Full-automatic vision printer

A printing machine, fully automatic technology, used in printing machines, rotary printing machines, screen printing machines and other directions, can solve problems such as cost increase, affecting PCB board calibration accuracy, affecting XYθ calibration work platform calibration accuracy, etc., to ensure quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

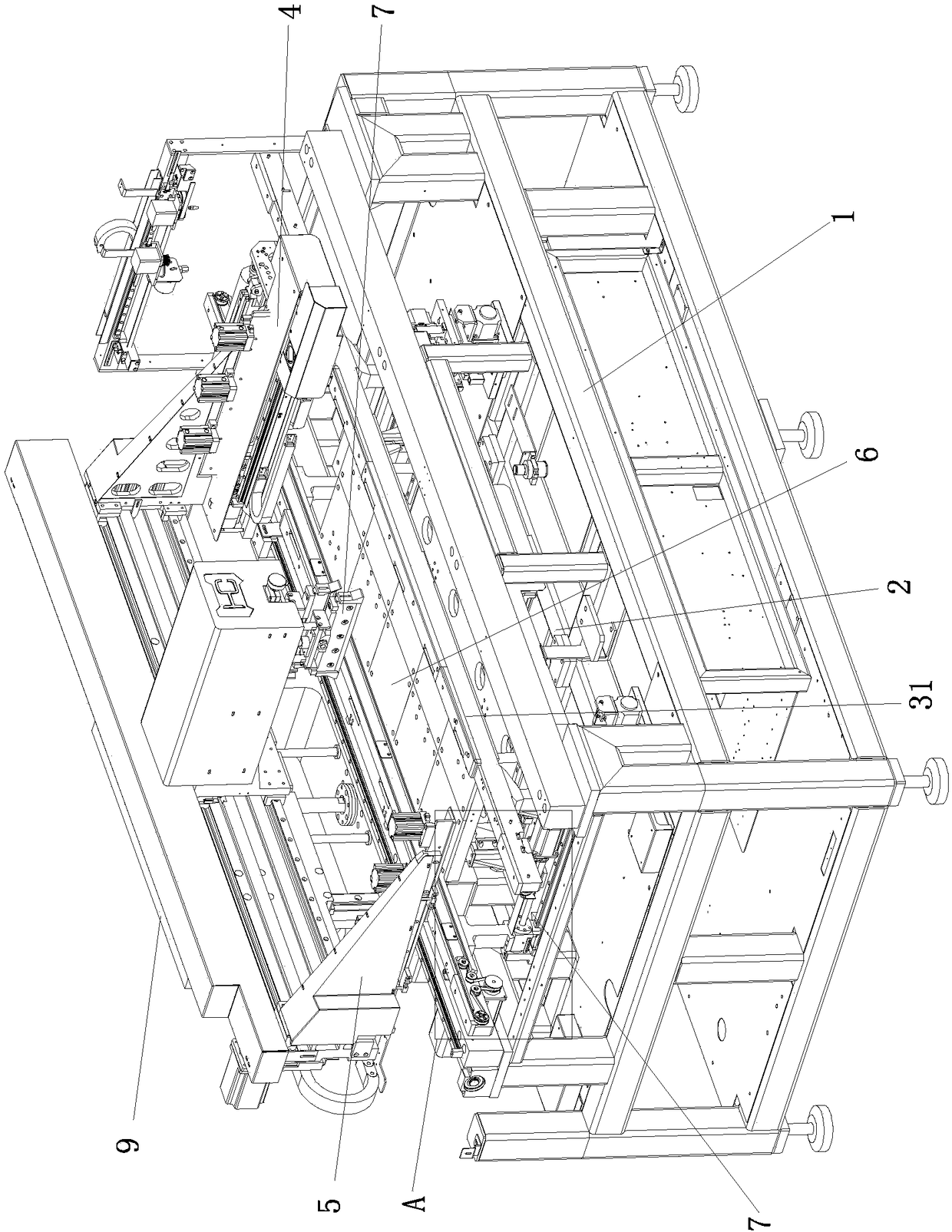

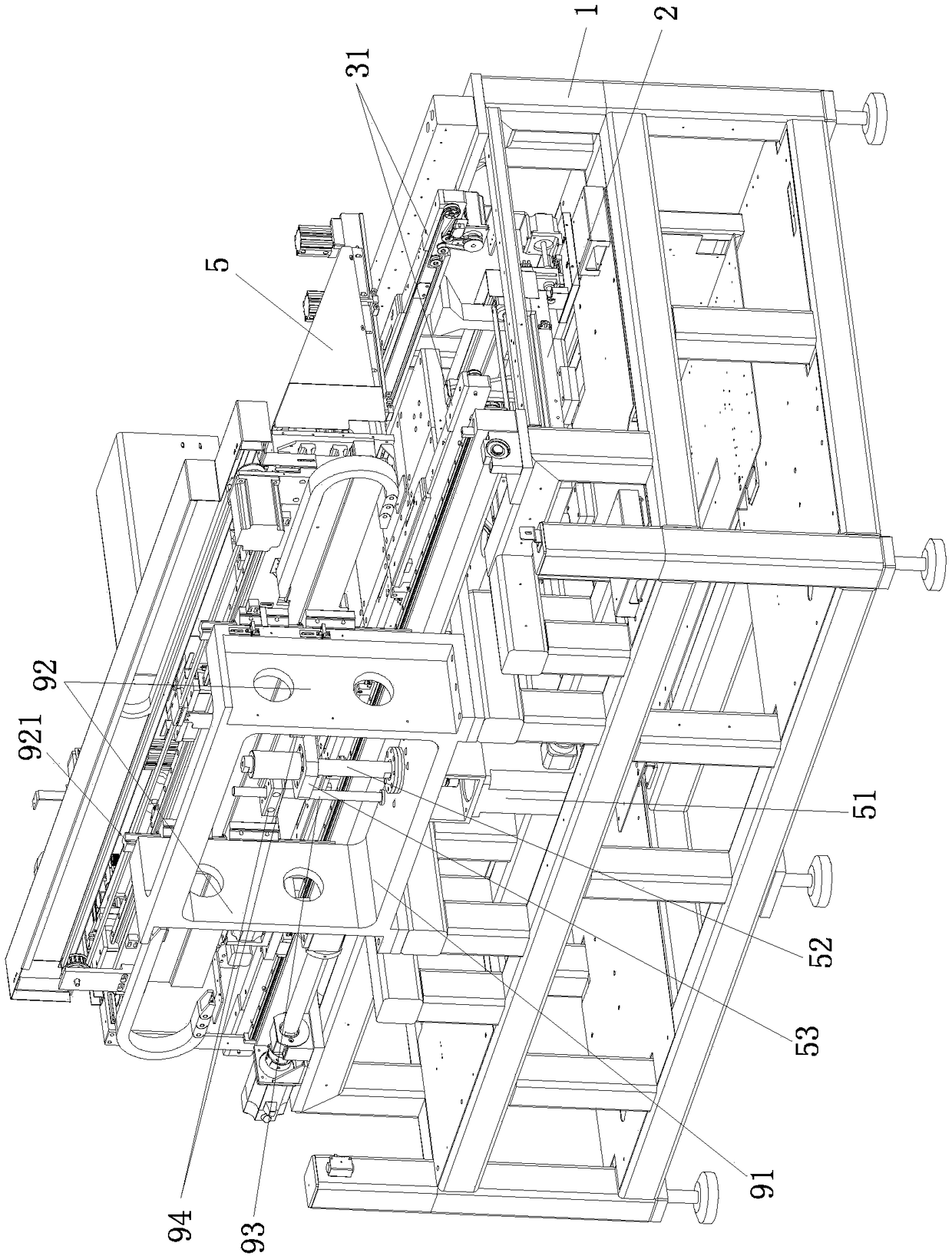

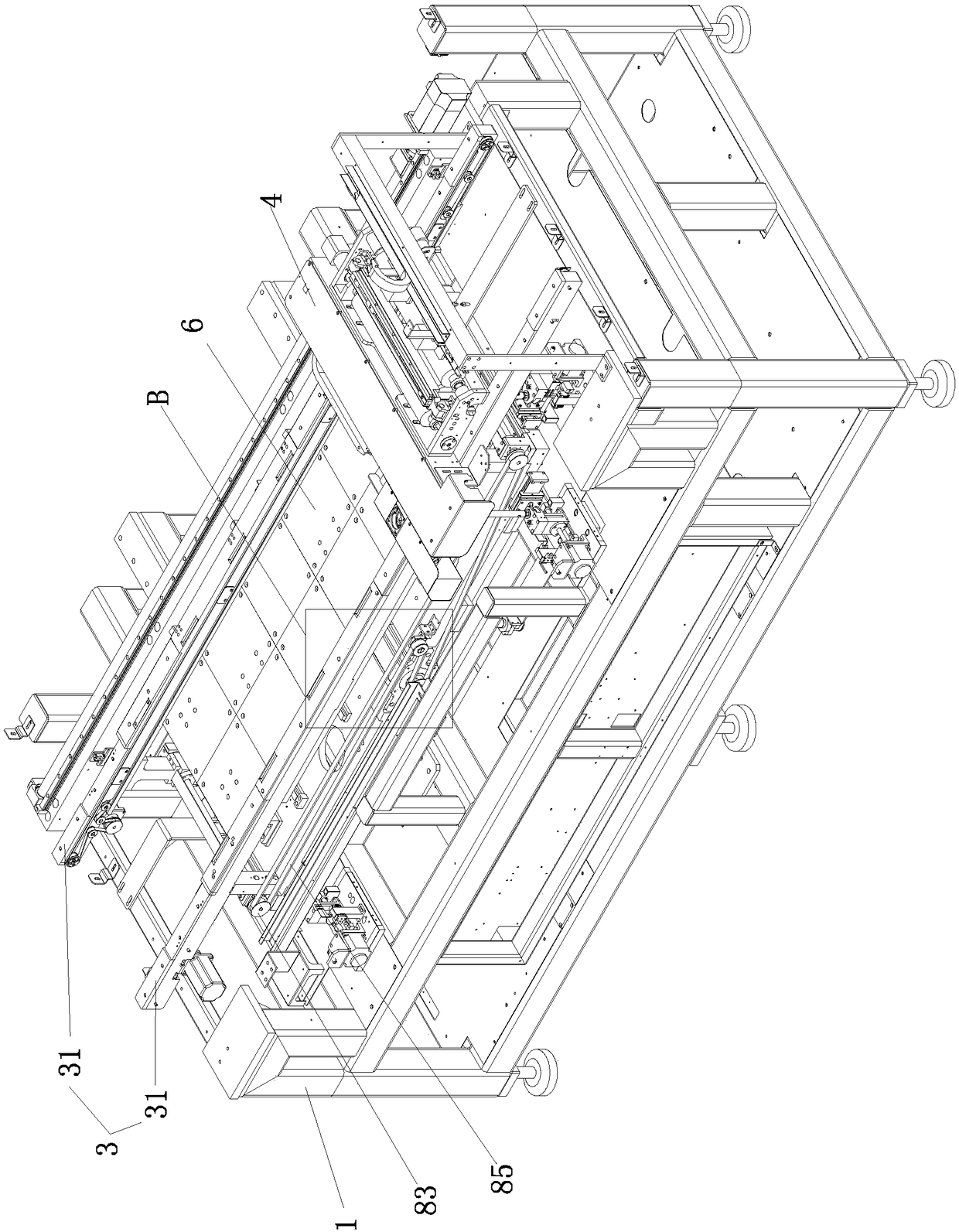

[0026] Such as Figures 1 to 6 As shown, the automatic visual printing machine of the present invention is used for solder paste printing of PCB boards. The automatic visual printing machine includes a frame 1, an XYθ correction work platform 2 connected to the frame 1, a transport track 3, CCD imaging system 4, steel mesh bracket 5, steel mesh 6 connected to said steel mesh bracket 5, scraper 61 connected to said steel mesh bracket 5 that can move up and down relative to left and right, said transport track 3 includes The front and rear two sub-tracks 31 that can be relatively close or far away, each sub-track 31 includes a support 32, a transport belt 33 arranged on the inside of the support 32, a first driving device for driving the transport belt 33, a fixed The splint 34 connected to the bracket 32 and arranged on the outside of the conveyor belt 33, the splint 34 on the outside of the front and rear two-point track 31 are respectively used to clamp the front and rear e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com