Streamer discharge test system for insulating oil

A technology of discharge test and insulating oil, which is applied in the direction of measuring electricity, measuring electrical variables, and testing dielectric strength, etc., can solve the problem of lack of discharge characteristics under large gaps of insulating oil, and achieve the effect of ensuring cleanliness and visualization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

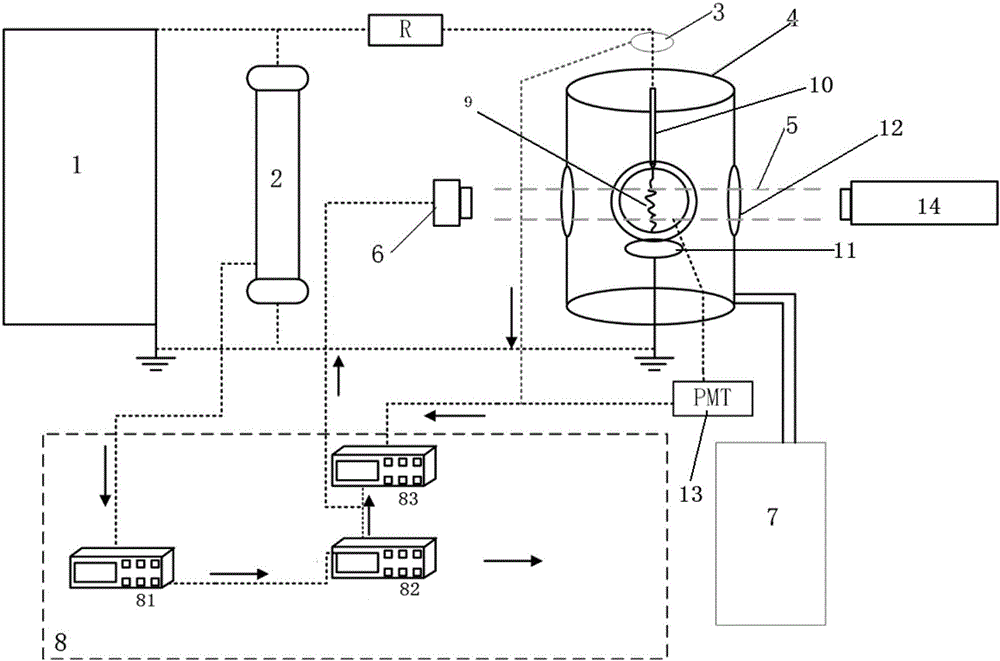

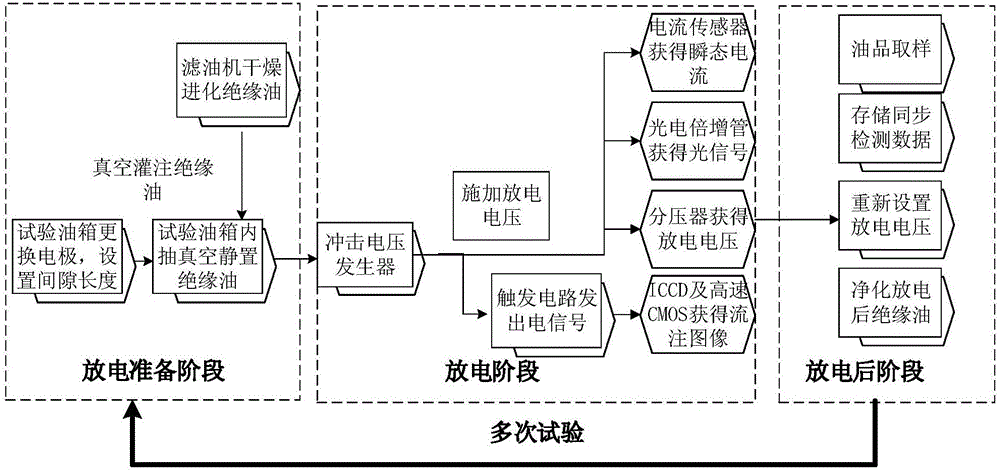

[0015] A flow discharge test system in insulating oil, including an impulse voltage generator 1, a voltage divider 2, a transient current detection device 3, a discharge test oil tank 4, a high-speed imaging recorder 6, a circulating oil filter system 7, a synchronous trigger and The measuring part 8, the photomultiplier tube 13, and the discharge current field enhancement mechanism 14, the voltage divider is connected in parallel to the two ends of the discharge test chamber and the voltage divider is connected with the synchronous trigger and the measuring part, and the discharge test oil tank is connected in parallel to the impulse voltage At both ends of the generato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com