A kind of high thermal conductivity nylon-graphite-low melting point metal composite material and preparation method thereof

A low-melting-point metal and composite material technology, applied in the field of thermally conductive materials, can solve the problems of unproven thermal conductivity, affecting material processing performance, not mentioning thermal conductivity, etc. Effects with low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 34wt% of nylon 6, 45wt% of 20 μm flake graphite, 20wt% of tin powder, 0.5wt% of antioxidant 1076, 0.5wt% of white mineral oil were mixed in a high-speed mixer for 10 minutes at room temperature, and the mixed The raw materials are put into a twin-screw extruder to be melted and extruded and granulated. The screw temperature of the extruder is 220-270 ° C, and the main engine speed is 180 r-min. After drying, a high thermal conductivity nylon-graphite-low melting point metal composite material is obtained. After testing, its thermal conductivity is 5.364W-m K and its density is 1.795g-cm 3 . The microscopic morphology analysis of the material, such as figure 1 As shown, the thermally conductive filler is well dispersed in the nylon matrix, and the sample made of this material is tested for mechanical properties. The tensile strength is 56MPa, and the bending strength is 78MPa. The test results show that the high thermal conductivity nylon-graphite-low melting point met...

Embodiment 2

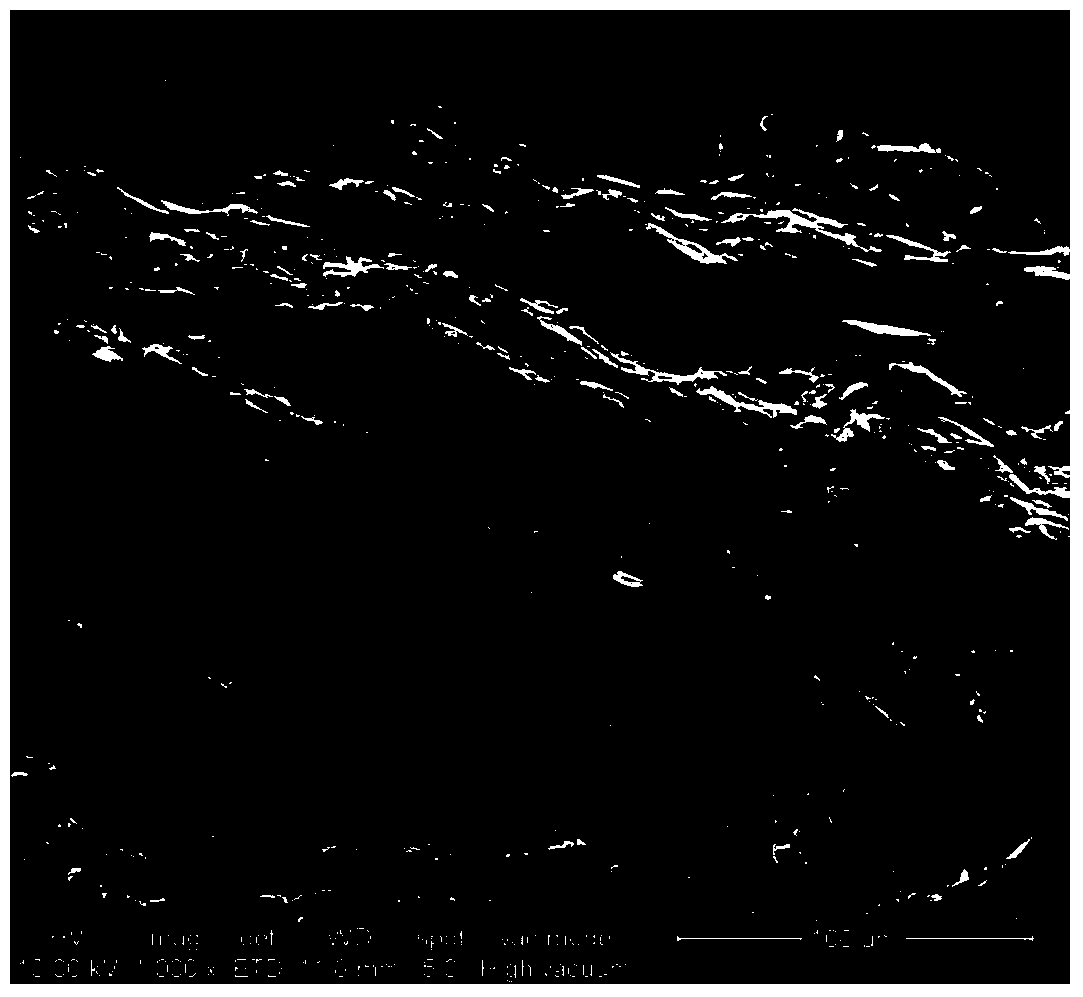

[0038] 37wt% nylon 66, 50wt% 15 μm flake graphite, 12wt% tin powder, 0.4wt% antioxidant 1010, 0.6wt% stearic acid amide were mixed at room temperature in a high-speed mixer for 5 minutes, mixed Good raw materials are melted and extruded into twin-screw extruder and granulated. The screw temperature of the extruder is 210-270°C, and the speed of the main engine is 180r-min. After drying, a high thermal conductivity nylon-graphite-low melting point metal composite material is obtained. Tested, its thermal conductivity is 3.162W-m K, density 1.695g-cm 3 . The microscopic morphology analysis of the material, such as figure 2 As shown, the thermally conductive filler is well dispersed in the nylon matrix.

Embodiment 3

[0040]50wt% nylon 66, 30wt% 30 μm dense crystalline graphite, 18wt% bismuth powder, 0.5wt% antioxidant 264, 0.5wt% antioxidant 168, 1wt% polypropylene wax at room temperature The high-speed mixer is mixed for 10 minutes, and the mixed raw materials are added to the twin-screw extruder to melt, extrude and pelletize. The screw temperature of the extruder is 220-270°C, and the main engine speed is 180r-min. Graphite-low melting point metal composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com