Dust removing and catalyzing integrated device

A technology of catalyst and gas supply device, which is applied in combination devices, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as reducing the toxicity of high-temperature dust-laden gas, and achieve the effect of increasing gas processing capacity and reducing equipment manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

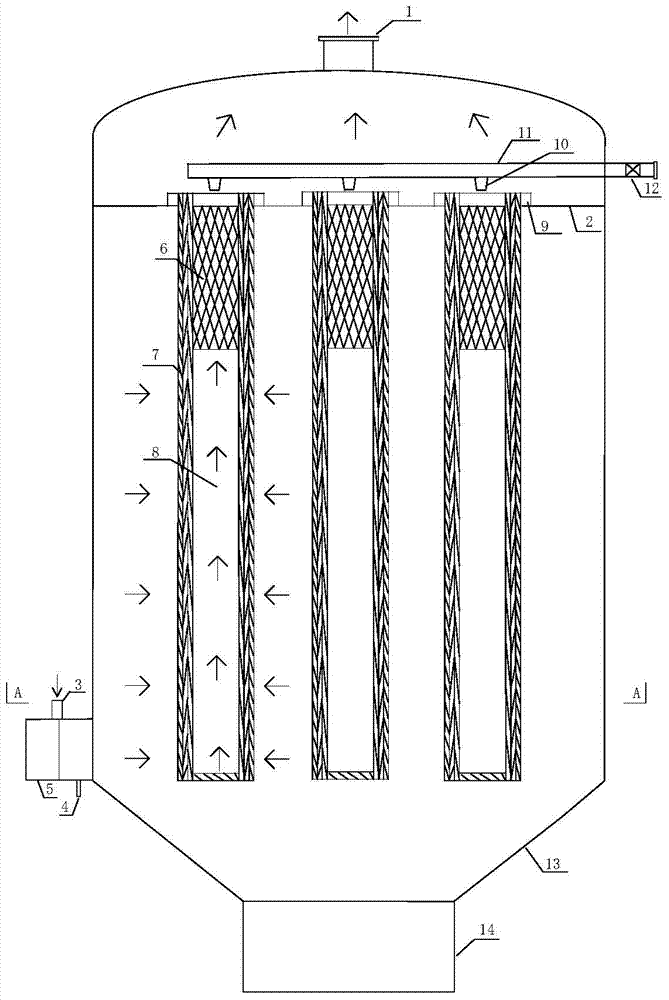

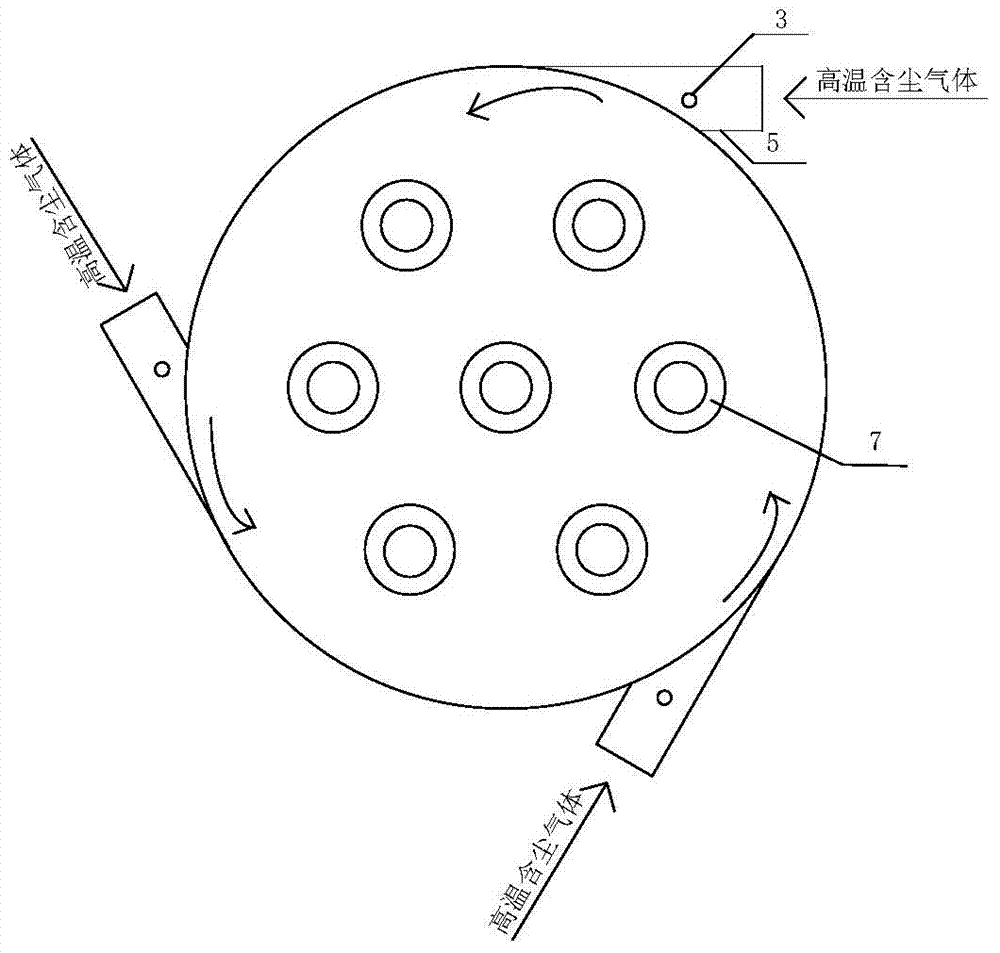

[0024] As shown in the figure, the integrated dust removal and catalysis device of the present invention is mainly composed of air outlet 1, ceramic membrane tube orifice plate 2, air supply device 3, ignition device 4, air inlet 5, catalytic ceramic body 6, ceramic membrane tube 7. Ceramic membrane tube cavity 8, ceramic membrane tube fixing plate 9, back blowing gas nozzle 10, back blowing air distribution pipe 11, back blowing air control valve 12, ash hopper 13, and ash unloading valve 14.

[0025] The high-temperature dust-containing gas enters in a swirling manner from the air inlet 5 located at the lower part of the reaction device. In the air inlet pipe, it is mixed with oxygen, air and other oxygen-containing gases provided by the gas supply device 3, and then is provided in the ignition device 4. When the high pressure coil is ignited, the oxidation-reduction reaction occurs, and then the mixed gas relies on centripetal force to throw the dust with a density far greater ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture range | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com