Flexible neutron radiation protection material and protective article preparation method

A radiation protection and neutron technology, applied in shielding, nuclear engineering, reactors, etc., can solve problems such as unfavorable protection, high biological toxicity, low melting point and Mohs hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

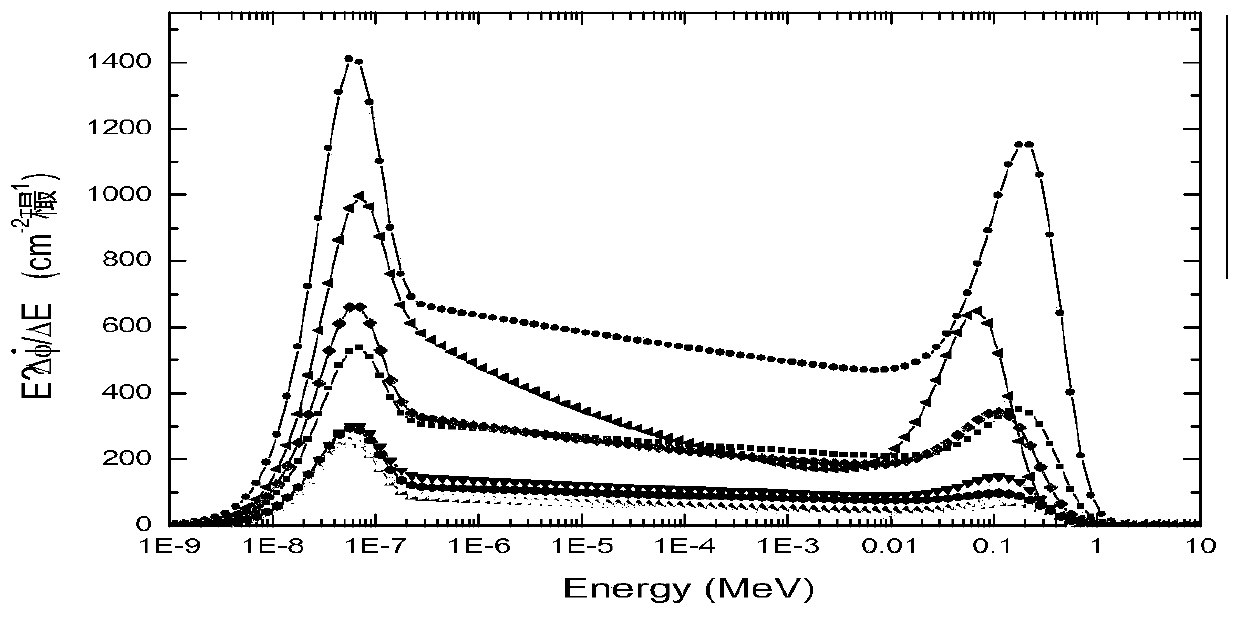

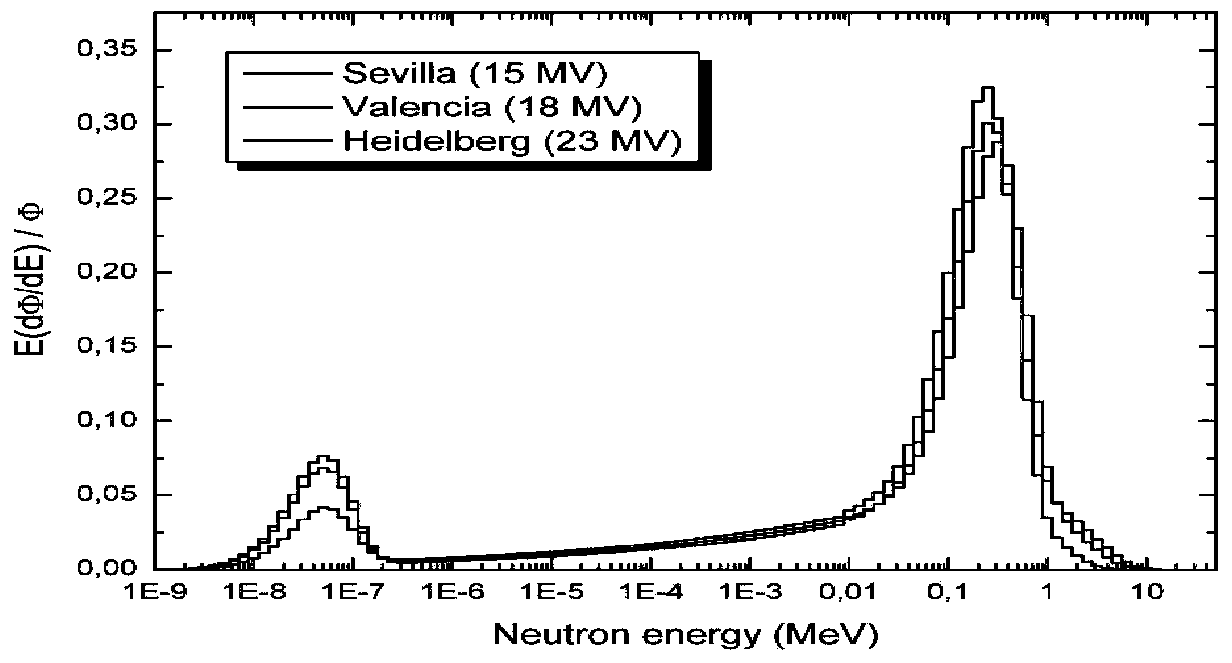

[0065] 1) Neutron source item: According to the actual neutron energy spectrum of the radiation field, an isotropic point neutron source located in the very center of the shield is simulated, and the neutron energy is 0.0253eV for thermal neutrons and 100keV for neutrons Neutrons (neutron production accounted for 70%: 30%).

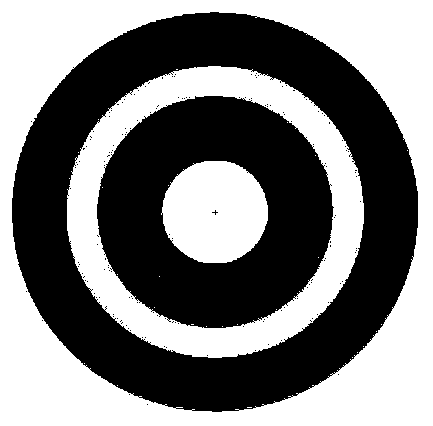

[0066] 2) Calculation model and material composition. A hollow spherical shield with an inner diameter of 0.5cm and an outer diameter of 2.5cm is established. The shield is divided into 4 layers, and the thickness of each layer is 0.5cm. The ingredients contained in each layer are the same, but the proportion of each mass component are not the same, see Table 1, and the established shielding body model is shown in image 3 . Rare earth mineral powders contain natural radionuclides, including 238 U0.74%; 232 Th1.23%; 226 Ra0.51%; 40 K1.13%, purchased from Sichuan Jiangtong Rare Earth Co., Ltd., natural rubber is a kind of natural polymer compound wit...

experiment example 2

[0074] 1) Neutron source item: According to the actual neutron energy spectrum of the radiation field, an isotropic point neutron source located in the very center of the shield is simulated, and the neutron energy is 0.0253eV for thermal neutrons and 100keV for neutrons Neutrons (neutron production accounted for 70%: 30%).

[0075] 2) Calculation model and material composition. A hollow spherical shield with an inner diameter of 0.5cm and an outer diameter of 2.5cm is established. The shield is divided into 4 layers, and the thickness of each layer is 0.5cm. The ingredients contained in each layer are the same, but the proportion of each mass component Not the same, as shown in the above example, see Table 2.

[0076] Table 2. The mass composition of the shielding material components of the neutron source (thermal neutron and neutral neutron) model

[0077]

[0078] 3) Result analysis

[0079] There are two types of energy neutrons produced by the point neutron source. ...

experiment example 3

[0083] Neutron-photon mixed radiation field evaluation. The shielding effects of two kinds of neutron flexible shielding materials on photons were compared, see Figure 10 and Figure 11 . It can be seen that the shielding body doped with tungsten-nickel alloy has better shielding performance on photons than that of aluminum alloy doped material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com