Patents

Literature

79results about How to "Convenient and efficient transportation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

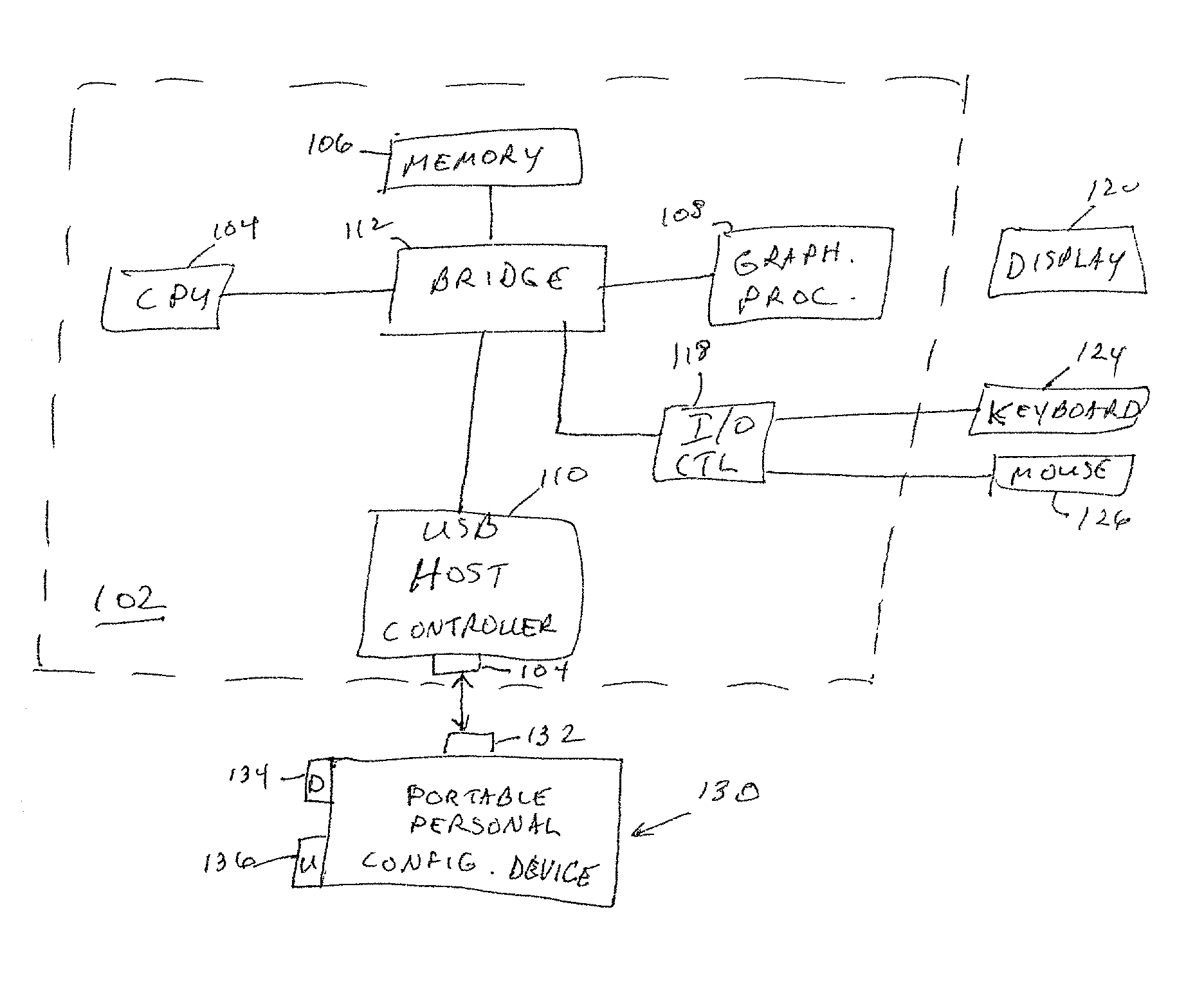

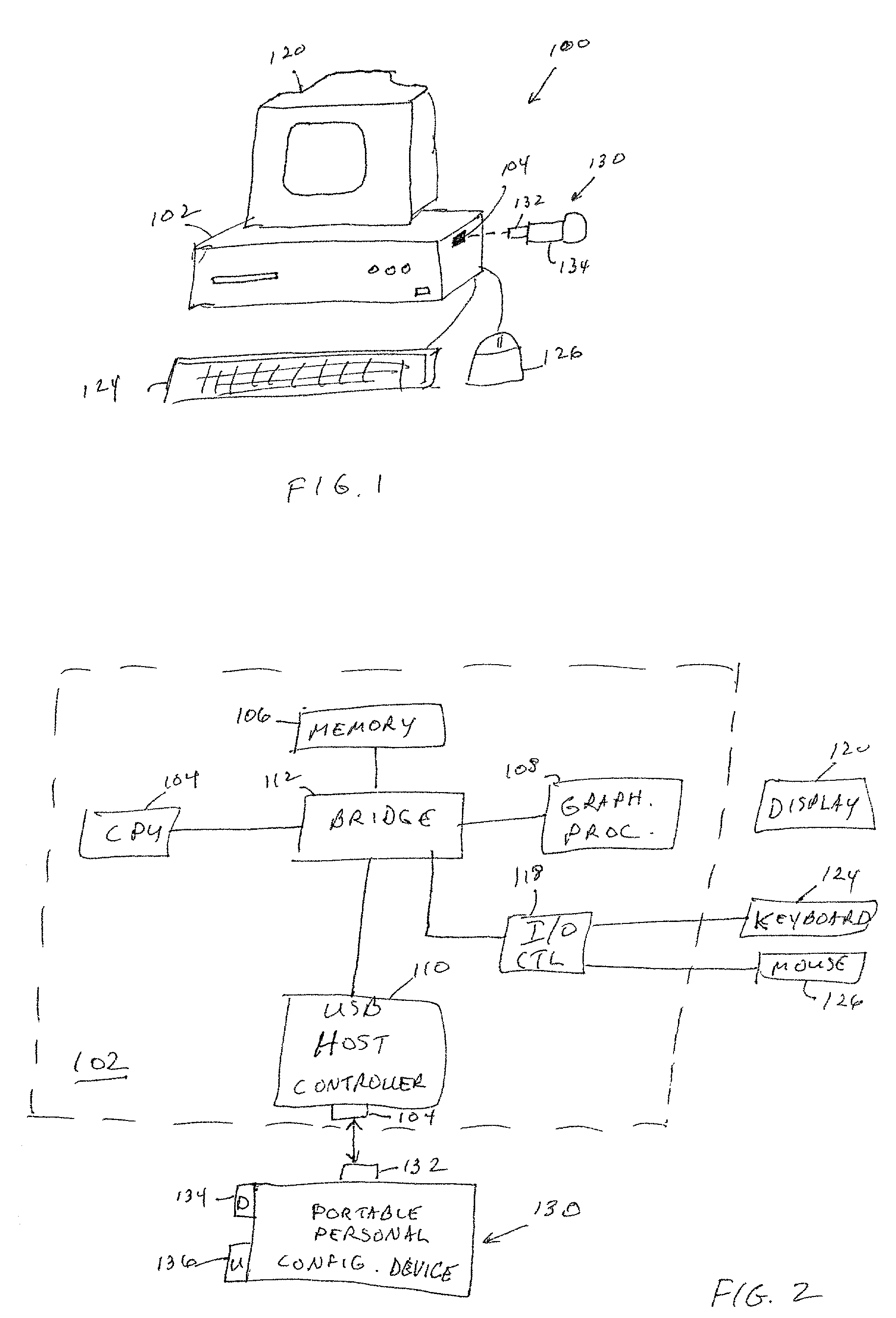

Portable electronic key providing transportable personal computing environment

InactiveUS20040001088A1Quickly and efficiently transportEasily and efficiently computingData processing applicationsCathode-ray tube indicatorsWeb sitePersonalization

A portable personal configuration device contains non-volatile memory and can be used to quickly and efficiently transport a user's personalized computing environment from one computer to another. The portable personal configuration device preferably is USB-compatible and thus plugs into a USB port in any computing device. In one embodiment, one or more files representing the user's computing environment are downloaded to the portable device and can then be uploaded to a different computer once connected to such new computer. Alternatively, the portable device can cause the computer's web browser to access a particular website containing the user's personalized computing environment which can then be readily downloaded to the computer. In this latter embodiment, the user's computing environment data is maintained on the web and once the portable device is plugged into a computer, the computer is caused to download the user's computing environment from the web.

Owner:HEWLETT PACKARD DEV CO LP

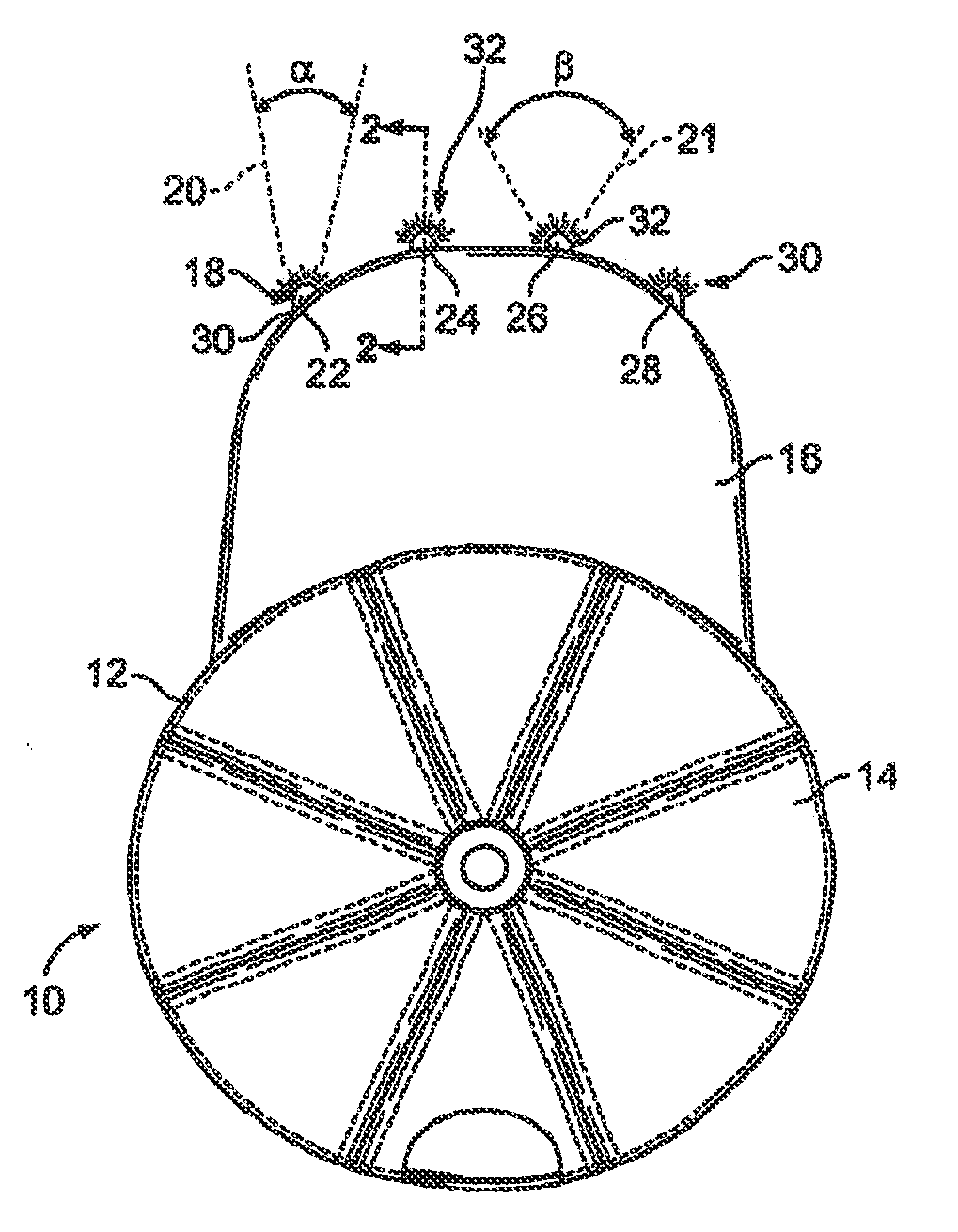

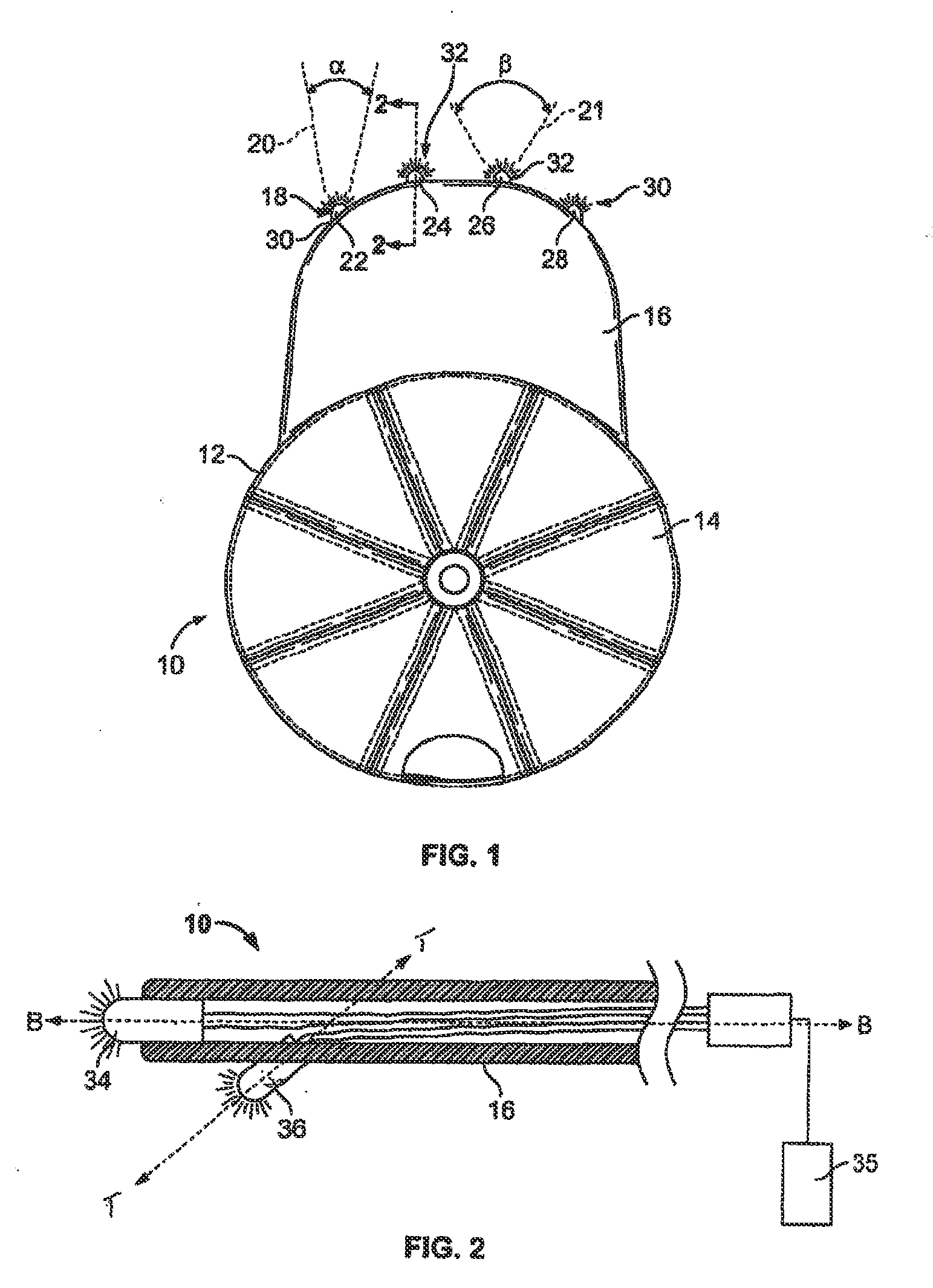

Hands free lighting devices

InactiveUS20100313335A1Convenient and efficient transportationPrevent inadvertent actuationTelevision system detailsHatsRotary switchHands free

There is provided headgear having a variety of components. In one form, the headgear includes a camera mounted to a brim thereof. Camera accessories that can be mounted to the headgear can include a switch, a control panel, a view finder, one or more lights. In another form, the headgear includes a heat sink mounted to the brim to dissipate heat generated by powered components of the headgear, such as the camera, a circuit board, one or more lights, or the like. In yet another form, the headgear includes a rotary switch for energizing the one or more lights and / or operating the camera.

Owner:WATERS

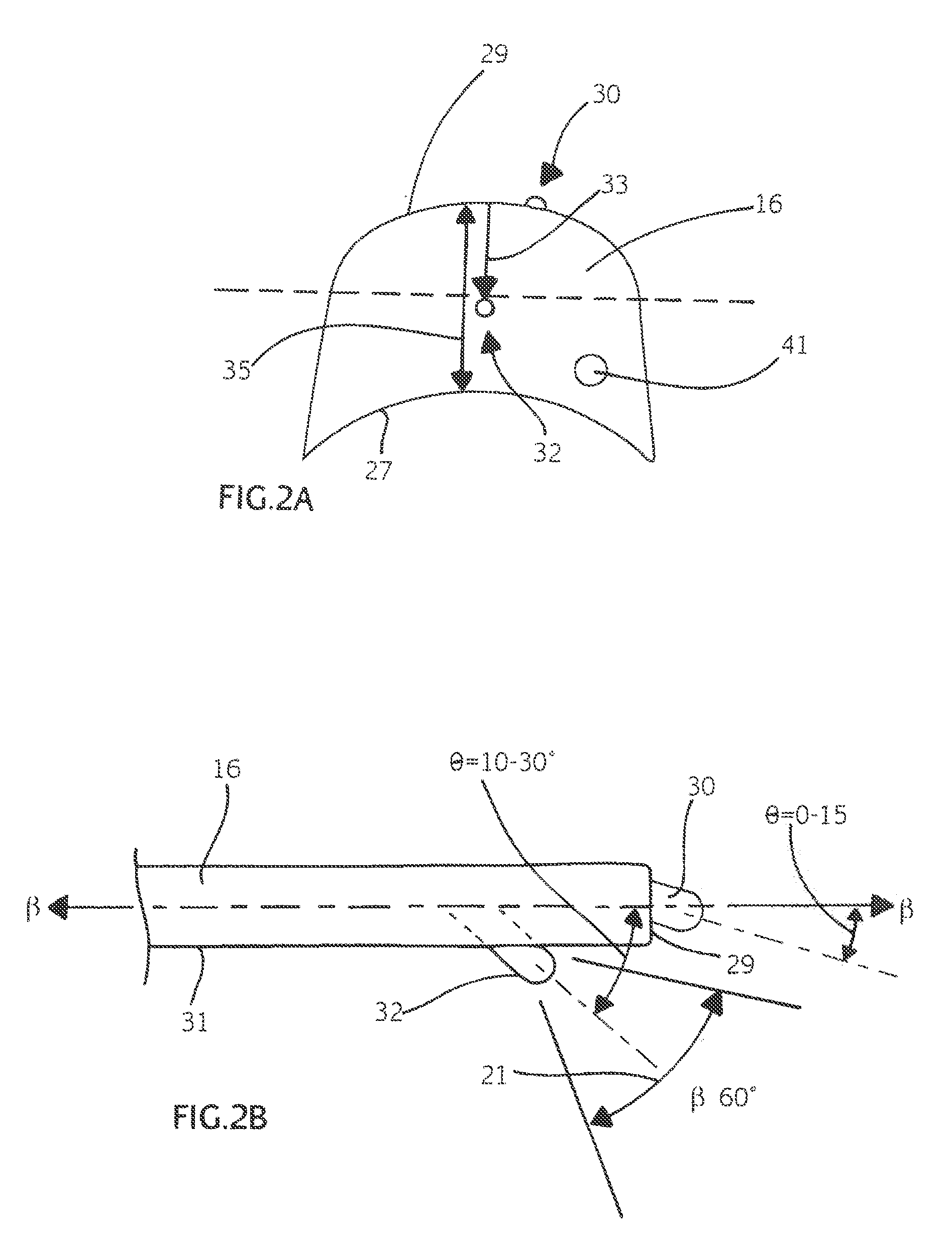

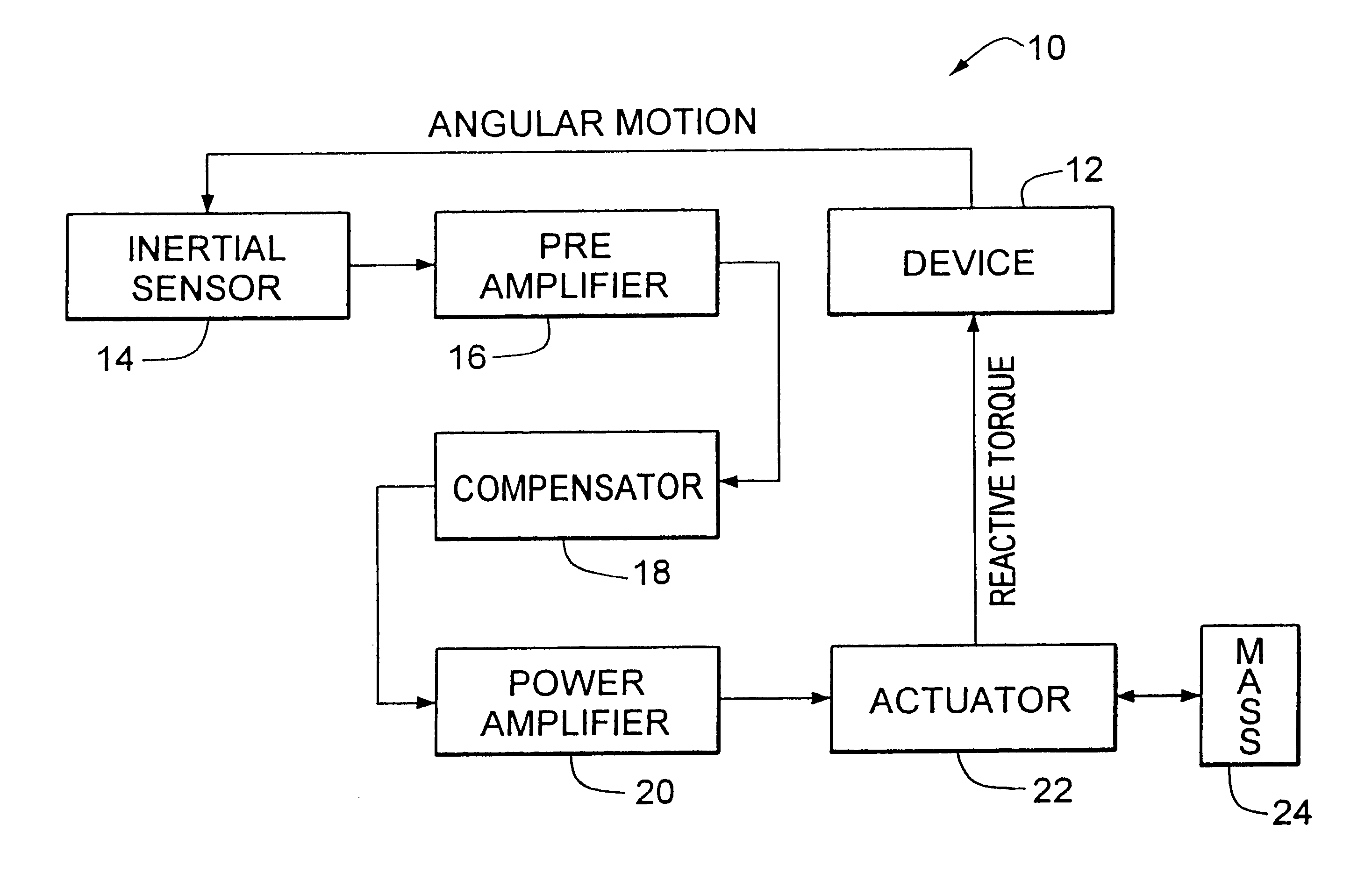

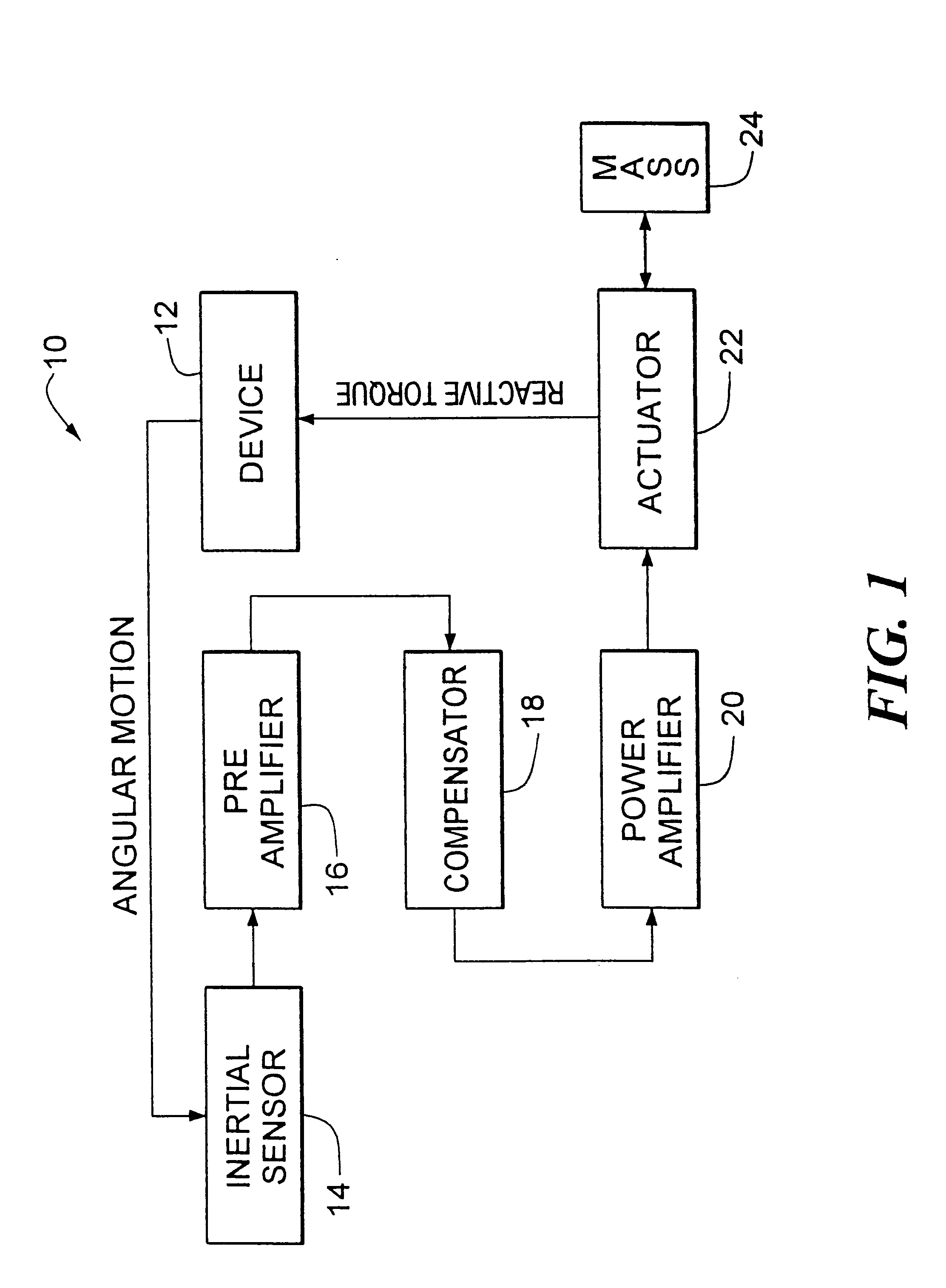

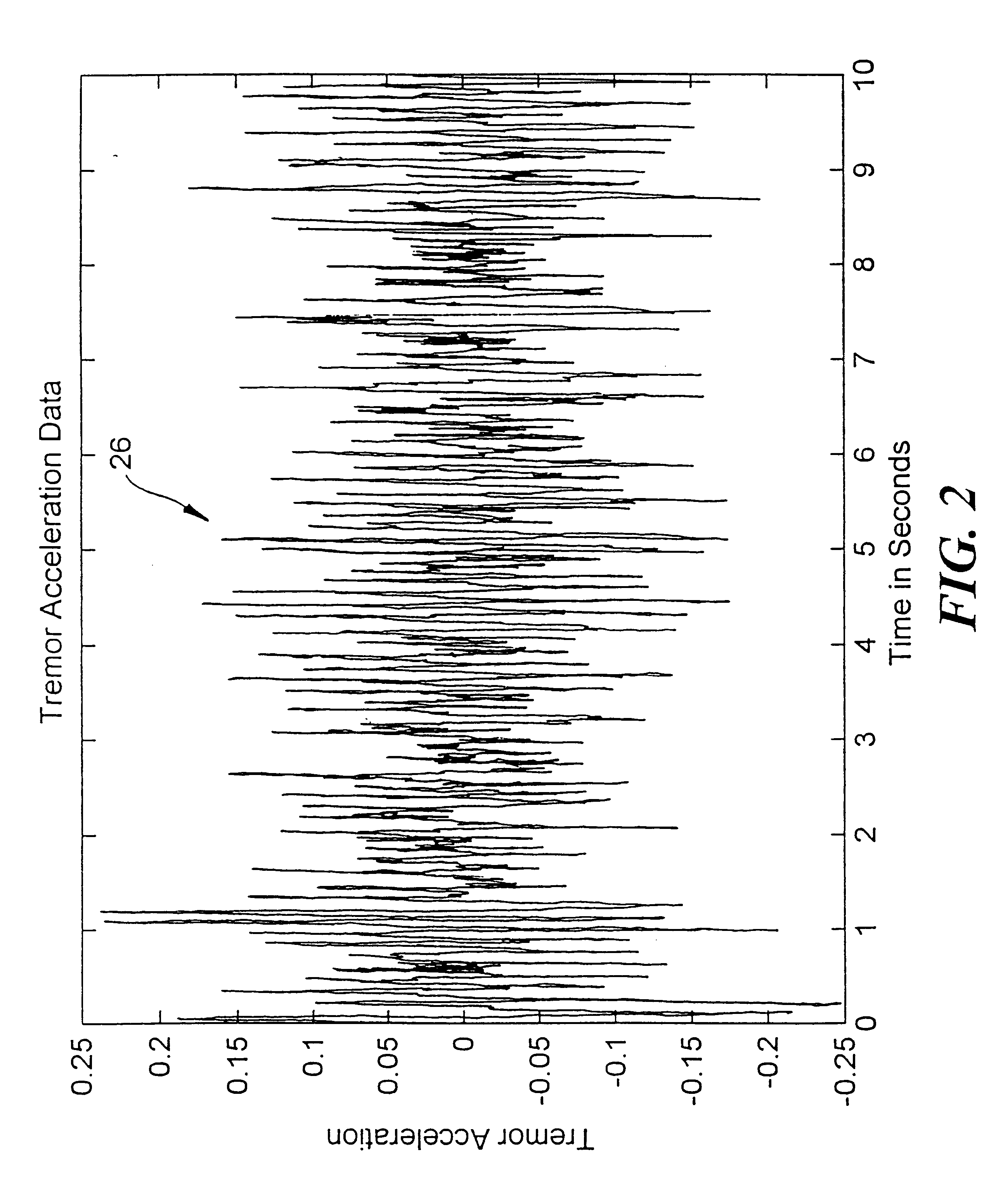

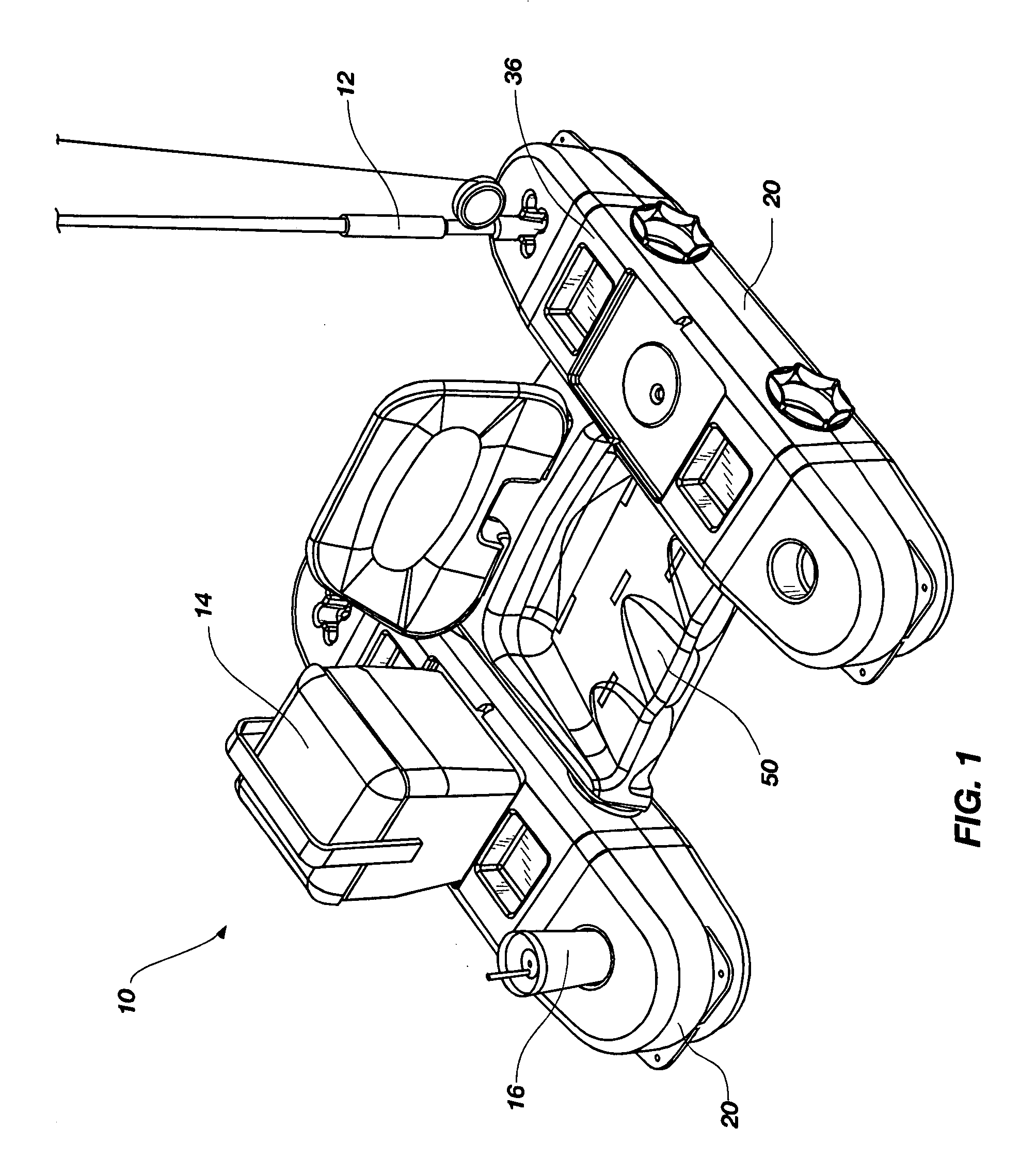

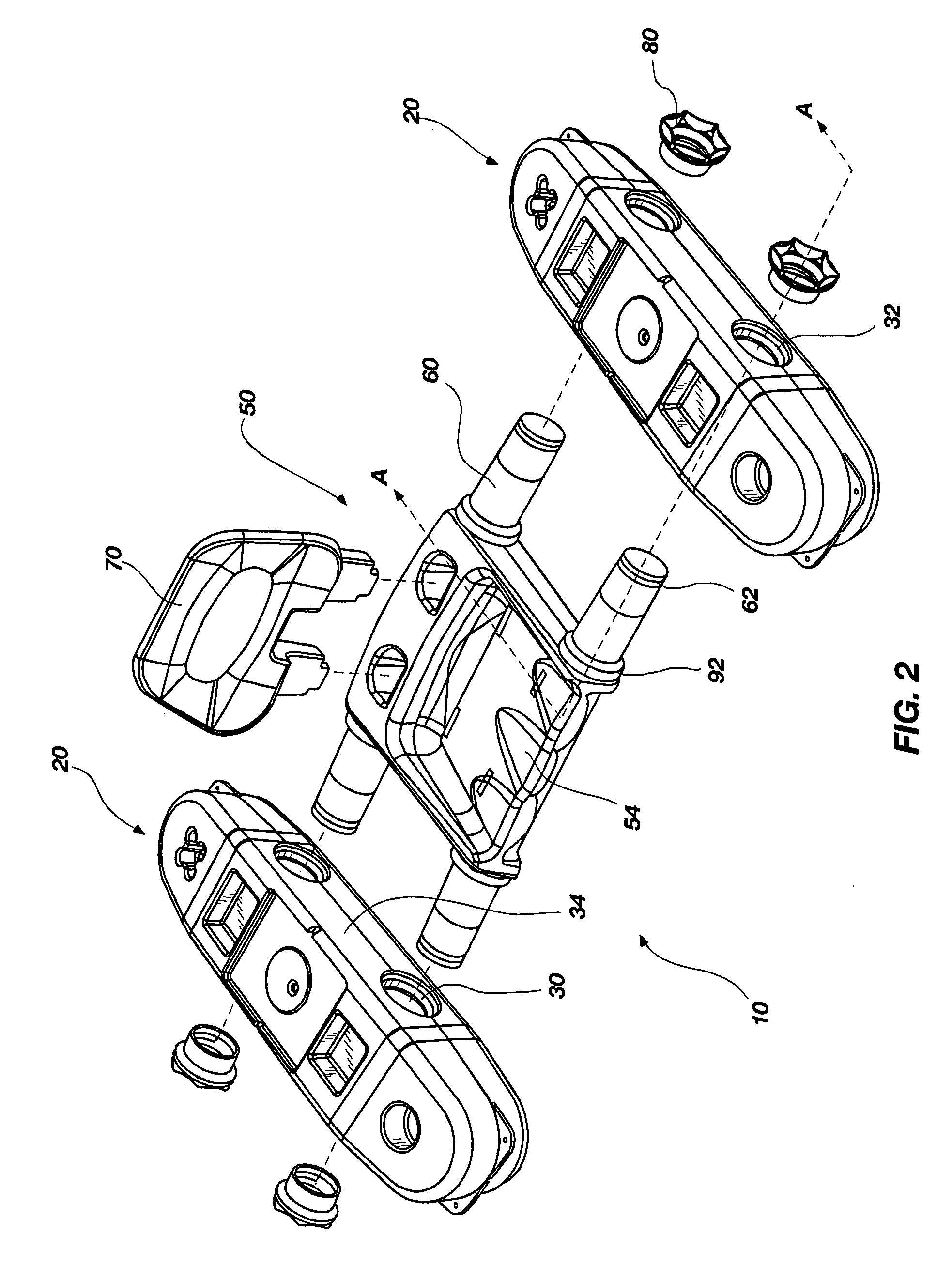

Active tremor control

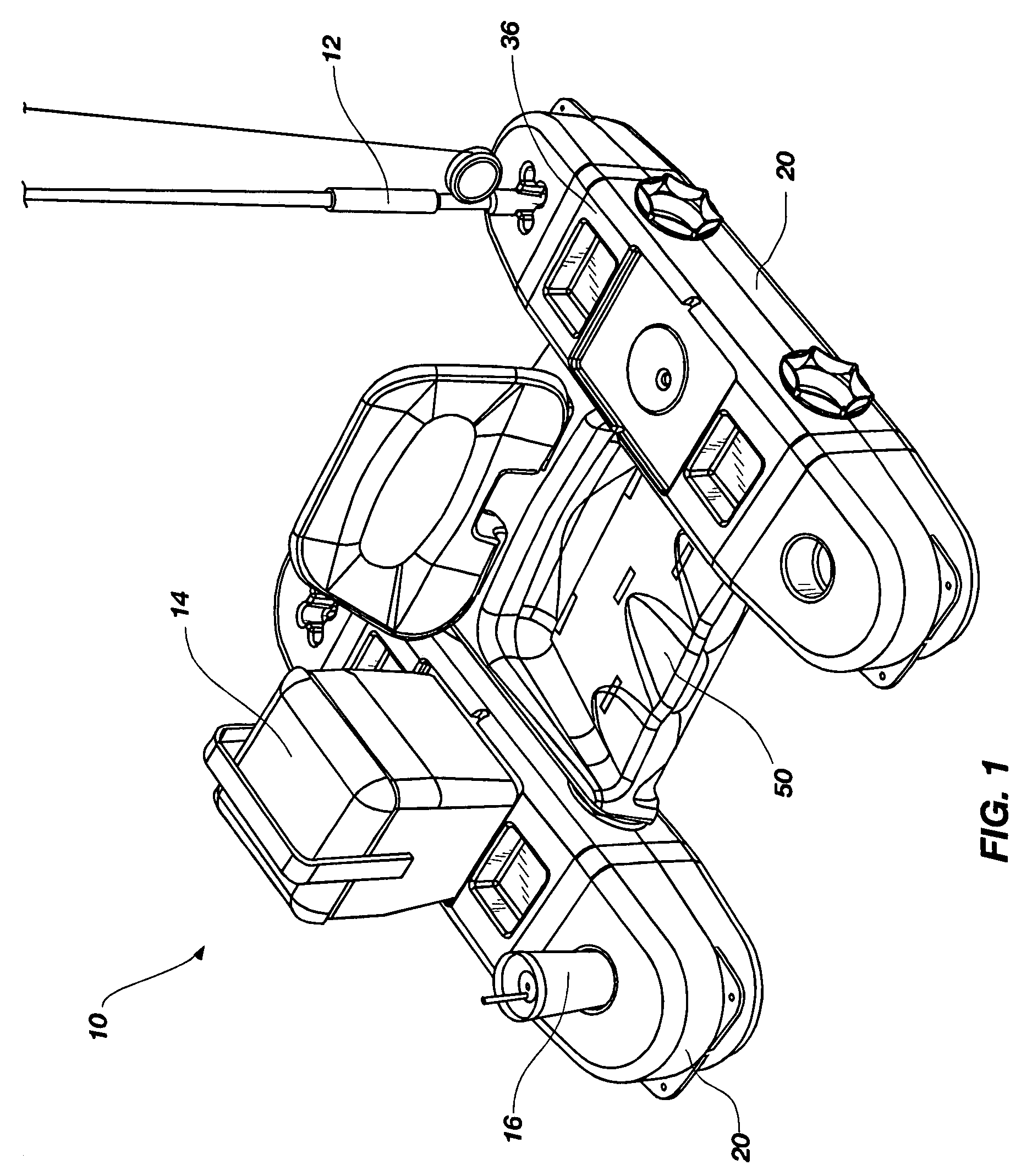

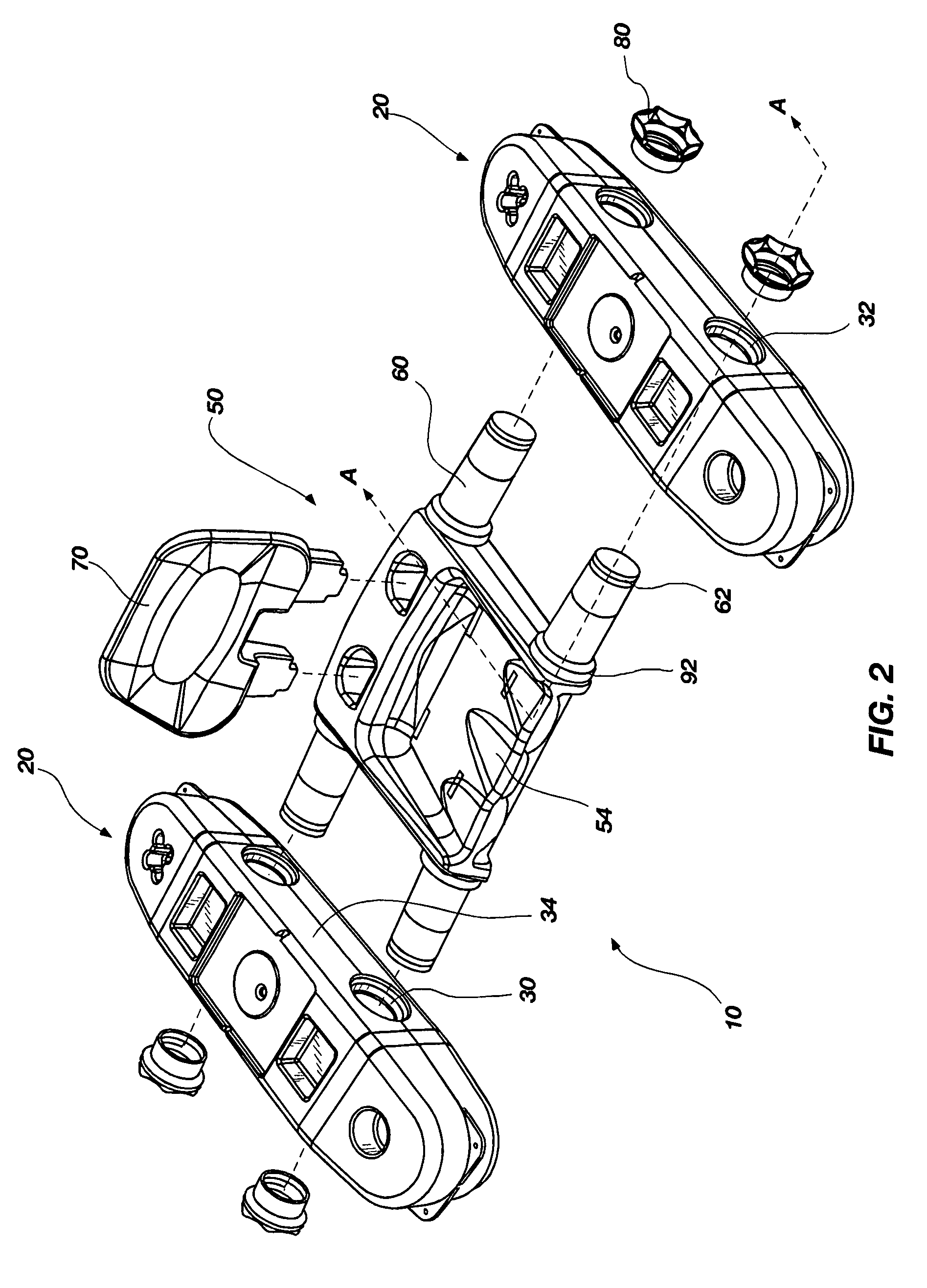

InactiveUS6234045B1Light weightConvenient and efficient transportationAiming meansRotary machine partsInertial massControl system

An active tremor control system for stabilizing against alternating perturbations includes: an inertial sensor for sensing angular motion about a first axis of an object induced by alternating perturbations; an inertial mass independent of the object; and an actuator coupled to the object and the mass and responsive to the inertial sensor for selectively applying a torque to the object representative of the sensed angular motion such that the angular motion about the first axis induced by the perturbation is cancelled, the actuator concurrently applying a reactive torque, equal and opposite to the to the applied torque, to the mass.

Owner:CHARLES STARK DRAPER LABORATORY

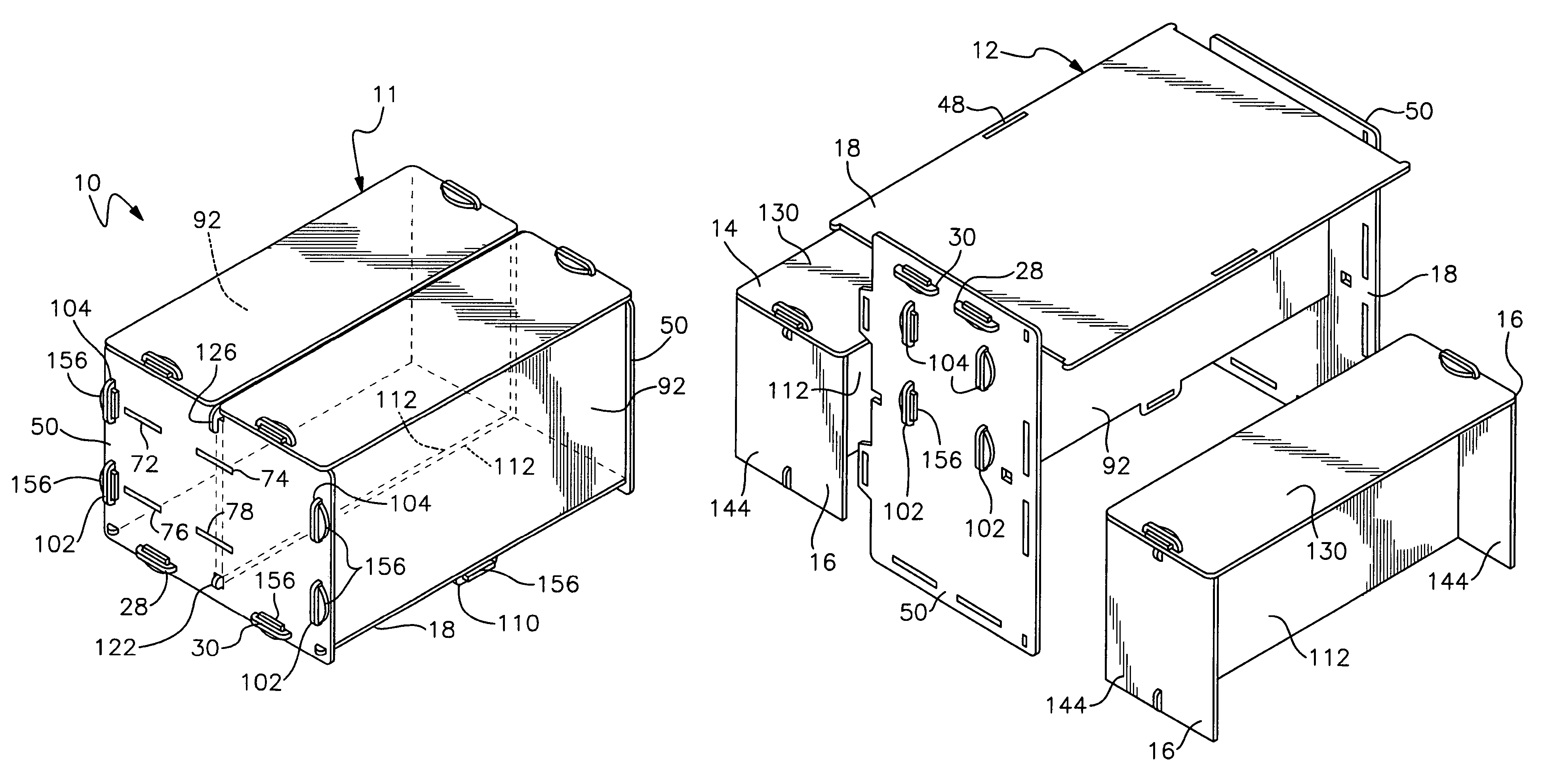

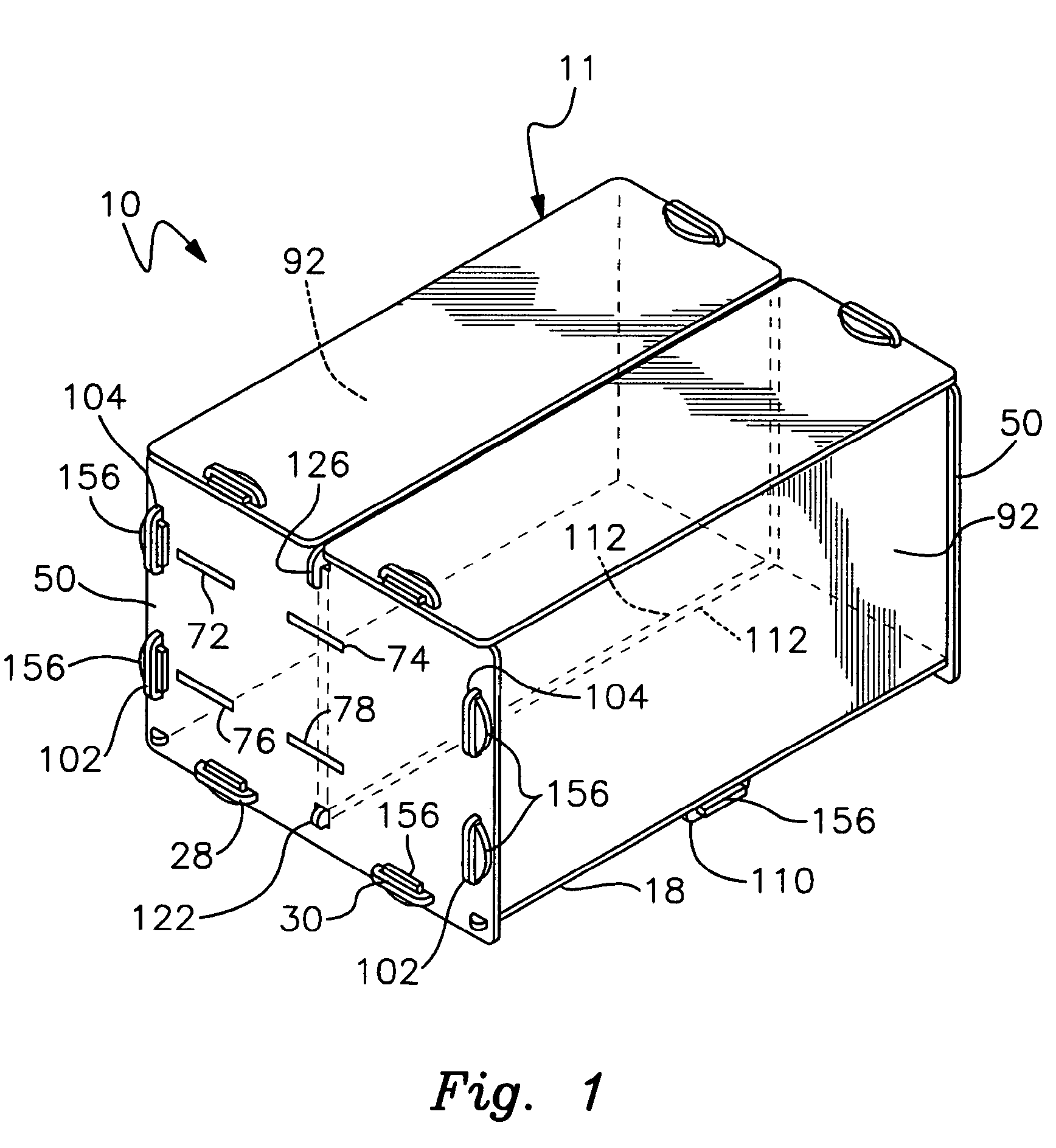

Convertible storage box assembly

InactiveUS7533940B1Quickly and effectively convertedRugged and efficientFurniture joining partsStoolsEngineeringSurface plate

A convertible multiple panel assembly includes a plurality of panels that carry complementary releasable interlocking components. The components are selectively interengagable in a first pattern such that the panels define a box. The components are selectively disengaged from one another and re-interengaged in an alternative, second pattern to define a table and at least one associated bench.

Owner:ZOOK JIMMY D

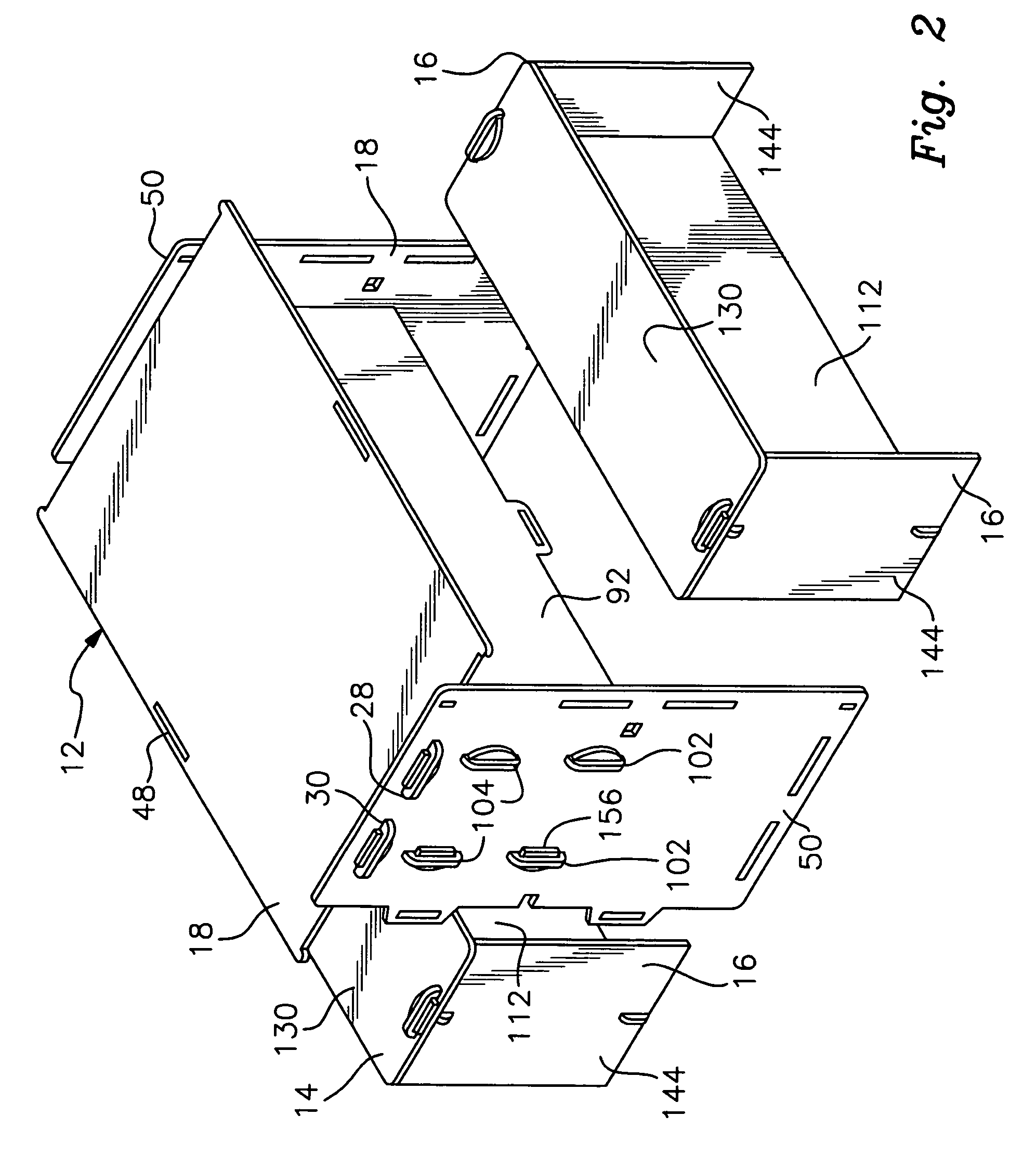

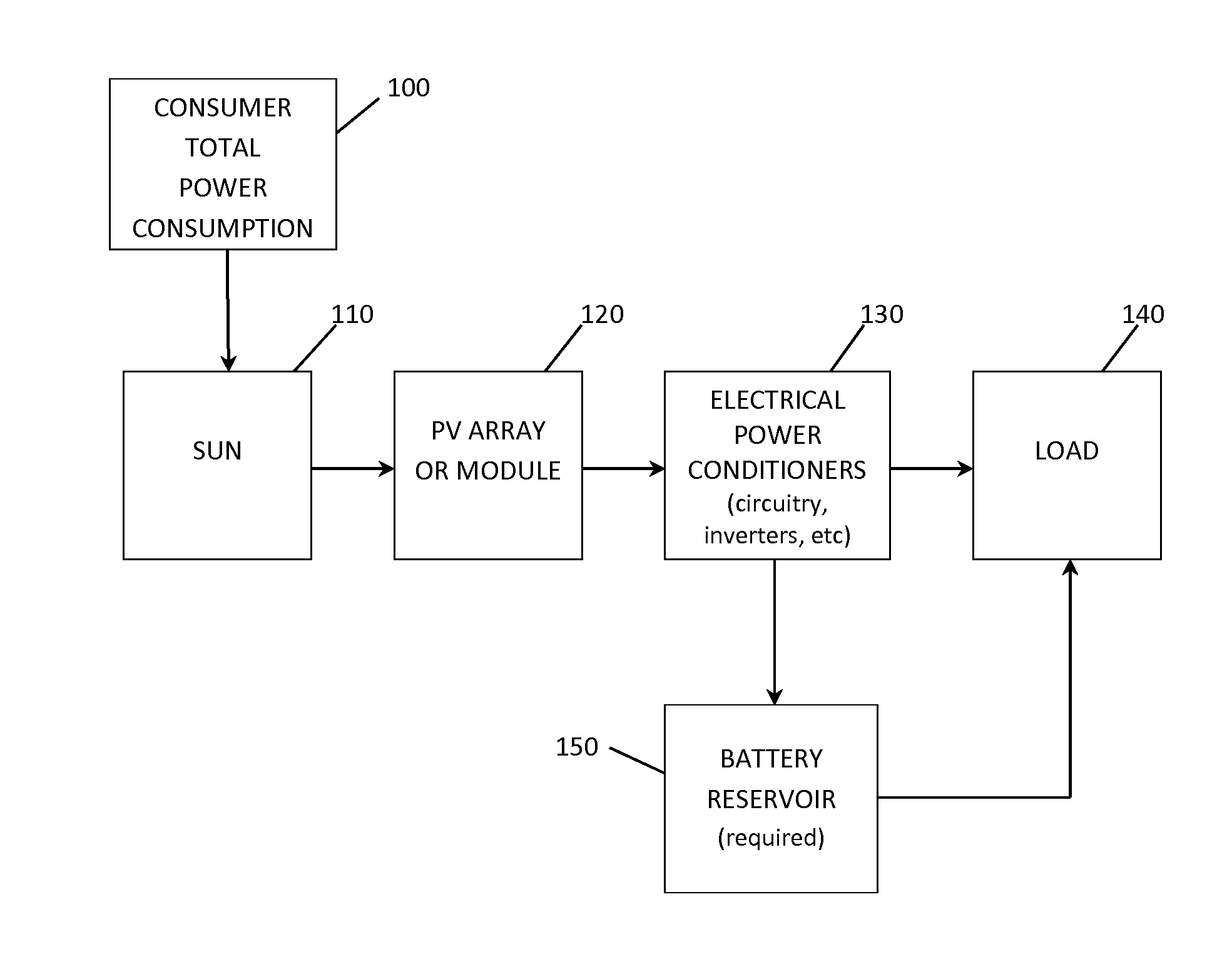

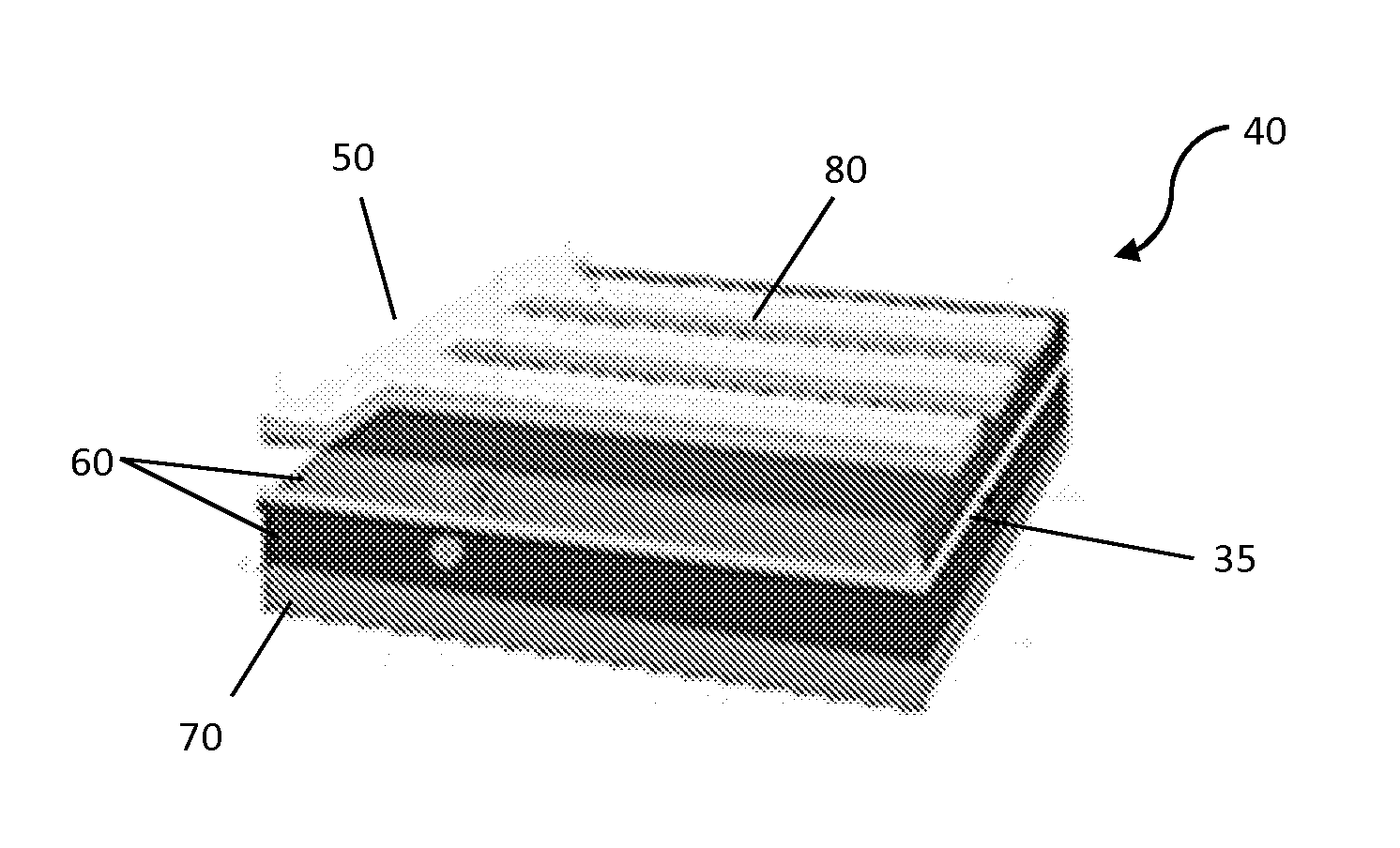

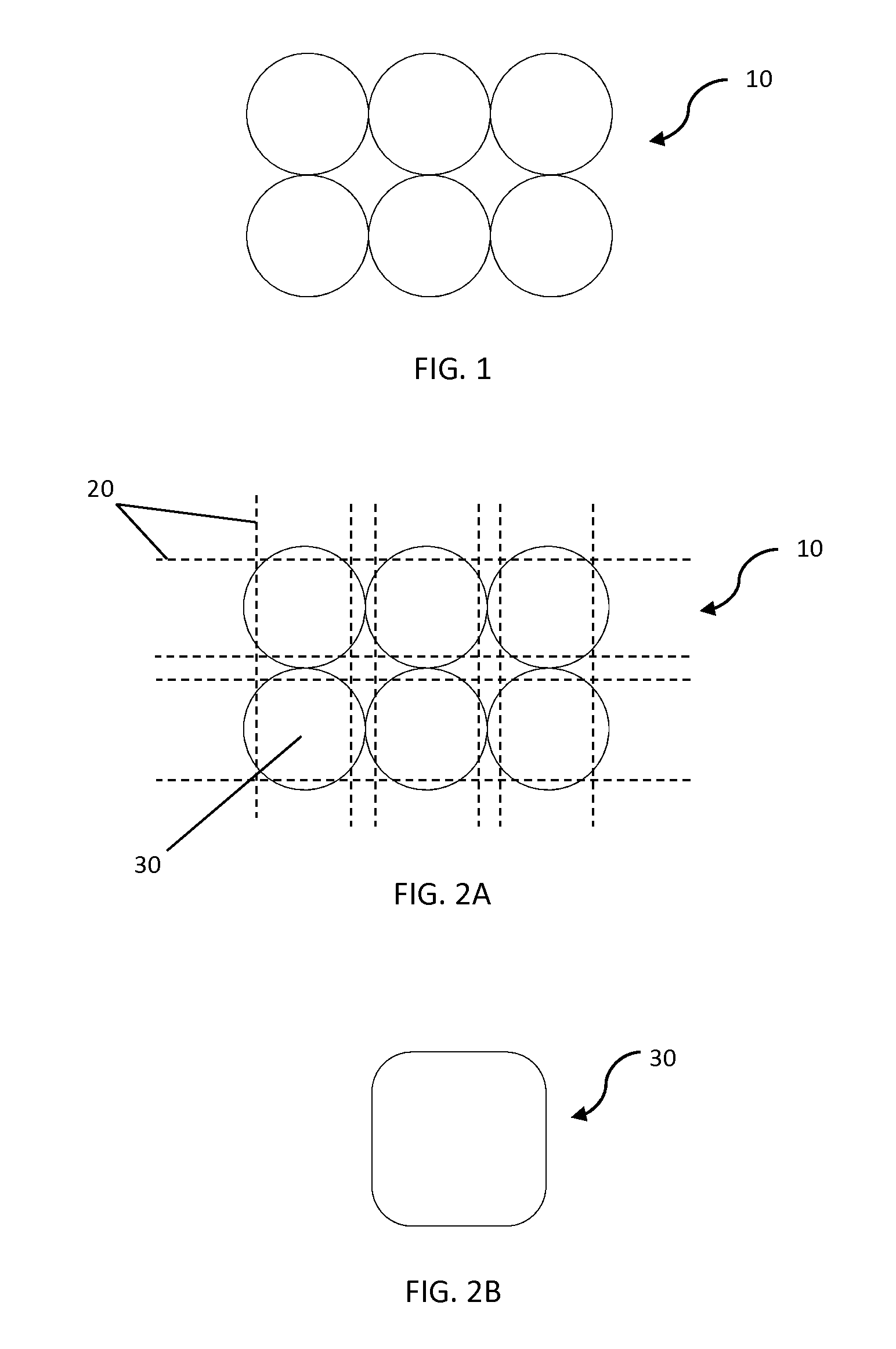

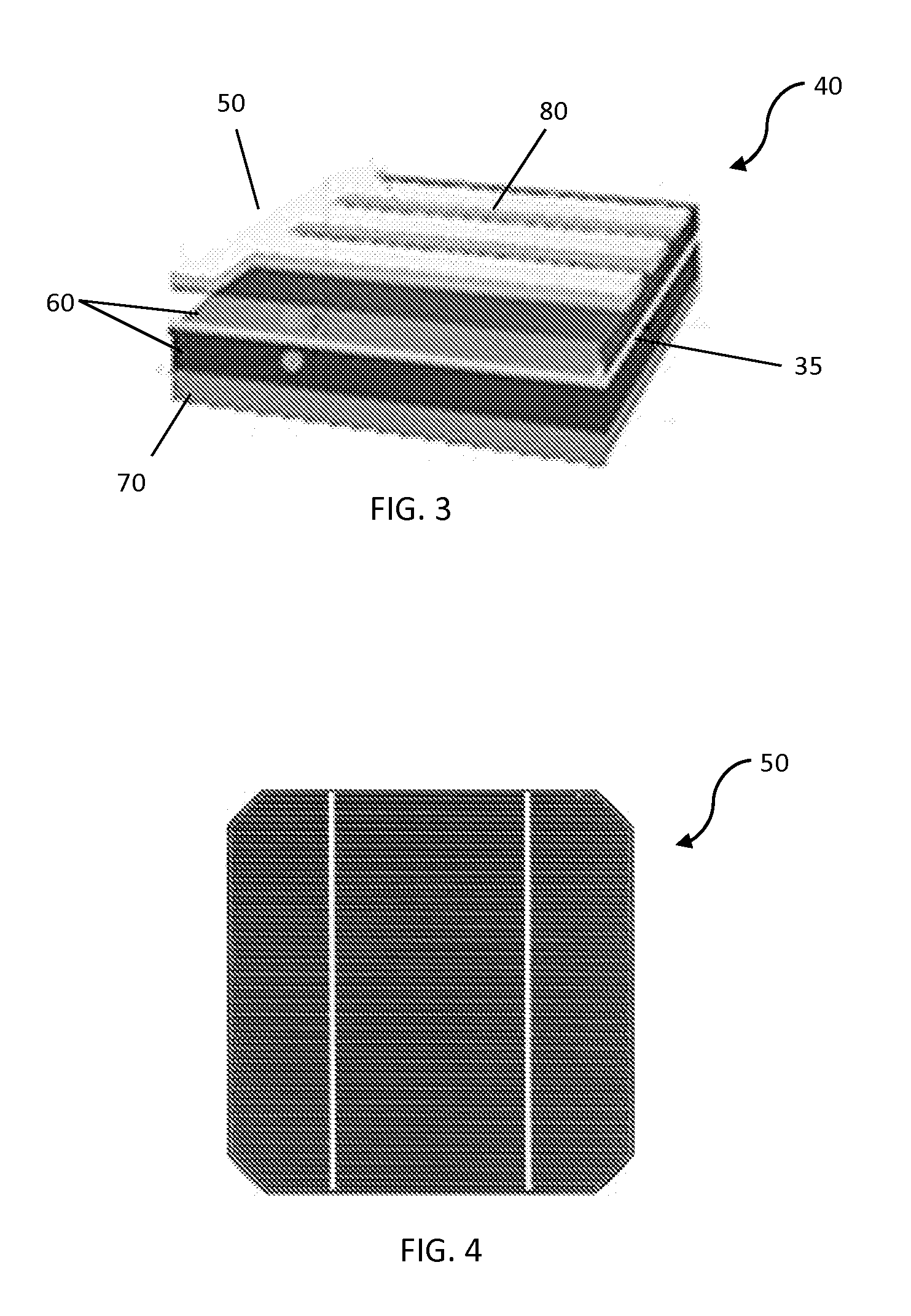

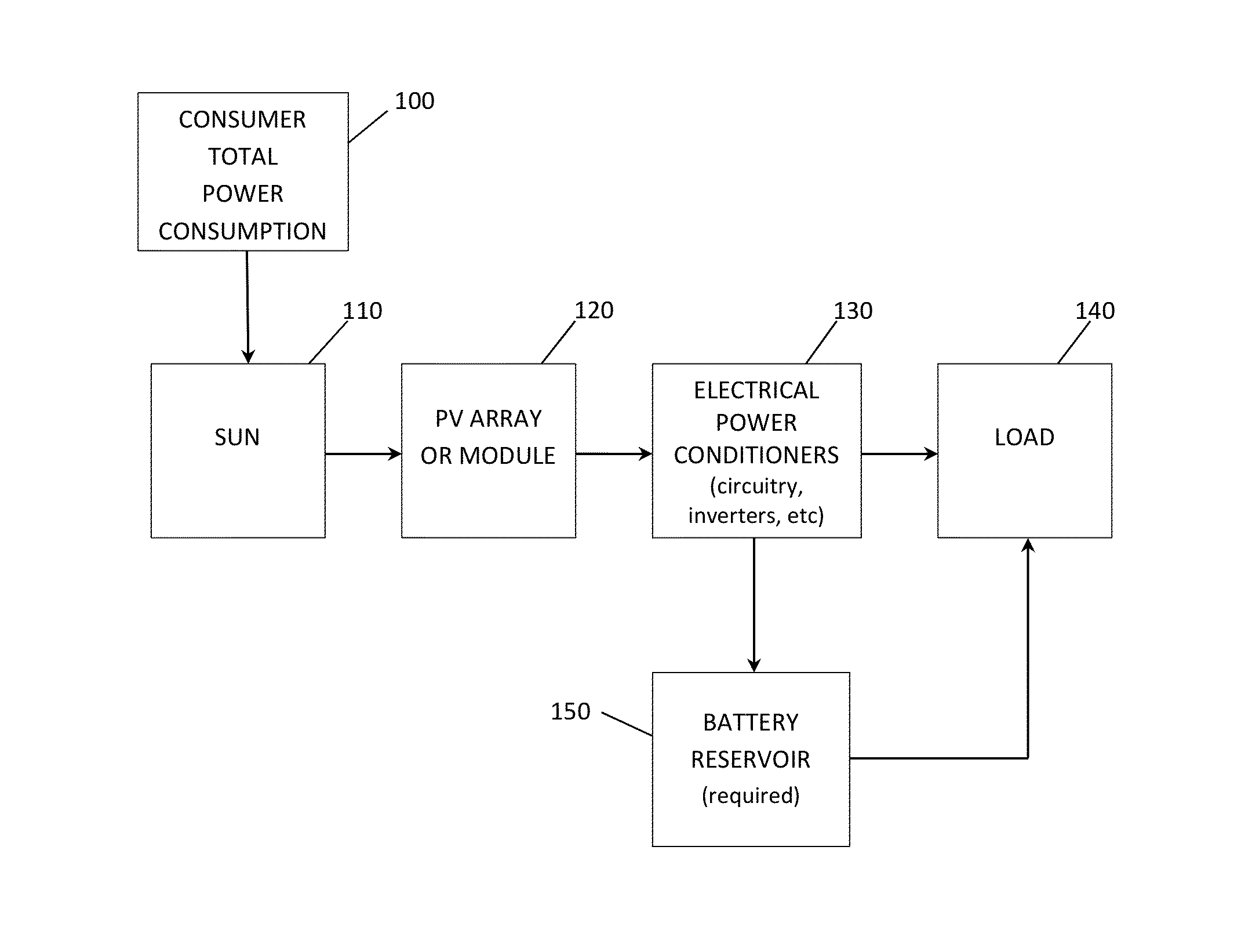

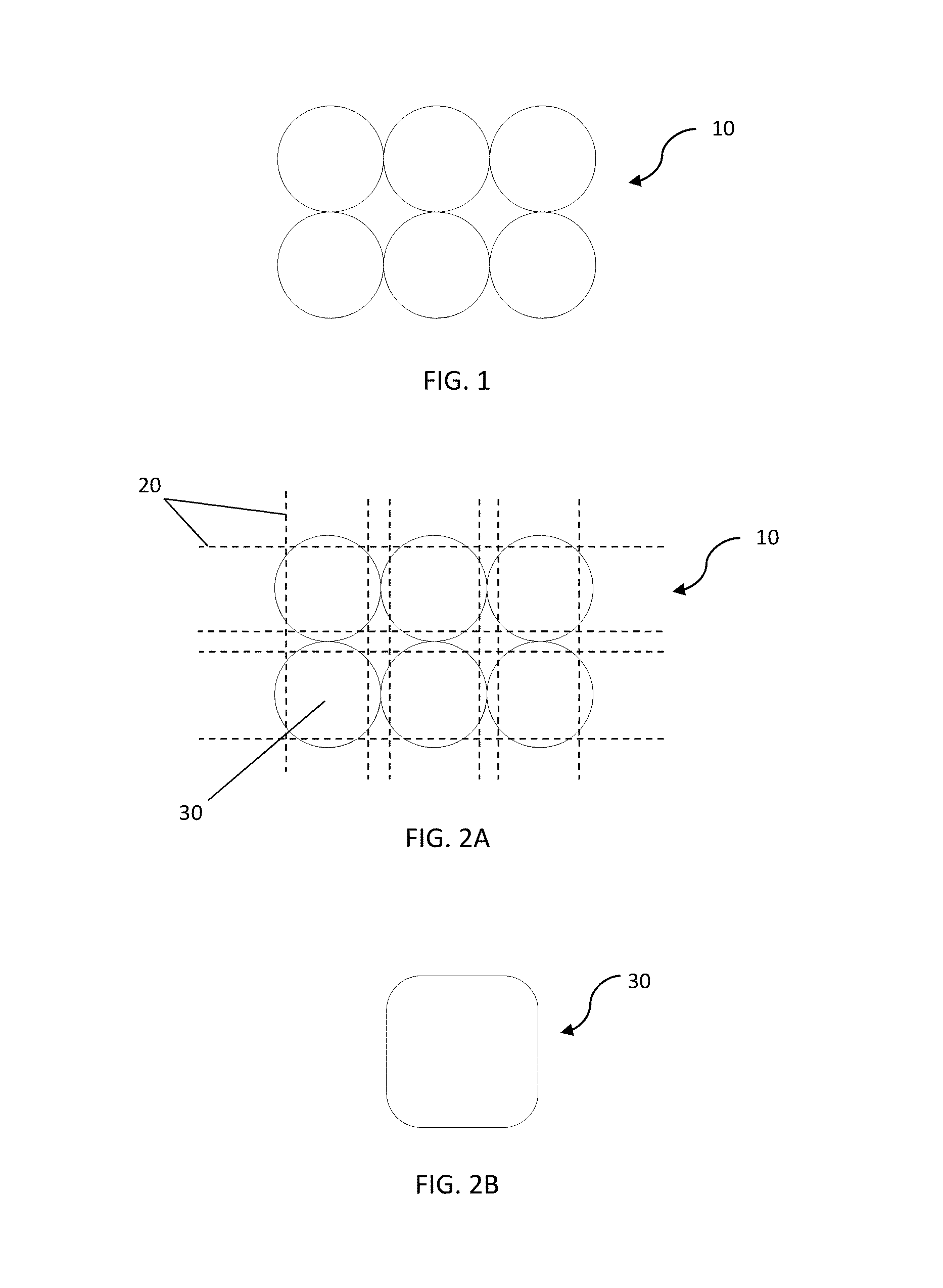

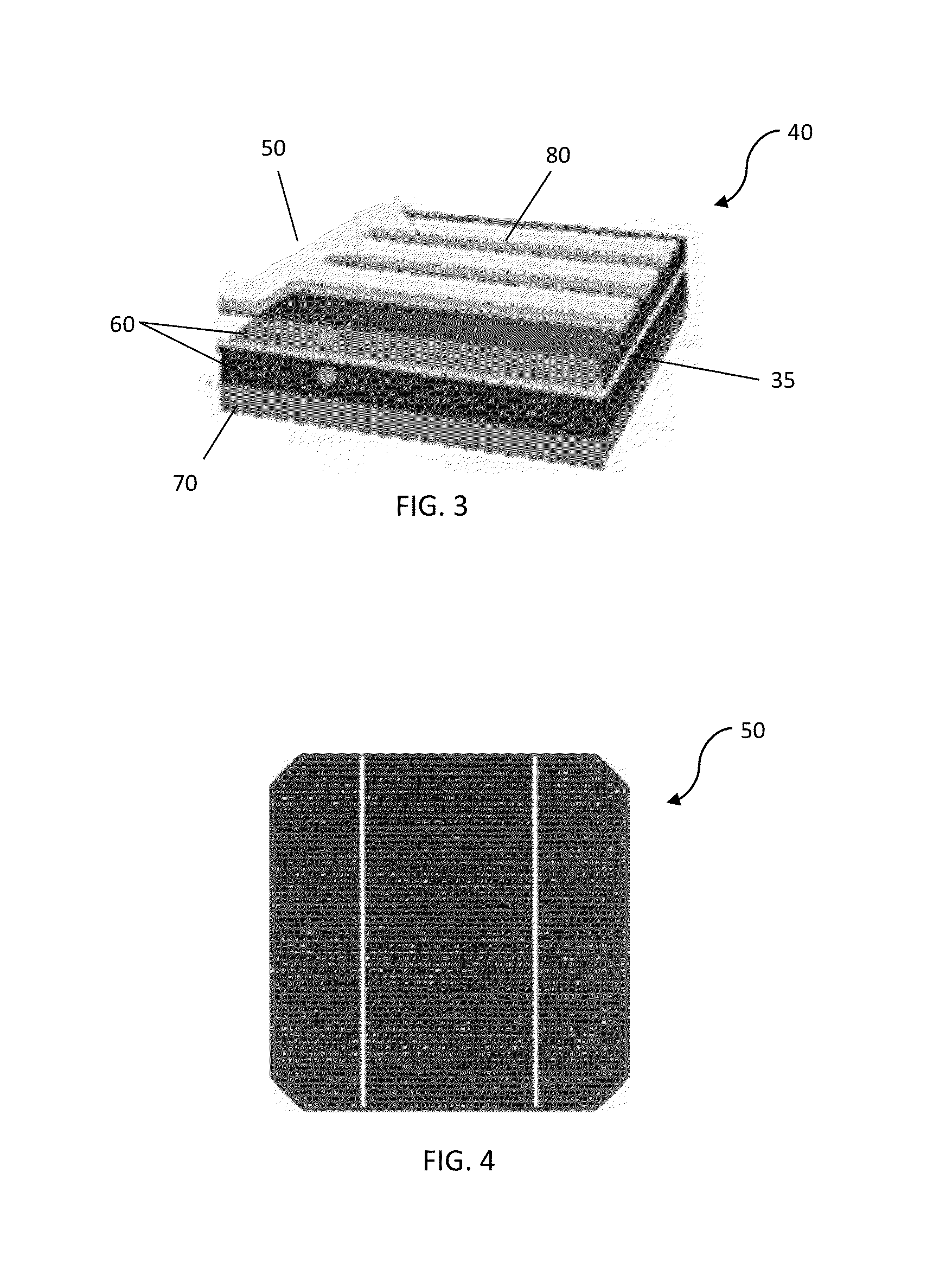

Power-Conditioned Solar Charger for Directly Coupling to Portable Electronic Devices

ActiveUS20130305528A1Easily replaceableShort work lifePhotovoltaic supportsLine/current collector detailsSolar chargerElectronic circuit

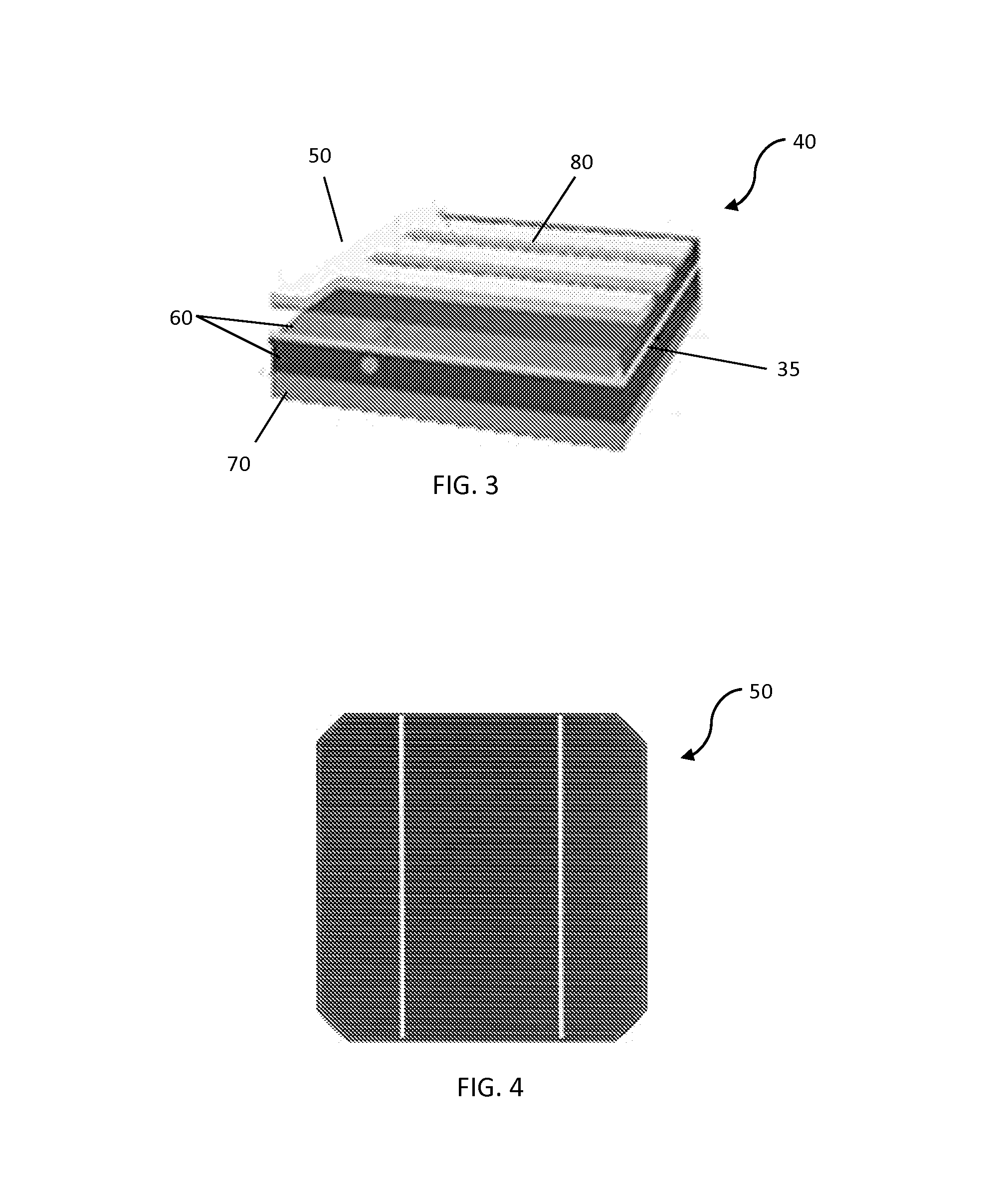

The present invention relates to methods, tools and systems for manufacturing a durable and portable power-conditioned personal solar system charging apparatus. Various voltage and amperage matching algorithms are manipulated to particularize the personal solar system to power and / or charge an intended portable device or a set of intended portable devices having direct current (DC) load requirements. The optimized personal solar system that is matched to an intended device allows direct coupling to the intended device without the use of an internal battery or ancillary electronic circuit boards to distract the personal solar system output, and facilitates “fast” charging modes.

Owner:ADVANCE ENERGY SOLUTIONS

Self-actuating and regulating heat exchange system

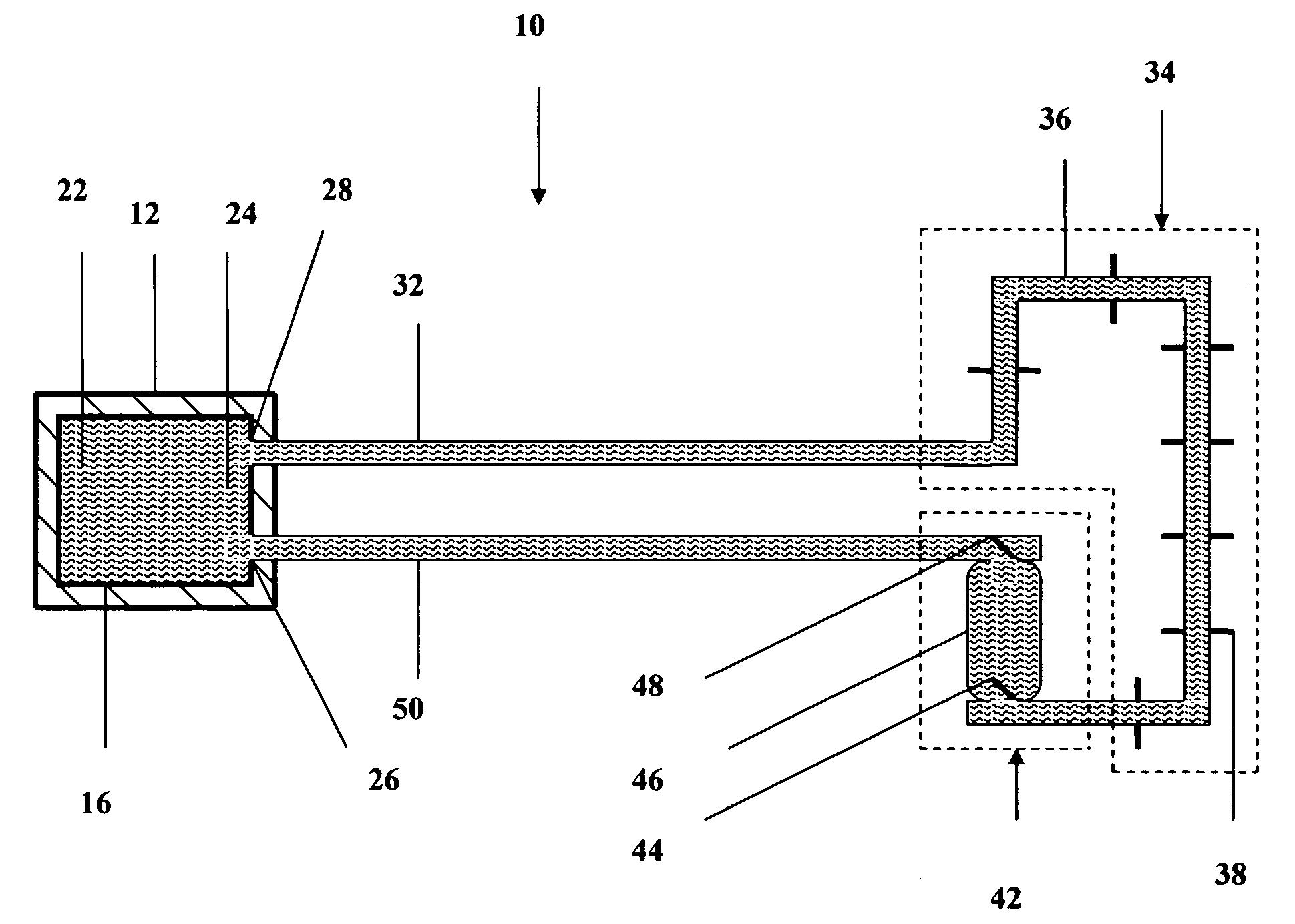

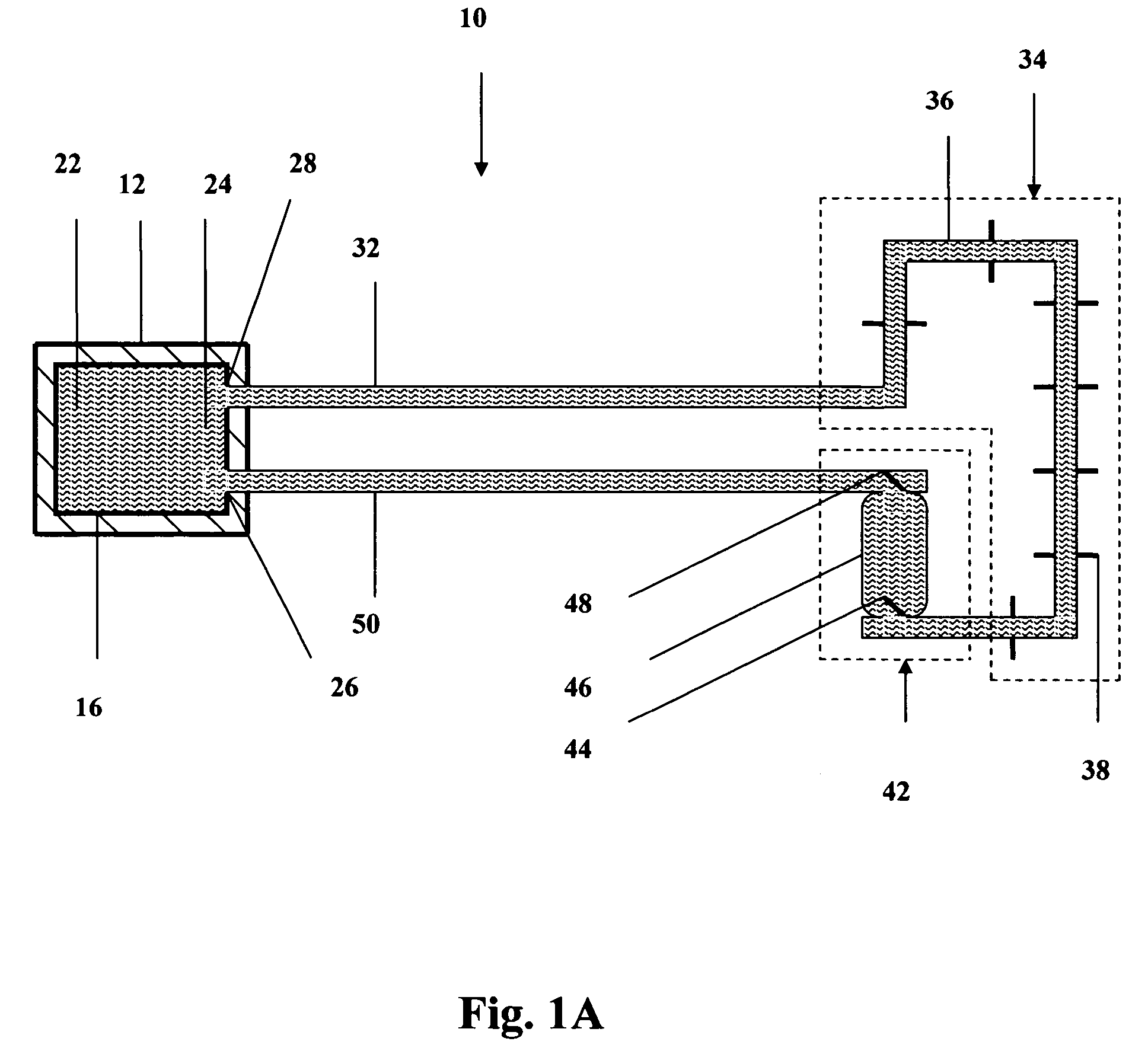

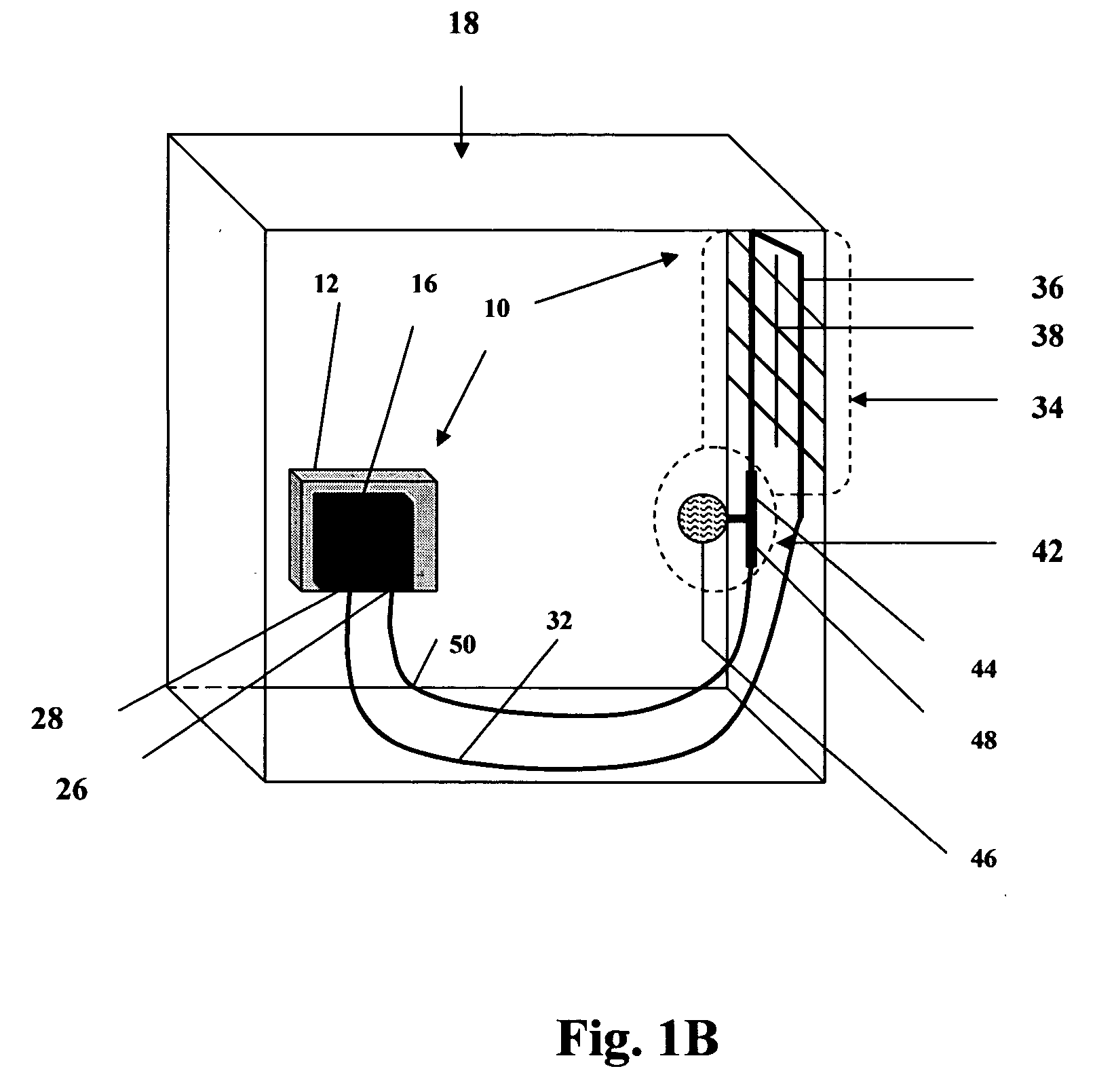

InactiveUS20060065386A1Efficient and convenient for transportGreat flexibilityDigital data processing detailsSemiconductor/solid-state device detailsHot zoneEvaporator

A self-actuating and self regulation heat exchange system comprising: evaporator 16, condenser 34, bladder sub-system 42, phase-change fluid 24 and connecting tubes, is a device and an apparatus useful to transport thermal energy from a relatively hot zone to a relatively cold zone, over distance, and around or through obstructions. The bladder sub system, consisting of an expandable bladder and two one-way check-valves, utilizes the pressure difference in the system created during evaporation and condensation to make the phase-change fluid circulate inside the closed loop system, transferring thermal energy from evaporator to condenser. The operation of the device is self started, self regulated and the device is almost independent of gravity, and the orientation.

Owner:ALAM MOHAMMED

Lighted headwear with brim sleeve

InactiveUS7753547B2Provide protectionConvenient and efficient transportationLighting support devicesGarmentsEffect lightEngineering

Owner:WATERS IND INC

Stand-Alone Solar Power Charger Directly Coupling to Portable Electronic Devices

InactiveUS20140261636A1Quickly and easily and inexpensively extend useful lifeLimited lifespanPhotovoltaic supportsBatteries circuit arrangementsElectrical batteryDirect coupling

A stand-alone solar power charger that may configured for direct coupling to a plurality of portable electronic devices. The solar power charger is particularized to power and / or charge an intended portable device or a set of intended portable devices having direct current (DC) load requirements. The solar power charger discharges energy without the use of an internal battery or ancillary electronic circuit boards, and facilitates “fast” charging modes. More specifically, the solar power charger incorporates a variety of features that make the design rugged, compact, waterproof, and durable.

Owner:SUNSTREAM TECH INC

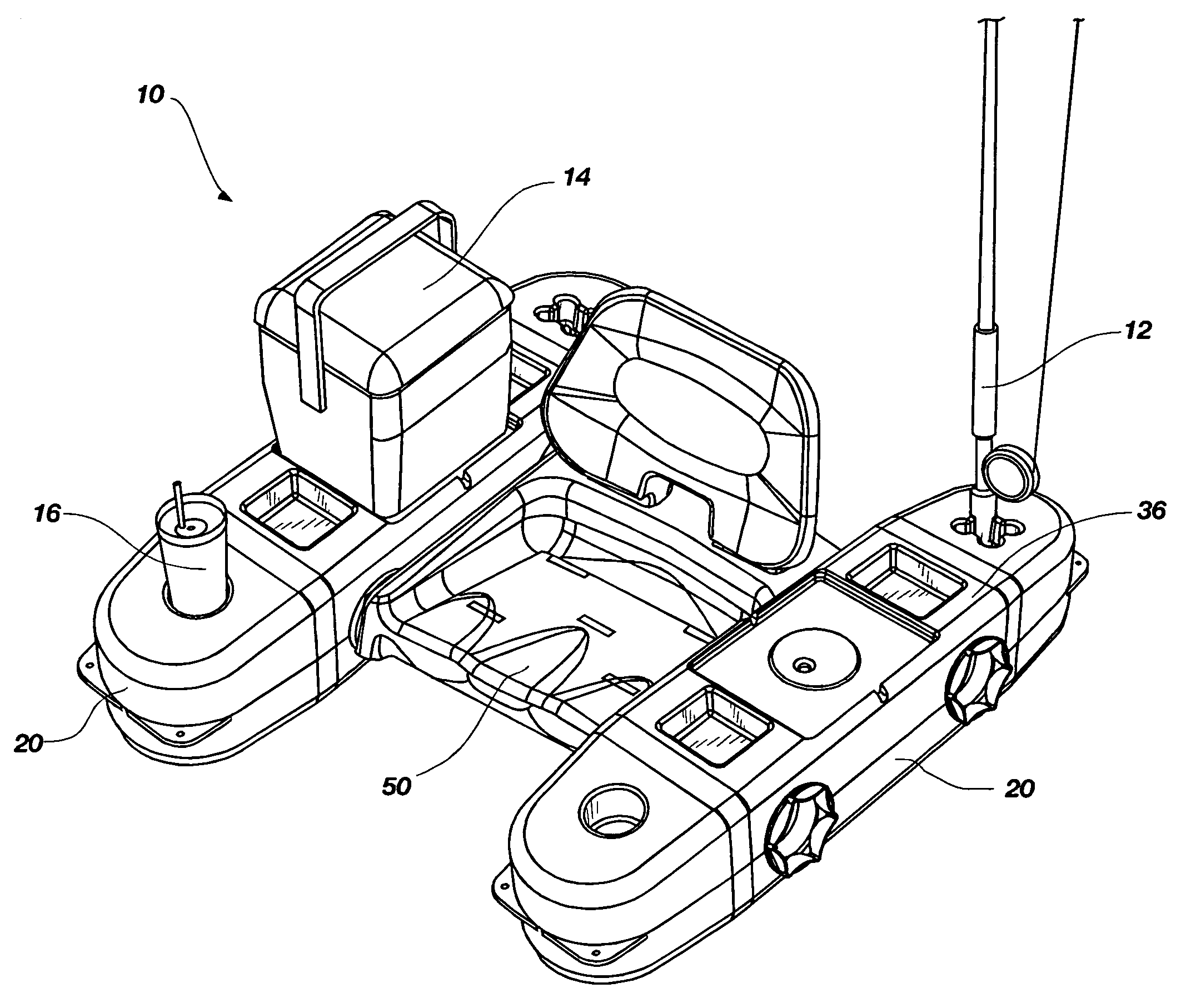

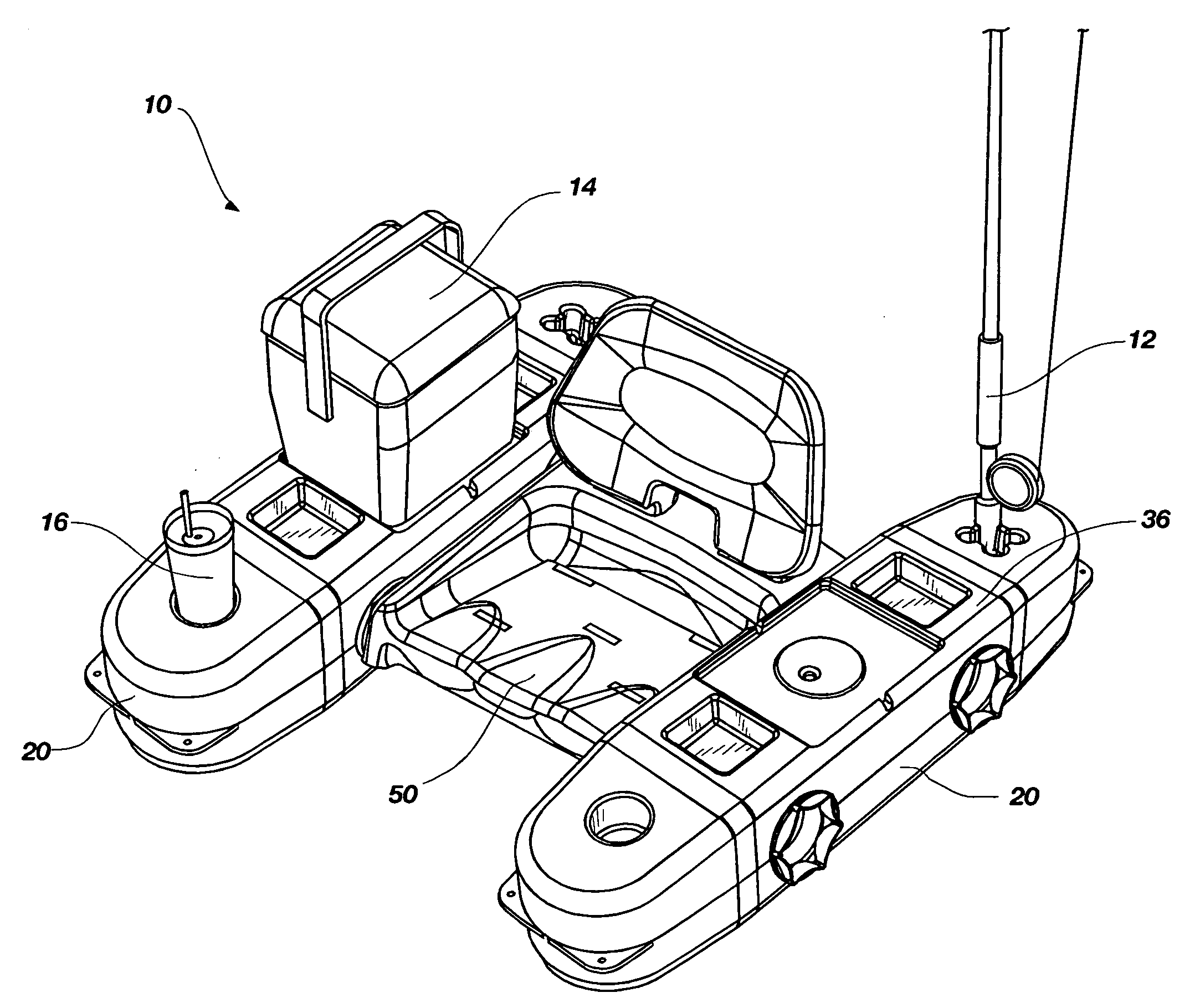

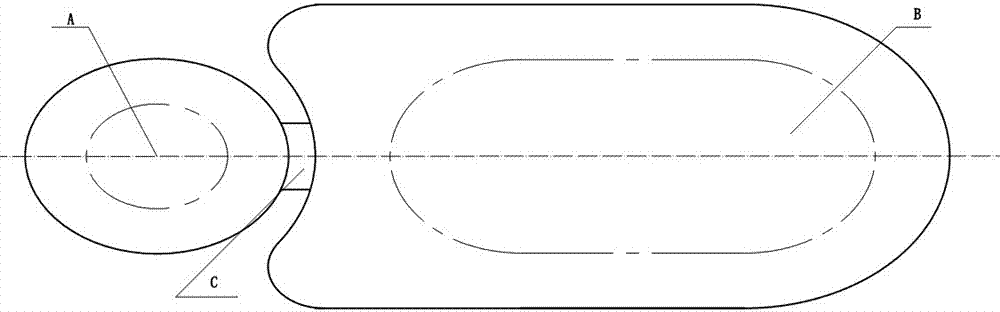

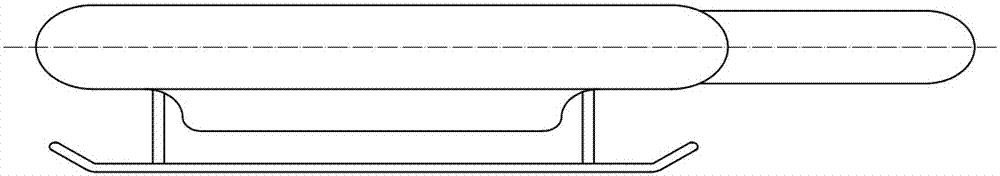

Modular personal pontoon boat

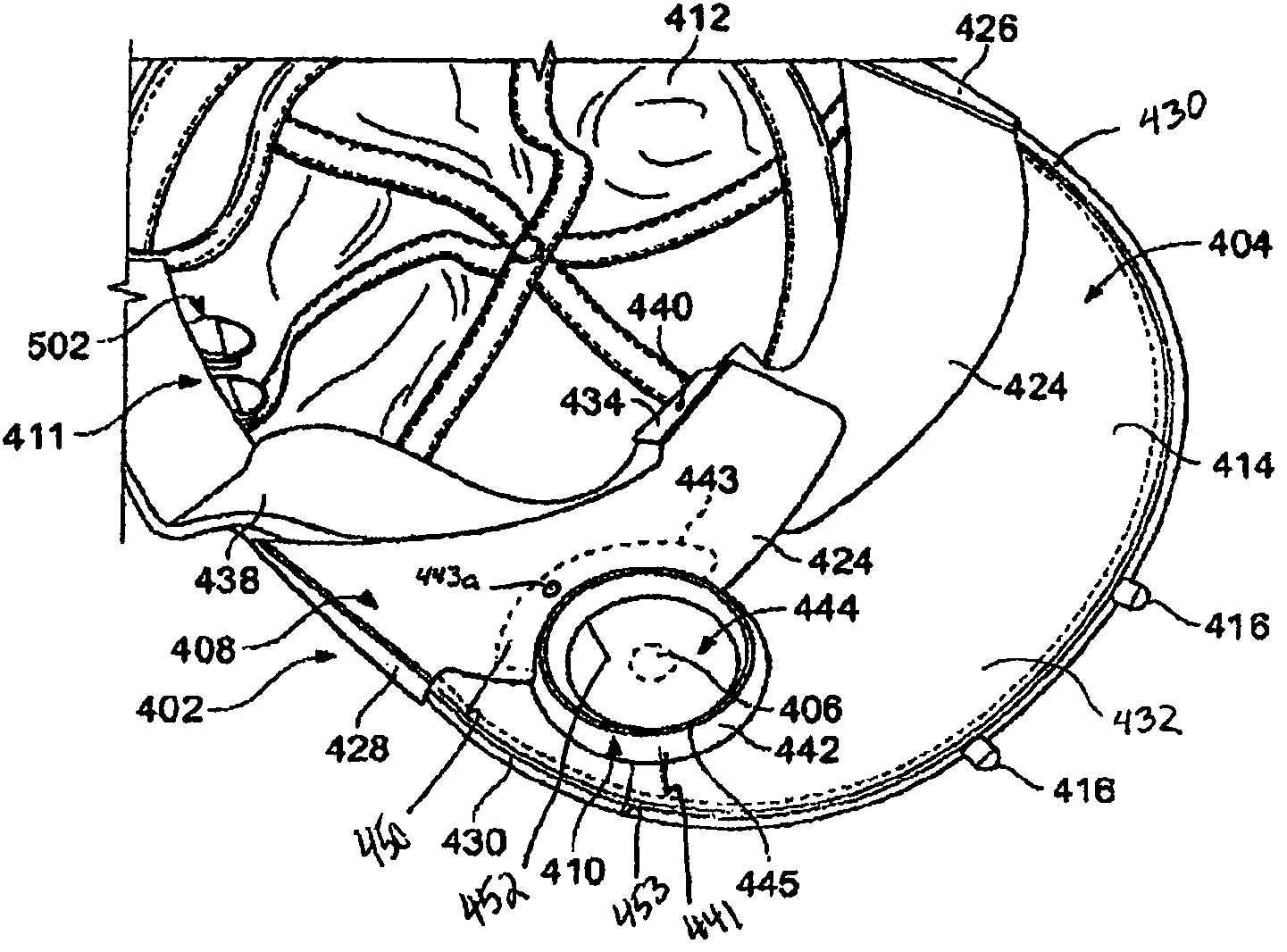

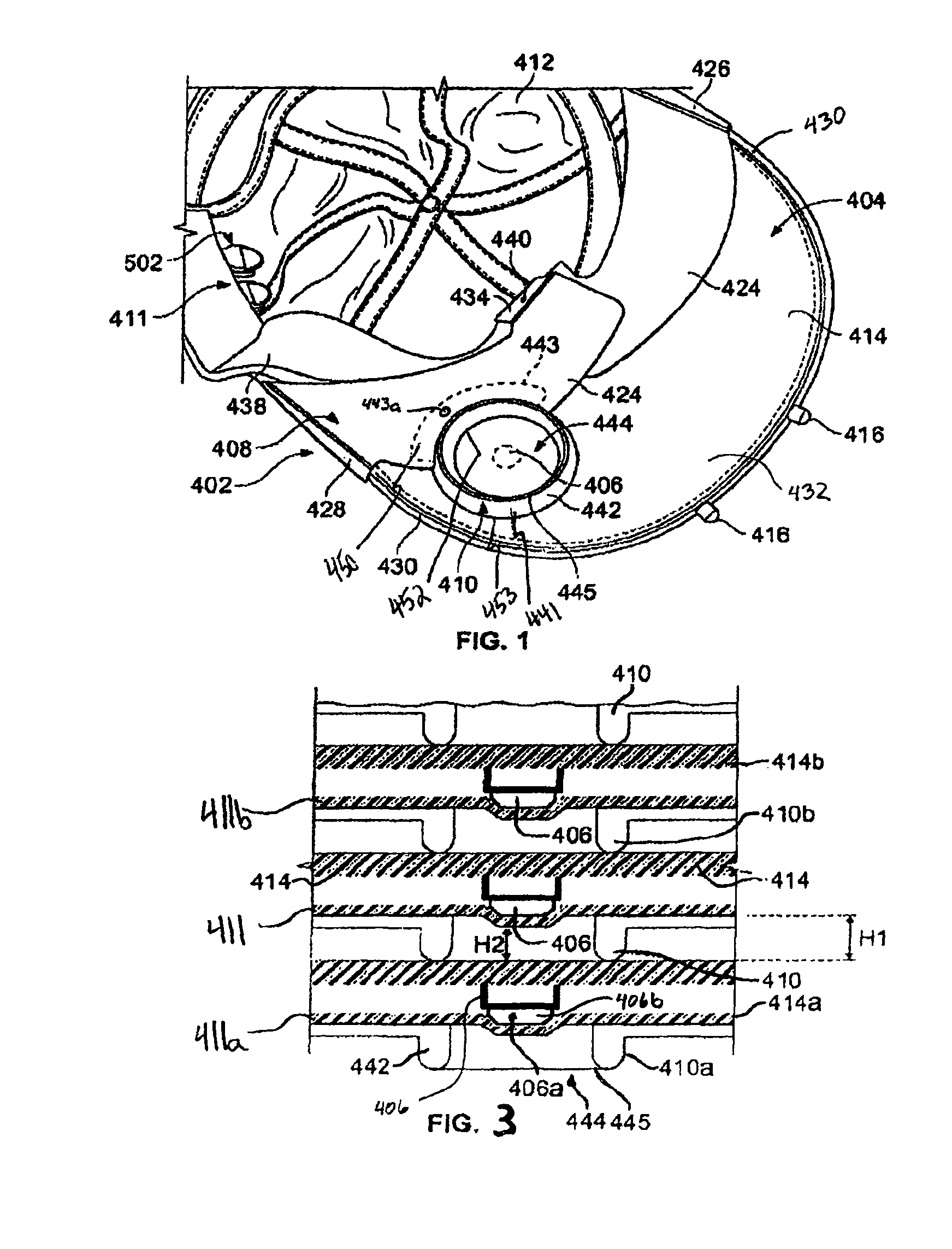

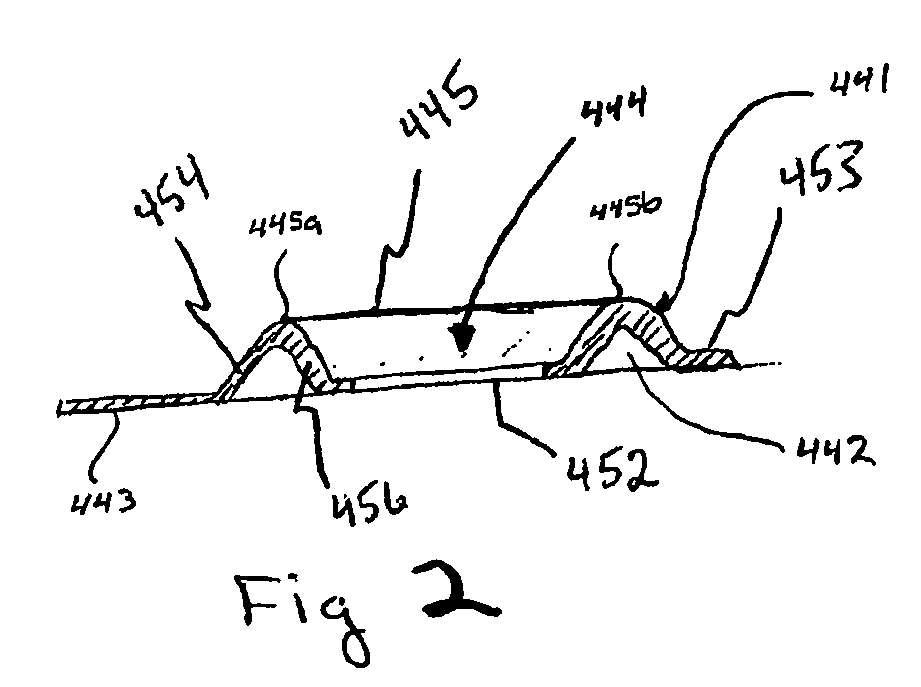

ActiveUS7587986B2Resistant to punctureImprove interchangeabilityLife-buoysRecreational vesselsLinear low-density polyethyleneMetal framework

A modular personal flotation system comprising, at least in part, rigid, seamless, non-woven modules, such as a seat module and various pontoon modules, formed by the process of rotational molding or blow molding, from a Linear Low Density Polyethylene (LLDPE), High Density Polyethylene (HDPE), or similar molding resin. The pontoon modules each have a rigid shape, which makes it both unnecessary to inflate and vastly improves the resistance to loss of flotation, creating safer conditions for the user. The pontoon modules are also tolerant of significant relative pressure changes without substantial deformation or change in its shape. Vent hole(s) formed during the molding process are closed to water ingestion via a low-cost bleeder valve assembly. An integral luggage rack can also be molded as part of the center seat module, positioned behind the seat. Open drain holes molded through the seat module double as slots to receive a backpacking harness. The seat module is removably coupled to the pontoon modules by complementary integrally-formed connection interfaces, or by a system of nylon straps with hook and loop fastening sections, eliminating the need for multiple components and fasteners, thus saving weight, complexity, and cost. In an alternative embodiment, a metal frame module may be interposed between oversized pontoon modules and the seat module to configure a flotation system capable of supporting more weight.

Owner:TILLICUM INT INC

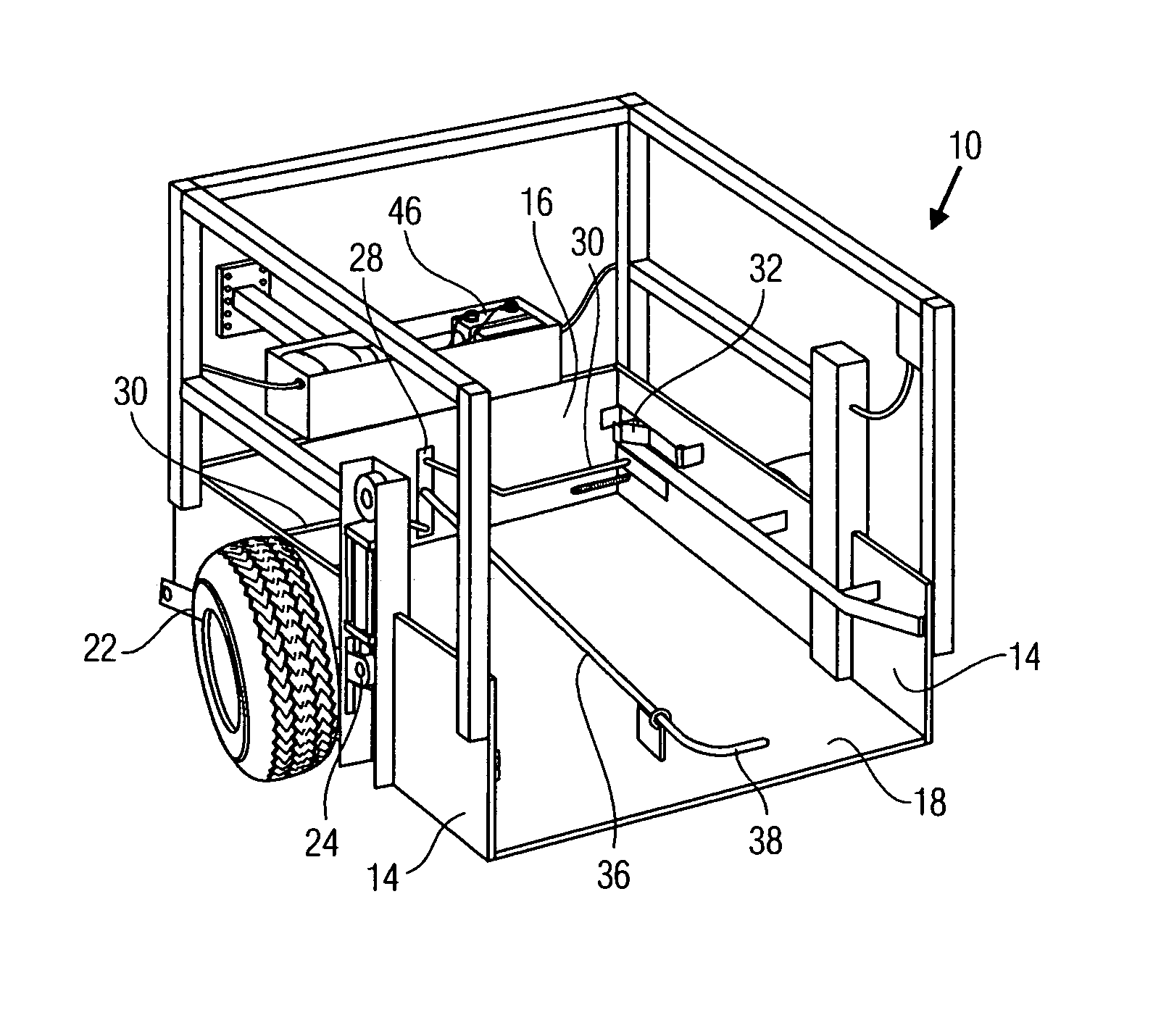

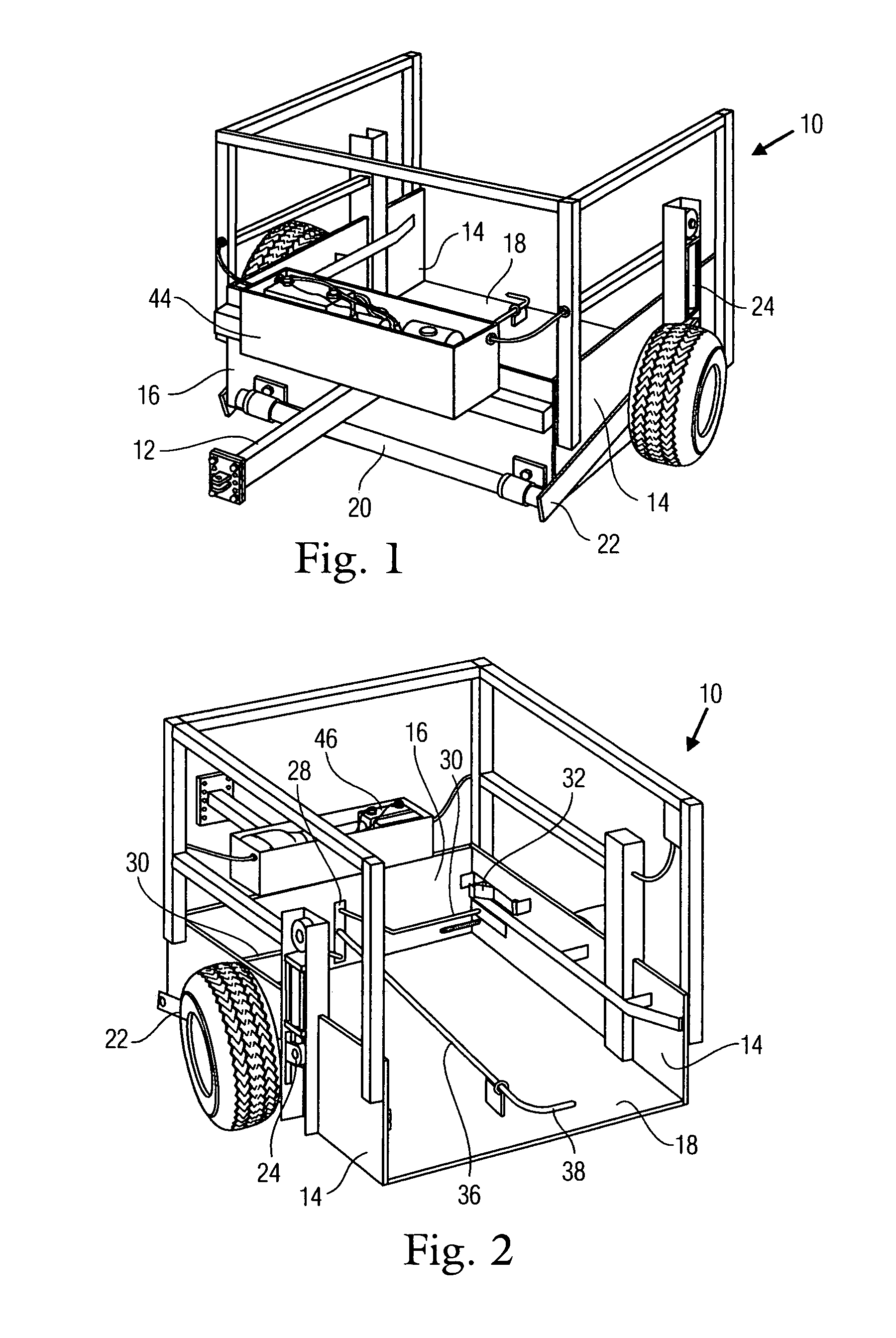

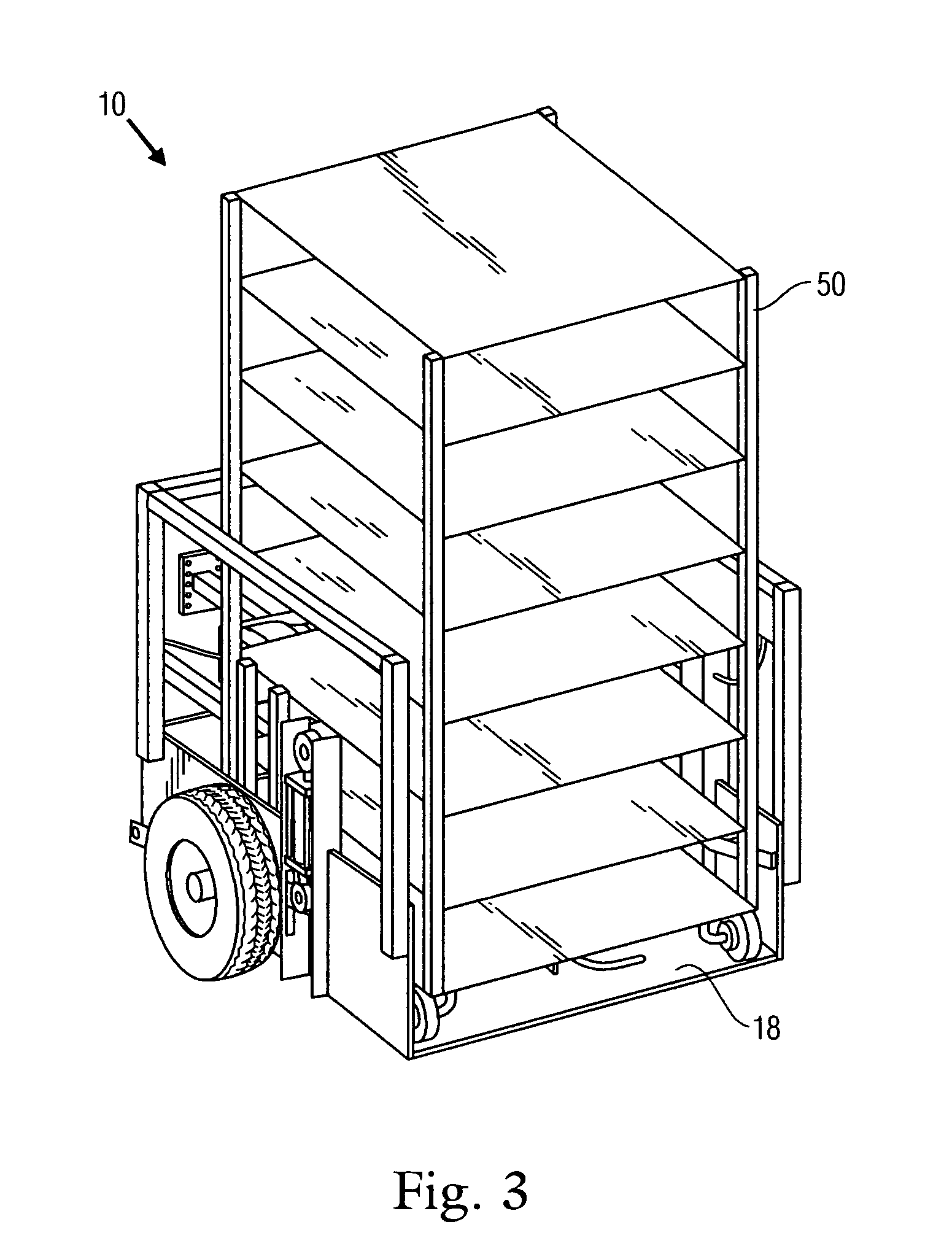

Apparatus and method for efficiently loading and unloading racks of potted plants in a wholesale nursery where the plants are growing

ActiveUS7559736B1Economical, labor-savingEfficiently and conveniently loadingVehicle with pivoted armsVehicle with removable loadingEngineeringPlant growth

A wheeled cart having a bed, two side walls, a front wall and an open end which is connected to a towing vehicle. The bed of the cart is raised or lowered to be inclined toward the open end to load the cart. The bed is level when the cart is loaded. A latch secures the rack within the cart and the latch is manually releasable.

Owner:MOHAN THOMAS STREETT

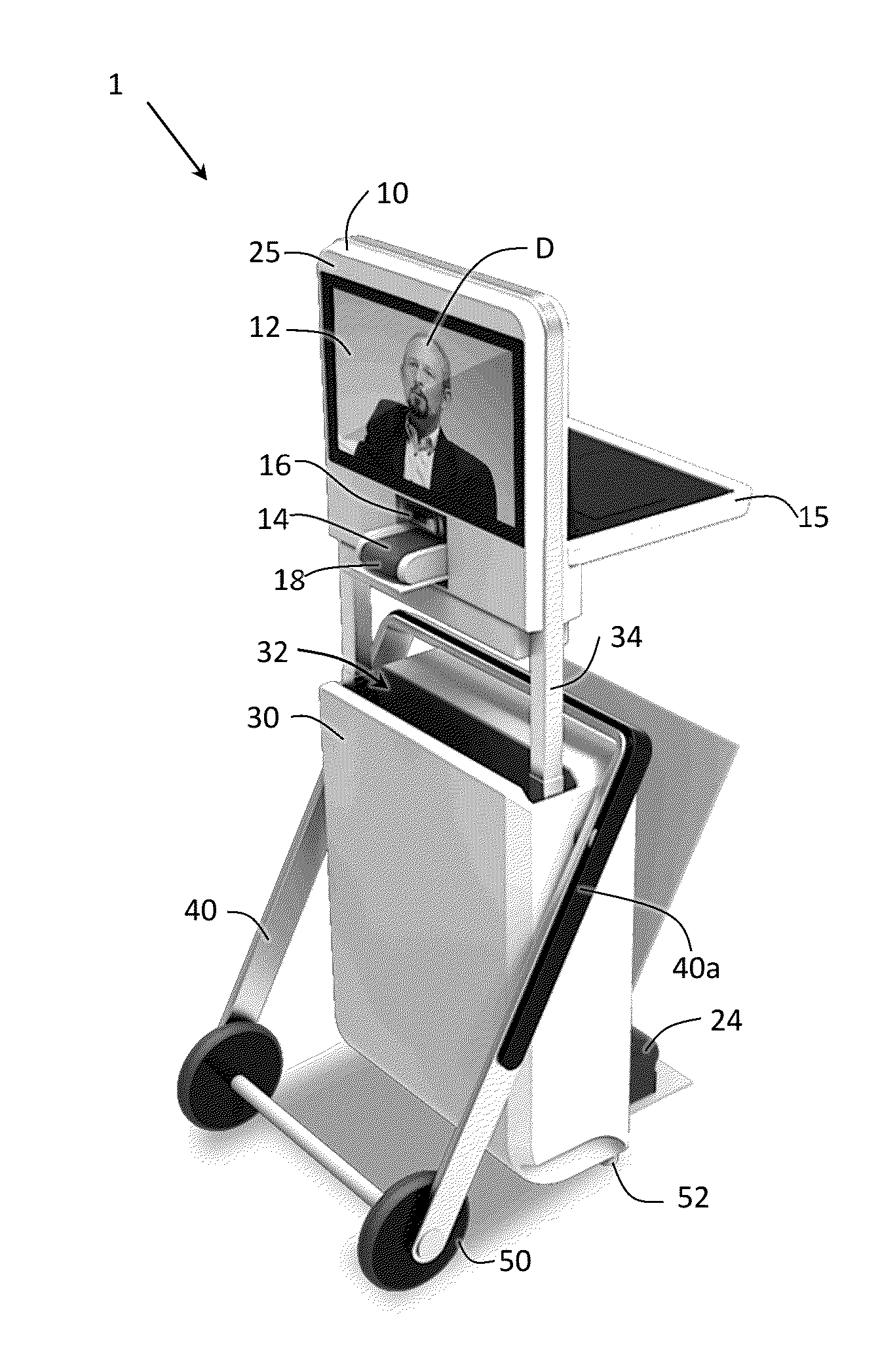

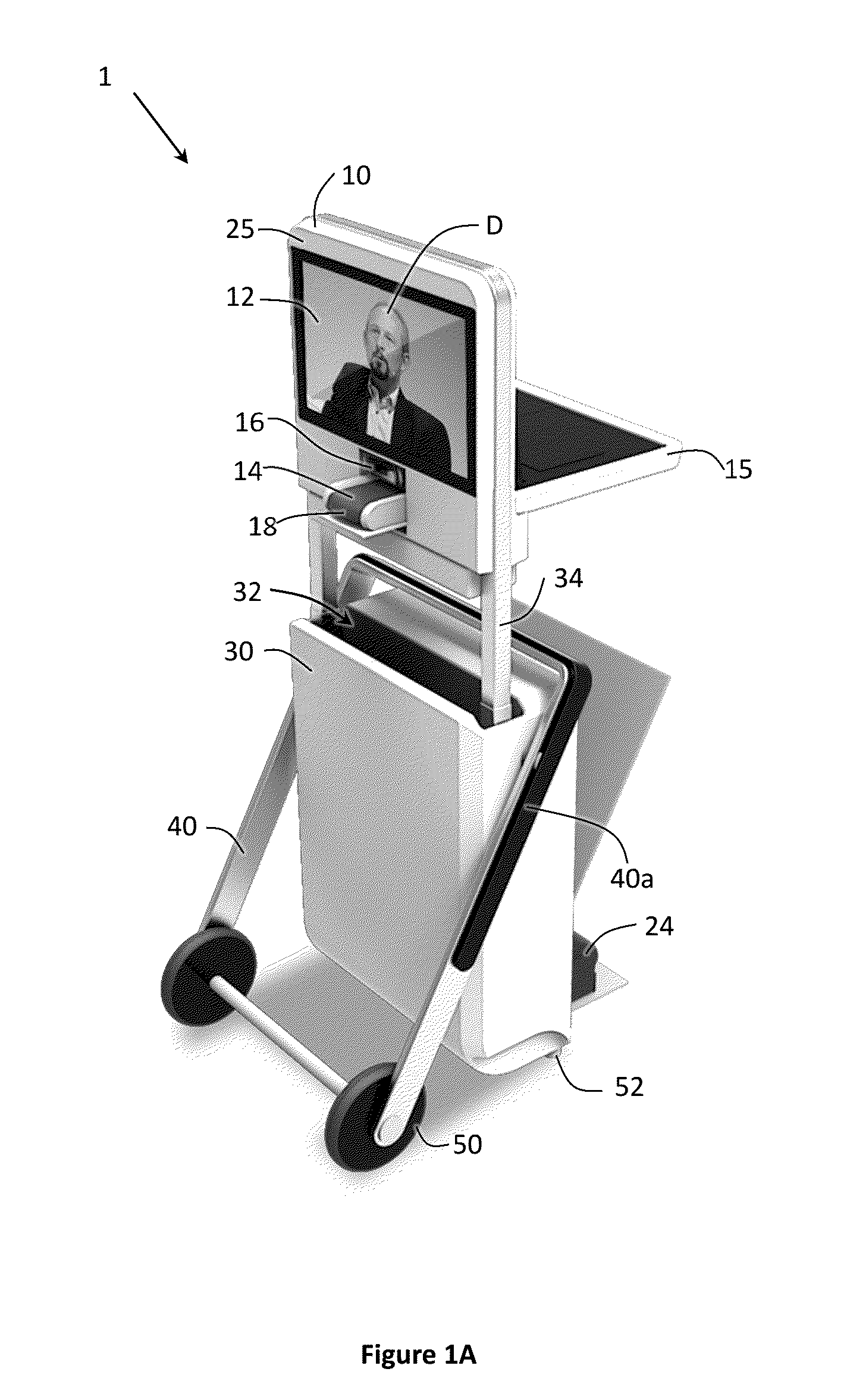

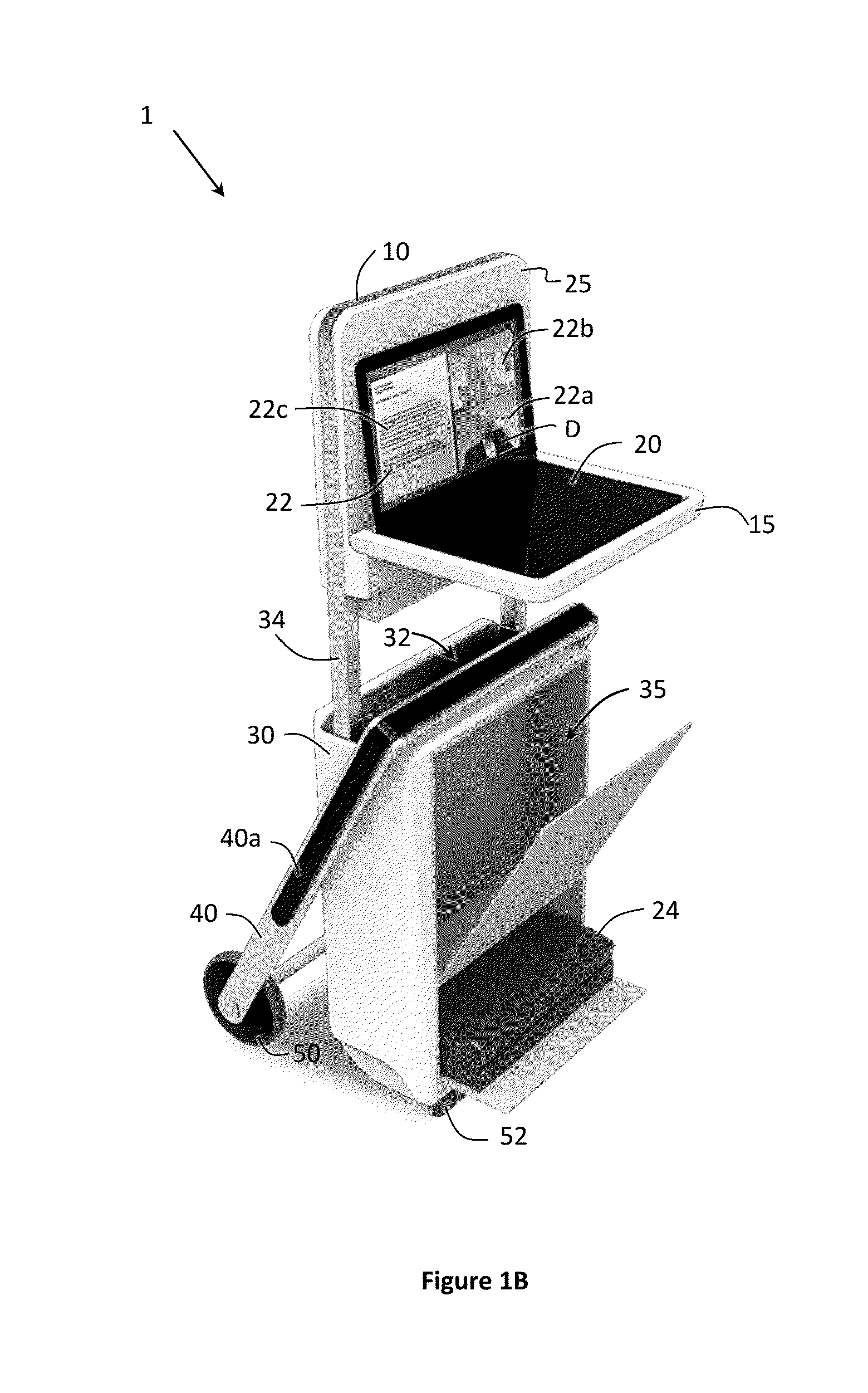

Medical cart system

InactiveUS20150305086A1Satisfactory experienceConvenient and efficient transportationCarriage/perambulator accessoriesWireless network protocolsDisplay deviceEngineering

A medical cart includes an interface assembly including a display, a speaker, a camera and a microphone. The interface assembly is operatively connected to an enclosure at a connecting portion that is operable to reposition the interface assembly from a transporting configuration in which the interface assembly is disposed inside the enclosure to a deployed configuration in which the interface assembly is disposed outside of the enclosure. The medical cart also includes a set of wheels operably connected to at least one of the enclosure or a pivoting assembly operable to pivot from the transporting configuration in which only the set of wheels makes contact with a transporting surface to the deployed configuration in which a portion of the cart in addition to the set of wheels makes contact with the transporting surface for stabilizing the cart in the deployed configuration.

Owner:HUNTINGDON TELEMED

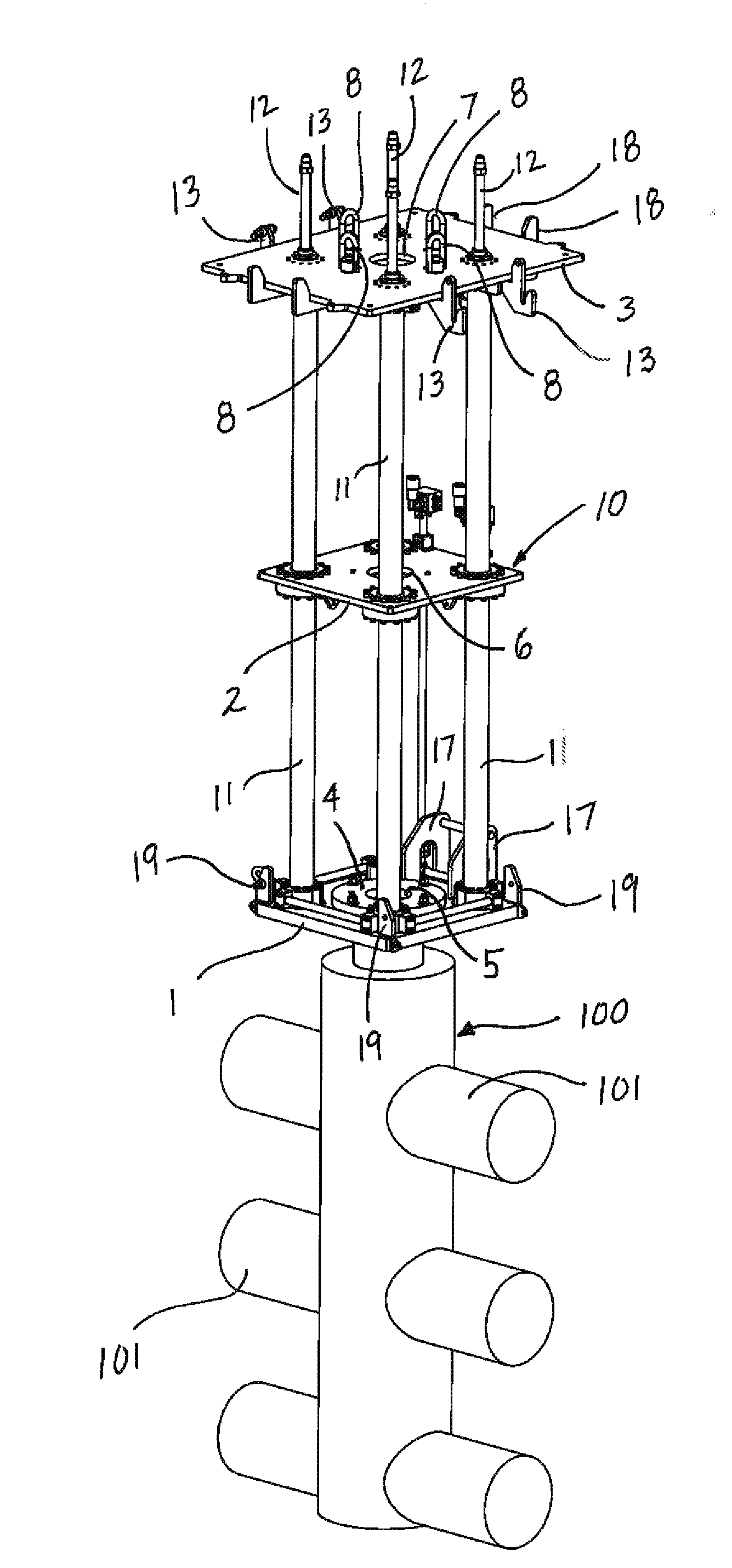

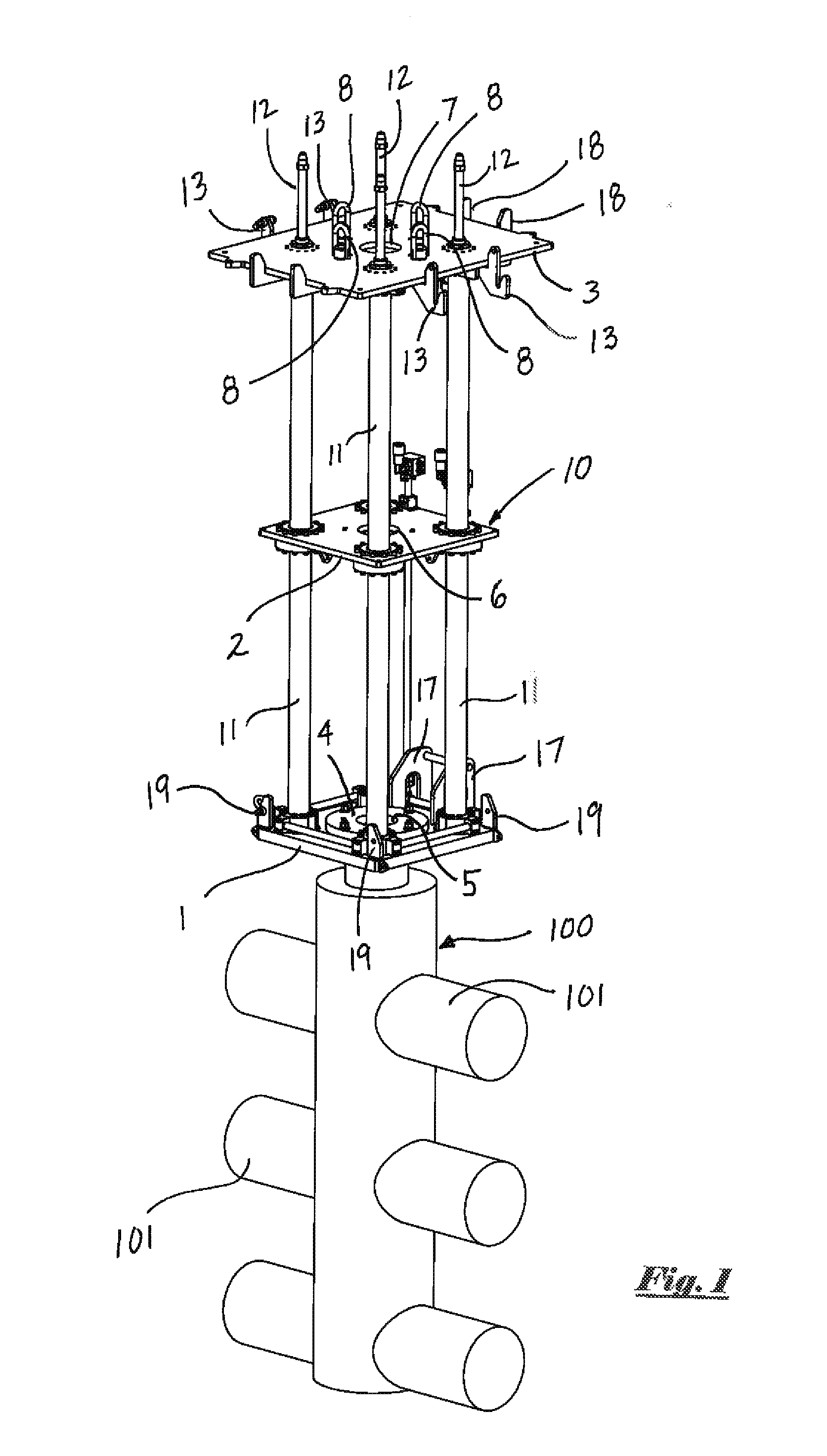

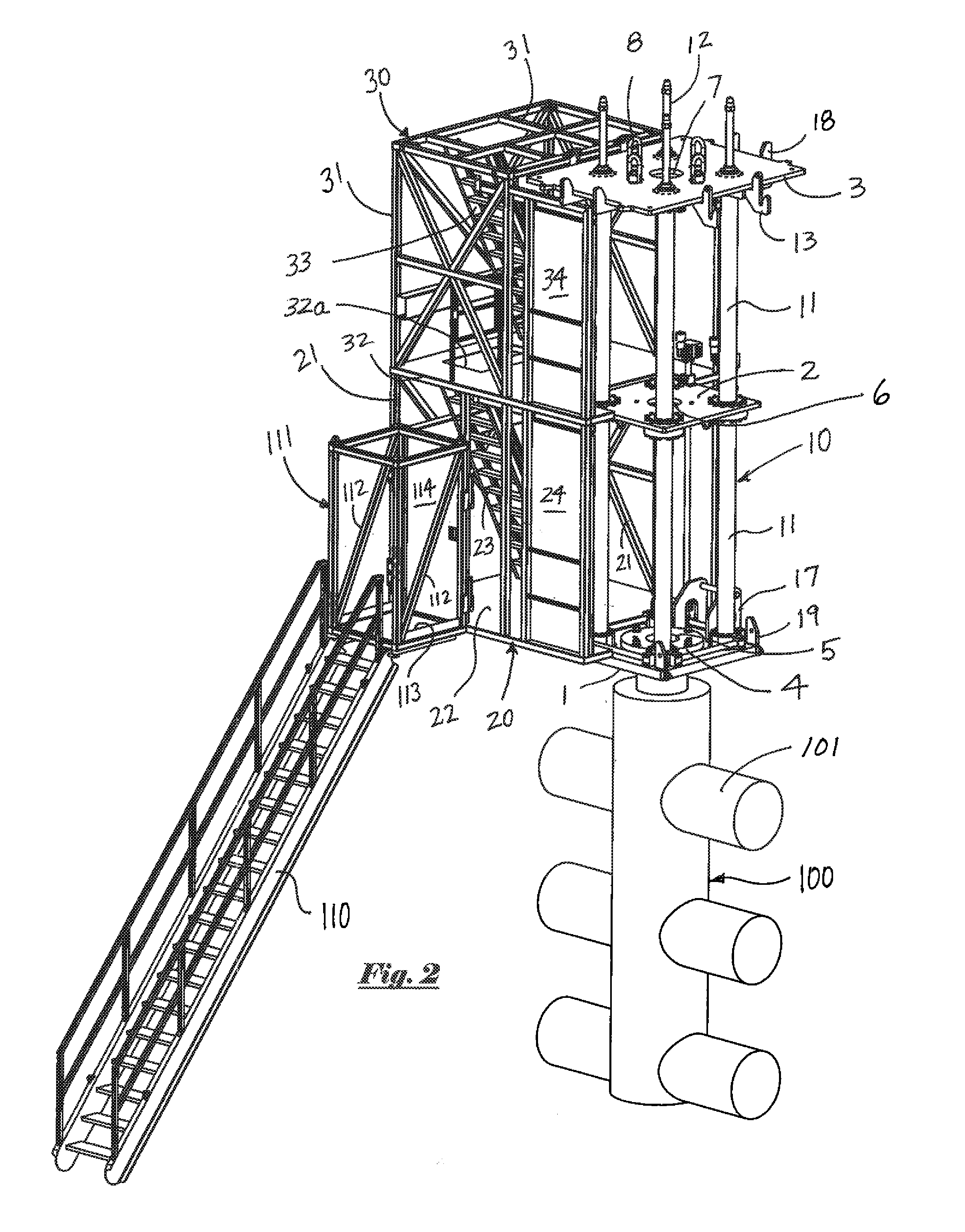

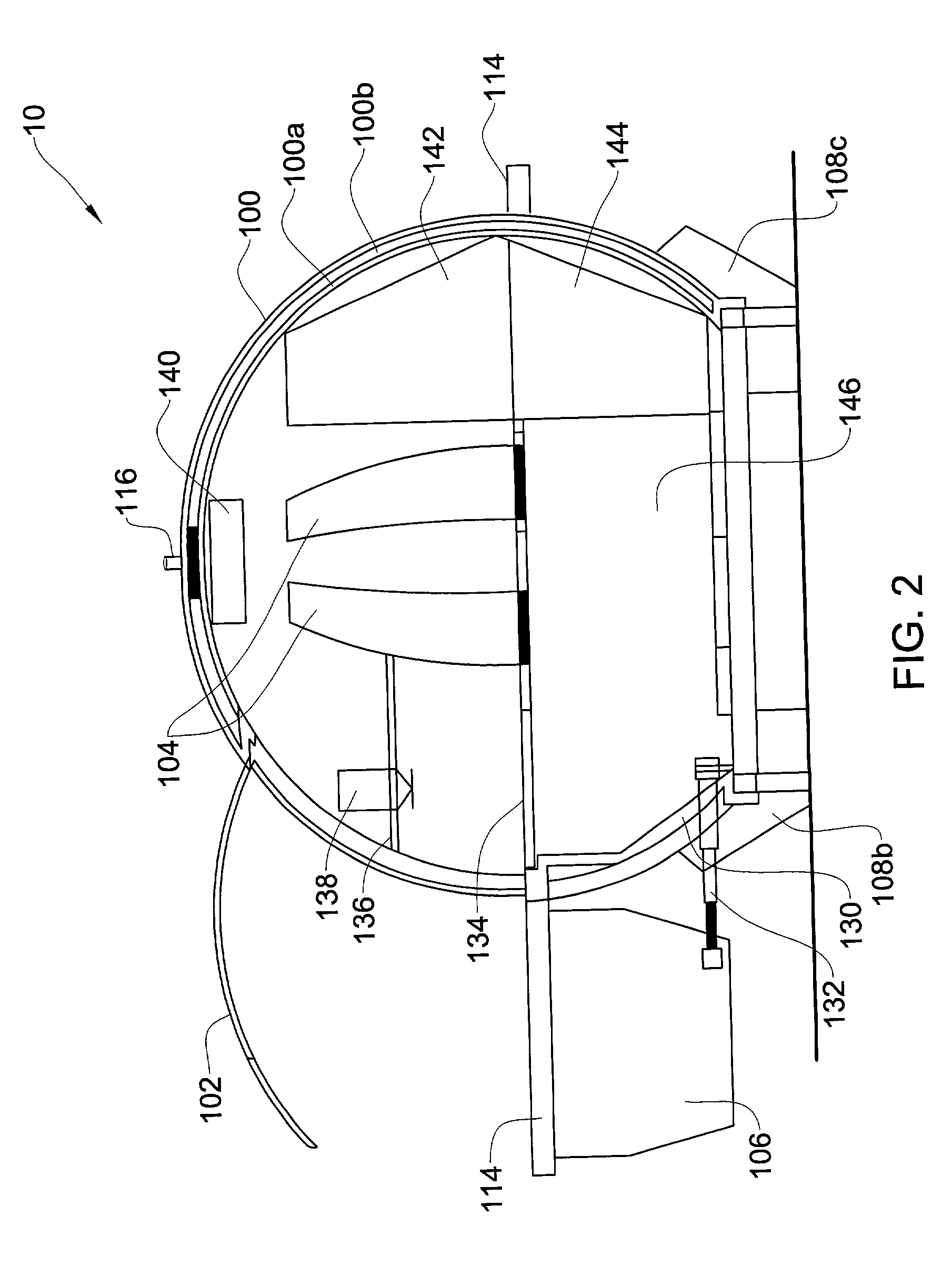

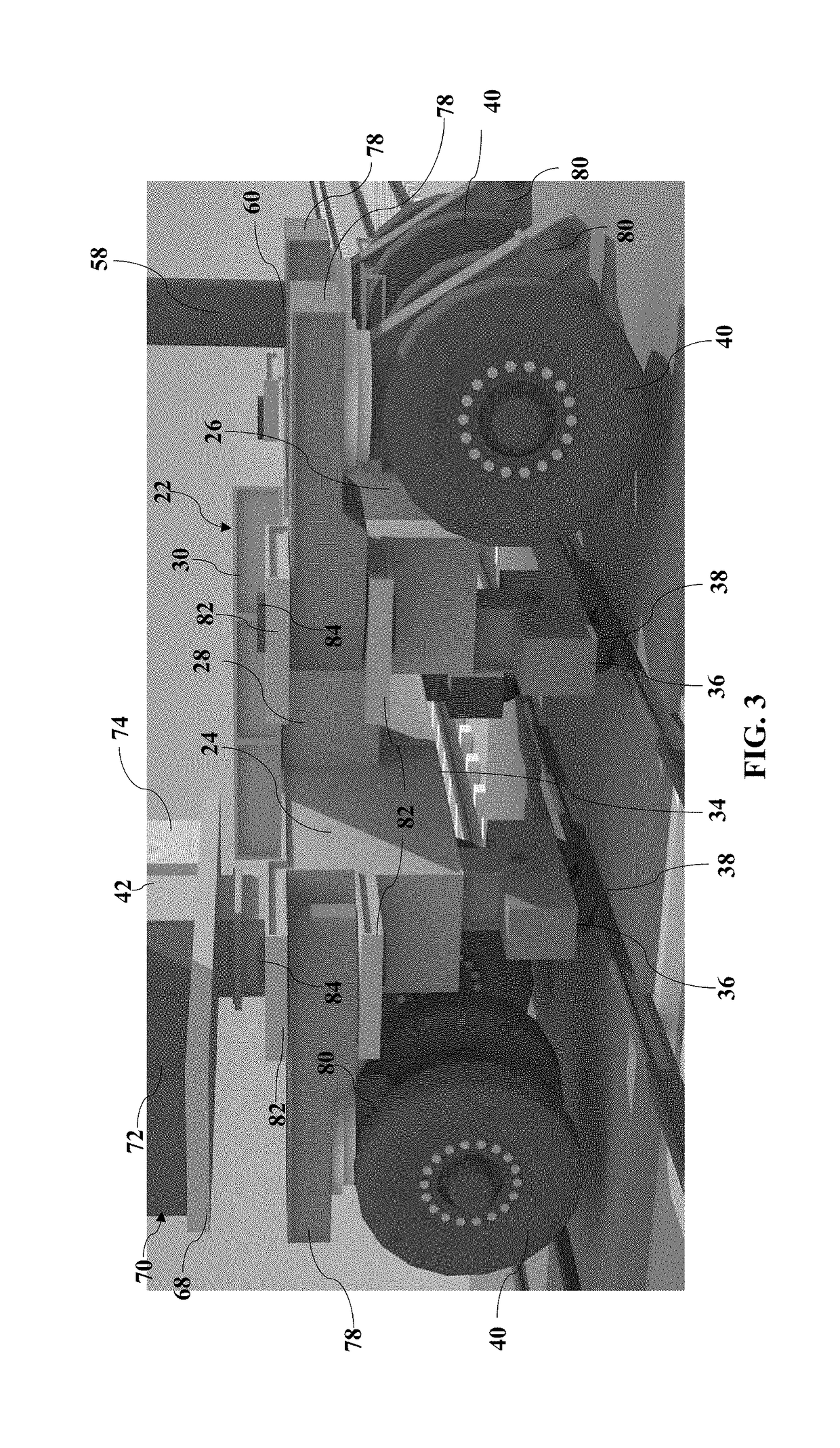

Modular well intervention assembly

A modular well intervention assembly includes a jack assembly having increased stroke length that can be installed directly over a well or above a BOP assembly. Modular work platforms and a telescoping mast assembly can be installed and secured in place around the jack assembly. Tongs can be suspended from a hydraulically operated “track system”, eliminating the need for a conventional tong pole and spring. Pipe can be manipulated relative to the well intervention assembly using a hydraulically powered pipe handling device.

Owner:ALTERNATIVE WELL INTERVENTION

Modular personal pontoon boat

ActiveUS20070249246A1Resistant to punctureRigid designLife-buoysRecreational vesselsLinear low-density polyethyleneMetal framework

A modular personal flotation system comprising, at least in part, rigid, seamless, non-woven modules, such as a seat module and various pontoon modules, formed by the process of rotational molding or blow molding, from a Linear Low Density Polyethylene (LLDPE), High Density Polyethylene (HDPE), or similar molding resin. The pontoon modules each have a rigid shape, which makes it both unnecessary to inflate and vastly improves the resistance to loss of flotation, creating safer conditions for the user. The pontoon modules are also tolerant of significant relative pressure changes without substantial deformation or change in its shape. Vent hole(s) formed during the molding process are closed to water ingestion via a low-cost bleeder valve assembly. An integral luggage rack can also be molded as part of the center seat module, positioned behind the seat. Open drain holes molded through the seat module double as slots to receive a backpacking harness. The seat module is removably coupled to the pontoon modules by complementary integrally-formed connection interfaces, or by a system of nylon straps with hook and loop fastening sections, eliminating the need for multiple components and fasteners, thus saving weight, complexity, and cost. In an alternative embodiment, a metal frame module may be interposed between oversized pontoon modules and the seat module to configure a flotation system capable of supporting more weight.

Owner:TILLICUM INT INC

Smart service unit

InactiveUS20030183456A1Facilitate efficient transportationConvenient and efficient transportationControlling coin-freed apparatusCoin-freed apparatus detailsData service unitEngineering

A non self-propelled mobile food service unit transportable to a desired location of service comprises computer controlled auxiliary systems for providing food service. The auxiliary systems including an environmental unit, a food preparation unit, a billing unit, a safety and security unit and a data communication unit.

Owner:HATZOR ERAN GOLAN

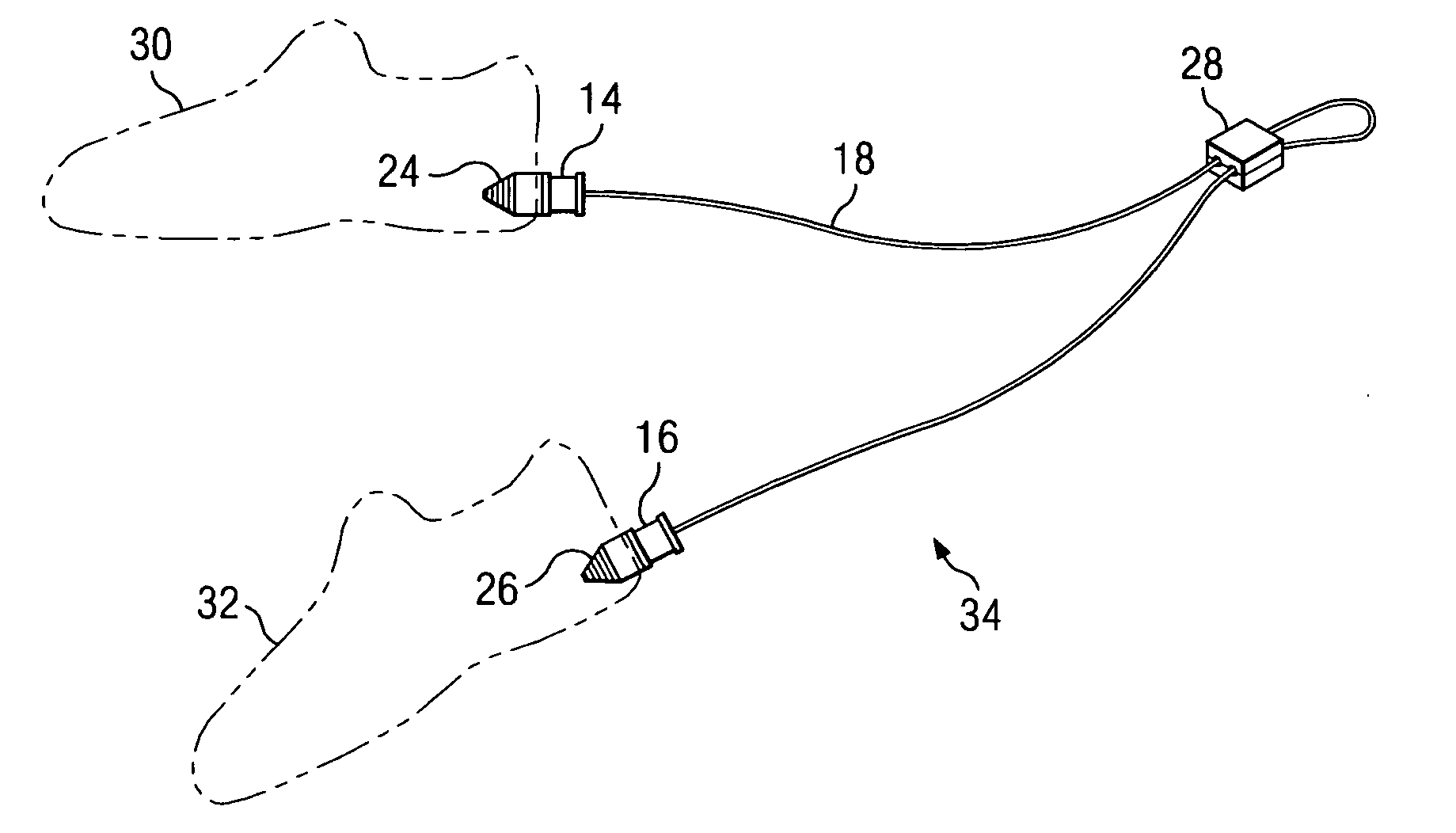

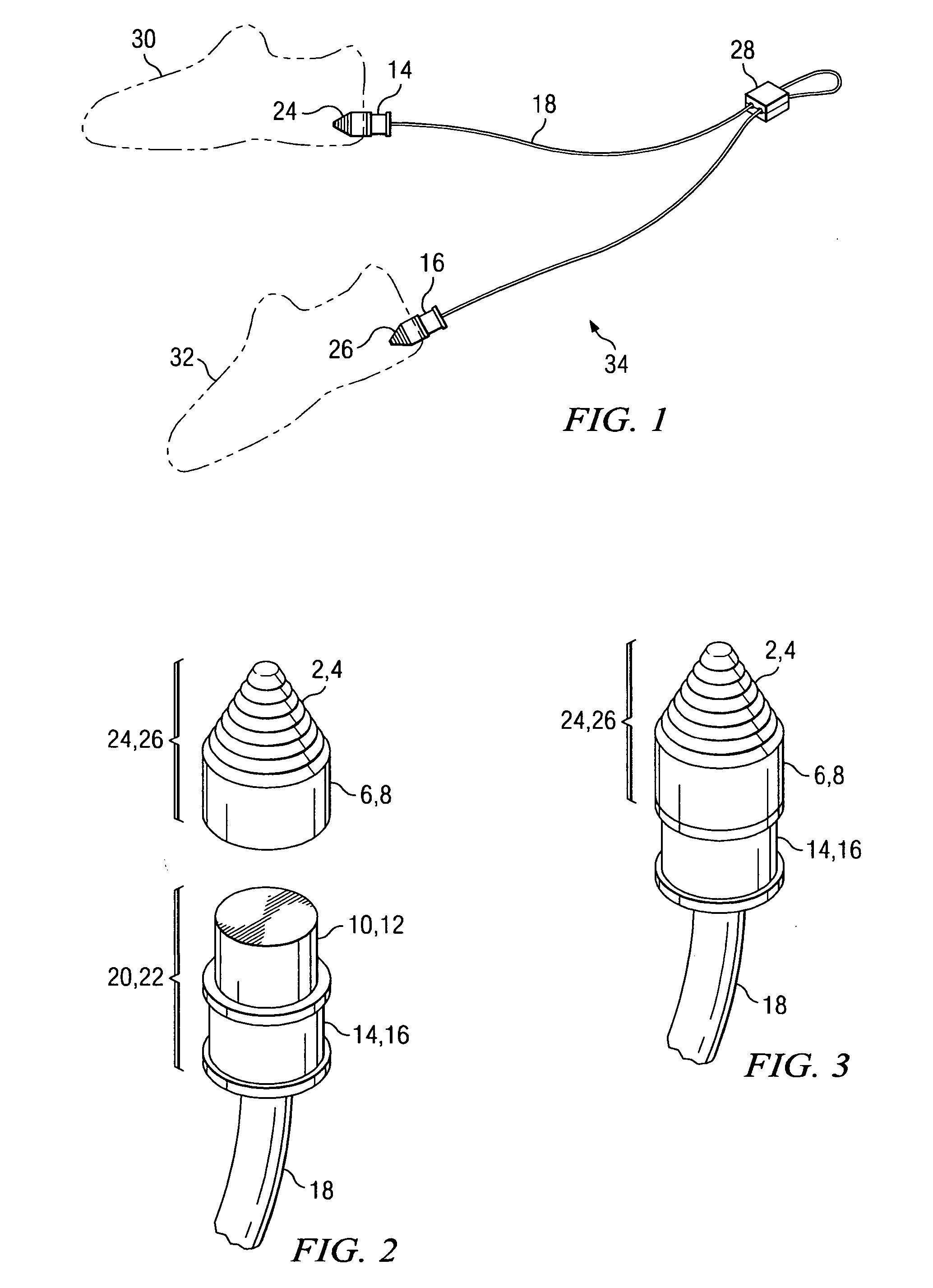

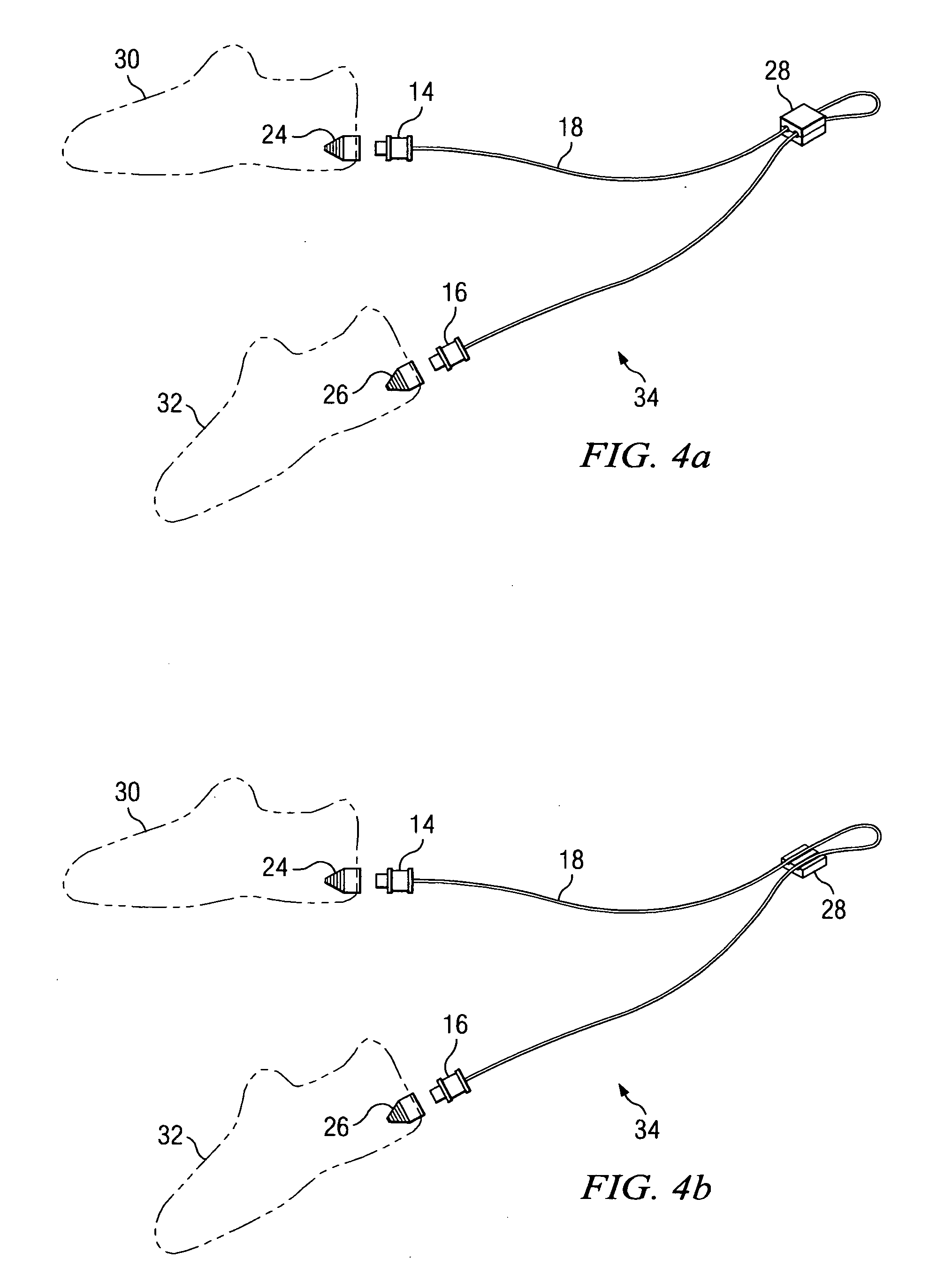

Carrier for footwear

InactiveUS20050194803A1Quickly and readily disconnectedThe process is convenient and fastTravelling sacksTravelling carriersEngineeringMechanical engineering

A convenient and efficient carrier for athletic shoes and the like is provided. The carrier has a connecting strap that is of a predetermined length. The connecting strap has two ends, with each end affixed to a quick release member. The quick release member is comprised of an engaging barrel portion and a heel barrel portion, with the heel barrel portion affixed to the end of the connecting strap. The engaging barrel portion is adaptable for connecting to a shoe that has a securing member inserted into the shoe's heel. The securing member has a tool portion and a receiving barrel portion, with the tool portion capable of boring a hole into the heel of the shoe and the receiving barrel portion allowing for connecting to the engaging barrel portion of the quick release member. Once the quick release member is connected to the securing member in the heel of the shoe, the carrier can be utilized to transport shoes.

Owner:PERRY RICHARD L

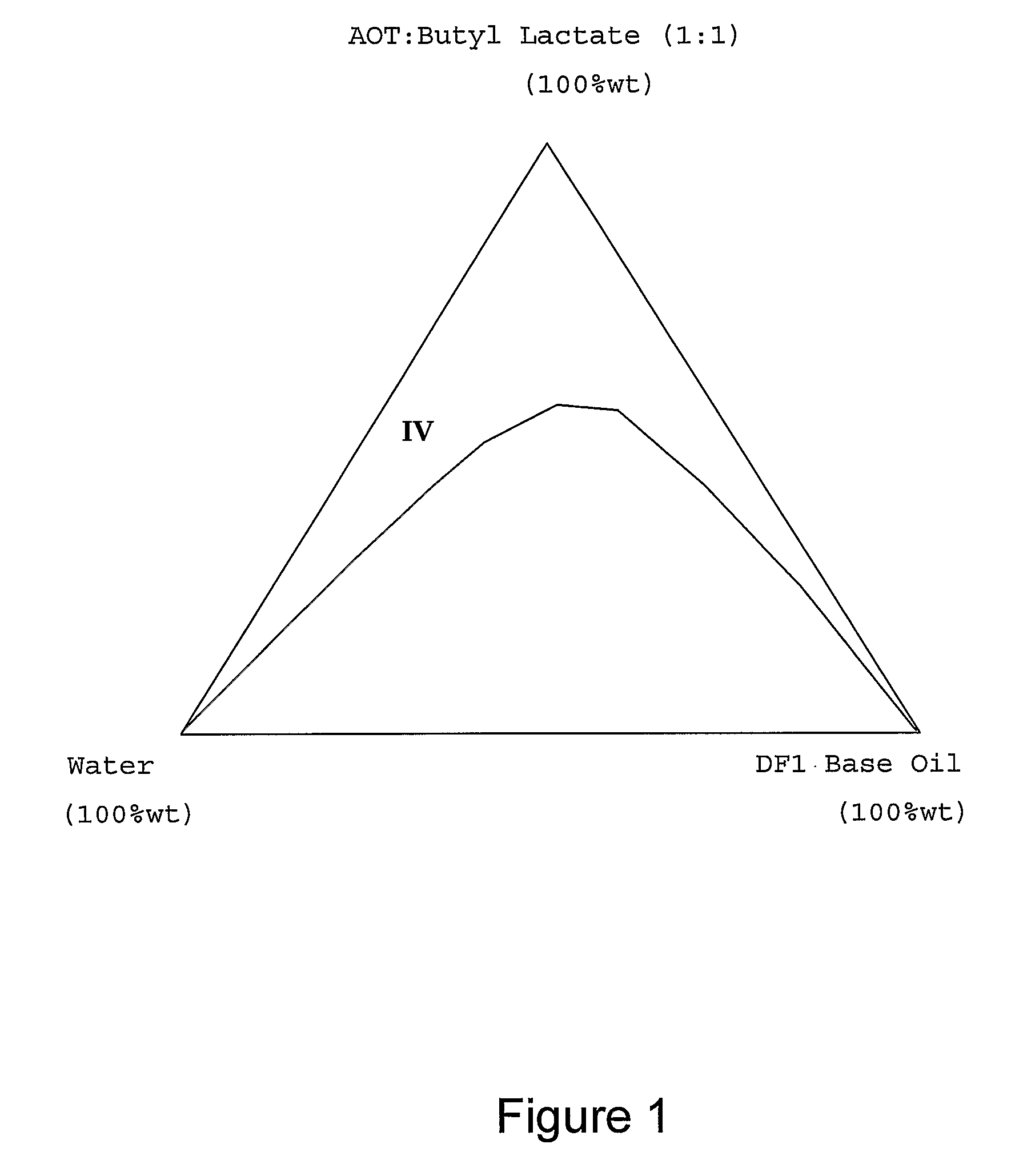

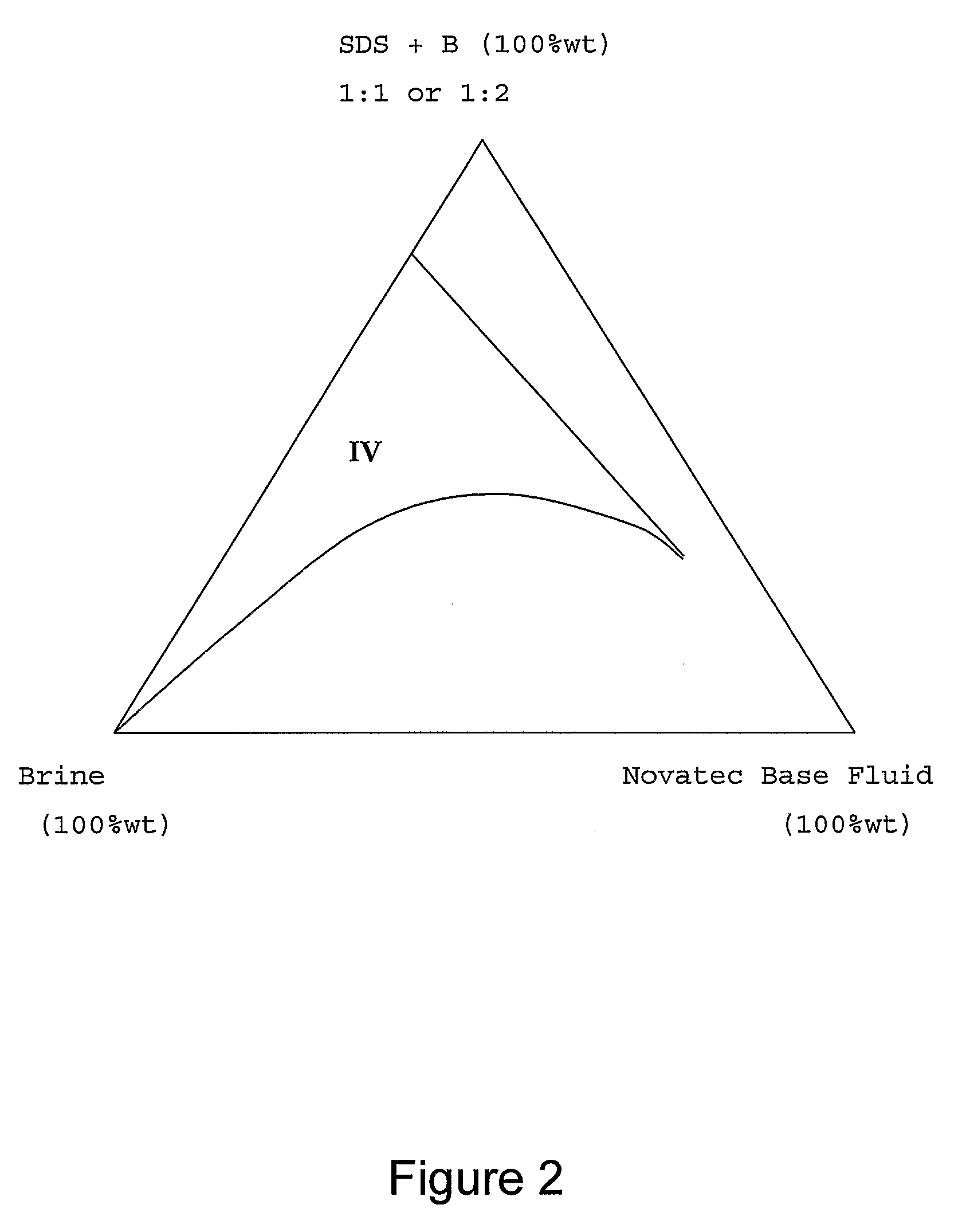

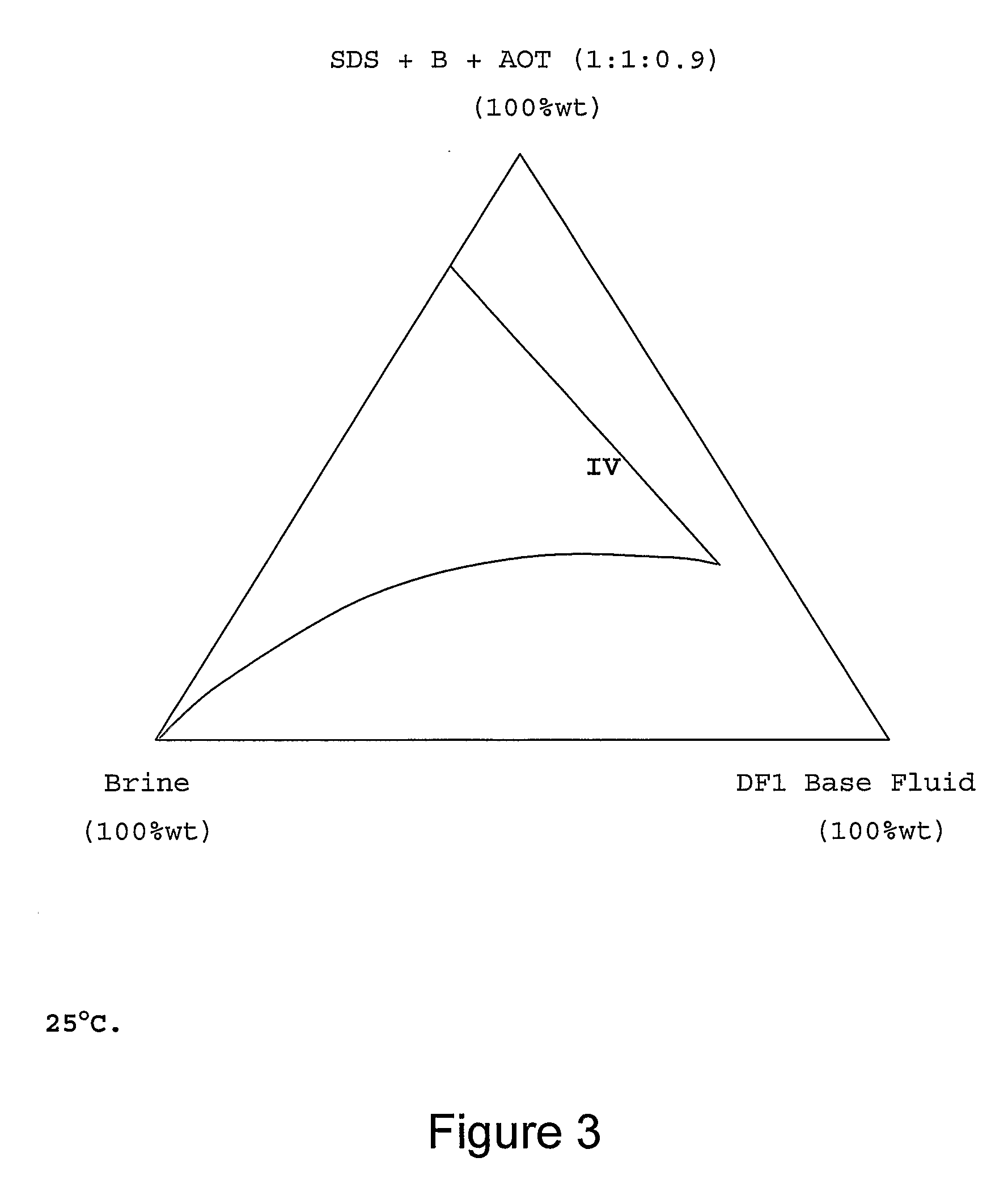

Enhanced Slurrification Method

InactiveUS20080296222A1Enhancing slurrificationConvenient and efficient transportationTransportation and packagingMixing methodsEmulsionSludge

A method of slurrifying oil contaminated materials by introducing a microemulsion or microemulsion-forming surfactant(s) to the material and subjecting the mixture to suitable shear or mixing forces to suitably blend such mixtures. The method may be applied directly to wastes such as waste drill mud cuttings and muds, emulsions, sludges, or soil substrates contaminated with water and / or oil drilling fluids in order to both reduce the viscosity and improve the lubricity, wetting, and flow properties of the substrate.

Owner:SURFACTANT TECH

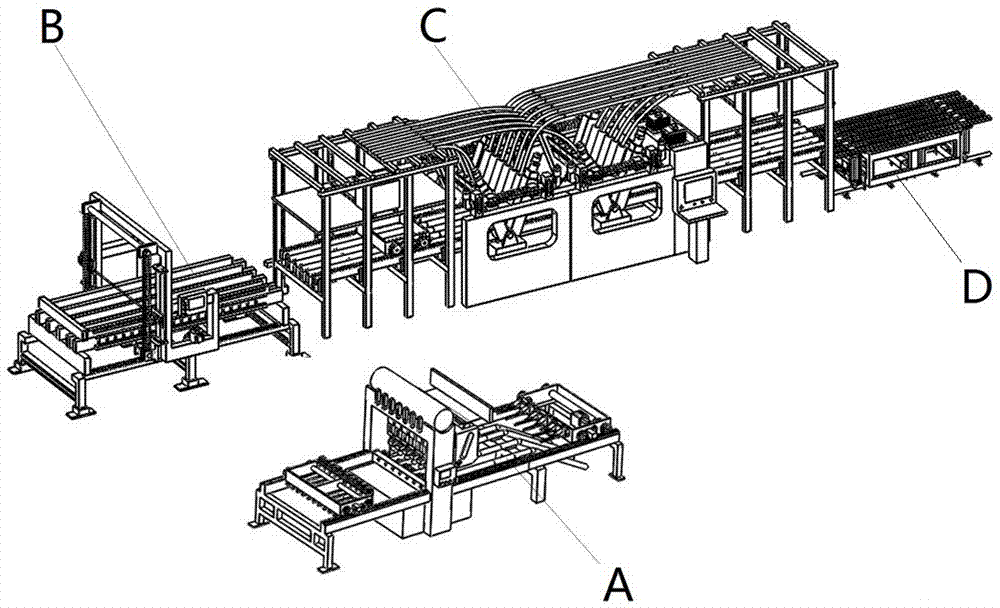

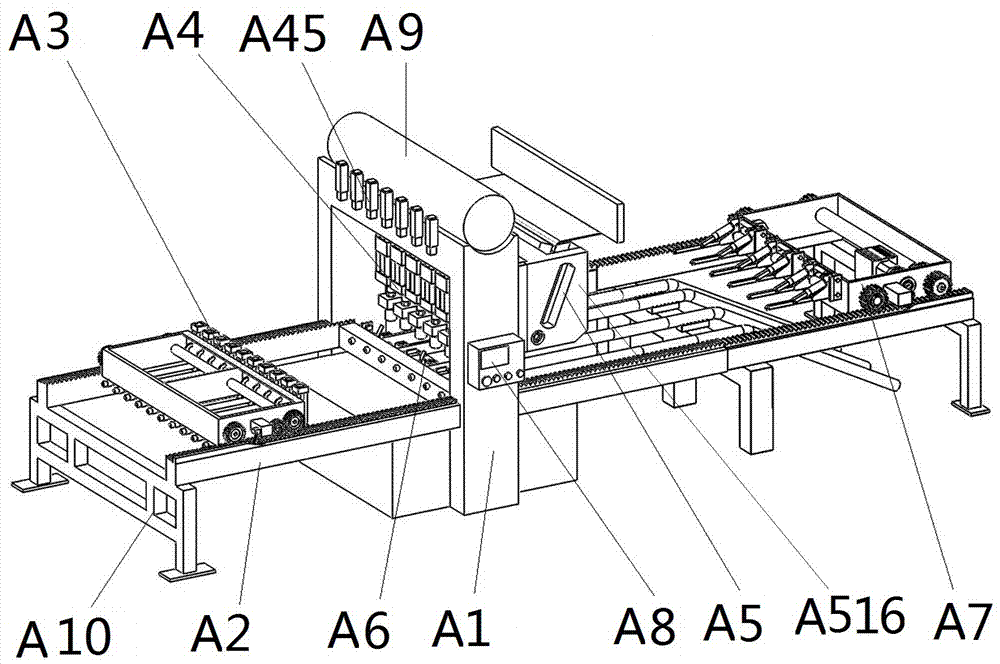

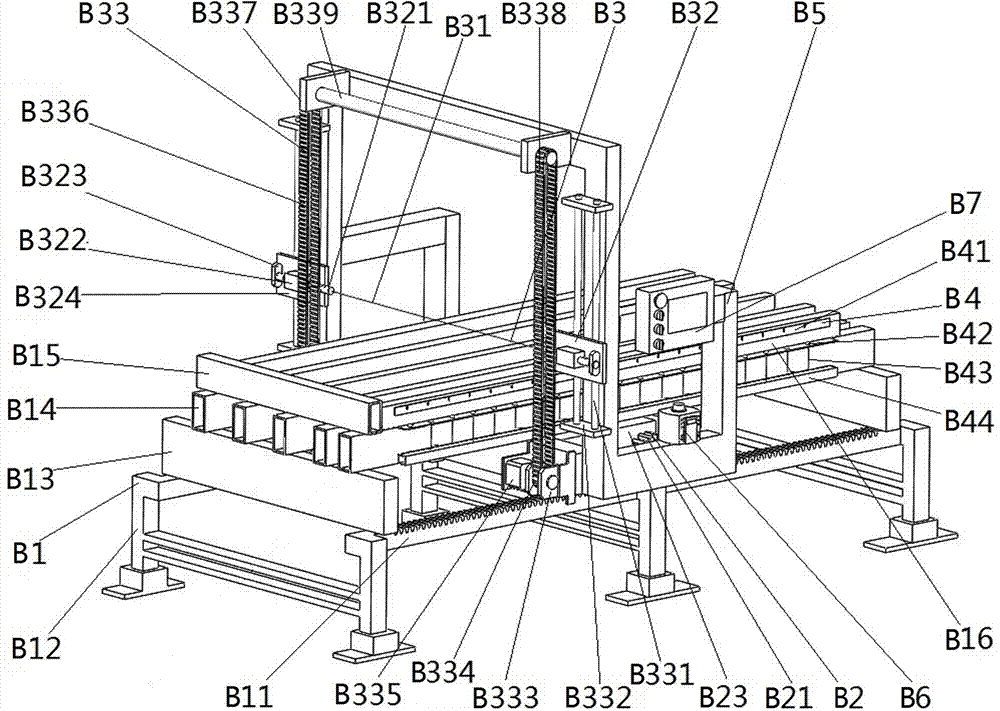

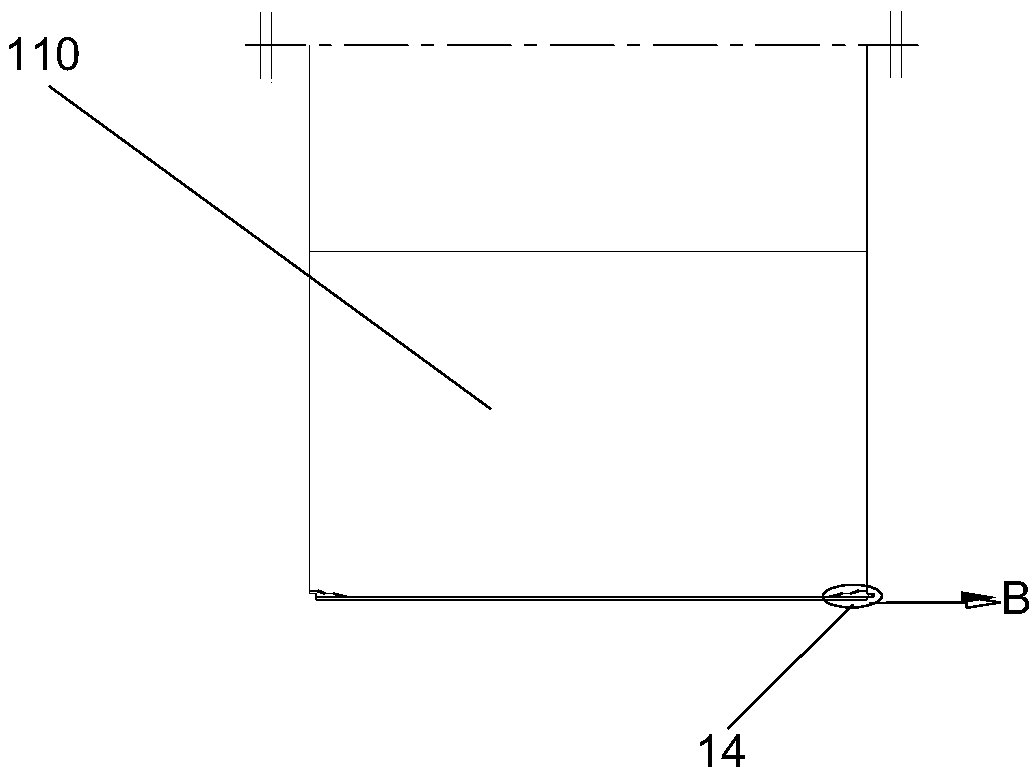

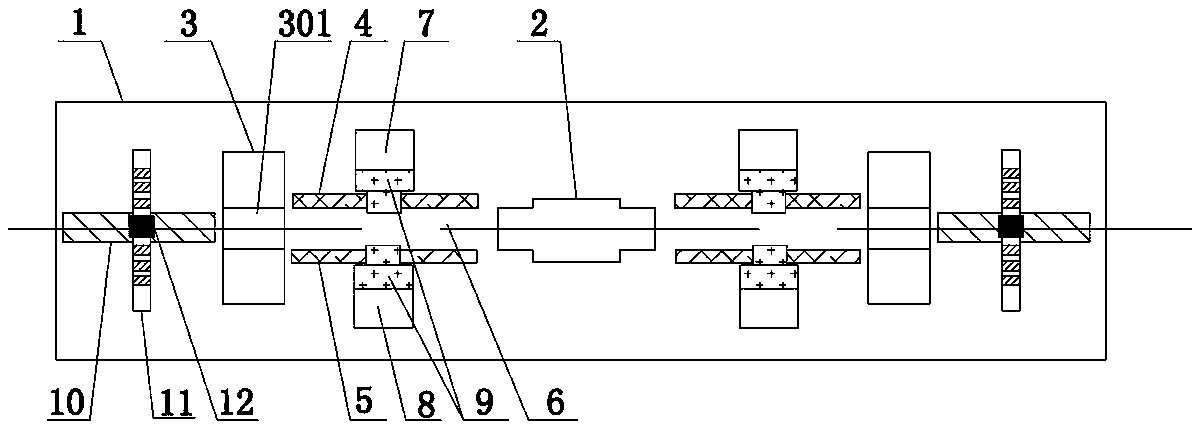

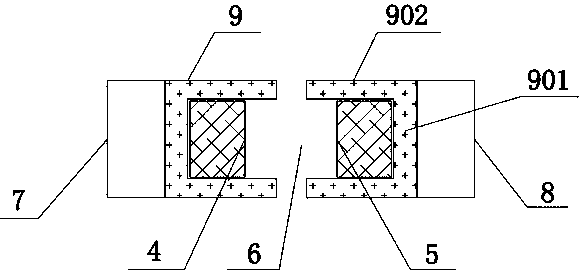

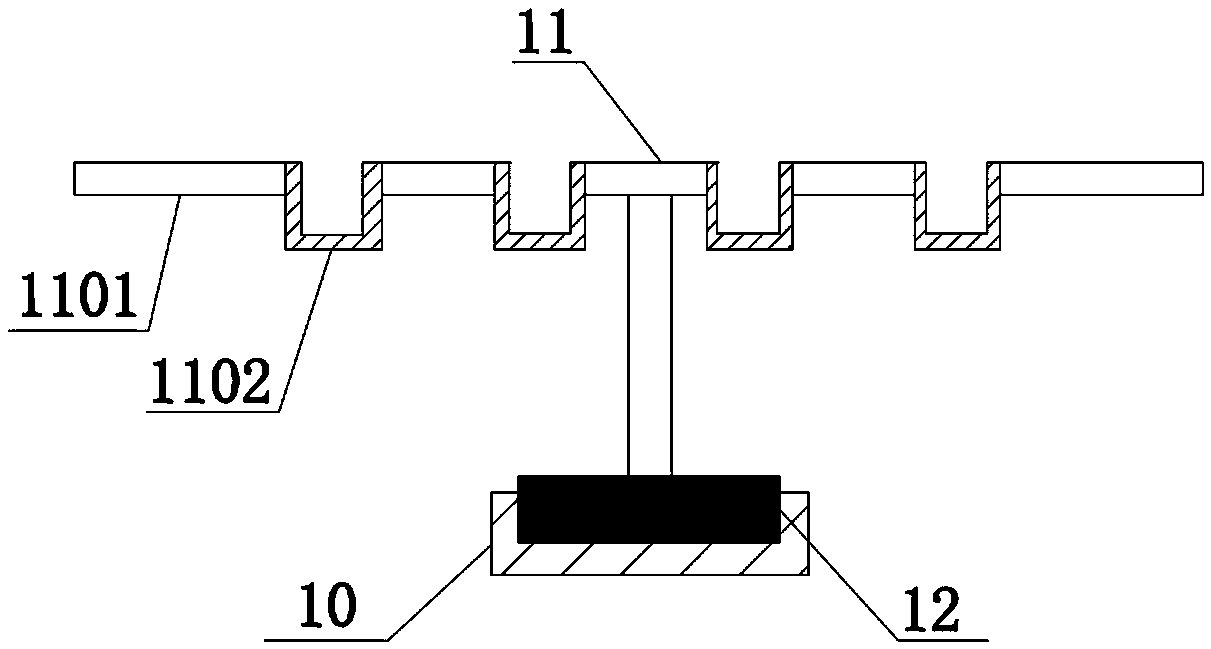

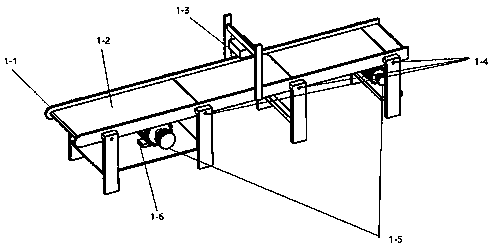

Net rack production line for producing heat insulation board wall

PendingCN107537959AEfficient productionMeeting urgent needsWire networkMetal working apparatusProduction lineEngineering

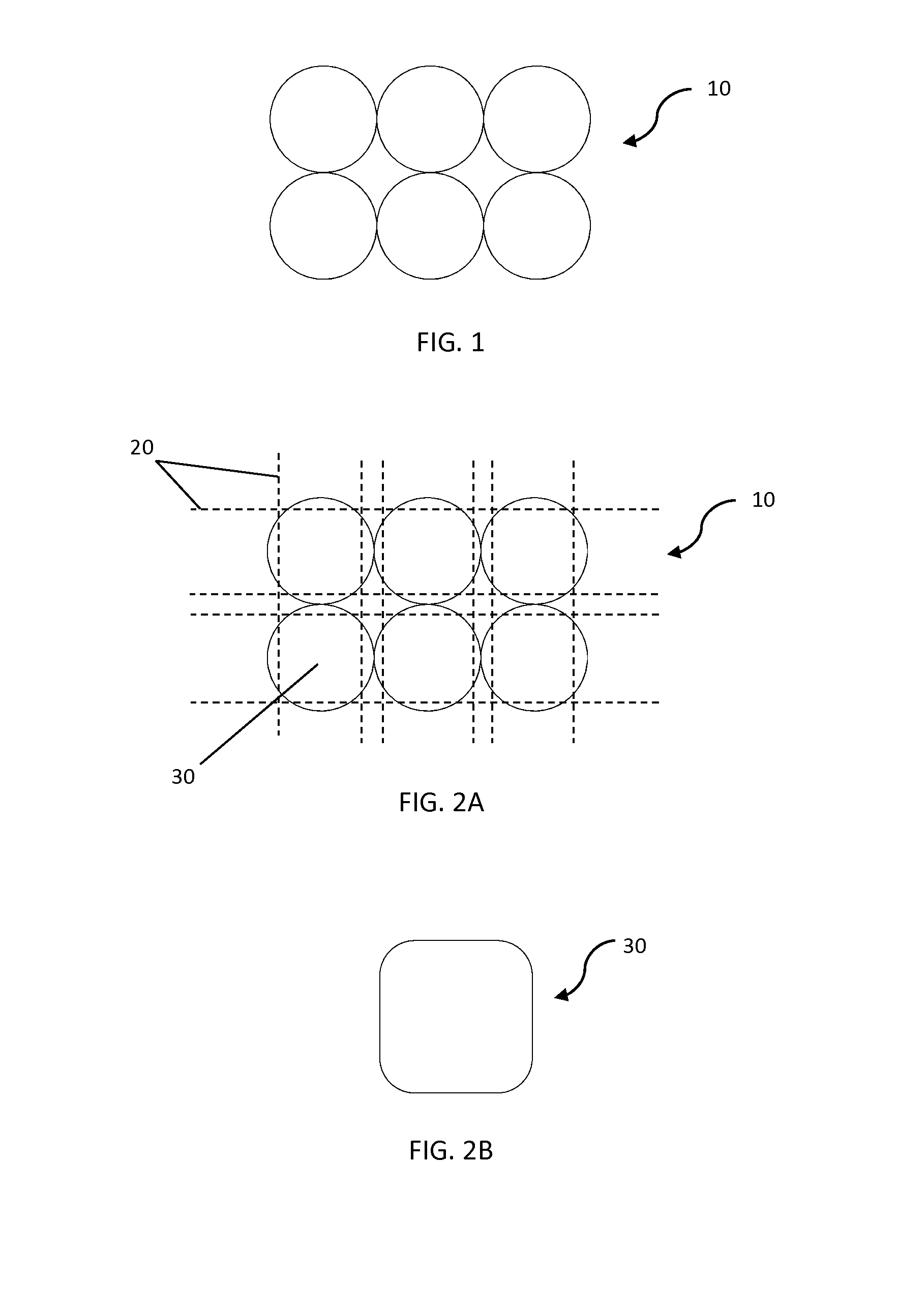

The invention discloses a net rack production line for producing a heat insulation board wall. The net rack production line comprises a flat net welding machine for welding already straightened longitudinal bars and transverse bars into flat net layers, a heat insulation board cutting machine for carrying out heat insulation board cutting in the thickness, length and width directions of an heat insulation board and forming the heat insulation boards meeting the specification requirements by cutting, an oblique inserting rib welding machine for inserting oblique inserting ribs into the heat insulation board and welding the oblique inserting ribs to the two flat net layers up and down, and a net rack heat insulation board conveyer for conveying an already produced net rack heat insulation board; the feed end of the oblique inserting rib welding machine corresponds to the discharge end of the flat net welding machine and the discharge end of the heat insulation board cutting machine; thedischarge end of the oblique inserting rib welding machine corresponds to the feed end of the net rack heat insulation board conveyer; and the flat net welding machine, the heat insulation board cutting machine, the oblique inserting rib welding machine and the net rack heat insulation board conveyer are each provided with control equipment for controlling various mechanisms in the flat net welding machine, the heat insulation board cutting machine, the oblique inserting rib welding machine and the net rack heat insulation board conveyer to carry out coordinative operation. Welding productionof the flat nets, efficient cutting of the heat insulation board, accurate insertion and welding of the oblique inserting ribs, conveying and transportation of the net rack heat insulation board are integrated in the net rack production line, so that the effect of efficiently producing the net rack heat insulation board throughout is realized.

Owner:河北森阳建筑设备科技有限公司

Power-conditioned solar charger for directly coupling to portable electronic devices

InactiveUS9088169B2Sacrificing spaceSacrificing weightPhotovoltaic supportsLine/current collector detailsElectrical batteryDirect coupling

The present invention relates to methods, tools and systems for manufacturing a durable and portable power-conditioned personal solar system charging apparatus. Various voltage and amperage matching algorithms are manipulated to particularize the personal solar system to power and / or charge an intended portable device or a set of intended portable devices having direct current (DC) load requirements. The optimized personal solar system that is matched to an intended device allows direct coupling to the intended device without the use of an internal battery or ancillary electronic circuit boards to distract the personal solar system output, and facilitates “fast” charging modes.

Owner:ADVANCE ENERGY SOLUTIONS

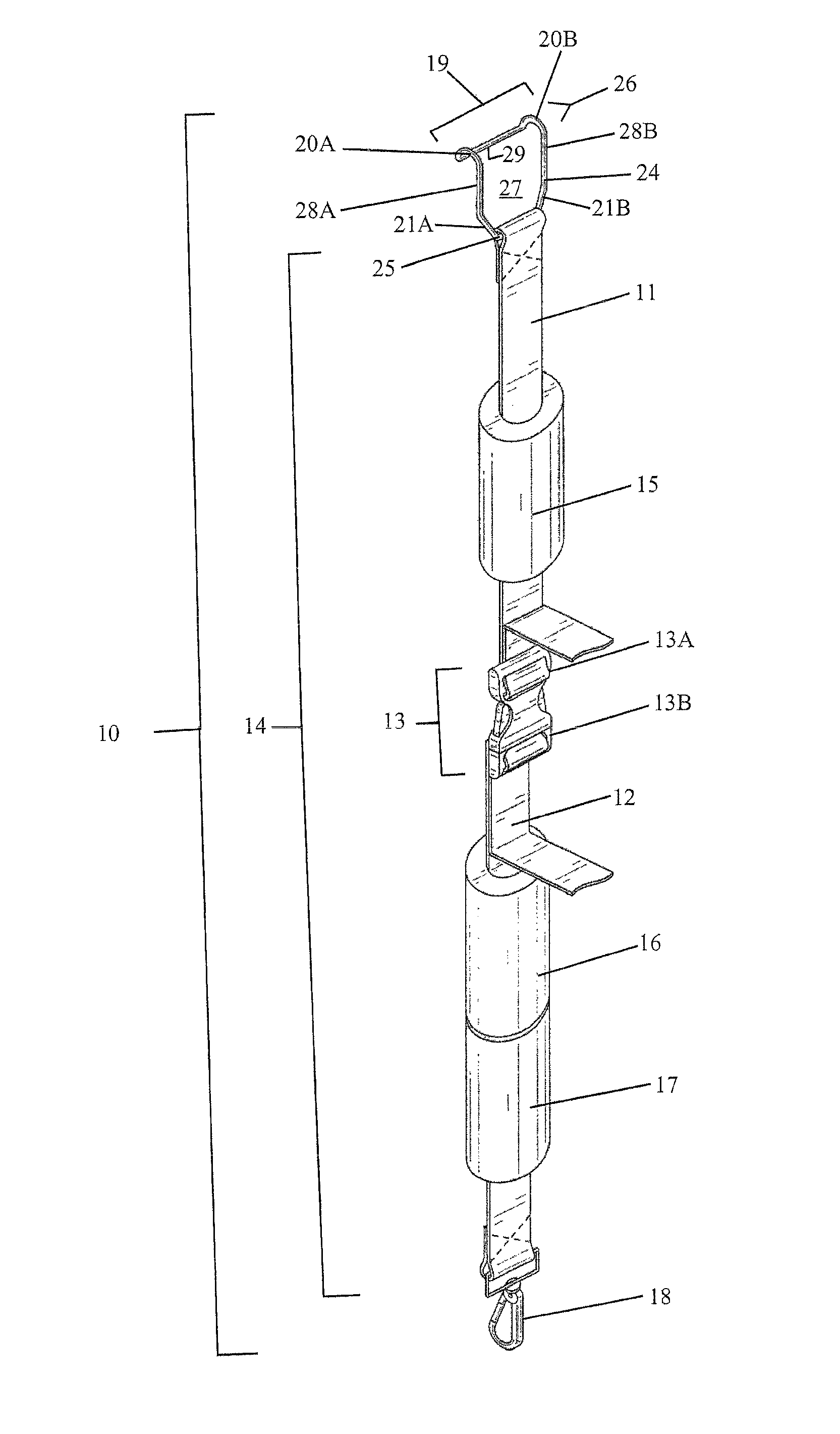

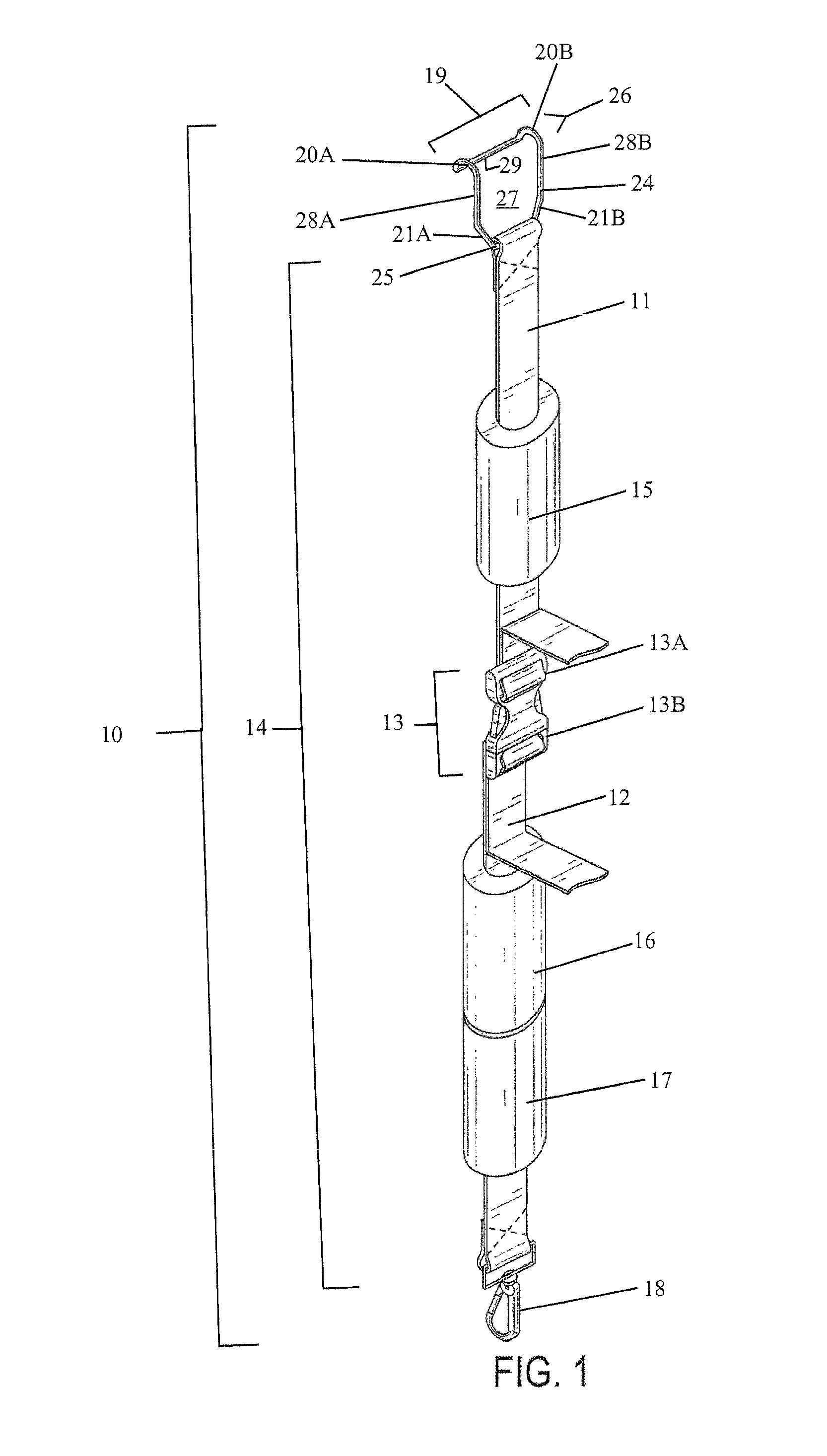

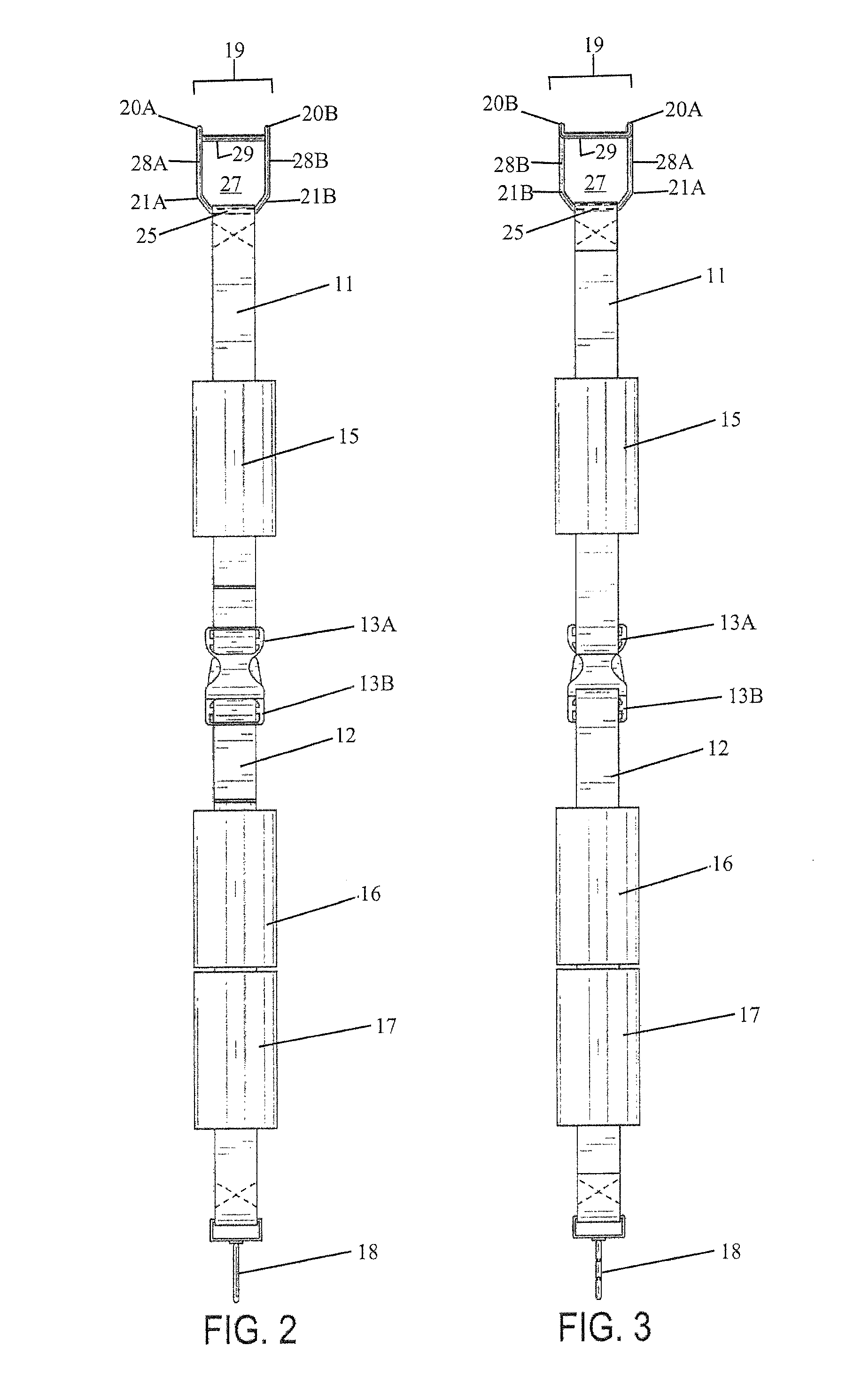

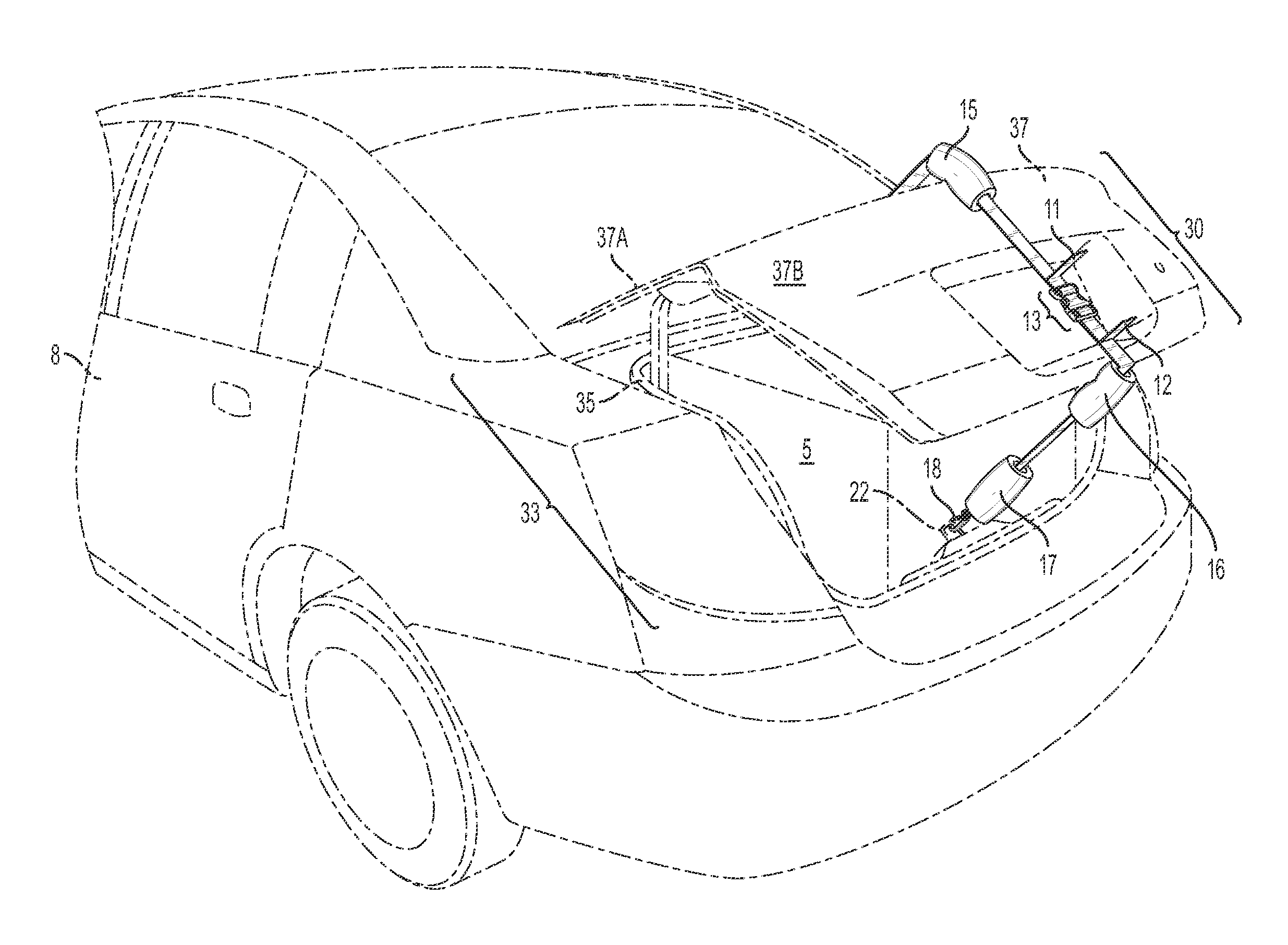

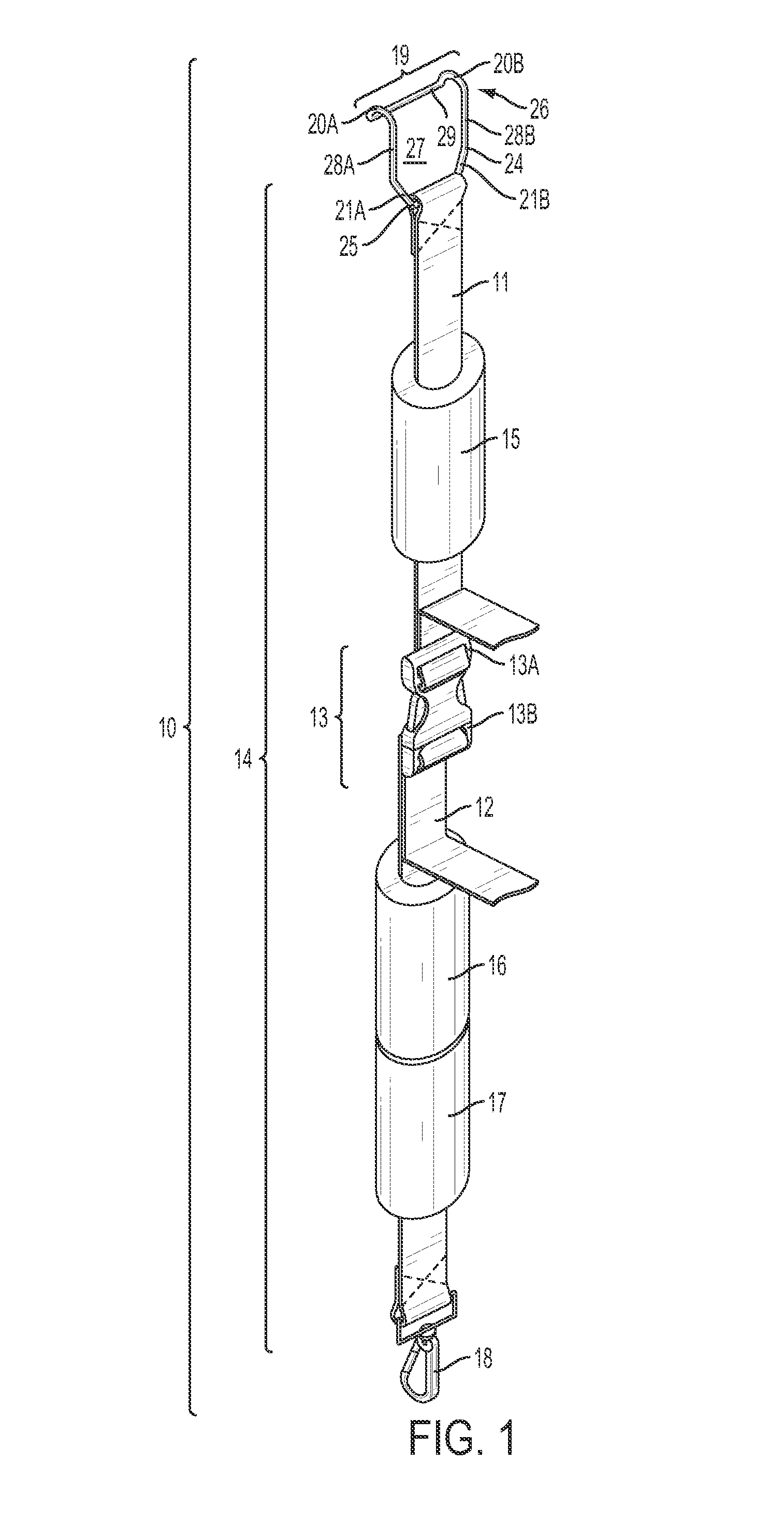

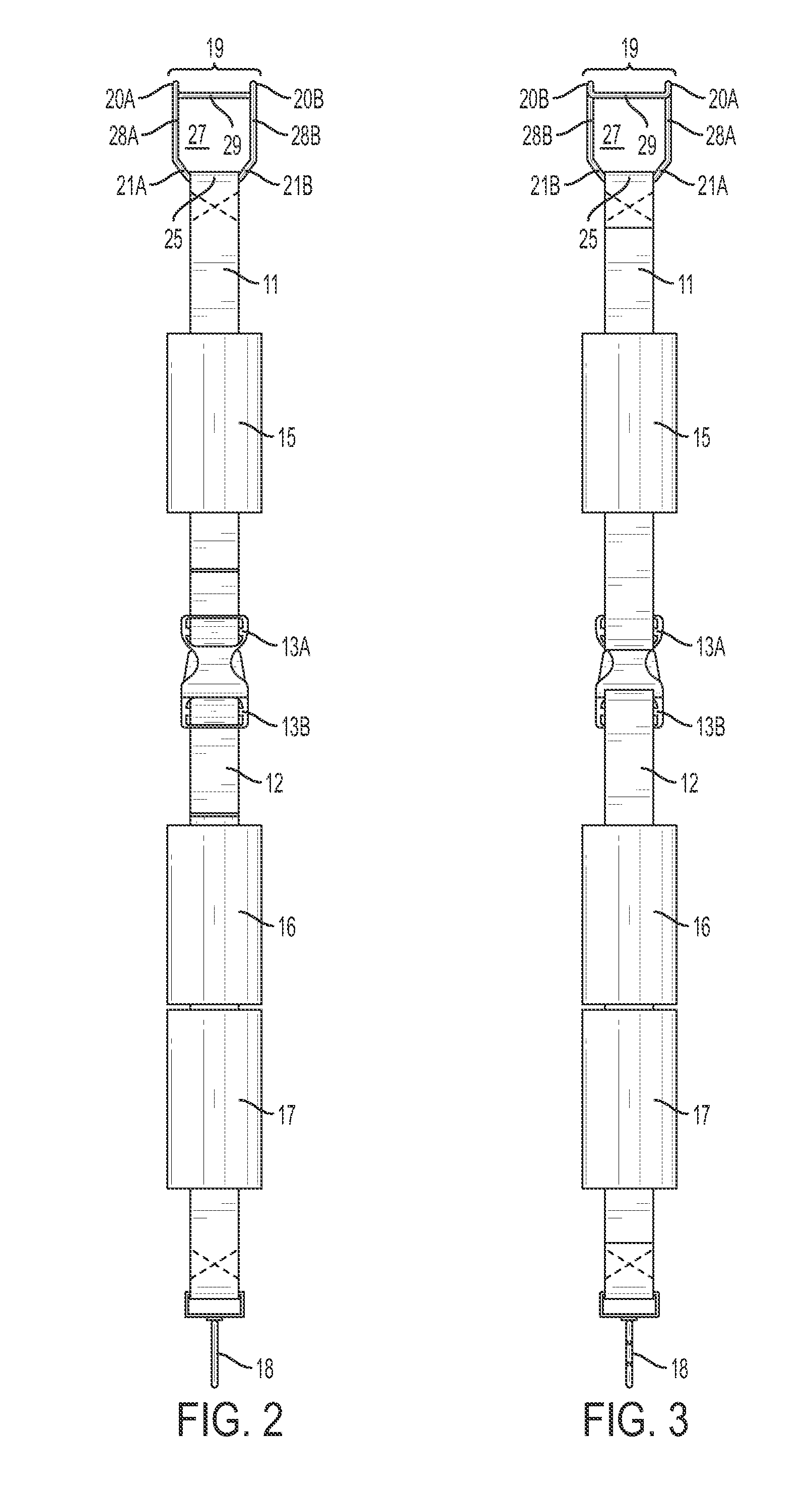

Vehicle tie-down device for hauling a load

InactiveUS8616593B2Convenient and efficient transportationImprove securitySnap fastenersBagsStructural engineeringMechanical engineering

The invention provides tie-down devices and related methods for securing oversized items in a vehicle trunk or rear storage compartment in preparation for transport. The tie-down devices include sections connected by a releasable buckle that allows for separately cinching the strap sections to desired lengths. The tie-down devices incorporate specialized connectors at each end in the form of at least one grip that is curved to attach to the edge of a panel on the vehicle and a latch that attaches to a fixed attachment mechanism at the opposite end.

Owner:GLOBAL CONSUMER PRODS

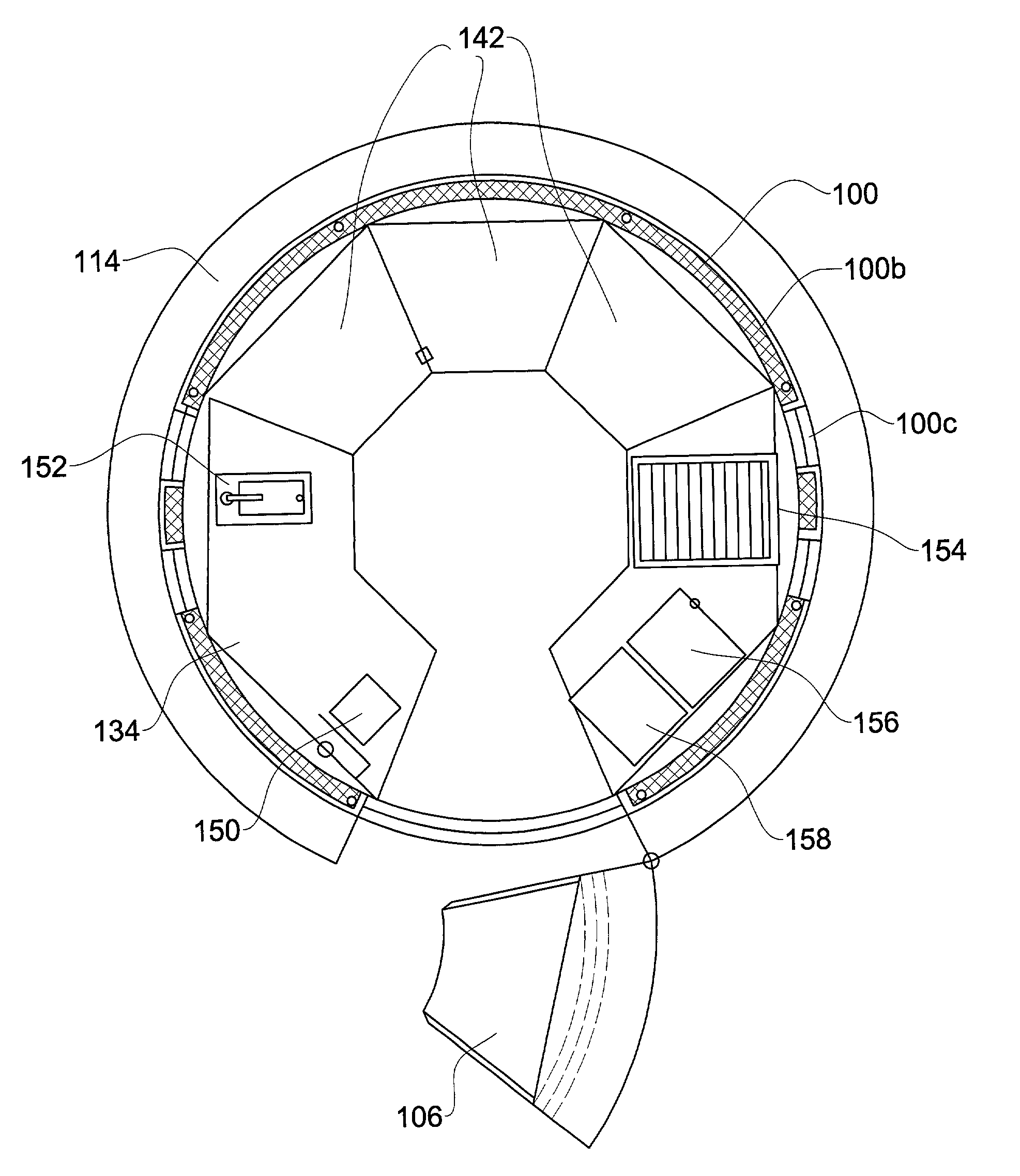

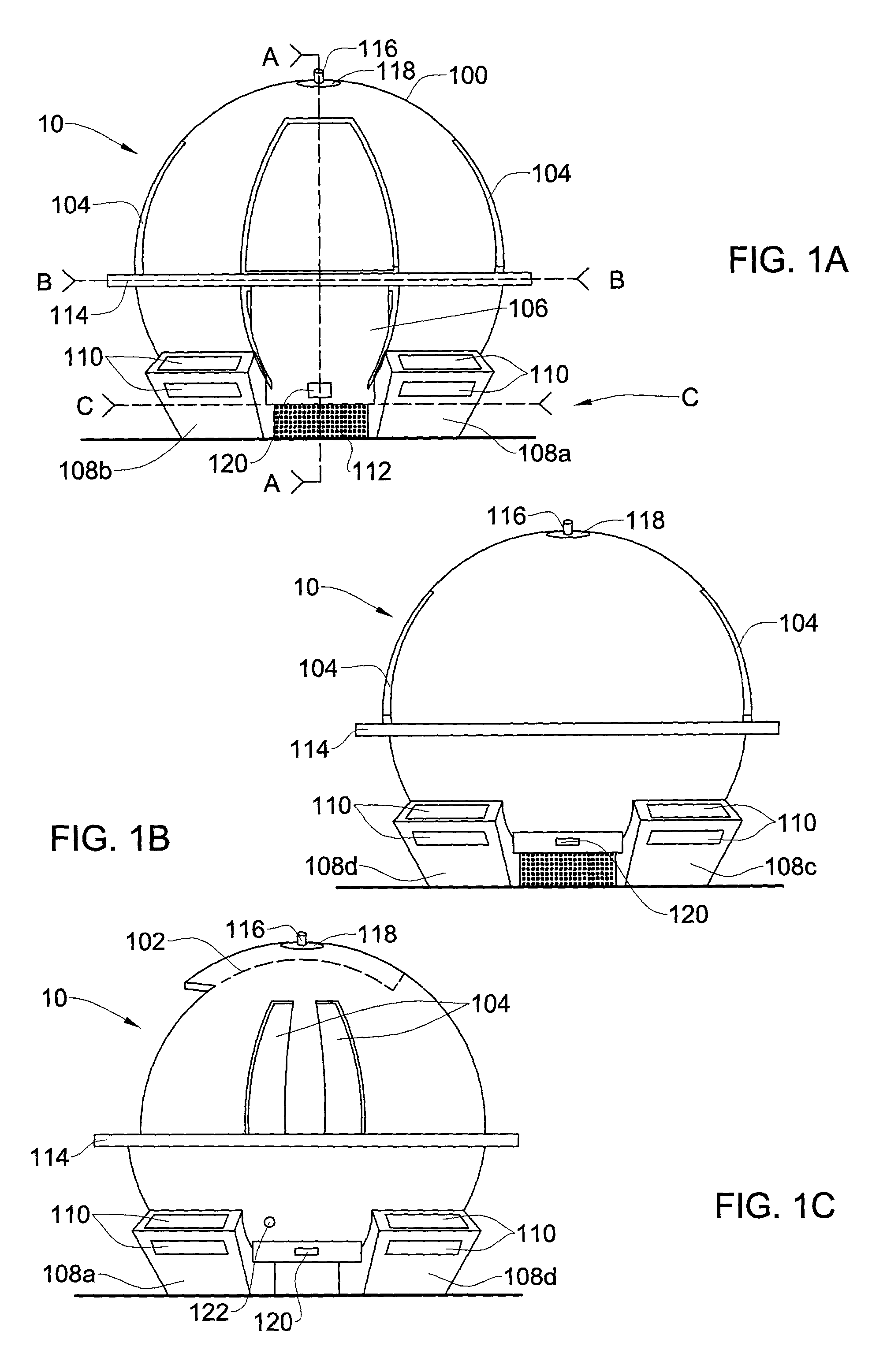

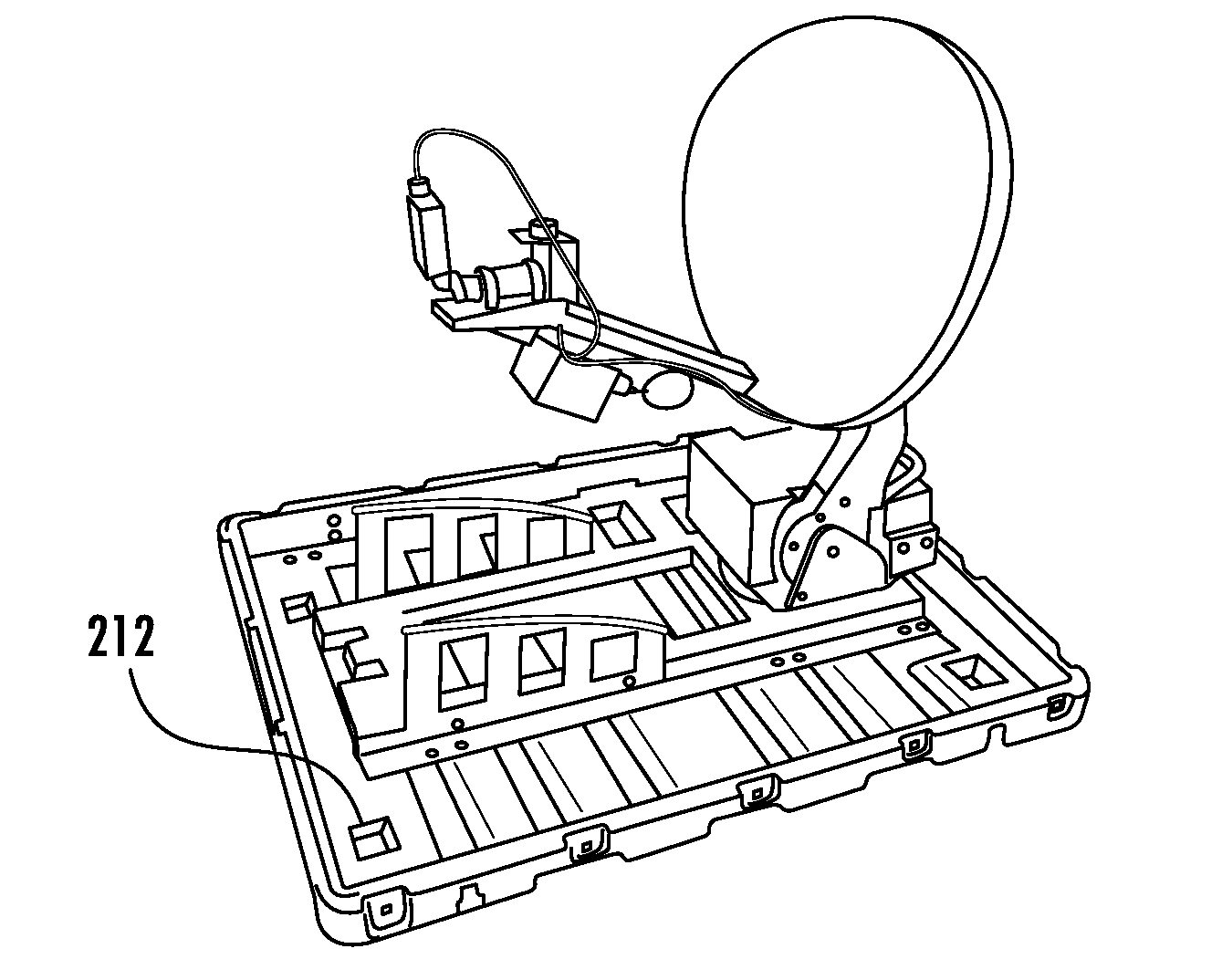

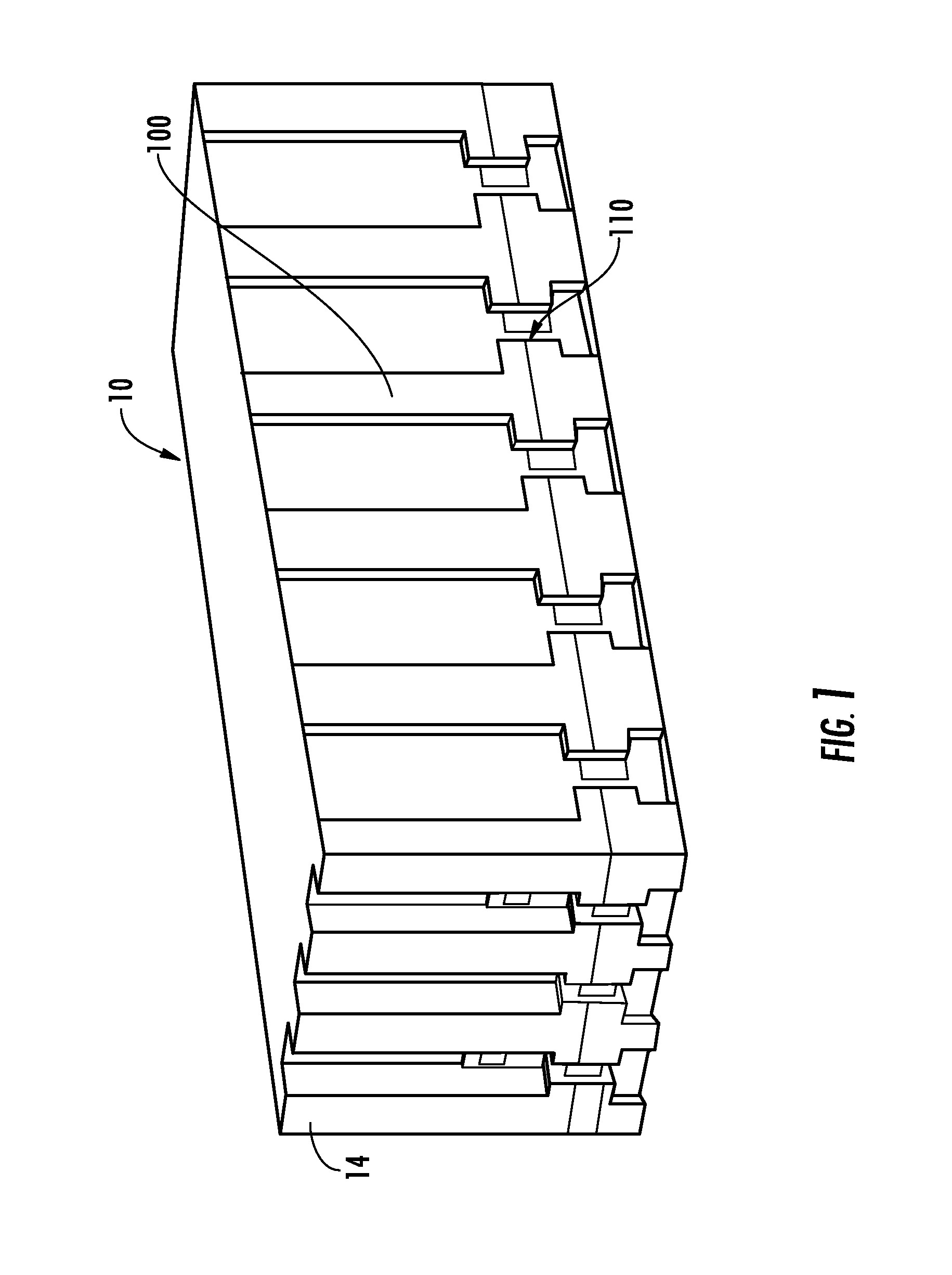

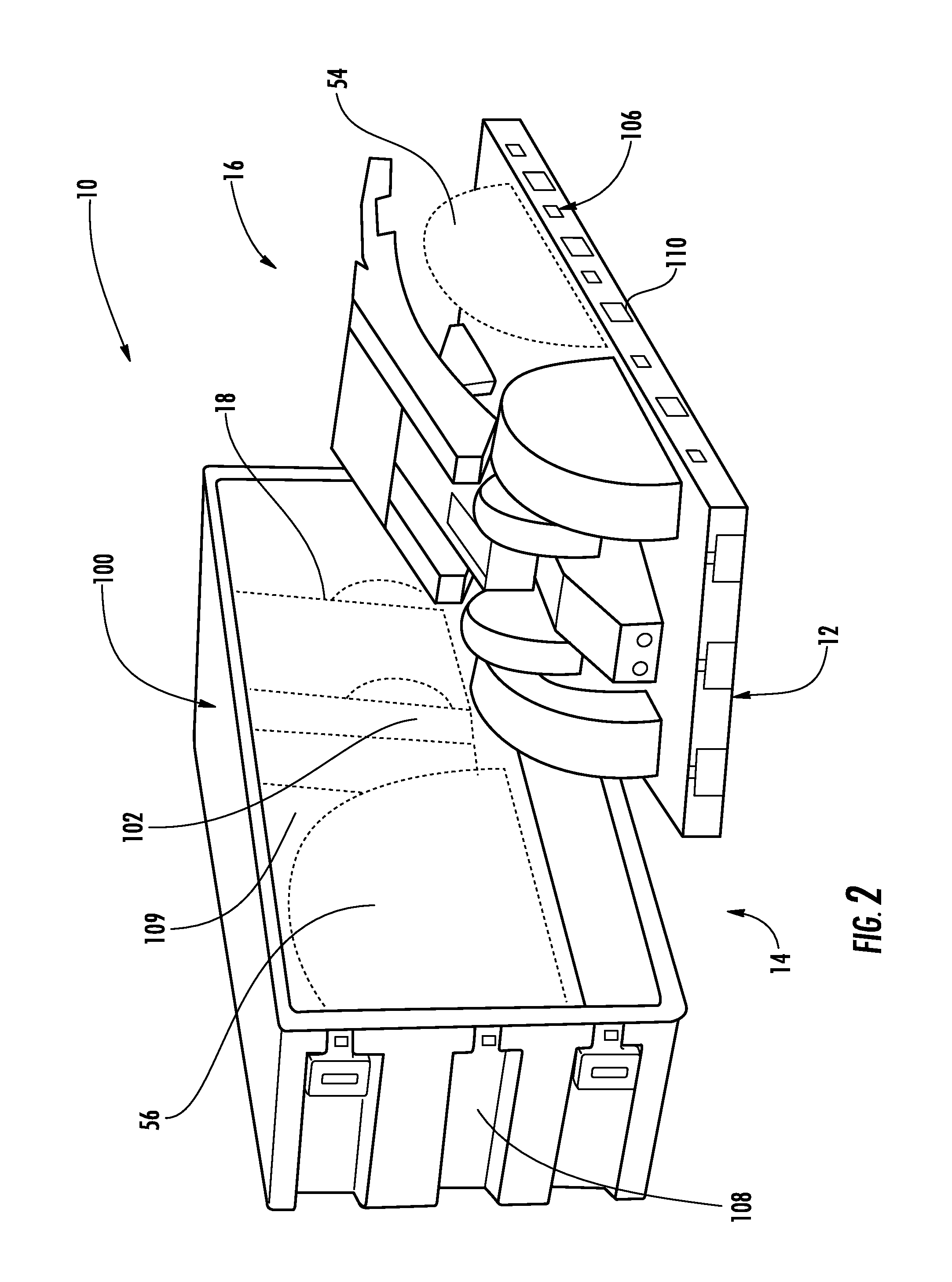

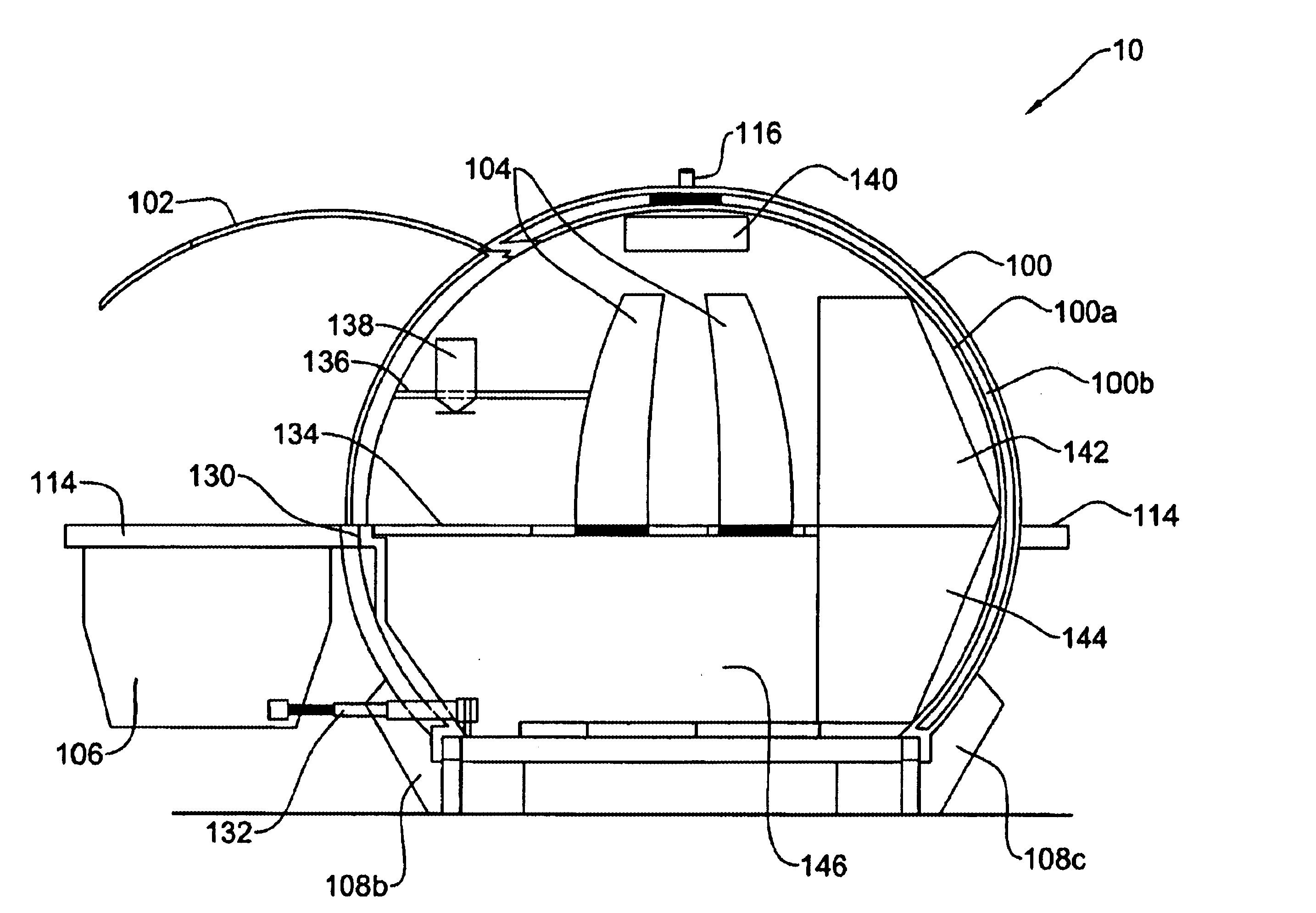

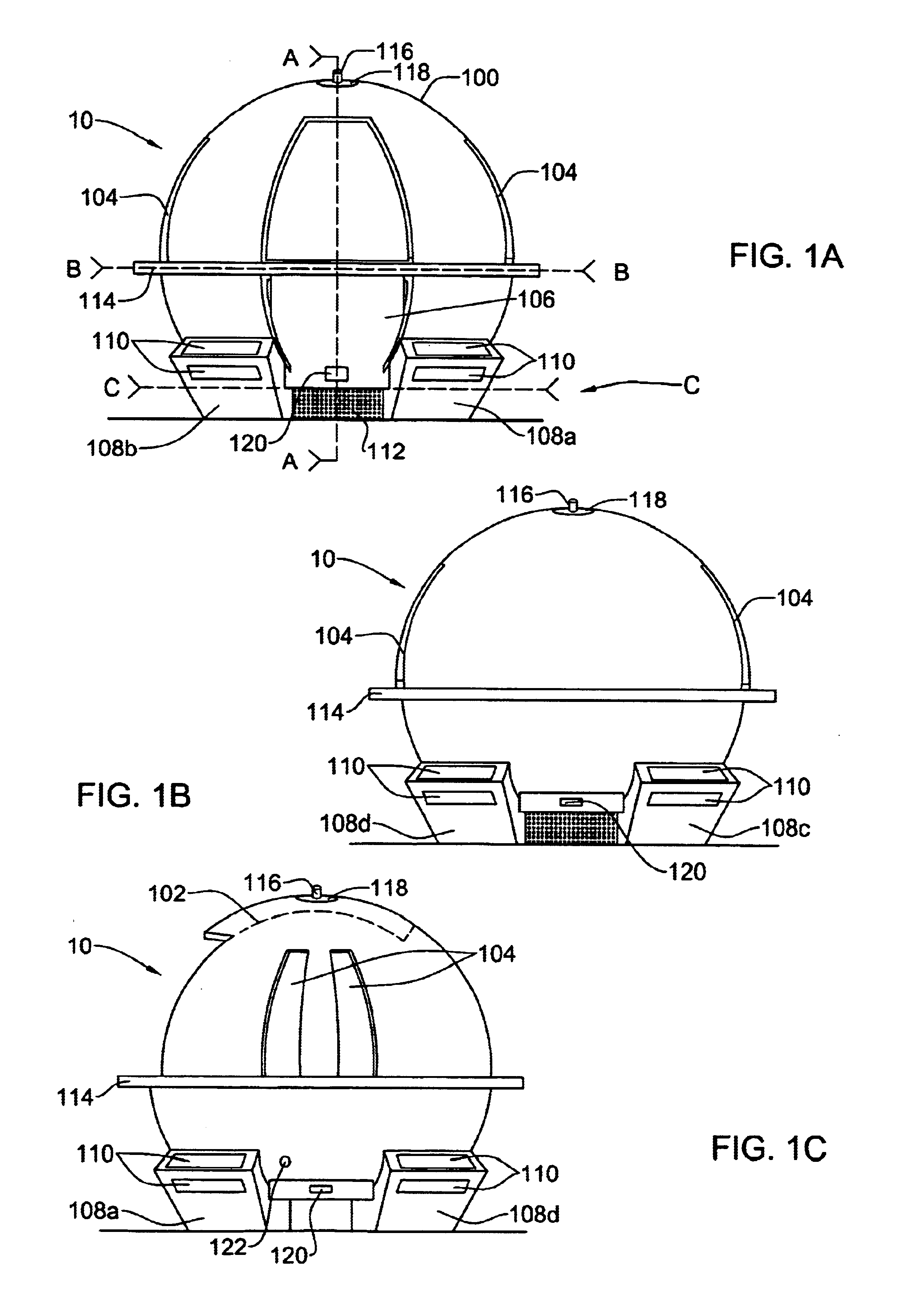

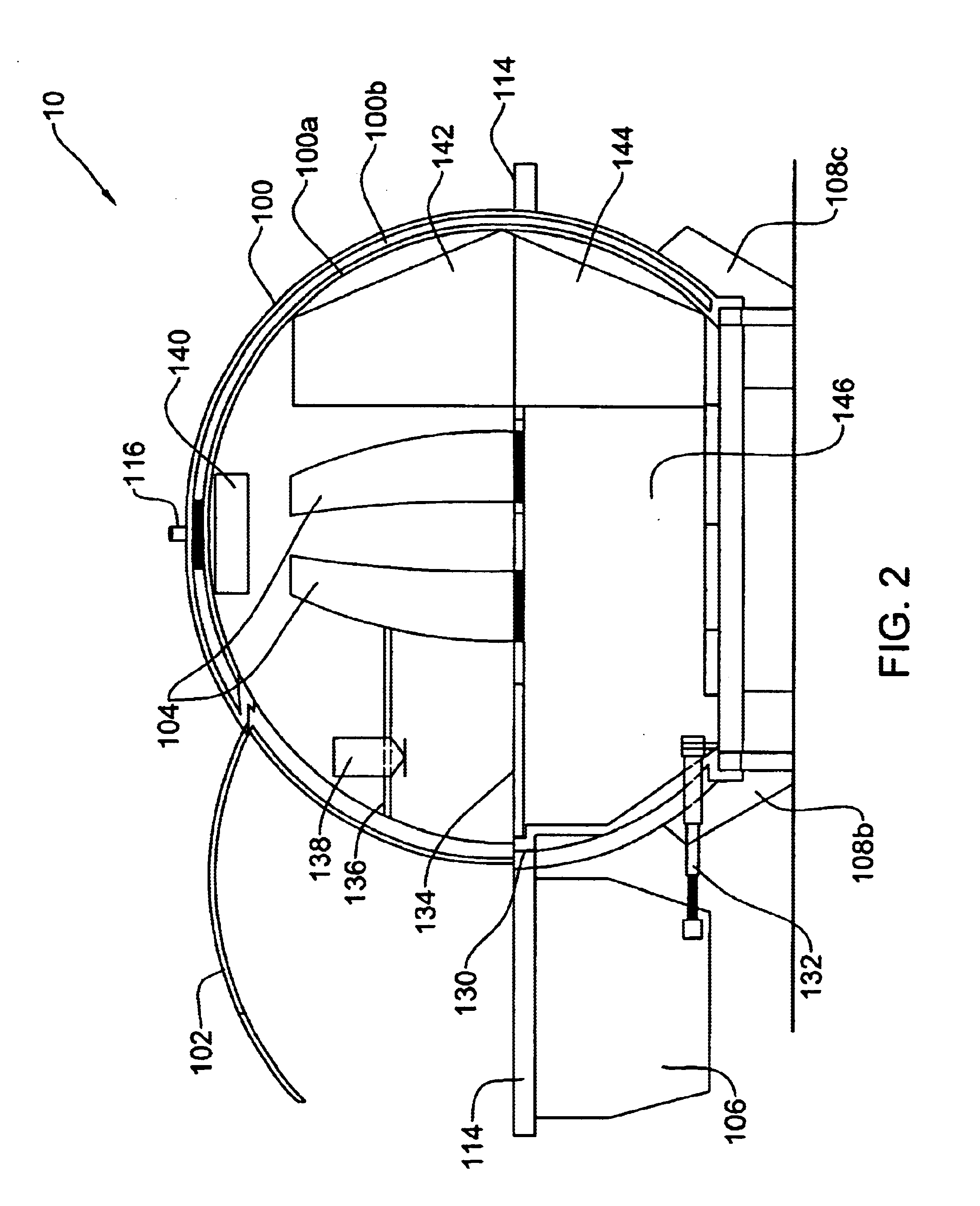

Enhanced mobile satellite communication system

InactiveUS8867986B1Improve versatilityReduce chanceResonant long antennasAntenna adaptation in movable bodiesAlternating currentTerminal system

There is provided a mobile satellite communication terminal system including a transmit / receive sub-system. The transmit / receive sub-system includes an antenna dish, a feed boom assembly, and a power supply unit having a first power input adapted to receive alternating current power and a second power input adapted to receive direct current power. The power supply unit is able to operate on either alternating current or direct current for supplying power to the transmit / receive sub-system. The power supply unit is received in a grip case. A transport container is provided. The antenna dish, the feed boom assembly, and the grip case are received in the transport container.

Owner:PATHFINDER DIGITAL

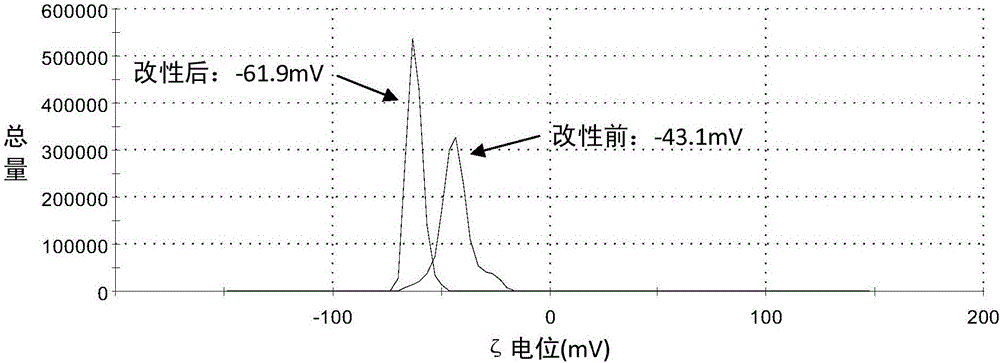

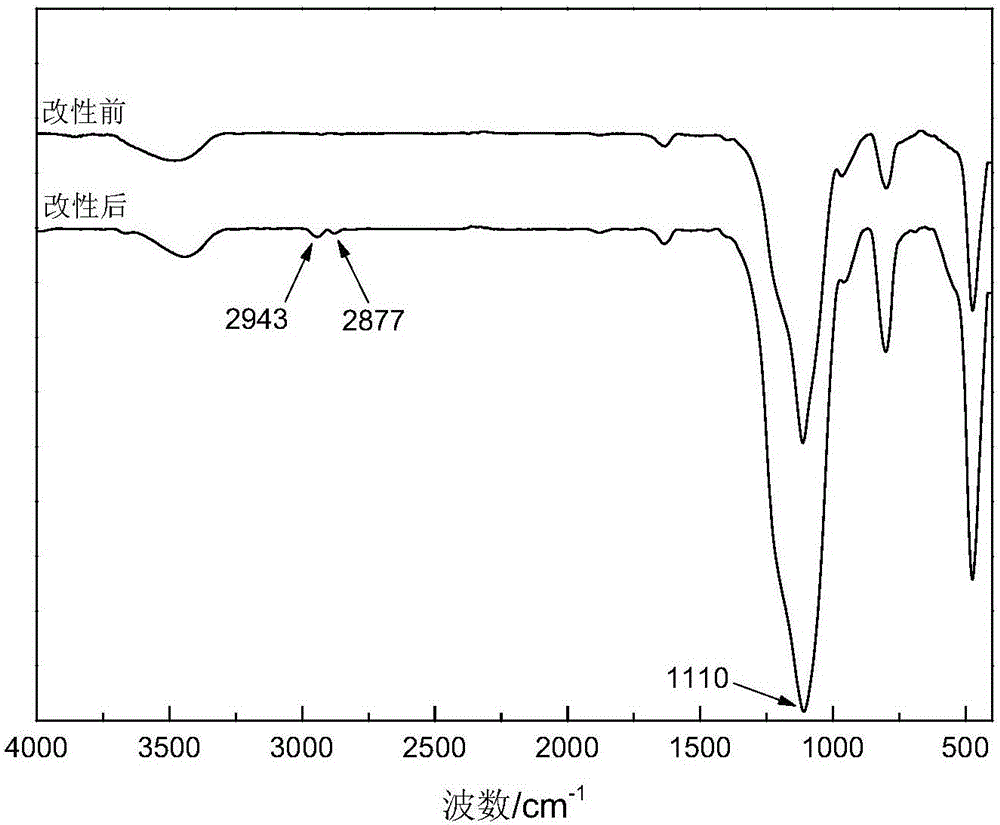

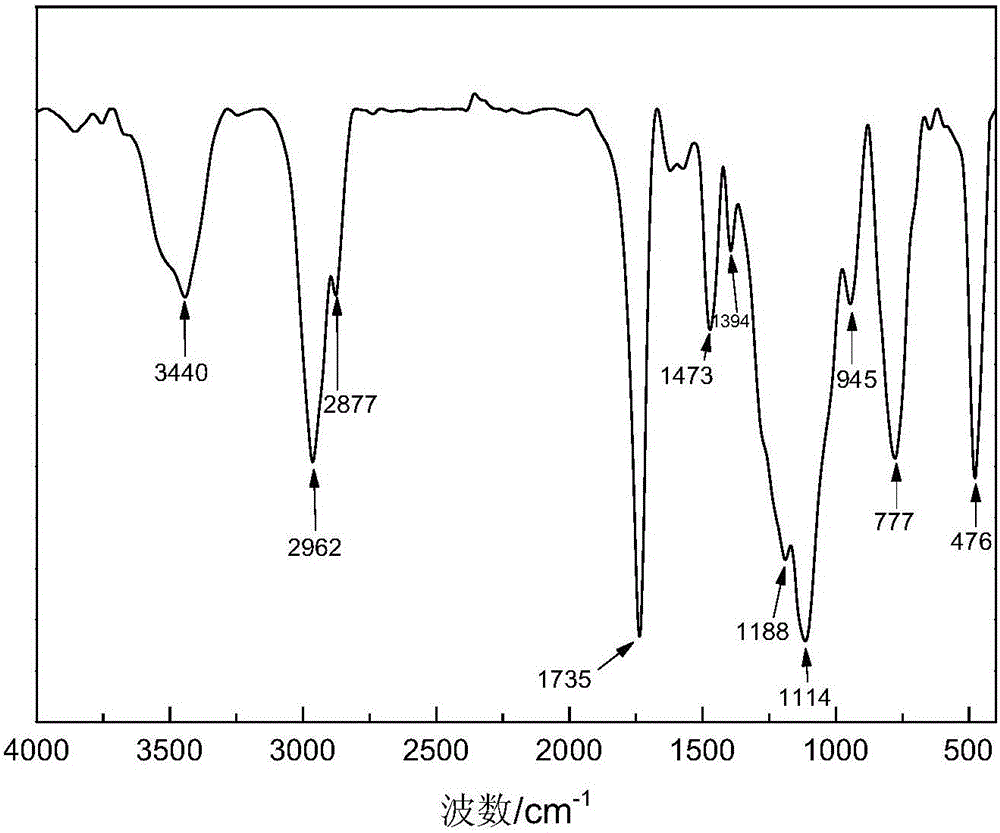

Single-component organic siloxane/inorganic silica sol hybrid high-silicone-content polyacrylate waterborne dispersion and preparation method thereof

ActiveCN106833244AImprove performanceHigh hardnessAntifouling/underwater paintsPaints with biocidesRoom temperatureResin-Based Composite

The invention discloses a single-component organic siloxane / inorganic silica sol hybrid high-silicone-content polyacrylate waterborne dispersion and a preparation method thereof. The preparation method comprises the steps of firstly preparing silylated polyacrylate resin and then preparing polysiloxane to obtain functionalized silica sol; mixing the silylated polyacrylate resin and polysiloxane at 40-80 DEG C evenly to prepare composite resin; diluting the obtained functionalized silica sol in 50-300 parts of deionized water at room temperature; and adding the composite resin to the diluted functionalized silica sol under high-speed agitation to prepare the single-component organic siloxane / inorganic silica sol hybrid high-silicone-content polyacrylate waterborne dispersion. By simply mixing a neutralized carboxyl-containing silylated polyacrylate resin, a polysiloxane segment and functionalized silica hydrosol, the formed waterborne composition can be stored for a long period of time without the problems of coagulation, viscosity increase and gelatinization.

Owner:SOUTH CHINA UNIV OF TECH

Smart service unit

InactiveUS6722474B2Convenient and efficient transportationControlling coin-freed apparatusArched structuresCommunication unitEngineering

Owner:HATZOR ERAN GOLAN

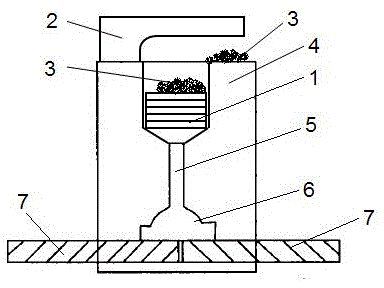

Novel heat emitting welding flux and welding method

ActiveCN104057216AEasy to transportLow cost of air freightWelding/cutting media/materialsSoldering mediaProcess engineeringPowder talcum

The invention discloses a novel heat emitting welding flux which comprises three constituents in parts by weight: 100-150 parts of powdery heat emitting welding flux, 0.3-1 part of graphite powder and 0.3-1 part of talcum powder; the three constituents are uniformly mixed and then pressed into flake. Meanwhile, the invention further discloses a welding method utilizing the novel heat emitting welding flux, wherein the igniting manners of the heat emitting welding flux comprise igniting gun ignition and electronic igniting device ignition. The novel heat emitting welding flux has the benefits that the new form, namely the flaky heat emitting welding flux, can be stacked in a multilayered manner to be packaged so as to save packing material and then reducing the packaging cost and the recycle cost of the waste; moreover the transportation of the flaky emitting welding flux is relatively convenient, and the air transportation cost is low; in welding, the flaky emitting welding flux in certain number can be taken according to needs, isolating gaskets are not needed to be used, the operation is relatively convenient and efficient, and the welding efficiency and the welding effect are better; through the adoption of the ignition manner of electronic igniting device, personnel remote control can be realized, and the operation is relatively convenient, efficient and safe.

Owner:宁波中创焊接技术有限公司

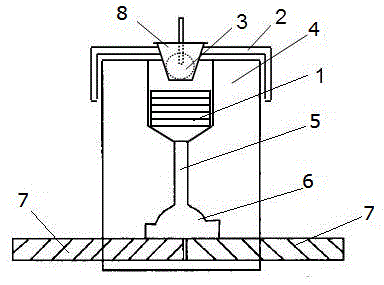

Electromagnetic driving aerodynamic vehicle provided with tandem wings

PendingCN106892106ANo crash hazardCause mechanical damagePower plant typeAircraftsVehicle dynamicsAviation

The invention relates to a technology of an electromagnetic driving aerodynamic vehicle provided with tandem wings, and belongs to the technical field of direct drive between vehicle dynamic devices and wing hub of rotors. The technology of the electromagnetic driving aerodynamic vehicle provided with the tandem wings is mainly applied in spacecraft vehicles and aims at improving aerodynamic efficiency of flight vehicles, at the same time solves the practical application problems of the flight vehicles. The technology of the electromagnetic driving aerodynamic vehicle provided with the tandem wings comprises an electromagnetic driving aerodynamic device provided with the tandem wings. The electromagnetic driving aerodynamic device provided with the tandem wings comprises the tandem wings, a magnetic suspension supporting system, an electromagnetic motor driving system, a duct and a machine frame. The electromagnetic driving aerodynamic device provided with the tandem wings is characterized in that a rotating magnetic field driven by electric energy through the electromagnetic motor driving system directly drives the tandem wings, which are supported and confined by the magnetic suspension supporting system, to generate lifting force by moving in the annular duct formed between the inner wall and the outer wall of the duct, so that the flight vehicle gains lifting force or thrust. The electromagnetic driving aerodynamic vehicle provided with the tandem wings has properties of full electric drive, acetabuliform integrated wing body, vertical lift, safe low altitude flight, high-efficient overload, and long hang time.

Owner:重庆鸿动翼科技有限公司

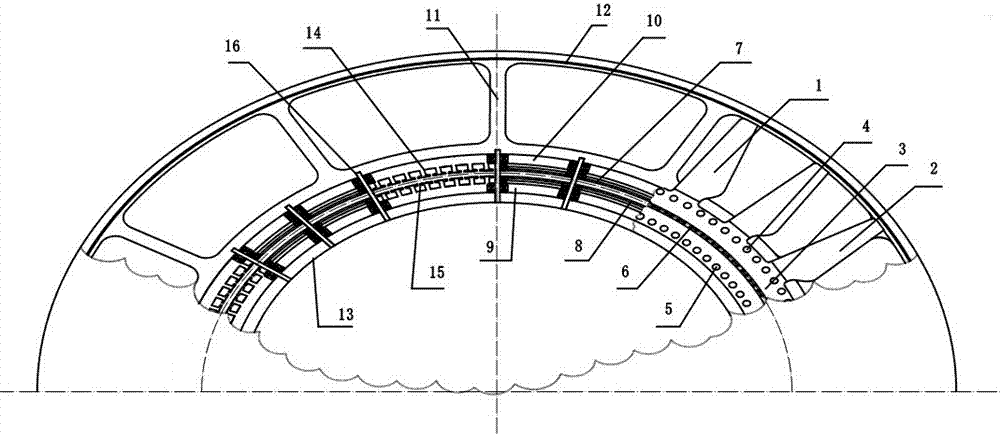

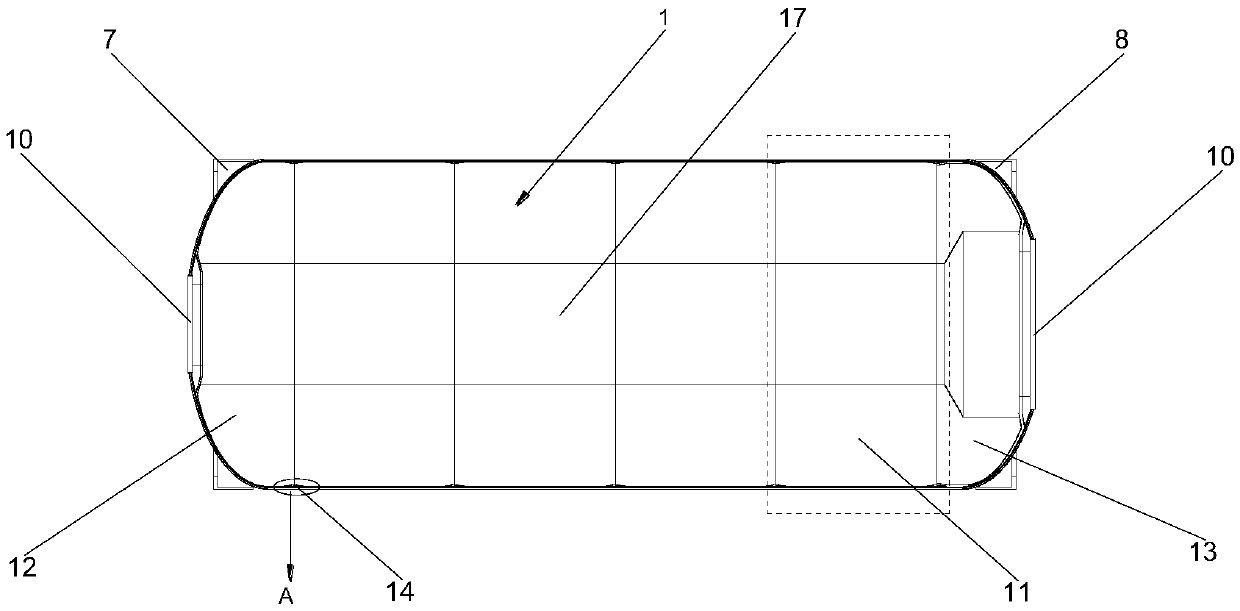

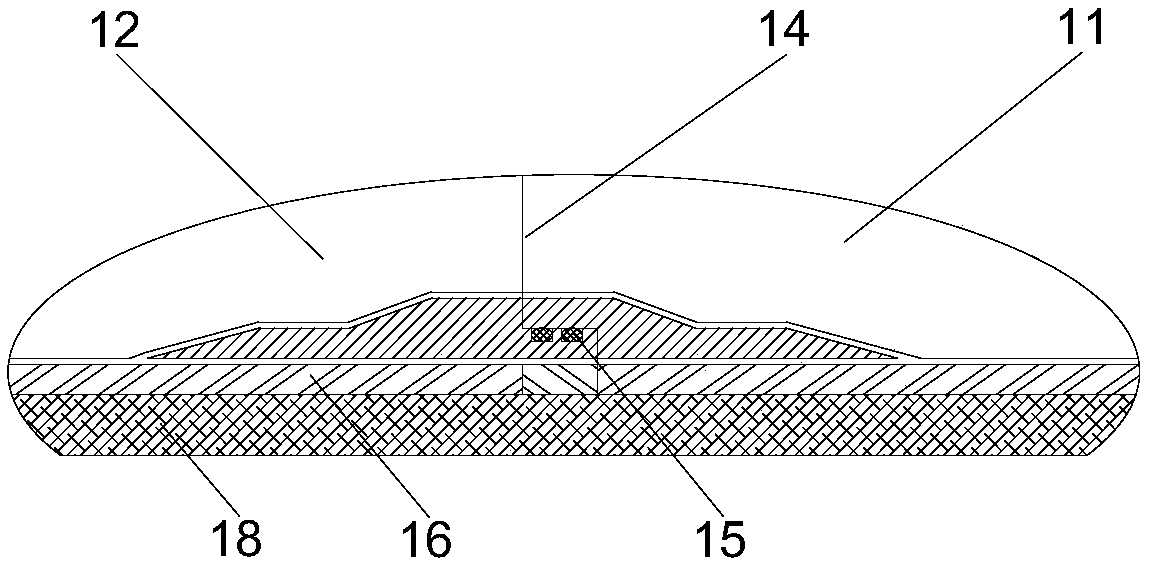

Ultra-large solid rocket engine sectional composite shell and manufacture method thereof

ActiveCN109681345AAvoid difficultyDifficulty satisfiedRocket engine plantsEngineeringTongue and groove

The invention discloses an ultra-large solid rocket engine sectional composite shell. The ultra-large solid rocket engine sectional composite shell is characterized in that the ultra-large solid rocket engine sectional composite shell comprises a shell body, the two ends of the shell body are each provided with an opening, the shell body is formed by assembling multiple prefabricated members, themultiple prefabricated members comprise a middle section and a front sealing head section and a back sealing head section which are connected to the two ends of the middle section separately, and thetwo openings are formed in the front sealing head section and the back sealing head section separately; and the end faces of the middle section and the front sealing head section which are connected form a mutual cooperative tongue-and-groove structure, and the end faces of the middle section and the back sealing head section which are connected form a mutual cooperative tongue-and-groove structure.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

High-voltage cable connecting device for transformer

InactiveCN108551127AInnovative designSimple structureApparatus for joining/termination cablesTransformerHigh pressure

The invention discloses a high-voltage cable connecting device for a transformer. The high-voltage cable connecting device comprises a fixed seat and a quick lock connector; wire-to-boards are respectively arranged at two horizontal sides of the fixed seat, and the quick lock connector is arranged between two opposite wire-to-boards, auxiliary connecting devices are respectively arranged on the fixed seat at two sides of the quick lock connector; the auxiliary connecting devices are respectively arranged between the fast lock connector and the wire-to-boards; the single auxiliary connecting device comprises a first linear mold and a second linear mold which are opposite to each other and arranged at intervals; wire conveying devices are arranged on the fixed seat at outsides of the wire-to-boards; each wire conveying device comprises a horizontal sliding rail arranged on the fixed seat and a waveform bracket. The high-voltage cable connecting device disclosed by the invention is novelin design, simple in structure, convenient and efficient for operation, capable of realizing the integration of wire conveying, correction and wire connecting, capable of performing straightening while performing the wire connecting, good in straightening effect and good in wire connecting effect; the clamping fixation of the connected wire is strong, the connection of large batch of high-voltagecable is convenient, and the practicability is stronger.

Owner:瑞普兰德电梯有限公司

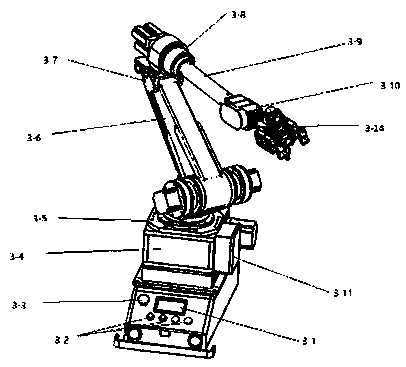

Automatic carrying system and method for model animals

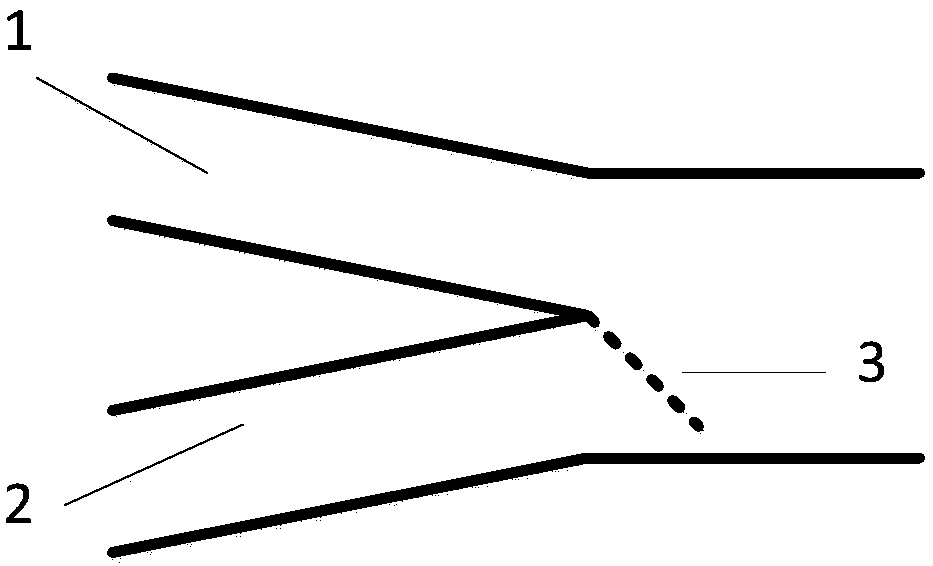

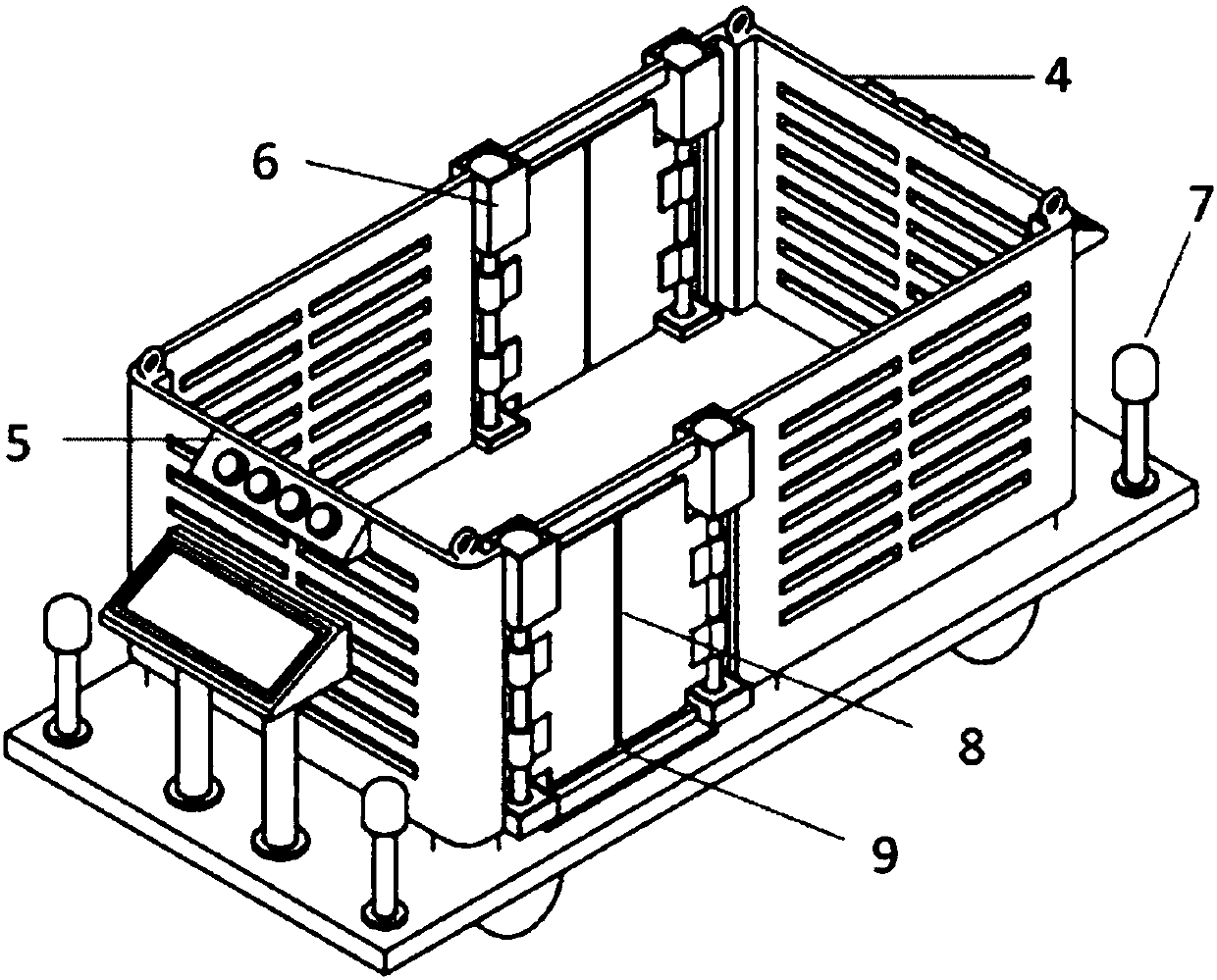

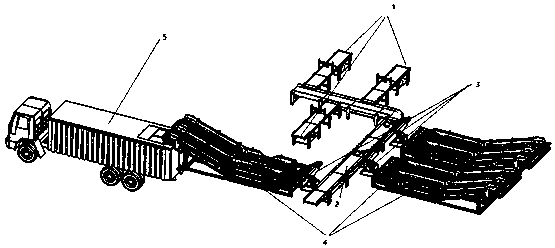

ActiveCN107649399AThe transportation process is compact and smoothConvenient and efficient transportationMemory record carrier reading problemsSortingEar tagComputer science

The invention provides an automatic carrying system for model animals. The automatic carrying system comprises a sorting device, a controller, a drive mechanism and a carrying device, wherein the sorting device is equipped with a first ear tag reader, is used for reading label information of model animals through the first ear tag reader and uploading the label information to the controller, and is further used for controlling a swing door to enable the model animals which meet conditions to enter a waiting region according to model animal sorting information sent by the controller; the controller is used for sorting the model animals according to the label information of the model animals, and sending the sorting information to the sorting device, and is further used for sending a controlinstruction to the drive mechanism; the drive mechanism is used for driving the carrying device according to the control instruction, and is further used for controlling an automatic door to open andclose; and the carrying device is dispatched to the waiting region to load the model animals which meet the conditions through the drive mechanism, and is further used for transporting the model animals which meet the conditions to a designated site from the waiting region. The model animal automatic carrying system realizes automatic sorting and transporting of the model animals, so that the animals are transported more efficiently and conveniently.

Owner:CHINA AGRI UNIV

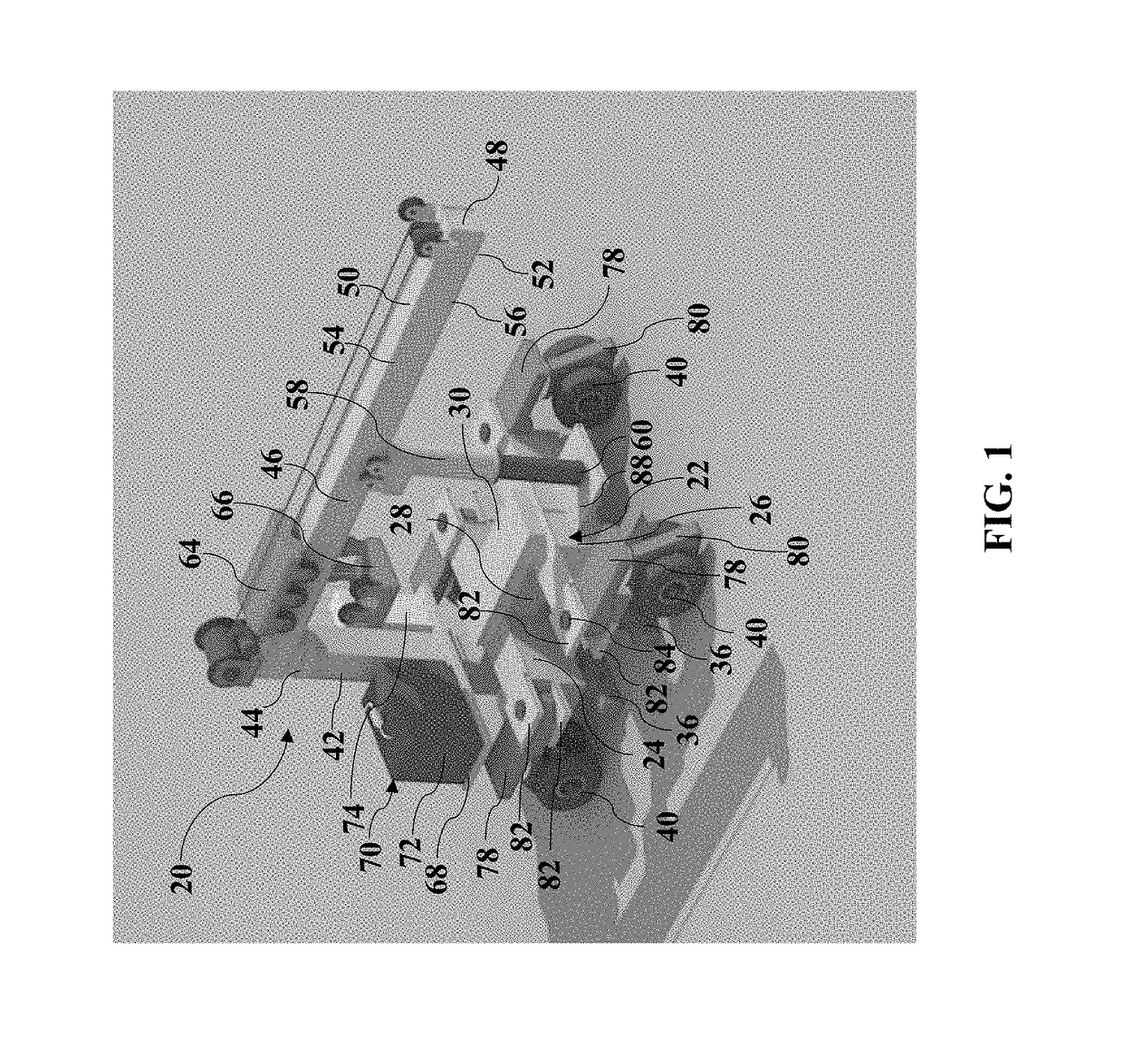

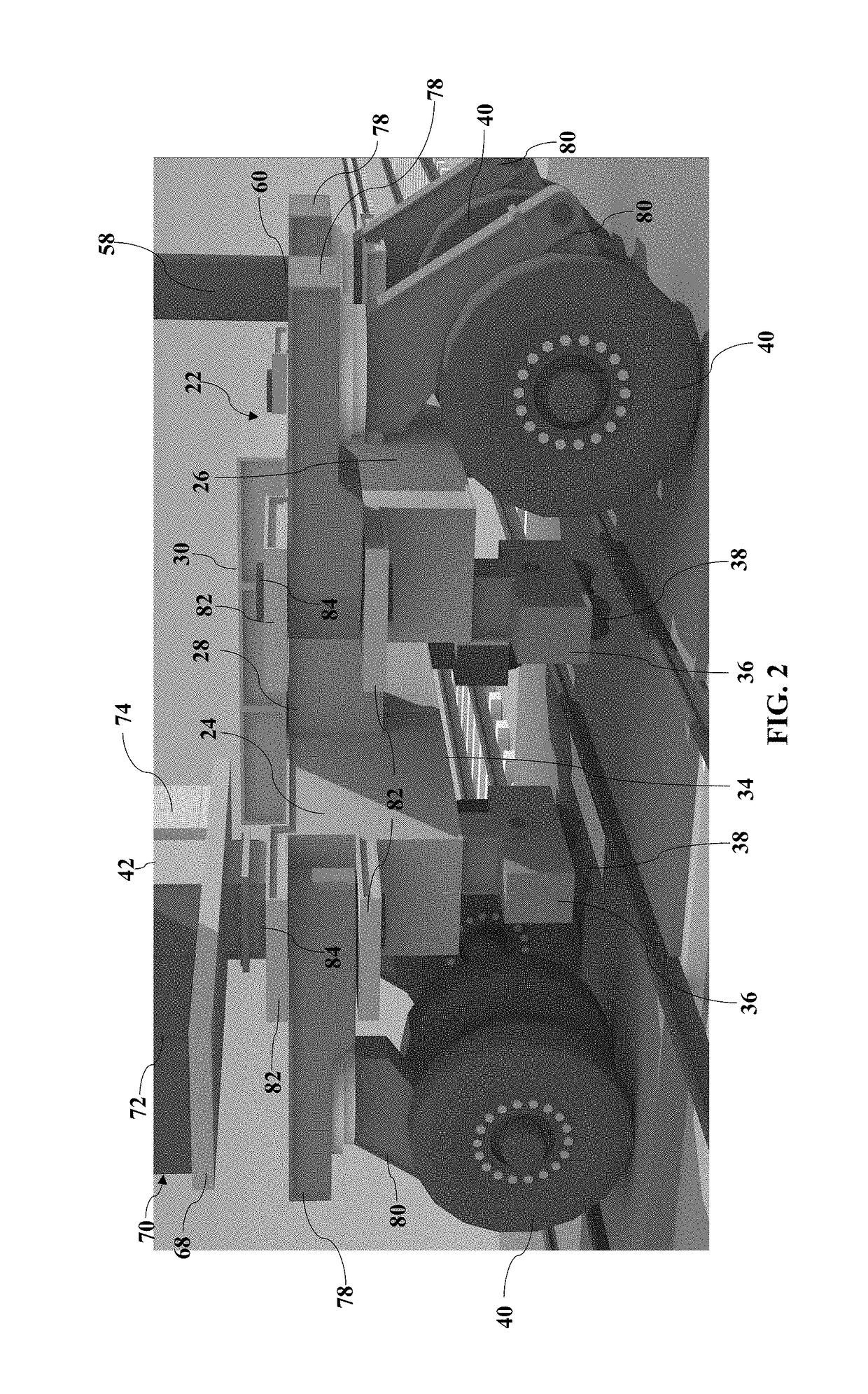

Logistics distribution sorting system and sorting method

PendingCN110976313AImprove work efficiencyImprove transportation efficiencySortingLogistics managementTruck

The invention discloses a logistics distribution sorting system and method. The system comprises feeding flow lines, a conveying flow line, sorting robots, double-way parallel conveying and lifting flow lines and a truck conveying flow line; multiple feeding flow lines, multiple sorting robots and multiple double-way parallel conveying and lifting flow lines are provided; the multiple feeding flowlines are staggered on the two sides of the conveying flow line at intervals, and communicate with the conveying flow line; each sorting robot is correspondingly provided with the double-way parallelconveying and lifting flow lines; the sorting robots are positioned in middles of the double-way parallel conveying and lifting flow lines; the double-way parallel conveying and lifting flow lines comprise higher ends and lower ends; the lower ends communicate with the sorting robots; and the higher ends communicate with the truck conveying flow line. Through the structure, part of the problems in an original structure are solved, the operation efficiency can be improved, the fund loss is reduced, and the logistics sorting and distribution are more convenient.

Owner:NANJING INST OF MECHATRONIC TECH

Lifter assembly and system for removing highway or railway bridges

ActiveUS20190085516A1Simple structureConvenient and efficient transportationRail and road vehiclesBridge erection/assemblyMechanical engineeringEngineering

A lifter assembly includes a base having a top and a bottom surface. Connectors are attached to the base extending outwardly from the bottom surface. Each of the connectors includes at least one rail wheel rotatably attached thereto. The base includes traveling wheels rotatably attached thereto. A post is attached to the base extending outwardly from the top surface to a distal end. An arm is disposed on the distal end, rotatably attached to the post, extending outwardly to a terminal end. A support is movably attached to the arm and extends outwardly to a support end. A trolley is slidably disposed on the arm and movable along the arm between the terminal end and the post. Each of the traveling wheels includes a leg pivotably attached to the base connecting the traveling wheel to the base and move the traveling wheel between a transport and a storage position.

Owner:BRIDGINNOVA INC

Vehicle tie-down device for hauling a load

InactiveUS8870249B2Convenient and efficient transportationImprove securitySnap fastenersWing fastenersEngineeringElectrical and Electronics engineering

The invention provides tie-down devices and related methods for securing oversized items in a vehicle trunk or rear storage compartment in preparation for transport. The tie-down devices include sections connected by a releasable buckle that allows for separately cinching the strap sections to desired lengths. The tie-down devices incorporate specialized connectors at each end in the form of at least one grip that is curved to attach to the edge of a panel on the vehicle and a latch that attaches to a fixed attachment mechanism at the opposite end.

Owner:GLOBAL CONSUMER PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com