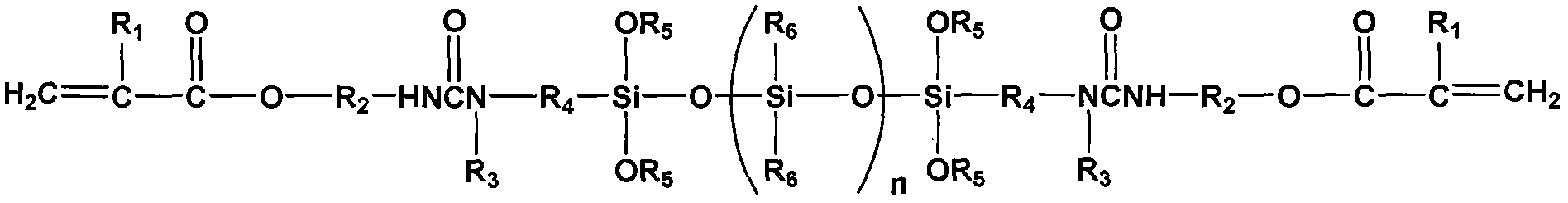

Polysiloxane with UV (Ultraviolet) and moisture double curing groups and preparation method thereof

A polysiloxane, dual-curing technology, used in coatings, adhesives, etc., can solve problems such as the inability to meet the curing of shadow parts, and the inability to achieve photo-curing in small-area shadow parts, achieving excellent photo-curing technology, avoiding inability to cure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

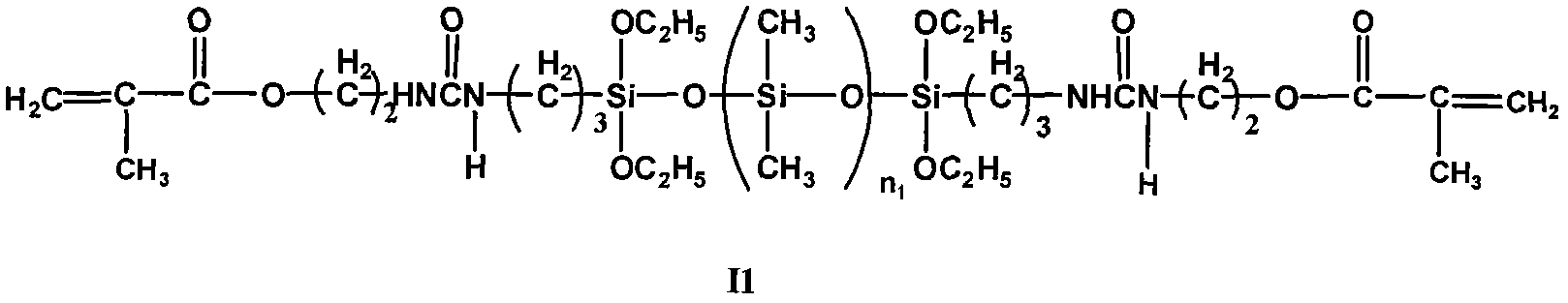

Embodiment 1

[0037] Add 100g of 2000cps hydroxyl silicone oil to a 2L reaction kettle equipped with a stirrer, thermometer and condenser, then heat to 110°C, stir in vacuum for 1h, then lower the temperature to 80°C, add r-aminopropyltriethoxysilane 110 g, add 10 g of sodium hydroxide, react for 2 h, then add 90 g of isocyanoethyl methacrylate, and stir for 2 h at 80° C. to obtain modified polysiloxane (I1).

[0038]

Embodiment 2

[0040] Add 100g of 30000cps hydroxyl silicone oil to a 2L reaction kettle equipped with a stirrer, thermometer and condenser, then heat to 130°C, stir in vacuum for 1h, then lower the temperature to 70°C, add 120g of r-aminopropyltrimethoxysilane , reacted for 3 h, then added 100 g of isocyanoethyl methacrylate, and stirred at 90° C. for 2 h to obtain modified polysiloxane (I2).

[0041]

Embodiment 3

[0043] Add 110g of isocyanoethyl methacrylate and 120g of r-aminopropyltrimethoxysilane to a 2L reaction kettle equipped with a stirrer, thermometer and condenser, then heat to 50°C, stir in vacuum for 1h, then 50 ℃ constant temperature, add 100 parts of 30000cps hydroxyl silicone oil 115g into the reaction kettle, react for 2h, and obtain the modified polysiloxane (I3).

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com