MEMS pressure sensor chip based on SOI technology and manufacturing method thereof

A pressure sensor and technology, applied in the field of micro-electromechanical systems (MEMS), can solve the problems of poor sensor repeatability and hysteresis, and achieve the effects of good repeatability and stability, high sensitivity, and improved operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

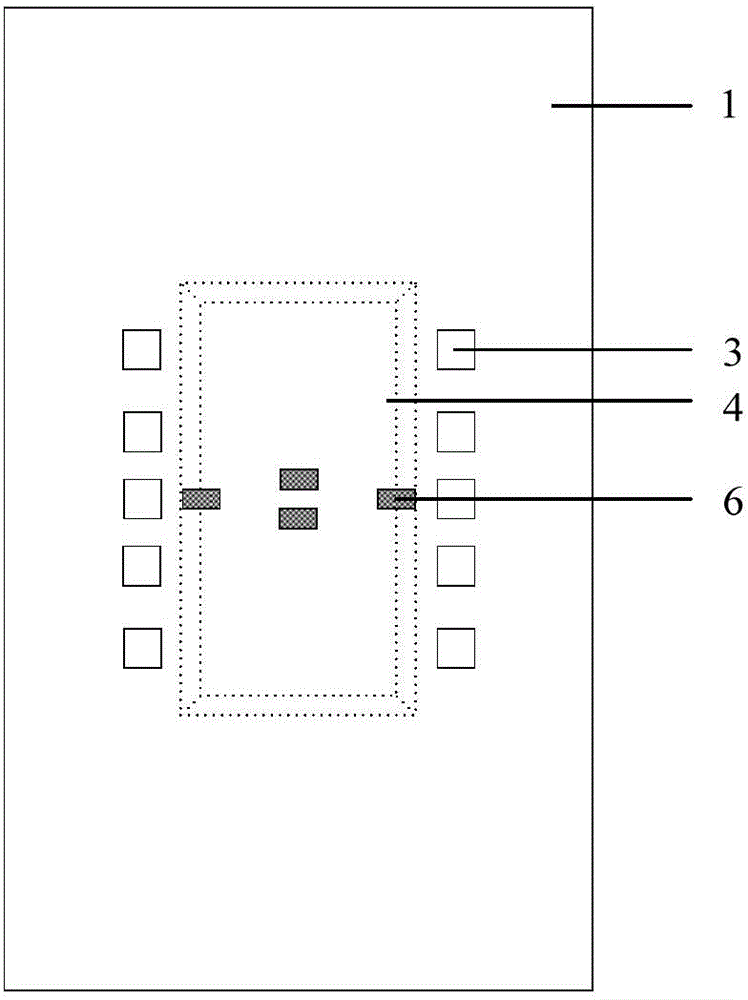

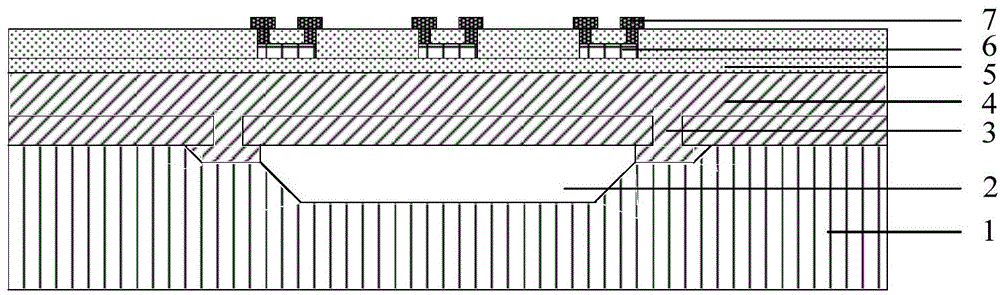

[0059] Manufacturing methods of MEMS pressure sensors based on SOI technology, such as Figure 2~Figure 9 As shown, the specific steps are:

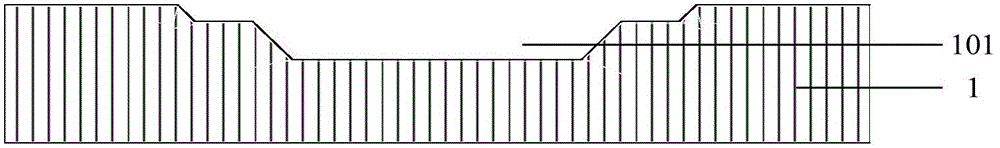

[0060] (1) Using isotropic etchant HNA (hydrofluoric acid / nitric acid / acetic acid) on the single crystal silicon substrate to form a stepped groove through two photolithography and etching, the result is as follows image 3 shown;

[0061] (2) Using PECVD to deposit silicon dioxide as the sacrificial layer 101 on the single crystal silicon substrate with stepped grooves, the substrate was restored to flatness by polishing, and the silicon dioxide in the area outside the groove was removed at the same time, the result Such as Figure 4 shown;

[0062] (3) Using LPCVD to deposit a layer of polysilicon to form the first layer of polysilicon 103, dry etching after annealing to form the cavity etching hole 3, the result is as follows Figure 5 shown;

[0063] (4) The chip is placed in a hydrofluoric acid solution to remove the silicon di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com