Jaw with reinforcement device

A technology of booster device and screw shaft, which is applied in the vise, positioning device, transmission device, etc., can solve the problems of damage, rapid wear, deformation, etc., and achieve the effect of suppressing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

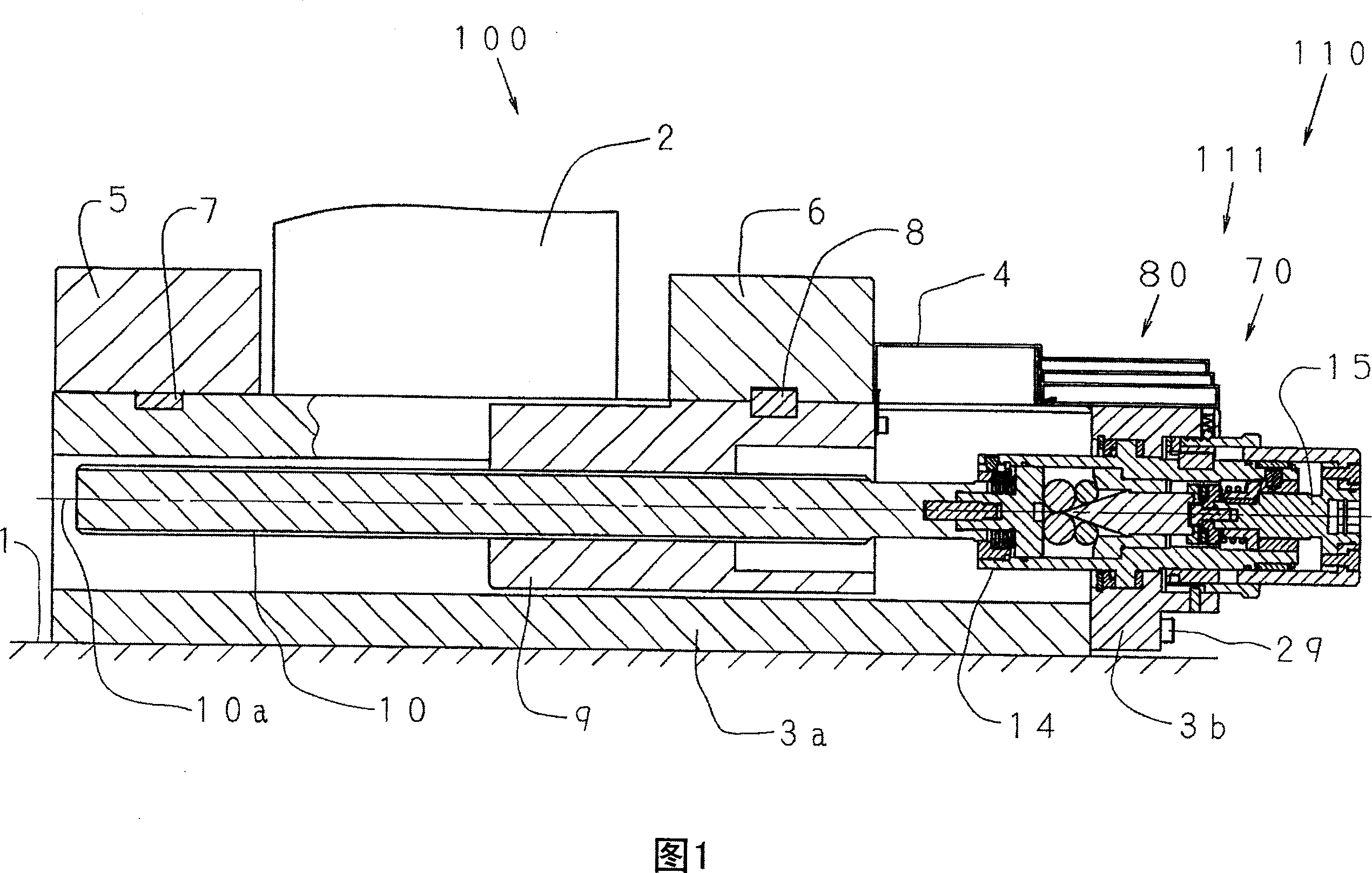

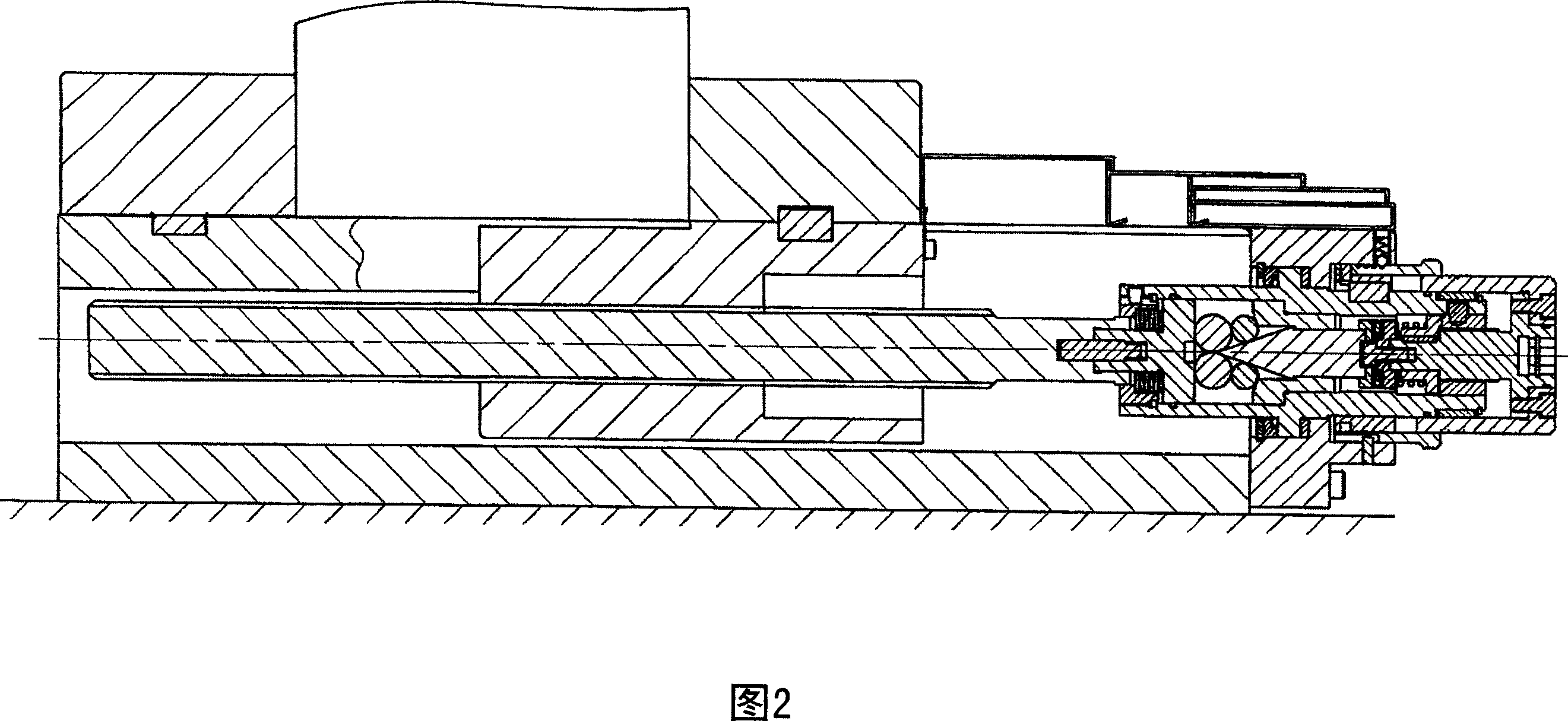

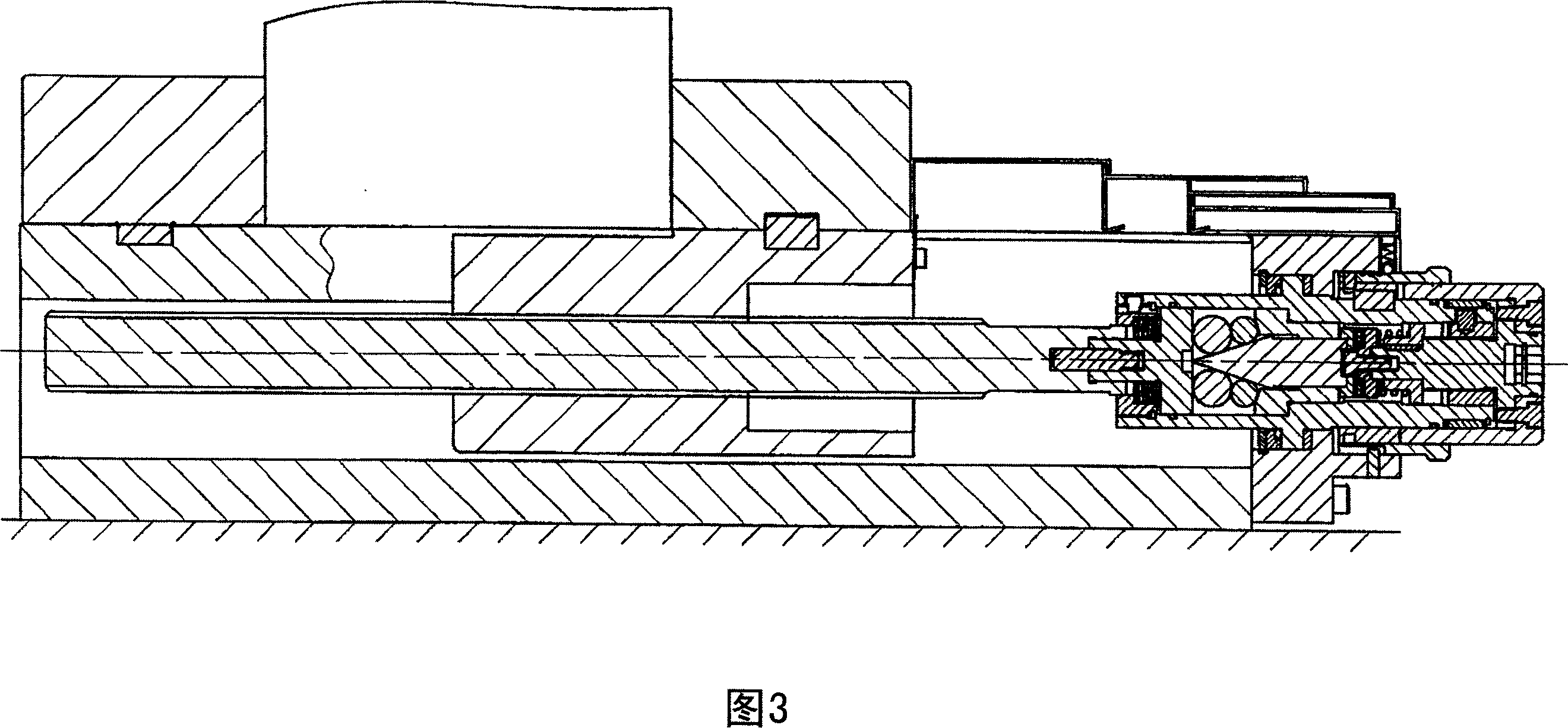

[0041] Hereinafter, embodiments of the present invention will be described with reference to the drawings. 1 to 7 show a vise 100 according to a first embodiment of the present invention. 1 to 3 are overall cross-sectional views of the vise 100, and FIG. 1 shows a state in which a workpiece is placed between the fixed jaw 5 and the movable jaw 6, and shows the state before the workpiece holding operation is started. 2 shows that the workpiece holding action is started, the rotation of the rotary propulsion shaft 15 is transmitted to the hollow shaft 14 through the clutch device 70 and the screw shaft 10 is rotated, and the workpiece 2 is clamped between the two jaws 5,6. FIG. 3 shows the state where the workpiece 2 is held with a predetermined clamping force after the rotation transmission of the clutch device 70 is released, and the rotary propulsion shaft 15 is further rotated. Fig. 4 is an enlarged view of main parts of Fig. 1 . FIG. 5 is an external view showing an inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com