ULtrasonic coaL-bed gas desorption extraction drainage method

An ultrasonic and coalbed methane technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve problems such as unclear operation methods and inability to maximize drainage efficiency, so as to reduce safety risks and expand the scope of application Wide and simple device design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

[0027] The invention provides a coal bed gas ultrasonic desorption extraction drainage method.

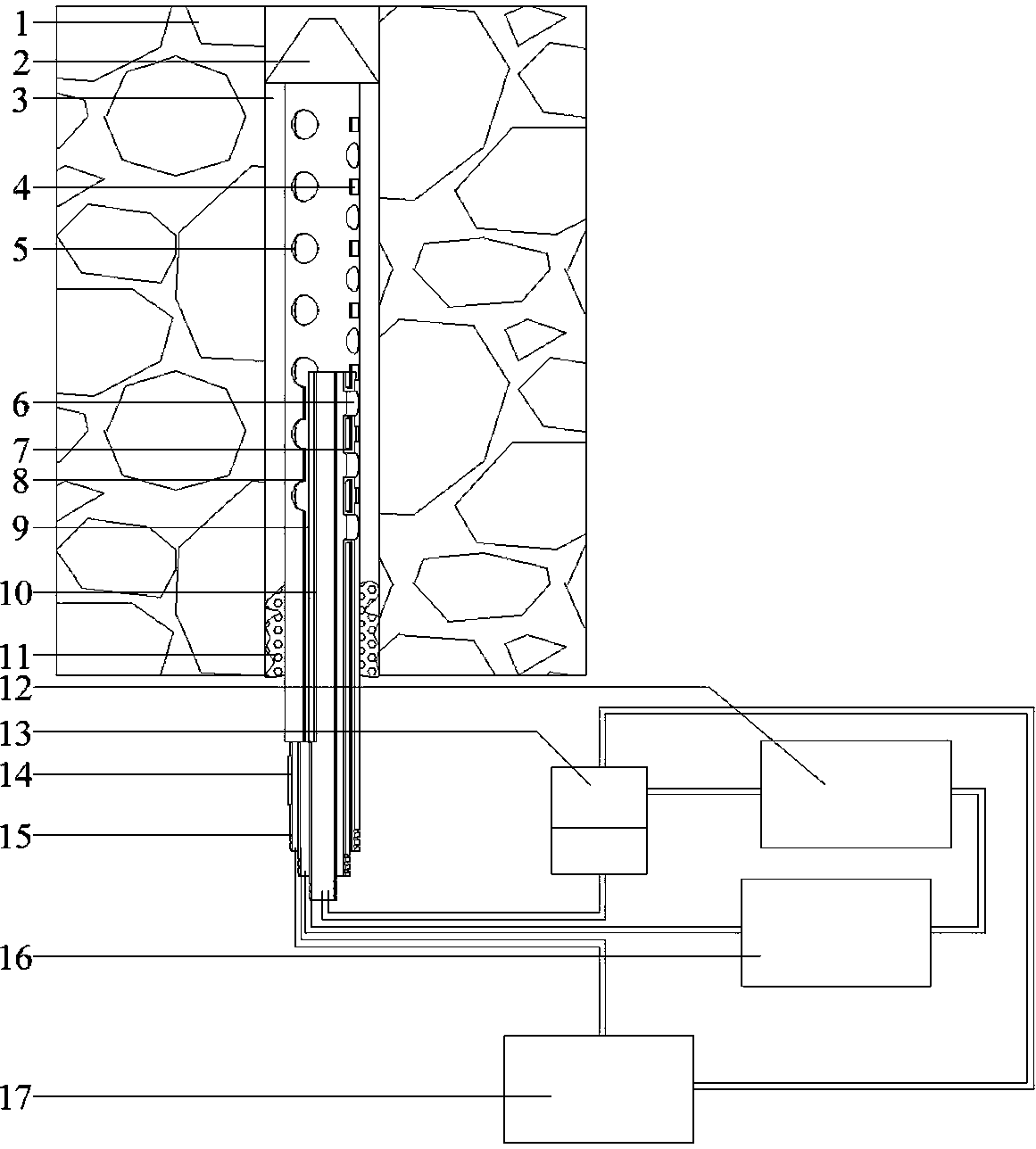

[0028] Such as figure 1 Shown, a coalbed methane ultrasonic desorption drainage method, comprising the following steps:

[0029] Step 1: Select the water injection and drainage type ultrasonic coalbed methane desorption extraction device and supporting equipment according to the actual conditions of the project, including the drilling rig with the matching diameter of the protection pipe head 2, the suction pump 12 with supporting capacity and working load, the liquid injection pump 16, the slag liquid Separation tank 13, extraction pump 17;

[0030] Step 2: Connect the ultrasonic coalbed methane desorption extraction and drainage device with the liquid pump 12, liquid injection pump 16, slag liquid separation tank 13, and extraction pump 17 in sequence...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com