Patents

Literature

223 results about "Involuntary shaking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Unintentional trembling or shaking movemnts in one or more parts of the body.

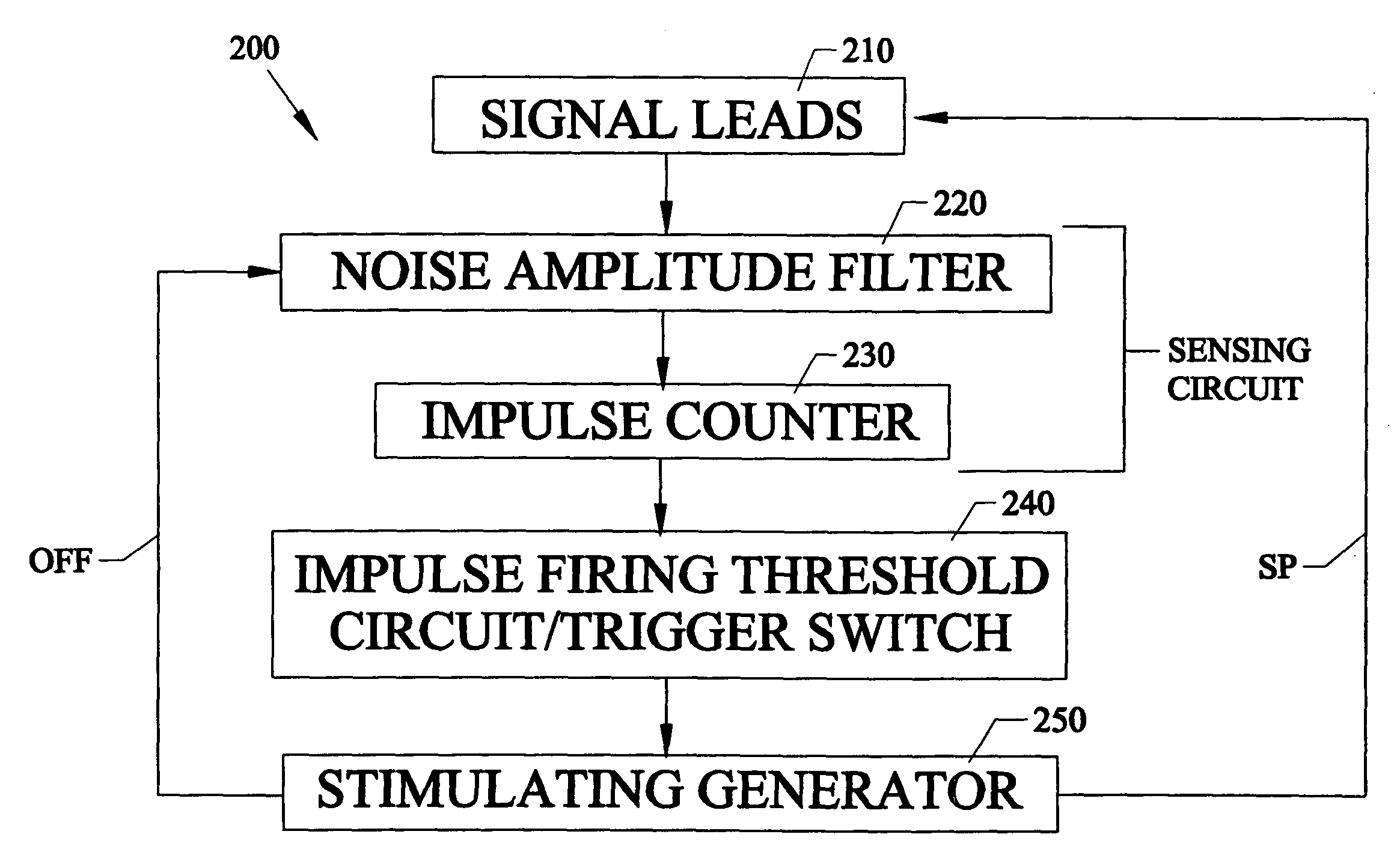

Method and device for treatment of medical conditions and monitoring physical movements

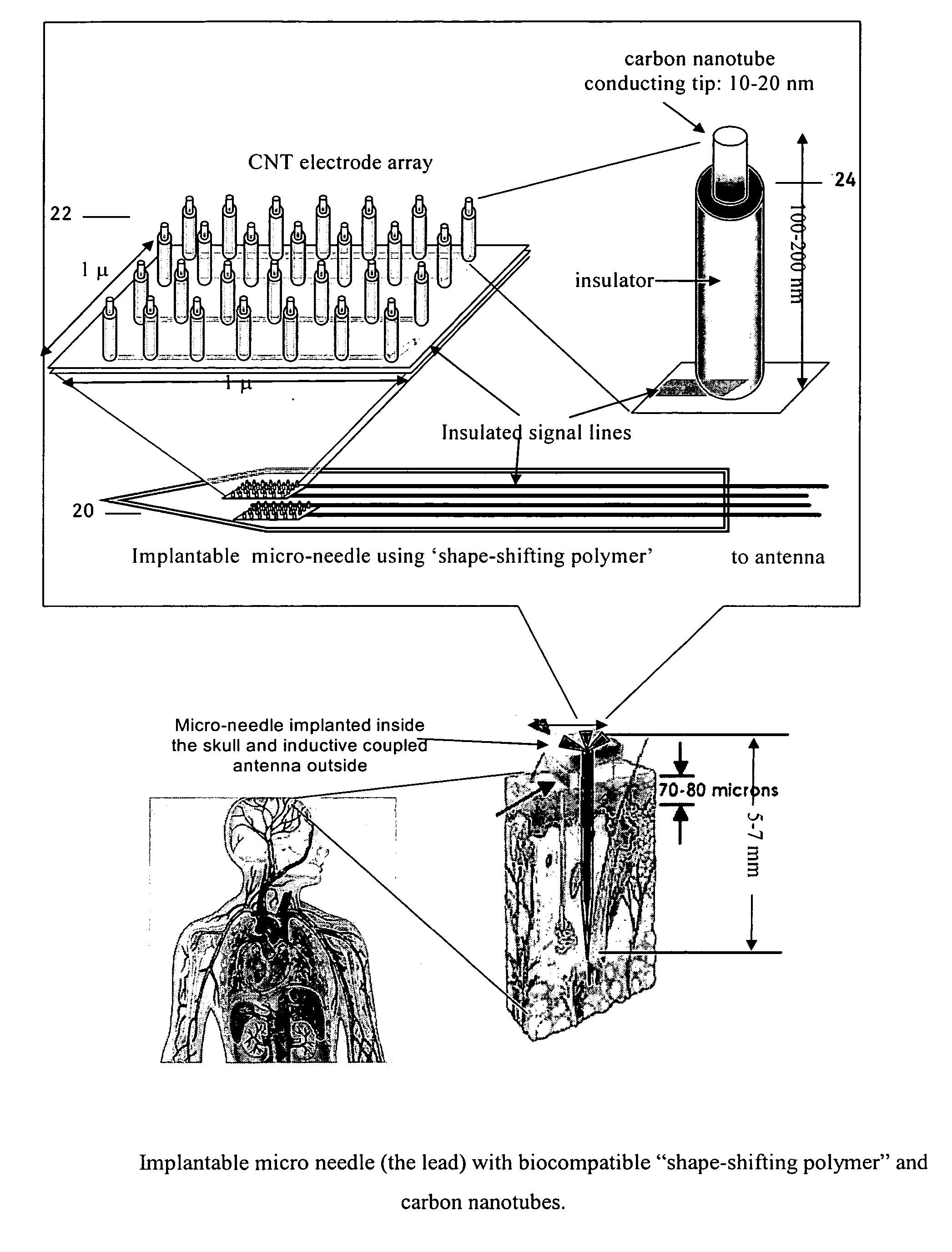

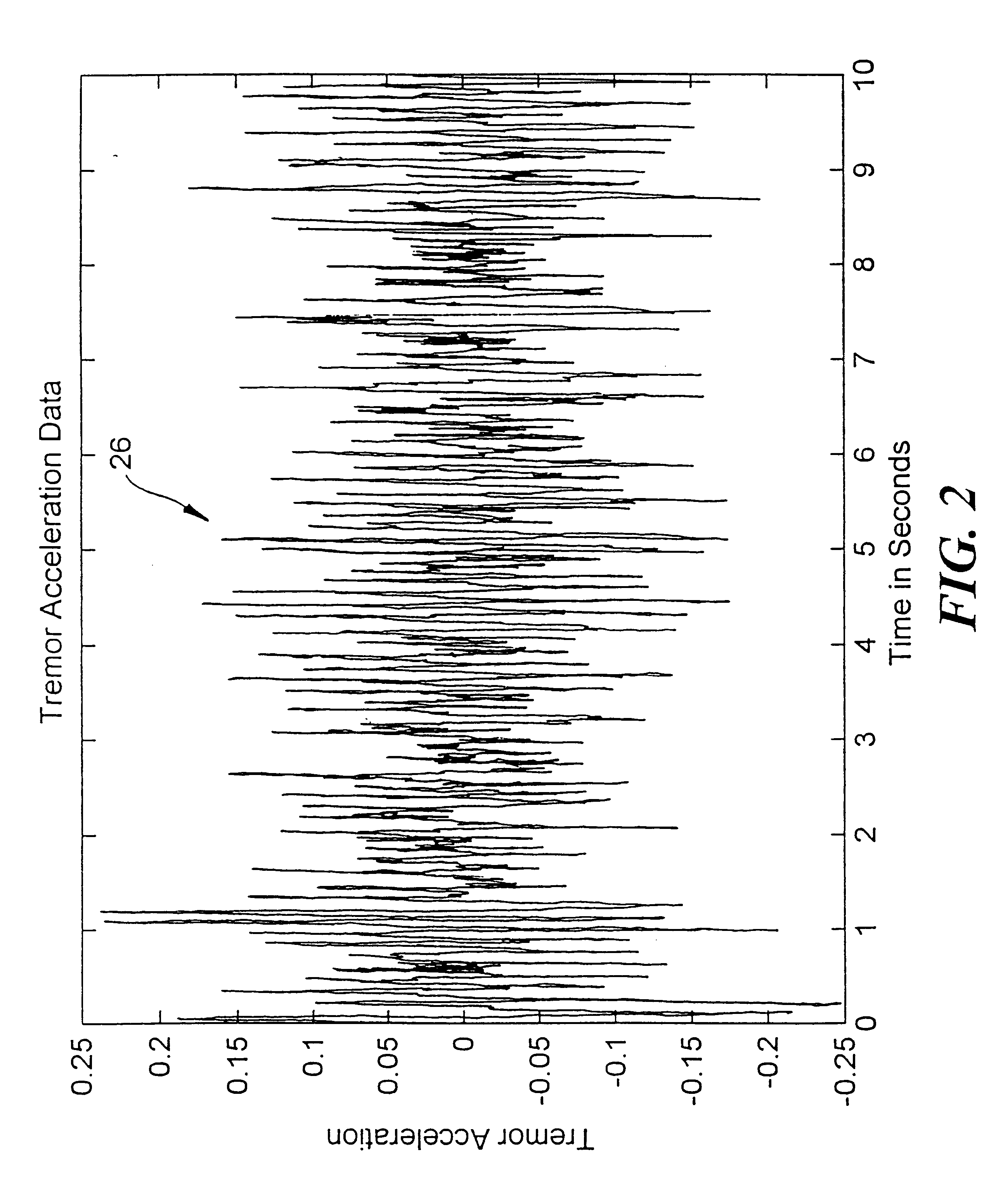

InactiveUS20060212097A1Accurate monitoringEffectively wirelessly transmit dataMaterial nanotechnologyElectrotherapyAccelerometerGyroscope

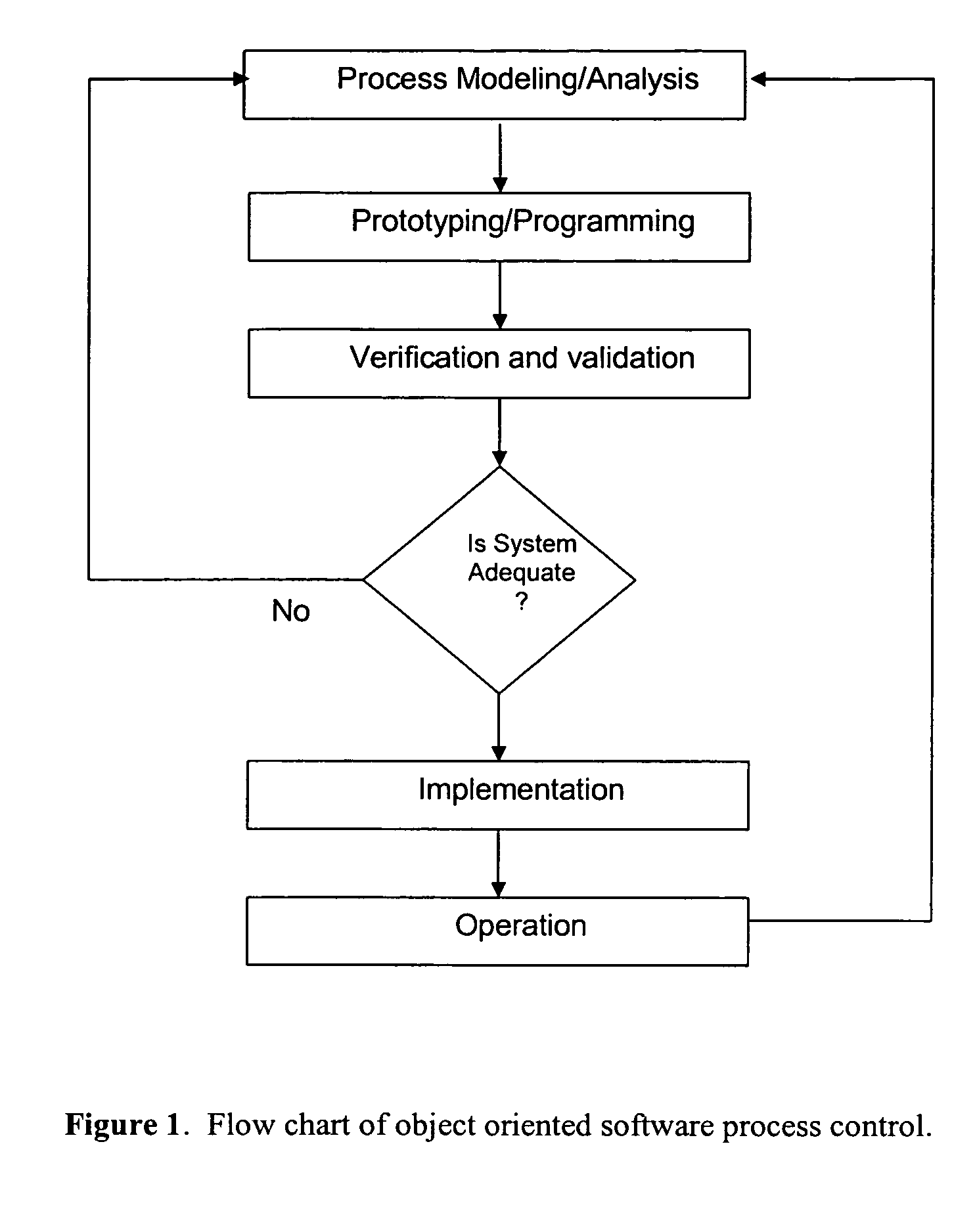

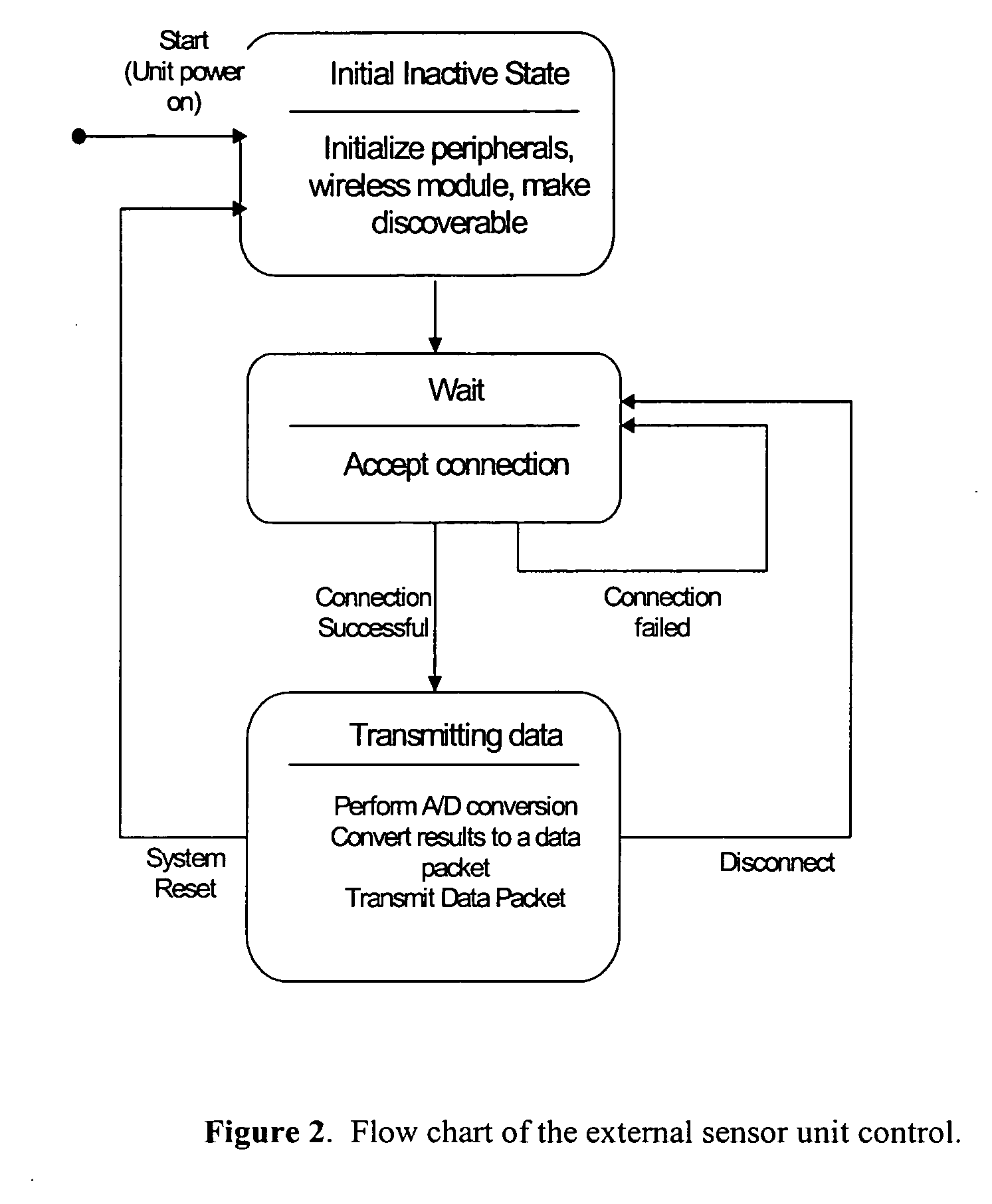

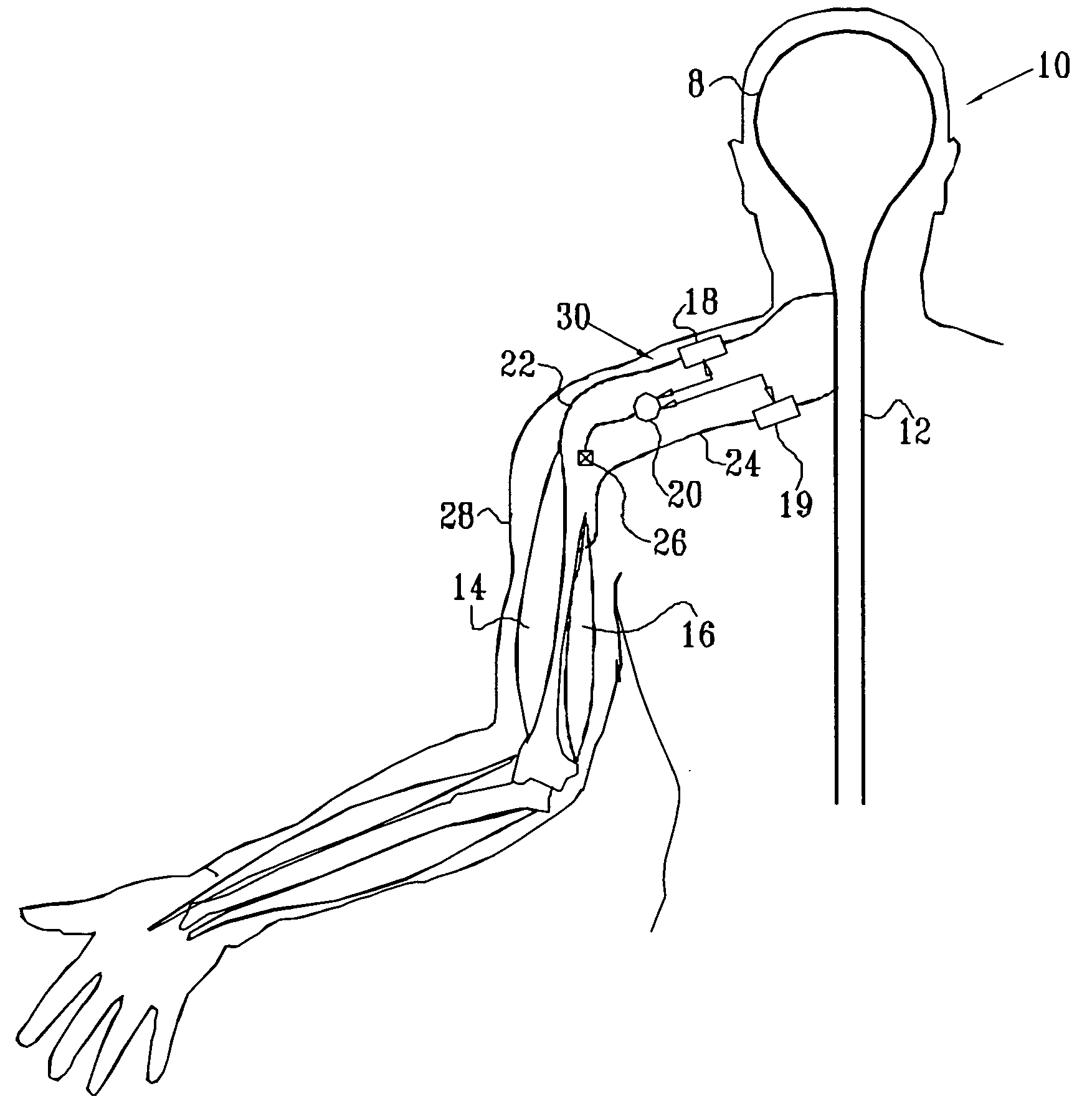

The subject invention utilizes MEMS devices and wireless data transmission means to monitor and sense certain patient conditions or reactions, such as changes in pressure, patient movements, and tremors. These sensor devices include but are not limited to MEMS gyroscopes, MEMS accelerometers, and MEMS pressure sensors. The data from the sensor means is then preferably wirelessly transmitted to a second MEMS device to treat or alter the medical condition that has been monitored.

Owner:PENN STATE RES FOUND

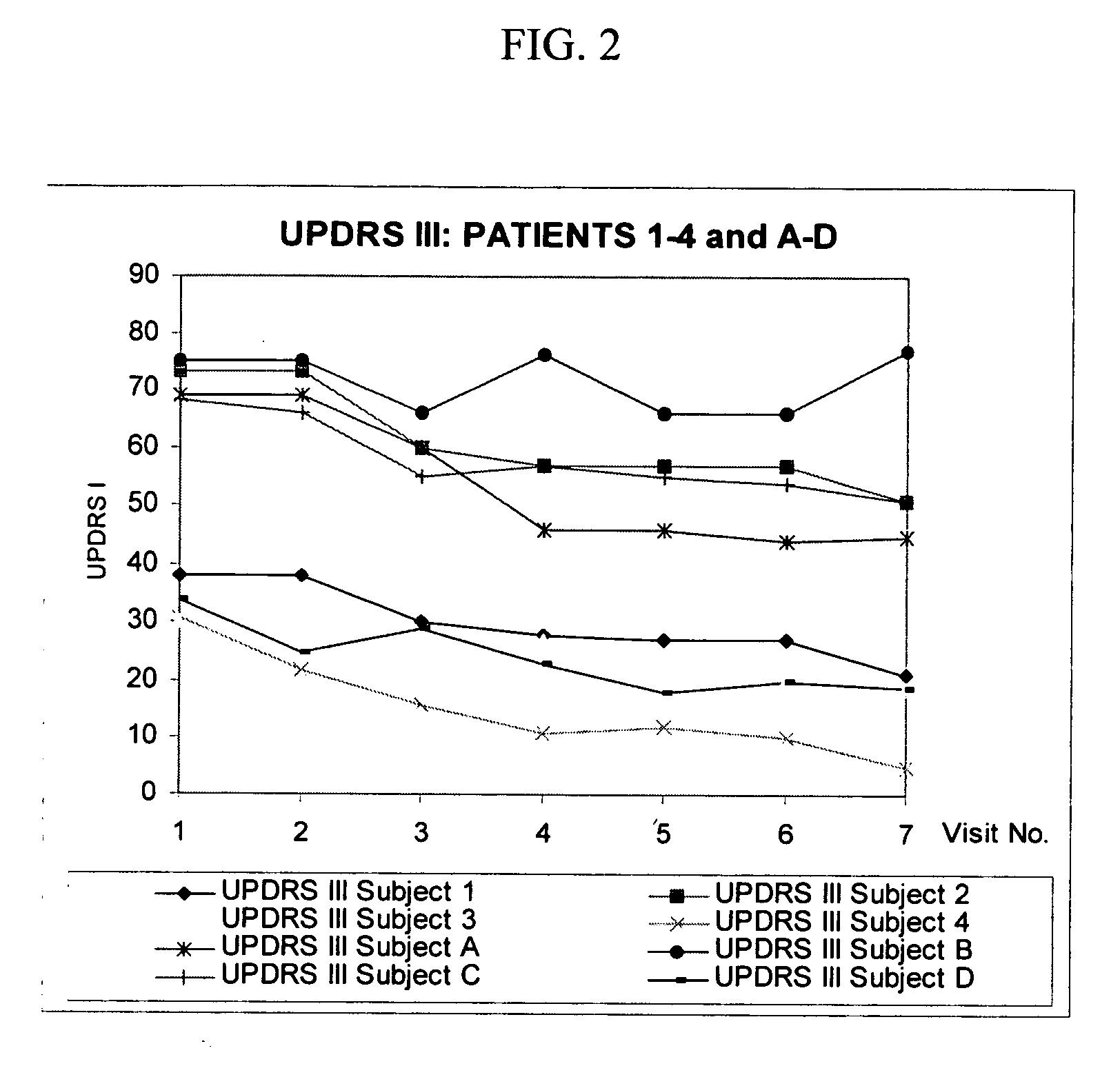

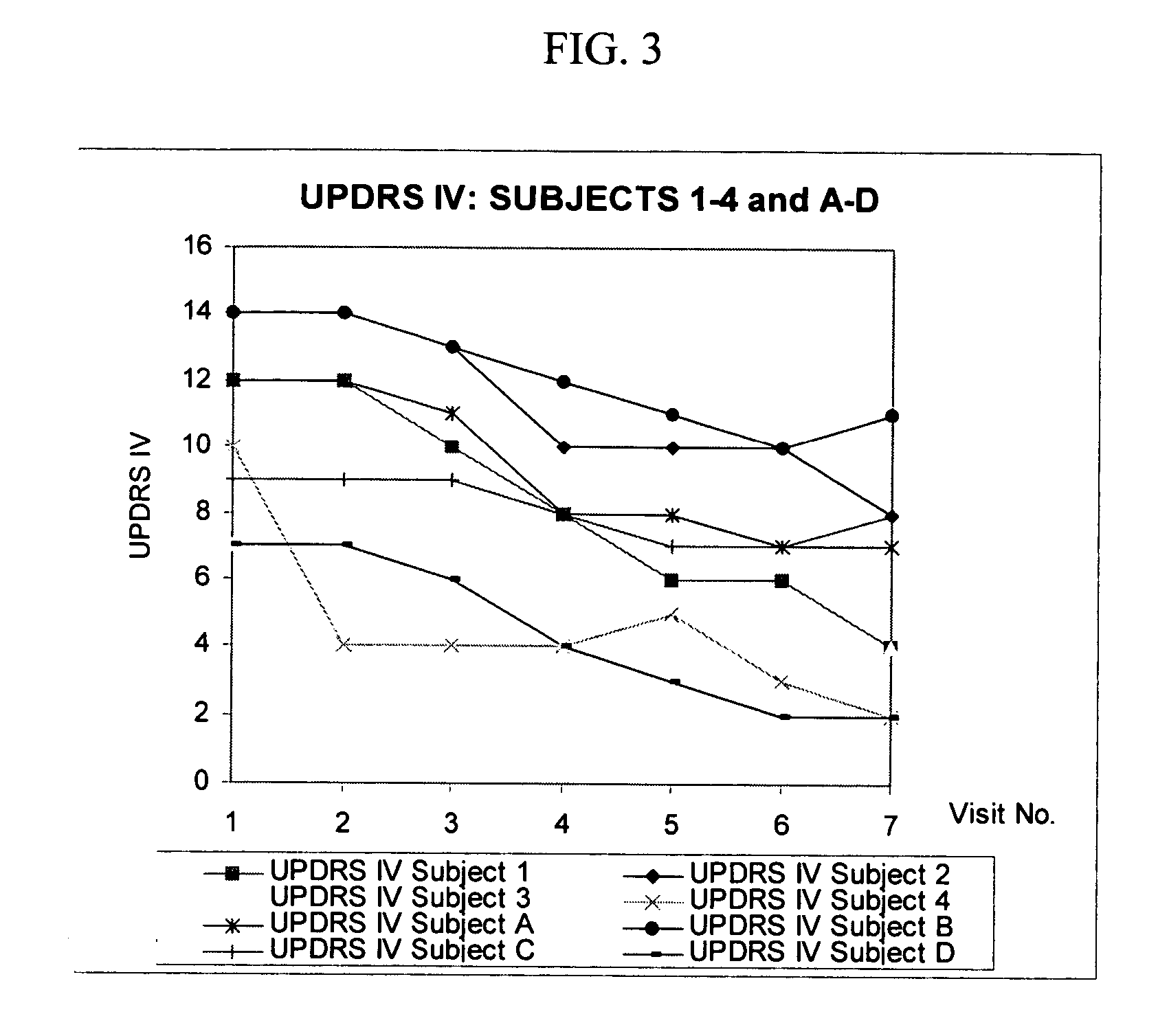

Combination treatment for impaired motor function in parkinson's disease

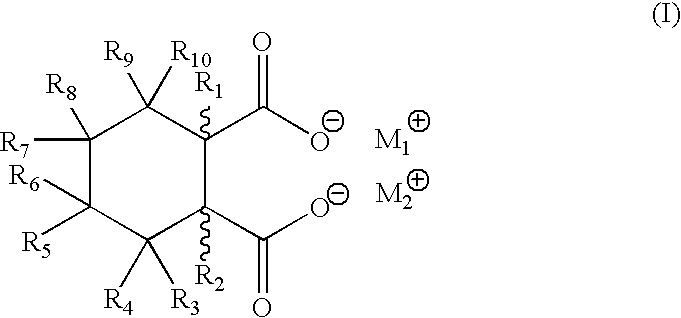

InactiveUS20060063810A1Shorten the timeIncreased “ on ” timeBiocideNervous disorderNR1 NMDA receptorNMDA receptor

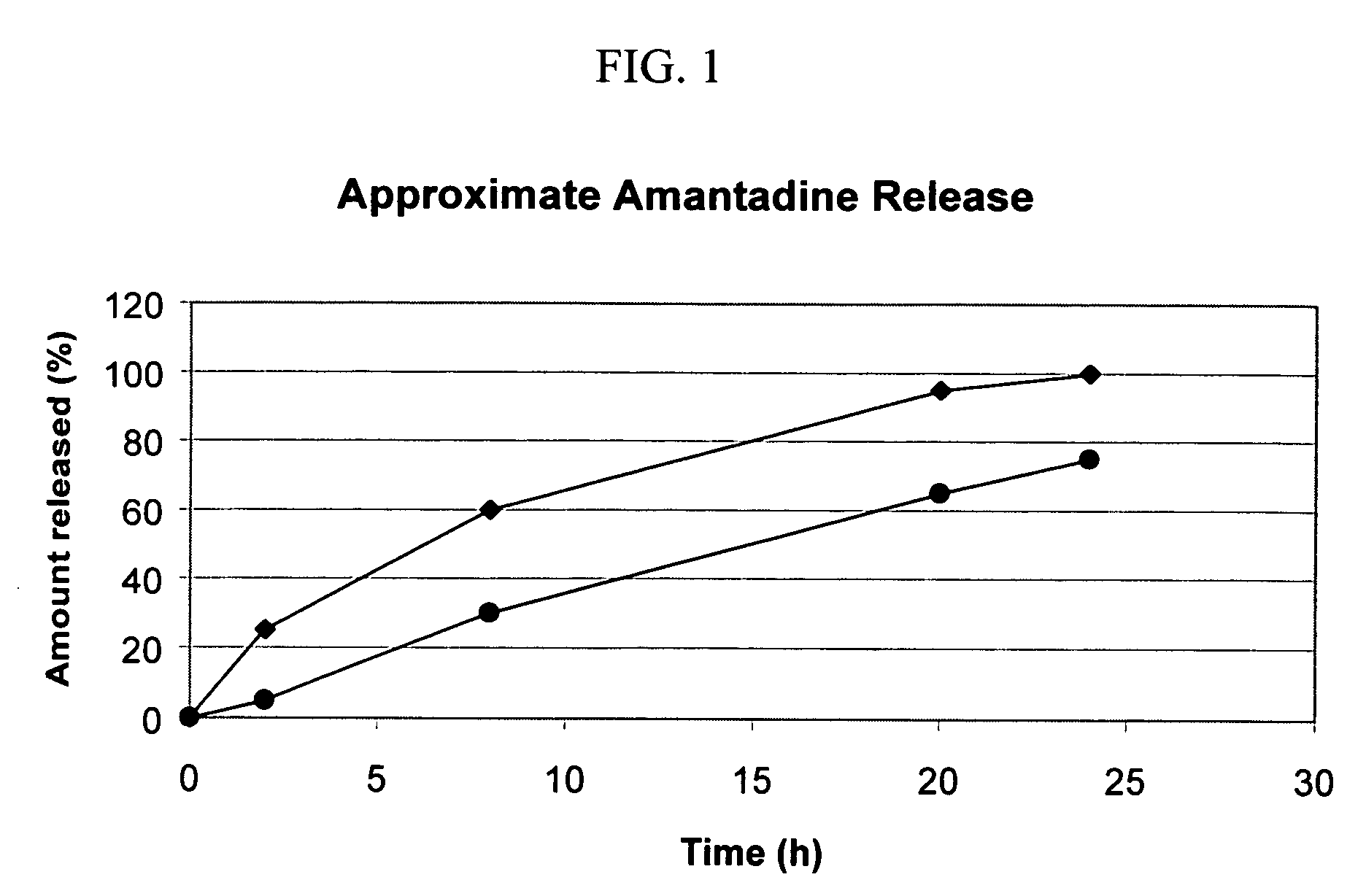

The invention provides a method, and dosage form therefor, of treating impaired motor function associated with Parkinson's disease, anti-Parkinson's drug treatment, e.g. L-Dopa therapy, and / or dementia associated with Parkinson's disease. The invention includes the combined administration of an NMDA receptor antagonist and an antidepressant, e.g., the combination of amantadine and citalopram or venlafaxine, or an NMDA receptor antagonist and an anxiolytic agent, e.g., amantadine and buspirone or trazodone, for the amelioration of undesired tremors, akinesia, dyskinesia, or bradykinesia associated with one or more different disorders or diseases. The drugs can be included in a single dosage form. One embodiment includes a combination dosage form containing each drug in controlled release forms. Another embodiment includes a combination dosage form providing a controlled release of an NMDA receptor antagonist and a rapid release of a neuroactive agent after administration to a subject.

Owner:OSMOTICA KERESKEDELMI & SZOLGALTATO

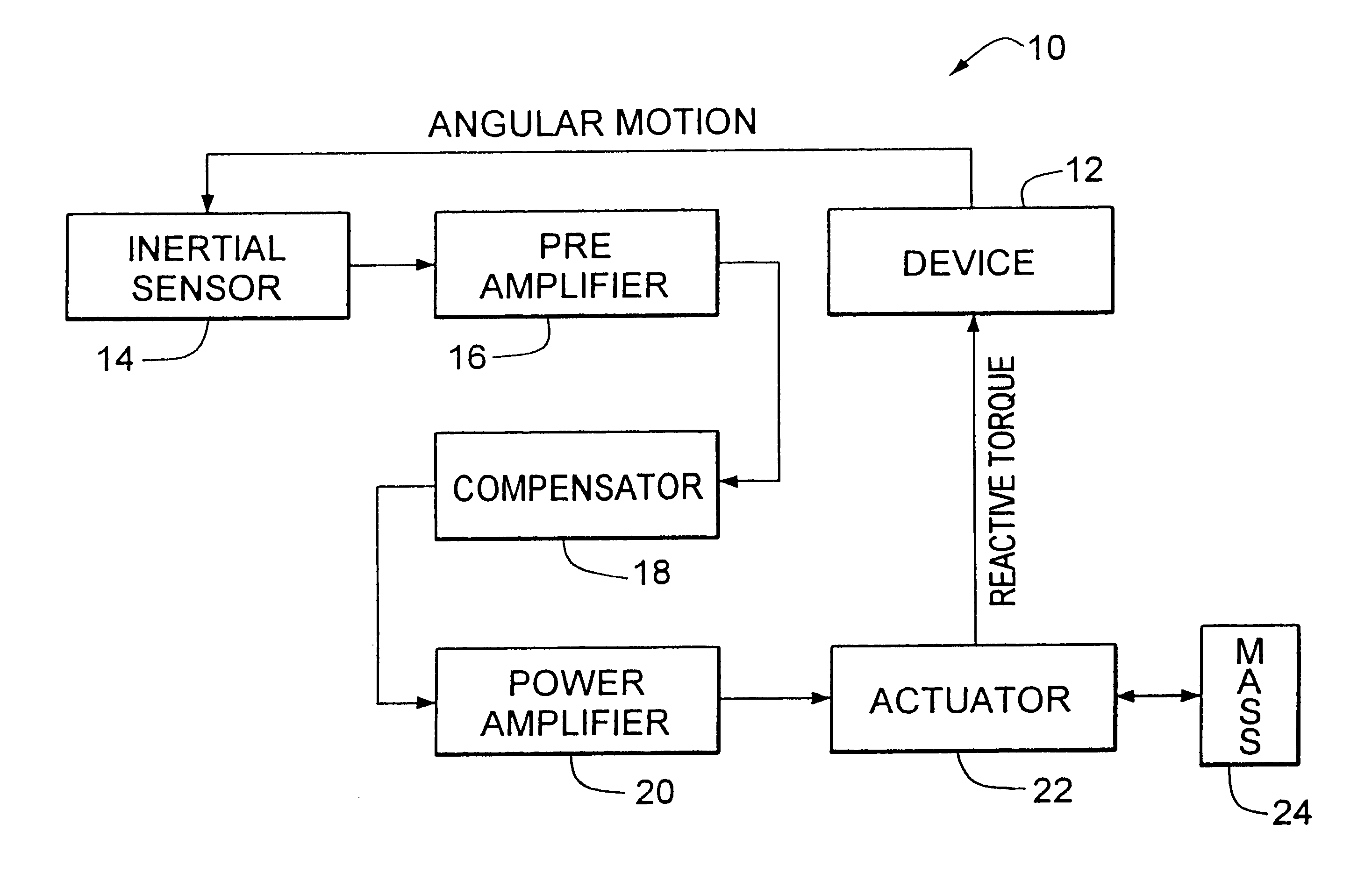

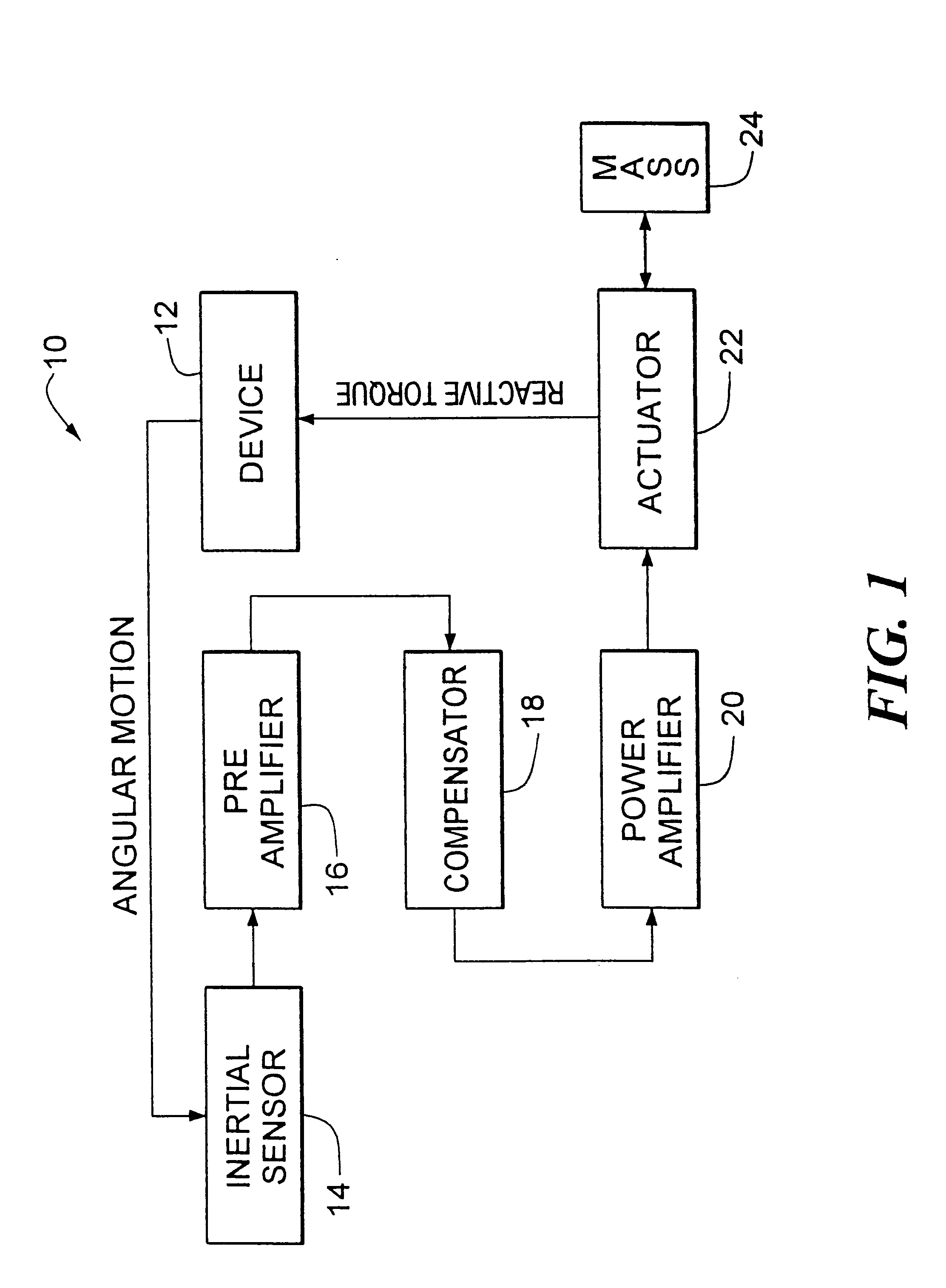

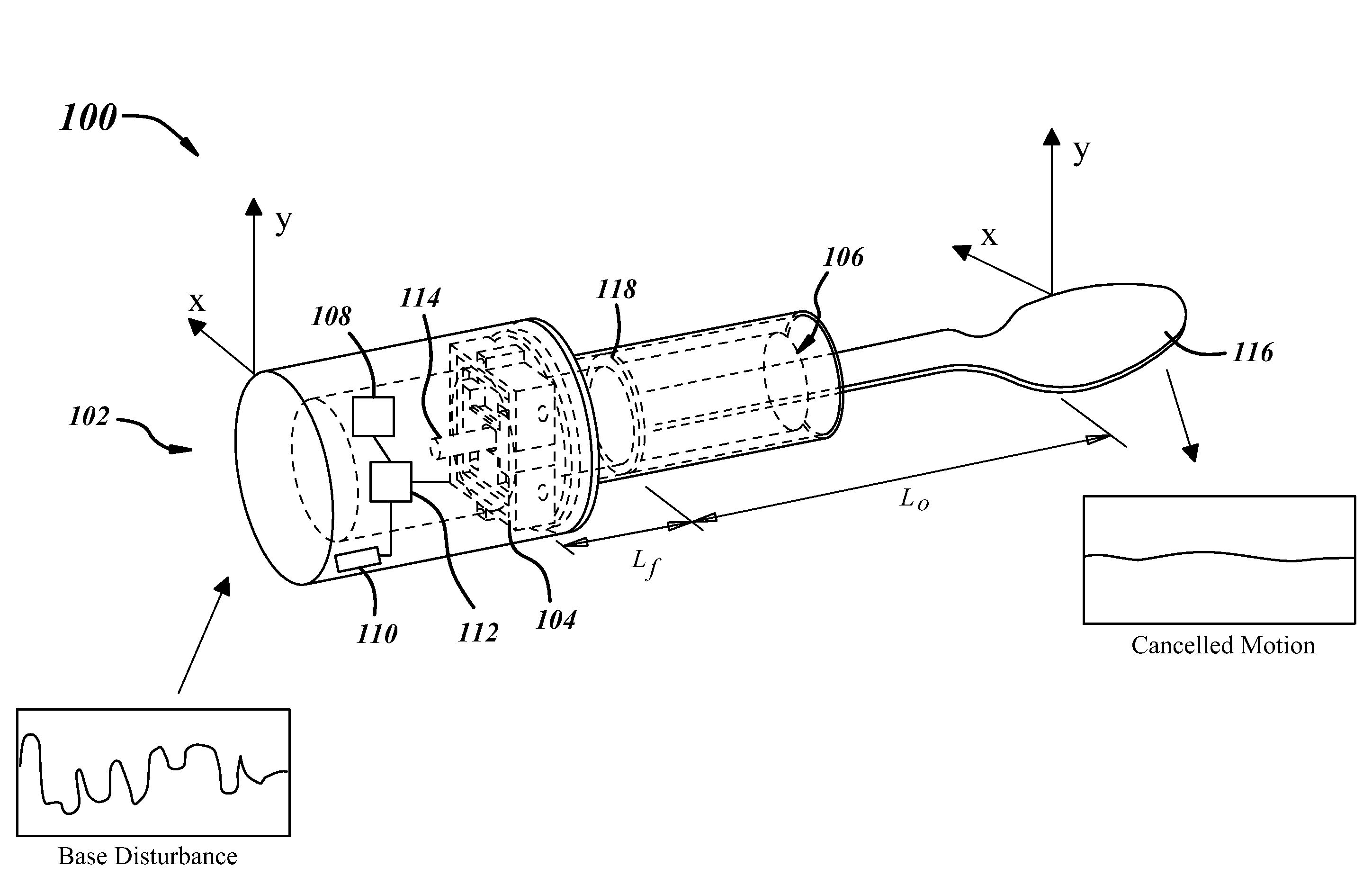

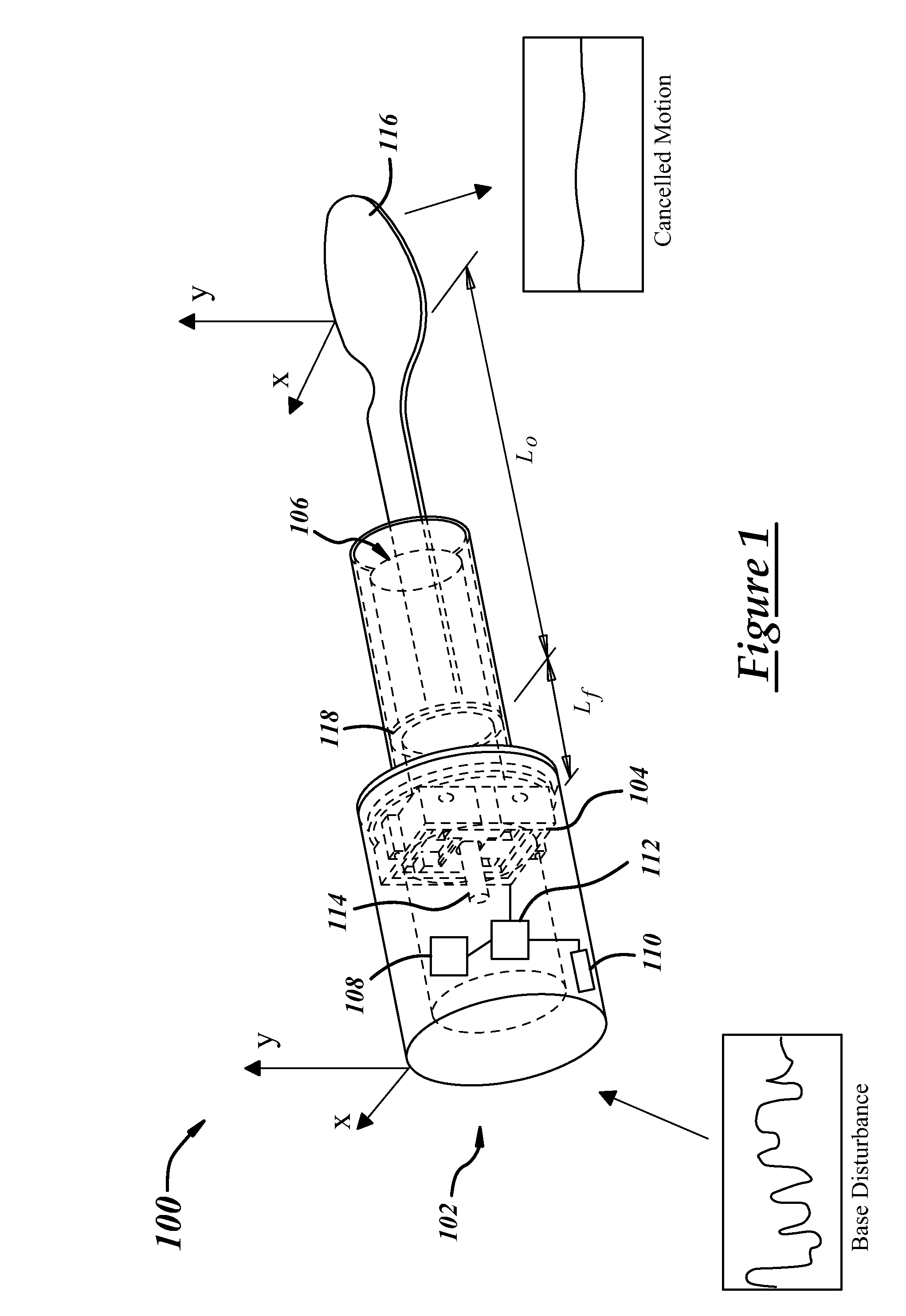

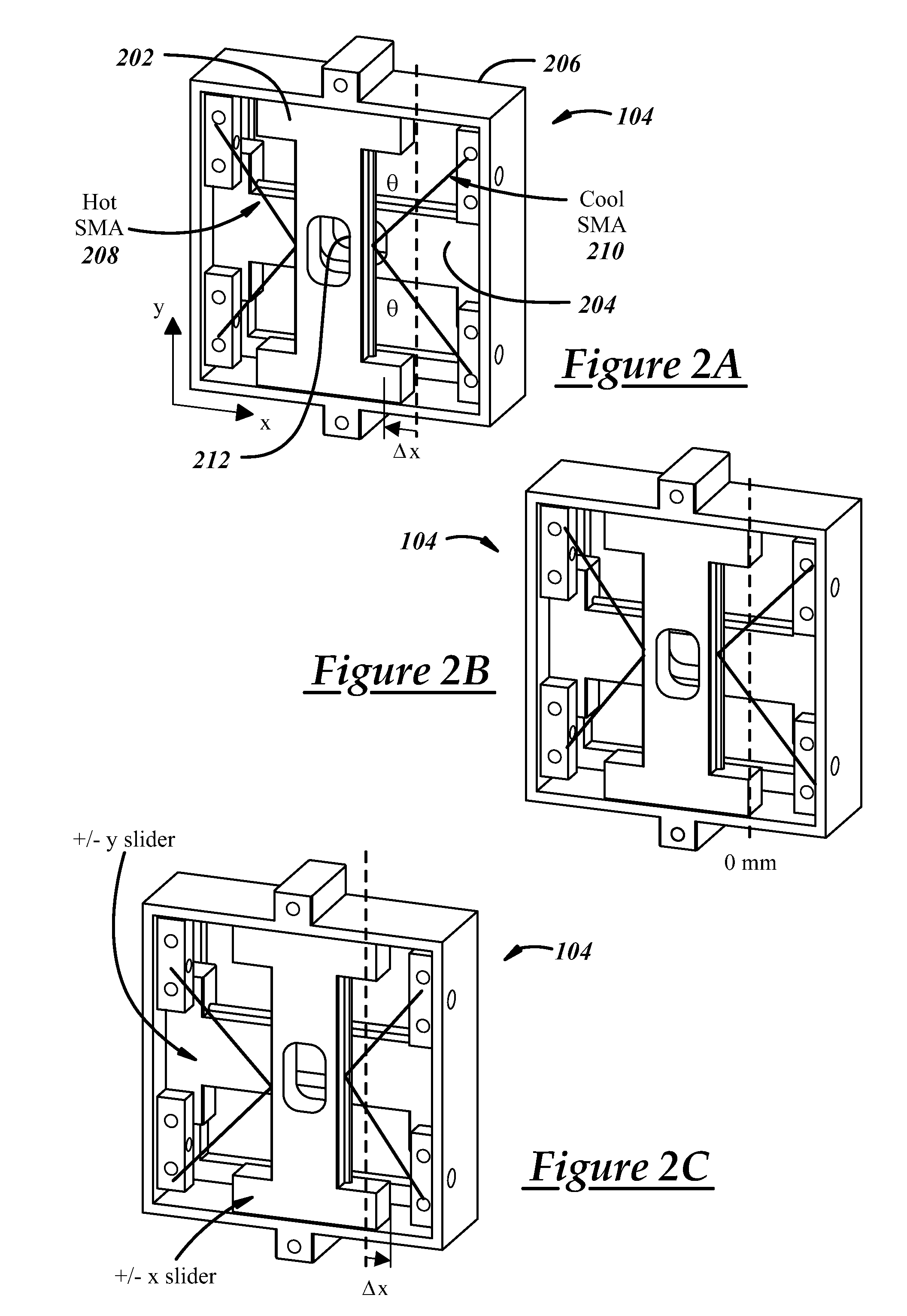

Active tremor control

InactiveUS6234045B1Light weightConvenient and efficient transportationAiming meansRotary machine partsInertial massControl system

An active tremor control system for stabilizing against alternating perturbations includes: an inertial sensor for sensing angular motion about a first axis of an object induced by alternating perturbations; an inertial mass independent of the object; and an actuator coupled to the object and the mass and responsive to the inertial sensor for selectively applying a torque to the object representative of the sensed angular motion such that the angular motion about the first axis induced by the perturbation is cancelled, the actuator concurrently applying a reactive torque, equal and opposite to the to the applied torque, to the mass.

Owner:CHARLES STARK DRAPER LABORATORY

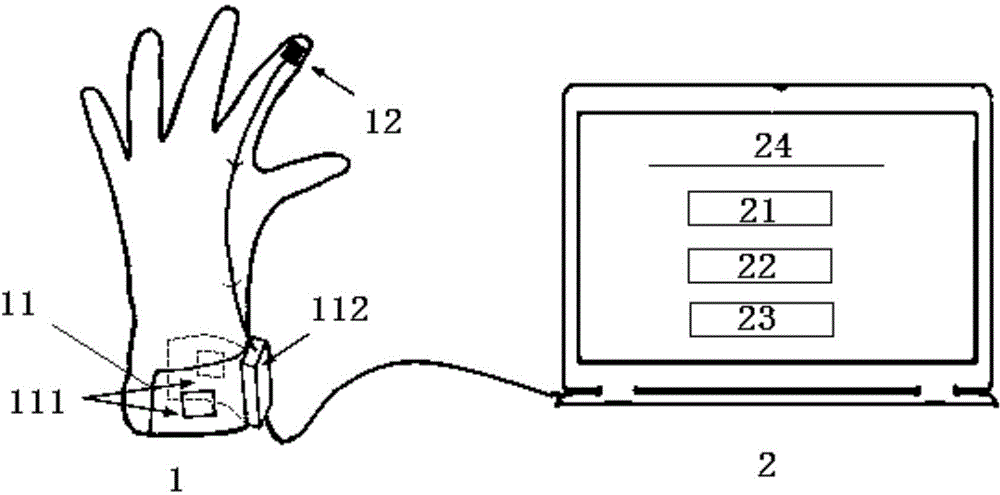

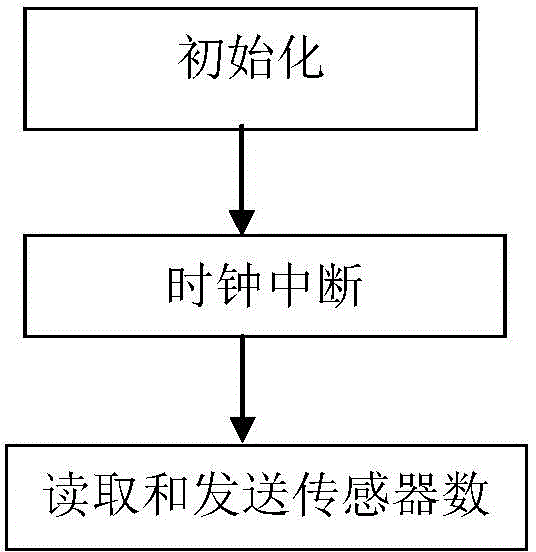

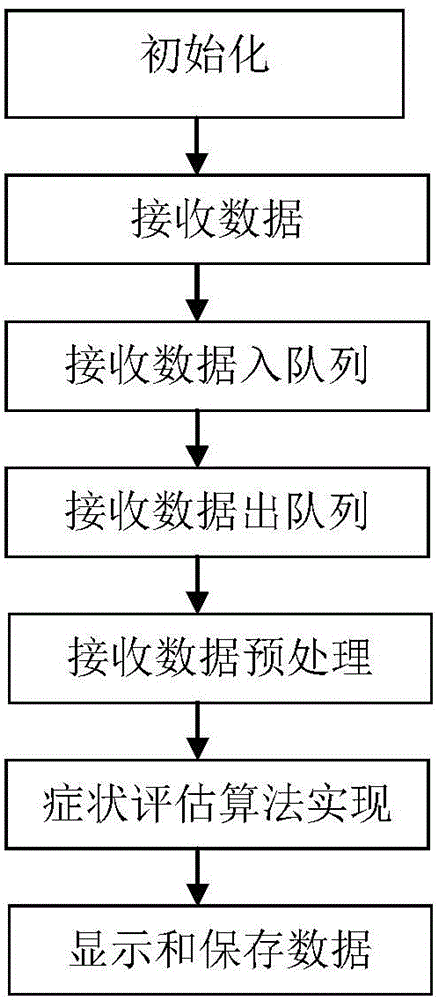

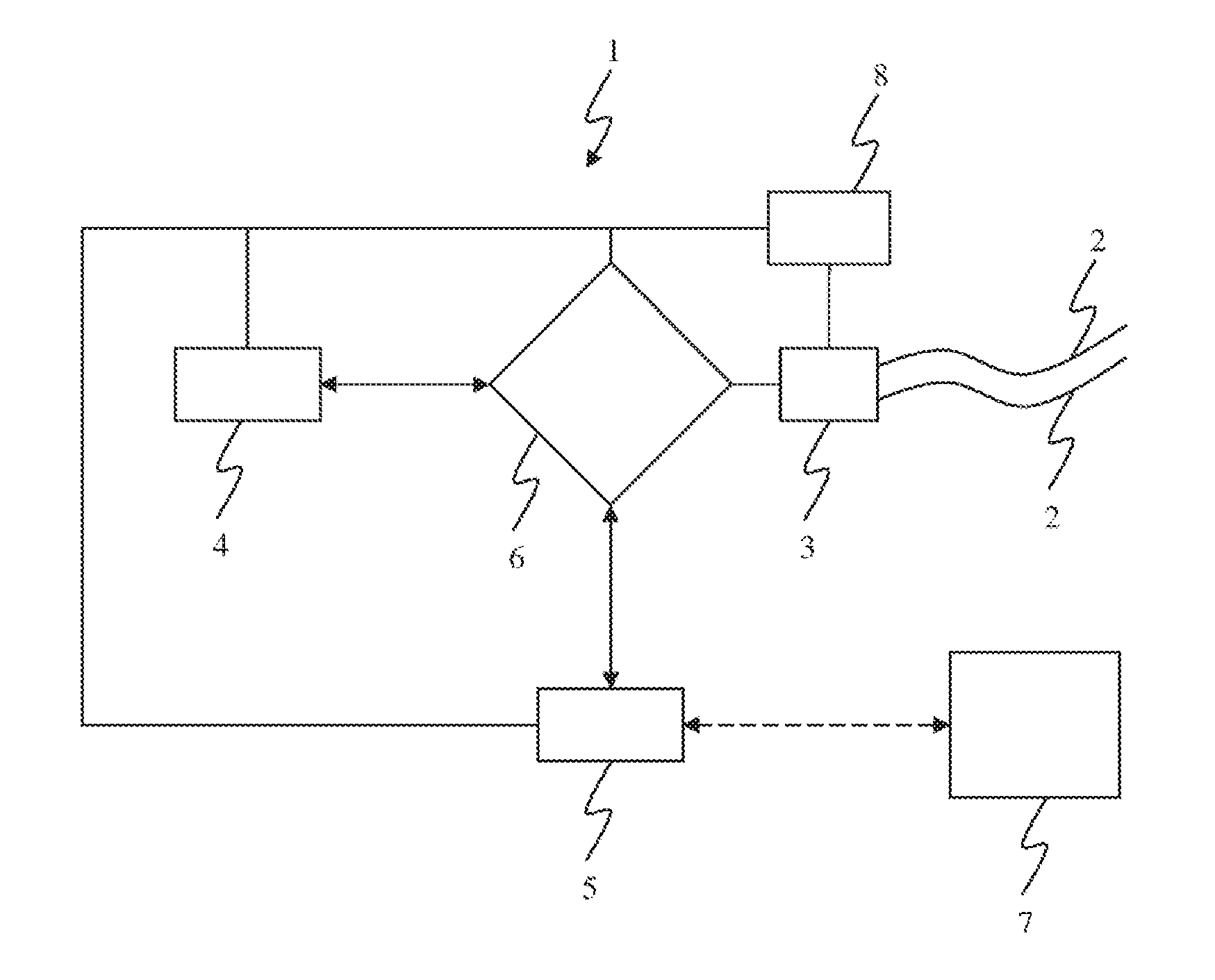

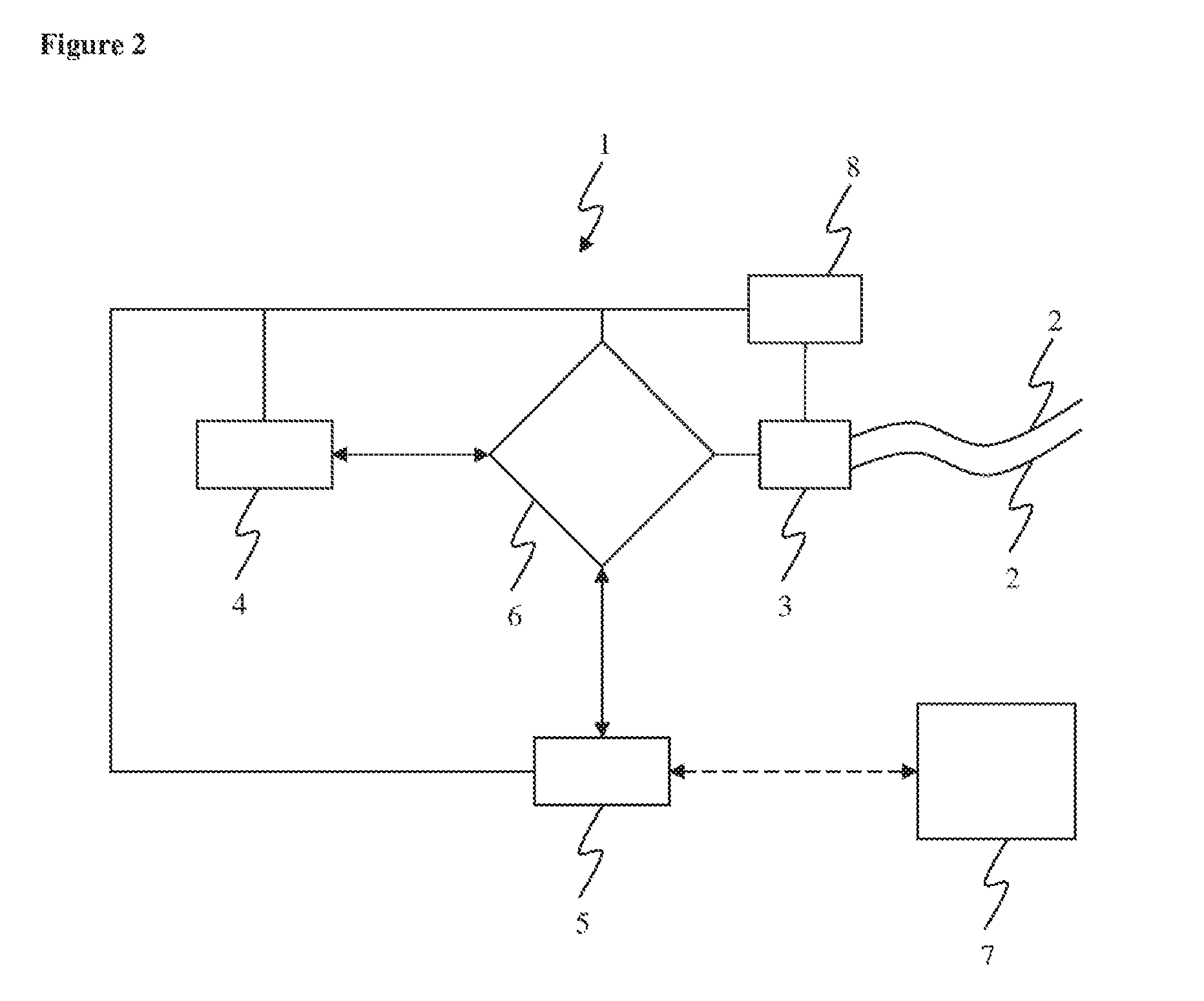

Wearable system and method for cardinal symptom quantitative detection of Parkinson patients

ActiveCN104127187AComplete and comprehensive disease detectionFilter chatter measurementsDiagnostic recording/measuringSensorsSteady state detectionTremor amplitude

The invention provides a wearable system and method for cardinal symptom quantitative detection of Parkinson patients. The system comprises a glove and a computer, wherein the glove and the computer are connected through wires or in a wireless mode. The glove further comprises a wrist module and a fingertip module. The wrist module and the fingertip module are worn on the fingertips and the wrist of a patient respectively. A tremor detection module, a tremor amplitude steady state detection module, a muscular rigidity detection module and a slow movement symptom detection module are arranged in the computer and are used for tremor detection, tremor amplitude steady state detection, muscular rigidity detection and slow movement symptom detection of the Parkinson patients and displaying detection results. For the situation that the symptom judgment of different neurologists for the same patient is different, the system has the uniform quantitative detection standard. Detection of three main symptoms is integrated in one system, and the system can provide complete and comprehensive illness state detection.

Owner:福建世新机器人科技有限公司

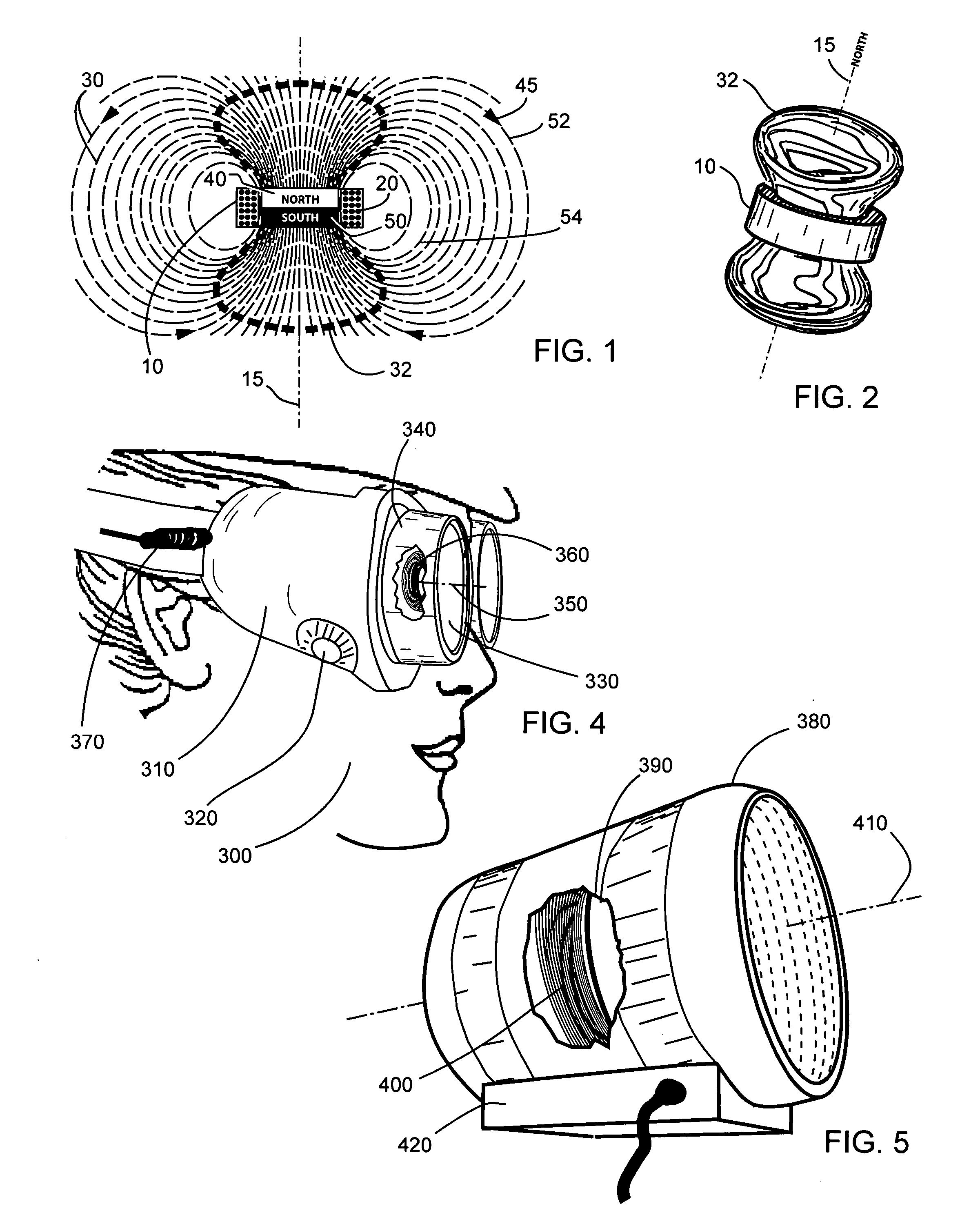

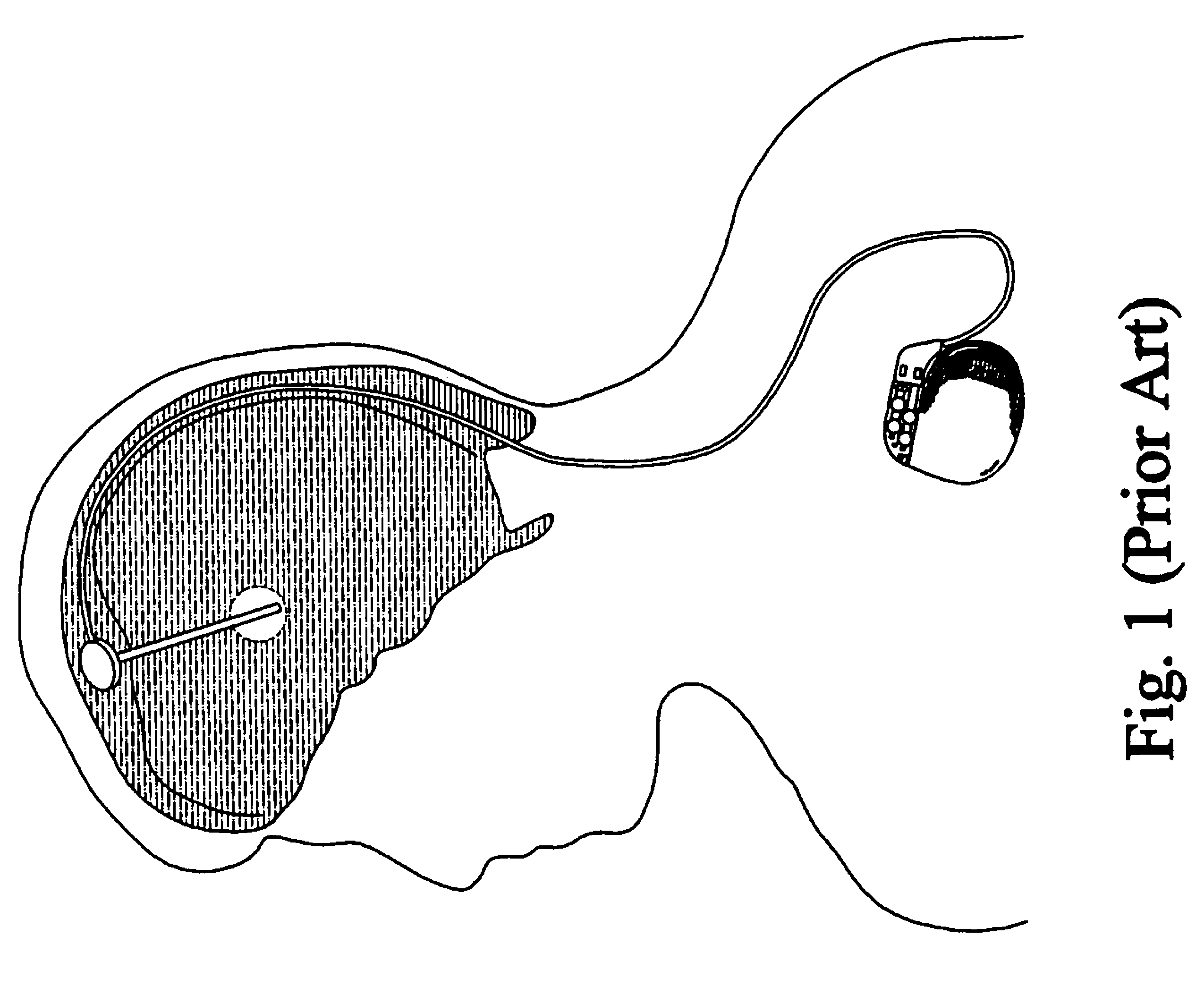

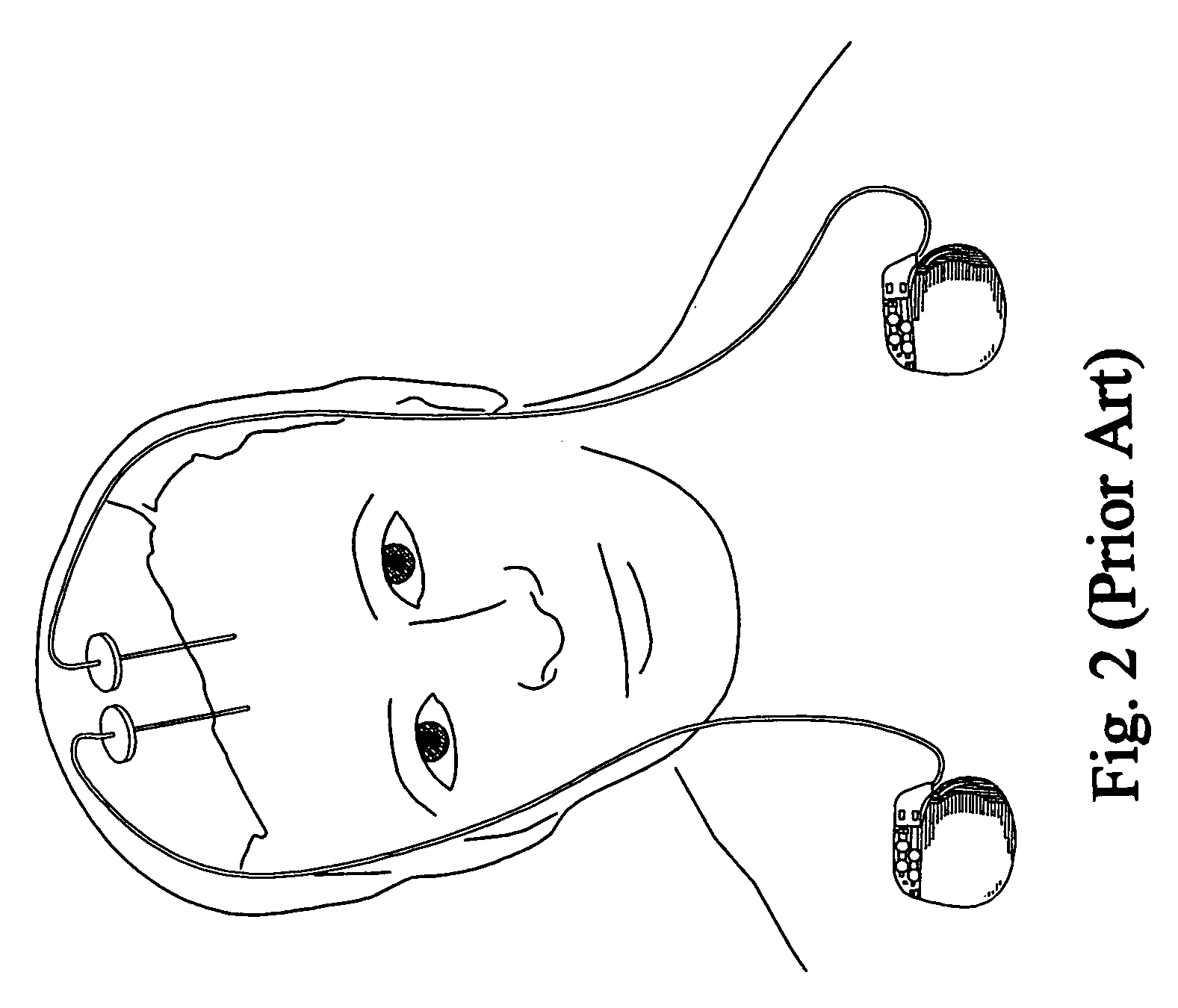

Method and apparatus for monitoring eye tremor

InactiveUS20060082727A1Low costReduce artifactsInertial sensorsEye diagnosticsSmall brainstemEXTREMITY TREMOR

An apparatus consistent with the present invention comprises a sensor for receiving a signal representing eye tremor and a processor for monitoring eye tremor while receiving the signal. A method consistent with the present invention includes receiving a signal representing eye tremor, comparing the received signal representing eye tremor to at least one reference value, and classifying a patient's brain stem function using the comparison of the received signal representing eye tremor to at least one reference value. An embodiment consistent with the present invention includes an ocular micro tremor (OMT) sensor and associated signal processing hardware and software for clinical analyses

Owner:EYETECT

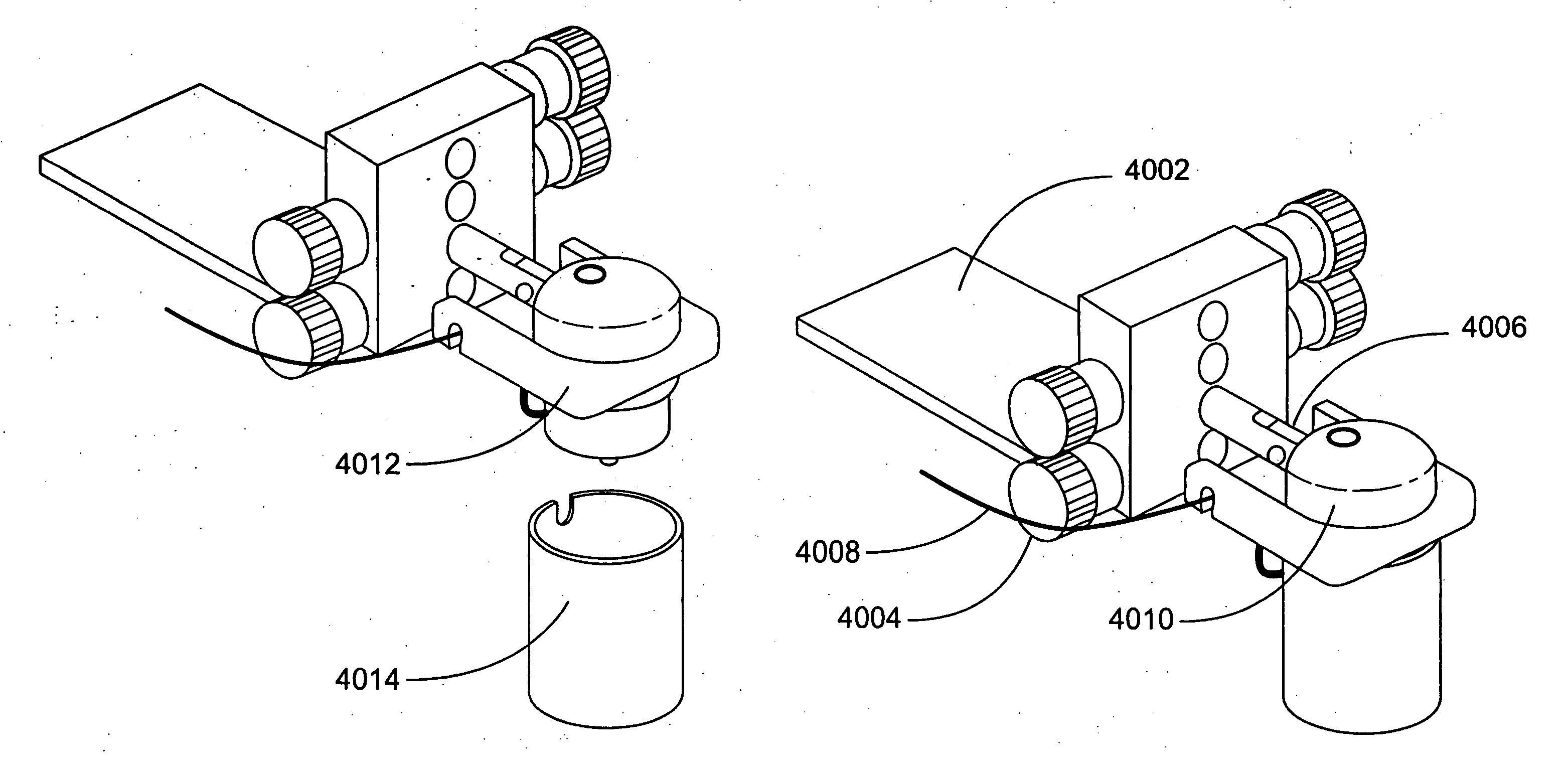

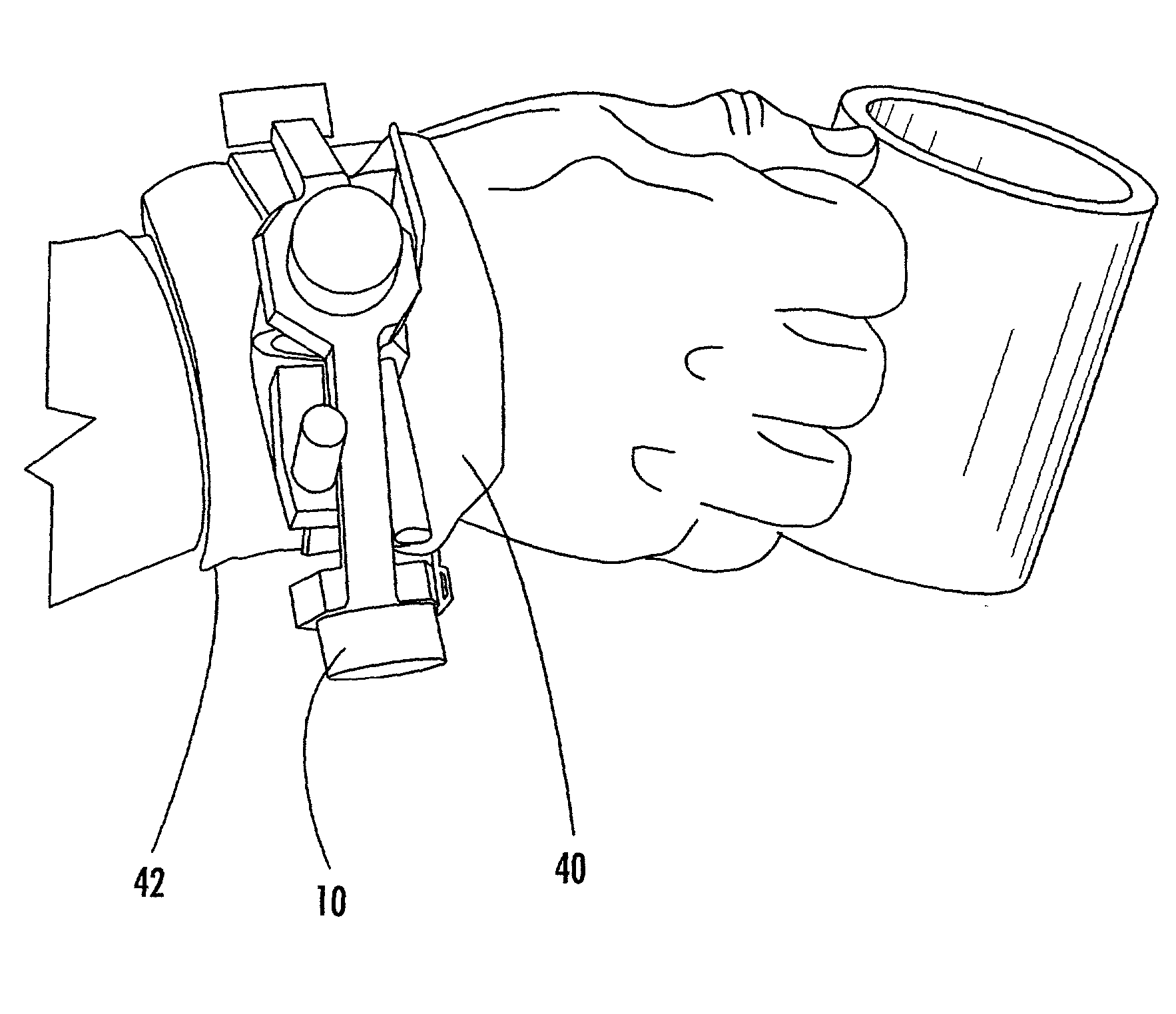

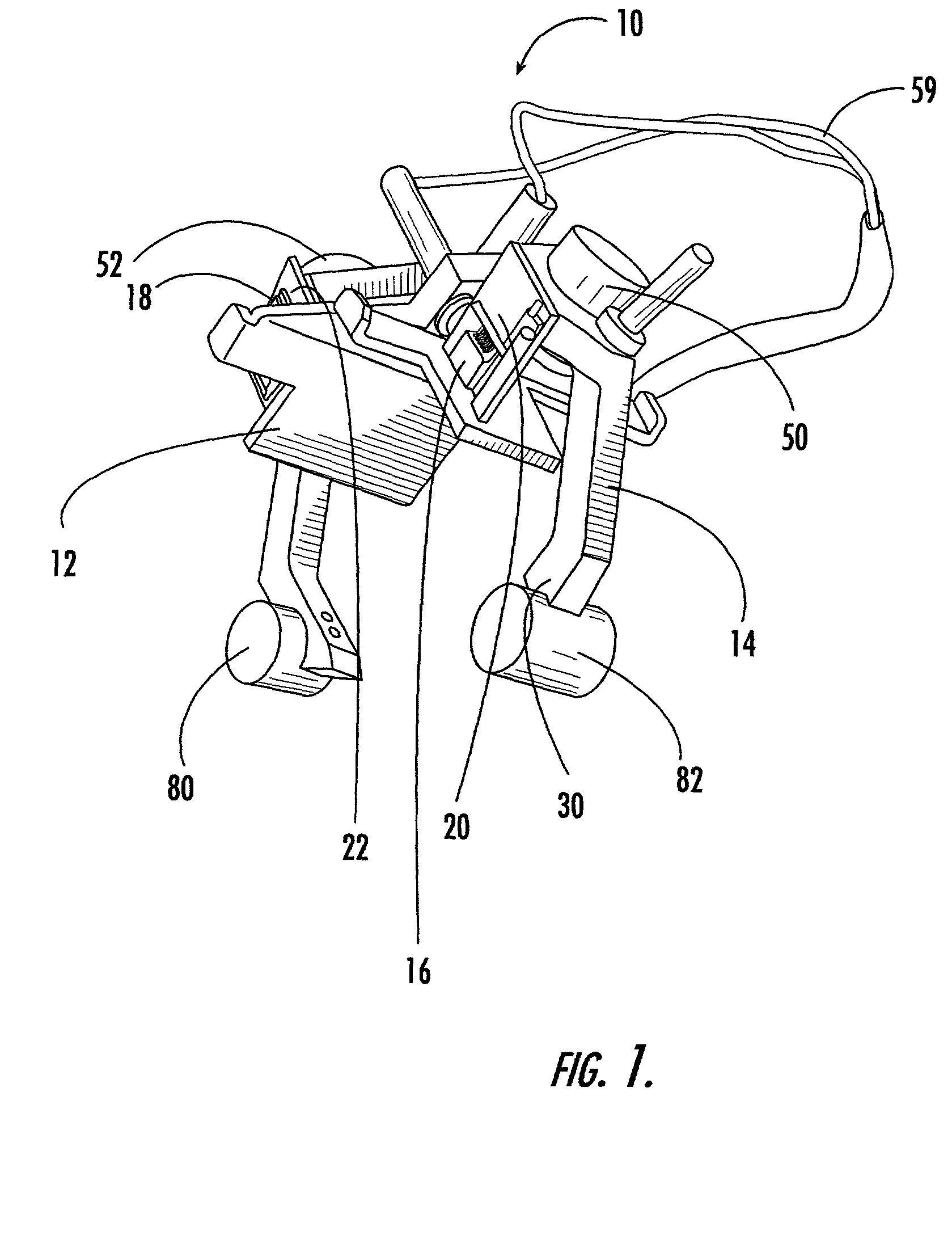

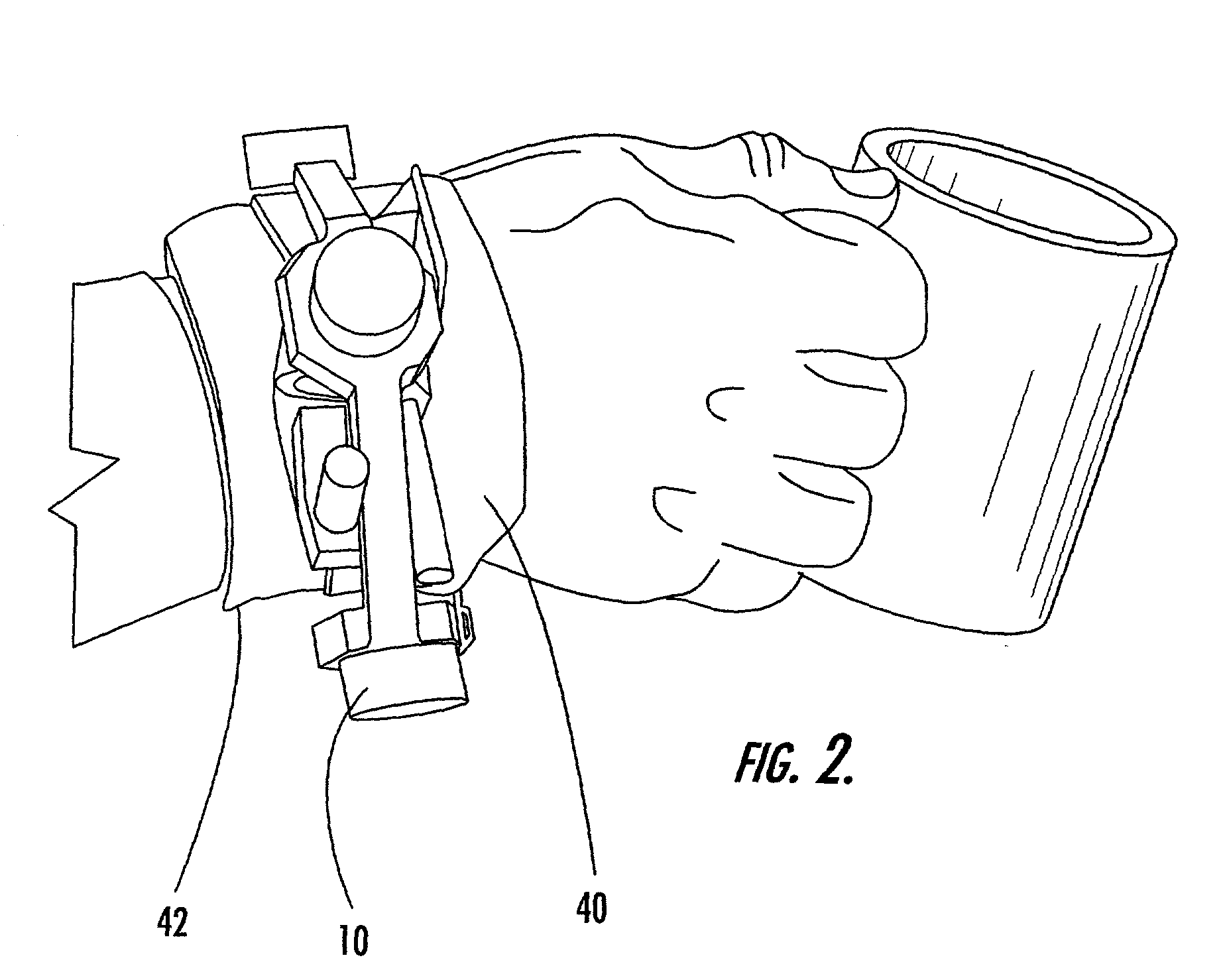

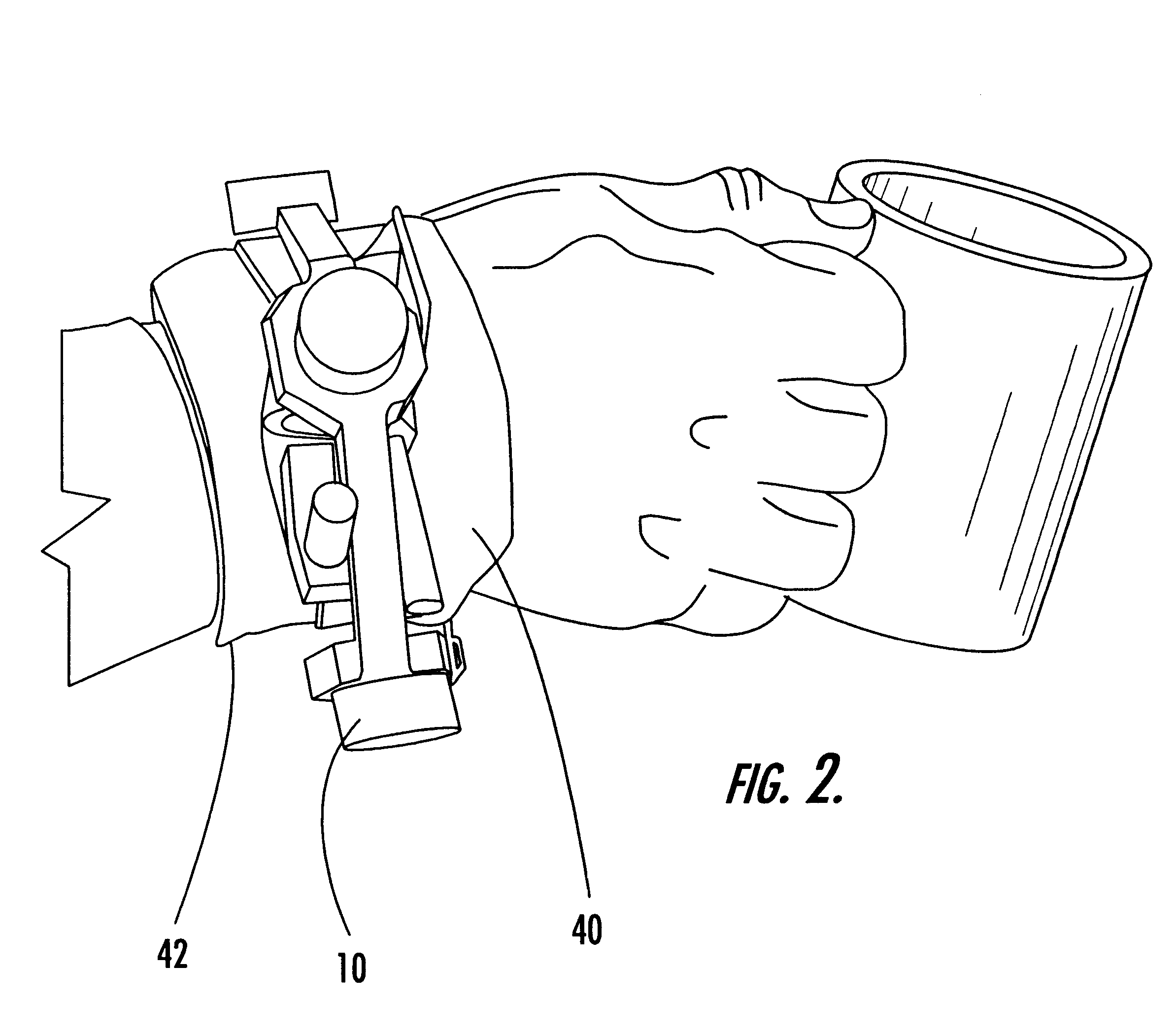

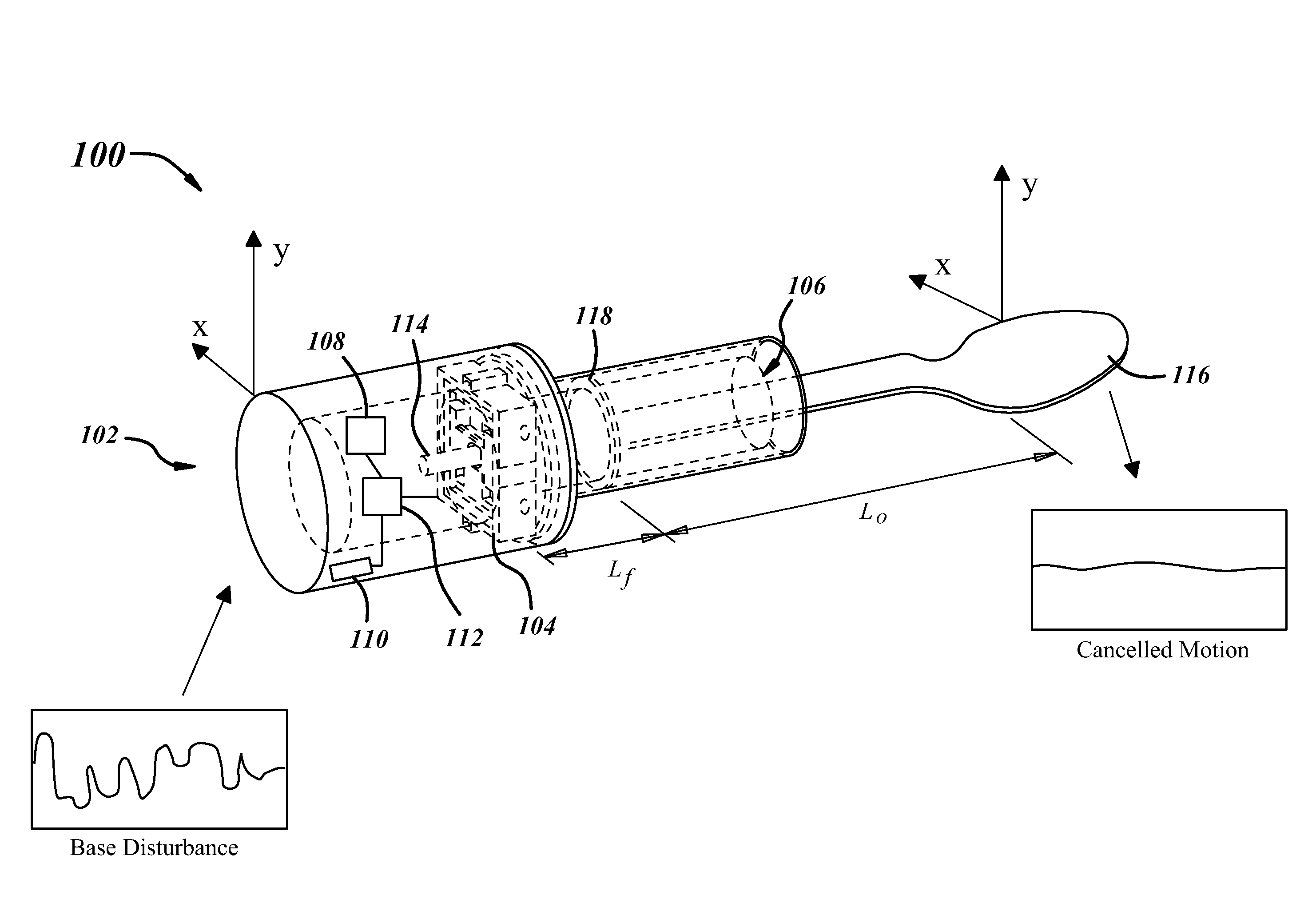

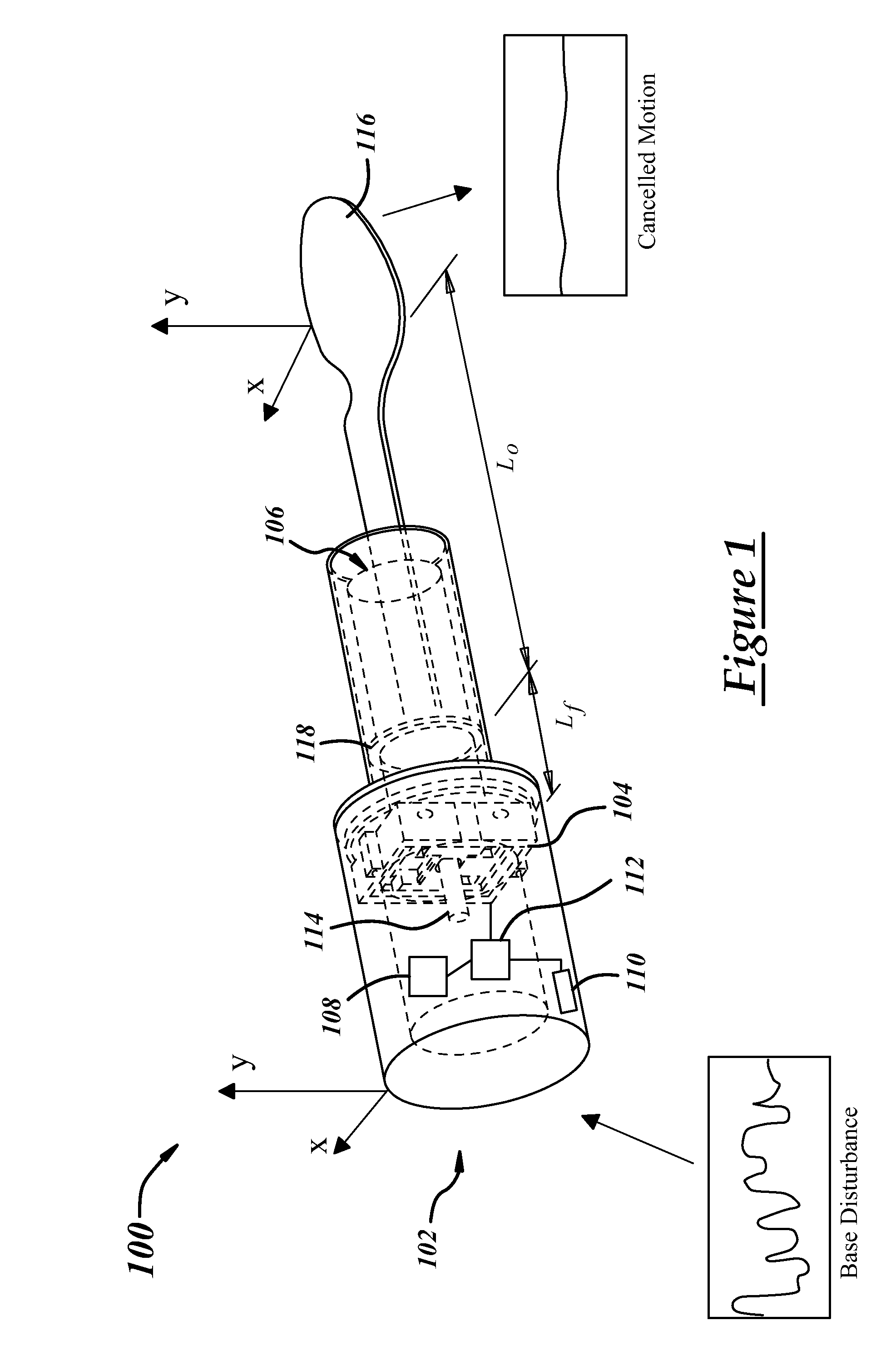

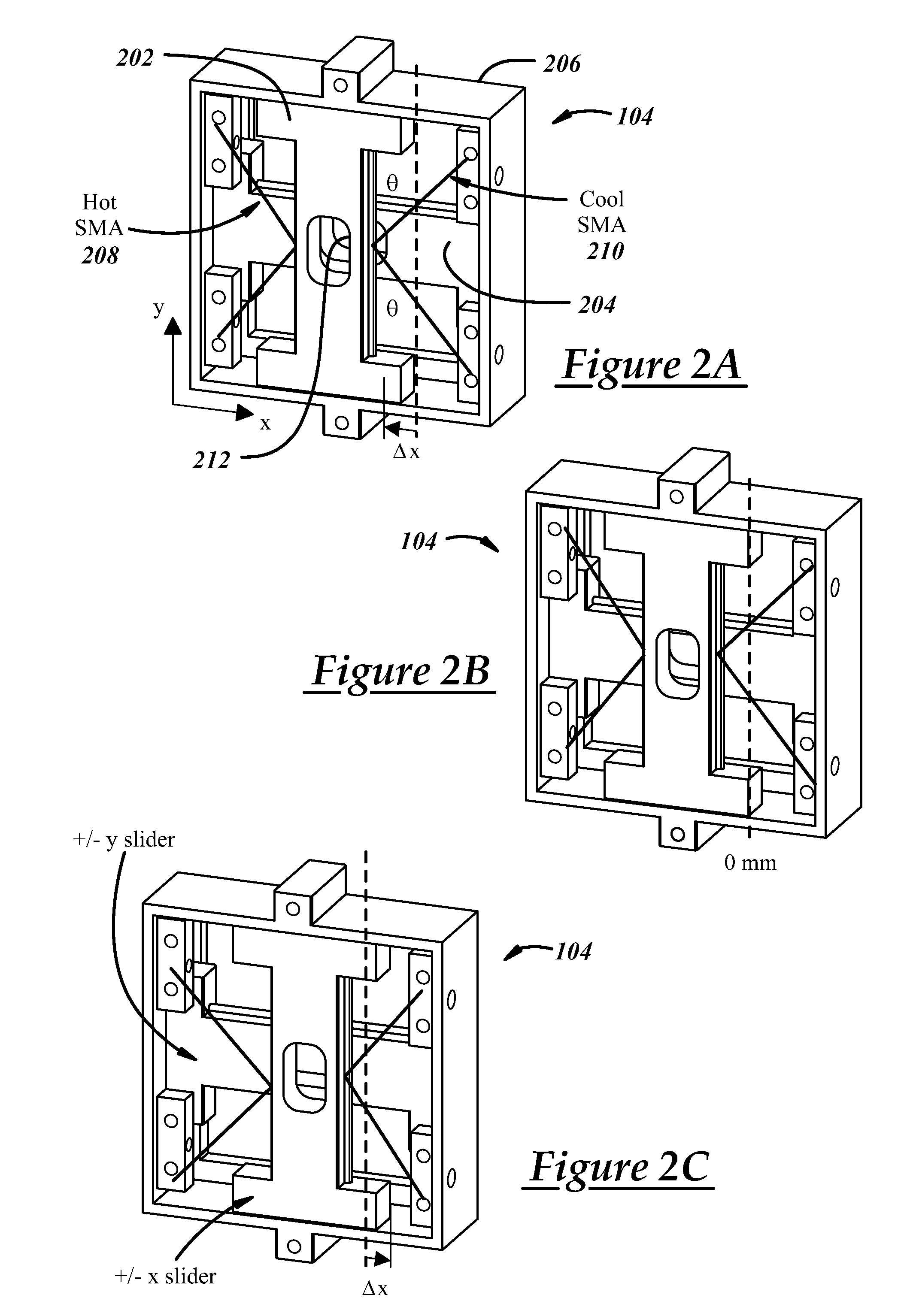

Tremor stabilizing system for handheld devices

A handheld device for canceling unintentional muscle movement. The device includes a base comprising a handgrip for a user to hold, a gripping element linked to the base for releasably connecting the handheld device to an object, a sensor that detects movement of the base, a controller linked to the sensor, and at least one actuator that operates under control of the controller to cause movement of the gripping element in a direction that at least partially counteracts the detected movement of the base.

Owner:RGT UNIV OF MICHIGAN

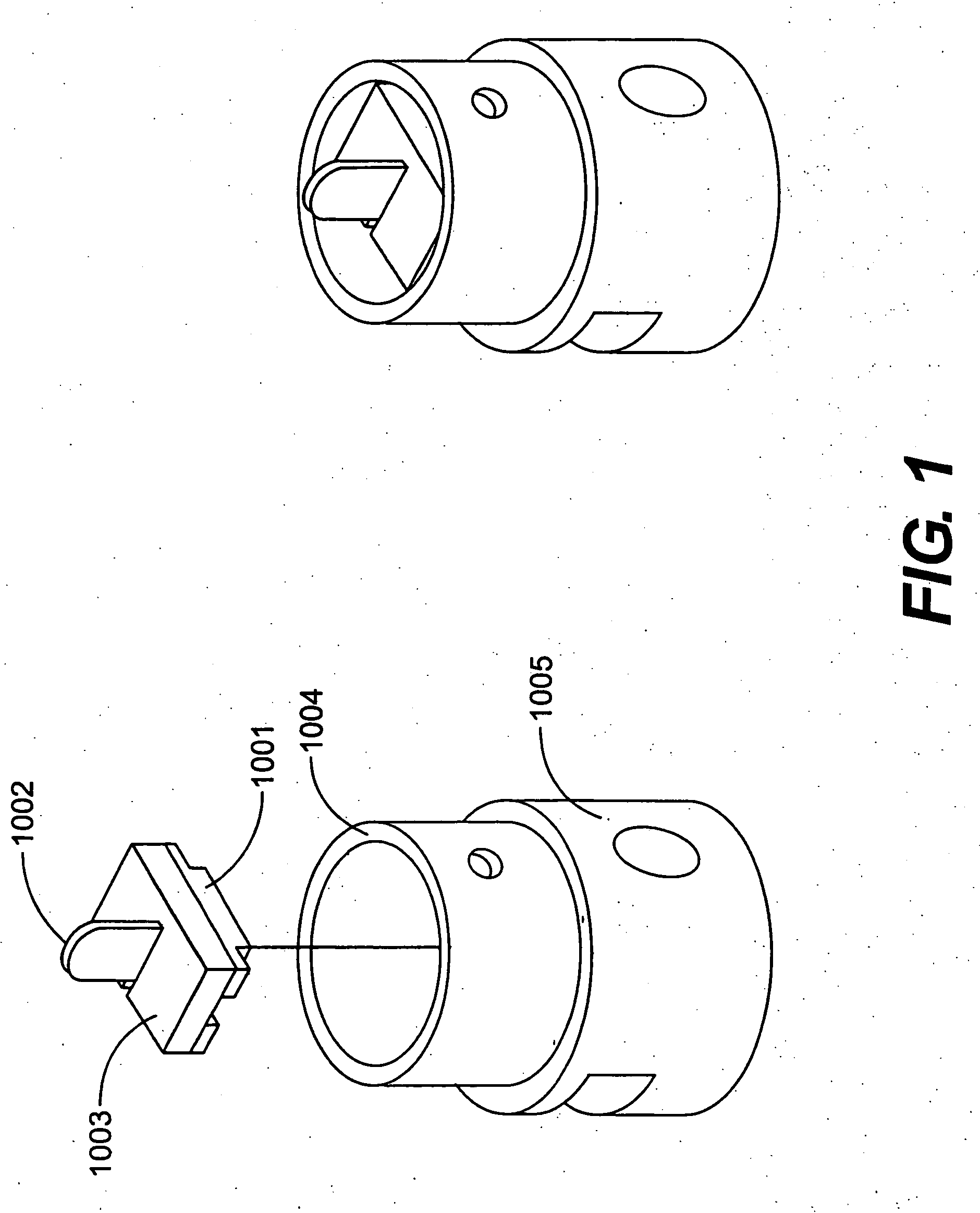

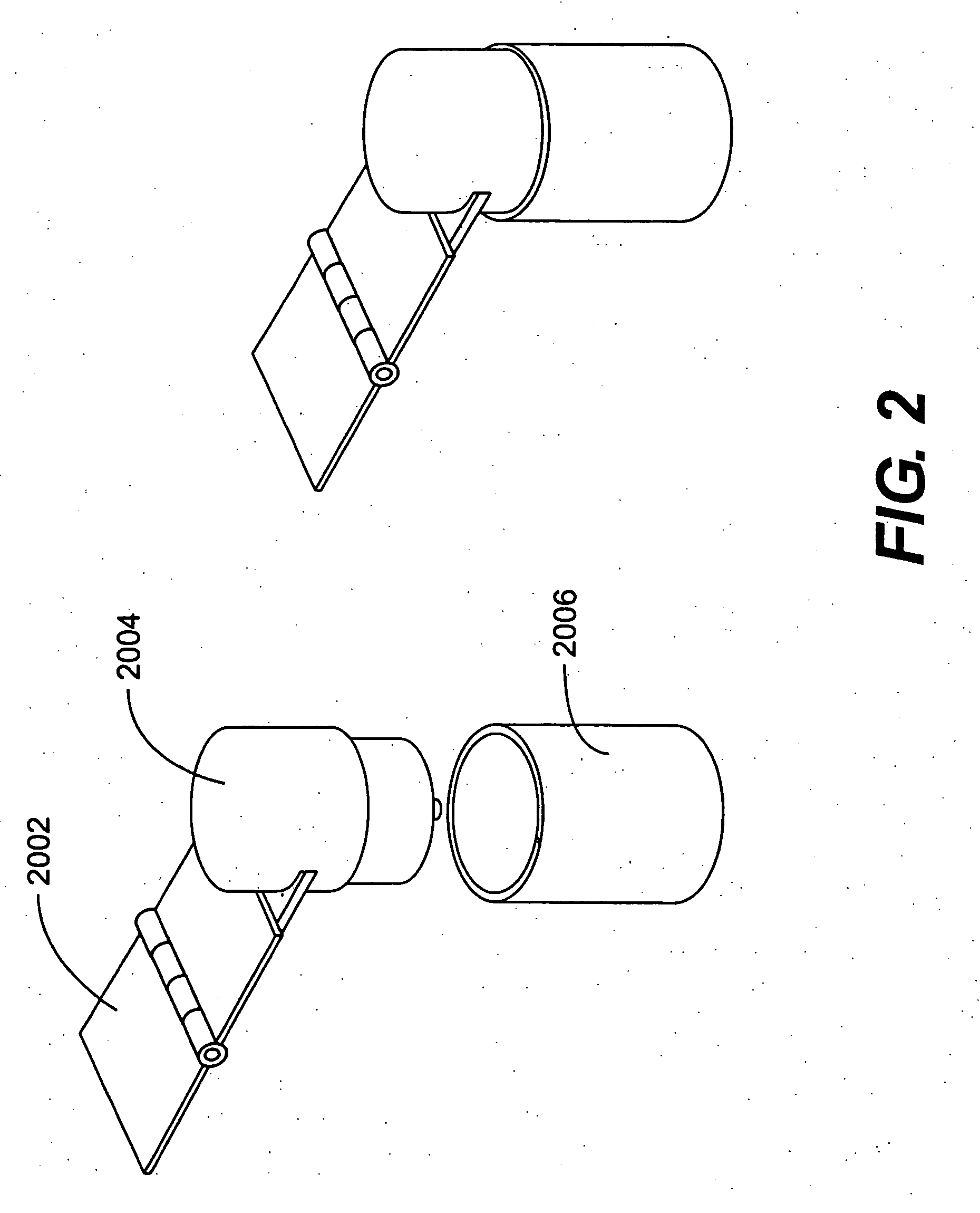

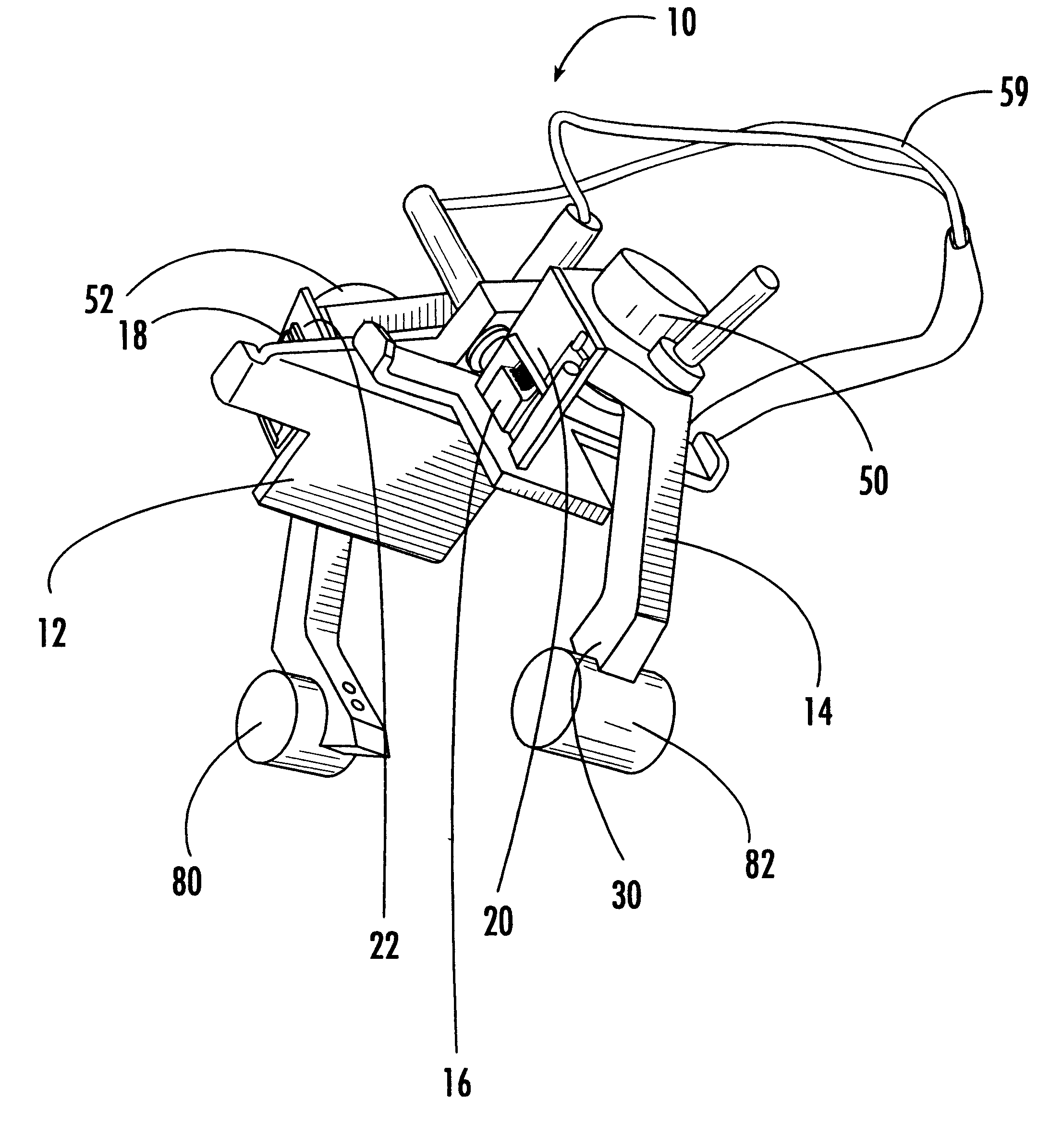

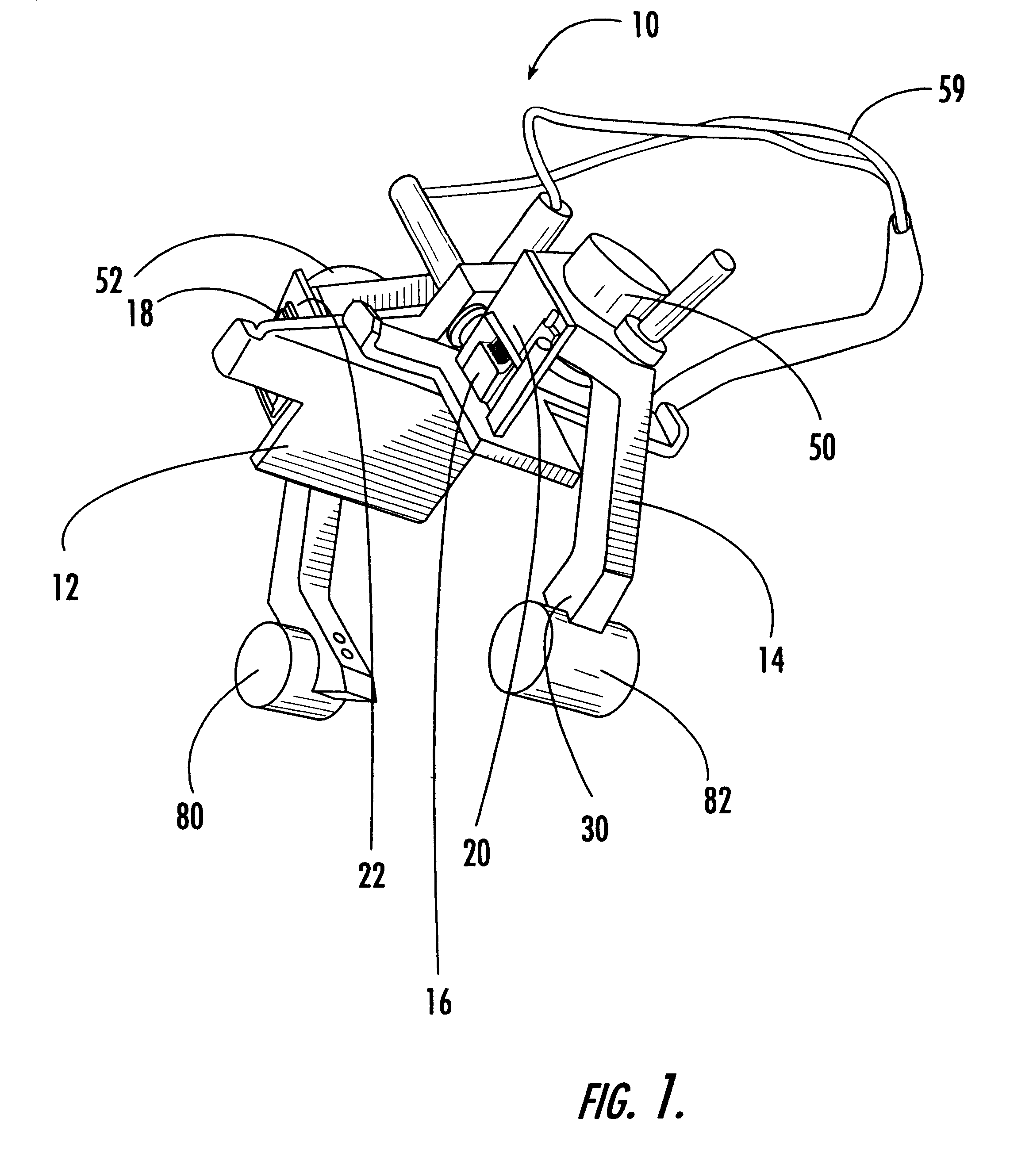

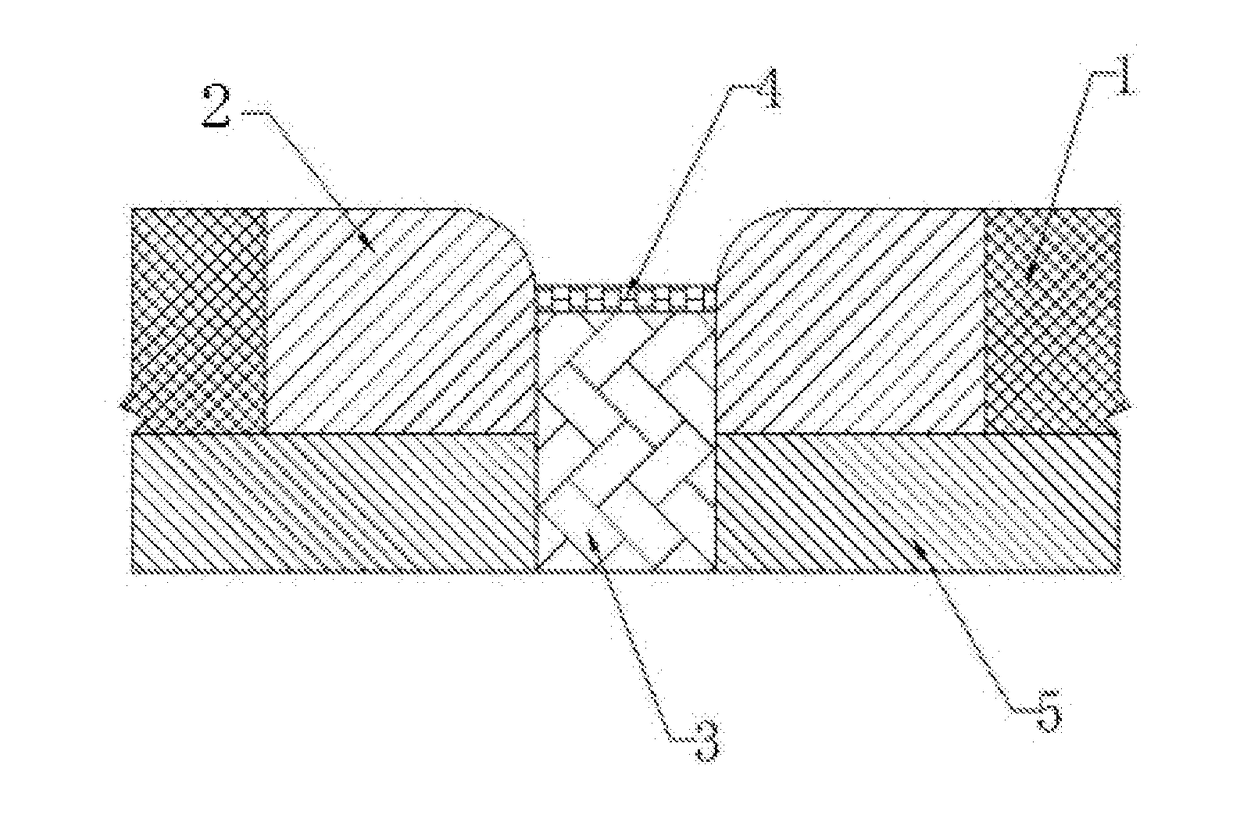

Active tremor control system

InactiveUS20030006357A1Effective controlManipulation is accuratePerson identificationInertial sensorsControl systemEXTREMITY TREMOR

A light weight, wearable, and balanced active tremor control system including a mount; a proof mass frame moveable with respect to the mount; at least one actuator on the proof mass frame for imparting a force on the mount; a motion sensor for detecting movement of the mount due to tremors; and a controller for driving the actuator in response to the motion sensor.

Owner:CHARLES STARK DRAPER LABORATORY

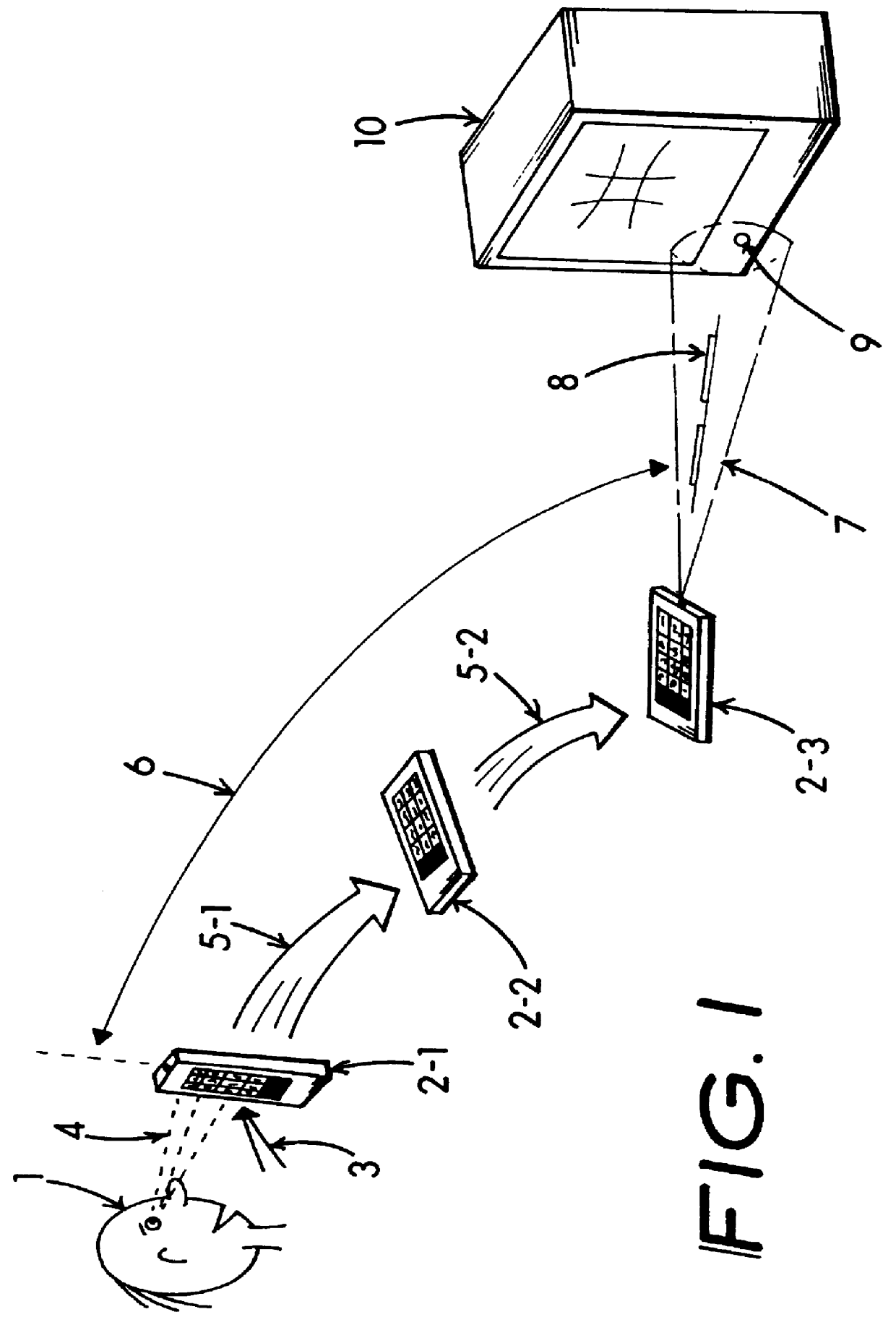

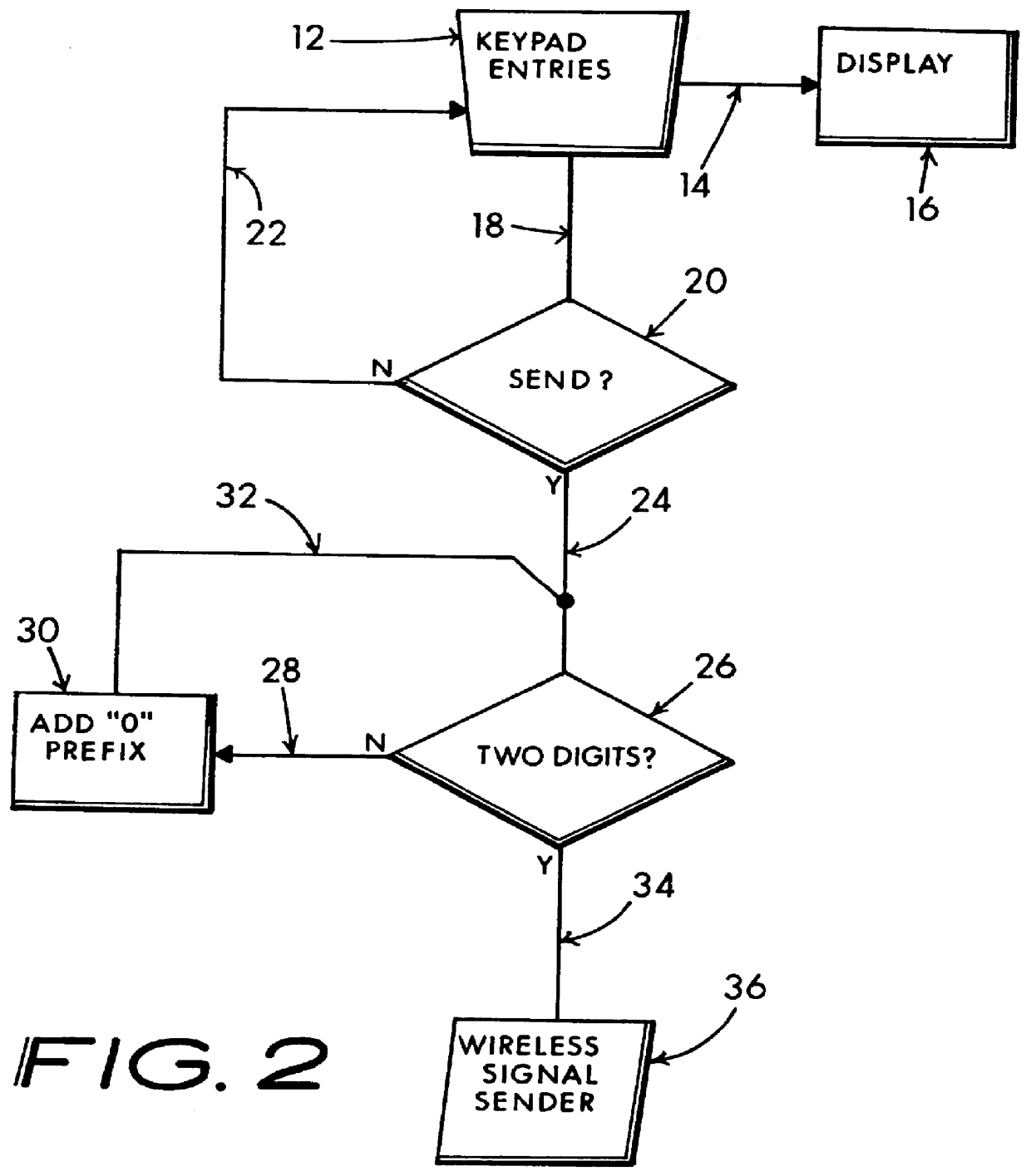

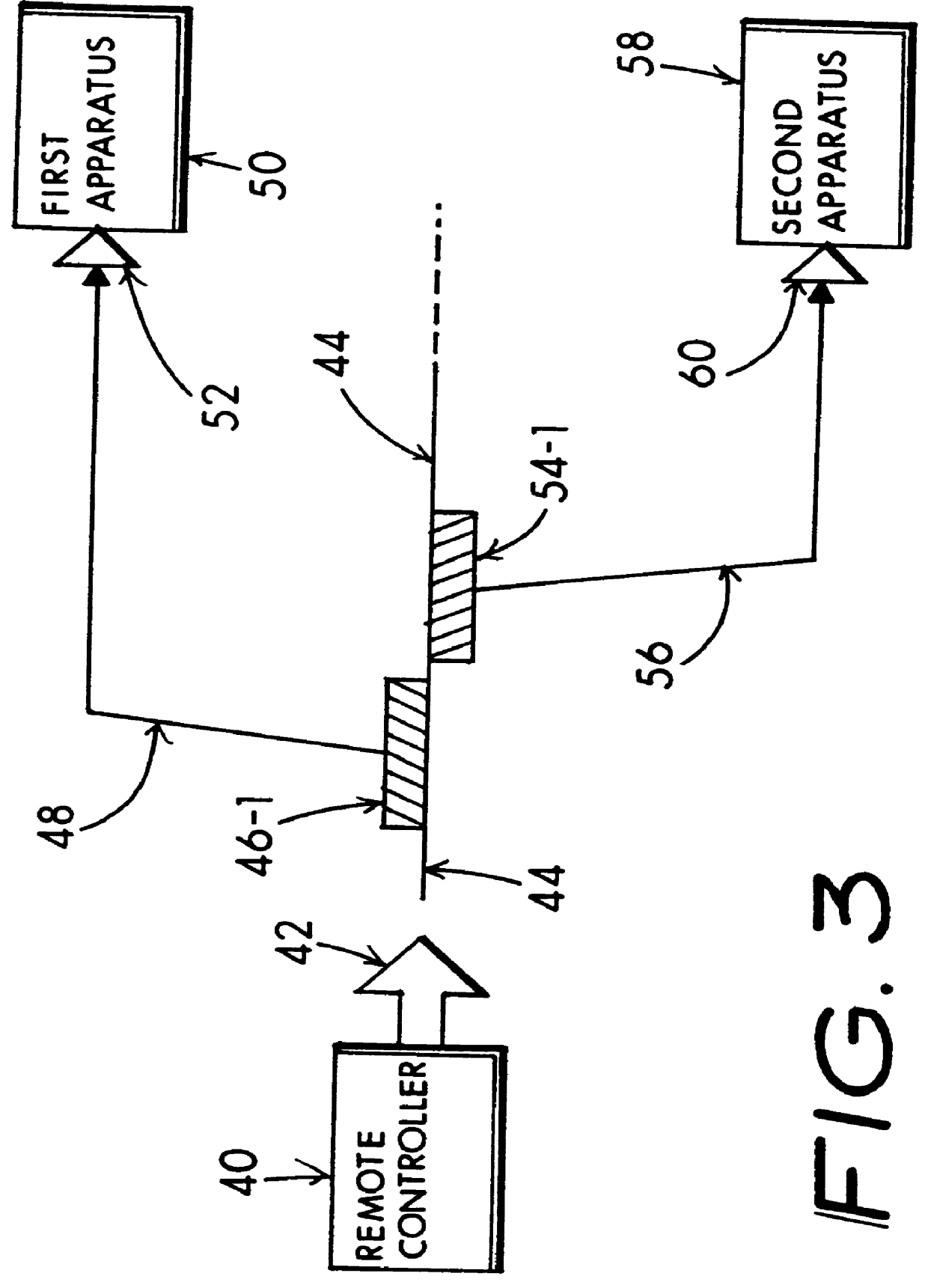

Remote control for a television enabling a user to enter and review a channel selection choice immediately prior to sending an encoded channel selection command to the television

InactiveUS6094239AEasy entryPreventing irritating switchingTelevision system detailsResonant circuit detailsNetwork packetRemote control

A handheld remote controller device that may be manually programmed while the keypad is conveniently supported in an easy to actuate and readily viewable position in front of a user. Individual keybutton entries are temporarily stored until the entry sequence is complete. Each keybutton entry may be visually displayed for review by the user. When the entry sequence is completed the remote controller device is then aimed at a remotely controlled television set, video tape or video disk player, cable or satellite signal converter. The user initiates a SEND command and the stored entries are retrieved and transmitted from the remote controller device to the receptor of the remotely controlled device as a packet of data which acts to change channel selection or accomplish other tasks in the remotely controlled device. A keybutton entry filter reduces a likelihood for accidental multiple entries which may be caused by tremors and other physical or mental maladies. In this way, physically challenged persons, or elderly persons in particular, may be enabled to utilize a remote control function with less chance for error. When only a single number channel, such as channel 5 is selected, a necessitous leading zero is automatically added to the SEND dispatched command.

Owner:HANGER SOLUTIONS LLC +1

Nerve stimulation for treating spasticity, tremor, muscle weakness, and other motor disorders

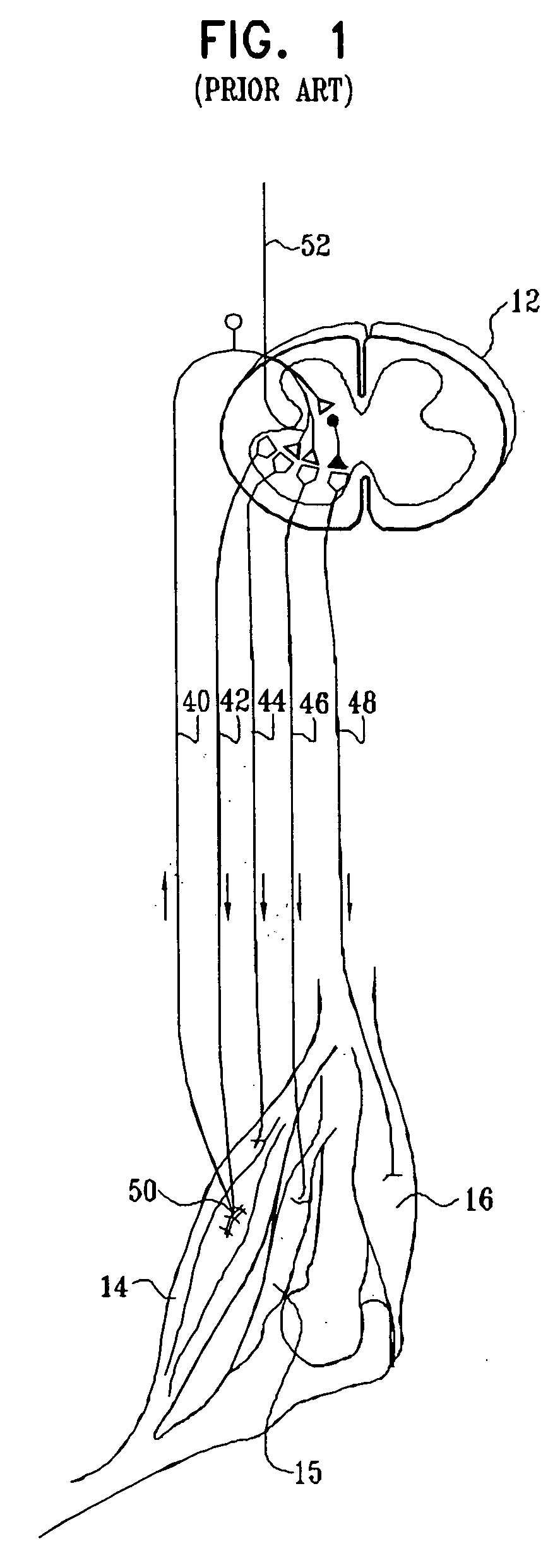

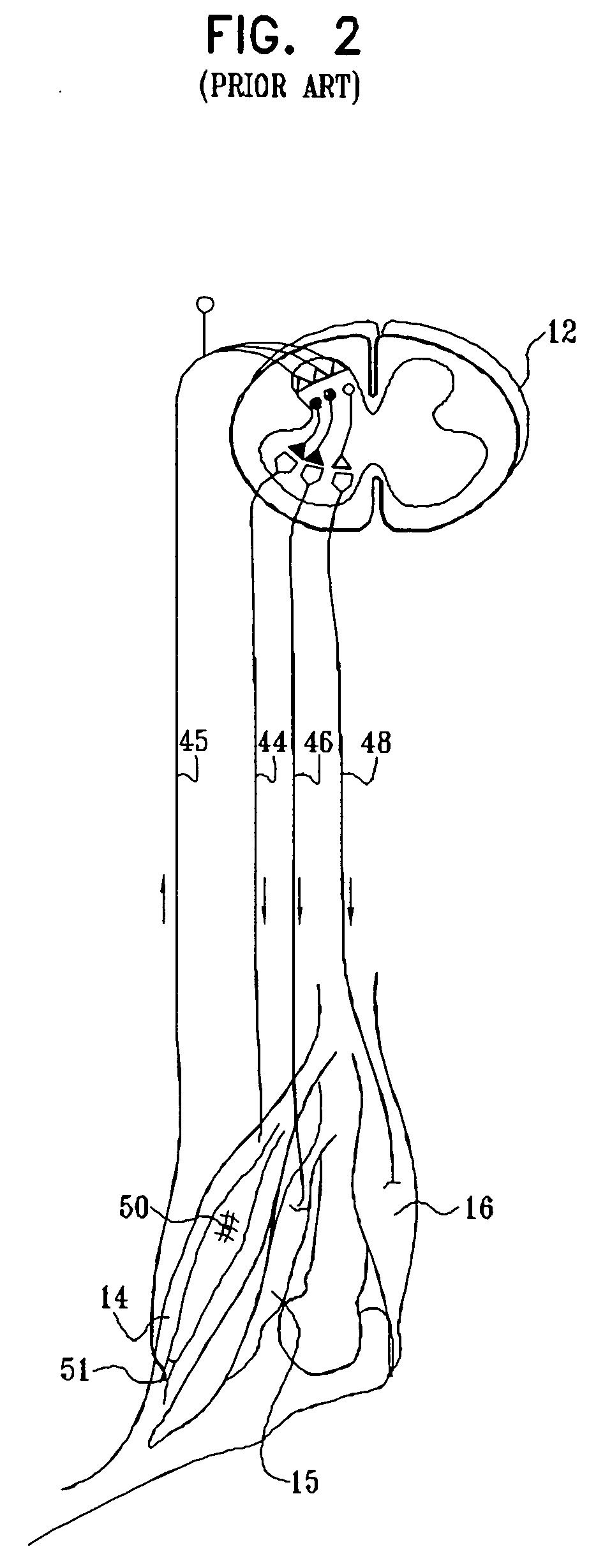

InactiveUS20050102007A1Induce antagonistic musclesReduce spasmsElectrotherapyArtificial respirationFiberTruncal muscle weakness

A method for treating spasticity of a subject is provided, including driving a current into a nerve of the subject that includes one or more sensory fibers, and configuring the current so as to inhibit propagation of action potentials in one or more of the sensory fibers, so as to treat the spasticity. In a preferred embodiment, the sensory fibers include one or more Ia sensory fibers, and configuring the current includes configuring the current so as to inhibit propagation of the action potentials in at least one of the Ia sensory fibers.

Owner:MEDTRONIC INC

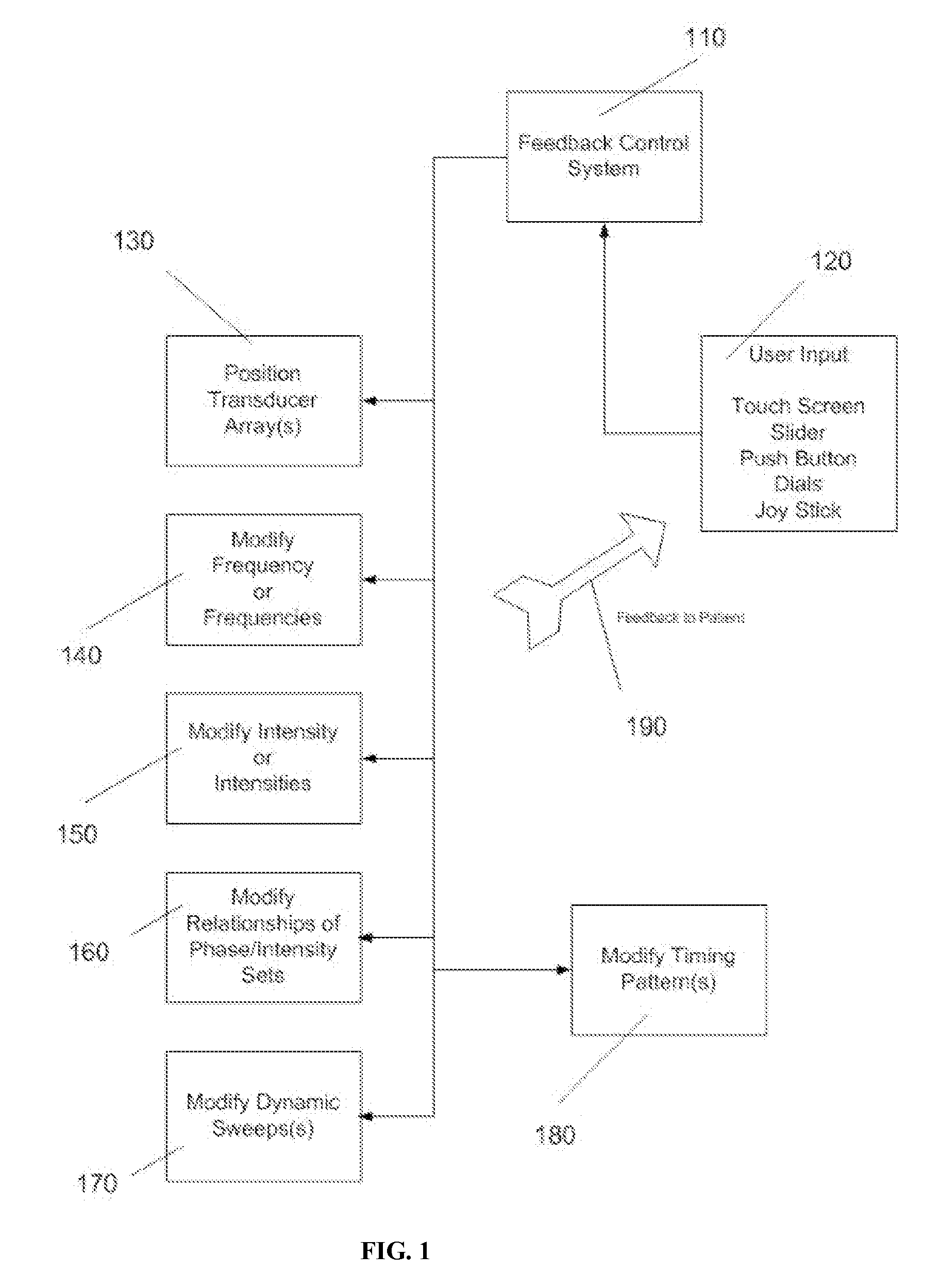

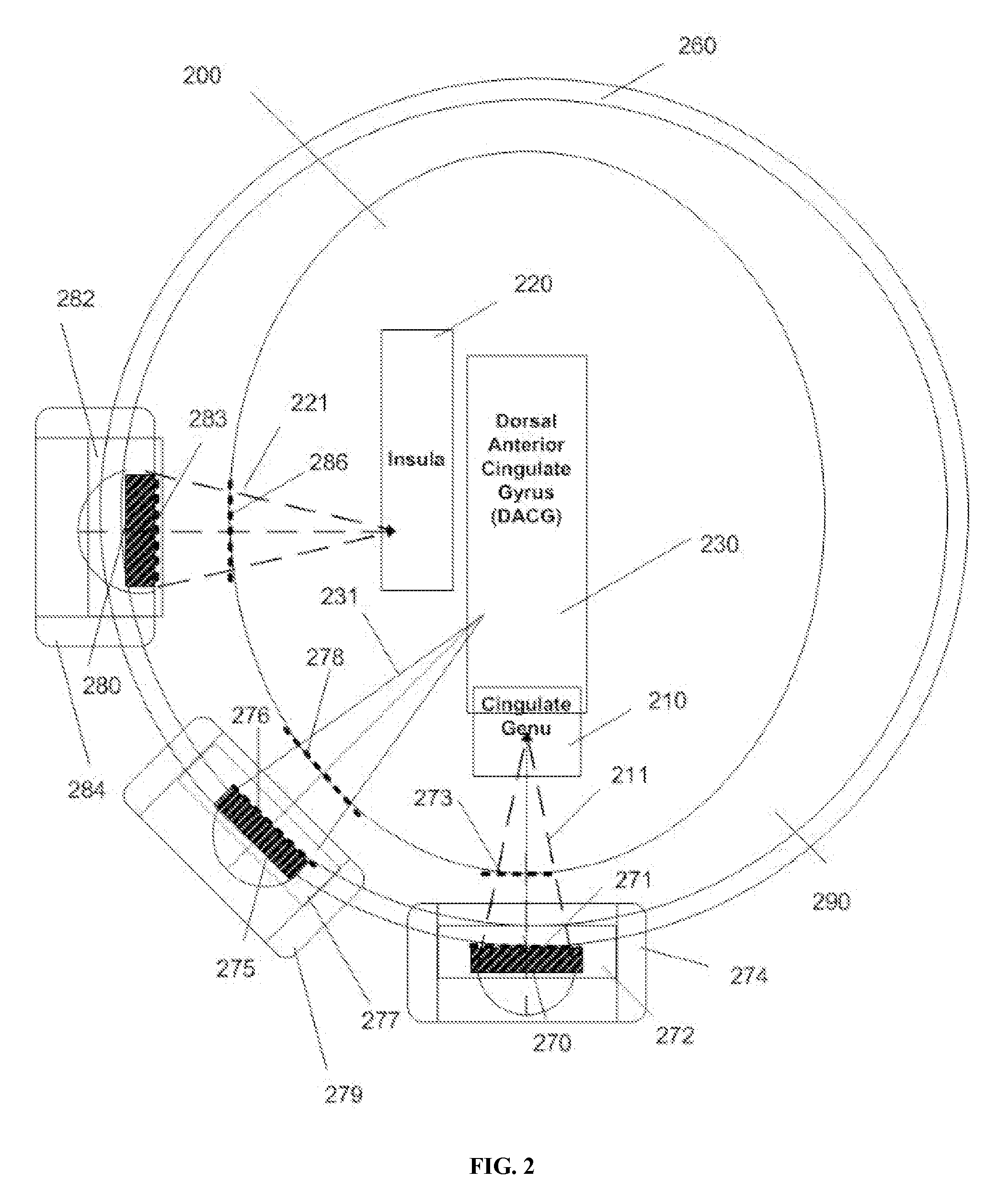

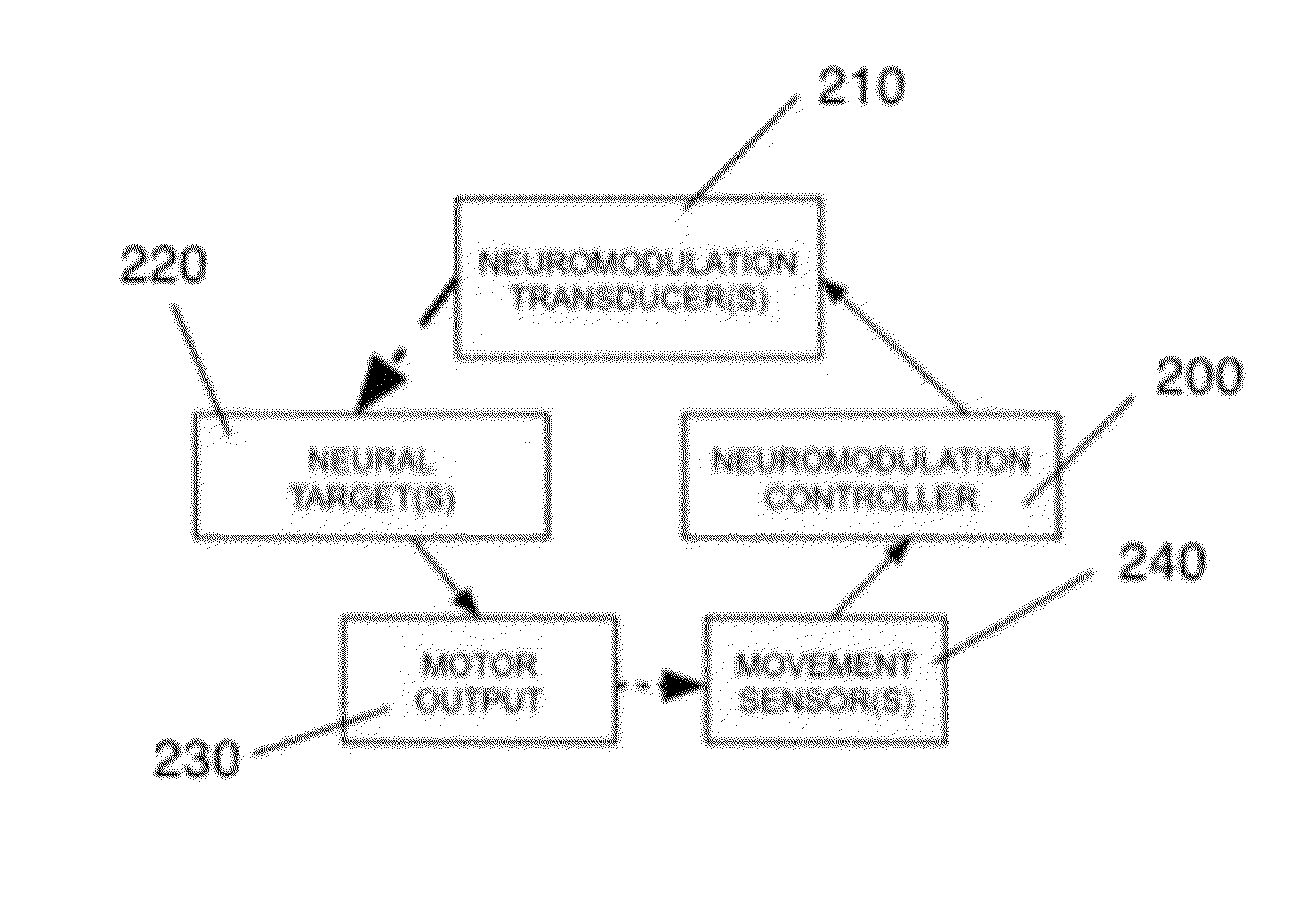

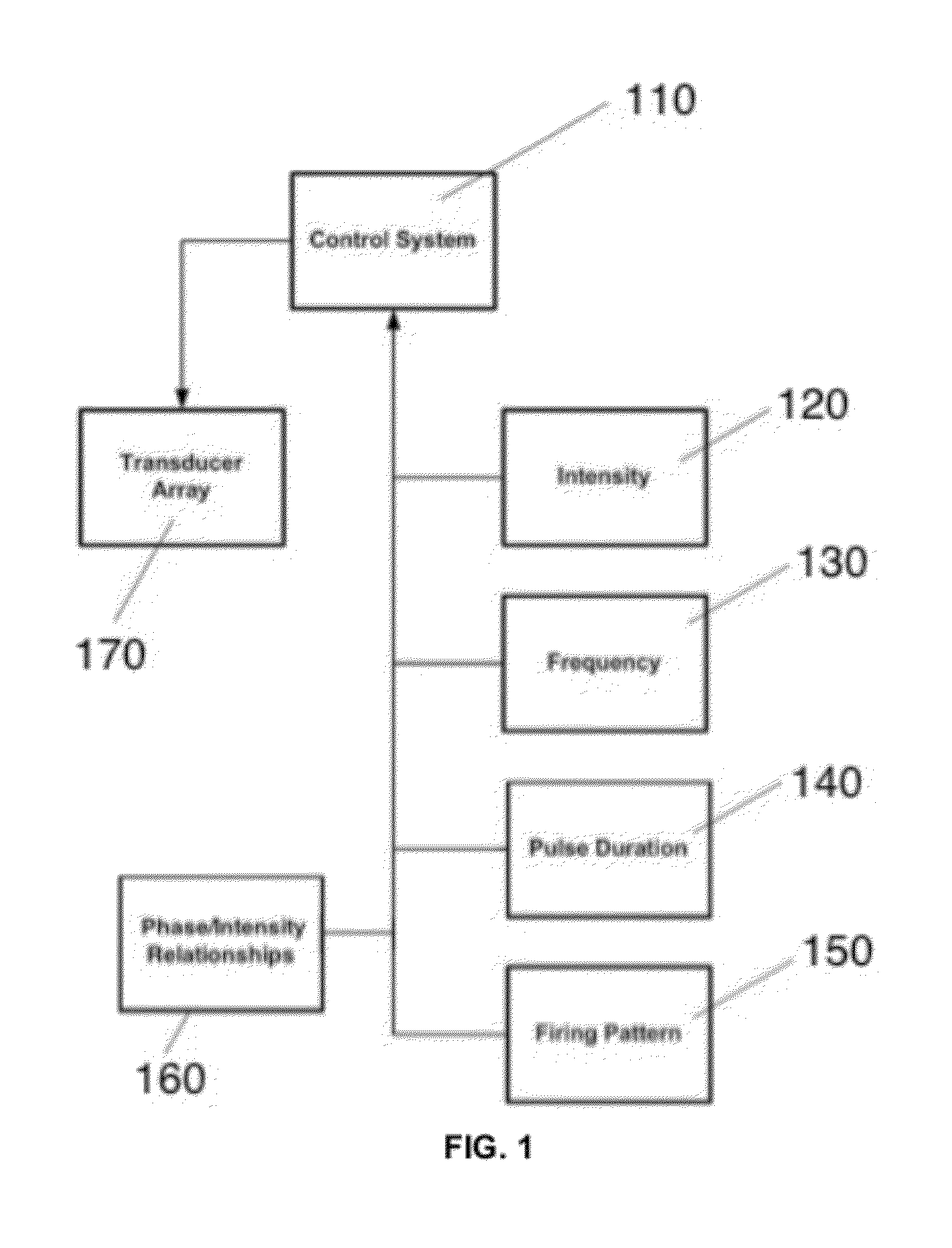

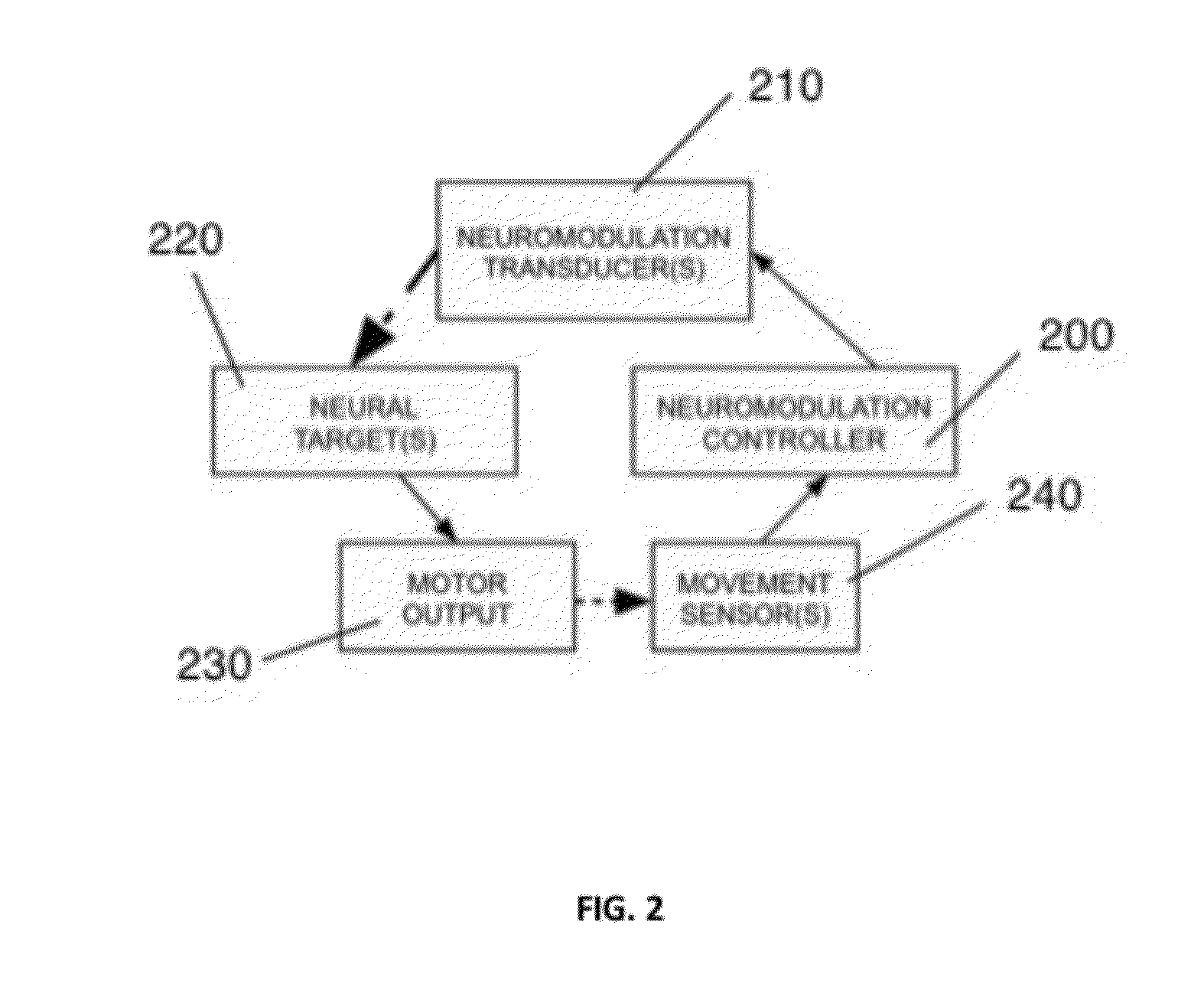

Patient feedback for control of ultrasound deep-brain neuromodulation

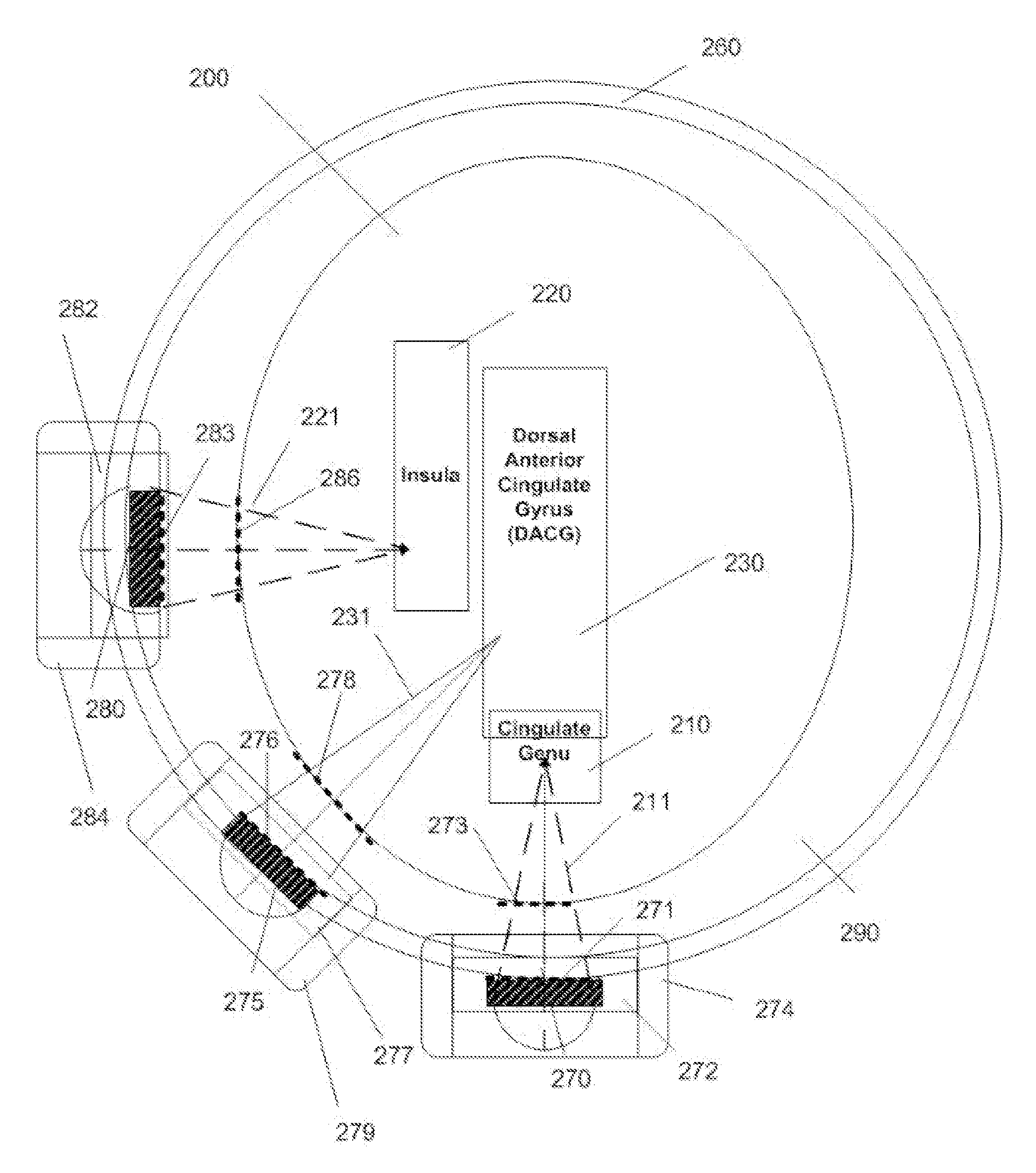

InactiveUS20110178442A1Optimize patient experienceDecrease in acute painUltrasound therapyChiropractic devicesDiseaseSonification

Disclosed are methods and systems and methods for patient-feedback control of non-invasive deep brain or superficial neuromodulation using sound impacting one or multiple points in a neural circuit to produce acute effects and, with application in multiple sessions, Long-Term Potentiation (LTP) or Long-Term Depression (LTD) to treat indications such as neurologic and psychiatric conditions. One or more of sonic transducer positioning, intensity, frequency, dynamic sweeps, phase / intensity relationships, and firing patterns are changed through feedback from the patient to optimize patient experience through up-regulation or down regulation. Examples are decreases in acute pain or tremor due to more effective impact on the neural targets.

Owner:MISHELEVICH DAVID J

Active tremor control system

InactiveUS6695794B2Effective controlManipulation is accuratePerson identificationInertial sensorsControl systemActuator

A light weight, wearable, and balanced active tremor control system including a mount; a proof mass frame moveable with respect to the mount; at least one actuator on the proof mass frame for imparting a force on the mount; a motion sensor for detecting movement of the mount due to tremors; and a controller for driving the actuator in response to the motion sensor.

Owner:CHARLES STARK DRAPER LABORATORY

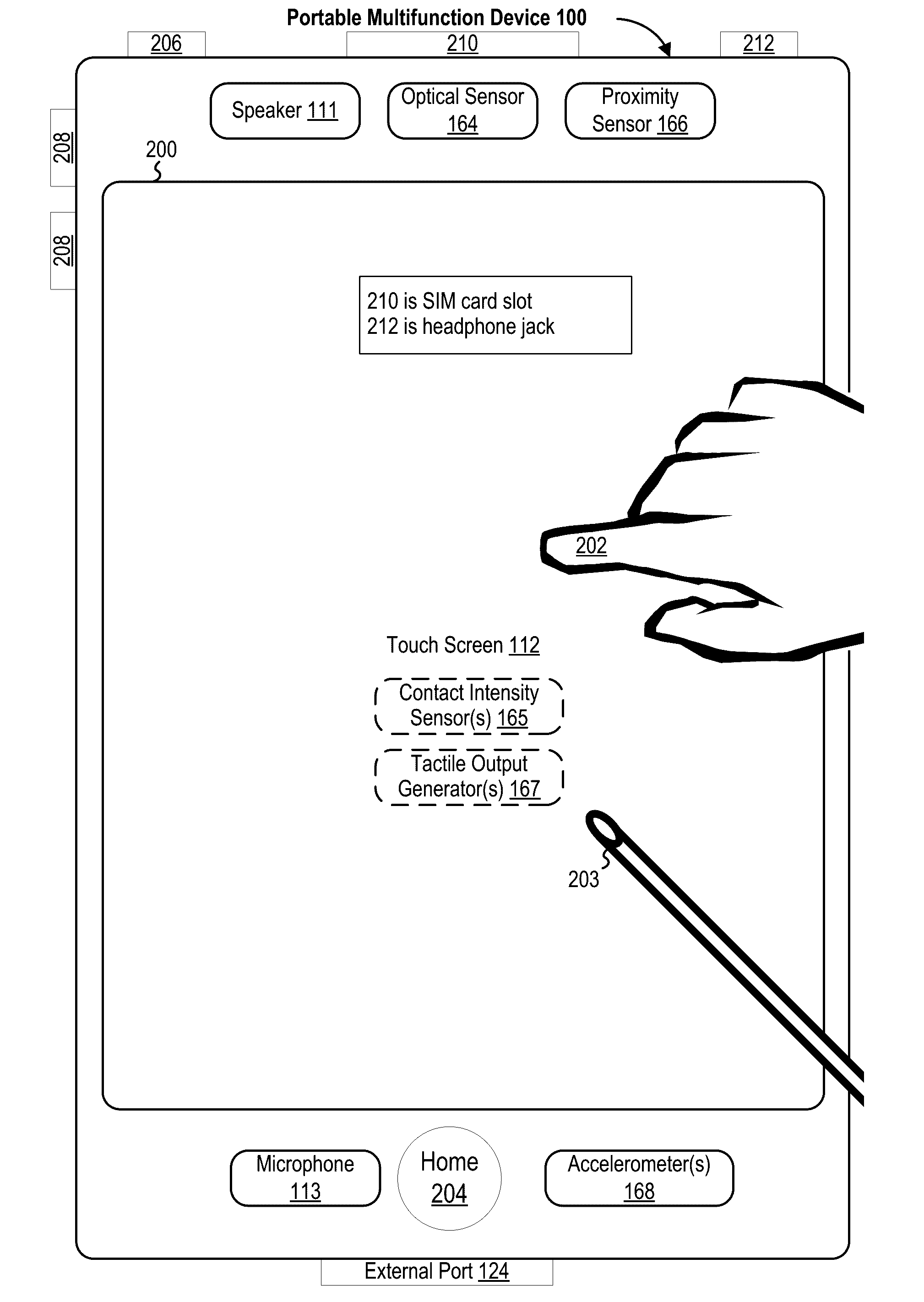

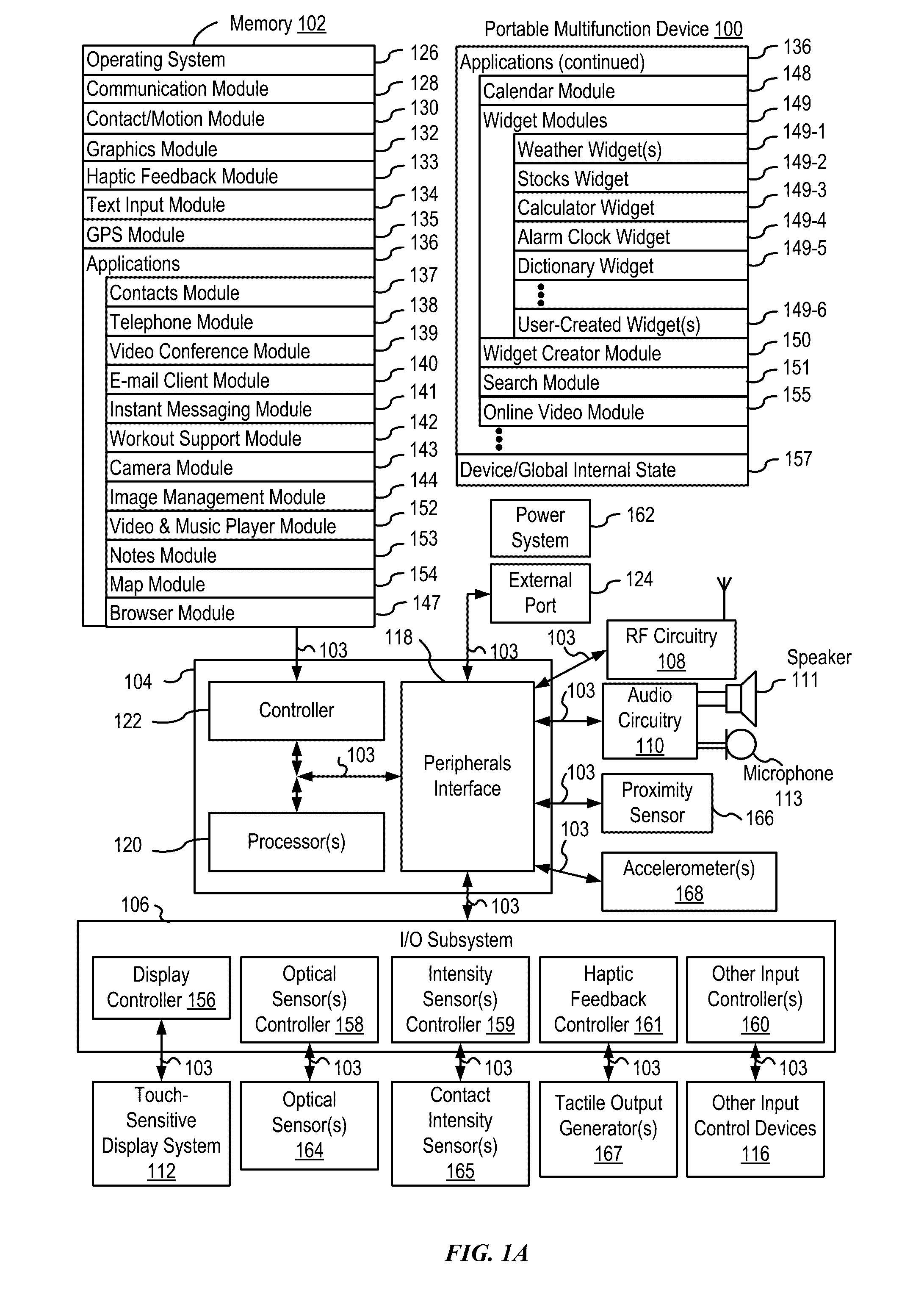

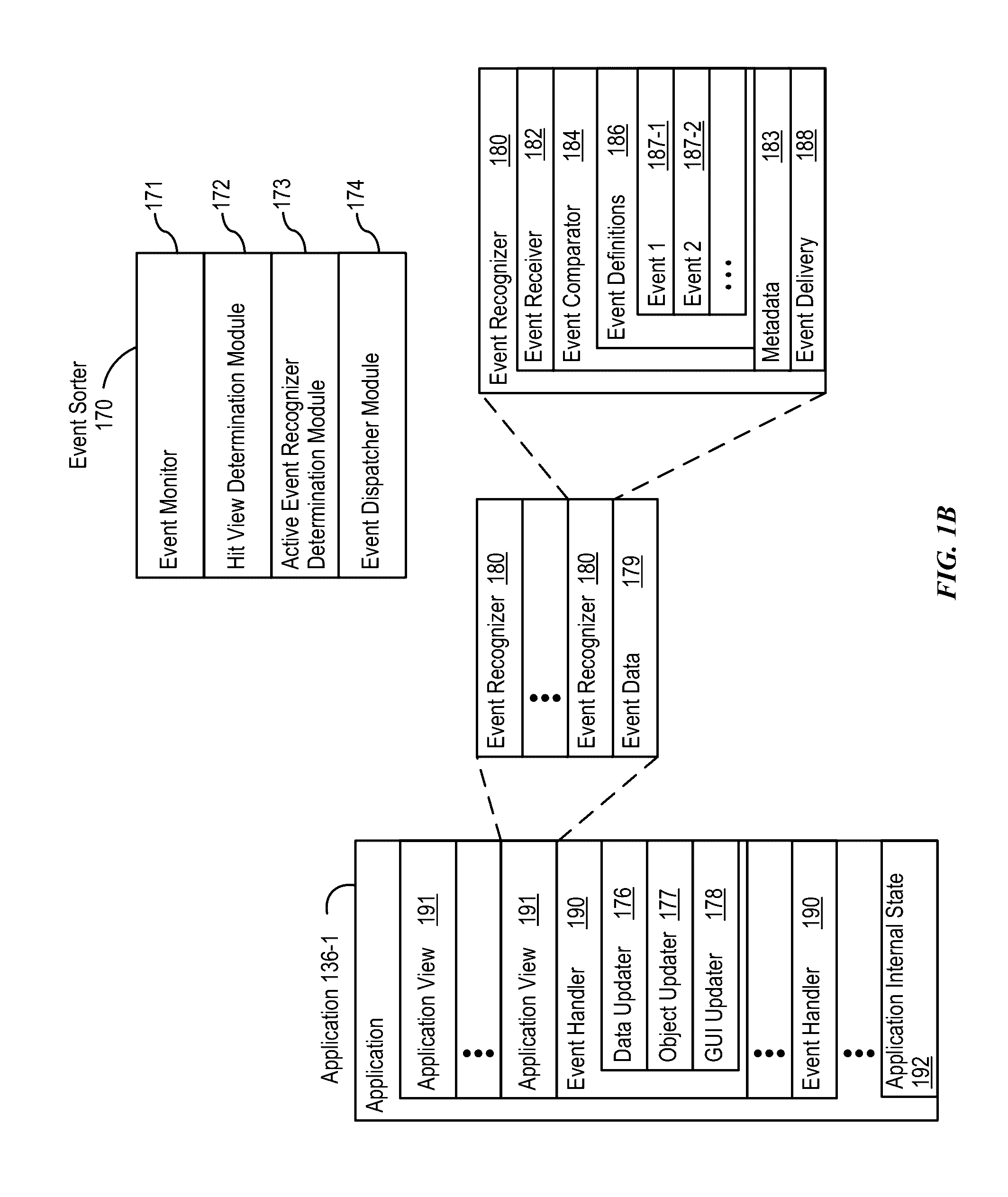

Touch accommodation options

ActiveUS20160357281A1Faster and efficient method and interfaceReduce cognitive loadInput/output for user-computer interactionTelevision system scanning detailsInvoluntary shakingHuman–computer interaction

The present disclosure generally relates to methods and devices for providing touch accommodations to users with tremors or other fine motor impairments to improve the accuracy of such users' touch inputs on touch-sensitive surfaces. Such methods and devices include various approaches for compensating for brief, inadvertent touch inputs; touch inputs with inadvertent motion across the touch-sensitive surface; and / or touch inputs with inadvertent recoil contacts. In some embodiments, the touch accommodations are implemented in a software layer separate from the application layer, such as the operating system.

Owner:APPLE INC

Electro-stimulation device

An electro-stimulation device where the supplementary motor area, premotor area and / or subthalamic nucleus is stimulated extracranially via intrinsic auricular muscles and the stimulation intensity of the supplementary motor area, premotor area and / or subthalamic nucleus is changed with the intensity of the tremors. The electro-stimulation device comprises; at least two primary electrodes which enables sending and receiving electric signals, at least one control unit which produces stimulating signals for reducing involuntary resting activities such as tremors and enables these signals to be sent to / received from primary electrodes.

Owner:STOPARKINSON HEALTHCARE SYST LLC

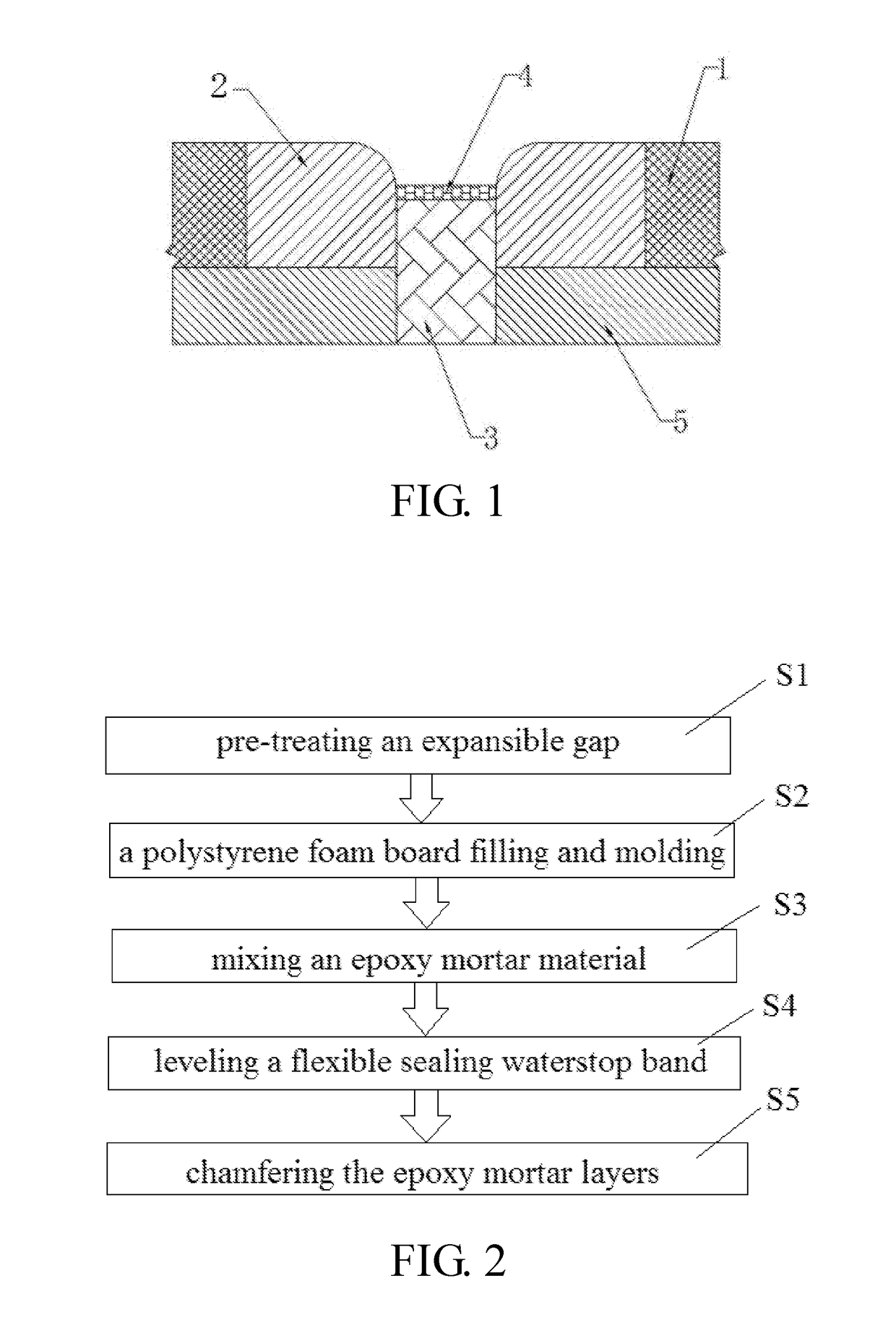

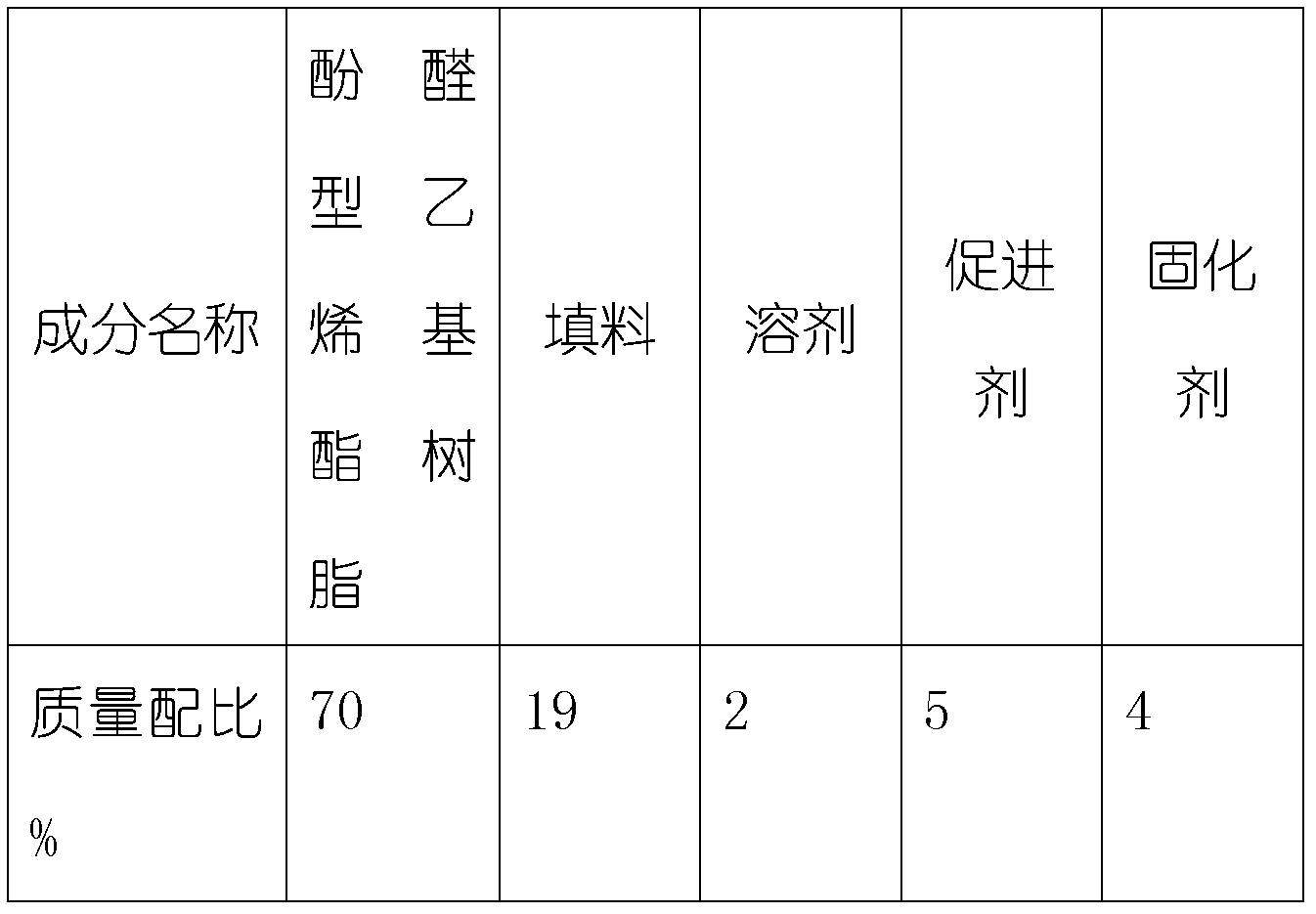

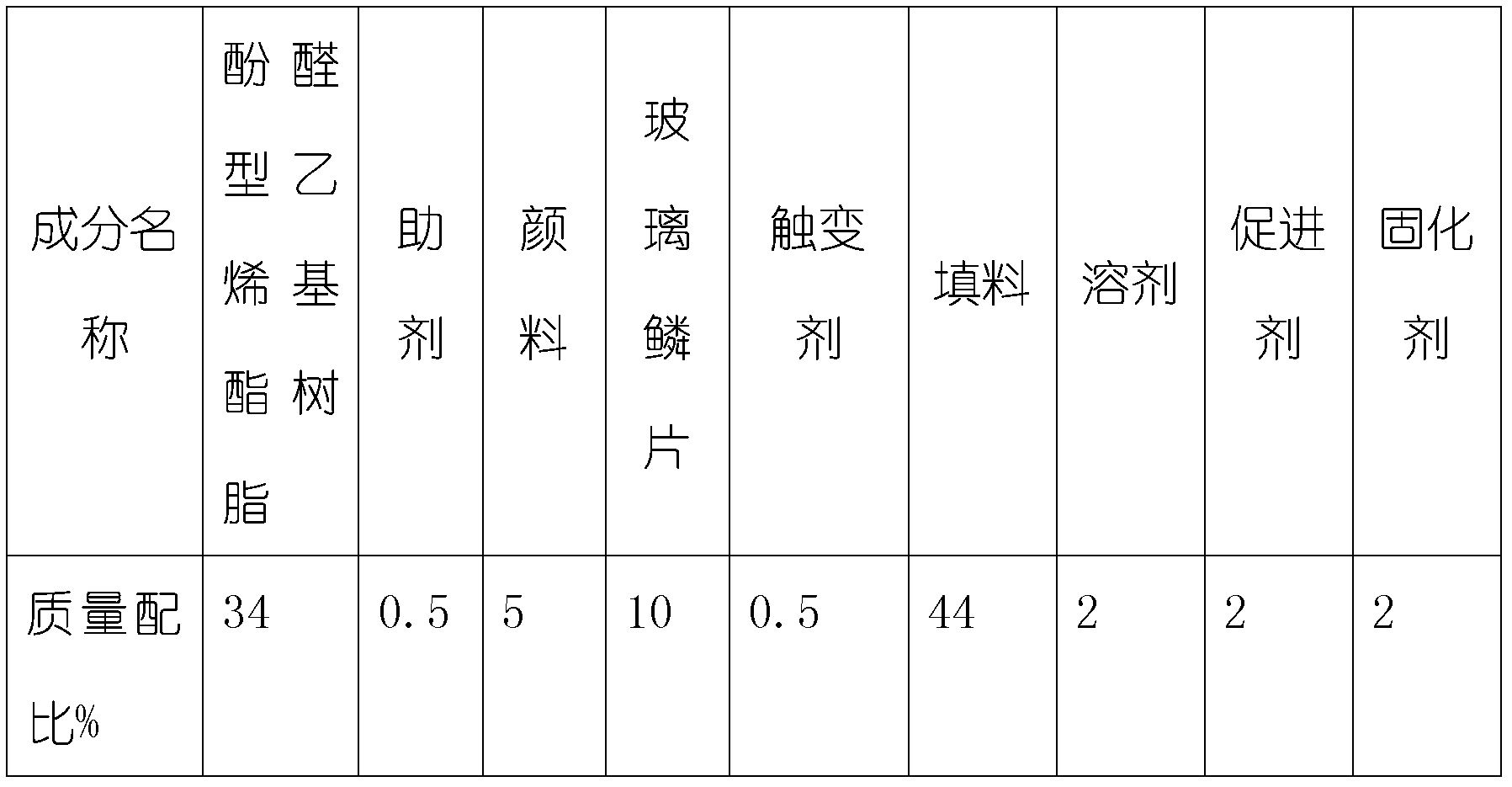

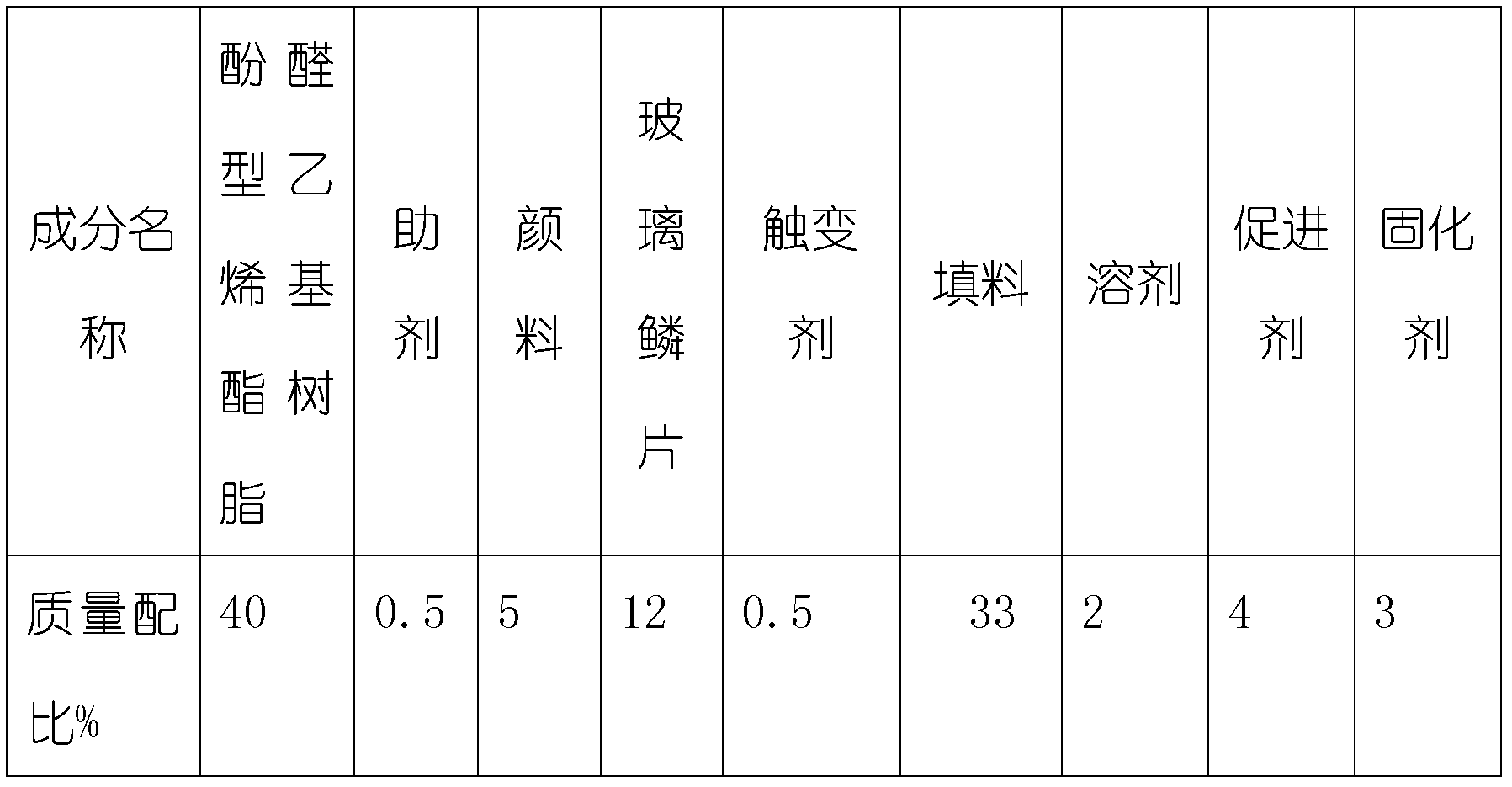

Epoxy mortar adapted in bridge expansion joint and construction method thereof

ActiveUS20170121918A1High strengthSimple construction processSolid waste managementBridge structural detailsEpoxyHeat resistance

An epoxy mortar material for a bridge expansion joint structure and a construction method thereof are provided. The epoxy mortar material includes a liquid A, a liquid B and a filler, wherein diamines D2000 and D230 are mixed to act as the epoxy resin curing agent. The curing agent has low viscosity, good compatibility with epoxy resin, long usable life, high bonding strength, and good flexible and heat shock resistance, so that it is suitable for the epoxy mortar material capable of absorbing the stress. Furthermore, the silicone adhesive is made into the sealing waterstop band, so that the present invention has good water resistant performance; the color of the expansion joint structure is the same as that of the adjacent concrete or asphalt, so that the bridge has beautiful appearance; the expansion joint structure has no tremors while vehicles passing through, noise generated by vehicle driving is lower.

Owner:HEERON TECH (WUHAN) NEW MATERIALS CO LTD

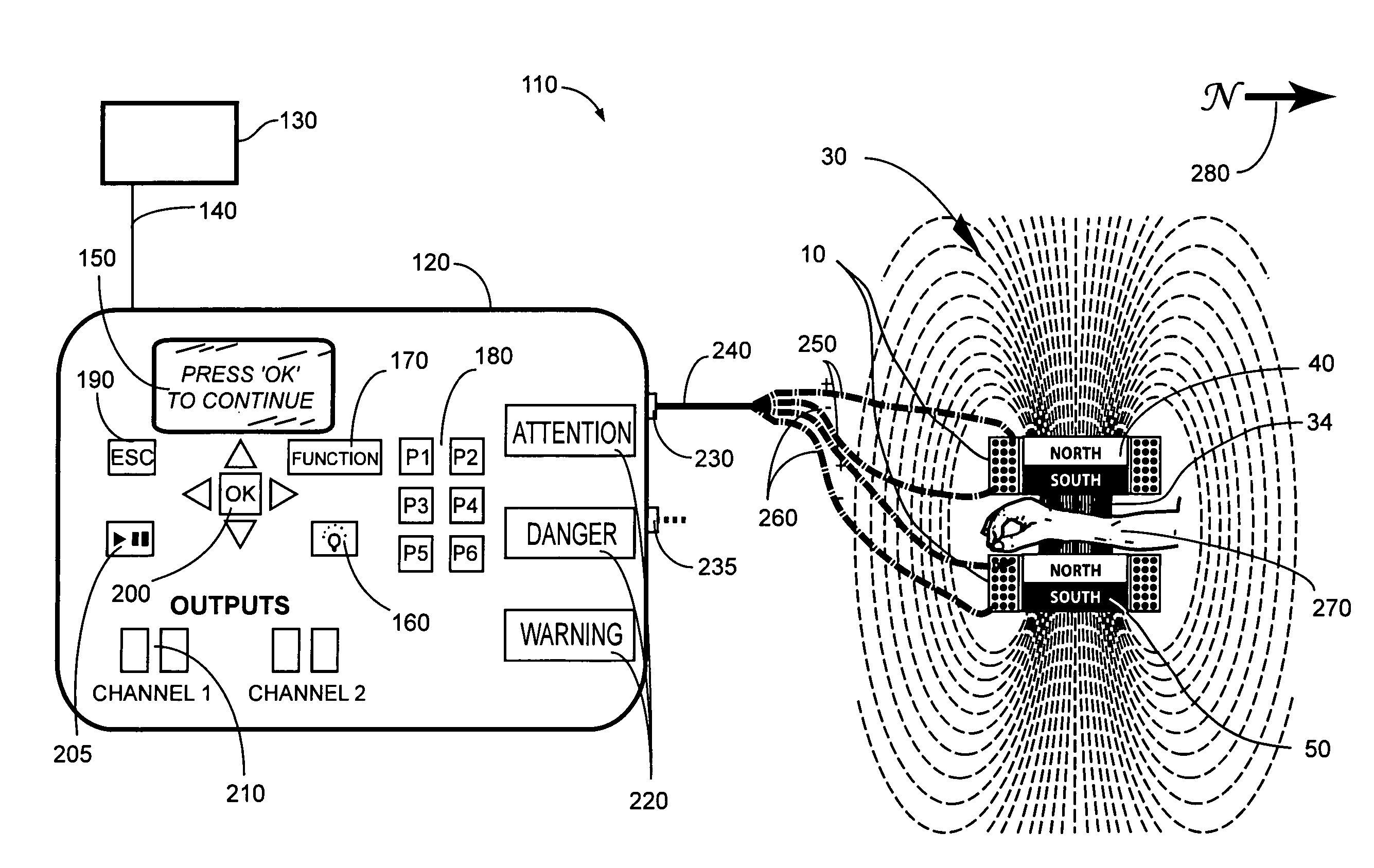

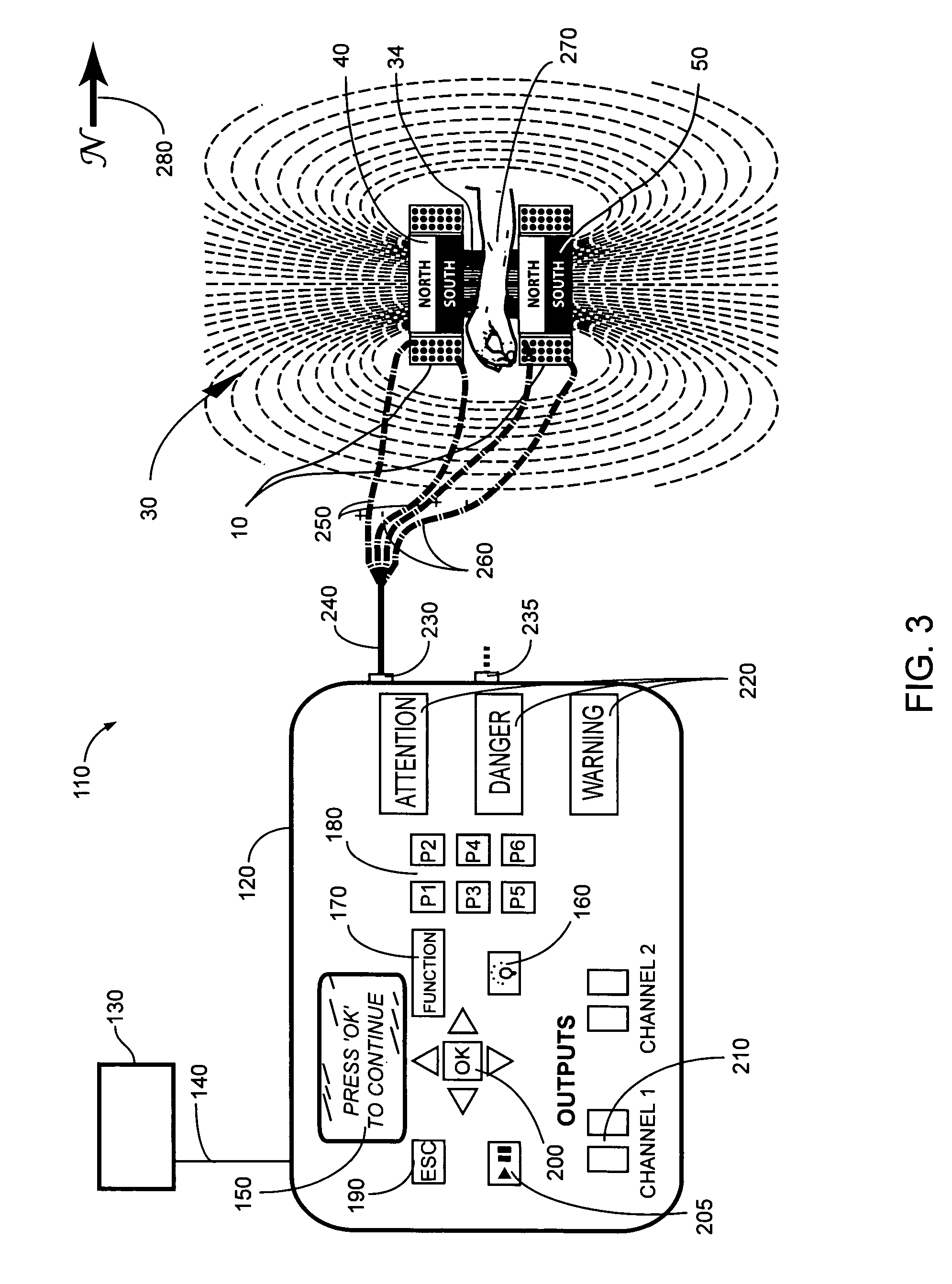

Digital electromagnetic pulse generator

ActiveUS20060224215A1Efficient and flexible generationCreate efficientlyElectrotherapyDiseaseMicrocontroller

Method and apparatus are provided for therapeutic administration to body parts digitally generated electromagnetic fields with trapezoidal, square, triangular and sawtoothed and other complex temporal field waveforms that are microcontroller controlled for a range of amplitude, frequency, and dc offsets; the apparatus providing programmed sequences of radiation waveforms. Multiple electromagnetic antennas establish a variety of field configurations for exposure of various body parts in the treatment of a wide range of afflictions including exfoliation of calcium deposits causing improvements in arthritis and other rheumatic diseases—osteoarthritis, nervous interconnection (neuropathies), etc., the treatment of tremors and seizures, migraine, hypertension, lower back pain, urinary incontinence, and premenstrual tension. Temperature sensors within the antennas are provided to limit the temperatures therein.

Owner:PATTERN ERNEST PAUL +1

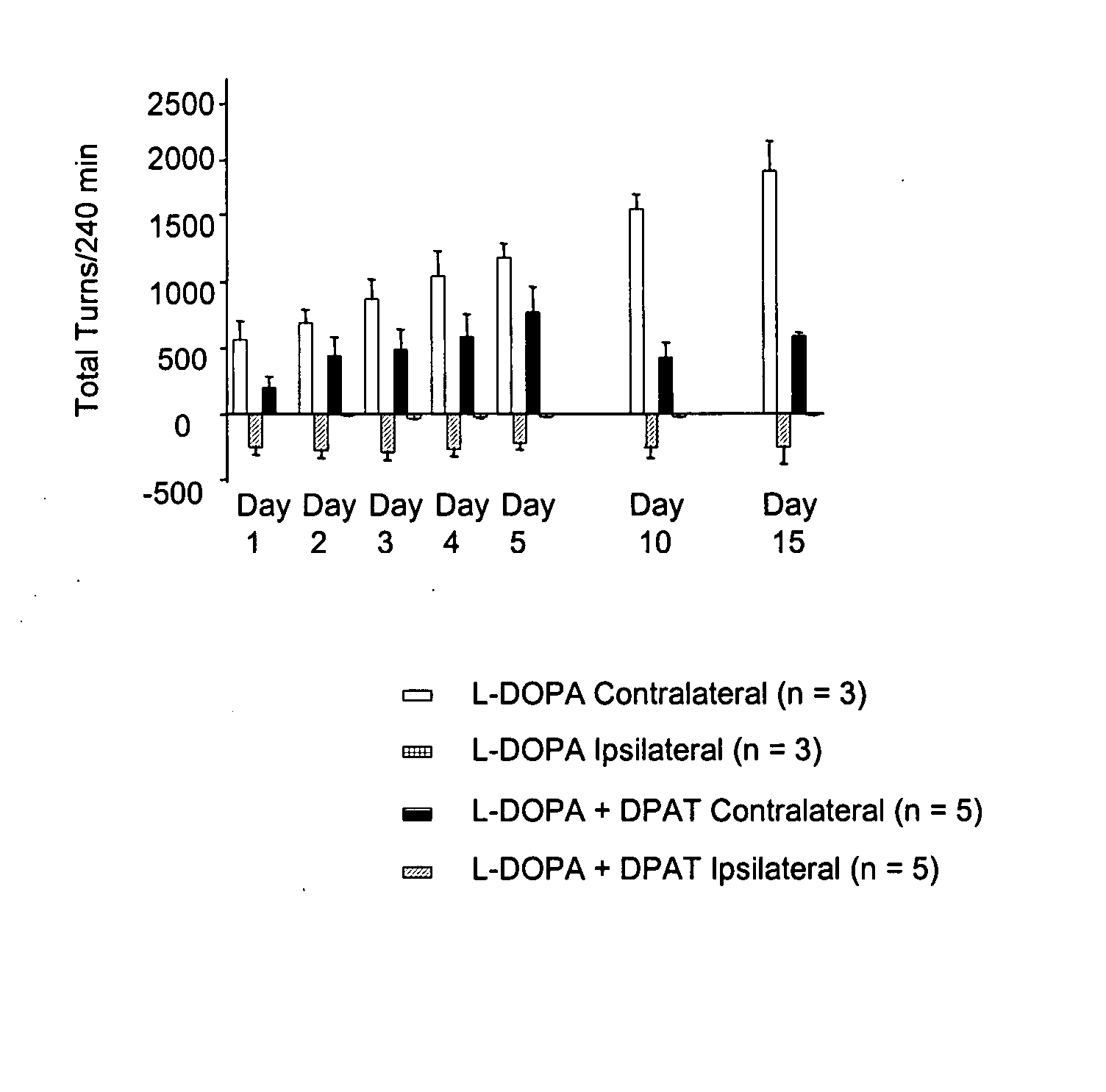

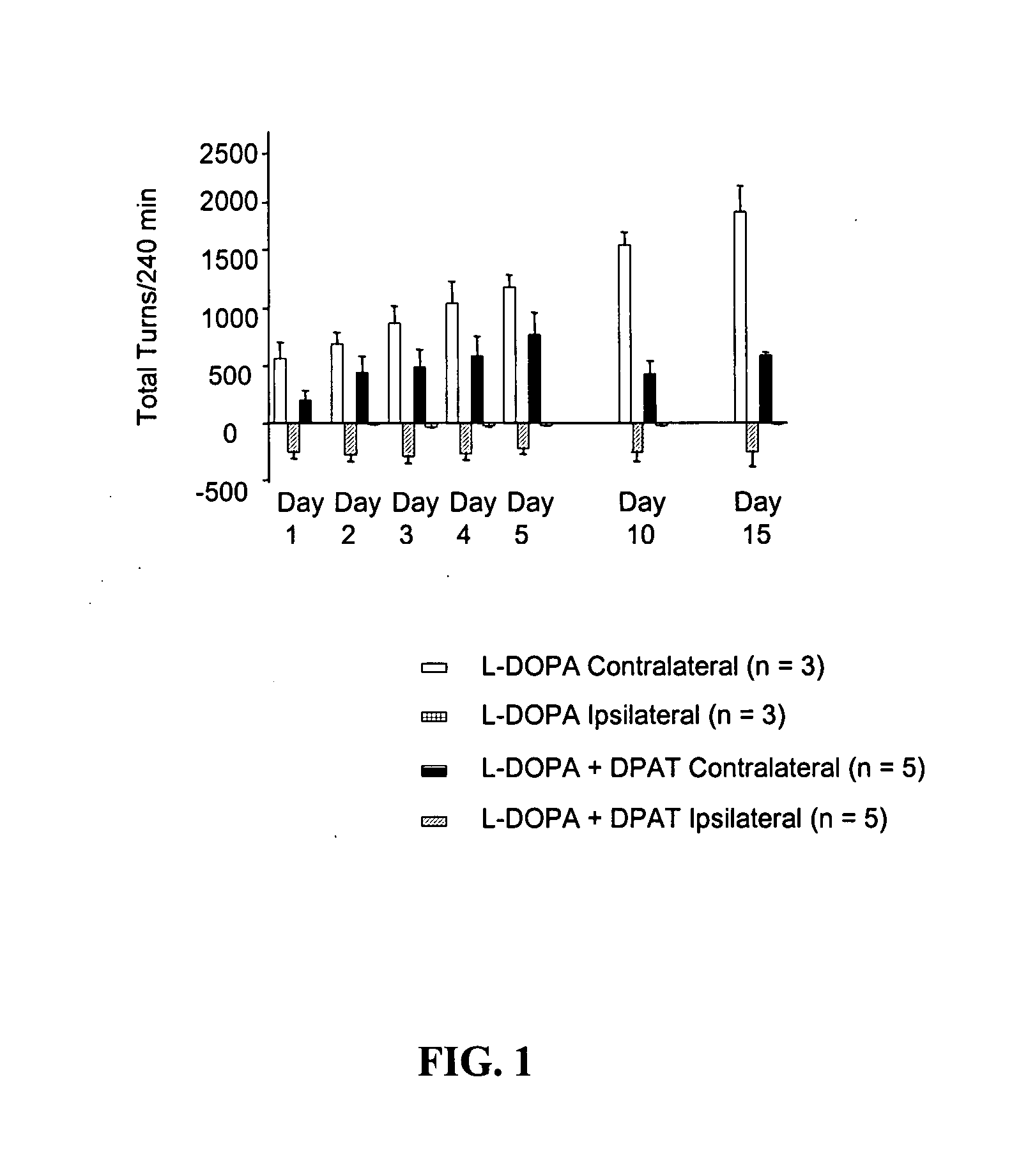

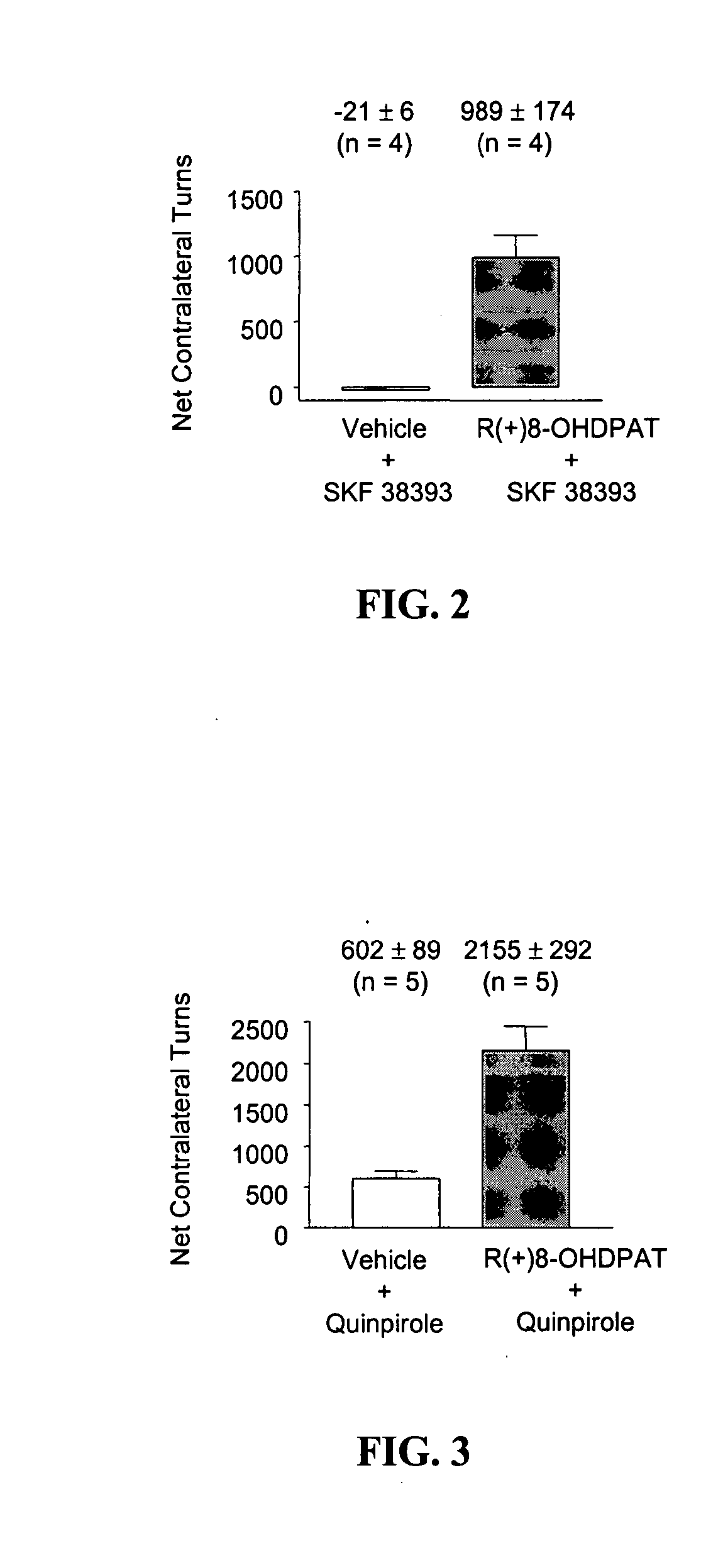

Pharmacological treatment of parkinson's disease

ActiveUS20070249621A1Relieve symptomsEliminate side effectsNervous disorderHeterocyclic compound active ingredientsCo administrationAgonist

The present invention relates to the co-administration of two neurotransmitter agonists to patients with motor disorders, for the purpose of symptom reduction. In particular the present invention provides methods and compositions for alleviation of akinesia, rigidity and / or tremor associated with Parkinson's disease.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE DEPT OF VETERANS AFFAIRS

Spatial-temporal deep brain stimulation methods and systems

ActiveUS8024049B1Easy to useImproving patient comfortHead electrodesArtificial respirationEfficacySmart technology

Methods, systems, and devices to reduce power demands substantially for current deep brain stimulation DBS using smart technology type applications. The invention uses miniaturized components that allow integration with the implanted probe(s) themselves, and includes a skull-sited housing having all the controls and battery power supply needed. This avoids implanting obtrusive card-deck size batteries in the chest area and the use of vulnerable wire leads under the skin from the chest area to connect with the implanted electrode(s) on the skull, improving comfort. The Generating of non-continuous pulses on demand of conditions such as the occurrence of a tremor occurs, without having to continuously run pulses at all times, substantially increasing life spans over current techniques. Shaped electrodes and their methods further reduce power demands and efficacy by directing electric fields to focus towards specific areas and regions of the brain rather than inefficient 360-degree emission.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

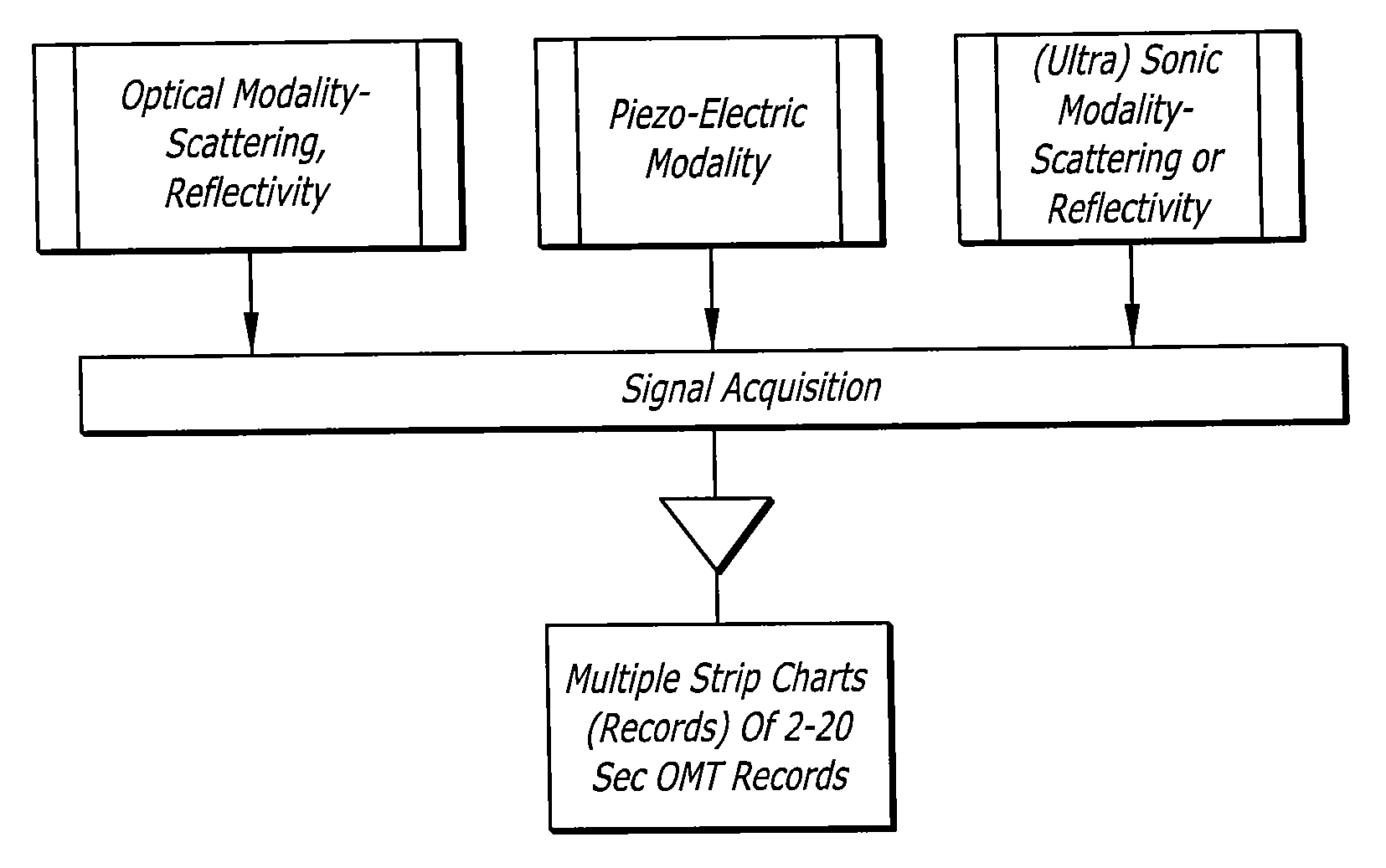

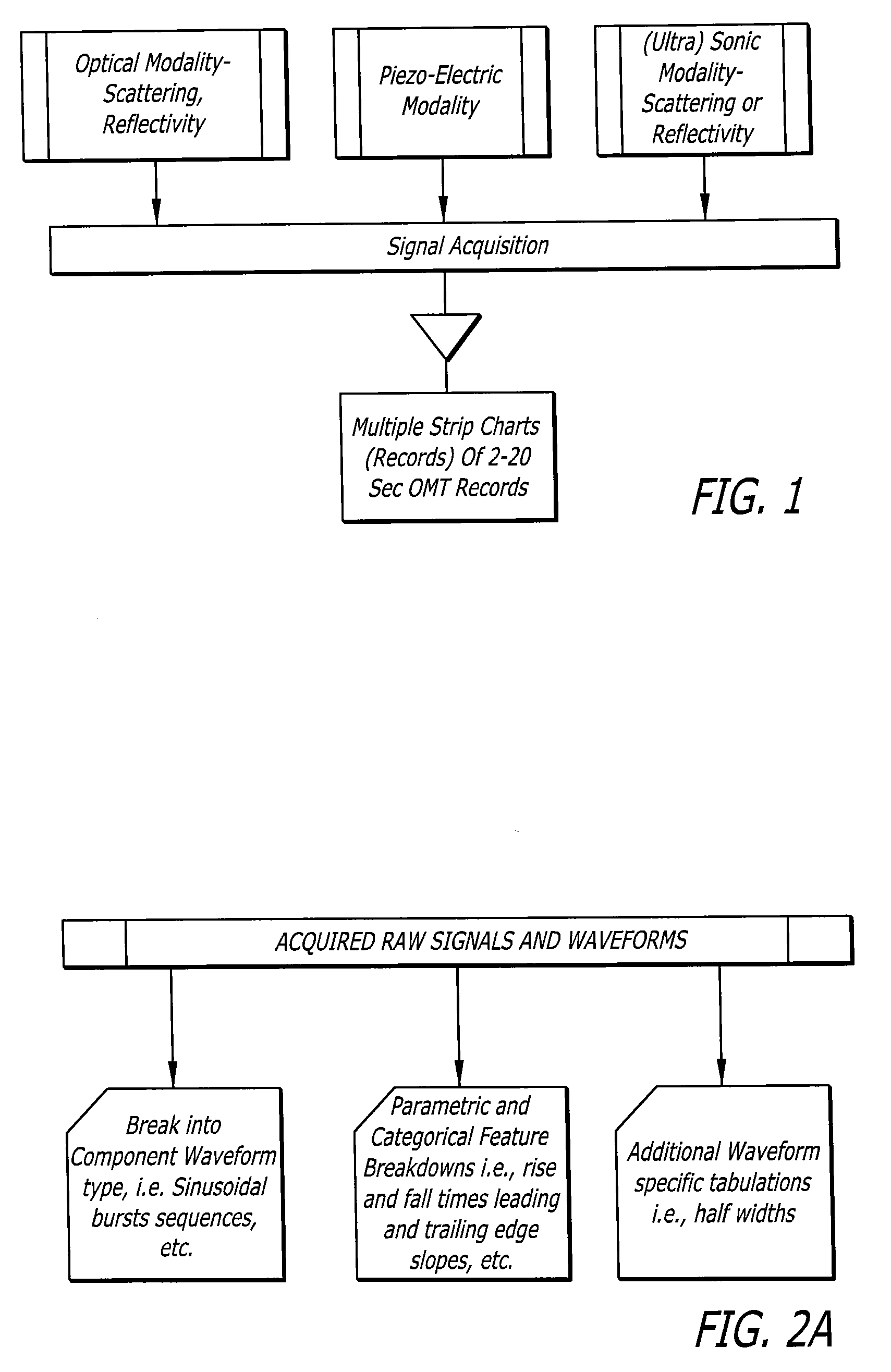

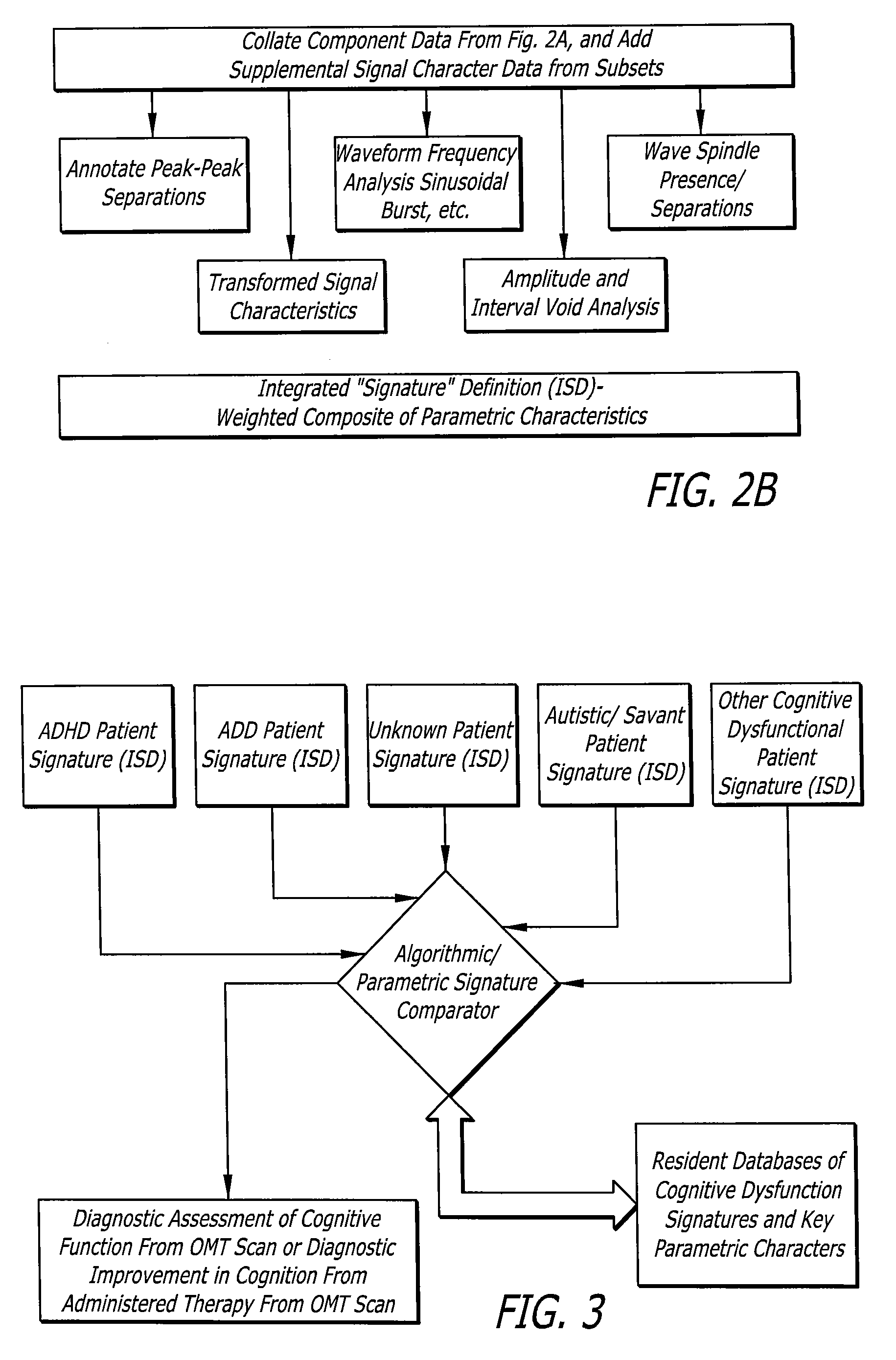

Methods and techniques to measure, map and correlate ocular micro-movement and ocular micro-tremor (OMT) signals with cognitive processing capabilities

InactiveUS20090198148A1Promote resultsCharacter and pattern recognitionDiagnostic recording/measuringMedicineCognition

An apparatus and method of collecting elements of and assembling various portions of ocular micro motions such as ocular micro-tremor (OMT) movements of the eye, and correlating them directly with OMT waveforms acquired from both known and unknown states of cognition and cognitive function. Comparing newly acquired waveforms from patients with undiagnosed cognitive dysfunctions, permits an individual or caregiver the ability to identify those unknown issues or cognitive states based on matching or relating statistically elements of their waveform with categories of other known cognitive processing normals and abnormals, functional and dysfunctional individuals. It also allows for measuring the effects of therapeutic agents (psychological or pharmacological) by relating them to measurable changes in cognitive function as a result of correlated changes in waveforms.

Owner:LONKY MARTIN L

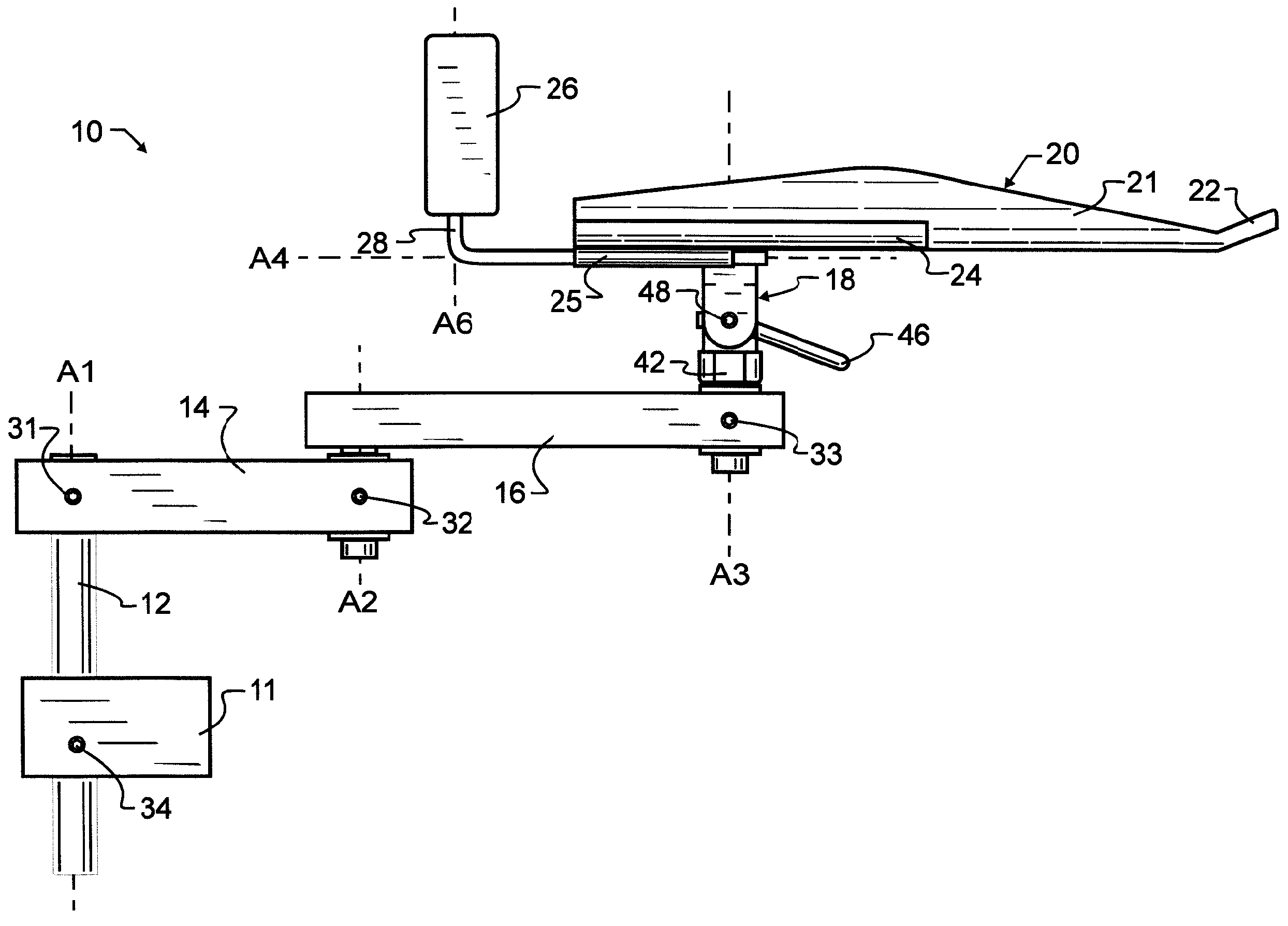

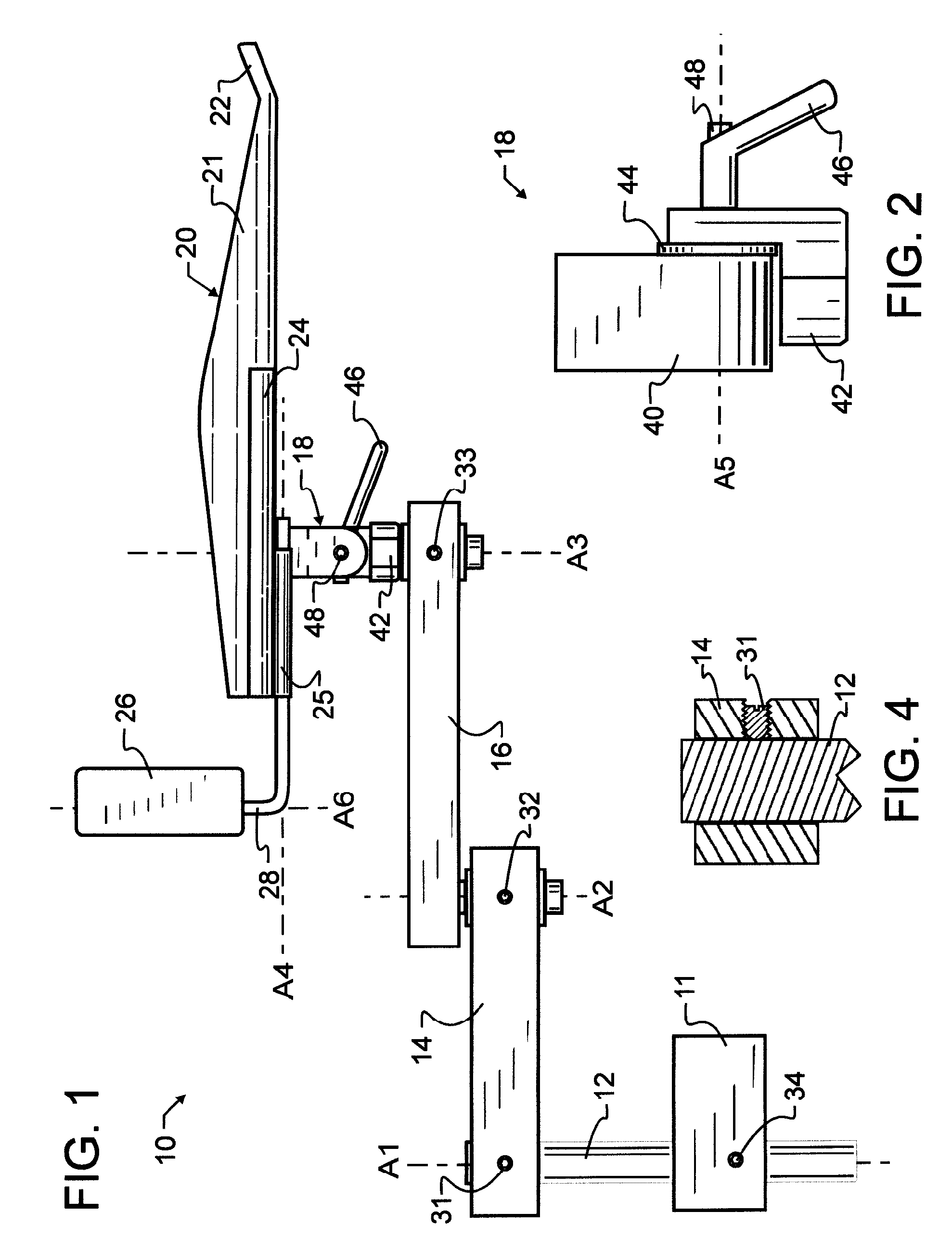

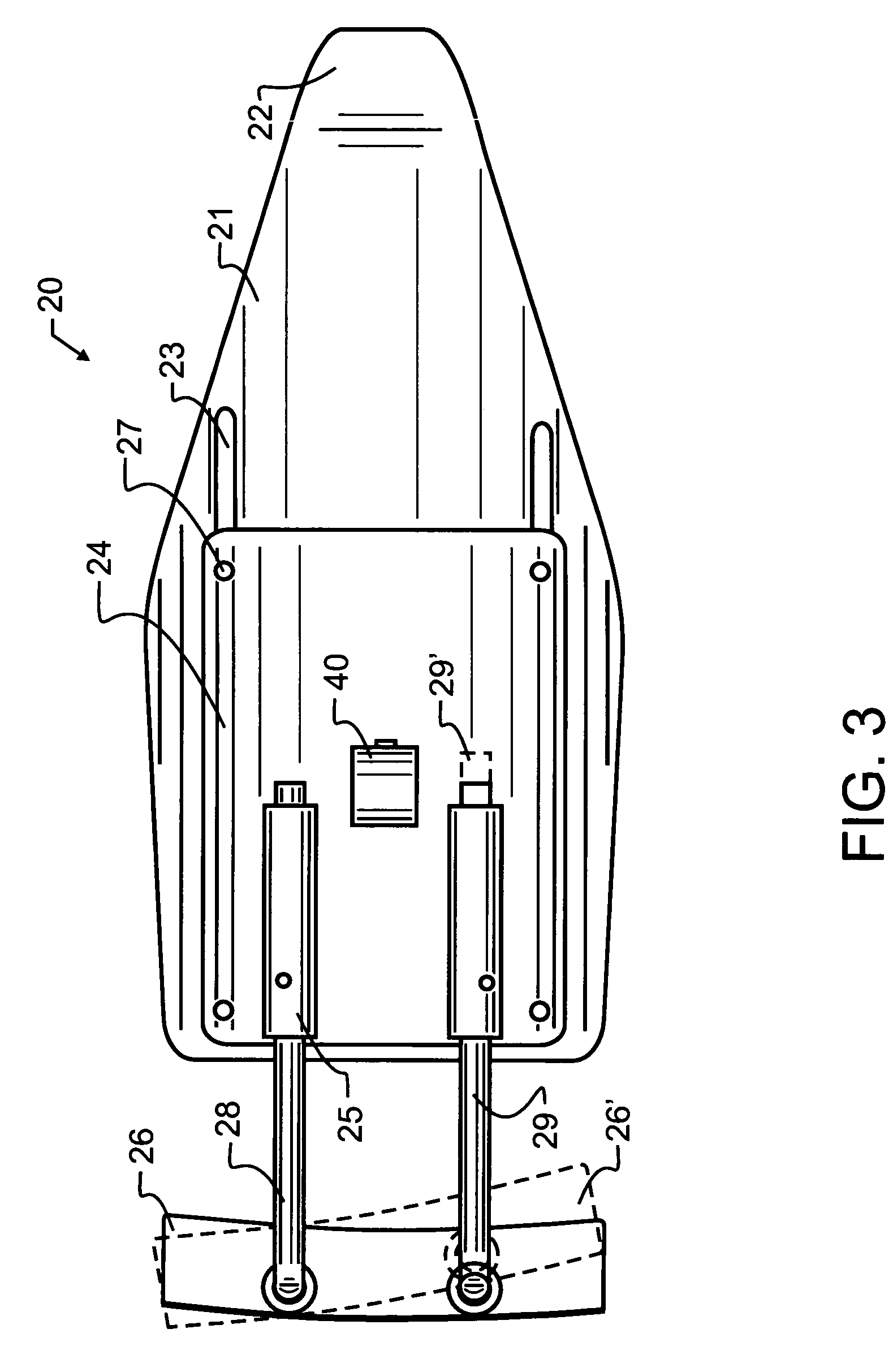

Adaptive arm support

InactiveUS7222826B1Reduce decreaseMinimal complexityOffice tablesWriting supportsSet screwAdaptive support

An adaptive arm support provides motion of an armrest within a plane through any direction of translation. A number of vertical rods and bearings permit at least two links to pivot with respect to each other, permitting translation in any direction while staying within the plane. Bushing-tipped set screws are provided which dampen movement, to reduce or eliminate the effects of unintentional tremors. The armrest includes a swivel mounting which is also damped, which permits the longitudinal axis of the armrest to swivel from horizontal orientation to inclined angles which are out of the plane of translation. An elbow pad is provided which also pivots from perpendicular to the armrest longitudinal axis to different angular orientation with respect thereto.

Owner:BERGLUND ANDREW

An impact-resistant anti-corrosion coating

InactiveCN102277066AExcellent resistance to media penetrationImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsFiberCarbon fibers

The invention relates to a special impact-resistant anti-corrosion coating, especially for the anti-corrosion of medium and small boiler flue gas wet desulfurization and dust removal integrated equipment, boilers, container tanks and other equipment, which can well solve the problems of anti-corrosion equipment. Physical corrosion damage such as peeling, delamination, cracking and falling off of the coating formed by the vinyl ester resin glass flake coating caused by tremors during hoisting, transportation and operation. The coating components are composed of: phenolic vinyl ester resin, additives, pigments, curing agents, accelerators, fillers, thixotropic agents, glass flakes, and solvents. The mass percentage range is: phenolic vinyl ester resin 20- 80%, auxiliary agent 2-5%, pigment 2-6%, curing agent 0.5-10%, accelerator 0.25-12%, thixotropic agent 0.5-5%, glass flake 0-45%, solvent 0-5% , the remaining fillers. Especially in the design and selection of fillers, carbon fiber, glass fiber reinforced chopped strand mat and other fillers are used to maximize the impact resistance of the coating. The coating of the present invention has good resistance to medium penetration, acid resistance, impact resistance, alkali resistance, wear resistance, small shrinkage rate when hardened, small thermal expansion coefficient, good adhesion to the substrate, and resistance to sudden temperature changes. Good, it can work at 185°C for a long time, and the maximum temperature can reach 235°C instantaneously, and it is convenient for construction, easy to repair, and low in cost.

Owner:陕西北方汇风能源科技有限公司

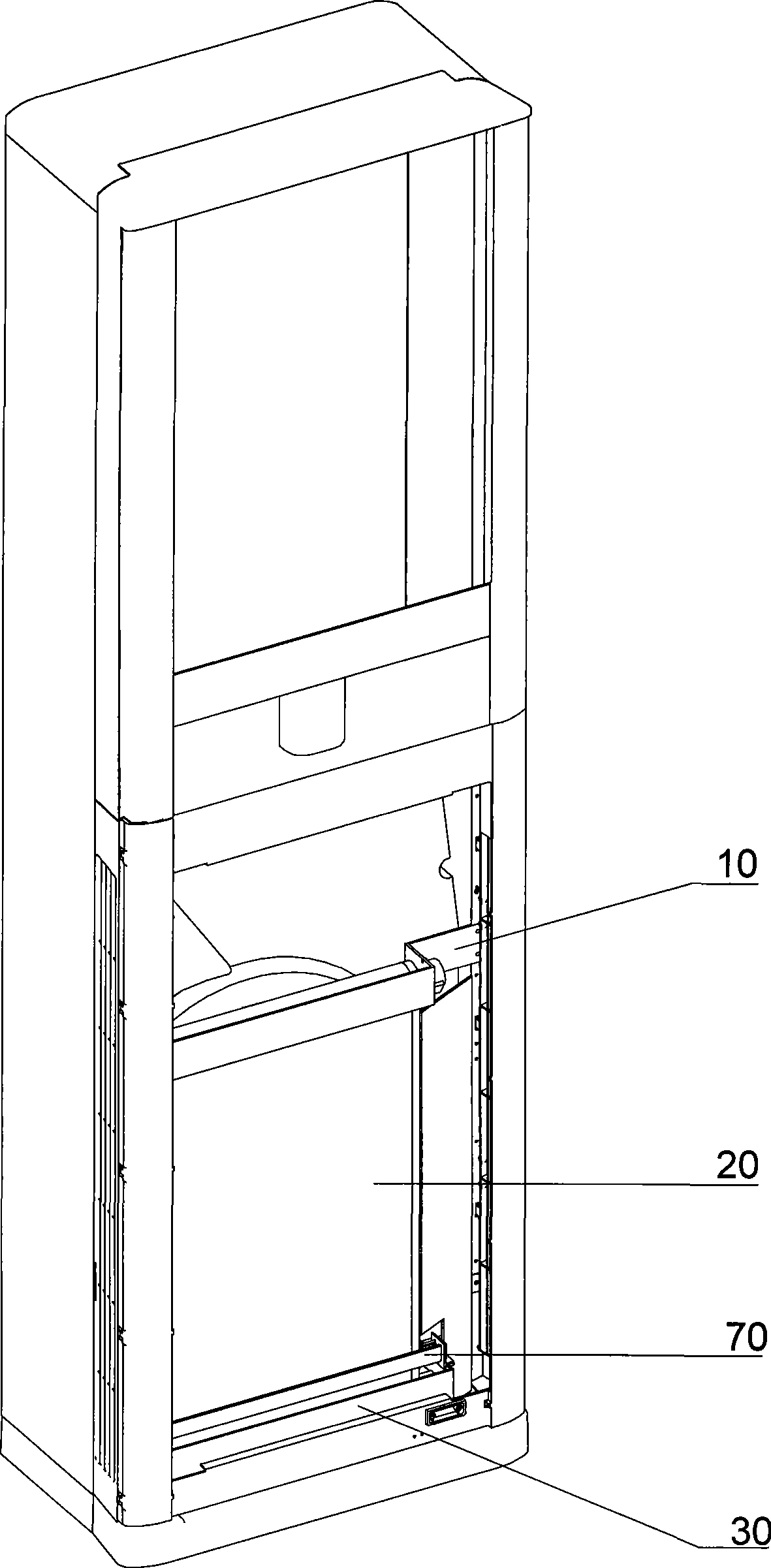

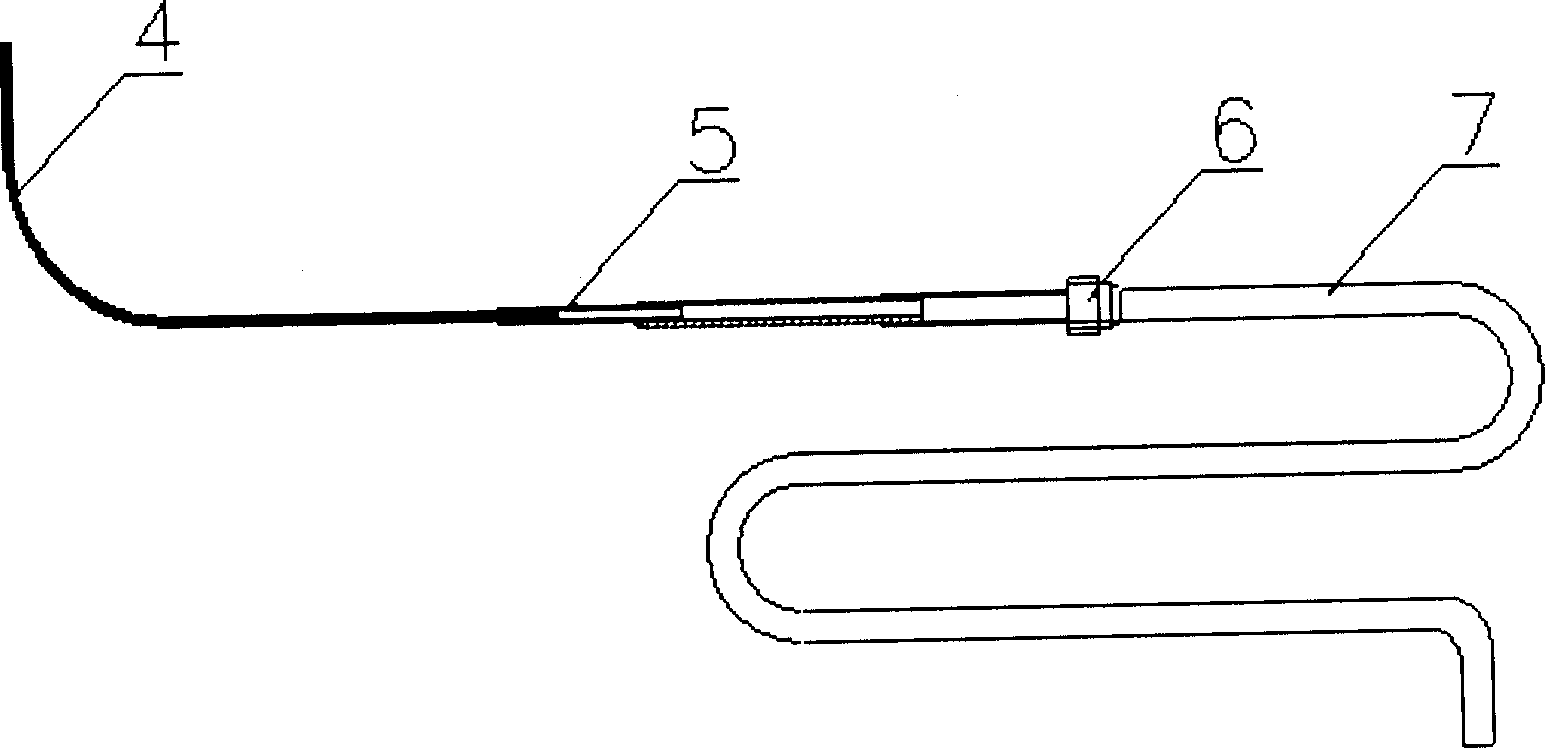

Air-conditioner filtering cleaning device

ActiveCN101422677ATo achieve the purpose of automatic cleaning filterSimple structureDispersed particle filtrationLighting and heating apparatusEngineeringInvoluntary shaking

The invention discloses a filtering and cleaning device of an air conditioner, which comprises a filter screen rolling device and a cleaning basin. The rolling device is arranged at the front part of fans of the air conditioner; the cleaning basin is arranged at a bottom disc of the air conditioner; the rolling device is wound with a filter screen; the lower part of the filter screen on the rolling device is positioned in the cleaning basin; the interior of the cleaning basin is provided with an ultrasonic cleaning device or a brush; and the cleaning basin is also provided with a water adsorption device, an automatic water injection device and an automatic water discharging device. The rolling device can lead the filter screen to realize circular constant rolling; the ultrasonic cleaning device can generate numberless bubbles which can instantly explode, so that the generated blow tremors the dusts on the filter screen to fall off; and the filter screen achieves the aim of rapidly eliminating the dusts after a period of cyclic rolling. The filtering and cleaning device has the advantages that: the structure is simple; the production is easy to realize; and the trouble of manual cleaning of the filter screen by users is avoided.

Owner:GREE ELECTRIC APPLIANCES INC

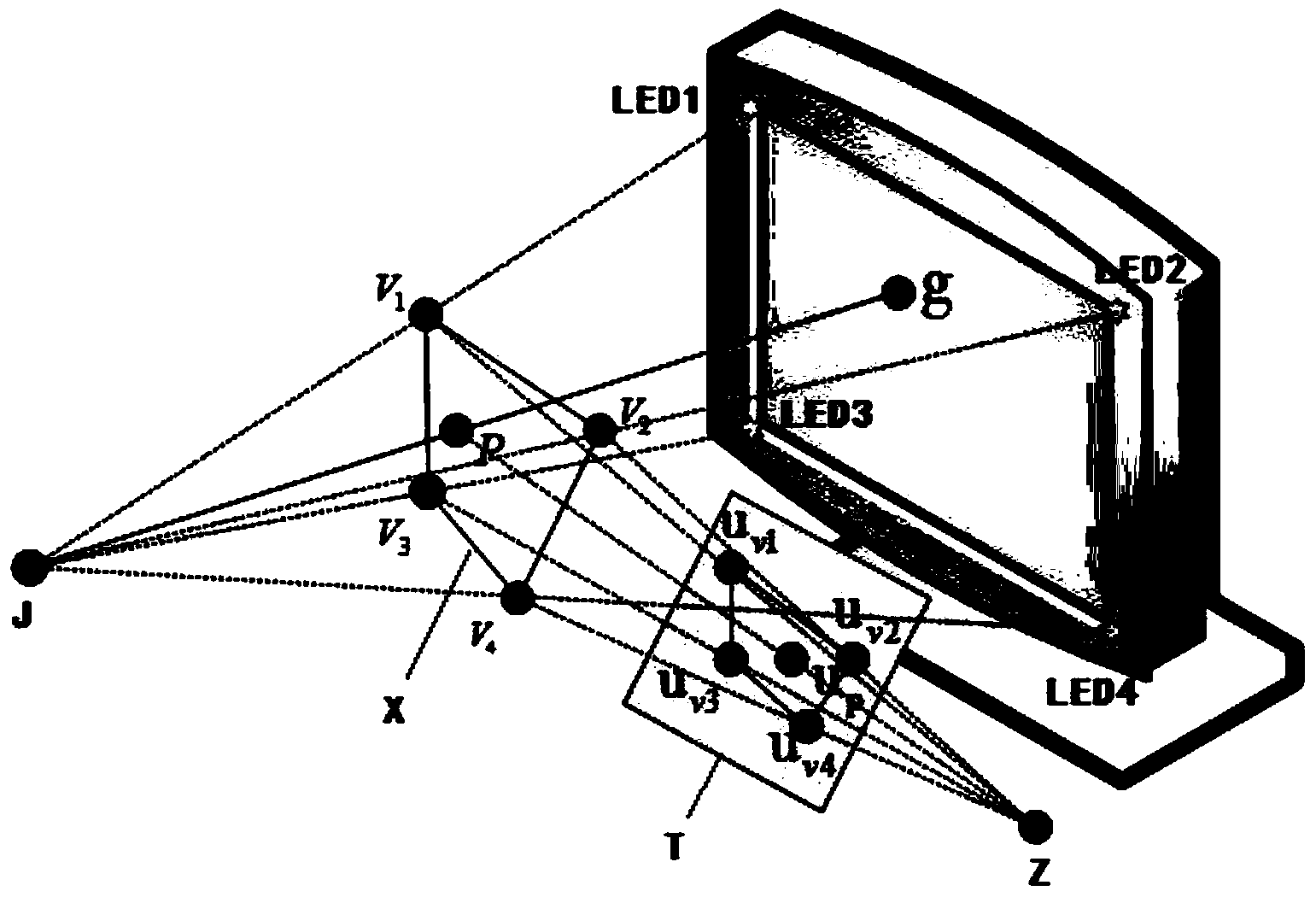

Human-computer interaction method based on eye movement tracking

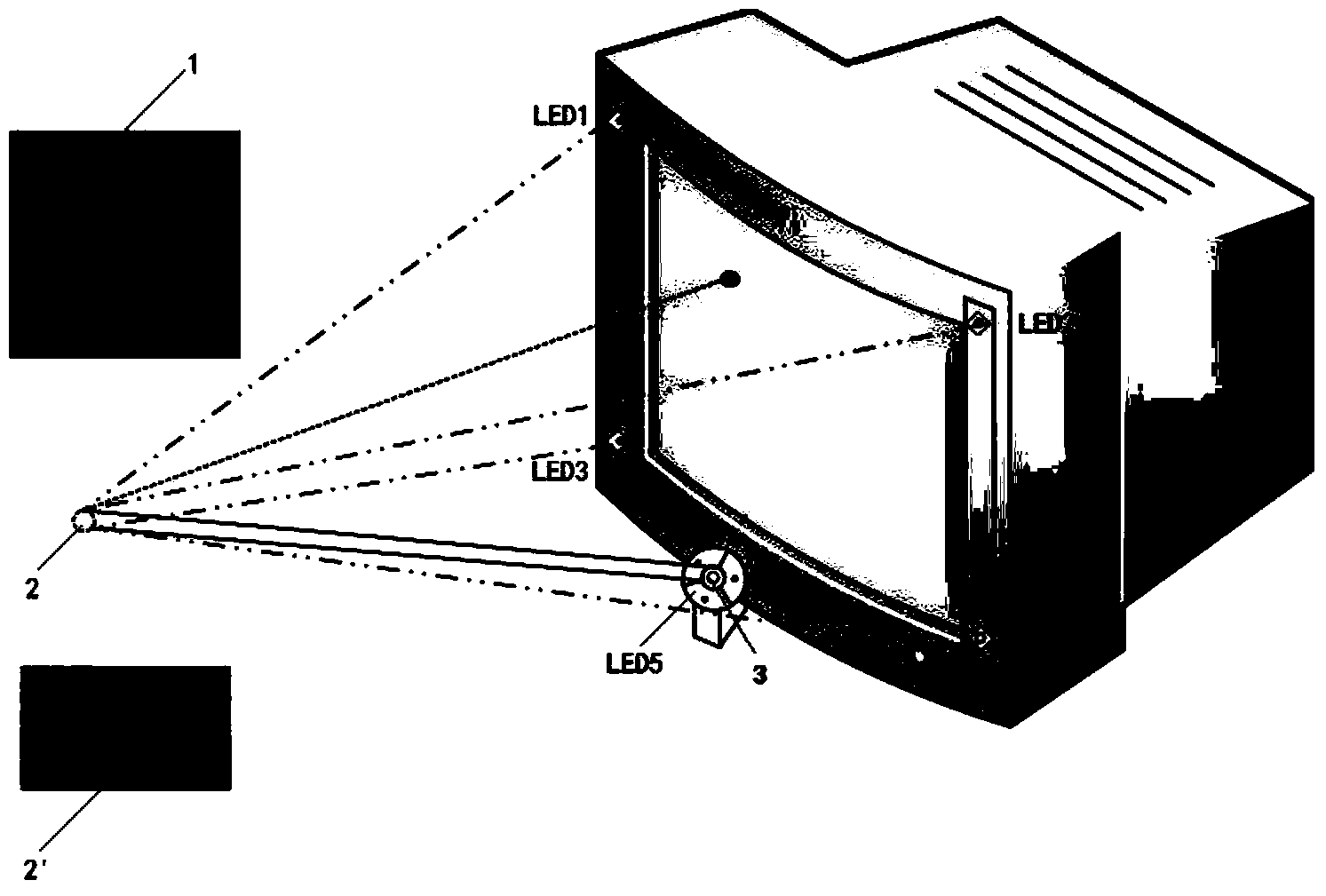

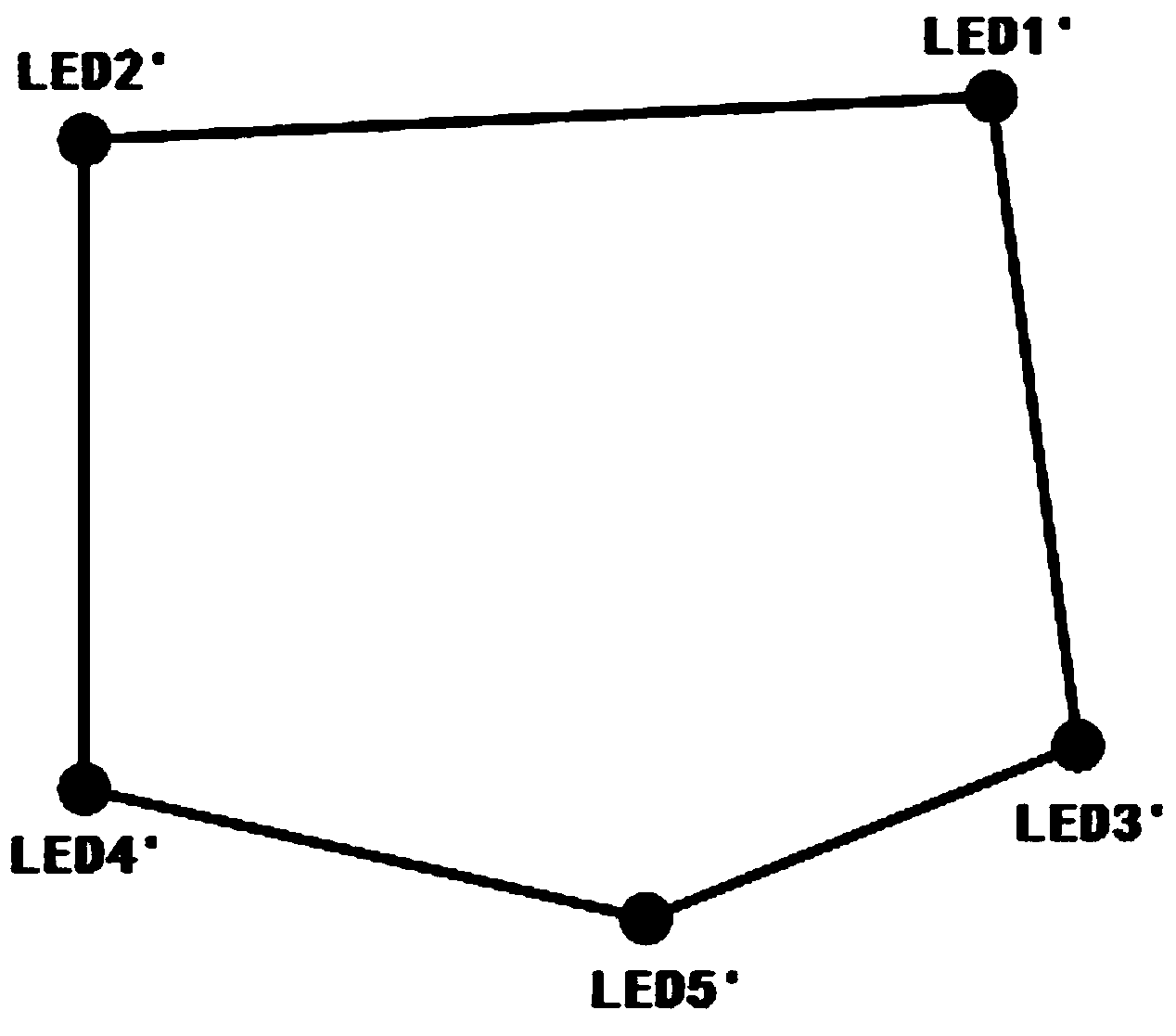

ActiveCN103677270AEasy CalibrationImprove portabilityInput/output for user-computer interactionGraph readingFixation pointPupil

The invention provides a human-computer interaction method based on eye movement tracking, wherein five infrared source sets which face a computer operator and a camera with a built-in infrared filter are used, four infrared source sets are arranged at four corners of a computer display screen, and the other infrared source set is arranged surrounding a lens of the camera; the camera is arranged below the computer display screen and connected to a computer, wherein the lens of the camera faces the face of the operator. The human-computer interaction method comprises the steps of calibration, image capturing and detection, blink judgment, fixation point judgment and interaction instruction output. The human-computer interaction method based on eye movement tracking has the advantages that calibration is simple and portability is good; the number of users who the method is applicable to is increased due to detection of dark pupils; interference caused by physiological human eye tremors is overcome through smoothing; system accuracy is still high even if the head of the operator moves within a wide range; only one camera is used, so that cost is lower; processing speed is quite high, and real-time human-computer interaction can be realized.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

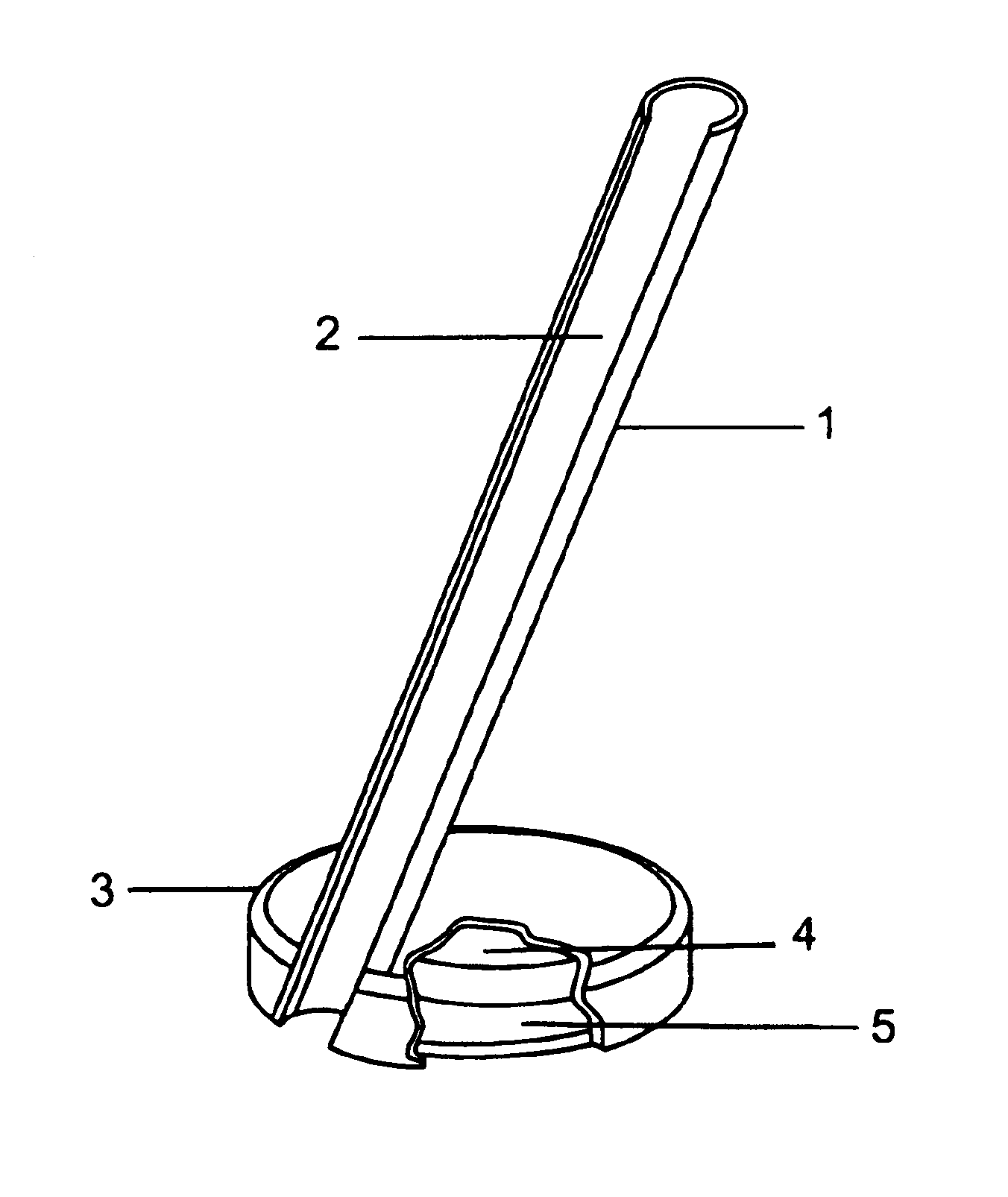

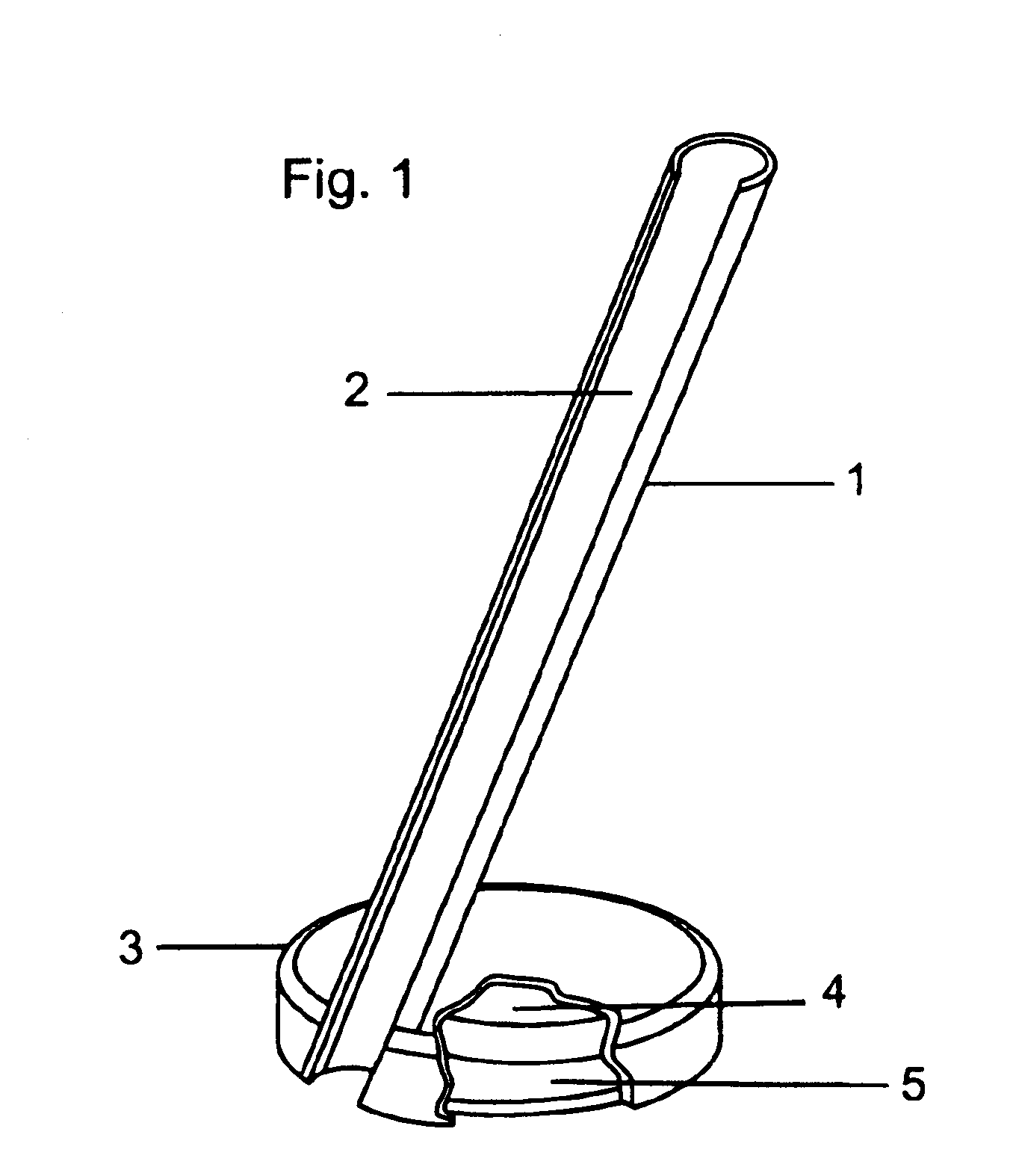

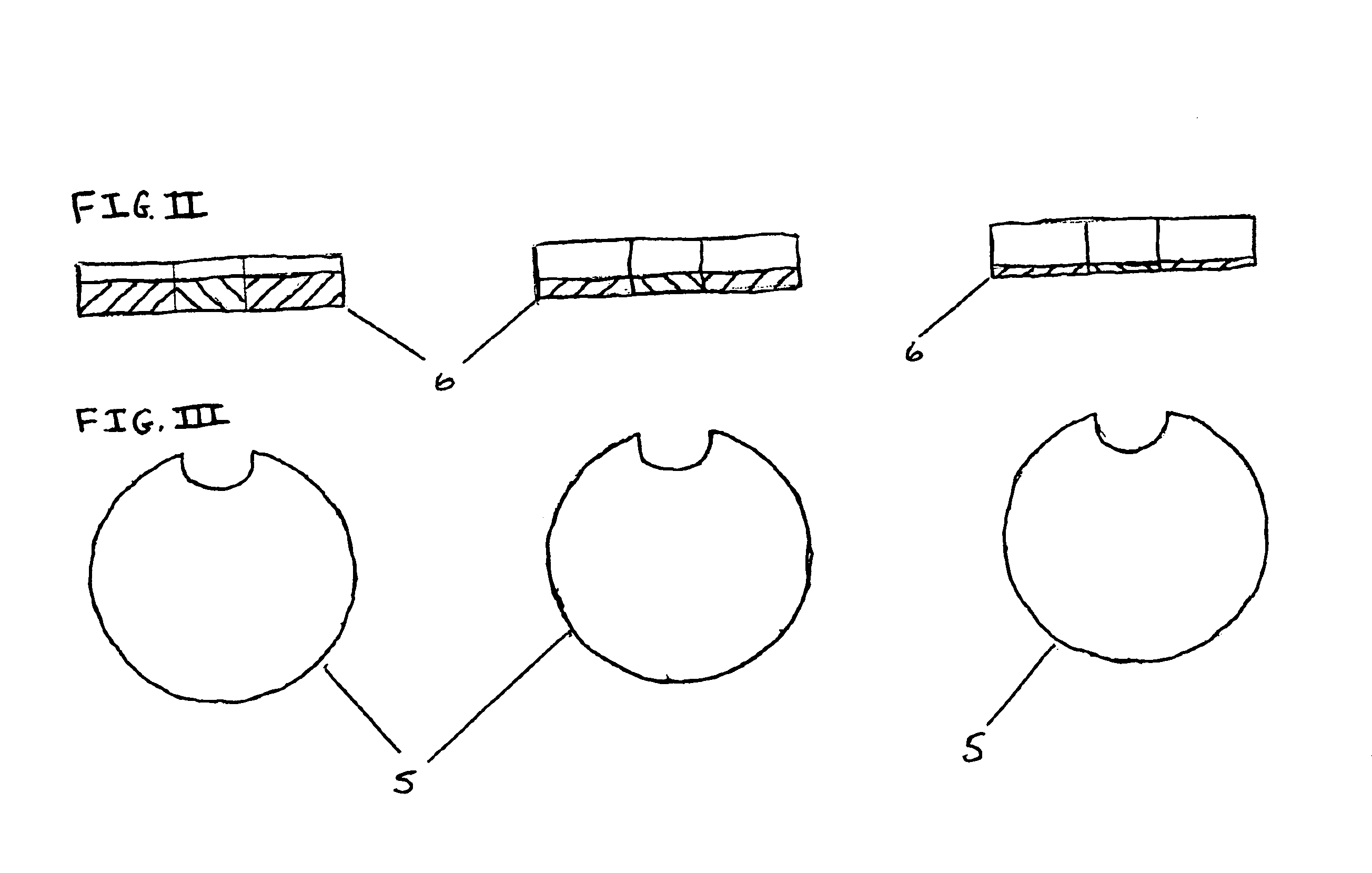

Magnetic writing apparatus

A magnetic writing instrument designed to allow people with hand tremors to write and draw with increased clarity. Consisting of a stylus attached to a base at an appropriate writing angle. The base houses a magnet and accommodates three caps of varying thickness to match the resistance needed with the users tremors. There is also a metal writing base that interacts with the magnet. The paper or writing stationary is placed between the metal writing base and the writing instrument.

Owner:SAEBO

Tremor stabilizing system for handheld devices

A handheld device for canceling unintentional muscle movement. The device includes a base comprising a handgrip for a user to hold, a gripping element linked to the base for releasably connecting the handheld device to an object, a sensor that detects movement of the base, a controller linked to the sensor, and at least one actuator that operates under control of the controller to cause movement of the gripping element in a direction that at least partially counteracts the detected movement of the base.

Owner:RGT UNIV OF MICHIGAN

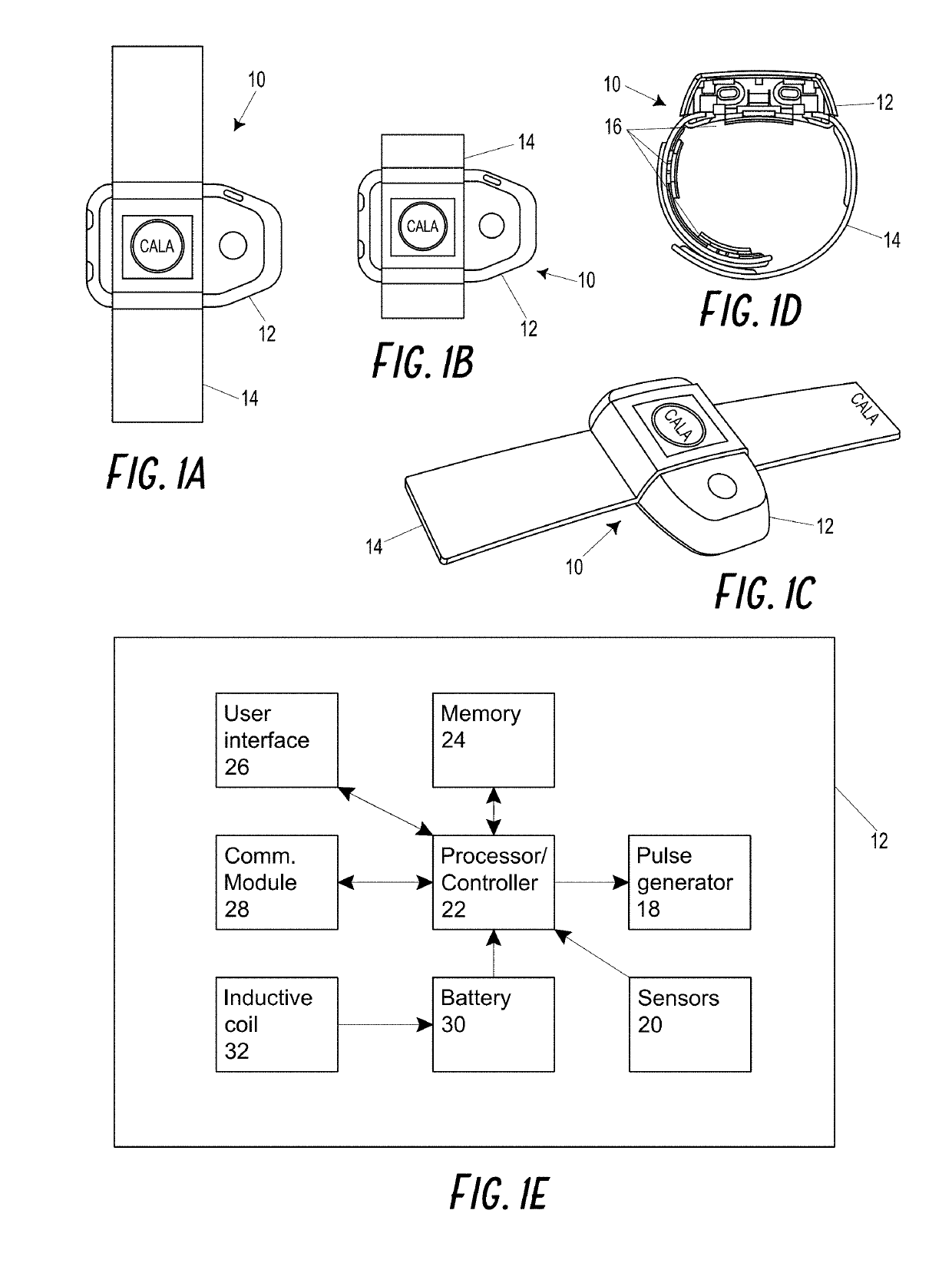

Dry electrodes for transcutaneous nerve stimulation

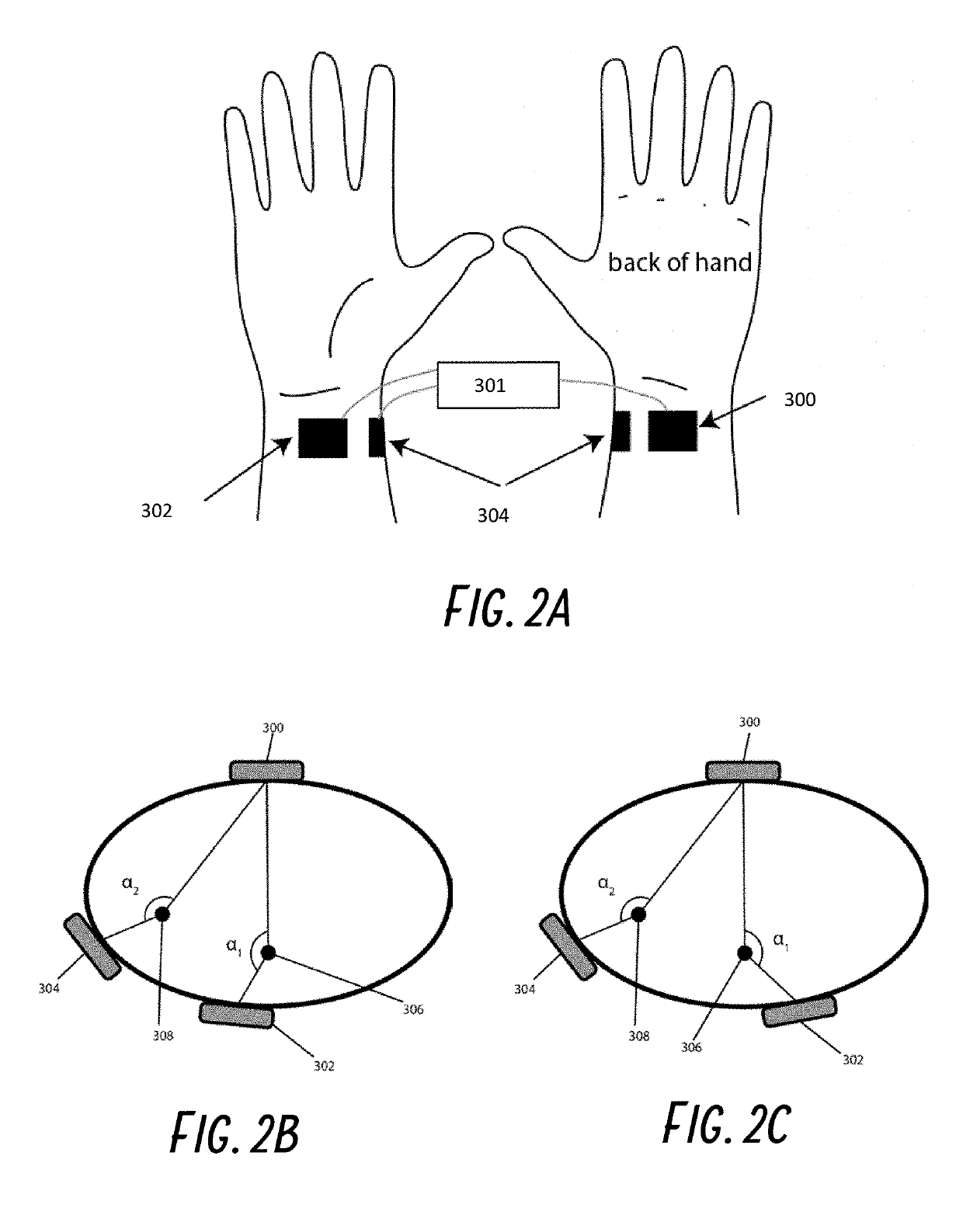

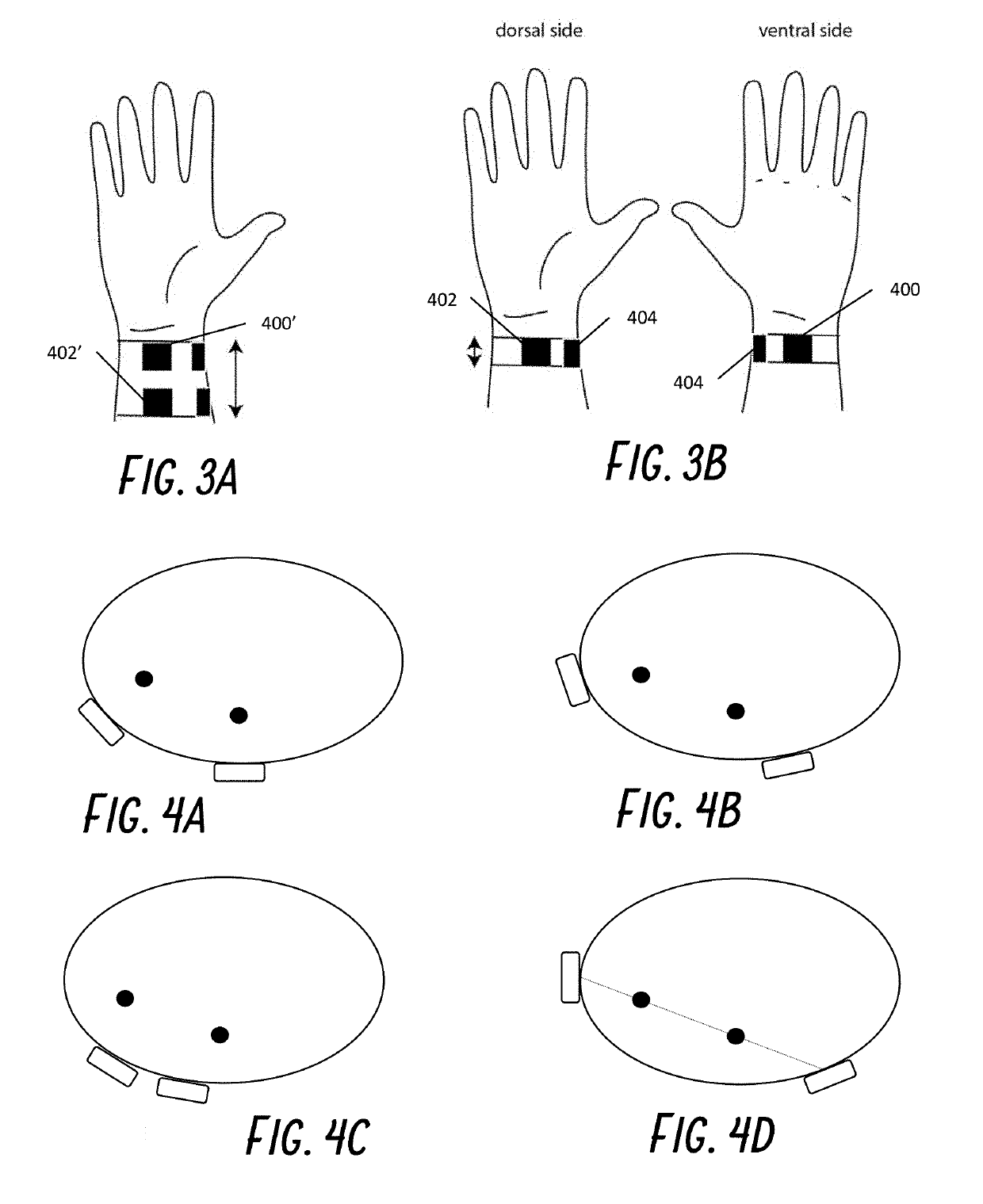

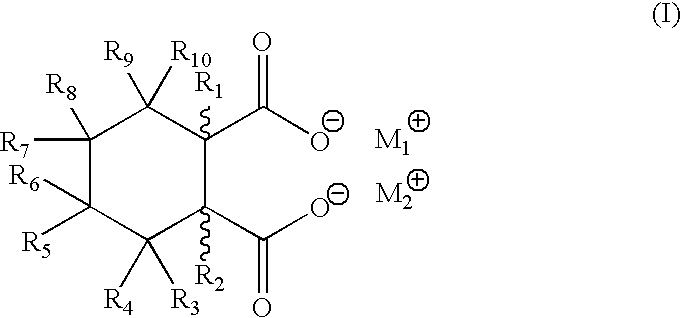

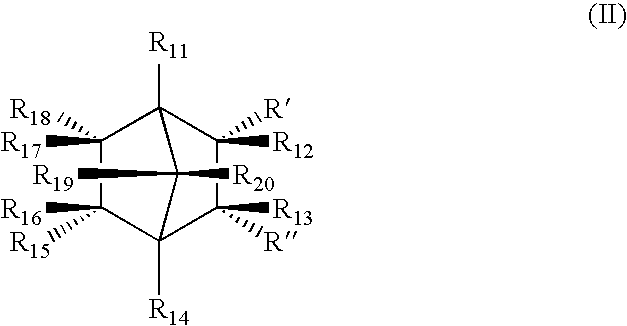

Disclosed herein are systems, devices, and methods for peripheral nerve stimulation, particularly for treating tremor. The nerve stimulation may be accomplished by a wearable nerve stimulation device, such as a band configured to be worn on the wrist or other body part. The device can accomplish targeted nerve stimulation using circumferentially spaced electrodes. In some embodiments, the device may use only the same number of electrodes as the number of nerves that are to be stimulated. A biphasic charge-balanced waveform may be used to selectively stimulate a nerve near one of the activated electrodes but not to stimulate the nerve near the other activated electrode. The device may use dry electrodes for long-term, repeated use. The dry electrodes may include a conductive base layer and a polymeric, plastic or rubber skin contact layer comprising a conductive filler. The filler may be a powder, fiber, conductive coating, etc.

Owner:CALA HEALTH

Thermoplastics exhibiting excellent long-term hydrostatic strength for high-pressure applications

InactiveUS20050038155A1Increased hydrostatic strengthViable alternativeThermoplasticTransport system

Novel thermoplastics and pipes made therefrom which can withstand extreme surface and / or internally generated pressures that make them excellent candidates for uses such as within underground liquid and gas transport systems are provided. Such pipes are improvements over standard metal (i.e., steel, copper, lead, and the like), concrete, ceramic, and the like, pipes due to toxicity issues (such as with lead pipes), raw material costs (such as with copper), construction costs, shipping costs, implementation costs (particularly underground), flexibility (and thus modulus strength allowances) to compensate for underground movements (i.e., earthquakes and tremors), non-rusting characteristics, reduced crack propagation possibilities, and ease in manufacture. Such thermoplastics exhibit excellent long-term hydrostatic strength characteristics that permit potential long-term reliable usage in such underground conditions and are preferably made from resins that include nucleating agents that provide such needed properties therein.

Owner:BERGHMANS STEPHANE +1

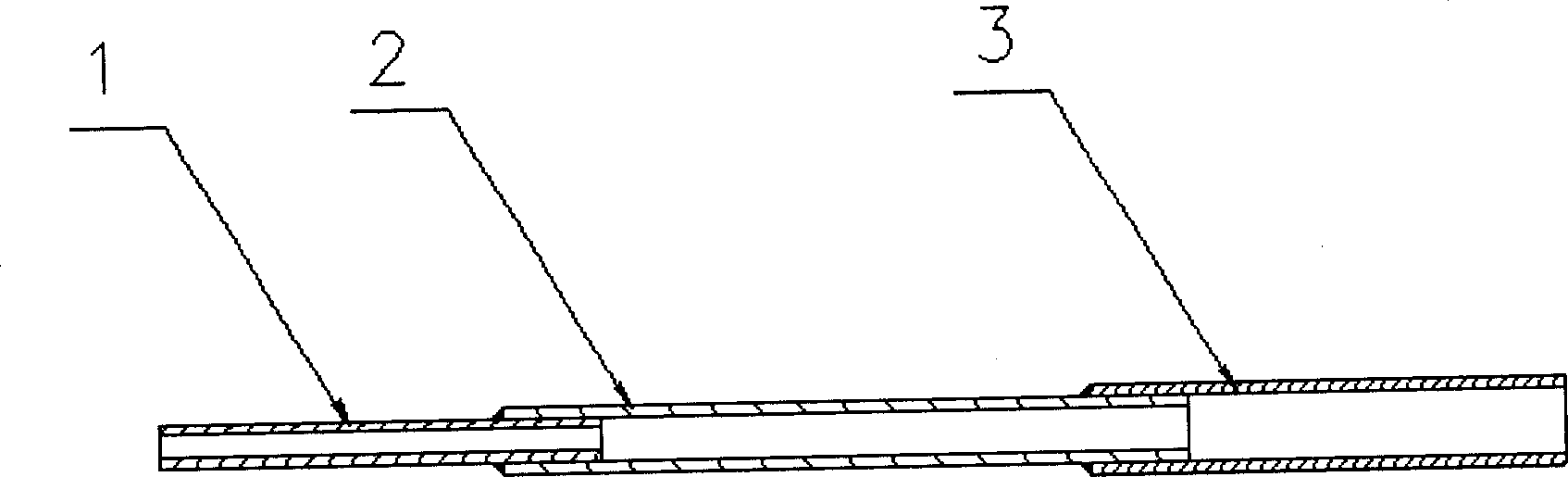

Silencer for refrigerator

InactiveCN1786623AReduce noise levelReduced outlet flow noiseFluid circulation arrangementEngineeringInvoluntary shaking

The invention relates to silencing apparatus used to reduce fridge noise pollution. It is connected between fridge evaporator inlet pipe and capillary outlet. And it is made up of three sections silencing tube with constant section. The silencing tube is formed by front, middle, back three cylindrical silencing small tubes. The invention can make the injection noise of the capillary outlet transit constant section to reduce speed, transit tube to stabilize flow, fix capillary outlet to reduce tremor by fully utilizing the silencing principle that flow speed is reduced to reduce injection noise; the flow is stable to reduce wheezing flow; depth of immersion of the capillary outlet is reduced to fix the capillary and reduce its tremor. Thus the whole noise of the fridge can be reduced. The flow noise of the capillary outlet can be greatly reduced. And the structure of the invention is simple; its manufacture and installation are convenient.

Owner:SHANGHAI FURONG IND

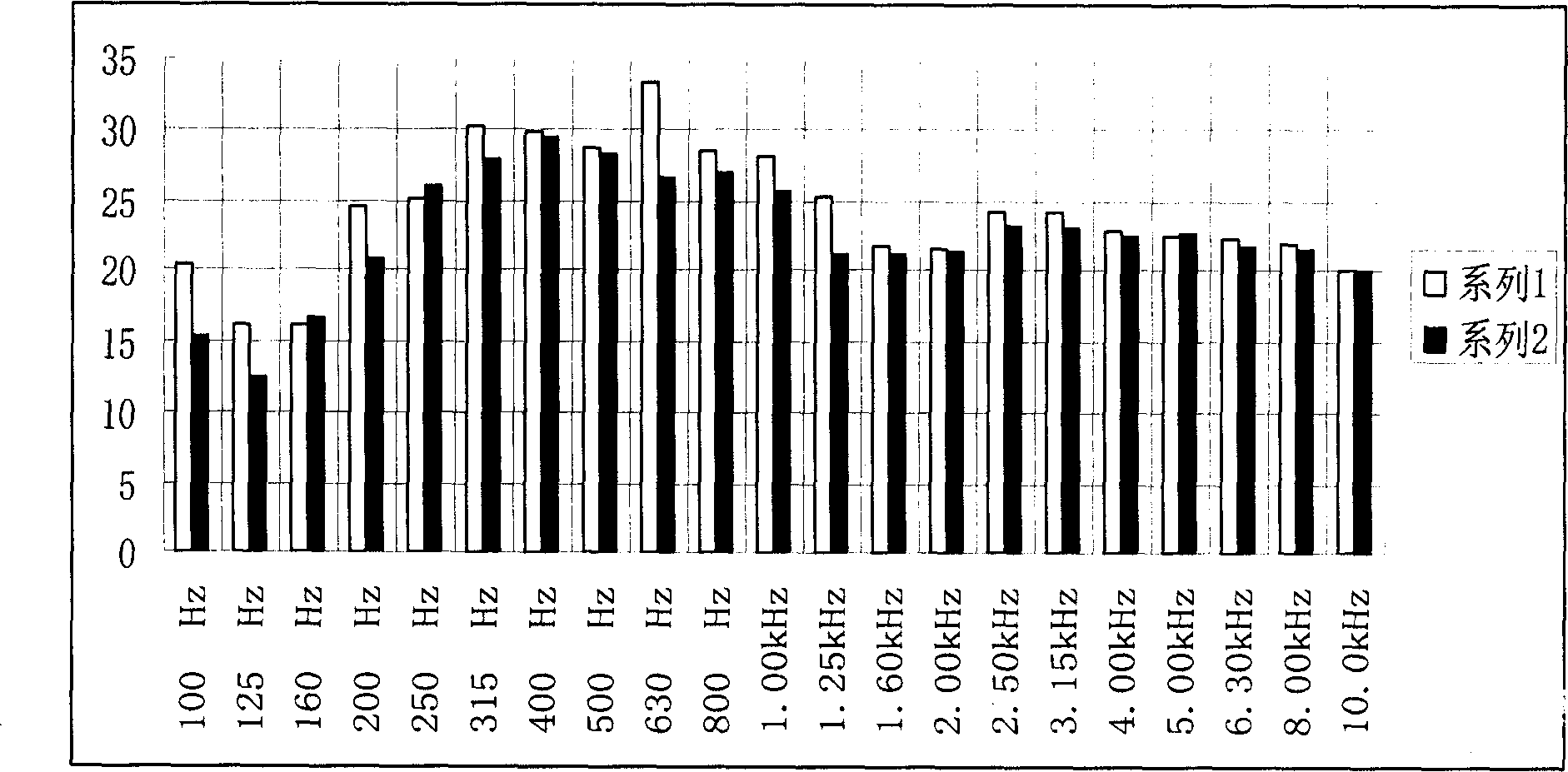

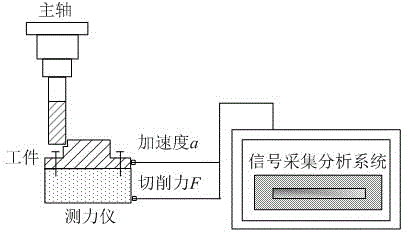

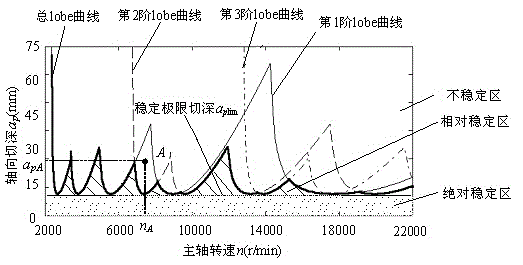

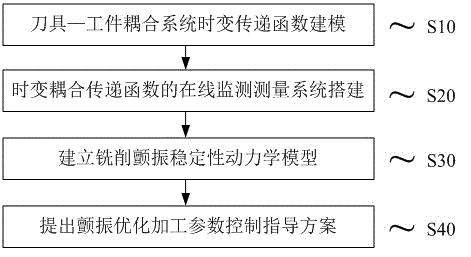

Large resection rate milling tremor monitoring method considering rigidity time-varying

InactiveCN105678043AAutomatic control devicesMeasurement/indication equipmentsTransfer function modelCoupling system

The invention relates to a large resection rate milling tremor monitoring method considering rigidity time-varying, and relates to the large resection rate high precision manufacture field with material resection rate above 80%; the monitoring method comprises the following steps: S10, cutter-workpiece coupling system time-varying transfer function modeling: substituting a relation between the transfer function and cutting force and displacement into a built displacement equation so as to obtain a cutter-workpiece coupling system time-varying transfer function model; S20, building a time-verying coupling transfer function online monitoring measuring system so as to monitor the transfer function in real time; S30, building a milling tremor stability kinetic model, substituting the transfer function value measured by the S20 into the kinetic model in the S30, monitoring tremor generation, and obtaining a non-tremor processing parameter scope; S40, providing a tremor optimization processing parameter control guide scheme according to the S30.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

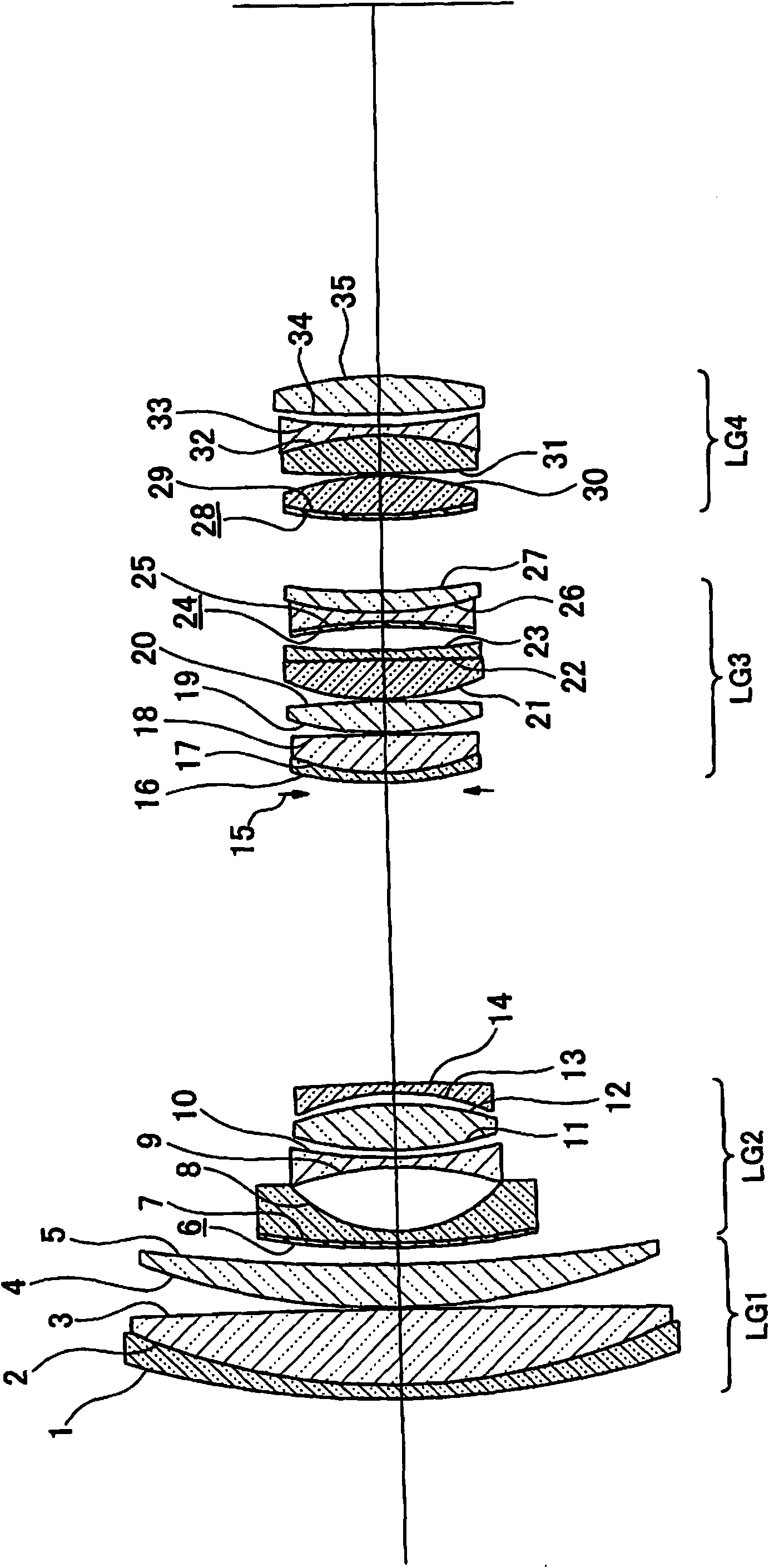

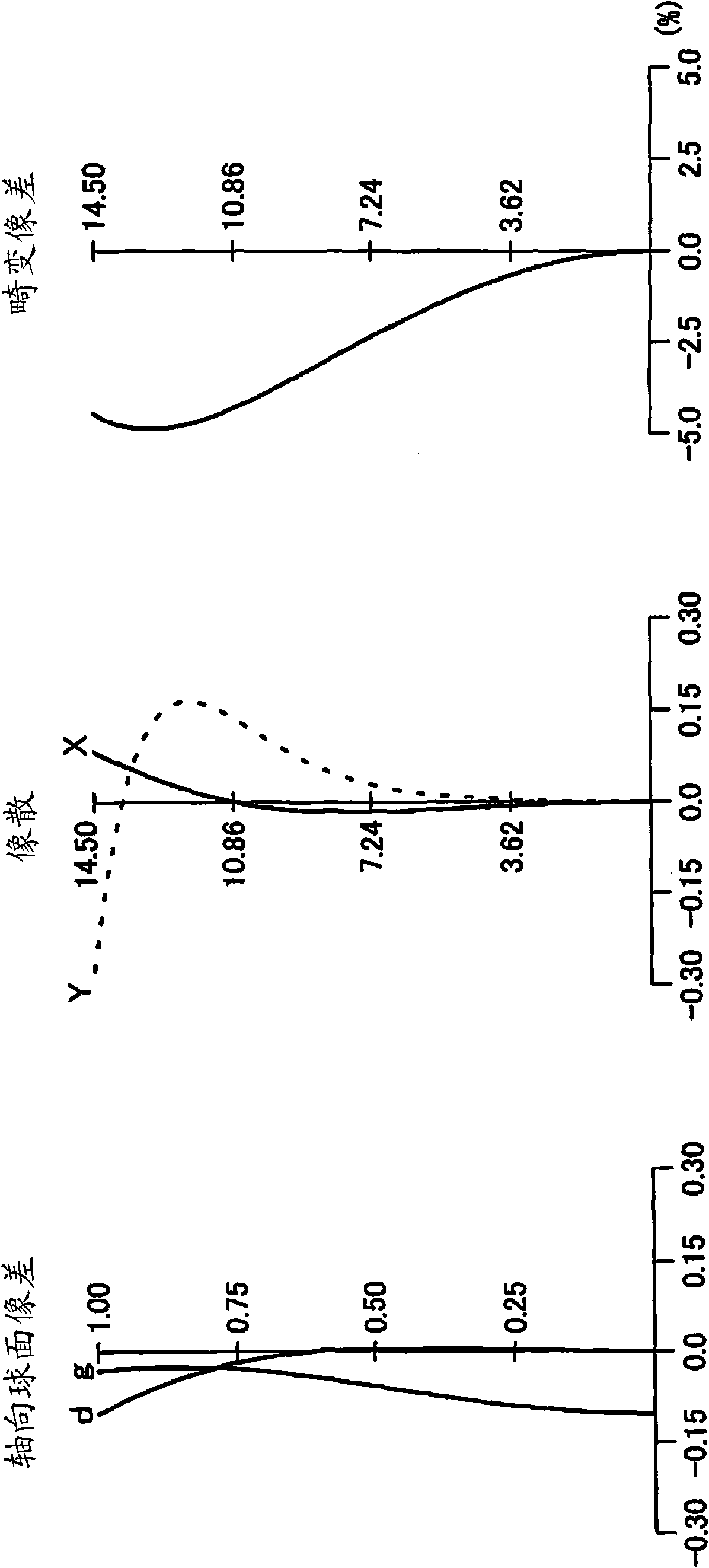

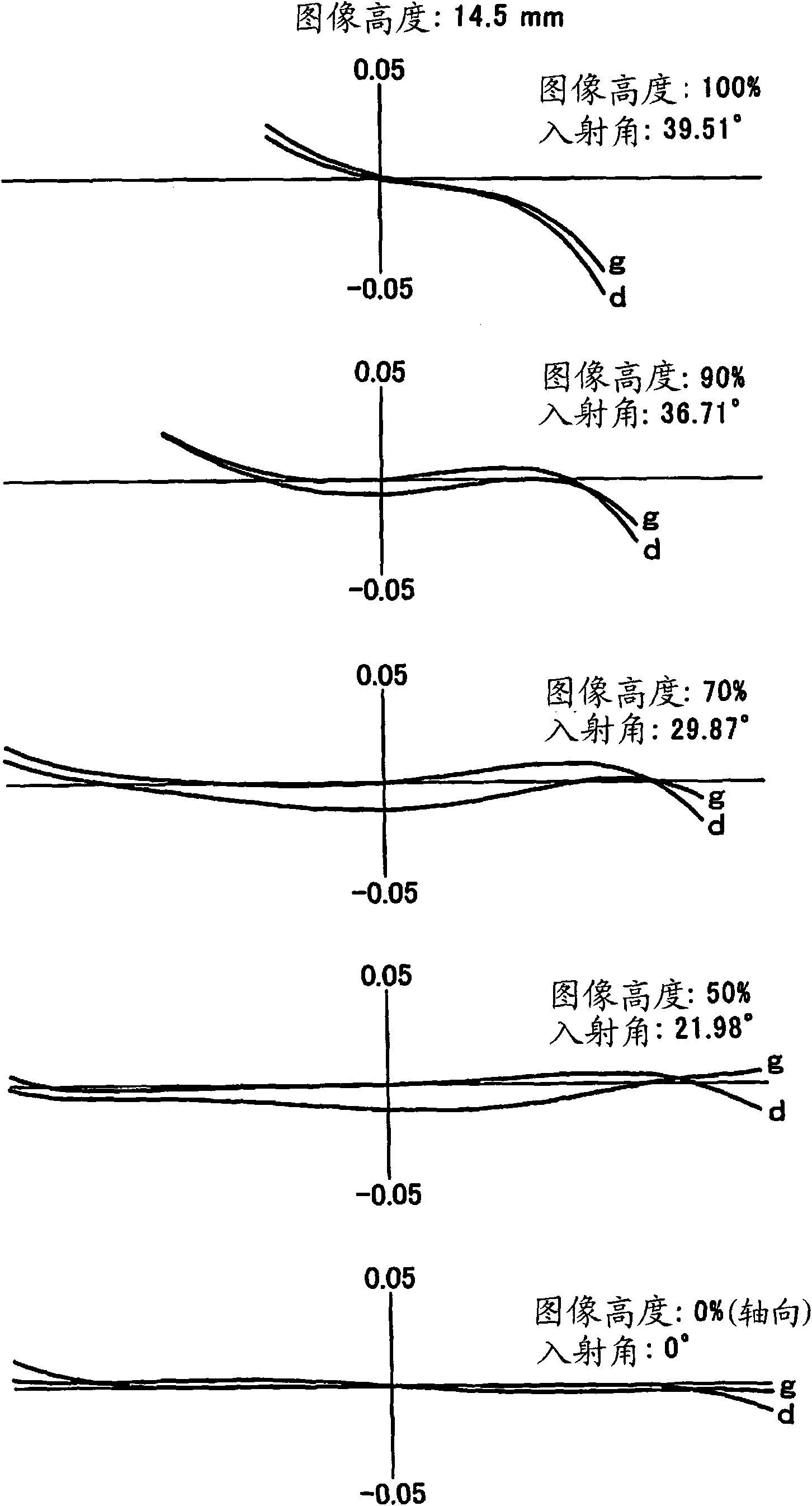

High variable power zoom lens

A compact and lightweight, high variable power zoom lens especially suitable for single-lens reflex digital cameras, which is 75 degrees or even wider in field angle at the wide-angle end, approximately 3 to 4 in F-number at the wide-angle end and approximately 6 to 7 at the telephoto end, and about 15x in variable power ratio. The zoom lens of four groups of lens pieces respectively exerting positive, negative, positive, and positive refractivities varies the power from the wide-angle end to the telephoto end as a result of the 1st and 2nd lens groups being split more, the 2nd and 3rd lens groups coming closer to each other, and the 3rd and 4th lens groups also coming closer to each other. The 3rd lens group has the leading set of lens pieces of positive refractivity closer to objects andthe trailing set of lens pieces of negative refractivity, and the trailing set alone are moved to be orthogonal to the optical axis to compensate for defocus in the imaging plane caused by a tremor of the user's hand(s). The 2nd lens group are displaced closer to objects for the focusing.

Owner:TAMRON

Ultrasound neuromodulation treatment of movement disorders, including motor tremor, tourette's syndrome, and epilepsy

Disclosed are methods and systems and methods for non-invasive neuromodulation using ultrasound to treat movement disorders (e.g., tremor disorders such as Parkinson's Disease and essential tremor, Tourette's Syndrome, and epilepsy). Also included are the Tourette's vocalizations. The neuromodulation can produce acute or long-term effects. The latter occur through Long-Term Depression (LTD) and Long-Term Potentiation (LTP) via training Included is control of direction of the energy emission, intensity, frequency, pulse duration, firing pattern, and phase / intensity relationships to targeting and accomplishing up regulation and / or down regulation.

Owner:MISHELEVICH DAVID J

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com