Motor with magnetic rotor

A magnetic pole rotor and rotor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit static parts, magnetic circuit shape/style/structure, etc., can solve the problems of affecting the service life of the motor, poor heat dissipation, etc., and achieve economical processing Materials, enhanced heat dissipation, and weight reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

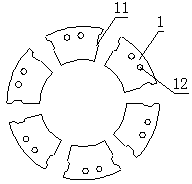

[0010] Such as figure 1 As shown, the motor with a magnetic pole rotor described in the embodiment of the present invention includes a rotor punch 1, the rotor punch 1 is set in an arc shape, and six rotor punches form a ring; on the outer arc surface of the arc There are slots 11 for winding wire groups, and a through hole 12 is provided on the plane between the two slots 11 . Optionally, an even number of rotor punches is used to form a corresponding integer number of magnetic pole pairs.

[0011] The stator of the motor with a magnetic pole rotor is configured as a permanent magnet magnetic pole structure, which is sheathed on the outer periphery of the rotor to provide magnetic field power and drive the rotor to run.

[0012] The through holes are provided on the rotor punching sheet to enhance the heat dissipation effect, reduce the weight and save materials at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com