Boron nitride oriented thermal-conductive nylon and preparation method thereof

A technology of boron nitride and nylon, which is applied in the field of boron nitride-oriented thermally conductive nylon and its preparation, can solve the problems of complex process, low efficiency, and difficulty in industrialization, and achieve the goal of simplifying the processing technology, improving processability, and facilitating industrialization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

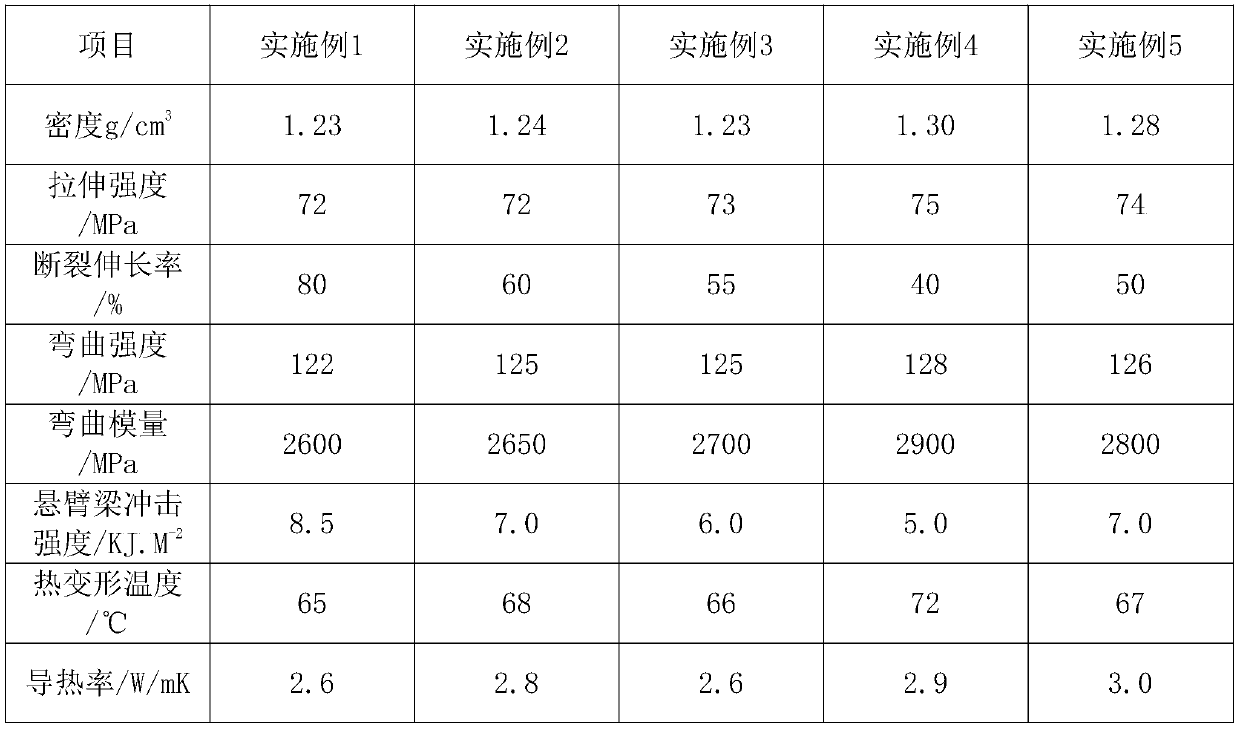

Examples

Embodiment 1

[0026] Step 1, mixing boron nitride particles and urea particles and adding them to a ball mill for ball milling, washing with deionized water for 3 times and drying after ball milling; the mass ratio of boron nitride particles to urea particles is 1:1 ; The mass ratio of the used balls and boron nitride particles for ball milling is 50:1, the ball milling speed is 100rpm, and the ball milling time is 8h;

[0027] Step 2, adding the boron nitride particles treated in step 1 to the N,N-dimethylformamide (DMF) solution of hyperbranched polyester (BE) with terminal hydroxyl groups for grafting reaction, and finally washing with acetone and dry to obtain grafted modified boron nitride; the grafting reaction temperature is 70°C, the grafting reaction stirring time is 2h, and the N,N-dimethylformaldehyde of the hyperbranched polyester (BE) with terminal hydroxyl groups Amide (DMF) solution concentration is 1.0mol / L;

[0028] Step 3, 50 parts by weight of the graft modified boron ni...

Embodiment 2

[0030] Step 1, mixing boron nitride particles and urea particles and adding them to a ball mill for ball milling, washing with deionized water for 3 times and drying after ball milling; the mass ratio of boron nitride particles to urea particles is 1:5 ; The mass ratio of the balls used for ball milling to boron nitride particles is 50:1, the ball milling speed is 100rpm, and the ball milling time is 3h;

[0031] Step 2, adding the boron nitride particles treated in step 1 to the N,N-dimethylformamide (DMF) solution of hyperbranched polyester (BE) with terminal hydroxyl groups for grafting reaction, and finally washing with acetone and dry to obtain grafted modified boron nitride; the grafting reaction temperature is 70°C, the grafting reaction stirring time is 2h, and the N,N-dimethylformaldehyde of the hyperbranched polyester (BE) with terminal hydroxyl groups Amide (DMF) solution concentration is 1.0mol / L;

[0032] Step 3, 20 parts by weight of the graft modified boron nit...

Embodiment 3

[0034] Step 1, mixing boron nitride particles and urea particles and adding them to a ball mill for ball milling, washing with deionized water for 3 times and drying after ball milling; the mass ratio of boron nitride particles to urea particles is 1:3 ; The mass ratio of the used balls and boron nitride particles for ball milling is 50:1, the ball milling speed is 100rpm, and the ball milling time is 5h;

[0035] Step 2, adding the boron nitride particles treated in step 1 to the N,N-dimethylformamide (DMF) solution of hyperbranched polyester (BE) with terminal hydroxyl groups for grafting reaction, and finally washing with acetone and dry to obtain grafted modified boron nitride; the grafting reaction temperature is 65°C, the grafting reaction stirring time is 2.5h, and the N,N-dimethyl of the hyperbranched polyester (BE) with terminal hydroxyl groups Formamide (DMF) solution concentration is 0.8mol / L;

[0036] Step 3, 30 parts by weight of the graft modified boron nitride,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com