Patents

Literature

107results about How to "Save processing materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

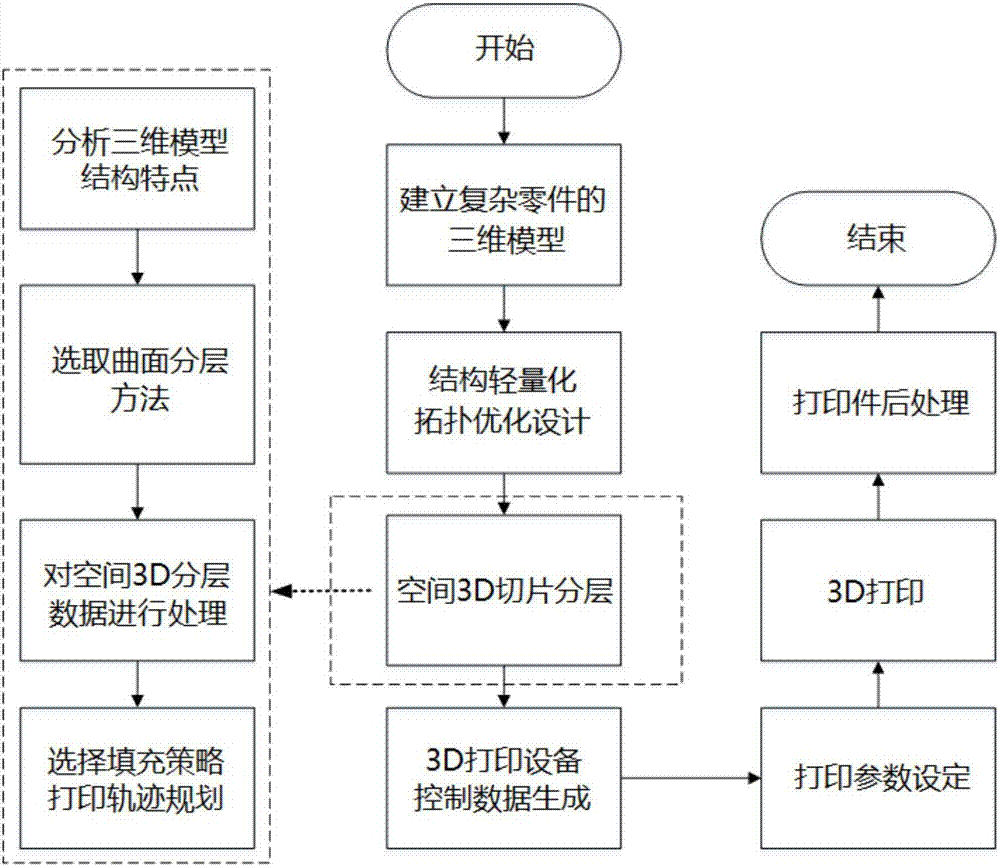

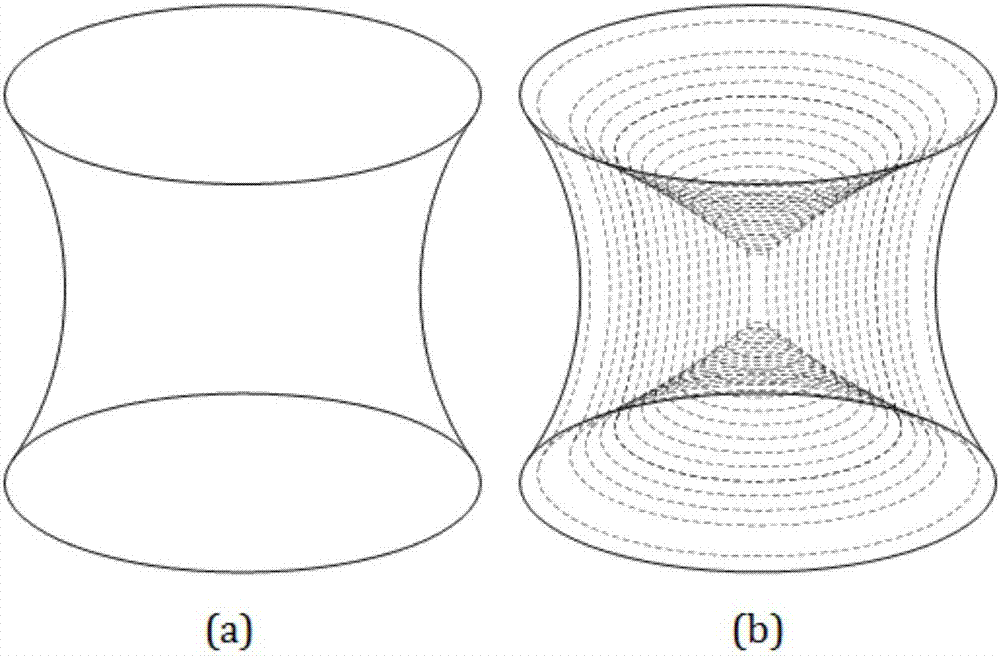

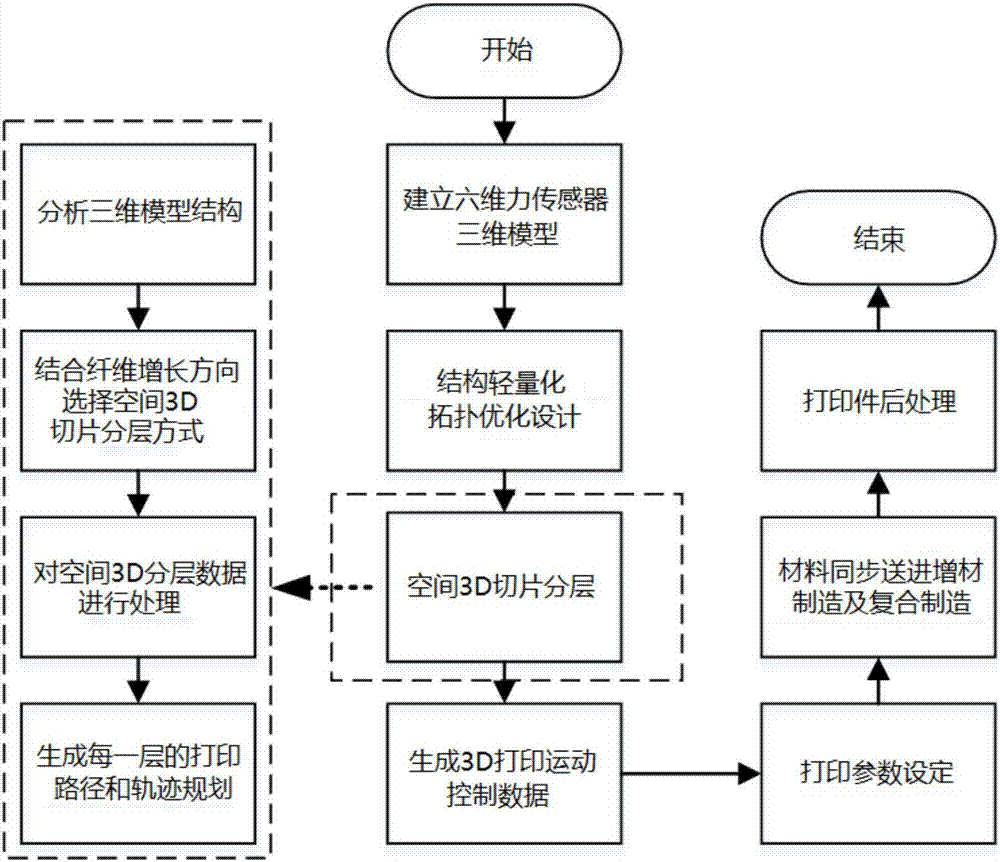

3D printing method and system for complicated parts based on curved surface layering

InactiveCN107187056AImprove carrying capacityLess print supportAdditive manufacturing apparatusManufacturing data aquisition/processingSurface layerTopology optimization

The invention discloses a 3D printing method and system for complicated parts based on curved surface layering. According to structures and the characteristics of curved surfaces of the complicated parts , a three-dimensional model is built, and lightweight structural topology optimization design and spatial 3D slicing and layering are carried out, so that control data for 3D printing can be generated; layer-by-layer 3D printing is carried out after printing parameters are set according to the control data so as to obtain 3D printing parts of the complicated parts, wherein the spatial 3D slicing and layering mean that the curved surface layering is carried out by choosing a curved surface layering method according to the structure characteristics of the three-dimensional mode of the complicated parts, the layered spatial 3D layering data is processed and a filling strategy is selected for printing of paths and planning of tracks. Compared with an existing CNC processing technology, the method and the system disclosed by the invention have the advantages that realization of continuous fiber reinforced manufacturing is facilitated, surface forming precision of the complicated parts is effectively improved, and the printing support is reduced.

Owner:SHANGHAI JIAO TONG UNIV

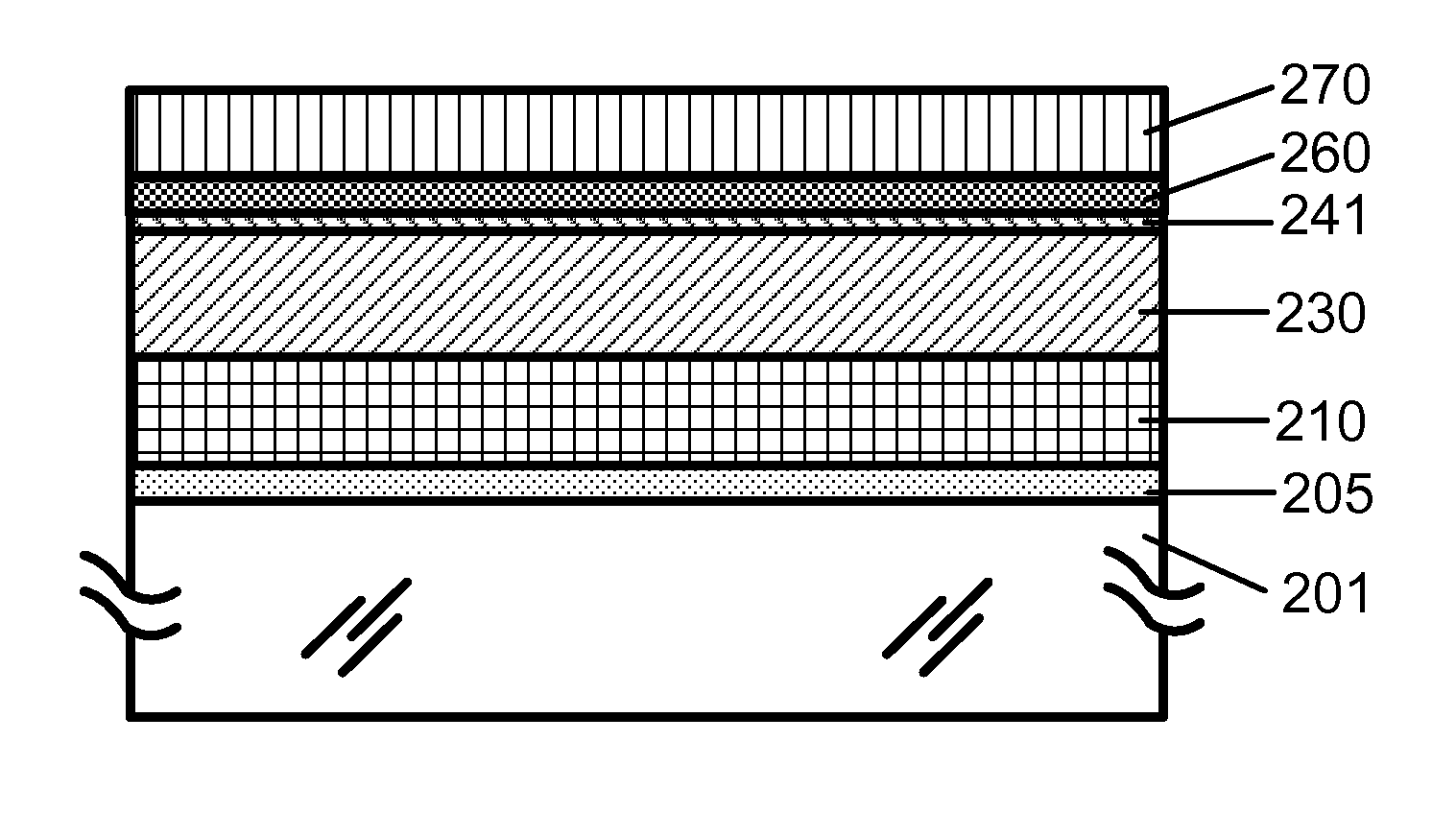

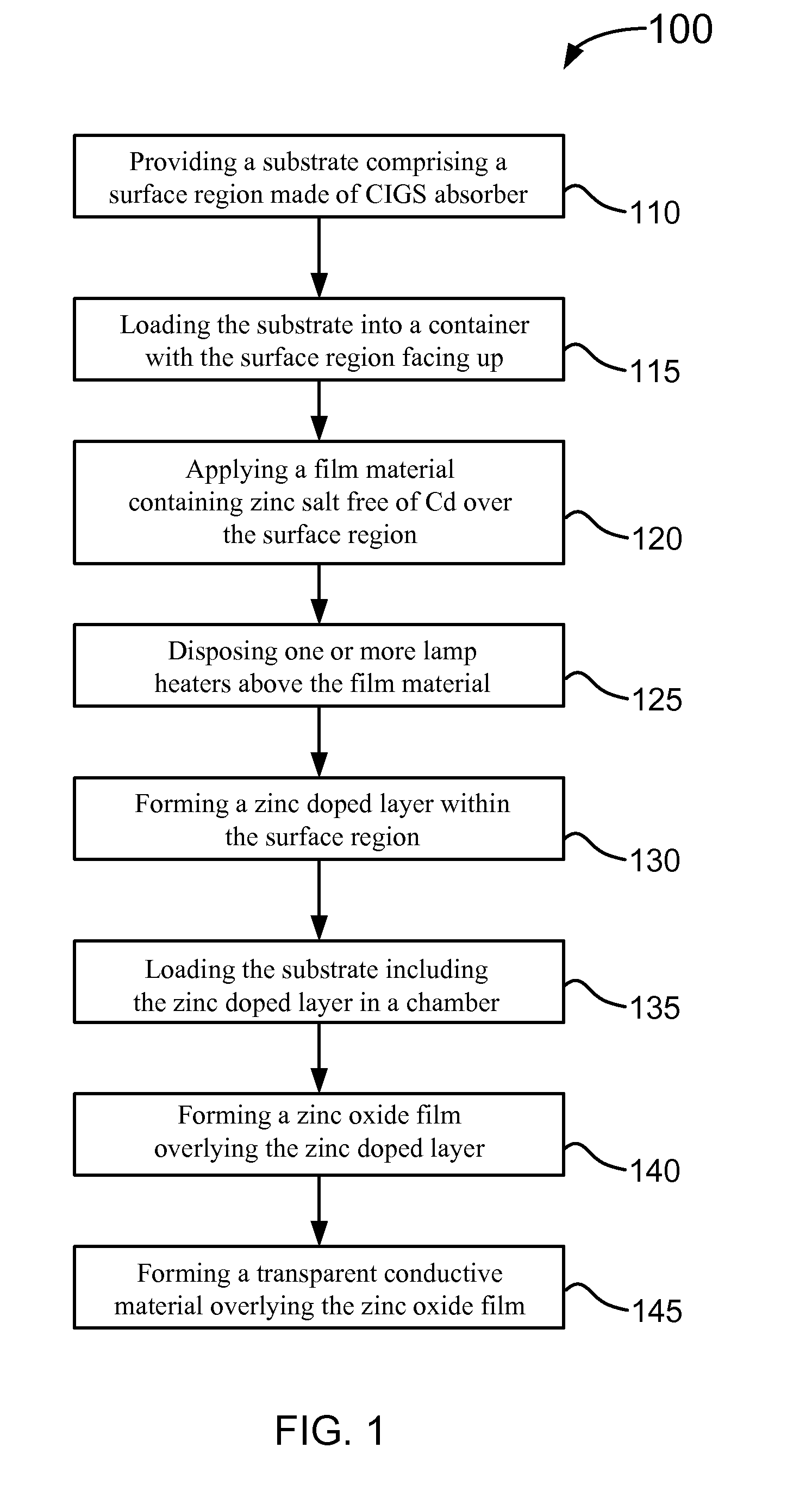

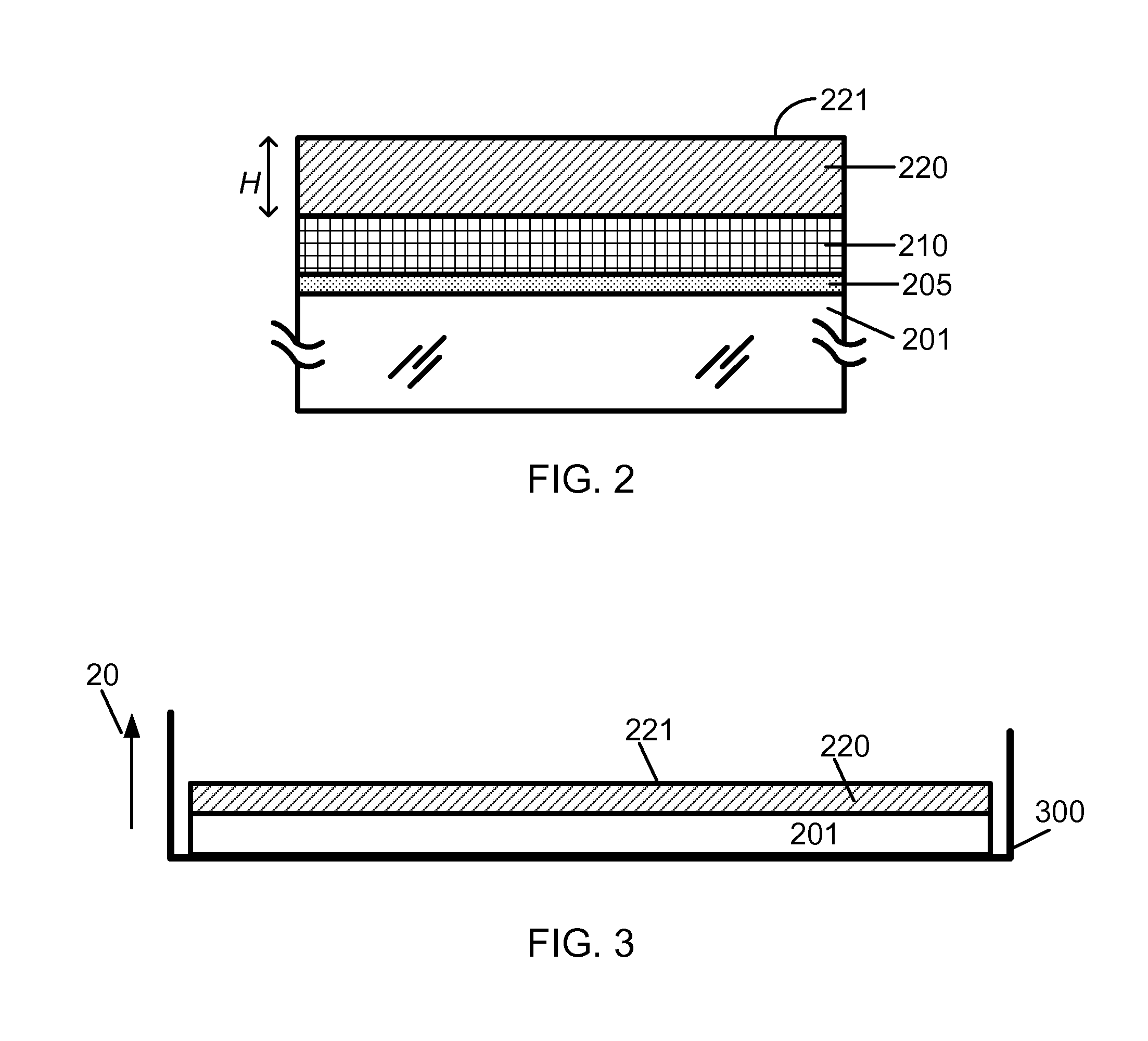

Method and Device for Cadmium-Free Solar Cells

InactiveUS20120240989A1SaveReduce harm to the environmentSemiconductor/solid-state device manufacturingPhotovoltaic energy generationIndiumSulfur

A method for fabricating a thin film photovoltaic device is provided. The method includes providing a substrate comprising a thin film photovoltaic absorber which has a surface including copper, indium, gallium, selenium, and sulfur. The method further includes subjecting the surface to a material containing at least a zinc species substantially free of any cadmium. The surface is heated to cause formation of a zinc doped material. The zinc doped material is free from cadmium. Furthermore the method includes forming a zinc oxide material overlying the zinc doped material and forming a transparent conductive material overlying the zinc oxide material.

Owner:CM MFG

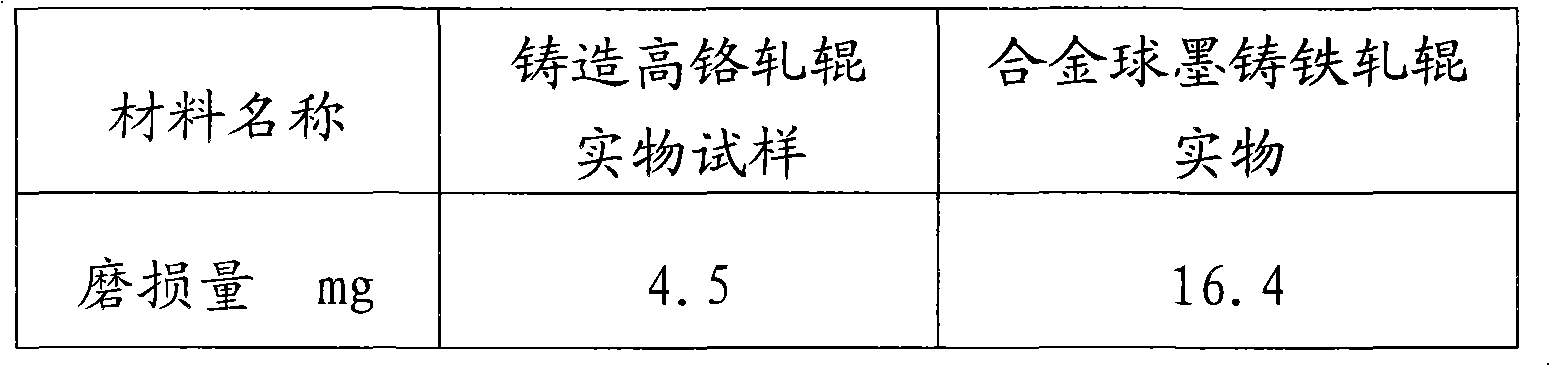

Preparation method of high-chromium roller for steel tube reducing mill or sizing mill and high-chromium roller prepared thereby

ActiveCN102251185AHigh hardnessReduce replacement cycleFoundry mouldsFurnace typesSand castingHardness

The invention discloses a high-chromium cast roller for a steel tube reducing mill or sizing mill and a preparation method thereof. The preparation method is characterized by optimizing the design of components, selecting the component proportioning of the roller according to the application of the roller and the specific in-service working conditions and technical requirements, and melting corresponding iron alloy, scrap steel and other raw materials to obtain required molten steel; carrying out centrifugal or sand casting to obtain blanks of a required size; and carrying out annealing, quenching, tempering and other thermal treatment on the cast blanks, and carrying out turning, milling and other machining operation to produce the high-chromium roller for a hot rolling seamless steel tube tension reducing mill and sizing mill. The surface hardness of the roller disclosed by the invention is obviously improved, and the macrohardness is up to 54-62 HRC, so that the service life of the high-chromium cast roller is increase by at least two times. Because of the increase of the wear resistance and service life, the replacement frequency of the roller is reduced, thereby saving the materials and production cost. Besides, the rolling capability and yield of the seamless steel tube unit is improved.

Owner:SHANDONG PROVINCE SIFANG TECHN DEV

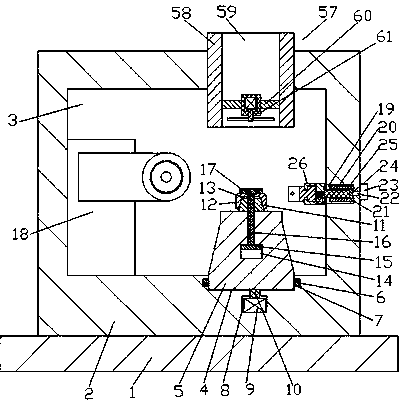

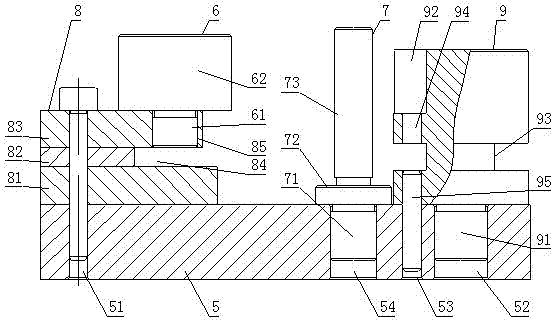

Process detecting device used in machine manufacturing

ActiveCN108481089AUniform growthGuaranteed accuracy requirementsMeasurement/indication equipmentsNumerical controlEngineering

The invention discloses a process detecting device used in machine manufacturing. The process detecting device comprises a fixed base plate, a numerical control machine case is arranged on the upper end face of the fixed base plate, the numerical control machine case and the fixed base plate are of an integrated structure, a clamp body is arranged in a clamp groove, a taper shaft is fixedly connected to the middle position of the upper end face of the clamp body, the upper side of the taper shaft is sleeved with an expanding sleeve, a hob module is fixedly arranged at the left end of the interior of a machining space, and the left end of a stretchable rod penetrates out of the left end wall of a stretchable space and a stretchable groove and is fixedly connected with an across-measured distance detecting device. When the process detecting device works, a dividing groove guarantees that the expanding sleeve can expand towards the periphery evenly, the coaxality is guaranteed, the accuracy requirement in the machining process is guaranteed, the measurement angle is automatically adjusted, and the accuracy of a measurement value is guaranteed; and in the measurement process, workpieces in machining do not need to be detached, tooth breaking caused by repeated clamping is avoided, machining materials are saved, and the technological controllability is increased.

Owner:XUAZHOU HEIBAILONG ENG NYLON

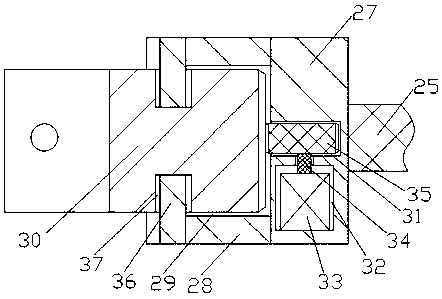

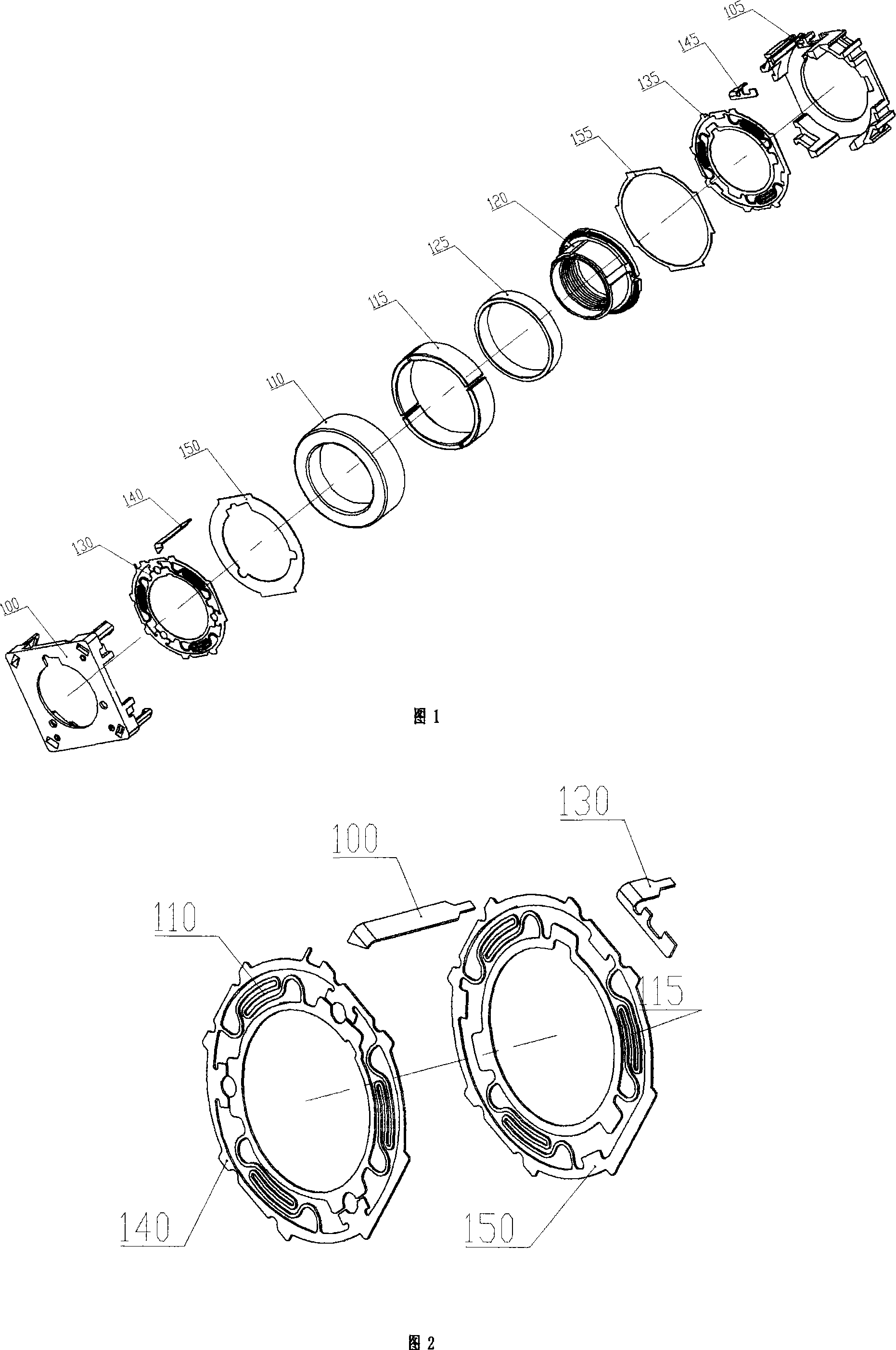

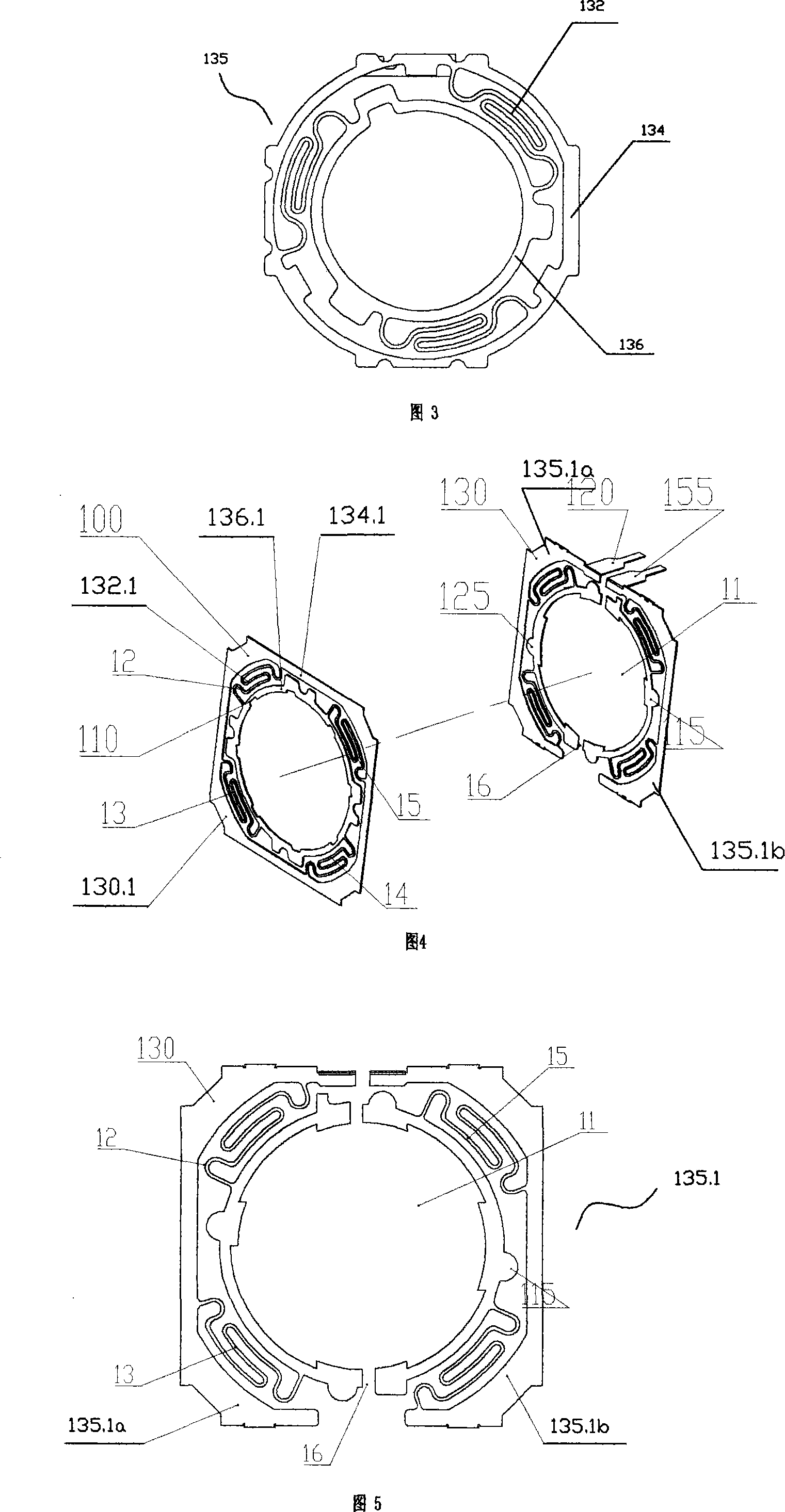

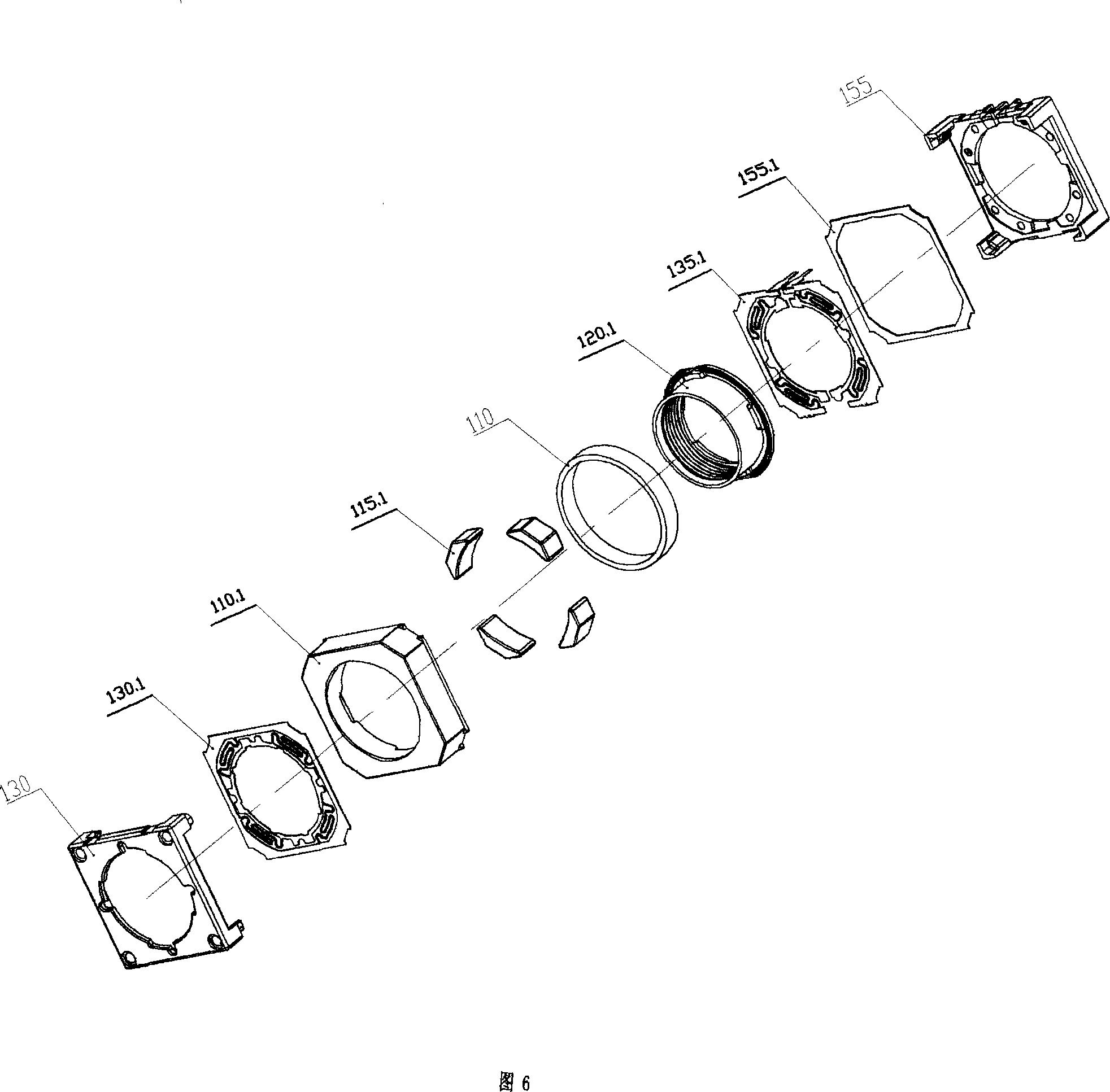

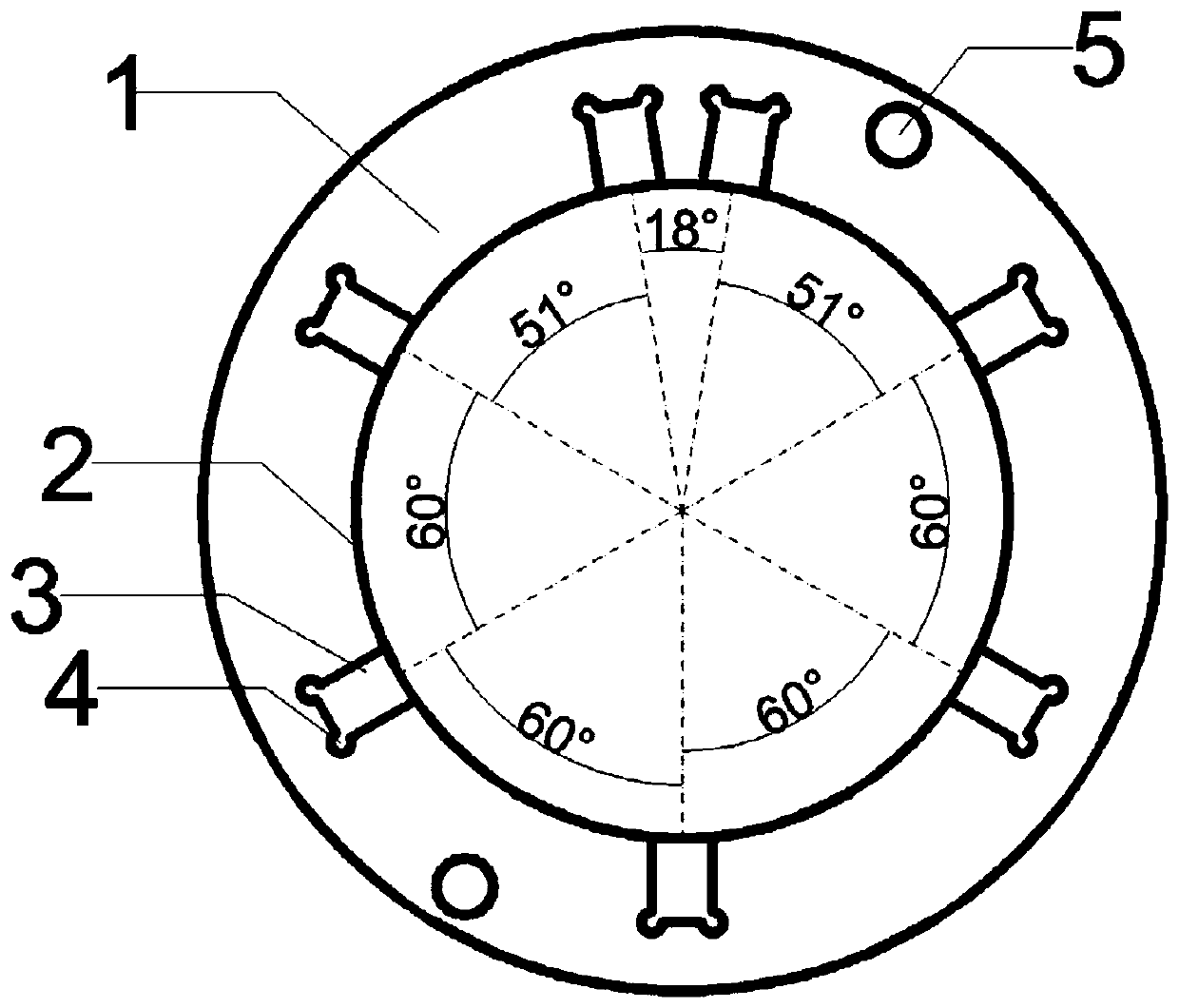

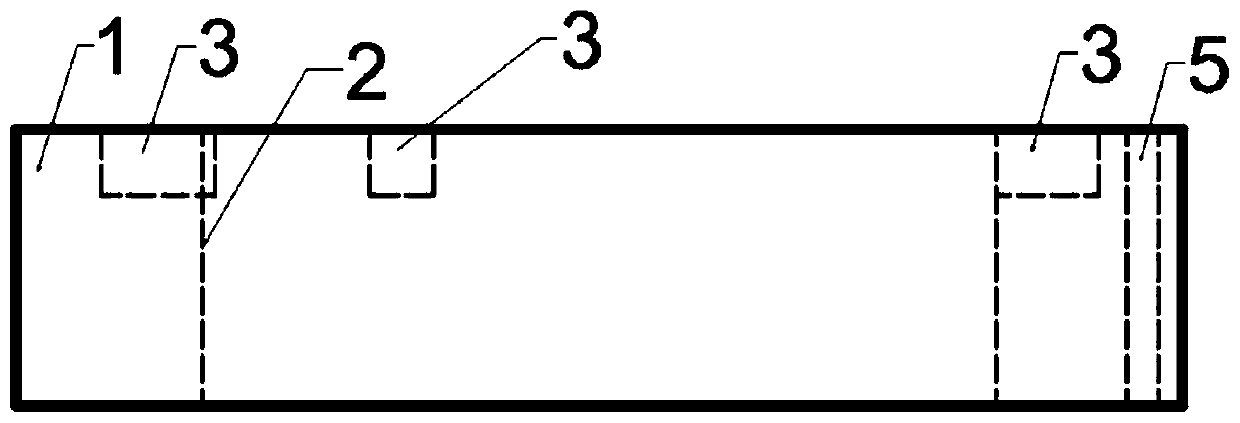

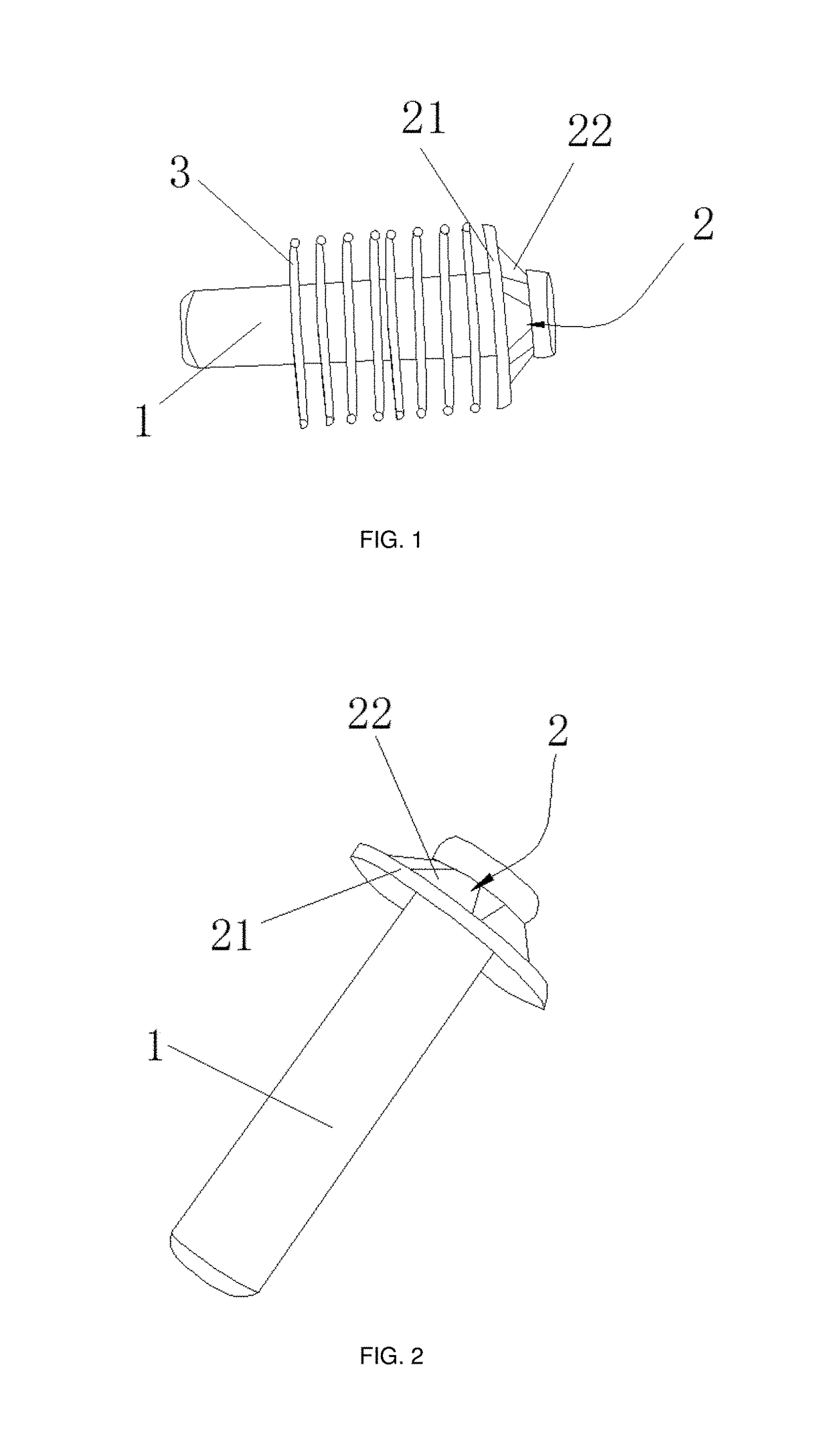

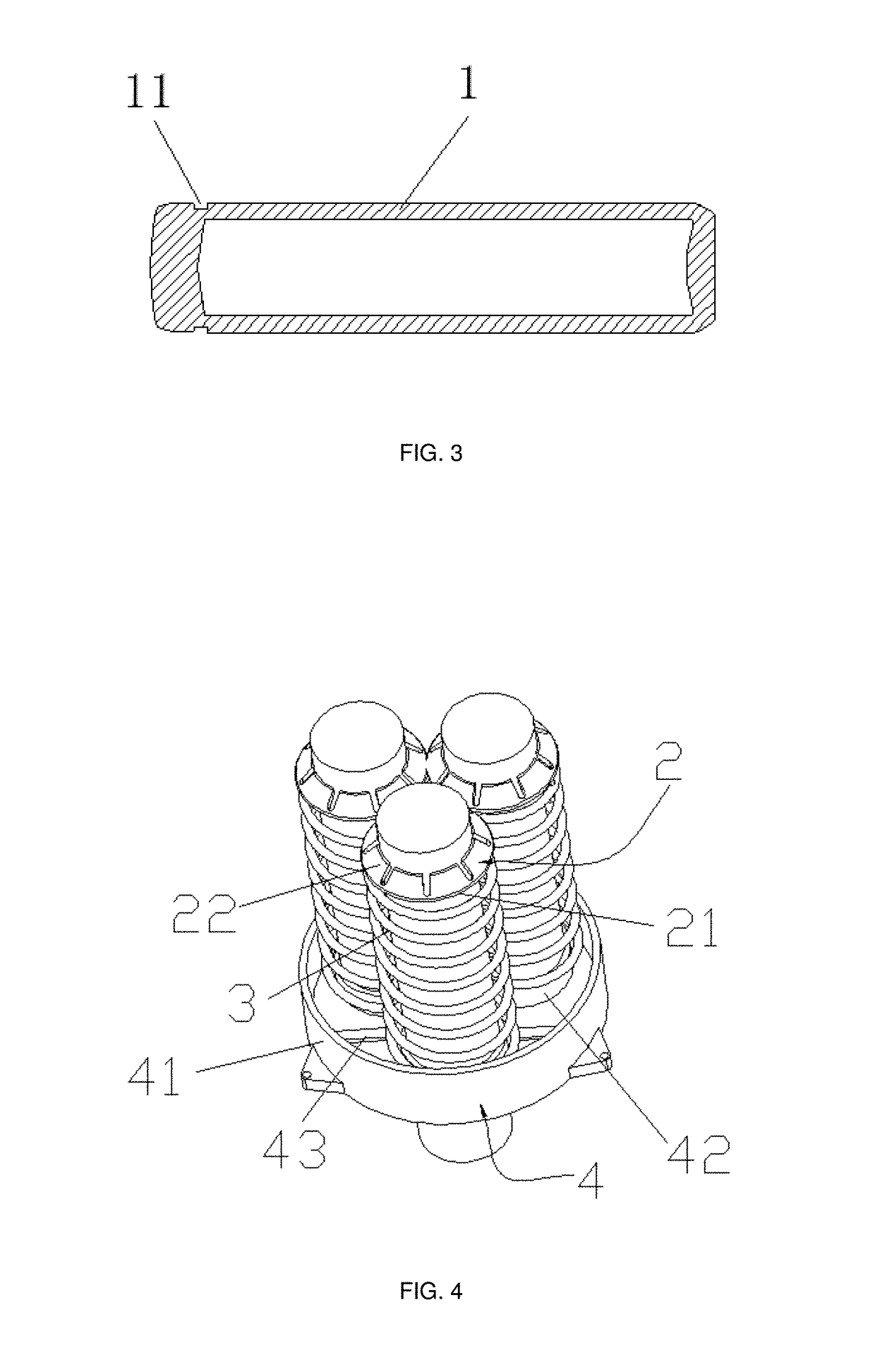

Spring lamination pair for microminiaturization voice coil motor

InactiveCN101227131AReduce the number and processing technologySave processing materialsDynamo-electric machinesLow internal friction springsEngineeringMechanical engineering

A spring lamination pair for a microminiature voice coil motor comprises a front and a rear spring laminations, wherein the front and rear spring laminations both comprise a base body which is opened with a central hole on the center, an inner circle moving ring and an outer circle fixing ring are distributed on the same axis from inner to outer along the peripheral radial direction of the central hole, the inner circle moving ring is provided with a clipping position structure, and the outer circle fixing ring is provided with a tortuous spring wire. The invention is characterized in that the rear spring lamination is formed by combining two half of spring laminations whose left and right are separated through a sheet separating insulating groove, and each half spring lamination is respectively connected with positive and negative input ends. The front and rear spring lamination base bodies are all rectangle plane structure, the outer circle fixing ring is provided with at least four interlaced and tortuous spring wires, each tortuous spring wire has same shape, which is evenly and symmetrically distributed between the inner circle moving ring and outer circle fixing ring. The invention is adopted to increase response speed of a moving carrier base, reduce component number and processing procedure of a voice coil motor, save processing material, reduce manufacturing cost and also reduce external dimension of the voice coil motor.

Owner:惠州龙德科技股份有限公司

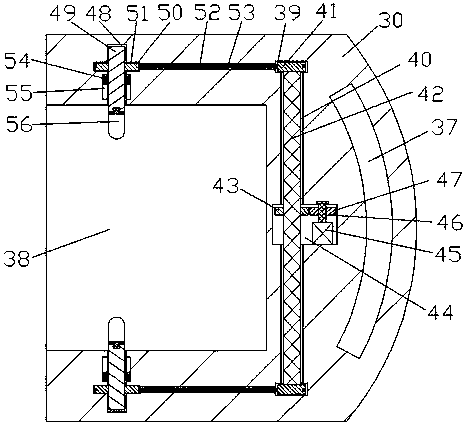

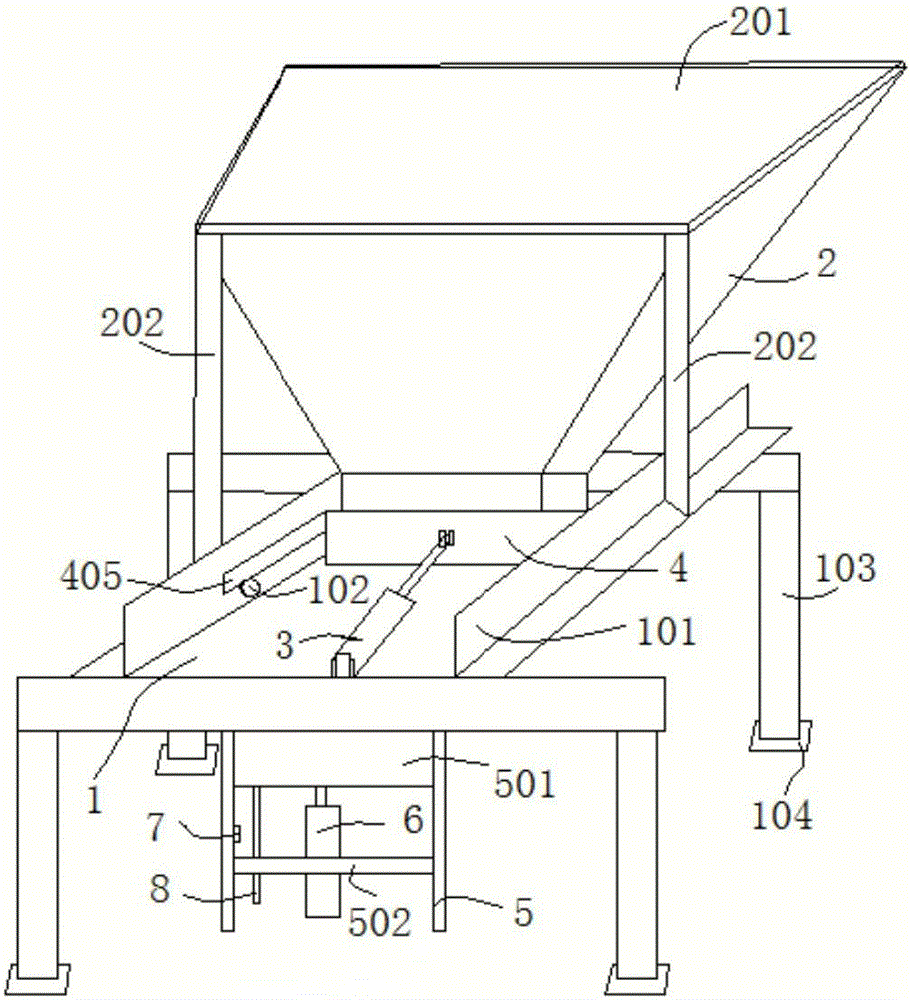

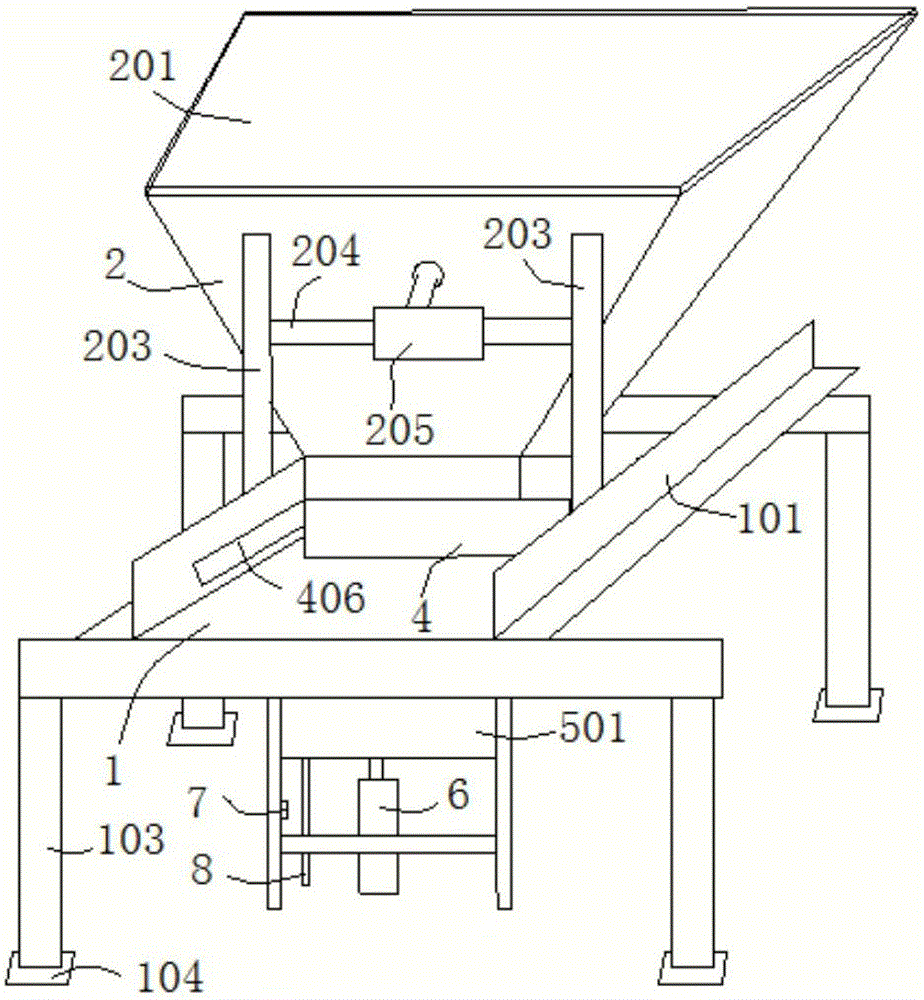

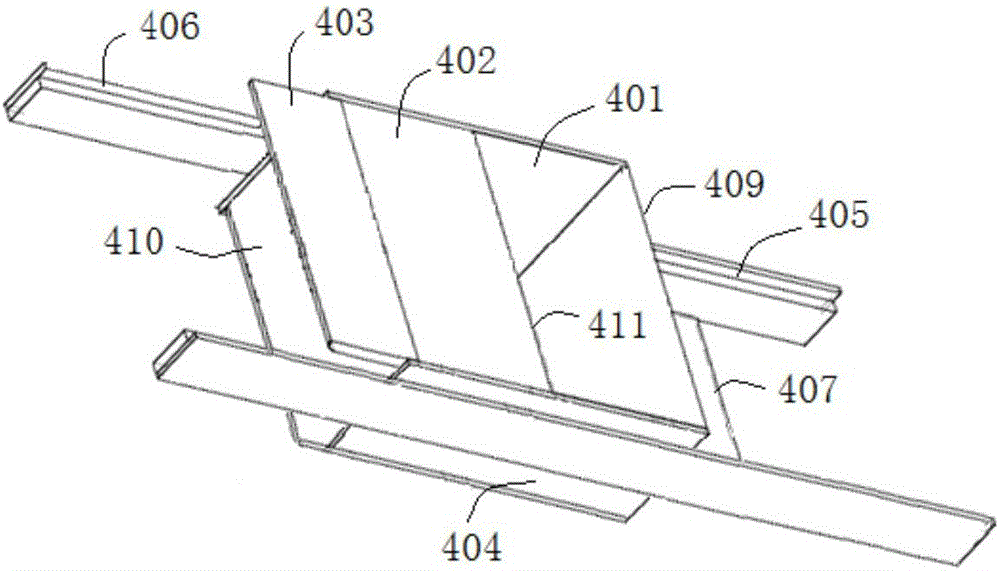

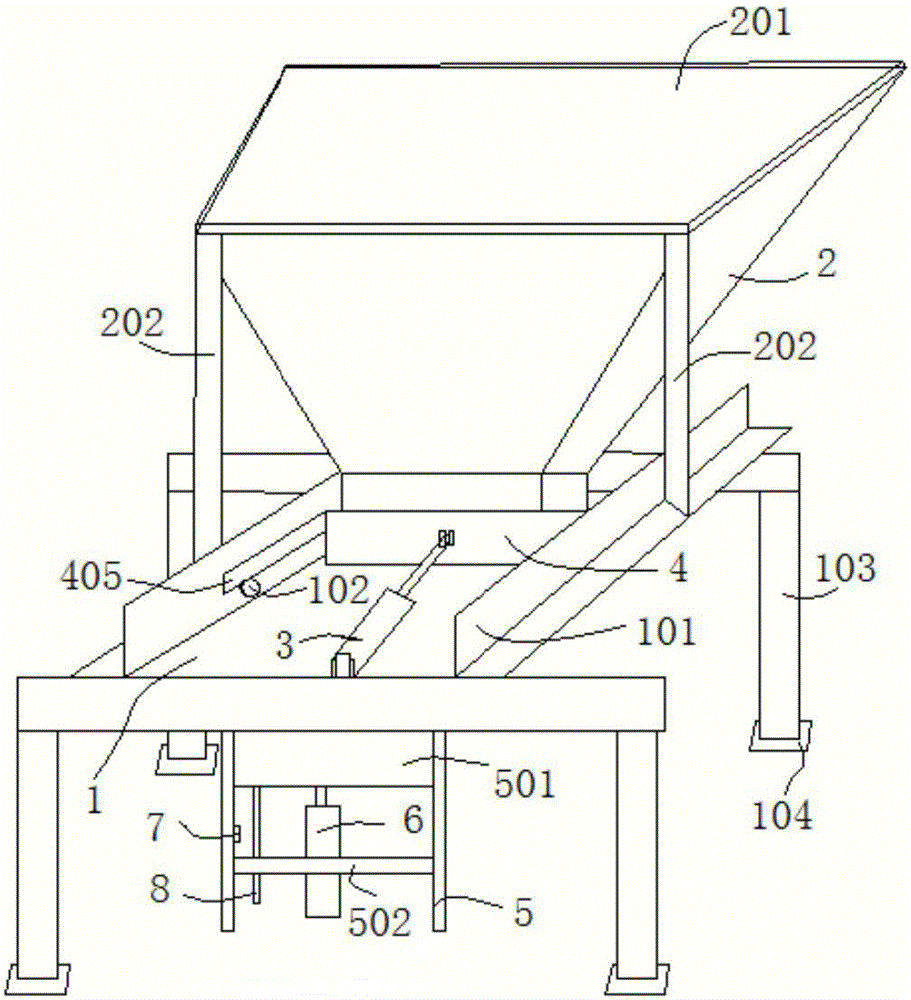

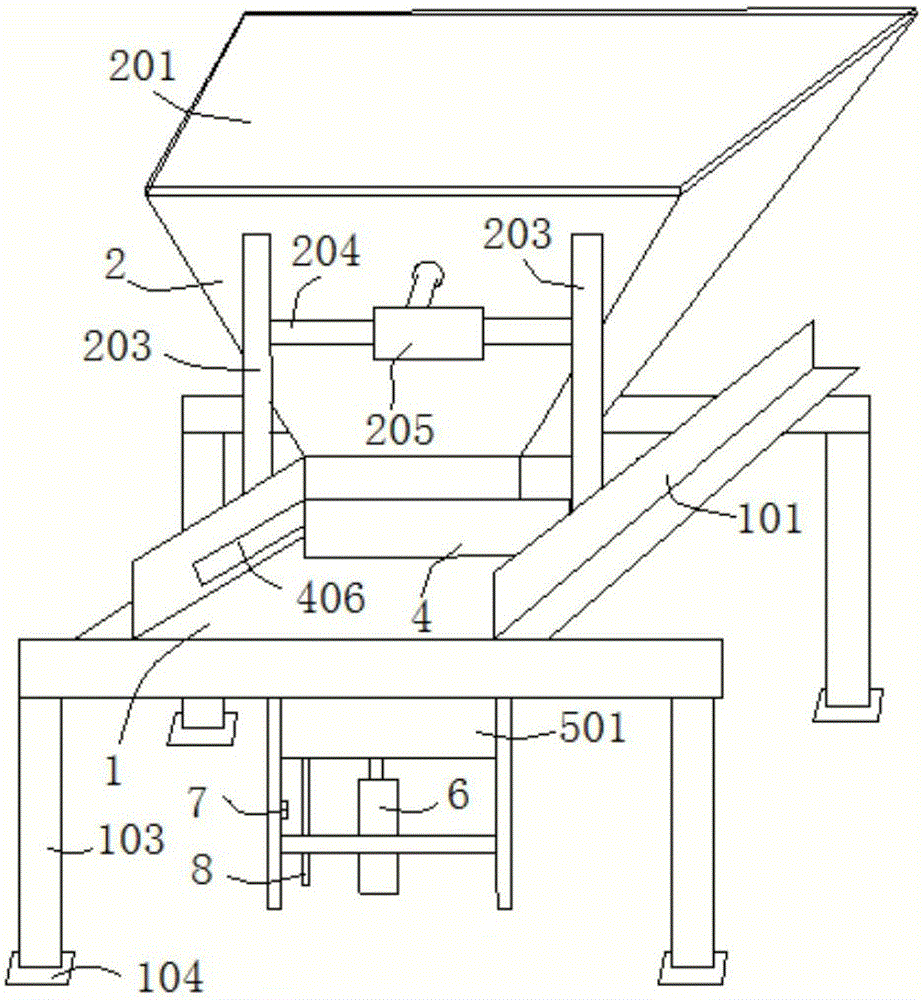

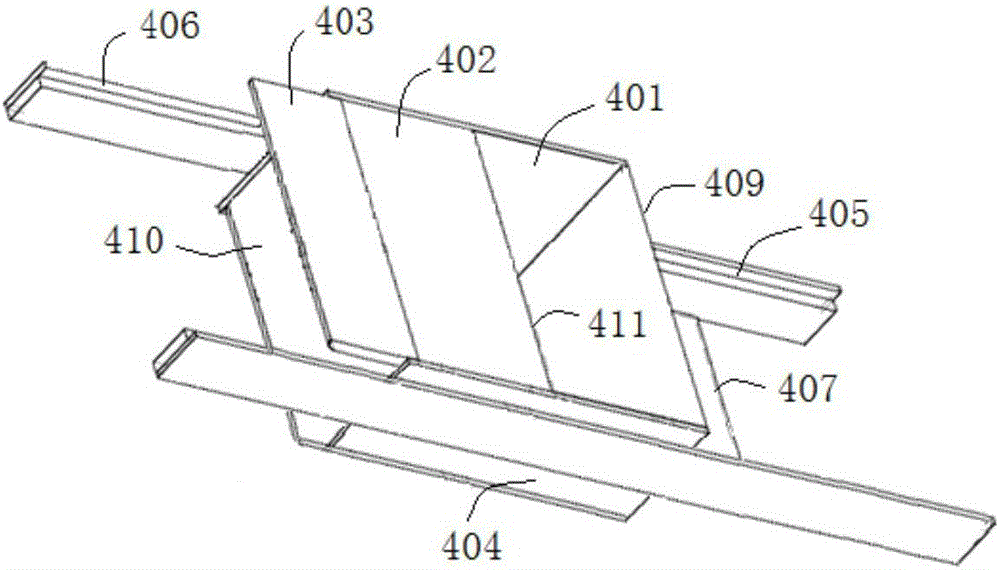

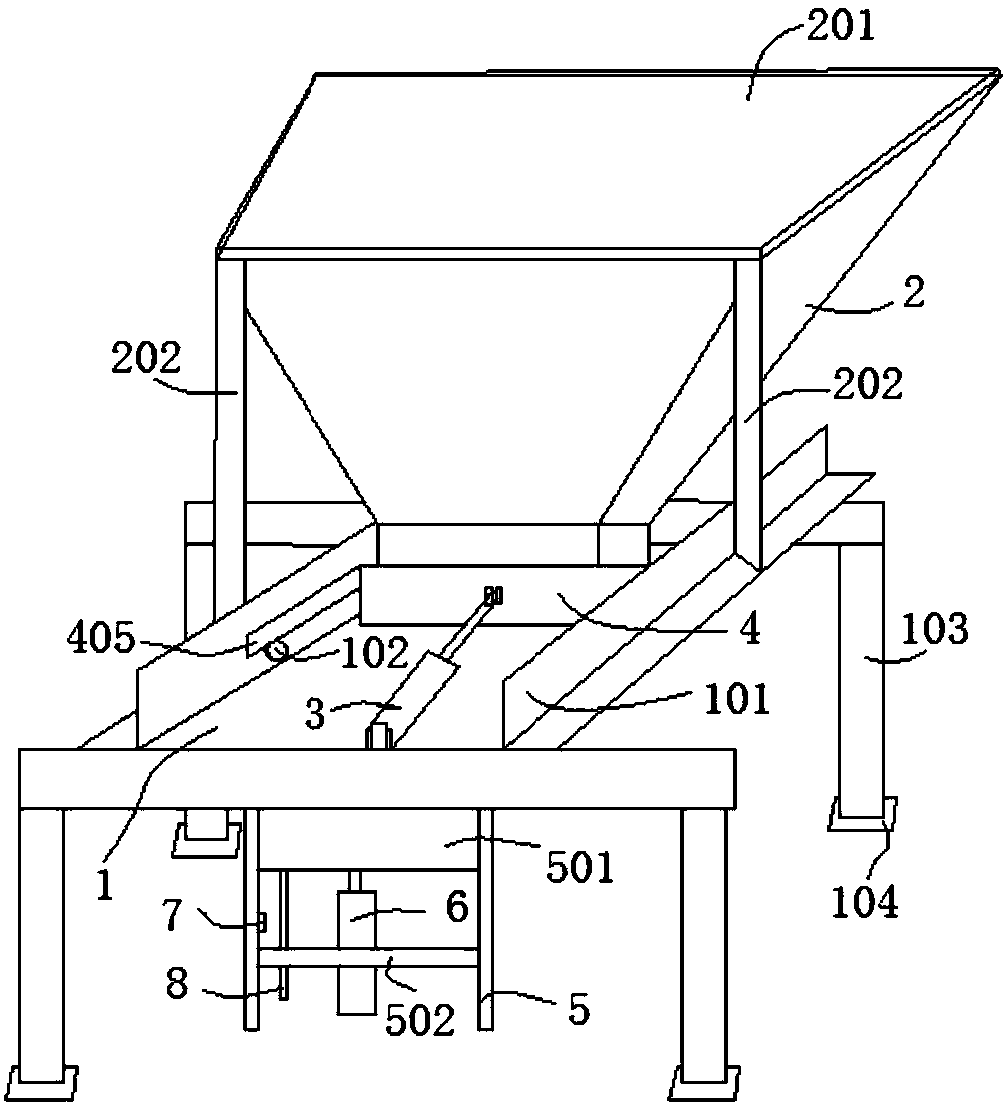

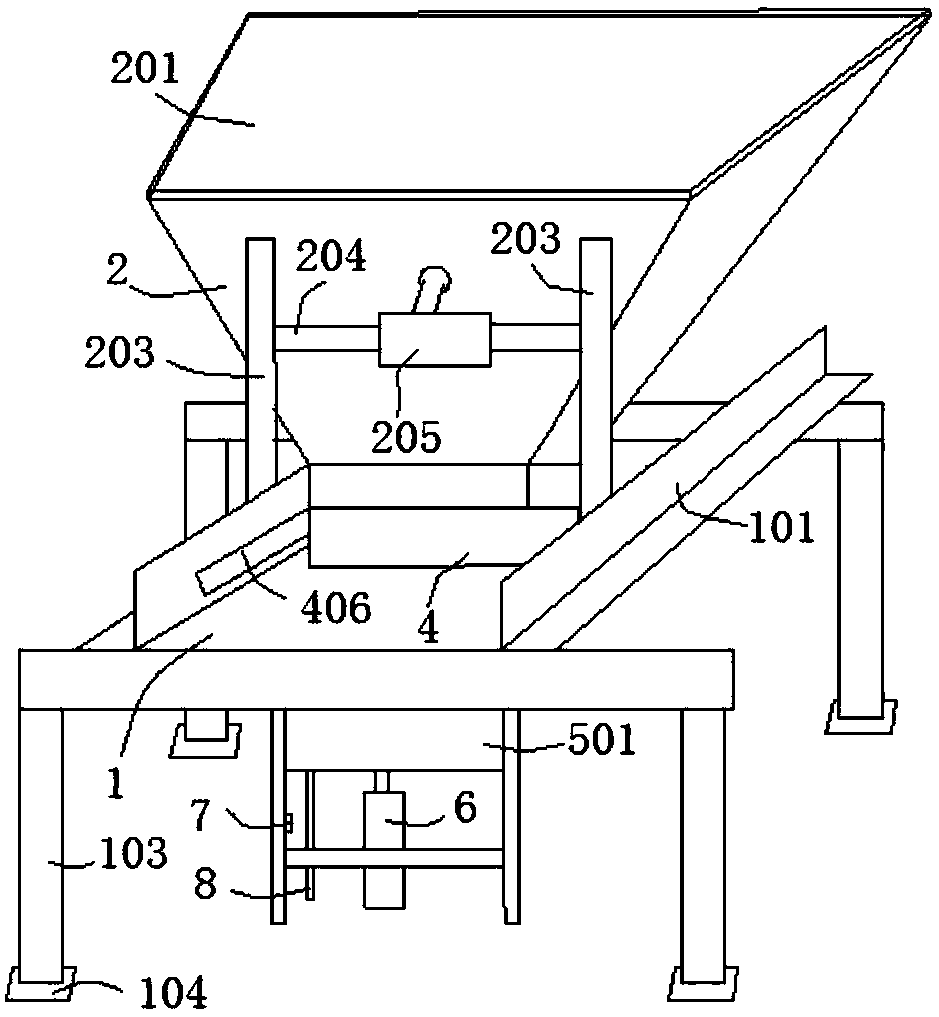

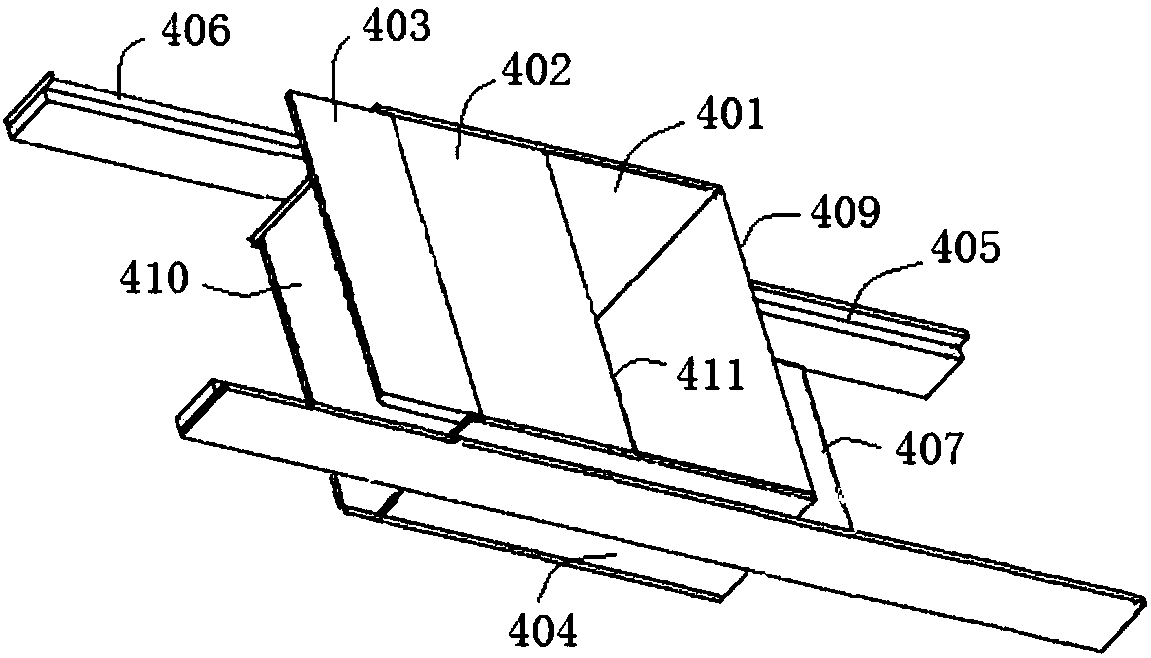

Automatic forming device for producing baking-free bricks

ActiveCN106313297AAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses an automatic forming device for producing baking-free bricks, and belongs to the field of brick making machines. The automatic forming device comprises a frame, a blanking opening is formed in the frame, a forming material pushing mechanism is arranged above the blanking opening and connected with a first hydraulic cylinder, a forming mechanism is arranged below the blanking opening and connected with a second hydraulic cylinder, raw materials penetrate the forming material pushing mechanism, enters the forming mechanism and squeezed into bricks by the second hydraulic cylinder, the bricks are pushed onto the frame by the second hydraulic cylinder, and the first hydraulic cylinder drives the forming material pushing mechanism, so that the bricks are pushed onto a delivery mechanism and conveyed. The automatic forming device helps to solve the problems of complicated structure and cumbersome production process of an existing brick making machine, the bricks can be continuously squeezed and formed, production efficiency is improved, the automatic forming device is simple in structure and low in machining cost, and productive benefits of enterprises can be improved.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

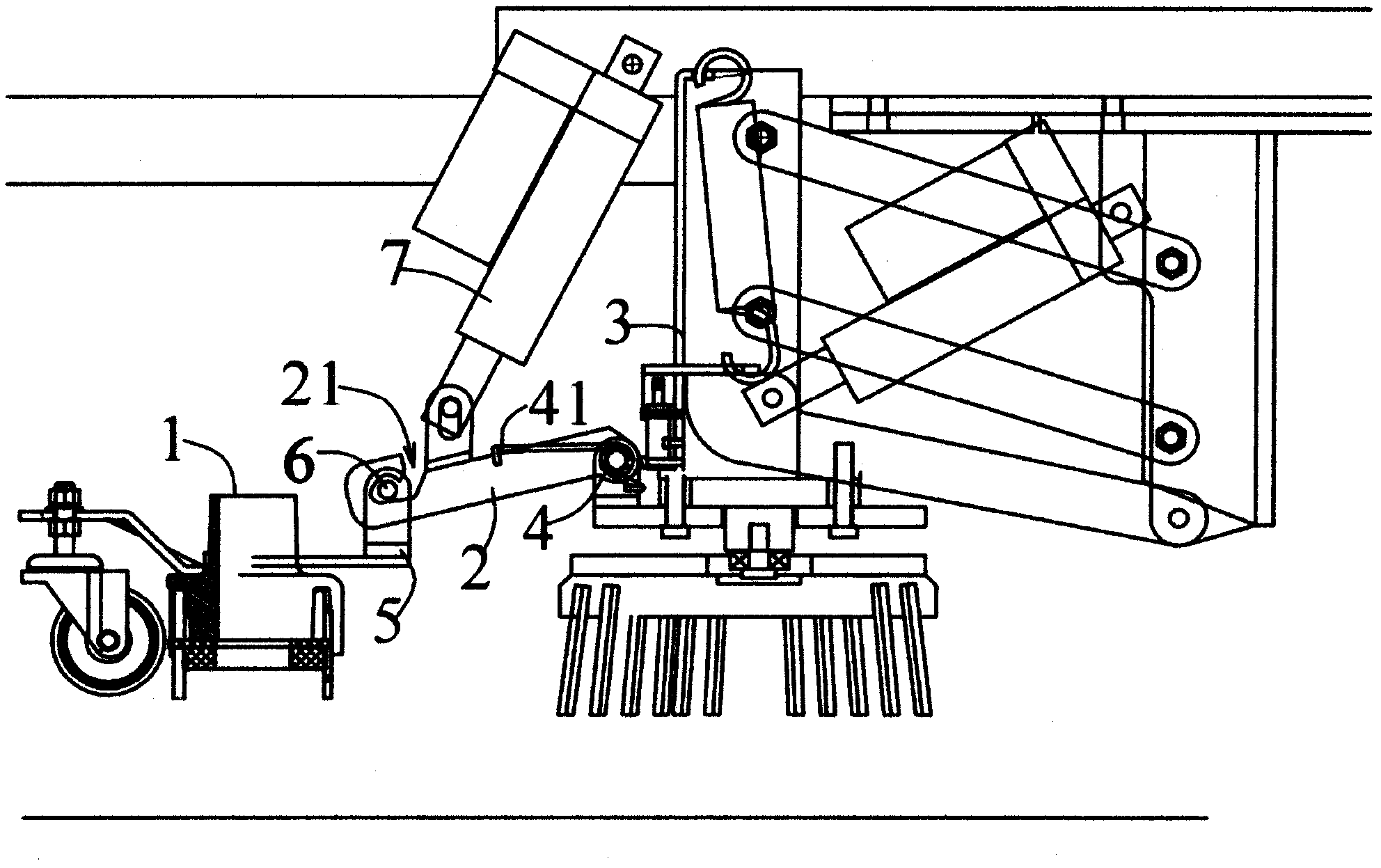

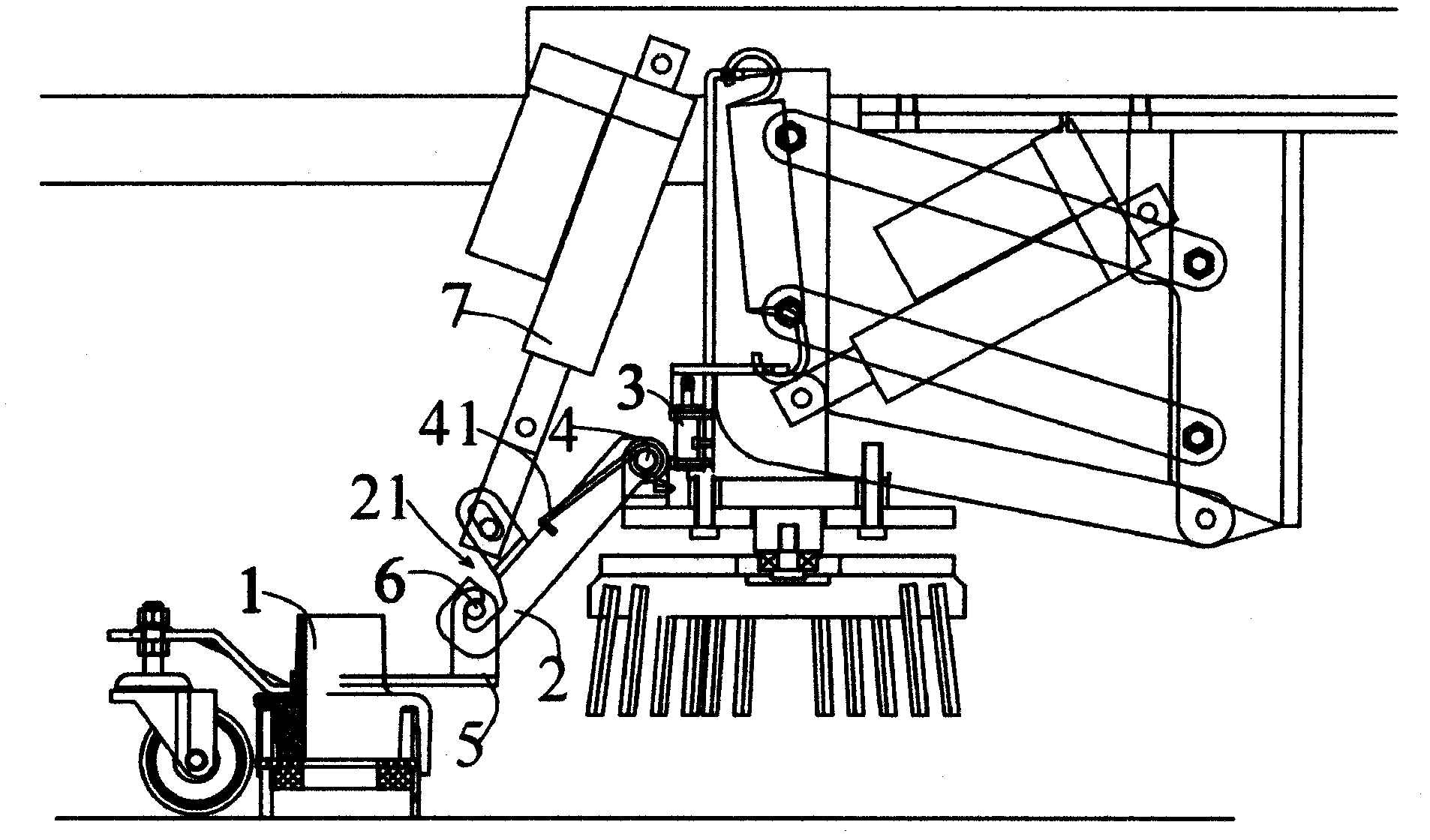

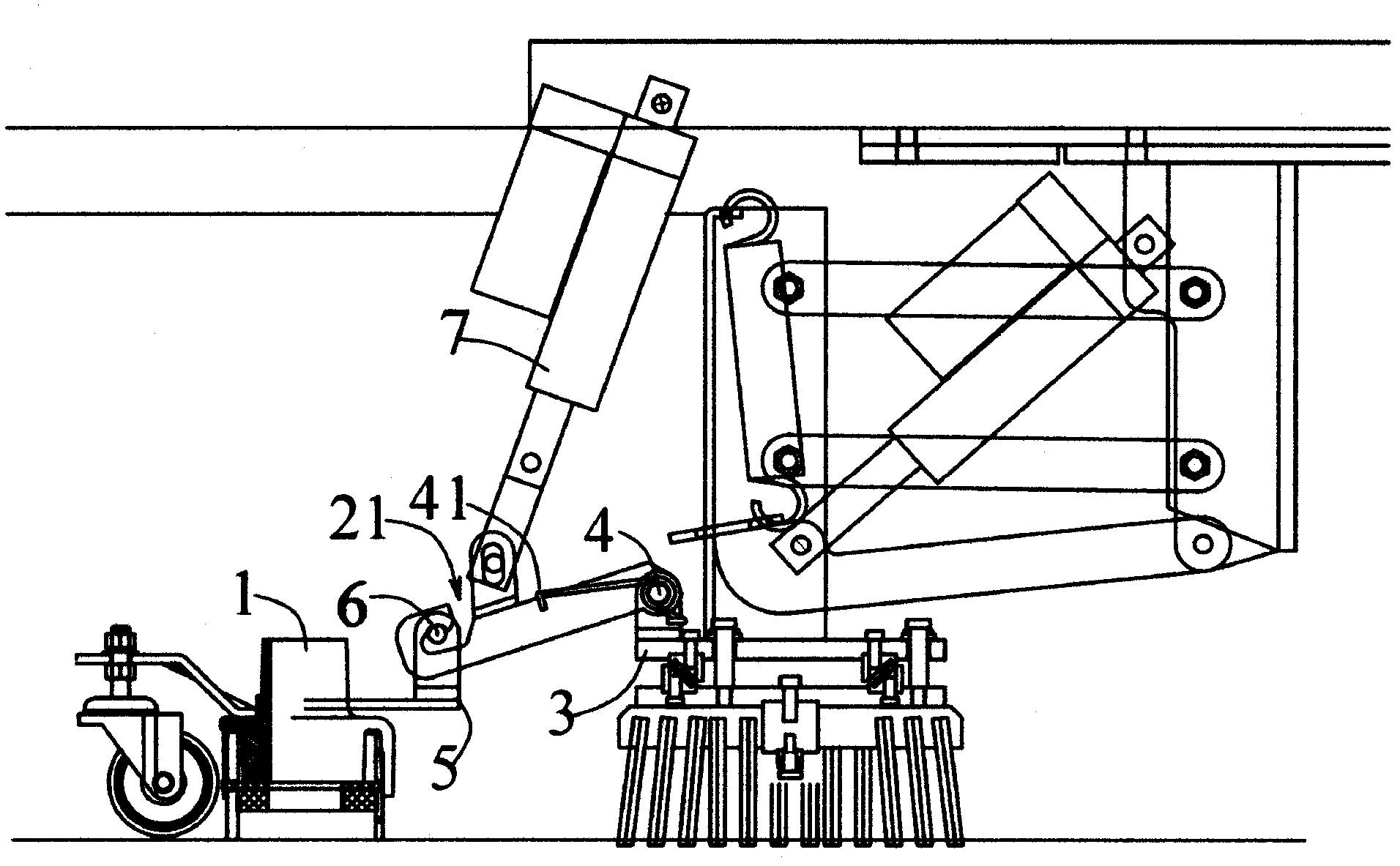

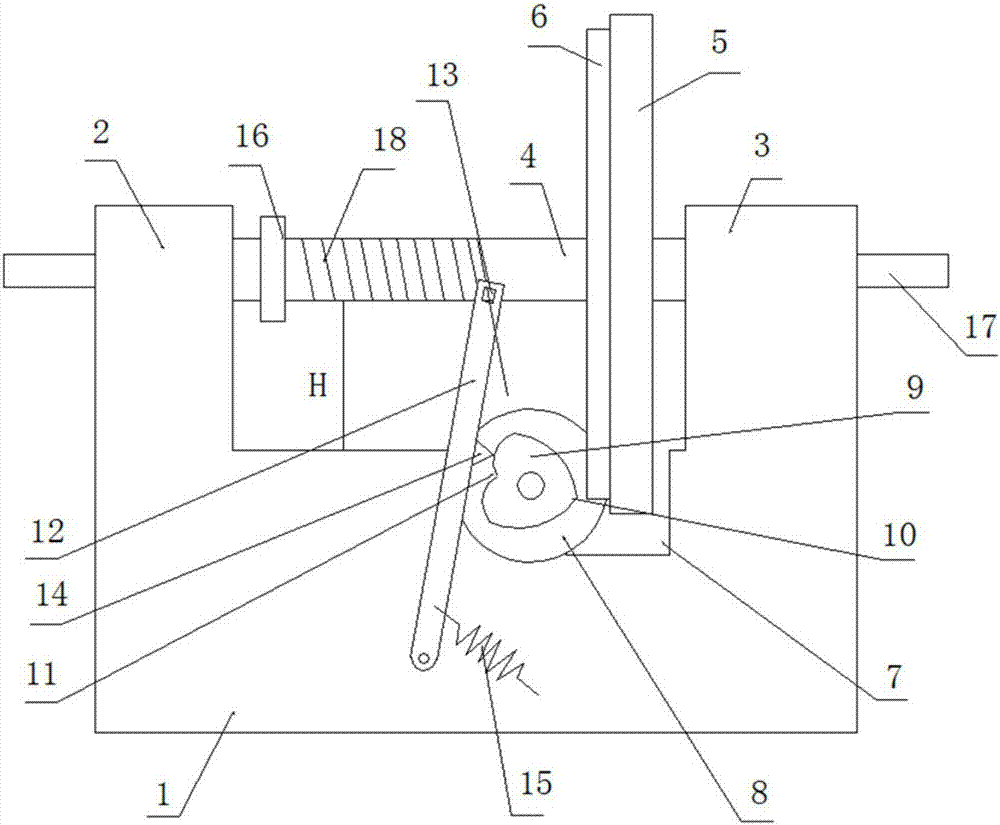

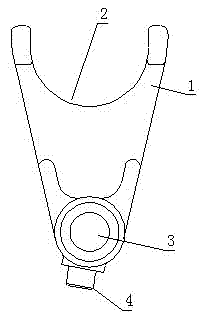

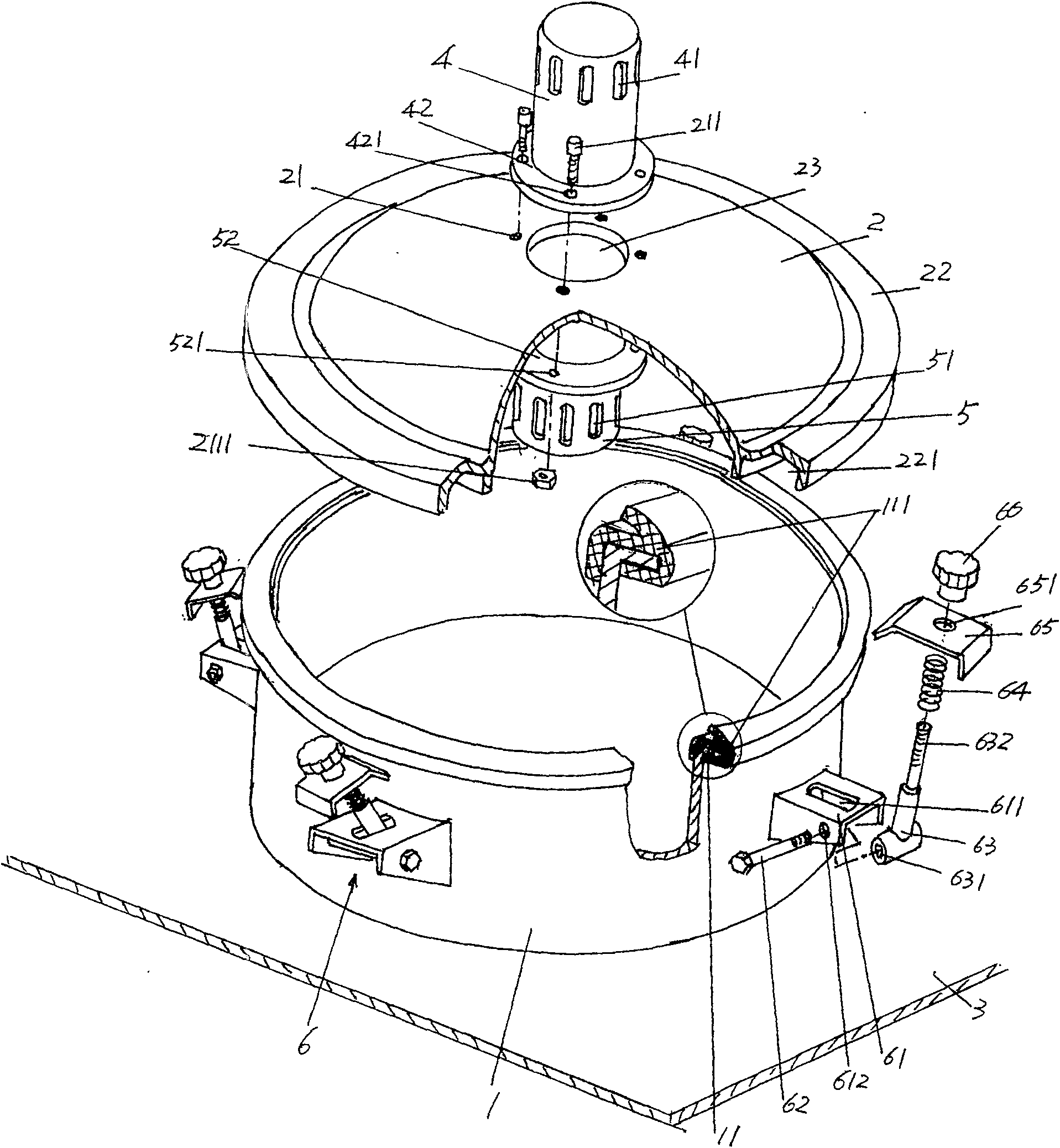

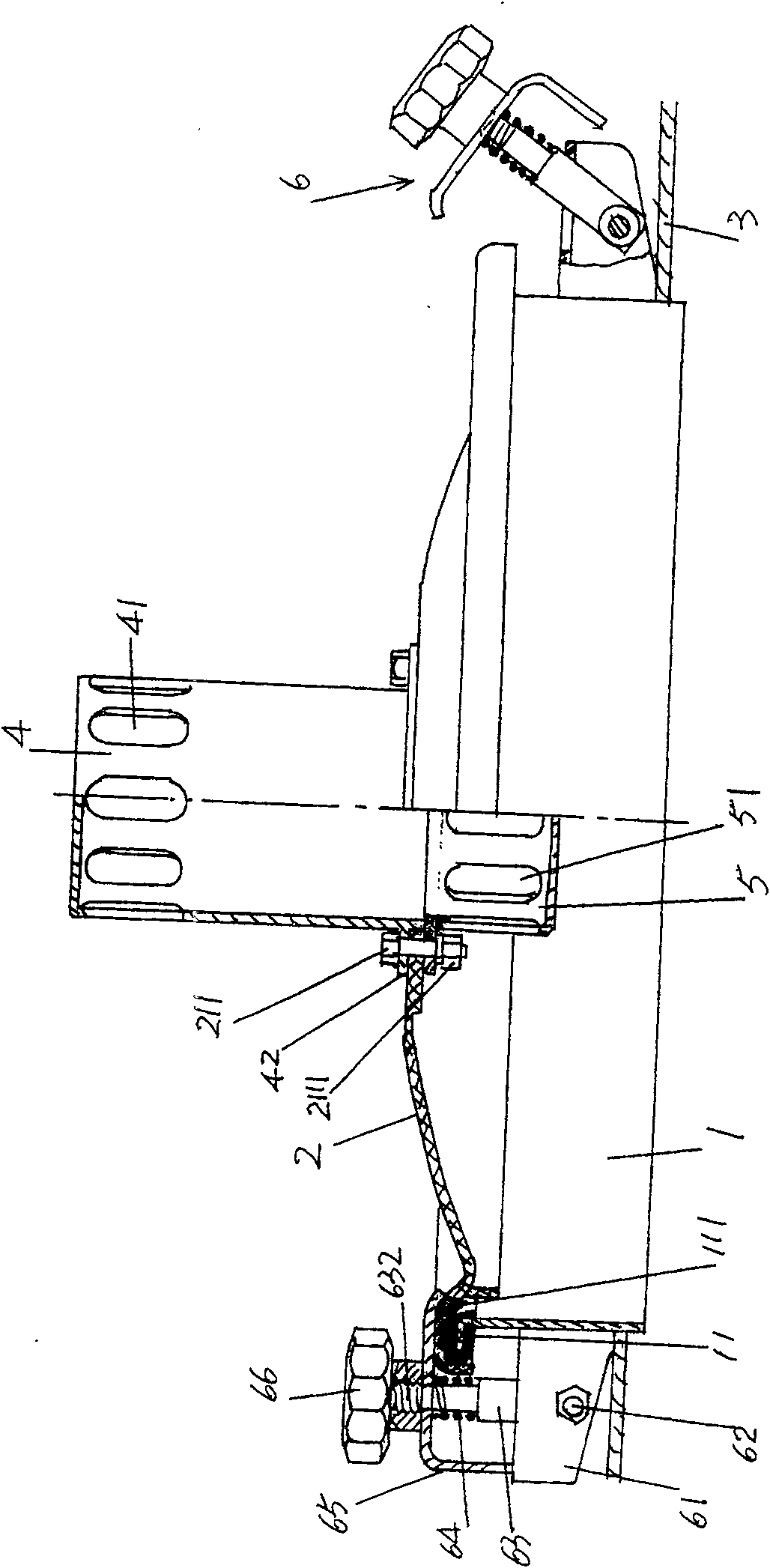

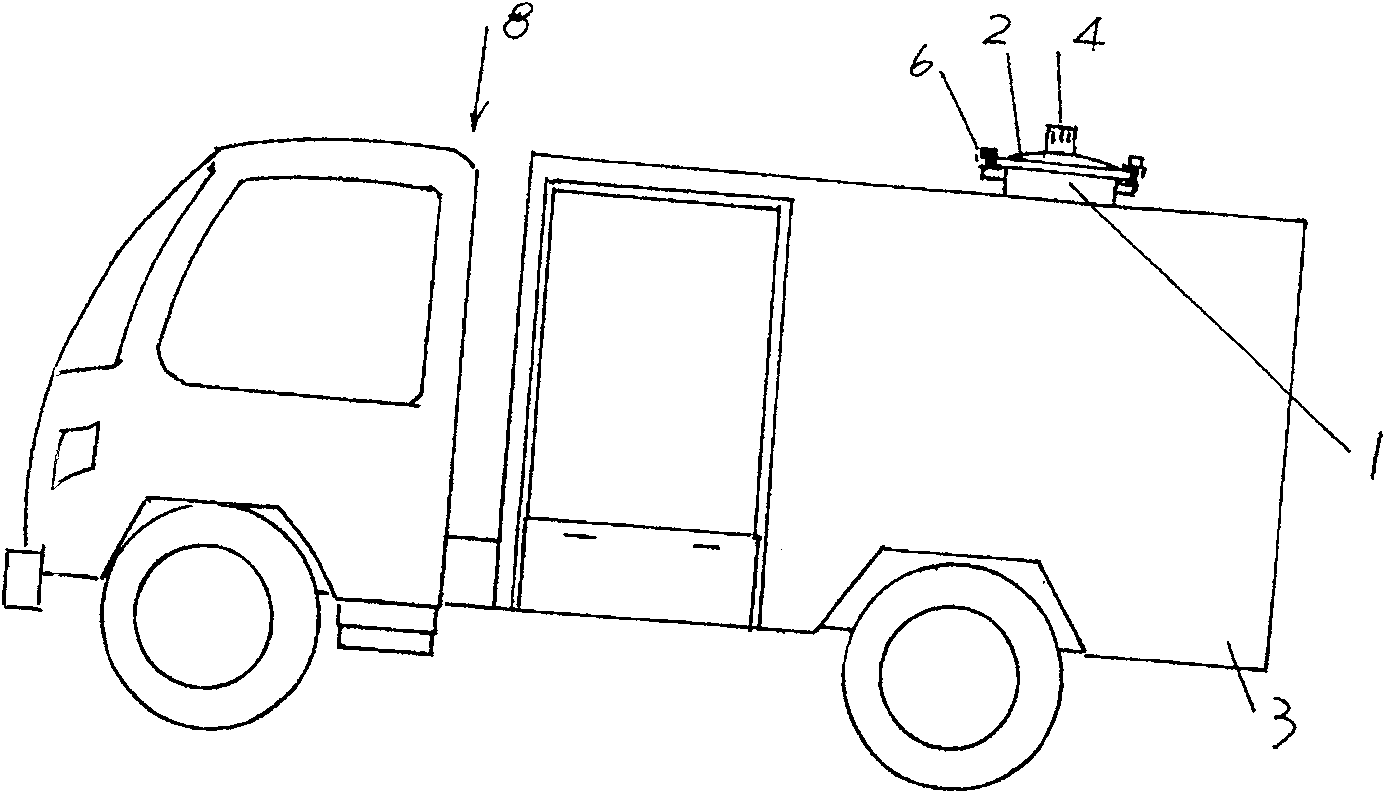

Force applying device used for ground washing vehicle wiper on ground

InactiveCN102835939ASave processing materialsWidely usedCarpet cleanersFloor cleanersEngineeringTorsion spring

A device for a sweeping vehicle wiper to apply a force to the ground. The device comprises a connection plate (2) movably connected to a wiper assembly (1) of a sweeping vehicle, and the other end of the connection plate (2) is hinge-connected to a brush disk support (3). The brush disk support (3) is provided with a torsion spring (4), and the force-applying end of the torsion spring (4) applies a downward pressure to the connection plate (2). The device uses a light wiper assembly to meet the pressure requirement specified in the industry, thereby saving the manufacturing material. By means of a structure that the torsion spring applies a downward pressure, the space for mounting the tension spring may be greatly reduced, so that the structure is still applicable when the gap between the wiper assembly and the brush disk assembly is small, and therefore, the present invention has higher adaptability.

Owner:GUANGDONG BAIYUN CLEANING TECH

Processing method for baking-free brick extrusion forming

ActiveCN106626003AAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses a processing method for baking-free brick extrusion forming and belongs to the technical field of brick making. By means of a continuous hydraulic brick making system, the processing method includes the following steps of feeding, wherein raw materials are added into a feeding hopper, penetrate through a feeding cavity and a feeding opening and enter a forming cavity; extrusion forming of the raw materials, wherein a first hydraulic cylinder drives a forming and pushing mechanism to move, so that a buffer cavity moves to the position under the feeding hopper, a second hydraulic cylinder drives an extrusion plate to move upward in the forming cavity, and the raw materials are extruded into bricks; pushing and conveying of the bricks, the first hydraulic cylinder drives the forming and pushing mechanism to move, and the second hydraulic cylinder drives the extrusion plate to push the bricks to a machine frame, and the first hydraulic cylinder drives the forming and pushing mechanism to push out the bricks. The defects that in the prior art, the brick continuous production degree is low and production efficiency is low are overcome easily, continuous extrusion forming of the bricks can be achieved, production efficiency is effectively improved, the operation process is simple, and the production cost is low.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

Technique for processing metallic surface

The invention relates to a processing technology of metal surfaces, which is characterized in that rolling treatment is carried out on the metal surface by using a rolling knife and the pre-tightening force F of the rolling knife is controlled to be equal to 3.4 multiplied by M, wherein, M is the brinell hardness of the metal surfaces. The processing technology has the following beneficial effects: (1) shortening processing time: compared with the original grinding technology, the rolling technology can improve efficiency by over 10 times, and processing materials are saved and environmental pollution is reduced; (2) wear resistance and hardness of work pieces are improved due to the densification of metallographic structure; and (3) the fatigue strength of processing parts is improved by the residual compression stress on the surface.

Owner:浙江富春江水电设备有限公司

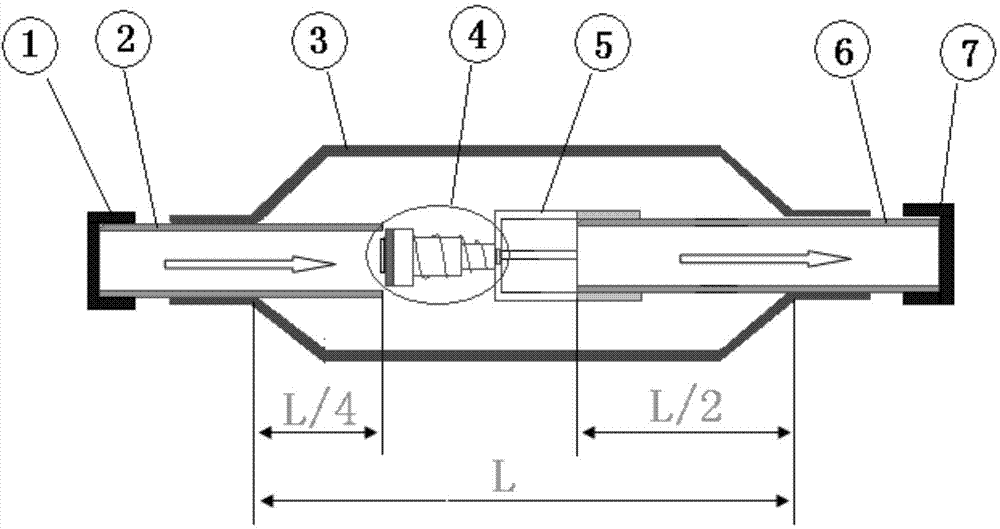

Composite one-way valve

ActiveCN104847929AImprove adaptabilityAdjustable preloadCheck valvesValve members for absorbing fluid energyEngineeringNoise reduction

The invention provides a composite one-way valve. The composite one-way valve comprises a one-way valve body and a valve core arranged in the one-way valve body. The one-way valve body comprises a fluid inlet pipe, a barrel and a fluid outlet pipe, both the fluid inlet pipe and the fluid outlet pipe are embedded in the barrel, one end of the valve core is arranged on the fluid outlet pipe, and the other end of the valve core is abutted against and seals the fluid inlet pipe. The valve core is arranged in the barrel of the one-way valve body, one end of the valve core is arranged on the fluid outlet pipe of the one-way valve body, and the other end of the valve core is abutted against and seals the fluid inlet pipe of the one-way valve body, so that functions of the one-way valve are realized. Fluid enters the barrel from the fluid inlet pipe and flows out of the barrel from the fluid outlet pipe after being subjected to noise reduction in the barrel, so that the composite one-way valve has the functions of conducting in one way and eliminating noise, and in the engineering application with the functions of one-way conduction and silencing, mounting procedures can be reduced, and engineering mounting efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

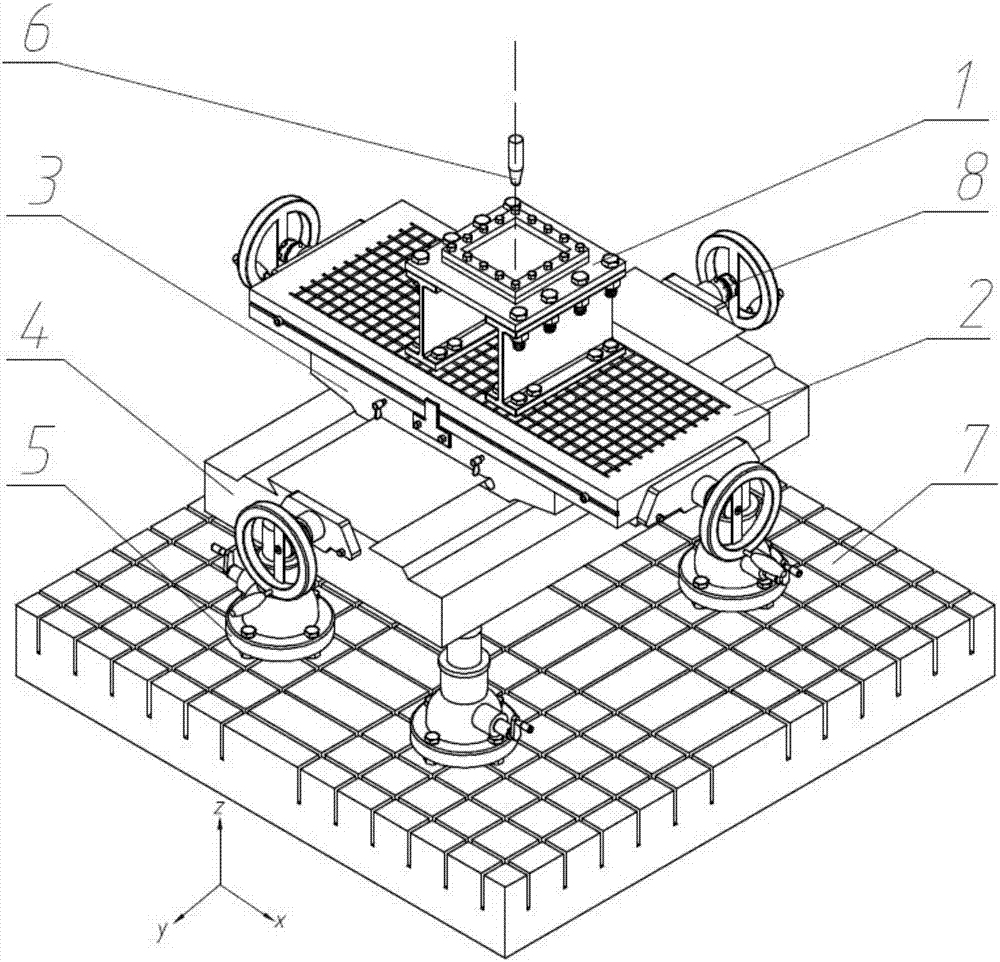

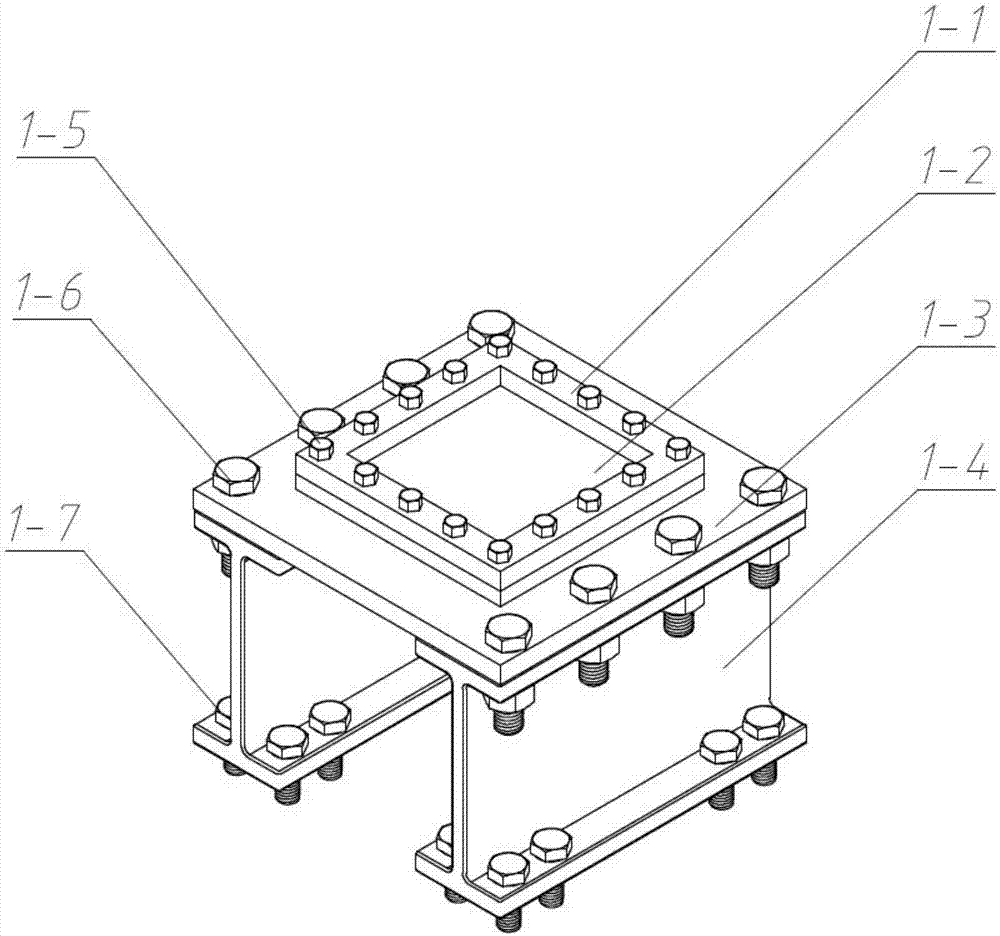

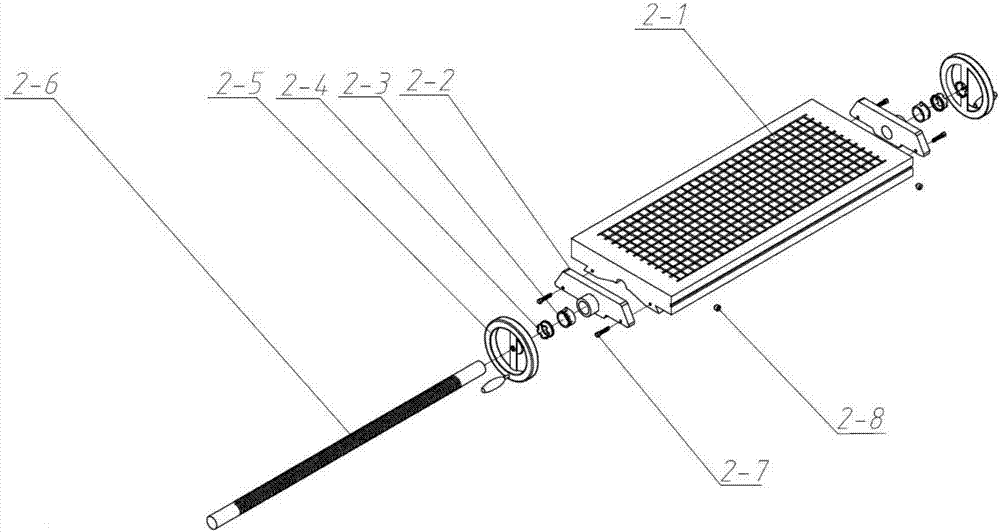

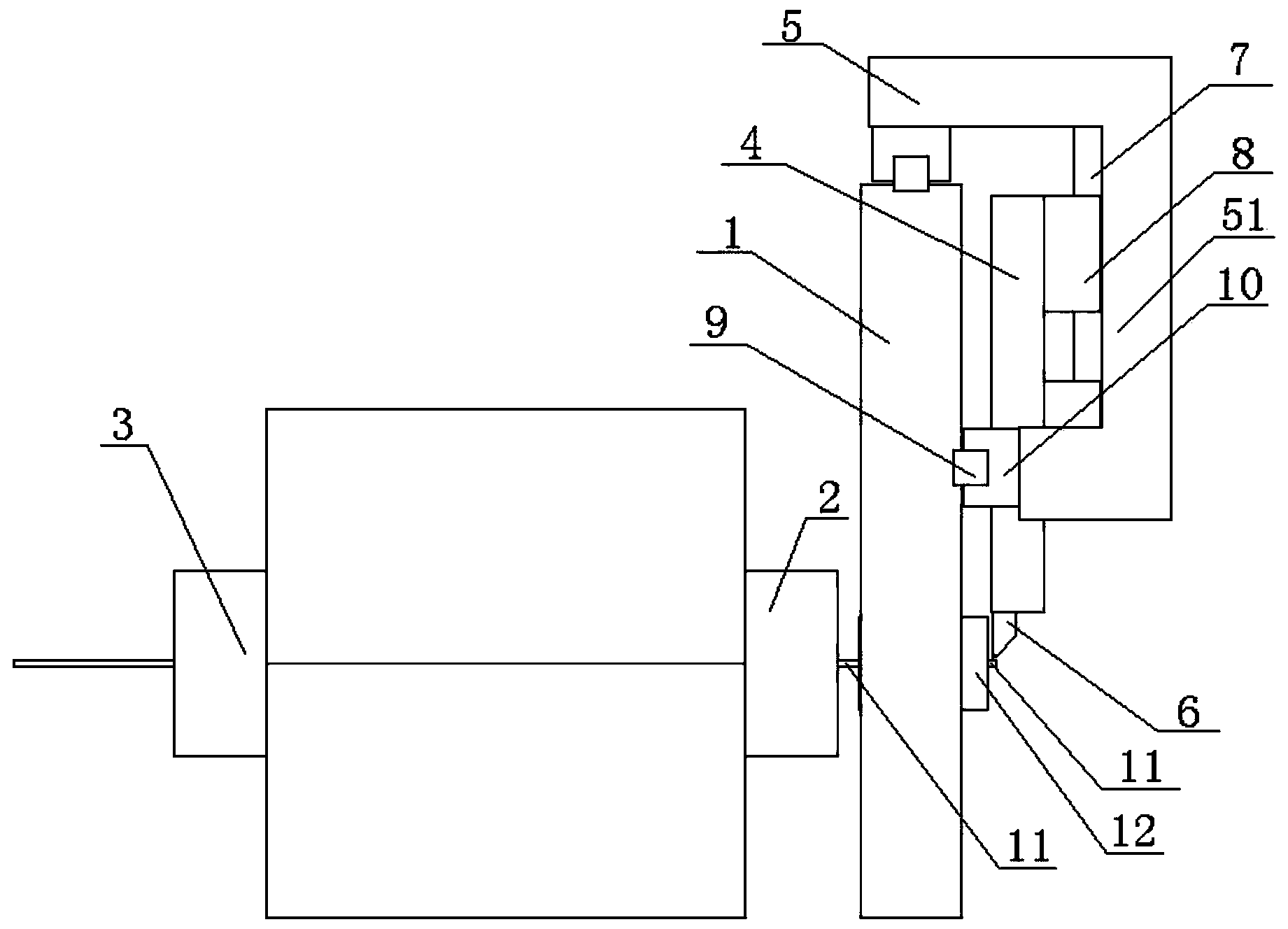

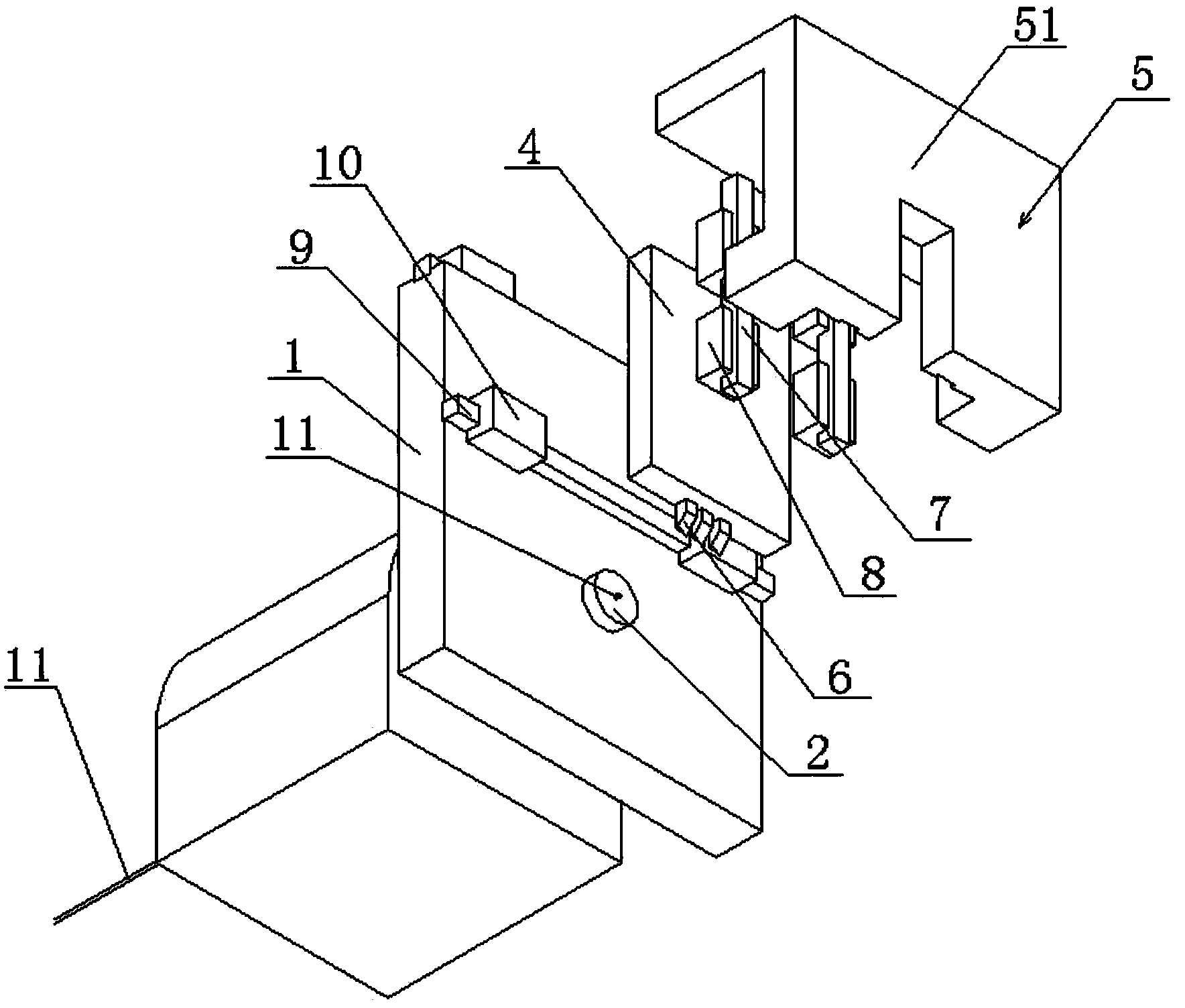

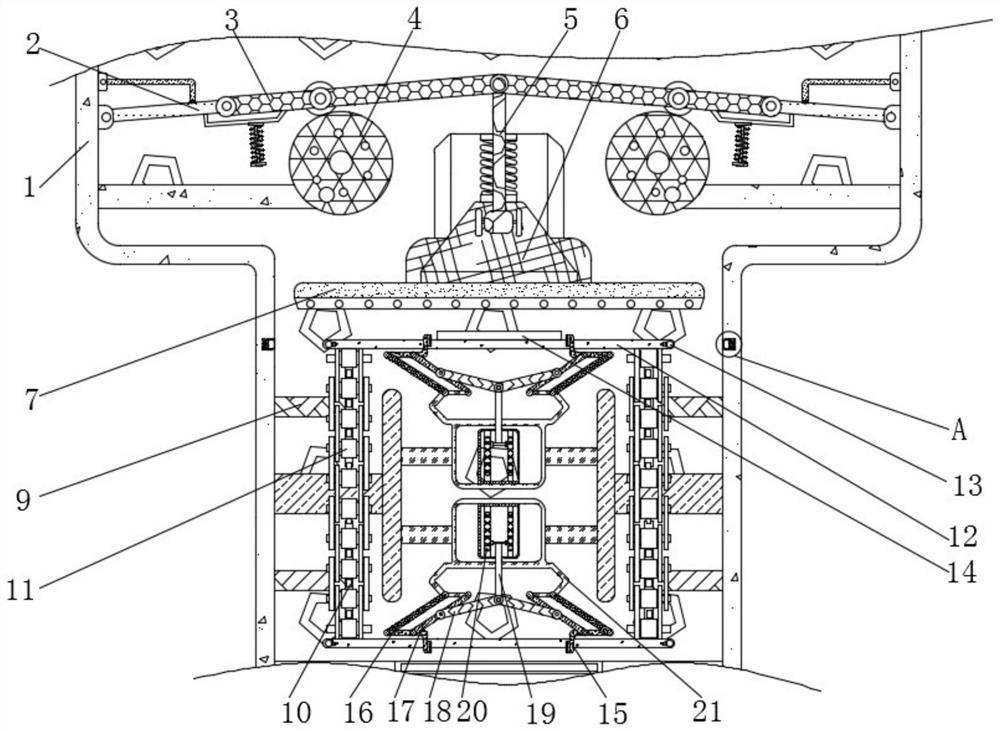

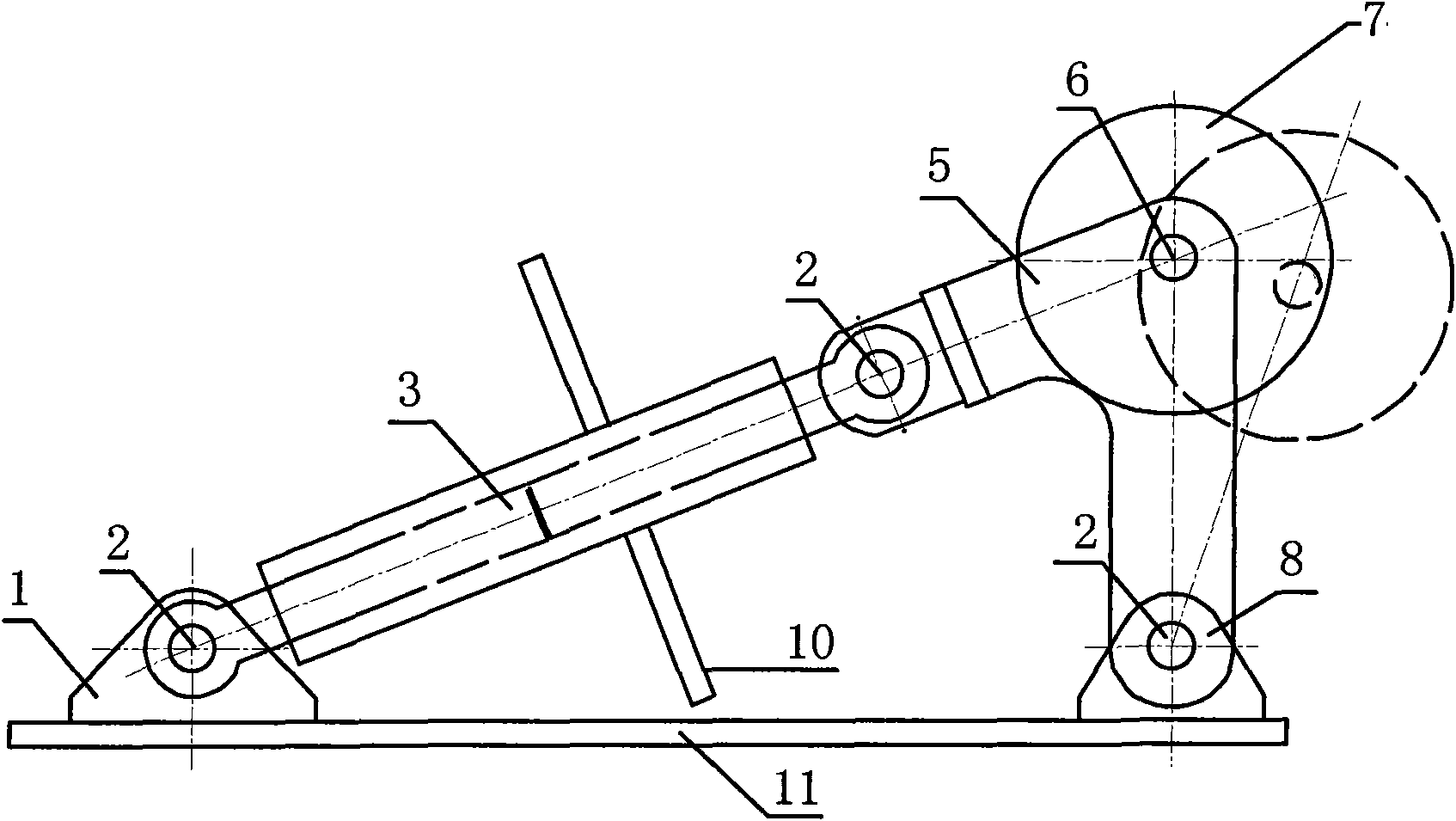

Three-dimensional adjustable dropping hammer experiment workbench system

InactiveCN106950123AAchieve impactSolve the problem of designing different workbenchesMaterial strength using single impulsive forceThree-dimensional spaceEngineering

The invention discloses a three-dimensional adjustable dropping hammer experiment workbench system which achieves impact experiment to any points on a test piece in a three-dimensional space coordinate. The system includes an experiment fixture and a test piece, a transversal workbench, a slide saddle, a longitudinal workbench, a vertical lifting column, a dropping hammer punch head, an anvil and a feed scale ring. All of the parts are assembled through dovetail grooves and are connected to each other through bolts, so that the system is easy to assembly and operate and is detachable and portable. In the system, the workbench transversally and longitudinally moves through a screw rod and the vertical lifting column moves vertically through a vertical lifting hand wheel. The movement distance can be accurately regulated through the feed scale ring. By measuring corresponding parameters and substituting the parameters into a calculation formula, accurate expressions of different dip angles can be obtained. The system can achieve impact on the test piece at any positions and any angles, is multi-functional, and effectively solves a problem of necessity of designing different workbenches for different types of test pieces during a dropping hammer experiment.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

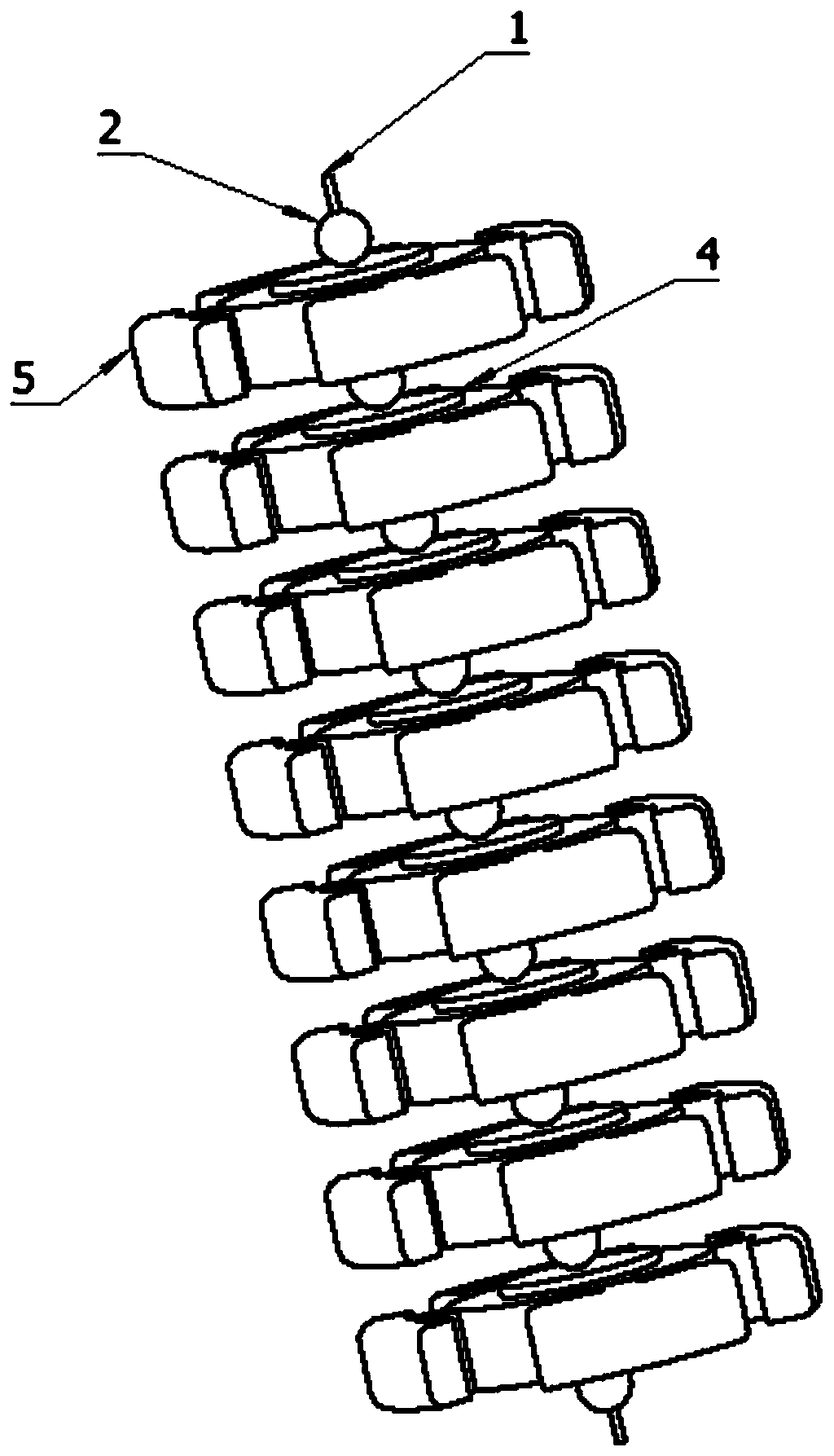

Variable-diameter bent pipe anti-wrinkle mandrel

The invention discloses a variable-diameter bent pipe anti-wrinkle mandrel. The variable-diameter bent pipe anti-wrinkle mandrel comprises a core wire, mandrel elements, arc T-shaped inserting pieces,disc covers and small balls. Round through holes are formed in the centers of the mandrel elements, the disc covers and the small balls; the adjacent mandrel elements are in series connection throughthe core wire and are isolated through the small balls, multiple round through holes symmetric about the center and equal in size are formed in the mandrel elements, and four cylindrical plug pins onthe disc covers are used for assembling; meanwhile, the round holes equal to the cylindrical plug pins on the disc covers in diameter are formed in the arc T-shaped inserting pieces, and the effect of fastening the arc T-shaped inserting pieces is achieved; multiple rectangular inserting grooves are formed in the side face of each mandrel element, and the arc T-shaped inserting pieces are inserted into the inserting grooves; and the variable-diameter bent pipe anti-wrinkle mandrel is suitable for a series of bent pipes of different pipe diameters, after use is finished, the core wire is pulled, the bent pipe mandrel can be simply and rapidly taken out of the pipe fitting, the structure is simple, and cost is saved.

Owner:HEFEI UNIV OF TECH

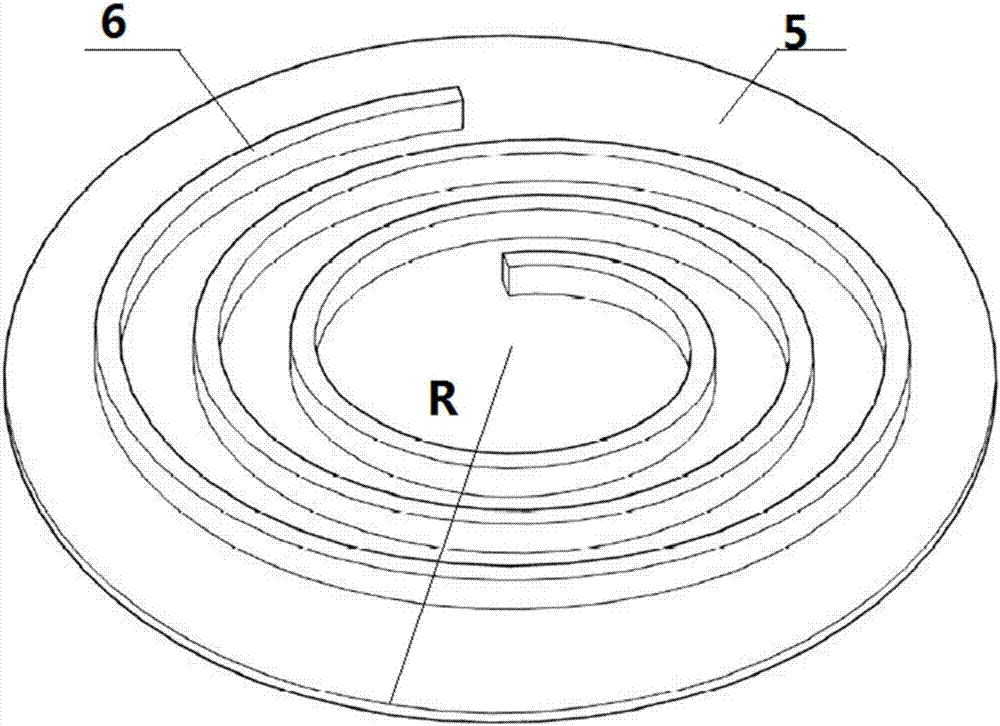

Uniform cable winding device

The invention provides a uniform cable winding device. The uniform cable winding device comprises a base. The base comprises a cuboidal support portion, a first vertical portion and a second verticalportion, wherein the first vertical portion and the second vertical portion are arranged at the two ends of the top face of the support portion correspondingly. A rotating disc is arranged on a cablewinding barrel close to the side of the second vertical portion in a sleeving manner. The end face, backing against the second vertical portion, of the rotating disc is provided with a transmission potion. The transmission portion is of a protruding structure, wherein the cross section of the protruding structure is in an Archimedes spiral shape. The top face of the support portion is provided with a groove, wherein the groove avoids the rotating disc and the transmission portion. A worm is rotatably arranged on the support portion, wherein the worm is matched with the transmission portion. Acam is arranged on the worm in a sleeving manner. The cam comprises a body, wherein the body rotates along with the worm. A protruding portion and a sunken portion are symmetrically arranged on the body. The support portion is further provided with a swing rod, wherein the swing rod is matched with the cam. The bottom of the swing rod is rotatably connected to the support portion. The top of the swing rod extends to the cable winding barrel. By means of the uniform cable winding device, cables can be wound on the cable winding barrel orderly and uniformly; and the cables can be stored to the greatest extent in a limited space, and the uniform cable winding device can be used in future conveniently.

Owner:重庆华旗线缆有限公司

Front test bed structure of motorcycle shifting fork checking fixture

InactiveCN103033108ARealize detectionShorten the lengthAngles/taper measurementsMechanical thickness measurementsEngineeringControl theory

The invention discloses a front test bed structure of a motorcycle shifting fork checking fixture. The structure is characterized by comprising a lower supporting block, a middle supporting block and an upper supporting block which are sequentially arranged in a stacked mode from bottom to top. The thickness of the middle supporting block is consistent with that of the end portion of the front end of a motorcycle shifting fork arm, and the length of the middle supporting block along the front-back direction of a bottom plate is smaller than that of the upper supporting block and that of the lower supporting block along the front-back direction of the bottom plate so that a detection cavity used for detecting the thickness of the end portion of the motorcycle shifting fork arm is formed in a rear portion position between the upper supporting block and the lower supporting block. The rear portion of the upper supporting block is further provided with a shifting fork concave portion detection block installation hole. The structure achieves test and locating of the front end concave portion and the fork arm of the shifting fork for two times, achieves test of a plurality of parameters of the shifting fork through match with a rear test bed, and has the advantages of being convenient to process and manufacture, capable of improving processing efficiency and saving processing materials, convenient to assemble and locate, compact and small in structure, and the like.

Owner:力帆科技(集团)股份有限公司

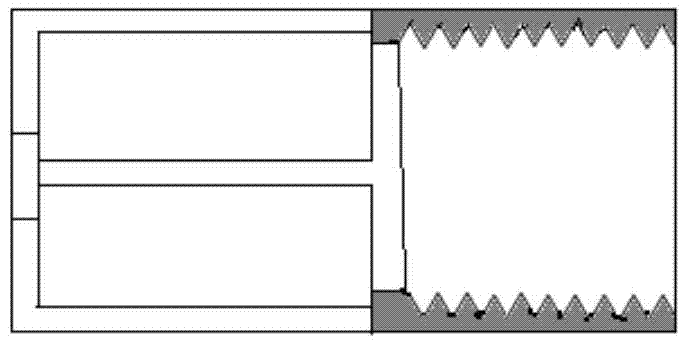

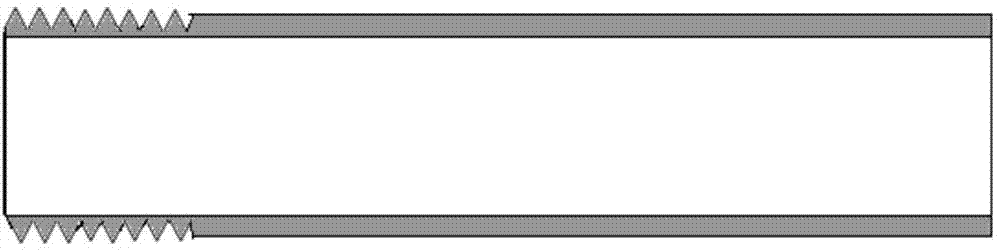

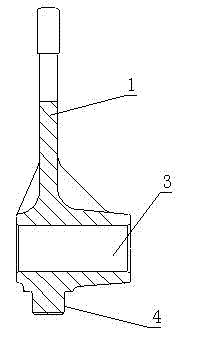

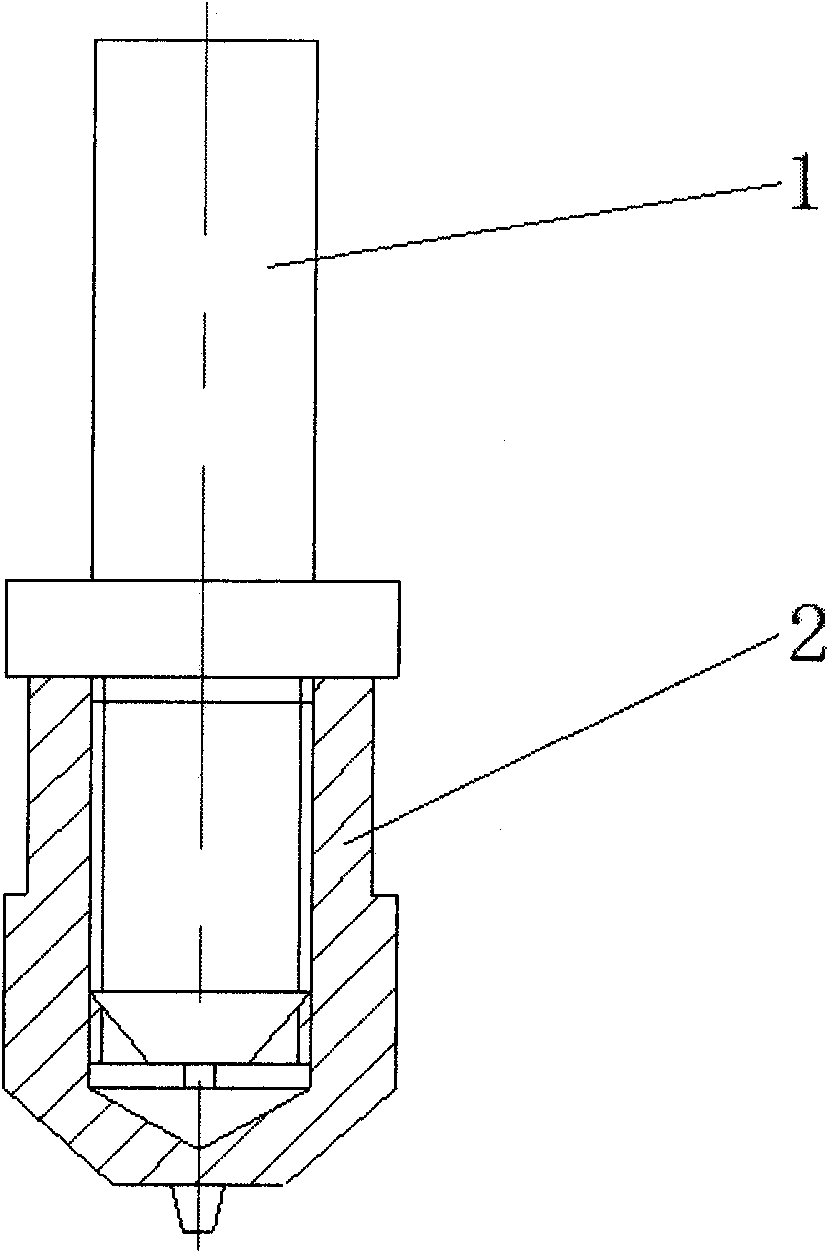

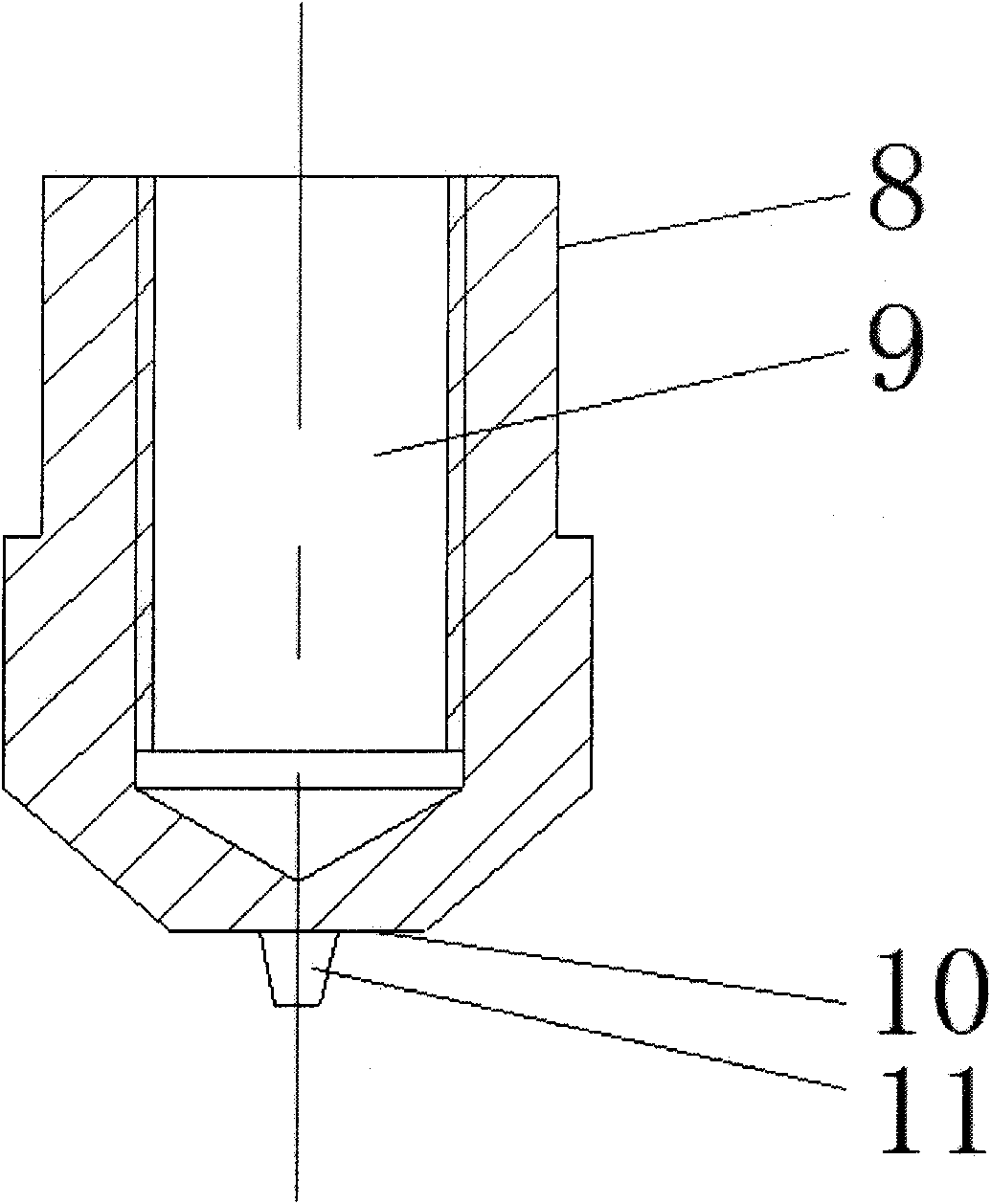

Combined friction stir welding mixing head aiming at different thicknesses of sheets

ActiveCN102151979AEven by forceImprove mechanical propertiesNon-electric welding apparatusEngineeringCentering matrix

The invention relates to a combined friction stir welding mixing head aiming at different thicknesses of sheets, which is characterized in that a center matrix is coaxially inserted into a sleeve; internal threads and external threads which are matched are respectively formed on a threaded connection column and a threaded connection hole; after the threaded connection column is in threaded fit with the threaded connection hole, a shaft shoulder of the center matrix is connected with a clamping body of the sleeve; and a matrix mixing needle is coaxially connected with a sleeve mixing needle. In the machining process, the center matrix is universal, and a series of sleeves with different dimensions and parameters only need to be machined, and a plurality of entire mixing heads are not required to be machined, so that the machining materials are saved. If the mixing head is abraded in the welding process, the sleeve is only required to be replaced, and the center matrix can be continuously used, so that the assembly and disassembly time of the mixing head is saved, and the welding efficiency is improved. Meanwhile, the center matrix and the sleeve can select dissimilar materials to adapt to the welding of various materials.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Can cover structure used in fire-fighting vehicle

The invention relates to a pot cover of fire-fighting truck, wherein it comprises the pot cover base at the top of liquid storage pot while it is through to the pot chamber, and a pot cover on the base; the center of pot cover has a cover hole; the outer side of pot cover relative to the cover hole has overflow ventilate cap with the first ventilate overflow hole; the inner side of pot cover relative to the cover hole has the water inlet anti-splash cap with the second ventilate overflow hole; the water inlet anti-splash cap and the overflow ventilate cap are relative; since said pot cover hasoverflow function, it can avoid ventilate overflow open at the top of storage pot. And the first ventilate overflow hole can avoid blocking.

Owner:JIEDA FIRE PROTECTION VEHICLE EQUIP CO LTD SUZHOU CITY

Ring piece angle detection tool and detection method and application using same

PendingCN110849248AGood industrial valueGuarantee no deformationAngles/taper measurementsEngineeringMechanical engineering

The invention provides a ring piece angle detection tool. According to the detection tool, axial grooves are formed in a detection sleeve with the inner ring surface in the radial direction; the axialgrooves are used for detecting the angle of a protruding block on a ring piece to be detected, the protruding block of the ring piece to be detected can be directly placed in the axial grooves, and ring piece angle detection can be achieved through one-man operation; meanwhile the detection tool is simple in structure and easy to machine. When the detection tool is used for testing the angle of the ring piece, the operation is convenient, the problem that the ring piece is easy to fall off or scratch in an original ring piece angle testing method is solved, and the detection tool can be wellapplied to the field of semiconductors or machining.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

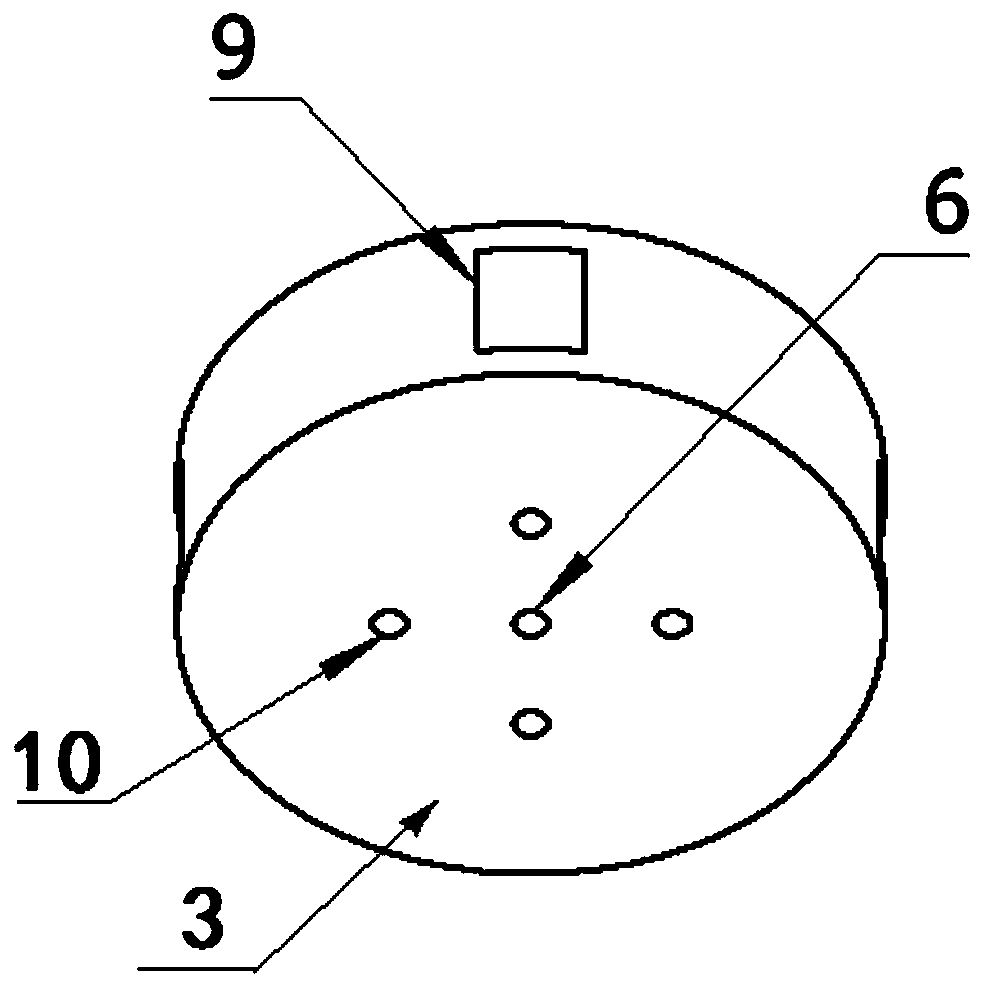

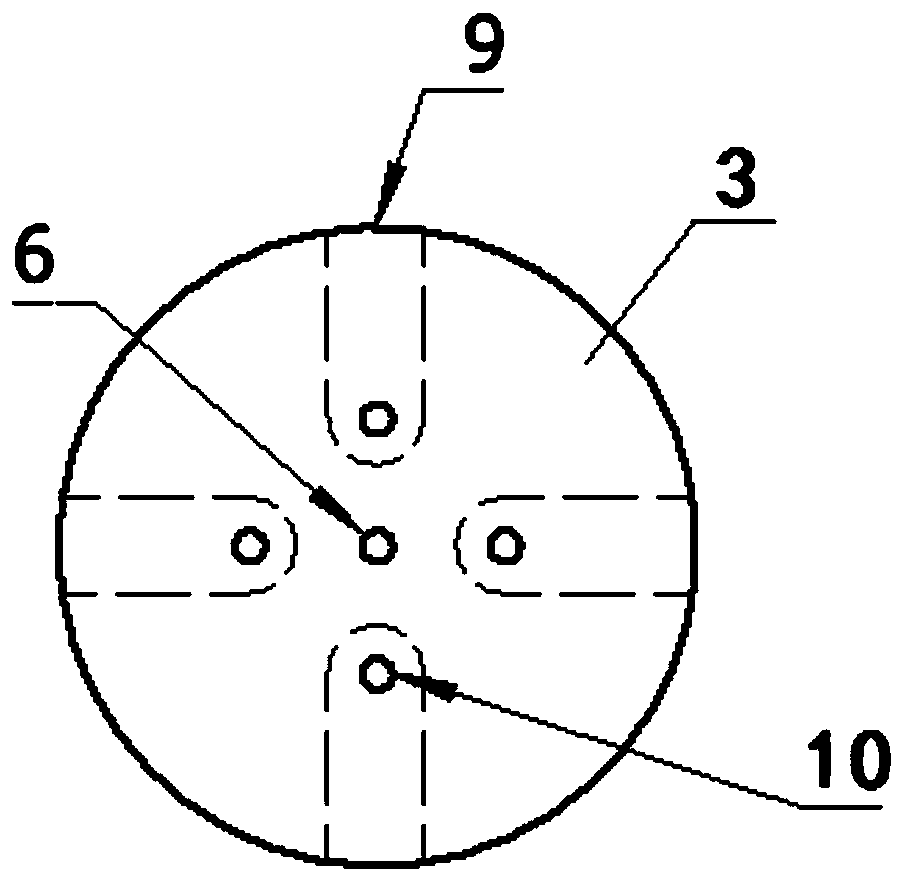

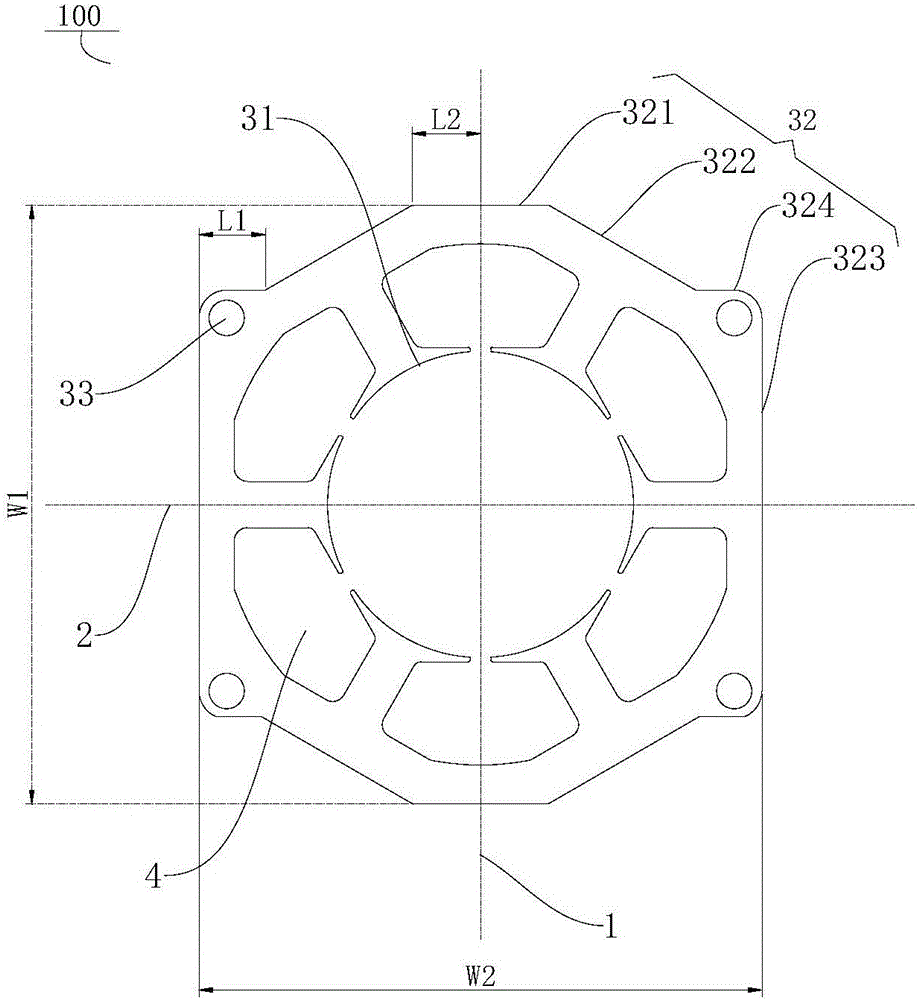

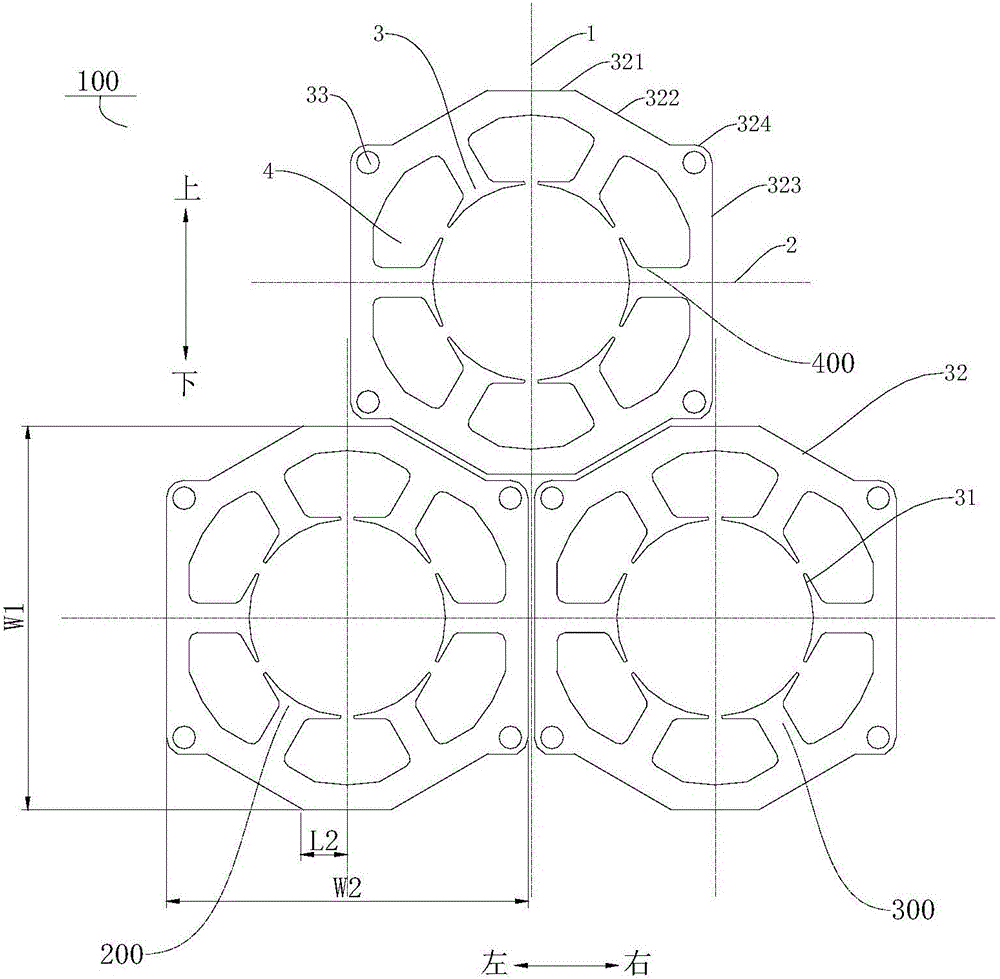

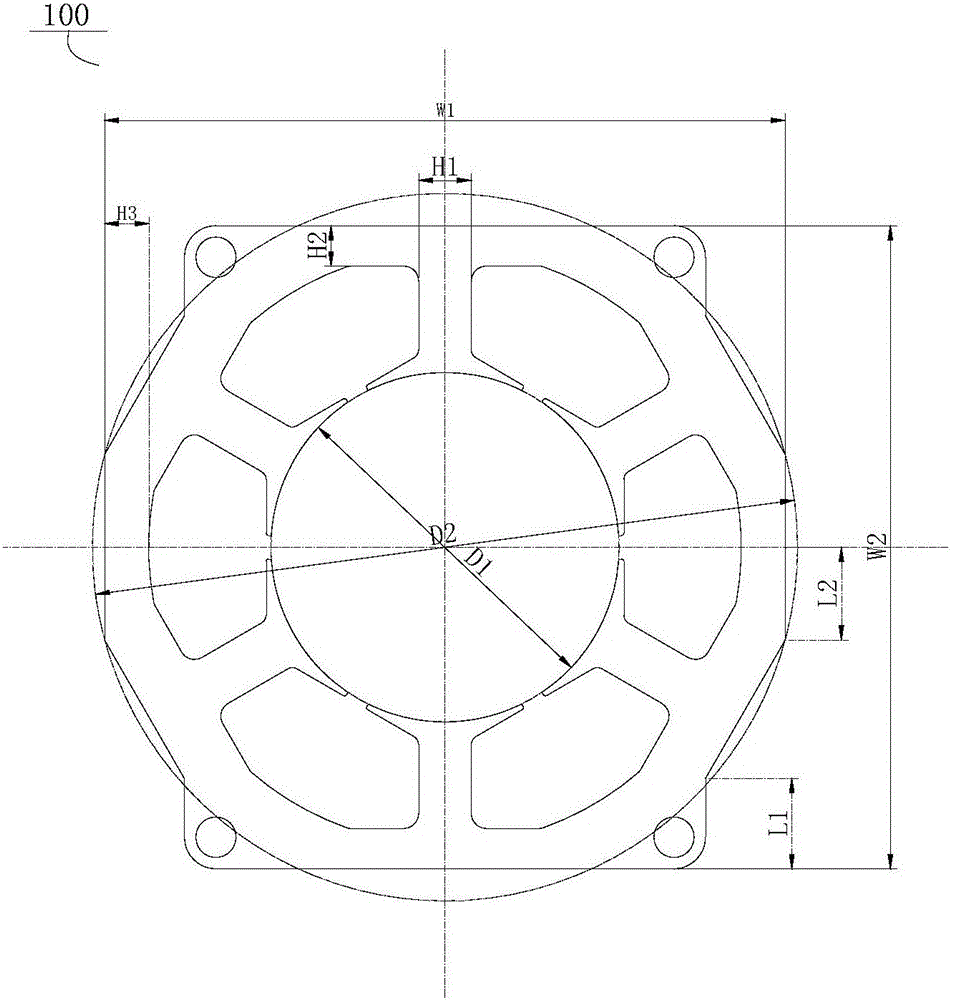

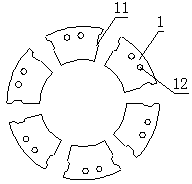

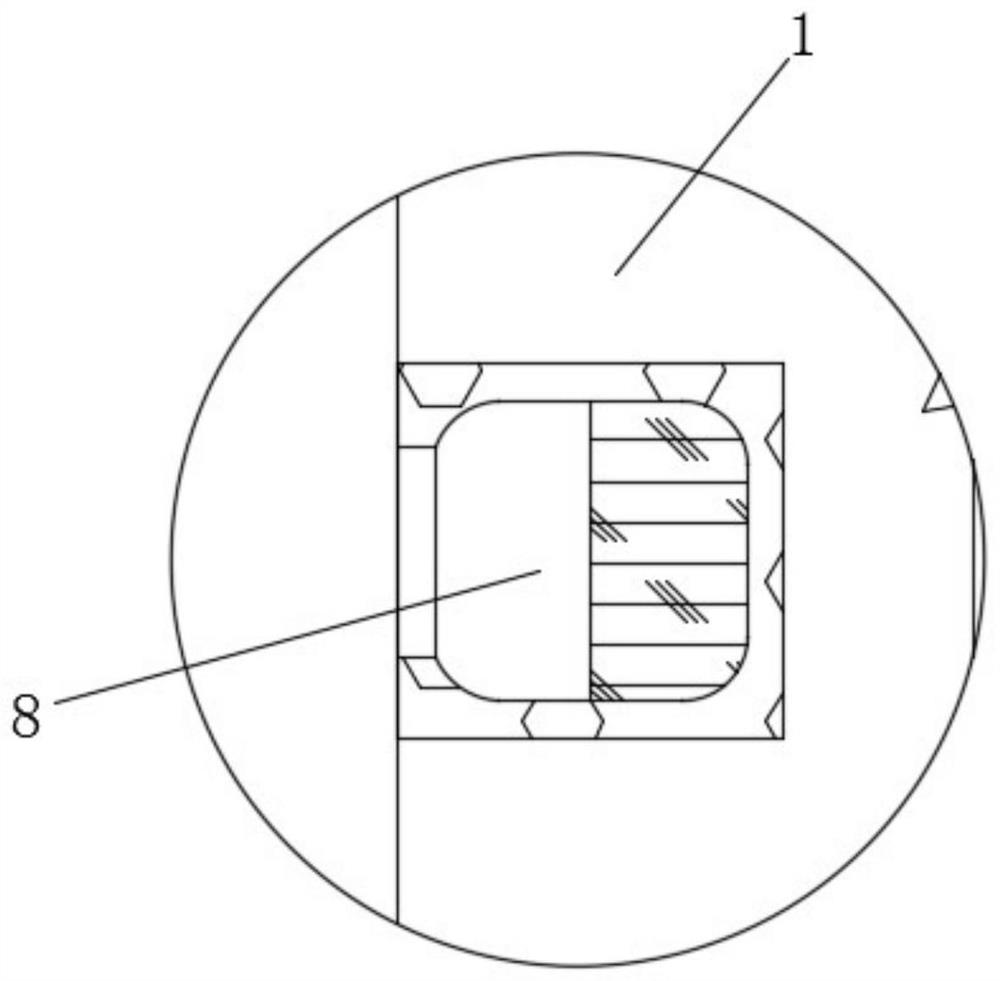

Compressor, variable frequency motor, stator punching sheet of motor, and machining method thereof

ActiveCN106026447AReduce areaGuaranteed magnetic inductionMagnetic circuit stationary partsManufacturing stator/rotor bodiesPunchingAxis of symmetry

The invention discloses a compressor, a variable frequency motor, a stator punching sheet of the motor, and a machining method thereof. The stator punching sheet comprises a first axis of symmetry, and a second axis of symmetry. The first axis of symmetry and the second axis of symmetry are perpendicular to each other and divide the stator punching sheet into four identically shaped unit parts. Each unit part comprises an inner-ring contour line segment and an outer-ring contour line segment. The outer-ring contour line segment comprises a first half edge, a bevel edge and a second half edge, wherein the first half edge, the bevel edge and the second half edge are successively connected. Close to the second half edge, the bevel edge is provided with a raised portion. The stator punching sheet is provided with an installation hole. At least one part of the installation hole is arranged on the raised portion. The intersection point of the first axis of symmetry and the second axis of symmetry is set to be O, and the inner-ring contour line segments of the four unit parts form an inner circle with the point O as the circle center thereof and the D1 as the diameter thereof. An outer circle is defined to pass through the point O and the two end points of the bevel edge. The diameter of the outer circle is set to be D2. D1 and D2 satisfy the relation of 1.9<=D2 / D1<=2.1. According to the technical scheme of the stator punching sheet of the motor, based on the mutual cooperation of the dimensions of the above parts, the performance requirements can be met. Meanwhile, the amount of raw materials is reduced at the same time.

Owner:ANHUI MEIZHI COMPRESSOR +1

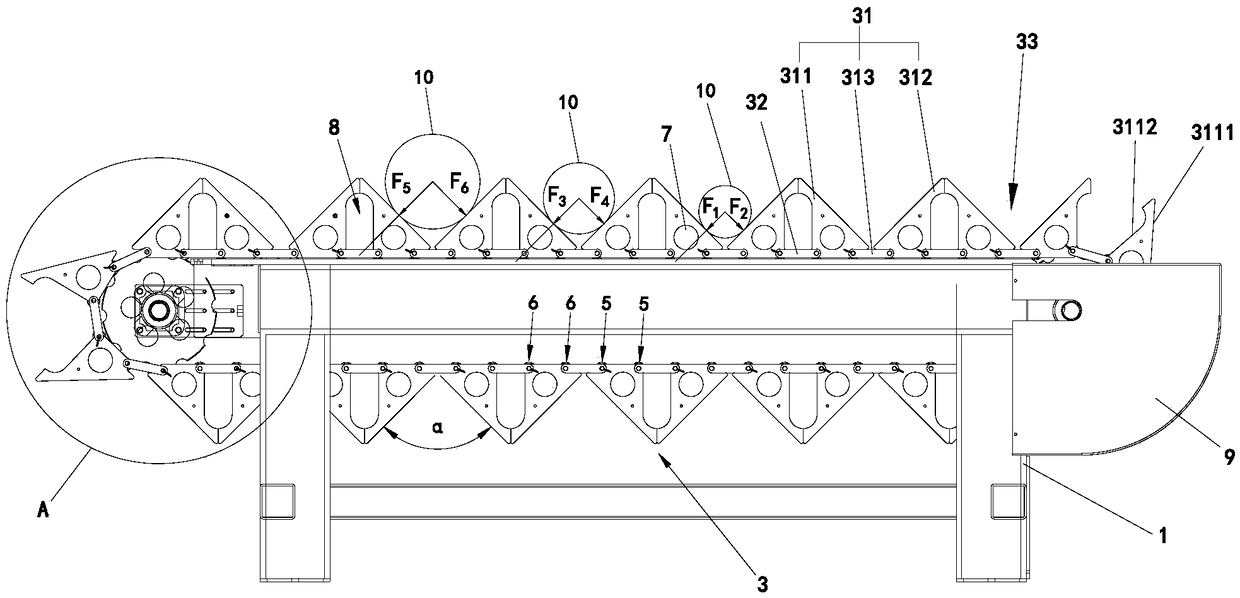

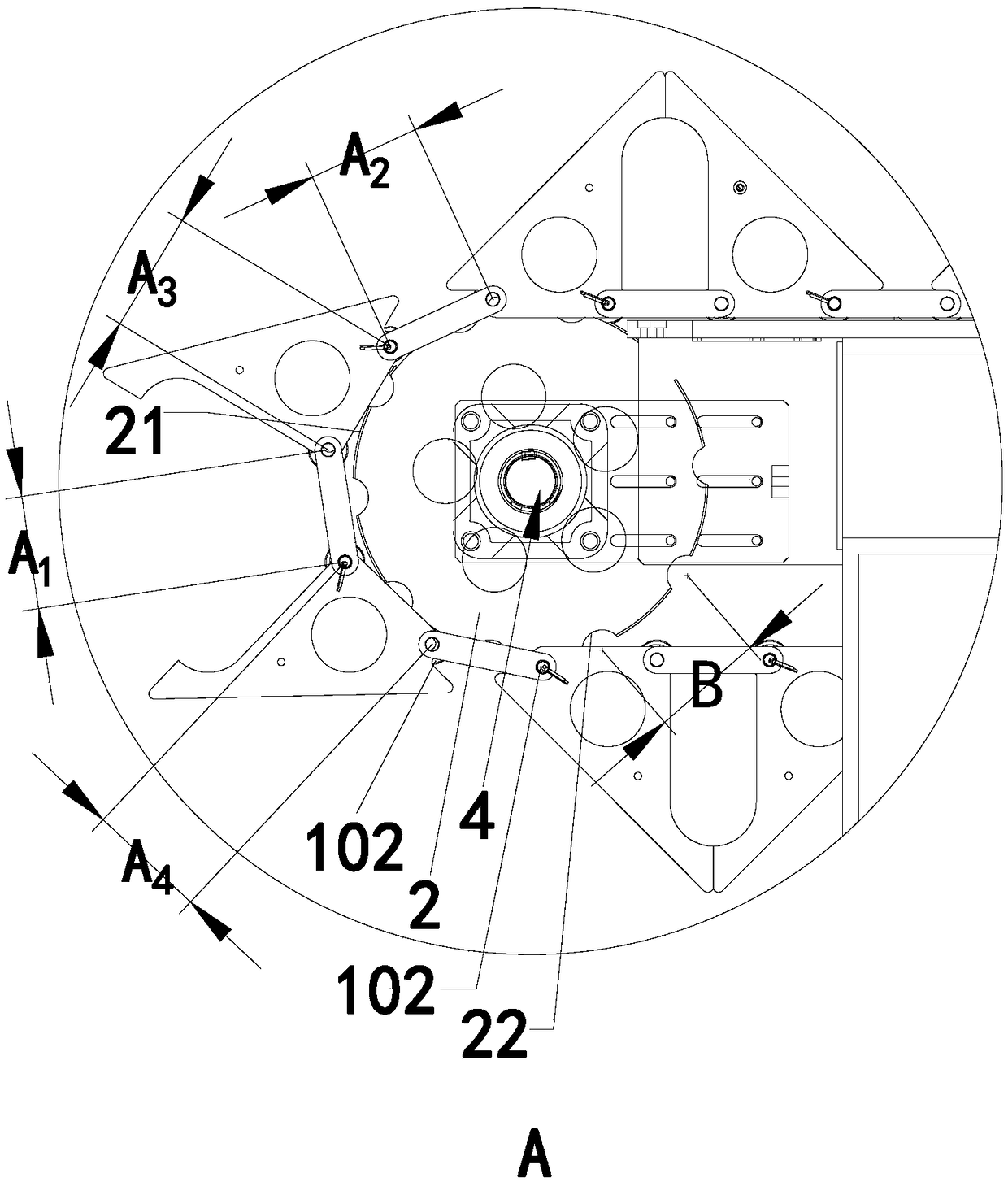

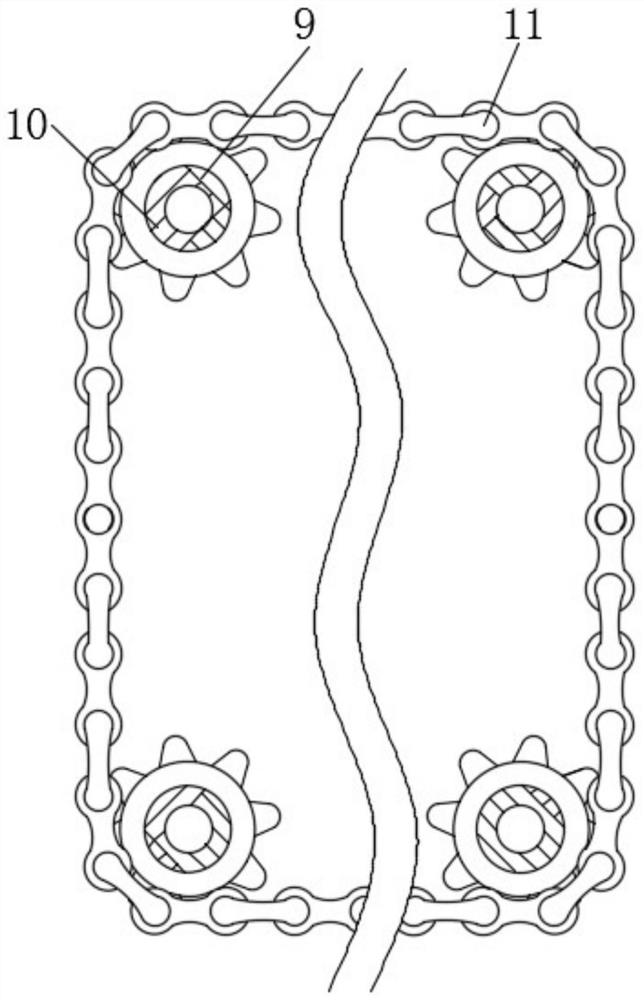

Chain type heavy load conveying device

The invention discloses a chain type heavy load conveying device. According to the scheme, the chain type heavy load conveying device includes a machine frame, and the machine frame is provided with achain wheel, a conveying chain wound around the chain wheel and a driving assembly driving the chain wheel to rotate. The conveying chain includes a plurality of supporting assemblies and a first chain plate, one end of the first chain plate is hinged to one of two adjacent supporting assemblies, and the other end of the first chain plate is hinged to the other of the two adjacent supporting assemblies. Each supporting assembly includes a first supporting block, a second supporting block and a second chain plate. One end of the second chain plate is hinged to the first supporting block, the other end of the second chain plate is hinged to the second supporting block, and the first supporting block and the second supporting block of the same supporting assembly form a V-shaped bearing groove. In the two adjacent supporting assemblies, the first supporting block of one supporting assembly abuts against the second supporting block of the other supporting assembly. The chain type heavy load conveying device has the advantages of being simple in structure, being capable of bearing a larger load and having a longer service life.

Owner:FOSHAN HONGSHI LASER TECH CO LTD

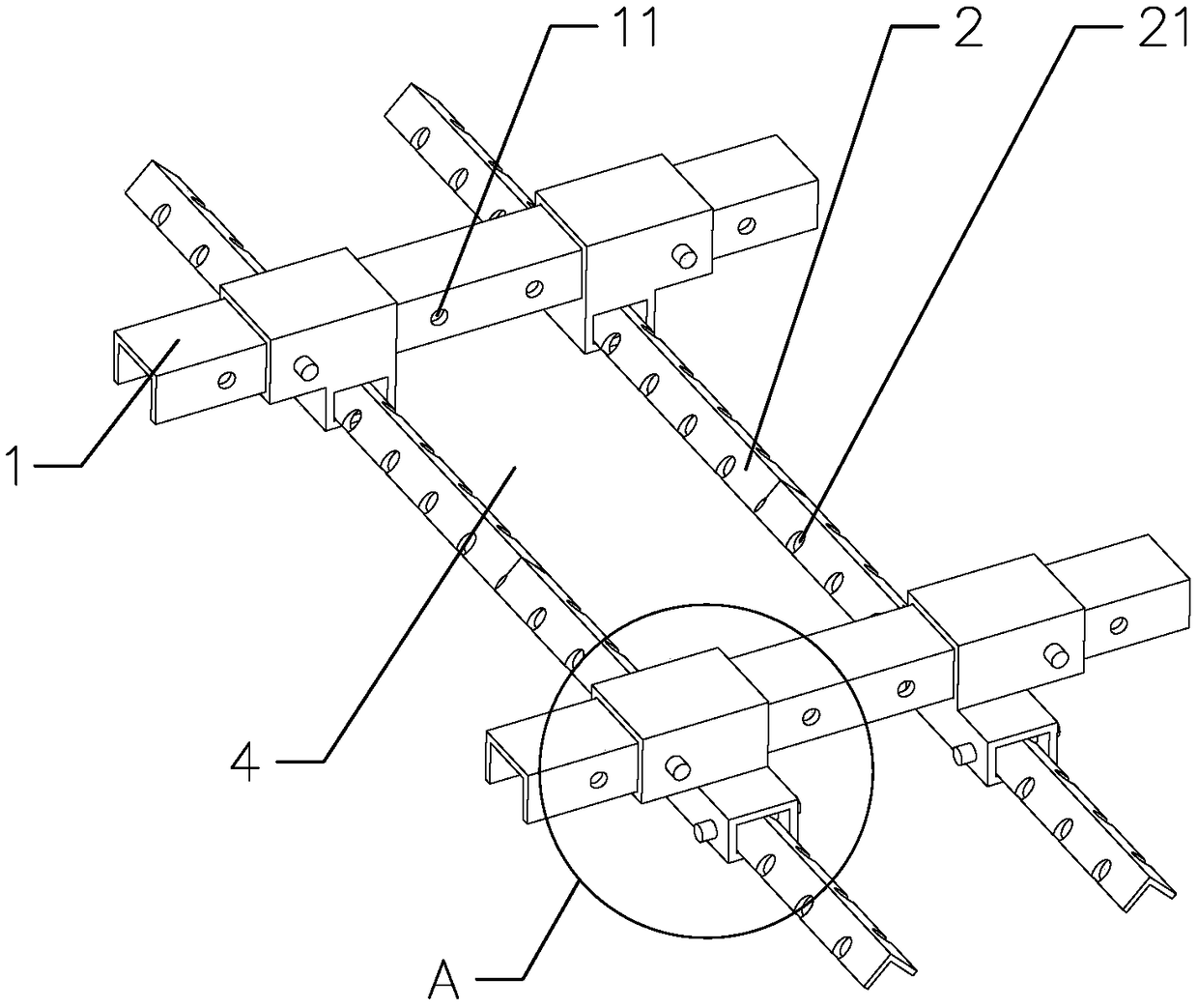

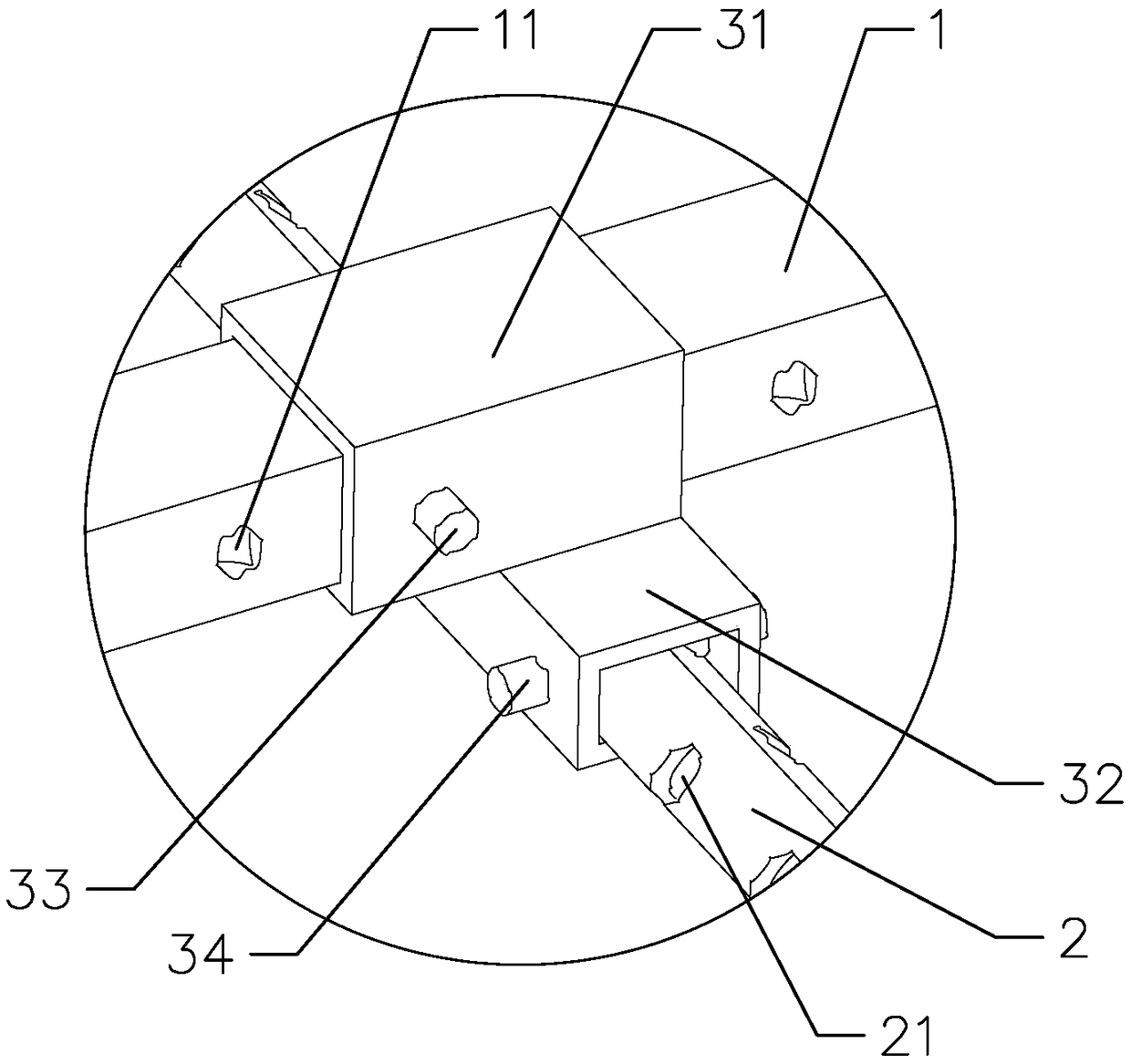

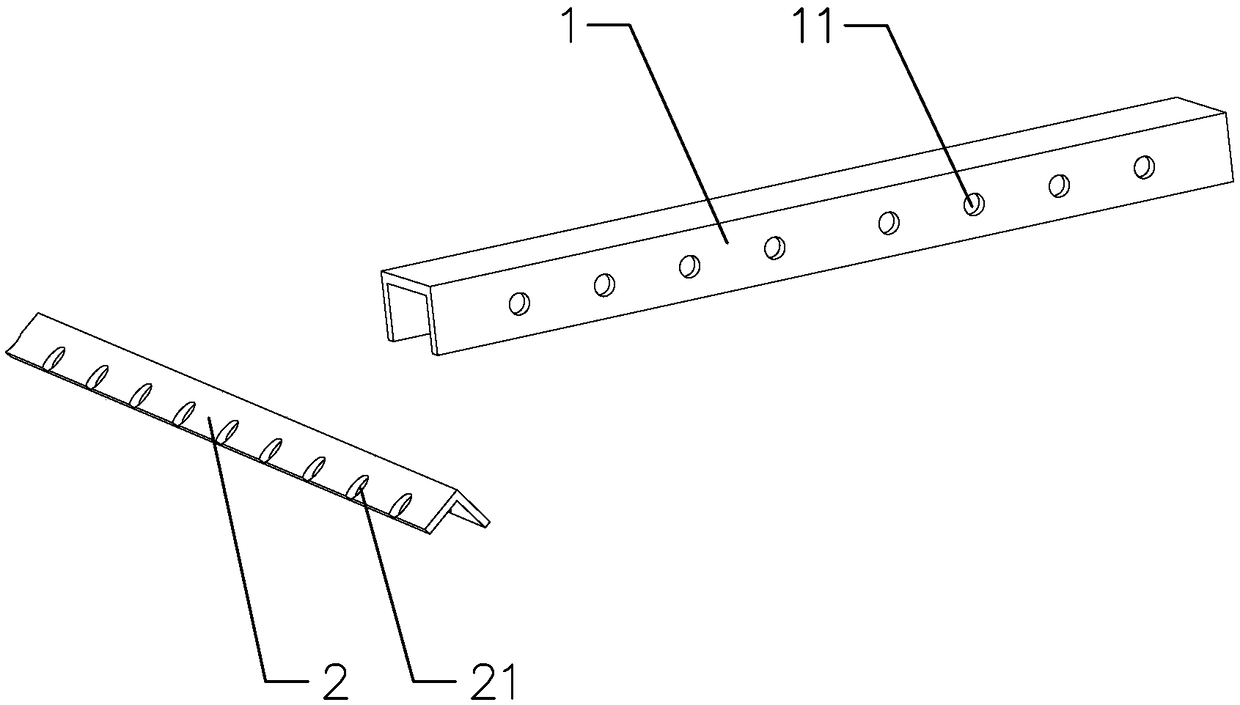

Cable tray ground fixing device adjustable in size

InactiveCN109229868AEasy to fixPrevent rollingContainers for annular articlesExternal framesCable trayEngineering

The invention provides a cable tray ground fixing device adjustable in size. The cable tray ground fixing device comprises two positioning plates, two limiting plates and locking devices; the two limiting plates are equidistantly arranged on the two positioning plates in parallel, the two limiting plates and the two positioning plates are laterally crossed so that a cable tray fixing groove can beformed between the two limiting plates, cable trays are laterally placed in the cable tray fixing groove to be prevented from rolling, the two ends of the two limiting plates are movably connected with the positioning plates through the locking devices so that the distance between the two limiting plates can be adjusted to adapt to the cable trays of different specifications, thus, the cable trays of different specifications can be adapted to, the use range of the fixing device is greatly enlarged, and the fixing device is simple in structure and easy to achieve; meanwhile, the cable trays are fixed by the two limiting plates in the circumferential direction, namely the rolling direction, and also fixed by the positioning plates in the axial direction, namely the lateral placement direction, so that the cable trays are comprehensively limited and fixed, and thus the fixation of the cable trays is more reliable.

Owner:YUYAO POWER SUPPLY BUREAU +2

Inverted type knife rest component

Owner:HANGZHOU FANGXING WATCHES

Motor with magnetic rotor

InactiveCN103001354AImprove cooling effectSave processing materialsMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringElectrical and Electronics engineering

The invention discloses a motor with a magnetic rotor. The motor comprises arc-shaped rotor sheets. Even number of rotor sheets form a circle. Tooth grooves for winding wires are arranged on the outer arc face of the arc. Through holes are arranged on the side face between two tooth grooves. By the through holes disposed on the rotor sheets or stator sheets, radiation performance is enhanced, machining materials are saved, and weight is reduced. In addition, the multi-sheet combining rotor or stator structure facilitates radiation.

Owner:无锡金阳电机有限公司

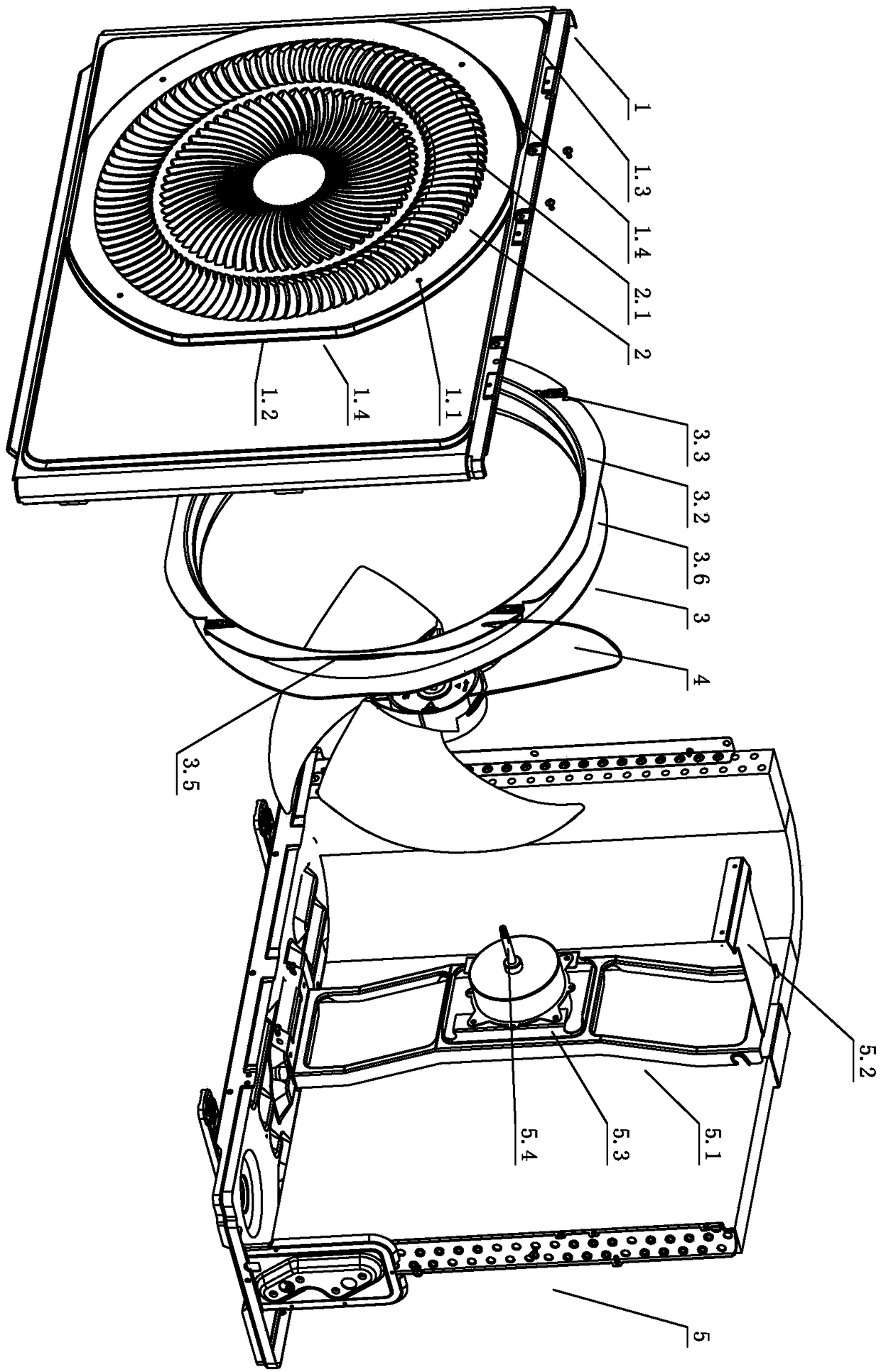

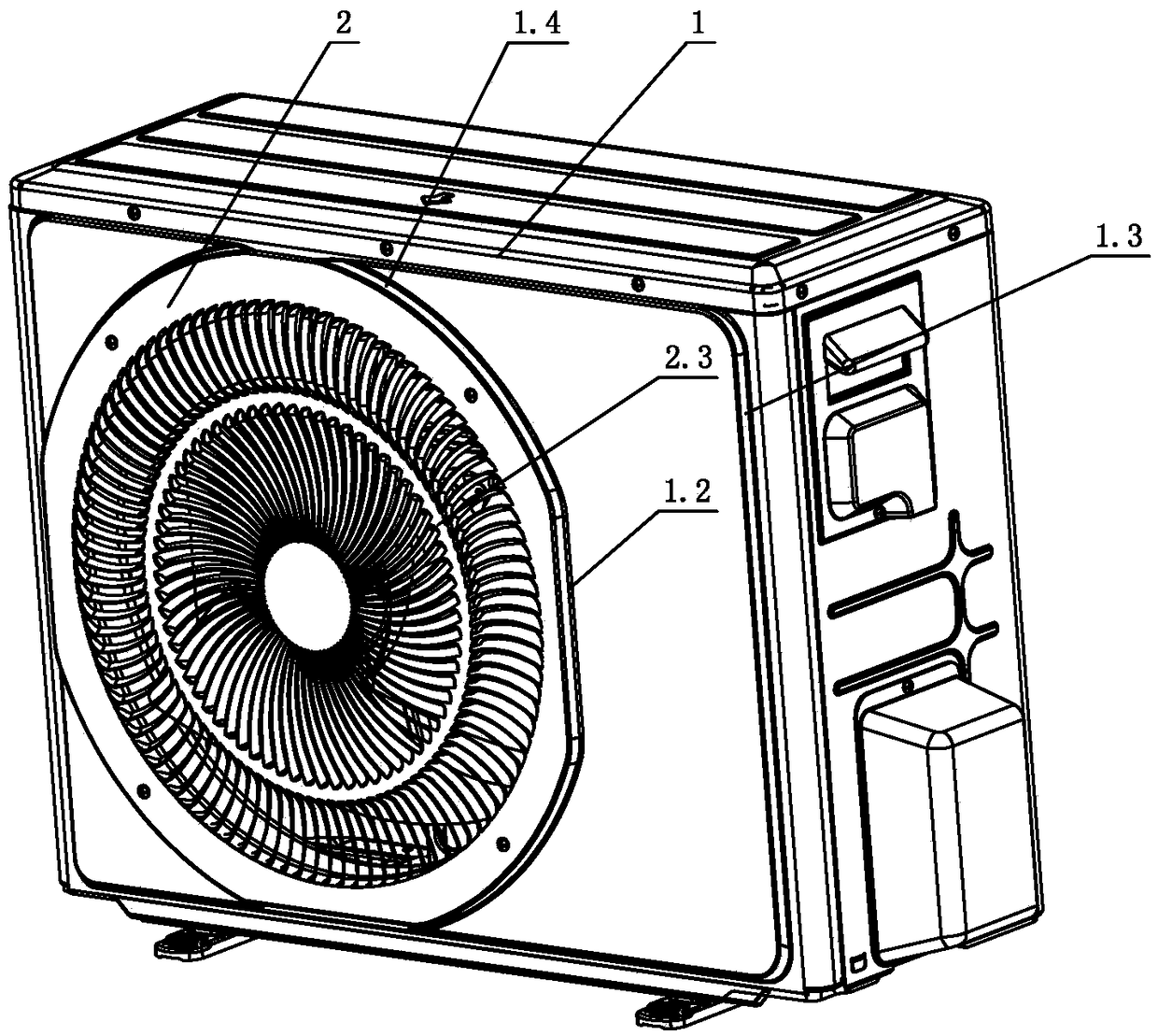

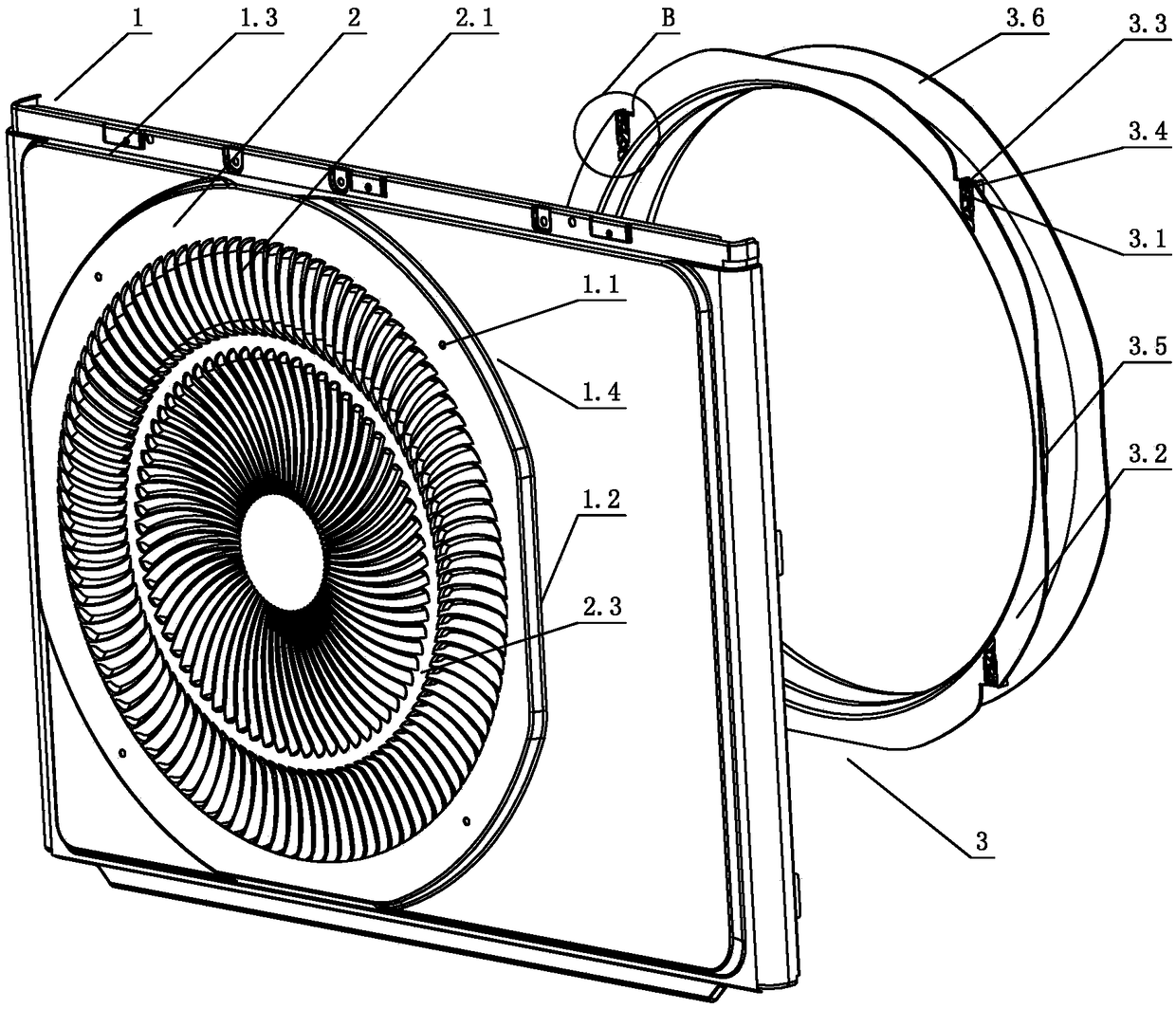

Outdoor unit of air conditioner

InactiveCN109340931ALarge internal spaceSolve the noiseLighting and heating apparatusNoise suppressionLow noiseWindow shutter

The invention discloses an outdoor unit of an air conditioner. The outdoor unit of the air conditioner comprises a front panel, an air outlet grid of the front panel and an air guide ring. The front panel is provided with the air outlet grid through stamping. The air outlet grid comprises more than one louver and a plurality of blades. The blades are circularly distributed in the louvers and are obliquely arranged in the louvers. The blades in the louvers are provided with notches for noise reduction. A limiting fitting piece is arranged between the front panel and the air guide ring, and theair guide ring is installed in the front panel through the limit fitting piece in a limiting mode, or the front panel and the air guide ring are mutually connected and fixed through welding and snap fit, the front panel is of a stepped structure, and a step protruding outwards is arranged on the surface of the front panel. Fan blades which are mutually assembled with the front panel and a condenser are further included. The fan blades are installed between the front panel and the condenser, and the fan blades are close to the inner side of the front panel. The outdoor unit of the air conditioner has the characteristics of low noise, high assembly efficiency of the whole machine, low production cost and simple processing technology.

Owner:GUANGDONG GALANZ GRP CO LTD

A processing method for extruding unburned bricks

ActiveCN106626003BAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses a processing method for baking-free brick extrusion forming and belongs to the technical field of brick making. By means of a continuous hydraulic brick making system, the processing method includes the following steps of feeding, wherein raw materials are added into a feeding hopper, penetrate through a feeding cavity and a feeding opening and enter a forming cavity; extrusion forming of the raw materials, wherein a first hydraulic cylinder drives a forming and pushing mechanism to move, so that a buffer cavity moves to the position under the feeding hopper, a second hydraulic cylinder drives an extrusion plate to move upward in the forming cavity, and the raw materials are extruded into bricks; pushing and conveying of the bricks, the first hydraulic cylinder drives the forming and pushing mechanism to move, and the second hydraulic cylinder drives the extrusion plate to push the bricks to a machine frame, and the first hydraulic cylinder drives the forming and pushing mechanism to push out the bricks. The defects that in the prior art, the brick continuous production degree is low and production efficiency is low are overcome easily, continuous extrusion forming of the bricks can be achieved, production efficiency is effectively improved, the operation process is simple, and the production cost is low.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

Plate shearing device facilitating plate fixing and clamping

PendingCN112317859AFixed and clampedEasy to operateShearing machinesShearing machine accessoriesGear wheelEngineering

The invention relates to the technical field of plate shearing machines, and discloses a plate shearing device facilitating plate fixing and clamping. The plate shearing device comprises a shell, wherein a support rod is movably connected to the interior of the shell, a long rod is movably connected to the exterior of the support rod, an eccentric rotating wheel is movably connected to the exterior of the long rod, a push rod is fixedly connected to the exterior of the long rod, an ejector block is fixedly connected to the exterior of the push rod, a cutting knife is fixedly connected to the exterior of the ejector block, a photosensitive assembly is fixedly connected to the exterior of the shell, a rotating shaft is movably connected to the interior of the shell, and a rotating gear is fixedly connected to the exterior of the rotating shaft. Under the mutual action of all structures of the device, after an operator places a to-be-machined plate into the device, the operator can selectthe needed length, the plate shearing device shears and cuts the to-be-machined plate, the effect of fixed-length cutting according to needs is achieved, therefore, the machining precision is improved, the requirements for different lengths are met, and machining materials can be saved.

Owner:杭州具彩网络科技有限公司

Vertical shaft hanging scaffold stabilizing device

InactiveCN101660417AChange displacementWon't scratchLoad-engaging elementsShaft liningEngineeringCycle time

The invention relates to a vertical shaft hanging scaffold stabilizing device, belonging to a pit shaft construction hanging scaffold of a vertical shaft. The scaffold stabilizing device comprises a base plate, support seats, a connecting rod, an adjuster and a rubber wheel. The base plate is provided with two support seats, wherein one support seat is connected with the connecting rod, the adjuster is arranged between the connecting rod and the other support seat, and the connecting rod is connected with the rubber wheel. An upper-layer scaffold and a lower-layer scaffold of the hanging scaffold are respectively provided with four scaffold stabilizing devices. When in work, the solid rubber wheel and the scaffold stabilizing devices tightly support the shaft wall, so the hanging scaffoldcannot shake in the annular space. The vertical shaft hanging scaffold stabilizing device has the advantages that: firstly, the device can be repeatedly used has simples processing and convenient installation and use, saves processing materials and the capital and is free from manual operation and control on the hanging scaffold when the hanging scaffold is lifted; secondly, the device can not only stabilize the hanging scaffold, but also can be used for adjusting the gap between a hanging bucket and a horn so as to ensure that the hanging bucket has enough safe distance in the running process; and thirdly, the device creates the conditions for quick construction of the vertical shaft, saves labor force and physical resource, is safe and reliable and shortens the circulation time.

Owner:CHINA COAL NO 5 CONSTR

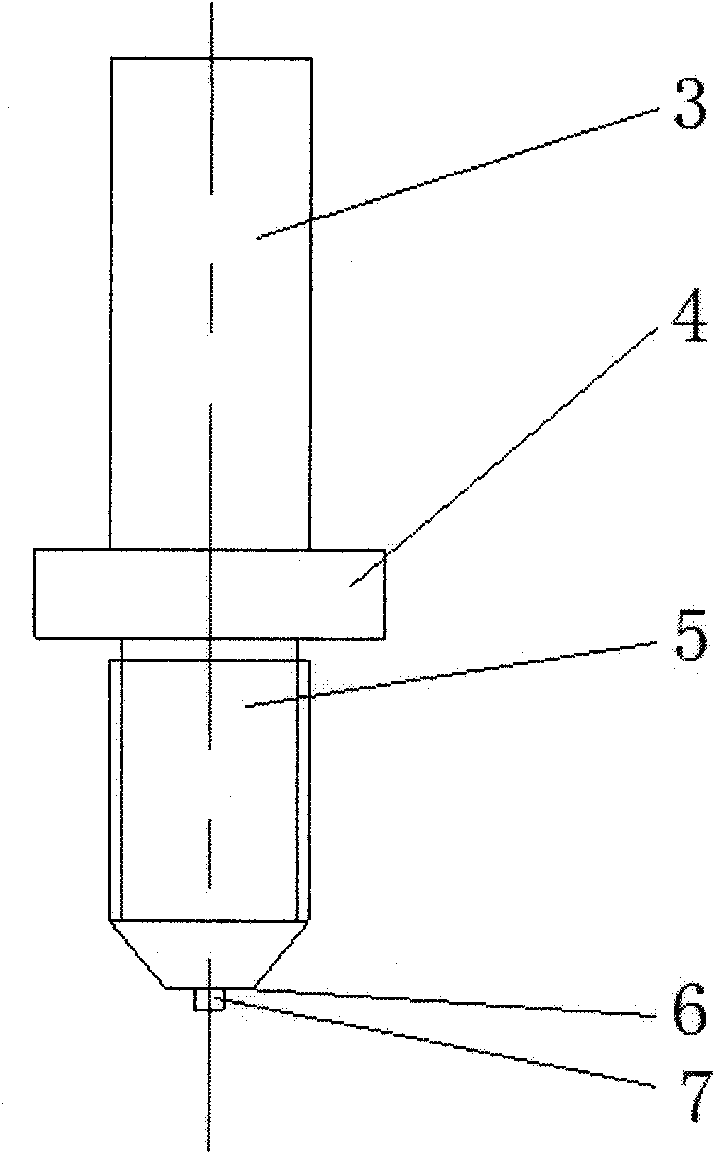

Plunger structure and plunger pump

InactiveUS20180363644A1Reduce inertiaIncrease rotation speedPositive displacement pump componentsPump controlEngineeringPlunger pump

A plunger structure and a plunger pump are provided, relating to the technical field of plunger pumps. In one exemplary implementation, the plunger structure may comprise a plunger body with both ends closed, an engagement groove disposed at the top of the plunger body, a plunger cap fixedly connected to the engagement groove, and / or an elastic member having one end fixedly disposed within the plunger cap. The plunger body may be sheathed in the elastic member. According to other aspects, a top end of the plunger body may be exposed out from the plunger cap, an engagement groove that is depressed inwardly may be formed in a circumferential direction of the top of the plunger body, an inside of the plunger body may be in a cavity structure, and / or the plunger body may be an integrally molded part.

Owner:NINGBO LUTENG PRECISION MACHINERY

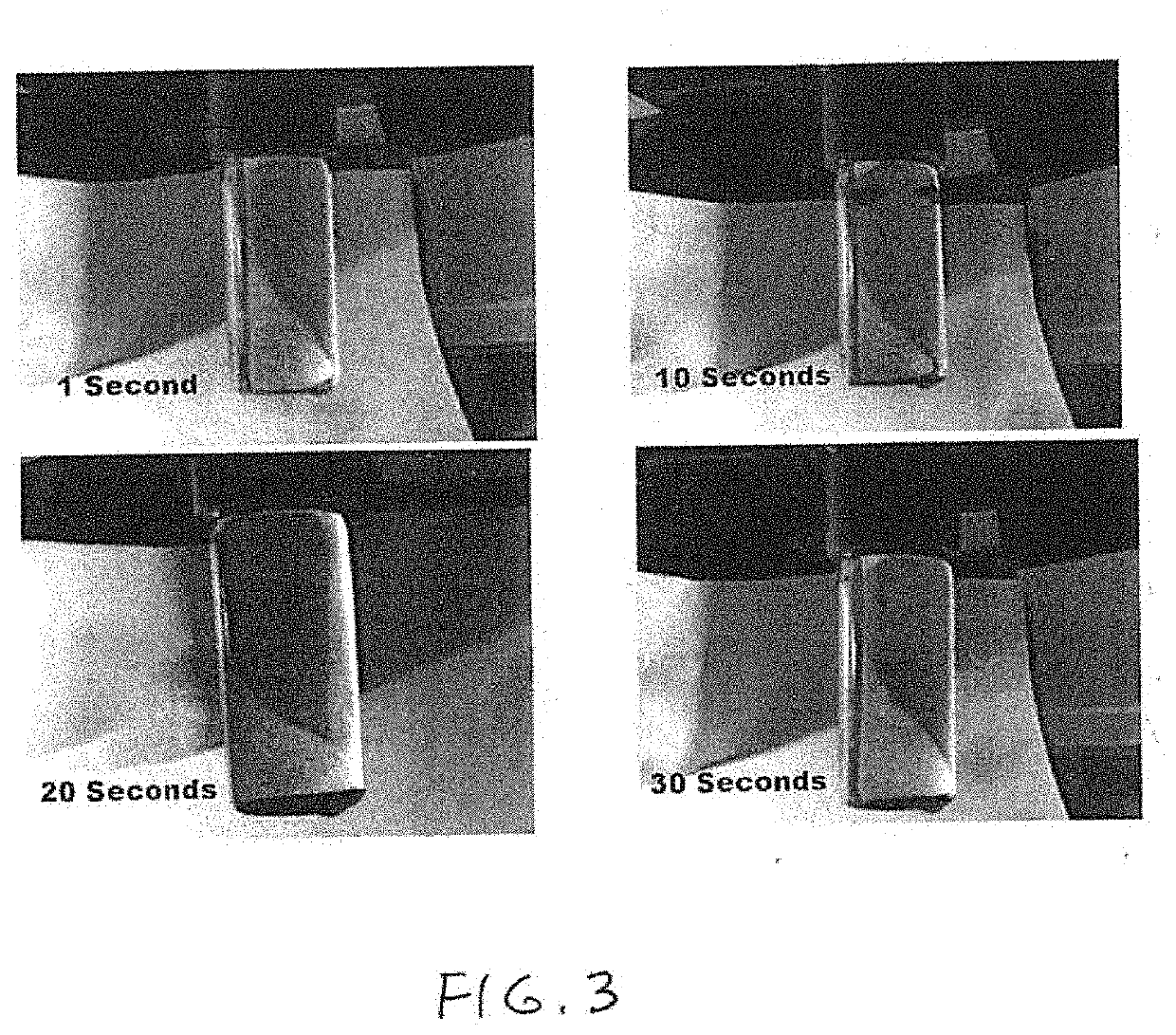

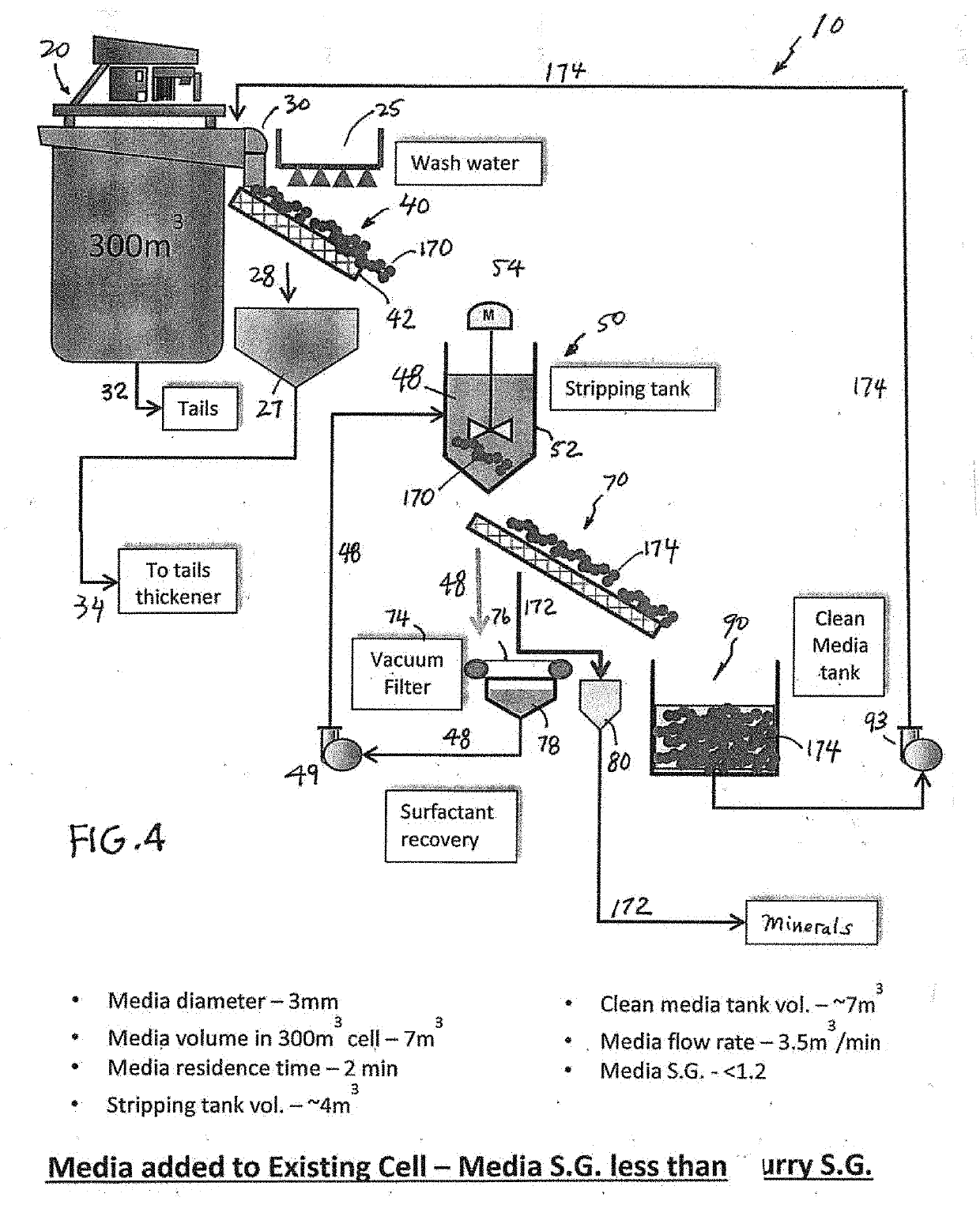

Utilizing engineered media for recovery of minerals in tailings stream at the end of a flotation separation process

Apparatus uses engineered collection media to recover mineral particles in a mineral extraction process, e.g., for processing a tailings stream at the end of a flotation separation process. The engineered collection media are added to slurry / tailings containing the mineral particles. The engineered collection media have collection surfaces coated with a chemical selected for attracting the mineral particles to the collection surfaces so the engineered collection media becomes mineral laden media in the slurry / tailings in a loading stage. The apparatus include three stages: removing unwanted material from mineral laden media; using a stripping agent to strip the mineral particles from the mineral laden media; and separating the engineered collection media from the mineral particles and the stripping agent. The stripping agent is reused for stripping, and the engineered collection media are returned to the loading stage. The engineered collection media can have a smooth or foam-like surface.

Owner:CIDRA CORP SERVICES

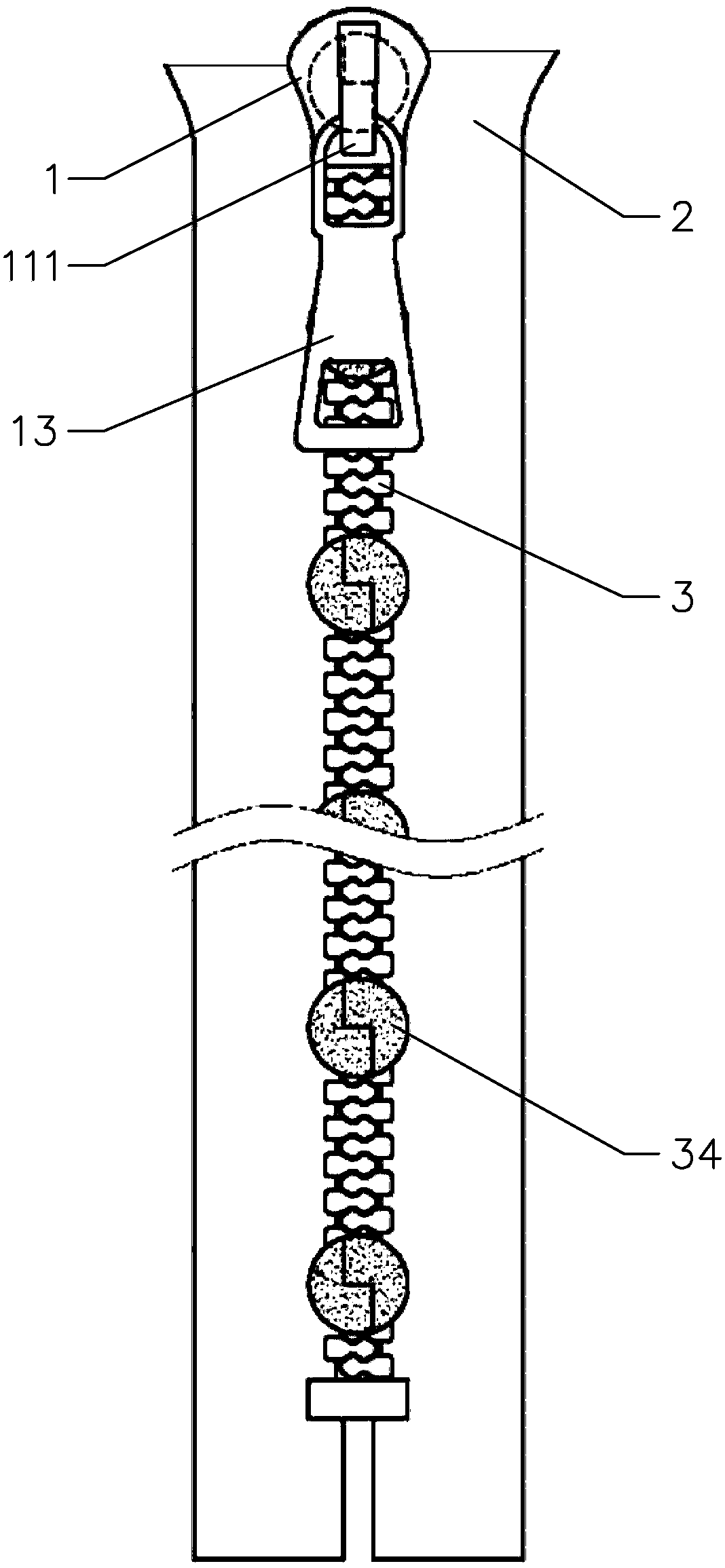

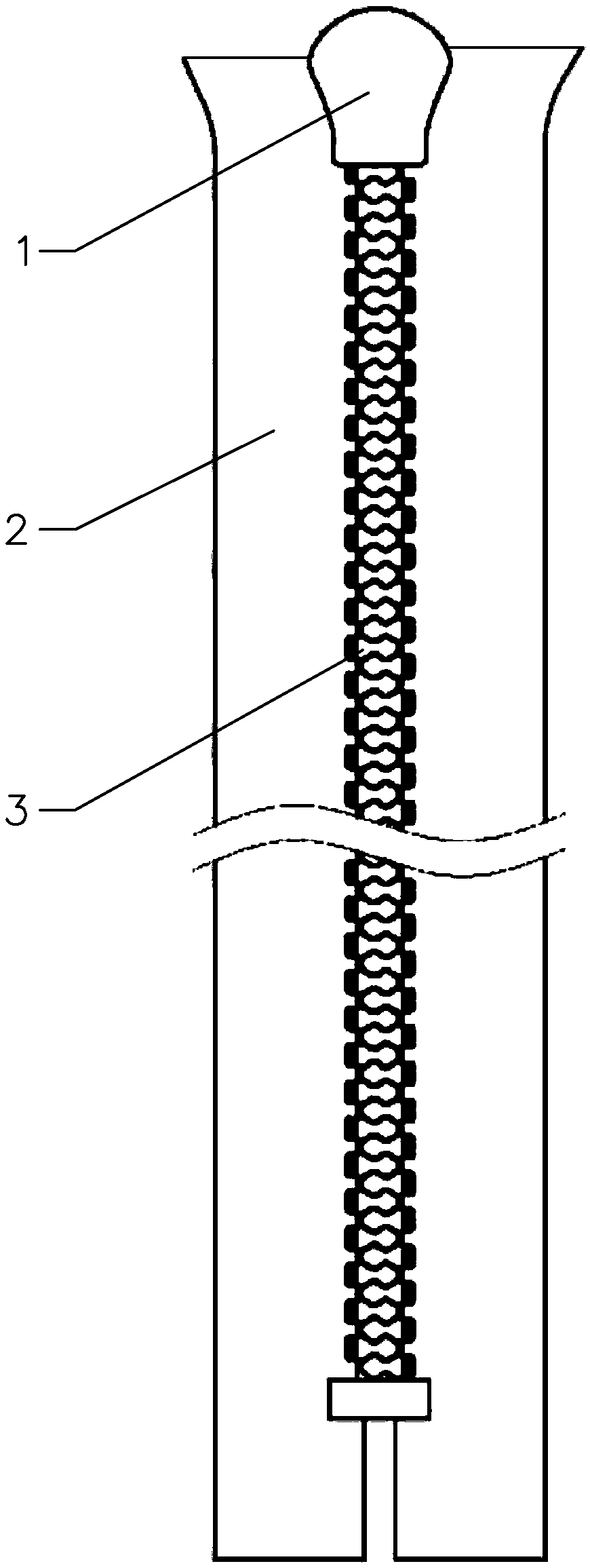

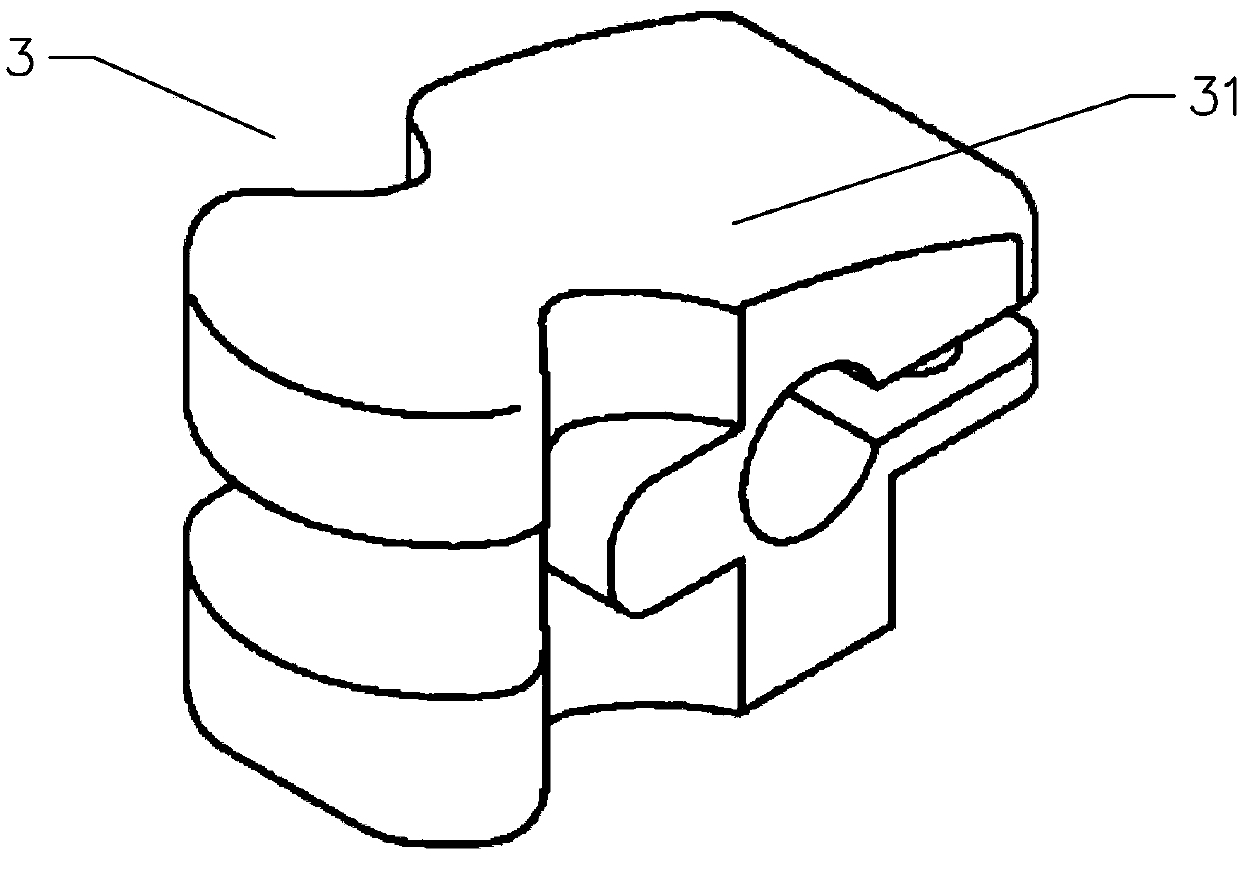

Zipper with different tooth patterns

The invention provides a zipper with different tooth patterns. The zipper includes a puller, a pair of link belts and a plurality of teeth arranged on the link belts. The puller includes an upper slide base disposed on the front face of the link belts, a lower slide based disposed on the back face of the link belts and a separator board connecting the upper slide base and the lower slide base. Thetransverse width between the two side edges of the upper slide base is W1. After two teeth on the link belts engage each other. The transverse width between the two side edges of the front face of the two teeth is W2, wherein W2 is greater than or equal to W1. In this way, the edge of the front face of the teeth is barrier-free, namely, side board free design is provided for the two sides of theupper slide base. When modeling the teeth, the side edges of the teeth can protrude from the side edges of the upper slide base, so that the size of the teeth can be increased and more space is for design of the teeth. For example, the teeth can be made into shapes of buttons, stars or brand symbols and the like. Therefore, the appearance of the teeth is improved, the integral appearance of the zipper is improved and a brand new visual effect is achieved.

Owner:KENQING ZHEJIANG ZIPPER

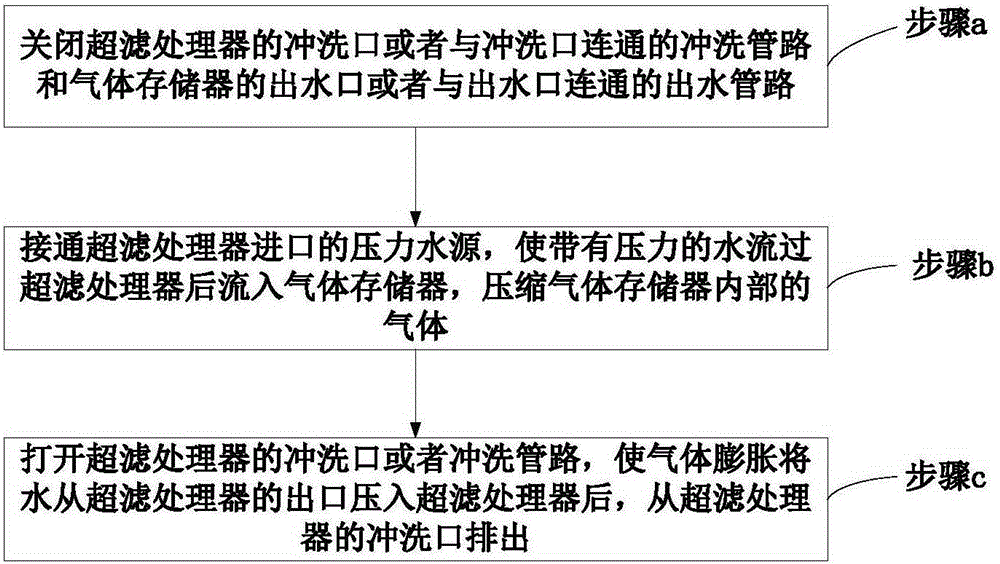

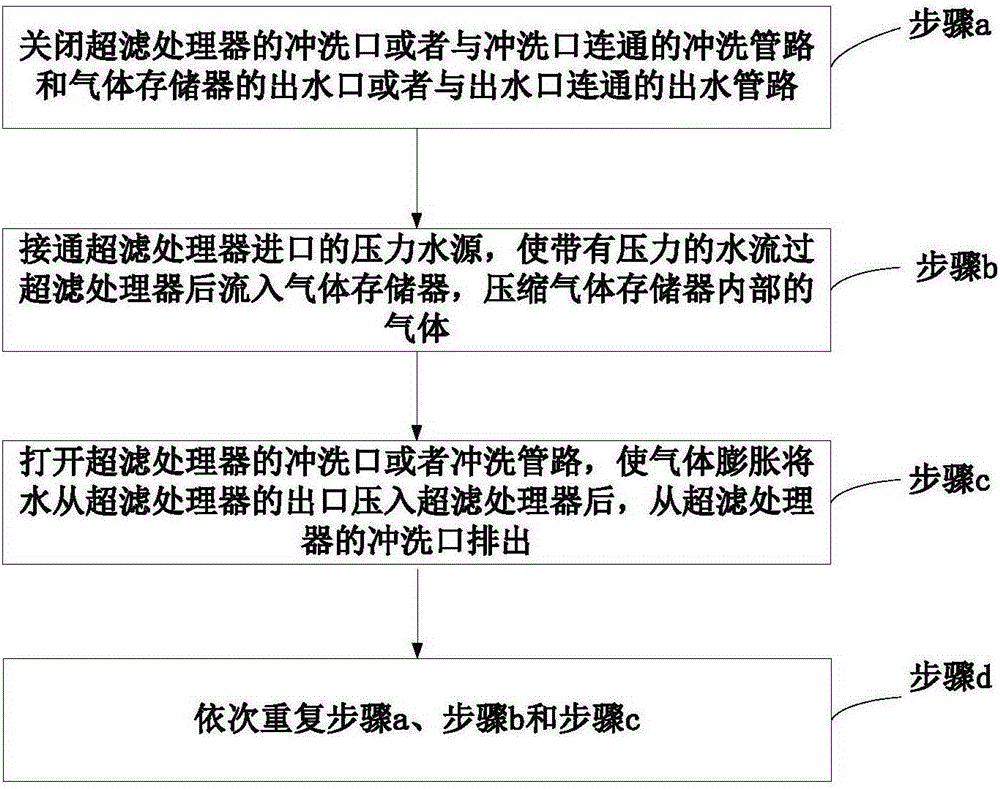

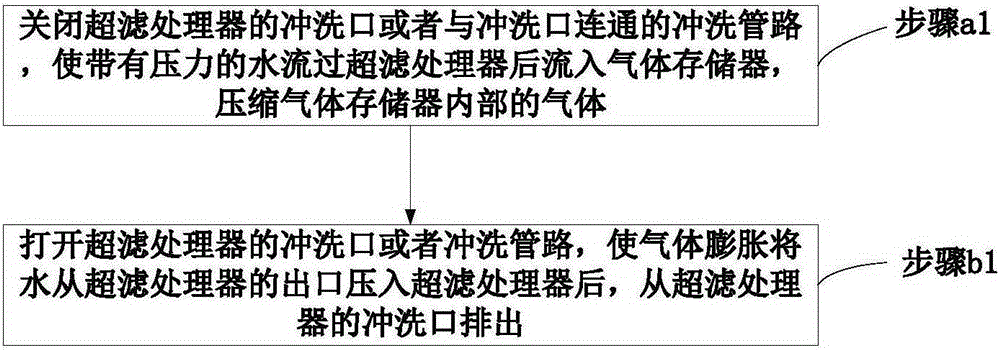

Ultrafiltration membrane washing method, ultrafiltration membrane washing device and water purifier provided with ultrafiltration membrane washing device

InactiveCN105251366ASave processing materialsAchieve flushingSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisHollow fibreFiber

The invention provides an ultrafiltration membrane washing method, an ultrafiltration membrane washing device and a water purifier provided with the ultrafiltration membrane washing device. The ultrafiltration membrane washing device comprises an ultrafiltration processor, wherein the ultrafiltration processor is provided with an inlet, an outlet and a washing port, the inlet is used for being communicated with a pressure water source, the washing port is used for discharging washing water, a hollow fiber ultrafiltration membrane assembly is arranged in the ultrafiltration processor, the ultrafiltration membrane washing device further comprises a gas storage device, the outlet is communicated with the inside of the gas storage device, and the washing port is communicated with a first washing valve through a washing pipeline; a gas storage area and a liquid storage area are arranged in the gas storage device, and gas is stored in the gas storage area. Compared with the prior art, the ultrafiltration membrane washing device adopting the technical scheme can wash an ultrafiltration membrane through pressure provided by a water source, the washing effect is improved, the service life of the ultrafiltration membrane can be prolonged remarkably, and water treatment materials are saved. The ultrafiltration membrane washing device is simple in system, low in cost and easy to popularize and apply.

Owner:JIANGSU CIKON ENVIRONMENTAL APPLIANCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com