Extractant, preparation method and application thereof

An extraction agent and reaction technology, applied in the field of extraction agent and its preparation, can solve the problems of difficult operation and low extraction efficiency, and achieve the effects of no secondary pollution, easy solid-liquid separation, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] A kind of preparation method of above-mentioned extractant, comprises the steps:

[0052] (1) phenolic compound reacts with alkali, obtains corresponding phenate compound;

[0053] (2) the phenoxide compound and the halogenated carboxylic acid derivative or the halogenated carboxylic acid salt react in a solvent to obtain an intermediate;

[0054] (3) The intermediate is acidified to obtain the extractant.

[0055] Further, in the step (1), the reaction temperature is 40-60°C.

[0056] Further, in the step (2), the pH of the reaction is 10-12, and the reaction temperature is 60-110° C. During the step (2), solid sodium hydroxide is used to control the pH value of the reaction process to be alkaline, but it cannot exceed 10.

[0057] A method for enriching rare earth elements from low-concentration rare earth ore leachate, comprising the following steps:

[0058] (1) using alkaline compound to saponify the above-mentioned extractant to obtain saponified extractant; ...

Embodiment 1

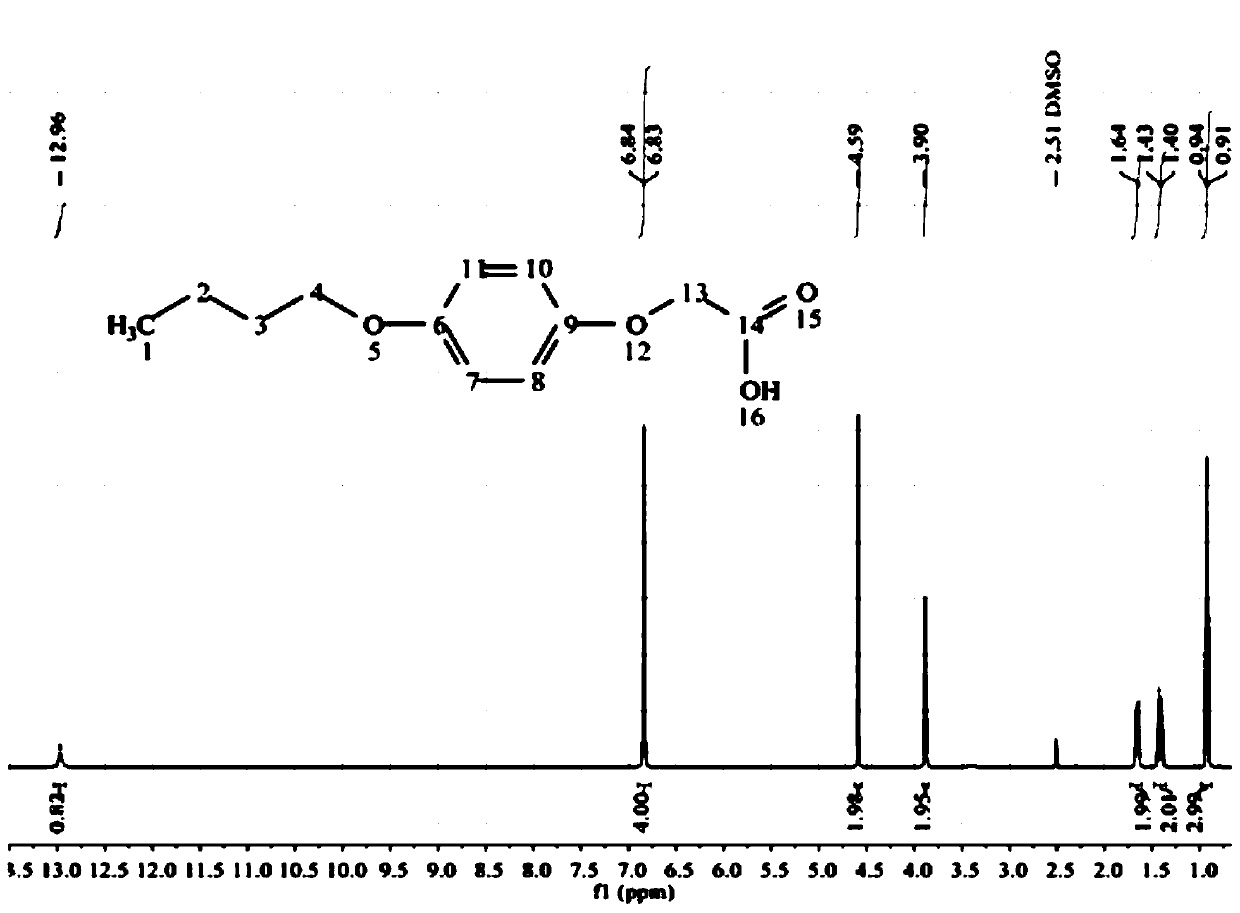

[0073] Example 1 Synthesis of 2-(4-butoxyphenoxy)acetic acid (BPAA)

[0074] Weigh 0.05mol of 4-n-butoxyphenol and dissolve it in 100mL of ethanol and water, the mass ratio of ethanol to water is 1:1. Add 0.05 mol of solid sodium hydroxide, slowly heat to 50°C and stir for 30 minutes. Weigh 0.08 mol of sodium chloroacetate and dissolve it in ethanol, add 0.2 g of KI, slowly add to the three-neck flask, then continue to slowly heat to 110°C, condense and reflux for 5 hours. During the control reaction, the pH value was about 10. Use a rotary evaporator to remove ethanol, use 3mol / L hydrochloric acid to acidify, control the pH value to about 2-3, produce a brown solid, filter, and use deionized water to wash to neutral, and then recrystallize with toluene several times BPAA with a yield of 86% and a purity of 98% was obtained.

[0075] NMR spectrum such as figure 1

[0076] BPAA: 1 H NMR (500MHz, DMSO-d6) δ12.95(s,1H),6.84(s,4H),4.59(s,2H),3.89(t,J=6.5Hz,2H),1.69-1.62(m, ...

Embodiment 2

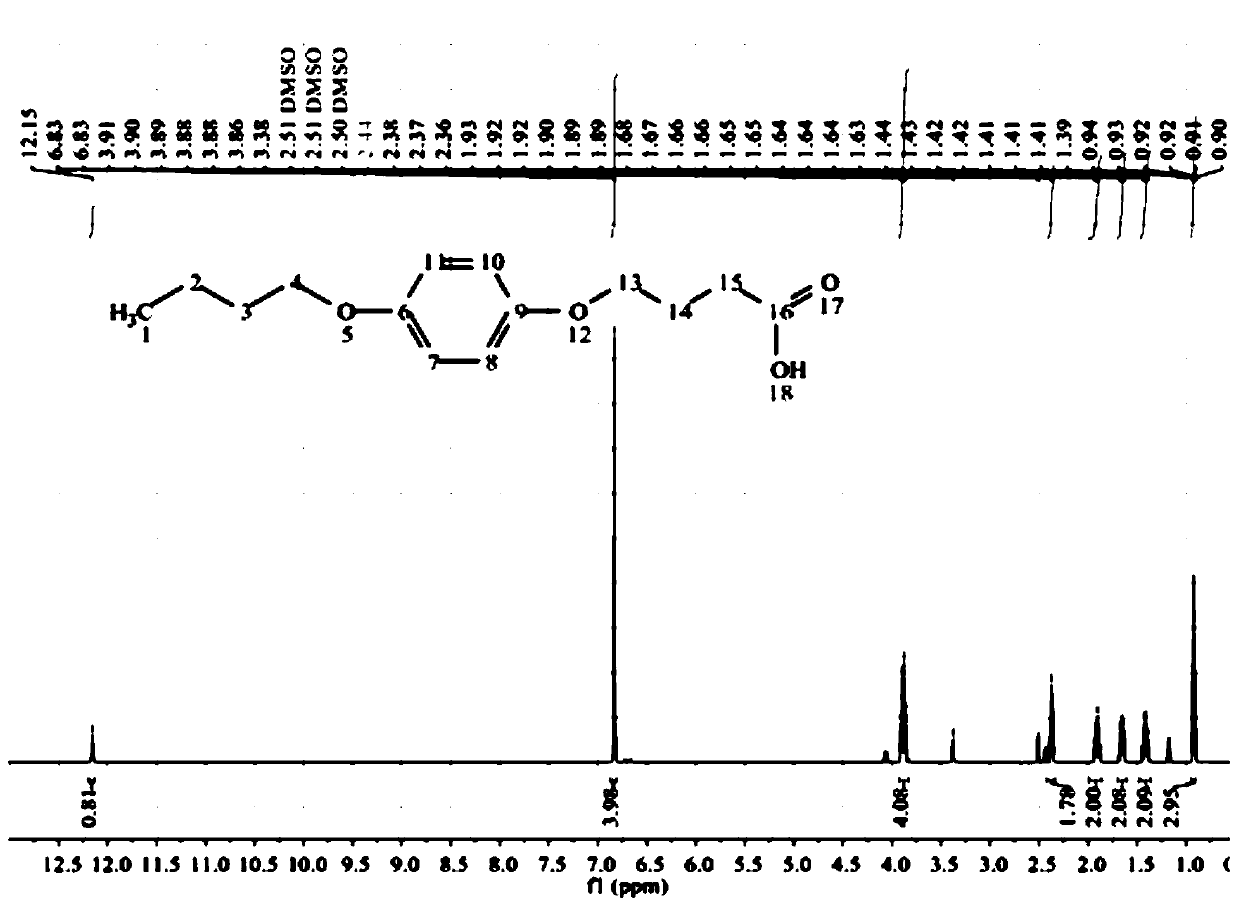

[0077] Example 2 Synthesis of 4-(4-butoxyphenoxy)butanoic acid (BPBA)

[0078] Weigh 0.05mol of 4-n-butoxyphenol into a three-necked flask, add 100mL of ethanol, add 0.5g of KI, weigh 0.05mol of solid sodium hydroxide, add it and slowly heat and stir, control the temperature at 40°C, and react 1 Cool down to room temperature after 1 hour, add 4-bromobutyrate methyl ester dissolved in ethanol (40mL) slowly in five times, and slowly heat to 60°C when adding 4-bromobutyrate methyl ester for the first time, and the temperature rise should not be too fast . When methyl 4-bromobutyrate is added completely, continue to heat up to 110°C, during which time solid sodium hydroxide is used to control the pH value of the reaction process to 12, react for 12 hours, then add 50mL of deionized water for ester hydrolysis reaction, continue After 3 hours of reaction, it was cooled to room temperature. Use a rotary evaporator to remove ethanol, use 3mol / L hydrochloric acid to acidify to produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com