Large resection rate milling tremor monitoring method considering rigidity time-varying

A milling chatter and stiffness time-varying technology, applied in the field of machining, can solve the problems of increased chatter, errors, and poor dynamic characteristics of the tool-workpiece system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

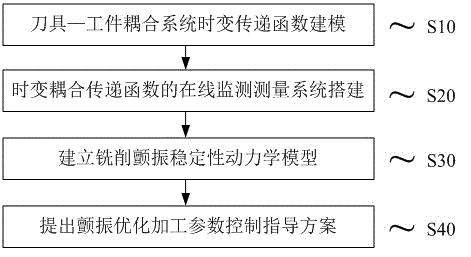

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

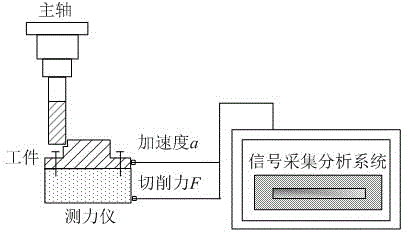

[0028] The tool-workpiece coupling system is simplified as a transfer function model with the cutting force as the excitation signal and the tool-workpiece coupling system as the frequency response object. The geometric relationship between the tool and workpiece displacement in the cutting process is established to carry out the transfer function coupling.

[0029] From the physical meaning of the transfer function, the transfer functions Hwx and Hwy in the x and y directions of the workpiece are expressed as

[0030] (4)

[0031] (5)

[0032] Among them, Re[Hwx], Re[Hwy] and Im[Hwx], Im[Hwy] are the real part and imaginary part of the workpiece transfer function matrix in the x and y directions, m / N; Xwx and Xwy are x and y The displacement of the workpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com