Preparation method of high-chromium roller for steel tube reducing mill or sizing mill and high-chromium roller prepared thereby

A technology of reducing machine and sizing machine, which is applied in the field of casting processing, can solve the problems of wear resistance and low comprehensive strength, and achieve the effects of good surface quality, increased hardness of rolls, and saving processing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

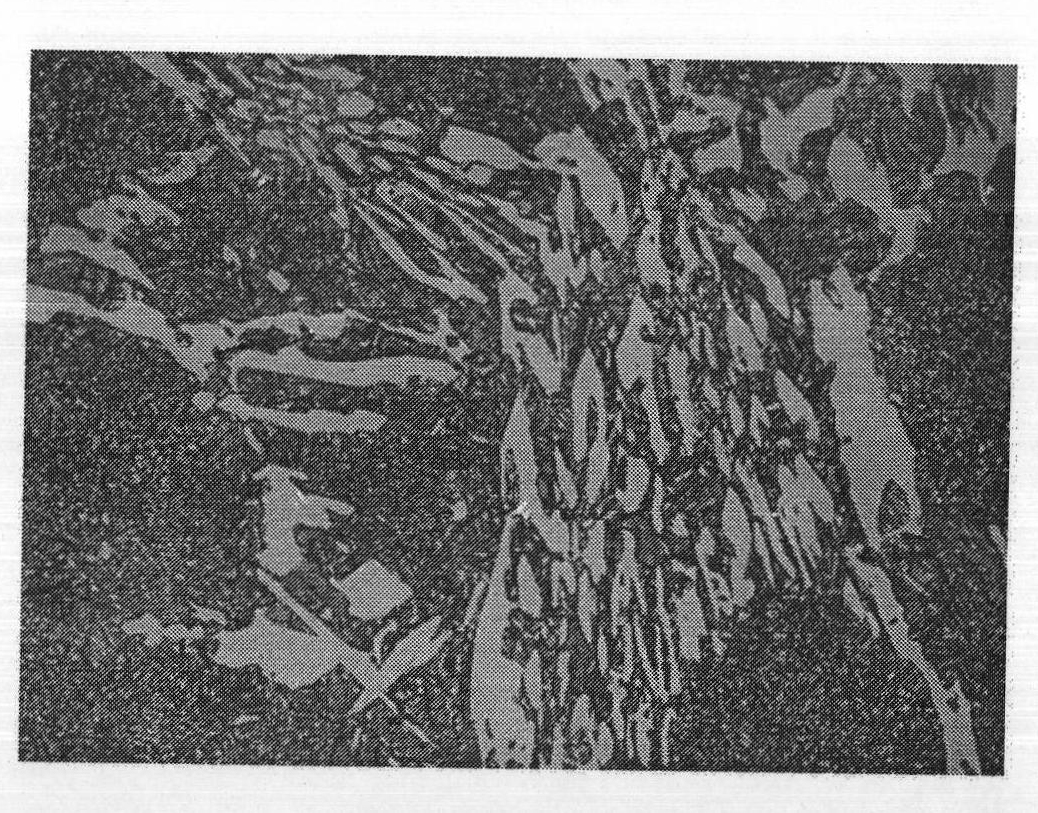

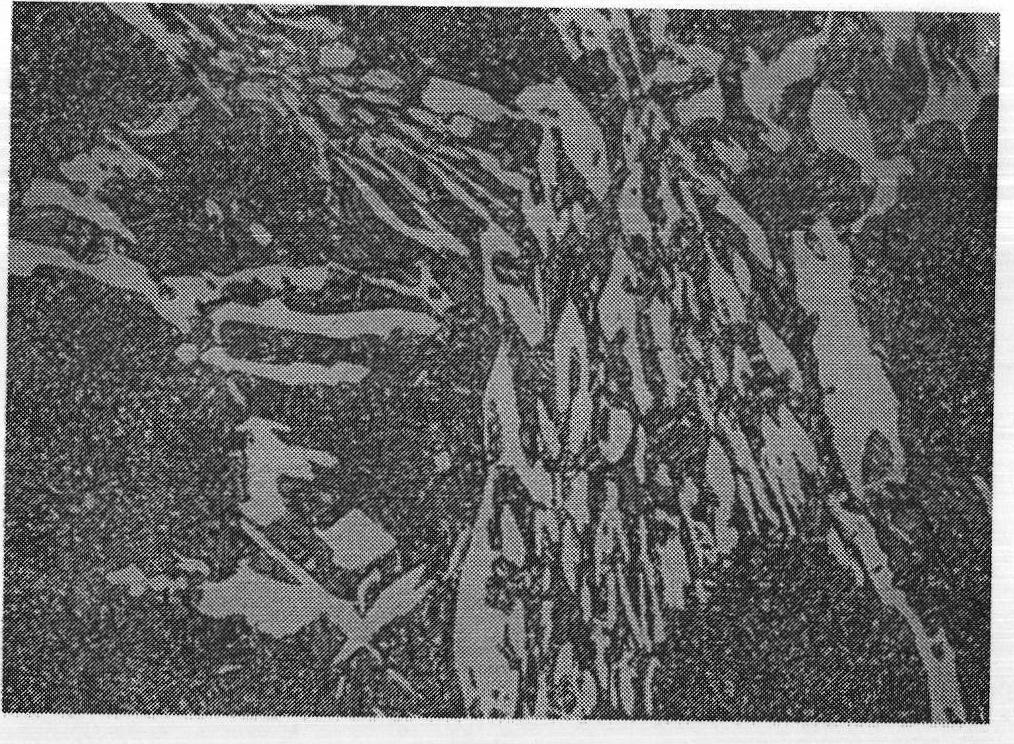

Image

Examples

preparation example Construction

[0018] The preparation method of the present invention mainly includes: smelting, casting, annealing heat treatment, rough machining, quenching and tempering heat treatment, and finally finishing.

[0019] Since the hot-rolled seamless steel pipe tension reducer and the high-chromium roll of the sizing machine require a sufficiently thick working layer, there are strict requirements on the quality of the slab, and the present invention has carried out several improvements on the casting and heat treatment methods as follows :

[0020] Smelting: It can be smelted in a medium frequency induction furnace. Select the composition ratio of high chromium rolls for smelting to obtain molten steel with the required composition. The invention adds degassing and argon blowing refining process in the smelting process to ensure pure molten steel.

[0021] Billet: It can be produced by centrifugal casting method or other sand casting methods. In the present invention, an integral cold ir...

Embodiment 1

[0037] Example 1 is to manufacture high chromium rolls for hot-rolled seamless steel tube sizing mills for Φ250 seamless steel tube continuous rolling mills. The roll components are shown in Table 1 by weight percentage (%Wt).

[0038] Table 1

[0039] C

Si

mn

P

S

Cr

Mo

Cu

Al

Nb

Ti

N

RE

1.63

0.30

0.70

0.029

0.017

9.00

0.6

0.15

0.10

0.16

0.18

0.06

0.02

[0040] The rest is Fe.

[0041] Select the ratio of raw materials according to the components listed in Table 1, and carry out smelting in an intermediate frequency induction furnace. During the smelting process, degassing and argon blowing refining processes are added to ensure that the required components and pure molten steel are obtained.

[0042] The cast billet is produced by centrifugal casting method. There is an integral cooling iron at the lower end of the casti...

Embodiment 2

[0046] Example 2 is to manufacture high chromium rolls for hot-rolled seamless steel tube sizing mills for Φ508 seamless steel tube peripheral rolling mills. The roll components are shown in Table 2 by weight percentage (%Wt).

[0047] Table 2

[0048] C

Si

mn

P

S

Cr

Mo

Cu

Al

Nb

Ti

N

RE

2.15

0.50

0.50

0.030

0.021

11.00

0.4

0.28

0.25

0.25

0.26

0.27

0.46

[0049] The rest is Fe.

[0050] Select the ratio of raw materials according to the components listed in Table 2, smelt in an intermediate frequency induction furnace, add degassing and argon blowing refining process in the smelting process, to obtain pure molten steel.

[0051] The cast billet is produced by centrifugal casting method. There is an integral cooling iron at the lower end of the casting mold, and 8-12mm thick molding sand is laid on the upper surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com