A kind of filter membrane cleaning method

A filter membrane technology to be cleaned, applied in the field of membrane separation, can solve the problems of unsatisfactory cleaning effect, secondary pollution, high cleaning cost, etc., and achieve the effects of low cost, efficient cleaning, and short cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The filter membrane cleaning method of the present embodiment specifically comprises the following steps:

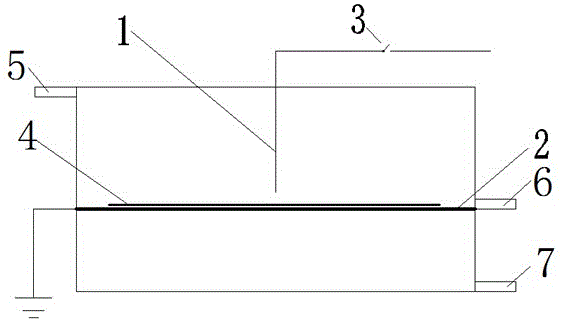

[0027] a. First obtain the cleaning device with the following structure, the cleaning device is as follows: figure 1 As shown, it includes a cleaning container, the upper end of the cleaning container is open and has a matching container cover to realize sealing, the upper end of the cleaning container is connected with a water inlet pipe 5, and the middle of the cleaning container is horizontally provided with a metal mesh grounding electrode 2, One end of the grounding electrode 2 is connected to the cleaning container through a grounding wire and grounded. The lower part of the cleaning container away from the water inlet pipe is connected to a water outlet pipe. The upper part of the grounding electrode 2 is vertically opposite to the needle electrode 1. The upper end of the needle-shaped electrode 1 is fixed and connected to the high-voltage pulse power suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com