Novel heat emitting welding flux and welding method

A technology of exothermic flux and welding method, applied in the direction of aluminothermic welding equipment, welding medium, welding equipment, etc., can solve the problems of inconvenient transportation, environmental pollution, high transportation cost, etc., achieve welding efficiency and welding effect, and operate Convenience, efficiency and low cost of air freight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

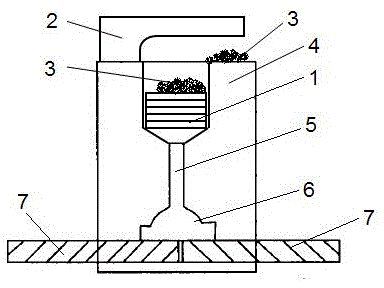

[0024] Composition of raw materials: 100 grams of powdery exothermic flux, 0.5 grams of graphite powder, and 0.5 grams of talcum powder. Put the raw materials into the mixer one by one and mix them evenly, then take them out, and use a mechanical tablet press to press the raw materials into several disc shapes for later use. As a specific requirement, the diameter of the disc-shaped exothermic flux 1 should be larger than the diameter of the mold diversion hole, so that the disc-shaped exothermic flux 1 can be placed directly above the diversion hole 5 without placing an isolation gasket , thus simplifying the welding process.

[0025] Specifically, the welding process of the present invention is as follows: clean the wire 7 and the mold 4, remove the oxide layer on the surface with a steel brush, heat the mold 4 with a blowtorch to remove moisture, then put the wire 7 into the mold 4, and fasten it The fixture is used to fix the mold 4; above the diversion hole 5 of the mold...

Embodiment 2

[0027] Composition of raw materials: 100 grams of powdery exothermic flux, 0.5 grams of graphite powder, and 0.5 grams of talcum powder. Put the raw materials into the mixer one by one and mix them evenly, then take them out, and use a mechanical tablet press to press the raw materials into several disc shapes for later use. Other specific requirements are the same as those in Embodiment 1, and will not be repeated here.

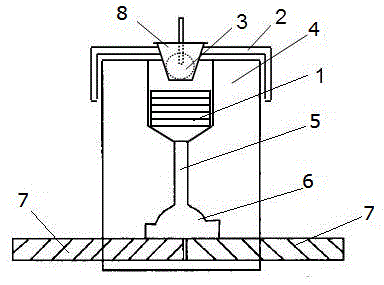

[0028] Specifically, the welding process of the present invention is as follows: clean the wire 7 and the mold 4, remove the oxide layer on the surface with a steel brush, heat the mold 4 with a blowtorch to remove moisture, then put the wire 7 into the mold 4, and fasten it The fixture is used to fix the mold 4; above the diversion hole 5 of the mold 4 (below the diversion hole 5 is the welding cavity 6), directly place a plurality of disc-shaped exothermic fluxes 1 that meet the quantity requirements, close the cover 2, and ignite the electron The device ...

Embodiment 3

[0031] Composition of raw materials: 130 grams of powdery exothermic flux, 0.3 grams of graphite powder, and 1 gram of talcum powder. Put the raw materials into the mixer in turn and mix them evenly, then take them out, press the raw materials into several square tablets with a mechanical tablet press, and set aside. The minimum passage size of the square piece is larger than the diameter of the diversion hole. The welding process is the same as that in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com