Display panel, production method thereof and display device

A technology for a display panel and a manufacturing method, which is applied to the manufacturing of semiconductor/solid-state devices, instruments, semiconductor devices, etc., can solve the problems of increasing the manufacturing cost of the display panel, increasing the number of masks used and processes, etc., so as to reduce the manufacturing cost and reduce the The effect of using the quantity and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

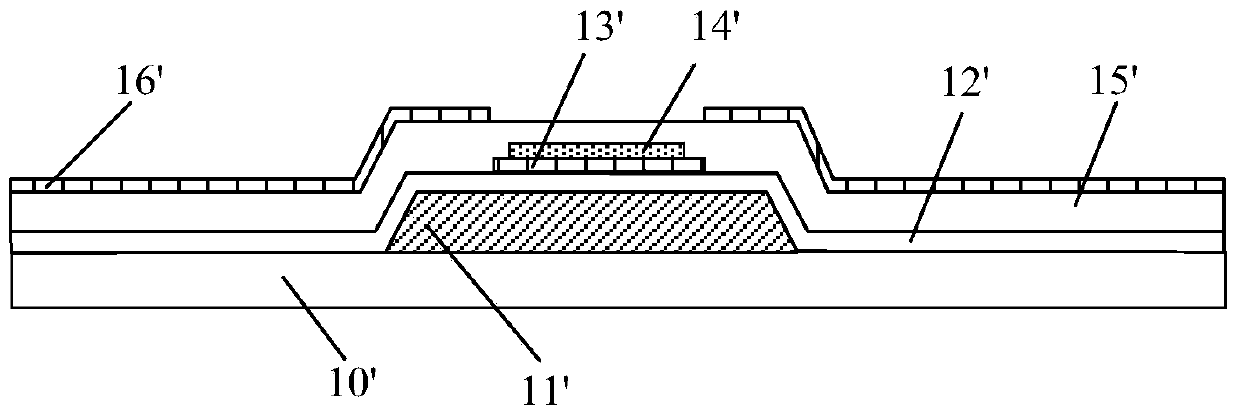

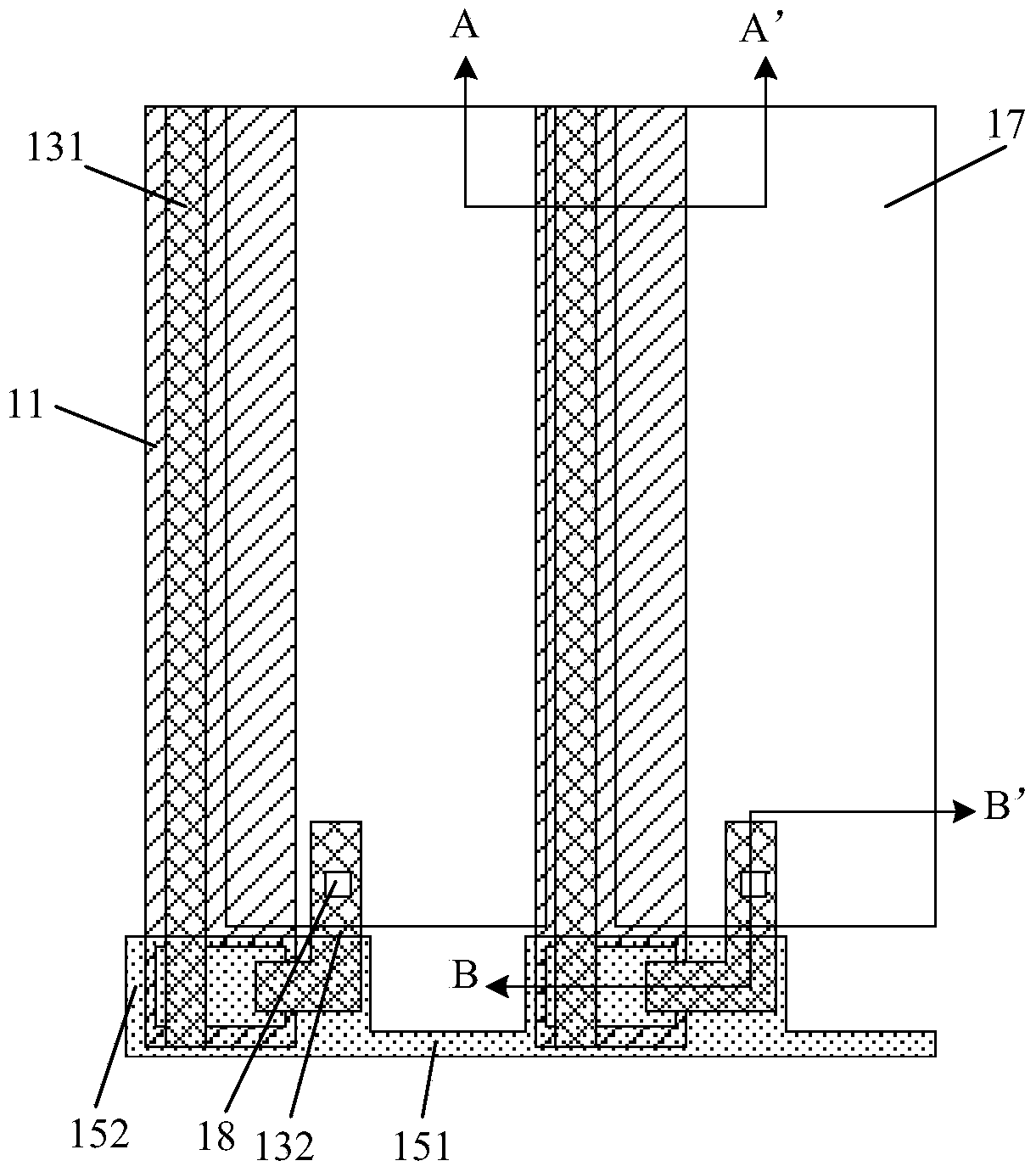

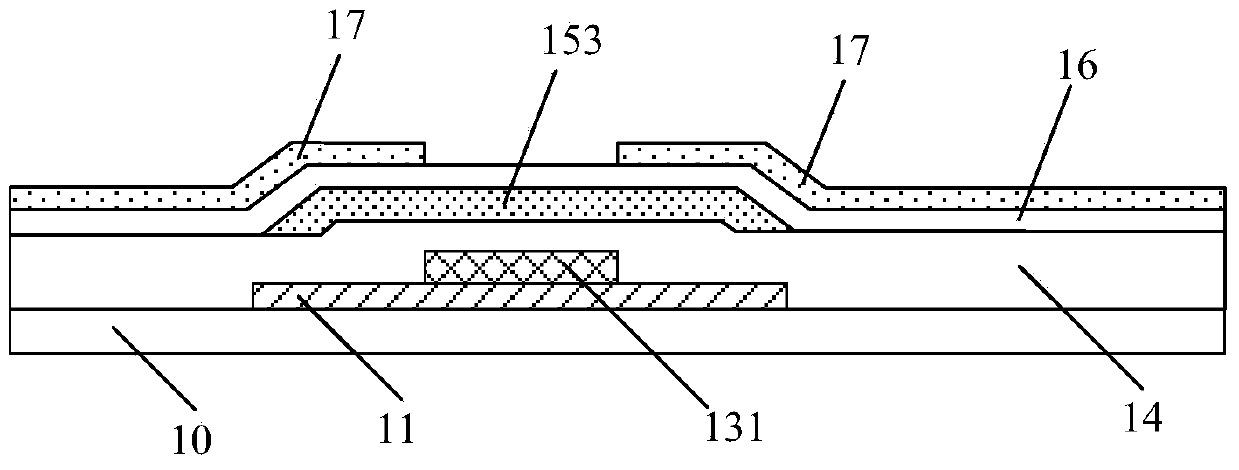

[0065] The embodiment of the present invention provides a display panel, which can reduce the manufacturing cost of the display panel on the premise of eliminating the crosstalk phenomenon. The display panel provided by the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0066] The display panel includes an array substrate, such as figure 2 , image 3 with Figure 4 As shown, the array substrate includes a plurality of film layers sequentially formed on the first base substrate 10, wherein the data line 131 and the drain electrode 132 are located in the same film layer, and the gate line 151, the gate electrode 152 and the first common electrode 153 are located in the same film layer. In the same film layer, the film layer where the gate line 151, the gate electrode 152 and the first common electrode 153 are located is located between the film layer where the data line 131 and the drain electrode 132 are located...

Embodiment 2

[0086] In order to prepare a display panel with the above structure, an embodiment of the present invention also provides a method for manufacturing a display panel, such as Figure 7 As shown, the manufacturing method of the display panel includes the following steps:

[0087] Step S701, forming a first metal layer on the substrate, and forming a pattern including a data line and a drain electrode through a patterning process.

[0088] First, the first metal layer is formed on the substrate by sputtering or thermal evaporation. Generally, the first metal layer is deposited by using metals such as Cr, W, Ti, Ta, Mo, Al, Cu, and their alloys. The thickness of a metal layer is

[0089] Then, coat photoresist on the first metal layer, use a mask with patterns including data lines 131 and drain electrodes 132 to cover the first metal layer coated with photoresist, and go through exposure, development, etching, etc. After the step, a pattern including the data line 131 and the drain ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com