Patents

Literature

208 results about "Rare-earth mineral" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

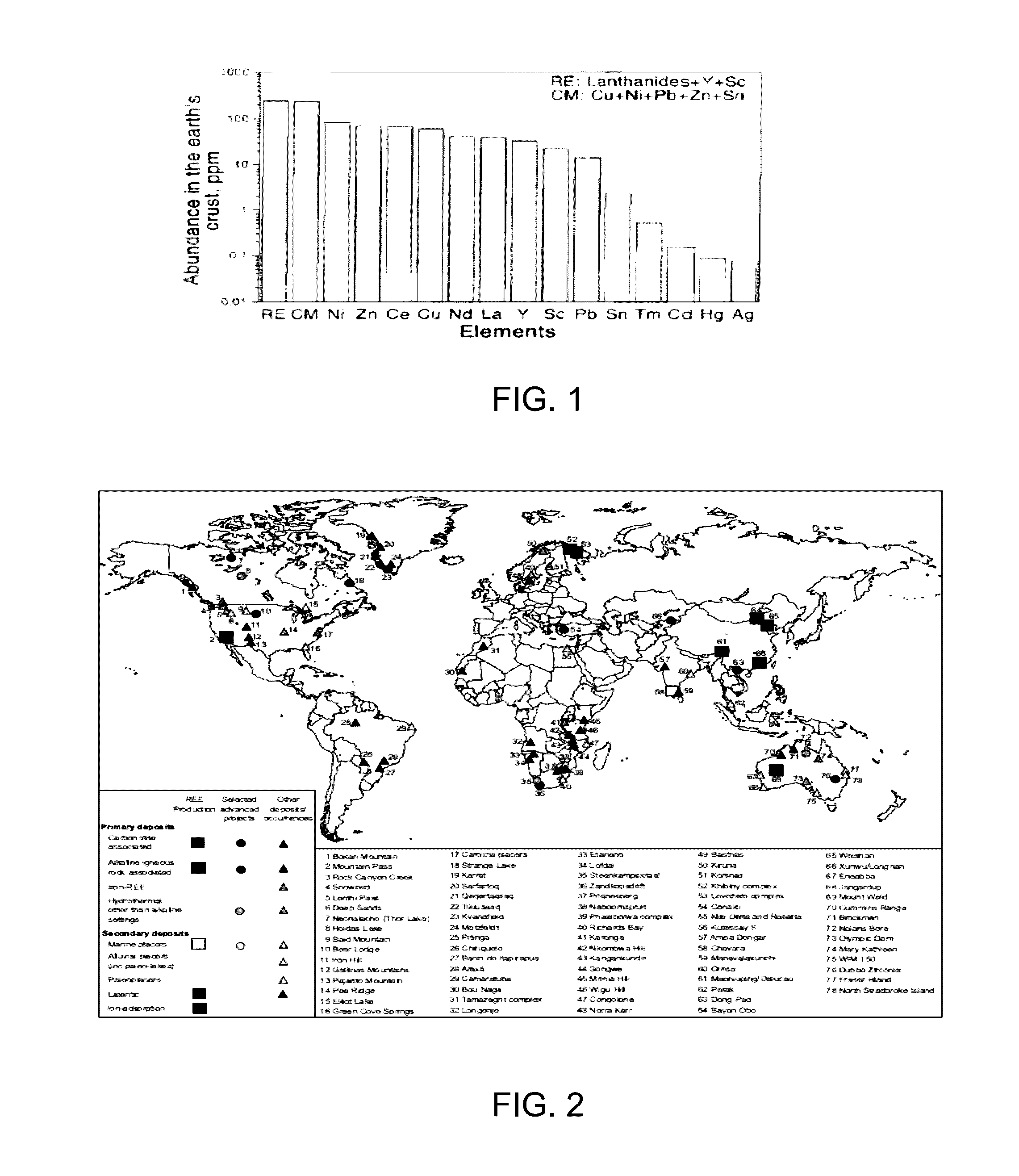

A rare-earth mineral contains one or more rare-earth elements as major metal constituents. Rare-earth minerals are usually found in association with alkaline to peralkaline igneous complexes, in pegmatites associated with alkaline magmas and in or associated with carbonatite intrusives. Perovskite mineral phases are common hosts to rare-earth elements within the alkaline complexes. Mantle-derived carbonate melts are also carriers of the rare earths. Hydrothermal deposits associated with alkaline magmatism contain a variety of rare-earth minerals.

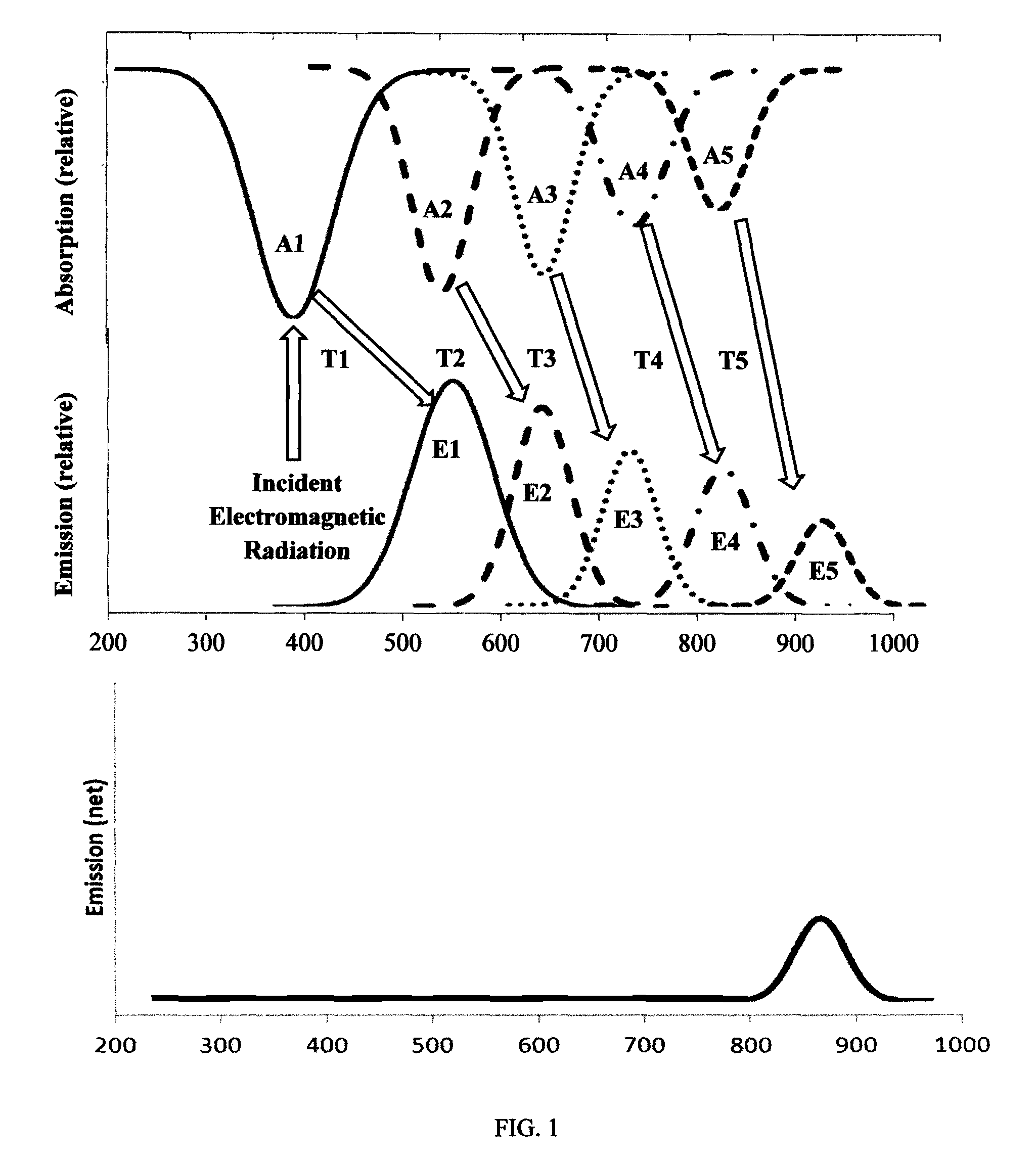

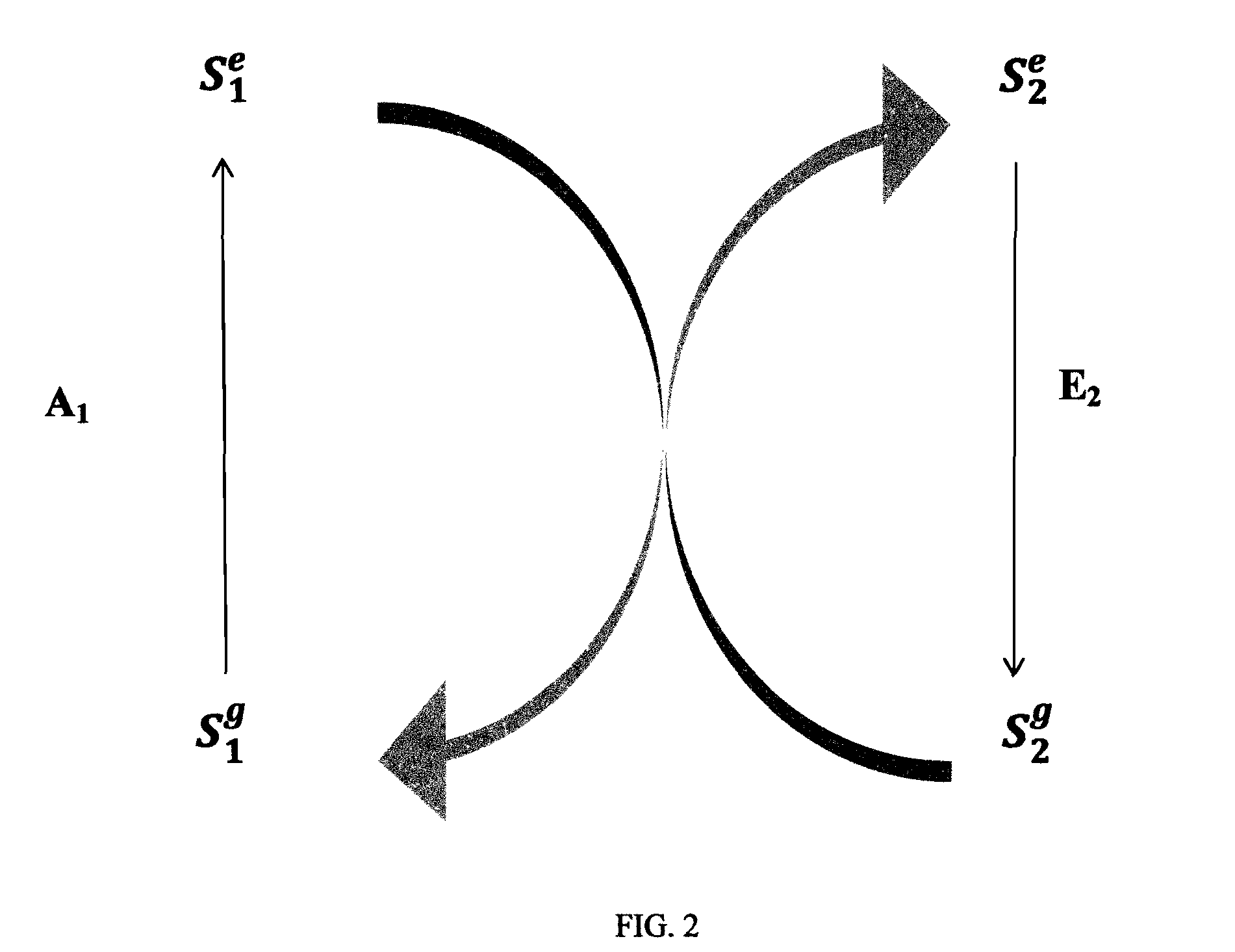

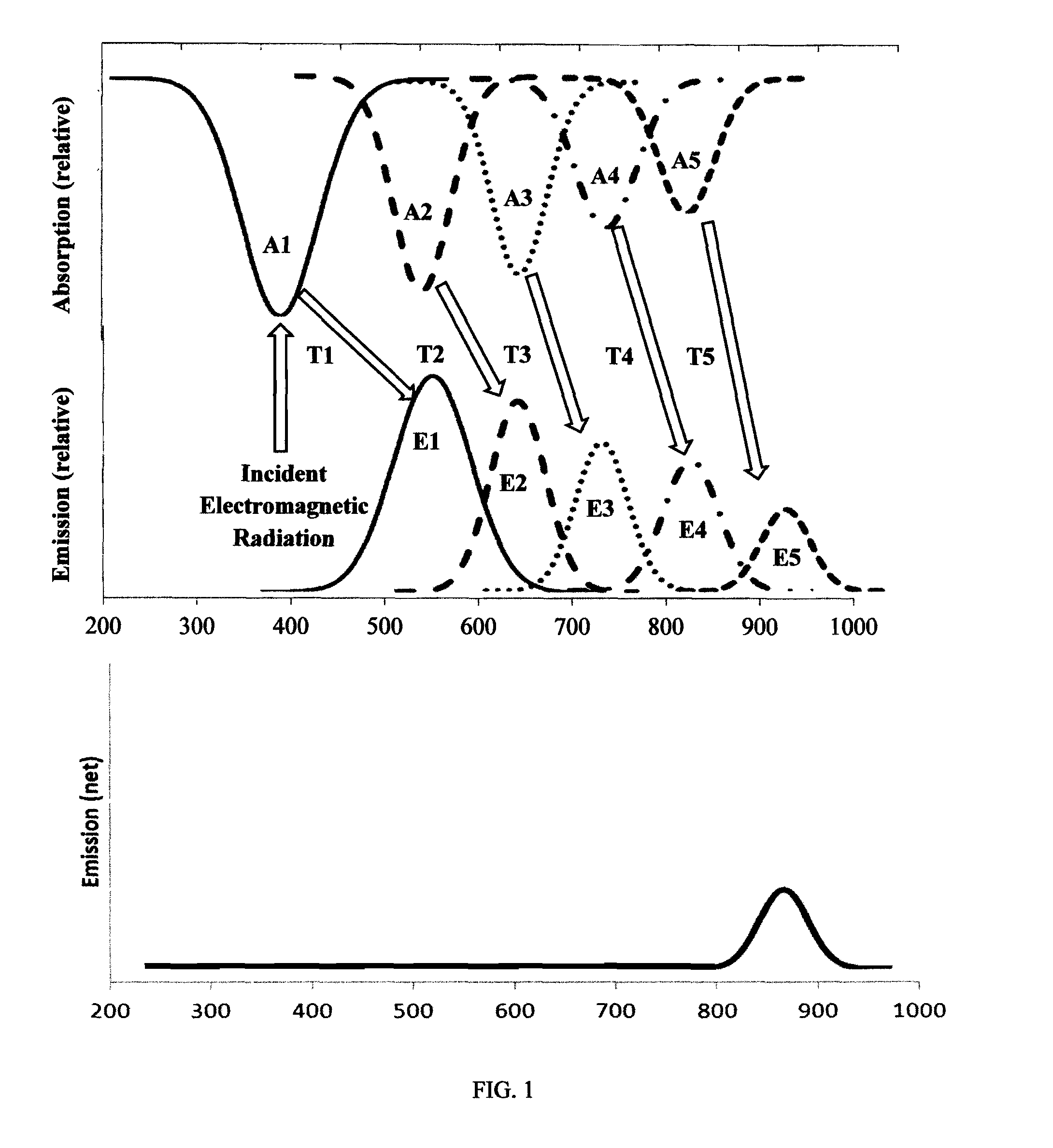

Low rare earth mineral photoluminescent compositions and structures for generating long-persistent luminescence

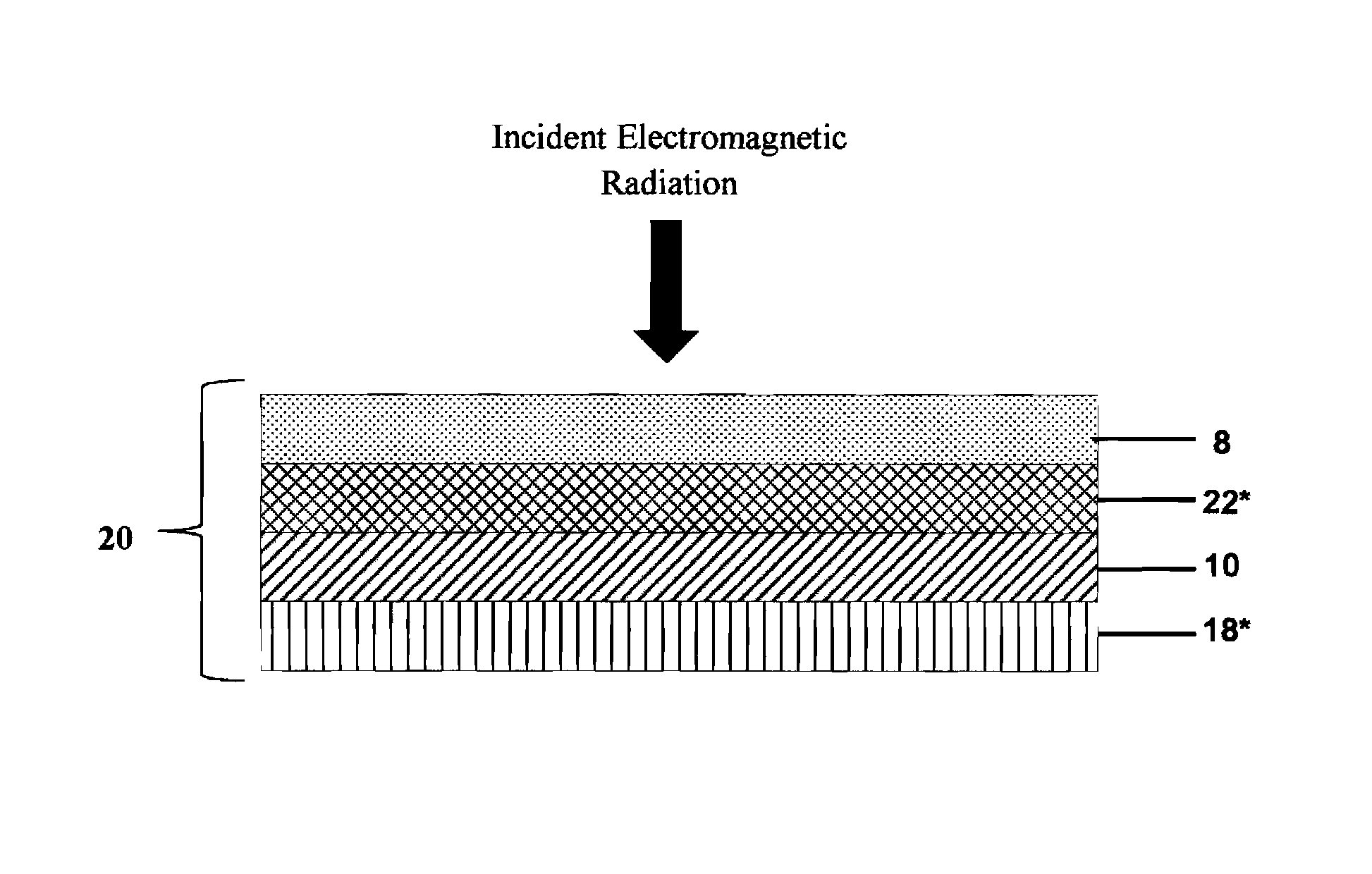

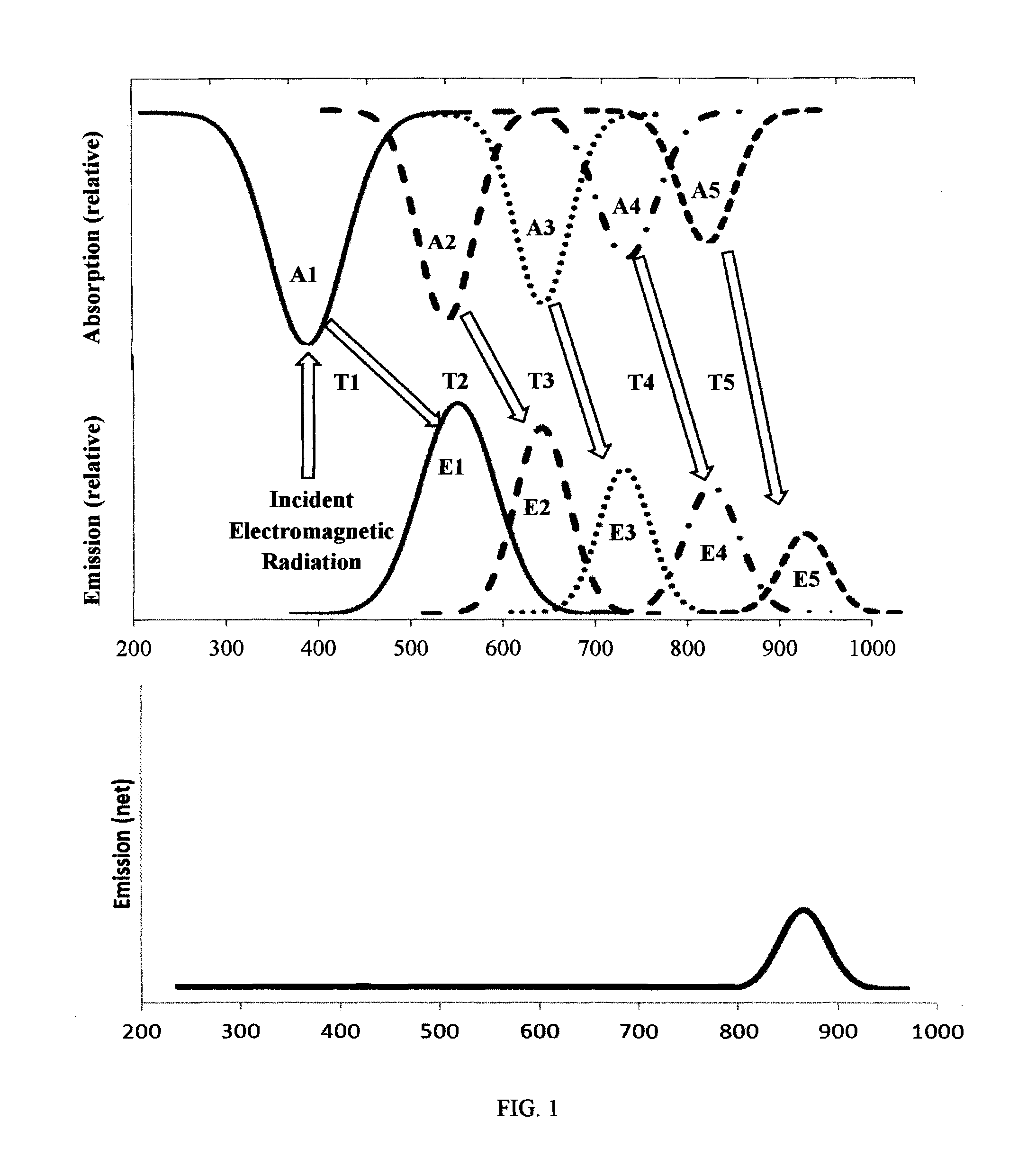

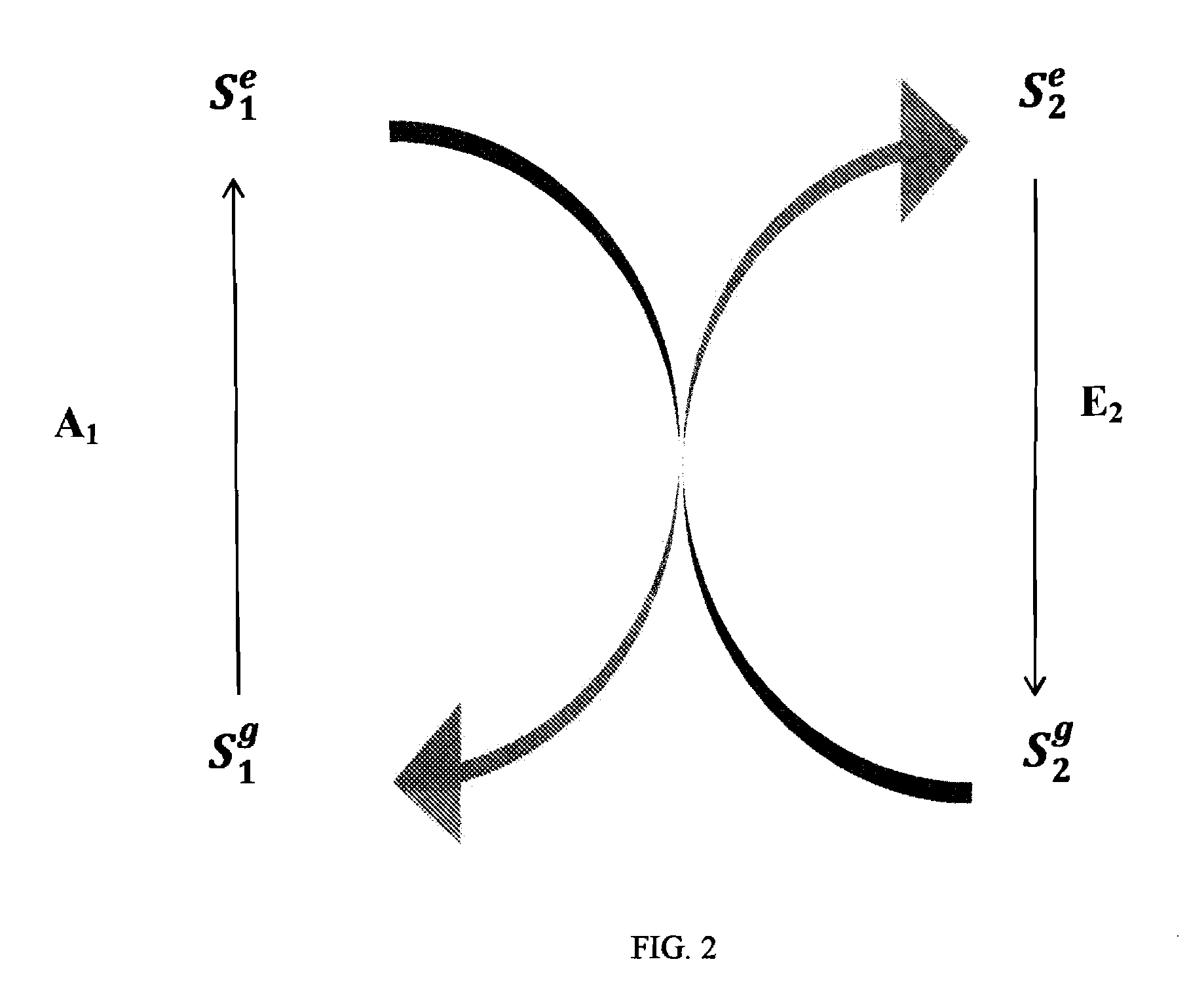

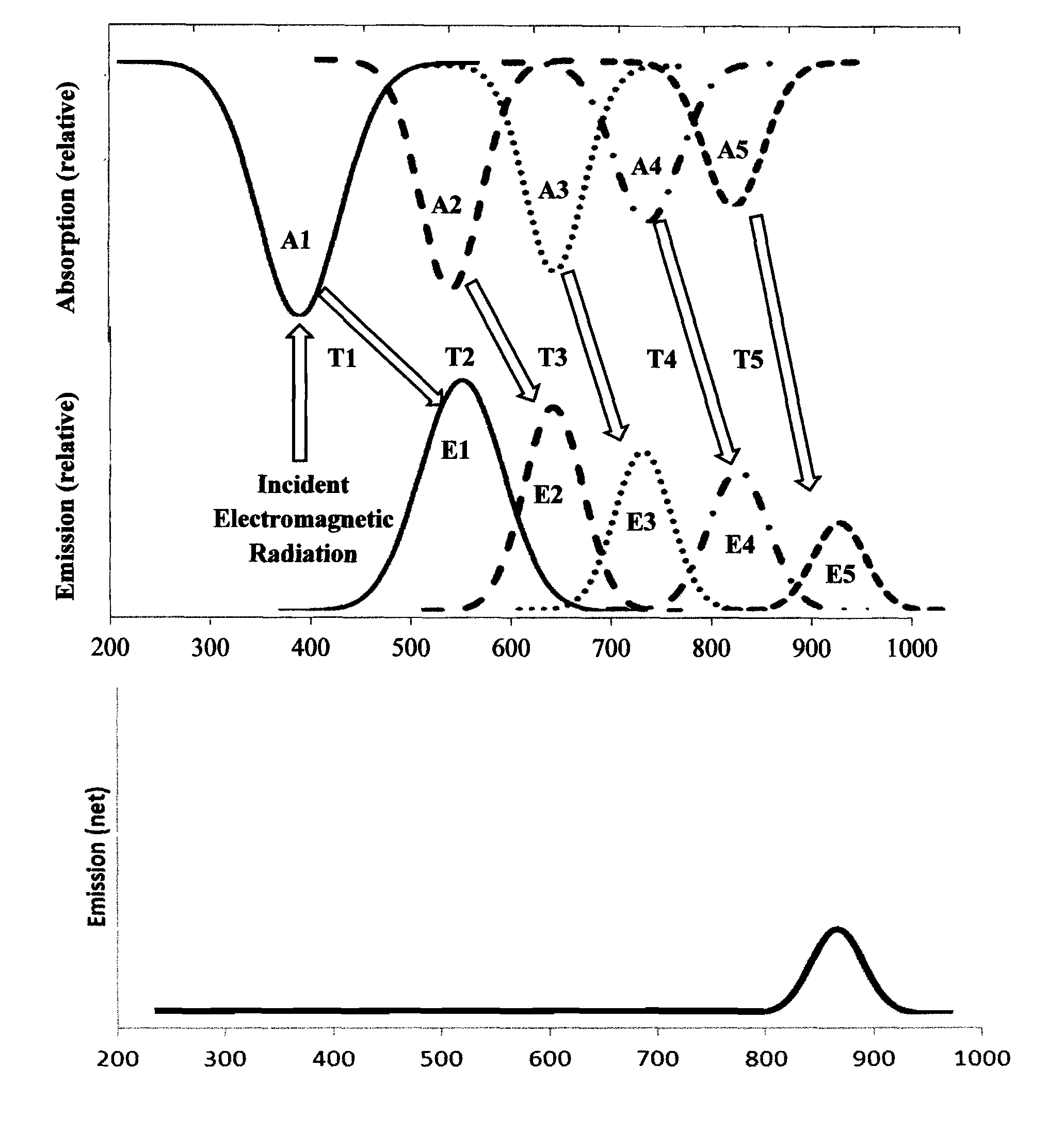

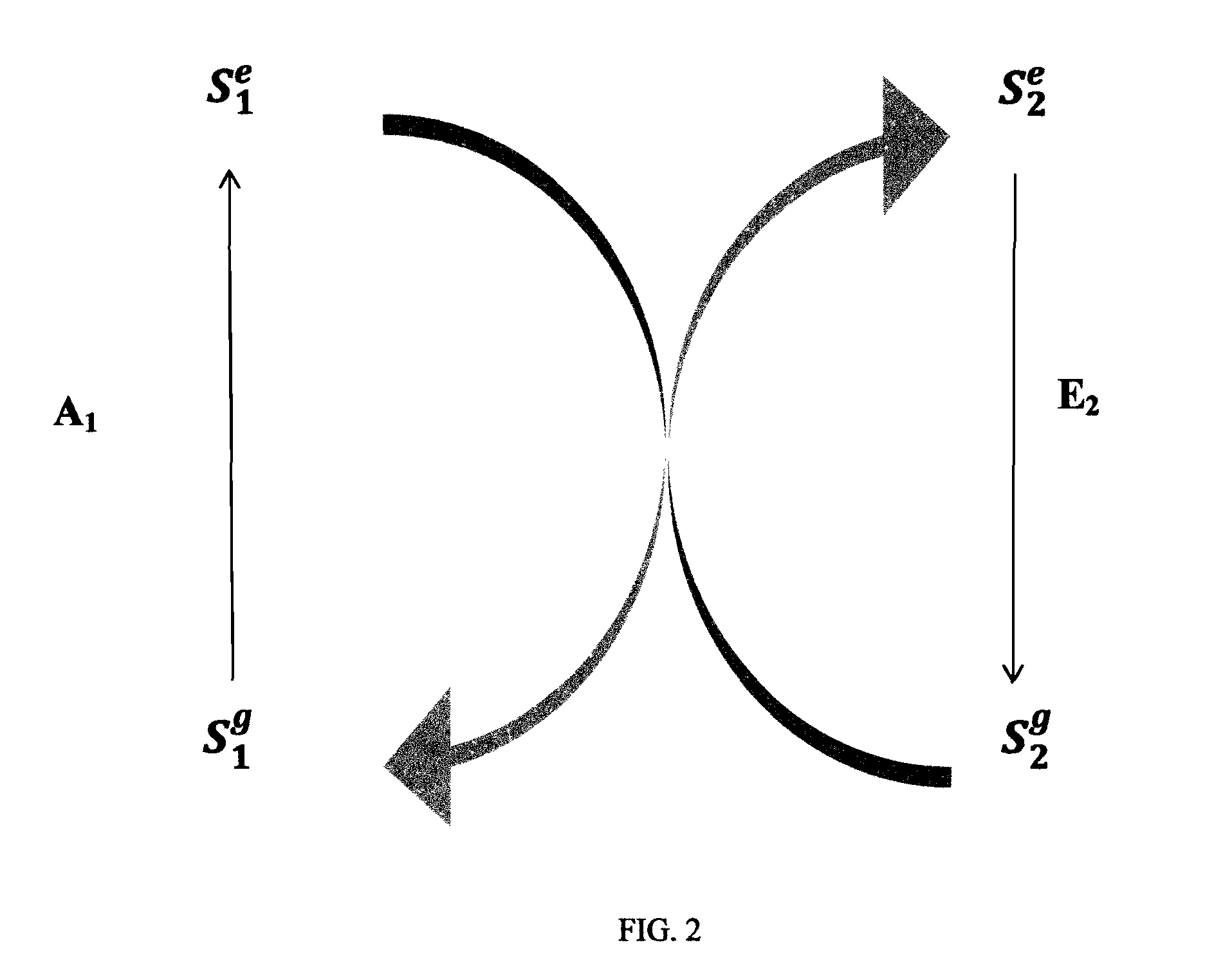

InactiveUS8952341B2Improve stabilityGeneration of luminanceLayered productsPhotometryMaterials scienceRare-earth mineral

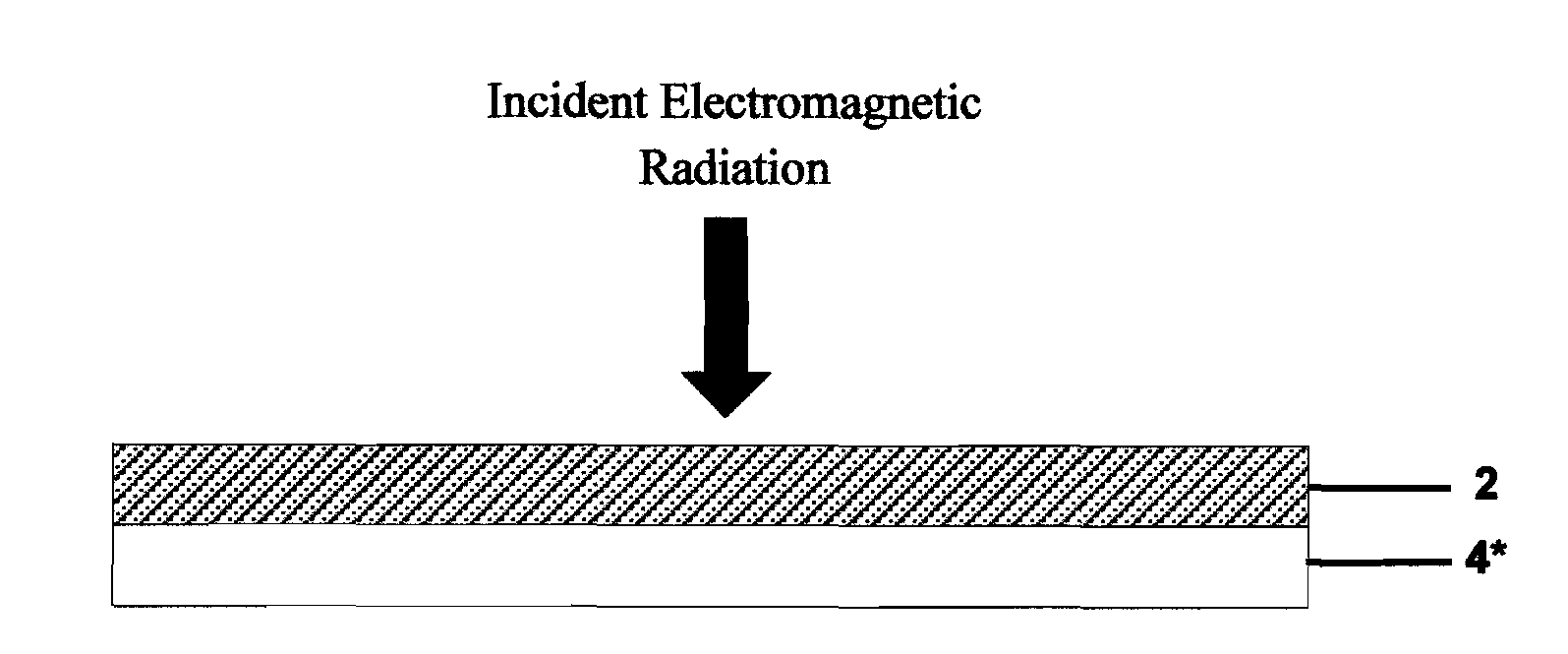

A low rare earth mineral photoluminescent structure for generating long-persistent luminescence that utilizes at least a phosphorescent layer comprising one or more phosphorescent materials having substantially low rare earth mineral content of less than about 2.0 weight percent, and one or more fluorescent layers is disclosed. Further disclosed are methods for fabricating and using the inventive low rare earth mineral photoluminescent structure. A low rare earth mineral photoluminescent composition for generating long-persistent luminescence that utilizes at least one or more phosphorescent materials having substantially low rare earth mineral content of less than about 2.0 weight percent and one or more fluorescent materials is also disclosed, as well as, the methods for fabricating and using the inventive low rare earth mineral photoluminescent composition.

Owner:PERFORMANCE INDICATOR LLC

Photoluminescent objects

InactiveUS9057021B2Improve stabilityGeneration of luminanceX-ray/infra-red processesCathode ray tubes/electron beam tubesPhotoluminescenceComputer science

Owner:PERFORMANCE INDICATOR LLC

Photoluminescent objects

InactiveUS20140065442A1Improve stabilityGeneration of luminanceCathode ray tubes/electron beam tubesSynthetic resin layered productsPhotoluminescenceComputer science

An object comprising a low rare earth mineral photoluminescent structure incorporated onto or into one or more portions of the object, the object being a photoluminescent object is disclosed. Further disclosed is a method for fabricating the object. An object comprising a low rare earth mineral photoluminescent composition incorporated onto or into one or more portions of the object, the object being a photoluminescent object is also disclosed, as well as, a method for fabricating the object.

Owner:PERFORMANCE INDICATOR LLC

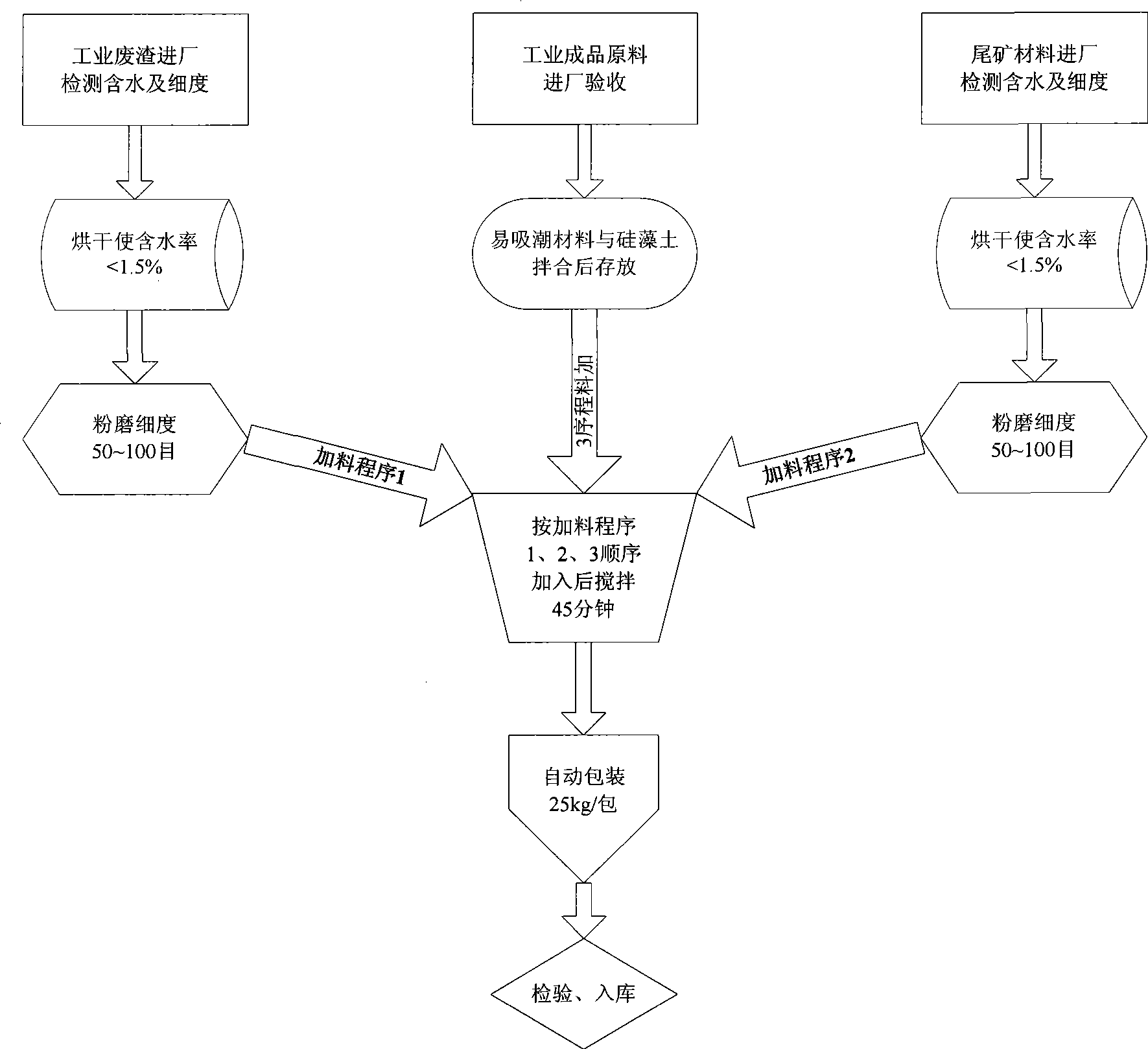

Non-sodium chloride environment-friendly type coal-saving combustion adjuvant special for cement

InactiveCN101475864AReduce contentReduce consumptionSolid fuelsClinker productionChromium CompoundsAdjuvant

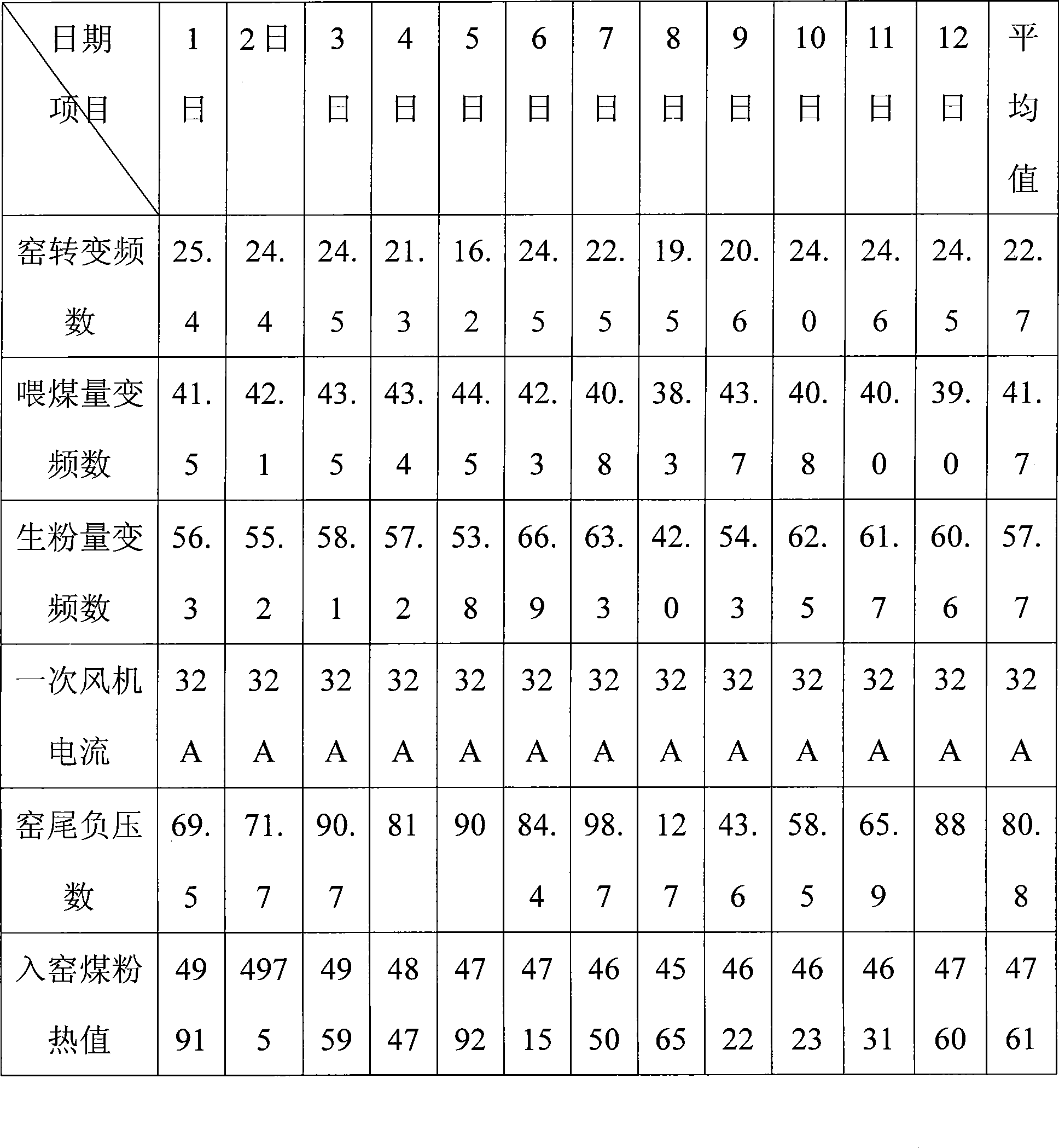

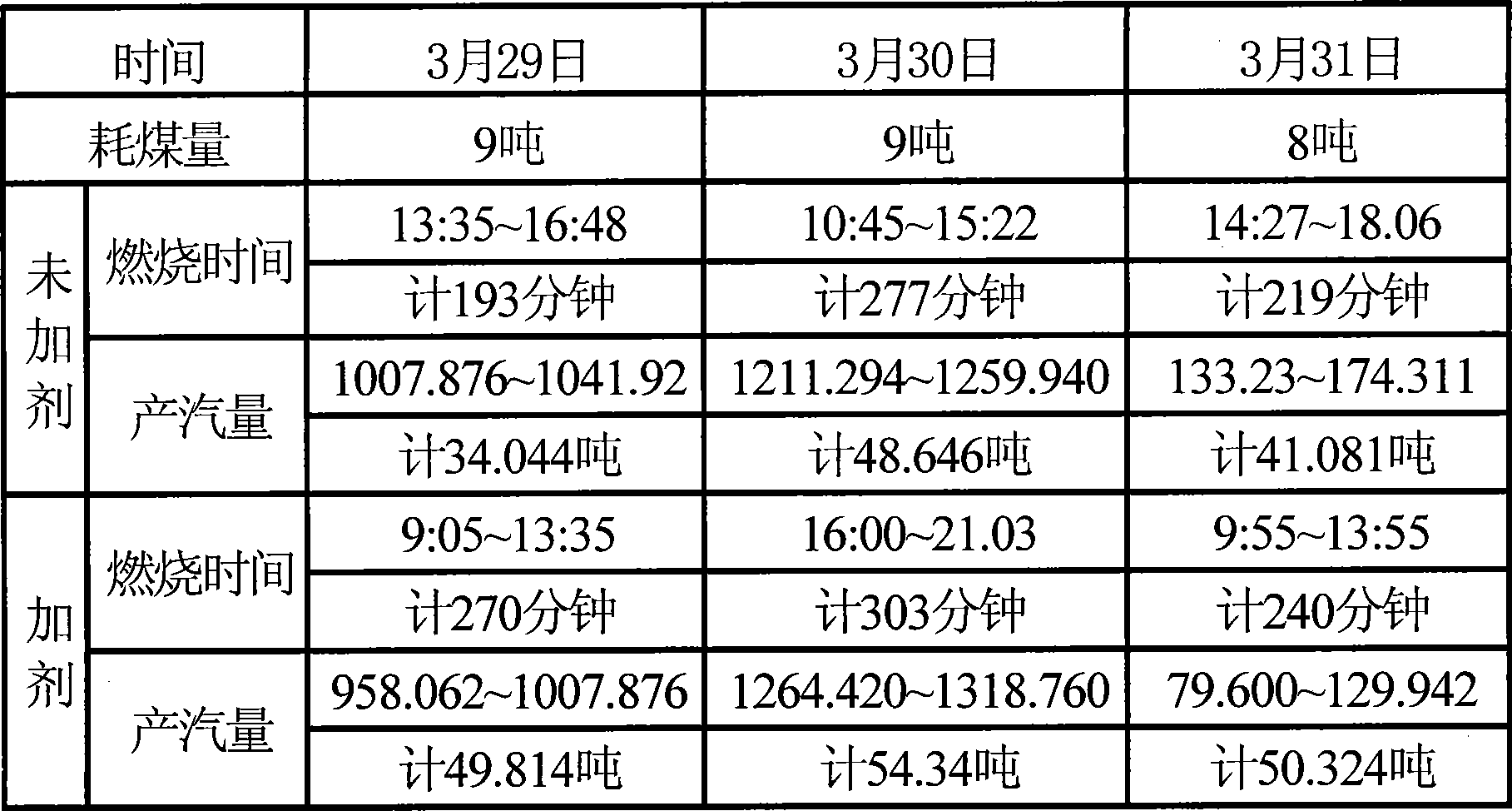

The invention discloses a sodium chloride-free environment-friendly coal-saving combustion improver special for cement, which aims to solve the technical problem of eliminating the damage of sodium chloride to furnaces, kiln bodies and the atmosphere. The combustion improver consists of an industrial grade finished product raw material, industrial residue, and a tailing material, and contains a barium compound, boride, carbonate, a chromium compound, fluoride, a magnesium compound, a manganese compound, nitride, a molybdenum compound II, a zirconium compound, industrial residue or tailings of rare earth, oxide and dicyclopentadienyl iron. Compared with the prior art, the combustion improver completely cancels the sodium chloride, furthest reduces the content of Cl<-> in ingredients, eliminates the damage of the sodium chloride to the furnaces, the kiln bodies and the atmosphere, reduces the damage of causing acid rain to the atmosphere, increases a plurality of metal acids, oxygen compounds and rare earth minerals, contains waste residue, ensures that the combustion is controllably performed, improves combustion environment, improves the combustion efficiency of fire coal, reduces energy consumption, prolongs the service life of equipment, and protects the environment.

Owner:深圳市伯益科技有限公司

Beneficiation of rare earth elements bearing ancylite

ActiveUS20170028410A1Small sizeHigh gradient magnetic separatorsFlotationStrontium carbonateRare-earth element

Disclosed herein are methods and systems for recovery of ancylite, a rare earth mineral comprising strontium carbonate, from rare earth ore. In many embodiments, the disclosed methods and systems provide for recovery of greater than 50% of the ancylite from an ancylite containing ore. In many embodiments, the ore is subjected to flotation in the presence of an acid, for example a hydroxamic acid, such as octanohydroxamic acid. The ore may also be subjected to magnetic separation, for example wet high intensity magnetic separation.

Owner:COLORADO SCHOOL OF MINES

Mineral processing technology for recycling fluorite from baotite, magnetite and tailing

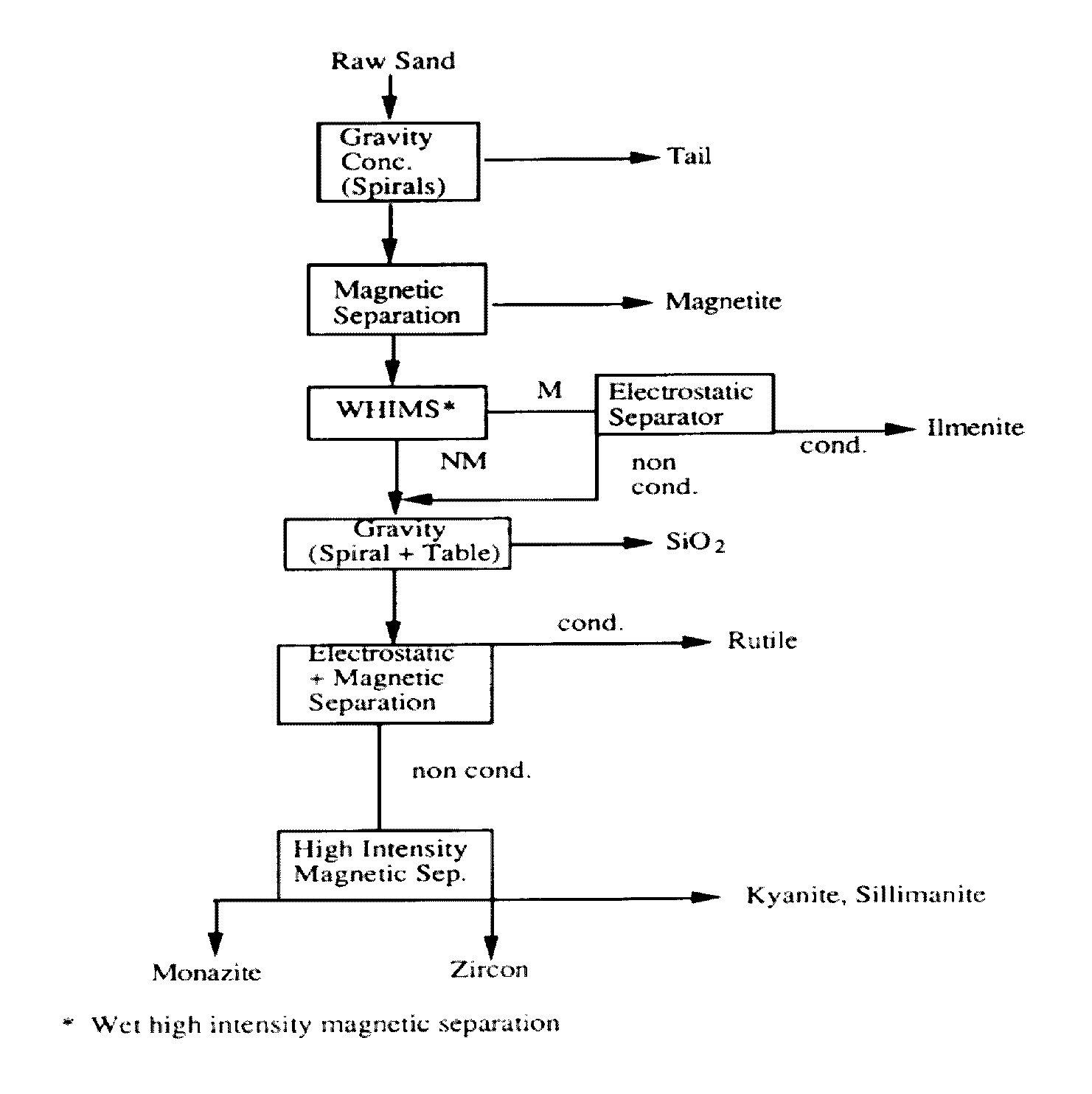

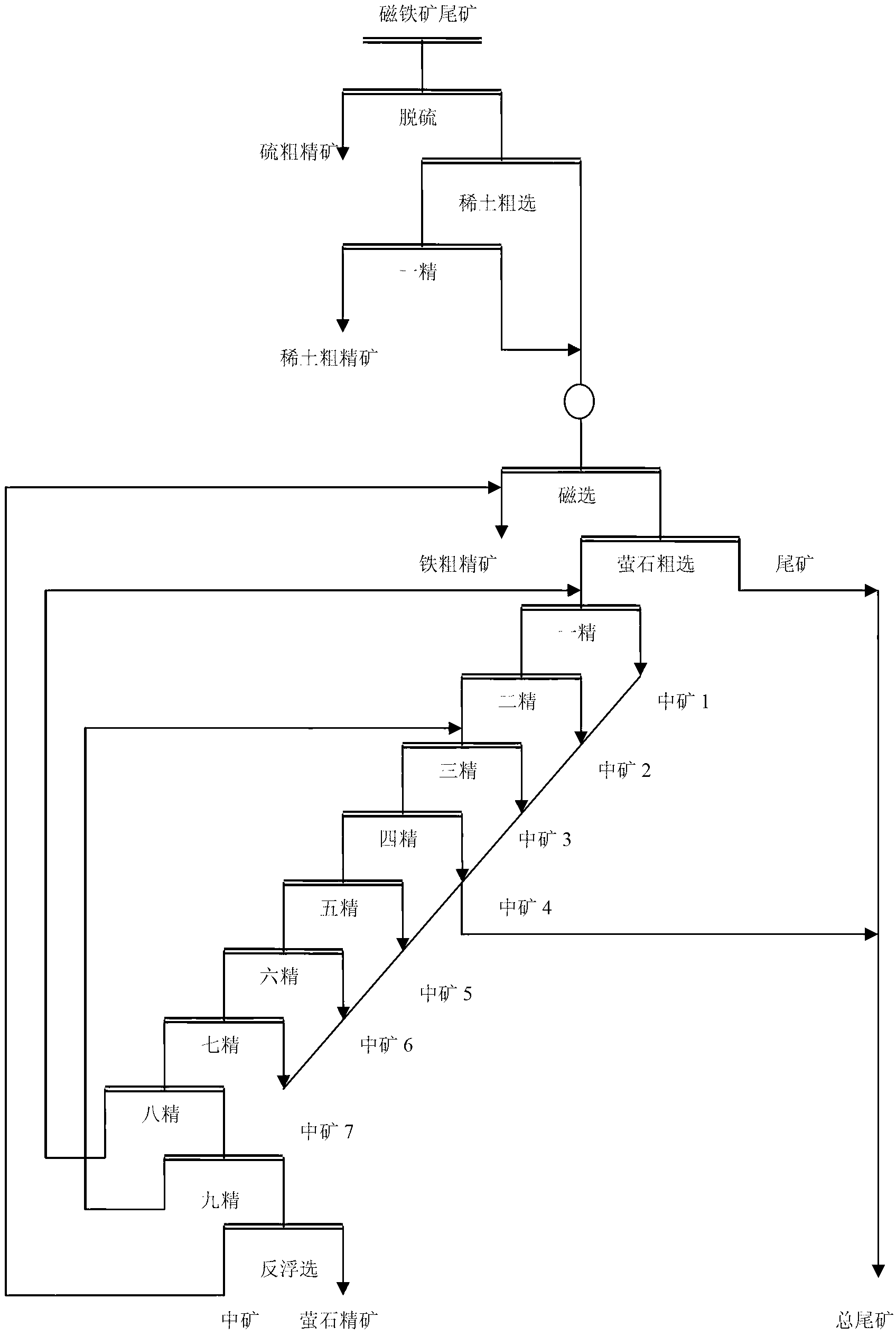

The invention belongs to the technical field of mineral engineering and provides a mineral processing technology for recycling fluorite from baotite, magnetite and tailing. In the tailing, mineral particle size of the fluorite is thin, iron-bearing mineral, rare-earth mineral, gangue mineral and the fluorite mineral are closely symbiotic and floatability of minerals such as rear earth, barite, apatite, calcite and dolomite is close to the fluorite mineral, so that separation of the fluorite mineral is difficult. According to the mineral processing technology for recycling the fluorite from the baotite, the magnetite and the tailing, priority desulfuration, rear earth flotation, ore grinding, iron selection through magnetic separation, fluorite selection through direct flotation and a reverse flotation sorting technology are performed on the magnetite and the tailing to enable pyrite, the rare earth, the iron-bearing mineral and the fluorite to be picked out in sections, efficient, high selective, easy-to-operate inhibitor and collecting agent combination is utilized in sorting of fluorite which is mostly performed monomer separation, so that fine fluorite of high grade and high recovery rate is obtained, a purpose of synthetically recycling valuable minerals is achieved, and effective separation of the fluorite mineral and the gangue mineral is achieved.

Owner:包钢集团矿山研究院(有限责任公司)

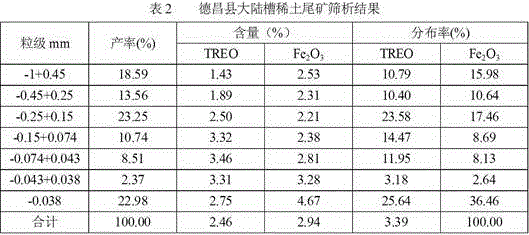

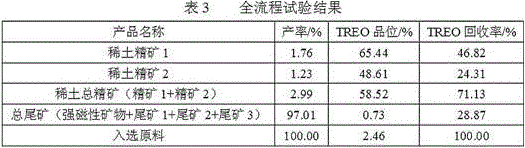

Benefication method for bastnaesite

The invention relates to a benefication method for bastnaesite. The benefication method for the bastnaesite is characterized by comprising the following steps: grinding and classifying the raw ore; performing magnetic separation to obtain magnetic concentrates and tailings; performing gravity separation on each grade of strong magnetic concentrate by using a table concentrator respectively to obtain table concentrates, table middlings and table tailings; combining each grade of table concentrate and table middling and performing high-gradient magnetic separation to obtain magnetic bastnaesite concentrates and magnetic middlings; combining the magnetic middlings and the table tailings; grinding the ores; performing closed-circuit flotation comprising one-time rough concentration, three-time scavenging and three-time concentration; and returning the middlings sequentially to obtain flotation bastnaesite concentrates and flotation tailings. The magnetic bastnaesite concentrates and the flotation bastnaesite concentrates are rare-earth total concentrates; the rare earth oxide (REO) grade of the rare earth is more than 65 percent; and the total recovery rate reaches 75 to 86 percent. According to the benefication method for the bastnaesite, fully-wet non-dust operation is adopted; separation efficiency is high; occupied area is small; production is performed continuously; flotation is performed at normal temperature; and environmental pollution is avoided. The benefication method for the bastnaesite is applicable to benefication of light rare earth minerals existing in the form of the bastnaesite.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI +1

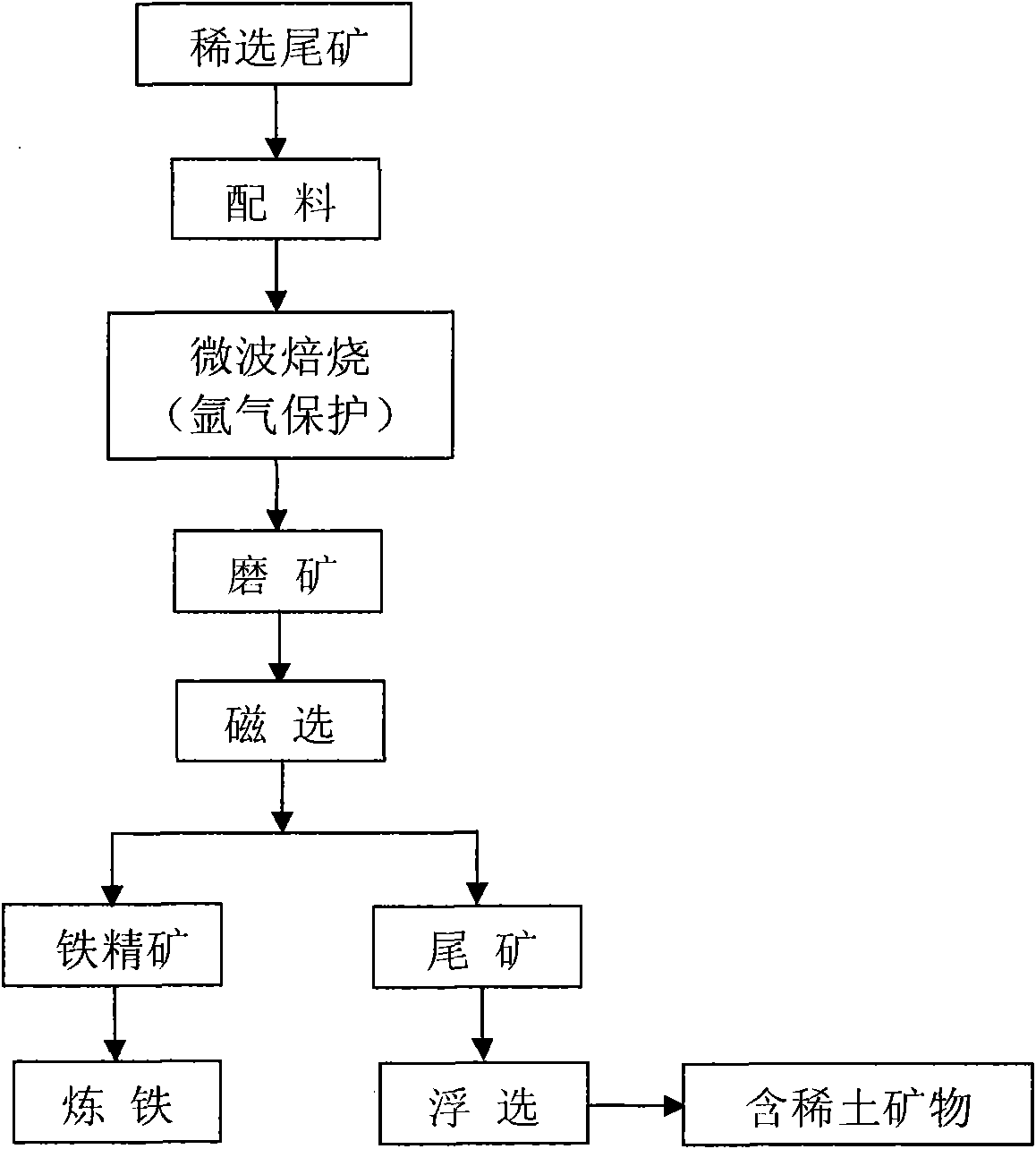

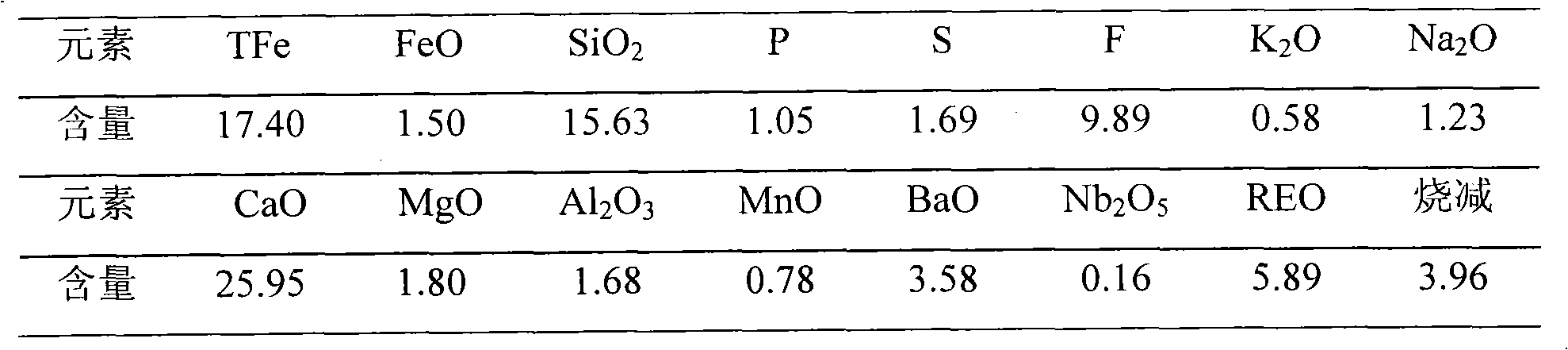

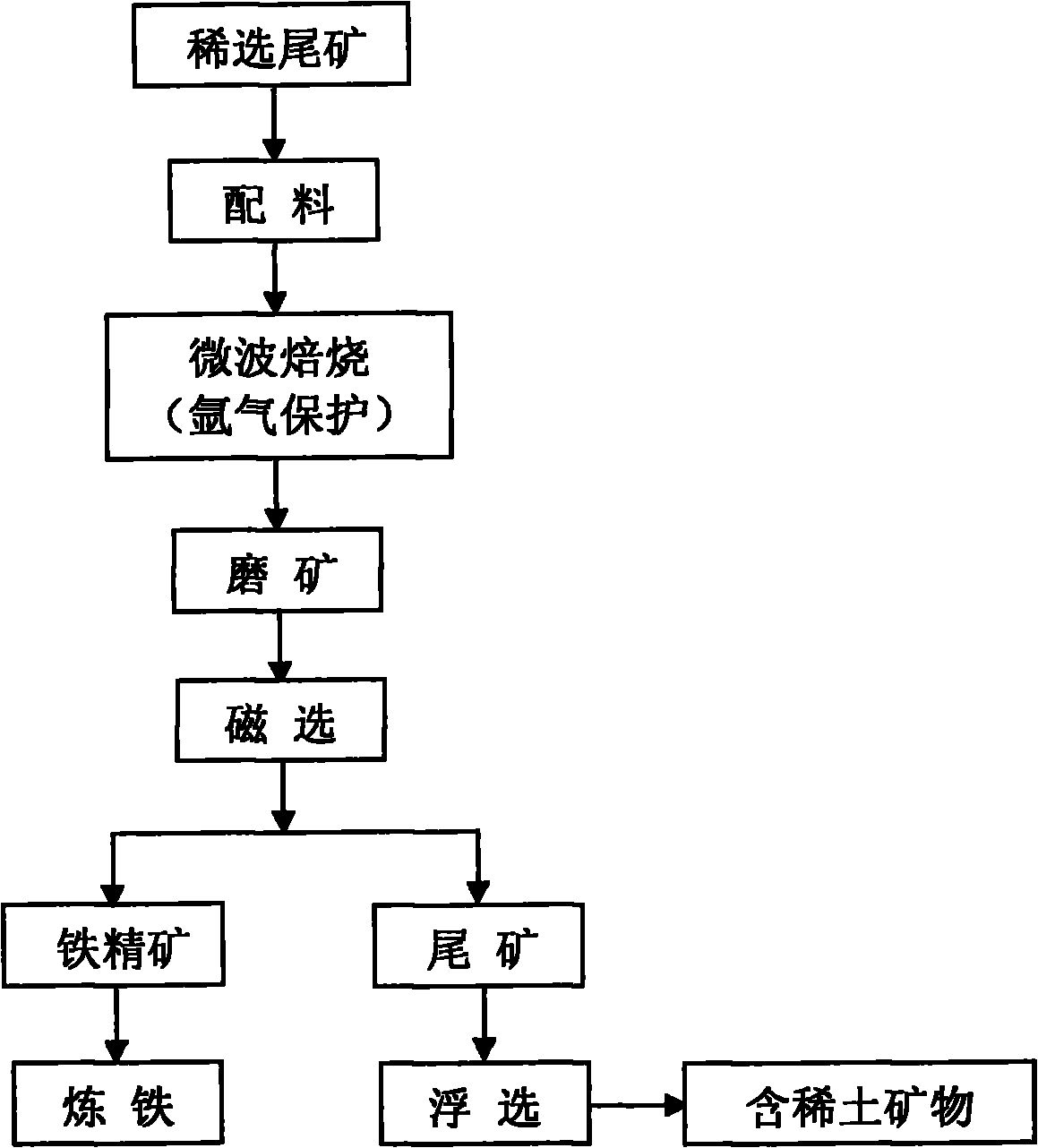

Method for extracting rare earth from rare earth tailings

The invention relates to a method for extracting rare earth from rare earth tailings, and belongs to the technical field of mineral extraction metallurgy. The method comprises the following steps of: (1) mixing the rare earth tailings and a carbon-containing reducing agent uniformly in a certain ratio, and roasting the mixture for 8 to 20 minutes in a microwave roasting oven; (2) performing magnetic separation on the roasted product in a weak magnetic separation tube to separate magnetic iron minerals so that the rare earth minerals are enriched in the tailings; and (3) treating the rare-earth-containing magnetic separation tailings by using a flotation method so as to realize effective extraction of the rare earth. The method has the advantages of short roasting time, low consumption of the reducing agent, energy and a flotation agent, and good flotation effect, can be used for realizing selective reduction of the iron minerals in the reducing process and eliminating environmental pollution caused by the tailings, and is economic and environmentally friendly. The iron mineral impurities such as S, P and the like obtained by the magnetic separation are fewer, the grade of the iron mineral is more than 60 percent, the iron mineral can be used for making iron, the rare earth oxide content of the mineral obtained by primary flotation is 34.12 percent, and the grade of the mineral can reach over 50 percent by concentration.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

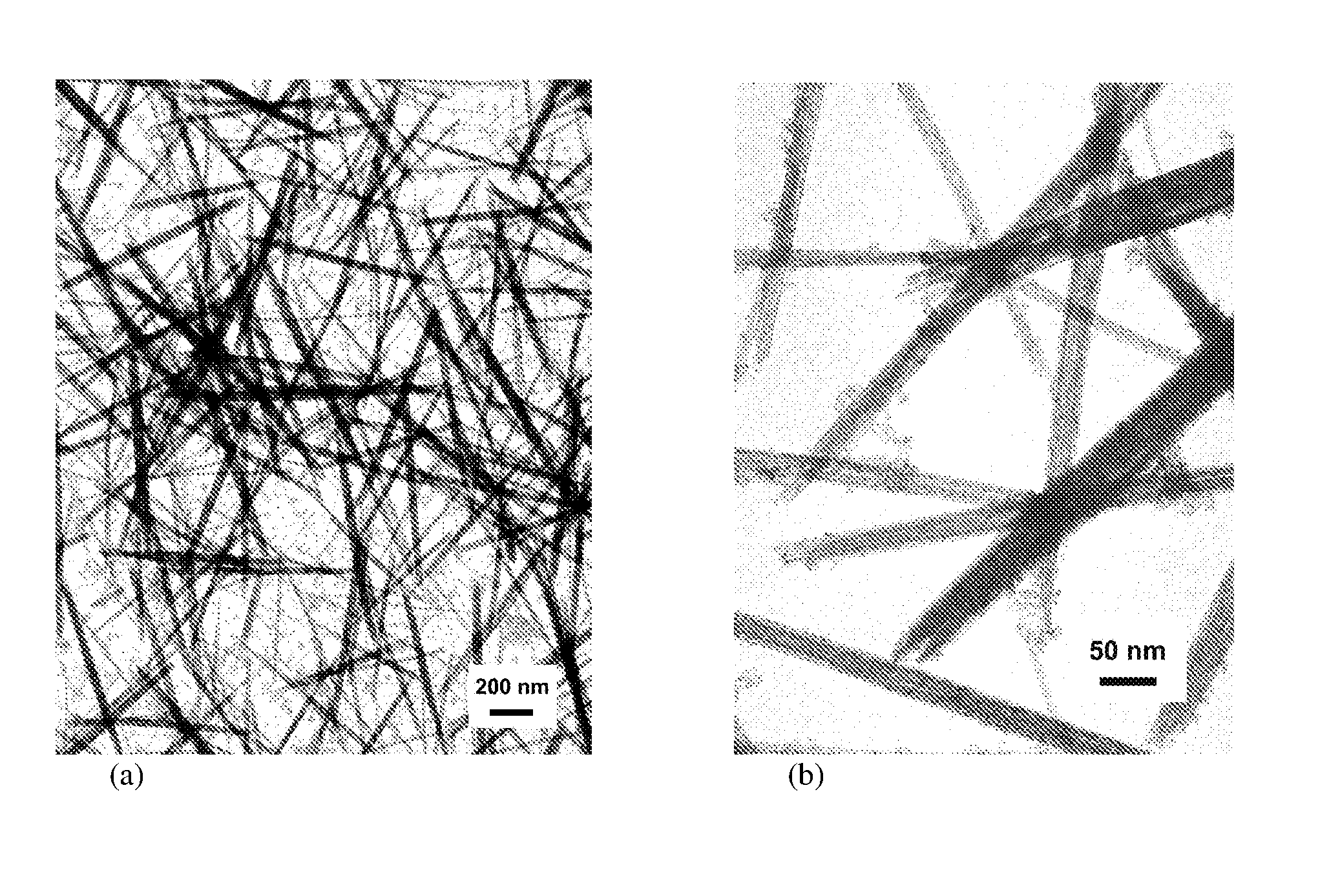

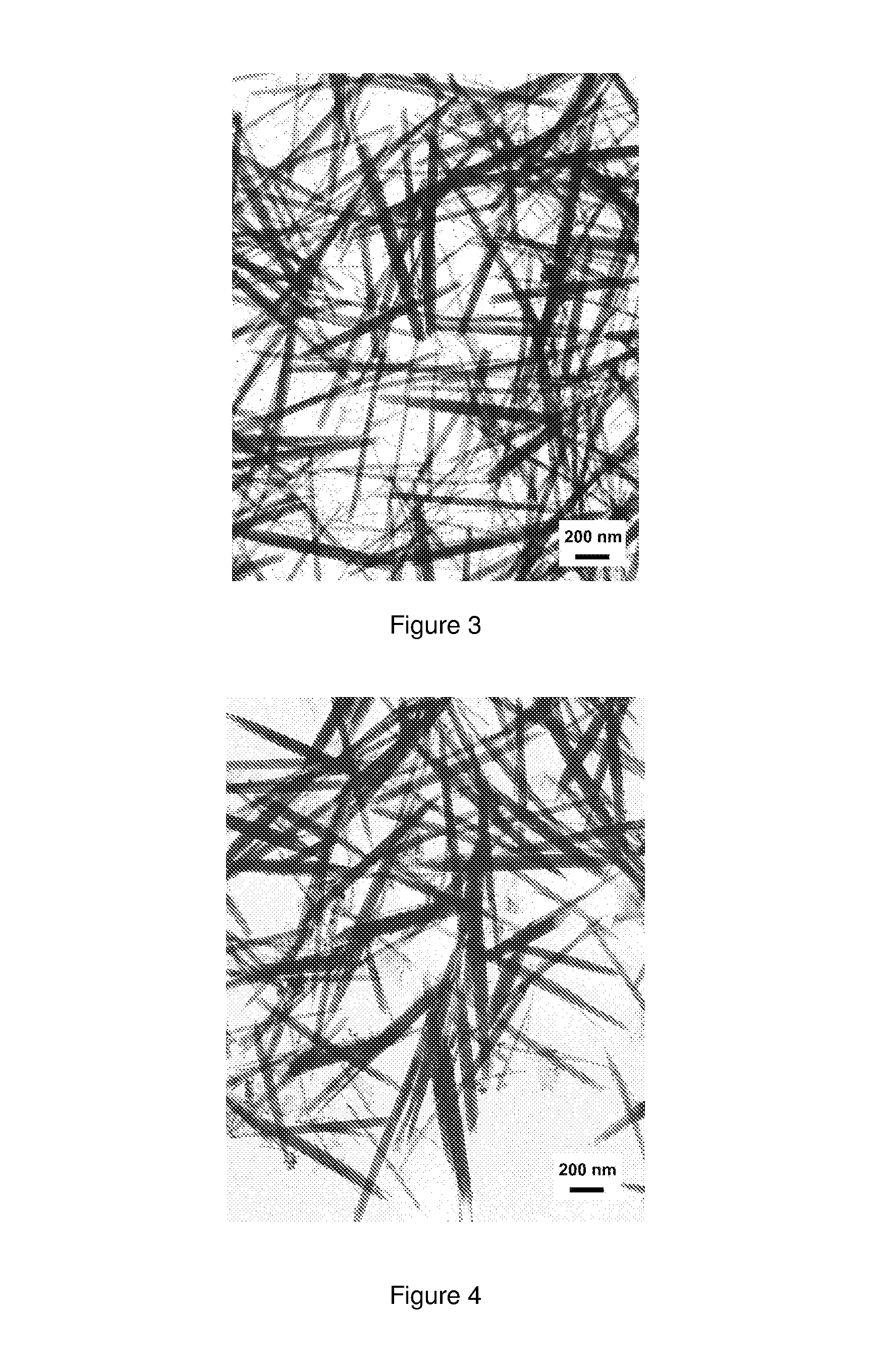

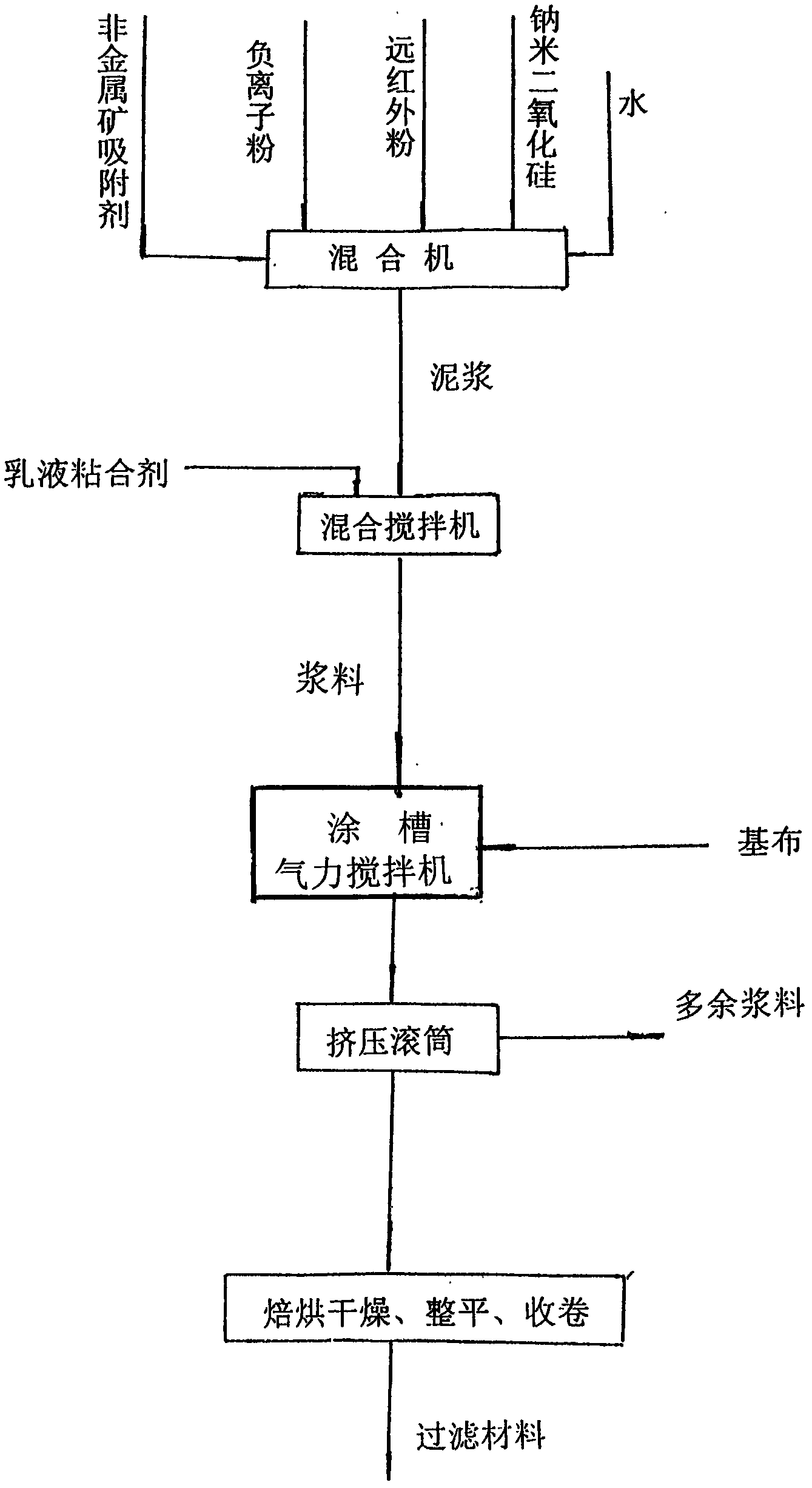

Rare earth nanorods

ActiveUS7943106B2Reduce expenditureMaterial nanotechnologyPolycrystalline material growthRare-earth elementAnisotropic growth

A process for the production of nanorods containing a rare earth metal is disclosed. The process comprises the steps of: (a) increasing the pH of an aqueous solution of the formula MX3, where M is a trivalent rare earth metal cation and X is a monovalent anion so as to produce a reaction product containing X anions in solution and a precipitate in the form of trivalent rare earth hydroxide nanoparticles of the formula M(OH)3, the nanoparticles having a hexagonal crystal structure; and, (b) ageing the nanoparticles of step (a) in the presence of the reaction product containing X anions in solution so as to cause rod-like anisotropic growth of the nanoparticles and form rare earth hydroxide nanorods.

Owner:ADVANCED NANO TECH

Method for separating and recycling uranium, thorium and rare earth in rare earth mineral decomposition residue

ActiveCN104498739AEasy to separateEasy to industrializeProcess efficiency improvementSlagThorium nitrate

The invention discloses a method for separating and recycling uranium, thorium and rare earth in rare earth mineral decomposition residue. The method comprises the following steps: carrying out acid leaching, carrying out pressure filtration, absorbing and recycling uranium by using anion resin, separating and recycling thorium and rare earth by suing cationic resin. The method specifically comprises the following steps: leaching rare earth mineral decomposition residue by using inorganic acid; carrying out pressure filtration on the leached slag, washing the leached slag to obtain a clear material solution, absorbing uranium element of the leached material solution by using 201*7 type resin, separating elements thorium and rare earth of an uranium-removal material by using 001*7 type resin, separating and purifying uranium, thorium and rare earth, then washing, complexing, eluting, precipitating and concentrating to obtain products comprising heavy oleate, thorium nitrate and rare earth carbonate and obtain products which comprise high-purity uranium, thorium and rare earth. The extracting and recycling process is simple in device structure, low in investment, low in energy consumption and easy to operate; the industrialization is liable to implement; the direct recovery rate is 99%; precious resources can be recycled; the waste is reduced; the environment is protected.

Owner:YIYANG HONGYUAN RARE EARTH

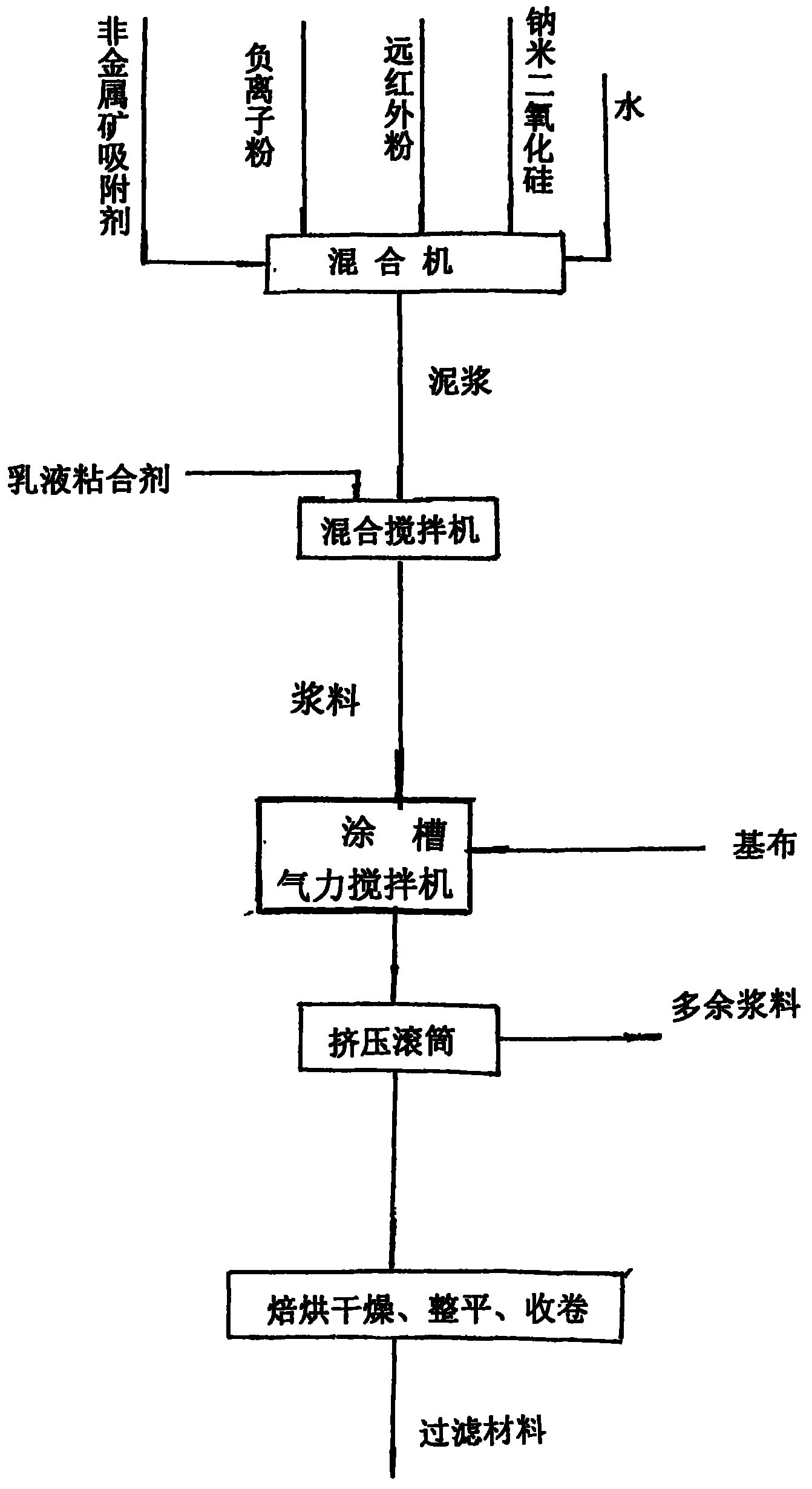

Filter material capable of purifying indoor air and eliminating second-hand smoke

InactiveCN102302876AHigh energyDeodrantsFiltration separationPolyethylene terephthalate glycolHazardous substance

The invention discloses a filter material capable of purifying indoor air and eliminating second-hand smoke. A slurry is synthesized from natural mineral sepiolite, attapulgite, tourmaline, rare-earth mineral, nanometer silica, a non-toxic adhesive and the like; and then the slurry is uniformly adhered in a PET (polyethylene terephthalate) fiber layer, and dried, shaped and folded to prepare the filter material with an unequal thickness of 15-60mm. Toxic and harmful materials and harmful sol materials obtained in indoor air after tobacco is combusted can be absorbed, filtered and catalyzed by the filter material provided by the invention. The filter material can release far infrared rays so as to excite the natural mineral tourmaline to permanently and stably release negative ions, wherein the concentration (more than 6000 / cm<3>) of the negative ions greatly exceeds the standard (1000-1500 / cm<3>) of indoor fresh air, confirmed by world health organization, therefore, the effects of sterilizing, removing toxicity and peculiar smell, eliminating the second-hand smoke, outputting clean air and thoroughly improving the indoor air pollution state are achieved.

Owner:蔡海康 +1

Functional ceramic powder material , preparation and use thereof

InactiveCN101353253APromote activationComprehensive activation functionWater/sewage treatmentMetallic materialsFar infrared

The invention relates to a functional ceramic powder material and a preparation method. The functional ceramic powder material is mainly made from the raw materials such as a far-infrared radiation functional inorganic nonmetallic material, a magnetic material, a rare-earth mineral material, a binding material, and the like; and the procedures comprise material mixing, shaping, sintering, crushing, grinding, etc. The functional ceramic powder material has the effects of activating water molecules, activating fuel and activating amino acid molecules, and has wide application prospect in the fields of healthy products, burning, energy saving, etc.

Owner:河北双灵保健品(集团)有限公司

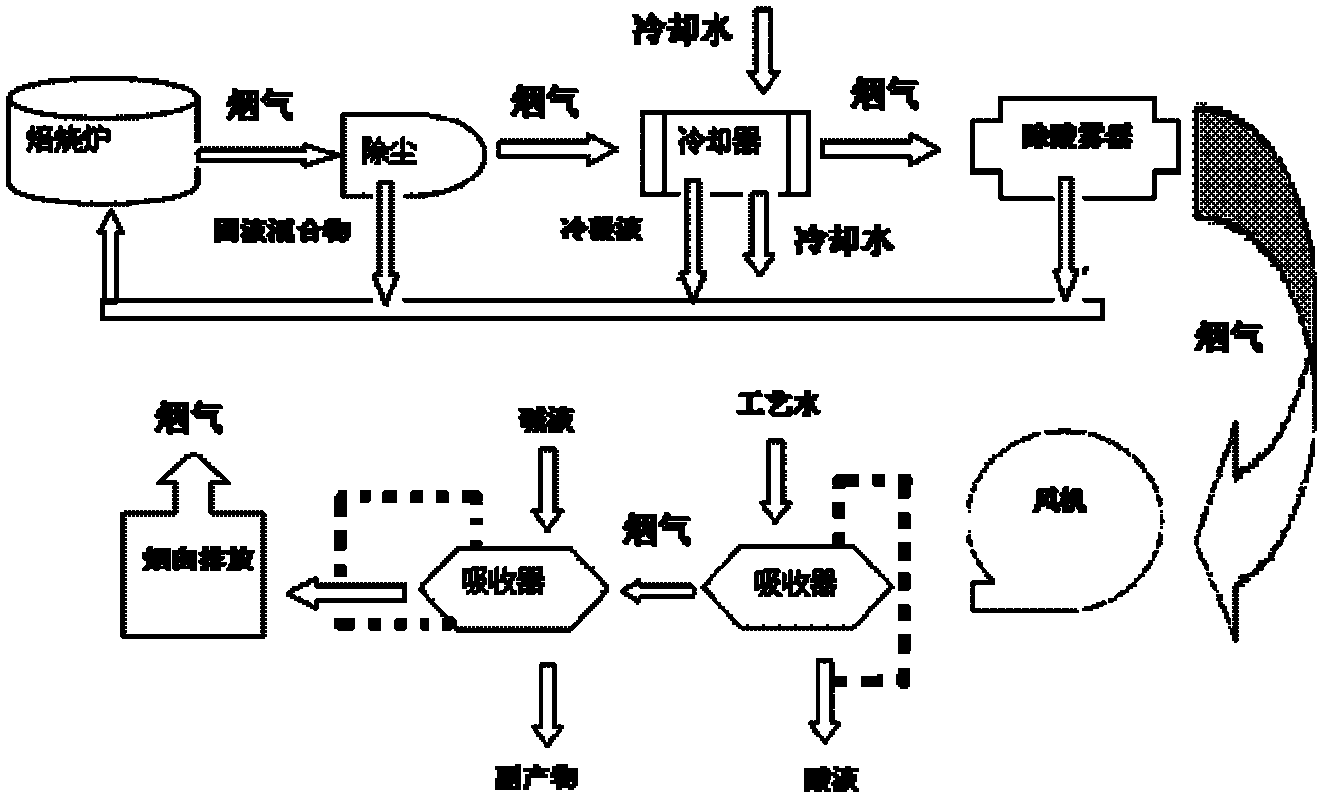

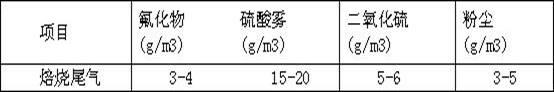

Process for treating tail gas of rare earth mineral powder and concentrated sulphuric acid roasting process

ActiveCN102247708AAvoid energy consumptionAvoid investmentDispersed particle separationVapor condensationHydrogen SulfateHexafluorosilicic acid

The invention relates to a process for treating tail gas of a rare earth mineral powder and concentrated sulphuric acid roasting process. The process comprises the following steps of: introducing the tail gas of 300 DEG C of the process into a dust remover for dust removal with a machine; then introducing the tail gas into a condenser for cooling, condensing massive sulphuric acid fog and water vapour in the smoke and recycling acid liquor; introducing the cooled smoke into an acid fog collector, collecting acid fog and water fog in the smoke for recycling; boosting the treated smoke by a fan, introducing the treated smoke into a first absorber, washing by diluted acid liquor or process water to remove residual sulphuric acid fog, hydrofluoric acid and fluosilicic acid from the smoke; andthen introducing the smoke into a second absorber, washing the smoke by an alkali washing tower to remove residual sulphuric acid fog, hydrofluoric acid and SO2 gas from the smoke, and discharging the smoke out after defogging. The process provided by the invention can save massive smoke cooling water, produce less waste water, reduce waste water treatment cost, and recycle the side product fluoric acid produced by solid mineral substances, sulphuric acid, hydrofluoric acid and the like in the tail gas as a raw material for recycling fluorine.

Owner:北京鸿源龙嘉环保科技有限公司

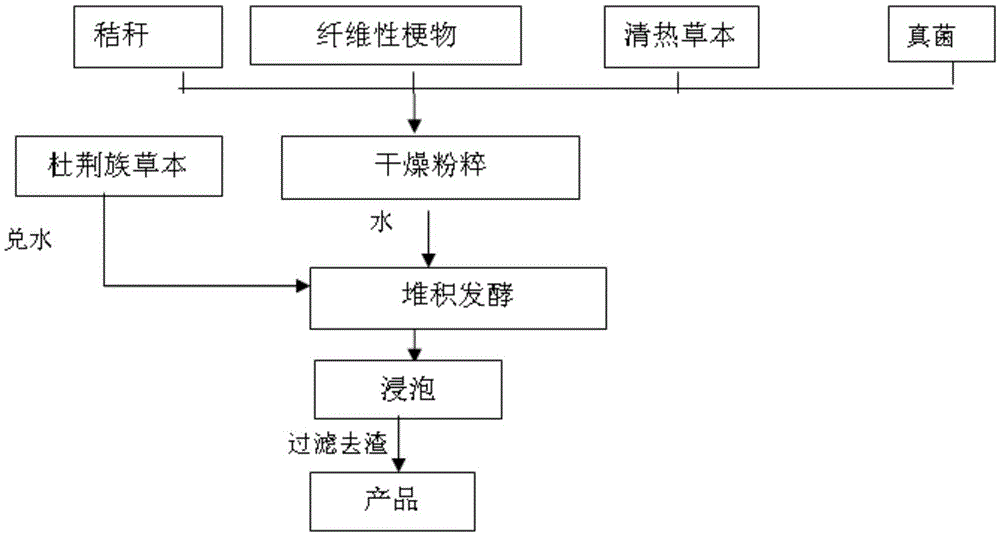

Herbaceous plant rare-earth precipitating agent and preparation method thereof

InactiveCN105603222AGood environmental effectRemarkable convenience for recyclingProcess efficiency improvementNitrogenVitex

The invention relates to the field of preparation of rare earth, in particular to a herbaceous plant rare-earth precipitating agent and a preparation method thereof. The herbaceous plant rare-earth precipitating agent is prepared from, by weight, 30-50 parts of straw, 25-65 parts of fibrous stalks, 0.5-5 parts of herb for clearing away heat, 0.5-5 parts of Vitex.negundo L.var. cannabifolia (sieb. et Zucc.) Hand.-Mazz. herb and 0.08-5 parts of fungi, and the raw materials are weighed, smashed, fermented and soaked so that the herbaceous plant rare-earth precipitating agent can be prepared. By means of the herbaceous plant precipitating agent, the mother liquid precipitating effect can reach 99.6% or above after mineral leaching is performed on rare earth minerals in different types, the concentration of ammonia and nitrogen in supernatant after precipitation is 0.94 mg / L, secondary pollution of ammonia and nitrogen is avoided, herb precipitate contained in the supernatant can be directly used circularly, and the herbaceous plant rare-earth precipitating agent is a natural and environment-friendly precipitating agent.

Owner:GUANGXI HAOZHAO ENVIRONMENT PROTECTION TECH CO LTD

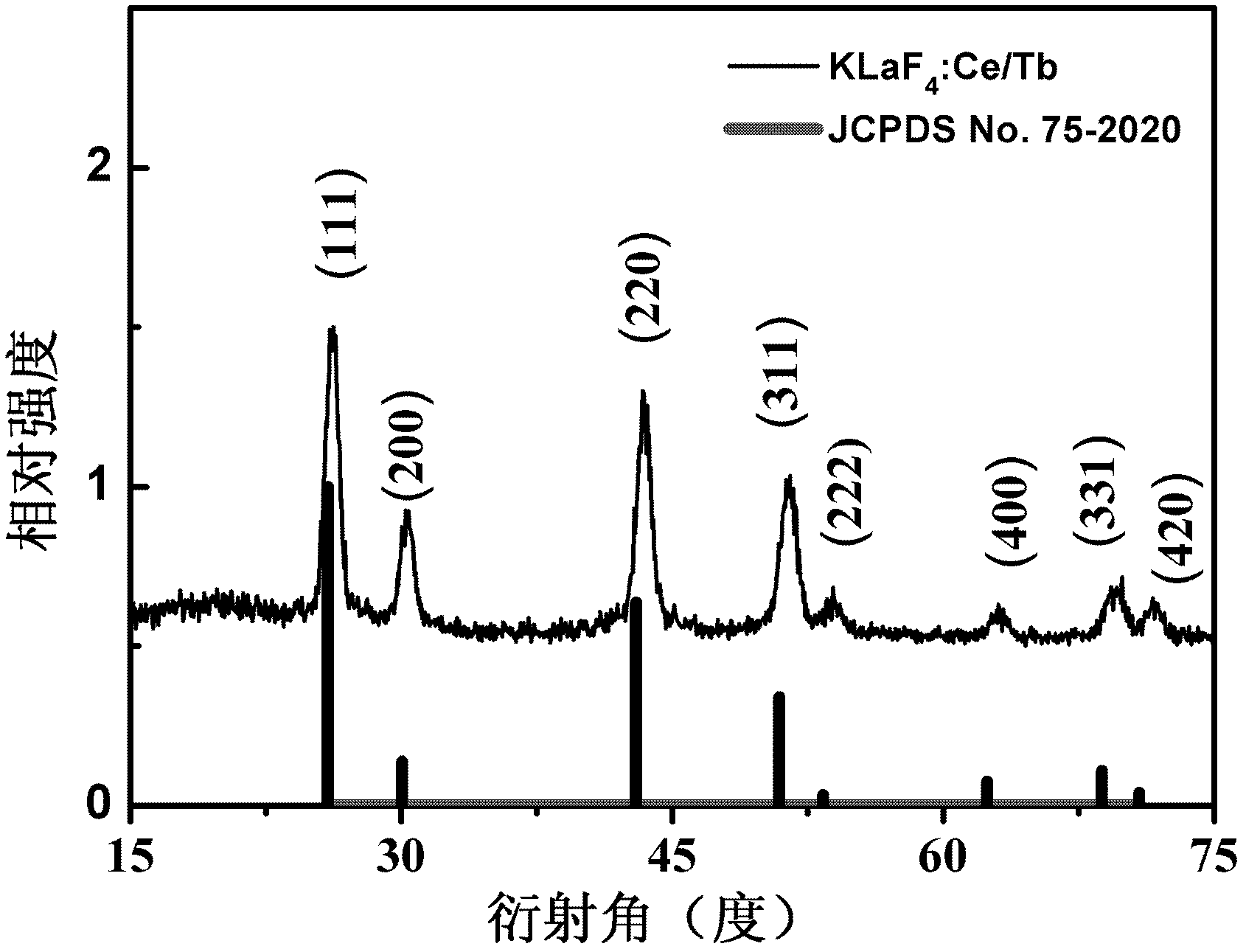

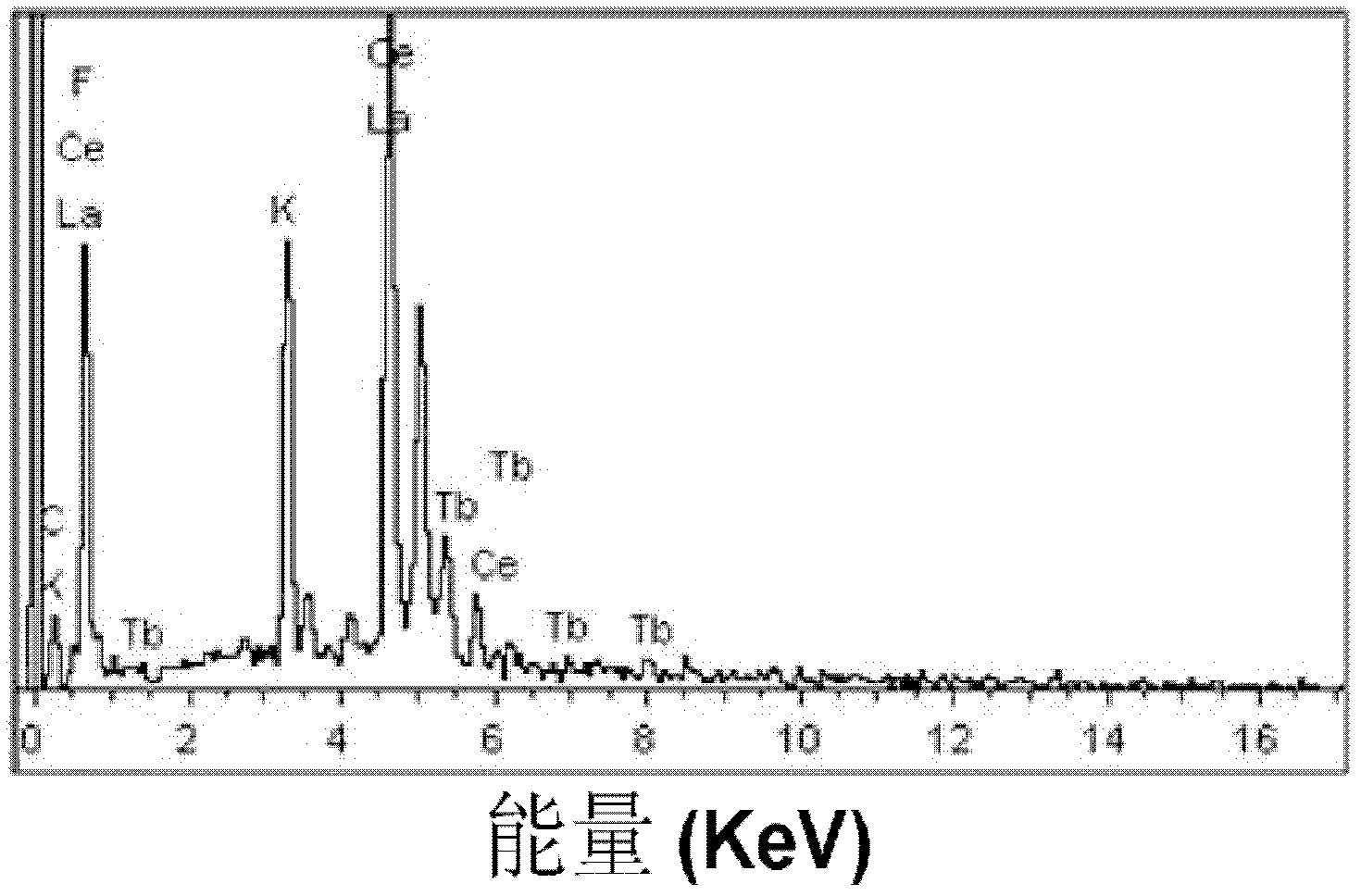

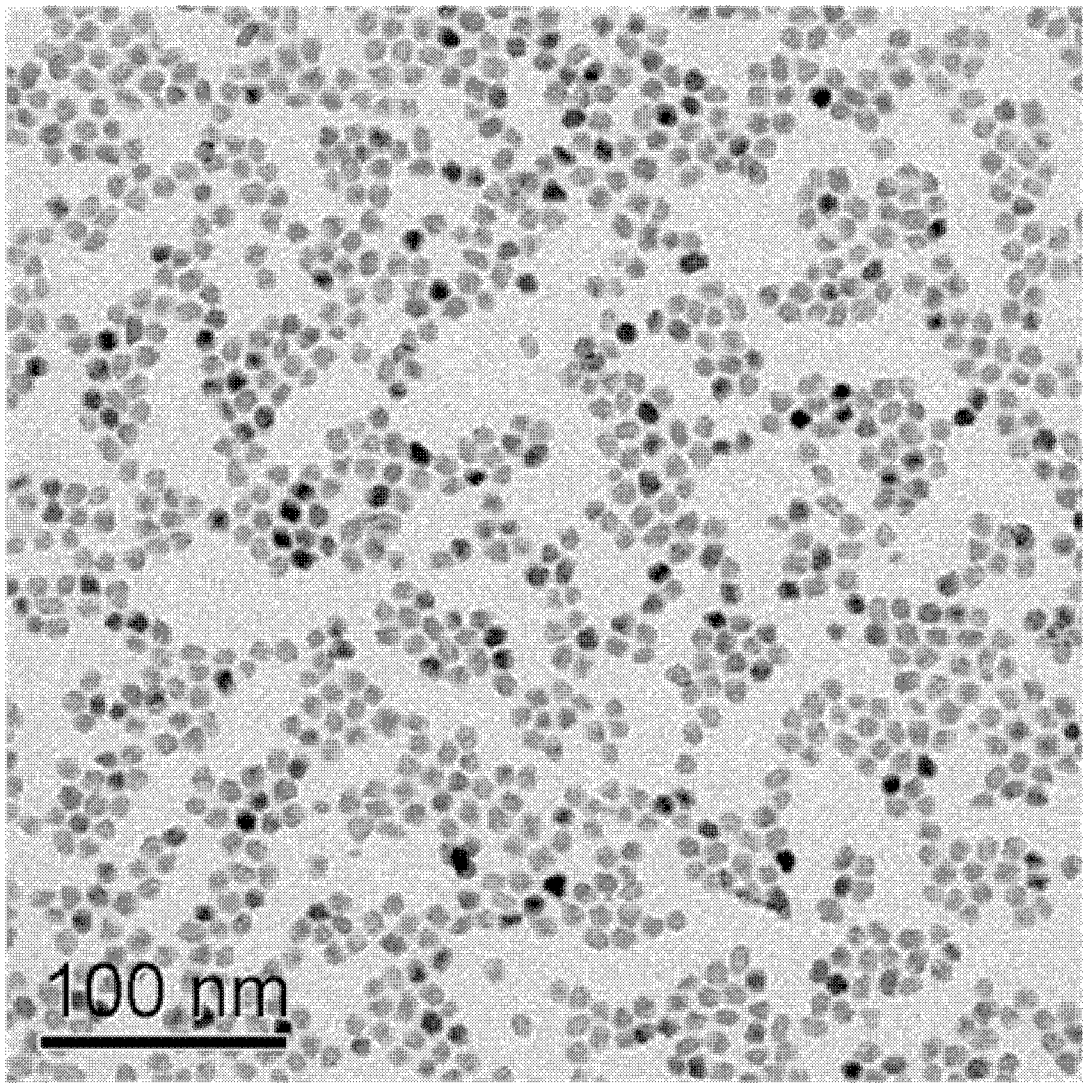

Rare earth-doped fluoride lanthanum potassium nano fluorescent marking material and preparation method thereof

ActiveCN102676172AEasy to makeSynthesis conditions are easy to controlFluorescence/phosphorescenceLuminescent compositionsPhosphateBiological imaging

The invention provides a rare earth-doped fluoride lanthanum potassium nano fluorescent marking material and a preparation method thereof. The preparation method comprises the following steps: firstly, carrying out high temperature cracking on in mixed solvent of oleic acid, oleyl amine and octadecylene to synthesize oil-soluble rare earth-doped fluoride lanthanum potassium nanocrystalline; and secondly, displacing the oleic acid on the surface of the nanocrystalline by using phosphate ethanol to enable the oleic acid to be converted into water-soluble nanocrystalline, wherein the size of the oil-soluble rare earth-doped fluoride lanthanum potassium nanocrystalline is about 10 nm; and the hydrated particle size of the improved water-soluble nanocrystalline is about 20 nm. The rare earth-doped fluoride lanthanum potassium nano fluorescent marking material obtained by synthesizing can be connected with a biological molecule by using an amino group on the surface of the rare earth-doped fluoride lanthanum potassium nano fluorescent marking material; and the application of the rare earth-doped fluoride lanthanum potassium nano fluorescent marking material in the fluorescent marking such as biological detection or biological imaging through rare earth ion doped light emitting can be realized.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

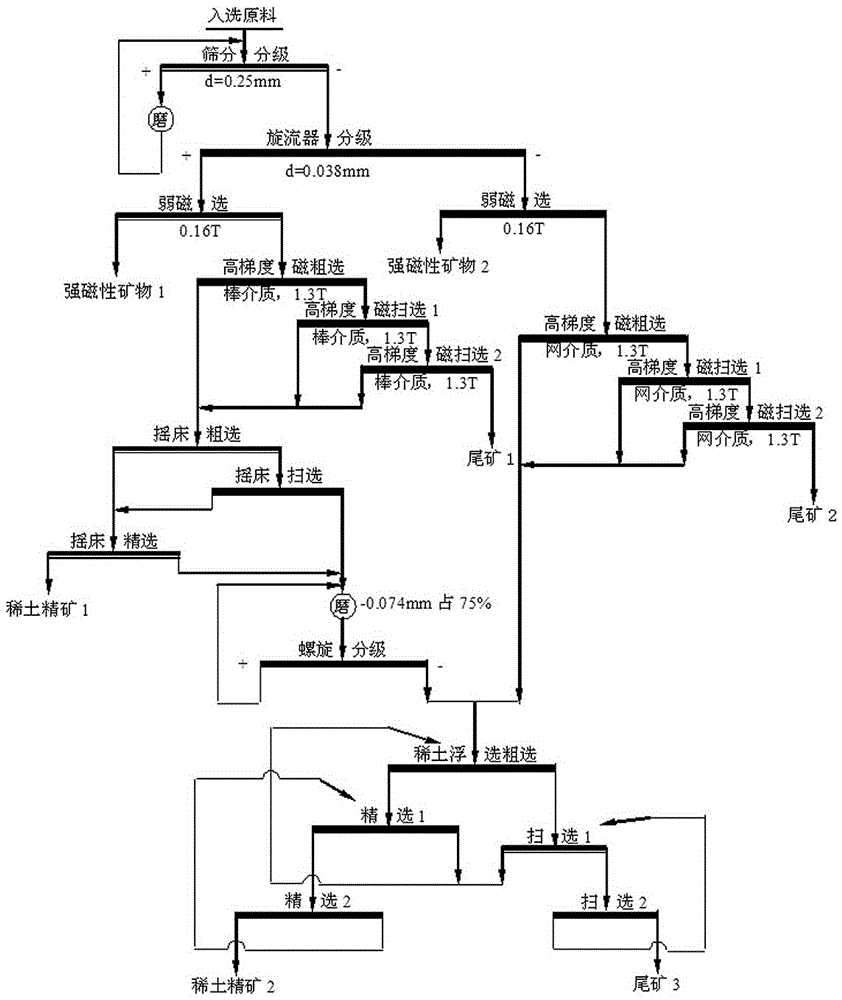

Method for recycling rare earth mineral from rare earth tailing with high fine grained iron mud content

ActiveCN106733146AFine granularityEasy to wearSolid separationMechanical material recoveryCeriumMaterials science

The invention discloses a method for recycling rare earth mineral from rare earth tailing with the high fine grained ion mud content. The problems that fluorocarbon cerium type rare earth ore with the high iron content, high mud content and uneven rare earth mineral size distribution is prone to excessive grinding, iron and mud affect the rare earth concentrate grade and recycling rate, and the mineral processing cost is high are solved. The method comprises the specific steps that rare earth tailing is screened and graded in advance (d=0.25 mm); the rare earth tailing with the diameter larger than +0.25mm is ground till the diameter is -0.25mm and combined with the product which is graded in advance to have the diameter of -0.25mm; secondary hydrocyclone grading is carried out (d=0.038mm); the 0.25mm-0.038mm product bar medium high-gradient magnetic separation-table reselection combined technology is adopted for recycling coarse grained rare earth tailing; the product with the diameter smaller than 0.038mm is subjected to 1.5mm mesh medium high-gradient magnetic selection; and reselected tailing is ground again till the -200-mesh tailing accounts for 75% and combined with magnetic concentrate with the diameter smaller than 0.038mm, and rare earth mine is recycled in a flotation mode. The method is applicable to mineral processing production of fluorocarbon cerium type rare earth ore with the high iron content, high mud content and uneven rare earth mineral size distribution.

Owner:四川省地质矿产勘查开发局成都综合岩矿测试中心

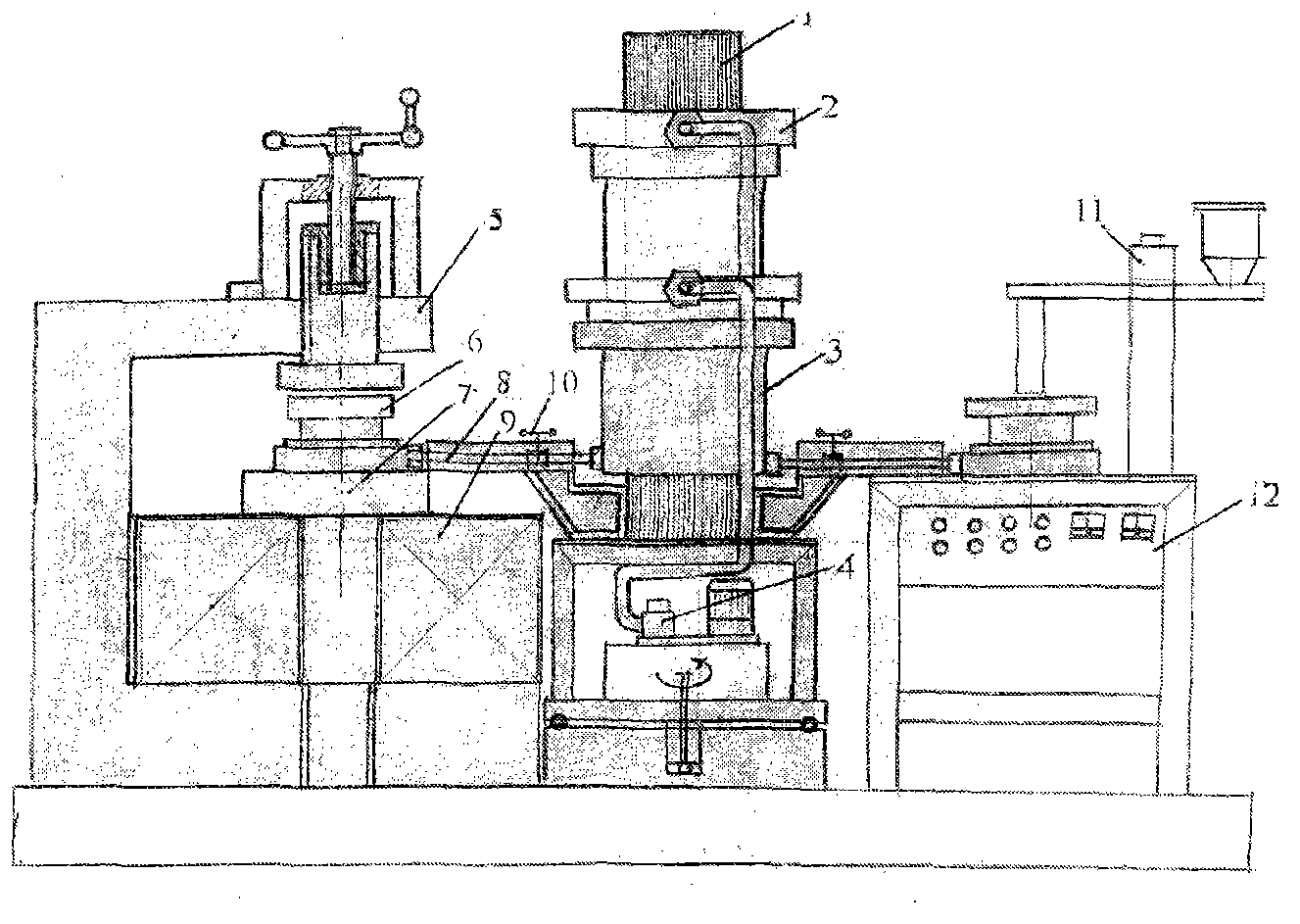

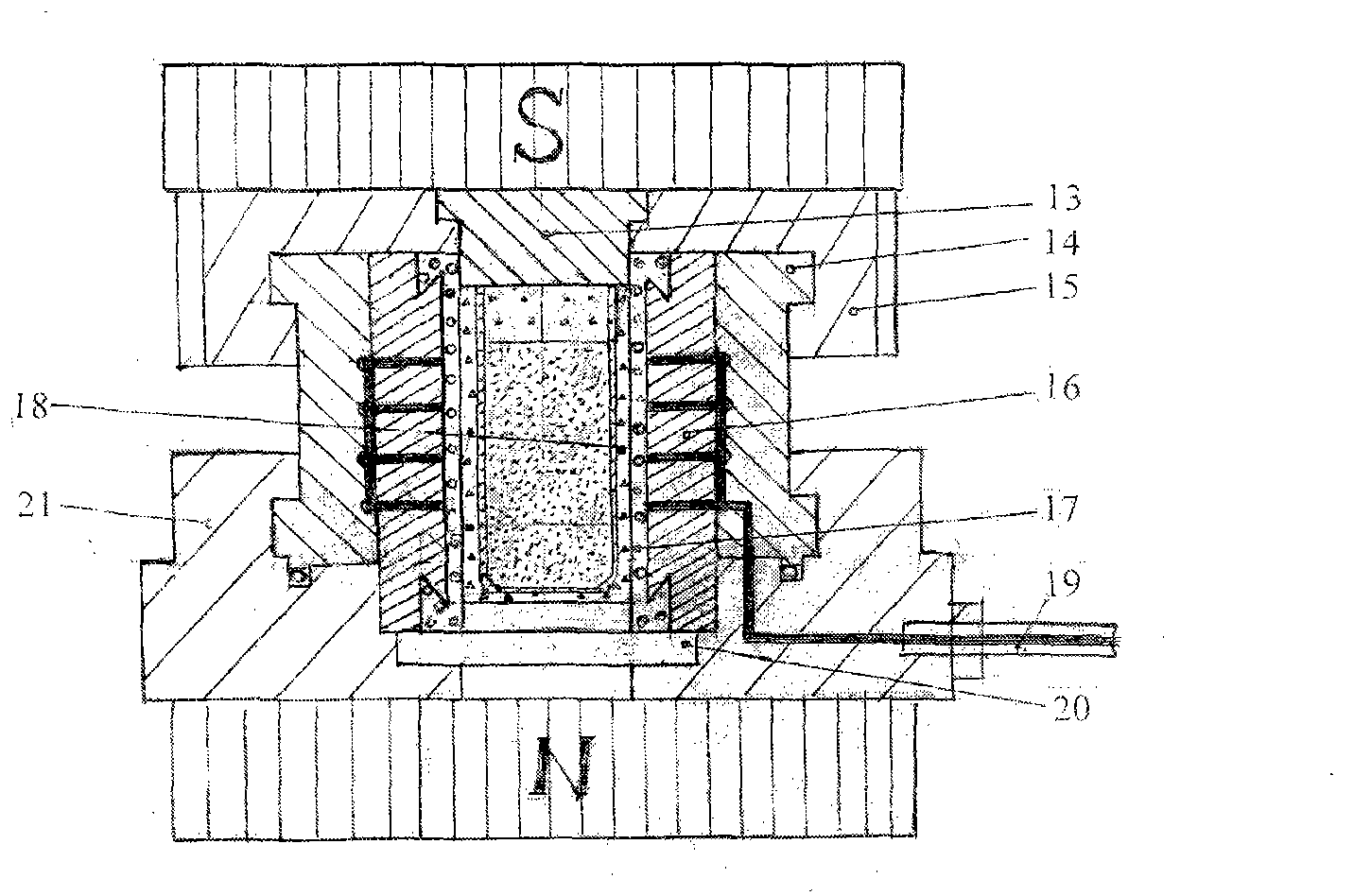

Technology and device for forming dry bag quick isostatic pressing in oriented magnetic fields

InactiveCN103878368AImprove automationIncrease the level of mechanizationInorganic material magnetismInductances/transformers/magnets manufactureResource utilizationMagnetic poles

The invention belongs to the field of technologies for manufacturing magnetic materials, and provides a technology and a device for forming dry bag quick isostatic pressing in oriented magnetic fields. The technology and the device have the advantages that an oriented magnetic field technology is ingeniously and organically combined with the technology and the device for forming dry bag isostatic pressing by the aid of a novel design concept, so that dry bag isostatic pressing can be formed in the oriented magnetic fields which have optional directions and optional magnetic field intensities by the aid of the novel technology and the novel device; orientation degrees of products can be obviously upgraded; two necessary working procedures in existing neodymium, iron and boron magnet production can be combined with each other to form one working procedure by the novel technology and the novel device, and the automation and mechanization levels are high; powder is not in contact with pressing blanks and oil in production procedures, and accordingly a latex sheath for binding the corresponding pressing blank can be omitted; the pressing blanks are quite uniform in density distribution and internal stress distribution; the pressing blanks can be machined, and original powder can be recycled; single-hole and multi-hole thin-walled pipes, sleeves and multi-magnetic-pole products which are heavy and are in complicated shapes or have large length-diameter (L / d) ratios can be produced by the aid of the technology and the device, the rare earth mineral resource utilization rate can be greatly increased, and the neodymium, iron and boron magnet industrial production level of China can be upgraded to the world leading level.

Owner:吴庆华 +2

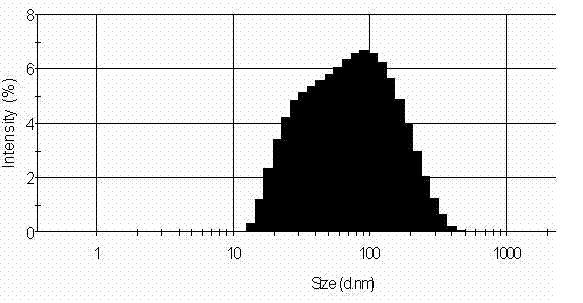

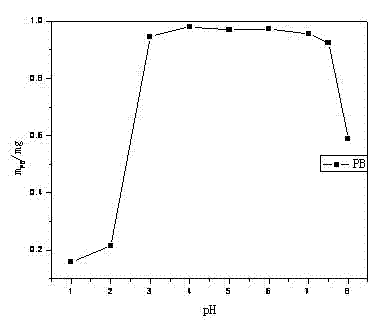

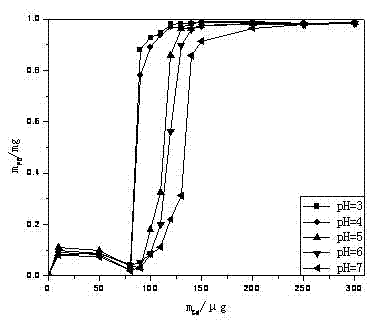

Method for recovering rare earth from low-concentration rare earth solution through prussian blue colloidal nanoparticles

InactiveCN102352448ASimple processLarge loading of rare earthWater/sewage treatment bu osmosis/dialysisProcess efficiency improvementDialysis membranesRare earth ions

The invention relates to a method for recovering rare earth from low-concentration rare earth solution through prussian blue colloidal nanoparticles (PB-CNP). The method comprises the following steps: firstly synthesizing a stable PB-CNP colloidal solution, loading into a bag produced by a dialysis membrane, enabling a dialysis bag containing PB-CNP suspension to be in contact with rare earth material liquid (the pH value is 4-7), and enabling rare earth ions to pass through membrane holes to be in contact with the PB-CNP for being adsorbed. Dilute acid solution is used for desorbing the rareearth from the PB-CNP suspension which absorbs the rare earth ions, thereby achieving the purpose of recovering the rare earth. The PB-CNP suspension and the rare earth material liquid can also be arranged in different channels on the two sides of the membrane of a membrane component for flowing in a countercurrent way, thereby achieving the high-efficient enrichment effect. The method has the advantages of simple process, large rare earth loading amount, high rare earth recovery rate and the like, and can be widely used for the rare earth material liquid of rare earth mines and separation factories; and furthermore, by adopting the method, the rare earth ions in low-concentration rare earth wastewater can be completed removed and recovered, thereby having wide application prospects.

Owner:NANCHANG UNIV

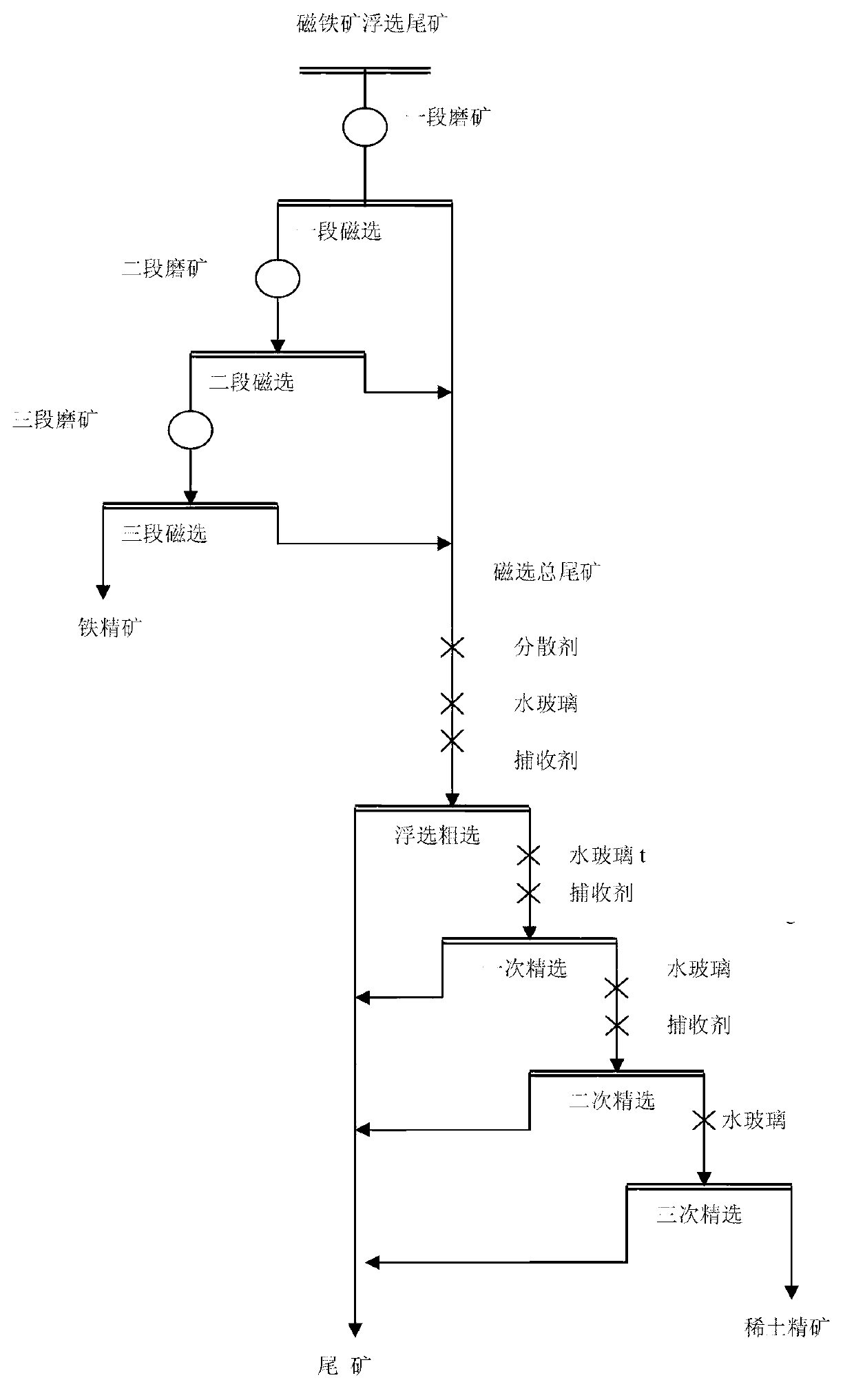

Mineral separation process for recycling iron and rare earth in baotite magnetite flotation tailings

ActiveCN103272698AEffective dissociationRaise the gradeFlotationMagnetic separationMagnetiteMaterials science

The invention belongs to the technical field of mineral engineering, and aims to provide a mineral separation process for recycling iron and rare earth in baotite magnetite flotation tailings. Three sections of ore grinding and three sections of magnetic separation are adopted, and iron ore concentrate which contains more than 63% of iron and has the recycling rate larger than 72% is obtained from the magnetite flotation tailings containing 28%-32% of iron. Then total tailings in an iron recycling process serve as rare earth flotation materials, sodium polyphosphate or sodium hexametaphosphate serves as pulp dispersing agents, 2-hydroxy3-naphthyl mevalonic acid or salicylhydroxami acid and alkyl hydroximic acid in a mass ratio of 6-8:1 serve as rare earth collecting agents, water glass serves as efficient flotation combination reagents of pH regulators and inhibitor, the dispersing state of pulp micro-fine particle minerals is well controlled, the rare earth separation process with once coarse separation and three-time fine separation is adopted, rare earth ore concentrate which contains more than 53% of rare earth and has the recovery rate larger than 47% is obtained from the tailings containing 5-7% of rare earth, and effective separation of rare earth minerals and gangue minerals is achieved.

Owner:包钢集团矿山研究院(有限责任公司)

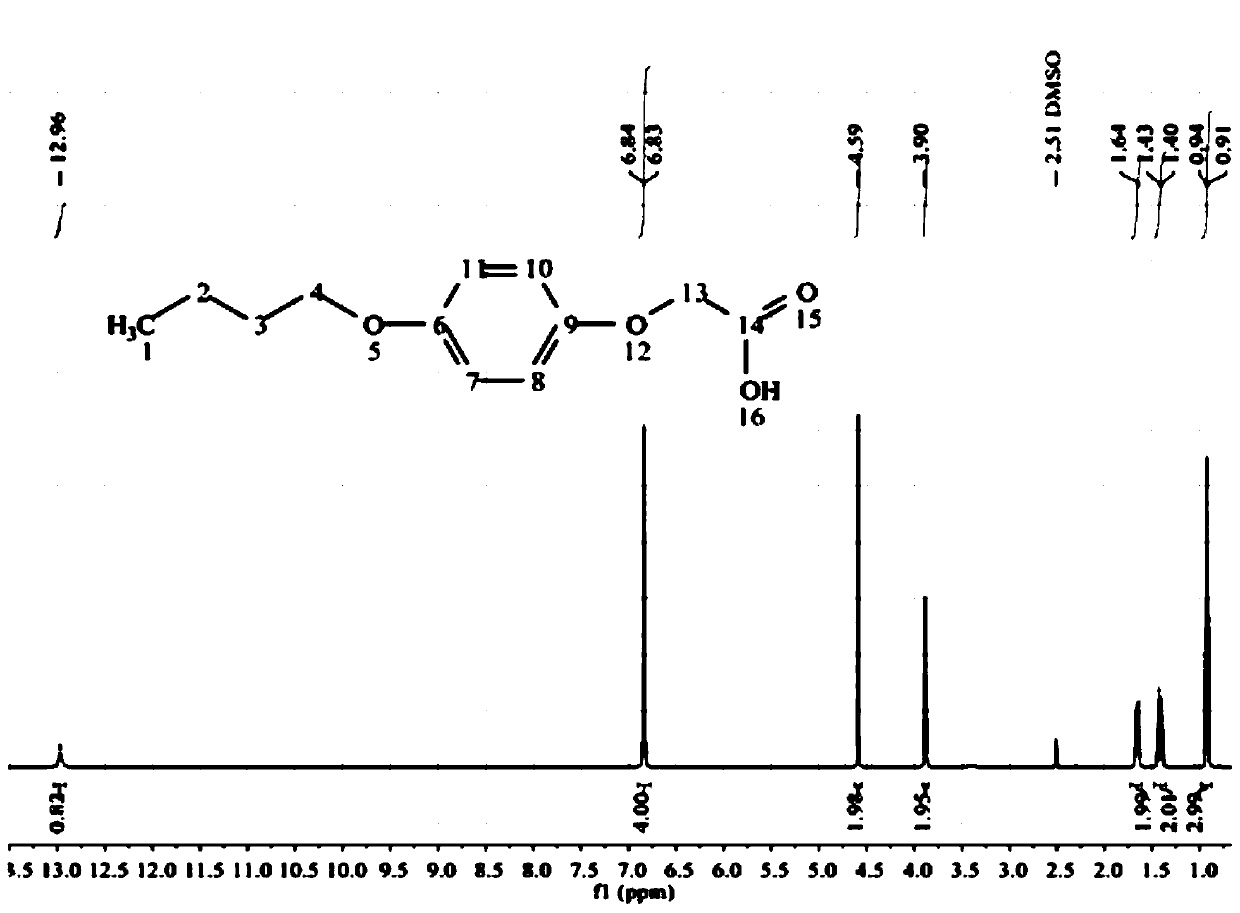

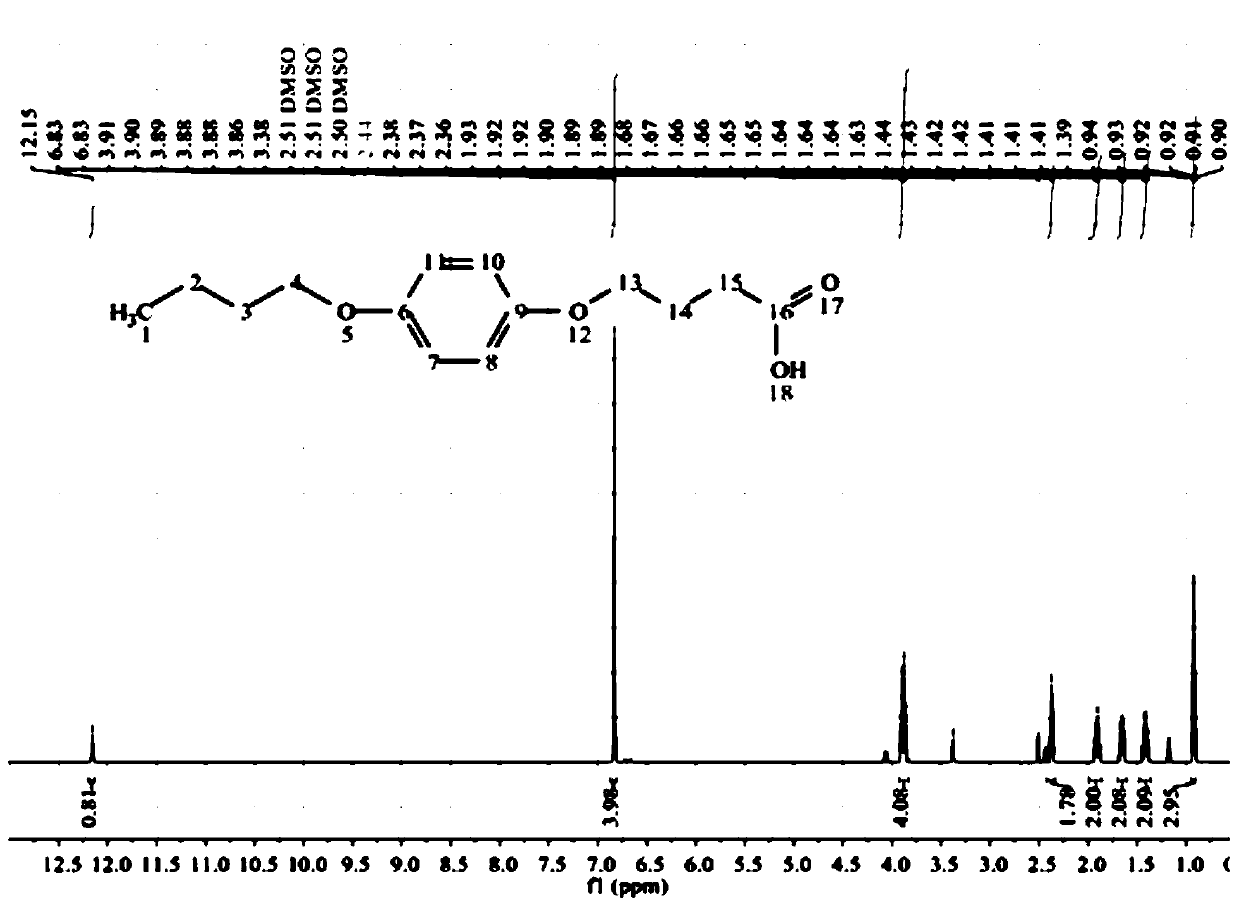

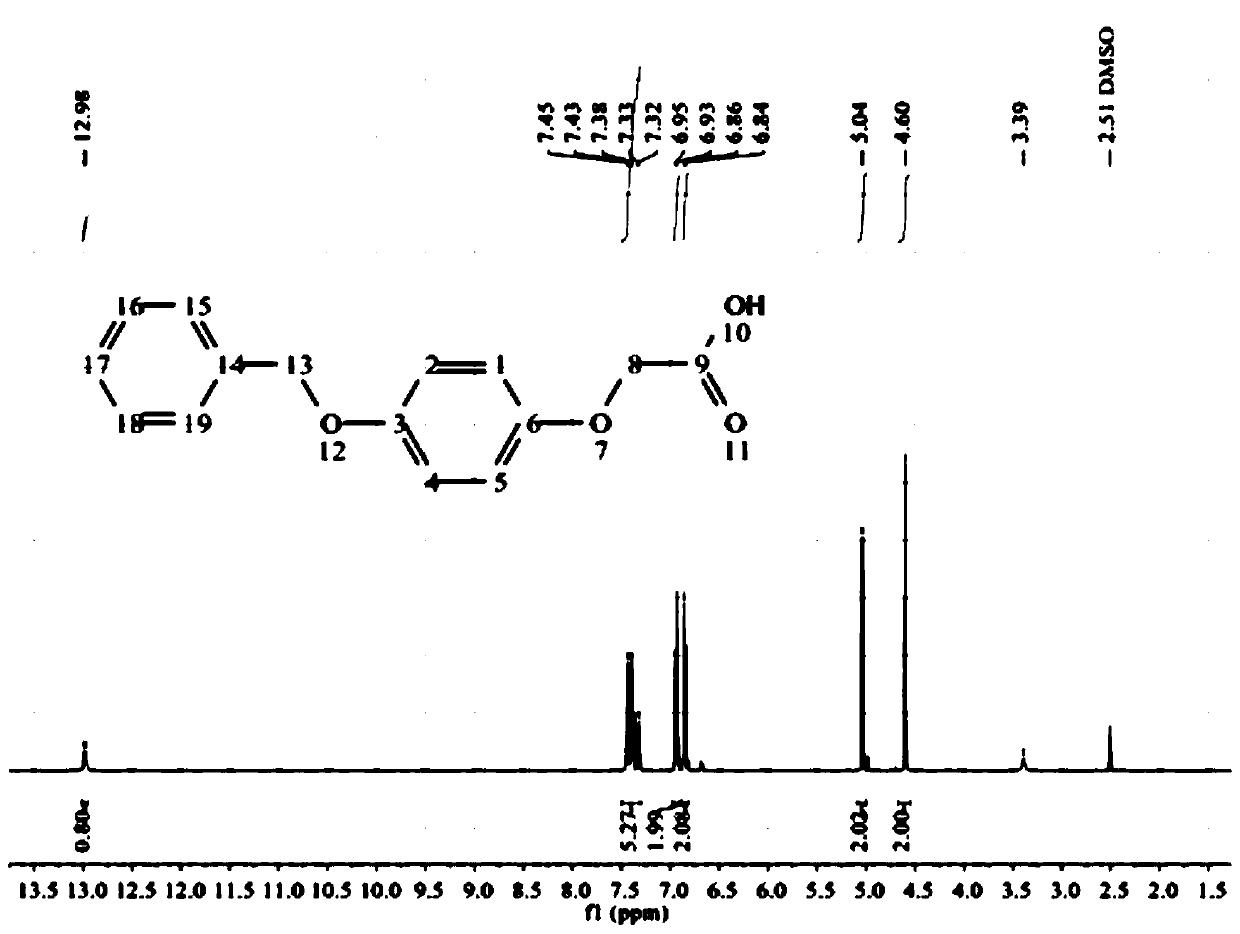

Extractant, preparation method and application thereof

ActiveCN111020188AEffective precipitationHigh saturated load capacityProcess efficiency improvementPhysical chemistryCarboxylic acid

The invention relates to the field of separation and enrichment of metals, in particular to an extractant, a preparation method and application thereof. The preparation method comprises the followingsteps that a phenol compound reacts with a halogenated carboxylic acid derivative or halogenated carboxylate in a solvent, then acidifying is carried out, and the phenoxy carboxylic acid extractant issynthesized. The prepared extractant can be used for enriching rare earth in rare earth mineral leachate after being saponified by an alkaline compound; compared with the existing extractant, the extractant has the advantages of being higher in precipitation capacity, high in precipitation efficiency and large in precipitation particles, facilitating the separation of a rare earth extraction complex and a water phase and improving the production efficiency; and moreover, the extractant can further be used for selectively recovering / separating valuable metals from different industries.

Owner:XIAMEN INST OF RARE EARTH MATERIALS

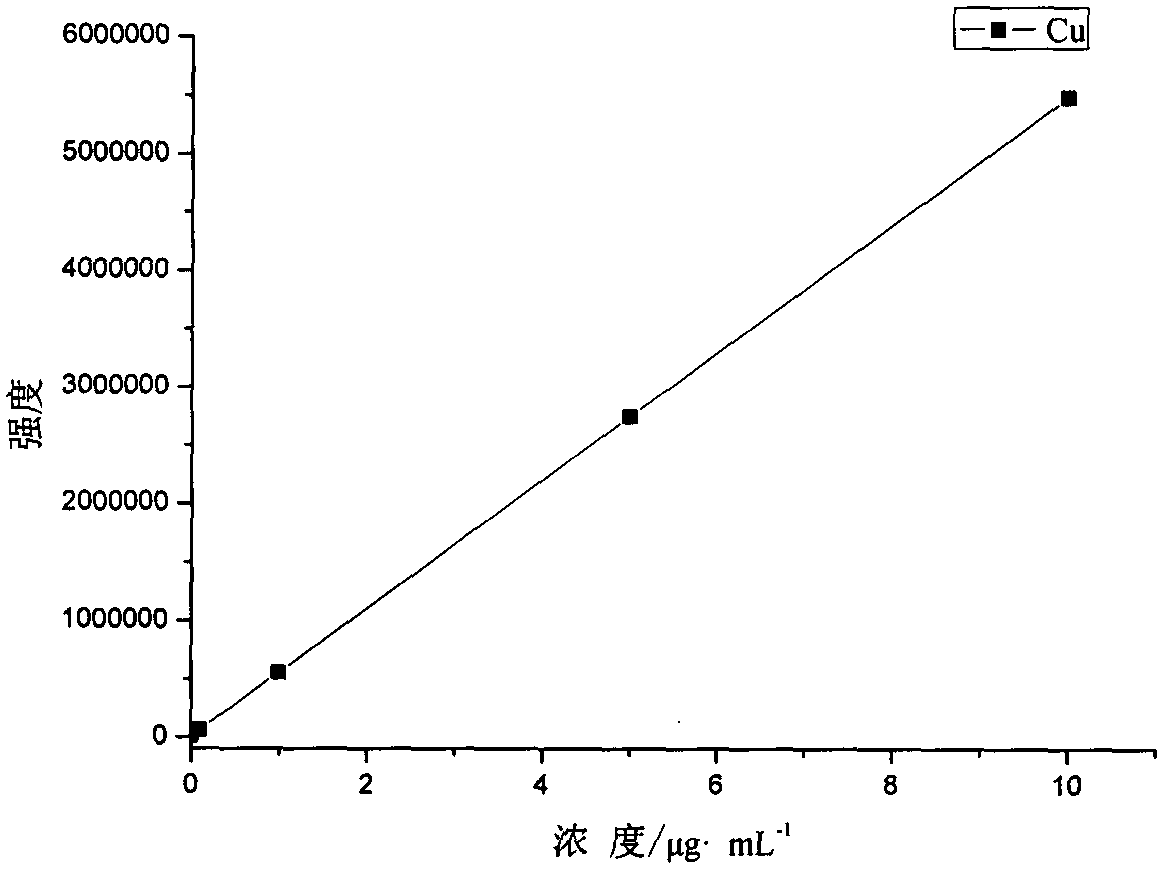

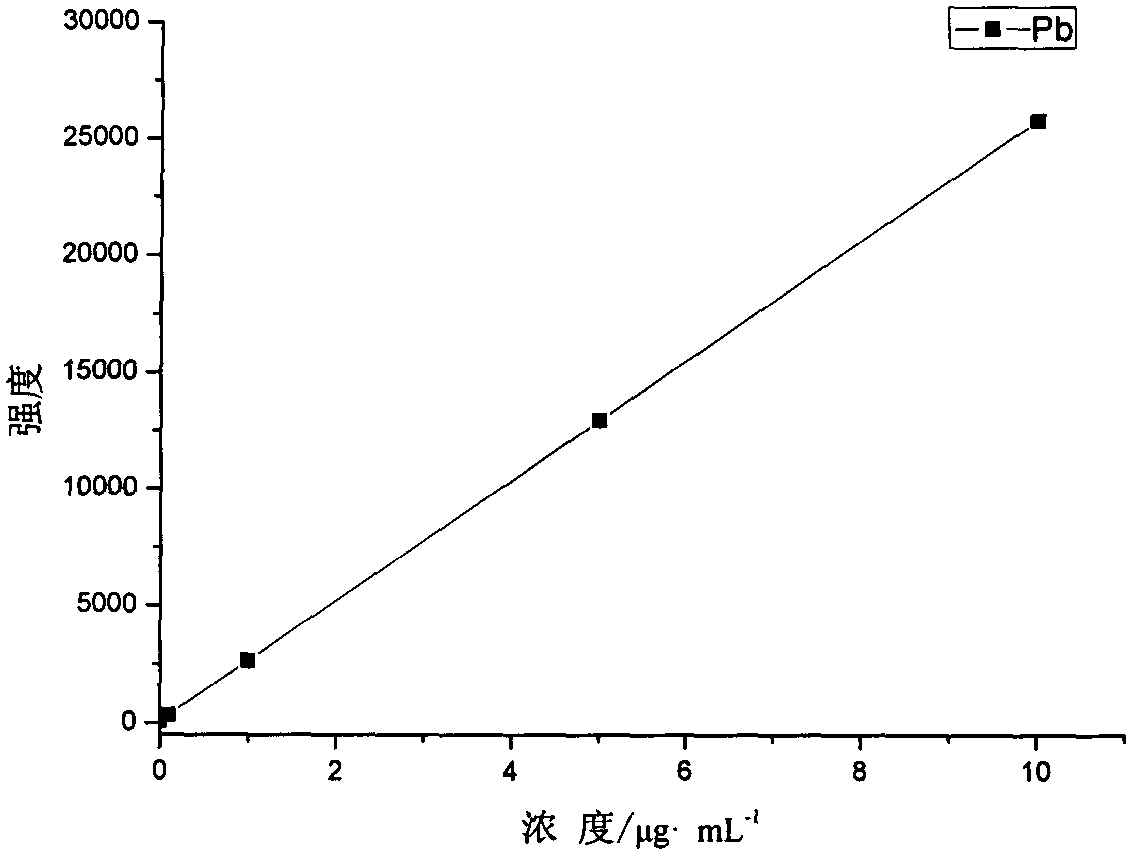

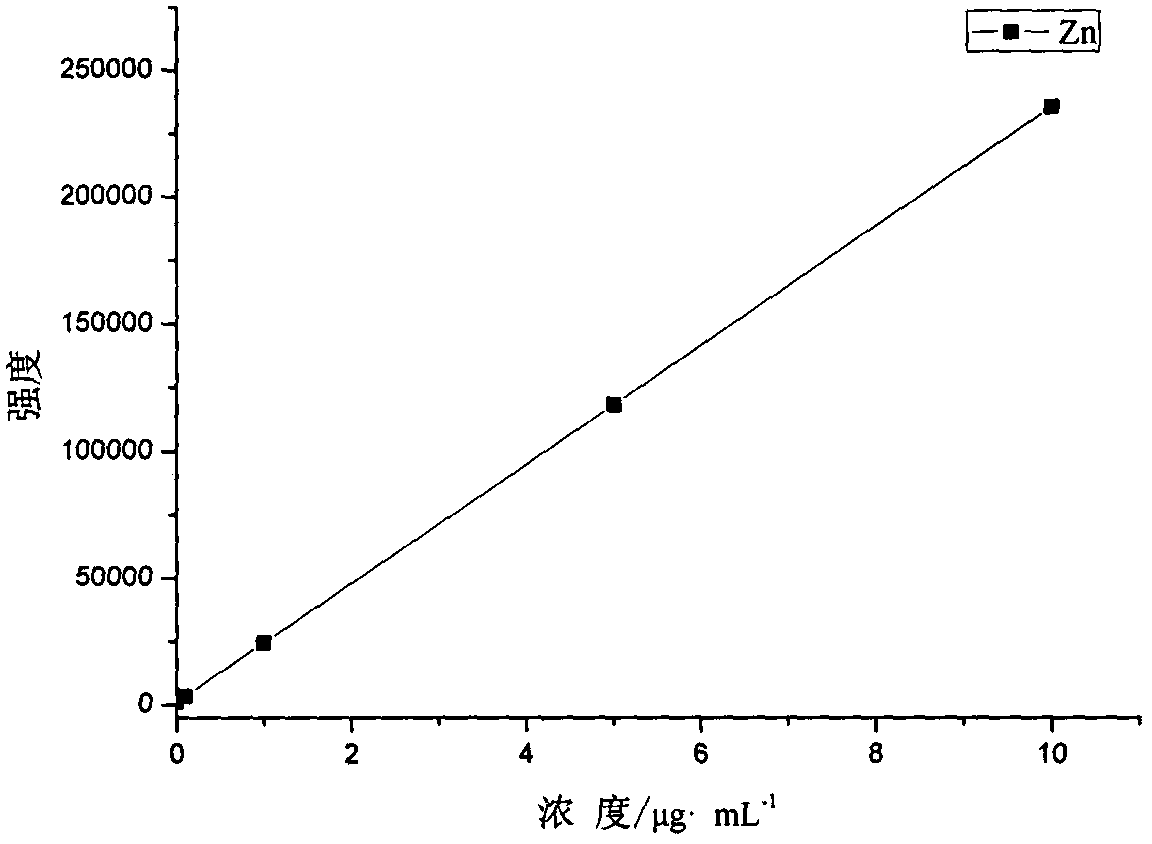

Method for determining copper, lead, zinc and cadmium elements in ionic type rare earth mineral slag through microwave digestion-ICP-OES

InactiveCN108458918AReduce consumptionReduce processing timePreparing sample for investigationAnalysis by thermal excitationSlagDigestion

The invention relates to a method for determining contents of copper, lead, zinc and cadmium in ionic type rare earth mineral slag. The method for determining the contents of copper, lead, zinc and cadmium in the ionic type rare earth mineral slag through microwave digestion-ICP-OES comprises the following steps: carrying out microwave digestion on an ionic type rare earth mineral slag sample through 8mL of lefort and 2mL of hydrofluoric acid; adding 2mL of HClO4 into a digestion tank and putting HClO4 in an acid repelling apparatus; repelling acid at 160 DEG C to ensure that HClO4 is nearly dried; cooling HClO4 and adding 5mL of HCl(1+1) to be transferred and fixing the volume into a 50mL of volumetric flask. A sample blank and the solution are formed aerosol through an inductively coupled plasma atomic emission spectrometer atomizer, and the aerosol is loaded into a high-temperature high-frequency plasma by argon gas, so that ionization is generated and characteristic spectrum is produced, the spectral line intensity of the copper, lead, zinc and cadmium elements in the sample blank and the solution are tested, and the strength of the various elements is in direct proportion to the contents of the elements; therefore, by using a calibration curve method, quantitative determination is carried out, and the contents of the copper, lead, zinc and cadmium elements in cosmetics arecalculated. The method has the characteristics of good determination stability, high sensitivity, and accurate results.

Owner:广西冶金研究院有限公司

Rare earth collector

The invention relates to a rare earth collector, in particular to a floatation rare earth mineral. The rare earth collector consists of the materials with the weight percentage as follows: 30-70 % of 1-naphthyl hydroxamic acid, 8-20 % of salicylaldoxime and 20-40 % of beta-furfural oxime. The rare earth collector is confected by a method as follows: (1) the 1-naphthyl hydroxamic acid is put in an enamel reactor and then is added with methanol and strong sulfuric acid to be put in a crystallizer tank for natural crystallization after heating reflux; (2) crystal, salicylal and beta-fufural are put into the enamel reactor and added with water and hydroxylamine hydrochloride to be heated to 35 DEG C to 55 DEG C for 5 hours; 30 percent liquid alkali is dipped during the reaction to keep pH at 10 always; after the reaction, solution is cooled to 30 DEG C, and 25 percent dilute sulphuric acid is added for acidifying, until the pH value equals to 5; and a product is put in a plastic bucket, and the product is the rare earth collector. The invention has less medicament dosage, low cost, simple medicament addition, strong adaptability, good selectivity and the strong ability of the collector.

Owner:NEIMENGGU BAOGANG RARE EARTH LINFENG TECH

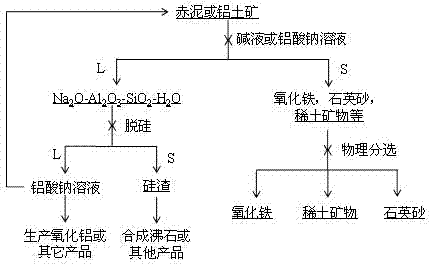

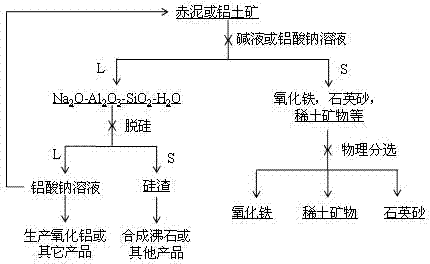

Comprehensive utilization method of aluminum-containing minerals

InactiveCN102328943AEfficient use ofAchieve separationSolid waste disposalAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationRare-earth elementSlag

The invention provides a comprehensive utilization method of aluminum-containing minerals and relates to a comprehensive utilization method of silicon, aluminum, ferrum, sodium, rare-earth elements and the like in bauxite, red mud, kaolin and the like. The comprehensive utilization method is characterized by comprising the following steps: carrying out silicon and aluminum dissolving reaction on an aluminum-containing mineral raw material, and then directly carrying out solid-liquid separation to obtain a solid phase A and a dissolving liquid phase, wherein the solid phase A can be used as iron ore concentrate or for other purposes; adding lime or other substances in the dissolving liquid phase so that a silicon compound in the solution turns into silicon slag solid phase B, wherein the silicon slag B obtained by reaction is used for preparing zeolite or for other purposes, and a part of the obtained sodium aluminate solution enters into an alumina process to produce alumina, and the other part of the obtained sodium aluminate returns to the dissolving step. According to the invention, most of dissolving liquid returns to the dissolving process after desilication, and a part of the dissolving liquid is used for producing products such as alumina or sodium aluminate and the like; the solid phase is mainly rich in Fe2O3 and rare-earth minerals, thereby being beneficial to further comprehensive utilization; and elements such as silicon, aluminum, sodium, ferrum and the like in the minerals can be well used. Thus, the method provided by the invention has good economic benefits and social benefits.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Treatment method for fluorine-contained rare-earth mineral grains

ActiveCN109022838AReduce extraction costsQuick breakdownProcess efficiency improvementDecompositionSulfate

The invention discloses a treatment method for fluorine-contained rare-earth mineral grains. The treatment method comprises the following steps of (1) mixing first fluorine-contained rare-earth mineral grains with a first sulfuric acid solution by weight ratio of (2-10) to 1 of sulfuric acid to the first fluorine-contained rare-earth mineral grains, then, performing heating and heat preservation for performing solid-liquid reaction, and condensing and absorbing steam by a tail gas system, wherein the sulfuric acid concentration of the first sulfuric acid solution is 40 to 85 wt%; (2) after thereaction is ended, performing solid-liquid separation to obtain acid filtrate and acid filter residues; (3) leaching the acid filter residues with water to obtain rare earth sulfate water extract andliquid leached residues; and (4) supplementing a second sulfuric acid solution into the acid filtrate so as to enable the sulfuric acid concentration of the acid filtrate to be 40 to 85 wt%; circularly treating the first fluorine-contained rare-earth mineral grains according to the steps (1) to (3). According to the method disclosed by the invention, rapid decomposition of the fluorine-containedrare-earth mineral grains is realized, the reaction is easy to control, and meanwhile, cyclic utilization of a spent acid resource is realized.

Owner:BAOTOU RES INST OF RARE EARTHS +1

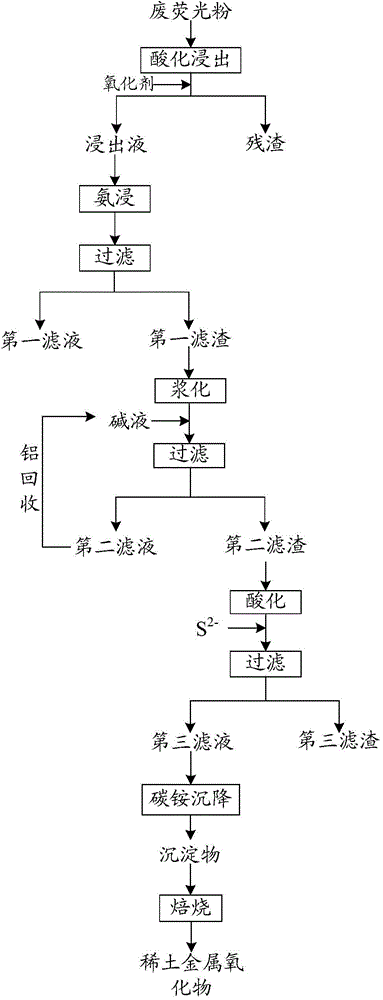

Method for recycling rare earth metal from waste fluorescent powder

ActiveCN105087934AAvoid Scatter LossReduce solubilityProcess efficiency improvementRecovery methodFiltration

The invention provides a method for recycling rare earth metal from waste fluorescent powder. The method includes the steps that the waste fluorescent powder is subjected to acidic leaching, and a leaching agent is obtained through filtration; the leaching agent is subjected to ammonia leaching processing, and a first filter residue and first filter liquor are obtained through filtration; the first filter residue is processed with alkali liquor, the solution pH is adjusted to be higher than 12.5, and a second filter residue and second filter liquor are obtained through filtration; the second filter residue is subjected to acid hydrolysis, the solution pH is adjusted to 3.5-4.5, then non-rare-earth metal precipitator is added for precipitation, and a third filter residue and third filter liquor are obtained through filtration; the third filter liquor is subjected to ammonium hydrocarbonate precipitation, and precipitate is taken; and the precipitate is roasted, and the rare earth metal oxide is prepared. According to the method for recycling rare earth metal from waste fluorescent powder, the rare earth metal in the waste fluorescent powder is extracted in an acidic leaching manner, the leaching rate reaches up to more than 99%. Zinc, aluminum and other non-rare-earth metal are removed from the leaching agent step by step, zinc and aluminum can be recycled step by step, and resource regeneration is achieved; and the technology can save energy and reduce emission, and is low in cost, reasonable and easy to implement.

Owner:荆门格林循环电子废弃物处置有限公司

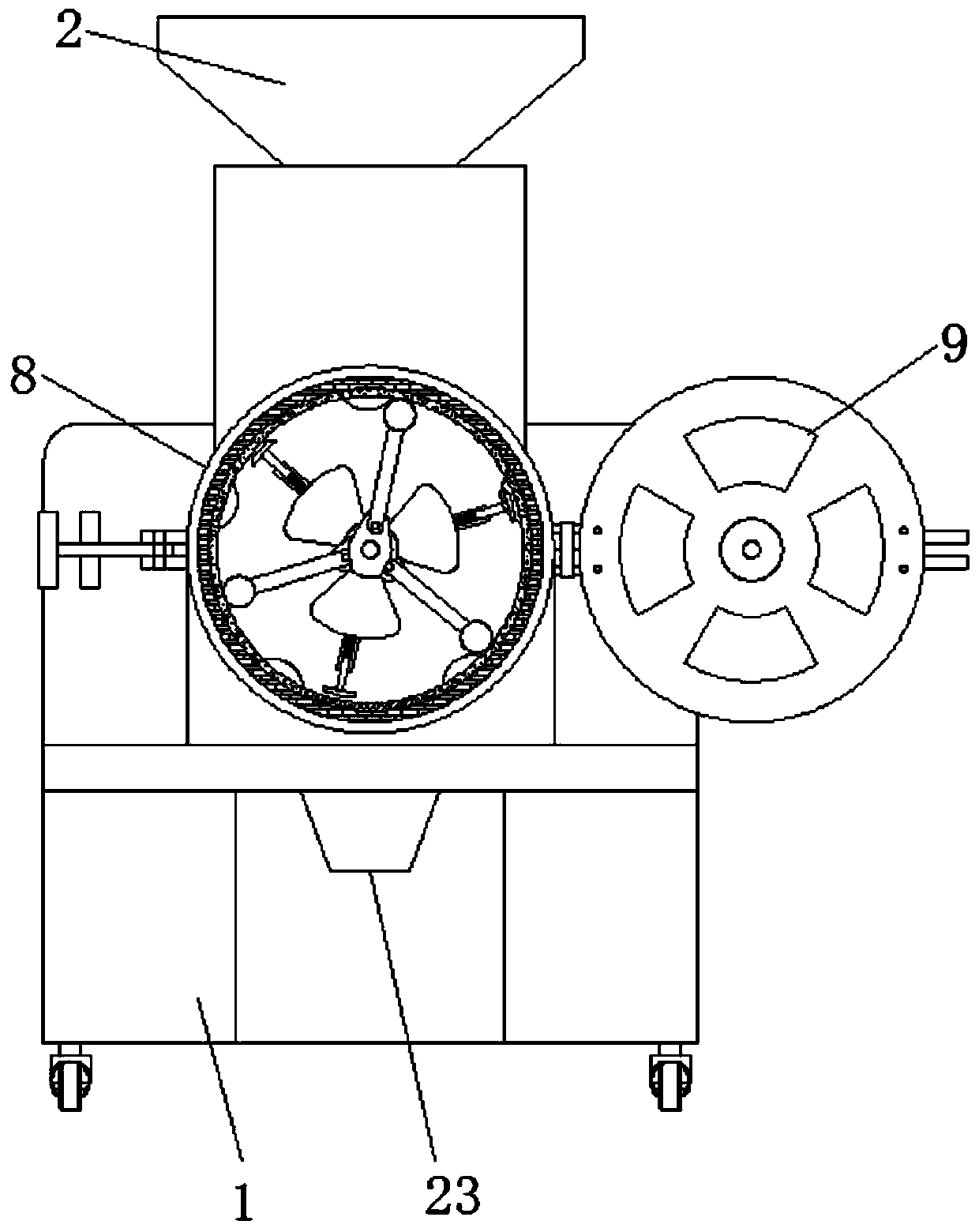

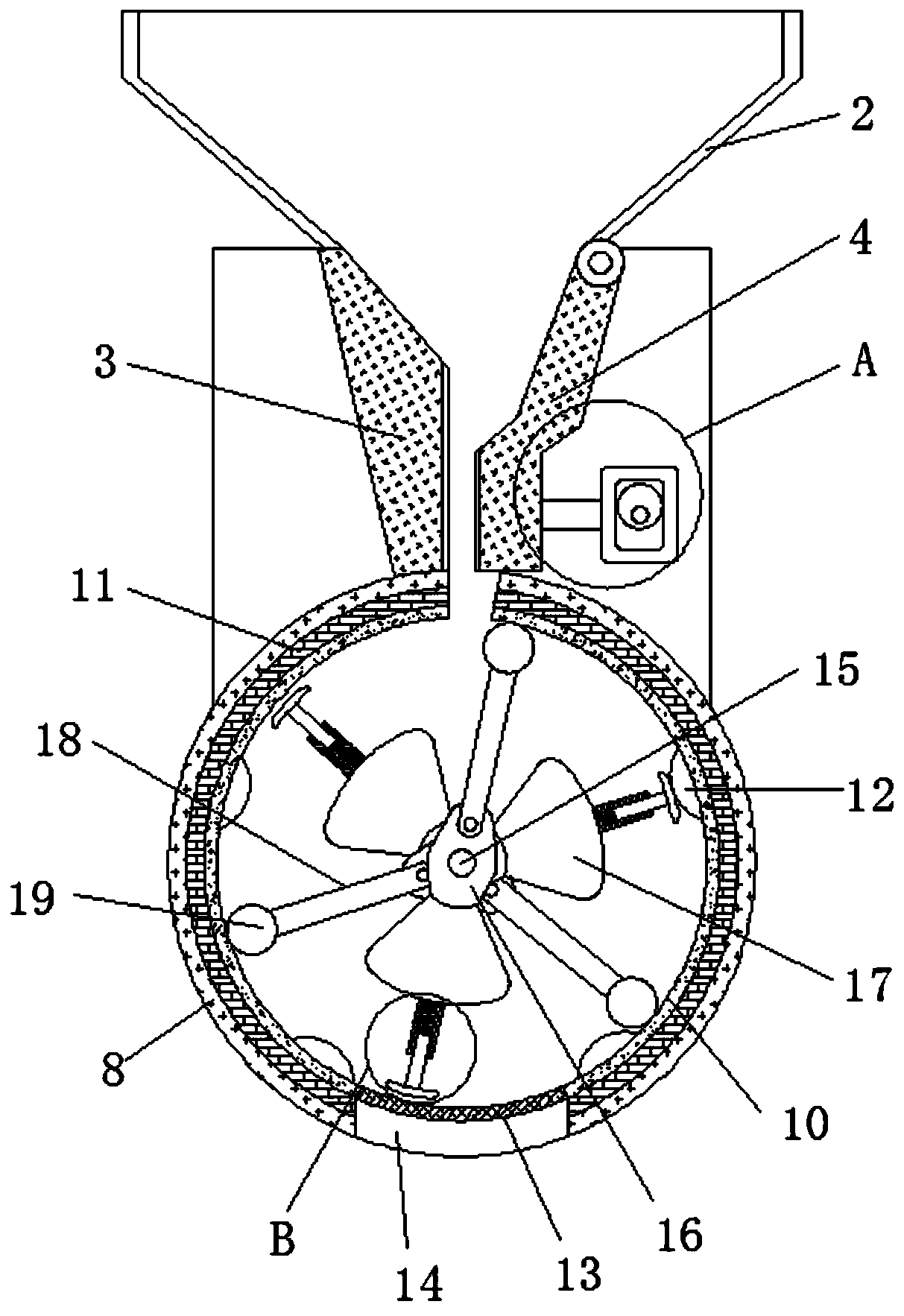

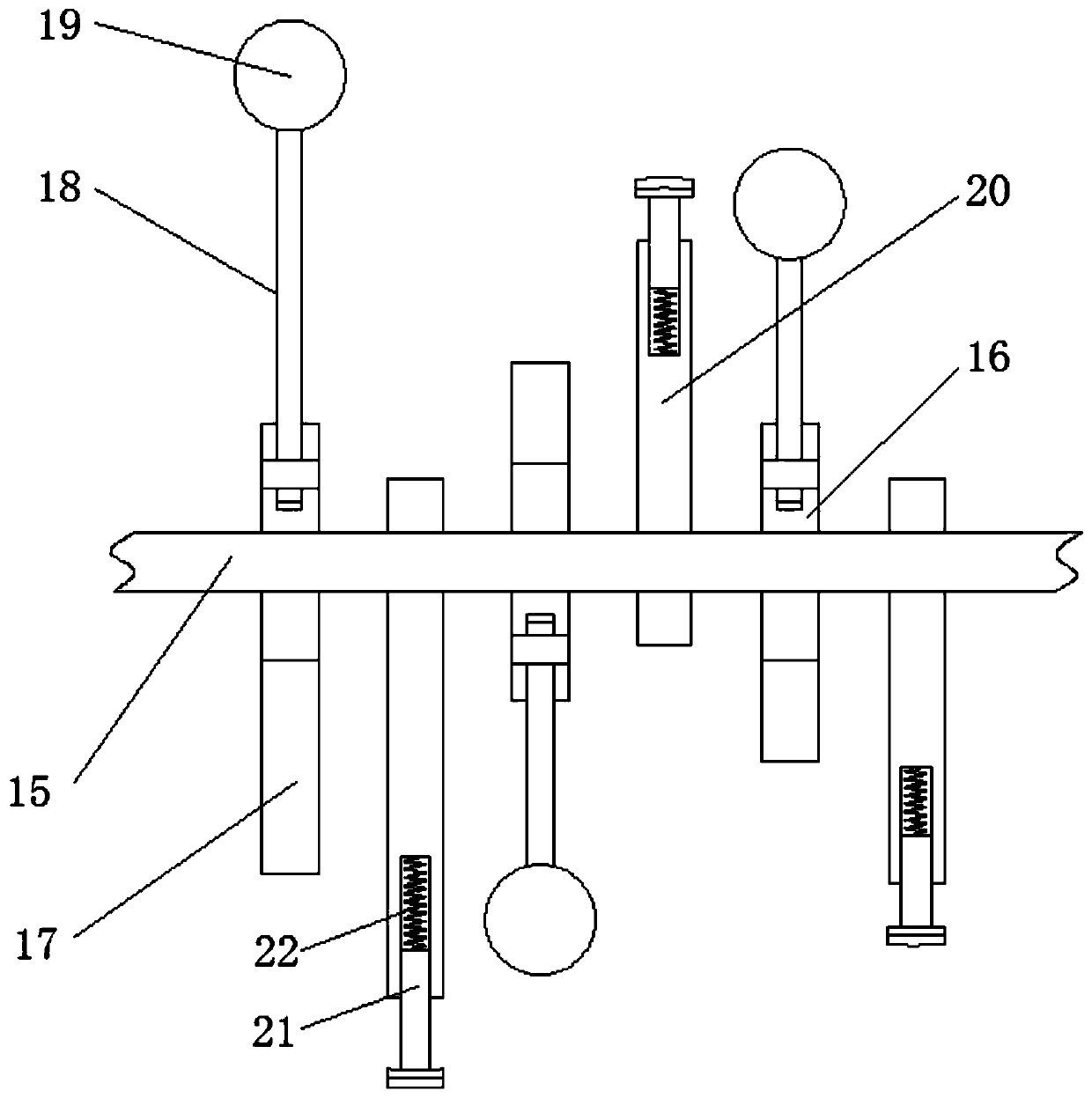

Novel material crushing device using rotational centrifugal force principle

InactiveCN111068816AGuaranteed crushing effectGood secondary crushing effectGrain treatmentsMoving jawEngineering

The invention relates to the technical field of new materials and discloses a novel material crushing device using a rotational centrifugal force principle. The novel material crushing device comprises a support, wherein the top of the support is fixedly connected with a feeding port, the bottom of the feeding port is fixedly connected with a fixed jaw, the inner part of the support is hinged witha movable jaw, the outer part of the movable jaw is fixedly connected with a push rod, the outer part of the push rod is fixedly connected with a push ring, the inner part of the push ring is movablyconnected with a cam, a fine crushing chamber is fixedly connected to the bottom of the fixed jaw, a cover plate is hinged to the outside of the fine crushing chamber, a reinforcing plate is fixedlyconnected to the inside of the fine crushing chamber, a sealing ring is fixedly connected to the inside of the fine crushing chamber, the effect of preliminarily crushing rare earth minerals is achieved through the matched use of the fixed jaw and the movable jaw, and the effect of twice crushing is achieved, so that the crushing effect is guaranteed and the secondary crushing effect and the crushing efficiency are improved.

Owner:中科纳通山东新材料有限公司

Mineral separation method for alkaline rock type rare earth mineral

The invention relates to a mineral separation method for an alkaline rock type rare earth mineral, which is characterized in that the mineral separation method comprises the following steps of: carrying out mineral grinding and magnetic separation to obtain magnetic separation roughing concentrates and magnetic separation roughing tailings; carrying out magnetic separation scavenging on the magnetic separation roughing tailings by using a high-gradient wet process to obtain magnetic separation scavenging concentrates and magnetic separation scavenging tailings; and combining the magnetic separation roughing concentrates with the magnetic separation scavenging concentrates, carrying out closed-route flotation of rough concentration for one time, scavenging for three times and fine concentration for three times after mineral grinding and sequentially returning middlings. Finally, flotation fluorine carbon cerium concentrates and flotation tailings are obtained. The mineral separation method has the advantages of simple and short process, small equipment floor area, no dust operation, normal temperature operation and high sorting index. The mineral separation method is suitable for the mineral separation of a light rare earth mineral existing in a bastnaesite form.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI +1

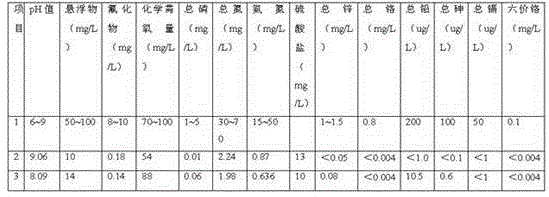

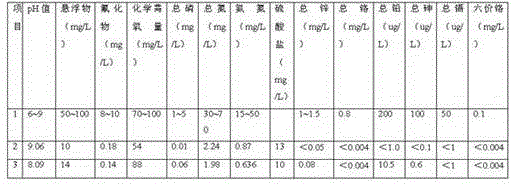

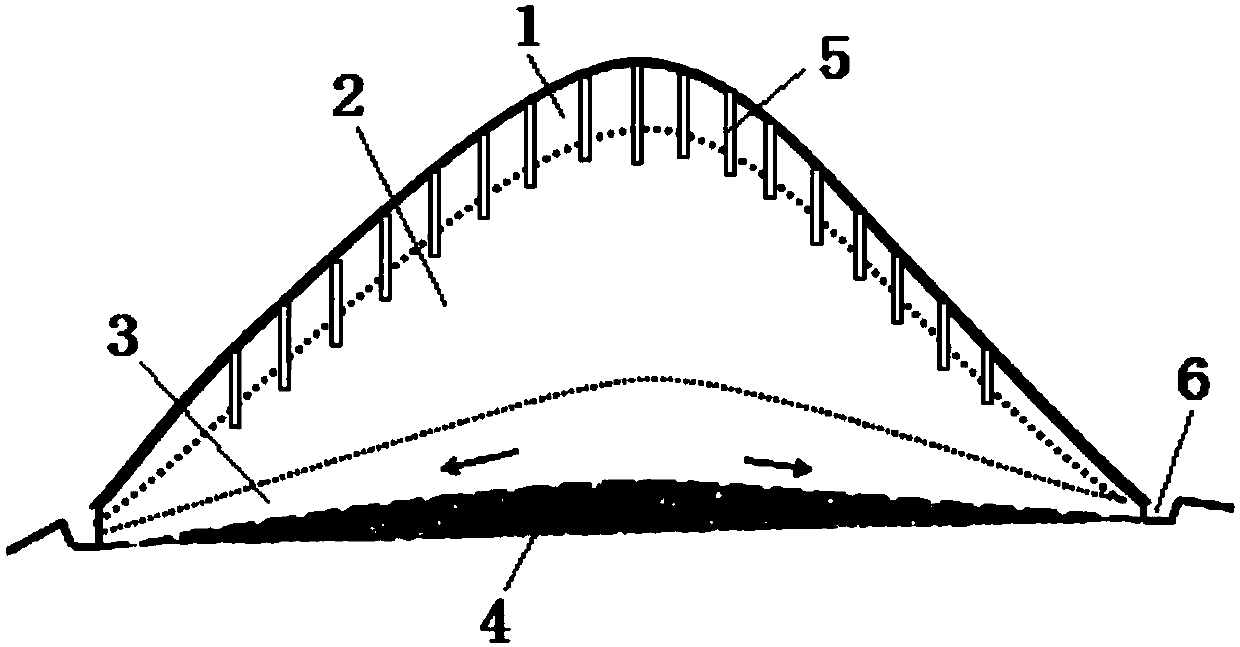

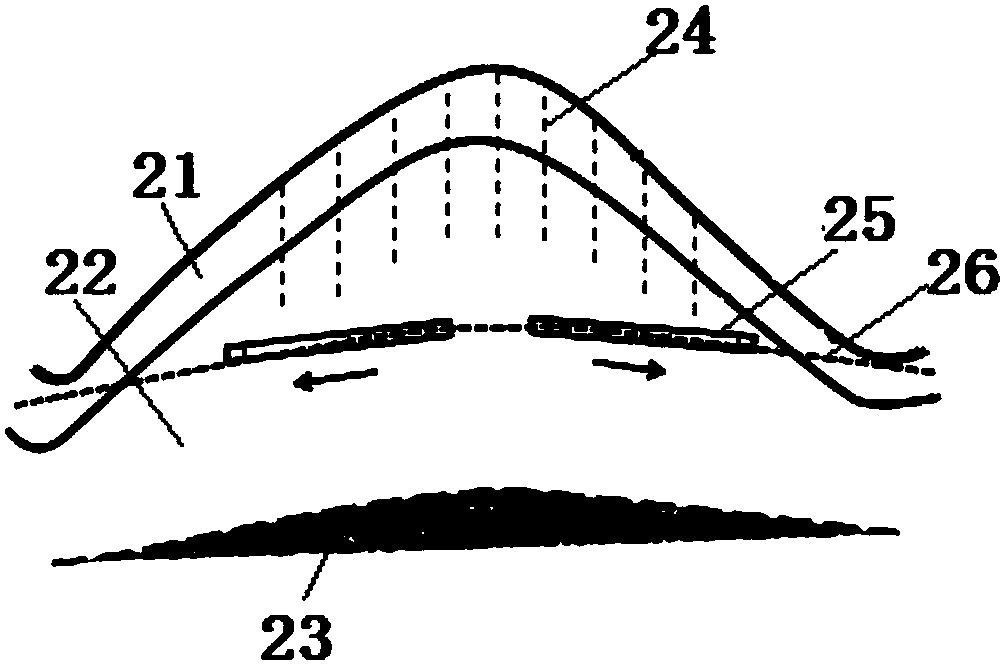

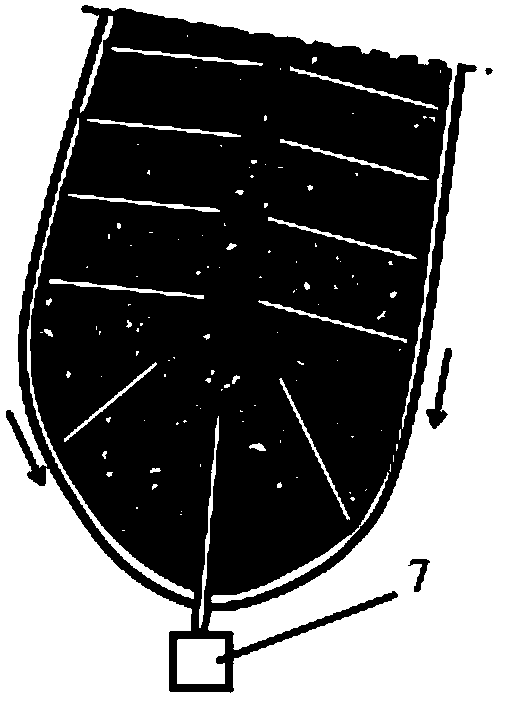

Ion-type rare-earth ore ammonium-free environment-friendly exploitation technique

InactiveCN108034842ANo pollution in the processPollution meetsProcess efficiency improvementEnvironmental resistanceIon exchange

The invention discloses an ion-type rare-earth ore ammonium-free environment-friendly exploitation technique. The ion-type rare-earth ore ammonium-free environment-friendly exploitation technique comprises the following steps that an ammonium-free ore leaching agent with a certain concentration is injected through liquid injecting holes distributed in a stope to be subjected to an ion exchanging reaction with rare-earth ores so as to obtain mother liquid enriched in rare-earth positive ions; the mother liquid seeps and gathers into liquid collecting engineering such as matching of ore-layer natural water partition bottom plates or artificial liquid collecting roadways with liquid collecting flow guiding holes; and then the mother liquid is conveyed to a hydrometallurgy workshop through a main conveying pipeline, ammonium-free agents are used for impurity removal and precipitation to obtain rare-earth carbonate, and supernatant liquid is circulated back to a liquid preparation pool andthen subjected to pH valve adjustment and agent adding, and returns to the stope to serve as a new ammonium-free ore leaching agent. The ion-type rare-earth ore ammonium-free environment-friendly exploitation technique has the advantages that ammonium is avoided in the overall process, and environmental friendliness is achieved on soil and water bodies; production waste water is circularly and comprehensively utilized, and harmful waste discharging is avoided; and the leaching rate, liquid collecting rate and precipitating rate of the rare-earth ions are high, and the resource mining comprehensive recovery rate is increased.

Owner:五矿勘查开发有限公司

Luminous fiber, luminous yarn and method for preparing luminous yarn

InactiveCN103361753AStable light storageImprove luminous performanceFilament forming substance formingArtificial filament heat treatmentFiberAviation

The invention discloses a luminous fiber. The luminous fiber comprises a fiber main body and photoluminescence materials, wherein the fiber main body is used for preparing a chemical fiber and consists of high-molecular compound materials; the photoluminescence materials are uniformly distributed in the fiber main body. The photoluminescence materials such as rare earth mineral substances with a luminance performance are added into spun threads, and are uniformly scattered in the fiber, so that the threads are stable in light storage and light emitting effects, non-toxic, innocuous, non-radiative, harmless to a human body, stable in luminance performance, and long in service life, has the environment-friendly effect, and can be permanently used in an endless loop. A luminous fiber material can be used for spinning, and are suitable for other purposes; people can regard the luminous fiber material as a carrier to manufacture a product by using sunlight which can be used as a clean and pollution-free energy source in accordance with environment protection and sustainable development, and the manufactured product is widely applied to the fields of aviation, navigation, national defense industry, building decoration, transportation, night operation, daily life, leisure and entertainment, and the like.

Owner:PUTIAN HUAFENG IND & TRADE CO LTD

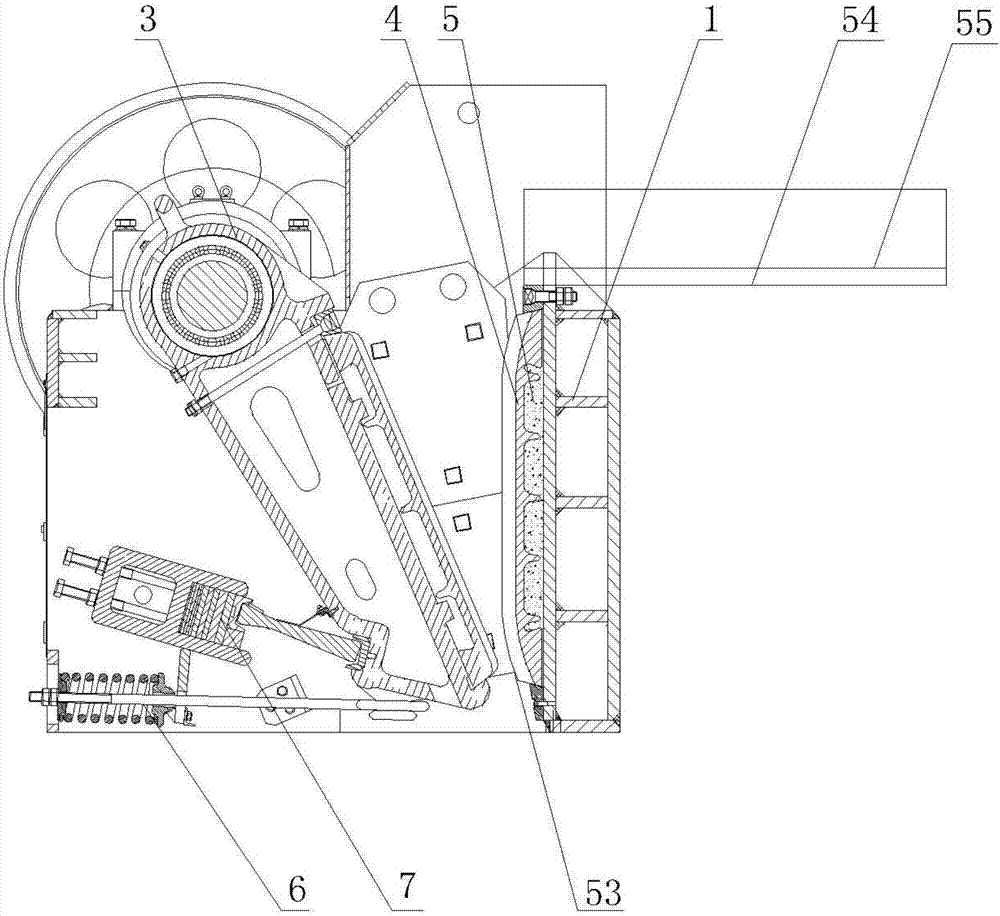

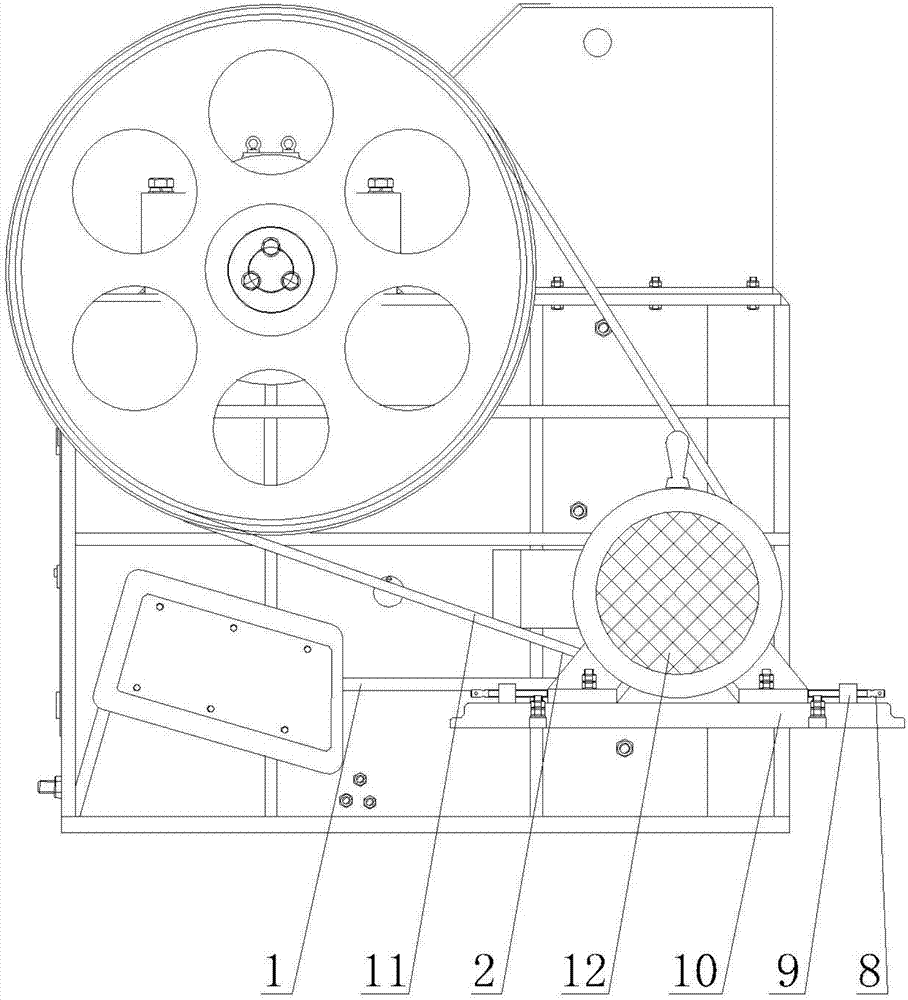

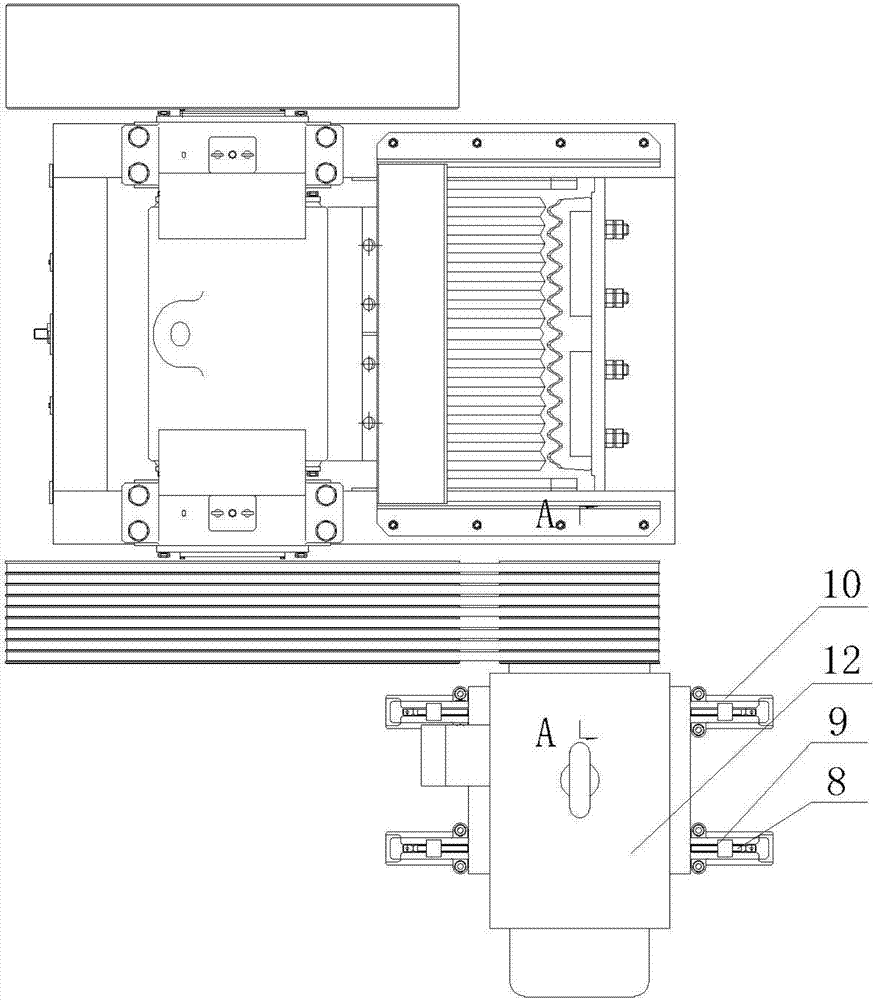

Jaw crusher for rare earth minerals and crushing method of jaw crusher

The invention relates to a jaw crusher for rare earth minerals and a crushing method of the jaw crusher. The jaw crusher for the rare earth minerals and the crushing method of the jaw crusher mainly solve the problems that an existing crusher is low in efficiency and poor in smashing effect and a lining plate is abraded easily. The jaw crusher for the rare earth minerals comprises a rack, a transmission mechanism, a movable jaw mechanism, a movable jaw pull rod mechanism and an adjusting mechanism, wherein the transmission mechanism, the movable jaw mechanism, the movable jaw pull rod mechanism and the adjusting mechanism are arranged on the rack, a tooth-shaped lining plate is perpendicularly arranged on the front wall inside the rack, a cement pouring layer is arranged between the tooth-shaped lining plate and the rack, the bottom of the movable jaw mechanism is connected with the movable jaw pull rod mechanism and the adjusting mechanism, the top of the movable jaw mechanism is connected with the transmission mechanism, and a crushing cavity is formed between the tooth-shaped lining plate and the movable jaw mechanism. The technical scheme solves the problems well and can be used for crushing of the rare earth minerals.

Owner:XINFENG BAOGANG XINLI RARE EARTH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com