Silencer for refrigerator

A technology of refrigerators and mufflers, which is applied in the direction of fluid circulation arrangements, refrigeration components, refrigerators, etc., can solve problems such as high outlet jet velocity capillary outlet vibration, etc., and achieve the effect of simple structure, convenient installation, and overall noise level reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

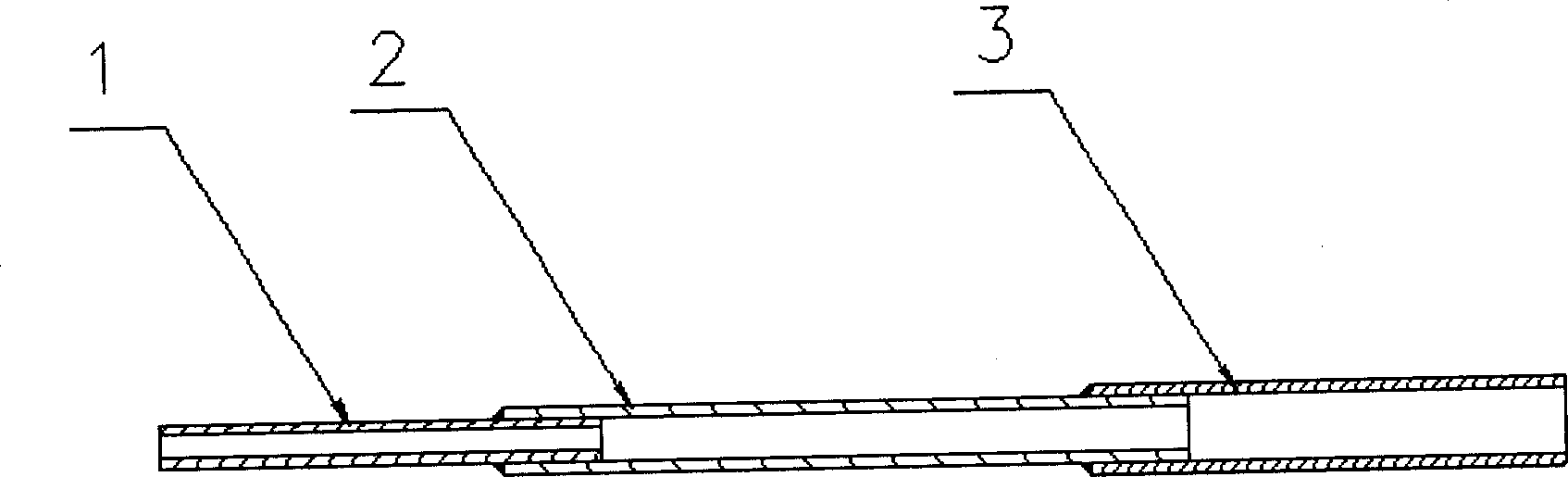

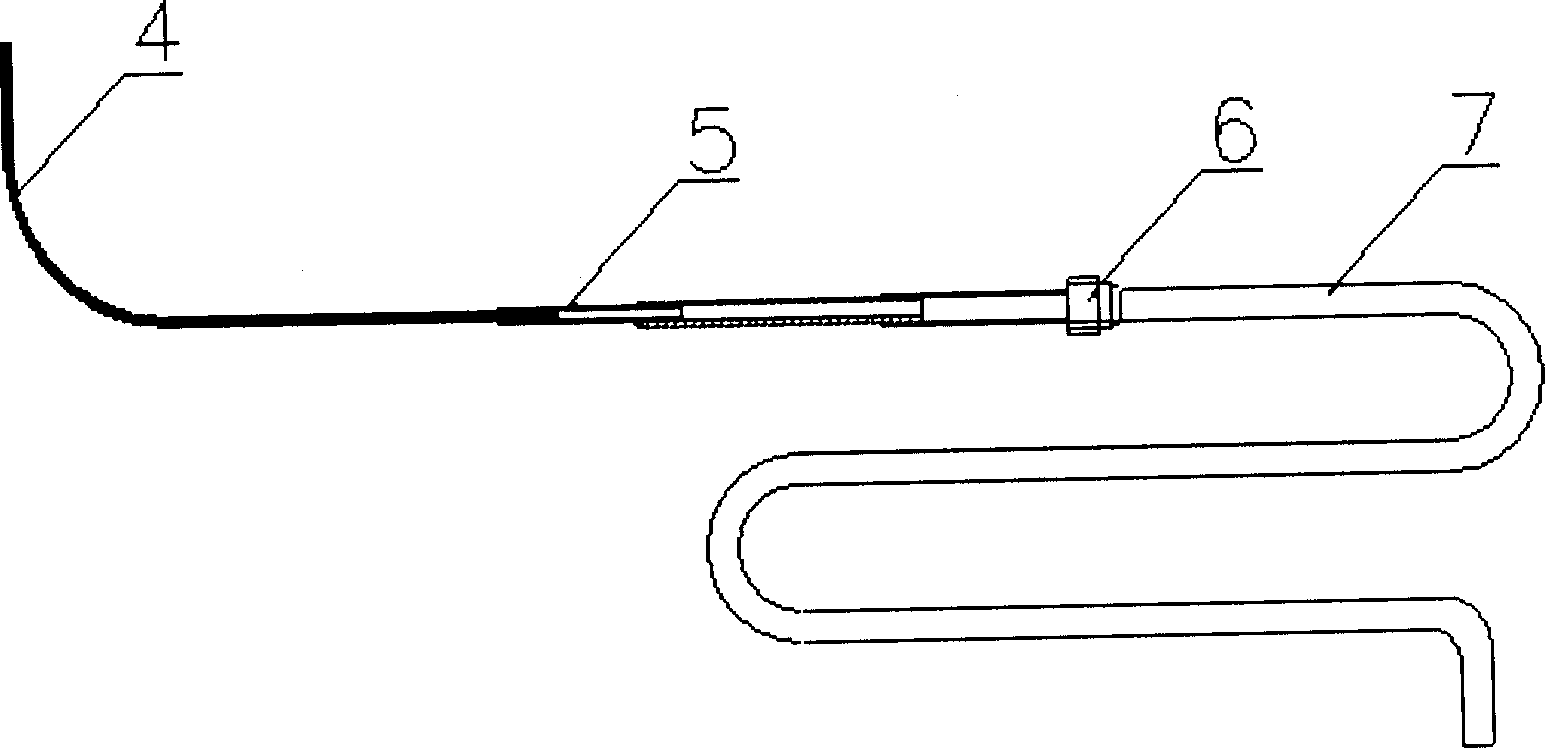

[0013] see figure 1 , the present invention is made up of equal cross-section muffler pipes, the muffler pipes are formed by connecting front, middle and rear three cylindrical muffler pipes of equal cross section, that is, the front pipe 1 is connected with one end of the middle pipe 2, and the rear pipe 3 is connected with the other end of middle pipe 2 again. The length of the front pipe 1 is 45-55mm, and the inner diameter of the front pipe 1 is 1.9-2mm; The inner diameter of the front tube 1 is the outer diameter of the front tube 1, the length of the middle tube 2 is 65-100 mm, the depth of the middle tube 2 inserted into the rear tube 3 is 12-15 mm, the outer diameter of the middle tube 2 is equal to the inner diameter of the rear tube 3, and the rear tube 3 The specifications and dimensions of the inner diameter and outer diameter of the evaporator are consistent with the specifications and dimensions of the pipeline (copper tube or aluminum tube or Bondi tube) of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com