Patents

Literature

234 results about "Mems pressure sensor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

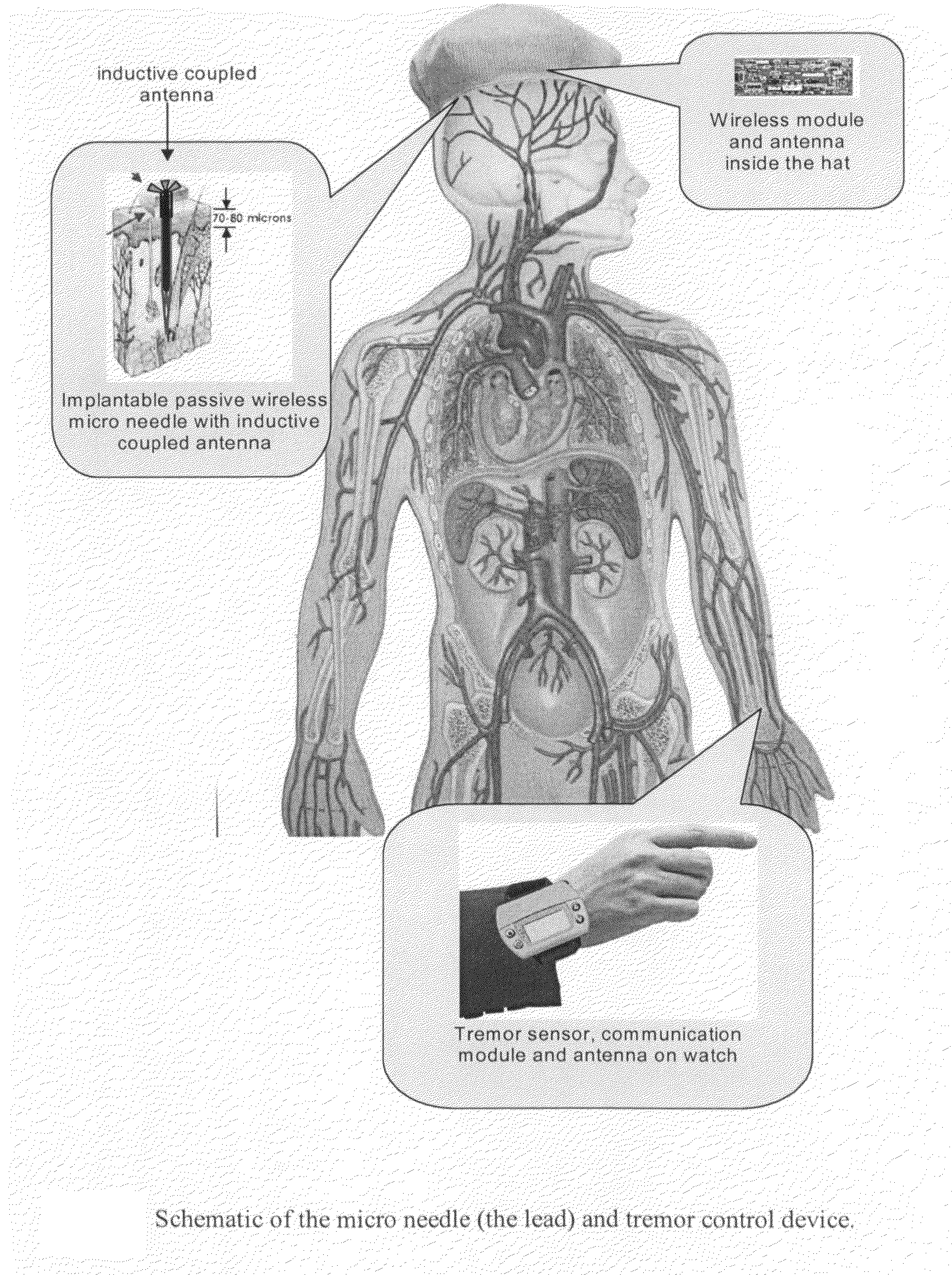

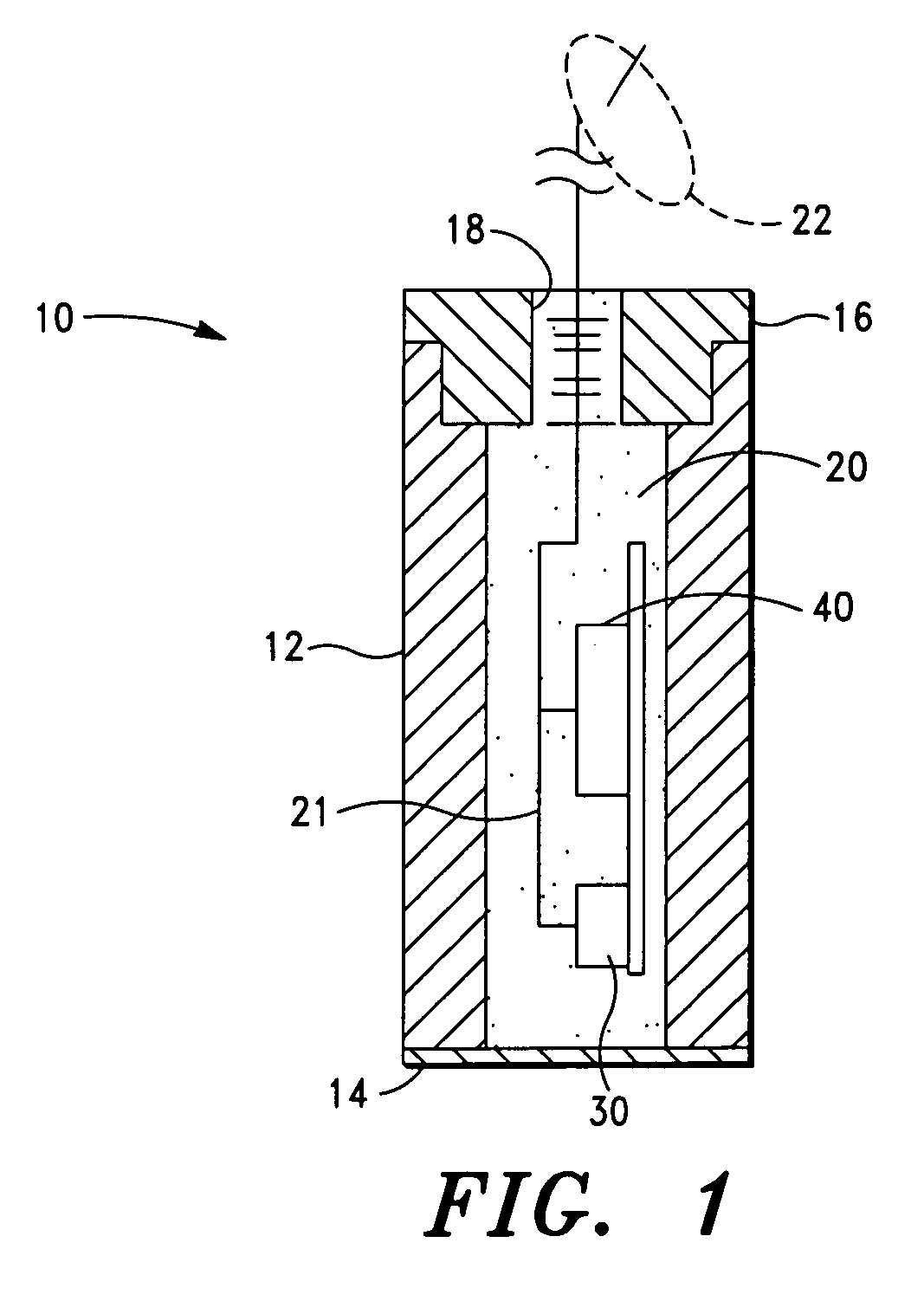

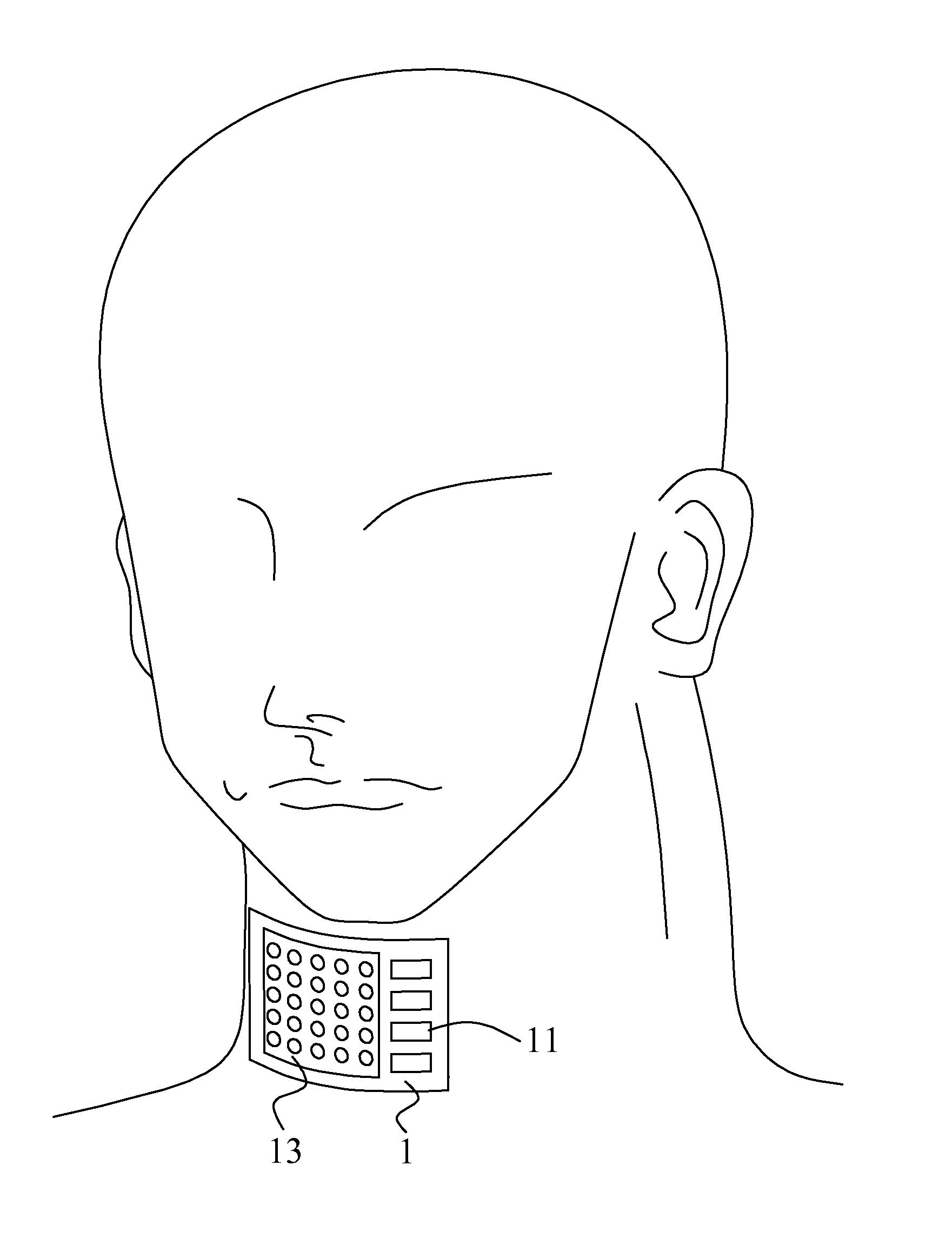

Method and device for treatment of medical conditions and monitoring physical movements

InactiveUS20060212097A1Accurate monitoringEffectively wirelessly transmit dataMaterial nanotechnologyElectrotherapyAccelerometerGyroscope

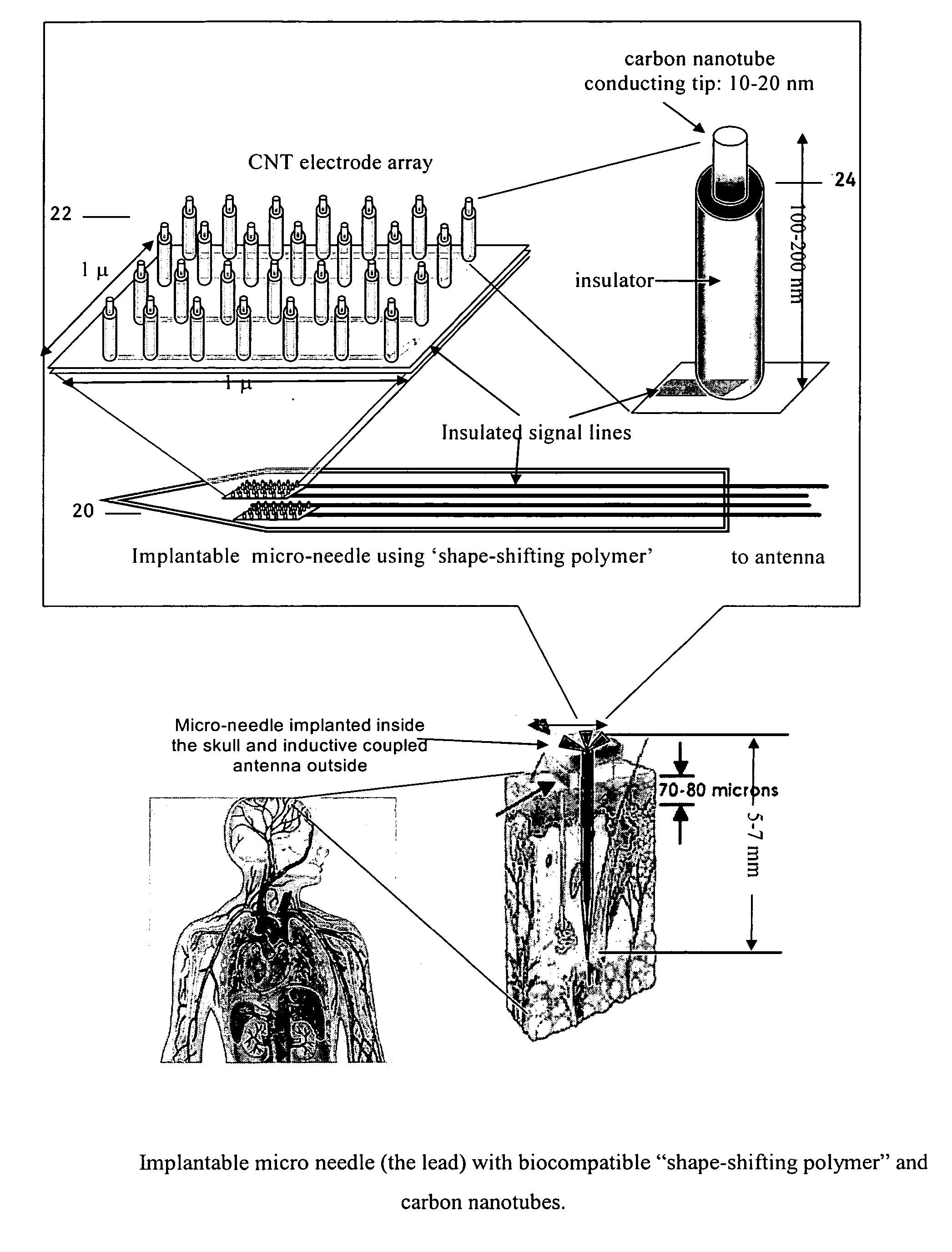

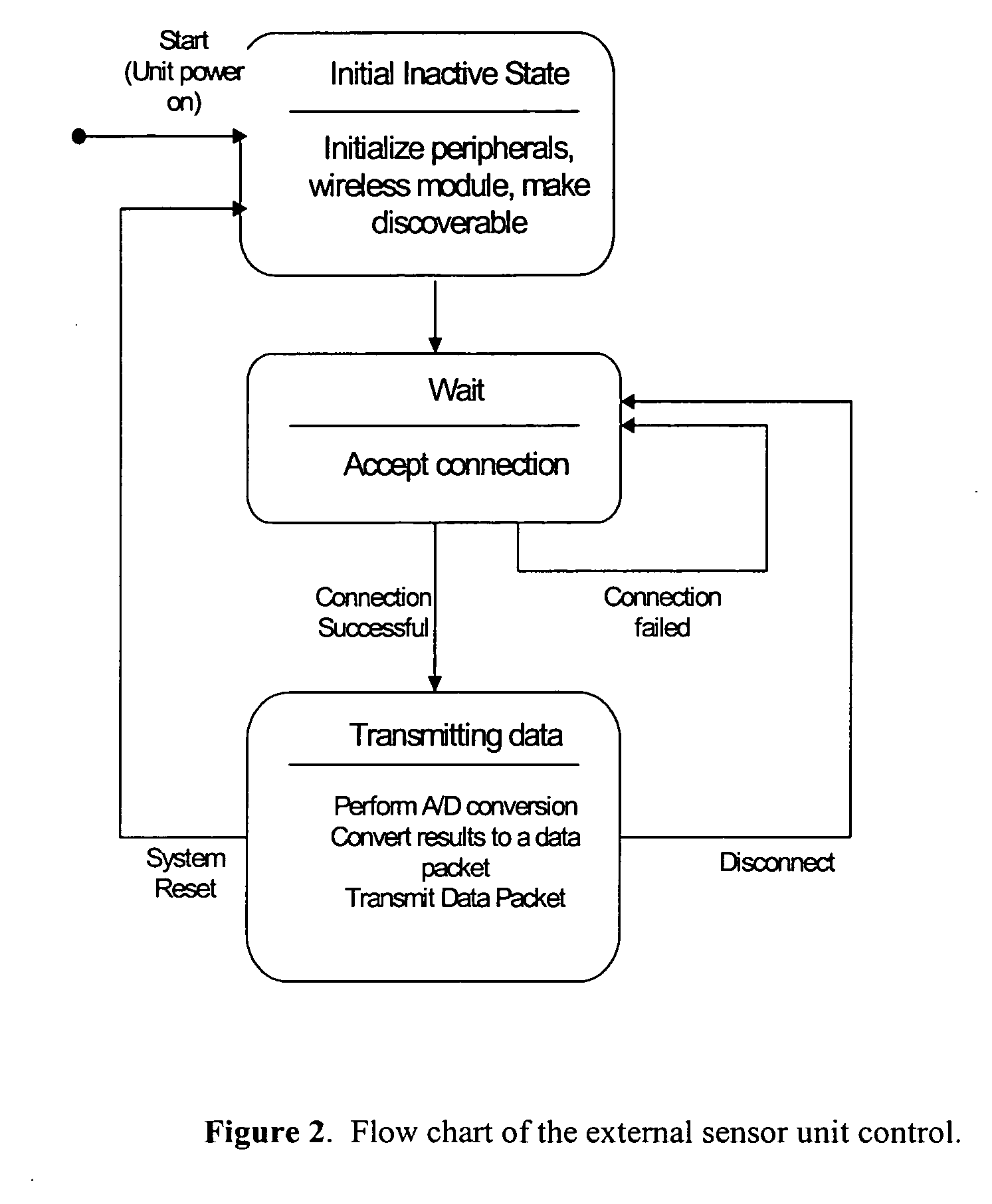

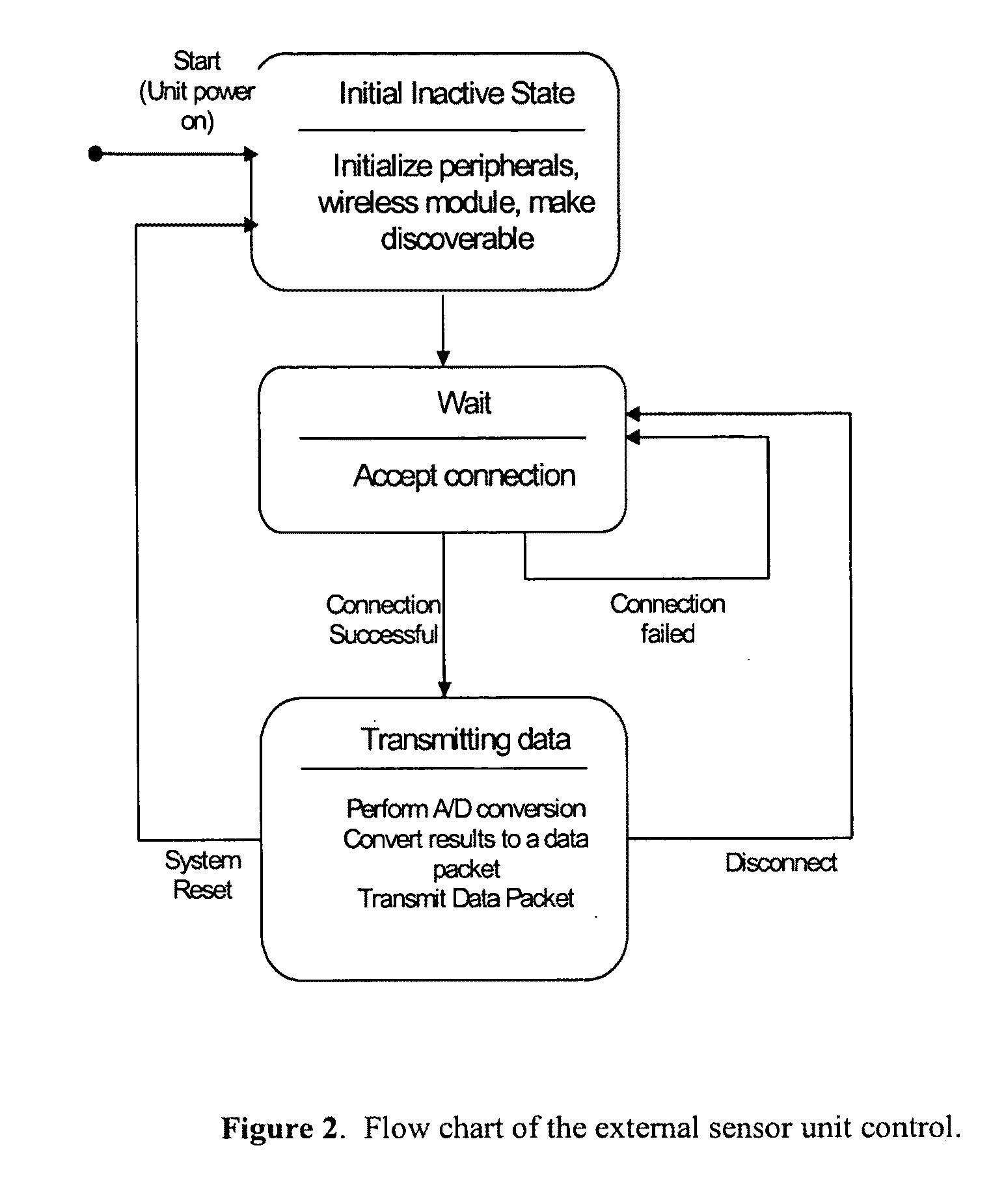

The subject invention utilizes MEMS devices and wireless data transmission means to monitor and sense certain patient conditions or reactions, such as changes in pressure, patient movements, and tremors. These sensor devices include but are not limited to MEMS gyroscopes, MEMS accelerometers, and MEMS pressure sensors. The data from the sensor means is then preferably wirelessly transmitted to a second MEMS device to treat or alter the medical condition that has been monitored.

Owner:PENN STATE RES FOUND

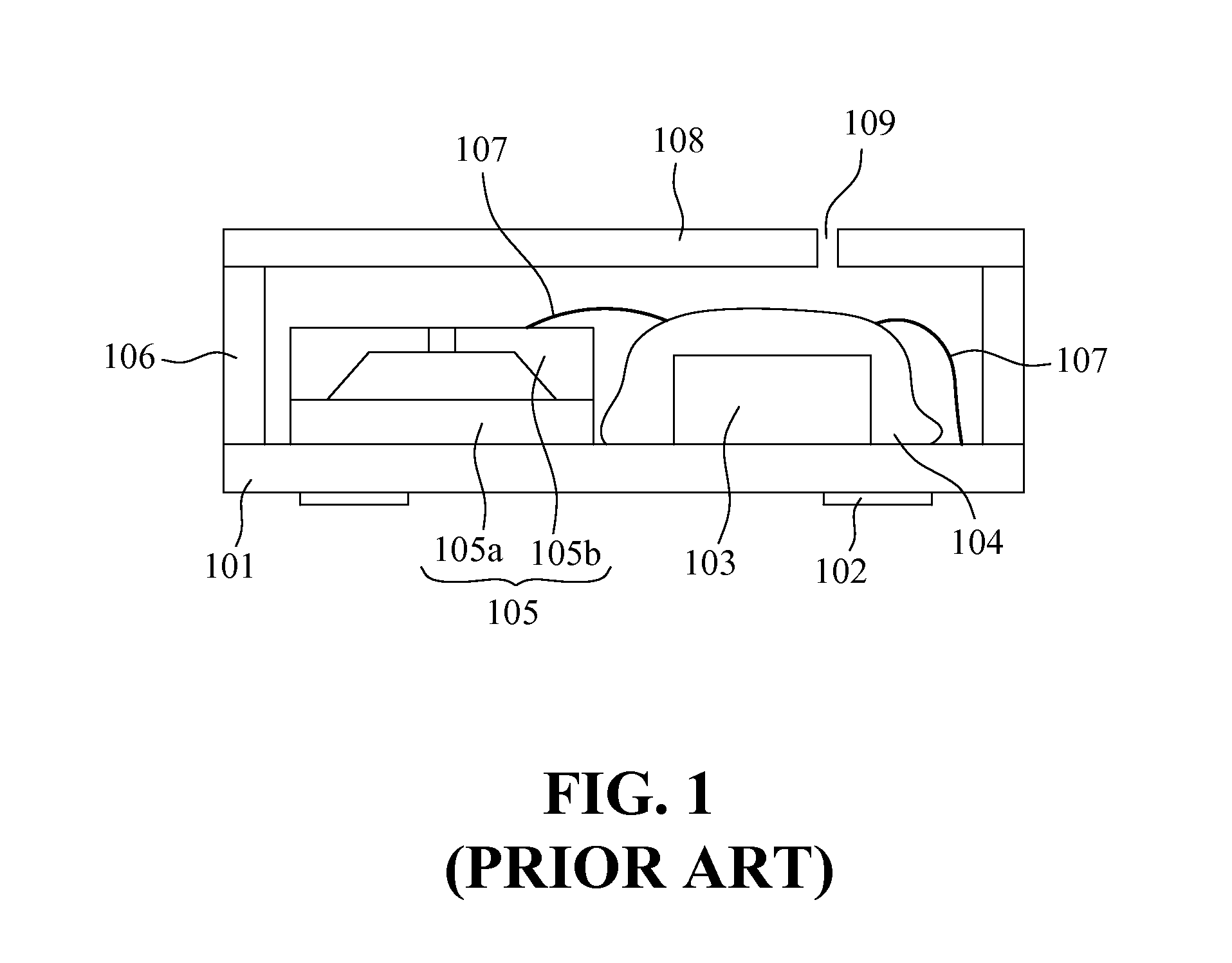

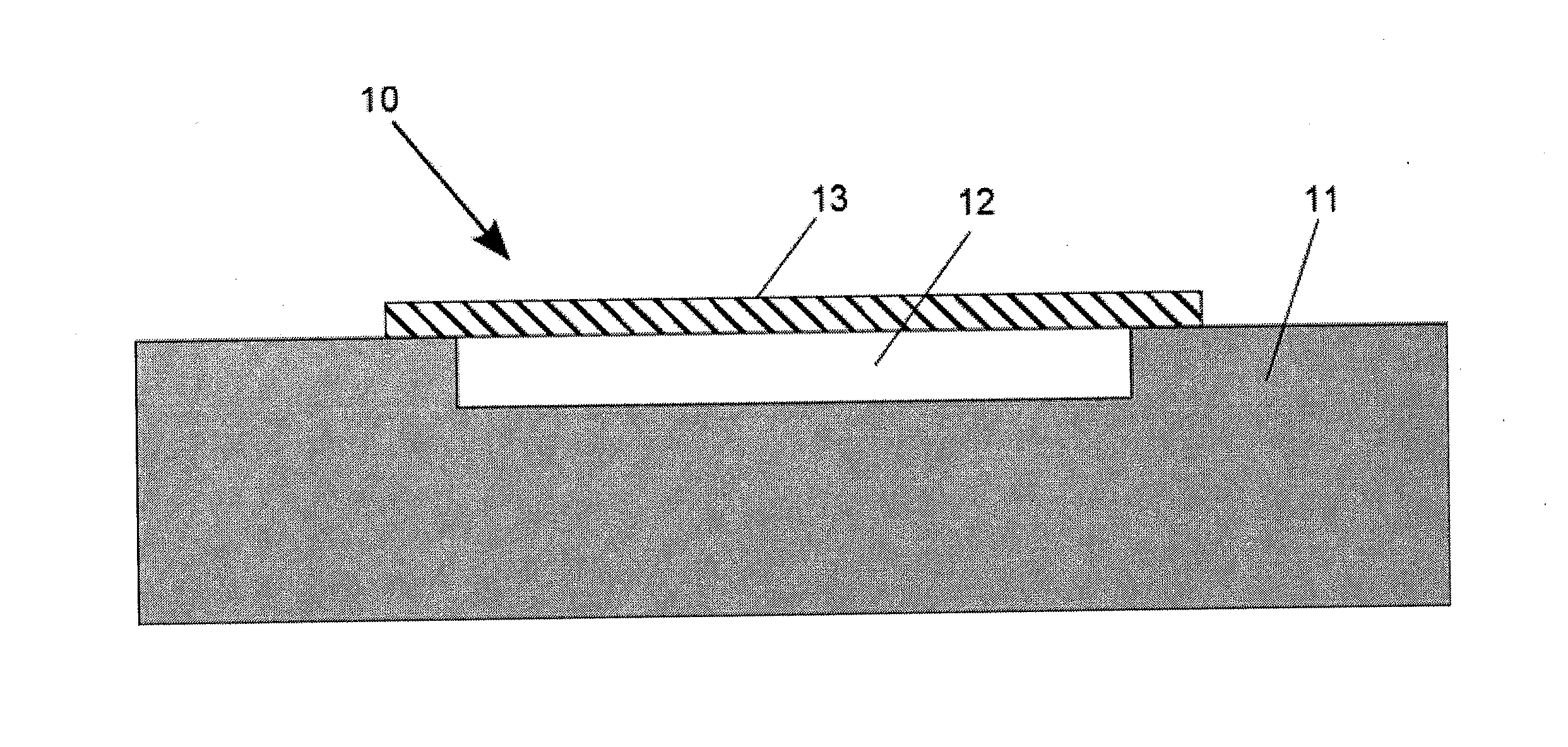

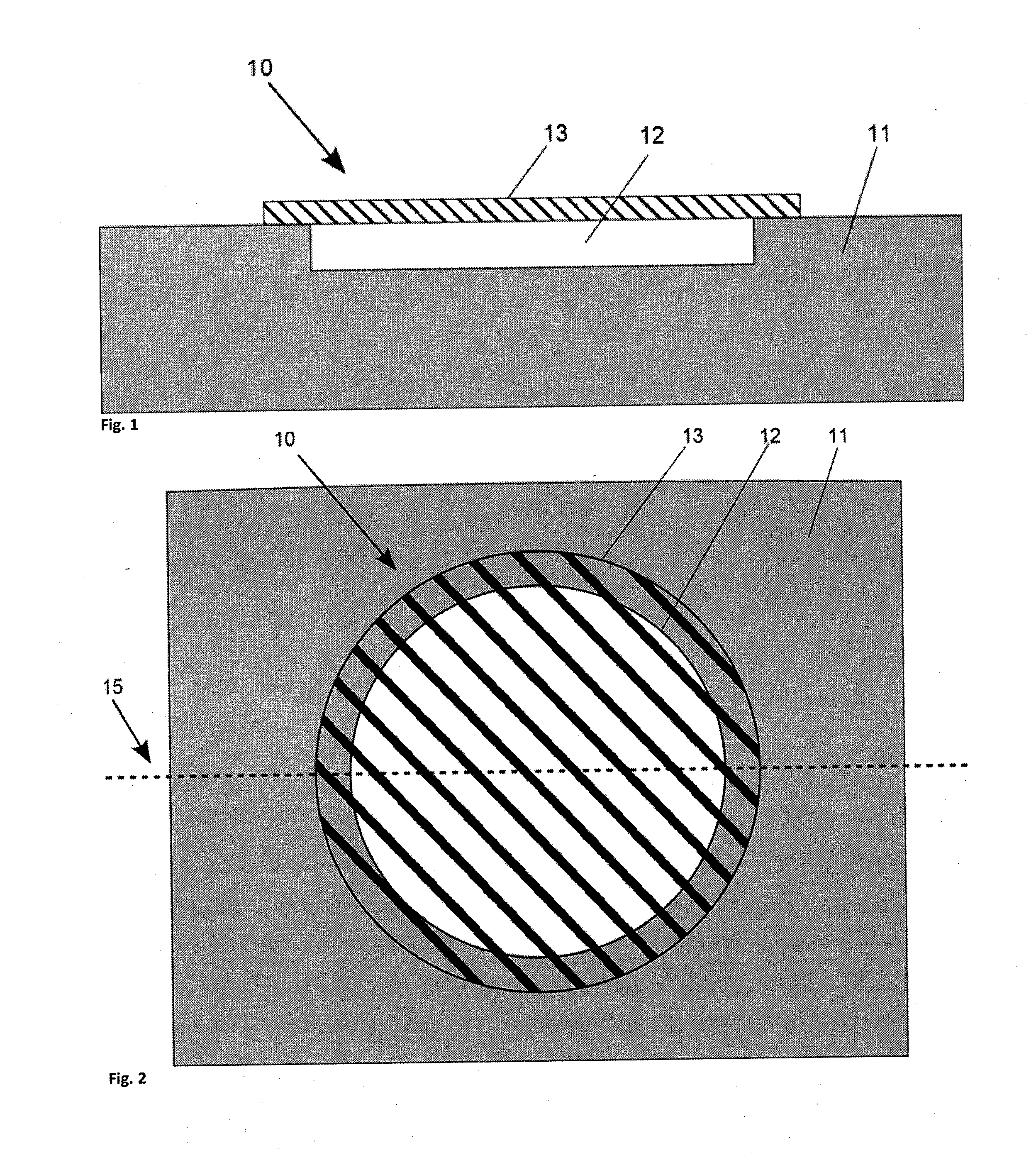

Method and structure of monolithically integrated pressure sensor using IC foundry-compatible processes

ActiveUS20100171153A1Improve performanceSmall sizeFluid pressure measurement by electric/magnetic elementsSemiconductor/solid-state device manufacturingCMOSFoundry

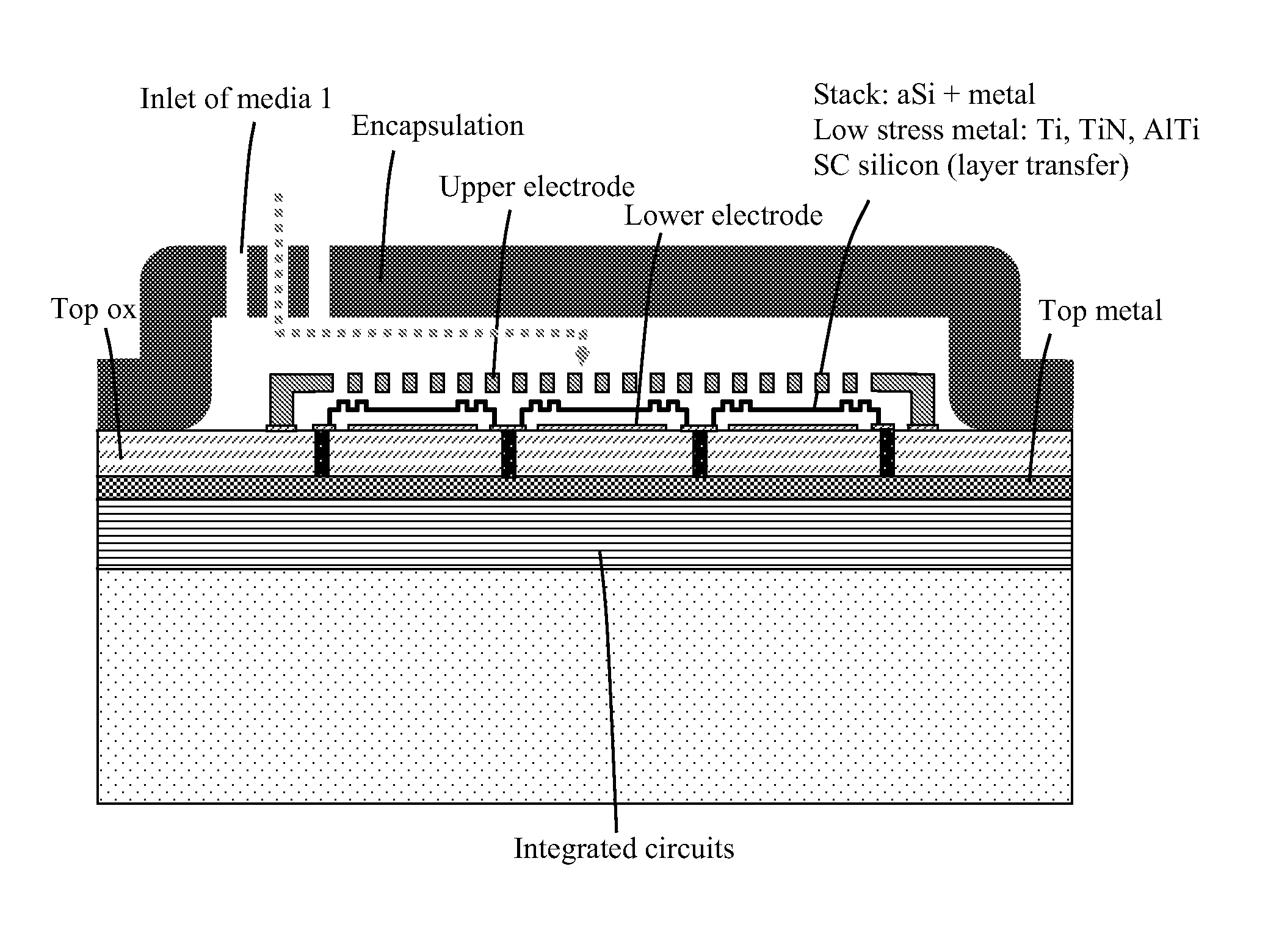

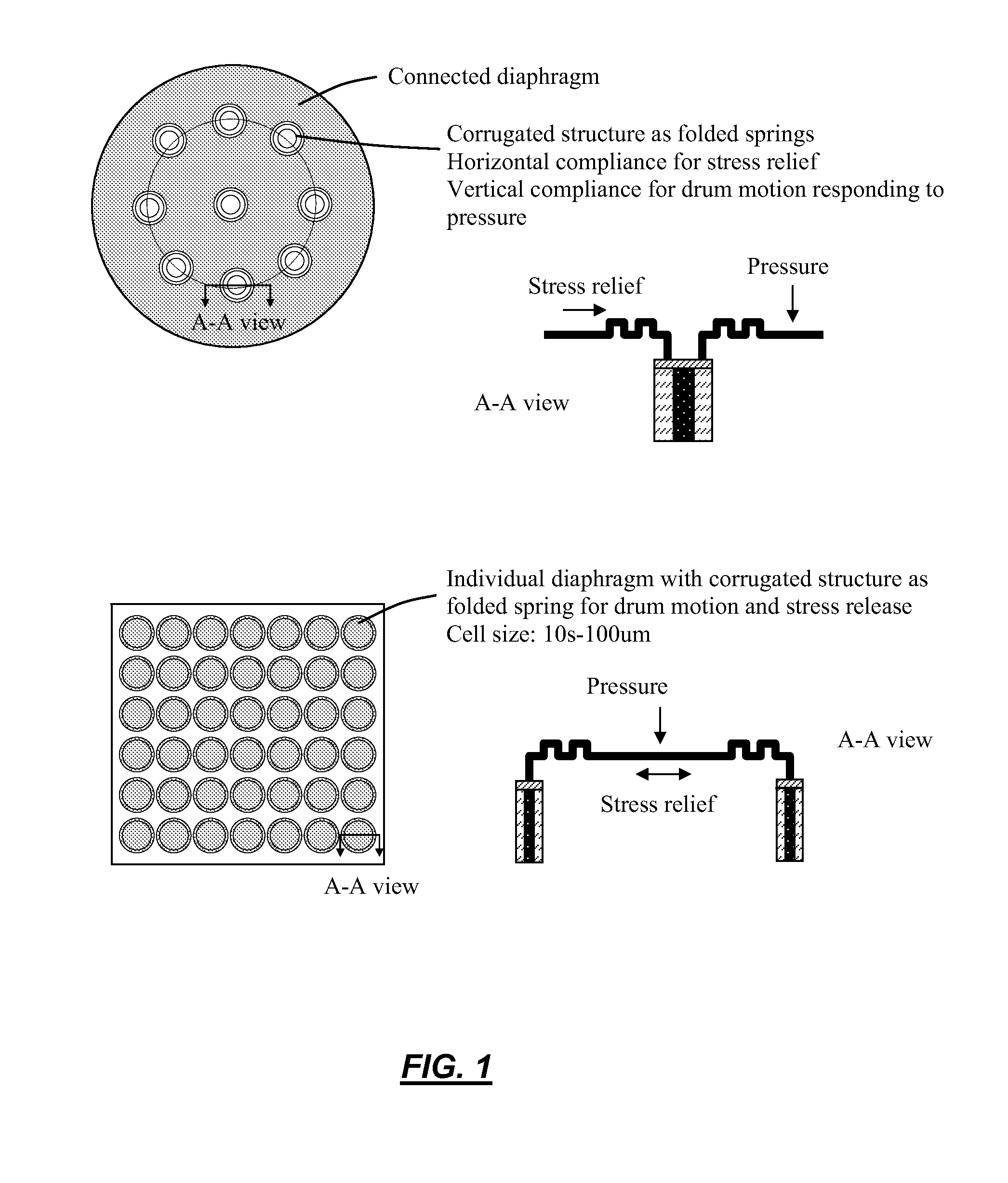

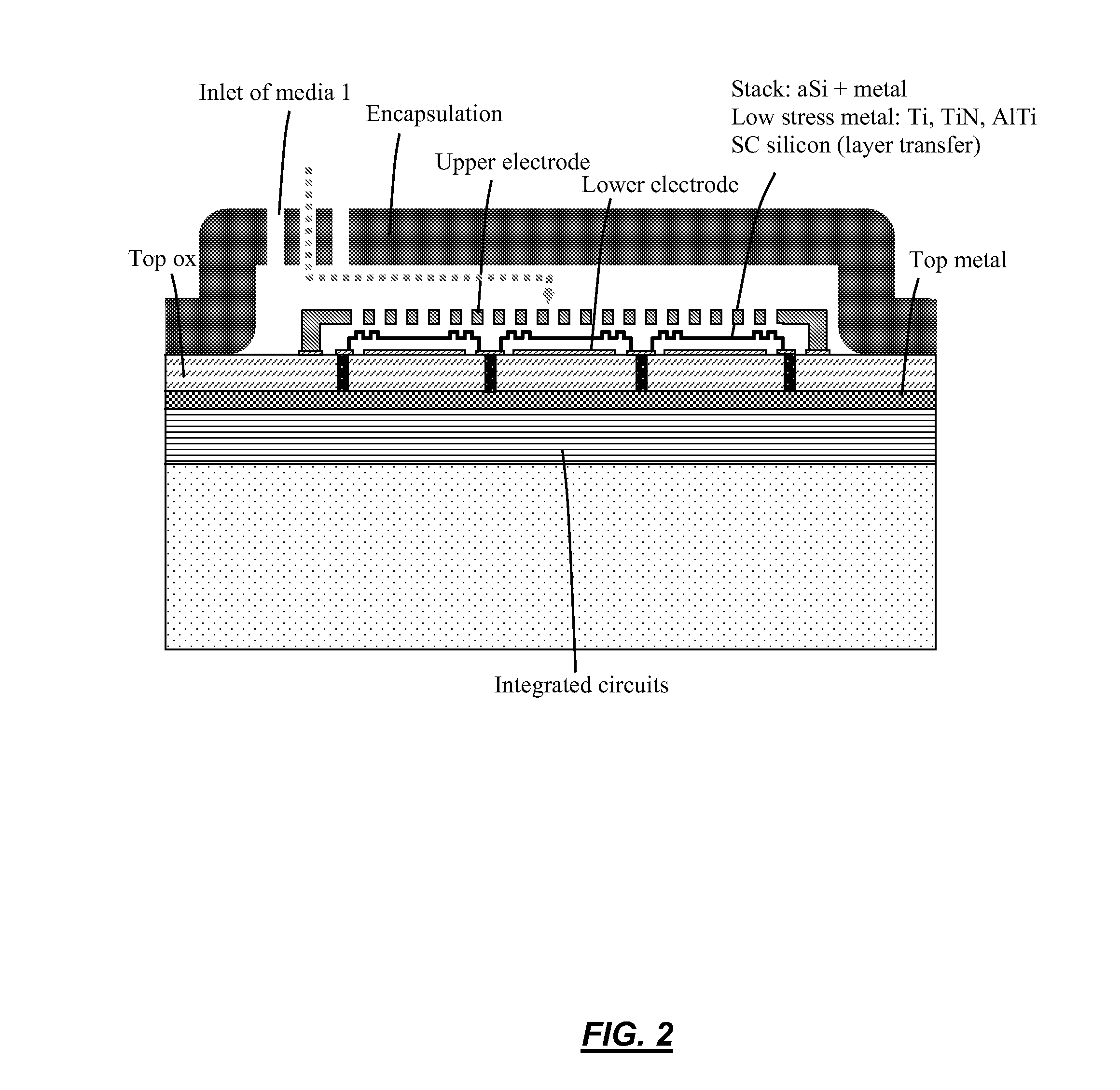

A monolithically integrated MEMS pressure sensor and CMOS substrate using IC-Foundry compatible processes. The CMOS substrate is completed first using standard IC processes. A diaphragm is then added on top of the CMOS. In one embodiment, the diaphragm is made of deposited thin films with stress relief corrugated structure. In another embodiment, the diaphragm is made of a single crystal silicon material that is layer transferred to the CMOS substrate. In an embodiment, the integrated pressure sensor is encapsulated by a thick insulating layer at the wafer level. The monolithically integrated pressure sensor that adopts IC foundry-compatible processes yields the highest performance, smallest form factor, and lowest cost.

Owner:MOVELLA INC

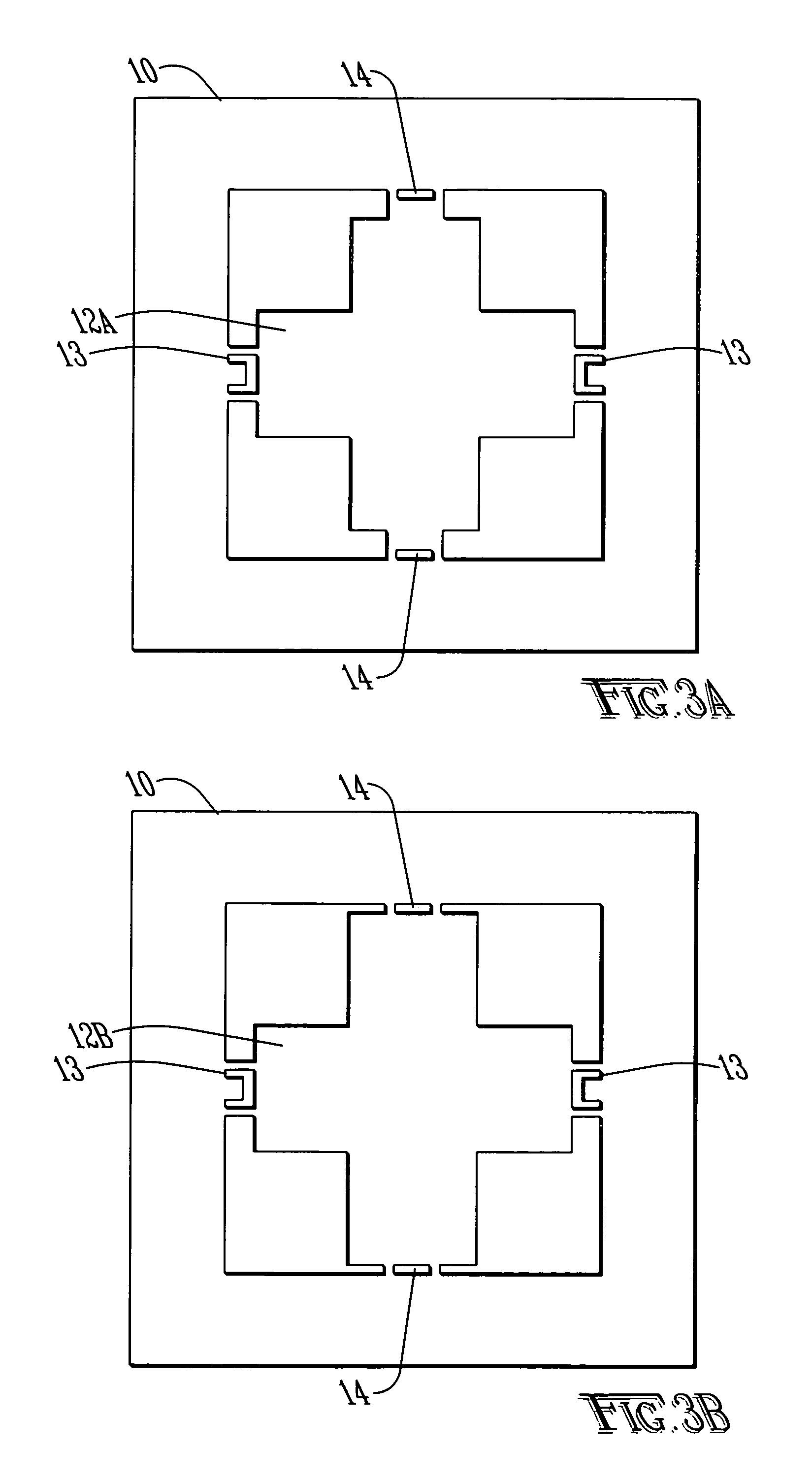

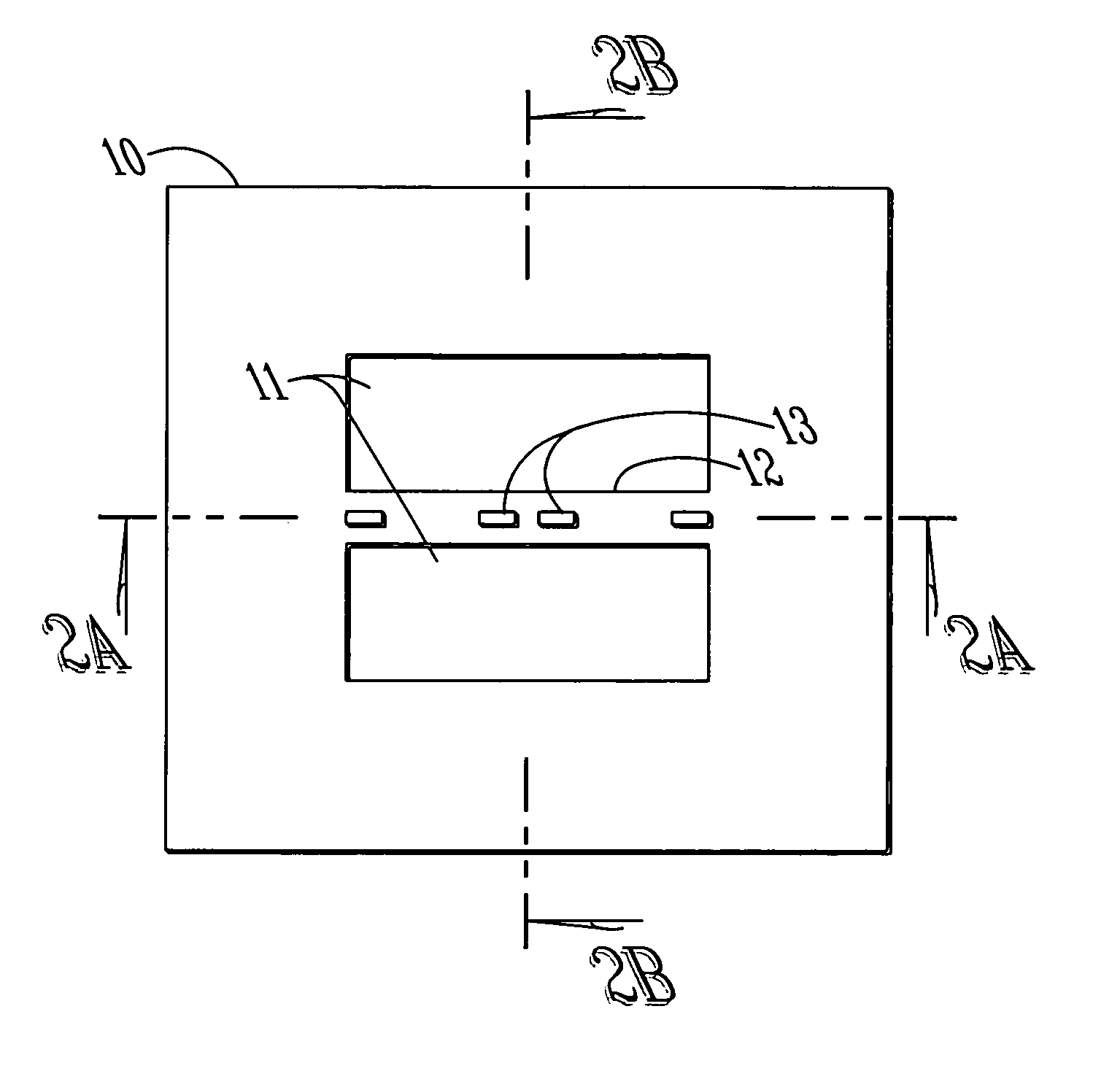

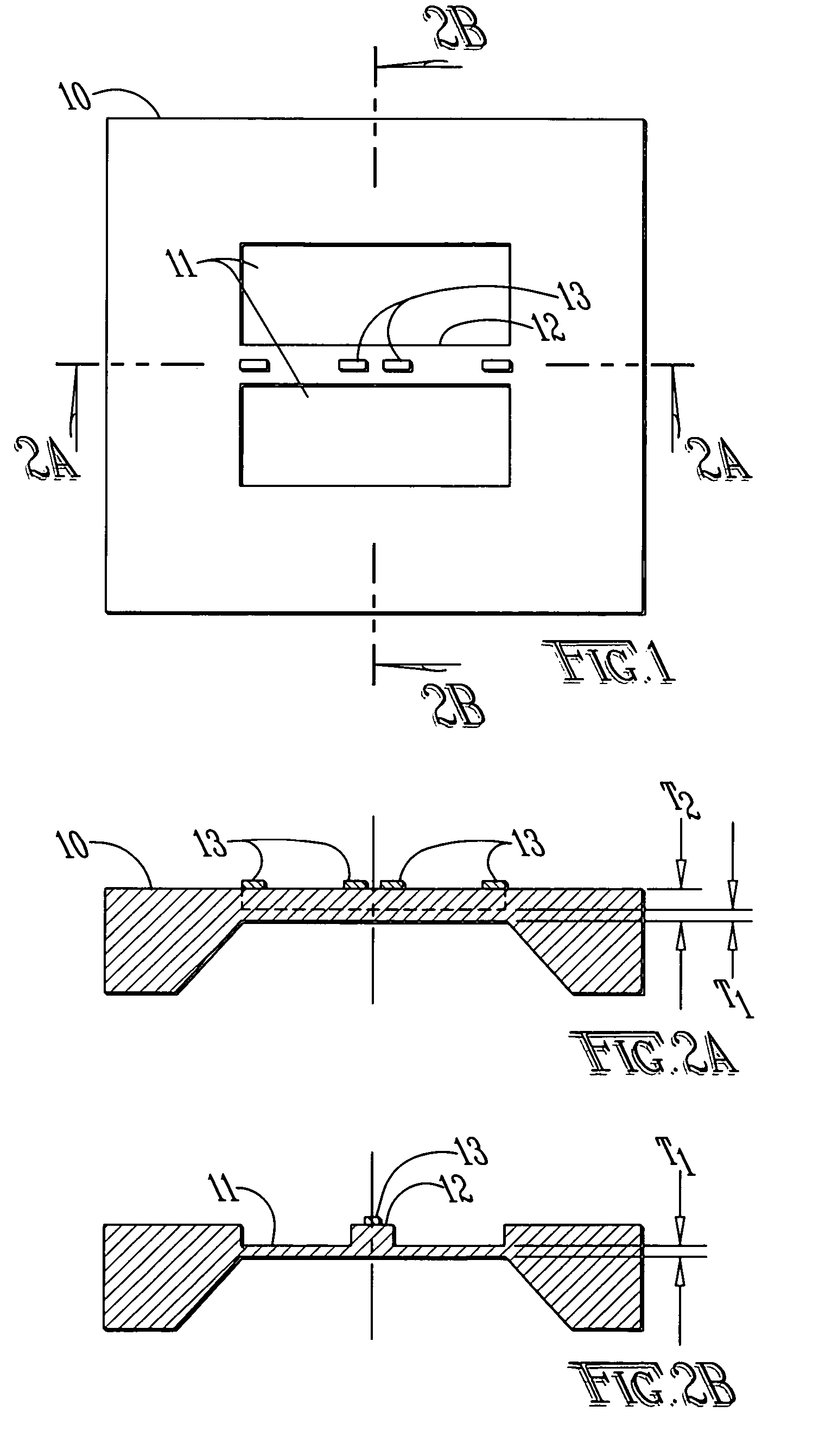

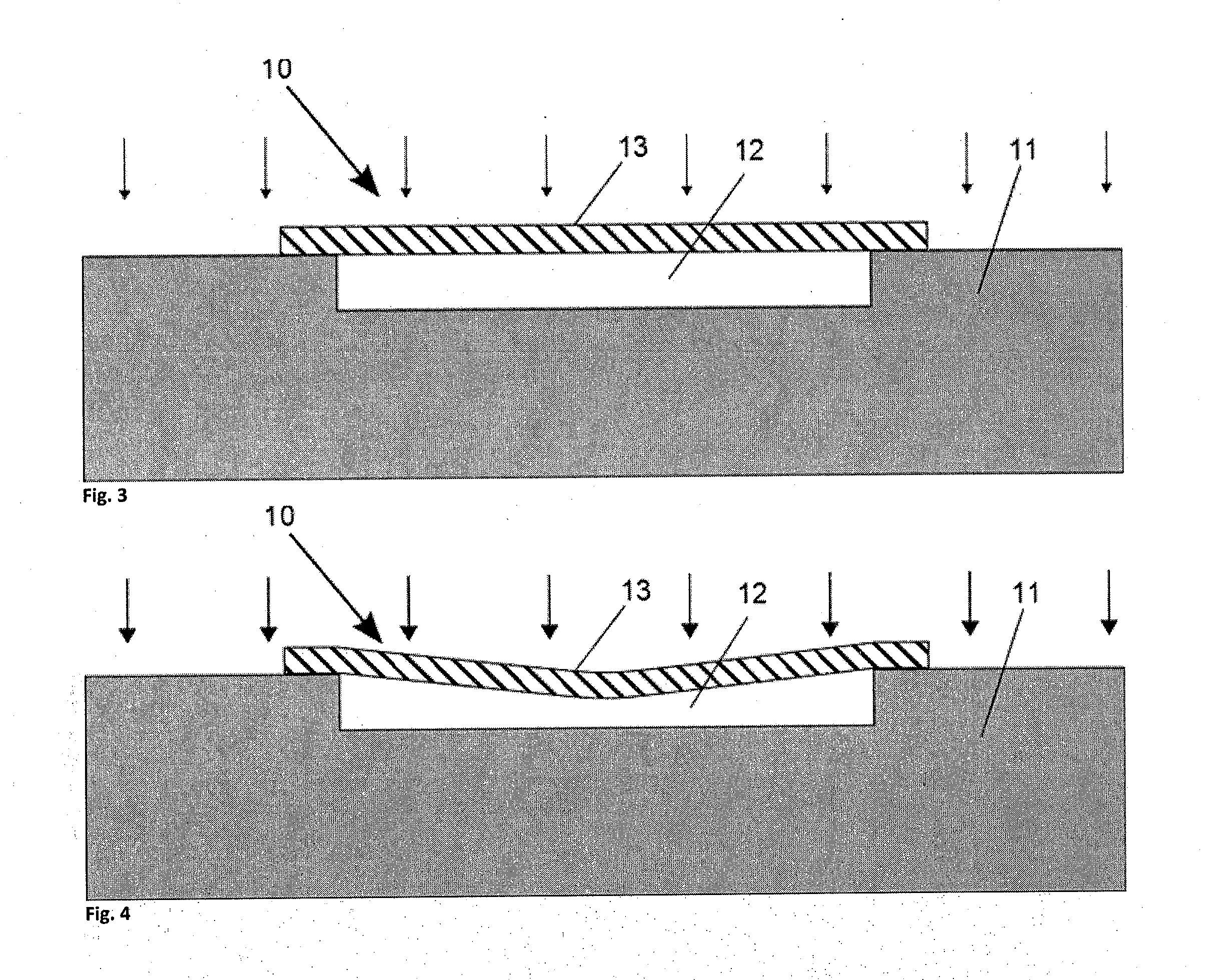

Composite MEMS pressure sensor configuration

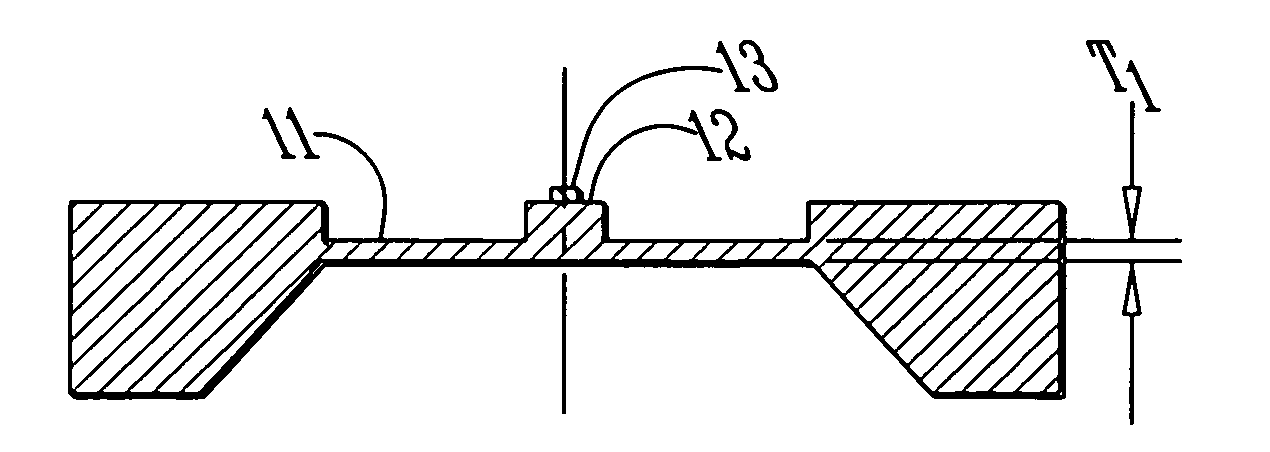

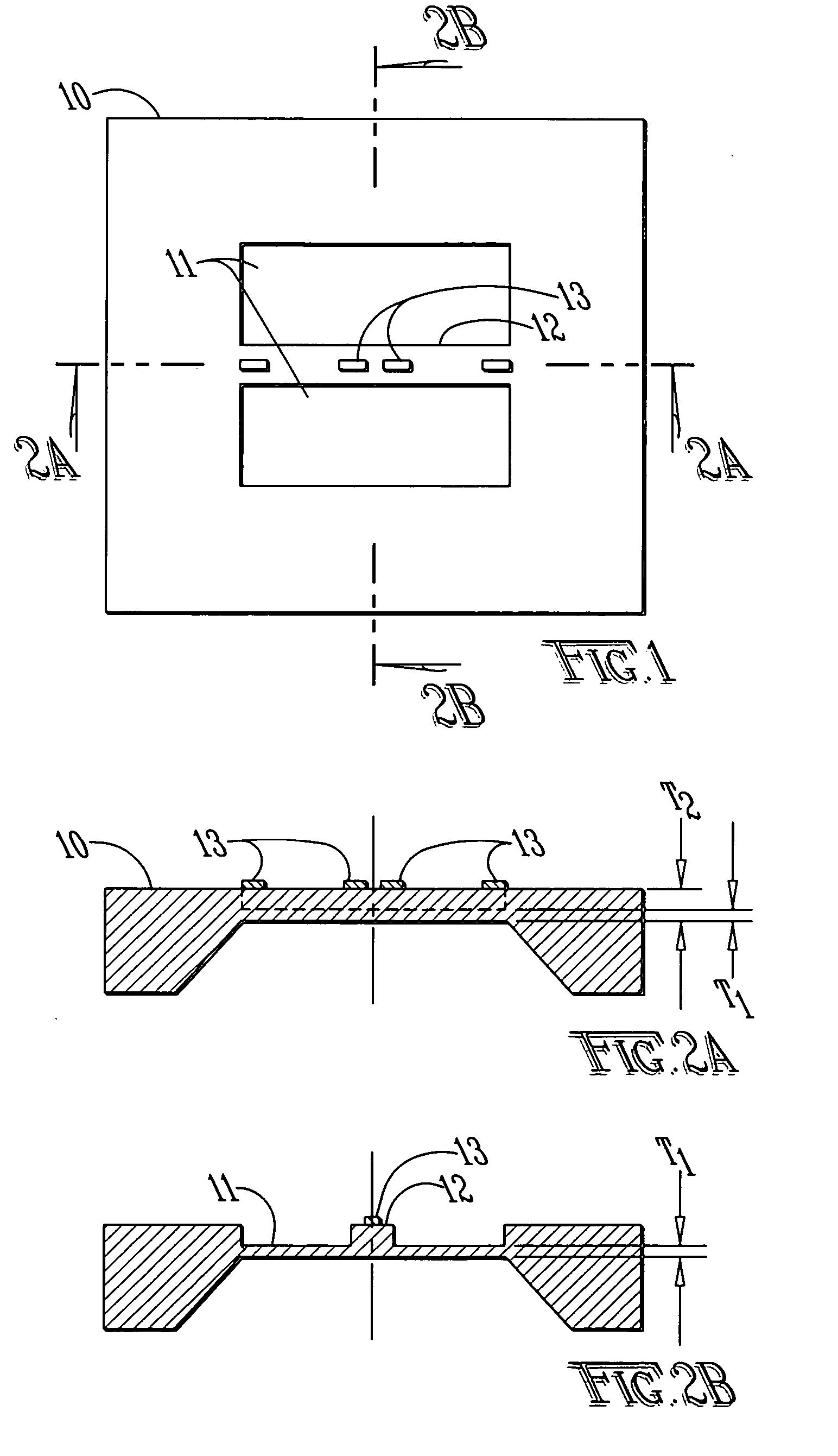

ActiveUS20060144153A1Control deflectionReduce gravity errorFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesCantilevered beamMems pressure sensor

A pressure sensor assembly comprised of a single and dual layer diaphragm with integrated force sensing flexure, such as a cantilever beam. Strain gages are positioned on the force sensing beam. The pressure forces the diaphragm to deflect. The deflection is constrained by the beam, which is compelled to bend. The bending induces strains in strain gages located on the beam. The strain gages are connected in a Wheatstone bridge configuration. When a voltage is applied to the bridge, the strain gages provide an electrical output signal proportional to the pressure. Composite diaphragm—beam pressure sensors convert pressure more efficiently and improve sensor performance.

Owner:BROSH AMNON

Methods and devices for treatment of medical conditions and monitoring physical movements

InactiveUS20090048542A1Accurate monitoringMaterial nanotechnologyElectrotherapyAccelerometerGyroscope

The present systems use nanotechnology, MEMS devices and wireless data transmission to monitor and treat physical activities, and medical and physiological conditions. The MEMS devices and wireless data transmission systems monitor and sense certain patient conditions or reactions, such as changes in pressure, movements, and tremors. These sensor devices include, but are not limited to, MEMS gyroscopes, MEMS accelerometers, and MEMS pressure sensors. Data from the sensor is wirelessly transmitted to a second MEMS device to treat or alter the medical condition being monitored.

Owner:VARADAN VIJAY +1

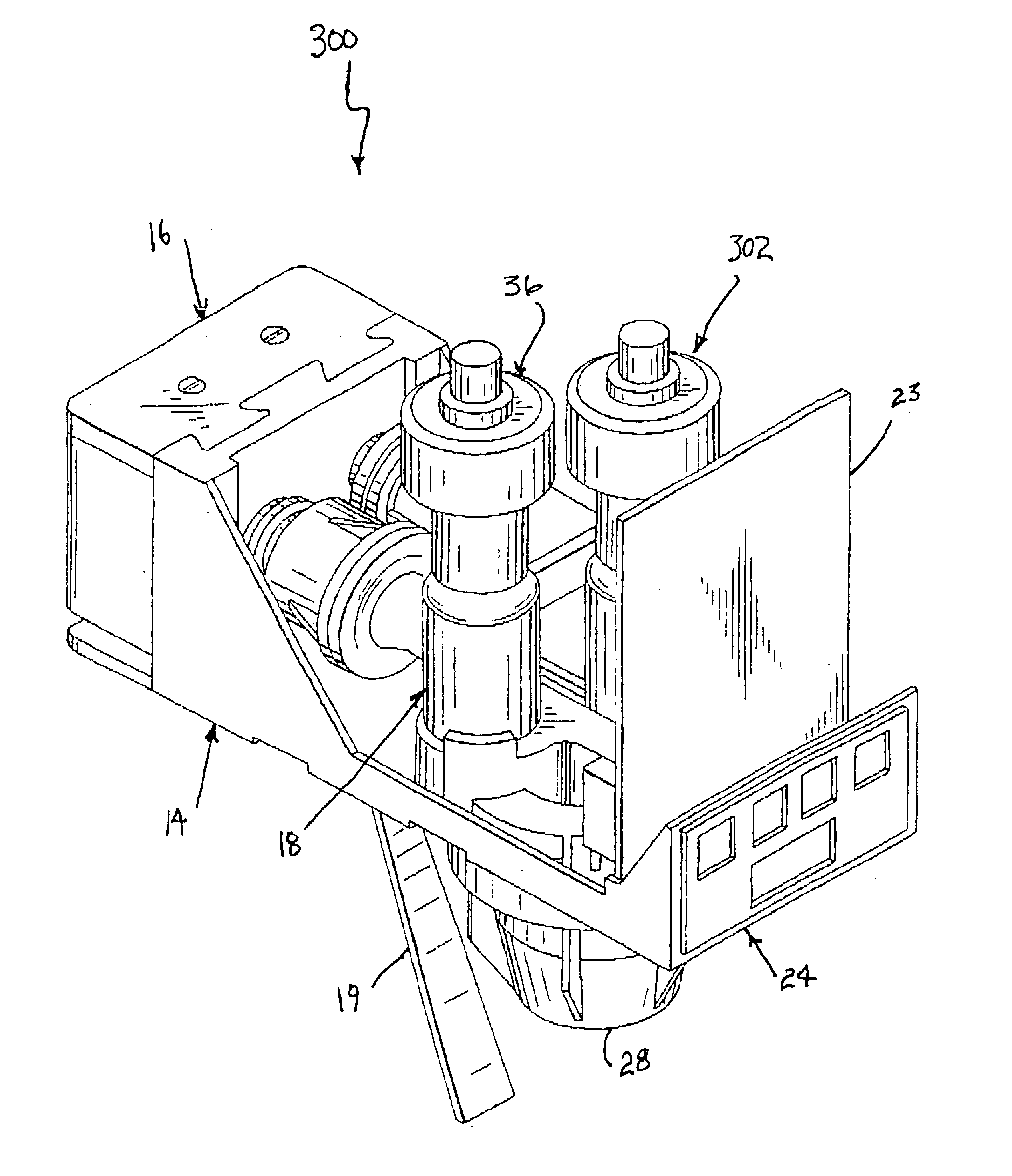

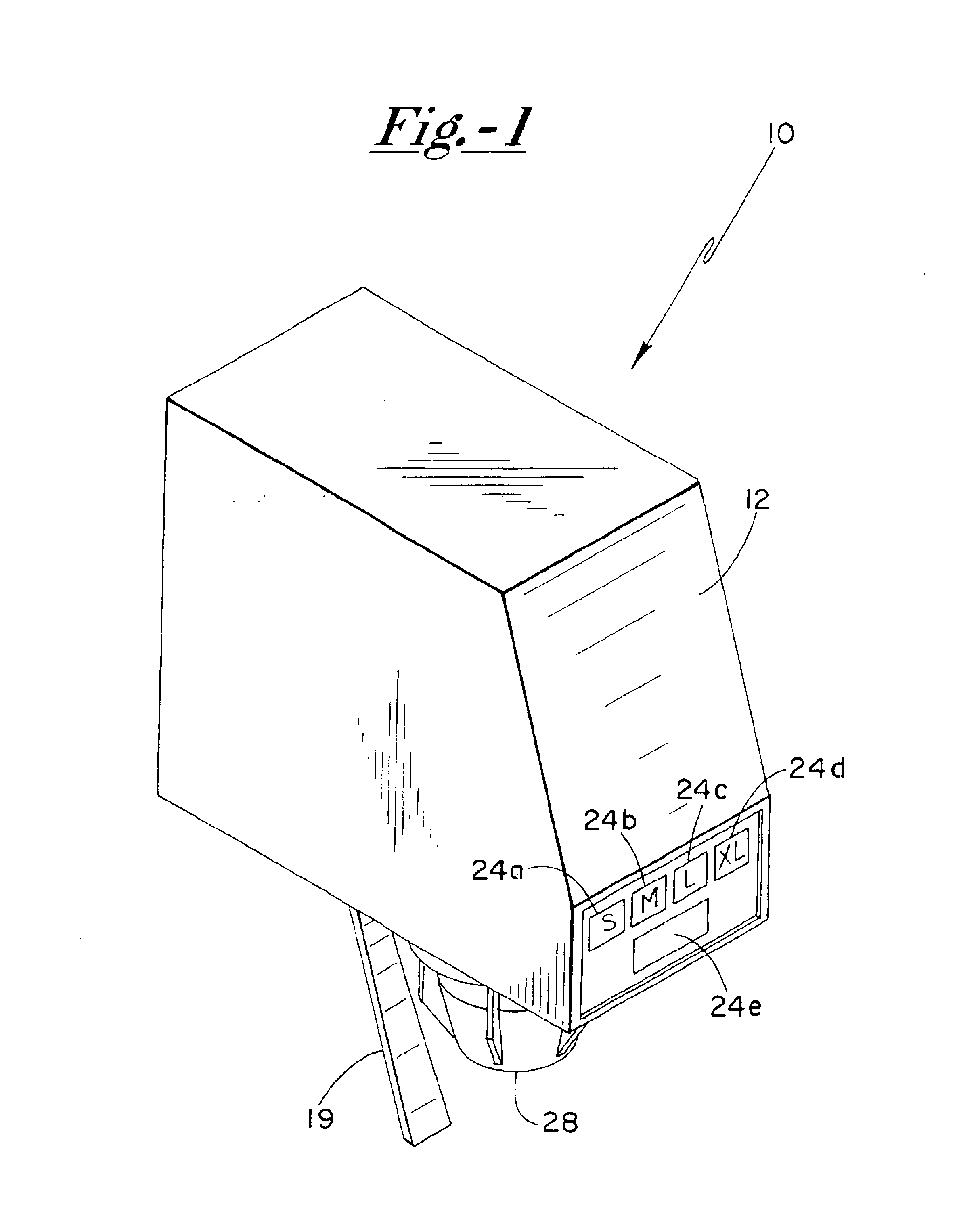

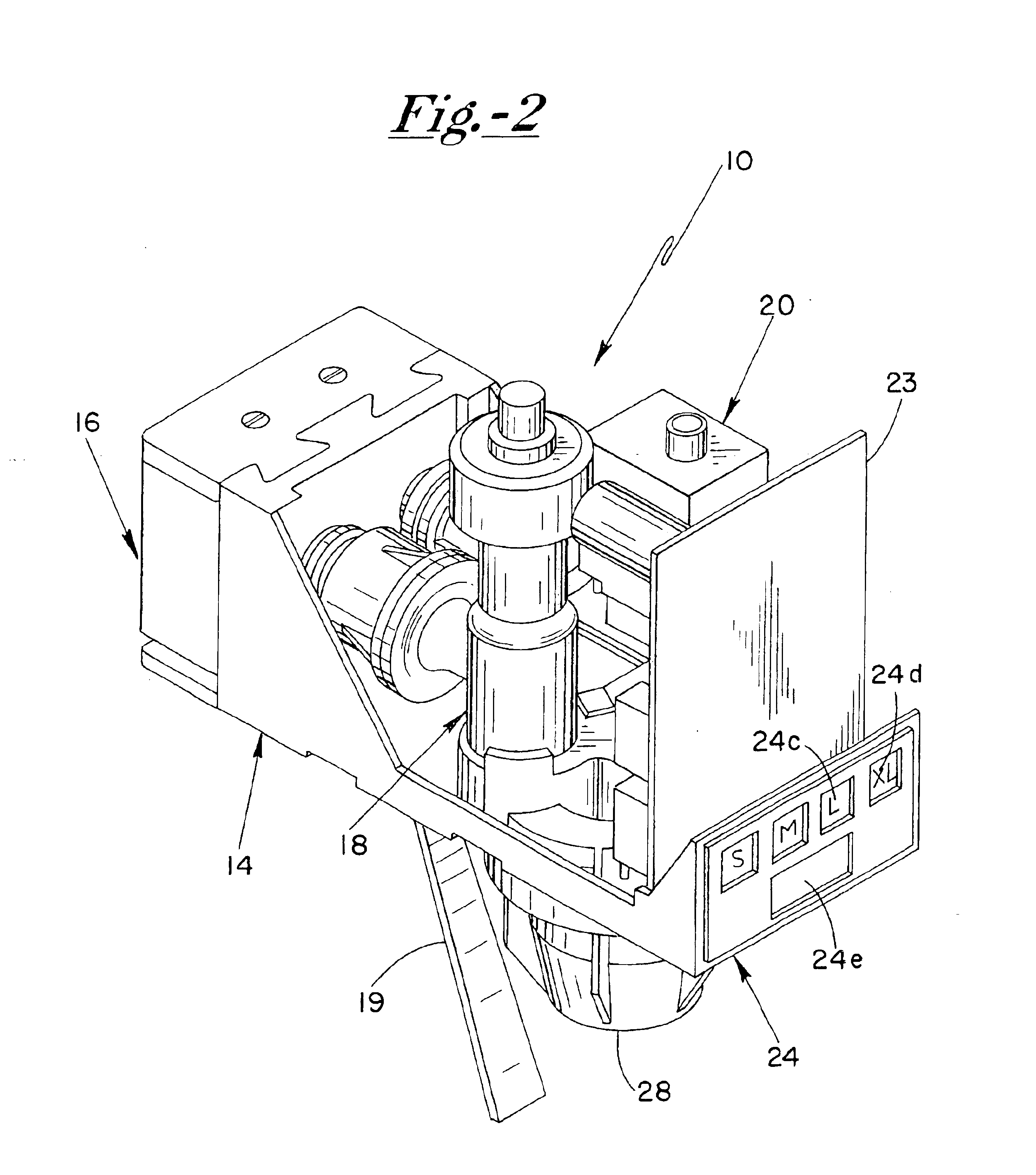

Valve for dispensing two liquids at a predetermined ratio

InactiveUS6845886B2Low costAccurate inductionPlug valvesLiquid transferring devicesMems pressure sensorDifferential pressure

A post-mix beverage valve provides for automatic, accurate beverage ratioing. A valve body can be assembled, and includes a water flow hard body, syrup body and common nozzle body. The water and syrup flow bodies define flow channels and include one end for connection to water and syrup respectively, and opposite ends for fluid connection to the nozzle body. The water flow channel includes a turbine flow sensor connected to a micro-controller determining the water flow rate. The syrup flow channel includes a flow sensor, two MEMS pressure sensors, monitoring the syrup. The sensors are connected to the micro-controller and positioned about an orifice and senses sense a differential pressure indicative of syrup flow rate solenoid regulates flow of syrup through the syrup body. A stepper motor on the water body controls a rod in the flow channel in conjunction with a v-groove.

Owner:IMI VISION LTD

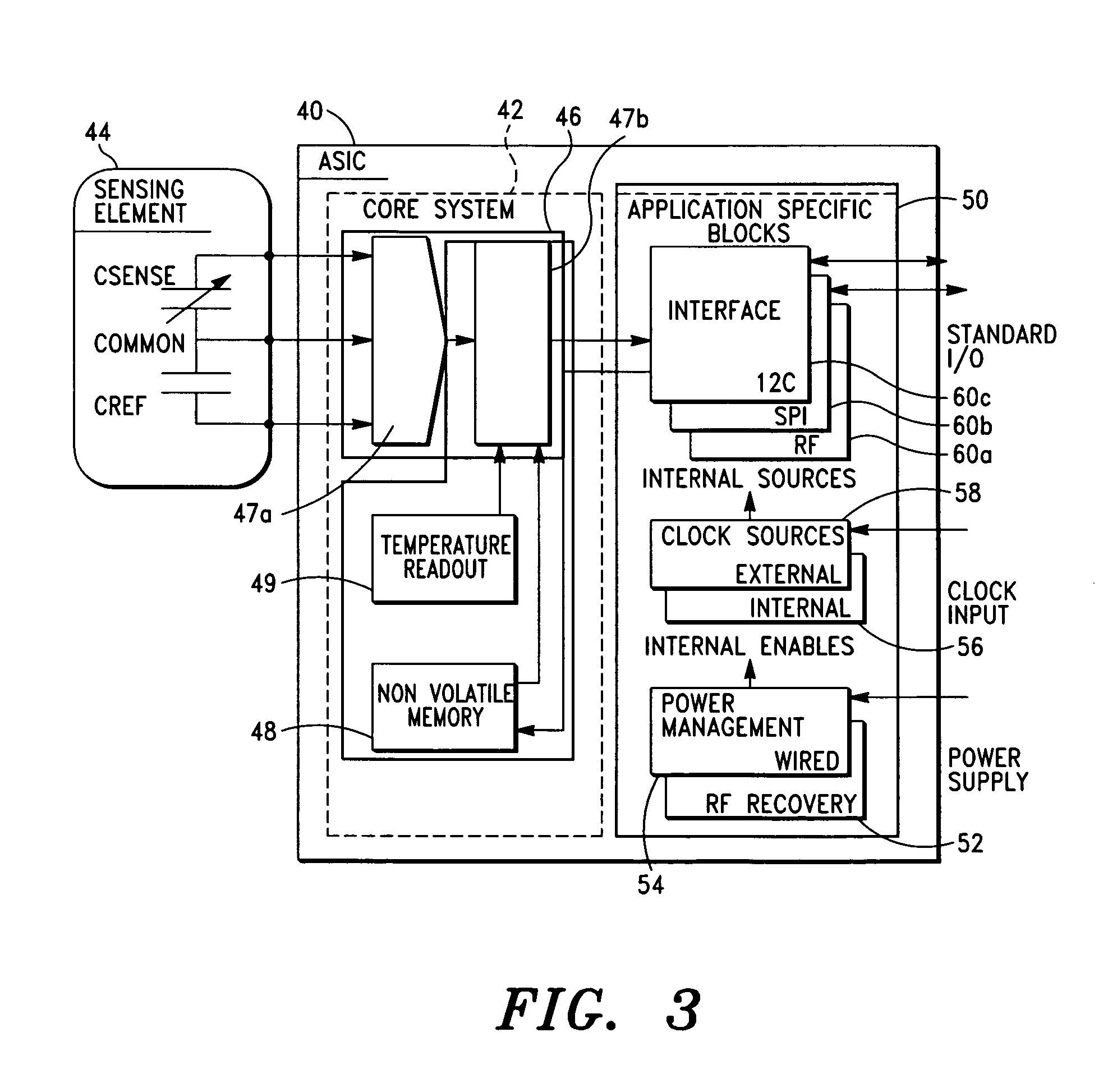

Method and system for monitoring pressure in a body cavity

InactiveUS20110160609A1Reduce the risk of infectionFluid pressure measurementIntracranial pressure measurementMems pressure sensorPressure sense

An implantable pressure sensor system having a sensor assembly configured and adapted to measure pressure in a volume, the sensor assembly including at least a first MEMS pressure sensor, an application-specific integrated circuit (ASIC) having memory means, temperature compensation system, drift compensation system, a sensor catheter, and power supply means for powering the sensor assembly, the first MEMS pressure sensor having a pressure sensing element that is responsive to exposed pressure, the pressure sensing element being adapted to generate a pressure sensor signal representative of the exposed pressure, the temperature compensation system being adapted to correct for temperature induced variations in the pressure sensor signal, the drift compensation system being adapted to correct for pressure and temperature induced pressure sensor signal drift.

Owner:TRONICS NORTH AMERICA

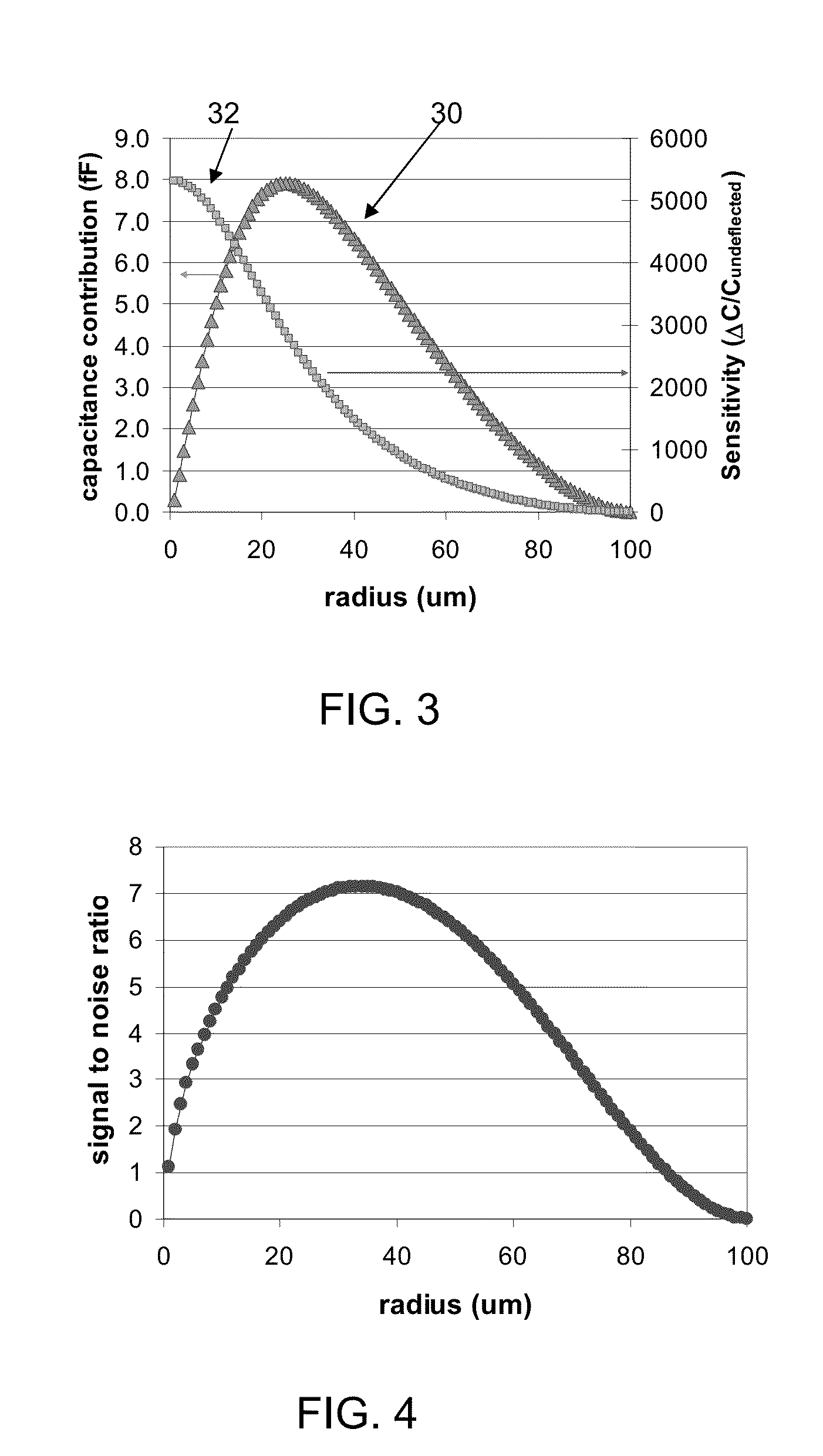

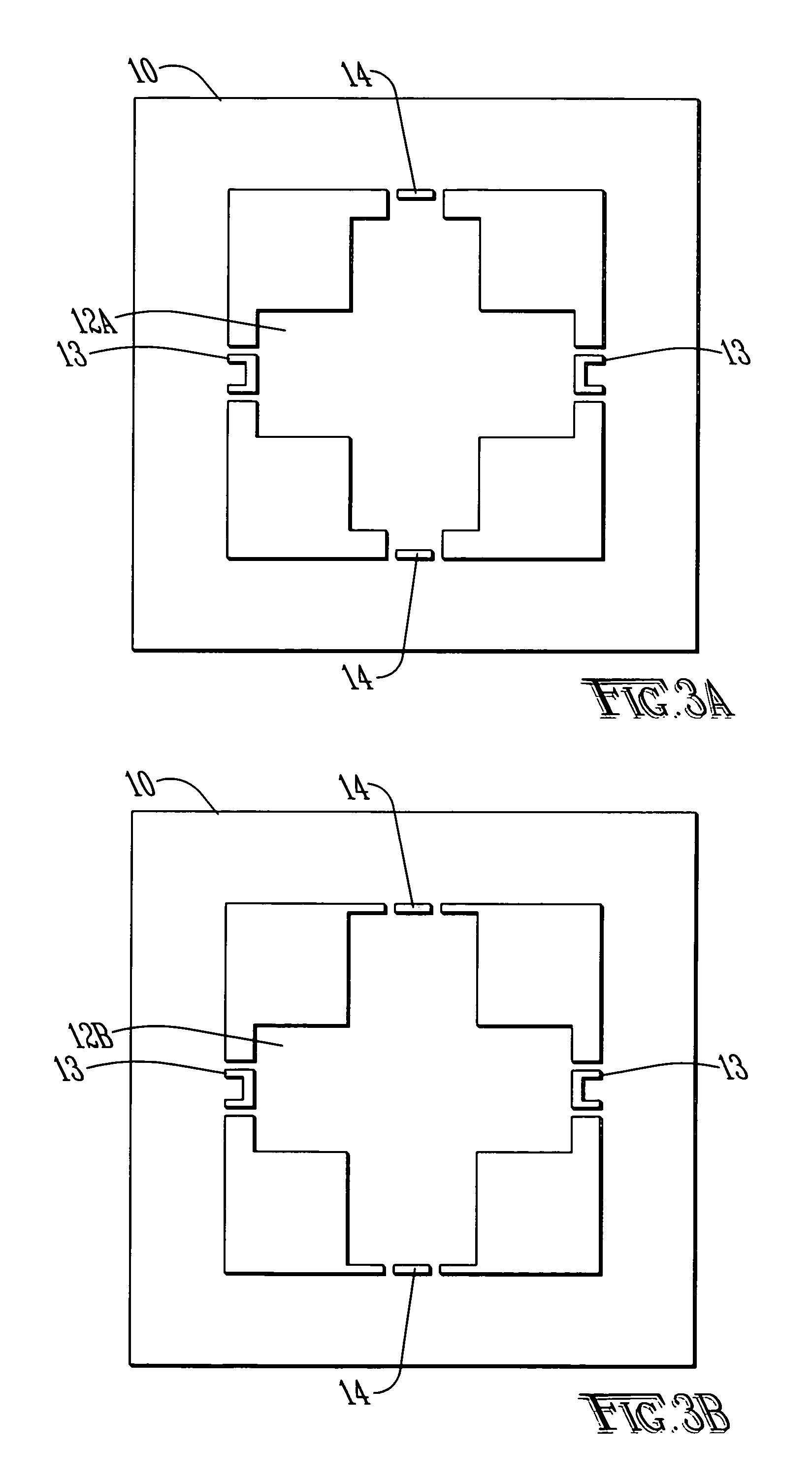

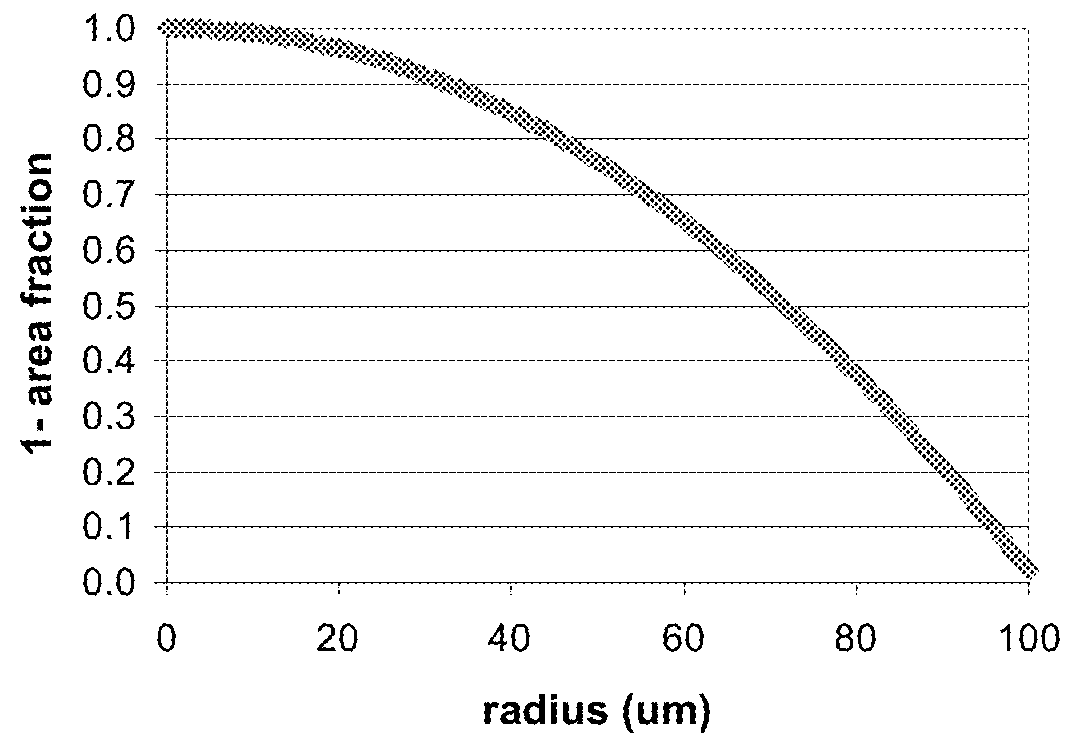

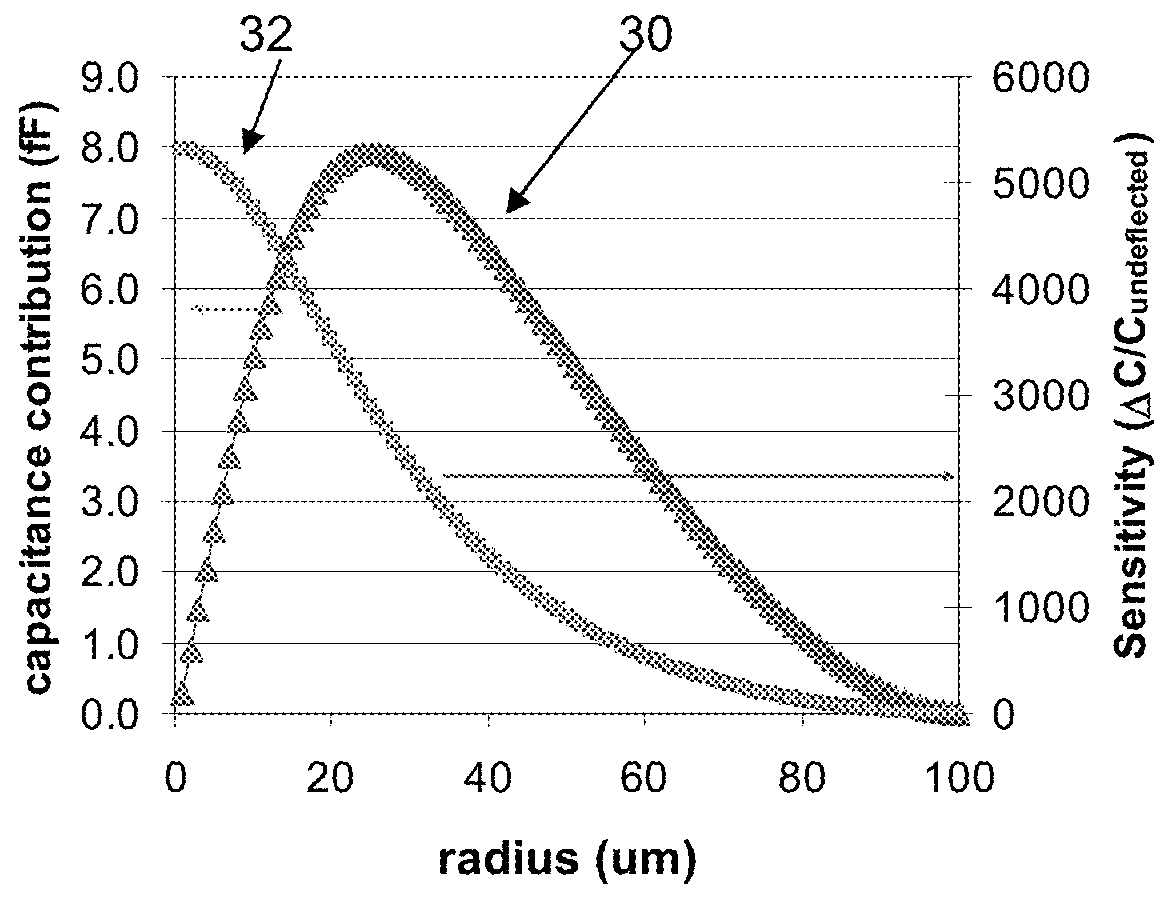

MEMS capacitive pressure sensor, operating method and manufacturing method

ActiveUS20130118265A1High sensitivityLarge dynamic rangeSpecial surfacesCoatingsCapacitive pressure sensorMems pressure sensor

A MEMS pressure sensor wherein at least one of the electrode arrangements comprises an inner electrode and an outer electrode arranged around the inner electrode. The capacitances associated with the inner electrode and the outer electrode are independently measured and can be differentially measured. This arrangement enables various different read out schemes to be implemented and also enables improved compensation for variations between devices or changes in device characteristics over time.

Owner:SCIOSENSE BV

Composite MEMS pressure sensor configuration

ActiveUS7290453B2Control deflectionMaximizes strainFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesMems pressure sensorEngineering

A pressure sensor assembly comprised of a single and dual layer diaphragm with integrated force sensing flexure, such as a cantilever beam. Strain gages are positioned on the force sensing beam. The pressure forces the diaphragm to deflect. The deflection is constrained by the beam, which is compelled to bend. The bending induces strains in strain gages located on the beam. The strain gages are connected in a Wheatstone bridge configuration. When a voltage is applied to the bridge, the strain gages provide an electrical output signal proportional to the pressure. Composite diaphragm—beam pressure sensors convert pressure more efficiently and improve sensor performance.

Owner:BROSH AMNON

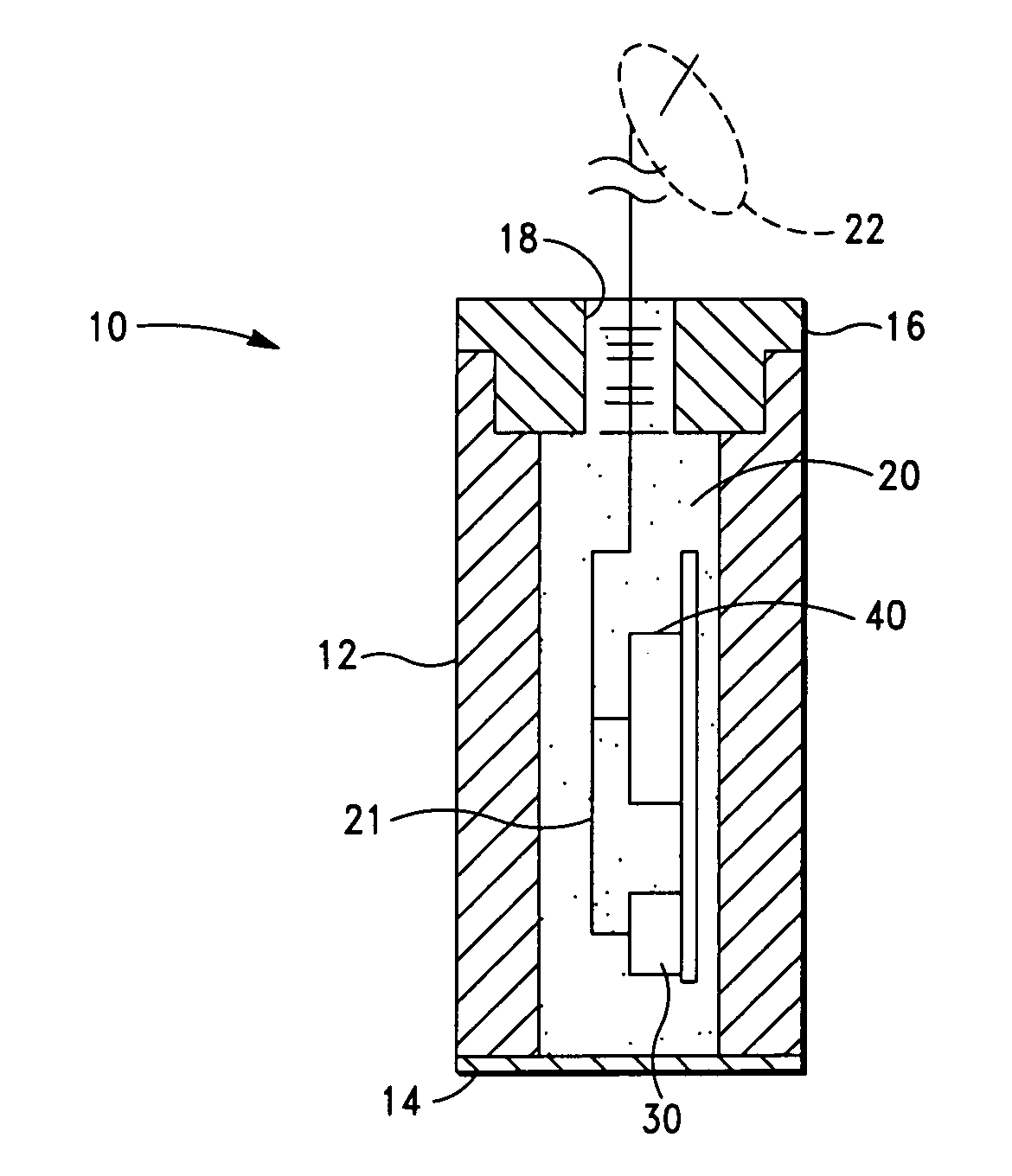

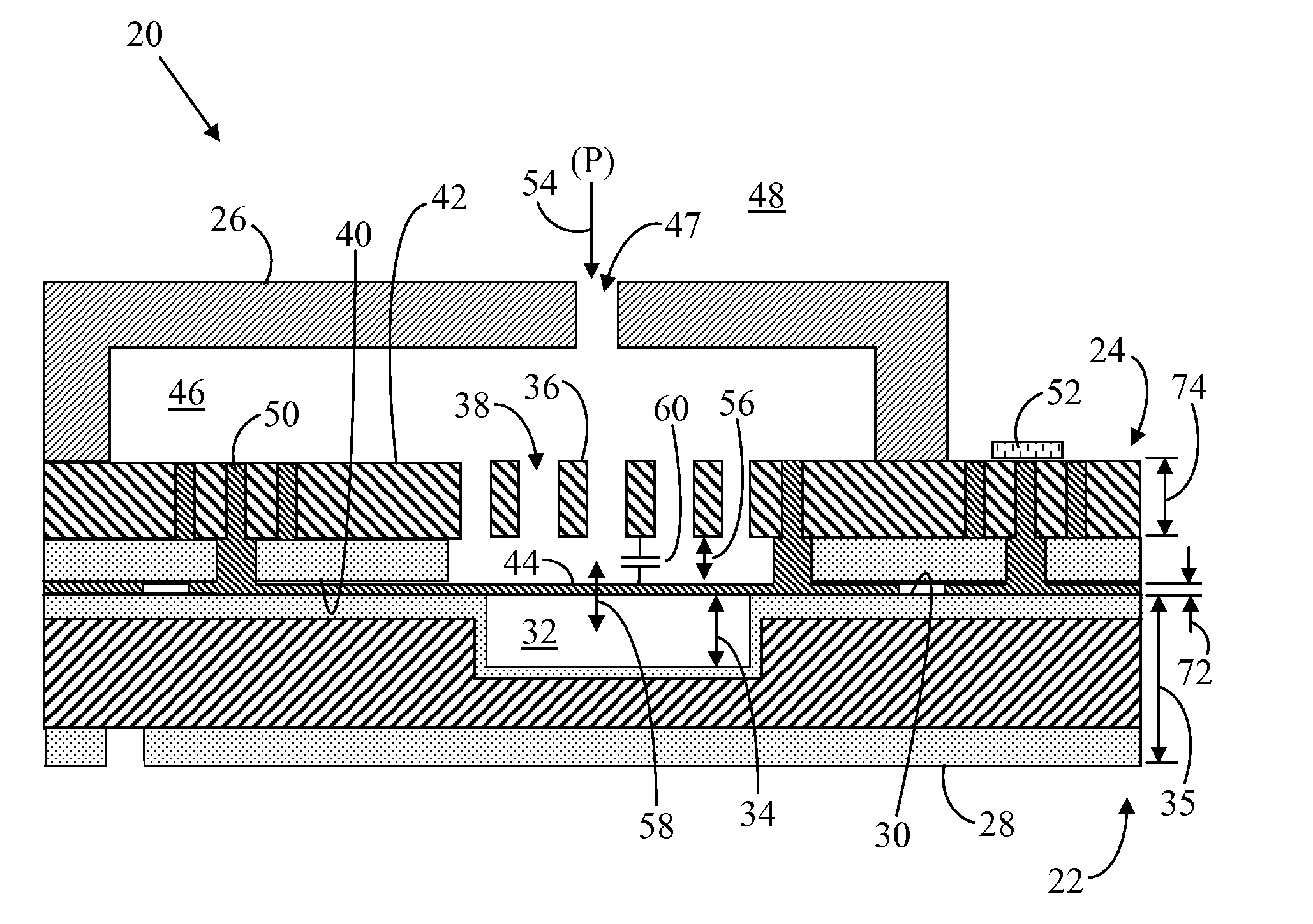

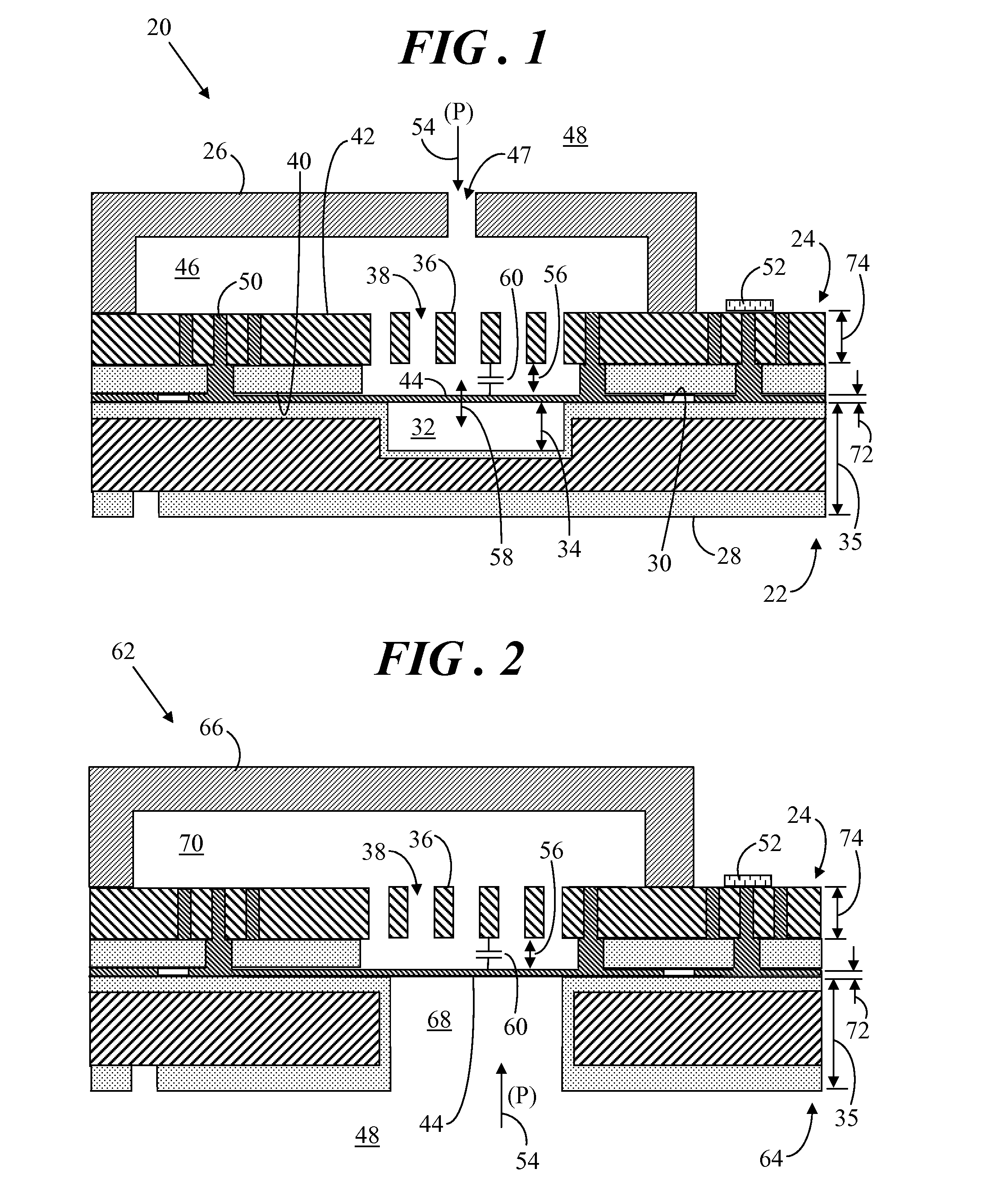

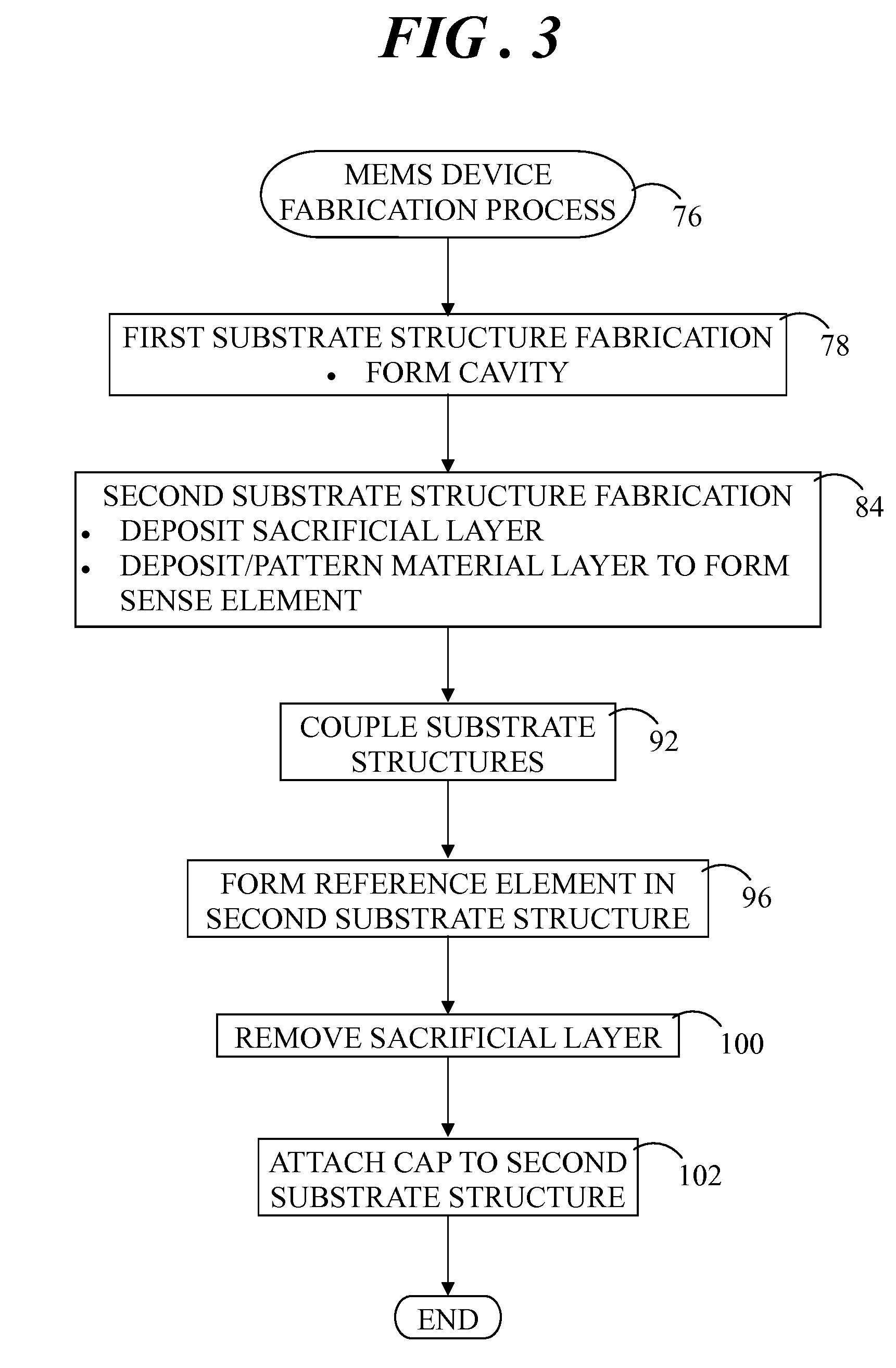

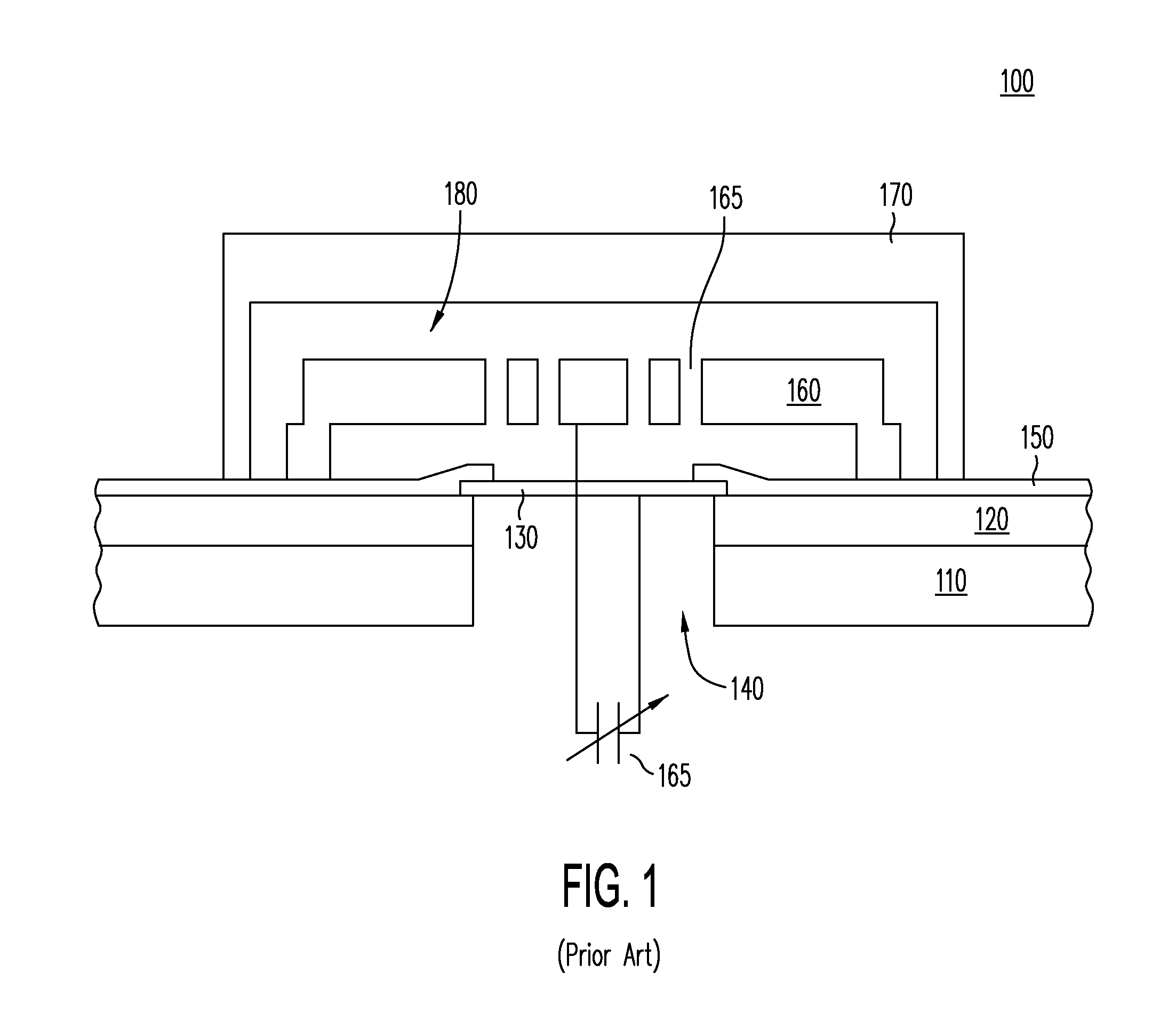

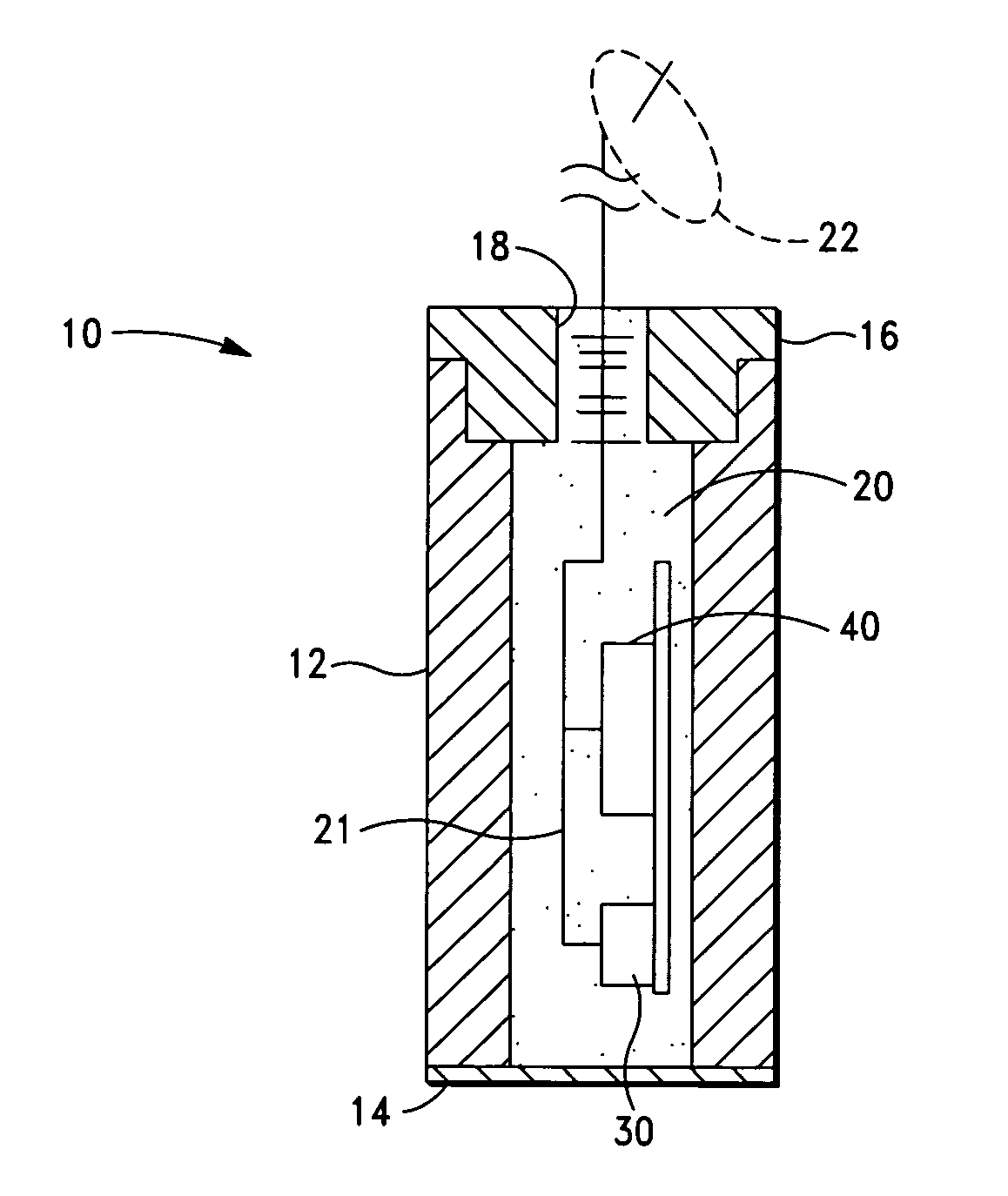

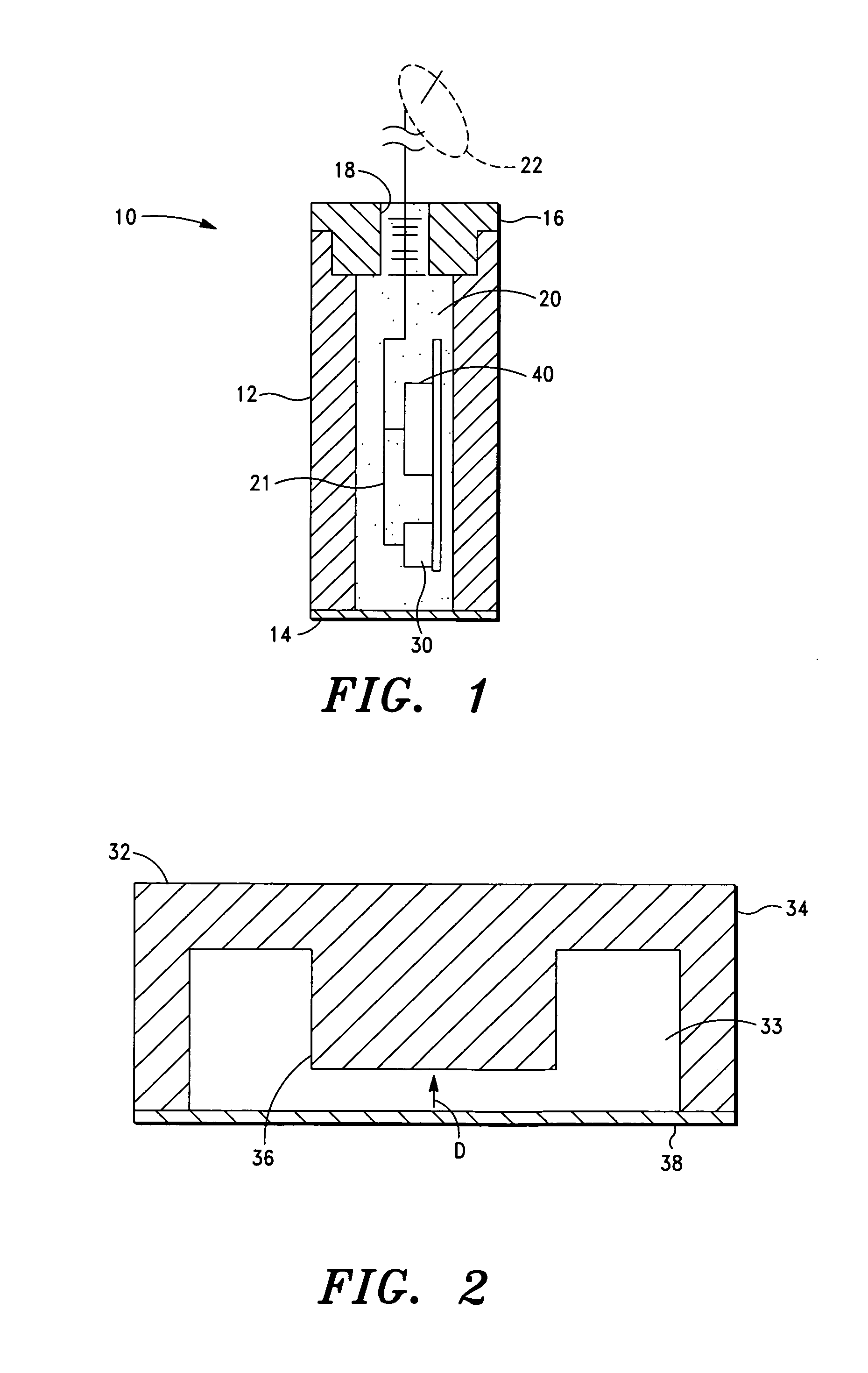

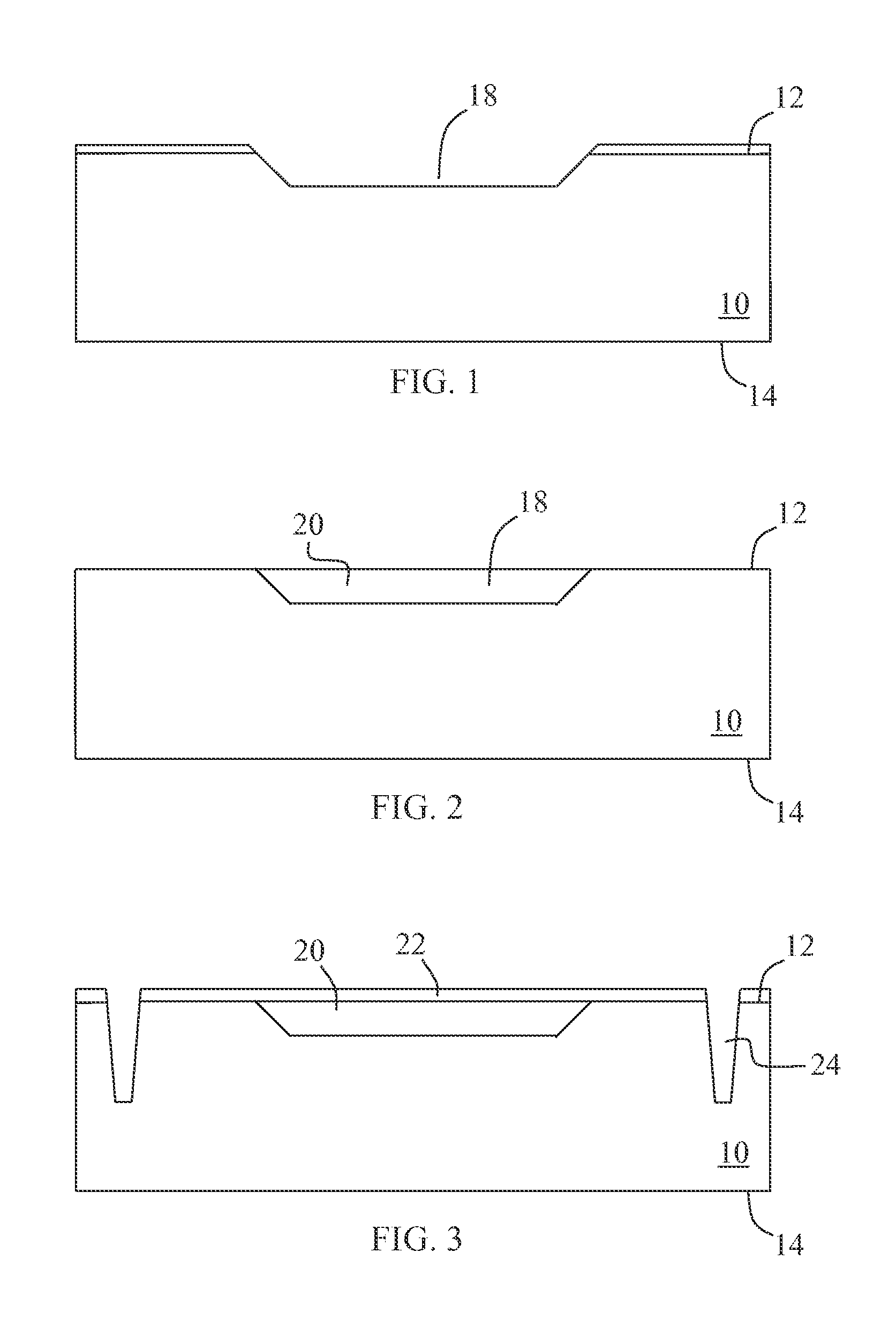

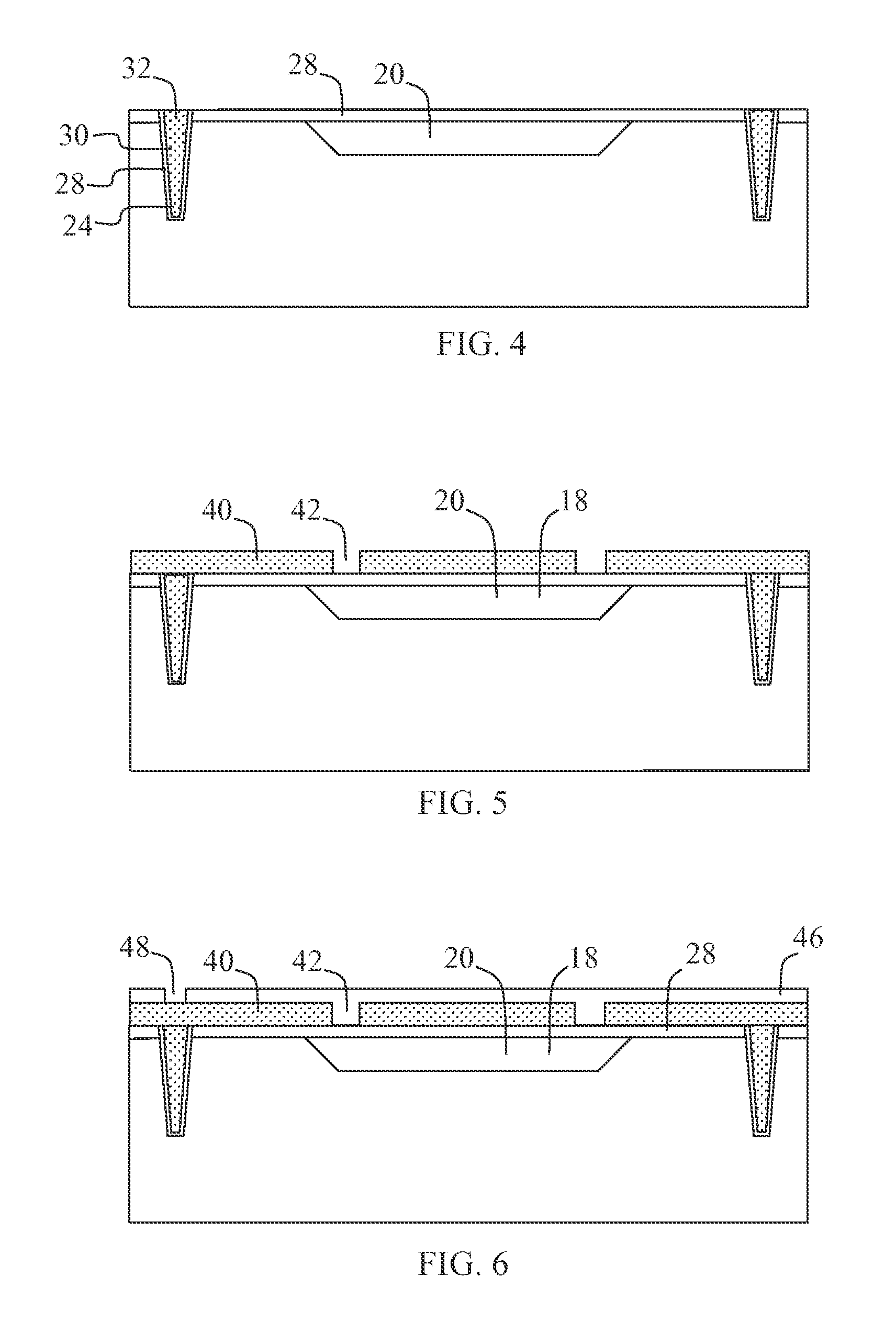

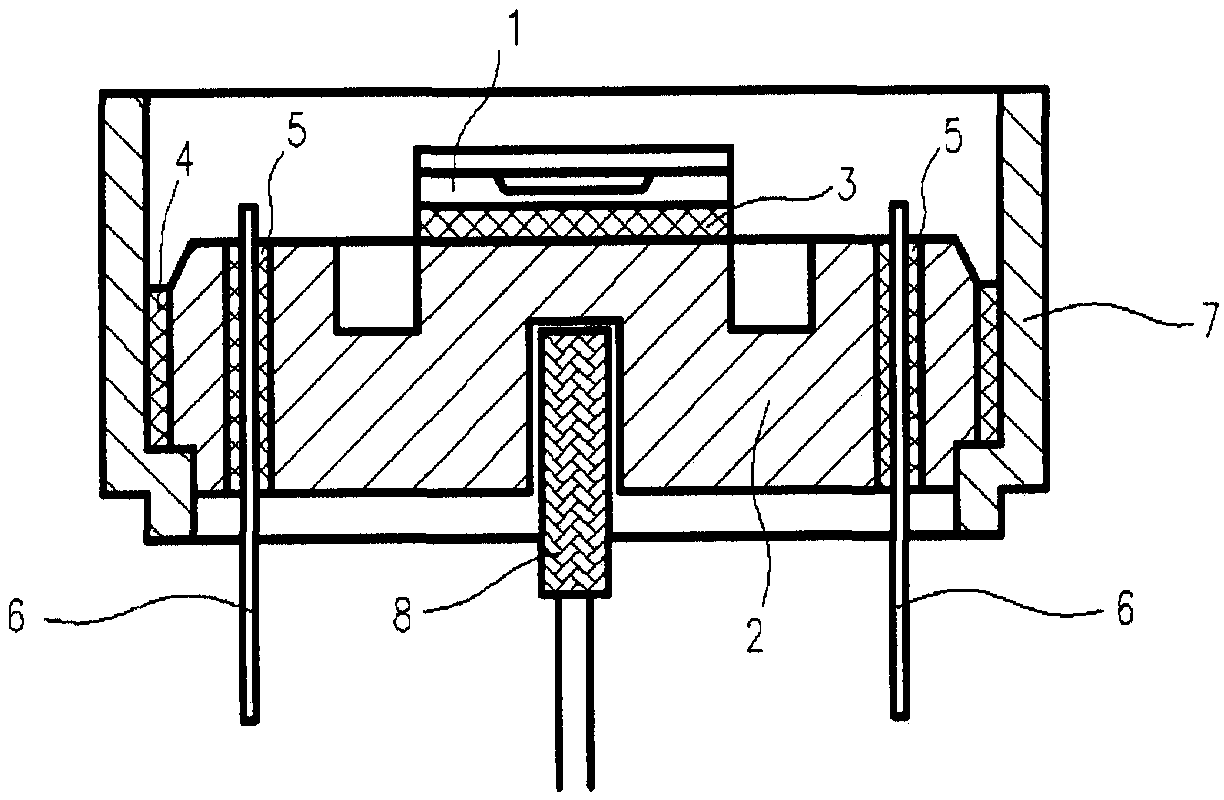

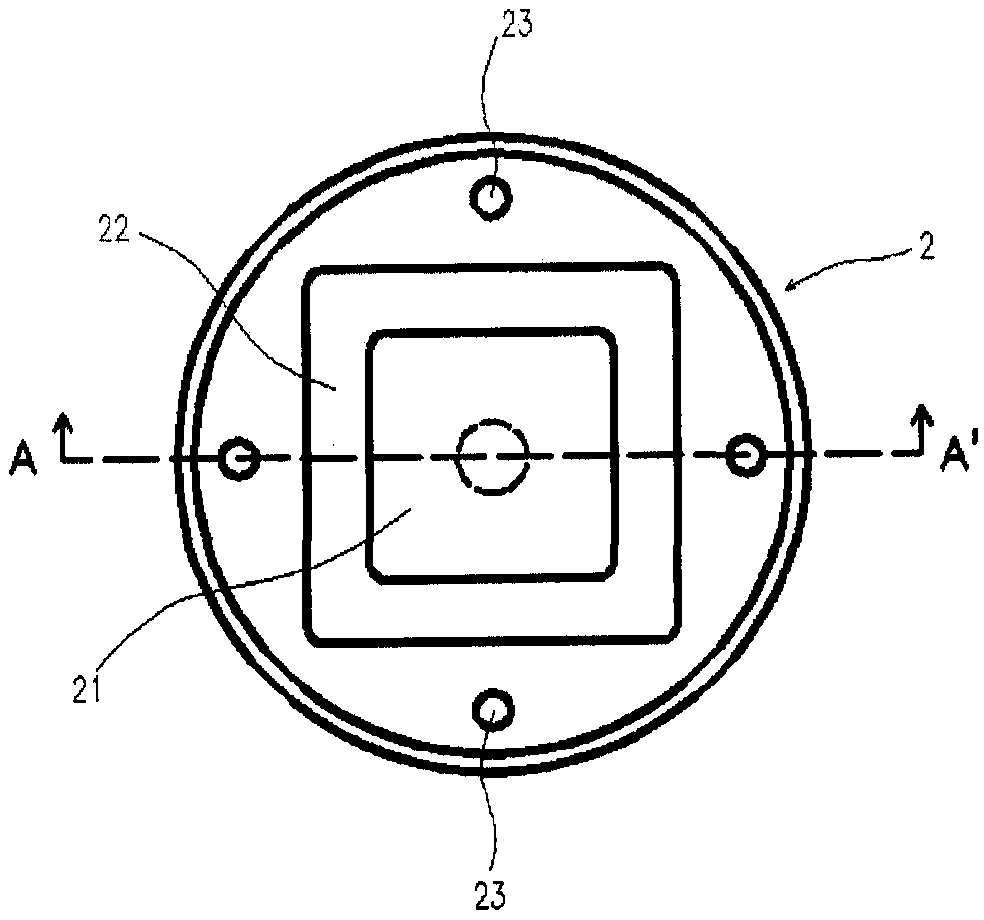

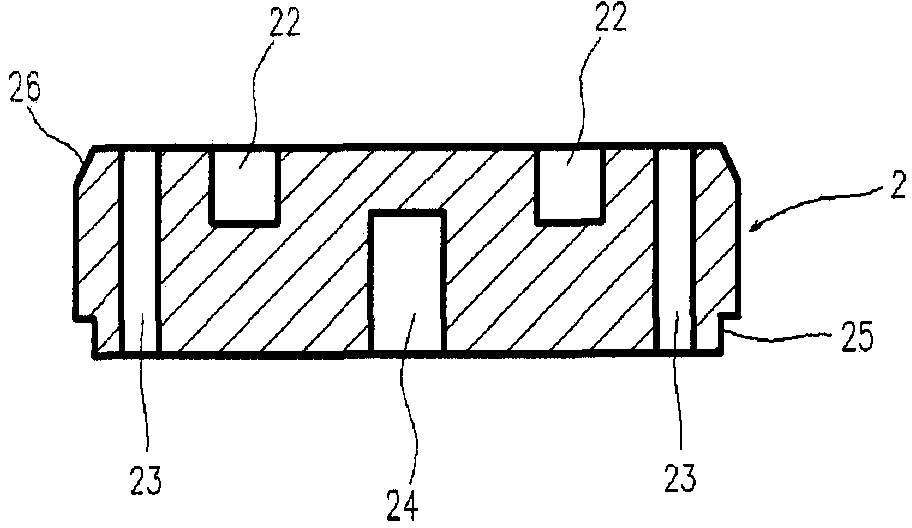

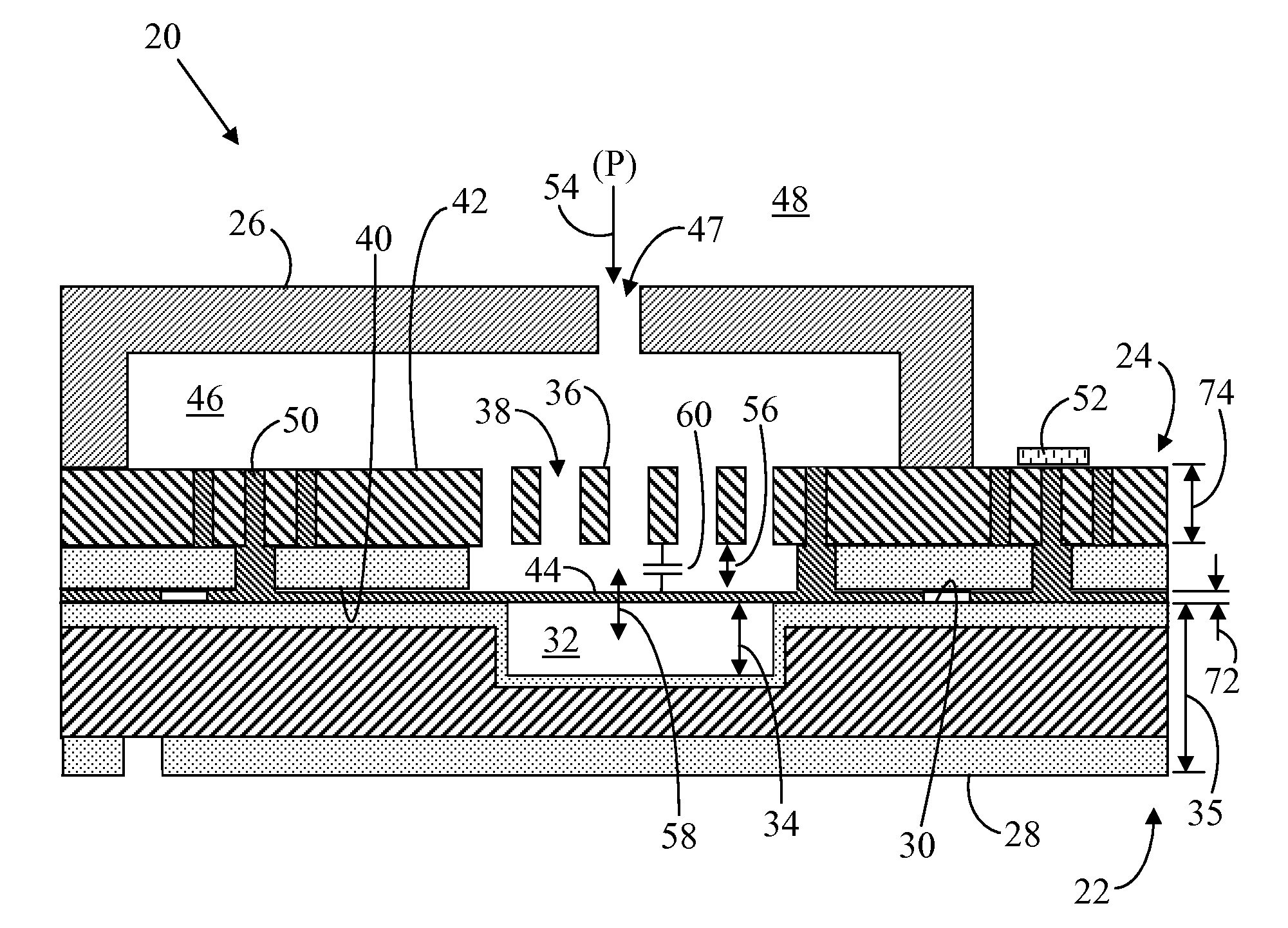

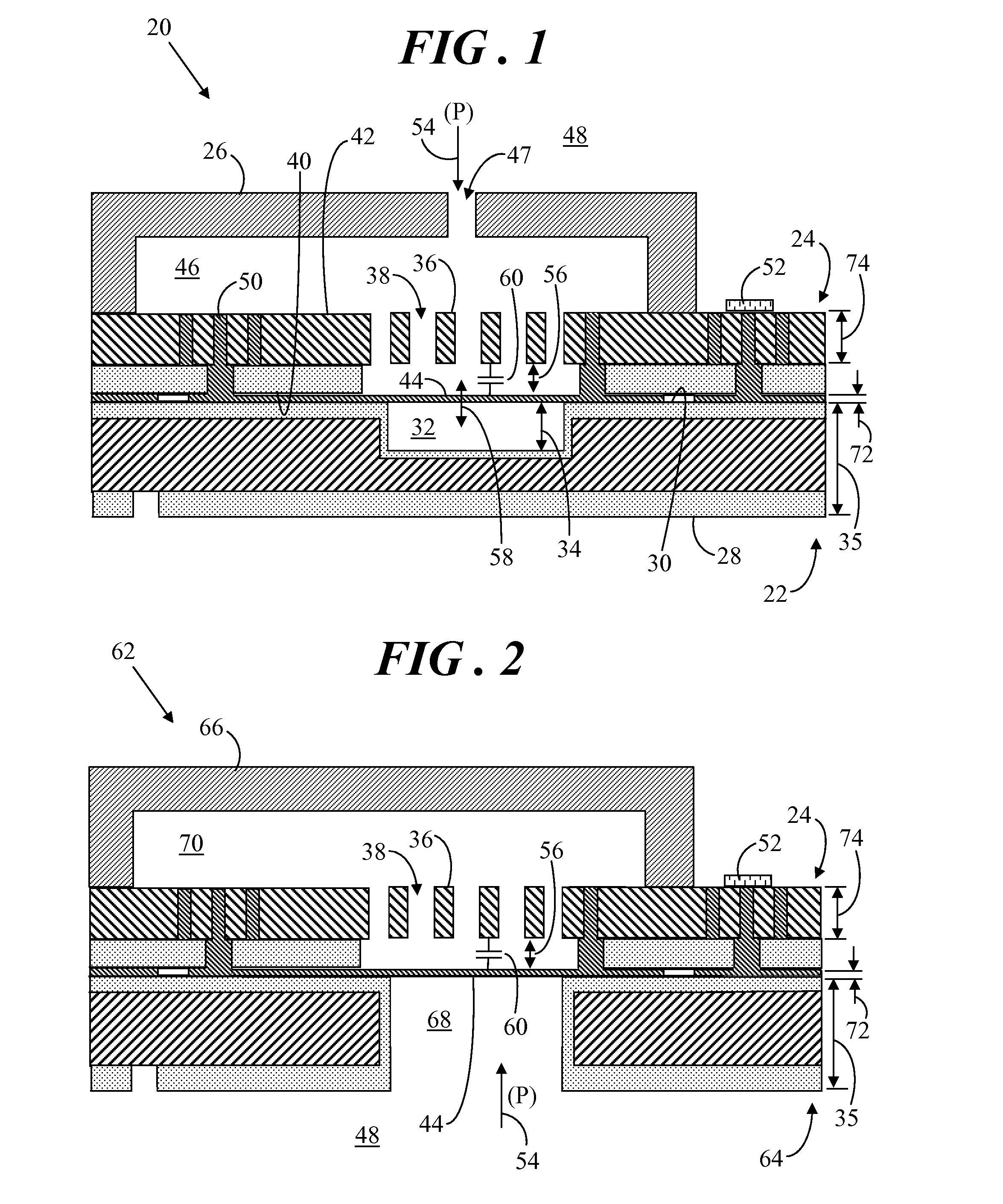

MEMS Pressure Sensor Device and Method of Fabricating Same

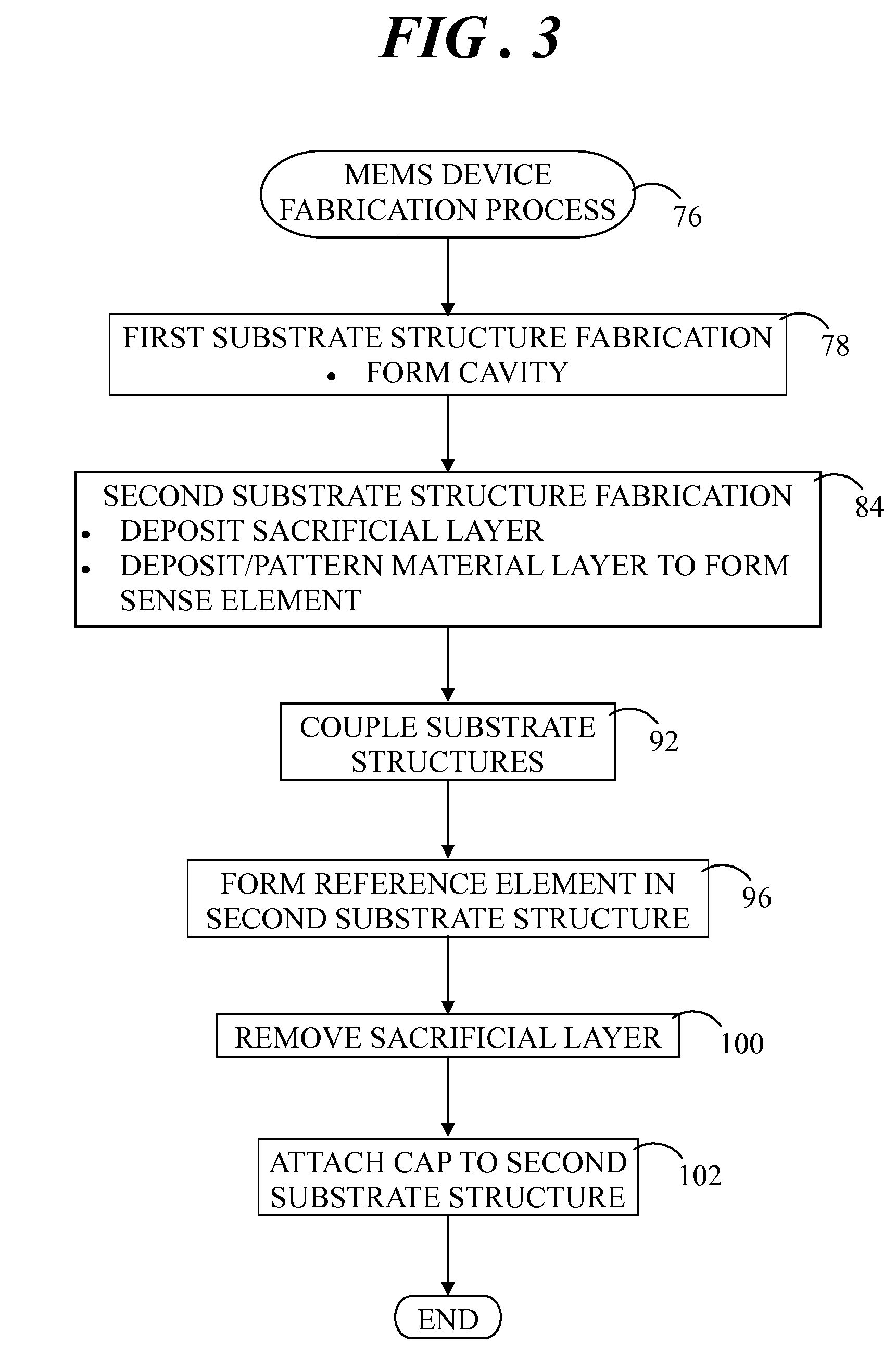

InactiveUS20120042731A1Printed circuit assemblingSemiconductor/solid-state device manufacturingMems pressure sensorForce sensor

A microelectromechanical systems (MEMS) pressure sensor device (20, 62) includes a substrate structure (22, 64) having a cavity (32, 68) formed therein and a substrate structure (24) having a reference element (36) formed therein. A sense element (44) is interposed between the substrate structures (22, 24) and is spaced apart from the reference element (36). The sense element (44) is exposed to an external environment (48) via one of the cavity (68) and a plurality of openings (38) formed in the reference element (36). The sense element (44) is movable relative to the reference element (36) in response to a pressure stimulus (54) from the environment (48). Fabrication methodology (76) entails forming (78) the substrate structure (22, 64) having the cavity (32, 68), fabricating (84) the substrate structure (24) including the sense element (44), coupling (92) the substrate structures, and subsequently forming (96) the reference element (36) in the substrate structure (24).

Owner:NORTH STAR INNOVATIONS

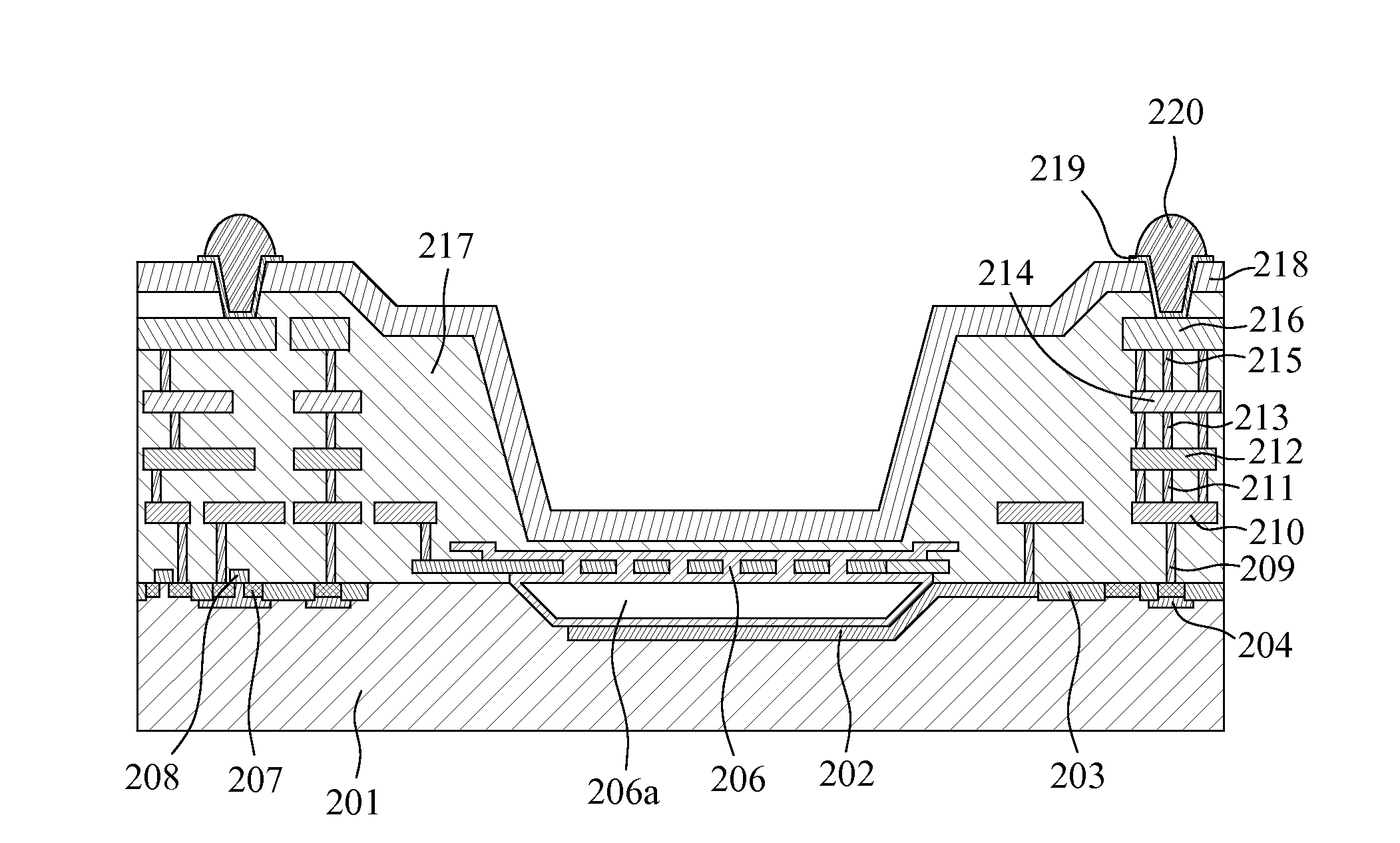

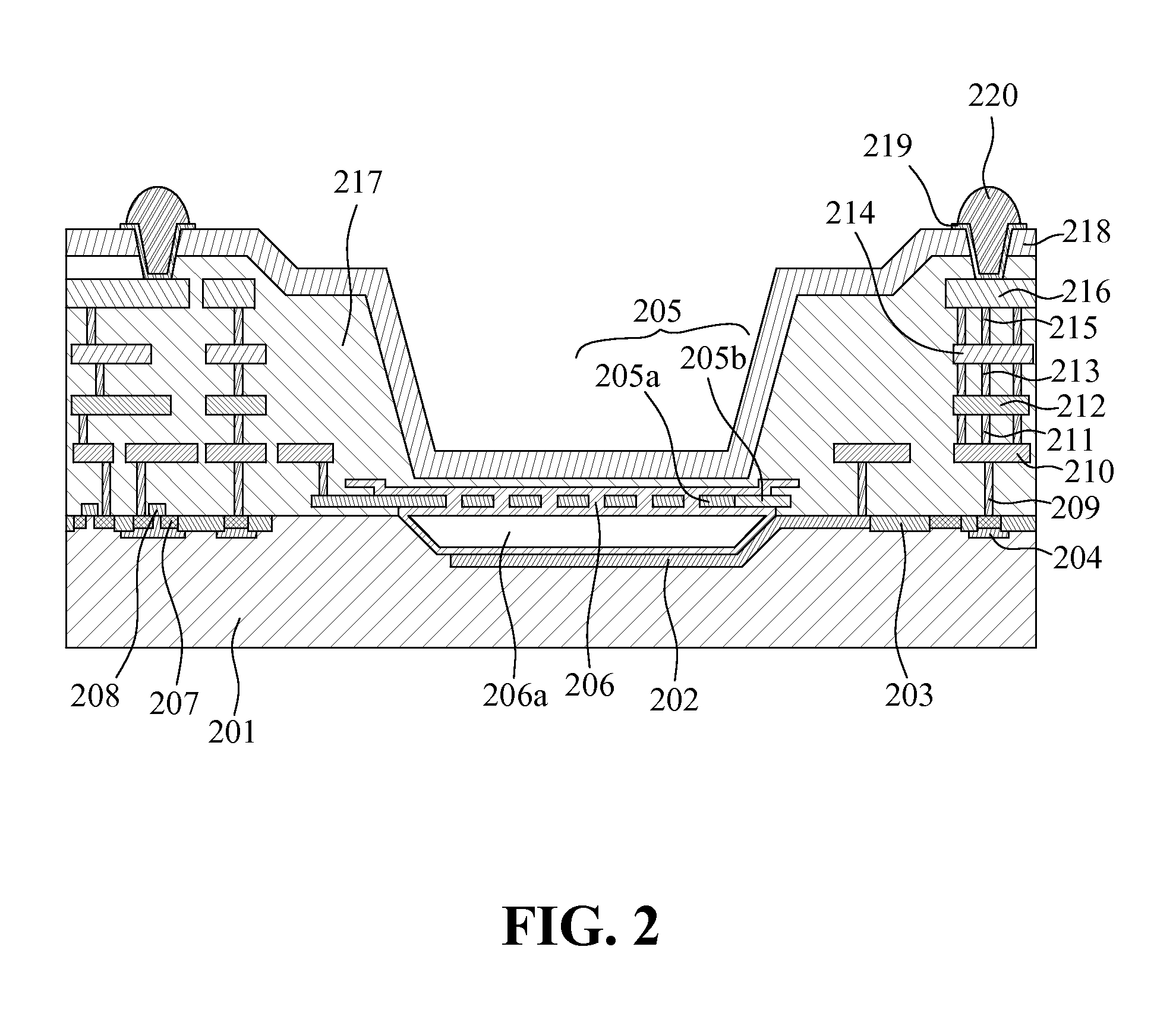

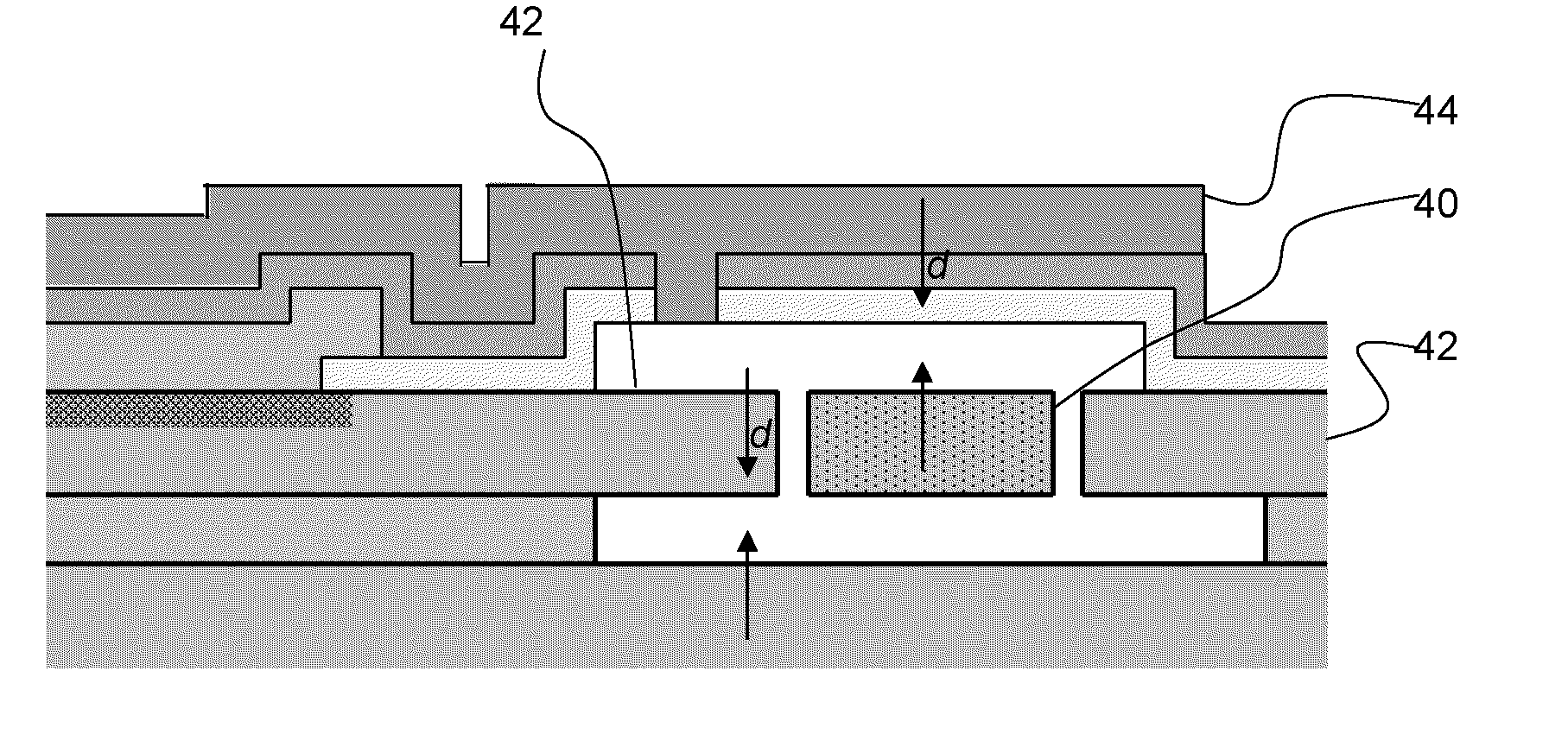

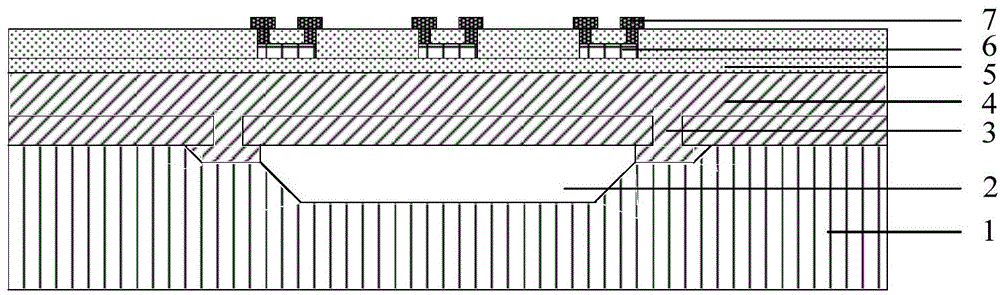

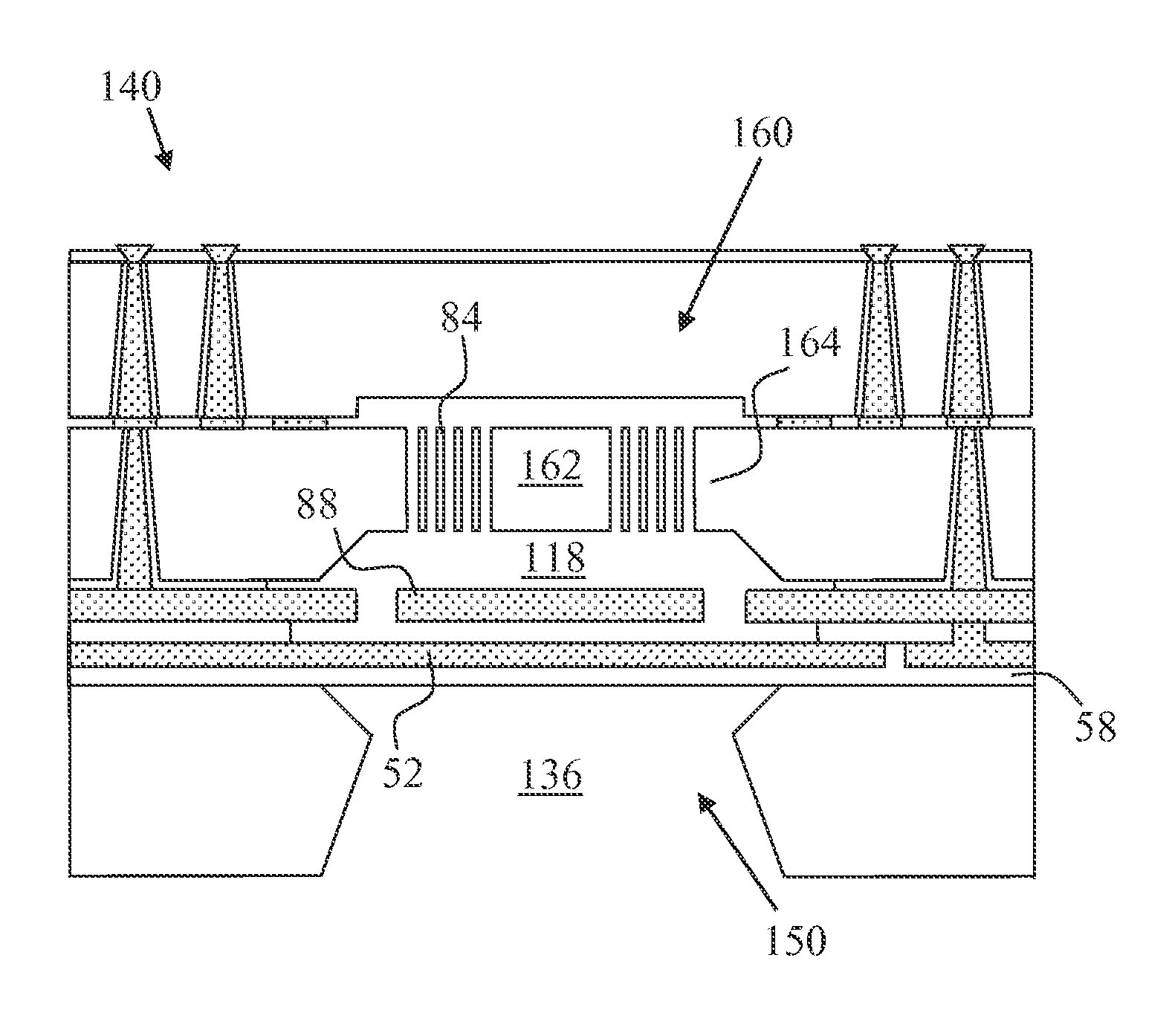

Integrated MEMS pressure sensor with mechanical electrical isolation

InactiveUS20150060956A1Improve reliabilityReduce manufacturing costDecorative surface effectsFluid pressure measurement by electric/magnetic elementsContact layerEngineering

An integrated MEMS pressure sensor is provided, including, a CMOS substrate layer, an N+ implant doped silicon layer, a field oxide (FOX) layer, a plurality of implant doped silicon areas forming CMOS wells, a two-tier polysilicon layer with selective ion implantation forming a membrane, including an implant doped polysilicon layer and a non-doped polysilicon layer, a second non-doped polysilicon layer, a plurality of implant doped silicon areas forming CMOS source / drain, a gate poly layer made of polysilicon forming CMOS transistor gates, said CMOS wells, CMOS transistor sources / drains and CMOS gates forming CMOS transistors, an oxide layer embedded with an interconnect contact layer, a plurality of metal layers interleaved with a plurality of via hole layers, a Nitride deposition layer, an under bump metal (UBM) layer and a plurality of solder spheres. N+ implant doped silicon layer and implant doped / un-doped composition polysilicon layer forming a sealed vacuum chamber.

Owner:WINDTOP TECH CORP

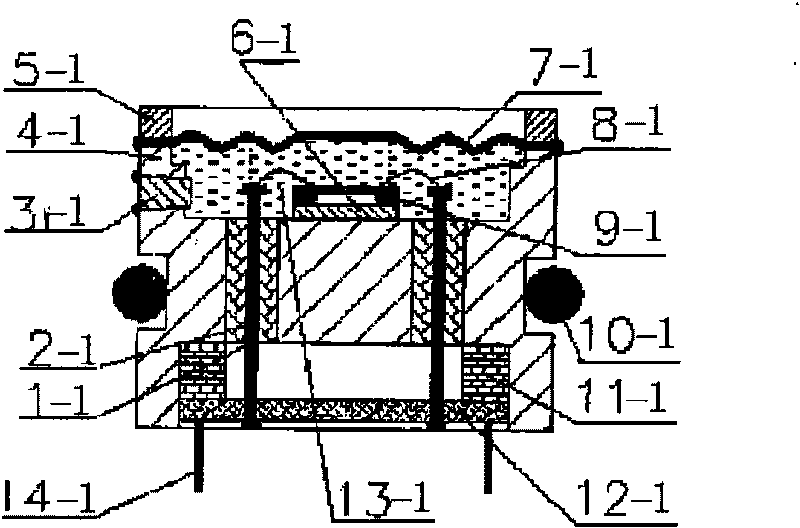

MEMS pressure sensor and manufacturing method thereof

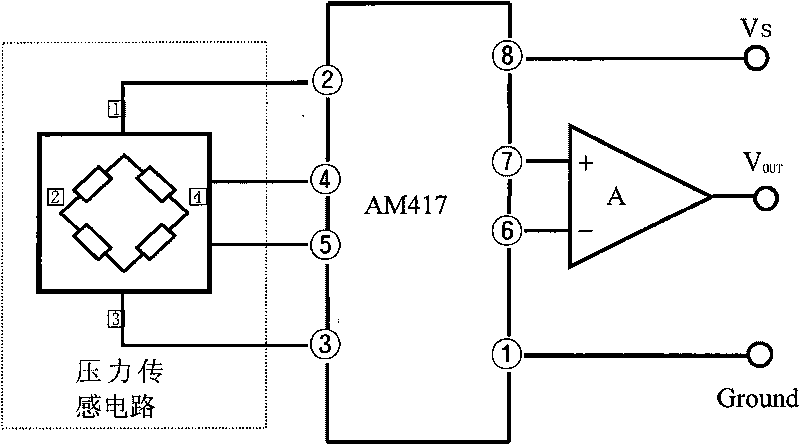

InactiveCN101738280AHigh bonding strengthLow costTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElectrical resistance and conductanceMems pressure sensor

The invention discloses an MEMS pressure sensor and a manufacturing method thereof. The MEMS pressure sensor comprises an MEMS pressure sensing chip, wherein the MEMS pressure sensing chip is arranged at a Wheatstone bridge formed on the crystallographic orientation of a monocrystalline silicon film (110) by four polycrystalline silicon resistors, the monocrystalline silicon film comprises a lower silicon wafer, an upper silicon wafer and a purification layer, a cavity body is arranged on the lower silicon wafer, the lower silicon wafer and the upper silicon wafer are bonded together by hot melt silicon-silicon, the surface of the upper silicon wafer is provided with a passivation layer, the polycrystalline silicon resistors are arranged on the upper silicon wafer by a diffusion process, and a conducting wire of a metal film and a press welding block are etched on the upper silicon wafer. The pressure sensor adopting a silicon-silicon bonding structure can be made in a very small size, the number of chips on each silicon wafer can be increased by 50% or more, the silicon-silicon bonding strength is higher, and the air tightness is better. The cost of the sensor is greatly lowered, and the performance is more stable and reliable. The sensor belongs to a pressure sensor with low cost and high performance and has very extensive application.

Owner:HENAN POLYTECHNIC UNIV

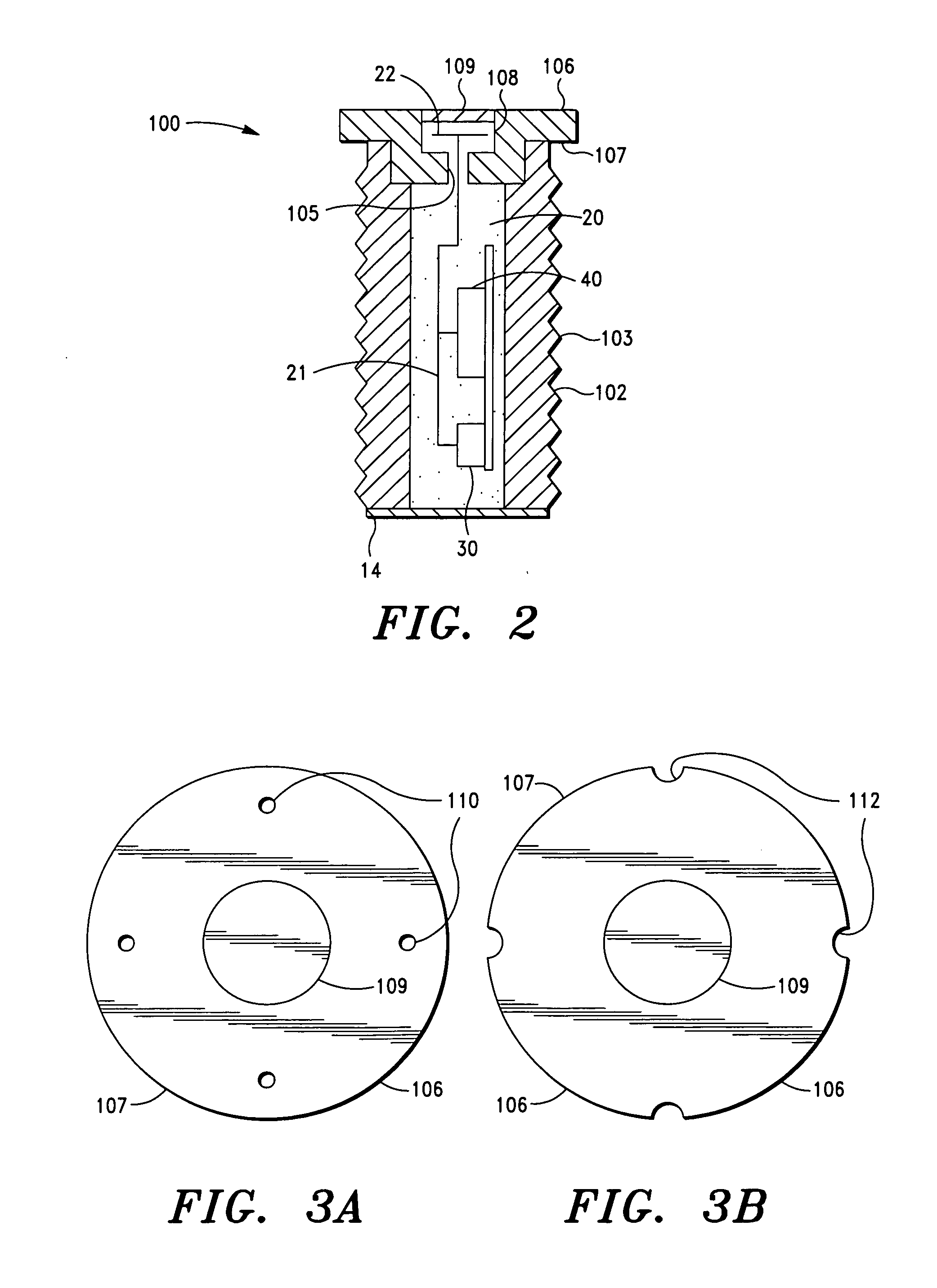

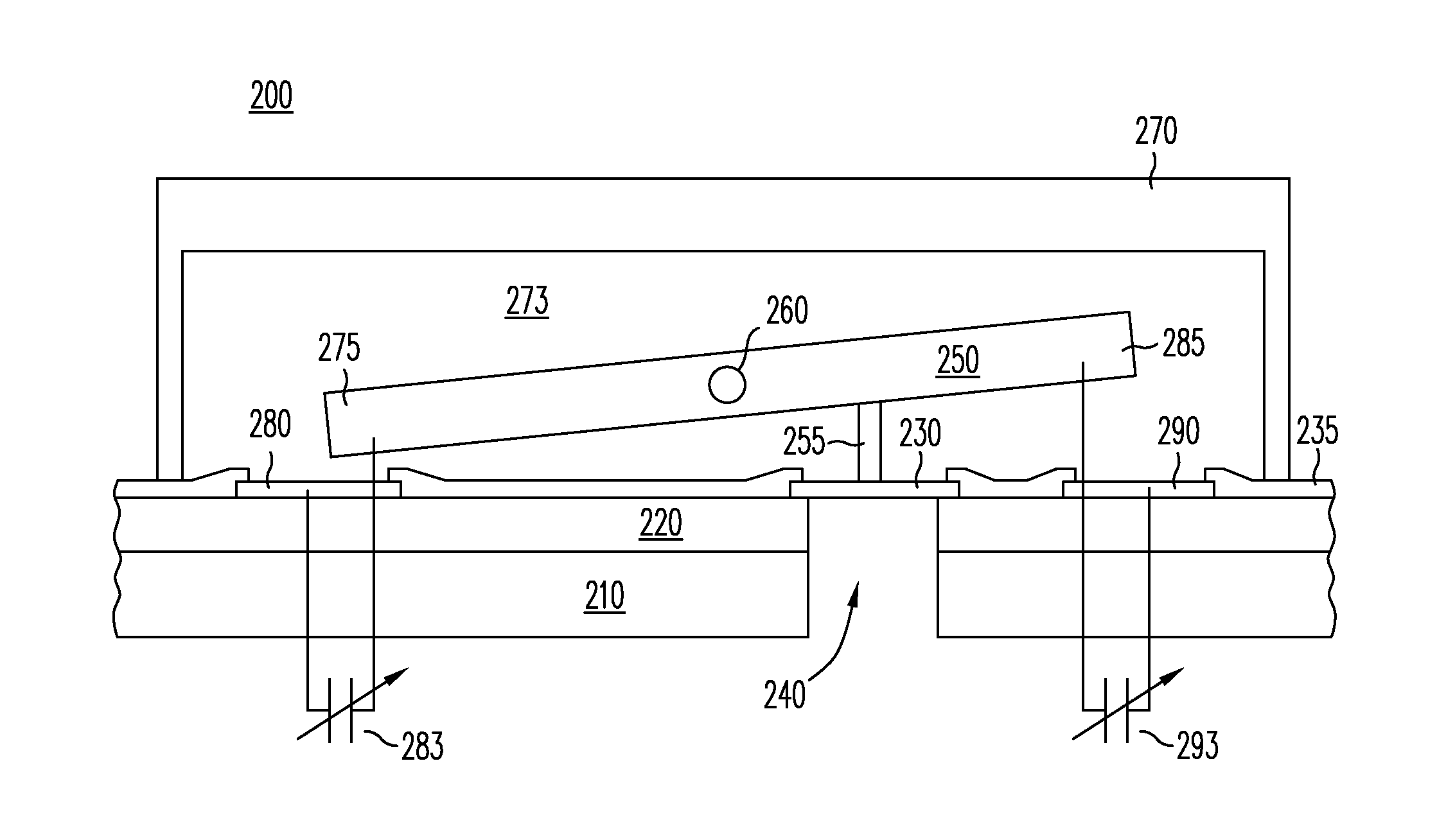

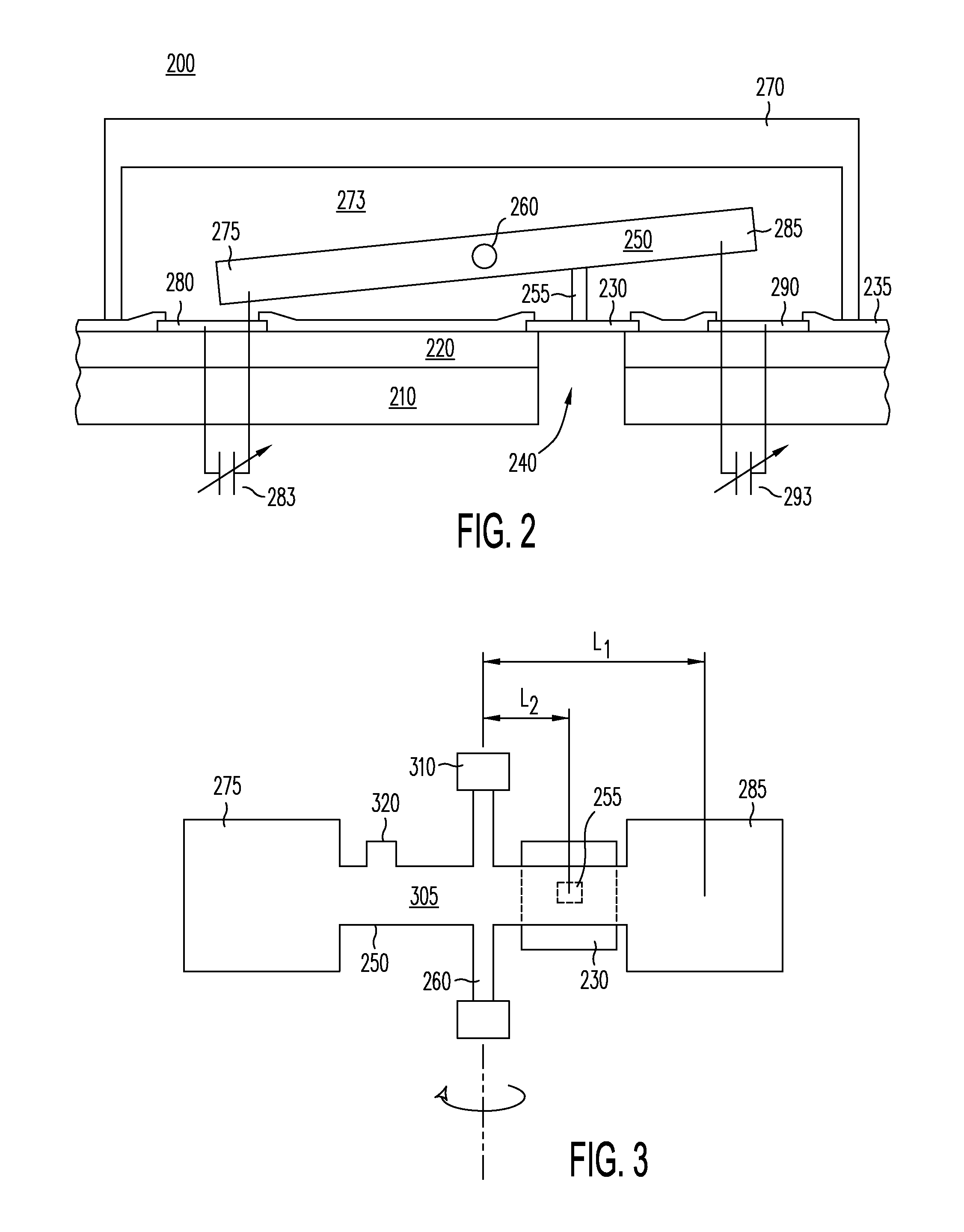

Pressure sensor with differential capacitive output

ActiveUS20140060169A1Tyre measurementsFluid pressure measurement using capacitance variationCapacitanceMems pressure sensor

A MEMS pressure sensor device is provided that can provide both a linear output with regard to external pressure, and a differential capacitance output so as to improve the signal amplitude level. These benefits are provided through use of a rotating proof mass that generates capacitive output from electrodes configured at both ends of the rotating proof mass. Sensor output can then be generated using a difference between the capacitances generated from the ends of the rotating proof mass. An additional benefit of such a configuration is that the differential capacitance output changes in a more linear fashion with respect to external pressure changes than does a capacitive output from traditional MEMS pressure sensors.

Owner:NXP USA INC

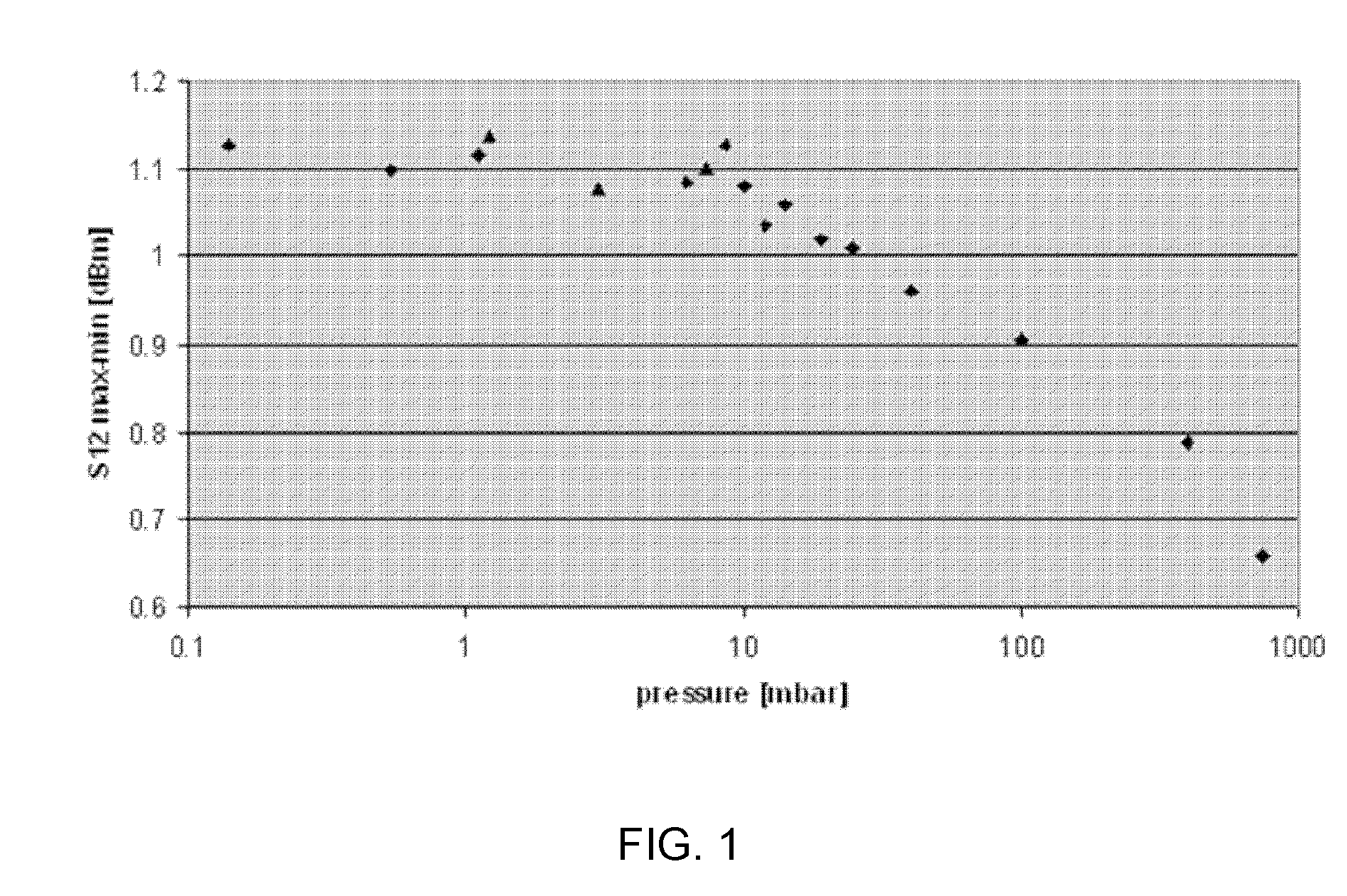

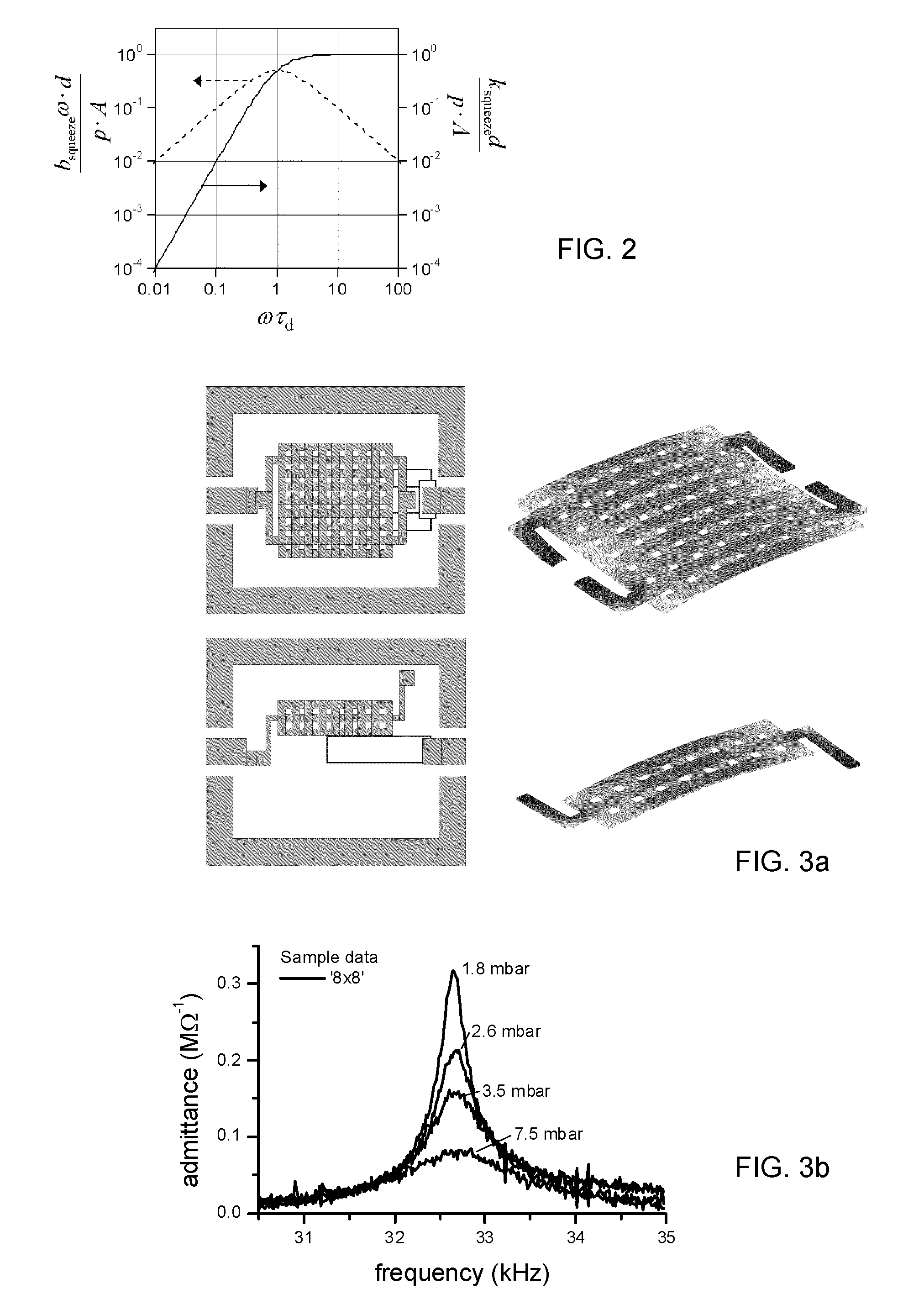

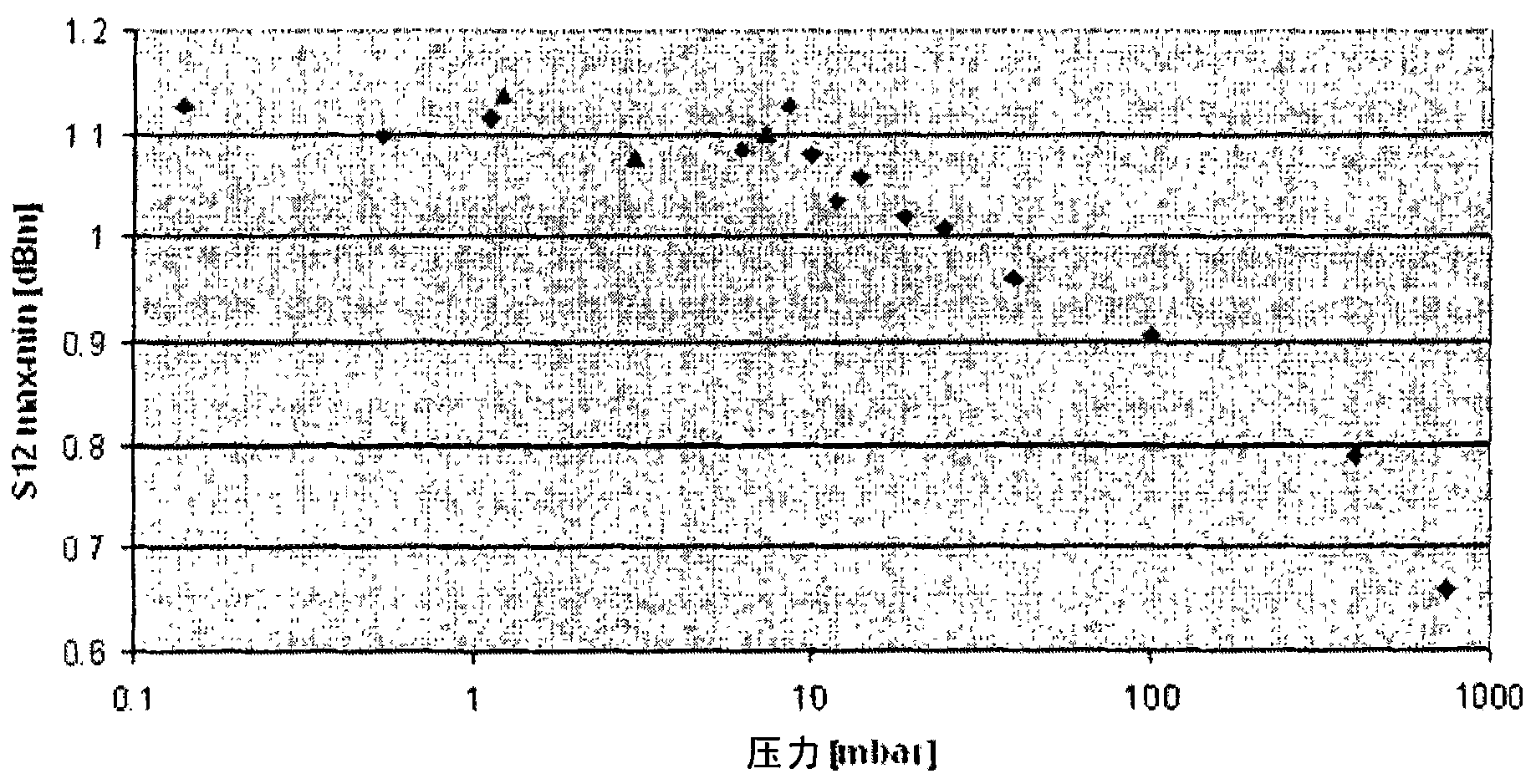

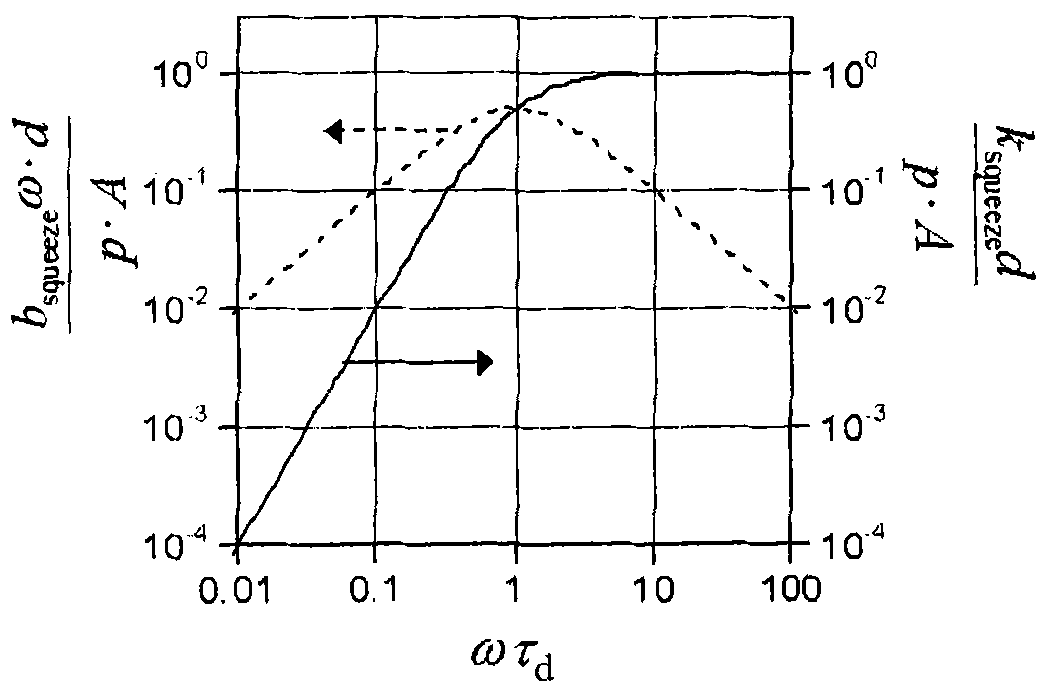

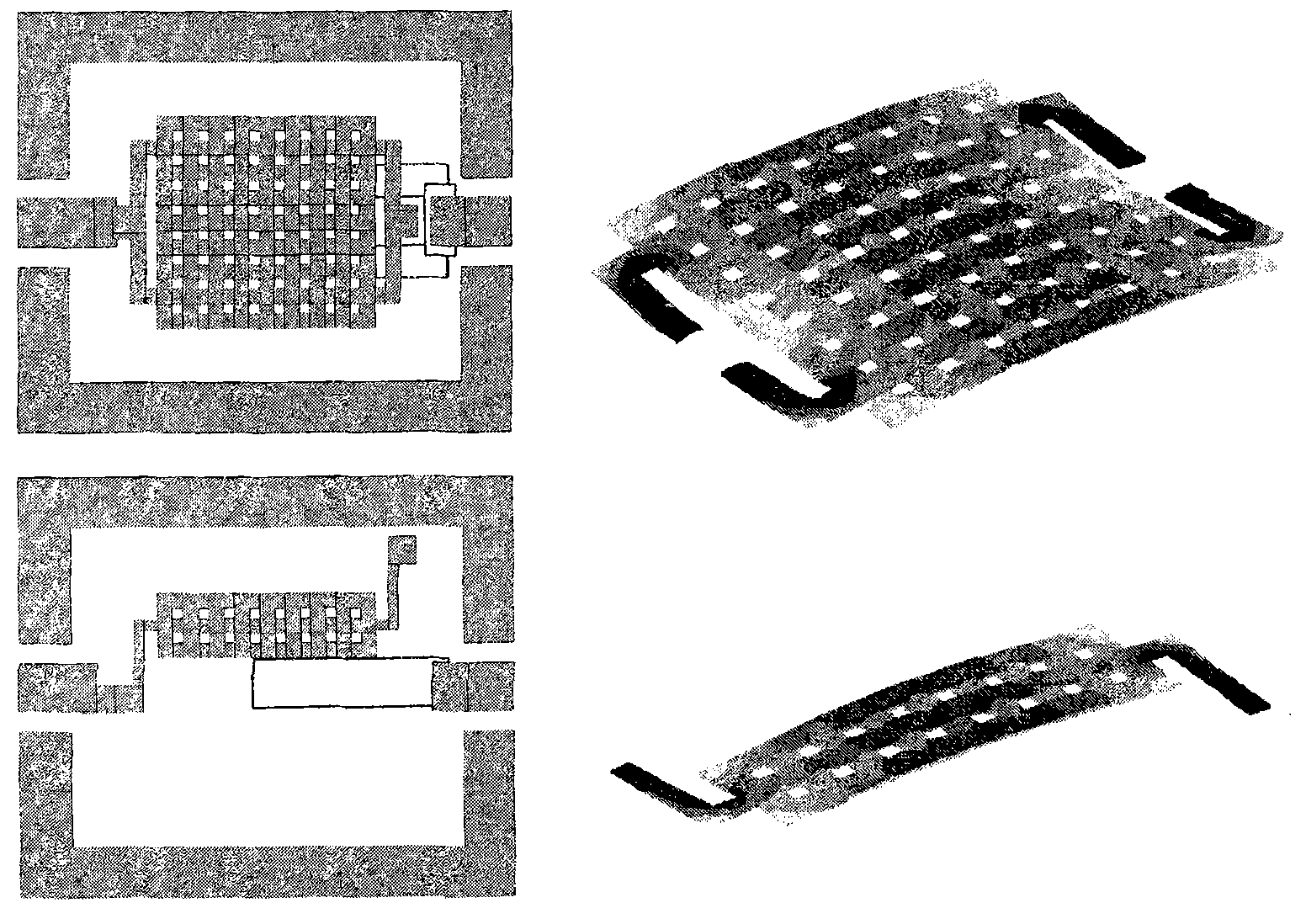

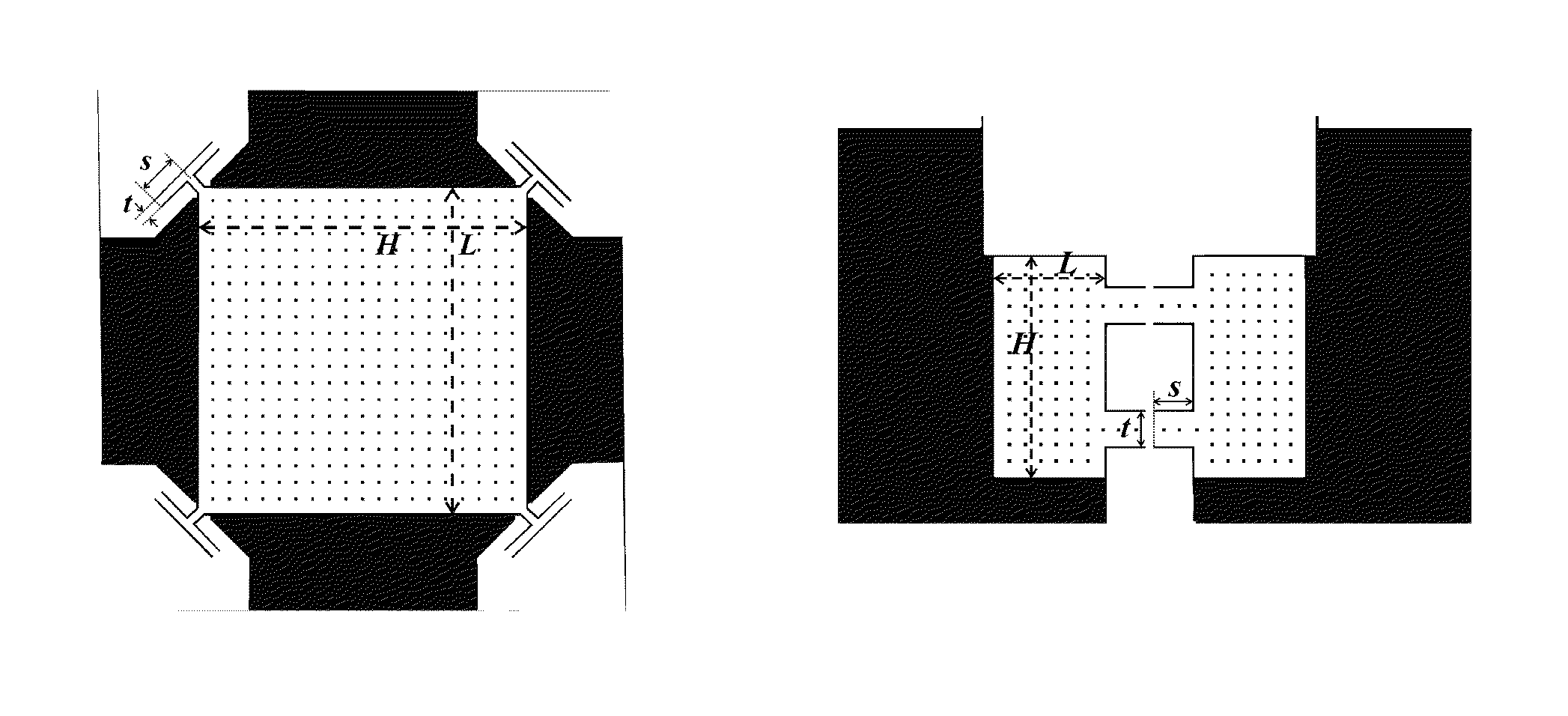

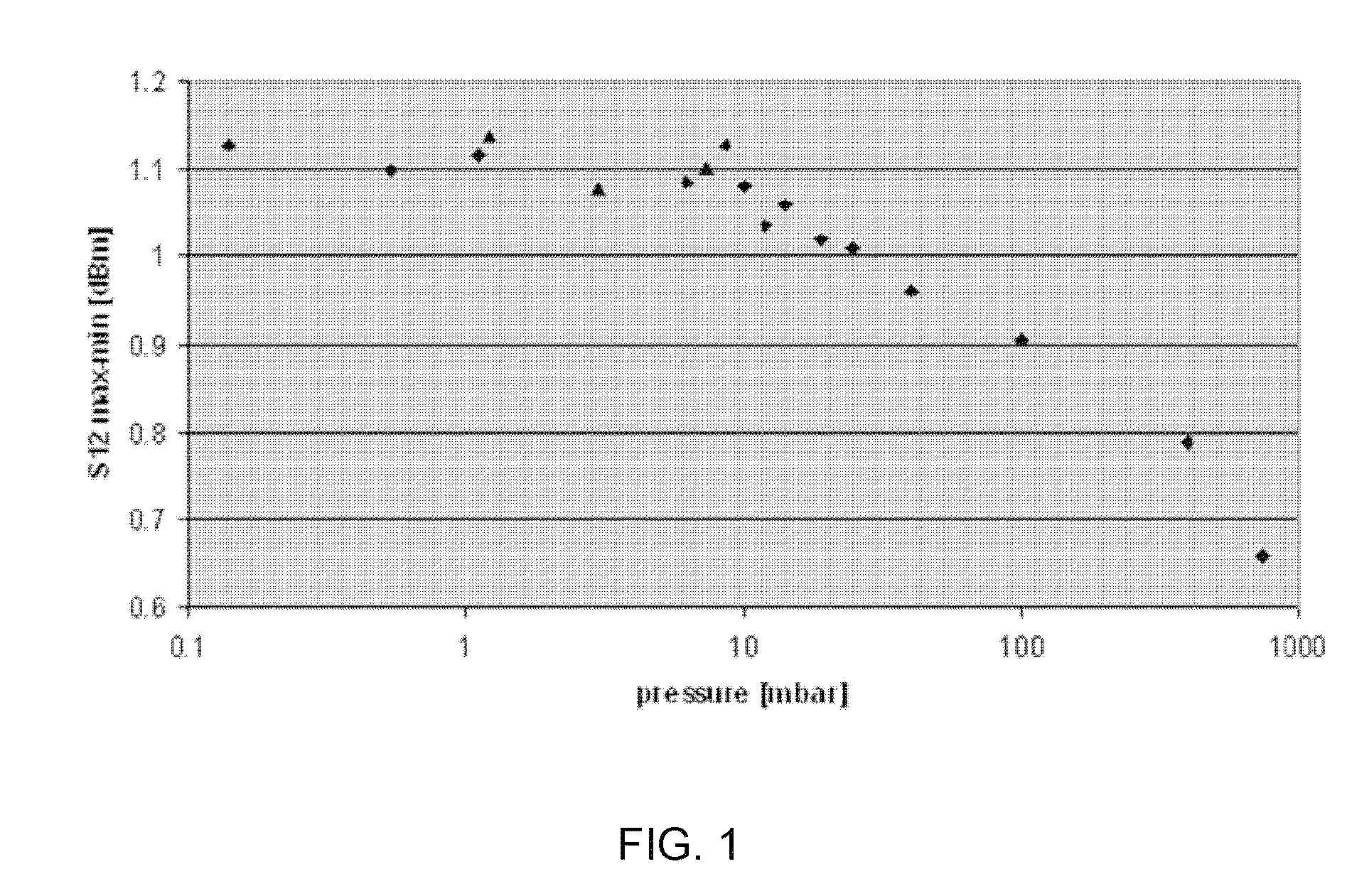

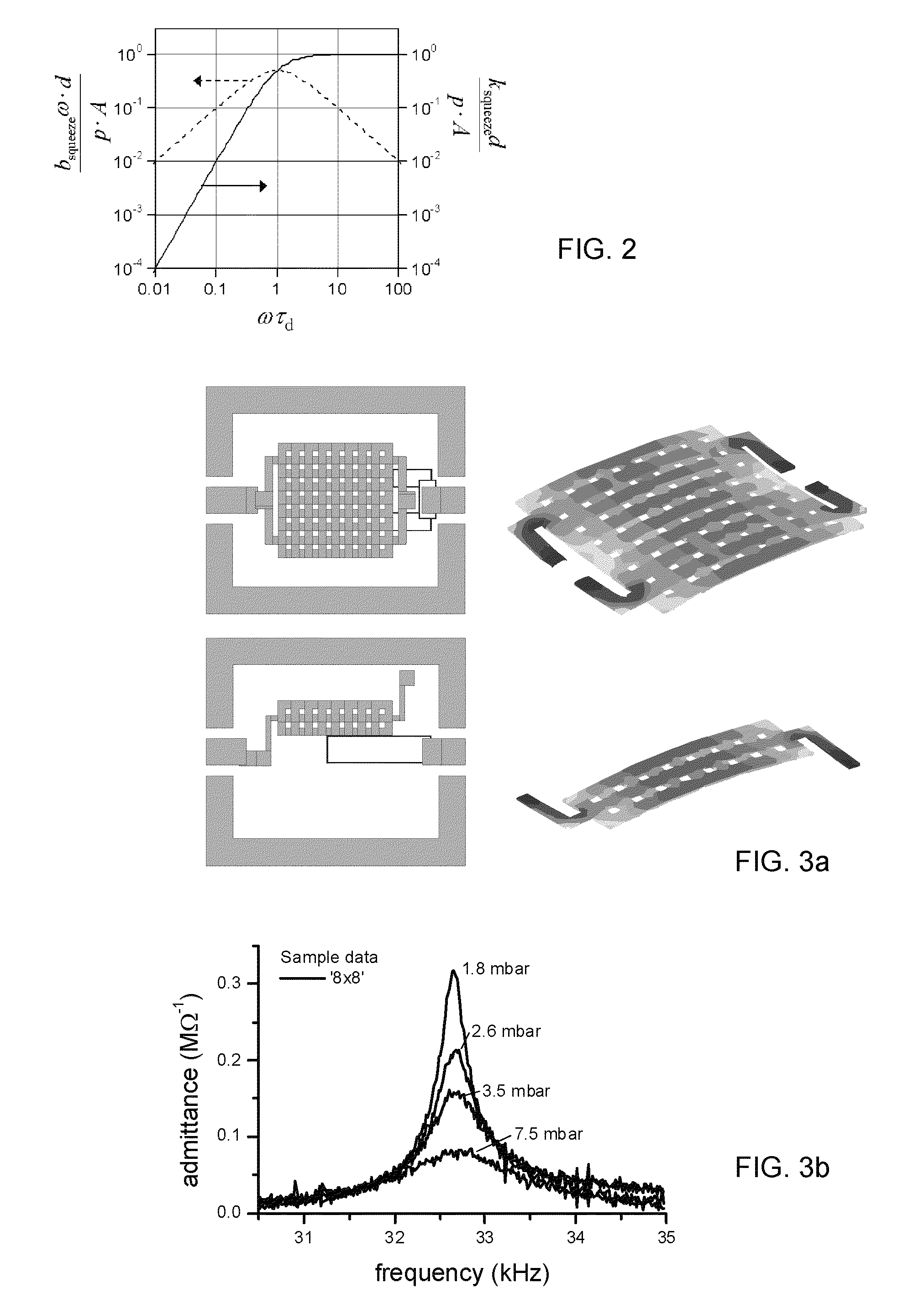

MEMS pressure sensor

ActiveUS20110107838A1Fluid pressure measurement by electric/magnetic elementsVacuum gauge using gaseous frictional resistance variationMems pressure sensorResonance

A MEMS pressure sensor for sensing the pressure in a sealed cavity of a MEMS device, comprises a resonant MEMS device having a pressure sensor resonator element which comprises an array of openings. The resonant frequency of the resonant MEMS device is a function of the pressure in the cavity, with resonant frequency increasing with pressure. Over the pressure range 0 to 0.1 kPa, the average change in frequency is at least 10−6 / Pa.The invention is based on the recognition that for fast oscillation, the elastic force causes the resonance frequency to shift. Therefore, it is possible to sense the pressure by a device with resonance frequency that is sensitive to the pressure.

Owner:SCIOSENSE BV

Pressure sensor apparatus, system and method

InactiveUS20110160560A1Accurate and stable sensor outputIntracranial pressure measurementTonometersMems pressure sensorPressure sense

An implantable pressure sensor system having a sensor assembly configured and adapted to measure pressure in a volume, the sensor assembly including at least a first MEMS pressure sensor, an application-specific integrated circuit (ASIC) having memory means, temperature compensation system, drift compensation system, and power supply means for powering the sensor assembly, the first MEMS pressure sensor having a pressure sensing element that is responsive to exposed pressure, the pressure sensing element being adapted to generate a pressure sensor signal representative of the exposed pressure, the temperature compensation system being adapted to correct for temperature induced variations in the pressure sensor signal, the drift compensation system being adapted to correct for pressure and temperature induced pressure sensor signal drift.

Owner:TRONICS NORTH AMERICA

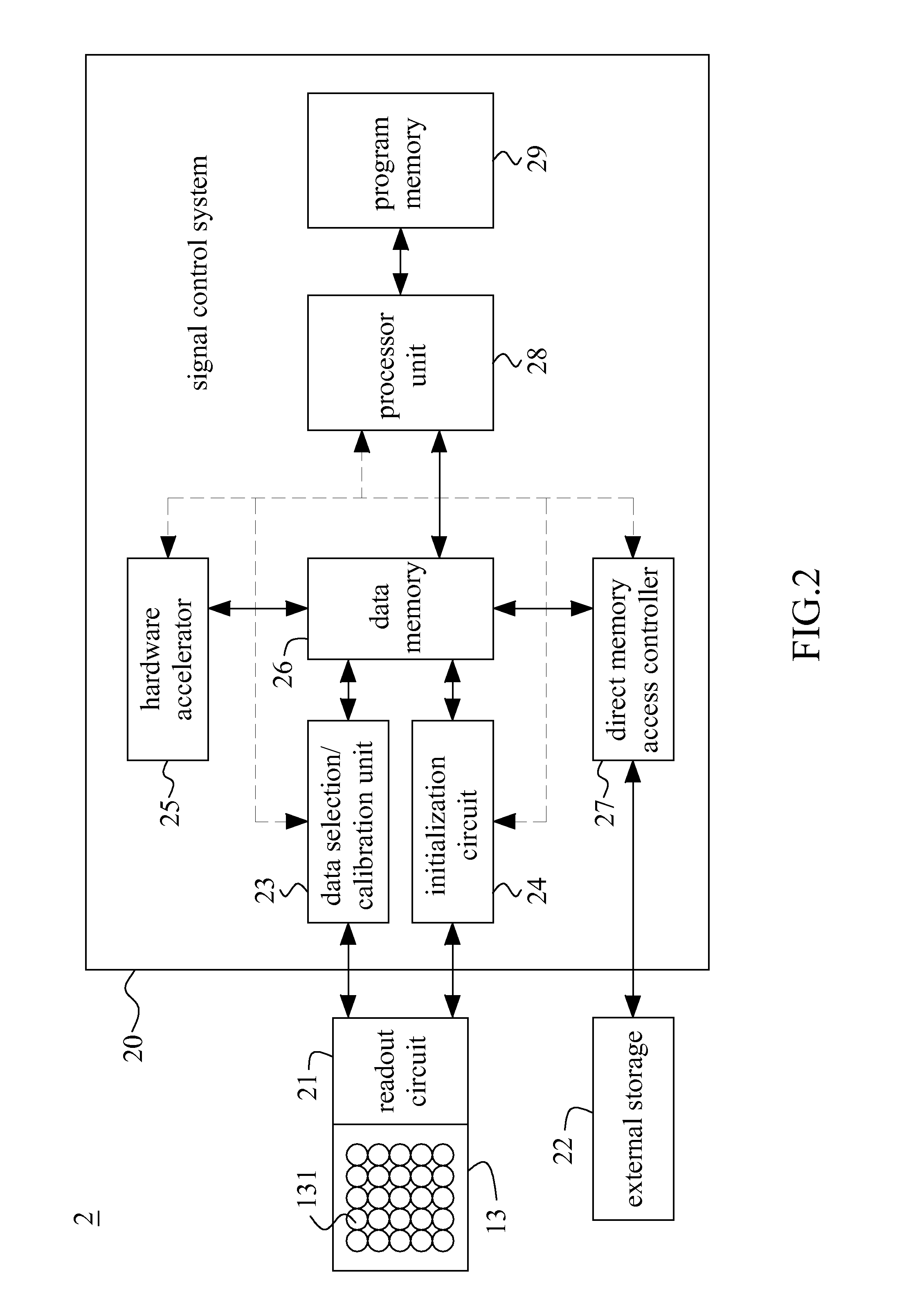

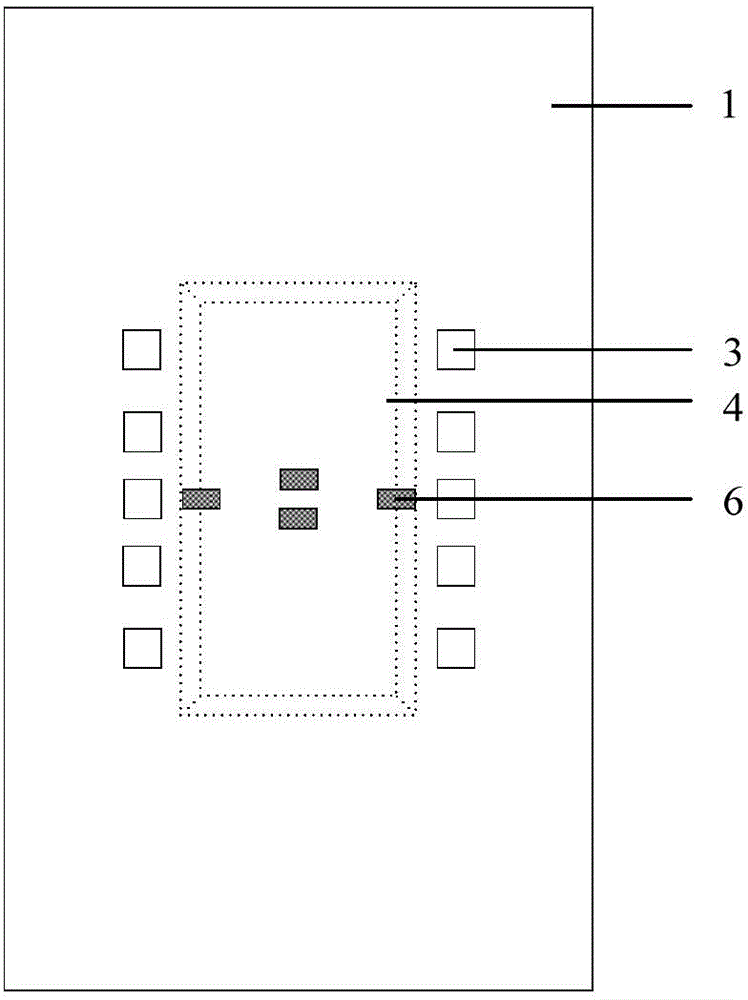

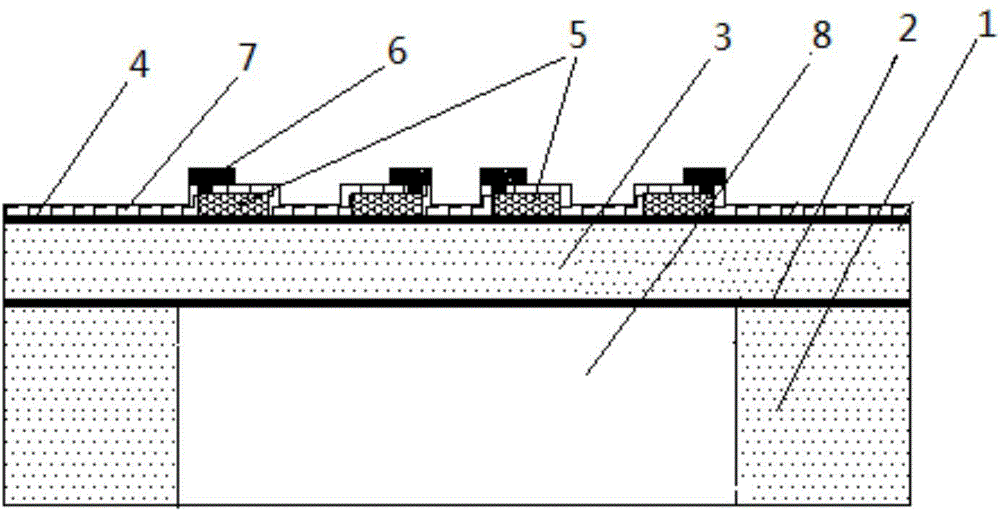

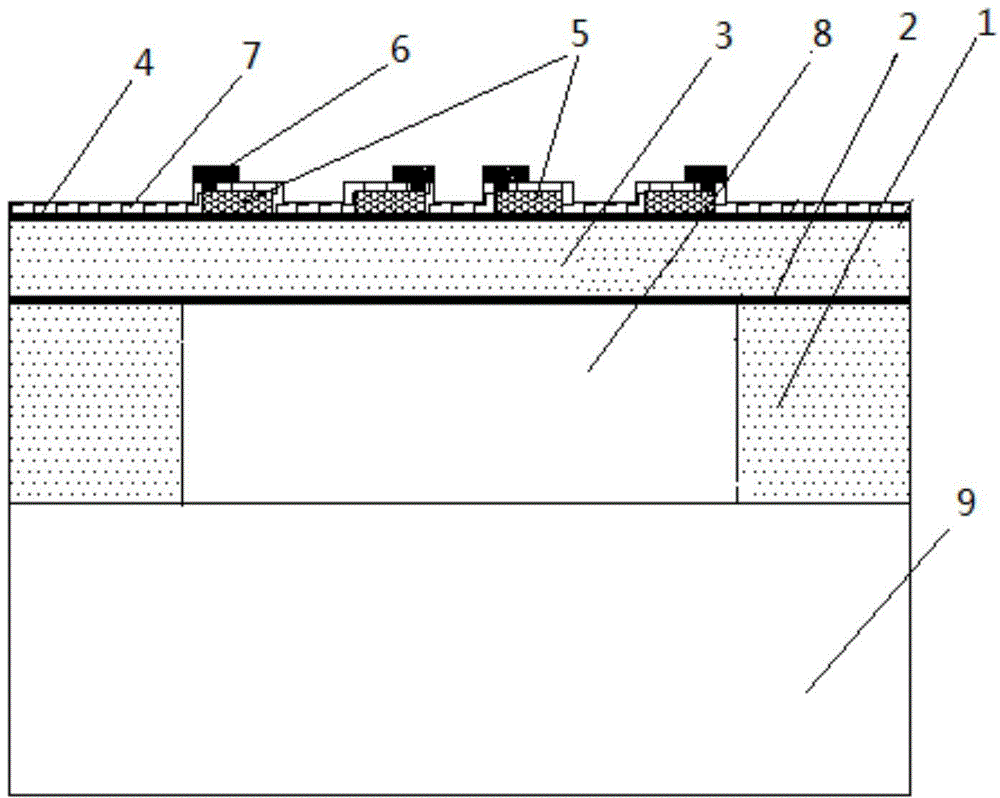

SMART NON-INVASIVE ARRAY-BASED HEMODYNAMIC MONITORING SYSTEM on CHIP AND METHOD THEREOF

A non-invasive array-based hemodynamic monitoring system on chip is disclosed. The non-invasive array-based hemodynamic monitoring system on chip comprises a CMOS MEMS pressure sensor array, a readout circuit, and a signal control system. The CMOS MEMS pressure sensor array is configured to sense a pulse wave of a blood vessel. The readout circuit is coupled with each of the CMOS compatible MEMS pressure sensors and is configured to read the pulse wave and transformed the pulse wave into a voltage signal. The signal control system is coupled with each of the readout circuit, and is configured to estimate a wave velocity according to the voltage signal.

Owner:NAT TAIWAN UNIV

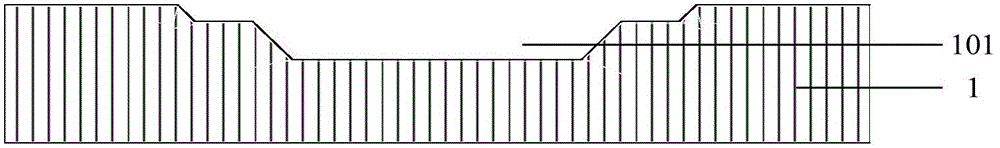

MEMS pressure sensor chip based on SOI technology and manufacturing method thereof

ActiveCN103604538AEasy to integrateEasy to miniaturizeDecorative surface effectsForce measurementHysteresisMems pressure sensor

The invention discloses an MEMS pressure sensor chip based on an SOI technology and a manufacturing method of the MEMS pressure sensor chip. The MEMS pressure sensor chip is suitable for absolute pressure measurement and comprises a monocrystalline silicon substrate. A flat elastic membrane is arranged on a groove of the monocrystalline silicon substrate. The edge of the elastic membrane is provided with corrosion holes. The elastic membrane and the groove of the silicon substrate form an airtight cavity. Four monocrystalline silicon strain resistors are arranged on the elastic membrane. All the monocrystalline silicon strain resistors are isolated from one another through insulating media, and the monocrystalline silicon strain resistors are also isolated from the elastic membrane through insulating media. The four strain resistors are connected through metal wires to form a Wheatstone bridge so as to convert pressure into a voltage and output the voltage. The MEMS pressure sensor chip has the advantages of being small in size, good in repeatability and hysteresis, high in sensitivity, wide in operating temperature range, and the like; besides, the manufacturing technique is compatible with the integrated circuit technique.

Owner:SHENYANG POLYTECHNIC UNIV

MEMS pressure sensor

ActiveCN102032970AFluid pressure measurement by electric/magnetic elementsVacuum gauge using gaseous frictional resistance variationMems pressure sensorResonance

A MEMS pressure sensor for sensing the pressure in a sealed cavity of a MEMS device, comprises a resonant MEMS device having a pressure sensor resonator element which comprises an array of openings. The resonant frequency of the resonant MEMS device is a function of the pressure in the cavity, with resonant frequency increasing with pressure. Over the pressure range 0 to 0.1 KPa, the average change in frequency is at least 10-6 / Pa. The invention is based on the recognition that for fast oscillation, the elastic force causes the resonance frequency to shift. Therefore, it is possible to sense the pressure by a device with resonance frequency that is sensitive to the pressure.

Owner:XIAO TESTING CO LTD

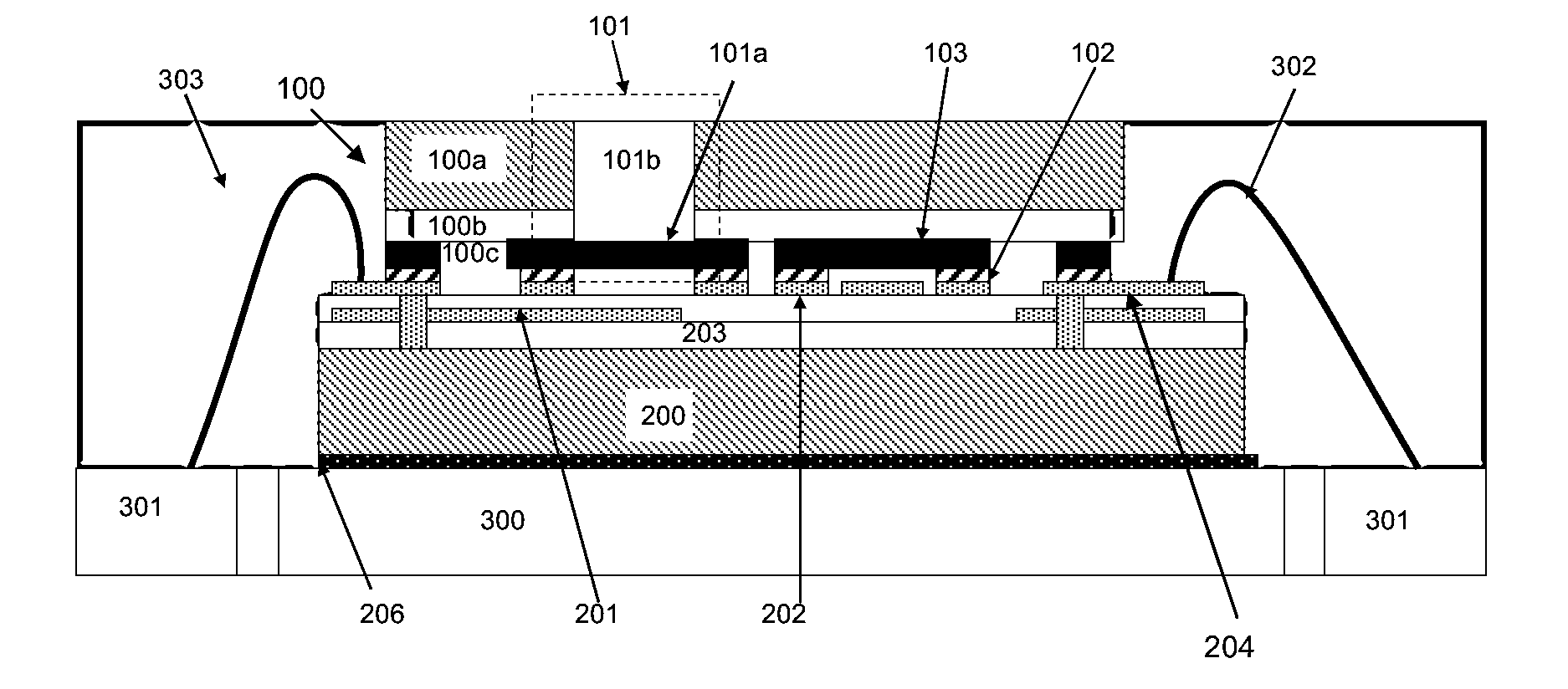

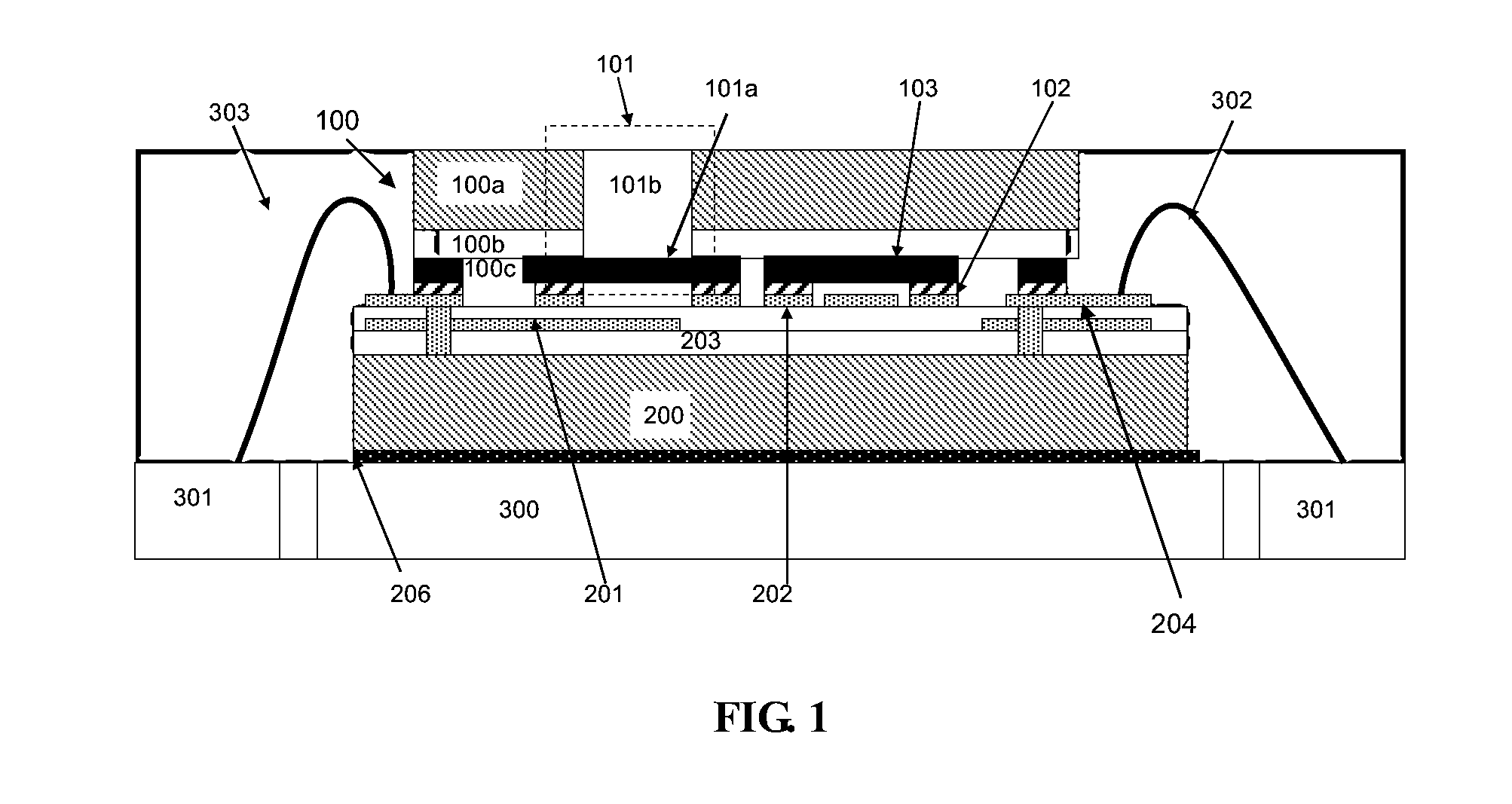

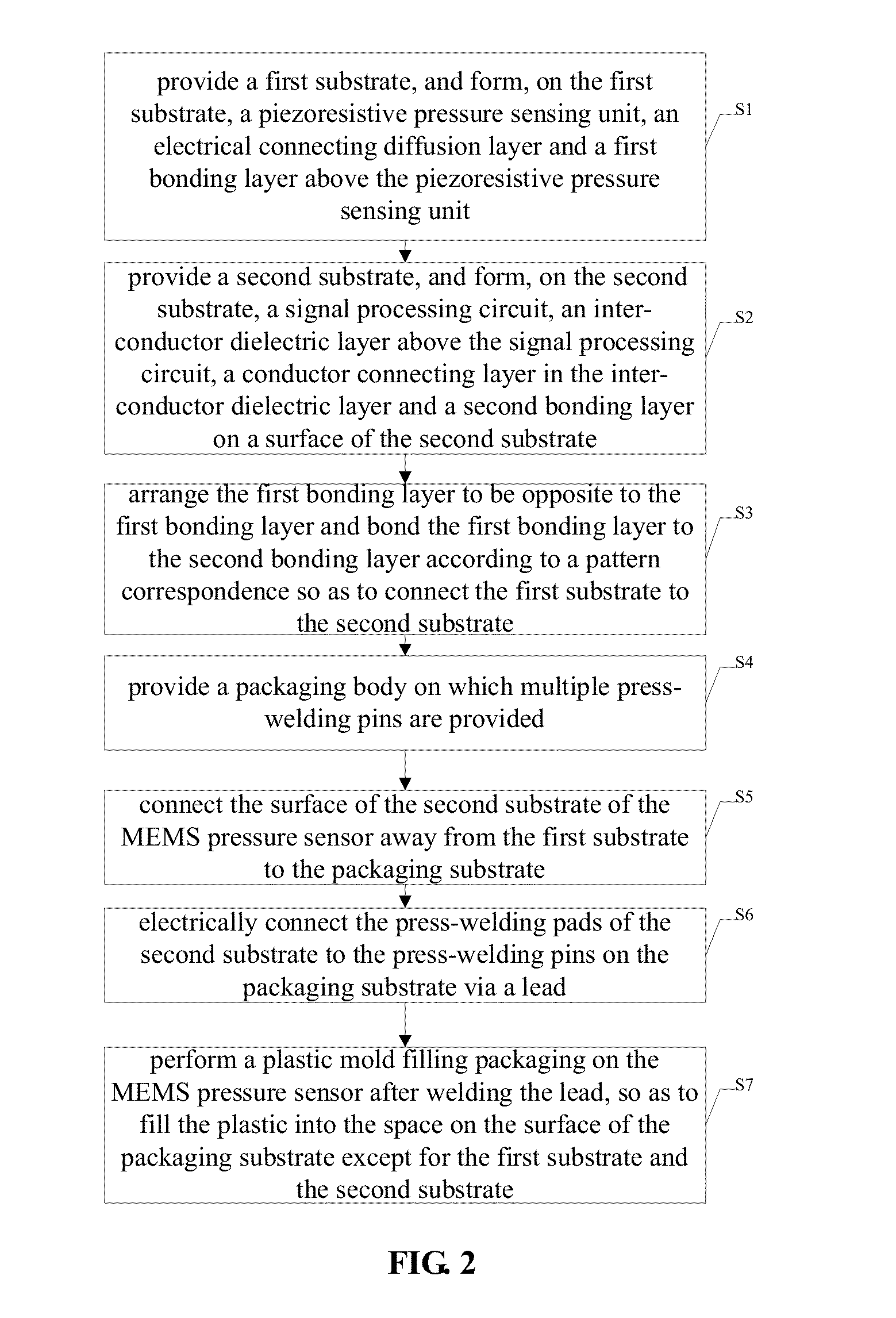

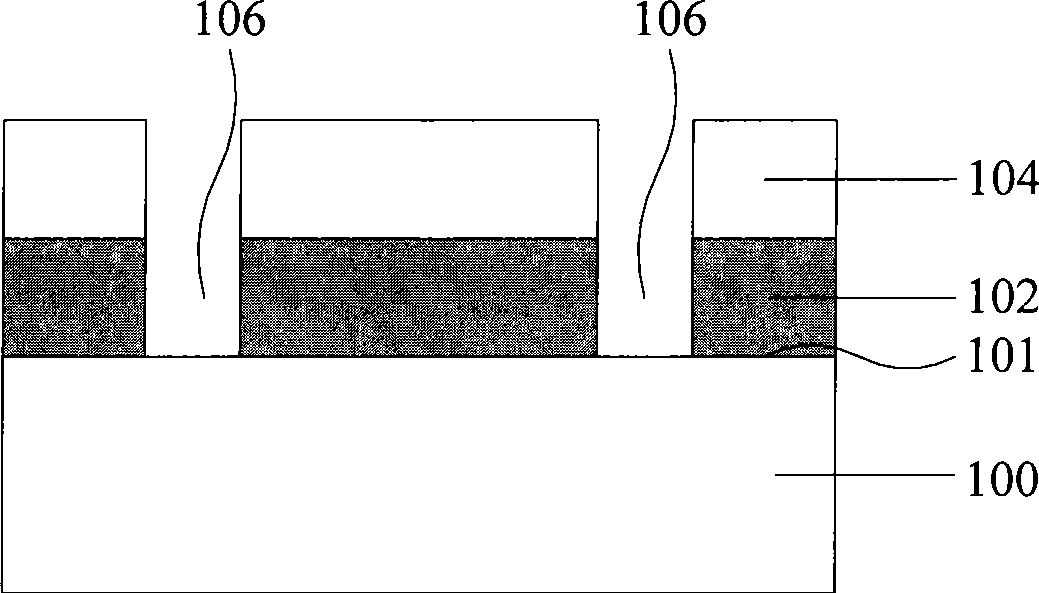

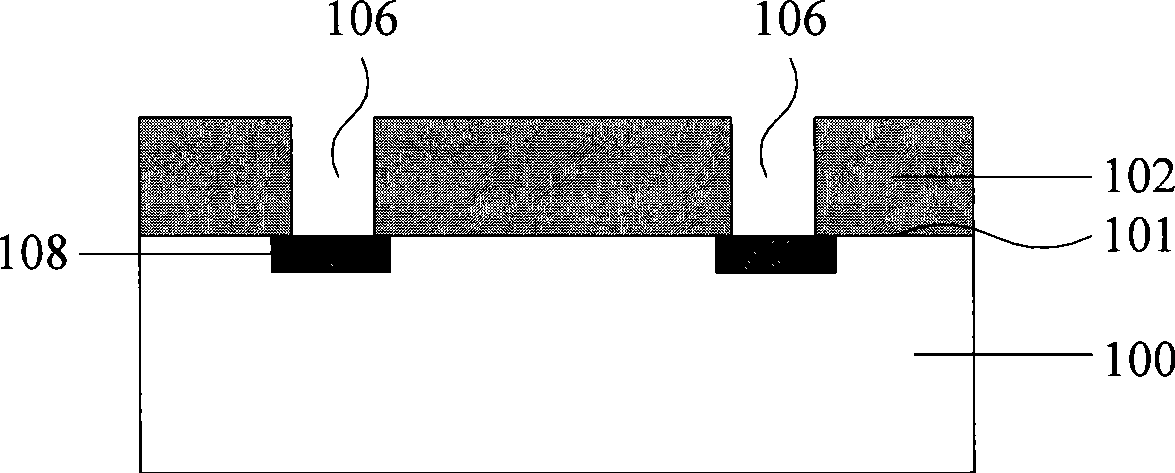

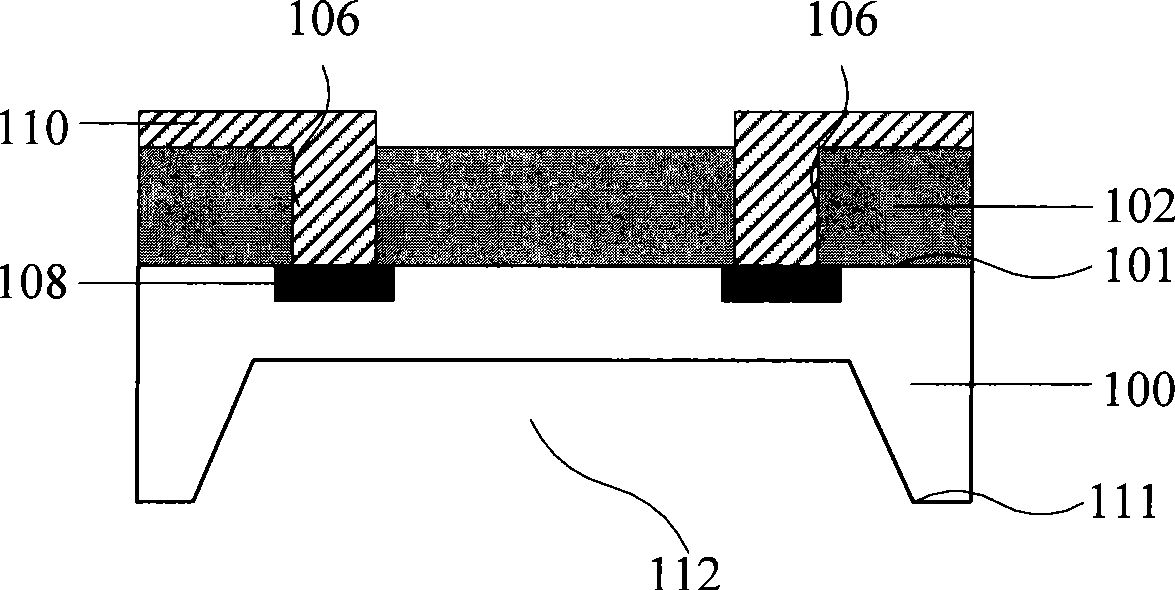

MEMS pressure sensor and manufacturing method therefor

ActiveUS20140001584A1Small sizeReduce manufacturing costDecorative surface effectsFluid pressure measurement by electric/magnetic elementsManufacturing cost reductionIntegrated circuit manufacturing

An MEMS pressure sensor comprising: a first substrate (100) having a sensing diaphragm (101a) of a piezoelectric pressure sensing unit (101), an electrical connection diffusion layer (103), and a first bonding layer (102) on a surface of the first substrate (100), a second substrate (200) having an inter-conductor dielectric layer (203), a conductor connection layer (201) arranged within the inter-conductor dielectric layer (203), and a second bonding layer (202) on a surface of the second substrate (200). The second substrate (200) and the first substrate (100) are oppositely arranged, and are fixedly coupled via the first bonding layer (102) and the second bonding layer (202); the first bonding layer (102) and the second bonding layer (202) have matching patterns and are both made from a conductive material. Also provided is a method for manufacturing the MEMS pressure sensor. The MEMS pressure sensor and the manufacturing method therefore allow for compatibility with integrated circuit manufacturing technique, for effectively reduced manufacturing costs, and for a downsized sensor.

Owner:MEMSEN ELECTRONICS

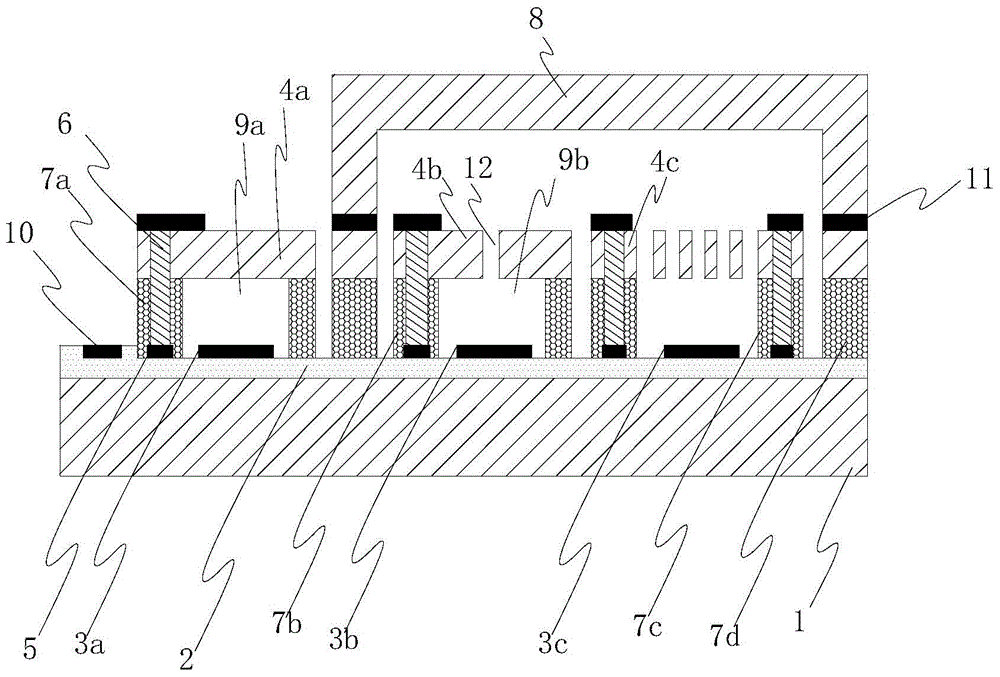

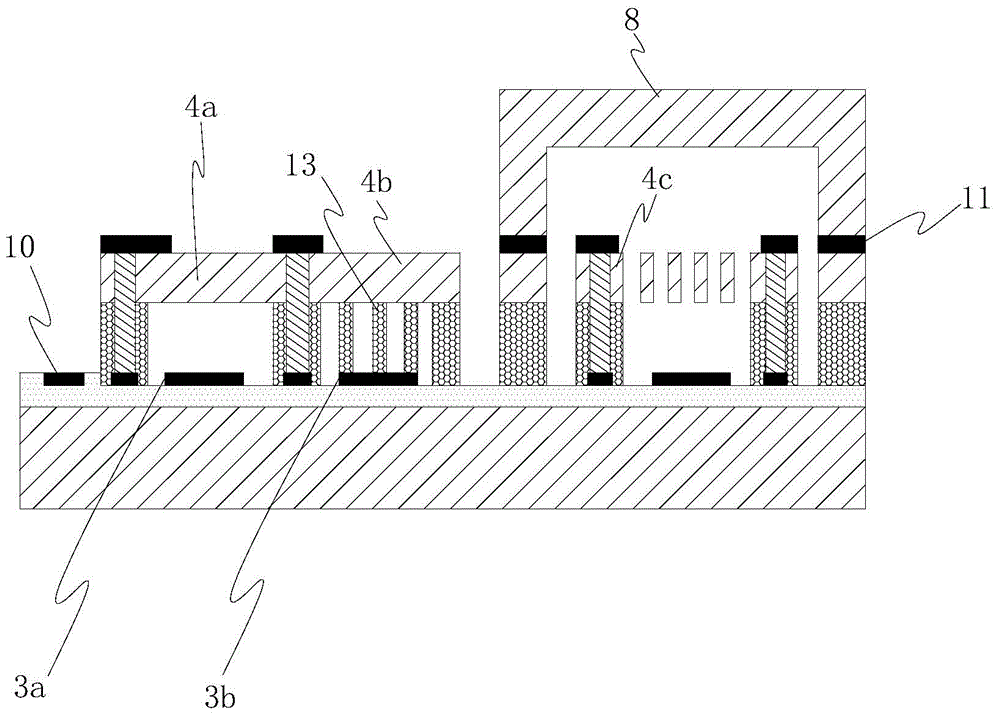

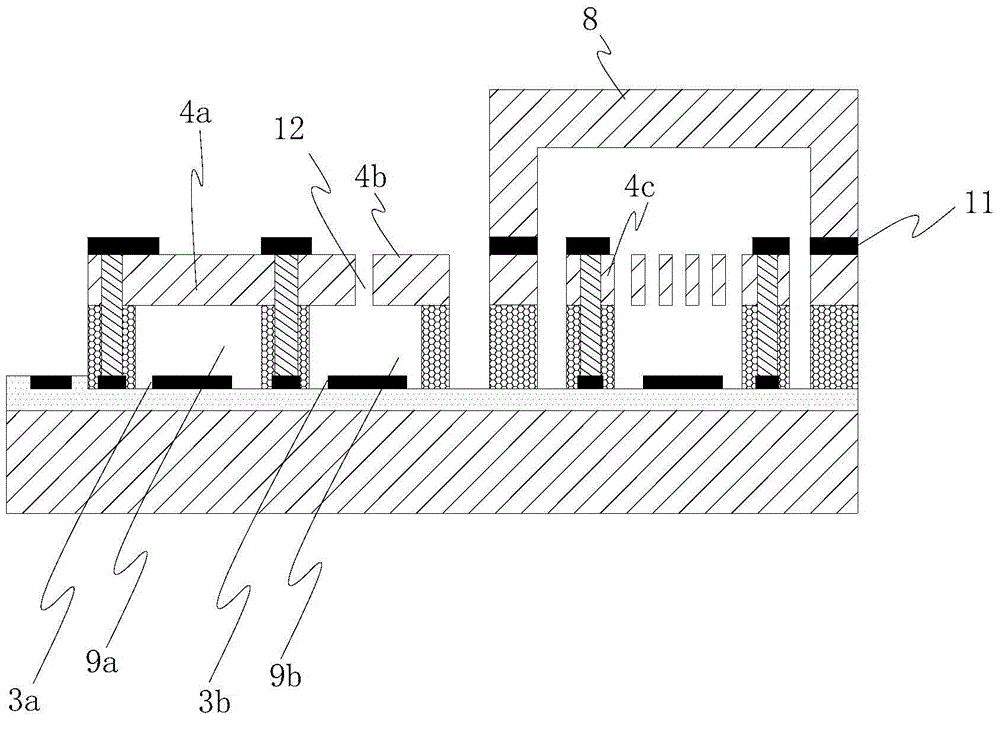

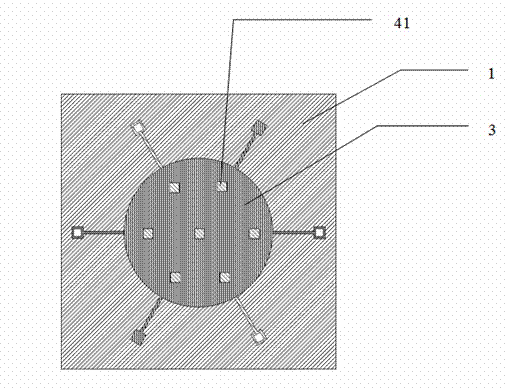

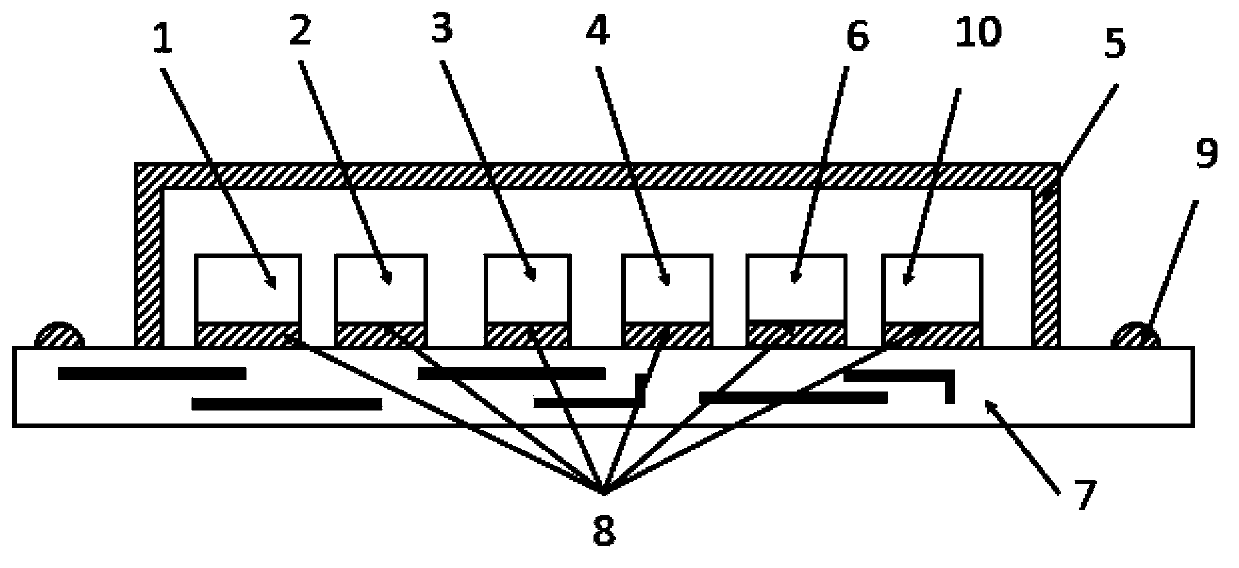

MEMS (Micro-Electro-Mechanical System) pressure sensor-MEMS inertial sensor integrated structure

ActiveCN104891418AReduce areaLow costTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesMems pressure sensorEngineering

The invention discloses an MEMS (Micro-Electro-Mechanical System) pressure sensor-MEMS inertial sensor integrated structure. The integrated structure comprises an insulating layer formed on a substrate, a first lower electrode and a second lower electrode formed on the insulating layer, a first upper electrode which constructs an air-pressure-sensitive capacitor with the first lower electrode, a second upper electrode which constructs a reference capacitor with and the second lower electrode, an inertial sensitive structure supported above the substrate through a third support part, a fixed polar plate which constructs an inertial detection capacitor of the inertial sensor with the inertial sensitive structure, and a cover body for encapsulating the inertial detection capacitor constructed by the inertial sensitive structure and the fixed polar plate on the substrate. According to the integrated structure, the MEMS inertial sensor and the MEMS pressure sensor are integrated on the same substrate, and the area of a chip can be lowered effectively, so that the cost of the chip is lowered. The encapsulation of the whole chip can be finished through one-time encapsulation, so that the cost of chip encapsulation is lowered.

Owner:GOERTEK MICROELECTRONICS CO LTD

Pressure sensor for micro electro-mechanical system and production method thereof

ActiveCN101450786AGuaranteed uniformityAvoid changeDecorative surface effectsChemical vapor deposition coatingSilicon oxideOxygen

The invention provides a method for manufacturing micro-electro-mechanical system (MEMS) pressure sensors. The method comprises the following steps: a pressure chamber opening is formed in a semiconductor substrate; an insulator upper silicon substrate is bonded to the semiconductor substrate so as to form a pressure chamber; the insulator upper silicon substrate comprises a top silicon layer, an oxygen embedding layer and a substrate silicon layer, wherein the top silicon layer is bonded to the semiconductor substrate; the substrate silicon layer is removed till exposing the oxygen embedding layer; a silicon oxide layer is formed on the oxygen embedding layer; the silicon oxide layer and the oxygen embedding layer are etched till exposing the top silicon layer, so as to form an opening corresponding to the position of a follow-up sensitive resistor; ions are injected into the top silicon layer along the opening, so as to form a sensitive resistor; a conducting layer is formed on the silicon oxide layer; and the opening is filled with the conducting layer, so as to form an electrode communicated with the sensitive resistor. The invention also provides an MEMS pressure sensor. The method can accurately control the thickness of a sensitive film and the position of the sensitive resistor, thereby improving the sensitivity and linearity of the pressure sensor.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Integrated MEMS pressure sensor and MEMS inertial sensor

ActiveUS9550668B1Well formedTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesMems pressure sensorForce sensor

Integrated MEMS devices for pressure sensing and inertial sensing, methods for fabricating such integrated devices, and methods for fabricating vertically integrated MEMS pressure sensor / inertial sensor devices are provided. In an example, a method for fabricating an integrated device for pressure and inertial sensing includes forming a MEMS pressure sensor on a first side of a semiconductor substrate. The method further includes forming a MEMS inertial sensor on a second side of the semiconductor substrate. The second side of the semiconductor substrate is opposite the first side of the semiconductor substrate.

Owner:VANGUARD INT SEMICON SINGAPORE PTE LTD

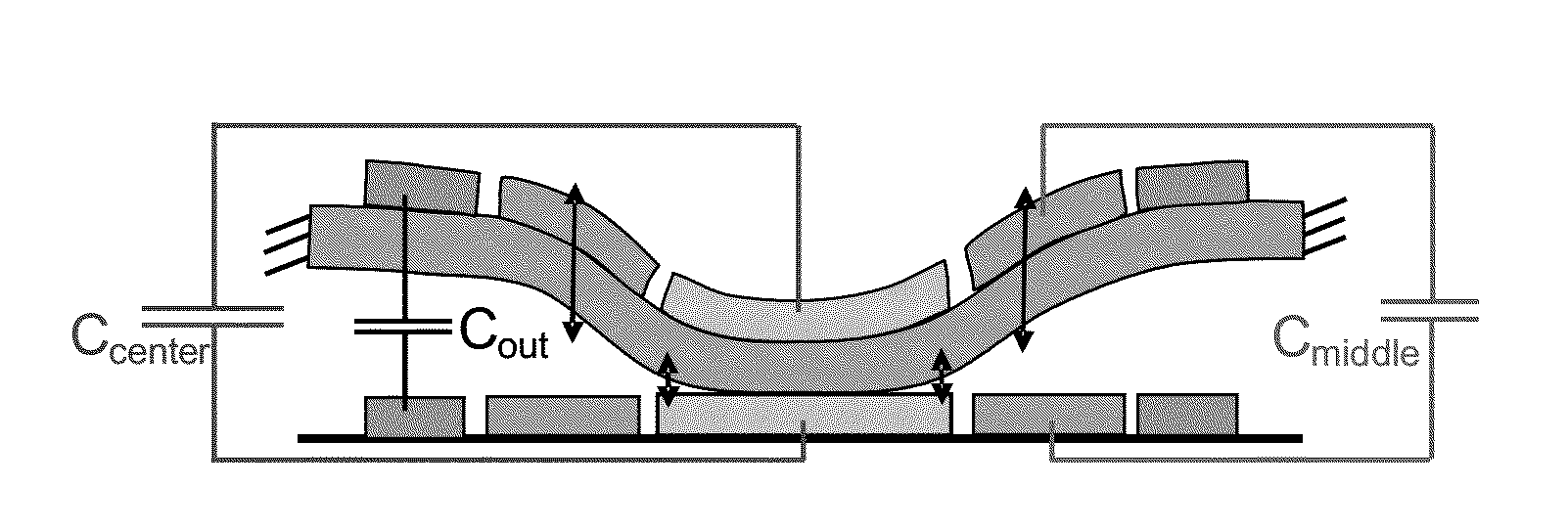

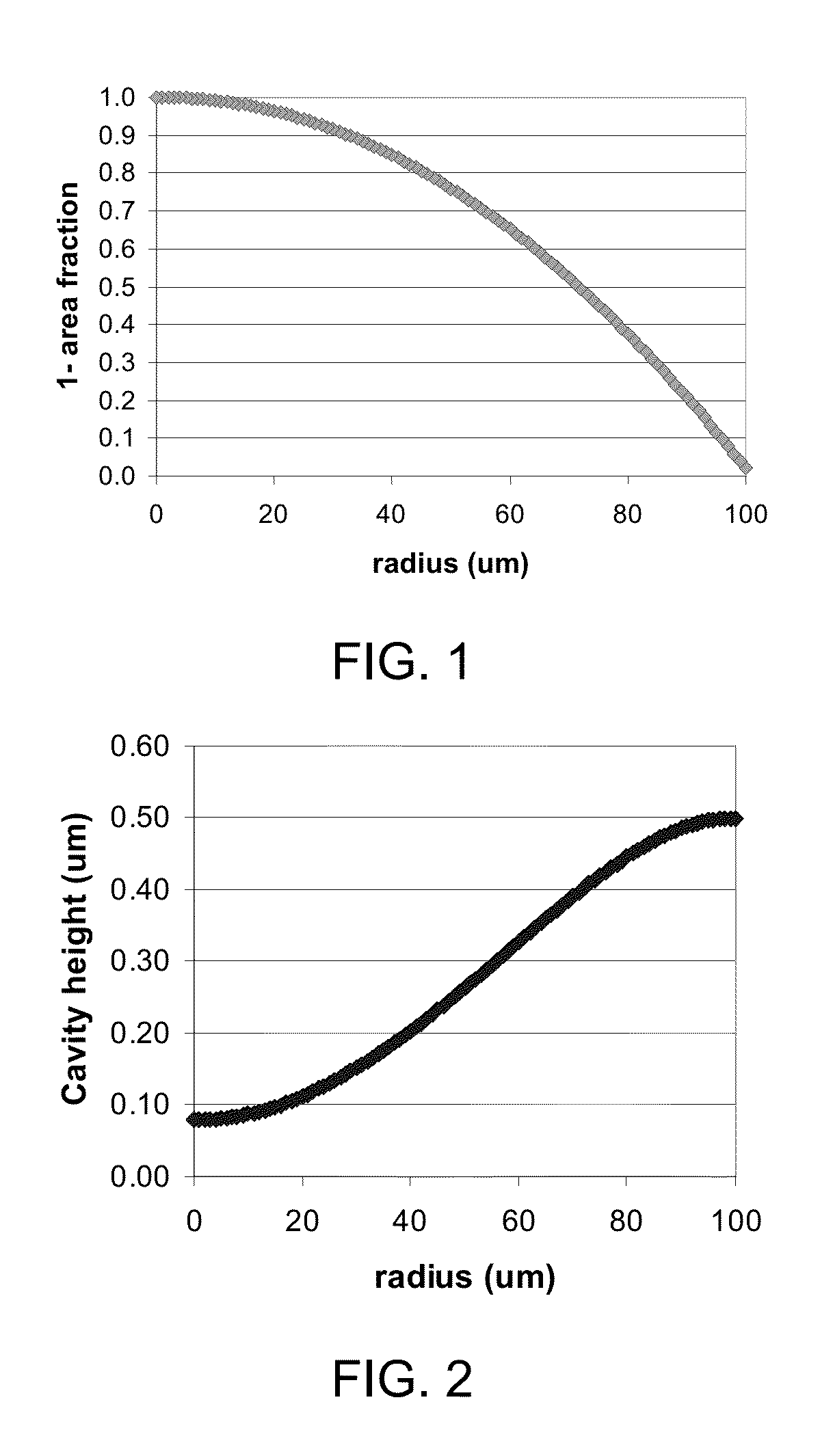

MEMS capacitive pressure sensor, operating method and manufacturing method

ActiveUS9383282B2High sensitivityCoatingsSpecial surfacesCapacitive pressure sensorMems pressure sensor

A MEMS pressure sensor wherein at least one of the electrode arrangements comprises an inner electrode and an outer electrode arranged around the inner electrode. The capacitances associated with the inner electrode and the outer electrode are independently measured and can be differentially measured. This arrangement enables various different read out schemes to be implemented and also enables improved compensation for variations between devices or changes in device characteristics over time.

Owner:SCIOSENSE BV

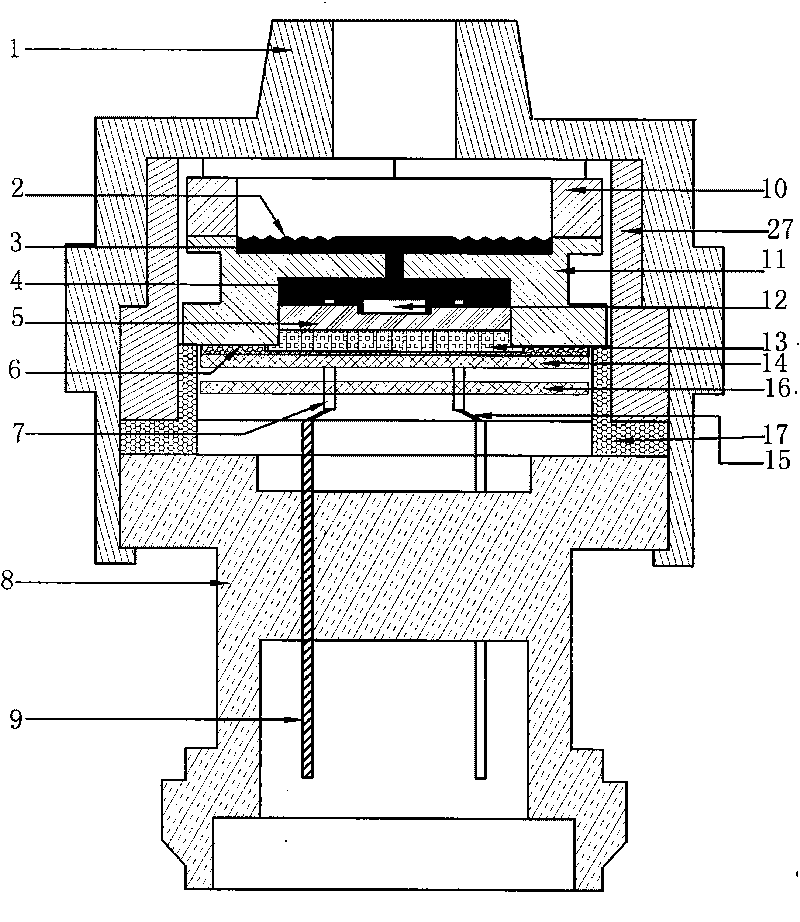

A high temperature pressure sensor packaging structure

ActiveCN106134489BReduce the impactMinimize adverse effects on high temperature performanceSemiconductor/solid-state device detailsSolid-state devicesMems pressure sensorNitrogen

The invention relates to a package structure of a high-temperature pressure sensor, comprising a silicon carbide sensitive chip, an aluminum nitride base, a stress buffer substrate, a high-temperature sealing glass, a lead post, a Kovar outer cover and a thermocouple, wherein the aluminum nitride base is There is a boss on the surface, a stress buffer substrate is placed on the boss, and a silicon carbide sensitive chip is placed on the stress buffer substrate; the periphery of the boss is a stress isolation groove, and there are two or more through holes on the periphery of the stress isolation groove. The column passes through the through hole and is sintered by high-temperature sealing glass to realize the fixed connection between the lead column and the aluminum nitride base. The thermocouple is installed on the lower surface of the aluminum nitride base, and the aluminum nitride base is placed on the Kovar housing through the positioning steps. In addition, the aluminum nitride base and the Kovar cover are sintered and connected through high-temperature sealing glass. The packaging structure is resistant to high temperature, effectively reduces the influence of process stress and high temperature thermal stress on the sensitive chip of the MEMS pressure sensor, and further improves the high temperature measurement accuracy of the sensor.

Owner:BEIJING RES INST OF TELEMETRY

MEMS pressure sensor

ActiveUS8256298B2Fluid pressure measurement by electric/magnetic elementsVacuum gauge using gaseous frictional resistance variationMems pressure sensorResonance

A MEMS pressure sensor for sensing the pressure in a sealed cavity of a MEMS device, comprises a resonant MEMS device having a pressure sensor resonator element which comprises an array of openings. The resonant frequency of the resonant MEMS device is a function of the pressure in the cavity, with resonant frequency increasing with pressure. Over the pressure range 0 to 0.1 kPa, the average change in frequency is at least 10−6 / Pa. The invention is based on the recognition that for fast oscillation, the elastic force causes the resonance frequency to shift. Therefore, it is possible to sense the pressure by a device with resonance frequency that is sensitive to the pressure.

Owner:SCIOSENSE BV

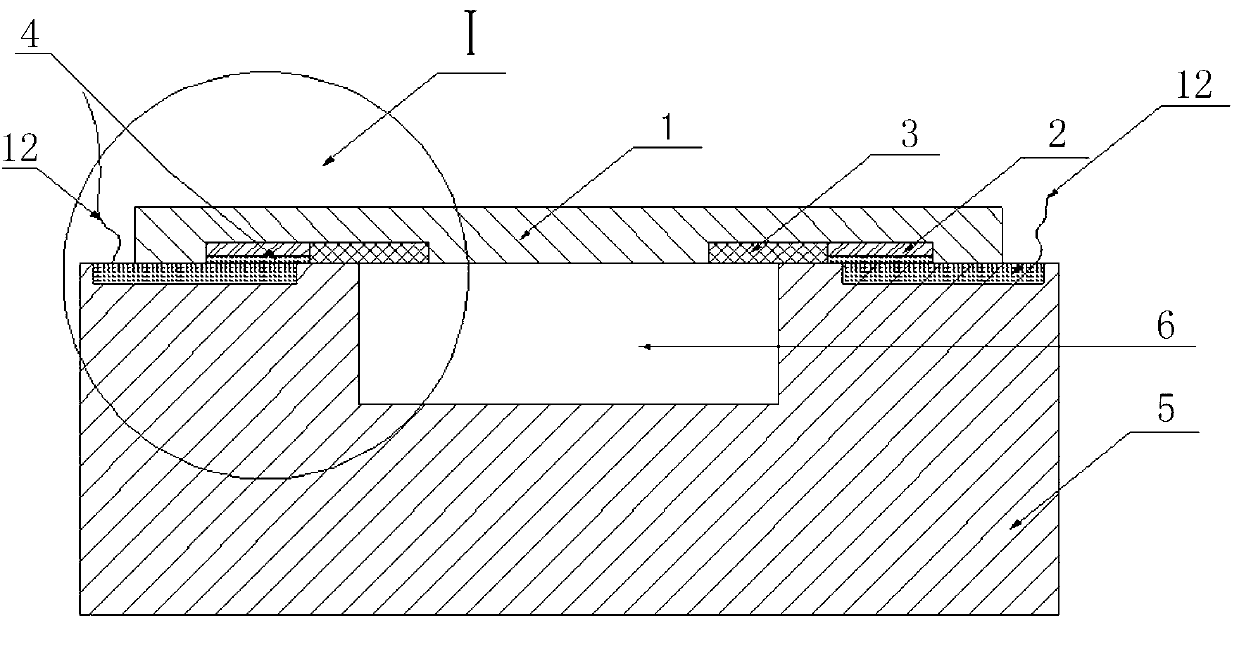

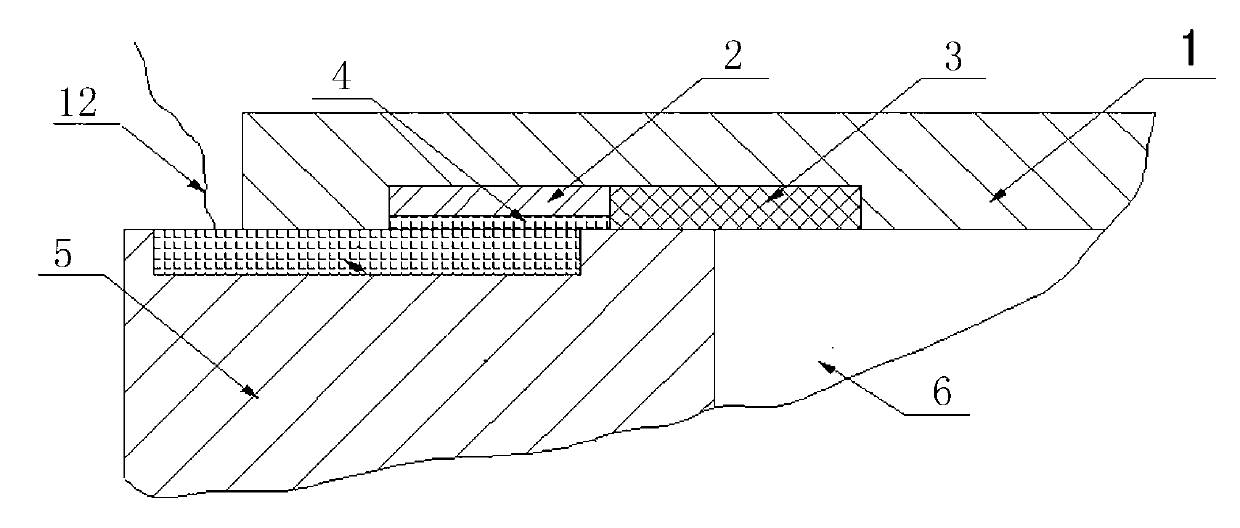

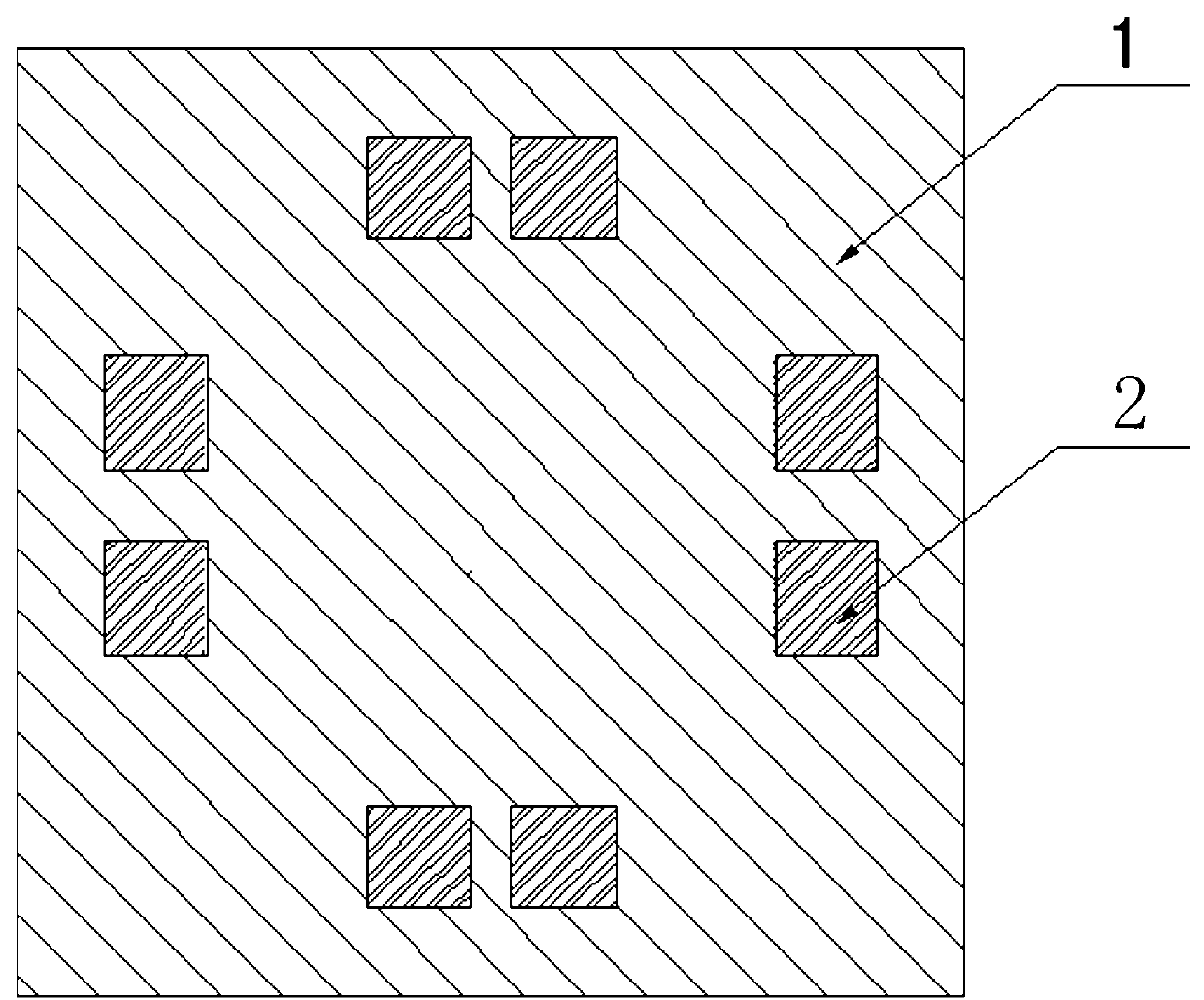

Hidden-type MEMS pressure sensor sensitive chip and manufacturing method thereof

InactiveCN103344374AGuaranteed tightnessMeet basic performance requirementsFluid pressure measurement using ohmic-resistance variationDecorative surface effectsMems pressure sensorHemt circuits

The invention relates to a sensitive chip of a pressure sensor, in particular to a hidden-type MEMS pressure sensor sensitive chip and a manufacturing method thereof. According to the hidden-type MEMS pressure sensor sensitive chip and the manufacturing method, the problem that component performance and service life of an existing silicon piezoresistive pressure sensor are not ideal is solved. The hidden-type MEMS pressure sensor sensitive chip comprises an SOI wafer component layer (1) and a glass substrate (5), wherein the SOI wafer component layer (1) is formed by the practice that a substrate layer of an SOI wafer is etched in an etching process based on a stopping layer, and the BOX layer of the SOI wafer is taken as the stopping layer. Four voltage dependent resistors of the Wheatstone bridge including R1, R2, R3 and R4, eight doping wires (3) and eight connection anchor points (2) are manufactured on the SOI wafer component layer (1). The hidden-type MEMS pressure sensor sensitive chip and the manufacturing method are reasonable in design, the manufacture hidden-type MEMS pressure sensor sensitive chip overcomes influences of external environment factors on a component circuit, the defect that component performance is reduced due to thermal mismatch of materials is eliminated, and service life of components is prolonged.

Owner:山西傲维光视光电科技有限公司

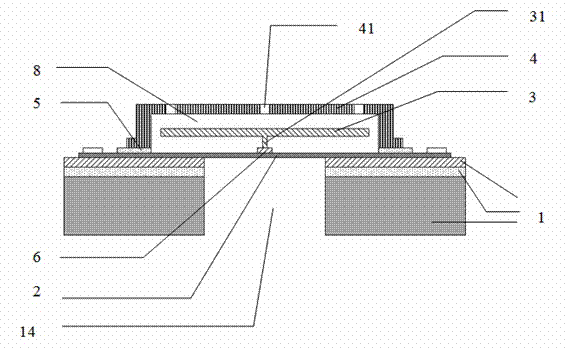

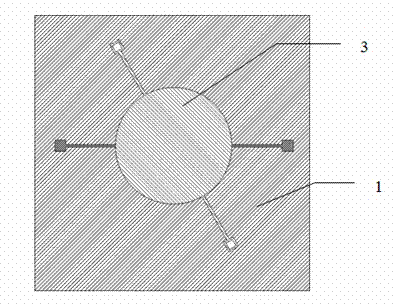

Capacitive MEMS (micro-electromechanical system) pressure sensor

ActiveCN104515640AFlexible adjustmentLow costFluid pressure measurement using capacitance variationCapacitanceMems pressure sensor

A capacitive type MEMS pressure sensor, comprising a substrate (1), a detection thin film (2), an upper electrode plate (4) with a leading wire, and a lower electrode plate (3) with a leading wire. The detection thin film (2) is fixedly laid on an upper surface of the substrate (1). The upper electrode plate (4) is fixedly connected to the upper surface of the substrate (1) or the detection thin film (2). The upper electrode plate (4) is located above the detection thin film (2) and a gap (8) is formed between same and the detection thin film (2). The lower electrode plate (3) is fixedly arranged on the detection thin film (2). The lower electrode plate (3) is located in the gap (8) between the detection thin film (2) and the upper electrode plate (4). The lower electrode plate (3) and the upper electrode plate (4) constitute a capacitor. When a device is designed, the dimensions of the device can be more flexibly adjusted under specified device parameters so as to reduce costs. Moreover, the problem of changes in nonlinear and dynamic response ranges in the traditional pressure sensor is avoided in the structure of the device.

Owner:CSMC TECH FAB2 CO LTD

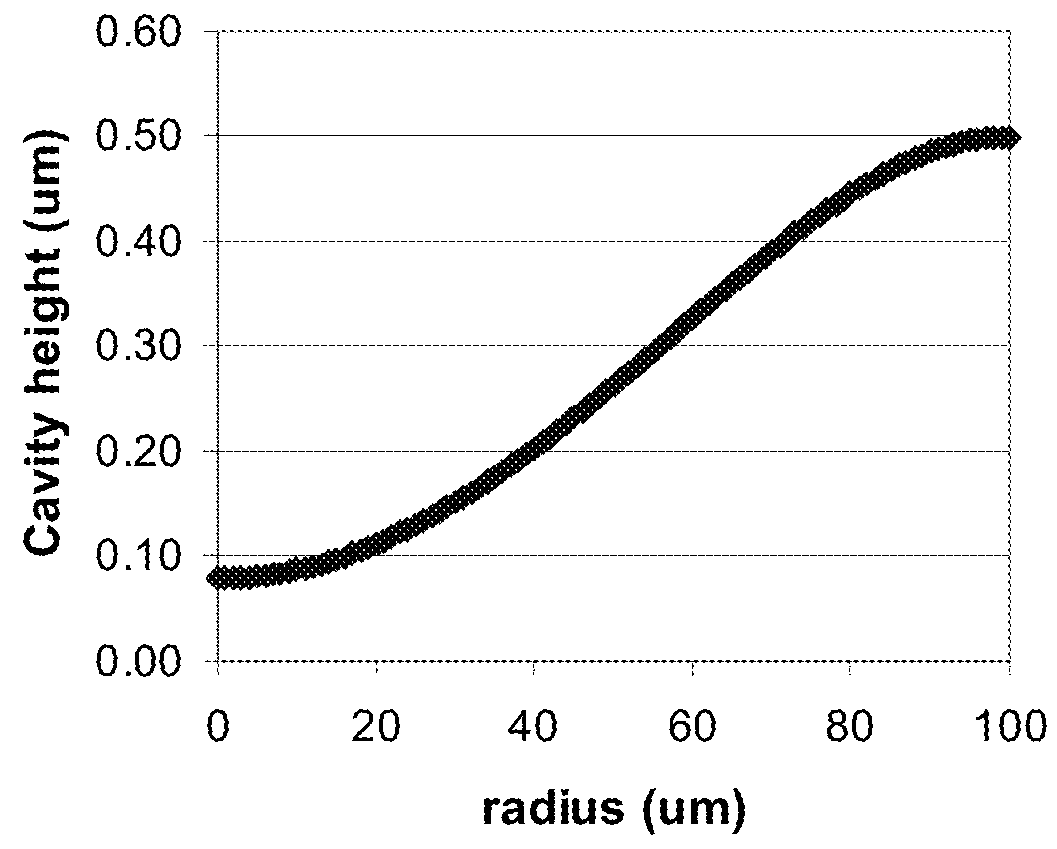

Sensor with vacuum cavity and method of fabrication

InactiveUS20130152694A1Low costIncrease volumeFluid pressure measurement using capacitance variationMems pressure sensorTransducer

A MEMS pressure sensor device comprises a sensor element positioned on top of a carrier and a cavity. The sensor element hermetically seals the cavity. An electrode is coupled to the cavity that forms a pressure transducer together with the sensor element. The cavity is created by a density changing material.

Owner:URVAS ILKKA +2

Dual-SOI-structured MEMS pressure sensor chip and manufacturing method thereof

ActiveCN104931163AExtended operating temperature rangeImprove stabilityFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsEngineeringOperating temperature range

The invention proposes a dual-SOI-structured MEMS pressure sensor chip and a manufacturing method thereof. The dual-SOI-structured MEMS pressure sensor chip comprises a first SOI structure and a second SOI structure, wherein the first SOI structure comprises a substrate and a pressure sensitive film of a pressure sensor, the second SOI structure is a surface-layer SOI structure and comprises a piezoresistor material which is formed by growing insulation isolation medium and depositing and doping alpha-silicon on the insulation medium, a Wheatstone bridge structure is formed through etching, and the second SOI structure replaces the conventional PN junction isolating mode and increases the operating temperature range of the sensor chip. The dual-SOI-structured high-temperature MEMS pressure sensor chip related by the invention is suitable for mass production, and has good consistency, precise measuring range, small chip size, high temperature resistance, high reliability and low cost.

Owner:无锡芯感智半导体有限公司

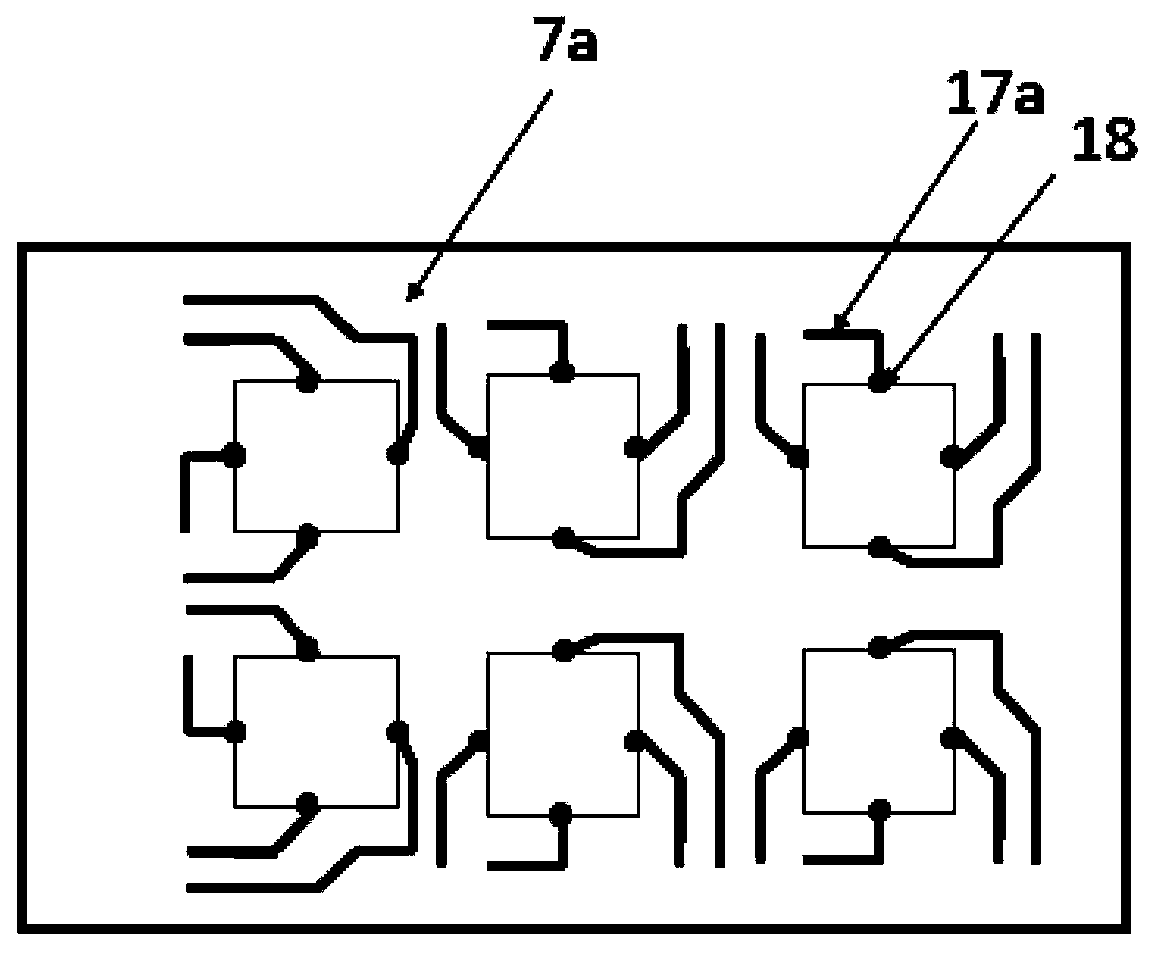

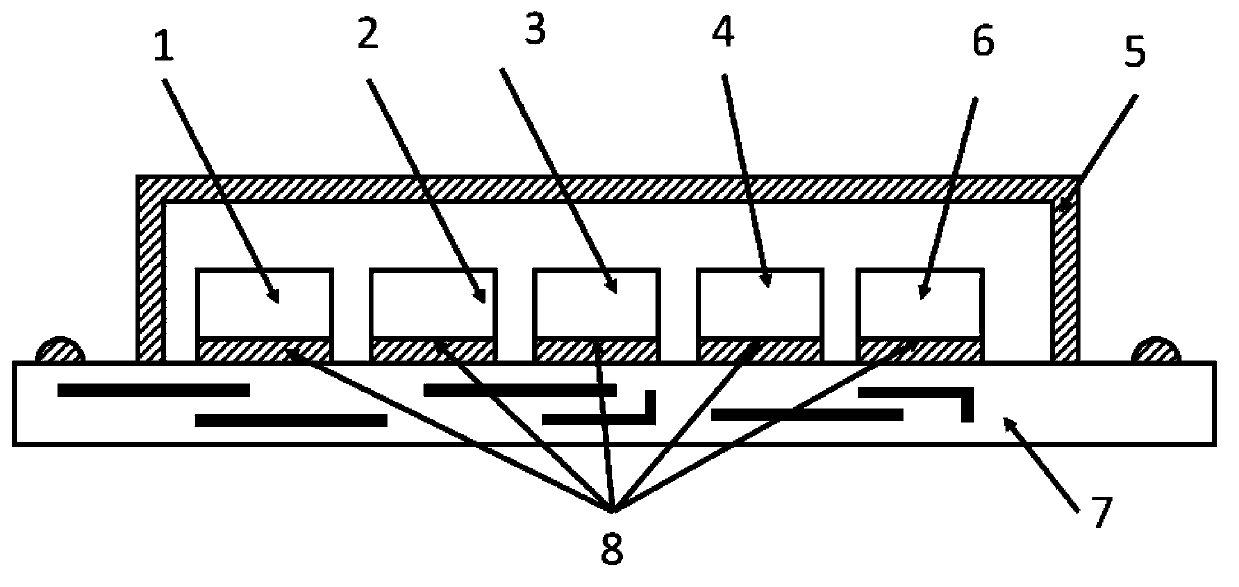

Multi-degree-of-freedom microsensor module and packaging modes thereof

InactiveCN103968886AAchieve high integrationReduce design costMeasurement devicesGyroscopeMems pressure sensor

Disclosed are a multi-degree-of-freedom microsensor module and packaging modes thereof. The multi-degree-of-freedom microsensor module comprises a multi-degree-of-freedom MEMS (micro-electro mechanical system) acceleration meter, a multi-degree-of-freedom MEMS gyroscope, a multi-degree-of-freedom MEMS magnetic sensor, an MEMS pressure sensor, a GPS (global positioning system) / Beidou navigation satellite system chip and an ASIC (application specific integrated circuit). The multi-degree-of-freedom microsensor module is characterized in that the multi-degree-of-freedom MEMS (micro-electro mechanical system) acceleration meter, the multi-degree-of-freedom MEMS gyroscope, the multi-degree-of-freedom MEMS magnetic sensor, the MEMS pressure sensor, the GPS (global positioning system) / Beidou navigation satellite system chip and the ASIC (application specific integrated circuit) are packaged and integrated by the substrate-based packaging technology or packaged into an integrated module by the system-level packaging technology. The invention further provides various packaging modes of the module. The multi-degree-of-freedom microsensor module and the packaging modes thereof have the advantages that multi-degree-of-freedom physical quantity detection can be provided for equipment, design and packaging cost of various sensors can be greatly reduced, reliability of the sensors is improved, and the multifunctional sensors are wider in application field.

Owner:刘胜

MEMS pressure sensor device and method of fabricating same

InactiveUS8316718B2Semiconductor/solid-state device manufacturingFluid pressure measurement using capacitance variationMems pressure sensorEngineering

A microelectromechanical systems (MEMS) pressure sensor device (20, 62) includes a substrate structure (22, 64) having a cavity (32, 68) formed therein and a substrate structure (24) having a reference element (36) formed therein. A sense element (44) is interposed between the substrate structures (22, 24) and is spaced apart from the reference element (36). The sense element (44) is exposed to an external environment (48) via one of the cavity (68) and a plurality of openings (38) formed in the reference element (36). The sense element (44) is movable relative to the reference element (36) in response to a pressure stimulus (54) from the environment (48). Fabrication methodology (76) entails forming (78) the substrate structure (22, 64) having the cavity (32, 68), fabricating (84) the substrate structure (24) including the sense element (44), coupling (92) the substrate structures, and subsequently forming (96) the reference element (36) in the substrate structure (24).

Owner:NORTH STAR INNOVATIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com