A dry processing device for blast furnace slag based on high temperature slag waste heat recovery

A blast furnace slag and dry processing technology, which is applied in the field of liquid blast furnace slag processing and blast furnace slag dry processing equipment, can solve the problems of difficult recovery of solid slag, high-quality heat source steam, large water consumption, etc., and achieve operating costs and The effect of low equipment manufacturing cost, reduced water consumption, and scientific device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

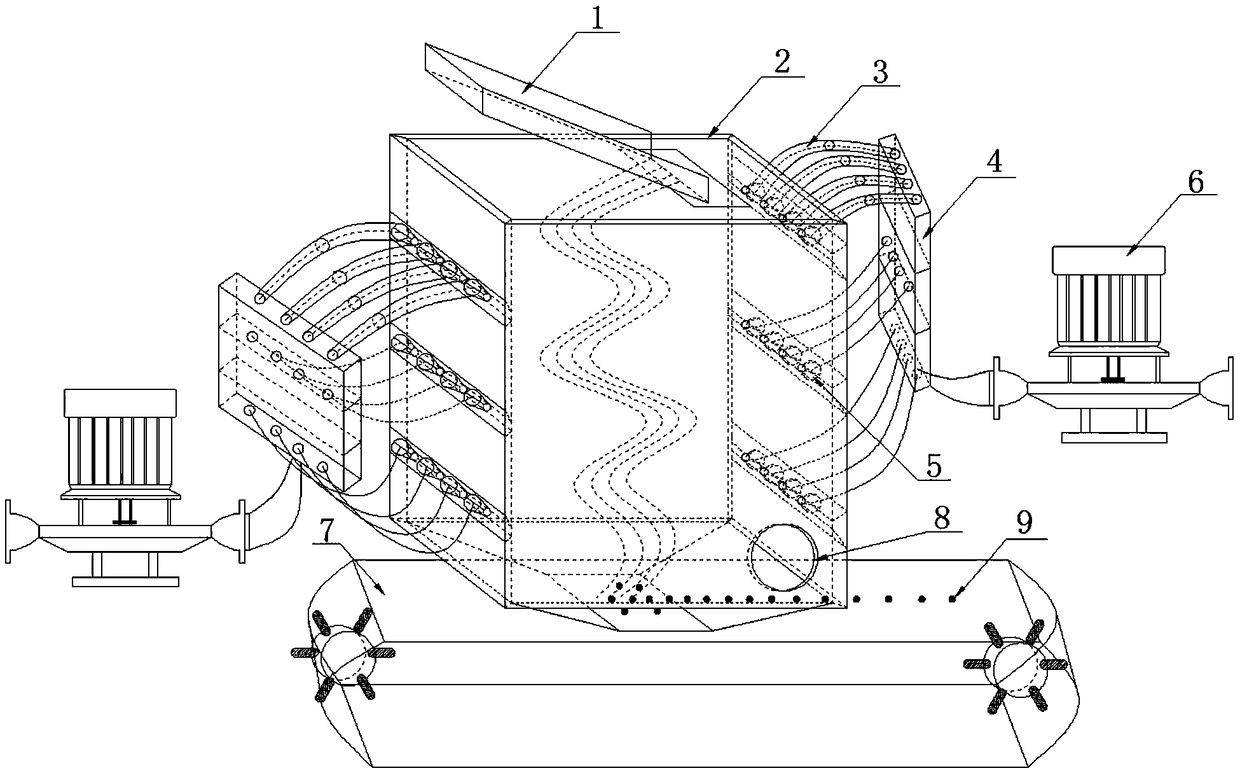

[0049] combine figure 1 , the blast furnace slag dry processing device based on high temperature slag waste heat recovery in this embodiment includes: a slag treatment box 2, blast furnace slag falls from the top of the slag treatment box 2, and is discharged from the bottom of the slag treatment box 2; cooling unit, cooling unit It includes a mechanism for forming a high-pressure water column inside the slag treatment box 2 to impact and cool the falling blast furnace slag. (In the blast furnace slag dry processing device based on high temperature slag waste heat recovery in this embodiment, "blast furnace slag" refers to the liquid blast furnace slag discharged from the blast furnace, and "dry processing" refers to the final treatment of the liquid blast furnace slag with a low water content. The slag particles 9, the slag particles 9 are solid particles)

[0050] In this embodiment, the blast furnace slag falls from top to bottom in the slag treatment box 2, which is condu...

Embodiment 2

[0052] combine figure 1 The structure of the blast furnace slag dry processing device based on high temperature slag waste heat recovery in this embodiment is basically the same as that in Embodiment 1, and further:

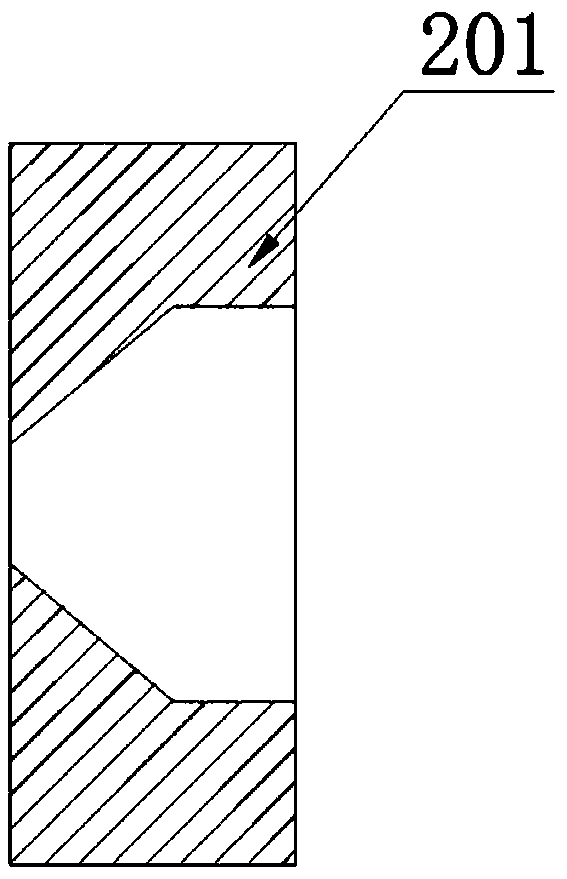

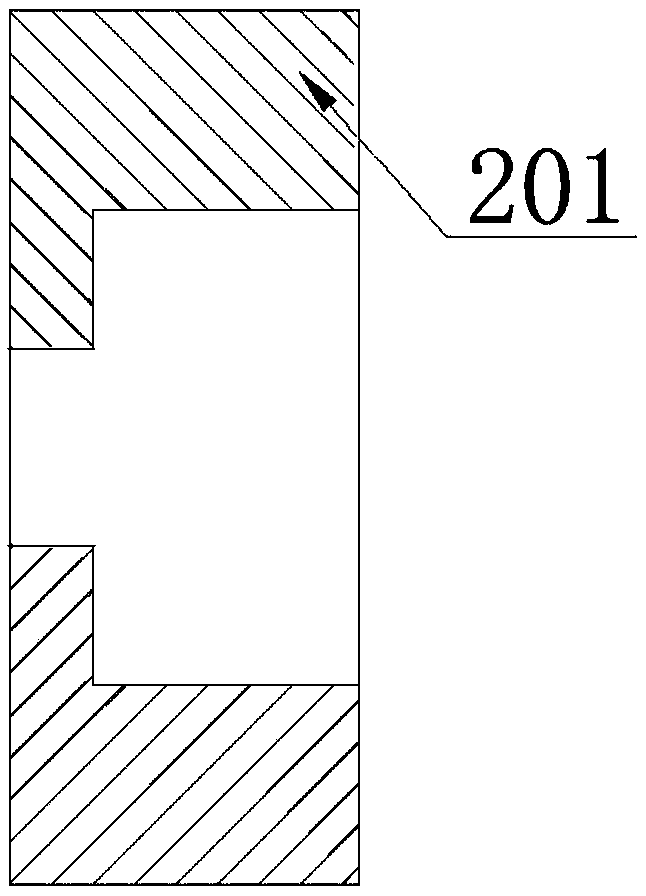

[0053] The blast furnace slag dry treatment device based on high temperature slag waste heat recovery of the present embodiment also includes a steam pipe 8, and the wall surface of the slag treatment box 2 is a cooling water interlayer 201 filled with cooling water inside (the design of the cooling water interlayer 201 ensures high The slag flows in the low-temperature environment surrounded by the slag treatment box 2, which improves the cooling efficiency of the blast furnace slag), and the steam pipe 8 communicates with the inside of the slag treatment box 2. A slag discharge tank 1 is arranged above the slag treatment box 2, and the liquid blast furnace slag to be treated flows out from the slag discharge tank 1 and enters the slag treatment box 2. The botto...

Embodiment 3

[0060] combine figure 1 The structure of the blast furnace slag dry processing device based on high temperature slag waste heat recovery in this embodiment is basically the same as that in Embodiment 2, further: the angle between the axis of each water column nozzle and the horizontal plane is the same, specifically in this embodiment , the angle between the axis of each water column nozzle and the horizontal plane is 0 to 30°. It should be noted that if the angle between the axis of the water column nozzle and the horizontal plane is too large, it is not conducive to the formation of blast furnace slag along the "zigzag" route. Specifically, this embodiment Take 30° in the center; the pressure of the water column sprayed by the water column nozzle is 0.2-2.0MPa. If the water column pressure is too small, it will not be able to impact the blast furnace slag. " font route flows, specifically gets 2.0MPa in the present embodiment. In the slag treatment box 2, two layers of wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com