Patents

Literature

36results about How to "Reduce processing viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Partially vulcanized shaped rubber composition and preparation of an article, including tires, having a component thereof

InactiveUS6426378B1Improve responseIncrease stiffnessOther chemical processesSpecial tyresElastomerPolymer science

The invention relates to the preparation of a partially vulcanized, pre-shaped rubber composition and use thereof as a component of an article of manufacture. In practice, the partially vulcanized rubber composition is adhered to an unvulcanized rubber substrate to form a composite thereof and the resulting composite vulcanized to create an article of manufacture. Such pre-vulcanized rubber composition is a composite comprised of at least one diene-based elastomer, amorphous silica, coupling agent and liquid diene-based polymer. Such partially vulcanized, pre-shaped rubber composition may be a component of a tire such as, for example, an apex, sidewall insert or tread. It may also be a component of an industrial rubber product such as, for example, a component of a conveyor belt, power transmission belt or a hose.

Owner:THE GOODYEAR TIRE & RUBBER CO

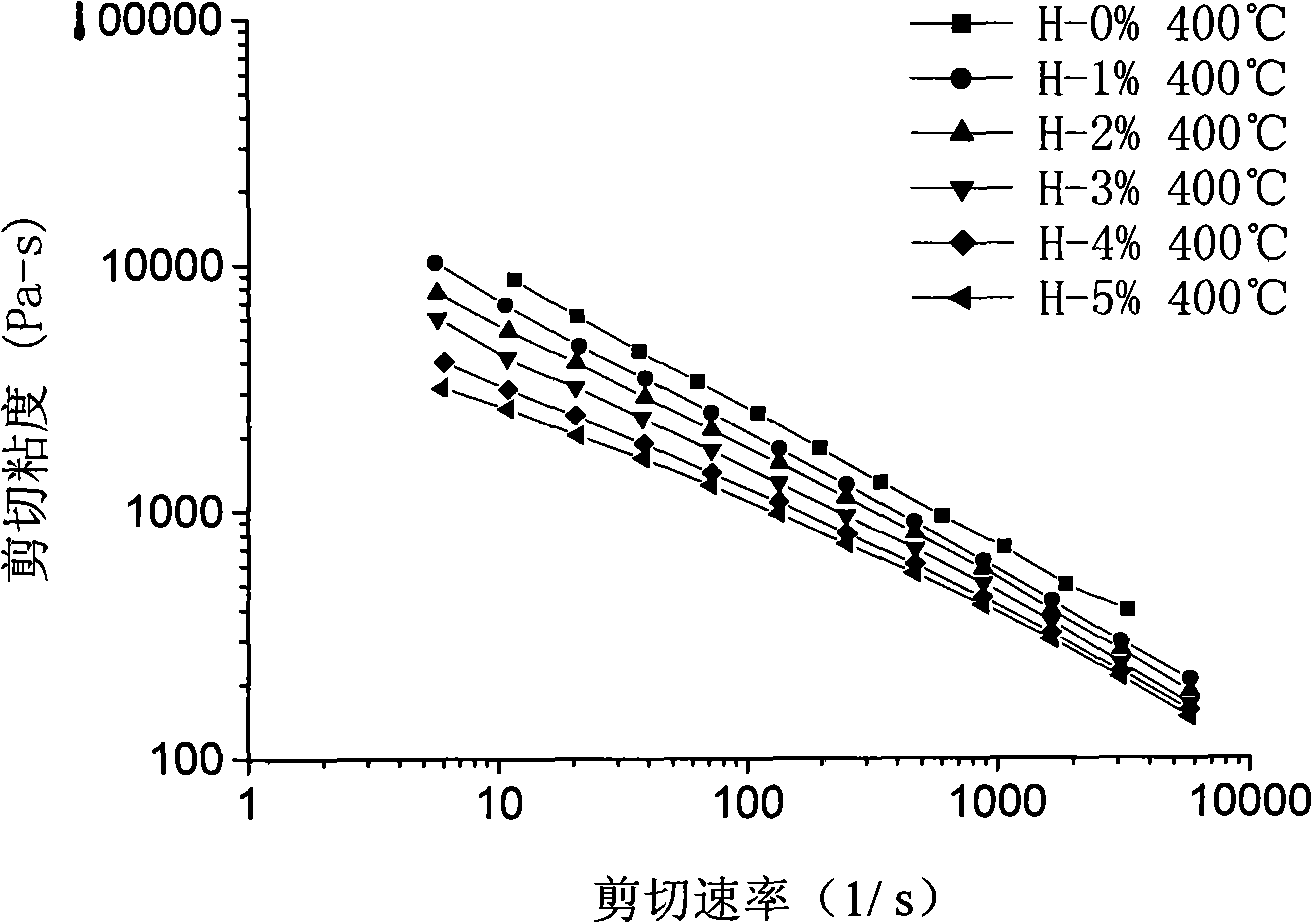

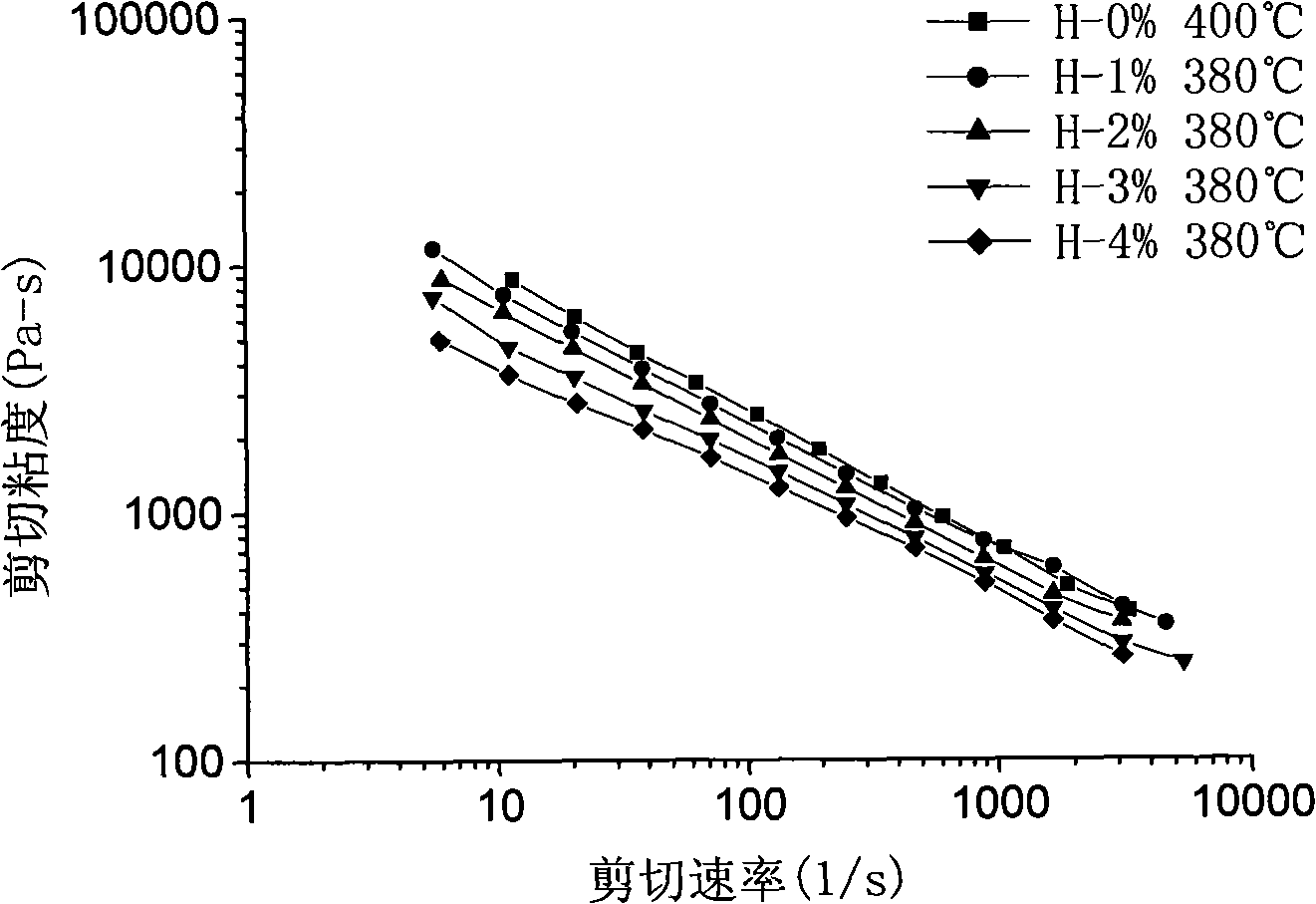

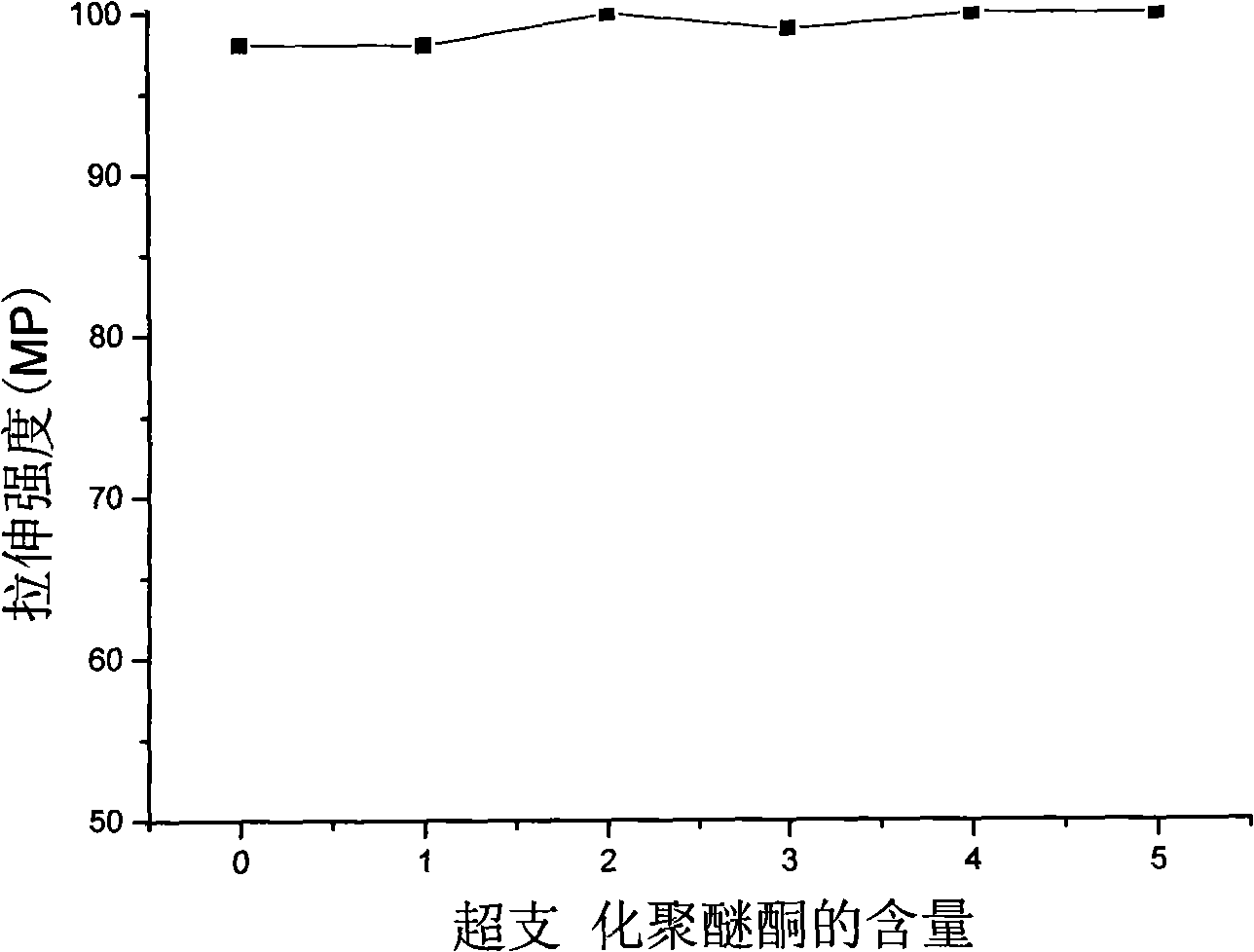

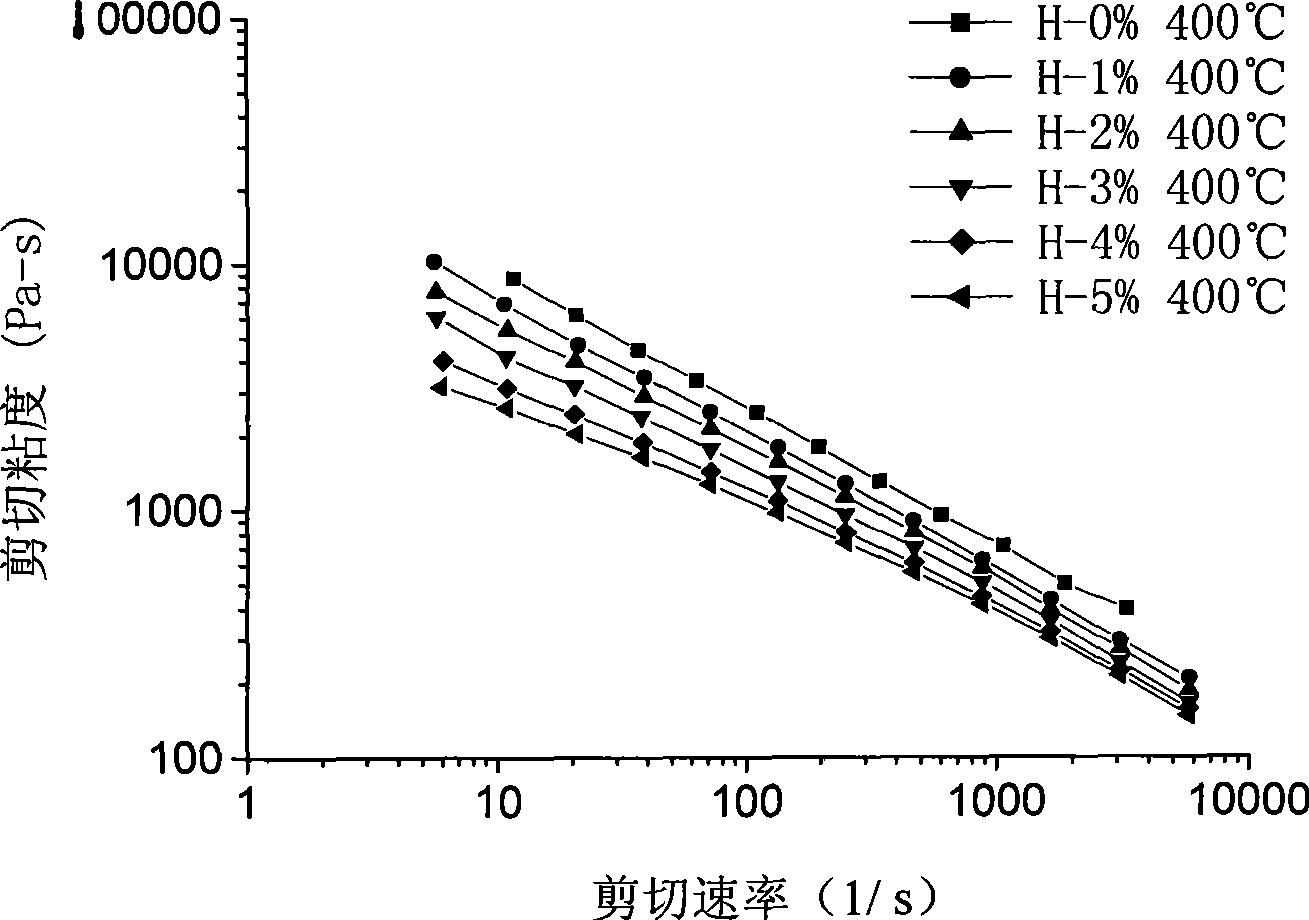

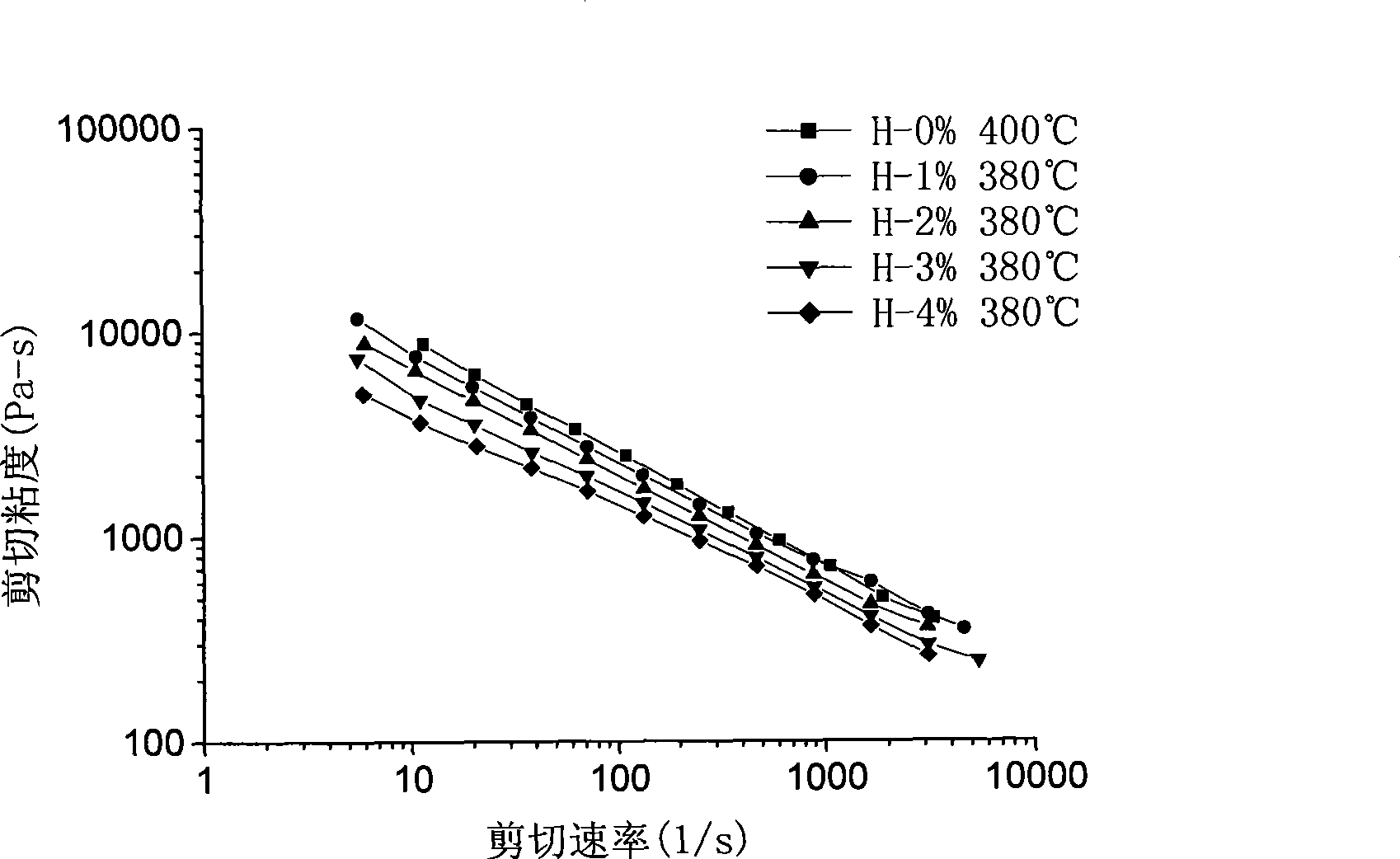

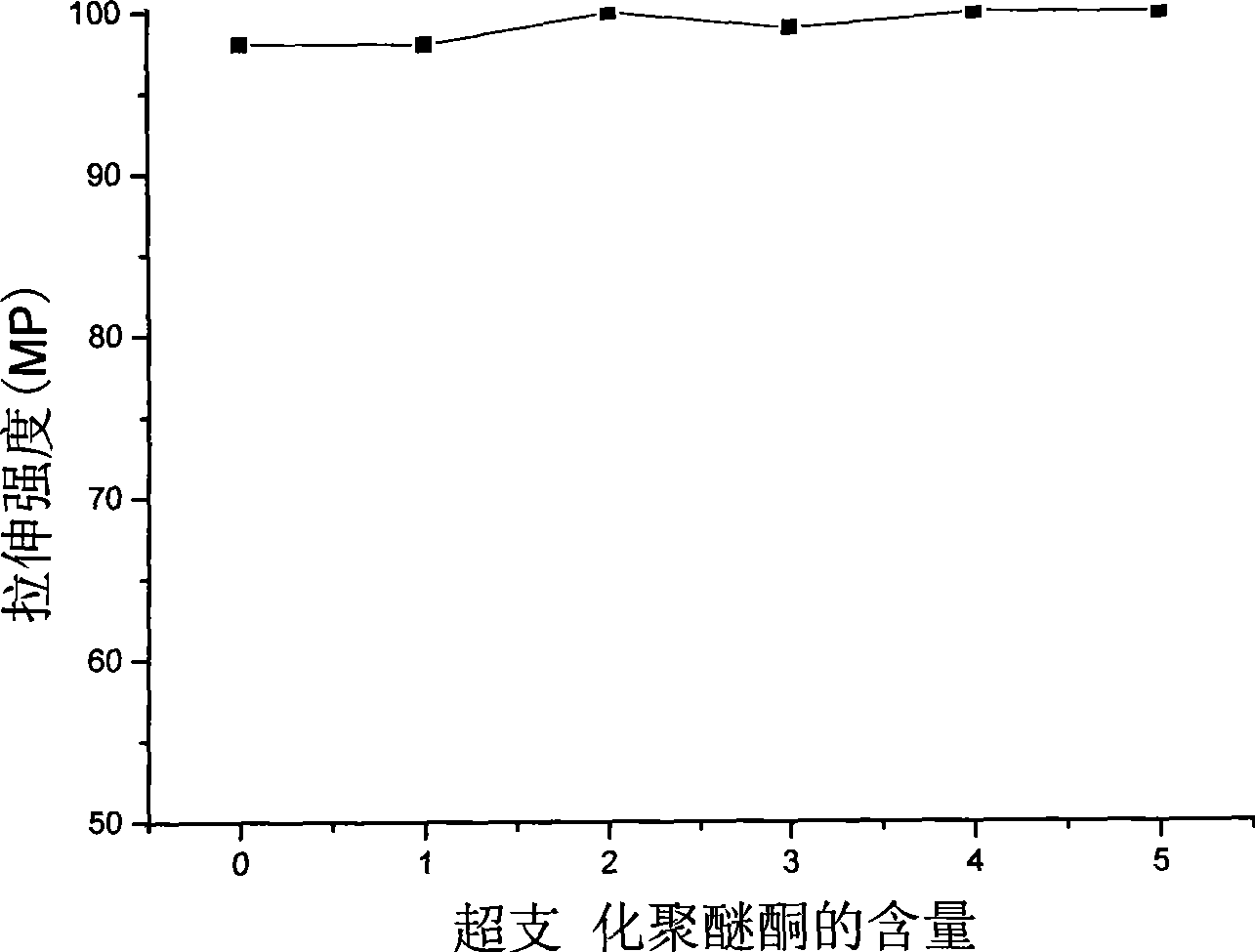

Hyperbranched poly(aryl ether ketone), preparation method and application thereof in viscosity modifier

The invention relates to a hyperbranched poly (ether ketone), a preparation method thereof and application of the material in viscosity modifiers. The hyperbranched poly(ether ketone) is prepared wit BB2-type monomers 2, 4, 6 trifluoro phenyl ketone and A2-type monomers hydroquinone, resorcin, bisphenol A, and hexafluoro-bisphenol A or biphenyl diphenol as reactants, potassium carbonate or sodium carbonate or the mixture of the potassium carbonate and the sodium carbonate as a salification agent, and sulfolane or N, N-dimethyl ketopyrrolidine as a solvent through mixing, salification, polycondensation reaction and after treatment. The solid content is 20 to 30 percent; the dosage of the salification agent is 1 to 1.1 time of the dosage of the A2 monomers. Fluorine terminated hyperbranched polyaryletherketone and hydroxy terminated superbranched polyaryletherketone are got respectively by adjusting the ratio of the dosages of the BB2-type and A2-type monomers. The hyperbranched poly (ether ketone) is characterized in that by adding the superbranched polyaryletherketone, the mechanical property and the thermostability of linear polyaryletherketone are not reduced while the melt viscosity of the linear polyaryletherketone is reduced.

Owner:JILIN UNIV

PET protective film having good wear resistance and strong impact resistance and preparation technology thereof

ActiveCN103602044AImprove curing effectImprove adhesionFilm/foil adhesivesCoatingsPolymer scienceThin membrane

The invention relates to the technical field of protective films and especially relates to a PET protective film having good wear resistance and strong impact resistance and a preparation technology thereof. The PET protective film comprises a PET film layer and an adhesive layer. The PET film layer comprises an outer layer, a middle layer and an inner layer, and the outer layer, the middle layer and the inner layer are films bonded by co-extrusion. The adhesive layer coats the inner layer of the PET film layer. The PET film layer has a three-layer structure. The raw material of the inner layer of the PET film layer retains good wettability, improves the adhesion of the inner layer of the PET film layer to the adhesive layer and prevents the PET film layer from falling off in use. The middle layer of the PET film layer keeps PET protective film strength. The raw material of the outer layer of the PET film layer retains good surface smoothness and wear resistance. The preparation technology of the PET protective film having good wear resistance and strong impact resistance has a low preparation cost and simple processes, improves wettability of the inner layer of the PET film layer by corona treatment and improves the adhesion of the inner layer of the PET film layer to the adhesive layer.

Owner:东莞市尼的科技股份有限公司

Polyethylene in super molecular weight modified by Nano silicon rubber its prepn. provess and usage

InactiveCN1696185AGuaranteed high molecular weightConvenience guaranteedNano siliconPolymer modified

A nano-class silica rubber modified ultrahigh-molecular polyethene used for antiwear pipe is prepared through proportionally mixing ultrahigh-molecular polyethene, nucleator, lubricant, rheological asistant and antioxidizing agent, high-speed stirring, adding silica rubber nanoparticles, stirring, and dual-screw extruding out to obtain granular product.

Owner:INST OF CHEM CHINESE ACAD OF SCI

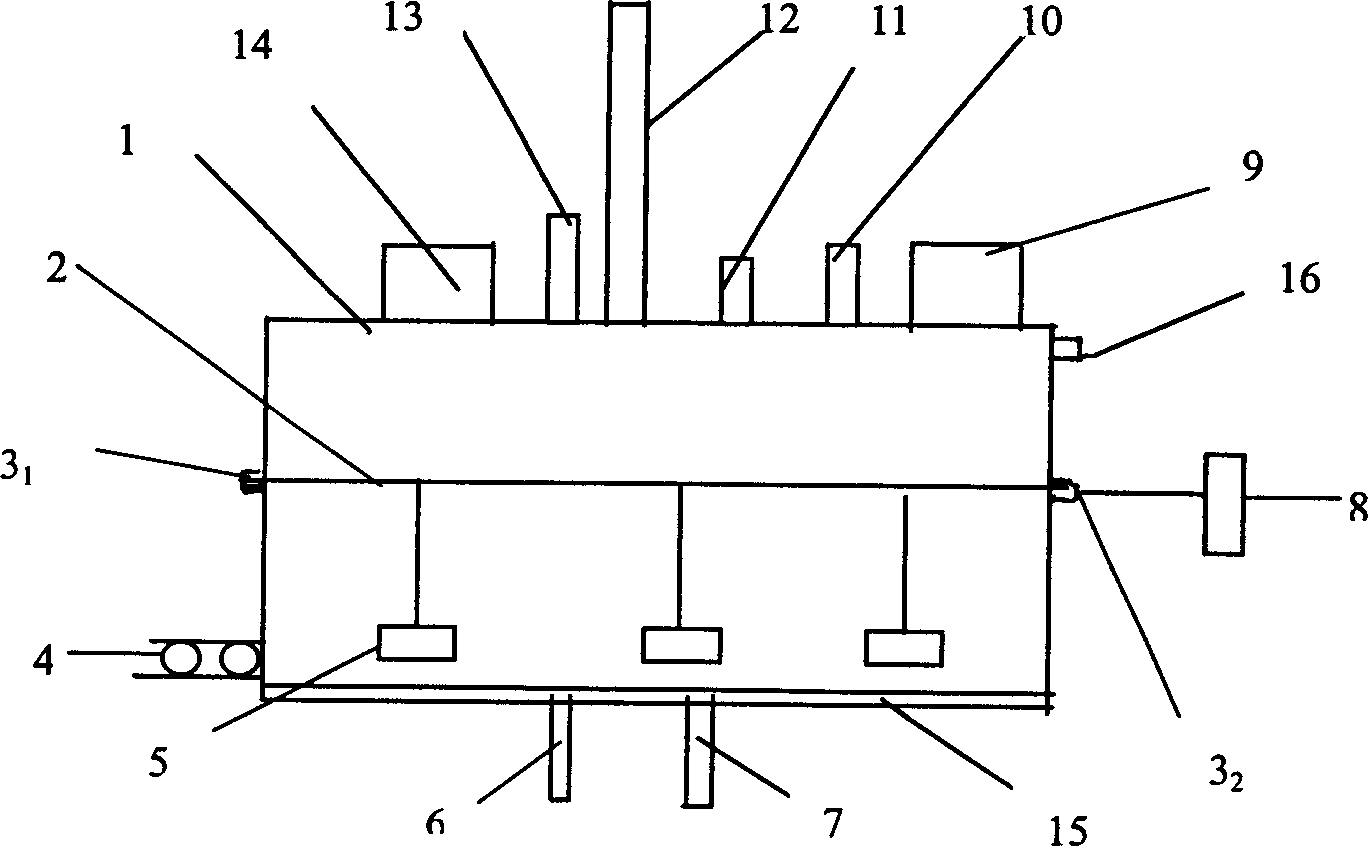

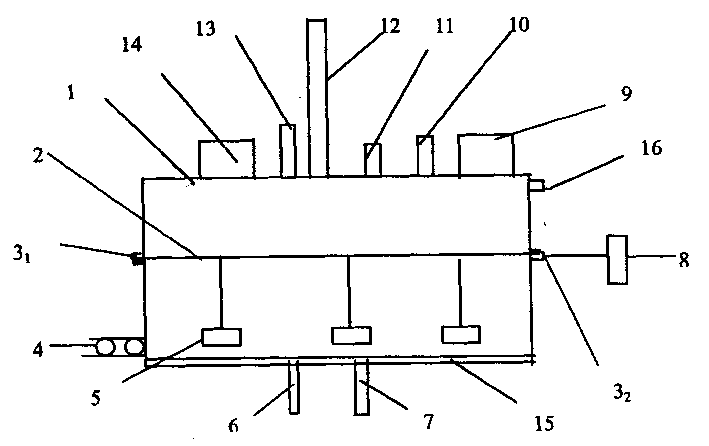

Preparation method of inorganic-organic composite particle and its special-purpose equipment

InactiveCN1515632AHigh hardnessHigh surface finishPigment treatment with macromolecular organic compoundsChemical LinkageInorganic particle

The present invention relates to a preparation method of inorganic-organic high-molecular composite particle and its special-purpose equipment. The inorganic particle can be directly reacted with organic high-molecular compound in a reactor still, under the action of mechanical energy and heat energy provided by reactor still the inorganic particle is reacted with organic high molecular to make chemical linkage, and one layer or several layers of organic high-molecular membranes can be formed on the surface of the particle so as to obtain the invented hydrophobic inorganic-organic high-molecular composite particle which can have an affinity for organic high-molecular material. Its special-purpose equipment is formed from horizontal reaction still with jacket, motor and control cabinet, etc.

Owner:WUHAN UNIV OF TECH

3,3',5,5'-tetramethyl-4,4'-biphenyldiglycid ether preparation method

InactiveCN1733745AReduce processing viscosityImprove solubilityOrganic chemistryPolymer scienceEther

The invention relates to a process for preparing 3,3',5,5'-tetramethyl-4,4'-biphenyl didycidyl ether, wherein the 3,3',5,5'-tetramethyl-4,4'-biphenol is reacted with excess epichlorohydrin under the action of phase transition catalyst. The prepared has low epoxy equivalent weight, high yield, and simple reaction steps.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

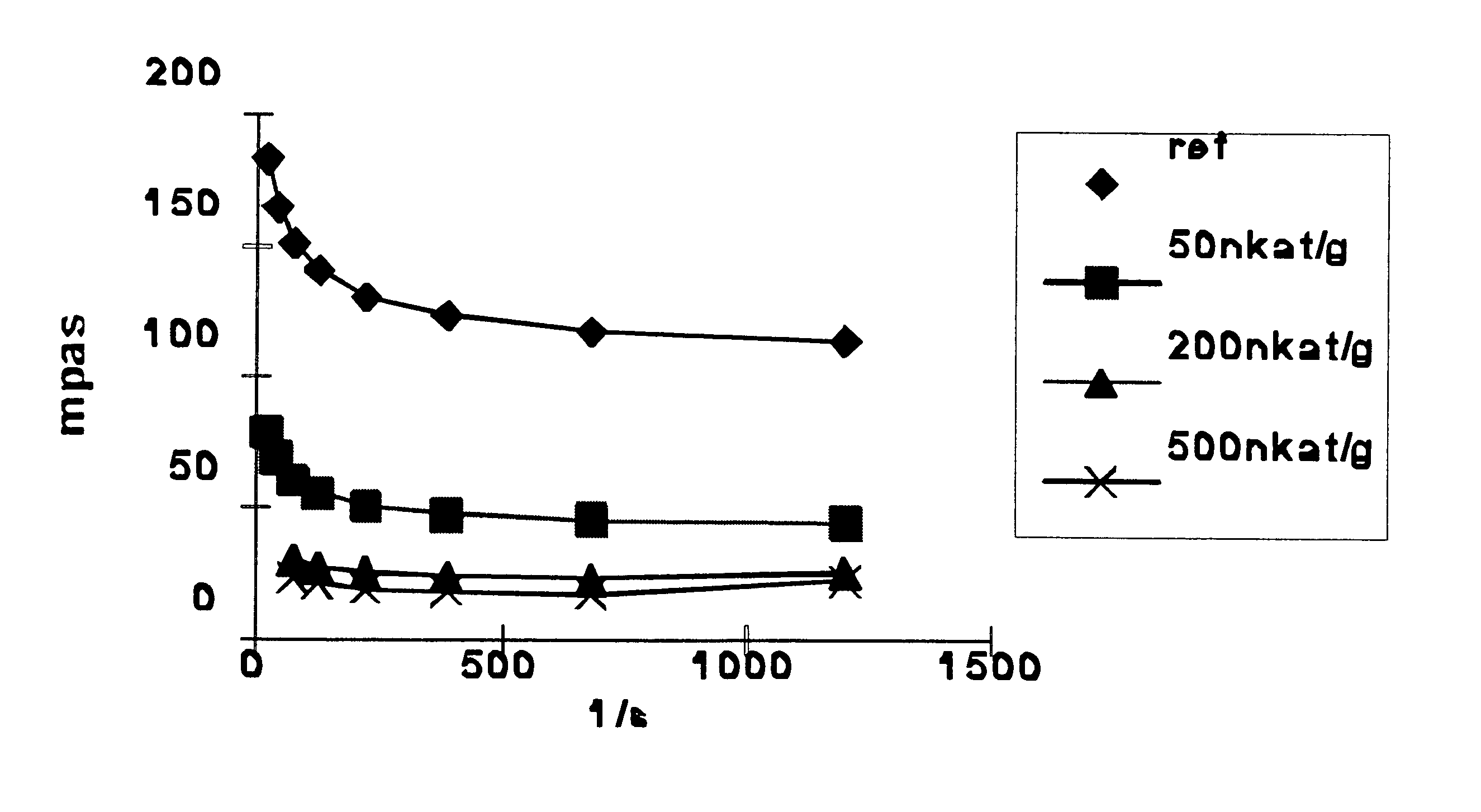

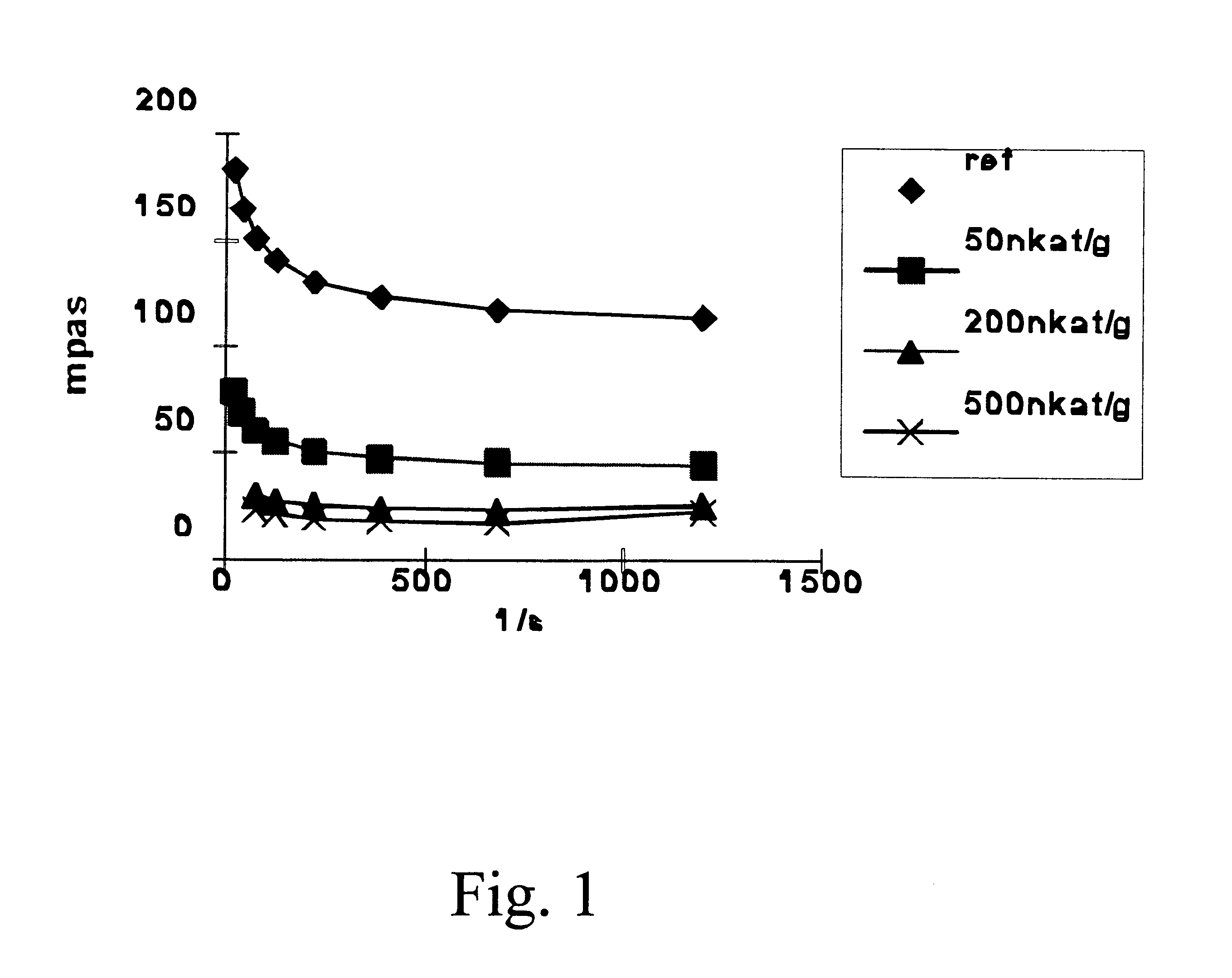

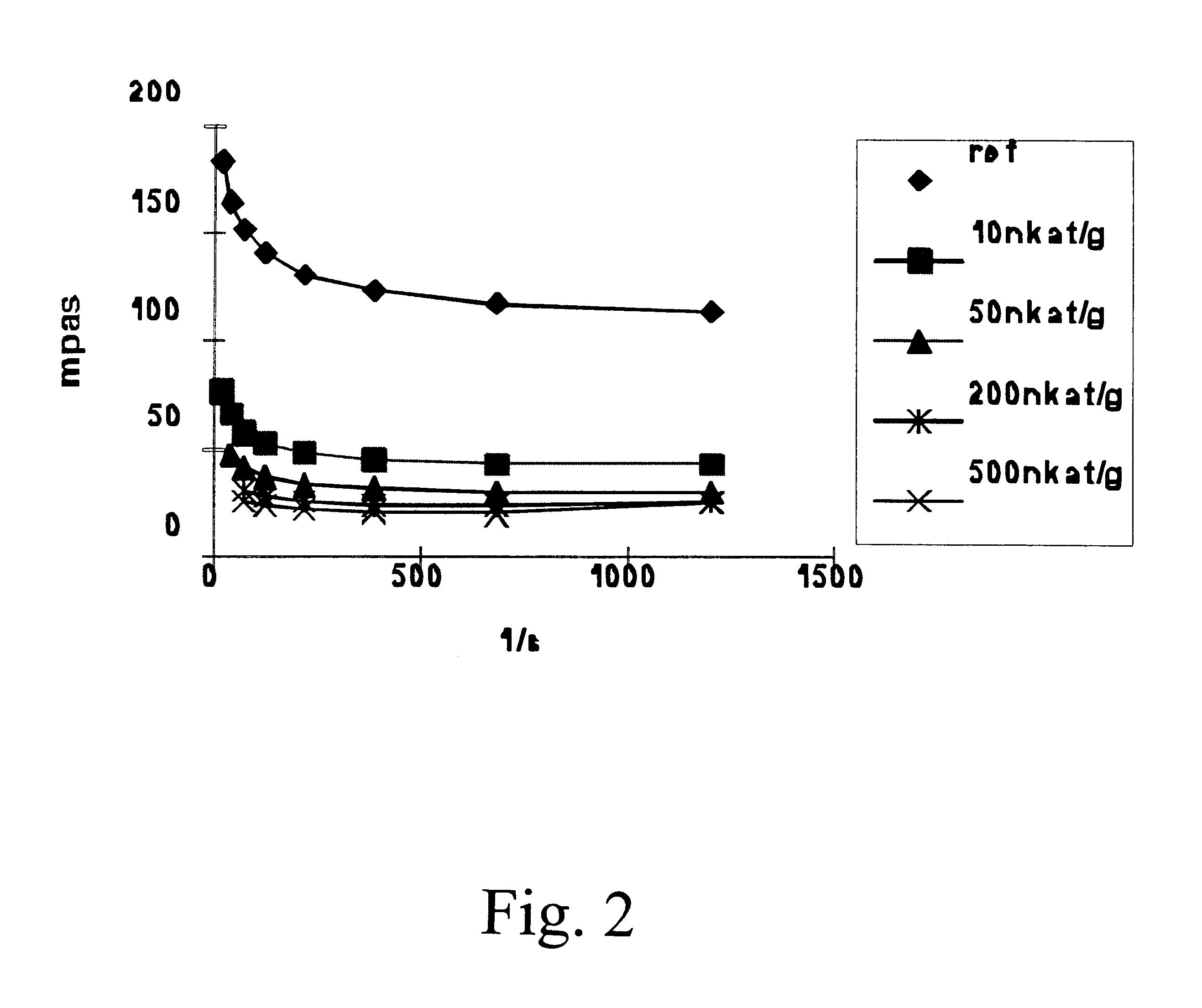

Process for concentrating soluble and colloidal substances in process waters

InactiveUS6425975B1High viscosityEconomic treatmentSludge treatment by de-watering/drying/thickeningPulp liquor regenerationFiberAfter treatment

The invention relates to a process for enhancing the concentration of the fiber derived dissolved and colloidal substances in process water that comes from mechanical pulping. According to the invention, process water is treated with enzyme preparations that have an effect on carbohydrates and that contain mannanase and / or endoglucanase, in particular, which break down the soluble carbohydrate polymers contained by the process water into low molecular weight oligosaccharides. The treatment prevents an increase in viscosity so that process water can be concentrated into a high dry content, or the treatment can be used to lower the viscosity of previously concentrated process water to facilitate after-treatment.

Owner:VALTION TEKNILLINEN TUTKIMUSKESKUS

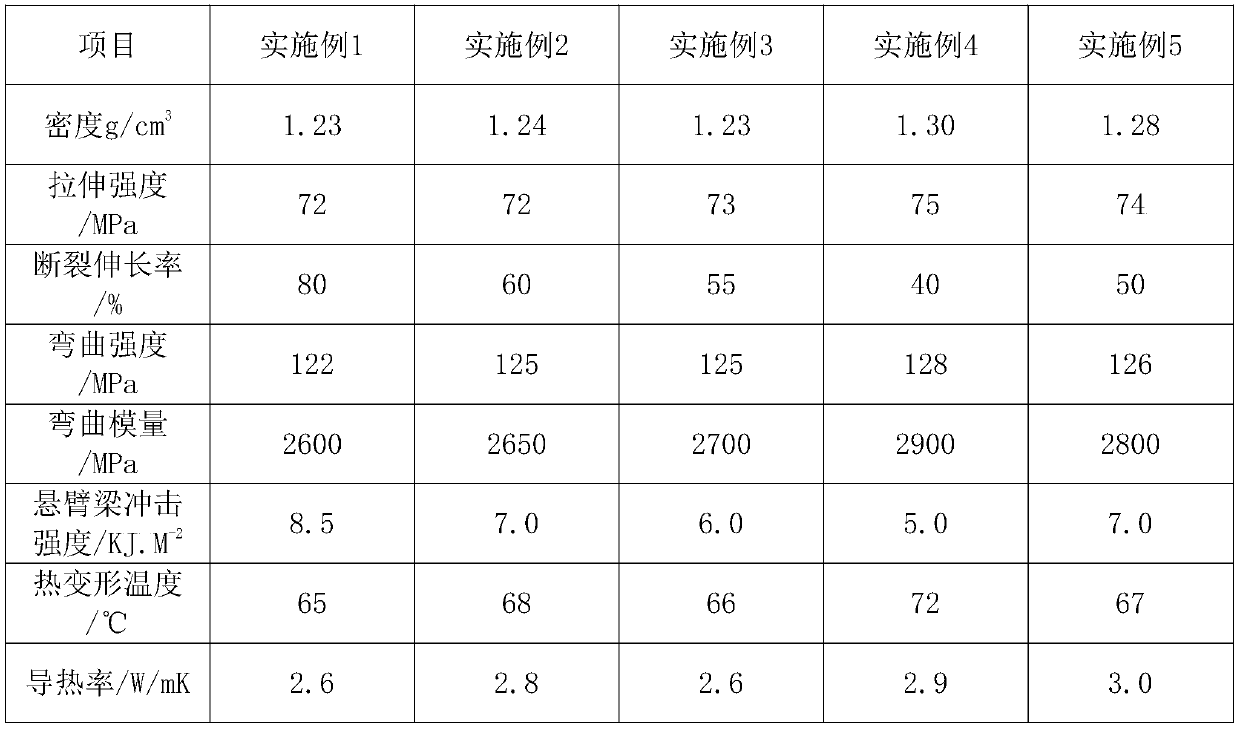

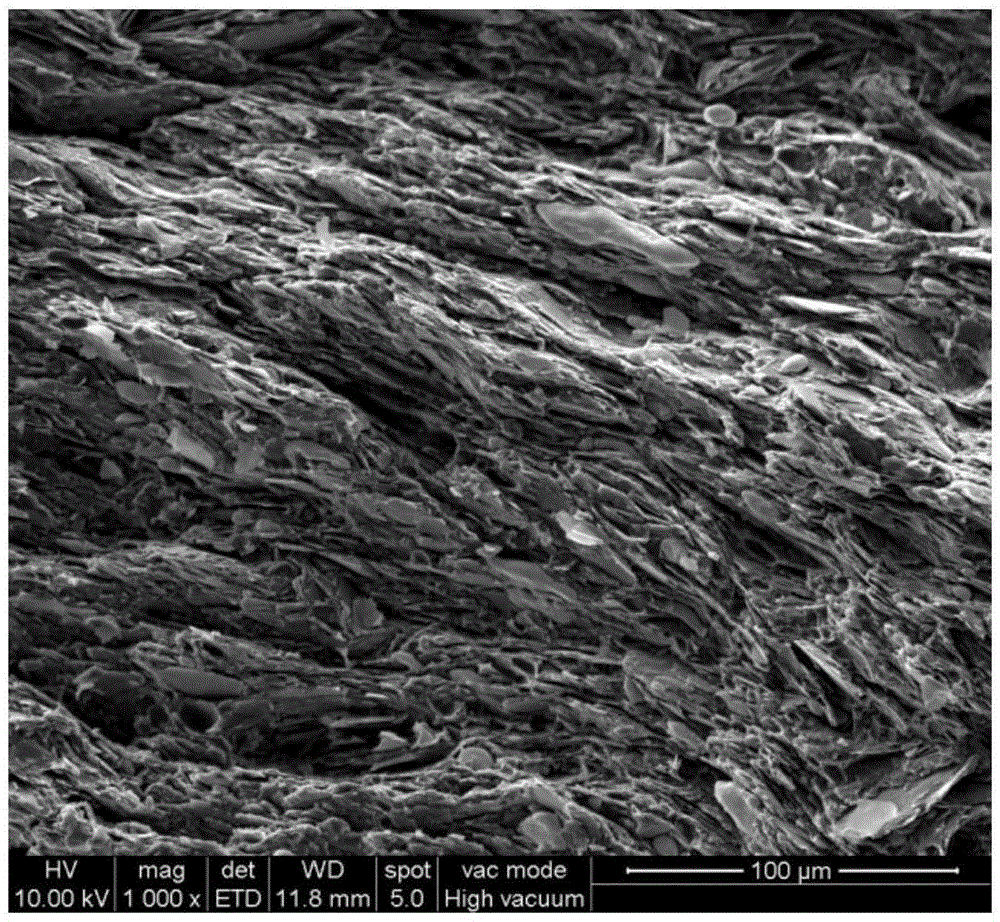

Boron nitride oriented thermal-conductive nylon and preparation method thereof

The invention relates to boron nitride oriented thermal-conductive nylon and a preparation method thereof. The preparation method comprises the following steps: mixing boron nitride particles and ureaparticles, adding the mixed material into a ball mill, performing ball milling, after ball milling is completed, performing washing by using deionized water, and performing drying, wherein a mass ratio of the boron nitride particles to the urea particles is 1:(1-5); adding the boron nitride particles treated in the step 1 into a N,N-dimethylformamide solution of a hyperbranched polyester having terminal hydroxyl, performing a grafting reaction, performing washing by using acetone, and performing drying to obtain graft modified boron nitride, wherein the temperature of the grafting reaction is65-75 DEG C, and the stirring time is 1.5-2.5 h; and performing mixing on 20-50 parts by weight of the graft modified boron nitride, 100 parts by weight of nylon, 0.2-1 part by weight of an antioxidant and 0.1-1 part by weight of a lubricant, and performing extrusion. According to the thermal-conductive nylon and preparation method provided by the invention, the boron nitride is induced to form an oriented thermal-conductive pathway while the processing viscosity of the system is reduced, the processing technology is simplified, and industrialization is facilitated.

Owner:ANHUI JIHONG MATERIAL TECH

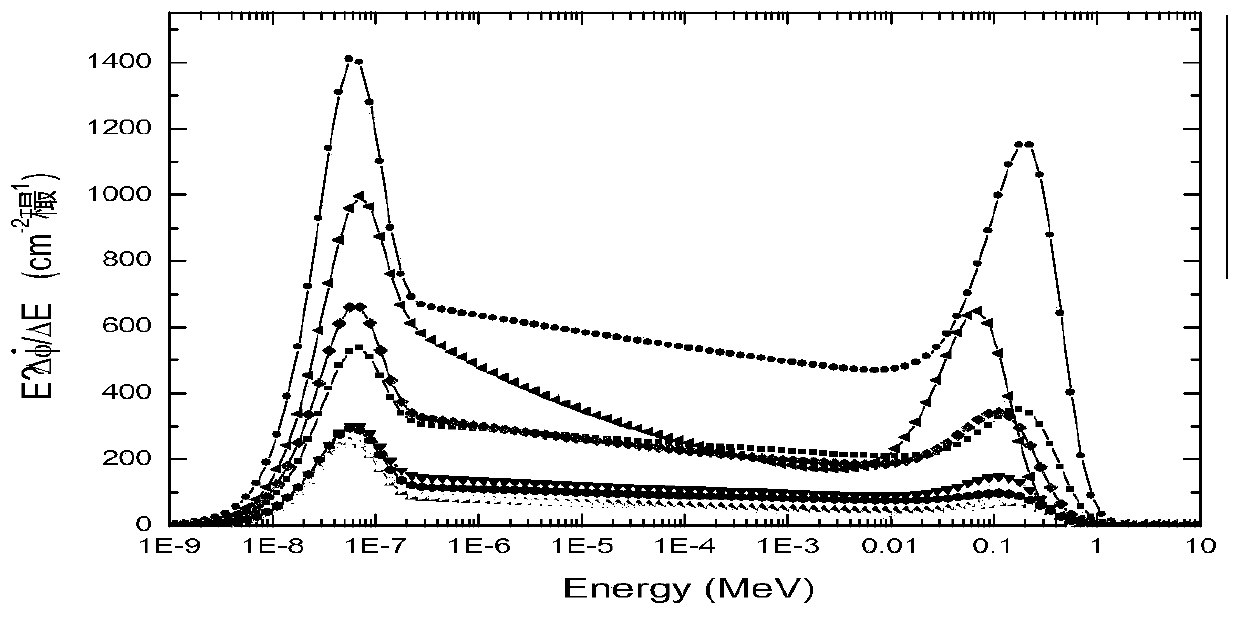

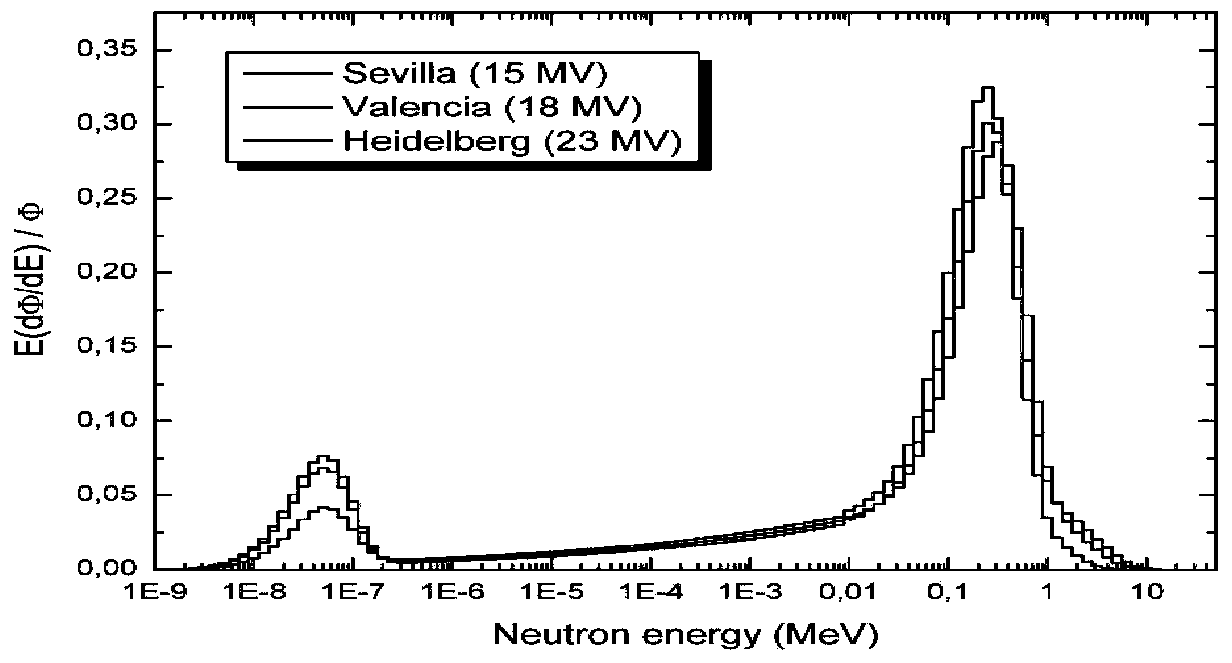

Flexible neutron radiation protection material and protective article preparation method

The invention discloses a flexible neutron radiation protection material. The material comprises four layers of structures, wherein the first-layer structure comprises the materials in parts by weight: 10 to 40 parts of rare earth mineral powder, 1 to 20 parts of a tungsten-nickel alloy and 50 to 90 parts of natural rubber; the second-layer structure comprises the materials in parts by weight: 5 to 20 parts of rare earth mineral powder, 50 to 80 parts of natural rubber, 5 to 20 parts of aluminum and 5 to 30 parts of a tungsten-nickel alloy; the third-layer structure comprises the materials inparts by weight: 50 to 100 parts of natural rubber, 5 to 25 parts of aluminum and 5 to 40 parts of a tungsten-nickel alloy; and the fourth-layer structure comprises the materials in parts by weight: 1-10 parts of gadolinium, 50-85 parts of natural rubber, 20-40 parts of aluminum and 2-10 parts of B4C. The material provided by the invention has certain radiation resistance, and can meet the radiation protection requirements of personnel, equipment and devices especially when working in places with complex nuclear radiation backgrounds near strong neutron radiation sources such as nuclear reactors and the like.

Owner:山东双鹰医疗器械有限公司 +1

High-heat-resistance PVC/ABS alloy material modified by nanometer calcium carbonate filling material and preparation method thereof

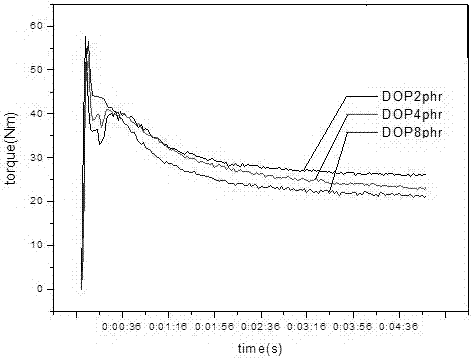

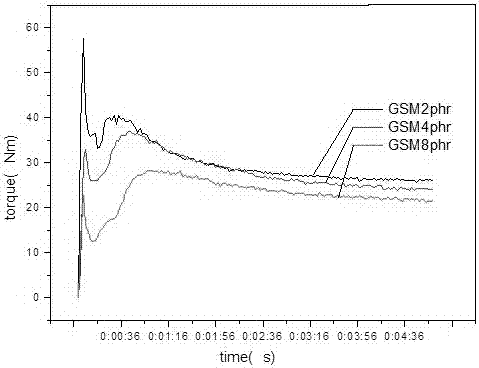

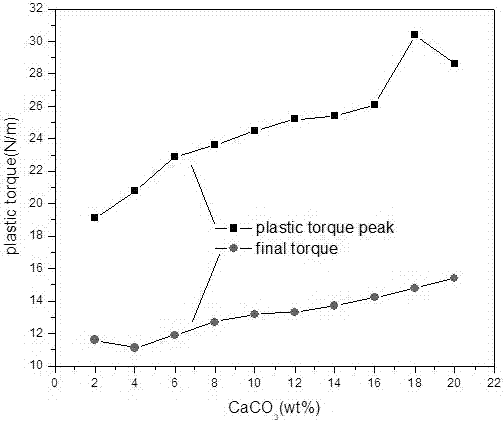

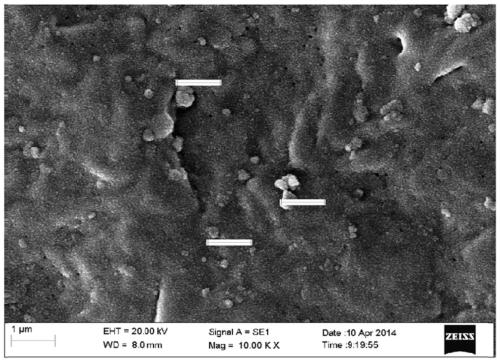

The invention especially relates to a high-heat-resistance PVC / ABS alloy material modified by a nanometer calcium carbonate filling material and a preparation method thereof, belonging to the technical field of high polymer materials. Calcium carbonate (CaCO3) is one of the frequently used additives and heatproof modifiers for polyvinyl chloride; however, too high addition amount of calcium carbonate leads to decline of mechanical properties, deterioration of the fluidity of PVC and degradation of processing properties. Directed at the above shortcomings in the prior art, the invention provides the high-heat-resistance PVC / ABS alloy material modified by the nanometer calcium carbonate filling material and the preparation method thereof. According to the invention, dioctyl phthalate and monoglyceride stearate are used for composite modification, so the processing viscosity of a system is greatly reduced and the compatibility between nanometer calcium carbonate and PVC is improved; and two-step processing, i.e., mixing via a mould pressing method and molding via an injection molding process, is carried out, so problems in uniform blending of nanometer calcium carbonate and PVC are further overcome. The high-heat-resistance PVC / ABS alloy material provided by the invention has the advantages of high nanometer calcium carbonate content (as high as 75 parts), high plasticization peaks and balance torque, high impact strength, high toughness, excellent heat resistance, etc.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

High-gloss polypropylene resin composition, preparation method and applications thereof

The invention belongs to the technical field of polymer materials, particularly relates to a high-gloss polypropylene resin composition, and further discloses a preparation method of the high-gloss polypropylene resin composition, and applications in preparation of high-gloss polypropylene composite materials. According to the present invention, by using the prepared high-gloss polypropylene matrix resin as the raw material and supplementing with the selected nucleating agent and the selected brightener, the anti-impact polypropylene resin with characteristics of good gloss, good impact resistance, good rigidity, high rigidity-toughness balance and low shrinkage rate is obtained while the shrinkage rate is significantly reduced, such that the assembly of injection molding parts and the substitutability of engineering plastics are improved, and the shortcomings in the prior art are effectively overcome.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-thermal-conductivity nylon-graphite-low-melting-point metal composite and preparation method thereof

The invention discloses a high-thermal-conductivity nylon-graphite-low-melting-point metal composite and a preparation method thereof. The high-thermal-conductivity nylon-graphite-low-melting-point metal composite is prepared from, by weight, 20%-50% of nylon resin, 30%-60% of graphite, 5%-20% of low-melting-point metal, 0.1%-1% of antioxidant and 0.1%-1% of lubricant. The low-melting-point metal has the low melting point, the high thermal conductivity, and the low viscosity in a molten state, dispersion of filler in a matrix can be promoted through addition of the low-melting-point metal, the thermal conducting property is improved, and processing viscosity is reduced. The composite has the advantages of being high in thermal conductivity, low in density, good in mechanical and processing property, uniform in filler dispersion and the like.

Owner:SOUTH CHINA UNIV OF TECH

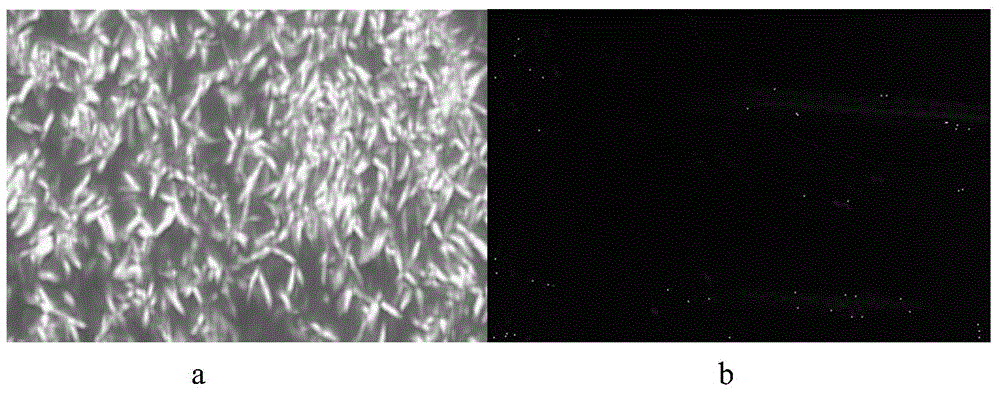

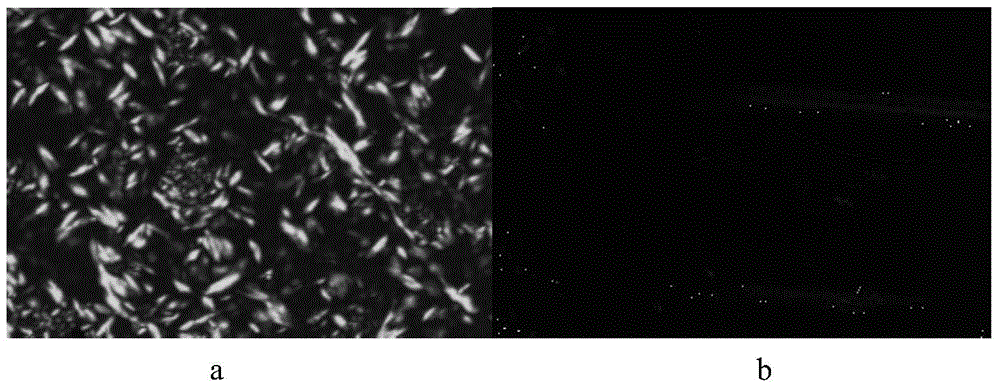

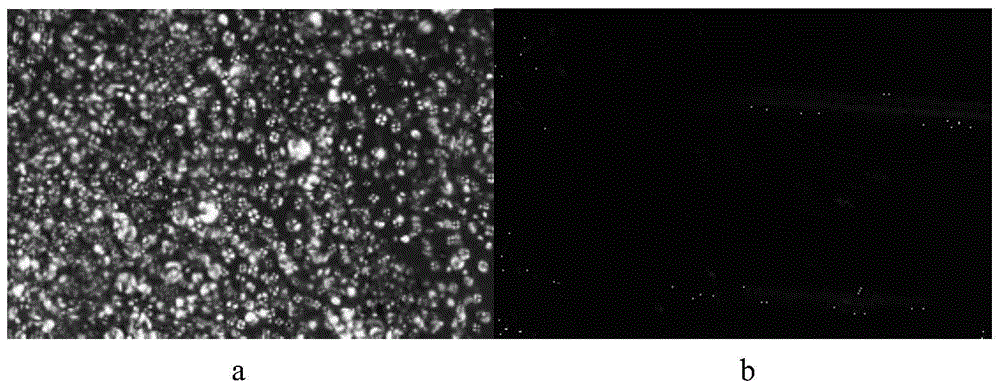

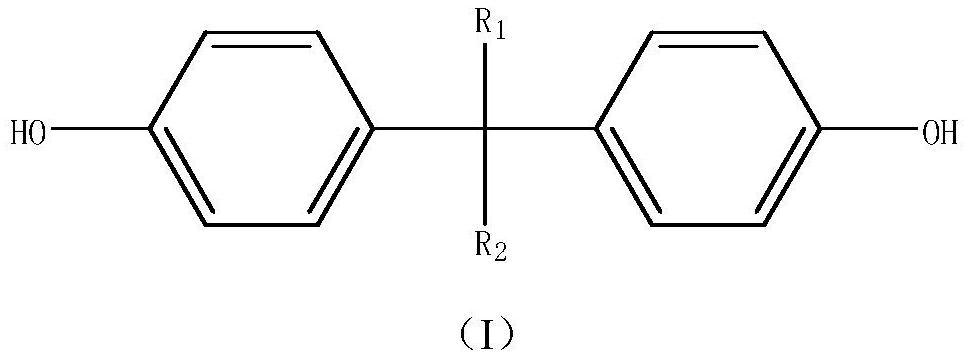

Liquid crystal polymer with ion groups and preparation method for liquid crystal polymer

InactiveCN105085888AHigh modulusGood shock absorbing propertiesLiquid crystal compositionsFiberEthyl acetate

The invention discloses a liquid crystal polymer with ion groups and a preparation method for the liquid crystal polymer. The liquid crystal polymer with the ion groups is formed by virtue of polycondensation of one or more of diol, diphenol or diamine, monomers with ion groups and acyl chloride. The preparation method for the liquid crystal polymer with the ion groups comprises: adding one or more of diol, diphenol or diamine into DMF, THF, acetonitrile, ethyl acetate or DMSO to obtain a mixed solution I; adding an acid-binding agent into the mixed solution I to obtain a mixed solution II; slowly dropwise adding the acyl chloride which is dissolved into the DMF, the THF, the acetonitrile, the ethyl acetate or the DMSO into the mixed solution II to obtain a mixed solution III; and adding alcohol substances into the mixed solution III, and performing washing and drying to obtain the liquid crystal polymer with the ion groups. The liquid crystal polymer with the ion groups disclosed by the invention is applied to the fields such as car parts, precise electronic instruments, light-guide fibers, medical apparatuses and instruments, waterproof materials, textile field, heat insulation materials, energy storage materials, body armors or parachutes and the like.

Owner:NORTHEASTERN UNIV

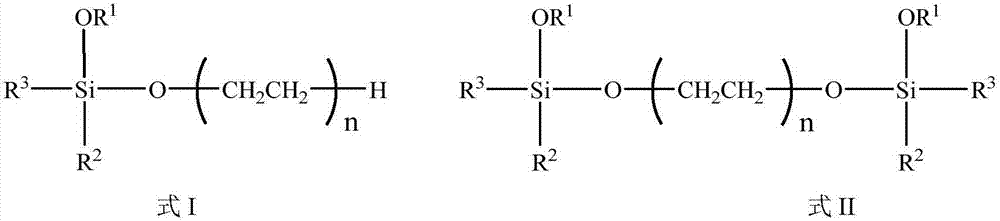

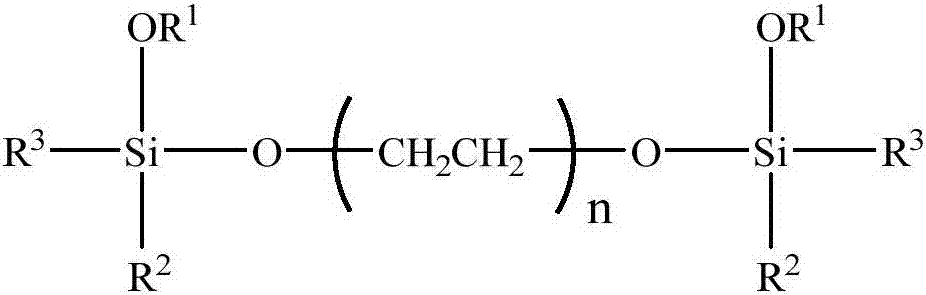

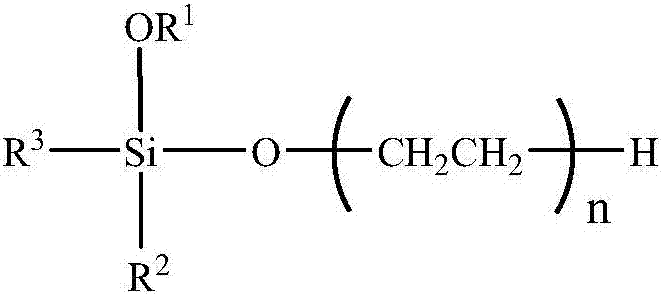

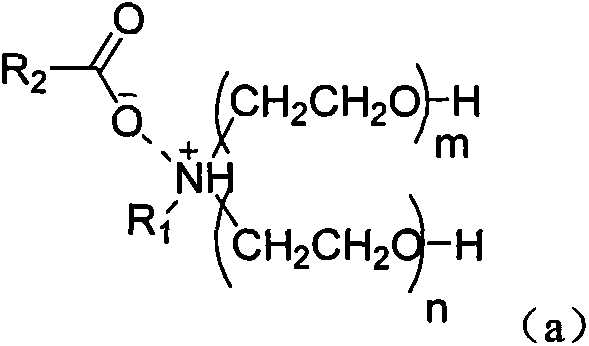

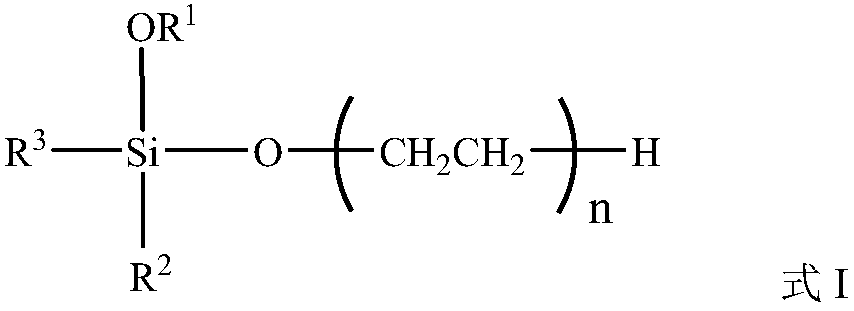

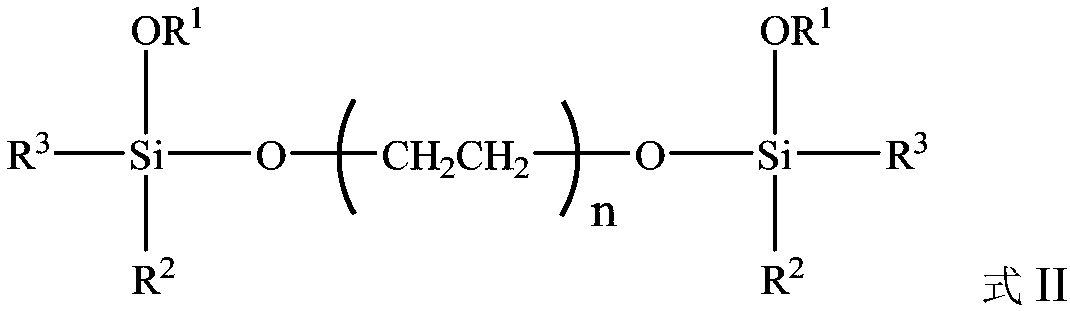

Surface modifier of inorganic powder as well as preparation method and application of surface modifier

The invention discloses a surface modifier of inorganic powder as well as a preparation method and application of the surface modifier. The surface modifier is terminal hydroxyl polyethylene modified organosilane, and is prepared by enabling alkoxy silane as a raw material, reacting alkoxy silane with single / double terminal hydroxyl polyethylene, and by removing generated alcohol and unreacted silane through distillation. The surface modifier can be applied to surface modification upon various inorganic powder materials, and dispersity of the inorganic powder in high polymers is improved.

Owner:黄驰

Preparation method of polymer blended functionally gradient composite material

The invention discloses a preparation method of a polymer blended functionally gradient composite material. The method comprises the following steps: 1) preparation of a blending system: dispersing charged polymer micronanospheres into a solvent-free liquid-state polymer matrix for blending, to obtain a blend; and 2) formation of a gradient structure through driving of a direct-current electric field: adding the blend between energized positive and negative electrodes, leading the charged polymer micronanospheres to move towards the electrode with opposite charges in the liquid-state polymer matrix to form gradient distribution under the driving of a high-voltage direct-current electric field, and moving the electric field after the liquid-state polymer matrix is cured. The long molecularchain of the polymer is curled into the polymer micronanospheres which are dispersed into another polymer matrix so as to reduce the processing viscosity and improve the phase separation speed, and then the microspheres are driven by utilizing the high-voltage electric field and the concentration gradient can be generated through electrophoresis movement, thus obtaining a gradient structure with gradually varied composition and properties.

Owner:JIANGHAN UNIVERSITY

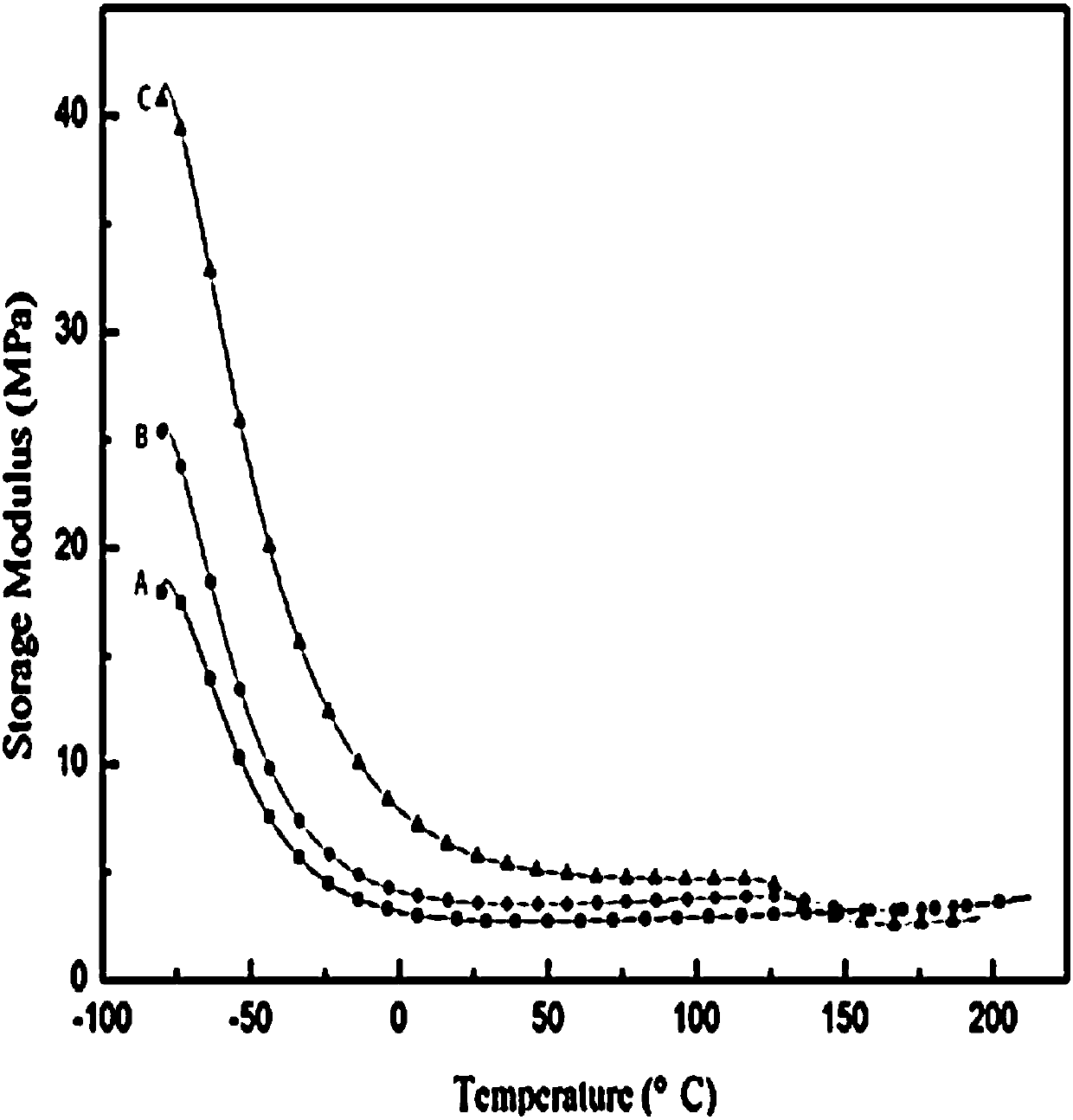

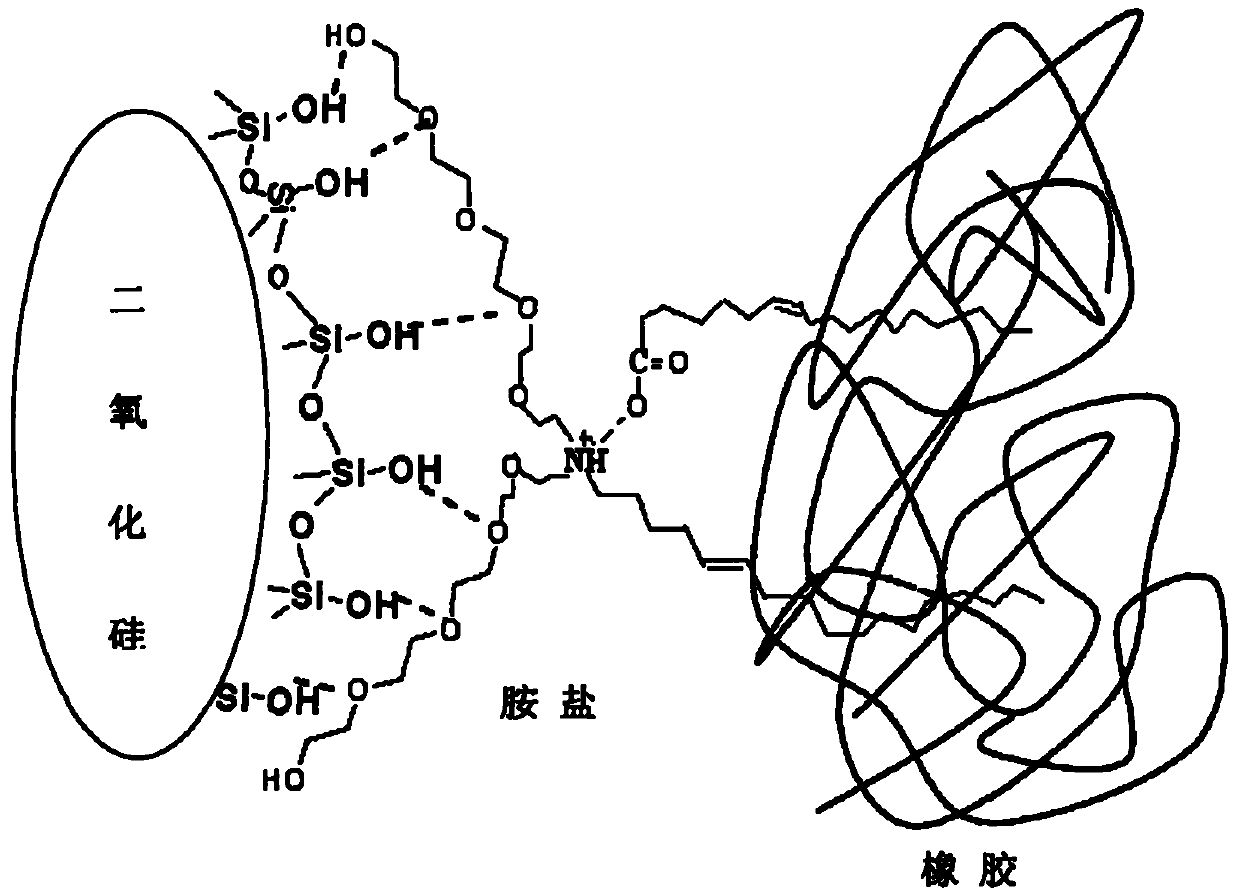

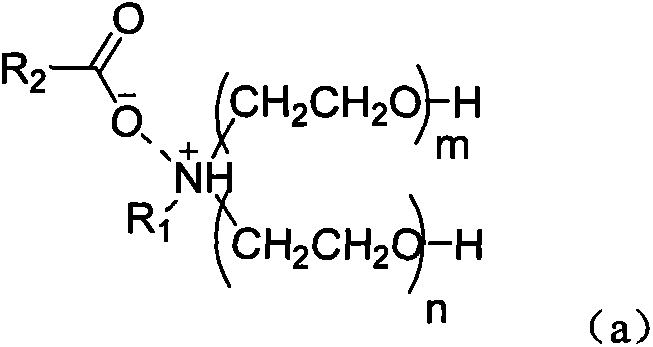

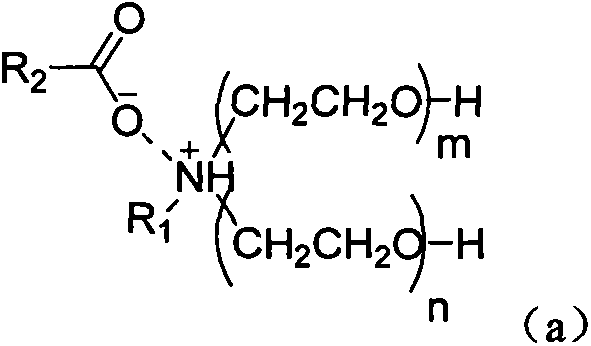

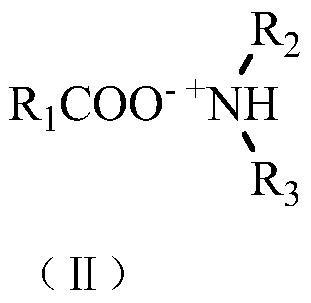

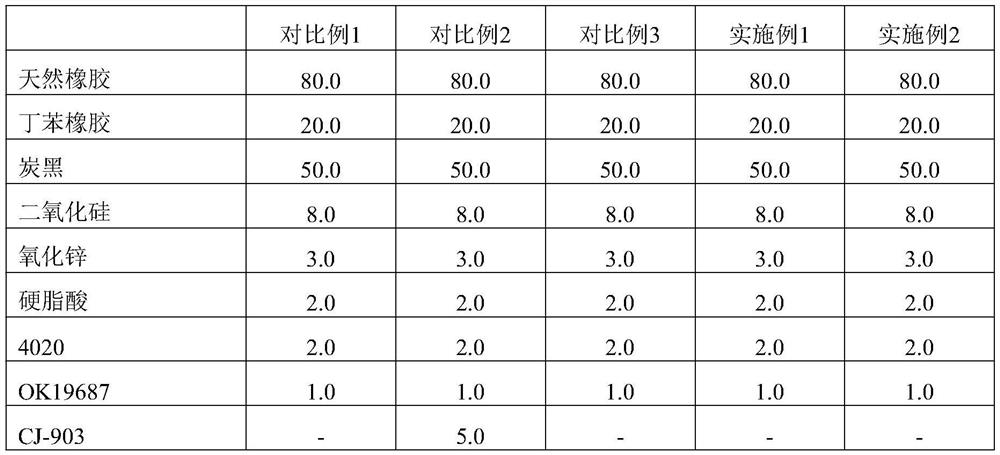

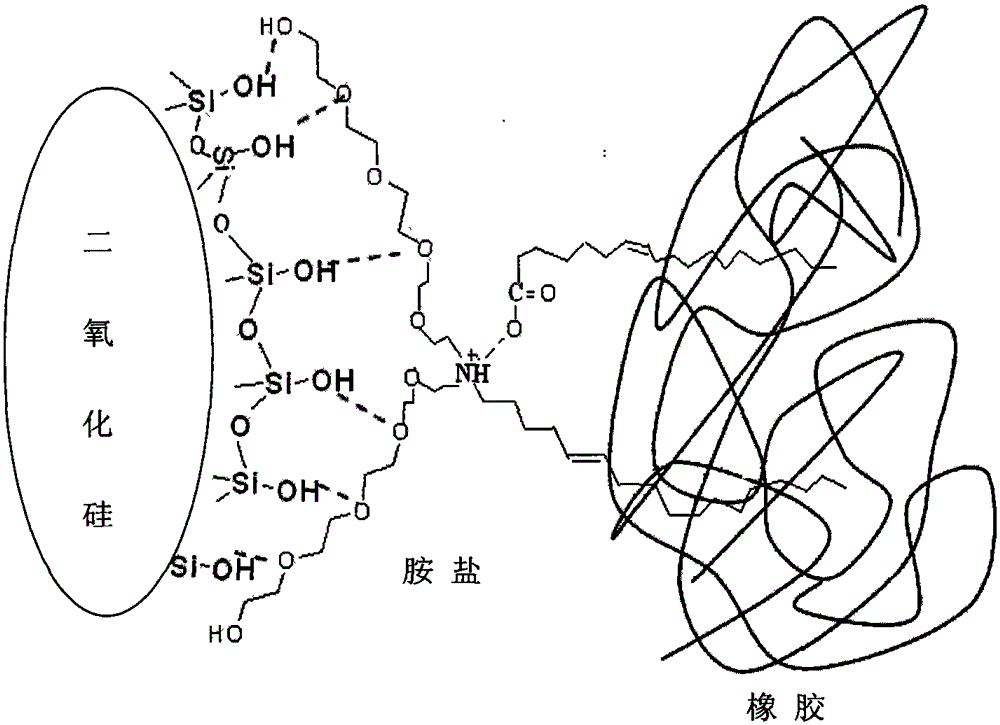

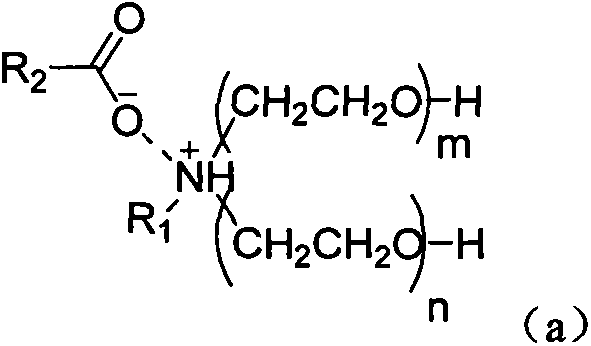

Tire tread rubber composition and tire using same

The invention provides a tire tread rubber composition which has good processing performance, packing dispersibility and wearing resistance and has no hysteresis loss increase. The rubber composition is prepared from the following components in parts by weight: 100 parts of rubber, 40-120 parts of silicon dioxide, 0.1-20 parts of amine salt and 1-20 parts of silane coupling agent in 100 parts of silicon dioxide. The invention also relates to an inflatable tire using the rubber composition for preparing the tire tread.

Owner:BEIJING RED AVENUE INNOVA

Preparation method and application of modified fly ash floating bead loaded DOPO

InactiveCN110818953AReduce processing viscosityImprove liquidityPolyurethane elastomerPolymer science

The invention relates to a fly ash floating bead surface modification loading technology, and concretely relates to a method for carrying out surface modification on fly ash floating beads by using aplurality of coupling agents and compounding the fly ash floating beads with a flame retardation synergist 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO). The preparation method comprisesthe following steps: carrying out bleaching, hydroxylation and acid pretreatment on fly ash, then carrying out surface modification treatment on the pretreated fly ash by using a coupling agent, and finally loading a flame retardant synergist DOPO. According to the method, after surface modification of fly ash, the physical and chemical properties of the surface of the obtained surface-modified fly ash floating bead are changed, so the compatibility of the filler and crystal interfaces such as the elastomer in the thermoplastic polyurethane elastomer is improved; and thus, the mechanical property, the flame retardant property and other properties of the thermoplastic polyurethane elastomer are improved, an improvement method is provided for better utilization of the fly ash, and the pollution to the environment is reduced.

Owner:FUZHOU UNIV

Lithium ion power battery and preparation method therefor

InactiveCN107706388AExcellent charge and discharge rateImprove cycle lifeMaterial nanotechnologyFinal product manufacturePower batteryCarbon nanotube

The invention discloses a lithium ion power battery and a preparation method therefor. A positive electrode plate of the lithium ion power battery consists of iron disulfide, carbon nanotubes, lithiumcobalt oxide, graphite and tin carbonate; and a negative electrode plate of the lithium ion power battery consists of lithium titanate, nanometer metal particles and a binder. The preparation methodprovided by the invention is simple and the prepared lithium ion power battery is excellent in rate charging and discharging, long in cycle life, and high in electrochemical performance and safety.

Owner:BEIJING JUNXIU CONSULTATION CO LTD

Calixarene solution for printed circuit board and preparation method thereof

The invention discloses a calixarene solution for a printed circuit board. The calixarene solution for the printed circuit board is characterized by comprising calixarene, terephthalaldehyde, plasticizer, coupling reagent and aromatic solvent. The components in parts by weight are as follows: 100 parts of calixarene, 50-70 parts of terephthalaldehyde, 10-20 parts of plasticizer, 5-10 parts of coupling reagent and 200-400 parts of aromatic solvent. The calixarene solution for the printed circuit board disclosed by the invention has high liquidity and is practically suitable for printing production of circuit board.

Owner:GUANGDONG CHENGDE ELECTRONICS TECH CO LTD +1

Hyperbranched poly(aryl ether ketone), preparation method and application thereof in viscosity modifier

The invention relates to a hyperbranched poly (ether ketone), a preparation method thereof and application of the material in viscosity modifiers. The hyperbranched poly(ether ketone) is prepared wit BB2-type monomers 2, 4, 6 trifluoro phenyl ketone and A2-type monomers hydroquinone, resorcin, bisphenol A, and hexafluoro-bisphenol A or biphenyl diphenol as reactants, potassium carbonate or sodiumcarbonate or the mixture of the potassium carbonate and the sodium carbonate as a salification agent, and sulfolane or N, N-dimethyl ketopyrrolidine as a solvent through mixing, salification, polycondensation reaction and after treatment. The solid content is 20 to 30 percent; the dosage of the salification agent is 1 to 1.1 time of the dosage of the A2 monomers. Fluorine terminated hyperbranchedpolyaryletherketone and hydroxy terminated superbranched polyaryletherketone are got respectively by adjusting the ratio of the dosages of the BB2-type and A2-type monomers. The hyperbranched poly (ether ketone) is characterized in that by adding the superbranched polyaryletherketone, the mechanical property and the thermostability of linear polyaryletherketone are not reduced while the melt viscosity of the linear polyaryletherketone is reduced.

Owner:JILIN UNIV

A kind of pet protective film with good wear resistance and strong impact resistance and its manufacturing process

ActiveCN103602044BImprove curing effectImprove adhesionFilm/foil adhesivesCoatingsPolymer scienceThin membrane

The invention relates to the technical field of protective films, in particular to a PET protective film with good wear resistance and strong impact resistance and its manufacturing process. The PET protective film includes a PET film layer and an adhesive layer. The PET film layer consists of an outer layer, The middle layer and the inner layer are composed of three co-extruded and bonded films. The adhesive layer is coated on the inner layer of the PET film layer. The PET film layer adopts a three-layer structure. The inner layer of the PET film layer maintains good The wettability of the PET film layer increases the cohesive force between the inner layer of the PET film layer and the adhesive layer, and prevents the PET film layer from falling off during use; the middle layer of the PET film layer plays a role in maintaining the strength of the present invention; the PET film layer The outer layer maintains good surface smoothness and wear resistance in terms of raw material selection. A PET protective film with good wear resistance and strong impact resistance of the present invention has low production process cost and simple process, and corona treatment increases the wettability of the inner layer of the PET film layer and increases the Adhesion to the adhesive layer.

Owner:东莞市尼的科技股份有限公司

A kind of high thermal conductivity nylon-graphite-low melting point metal composite material and preparation method thereof

The invention discloses a high-thermal-conductivity nylon-graphite-low-melting-point metal composite and a preparation method thereof. The high-thermal-conductivity nylon-graphite-low-melting-point metal composite is prepared from, by weight, 20%-50% of nylon resin, 30%-60% of graphite, 5%-20% of low-melting-point metal, 0.1%-1% of antioxidant and 0.1%-1% of lubricant. The low-melting-point metal has the low melting point, the high thermal conductivity, and the low viscosity in a molten state, dispersion of filler in a matrix can be promoted through addition of the low-melting-point metal, the thermal conducting property is improved, and processing viscosity is reduced. The composite has the advantages of being high in thermal conductivity, low in density, good in mechanical and processing property, uniform in filler dispersion and the like.

Owner:SOUTH CHINA UNIV OF TECH

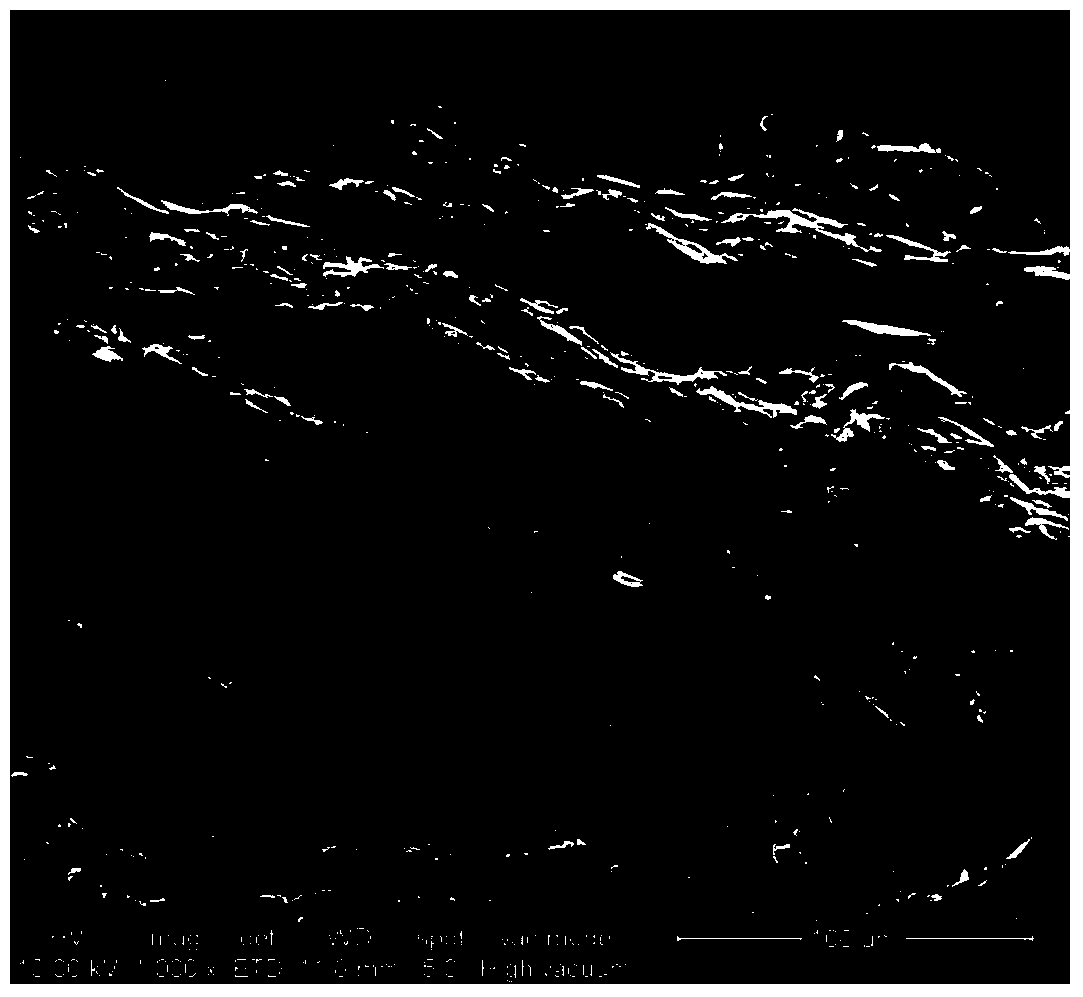

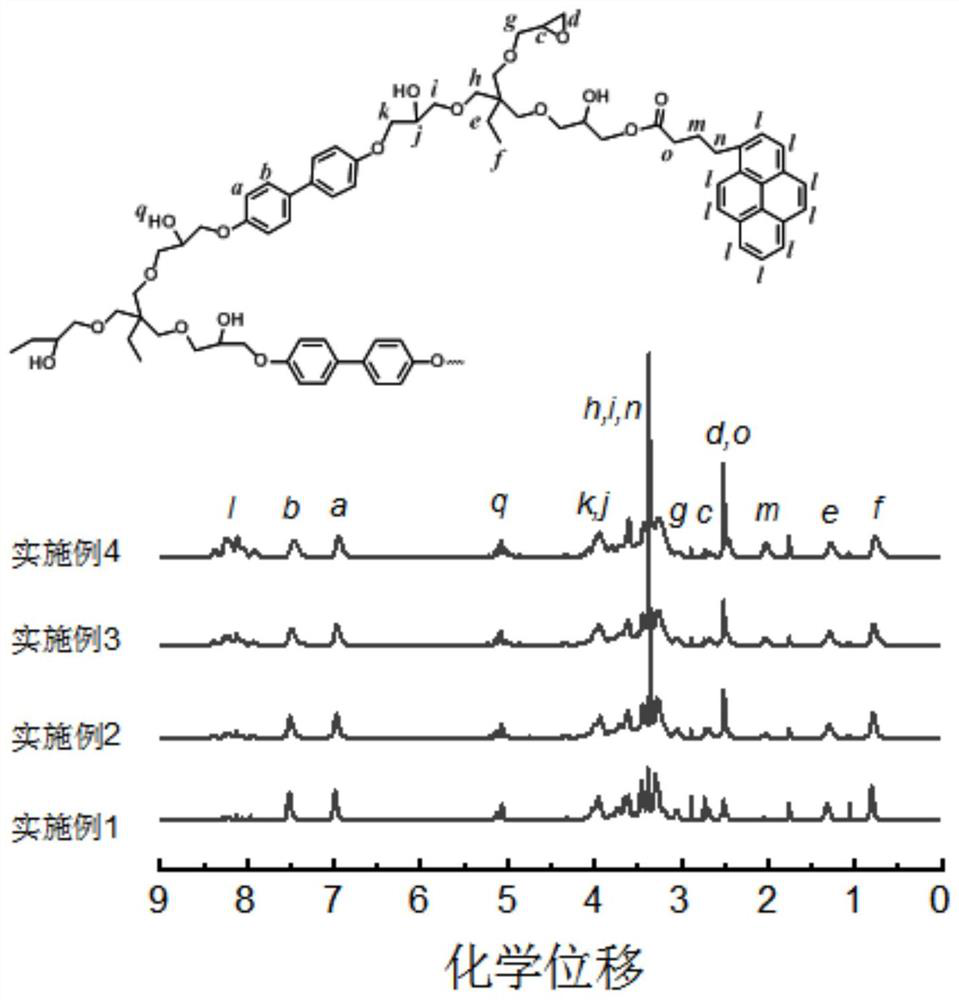

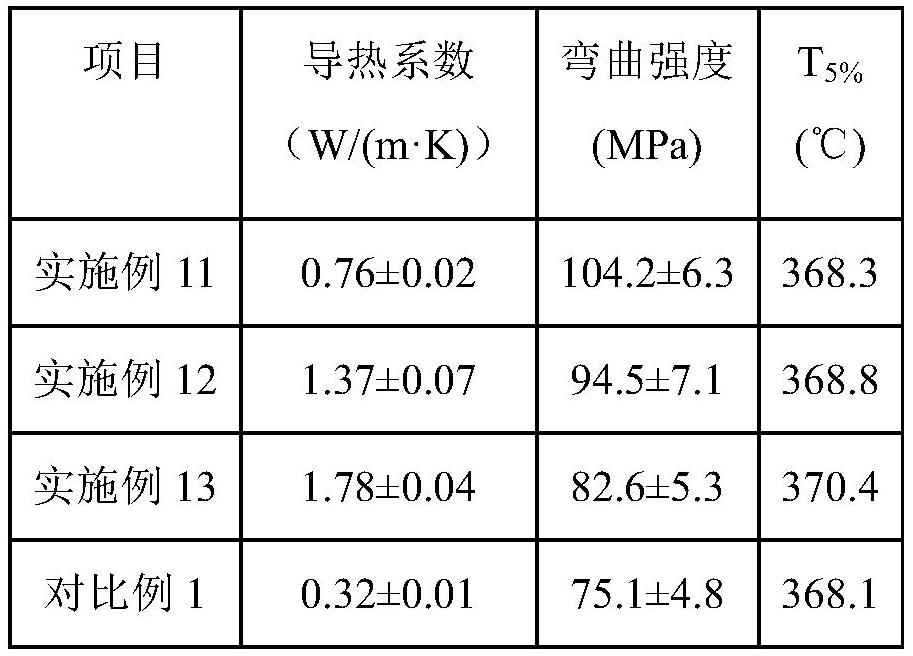

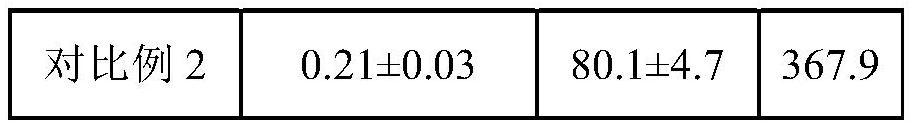

A preparation method of hyperbranched polymer modified boron nitride thermally conductive and insulating composite material

The invention discloses a method for preparing a hyperbranched polymer-modified boron nitride heat-conducting and insulating composite material. The preparation method comprises the following steps: (1) adding hyperbranched polymers, boron nitride fillers and organic solvents into a container , centrifuged and dried to obtain hyperbranched polymer modified boron nitride after ultrasonic treatment; (2) the hyperbranched polymer modified boron nitride prepared in step (1) and matrix resin, curing agent, curing agent accelerator mixing and curing to obtain the thermally conductive and insulating composite material. The invention reduces the processing viscosity of the composite material, improves the processing performance of the composite material, improves the dispersion of boron nitride and its interface compatibility with the resin matrix, and prepares a composite material with high thermal conductivity and excellent mechanical properties. composite material.

Owner:JIANGNAN UNIV

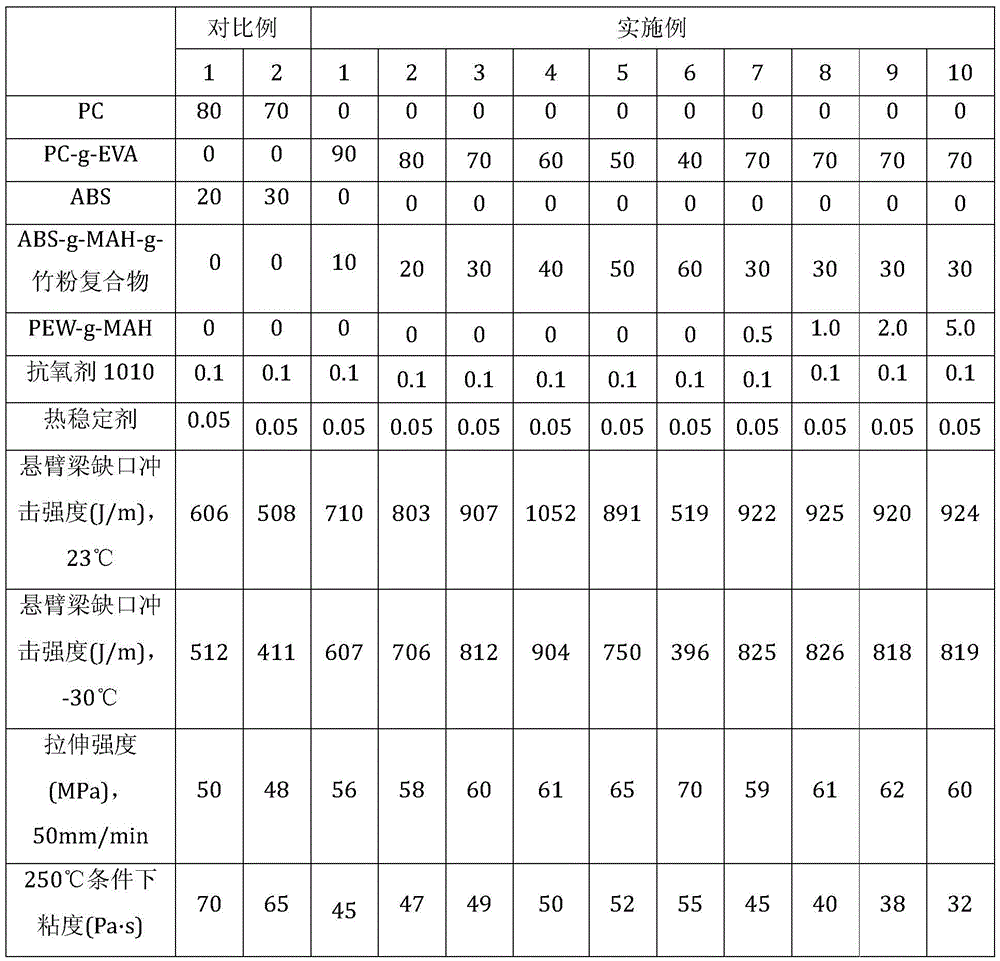

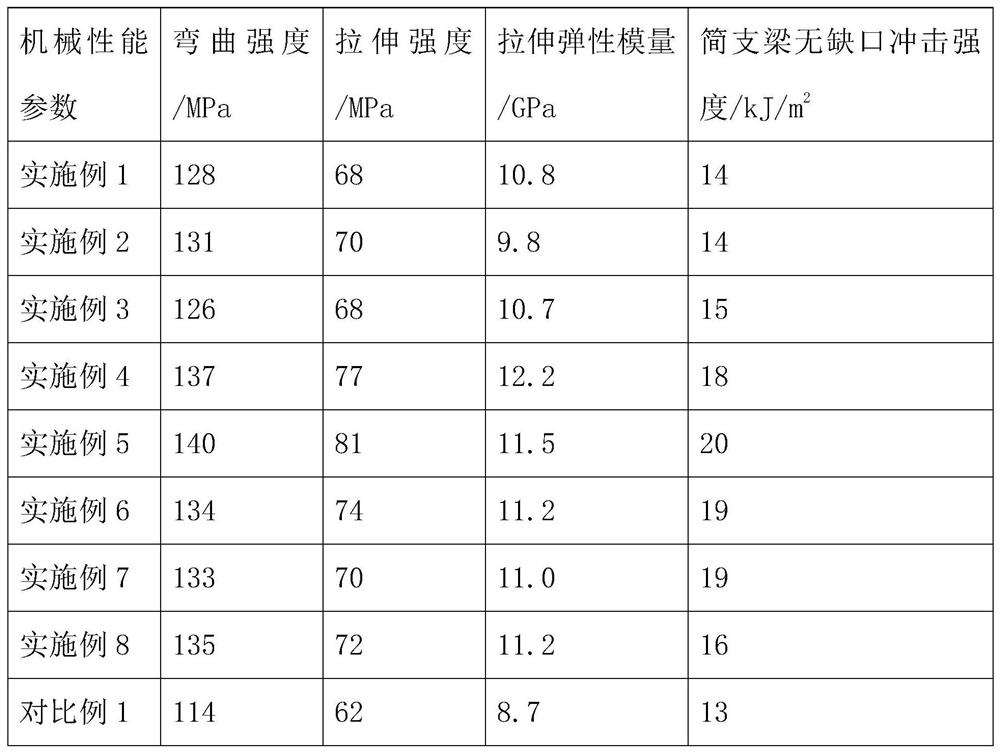

Based on modified bamboo powder pc/abs alloy and preparation method thereof

ActiveCN104804400BImproved impact characteristicsReduce processing viscosityFiberAcrylonitrile butadiene styrene

The invention relates to a manufacturing method of a modified bamboo powder-based PC / ABS (Poly carbonate / Acrylonitrile Butadiene Styrene) alloy in the field of high polymer materials. The manufacturing method comprises the following steps: carrying out blending and internal mixing on bamboo powder, ABS-g-MAH (Maleic Anhydride), a fiber pre-dispersing agent and a coupling agent to obtain an ABS-g-MAH-g-bamboo powder composite; blending the ABS-g-MAH-g-bamboo powder composite, PC-g-EVA (Ethylene Vinyl Acetate) and PEW (polyethylene wax)-g-MAH at high speed and carrying out melt blending to obtain the modified bamboo powder-based PC / ABS alloy. The alloy material manufactured by the method disclosed by the invention not only has superhigh normal-temperature impact tenacity and low-temperature impact tenacity, but also has low viscosity property, is easy for molding processing of larger products, and has relatively high tensile strength, relatively low cost and an environment-friendly effect as well as a wide market value.

Owner:SHANGHAI ZHONGLEI NEW MATERIAL SCI CO LTD

A kind of rubber composition for engineering tire tread and application

The invention discloses a rubber composition for an engineering tire tread, comprising the following components: 100 parts by weight of a diene-based rubber component, 5-100 parts by weight of carbon black, 1-50 parts by weight of silicon dioxide, 1 -30 parts by weight of modified bisphenol phenolic resin, 1-10 parts by weight of fatty acid amine salt compound, as engineering tire tread compound, its aging resistance, tear resistance and wear resistance have been improved, In addition, it maintains good mechanical properties and processing properties.

Owner:BEIJING RED AVENUE INNOVA +1

A kind of epoxy resin composition and its preparation method and application

ActiveCN110218414BSmall coefficient of thermal expansionReduce the impact of brittlenessElastomerThermal dilatation

The application provides an epoxy resin composition, its preparation method and application. The epoxy resin composition comprises the following components by weight: 100 parts of epoxy resin, 55-90 parts of curing agent, 0.1-0.8 parts of accelerator, 300-420 parts of inorganic filler and 4-15 parts of Elastomer particles. The epoxy resin composition provided by this application reduces the curing shrinkage rate through the high filling of inorganic fillers, reduces the thermal expansion coefficient of the cured product formed by pouring, and mixes a certain proportion of elastomer particles to reduce the brittleness of the high filling of inorganic fillers on the cured product, significantly The impact strength of the material is improved, and its anti-fatigue vibration and anti-cracking properties are enhanced without affecting the high temperature resistance of the material, and has no obvious impact on the glass transition temperature. It has good thermal stability and good electrical properties.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Epoxy resin and preparation method and application thereof

InactiveCN102336635BReduce processing viscosityImprove heat resistanceOrganic chemistryOrganic compound preparationEpoxyDiphenyl ether

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

A tire tread rubber composition and tire using the same

Owner:BEIJING RED AVENUE INNOVA

A kind of modified calcium carbonate and its preparation method and application

The invention discloses modified calcium carbonate. Modified calcium carbonate is prepared by modifying by virtue of amino alkoxy silane modified through a modifying agent, namely hydroxyl-terminated polyethylene. Obtained modified calcium carbonate has good lipophilicity and can be well dispersed into polymer molecules, so that the filling amount of calcium carbonate is substantially increased, the processing viscosity of a mixed system is reduced, and the mechanical property of the mixed system is substantially improved.

Owner:黄驰

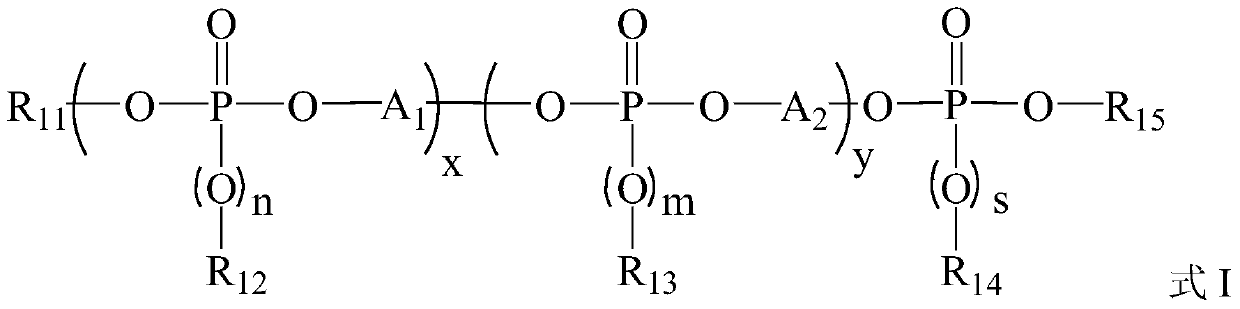

A compound and a polymer material using it

ActiveCN105601996BReduce the effect of heat deflection temperatureReduce processing viscosityGroup 5/15 element organic compoundsPhenolphthaleinEngineering plastic

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com