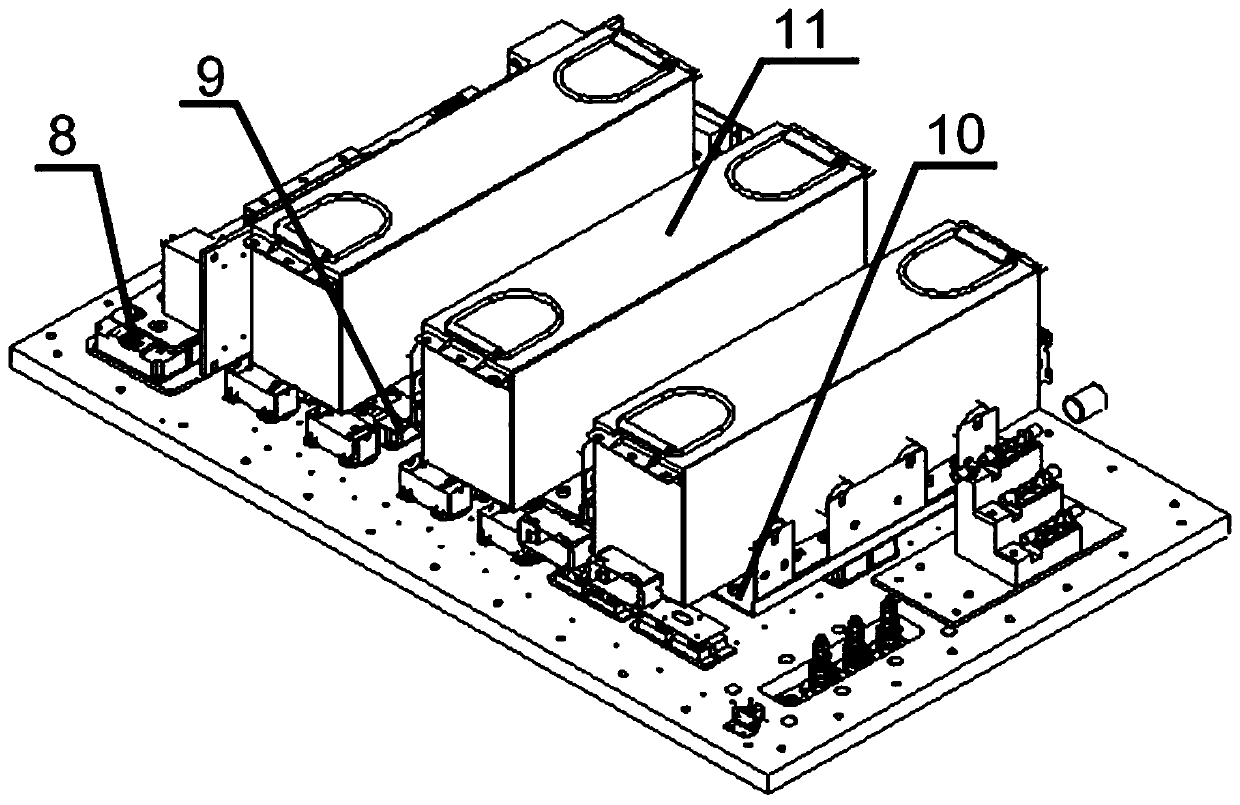

3300V mining explosion-proof and intrinsic safety type permanent magnet synchronous frequency conversion and speed regulation all-in-one machine

ActiveCN110739809AReduce equipment manufacturing costsReduce the amount usedAssociation with control/drive circuitsAC motor controlCapacitanceBusbar

The invention relates to a 3300V mining explosion-proof and intrinsic safety type permanent magnet synchronous frequency conversion and speed regulation all-in-one machine. The 3300V mining explosion-proof and intrinsic safety type permanent magnet synchronous frequency conversion and speed regulation all-in-one machine comprises a permanent magnet synchronous motor, a frequency converter and an input filter box body; the frequency converter is installed on the upper portion of the permanent magnet synchronous motor; the input filter box body is installed at the rear end of the end of the permanent magnet synchronous motor; the frequency converter comprises a rectification module, an energy storage capacitor module and an inversion power module which are used for processing current in sequence; the energy storage capacitor module and the inversion power module are separated through laminated busbars; and the input filter box body is connected with the rectification module. According tothe3300V mining explosion-proof and intrinsic safety type permanent magnet synchronous frequency conversion and speed regulation all-in-one machine of the invention, equipment manufacturing cost is reduced; the output current of an inverter can be smoother; influence on the harmonic voltage and instantaneous impulse voltage of the permanent magnet synchronous motor can be remarkably reduced; theoverall size of the frequency converter is reduced; and protruding terminals are used for hanging the laminated busbars on an inverter power device, so that workshop production and assembly personneland after-sales service personnel can be facilitated to integrally disassemble and assemble the inverter.

Owner:华夏天信智能物联股份有限公司

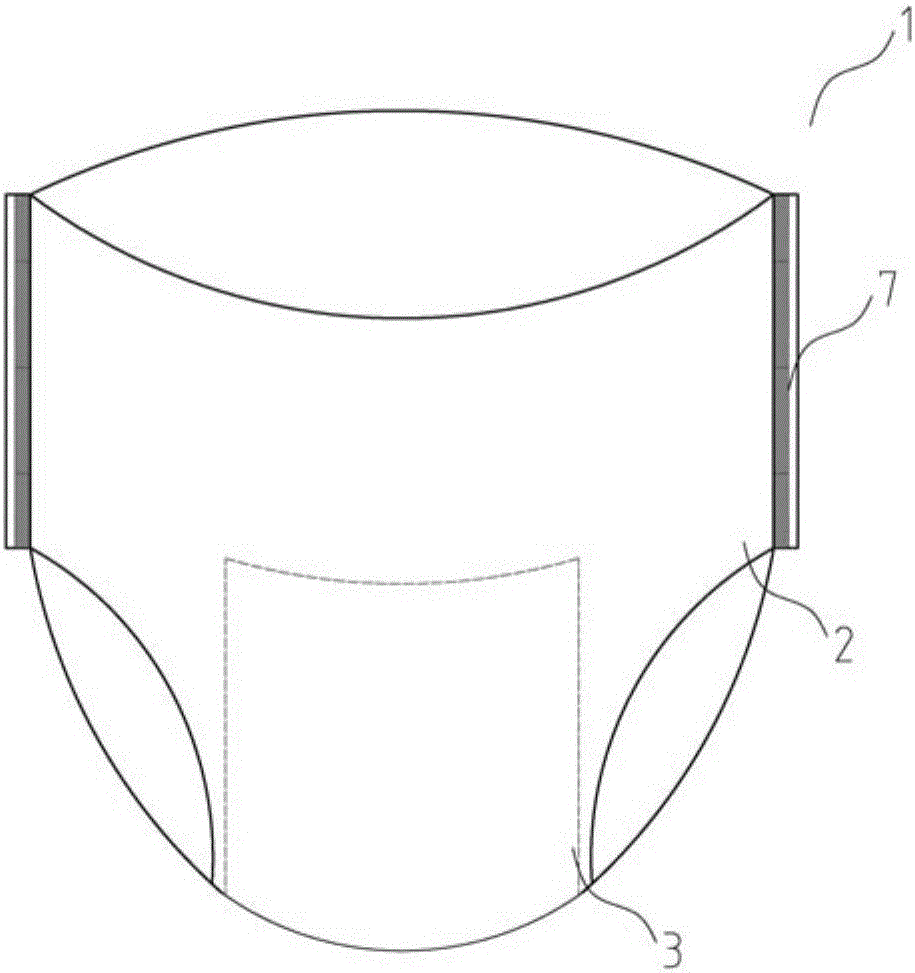

Absorptive article and manufacturing method thereof

InactiveCN106109104AReduce equipment manufacturing costsSimple structureAdhesive articlesAbsorbent padsStretch ratioSheet material

Owner:HUANGSHAN FUTIAN MACHINERY CO LTD

Spool conveying and storing device used for spinning machine

The invention discloses a spool conveying and storing device used for a spinning machine. The device comprises a rack, a fixing plate is arranged on the top surface of the rack, a spool conveying assembly is arranged on the fixing plate, a containing box is arranged on the rear portion of the spool conveying assembly, a rectangular groove is formed in the position, on the rear portion of the containing box, on the top surface of the rack, two sliding rails are parallelly arranged on the bottom surface in the rack and located below the rectangular groove, and a collection box capable of movingalong the sliding rails is arranged on the sliding rails; two mechanical grippers are correspondingly arranged on the two lateral sides of the rack respectively, each mechanical gripper comprises a X-direction guide rail which is horizontally arranged on the lateral side of the rack, a Y-direction guide rail is vertically connected with each X-direction guide rail, each Y-direction guide rail is connected with a mechanical arm capable of moving up and down along the Y-direction guide rail, and a clamping jaw is arranged downwards at the front end of each mechanical arm. The spool conveying andstoring device is simple in structure, stable in running and low in cost, the labor cost and the device manufacturing cost are effectively reduced, and the spool conveying and storing device can be widely used in various spinner equipment.

Owner:SUZHOU OUBBOO FASHION CO LTD

Optical drive device and tilt detection method

InactiveUS20110096648A1Reduce equipment manufacturing costsRealize miniaturizationCombination recordingRecord information storageOptical recordingPosition control

An optical drive device for performing information recording or reproduction of recorded information by formation of a mark by focusing a first light at a necessary position in a recording layer of an optical recording medium by an objective lens includes a position control unit configured to focus a second light on a reflection film, in which a position guide element of the optical recording medium is formed, through the objective lens and to enable the spot position of the second light to follow the position guide element based on the reflected light of the second light focused on the reflection film so as to control the position of the objective lens. The optical drive device further includes a first focusing unit, a first light-sensing portion, and a surface reflection light deviation amount detection unit.

Owner:SONY CORP

A dry processing device for blast furnace slag based on high temperature slag waste heat recovery

ActiveCN106435068BSimple structureReduce consumptionRecycling and recovery technologiesProcess efficiency improvementSpray nozzleMolten slag

The invention discloses a blast furnace molten slag dry method treatment device based on high-temperature slag waste heat recovery. The blast furnace molten slag dry method treatment device comprises a furnace slag treatment box and a cooling unit, wherein blast furnace slag falls from the top of the furnace slag treatment box; and the cooling unit comprises a mechanism used for forming water columns in the furnace slag treatment box to impact and cool the fallen blast furnace slag. The cooling unit comprises spray nozzles. The spray nozzles comprise a plurality of layers of water column spray nozzle bodies used for spraying out the water columns. The multiple layers of water column spray nozzle bodies are arranged on the two opposite side faces of the inside of the furnace slag treatment box up and down in a staggered mode, so that the blast furnace slag falling in the corresponding positions can fall in a Z-shaped path. The blast furnace molten slag dry method treatment device based on high-temperature slag waste heat recovery is relatively simplified, water consumption is reduced, and particularly, solid-state furnace slag particles maintained in a high-temperature state can be provided; and the temperature of the furnace slag particles are controllable, so that a high-quality heat source is provided for waste heat recovery.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com