Patents

Literature

146results about How to "Good industrial value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Static multistage melting crystallization method for preparing electronic grade phosphoric acid

InactiveCN102198937AEasy to operateReduce energy consumptionPhosphorus compoundsLiquid productPhosphoric acid

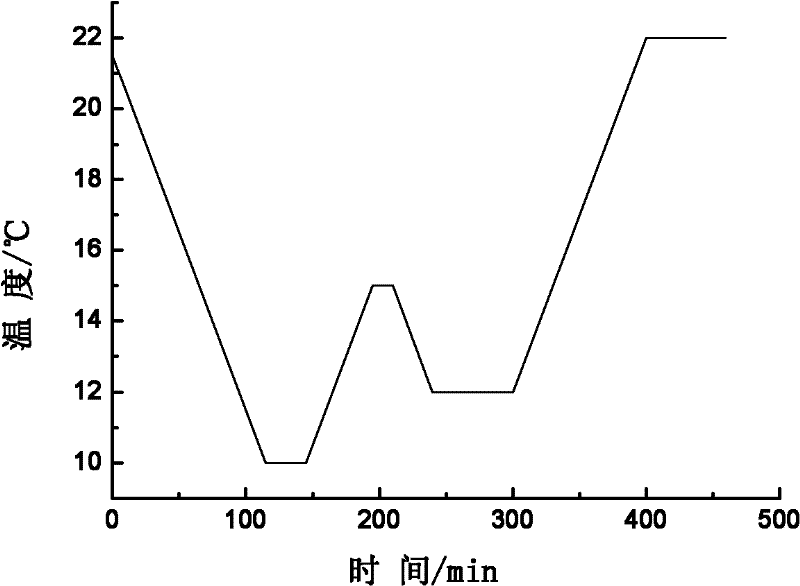

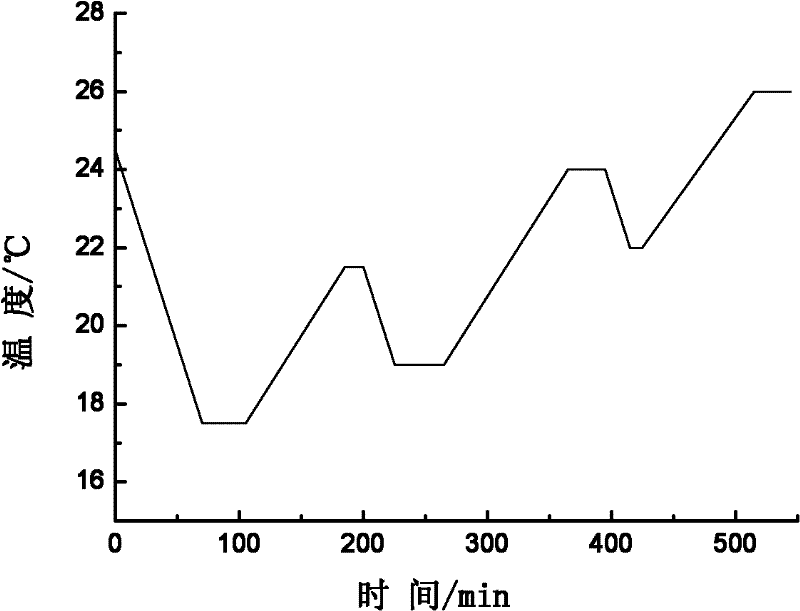

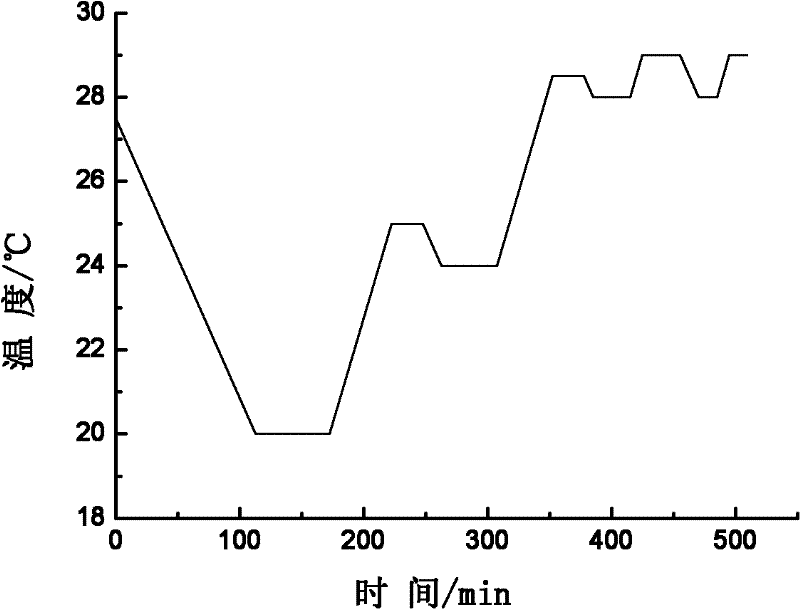

The invention provides a static multistage melting crystallization method for preparing electronic grade phosphoric acid. The method comprises the following steps of: adding phosphoric acid liquid serving as a raw material into a crystallization tower at one time, and introducing a cooling / heating medium to a crystallization tower jacket to control the temperature of the phosphoric acid liquid; adding crystal seeds into the crystallization tower at constant temperature when the phosphoric acid liquid is cooled to the temperature of between 15 and 28 DEG C; and performing static melting crystallization operations of two to four stages by the following steps of: cooling and crystallizing the materials, discharging partial mother solution at constant temperature, heating and melting to the constant temperature, continuously performing the operation of next stage at the temperature, and gradually discharging the mother solution for N times in equal mass to gradually improve the purity of the phosphoric acid crystal. Finally, the left crystal in the tower is the product, and the crystal is melted by heating and collected. The method is simple in operation, low in energy consumption and mild in operating conditions; the product has high purity; an 88 to 90 percent electronic grade phosphoric acid liquid product is directly obtained; and the product purity index accords with multiple standards of domestic and foreign users.

Owner:TIANJIN UNIV

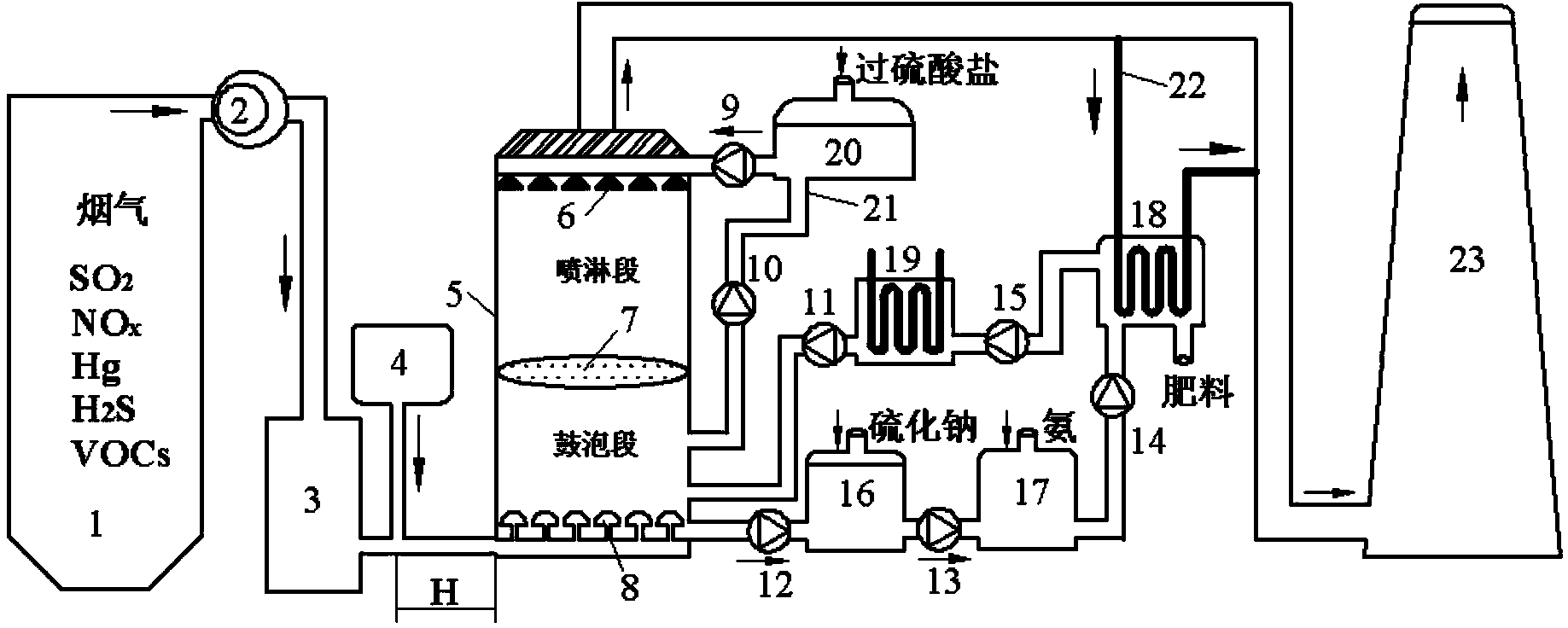

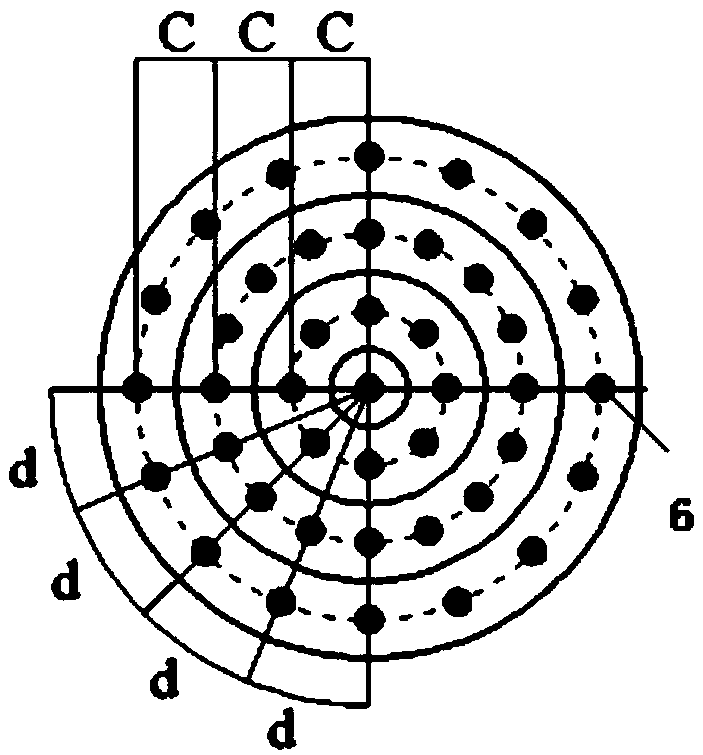

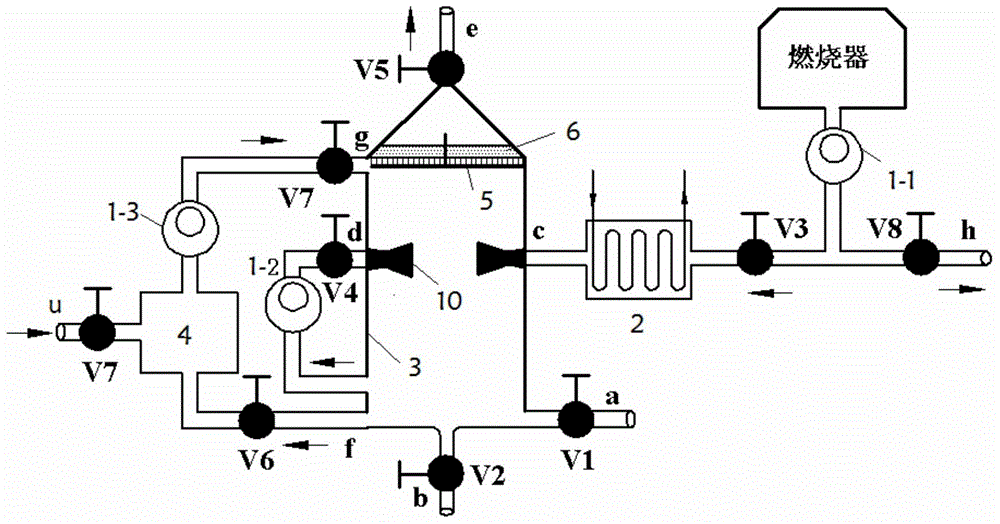

Method for purifying flue gas through activating persulfate by ozone, and apparatus thereof

ActiveCN104043325ATo achieve the purpose of removalNo secondary pollutionDispersed particle separationAir quality improvementSulfate radicalsAmmonium nitrate

The invention discloses a method for purifying flue gas through activating persulfate by ozone, and an apparatus thereof. Ozone in the flue gas contacts with persulfate in a solution in a bubbling-spray two stage reactor to generate sulfate radicals and hydroxy groups having strong oxidizability in order to oxidize and remove SO2, NOx, mercury, H2S and VOCs in the flue gas; and a reaction product solution enters a mercury separation tower to remove mercury, a mercury removed sulfuric acid and nitric acid solution enters an ammonia feeding tower, an ammonium sulfate and ammonium nitrate solution generated through the above reaction enters a product crystallization tower, and a flue gas waste heat utilizing device is used to evaporate and crystal recyclable agricultural fertilizers ammonium sulfate and ammonium nitrate. In the invention, ozone is adopted to induce persulfate to generate the sulfate radicals and hydroxy groups having extremely strong oxidizability, and the oxidbillities of the sulfate radicals and the hydroxy groups are second to that of fluorine, and are far higher than that of single ozone or persulfate, so the five pollutants can be efficiently simultaneously removed.

Owner:JIANGSU UNIV

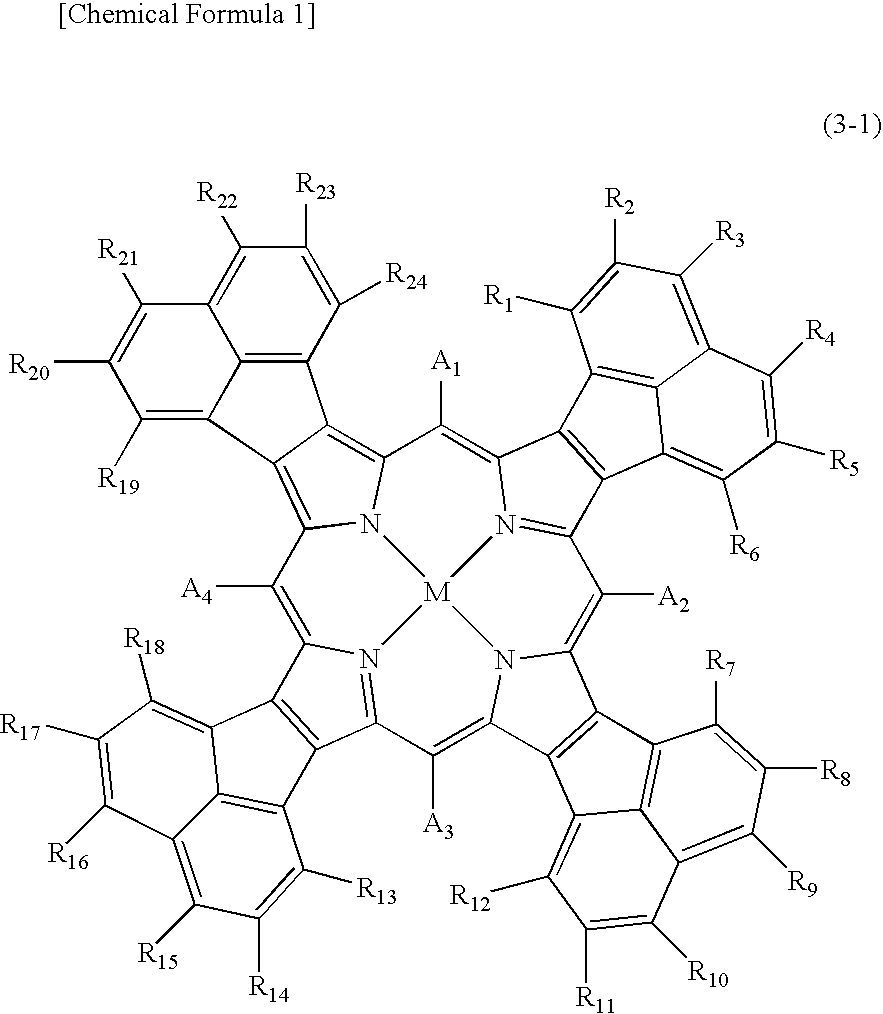

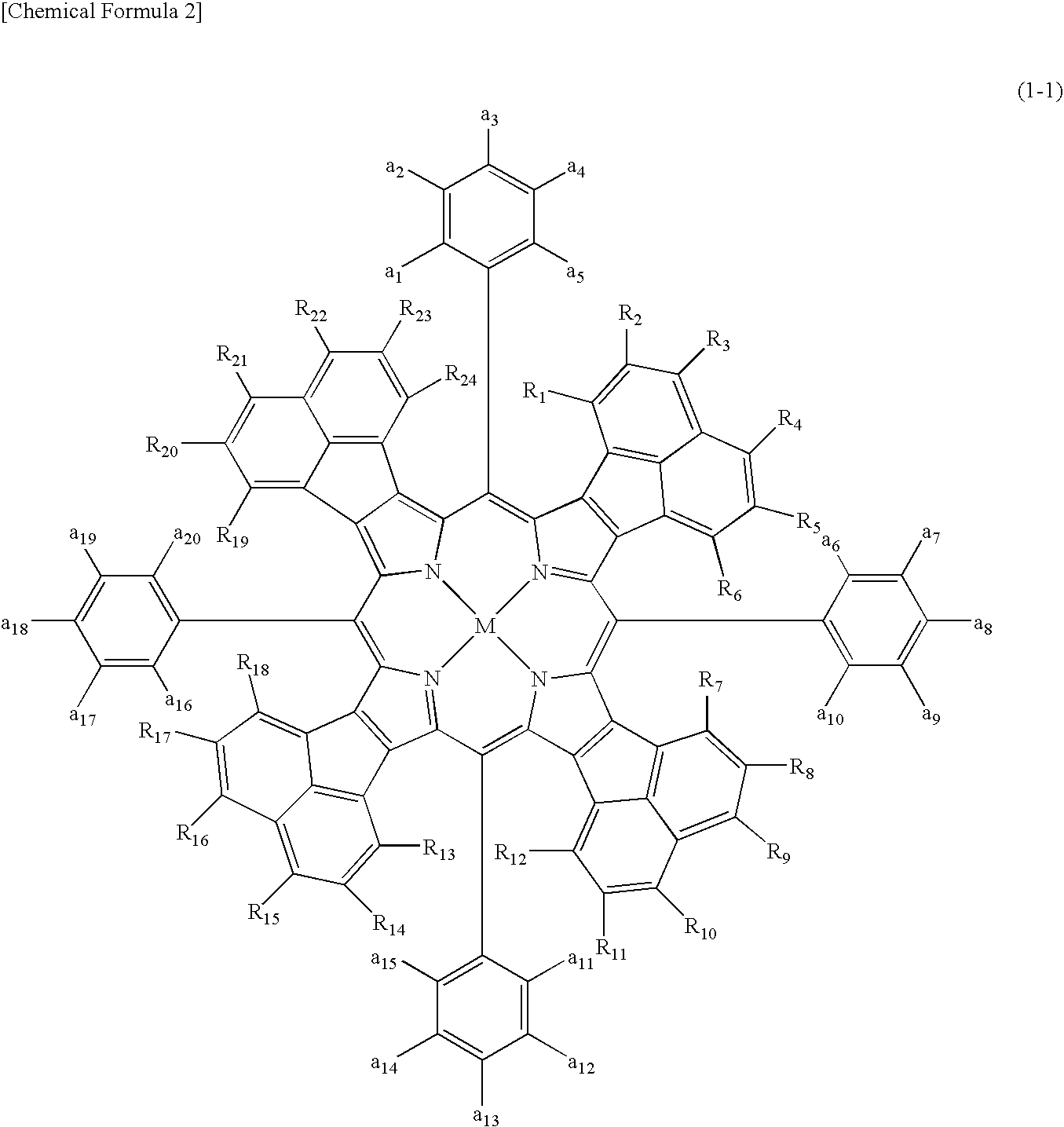

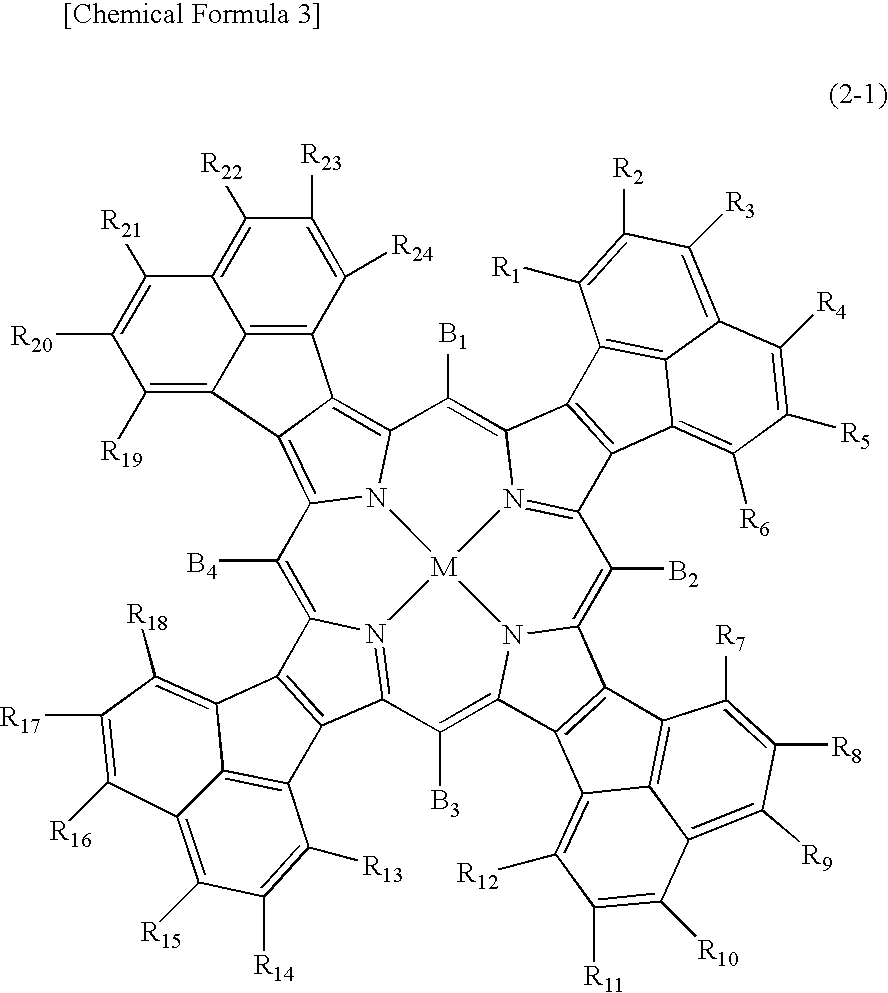

Optical Filter and Its Applications, and Porphyrin Compound Used in Optical Filter

InactiveUS20070293666A1Reduce unnecessary lightingIncreased durabilityOptical filtersFunctional group formation/introductionPorphyrinOptical transmittance

An optical filter of the present invention contains at least one tetra-acenaphthoporphyrin compound. The tetra-acenaphthoporphyrin compound has preferably its absorption maximum in a wavelength range of from 530 to 570 nm and a ratio of an absorption coefficient at 550 nm to an absorption coefficient at 525 nm of not less than 1.2. Also, a percentage of light transmittance at 550 nm to light transmittance at 525 nm is preferably not more than 85%. According to the present invention, it is possible to provide the optical filter which can eliminate an unnecessary light mainly existing in a wavelength of from 520 to 700 nm and is excellent in durability. A display unit using the optical filter of the present invention can improve contrast in a bright place, and improve color purity of luminescent color.

Owner:MITSUI CHEM INC

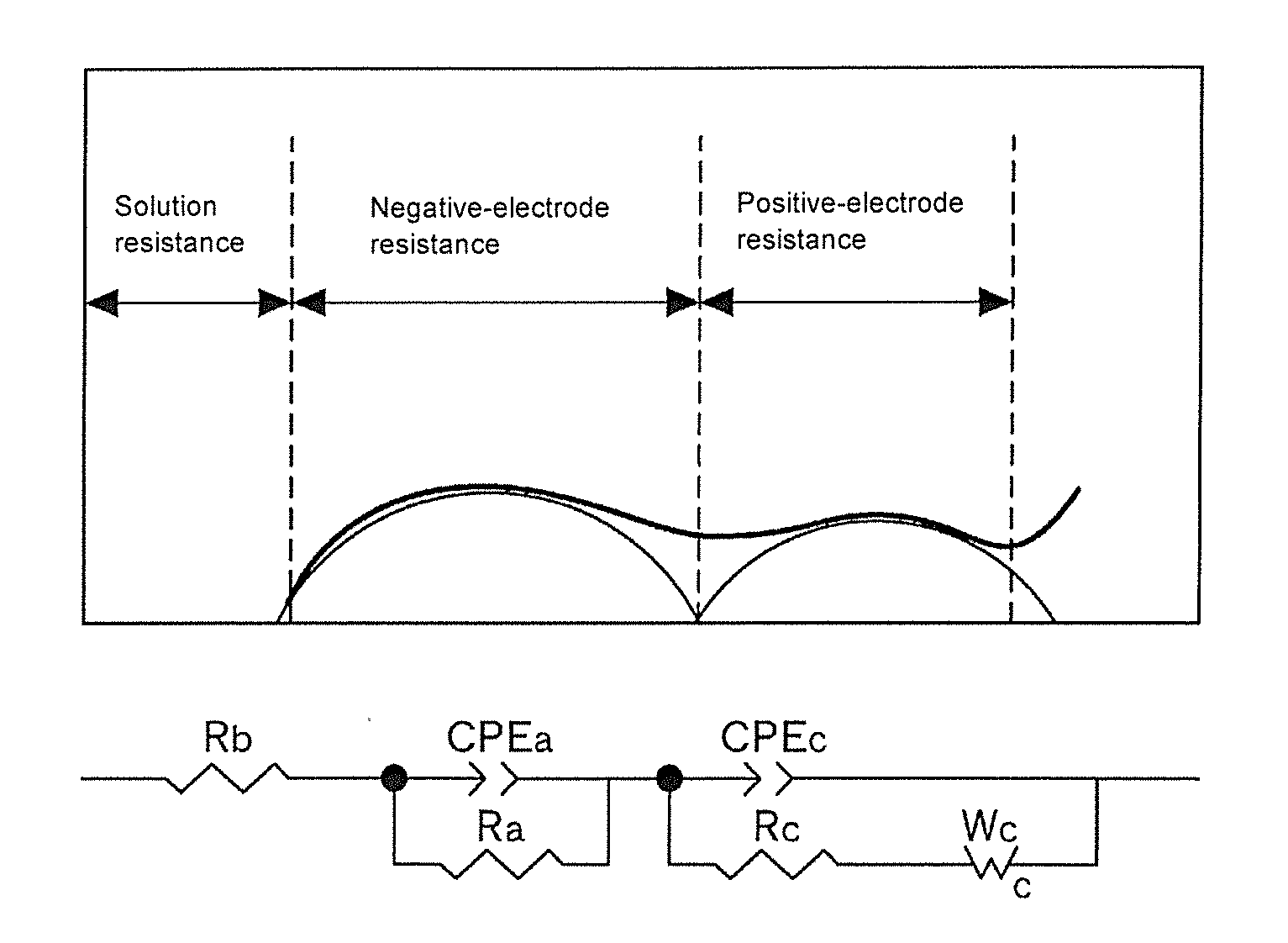

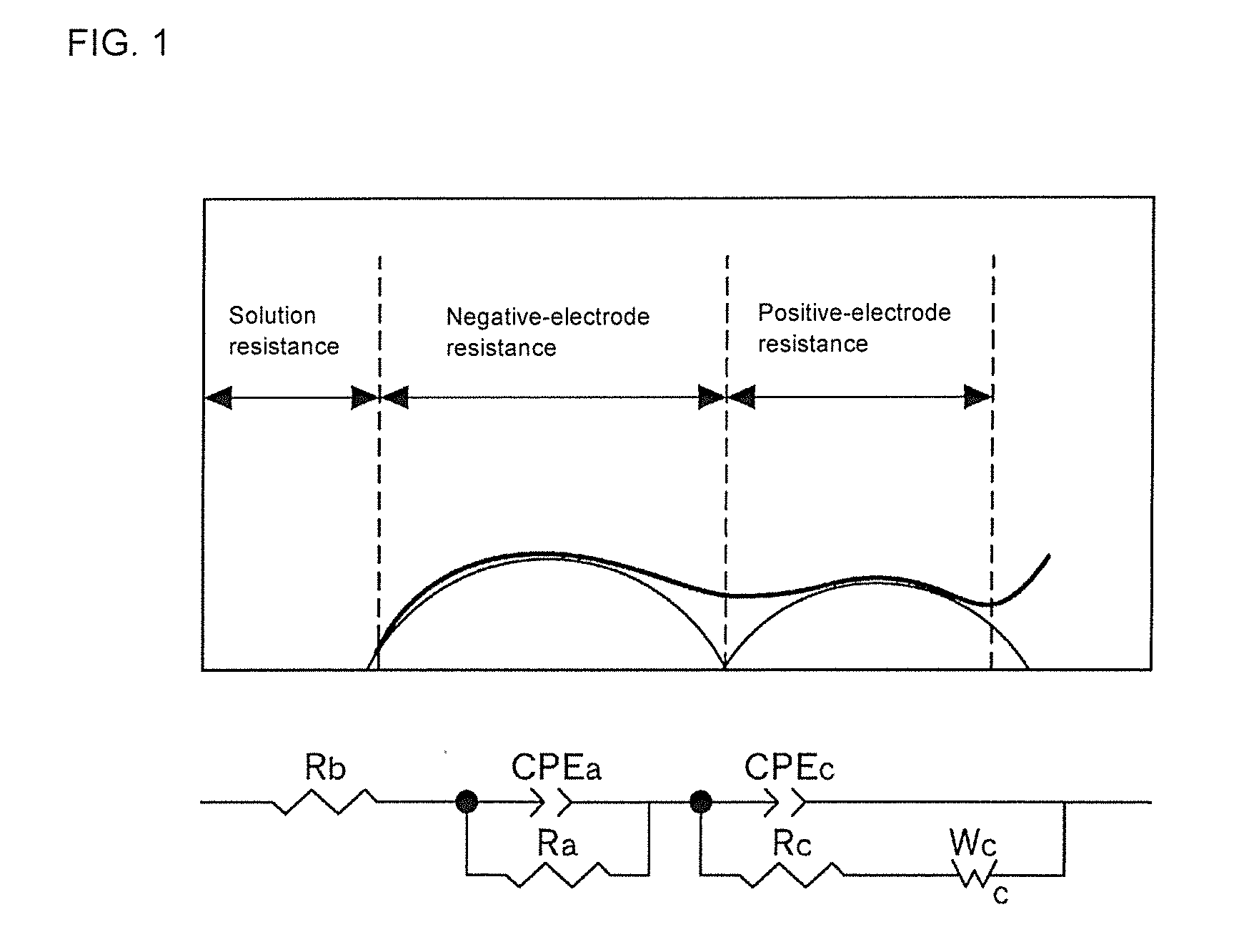

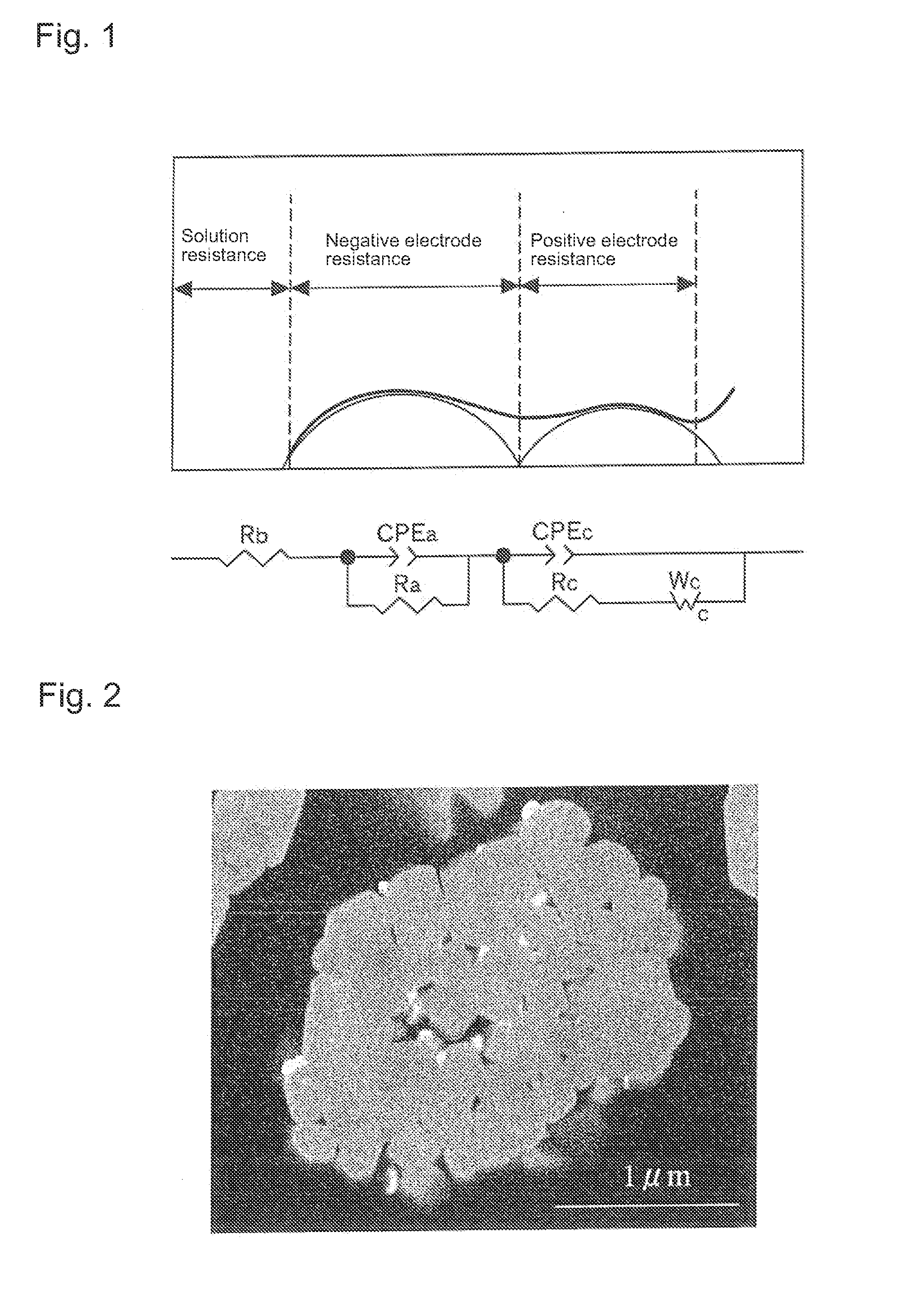

Positive-electrode material for nonaqueous-electrolyte secondary battery, method for manufacturing the same, and nonaqueous-electrolyte secondary battery using said positive-electrode material

ActiveUS20150021518A1Increase productionGood industrial valuePositive electrodesLi-accumulatorsLithium metalLithium tungstate

Provided is a positive-electrode material for nonaqueous-electrolyte secondary batteries, the positive-electrode material being capable of achieving both high capacity and high output when used for a positive electrode for nonaqueous-electrolyte secondary batteries. Also, provided is a method for manufacturing the positive-electrode material for nonaqueous-electrolyte secondary batteries, wherein a lithium metal composite oxide powder is mixed with lithium tungstate, the lithium metal composite oxide powder being represented by a general formula LizNi1-x-yCoxMyO2 (wherein 0.10≦x≦0.35, 0≦y≦0.35, 0.97≦z≦1.20, and M is an addition element and at least one element selected from Mn, V, Mg, Mo, Nb, Ti, and Al) and comprising primary particles and secondary particles composed of aggregation of the primary particles.

Owner:SUMITOMO METAL MINING CO LTD

Positive electrode active material for nonaqueous electrolyte secondary batteries, method for manufacturing the same, and nonaqueous electrolyte secondary battery using said positive electrode active material

ActiveUS20150228974A1Increase productionLarge capacityMaterial nanotechnologyFinal product manufactureLithium metalComposite oxide

Provided is a method for manufacturing the positive electrode active material for nonaqueous electrolyte secondary batteries, the method comprising: a first step, wherein an alkaline solution with a tungsten compound dissolved therein is added to and mixed with a lithium metal composite oxide powder represented by a general formula LizNi1—x—yCoxMyO2 (wherein, 0.10≦x≦0.35, 0≦y≦0.35, 0.97≦Z≦1.20, and M is at least one element selected from Mn, V, Mg, Mo, Nb, Ti, and Al), including primary particles and secondary particles composed of aggregation of the primary particles, and thereby W is dispersed on a surface of the primary particles; and a second step, wherein, by heat treating the mixture of the alkaline solution with the tungsten compound dissolved therein and the lithium metal composite oxide powder, fine particles containing W and Li are formed on a surface of the primary particles.

Owner:SUMITOMO METAL MINING CO LTD

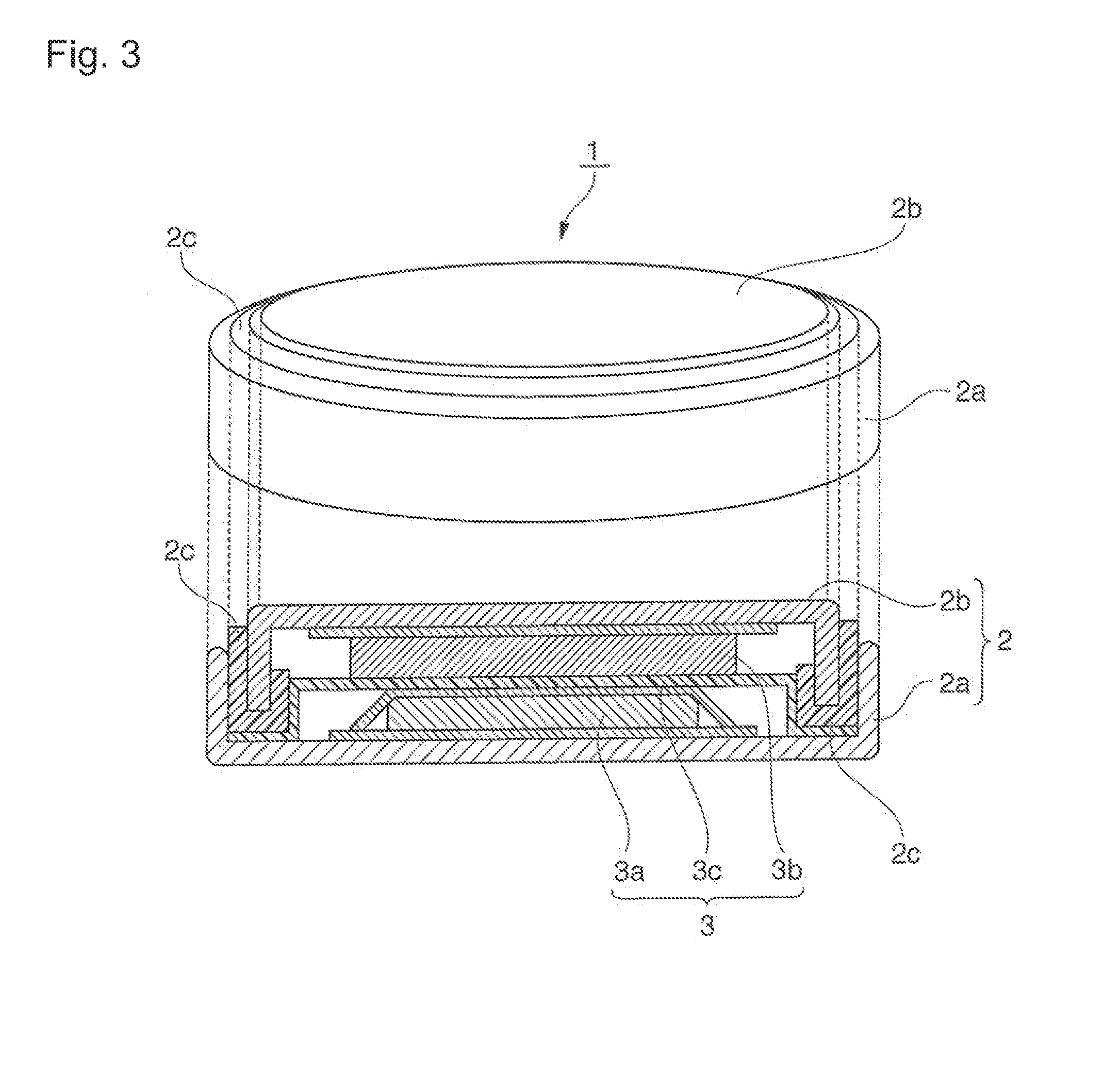

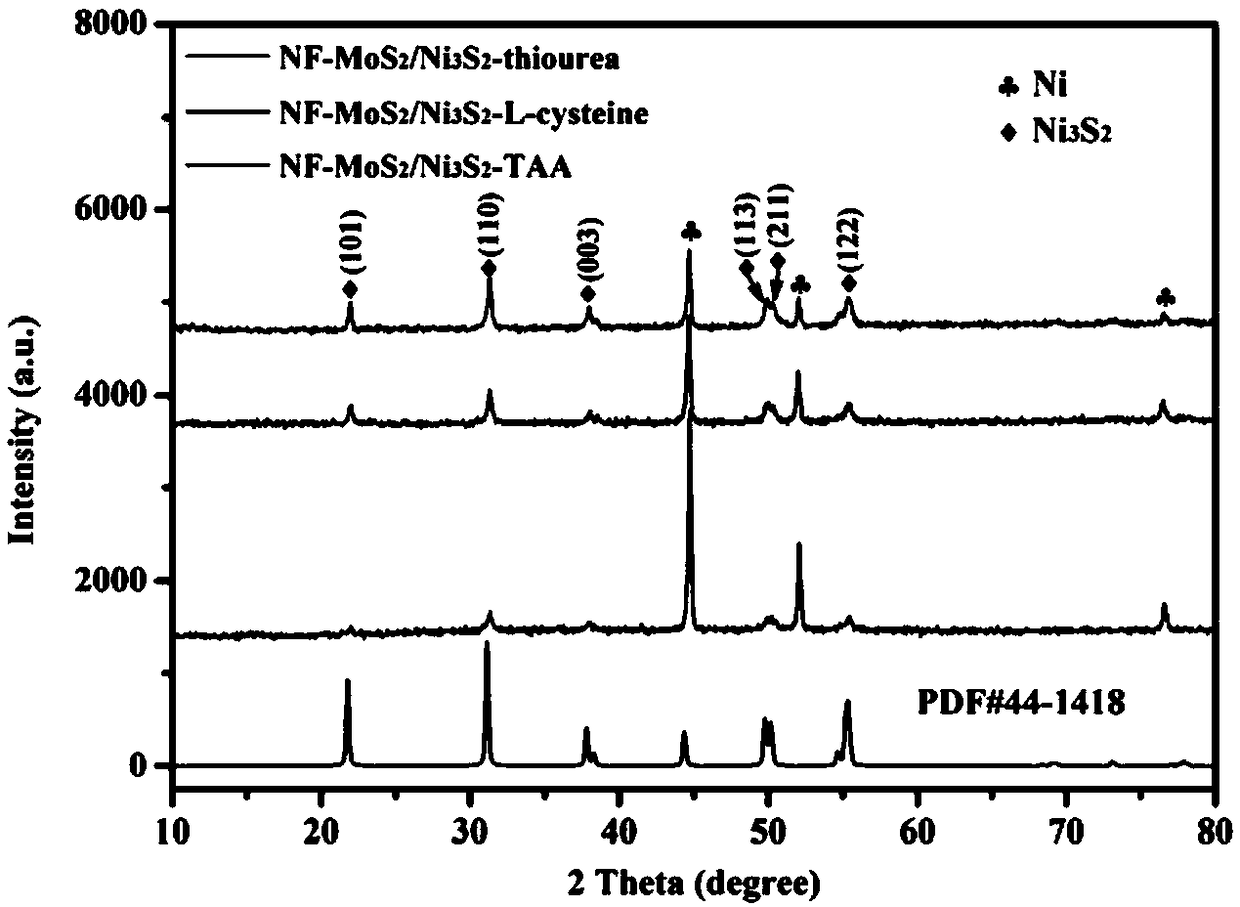

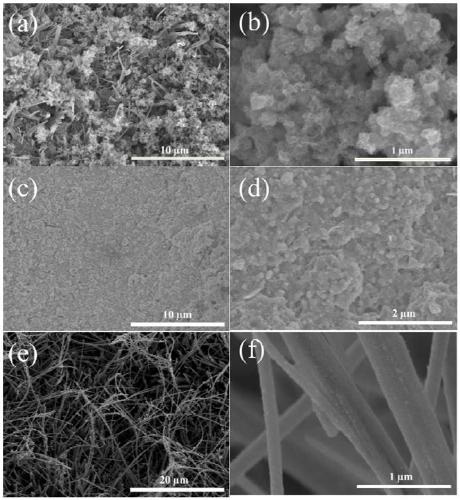

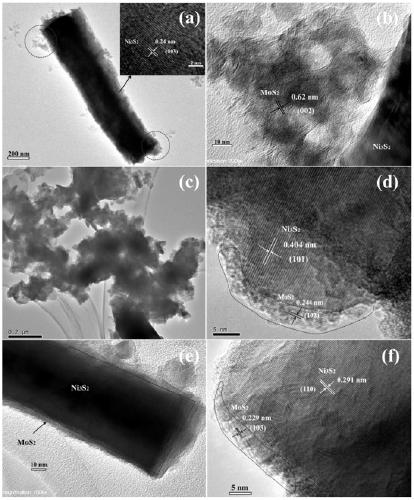

MoS2/Ni3S2 electrode material as well as preparation method and application thereof

ActiveCN109046383AThe synthesis method is simpleBest production conditionsPhysical/chemical process catalystsElectrodesEnvironmental resistanceElectricity

The invention relates to a MoS2 / Ni3S2 electrode material as well as a preparation method and application thereof, which belongs to the technical field of environmental protection and energy of hydrogen production by virtue of electric decomposition of water. The application of different sulfur sources is verified to have great influence for the morphology and performance of a catalyst; and by virtue of comparison, the MoS2 / Ni3S2 electrode synthesized by using thioacetamide as a sulfur source has optimum morphology, performance and reaction active site, the over-potential for the reaction can be greatly reduced, and the energy loss in the electrochemical hydrogen production process can be reduced. Meanwhile, the synthetic method is simple, and the foam nickel self-supported MoS2 / Ni3S2 electrode can be synthesized by adopting a one-step hydrothermal method, so that the industrialized production and actual application value is high.

Owner:SHANDONG UNIV

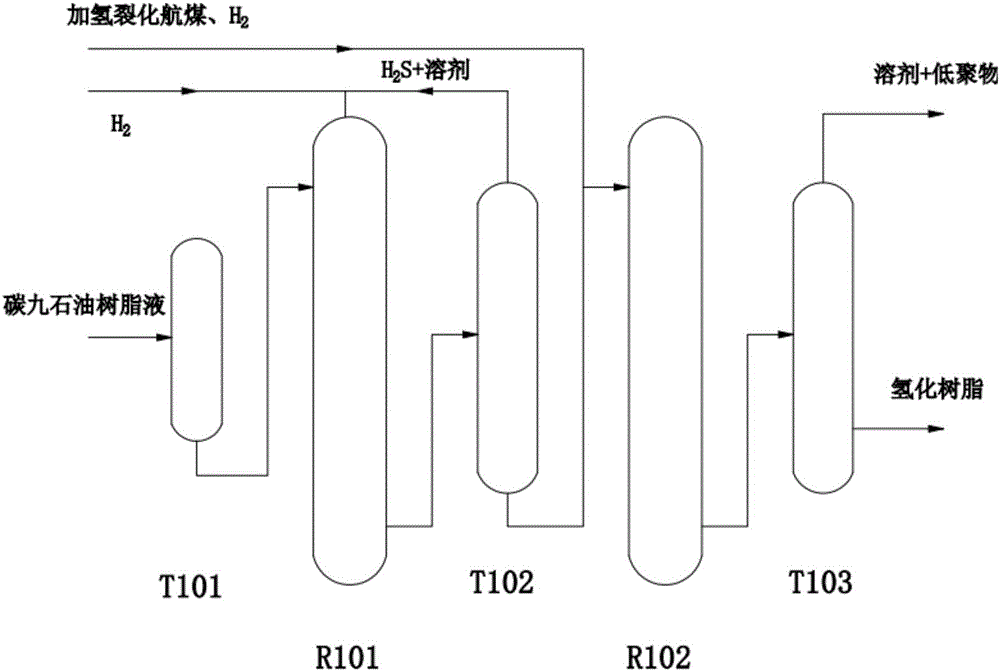

Method for preparing hydrogenated C9 petroleum resin by directional hydrogenation

The invention relates to a method for preparing hydrogenated C9 petroleum resin by directional hydrogenation. The method comprises the following steps: (1) uniformly mixing C9 petroleum resin with a mixing solvent and then removing impurities through a Al2O3 packed bed; (2) conveying a pretreated liquid resin into a one-stage hydrogenation reactor loaded with Ni / Mo / W-Al2O3 catalyst and performing hydrogenation reaction, thereby acquiring a one-stage hydrogenated liquid resin; (3) conveying the one-stage hydrogenated liquid resin into a pressure-stabilizing flash column, thereby acquiring desulfurized liquid resin at the column bottom; (4) uniformly mixing the desulfurized liquid resin with hydrocracking aviation fuel and then feeding into a two-stage hydrogenation reactor, and performing hydrogenation reaction, thereby acquiring two-stage hydrogenated liquid resin; and (5) conveying the two-stage hydrogenated liquid resin into a decompression rectifying column, thereby acquiring the hydrogenated C9 petroleum resin at the column bottom. According to the method provided by the invention, the process is simple and convenient; the hydrogenation cost is low; the middle solvent is basically recycled; the prepared hydrogenated C9 petroleum resin has an excellent performance and a higher industrial value.

Owner:HENGHE MATERIALS & SCI TECH CO LTD

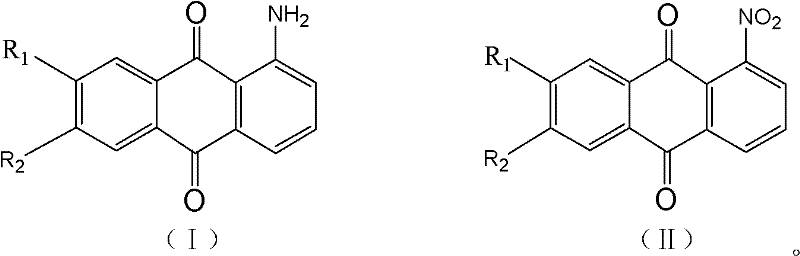

Method for preparing high-purity 1-aminoanthraquinone through catalytic hydrogenation

ActiveCN102531925AReduce dosageNo emissionsOrganic compound preparationAmino compound preparationHydrogenation reactionReaction temperature

The invention discloses a method for producing high-purity 1-aminoanthraquinone through catalytic hydrogenation. The method has the advantages of simple equipment, safe operation, low production cost and no pollution. The method comprises the following steps of: preforming hydrogenation on 1-nitroanthraquinone and a solvent in the presence of a catalyst in a reactor, filtering off the catalyst, stirring or standing a reducing solution in an oxidant, and obtaining 1-aminoanthraquinone through oxidation of a small amount of perhydrogenation product in the reducing solution to promote solution oversaturation to realize homogeneous crystallization, so that the high-purity 1-aminoanthraquinone is obtained; and continuously applying a motor solution of which crystals are filtered off, and the catalyst mechanically, and after multiple mechanical application, adding a diluent into the reducing solution to obtain 1-aminoanthraquinone crystals, wherein in the catalytic hydrogenation reaction, a weight ratio of the solvent to the 1-nitroanthraquinone is (1.0-10.0):1, and the reaction temperature ranges from normal temperature to 120DEG C. The purity of the obtained 1-aminoanthraquinone is over 99 percent, the total yield in the process is over 98 percent, and in the production process, the consumption of the solvent is low, three-waste emission is avoided, and the production process is clean.

Owner:JIANGSU YABANG DYE +1

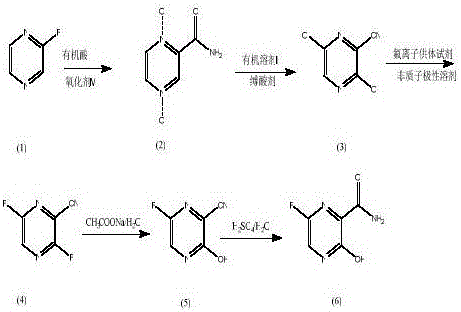

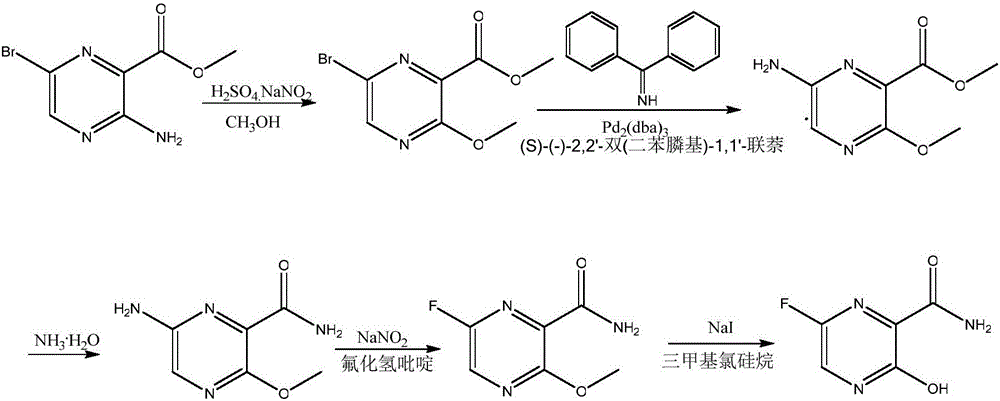

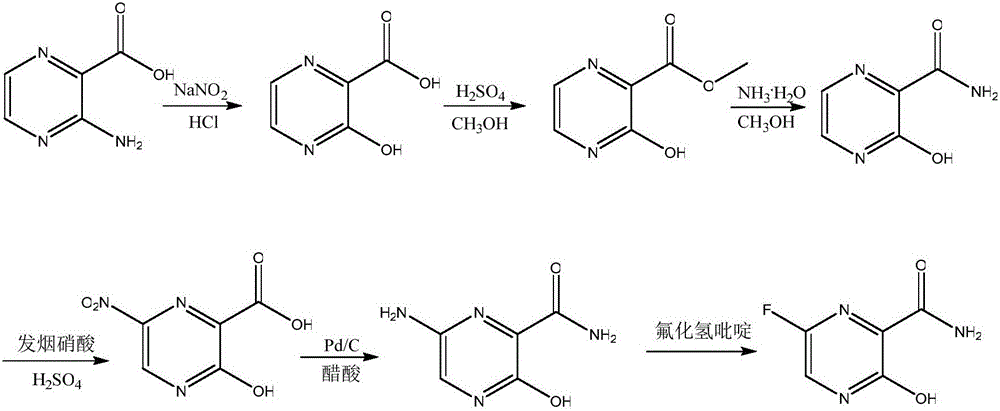

Favipiravir synthesis process

InactiveCN106478528AThe synthesis process is simpleRaw materials are easy to obtainOrganic chemistrySodium acetatePyrazine

The invention relates to a favipiravir synthesis process, which comprises: 1) dissolving a pyrazine compound in an organic reagent I, adding an oxidizing agent M, and carrying out a nitrogen oxidation reaction to obtain a white solid; 2) adding the obtained white solid to an organic reagent II, and carrying out a chlorination reaction to obtain a pale yellow solid; 3) uniformly mixing the obtained pale yellow solid, a dried aprotic polar solvent, a dried fluorine ion donor reagent and tetrabutylammonium bromide, and carrying out a stirring reaction to obtain a pale yellow solid; 4) adding the obtained pale yellow solid to water, and carrying out a reaction with 1,4-dioxane and sodium acetate to obtain a yellow oily matter; and 5) uniformly mixing the obtained yellow oily matter and concentrated sulfuric acid to obtain the target product favipiravir. According to the present invention, the method has advantages of simple and easily available raw materials, simple synthesis process and mild conditions, nitrogen oxidation, chlorination, fluorization and hydrolysis are performed to finally prepare the 6-fluoro-3-hydroxypyrazine-2-formamide, and the good industrial value is provided.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

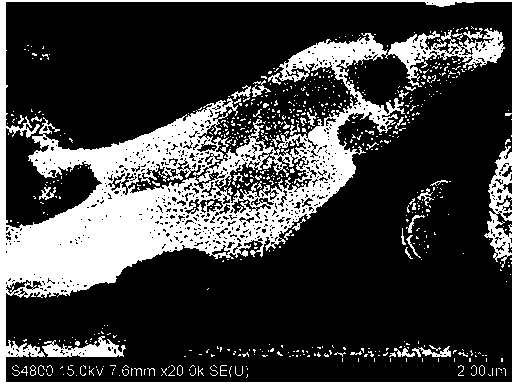

Method for preparing nano porous silicon by utilizing doped silicon particles

ActiveCN103985848AIncrease concentrationHigh hole densityCell electrodesSecondary cellsHydrofluoric acidReaction temperature

The invention discloses a method for preparing nano porous silicon by utilizing doped silicon particles. The method comprises the following steps: selecting silicon particles with a certain doping concentration, washing with hydrofluoric acid, then enabling the silicon particles to react in a solution which is prepared by selecting nitrate, hydrofluoric acid and oxidant with assistance of ultrasonic process centrifugally washing the silicon particles, and finally washing the silicon particles by using dilute nitric acid to obtain the three-dimensional nano porous silicon. The optimal process parameters such as best constitution of chemical etching corrosive agent, volume ratio and specific concentration of a reaction reagent, reaction time, reaction temperature, ultrasonic frequency, processing time and the like are screened out through a great number of experiments, and the prepared high-purity three-dimensional doped porous silicon is regular in pore shape, uniform in distribution and applicable to the fields such as lithium batteries, solar batteries, semiconductors and sensors. The method is strong in process maneuverability, low in cost, high in yield and applicable to industrialized mass production.

Owner:南京卓胜自动化设备有限公司

Luminous antibacterial aqueous inner wall coating and preparation method and application thereof

InactiveCN101967324AThe implementation process is simpleGood antibacterial and antifungal effectCovering/liningsAntifouling/underwater paintsEmulsionPhosphonium salt

The invention discloses a luminous antibacterial aqueous inner wall coating and a preparation method and application thereof. The formula of the luminous antibacterial aqueous inner wall coating comprises the following components in part by weight: 30 to 60 parts of film-forming emulsion, 5 to 50 parts of luminous pigment, 5 to 40 parts of white pigment and filler, 0.5 to 15 parts of montmorillonoid filler, 0.1 to 5 parts of auxiliary agent and 5 to 15 parts of water. In the coating, aluminate long-afterglow luminous material subjected to surface treatment is used as the luminous pigment, pillared montmorillonite of loaded germicide quaternary phosphonium salt is used as antibacterial filler, and acrylic acid emulsion is used as base resin; and the multifunctional inner wall coating with good luminous, antibacterial and waterproof properties is obtained by adding the auxiliary agent. The coating is endowed with excellent luminous, antibacterial and mildew-proof properties based on the traditional inner wall coating; the preparation process is simple and feasible; the raw materials have low cost; and the coating can be used for large-area decoration of multiple places, combines the traditional decoration and emergency indication or weak light illumination functions, and has good industrialized value and broad application prospect.

Owner:JINAN UNIVERSITY

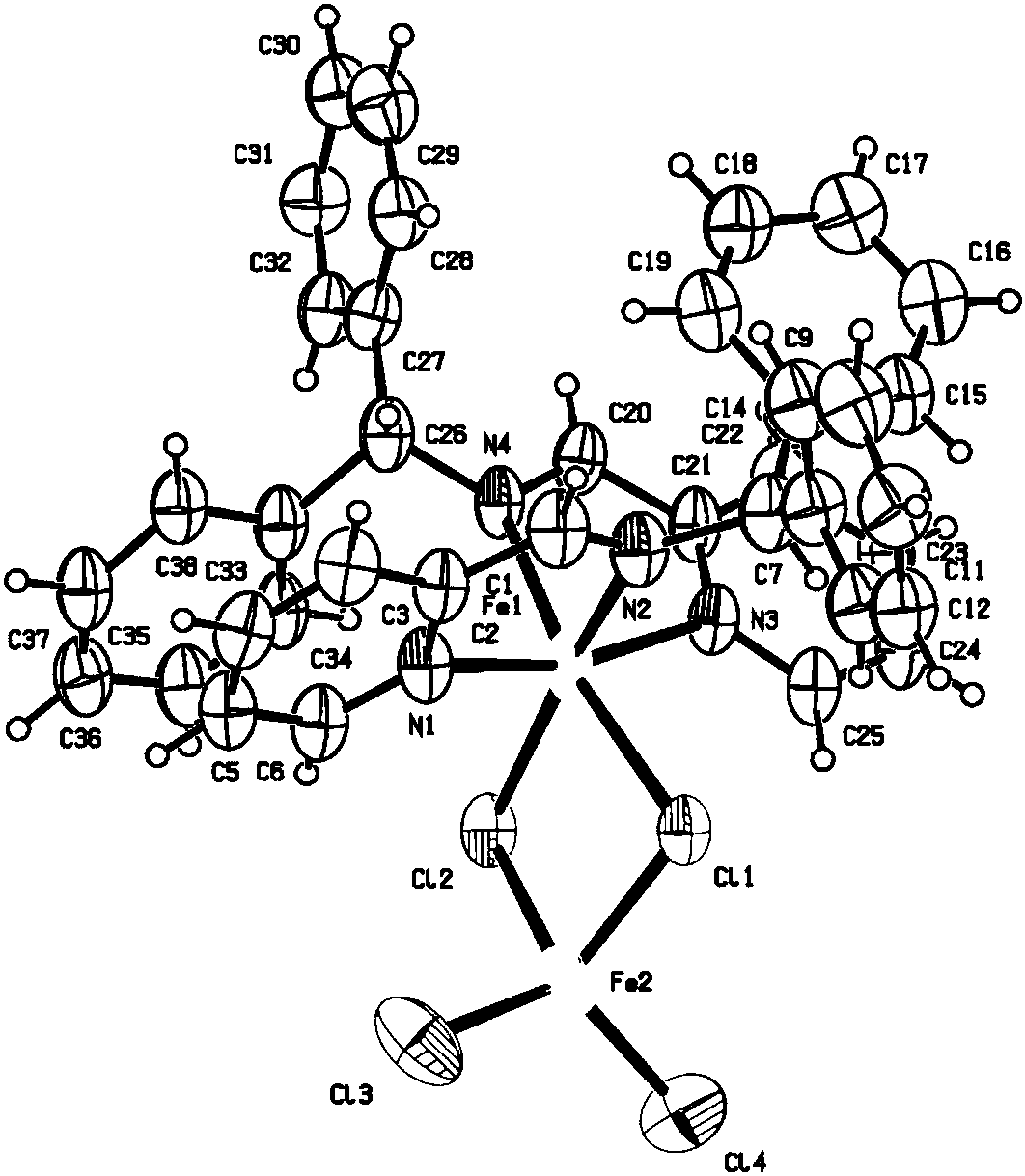

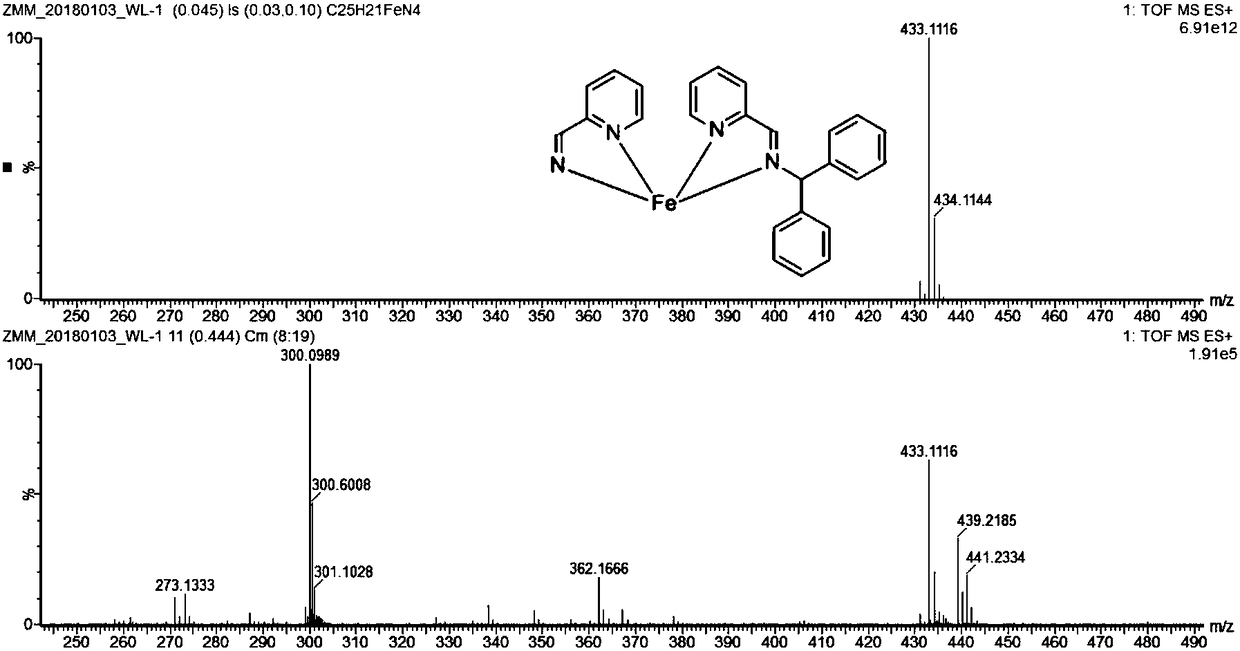

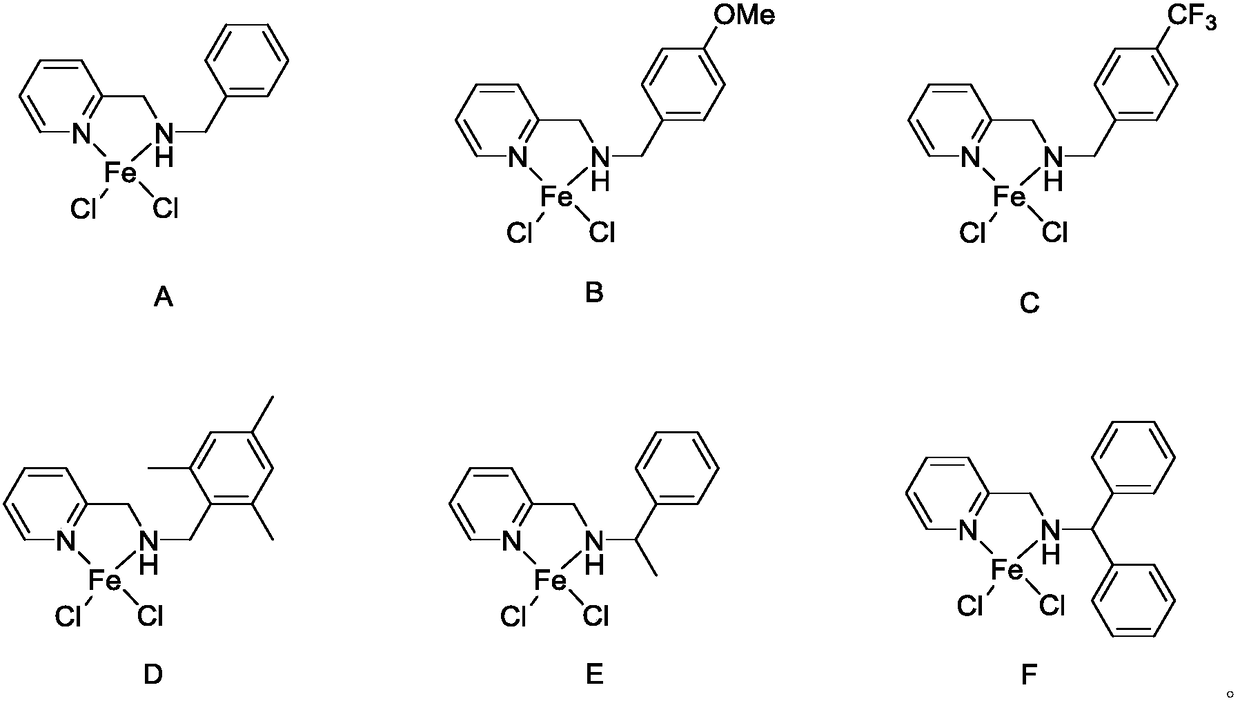

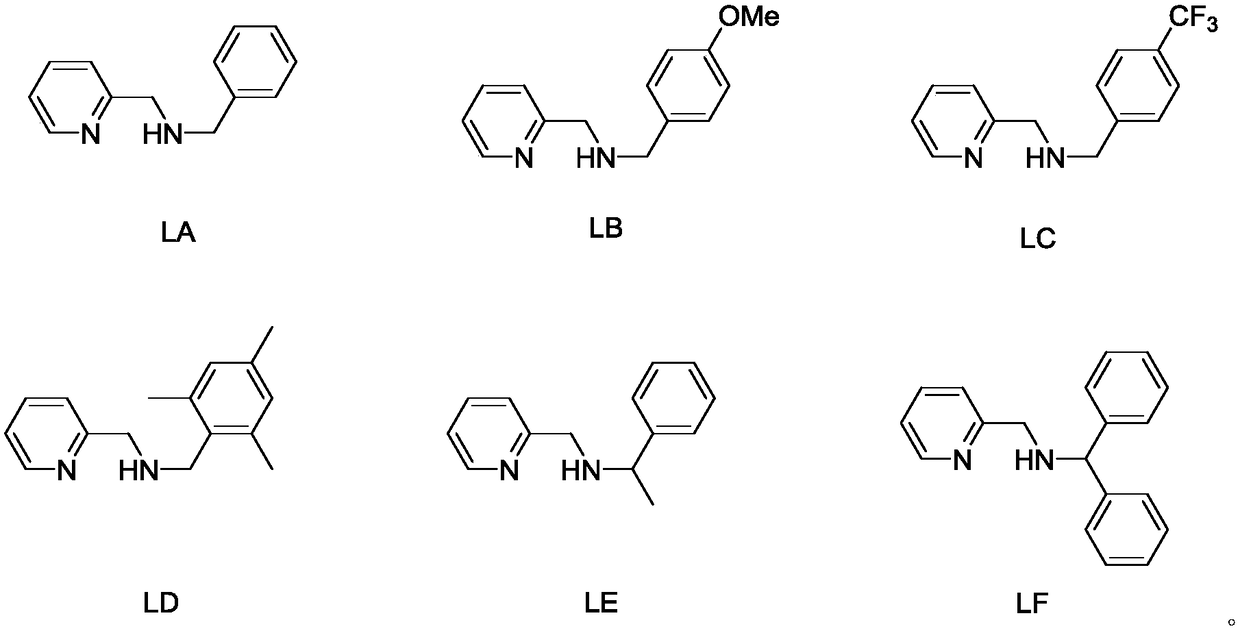

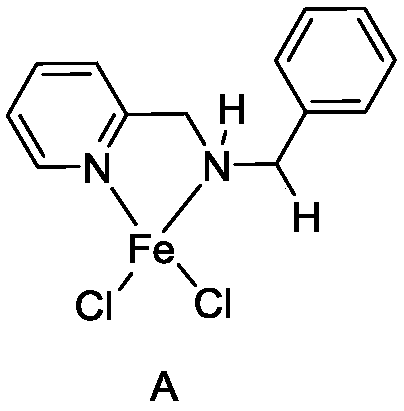

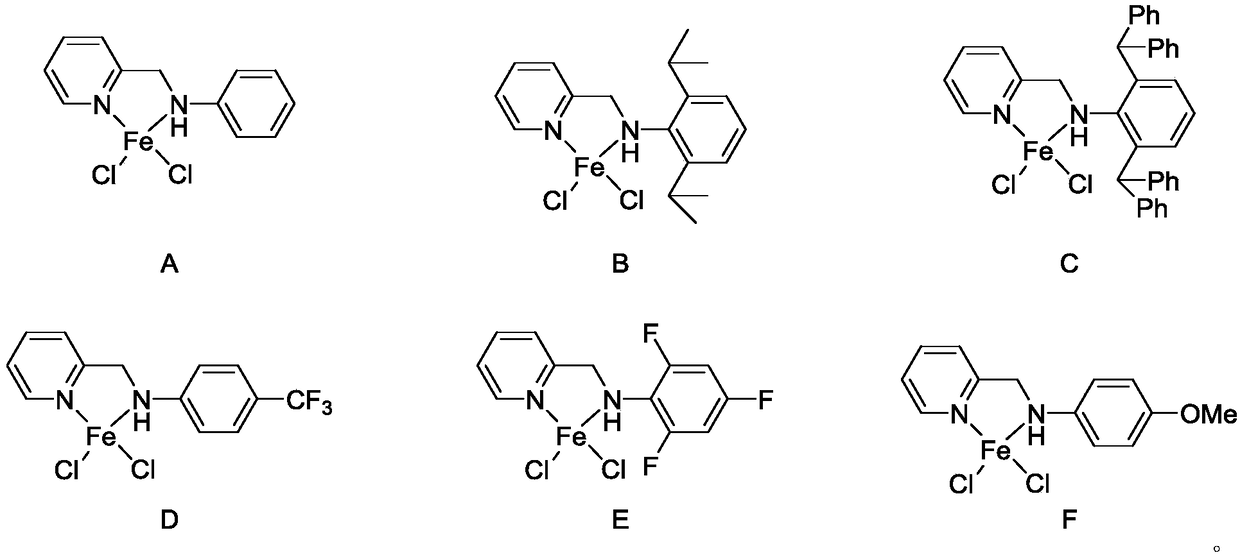

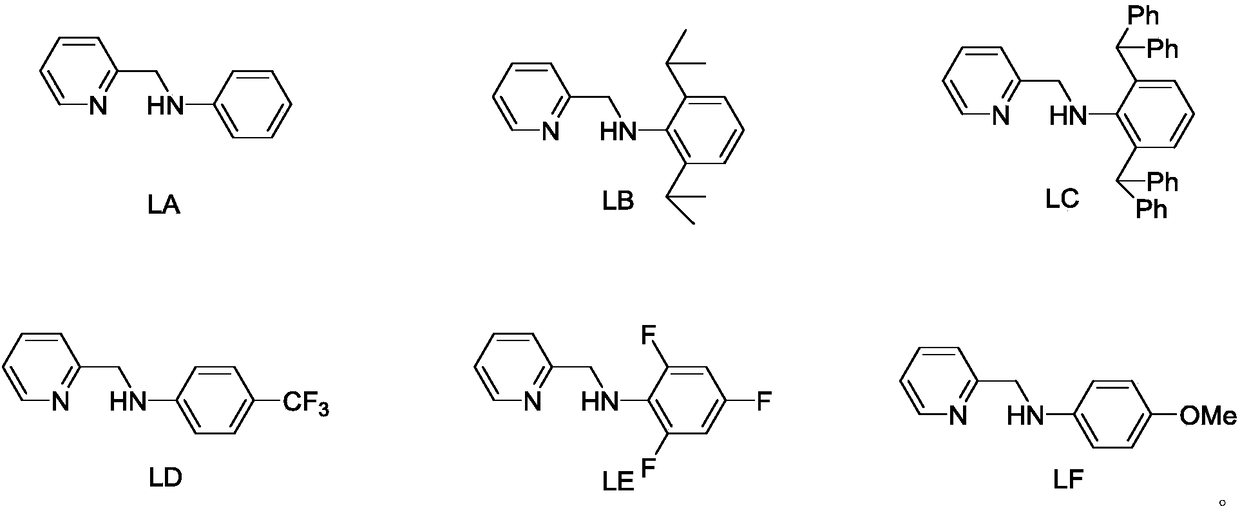

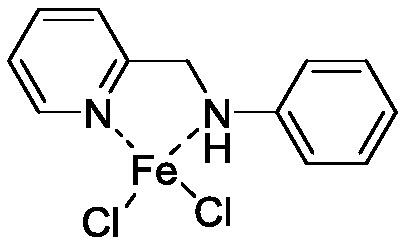

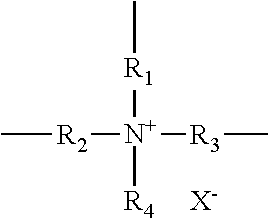

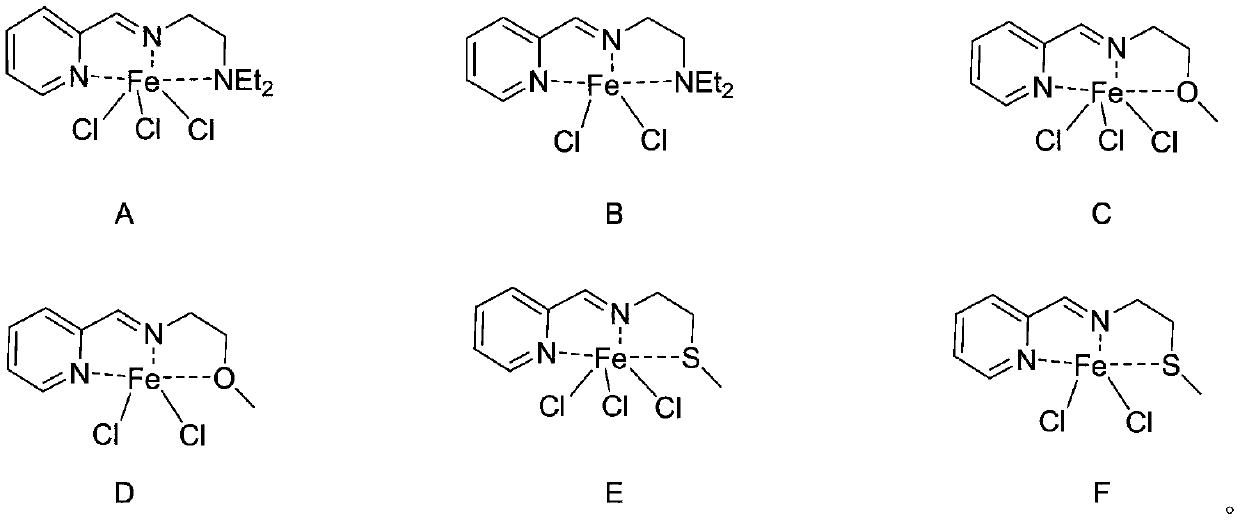

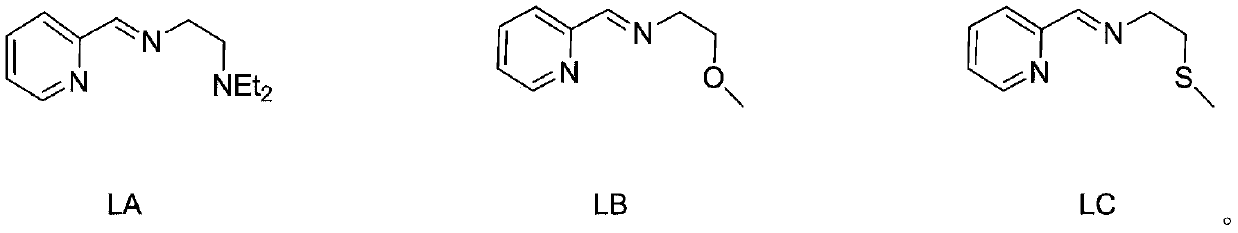

Efficient iron series catalyst for catalyzing isoprene polymerization as well as preparation method and application thereof

ActiveCN108586641AEasy to prepareConvenient sourceIron group organic compounds without C-metal linkagesPyridineIsoprene

The invention discloses an efficient iron series catalyst for catalyzing isoprene polymerization as well as a preparation method and application thereof, and relates to the technical field of conjugated diene catalytic synthesis. The catalyst is prepared from iron pyridine compounds and methylaluminoxane. The preparation raw materials of the catalyst are simple and can be easily obtained; the costis low. When the catalyst is used for catalyzing isoprene polymerization, the ultrahigh activity is shown; the obtained polymers have high molecular weight; the molecular weight distribution is narrow; meanwhile, the structure of a main catalyst can be regulated and controlled by regulating ligands; the polymer structure can be further regulated in controllable way; in the same reaction, the influence of cocatalysts, the temperature and the main catalyst quantity on the reaction selectivity is not great.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

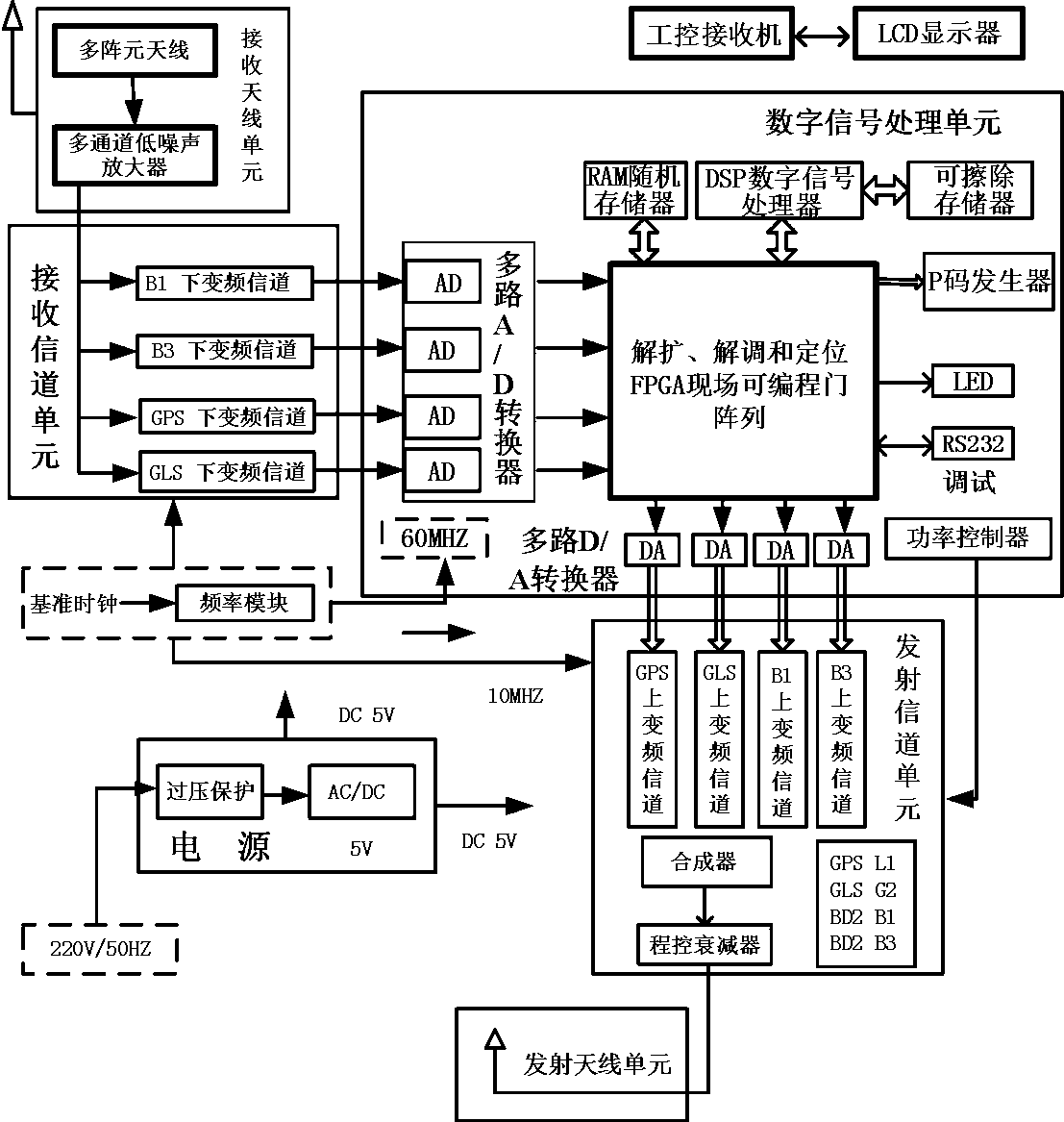

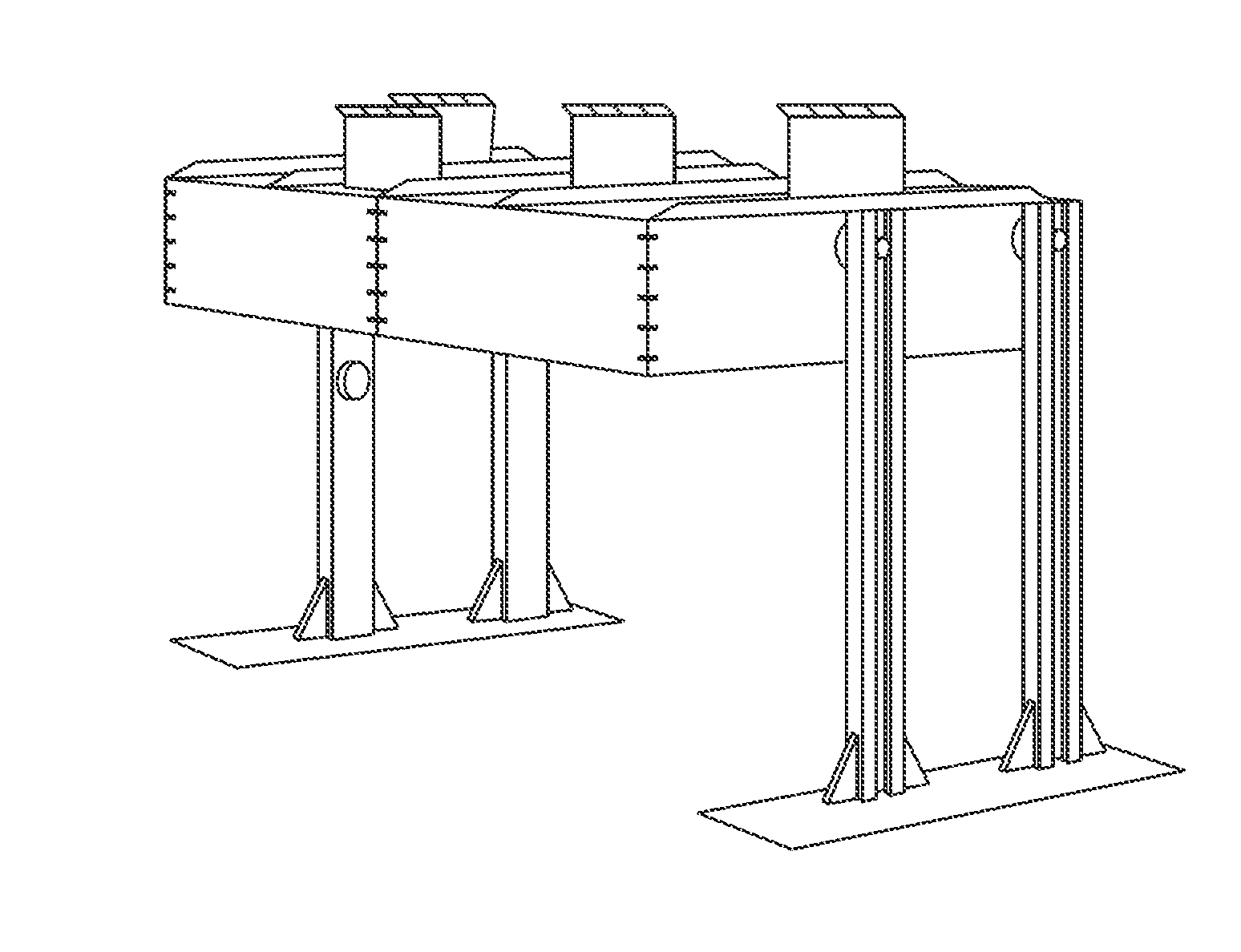

Monitoring simulator for transponding satellite signals

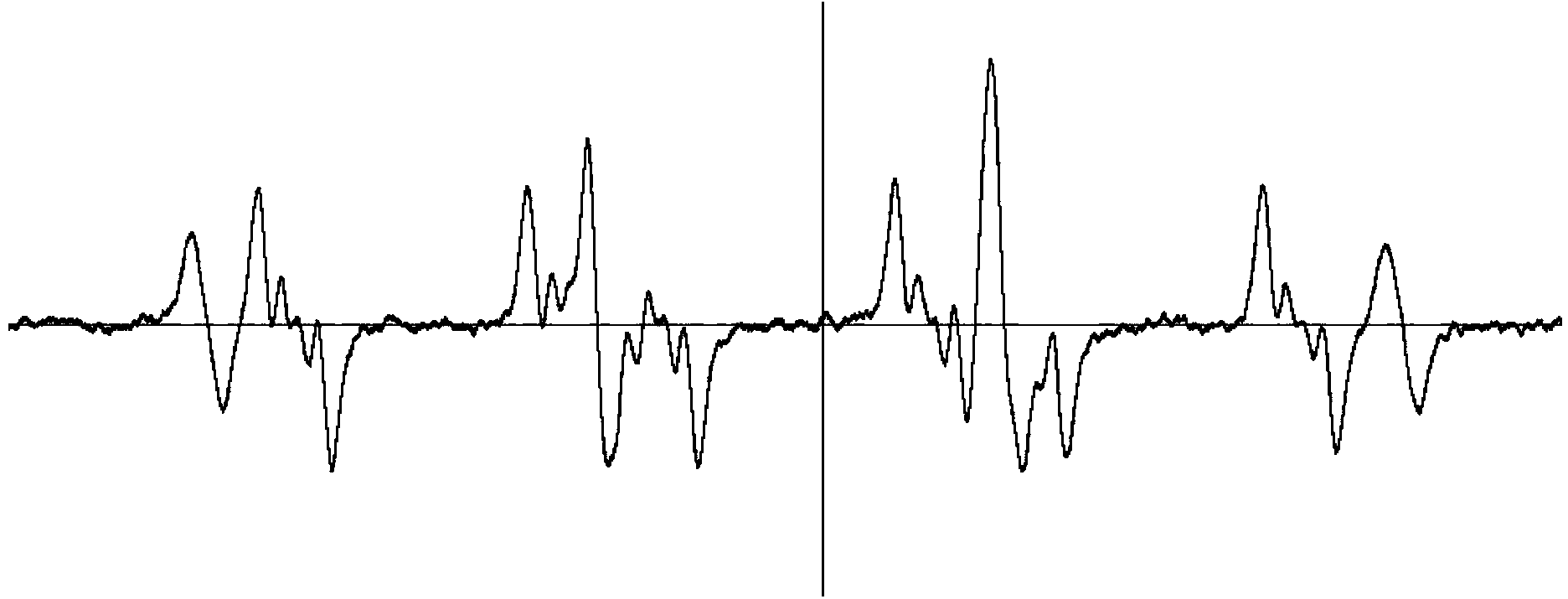

InactiveCN103684633ASolve the problem of noise interferenceSubstantiveRadio transmissionTransmission monitoringDigital signal processingPersonal computer

The invention discloses a monitoring simulator for transponding satellite signals. The monitoring simulator comprises a receiving antenna unit, a receiving channel unit, a transmitting channel unit, a transmitting antenna unit, a power source, an industrial personal computer and a digital signal processing unit. The receiving antenna unit is connected with the receiving channel unit. The receiving channel unit is connected with the digital signal processing unit. The digital signal processing unit is connected with the transmitting channel unit. The transmitting channel unit is connected with the transmitting antenna unit. The transmitting channel unit, the digital signal processing unit and the receiving channel unit are connected with the power source respectively. The digital signal processing unit is connected with the industrial personal computer. By the monitoring simulator, the problem of noise interference of the transponding satellite signals is effectively solved, and trackability of the transponding satellite signals is guaranteed.

Owner:CHENGDUSCEON TECH

3,3',5,5'-tetramethyl-4,4'-biphenyldiglycid ether preparation method

InactiveCN1733745AReduce processing viscosityImprove solubilityOrganic chemistryPolymer scienceEther

The invention relates to a process for preparing 3,3',5,5'-tetramethyl-4,4'-biphenyl didycidyl ether, wherein the 3,3',5,5'-tetramethyl-4,4'-biphenol is reacted with excess epichlorohydrin under the action of phase transition catalyst. The prepared has low epoxy equivalent weight, high yield, and simple reaction steps.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

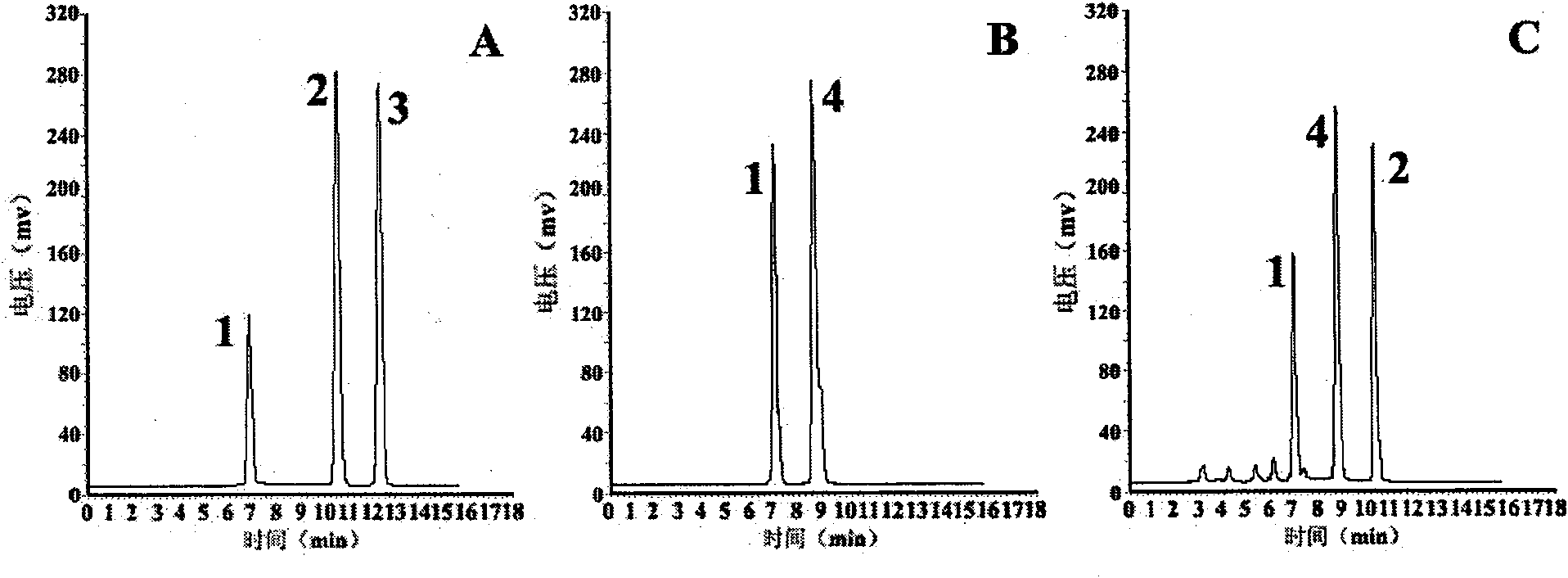

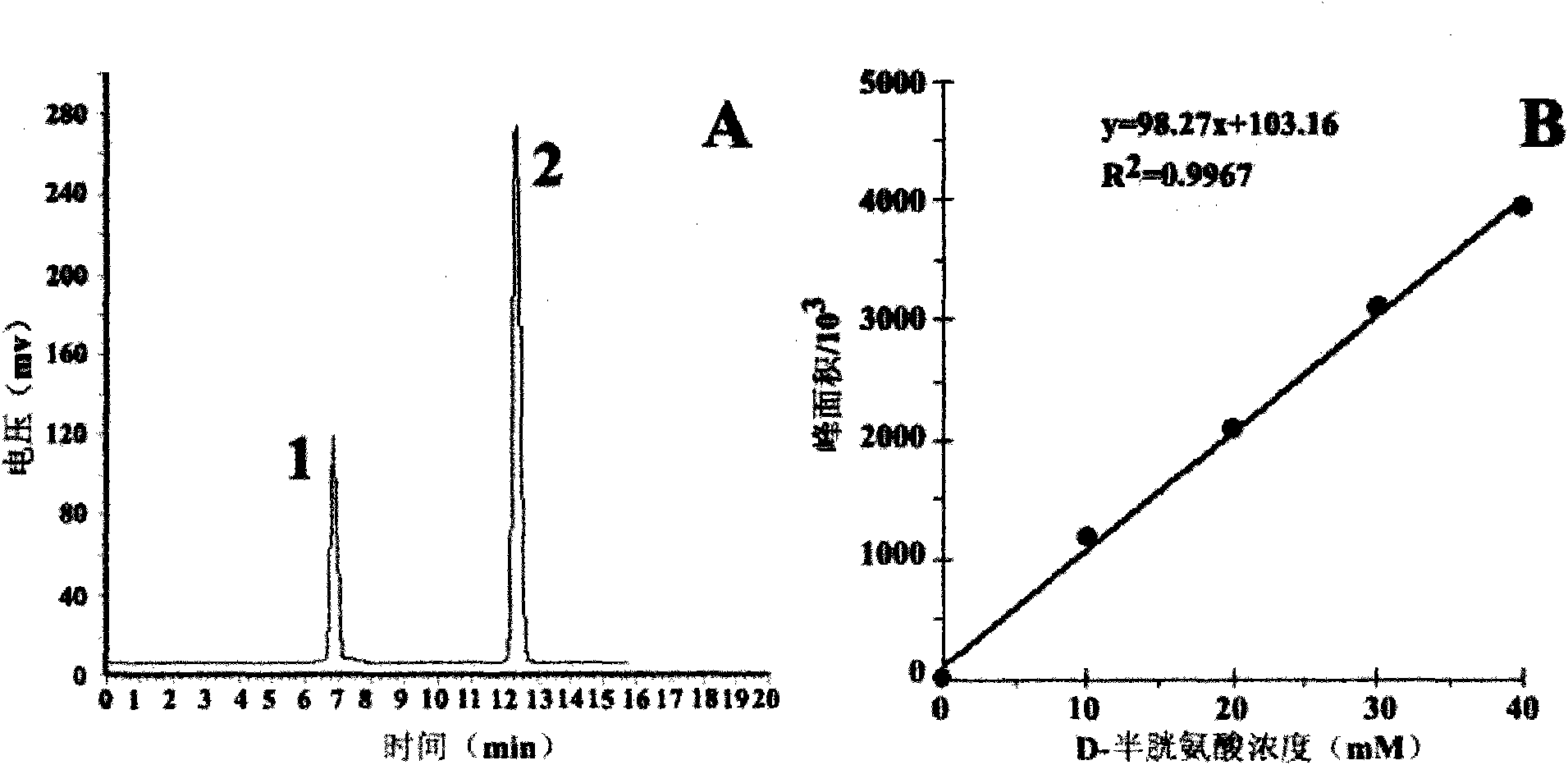

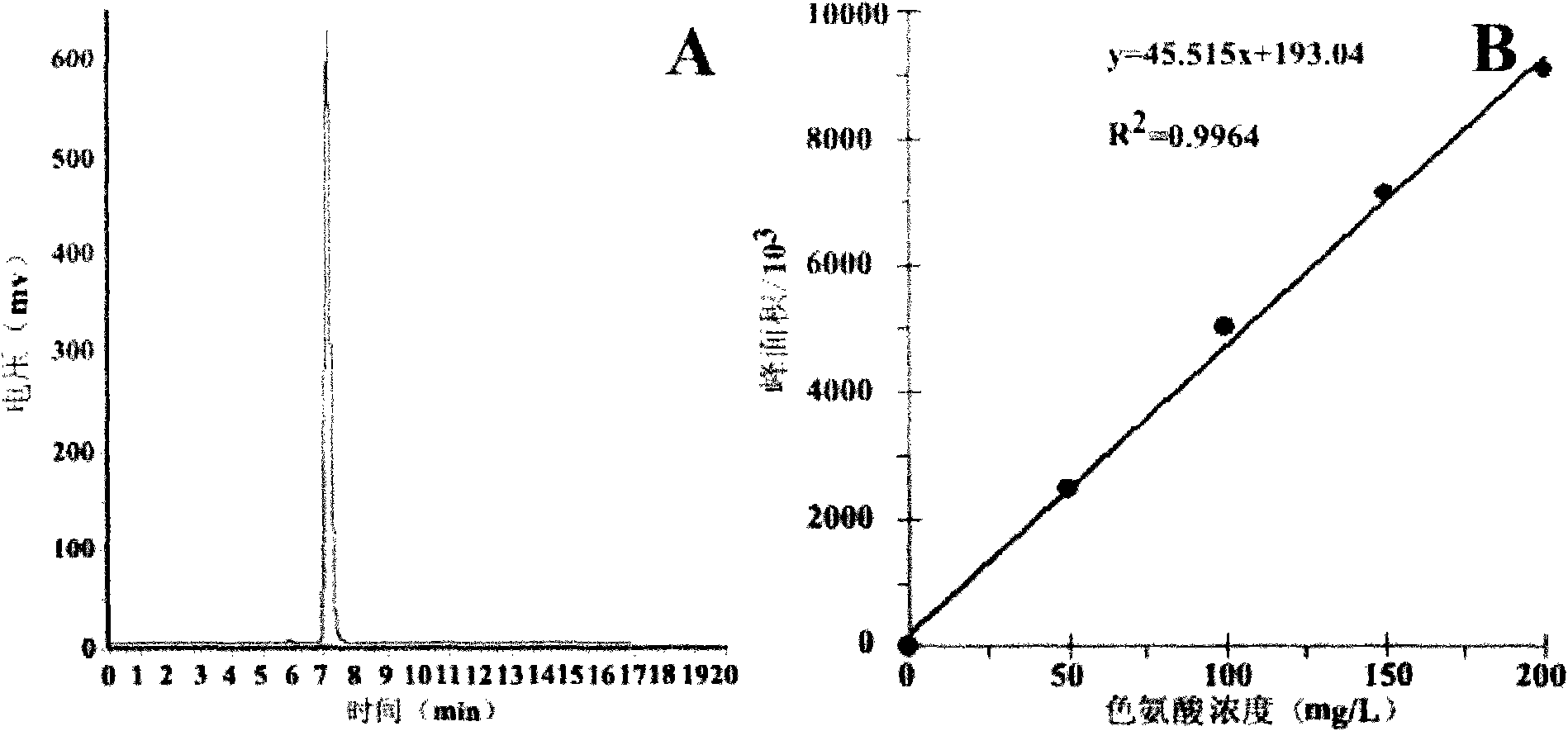

Method for preparing D-cystine and L-tryptophane by using DL-cysteine split by microbial enzyme method

InactiveCN101812488AHigh catalytic efficiencyGood temperature toleranceMicroorganism based processesFermentationMicrobial enzymesTryptophanase

The invention discloses a method for preparing D-cystine and L-tryptophane by using DL-cysteine split by a microbial enzyme method. The method comprises the following steps of: splitting the DL-cysteine to produce D-cysteine and L-tryptophane through an enzymatic reaction by using fermentation liquor of recombined Bacillus subtillis which efficiently express tryptophanase as an enzyme source and using the DL-cysteine and indole as a substrate; and oxidizing the enzymatic reaction liquor to ensure that the D-cysteine is oxidized into D-cystine, then regulating pH to be 5 and performing isoelectric point crystallization to separate the D-cystine out, and collecting the precipitation to obtain the D-cystine. A method for purifying the L-tryptophane comprises the following steps of: removing the residual indole from the supernatant which is subjected to the isoelectric point crystallization by adopting an S-8 type macroporous resin, then absorbing the L-tryptophane in the supernatant by adopting an NKA-II type macroporous resin, eluting by using 50 percent ethanol, reducing pressure, concentrating and drying to obtain the L-tryptophane. The invention provides a novel process route of green production of the D-cystine and the L-tryptophane.

Owner:天津启仁医药科技有限公司

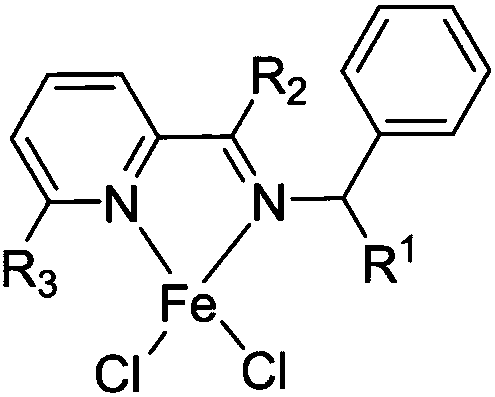

Alkyl-substituted pyridinamine iron-based catalyst and preparation method and application thereof

The invention discloses an alkyl-substituted pyridinamine iron-based catalyst and a preparation method and application thereof, and relates to the technical field of catalytic polymerization of conjugated diene. The alkyl-substituted pyridinamine iron-based catalyst consists of a main catalyst and an auxiliary catalyst, wherein the main catalyst is an alkyl-substituted pyridinamine iron-based complex, the auxiliary catalyst is methylaluminoxane or aluminum alkyl, and the molar ratio of the main catalyst to the auxiliary catalyst is 50:1 to 2000:1. The alkyl-substituted pyridinamine iron-basedcatalyst has superhigh activity in the polymerization of isoprene, so that the obtained polymer has high molecular weight and narrower molecular weight distribution; the micro-structure of the polymercan be regulated and controlled by adjusting the structure of the main catalyst; the reaction activity is determined by the main catalysts of different substitution groups and the auxiliary catalystsof different types.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

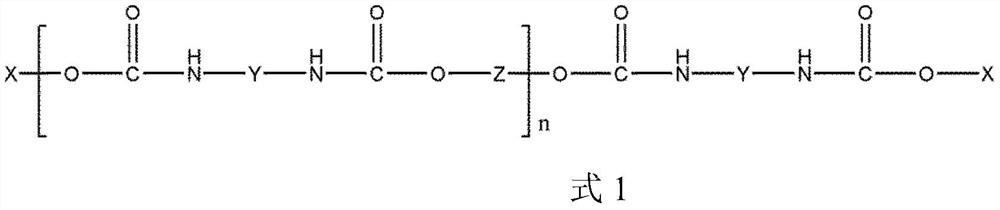

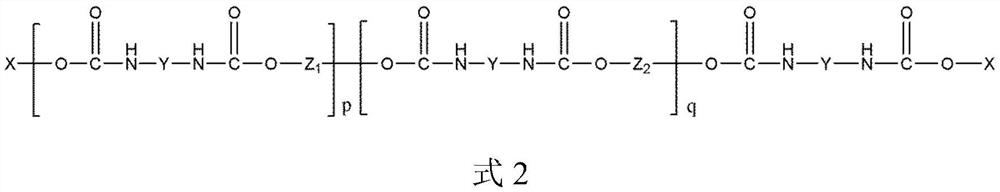

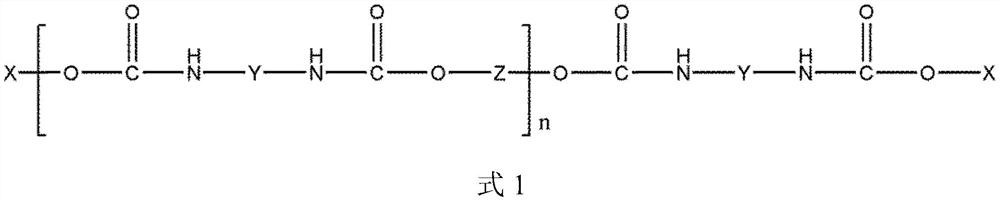

Urethane acrylate resin and preparation method thereof

ActiveCN112048051AIncrease elasticityGood value for moneyPolyurea/polyurethane coatingsPolyesterEndcapping

The invention discloses urethane acrylate resin and a preparation method thereof. According to the method, polyurethane acrylate resin is prepared through reaction of organic isocyanate and polyesterpolyol and end capping of hydroxyalkyl acrylate, when the prepared resin is applied to the field of ultraviolet curing coatings, the shrinkage rate of a paint film in the curing process is low, and the cured paint film has excellent elasticity and is low in cost.

Owner:WANHUA CHEM BEIJING +1

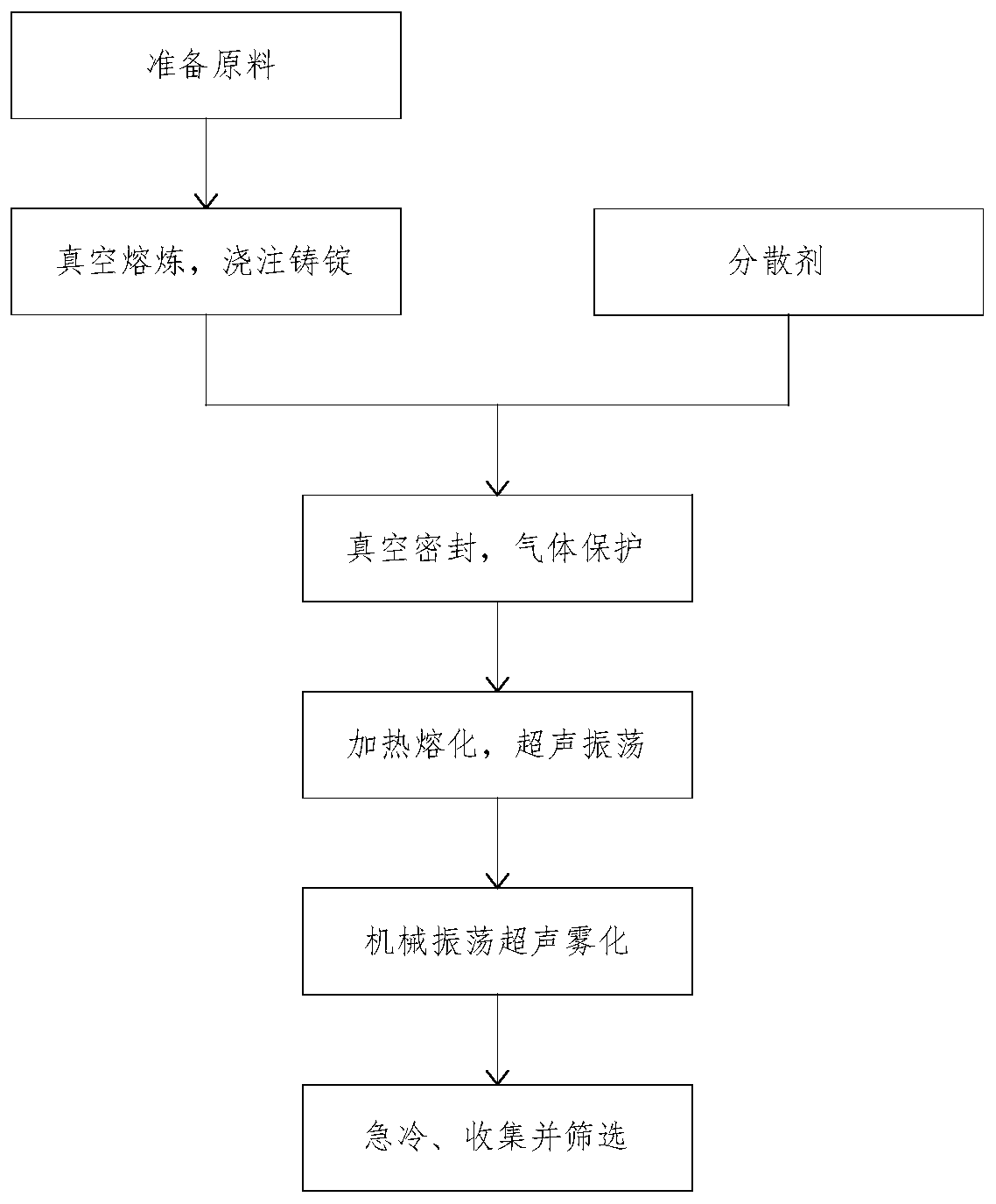

Low-melting-point metal powder as well as preparation method and application thereof

The invention discloses low-melting-point metal powder as well as a preparation method and application thereof. The preparation method comprises the following steps that after low-melting-point metaland a dispersing agent are heated and melted under an oxygen-free condition, ultrasonic oscillation is conducted to obtain a mixed solution, ultrasonic atomization treatment is conducted on the mixedsolution, and quenching is conducted and then the low-melting-point metal powder is obtained; the prepared low-melting-point metal powder can be applied to silk-screen printing, 3D printing and low-melting-point metal electronic pulped raw materials. The metal powder prepared by the preparation method is fine in particle size, good in sphericity, low in cost and prone to popularize the industrialproduction; the metal powder prepared by the preparation method is suitable for traditional printing methods such as the silk-screen printing, can be widely applied to the fields of novel printing ofthe 3D printing, can be widely applied to the fields of preparation of various low-melting-point metal electronic pulped raw materials, the field of phase change materials and even the field of biological medical treatment, so that the application range of the low-melting-point metal is greatly expanded, and the industrial value of the metal powder and the application is remarkable.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

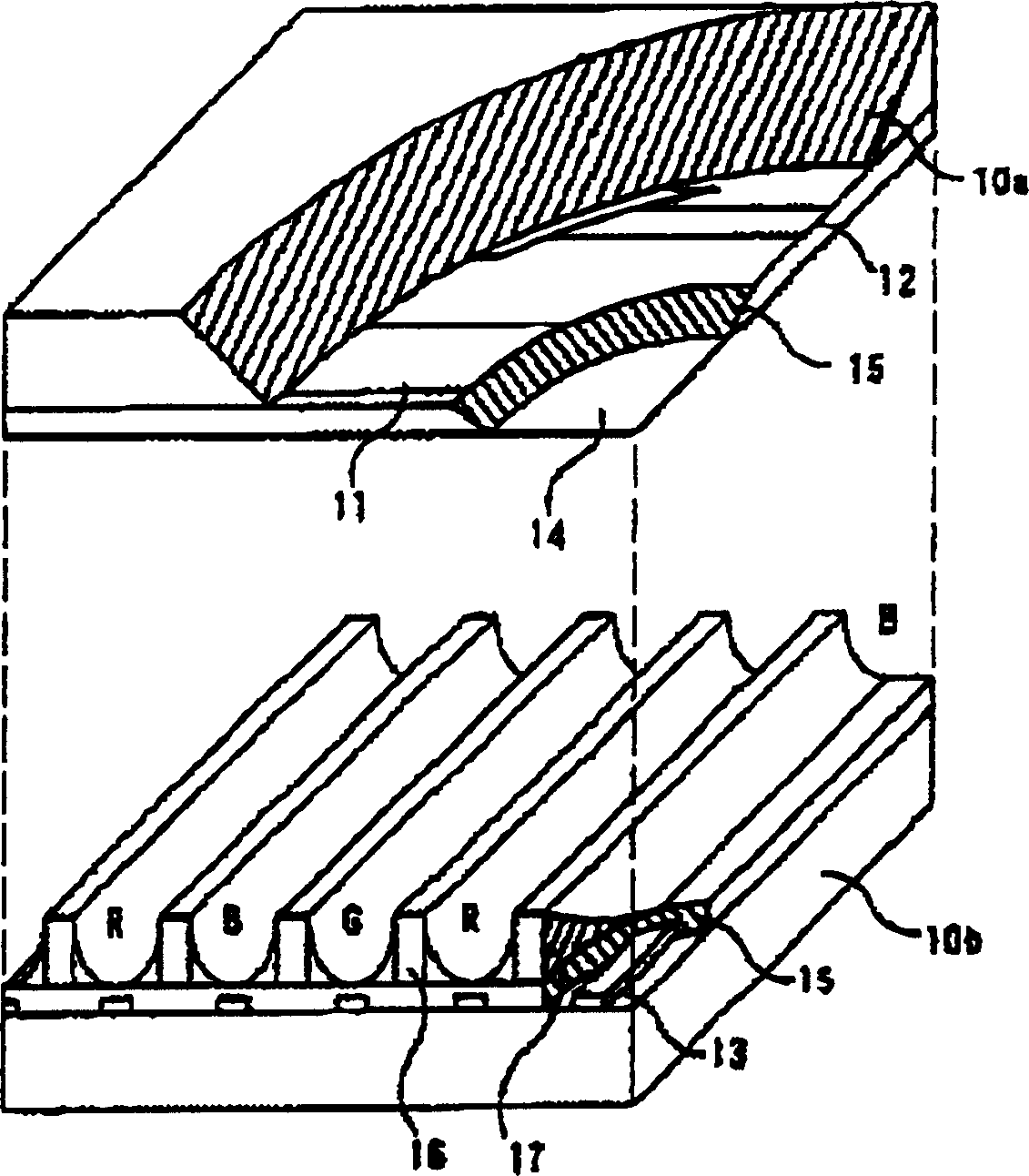

Glass composition and glass pulp composition

InactiveCN1840496ACurb bendingGood industrial valueGas discharge electrodesImage/pattern display tubesAlkali metal oxideFluorescence

PROBLEM TO BE SOLVED: To provide a glass composition which is used for forming a dielectric body or a partition wall of a plasma display panel, a fluorescent indicator tube or a field emission display, does not contain harmful matters and causes little environmental load, and to provide a glass paste composition which can greatly reduce the warping of the substrate by using this glass composition. ŽSOLUTION: The glass composition is one that does not substantially contain Pb and Bi and has a glass transition point of 430°C-540°C, and it is characterized by containing 1-15 mol% of SiO<SB>2< / SB>, 10-50 mol% of B<SB>2< / SB>O<SB>3< / SB>, 30-50 mol% of ZnO, 0-12 mol% of an oxide of an alkali metal:R<SB>2< / SB>O (in the formula, R exhibits at least one alkali metal selected from among K, Na and Li), and 3-20 mol% of BaO in terms of oxides. Ž

Owner:SUMITOMO METAL MINING CO LTD

Method for producing molten salt-grade sodium nitrate

ActiveCN106698483AGood industrial valueEasy to controlAlkali metal nitrate preparationEvaporationMolten salt

The invention discloses a method for producing molten salt-grade sodium nitrate, wherein the method comprises the following steps: step S1, a neutralization process: neutralizing a sodium carbonate solution and a nitric acid solution to form a first sodium nitrate raw material solution with the pH value of 3.5-4.5 and the mass percentage concentration of 23-28%; step S2, a carbon dioxide removal process: removing carbon dioxide in the first sodium nitrate raw material solution to form a second sodium nitrate raw material solution; step S3, an evaporation process: carrying out evaporation concentration on the second sodium nitrate raw material solution to obtain a third sodium nitrate raw material solution with the mass percentage concentration of 63-67%; step S4, a crystallization dehydration process: crystallizing and dehydrating the third sodium nitrate raw material solution to prepare a solid sodium nitrate raw material; and step S5, a drying process: drying the solid sodium nitrate raw material, to prepare the final product molten salt-grade sodium nitrate. The method can directly produce the high-purity molten salt-grade sodium nitrate, is simple and easy to control, can realize automatic production, and is suitable for safe, continuous, stable and rapid production of the high-purity sodium nitrate.

Owner:QINGHAI SALT LAKE IND

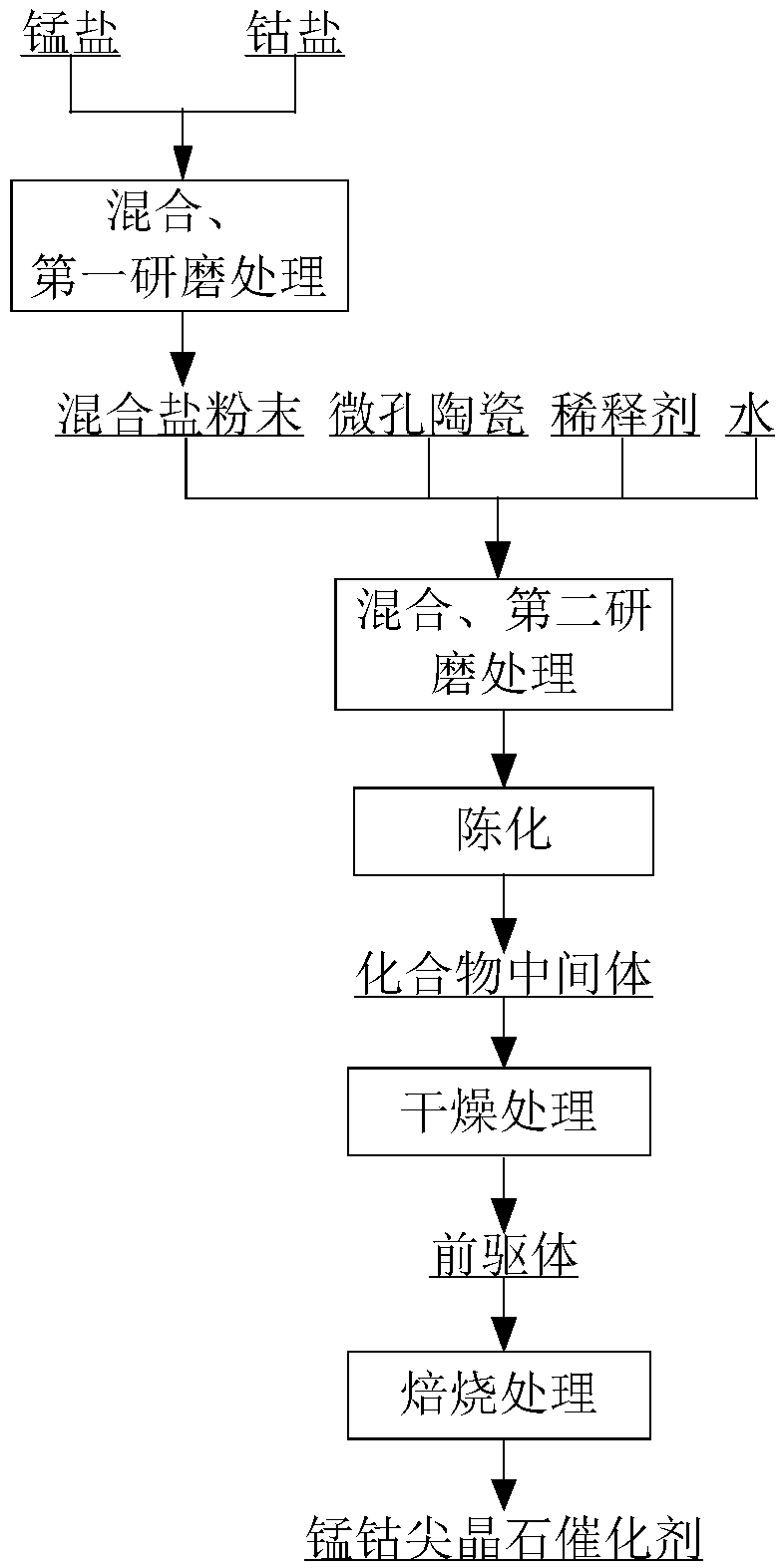

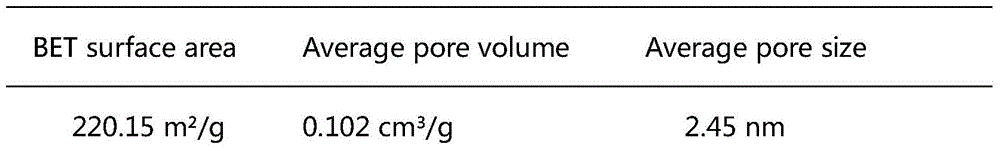

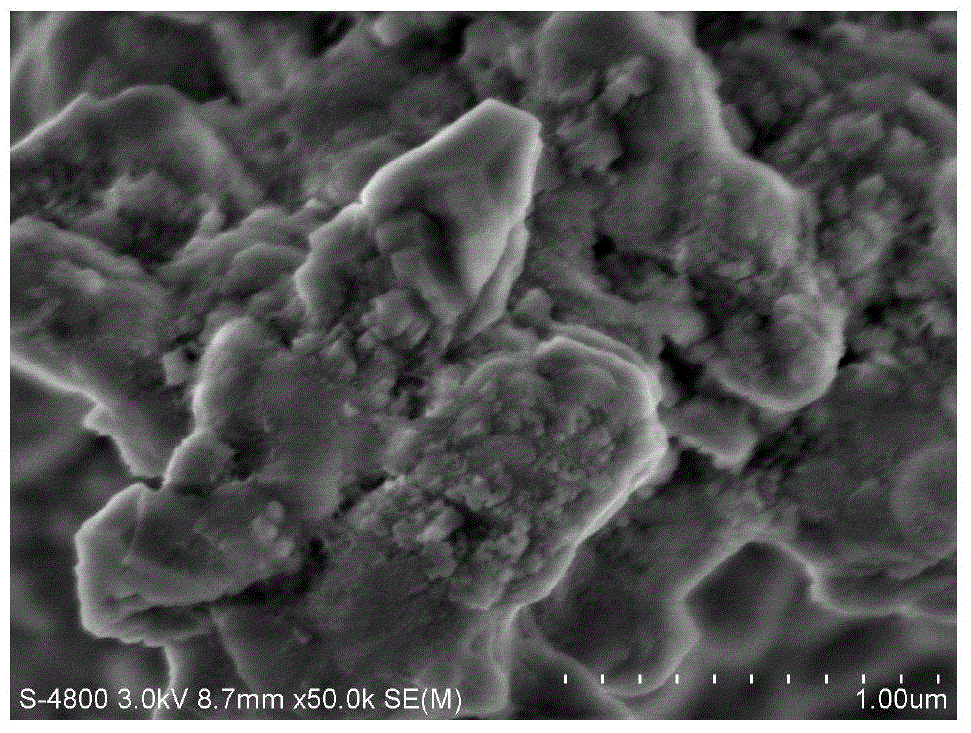

Manganese-cobalt spinel catalyst and preparation method thereof

InactiveCN108636422ALarge specific surface areaHigh mechanical strengthMetal/metal-oxides/metal-hydroxide catalystsActive componentSpinel

The invention discloses a manganese-cobalt spinel catalyst and a preparation method thereof. The manganese-cobalt spinel catalyst adopts manganese-cobalt spinel as an active component and microporousceramic as a carrier. The manganese-cobalt spinel catalyst not only has excellent mechanical strength, high-temperature resistance, alkali corrosion resistance and good storage stability, but also hasgood catalytic activity in oxygen reduction catalysis.

Owner:YUNNAN ALUMINUM

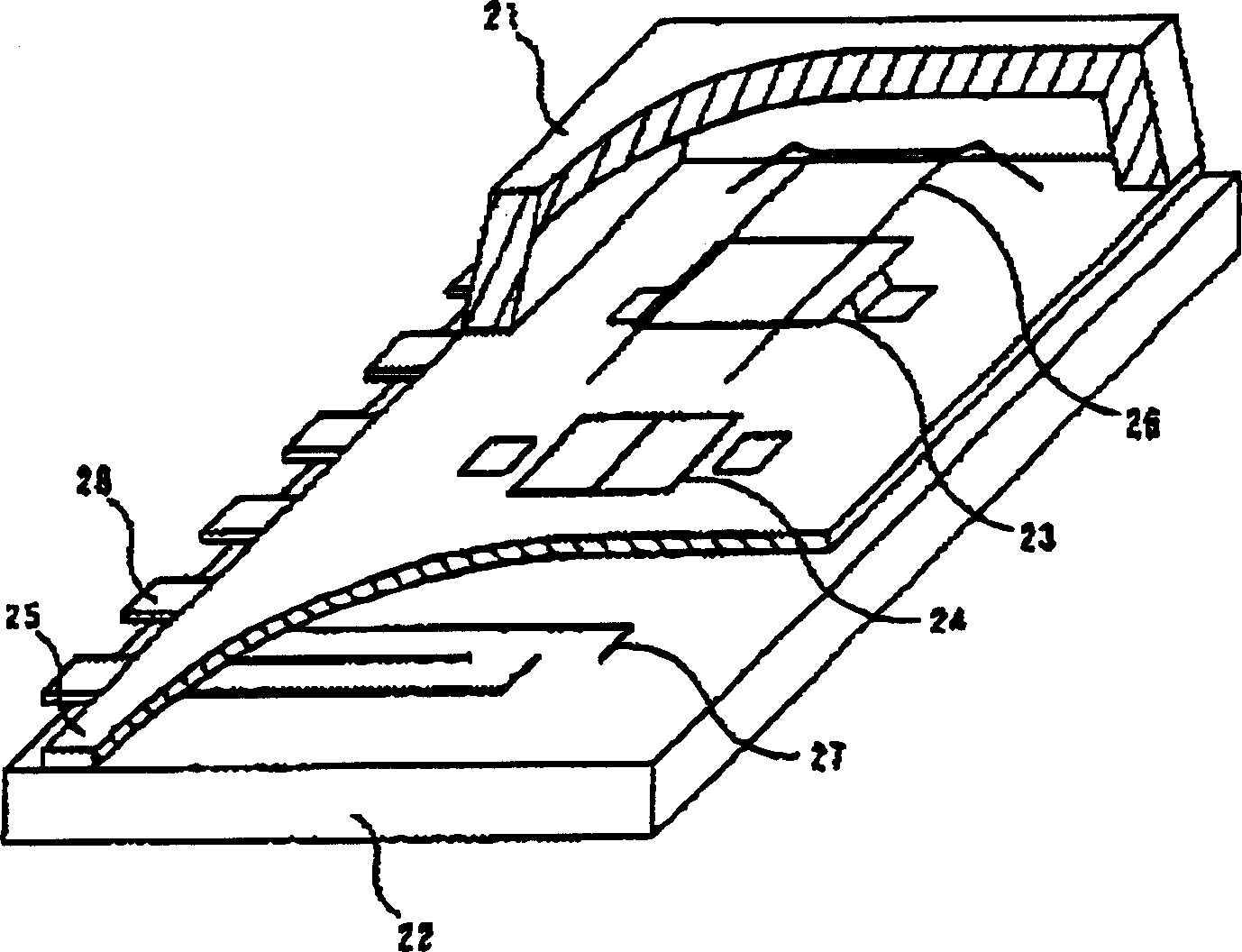

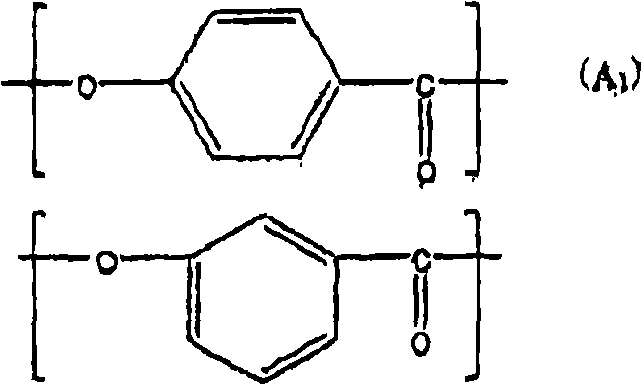

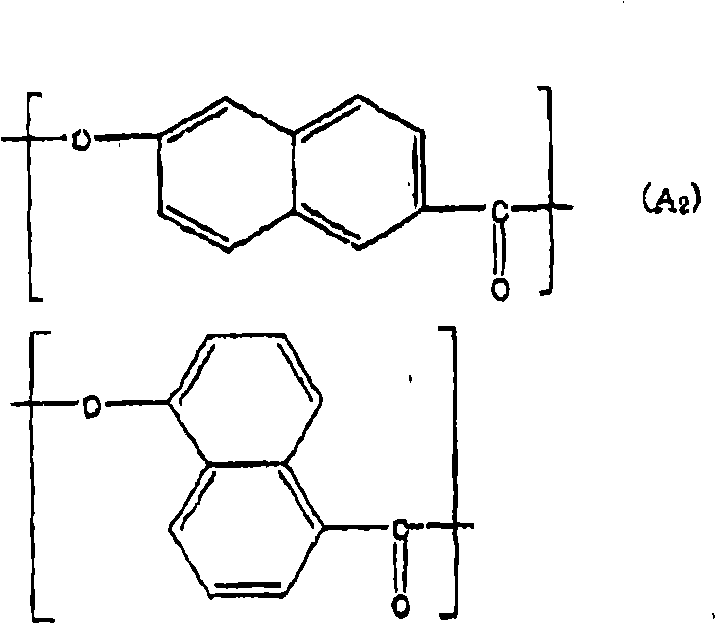

Liquid crystalline polyester resin composition and molded article thereof

InactiveCN101845203AInhibit breakageGood industrial valueLiquid crystal compositionsOptical record carriersChemistryElastic modulus

The present invention provides a liquid crystalline polyester resin composition suitable for an optical pickup unit. The composition comprises a liquid crystalline polyester, a mica and a hollow filler. Using the liquid crystalline polyester resin composition, an optical pickup unit with a high soldering resistance and a high torsional elastic modulus can be produced while suppressing breakage of the hollow filler in the composition.

Owner:SUMITOMO CHEM CO LTD

Algae-char-impact-tower-based mercury removal method and preparation method of algae char

InactiveCN104436994AImprove protectionEmission reduction benefits are obviousOther chemical processesDispersed particle separationFlue gasMercury adsorption

The invention relates to an algae-char impact-tower-based mercury removal method. The method comprises the following steps: performing pyrolysis on algae to prepare biomass char as a flue gas mercury removal adsorbent, and adsorbing and removing mercury in one impact tower reactor; recycling mercury resource and regenerating the adsorbent in a separator; cooling mercury-containing flue gas from a burner and spraying the flue gas into the impact tower reactor through a Laval spray pipe, spraying the algae char adsorbent into the impact tower reactor through the Laval spray pipes which are coaxially and oppositely arranged, and enabling two strands of gas flows to have opposite impact in the impact tower reactor so as to realize the adsorption and removal of mercury. When regeneration is performed in one impact tower reactor, flue gas from the burner is automatically switched and flows into the other impact tower reactor. The two impact tower reactors are alternatively used for performing regeneration. According to the method and the device, the biomass char is prepared by utilizing pyrolysis of algae and used for adsorbing and removing mercury, the removal process has no secondary pollution, the raw material of the adsorbent is a regenerative resource with wide reserves, and wide application prospects can be achieved.

Owner:南京朗洁环保科技有限公司

Aryl substituted pyridylamine iron-based catalyst and preparation method and application thereof

The invention discloses an aryl substituted pyridylamine iron-based catalyst and a preparation method and application thereof, and relates to the technical field of catalytic polymerization of conjugated diene. The iron-based catalyst comprises a main catalyst body and an auxiliary catalyst body, wherein the main catalyst body is an aryl substituted pyridylamine iron complex, the auxiliary catalyst body is methylaluminoxane or aluminum alkyl, and the molar ratio of the auxiliary catalyst body to the main catalyst body ranges from 100:1 to 2000:1. An iron-based catalyst system has high activityin isoprene polymerization, and an obtained polymer is high in molecular weight and narrow in molecular weight distribution. Meanwhile, the microstructure of the polymer can be controlled by adjusting the structure of the main catalyst body, and the reaction activity depends on main catalyst bodies with different substituent groups and different types of auxiliary catalyst bodies.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Surface treatment composition for coated steel sheet, surface treated plated steel sheet and method of production of same, and coated plated steel sheet and method of production of same

ActiveUS20160083590A1Excellent in overhang corrosion resistanceGood industrial valueGroup 4/14 element organic compoundsSynthetic resin layered productsVanadium CompoundsAqueous medium

An aqueous surface treatment composition for coated steel sheet securing sufficient working adhesion while causing the formation of a surface treatment layer imparting excellent overhang corrosion resistance even without containing chrome, that is, a surface treatment composition containing a specific organic silicon compound, hexafluorometallic acid, a urethane resin having specific cationic groups, a vanadium compound, and an aqueous medium and sufficiently securing working adhesion while imparting excellent overhang corrosion resistance by the urethane resin having cationic groups and a total amine value of specific values is provided.

Owner:NITTETABU STEEL SHEET CORP +1

Tridentate pyridyl imine iron-based catalyst and preparation method and application thereof

The invention discloses a tridentate pyridyl imide iron-based catalyst and a preparation method and application thereof, and relates to the technical field of conjugated diene catalytic polymerization. The iron-based catalyst consists of a main catalyst and a cocatalyst, the main catalyst is a tridentate pyridyl imide iron complex, and the cocatalyst is a methyl aluminoxane or alkyl aluminum. Theabove-mentioned iron catalytic system exhibits relatively high activity in isoprene polymerization, the obtained polymer has high molecular weight and relatively narrow molecular weight distribution,the micro-structure of the polymer can be controlled by adjusting the structure of the main catalyst, and the activity of the reaction depends on the main catalyst of different substituents and different kinds of the co-catalysts.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

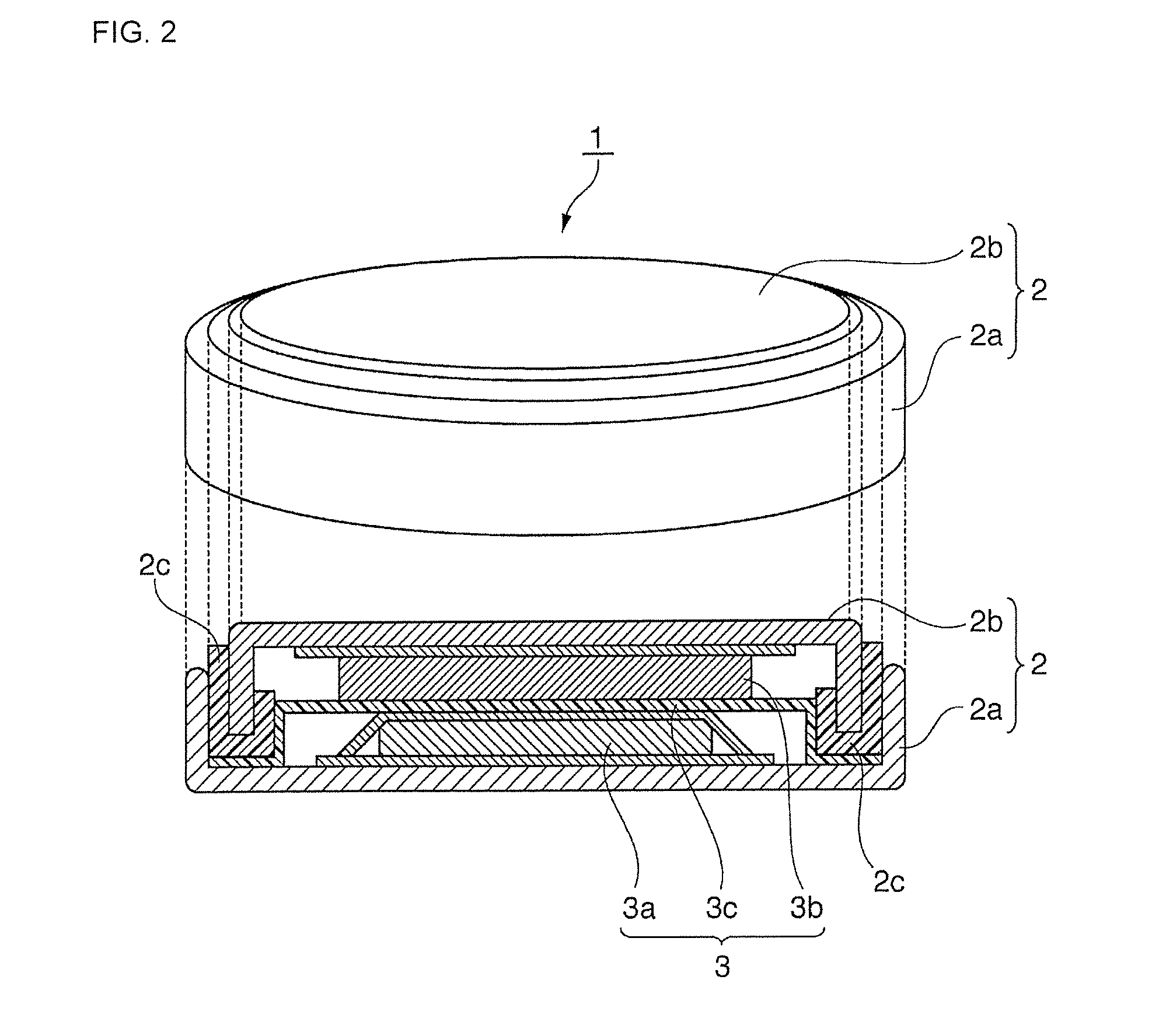

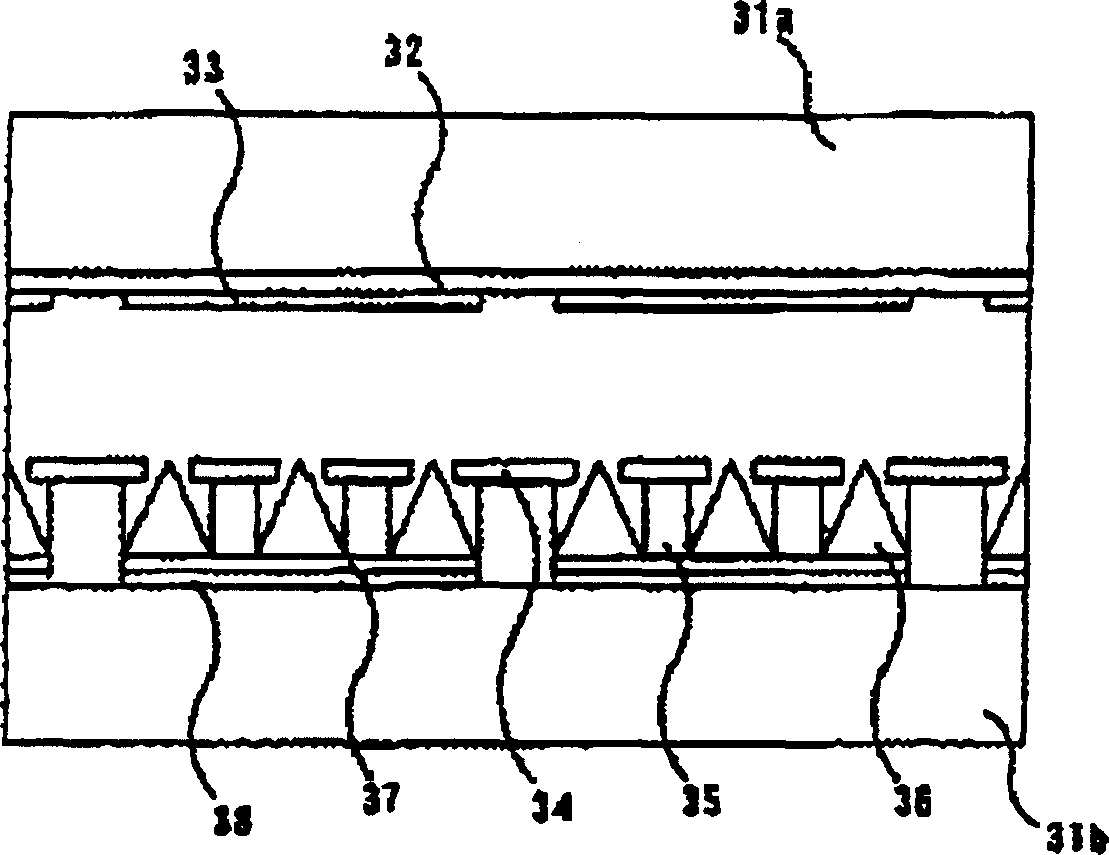

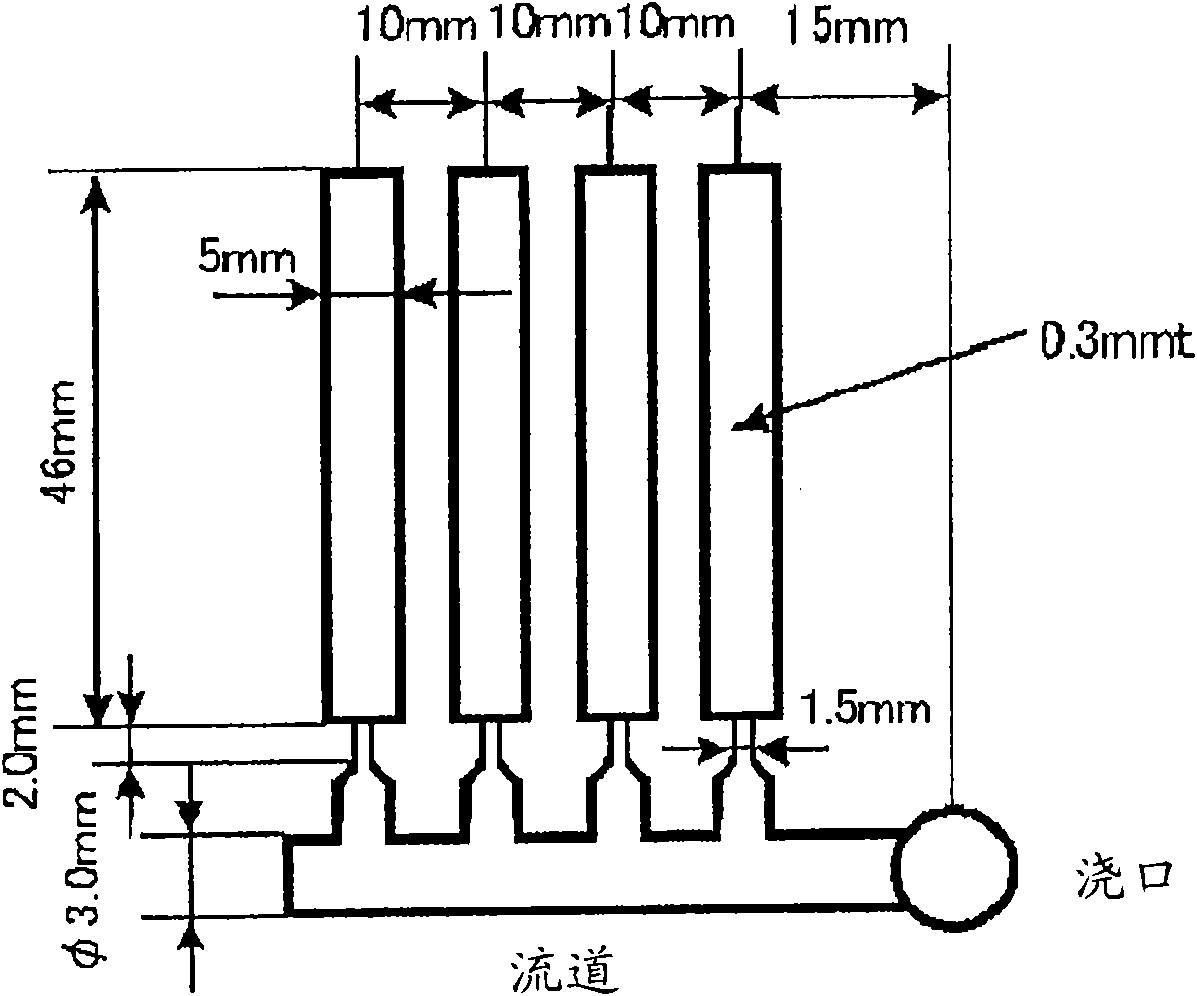

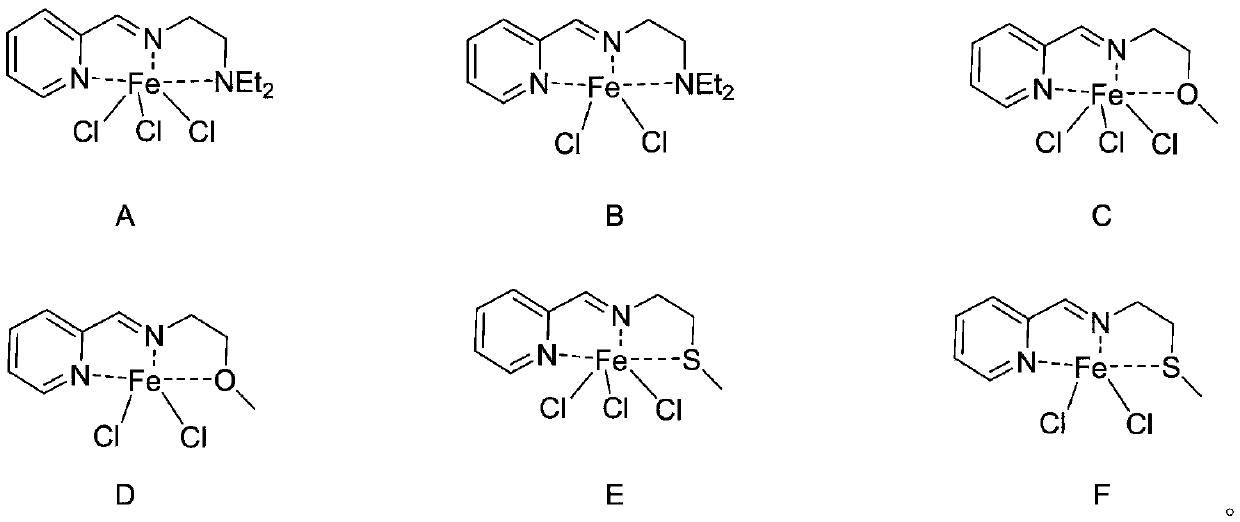

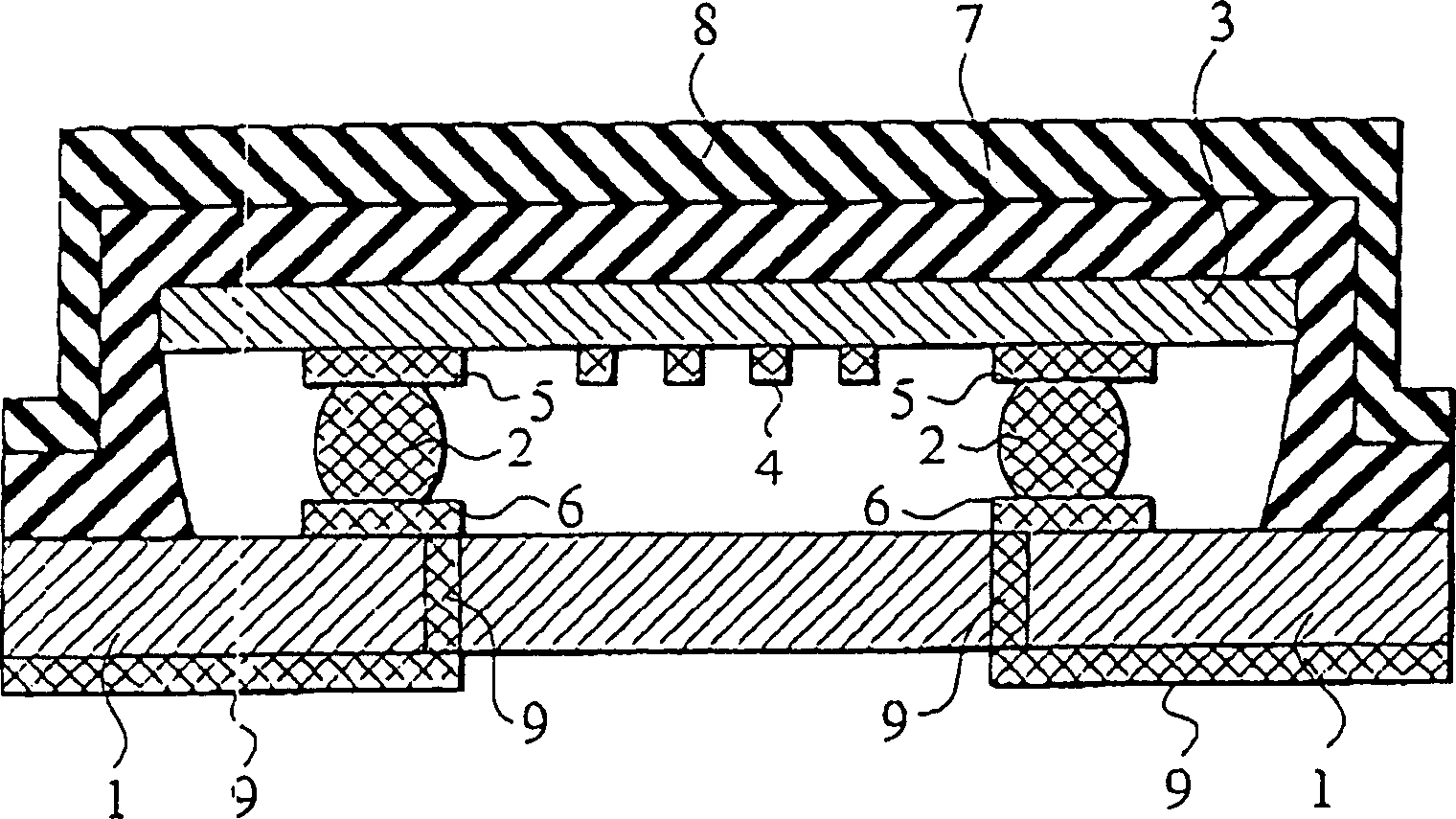

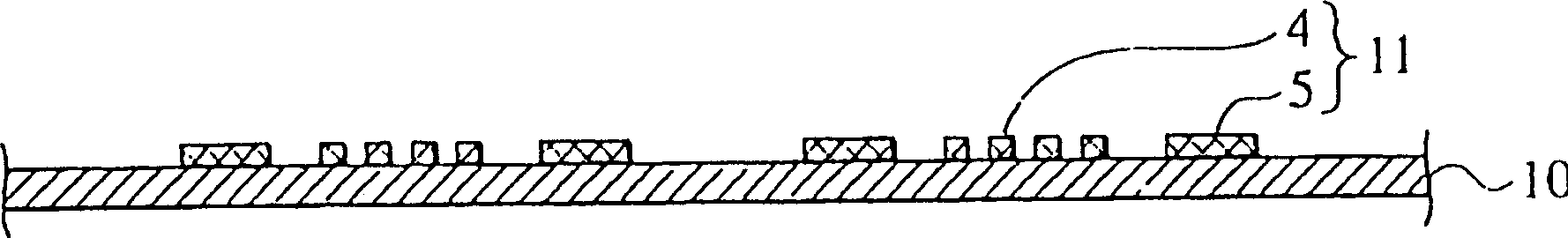

Surface acoustic wave device and method of manufacturing device

InactiveCN1440590AImprove production efficiencySufficient sealing functionImpedence networksSemiconductor/solid-state device detailsParticulatesSurface mounting

A surface acoustic wave device used in, for example, a mobile communications field as a filter or duplexer and the like to handle high frequencies of about several GHz is fabricated by flip-chip-connecting a surface of a piezoelectric substrate to a base board facing thereto, emitting particulate first sealing material from above a back face of the piezoelectric substrate to apply the first sealing material to the back face of the piezoelectric substrate and hang the first sealing material from edges of the piezoelectric substrate to the base board to form bridging, and forming second sealing material on the first sealing material. These operations provide a manufacturing method of a small-sized surface-mounting surface acoustic wave device appropriate for flip-chip connection.

Owner:KK TOSHIBA

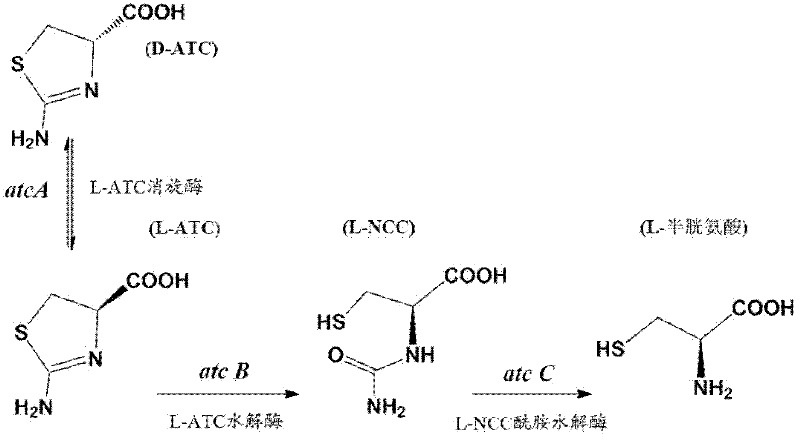

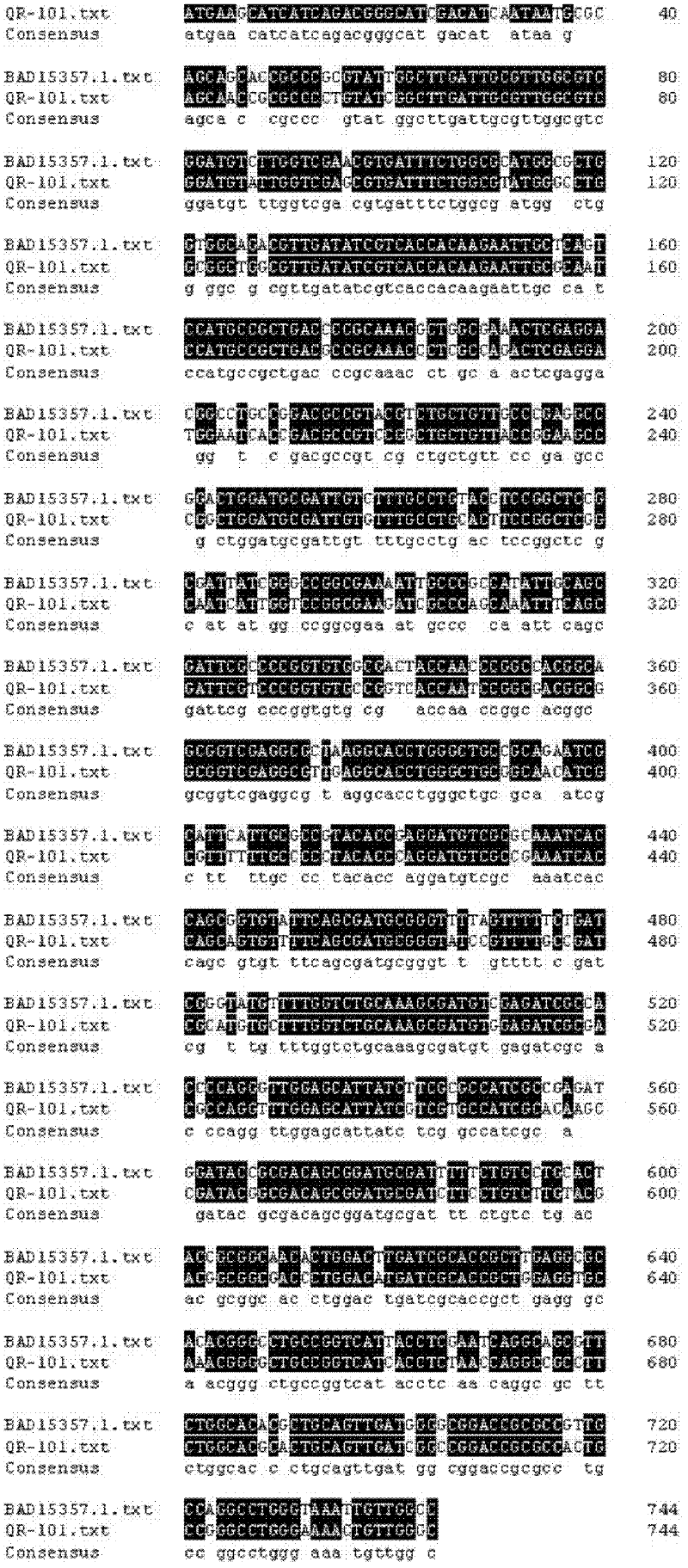

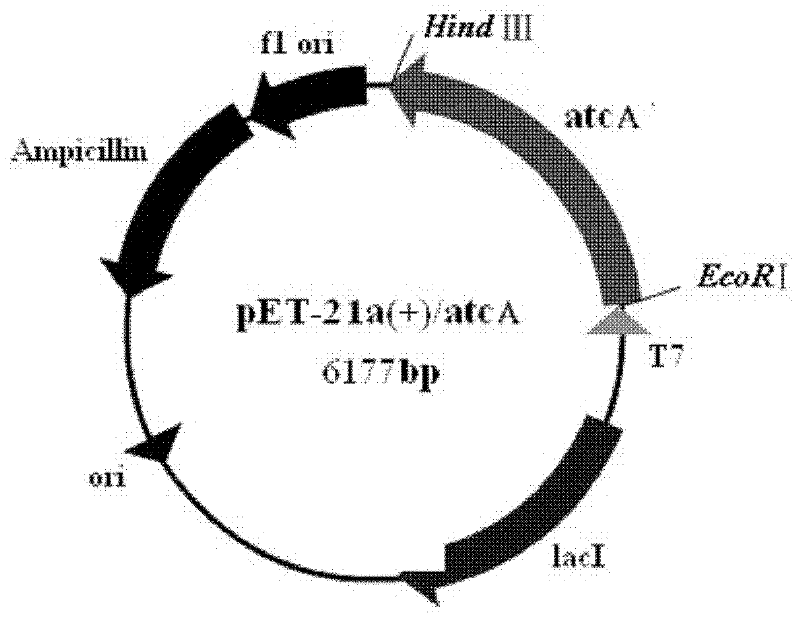

ATC racemase and coding gene thereof, and application of recombinant expression protein thereof

InactiveCN102417900ASingle ingredientHigh catalytic efficiencyBacteriaMicroorganism based processesNucleotideNucleotide sequencing

The invention discloses ATC racemase and a coding gene thereof, and a preparation method and an application of a recombinant expression protein thereof. The provided ATC racemase is derived from pseudomonas with a collection number of CGMCC No. 5315. The ATC racemase is a protein with an amino acid residue sequence represented by SEQ ID No.1 or a protein derived from that with an amino acid residue sequence represented by SEQ ID No.1, wherein the derived protein has a same activity with that of SEQ ID No.1, and the derived protein is derived from the protein with the amino acid residue sequence represented by SEQ ID No.1 through substitution, deletion and addition of one or more amino acid residues. The sequence of the coding gene is a nucleotide sequence represented by SEQ ID No.2 in the sequence list. According to the invention, an ATC racemase gene derived from pseudomonas is cloned and used for expressing and preparing recombinase. The recombinase can be used for catalytically separating DL-ATC into L-ATC with a biological method; the produced L-ATC can be used as a substrate in enzymatic production of L-cysteine.

Owner:天津启仁医药科技有限公司 +1

Preparation method for black abrasion-resistant micro-arc oxidization ceramic layer of magnesium alloy

ActiveCN108004581AImprove corrosion resistanceImprove stabilityAnodisationPlasma electrolytic oxidationPotassium fluoride

The invention provides a preparation method for a black abrasion-resistant micro-arc oxidization ceramic layer of a magnesium alloy. The magnesium alloy is dipped into electrolyte to be subjected to micro-arc oxidization so that the black abrasion-resistant micro-arc oxidization ceramic layer can be prepared; the electrolyte comprises 5-20 g / L of sodium silicate, 5-15 g / L of potassium fluoride, 1-60 g / L of potassium hydroxide, 5-25 g / L of triethanolamine, 2-6 g / L of ammonium meta-vanadate, 2-6 g / L of sodium orthovanadate, 2-10 g / L of nanometer SiC and 2-5 g / L of nanometer graphite. The black abrasion-resistant ceramic layer of the magnesium alloy can reach the level 9 according to 350 h of a neutral salt spray test, the Vickers hardness HV can reach 553-605, the friction coefficient is 0.08-0.14, the abrasion rate is 0.006-0.009 mg / min, the beneficial effects that stability is good, color is uniform and color fading is not prone to occurrence are all achieved, and the black abrasion-resistant micro-arc oxidization ceramic layer of the magnesium alloy is very suitable for preparing an optical collimator and other systems. The preparation method for the black abrasion-resistant micro-arc oxidization ceramic layer of the magnesium alloy is simple in technological process, convenient to operate, small in pollution and remarkable in industrial value.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

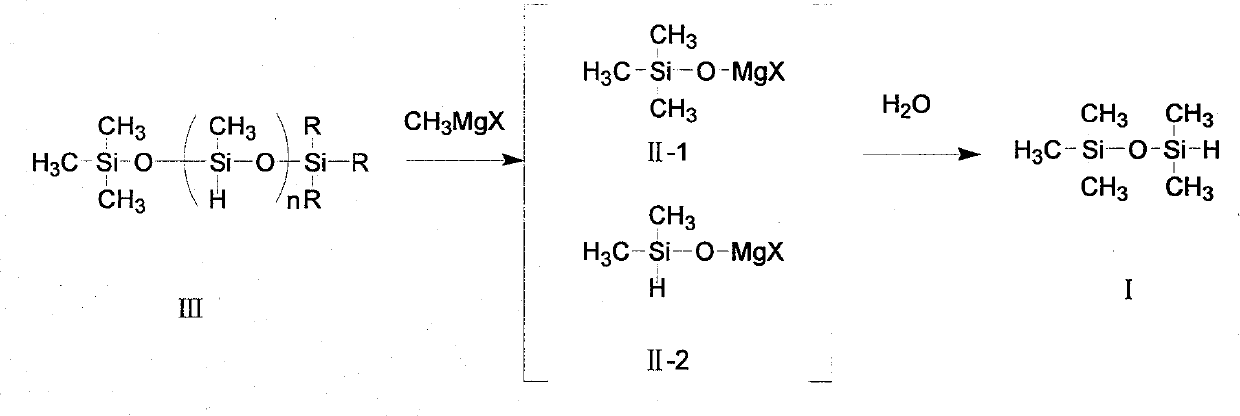

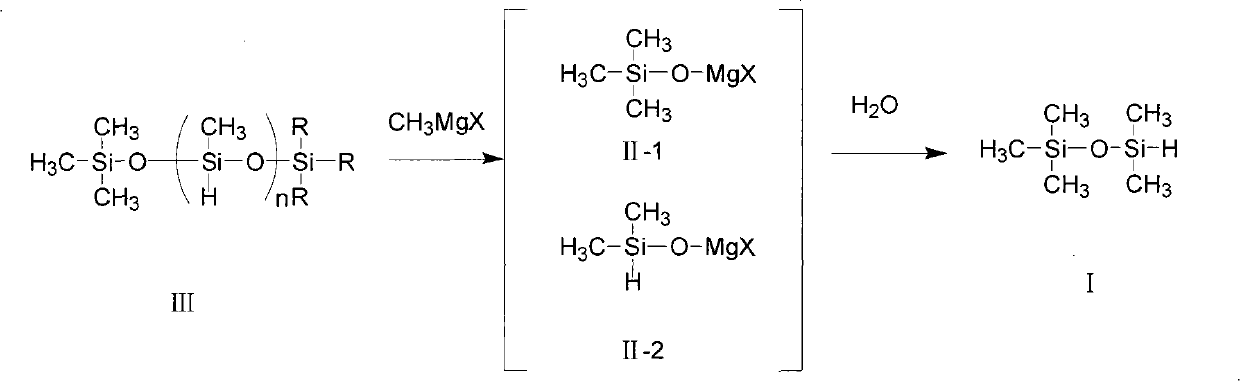

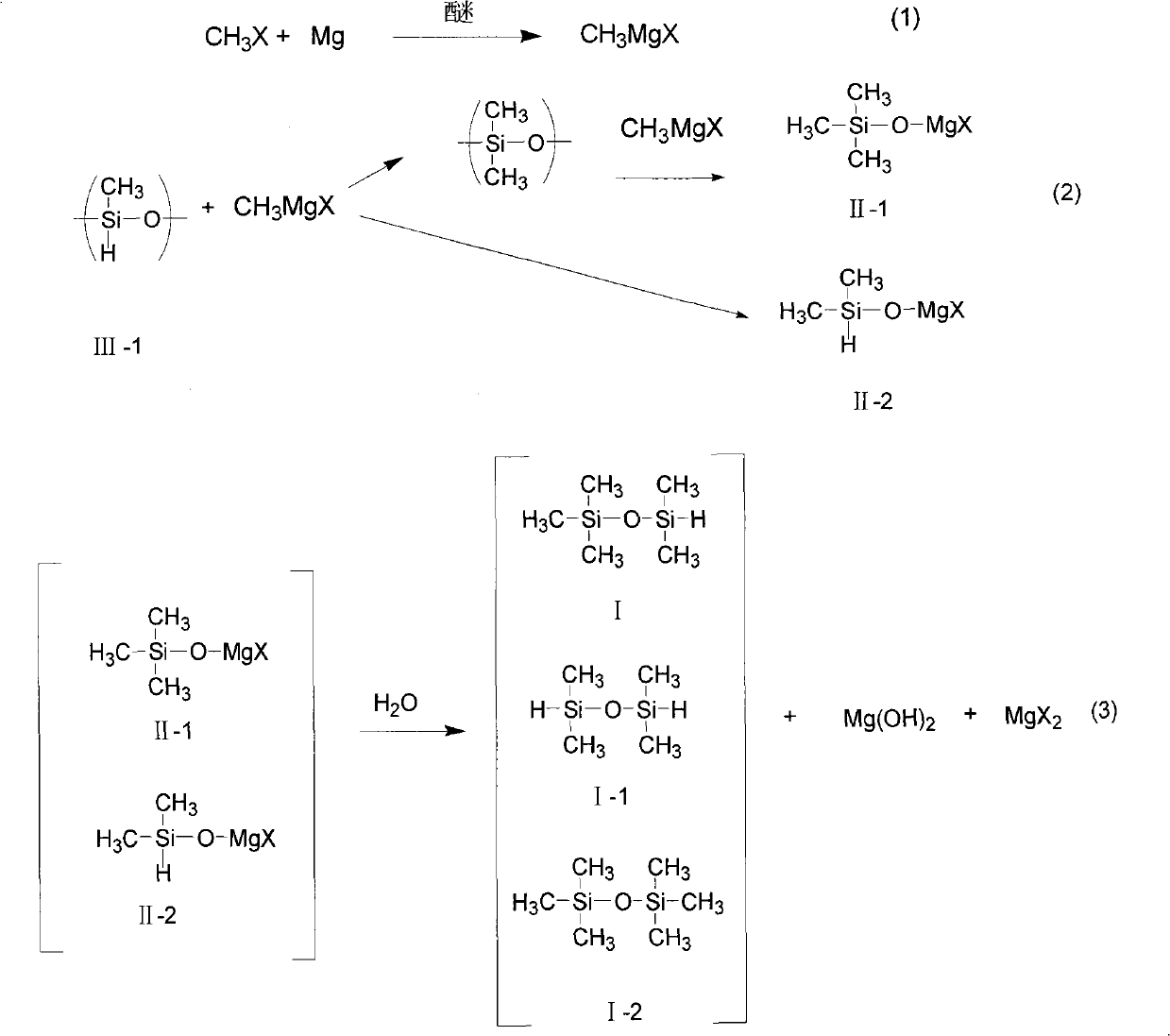

Method for preparing pentamethyl disiloxane

Owner:中国中化股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com