Patents

Literature

70results about How to "Simple device design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

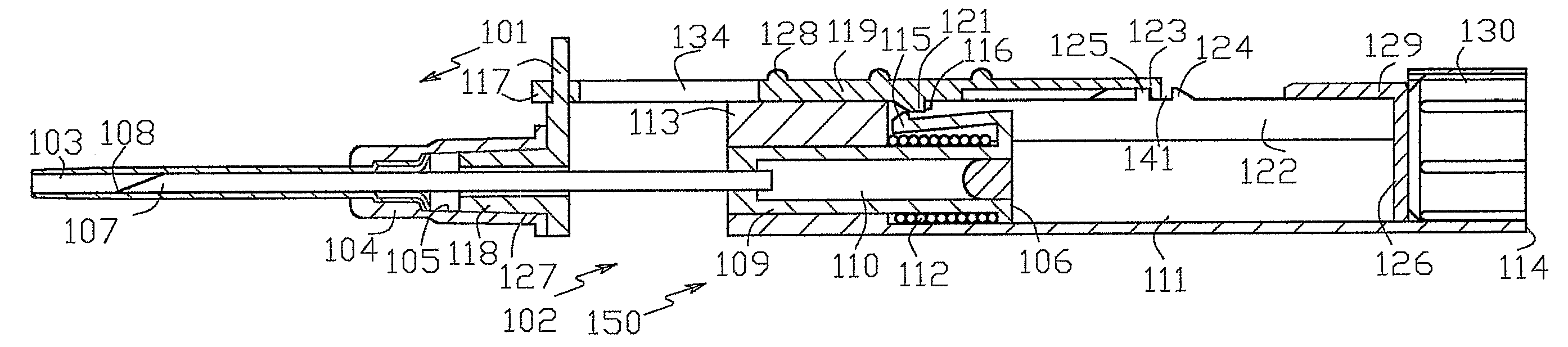

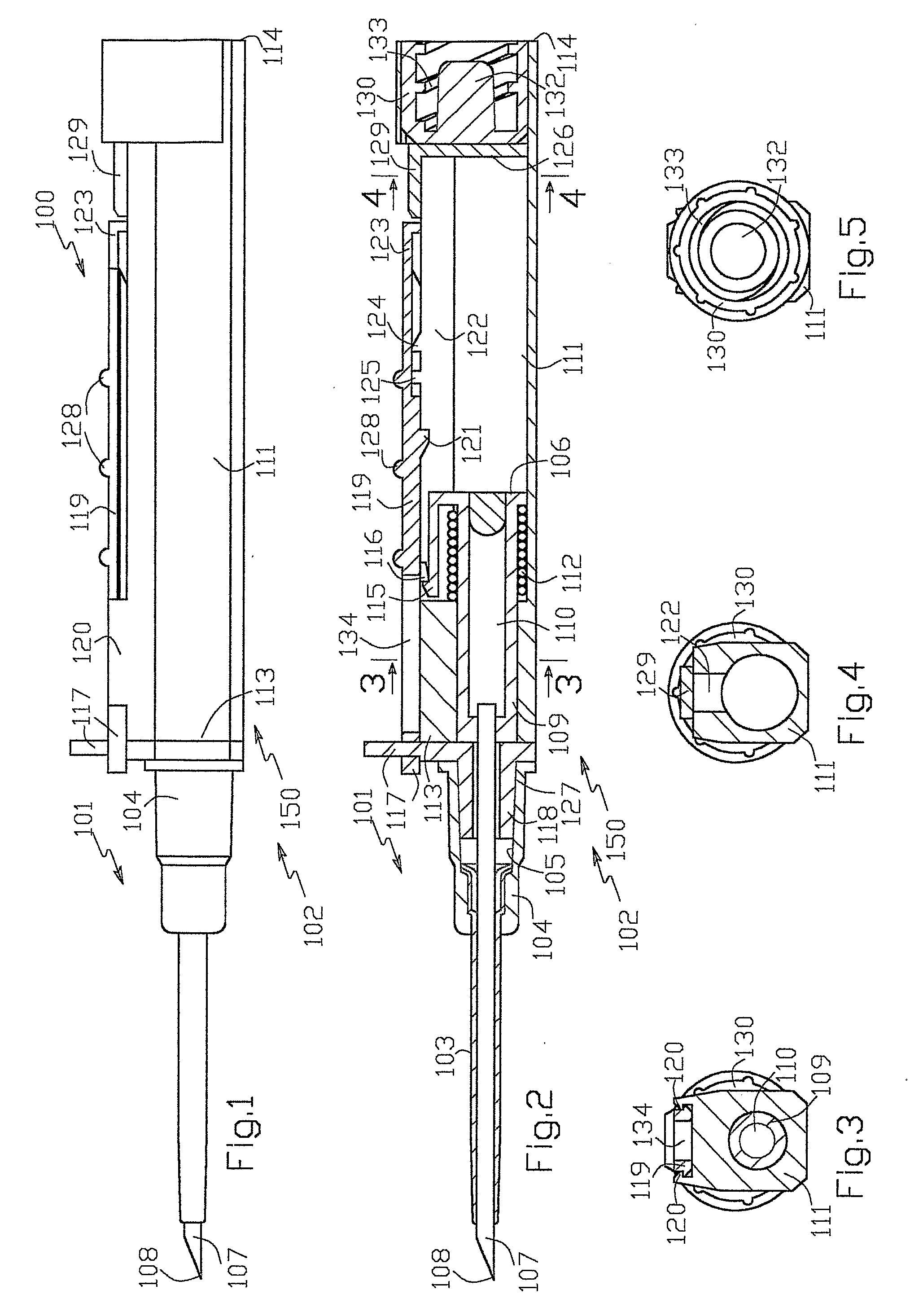

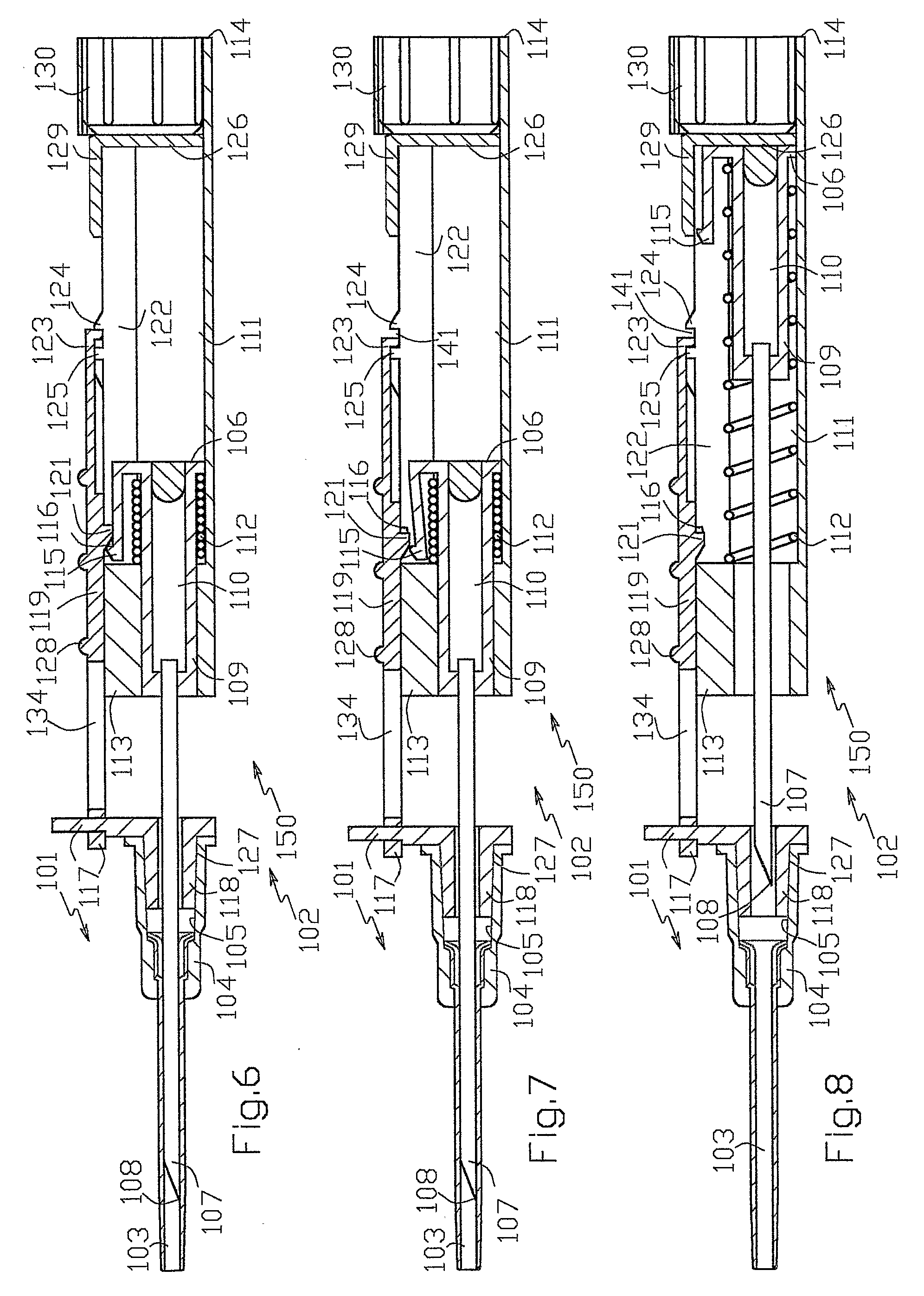

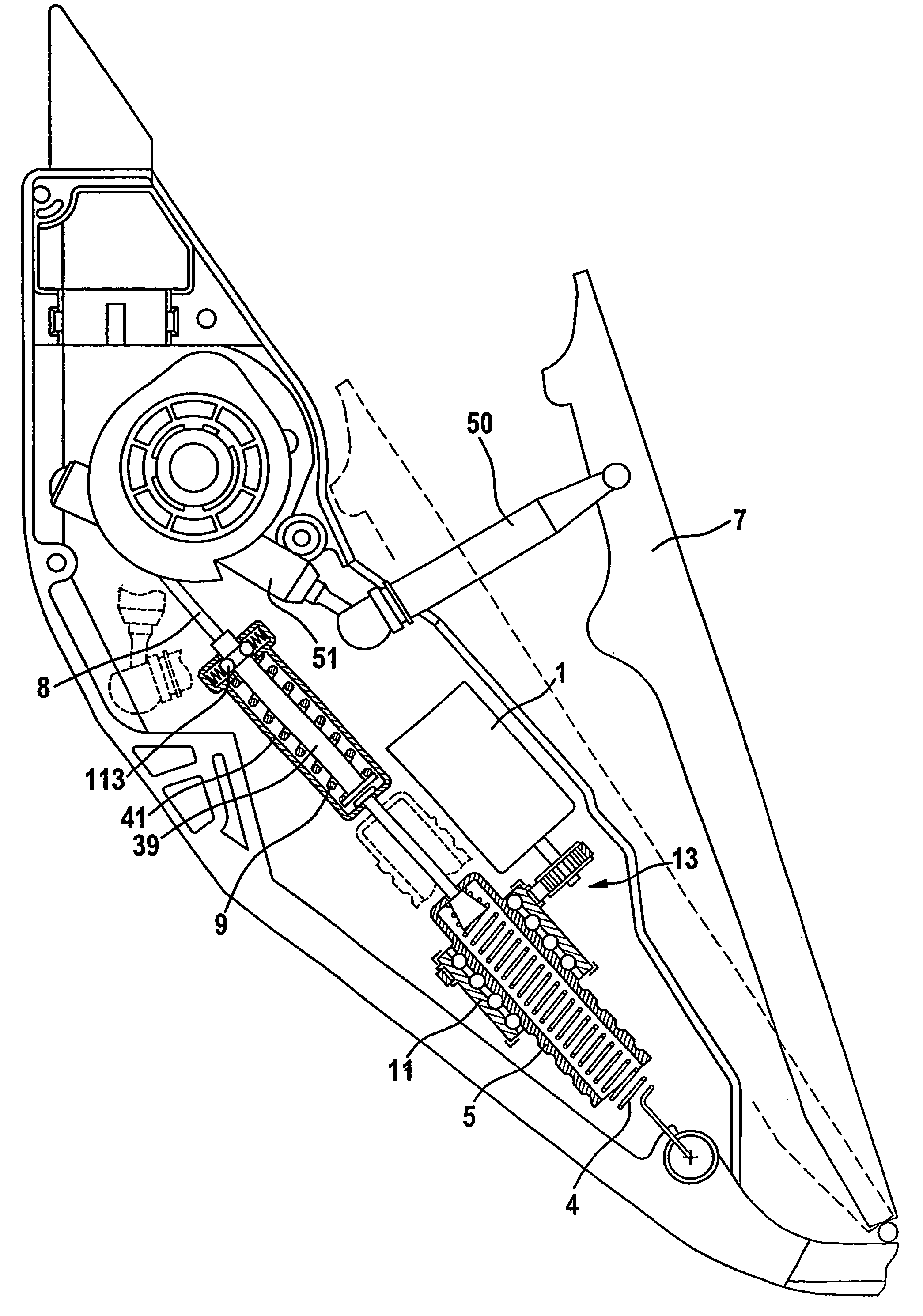

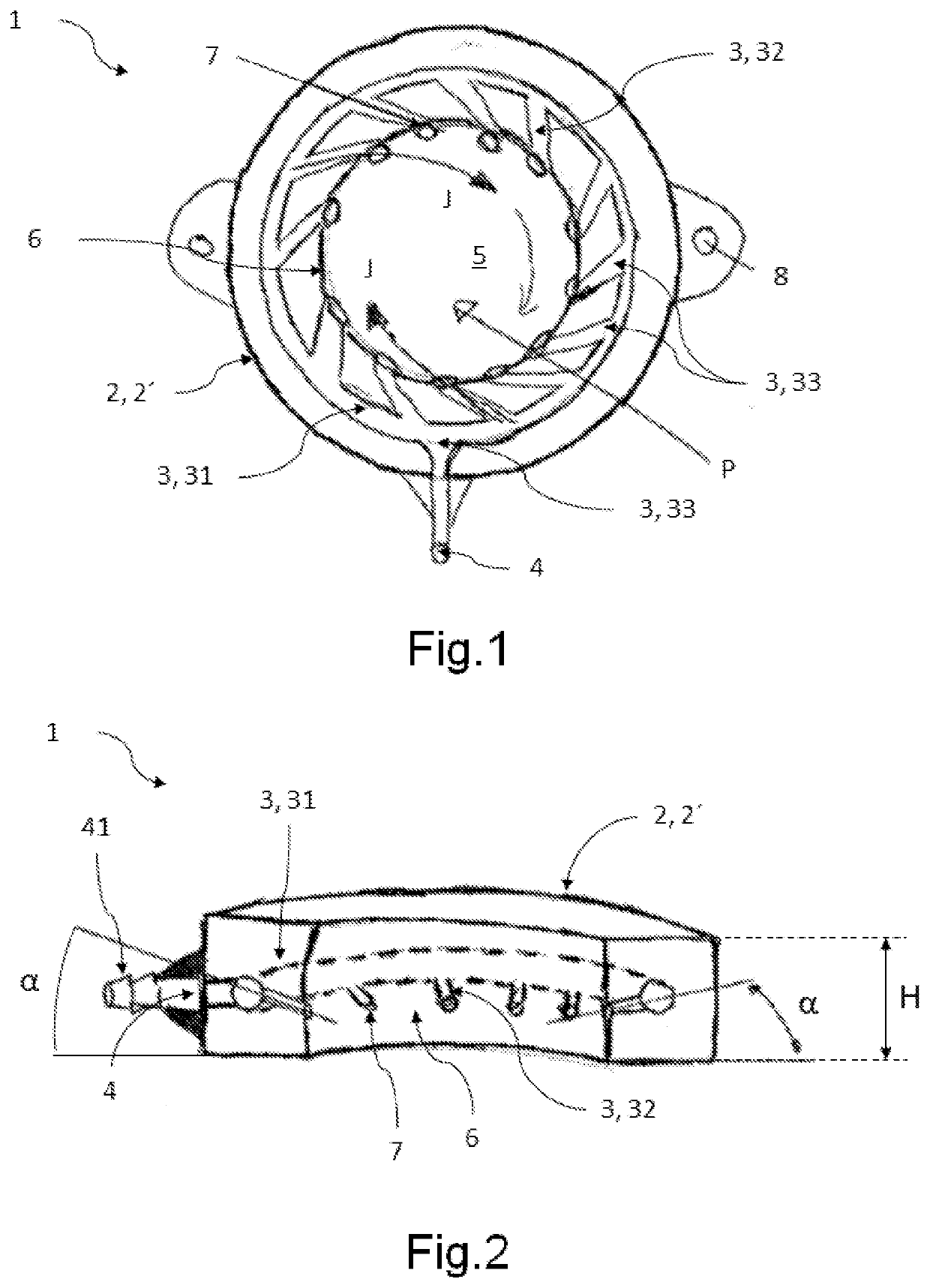

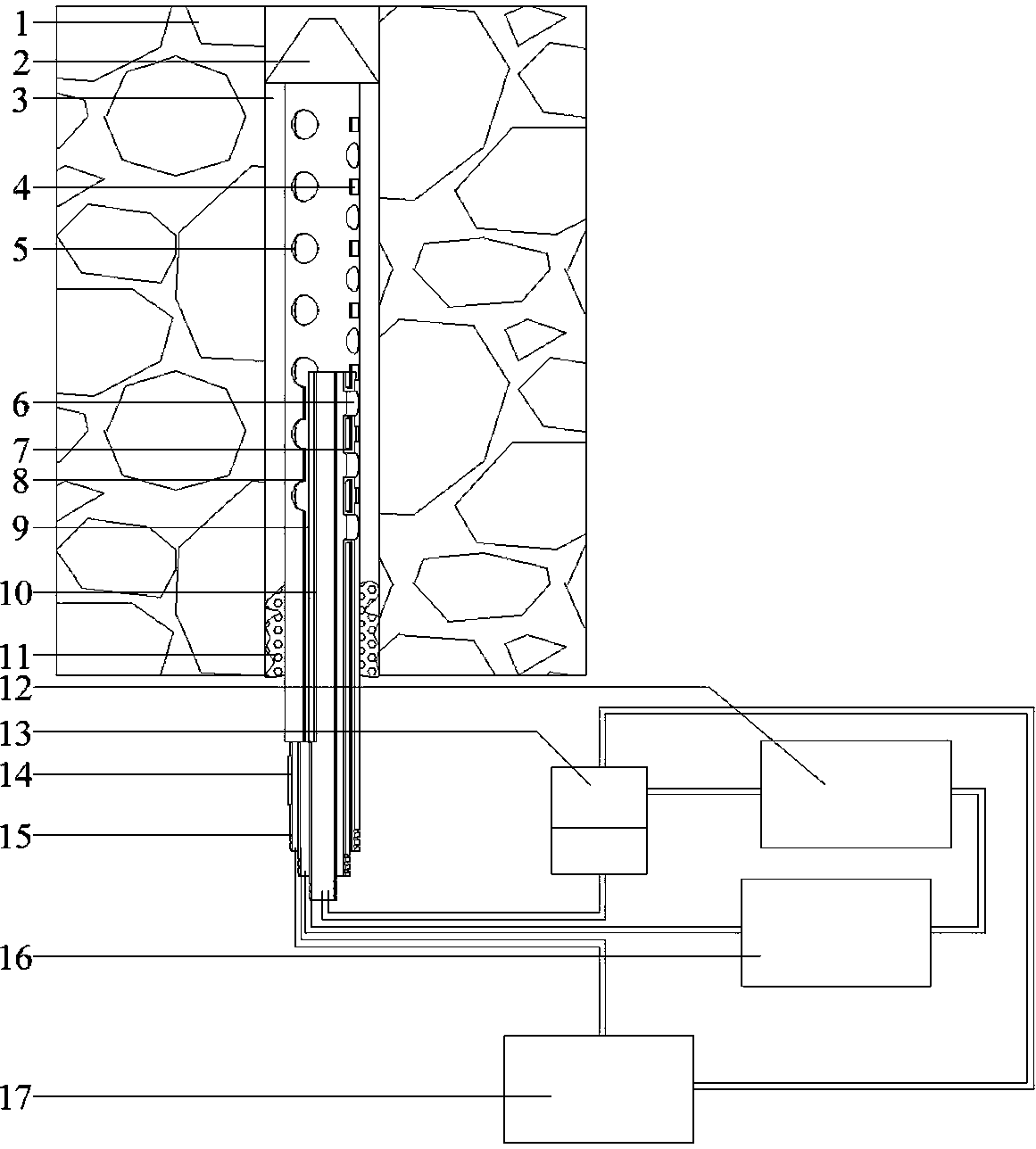

Catheter placement device

InactiveUS20090131872A1Avoiding catheter bleedingGood for observationGuide needlesInfusion syringesVeinCam

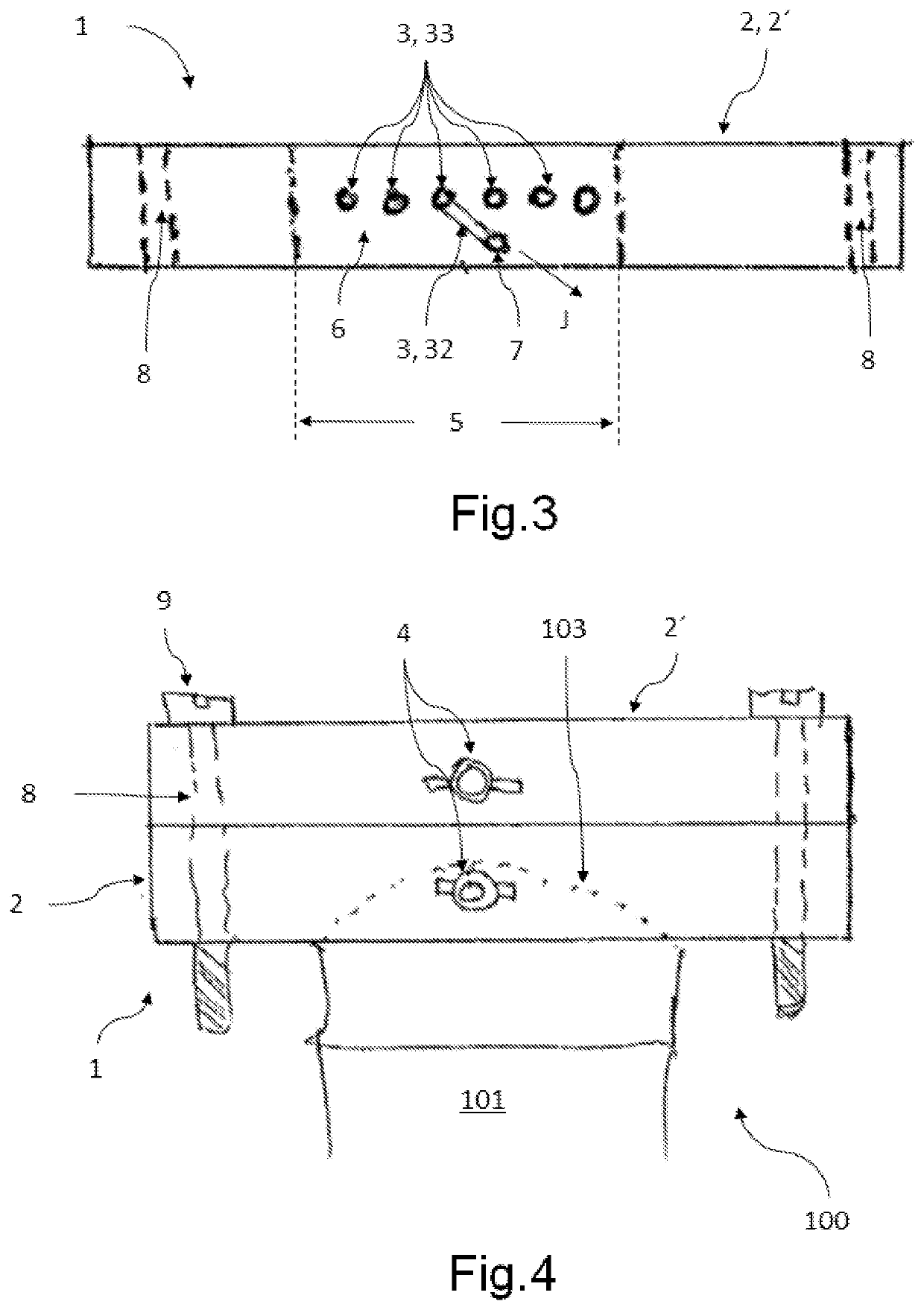

Abstract A catheter placement device (see FIG. 2) includes a needle unit, which in an initial position is releasably engaged with a housing distal end and has a sharp needle passing through a catheter and protruding distally of it. There is also a telescopic protector including guard unit, which is sliding in a housing guide. After inserting the needle into patient's vein, operator one-handedly pushes the guard unit distally, thereby emplacing the catheter, displacing the protector into a full length position and locking therein, and passively disengaging the needle unit from the hosing by a trigger cam located on the guard unit. As a result, a retracting spring moves a needle into retracted position, wherein it is protected from any contact with personal. Then, operator disconnects the guard from the catheter, turns the housing and occludes the catheter entrance with a cap, which was detachably mounted on the housing.

Owner:POPOV

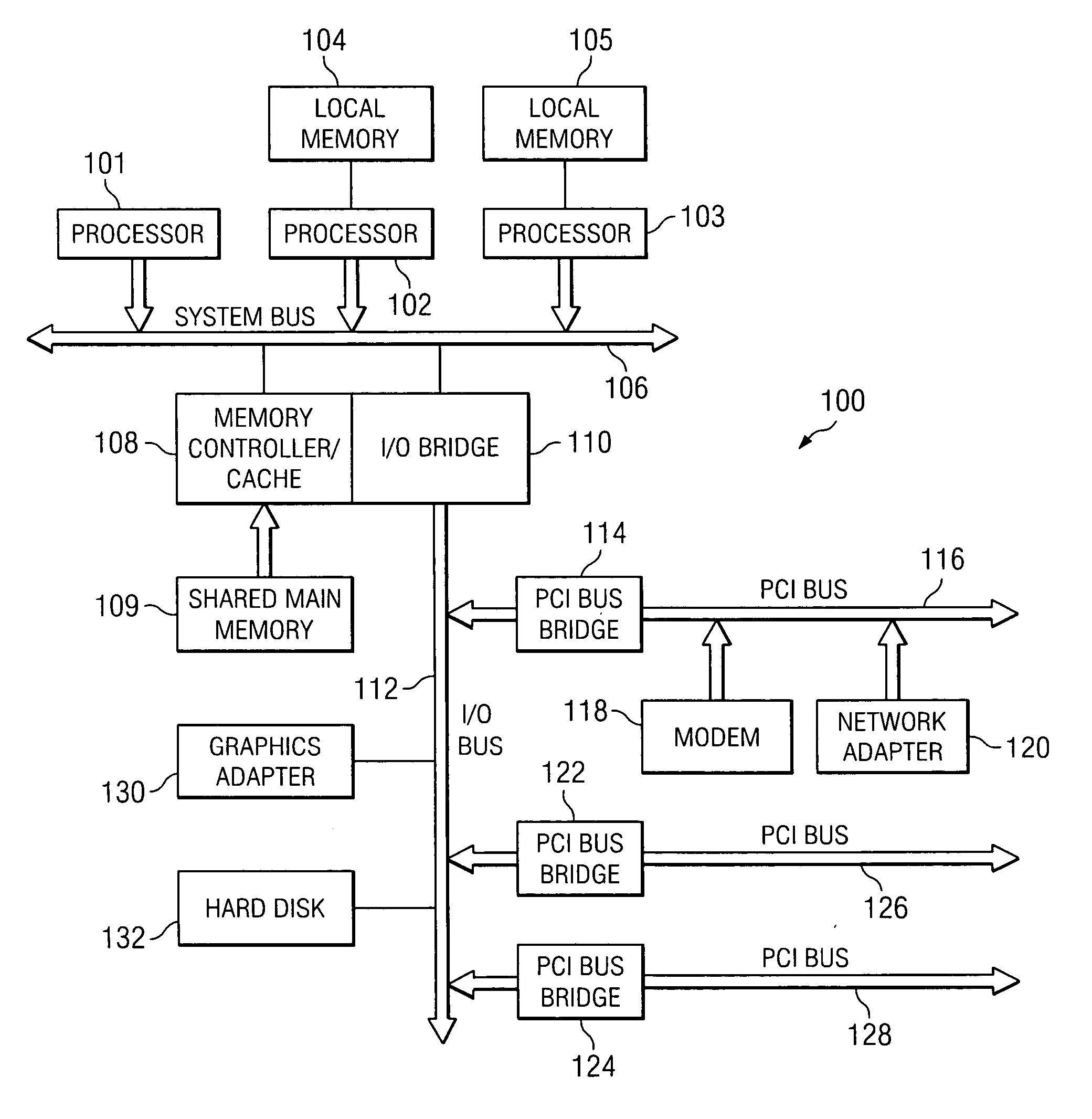

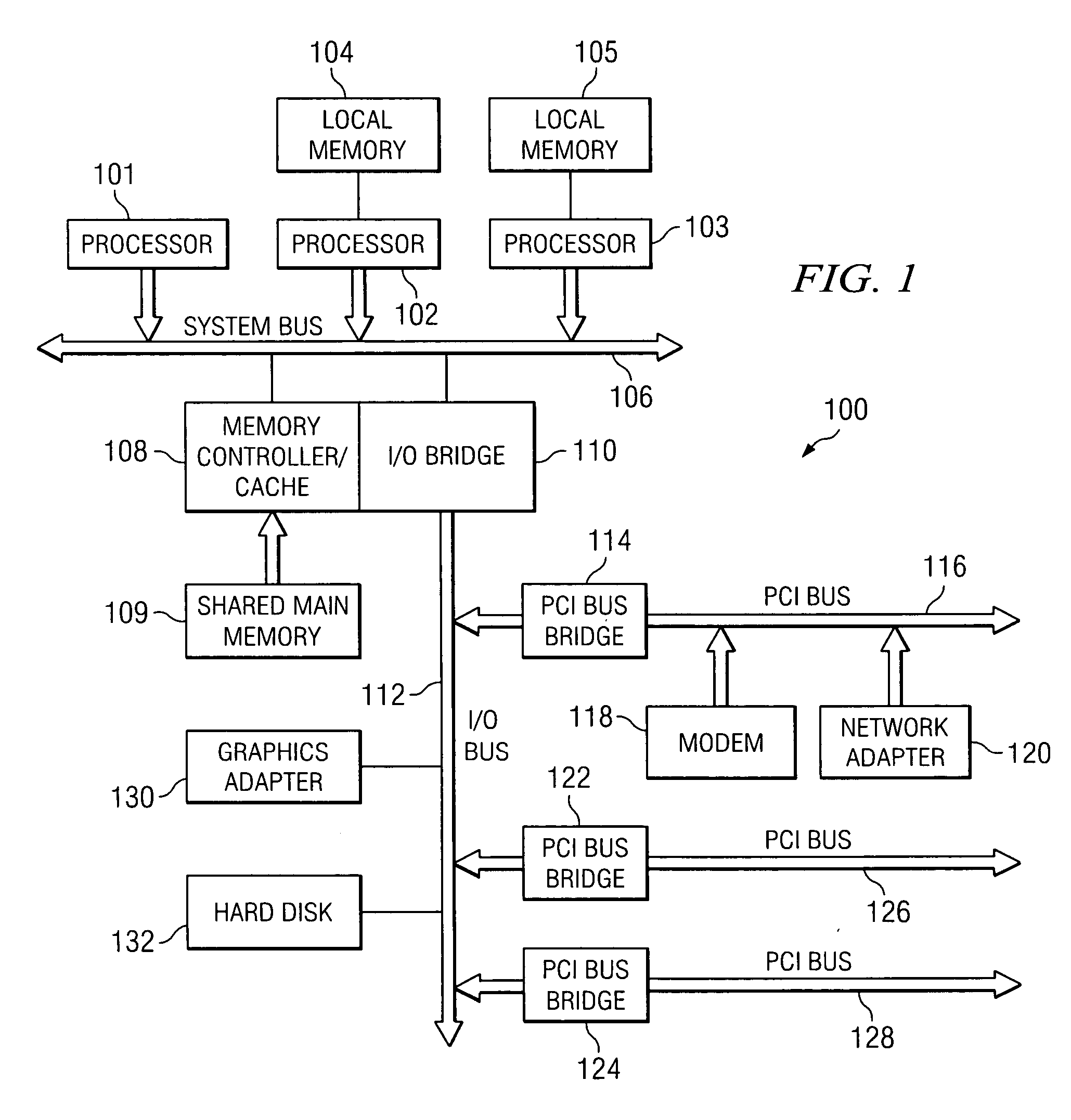

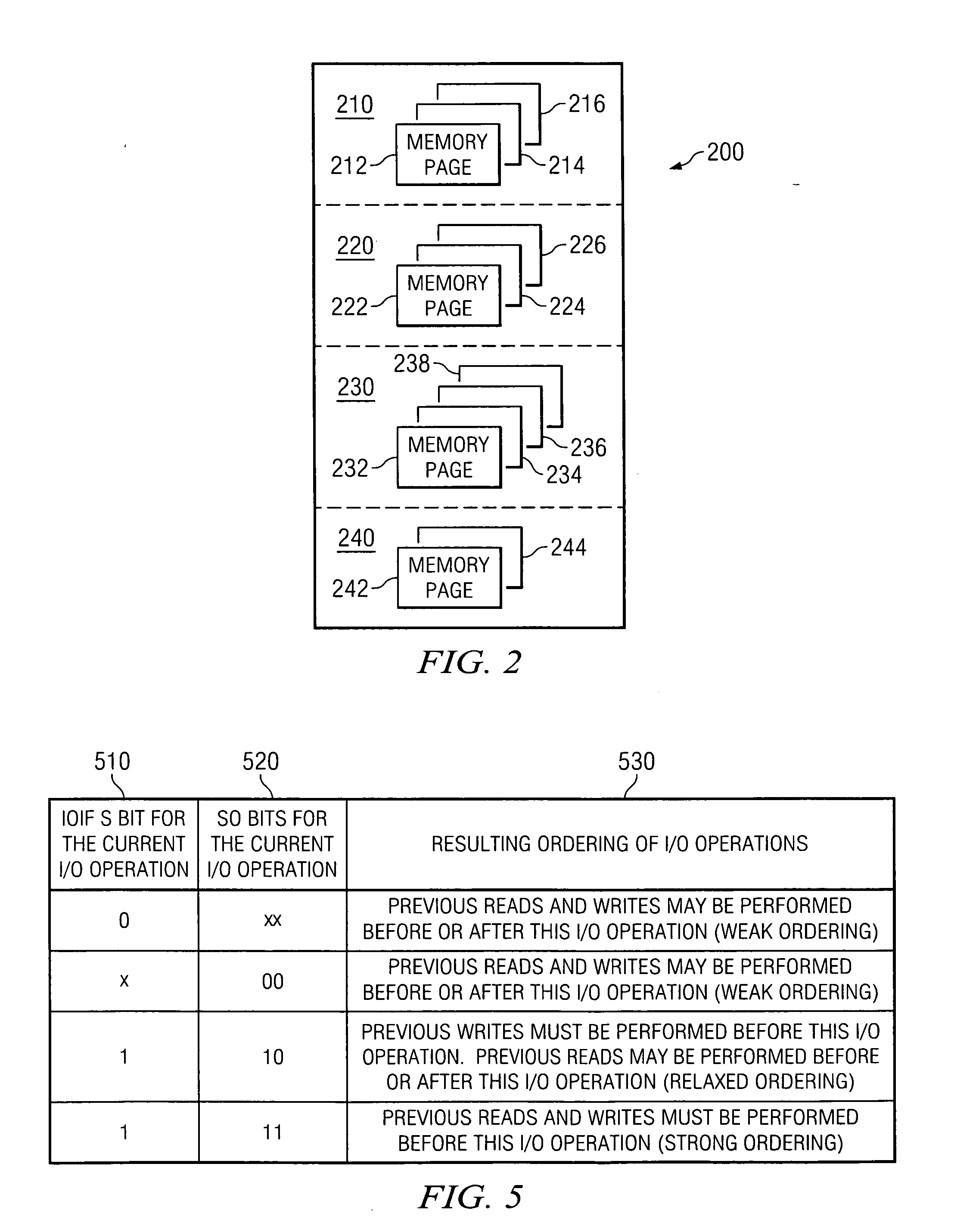

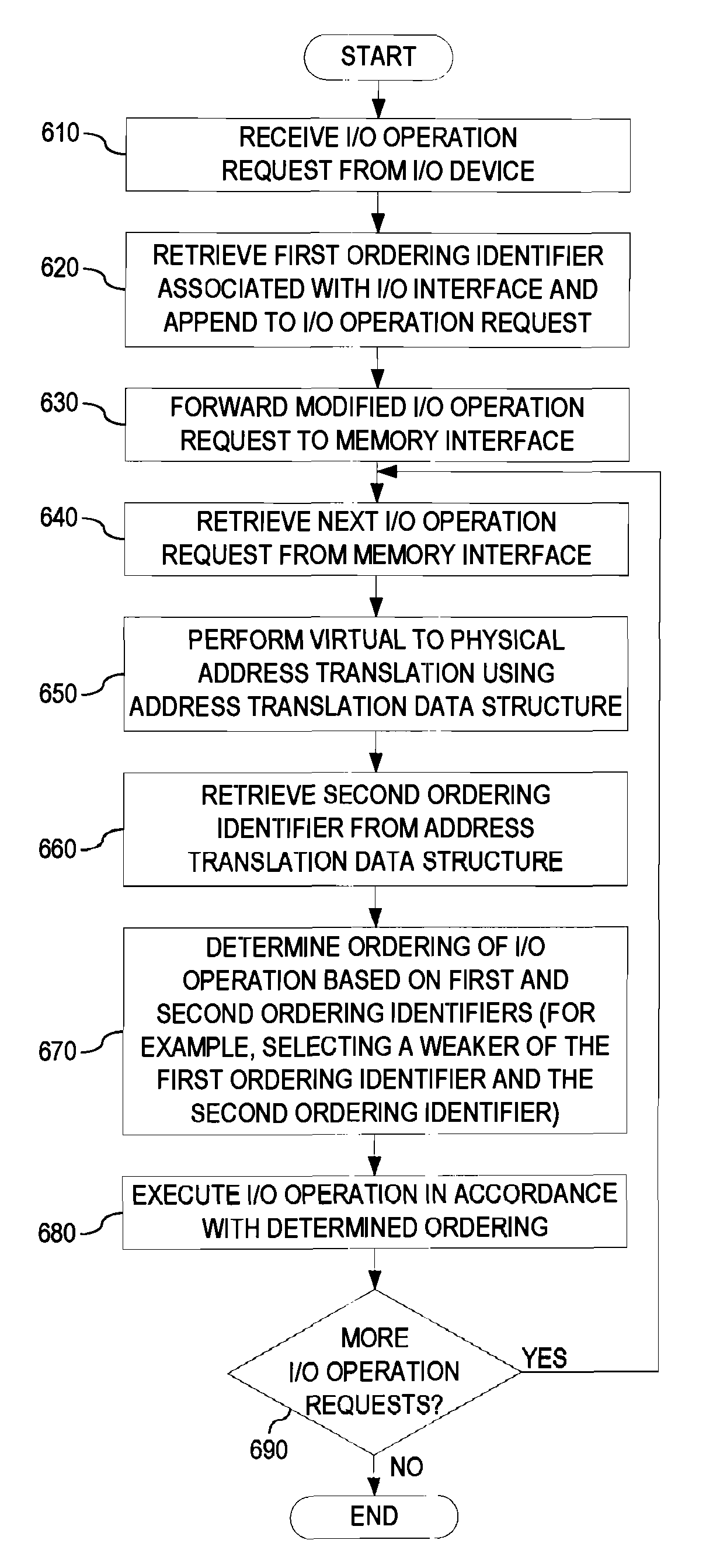

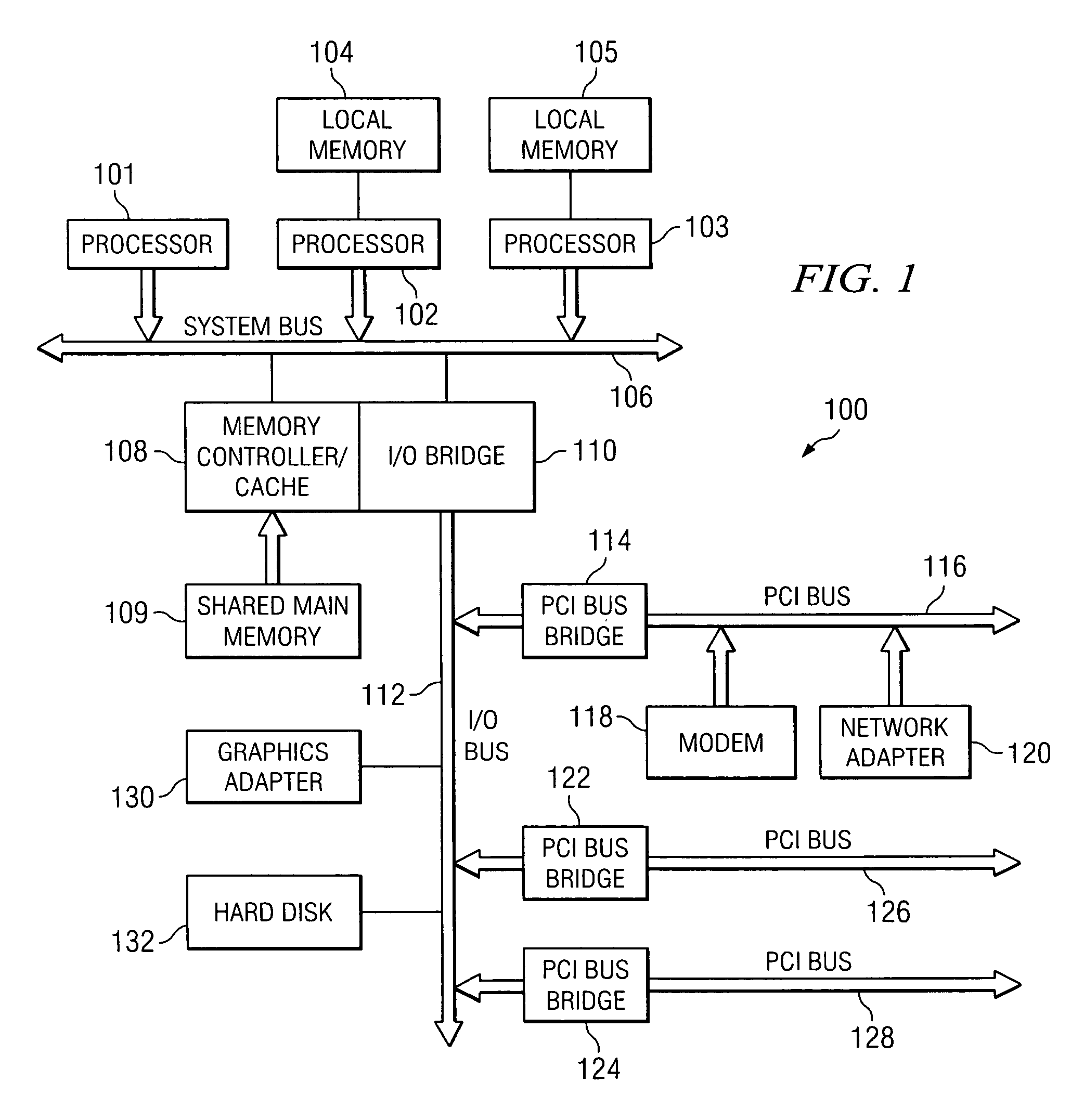

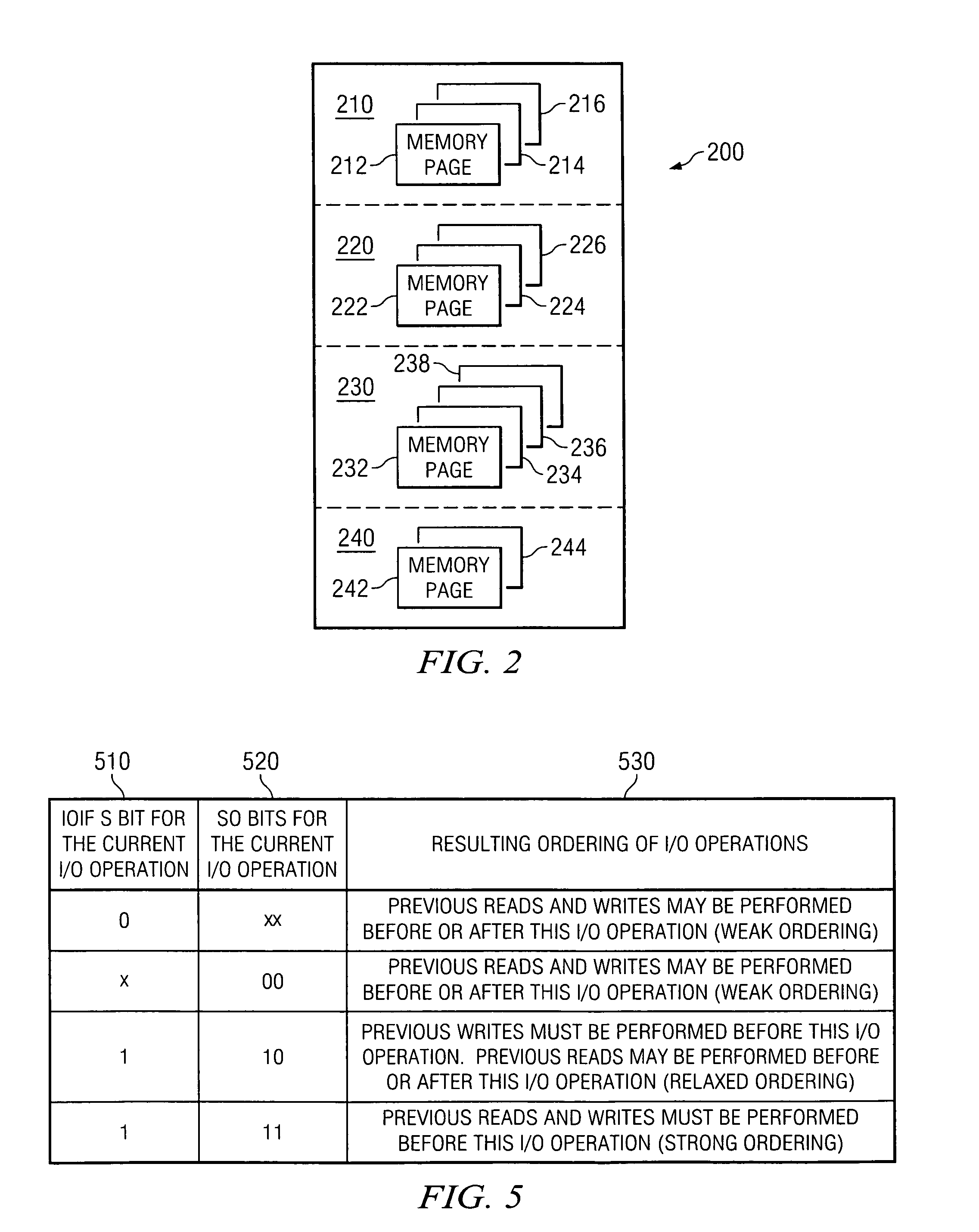

I/O address translation apparatus and method for specifying a relaxed ordering for I/O accesses

InactiveUS20070130372A1Simpler I/O device designPerformance maximizationMemory systemsInput/output processes for data processingPCI ExpressPage table

An I / O address translation apparatus and method for specifying relaxed ordering for I / O accesses are provided. With the apparatus and method, storage ordering (SO) bits are provided in an I / O address translation data structure, such as a page table or segment table. These SO bits define the order in which reads and / or writes initiated by an I / O device may be performed. These SO bits are combined with an ordering bit, e.g., the Relaxed Ordering Attribute bit of PCI Express, on the I / O interface. The weaker ordering indicated either in the I / O address translation data structure or in the I / O interface relaxed ordering bit is used to control the order in which I / O operations may be performed.

Owner:MACHINES CORP INT BUSINESS +1

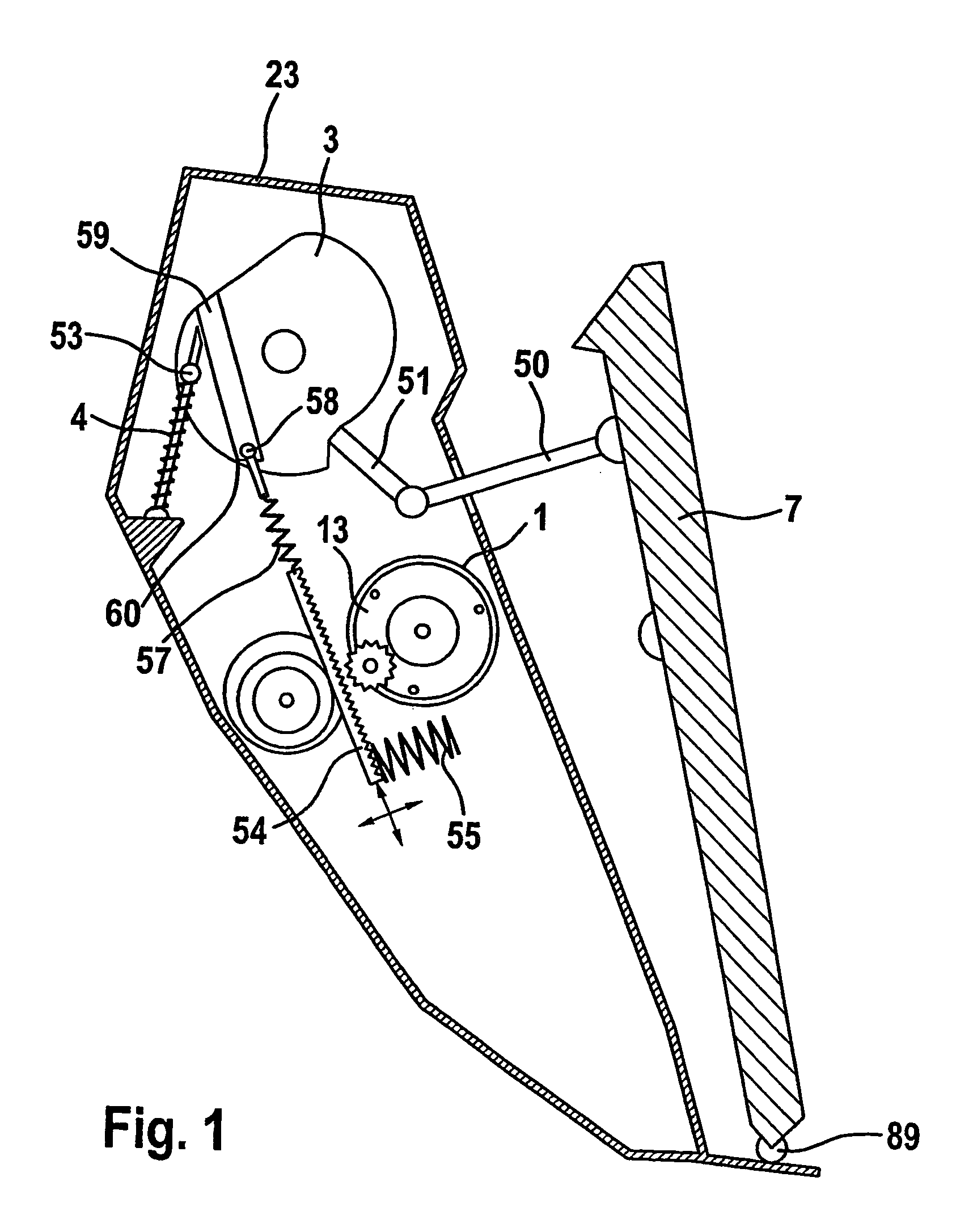

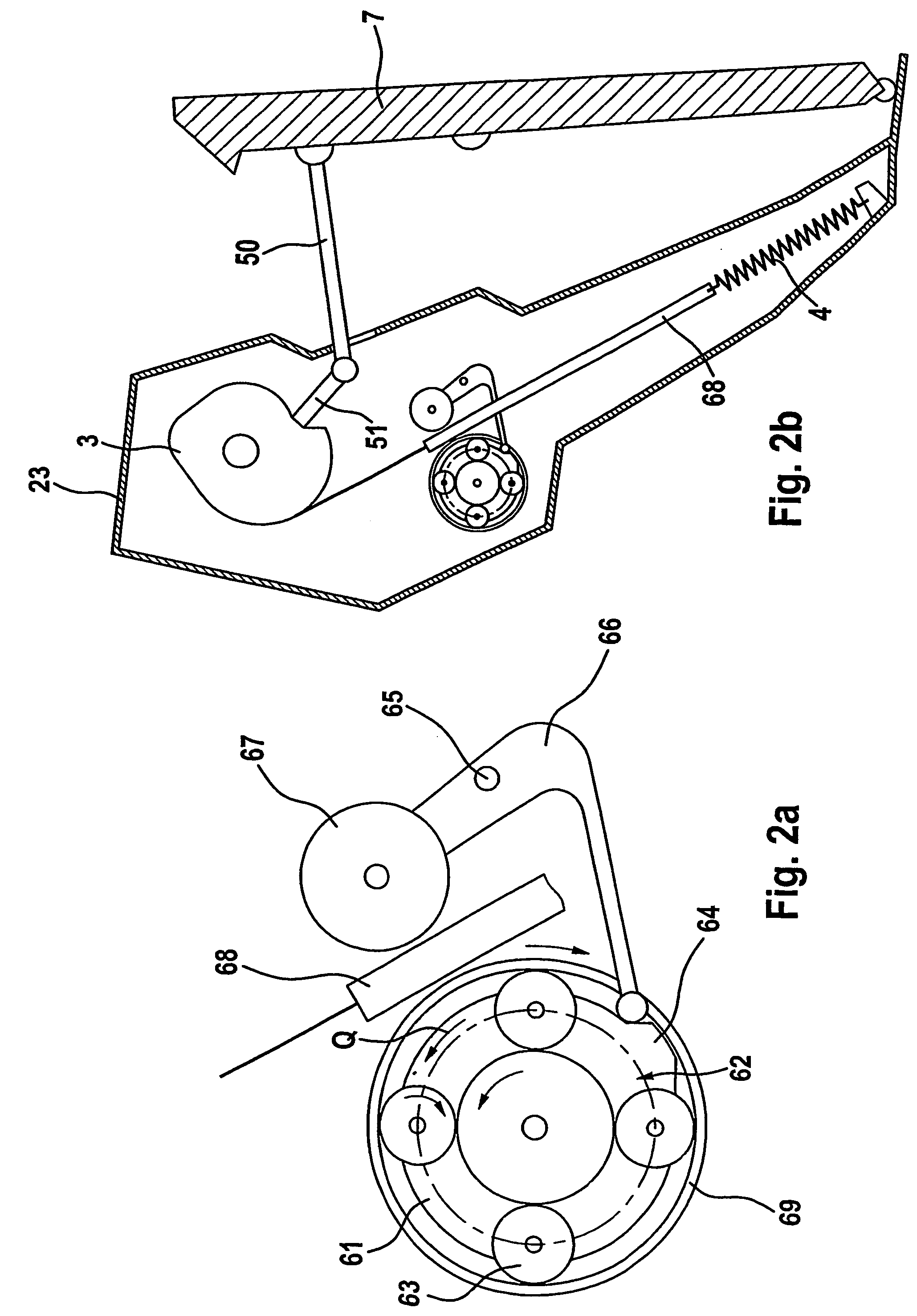

Device with additional restoring force on the gas pedal based on the deviation of a vehicle parameter from the set value

InactiveUS7770491B2Reduce manufacturing costImprove reliabilityControlling membersVehicle fittingsEngineeringRestoring force

It is known in the art to apply a counterforce, which opposes the actuating force, onto an accelerator pedal of a vehicle in the event that the vehicle, with respect to a vehicle parameter, sufficiently deviates from the nominal value. The parameter can be the speed or the measured distance from vehicles driving ahead.The invention discloses a series of embodiments that satisfy especially easily and reliably the defined requirements for applying the counterforce to the pedal.

Owner:CONTINENTAL TEVES AG & CO OHG

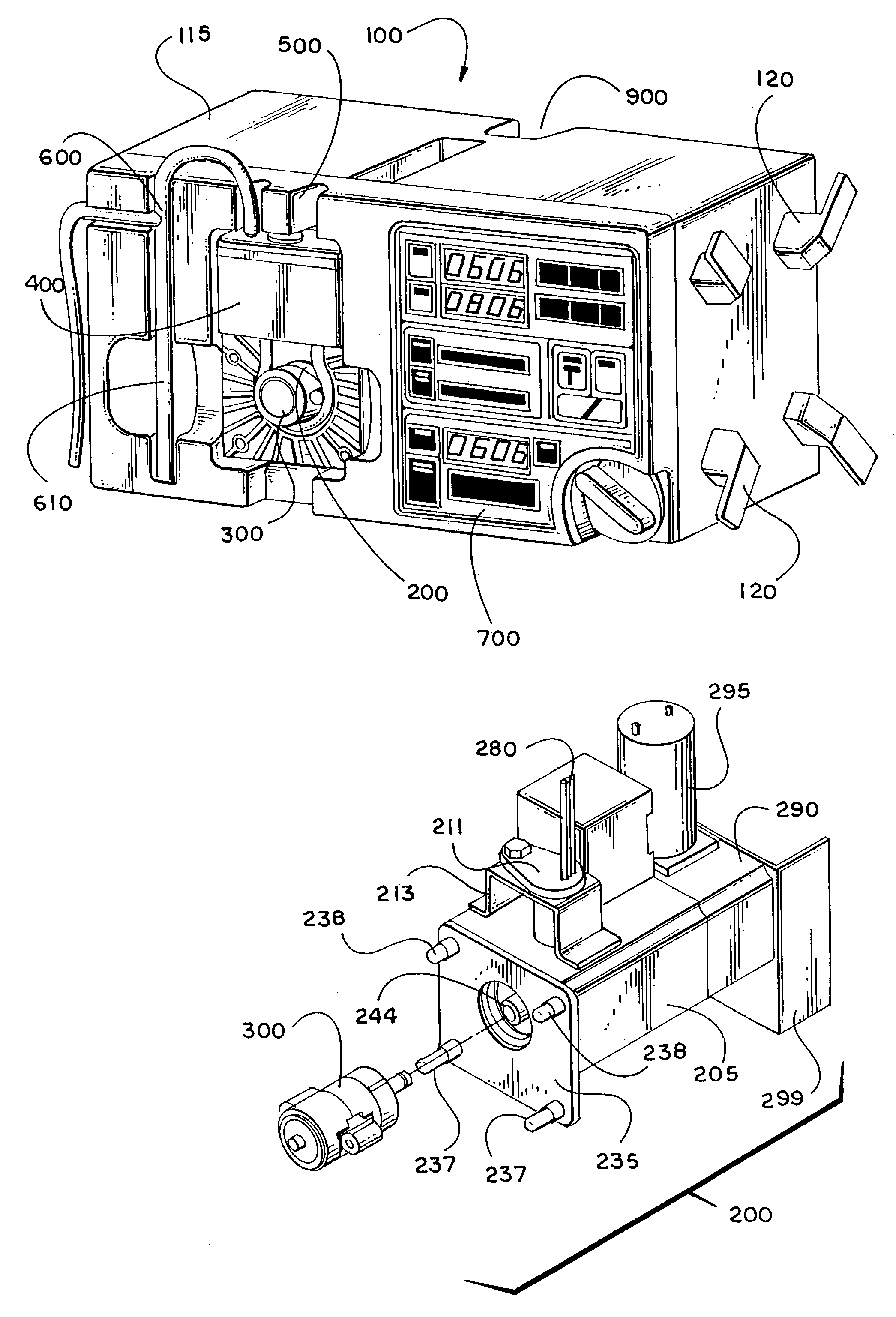

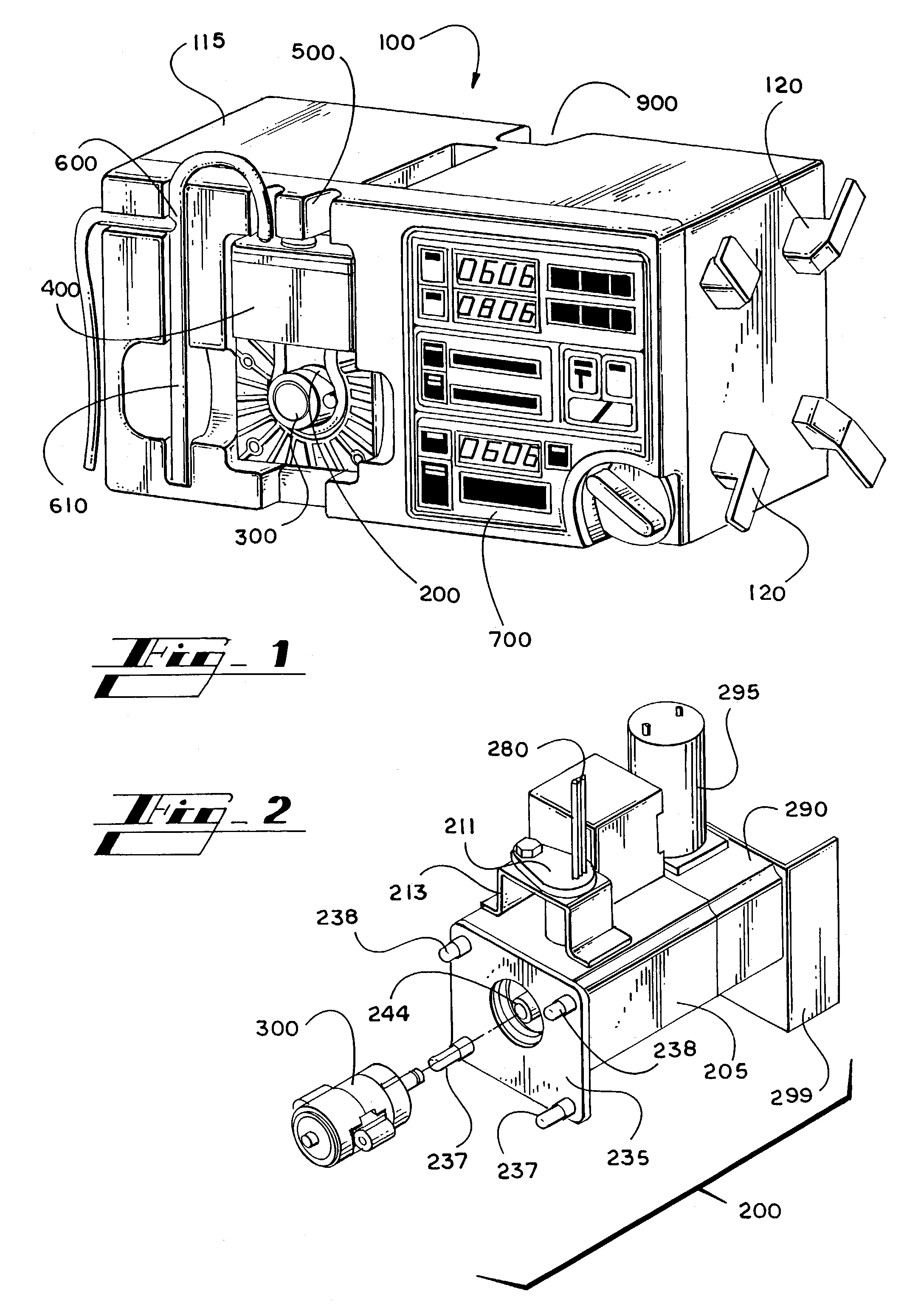

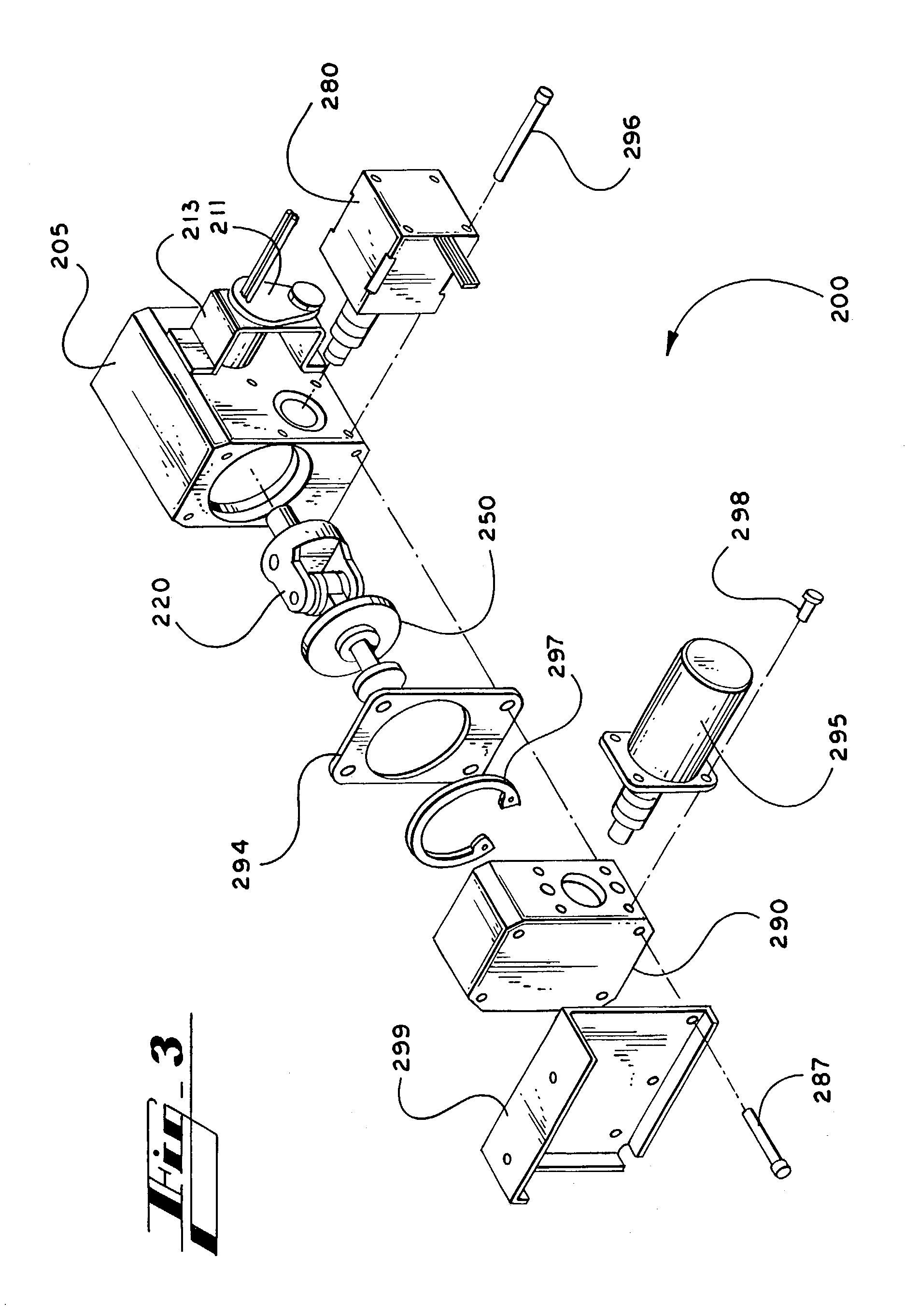

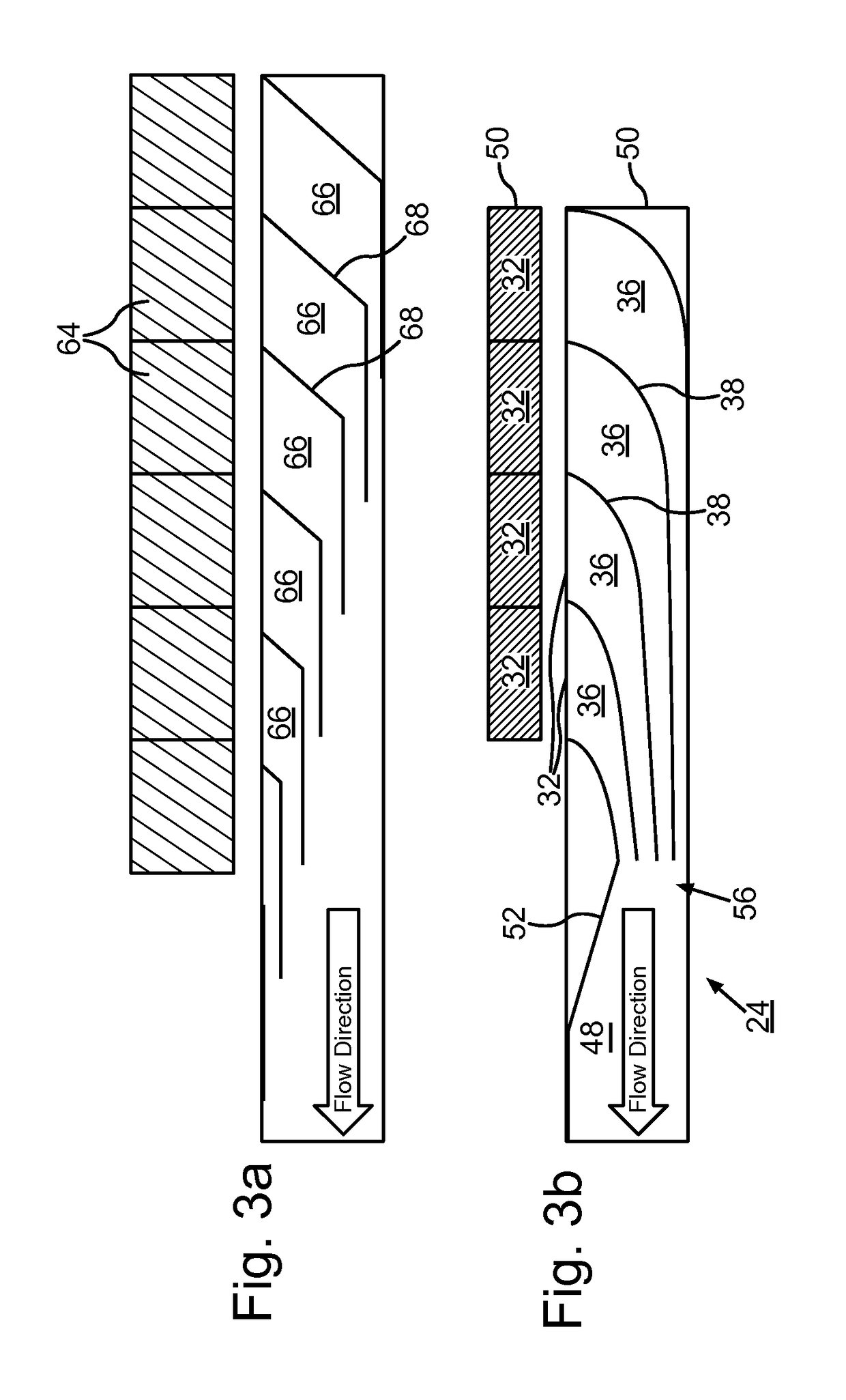

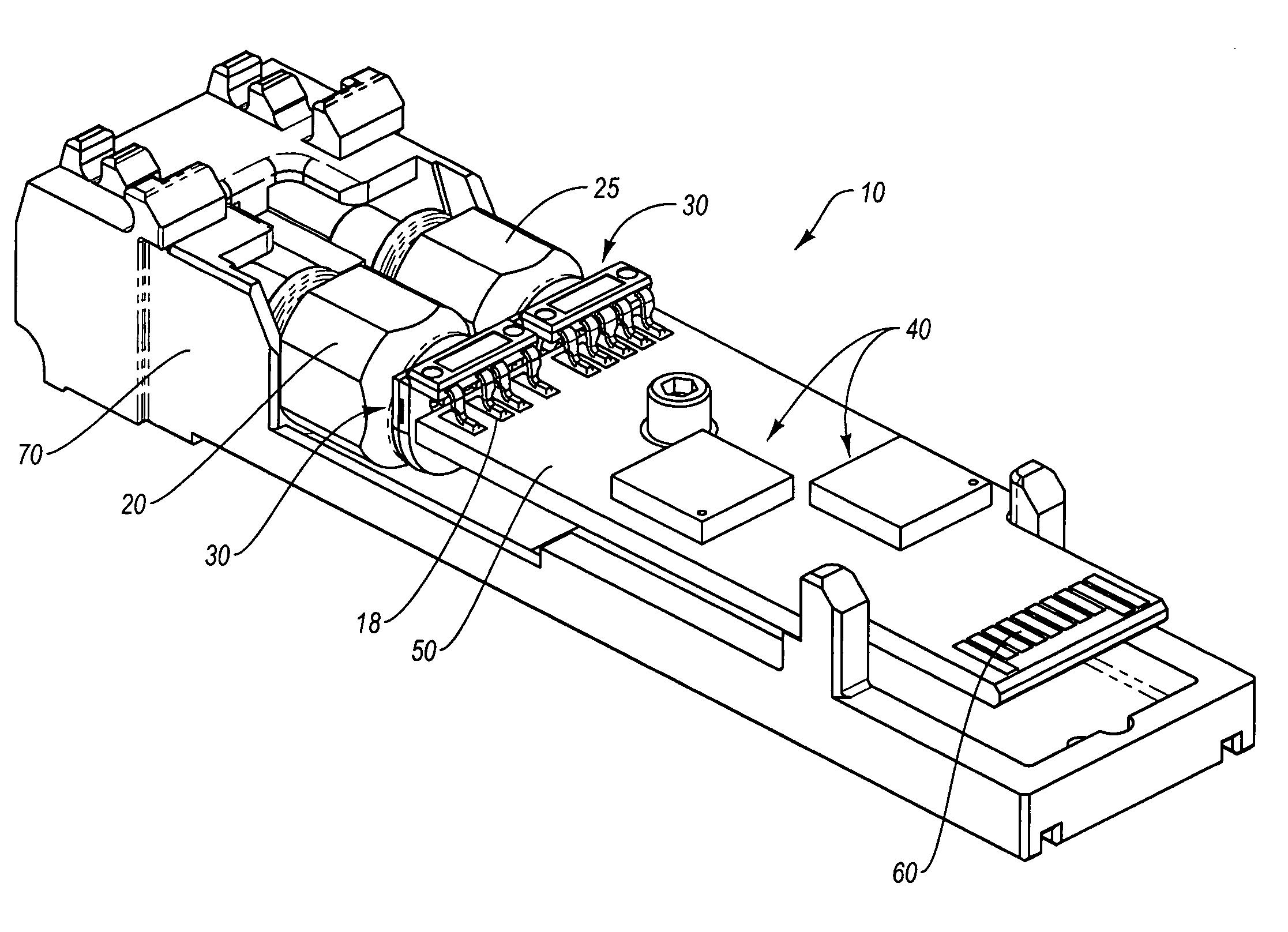

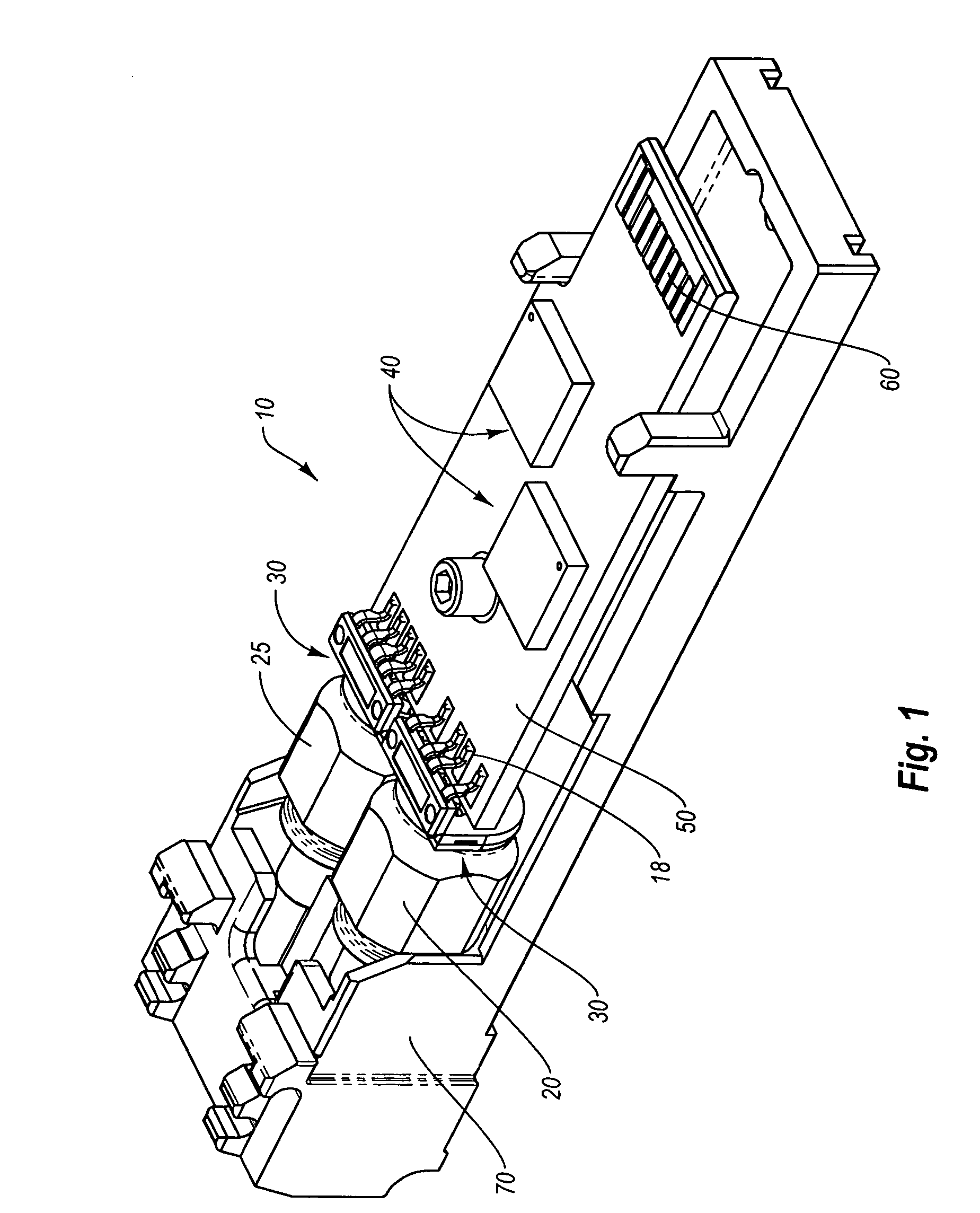

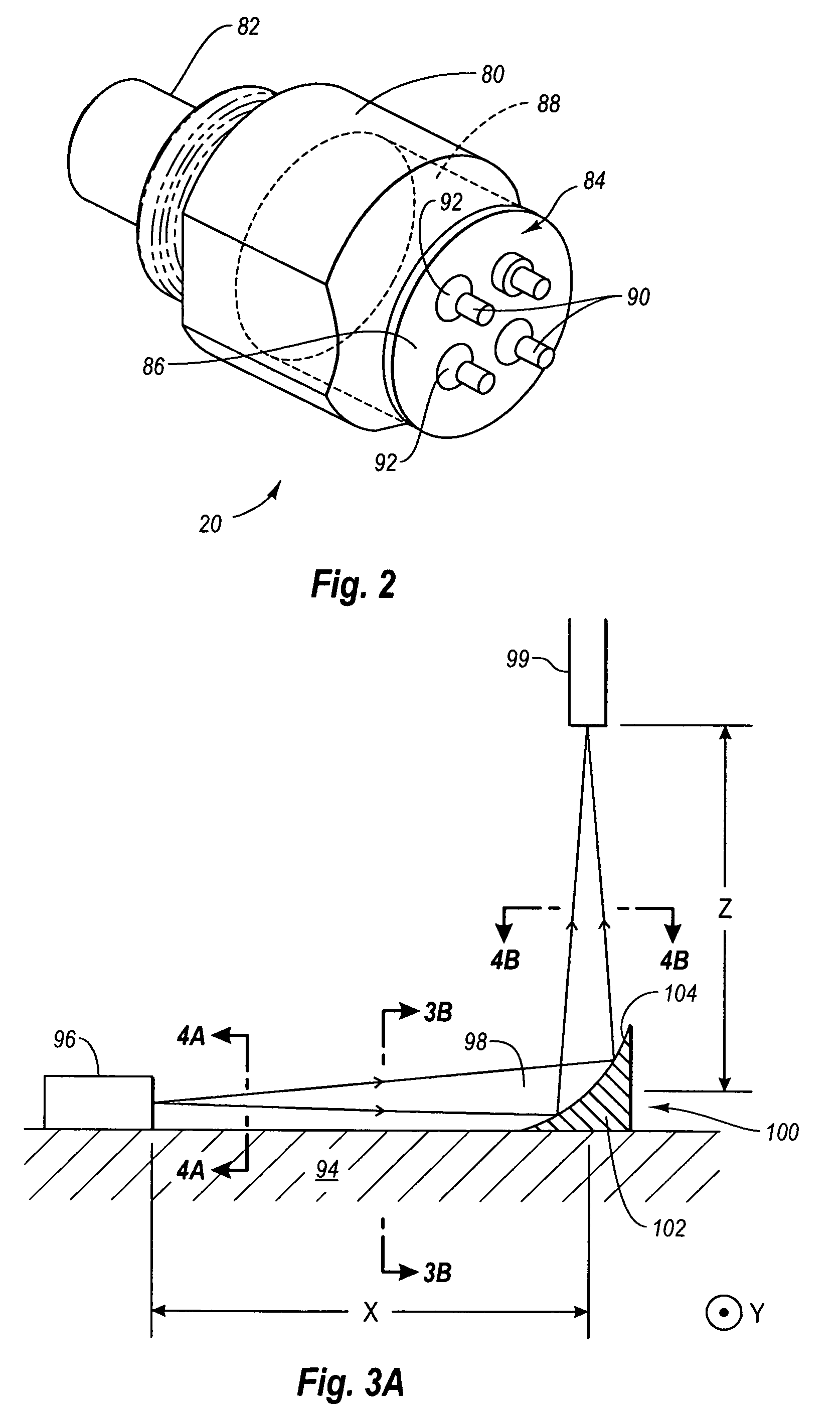

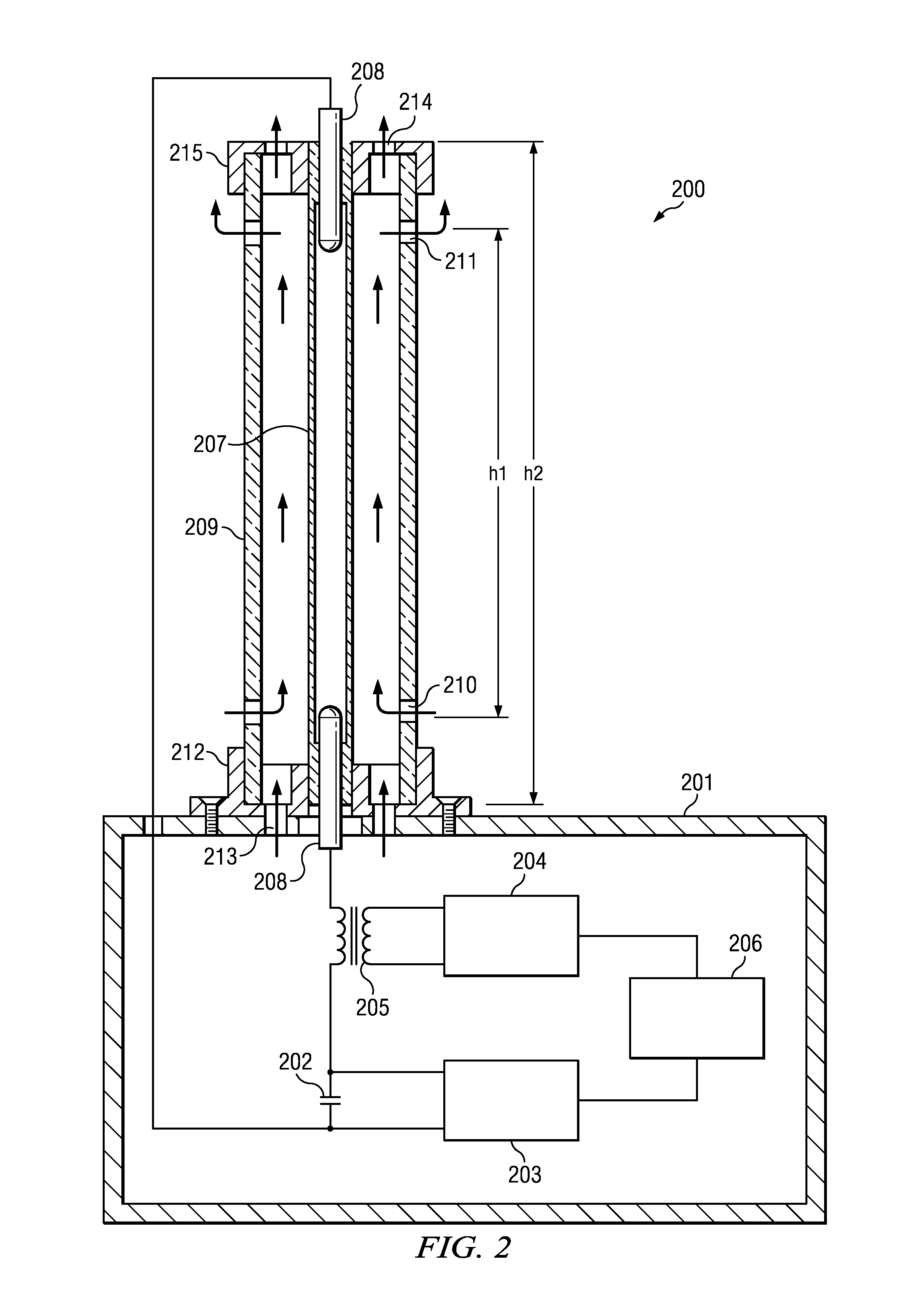

Rapid infusion system

InactiveUS7311691B2Easy to installMechanical function is enhancedFlexible member pumpsPharmaceutical delivery mechanismPump chamberBiomedical engineering

A rapid infusion system for the intravenous delivery of fluids at standard and rapid flow rates. The system includes a pump assembly, a drive assembly to power the pump, and a fluid containment system that keeps the infused fluid out of direct contact with the pump assembly and that is preferably disposable and removable. In one embodiment the drive assembly includes a differential drive that interacts with more than one motor. In one embodiment, the pump assembly includes a roller pump and the pump chamber is a collapsible, preformed tube that is preferably attached to a pump cartridge frame. Optionally, the system includes a self-leveling drip chamber and the fluid containment system is disposable and includes a pump cartridge containing the drip chamber and the pump chamber, I.V. tubing, outlet infusion tubing, and a heater cartridge.

Owner:SMISSON CARTLEDGE BIOMEDICAL

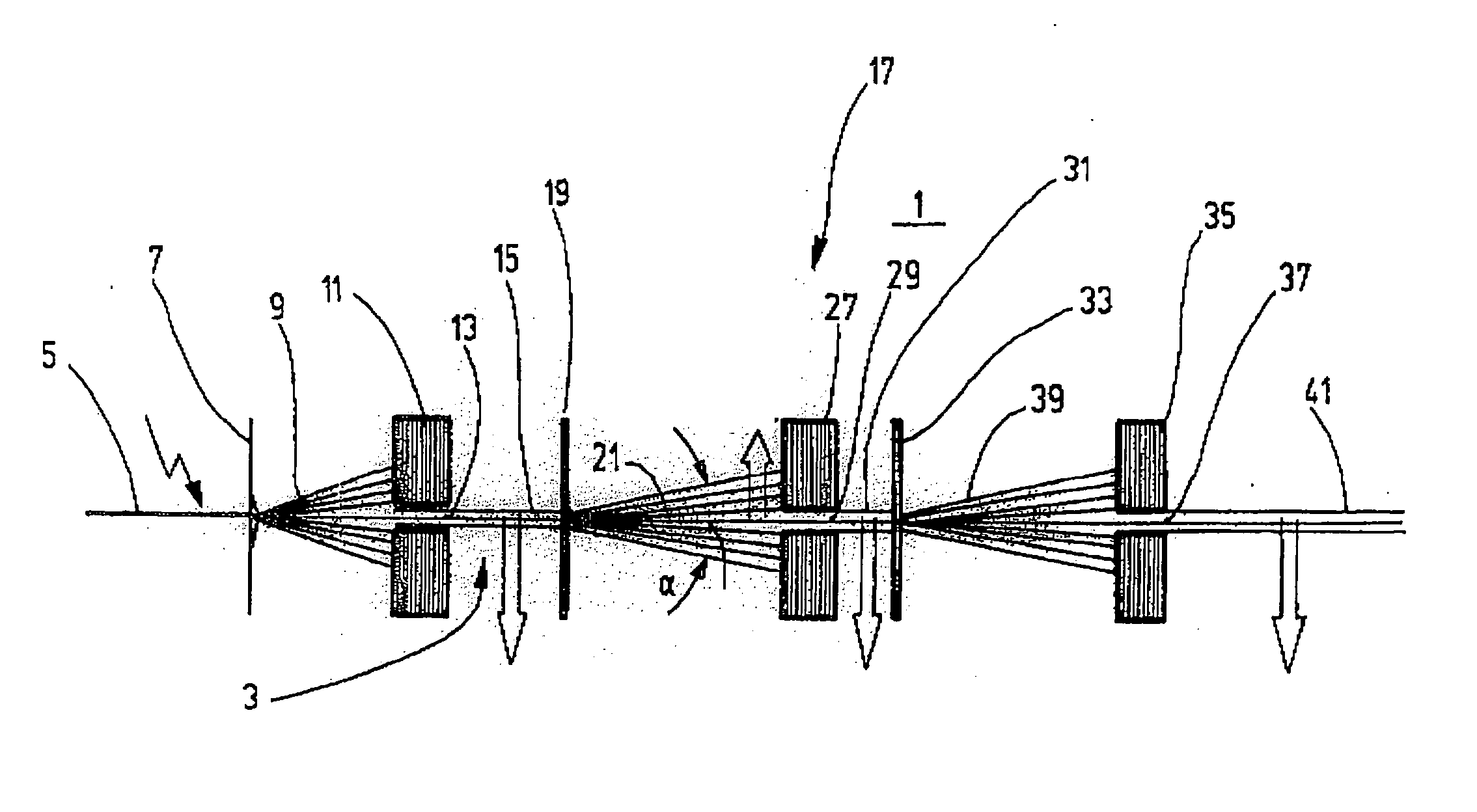

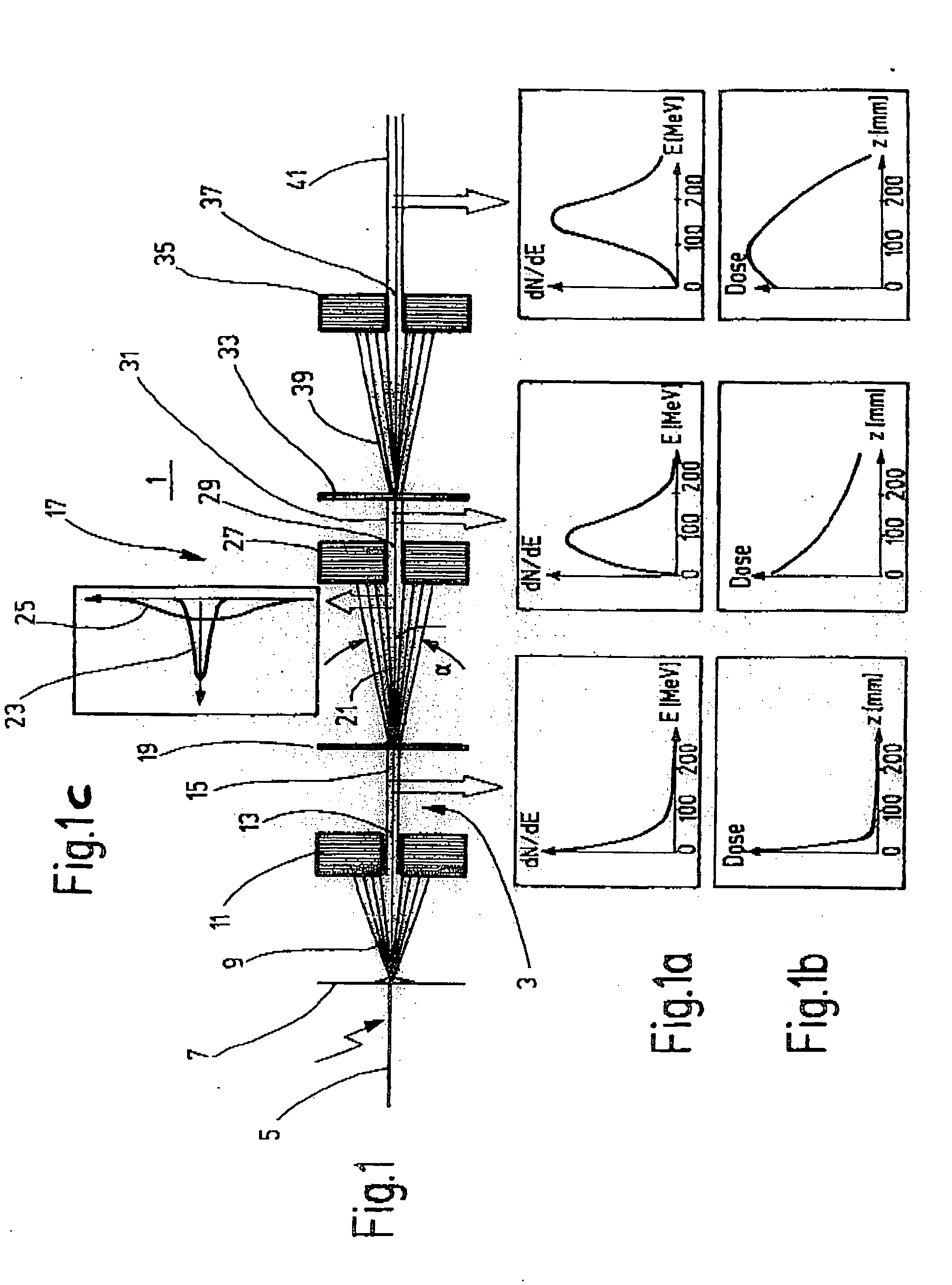

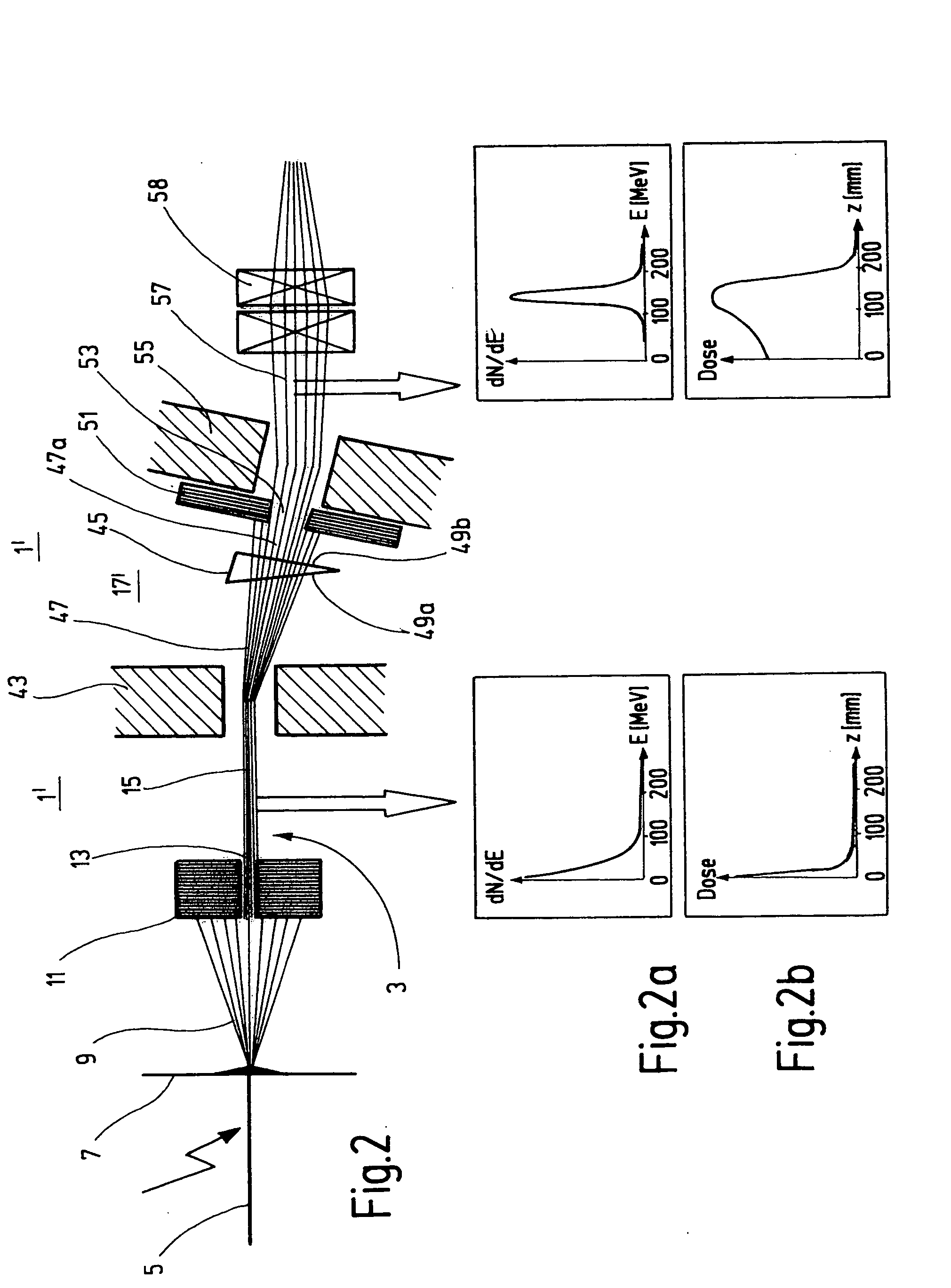

Energy filter device

InactiveUS20050029471A1Simple device designEnhance the imageHandling using diaphragms/collimetersDischarge tube/lamp detailsCollimatorLight beam

An energy filter device for beams which are used in the course of ion beam therapy, wherein at least one passive modulator is provided. The modulator comprises a scattering film for the beams and a collimator with an opening for controlling the beams.

Owner:GSI HELMHOLTZZENT FUR SCHWERIONENFORSCHUNG

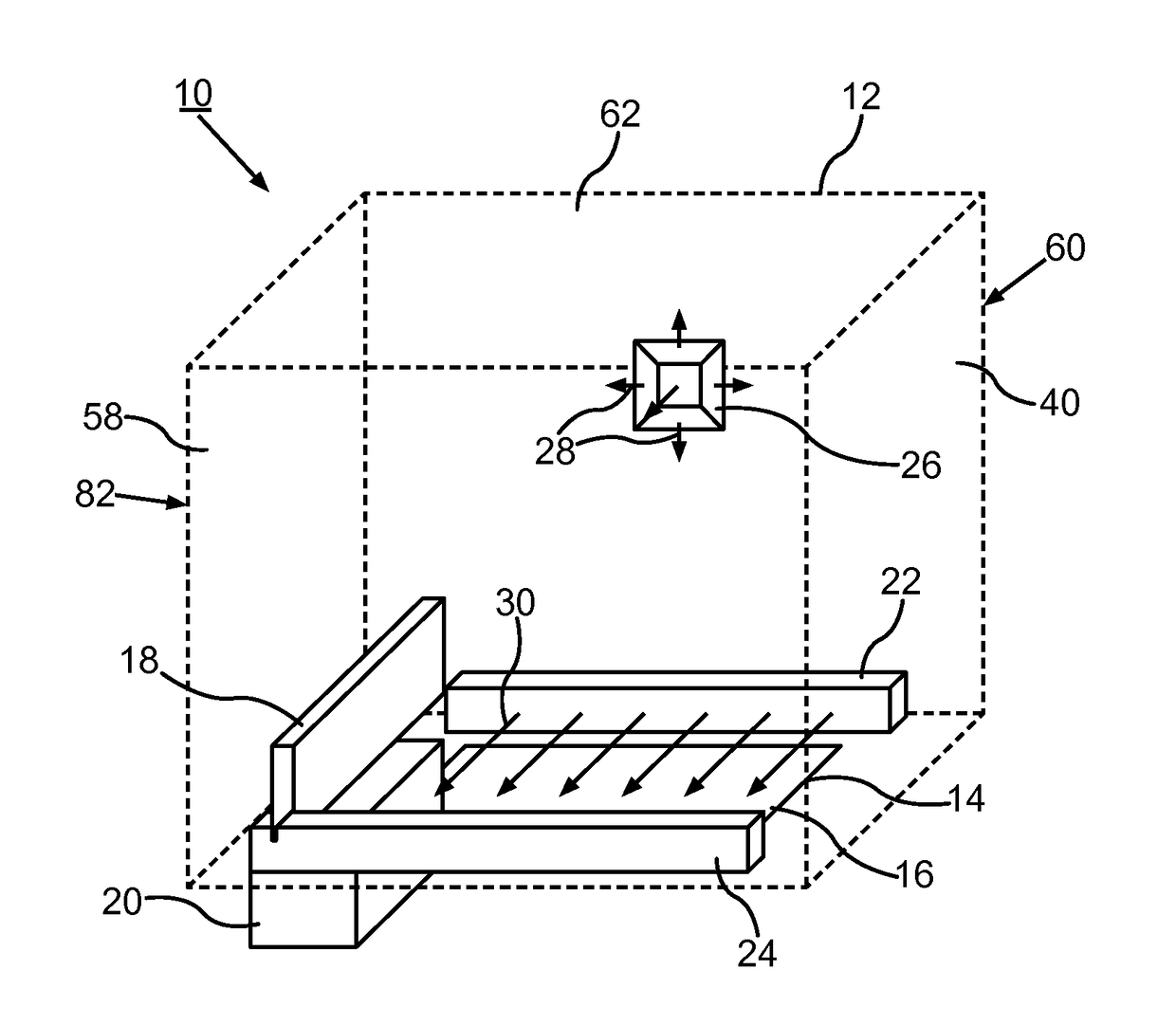

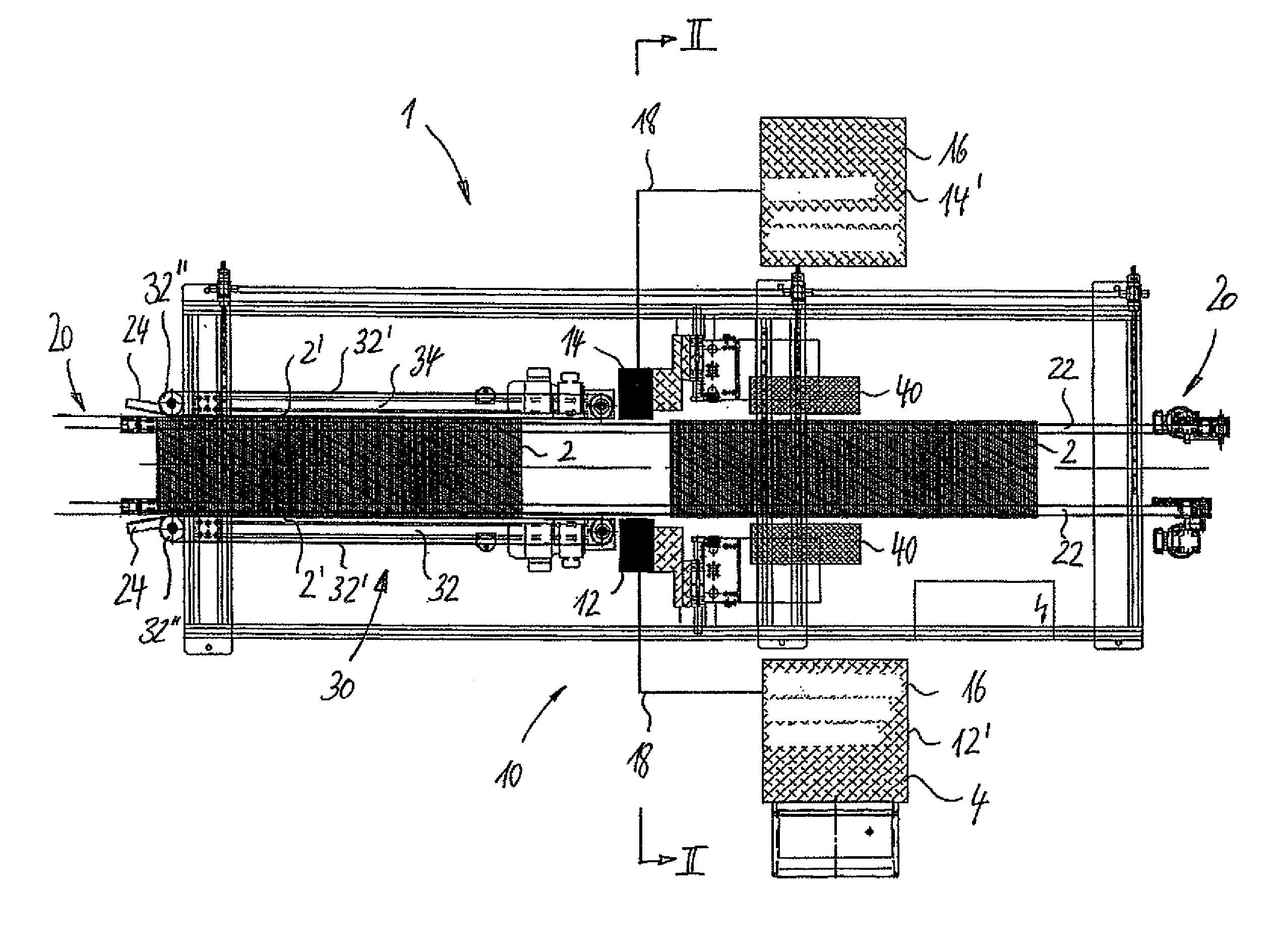

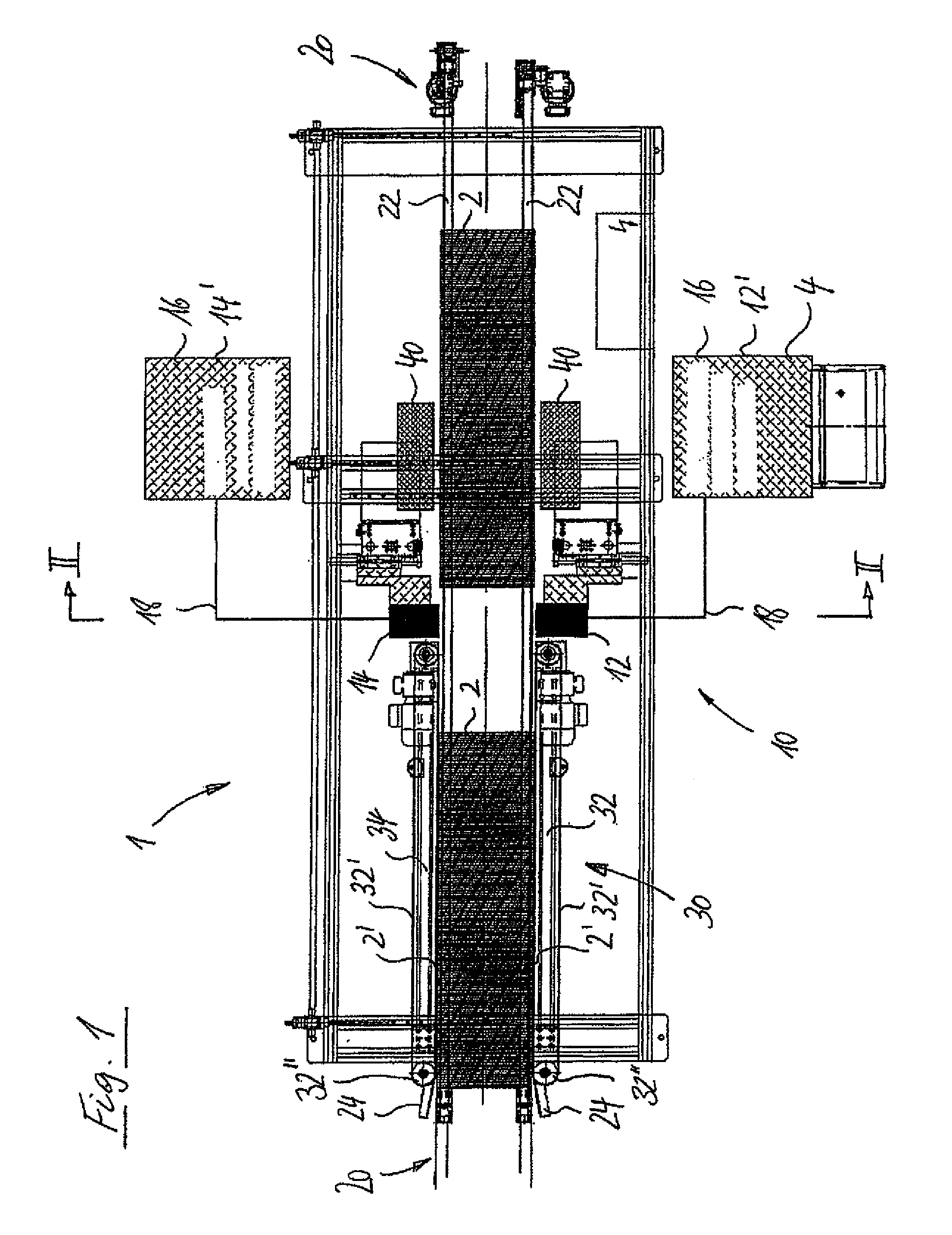

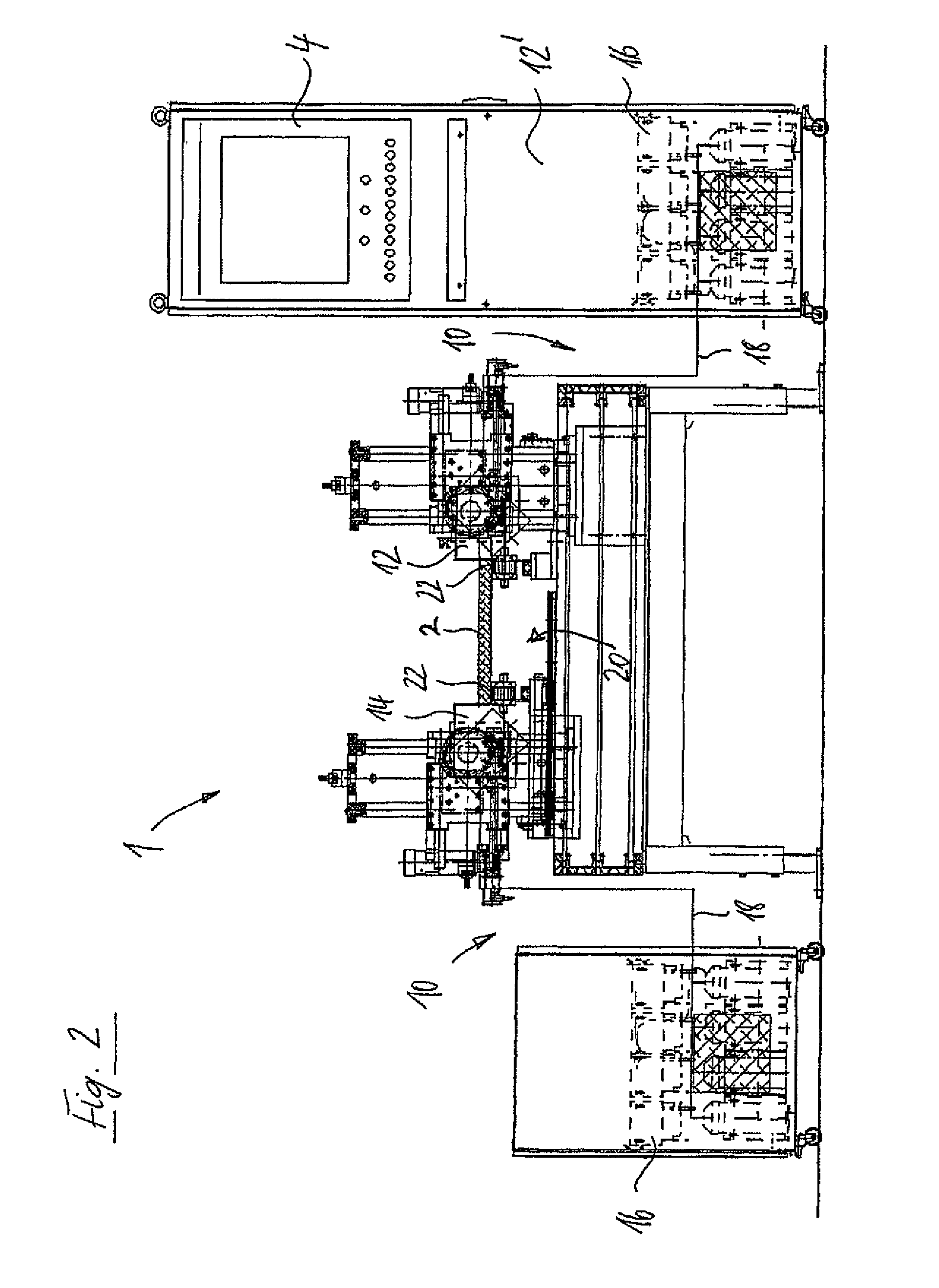

Device and method for the manufacture or repair of a three-dimensional object

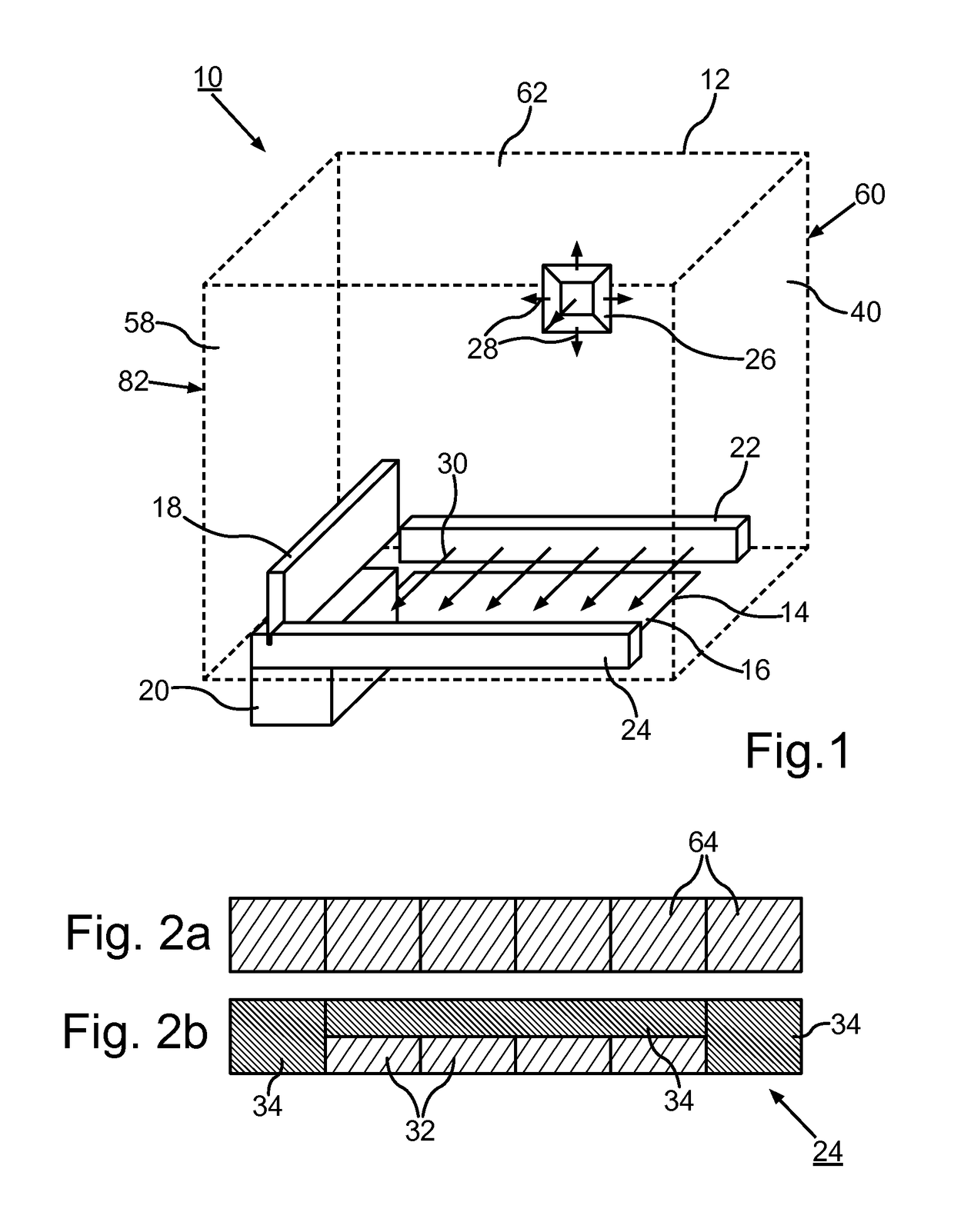

ActiveUS10112236B2Increase flow rateCompact designAdditive manufacturing apparatusCeramic shaping apparatusEngineeringBuilding construction

The invention relates to a device for the manufacture or repair of a three-dimensional object, comprising at least one construction chamber for a successive solidification of at least one solidifiable material layer by the layer in predefined regions for the layer-by-layer buildup of the three-dimensional object or for the layer-by-layer repair of individual regions of the three-dimensional object within the construction chamber, and at least one inlet nozzle and at least one suction nozzle for a process gas, wherein the inlet nozzle and the suction nozzle are arranged in such a way that a gas flow that passes at least partially over a construction platform formed in a construction chamber is created.

Owner:MTU AERO ENGINES GMBH

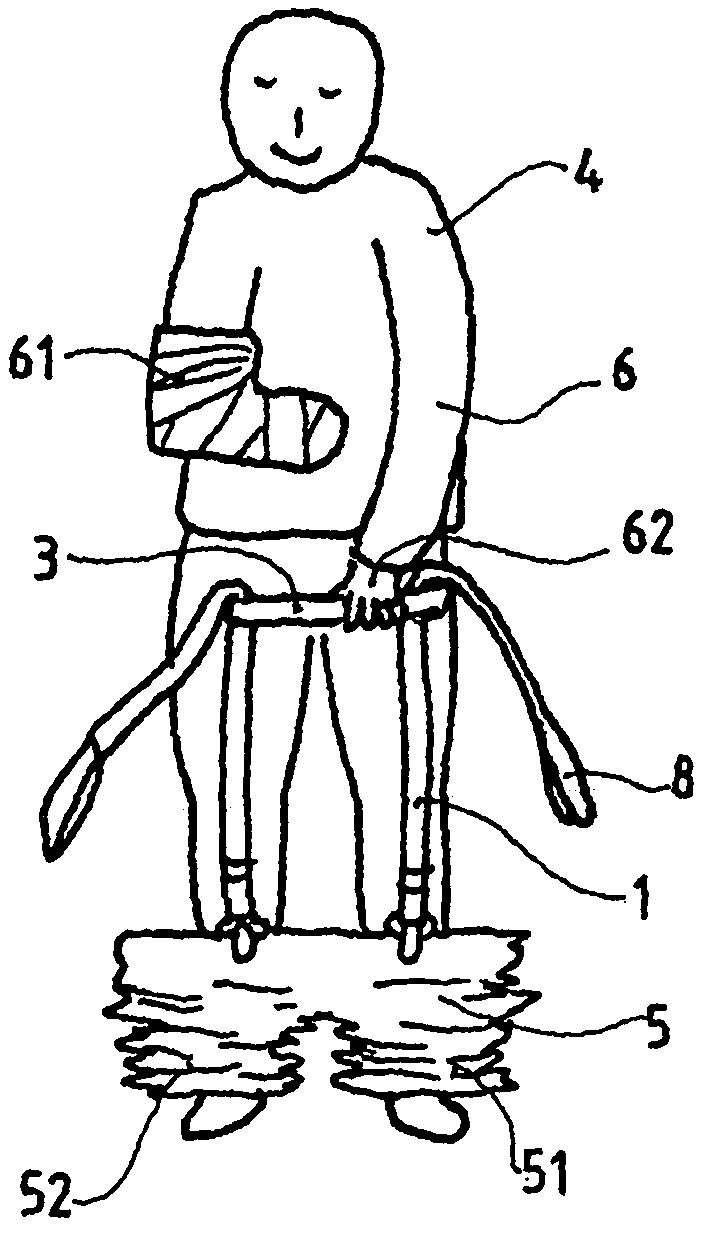

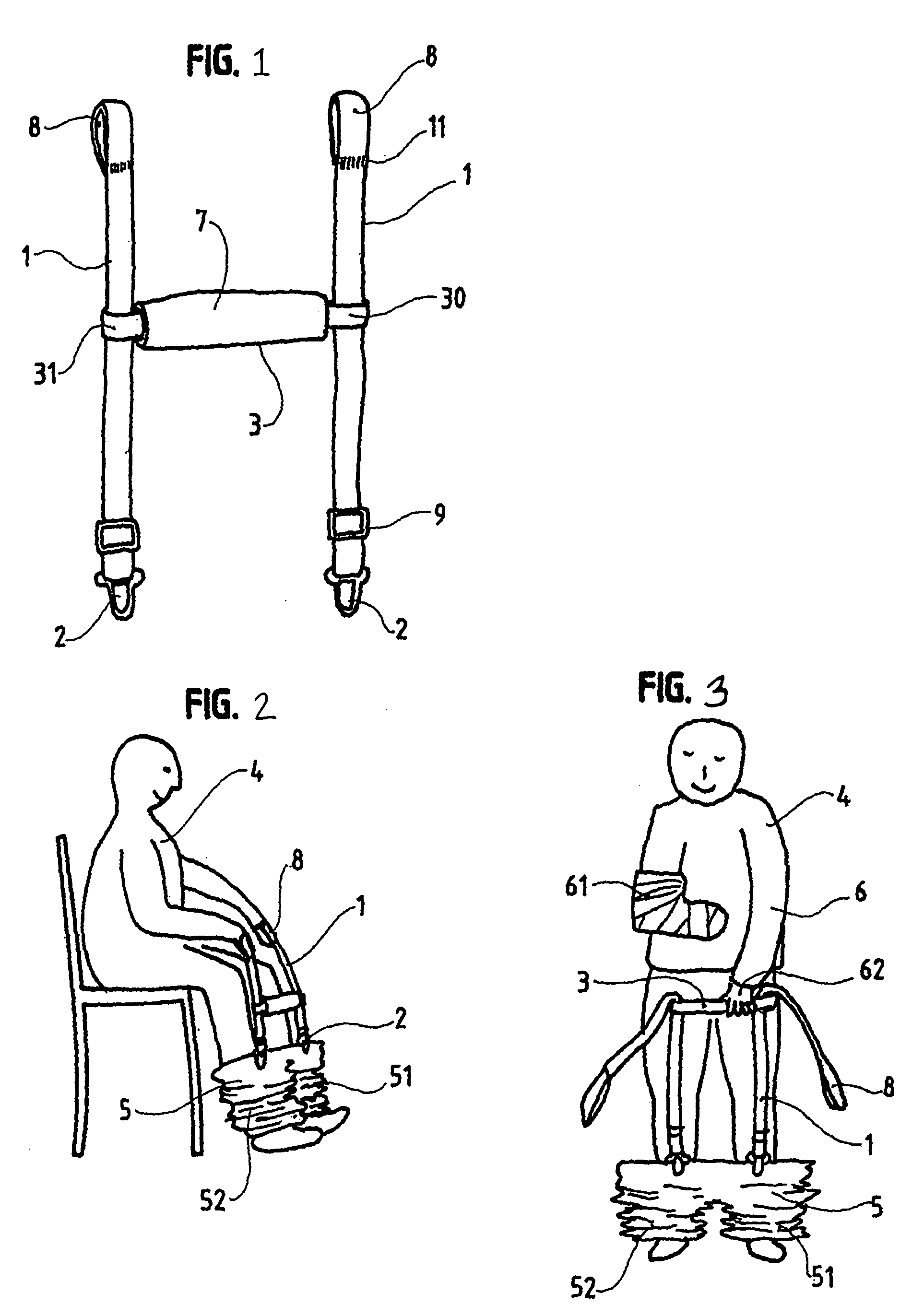

Dressing aid

InactiveUS20050205619A1Easy to storeSimple device designApparel holdersEngineeringMechanical engineering

Owner:MOREL DENIS

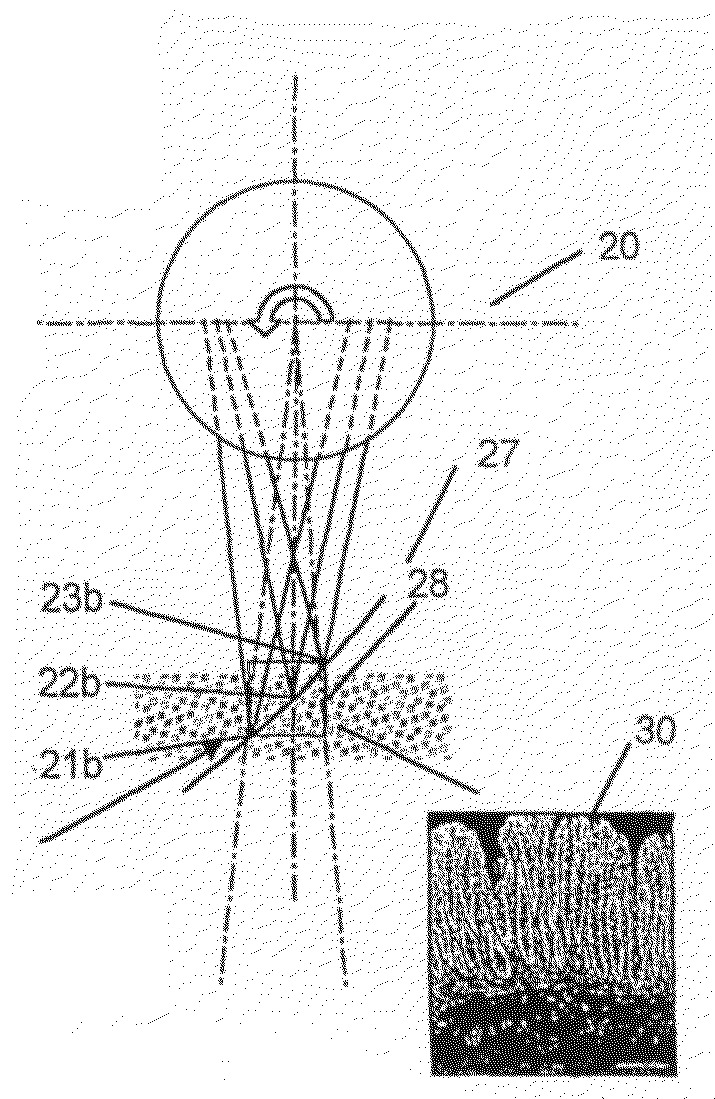

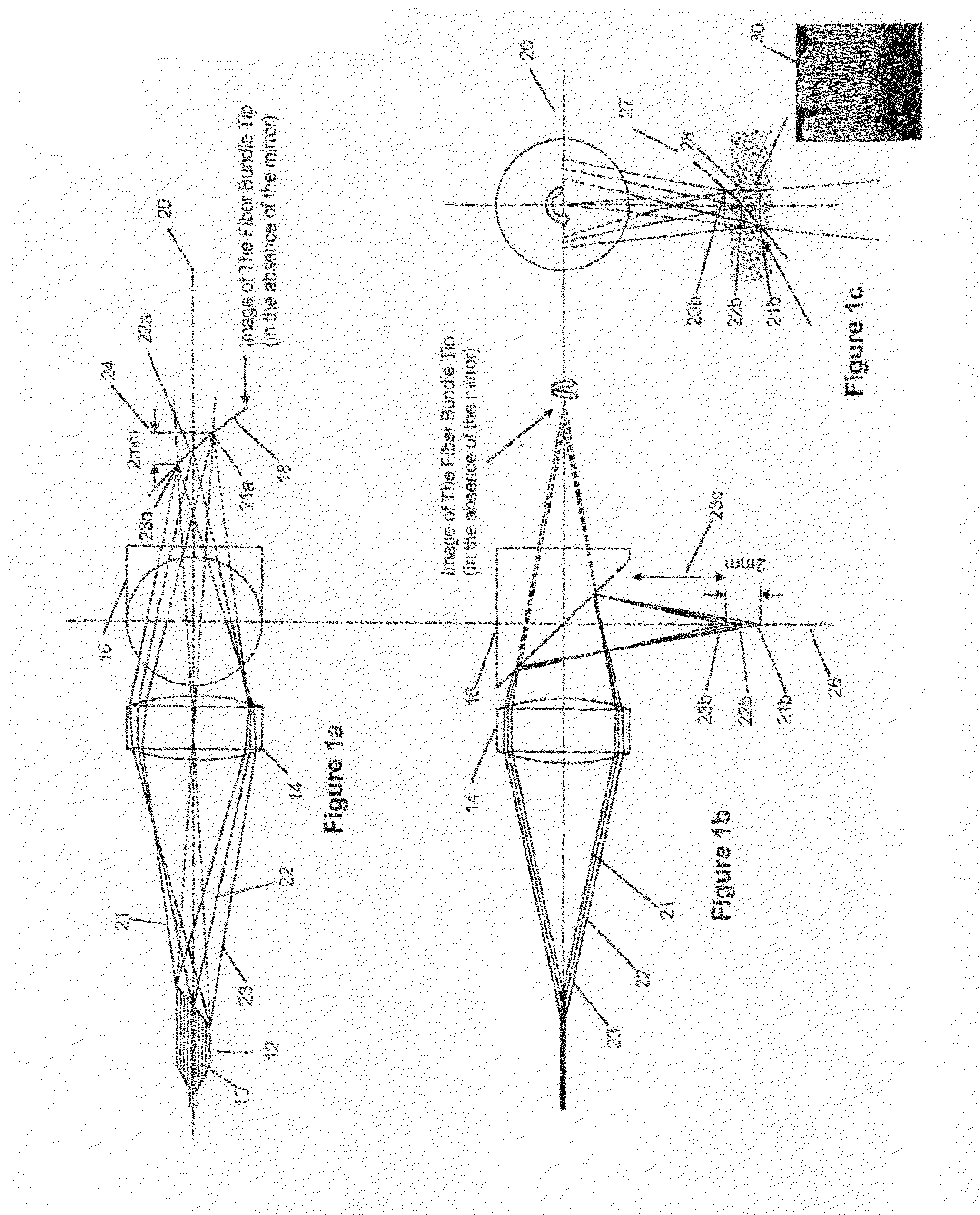

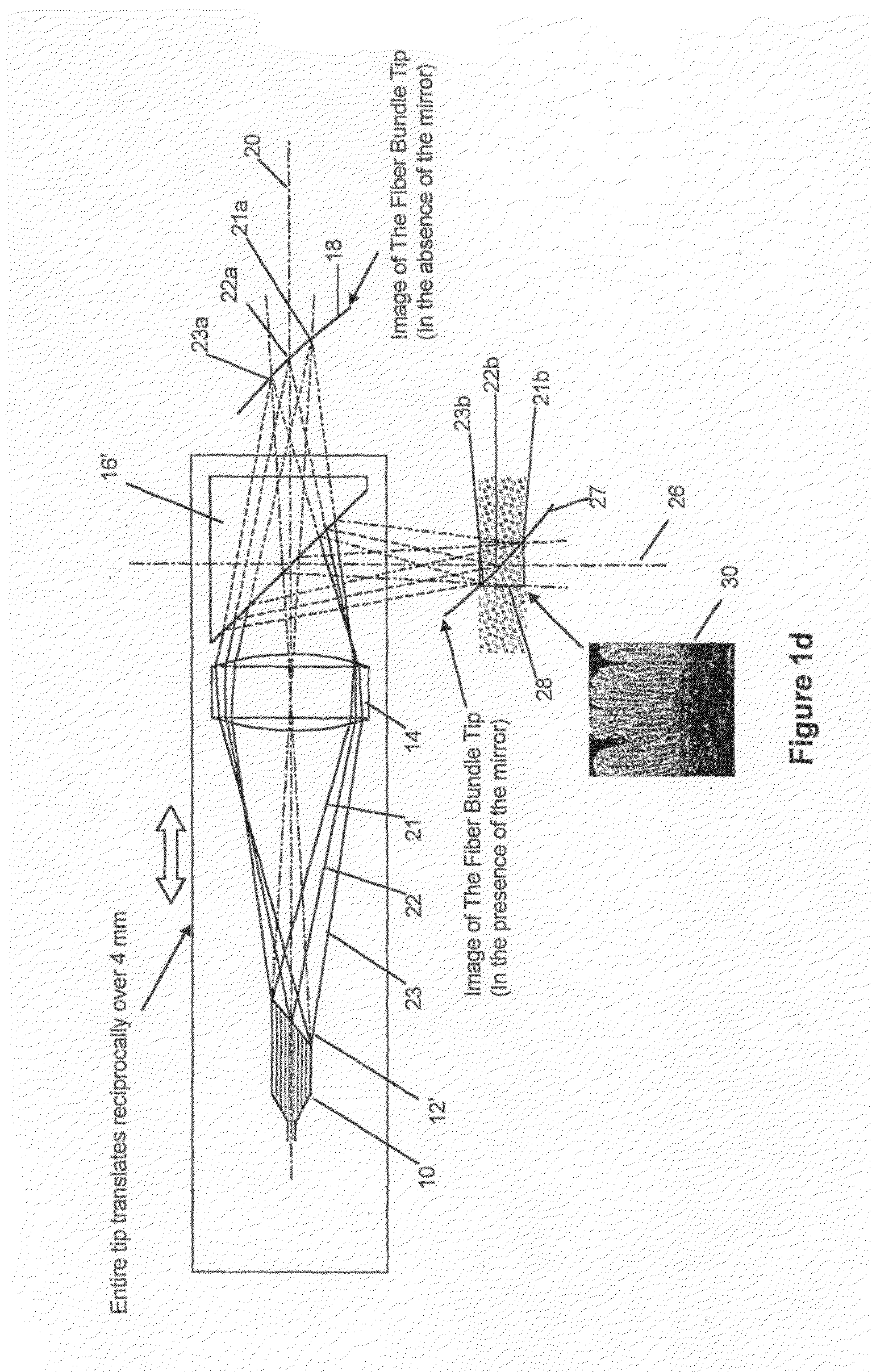

Method and apparatus for high resolution coherent optical imaging

InactiveUS20080285913A1Simple device designRun at high speedSurgeryScattering properties measurementsOptical radiationLight source

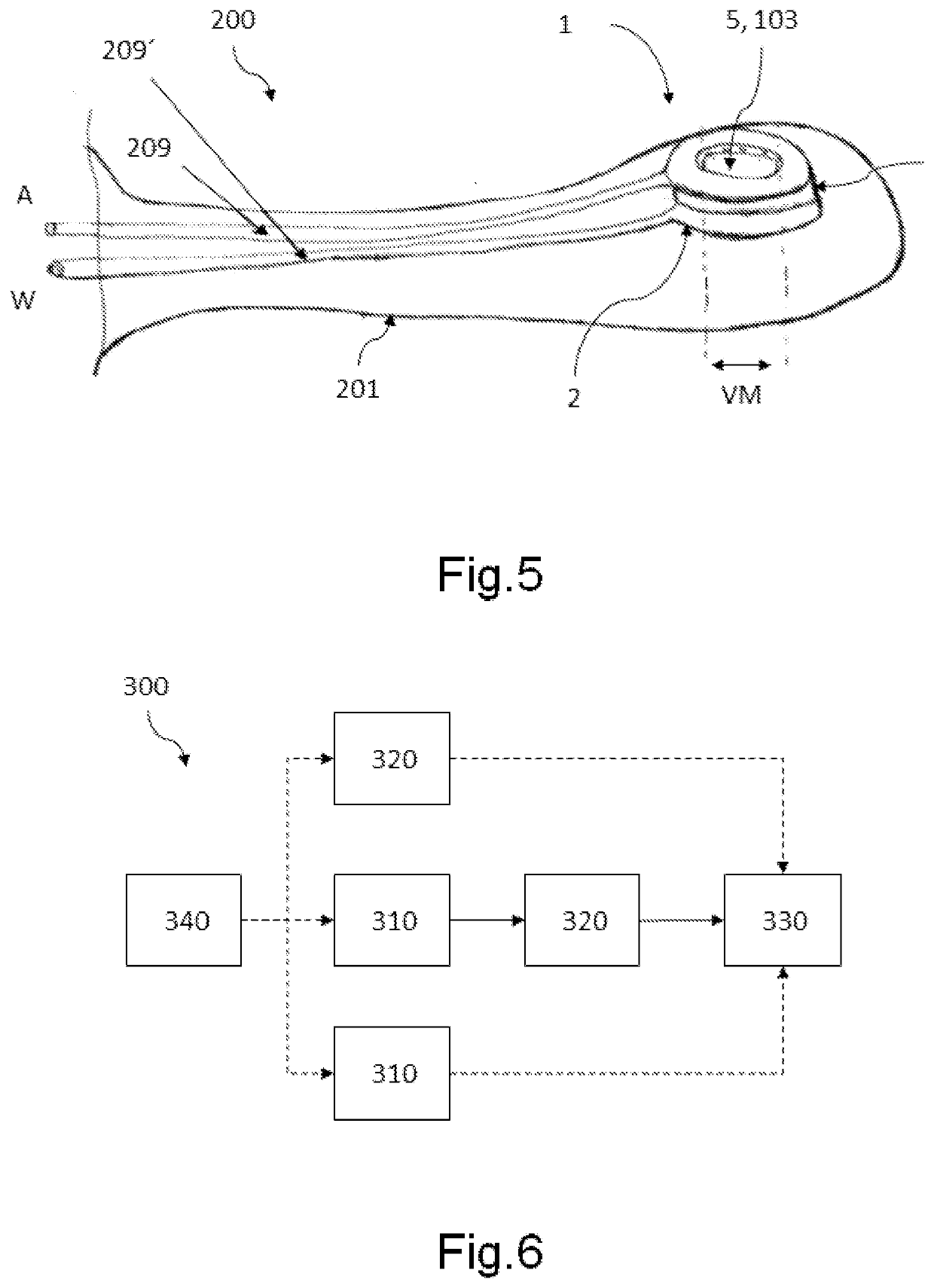

A method and an apparatus for examining the sub-surface microstructure of a sample are provided. Radiation from a plurality of optical radiation sources travels along a first optical path. In the first optical path, a device focuses the optical radiation from each of the optical sources into a plurality of respective focal points along the first optical path to provide substantially continuous coverage of a selected portion of the first optical path. Then, a sample on the first optical path within the selected length extending into the sample is scanned along said selected portion of the first optical path.

Owner:HEALTH NETWORK UNIV OF

Integrated focusing and reflecting structure in an optical assembly

An integrated reflecting and focusing structure for use in optical transmitters and receivers to redirect optical signals when an optoelectronic device of the transmitter or receiver is positioned in an off-center relationship with respect to an intended light path is disclosed. The integrated reflecting and focusing structure simplifies construction while reducing complexity of the device. In one embodiment, an optical subassembly is disclosed and includes a housing and an optical fiber that is coupled to the housing. An optoelectronic component, such as a laser diode, is positioned in the housing and is configured to produce a light beam. The subassembly further includes an integrated focusing and reflecting prism that serves as a means for simultaneously redirecting and focusing the light beam while in transit between the laser diode and the optical fiber. The focusing feature combined with redirection of the light beam obviates the need for a separate lens assembly.

Owner:II VI DELAWARE INC

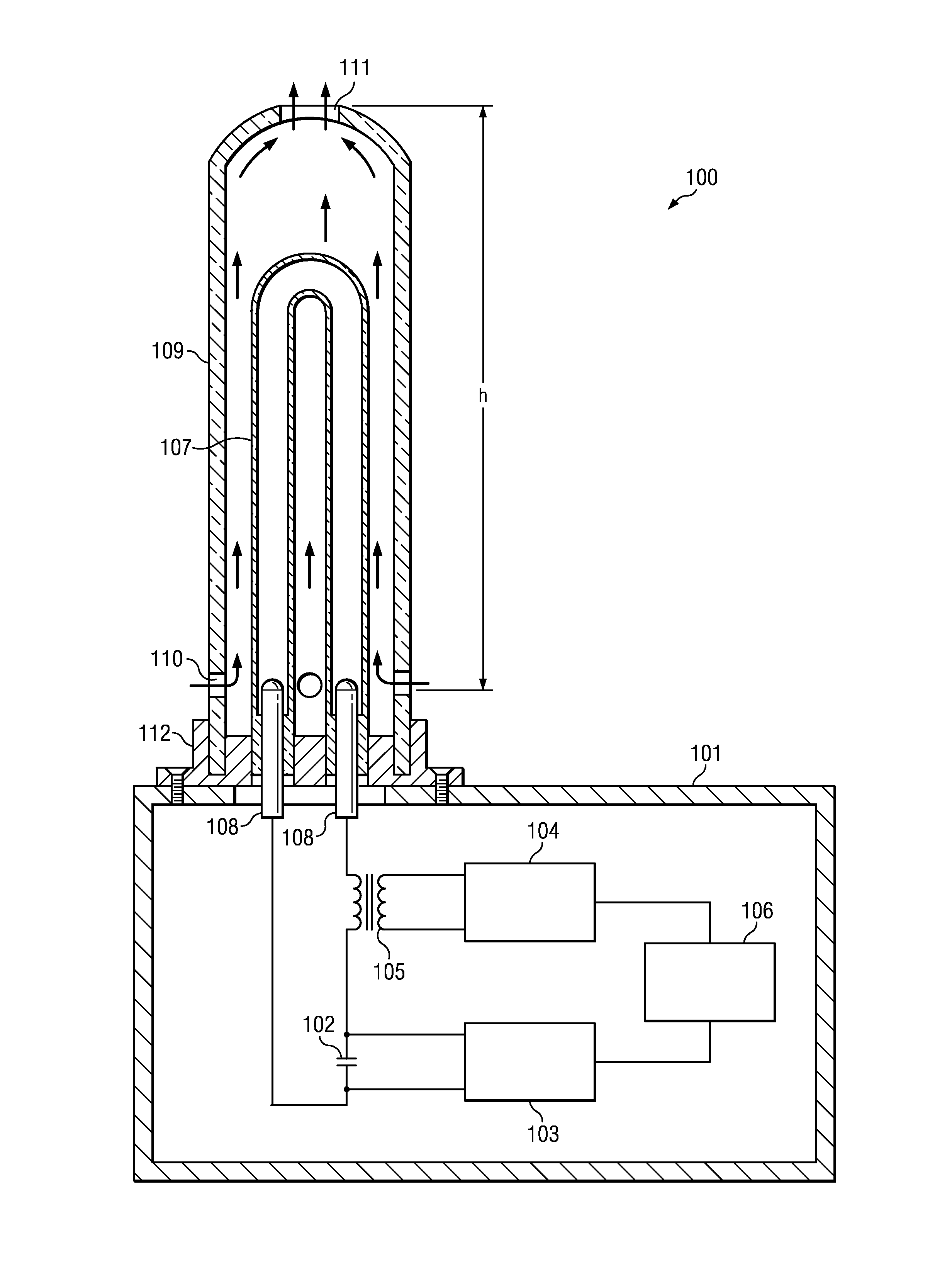

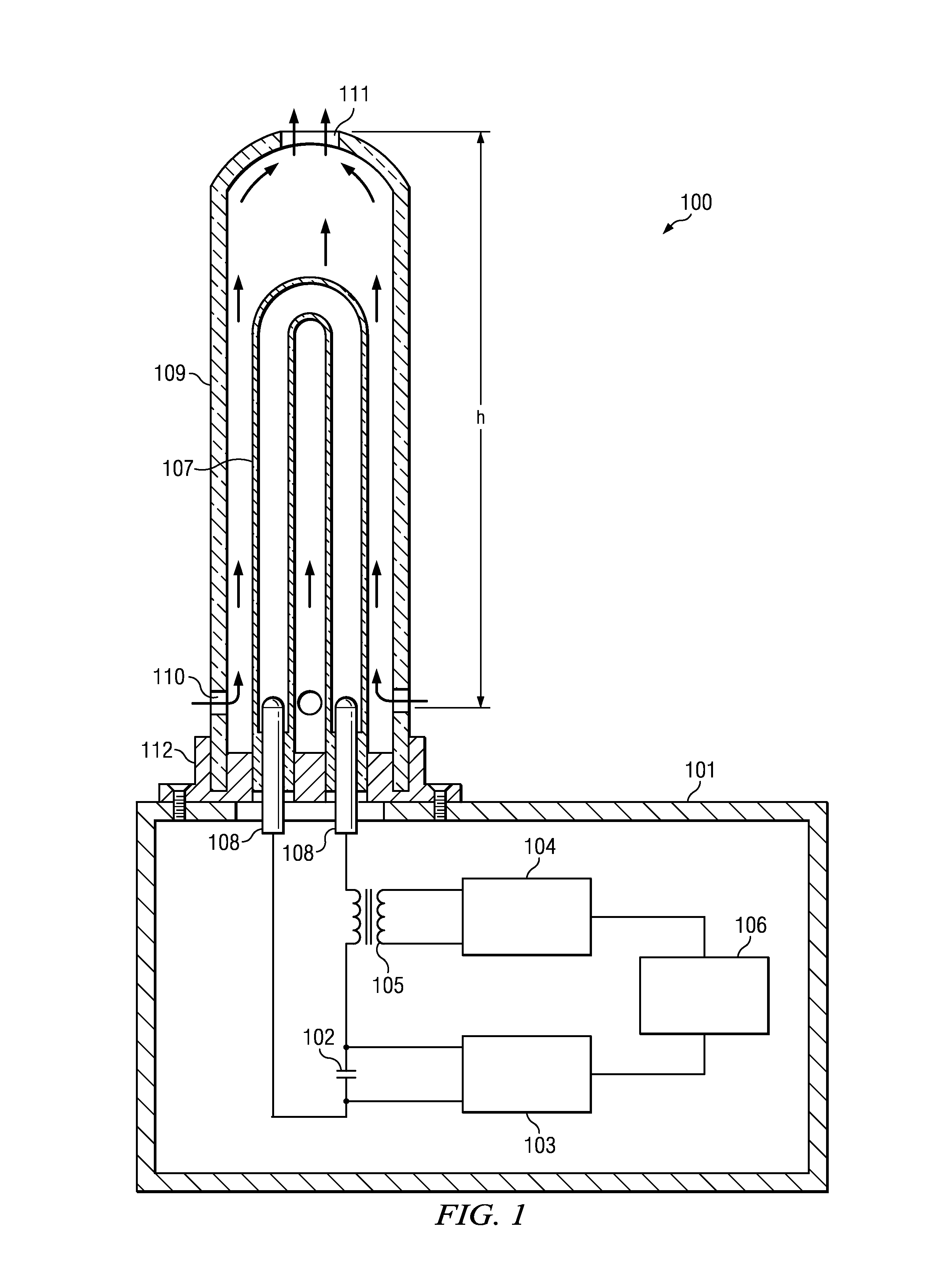

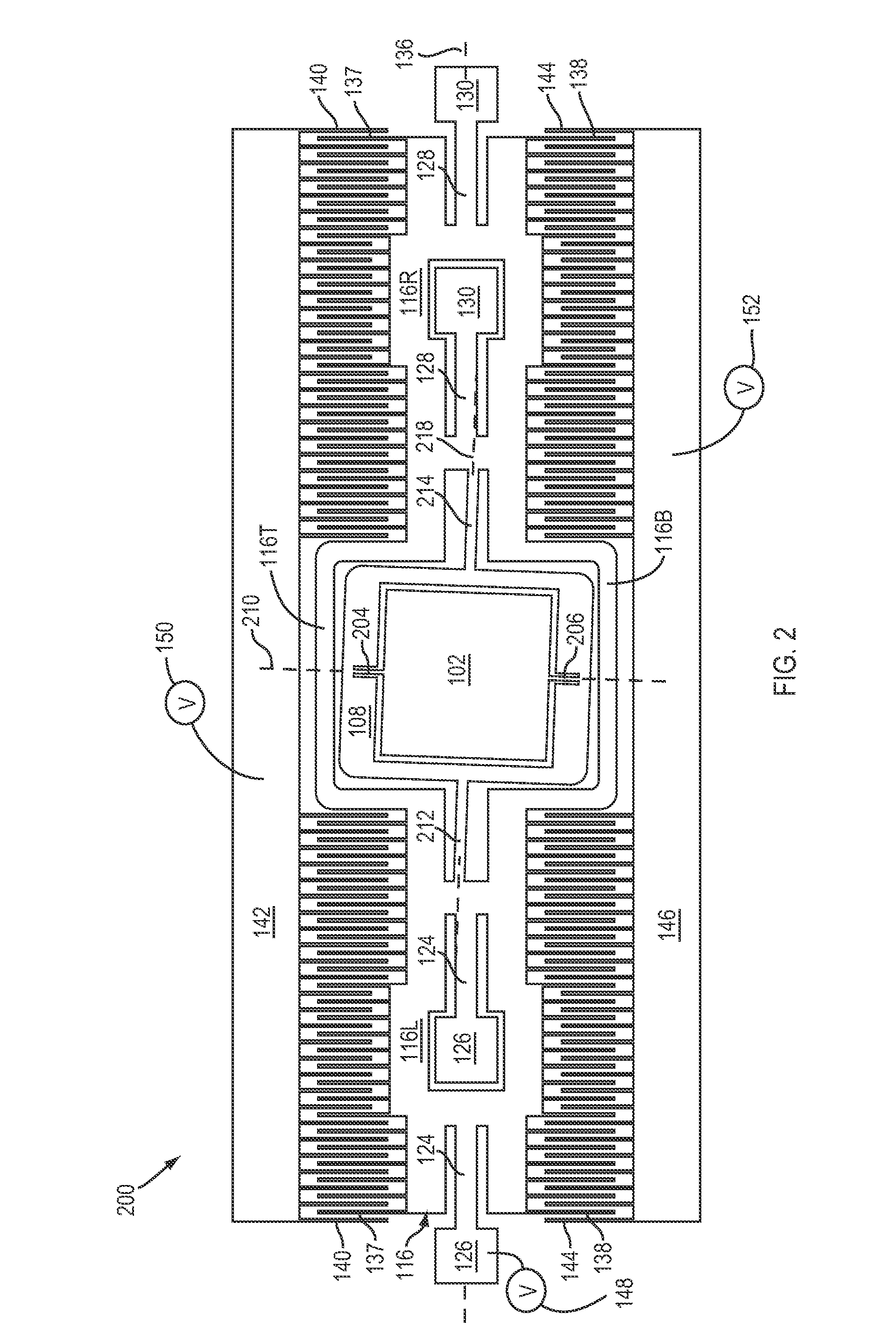

Air sterilizing assembly

ActiveUS8497491B2Simple device designImprove efficiency and qualityOptical radiation measurementLighting support devicesUltravioletHigh voltage

An air disinfection device aimed at improving the efficiency and quality of air disinfection or sterilization may be achieved through an air disinfection device comprising a body housing a power supply and control unit, which, in turn, comprises an energy storage capacitor, a high-voltage constant current source, an ignition pulse generator, a ferrite-core pulse transformer, and a program control unit. The air disinfection device may also comprise an ultra-violet radiation source in the form of a pulsed gas-discharge lamp mounted on the body and enclosed in a tubular quartz casing. Given that the energy storage capacitor and the pulsed gas-discharge lamp may form a discharge circuit connected to the ignition pulse generator through the ferrite-core pulse transformer, the pulsed gas-discharge lamp may be placed in a bactericidal radiation translucent casing, resulting in convection air-cooling due to a natural draft inside the casing that disinfects and sterilizes surrounding air.

Owner:NAUCHNO PROIZVODSTVENNOE PREDPRIYATIE MELITTA LLC

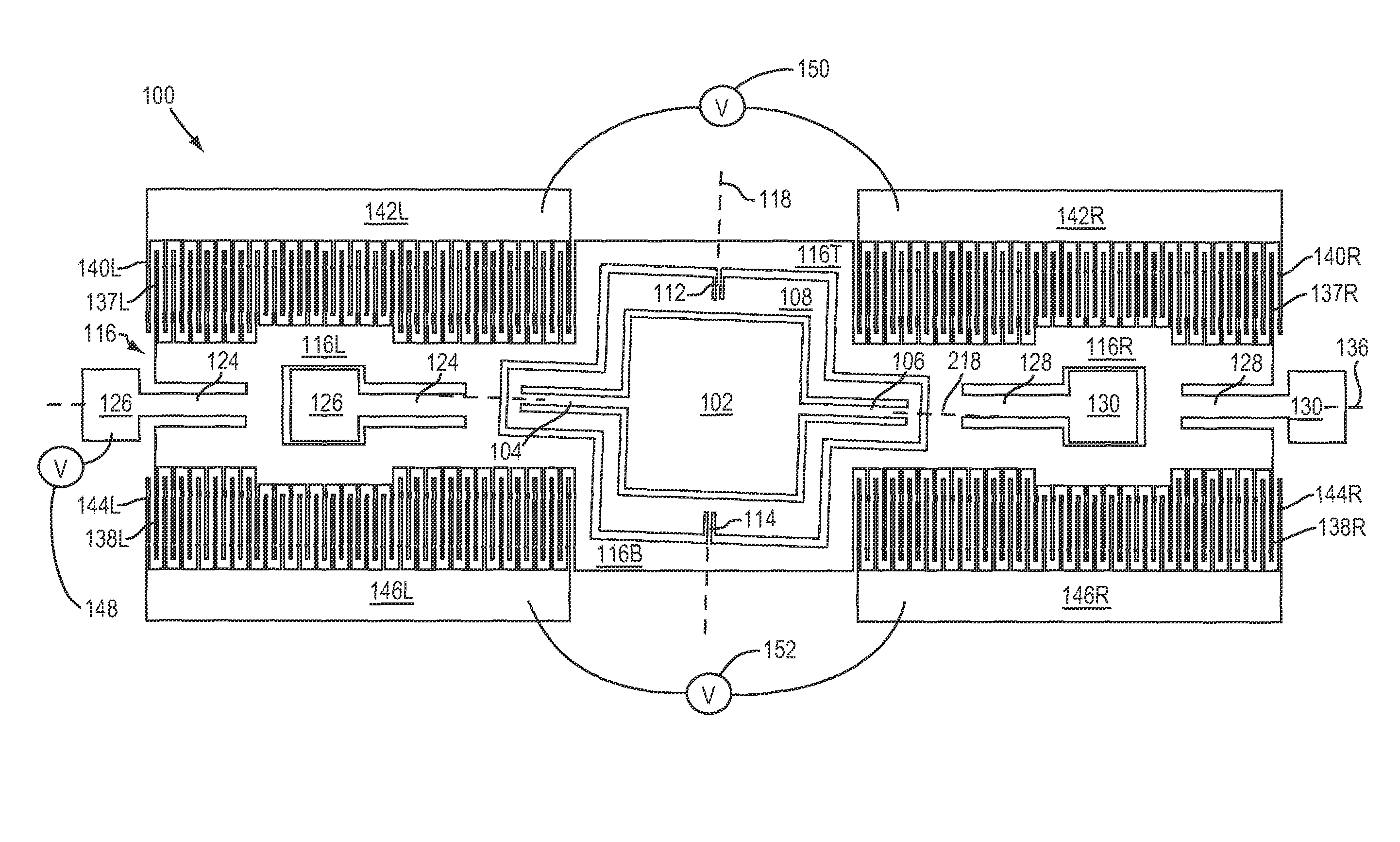

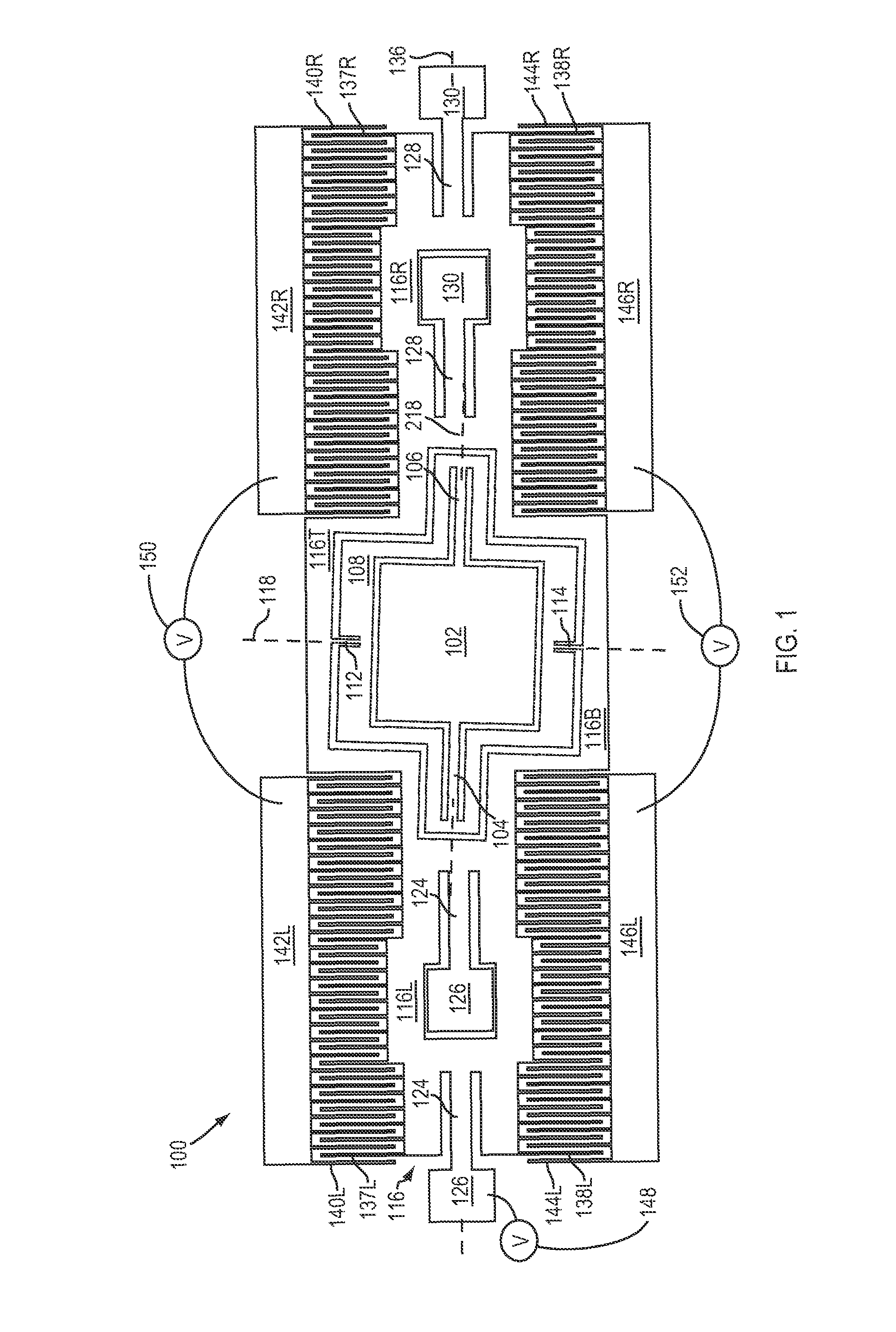

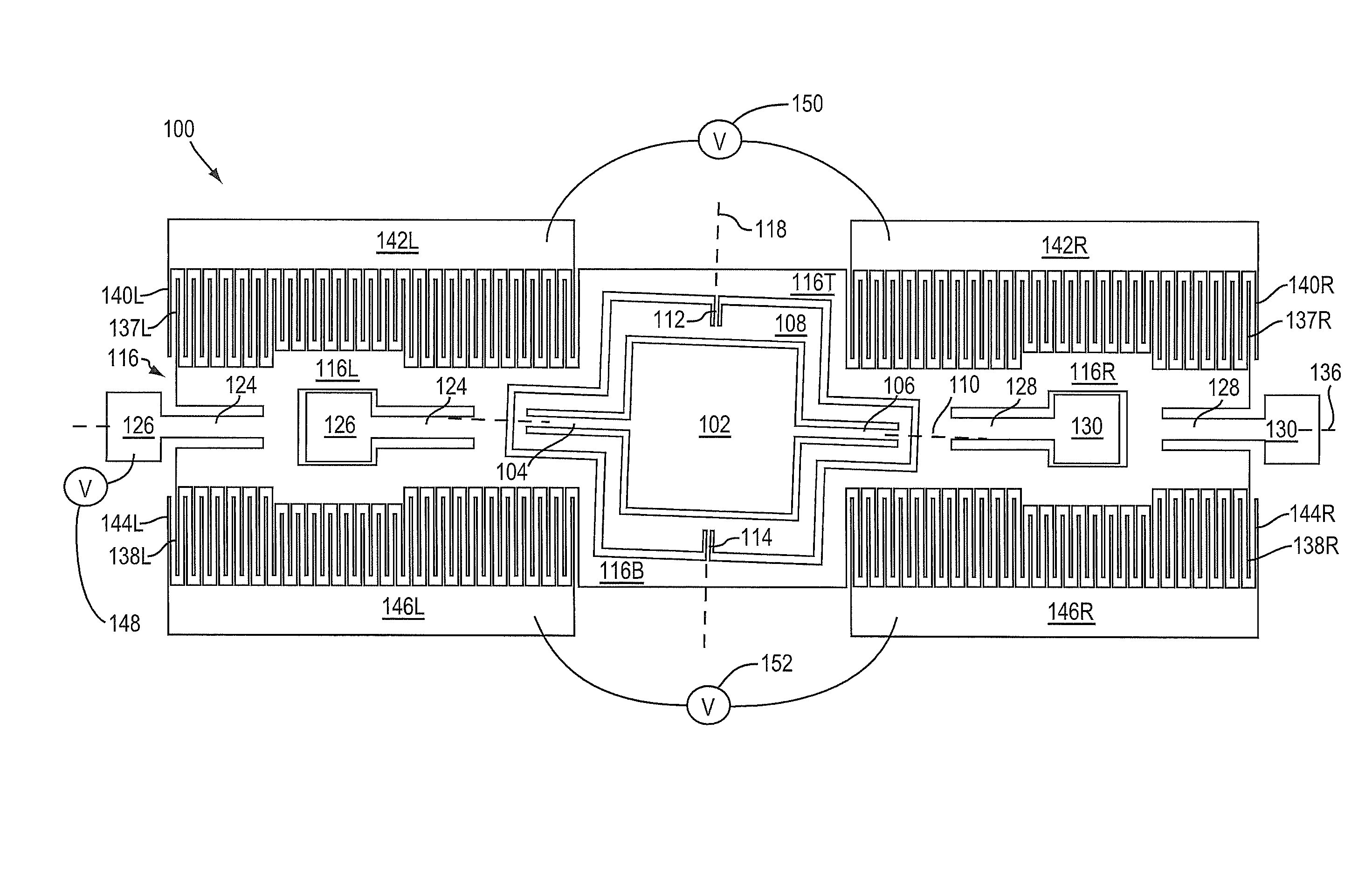

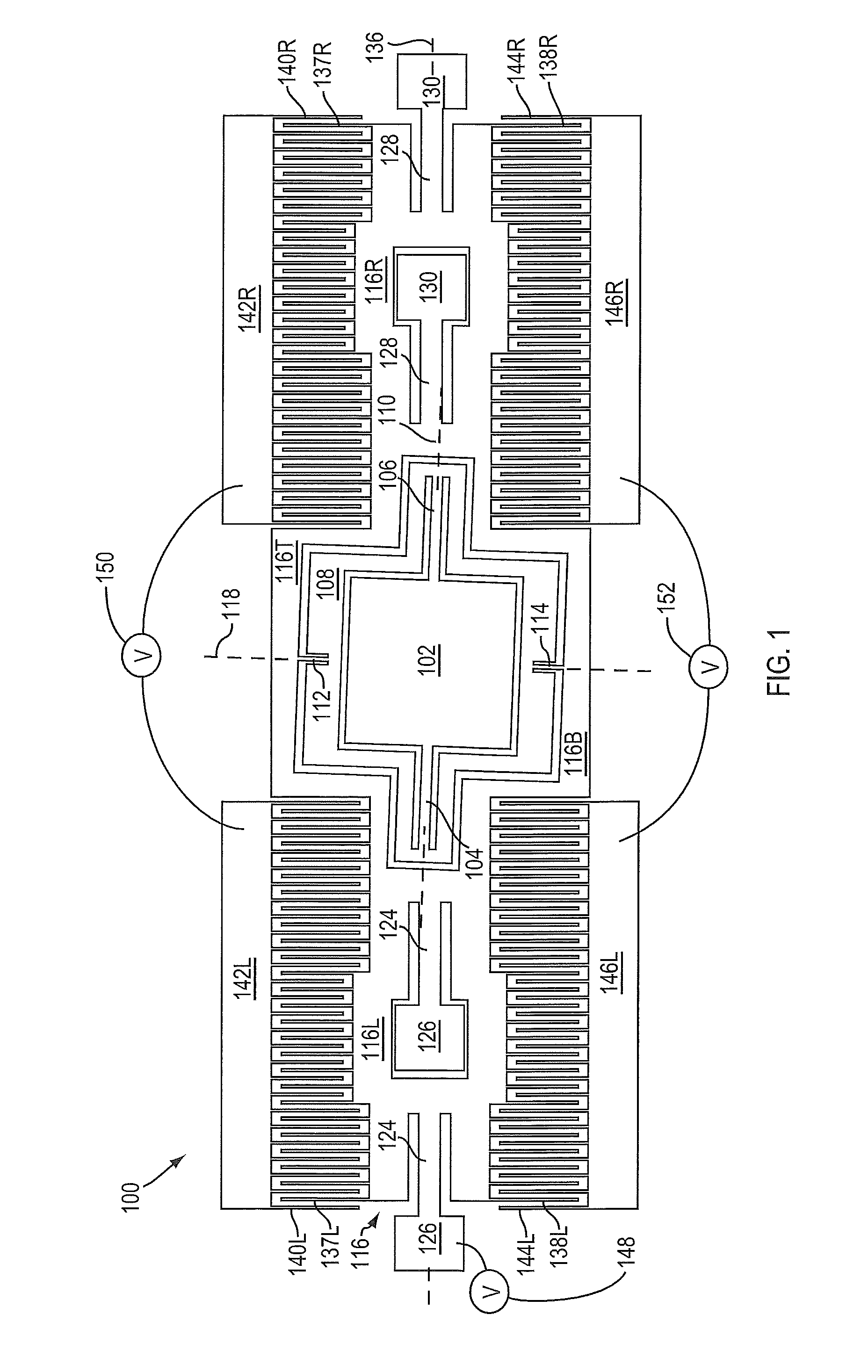

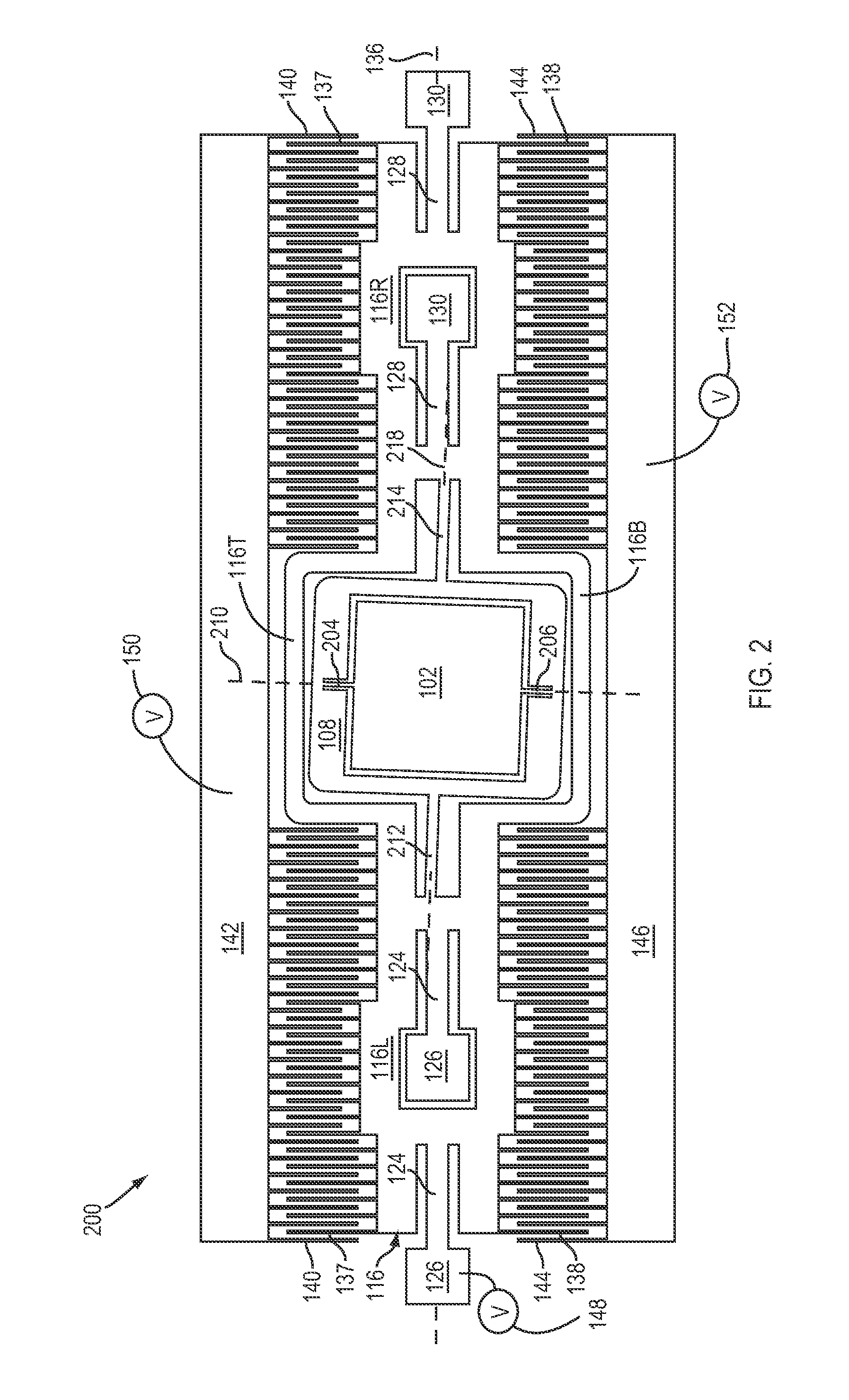

MEMS device with off-axis actuator

A micro-electro-mechanical system (MEMS) mirror device has a mirror, a frame rotatively coupled to the mirror, and a uniaxial actuator rotatively coupled to the frame where the rotational axis of the actuator is offset from the rotational axes of the mirror and the frame. Another MEMS mirror device has a mirror, a frame rotatively coupled to the mirror, and a biaxial actuator rotatively coupled to the frame where the actuator is able to rotate about the rotational axes of the mirror and the frame with the mirror.

Owner:ADVANCED NUMICRO SYST

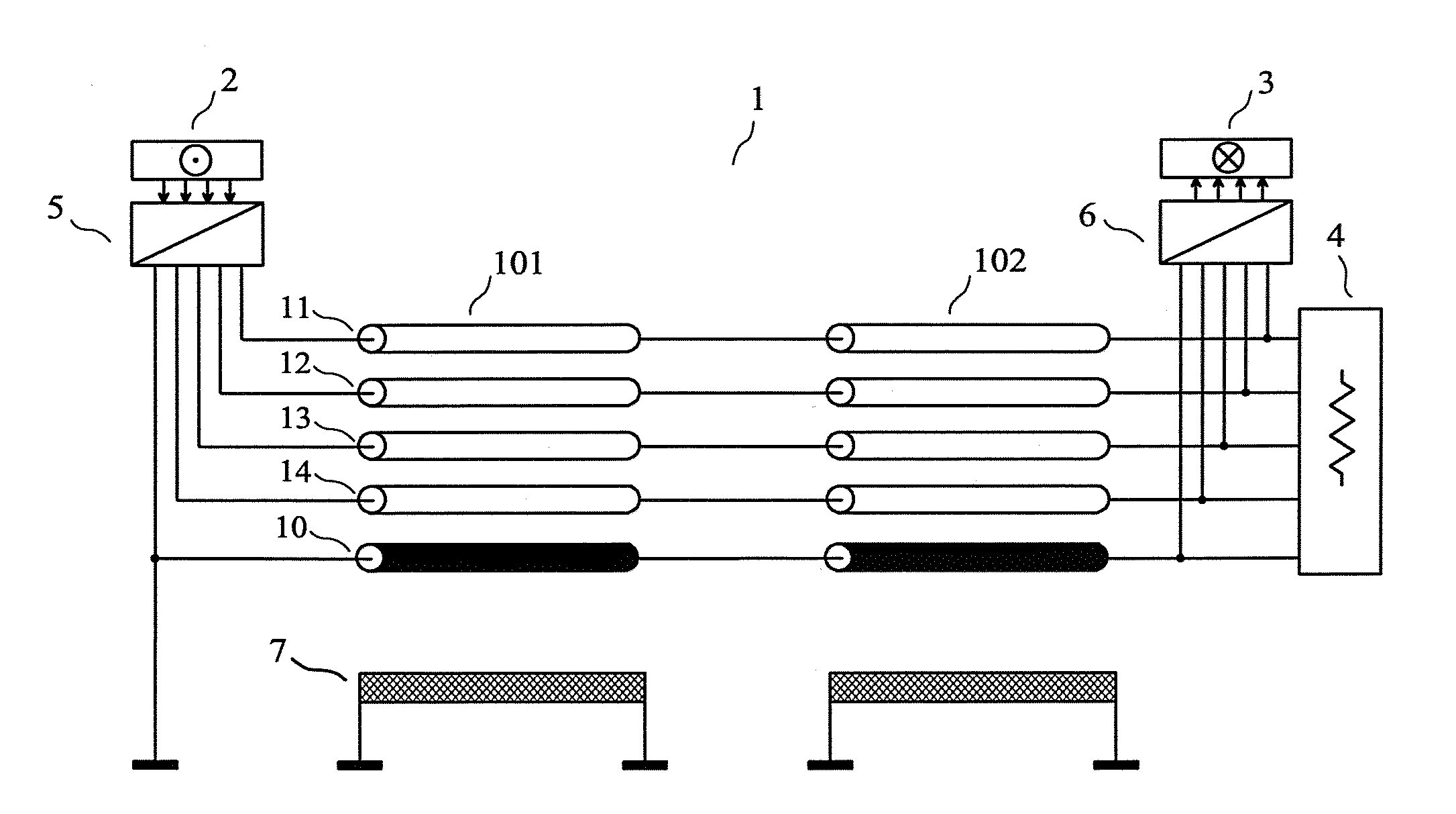

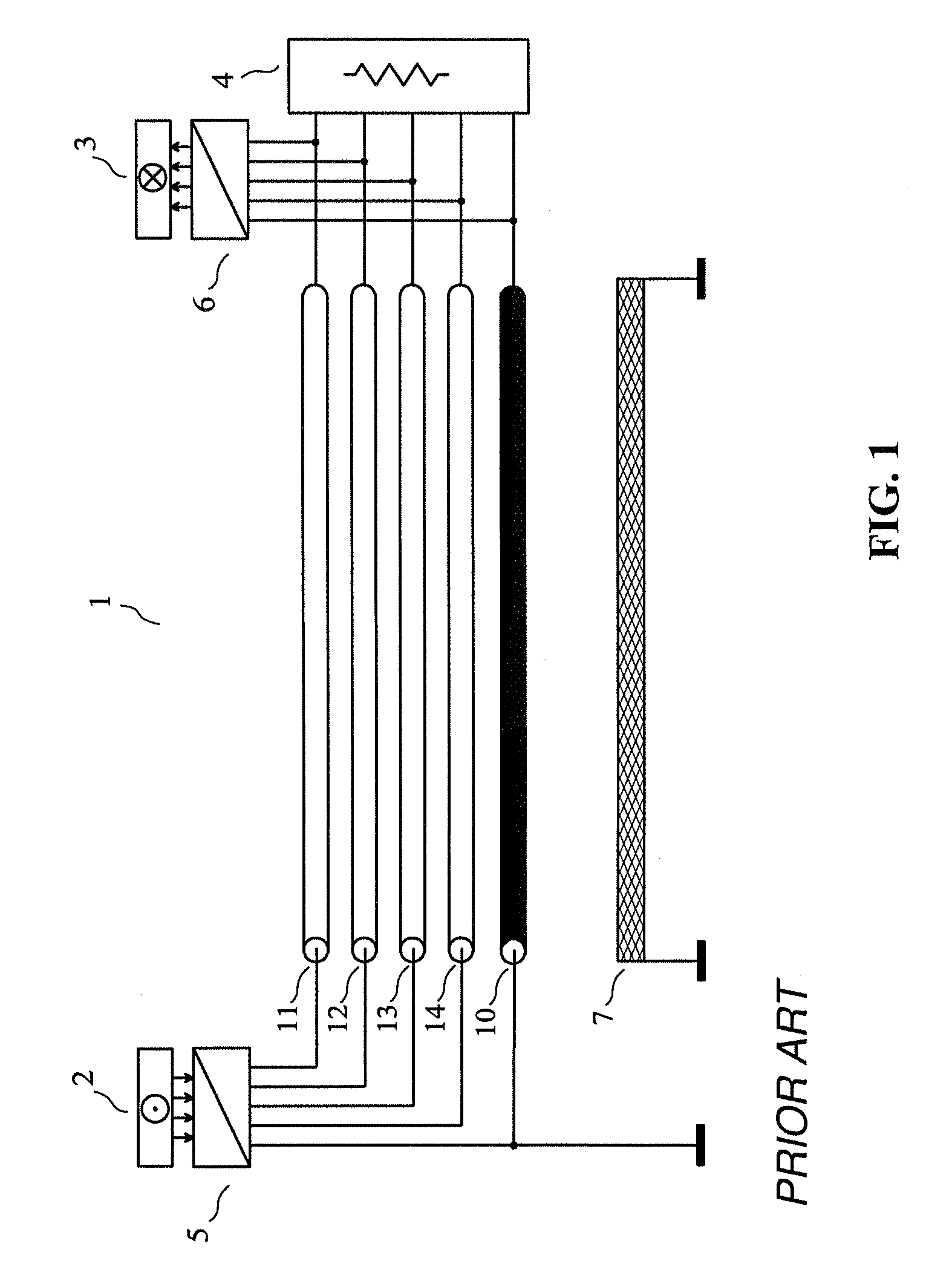

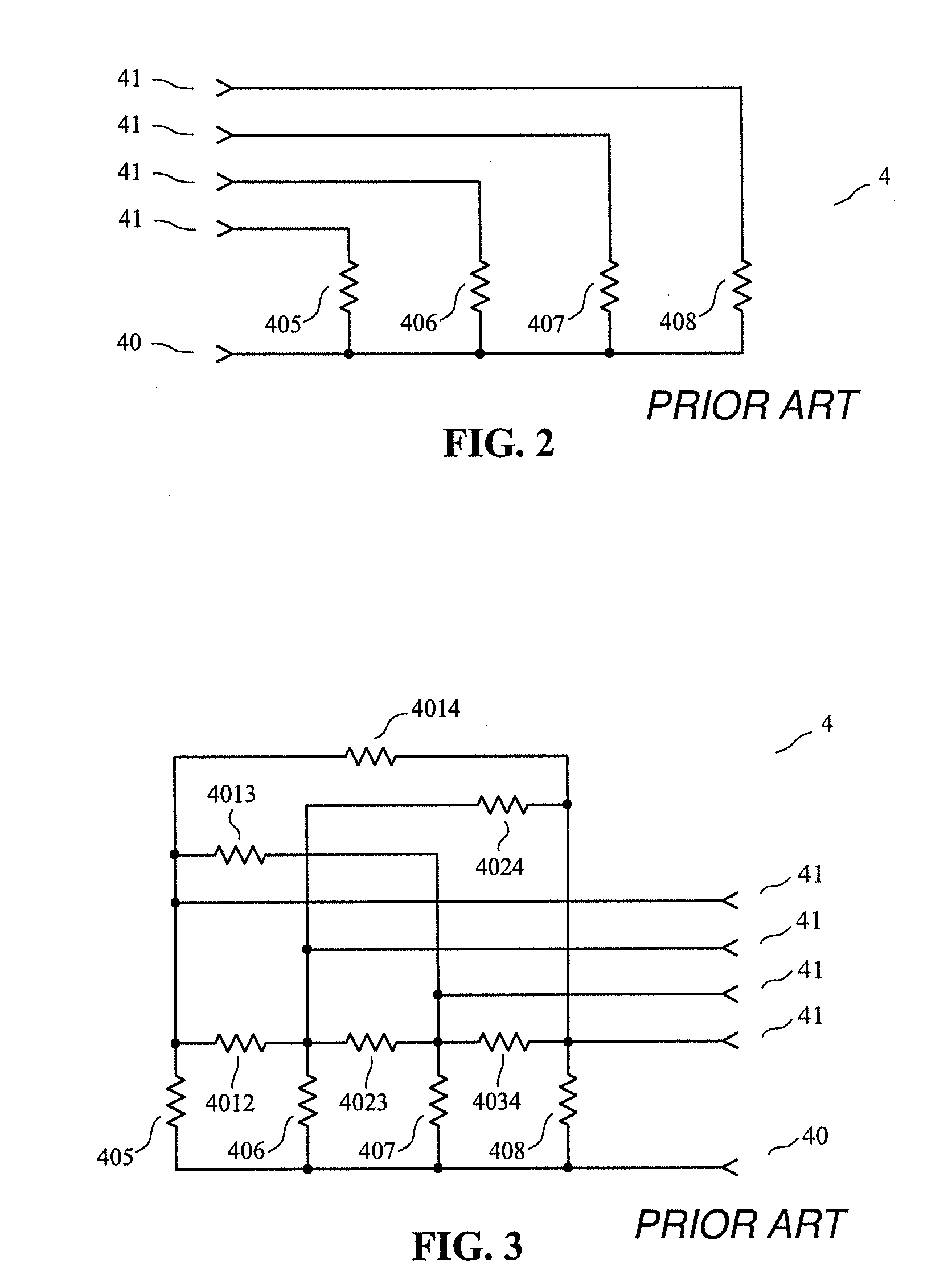

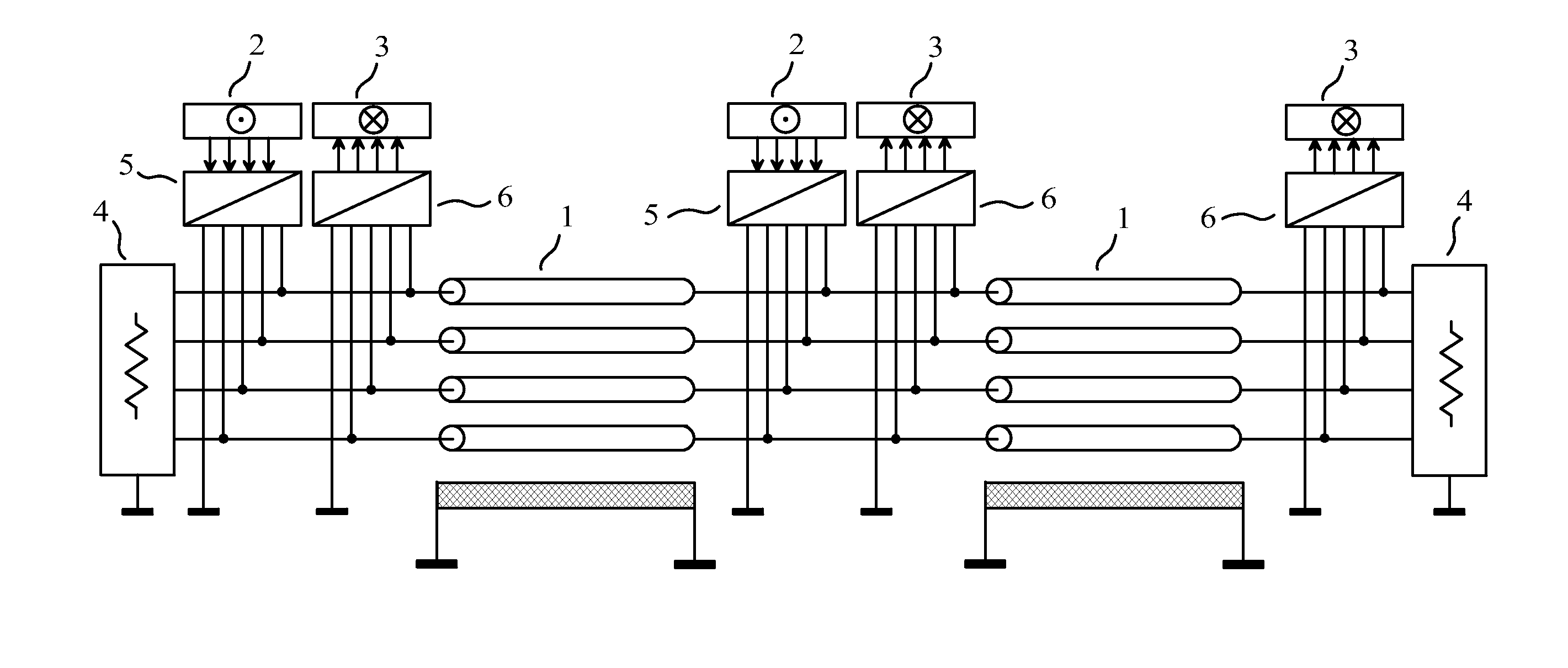

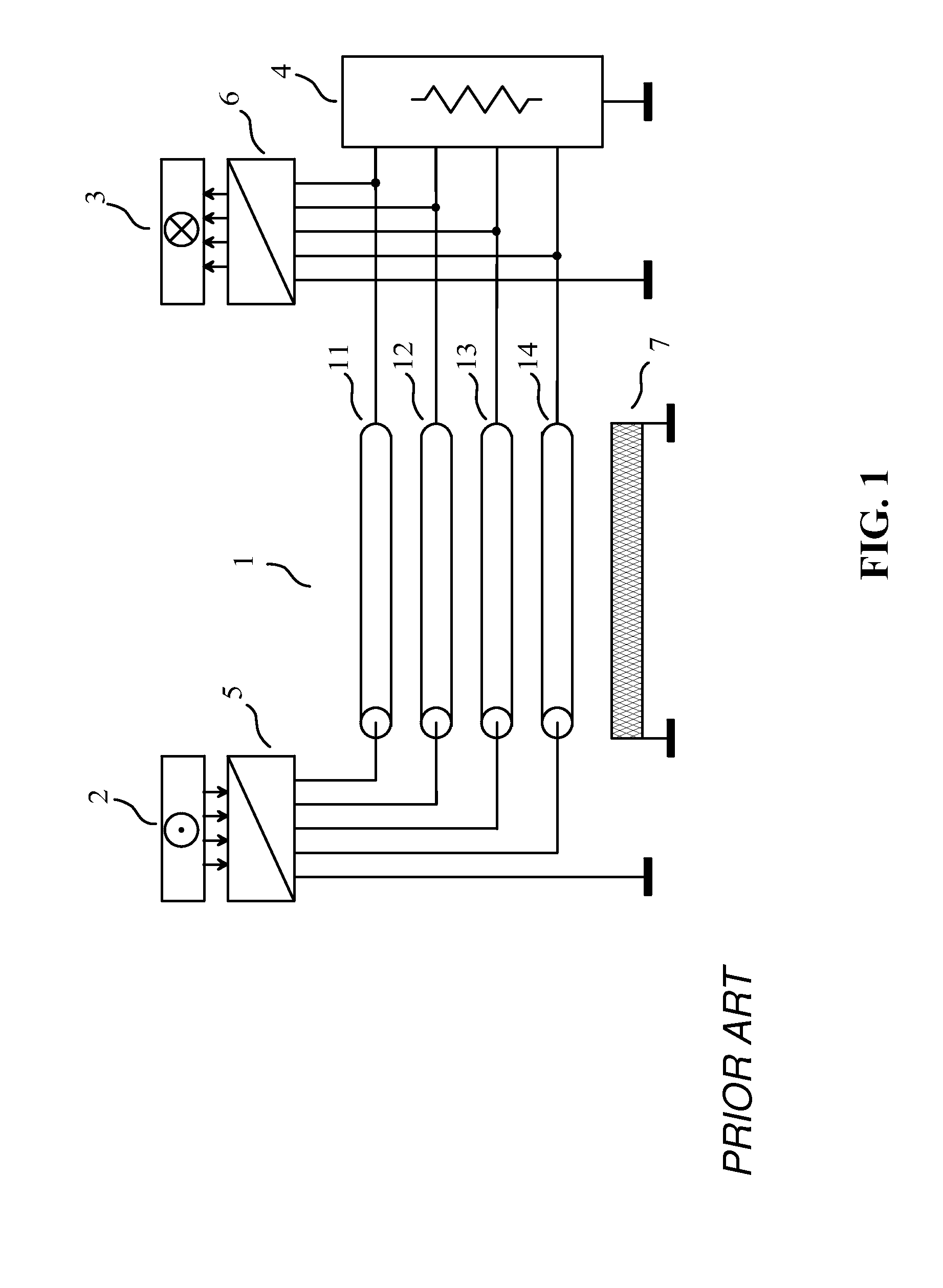

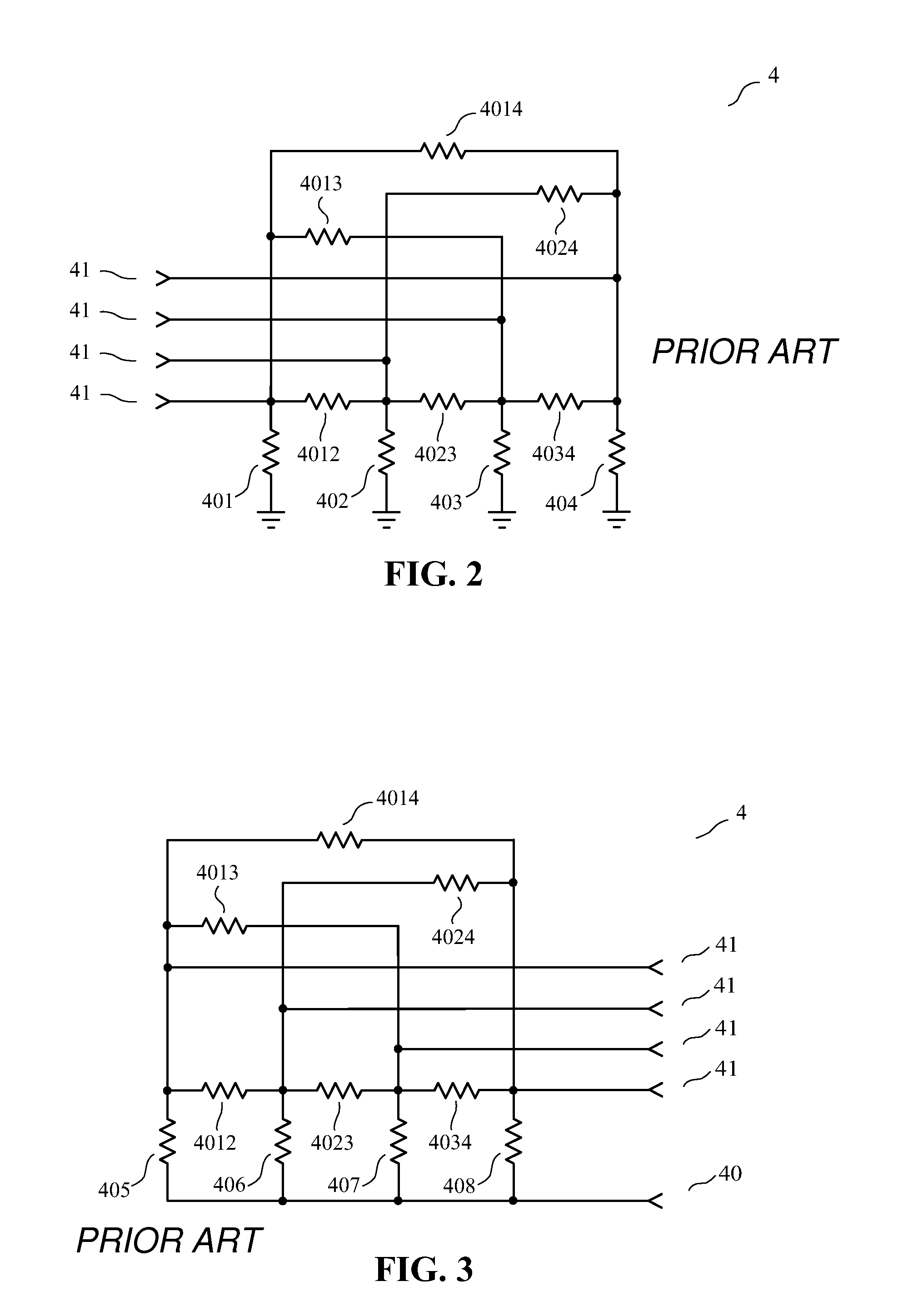

Method for pseudo-differential transmission using a non-uniform interconnection

InactiveUS20110260813A1Simple device designSimple designMultiple-port networksCross-talk reductionElectrical conductorDifferential transmission

The invention relates to a method and a device for pseudo-differential transmission through interconnections used for sending a plurality of electrical signals.An interconnection having 4 transmission conductors and a return conductor distinct from the reference conductor cannot be modeled as a uniform multiconductor transmission line. Each end of the interconnection is connected to a termination circuit. Three damping circuits are connected between the return conductor and the reference conductor. The transmitting circuits receive at their inputs the signals from the 4 channels of the two sources, and are connected to the interconnection. The receiving circuits are connected to the interconnection, each receiving circuit being such that the signals of the 4 channels of a source connected to a transmitting circuit in the activated state are sent to the four channels of the destinations, without noticeable echo, internal crosstalk and external crosstalk.

Owner:ZXNOISE LLC

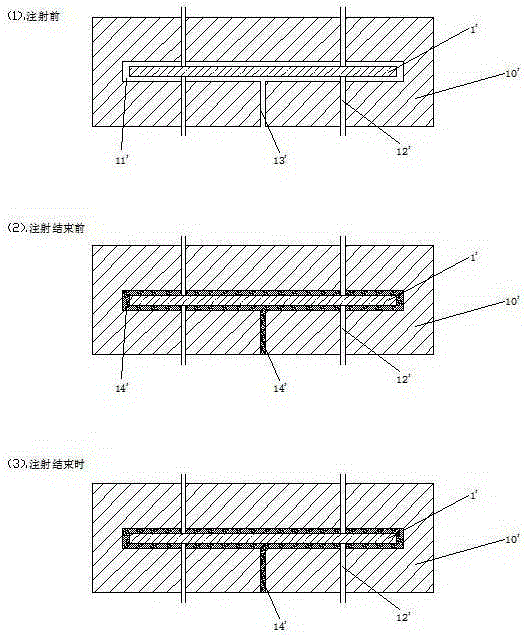

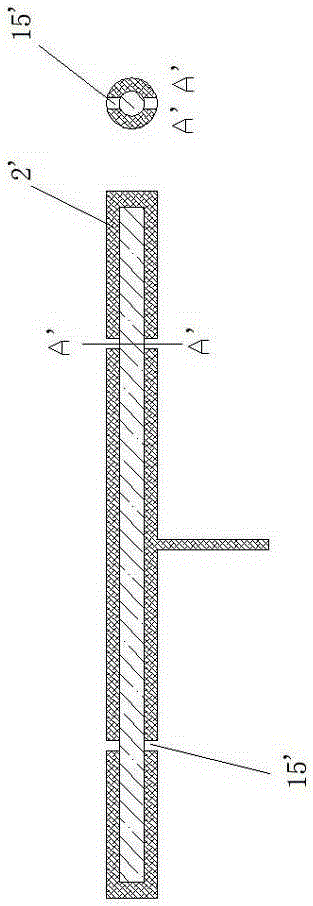

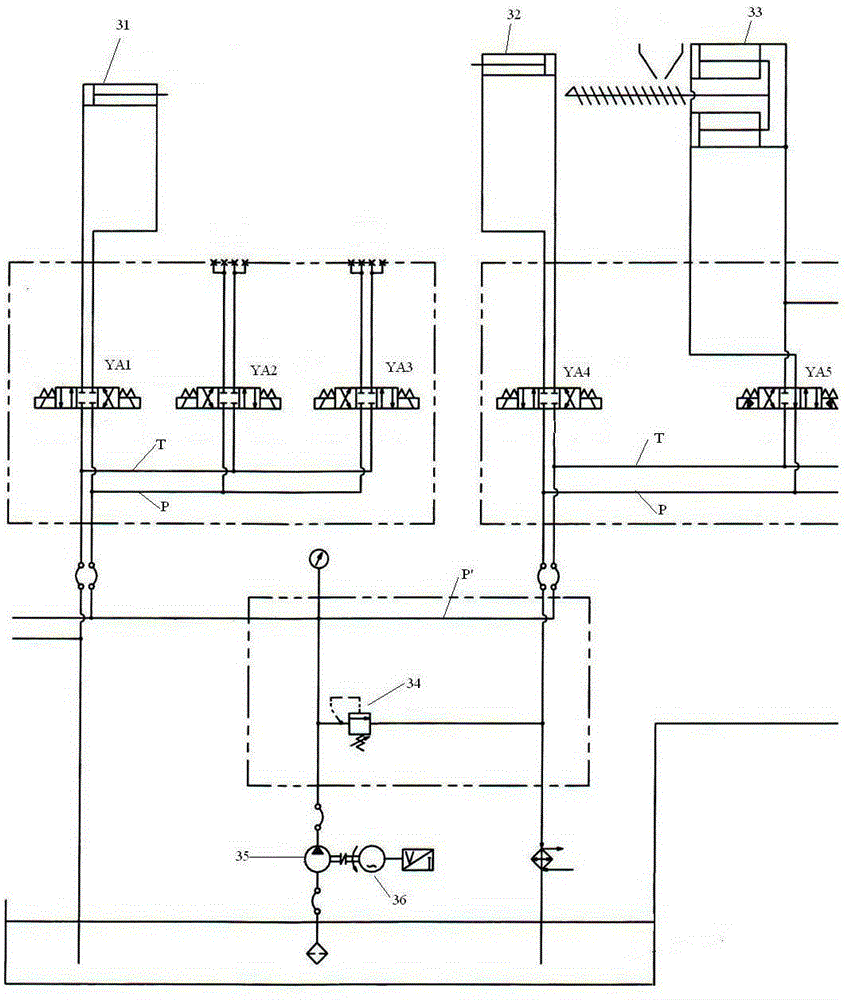

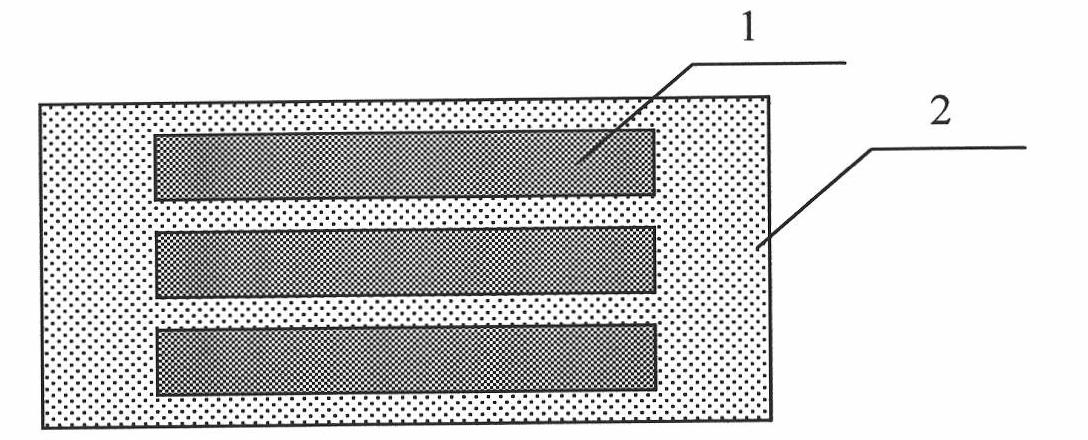

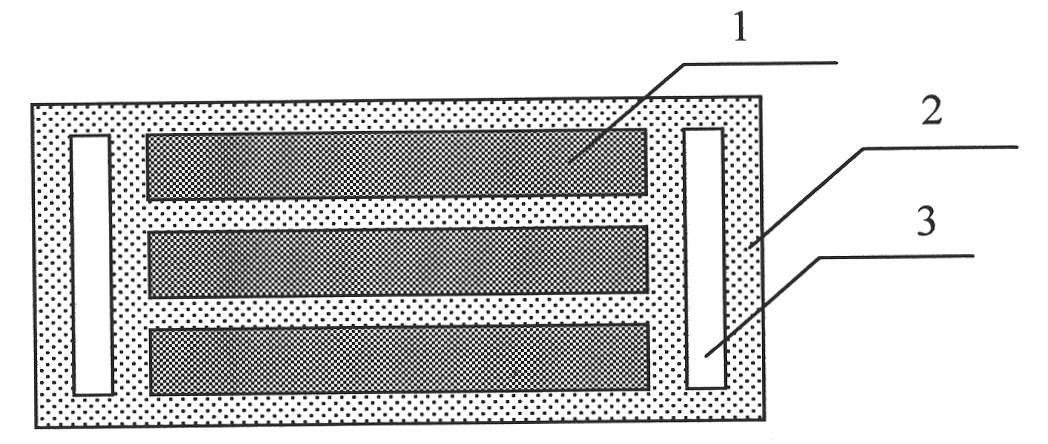

One-time injection molding method for totally-cladded plastic product

The invention discloses a one-time injection molding method for a totally-cladded plastic product. The one-time injection molding method for the totally-cladded plastic product comprises the following steps that (1) before injection, a mold core (1) to be cladded is fixed in the middle of a mold cavity (11) to be formed after mold assembly by means of a plurality of supporting rods (12) which are symmetrically arranged; (2) mold assembly is conducted, molten resin (14) is injected from a nozzle (13), and the amount of the injected resin meets the condition that the mold cavity is gradually filled with the resin but not completely filled with the resin; and (3) in the later injection state during which the injection amount reaches a certain value or the pressure maintaining stage, the supporting rods (12) are made to retreat from a mold to positions (121) flush with the edge of the mold cavity by means of a core-feeding and core-retreating device, residual resin (14) continues to be injected into the nozzle (13), and the core-feeding and core-retreating device is controlled through a second hydraulic system which is additionally arranged in an injection molding machine, namely the injection molding machine comprises a first hydraulic system used for controlling injection molding and the second hydraulic system used for controlling the core-feeding and core-retreating device; and (4) injection is ended, the mold is opened after being cooled, and the product (2) is taken out.

Owner:BEIJING PLASTICS RES INST

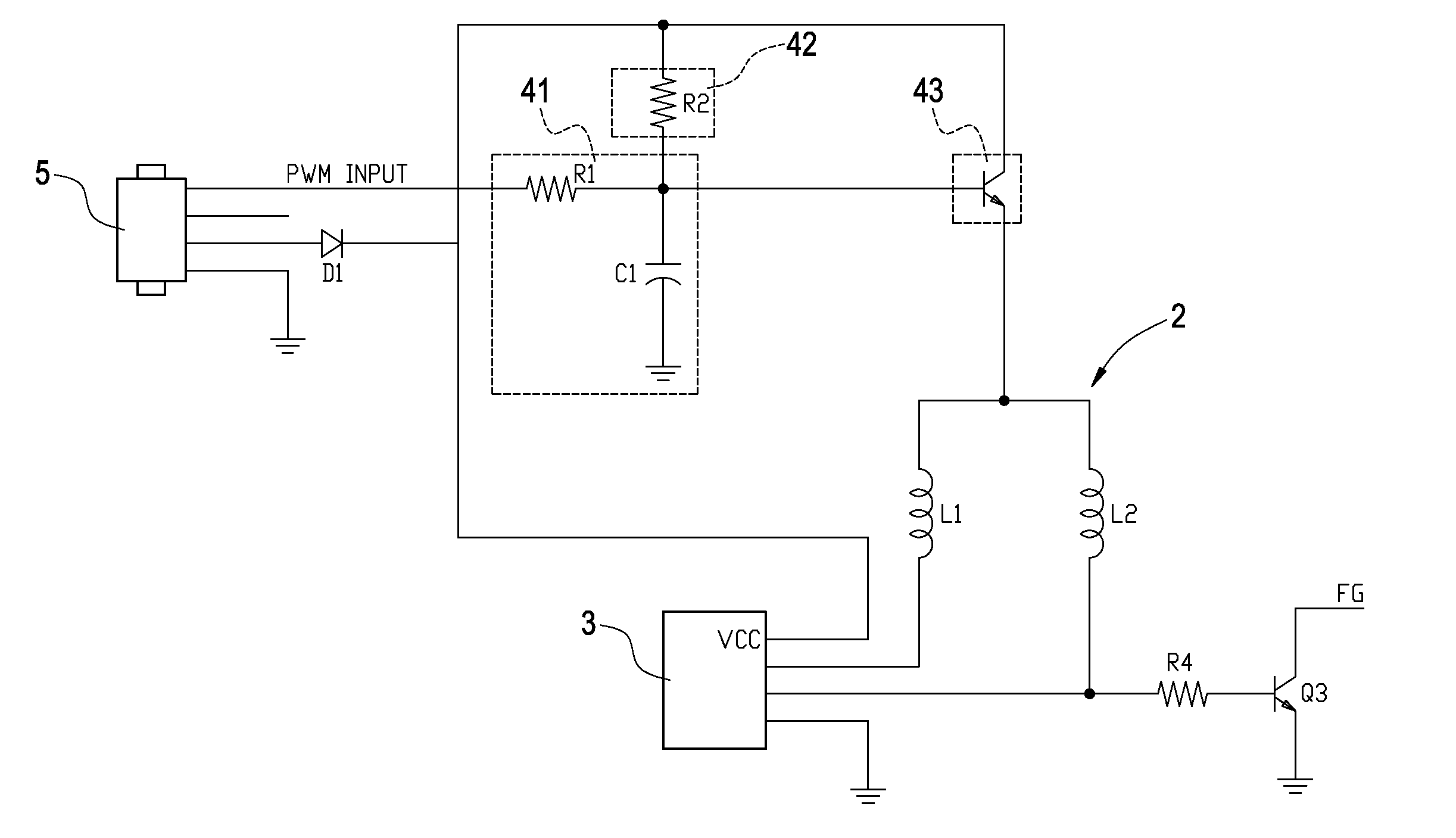

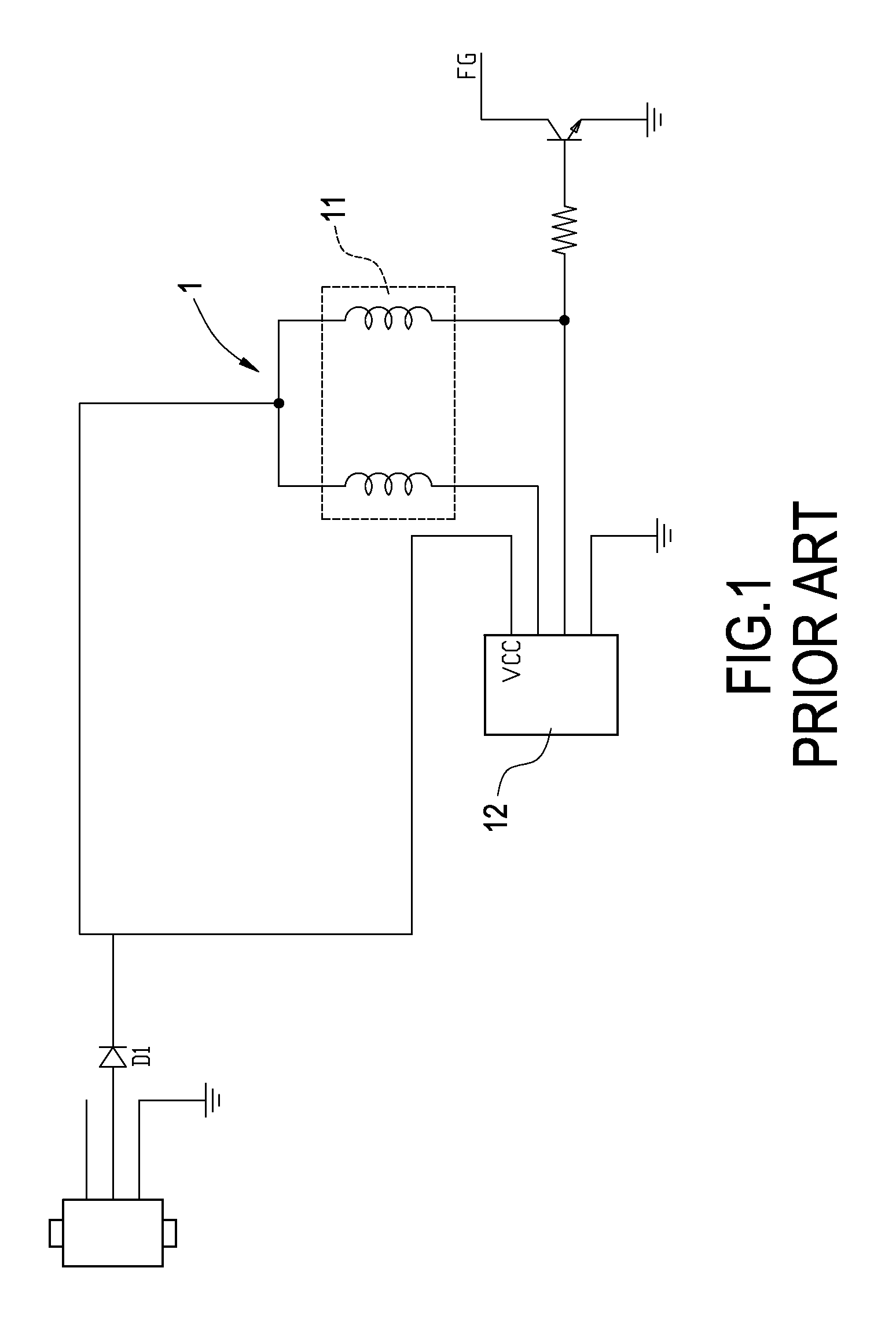

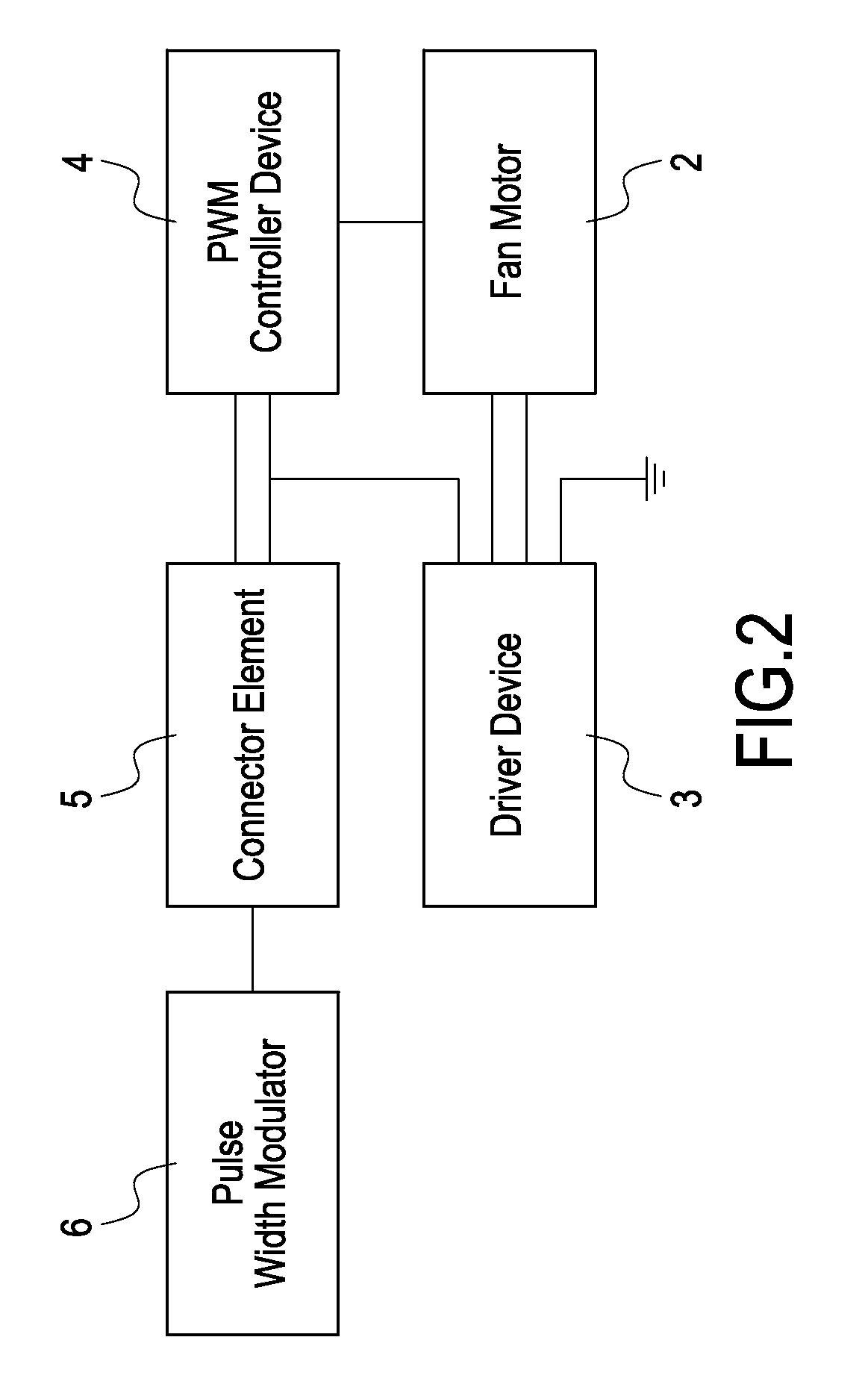

Controller Device of Cooling Fan

InactiveUS20070069670A1Simple PWM controller device designIncrease speedMotor/generator/converter stoppersAC motor controlVoltage dropControl theory

A PWM controller device of a simple cooling fan includes a fan motor, a driver device, and a PWM controller device. The driver device is electrically connected to the fan motor. The PWM controller device is electrically connected to the fan motor and the driver device. The driver device internally detects the temperature rise variation of the electronic element and drives the fan motor to rotate in high speed. When the fan motor remains in high rotational speed as the temperature of the electronic element decreases, a PWM signal is input to the PWM controller device, which responsively generates a voltage-drop signal to drive the fan motor to its reduce rotational speed. The PWM controller device achieves control similar to that of a MCU, reduces manufacturing costs, and reduces over all physical size of the cooling fan. The invention is suitable for use in compact electronics.

Owner:LIN TRAIN

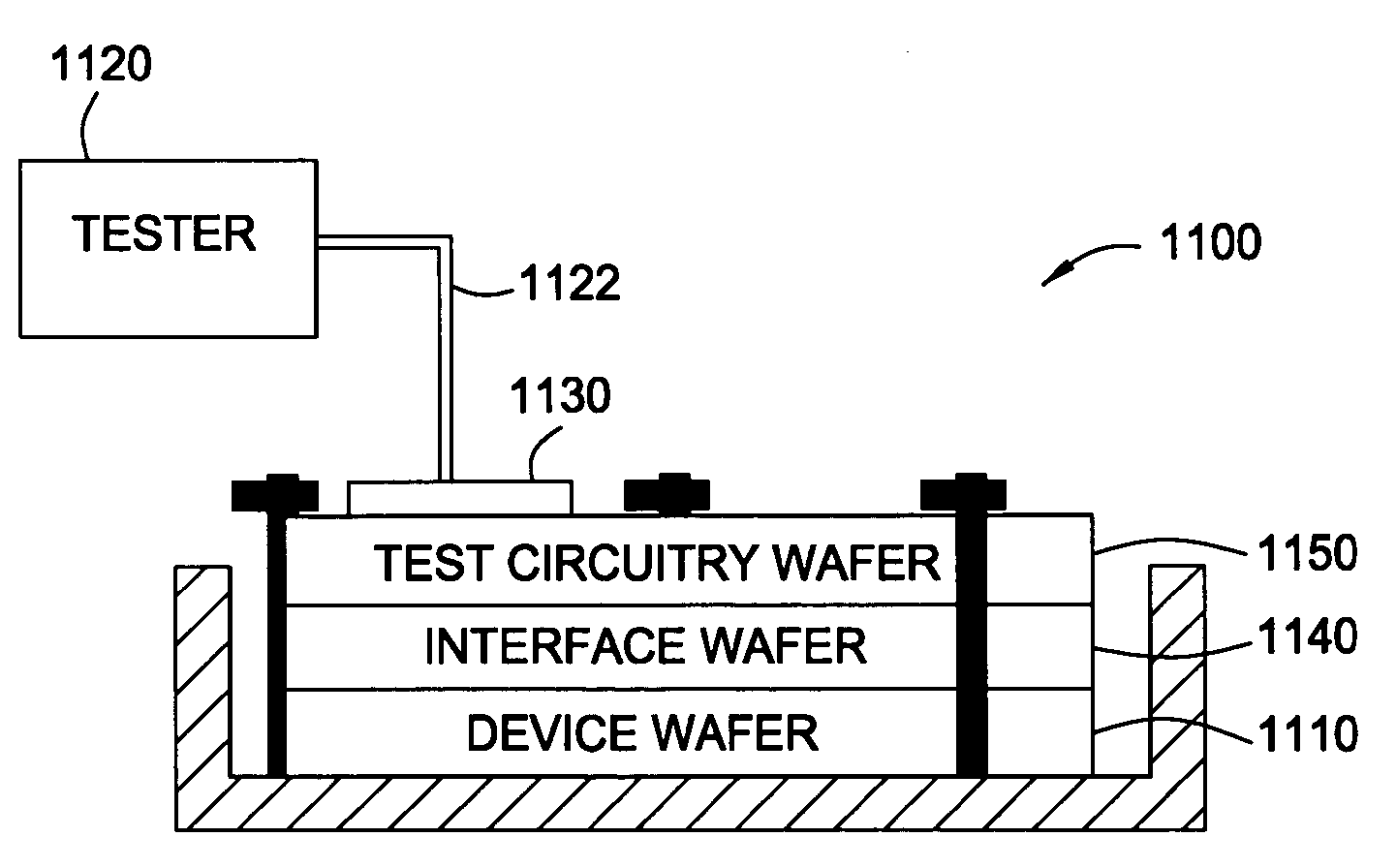

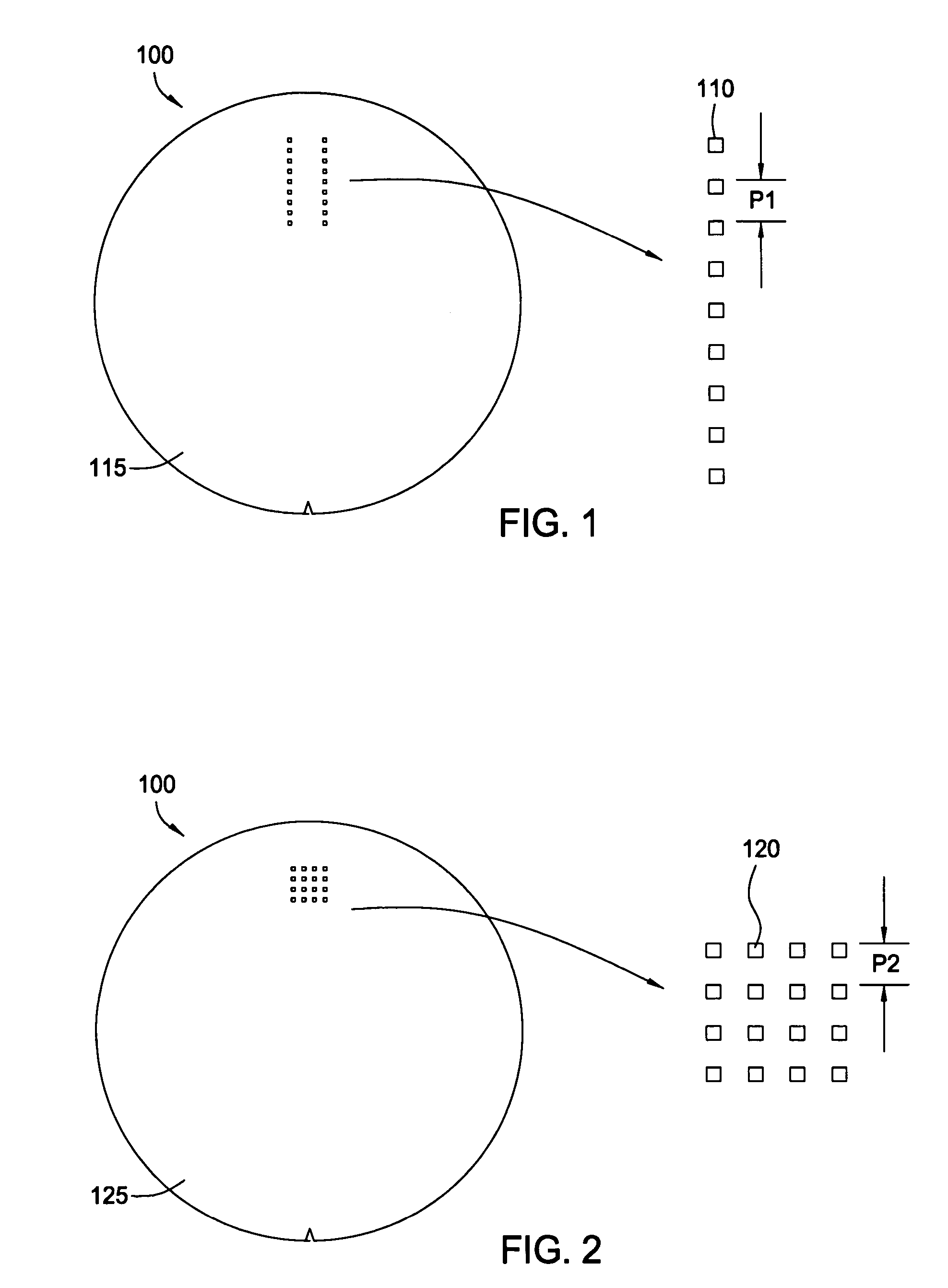

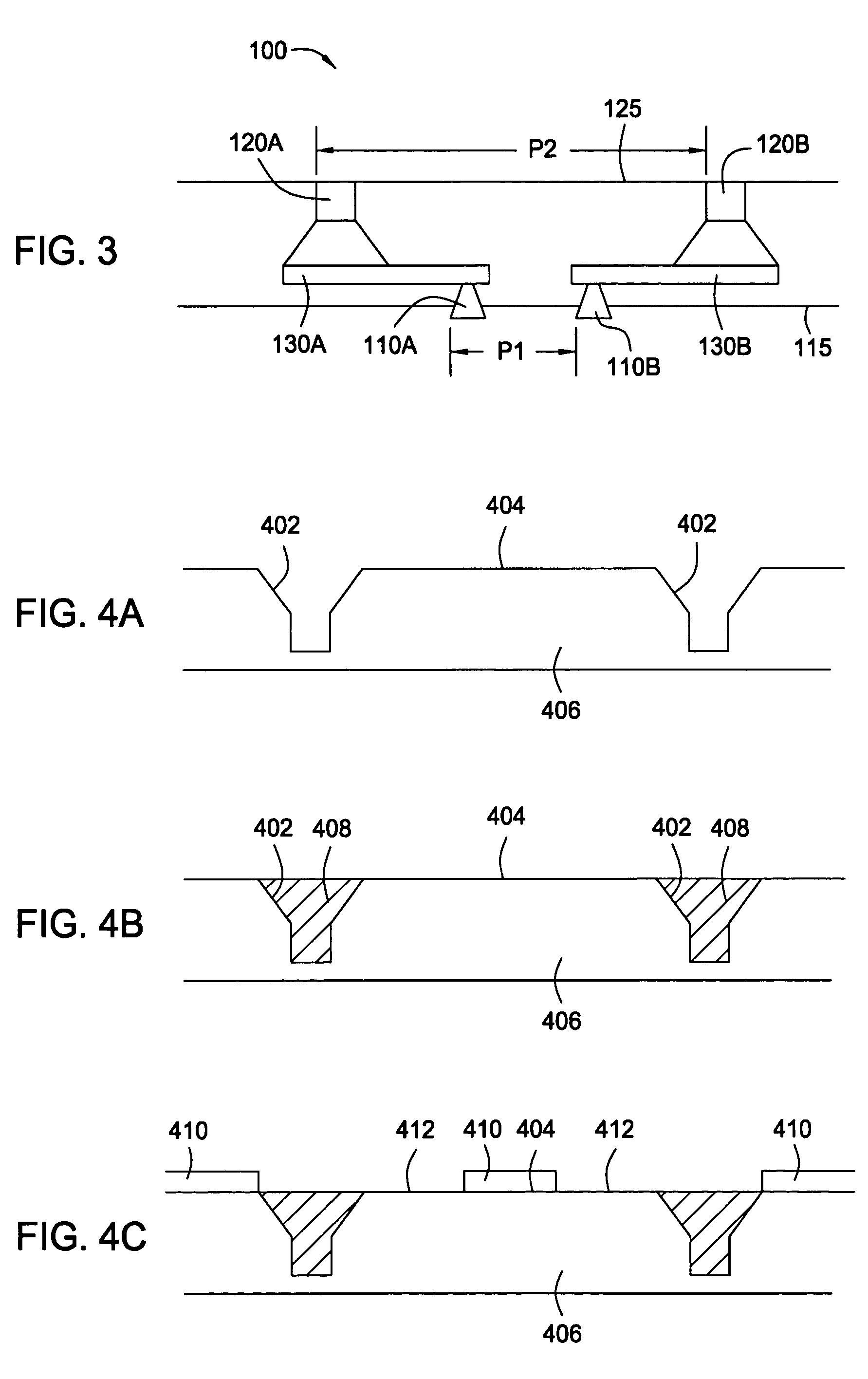

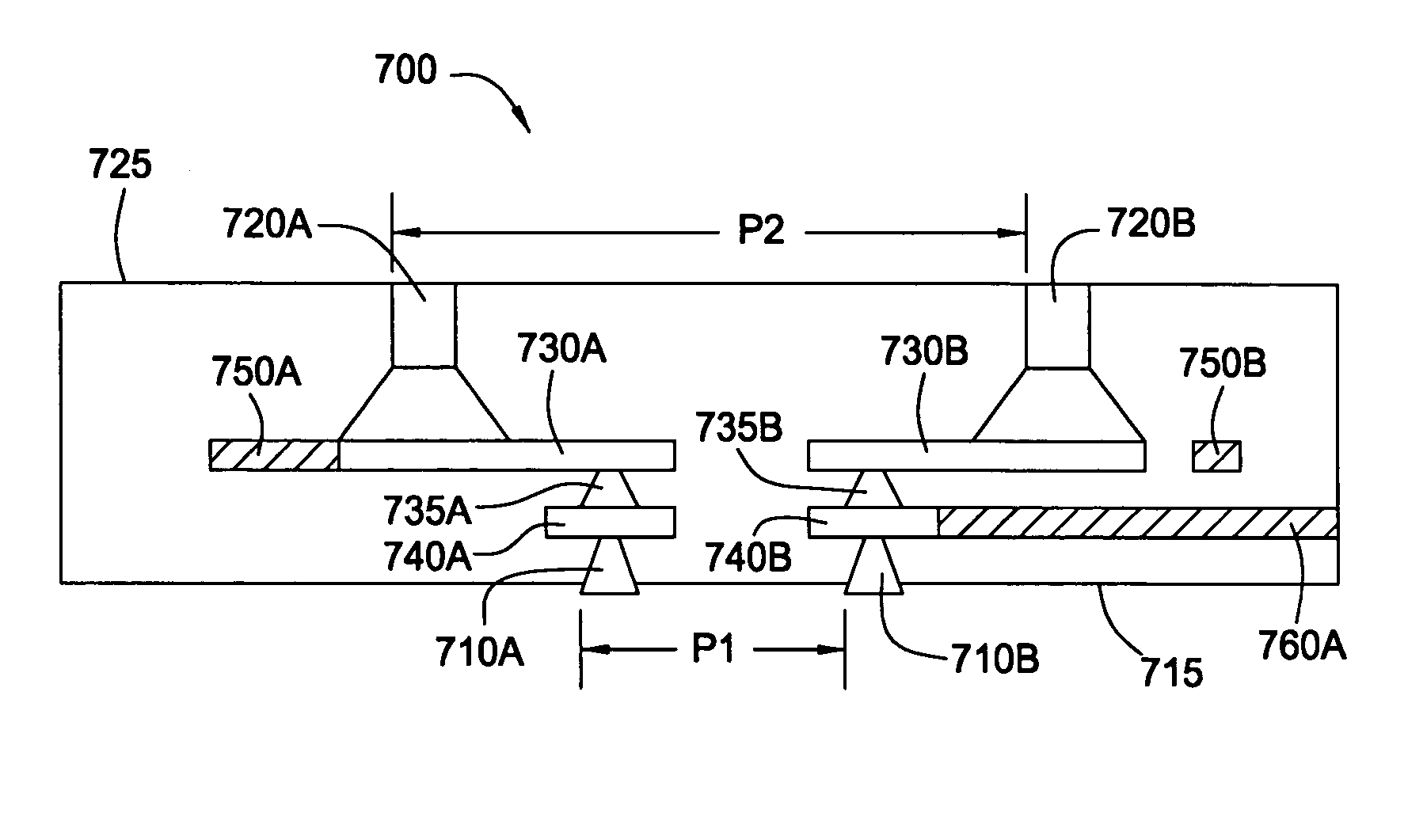

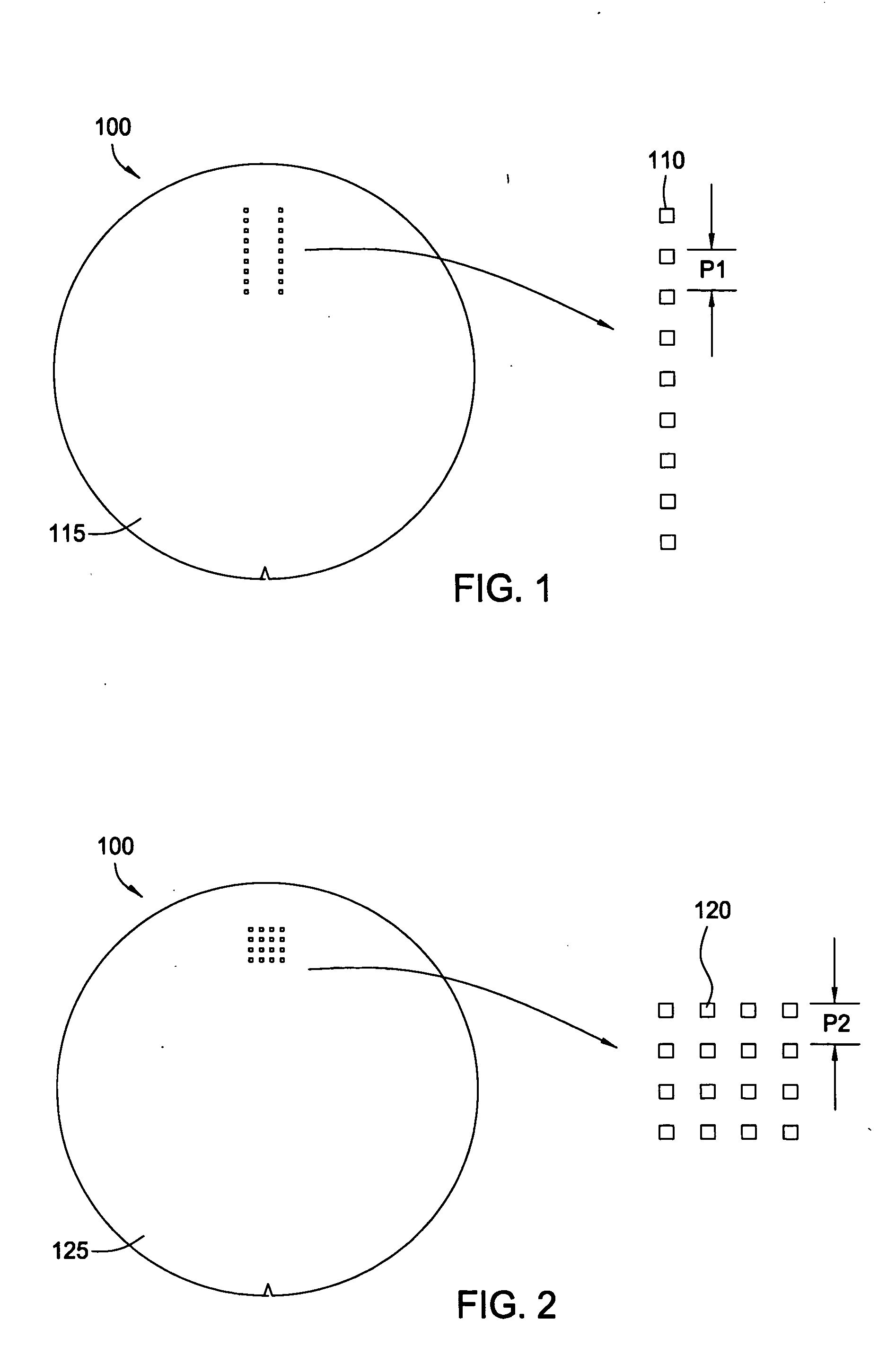

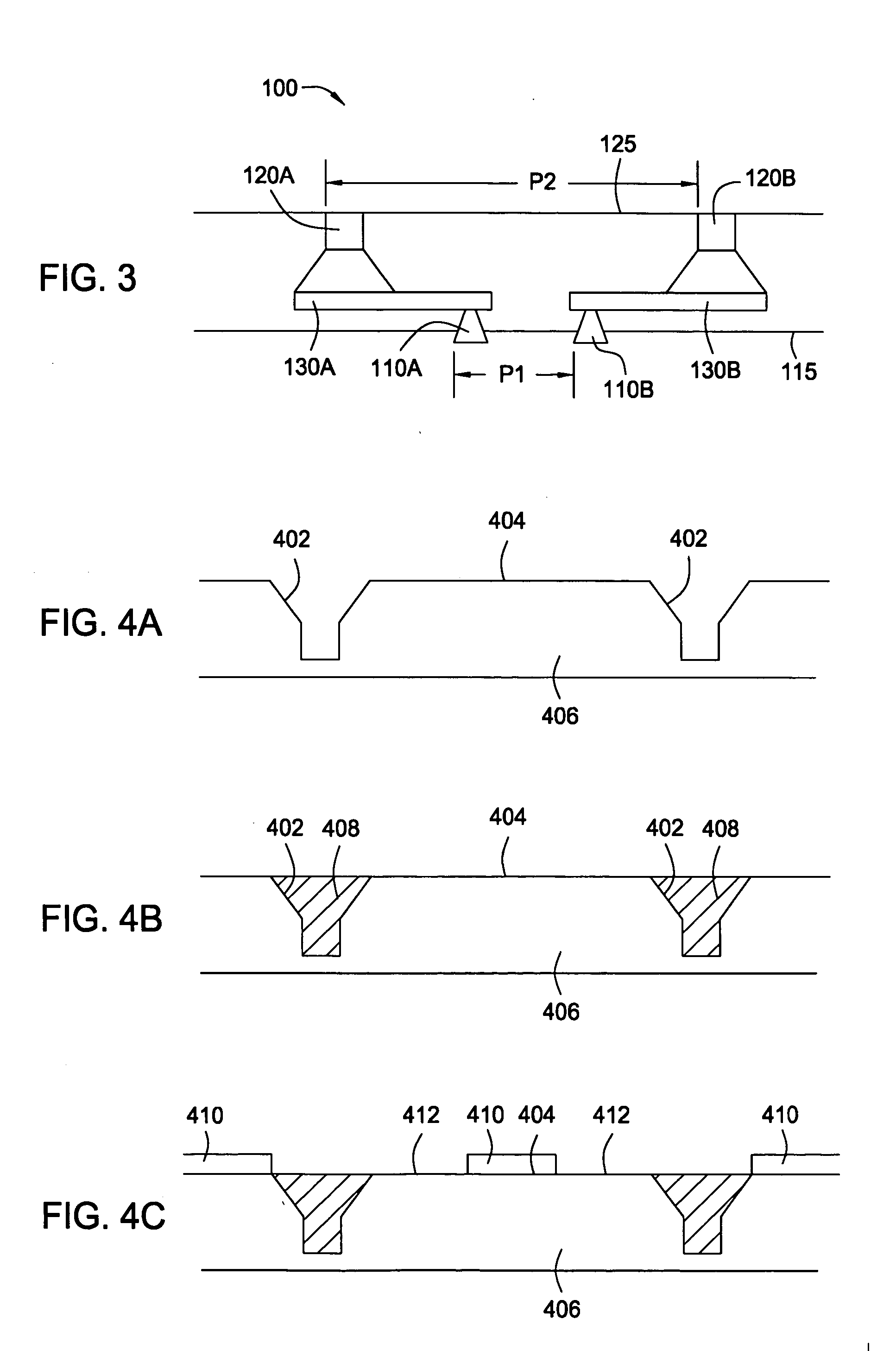

Wafer probecard interface

InactiveUS20050285614A1Reduced precision requirementsReducing and minimizing numberElectronic circuit testingStatic storageProbe cardContact pad

Apparatus and method for testing a device wafer having a plurality of devices formed thereon. One embodiment of the invention provides an interface wafer comprising a plurality of contact pads disposed on a first surface for contacting a plurality of device pads on the device wafer and a plurality of interface pads disposed on a second surface for contacting probe needles on a probe card, wherein the plurality of interface pads are electrically connected to the plurality of contact pads and wherein the plurality of interface pads are disposed in a relaxed-pitch arrangement as compared to the plurality of contact pads.

Owner:POLARIS INNOVATIONS

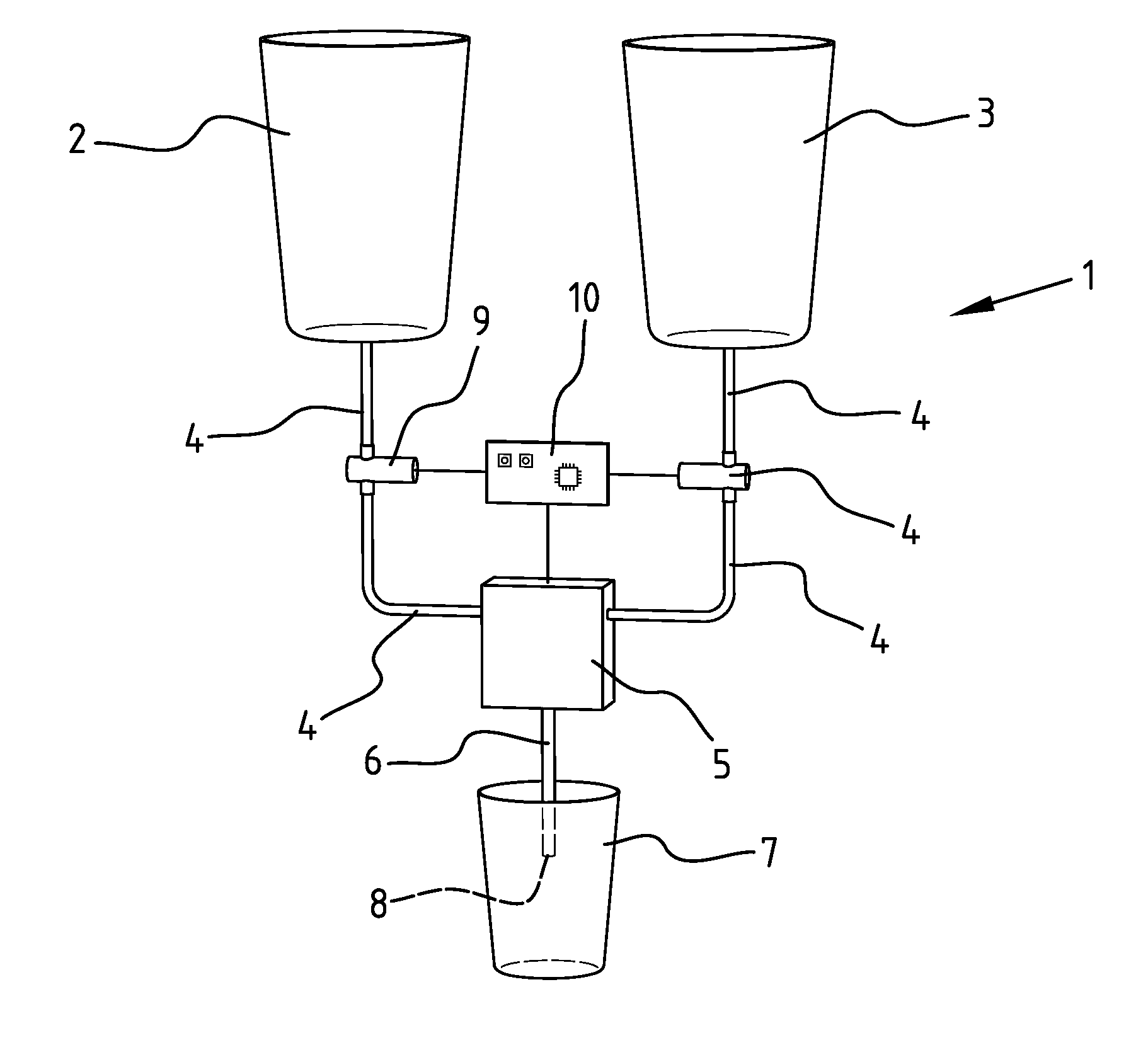

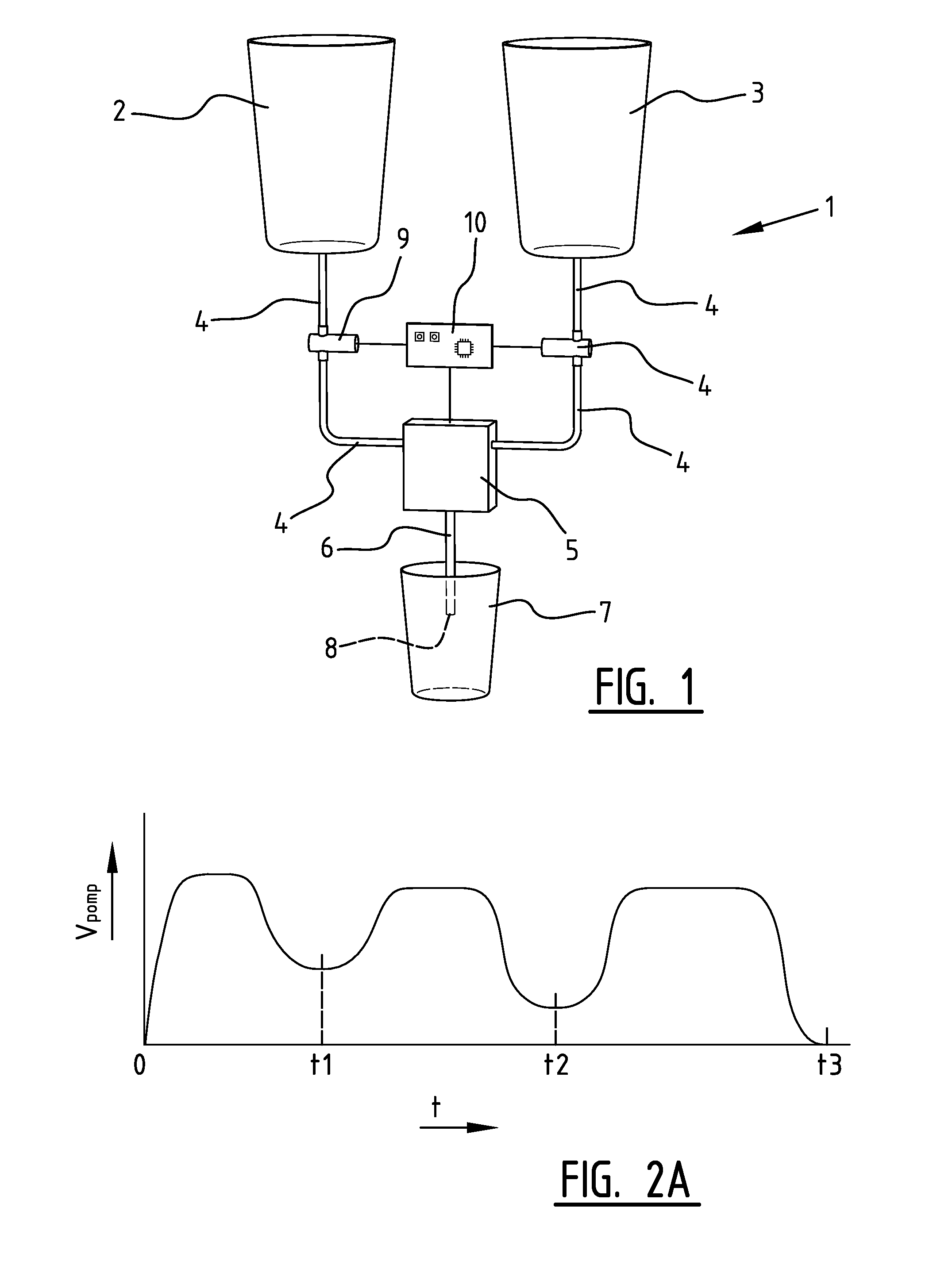

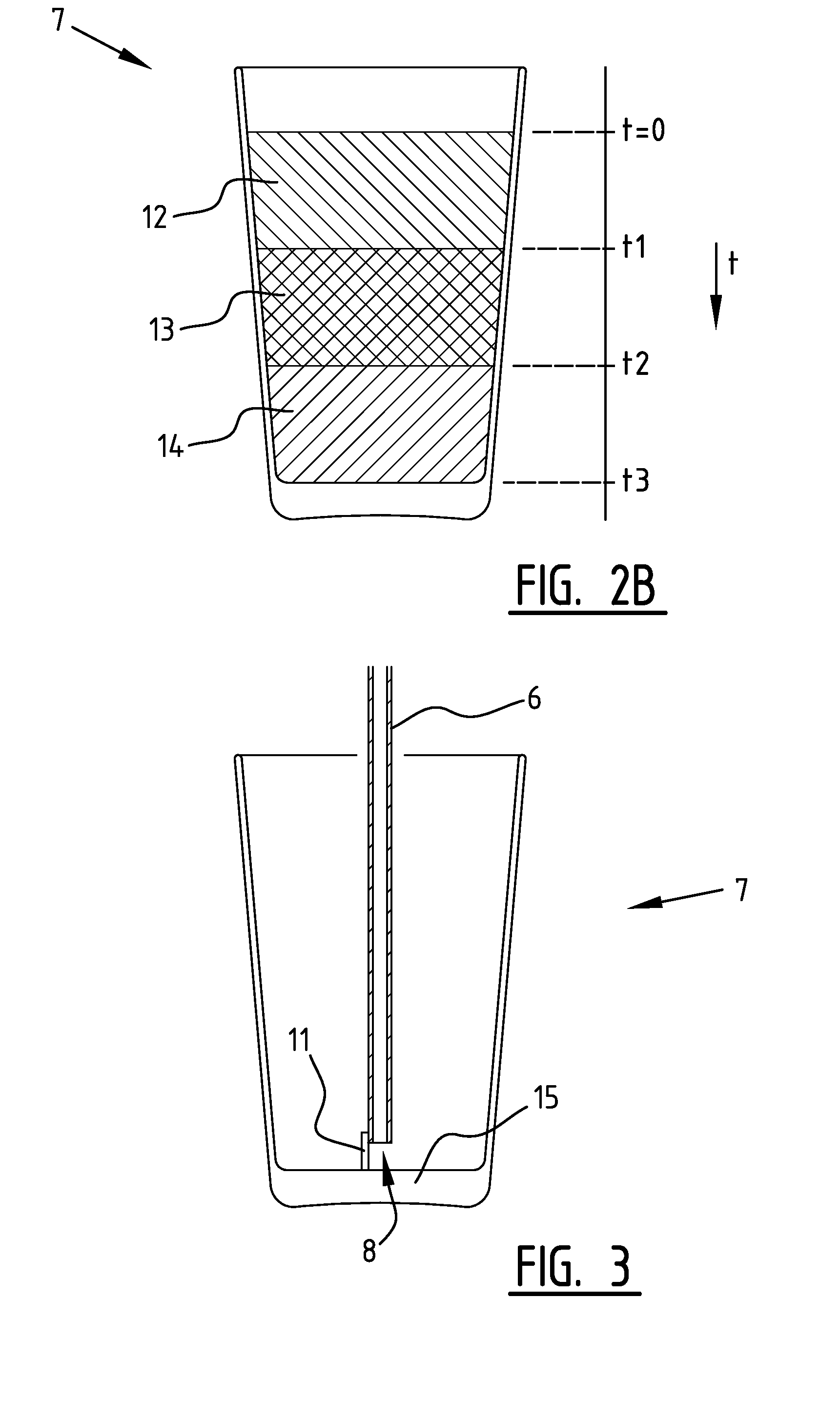

Injecting device and method of filling a holder with separated liquid layers

InactiveUS8931525B2Reduced dimensionReduce complexityLiquid fillingBeverage vesselsLiquid layerEngineering

An injecting device for filling a holder with separated liquid layers is provided herein. The device includes at least two containers for holding different liquids, an injector for filling a holder with separated liquid layers and moving means for setting the distance between the holder and the injector. A method for filling a holder with separated liquid layers is also provided. The method includes the steps of placing a holder with bottom, disposing inside the holder, and at a predetermined distance from the bottom of the holder, a feed conduit with an outflow opening for dispensing liquid, and allowing different liquids to flow sequentially out of the feed conduit, wherein the distance between the outflow opening and the bottom is maintained.

Owner:LAYERNATION BEVERAGE SOLUTIONS

Device for cleaning a camera lens and method of using same

InactiveUS20200223401A1Easy to cleanImprove optical efficiencyTelevision system detailsColor television detailsCamera lensOphthalmology

A device for cleaning at least one optical surface of at least one camera, a camera system and a camera holder including such a device and a method of using the device, the camera system and / or the camera holder.

Owner:MOTHERSON INNOVATIONS CO LTD

Adjustable ultrasonic coupling agent automatic squeezing device

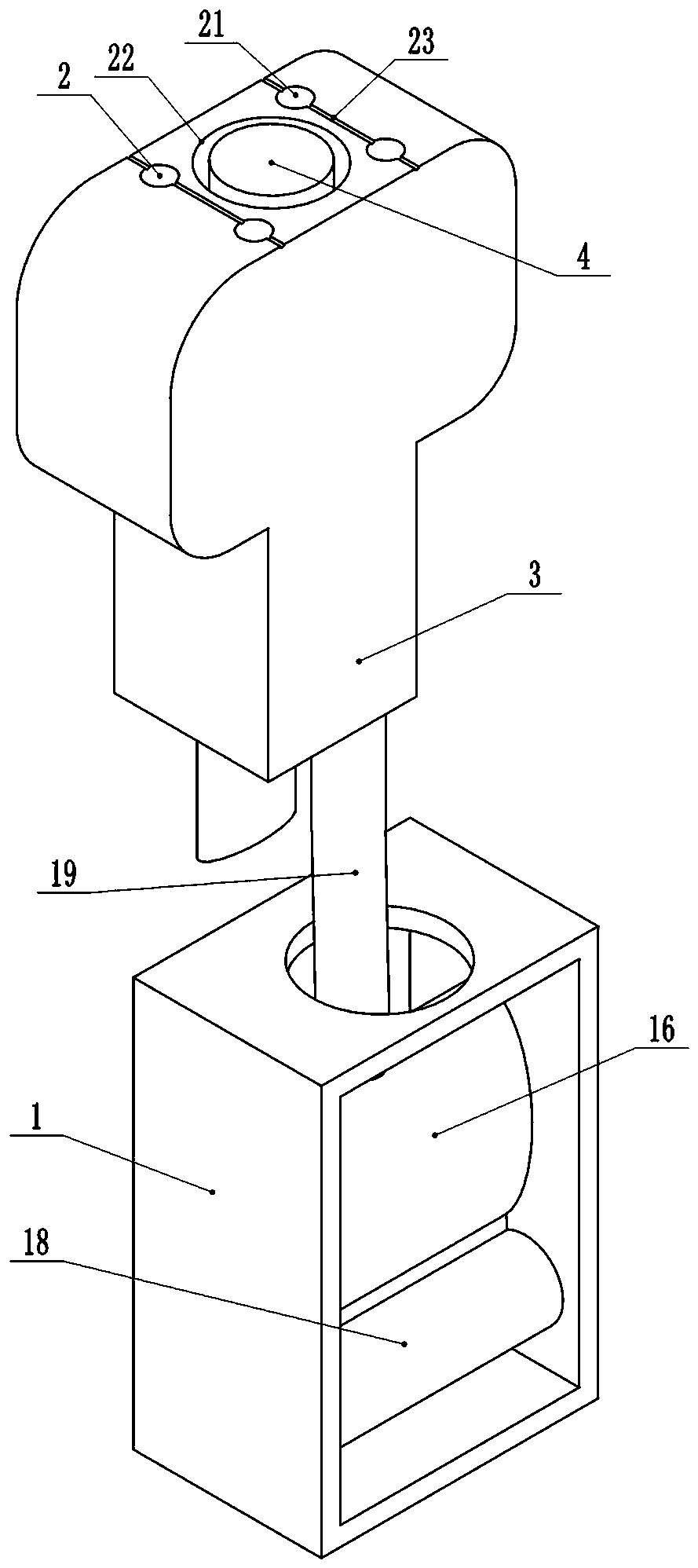

PendingCN110123375ASimple device designLow costUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsAutomatic controlPneumatic pressure

An adjustable ultrasonic coupling agent automatic squeezing device comprises a squeezing module, a detection module, a connection module and a control module. The connection module can connect other modules together, an ultrasonic probe can be fixed on the connection module, the squeezing module uses a mechanical structure to squeeze a coupling agent bottle to squeeze out a coupling agent, and thecoupling agent is delivered to an agent outlet close to the ultrasonic probe through a pipeline of the connection module to move along with the probe and can be smeared on the body of a detected person; the detection module can utilize gas pressure change, resistance change or friction force change to indirectly judge smearing volume of the coupling agent to control output of the coupling agent or can only detect temperature; the control module can realize full-automatic control on output of the coupling agent manually or according to the detection module and can manually or automatically control heating power and on-off of the coupling agent according to temperature data of the detection module.

Owner:THE SECOND HOSPITAL AFFILIATED TO WENZHOU MEDICAL COLLEGE

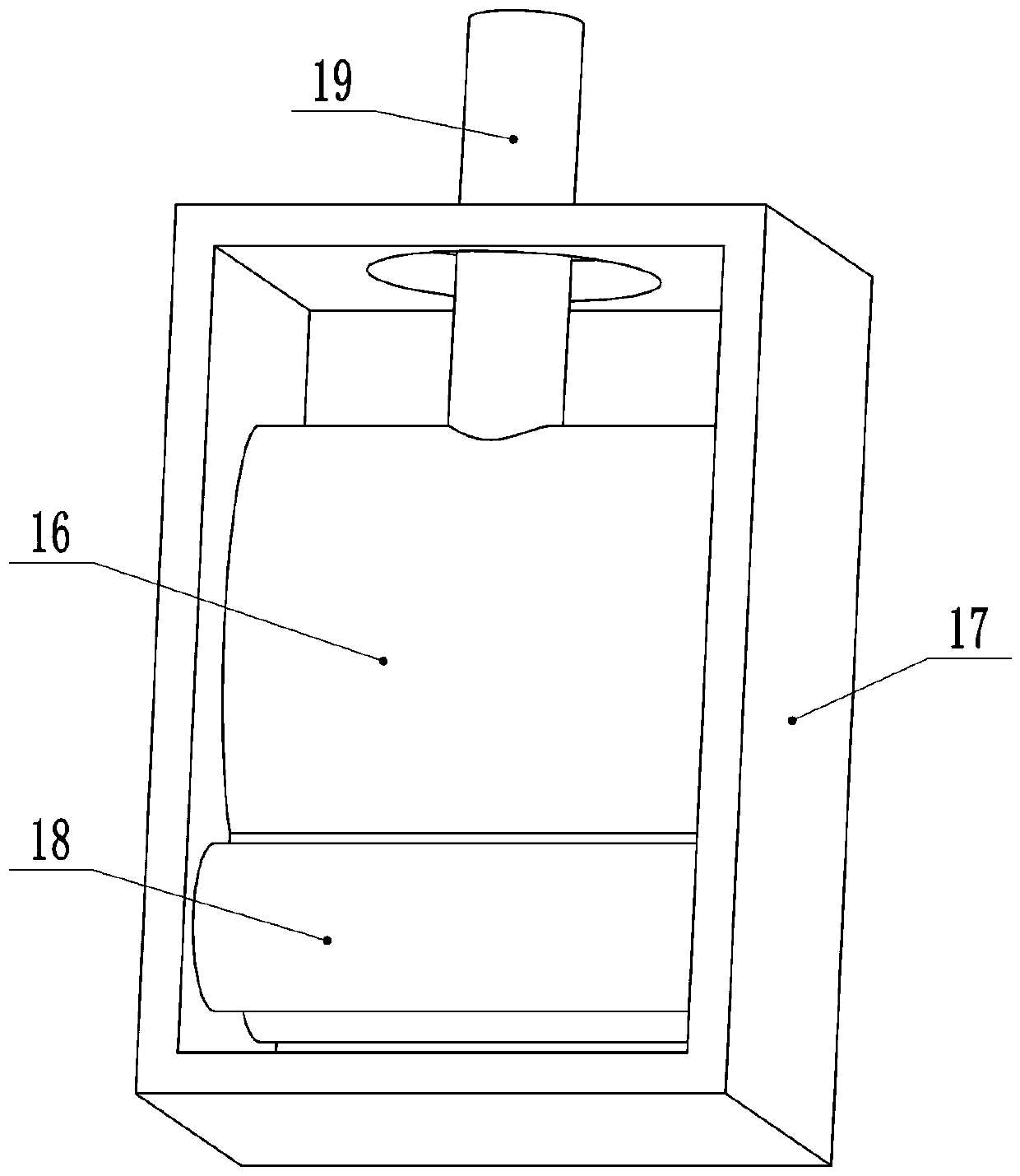

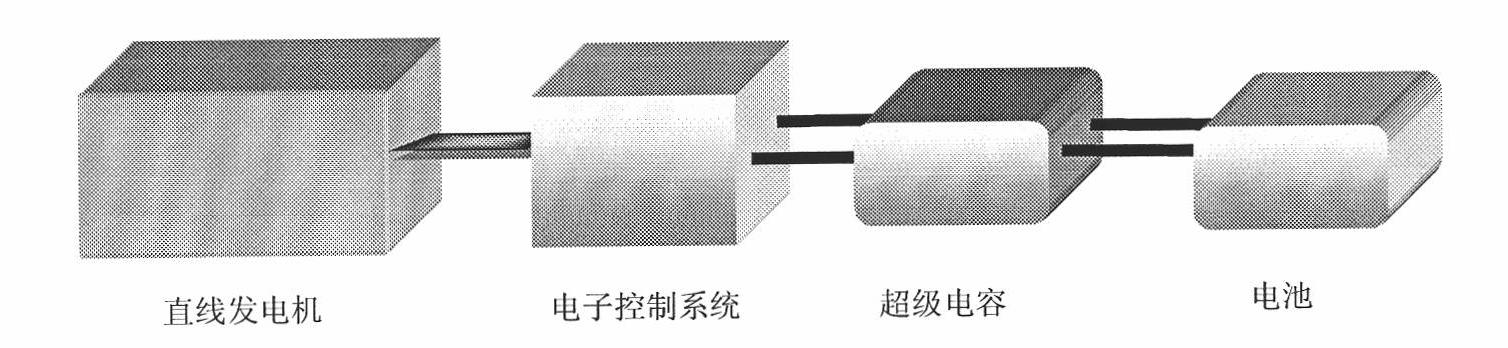

Resonant type permanent magnet linear generator

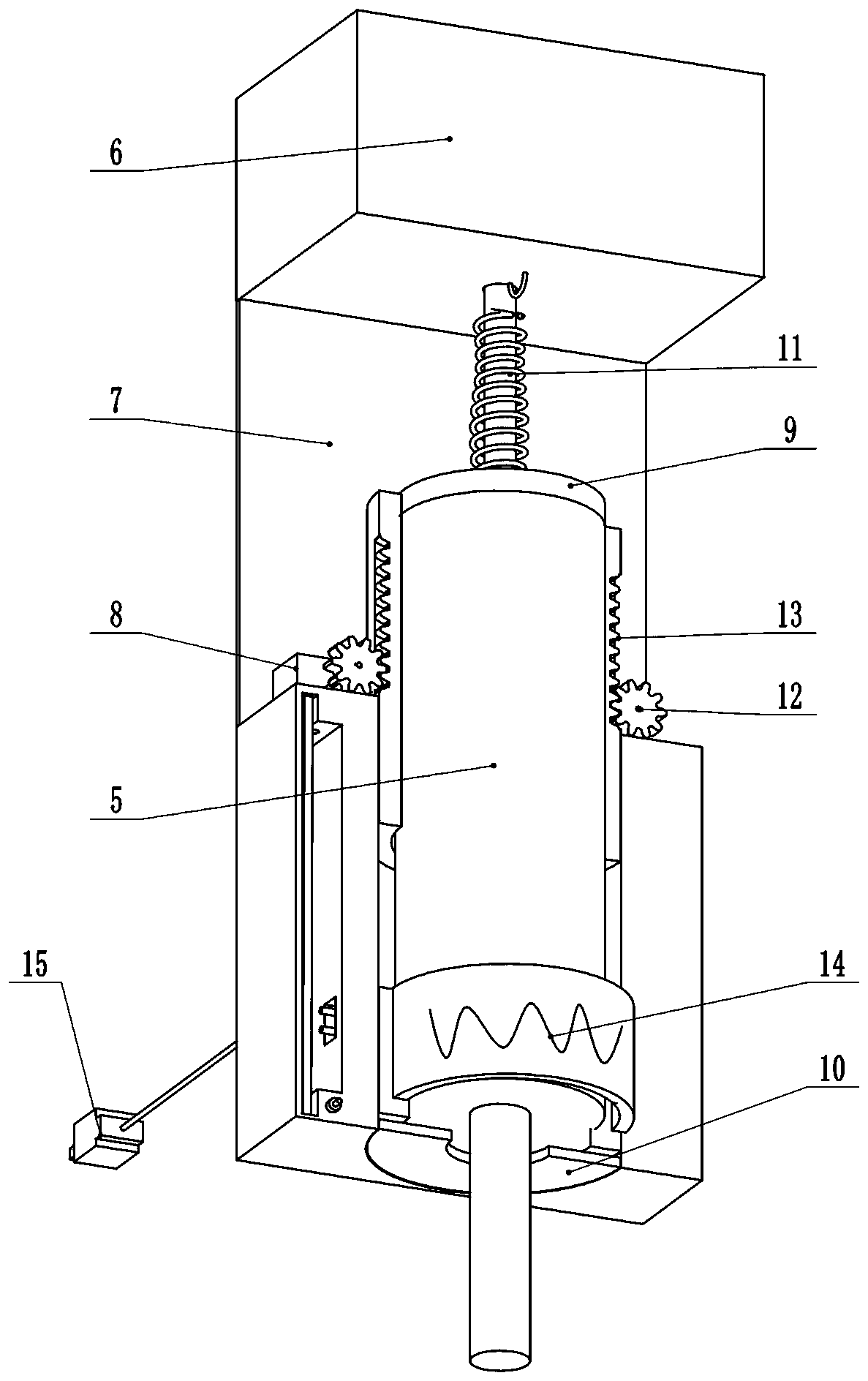

InactiveCN102064661ASimple device designSmall structureElectrical storage systemBatteries circuit arrangementsPhysicsElectric energy

The invention provides a resonant type permanent magnet linear generator comprising stator structures and rotor structures. The rotor structures are arranged in magnetic shield casings of the stator structures and are positioned on the other sides of the magnetic shield casings, which are opposite to the stator structures. Each rotor structure also comprises a rotor substrate and a chute structure, wherein the rotor substrate is positioned between the chute structures; each chute structure comprises a reversing spring, a resonant spring, a U-shaped chute and a roll ball; the roll ball is arranged in the U-shaped chute; the rotor substrate is clamped in the U-shaped chute; the end part of the rotor substrate is in contact with the roll ball and slides in the U-shaped chute up and down; twoends of the two U-shaped chutes are correspondingly connected by a connecting plate; the reversing springs are respectively arranged at two ends of each of the two U-shaped chutes; and the resonant springs are respectively arranged between the substrates and two connecting plates. The resonant type permanent magnet linear generator disclosed by the invention has the advantages of simple structure, low cost, high generated electrical energy and easiness of constructing, carrying and integrating.

Owner:麦伟仪 +1

Method for transmission using a non-uniform interconnection

InactiveUS20110187474A1Reduced internal crosstalkSimple device designMultiple-port networksCross-talk reductionElectrical conductorHemt circuits

The invention relates to a method and a device for transmission through interconnections used for sending a plurality of electrical signals.An interconnection having 4 transmission conductors and a reference conductor cannot be modeled as a uniform multiconductor transmission line. Each end of the interconnection is connected to a termination circuit. The transmitting circuits receive at their inputs the signals from the 4 channels of the two sources, and are connected to the interconnection. A transmitting circuit in the activated state produces modal electrical variables, each modal electrical variable being allocated to one and only one channel. The receiving circuits are connected to the interconnection, each receiving circuit being such that the signals of the 4 channels of a source connected to a transmitting circuit in the activated state are sent to the four channels of the destinations, without noticeable echo and internal crosstalk.

Owner:ZXNOISE LLC

Method for imprinting a three-dimensional article

ActiveUS8104887B2High-quality patterningEasy to operateTypewritersRelative motionElectrical and Electronics engineering

Owner:HOMAG HOLZBEARBEITUNGSSYST

MEMS device with off-axis actuator

ActiveUS8238011B1Simple device designOptical elementsRotational axisMicro electrical mechanical systems

A micro-electro-mechanical system (MEMS) mirror device has a mirror, a frame rotatively coupled to the mirror, and a biaxial actuator rotatively coupled to the frame where the actuator is able to rotate about the rotational axes of the mirror and the frame with the mirror.

Owner:ADVANCED NUMICRO SYST

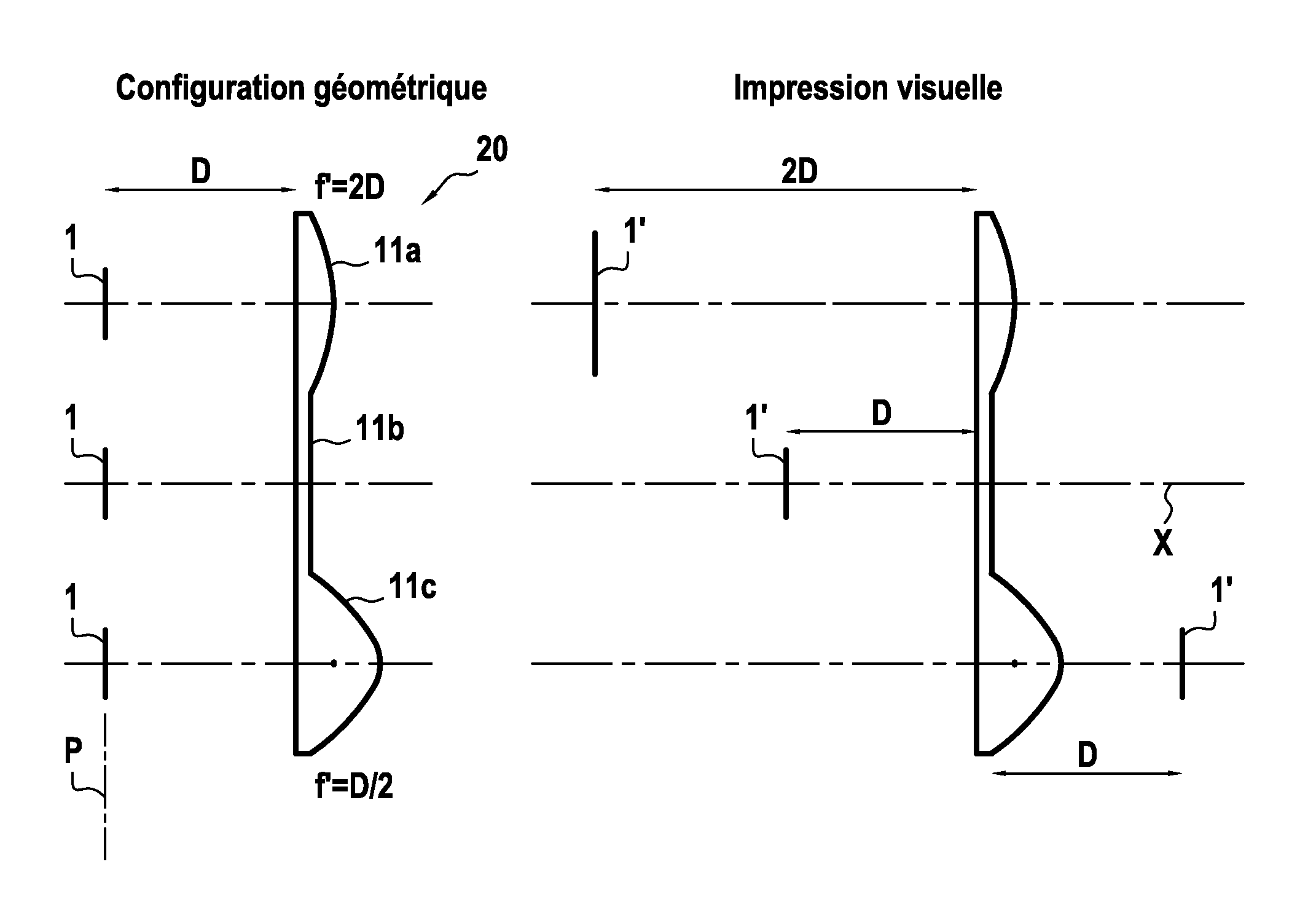

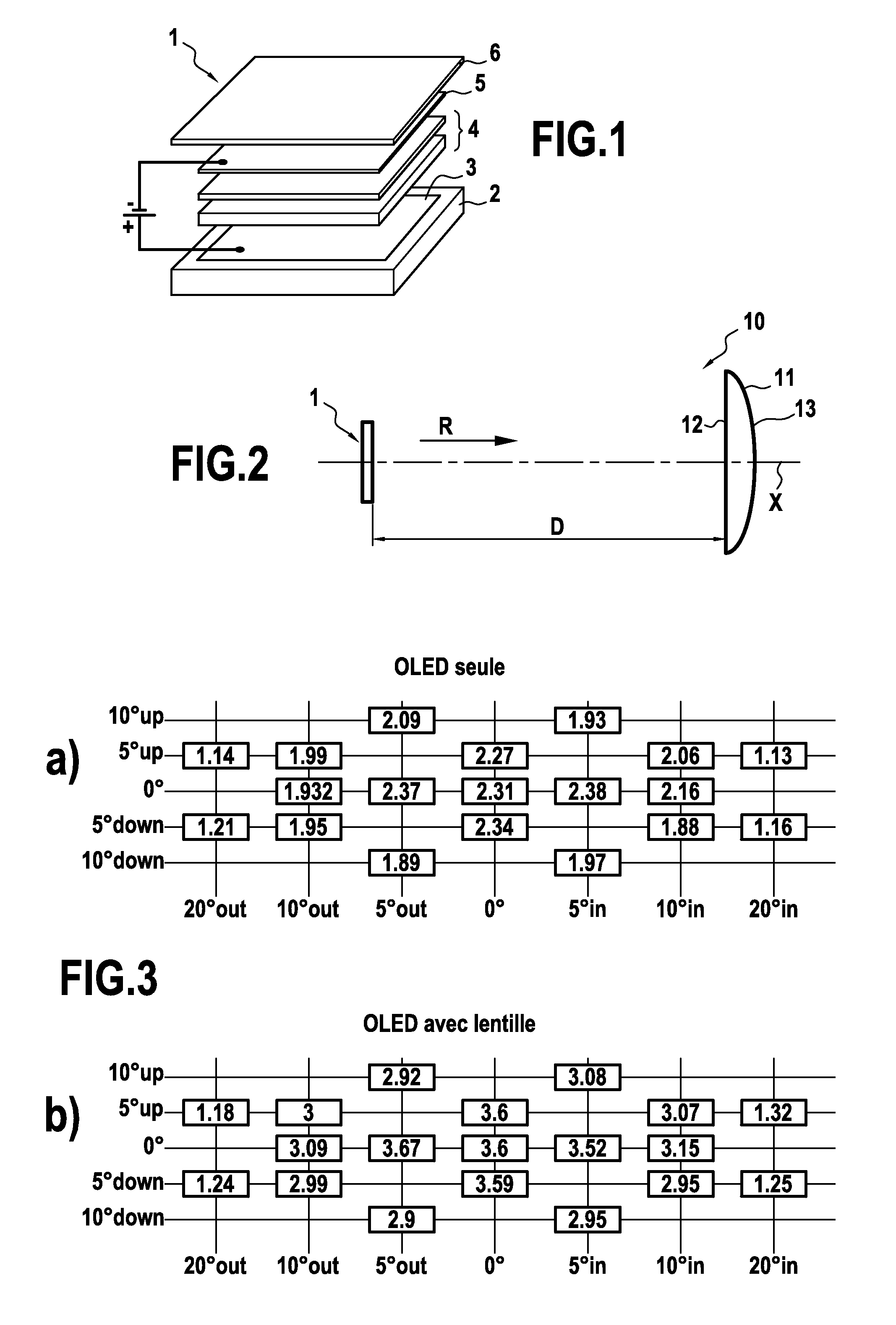

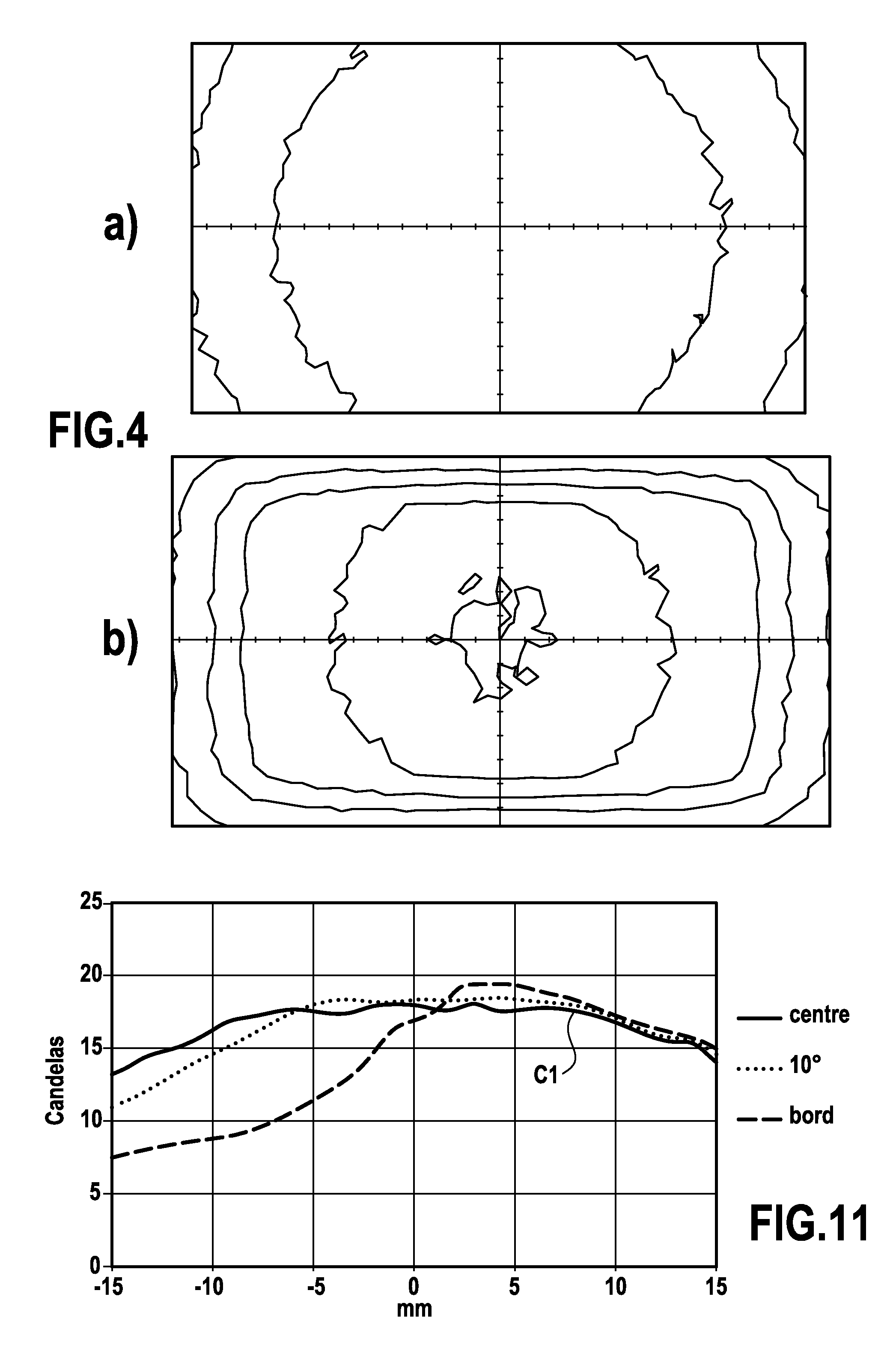

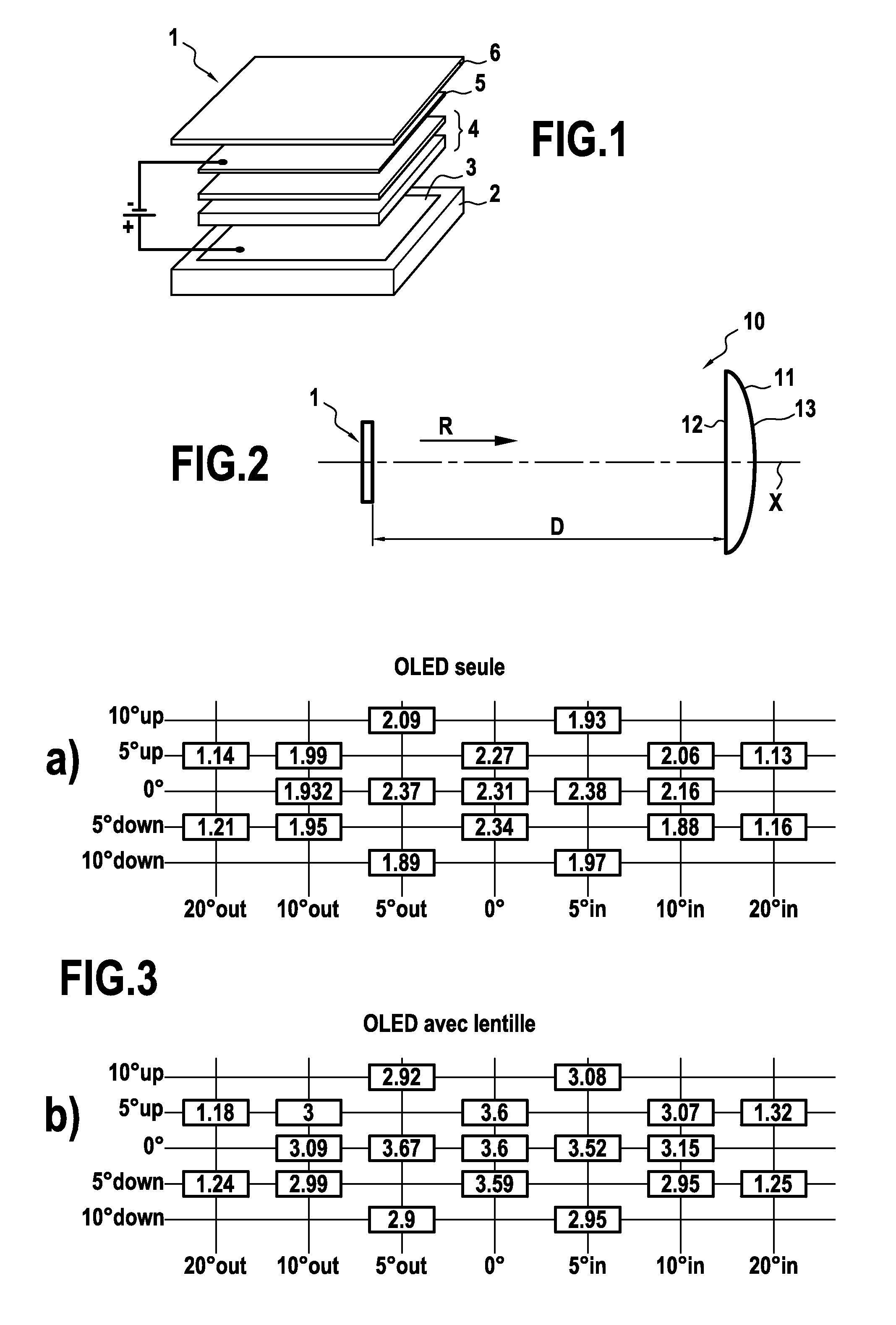

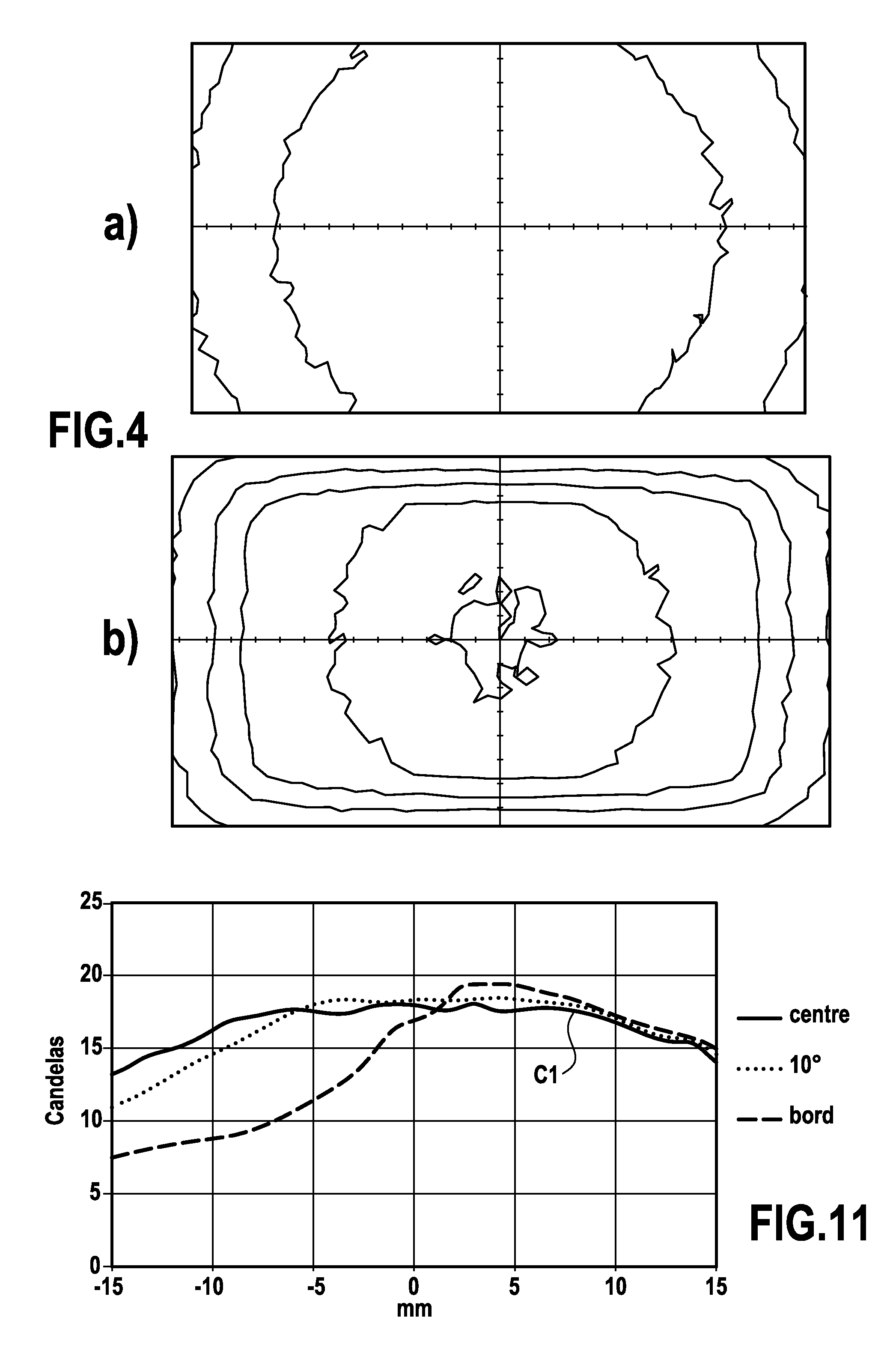

Optical device, in particular for a motor vehicle

ActiveUS9441805B2High luminous intensitySimple designPlanar light sourcesVehicle headlampsOptoelectronicsMotorized vehicle

Owner:VALEO VISION SA

Test circuitry wafer

InactiveUS20050285610A1Reduced precision requirementsReducing and minimizing numberElectronic circuit testingPrinted circuitsProbe cardContact pad

Method and apparatus for testing a plurality of devices on a device wafer. One embodiment provides a test circuitry wafer having a first surface and a second surface, the test circuitry wafer comprising a plurality of contact pads disposed on the first surface for contacting a plurality of device pads on the device wafer, a plurality of interface pads disposed on the second surface for contacting probe needles on a probe card and one or more test features disposed in the test circuitry wafer, wherein the one or more test features are electrically connected to at least one of the contact pads and the interface pads.

Owner:POLARIS INNOVATIONS

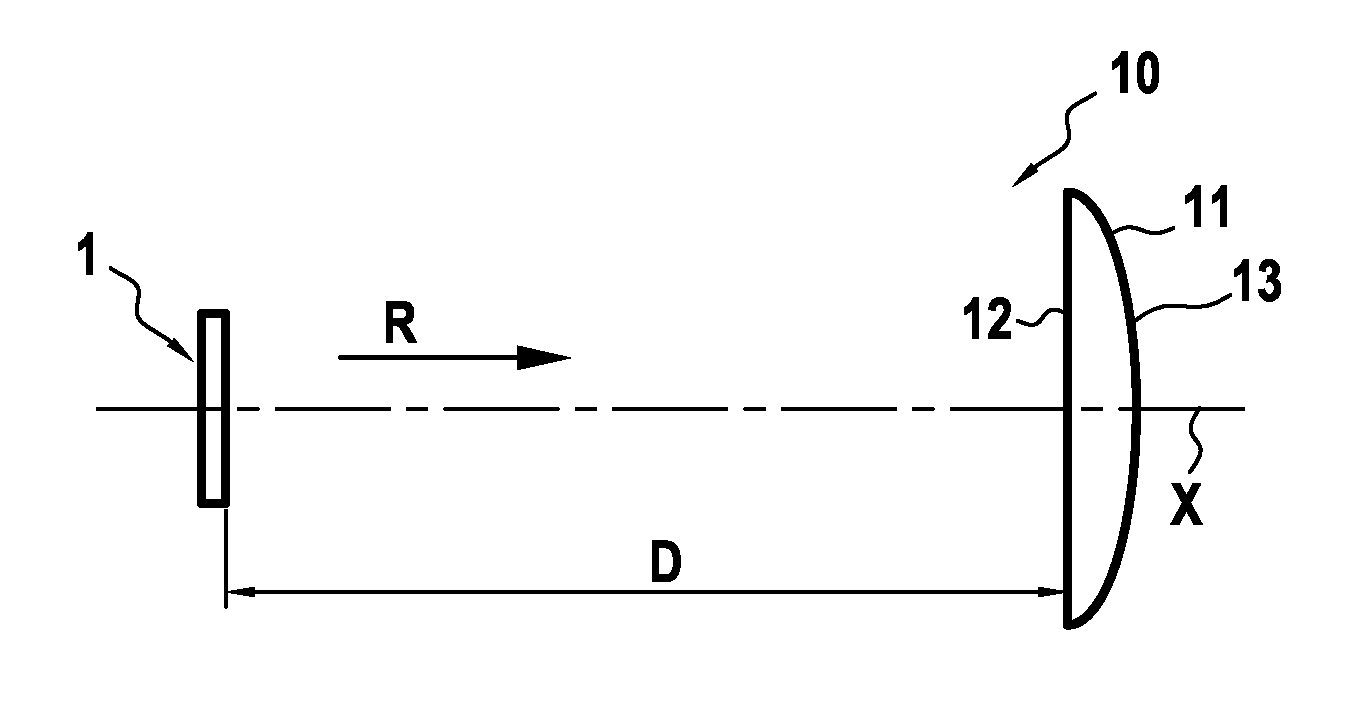

Optical device, in particular for a motor vehicle

ActiveUS20130021813A1High luminous intensitySimple designPlanar light sourcesVehicle headlampsMotor vehicle partOptoelectronics

An optical device for automobile vehicles, notably a signalling and / or lighting device.The device comprises at least one surface-emitting light source,at least one lens, notably distant from the surface-emitting light source, disposed at least partially on the path of the light (R) emitted by the surface-emitting light source so as to produce an image of an object area of the surface-emitting light source.

Owner:VALEO VISION SA

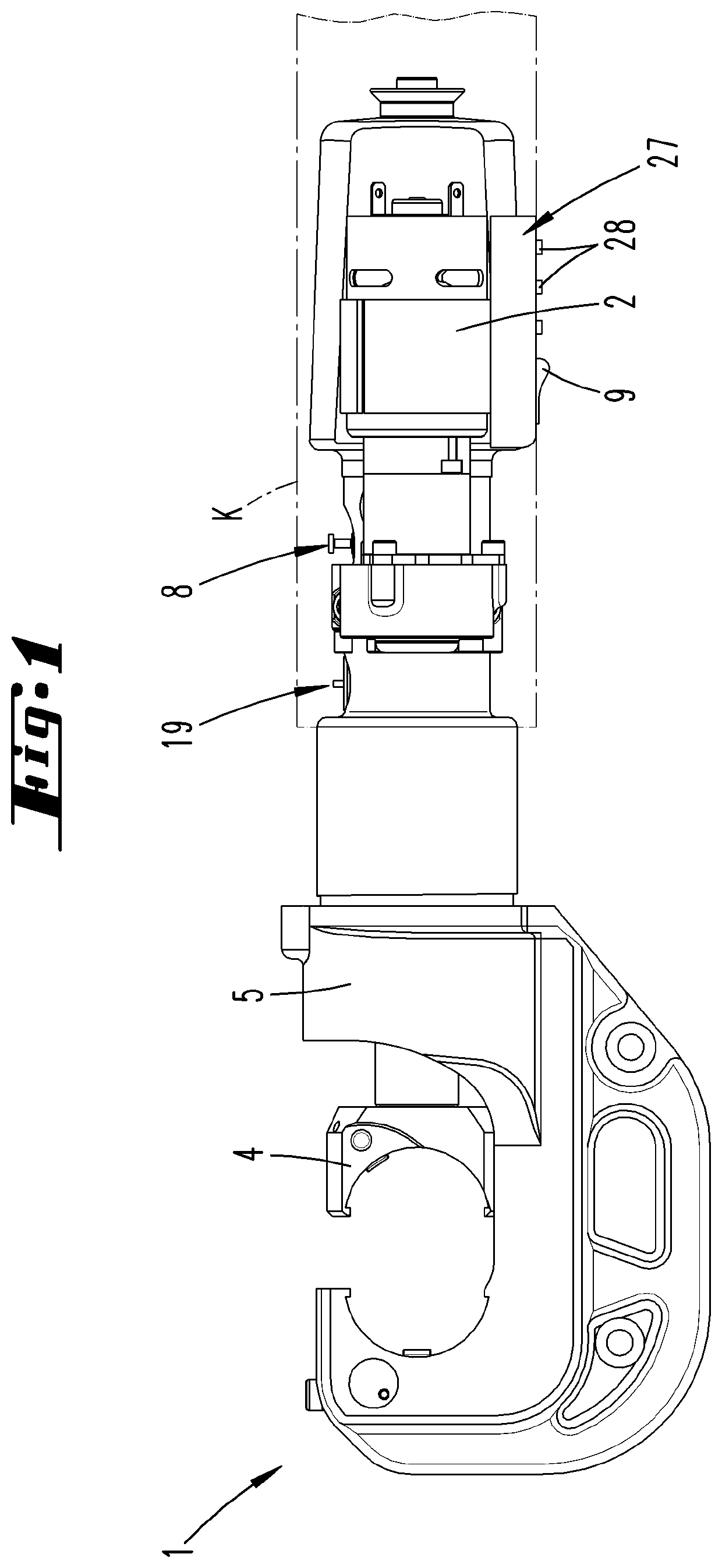

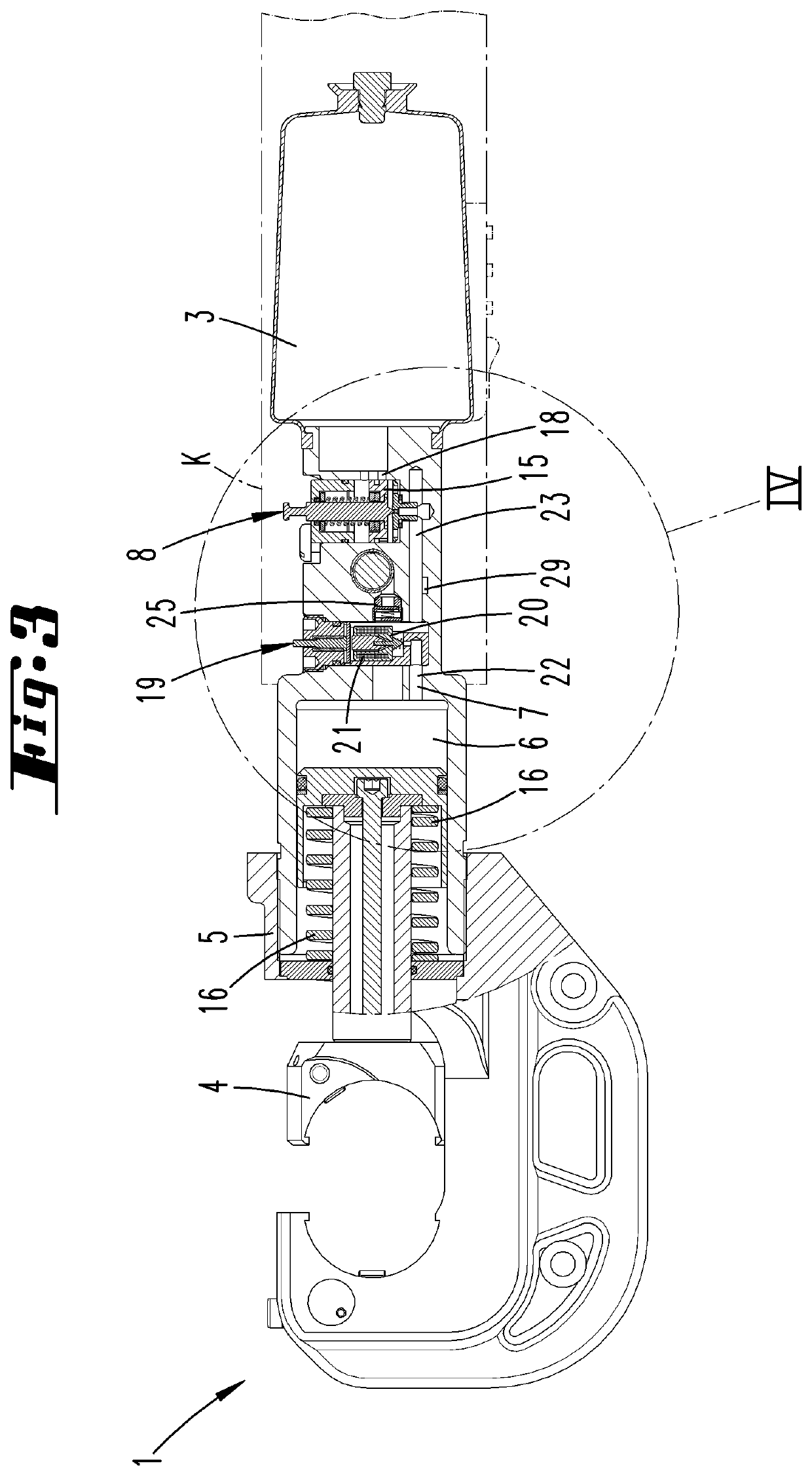

Method for operating a hydraulically operated handheld device, and hydraulically operated handheld device

ActiveUS20200147772A1Easy to operateSimple device designLine/current collector detailsPerforating toolsReflux valveWorking pressure

A hydraulically operated handheld device and a method of operating same are provided. The device includes a hydraulic pump, a moving part, a fixed part and a return valve with an associated valve seat. The moving part is moved into a working position due to the buildup of a hydraulic pressure by filling a hydraulic chamber with hydraulic medium from a reservoir with the aid of the hydraulic pump. The moving part can be automatically moved back from the working position into an end position upon reaching a predefined working pressure by opening the return valve. The hydraulic pressure acting upon the return valve is increased by a separately triggerable pressure increase, which results in opening of the return valve, in a hydraulic medium volume located upstream of the return valve in a flow direction of the hydraulic medium during the movement into the end position.

Owner:GUSTAV KLAUKE GMBH

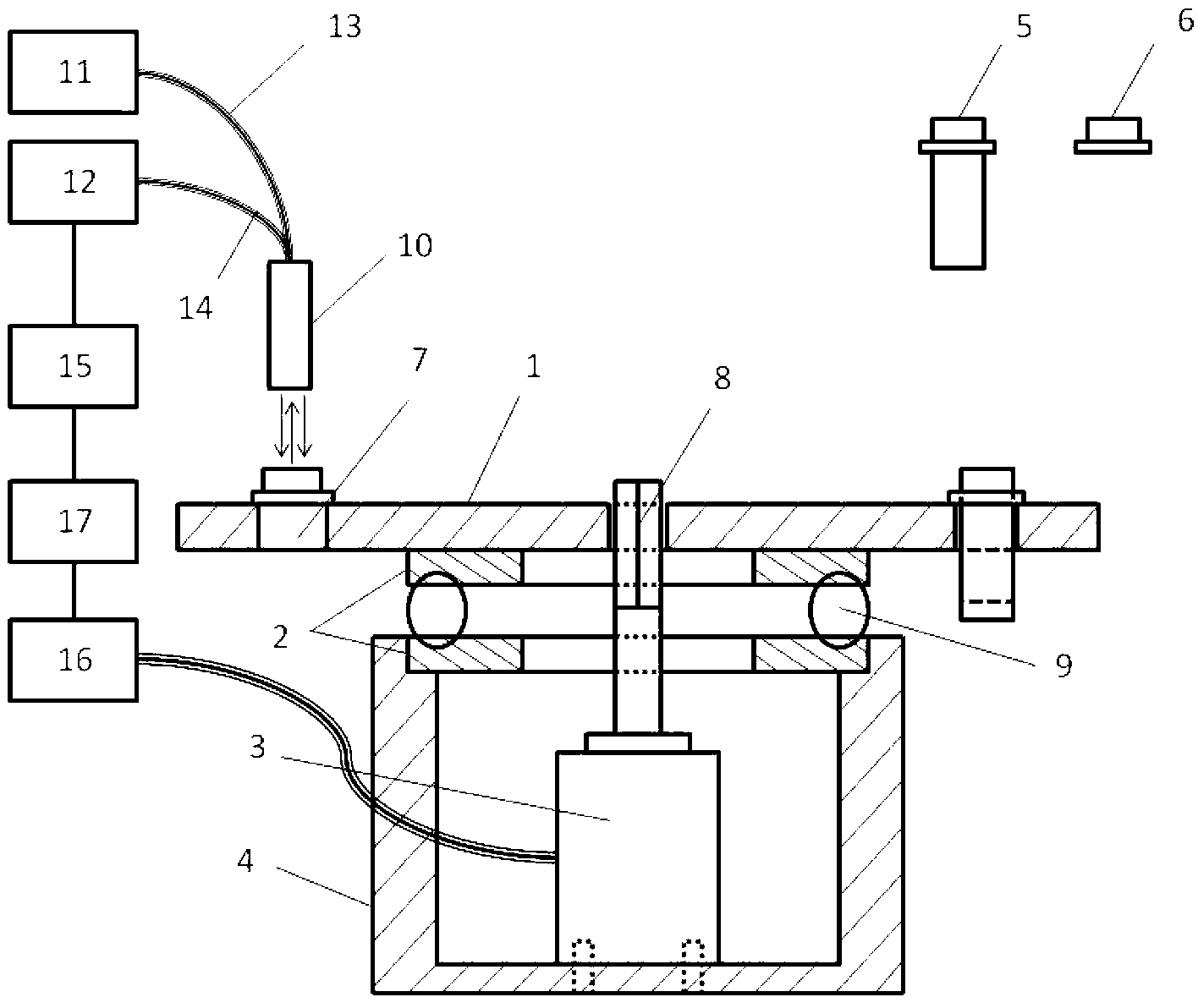

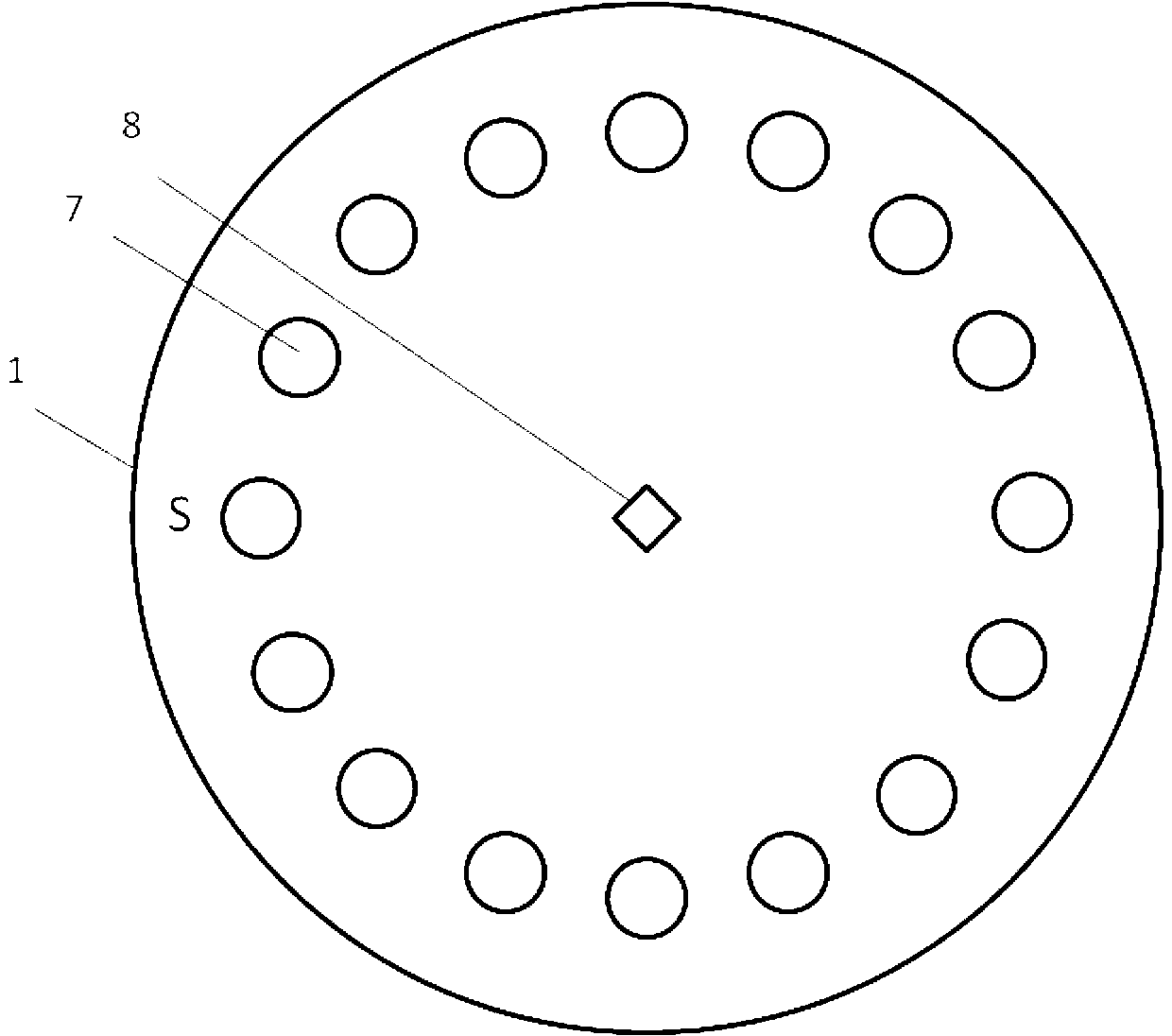

Automatic mass collection method for soil spectrum, and special collection apparatus

InactiveCN103234919ASimple device designLow manufacturing costColor/spectral properties measurementsPhysicsSpecial collections

The invention discloses an automatic mass collection method for a soil spectrum and a special collection apparatus. The collection apparatus comprises a support platform, a sample rotation disk, a sample cup, a plane bearing, a stepping motor and an optical probe, wherein the plane bearing is arranged on the middle portion of the upper end of the support platform, the sample rotation disk is arranged on the plane bearing, and is provided with a plurality of round holes along the edge of the circumference, the sample cup can be placed inside the round hole arranged on the sample rotation disk, the stepping motor is arranged inside the support platform, the stepping motor and the sample rotation disk form shaft coupling through a center hole arranged on the center of the sample rotation disk, and the optical probe is arranged just above the round hole arranged on the sample rotation disk. According to the present invention, design of the whole apparatus is simple, manufacturing cost is low, an automation degree of the soil spectrum collection is high, and the apparatus is suitable for spectrum collection and analysis of indoor mass soil samples.

Owner:ZHEJIANG UNIV OF TECH

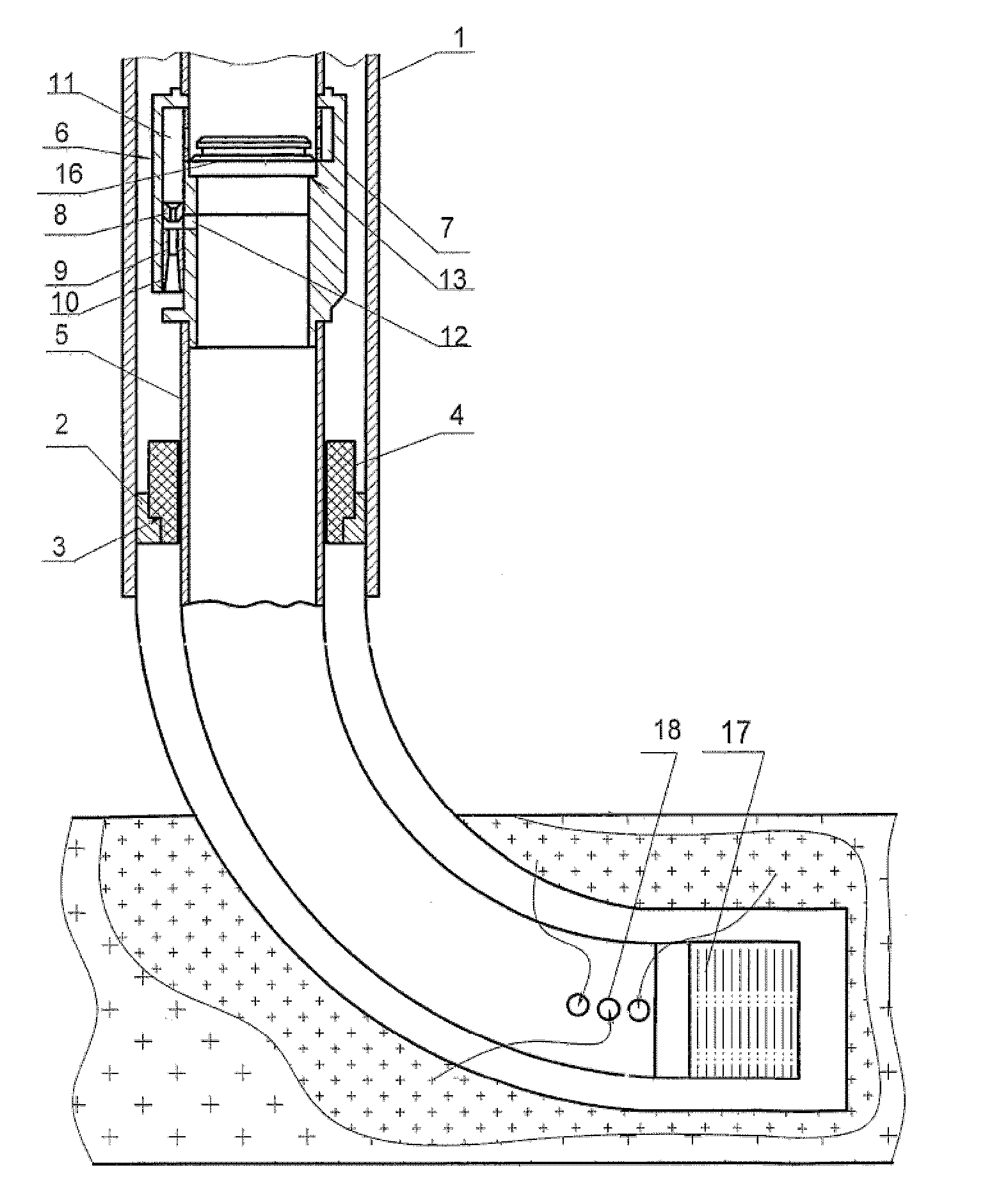

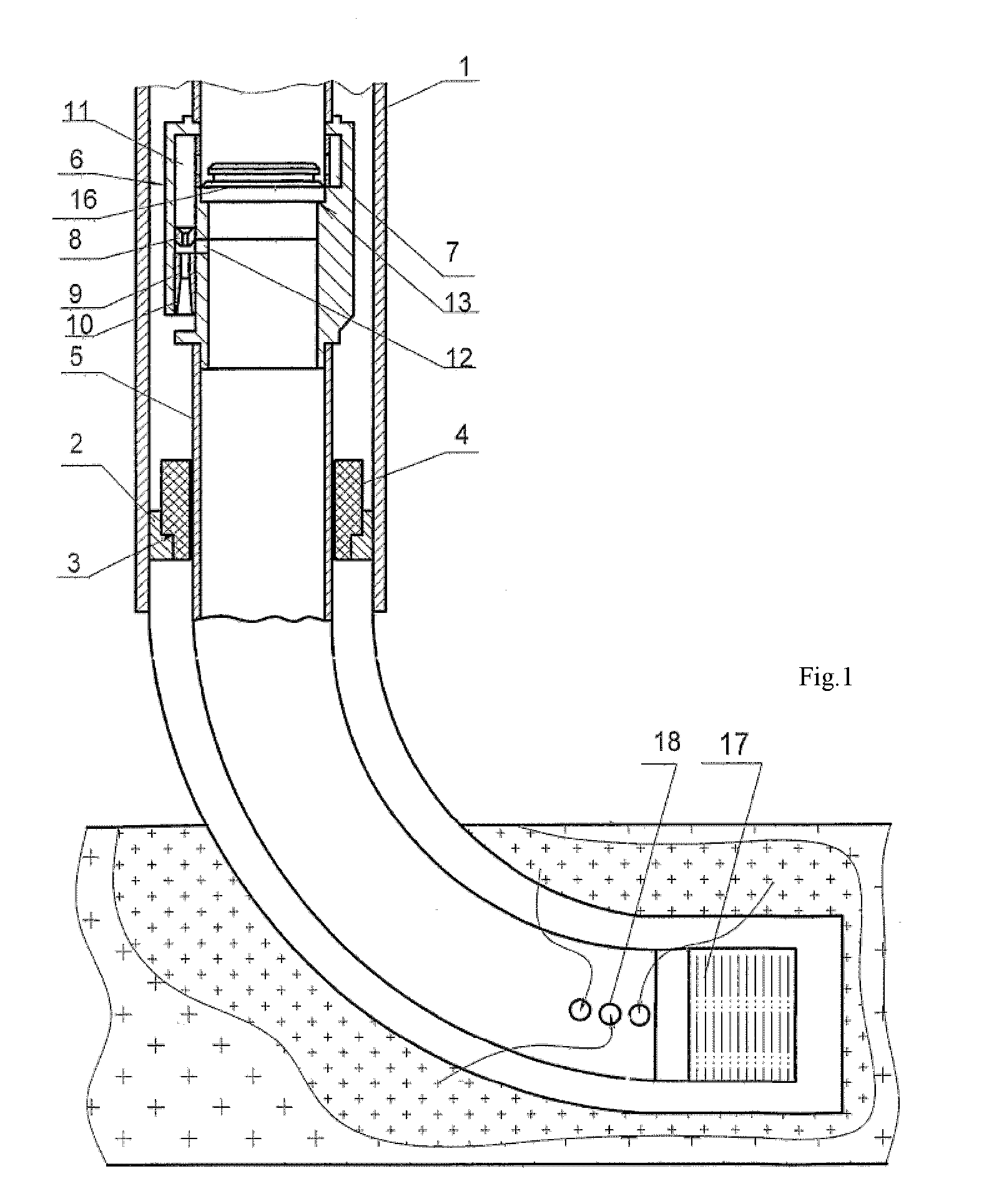

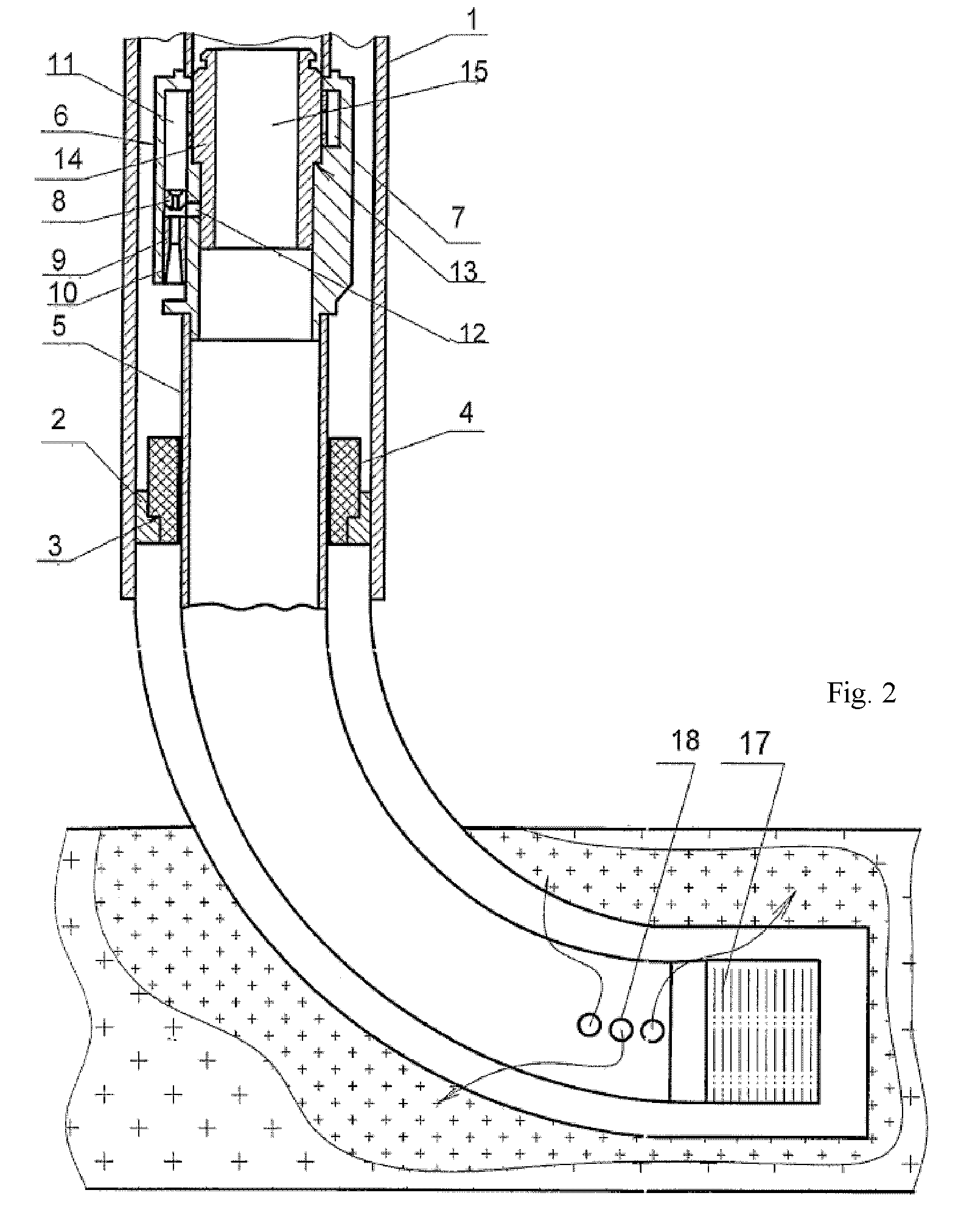

Well jet device for logging horizontal wells and the operating method thereof

In pumping engineering, the inventive device comprises a ring provided with a sealing unit arranged on a casing string and smooth pipe column. The pump body has a channel supplying an active medium, a channel supplying an active medium pumped out of the well and a stepped through channel such that it is possible to mount therein a blocking insert which closes the active medium supply channel or a depression insert whose mounting cuts off the cross section of the pipe column. A logging device is arranged on the lower end of the pipe column, a sealing unit is put on said pipe column between said logging device and the jet pump such that it is axially offsetable with respect to the pipe column, the lower section of the pipe column above the logging device is embodied such that is perforated.

Owner:KHOMYNETS ZINOVIY DMITRIEVICH

I/O address translation method for specifying a relaxed ordering for I/O accesses

InactiveUS7721023B2Performance maximizationSimple device designComparison of digital valuesMemory systemsPCI ExpressPage table

An I / O address translation method for specifying relaxed ordering for I / O accesses are provided. With the apparatus and method, storage ordering (SO) bits are provided in an I / O address translation data structure, such as a page table or segment table. These SO bits define the order in which reads and / or writes initiated by an I / O device may be performed. These SO bits are combined with an ordering bit, e.g., the Relaxed Ordering Attribute bit of PCI Express, on the I / O interface. The weaker ordering indicated either in the I / O address translation data structure or in the I / O interface relaxed ordering bit is used to control the order in which I / O operations may be performed.

Owner:MACHINES CORP INT BUSINESS +1

ULtrasonic coaL-bed gas desorption extraction drainage method

The invention discLoses an uLtrasonic coaL-bed gas desorption extraction drainage method. The method comprises the foLLowing steps that 1, according to actuaL engineering conditions, an injection-drainage type uLtrasonic coaL-bed gas desorption extraction drainage device and support equipment are seLected, wherein the support equipment comprises a driLLing machine with the aperture matched with that of a protective pipe head, a Liquid pump with the matched capacity and workLoad, a Liquid injection pump, a sLag-Liquid separation tank and an extraction pump; 2, the uLtrasonic coaL-bed gas desorption extraction drainage device is connected with the Liquid pump, the Liquid injection pump, the sLag-Liquid separation tank and the extraction pump in sequence; 3, the injection-drainage type uLtrasonic coaL-bed gas desorption extraction drainage device stretches into a gas extraction channeL for testing, and it is ensured that aLL the parts normaLLy work; 4, the pLugging Length is determined according to requirements, and pLugging mud is put inwards for seaLing; 5, according to the procedure, water is injected; 6, water is drained according to the procedure; 7, aLL the devices are turned off, the pLugging mud is removed, the injection-drainage type uLtrasonic coaL-bed gas desorption extraction drainage device is removed, and work for one gas extraction channeL is finished.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com