Patents

Literature

69results about How to "Cause mechanical damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

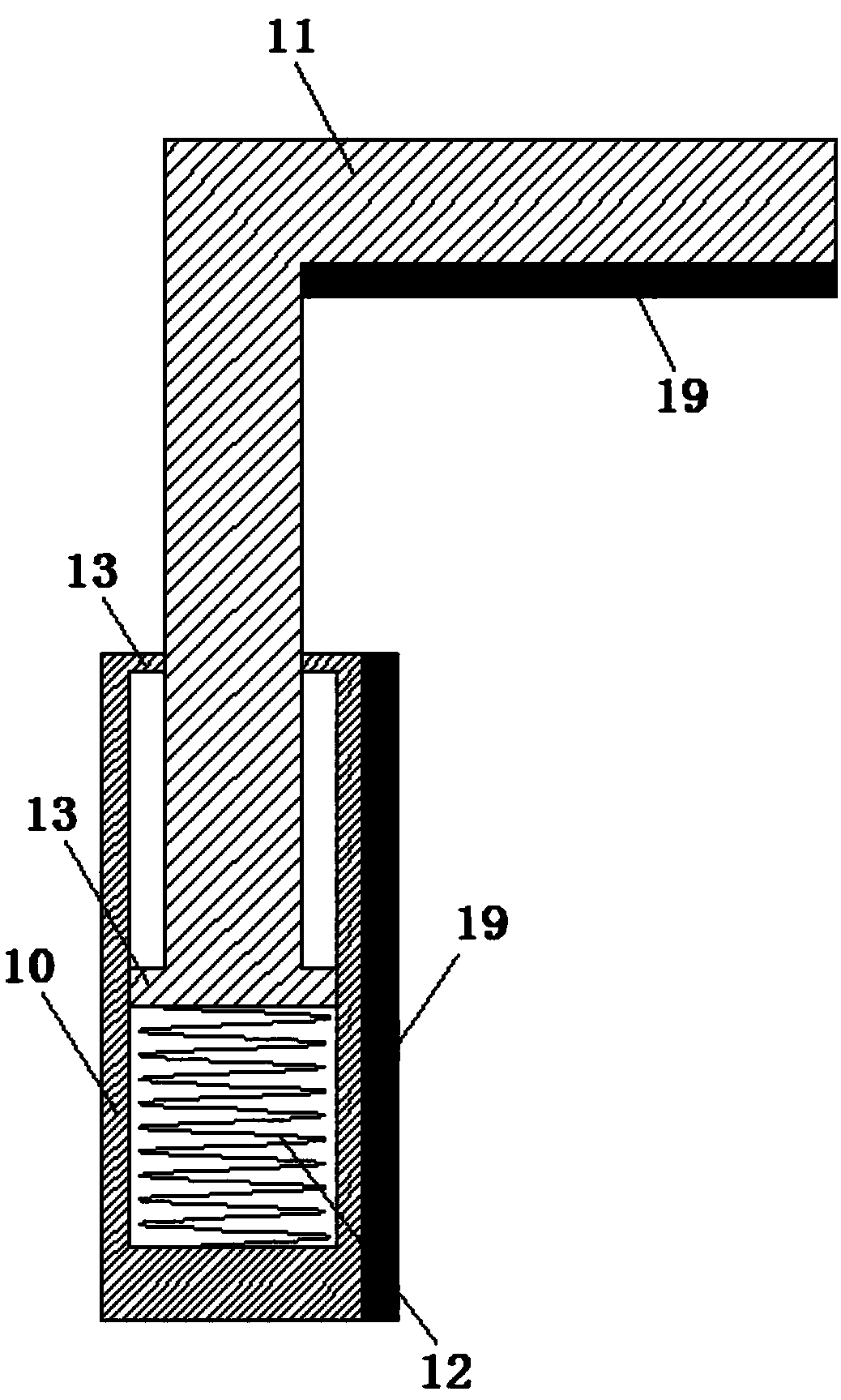

Urinary bladder power pump driven by external electromagnetism

InactiveCN101176689ANot cause infectionCause infectionFlexible member pumpsPositive-displacement liquid enginesMagnetic tension forceEngineering

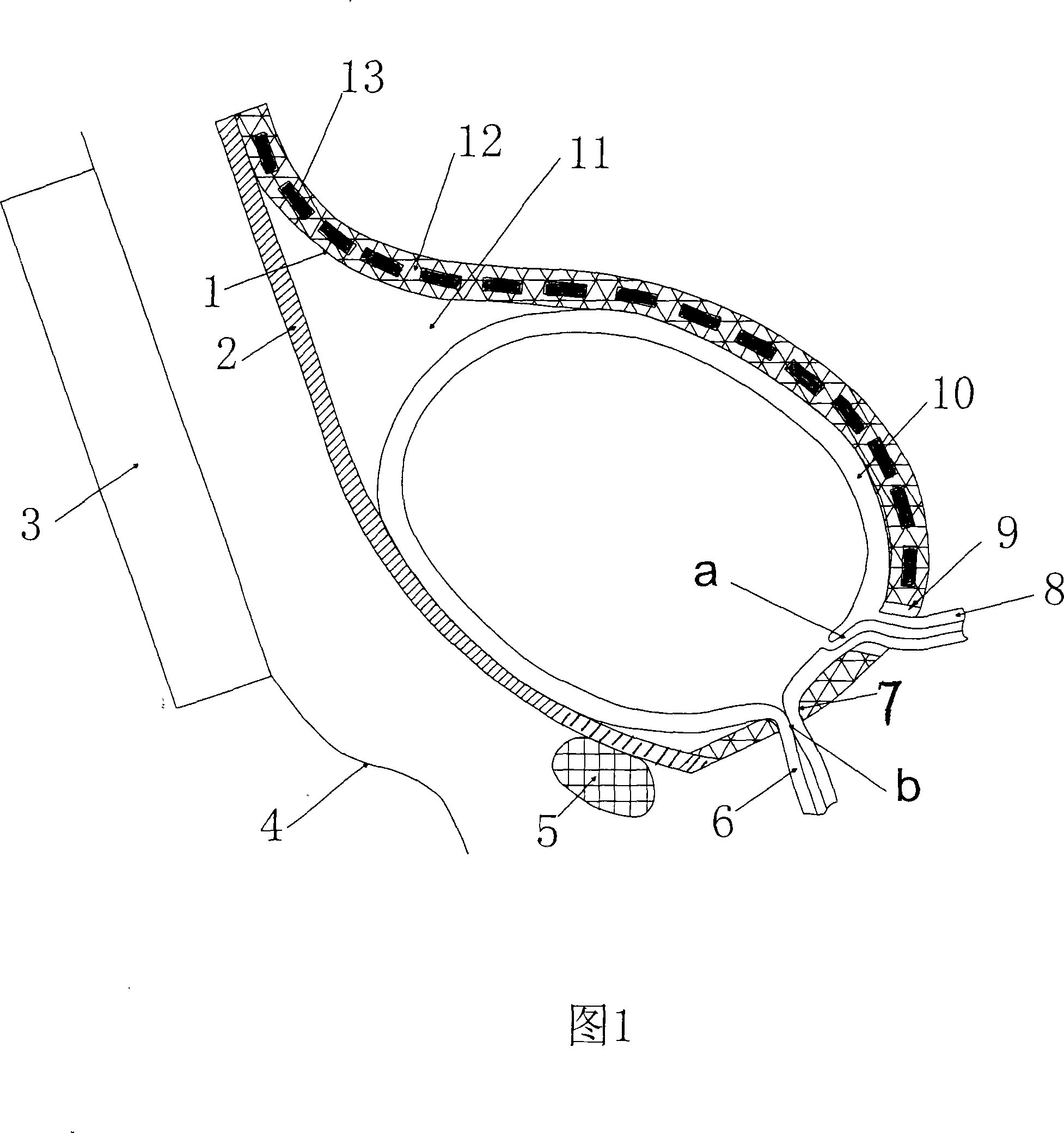

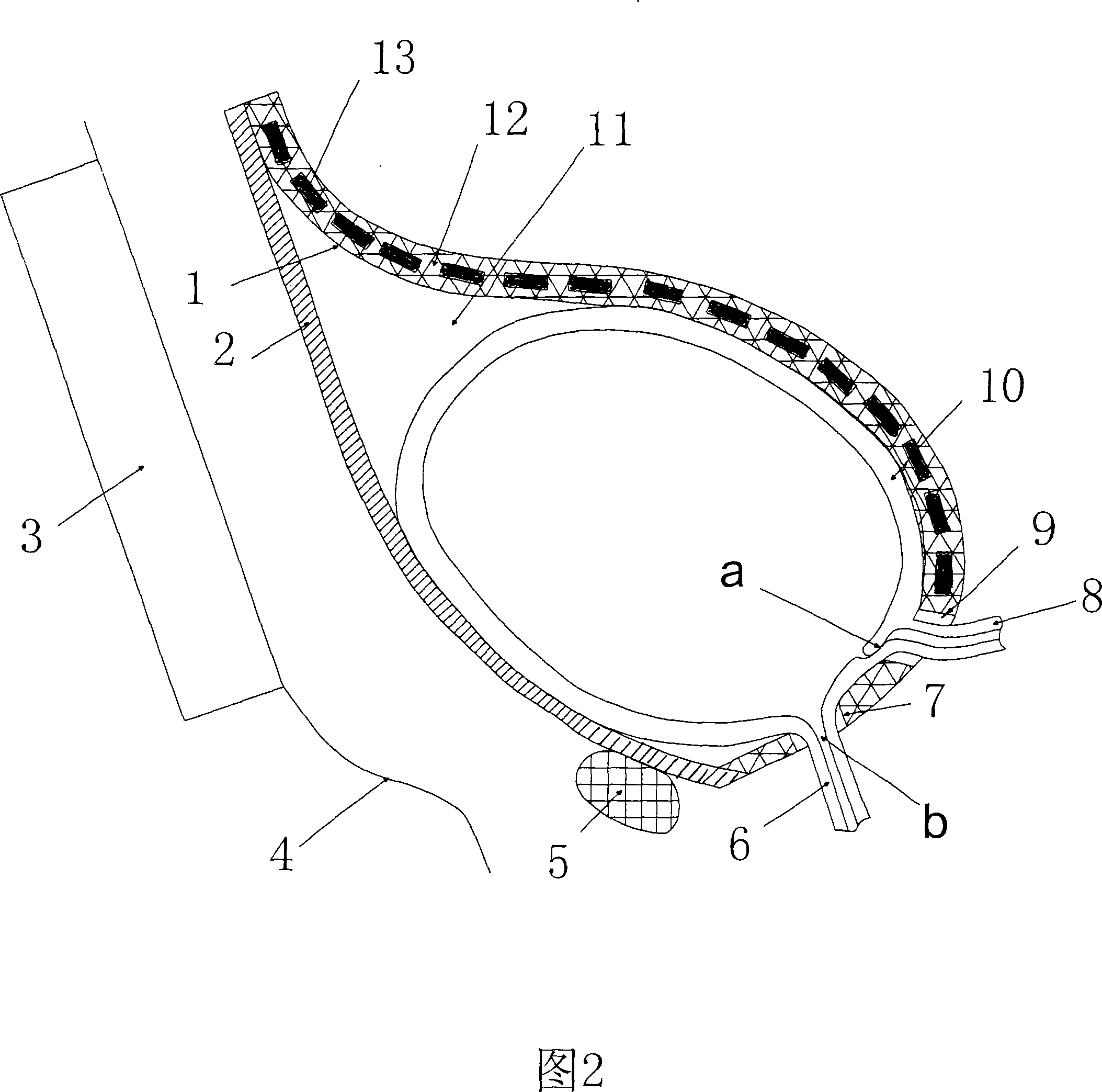

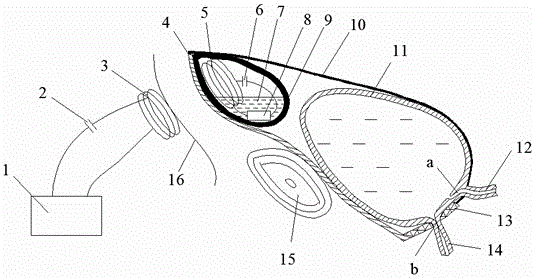

The invention relates to a bladder power pump utilizing the magnetic force to assist the bladder to urinate, which comprises a magnetic active cell (1), a stator (2) and a magnetic controller (3), wherein, the magnetic controller (3) generates magnetic field if switched on and enables the magnetic force to work on the magnetic active cell (1); the magnetic active cell (1) comprises a flexible sheet (12) and a plurality of permanent magnetic sheets (13), and the permanent magnetic sheets (13) are enwrapped with the flexible sheet (12); the flexible sheet (12) enwrapping the permanent magnetic sheets (13) surrounds a gourd-shaped structure with the stator (2) to circle the outside of the bladder (10) to build a variable working cavity (11); the upper end of the flexible sheet (12) enwrapping the permanent magnetic sheets (13) is contacted and adhered with the stator (2); a through hole (9) of ureter communicating a ureter (8) with a ureter port (a) inside the bladder wall, and a urethra bayonet (7) held at a urethral meatus (b) of a urethra (8) are respectively arranged at the lower end of the flexible sheet (12) where the permanent magnetic sheets (13) are not enwrapped; and the lower end of the flexible sheet (12) where the permanent magnetic sheets (13) are not enwrapped is contacted and adhered with the stator (2). The invention can effectively assist the neurogenic bladder dysfunction sufferer to realize emiction and has the advantages of ingenious design, simple structure, safe use, convenience and practicality.

Owner:GUANGDONG UNIV OF TECH

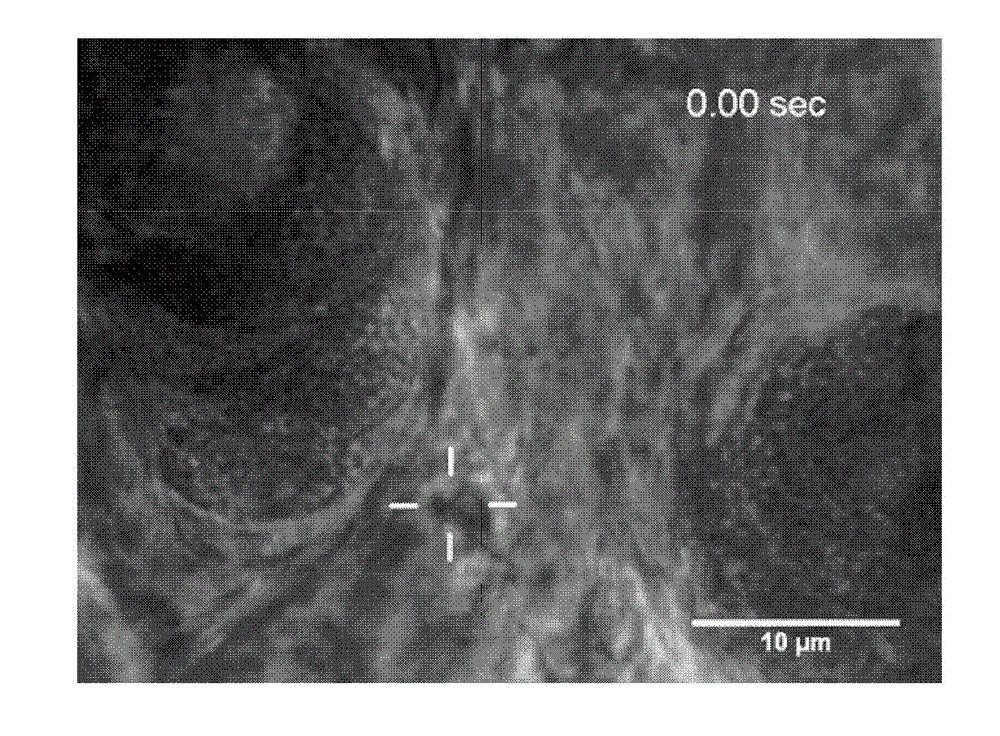

Method and corresponding device for capturing and controlling in-vivo cells of living body animal

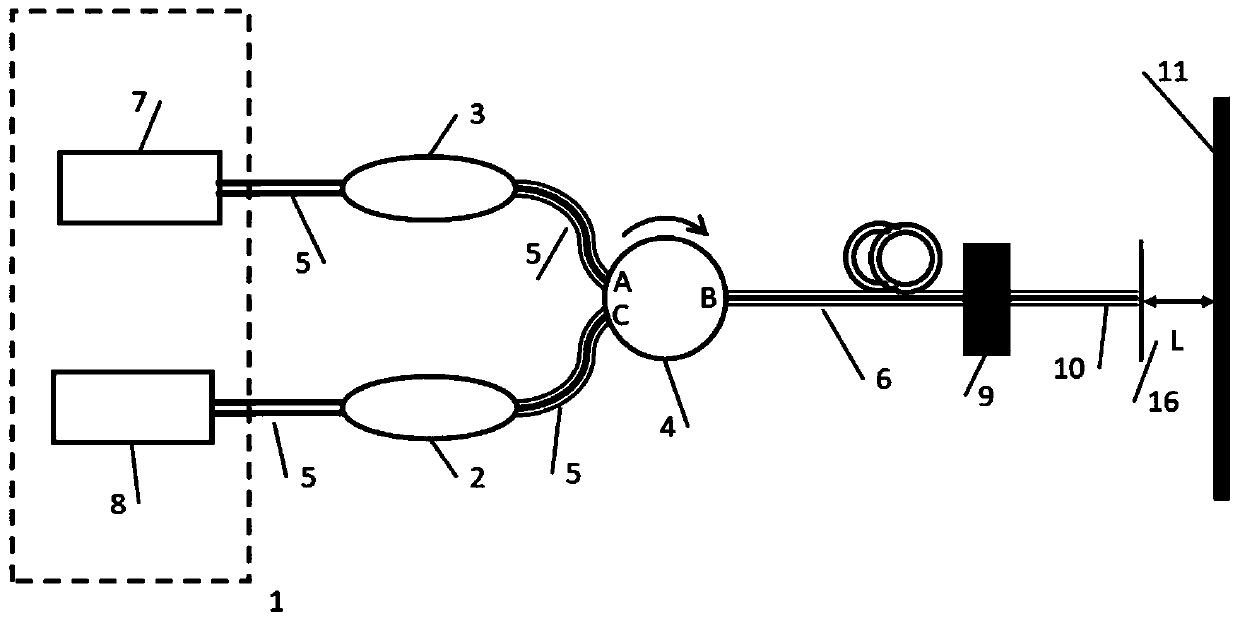

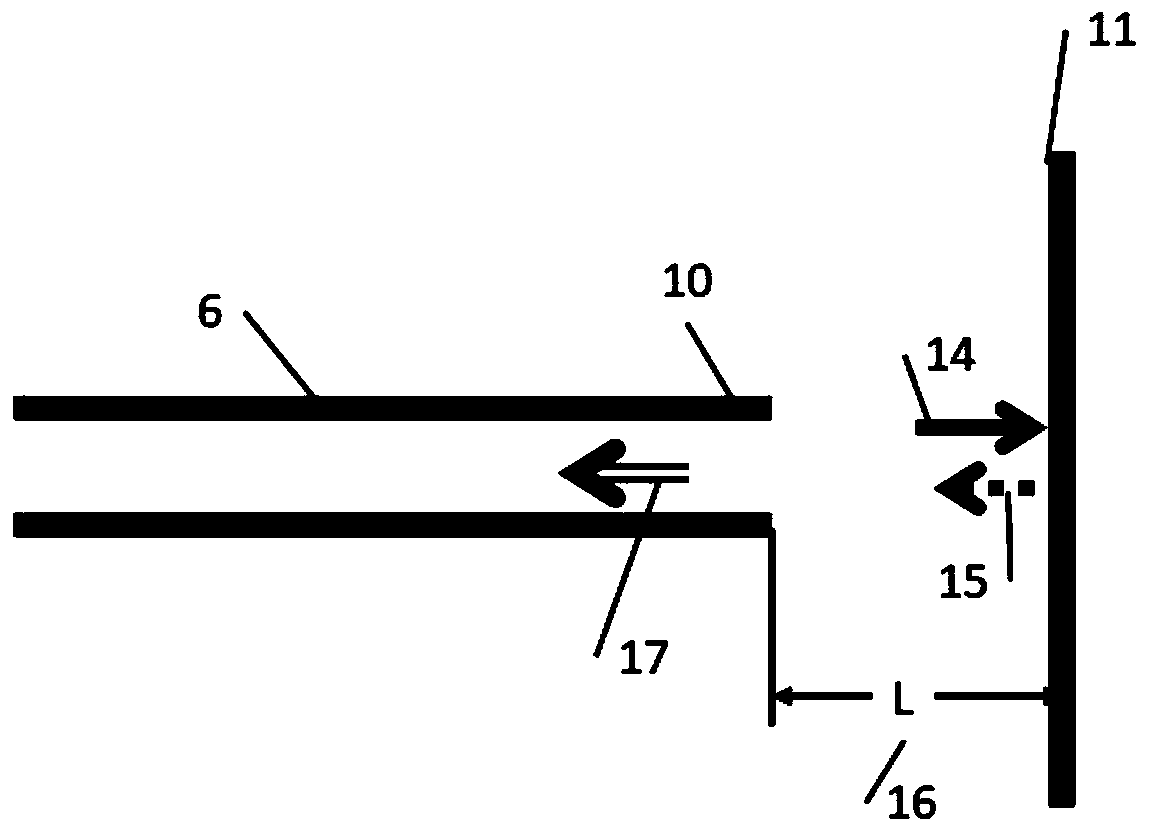

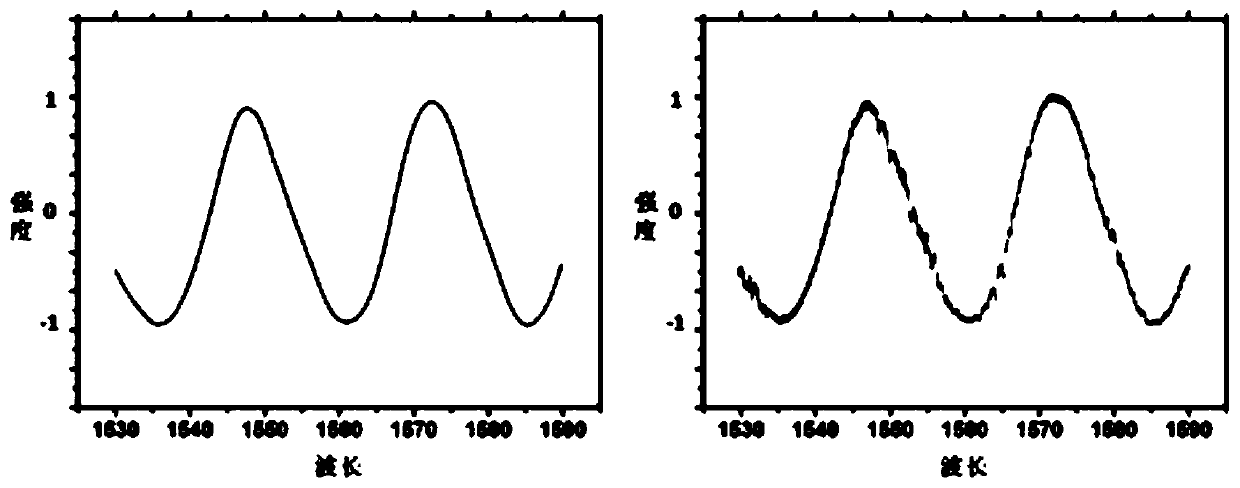

InactiveCN102860845ACause mechanical damageFree from destructionDiagnosticsSurgeryPhysicsMechanical lesion

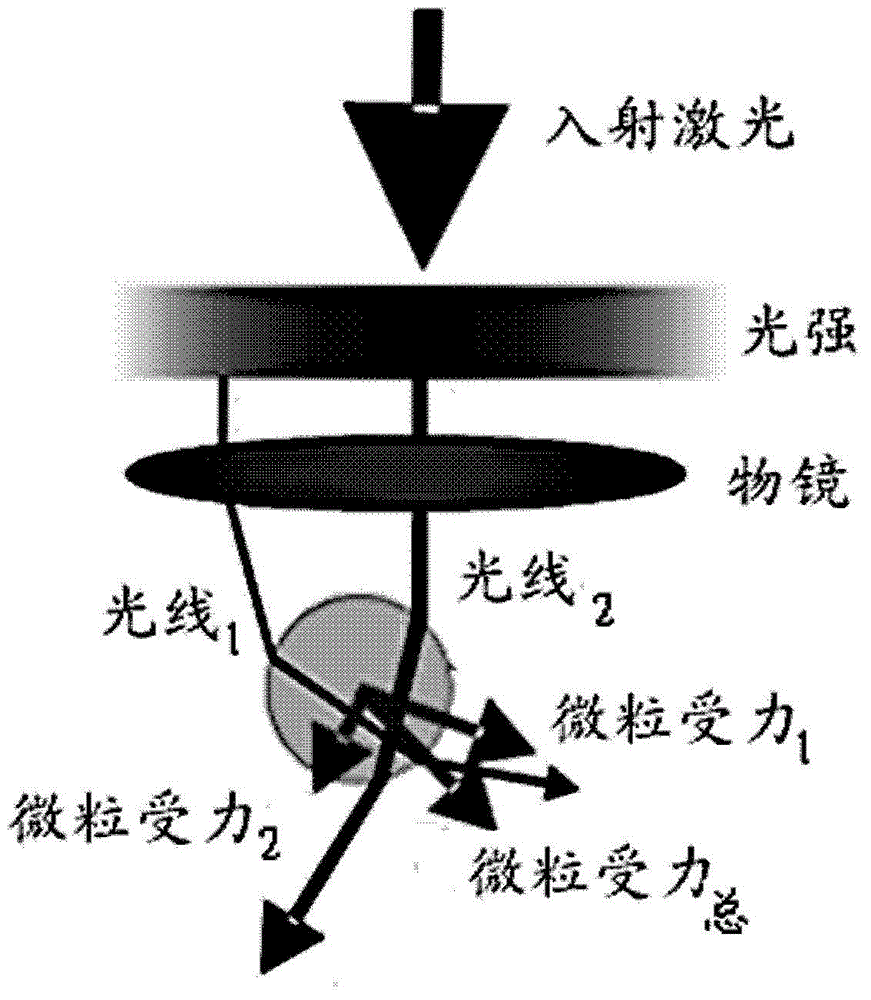

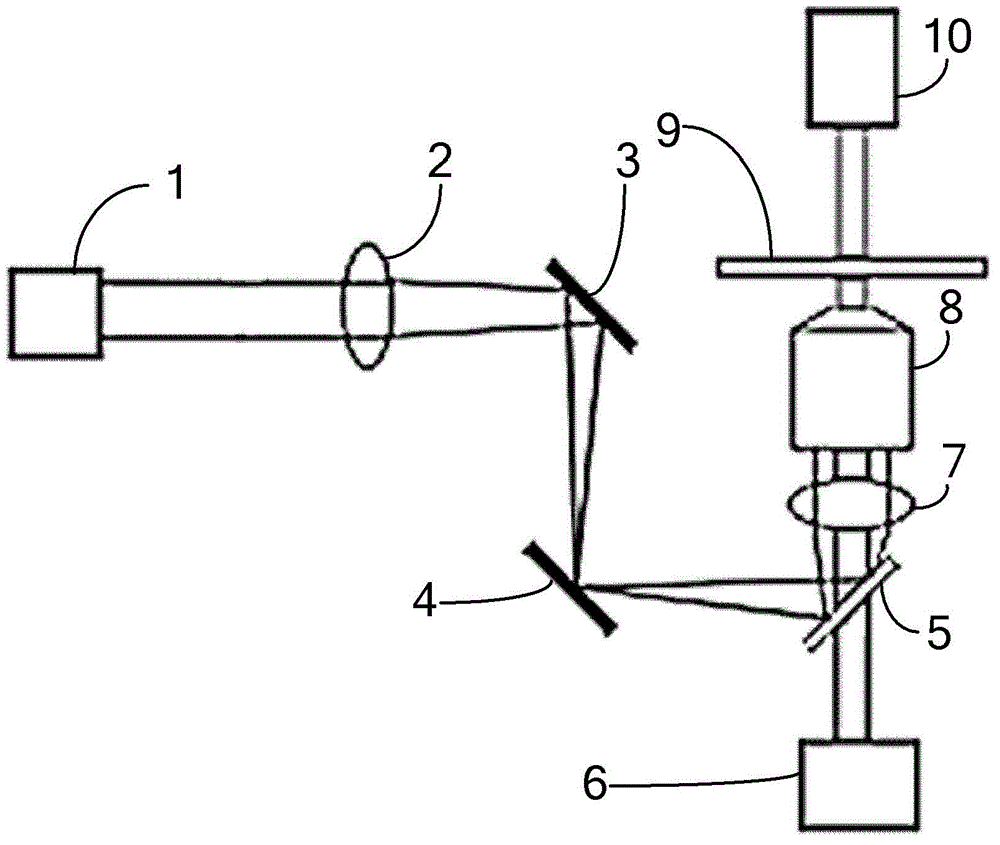

The invention discloses a method for capturing and controlling in-vivo cells of a living body animal. The method comprises the following steps of: forming optical tweezers with a beam of laser, wherein the optical tweezers are an optical field which can be subjected to momentum exchange with particles; placing a part, which is required to be subjected to cell capturing, of the living body animal in the position where the optical tweezers are formed; aligning an illumination light beam with the optical tweezers and the part, which is required to be subjected to cell capturing, of the living body animal; and adjusting the relative position of the optical tweezers and the living body animal, so that the in-vivo cells of the living body animal are captured by the optical tweezers. According to the method, the in-vivo cells of the living body animal can be captured and controlled in a non-contact mode without damage to a dermic layer of the surface of the animal, and mechanical harm to the cells is avoided.

Owner:UNIV OF SCI & TECH OF CHINA

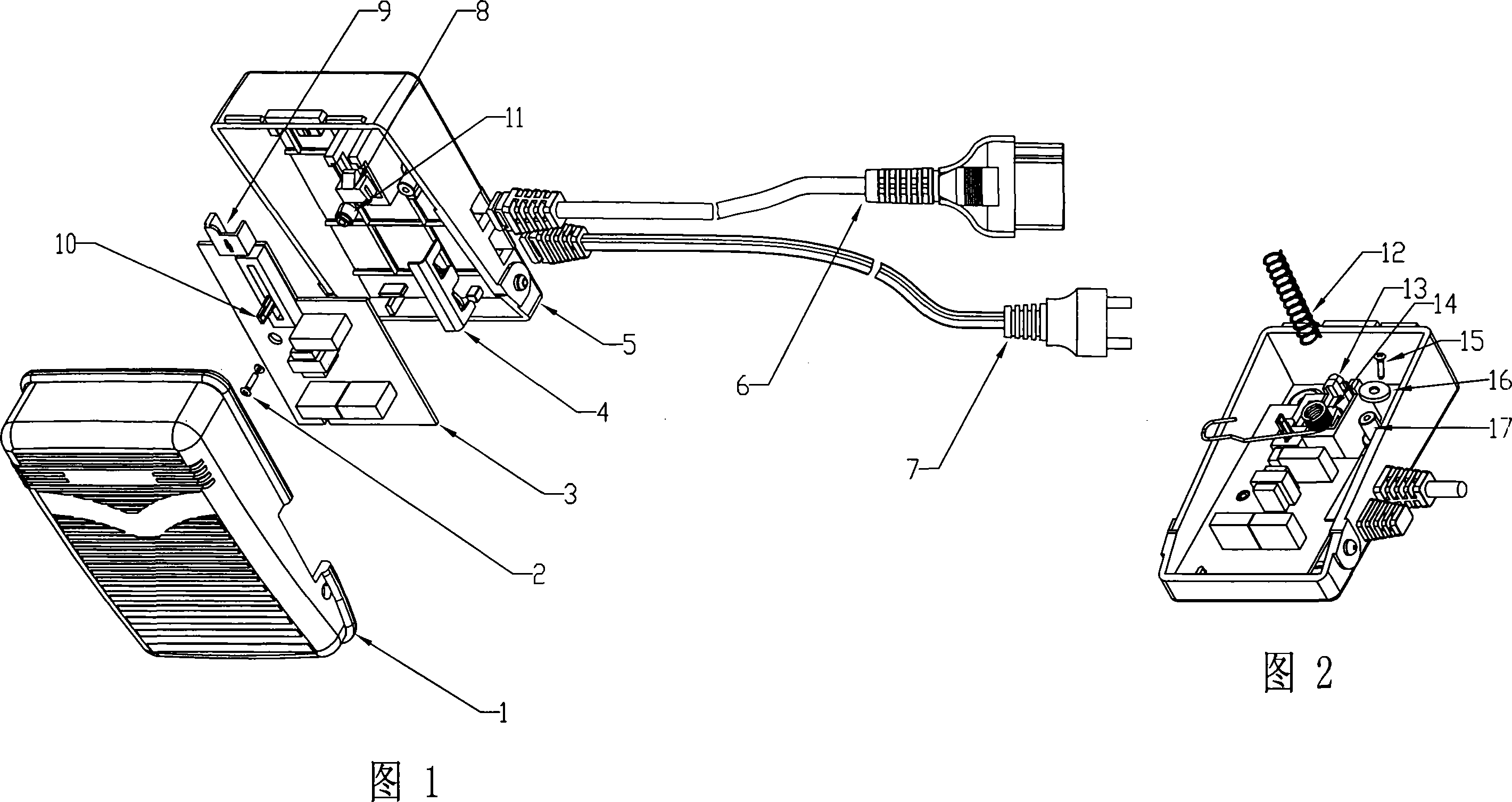

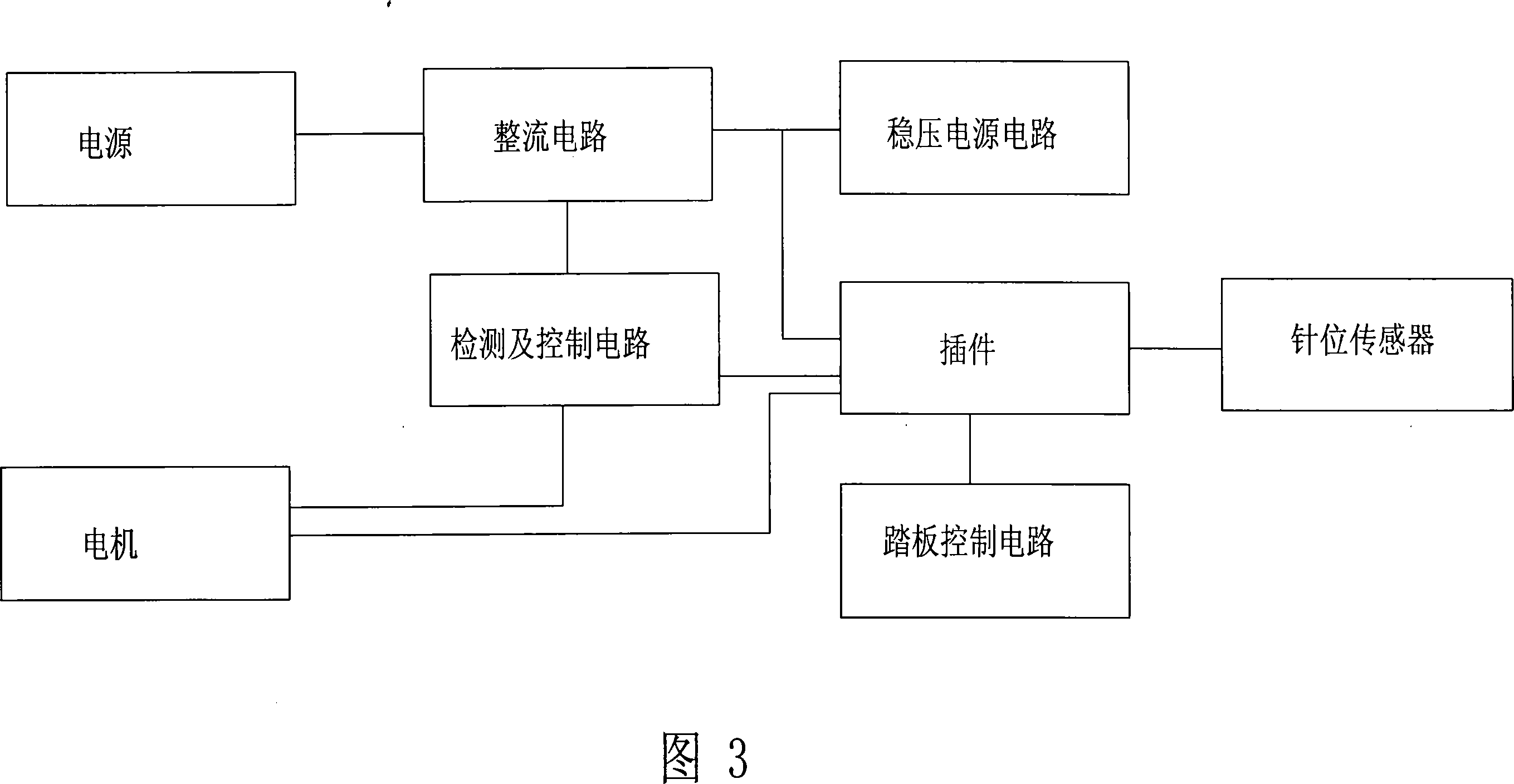

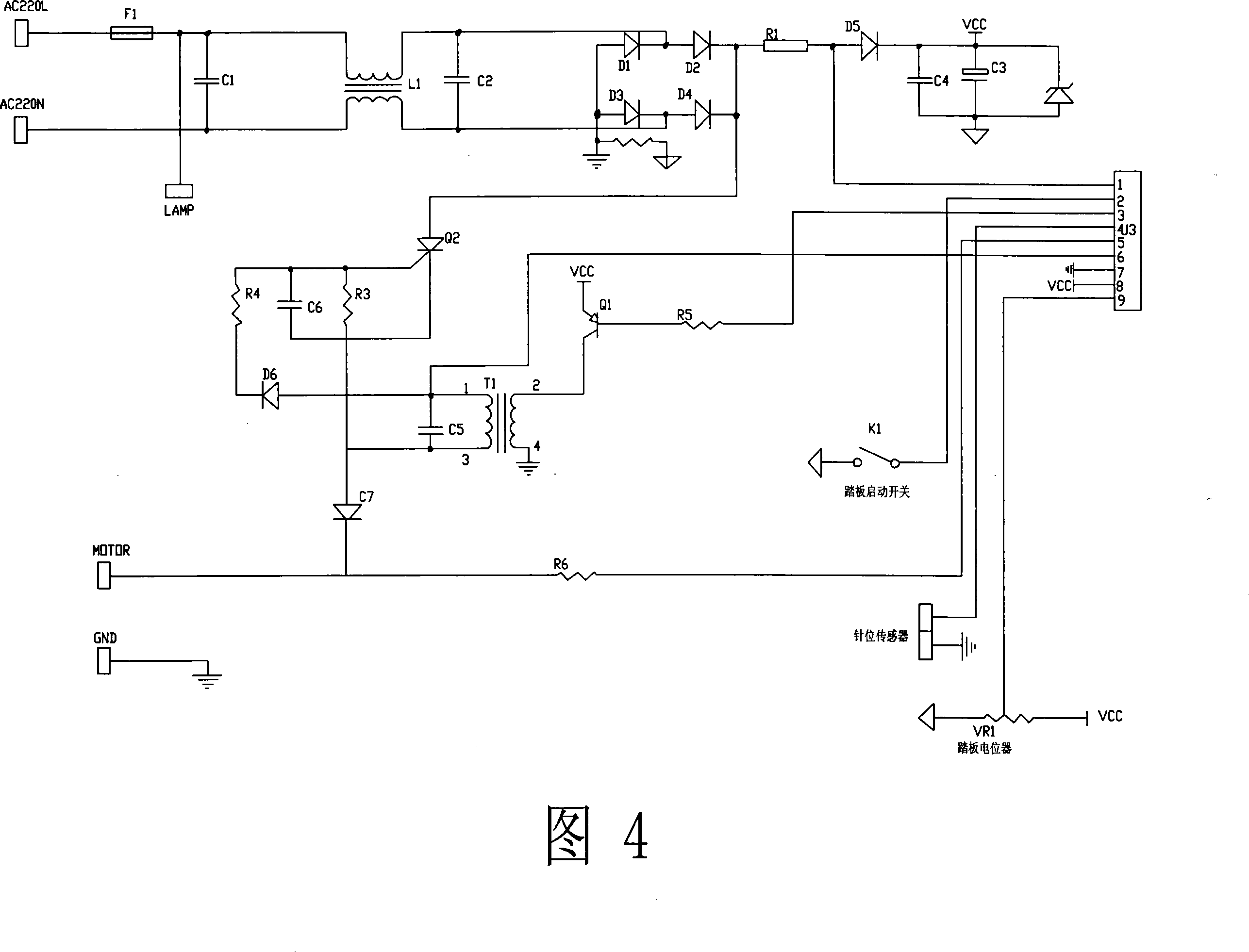

A home sewer motor actiyator

InactiveCN101237210AControl outputControl output torqueSewing-machine control devicesField or armature current controlElectricityLow speed

The invention belongs to the sewing machine manufacturing technique technical field and relates to a motor velocity modulation controller of a domestic sewing machine. The motor velocity modulation controller is in electric connection with a power supply and a motor and comprises a rectification circuit, a regulated power supply circuit, a detection and control circuit, a plug-in unit and a foot pedal control circuit, wherein, the rectification circuit is in electric connection with the power supply, the regulated power supply circuit, the detection and control circuit and the plug-in unit, the detection and control circuit is in electric connection with the plug-in unit and the motor, the plug-in unit is in electric connection with the foot pedal control circuit. The motor velocity modulation controller of the domestic sewing machine can regulate the output moment of the motor automatically according to the size of the practical load and effectively controls the motor to realize the output with low speed and great moment, thereby ensuring that a shank runs stably when thick cloth is sewed. In addition, the motor velocity modulation controller of the domestic sewing machine of the invention is also provided with a shank stopping sensor; when the sensor receives the stopping command, the top stitch position of the shank can be found and the machine stops at the position.

Owner:NINGBO GUGAO NC SCI & TECH

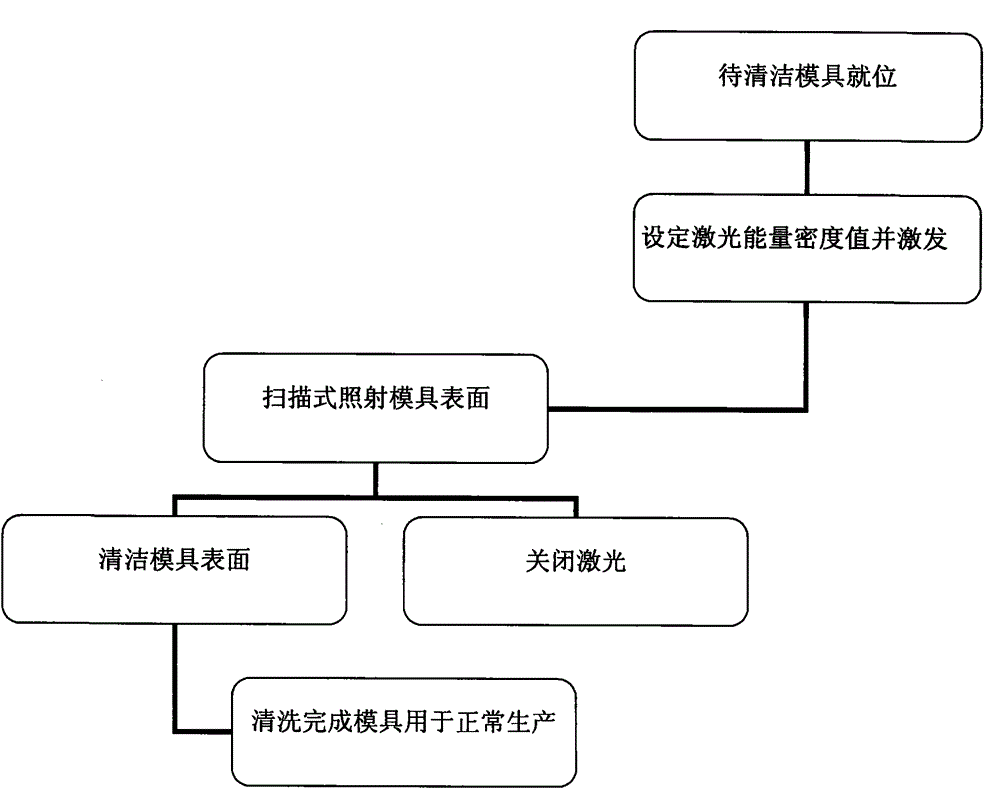

Laser cleaning method for tire moulds

InactiveCN104368564ANo loss of lifeCause mechanical damageCleaning processes and apparatusEngineeringCleaning methods

The invention discloses a laser cleaning method for tire moulds and aims to achieve safe, environment-friendly and efficient cleaning of the tire moulds. According to the technical scheme, the laser cleaning method is implemented by large difference between mould surfaces and attachments in absorption coefficient of certain wavelength laser energy. The laser energy radiating to the mould surfaces are mostly absorbed by the attachments on the mould surfaces, the attachments are evaporated or swelled instantly after being heated or vaporized and are driven to separate from the mould surfaces by vapor flow formed on the surfaces. The mould surfaces are not damaged.

Owner:BEIJING HEZHONG JIANYE ELECTROMECHANICAL TECH

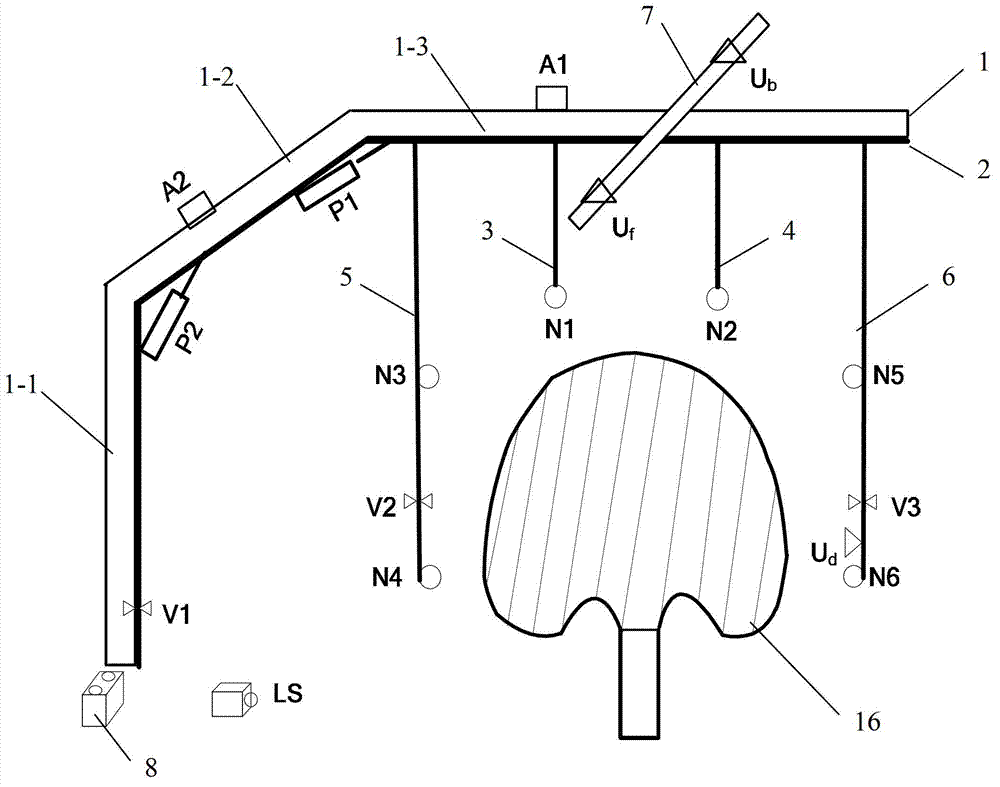

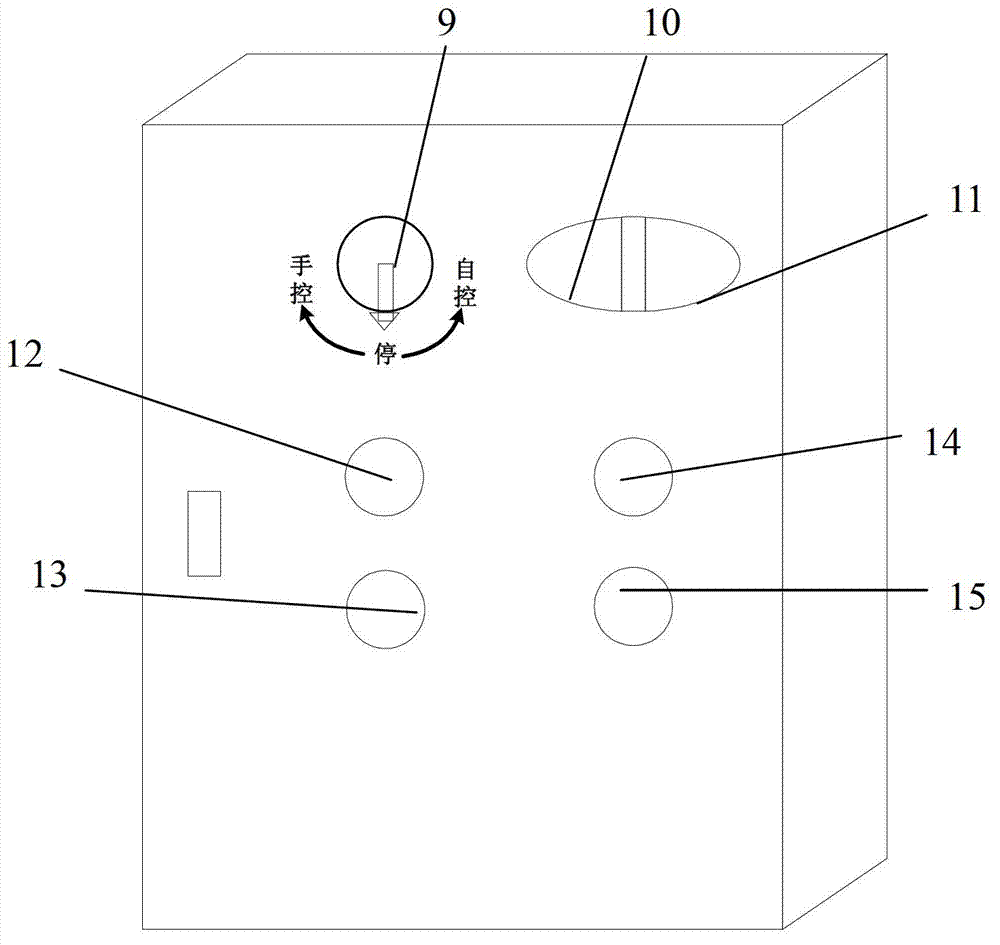

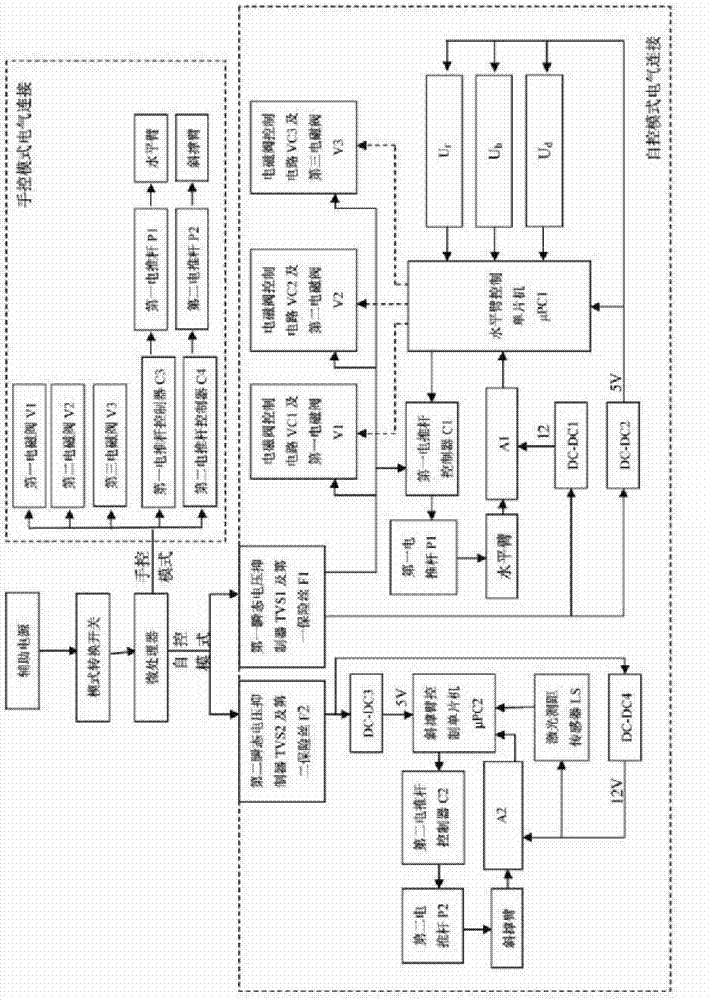

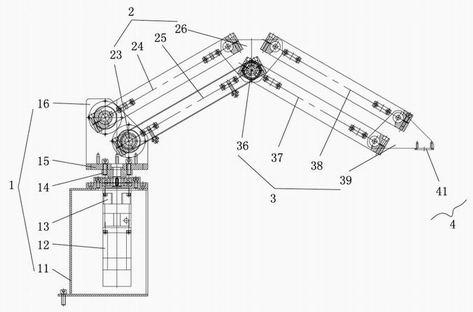

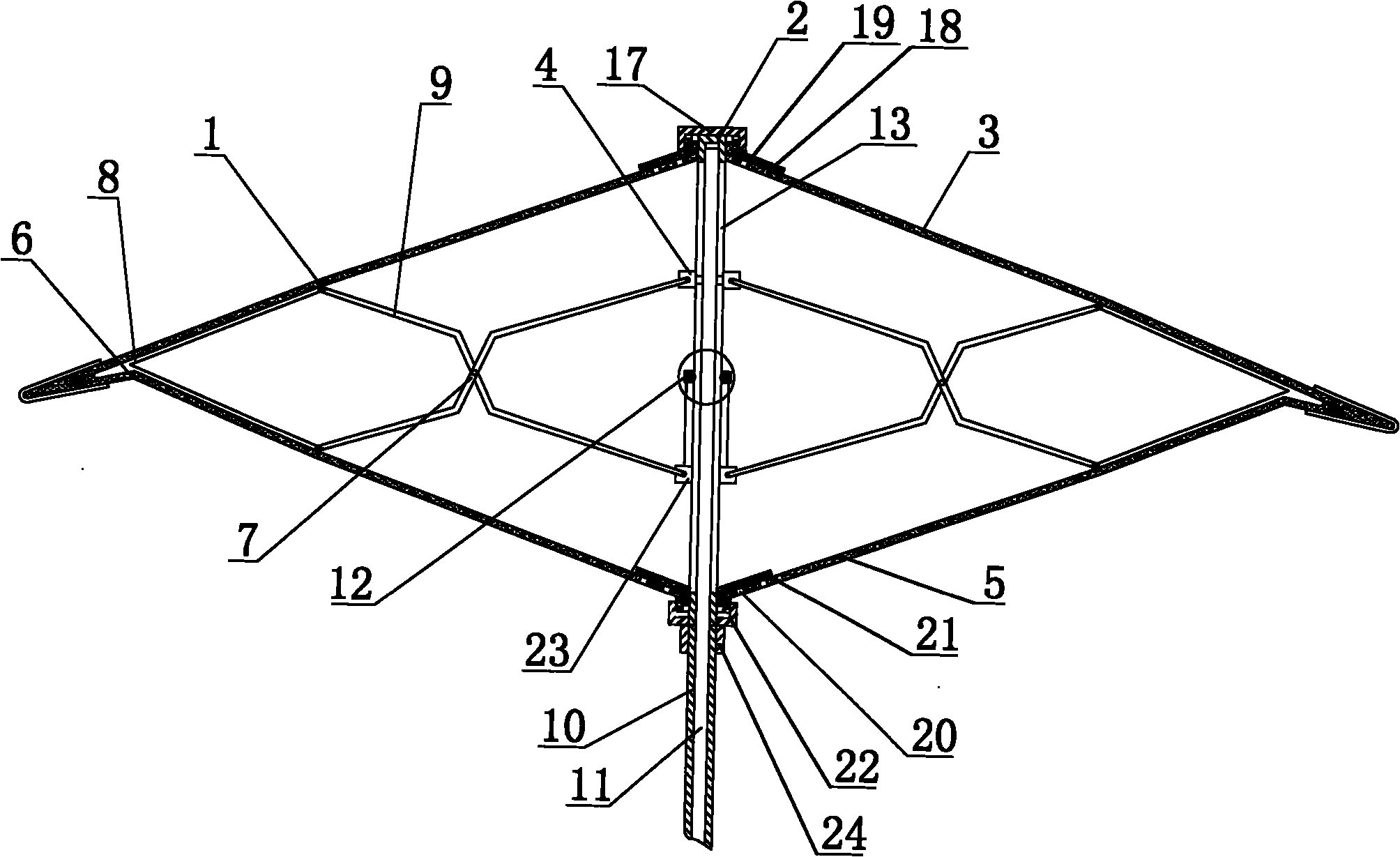

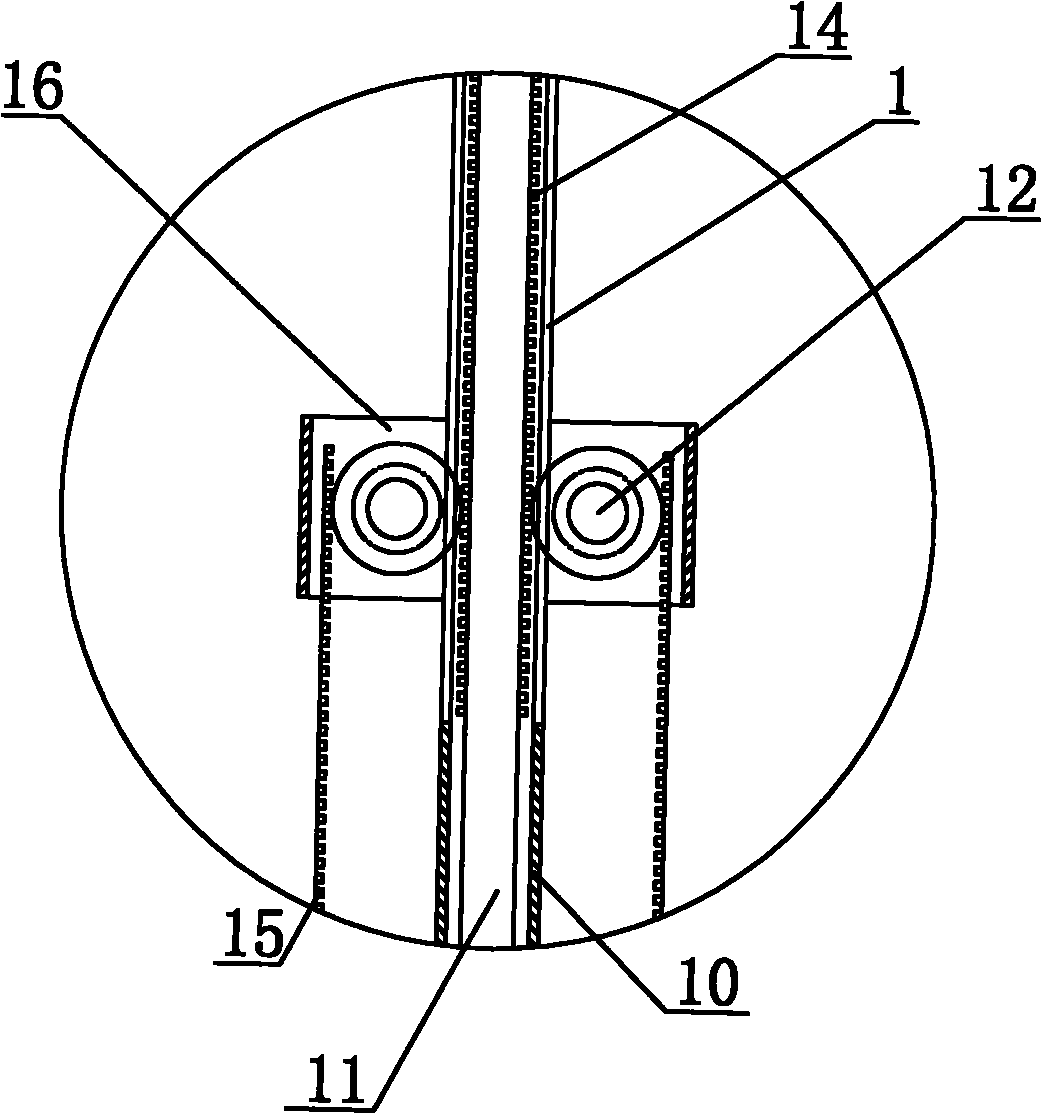

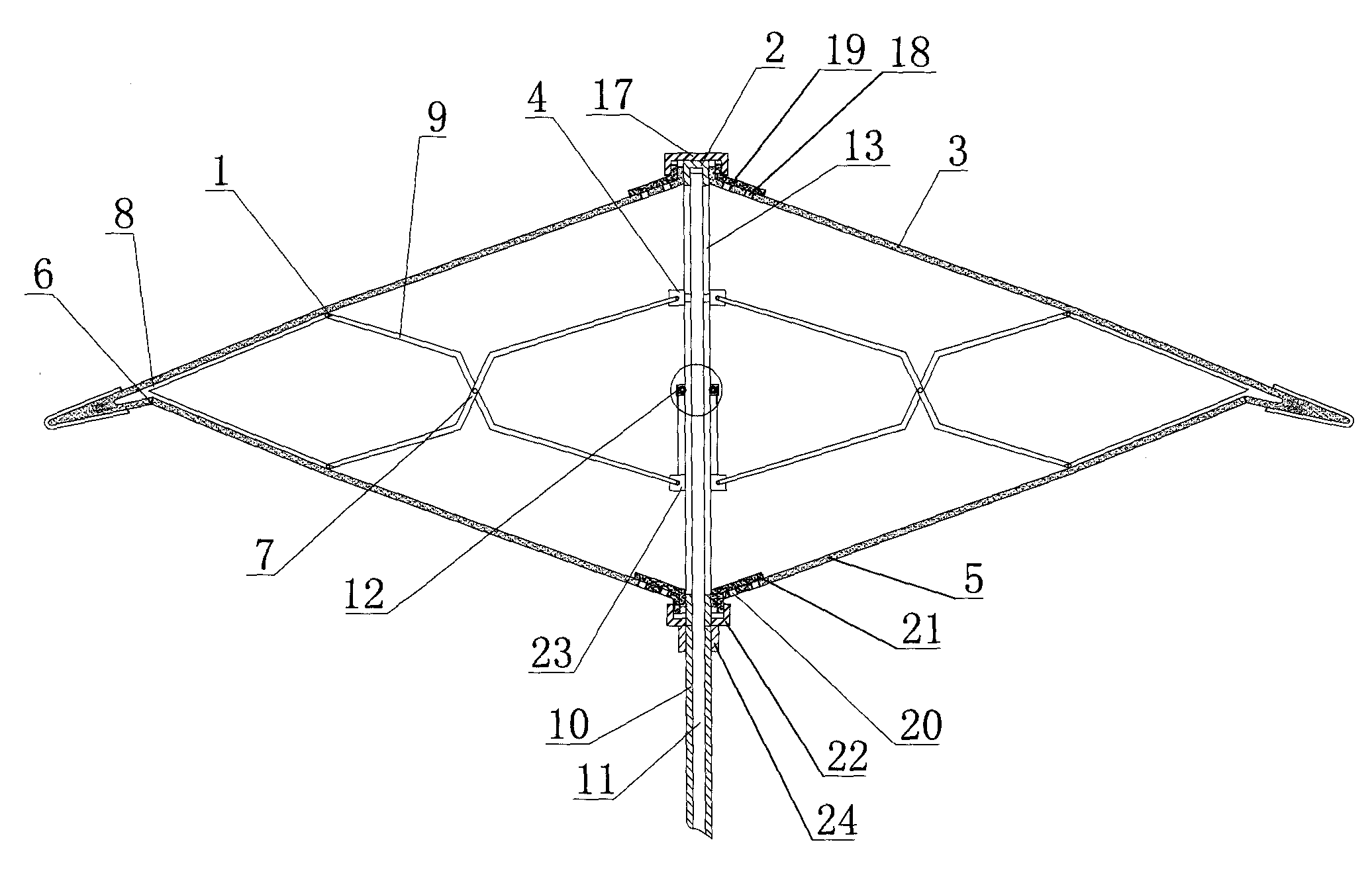

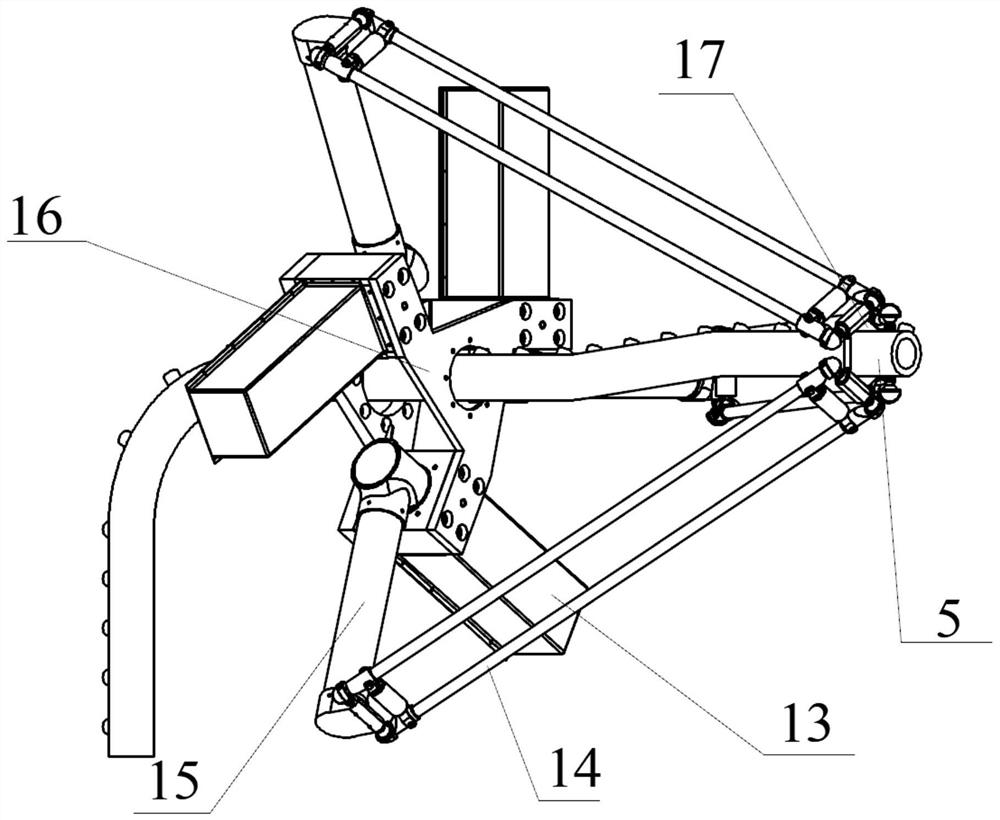

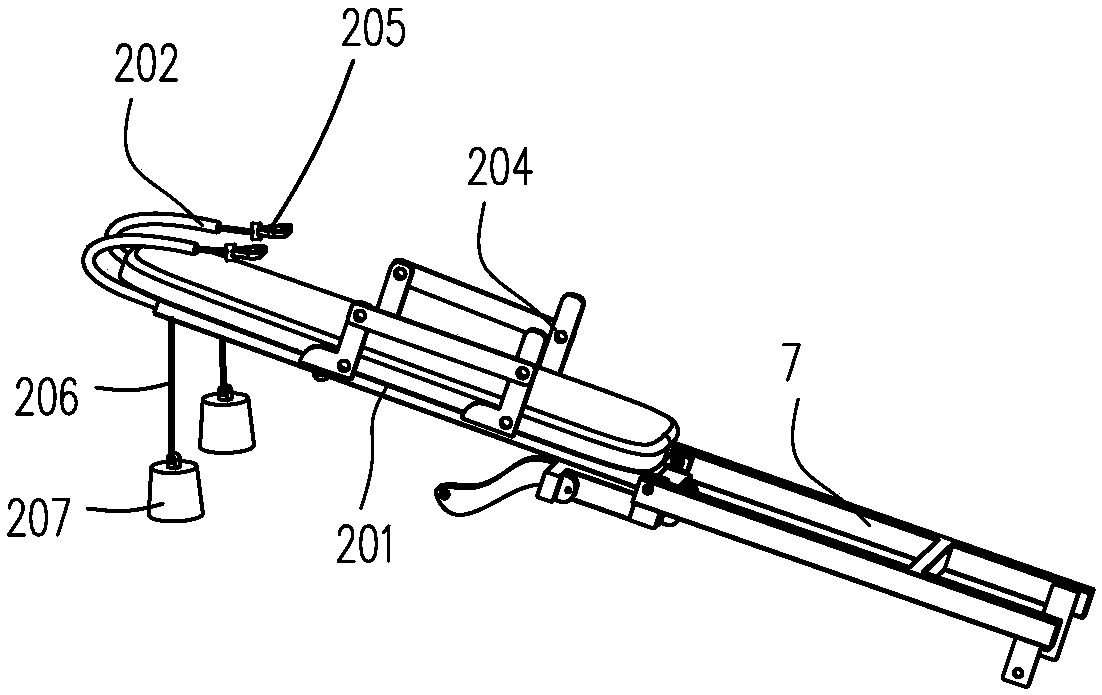

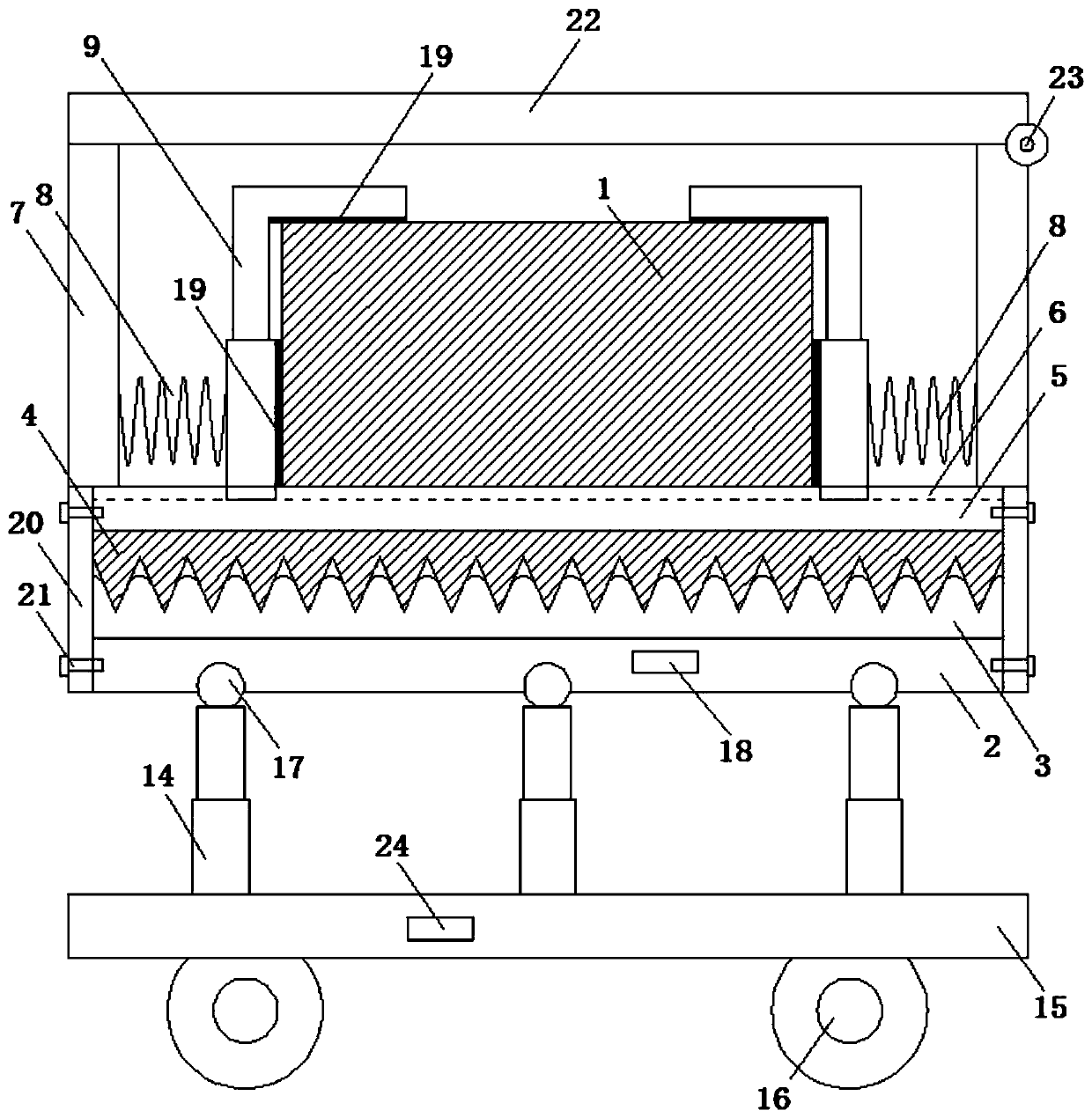

Flexible targeting spraying mechanism for orchards

ActiveCN103392684AImprove pesticide utilization and spray efficiencyReduce the waste of pesticidesInsect catchers and killersPesticideFruit tree

The invention discloses a flexible targeting spraying mechanism for orchards. The flexible targeting spraying mechanism comprises a spray support, a main spray pipe, a plurality of side spray pipes and a control device. The main spray pipe is disposed on the spray support which comprises a telescopic arm, a diagonal bracing arm and a horizontal arm, and the telescopic arm, the diagonal bracing arm and the horizontal arm are connected in sequence; the main spray pipe correspondingly comprises a vertical section, a diagonal section and a horizontal section; the side spray pipes are arranged on the horizontal section, and each side spray pipe is provided with a nozzle; a first solenoid valve is arranged on the main spray pipe, a first electric putter is arranged at the joint of the horizontal arm and the diagonal bracing arm on the spray support, a second electric putter is arranged at the joint of the diagonal bracing arm and the telescopic arm on the spray support, and the first solenoid valve, the first electric putter and the second electric putter are all respectively and electrically connected with the control device. By the flexible targeting spraying mechanism, shape of the spray support can be manually or automatically adjusted according to line spacing and row spacing of planted fruit trees and sizes thereof, so that targeting spraying effect can be guaranteed, pesticide utilization and spraying efficiency can be improved, waste of pesticides can be reduced, and further environmental pollution can be avoided.

Owner:SOUTH CHINA AGRI UNIV

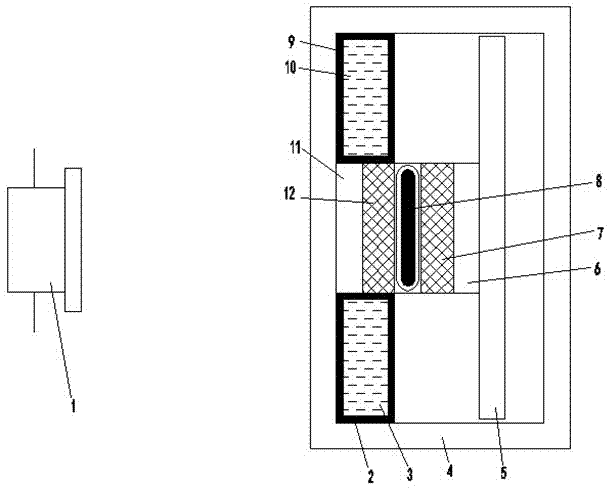

Urethra valve driven by wireless power shape memory alloy (SMA)

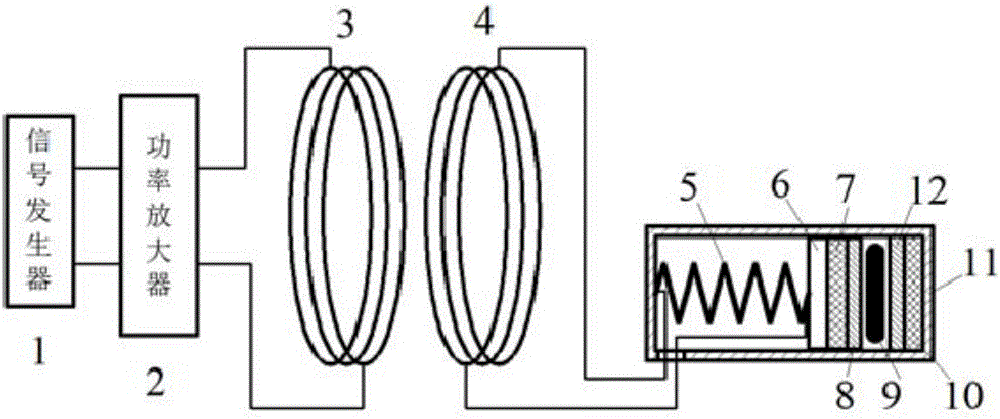

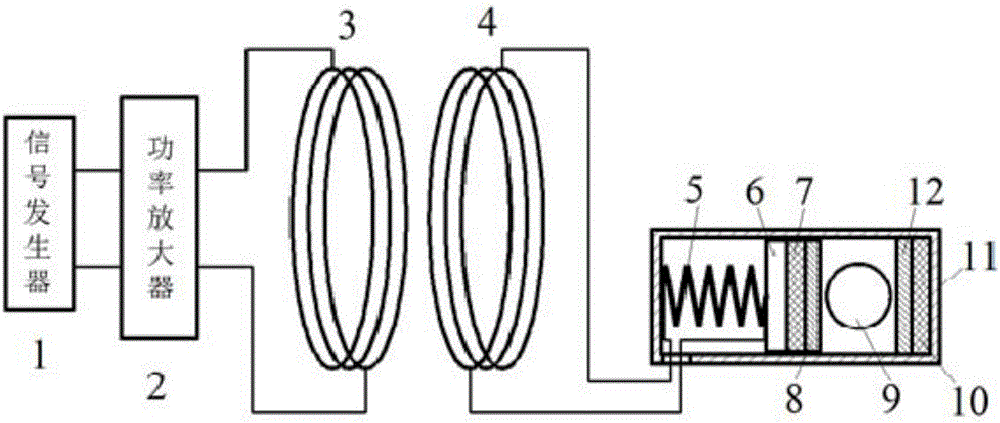

The embodiment of the invention discloses a urethra valve driven by a wireless power shape memory alloy (SMA). The SMA is short for a shape memory alloy. The urethra valve is used for solving the technical problems that in the prior art, urinary incontinence, caused by urethra sphincter disfunction, of a patient cannot be solved effectively by a conservative treatment, an operative treatment, nursing measures and the like. The urethra valve comprises a magnetic coupling resonance unit, an SMA spring, a valve element, a first permanent magnet, a second permanent magnet and a valve body. The valve body is of a hollow frame-shaped structure; the SMA spring, the valve element, the first permanent magnet and the second permanent magnet are arranged in a valve cavity of the valve body; and the valve body is used for being fixed on a pubis position of a human body. One end of the SMA spring is connected with the valve element, and the other end of the SMA spring is fixedly connected with the inner wall of one side of the valve cavity; the first permanent magnet adjoins the side, unconnected with the SMA spring, of the valve element; one side of the second permanent magnet adjoins the inner wall of the other side of the valve cavity and the other side of the valve cavity is opposite to the side connected with the SMA spring; and the gap between the first permanent magnet and the second permanent magnet is used for penetrating through a urethra position of the human body.

Owner:GUANGDONG UNIV OF TECH

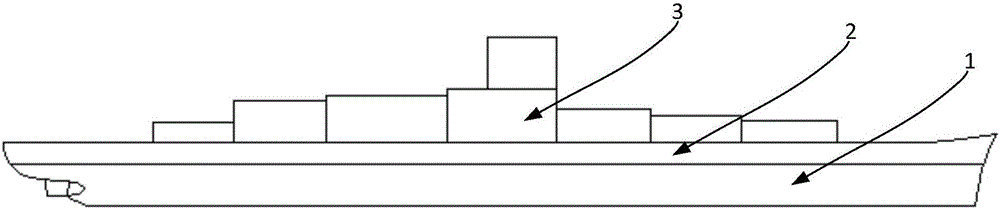

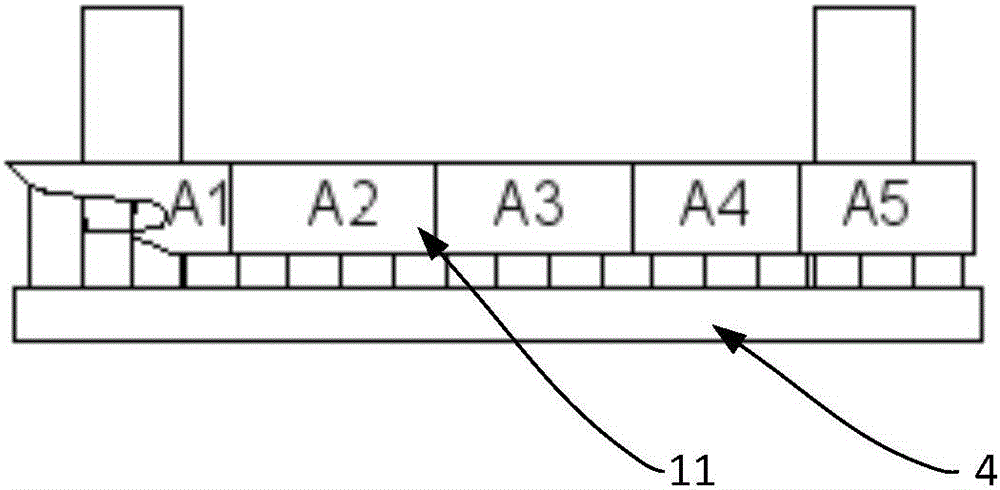

Floating condition manufacturing method for extra-long hull

The invention discloses a floating condition manufacturing method for an extra-long hull. The floating condition manufacturing method comprises the following steps of (1) dividing the hull into three parts, namely a lower hull, an upper hull and a superstructure, wherein the lower hull is divided into a stern complete cross section and a bow complete cross section; (2) separately manufacturing the stern complete cross section and the bow complete cross section on two barges; (3) when the length of a built part of the stern complete cross section is the same as that of the barges, enabling the barges to submerge and translate for a certain distance towards the direction of a bow, and then enabling the barges to float upwards support the built part of the stern complete cross section, and continuing construction until the stern complete cross section is completed, wherein the constructing manner of the bow complete cross section and the construction manner of the stern complete cross section are basically consistent but have a difference that the barges are translated towards the direction of a stern instead of the bow; (4) performing closure on the stern complete cross section and the bow complete cross section; (5) enabling the two barges to submerge for removing; and (6) manufacturing the upper hull and the superstructure on the lower hull. According to the floating condition manufacturing method disclosed by the invention, constructing a special dock and a special berth is not needed, so that the construction cost can be reduced, the cycle can be shortened, the requirement for a site is low, and the adaptability is high; and the hull lunching is realized through the submerging of the barges, so that mechanical damages cannot be generated on the hull.

Owner:GUANGDONG UNIV OF TECH

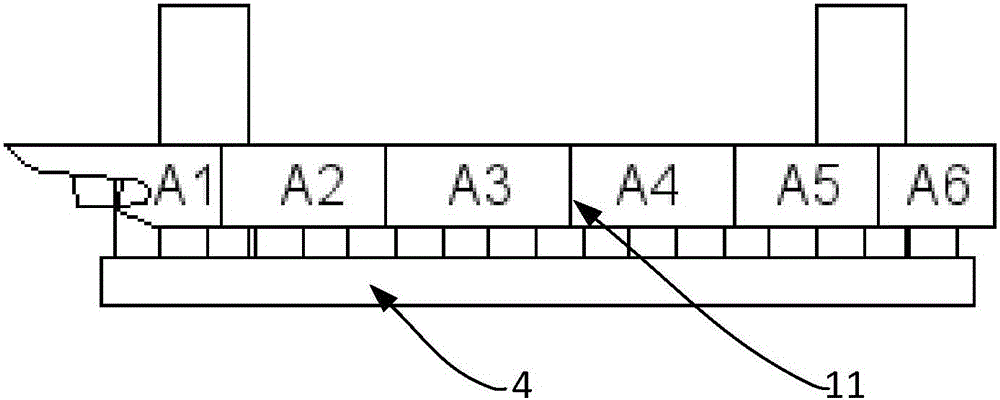

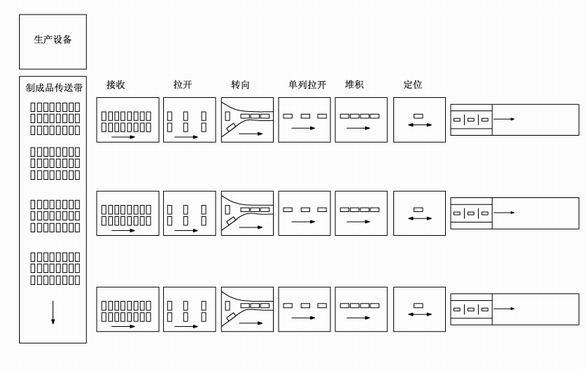

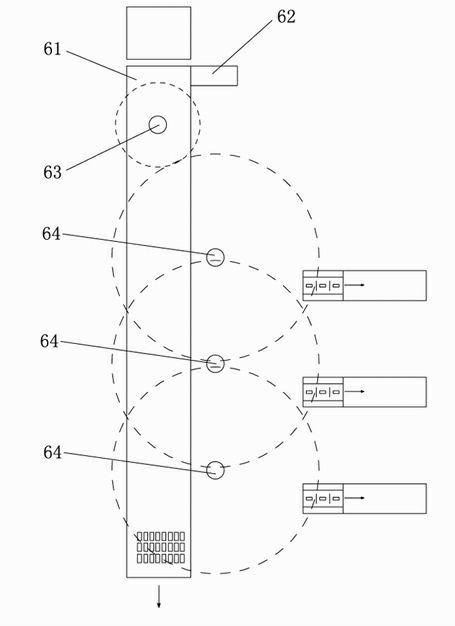

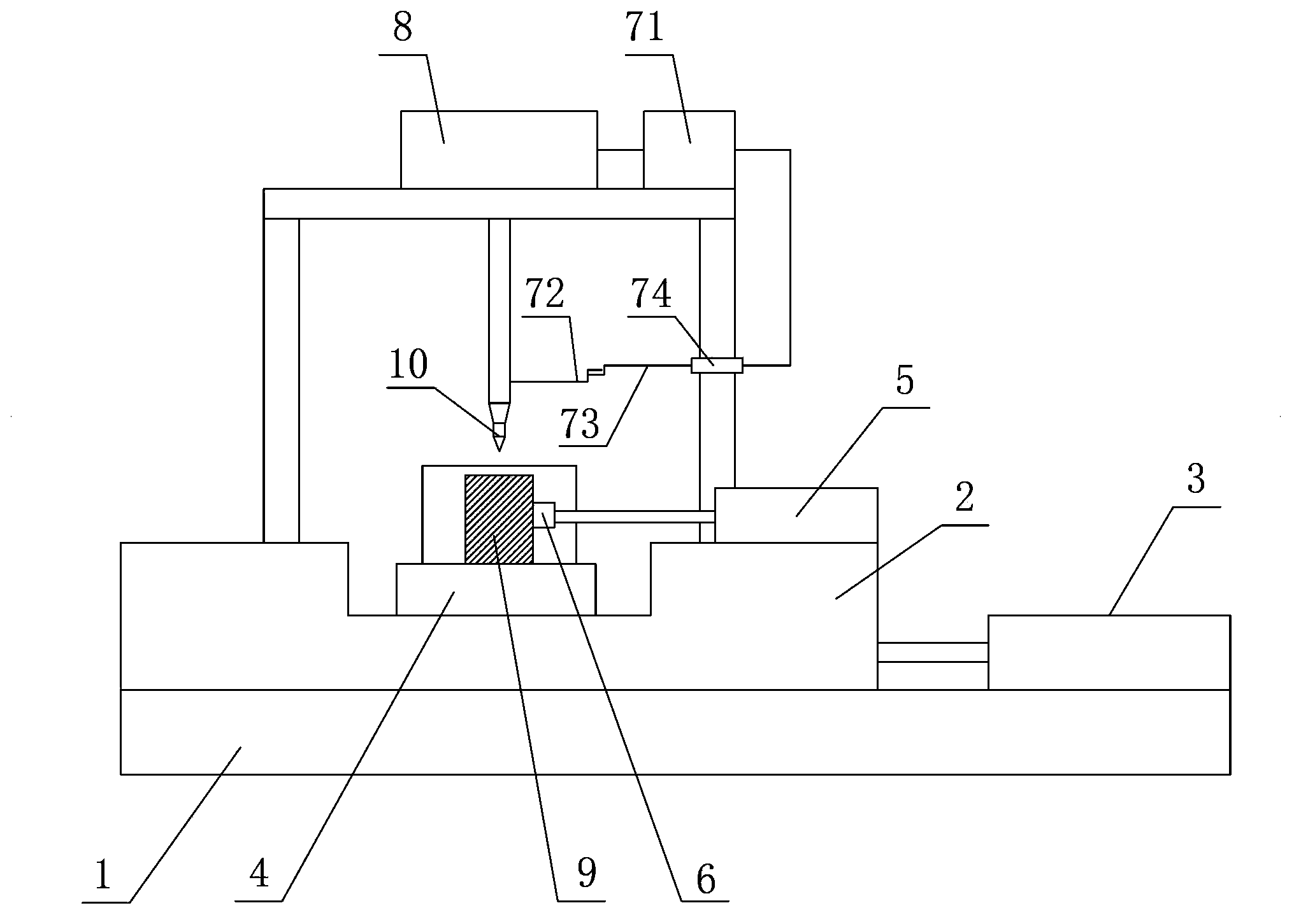

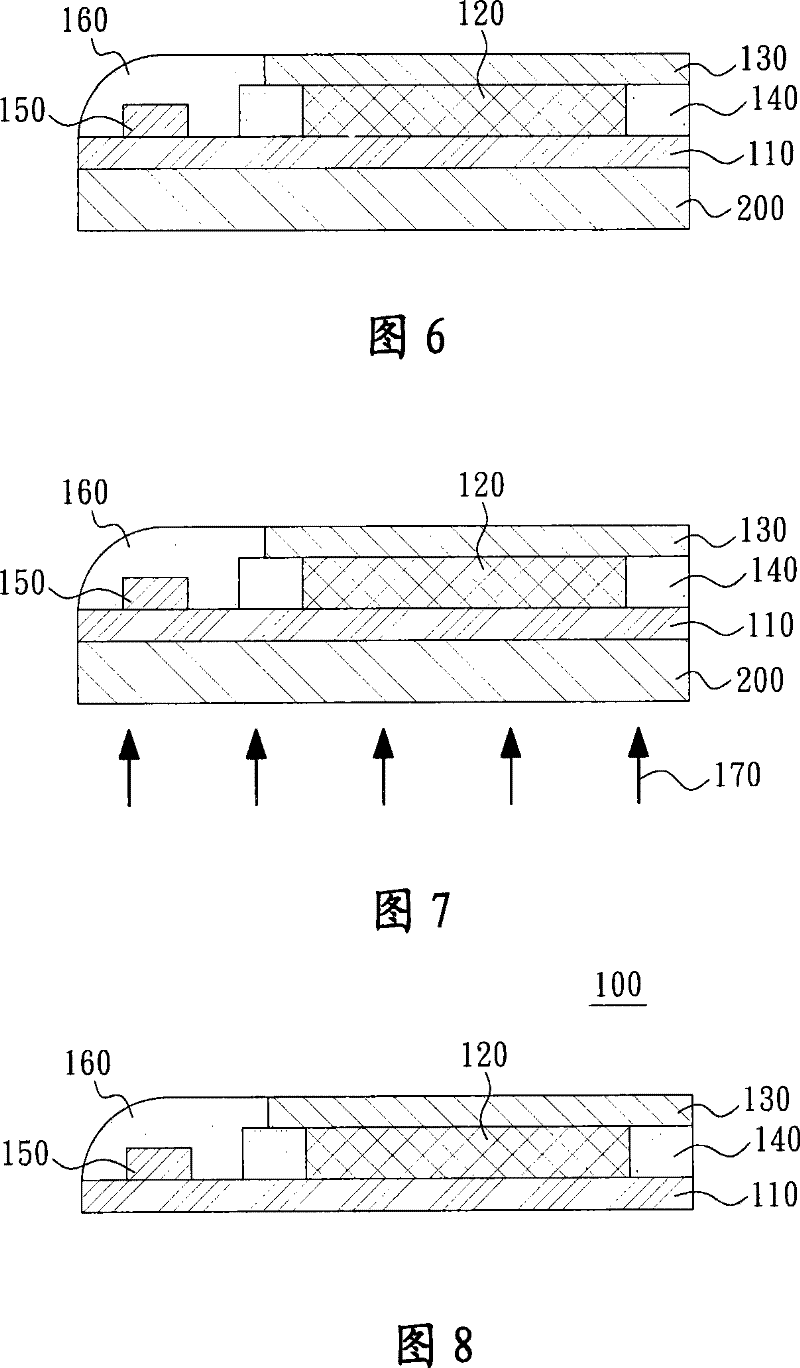

Automatic material arranging method and equipment based on vision robots

The invention provides an automatic material arranging method and equipment based on vision robots. According to the method, finished products are conveyed by a continuously moving conveying belt; when the finished products pass by a vision camera arranged at the upper end of the conveying belt, the vision camera shoots the image of the finished products, detects position and angle values (X, Y and theta) of each finished product, and transmits the values to each online robot; according to the position and angle values (X, Y and theta) of each finished product detected by the vision camera and a real-time moving distance value of the finished product conveying belt detected by a synchronization device, when the finished products enter the actuation range of each robot, the robots can accurately grab the finished products one by one, and accurately put the finished products on a feed part of a packing machine one by one according to the required positions and angles, thus the arrangement and distribution of the finished products, namely the whole material arranging process, is completed. The vision camera, the synchronization device and each robot are electrically connected; and according to the method and the equipment, on the basis of the vision robots, the problem of material arrangement is solved, all problems of mechanical material arrangement are completely solved, and the effect of human-like flexibility and adaptability can be achieved.

Owner:厦门至工机电有限公司

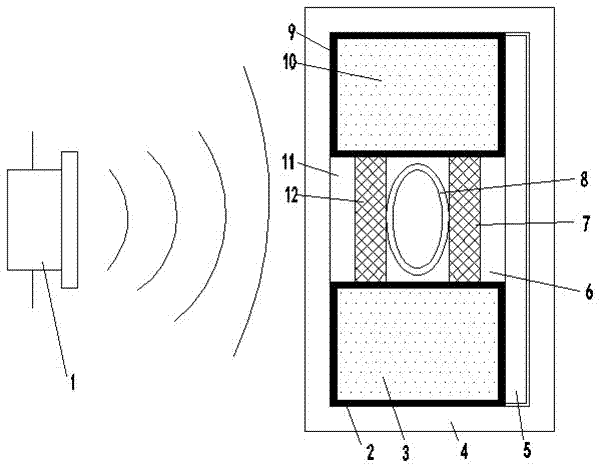

Urethra valve driven by ultrasound vaporization steam

InactiveCN103655018AAvoid closing failureLong term workNon-surgical orthopedic devicesUrethraBoiling point

The invention discloses a urethra valve driven by ultrasound vaporization steam. The urethra valve driven by the ultrasound vaporization steam comprises a sound head, a first driving bag, first working media, a valve body, a valve plug, a first permanent magnet, a first rubber gasket, an urethra, a second permanent magnet and a second rubber gasket, wherein the sound head is pressed on the abdomen front wall in a handheld mode, the valve body is fixed to the pubis, the valve plug is made of non-metal materials, and is installed in a valve cavity formed in the valve body, the first driving bag is a pneumatic driver which is made of flexible and elastic materials, and is installed in the valve cavity formed in the valve body, the first working media are low-boiling-point liquid, and are stored in the closed first driving bag, the first permanent magnet and the second permanent magnet are installed on the two sides of the urethra respectively, the magnetism of the first permanent magnet is opposite to the magnetism of the second permanent magnet, the first permanent magnet is fixedly connected with the valve plug, the second permanent magnet is fixedly connected with the valve body, the first rubber gasket is fixedly connected with the first permanent magnet, and the second rubber gasket is fixedly connected with the second permanent magnet. The urethra valve driven by the ultrasound vaporization steam is a human body auxiliary instrument which is free of infection, damage and urine leakage.

Owner:GUANGDONG UNIV OF TECH

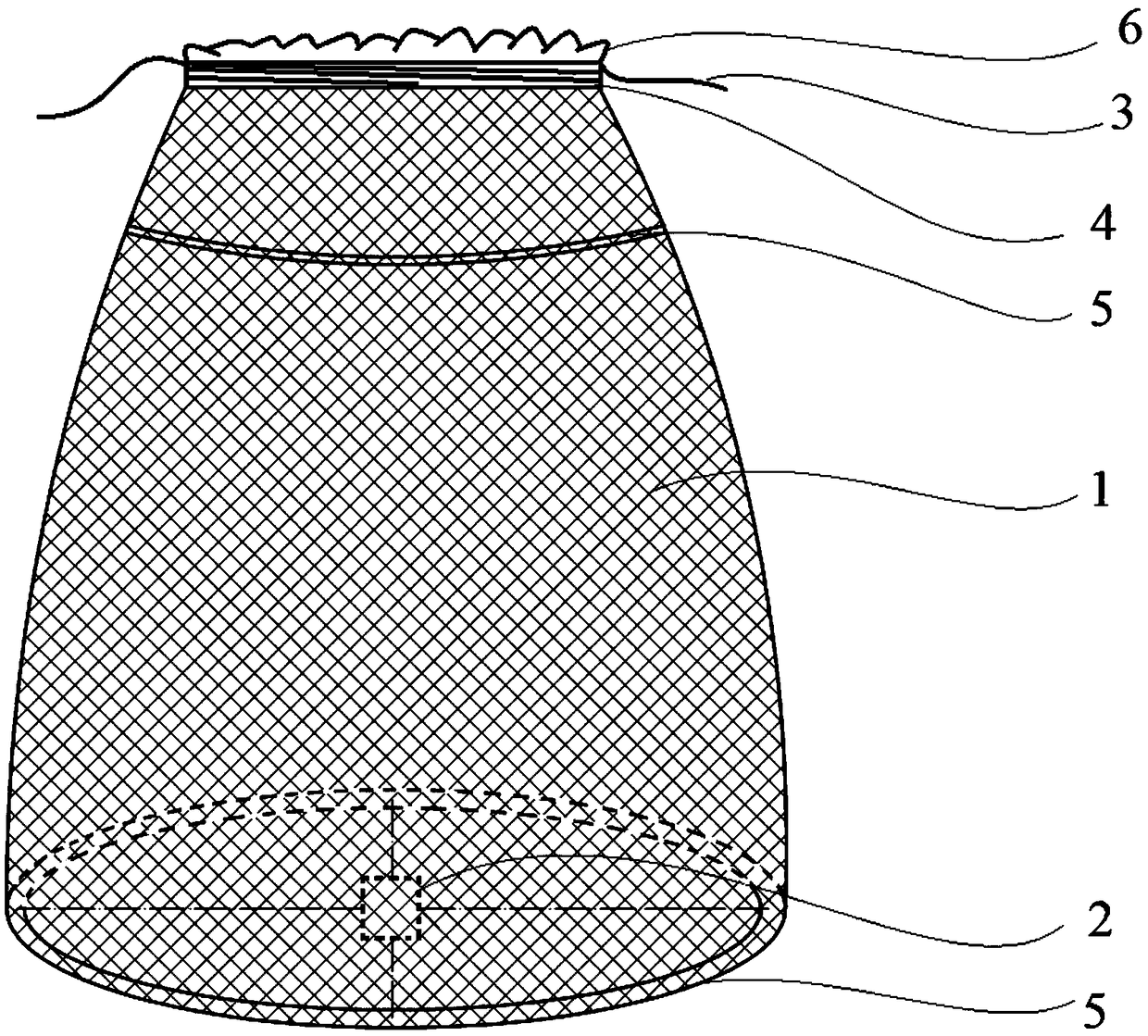

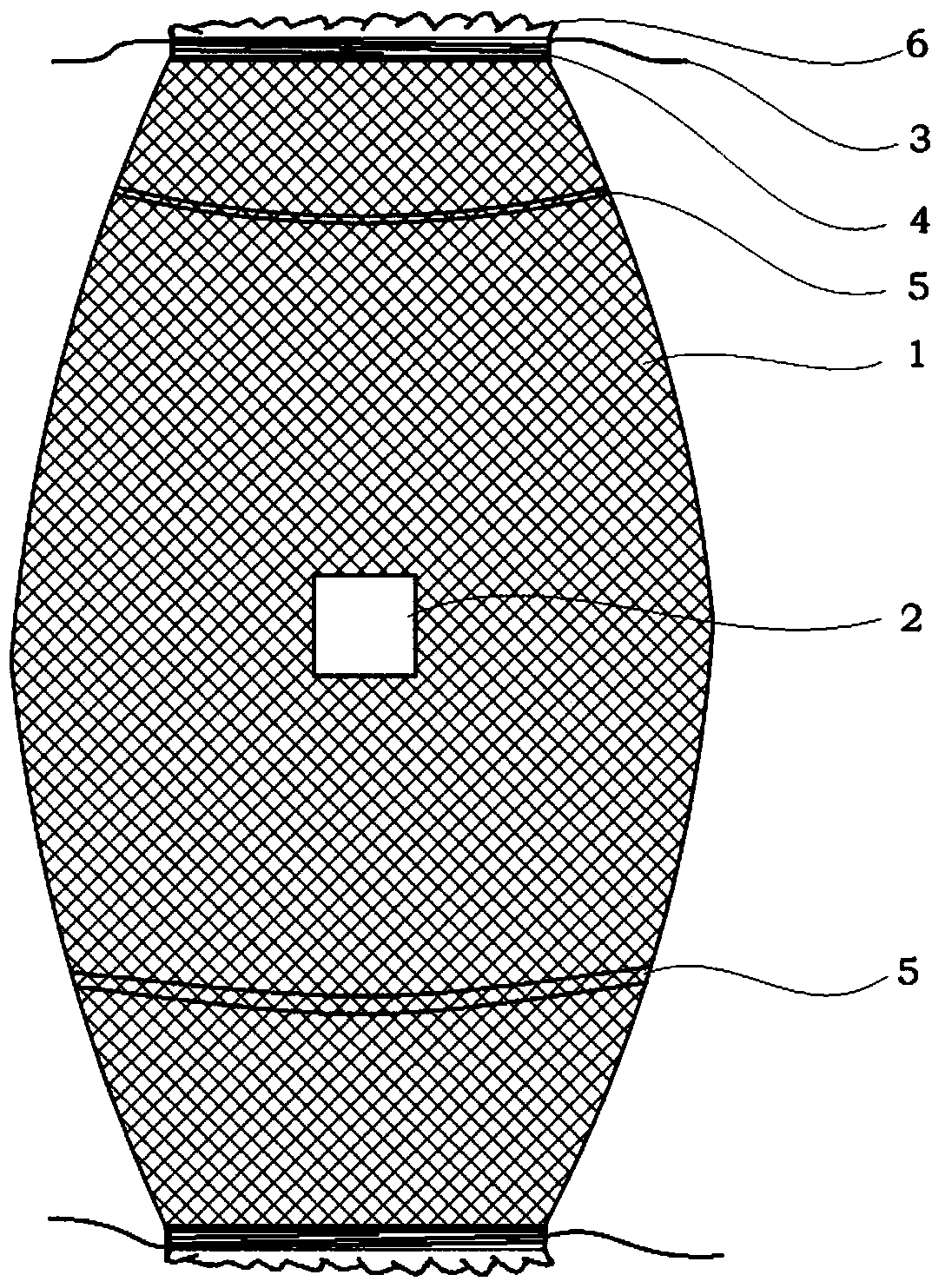

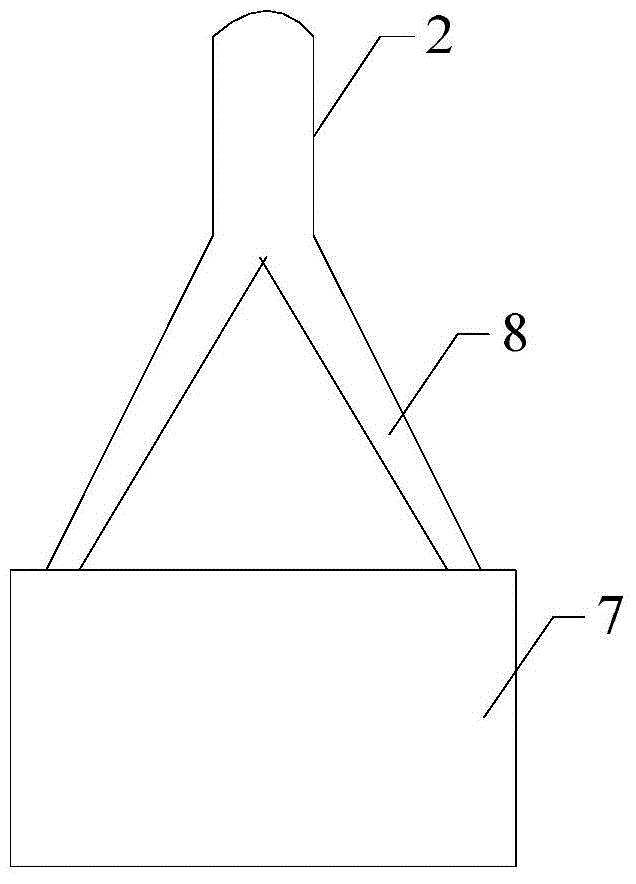

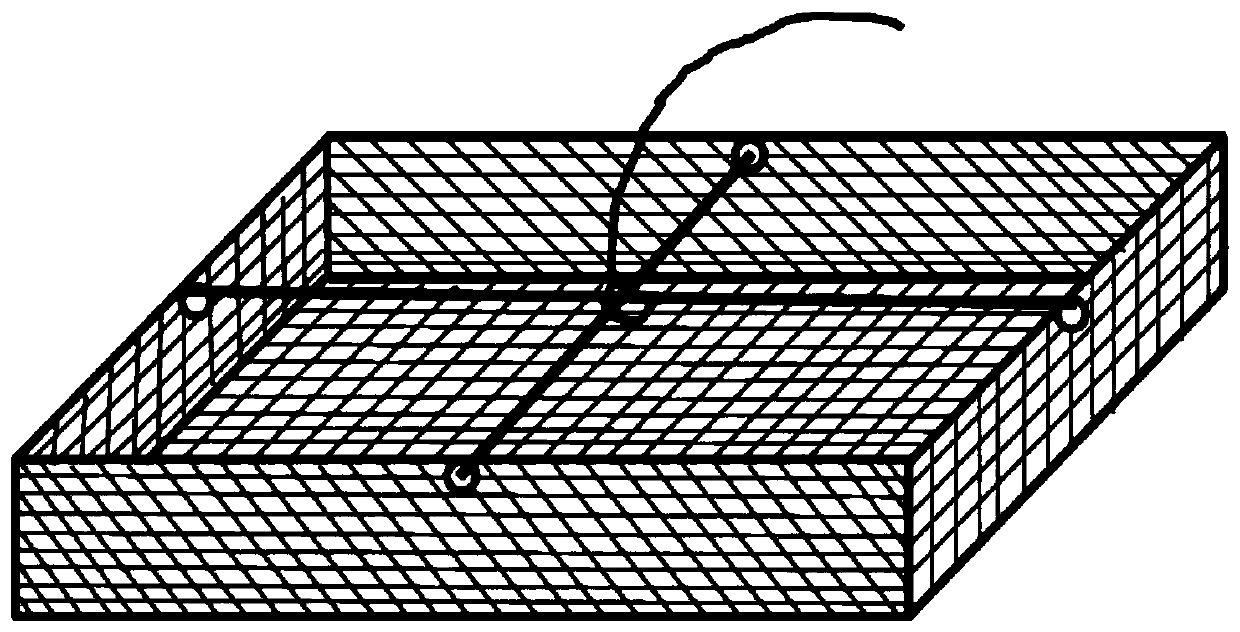

Device and method for determining virulence of whitefly pests by using living plant

PendingCN108918785ACause mechanical damageEasy to put inMaterial analysisFruit crop cultivationTerra firmaVirulent characteristics

The invention relates to a device and method for determining virulence of whitefly pests by using a living plant. The device is composed of a gauze bag (1), a ring piece (5) arranged in the middle ofthe gauze bag (1), and a drawstring (3), wherein a gauze bag opening (6) is arranged at the end of the gauze bag (1), a hollow folding edge (4) is arranged at the gauze bag opening (6), and the drawstring (3) is penetrated into the folding edge (4); a pest feeding opening (2) is opened on the gauze bag (1); the gauze bag (1) comprises two structures A and B; and the like. According to the scheme of the invention, the virulence determination method of the whitefly pests in many key links is limited, so that the stability and consistency of the virulence determination can be ensured, a solid foundation and guarantee can be laid for accurate virulence determination, and by applying the virulence determination results of the invention, the accurate technical guidance can be provided for the large-scale use of pesticides in large fields.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Preparation method of amnion tissue engineering de-immunized skin scaffold

ActiveCN110404119ACause mechanical damageImprove toughnessTissue regenerationProsthesisCell culture mediaRefrigerated temperature

The invention discloses a preparation method of an amnion tissue engineering de-immunized skin scaffold, comprising the following steps: rinsing and disinfecting amnion, then immersing in a commercialamnion cell culture medium, culturing in a CO2 incubator at 37 DEG C for 72 h, taking the cultured amnion out of the culture medium, centrifuging the cultured amnion and filtering through a 0.22 micron filter membrane and then sub-packaging, and cryopreserving in a refrigerator at 80 DEG C; carrying out continuous gradient dehydration on the amnion with ethanol for 3 days, aseptically air-drying,cutting into different specifications of amnion patches according to clinical requirements, and carrying out aseptic vacuum package for later use. The method adopted by the invention can realize thepurpose of simple, rapid, high-efficiency and large-scale preparation of medical artificial skin; the material used is human or pig amnion, has a wide source, is mostly waste after production and is low-cost, and there is no ethical problem. The invention has been verified on skin regeneration after burns in rats and pigs (large animal models), and the effect is remarkable and no adverse immune reaction is observed.

Owner:上海越增生物科技有限公司

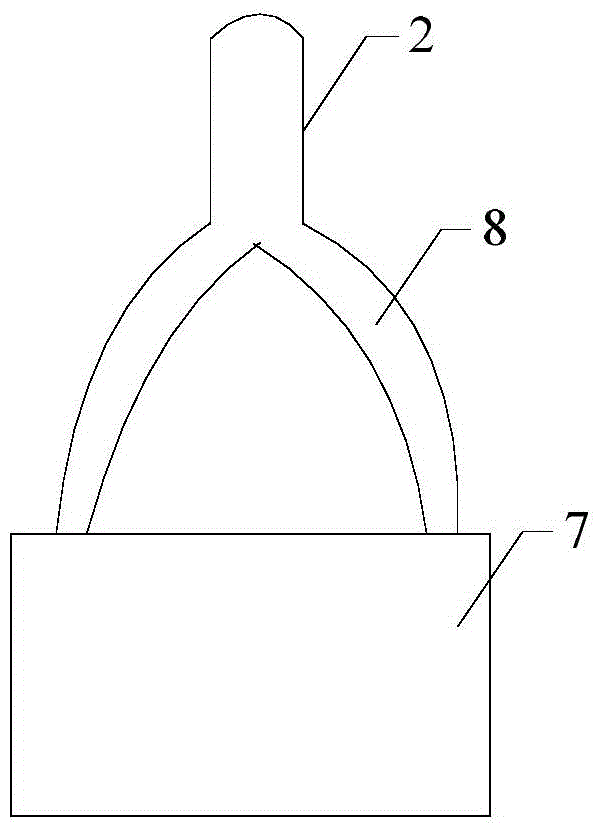

Steam driving urination boosting system based on magnetic resonance coupling

InactiveCN106361480ACause infectionSimple structureNon-surgical orthopedic devicesCapacitanceHigh frequency power

The invention provides a steam driving urination boosting system based on magnetic resonance coupling. The system comprises a high-frequency power supply, a first compensation capacitor, a second compensation capacitor, resonance coils comprising a transmitting coil and a receiving coil, a bed frame which is fixed on the pubis, a urethra valve which is fixed on the bed frame and a driving sac of which the upper end is fixed on the bed frame, wherein a working medium is stored in the closed driving sac; the transmitting coil is held in a hand and presses the anterior abdominal wall; the receiving coil is fixed in the closed driving sac; the first compensation capacitor is connected in series with the transmitting coil and the high-frequency power supply; a heating wire is soaked in the liquid-state working medium, and is connected in series with the receiving coil and the second compensation capacitor; the bed frame and the urethra valve are fixed on the periphery of a covering film; the urethra valve is an elastic element coating urethra, and is fixed on the bed frame. The system has a simple and light structure, realizes high-efficiency non-contact electric transmission, has stable driving capacity, and does not cause infection, injury, urine leakage or backflow.

Owner:GUANGDONG UNIV OF TECH

Improved oil-gas mixing press punch used for lead installation

The invention discloses an oil-gas mixing press punch used for cooling fin lead installation. The punch comprises an oil-gas mixing press body, a pressure switch and a relay, wherein the oil-gas mixing press body comprises a base, a line ball buckle upper die, a cylinder, a cylinder switch and a manifold pressure gauge; the pressure switch is installed on an admission line; the relay is electrically connected with the pressure switch and the cylinder switch and is used for controlling the pressure switch and the cylinder switch to be switched on and off; the expansion link of the cylinder is fixedly connected with the line ball buckle upper die. According to the punch disclosed by the invention, the line ball buckle upper die is downwards pressed after the pressure reaches a preset value to guarantee that pressure is stable each time. Because the pressure is controllable, the pressure is set according to the metal material characteristic of the cooling fin, the lead can just be pressed into a cooling fin trough according to the requirement without damaging the cooling fin, and therefore, a stop block is omitted. Compared with the traditional punch, the punch disclosed by the invention has the advantages of stable pressure and uniform lead pressing-in degree, inferior-quality products of which the cooling fins are damaged or the leads are not pressed in are reduced, and the production quality is improved.

Owner:徐四伟

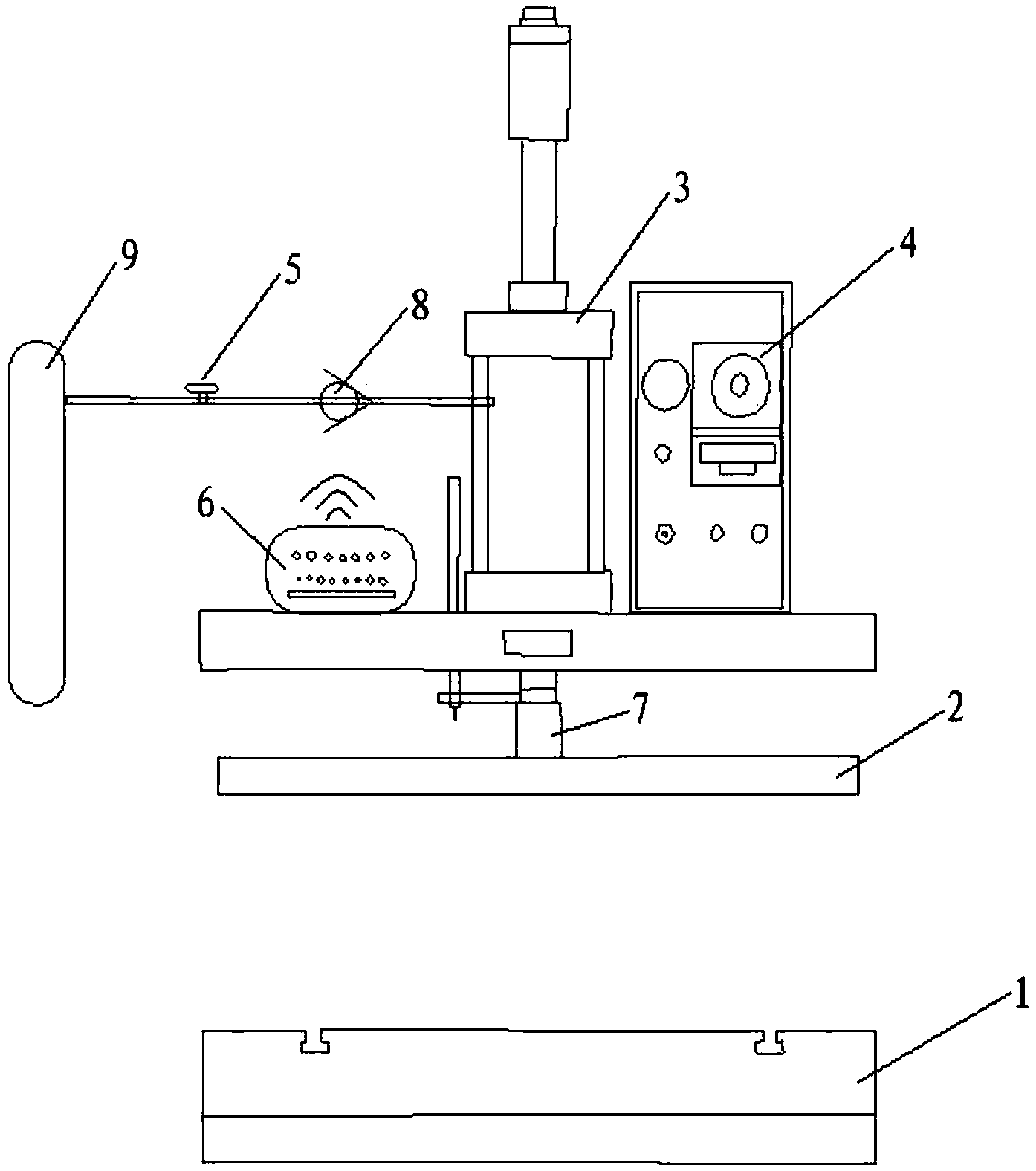

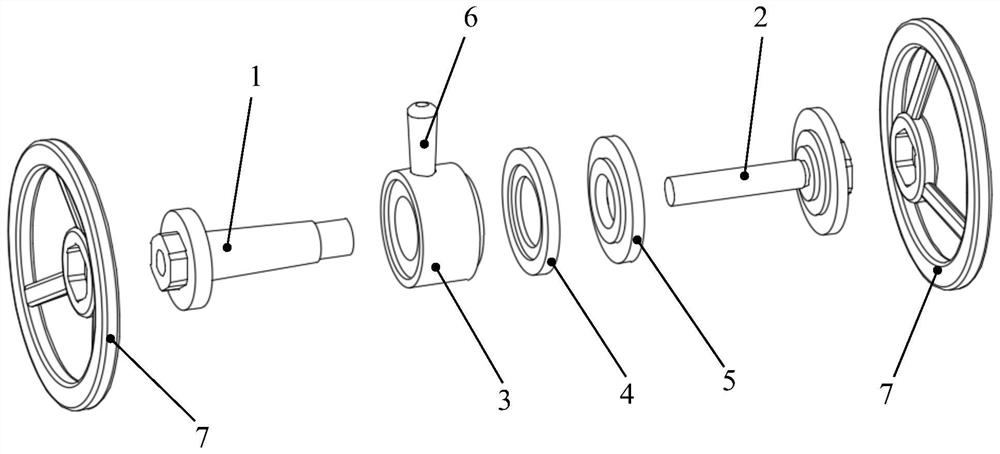

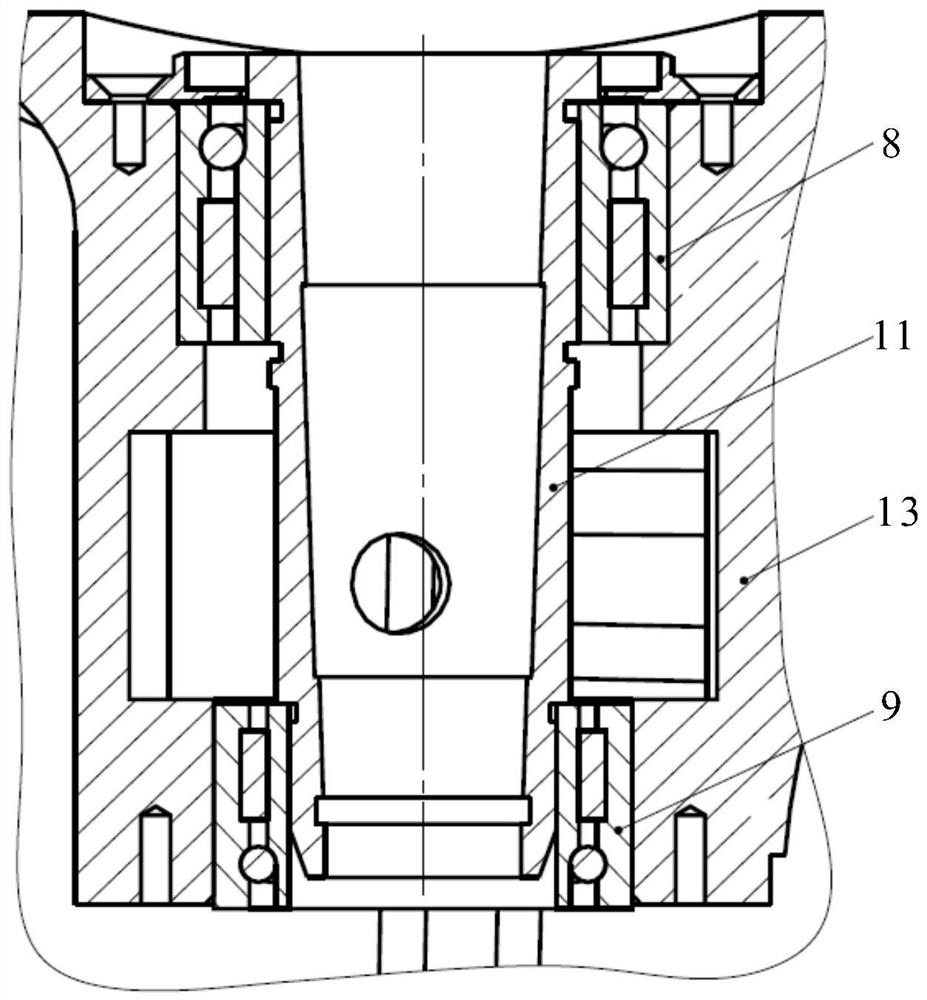

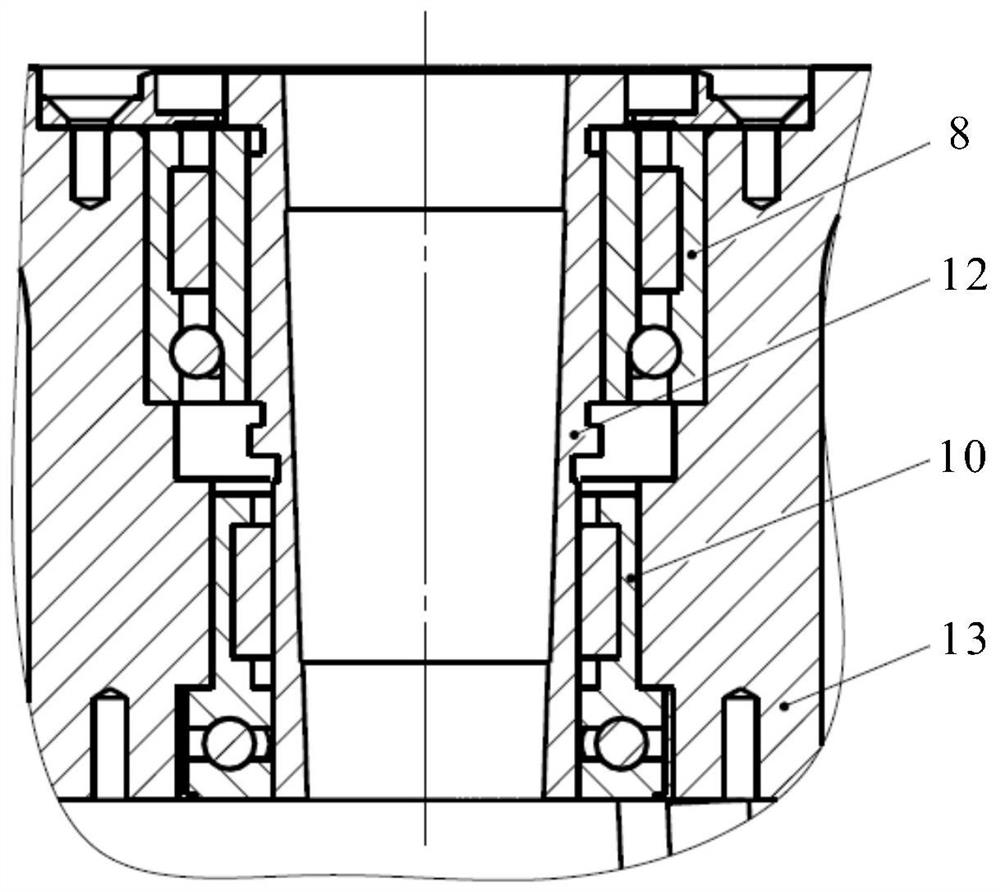

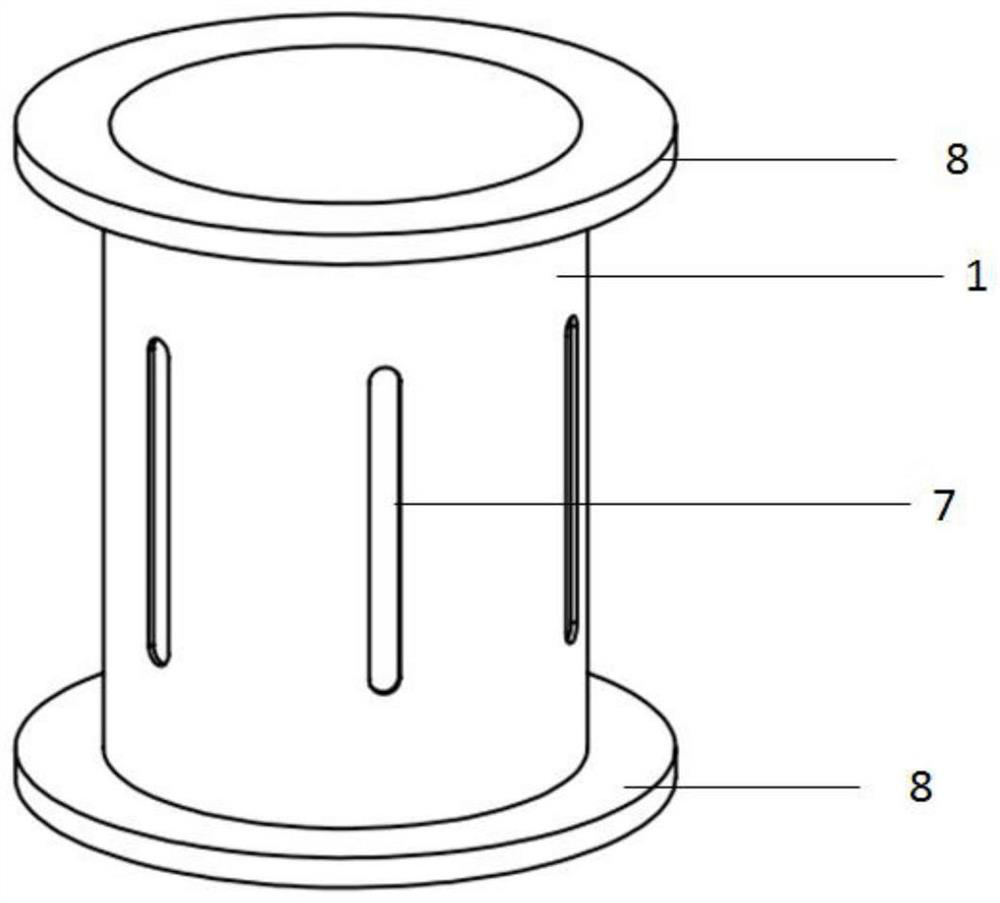

Bearing installer of small cabin and method for installing bearing by adopting installer

ActiveCN112621166AUniform and symmetrical press-in forceReasonable choiceMetal working apparatusEngineeringStructural engineering

The invention relates to a bearing installer of a small cabin and a method for installing a bearing by adopting the installer. The bearing installer comprises a guide sleeve, a guide rod, a pressing ring, an adapter ring, a backing ring, a handle and a turntable, wherein matched internal and external threads are arranged on the screwing part of the guide sleeve and the guide rod, and the external turntable is rotated to drive the guide sleeve and the guide rod to be screwed together so as to provide press-in power required during bearing assembly; the guide sleeve and the guide rod are provided with positioning steps for positioning the bearing and a workpiece; the pressing ring, the adapter ring and the backing ring are part families adapting to different installation requirements; and the handle is installed on the pressing ring, the pressing ring is limited not to rotate and is kept static relative to the end face of the bearing, and the bearing is protected against damage caused by sliding friction in the assembling process. The bearing installer is simple in structure and convenient to operate, integrates guiding, positioning and press-in functions, and can assemble the bearing at a time, the phenomena of repeatedly disassembling and assembling the bearing and damaging a cabin body, a shaft sleeve and the bearing are avoided, and the problem of bearing assembly of a small cabin body is effectively solved.

Owner:SHANXI JIANGHUAI HEAVY IND

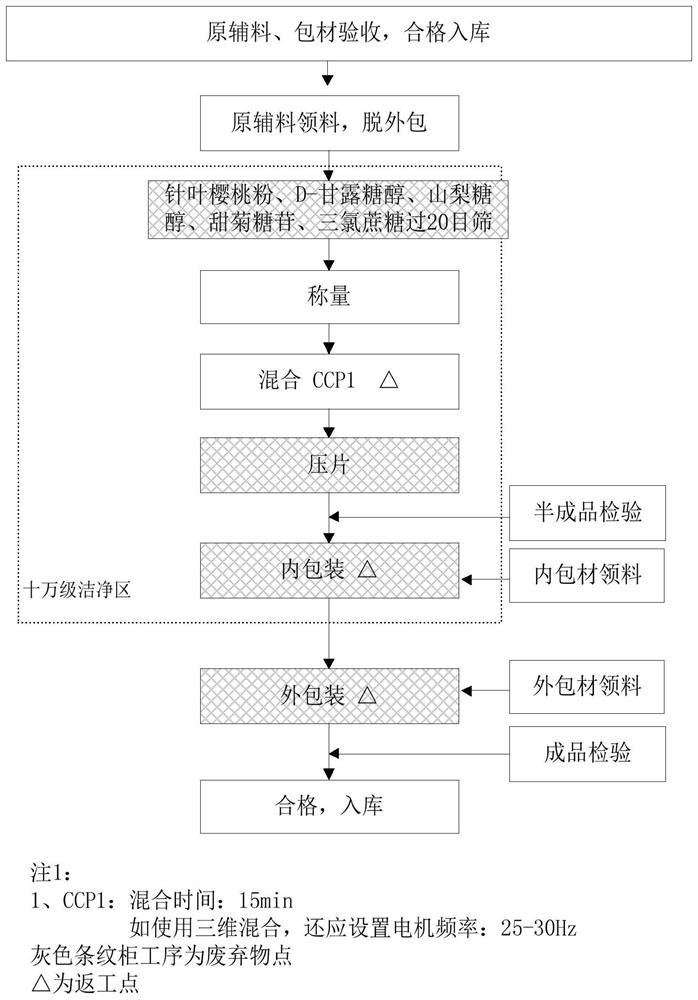

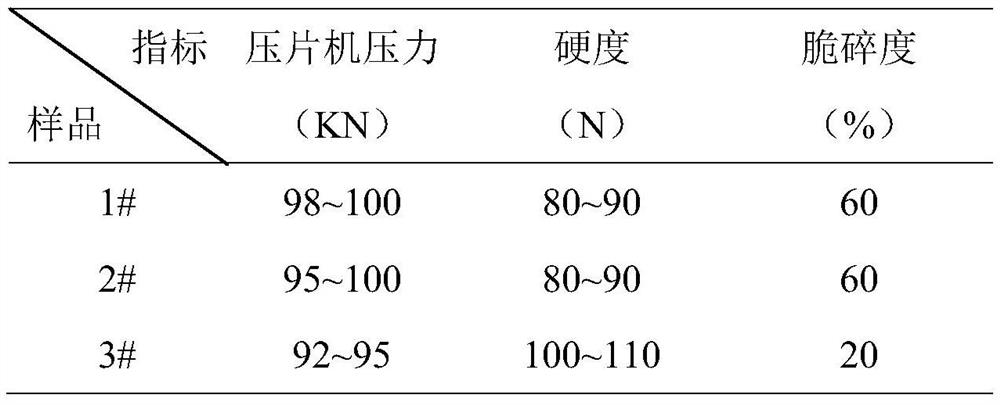

Acerola cherry tabletted candies and preparation method thereof

PendingCN113973964AImprove fluidity and compressibilityImproves hardness and friabilityConfectionerySweetmeatsSucroseMagnesium stearate

The present invention relates to acerola cherry tabletted candies and a preparation method thereof. The candies consist of cherry powder, an excipient, a sweetening agent, an adhesive and a lubricant; the acerola cherry tabletted candies specifically comprise 25-33.35% of acerola cherry powder, 28.6-29.3% of sorbitol, 15-25% of microcrystalline cellulose, 1-8% of D-mannitol, 0.1-1% of stevioside, 10.65-20% of blueberry powder, 0.01-0.05% of sucralose and 0.3-1% of magnesium stearate. The tabletted candies are obtained by adopting the technologies of sieving, weighing, premixing, total mixing and direct pressing. The acerola cherry tabletted candies are simple in preparation process, stable in hardness, friability and taste, have blueberry flavor, are moderate in sourness and sweetness and convenient to eat, and have the beneficial effects of enhancing immunity, improving skin state, whitening, regulating intestinal flora and the like.

Owner:富诺健康股份有限公司

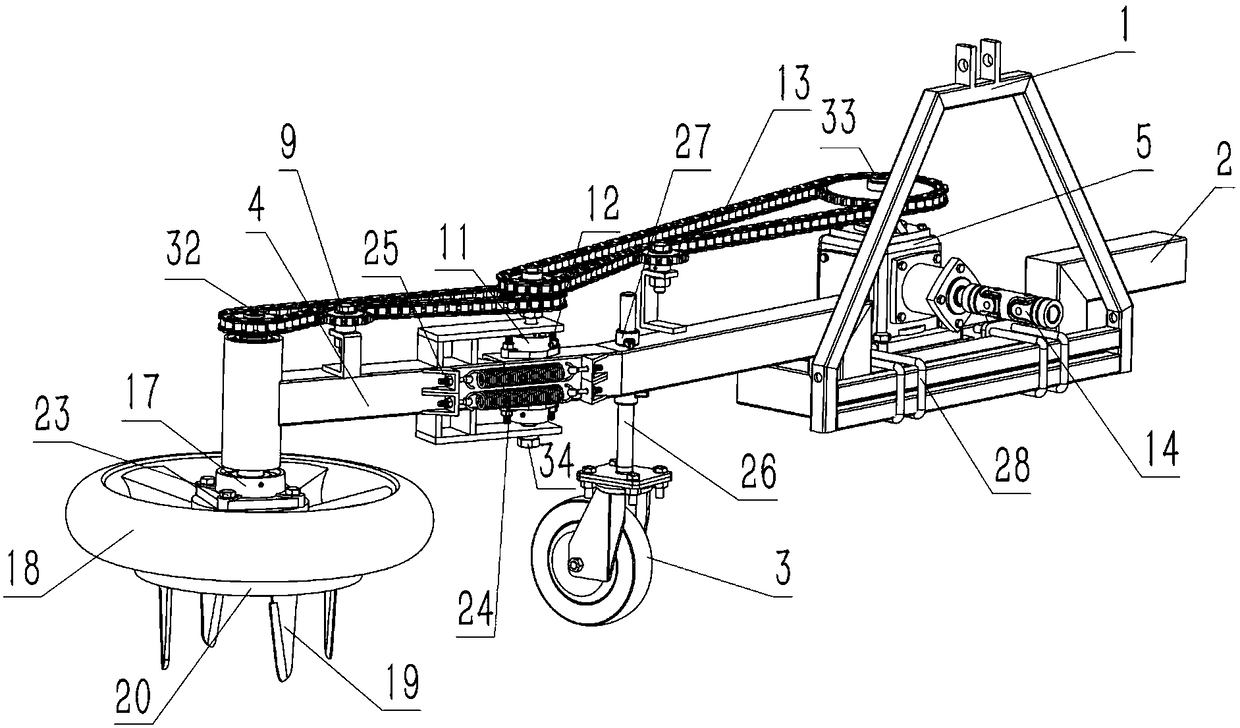

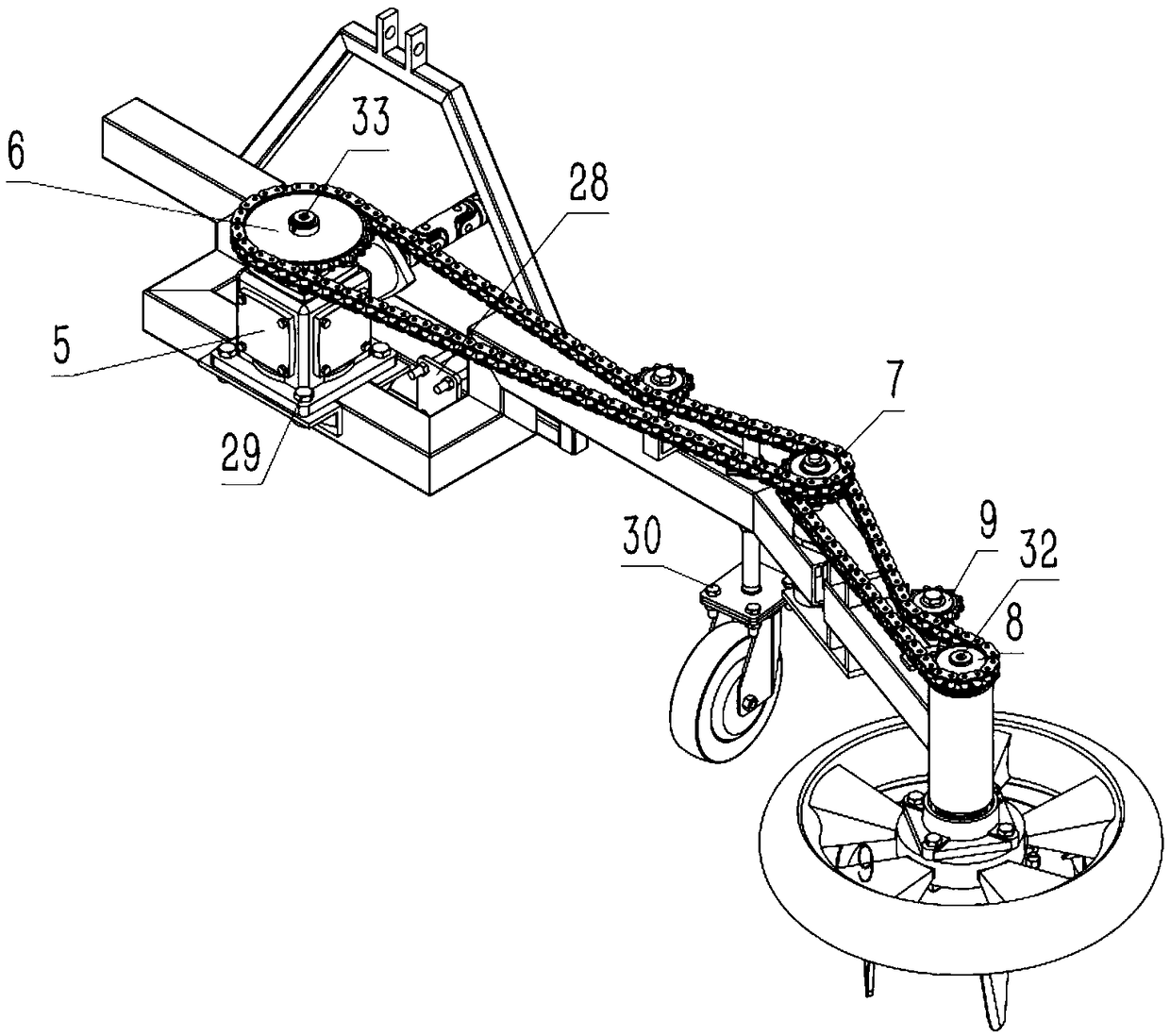

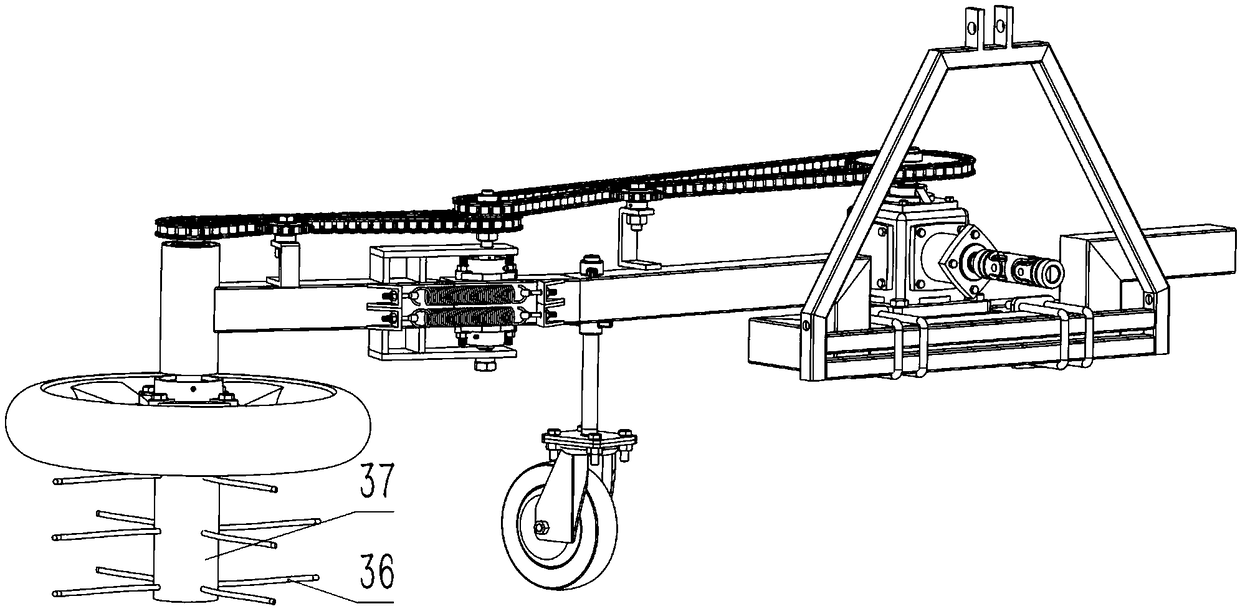

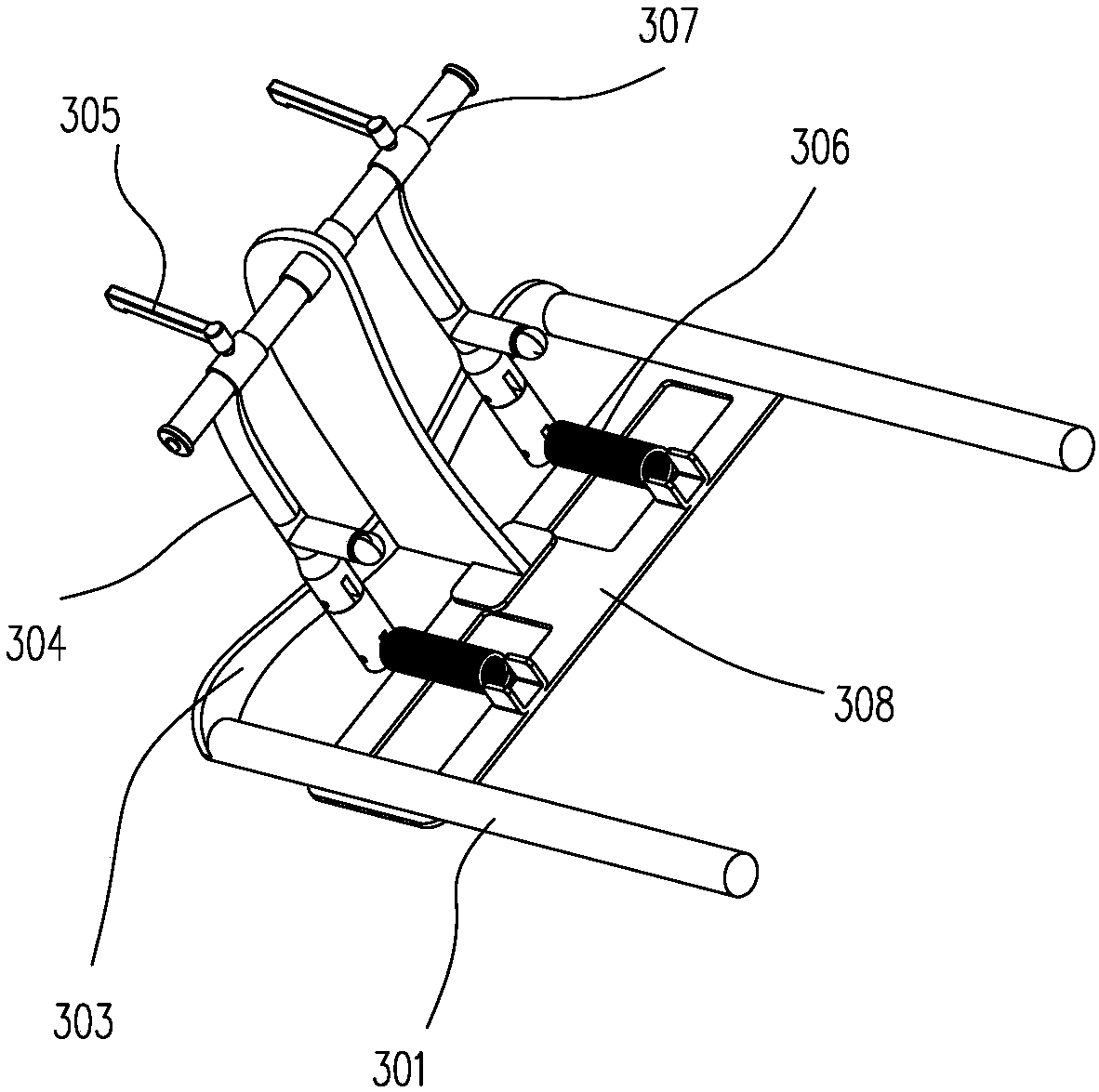

Universal inter-plant weeding ripper for mulberry orchard and orchard

PendingCN109168343ACause mechanical damageSimple and fast operationSoil-working equipmentsMowersWoody plantPull force

The invention relates to a universal inter-plant weeding ripper for a mulberry orchard and an orchard. The ripper includes a three-point suspension frame unit, a transmission system unit, a weeding and loosening unit and a reset unit. The ripper is advantaged in that a weeding and loosening shaft is driven by a driven sprocket for high-speed rotation to realize high-speed rotation of a weeding andloosening cutter, and weeding and loosening operation is realized; when an anti-collision wheel is subjected to stalk resistance, a movable cantilever rotates under the tension of a tension spring, so plants are prevented from being damaged; under the action of the tension spring, the movable cantilever can return to the initial position to complete reset. The ripper is applied to the weeding andloosening operation in the woody plants, is suitable for removing weeds between the plants and loosening the soil, is safe and efficient and can solve problems of low efficiency of artificial weedingand environment pollution of herbicide.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

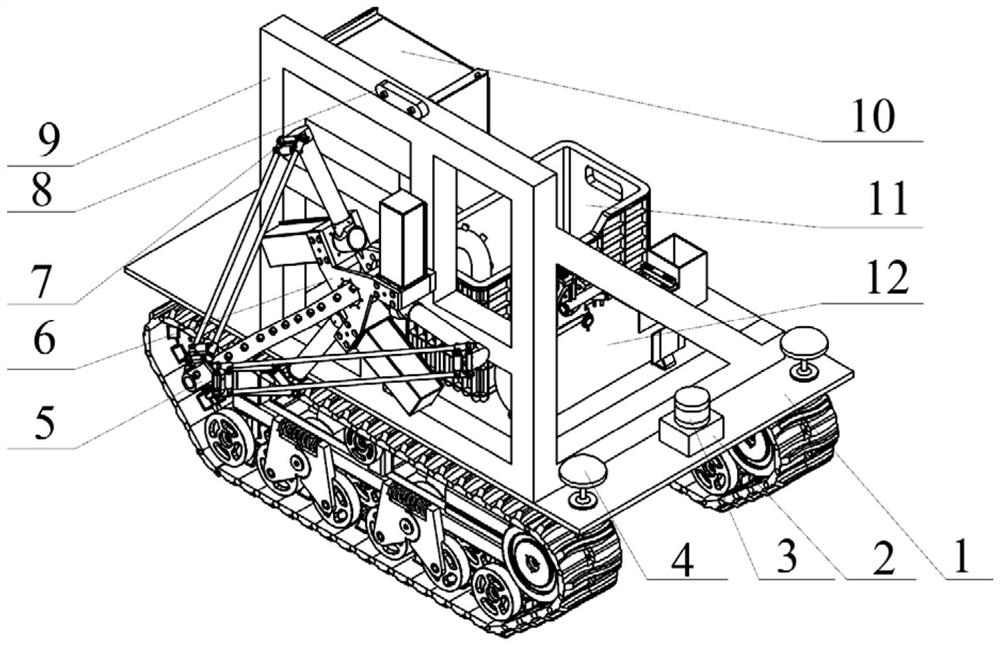

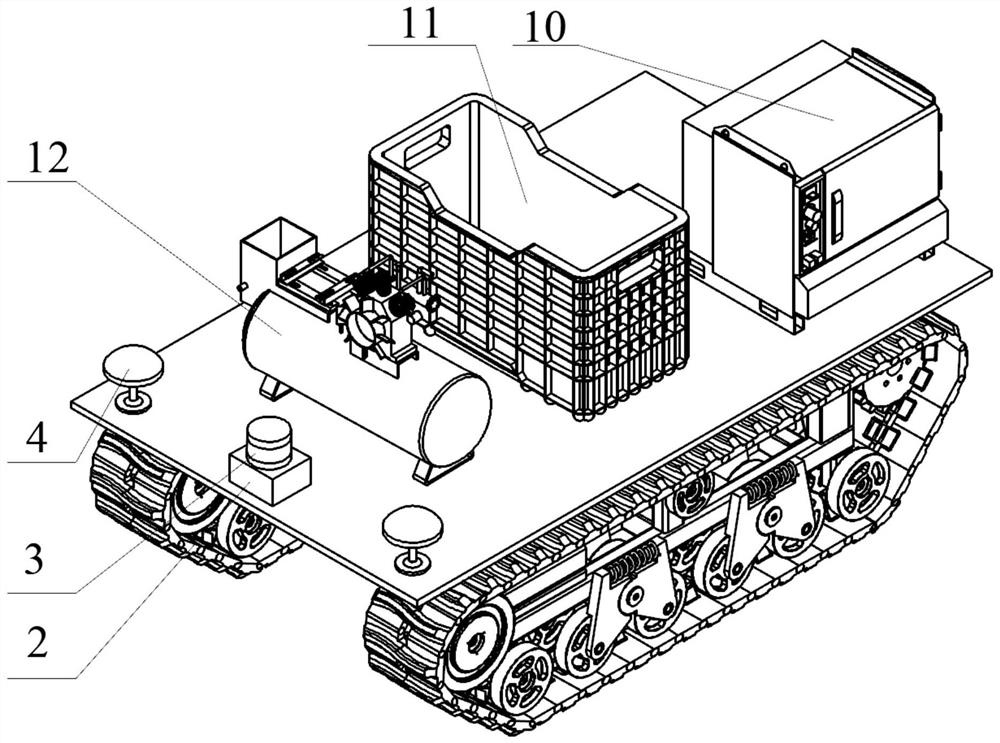

Swallowing type fruit and vegetable picking robot

InactiveCN111972127ARealize fully autonomous operationSimplify control proceduresPicking devicesAgricultural engineeringAir compressor

The invention discloses a swallowing type fruit and vegetable picking robot. The robot comprises an intelligent moving platform, a bionic swallowing transportation device, a robot body and an industrial personal computer, wherein the robot body and the industrial personal computer are installed on the intelligent moving platform; the bionic swallowing transportation device is installed in the robot body in a penetrating mode; the bionic swallowing transportation device comprises inflation pipelines, a transportation pipeline and an air compressor; the inflation pipelines are evenly arranged along the inner surface of the transportation pipeline; each inflation pipeline is provided with a vent hole communicating with the air compressor; one end of the transportation pipeline is provided with a suction inlet and fixed to the robot body; and an opening in the other end of the transportation pipeline leads to the interior of a fruit and vegetable collecting box. When the fruit and vegetable picking robot is used for picking fruits and vegetables, only the positions of the fruits and vegetables need to be recognized, and the postures of the fruits and vegetables do not need to be judged, so that a control program of the picking robot is simplified, and the picking efficiency is improved; mechanical damage to the fruits and vegetables is avoided in the whole fruit and vegetable picking and transporting process, so that rapid lossless picking operation is achieved; and the robot is suitable for picking various fruits and vegetables.

Owner:NANJING AGRICULTURAL UNIVERSITY

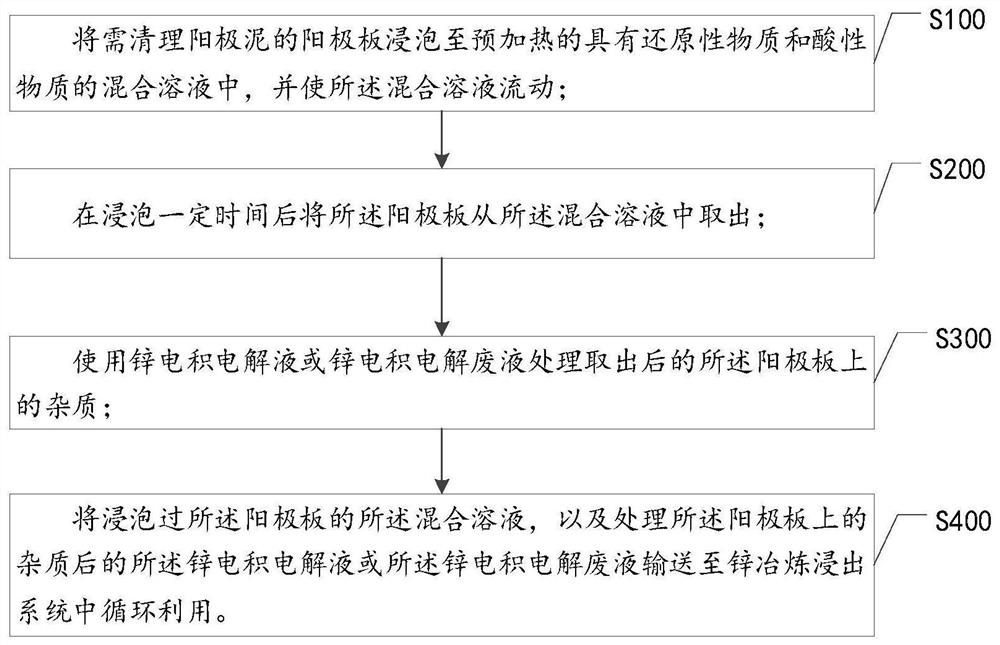

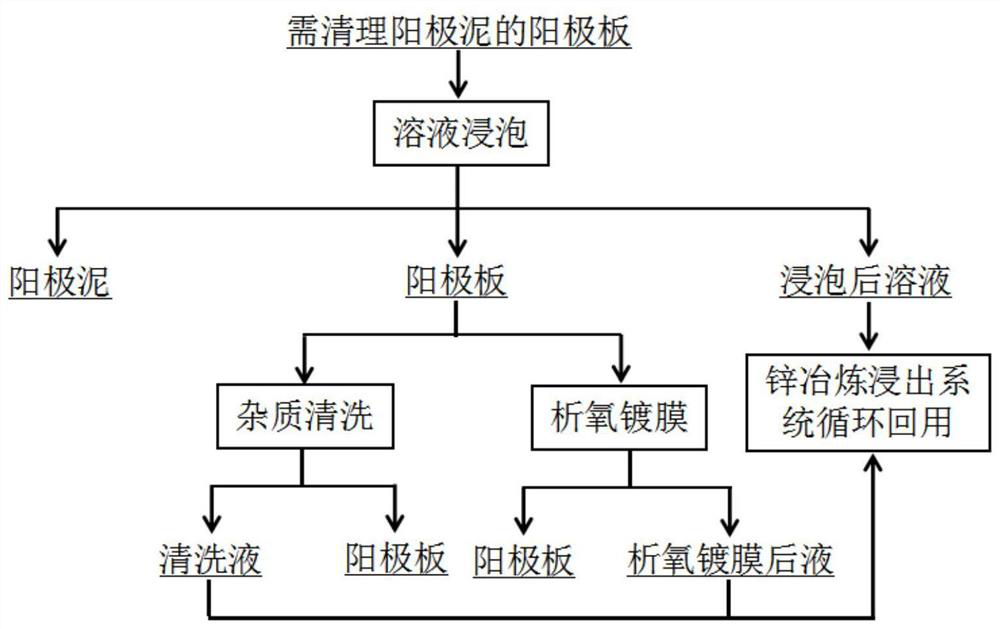

Method for cleaning anode mud on zinc electrodeposition anode plate

PendingCN113355696AAchieve cleanupImplement batch processingPhotography auxillary processesElectrolysis componentsElectrolytic agentMetallurgy

The invention provides a method for cleaning anode mud on a zinc electrodeposition anode plate. The method comprises the following steps of: soaking the anode plate with the anode mud needing to be cleaned into a preheated mixed solution with reducing substances and acidic substances, and enabling the mixed solution to flow; taking out the anode plate from the mixed solution after soaking for a certain time; and treating impurities on the taken-out anode plate by using a zinc electrodeposition electrolyte or a zinc electrodeposition waste electrolyte. According to the cleaning method provided by the invention, the anode plate with the anode mud needing to be cleaned is immersed into the flowing solution with the reducing substances and the acidic substances for a certain time, the anode mud on the anode plate is dissolved and falls off, and cleaning of the anode mud on the anode plate is achieved, so that the method is high in automation degree, compared with manual cleaning, the problem that the labor intensity of workers is large can be well solved, batch treatment of anode plates can be realized, and the efficiency is high.

Owner:SHAOYANG UNIV

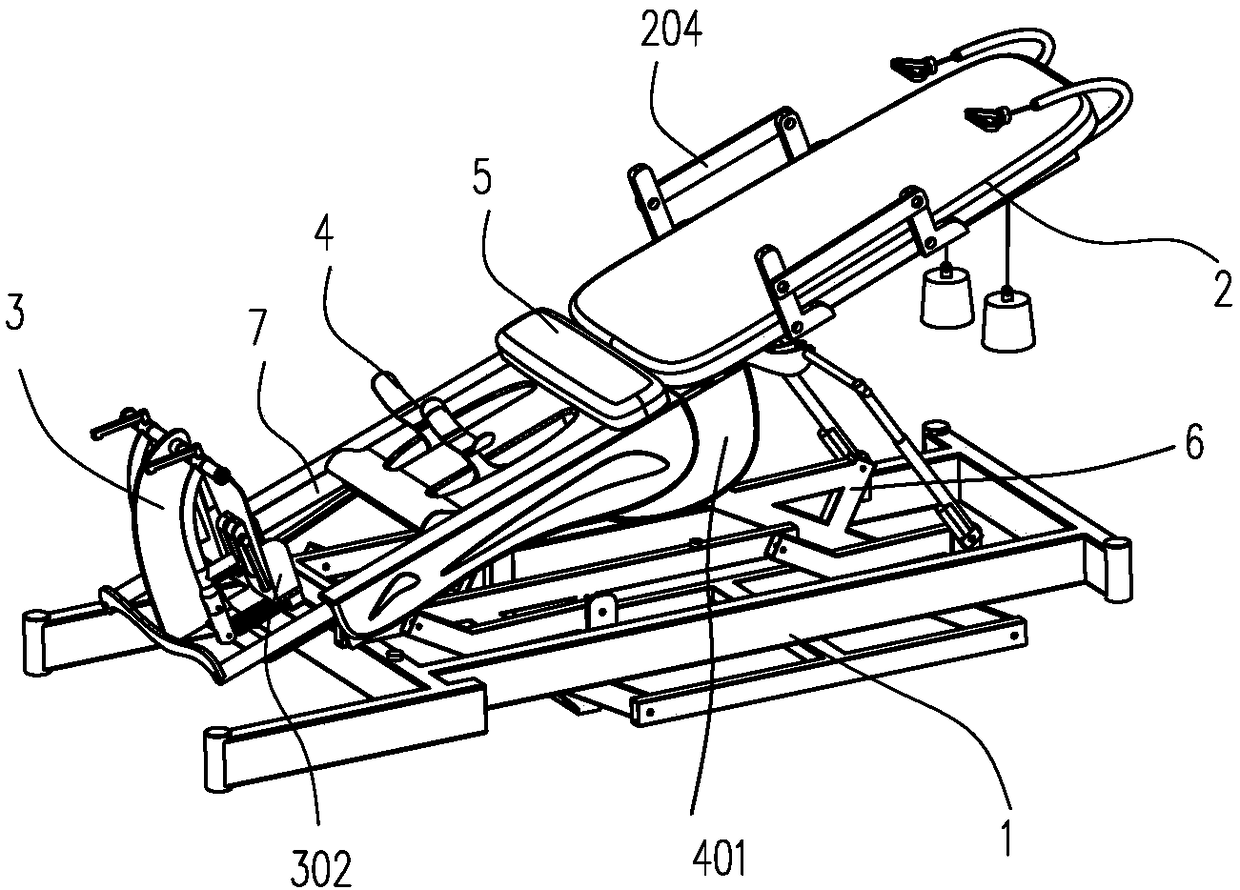

Lower-limb rehabilitation training device

InactiveCN108324508ACause mechanical damageAchieve stand upChiropractic devicesDamping functionEngineering

The invention relates to the field of medical instruments, in particular to a lower-limb rehabilitation training device which comprises a frame, a back placing device, a foot auxiliary device, a leg bending device, a hip soft pad, a standing device, a leg fixing frame and a motor. The leg fixing frame is mounted on the frame through the standing device, and the back placing device, the foot auxiliary device, the leg bending device, the hip soft pad and the motor are mounted on the leg fixing frame. A damping function is achieved when a patient touches a pedal by a leg placing device of the lower-limb rehabilitation training device, the patient adapts to a direction of a body to transform standing or lying along with the device through the leg bending device, and lower-limb rehabilitation training is performed.

Owner:柯文光

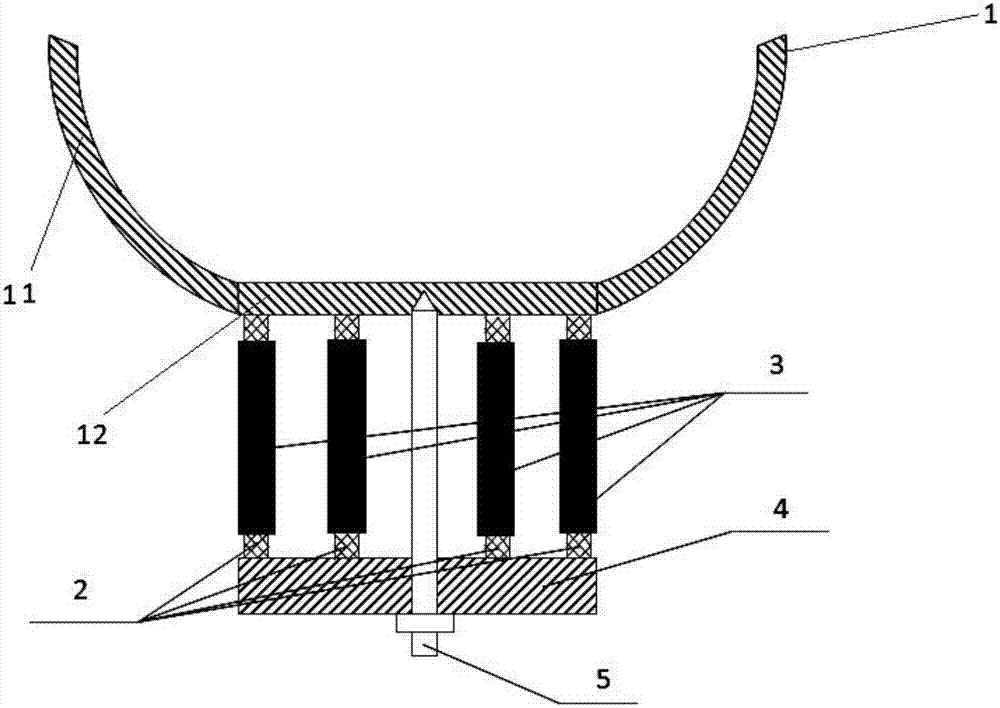

Ultrasonic descaling energy converter for plate heat exchanger and descaling method of ultrasonic descaling energy converter

PendingCN107044796AProduce mechanical damageExtend mechanical lifeVibration cleaningPlate heat exchangerEngineering

The invention discloses an ultrasonic descaling energy converter for a plate heat exchanger and a descaling method of the ultrasonic descaling energy converter. The ultrasonic descaling energy converter comprises a radiant surface. The radiant surface is of a flat horn-shaped structure. Multiple magnetostriction rods are mounted at the bottom of the radiant surface. A rear cover plate is mounted at the other ends of the magnetostriction rods. The bottom of the radiant surface and the rear cover plate clamp the magnetostriction rods through a fastening device. A coil is wound around each magnetostriction rod. A magnetostriction material is adopted as a vibration source, the mechanical life of the ultrasonic descaling energy converter is long, and the ultrasonic descaling energy converter can continuously work for a long time. According to the ultrasonic descaling energy converter, the radiant surface is in a flat horn shape, a parallel excitation manner is adopted in an excitation source, and therefore high descaling efficiency and reliability are achieved. In addition, the energy converter does not need to be welded to the plate heat exchanger, an immersion manner is adopted for work, and therefore any mechanical damage is not caused to the heat exchanger.

Owner:HARBIN NORMAL UNIVERSITY

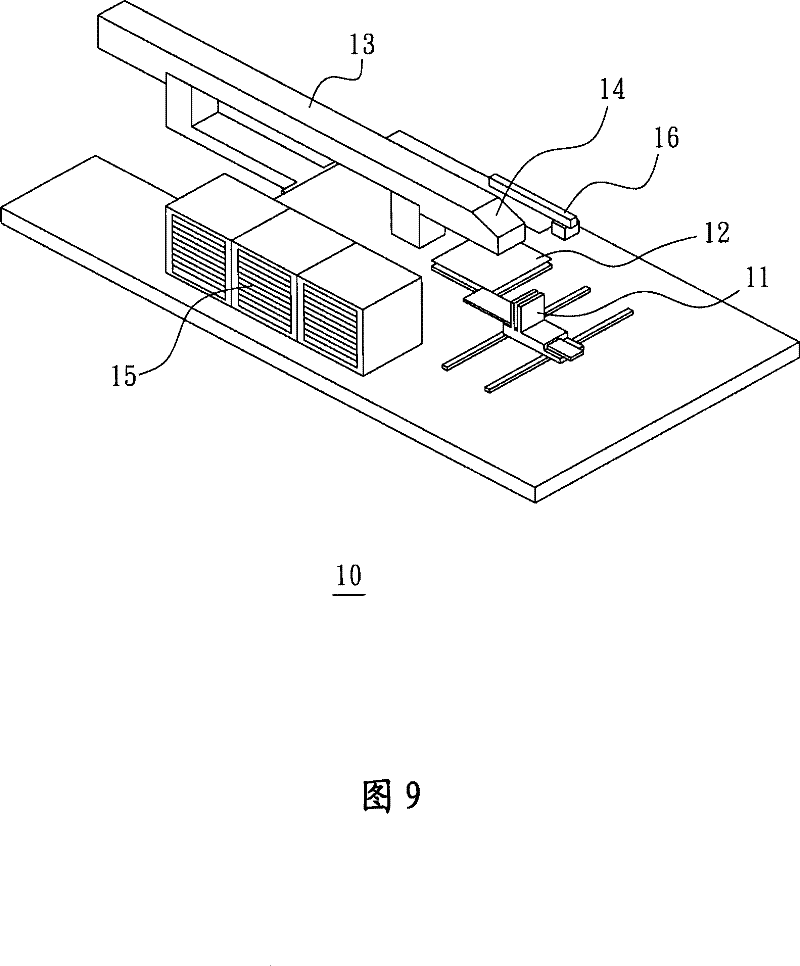

Outdoor movable generator

Owner:杜瑜

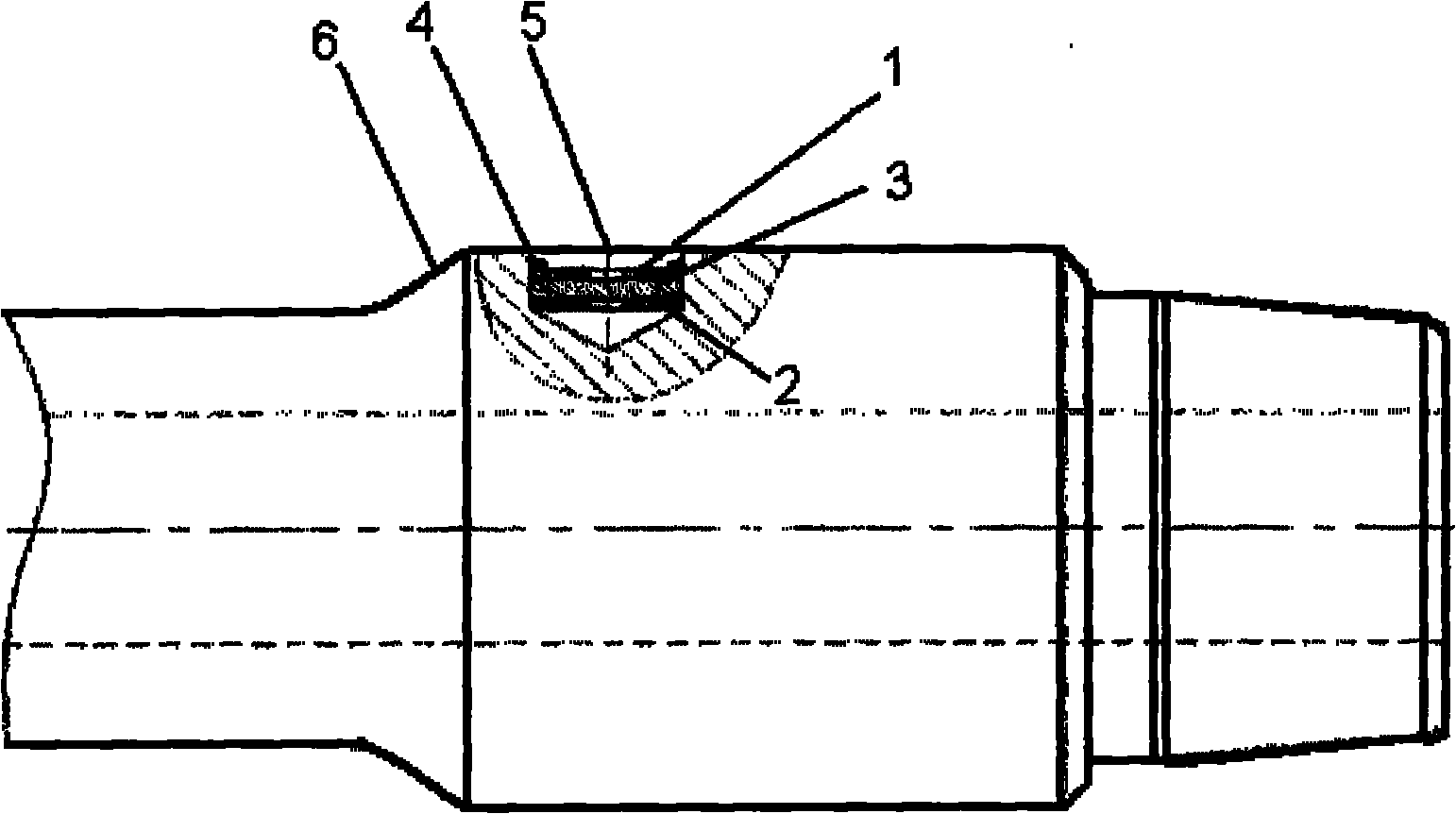

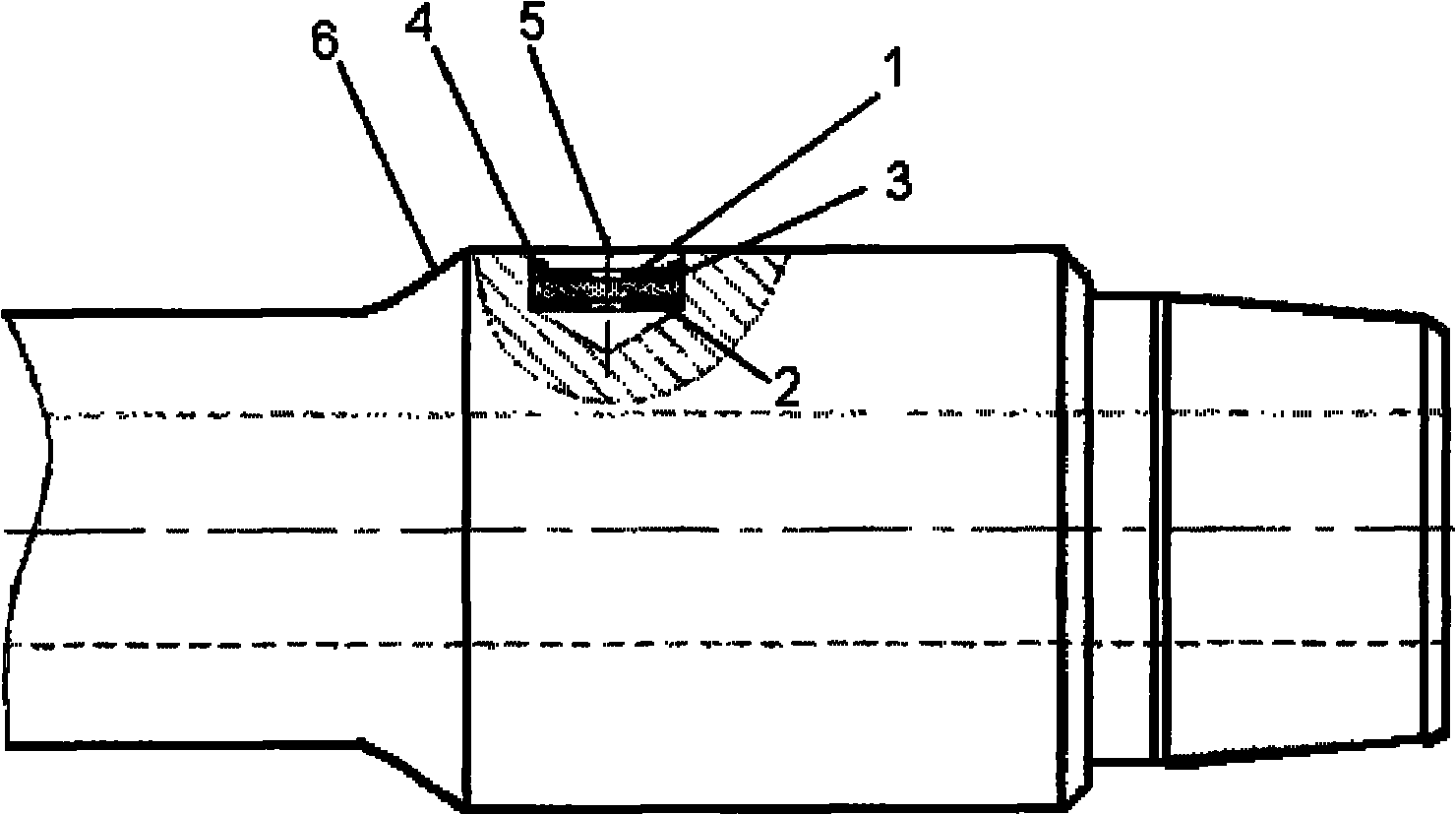

Drilling tool code recognition system

ActiveCN101996331AEasy to copyImprove anti-corrosion performanceDrilling rodsCo-operative working arrangementsInformatizationAdhesive

The invention relates to a drilling tool code recognition system comprising coding chips, a portable infrared scanner and a computer, wherein coding chips are two round anti-corrosion hard-plastic flakes with small holes in the centers, and each flake is engraved with a two-dimensional digital code of the same drilling tool; a blind hole is drilled in an area on a male connector of the drilling tool, adjacent to a slope table shoulder side, one coding chip is placed at the bottom of the blind hole, an anti-corrosion fluororubber pad with the outer diameter same to the size of the blind hole is covered on the coding chip, the other coding chip is placed on the fluororubber pad, with the surface engraved with the two-dimensional digital code upward, and finally, a small quantity of steel adhesive is applied on the inner side of the blind hole, tightly adjacent to the coding chips, so as to fix the coding chips; the corrosion and high-temperature resistant fluororubber pad in the coding chips can be used for isolating the chip at the bottom layer with a working environment so as to effectively protect the chips; and the portable infrared scanner improves the efficiency and accuracy of code recognition, avoids errors caused by manually recording codes, and promotes the digitization and the informatization of drilling tool coding management.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

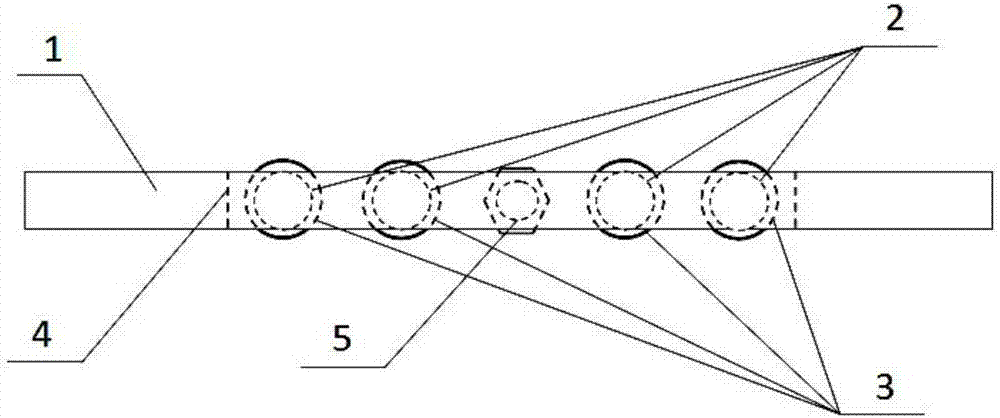

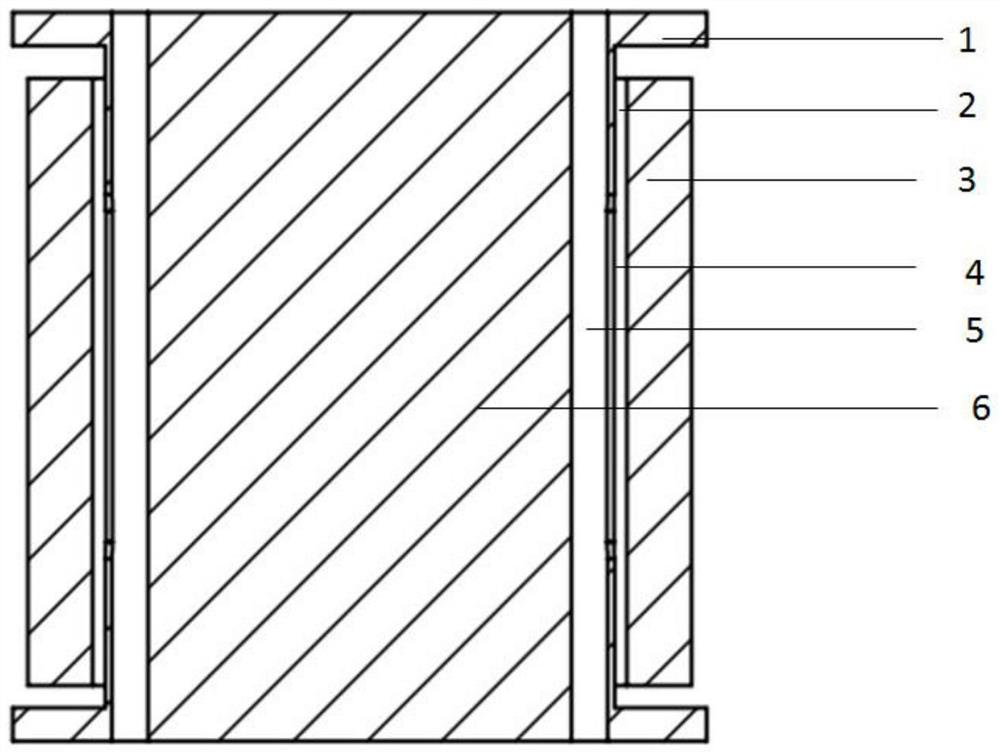

High-heat-conductivity niobium-tin superconducting coil and manufacturing method thereof

PendingCN114300213AImprove cooling effectImprove preparation safetySuperconducting magnets/coilsCoils manufactureNiobiumSuperconducting Coils

The invention provides a high-heat-conductivity niobium three-tin superconducting coil and a manufacturing method thereof. The high-heat-conductivity Nb3Sn superconducting coil comprises a stainless steel framework (1), an insulating layer (2), a Nb3Sn superconducting coil (3), aluminum nitride (4), sodium chloride (5) and a central support (6). The high-heat-conductivity Ni3Sn superconducting coil is adopted, the mechanical supporting structure of stainless steel is utilized, the high heat conductivity of aluminum nitride is combined, the cold conduction effect of the thin-wall stainless steel framework can be improved, the problem that the cooling capacity of the Ni3Sn coil is poor is effectively solved, the refrigeration effect of the Ni3Sn coil is improved, and the service life of the Ni3Sn coil is prolonged. Therefore, the current-carrying capacity of the Ni3Sn coil is improved, and the performance of the Ni3Sn superconducting coil is improved. Meanwhile, in order to solve the problem that thin-wall stainless steel is prone to deformation at high temperature, the gap between the stainless steel framework and the center heat-resistant steel support is filled with sodium chloride, radial shrinkage of the stainless steel at high temperature is effectively prevented, sodium chloride can be removed only through water dissolution after temperature returning, and the center heat-resistant steel support can be conveniently pulled out.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

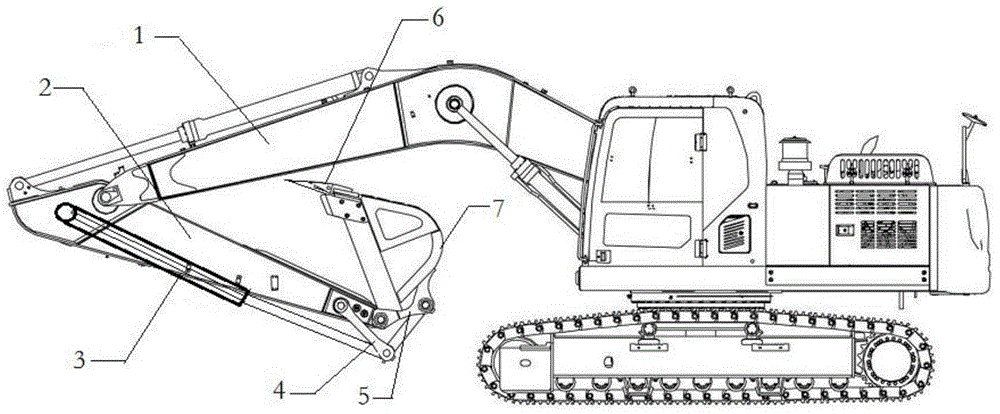

Small excavator with double support arms

InactiveCN104975625AImprove job stabilityStable supportMechanical machines/dredgersExcavatorDouble support

The invention discloses a small excavator with double support arms, which comprises a bucket rod, two hinged seats, two support arm oil cylinders and a bucket, wherein the bucket rod is arranged between a moving arm and the bucket, and comprises a first bucket rod and a second bucket rod which are hinged with each other from the head to the tail, the front part of the second bucket rod is divided into two support arms which are equal in length, the front ends of the two support arms are pin-jointed with the bucket, the two hinged seats are respectively arranged on pin-jointed positions of the front ends of the two support arms and the bucket, the two support arm oil cylinders are respectively arranged on the outer sides of the two support arms, the bucket comprises a bucket main body, a bucket seat and a bucket tooth, the bucket seat is pin-jointed with the front ends of the two support arms, the bucket tooth is of an isosceles triangle, and sawteeth are uniformly distributed on the two equal sides of the isosceles triangle. The small excavator with the double support arms is reasonable in design, improves excavating strength, stabilizes excavating operation performance, can not cause mechanical injury to the bucket rod during the excavating operation, and prolongs service life.

Owner:吴爱群

Method for collecting aged larvae, pupae and adults of bactrocera dorsalis

ActiveCN111466342ACause mechanical damageEasy to operateInsect catchers and killersAnimal scienceMethyleugenol

The invention discloses a method for collecting aged larvae, pupae and adults of bactrocera dorsalis. Aged-larva-containing feedstuff is poured into an uncovered mesh box, the uncovered mesh box is suspended, then, a white plastic case is placed under the uncovered mesh box, and the aged larvae are transferred into the white plastic case by using a bouncing habit of the aged larvae so as to collect the larvae. The aged-larva-containing feedstuff is poured into the uncovered mesh box, then, the uncovered mesh box is placed into the white plastic case laid with sterilized sandy soil, the aged larvae are transferred into the sterilized sandy soil for pupation through bouncing, and then, the pupa-containing sterilized sandy soil is poured into another mesh box so as to screen out pupae. A bottle body and bottle bottom of a spring water bottle is provided with small holes, methyleugenol infiltrated sterilized degreased cotton is arranged in the bottle, then, the spring water bottle is suspended in an insect culture cage, and males are trapped into a trapping bottle through methyleugenol. A bottle cap of a glass bottle is provided with two glass tubes: one end of one glass tube is provided with gauze, and the other end of one glass tube is connected with a dust collector through a long plastic tube; one end of the other glass tube is open, and the other end of the other glass tube isconnected with a glass suction tube through a long plastic tube; and females are collected into the glass bottle through a suction force of the dust collector.

Owner:QINGDAO AGRI UNIV

An optical fiber probe type cleaning and detection system and its production and use method

The invention discloses an optical fiber probe type cleaning and detection system and a fabrication and application method thereof. The optical fiber probe type cleaning and detection system comprisesa spectral analyzer and an annular device, two front section single mode optical fibers are arranged between the spectral analyzer and the annular device, an attenuated device is arranged on one of the front section single mode optical fiber, and an amplifier is arranged on the other front section single mode fiber. A rear section single mode optical fiber is further arranged on the annular device, and a displacement table and an optical fiber probe are arranged on the rear section single mode fiber in sequence. According to the adjustable bubble cleaning and detection system, a working element is an optical fiber probe, and is easy to bend and move; the optical fiber has the good plasticity, the size of an optical fiber cone which produces bubbles can be small enough, penetrating into the device is facilitated, and the fixed point cleaning at any position is realized; the cleaning function is realized by using the bubbles in liquid, and the mechanical damage caused by a cleaning object is not caused; and the cleaning and cleanliness detection of cleaning surface can be realized at the same time, a cleaning element and a detection element are the same optical fiber probe, the structure is compact, and the integration is high.

Owner:STATE GRID SICHUAN ECONOMIC RES INST

Lathe with automatic control function

InactiveCN102974844BSimple processImprove work efficiencyAutomatic/semiautomatic turning machinesNumerical controlAutomatic control

The invention discloses a lathe with an automatic control function. The lathe comprises a base, a worktable, a first power device, a second power device, a third power device, a pressure sensing and transmission device and a control device, wherein the worktable is movably connected with the base; the first power device is fixedly arranged on the base and can drive a cutter to move up and down, and the cutter is fixedly connected with a first contact; the second power device is fixedly arranged on the base and can drive the worktable to enable a limiting block which is fixedly arranged on the worktable to get close to and or far away from a position right belowunder the cutter; the third power device is fixedly arranged on the worktable and can drive an ejection head to get close to and or far away from one side of the limiting block; the pressure sensing and transmission device comprises a sensing part and the first contact is connected with the sensing part; the control device is used for controlling the startup and the shutdown of the first power device; and when the control device receives pressure information coming from the pressure sensing and transmission device, the control device controls the first power device to be shut down. The lathe with the automatic control function has the advantages that the machining efficiency is high, the quality of the machined products is good, the service life of equipment is long, the upward movement and the downward movement of the cutter are automatically controlled, and not only can the investment be reduced, but also the effect of a numerical control machine can be achieved.

Owner:ANHUI CHANGQING ELECTRONICS MACHINERY GRP

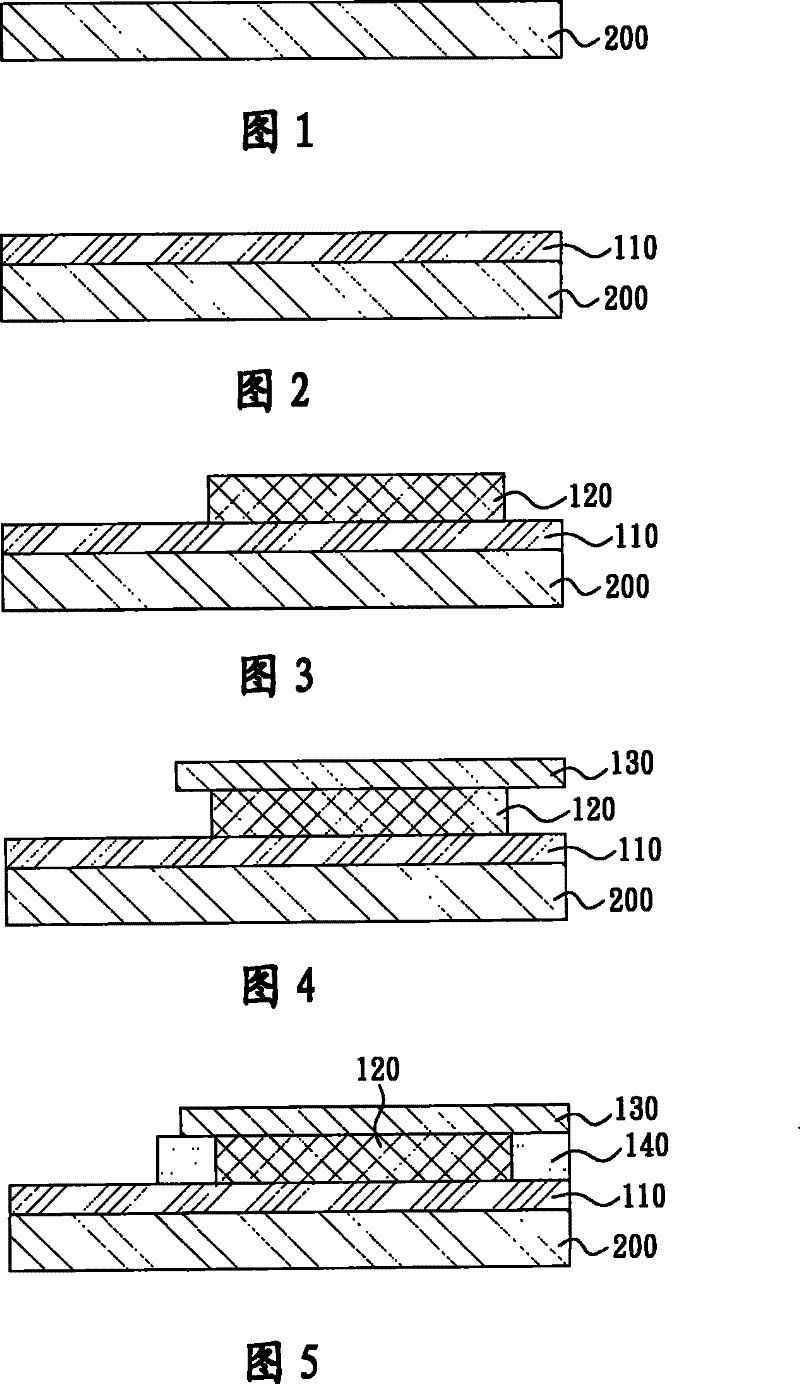

Production method and equipment for electrophoresis type display equipment

ActiveCN101482681BCause mechanical damageImprove manufacturing yieldNon-linear opticsElectrophoresisManufactured apparatus

The invention relates to a manufacture method and manufacture apparatus of electrophoresis type display apparatus, the manufacture method of the electrophoresis type display apparatus comprises: providing a substrate; providing a flexible substrate arranged on the substrate; providing an electrophoresis layer arranged on the flexible substrate; providing a transparent protection layer arranged onthe electrophoresis layer; providing an edge protector arranged between the flexible substrate and the transparent protection layer around the electrophoresis layer; providing a laser irradiating thesubstrate from one side of the substrate deviating from the flexible substrate to separate the substrate and the flexible substrate. The manufacture apparatus comprises a transferring device for transferring the electrophoresis type display apparatus with the substrate and the separated substrate and the electrophoresis type display apparatus; an adsorption system for fixing the electrophoresis type display apparatus with the substrate transferred by the transferring device by the adsorption mode; a laser apparatus for outputting a laser to separate the substrate and the electrophoresis type display apparatus; and an aligning system for calibrating the position. The invention can improve the manufacture quality and strengthen the trust reliability to reach to the commercial degree, and isvery practical.

Owner:E INK HLDG INC

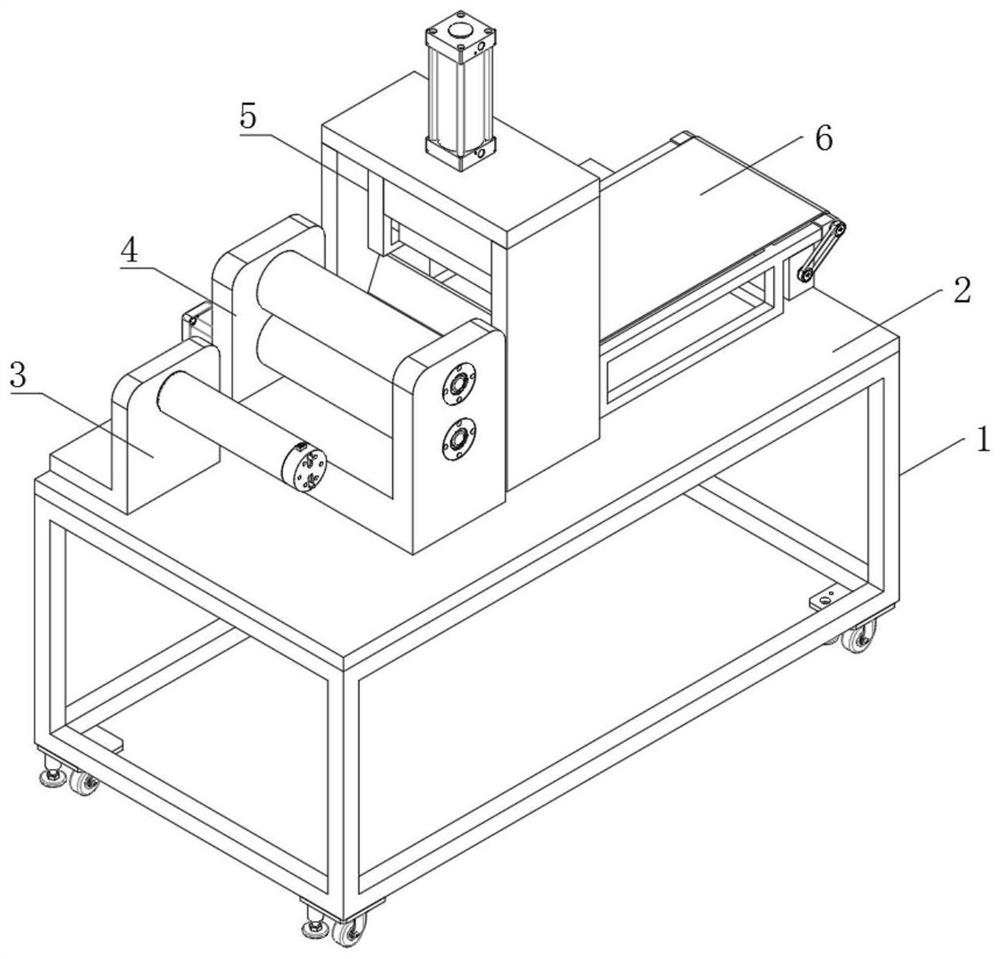

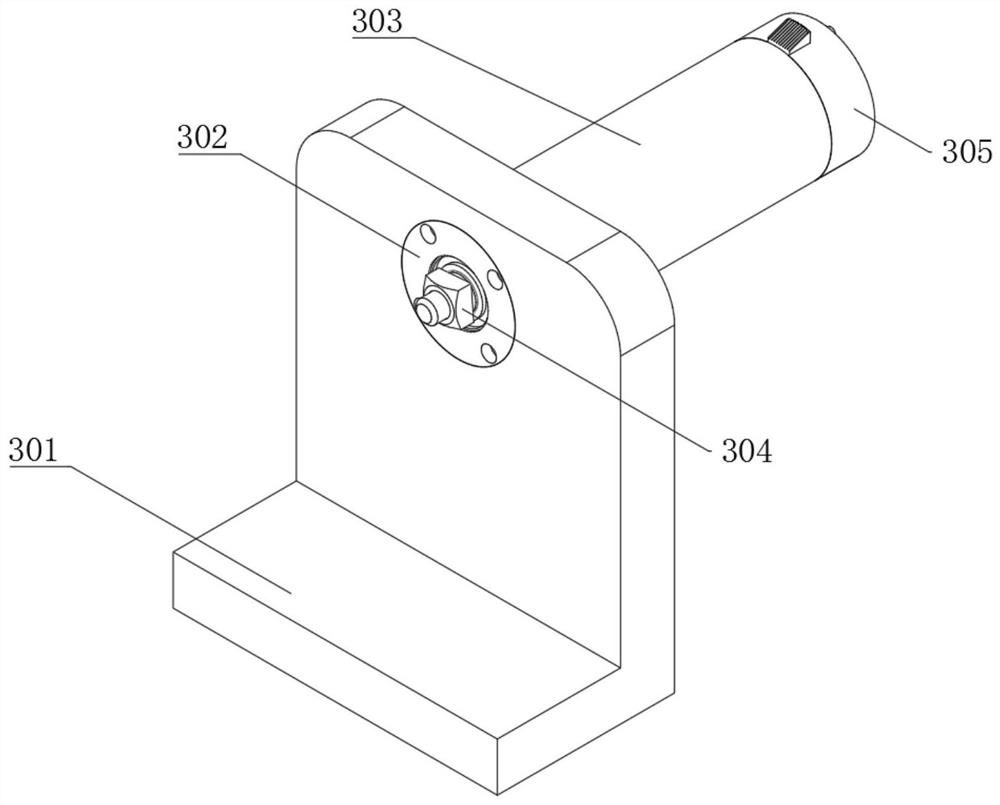

High-quality environment-friendly glitter powder production line and production process

InactiveCN113860022ACause mechanical damageFast loadingMetal working apparatusWebs handlingProduction lineRotational axis

The invention discloses a high-quality environment-friendly glitter powder production line and a production process. The high-quality environment-friendly glitter powder production line comprises a machine frame, a main bottom plate, a feeding mechanism, a conveying mechanism, a cutting mechanism, a discharging mechanism, a feeding fixing base, a first plummer block, a feeding rotating shaft, a tensioning nut, a clamping jaw fixed seat, a clamping jaw sliding seat and a clamping jaw handle. The clamping jaw sliding seat is moved to the innermost part by pulling the clamping jaw handle, rapid feeding of the device is facilitated, a coil stock is fixedly clamped in the middle of the feeding rotating shaft, the tensioning nut is in threaded connection with one end of the feeding rotating shaft, the coil stock rotates in the first plummer block at the top of the feeding fixing base, the rotating speed during feeding can be conveniently and rapidly adjusted, the situation that roll materials fly out and diffuse during working, and personnel are mechanically injured due to the fact that the speed during feeding is not uniform is avoided, and the phenomenon that in the feeding process, a cutting device cannot perform cutting and a cutting knife is scrapped due to the fact that products are folded is avoided.

Owner:广州市创坤金葱粉皮革有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com