Liquid crystalline polyester resin composition and molded article thereof

A technology of resin composition and liquid crystal polyester, applied in the direction of liquid crystal materials, optical record carriers, chemical instruments and methods, etc., can solve the problem of increased melt viscosity of liquid crystal polyester, difficulty in compliance, insufficient soldering resistance of liquid crystal polyester, etc. problems, achieve huge industrial value, and suppress damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0089] The present invention is illustrated in more detail by the following examples, which should not be construed as limiting the scope of the present invention. The evaluation method is as follows.

[0090] (1) specific gravity

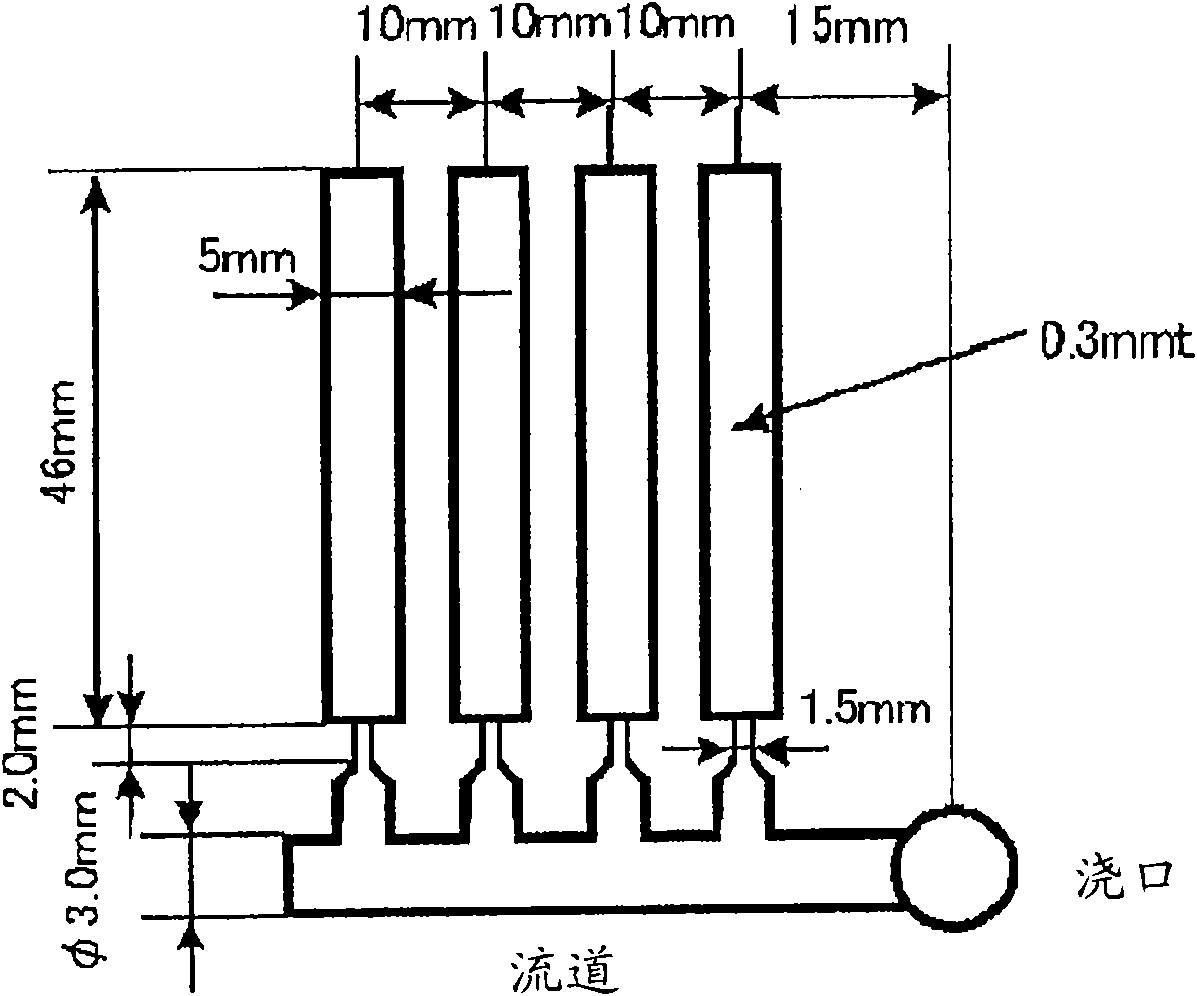

[0091] The liquid crystal polyester resin composition was molded using an injection molding machine (“PS40E1ASE”, manufactured by Nissei Plastic Industrial Co., Ltd.) under molding conditions of a cylinder temperature of 350° C., a mold temperature of 130° C., and an injection rate (injection rate) of 60%. A dumbbell-shaped sample [JIS K7113 (1 / 2)] (thickness: 0.5 mm) was formed. The obtained specific gravity of each sample was determined according to ASTM D792 (Method A).

[0092] (2) Izod impact strength

[0093] The liquid crystal polyester resin composition was molded into a length using an injection molding machine (“PS40E1ASE”, manufactured by Nissei Plastic Industrial Co., Ltd.) under the molding conditions of a cylinder temperature of 35...

preparation example 1

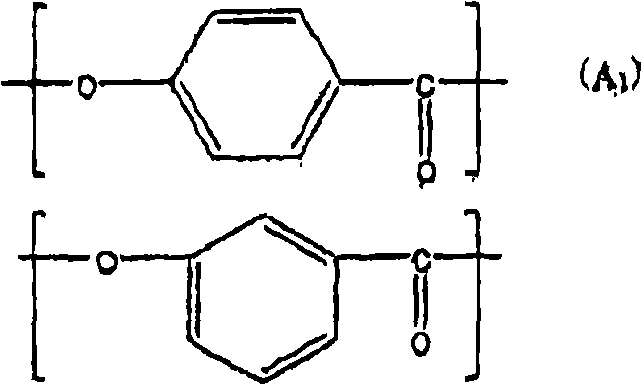

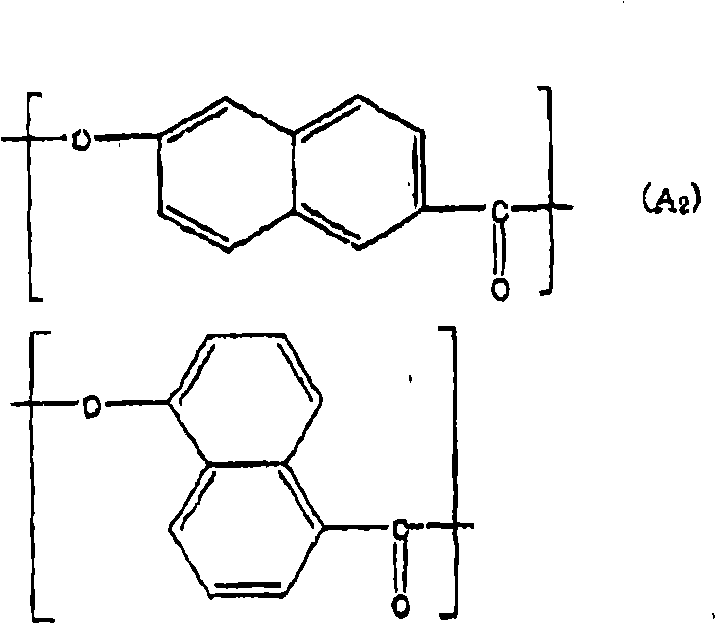

[0101] Add 830.7 g (5.0 mol) of p-hydroxybenzoic acid, 465.5 g (2.5 mol) of 4,4'-dihydroxybiphenyl to a reactor vessel equipped with stirrer, torque meter, nitrogen inlet, thermometer and reflux condenser , 394.6 g (2.375 mol) terephthalic acid, 20.8 g (0.125 mol) isophthalic acid, and 1153 g (11.0 mol) acetic anhydride. After the inside of the reactor vessel was sufficiently replaced with nitrogen, the reactor vessel was heated to 150° C. over 15 minutes under nitrogen flow and maintained at this temperature, and refluxed for 180 minutes. After that, while distilling off acetic acid and unreacted acetic anhydride produced as by-products, the temperature was raised to 320° C. over 2 hours and 50 minutes. The reaction was considered complete when an increase in torque was observed and the contents were removed. The obtained content was cooled to room temperature and pulverized with a coarse pulverizer to obtain a powder. The powder was heated from room temperature to 250°C ov...

preparation example 2

[0103] Add 994.5 g (7.2 mol) of p-hydroxybenzoic acid, 446.9 g (2.4 mol) of 4,4'-dihydroxybiphenyl to a reactor vessel equipped with stirrer, torque meter, nitrogen inlet, thermometer and reflux condenser , 299.0 g (1.8 mol) terephthalic acid, 99.7 g (0.6 mol) isophthalic acid, and 1347.6 g (13.2 mol) acetic anhydride. After the inside of the reactor vessel was sufficiently replaced with nitrogen, the reactor vessel was heated to 150° C. over 30 minutes under nitrogen flow and kept at this temperature, and refluxed for 30 minutes. After that, while distilling off acetic acid and unreacted acetic anhydride produced as by-products, the temperature was raised to 320° C. over 2 hours and 50 minutes. The reaction was considered complete when an increase in torque was observed and the contents were removed. The obtained content was cooled to room temperature and pulverized with a coarse pulverizer to obtain a powder. The powder was heated from room temperature to 250°C over 1 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Volume average particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com