Capacitive MEMS (micro-electromechanical system) pressure sensor

A pressure sensor, capacitive technology, applied in fluid pressure measurement using capacitance changes, fluid pressure measurement through electromagnetic components, fluid pressure measurement, etc., can solve the problem of degradation of dynamic response range of nonlinear devices, increase in cost, and increase in device size and other issues, to achieve the effect of flexible device size, flexible adjustment, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

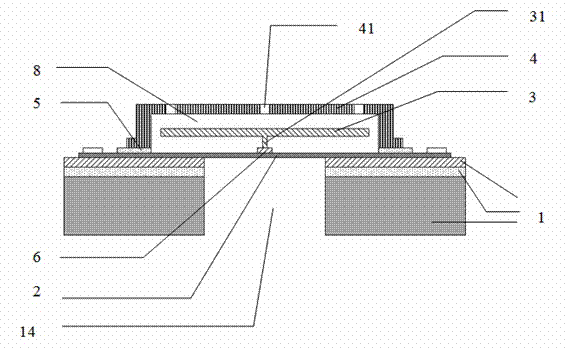

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. figure 1 A first embodiment of the invention is shown.

[0030] A capacitive MEMS pressure sensor is provided with:

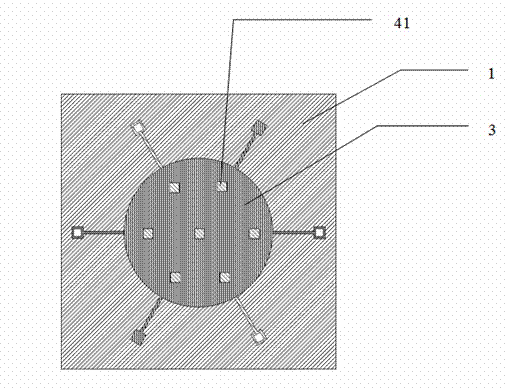

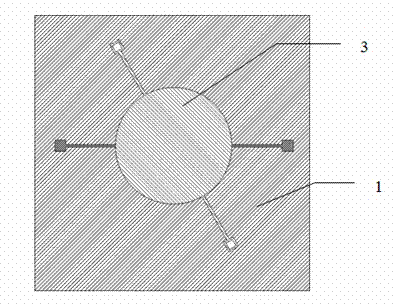

[0031] A substrate 1, a detection film 2, and a lower electrode plate 3 and an upper electrode plate 4 with lead wires.

[0032] The detection film 2 is fixedly laid on the upper surface of the substrate 1; the substrate 1 is provided with a through hole 14 (or any shape or groove) for the detection film 2 to be in contact with the external working medium and withstand its pressure;

[0033] The upper electrode plate 4 with lead wires is fixedly connected to the detection film 2 (it can also be fixed on the upper surface of the substrate 1, determined according to the size of the detection film 2 or the design and production process), and is located above the detection film 2 and connected to the detection film 2. A gap 8 is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com