MoS2/Ni3S2 electrode material as well as preparation method and application thereof

An electrode material, a technology for hydrothermal reaction, applied in electrodes, chemical instruments and methods, electrolysis components, etc., can solve problems such as poor electrical conductivity, and achieve the effects of high preparation yield, good electrocatalytic activity, and large industrialization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In a specific embodiment of the present invention, a MoS 2 / Ni 3 S 2 The preparation method of electrode material, described method comprises:

[0037]S1. After adding the Mo source and the S source to the water and mixing them evenly, add nickel foam thereto;

[0038] S2. Perform hydrothermal reaction on the mixed solution with nickel foam added in step S1, and purify after cooling.

[0039] In the present invention, the foamed nickel is used as the substrate, and the foamed nickel is directly hydrothermally grown on it, and the foamed nickel not only participates in the reaction as a nickel source, but also serves as a substrate supporting material.

[0040] In yet another specific embodiment of the present invention, in the step S1,

[0041] Mo source is sodium molybdate;

[0042] The S source is any one of thiourea, thioacetamide, and L-cysteine;

[0043] In yet another specific embodiment of the present invention, the S source is thioacetamide; it has been pr...

Embodiment 1

[0056] Synthesis of MoS by a one-step hydrothermal method 2 / Ni 3 S 2 Electrode: cut 1*4cm 2 The foamed nickel was ultrasonically cleaned in ethanol, acetone, water and 3M hydrochloric acid for 15 minutes each. 0.331 mmol Na 2 MoO 4 2H 2 O (80 mg) and 1.43 mmol thioacetamide (108 mg) were added to 30 mL of water, wherein the molar ratio of Mo source to S source was 1:4.32, and after stirring for 30 minutes, a piece of 1 cm*4 cm nickel foam was added. Transfer to a 40mL autoclave lined with polytetrafluoroethylene, heat in an oven at 200°C for 21h, and cool to room temperature naturally. After cooling, the material was removed, rinsed with water and ethanol, and dried for use. MoS synthesized from other sulfur sources 2 / Ni 3 S 2 For the electrode, just replace thioacetamide with thiourea or L-cysteine, and keep other conditions unchanged.

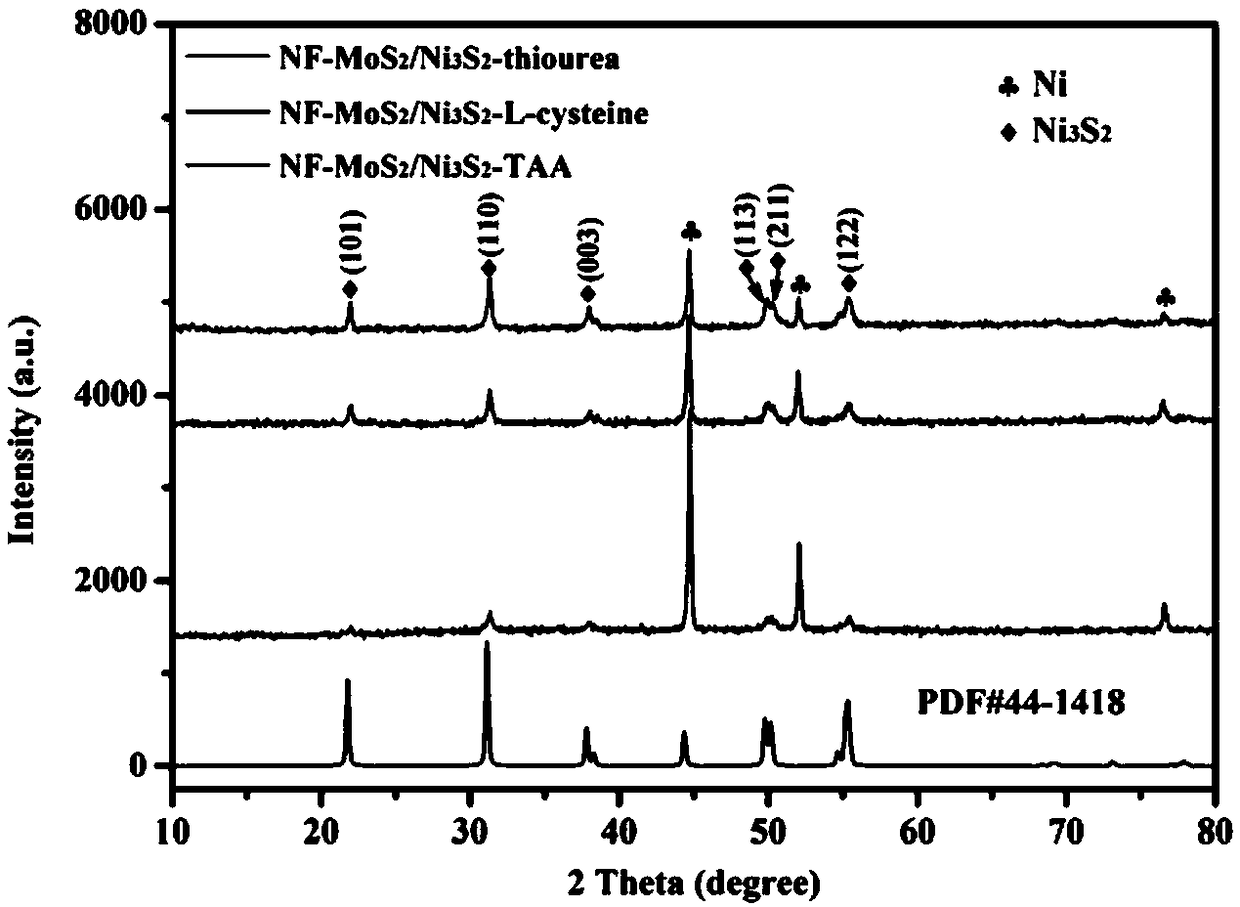

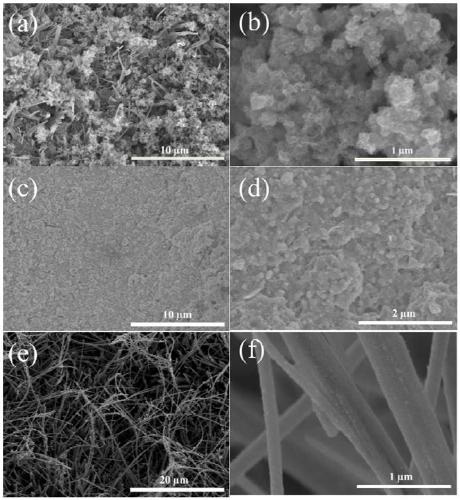

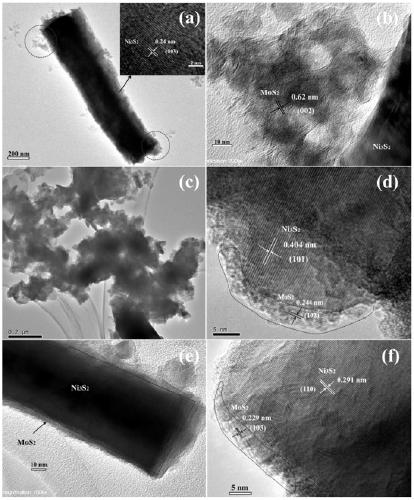

[0057] attached figure 1 It is the X-ray diffraction pattern of the product obtained in this embodiment, as can be seen from t...

Embodiment 2

[0065] Synthesis of MoS by a one-step hydrothermal method 2 / Ni 3 S 2 Electrode: cut 1*4cm 2 The foamed nickel was ultrasonically cleaned in ethanol, acetone, water and 3M hydrochloric acid for 15 minutes each. 0.331 mmol Na 2 MoO 4 2H 2 O (80 mg) and 1 mmol thioacetamide (75 mg) were added to 25 mL of water, where the molar ratio of Mo source to S source was 1:3, and after stirring for 30 minutes, a piece of 1 cm*4 cm nickel foam was added. Transfer to a 40mL autoclave lined with polytetrafluoroethylene, heat in an oven at 180°C for 24h, and cool to room temperature naturally. After cooling, the material was removed, rinsed with water and ethanol, and dried for use.

[0066] MoS synthesized from other sulfur sources 2 / Ni 3 S 2 For the electrode, just replace thioacetamide with thiourea or L-cysteine, and keep other conditions unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com