Patents

Literature

155results about How to "Reduce the amount used" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

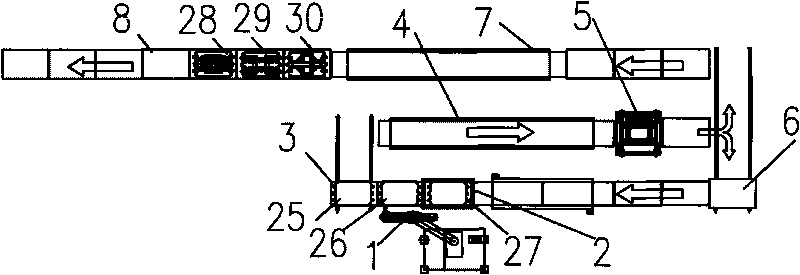

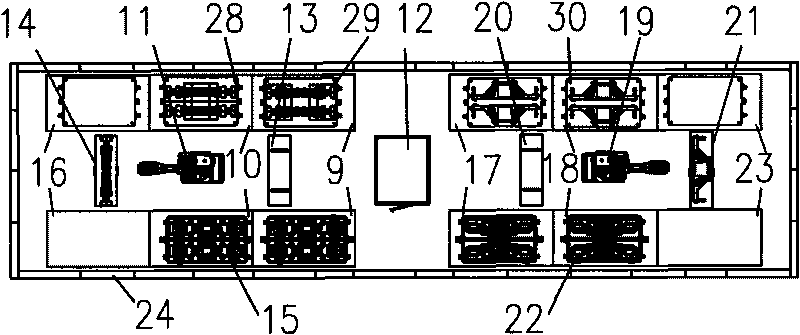

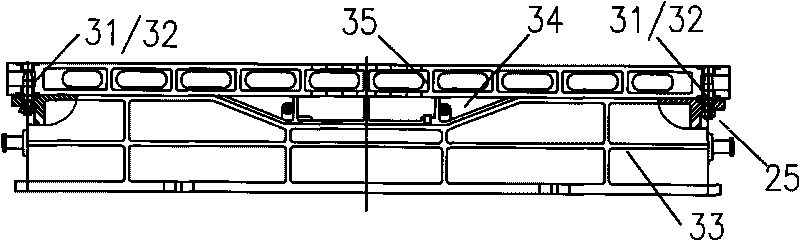

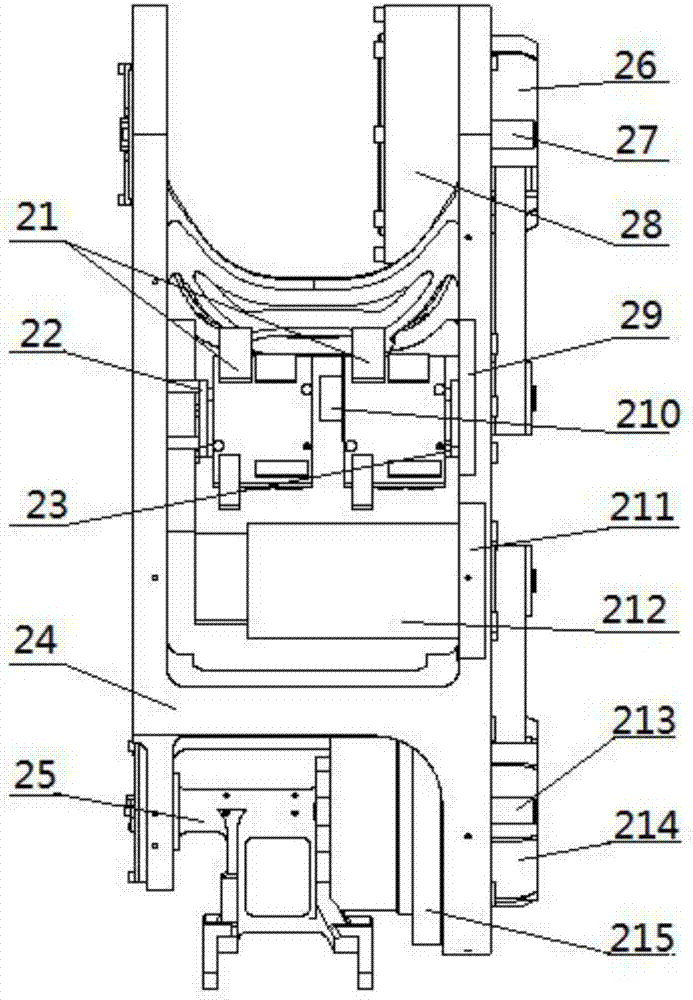

Swing bolster and side frame integrated core preparation and core setting technology

InactiveCN101733365AReduce the amount usedGuaranteed wall thickness dimensional accuracyFoundry mouldsFoundry coresLaser scanningBolster

The invention belongs to the technical field of casting technique and flexible manufacturing, and relates to a swing bolster and side frame integrated core preparation and core setting technology. The technology mainly comprises an ester cured molding production line and a robot core locking and core setting production line. The technology uses an ester cured water glass sand self-curing technology to respectively integrate the original multichip sand cores of the swing bolster and the side frame into upper sheets and lower sheets, the upper and lower sheets are transmitted to the robot core locking and core setting production line after surface drying and placement for a certain time, the robot finishes the core locking operation of the sand core by using tri-dimensional laser scanning for precise positioning, and the well-locked integrated sand core is placed in a sand mould cavity accurately. The invention has the advantages as follows: in the operation process, chilling materials are placed easily, has good deformability and small crackle tendency of casting, thus realizing no fash and step in the inner cavity of the important parts of the swing bolster and the side frame and the expansive regions thereof, eliminating the defects such as crack caused by fash and step in the inner cavity and the like, reducing the use amount of the chaplets and ensuring the size precision of the casting thickness.

Owner:JINXI RAILWAY VEHICLE CO LTD

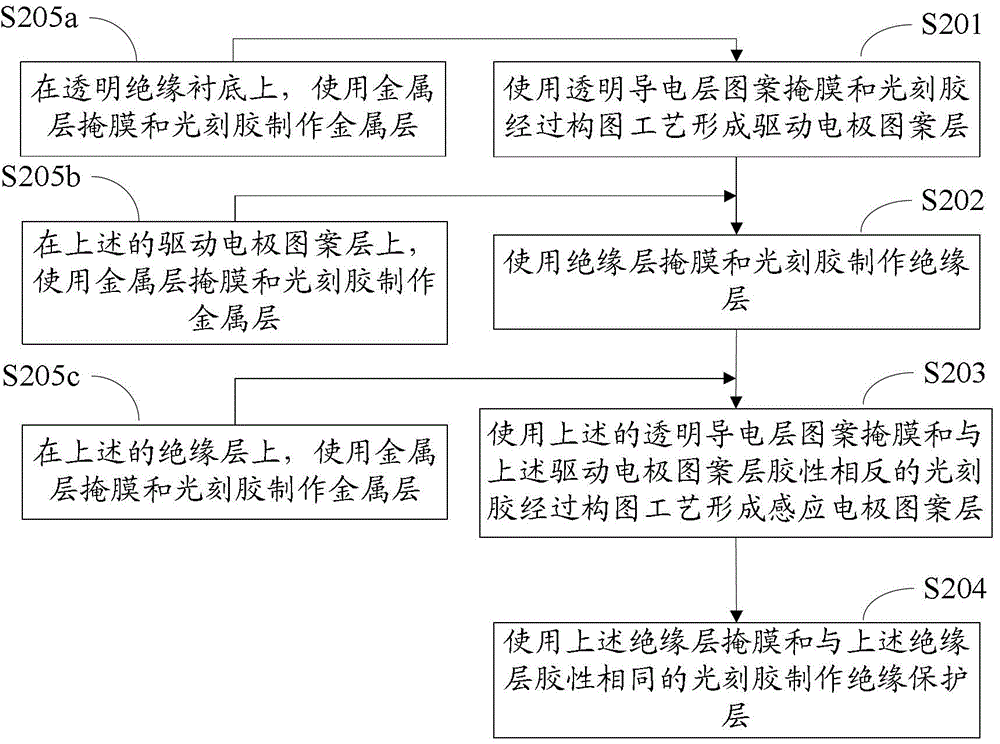

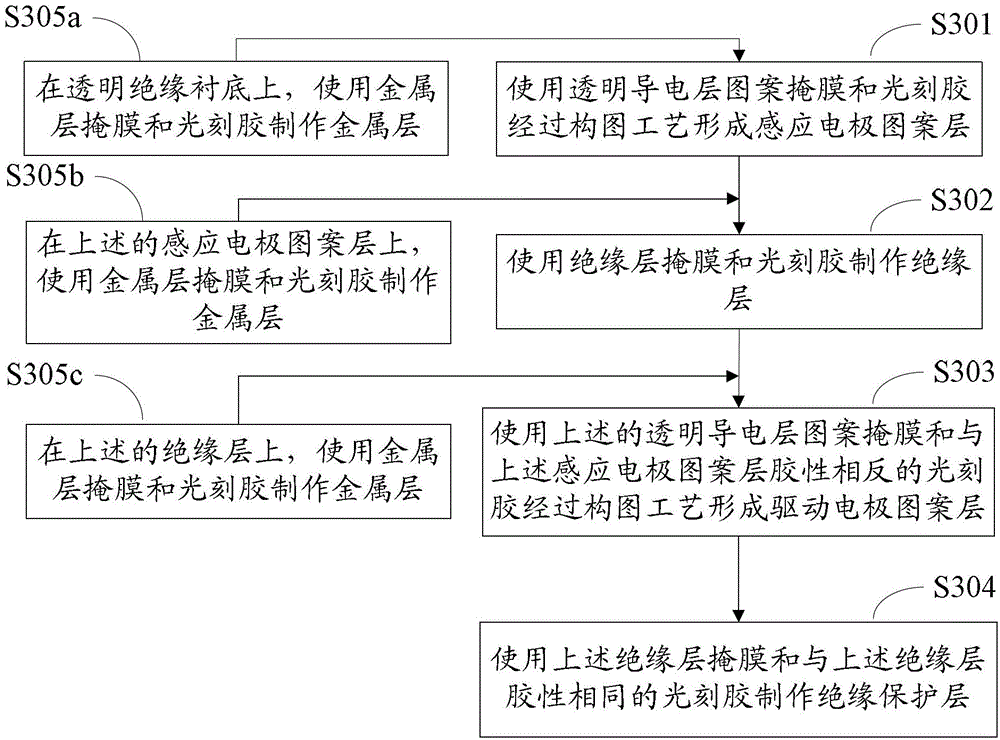

Capacitive touch sensor, manufacturing method thereof, touch screen and display device

InactiveCN102866816AReduce the amount usedLow production costInput/output processes for data processingPhotoresistElectric field

The invention discloses a manufacturing method of a capacitive touch sensor. The manufacturing method comprises the following steps of: manufacturing a drive electrode pattern layer by using a transparent conductive layer pattern mask and a photoresist; manufacturing an insulating layer by using an insulating layer mask and a photoresist; manufacturing a sensing electrode pattern layer by using the transparent conductive layer pattern mask and a photoresist which has the stickability opposite to that of the drive electrode pattern layer, wherein the drive electrode pattern layer and the sensing electrode pattern layer are located at different sides of a plane where the insulating layer is located; and manufacturing an insulating protection layer by using the insulating layer mask and a photoresist. The invention further discloses a capacitive touch sensor, a touch screen and a display device. As the insulating layer and the insulating protection layer are manufactured by using the same mask, the consumption number of masks is reduced, and then, the manufacturing cost of the touch screen is reduced. Furthermore, the sensing electrode pattern layer and the drive electrode pattern layer which are provided with transparent conductive layer patterns are respectively formed at different sides of the insulating layer, so that electric field lines from a drive electrode to a sensing electrode are enabled to be more divergent, and the sensitive touch degree is increased.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

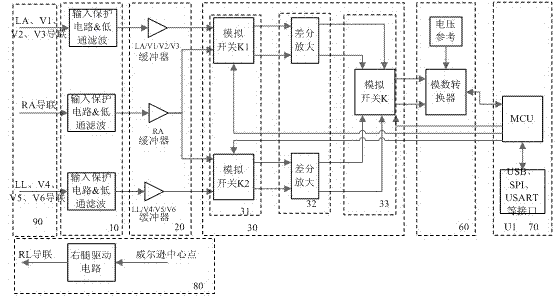

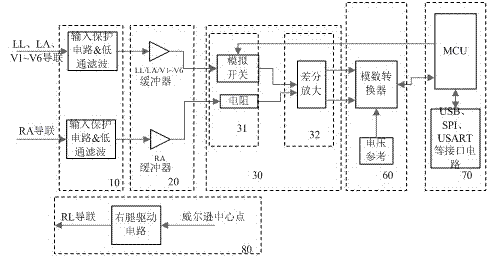

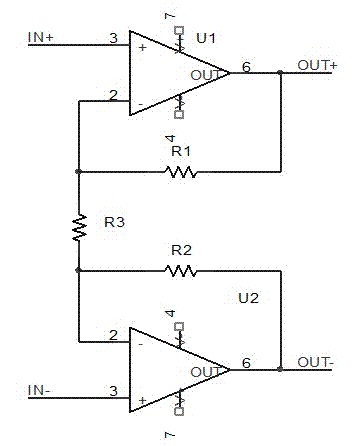

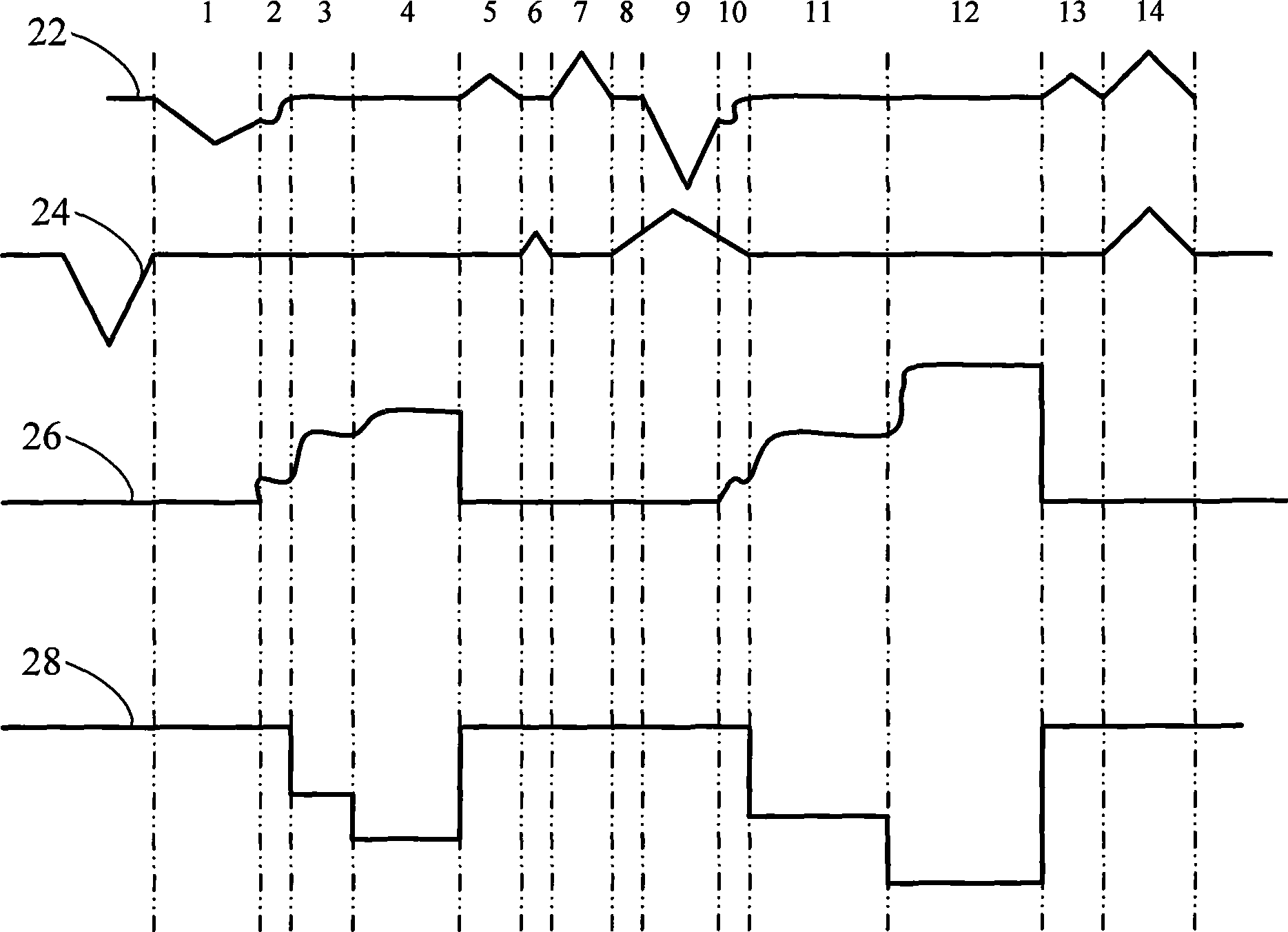

Device and method for acquiring biological electric signals

ActiveCN102488509AReduce the amount usedReduce system costDiagnostic recording/measuringSensorsTime constantDifferential amplification

The invention relates to a device and a method for acquiring biological electric signals. The full differential amplification technology is used on a signal acquisition channel, so that a link that transition is performed by using a single-ended signal in the processes of converting a differential signal into the single-ended signal and converting the single-ended signal into the differential signal in the conventional products is avoided; an analogue switch is utilized reasonably by utilizing the cost advantage of the analogue switch relative to instrument amplifiers and computing amplifiers according to system parameters to reduce the using quantity of the instrument amplifiers; a system can detect a pace-making pulse signal directly in an undistorted mode when reaching the sampling rate of 20 kilo samples per second (Ksps), so that a complex PACE widening circuit is not required to be used; the cost of the system is reduced; in a direct-current amplifying circuit structure, a time constant circuit is not provided, the signals are quickly detected, a baseline is stable, the dynamic input range of the signals is large, a small number of devices are provided, the reliability is high, and the miniaturization of products is facilitated; and by the matching of a high-speed analog-digital converter, the sampling rate of the system can be improved.

Owner:EDAN INSTR

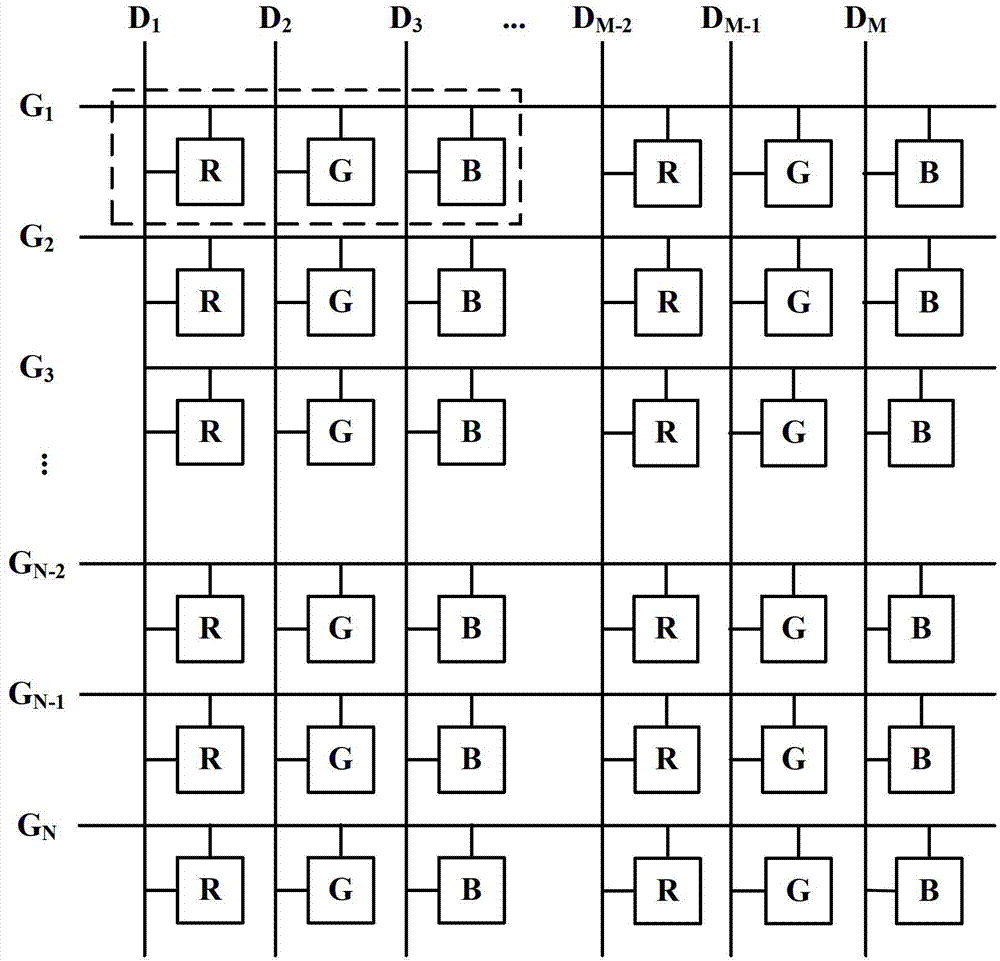

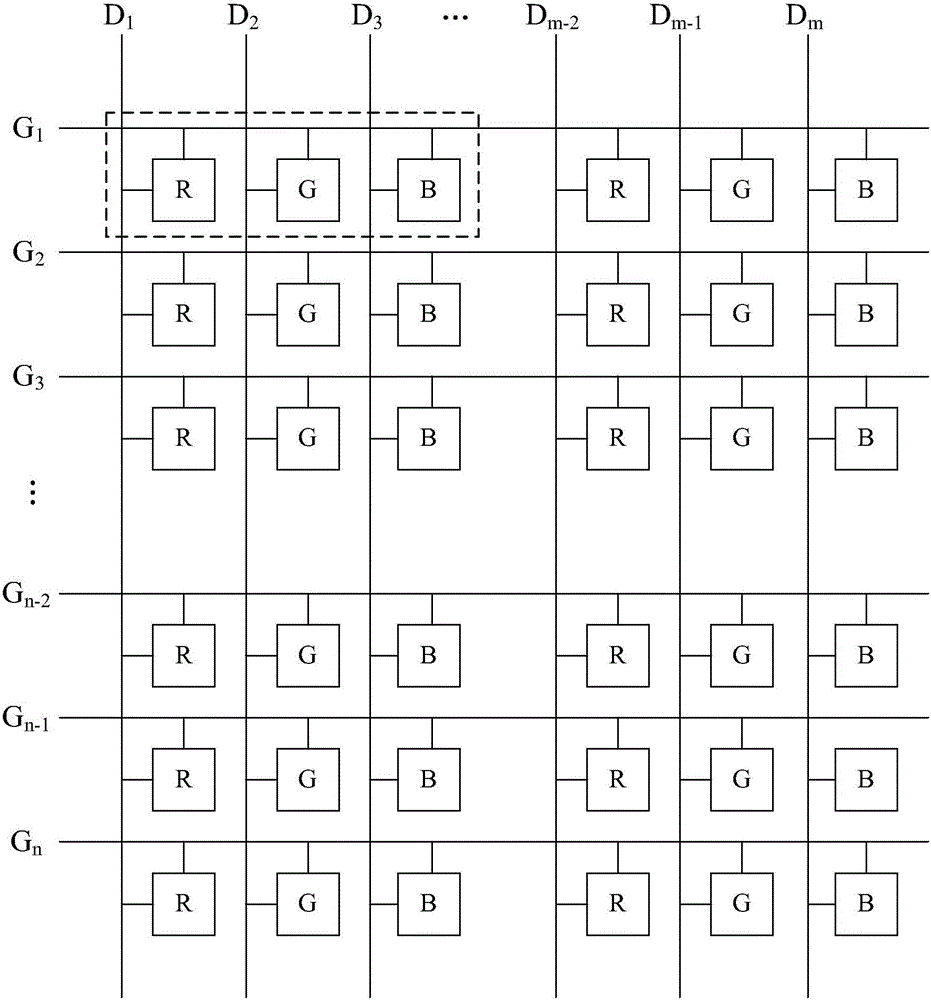

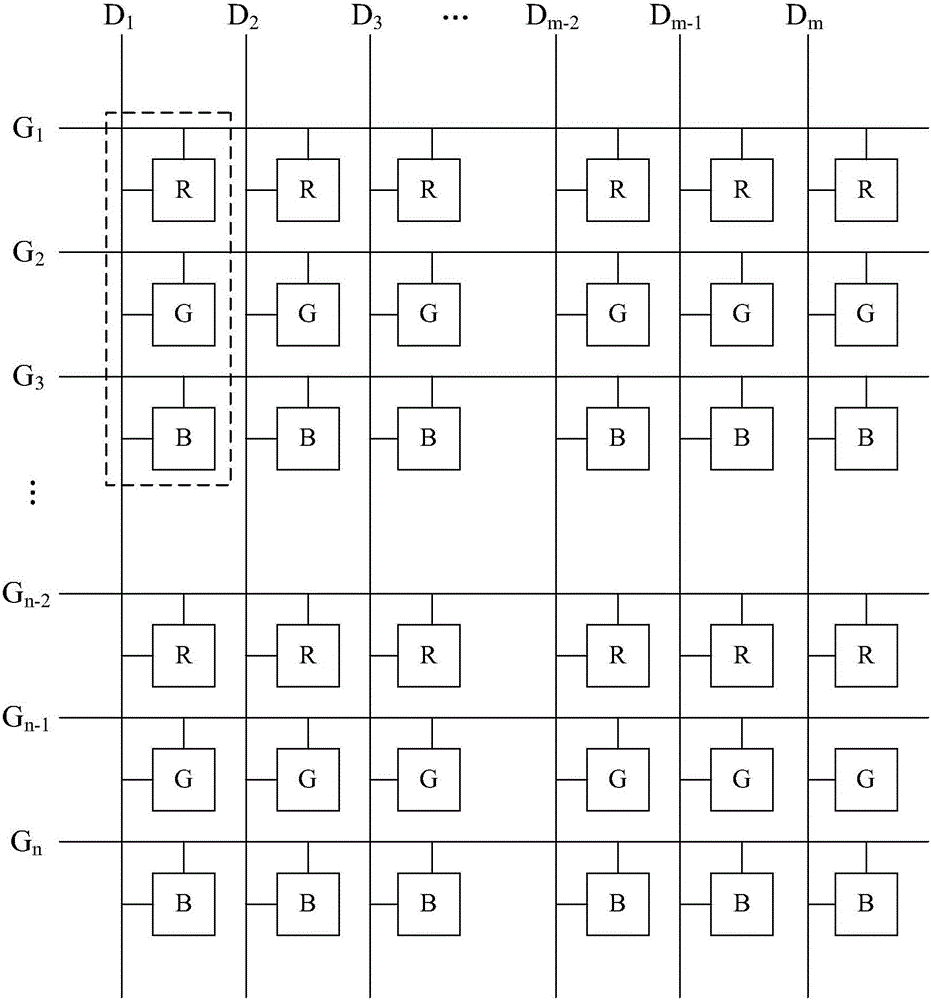

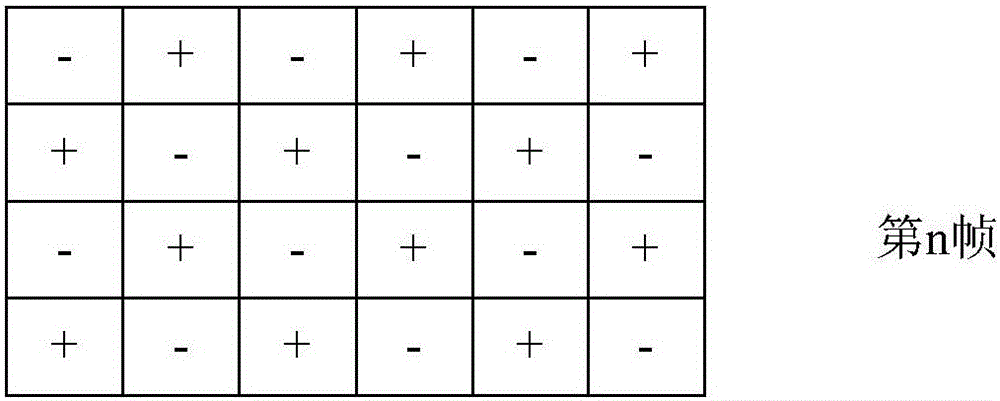

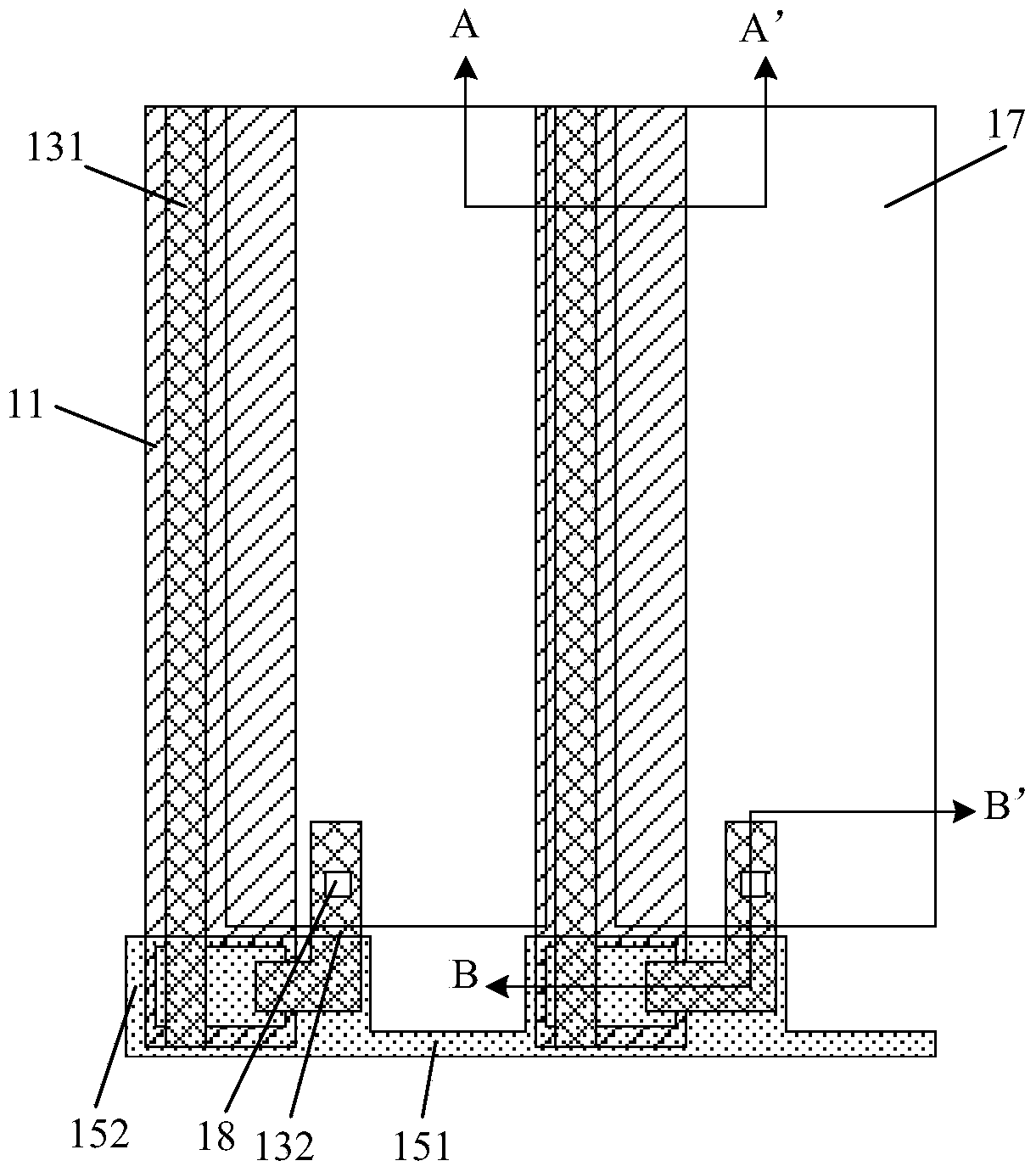

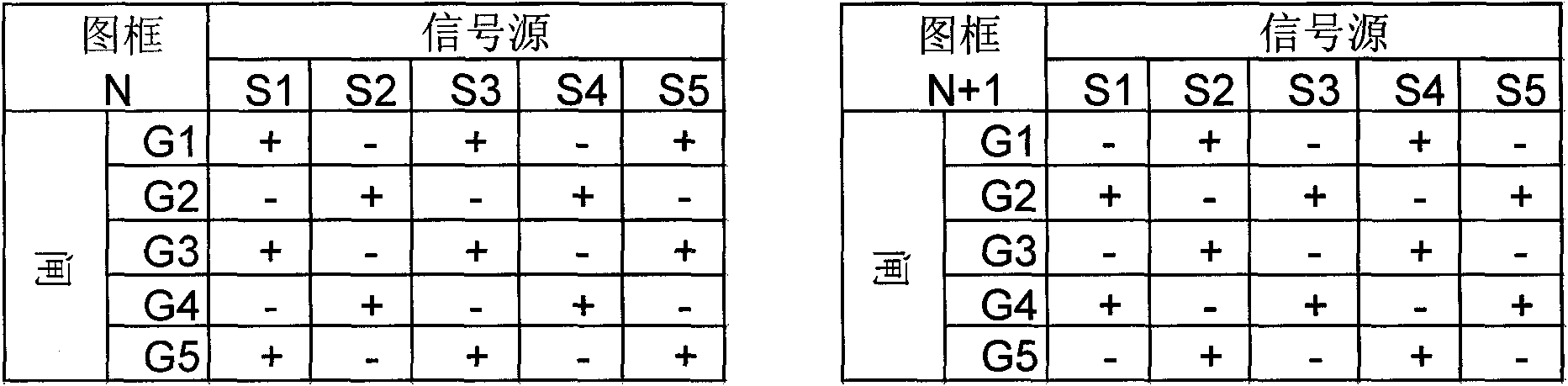

Pixel driving structure, driving method and display device

ActiveCN102955310AReduce the amount usedLow costStatic indicating devicesNon-linear opticsData linesDisplay device

The invention discloses a pixel driving structure, a driving method and a display device. The structure comprises a plurality of pixel units which are formed by crossing a plurality of data wires and scanning wires and are in matrix arrangement, wherein each pixel unit respectively at least comprises two sub pixels. By aiming at a connecting unit formed by the pixel unit of any one uneven row in each line of pixel unit and the adjacent subsequent pixel unit in the even row, the sub pixels in the uneven digits and the sub pixels in the even digits in the connecting unit are respectively connected with one of two data wires used for controlling the connecting unit, in addition, the sub pixels in any one uneven digit and the sub pixels in any one even digit in the connecting unit are connected with any one of the scanning wires of the connecting unit, and the scanning wires connected with the sub pixels in any two uneven digits or any two event digits in the connecting unit are respectively different. In the pixel driving structure disclosed by the invention, the use number of the data wires is reduced, in addition, the Z reverse rotation can be realized, and low cost and low power consumption are realized.

Owner:BOE TECH GRP CO LTD +1

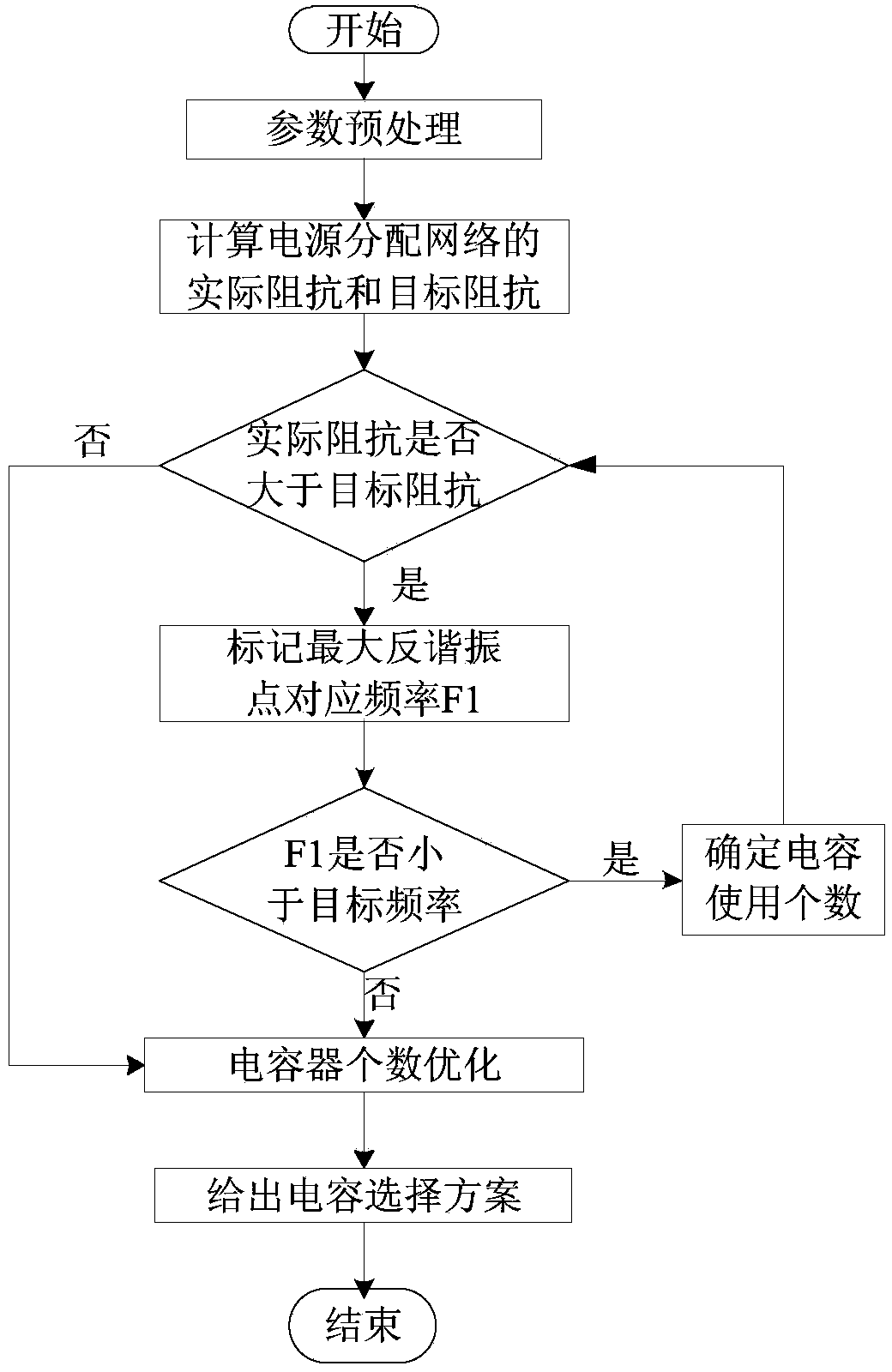

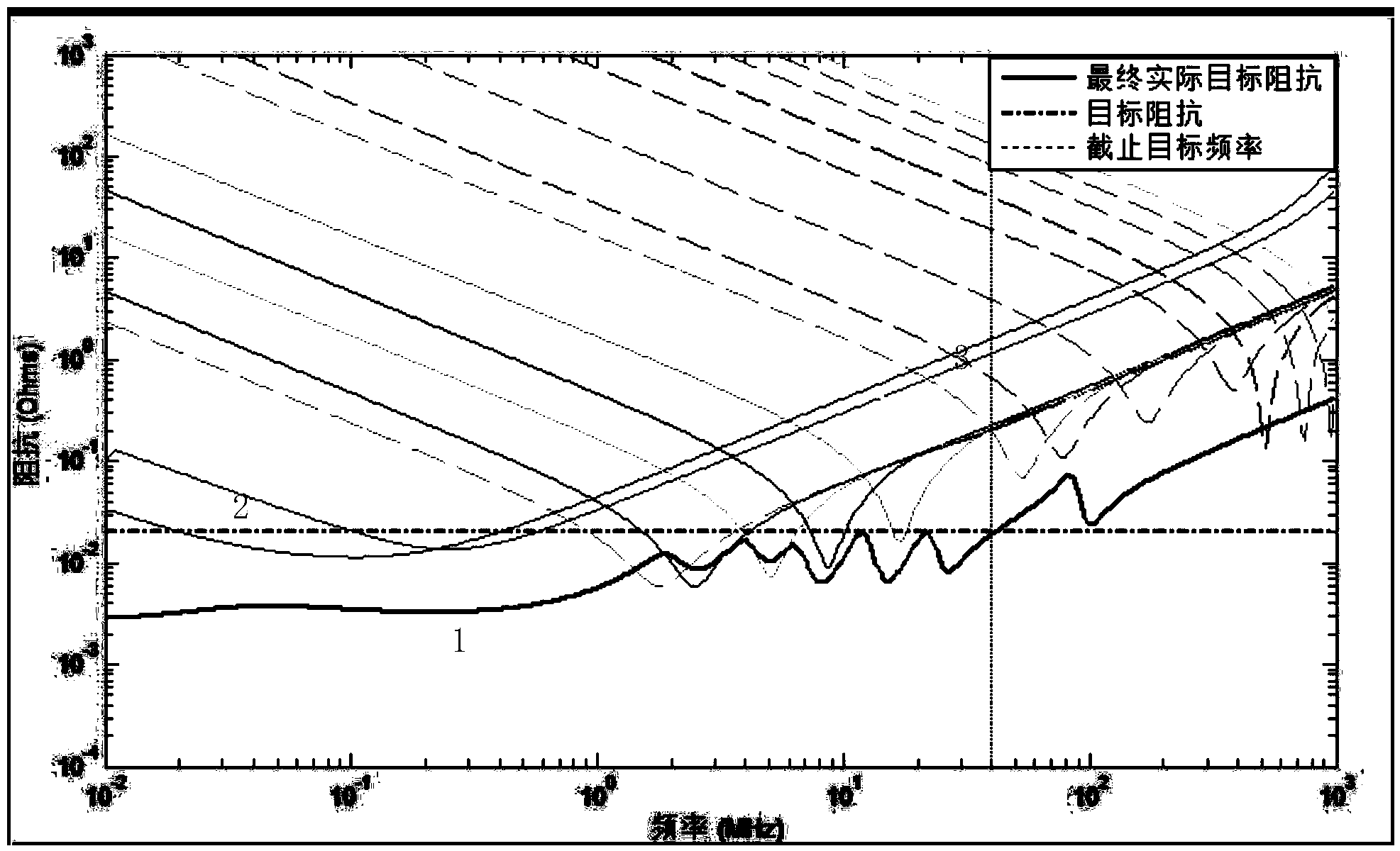

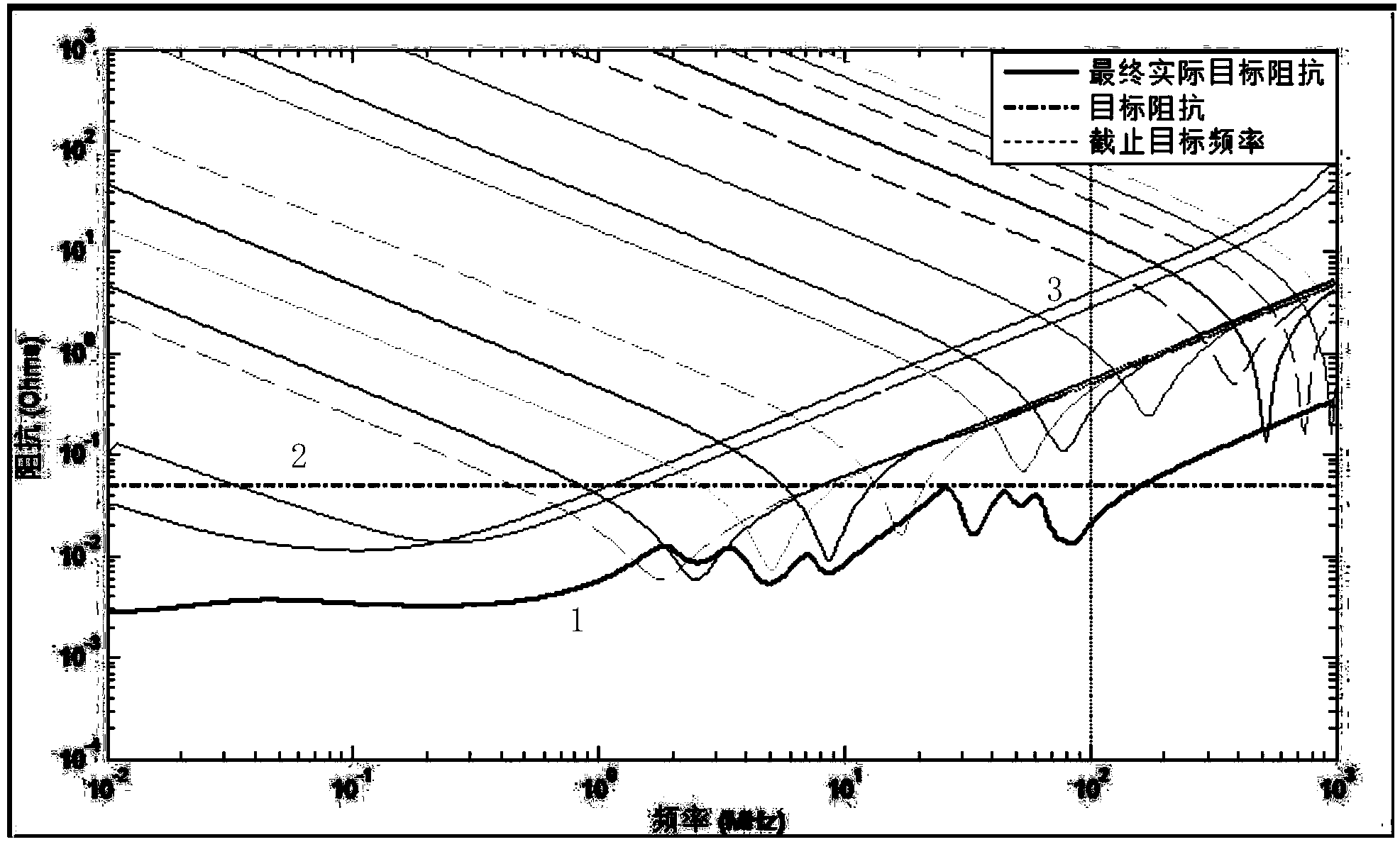

Method for selecting decoupling capacitors from power supply distribution network on basis of maximum anti-resonance point

ActiveCN104112048AReduce the amount usedReduce the number of calculationsSpecial data processing applicationsResonance pointSupply & distribution

The invention discloses a method for selecting decoupling capacitors from a power supply distribution network on the basis of the maximum anti-resonance point in order to solve the problems that the number of capacitors is large and computation time is long when decoupling capacitors are selected from a power supply distribution network in the prior art. The method includes the implementation steps that (1) circuit board parameters are input, and the self-resonance frequency and quality factor of capacitors are calculated; (2) cut-off target frequency is determined, and actual impedance and target impedance of the power supply distribution network are worked out; (3) within the cut-off target frequency, frequency corresponding to the maximum anti-resonance point is determined, and decoupling capacitors and the number of decoupling capacitors to be used are selected according to the determined frequency; (4) the number of all the selected capacitors is optimized, and the number of decoupling capacitors is reduced; (5) the optimized number of the capacitors is recorded and a final power supply distribution network actual impedance curve is drawn. According to the method, the number of decoupling capacitors selected from the power supply distribution network can be reduced, computation time for selection of the decoupling capacitors is shortened, and the method can be used for high-speed circuit design.

Owner:XIDIAN UNIV

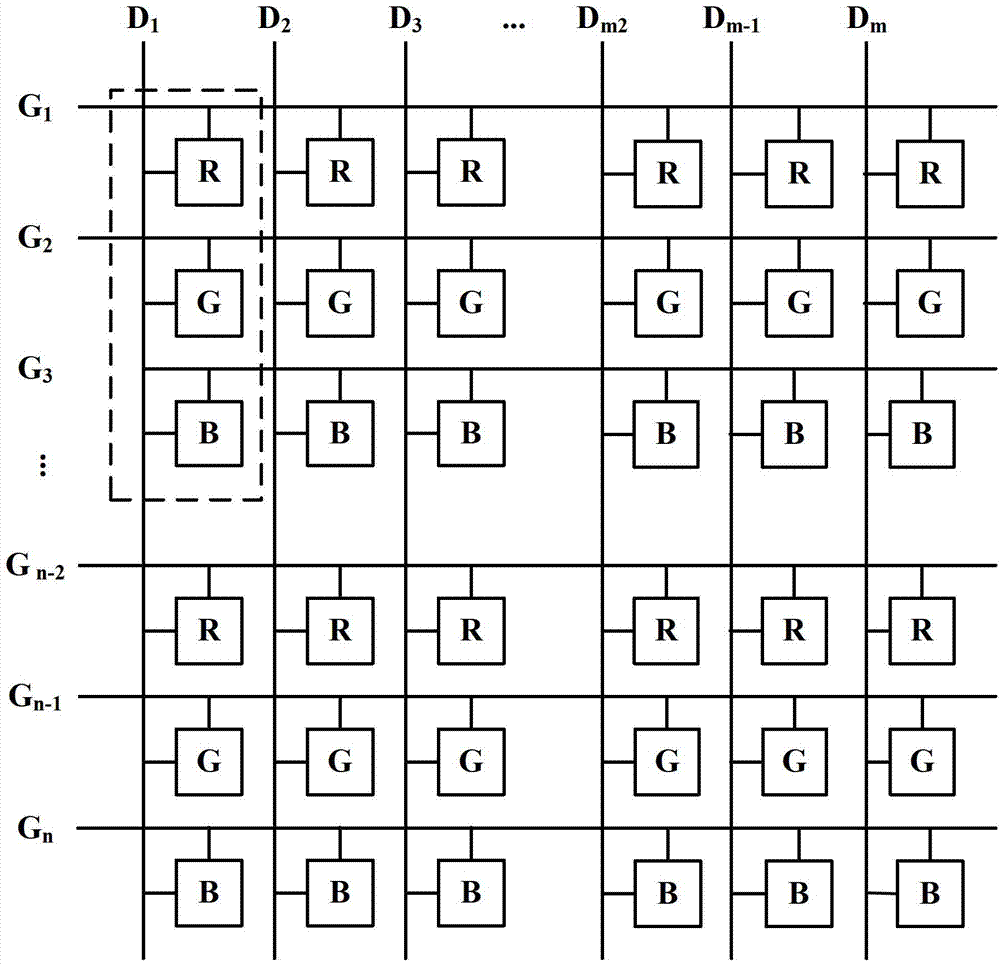

Pixel driving structure, driving method and display device

The invention discloses a pixel driving structure, which comprises multiple sub pixel electrodes, multiple data lines and multiple scanning lines, wherein the multiple sub pixel electrodes are arranged in an array; and the multiple data lines and the multiple scanning lines are arranged in a crossed mode. The pixel driving structure is characterized in that at least one data line is electrically connected with at least three sub pixel electrodes with the same data signal voltage polarity, and in a row direction or a column direction, the sub pixel electrodes connected with the same data line are connected with different scanning lines; and when a frame of image is displayed, the voltage polarity of the data signals applied to each data line remains unchanged, and the voltage polarities of data signals applied to adjacent two data lines are opposite. The pixel driving structure provided by the invention reduces the data line use amount, Z inversion can be realized, and low cost and low power consumption are realized.

Owner:KUSN INFOVISION OPTOELECTRONICS

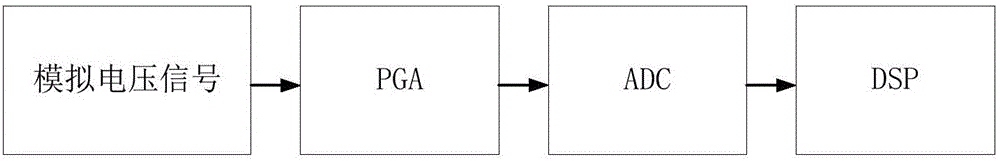

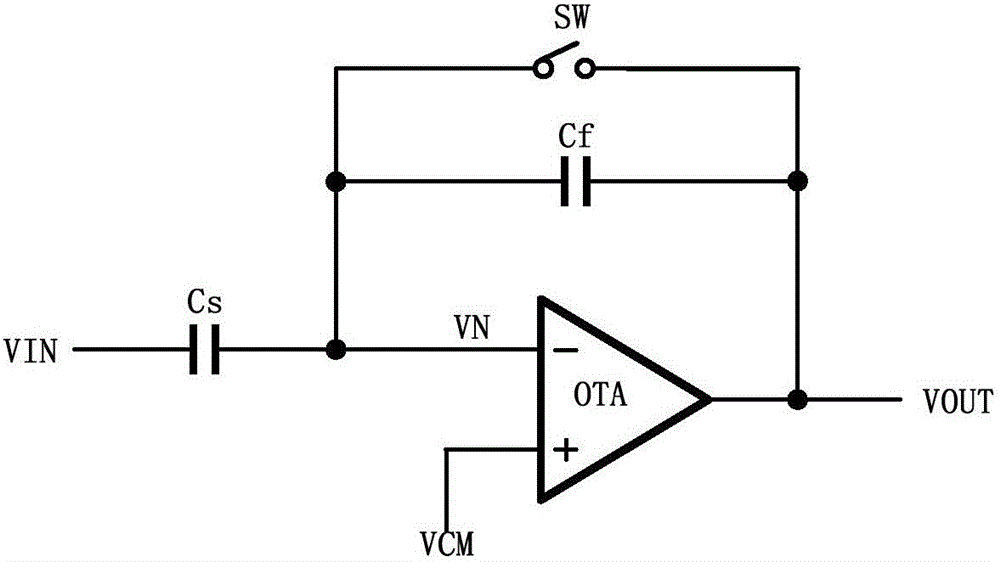

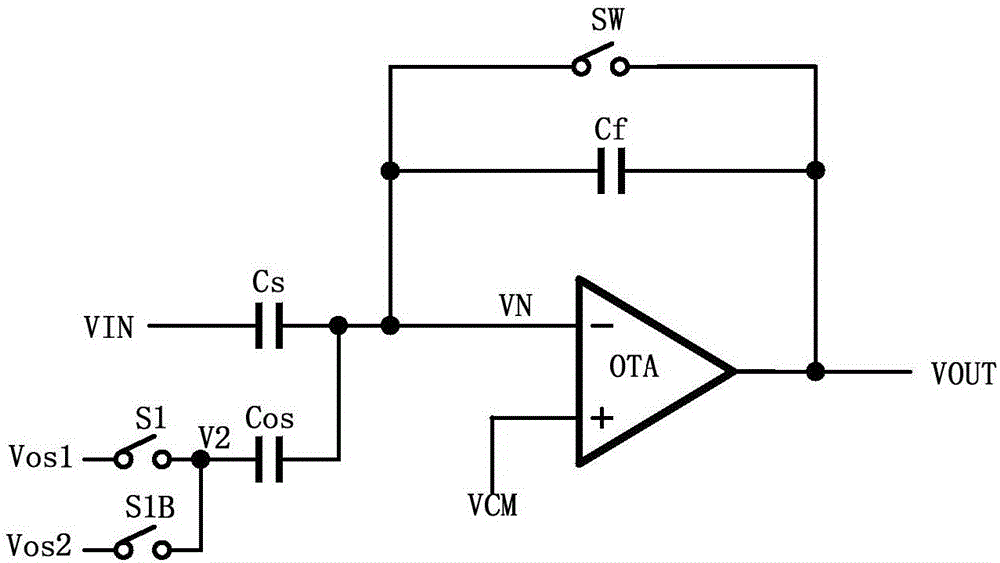

Programmable gain amplifier capable of adjusting signals

ActiveCN106712730AReduce the amount usedReduce areaNegative-feedback-circuit arrangementsDifferential amplifiersProgrammable-gain amplifierCapacitance

The invention provides a programmable gain amplifier capable of adjusting signals. The programmable gain amplifier adopts a PGA circuit and comprises: an operational amplifier circuit, an input end, an output end, a first feedback capacitor, a second feedback capacitor, a first switch and a second switch, wherein the first feedback capacitor is connected between the output end of a reserve input end of the operational amplifier circuit, one end of the second feedback capacitor is connected with the reserve input end of the operational amplifier circuit, and the other end of the second feedback capacitor is separately connected with the output end and a reference voltage through the first switch and the second switch. The programmable gain amplifier reduces the number of the used capacitors, thereby saving the area; the number of the input voltages is decreased, thereby simplifying the circuit design; meanwhile the area, the power consumption and the noise are reduced; the feedback coefficient of the PGA circuit is increased, the design difficulty of the operational amplifier circuit is reduced, and meanwhile the power consumption is reduced; and the programmable gain amplifier can be configured to be the PGA circuit that only has an amplification function, thereby being more flexible.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT +1

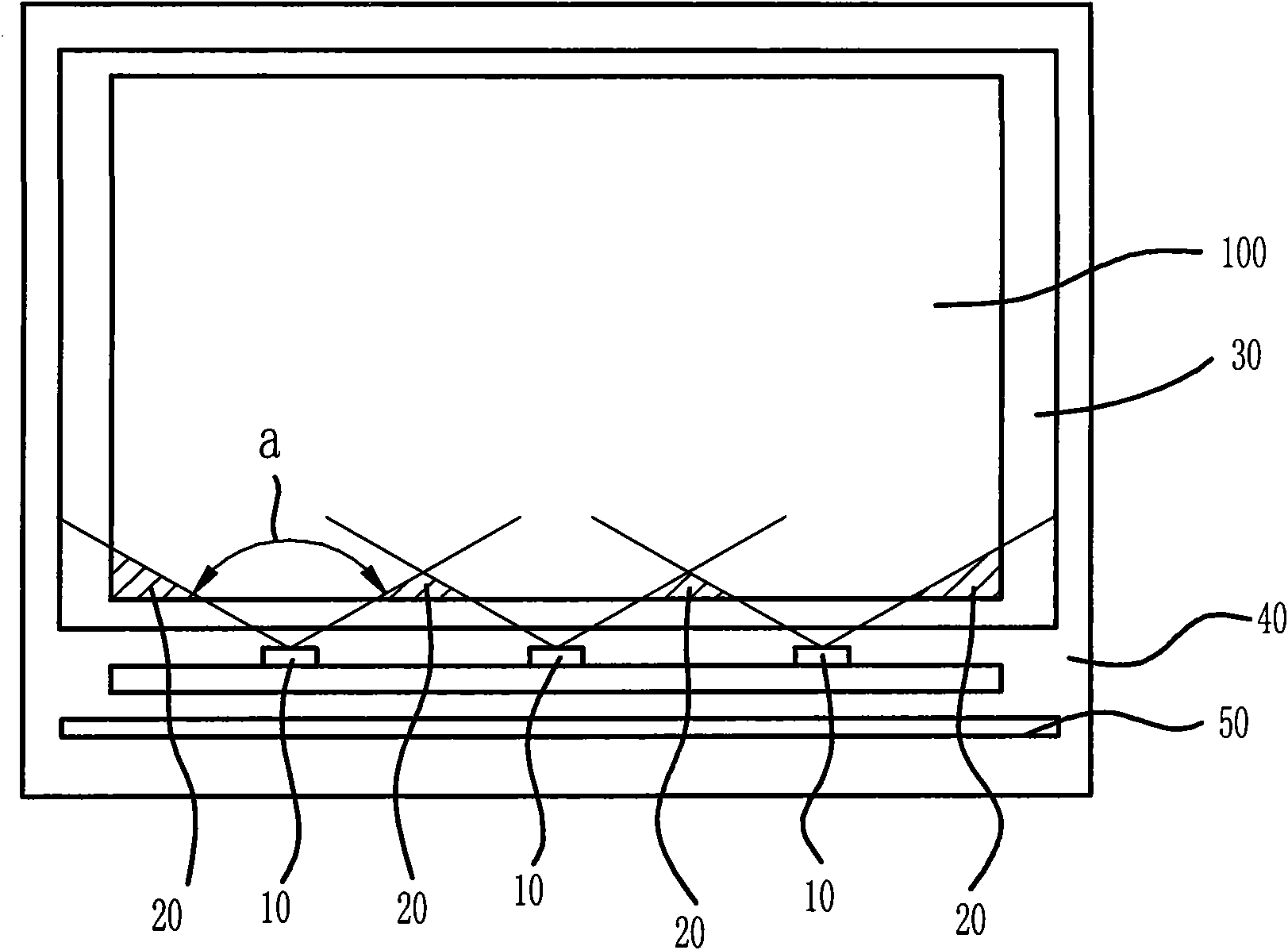

LED backlight module

ActiveCN101571264AShorten the mixing distanceReduce the amount usedMechanical apparatusPoint-like light sourceLight guideLight emission

The invention discloses an LED backlight module which comprises a light guide plate and at least one LED luminous source, wherein the light guide plate is at least provided with a light incidence surface; the LED luminous source is arranged opposite to the light incidence surface of the light guide plate; the LED luminous source is provided with a light emission surface facing to the light incidence surface of the light guide plate and at least arranged at one side of the light guide plate; the light emission surface of the LED luminous source forms an inclination angle of larger than 0 DEG and less than 90 DEG relatively to the light incidence surface of the light guide plate. The LED backlight module can reduce a mixed light distance between adjacent LEDs in the prior LED backlight source art, reduce and even eliminate a dark area, save the cost and reduce the heat emission of the module.

Owner:SHANGHAI AVIC OPTOELECTRONICS

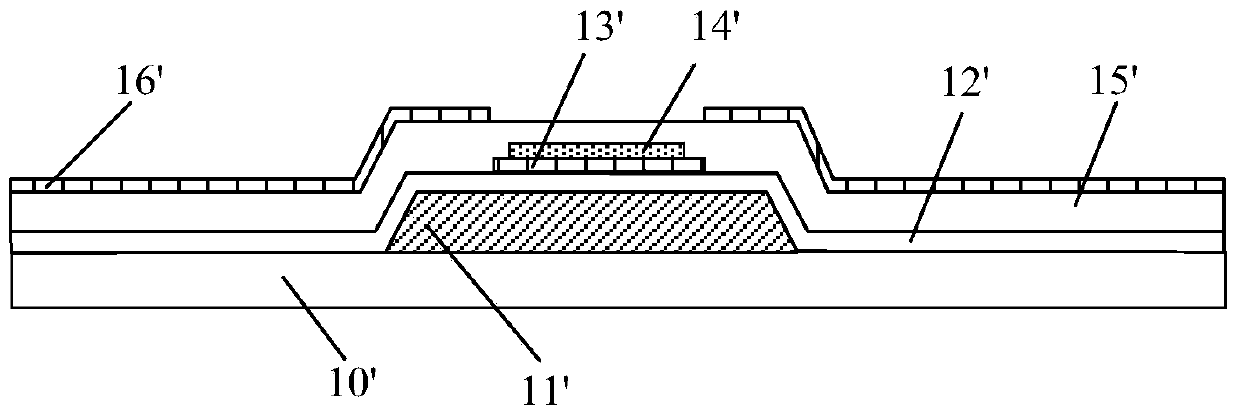

Display panel, production method thereof and display device

ActiveCN103728797AEliminate crosstalkReduce the amount usedSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringData lines

An embodiment of the invention discloses a display panel, a production method thereof and a display device, and relates to the technical field of display. Production cost of the display panel can be reduced on the premise of crosstalk elimination. The display panel comprises an array substrate. The array substrate comprises a plurality of film layers sequentially formed on a first substrate. A data line and a drain electrode are positioned on the same film layer. A grid line, a grid electrode and a first common electrode are positioned on the same film layer. The film layer where the grid line, the grid electrode and the first common electrode are positioned is positioned between the film layer where the data line and the drain electrode are positioned and the film layer where a pixel electrode is positioned.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

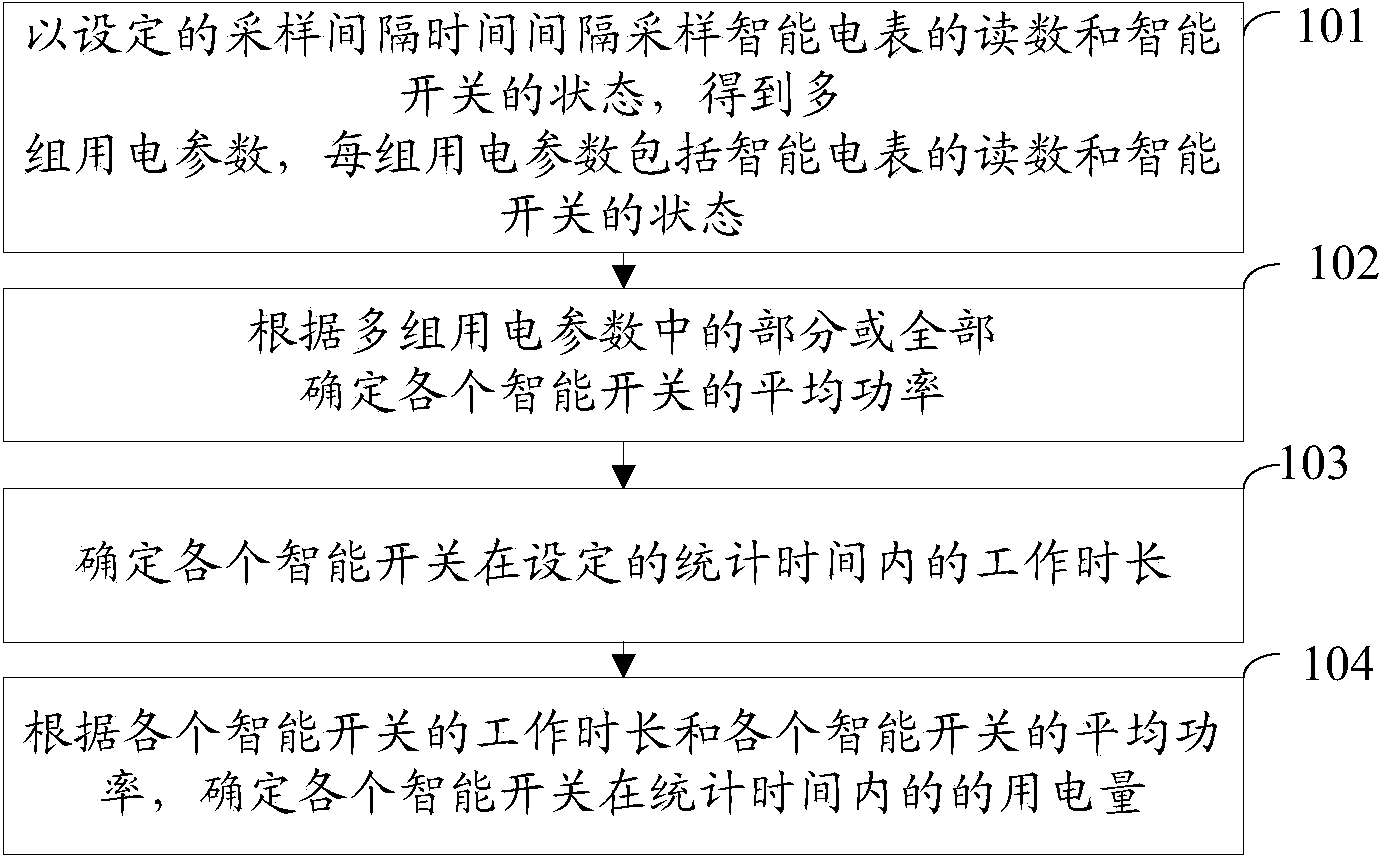

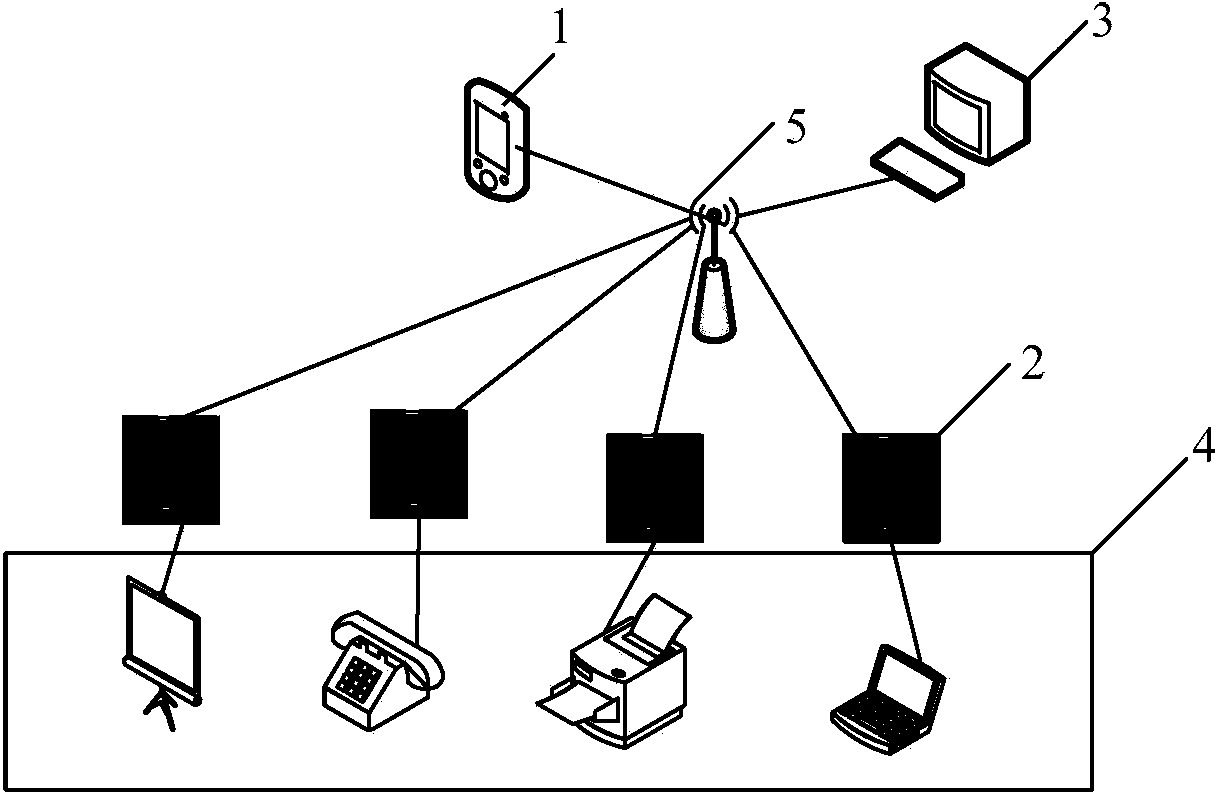

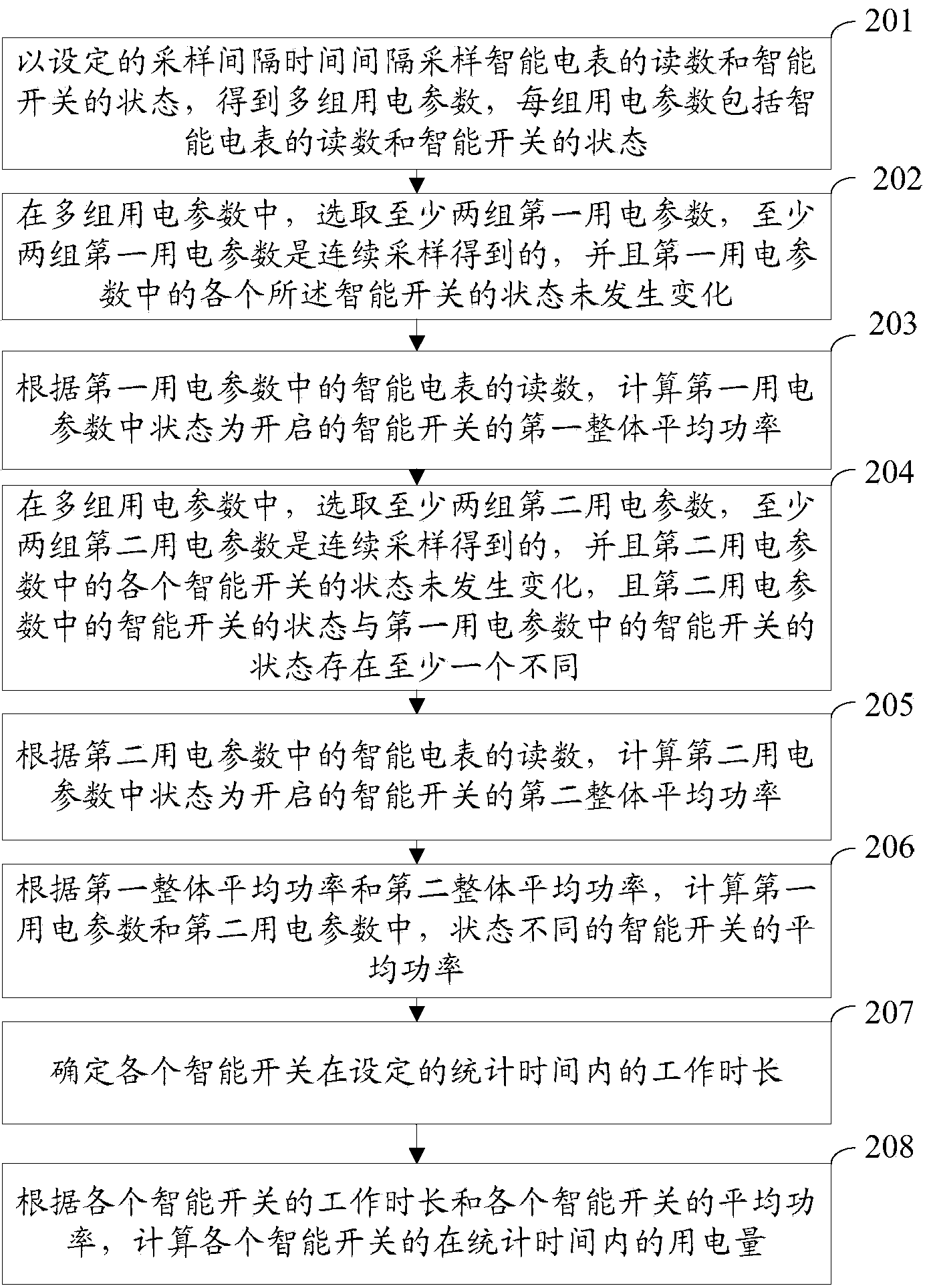

Power consumption statistics method, apparatus and system

ActiveCN104111641AReduce the amount usedReduce usageTransmission systemsTariff metering apparatusElectrical devicesPower consumption

The invention relates to a power consumption statistics method, apparatus and system, and belongs to the field of intelligent households. The power consumption statistics method comprises: sampling the reading of an intelligent ammeter and the states of intelligent switches at intervals by set sampling interval time to obtain multiple groups of power consumption parameters, each group of power consumption parameters comprising the reading of the intelligent ammeter and the states of the intelligent switches; according to a part of the power consumption parameters or all the power consumption parameters, determining average power of each intelligent switch; determining a work time length of each intelligent switch within set statistics time; and according to the work time length of each intelligent switch and the average power of each intelligent switch, determining a power consumption quantity of each intelligent switch within the statistics time. According to the invention, statistics of the power consumption quantity of one or more electrical devices controlled by each intelligent switch can be automatically finished by use of one intelligent ammeter and the more intelligent switches, such that flower intelligent ammeters are used, the cost is saved, and the trouble of manual reading and statistical analysis is also eliminated.

Owner:XIAOMI INC

Method for continuous casting by using continuous casting dummy bar assembly and continuous casting dummy bar assembly

The invention relates to a method for continuous casting by using a continuous casting dummy bar assembly. The continuous casting dummy bar assembly comprises a dummy bar hook, a baffle and a chill cage. When the continuous casting dummy bar assembly is used for performing continuous casting, a dummy bar head is firstly fed into a secondary cooling chamber, the lower end of the dummy bar hook and a cross bar are installed in an open slot of the dummy bar head, then the dummy bar head continuously enters a process required position of a dummy bar section of a mold copper pipe, an asbestos rope is used for blocking a gap between the dummy bar head and the mold copper pipe, a first iron shot layer is laid on the dummy bar head, the baffle penetrates through the first iron shot layer at the dummy bar head from a penetrating head at the upper end of the dummy bar hook, a second iron shot layer is laid on the baffle, the chill cage is put in the center of a dummy bar chamber formed by the dummy bar head and the mold copper pipe, and finally a certain quantity of deformed steel bars are inserted into the chill cage. Casting is started after the continuous casting dummy bar assembly is installed, molten steel forms a blank head which is connected with the dummy bar head and the continuous production of casting blanks is realized under the traction of a withdrawing and straightening machine.

Owner:HENGYANG VALIN STEEL TUBE

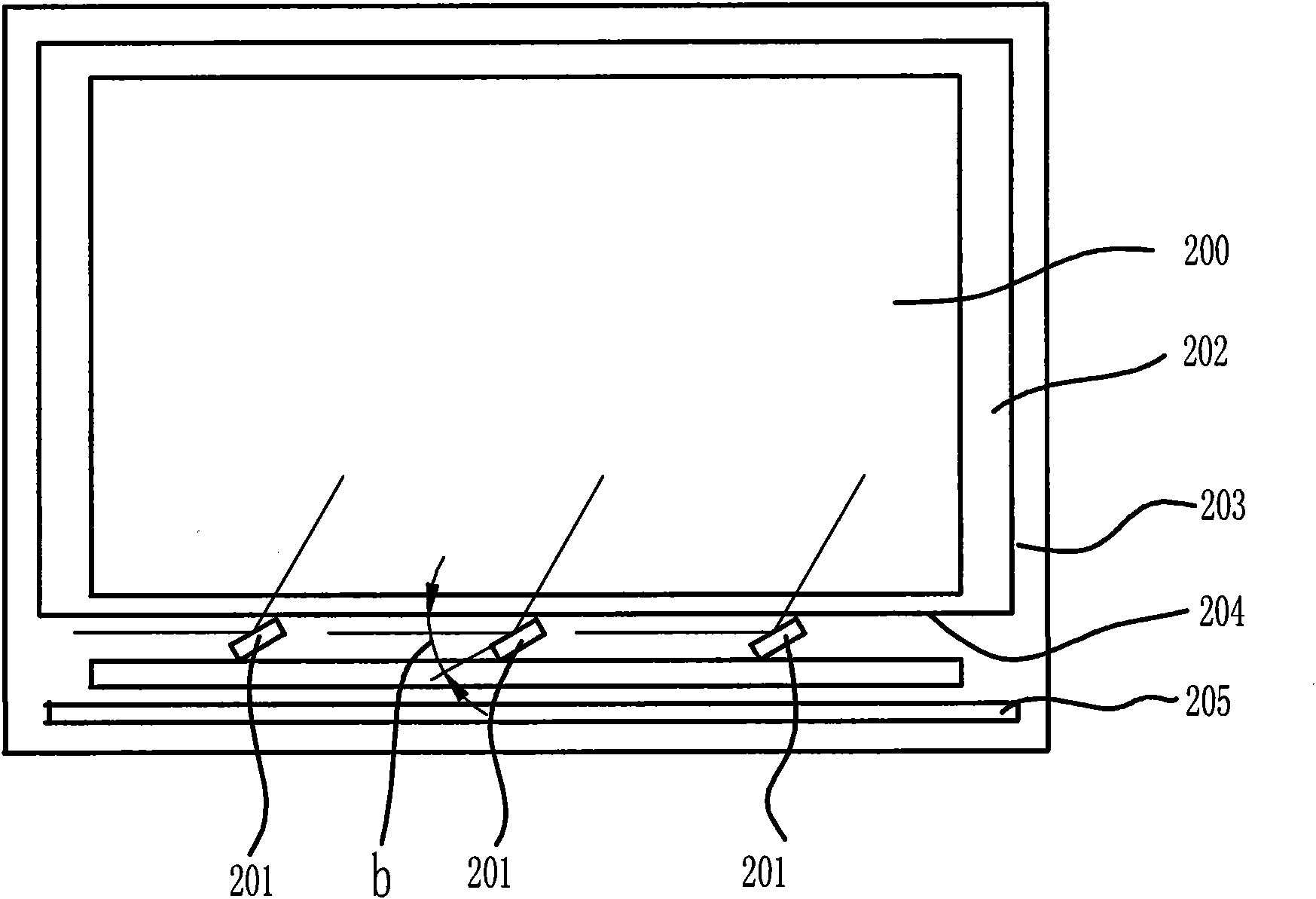

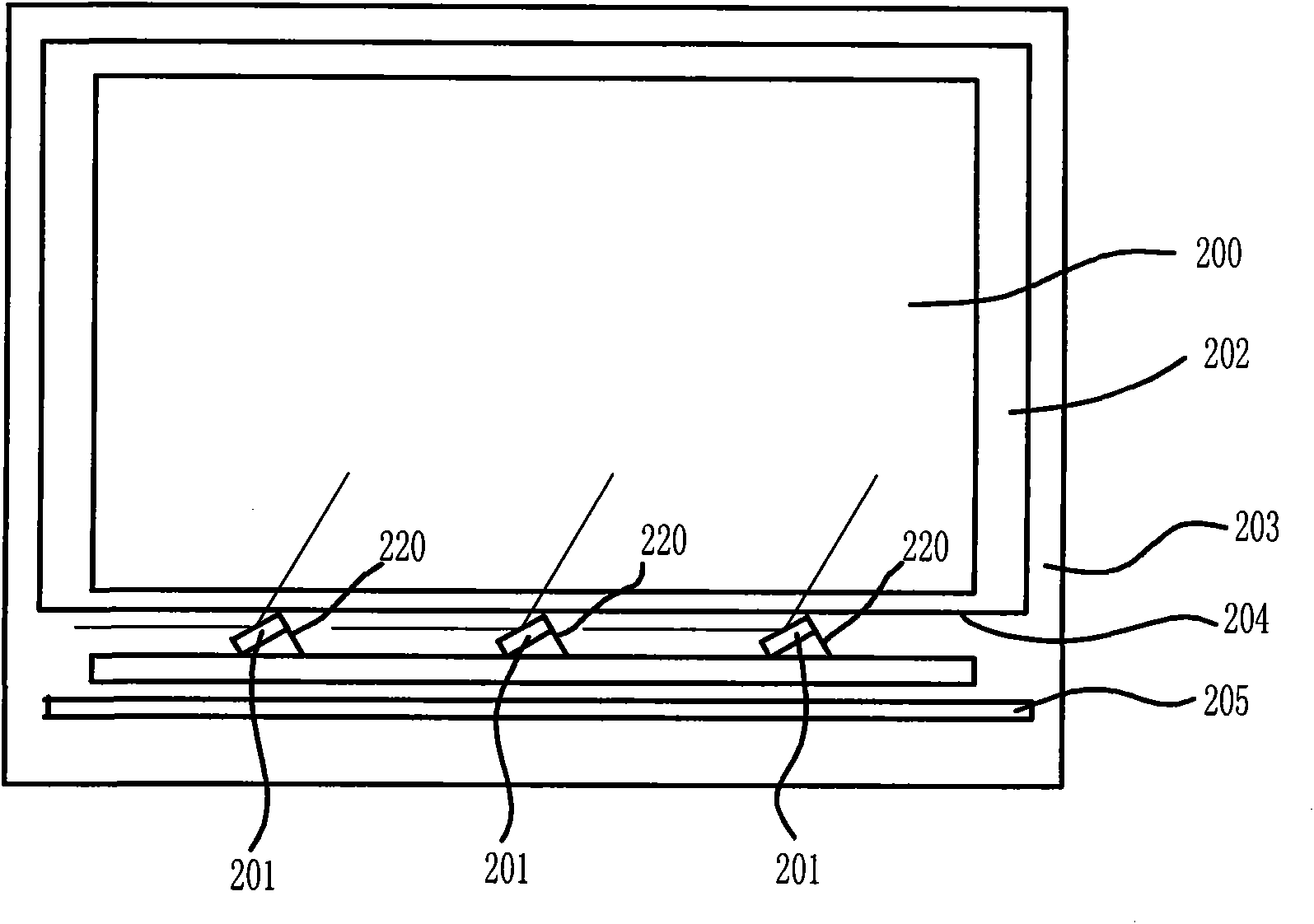

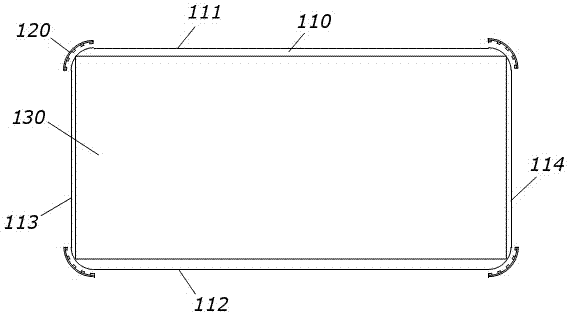

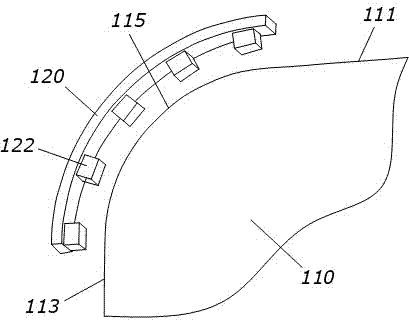

Lateral incidence type backlight module and liquid crystal television

InactiveCN103047585AReduce the amount usedLow costTelevision system detailsMechanical apparatusLiquid crystalLCD television

The invention discloses a lateral incidence type backlight module and a liquid crystal television. The backlight module comprises a rectangular light guide plate and LED (Light-Emitting Diode) lamp bars, wherein the light guide plate is composed of two parallel long sides and two parallel short sides; arc-shaped sides for smooth transitional connection are arranged at the joints of the long sides and the short sides; the LED lamp bars are arranged at the outer sides of the arc-shaped sides; the LED lamp bars are arc-shaped to be adaptable to the arc-shaped sides; and the LED lamps on the LED lamp bars are arranged towards the arc-shaped sides. As the light guide plate with arc-shaped corners is adopted, and the arc-shaped LED lamp bars are arranged on the arc-shaped corners, the number of used LED lamps is reduced greatly while the same brightness requirement is satisfied, and the cost of the lateral incidence type backlight module is also reduced obviously; and as the arc-shaped LED lamp bars are dispersed at the four corners of the light guide plate, the disadvantage of too intensive heat energy generated by the traditional LED lamp bars which are arranged on the upper sides or the short sides is avoided, heat dissipation effects are improved efficiently, and service life of the LED lamps is prolonged.

Owner:KONKA GROUP

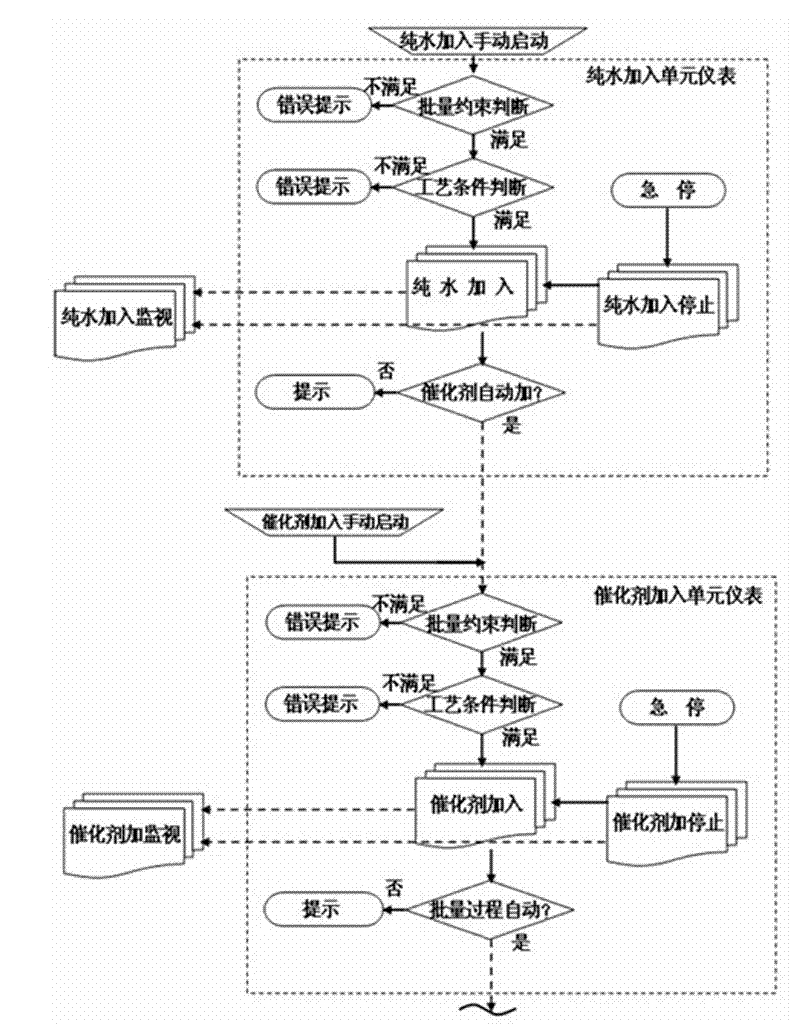

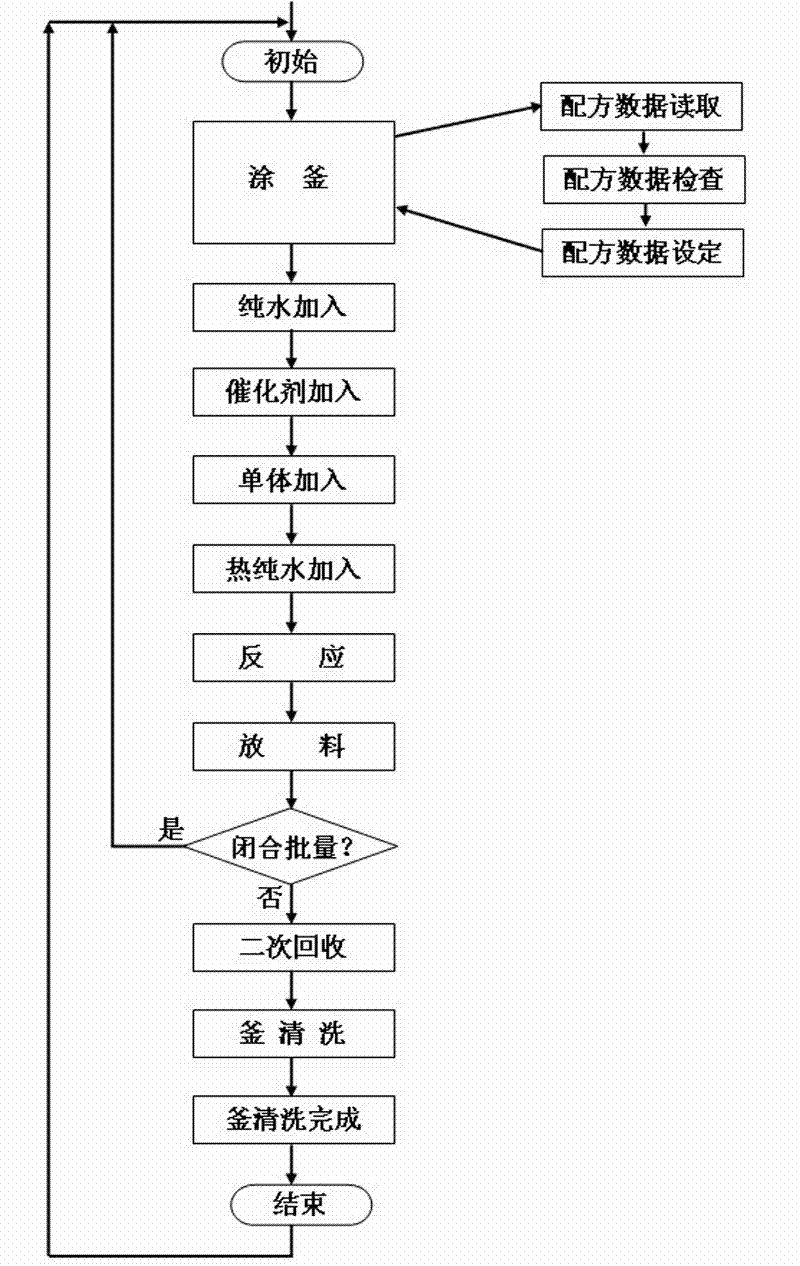

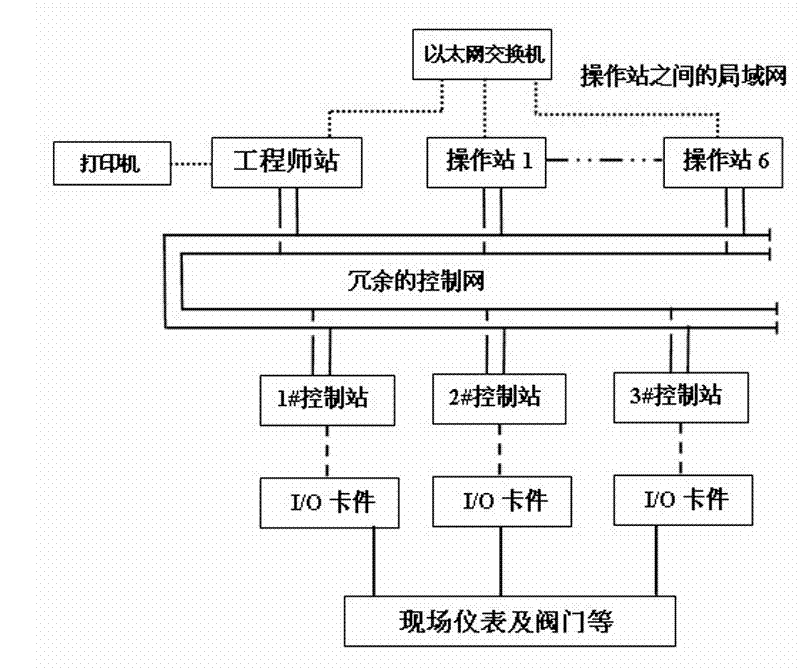

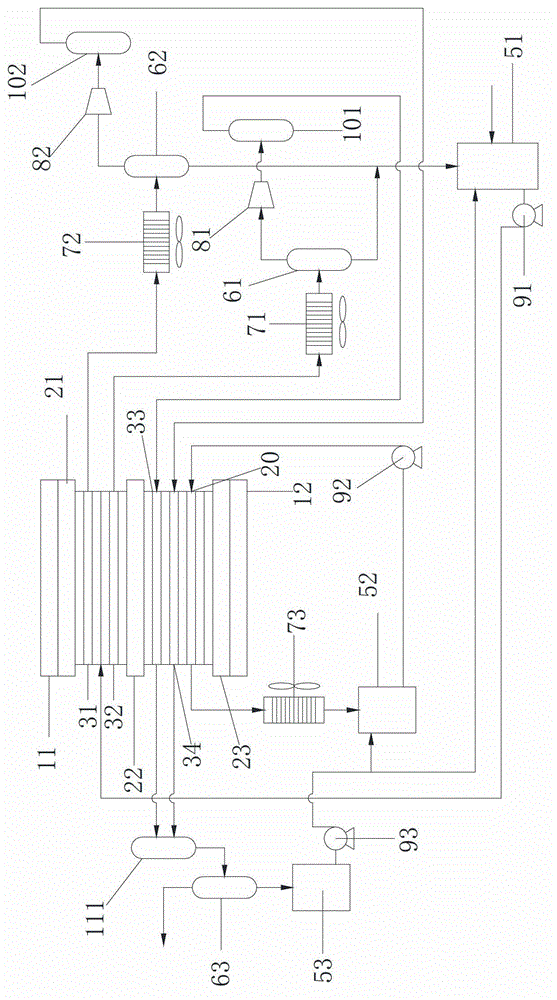

Process control system for mass production of polrvinyl chloride

ActiveCN102585059AReduce the amount usedReduce usageProgramme total factory controlSet operatorsControl system

A process control system for mass production of polrvinyl chloride comprises CS3000 data communication system (CS3000DCS) hardware and software. The hardware comprises an engineer station (also serving as a formula management station and an object linking and embedding process control (OPC) station), a multi-set operator station, a multi-set redundant control station, a network exchanger, a printer and the like. The engineering station is used for finishing the functions of programming configuration, program downloading, system maintenance and the like of the whole control system, and the engineering station simultaneously has the functions of formula data management and OPC data sending. Various data collecting input / output (I / O) cards are installed on the control station and connected with an on-site meter and a valve to finish the control of the whole production process. The DCS operation software can finish formula management, dosing, feeding, operation of a polymerizer, temperature control and the operation of kettle coating, purified water addition, catalyst addition, monomer addition, reaction, discharging, recovery and kettle cleaning for each unit. The process control system for the mass production of the polrvinyl chloride optimizes the control mass process of polymerizing production, is various in function and flexible and reliable in mass control method, fully utilizes the functions of the control station, reduces the number of the control station, and has good technical effects.

Owner:SHENYANG HUAKONG TECH DEV

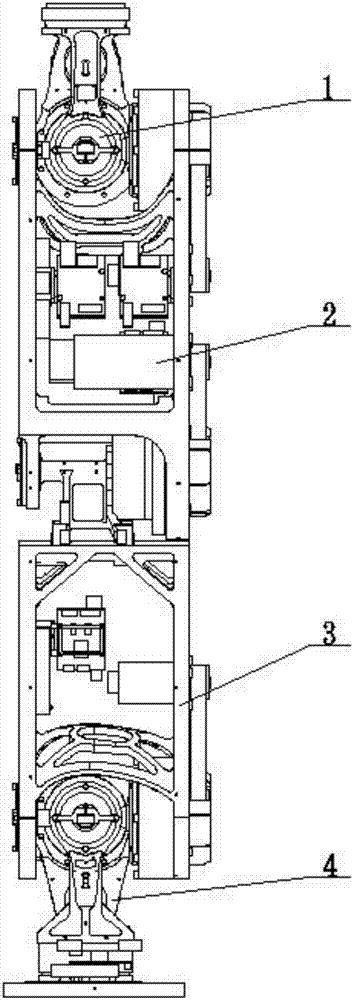

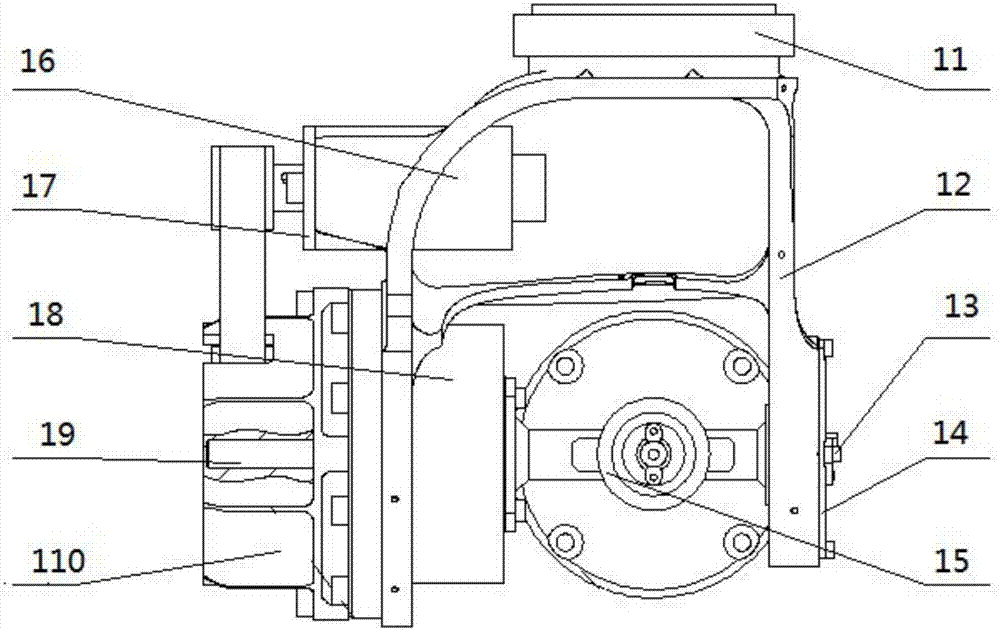

Humanoid robot leg mechanism

PendingCN107985439AReduce the amount usedReduce overall weight and installation errorsVehiclesSix degrees of freedomInstallation Error

The invention discloses a humanoid robot leg mechanism. The mechanism comprises a thigh mechanism, a hip joint mechanism is in threaded connection with the upper end of the thigh mechanism, a shank mechanism is in threaded connection with the lower end of the thigh mechanism, and an ankle and sole mechanism is connected with the lower end of the shank mechanism through bolts; the hip joint mechanism has degrees of freedom in directions of YAW and ROLL; the thigh mechanism has degrees of freedom in upper and lower directions of PITCH; the shank mechanism has one degree of freedom in the direction of PITCH; the ankle and sole mechanism has one degree of freedom in the direction of ROLL; human-like walking gait movements can be completed by the humanoid robot leg mechanism through the combination of six degrees of freedom. According to the humanoid robot leg mechanism, all components in the humanoid robot leg mechanism are processed to reduce weights, a large number of integrated spare parts and universal spare parts are designed, the using number of the bolts, overall weight and installation errors are reduced, and installation simplicity and strength of the spare parts are increased.

Owner:BEIJING GANGTIEXIA TECH CO LTD

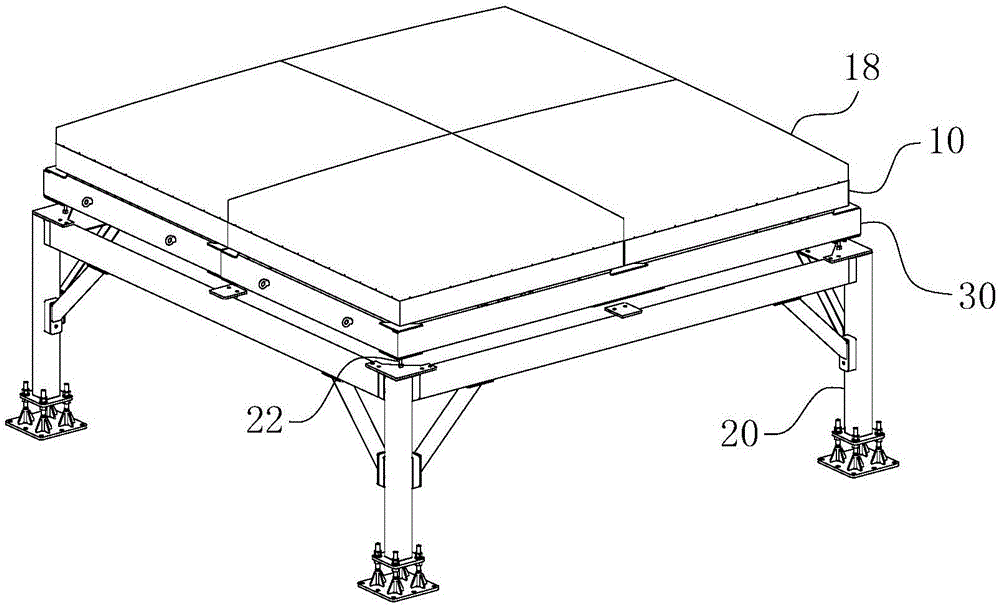

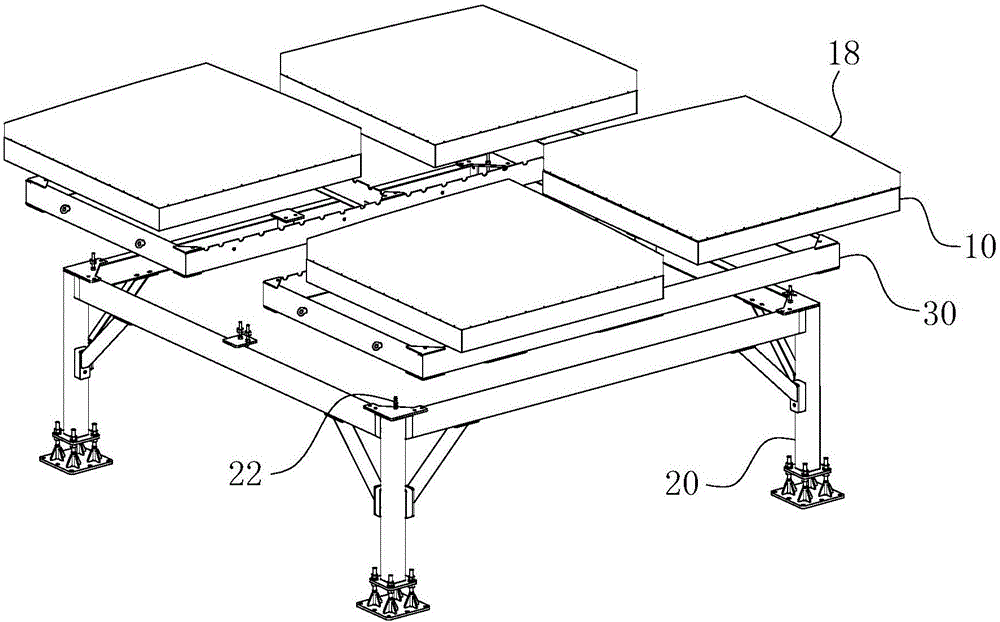

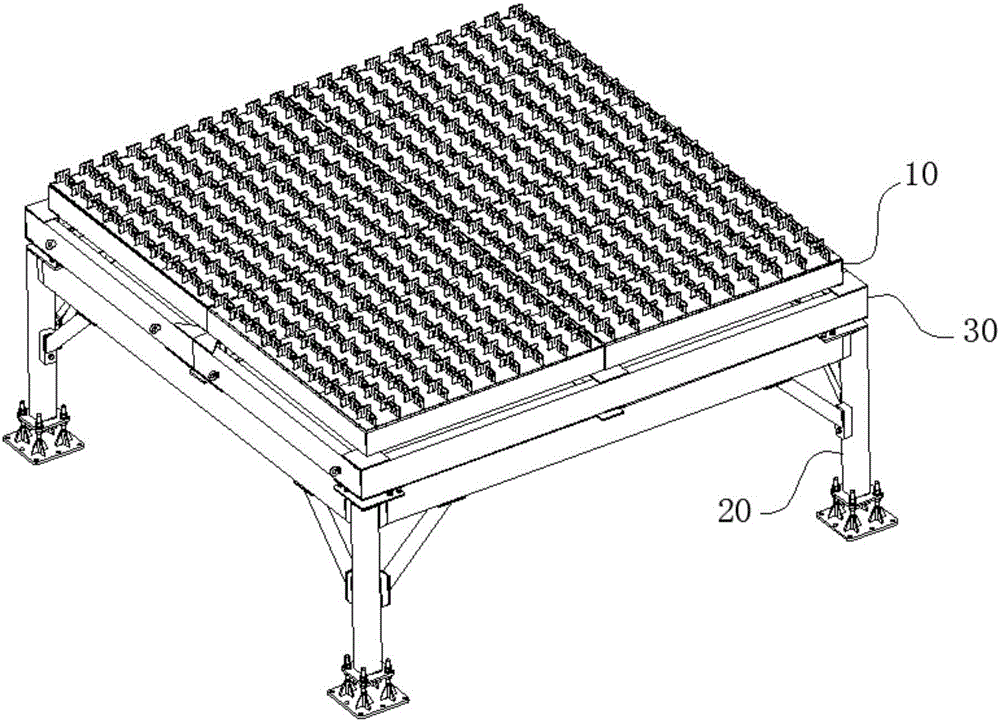

Large-array surface phased array radar antenna

InactiveCN106374236AReduce the amount usedHigh working reliabilityIndividually energised antenna arraysPhysicsDipole

The invention belongs to the technical field of radar electronics, in particular relates to a large-array surface phased array radar antenna. The large-array surface phased array radar antenna comprises an array surface antenna and a support rack, wherein the array surface antenna comprises antenna line oscillators and antenna row oscillators, the number of the antenna row oscillators is equal to the number of the antenna line oscillators, the distance between two adjacent groups of antenna line oscillators is equal to the distance between two adjacent groups of antenna row oscillators, each antenna line oscillator and each antenna row oscillator cross to form a cross meshed structure of the array surface antenna, top end surfaces of dipoles after each antenna line oscillator and each antenna row oscillator cross are arranged on the same plane, symmetric surfaces of two adjacent dipoles on each group of antenna line oscillator are arranged on a plane where the group of antenna line oscillators are located, and the symmetric surface of each dipole on each group of line oscillators is arranged on a plane where the group of antenna row oscillators are located. By the large-array surface phased array radar antenna, the usage quantity of T / R modules can be effectively reduced on the premise that the working accuracy of the radar antenna can be ensured, and the purpose of effectively controlling cost is further achieved.

Owner:ANHUI SUN CREATE ELECTRONICS

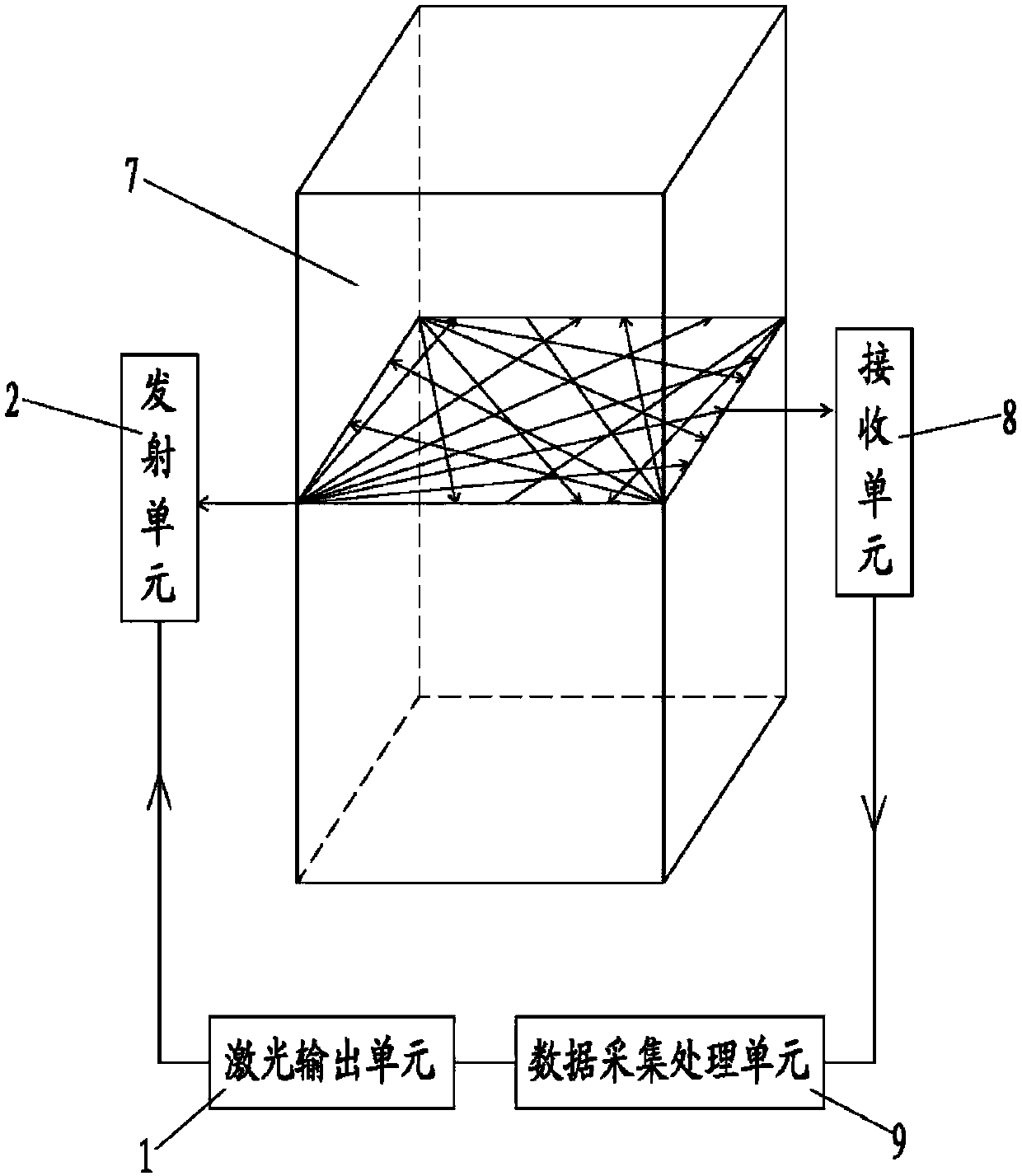

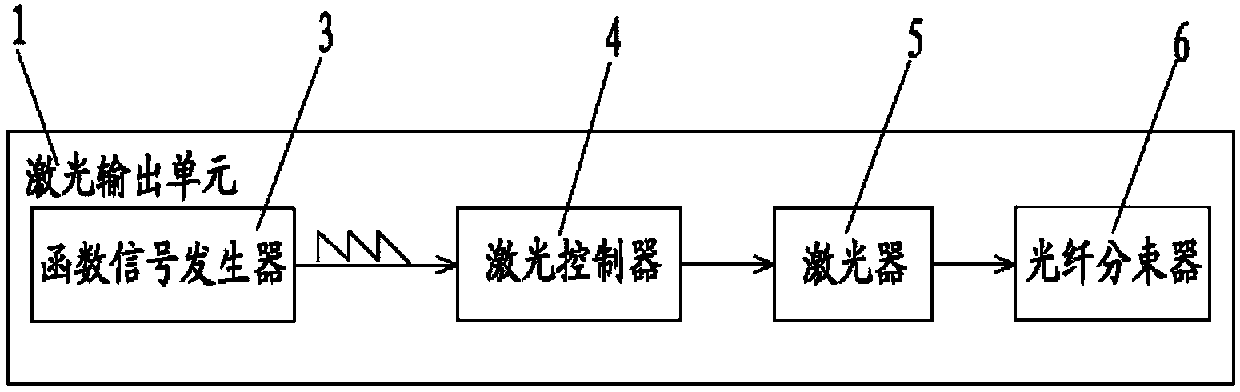

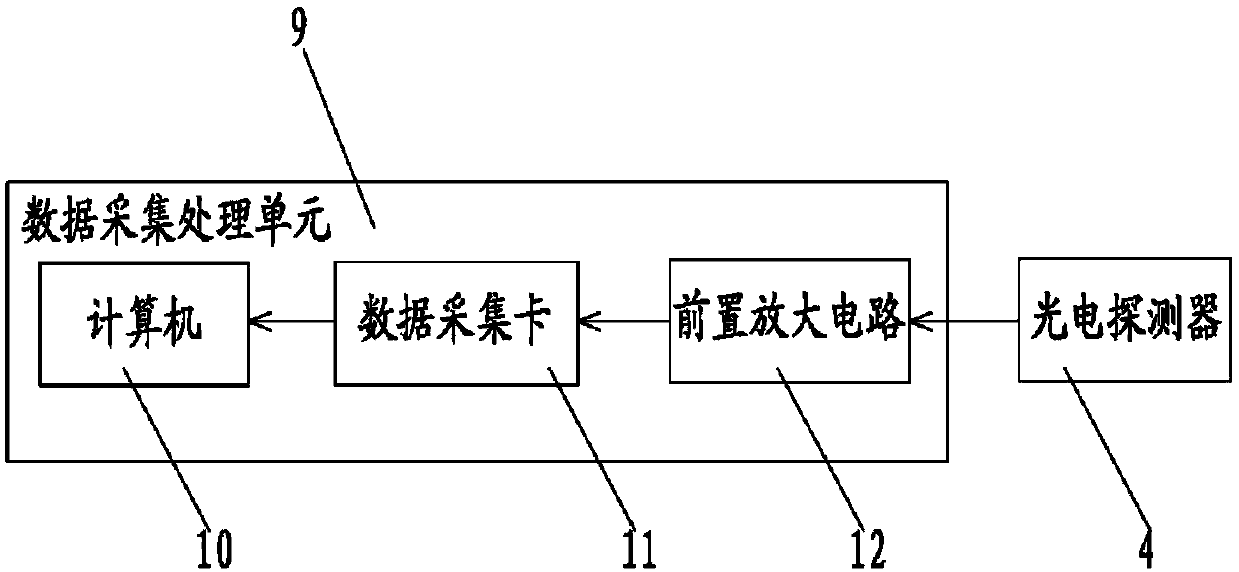

TDLAS boiler gas two-dimensional concentration distribution detecting method and device based on automatic scanning system

PendingCN107688009AImprove reconstruction accuracyReduce the amount usedColor/spectral properties measurementsOptical beamGas concentration

The invention discloses a TDLAS boiler gas two-dimensional concentration distribution detecting method based on an automatic scanning system. The method includes that a transmitting unit is mounted ateach of four corners of a boiler hearth section detection platform; multiple receiving units are mounted on four sides of the detection platform; the transmitting units and the receiving units are enabled to rotate according to a preset mode through a control module, and when a laser beam rotates to scan a hearth inside section, the laser beam directly faces the receiving units scanned by the laser beam when rotating sequentially to enable the receiving units to sequentially complete receiving of laser transmission signals and convert the same into electric signals; collected analog signals are converted into digital signals and output to a computer through a data collection card, and to-be-detected gas two-dimensional concentration distribution of a scanned area is calculated inversely through an image reconstruction algorithm. A detecting device comprises a laser output unit, a transceiving unit and a data collecting and processing unit. By the method, boiler hearth inside section gas product concentration distribution can be detected accurately in real time, gas concentration two-dimensional distribution reconstruction quality is improved effectively, and detection cost is lowered.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Slot type MOSFET and manufacturing method thereof

ActiveCN101383304AReduce the amount usedFast welding speedSemiconductor/solid-state device detailsSolid-state devicesOxide semiconductorType metal

The invention relates to a method for preparing a groove type metal oxide semiconductor field effect transistor, which comprises the following steps: one end of a copper wire near a chip is melted into a welding ball which is welded on the chip by exerting ultrasonic sound and pressure, and the other end of the copper wire is welded on a frame of the groove type metal oxide semiconductor field effect transistor by using the ultrasonic sound and the pressure. In the groove type metal oxide semiconductor field effect transistor and the preparing method thereof, the copper wire is used for welding, because the electric conductivity of the copper wire is superior to that of gold and aluminium, the copper wire is used for replacing a gold wire, and the cost can be greatly reduced. The preparing method breaks through the forbidden zone that the traditional copper wire ball welding can not be used for a Trench MOSFET technology, and moreover, the invention also provides the groove type metal oxide semiconductor field effect transistor.

Owner:SHENZHEN JINGDAO ELECTRONICS

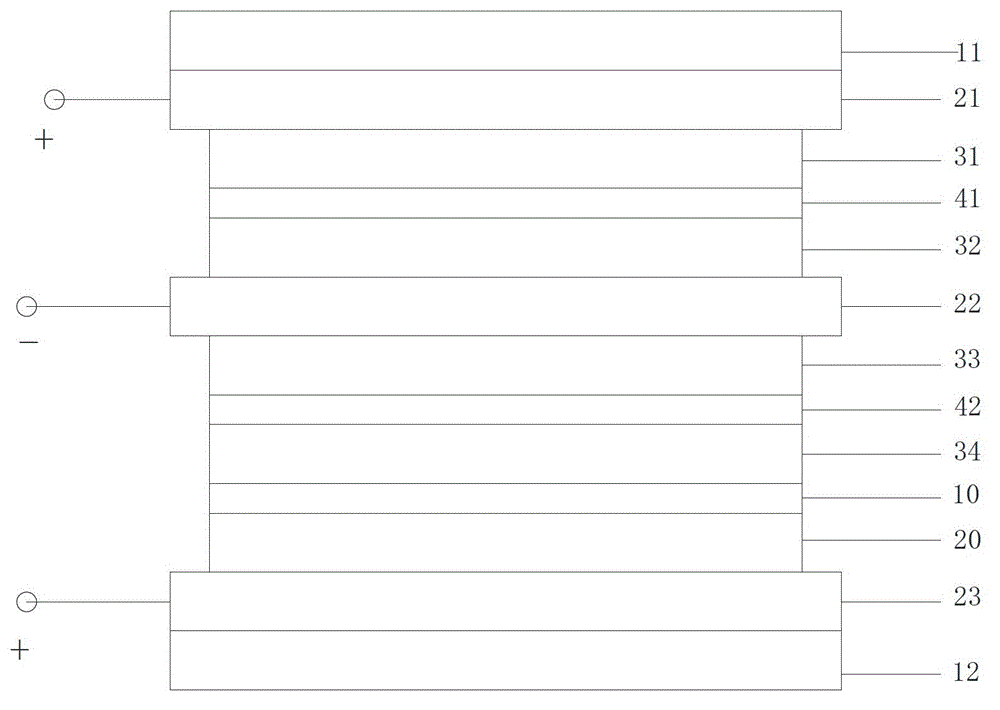

Integrated cell, integrated cell stack including integrated cell and integrated cell system

ActiveCN102751523AReduce the amount usedLow costFuel cells groupingFuel cell detailsCell systemElectricity

The invention discloses an integrated cell, an integrated cell stack including the integrated cell and an integrated cell system. The integrated cell comprises an electrolytic cell for generating hydrogen and oxygen, and a fuel cell for generating electricity by the hydrogen and oxygen, wherein the fuel cell and the electrolytic cell share a collector plate and receive the hydrogen and oxygen generated by the electrolytic cell. According to the invention, the electrolytic cell and the fuel cell are integrally arranged to form the integrated cell; the number of the collector plates used is reduced; the cost is greatly saved; the integration is higher after integral arrangement; the management and maintenance of the integrated cell are facilitated; the reliability is enhanced in the process of conveying the hydrogen generated by the electrolytic cell to the fuel cell to generate electricity by the fuel cell at short range; a complicated process of purifying the air when the air is utilized is avoided by utilization of the oxygen, and output voltage of the cell is further improved by utilizing pure oxygen as reaction gas.

Owner:DONGFANG ELECTRIC (CHENGDU) HYDROGEN FUEL CELL TECH CO LTD

Additive for electrolyte of lead acid accumulator

InactiveCN1453894AReduce the amount usedConducive to environmental protectionLead-acid accumulatorsBenzimidazoleVoltage

The additive for electrolyte of lead acid accumulator consists of 2, 6-ditert-butyl-4-methyl phenol and 1(H)-2-p-chlorobenzyl benzimidazole in the weight ratio of 9:1. The accumulator with the additive has 1-2 times increased service life, excellent long time charge performance, very low evaporated electrolyte amount, 5 % raised output voltage and excellent low temperature use effect up to -40 deg.c. The additive is white powder, non-toxic, smell-less, no corrosive, and suitable for all kinds of lead acid accumulators, and has no environmental pollution. The additive is convenient in use and once addition is enough to each accumulator.

Owner:南京福龙科技有限公司

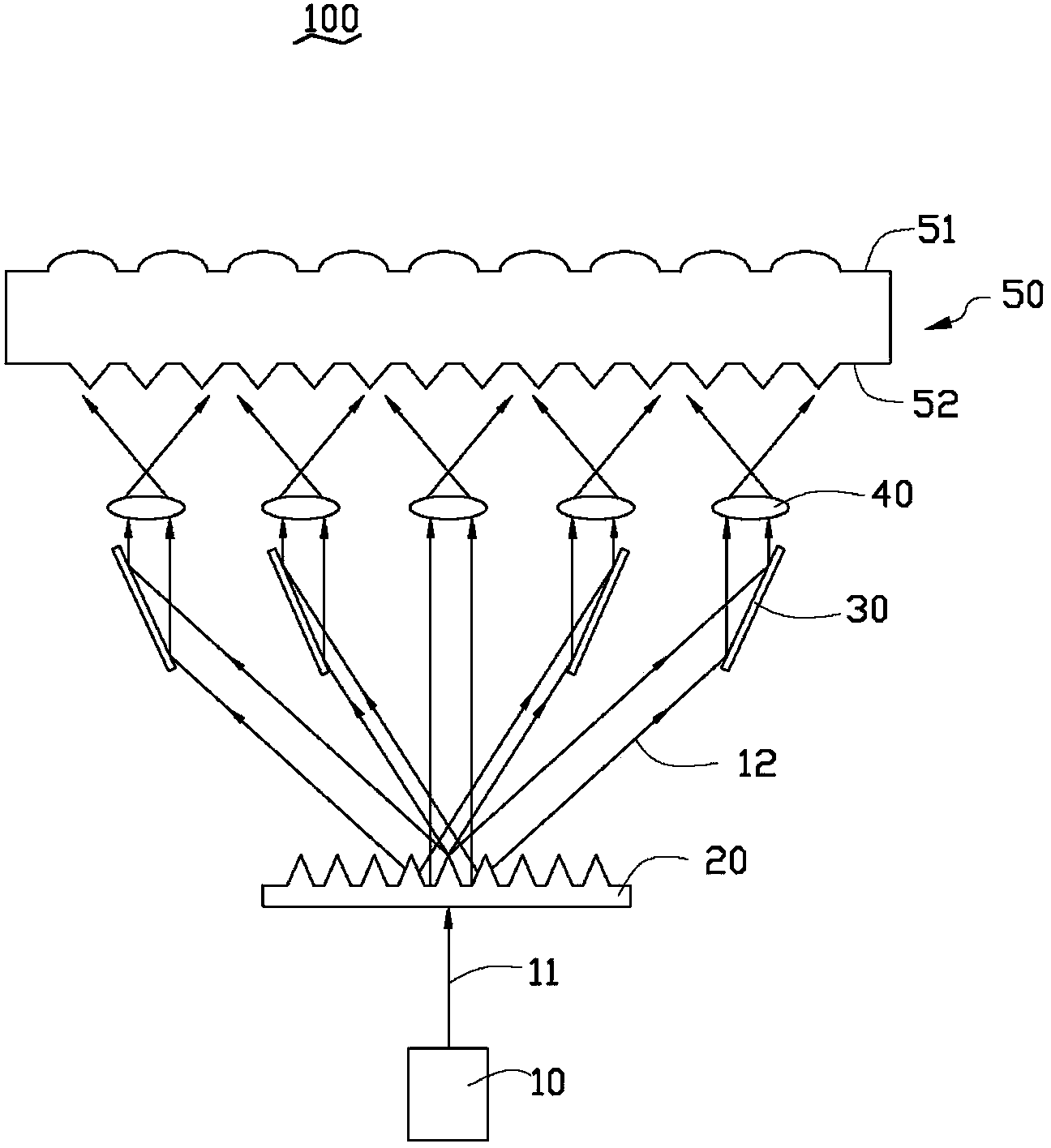

Daytime running light and automobile with same

InactiveCN104110625AReduce the amount usedReduce heat buildupOptical signallingLighting device detailsOptical pathLaser light

The invention discloses a daytime running light which comprises a laser light source, a light splitting element, a plurality of light ray correctors, a plurality of scattering elements and a light shade. The light splitting element is used for splitting each laser beam to obtain split light beams at various angles, and the laser beams are emitted by the laser light source. The light ray correctors are positioned on emergent light paths of the light splitting element, and each light ray corrector is used for correcting one of the split light beams to obtain a parallel light beam which is parallel to the laser beams emitted by the laser light source. The multiple scattering elements are parallelly arranged at intervals, and each scattering element is used of receiving one of the parallel light beams and scattering the received parallel light beam. The scattered light beams can directly reach the light shade. The invention further relates to an automobile with the daytime running light.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

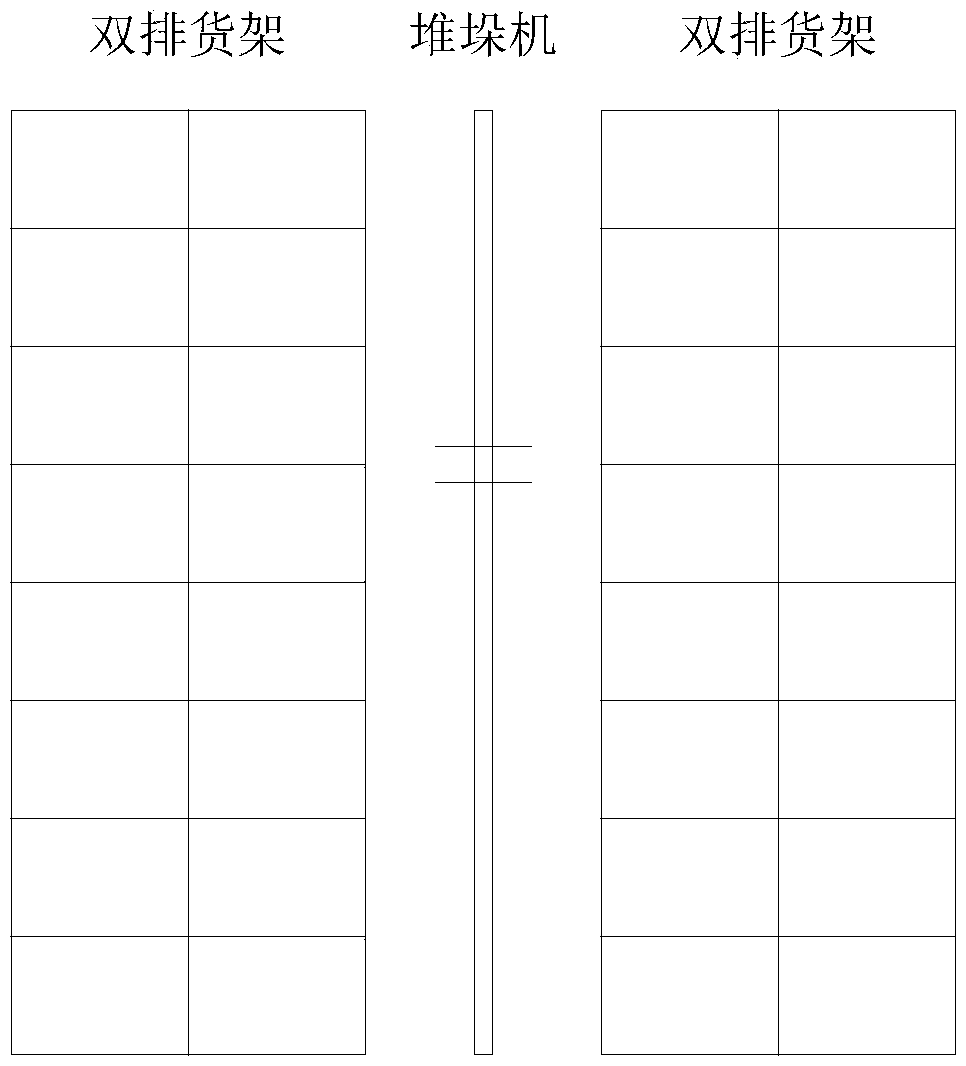

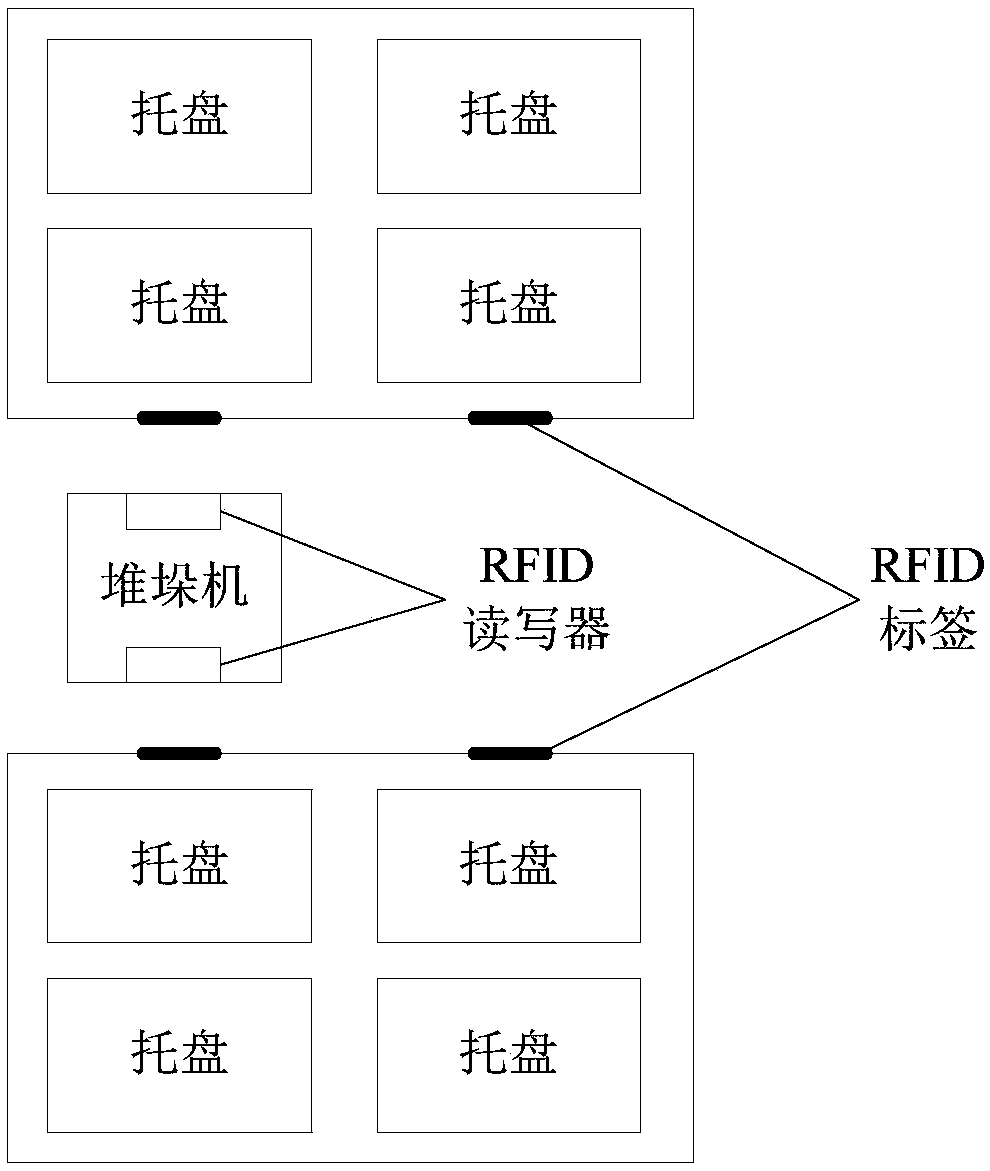

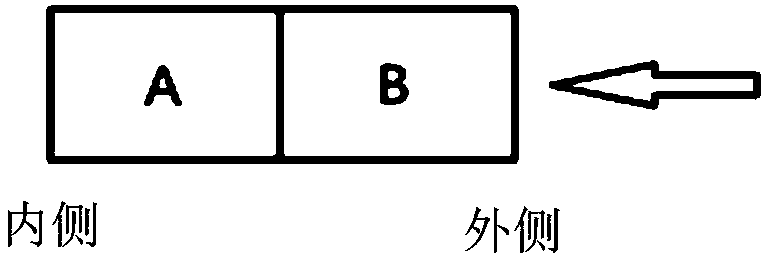

Warehouse, warehouse location state identification method, logistics execution system and electronic equipment

InactiveCN109492724AMeet automation management and control needsReduce the amount usedCo-operative working arrangementsLogisticsLogistics managementUtilization rate

The invention provides a warehouse, a warehouse location state identification method, a logistics execution system and an electronic equipment, which relate to the technical field of logistics management. The warehouse comprises a plurality of multi-row shelves, wherein laneways are formed between oppositely arranged multi-row shelves. Each warehouse location of the multi-row shelves comprises a plurality of warehouses, and each warehouse location is provided with an electronic tag; the electronic tag stores location information and location storage information. The layout of multi-row shelvesreduces the use of electronic tags and increases the number of storage locations in the same warehouse space, thus reducing the hardware cost of the warehouse and improving the utilization rate of the warehouse.

Owner:NINGBO GEELY AUTOMOBILE RES & DEV CO LTD +2

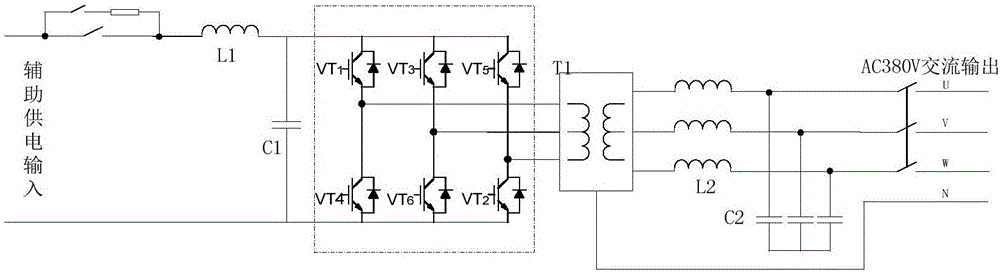

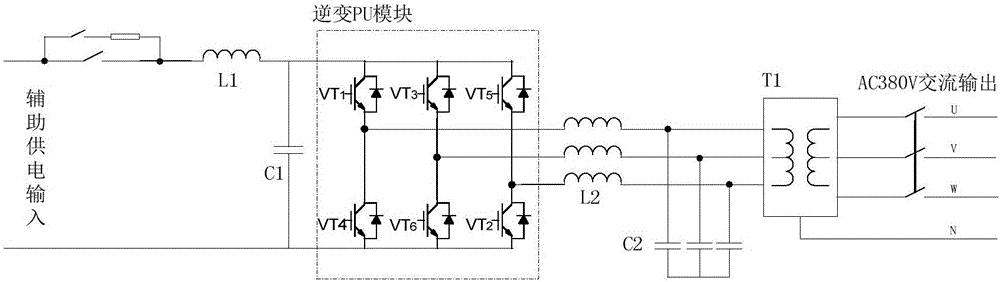

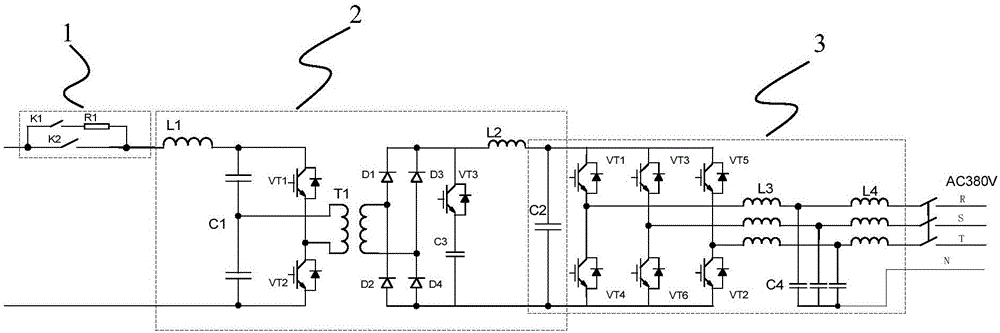

Auxiliary inverter power source

InactiveCN106849724AReduce the amount usedReduce design costAc-dc conversionDc-dc conversionContactorHigh energy

The invention provides an auxiliary inverter power source. The auxiliary inverter power source comprises an input switch unit, a DC / DC unit and an auxiliary inverter unit, wherein the input switch unit, the DC / DC unit and the auxiliary inverter unit are sequentially connected. The input switch unit comprises a contactor K1, a resistor R1 and a contactor K2 connected with a pre-charging loop in parallel, wherein the contactor K1 and the resistor R1 serve as the pre-charging loop and are connected in series; the DC / DC unit comprises an input filter loop, a transformer and an output rectification loop, wherein the input filter loop, the transformer and the output rectification loop are sequentially connected; the auxiliary inverter unit comprises an inverter loop and a three-phase filter loop. According to the auxiliary inverter power source, an auxiliary inverter power source of a traditional industrial frequency transformer is replaced with a medium frequency transformer, the voltage grade of an input power source is reduced, the using number of a high-voltage IGBT is reduced, the design cost and the total weight are reduced, the conversion efficiency of energy is greatly improved, and the auxiliary inverter power source has the high energy-saving benefits.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

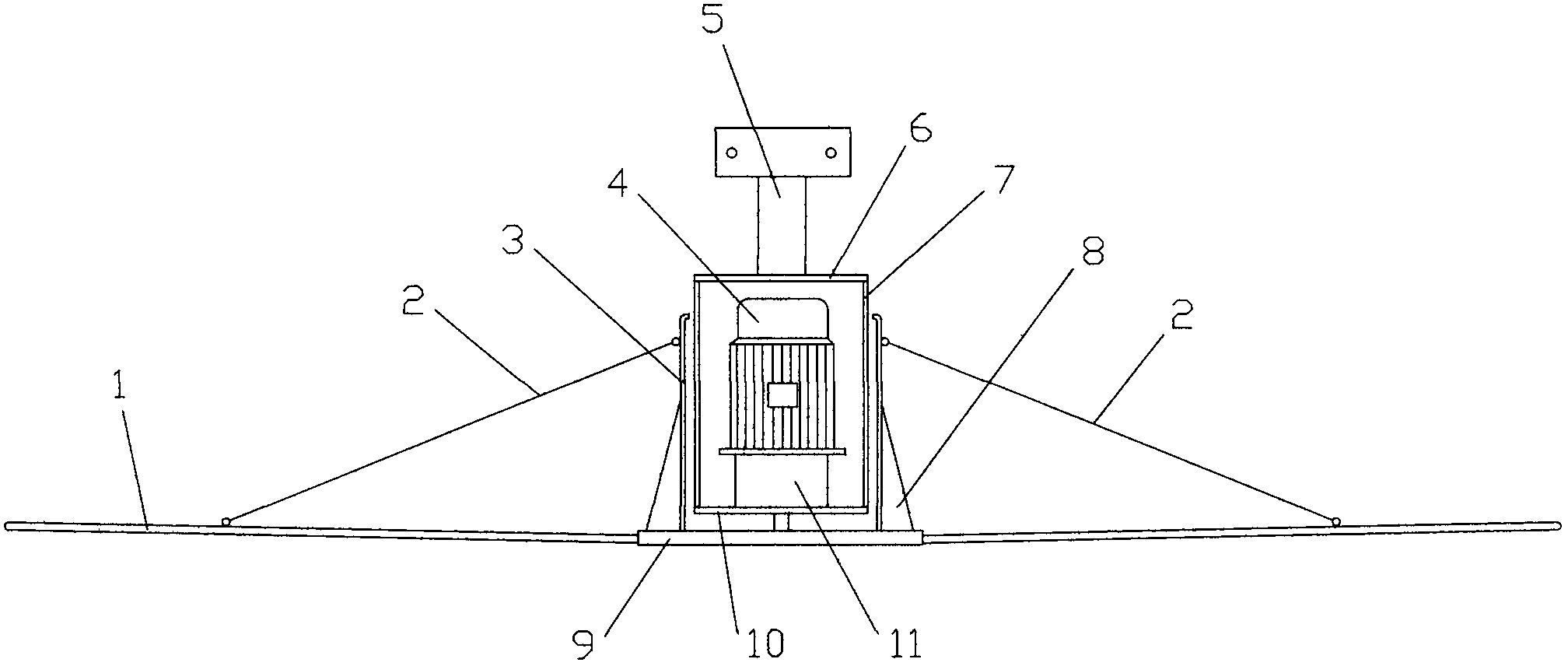

Large-scale industrial fan

InactiveCN103233906AReduce the amount usedCost safe and reliablePump componentsPump installationsIndustrial fanPulp and paper industry

The invention discloses a large-scale industrial fan which comprises a motor, a plurality of fan blades and a fan blade fixing disc. A working spindle of the motor is connected with the fan blade fixing disc, and the plurality of fan blades are fixedly connected with the fan blade fixing disc. The large-scale industrial fan is characterized in that a pulling rope connecting piece is further arranged on the fan blade fixing disc, the pulling rope connecting piece and the plurality of fan blades are connected through pulling ropes respectively, and the fan blades are pulled through the pulling ropes. The large-scale industrial fan improves fan blade balance, long fan blades are pulled by setting a pulling device of the fan blades, and fan blade bending and deformation caused by large length is avoided, so that the fan blades can be in a balanced state throughout. The fan blades can be made longer to cover larger space so that use amount of fans is reduced, and the large-scale industrial fan is energy-saving and safe and reduces the cost.

Owner:SUZHOU RUIEN IND PROD DESIGN

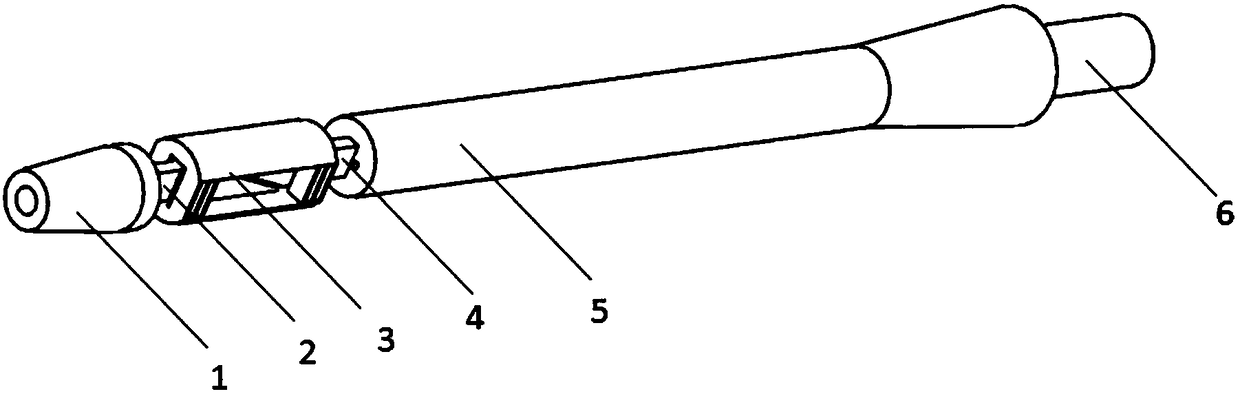

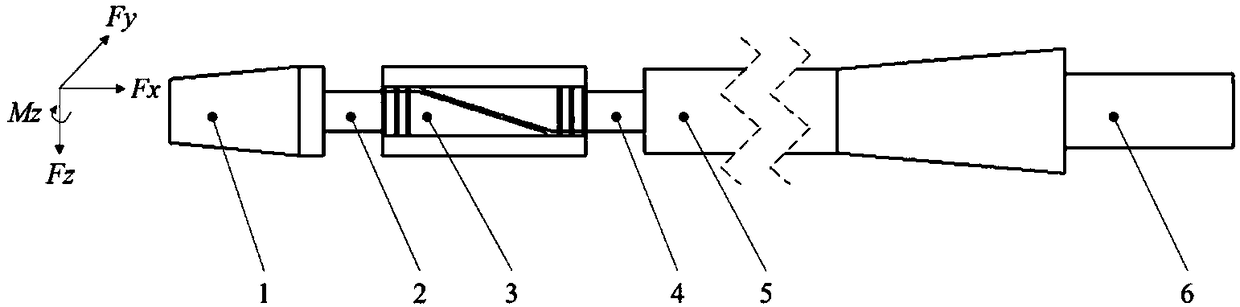

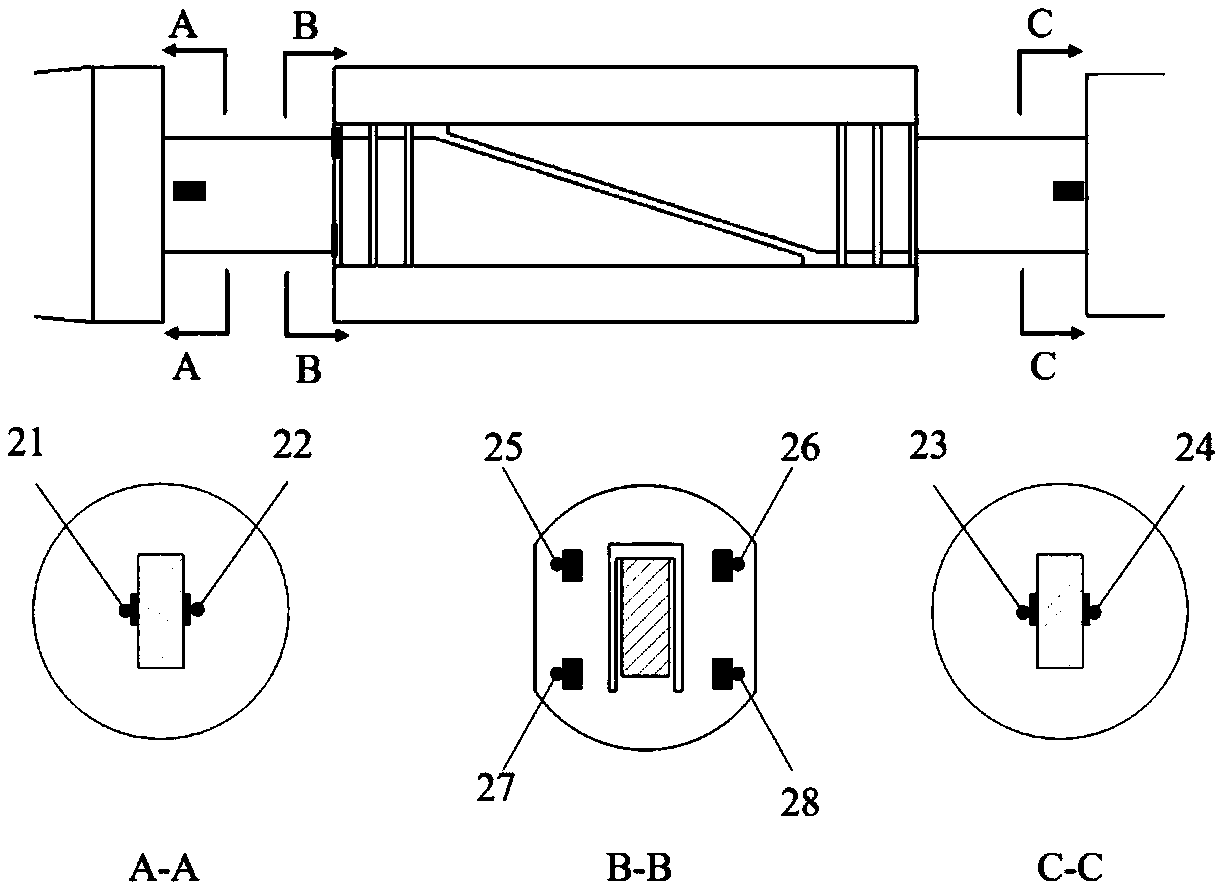

Output signal combination method for three-component optical fiber balance

The invention discloses an output signal combination method for a three-component optical fiber balance. The three-component optical fiber balance includes a model connecting end, a first single column beam, an axial force element, a second single column beam, a supporting rod and a bracket connecting end which are arranged in sequence. A measurement beam of the axial force element, the first single column beam and the second single column beam each are provided with an optical fiber strain gauge. The first single column beam and the second single column beam jointly form a normal force / pitchmoment combination element. A signal output value of a normal force component of the three-component optical fiber balance is the sum of an output value of the optical fiber strain gauge on the firstsingle column beam and an output value of the optical fiber strain gauge on the second single column beam; a signal output value of a pitch moment component of the three-component optical fiber balance is the sum of the output value of the optical fiber strain gauge on the first single column beam and the output value of the optical fiber strain gauge on the second single column beam; and a signaloutput value of an axial force component of the three-component optical fiber balance is an output value of the optical fiber strain gauge on the axial force element.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

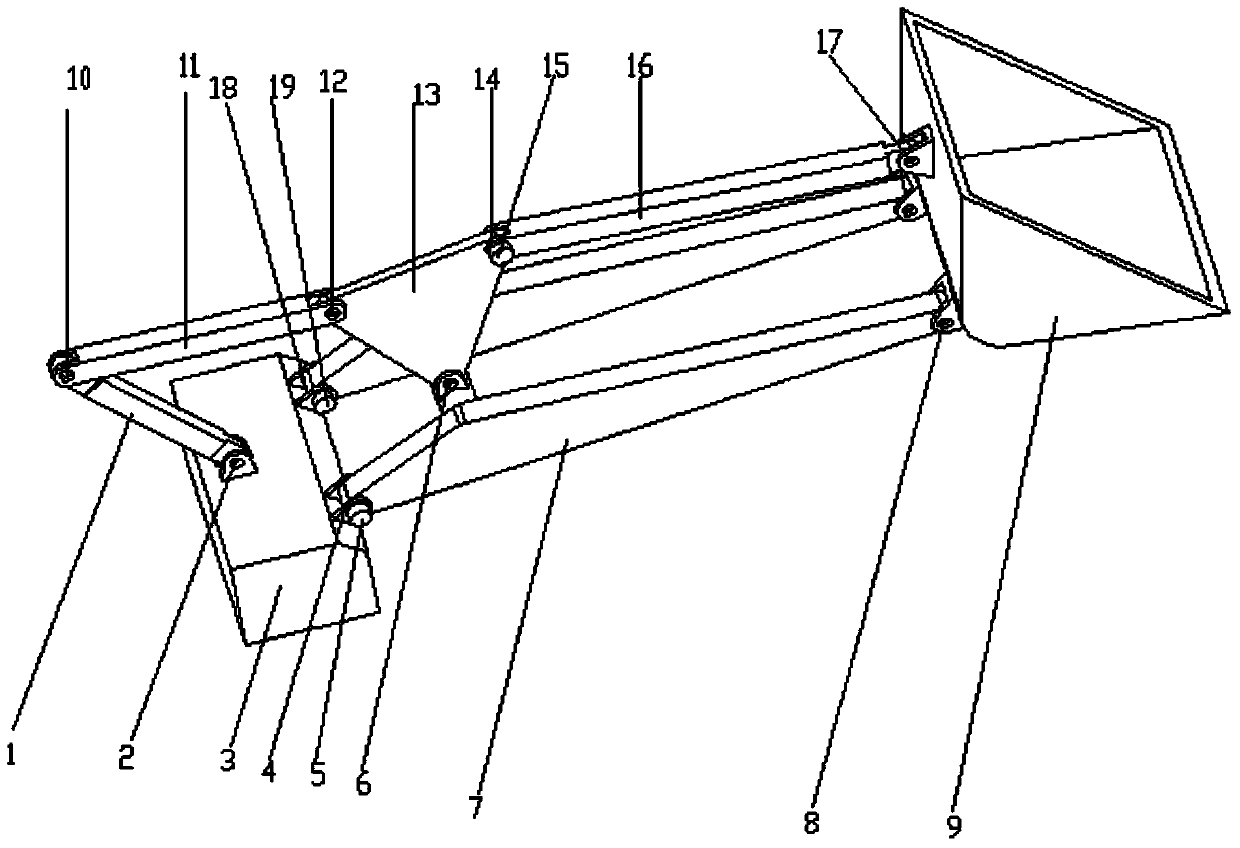

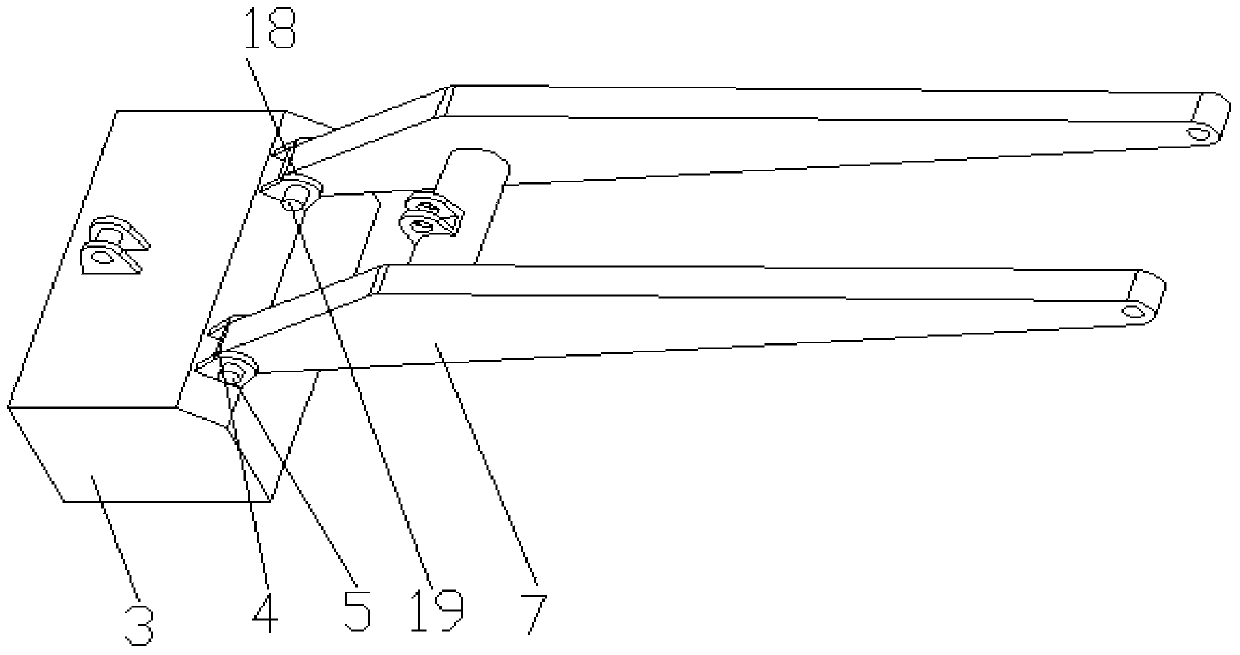

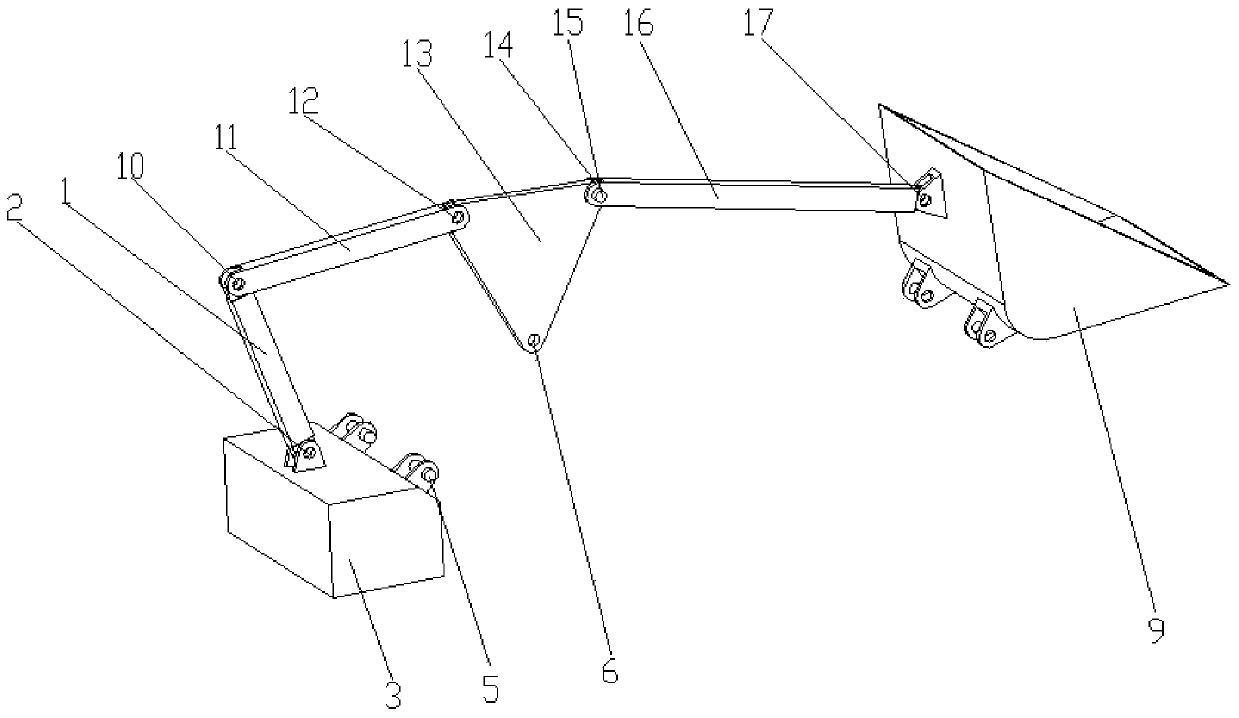

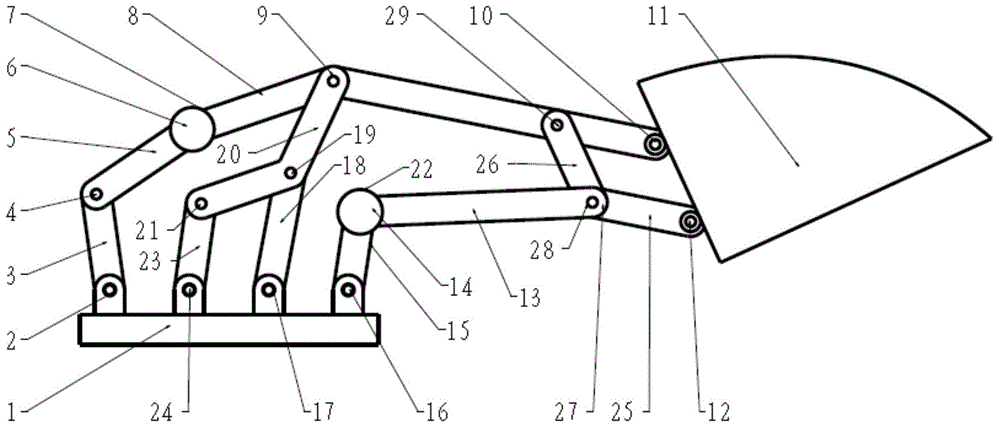

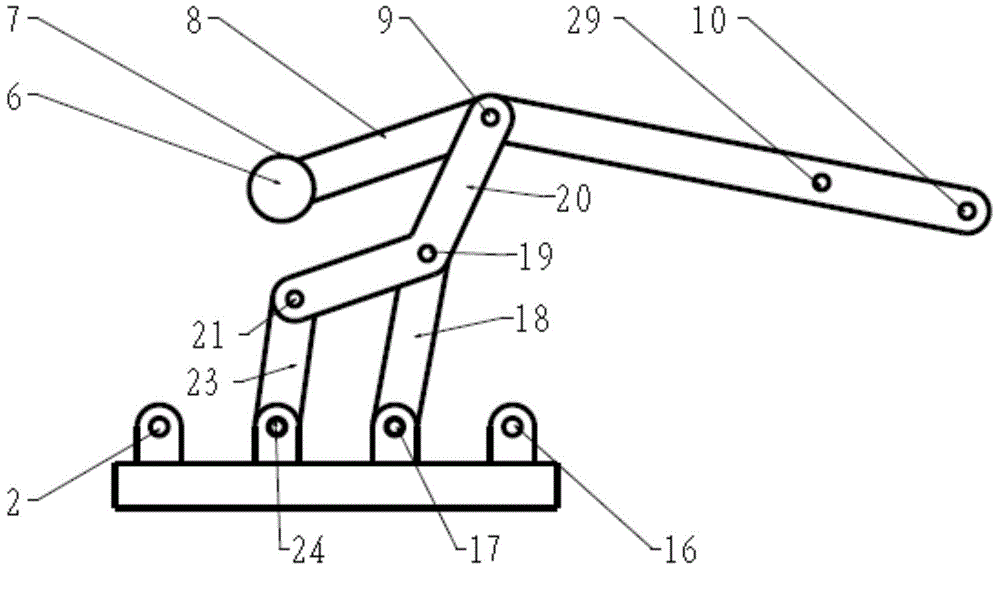

Simple multi-connecting-rod controllable loader with active metamorphic function

InactiveCN104047312ALess freedomReduce the amount usedMechanical machines/dredgersTwo degrees of freedomEngineering

The invention relates to a simple multi-connecting-rod controllable loader with the active metamorphic function. A big arm of the loader is connected to a rack; a lifting mechanism is composed of the big arm and the rack, and the big arm is connected to the rack; a bucket turnover mechanism is composed of a bucket and a turnover mechanism, the bucket is connected to the big arm, and the turnover mechanism is composed of a driving rod, a first connecting rod, a second connecting rod and a third connecting rod. One end of the driving rod is connected to the rack, the other end of the driving rod is connected with the first connecting rod, the other end of the first connecting rod is connected to the second connecting rod, the other two ends of the second connecting rod are connected with the big arm and the third connecting rod respectively, the other end of the third connecting rod is connected with the bucket, and a locking device is installed on a revolute pair. The simple multi-connecting-rod controllable loader overcomes the defects that a hydraulic loader is complex in hydraulic system, high in requirement for machining precision and prone to oil leakage, active metamorphic operation can be carried out according to different operation working conditions, loading operation with two degrees of freedom is achieved, and it is suitable for manufacturing various loaders and other engineering machines.

Owner:GUANGXI UNIV

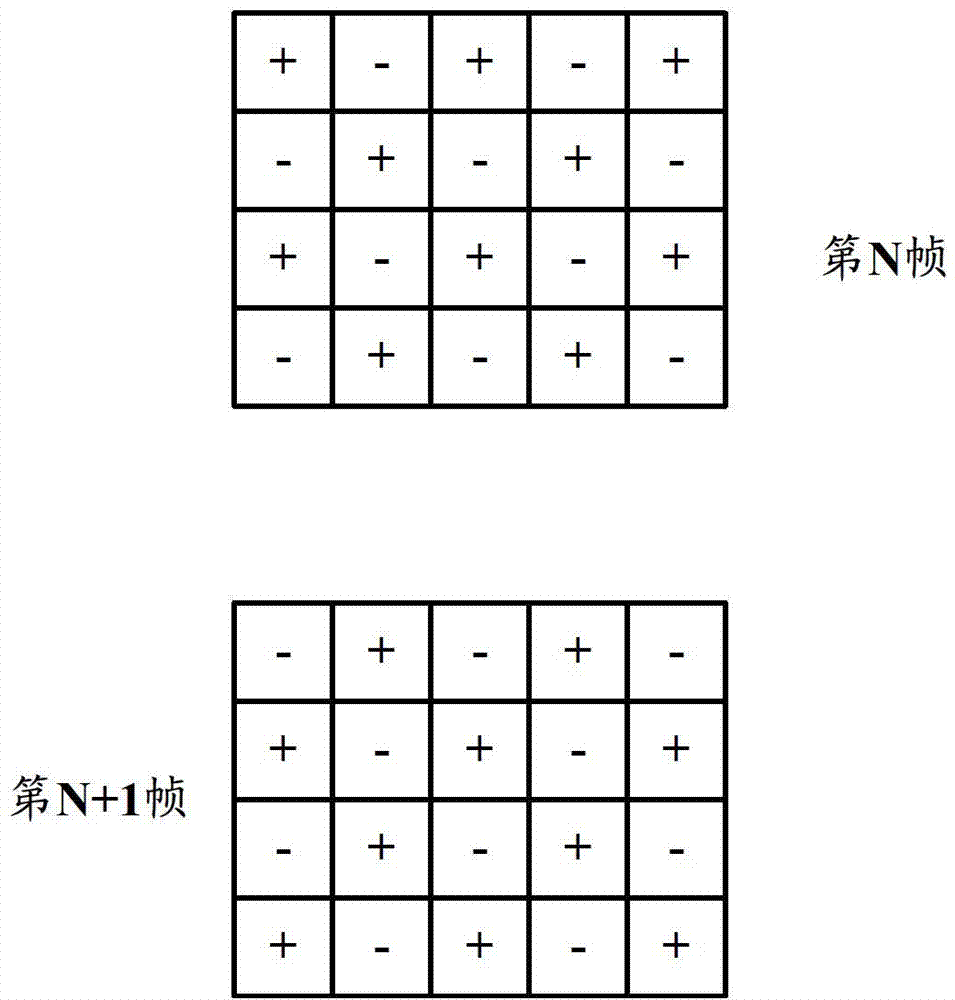

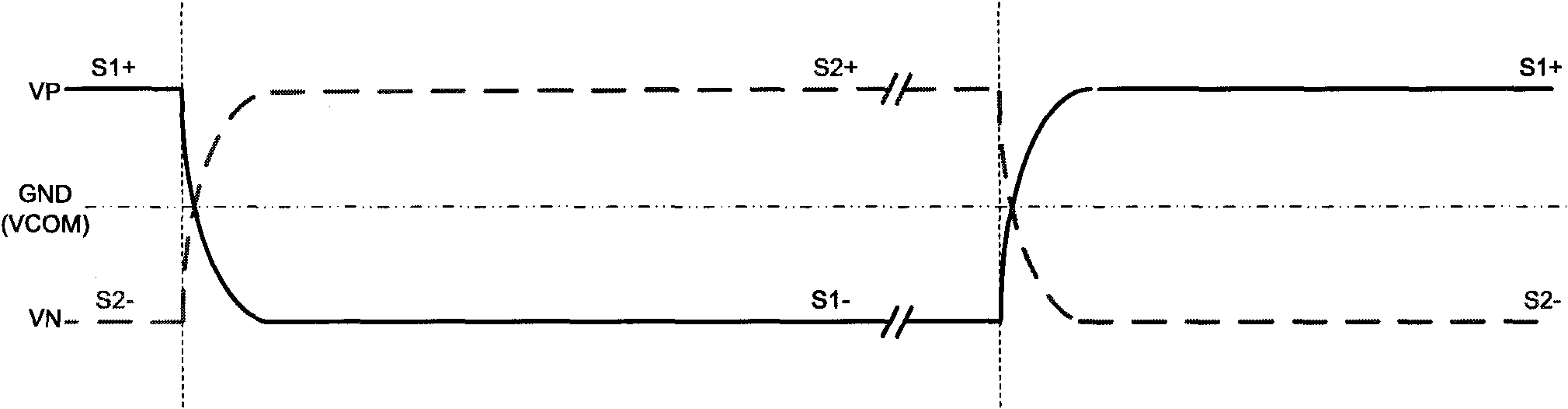

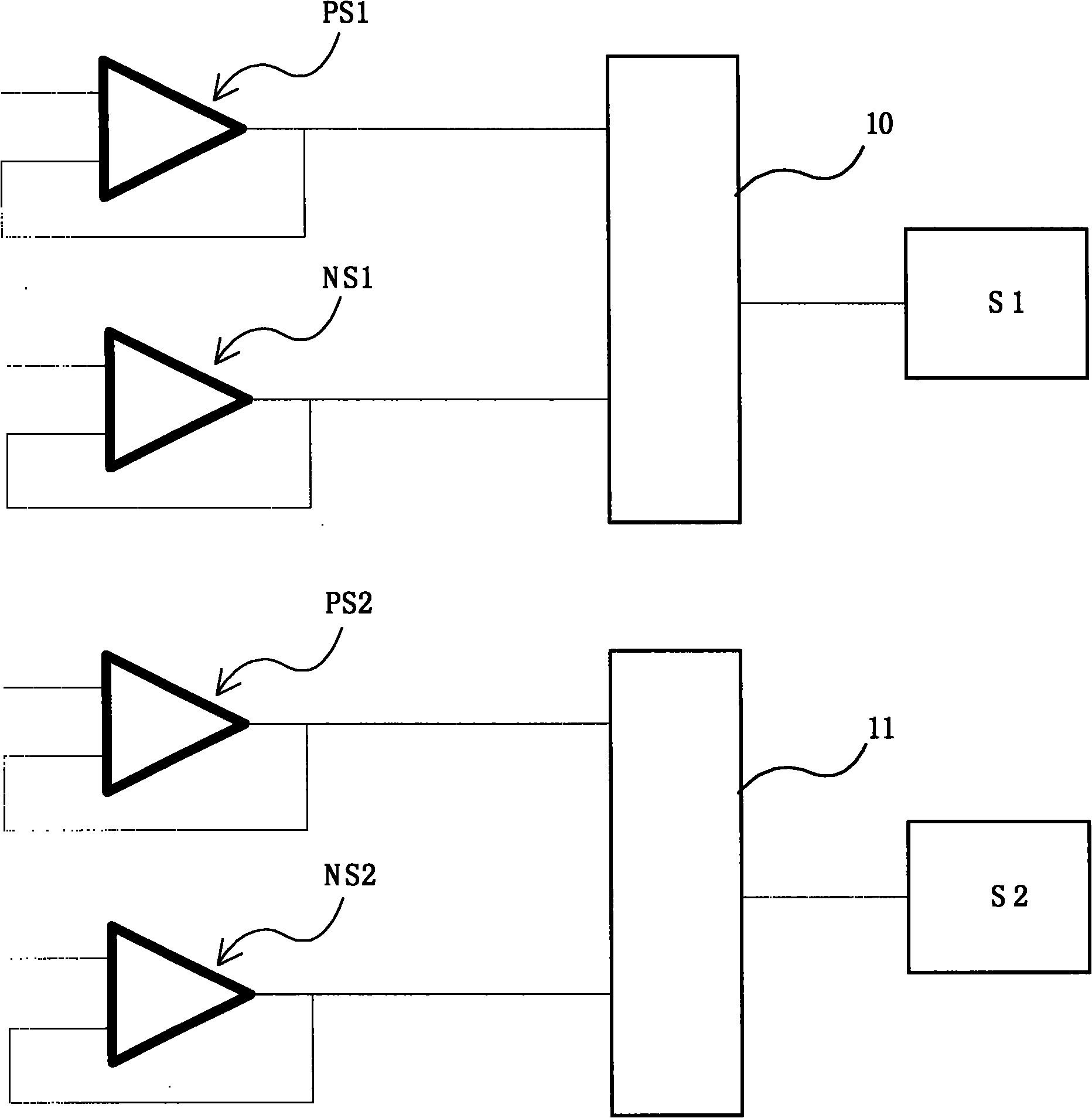

Liquid crystal point reversing drive circuit

InactiveCN101877216AReduce the amount usedReduced size and energy consumptionStatic indicating devicesLiquid crystalNegative voltage

The invention provides a liquid crystal point reversing drive circuit, comprising a positive signal source, a negative signal source, a first selection unit and a second selection unit, wherein, the positive signal source provides a first positive signal and a second positive signal; the negative signal source provides a first negative signal source and a second negative signal source; the first selection unit is connected with the positive signal source and the negative signal source and used for receiving the first positive signal of the positive signal source and the first negative signal of the negative signal source, and the unit is composed of low-voltage elements; the second selection unit is connected with the positive signal source and the negative signal source and used for receiving the second positive signal of the positive signal source and the second negative signal of the negative signal source, and the unit is composed of low-voltage elements; the first signal source is connected with the first selection unit to alternately output a first positive voltage and a first negative voltage; and the second signal source is connected with the second selection unit to alternately output a second positive voltage and a second negative voltage. The drive circuit forms output of the positive voltage and the negative voltage of two source electrodes by single positive signal source and single negative signal source, thus reducing the usage quantity of a computing amplifier.

Owner:SITRONIX TECH CORP

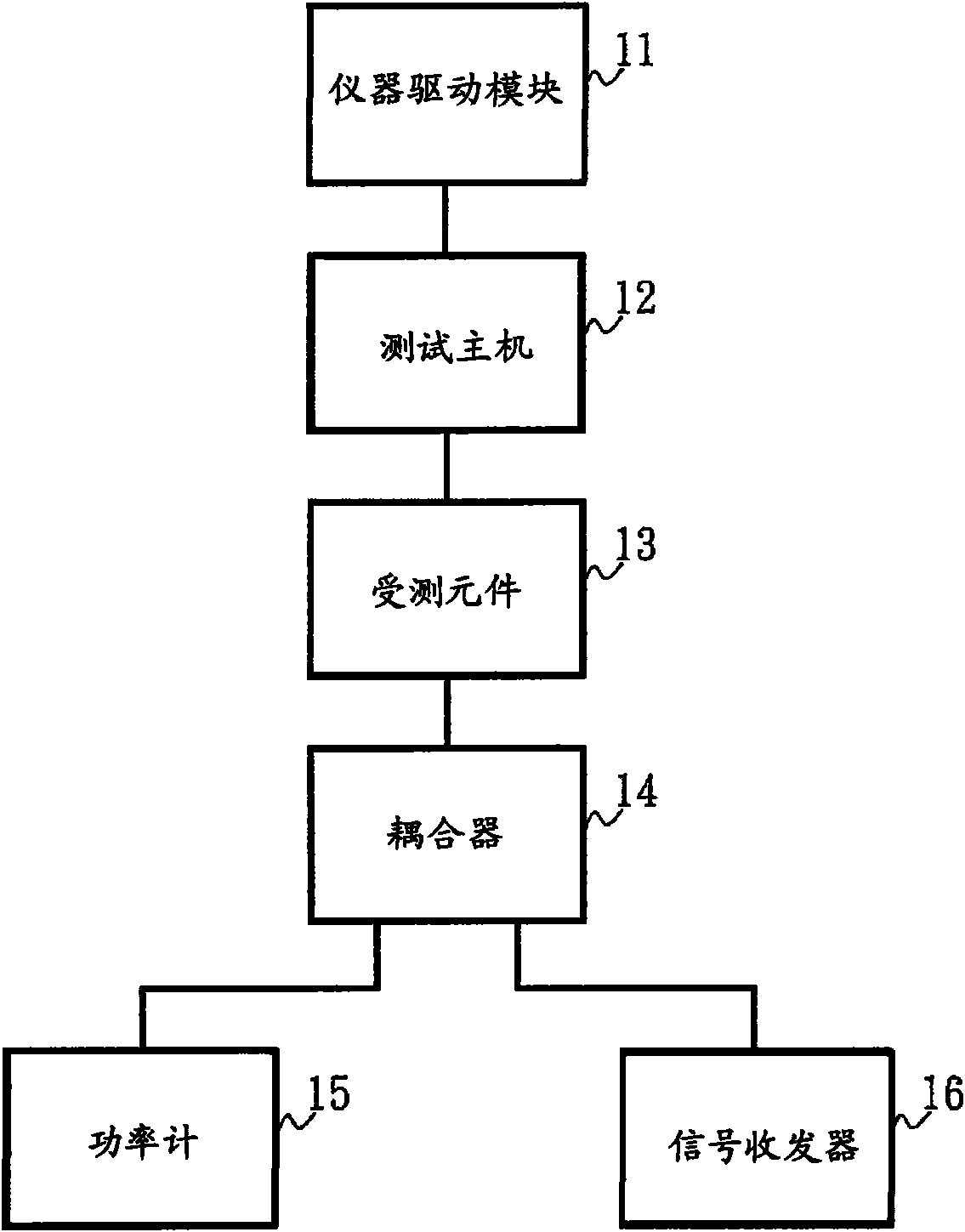

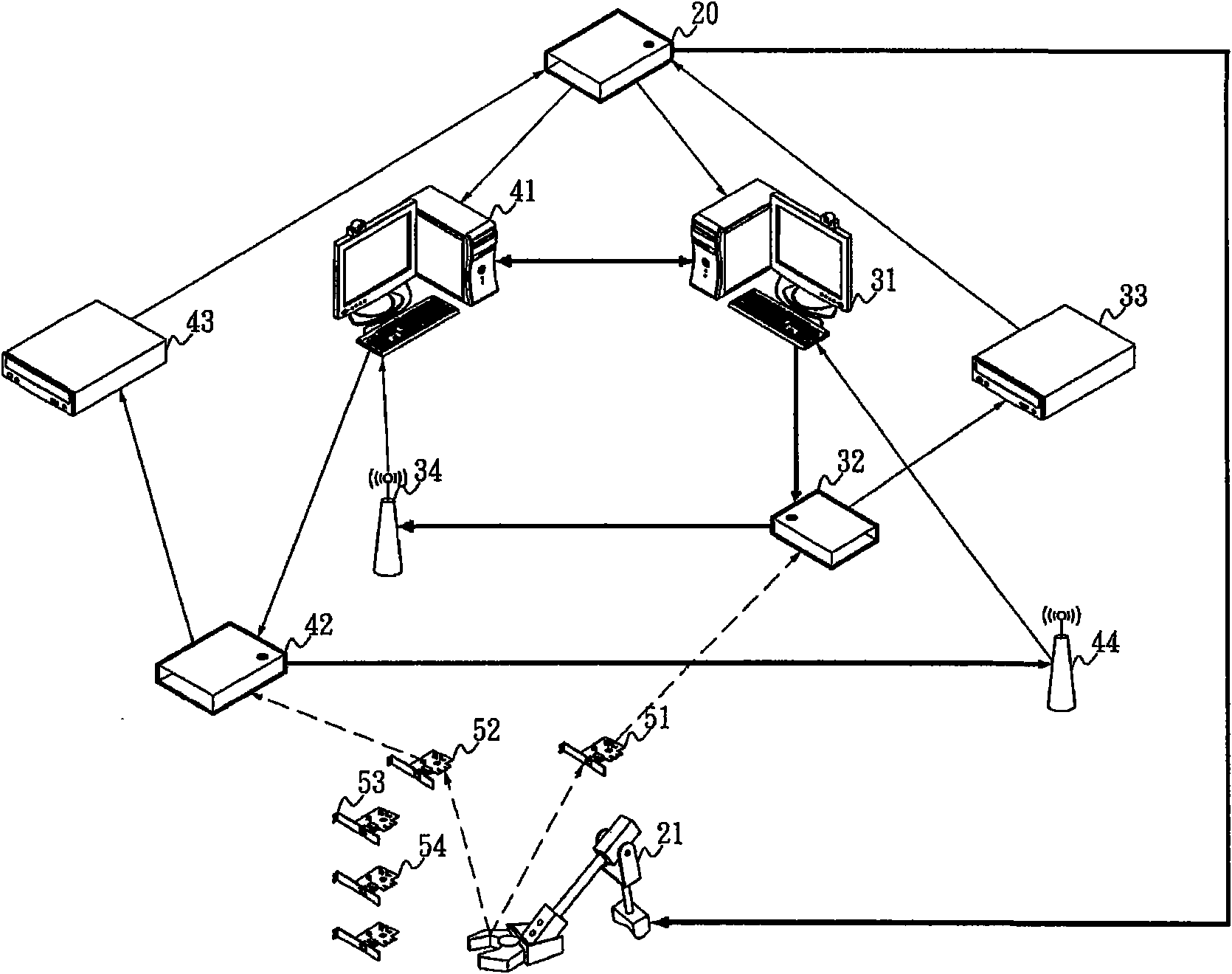

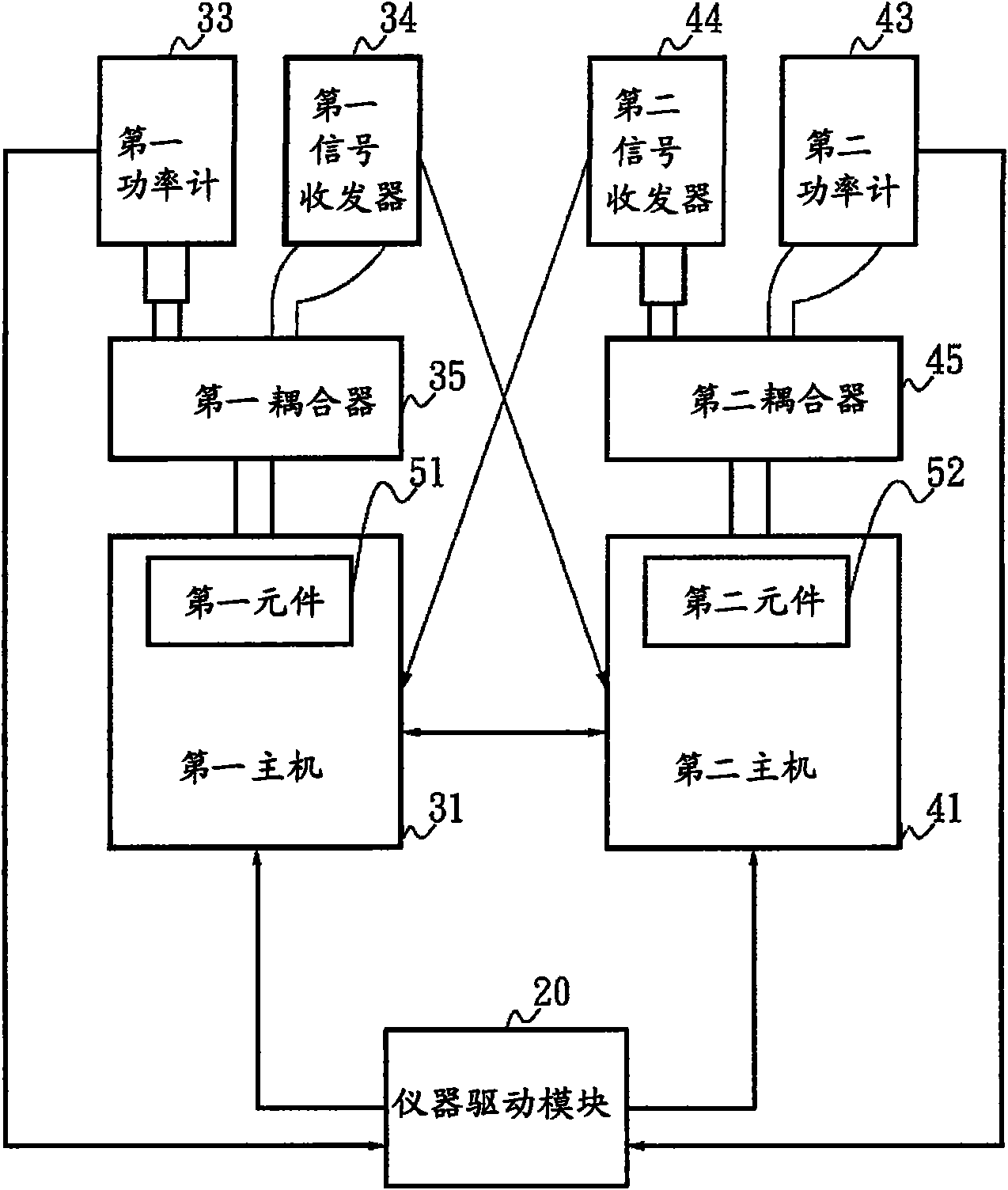

Element test system and method

InactiveCN101943731AReduce the amount usedReduce equipment costsElectronic circuit testingTransmission monitoringInstrumentationSoftware engineering

The invention relates to an element test system and an element test method. In the element test system, first equipment tests a first element when monitoring the first element is loaded; second test equipment detects a second element when monitoring the second element is loaded; an apparatus driving module controls a loading and unloading module to load a first element on the first test equipmentand controls the loading and unloading module to load the second element on the second test equipment when the first test equipment test the first element; and the time for loading the elements onto or unloading the elements from the first test equipment and the second equipment are staggered by controlling the loading and unloading module, so that the first equipment and the second equipment test the first element and the second element parallelly.

Owner:ACCTON TECHNOLOGY CORPORATION

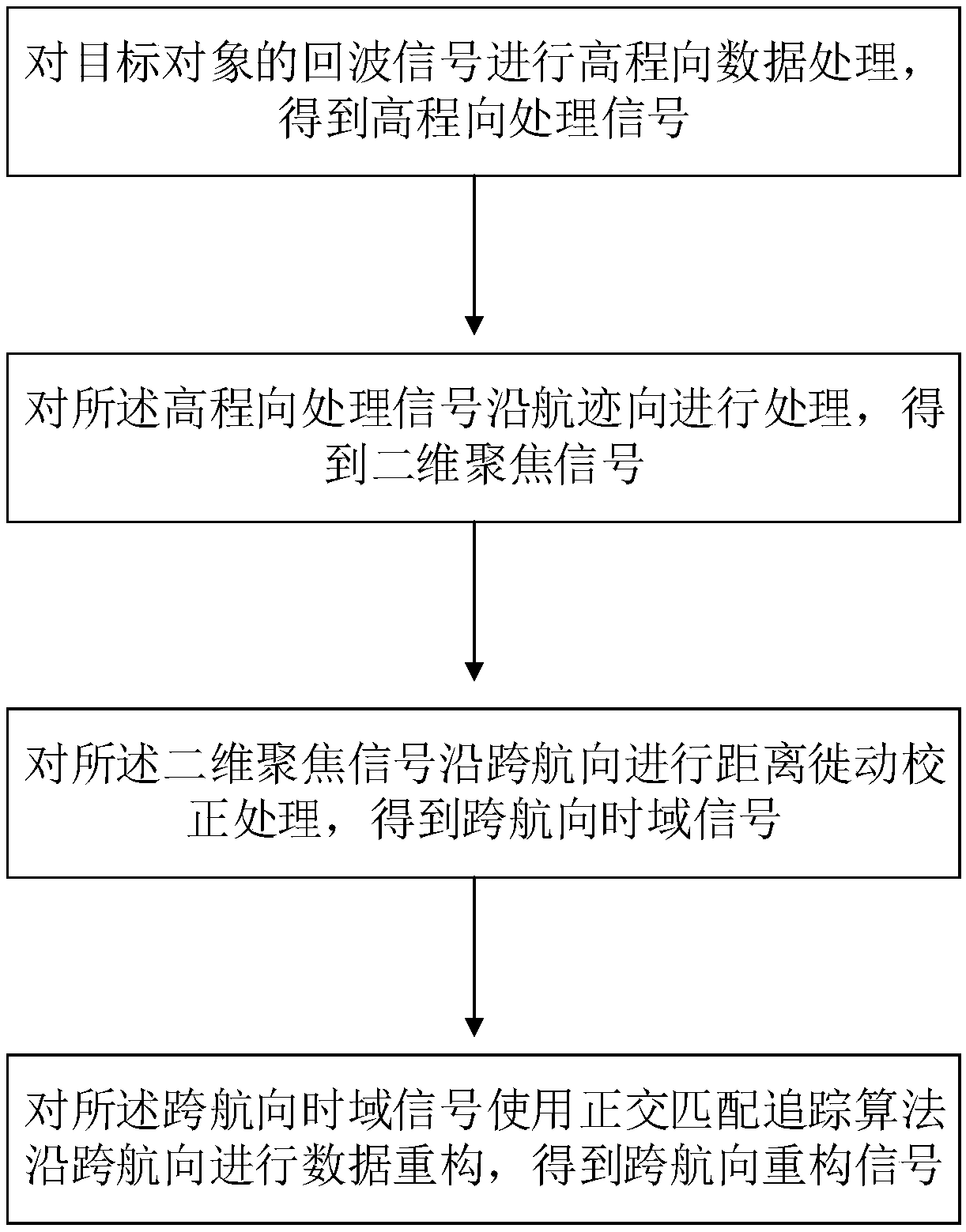

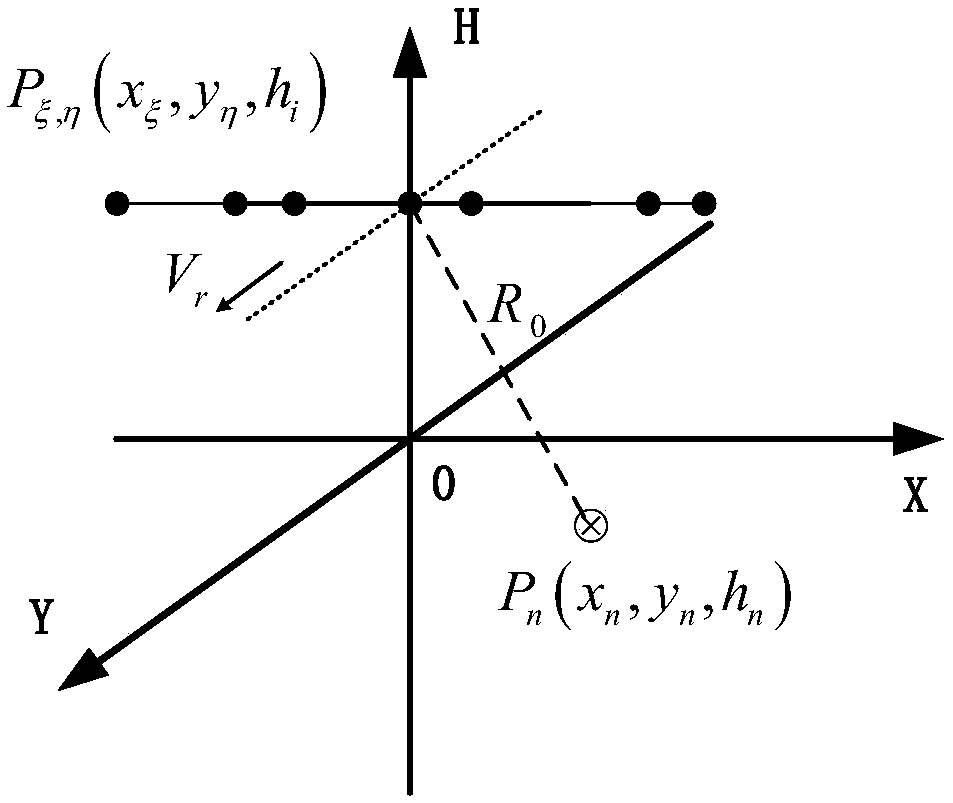

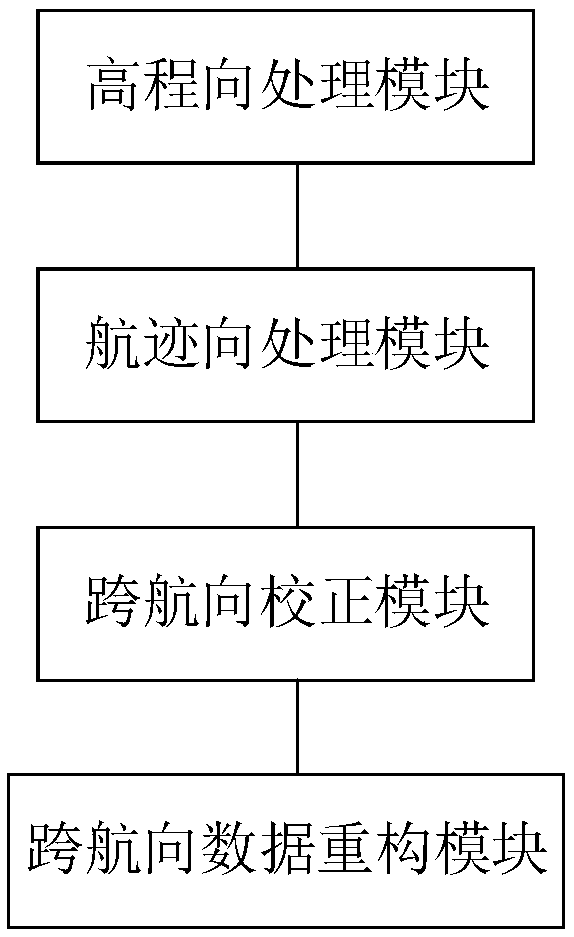

Sparse array-based imaging method and imaging device

ActiveCN109597075AReduce the amount usedLow costRadio wave reradiation/reflectionElevation dataEcho signal

Embodiments of the invention provide a sparse array-based imaging method and imaging device. The method comprises steps of performing elevation data processing on an echo signal of a target object soas to obtain an elevation processing signal; processing the elevation processing signal in a track direction so as to obtain a two-dimensional focus signal; performing distance migration correction processing on the two-dimensional focus signal in a transverse direction so as to obtain a transverse time domain signal; performing data reconstruction on the transverse time domain signal by using anorthogonal matching pursuit algorithm in the transverse direction so as to obtain a transverse reconstruction signal, and generating, based on the sparse array and using the transverse reconstructionsignal, a three-dimensional SAR image of the target object. Through adoption of the imaging method and imaging device, problems of a large number of array elements in a 3D-SAR array, highly complex system and high cost in the prior art are solved.

Owner:INNER MONGOLIA UNIV OF TECH

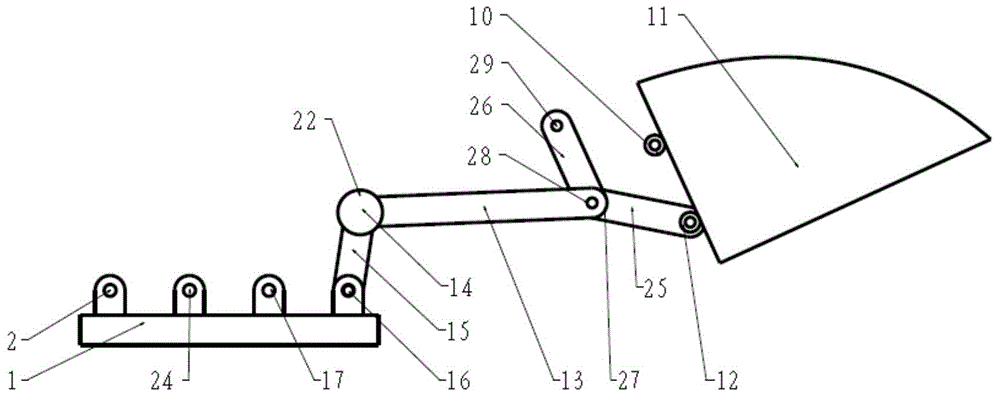

Multi-connecting-rod controllable excavation mechanism based on electromagnetic initiative metamorphism

InactiveCN104631524AReduce the amount usedLow costMechanical machines/dredgersMechanism basedMetamorphism

A multi-connecting-rod controllable excavation mechanism based on electromagnetic initiative metamorphism comprises a rack, a large arm swing mechanism, a bucket rod lifting mechanism, a bucket turnover mechanism and an electromagnetic locking device. The large arm swing mechanism comprises a large arm and a swing mechanism. The bucket rod lifting mechanism comprises a bucket rod and a lifting mechanism. The bucket turnover mechanism comprises a bucket and a turnover mechanism. The electromagnetic locking device is installed on a revolute pair, and an initiative metamorphism function can be achieved by electromagnetically locking the revolute pair. According to the excavation mechanism, a traditional hydraulic transmission mechanism is replaced by a connecting rod transmission mechanism, so the defects that a hydraulic system of a hydraulic excavator is complex and prone to oil leakage and the like are overcome. Due to the fact that the electromagnetic locking device is adopted in the revolute pair, initiative metamorphism can be achieved according to different operation working conditions, and the excavation mechanism not only has the flexibility of the hydraulic excavator, but also can achieve 3-DOF excavation operation by utilizing two initiative rods, lowers the manufacturing cost and is suitable for manufacturing various excavators and other engineering machinery.

Owner:GUANGXI UNIV

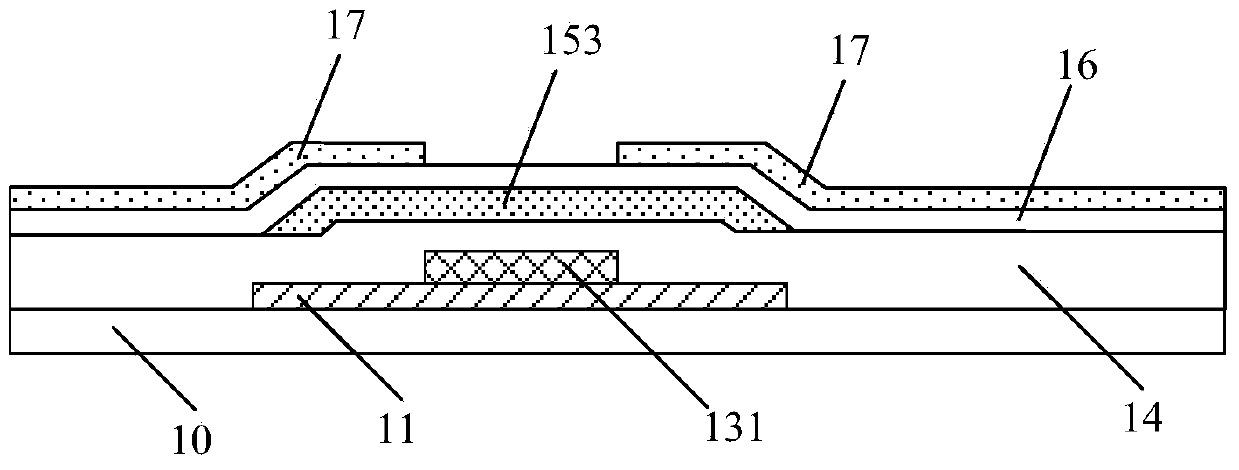

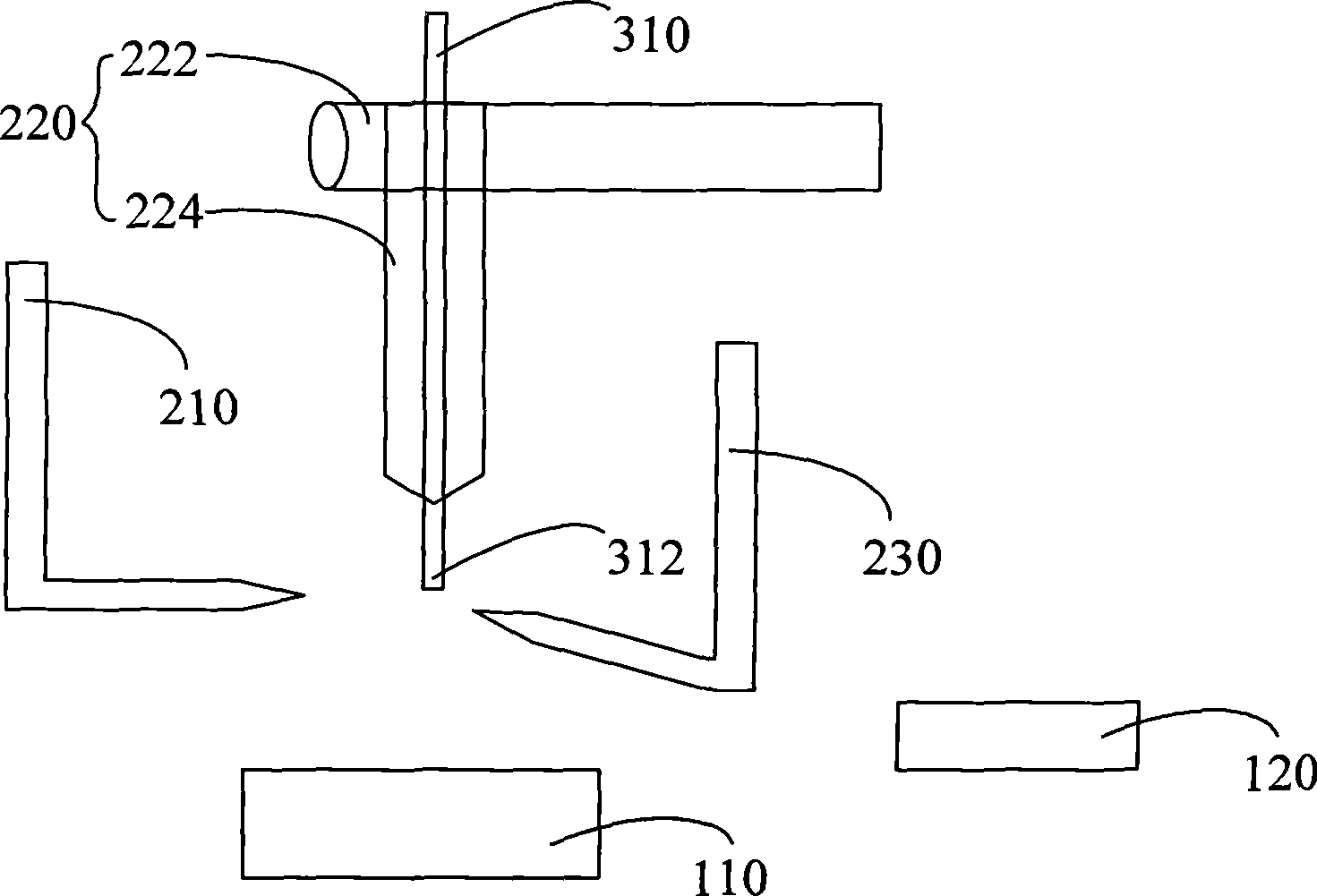

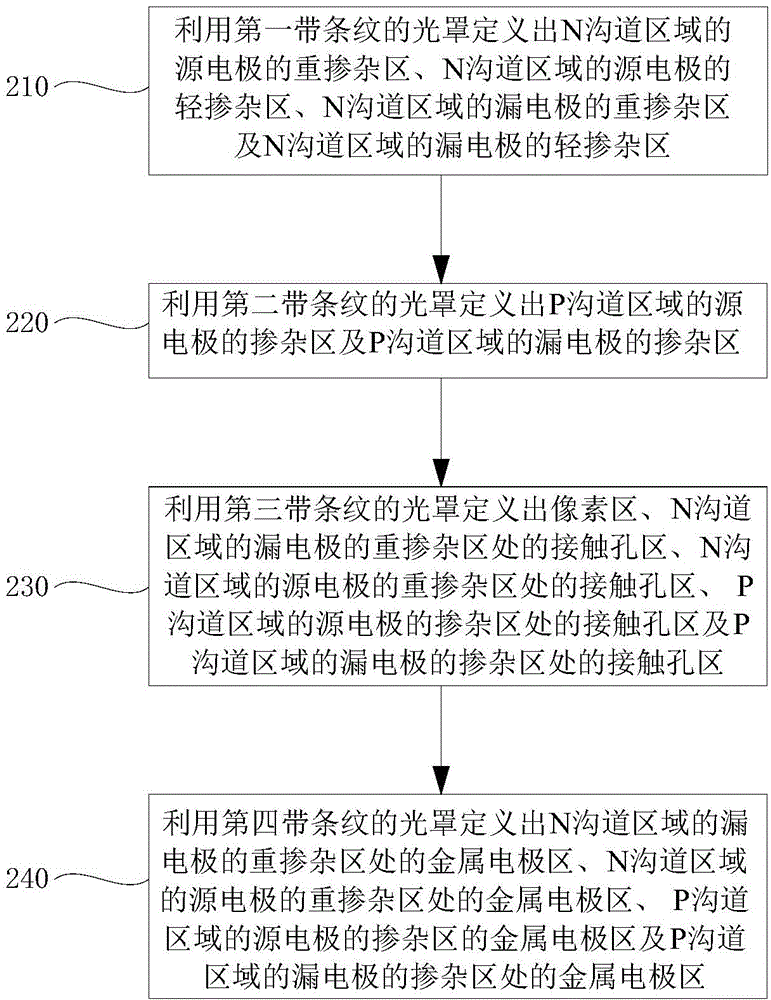

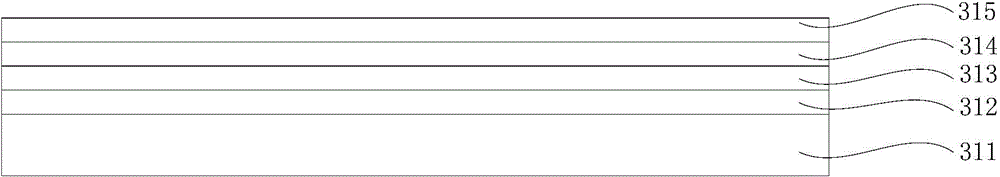

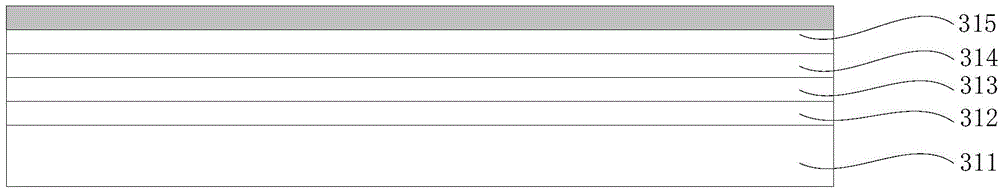

Manufacturing method of low-temperature polycrystalline silicon thin-film transistor array substrate

ActiveCN104701254AReduce the amount usedLow production costSolid-state devicesSemiconductor/solid-state device manufacturingN channelPhotomask

The invention discloses a manufacturing method of a low-temperature polycrystalline silicon thin-film transistor array substrate; the method comprises the step: (A) defining a heavily doped region (316a) and a lightly doped region (316b) of an N-channel source electrode, a heavily doped region (317a) and a lightly doped region (317b) of an N-channel drain electrode by means of a first striped photomask; (B) defining a doped region (318) of a P-channel source electrode and a doped region (319) of a P-channel drain electrode by means of a second striped photomask; (C) utilizing a third striped photomask to define a pixel region, a contact hole region at the heavily doped region (317a) of the N-channel source electrode and the heavily doped region (316a) of the source electrode and a contact hole region at the doped region (318) of the P-channel source electrode and the doped region (319) of the drain electrode; and (D), utilizing a fourth striped photomask to define a metal electrode region at the heavily doped region (317a) of the N-channel drain electrode and the heavily doped region (316a) of the source electrode, and a metal electrode region at the doped region (318) of the P-channel source electrode and the doped region (319) of the drain electrode.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com