Patents

Literature

86 results about "Streamer discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

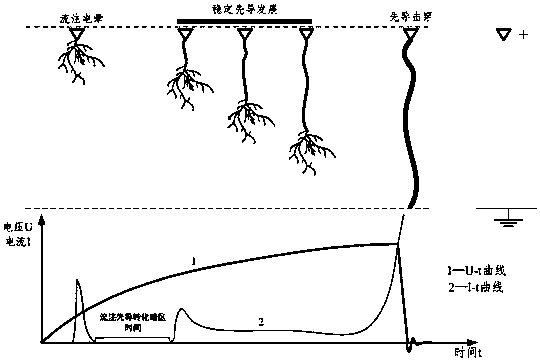

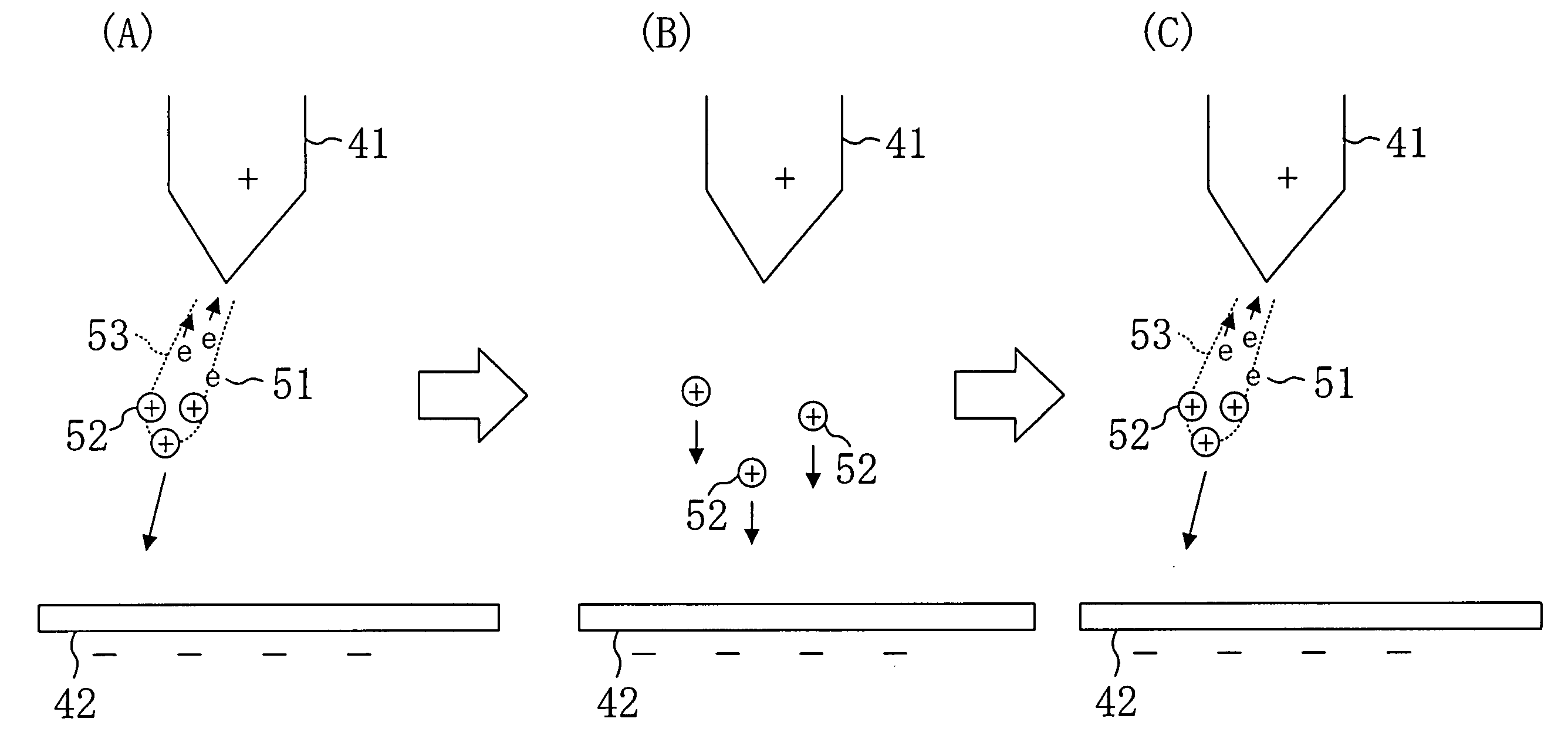

A streamer discharge, also known as filamentary discharge, is a type of transient electrical discharge. Streamer discharges can form when an insulating medium (for example air) is exposed to a large potential difference. When the electric field created by the applied voltage is sufficiently large, accelerated electrons strike air molecules with enough energy to knock other electrons off them, ionizing them, and the freed electrons go on to strike more molecules in a chain reaction. These electron avalanches (Townsend discharges) create ionized, electrically conductive regions in the air near the electrode creating the electric field. The space charge created by the electron avalanches gives rise to an additional electric field. This field can enhance the growth of new avalanches in a particular direction. Then the ionized region grows quickly in that direction, forming a finger-like discharge called a streamer.

Plasma reactor and purification equipment

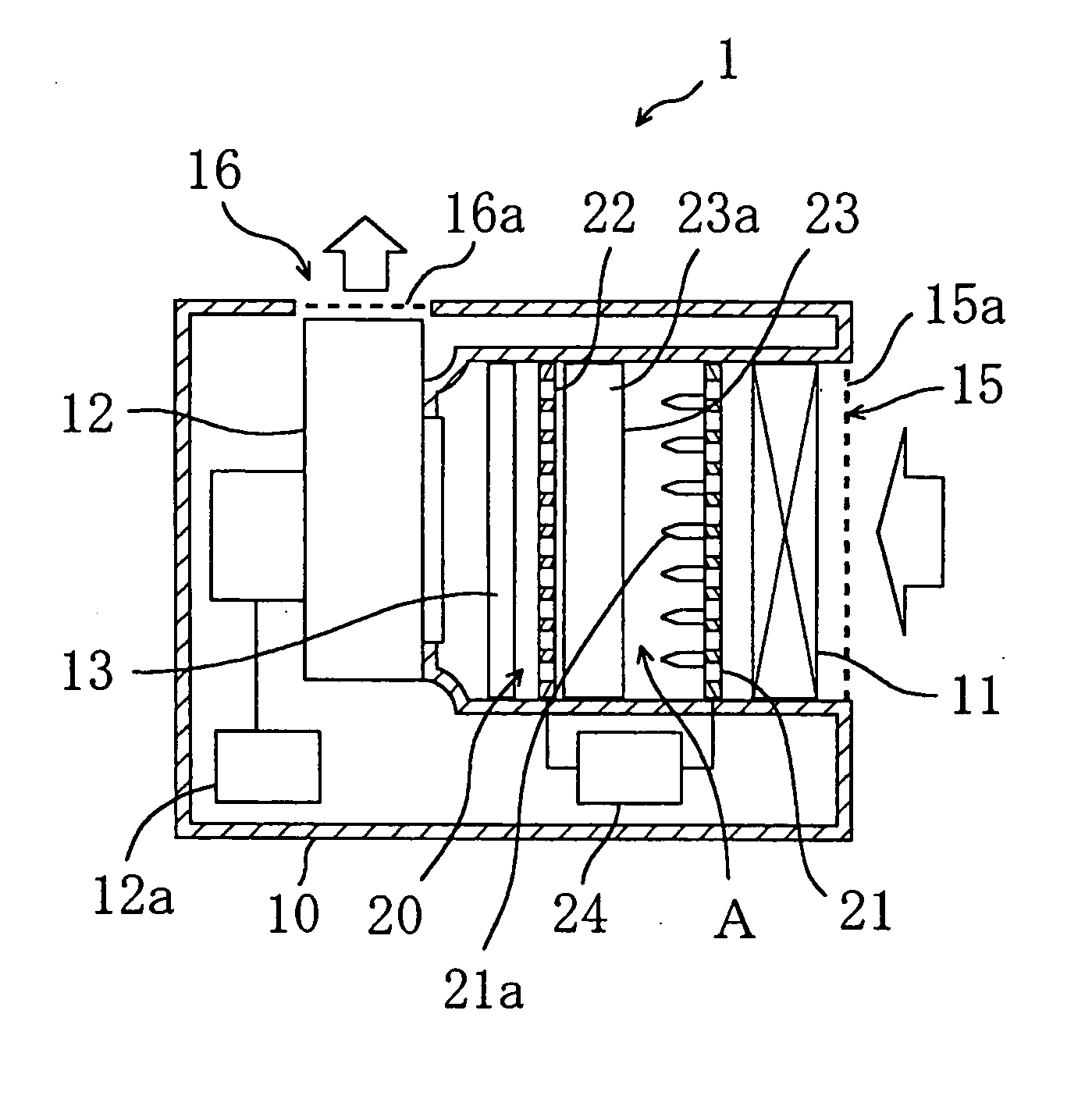

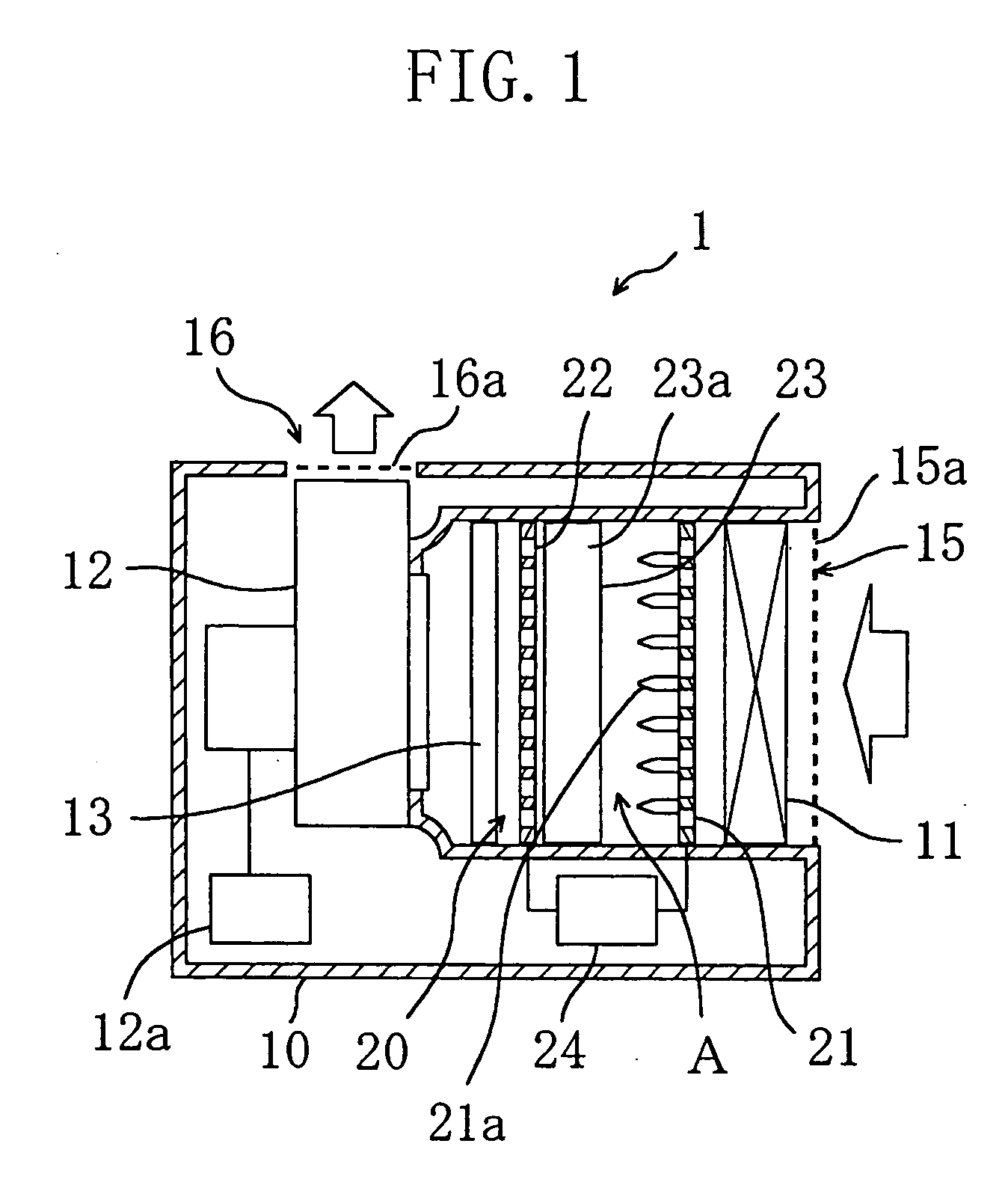

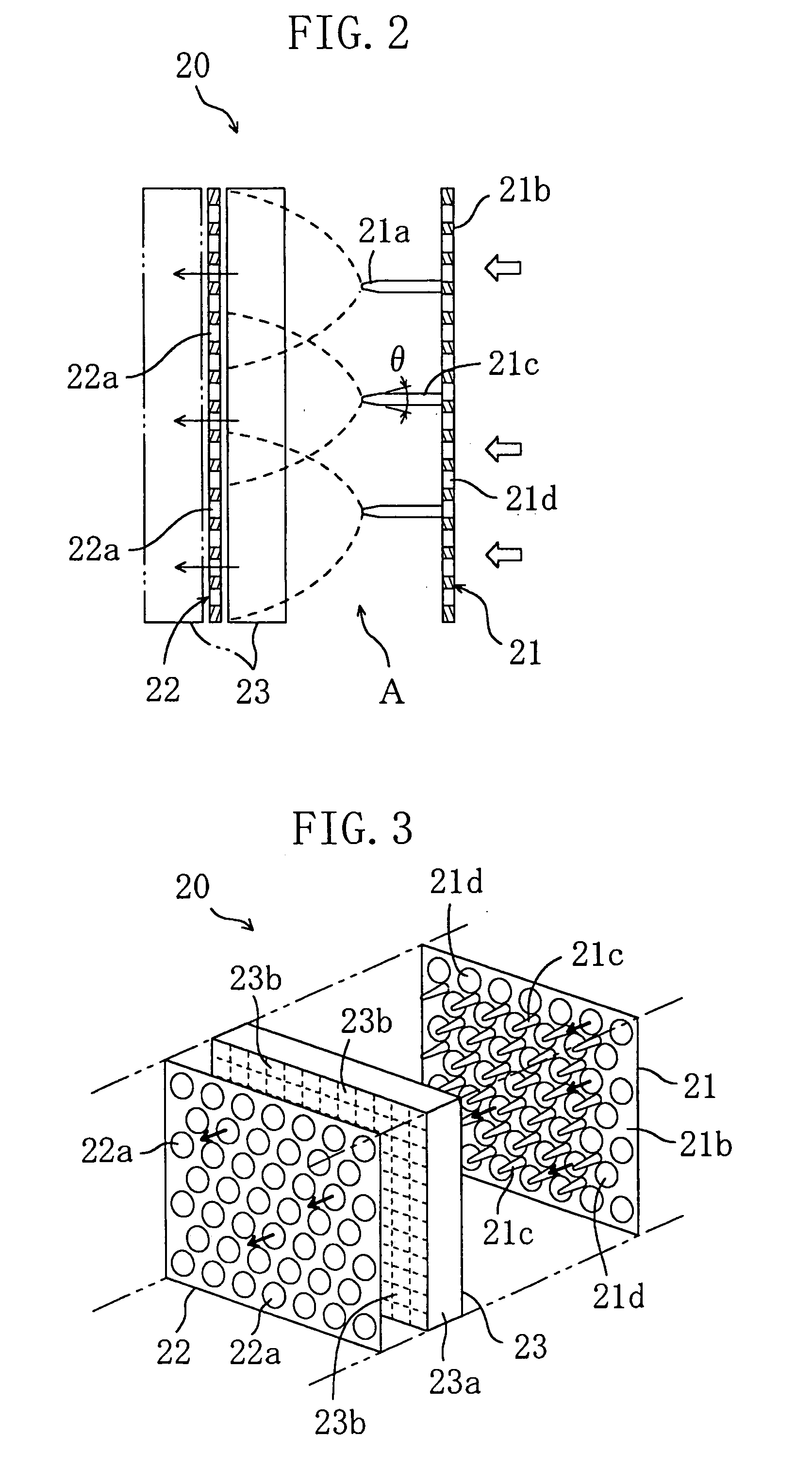

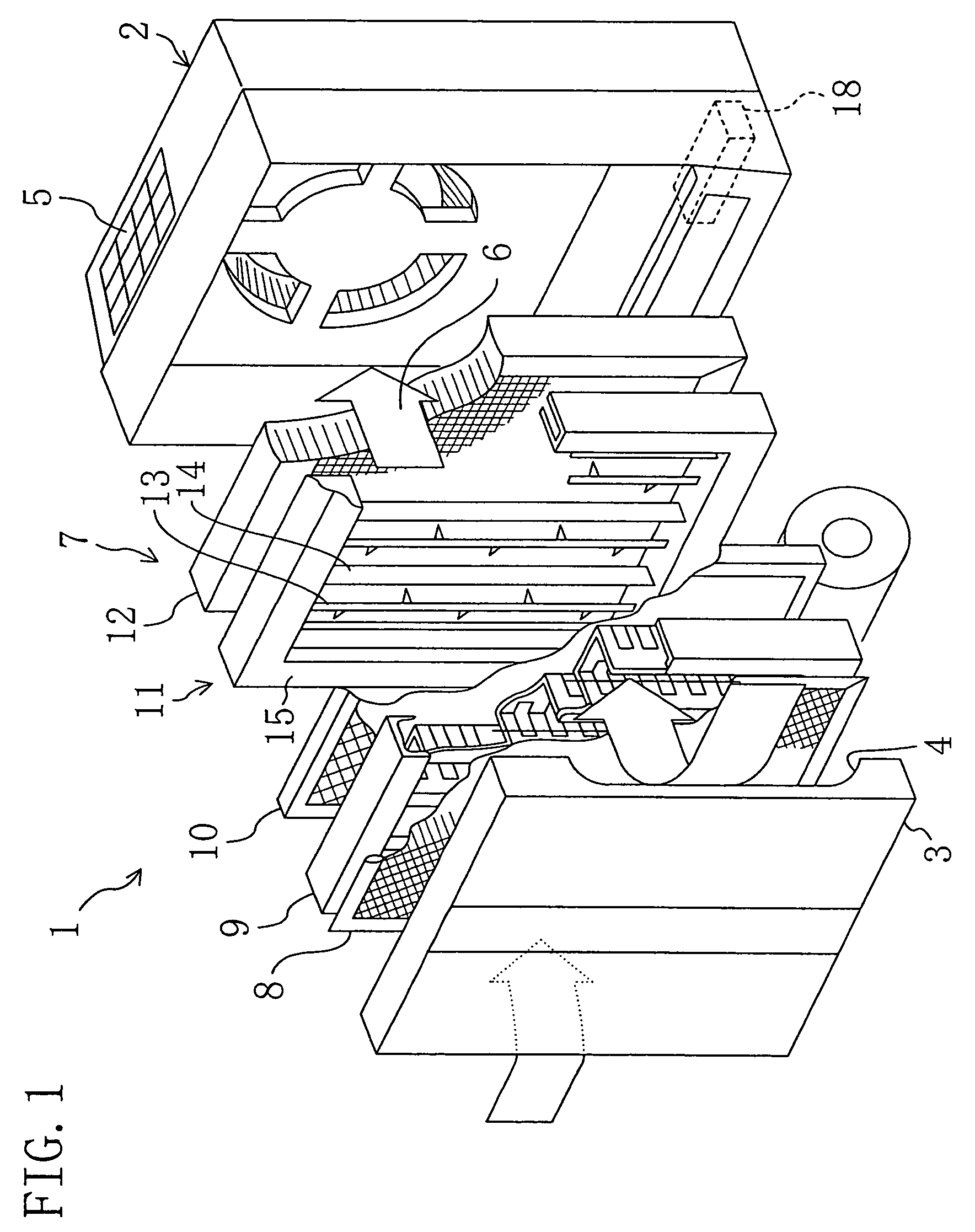

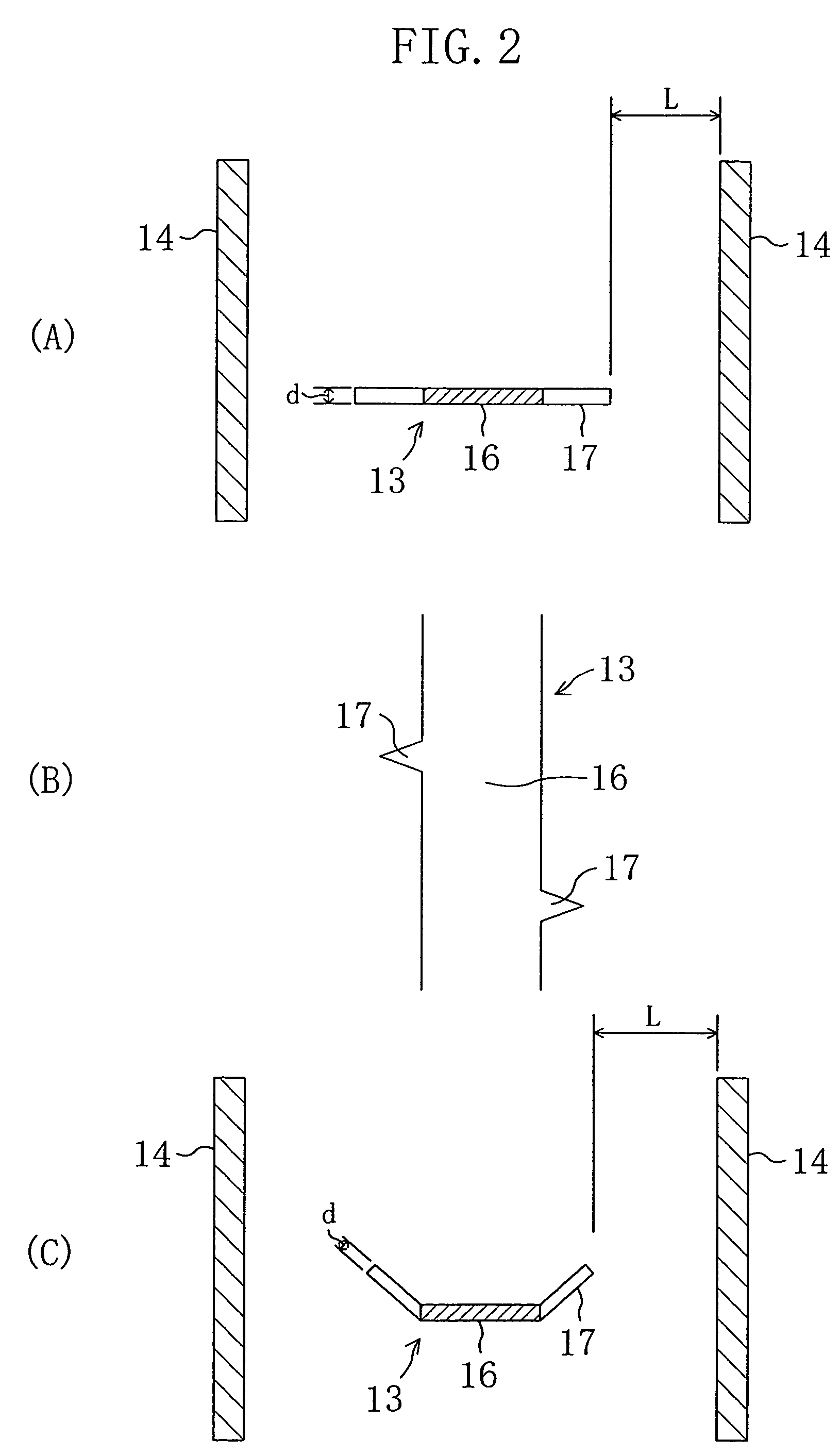

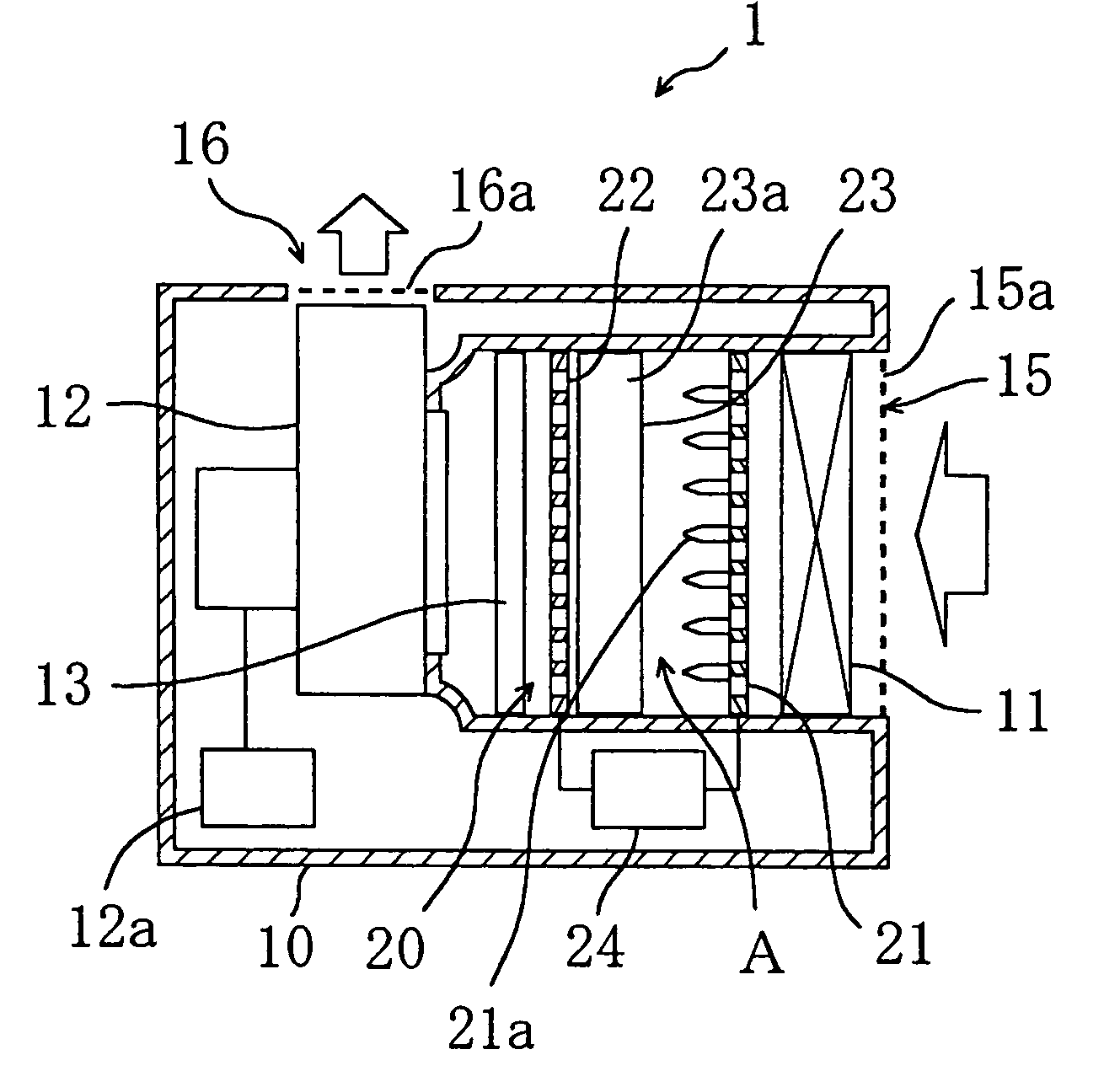

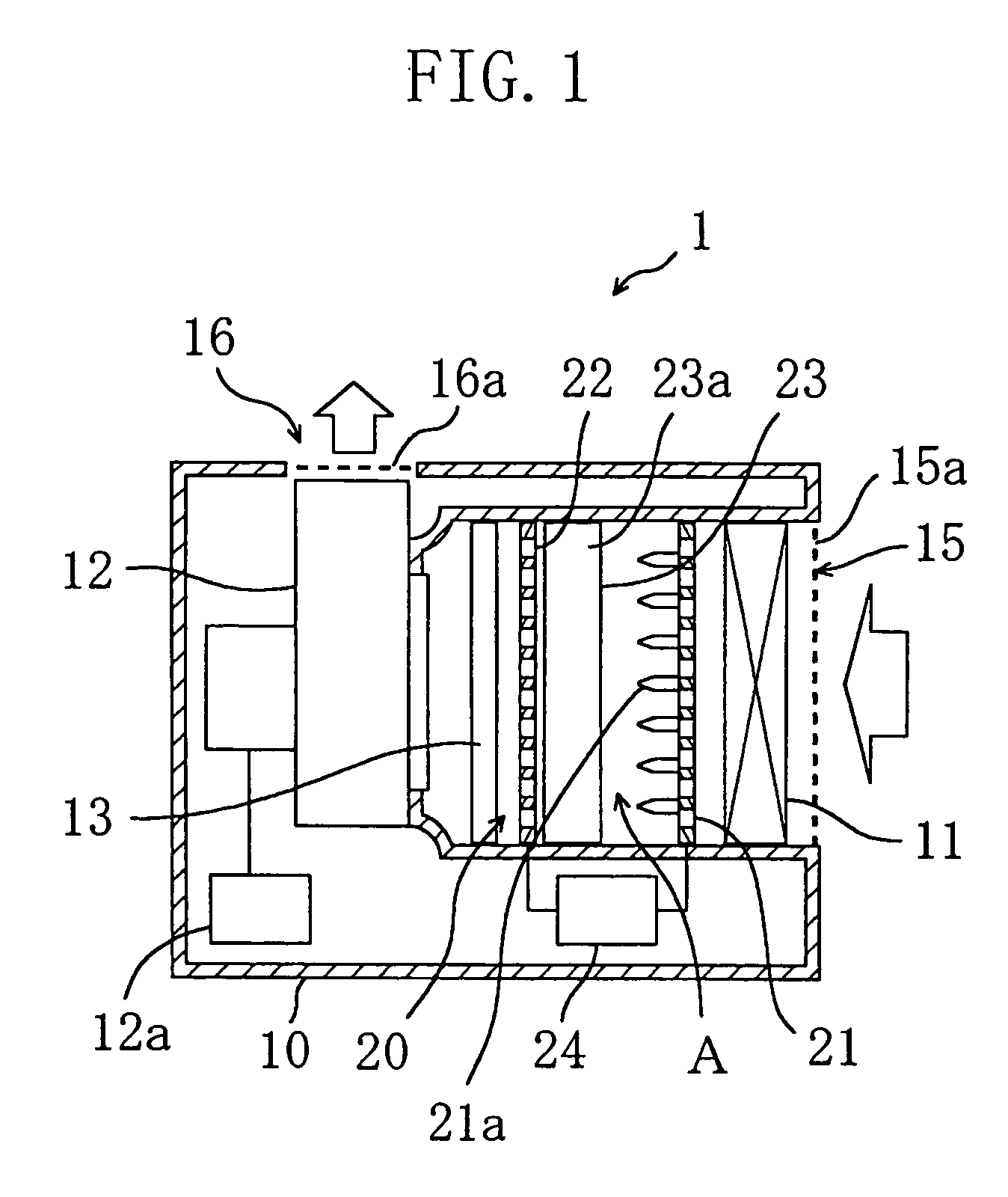

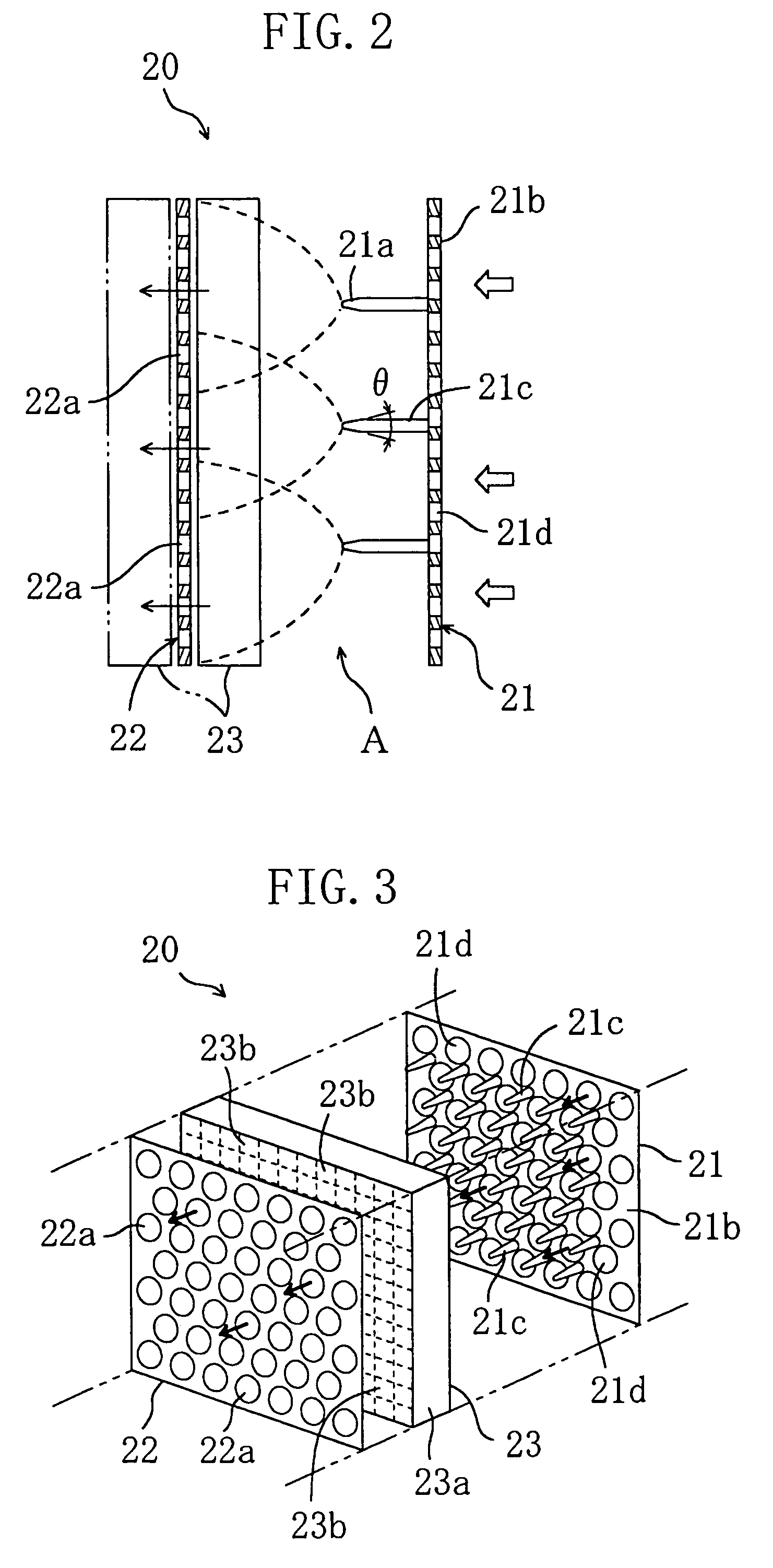

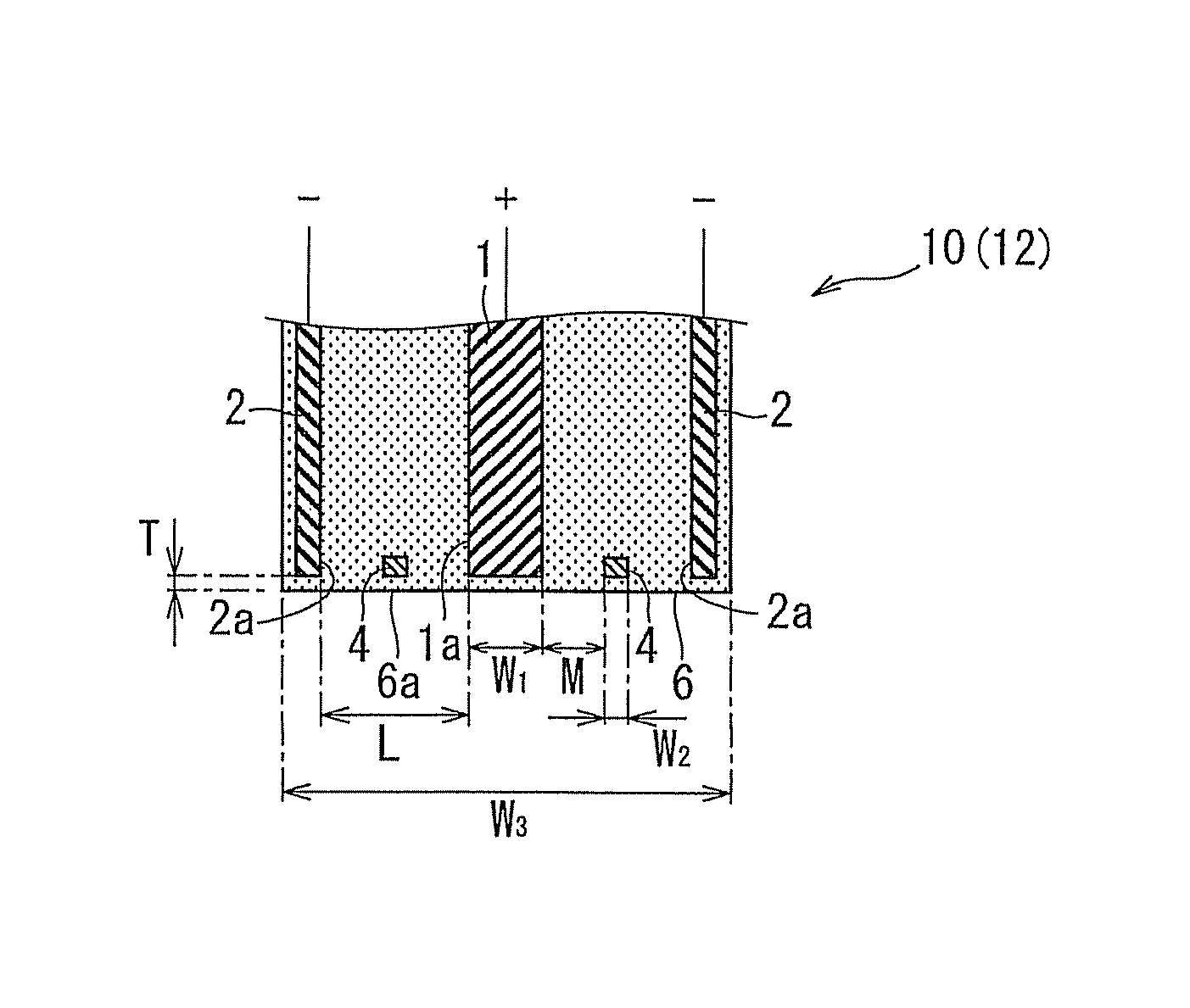

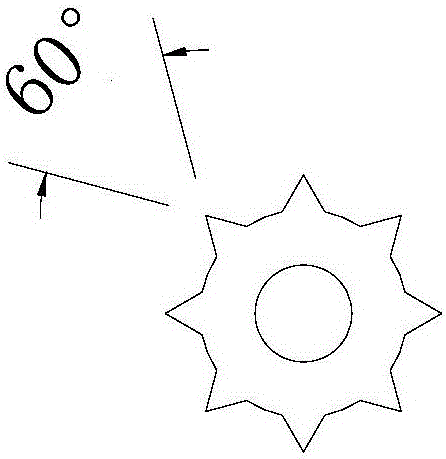

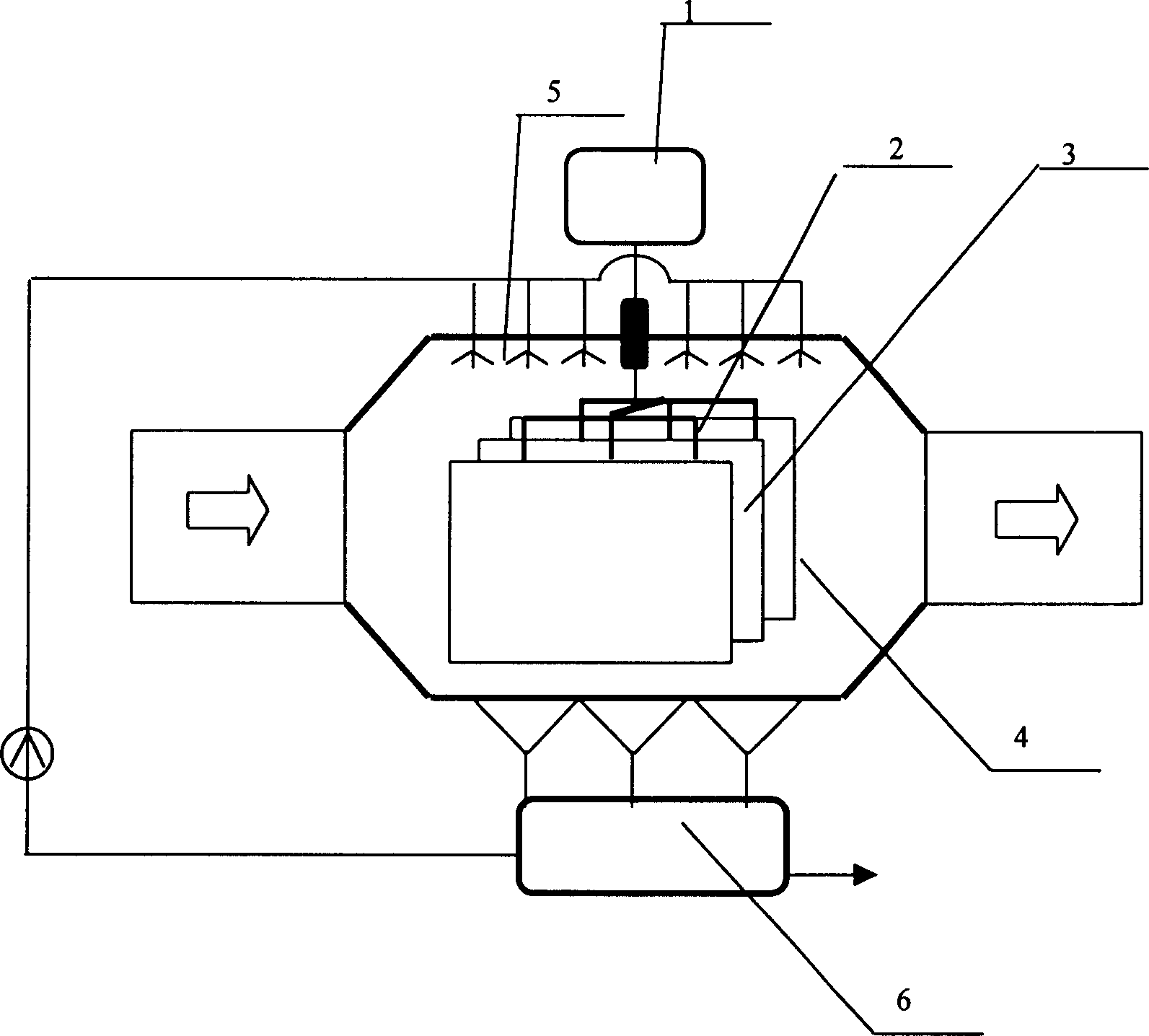

InactiveUS20050174062A1Easily progressGentle fallCombination devicesGas treatmentPlasma reactorNeedle Shape

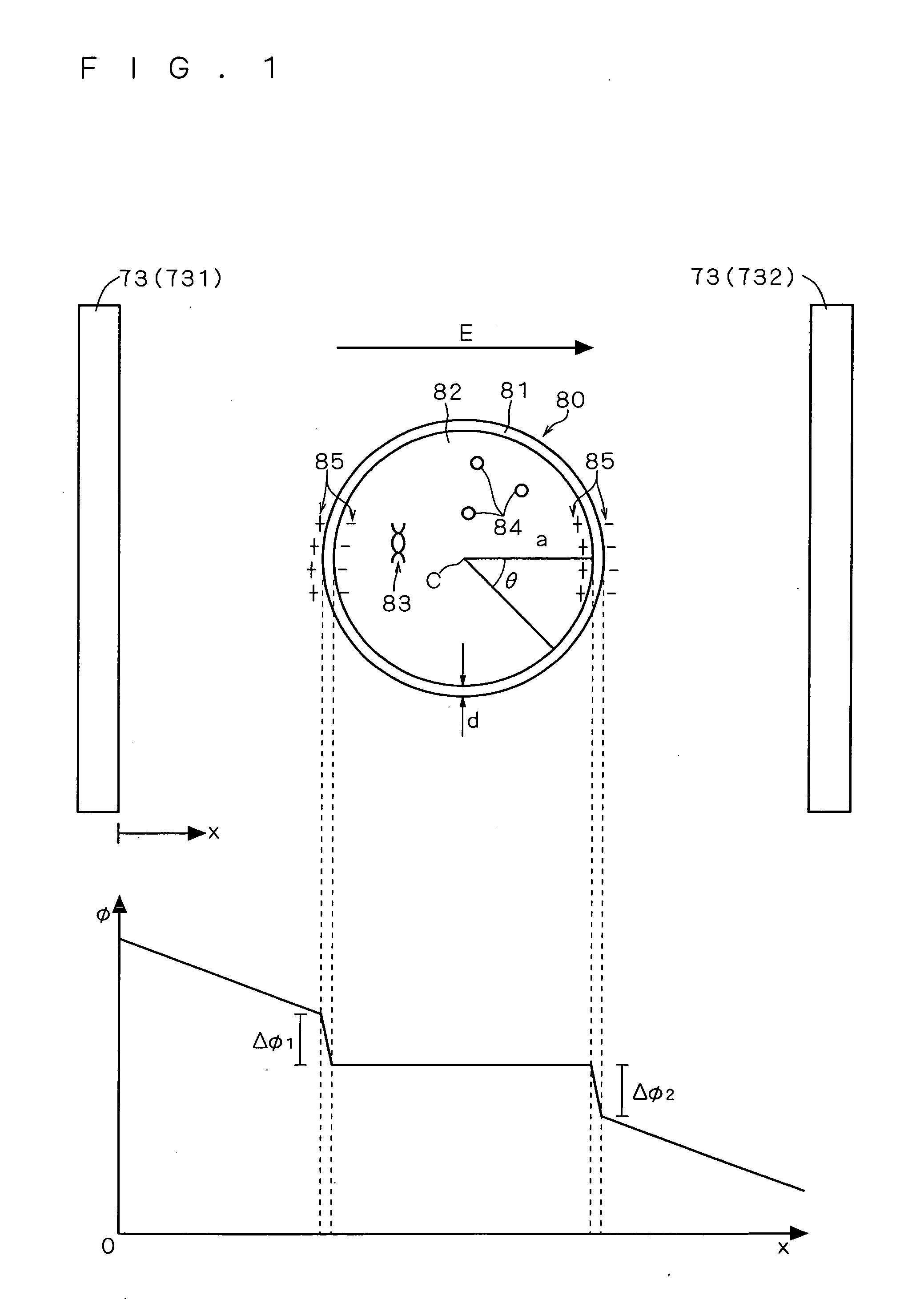

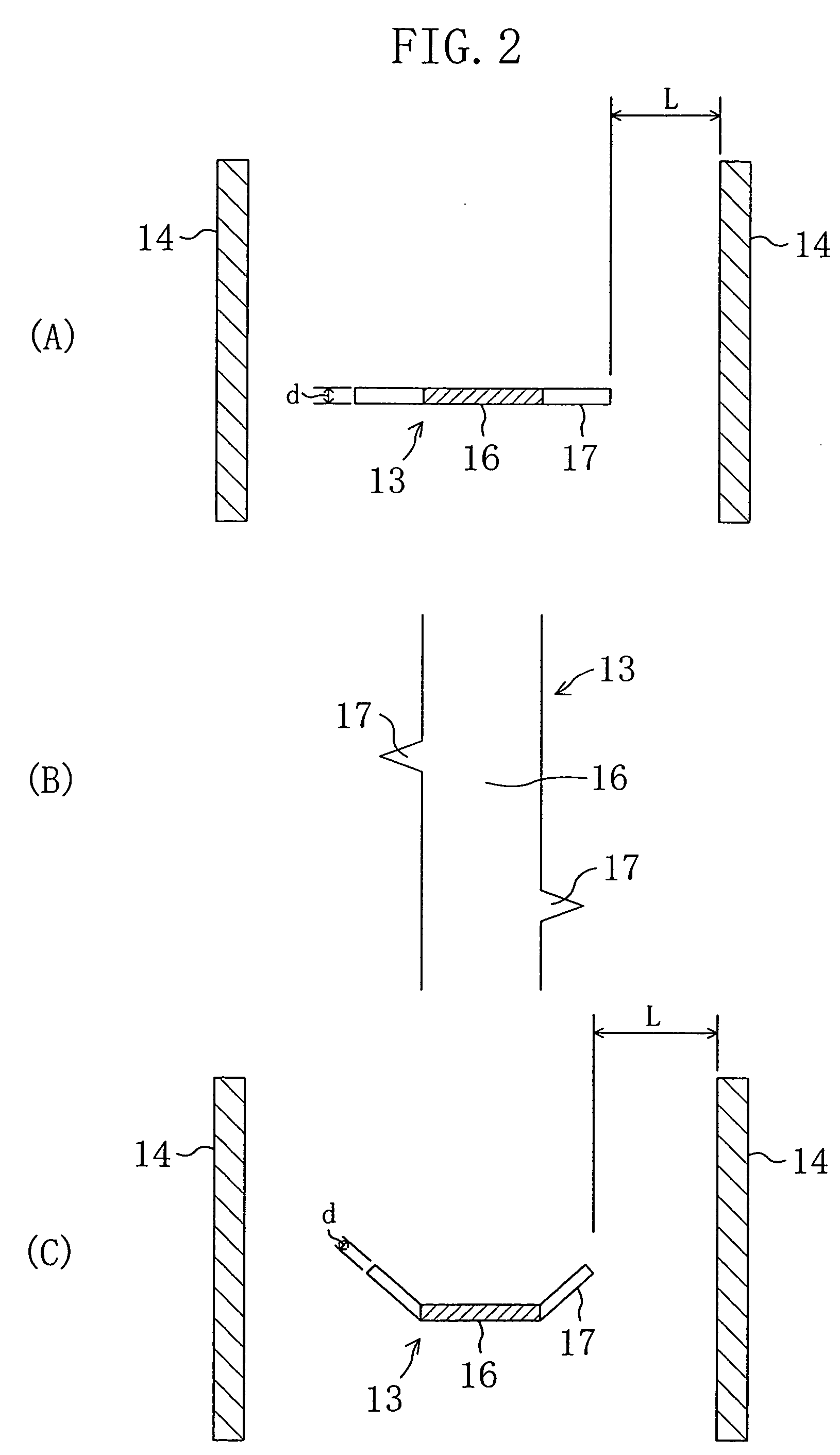

In the plasma reactor of the present invention, streamer discharge is caused in a wide region so as to increase a plasma generation region without complicating the architecture of the plasma reactor and increasing the cost. In the plasma reactor of the invention, a needle-shaped first electrode and a plate-shaped second electrode are disposed to oppose and to be perpendicular to each other, and the first electrode has a pointed portion as the end thereof on the side of the second electrode and the pointed portion has a point angle θ not less than 30 degrees and not more than 90 degrees, and preferably not less than 60 degrees and not more than 90 degrees.

Owner:DAIKIN IND LTD

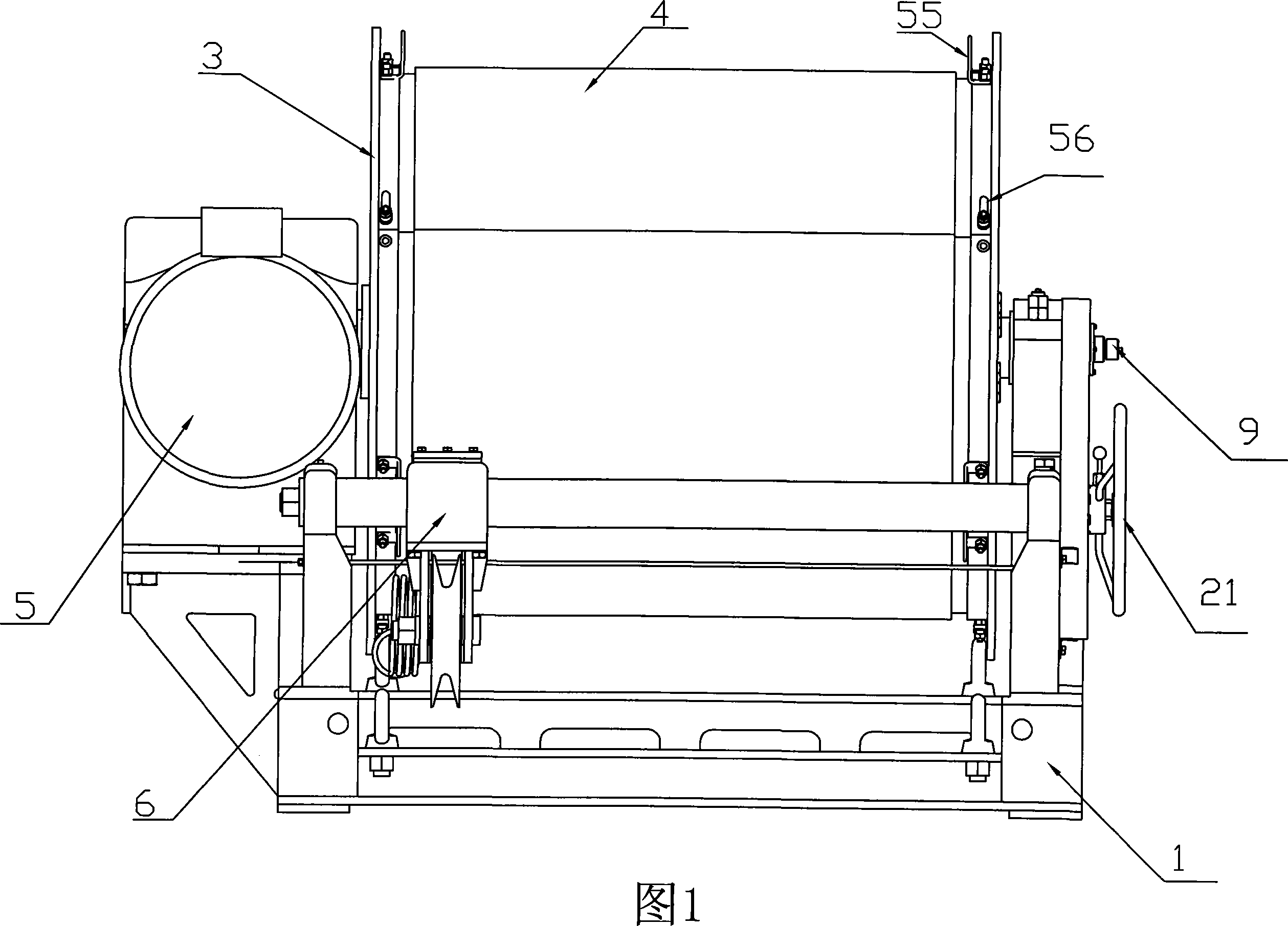

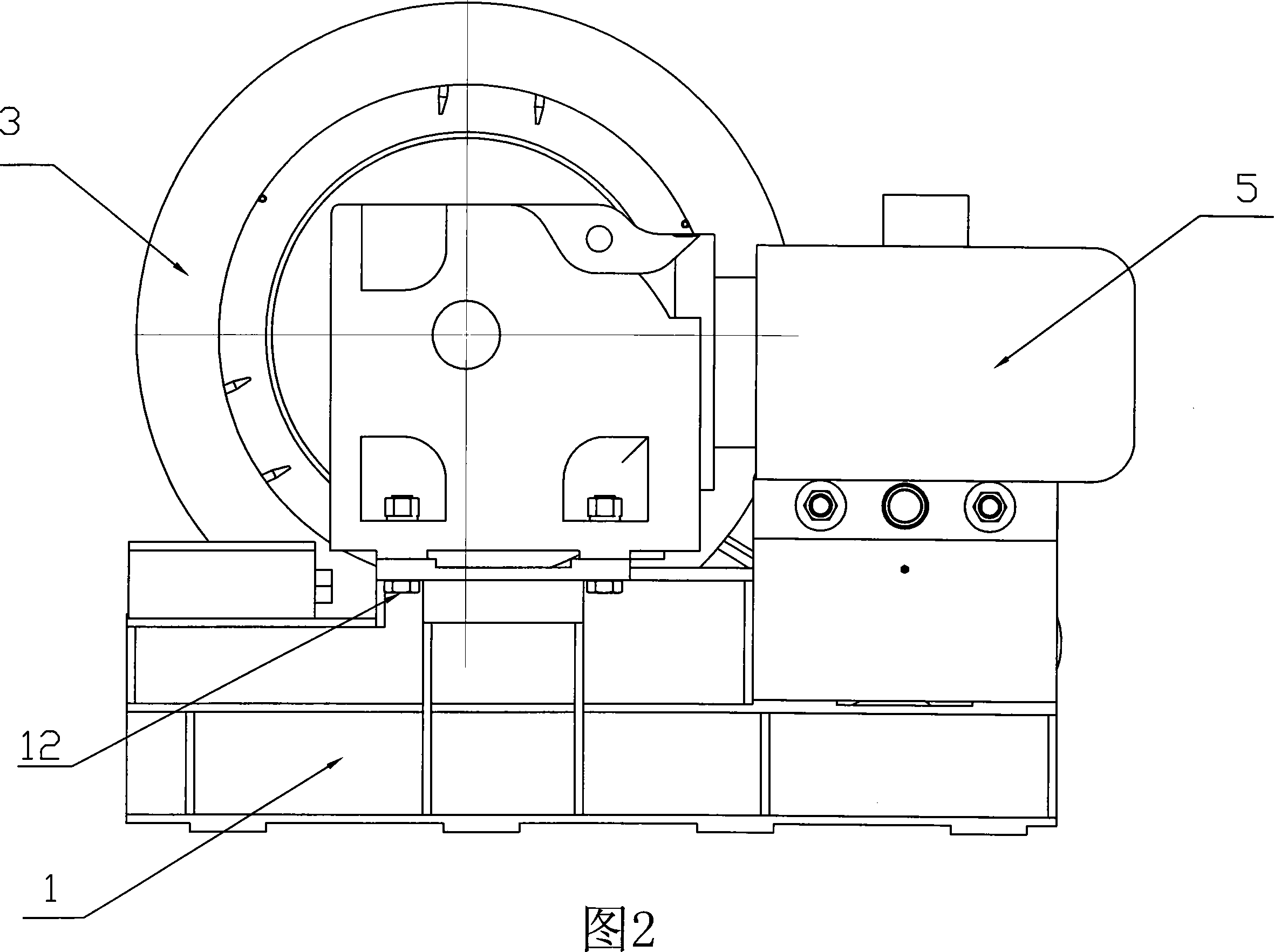

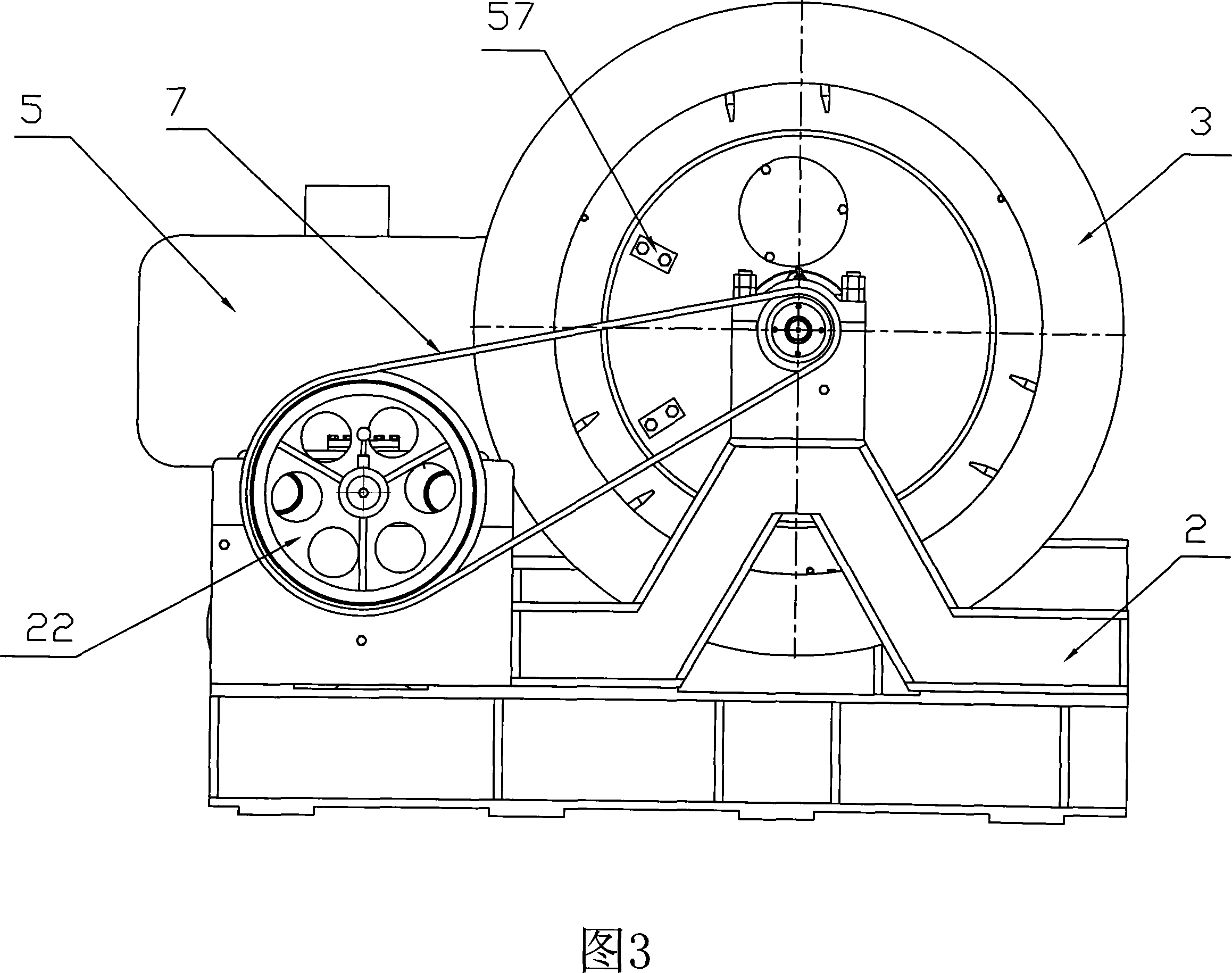

Intelligent towing winch for arranging multi-layer streamline towing line

The invention relates to an intelligent towing winch for arranging multi-layer streamlined tow cables. platform; the integral reel is installed on the base through the wall frame device and the deceleration motor, the split reel is installed on the integral reel, the cable discharge mechanism and the integral reel are installed side by side on the base, and the deceleration The motor transmits the power to the integral reel, and transmits the power to the cable discharge mechanism through the sprocket transmission mechanism; the console is used to control the work of the variable frequency deceleration motor, and displays parameters such as tension, cable length, and speed in real time, forming a complete towing winch. The beneficial effects of the present invention are: providing an intelligent towing winch with multi-layer streamlined towing cables, which makes the winch small in size, light in weight, and reduces the motor rate, thereby improving the suitability and operability of the equipment.

Owner:杭州瑞利海洋装备有限公司

Gas treating device

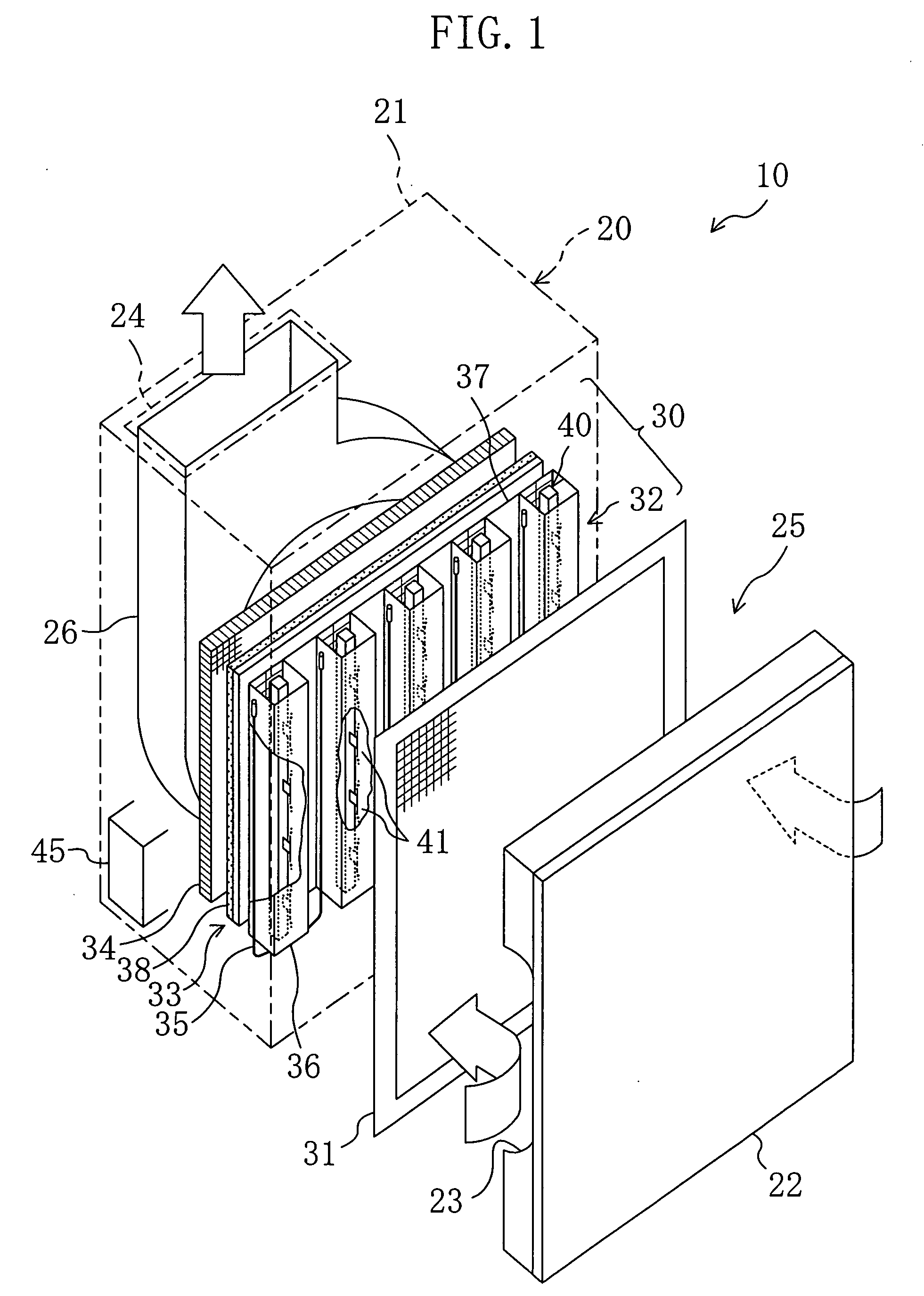

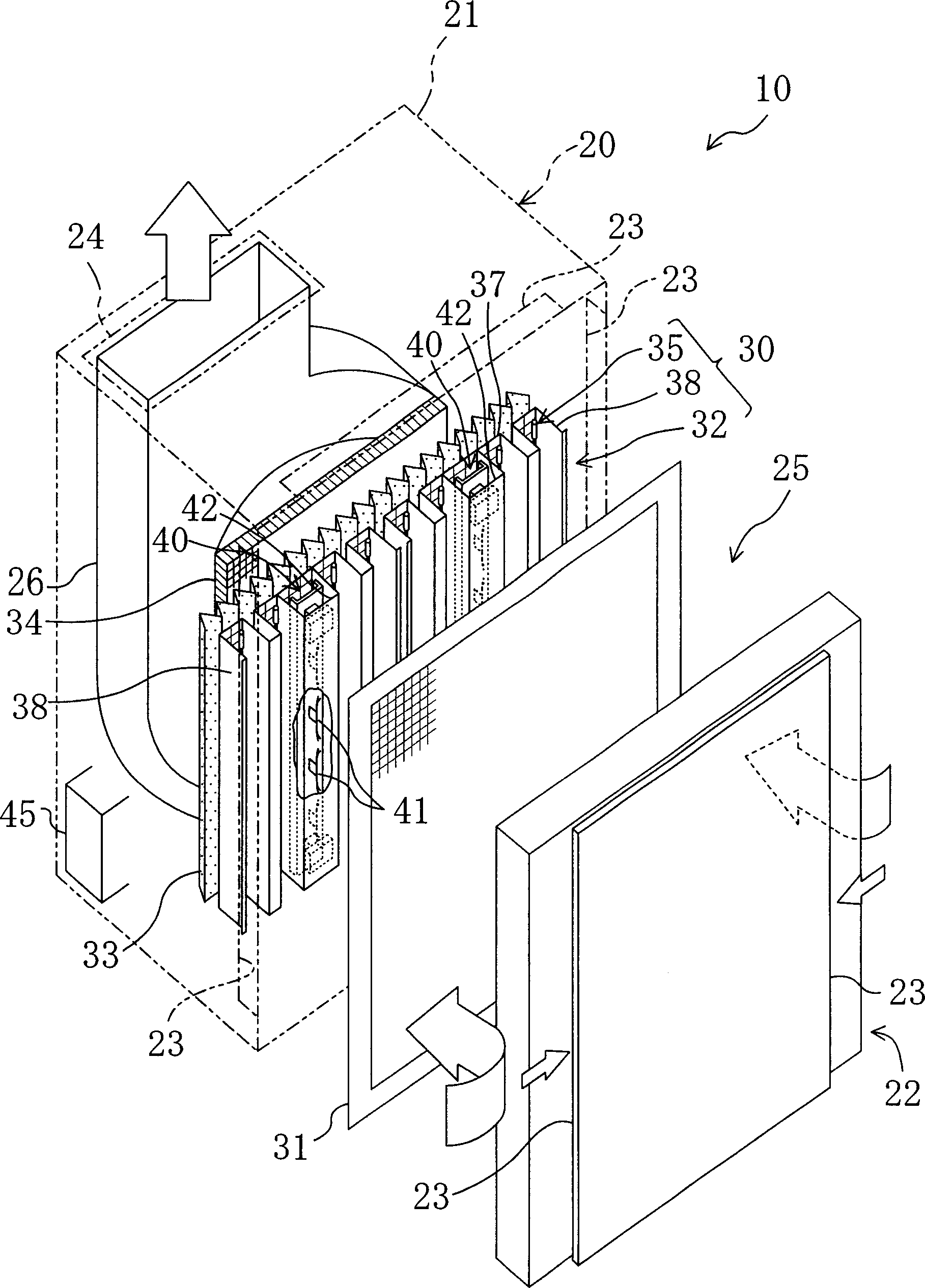

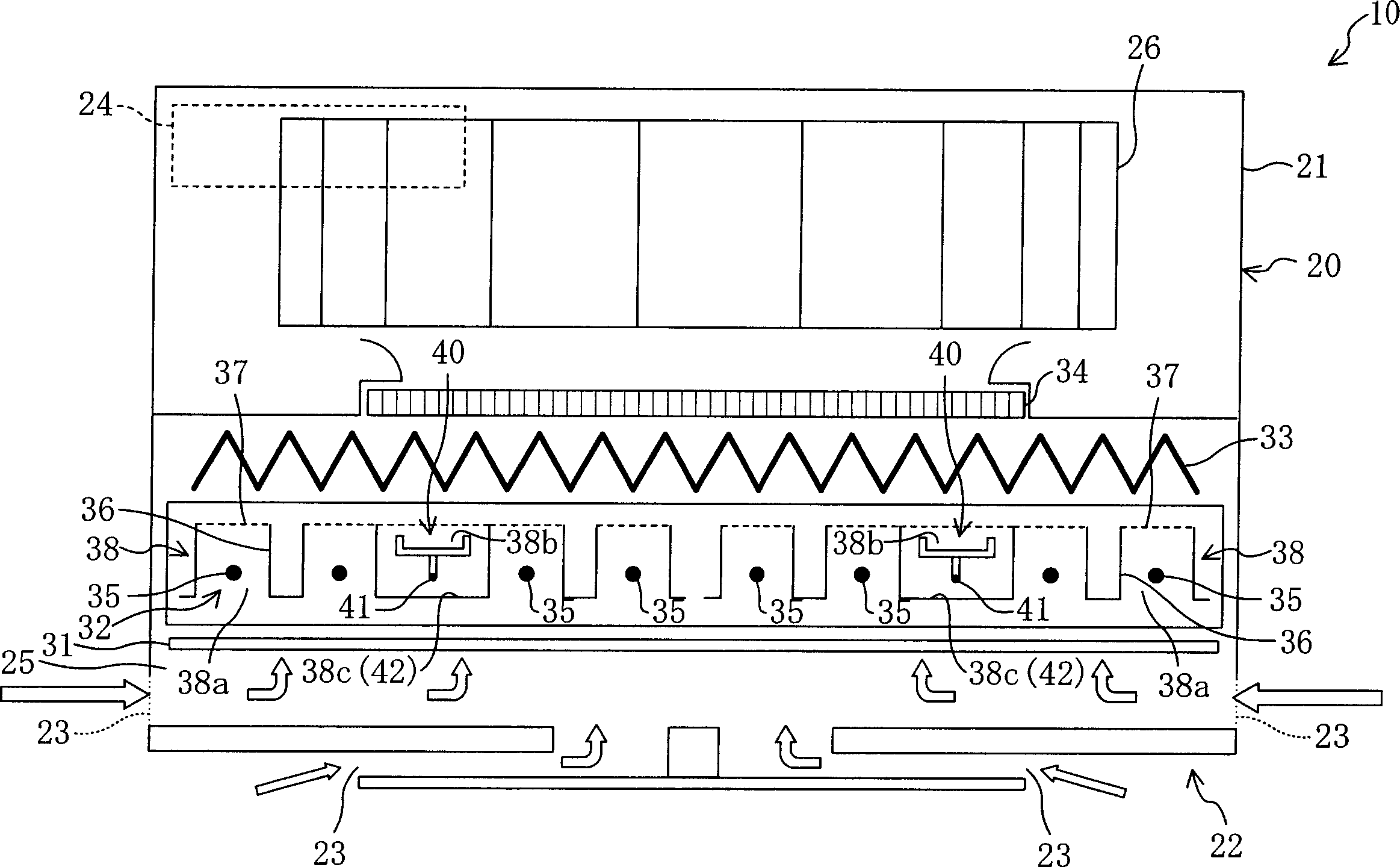

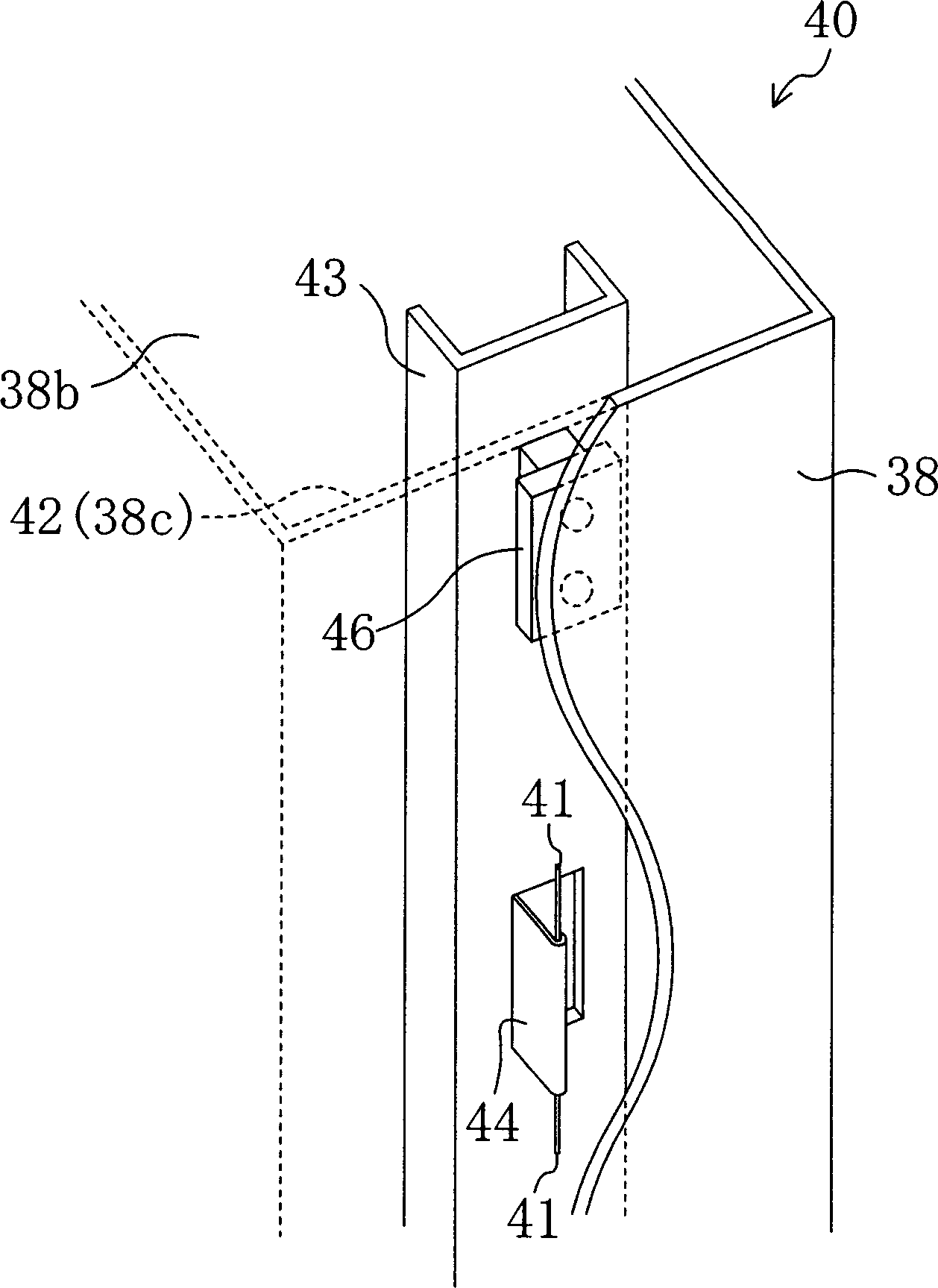

InactiveUS7332020B2Improve reliabilityReduced space requirementsEnergy based chemical/physical/physico-chemical processesElectrode constructionsElectricityHazardous substance

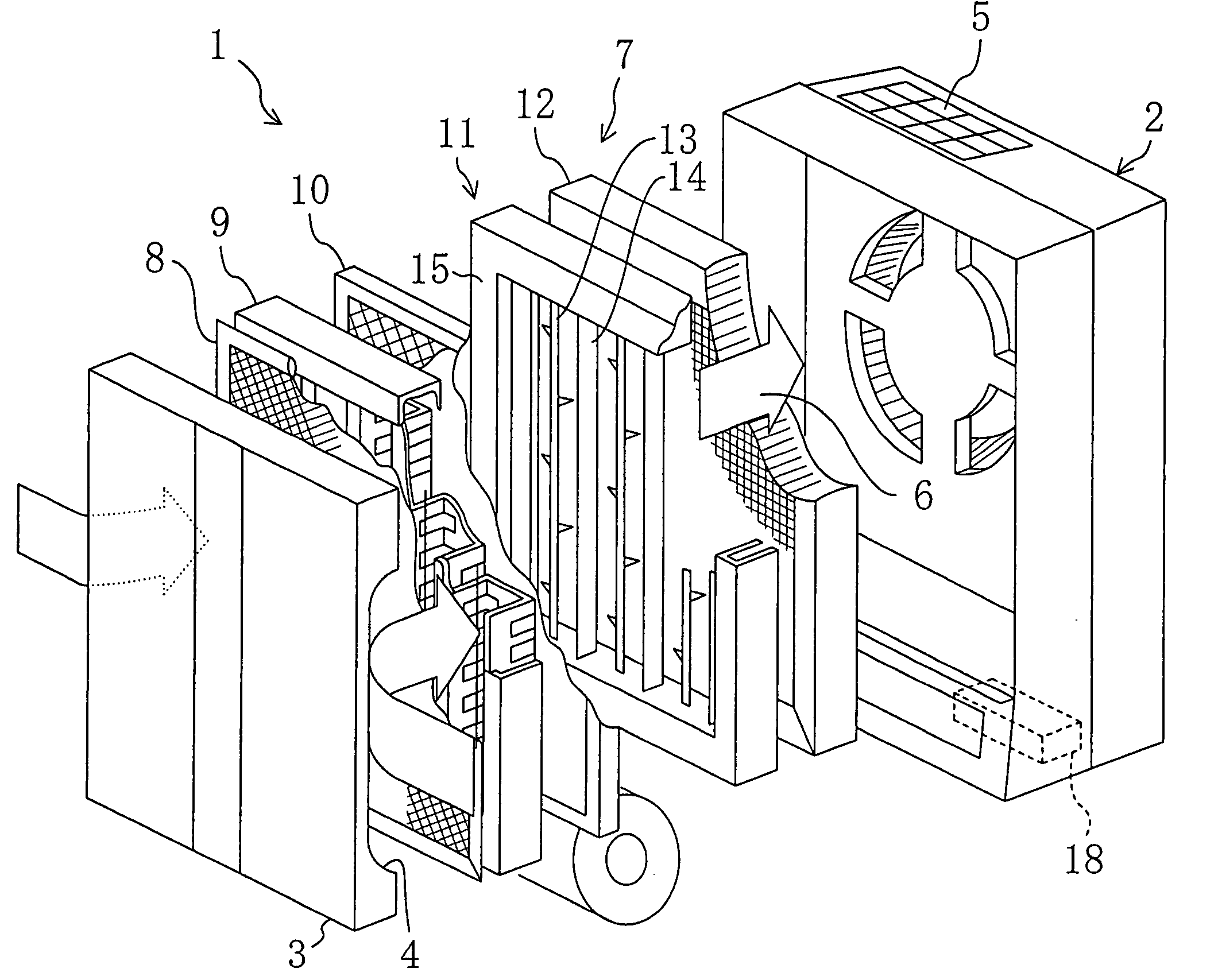

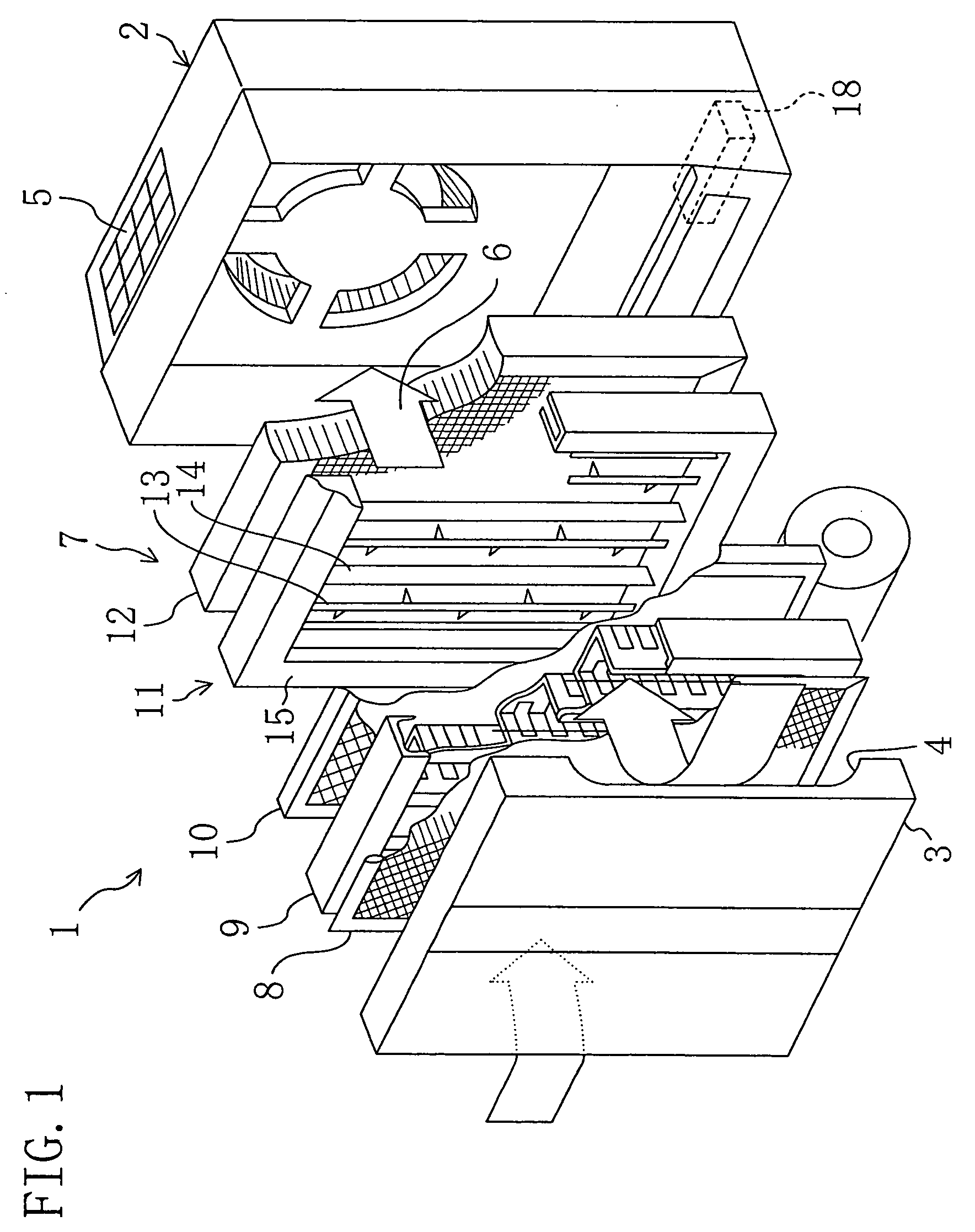

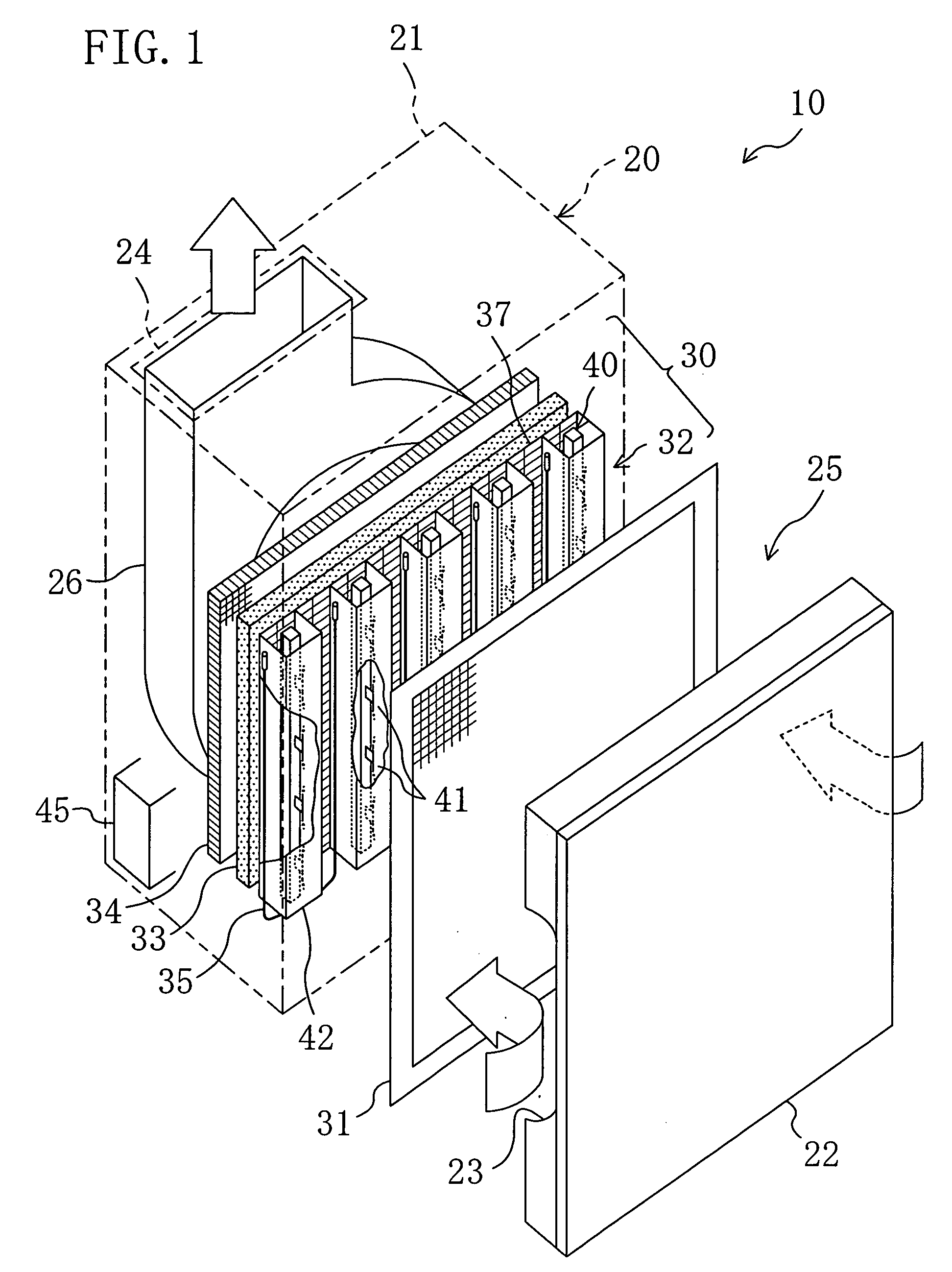

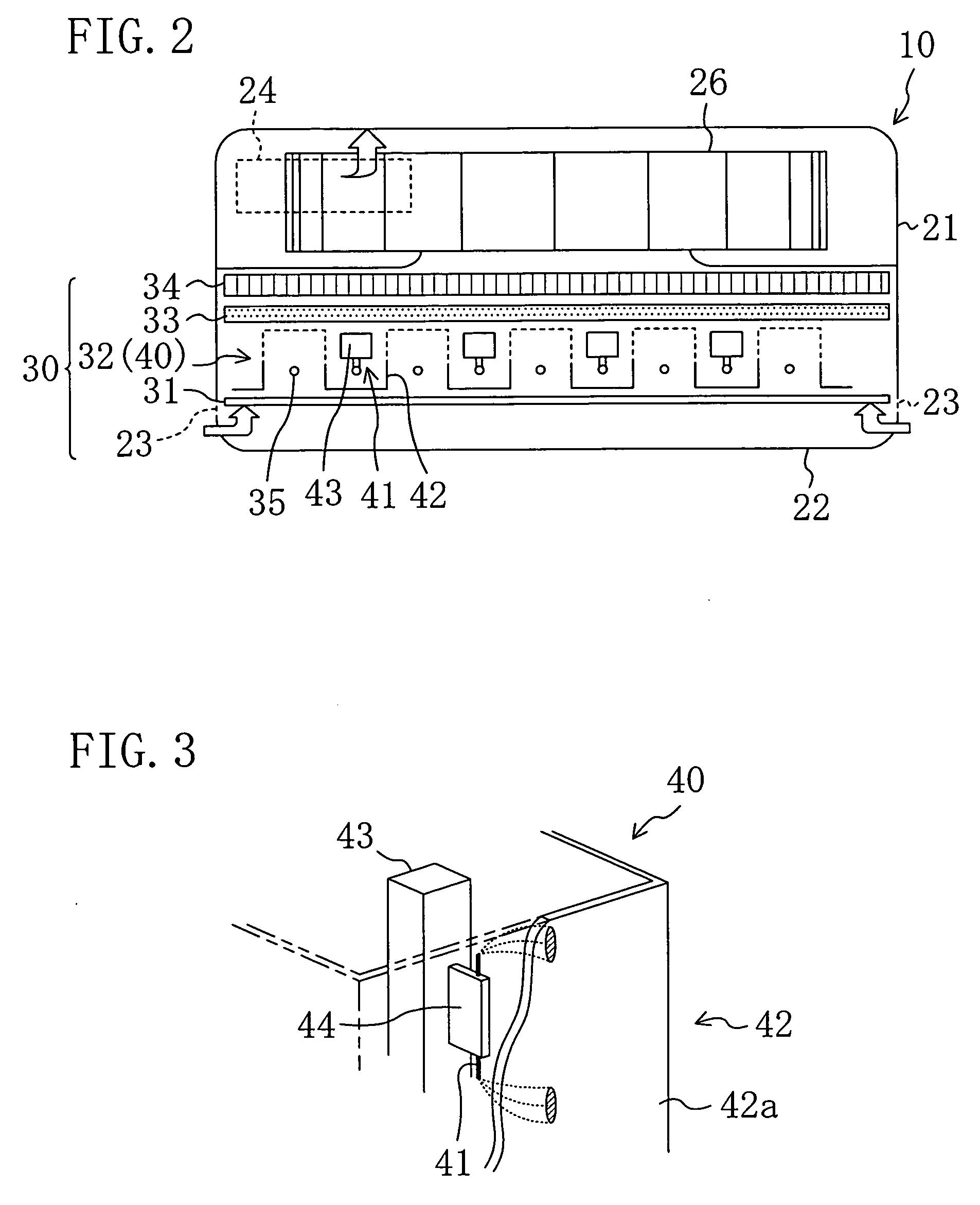

A gas treating device capable of electrically collecting dust and of decomposing odors and other matter by plasma includes a plasma generating device integrally incorporated into an ionization part in a casing. The ionization part has an ionization line and a columnar portion of a negative electrode member. The plasma generating device includes a discharge electrode which shares a counter electrode with the ionization line. During operation, dust of a relatively small size in room air is electrically charged by discharge between the ionization line and the counter electrode. An electrostatic filter entraps and collects the electrically charged dust. A plasma of low temperature is generated by streamer discharge between the discharge electrode and the counter electrode. Harmful substances and odorous substances in the room air are decomposed by an activated species contained in the generated low-temperature plasma.

Owner:DAIKIN IND LTD

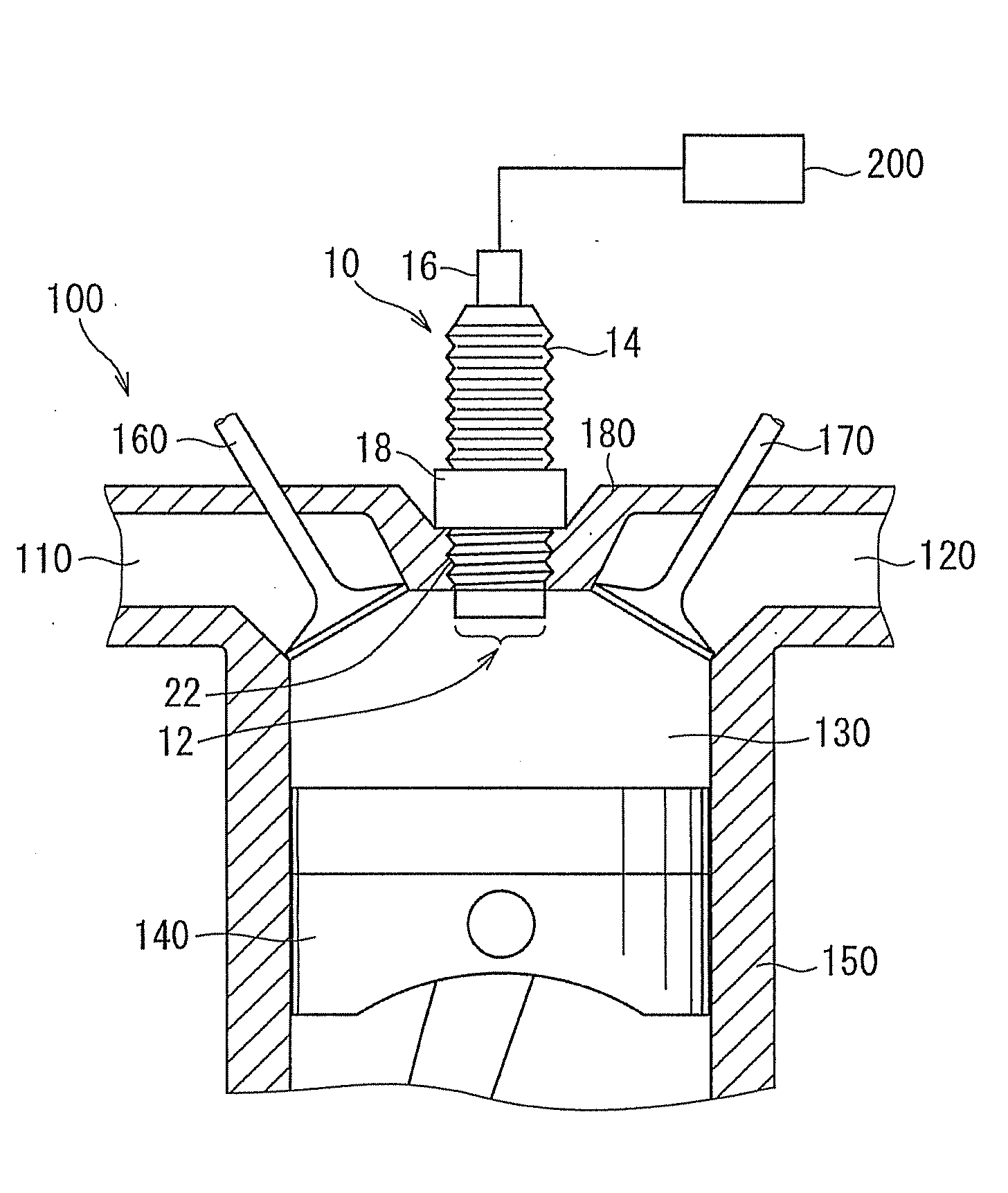

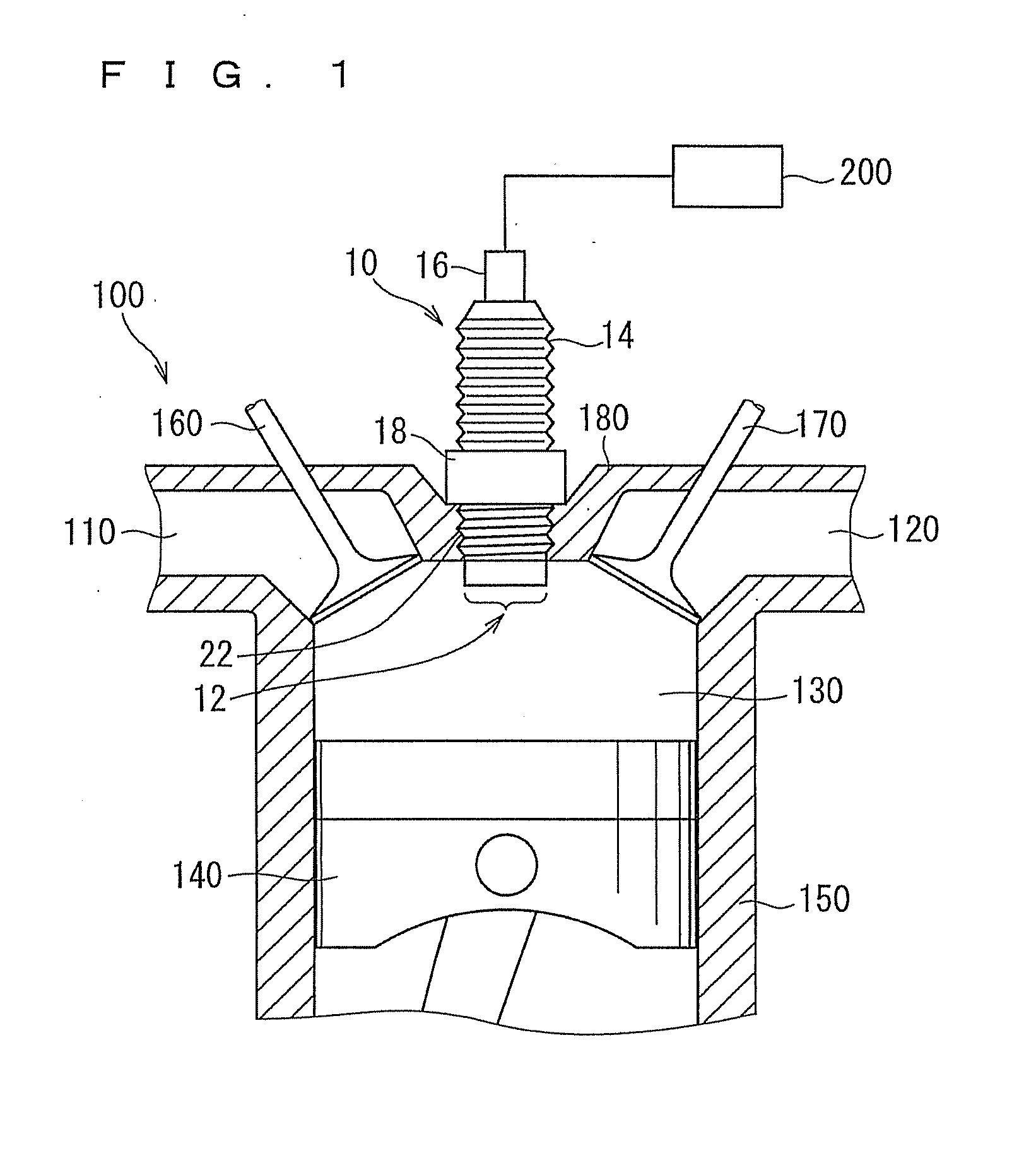

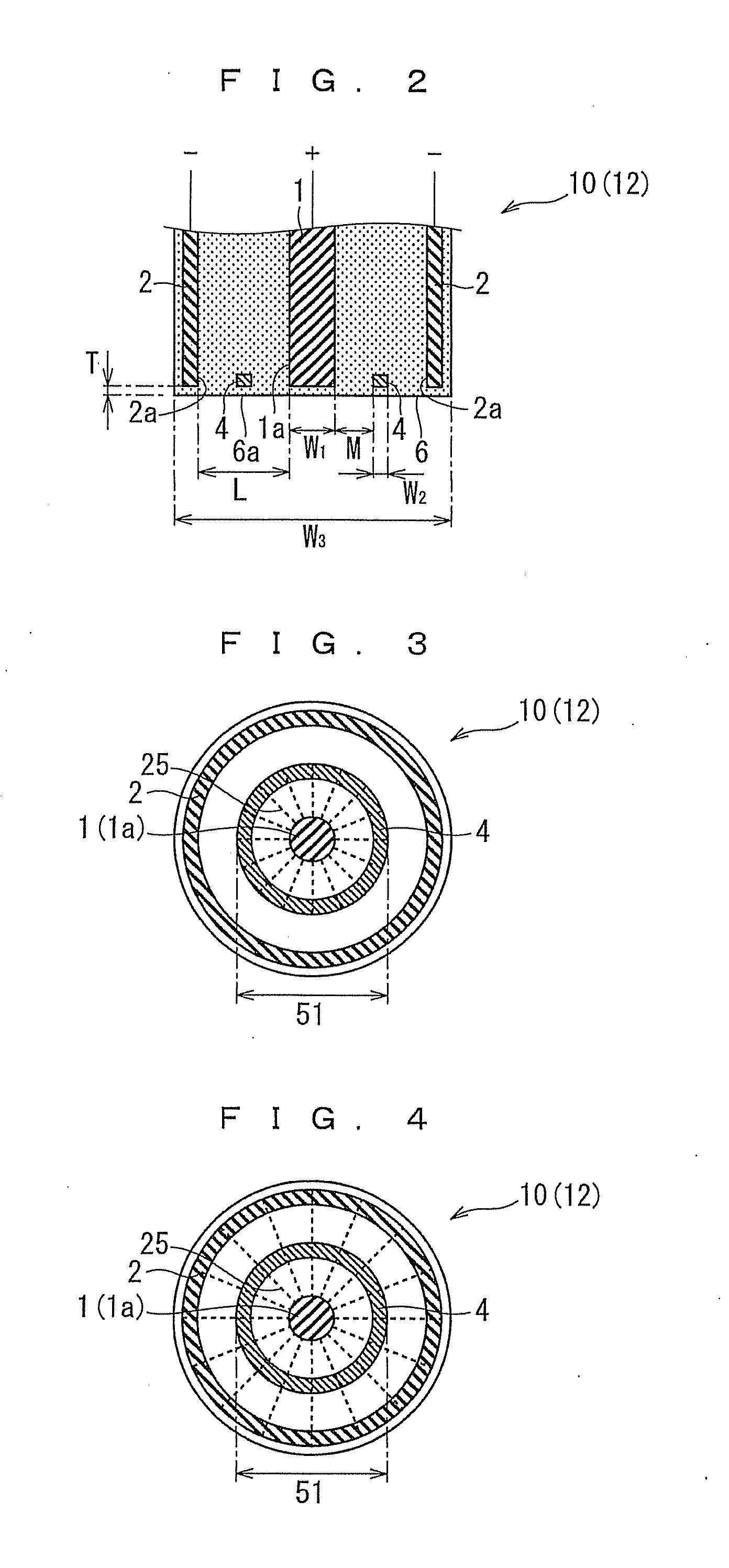

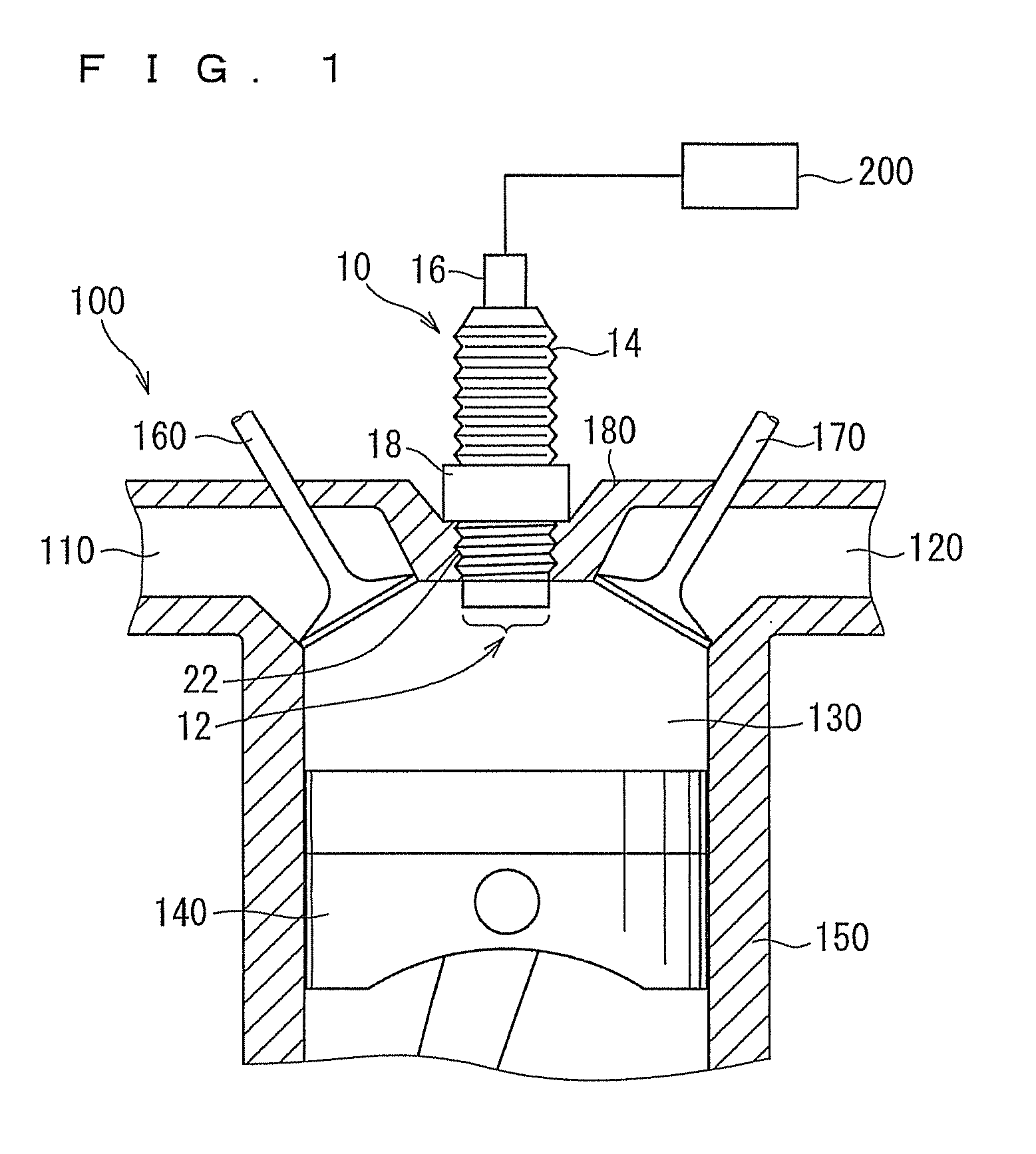

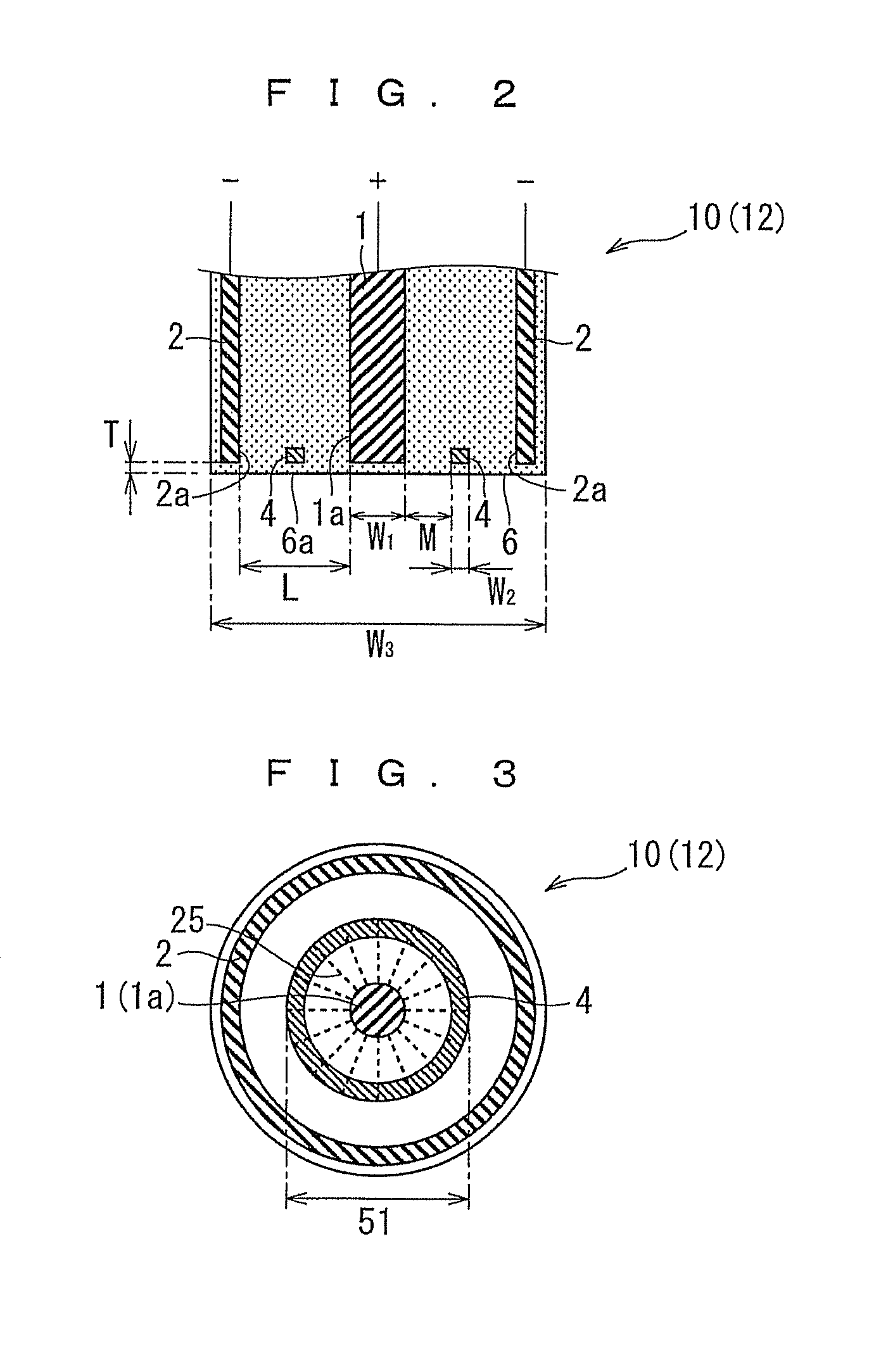

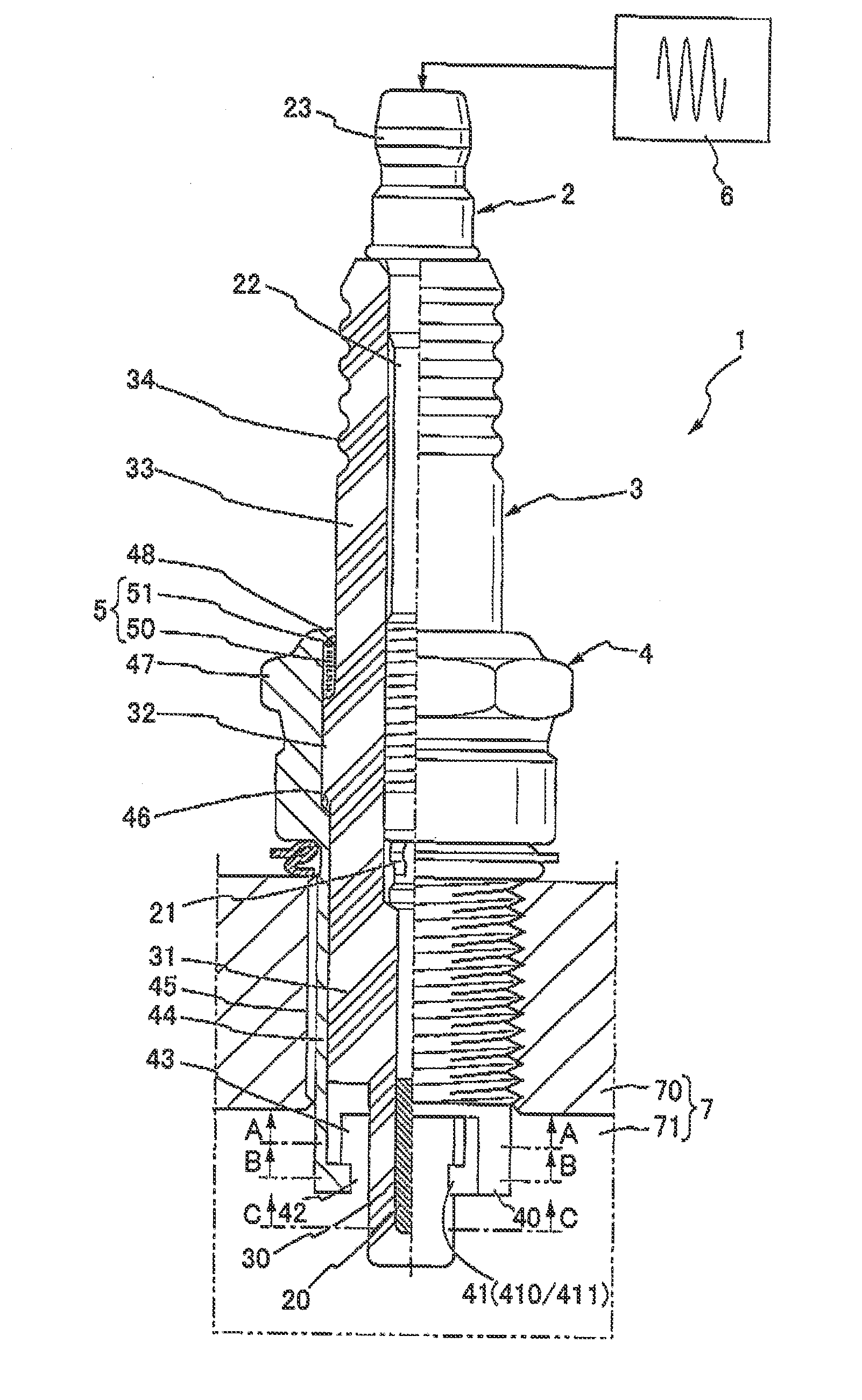

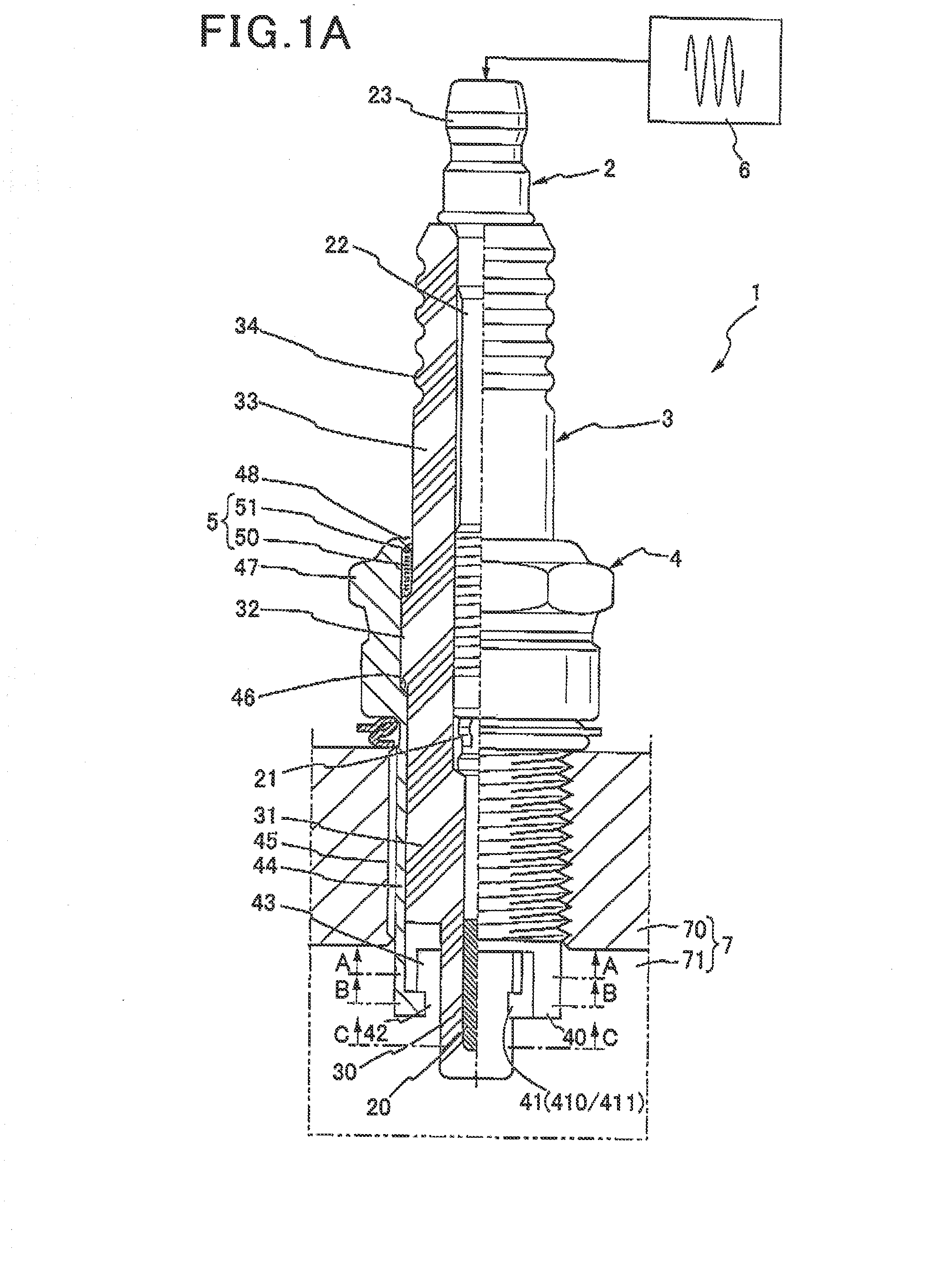

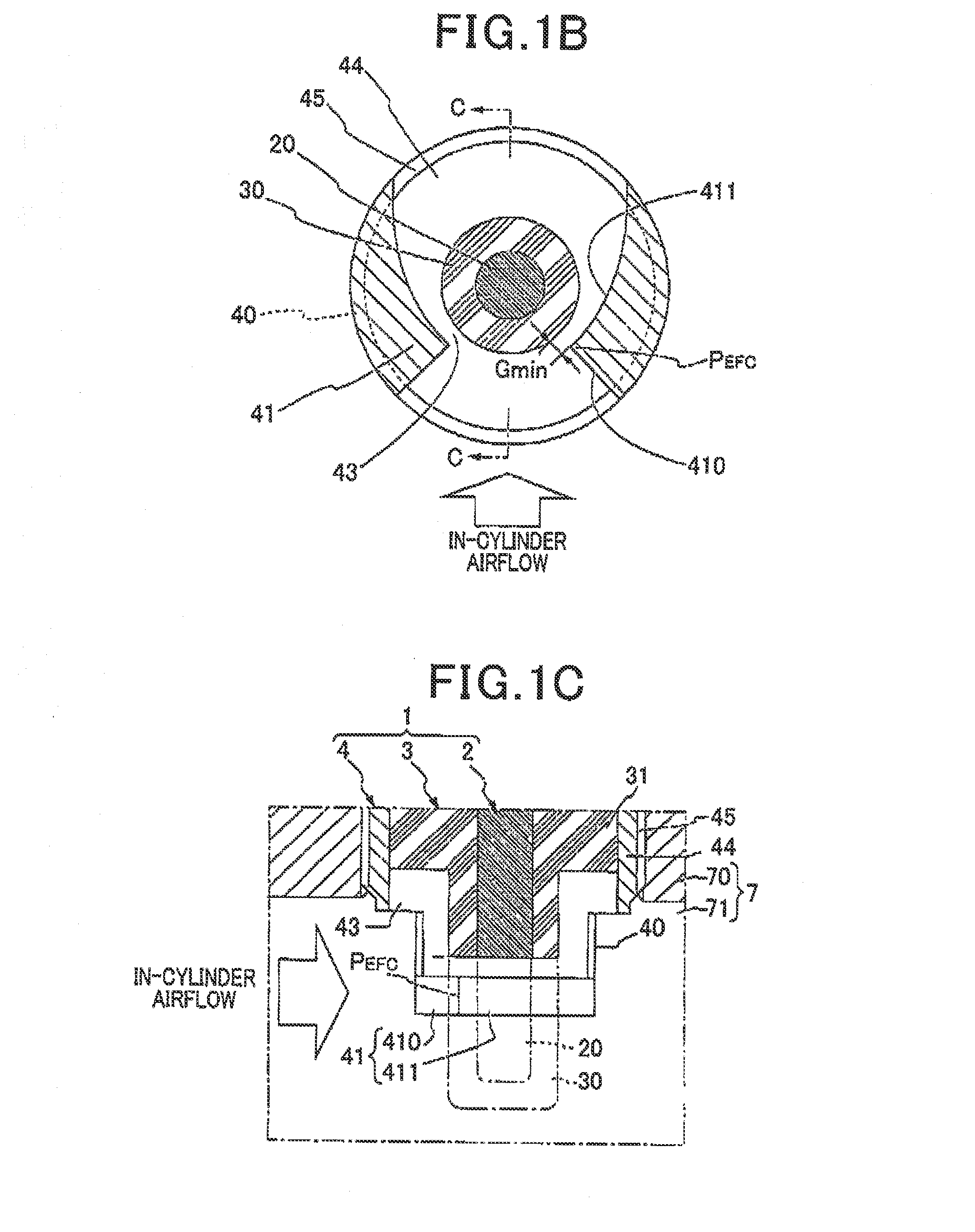

Plasma igniter and ignition device for internal combustion engine

InactiveUS20100212620A1Reduced areaLow degreeSparking plugsCombustion enginesCombustion chamberLow voltage

To provide a plasma igniter capable of generating a discharge such as a pulse streamer discharge in a large region even by application of a low voltage, implementing powerful ignition by pulse voltage application in two or more stages, improving an air-fuel ratio (A / F), and reducing a CO2 emission amount.A plasma igniter includes an igniter part having a combustion chamber, and a discharge part arranged in such a manner that its discharge tip end is exposed to the combustion chamber. The discharge tip end has a column-shaped anode, an annular cathode arranged to be a predetermined interval away from an anode tip end part, and an annular floating electrode arranged between the anode tip end part and the cathode.

Owner:NGK INSULATORS LTD

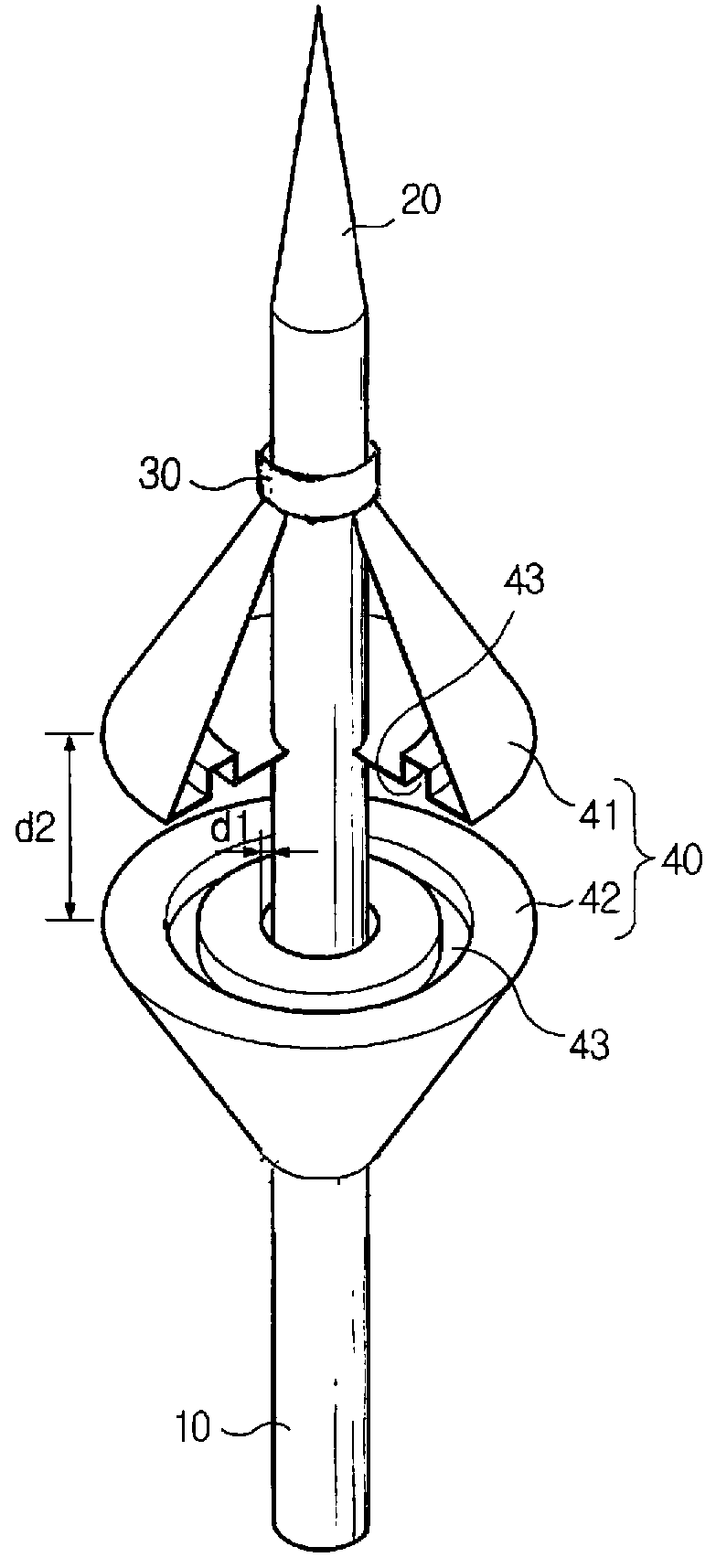

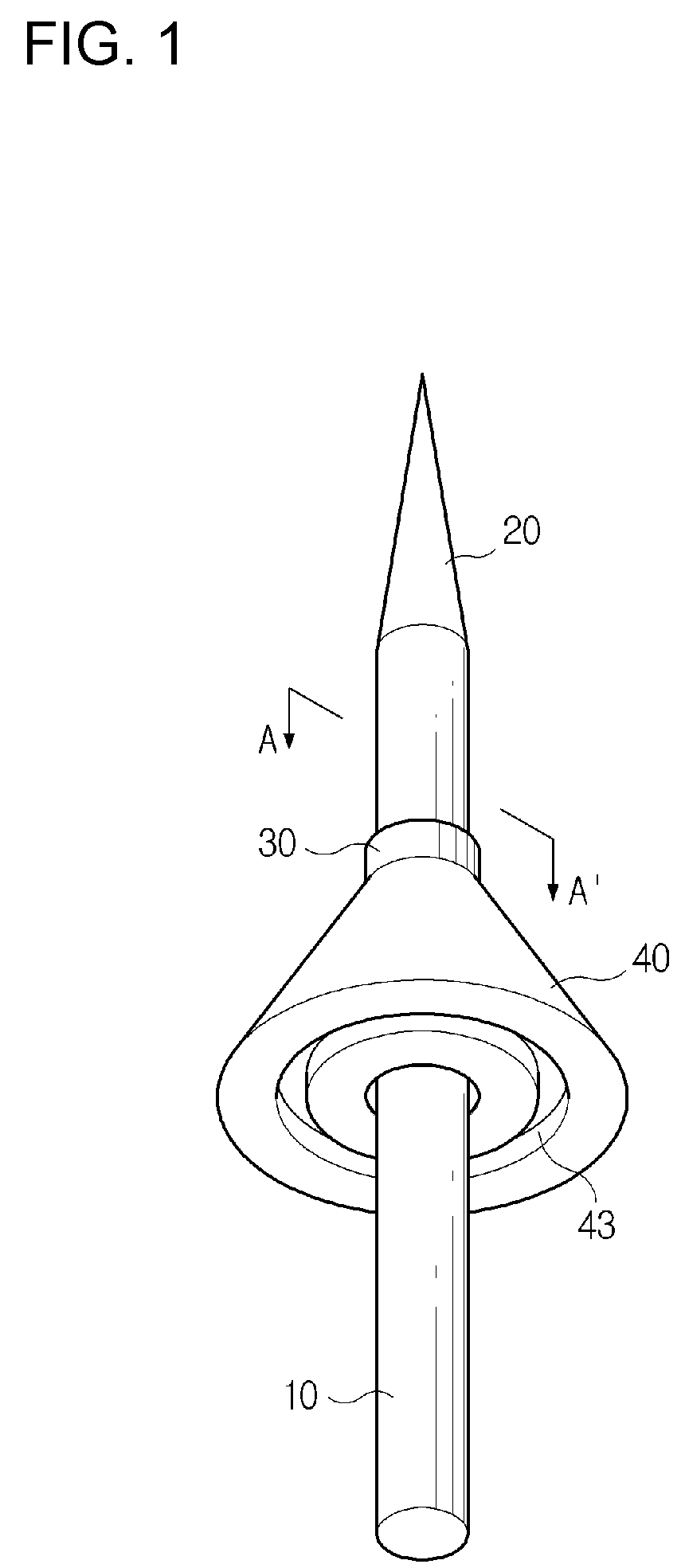

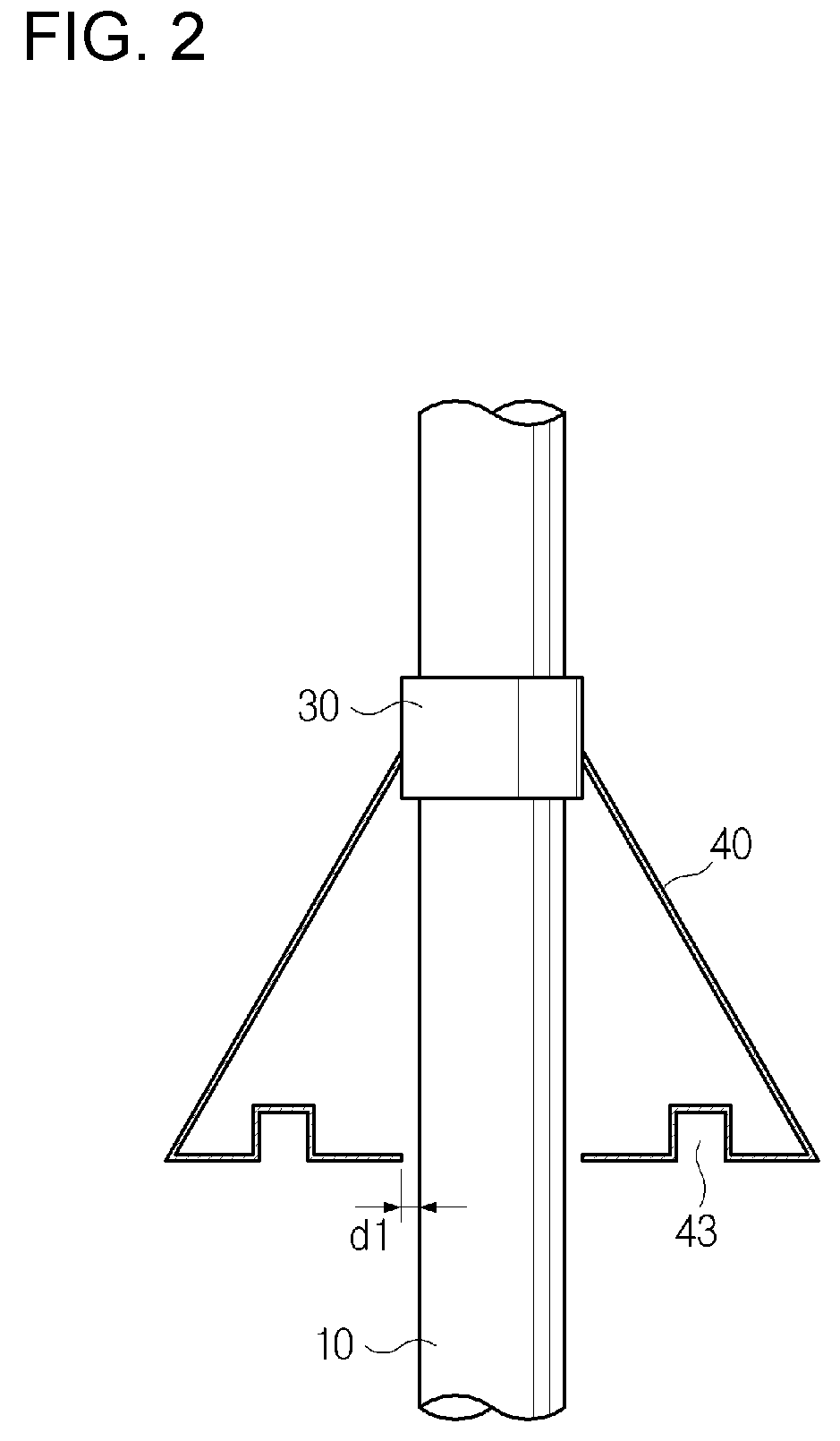

Electric dipole streamer discharge type lightning conductor

InactiveUS7495168B2Casings/cabinets/drawers detailsEmergency protective arrangement detailsElectrical conductorElectric discharge

Disclosed therein is an electric dipole streamer discharge type lightning conductor, which can gather electric charges in the atmospheric air at one side thereof and generate an electric discharge due to a dielectric breakdown when a potential difference is formed between the electric charges gathered by an electric dipole and the electric charges of the earth so as to emit a great deal of electric charges of the earth toward thunderclouds to thereby induce a thunderbolt.

Owner:SUNKWANG LIGHTNING PROTECTION TECHN INST

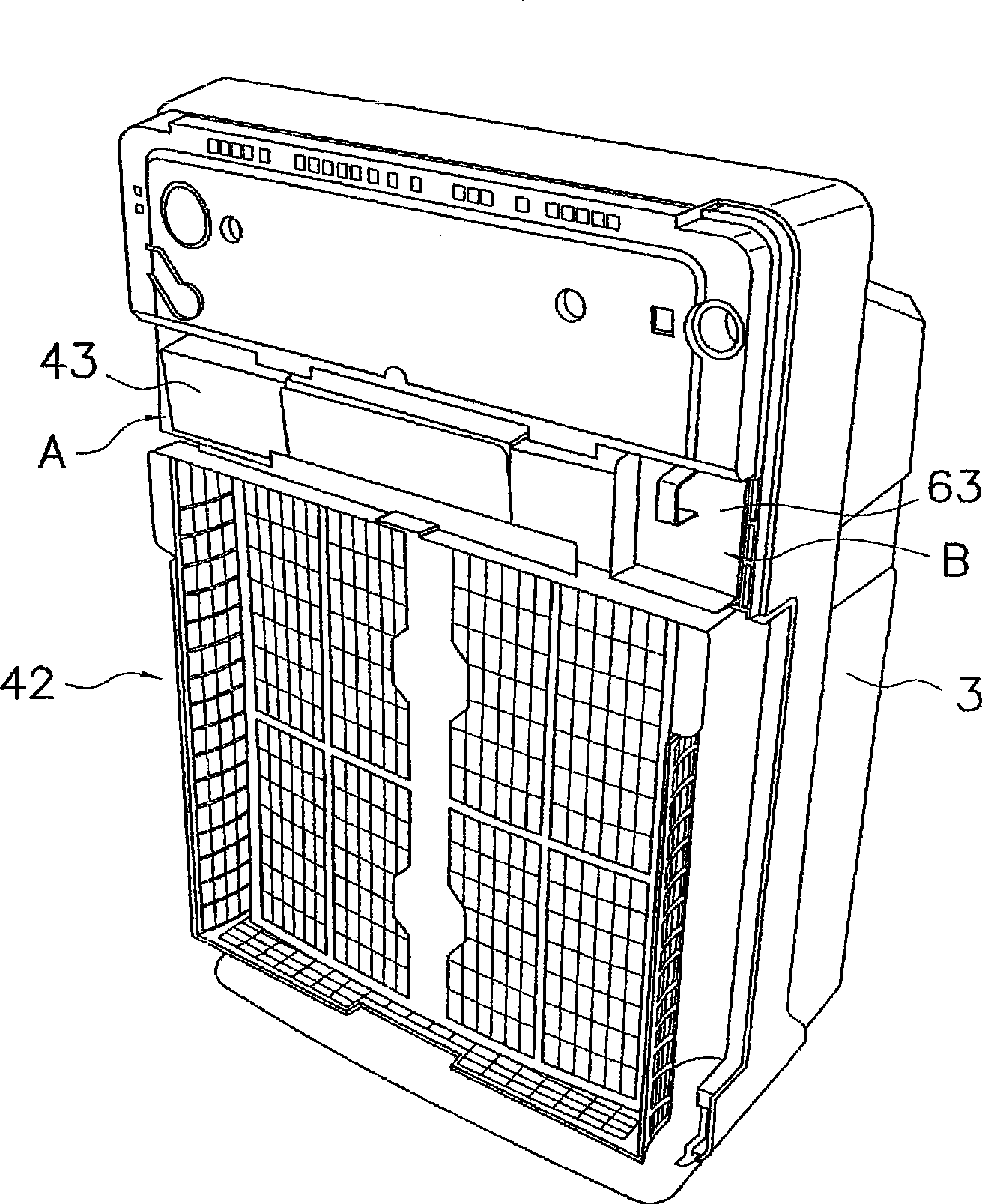

Discharge device and air purifier

InactiveUS7270698B2Reduce noiseImprove performanceMechanical apparatusElectrical apparatusAir purifiersHearing perception

The distance between a discharge electrode and a counter electrode of a discharge device is set to not more than 10 mm such that a streamer discharge is caused between the electrodes. The frequency of sound made by the streamer discharge is raised to 6 kHz or higher to exceed the frequency range which is easily perceivable by human hearing.

Owner:DAIKIN IND LTD

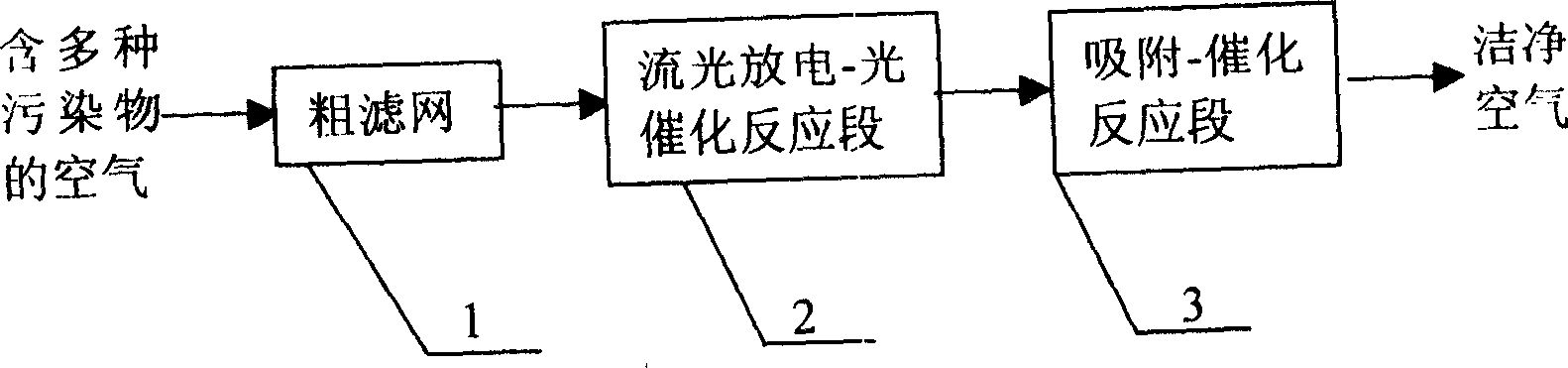

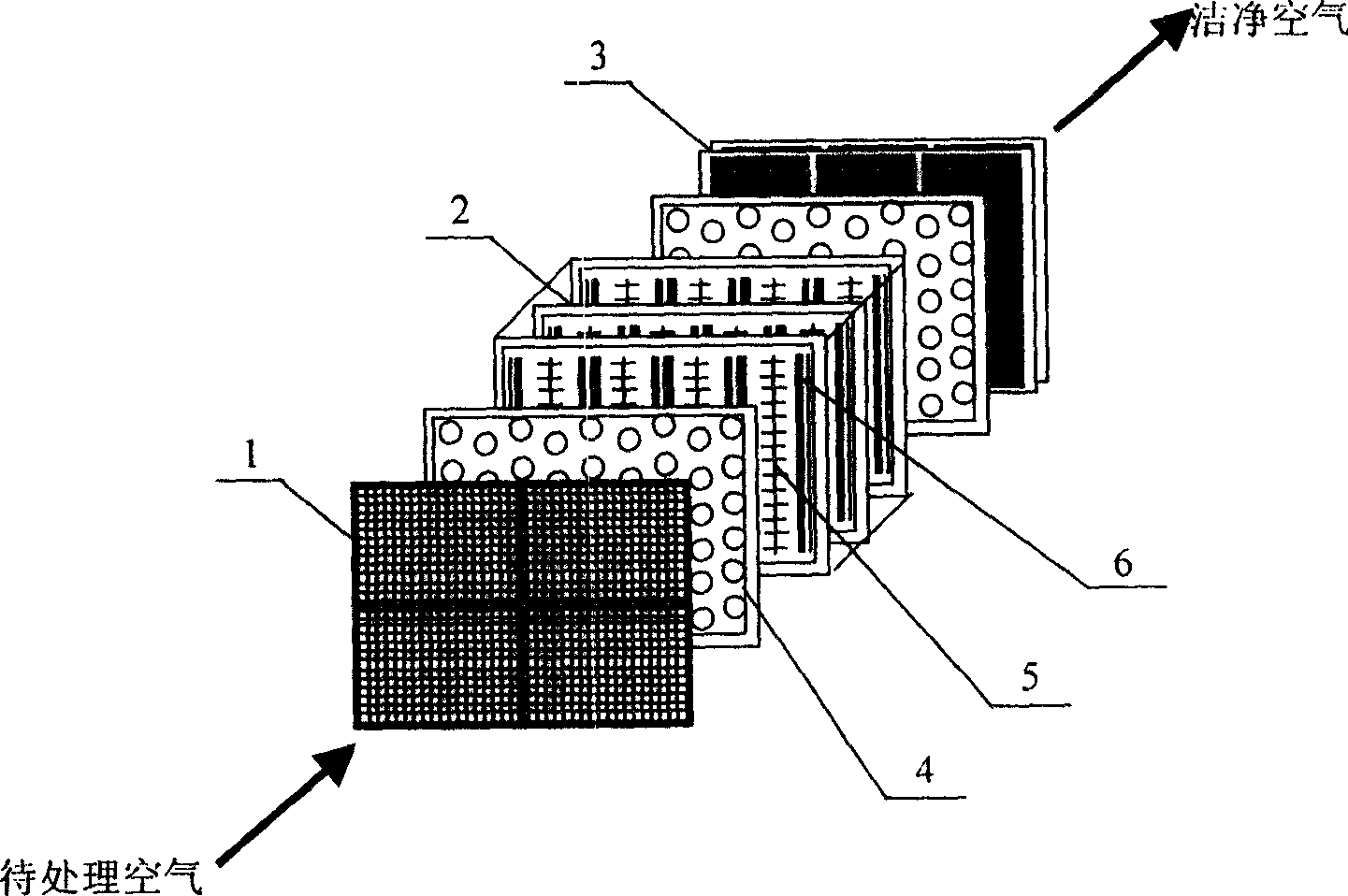

Method of cleaning air pollutant using synergistic action of streamer discharge and photo catalysis

InactiveCN1597068AEasy to separateEfficient PurificationLighting and heating apparatusDispersed particle separationParticulatesPhotocatalytic reaction

A method for removing pollutants from air by use of both streamer discharging and photocatalysis features that under the drive of blower, the air to be treated sequentially through coase net filter, streamer, discharge-photocatalysis reaction segment, and adsorption-catalysis reaction segment to exhaust clean air.

Owner:朱天乐 +2

Plasma reactor and purification equipment

In the plasma reactor of the present invention, streamer discharge is caused in a wide region so as to increase a plasma generation region without complicating the architecture of the plasma reactor and increasing the cost. In the plasma reactor of the invention, a needle-shaped first electrode and a plate-shaped second electrode are disposed to oppose and to be perpendicular to each other, and the first electrode has a pointed portion as the end thereof on the side of the second electrode and the pointed portion has a point angle θ not less than 30 degrees and not more than 90 degrees, and preferably not less than 60 degrees and not more than 90 degrees.

Owner:DAIKIN IND LTD

Plasma igniter and ignition device for internal combustion engine

InactiveUS8418668B2Reduced areaLow degreeSparking plugsCombustion enginesLow voltageExternal combustion engine

Owner:NGK INSULATORS LTD

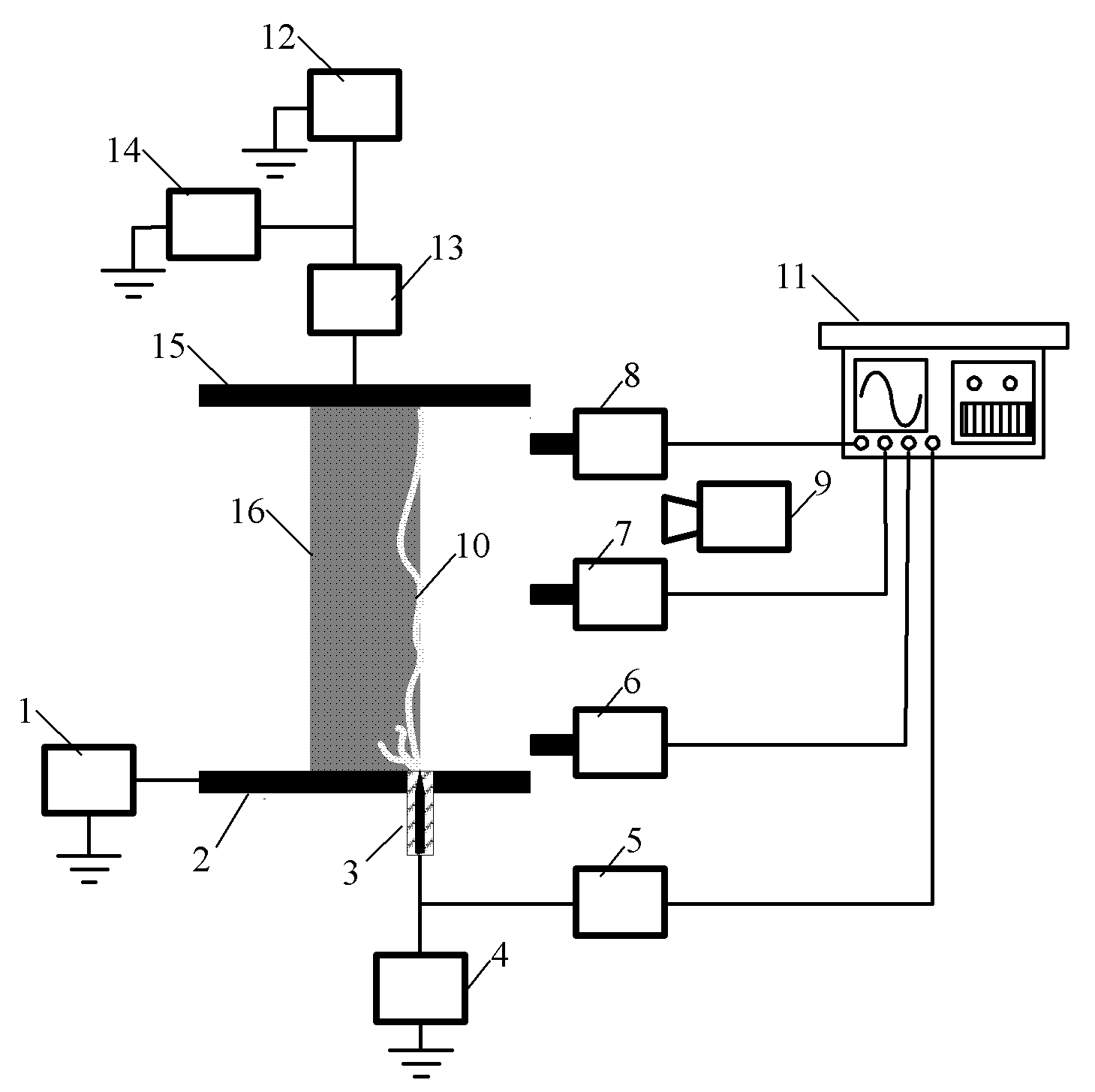

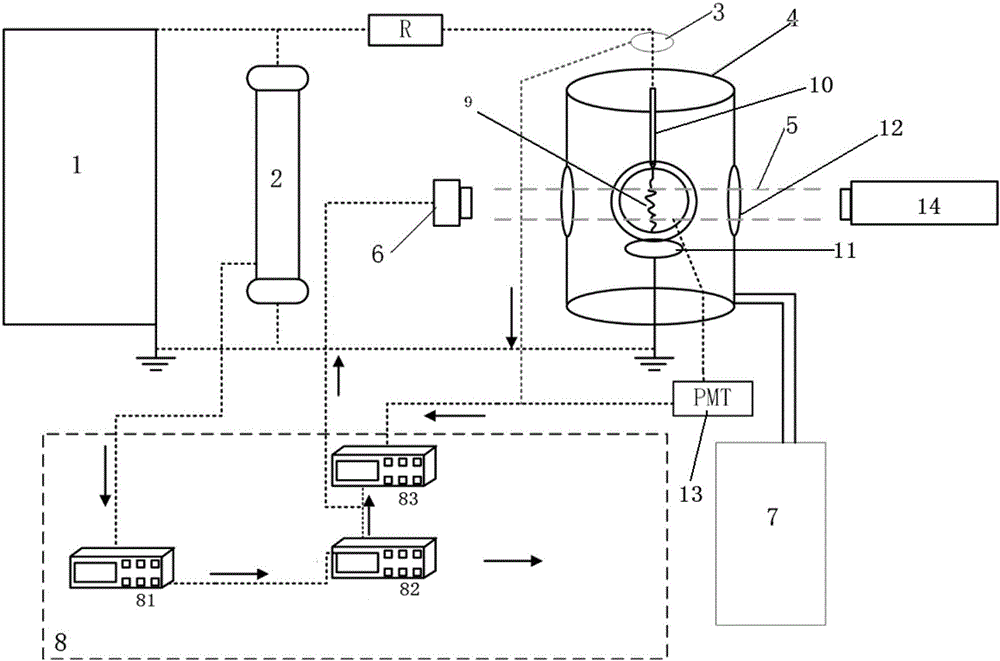

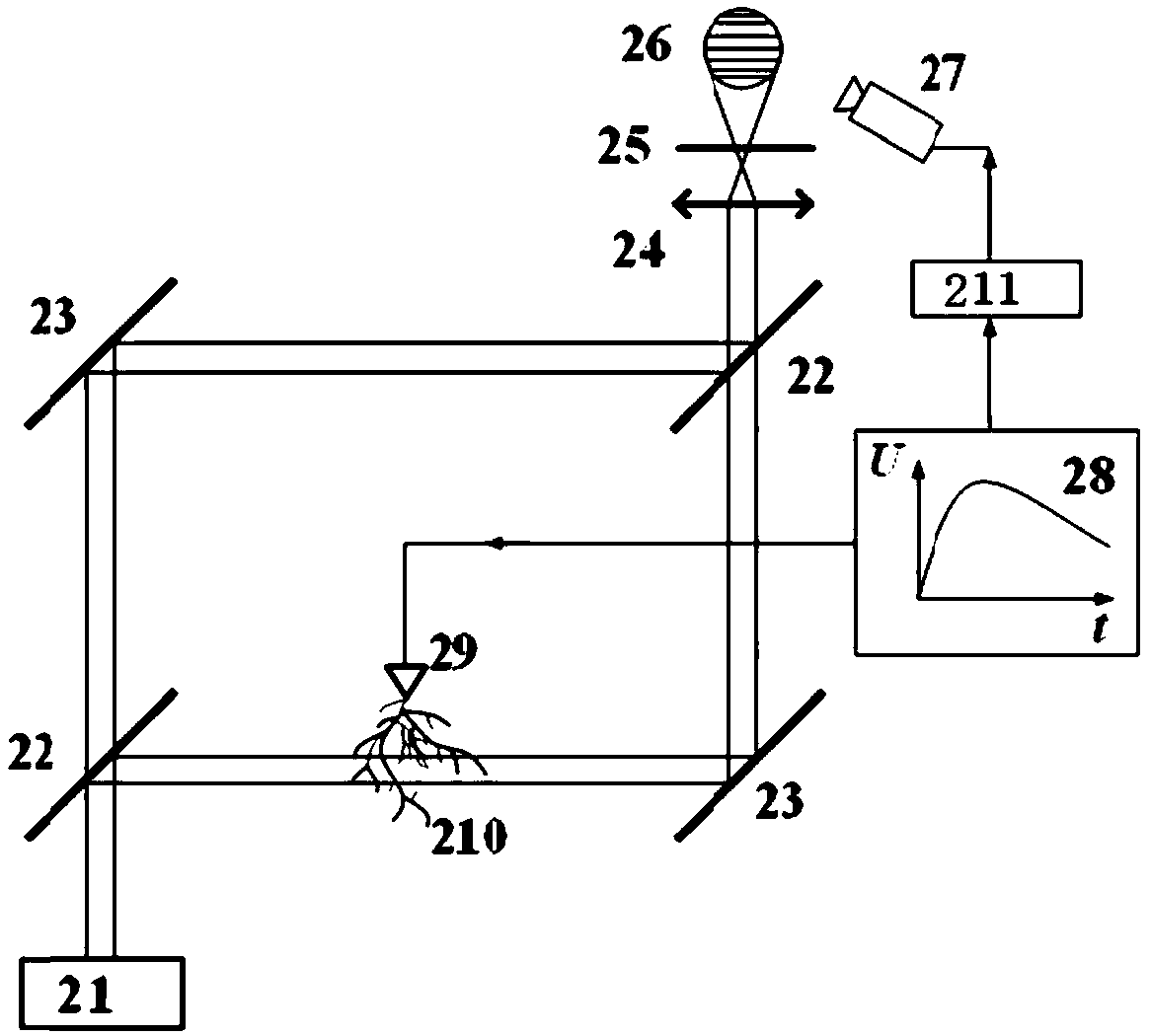

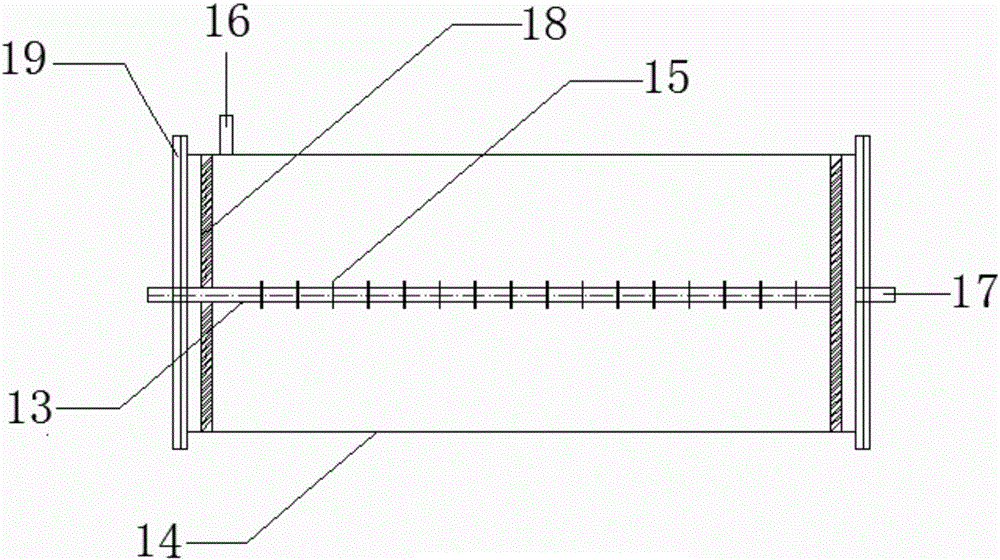

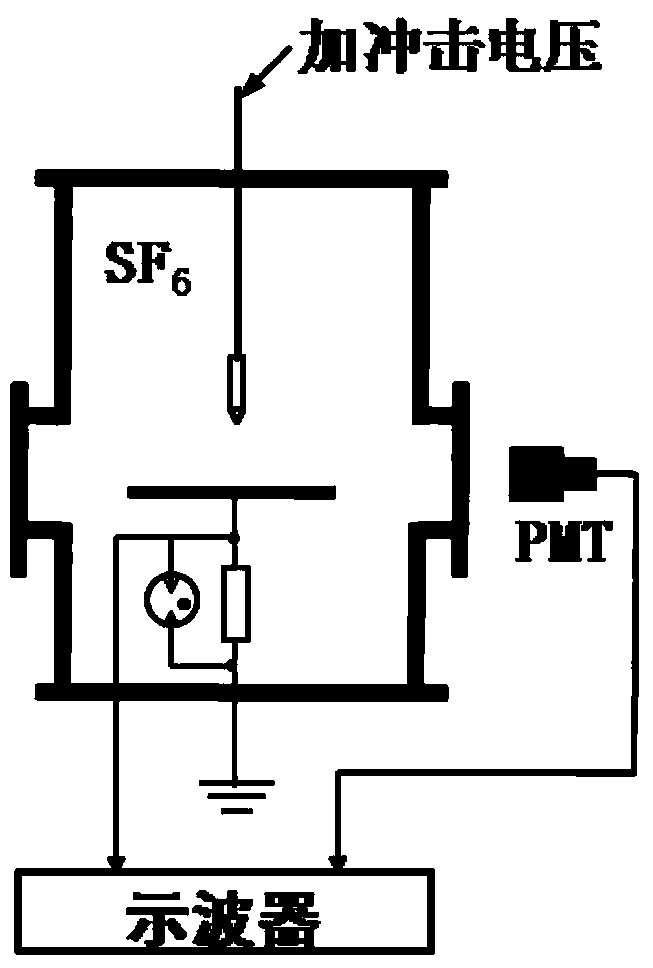

Streamer discharge test system, method, streamer generating device and measuring system thereof

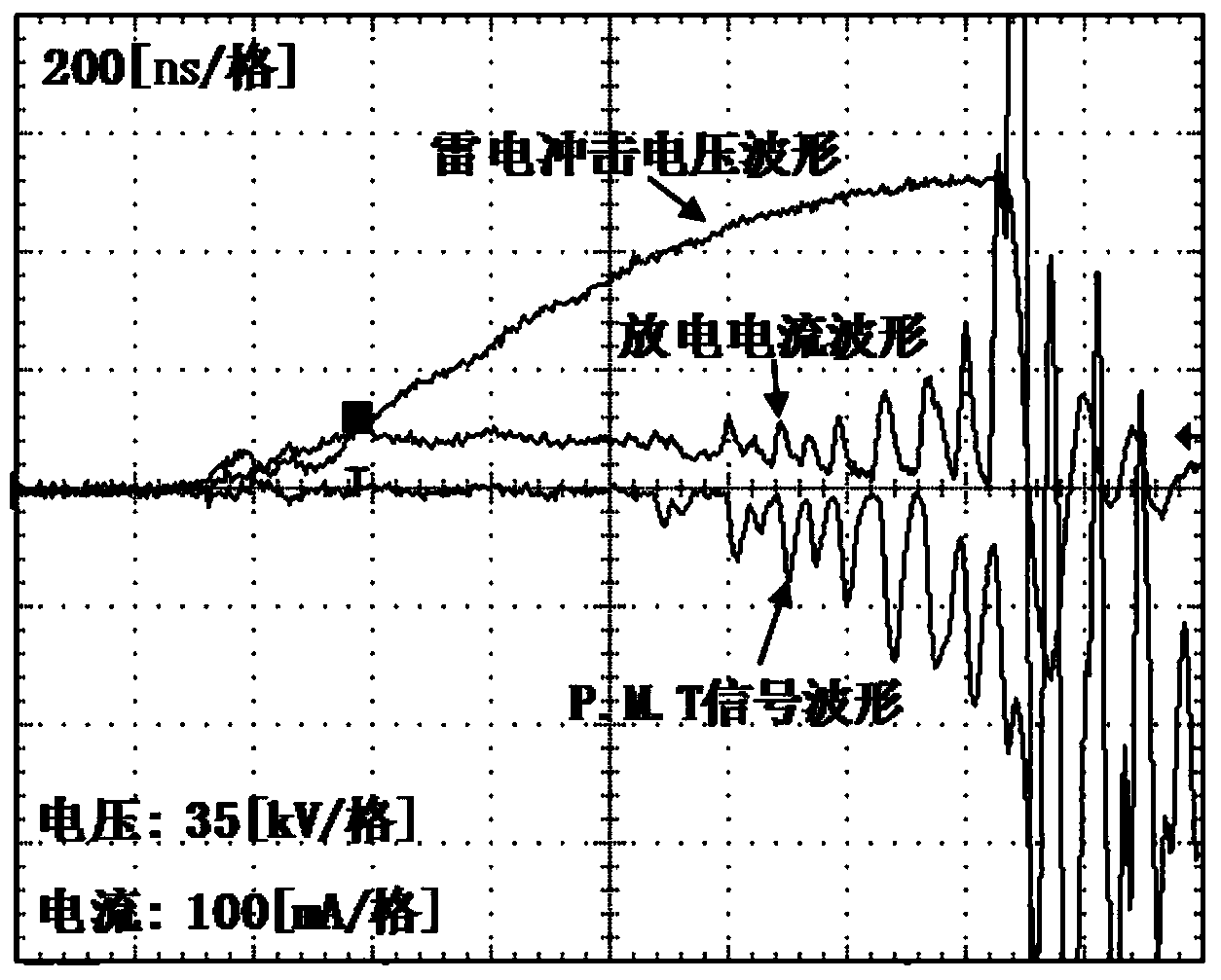

InactiveCN104280669AMeet the requirements of streamer discharge characteristics experimental researchTesting circuitsHigh-voltage direct currentPhotomultiplier

The invention relates to a streamer discharge test system along a surface of an insulating medium, and a method thereof. The streamer discharge test system comprises a streamer discharge generating device and a measurement system. The streamer discharge generating device comprises the components of: a three-electrode structure which is composed of an upper polar plate, a lower polar plate and a needle electrode; a high-voltage DC power supply which is connected with the upper polar plate; and a trigger pulse generating device which is connected with the needle electrode. The measurement system comprises a first processor and three photomultiplier tubes which are connected with three input ends of the first processor. The other input end of the first processor is connected with the output end of the trigger pulse generating device. The three photomultiplier tubes are correspondingly aligned with the tip of the needle electrode, the middle position between the upper polar plate and the lower polar plate, and the lower surface of the upper polar plate. The method of the invention comprises the steps of: arranging an insulating material sample between the upper polar plate and the lower polar plate; applying a high-voltage square-wave pulse on the needle electrode; generating a uniform electric field between the upper polar plate and the lower polar plate; acquiring output signals of the three photomultiplier tubes; measuring a streamer current; and photographing a streamer discharge process and a travel path. The streamer discharge test system can satisfy a requirement for test and research.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

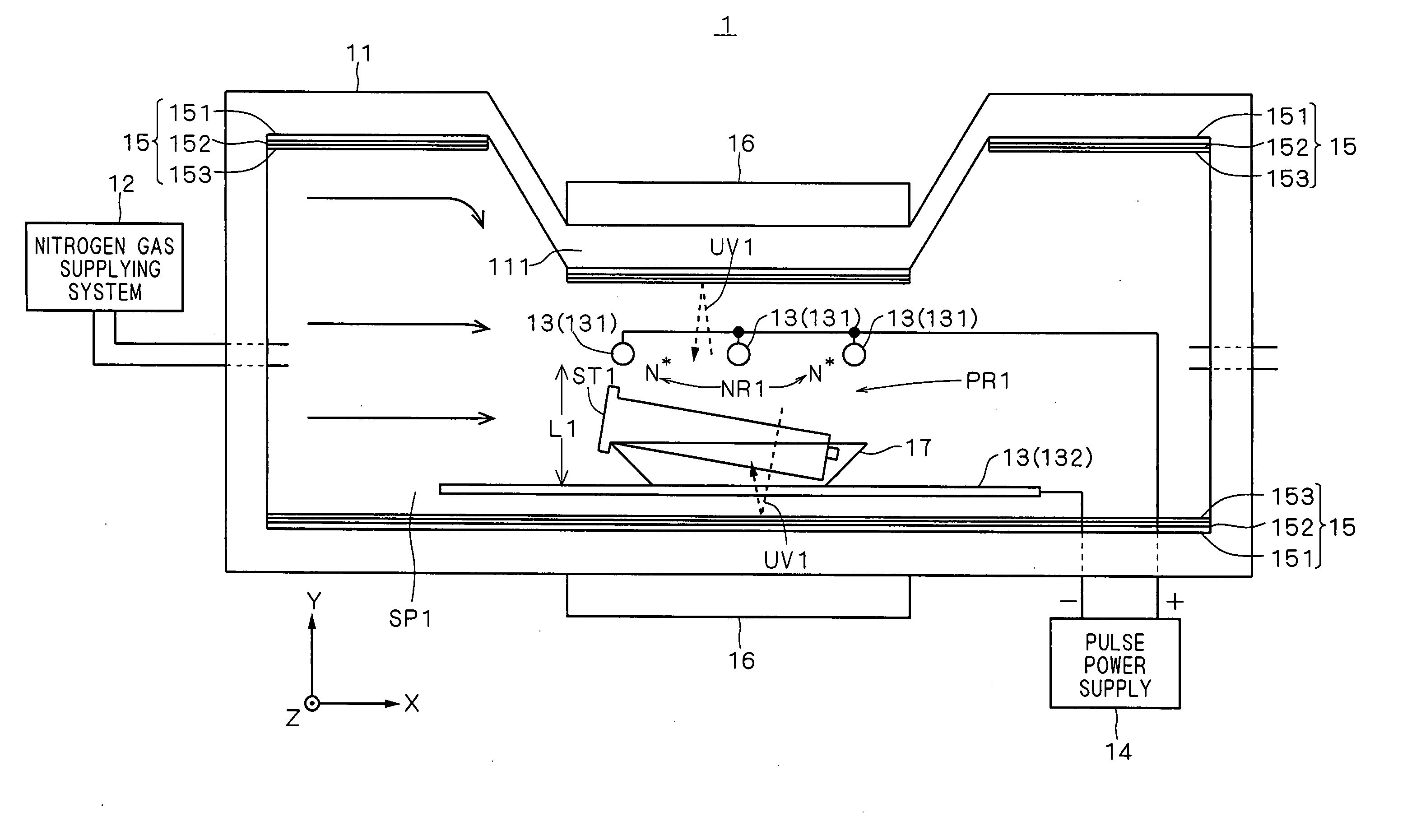

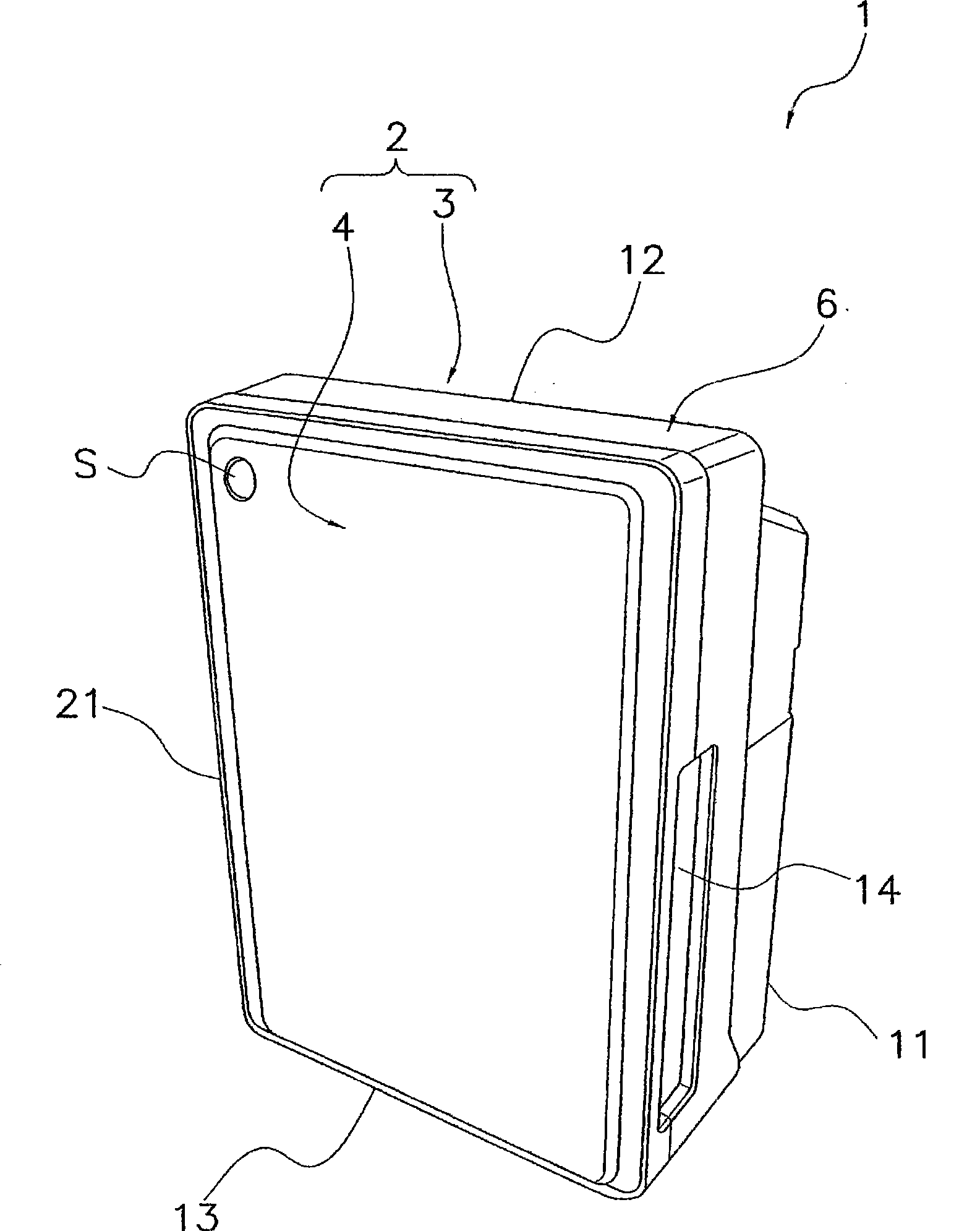

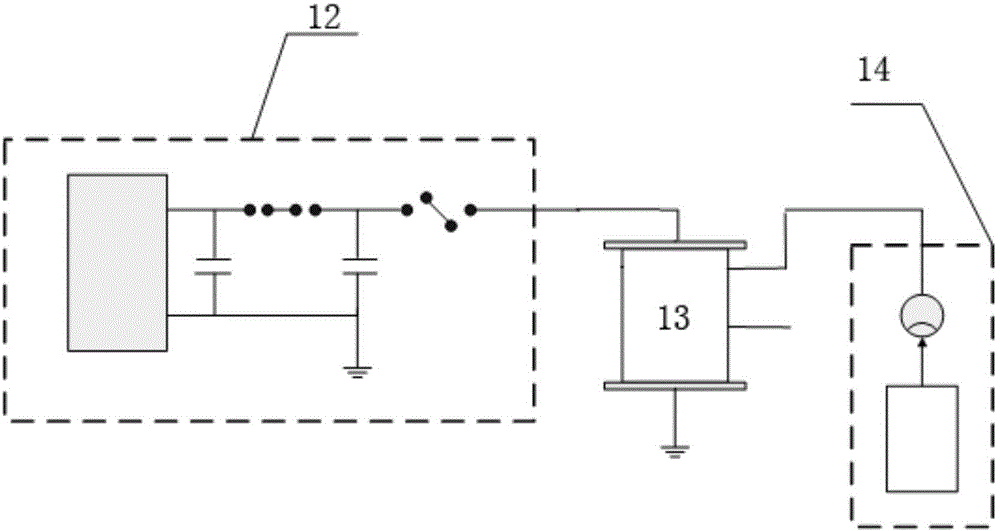

Sterilization/Aseptization Apparatus

InactiveUS20100221155A1High bactericidal effectSmall amount of energyLavatory sanitoryEnergy based chemical/physical/physico-chemical processesUltravioletNitrogen

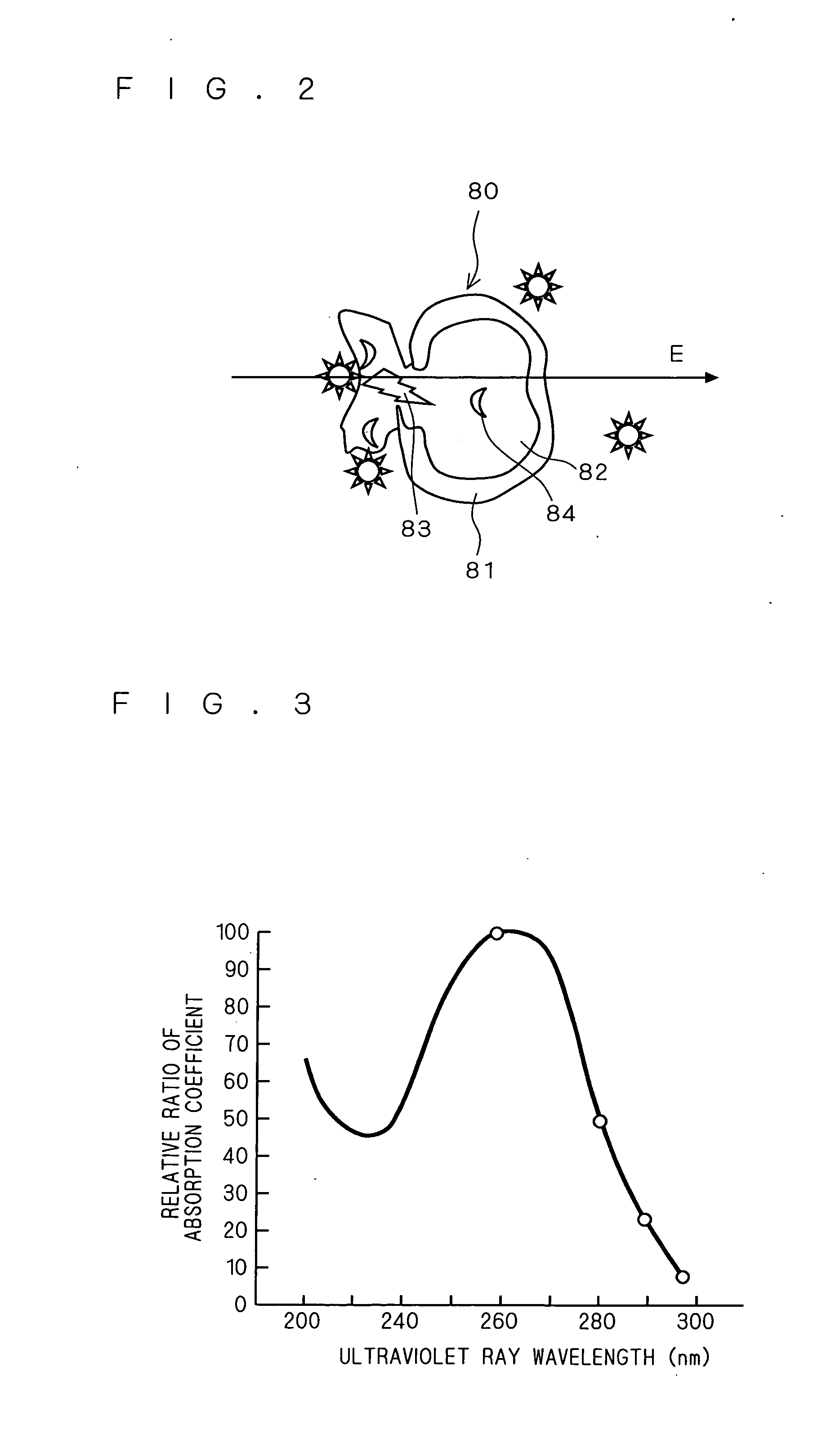

An aseptization apparatus 1 includes a sealed container 11 forming an aseptization space 191, a nitrogen gas supplying system 12 for converting atmosphere of the aseptization space 191 into nitrogen atmosphere, an electrode pair 13 disposed in the aseptization space 191, a pulse power supply 14 for repeatedly applying an electric pulse to the electrode pair 13, and a mirror 15 for returning a short-wavelength ultraviolet ray going from inside of the aseptization space 191 to outside to inside of the aseptization space 191. In a state where an aseptization object substance ST1 is present in a plasma generation region 192 between the electrode pair 13, the aseptization apparatus 1 causes a pulse electric field generated by electric pulse application to the electrode pair 13, a nitrogen radical 195 contained in plasma generated in nitrogen atmosphere resulting from fine streamer discharge, and a short-wavelength ultraviolet ray 196 emitted by nitrogen atmosphere resulting from fine streamer discharge to act on bacteria for aseptization of the aseptization object substance ST1.

Owner:NGK INSULATORS LTD

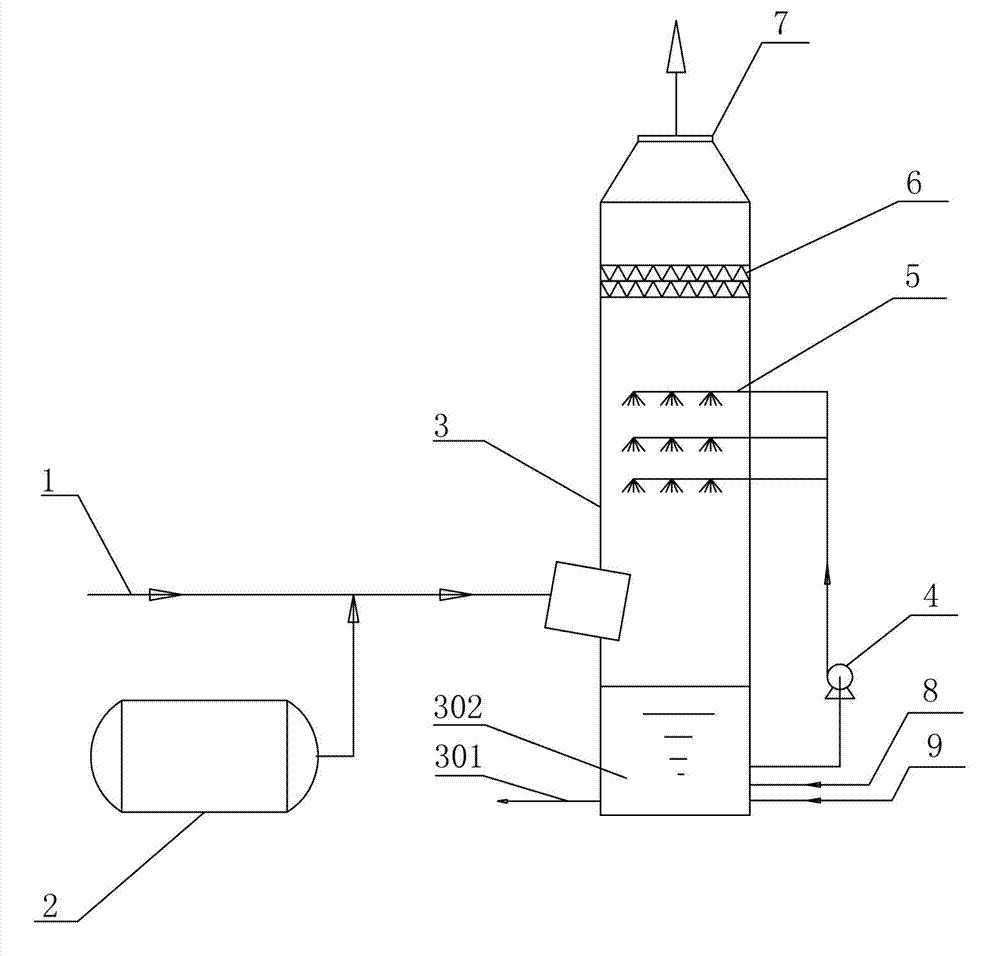

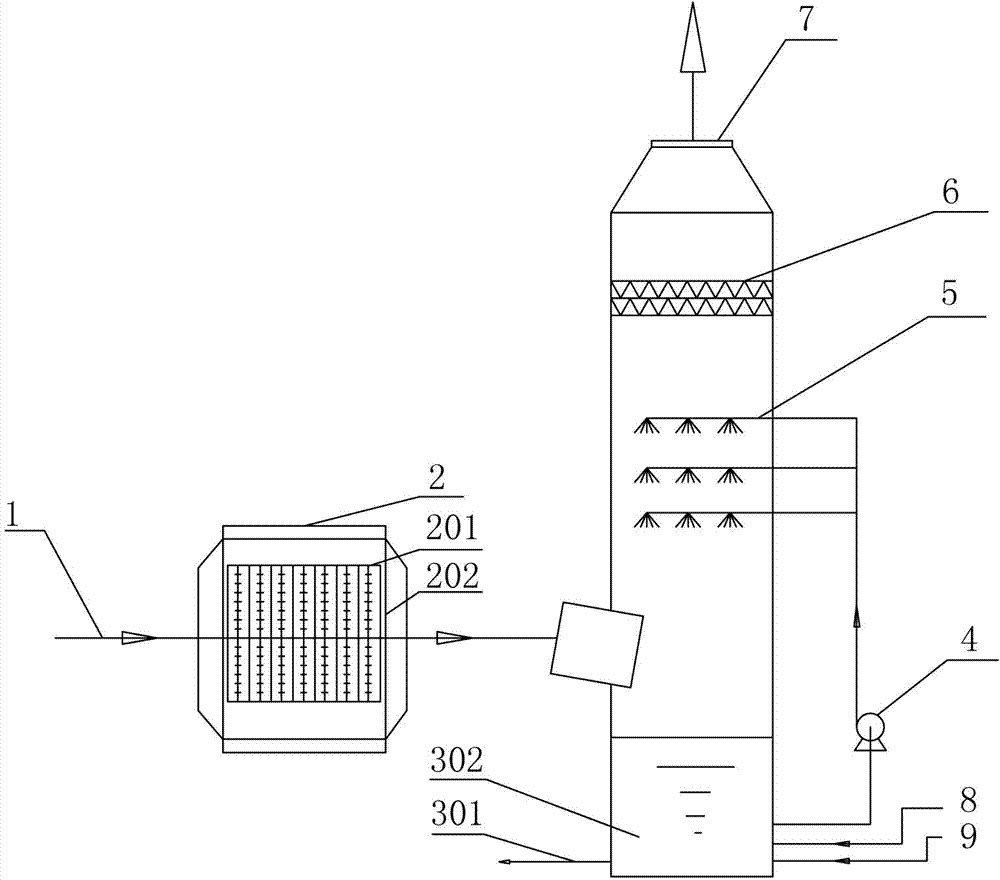

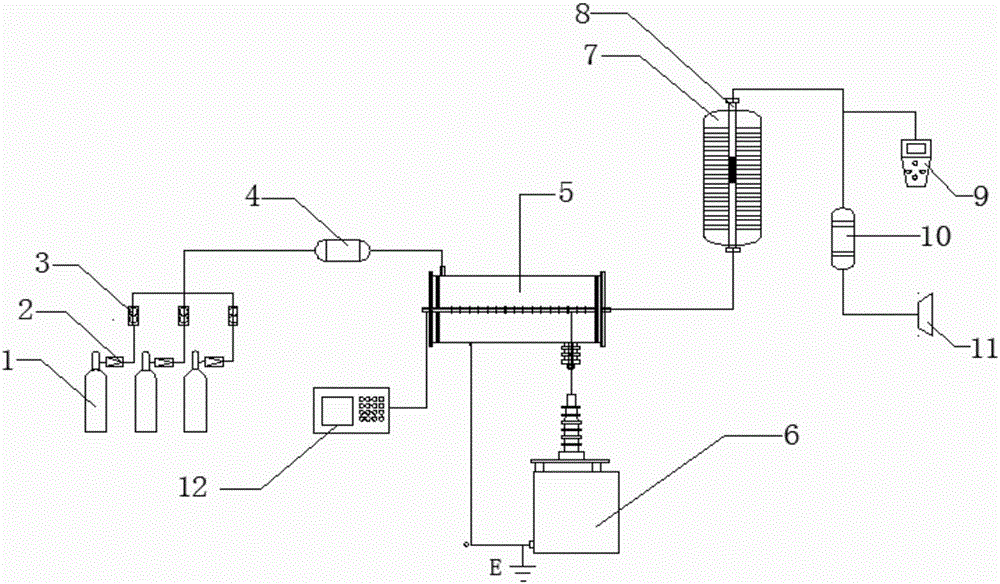

Desulfurization and denitrification method for streamer discharge plasma free radical injected flue gas

InactiveCN102764574ACapable of synchronous desulfurization and denitrificationNo special reaction temperature requirementsDispersed particle separationAir quality improvementPtru catalystFluid phase

The invention discloses a desulfurization and denitrification method for streamer discharge plasma free radical injected flue gas. The method comprises the following steps of: 1) discharging oxygen or air to produce plasma free radicals by using a streamer discharge plasma reactor; 2) injecting the gas containing the plasma free radicals into a flue, and mixing the gas and flue gas containing sulfur oxides and nitrogen oxides, wherein the sulfur oxides and the nitrogen oxides in the flue gas are converted into high-valent oxides by the plasma free radicals; 3) delivering the flue gas in the last step to a desulfurization tower for circular spraying absorption, so that the sulfur oxides and the nitrogen oxides enter a liquid phase; and 4) demisting the flue gas subjected to the circular spraying absorption, and discharging through a chimney. The method has synchronous desulfurization and denitrification capability; a catalyst and a special reaction temperature requirement are not required in the denitrification process; desulfurization and denitrification are integrated, so that the investment is low, and a small space is occupied; and the system is low in resistance and low in energy consumption.

Owner:GUANGDONG J TECH ENVIRONMENT SCI CO LTD

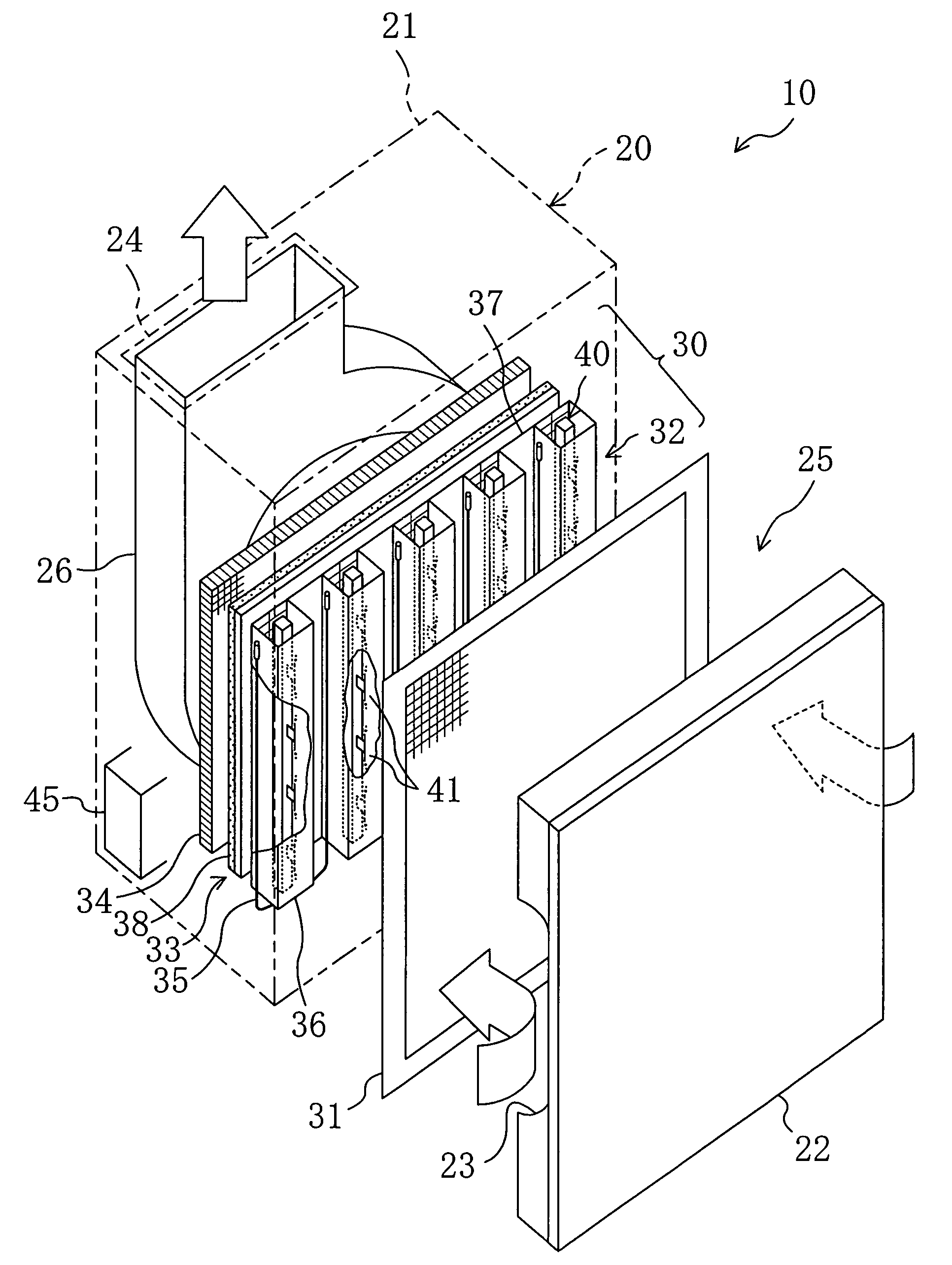

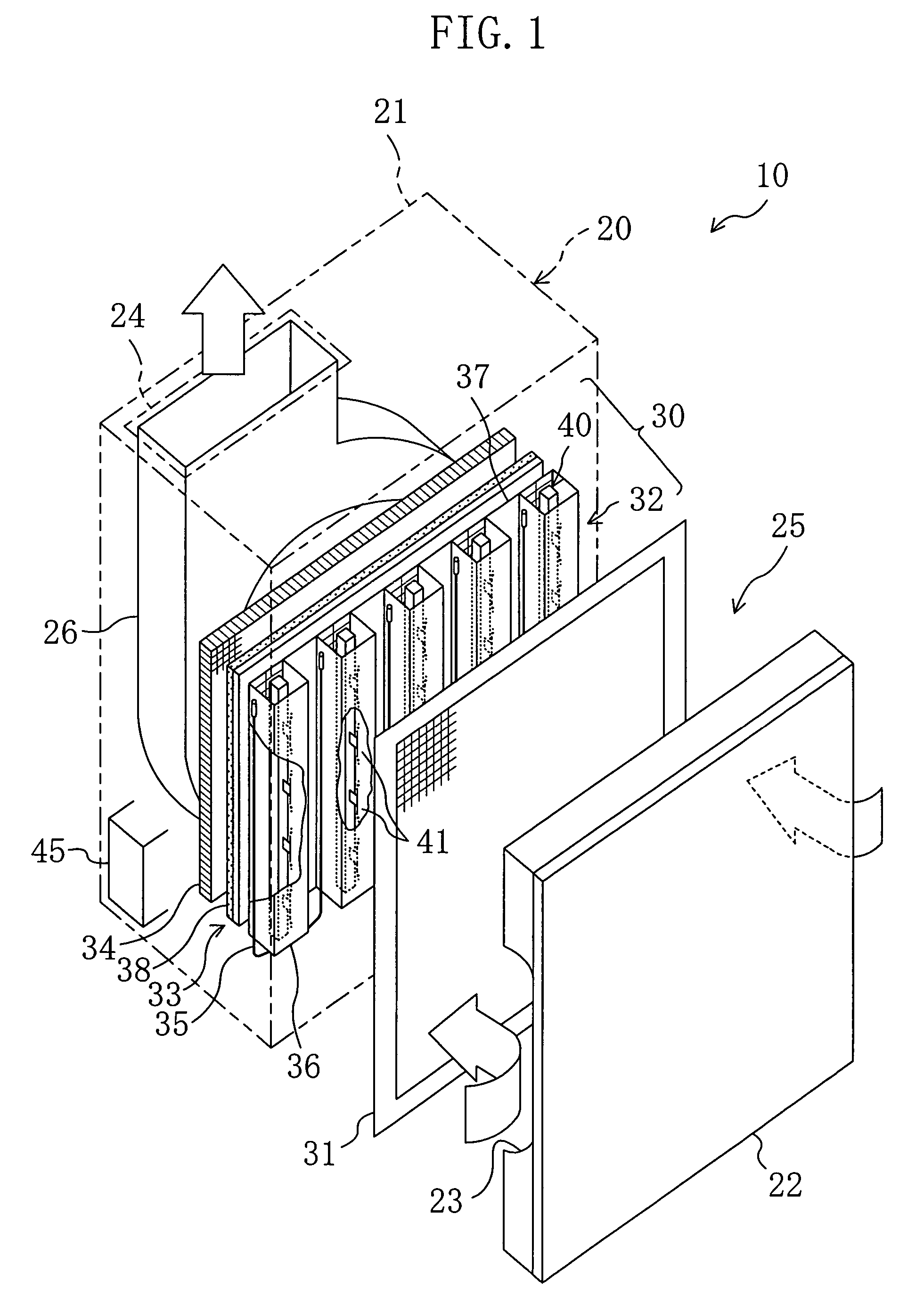

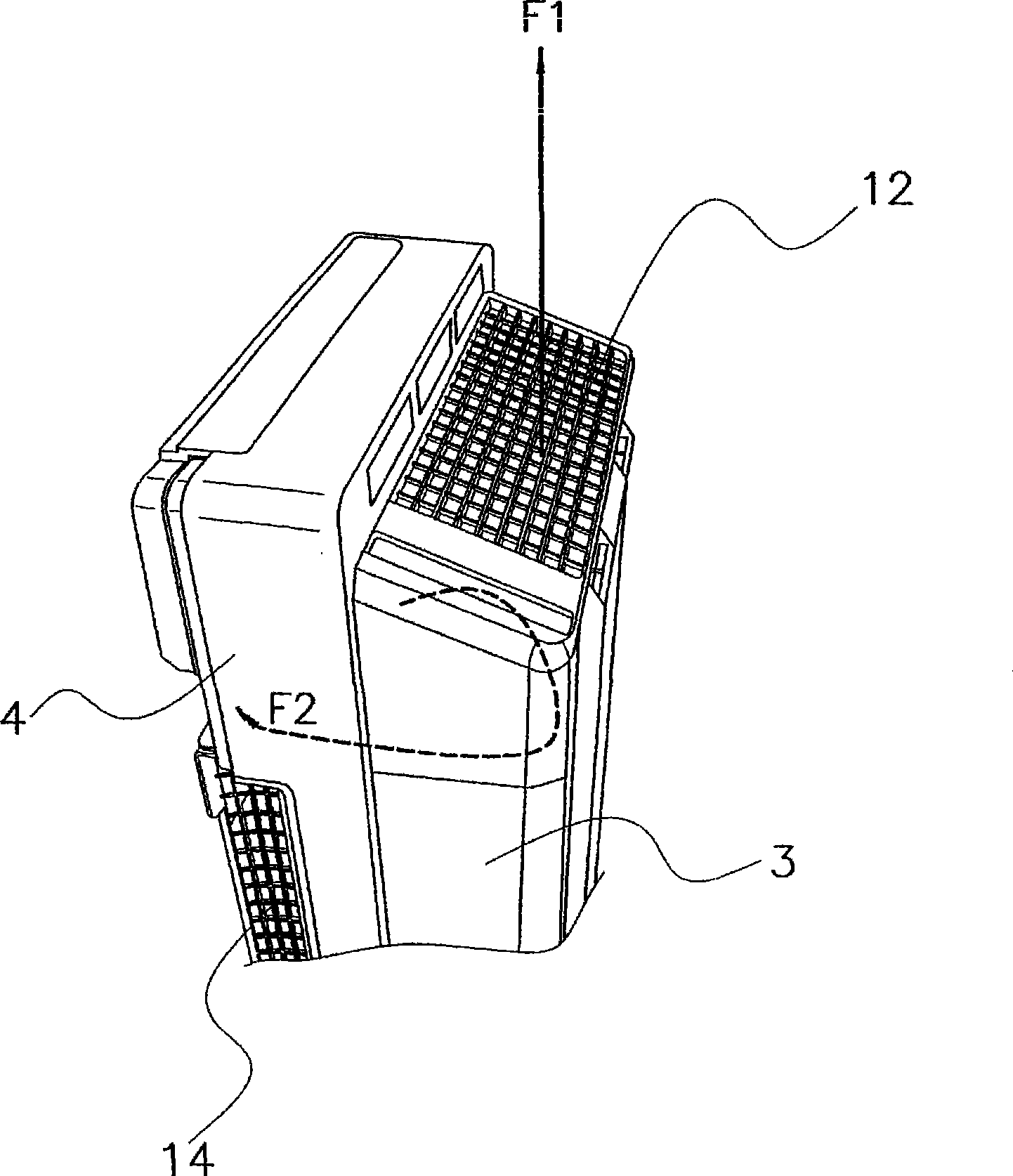

Air cleaner

ActiveCN101484191APlay stabilizationInhibit deteriorationDeodrantsExternal electric electrostatic seperatorAir cleaningEngineering

Provided is an air cleaner capable of stabilizing the exhibition of a function even in case the function adopted is a cleaning function, the exhibition of which may be reduced in efficiency by a contaminant in the air. A body portion (2) has an inlet port (13, 14) and an outlet port (12). A main air passage connects the inlet port (13, 14) and the outlet port (12). An air cleaning unit (40) is arranged on the main air passage to clean the air to be passed therethrough. A bypass air passage bypasses the space on the inlet port side and the space on the outlet port side in the main air passage. A streamer discharge unit (63) is arranged in the bypass air passage to produce active seeds. A blowing fan (31) is disposed in the body portion (2) and is rotationally driven to generate a main air flow (F1) in the main air passage from the inlet port (13, 14) to the outlet port (12) and a bypass air flow (F2) in the bypass air passage from the space on the side of the outlet port (12) to the space on the side of the inlet port (13, 14).

Owner:DAIKIN IND LTD

Streamer corona plasma flue gas denitrification method

InactiveCN102764573AImprove denitrification efficiencyCapable of desulfurizationDispersed particle separationPtru catalystNitrogen oxides

The invention discloses a streamer corona plasma flue gas denitrification method which comprises the following steps of: 1, sending boiler flue gas containing nitric oxide to a streamer corona oxidation reactor after being subjected to dust removal, and under an environment of streamer corona discharge, oxidizing low valent nitric oxide into high valent nitric oxide; 2, enabling the boiler flue gas after passing through the streamer corona oxidization reactor to enter an absorption tower for circularly spraying and absorbing, and enabling the high valent nitric oxide in the flue gas to enter a liquid phase; and 3, discharging the flue gas subjected to circular spraying and absorbing through a chimney after being subjected to defogging. The streamer corona plasma flue gas denitrification method has the advantages of high denitrification efficiency, denitrification capacity, no need of catalysts, wild reaction conditions, little resistance and low energy consumption; and NOx is recycled, and a byproduct of an NH3NO3 fertilizer is obtained.

Owner:GUANGDONG J TECH ENVIRONMENT SCI CO LTD

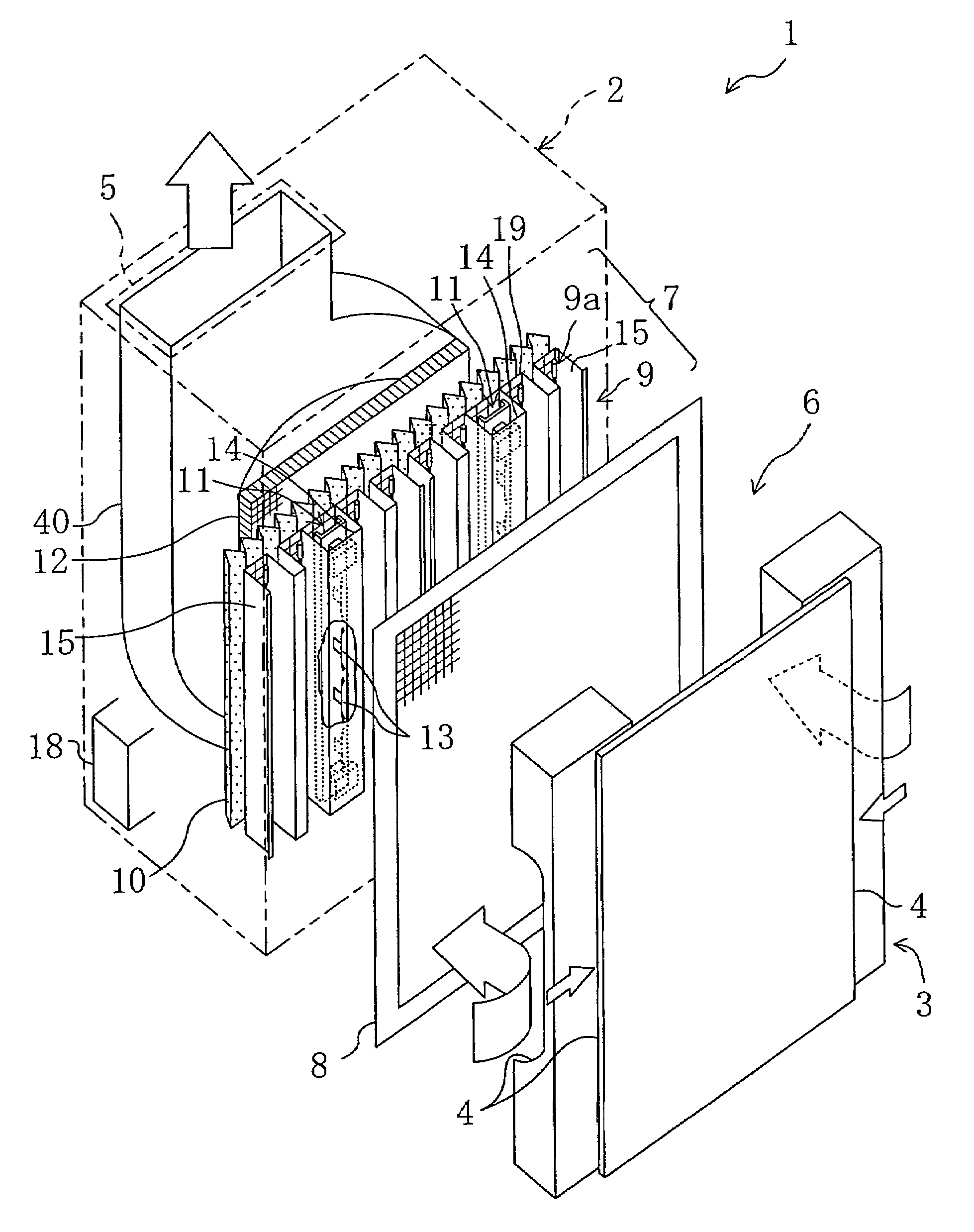

Gas treating apparatus

InactiveUS20060254423A1DownsizeReduced space requirementsElectrode constructionsElectricityHazardous substance

A gas treating device capable of electrically collecting dust and of decomposing odors and other matter by plasma includes a plasma generating device integrally incorporated into an ionization part in a casing. The ionization part has an ionization line and a columnar portion of a negative electrode member. The plasma generating device includes a discharge electrode which shares a counter electrode with the ionization line. During operation, dust of a relatively small size in room air is electrically charged by discharge between the ionization line and the counter electrode. An electrostatic filter entraps and collects the electrically charged dust. A plasma of low temperature is generated by streamer discharge between the discharge electrode and the counter electrode. Harmful substances and odorous substances in the room air are decomposed by an activated species contained in the generated low-temperature plasma.

Owner:DAIKIN IND LTD

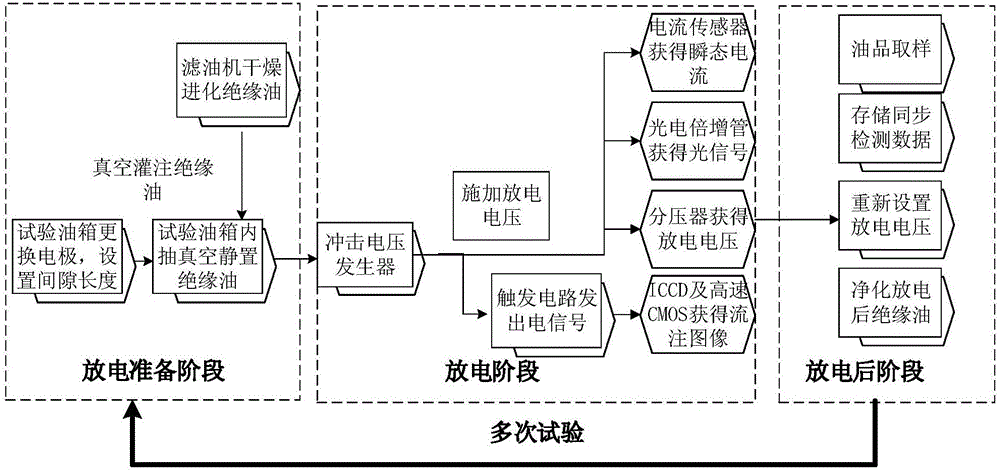

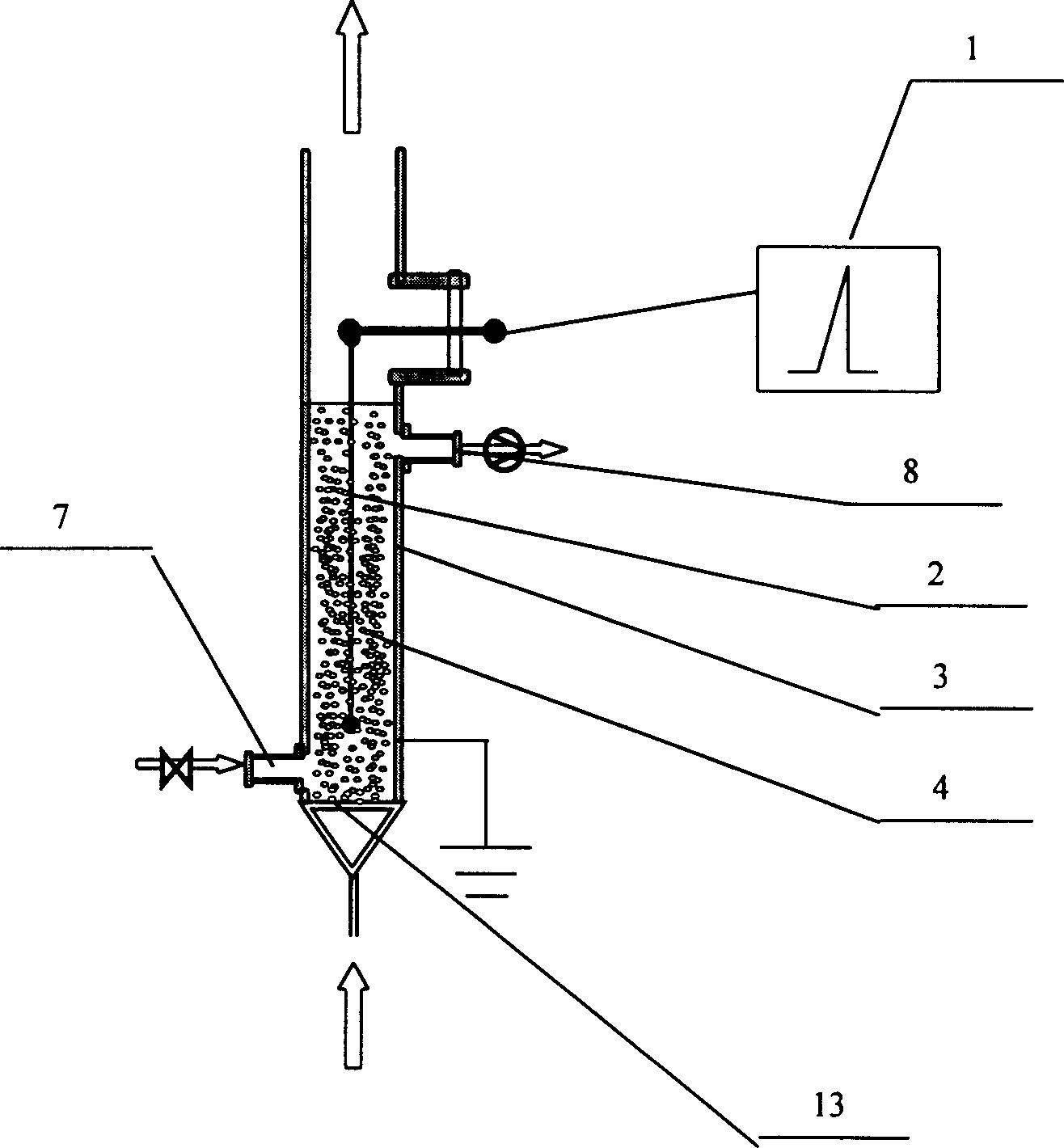

Streamer discharge test system for insulating oil

PendingCN106443386AImprove cleanlinessGuaranteed Visual EffectsTesting dielectric strengthFuel tankEngineering

The present invention discloses a streamer discharge test system for insulating oil. The streamer discharge test system comprises an impulse voltage generator, a voltage divider, a transient current detection device, a discharge test oil tank, a high-speed imaging recorder, a synchronous triggering and measuring part and a photomultiplier; a high-voltage electrode and a grounding electrode are arranged in the discharge test oil tank; discharge streamers are formed between the high-voltage electrode and the grounding electrode under impulse voltage; the transient current detection device is used for detecting current generated immediately when the high-voltage electrode carries out discharge; the output end of the photomultiplier is connected with a signal channel corresponding to the synchronous triggering and measuring part; the photomultiplier is used for receiving photons of the streamers generated between the high-voltage electrode and the grounding electrode; and the high-speed imaging recorder photographs the streamers generated between the high-voltage electrode and the grounding electrode through an observation hole. With the streamer discharge test system of the invention adopted, pre-discharge phenomena can be controllable, and basic discharge electrical parameters can be obtained, and at the same time, the transient image of discharge can be captured timely and enhanced, and the cleanliness and visual effect of a test sample can be ensured trough an oil filtering system.

Owner:CHONGQING UNIV

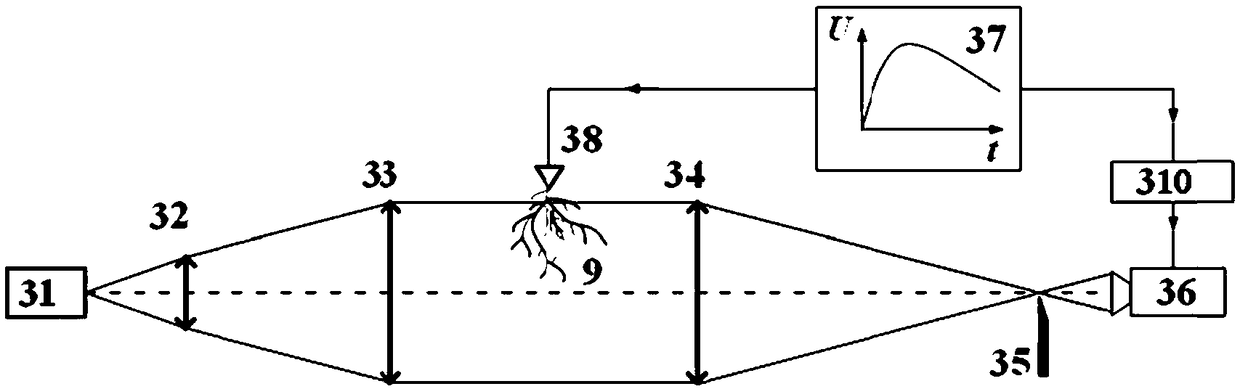

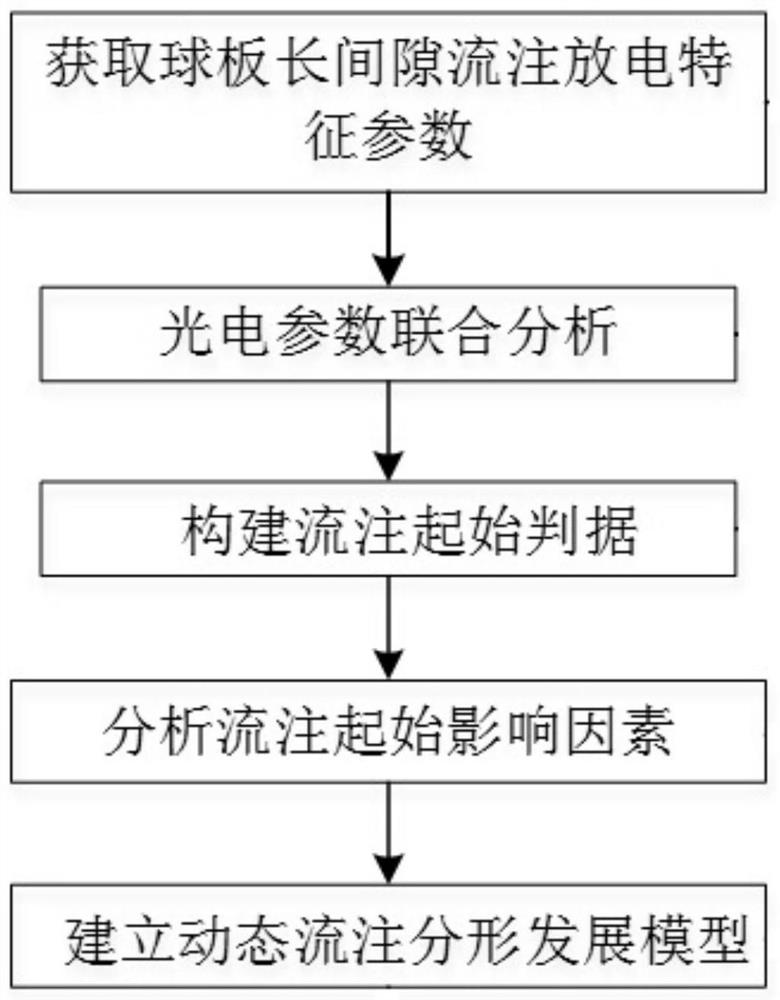

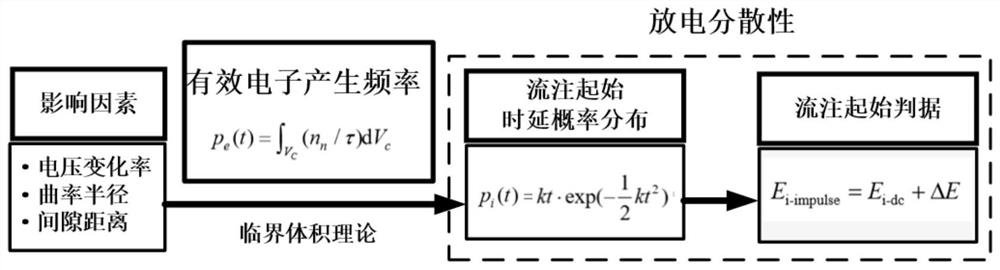

System and method for measuring instantaneous gas density for conversion from long-air-gap streamer discharge to leader discharge

ActiveCN108931459AImprove spatial resolutionOvercoming the problem of reduced spatial resolutionSpecific gravity measurementTelephoto lensTime domain

The invention relates to a system and method for measuring instantaneous gas density for conversion from long-air-gap streamer discharge to leader discharge. The system includes an LED chip, a bean expanding lens, a main lens, a convergent lens, a knife edge, a telephoto lens and an ICCD camera. A discharge zone is generated between the main lens and the convergent lens. A coupling lens focuses self-luminescence generated by discharging and transmits the self-luminescence into a photomultiplier. The photomultiplier converts optical intensity time domain signals of the discharge self-luminescence into a voltage waveform and inputs the voltage waveform into a TTL pulse formation circuit. An output end of the TTL pulse formation circuit is connected to an input end of a digital delay generator, and the output end of the digital delay generator is connected to a pulse drive power supply and the ICCD camera separately. The system and the method can achieve accurate inversion measurement ofan ns-stage instantaneous gas density distribution rule in a process of conversion from long-air-gap streamer discharge to leader discharge, and have advantages of high system reliability and a high capturing efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

Denitration system and denitration processing method of plasma synergistic catalyst

InactiveCN105833718AAvoid scourAvoid cloggingGas treatmentDispersed particle separationFixed bedCatalytic effect

The invention provides a denitration system and denitration processing method of a plasma synergistic catalyst. The system includes a gas mixing system, a plasma reaction system, a fixed-bed catalytic reactor, an absorbing device, and an induced draft device, which are connected in sequence. The method comprises: introducing mixed to-be-processed flue gas and ammonia gas into a plasma reactor, performing streamer discharge under the action of high voltage to generate active substances, such as electrons, ions, and free radicals, and performing primary denitration; mixing the flue gas subjected to primary denitration with ammonia gas under the catalytic action of a catalyst, and reacting NOx in flue gas with ammonia gas to achieve denitration; and discharging tail gas after absorption. A synergistic effect between streamer discharge plasma and the low-temperature catalyst is utilized to remove nitric oxide from flue gas at a low temperature with low energy consumption. The inhibition of oxygen on nitric oxide removal is overcome, low-dust arrangement or tail arrangement of an SCR device is realized, and the life of the catalyst is prolonged.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +2

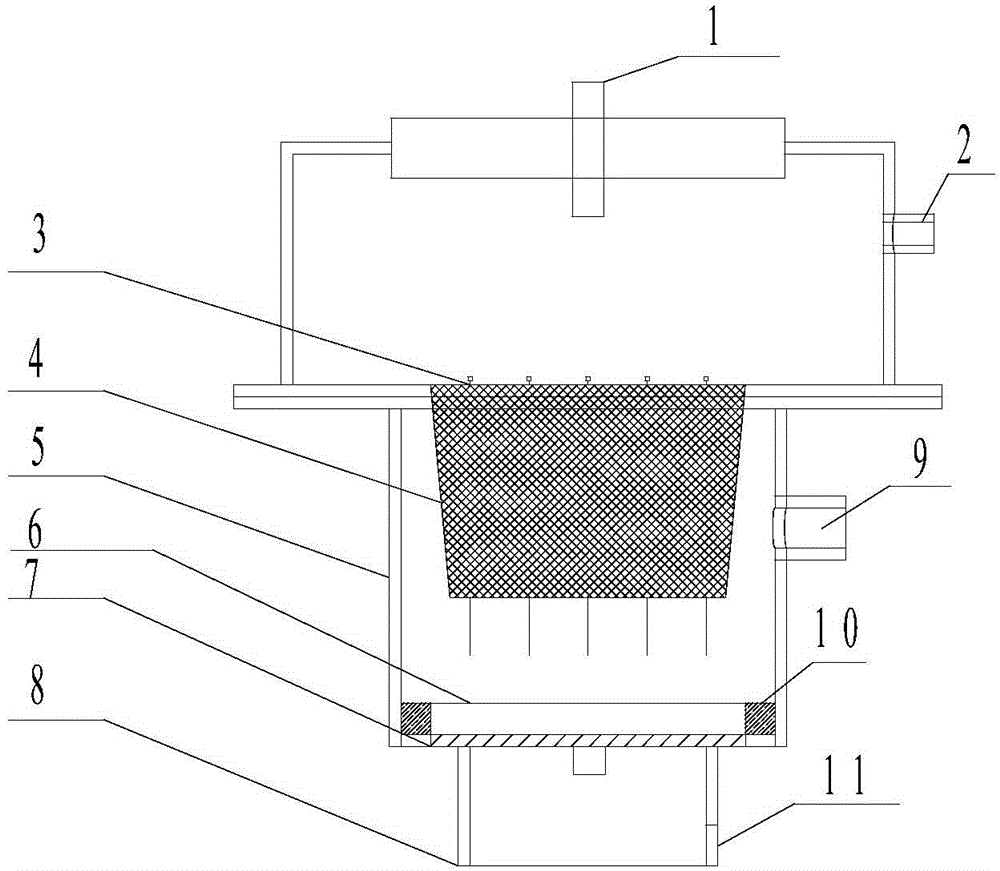

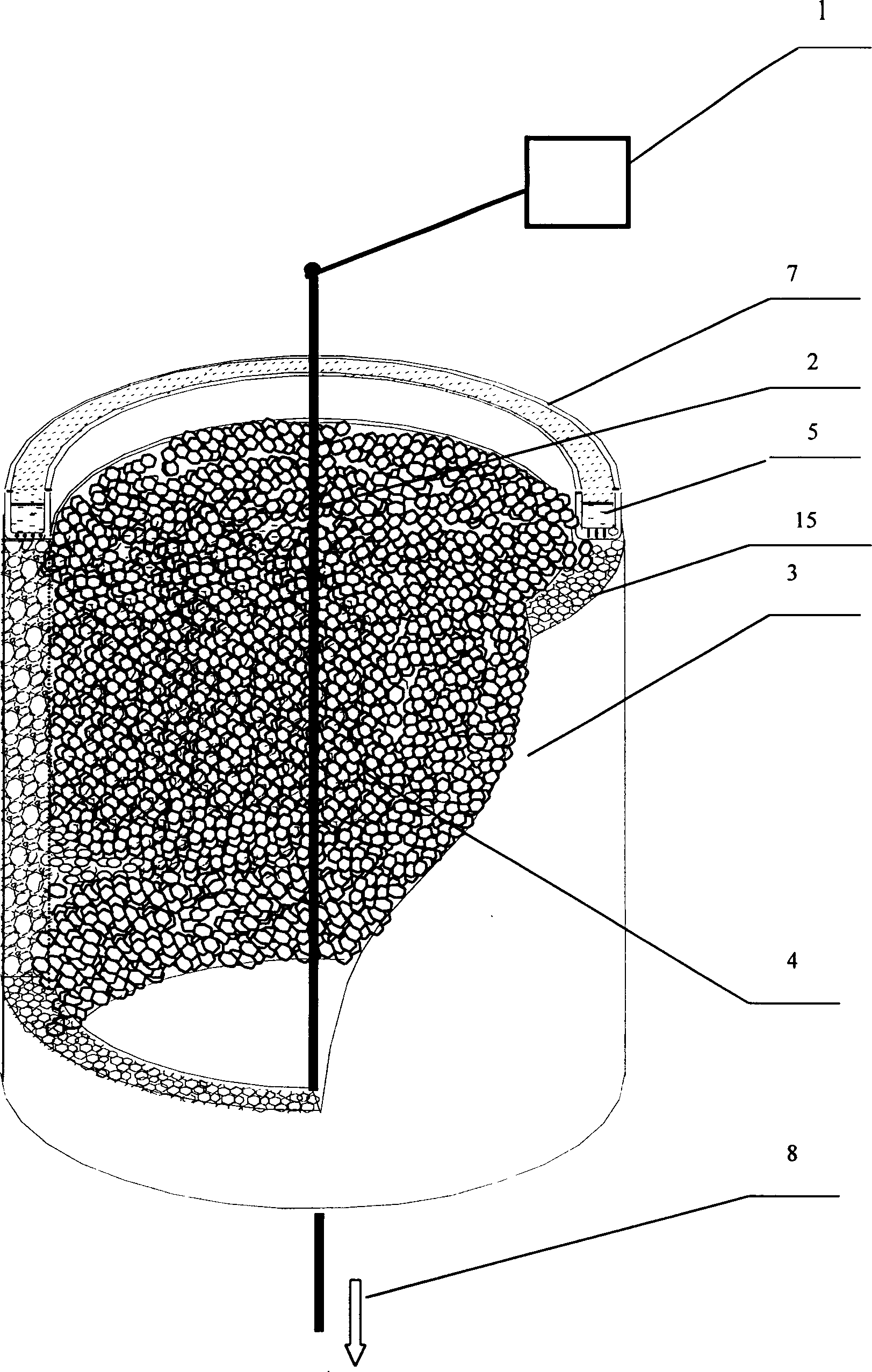

Method and device for regenerating activated carbon by virtue of pulse discharge plasma

ActiveCN104475068AReduce lossesShort cycleOther chemical processesCombustible gas purificationActivated carbonEngineering

The invention provides a method and device for regenerating activated carbon by virtue of pulse discharge plasma. The device comprises a pulse power supply, a reactor and a carrier gas system, wherein the reactor comprises an upper cover, an outer cylinder and a pedestal, and the outer cylinder is located between the upper cover and the pedestal and are connected each other; the output terminal of the pulse power supply is connected with the high-voltage terminal wiring port of the upper cover and the output terminal of the carrier gas system is connected with the gas inlet of the upper cover; the outer cylinder is internally and sequentially provided with high-voltage electrodes, an activated carbon placement layer and a ground electrode; activated carbon is paved on the nylon net of the reactor, water is injected into the reactor and the reactor is sealed; a gas pump of the carrier gas system is started, a flow meter is adjusted and the circuit of the system is closed; the pulse power supply is started and parameters are adjusted so that streamer discharge is formed between the high-voltage pin electrode and the ground electrode; the circuit of the system is disconnected, the gas pump is turn off, the outer cylinder is opened to take the activated carbon out, the activated carbon is washed with deionized water and dried to obtain the regenerated activated carbon. According to the device and the method, by the pulse discharge technology, organic pollutants adsorbed on activated carbon are degraded so as to achieve the regeneration of activated carbon.

Owner:江阴智产汇知识产权运营有限公司

Flowing light discharge plasma oxygenized sulfite

The present invention discloses one industrial method of oxidizing four-valent sulfide with non-thermal plasma in the co-existence of OH, H, O, N and other high chemical activity free radicals. High voltage power source is applied to the discharge system of streamer discharge plasma reactor to form the streamer discharge plasma reaction area while sulfite solution is fed into the reaction area, and the four-valent sulfur is oxidized into six-valent sulfur during the streamer discharge oxidizing process. Meanwhile, atomizing mode, bubbling mode or high specific surface area electrode is used to increase the gas-liquid mass transfer interface and raise the mass transfer efficiency. Compared with conventional method, the present invention has high oxidization rate, low power consumption, short processing time, small covered area, less ammonia leakage and other advantages.

Owner:GUANGDONG J TECH ENVIRONMENT SCI CO LTD

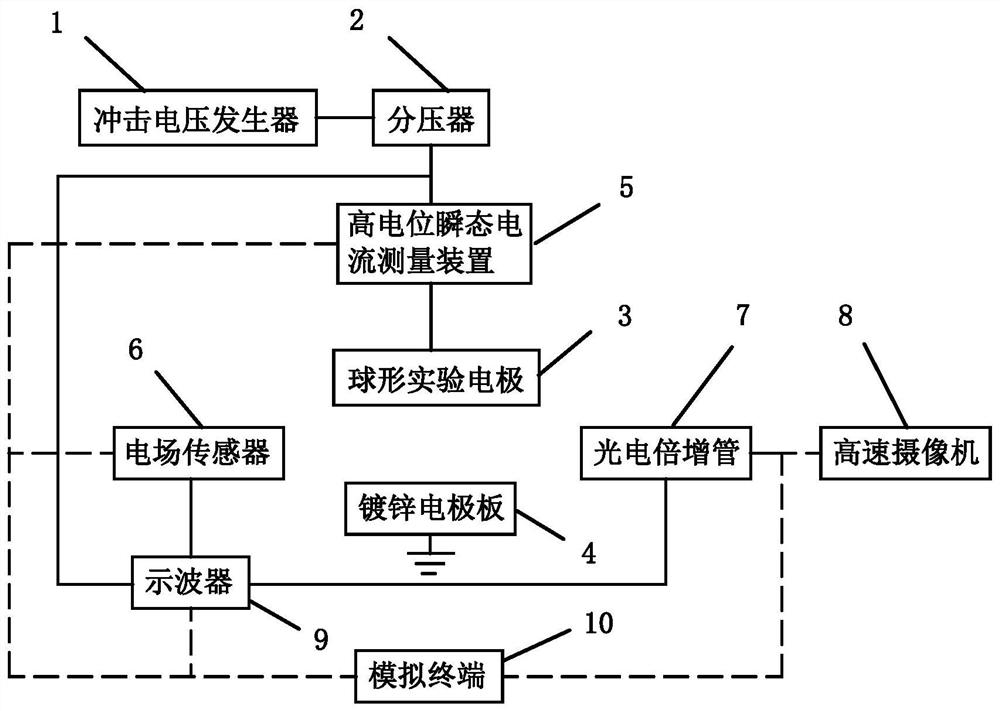

Long-air-gap spherical electrode streamer discharge simulation system and simulation method thereof

ActiveCN111766483ATesting dielectric strengthEducational modelsElectric field sensorElectrical connection

The invention discloses a long air gap spherical electrode streamer discharge simulation system. The system comprises an impulse voltage generator, a voltage divider, a spherical experimental electrode, a galvanized electrode plate, a high-potential transient current measuring device, an electric field sensor, a photomultiplier, a high-speed camera, an oscilloscope and an analog terminal, whereinthe impulse voltage generator and the voltage divider are electrically connected with each other; and the spherical experimental electrode is electrically connected with the voltage divider, the galvanized electrode plate is grounded, and the analog terminal is in communication connection with the high-potential transient current measuring device, the electric field sensor, the photomultiplier, the high-speed camera and the oscilloscope. The defects in the prior art can be overcome, a ball-plate gap dynamic streamer fractal development model based on charge accumulation is established, and a guide mechanism of generation, accumulation and dissipation of space charges of a discharge channel on discharge development is conveniently researched.

Owner:CHINA ELECTRIC POWER RES INST +3

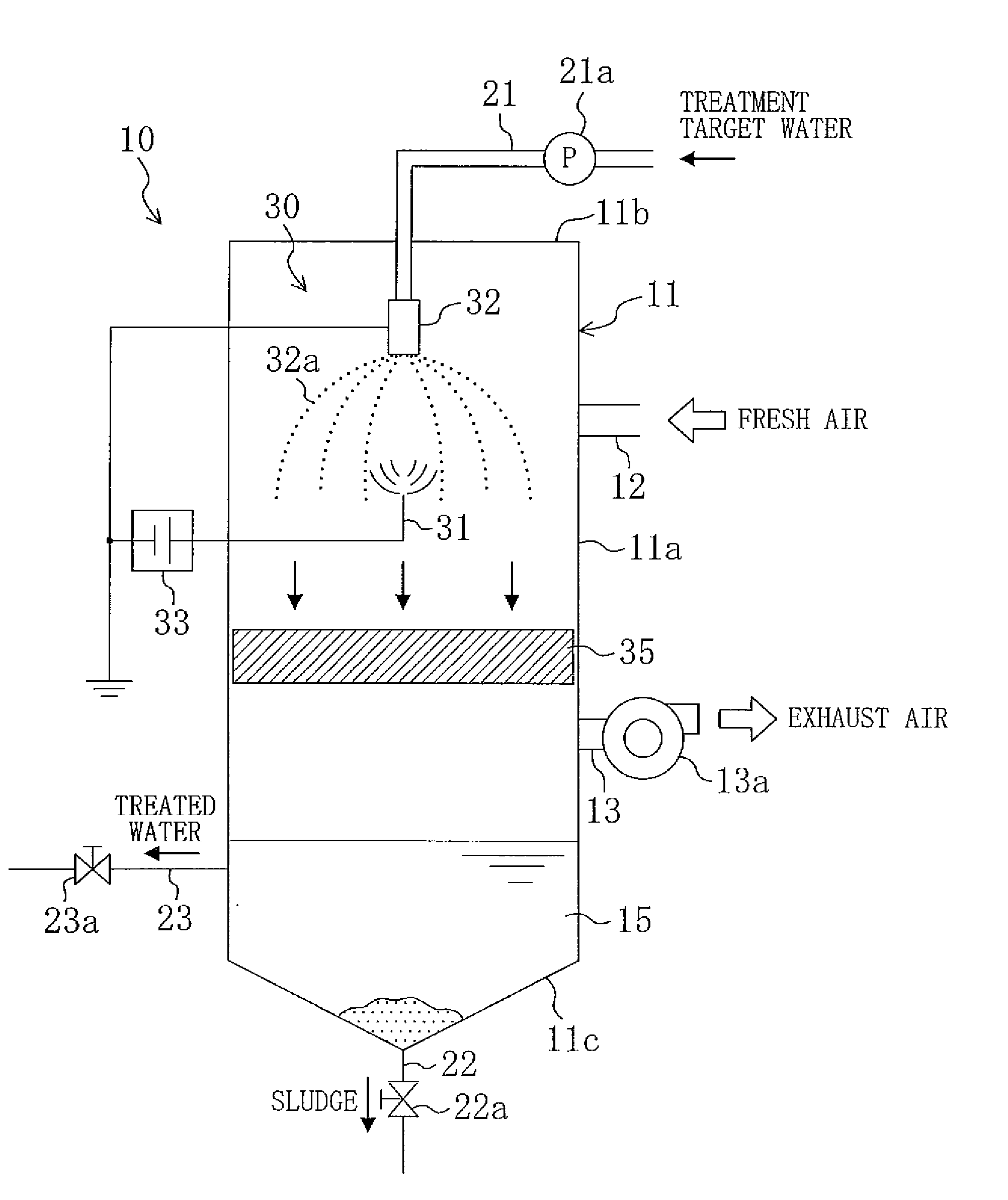

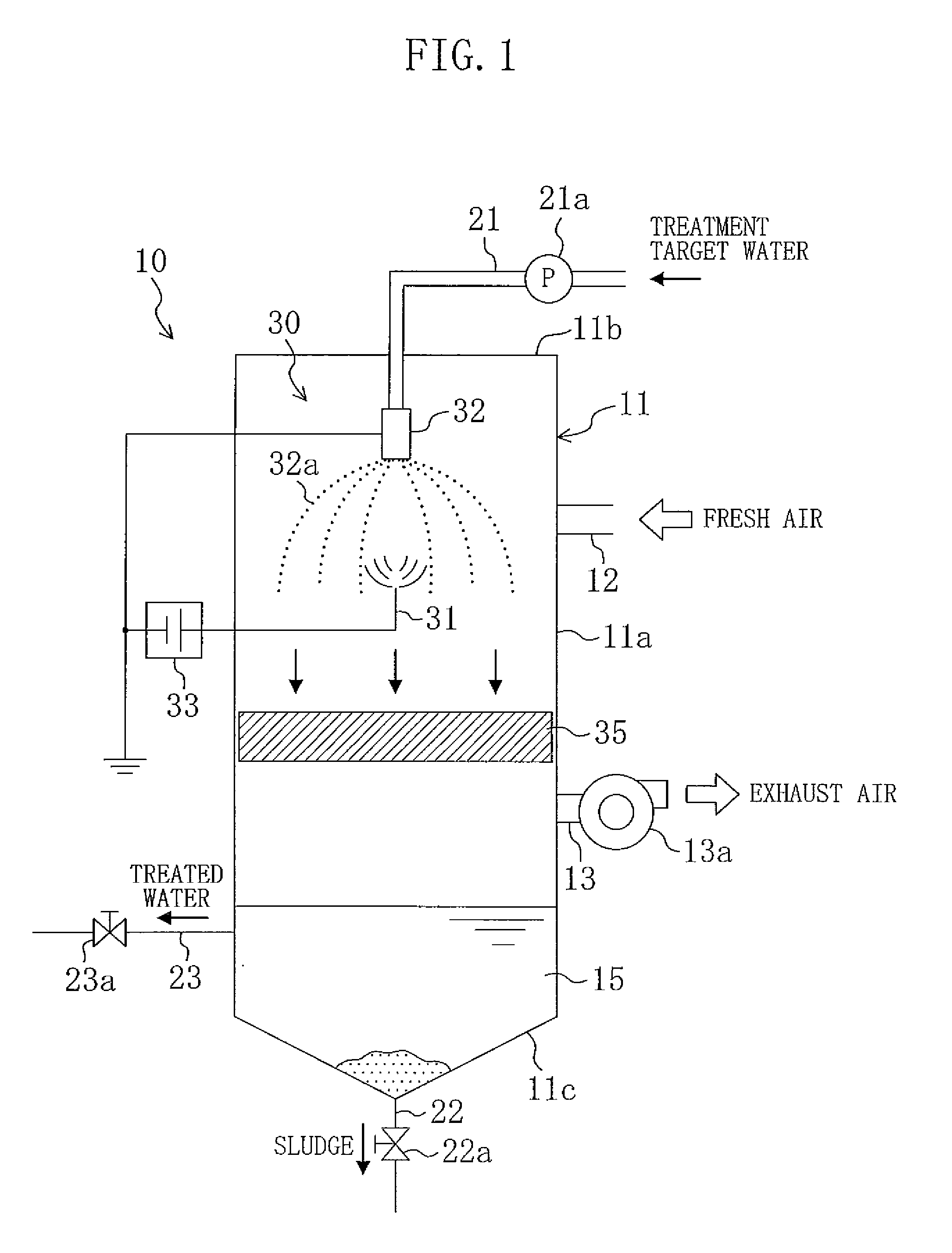

Liquid treating apparatus, air-conditioning apparatus, and humidifier

InactiveCN101466465AImprove purification effectEffectively eliminateAir treatment detailsCondensate preventionPotential differenceEnvironmental engineering

Owner:DAIKIN IND LTD

Discharge apparatus and air purifying apparatus

InactiveUS20050257687A1A large amountImprove efficiencyMechanical apparatusElectrical apparatusAir cleaningEngineering

The distance between a discharge electrode and a counter electrode of a discharge device is set to not more than 10 mm such that a streamer discharge is caused between the electrodes. The frequency of sound made by the streamer discharge is raised to 6 kHz or higher to exceed the frequency range which is easily perceivable by human hearing.

Owner:DAIKIN IND LTD

Discharge Device and Air Purification Device

InactiveUS20080314251A1Stable generationReduce discharge delayMechanical apparatusLighting and heating apparatusAir cleaningEmbedded system

The frequency of a cyclically varying voltage, (fv), is made equal to or higher than the frequency of a streamer discharge, (fs), thereby making it possible to reduce the discharge delay time which is caused in a single streamer discharge.

Owner:DAIKIN IND LTD

Multi-stage collector for multi-pollutant control

InactiveUS20080092736A1Improve efficiencyIncrease the electric field strengthParticle charging/ionising stationsMagnetic separationPulse power supplyElectric field

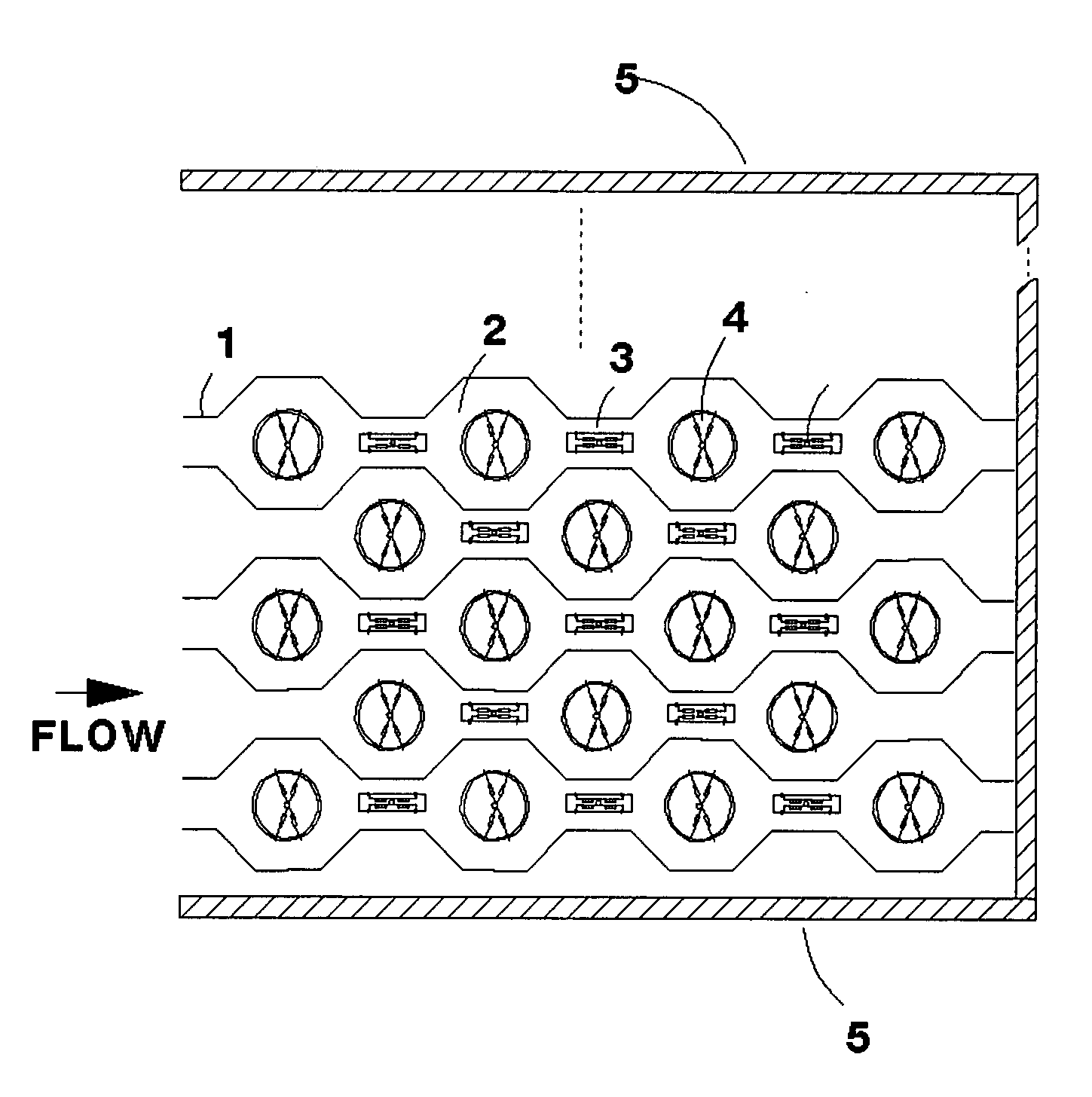

A multi-stage collector for multi-pollutant control that contains alternating narrow and wide sections with glow discharge electrodes in some narrow sections, a uniform electric field in wide sections for collecting particles charged by the glow discharge and streamer discharge electrodes in wide or narrow sections that convert and destroy harmful gaseous pollutants such as SO2, NOx and volatile organic compounds as well as convert heavy metals such as mercury into a particulate form. Steady state streamer discharge is supported by non-pulsed power supply. The streaming discharge can convert the polluting gases into nitric and sulfuric acid which can be removed by combining it with ammonia to form solid salts.

Owner:ALLIED ENVIRONEMTAL TECH

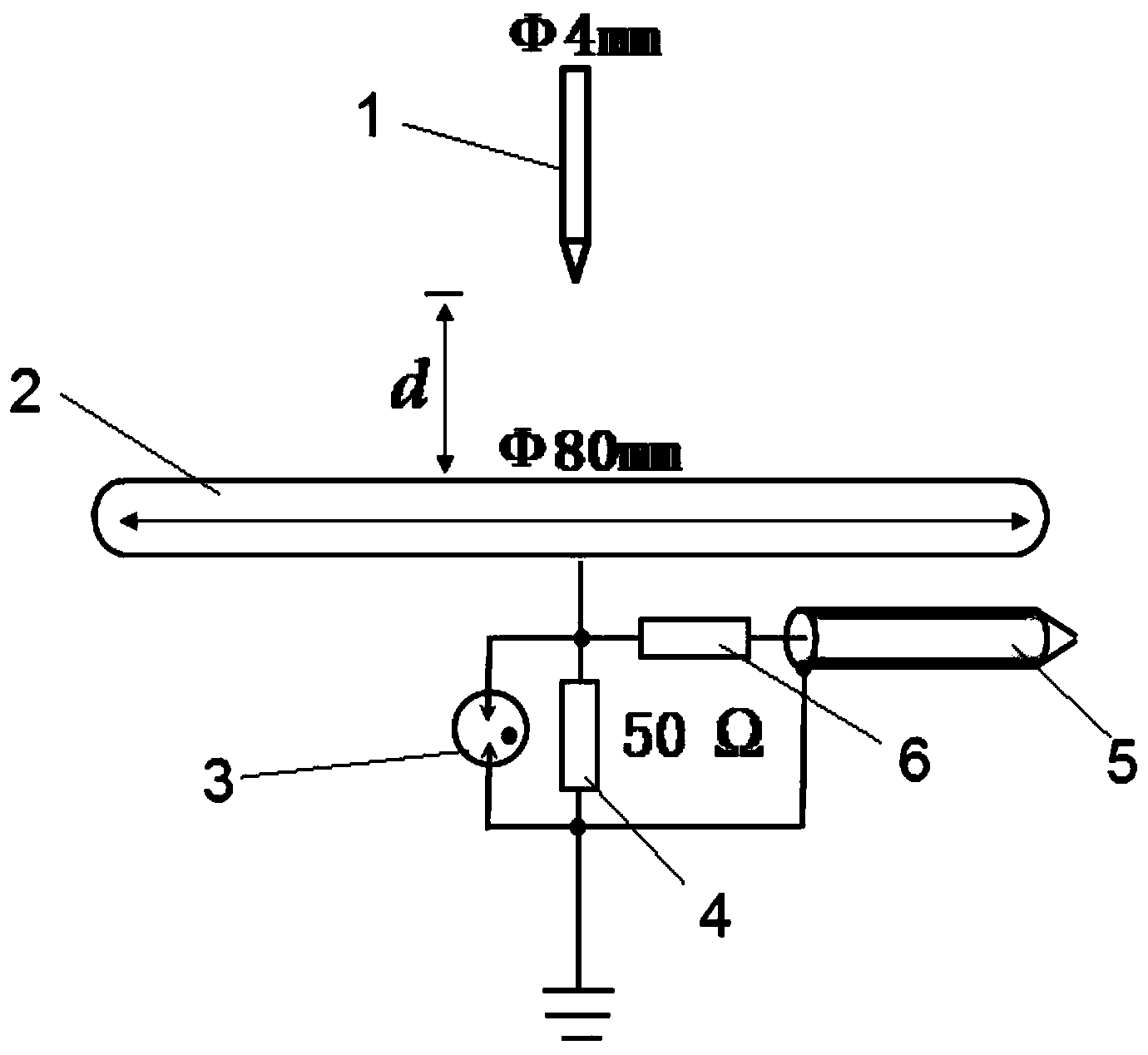

High-frequency unipolarity noninductive pulse discharge signal detecting method

InactiveCN104166077AEfficient detectionImprove accuracyTesting dielectric strengthSignal onElectrical polarity

The invention relates to a high-frequency unipolarity noninductive pulse discharge signal detecting method. The high-frequency unipolarity noninductive pulse discharge signal detecting method comprises the steps that needle plate electrodes are charged with surge voltage, and a voltage divider is used for collecting surge voltage signals; a current detecting unit collects current signals on the needle plate electrodes in a set sampling period; a photomultiplier observes optical signals produced during interval streamer discharge among the needle plate electrodes; the voltage divider, the current detecting unit and the photomultiplier transmit the detected signals to an oscilloscope. Compared with the prior art, the high-frequency unipolarity noninductive pulse discharge signal detecting method has the advantages of being high in precision, high in reliability and the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

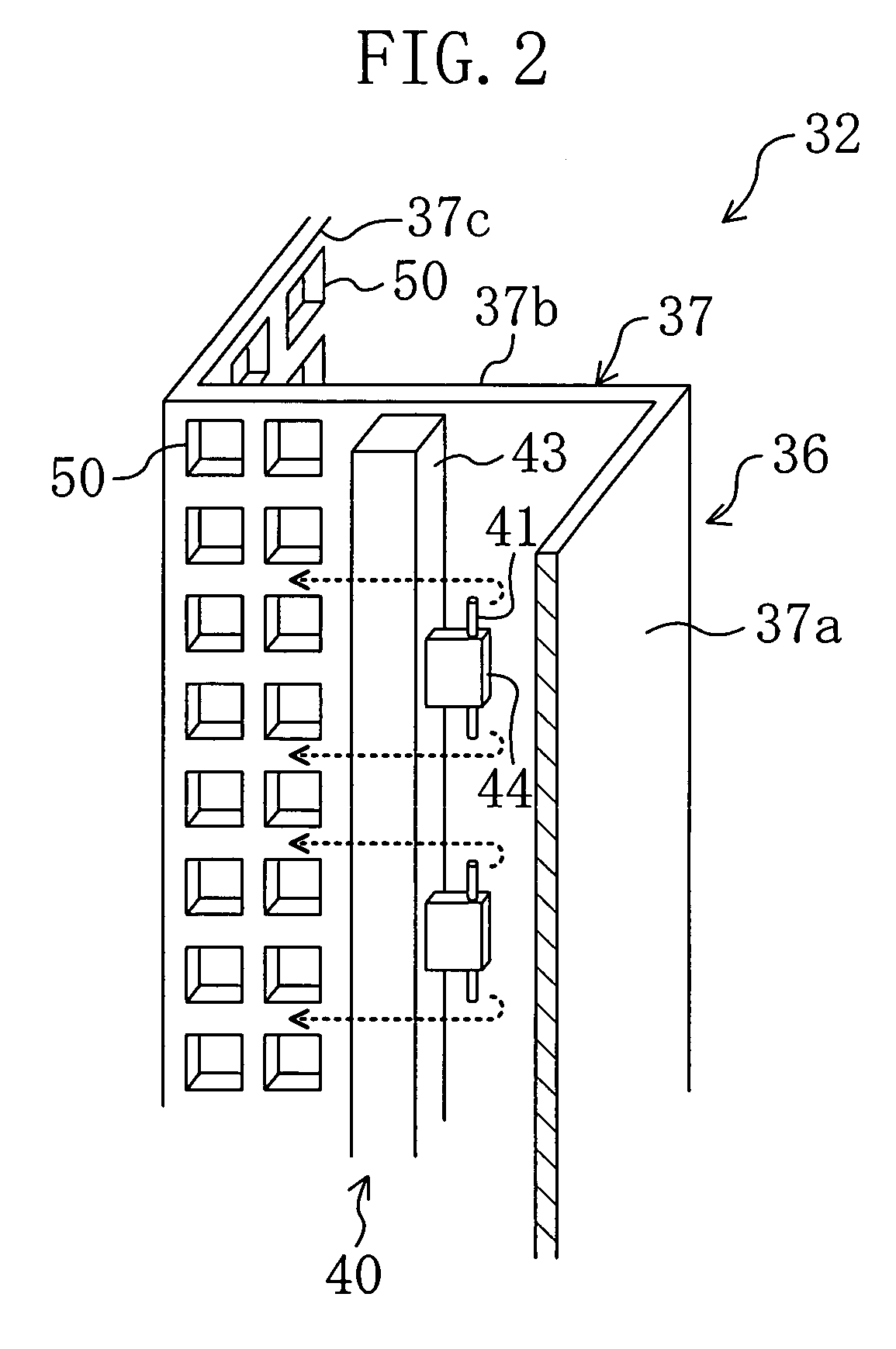

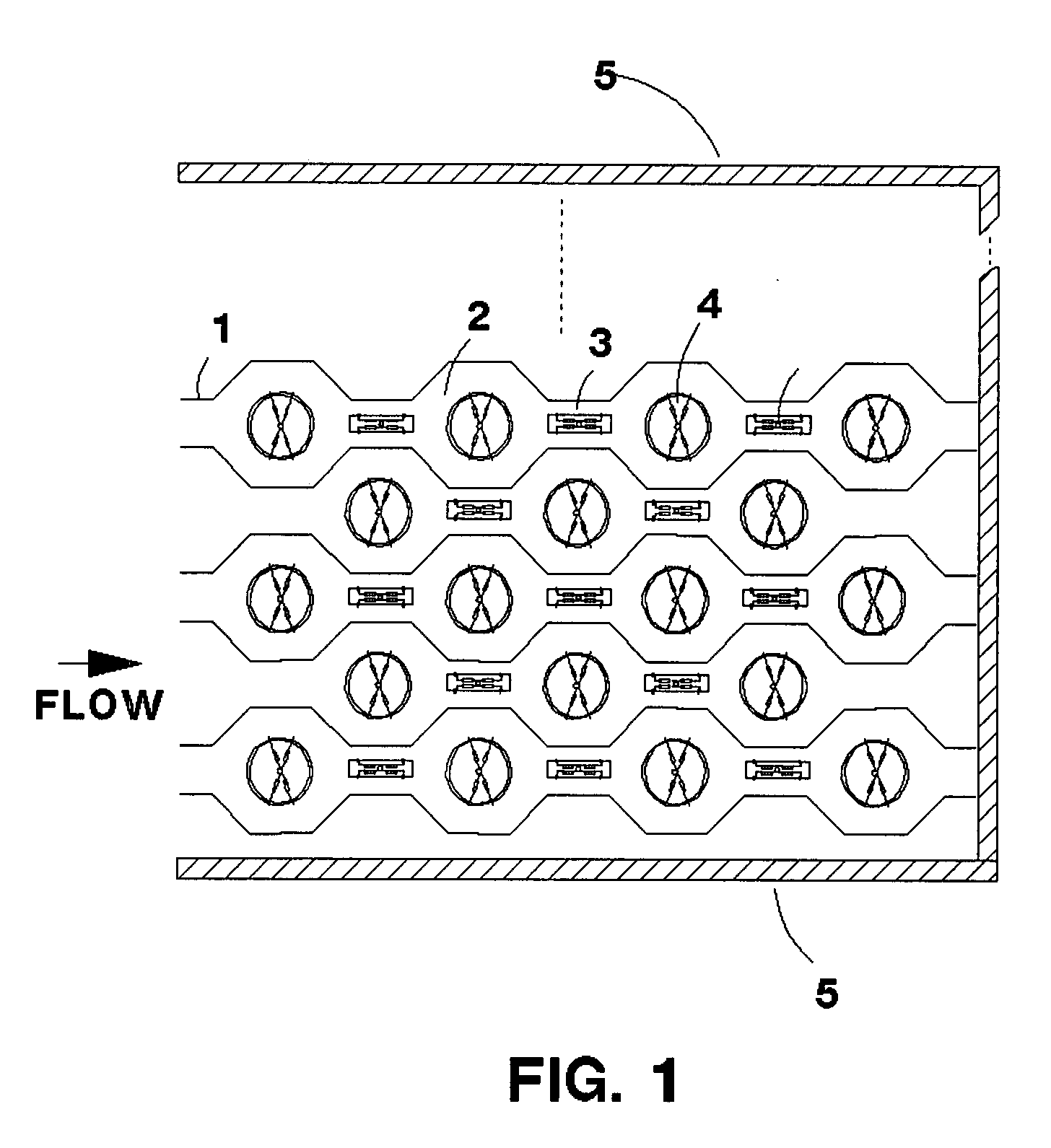

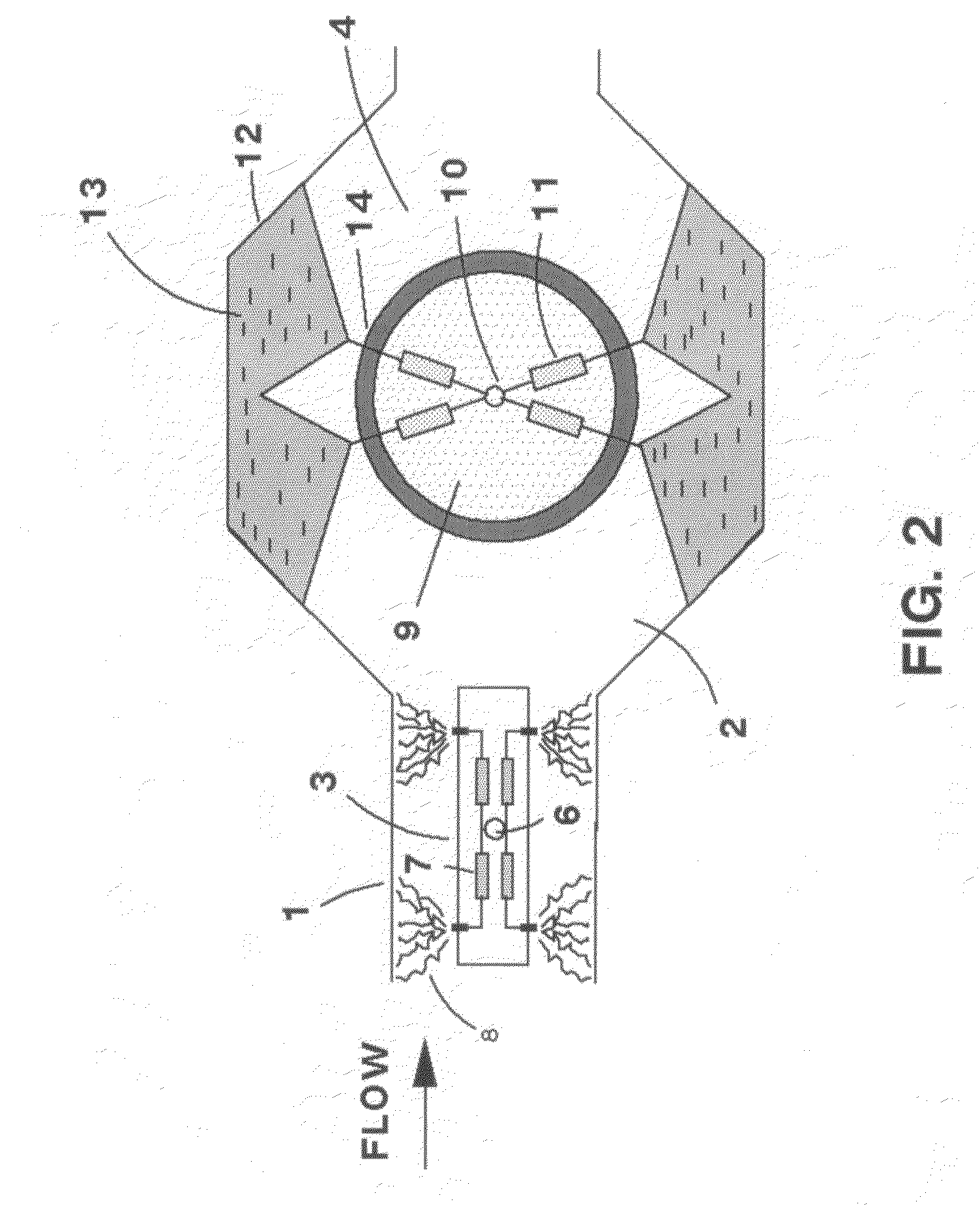

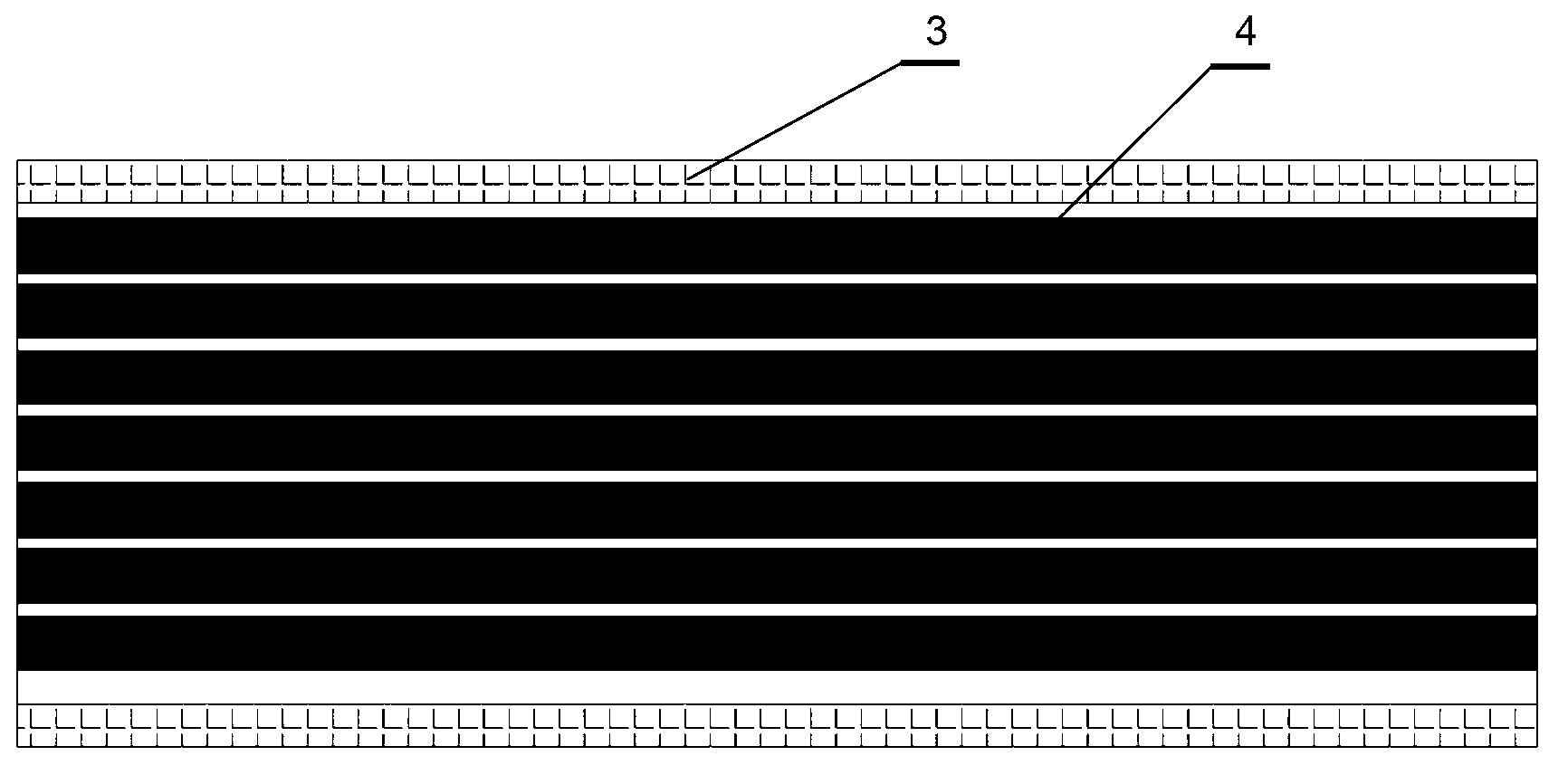

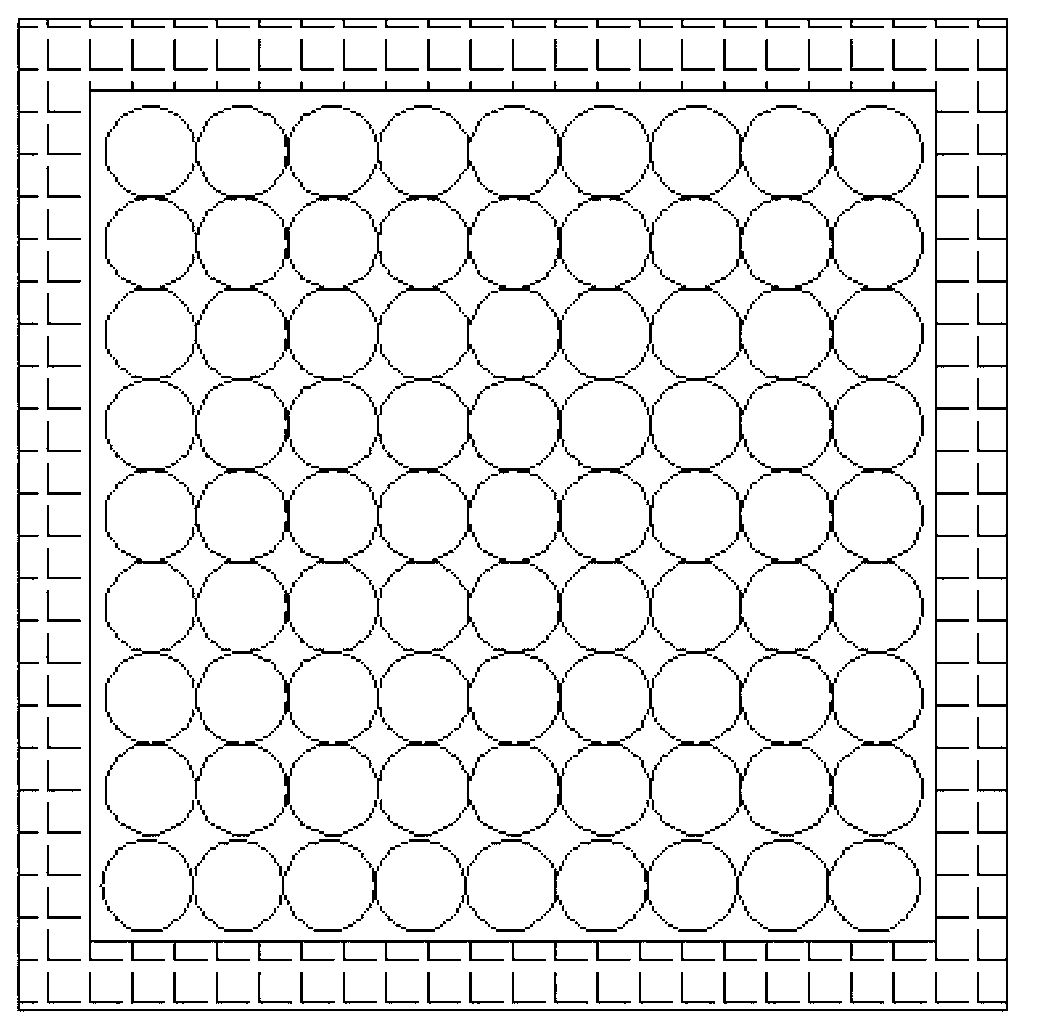

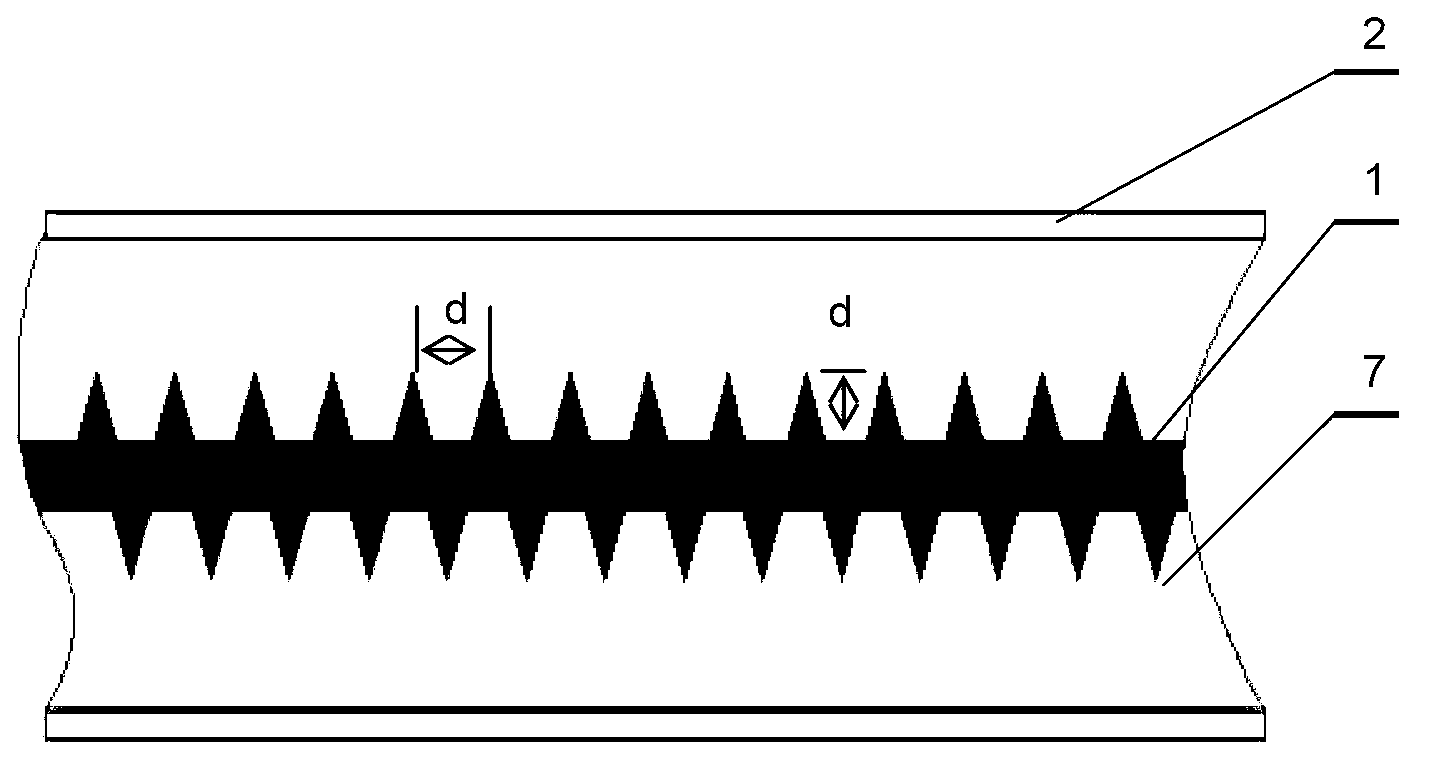

Array-type narrow-gap coaxial streamer discharge reactor for gaseous pollutant pretreatment

Provided is an array-type narrow-gap coaxial streamer discharge reactor for gaseous pollutant pretreatment. A plurality of groups of narrow-gap streamer discharge sub reactors which are connected in parallel are allocated inside the reactor, and the sub reactors are distributed in an array. Each narrow-gap streamer discharge sub reactor is formed by a high-voltage discharge electrode and a low-voltage electrode, the low-voltage electrode is a metal cylinder or a metal tube with the diameter of 5-80mm, the high-voltage discharge electrode is that electrodes are evenly distributed on a metal rod, the high-voltage discharge electrode is installed on a centre shaft of the metal cylinder or the metal tube, and a distance between the tip end of the high-voltage discharge electrode and an inner wall of the low-voltage electrode is 1-20mm. When high voltage is applied between the high-voltage discharge electrode and the low-voltage electrode, streamer discharge with high strength is produced at the position of the discharge gap. The reactor serves as a part of waste gas tube or flue, treated smoke or waste gas firstly enters the array-type narrow-gap coaxial streamer discharge reactor for pretreatment and then enters a conventional smoke waste gas treatment reactor for treatment.

Owner:DALIAN UNIV OF TECH

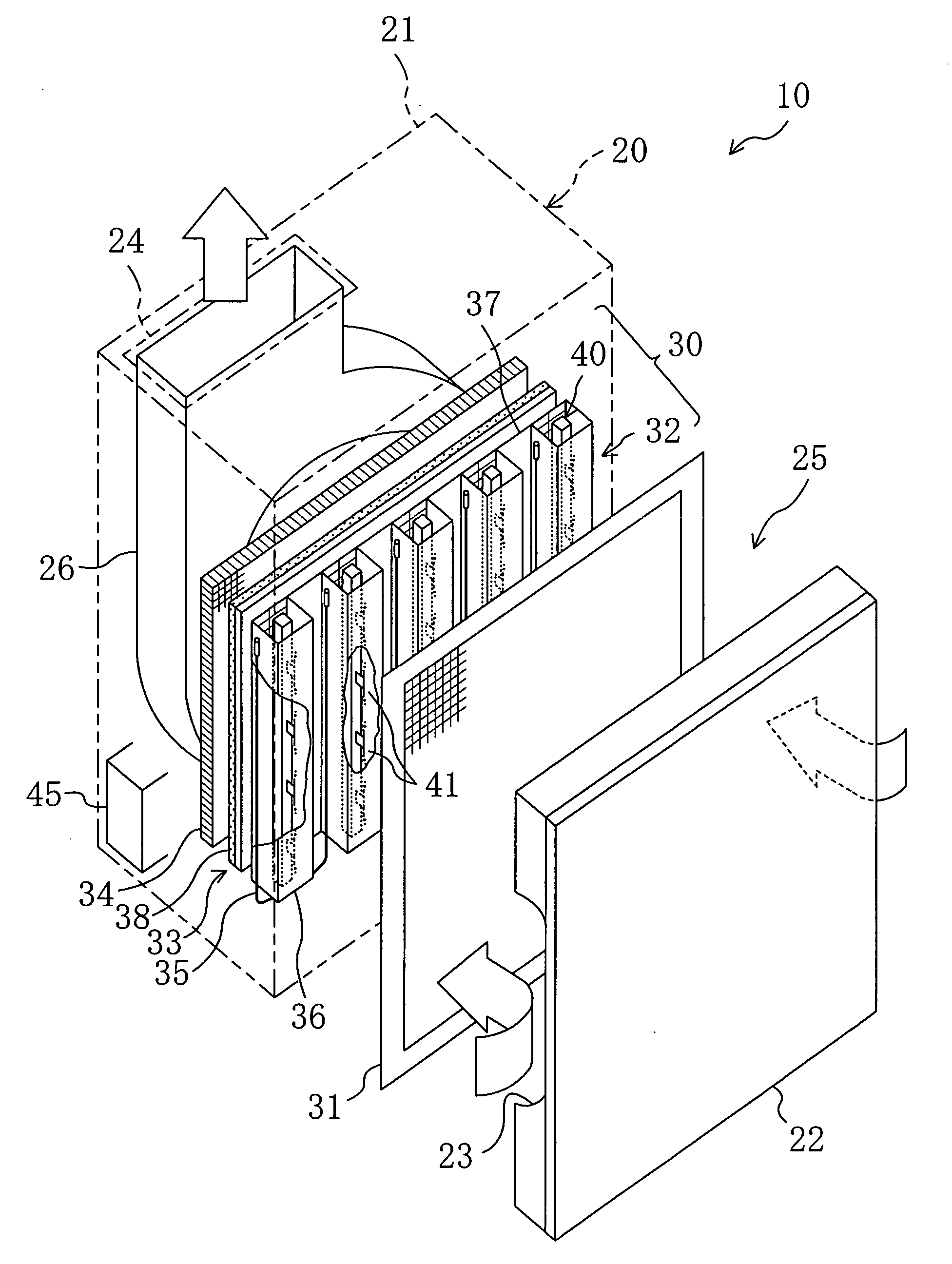

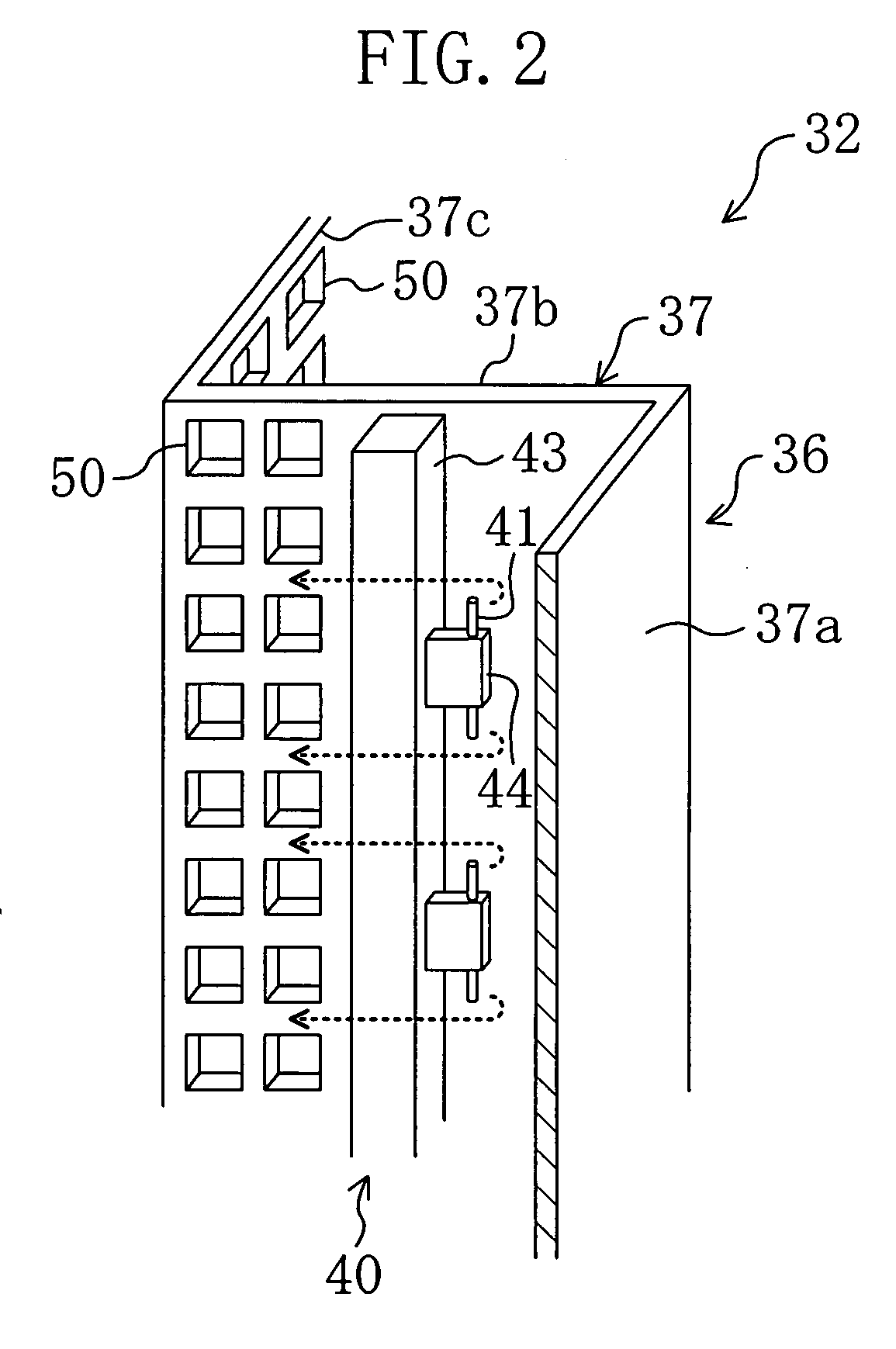

Air cleaner

InactiveCN1842374APlay effectivelyFully playMechanical apparatusDispersed particle filtrationAir cleaningAir treatment

In an air purifier including a streamer discharge part (40) generating plasma by streamer discharge, a catalytic part (34) promoting the treatment of air using active species contained in the plasma and a dust collecting part (33) collecting dust in the air, the streamer discharge part (40), the dust collecting part (33) and the catalytic part (34) are arranged in sequence from the upstream side of the air flow to allow the entire face of the catalytic part (34) to effectively work and also permit the elimination of fungi and the inactivation of allergens in a dust collecting part (33).

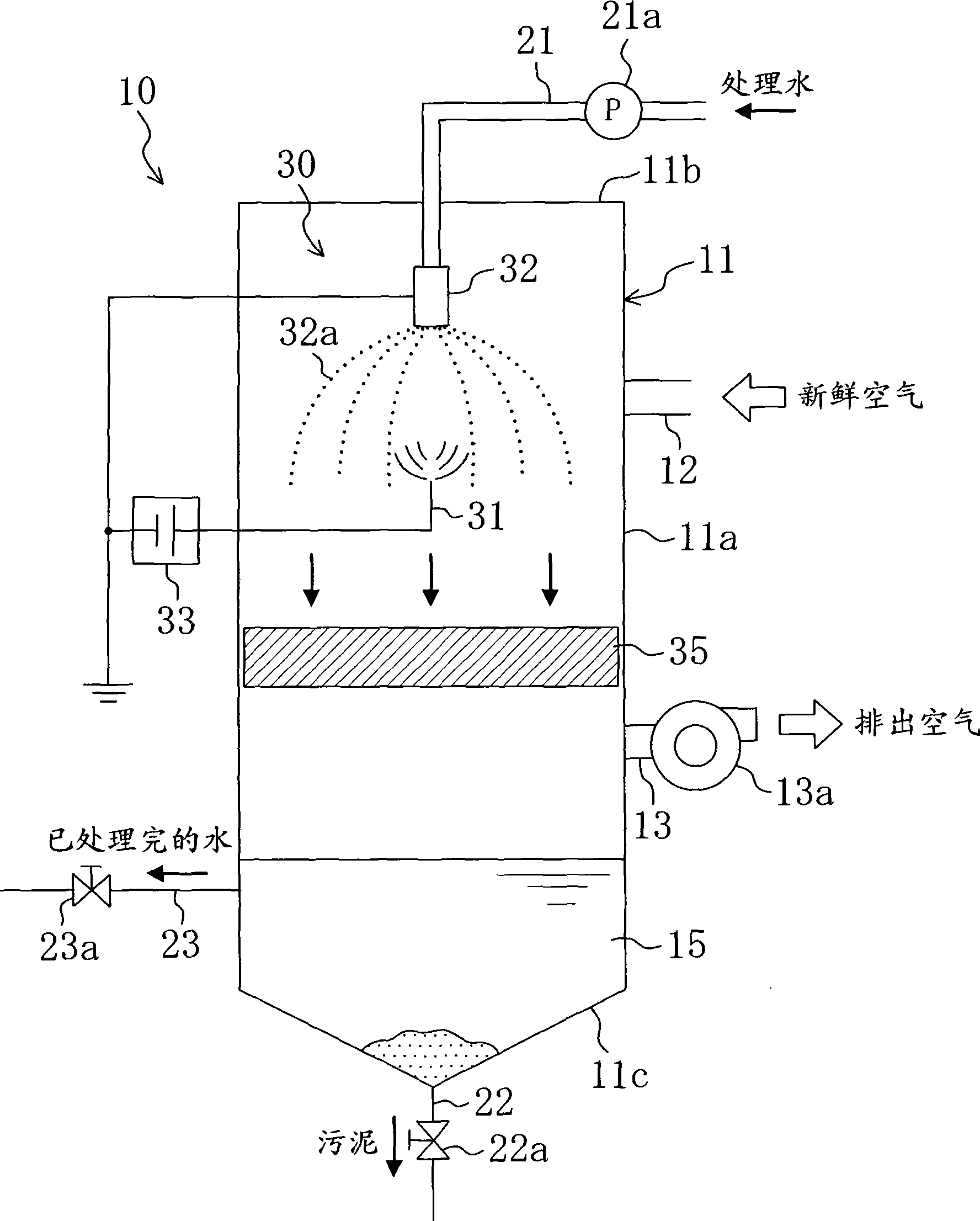

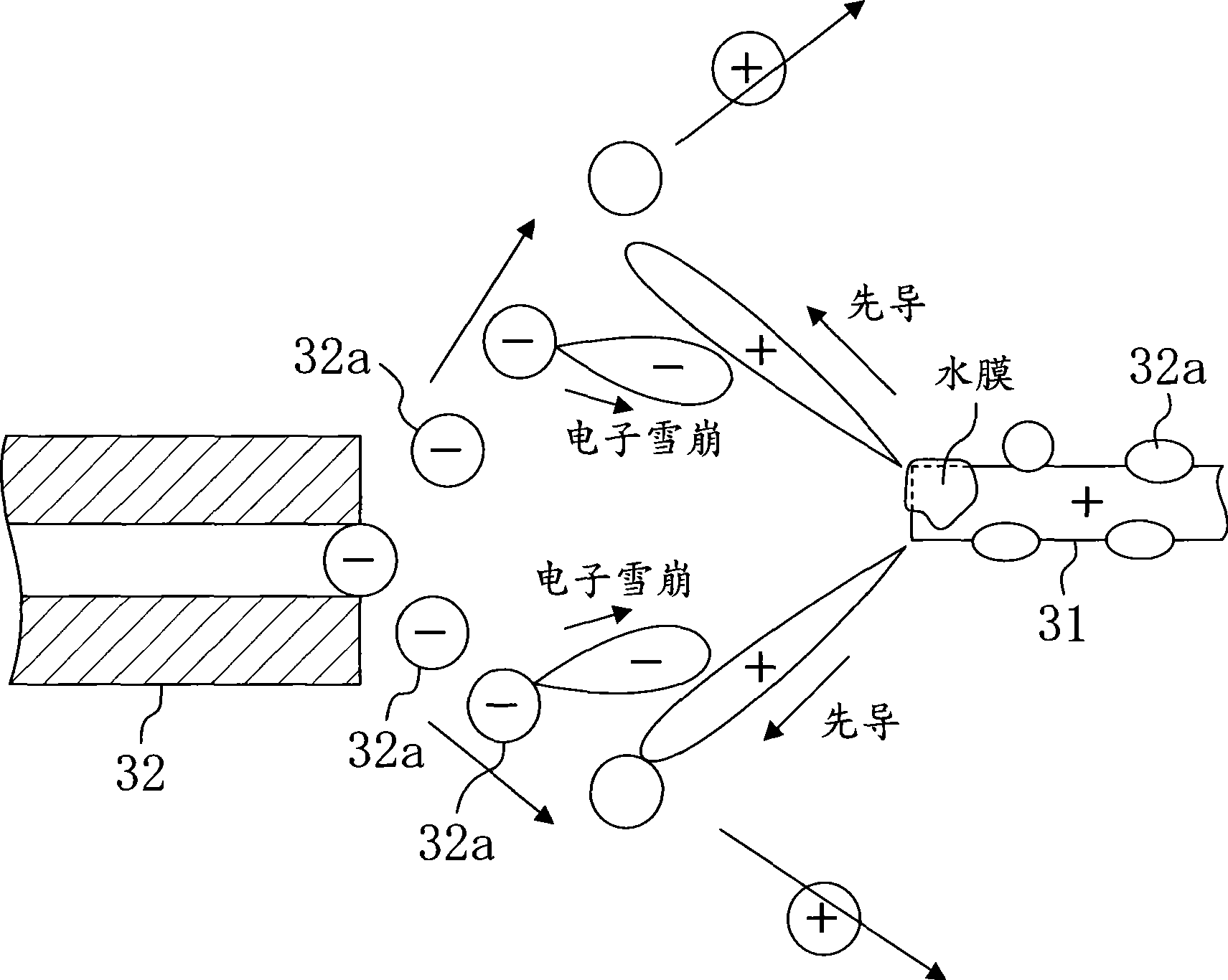

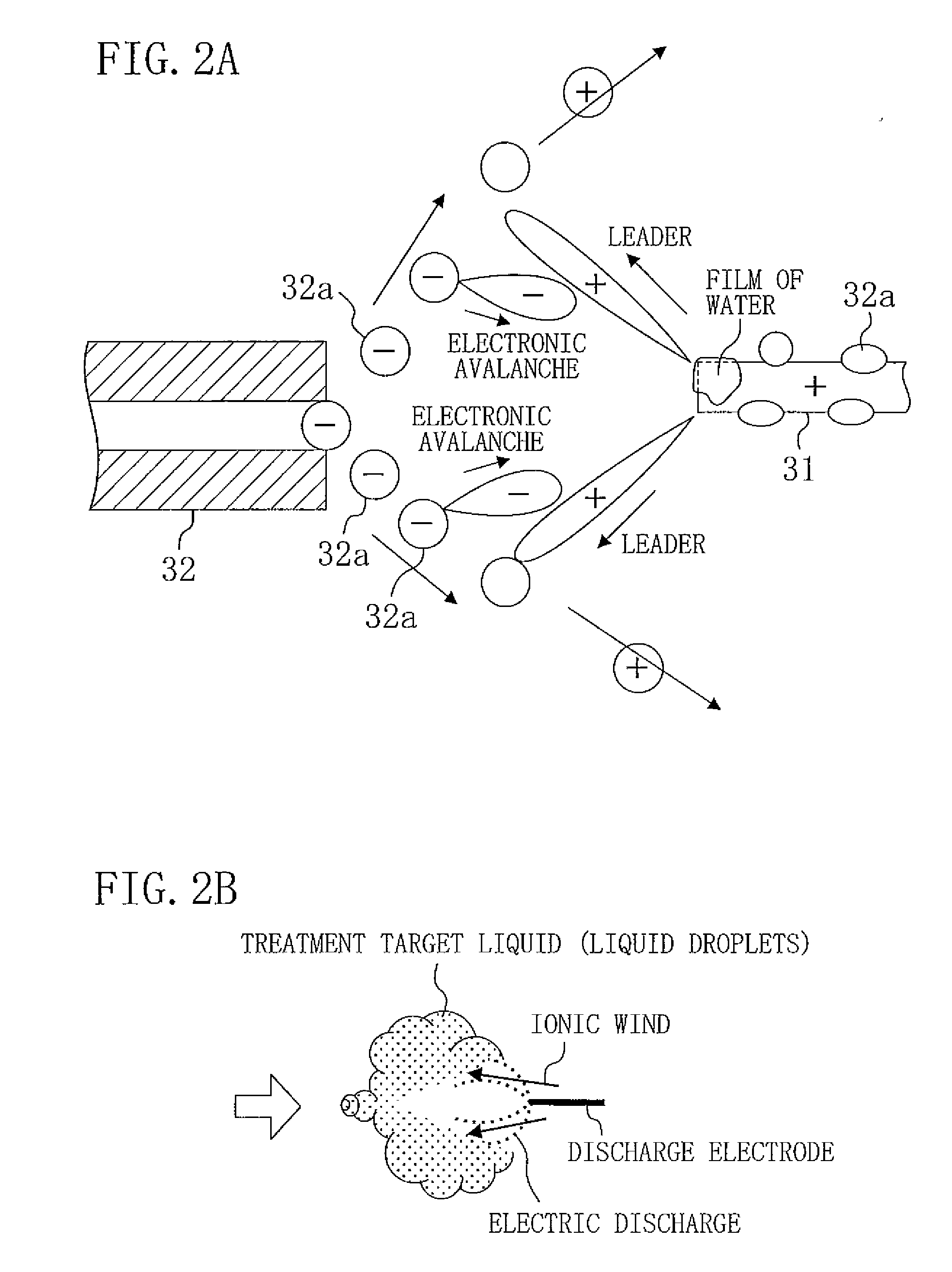

Liquid treatment apparatus, air conditioning system, and humidifier

InactiveUS20090241579A1Effective destructionEffectively oxidatively decompose pollutantsCondensate preventionMixing methodsTreatment targetsEngineering

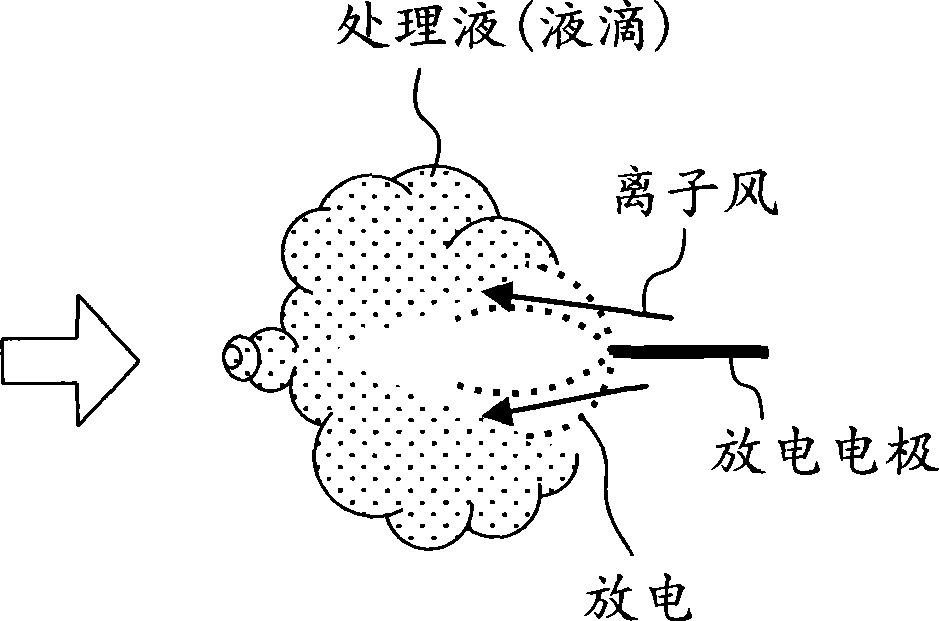

In a liquid treatment apparatus, a discharge electrode (31) and an ejector (32) are arranged face to face with each other. An electric power supply (33) establishes an electric potential difference between the discharge electrode (31) and the ejector (32). As a result, a streamer discharge occurs from the discharge electrode (31) towards liquid droplets (32a) emitted from the ejector (32). Active species produced in association with the generation of the streamer discharge are absorbed in the liquid droplets (32a), whereby the treatment target water (32a) is sterilized and purified.

Owner:DAIKIN IND LTD

Ignition device

ActiveUS20150144115A1Promote generationImprove conductivitySparking plugsMachines/enginesDielectricElectricity

An ignition device includes a center electrode, a center dielectric covering the center electrode, a ground electrode disposed so as to form a discharge space with the center dielectric, and a high energy source for applying an AC voltage between the center electrode and the ground electrode to generate a streamer discharge. A distal end portion of the center electrode projects beyond a distal end of the ground electrode to an inside of the combustion chamber of an internal combustion engine to make a dielectric discharge portion. The ground electrode is formed with an airflow inlet and en airflow outlet at a lateral portion thereof for enabling an in-cylinder airflow to be introduced into the discharge space. A distal end portion of the ground electrode projects radially inward to make a ground electrode projecting portion so that a discharge space narrow portion is formed with the dielectric discharge portion.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com