Patents

Literature

249results about How to "Reduce replacement cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

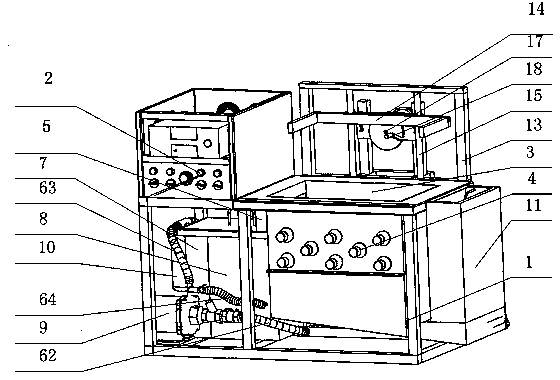

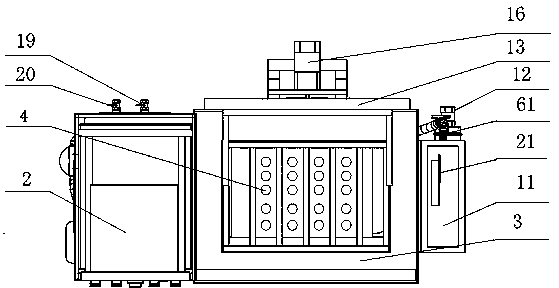

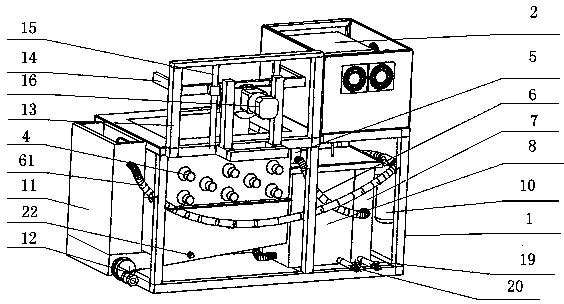

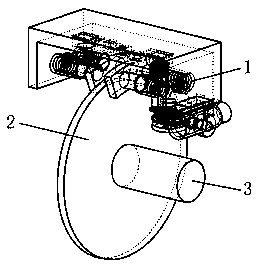

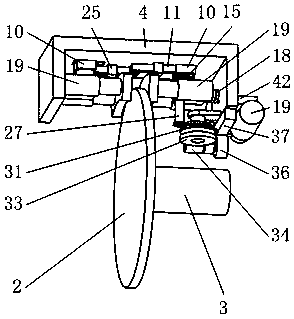

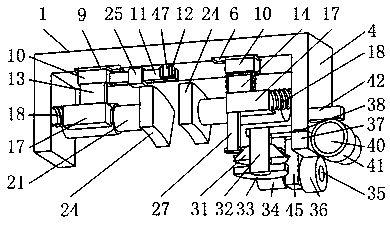

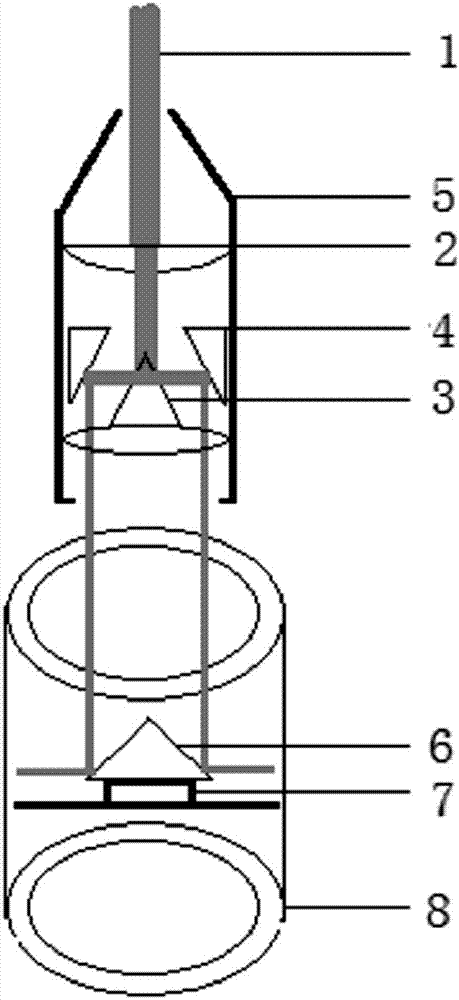

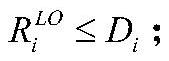

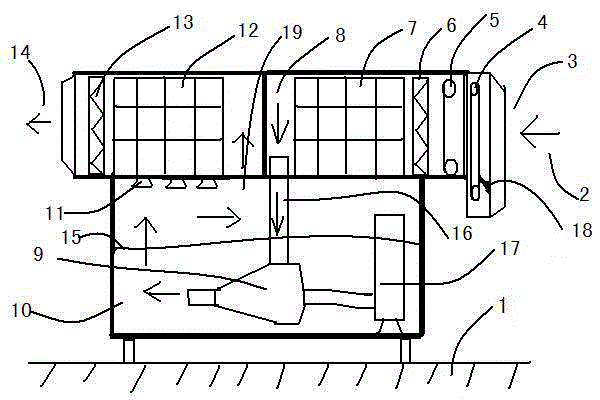

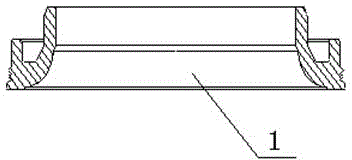

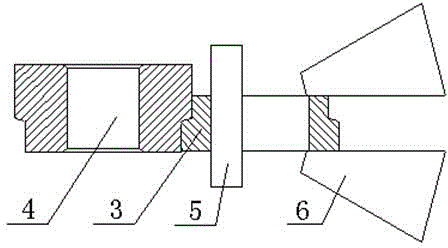

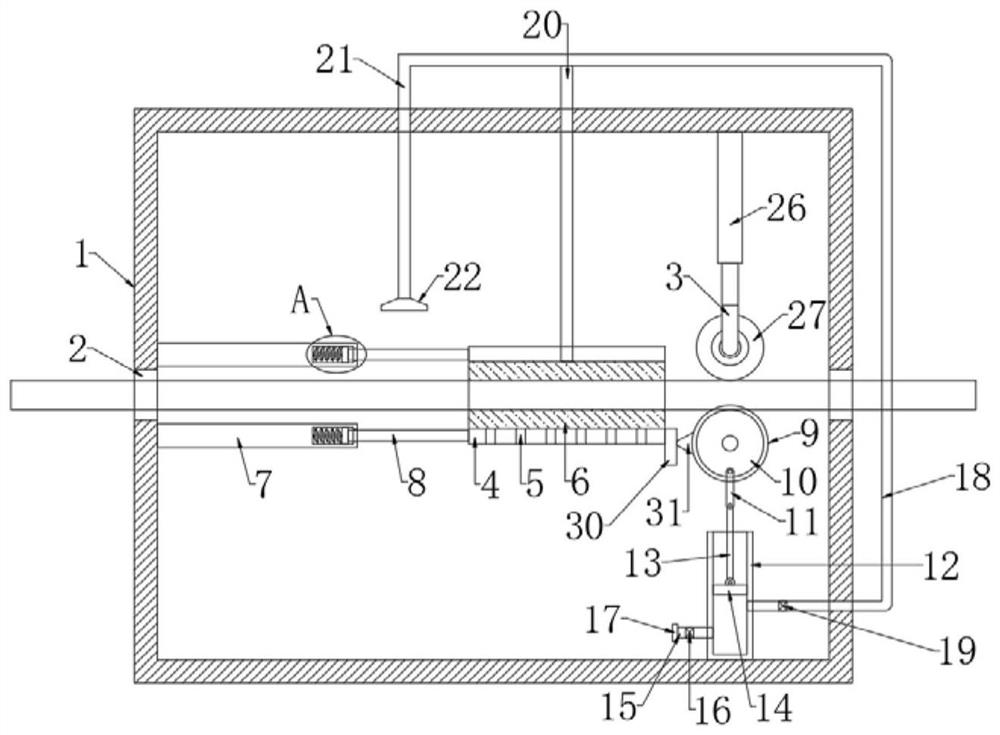

Ultrasonic cleaner

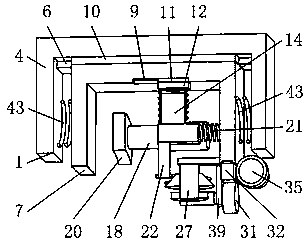

ActiveCN103878143AConsistent cleanlinessReduce replacement cycleCleaning using liquidsFiltrationWater storage tank

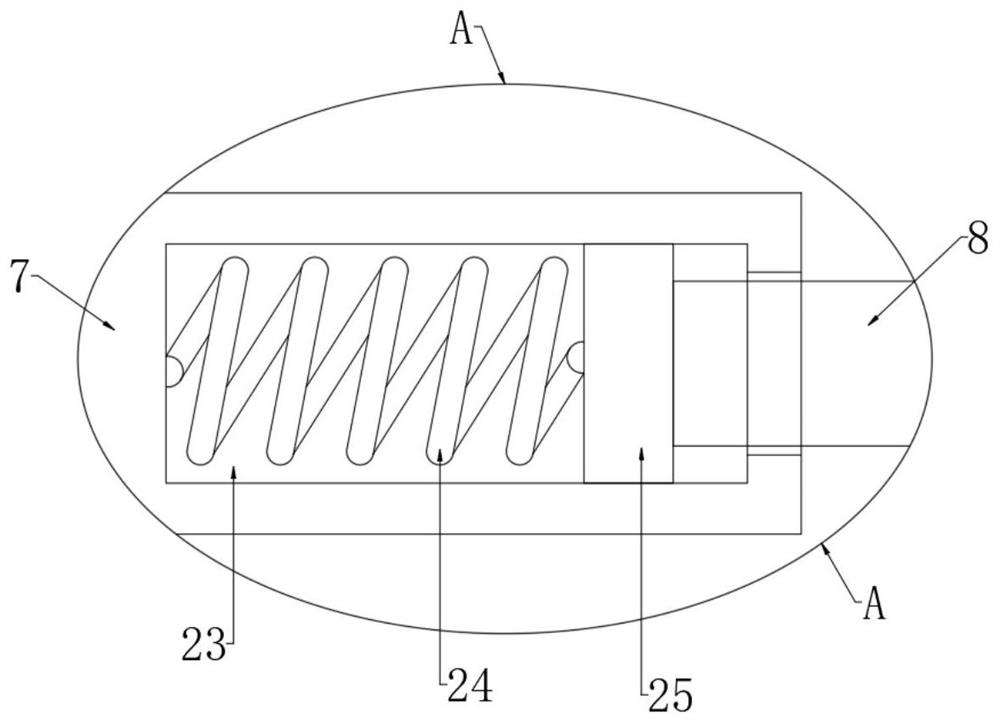

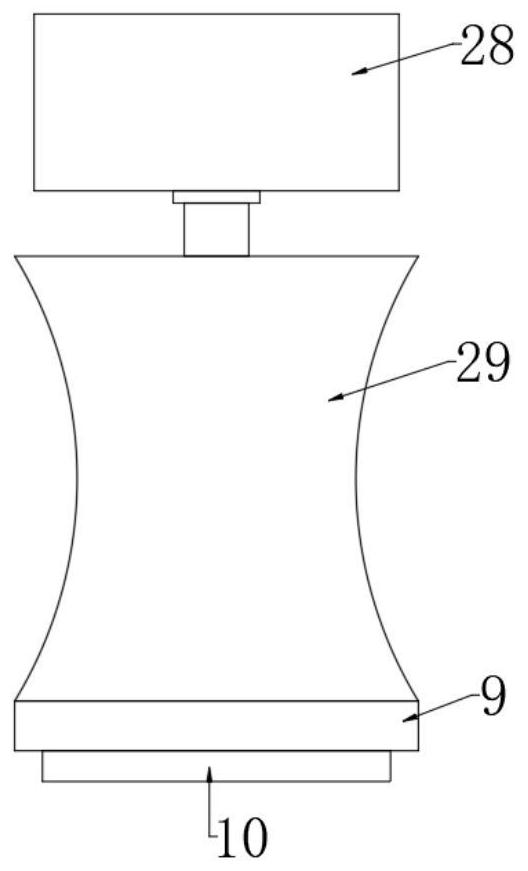

The invention discloses an ultrasonic cleaner and belongs to the field of mechanical equipment cleaning. The ultrasonic cleaner solves the problems that cleaning fluid in an existing ultrasonic cleaner cannot remove impurities in time, and the cleaning fluid is wasted. The ultrasonic cleaner comprises a rack (1), an ultrasonic generator (2), a cleaning tank (3) and ultrasonic vibrators (4). A water circulation device is arranged on the outer side of the cleaning tank (3) and comprises an overflow tank (5) arranged on one side of the cleaning tank (3). The water circulation device further comprises the overflow tank, an oil contamination tank (7), a water storage tank (8), a water pump (9), a filter (10) and a water injection tank (11). The bottom of the water injection tank (11) is communicated with the cleaning tank (3). The bottom of the cleaning tank (3) is an inclined plane. The ultrasonic cleaner integrates the functions of heating, ultrasonic waves, circulating filtration, oil-water separation and article movement, the cleaning speed is high, and the cleaning effect is good; besides, the ultrasonic cleaner is multifunctional, low in energy consumption and capable of prolonging the replacement cycle of the cleaning fluid and reducing environmental pollution, thereby being wide in application range.

Owner:台州鸿辰机械制造有限公司

High performance concrete reinforced by assorted fiber

The present invention relates to a high-performance mixed fibre reinforced concrete, its composition includes (by volume %) high elastic modulas fibre 1%-5%, low elastic modulus fibre 0.2%-3% and the rest general concrete, the described high elastic modulus fibre is one of steel fibre, carbon fibre and glass fibre, and the described low elastic modulus fibre is one of vinylon fibre, polypropylene fibre, acrylic fibre, nylon fibre and polyethylene fibre. Said invention can be used for making manhole cover which not only has higher strength, but also has higher impact resistance.

Owner:SHANGHAI JIAO TONG UNIV

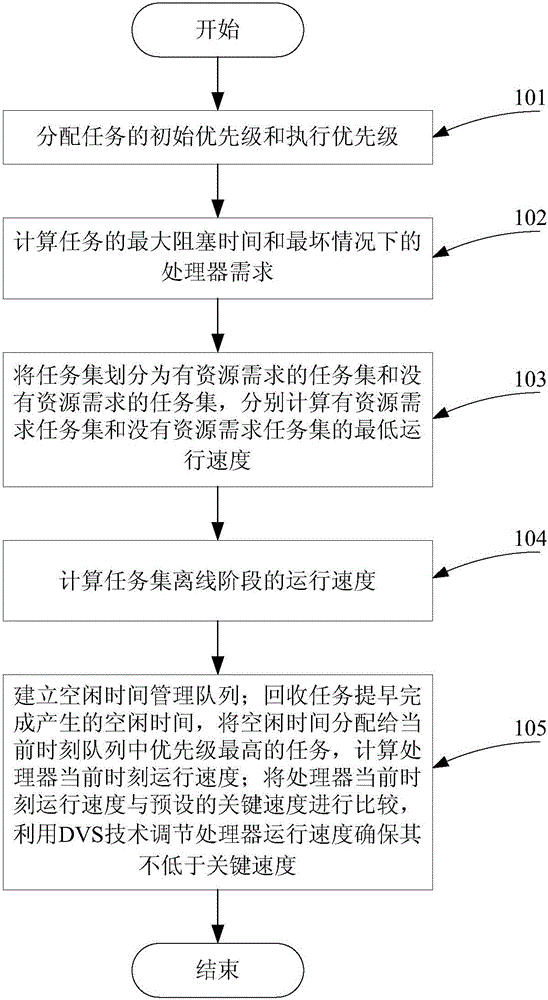

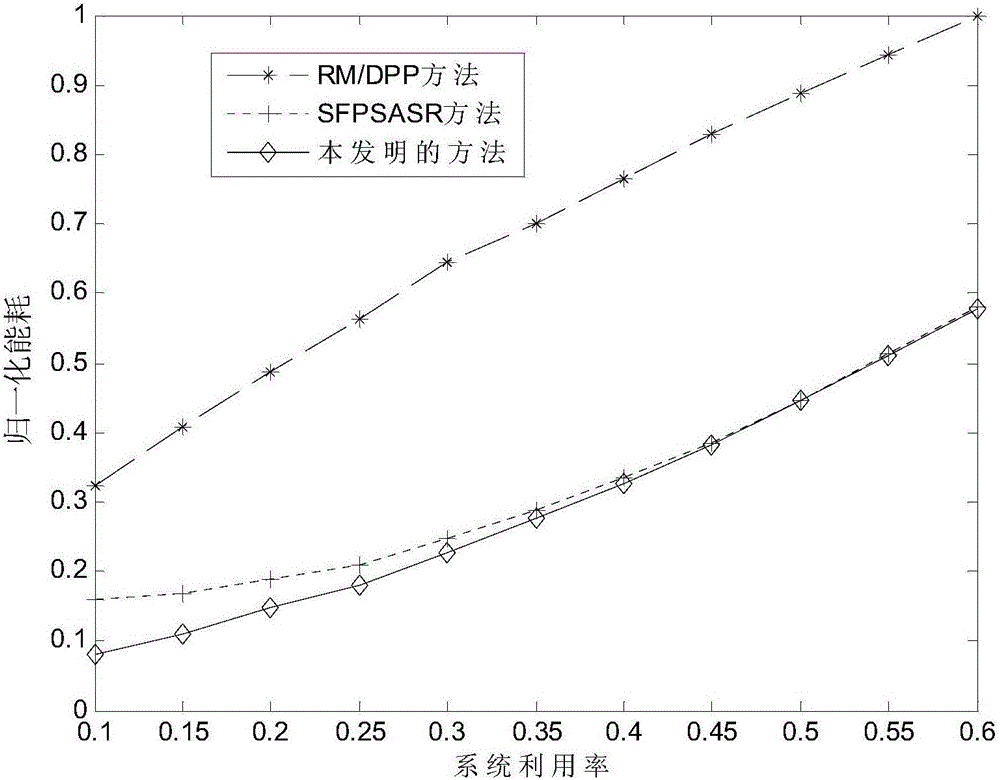

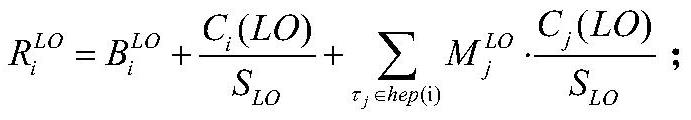

Low-energy-consumption aporadic task scheduling method based on RM strategy

ActiveCN105893148AReduce energy consumptionReduce replacement cycleResource allocationPower supply for data processingIdle timeLinear relationship

The invention discloses a low-energy-consumption aporadic task scheduling method based on an RM strategy. The method comprises the steps that the initial priority and the execution priority of tasks are allocated before task set scheduling; the largest blocking time of the tasks and the processor demands under the worst condition are calculated; task sets are partitioned into the task set with the resource demands and the task set without the resource demands, the lowest running speed of the task set with the resource demands is calculated, and the lowest running speed of the task set without the resource demands is calculated; the running speed of the task sets in the off-line stage is calculated; an idle time management queue is built, the idle time of the tasks is calculated, the running speed of a processor is regulated through a DVS technique, and it is guaranteed that the final running speed is not lower than the key speed. According to the method, the condition that a universal power consumption model, the execution time of the tasks and the processor speed have the non-linear relationship and the processor speed switching expense are taken into account, the DVS technique and a DPM technique are combined, and therefore the energy consumption is greatly reduced.

Owner:HUAQIAO UNIVERSITY

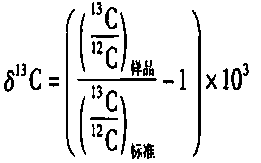

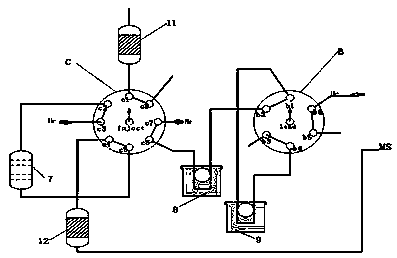

Enrichment analyzer for carbon and hydrogen elements in greenhouse gas CH4

ActiveCN103743846AGuaranteed purityEliminate the effects of humidityComponent separationMass spectrometryIsotope

The invention discloses an enrichment analyzer for carbon and hydrogen elements in greenhouse gas CH4. Guiding in a greenhouse gas sample collected by a sample pipe at the presence of gas He by a sample guide valve; removing CO in air by a chemical trap; removing other miscellaneous gases by a pre-refrigerating cold trap, entering an oxidizing furnace, oxidizing into CO2 and H2O; enriching and transferring the generated CO2 in a liquid nitrogen cold trap; separating by a chromatographic column, adsorbing and dewatering by a water trap; guiding into a gas isotope ratio mass spectrometer by a shunt interface to detect; releasing the generated H2O by a water collecting cold trap to enter a Cr reaction furnace; guiding the generated H2 after reaction into the gas isotope ratio mass spectrometer by the open shunt interface to detect. The enrichment analyzer provided by the invention is provided with an interface directly connected with a host machine of the isotope ratio mass spectrometer, is an independent isotope mass spectrometer accessory device, meanwhile analyzes and determines the enrichment of carbon and hydrogen elements of the greenhouse gas CH4 and the isotope abundance; a target gas is purified and converted by utilizing a cold trap combination; the purity of a sample entering the mass spectrum is ensured; oxygen is timely and automatically supplied to the oxidizing furnace, and the oxidation capability of CuO is kept.

Owner:NORTHWEST INST OF ECO ENVIRONMENT & RESOURCES CAS

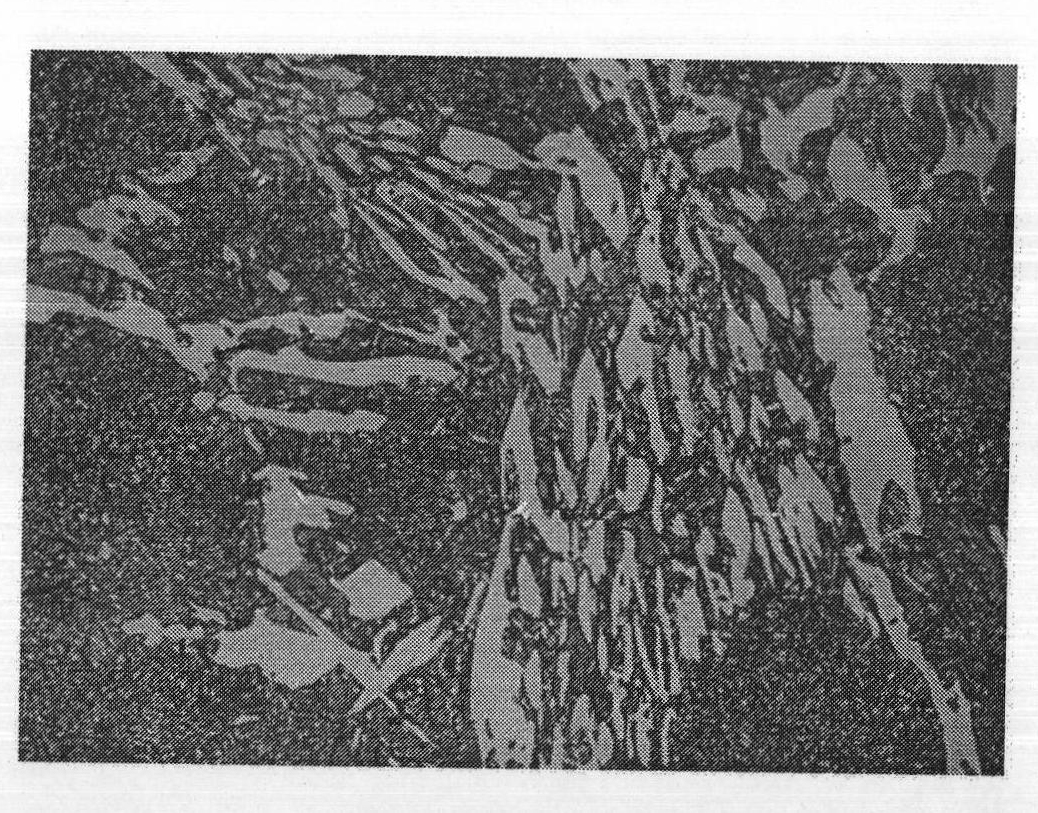

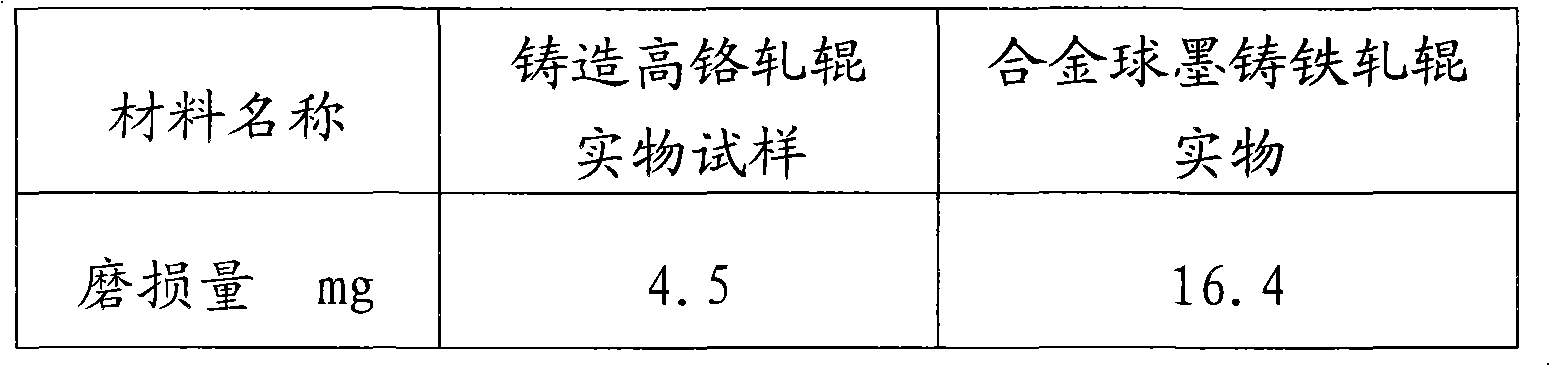

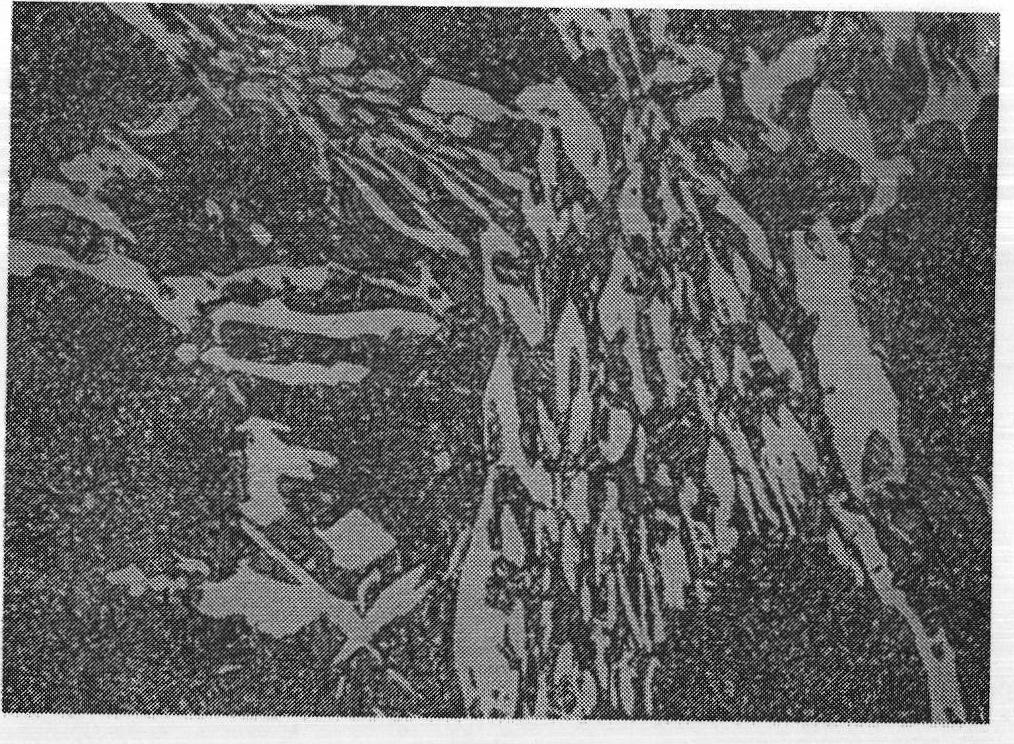

Preparation method of high-chromium roller for steel tube reducing mill or sizing mill and high-chromium roller prepared thereby

ActiveCN102251185AHigh hardnessReduce replacement cycleFoundry mouldsFurnace typesSand castingHardness

The invention discloses a high-chromium cast roller for a steel tube reducing mill or sizing mill and a preparation method thereof. The preparation method is characterized by optimizing the design of components, selecting the component proportioning of the roller according to the application of the roller and the specific in-service working conditions and technical requirements, and melting corresponding iron alloy, scrap steel and other raw materials to obtain required molten steel; carrying out centrifugal or sand casting to obtain blanks of a required size; and carrying out annealing, quenching, tempering and other thermal treatment on the cast blanks, and carrying out turning, milling and other machining operation to produce the high-chromium roller for a hot rolling seamless steel tube tension reducing mill and sizing mill. The surface hardness of the roller disclosed by the invention is obviously improved, and the macrohardness is up to 54-62 HRC, so that the service life of the high-chromium cast roller is increase by at least two times. Because of the increase of the wear resistance and service life, the replacement frequency of the roller is reduced, thereby saving the materials and production cost. Besides, the rolling capability and yield of the seamless steel tube unit is improved.

Owner:SHANDONG PROVINCE SIFANG TECHN DEV

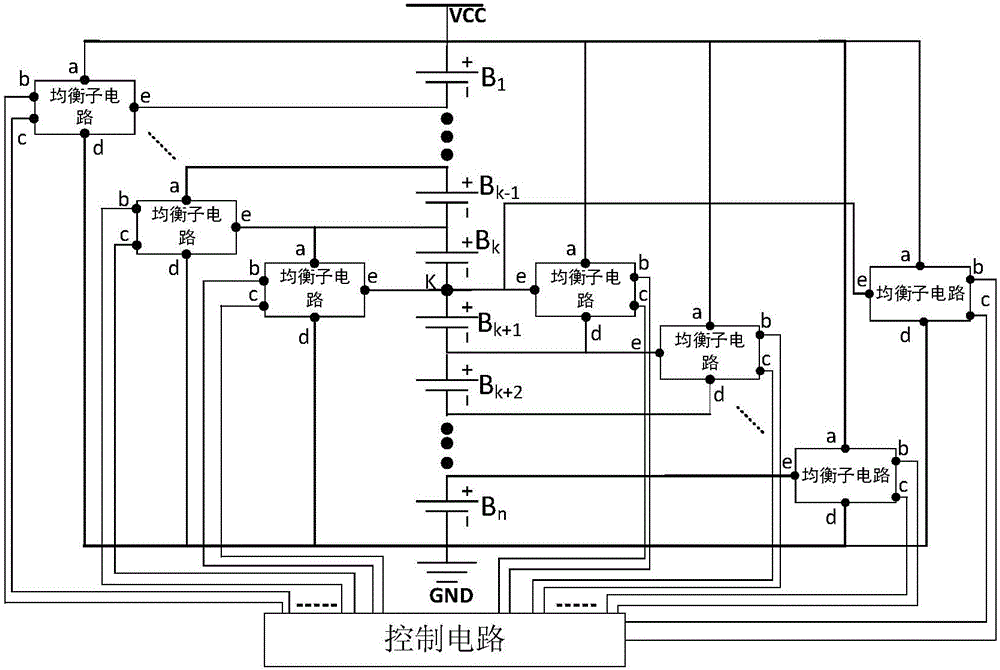

Battery pack electricity equalization circuit and equalization method

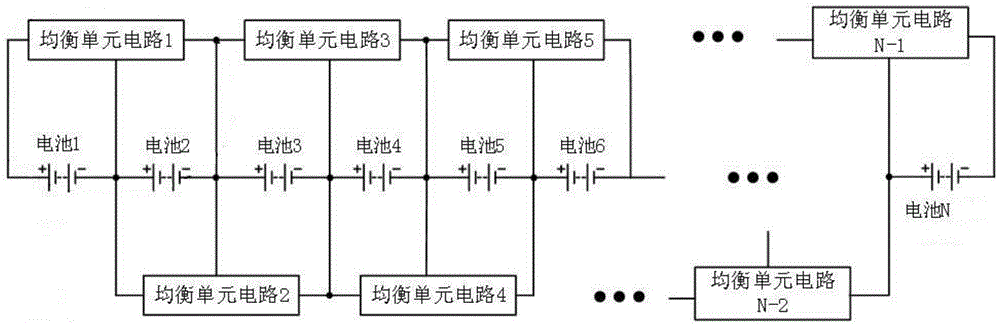

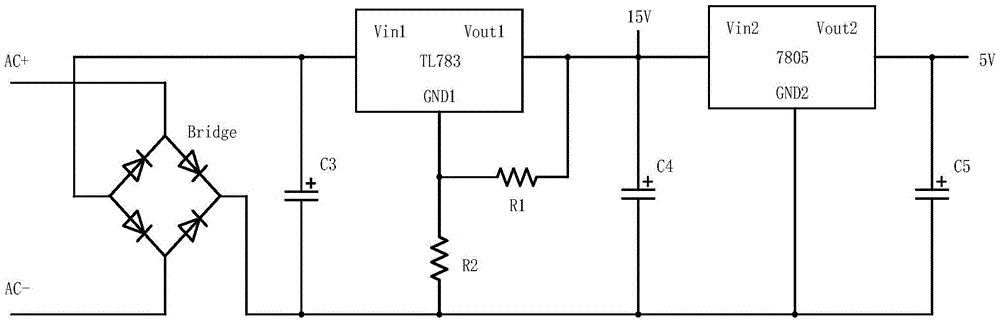

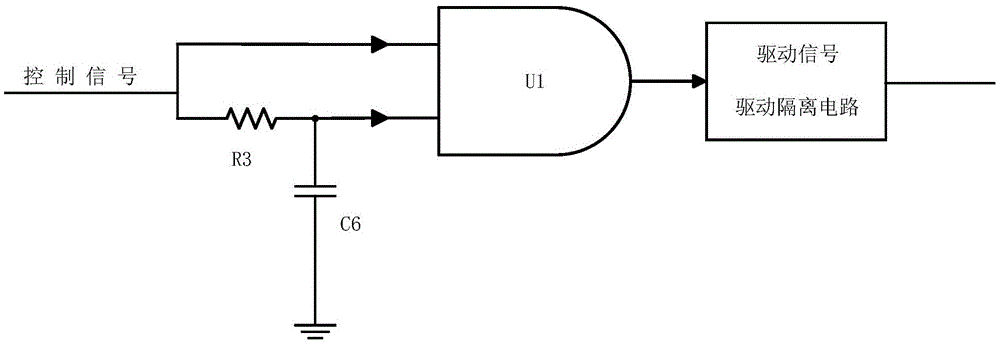

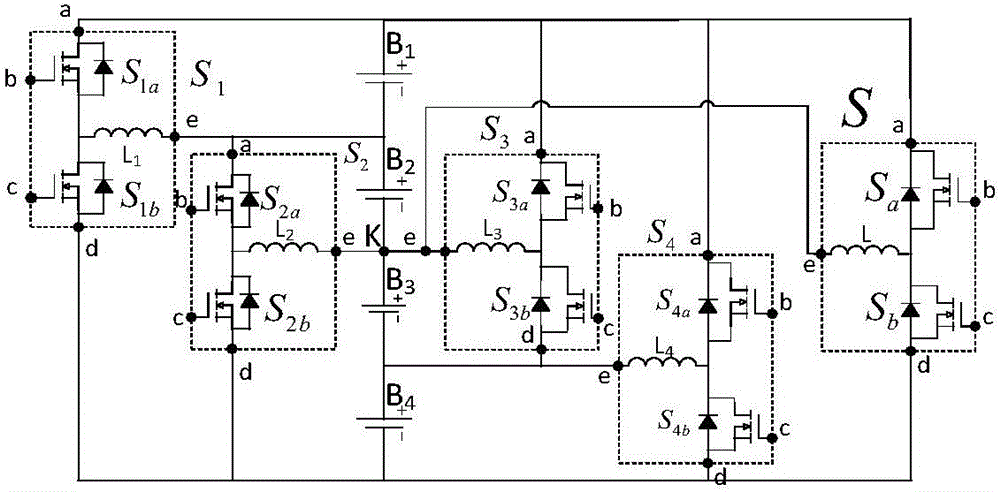

InactiveCN105553026AImprove imbalanceIncrease usable capacityCharge equalisation circuitSafety/protection battery circuitsMicrocontrollerElectricity

The invention discloses a battery pack electricity equalization circuit. The battery pack electricity equalization circuit comprises N-1 battery equalization unit circuits, N voltage sampling circuits, an auxiliary power module, a single-chip microcomputer control module and a driver module, wherein the Kth voltage sampling circuit and the (K+1)th voltage sampling circuit acquire a voltage at two ends of a Kth battery and a voltage at two ends of a (K+1)th battery, and transmit the voltages to the single-chip microcomputer control module; the single-chip microcomputer control module outputs a driver signal to the driver module according to the voltages; the driver signal output by the driver module is transmitted to the Kth battery equalization unit circuit; and the Kth battery equalization unit circuit controls the Kth battery to be discharged and the (K+1)th battery to be charged or controls the Kth battery to be charged and the (K+1)th battery to be discharged, so that electricity equalization of the Kth battery and the (K+1)th battery can be achieved, wherein K is greater than or equal to 1 and less than or equal to N-1. According to the equalization circuit and method, the equalization circuit is simple in structure, high in conversion efficiency, low in cost and high in reliability, and can expand the available capacity of a battery pack and prolong the service life of the battery pack.

Owner:SOUTH CHINA UNIV OF TECH

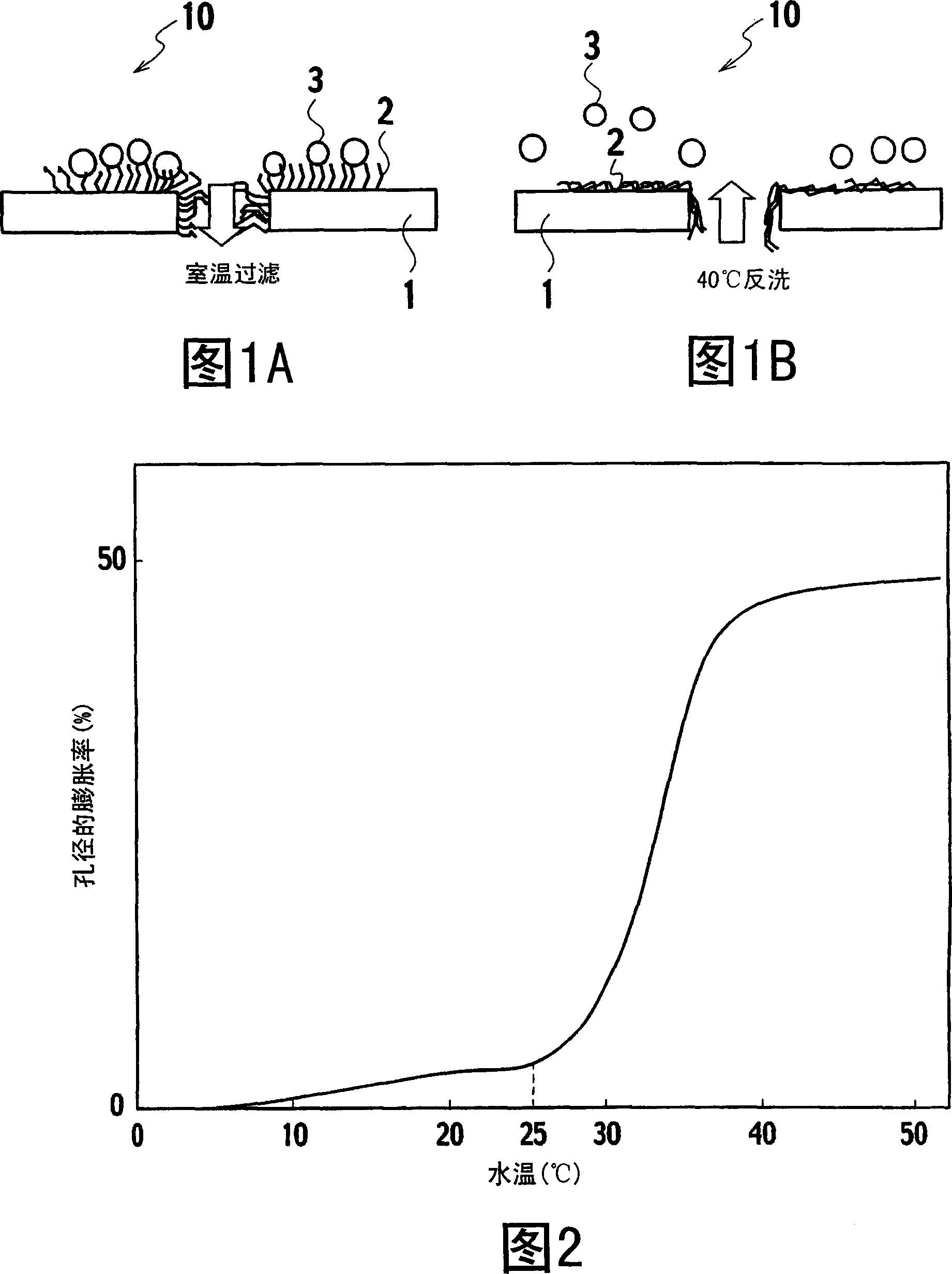

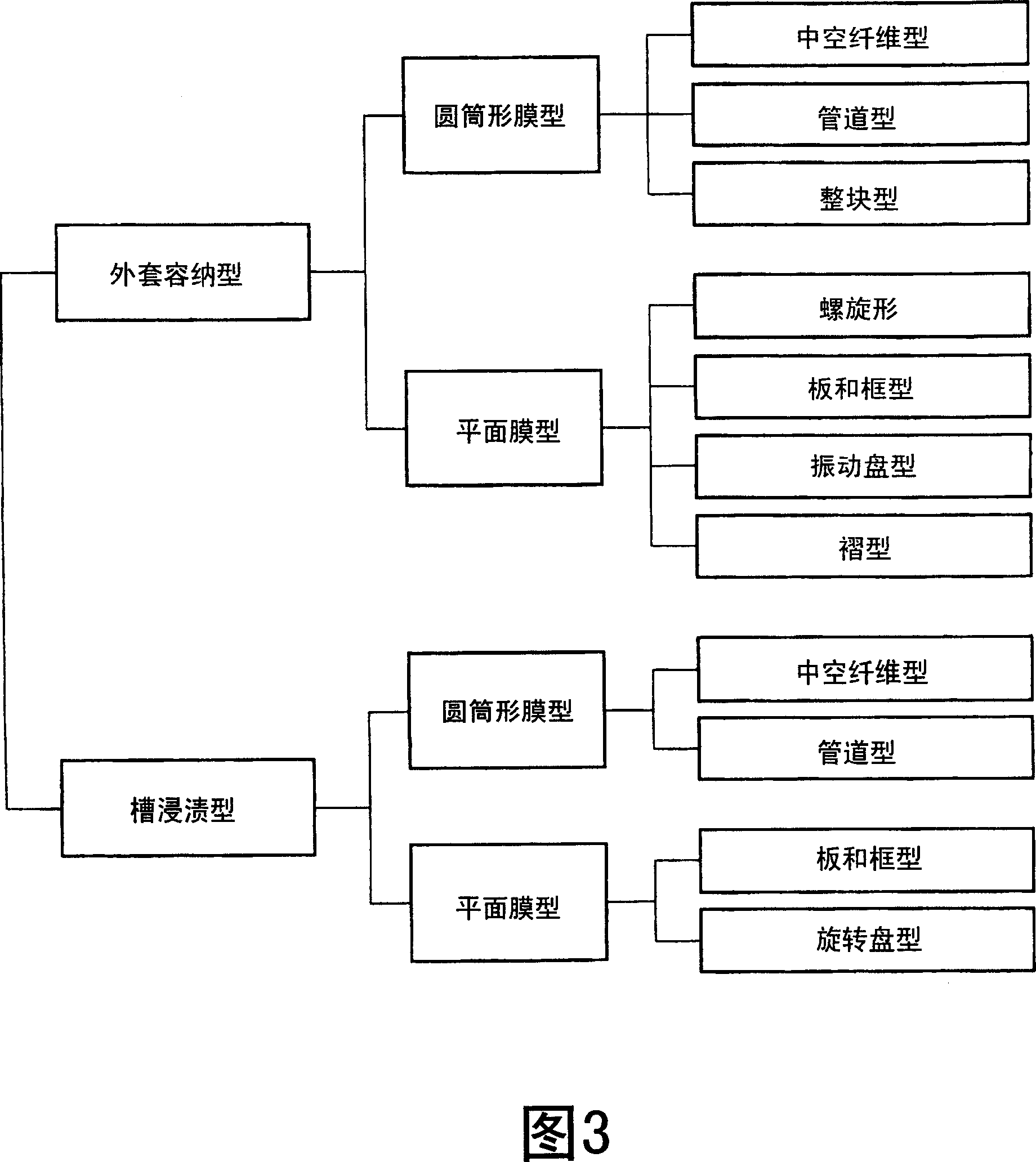

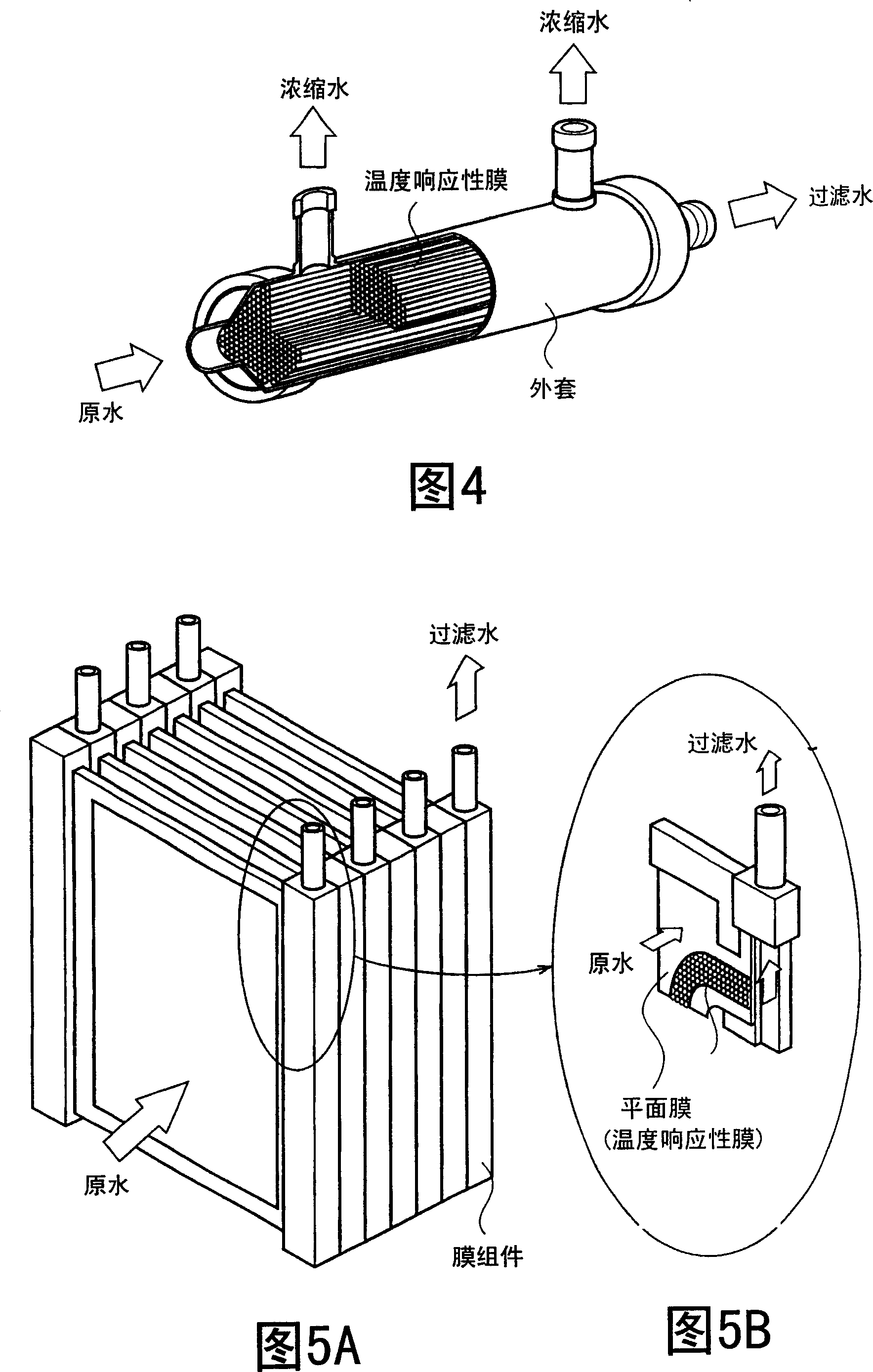

Temperature-responsive membrane, temperature-responsive membrane module, and membrane filtration system in which the same are used

InactiveCN1962040AReduce replacement cycleLow costMembranesWater treatment parameter controlFiltrationTreated water

Provided is a membrane filtration system which makes it possible to improve operation rate of the system by increasing the amount of water to be treated, and to reduce costs required for chemical washing and replacement of a membrane. Accordingly, a total running cost is reduced. The membrane filtration system is provided with temperature-responsive membrane modules for filtering supplied raw water to discharge it as treated water. In each of the temperature-responsive membrane modules, temperature-responsive membranes are formed into any one of planar and cylindrical forms, and are then filled into a container.

Owner:KK TOSHIBA

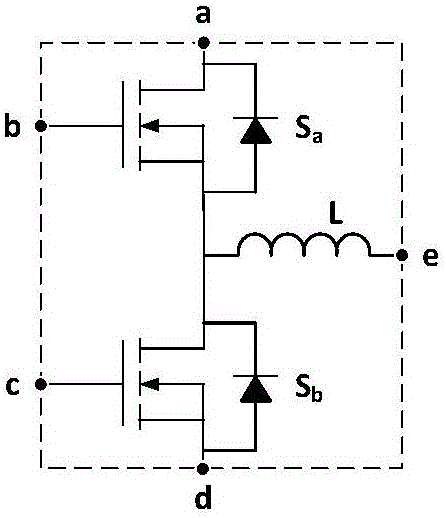

Bidirectional lossless equalization circuit of series battery pack based on inductive energy storage

ActiveCN105140998AIncrease usable capacityExtended service lifeBatteries circuit arrangementsElectric powerMOSFETPower station

The present invention discloses a bidirectional lossless equalization circuit of a series battery pack based on inductive energy storage, wherein, the series battery pack is divided into an upper part and a lower part, the upper half part battery is an upper battery pack, and the lower half part battery is a lower battery pack. Each battery connects an equalization branch circuit, a total equalization branch circuit bestrides and connects a power supply and the earth, and each equalization branch circuit connects a control circuit. The circuit can realize a dynamic equalization during the charge-discharge process of the battery pack, improve a non-equalization phenomenon of the series battery pack, improve an available capacity of the battery pack, reduce a repairing and replacing cycle of the series battery pack, and prolong a service life of the battery pack by controlling the on and off of an upper bridge and a low bridge MOSFET in the equalization branch circuit and the inductive energy storage. Thus, the circuit is suitable for a battery management system of an energy storage device of a hybrid electric vehicle, a pure electric vehicle, or a storage power station.

Owner:SOUTH CHINA UNIV OF TECH

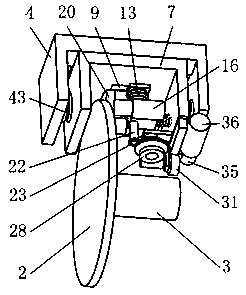

Automobile brake device

ActiveCN109050497AAvoid damageReduce replacement cycleBraking element arrangementsBraking action transmissionFriction forceBraking system

The invention belongs to the automobile brake field, in particular to an automobile brake device, which comprises a brake mechanism, a brake disc and a wheel axle, wherein the brake disc is mounted onone end of the wheel axle of the automobile; The brake mechanism is fixedly installed on the vehicle body, and the brake mechanism is matched with the brake disc; During the braking process, the contact area between the brake pads and the brake discs increases, which decreases the friction force per unit area on the friction surface between the brake pads and the brake discs, effectively controlsthe wear of the brake pads and the brake discs, and further prolongs the service life of the brake pads and the brake discs. During the braking process, two brake pads of the two brake pad mechanismsrespectively contact with two end faces of the brake disc and generate friction, so that the forces on the two end faces of the brake disc are balanced, the damage of the brake disc caused by long-term unilateral force is avoided, the brake disc replacement cycle is delayed, and the maintenance cost of the brake system of the automobile is reduced.

Owner:上海八幡五金有限公司

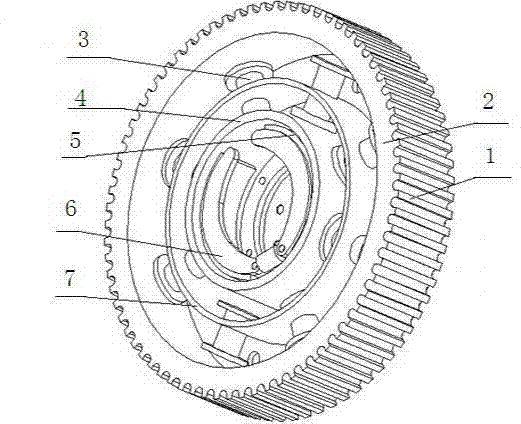

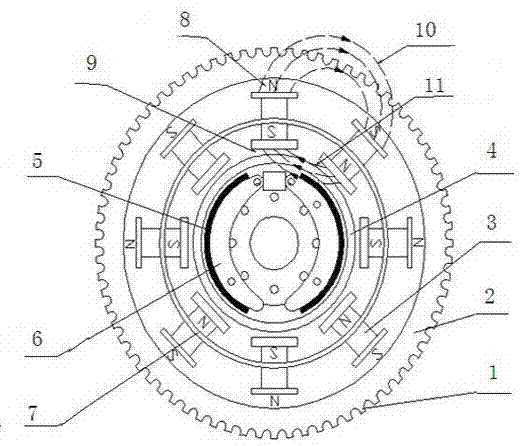

Brake integrating rotary barrel type eddy current retarder and drum brake

ActiveCN103089857AReduce generationIncreased braking safetyElectrodynamic brake systemsDrum brakesEddy currentElectromagnetic brake

The invention discloses a brake integrating a rotary barrel type eddy current retarder and a drum brake, wherein the brake is used for braking and speed reduction of an automobile. A retarder outer rotor, a brake drum and a coil support are coaxial, and the coil support is located between the retarder outer rotor and the brake drum. A plurality of magnet exciting coils provided with iron cores are fixed on the coil support and are evenly distributed along the circumferential direction of the outer circle of the brake drum, the axial leads of the magnet exciting coils are located in the radial direction of the brake drum, and first gas intervals are formed between the magnet exciting coils and the retarder outer rotor, and second gas intervals are formed between the magnet exciting coils and the brake drum. Two adjacent magnet exciting coils provided with the iron cores, facing to the same gas interval, are opposite in polarity. When the automobile speed is low, a brake shoe enables a friction liner to be pressed towards the brake drum to achieve friction braking; when the automobile runs at a normal automobile speed, the magnet exciting coils are powered on to produce electromagnetic braking torque to reduce the automobile speed, and then the automobile is braked through friction. When the automobile speed is high, electromagnetic braking and friction braking act in a combined mode. Braking thermal failure is avoided, and safety performance of automobile braking is improved.

Owner:BAOHUA SEMI TRAILER FITTINGS CO LTD ZHENJIANG CITY

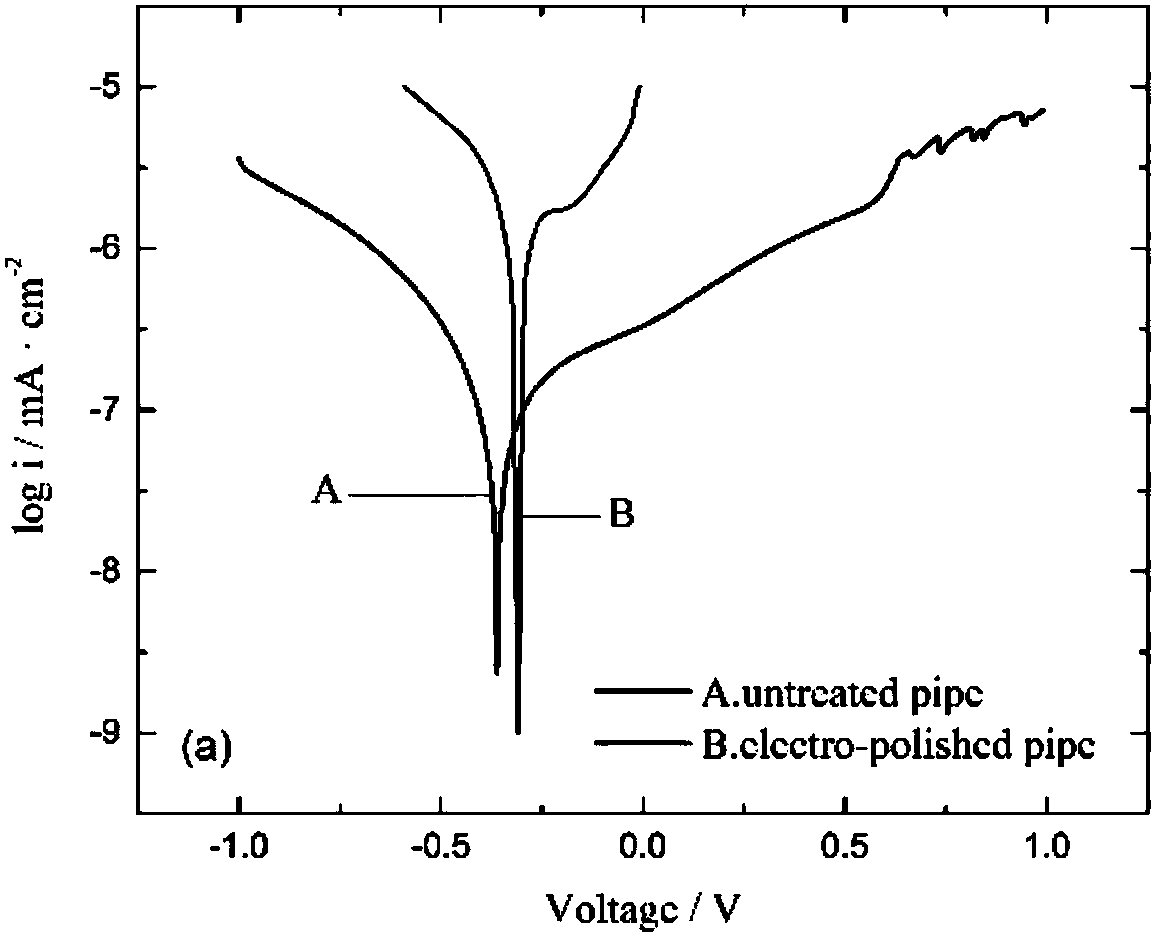

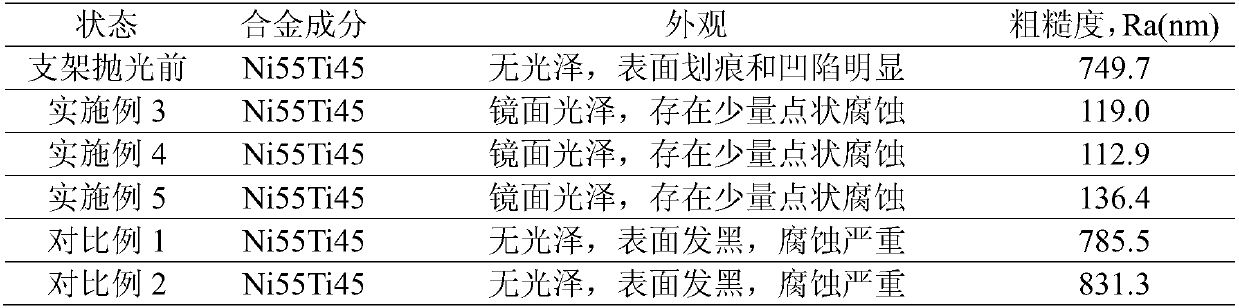

Polishing solution for electrochemical polishing of nickel-titanium alloy and application

InactiveCN107675244AGood corrosion inhibition effectImprove the leveling effectElectrochemistryTitanium alloy

The invention provides a polishing solution for electrochemical polishing of a nickel-titanium alloy, and belongs to the field of nickel-titanium alloy surface treatment. The polishing solution is composed of the following matter of, by volume, 22%-43% of concentrated sulfuric acid, 37%-50% of ethylene glycol, 5%-10% of an additive agent and the balance water. The invention further discloses a method for electrochemical polishing of the nickel-titanium alloy, the nickel-titanium alloy is treated as the anode, a stainless steel plate is treated as the cathode, the anode and the cathode are placed into the electrical polishing solution, and electrochemical polishing is conducted. The electrochemical polishing solution and the polishing method can be used for polishing a medical nickel-titanium alloy, the nickel-titanium alloy which is subjected to polishing treatment is good in corrosion resistance. The formula of the nickel-titanium alloy electrochemical polishing solution is not proneto volatilizing, stable and environmentally friendly, low in cost and good in operating environment.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

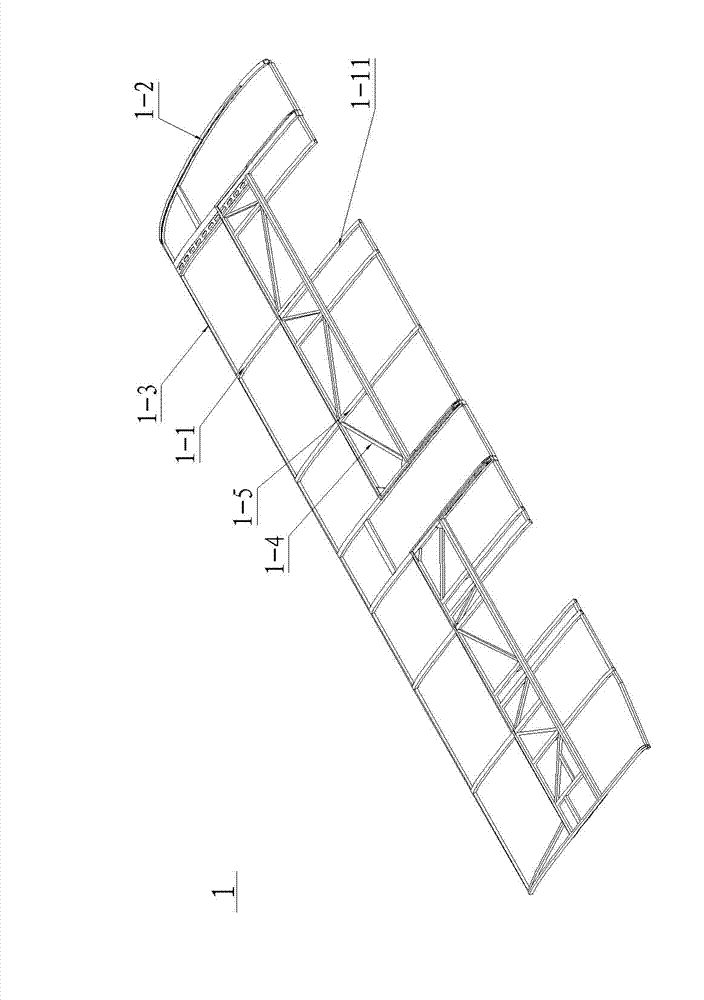

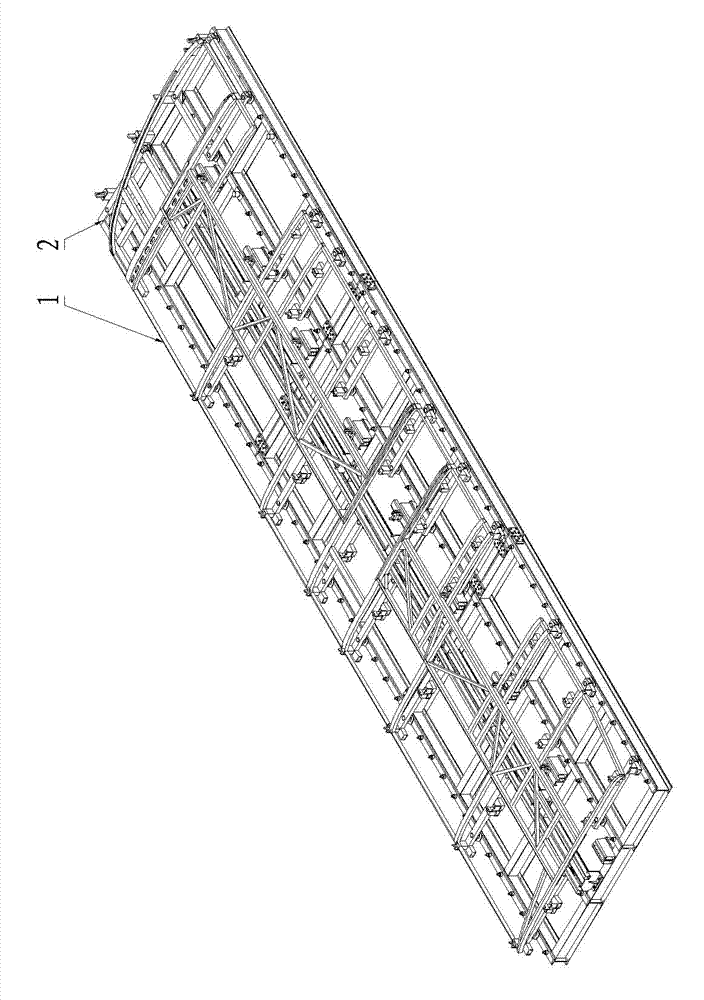

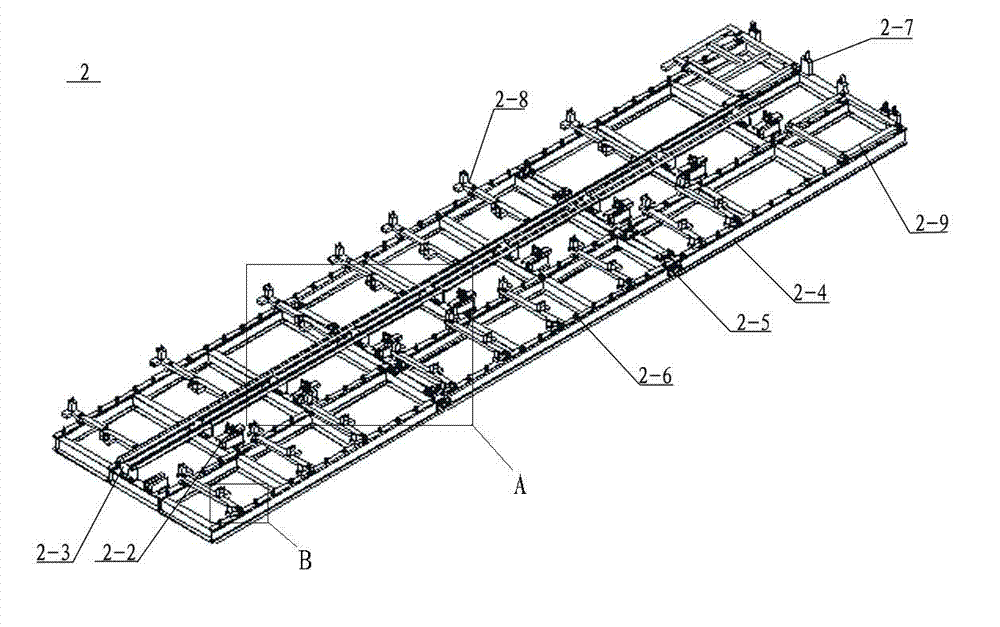

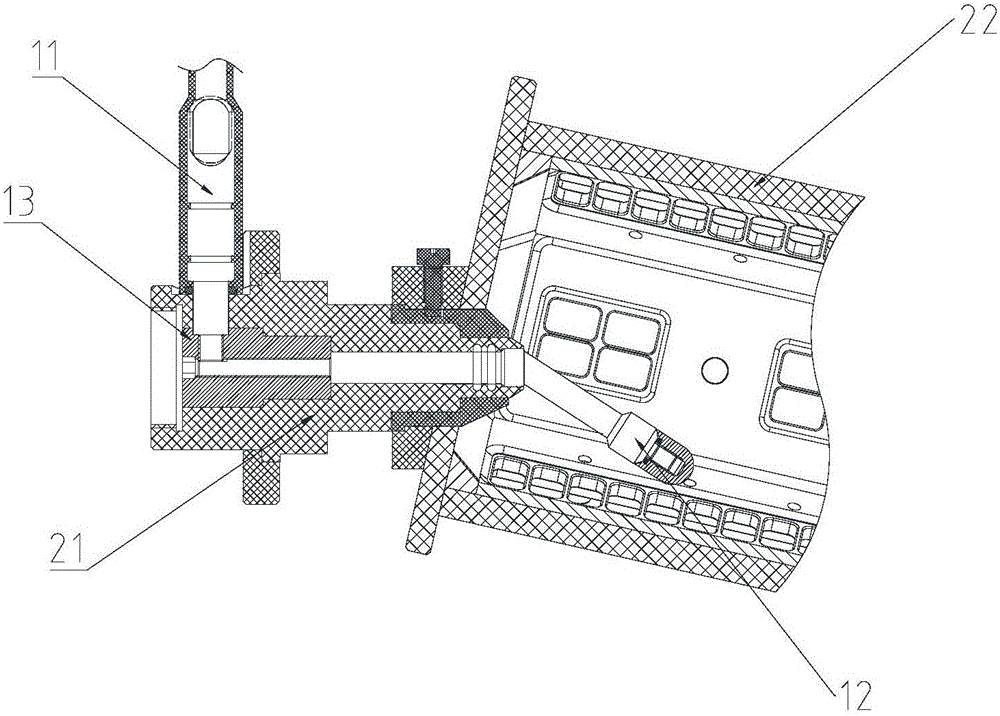

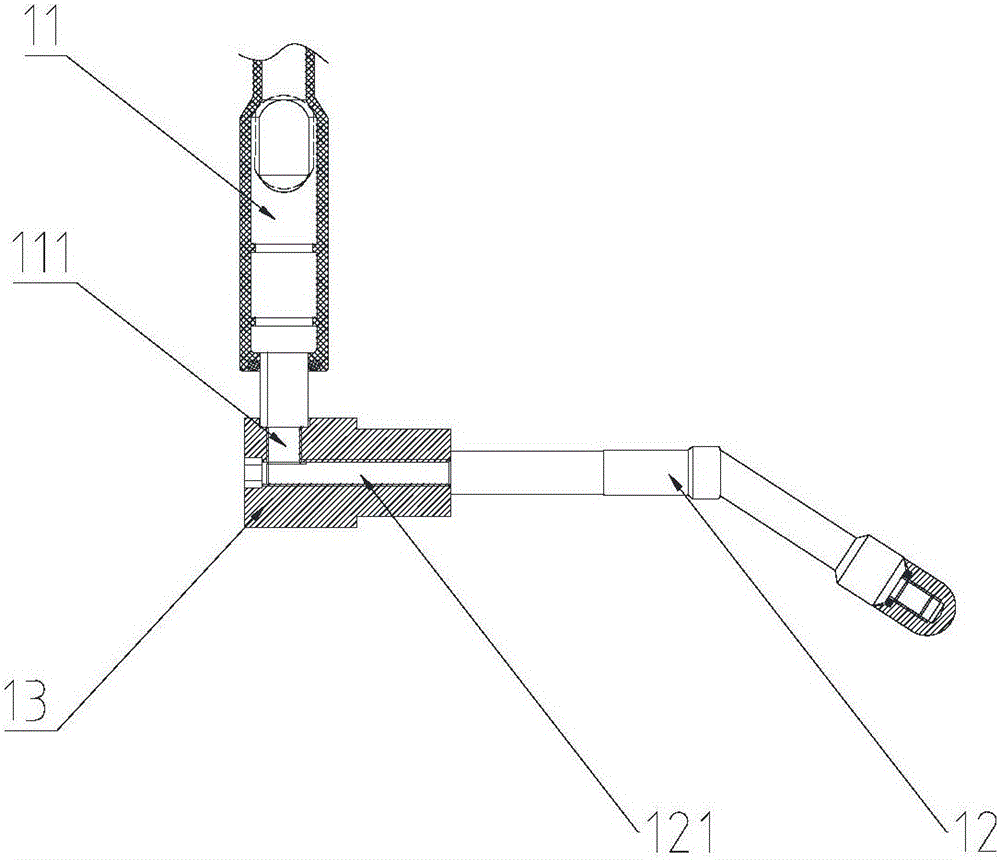

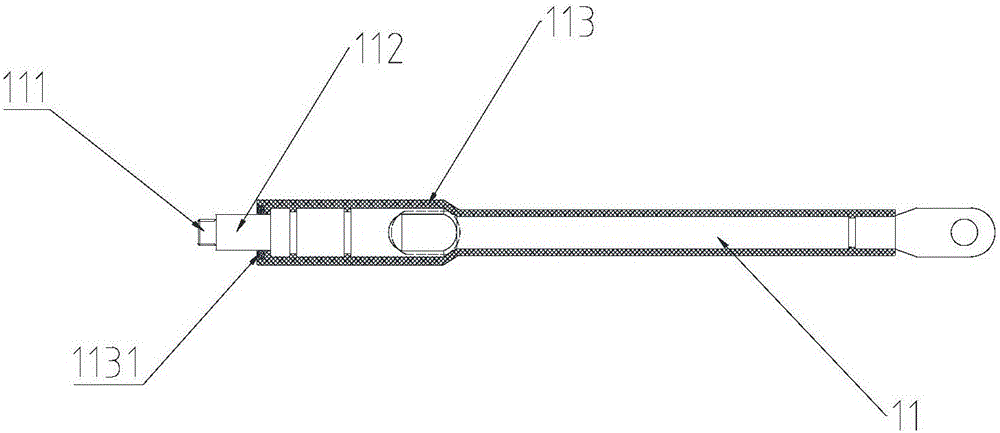

Side wall welding mould for passenger bus

InactiveCN102756231AImprove versatilityReduce manufacturing difficultyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringUltimate tensile strength

The invention relates to a side wall welding mould for a passenger bus. In a fixed connection structure between stand post positioning frames and a bottom frame provided by the invention, a positioning pin is provided with a distribution structure, which respectively corresponds to a positioning pin hole on each stand post positioning frame in at least two different arrangement manners of the stand post positioning frames on the bottom frame, so that the stand post positioning frame can be arranged in at least two different arrangement manners by matching the positioning pin with the positioning pin hole in use, and can be positioned by matching the positioning pin and the positioning pin hole in an inserting manner. Therefore, the generality of the side wall welding mould for the passenger bus is improved; the labor strength and the difficulty aiming to that the different types of side wall frameworks of the passenger bus are located at positions of the stand post positioning frames can be reduced; the manufacturing difficulty of the side wall welding mould for the passenger bus is reduced; and the replacement period of the side wall welding mould for the passenger bus is saved when the types of the side wall frameworks of the passenger bus are changed.

Owner:ZHENGZHOU YUTONG BUS CO LTD

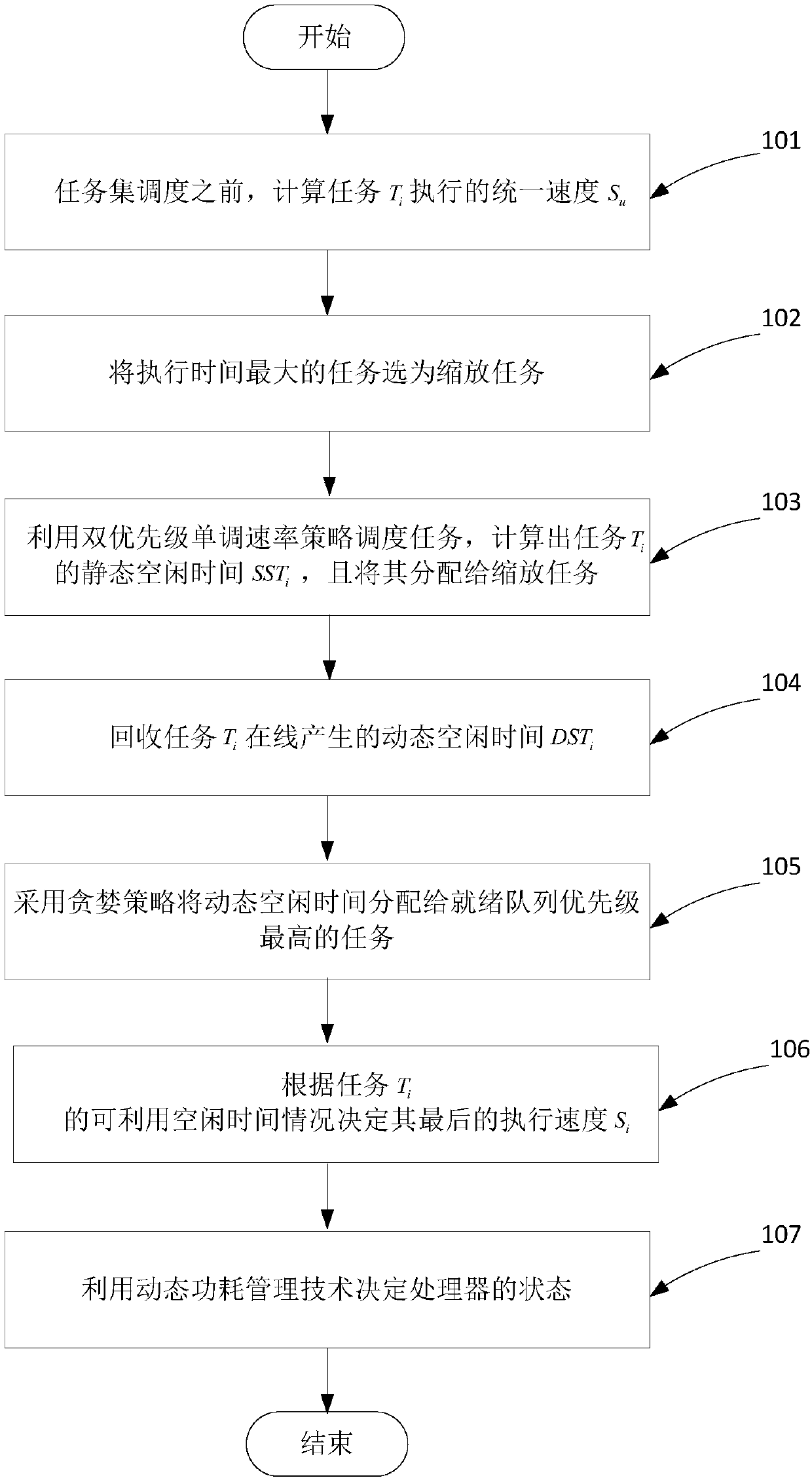

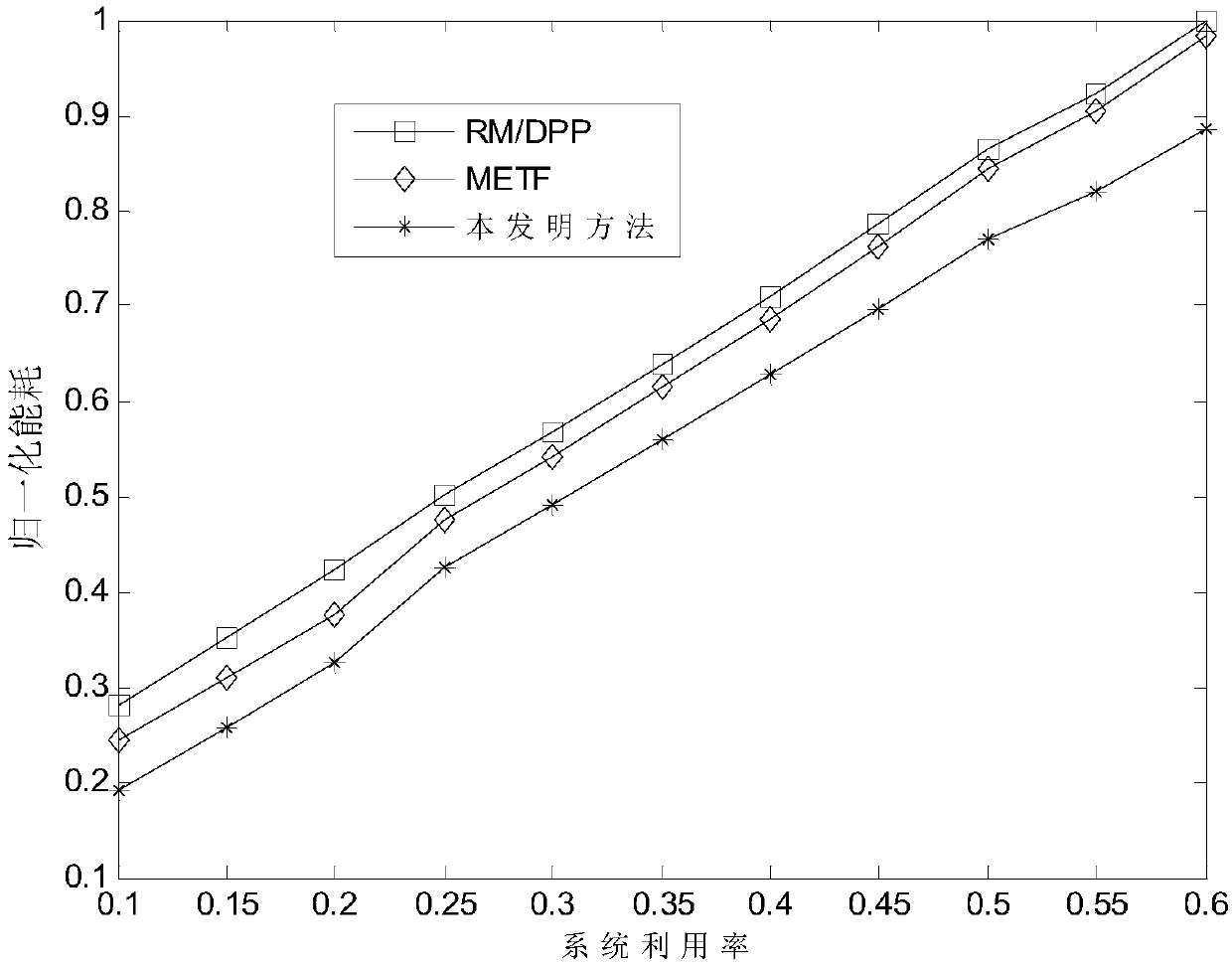

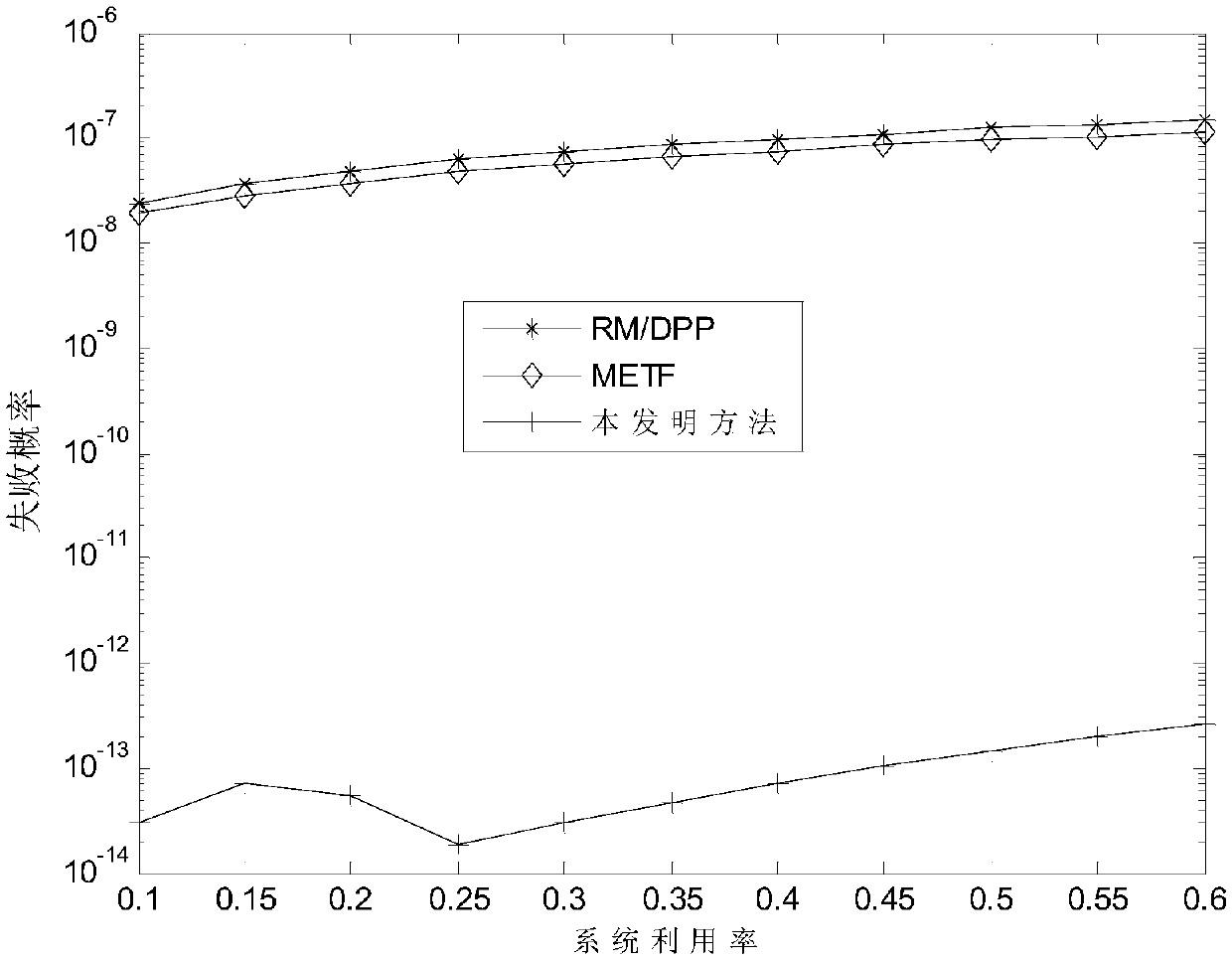

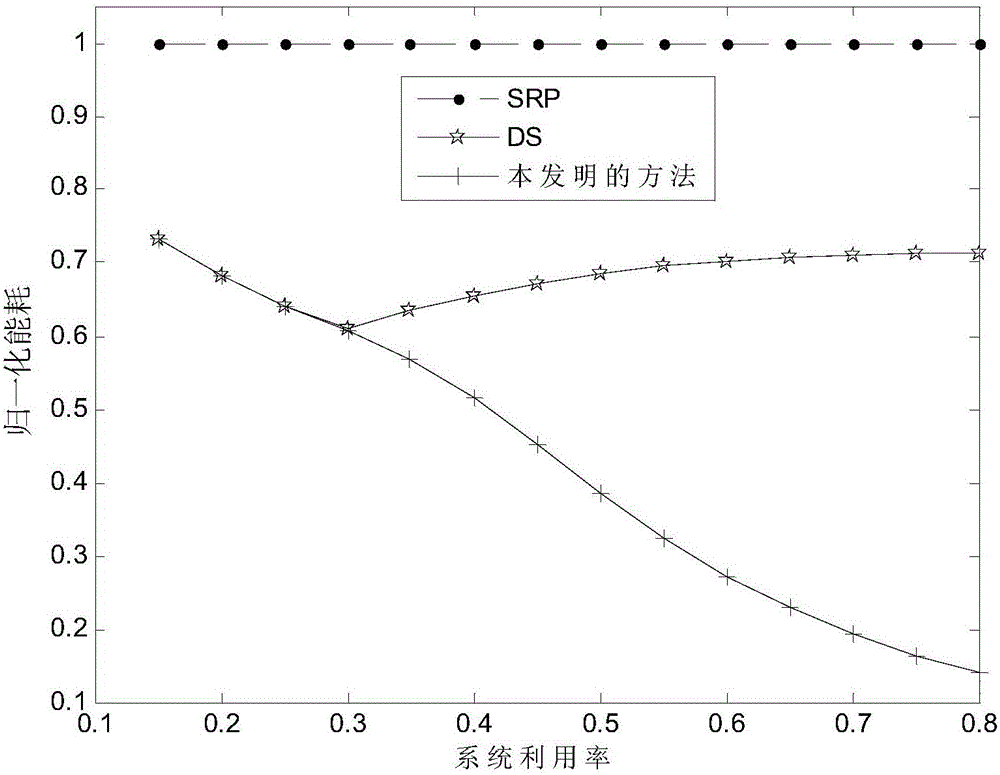

Fixed priority reliability perception energy consumption optimization method suitable for numerical control system

The invention relates to a fixed priority reliability perception energy consumption optimization method suitable for a numerical control system. The method includes the steps of calculating the unified speed SU of executing a task Ti before task calling; and selecting the task with the largest execution time as a scaling task; calculating the static spare time SSTi of the task Ti by utilizing a double-priority monotonous rate strategy scheduling task, and distributing the SSTi to the scaling task; recovering the dynamic spare time DSTi generated by the task Ti on line; allocating the dynamic spare time to the task with the highest priority of a ready queue; determining the final execution speed Si of the task Ti according to the available spare time condition of the task Ti; determining the state of a processor through a dynamic power consumption management technology. The method can fully utilize the spare time generated by a system, and the energy consumption is saved by 11.51% compared with that of an existing method on the premise of ensuring the reliability of the system.

Owner:HUAQIAO UNIVERSITY

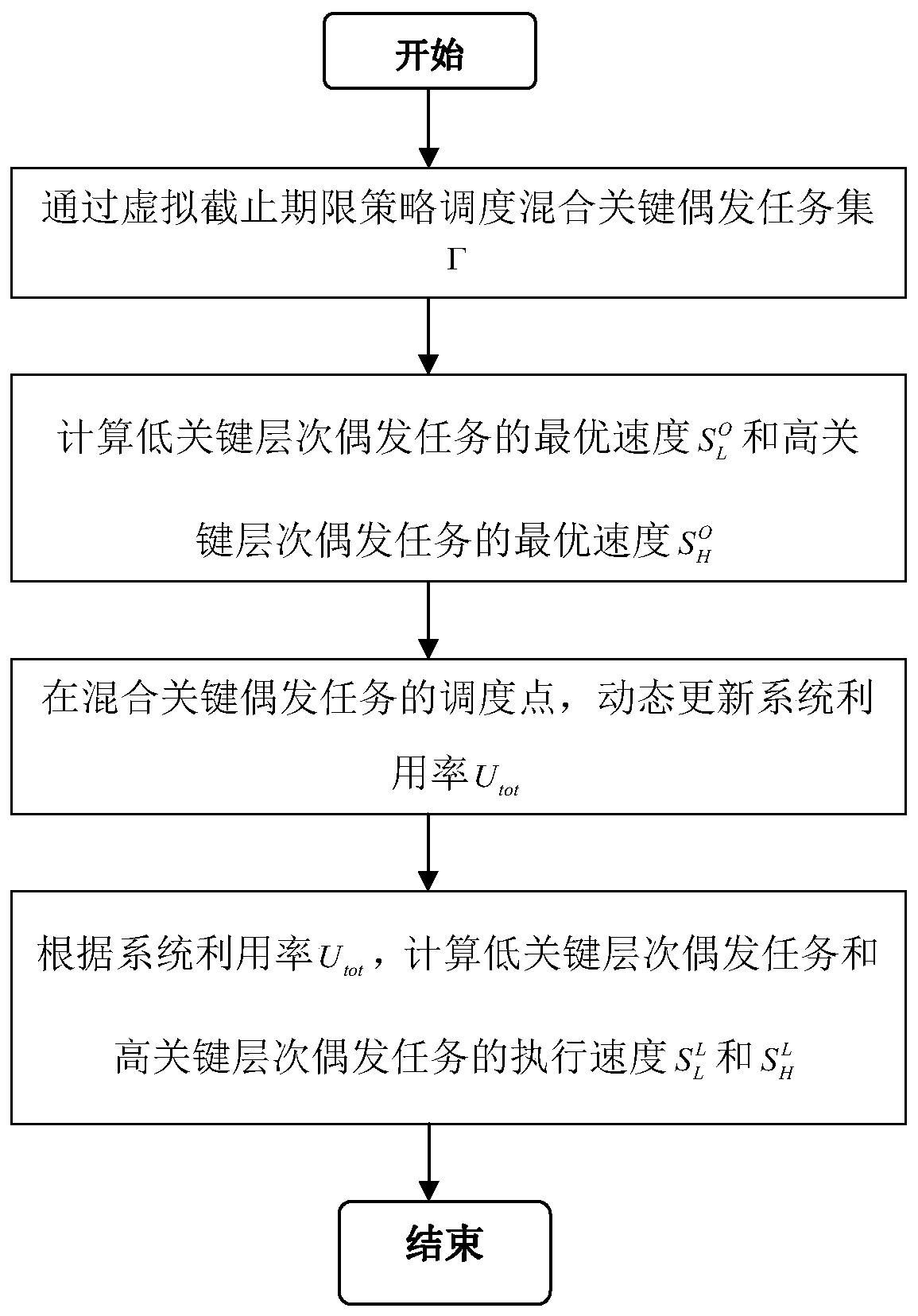

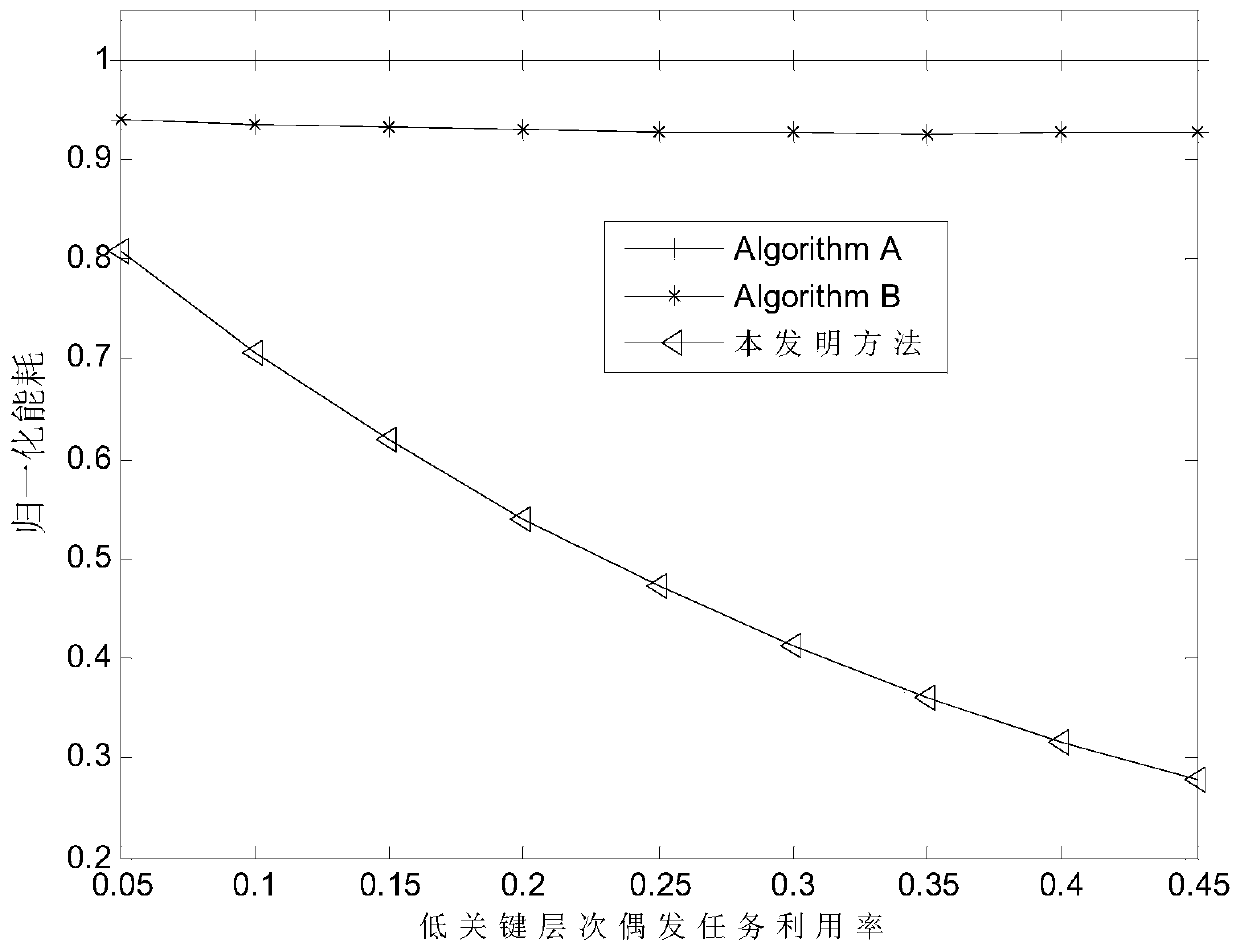

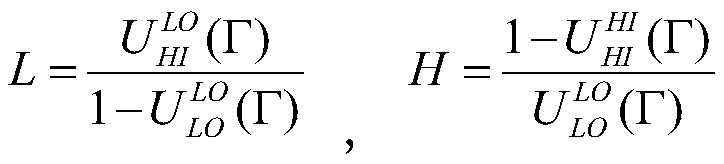

Low-energy-consumption method for updating mixed key accidental tasks with dynamic utilization rate

ActiveCN110308977AReduce energy consumptionReduce replacement cycleProgram initiation/switchingDigital data processing detailsEnergy consumptionOperating system

The invention discloses a low-energy-consumption method for updating a mixed key accidental task with a dynamic utilization rate. The method comprises the following steps of scheduling a mixed key accidental task set gamma through a virtual deadline strategy; calculating the scheduling point of the optimal speed of the low-key-level accidental task and the optimal speed of the high-key-level accidental task at the mixed key accidental task, and dynamically updating the system utilization rate Utot; and according to the system utilization rate Utot, calculating the execution speeds of the low-key-level accidental task and the high-key-level accidental task. According to the present invention, through the dynamic utilization rate updating, the final execution speeds of the low-key-level accidental task and the high-key-level accidental task are calculated, so that the energy consumption of the system is effectively reduced.

Owner:HUAQIAO UNIVERSITY

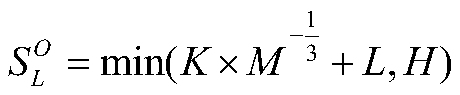

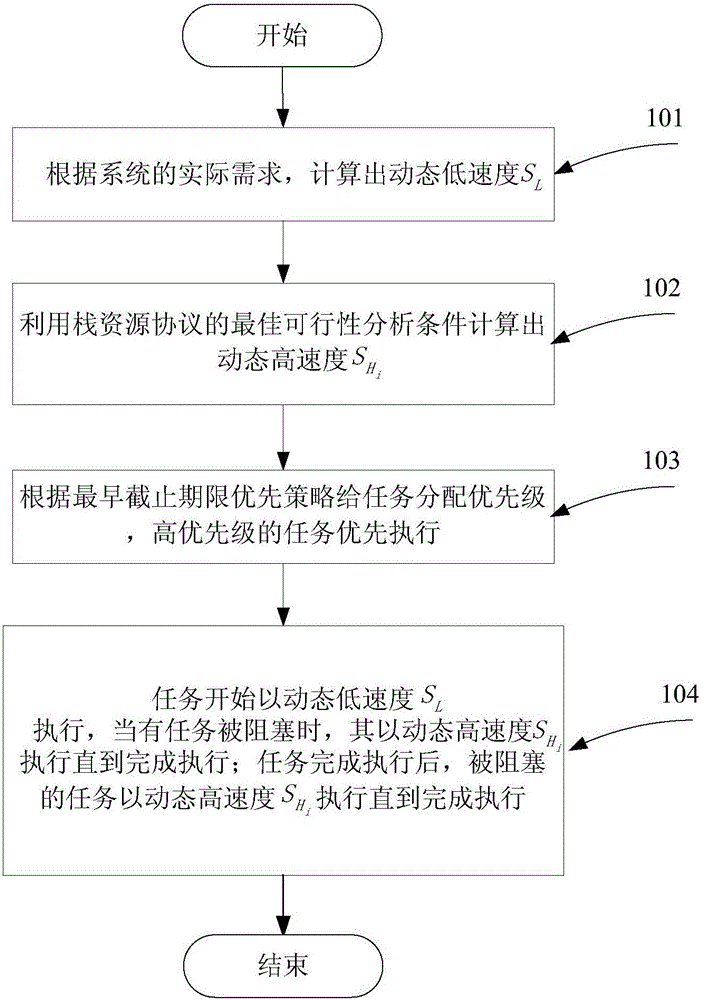

Task synchronization-based low-power dispatching method for sporadic tasks

ActiveCN105975049AUse free time effectivelyReduce energy consumptionPower supply for data processingTask completionData synchronization

The invention discloses a task synchronization-based low-power dispatching method for sporadic tasks. The method comprises the following steps of calculating a dynamic low speed SL according to an actual demand of a system; calculating a dynamic high speed SHi by utilizing an optimal feasibility analysis condition of a stack resource protocol; allocating priorities to the tasks according to an earliest deadline first policy, and preferentially executing the task with high priority; executing the task at the dynamic low speed SL at the beginning, and when the task is blocked, executing the task at the dynamic high speed SHi until the execution of the task is finished; and after the execution of the task is finished, executing the blocked task at the dynamic high speed SHi until the execution of the task is finished. According to the method, the task can be executed at the dynamic low speed SL or the dynamic high speed SHi, so that idle time of a processor is fully utilized and system energy consumption is effectively reduced.

Owner:HUAQIAO UNIVERSITY

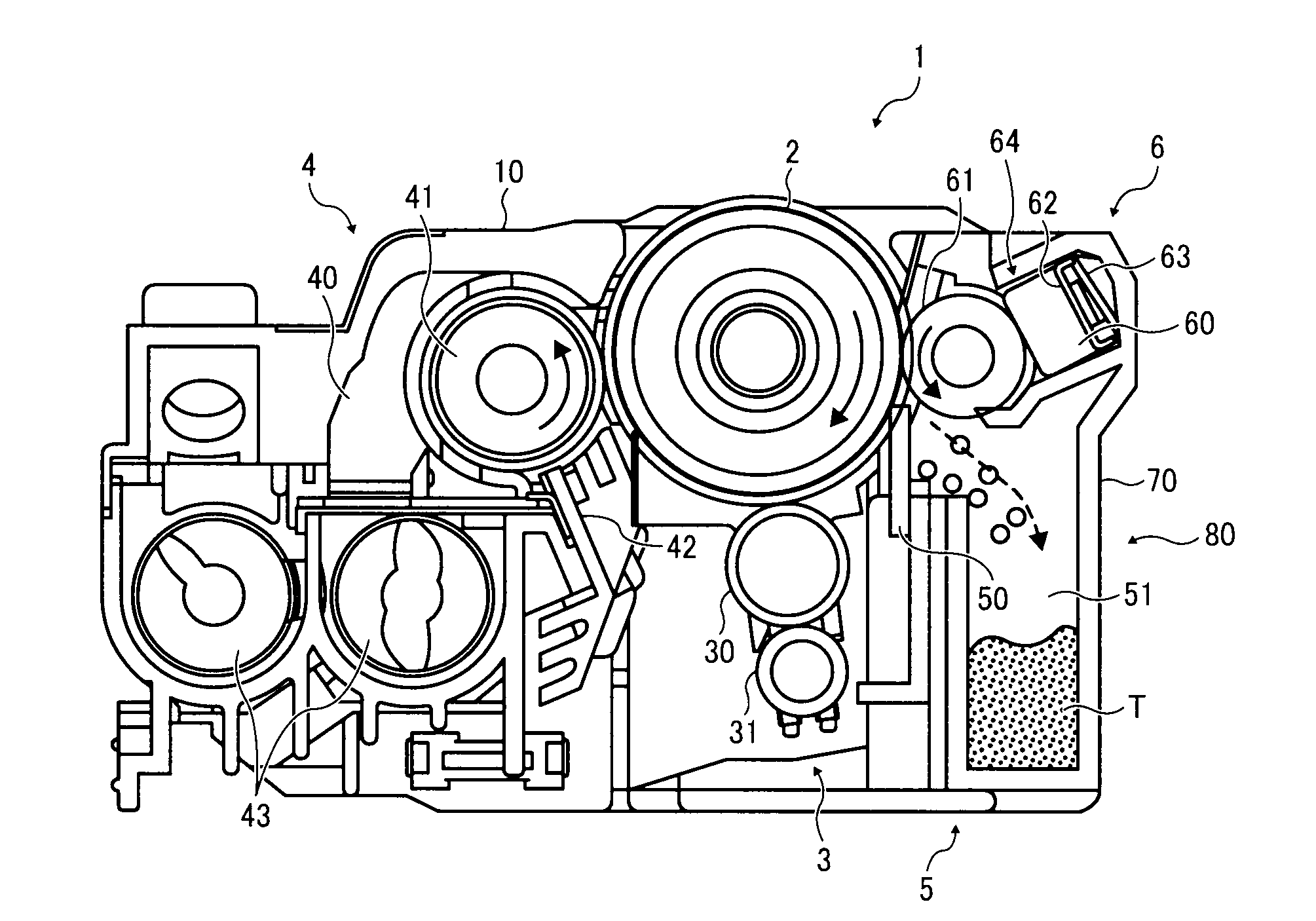

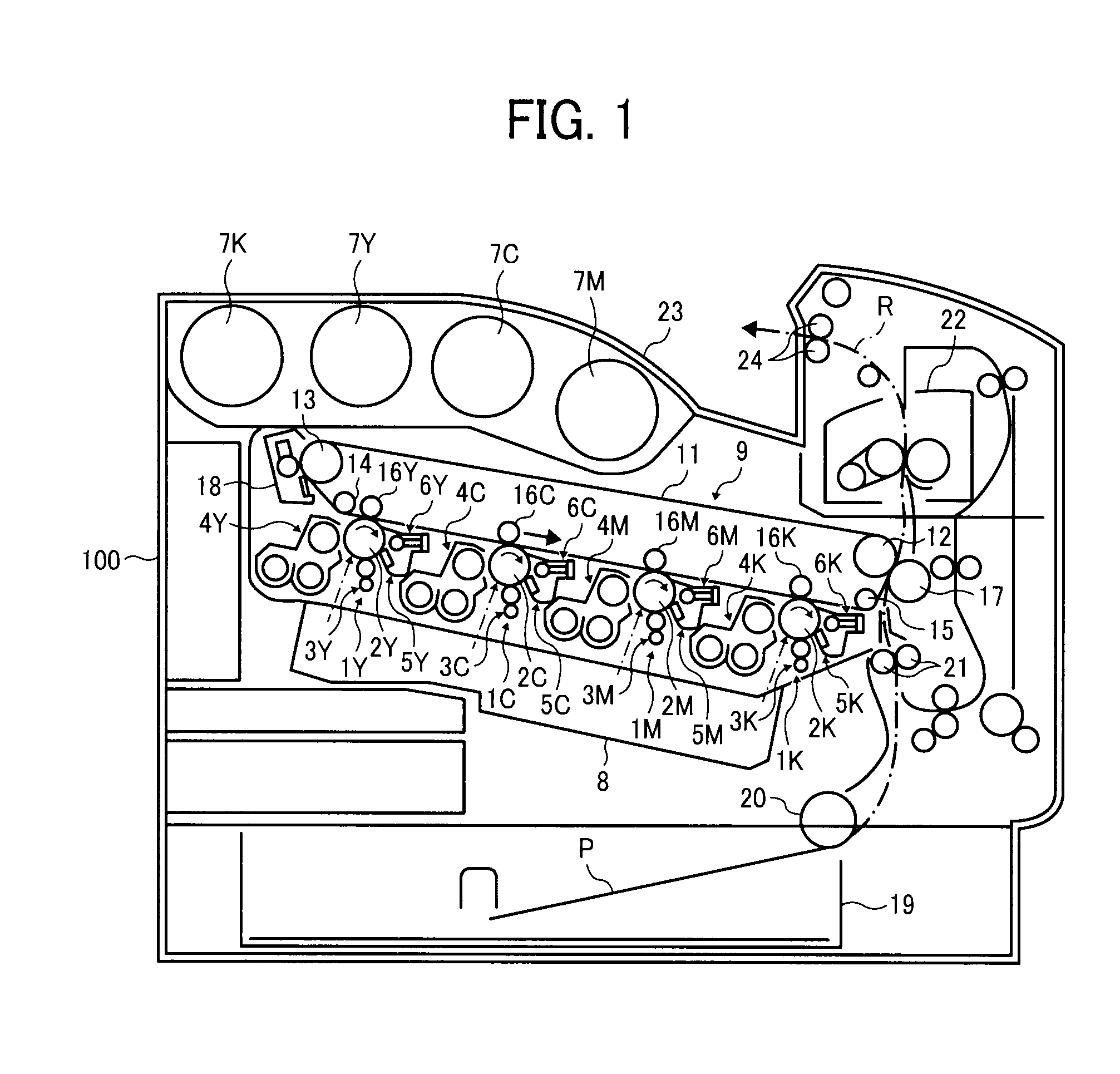

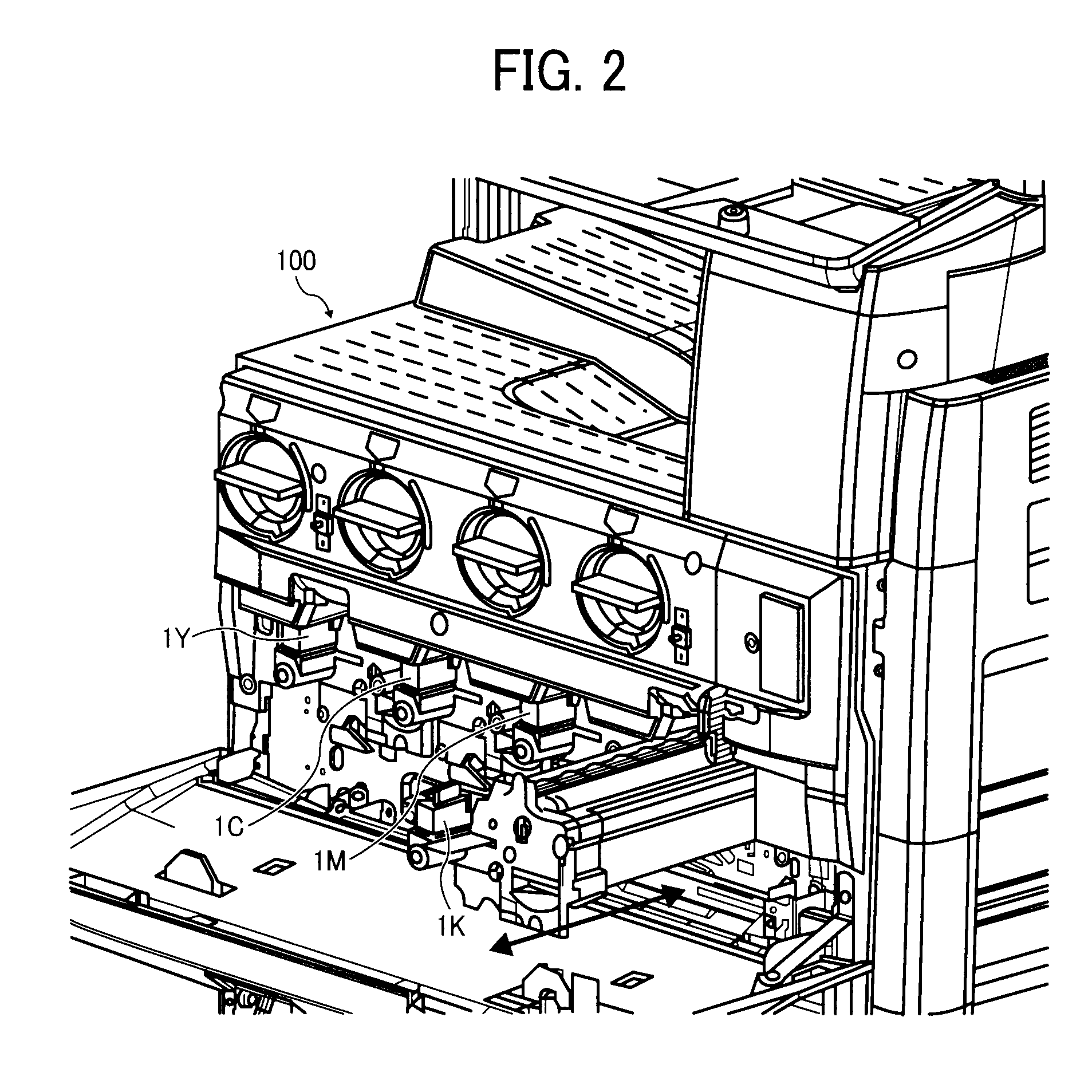

Process unit and image forming apparatus including same

InactiveUS20110274447A1Efficient replacementEasy to useElectrographic process apparatusImage formationLubricant

A process unit including a first housing detachably attachable to an image forming apparatus, an image carrier to carry an image on a surface thereof, a charger to charge the surface of the image carrier, a developing device to form the image on the surface of the image carrier, a cleaning device to remove toner from the surface of the image carrier, a lubricant to be supplied to the surface of the image carrier, a lubricant container to contain the lubricant, and a waste toner container to store the toner removed from the surface of the image carrier. The first housing includes the image carrier and at least one of the charger, the developing device, and the cleaning device. The lubricant, the lubricant container, and the waste toner container together are detachably attachable to the first housing.

Owner:RICOH KK

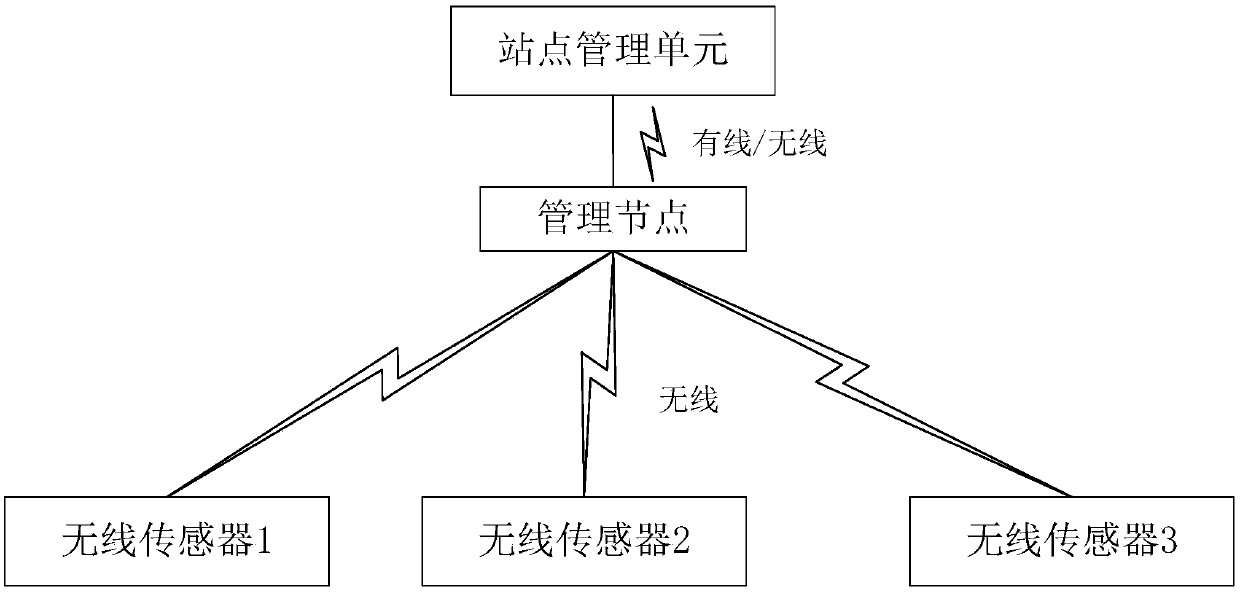

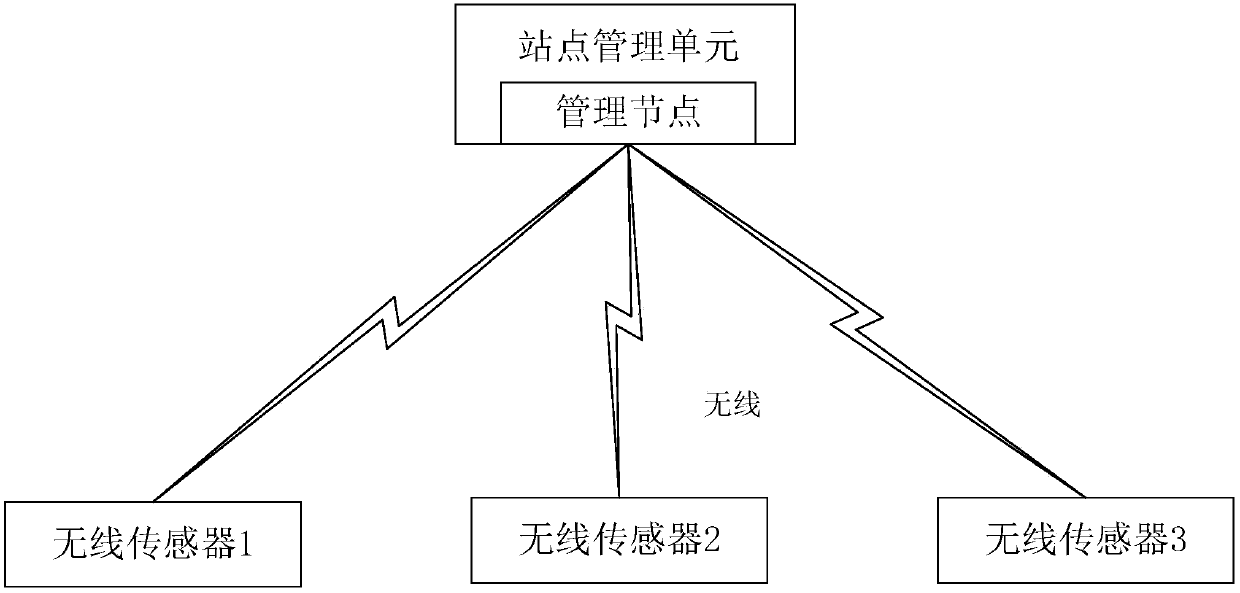

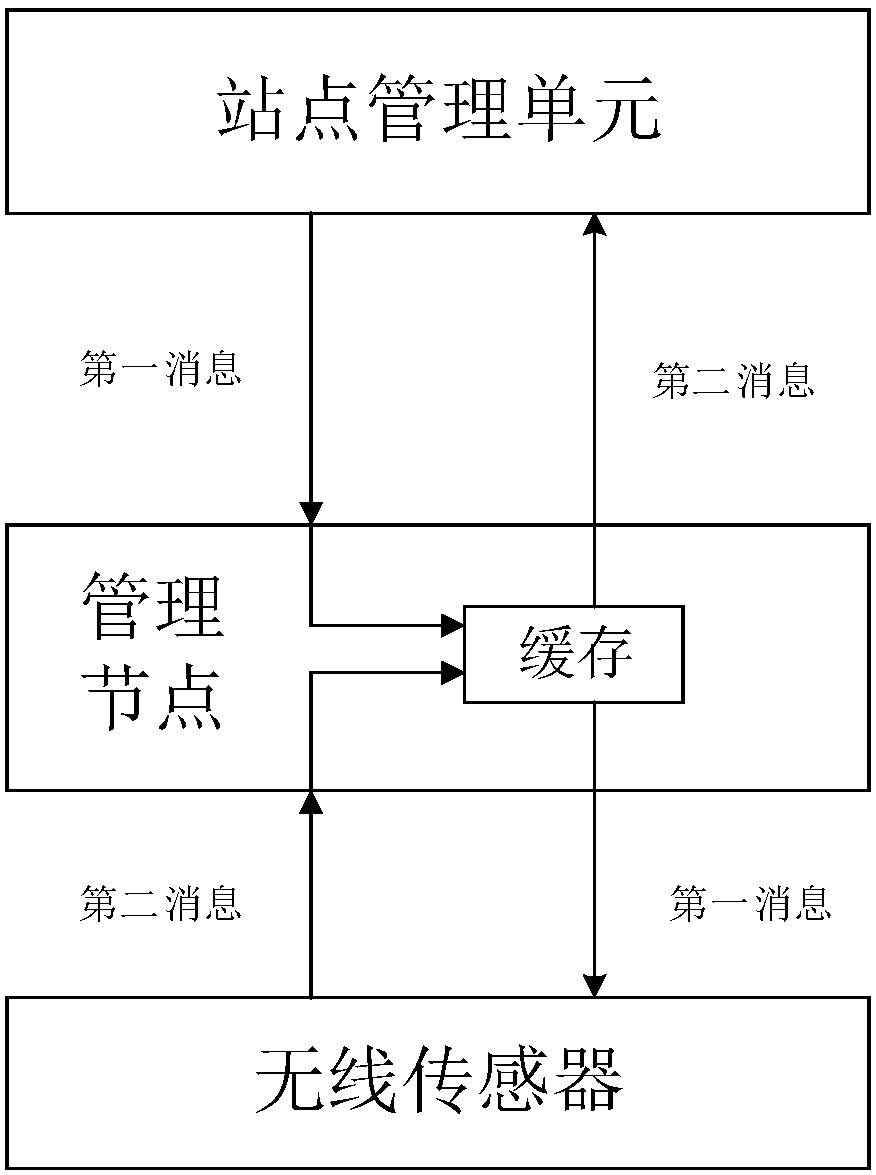

Wireless sensor management method, device and system

ActiveCN107949046AFast sleepShorten the durationPower managementNetwork topologiesLine sensorManagement unit

The application discloses a wireless sensor management method and device, and a communication system. The communication system comprises a site management unit, a management node, and a wireless sensor; the wireless sensor sends a connection request to a management node in an awakening state; the management node queries whether a first message is cached at local in advance; the first message is the message of the site management unit received by the management node when the wireless sensor is in a dormancy state; the management node sends a response to the wireless sensor according to a queryresult; the response carries the first message when the query result is that the first message is cached at the local in advance; the response indicates that the first message is not cached in the management node when the query result is that the first message is not cached at the local in advance, and the wireless sensor quickly switches to the dormancy state from the awakening state after receiving the response. By implementing the management method disclosed by the application, the battery life of the wireless sensor can be prolonged, and the demand that the wireless sensor is applied to anaccess side site in scale is satisfied.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

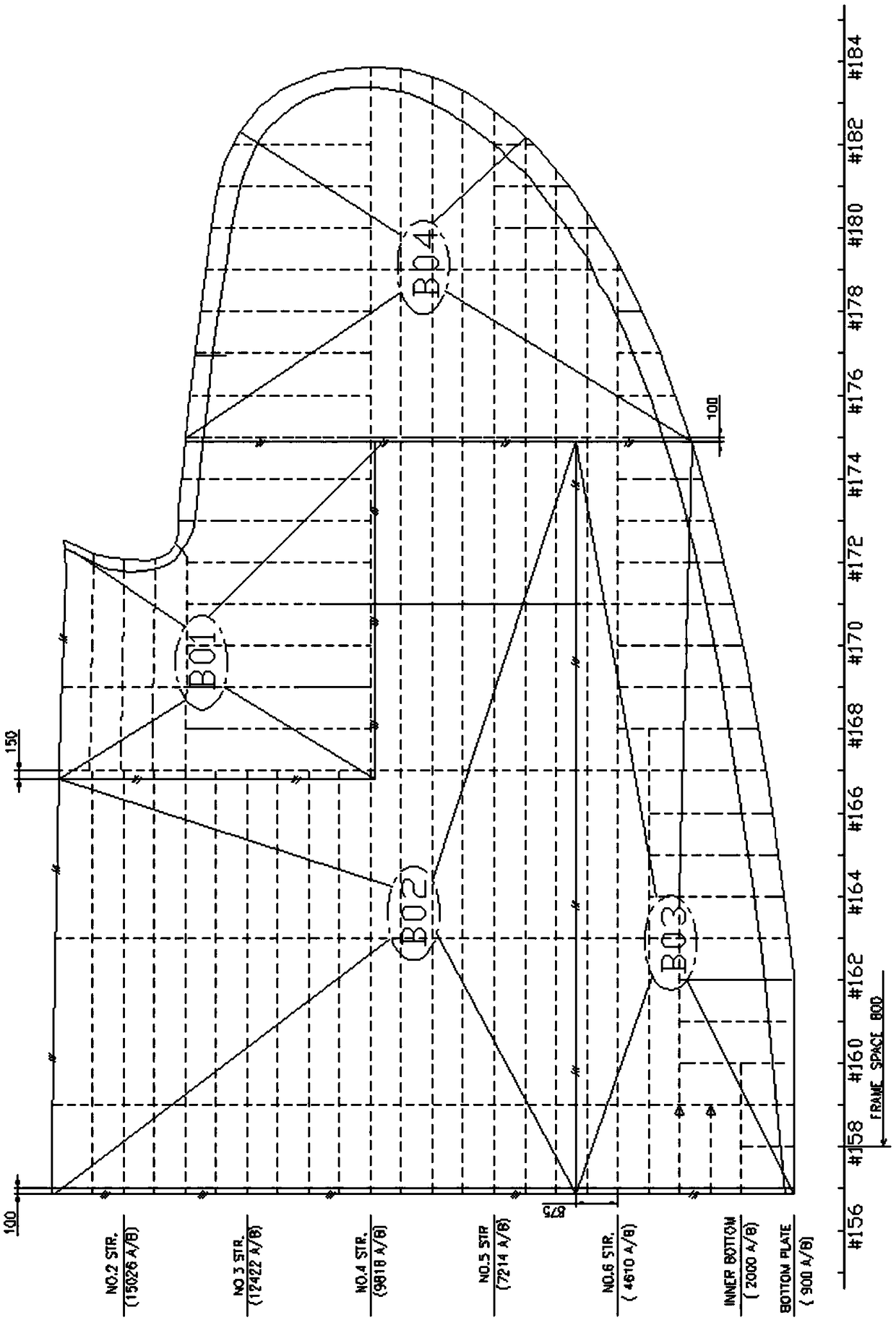

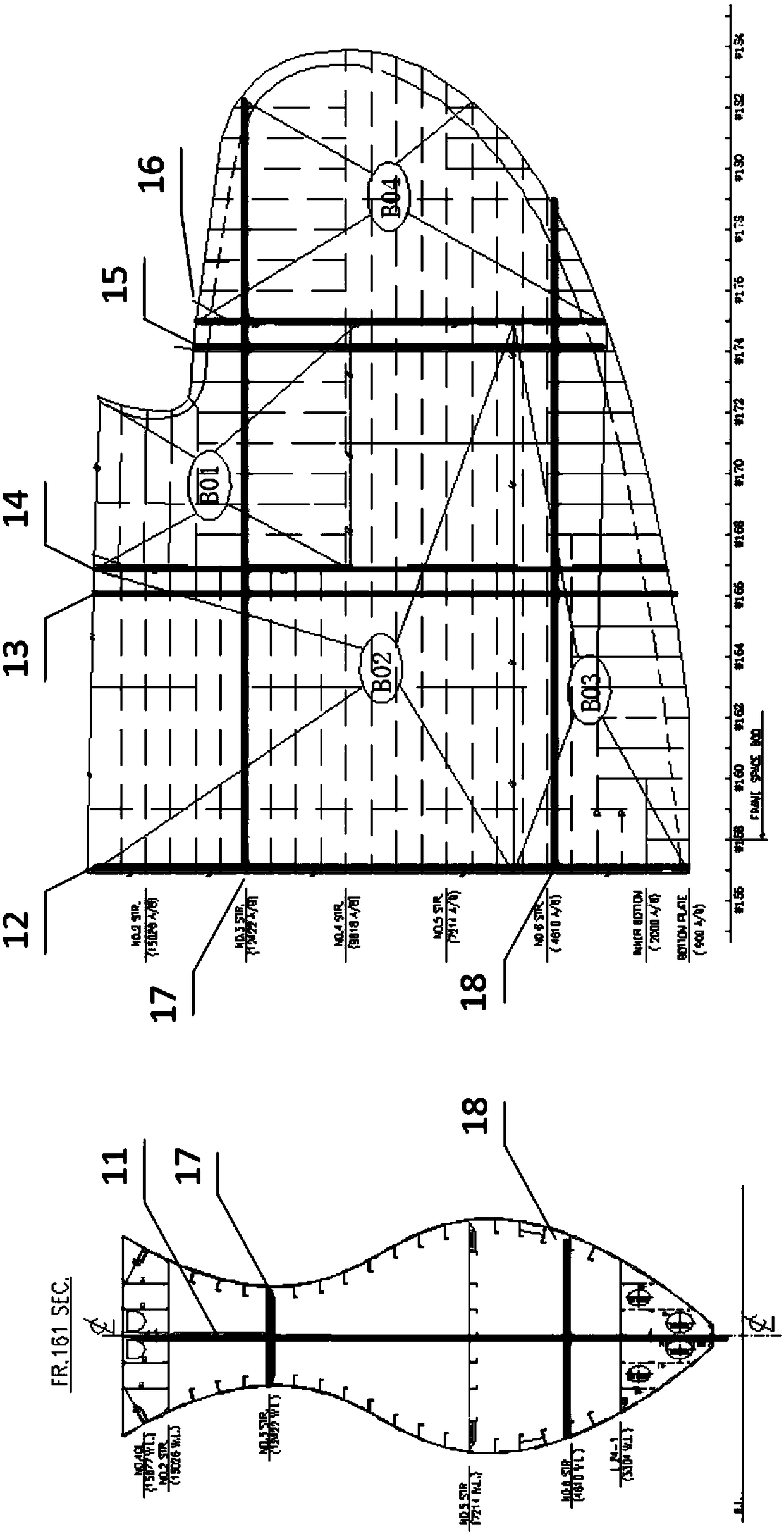

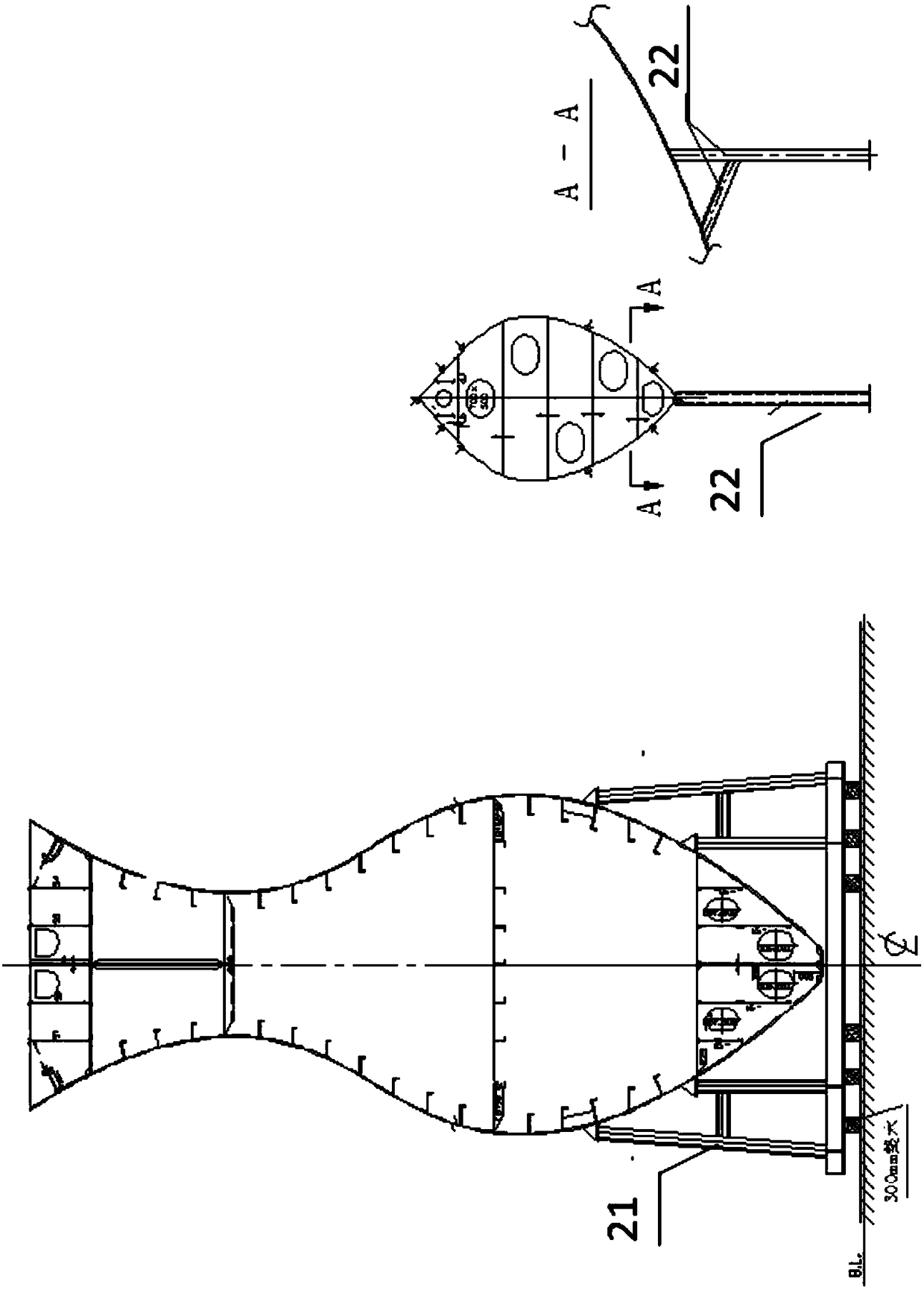

Bulbous bow refit technology

ActiveCN108773455AShorten docking periodReduce workloadWatercraft hull designVessel partsMarine engineeringProjection line

The invention provides a bulbous bow refit technology. The bulbous bow refit technology comprises the three main processes of manufacturing of a new bulbous bow, removing of an old bulbous bow, and hoisting of the new bulbous bow. During hoisting of the new bulbous bow, an original ship center line, a rib position line and a horizontal detecting line are drawn on an original ship outer plate, projection lines of the original ship center line and the rib position line are drawn on the dock floor, and by combining a floating crane, a large segmented positioning tool and a segmented positioning trolley and taking the center line, the rib position line, the horizontal detecting line and the projection lines of the center line and the rib position line as the standard, precise positioning of the new bulbous bow in transverse, longitudinal and height directions is achieved. The bulbous bow refit technology can fully utilize existing equipment to shorten the docking period, and operation is accurate and quick.

Owner:广州文冲船舶修造有限公司

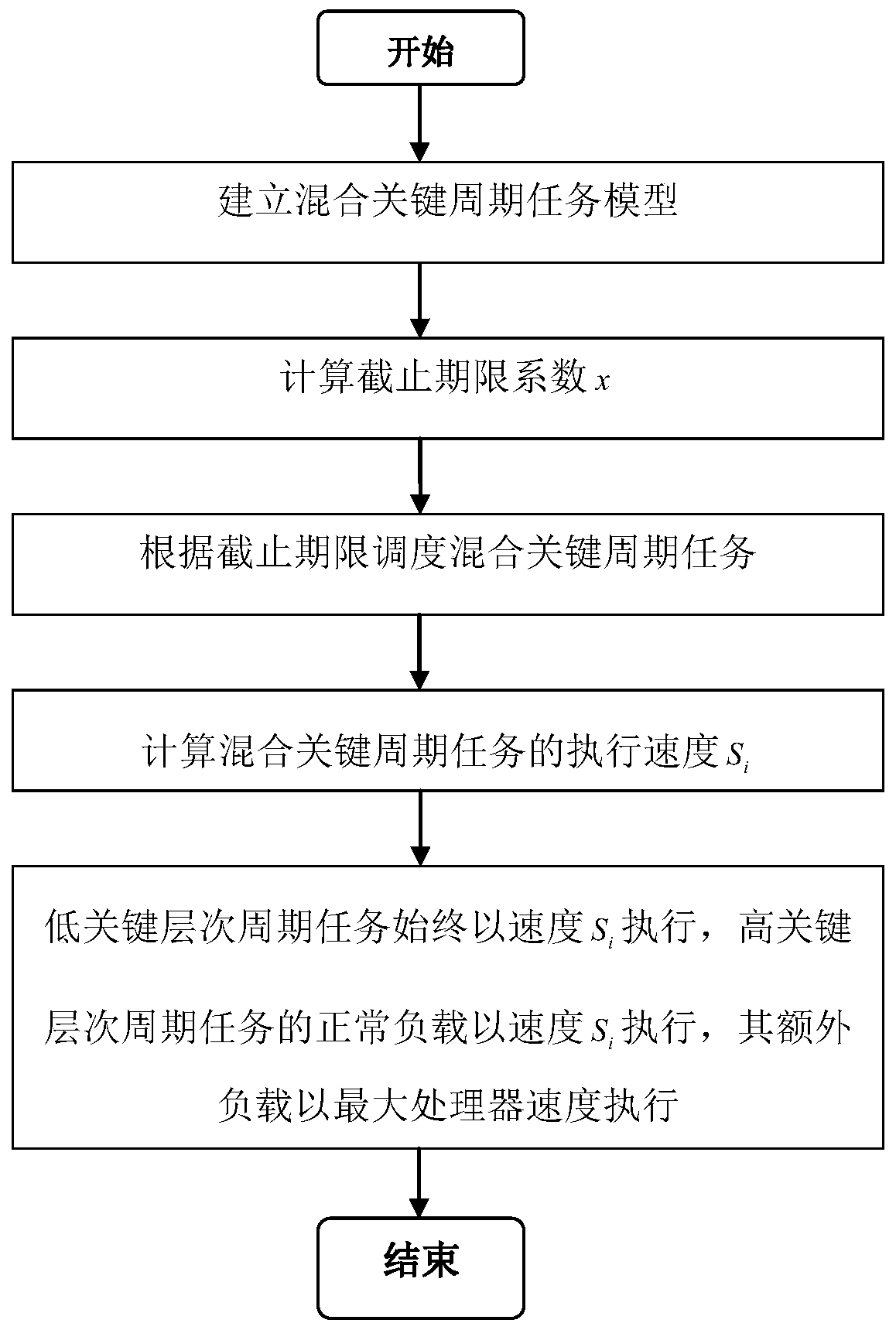

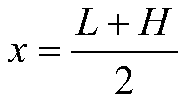

Deadline-based hybrid key system static energy consumption optimization method

InactiveCN110070219AReduce energy consumptionReduce replacement cycleForecastingResourcesNormal loadCritical system

The invention discloses a deadline-based hybrid key system static energy consumption optimization method. The method comprises the following steps: establishing a hybrid key period task model; calculating a deadline coefficient x; scheduling the mixed key period task according to the deadline; calculating the execution speed Si of the mixed key period task,wherein the low-key-level periodic task is executed at the speed Si all the time, the normal load of the high-key-level periodic task is executed at the speed Si, and the additional load of the high-key-level periodic task is executed at themaximum processor speed. According to the method, the mixed key period task is scheduled according to the deadline, the lowest execution speed Si is determined, and the system energy consumption is effectively reduced.

Owner:HUAQIAO UNIVERSITY

Inner bore laser quenching head and quenching method

ActiveCN104294011AChange the quenching methodIncrease productivityFurnace typesHeat treatment furnacesLaser quenchingLaser beams

The invention provides an inner bore laser quenching head and a quenching method. After passing through a collimation lens, a laser beam passes through a full-reflection lens and a full-reflection focusing lens to form a ring-shaped laser beam; the ring-shaped laser beam enters into an inner bore part to be quenched; and through a second full-reflection lens in the inner bore part, the ring-shaped laser beam is irradiated on the inner wall of the inner bore part so as to achieve the aim of simultaneously carrying out laser quenching on the circumference of the inner wall of the inner bore part. Inner bore movement equipment 7 is consistent with an outer laser quenching head in the aspect of movement.

Owner:SHENYANG POLYTECHNIC UNIV

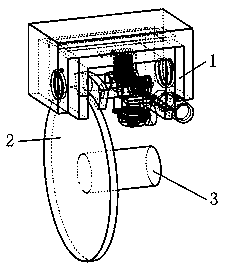

Automobile brake calliper

ActiveCN109050496AWear controlAvoid damageBraking element arrangementsAxially engaging brakesCalipersFriction force

The invention belongs to the automobile brake field, in particular to an automobile brake caliper, which comprises a caliper mechanism, a brake disc and an axle, wherein the brake disc is mounted on one end of the axle of the automobile; The caliper mechanism is fixedly installed on the vehicle body, and the caliper mechanism is matched with the brake disc; During the braking process, the contactarea between the brake pads and the brake discs increases, which decreases the friction force per unit area on the friction surface between the brake pads and the brake discs, effectively controls thewear of the brake pads and the brake discs, and further prolongs the service life of the brake pads and the brake discs. During the braking process, while the brake pads are in contact with the brakediscs, the sides of the second cut-out on the equalizer block are in contact with and rub against the brake discs, so that the forces on the two end faces of the brake discs are balanced, damage to the brake discs due to long-term unilateral force is avoided, the brake disc replacement cycle is delayed, and the maintenance cost of the brake system of the automobile is reduced.

Owner:秦皇岛科泰工业有限公司

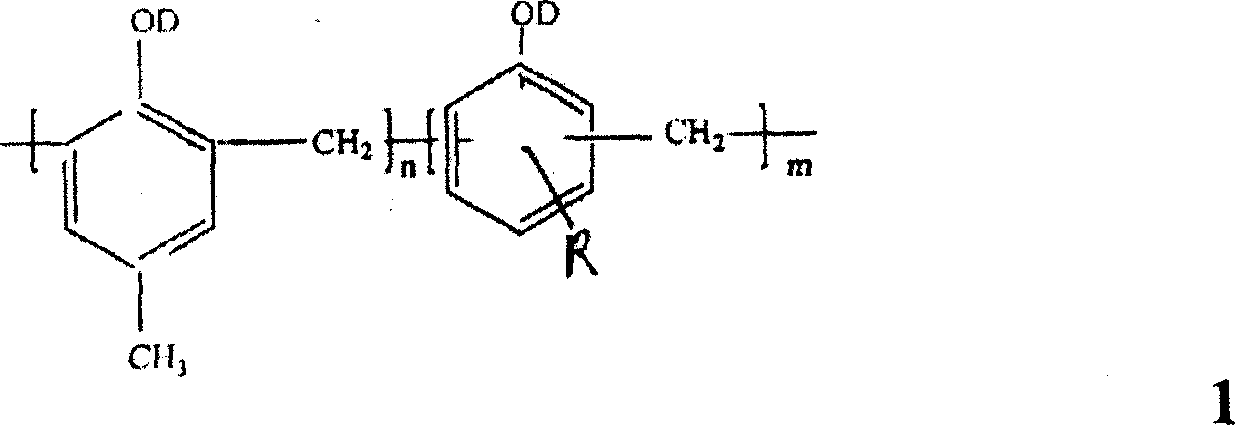

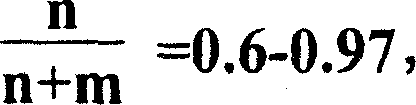

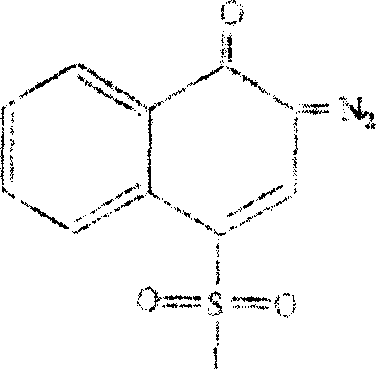

Positive photoresist consumed reactive compound and light sensitive complexes thereof

ActiveCN101158813AIncreased sensitivityImprove development latitudePhotomechanical apparatusSolventPolyphenol

The present invention relates to light-activated compound indicated in below formula 1, wherein, each substituent and symbols are defined by a specification. The light-activated compound of the present invention is obtained from products by reaction and subsequently separation between 2, 1, 4-diazo naphthoquinone sulfonyl chlorine and Ballast in solvent when catalyst exists. The selection of the Ballast is mainly cresol and contains linear phenol resin or polyphenol compound formed by the condensation of at least one of phenol, o-cresol, m-cresol, o-chlorophenol or inter-chlorophenol and formaldehyde. Wherein, the content of the formaldehyde is 60 percent to 97 mol percent and the content of other phenol is 3 percent to 40 mol percent. A PS plate formed by coating of a photosensitive complex prepared by the light-activated compound of the present invention has excellent performance of plate making and imaging, and has better sensitivity and development latitude compared with the traditional PS plate. The light-activated compound of the present invention has favorable matching performance with the linear phenol resin of home and abroad renowned resin manufactures besides having the favorable matching performance with the nine kinds of film forming linear phenol resin of industrialized BTB-21-BTB-29.

Owner:LUCKY HUAGUANG GRAPHICS

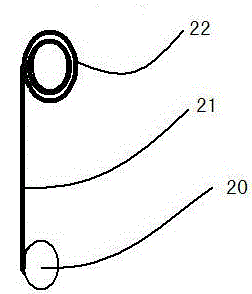

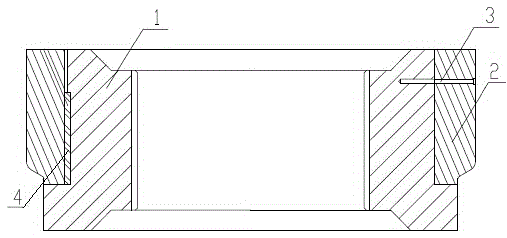

Electrode bar of electroplating machine roller

ActiveCN105951160AReduce replacement cycleReduce in quantityElectrolysis componentsCathode rayFlexible cable

The invention relates to the field of electroplating machine rollers and particularly relates to an electrode bar of an electroplating machine roller. The electrode bar comprises a conductive bar, a cathode bar and a support fixed seat, wherein one end of the conductive bar is connected with an external flexible cable, and a first fine thread connecting part is arranged at the end part of the other end of the conductive bar; one end of the cathode bar is arranged in a cavity of the roller, and a second fine thread connecting part in fit connection with the first fine thread connecting part is arranged at the end part of the other end of the cathode bar; and both the first fine thread connecting part and the second fine thread connecting part are arranged in the support fixed seat. According to the electrode bar of the electroplating machine roller, designed by the invention, the support fixed seat is arranged between the conductive bar and the cathode bar, the conductive bar is connected with the cathode bar through threads, and the support fixed seat separately adjoins with the conductive bar and the cathode bar, so that no connecting gaps are left among the conductive bar, the support fixed seat and the cathode bar, and a stable technical environment is provided for electroplating process.

Owner:珠海瑟泊特科技有限公司

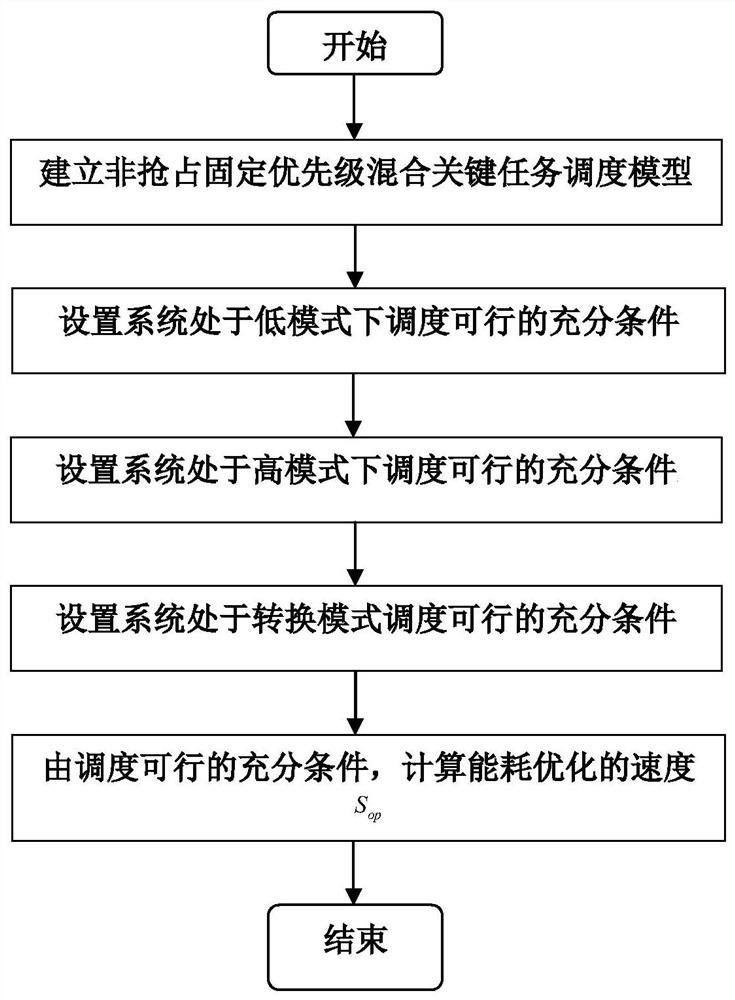

Non-preemptive fixed priority hybrid key task energy consumption optimization scheduling method

ActiveCN112486652AReduce energy consumptionReduce replacement cycleProgram initiation/switchingResource allocationEngineeringDistributed computing

The invention relates to a non-preemptive fixed-priority hybrid key task energy consumption optimization scheduling method. The method comprises the following steps: establishing a non-preemptive fixed-priority hybrid key task scheduling model; giving a sufficient condition for feasible scheduling when the system is in a low mode; giving a sufficient condition for feasible scheduling of the systemin a high mode; giving a sufficient condition for feasible scheduling of the system in the conversion mode; and calculating the speed Sop of energy consumption optimization according to the feasiblesufficient conditions of scheduling. Compared with a hybrid key system periodic task scheduling method in the prior art, about 33.08% of energy consumption can be saved; the periodic task can be ensured to be executed within the deadline of the periodic task; the energy consumption of the hybrid key system is reduced, so that the production cost of products can be reduced, the service life of equipment is prolonged, and the battery replacement period is shortened.

Owner:HUAQIAO UNIVERSITY

Air inlet structure of air purifying apparatus

InactiveCN104906889AReduce replacement cycleExtended replacement cycleDispersed particle filtrationAir filterAir exchange

The invention relates to an air inlet structure of an air purifying apparatus. The air inlet structure allows the air purifying or air exchange apparatus with the air inlet structure to be free from artificial maintenance for a long term. The air inlet structure can adapt to different climate conditions, can adapt to different pollution types of air, and allows blocked pollutants, dusts and other impurities to be conveniently cleaned. The designed air inlet structure of the air purifying apparatus is characterized in that the inlet of an air inlet pipeline is provided with at least one automatic-dedusting air filtering device with a rotatable filter screen, and a fixed fan housing. The automatic-dedusting air filtering device is an air filtering device or unit with an automatic dust processing function, and mainly comprises a filter screen cycle rotating type automatic-dedusting air filtering device and a filter screen single-shaft rewinding type automatic-dedusting air filtering device. Compared with air inlet structures in the prior art, the air inlet structure provided by the invention has the advantages of prolongation of the replacement cycle of a filtering material, and reduction of the special labor of manpower.

Owner:张国柱

Method for milling step-shaped roller ring blank element by using numerical control ring milling machine

ActiveCN104550582AStable processingSmall machining allowanceMetal rollingNumerical controlRing device

The invention discloses a method for milling a step-shaped roller ring blank element by using a numerical control ring milling machine. The method comprises the following steps that materials are prepared according to the designed dimension; hammering upsetting is carried out, a primary blank is manufactured through punching; the primary blank is installed, a milling ring device of the numerical control ring milling machine is debugged, the milling ring device comprises a main roller, a core roller and an auxiliary roller, the rolling surface of the main roller is of a step structure matched with the step shape of the step-shaped roller ring blank element, the core roller is arranged in a center through hole of the primary blank in a penetrating way with a gap, and the auxiliary roller is positioned at the other end, relative to the main roller, of the primary blank, and comprises two cone rollers arranged at the upper end surface and the lower end surface of the primary blank; a numerical control program of the numerical control ring milling machine is started for milling and forming. The method has the advantages that the main roller of the step-shaped structure is used as a major component, the core roller and the main roller simultaneously act for milling the blank element, meanwhile, the symmetrical cone rollers are used for the auxiliary roller position limitation, the blank element of the step-shaped roller ring can be stably processed and formed, the working allowance of the blank element can be reduced, and the utilization rate of raw materials is improved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

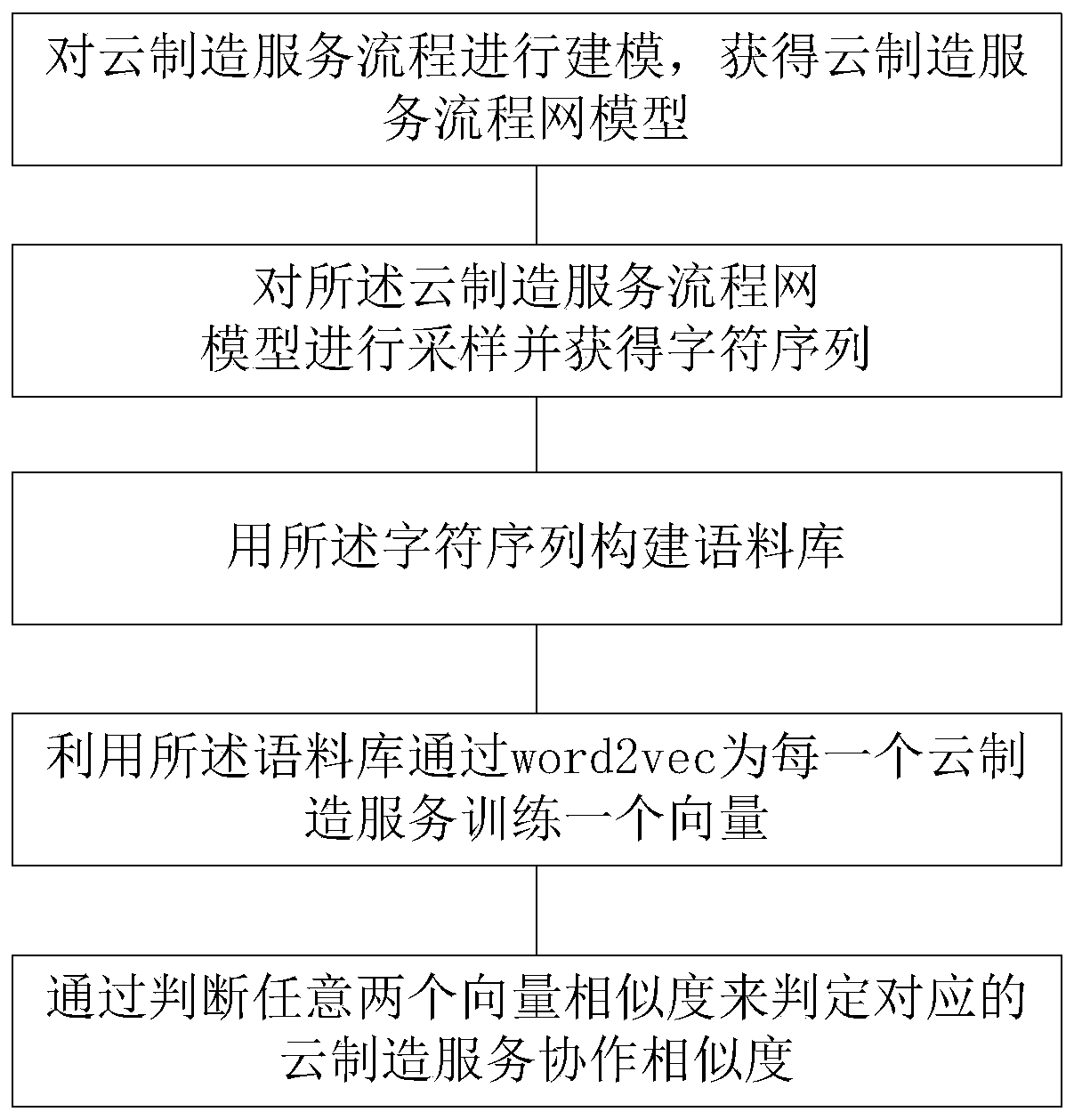

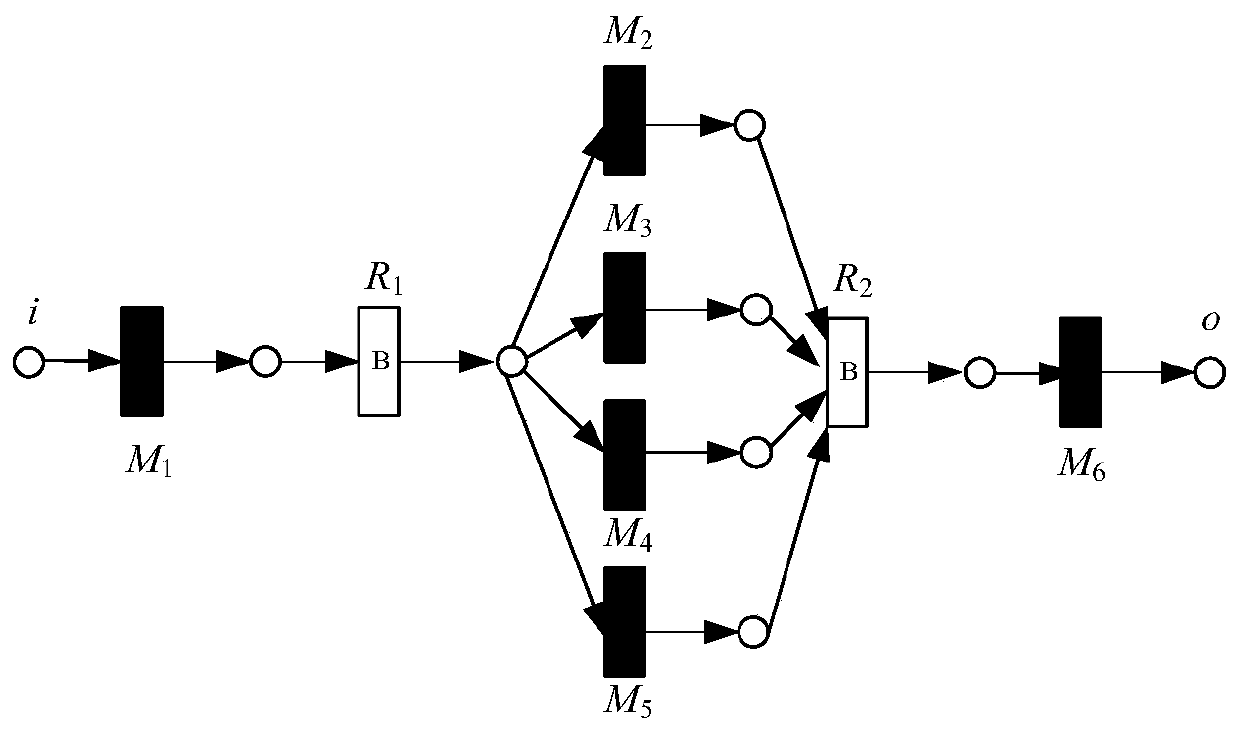

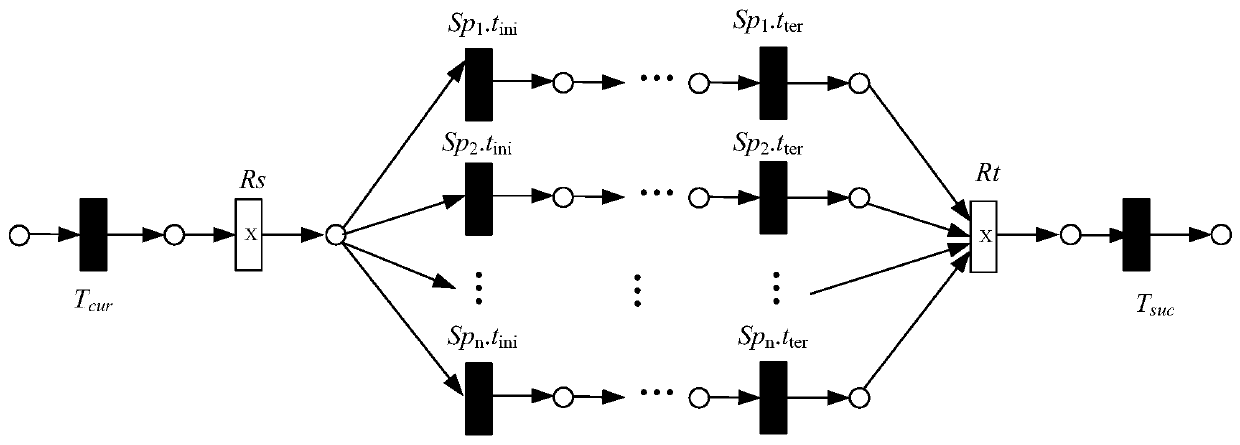

Cloud manufacturing service cooperation similarity calculation method based on Word2Vec

ActiveCN110661875AImprove collaboration similarityShorten the timeBiological neural network modelsData switching networksQuality of serviceNetwork model

The invention discloses a cloud manufacturing service cooperation similarity calculation method based on Word2Vec which comprises the following steps of S1, modeling a cloud manufacturing service process to obtain a cloud manufacturing service process network model; S2, sampling the cloud manufacturing service process network model and obtaining a character sequence; S3, constructing a corpus by using the character sequence; S4, training a vector for each cloud manufacturing service through Word2Vec by utilizing the corpus; and S5, judging the corresponding cloud manufacturing service cooperation similarity by judging the similarity of any two vectors. The manufacturing process needs a plurality of links. When individual services fail or functions are changed , the service with high cooperation similarity can be quickly matched for replacement, the replaced service takes multiple dimensions such as service functions, service quality and process cooperation into consideration, the timeused by a user for self retrieval can be shortened, the adaptation efficiency and compatibility are improved, the replacement period is shortened, and the rent seeking cost of the replacement serviceis reduced.

Owner:QINGDAO UNIV OF SCI & TECH

Power cable recycling and cleaning device

PendingCN112474480AAchieve flushingEfficient removalBasic electric elementsCleaning using toolsPower cablePower equipment

The invention discloses a power cable recovering and cleaning device. The power cable recovering and cleaning device comprises a cleaning box; conveying holes are formed in two ends of the cleaning box in a penetrating mode; a round pipe is arranged in the cleaning box; cleaning cotton is installed in the round pipe; the round pipe is connected with the inner wall of the cleaning box through two reset supporting pieces; a piston cylinder is installed at the inner bottom of the cleaning box; a piston is connected with the interior of the piston cylinder in a sliding mode; a piston rod is hingedto the upper end of the piston; a water inlet pipe is installed on the piston cylinder; a water inlet one-way valve is installed on the water inlet pipe; and a water outlet pipe is installed on the piston cylinder. The power cable recovering and cleaning device is reasonable in structure, by adopting one piece of power equipment, cleaning cable can be conveyed for being conveniently cleaned, clear water can be pumped for flushing the cable, brushing of the outer wall of the cable can be achieved, and dust on the outer part of the cable can be effectively and efficiently cleaned; and the investment of power equipment is reduced, and the production cost can be reduced.

Owner:万金国

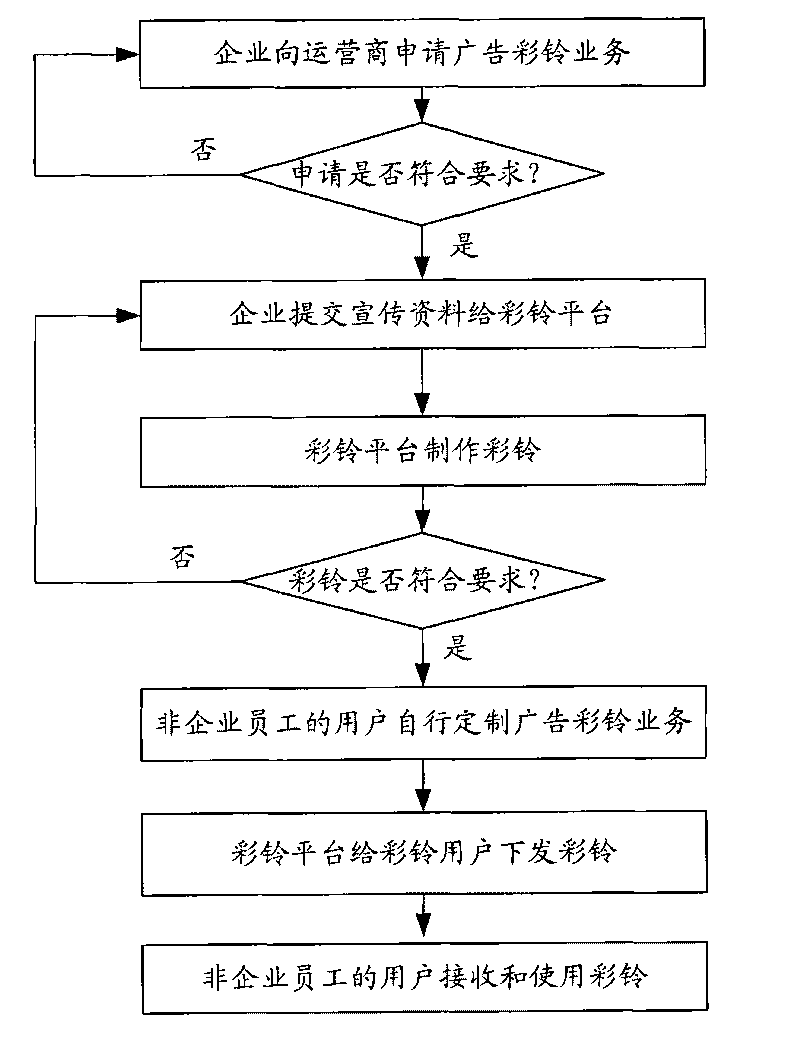

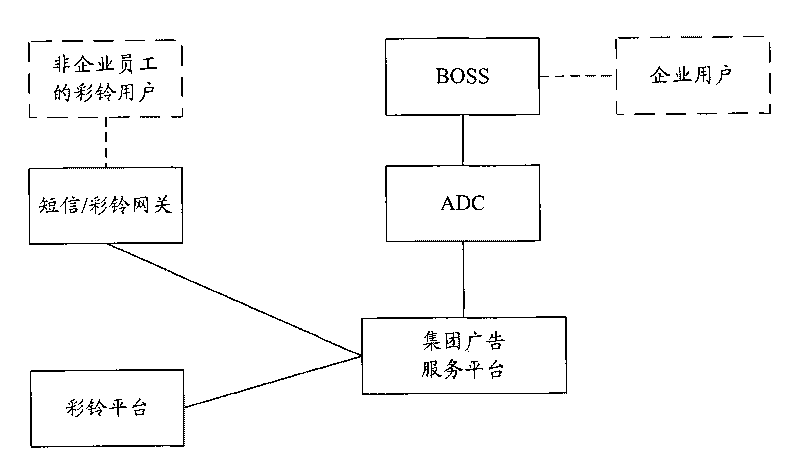

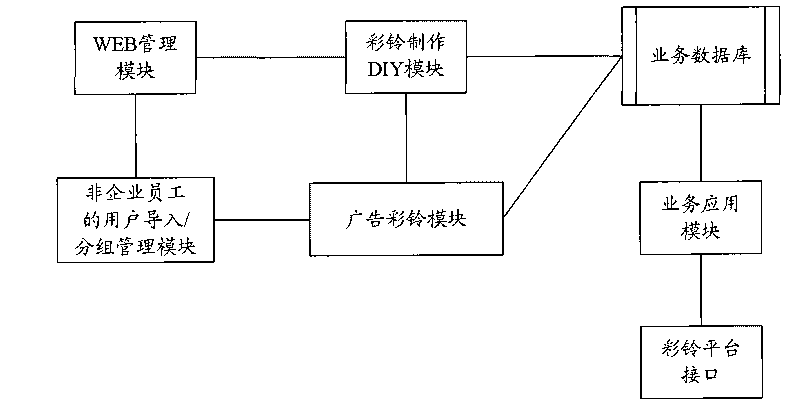

System and method for providing coloring ring back tone users with group advertising service

InactiveCN101729996AIncrease flexibilityExpand the scope of publicityMessaging/mailboxes/announcementsRing back toneApplication module

The invention relates to a system and a method for providing coloring ring back tone (CRBT) users with group advertising service. The system comprises BOSS, ADC, a CRBT platform, a short message / CRBT gateway and a group advertisement service platform, wherein the group advertising service platform is used for managing CRBT enterprise users, modifying enterprise advertisement CRBT, and providing CRBT service to non-staff users. Software modules comprise a WEB management module, a CRBT preparation DIY module, a non-staff user importing / grouping management module, an advertisement CRBT module, a service database module, a service application module and a CRBT platform interface module. Enterprises can use the DIY technology in the group advertisement service platform to prepare advertisement CRBT that conforms to enterprise images and marketing purposes through a WEB network according to the demands for development and propaganda, and can directly import a group of non-staff CRBT users as the advertisement CRBT users of the enterprises, thereby quickening the advertising campaign, and expanding the propaganda range.

Owner:CHINA MOBILE COMM CORP TIANJIN

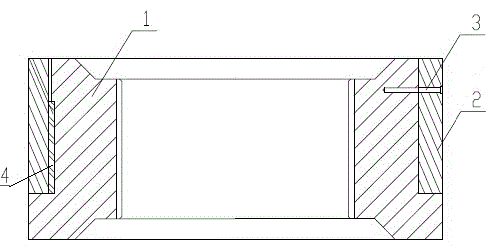

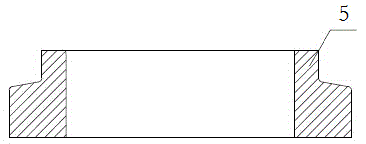

Combined main roll of ring rolling mill

InactiveCN104438992AReduce replacement cycleFlexible roll changeMetal rollingEngineeringMultiple forms

The invention discloses a combined main roll of a ring rolling mill, and relates to the technical field of metal rolling mill rolls. The main roll comprises a main roll body with a vertical passing hole formed in the middle, and two or more forming tiles fixed to the periphery of the main roll body through bolts. Because the multiple forming tiles are fixedly connected to the periphery of the main roll body through the bolts, it is only needed to replace the forming tiles with different ones when different ring blanks are manufactured, so that the replacement time of the main roll is shortened, the different shapes of ring blanks are produced at the same time, the working efficiency is improved, and the manufacturing cost of the main roll is lowered.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com