Optical fiber microelectronic pressure sensor for mechanical system and multiplexing structure thereof

A micro-electromechanical and system pressure technology, which is applied in the direction of force measurement by measuring the change of optical properties of materials when they are stressed, can solve problems such as the influence of sensor output sensitivity, the inability to achieve distributed pressure measurement, etc., to avoid residual pressure. Stress instability, high speed, and simple detection of the effect of the optical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

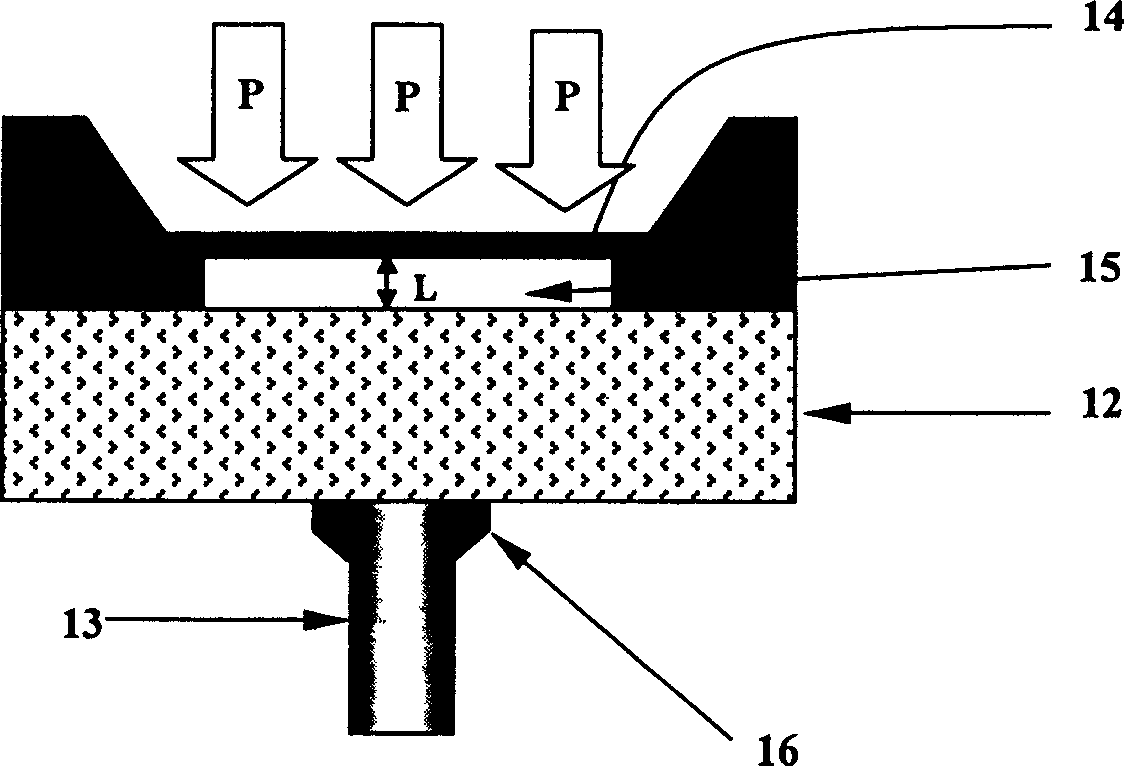

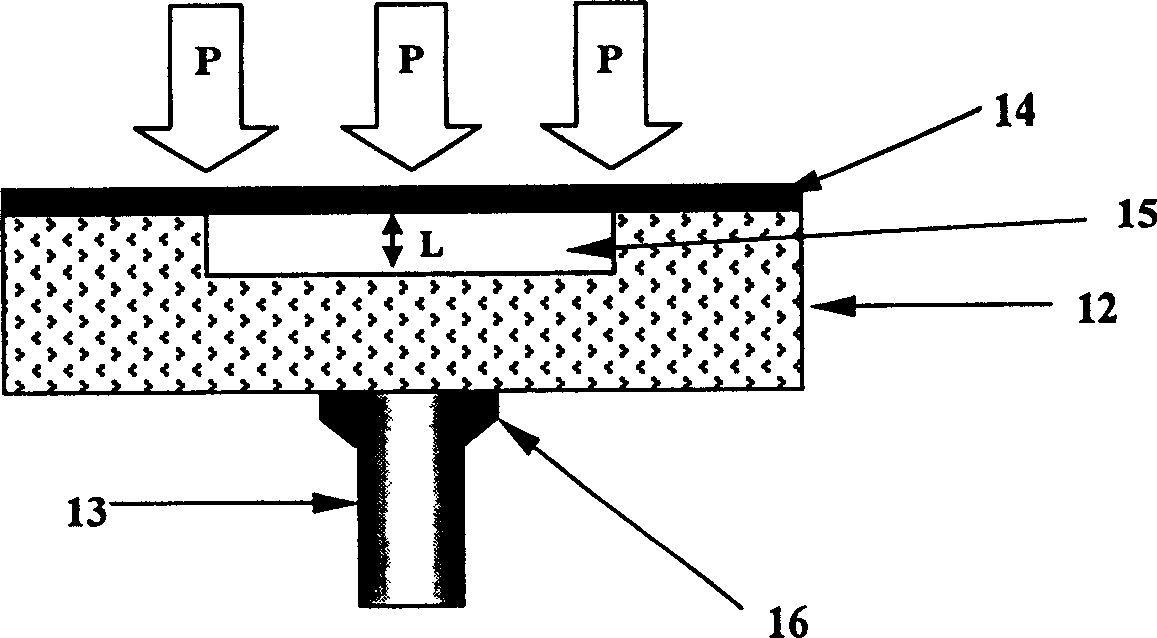

[0041] Since the borosilicate glass 12 and the single crystal silicon film 14 are bonded together by a vacuum anodic bonding process, the internal air pressure of the Fabry-Perot chamber is approximately equal to the ambient air pressure in the vacuum anodic bonding chamber, so it can be used as an absolute Reference pressure for the pressure sensor.

[0042] The light of wavelength λ is coupled into the Fabry-Perot cavity through the optical fiber, and the light is reflected back and forth on the upper surface of the borosilicate glass and the lower surface of the single crystal silicon film to form multi-beam interference. When the single crystal silicon film 14 is under pressure, it will Bending occurs so that the cavity length L of the Fabry-Perot cavity becomes L′. According to the multi-beam interference principle of the Fabry-Perot cavity, for light with a wavelength of λ, the interference light intensity will change, resulting in a wavelength The reflectivity of λ ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com