Surface modifier of inorganic powder as well as preparation method and application of surface modifier

A surface modifier and inorganic powder technology, applied in the field of organic materials, can solve the problems of weak effect, limited efficiency improvement of polymer materials, weak force, etc., to reduce processing viscosity, improve mechanical properties, and increase filling capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

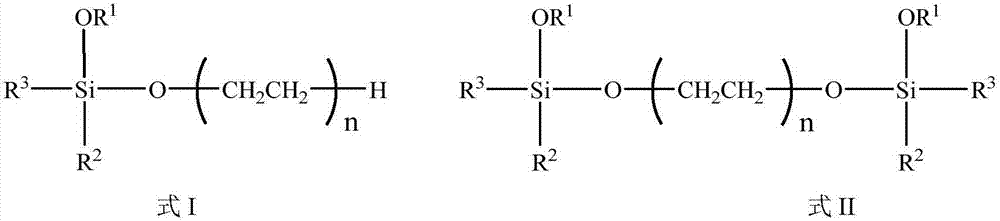

[0024] A surface modifier for inorganic powder, which is a double-terminated hydroxyl polyethylene modified organosilane or a mixture thereof, and its chemical structure is as follows:

[0025]

[0026] Among them, the degree of polymerization n is 100; R 1 is methyl, R 2 is methoxy, R 3 for—CH 2 CH 2 CH 2 NH 2 .

[0027] The preparation method of the above-mentioned inorganic powder modifier is: add 100 parts by mass of petroleum ether at 60-90°C and 100 parts by mass of aminopropyltrimethoxysilane into the reactor, stir evenly, then add 300 parts by mass of 100 double-ended hydroxyl polyethylene, after reflux reaction at 80°C for 10h, distill petroleum ether and produced methanol at 100°C, heat up and distill under reduced pressure to remove unreacted aminopropyltrimethoxysilane, that is The hydroxyl-terminated polyethylene-modified organosilane, that is, the surface modifier of the inorganic powder, is obtained.

[0028] Application: Take 5 parts by mass of the a...

Embodiment 2

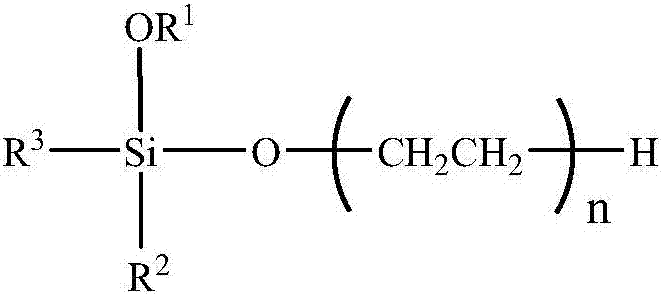

[0031] A surface modifier for inorganic powder, which is a mixture of two kinds of single-end hydroxyl polyethylene modified organosilanes. The chemical structure is as follows:

[0032]

[0033] Where modifier 1 is: n is 5, R 1 is ethyl, R 2 is ethoxy, R 3 for—CH 2 NH 2 ; Modifier 2 is: n is 5, R 1 is methyl, R 2 is methoxy, R 3 for—CH 2 CH 2 NH 2 .

[0034] The preparation method of above-mentioned inorganic powder modifier is:

[0035] Based on organosilane, 100 parts by mass. Add 20 parts by mass of aminomethyltriethoxysilane and 80 parts by mass of aminoethyltrimethoxysilane into the reactor. After stirring evenly, add 50 parts by mass of single-ended hydroxyl polyethylene with a degree of polymerization of 5. After reflux reaction at high temperature for 0.5h, distill petroleum ether and the produced methanol and ethanol at 100°C, heat up and distill under reduced pressure to remove unreacted aminomethyltriethoxysilane and aminoethyltrimethoxysilane, That...

Embodiment 3

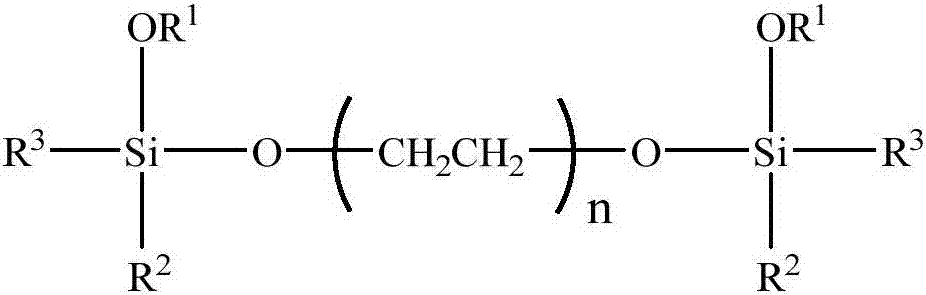

[0039] A surface modifier for inorganic powder, which is a mixture of two double-ended hydroxyl polyethylene modified organosilanes. The chemical structure is as follows:

[0040]

[0041] Where modifier 1 is: n is 500, R 1 is ethyl, R 2 is ethoxy, R 3 for—CH 2 CH 2 CH 2 NHCH 2 CH 2 NH 2 , modifier 2 is: n is 500, R 1 is ethyl, R 2 is methyl, R 3 for—CH 2 NH 2 .

[0042] The preparation method of above-mentioned inorganic powder modifier is:

[0043] Based on organosilane, 100 parts by mass. Add 300 parts by mass of cyclohexane, 99 parts by mass of N-aminoethyl-aminopropyltriethoxysilane and 1 part by mass of aminomethylmethyldiethoxysilane into the reactor, stir well, then add 900 parts by mass Parts by mass of hydroxyl-terminated polyethylene with a degree of polymerization of 500, after reflux reaction at 80°C for 48 hours, distill off petroleum ether and ethanol at 100°C, then heat up and distill under reduced pressure to remove unreacted N-aminoethyl -A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com