Patents

Literature

37results about How to "Short cleaning cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

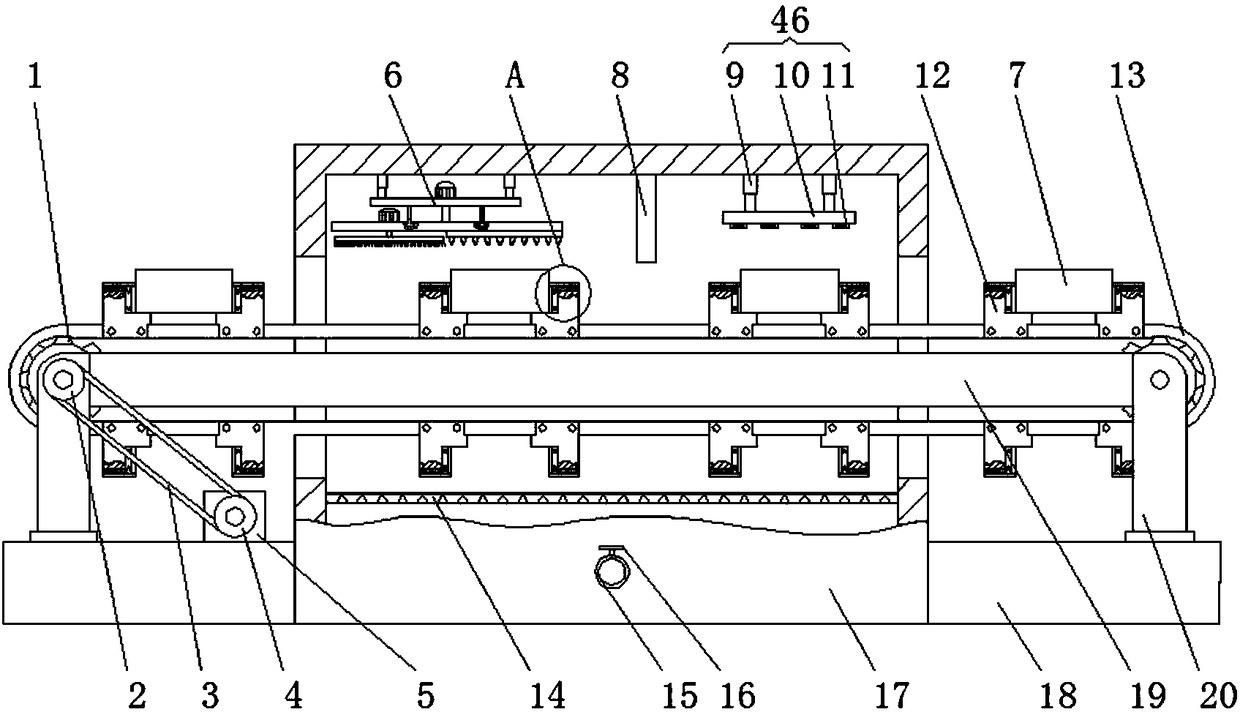

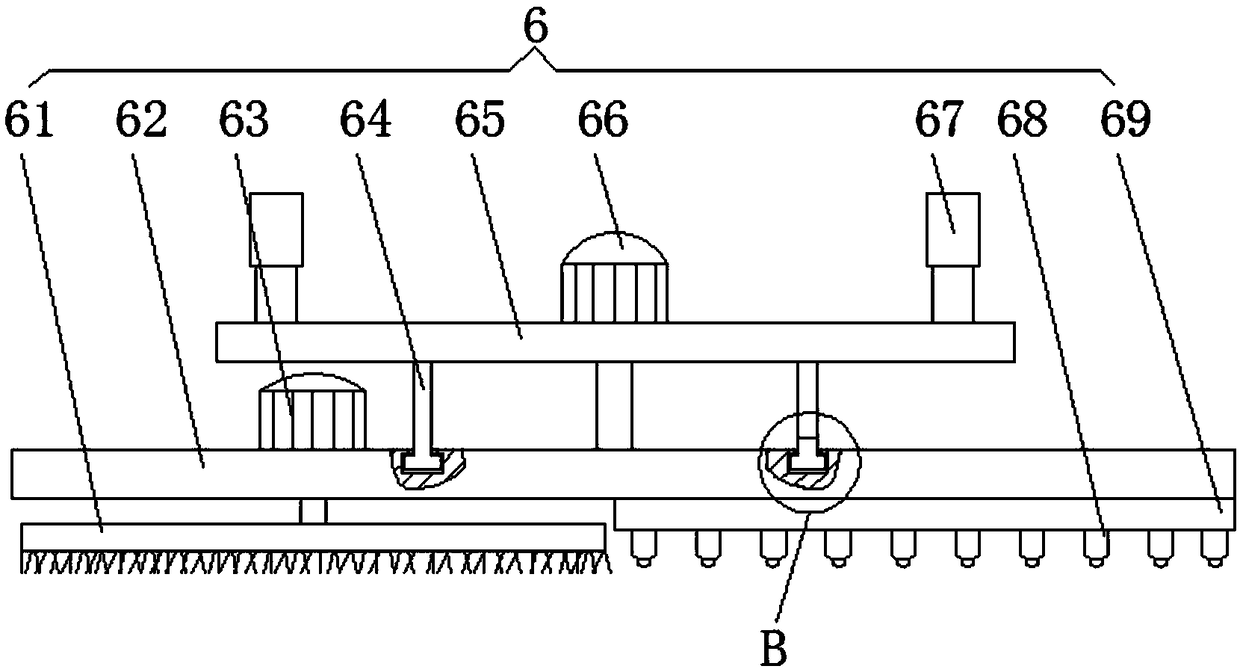

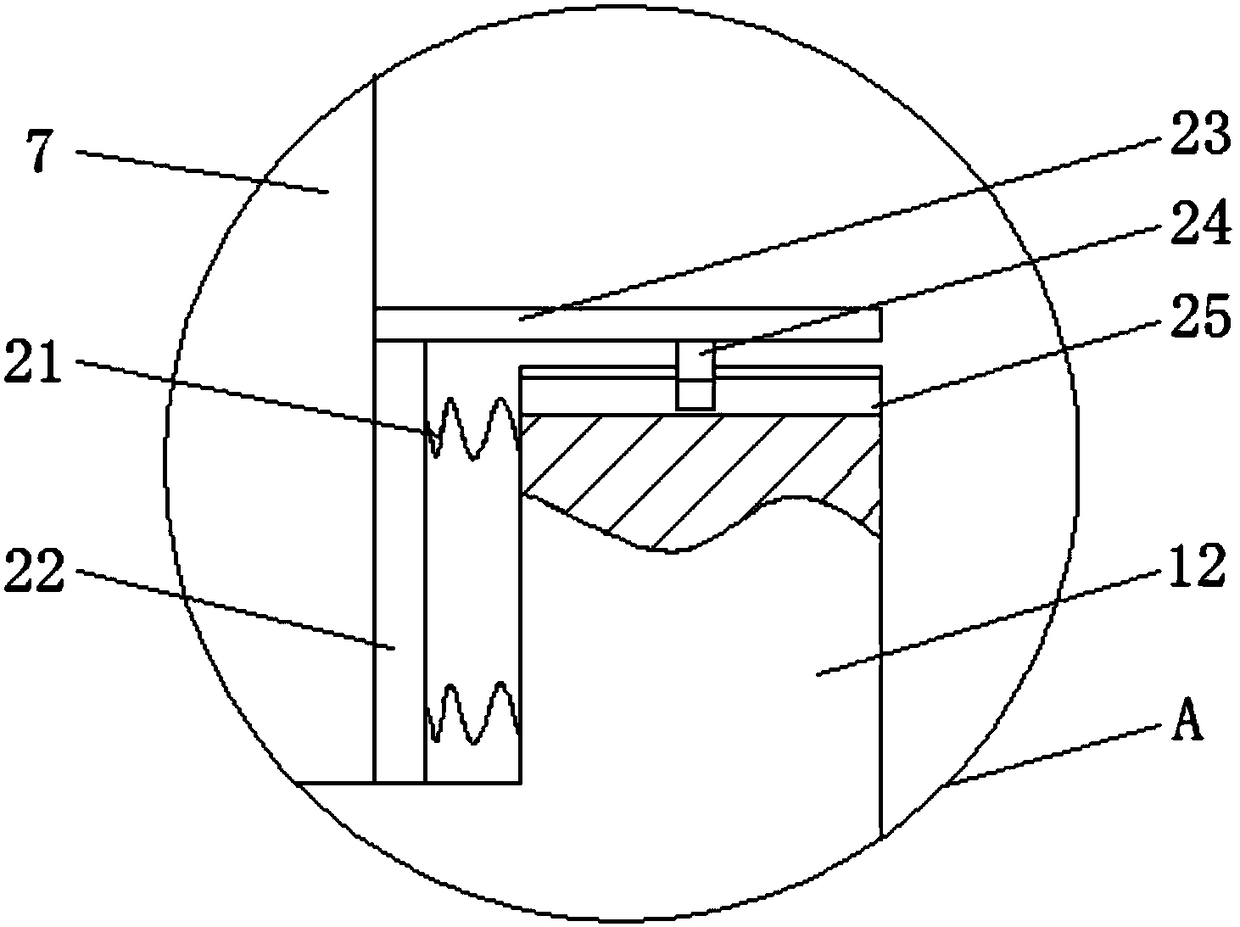

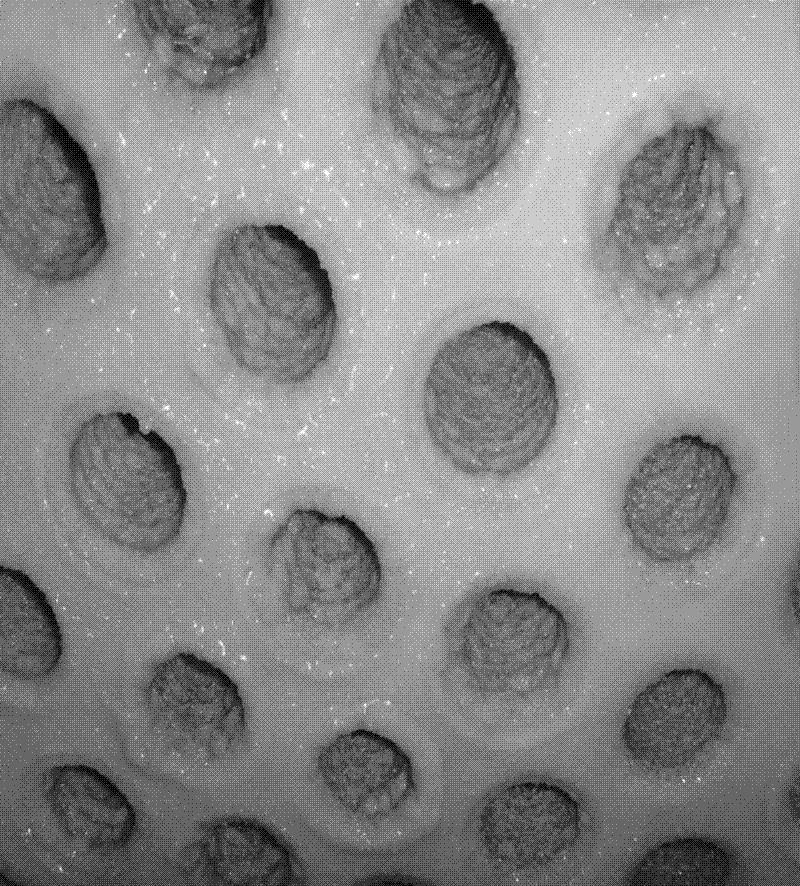

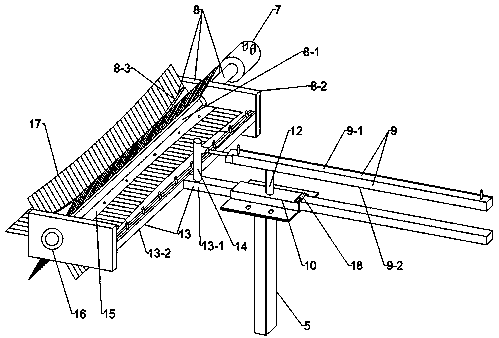

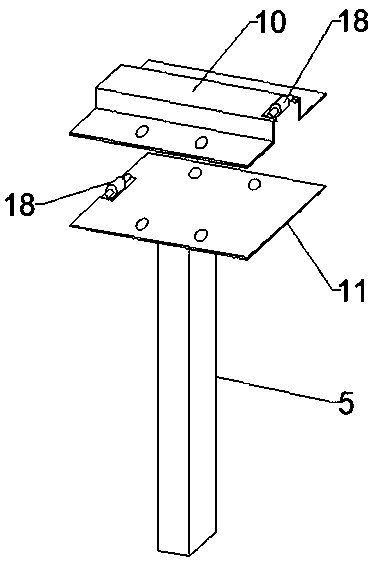

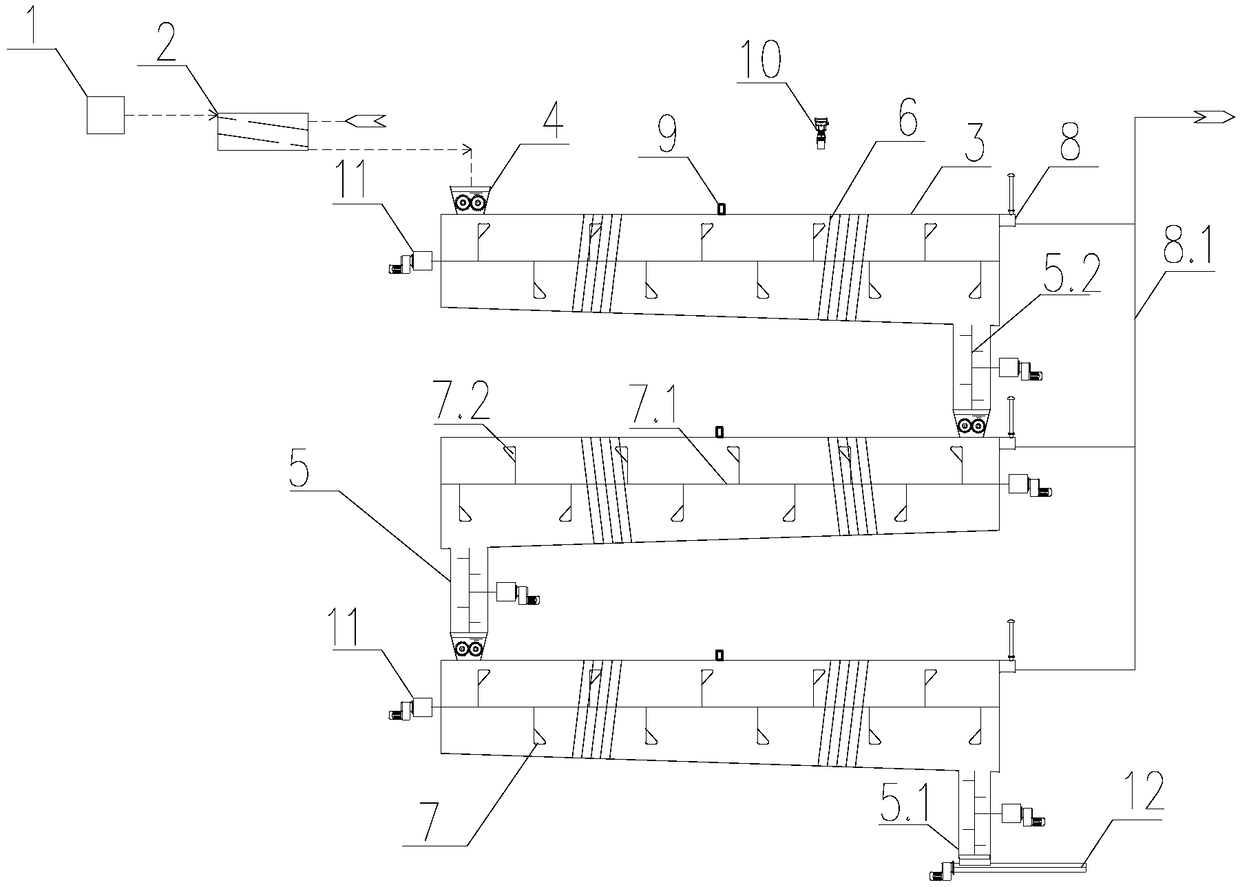

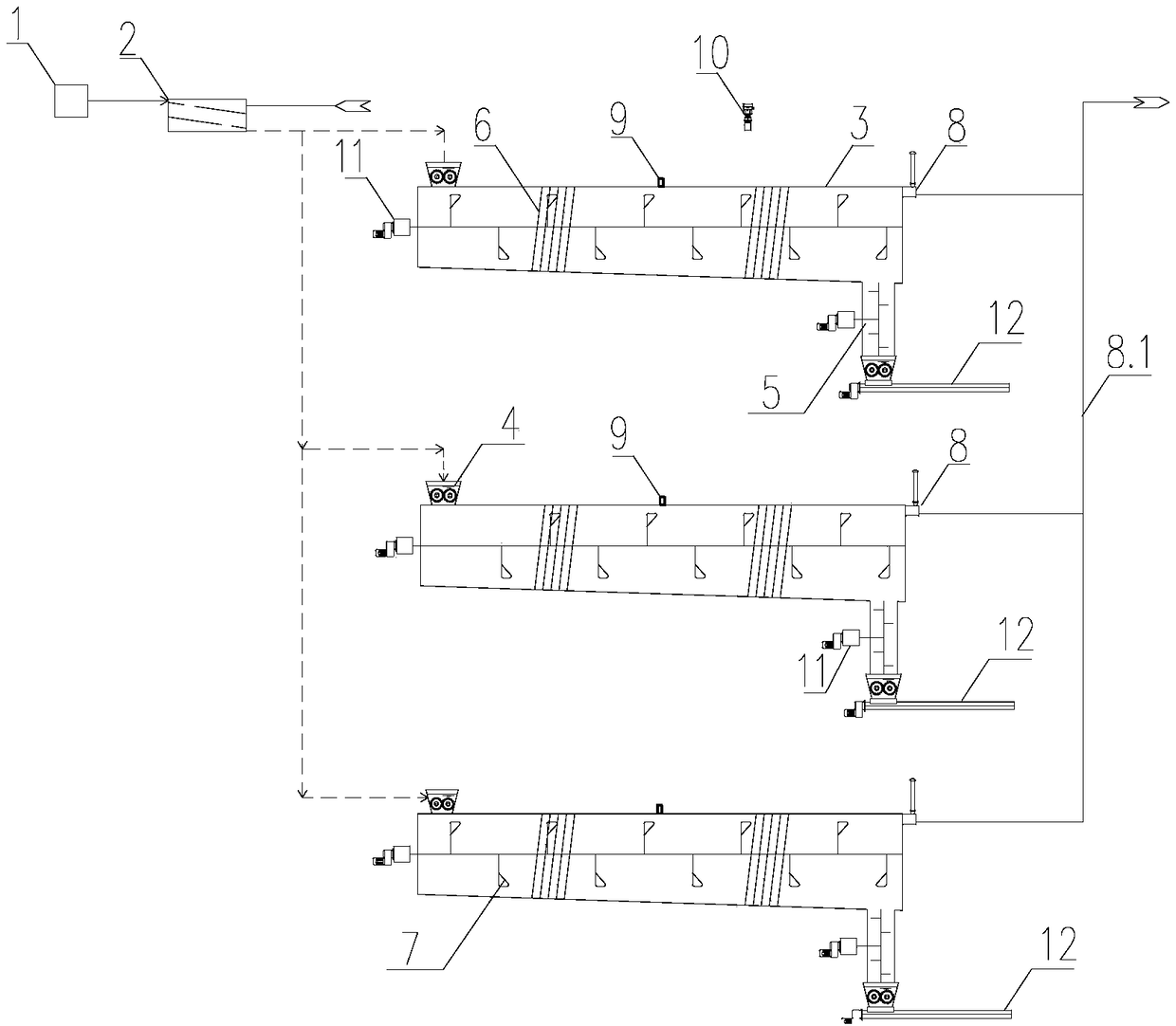

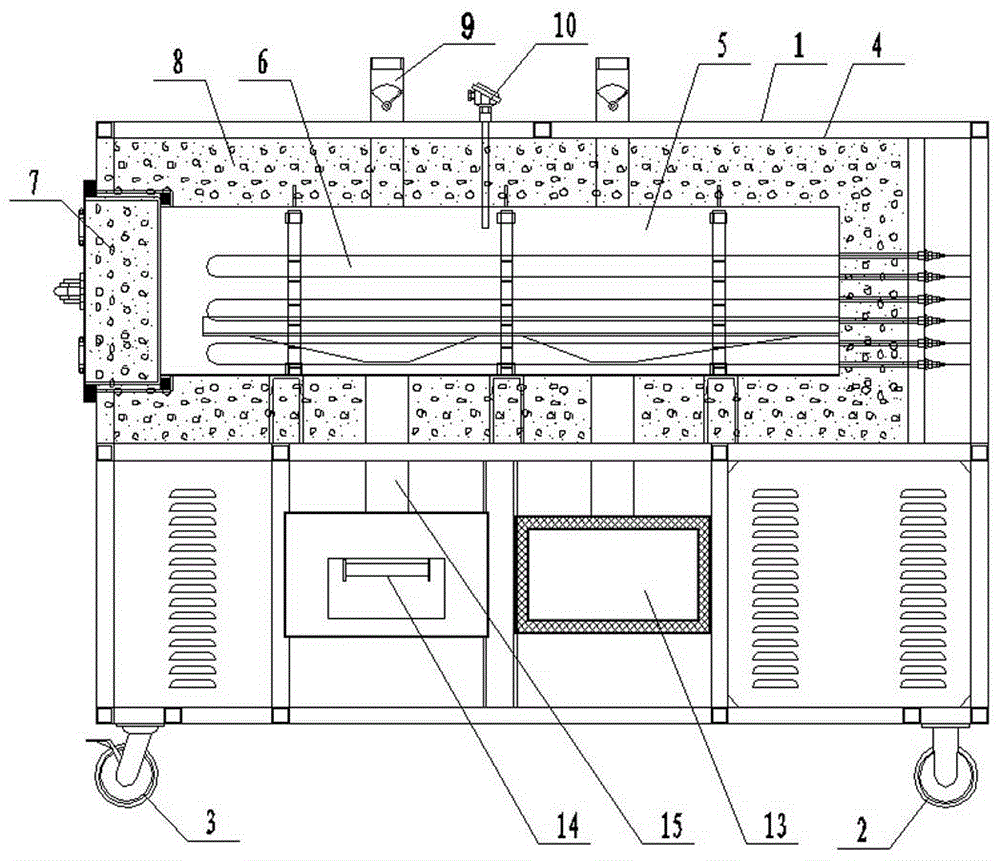

Working method of automatic mold cleaning and drying device

ActiveCN108543752AEasy to cleanShort cleaning cycleCleaning using toolsDrying machines with progressive movementsEngineeringMechanical engineering

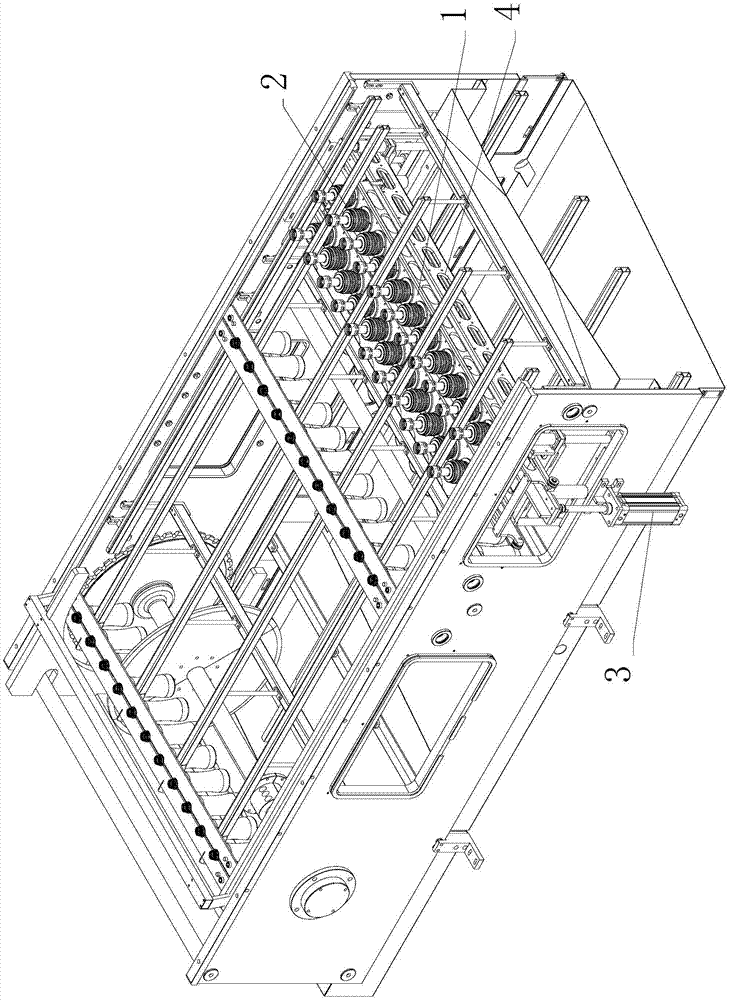

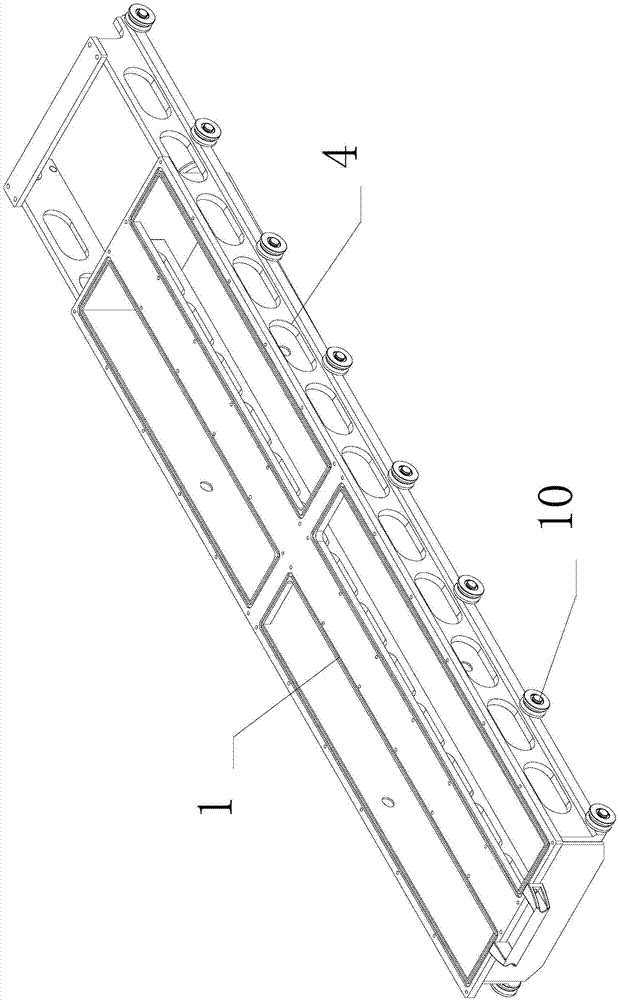

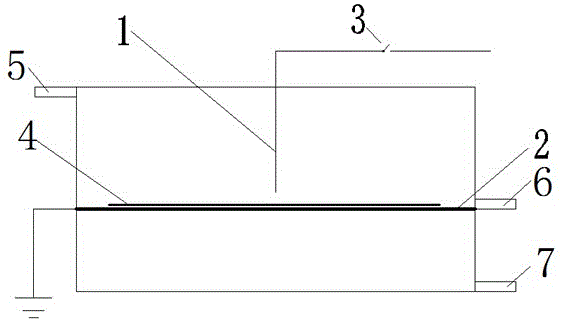

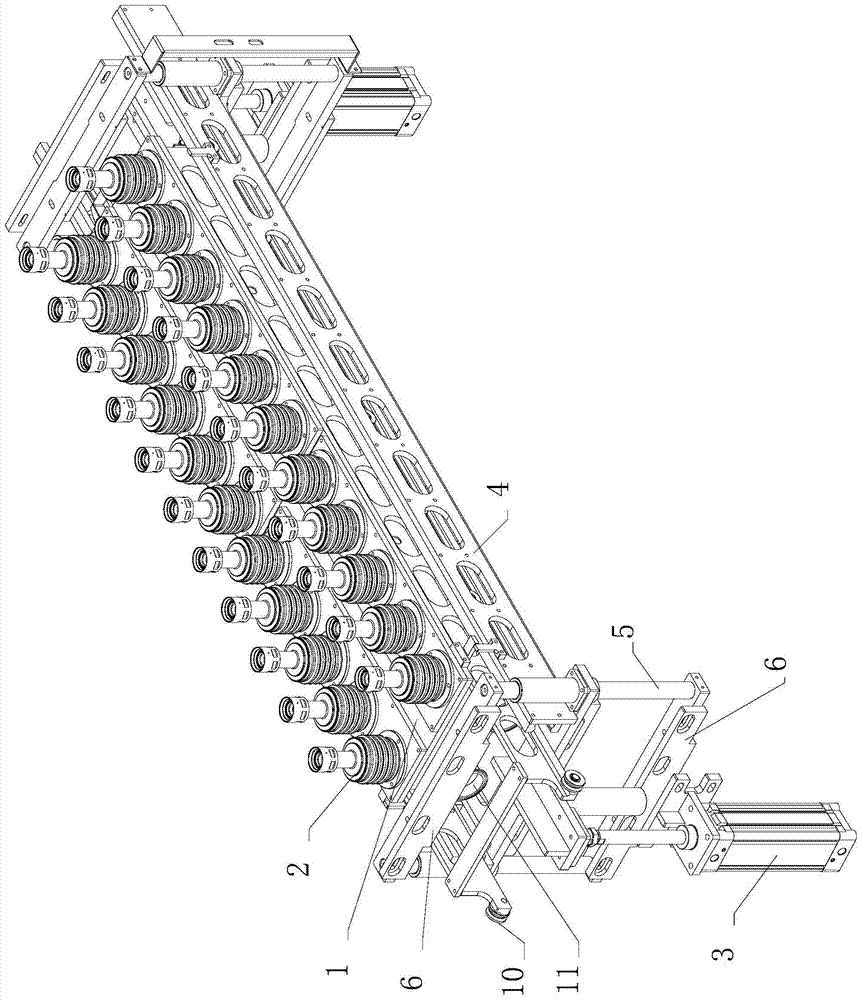

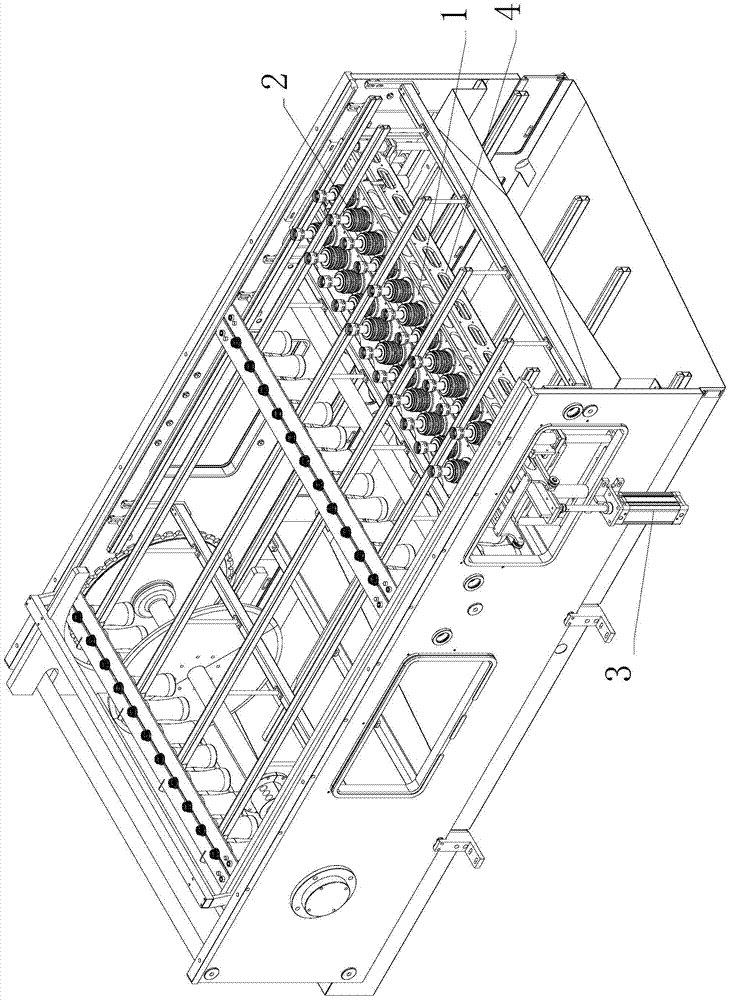

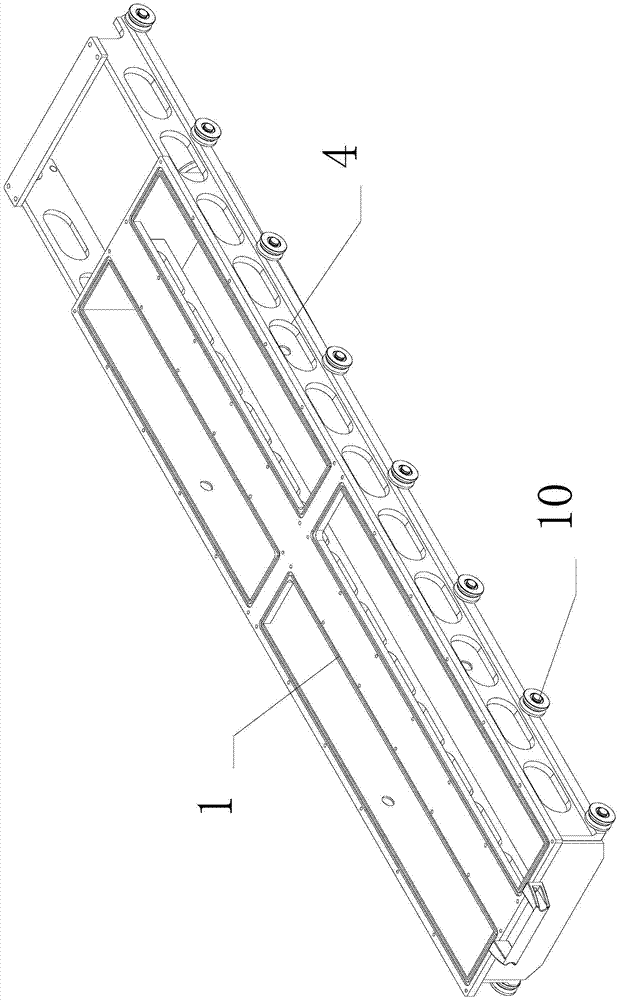

The invention relates to the technical field of mold cleaning, in particular to an automatic mold cleaning and drying device. The automatic mold cleaning and drying device comprises a first shell, wherein supporting rods are arranged at the upper ends of fixing plates, the upper ends of the supporting rods are connected with chain wheels through rotating shafts respectively, and the two chain wheels are in transmission connection through a chain; a first belt wheel is arranged on one side of the chain wheel on the left side, and a plurality of groups of L-shaped pieces are symmetrically arranged on one side of the chain; and a cleaning device is arranged on one side of the upper end of the inner wall of the first shell, and a drying device is arranged on the side, far away from the cleaning device, of the upper end of the inner wall of the first shell. According to the automatic mold cleaning and drying device, the cleaning device is arranged to omnidirectionally clean a mold, and therefore the cleaning effect of the mold is better, and meanwhile, the cleaning efficiency of the mold can be improved; the drying device is arranged to dry the mold subjected to cleaning; a motor is arranged to drive the chain wheels to rotate, and therefore the mold can be moved through the chain; and automatic cleaning and drying can be realized, the cleaning period is short, the time and the labor are saved, the use is convenient, and the device is worthy of popularization.

Owner:TAICANG XINLIU PRECISION HARDWARE CO LTD

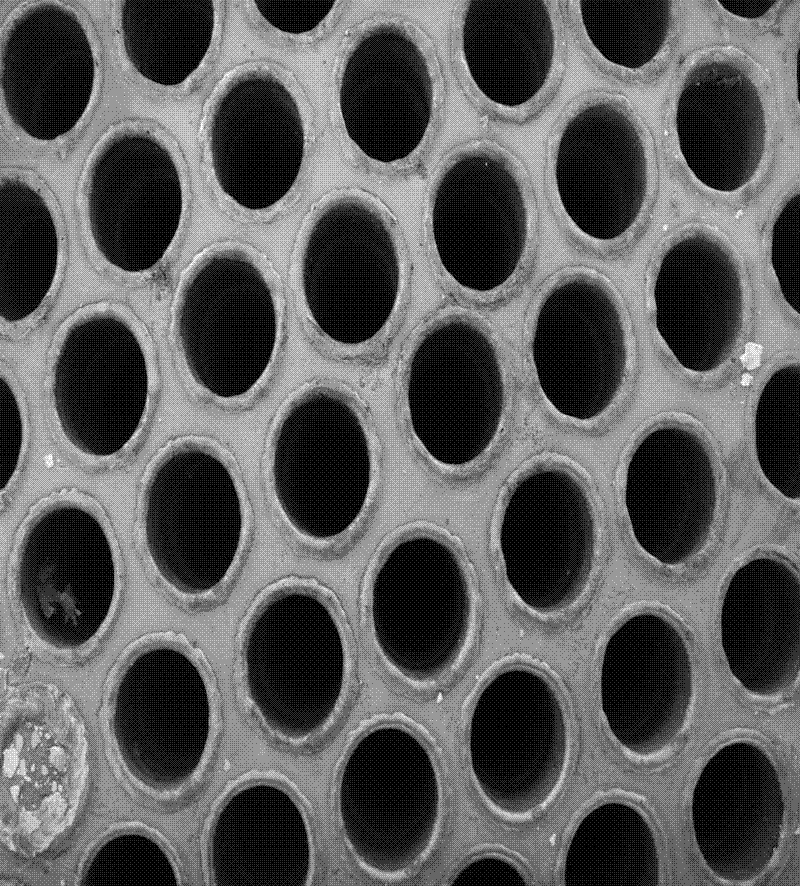

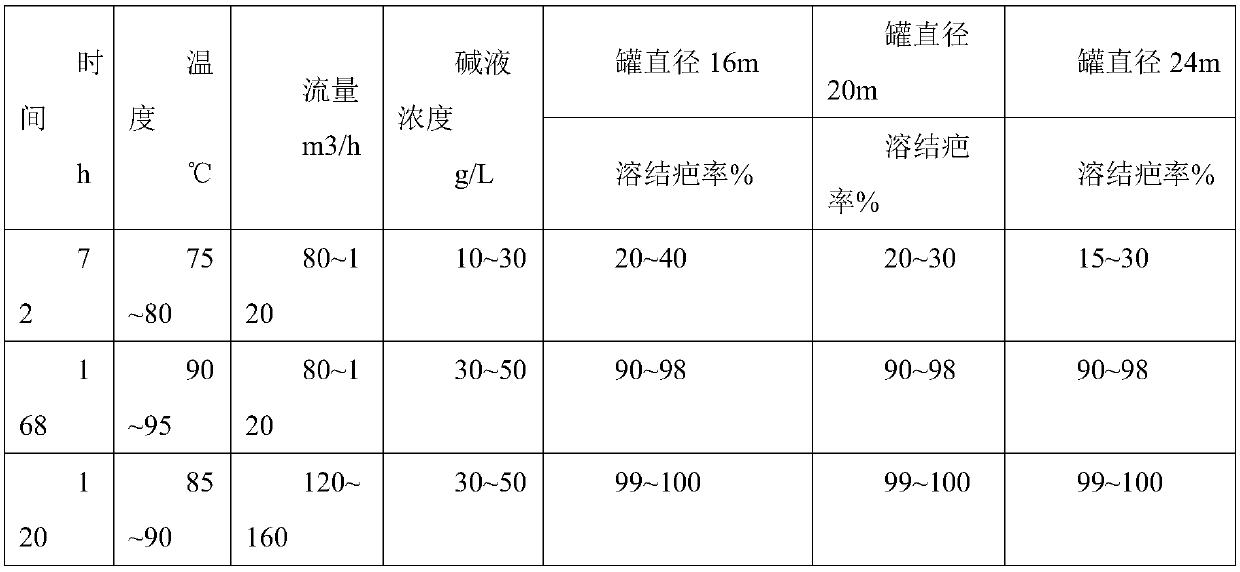

Chemical cleaning method for scales on tube of evaporator for producing ammonium sulfate

ActiveCN102400167ASolve cleaning problemsSimple processMetallic material coating processesSulfateSURFACTANT BLEND

The invention belongs to the field of the cleaning of scales on a tube of an evaporator, and discloses a chemical cleaning method for the scales on the tube of the evaporator for producing ammonium sulfate, which comprises the following steps: dredging and water washing; alkali washing: namely, adding water to carry out circulation, adding 10-40% of alkali, 0.5-1.0% of anionic surfactant and 0.5-3.3% of trisodium orthophosphate according to the amount of the water, and then, heating up to 65-95 DEG C, maintaining the temperature, monitoring the concentration of the alkali once per two hours, replenishing the alkali in time when the concentration of the alkali is less than 5%, so that the final concentration of the alkali is not less than 5%, discharging a cleaning solution outside, and adding the water again for cleaning, thereby completing the alkali washing; pickling: namely, adding the water for carrying out the circulation, adding 0.2-1.0% of pickling corrosion inhibitor and 5-10%of acid according to the amount of the water, reacting at a normal temperature, monitoring the concentration of the acid once per 0.5 hour, replenishing the acid in time when the concentration of theacid is less than 2%, and maintaining the final concentration of the acid to be 0.5-2.0%, thereby completing the pickling; and the water washing and passivating: namely, adding the water to carry outthe circulation, cleaning to be neutral, adding 2-5% of the alkali and 0.5-1.0% of the trisodium orthophosphate, circulating at the normal temperature, and carrying out passivation. By using the chemical cleaning method for the scales on the tube of the evaporator for producing the ammonium sulfate, the scales of sulfates and silicates on the tube of the evaporator can be thoroughly cleaned cleanly, thereby reaching a mirror face state.

Owner:HENAN ZHONGYUAN GOLD SMELTERY

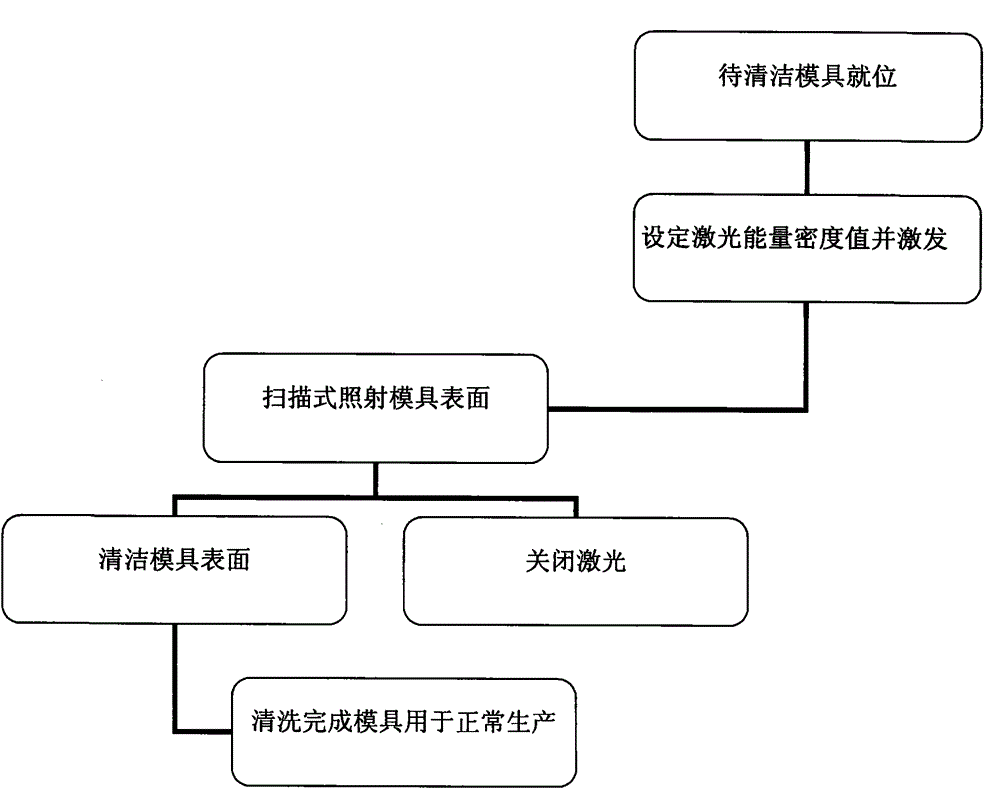

Laser cleaning method for tire moulds

InactiveCN104368564ANo loss of lifeCause mechanical damageCleaning processes and apparatusEngineeringCleaning methods

The invention discloses a laser cleaning method for tire moulds and aims to achieve safe, environment-friendly and efficient cleaning of the tire moulds. According to the technical scheme, the laser cleaning method is implemented by large difference between mould surfaces and attachments in absorption coefficient of certain wavelength laser energy. The laser energy radiating to the mould surfaces are mostly absorbed by the attachments on the mould surfaces, the attachments are evaporated or swelled instantly after being heated or vaporized and are driven to separate from the mould surfaces by vapor flow formed on the surfaces. The mould surfaces are not damaged.

Owner:BEIJING HEZHONG JIANYE ELECTROMECHANICAL TECH

Tower cylinder cleaning device

PendingCN110201956AAchieve cleaningIncrease profitHollow article cleaningPulp and paper industryTower

The invention relates to a tower cylinder cleaning device. The tower cylinder cleaning device comprises a bracket and a cleaning mechanism; the bracket is fixedly connected with a plurality of supporting columns which are staggered high and low and distributed uniformly; the top of each supporting column is fixedly connected with a lower bottom plate; the cleaning mechanism comprises a T-shaped connecting frame, an air cylinder assembly and a roller brush; the T-shaped connecting frame is in sliding connection with an upper cover plate and a lower bottom plate; the roller brush is fixedly arranged at one end of the T-shaped connecting frame; and the T-shaped connecting frame is fixedly connected with an air cylinder assembly. The invention aims to achieve the technical effect that the tower cylinder cleaning device which can clean a fan tower cylinder mechanically instead of manually and can change along with the diameter of the tower cylinder is provided.

Owner:酒泉鑫达实业有限责任公司

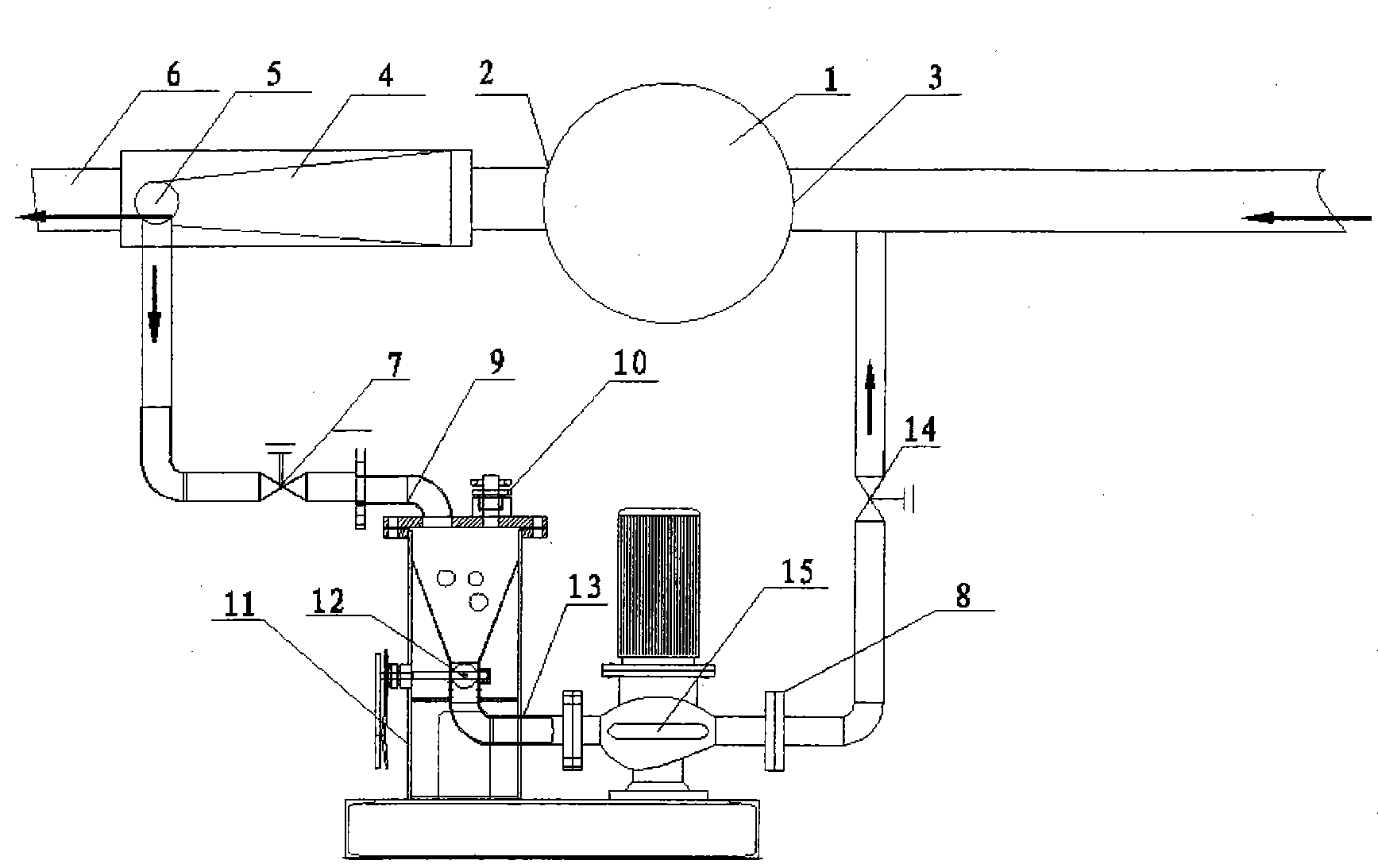

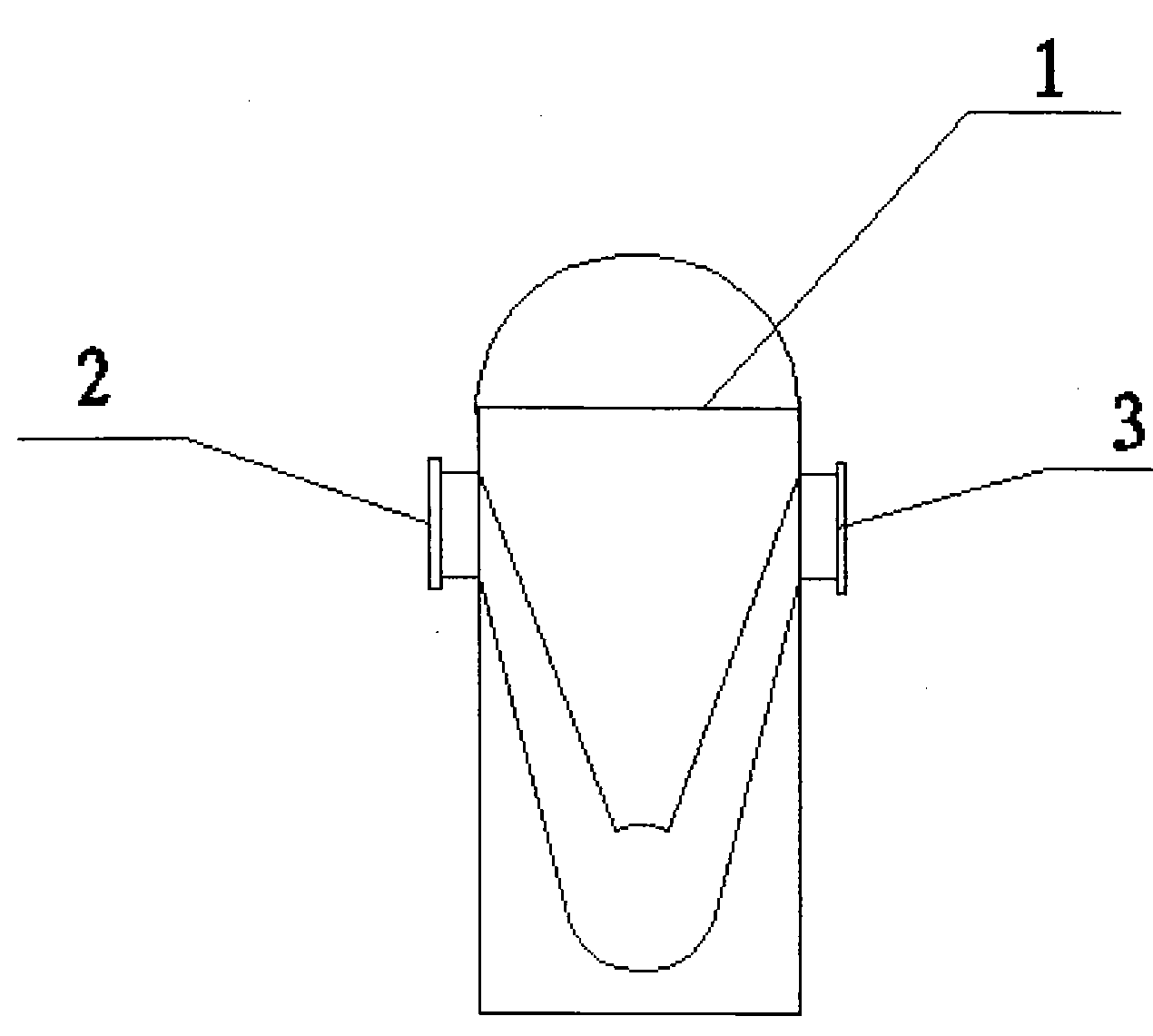

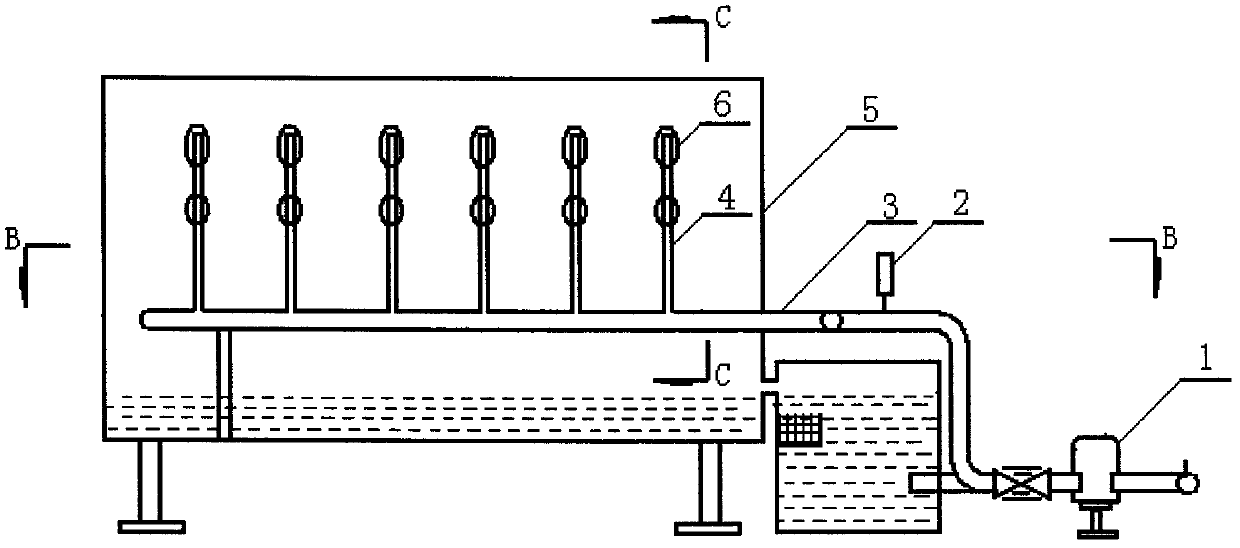

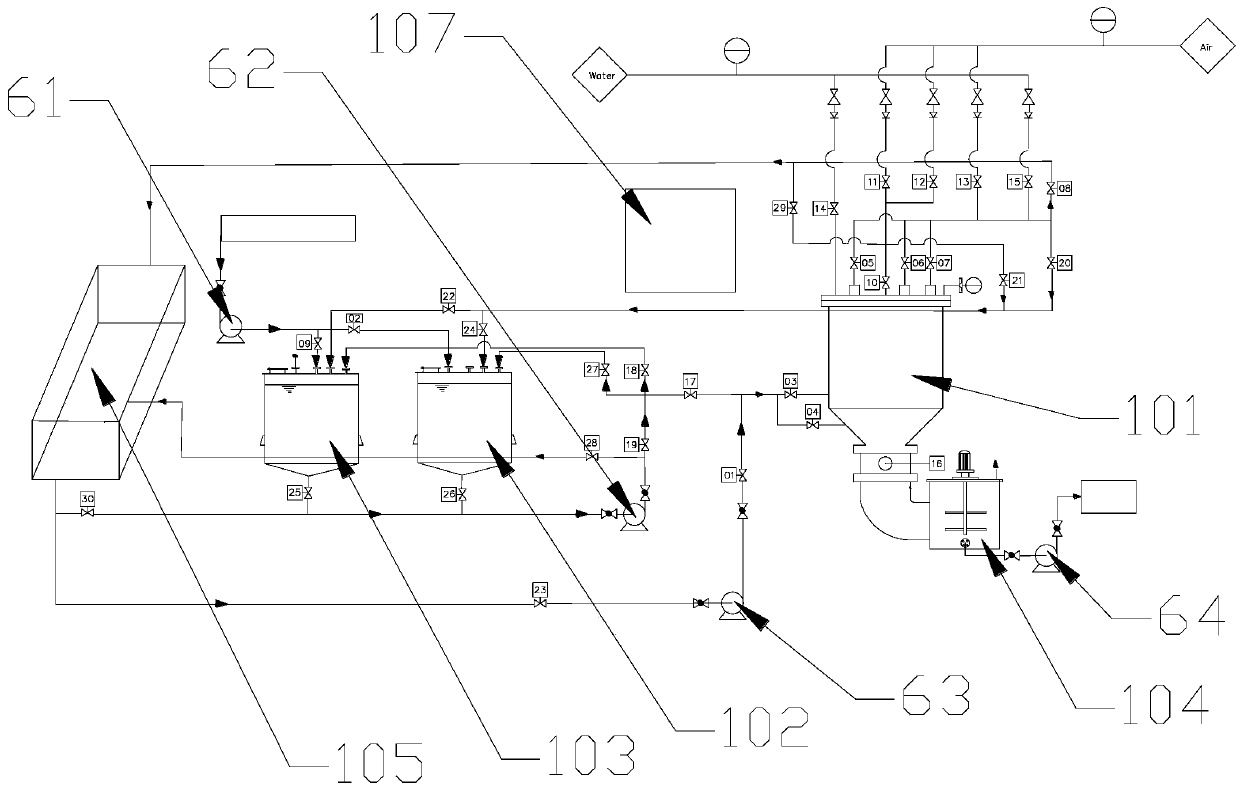

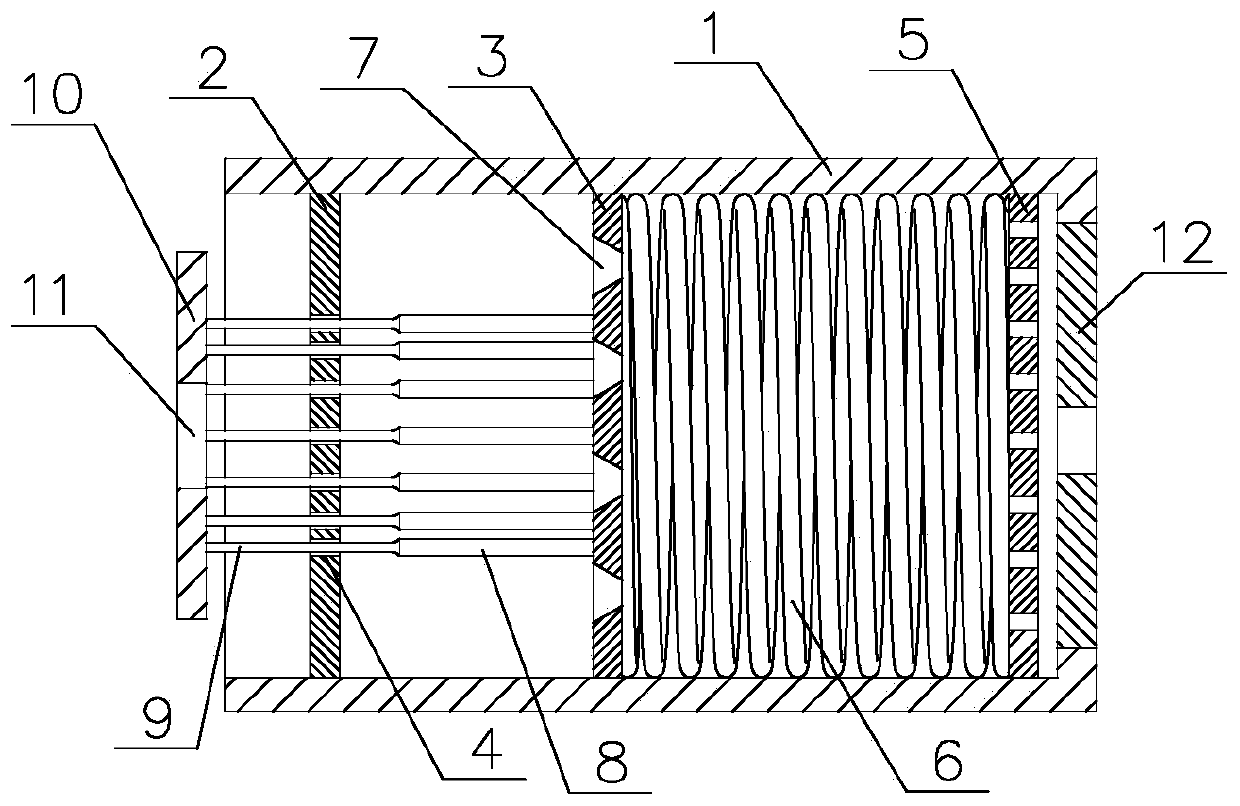

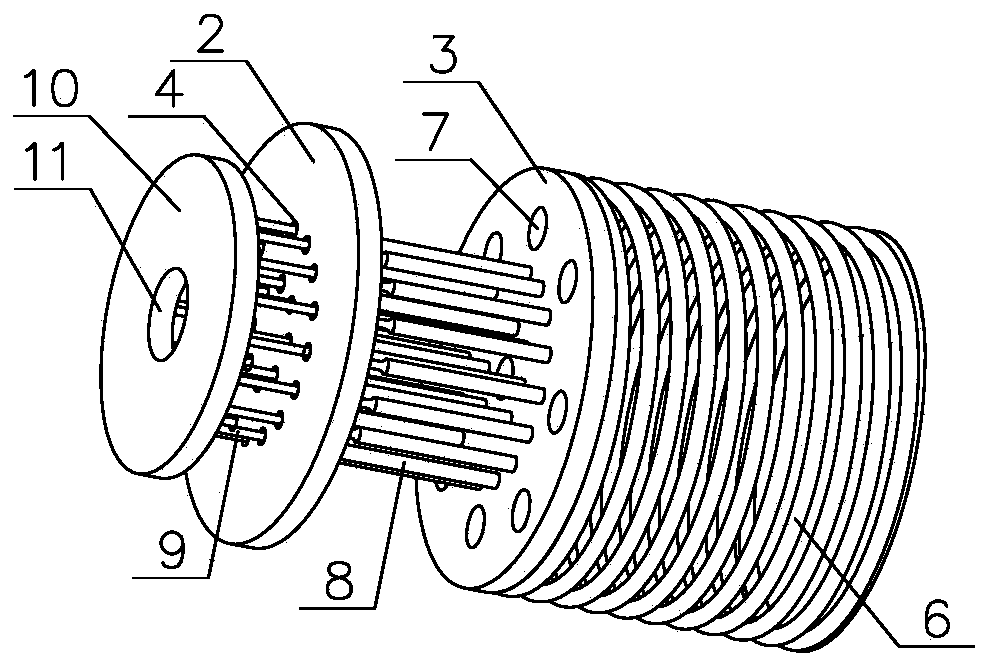

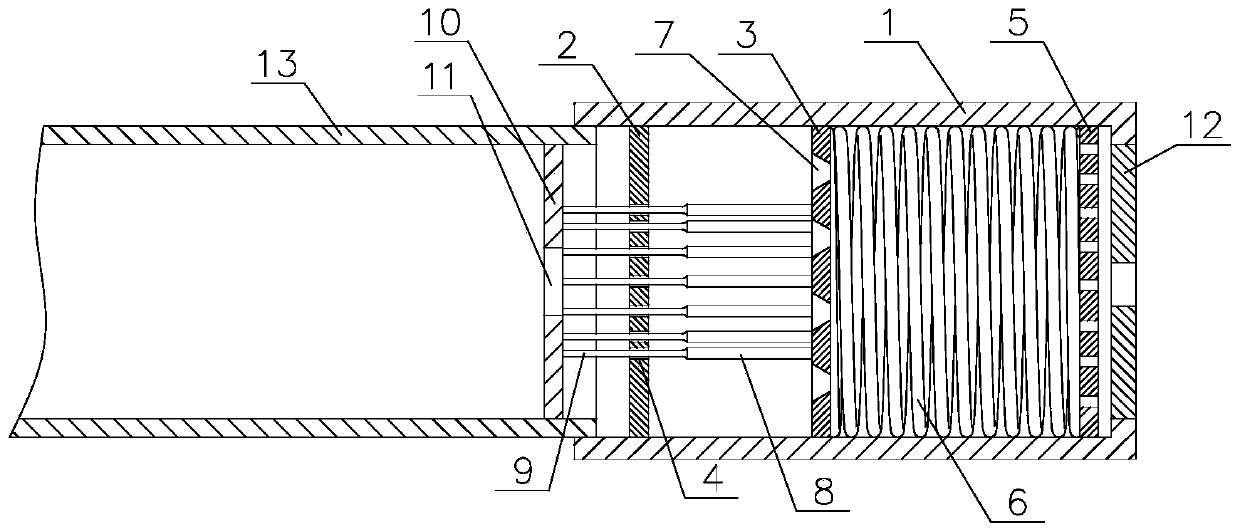

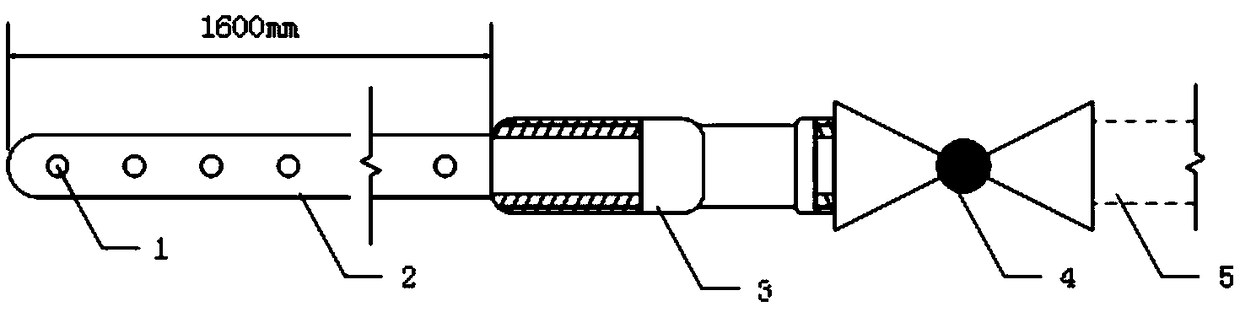

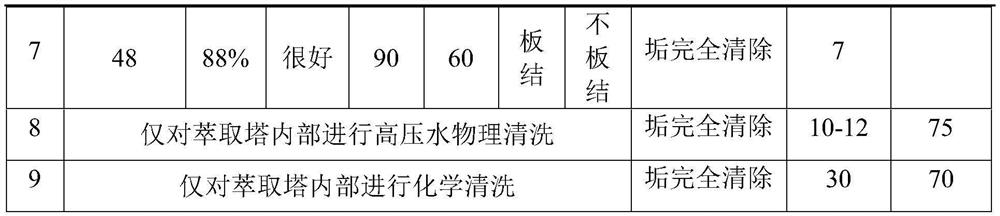

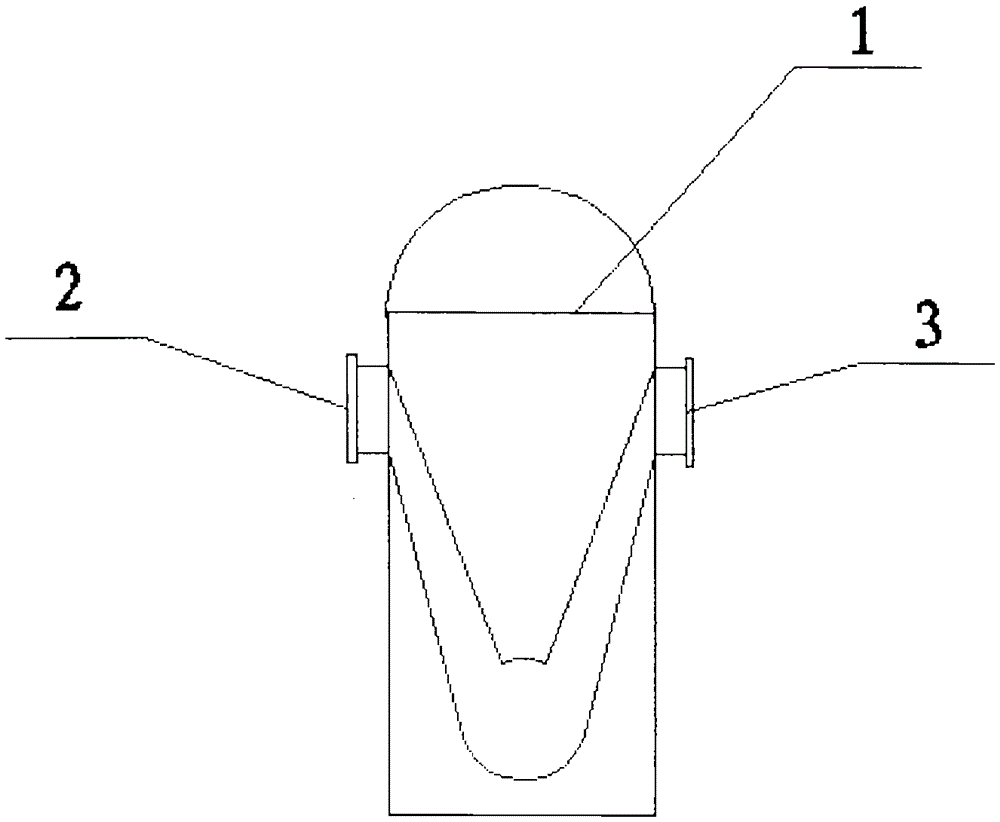

Online cleaning device of heat exchanger

ActiveCN104315919AImprove the efficiency of ball collectionPerfect cleaning efficiencyNon-rotary device cleaningPlate heat exchangerClean energy

Disclosed is an online cleaning device of a heat exchanger. The online cleaning device of the heat exchanger comprises the heat exchanger, a ball injector and a rubber ball delivery pump, wherein an inner pipeline of the heat exchanger is of a U structure, the right side of the heat exchanger is provided with a water inlet pipe orifice, the left side of the heat exchanger is provided with a water outlet pipe orifice, the water outlet pipe orifice is connected with the front end of a funneling ball collector through a pipeline, the rear end of the funneling ball collector is provided with a cooling water outlet, an inverted cone ball collection net is arranged in the funneling ball collector, a variable diameter type ball conveyor is arranged at the tail end of the inverted cone ball collection net, the variable diameter type ball conveyor is connected with a ball discharge pipe orifice, the ball discharge pipe orifice of the funneling ball collector is connected with a ball feed pipe orifice of the rapid ball injector through a flange, and a ball collection valve is arranged on the pipeline of the funneling ball collector. The online cleaning device of the heat exchanger can integrate collection and injection of rubber balls, and greatly improves ball collection efficiency. Ball collection efficiency of a common rubber ball cleaning device ranges from 30% to 70%, and ball collection efficiency of the online cleaning device of the heat exchanger reaches 100%. Additionally, the online cleaning device of the heat exchanger achieves a circulation cleaning function, is simple to operate for cleaning the rubber balls, low in cleaning energy consumption and short in cleaning period.

Owner:连云港市宏庆电力辅机开发有限公司

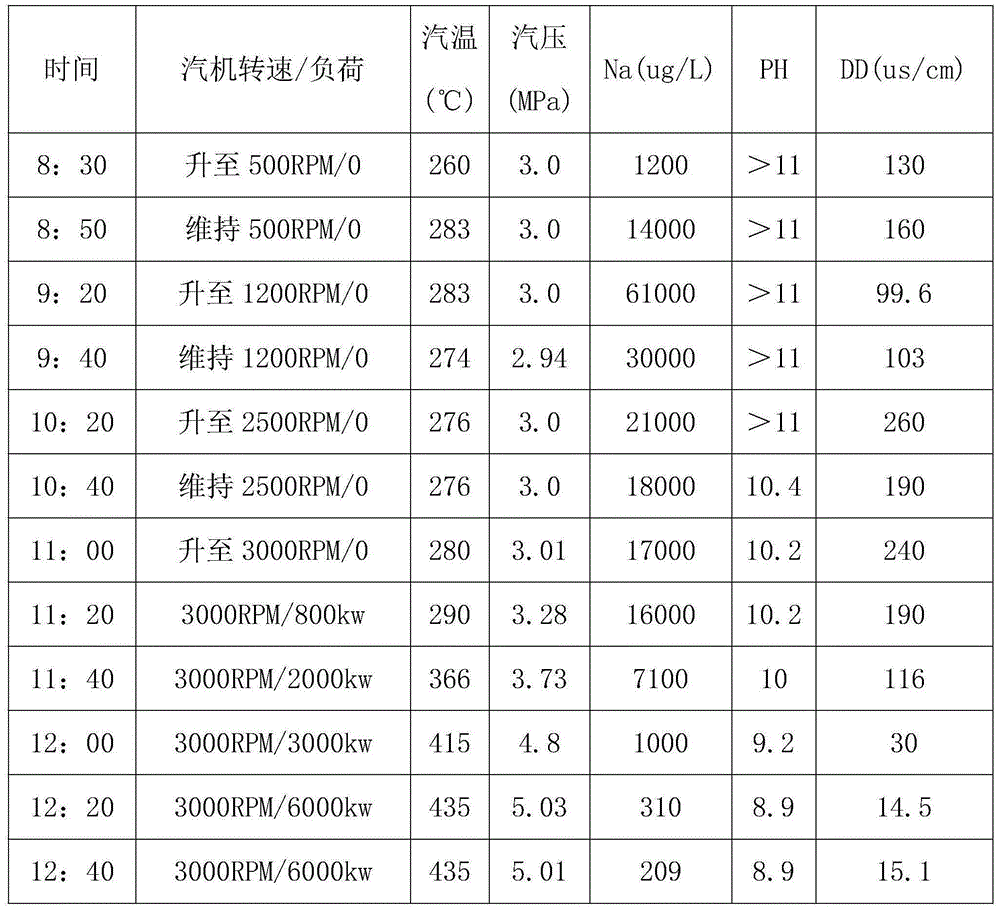

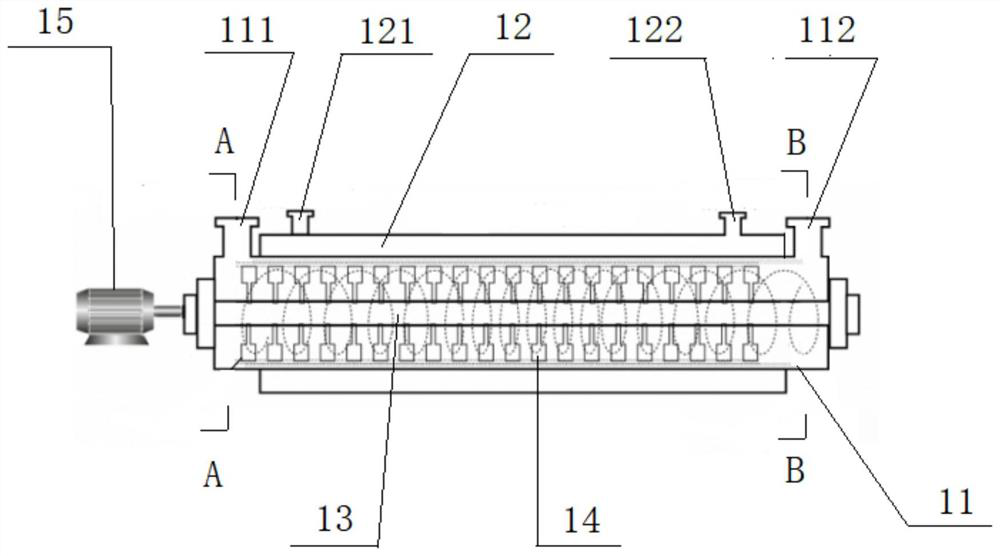

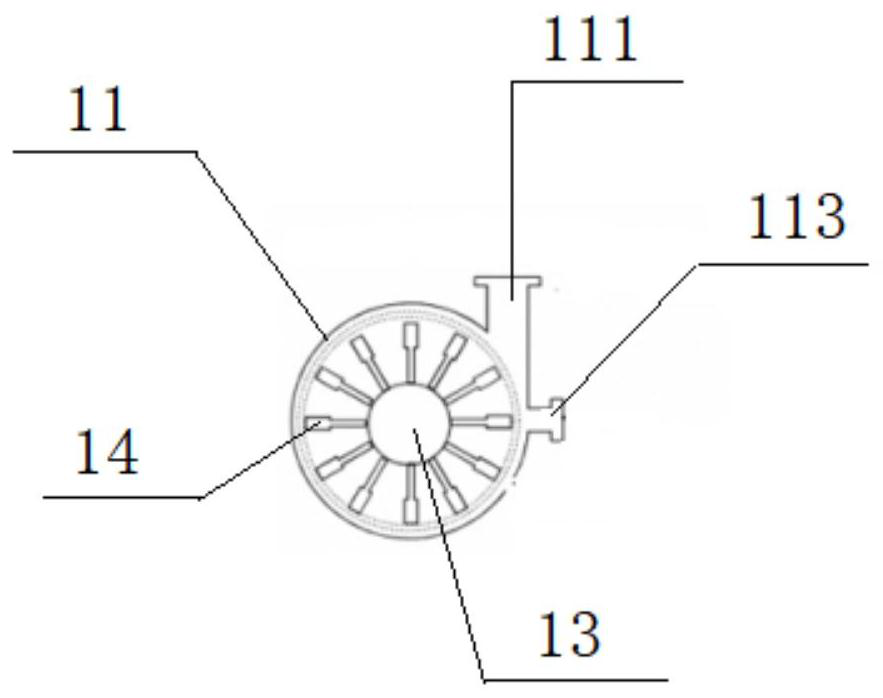

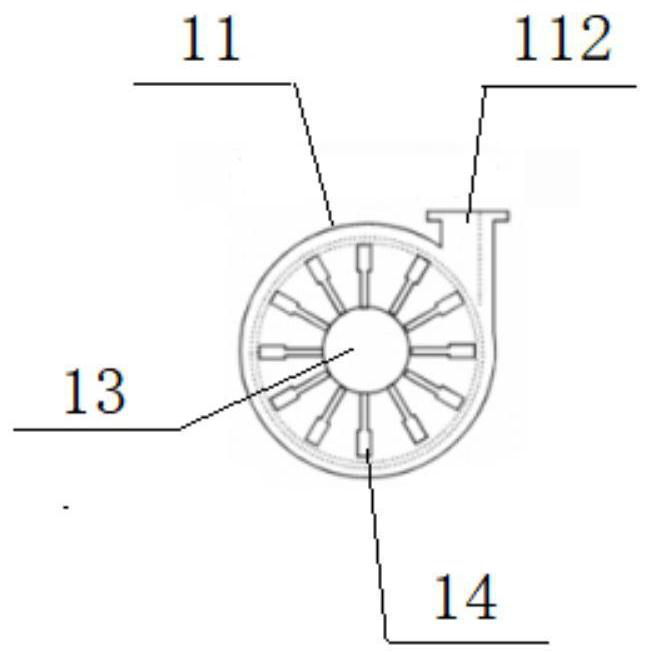

Steam turbine circulation part cleaning system and cleaning method

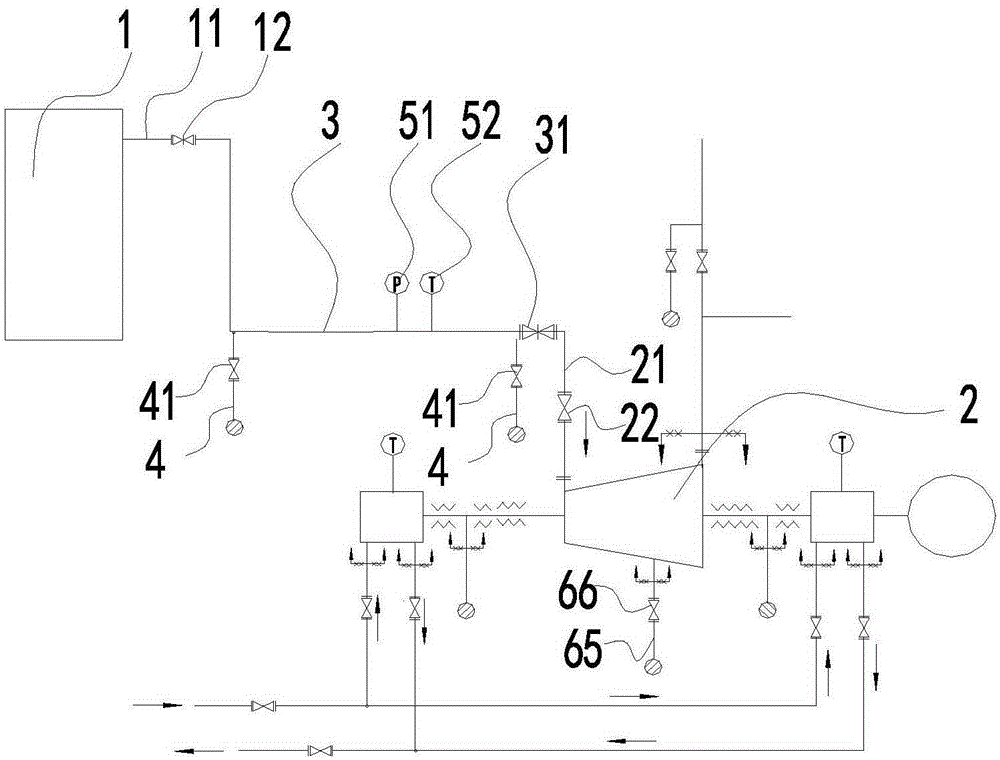

InactiveCN105201567AImprove securityReduce the temperatureMachines/enginesEngine componentsImpellerSteam pressure

The invention discloses a steam turbine circulation part cleaning system and cleaning method. The steam turbine circulation part cleaning system comprises a steam turbine and a steam generator, wherein a generator steam outlet pipe is arranged on the steam generator; a generator steam outlet valve is arranged on the generator steam outlet pipe; a steam turbine steam inlet pipe is arranged on the steam turbine; a steam turbine steam inlet valve is arranged on the steam turbine steam inlet pipe; the generator steam outlet pipe and the steam turbine steam inlet pipe are connected through a steam main pipe; a main valve, an outlet steam pressure gauge and an outlet steam temperature gauge are arranged on the steam main pipe; both the outlet steam pressure gauge and the outlet steam temperature gauge are located at the upstream part of the main valve; a plurality of drain pipes are arranged on the steam main pipe, and drain valves are arranged on the drain pipes respectively; during cleaning of a steam turbine circulation part, the main valve is opened when the steam pressure of the steam generator reaches 3.0 MPa and the steam temperature reaches 235 DEG C, steam impulses the steam turbine to start, and flowing steam washes out scales on an impeller, blades, a partition and a spray nozzle group of the steam turbine.

Owner:苏州市江远热电有限责任公司

Rotational flow thermal vibration drying machine and rotational flow thermal vibration drying system

PendingCN113024056ARealize self-cleaningThere will be no sticking phenomenonCombination devicesSludge treatment by de-watering/drying/thickeningSludgeElectric machinery

The invention relates to the technical field of wet sludge drying, in particular to a rotational flow thermal vibration drying machine and a rotational flow thermal vibration drying system. The rotational flow thermal vibration drying machine comprises: a hollow drying chamber, wherein one end of the drying chamber is provided with a feeding port and an air inlet, and the other end of the drying chamber is provided with a discharging port; a heat source jacket which is arranged around the outer side of the drying chamber, wherein a medium serving as a heat source circulates in the heat source jacket, and a heat source outlet and at least one heat source inlet are formed in the heat source jacket; a rotating shaft which is arranged in the middle of the drying chamber and penetrates through the two ends of the drying chamber, wherein a driving motor used for driving the rotating shaft to rotate is arranged on the outer side of the drying chamber; and paddles which are mounted on the rotating shaft. The drying machine has a self-cleaning capability, so that the wall sticking phenomenon is avoided; The safe operation of the system is ensured by high-degree inerting circulation; and the drying machine is high in heat exchange efficiency, high in heat transfer speed and high in sludge drying speed. When the drying system is used, irritant gas cannot be discharged to the periphery, and secondary pollution to air is avoided.

Owner:山东驰盛新能源设备有限公司

Automatic rain boot cleaning machine

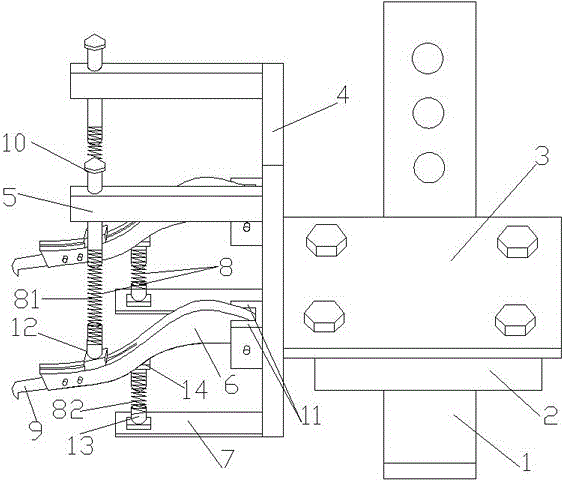

InactiveCN103371790ALiberate labor productivityReduce labor intensityFootwear cleanersWater dischargeElectrical control

Disclosed is an automatic rain boot cleaning machine aiming at solving the problem of difficulty in large-batch manual cleaning of rain boots for labor protection. The automatic rain boot cleaning machine is characterized in that the automatic rain boot cleaning machine comprises a water tank, a water pump, a water pipe, a valve, cleaning heads, a spraying chamber and an electrical control system, a water incoming end of the water pump is connected with the water tank, a water outgoing end of the water pump is communicated into the spraying chamber, a main water pipe in the spraying chamber is divided into a plurality of branches, each branch is connected with one cleaning head which is formed by a spraying head, and a sole rack and a boot barrel support which are arranged around the spraying head, and the spraying chamber is provided with a water discharging port. The automatic rain boot cleaning machine depends on the quincuncial spraying heads to spray large-coverage-area and high-impact-force water flow to wash and brush inner cavities of boots, and dirt and sweat in the rain boots can be quickly washed and cleaned while no detergent is needed. Cleaning can be completed in only 1-3 minutes, and 15-35 pairs of the rain boots can be cleaned simultaneously. The automatic rain boot cleaning machine is short in cleaning cycle, high in working efficiency, good in cleaning effect and suitable for all walks of life like coal mines, all places needing the rain boots to be worn for operation and all units needing large-batch cleaning of the rain boots.

Owner:张勤

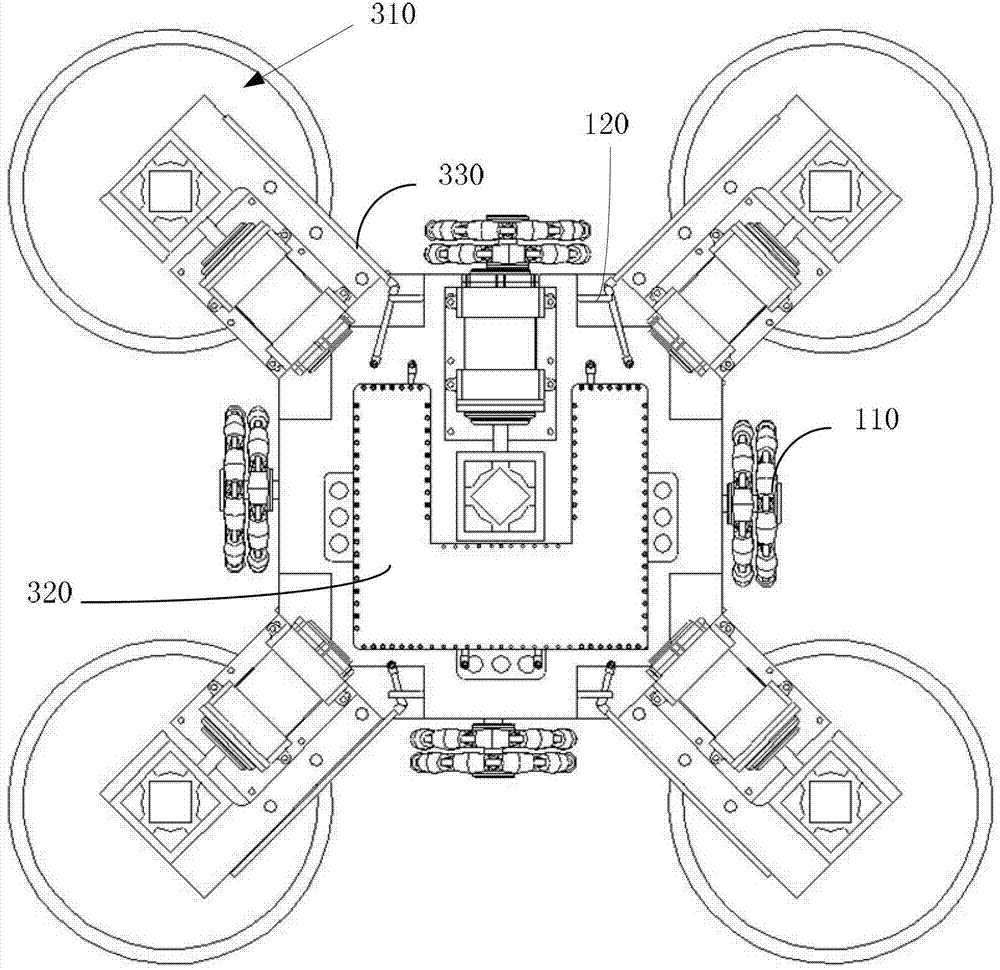

Cleaning robot for wind driven generator tower

The invention discloses a cleaning robot for a wind driven generator tower. The robot comprises a cabin, an omnidirectional wheel which is installed on the cabin, a magnet, a cleaning device, a hanging ring and a control mechanism, wherein the omnidirectional wheel is used for supporting the cabin to move on the surface of the tower, the magnet is installed on the cabin and is used for providing the adsorption force through which the robot can be attached to the surface of the tower tightly, the cleaning device is installed on the cabin and is used for cleaning the surface of the tower, the hanging ring is installed on the cabin and is used for being connected to a winch through a cable, and the control device is used for controlling the cabin to move vertically through the control of the winch and controlling the cabin to move along the circumferential direction of the surface of the tower through the control of a yaw system of a wind driven generator. By the aid of the robot, the surface of the tower can be cleaned completely, the robot can replace the manual power to conduct the high cleaning operation of the surface of the wind driven generator tower, and the time and the fee of the cleaning working can be saved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Dry anaerobic system for treating high-concentration organic wastes

PendingCN109136073ASolve the problem that cannot be fully utilizedSolutions for small, mass transferBioreactor/fermenter combinationsBiological substance pretreatmentsHigh concentrationEconomic benefits

The invention discloses a dry anaerobic system for treating high-concentration organic wastes. The dry anaerobic system sequentially comprises an anaerobic feeder and an anaerobic inoculator, whereinthe anaerobic inoculator is connected with a plurality of dry anaerobic reactors in parallel or is serially connected with a plurality of dry anaerobic reactors end to end; each dry anaerobic reactorcomprises an anaerobic fermentation chamber; anaerobic feeding hoppers are arranged on the upper parts of the anaerobic fermentation chambers; the other ends of the anaerobic feeding hoppers are sequentially connected with the anaerobic inoculator through pipes; anaerobic discharging devices are arranged on the lower parts of the anaerobic fermentation chambers; the inner walls of the anaerobic fermentation chambers are wound with heating and heat-insulating devices; horizontal plow-shaped stirrers hinged to the two ends of the anaerobic fermentation chambers are arranged inside the anaerobicfermentation chambers; biogas collecting devices are mounted on the outer walls of the other ends of the anaerobic fermentation chambers; each biogas collecting device is connected with a connecting pipe. In a process technology from pollution to recycling, the efficiency of converting organic matters into inorganic matters is improved, the yield of biomass gas is increased, economic benefits areincreased, and the difficulty of difficult elimination in the process of returning a biogas slurry to a field is overcome.

Owner:湖北农谷能源建设有限公司 +1

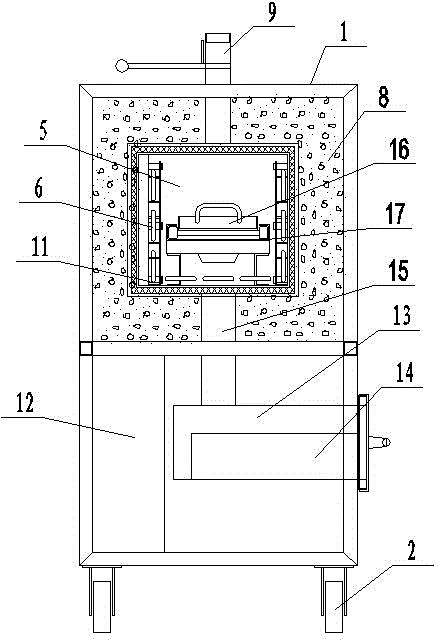

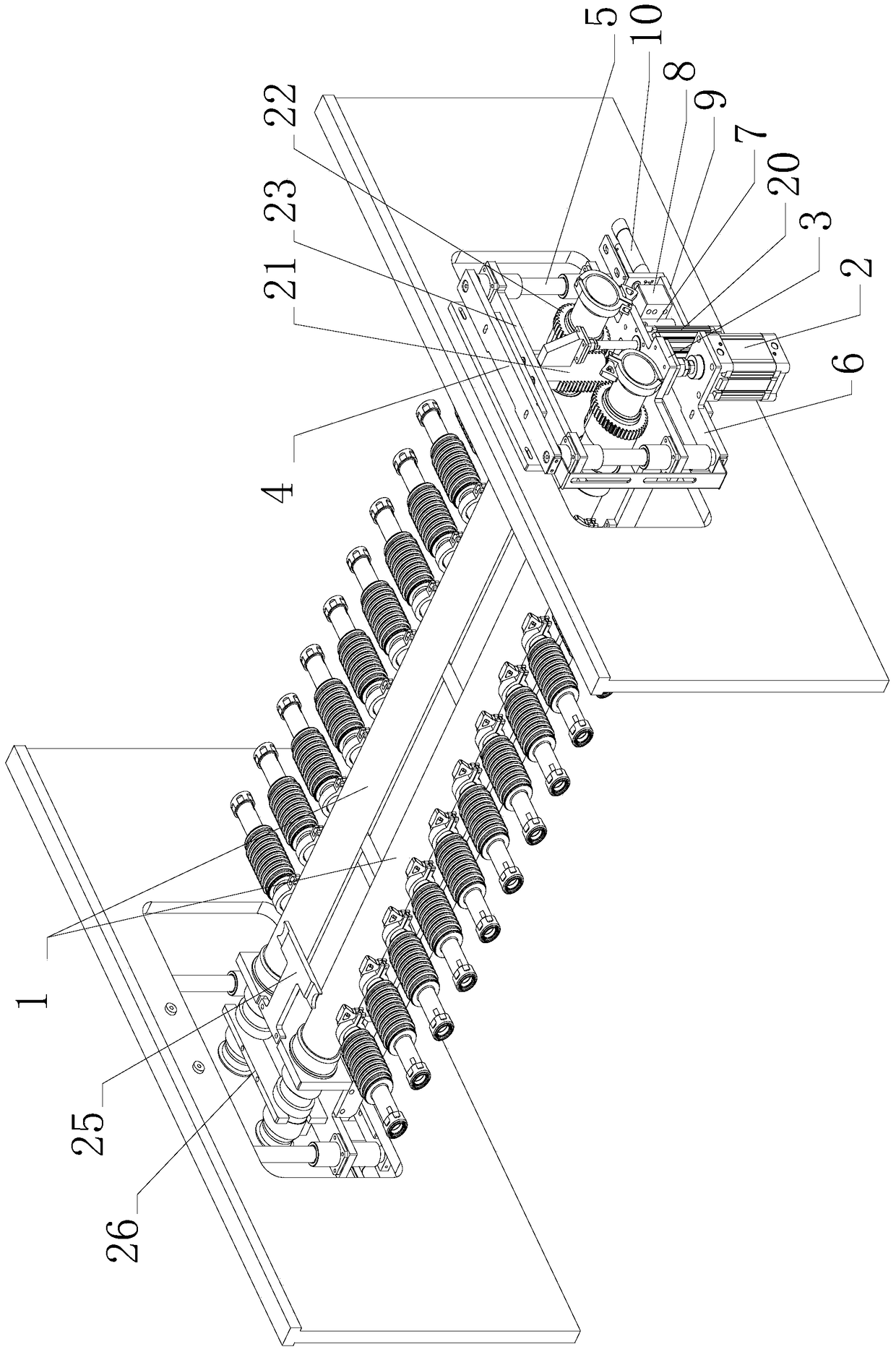

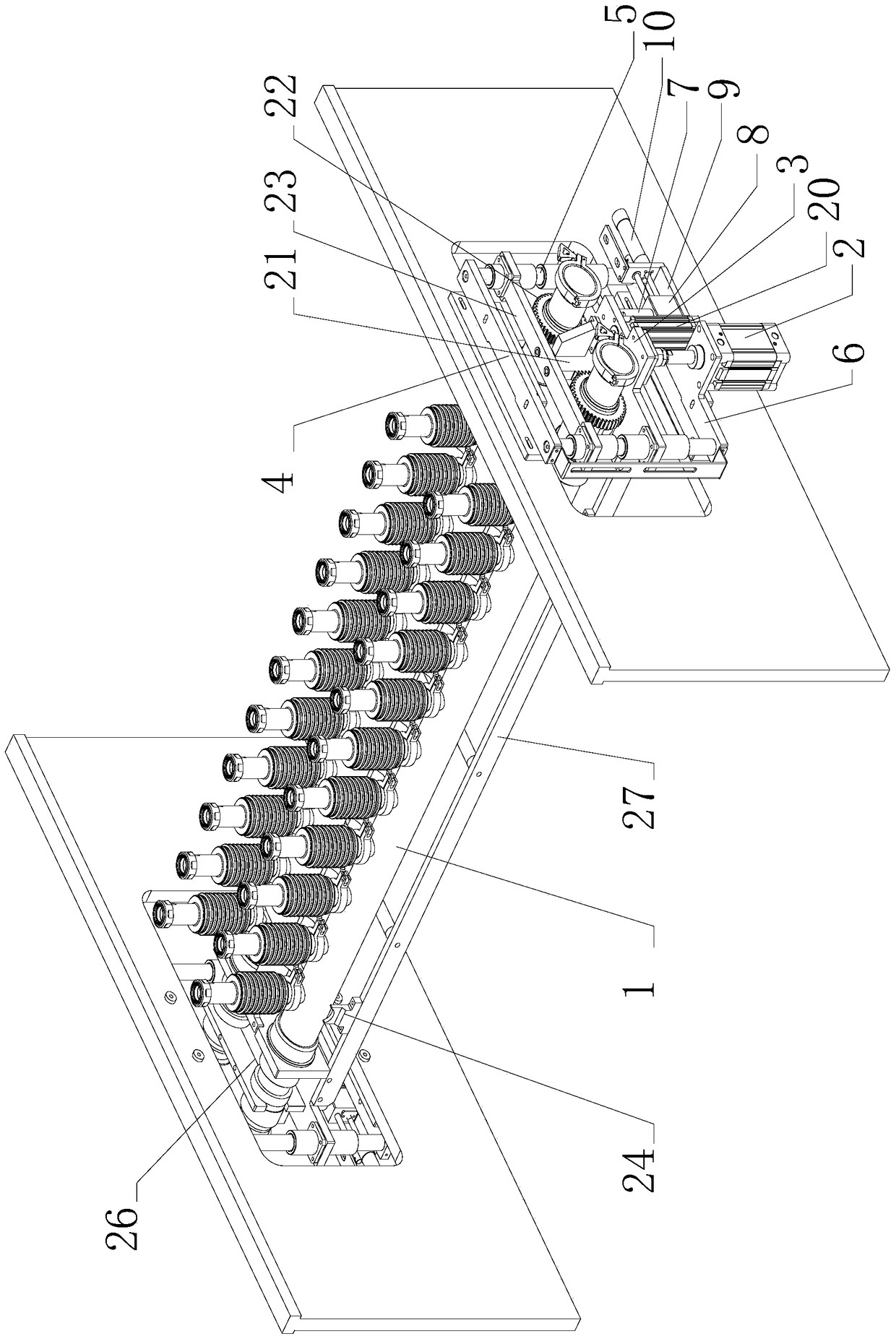

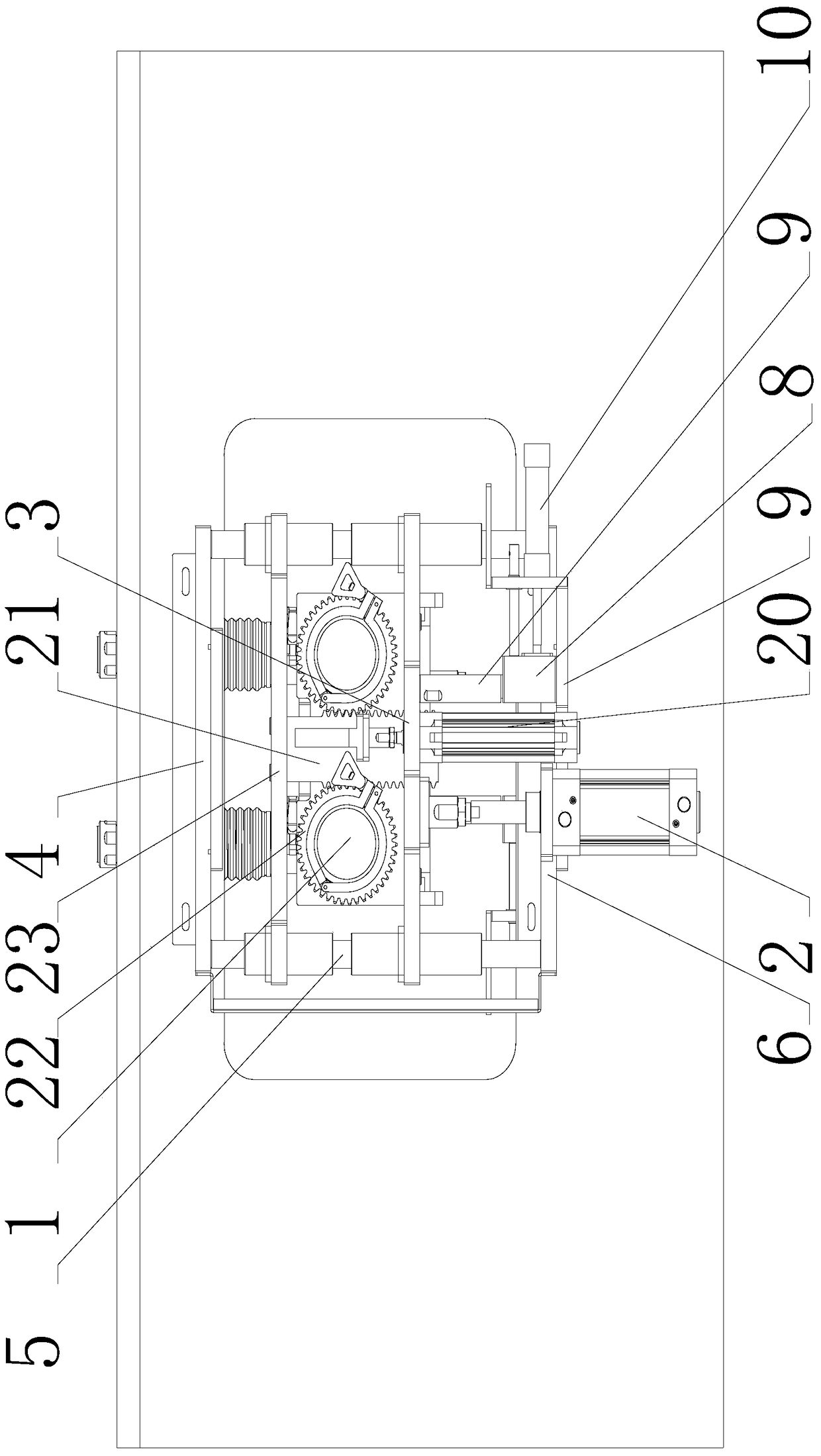

Special incinerator for cleaning extruder screws

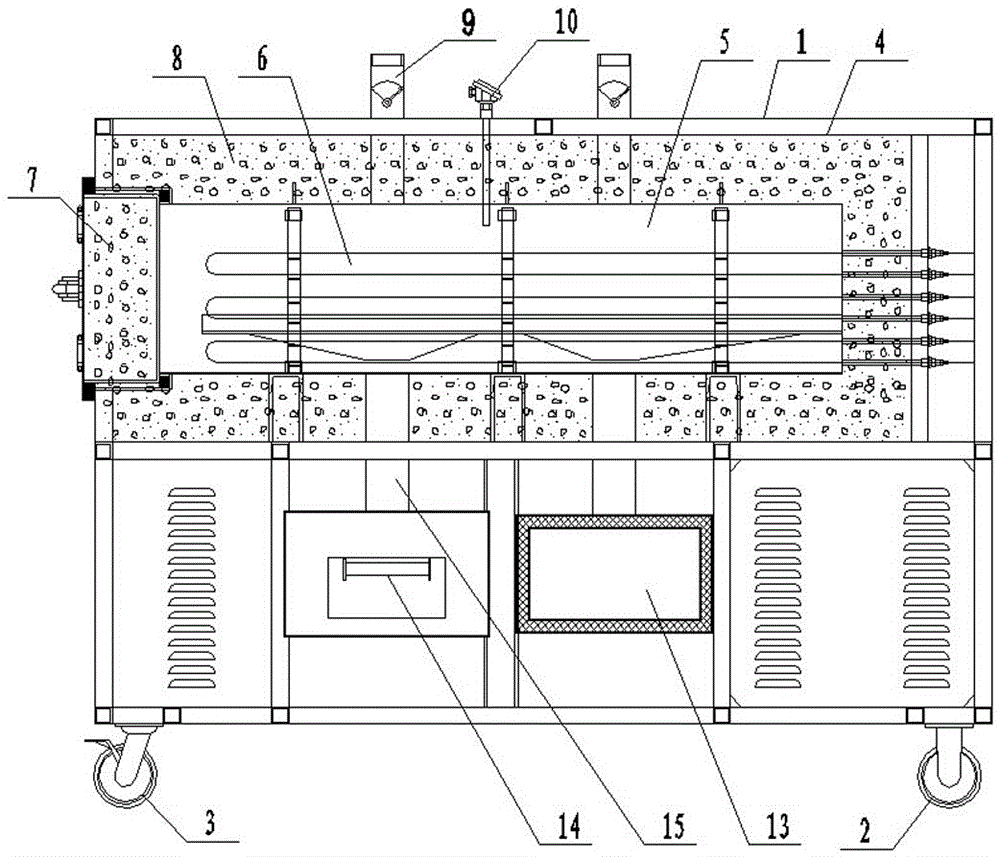

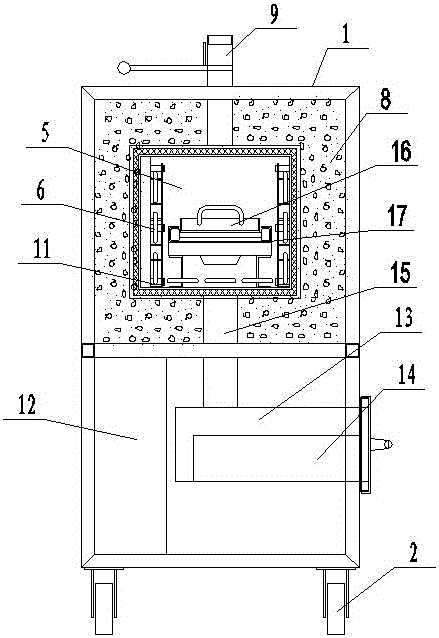

ActiveCN104406171ABurn fullyShort cleaning cycleIncinerator apparatusCleaning processes and apparatusCombustionIncineration

The invention discloses a special incinerator for cleaning extruder screws with good incineration effect. The special incinerator comprises an incinerator body, and a directional wheel and a universal wheel arranged at the bottom of the incinerator body, wherein a shield is arranged on the upper end of the incinerator body; a furnace is arranged in the shield; a plurality of electric heating pipe are evenly arranged in the furnace; an airtight door is arranged at one end of the furnace; an insulating layer is arranged between the furnace and the shield; a smoke outlet and a temperature measurement component are arranged on the shield; an electric heating pipe shelf, a drawer-type tray and a drawer-type guide rail are arranged in the furnace; a control cabinet and a dust collection chamber are arranged in the incinerator body; a drawer-type dust collection tray is arranged in the dust collection chamber; the dust collection chamber is communicated with the lower end of the furnace by use of an ash conveying pipe. The special incinerator for cleaning extruder screws has the advantages of sufficient combustion, short cleaning period, good cleaning effect, convenient ash cleaning, energy conservation and environmental protection, safety and reliability, and convenience for movement.

Owner:JIANGSU DOUSHENG TECH DEV CO LTD

Cleaning device of high-efficiency filter recovery system

InactiveCN111558248AEasy to operateWash thoroughlyStationary filtering element filtersProcess engineeringCleansing Agents

The invention discloses a cleaning device of a high-efficiency filter recovery system. The device comprises a filter, a proportioning hydrochloric acid barrel tank, a cleaning agent barrel tank, a sand discharging barrel tank and an etching tank. The filter, the proportioning hydrochloric acid barrel tank, the cleaning agent barrel tank, the sand discharging barrel tank and the etching tank are connected together through pipelines. The cleaning agent barrel tank is used for placing a cleaning agent. The proportioning hydrochloric acid barrel tank is used for placing a hydrochloric acid proportioning solution. The cleaning agent is used for cleaning glass slag crystals generated after glass etching of the etching tank, pipelines, nozzles and the like. The device further comprises pumps andan electric cabinet PLC module. The pumps are arranged on a plurality of pipelines, and a control valve is mounted on each pump. The electric cabinet PLC module is used for controlling the pumps and the control valves mounted on the pumps, so that the structures form a cleaning circulation loop through the pipelines. By arranging the electric cabinet PLC module in the device, people do not need toput on chemical protective clothing and other protective articles to clean glass slag in the etching tank body, the barrel tanks, filter cloth, the pipelines, the nozzles and the like, and the problems of complex operation and low working efficiency are solved.

Owner:苏州晋昌胶粘制品有限公司

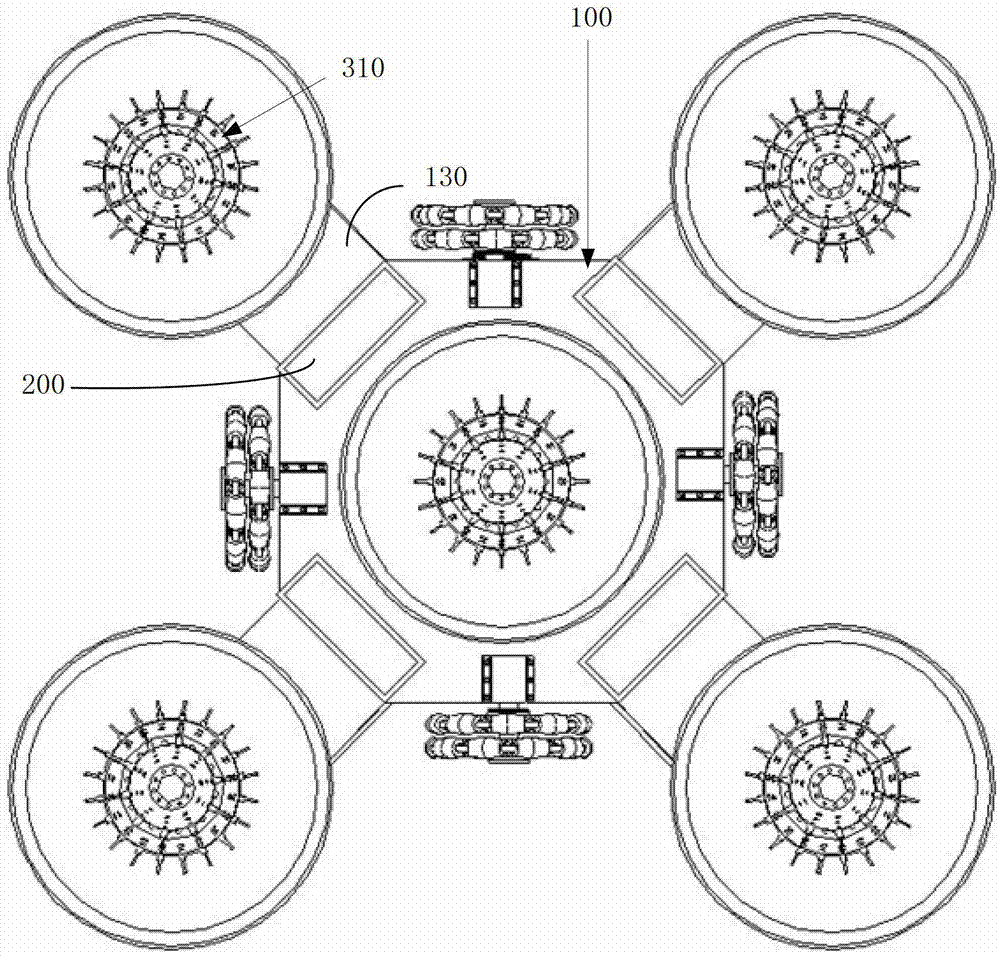

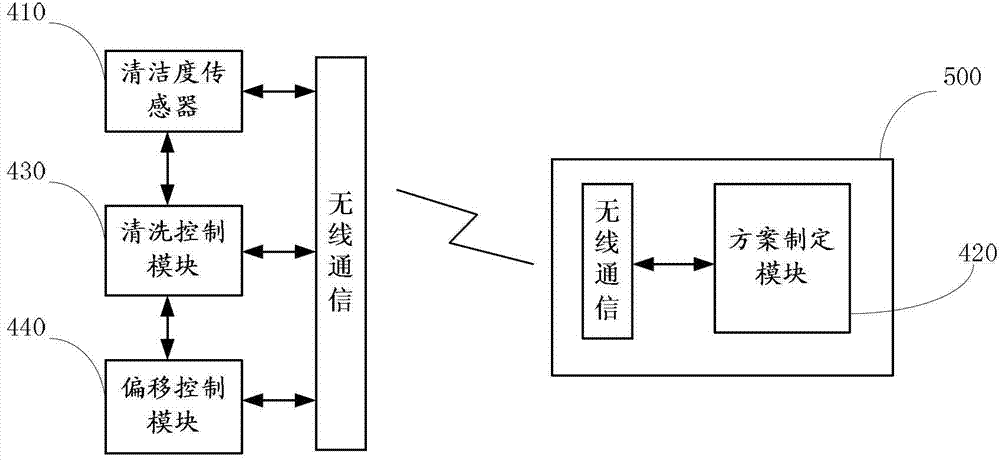

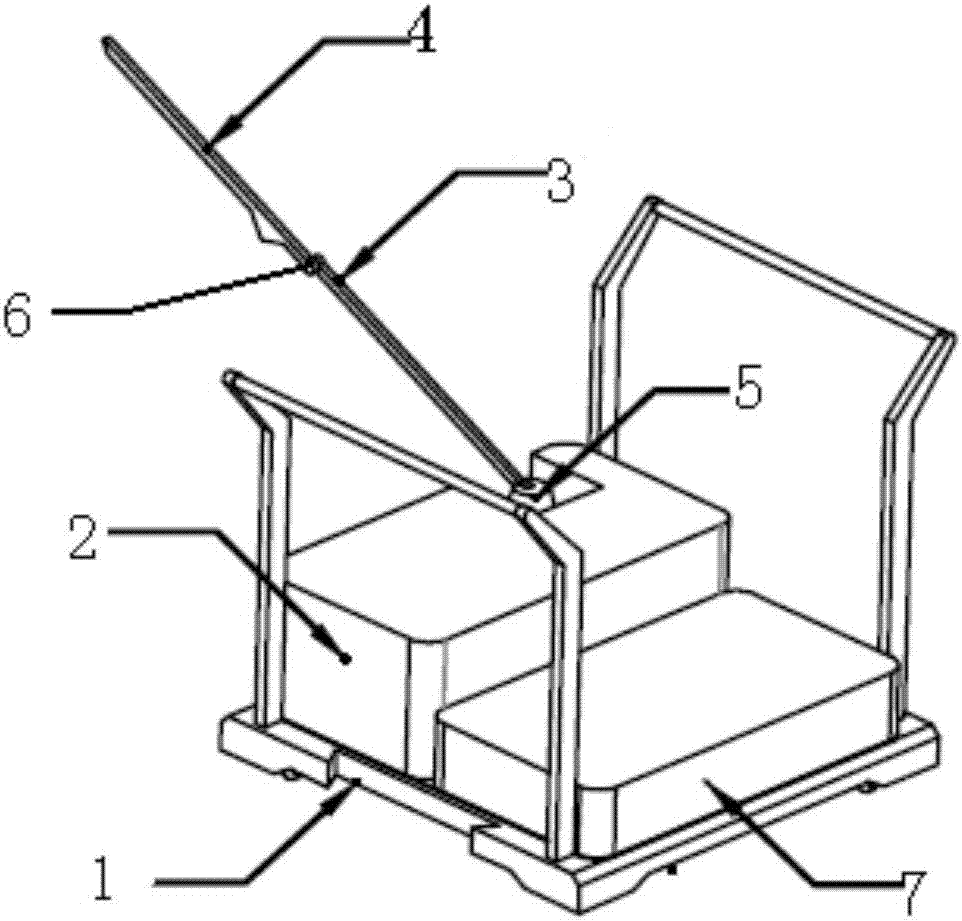

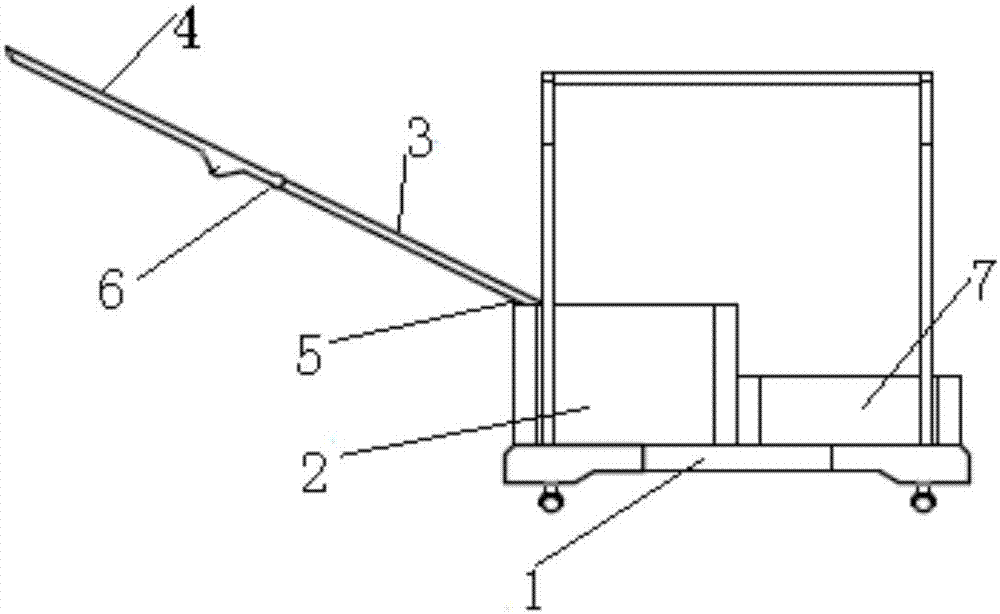

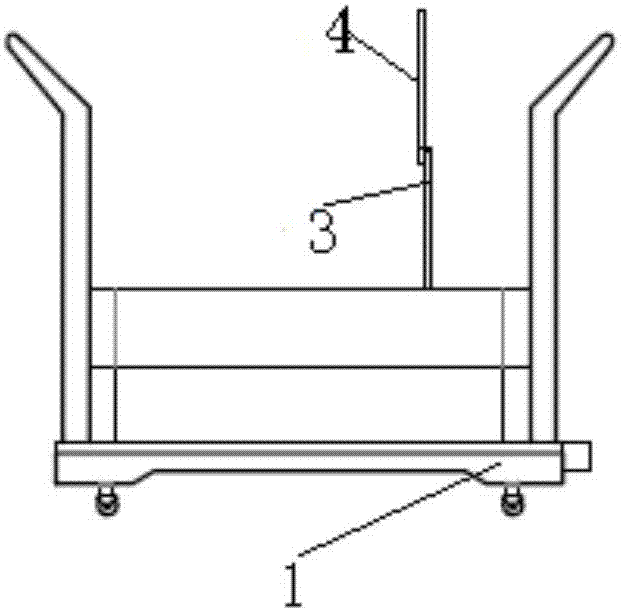

Floating photovoltaic power station operation and maintenance trolley system

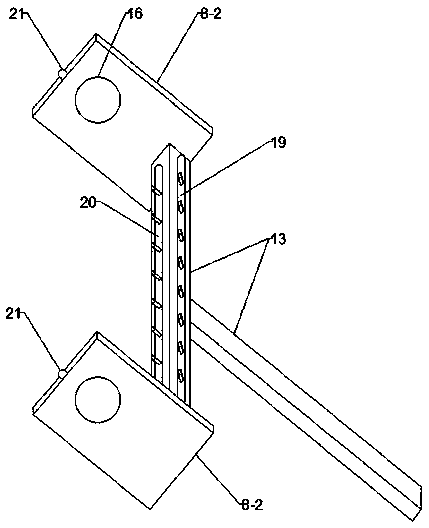

PendingCN107395111AEasy splicingEasy detachable connectionPhotovoltaicsCleaning using liquidsPhotovoltaic power stationWater spray

The invention discloses a floating photovoltaic power station operation and maintenance trolley system, comprising an operation and maintenance trolley, a clean water tank mounted on the operation and maintenance trolley and a water spray rod connected with the clean water tank, wherein the operation and maintenance trolley comprises an operation and maintenance platform, upright posts detachably connected with four corners of the operation and maintenance platform and cross rods detachably connected with the upright posts; a lug raised outward is arranged at one end of the operation and maintenance platform, a gap sunken inward is arranged at the other end, and the operation and maintenance platform is connected in an extensible clamping manner via the lug and the gap; the water spray rod comprises a first water spray rod and a second water spray rod, the first water spray rod is connected with the clean water tank via a first electric rotating shaft, the first water spray rod is connected with the second water spray rod via a second electric rotating shaft, and the clean water tank is connected with the water spray rod via a water pump; the operation and maintenance trolley system further comprises a control device located on the operation and maintenance trolley; and the operation and maintenance trolley system can be conveniently extended and connected, the angle of the clean water spray rod is adjustable, and the system using the existing photovoltaic support is low in cost and simple in structure.

Owner:武汉协鑫新能源电力设计有限公司

Rotational flow thermal vibration sludge drying machine

InactiveCN112279490AImprove heat transfer efficiencyLow running costSludge treatment by de-watering/drying/thickeningSludgeEngineering

The invention discloses a rotational flow thermal vibration sludge drying machine which comprises a machine body, a rotating shaft is rotatably connected to the interior of the machine body through abearing, blades are detachably connected to the outer side of the rotating shaft through bolts, four blades are evenly distributed on the circumference of each column of the rotating shaft, and the outer side of the machine body is sleeved with a jacket; a spirally-arranged grating is fixedly connected between the jacket and the machine body, a hot oil inlet and a hot oil outlet are formed in theupper end face of the jacket, a hot oil outlet is formed in the lower end face of the jacket, a hot air inlet is formed in the outer side surface of one end of the machine body, and a dry mud outlet is formed in the outer side surface of the other end of the machine body. A wet sludge inlet is formed in the upper end surface of the machine body. The rotational flow thermal vibration sludge dryingmachine is high in heat exchange efficiency, an efficient heat transfer mode combining heat conduction and heat convection is adopted, solid waste sludge with the water content of 80% or above can bedried to the water content of 30% or below, the heat transfer efficiency of rotational flow thermal vibration drying is higher, the drying time is shorter, and the operation cost is lower.

Owner:山东智奇环境技术有限公司

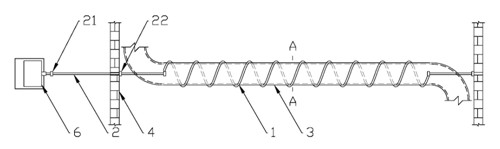

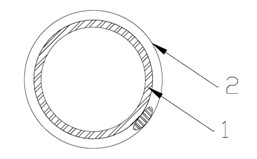

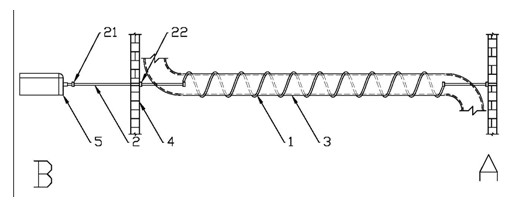

Ash removal device for heat exchange pipe of tail flue of boiler

InactiveCN102644931AReduce consumptionImprove mechanical efficiencySolid removalCoil springEngineering

The invention relates to an ash removal device for a heat exchange pipe of a tail flue of a boiler, which comprises a helical spring and a pull rod. The axial direction of the pull rod is parallel to the extension and retraction direction of the helical spring; one end of the pull rod is connected with one end of the helical spring; the helical spring is wound outside the cleaned heat exchange pipe; the pull rod passes through the flue wall of the boiler; a first stop sealing plate is arranged on a rod section of the pull rod, which is positioned outside the flue wall; and a second stop sealing plate is arranged on a rod section of the pull rod, which is positioned inside the flue wall. According to the device disclosed by the invention, the accumulated dust attached onto the outer surface of the heat exchange pipe is removed by utilizing the relative motion of the helical spring along the axial direction of the outer wall of the heat exchange pipe, which is generated by the retracting and extending motion of the helical spring wound on the outer wall of the heat exchange pipe.

Owner:SOUTHEAST UNIV

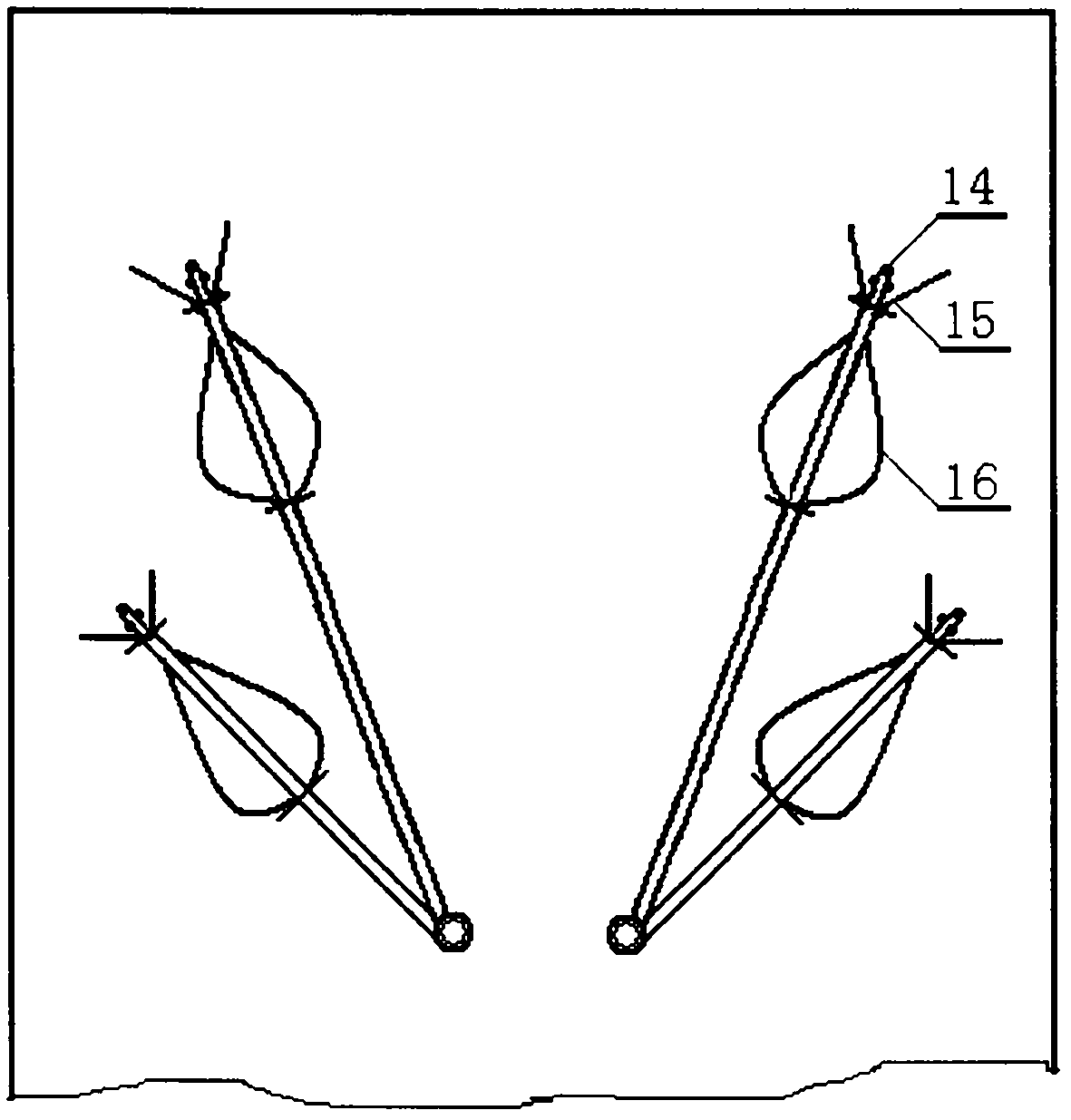

Ignition oil gun head with blockage removal device

The invention discloses an ignition oil gun head with a blockage removal device. The ignition oil gun head comprises a slag intercepting disc. Slag pushing rods are evenly distributed on the plate surface of a first pushing plate adjacent to the slag intercepting disc. The slag pushing rods slidingly penetrate through oil via holes. The top end of each slag pushing rod is provided with a connecting rod. The ignition oil gun head has the advantages that in the normal operation process, springs are compressed under stress, the connecting rods are placed in the oil via holes of the slag intercepting disc, and fuel oil sequentially passes through the gaps between the oil via holes and the connecting rods and oil passing holes in the first pushing plate, passes through a flow dividing piece anda flow rotating piece and is then sprayed out; when the gaps between the oil via holes and the connecting rods are blocked by the oil slag, a user only needs to stop supplying fuel oil with certain pressure into an ignition oil gun, and at the moment, the springs push the first pushing plate to slide towards the slag intercepting disc; meanwhile, the slag pushing rods are inserted in the oil viaholes and eject out the oil slag, so that the blockage removal function is realized; and the gun head does not need to be detached in the blockage removal mode, operation is simple, the cleaning cycleis short, efficiency is high, and manpower and material resources can be reduced.

Owner:内蒙古大唐国际托克托第二发电有限责任公司 +1

Chemical cleaning method for scales on tube of evaporator for producing ammonium sulfate

ActiveCN102400167BSolve cleaning problemsSimple processMetallic material coating processesSulfateSURFACTANT BLEND

The invention belongs to the field of the cleaning of scales on a tube of an evaporator, and discloses a chemical cleaning method for the scales on the tube of the evaporator for producing ammonium sulfate, which comprises the following steps: dredging and water washing; alkali washing: namely, adding water to carry out circulation, adding 10-40% of alkali, 0.5-1.0% of anionic surfactant and 0.5-3.3% of trisodium orthophosphate according to the amount of the water, and then, heating up to 65-95 DEG C, maintaining the temperature, monitoring the concentration of the alkali once per two hours, replenishing the alkali in time when the concentration of the alkali is less than 5%, so that the final concentration of the alkali is not less than 5%, discharging a cleaning solution outside, and adding the water again for cleaning, thereby completing the alkali washing; pickling: namely, adding the water for carrying out the circulation, adding 0.2-1.0% of pickling corrosion inhibitor and 5-10%of acid according to the amount of the water, reacting at a normal temperature, monitoring the concentration of the acid once per 0.5 hour, replenishing the acid in time when the concentration of theacid is less than 2%, and maintaining the final concentration of the acid to be 0.5-2.0%, thereby completing the pickling; and the water washing and passivating: namely, adding the water to carry outthe circulation, cleaning to be neutral, adding 2-5% of the alkali and 0.5-1.0% of the trisodium orthophosphate, circulating at the normal temperature, and carrying out passivation. By using the chemical cleaning method for the scales on the tube of the evaporator for producing the ammonium sulfate, the scales of sulfates and silicates on the tube of the evaporator can be thoroughly cleaned cleanly, thereby reaching a mirror face state.

Owner:HENAN ZHONGYUAN GOLD SMELTERY

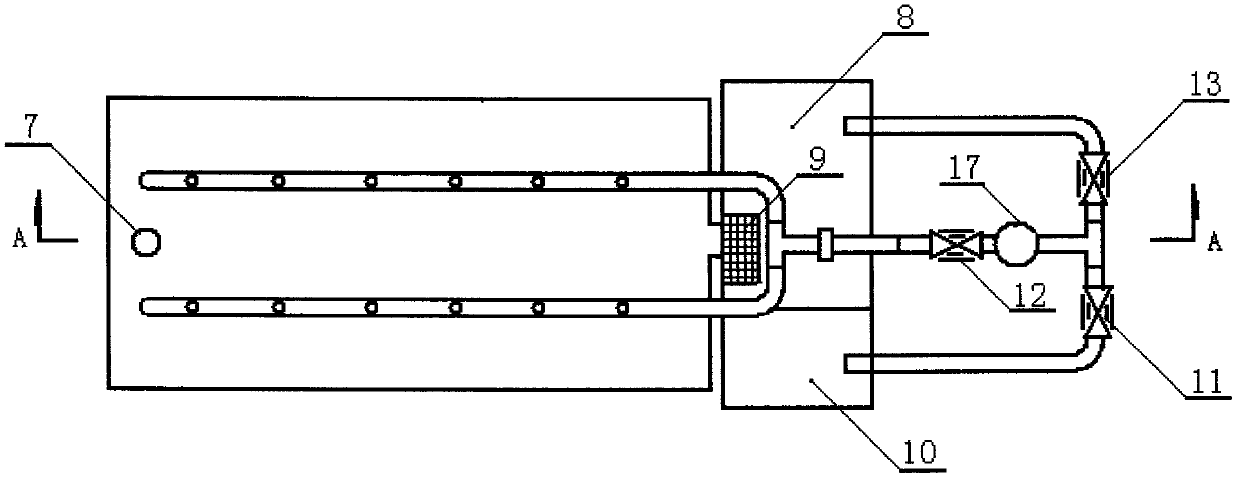

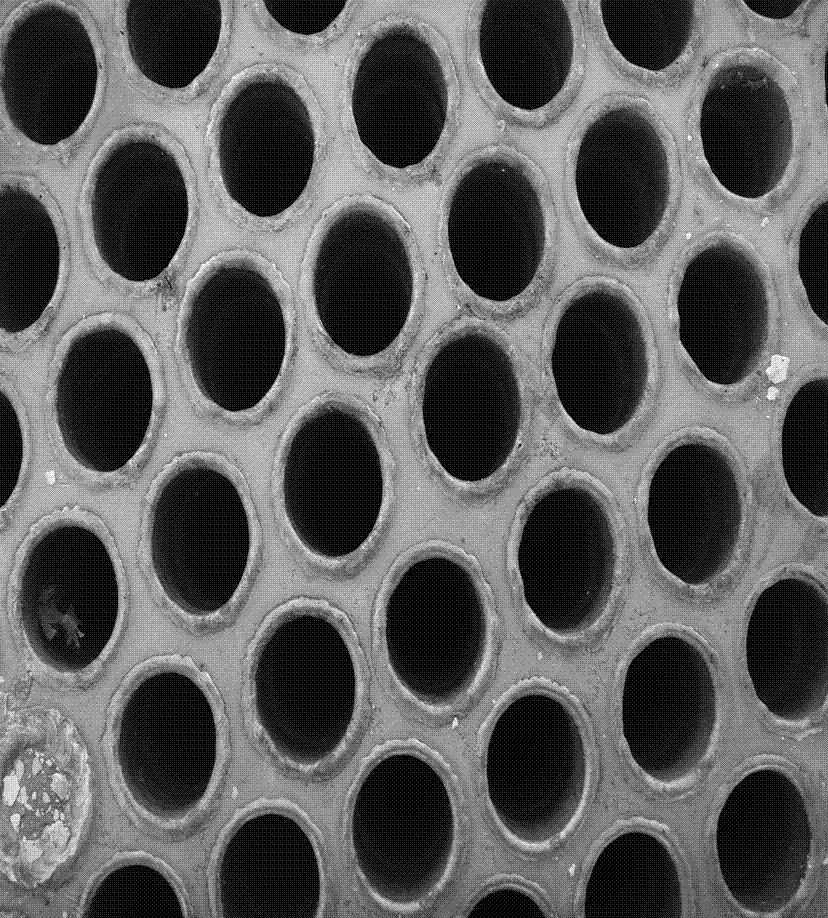

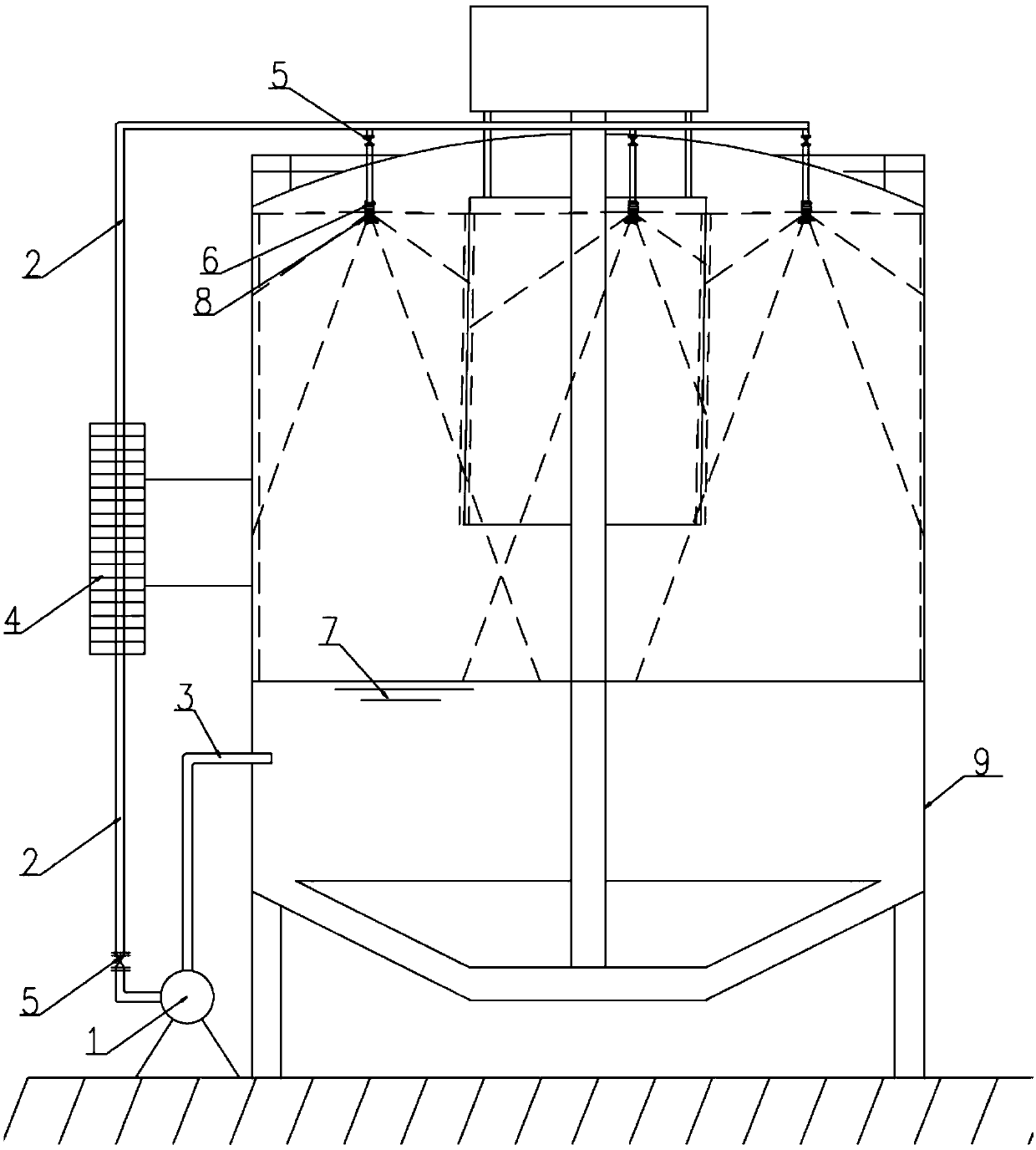

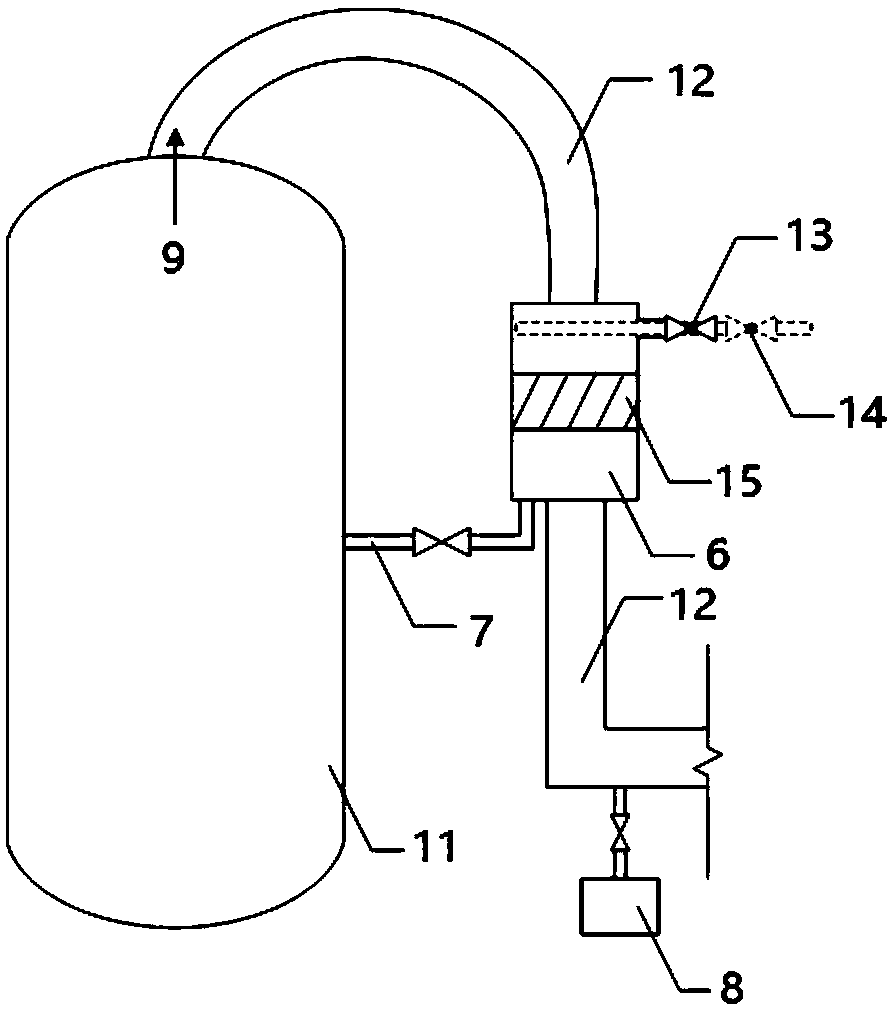

Aluminium oxide settlement tank full-direction scab cleaning device and application method thereof

ActiveCN108672446ANo damageShort cleaning cycleChemical industryHollow article cleaningControl valvesCirculating pump

The invention relates to an application method of an aluminium oxide settlement tank full-direction scab cleaning device, and the application method is used for the full-direction scab cleaning devicein the volume of a separating settlement tank in the continuous production of aluminium oxide, and further suitable for a washing settlement tank, a decomposing tank and other volume. The aluminium oxide settlement tank full-direction scab cleaning device mainly comprises a circulating pump, a feed pipe, a circulating collecting pipe and scab cleaning machines. An inlet of the circulating pump isconnected with a settlement tank through the feed pipe, the settlement tank is filled with alkaline liquor, the height of the alkaline liquor is greater than the height of a joint of the settlement tank and the feed pipe, an outlet of the circulating pump is connected with the circulating collecting pipe, and a plurality of scab cleaning machines arranged side by side are arranged on the circulating collecting pipe. The scab cleaning machines are arranged at the top of the settlement tank, control valves are arranged above the scab cleaning machines, and a heating device is arranged on the circulating collecting pipe. The application method of the aluminium oxide settlement tank full-direction scab cleaning device can perform full-direction cleaning of a scab in the settlement tank, and the manual removal of the scab in the settlement tank is eliminated.

Owner:江阴市华能电热器材有限公司

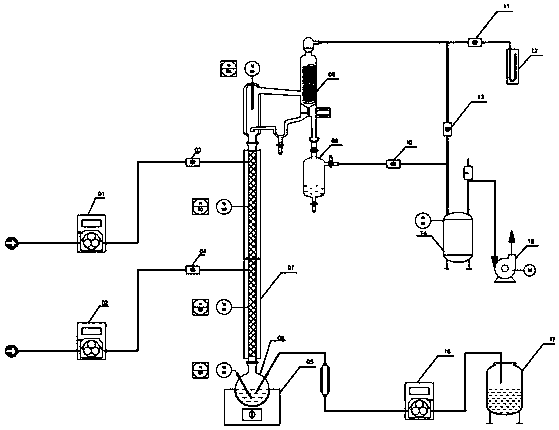

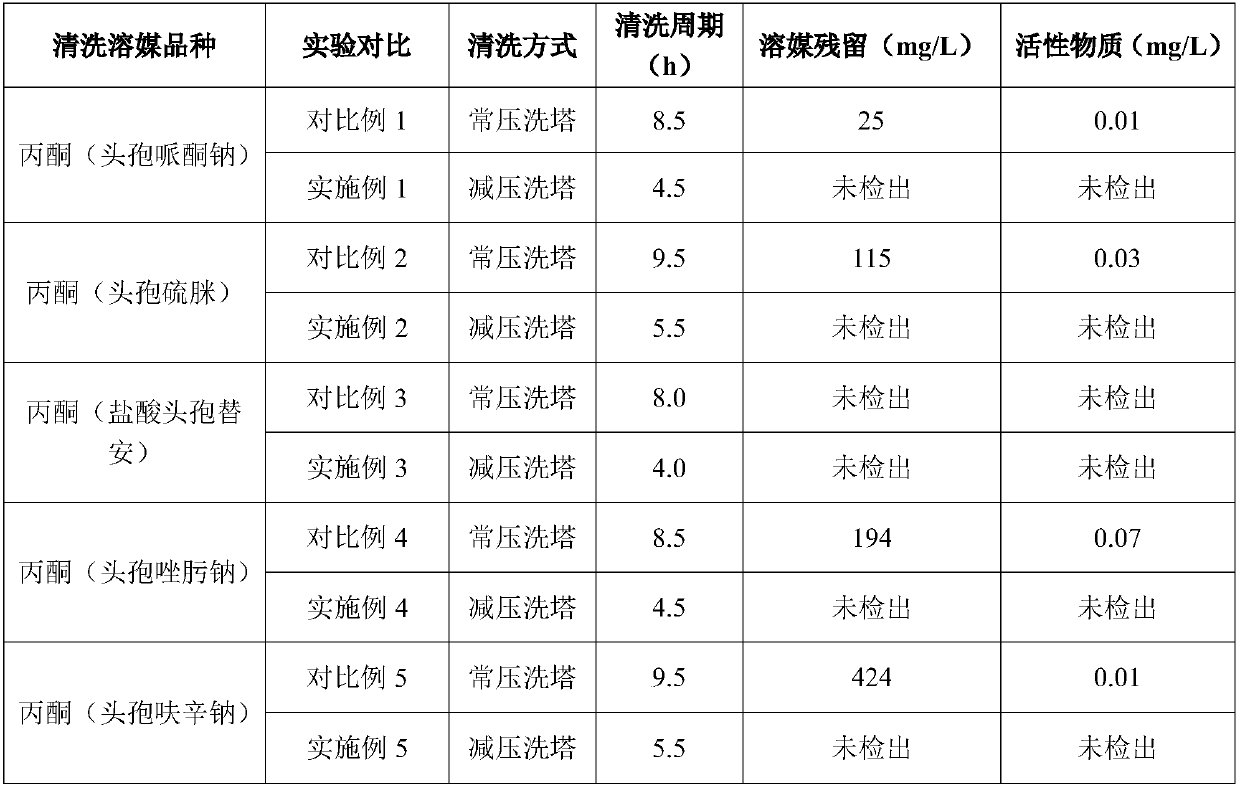

Method for rapidly cleaning rectifying tower

InactiveCN109622535AShort cleaning cycleHollow article cleaningCleaning using liquidsEngineeringTower

The invention belongs to the field of cleaning devices and particularly relates to a method for rapidly cleaning a rectifying tower. The method for rapidly cleaning the rectifying tower comprises thesteps of water washing, alkaline washing and secondary water washing. According to the method for rapidly cleaning the rectifying tower, optimization and improvement are conducted on the basis of original cleaning, and compared with a traditional normal-pressure rectifying cleaning method, the adopted decompression rectifying cleaning method shortens the cleaning period and achieves that the contents of residual solvent and active substances in the tower are low.

Owner:SHANDONG LUOXIN PHARMA GRP CO LTD +2

Online cleaning method for mist catcher

PendingCN108619796AReduce resistanceReduce difficultyDispersed particle separationEngineeringMaterial resources

The invention discloses a cleaning spraying tube. The cleaning spraying tube comprises a steel tube, wherein a through hole is formed in the steel tube; one end of the steel tube is welded, and the other end of the steel tube is equipped with a sleeve; the other end of the sleeve is equipped with a control ball valve; and the two ends of the sleeve are equipped with outer wire buckles with diameters being DN25. The invention further discloses a mist catcher online cleaning method based on the cleaning spraying tube. According to the cleaning spraying tube and the cleaning method, the cleaningoperation is simple, the period is short, complex processes such as desulfurizing tower halt production, mist catcher dismounting, cleaning and re-fitting are simplified, manpower and material resources are saved, production is not affected by cleaning, working efficiency is improved, equipment corrosion and industrial pollution of fuel gas system cleaning are reduced, and safety is high.

Owner:BAOTOU IRON & STEEL GRP

Waste liquor collector

ActiveCN105436183AOnly the distance factor is involvedAvoid manual connection of tubingDirt cleaningLiquid waste

The invention discloses a waste liquor collector. The waste liquor collector is provided with a lifting component, a waste liquor tank and a connecting part, wherein the waste liquor tank is fixedly mounted on the lifting component, the connecting piece adopts a tubular structure, one end of the tubular structure is provided with a connector used for inputting a waste liquor, the other end of the tubular structure is fixedly connected with the waste liquor tank, the inner cavity of the waste liquor tank is communicated with the inner cavity of the connecting piece, a liquor drainage port is formed in the waste liquor tank, and the connecting part is movably connected with a filling valve through the lifting component. By controlling a connecting process, the waste liquor collector can quickly transfer a waste liquor discharging function onto a linear filling device, therefore, the purpose of discharging waste liquor automatically is achieved, moreover, manually connecting pipelines can be avoided, the cleaning period is shortened greatly, and secondary pollution can be avoided.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

Special incinerator for extruder screw cleaning

ActiveCN104406171BBurn fullyShort cleaning cycleIncinerator apparatusCleaning processes and apparatusCombustionIncineration

Owner:JIANGSU DOUSHENG TECH DEV CO LTD

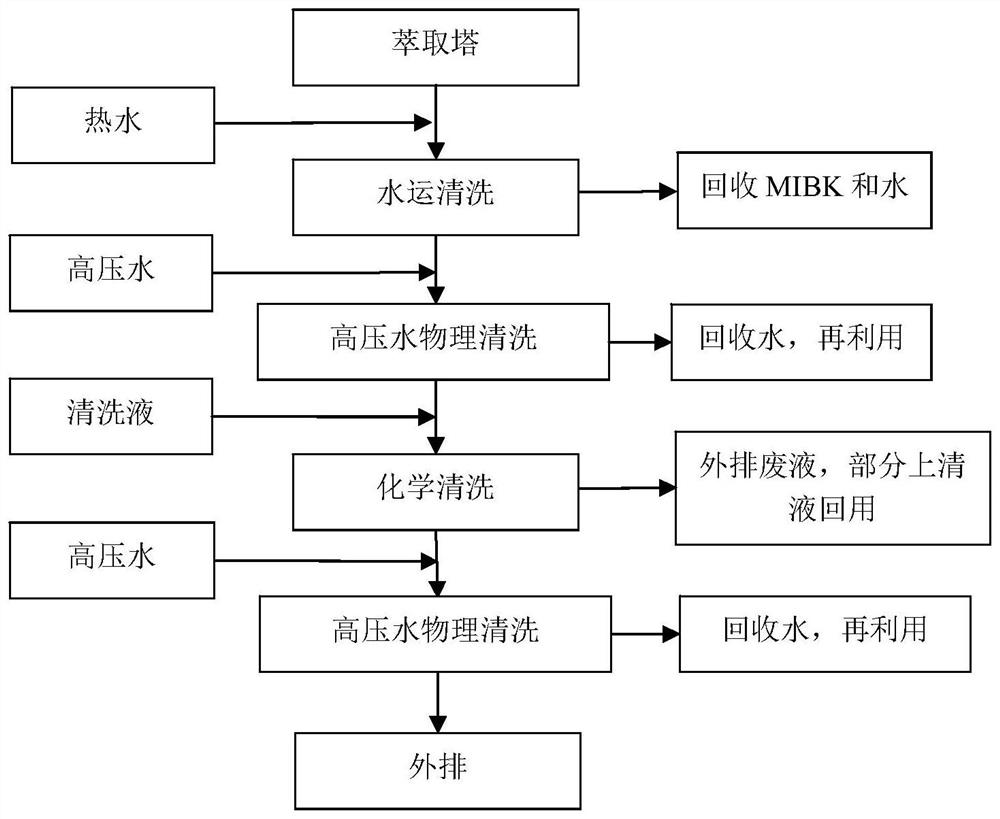

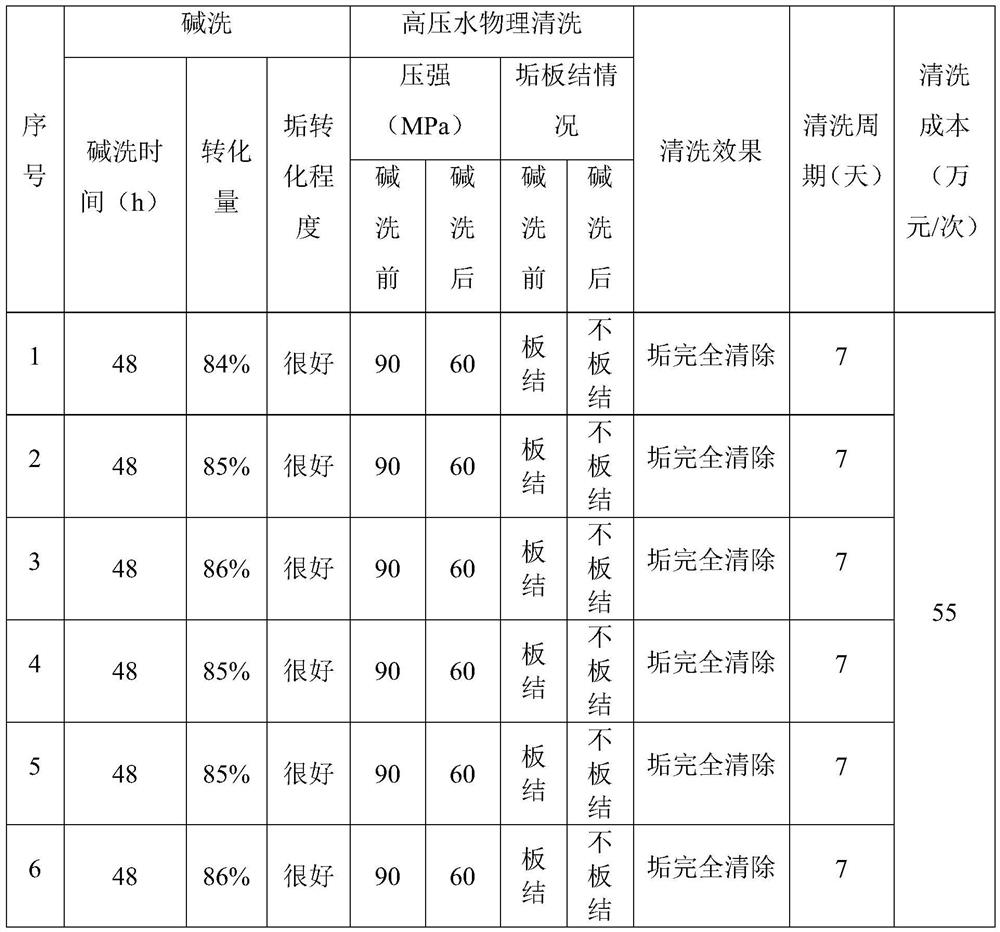

Wet-process phosphoric acid extraction tower cleaning method

ActiveCN113020064APromote full accessReduce security management costsCleaning using liquidsO-Phosphoric AcidEngineering

The invention discloses a wet-process phosphoric acid extraction tower cleaning method. The method comprises the following steps of performing high-pressure water physical cleaning on the interior of an extraction tower, and opening a channel in dirt; performing chemical cleaning on the interior of the extraction tower by adopting a cleaning solution with the temperature of 70 DEG C or above, and controlling the pressure intensity of the cleaning solution to be 0.05 MPa or above in the chemical cleaning process, so that the hard scale is converted into soft scale; and performing high-pressure water physical cleaning on the interior of the extraction tower, so that soft dirt falls off and is discharged outwards, and finishing cleaning of the extraction tower. The cleaning method has the advantages of being short in cleaning period, low in cleaning cost, high in cleaning efficiency, good in cleaning effect, safe, environmentally friendly and the like, efficient and thorough cleaning of the wet-process phosphoric acid extraction tower can be achieved, the use value is high, and the application prospect is good.

Owner:湖南瑞寰环境科技有限公司

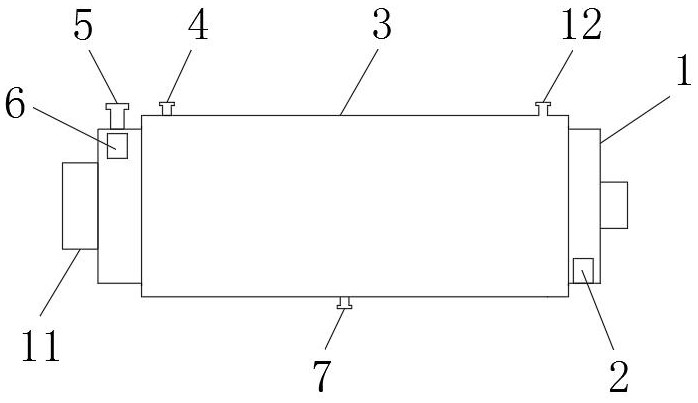

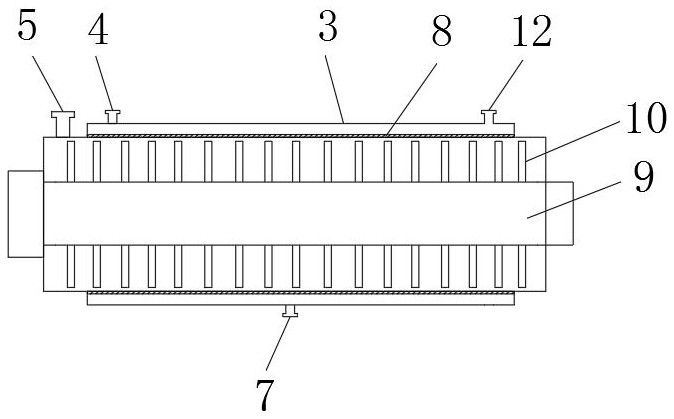

Heat exchanger online cleaning device

ActiveCN104315919BImprove the efficiency of ball collectionPerfect cleaning efficiencyNon-rotary device cleaningClean energyEnergy consumption

Disclosed is an online cleaning device of a heat exchanger. The online cleaning device of the heat exchanger comprises the heat exchanger, a ball injector and a rubber ball delivery pump, wherein an inner pipeline of the heat exchanger is of a U structure, the right side of the heat exchanger is provided with a water inlet pipe orifice, the left side of the heat exchanger is provided with a water outlet pipe orifice, the water outlet pipe orifice is connected with the front end of a funneling ball collector through a pipeline, the rear end of the funneling ball collector is provided with a cooling water outlet, an inverted cone ball collection net is arranged in the funneling ball collector, a variable diameter type ball conveyor is arranged at the tail end of the inverted cone ball collection net, the variable diameter type ball conveyor is connected with a ball discharge pipe orifice, the ball discharge pipe orifice of the funneling ball collector is connected with a ball feed pipe orifice of the rapid ball injector through a flange, and a ball collection valve is arranged on the pipeline of the funneling ball collector. The online cleaning device of the heat exchanger can integrate collection and injection of rubber balls, and greatly improves ball collection efficiency. Ball collection efficiency of a common rubber ball cleaning device ranges from 30% to 70%, and ball collection efficiency of the online cleaning device of the heat exchanger reaches 100%. Additionally, the online cleaning device of the heat exchanger achieves a circulation cleaning function, is simple to operate for cleaning the rubber balls, low in cleaning energy consumption and short in cleaning period.

Owner:连云港市宏庆电力辅机开发有限公司

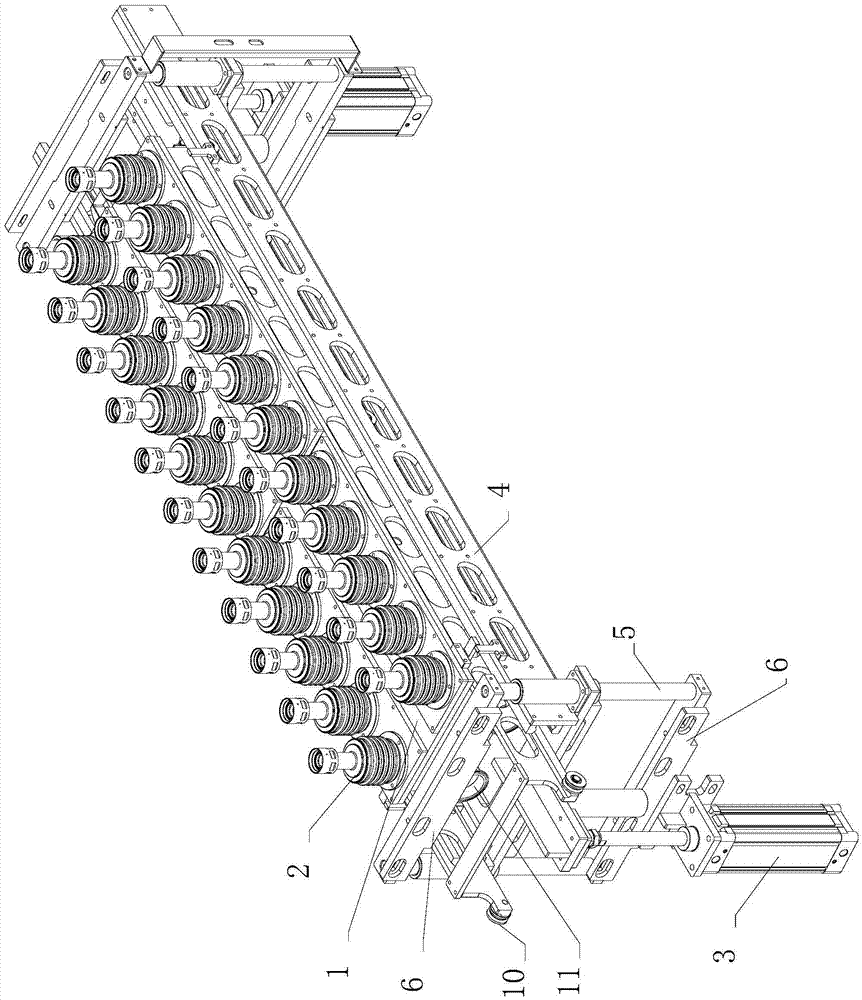

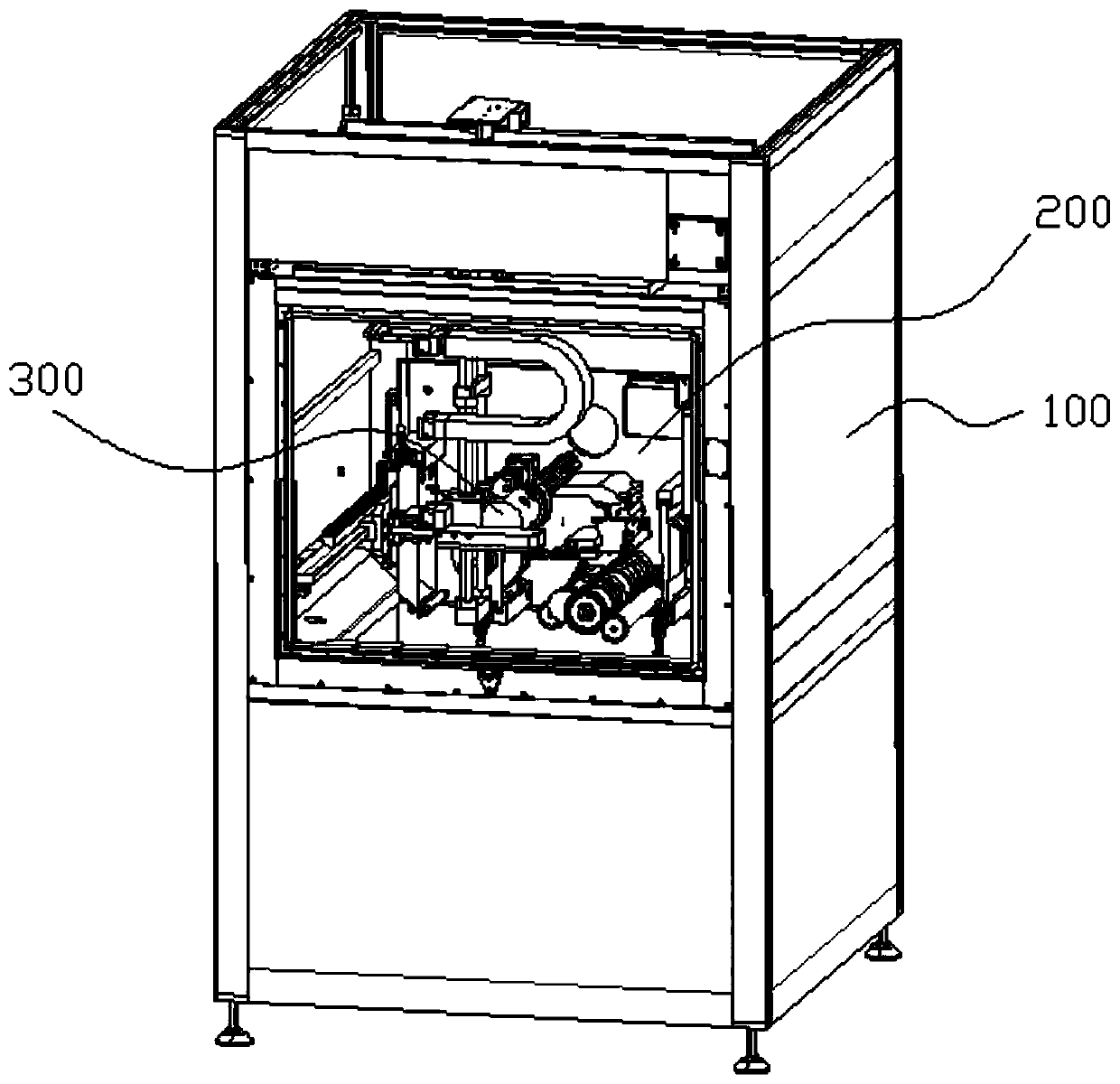

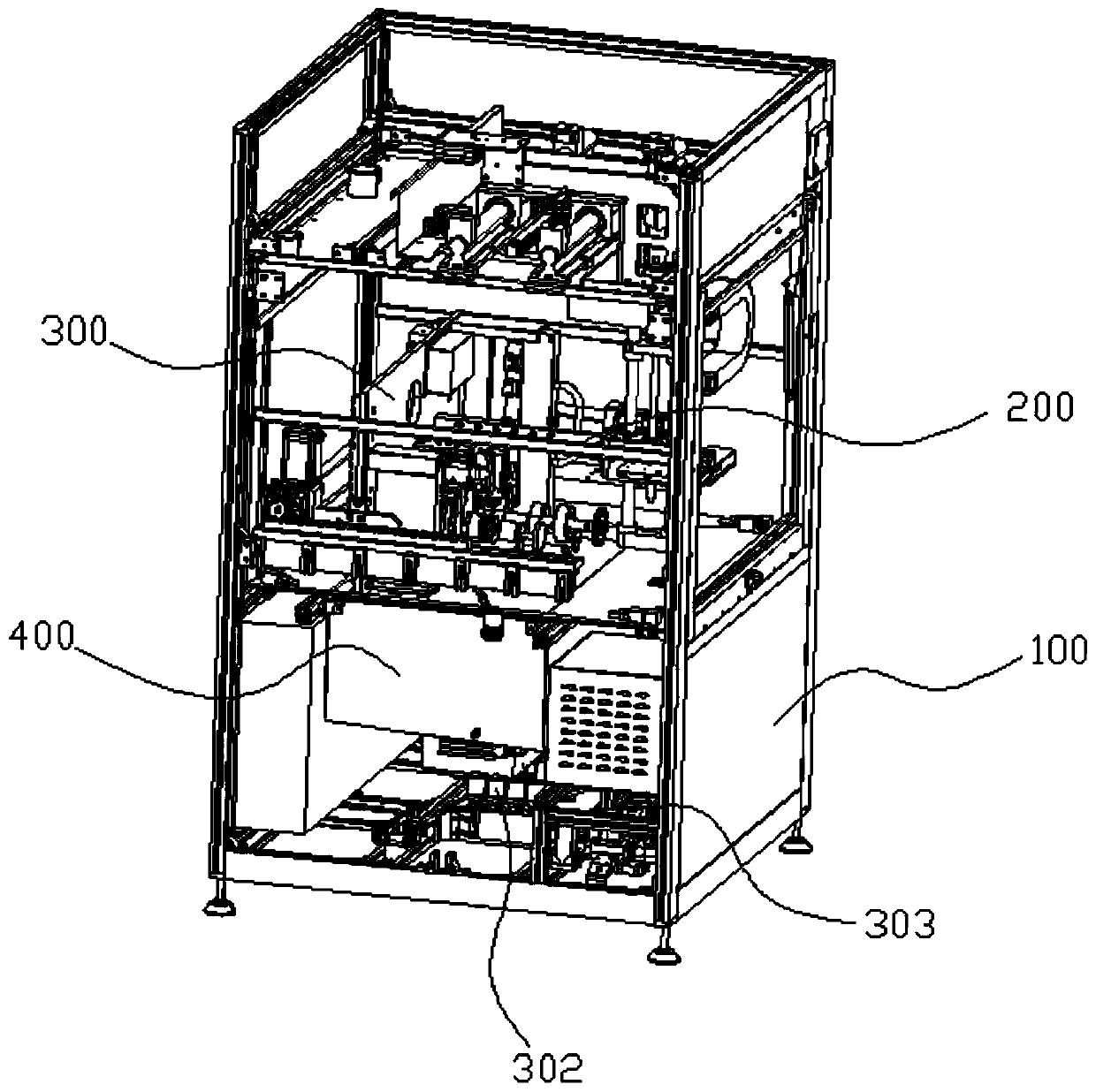

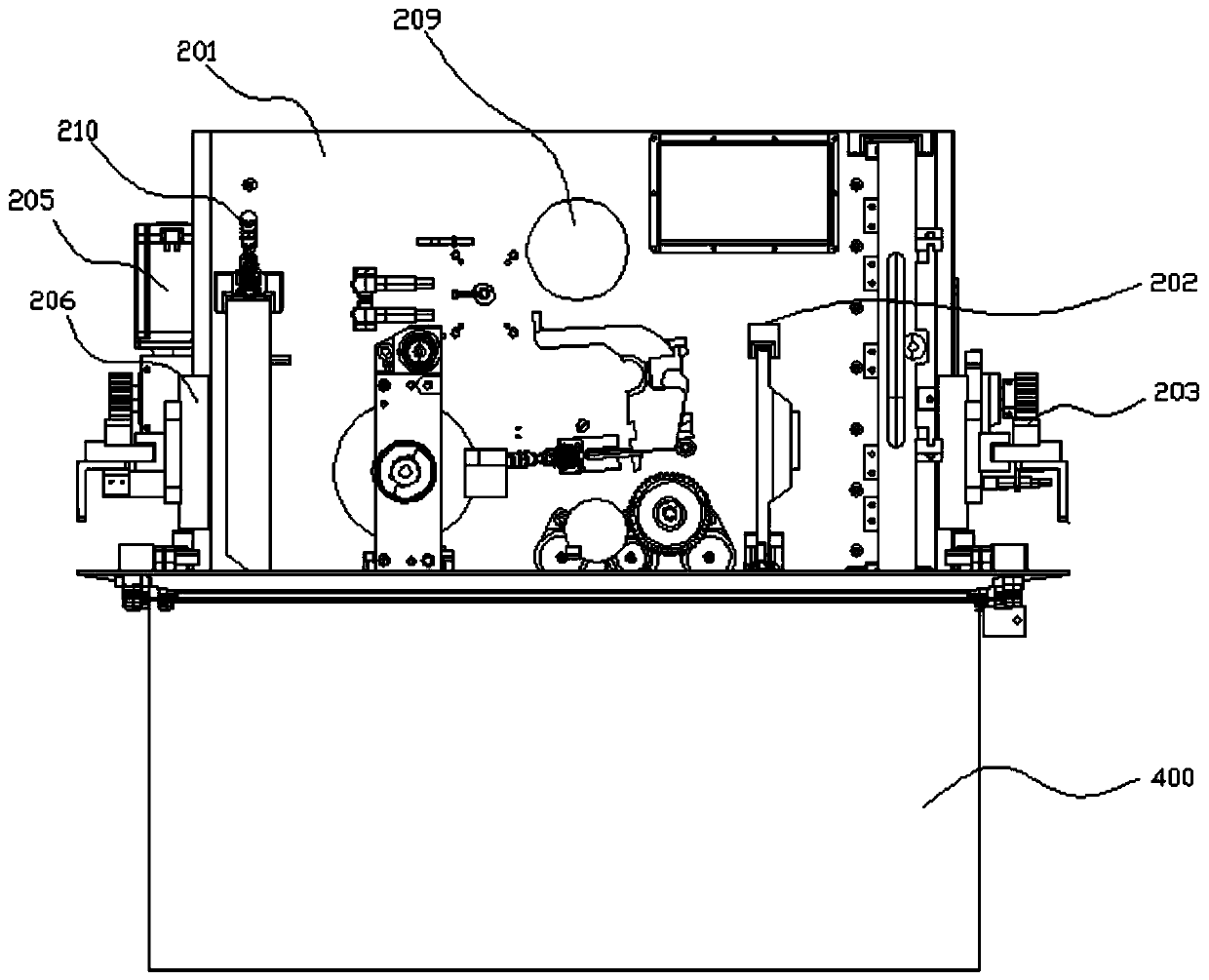

Glue cylinder cleaning machine and cleaning method

InactiveCN111229758AGood cleaning effectShort cleaning cycleHollow article cleaningWrapper twisting/gatheringPhysicsUltrasonic generator

The invention belongs to the technical field of cigarette production and discloses a glue cylinder cleaning machine and a cleaning method. The glue cylinder cleaning machine comprises a case, whereina support plate mechanism, a spray-washing mechanism and an ultrasonic cleaning mechanism are arranged in the case, and a controller is arranged on an outer side wall of the case; the support plate mechanism comprises a support plate and a support plate driving mechanism for driving the support plate to move in multiple directions, and a plurality of glue cylinder fixing station positions for fixing glue cylinder components are arranged on the support plate; the spray-washing mechanism comprises a spray rod and a spray rod driving mechanism for controlling the spray rod to move in multiple directions, an input end of the spray rod is connected with a high-pressure water valve group and a high-pressure air valve group, and a plurality of spray holes are formed in an output end of the sprayrod; the ultrasonic cleaning mechanism comprises an ultrasonic cleaning tank connected with an ultrasonic generator; the controller is electrically connected with the support plate driving mechanism,the spray rod driving mechanism, the high-pressure water valve group, the high-pressure air valve group and the ultrasonic wave generating device. The glue cylinder cleaning machine can achieve high-pressure spray cleaning at accurate angle and has good cleaning effect.

Owner:成都慧晶机械设备有限公司

A kind of filter membrane cleaning method

ActiveCN104607051BEasy to cleanRestore fluxSemi-permeable membranesFiltration membraneChemical effects

The invention discloses a filtering membrane cleaning method. The filtering membrane cleaning method is characterized in that a to-be-cleaned filtering membrane is placed in a liquid phase and subjected to liquid phase discharge through electrodes of a high-voltage pulsed power supply, so that corona discharge, glow discharge or streamer discharge occurs in the liquid phase; under the physical and chemical effect produced in the discharge process, substances blocking membrane holes are separated from the membrane holes, and the filtering membrane is cleaned. The filtering membrane can be efficiently cleaned, and membrane flux is rapidly recovered to realize membrane regeneration. The filtering membrane cleaning method has the advantages of short cleaning period, low cost and good effect.

Owner:CHONGQING XINHE QIYUE TECH CO LTD

a waste collector

ActiveCN105436183BOnly the distance factor is involvedAvoid manual connection of tubingDirt cleaningPollutionWaste management

The invention discloses a waste liquor collector. The waste liquor collector is provided with a lifting component, a waste liquor tank and a connecting part, wherein the waste liquor tank is fixedly mounted on the lifting component, the connecting piece adopts a tubular structure, one end of the tubular structure is provided with a connector used for inputting a waste liquor, the other end of the tubular structure is fixedly connected with the waste liquor tank, the inner cavity of the waste liquor tank is communicated with the inner cavity of the connecting piece, a liquor drainage port is formed in the waste liquor tank, and the connecting part is movably connected with a filling valve through the lifting component. By controlling a connecting process, the waste liquor collector can quickly transfer a waste liquor discharging function onto a linear filling device, therefore, the purpose of discharging waste liquor automatically is achieved, moreover, manually connecting pipelines can be avoided, the cleaning period is shortened greatly, and secondary pollution can be avoided.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

Card clothing cleaner for carding machine

Owner:CHANGSHU ZHENTAI NONWOVEN MACHINERY

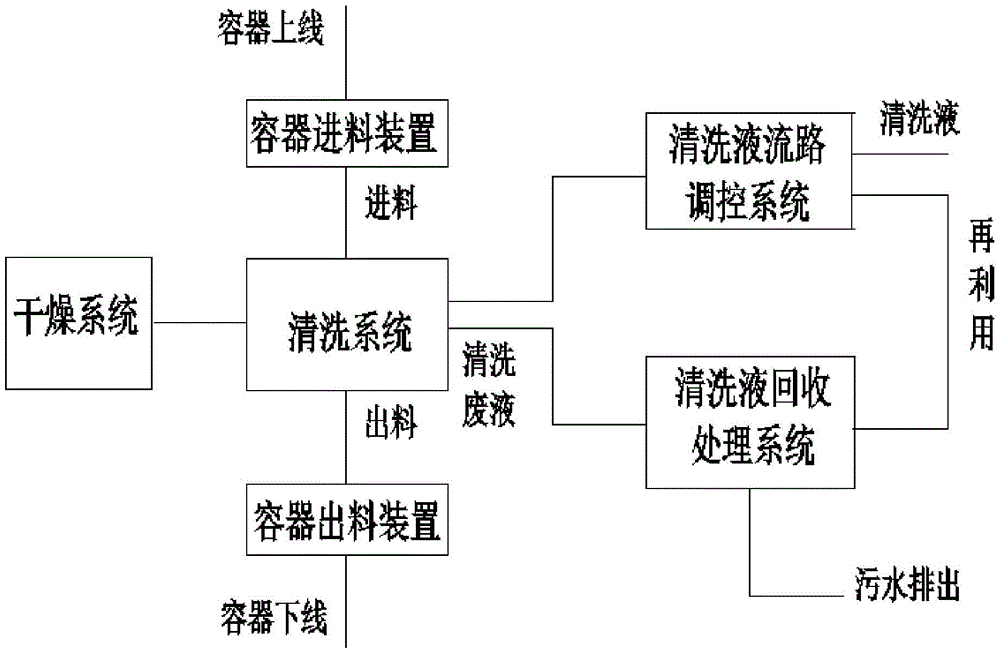

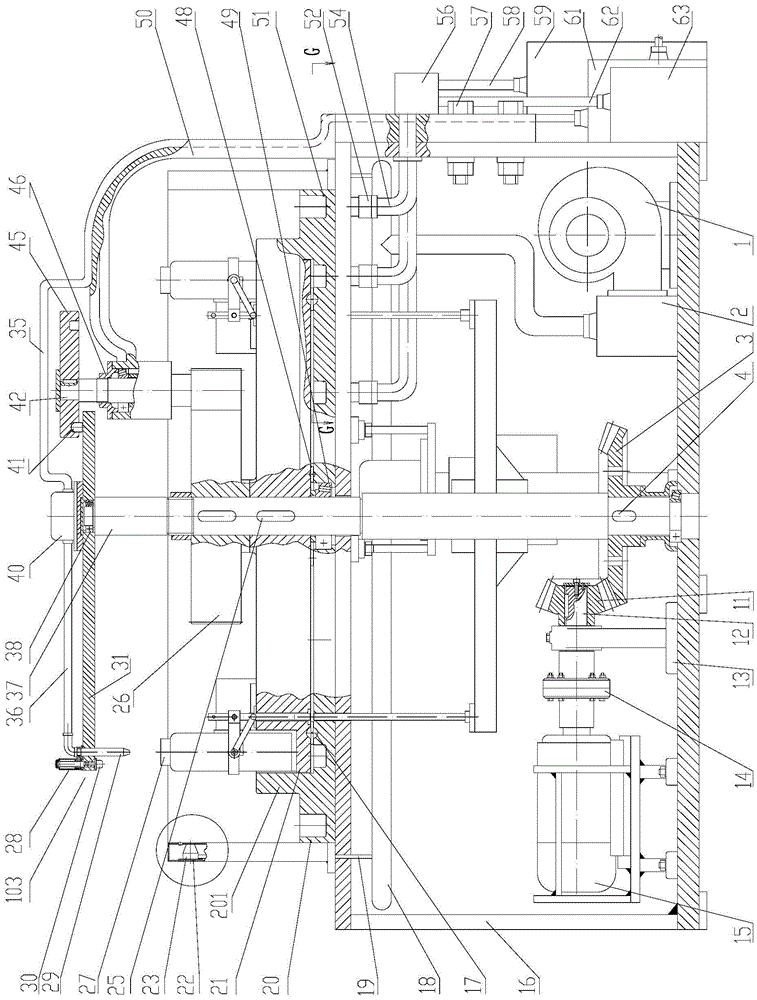

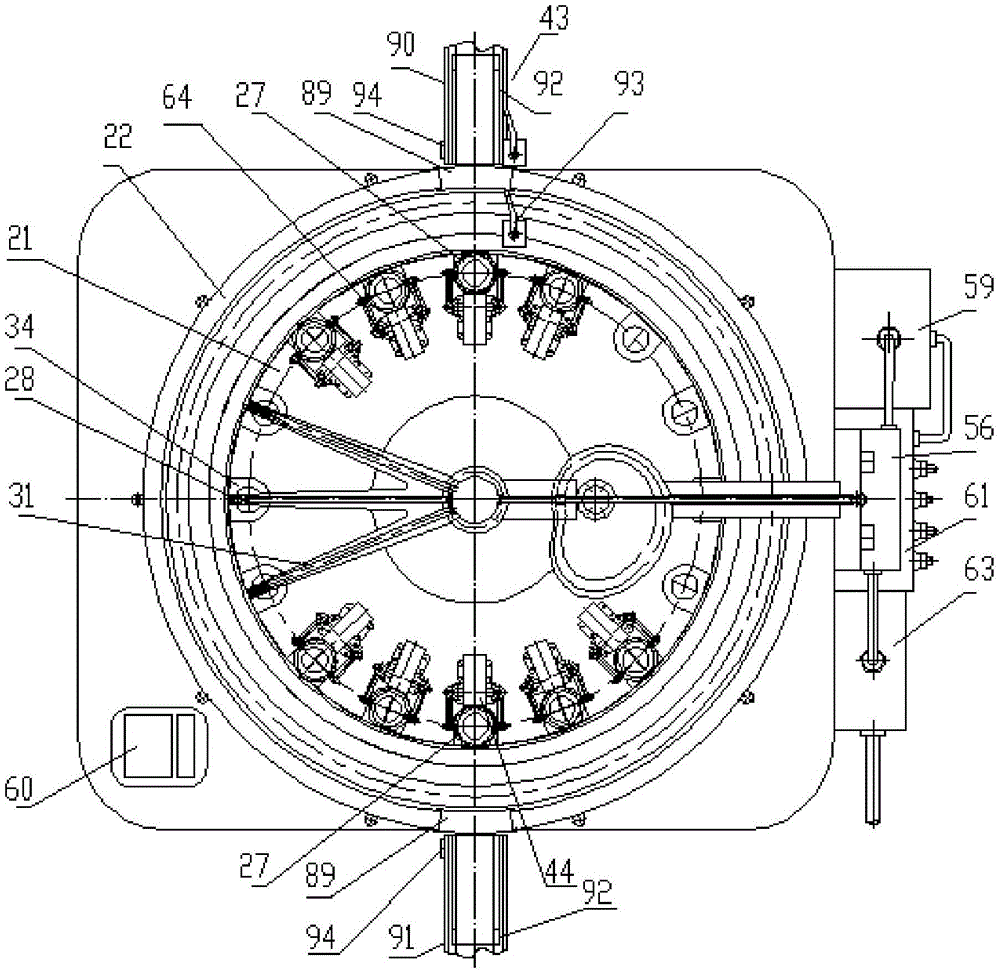

Auxiliary oil container automatic cleaning machine

InactiveCN104275337BSimple and fast operationImprove cleaning efficiencyHollow article cleaningCleaning using liquidsControl systemWastewater

The invention relates to an automatic cleaning machine for auxiliary oil containers. The automatic cleaning machine comprises a cleaning system, a cleaning liquid flow path adjusting and controlling system, a drying system, a containing conveying system and a controlling system, and combined cleaning diversification of the auxiliary oil container is realized through multiple processes of soaking, flushing, spin-drying and drying; the cleaning system comprises a turnplate, a rotation driving mechanism, container clamps, an ejector rod lifter and a liquid spraying mechanism, the turnplate can be in intermittent rotation under drive of the rotation driving mechanism, container grooves are uniformly distributed in the periphery of the turnplate, and the container clamps capable of clamping and turning the containers are arranged at the container grooves. The automatic cleaning machine can automatically complete feeding, soaking, cleaning, flushing and discharging of the auxiliary oil containers, and is unintermittent in cleaning process, high in cleaning efficiency, easy in adjusting, controlling and unifying of cleaning quality of the auxiliary oil containers, low in labor intensity of workers, easy in recovery treatment of cleaning wastewater, environment friendly and clean.

Owner:周庆忠

A linear filling device

ActiveCN105502252BAvoid secondary pollutionShorten the cleaning cycleFilling device cleaningWaste managementFill device

The invention discloses a straight type filling device. The straight type filling device is provided with a waste liquid collector, wherein the waste liquid collector is located under a container transporting path and comprises a lifting assembly, a waste liquid pipe, a connecting part and a rotating assembly; the waste liquid pipe is movably arranged on the lifting assembly, the rotating assembly is fixedly arranged on the lifting assembly, is connected with the waste liquid pipe and drives the waste liquid pipe to do spinning motion; the connecting part is of a tubular structure, one end of the connecting part is provided with a connector for connecting the connecting part with a filling valve, and the other end of the connecting part is fixedly connected with the waste liquid pipe; the inner cavity of the waste liquid pipe is communicated with the inner cavity of the connecting part, a liquid drainage hole is formed in the waste liquid pipe, and the connecting part is movably connected with the filling valve by the lifting assembly and the rotating assembly. As the straight type filling device is provided with the waste liquid collecting structure, only the connecting process is required to be controlled so as to rapidly achieve the waste liquid drainage function, and thus, the automatic waste liquid drainage purpose is achieved.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com