Thermal stretch processing method of ultra-high molecular weight polyethylene diaphragm

A technology of ultra-high molecular weight and polyethylene film, which is applied in the field of thermal stretching processing of ultra-high molecular weight polyethylene film, can solve the problem of hindering the expansion of the application range of ultra-high molecular weight polyethylene film, the width of the film cannot be arbitrarily increased according to needs, The problem of expensive film manufacturing cost and other issues, to achieve the effect of low cost, reduced manufacturing cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

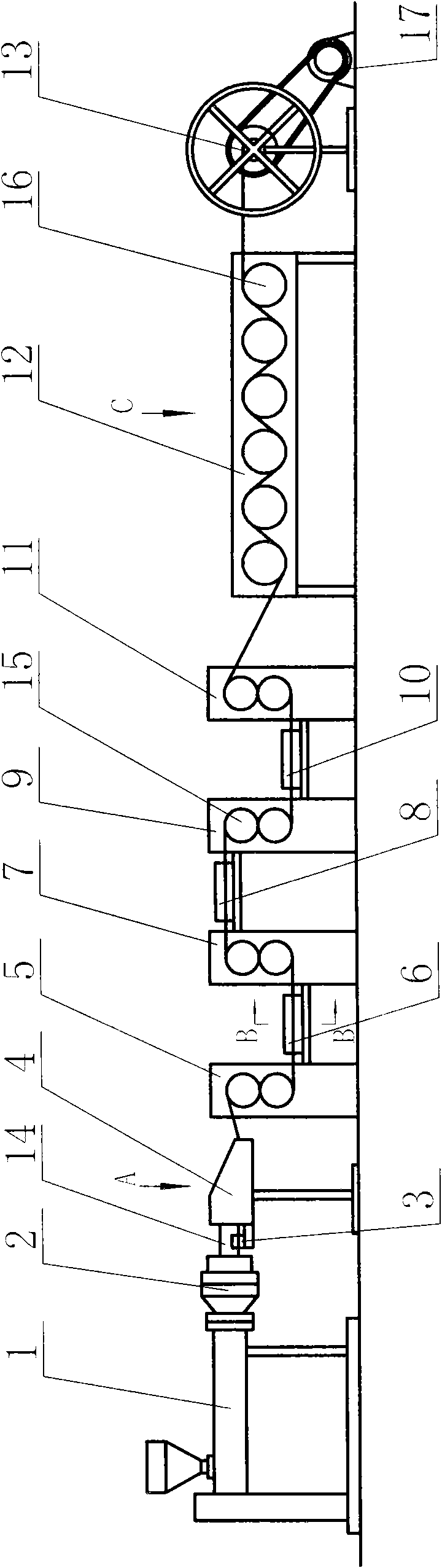

[0019] Further description of the present invention is as follows:

[0020] The processing method of the present invention is to heat and stretch the ultra-high molecular weight polyethylene material to finally produce the product of the diaphragm. The thickness of the diaphragm is more than 0.01 mm. According to the difference in the place of use, the thickness of the product diaphragm is different. During processing , the thickness of the pipe can be adjusted according to the needs to adapt to the stretching ratio during processing, or the length and temperature of the heating channel can be adjusted, and the roller speed of the calender can be adjusted at the same time to adapt to the stretching ratio during processing to obtain the required Different membrane thicknesses, for example: a pipe with a thickness of 8 millimeters, after the heat stretching method of the embodiment of the present invention, a membrane with a thickness of 0.5 millimeters can be obtained.

[0021]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com