Patents

Literature

1020results about "Screen printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

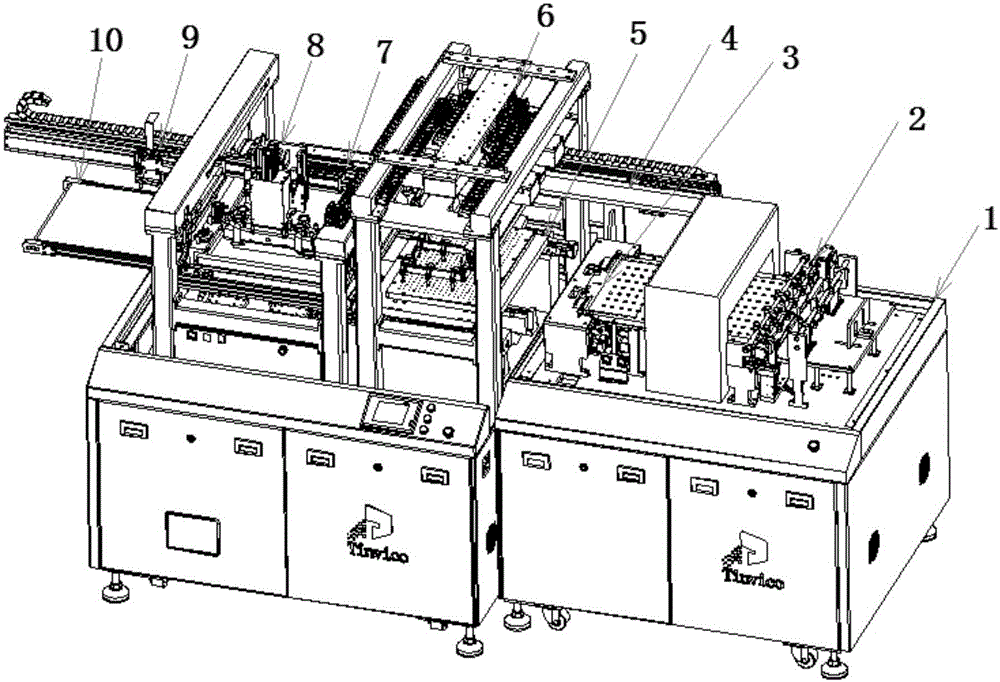

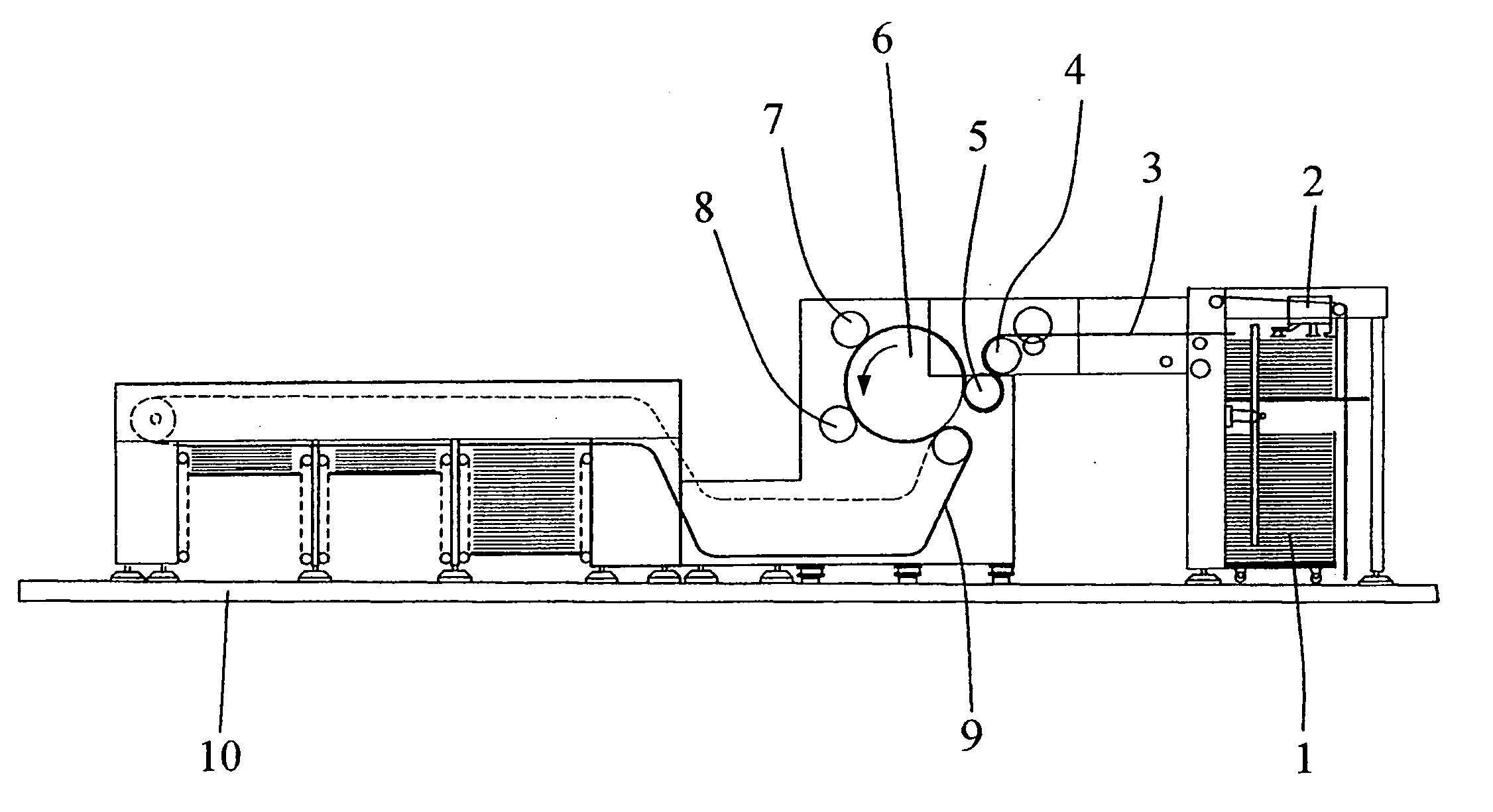

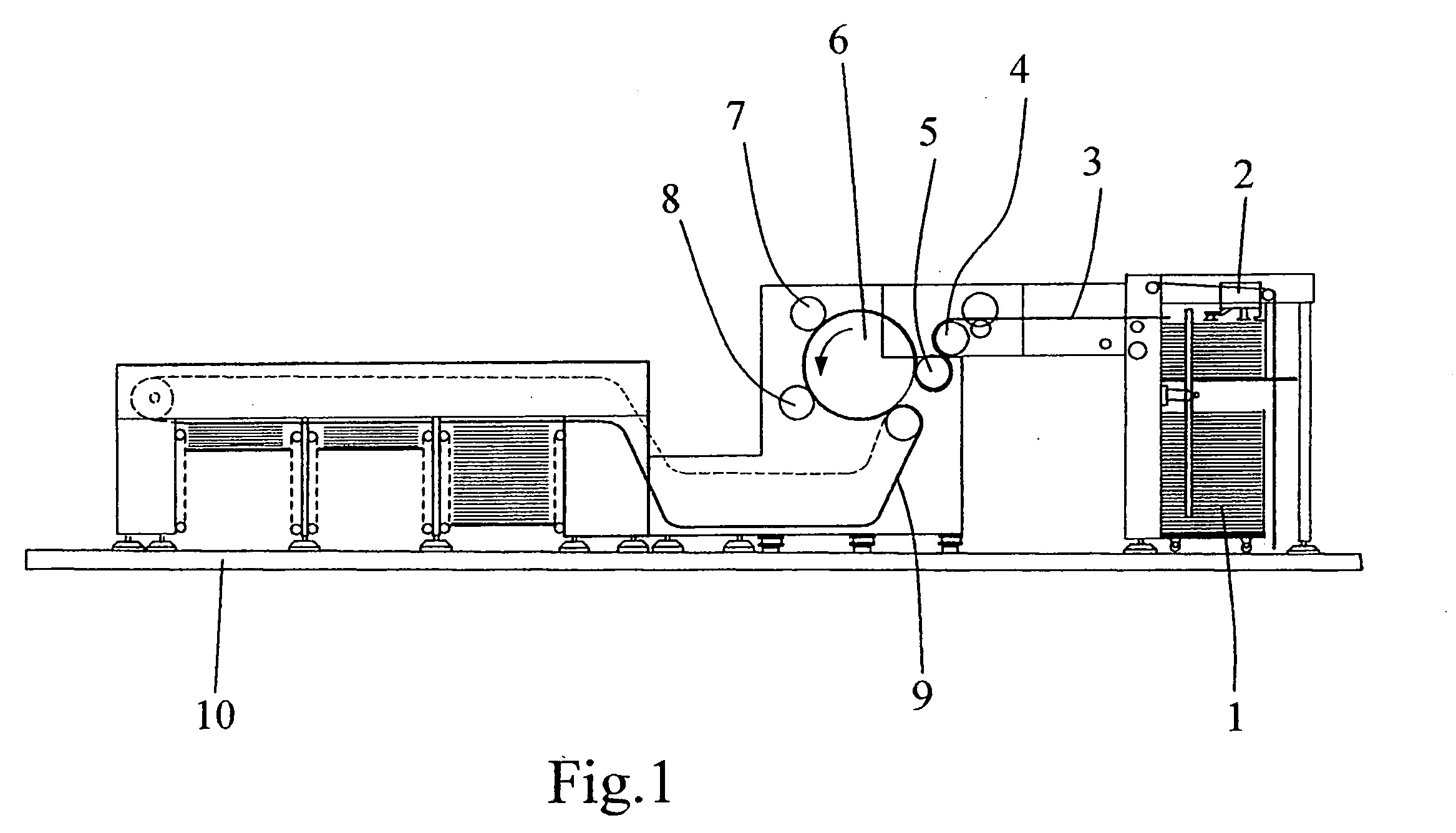

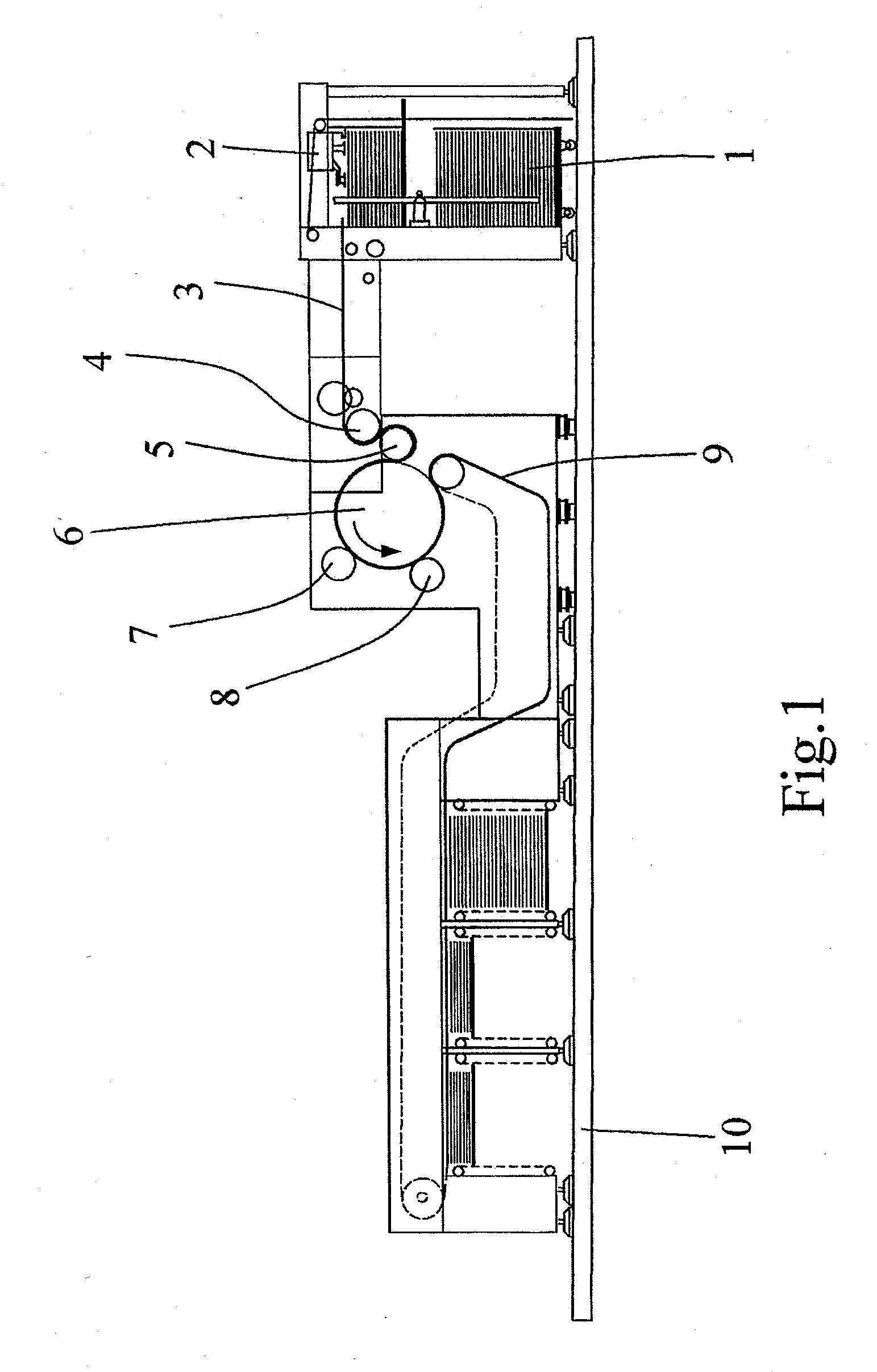

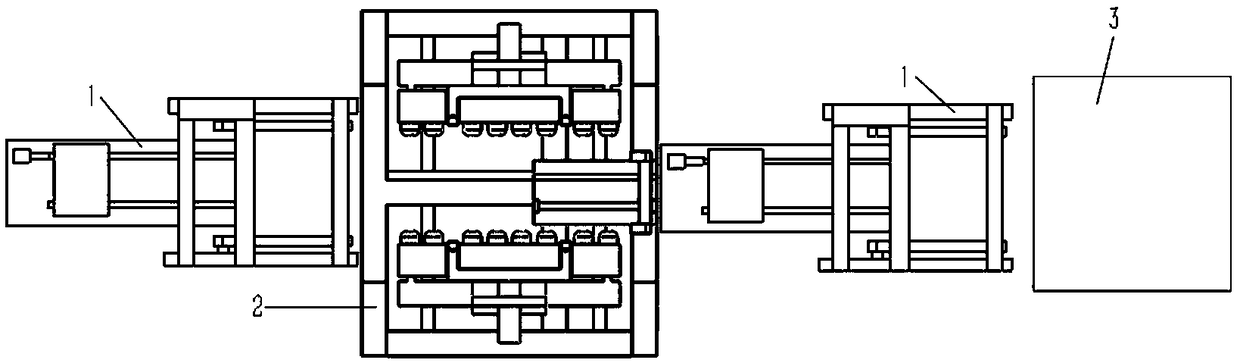

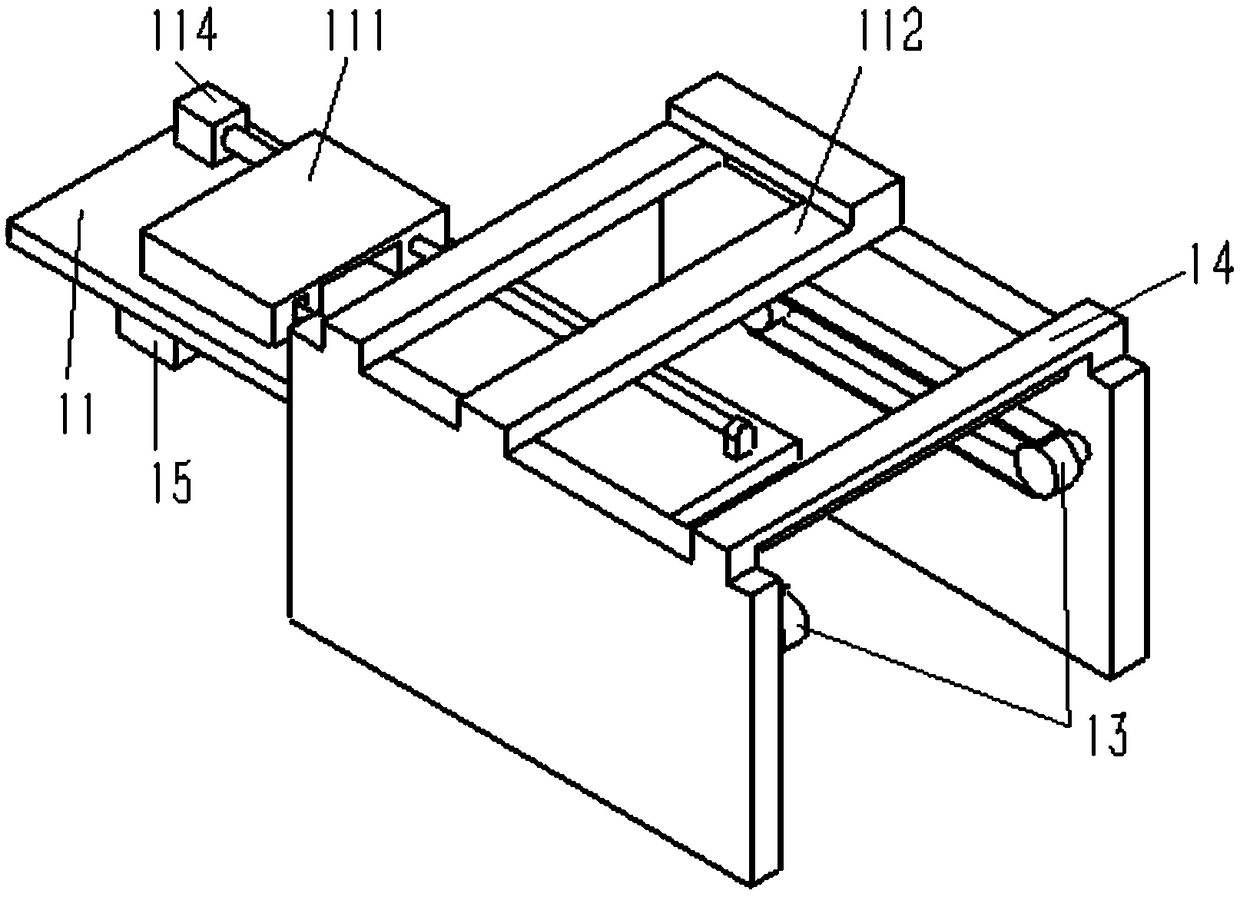

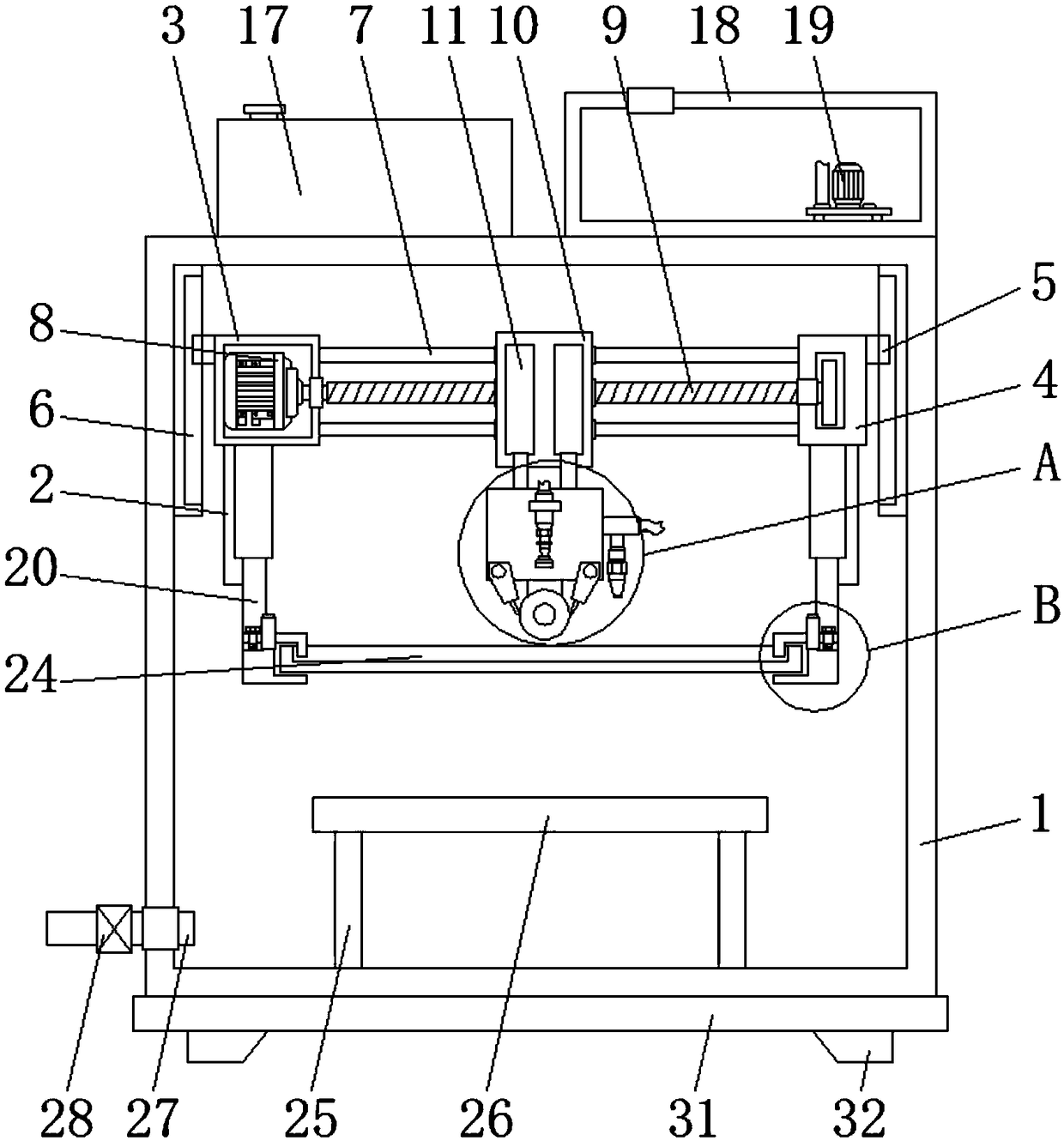

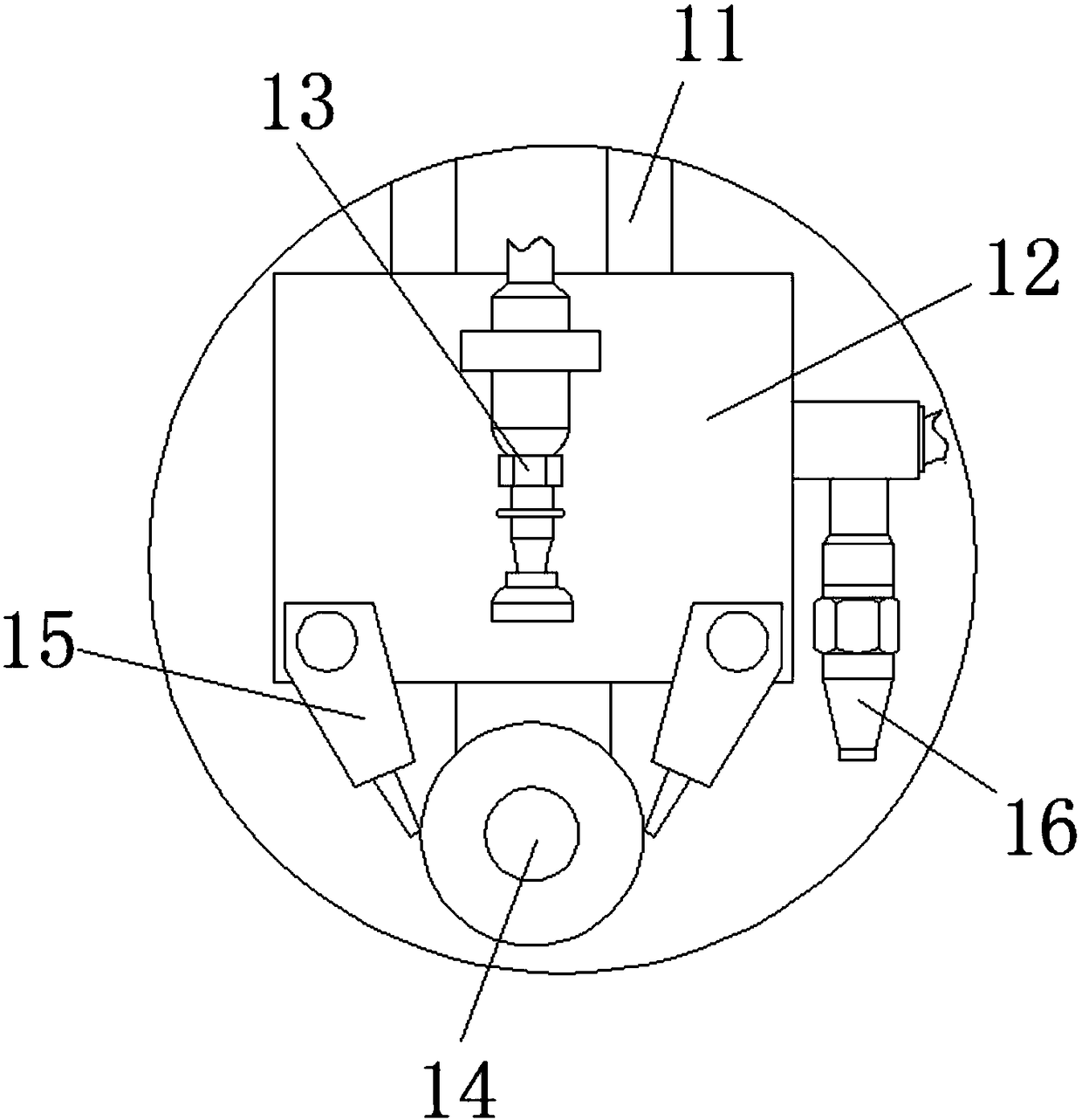

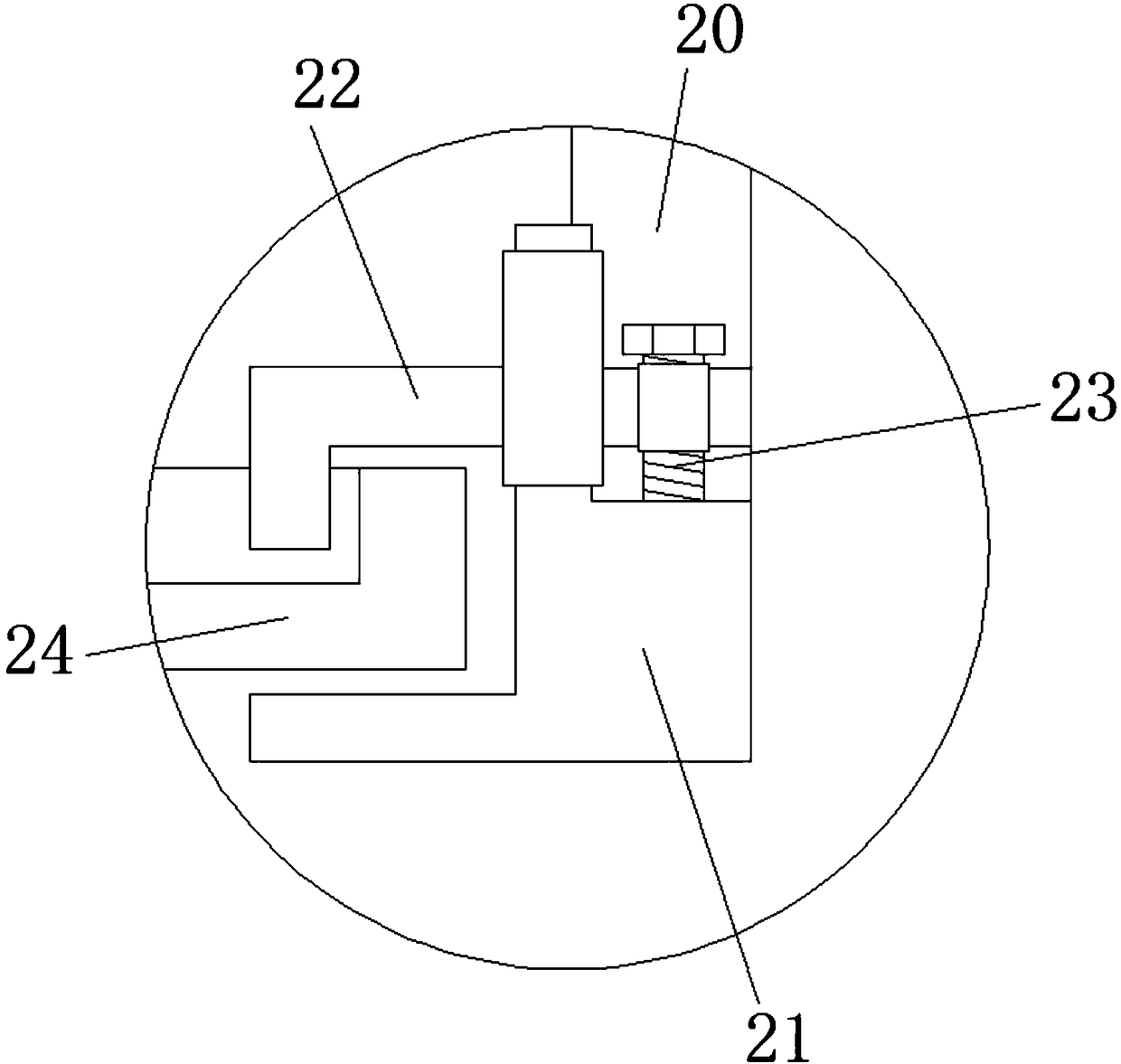

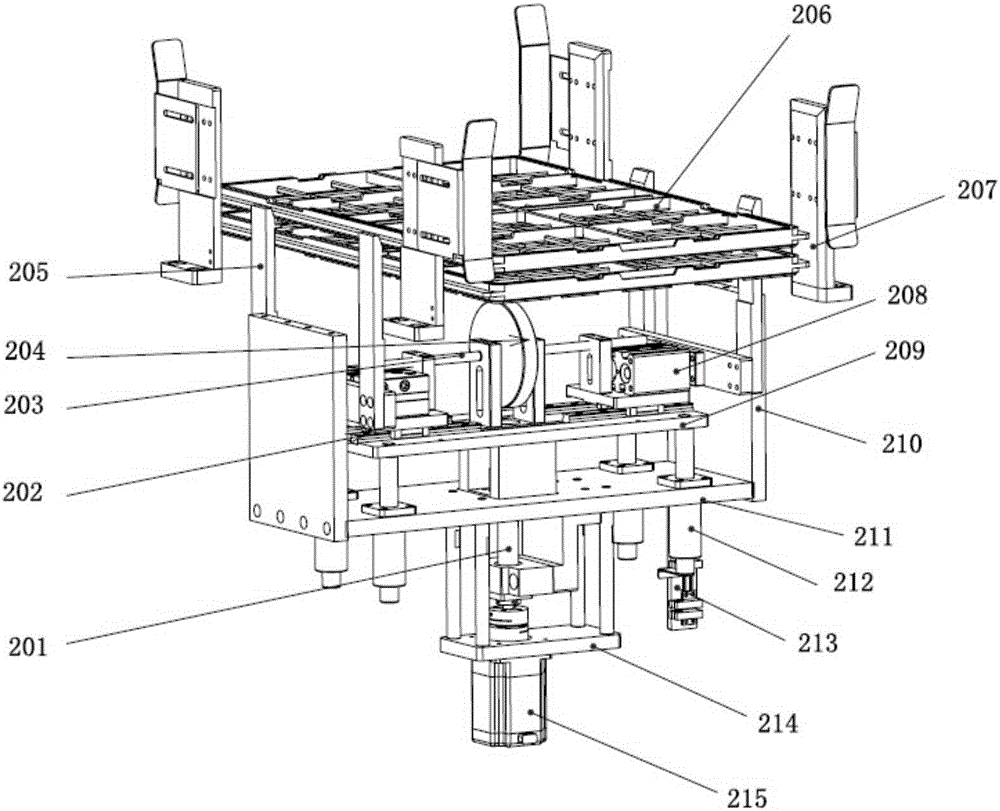

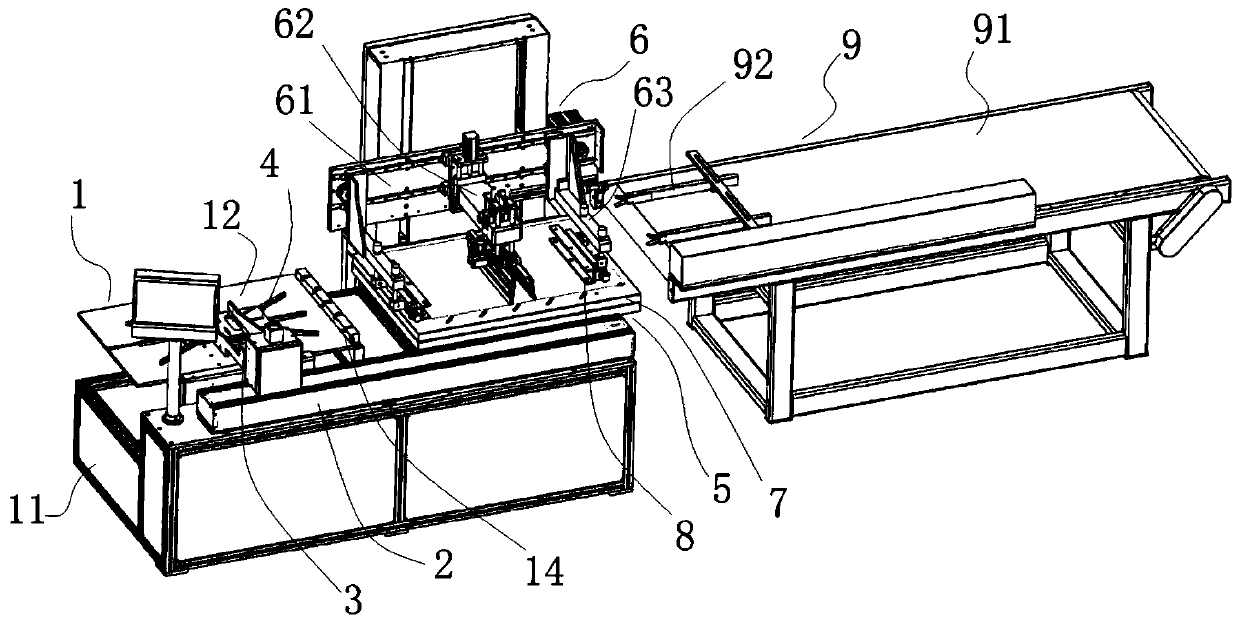

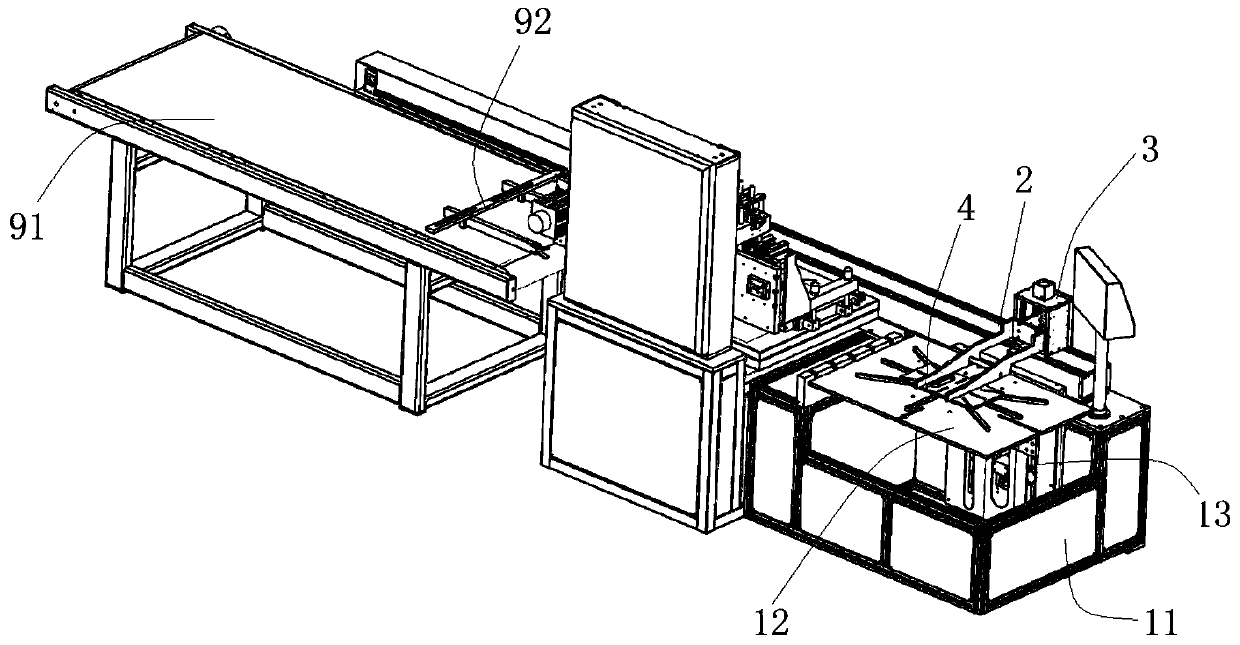

Full-automatic high-precision double-printing-platform screen printing machine

InactiveCN106671579ASolve the problem of manual loading and unloadingReasonable layoutScreen printersConveyor partsEngineeringPrinting press

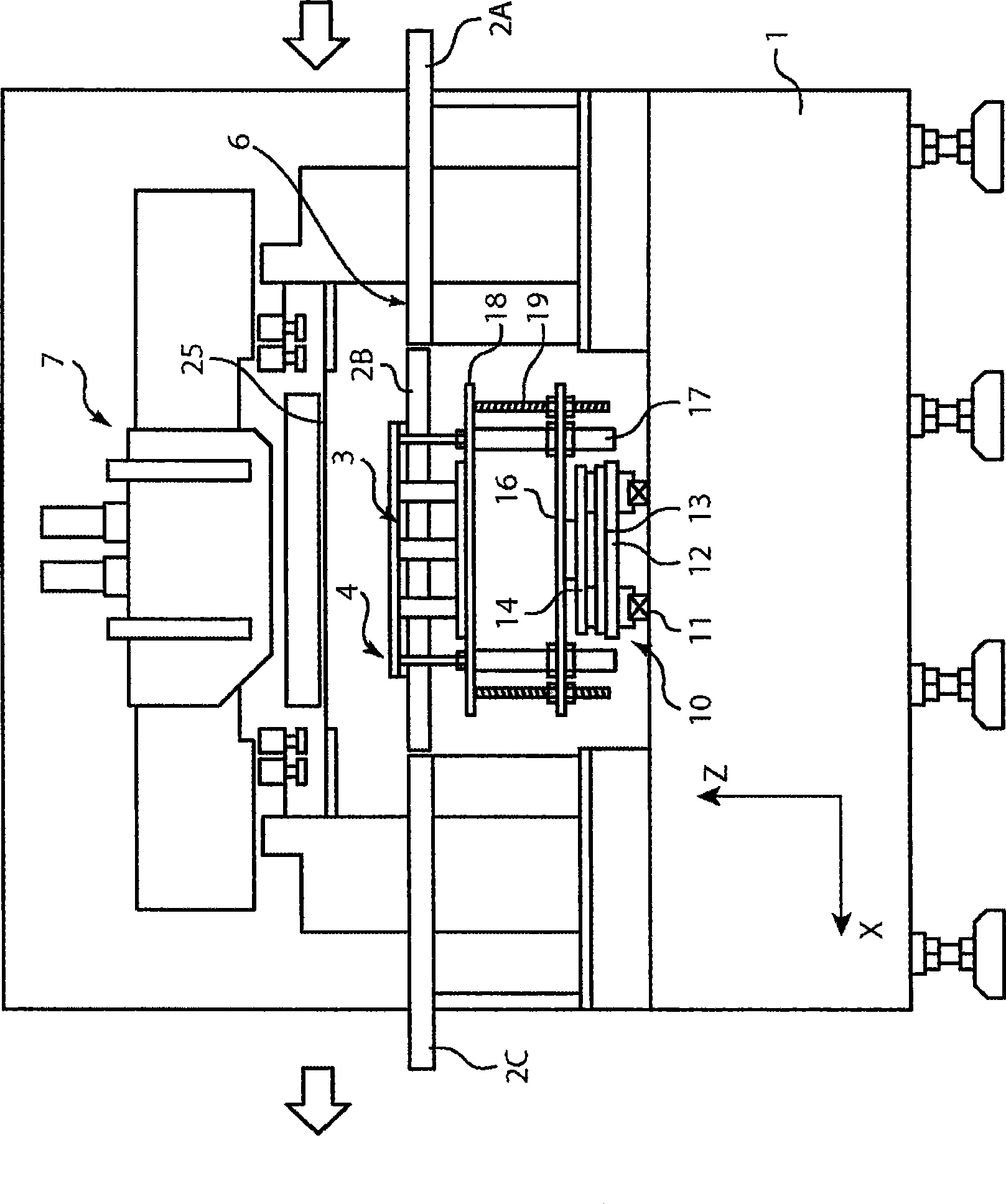

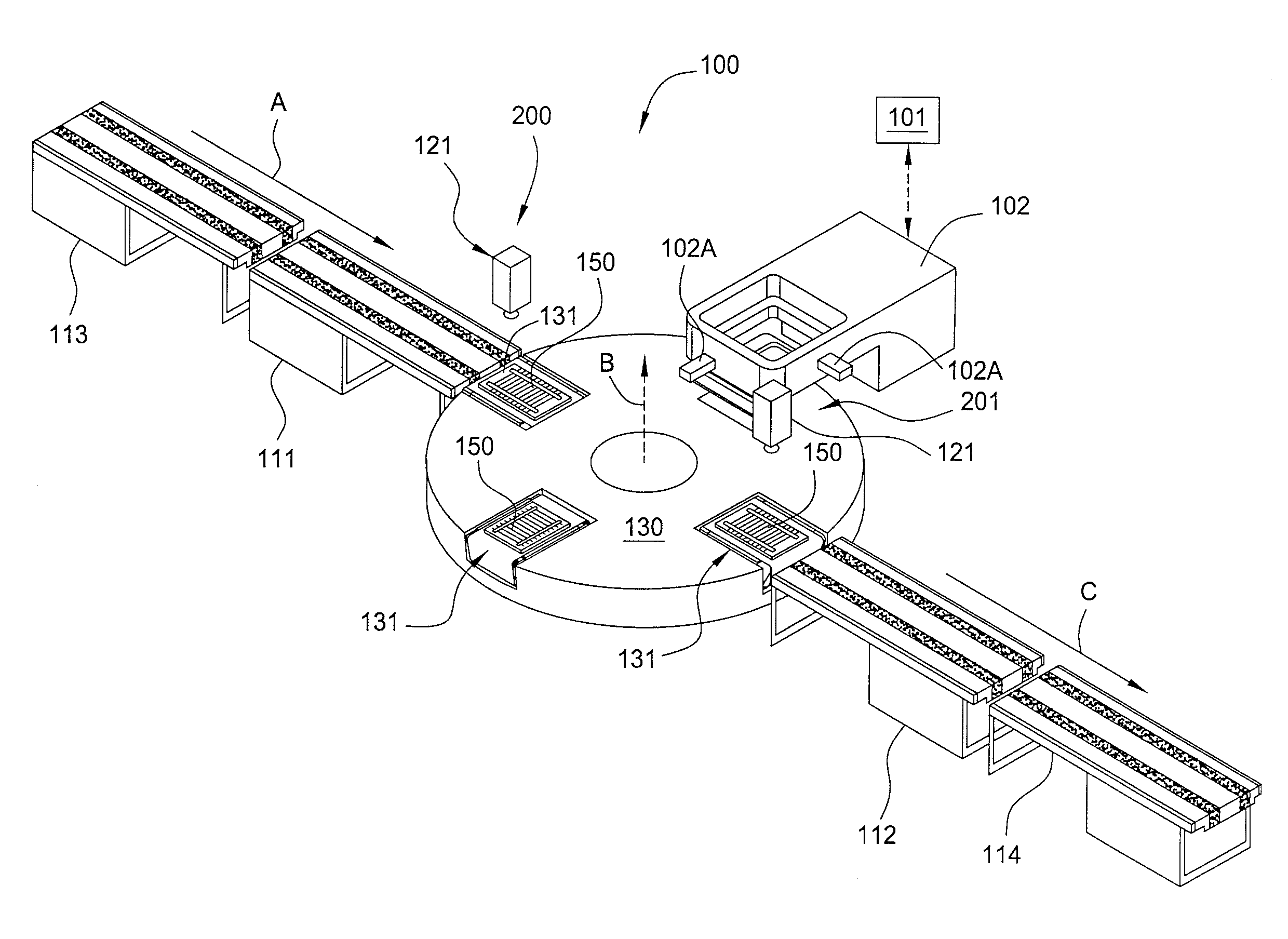

The invention discloses a full-automatic high-precision double-printing-platform screen printing machine. The full-automatic high-precision double-printing-platform screen printing machine comprises a machine frame, material conveying mechanism, a screen printing plate mounting and alignment mechanism and a screen printing mechanism and further comprises a double-printing-platform transfer assembly located on the machine frame, wherein the material conveying mechanism is located on the machine frame; the double-printing-platform transfer assembly comprises a positioning position, a printing position, a lifting printing platform and a printing platform, the lifting printing platform and the printing platform are located in the positioning position or the printing position alternately and switched between the positioning position or the printing position; the material conveying mechanism is used for conveying to-be-printed materials to the positioning position; and the screen printing plate mounting and alignment mechanism and the screen printing mechanism are arranged above the printing position for printing the to-be-printed materials located in the printing position. By means of the full-automatic high-precision double-printing-platform screen printing machine, while one to-be-printed material is printed, another to-be-printed material is automatically fed onto the printing platform and photographed and positioned, and the technical problems that most of existing full-automatic flexible-plate screen printing machine adopts single-platform linear material conveying, and consequently the system efficiency is low are solved.

Owner:SHENZHEN TINVICO TECH CO LTD

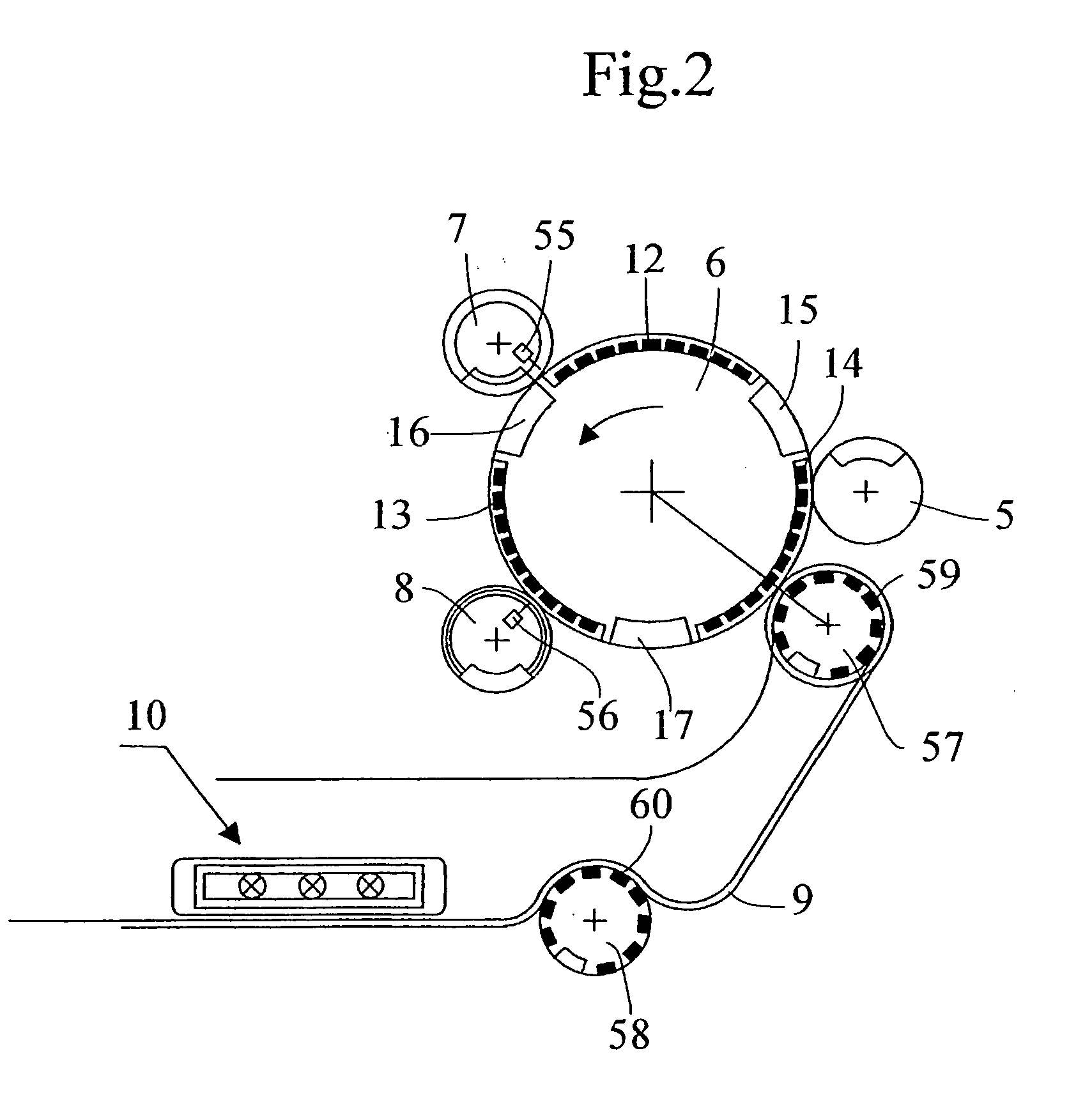

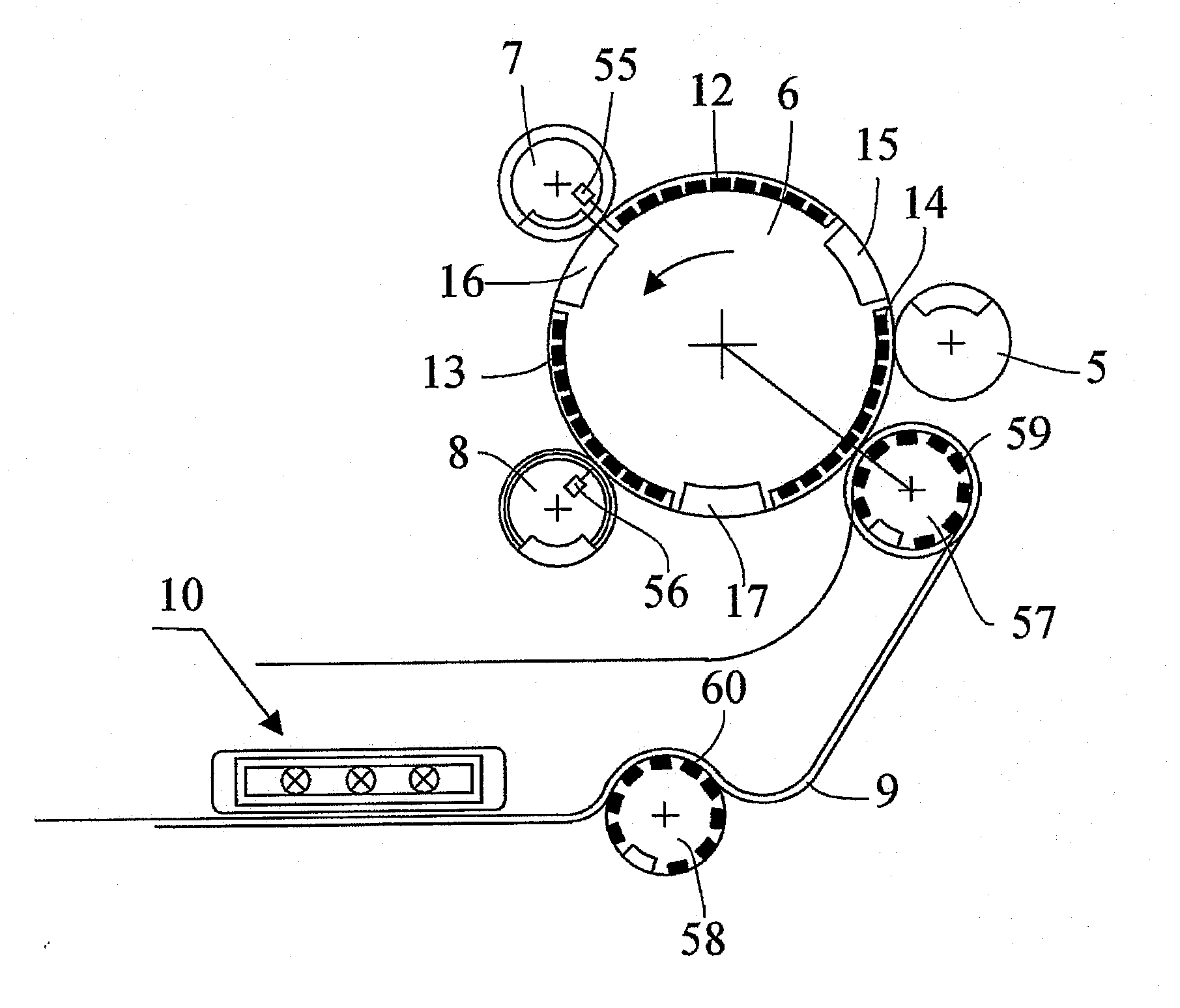

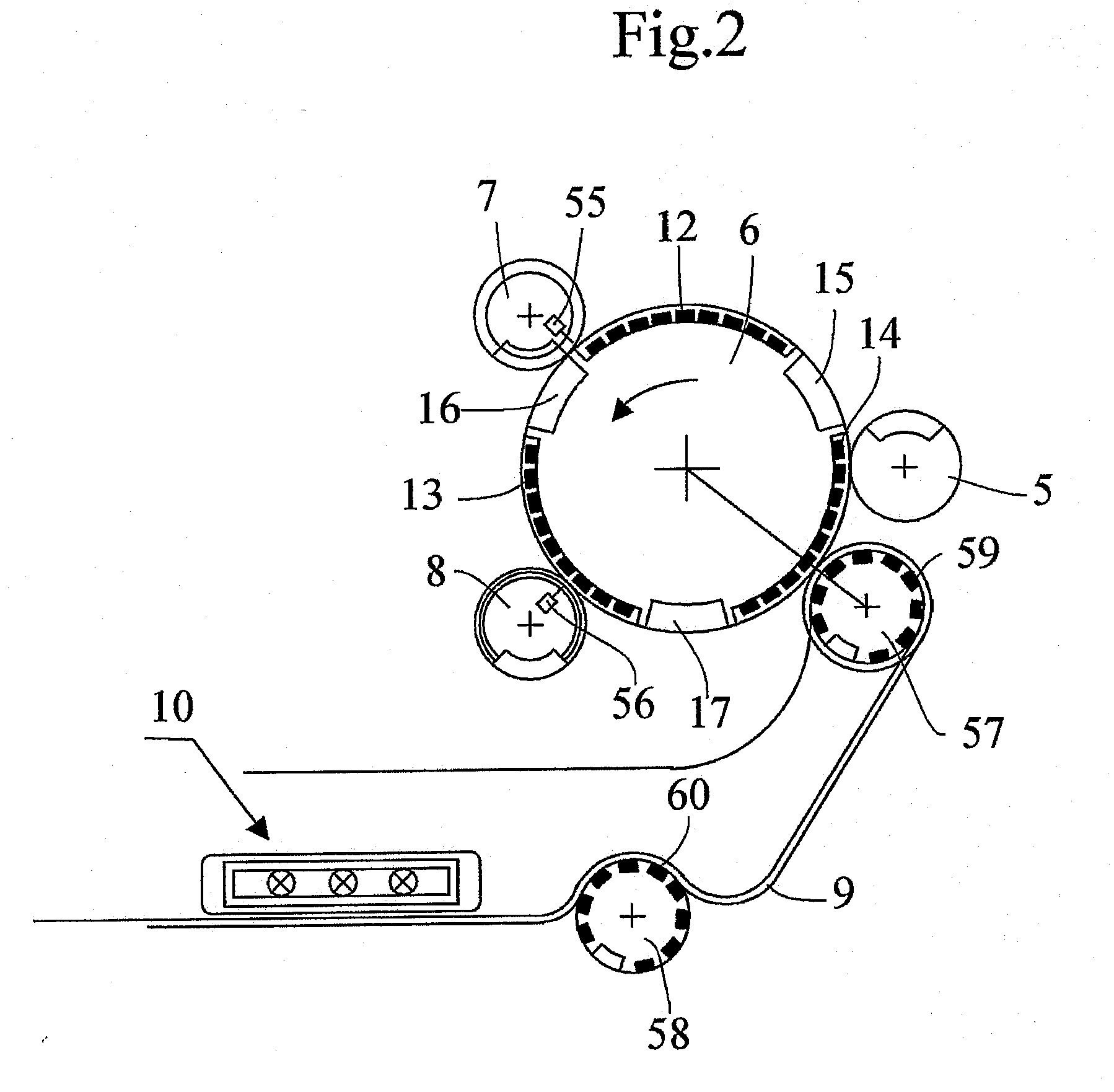

Printing machine

The printing machine comprises at least one transfer system (5) for conveying a substrate (1) onto an impression cylinder (6) and at least one screen (7, 8) of cylindrical or flat shape, with a doctor blade, said screen collaborating with the impression cylinder (6) and intended to print the substrate with an ink containing pigments that can be orientated by a magnetic field and an unloading system (9) for carrying the substrate (1) away. The impression cylinder comprises at least one magnetic element on its impression surface, said magnetic element being positioned at a point corresponding to said impression performed by said screen (7, 8) on said substrate.

Owner:KBA NOTASYS SA

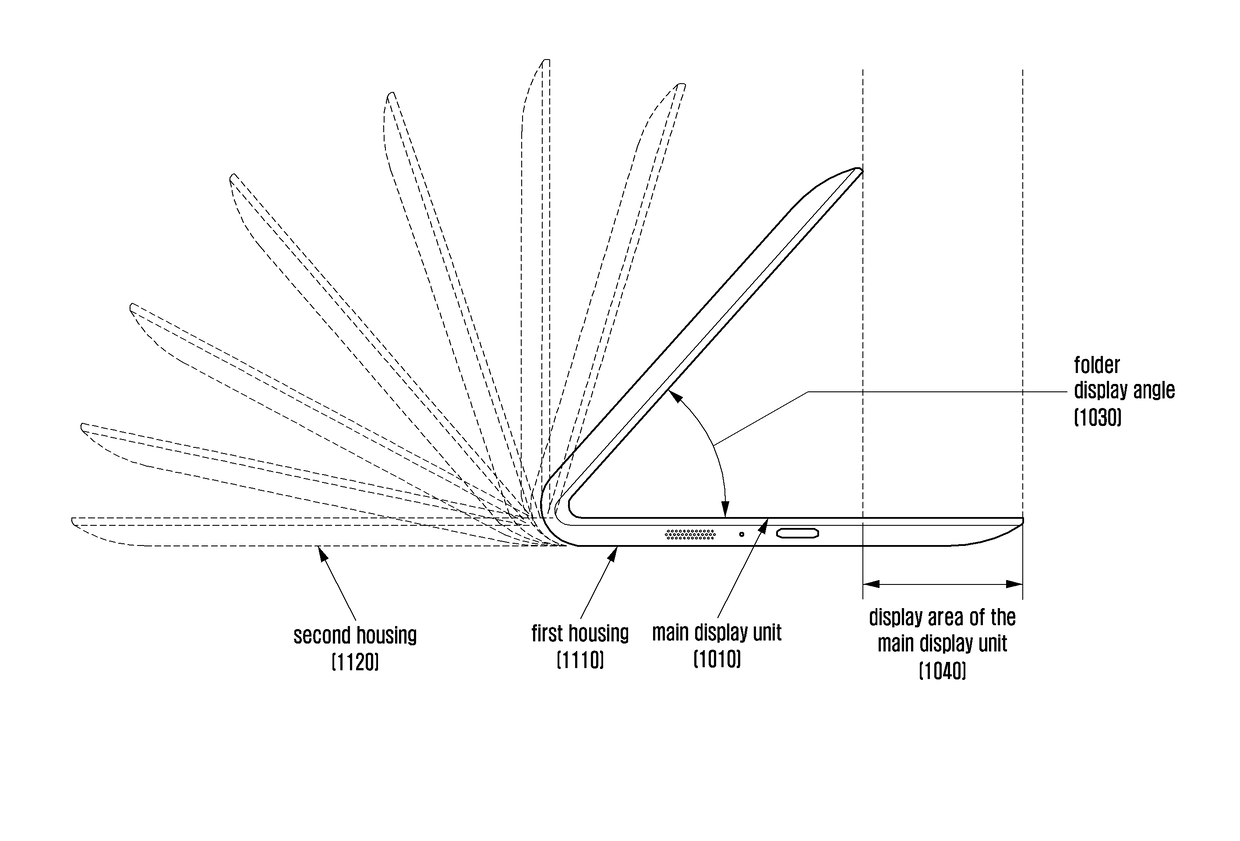

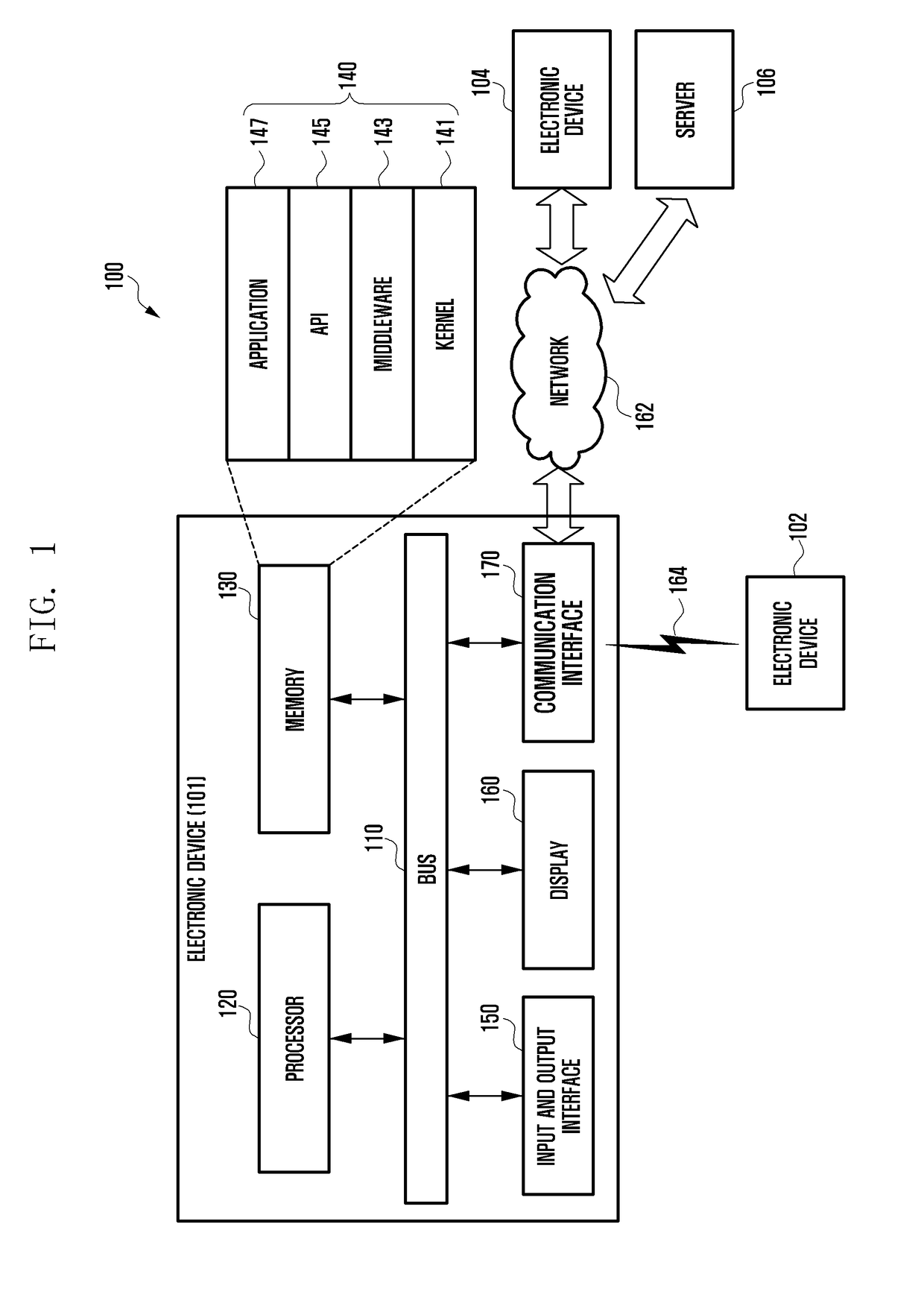

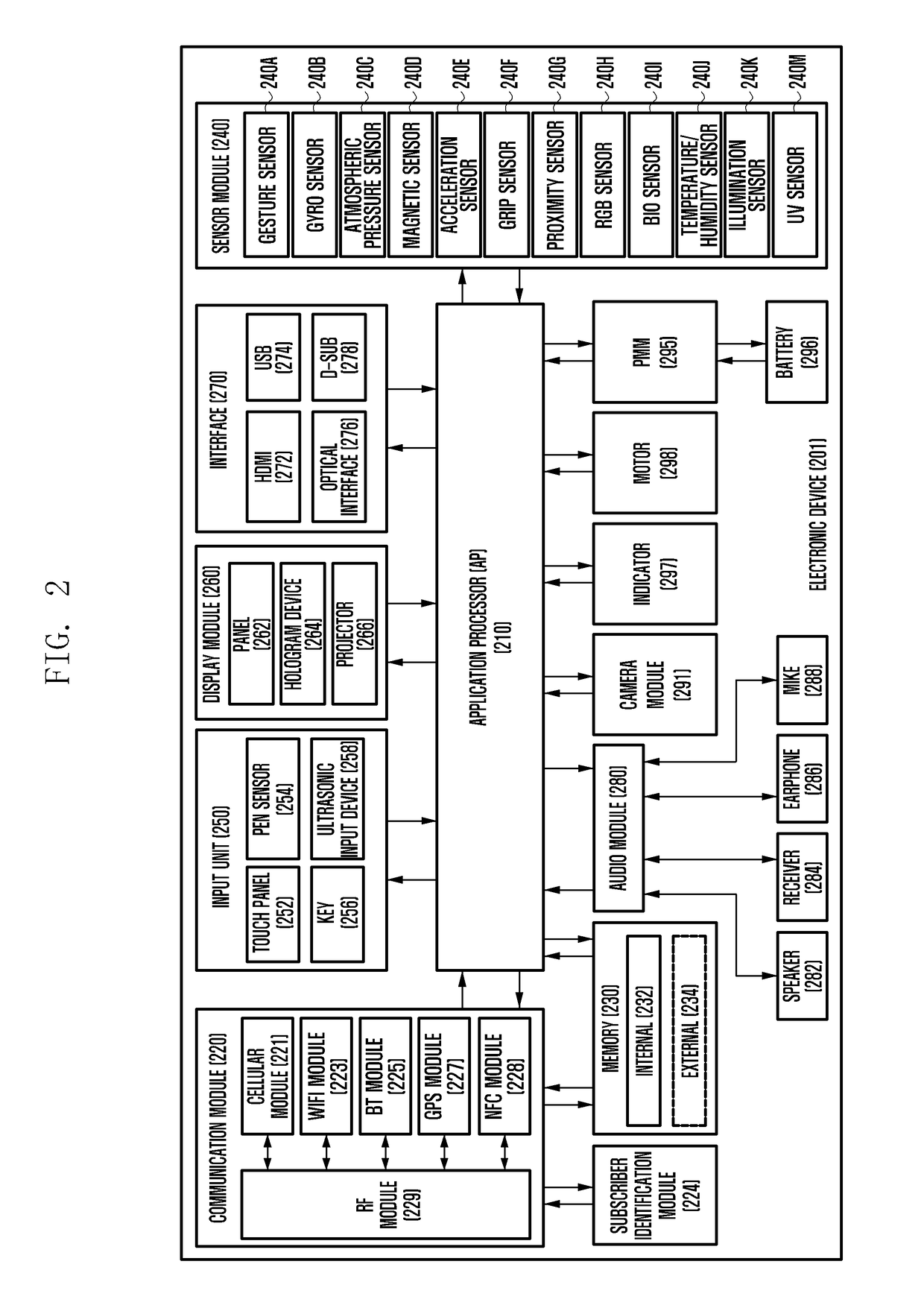

Display controlling method and electronic device adapted to the same

ActiveUS20170206049A1Control brightnessScreen printersCathode-ray tube indicatorsIlluminanceDisplay device

An electronic device is provided. The electronic device includes a foldable housing. The foldable housing includes a first housing including a first display and an illuminance sensor on a front surface, and a second housing, adjacent to the first housing, including a hole formed through a front surface and a rear surface of the second housing. The front surface of the first housing faces the front surface of the second housing when the second housing is folded in a first direction with respect to the first housing, and a rear surface of the first housing faces the rear surface of the second housing when the second housing is folded in a second direction with respect to the first housing.

Owner:SAMSUNG ELECTRONICS CO LTD

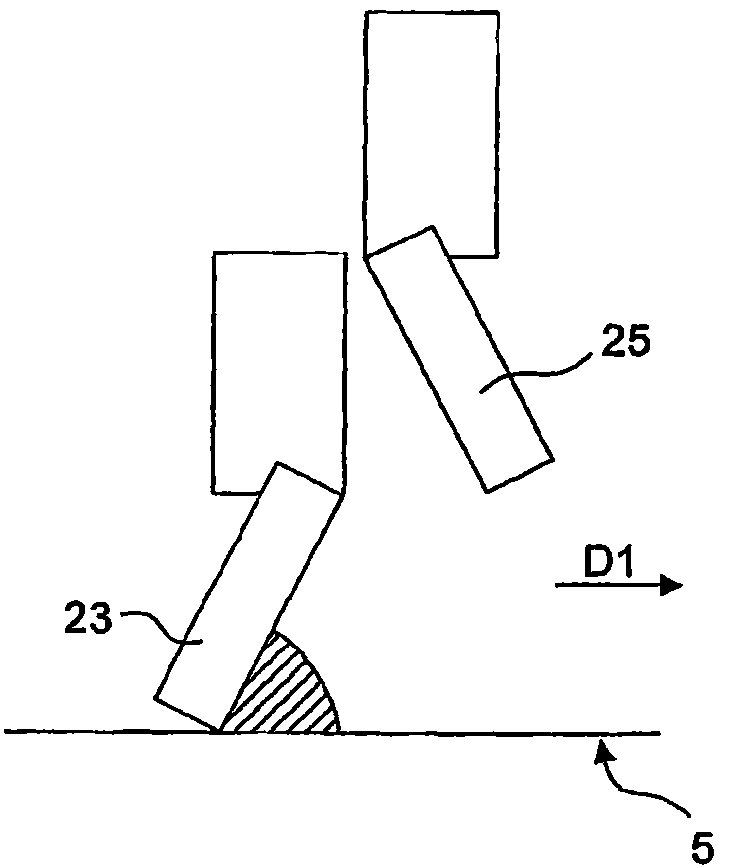

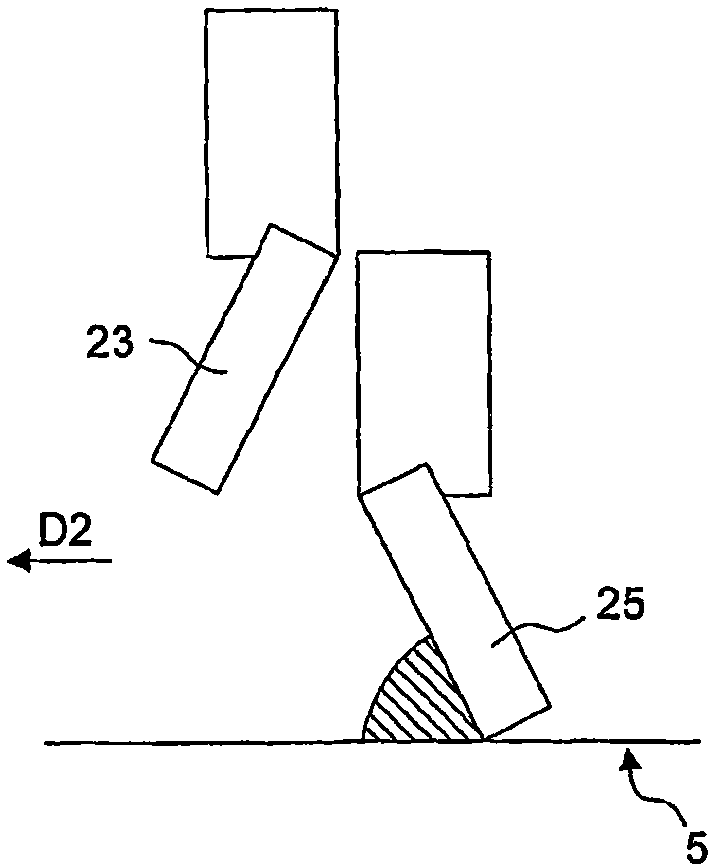

Solder feeder, printer, and printing method

ActiveUS20120138664A1Improve versatilityAvoid it happening againScreen printersFeeding apparatusEngineering

Disclosed is a print technology in which a solder pool staying on the surface of a mask is driven by means of a squeegee, and solder is applied onto a substrate onto which the lower surface of a mask is placed. A forward print process where solder is applied by driving a squeegee in a predetermined forward direction relative to a mask, and a backward print process where the solder is applied by driving the squeegee in a returning direction opposite to the forward direction are switched alternately. When the squeegee passes through the solder pool on the downstream side in a moving direction before switching in the course of switching from any one of the forward and backward print processes to the other one of these processes, the amount of solder in the solder pool is measured. Based on the amount of solder thus measured, the necessity of replenishing solder is determined The solder pool is supplemented with solder, based on the result of the decision on whether solder replenishment is required.

Owner:YAMAHA MOTOR CO LTD

Method to print multicolor images on edible pieces

InactiveUS7114445B2Platen pressesDuplicating/marking methodsPressure differenceMechanical engineering

Multicolor image, formed from at least two component images, are printed on non-planar surfaces of edible pieces by maintaining registration of the pieces from one printing station to another. The registration is maintained by firmly securing the pieces to the transporting surface by applying a pressure differential, by a combination of a pressure differential with a resilient surface, or by trapping the pieces between a retaining member and a recess portion.

Owner:ACKLEY MACHINE +1

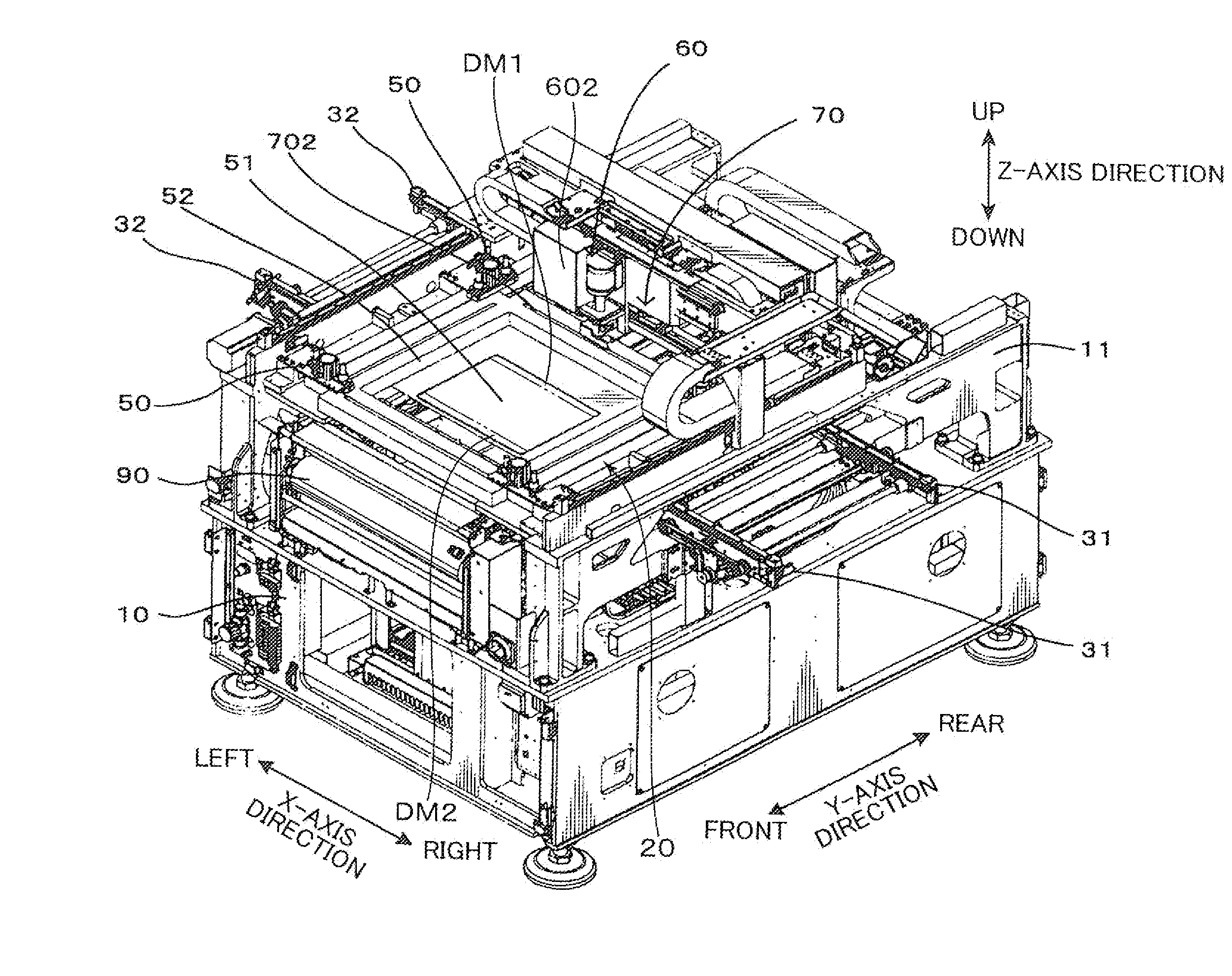

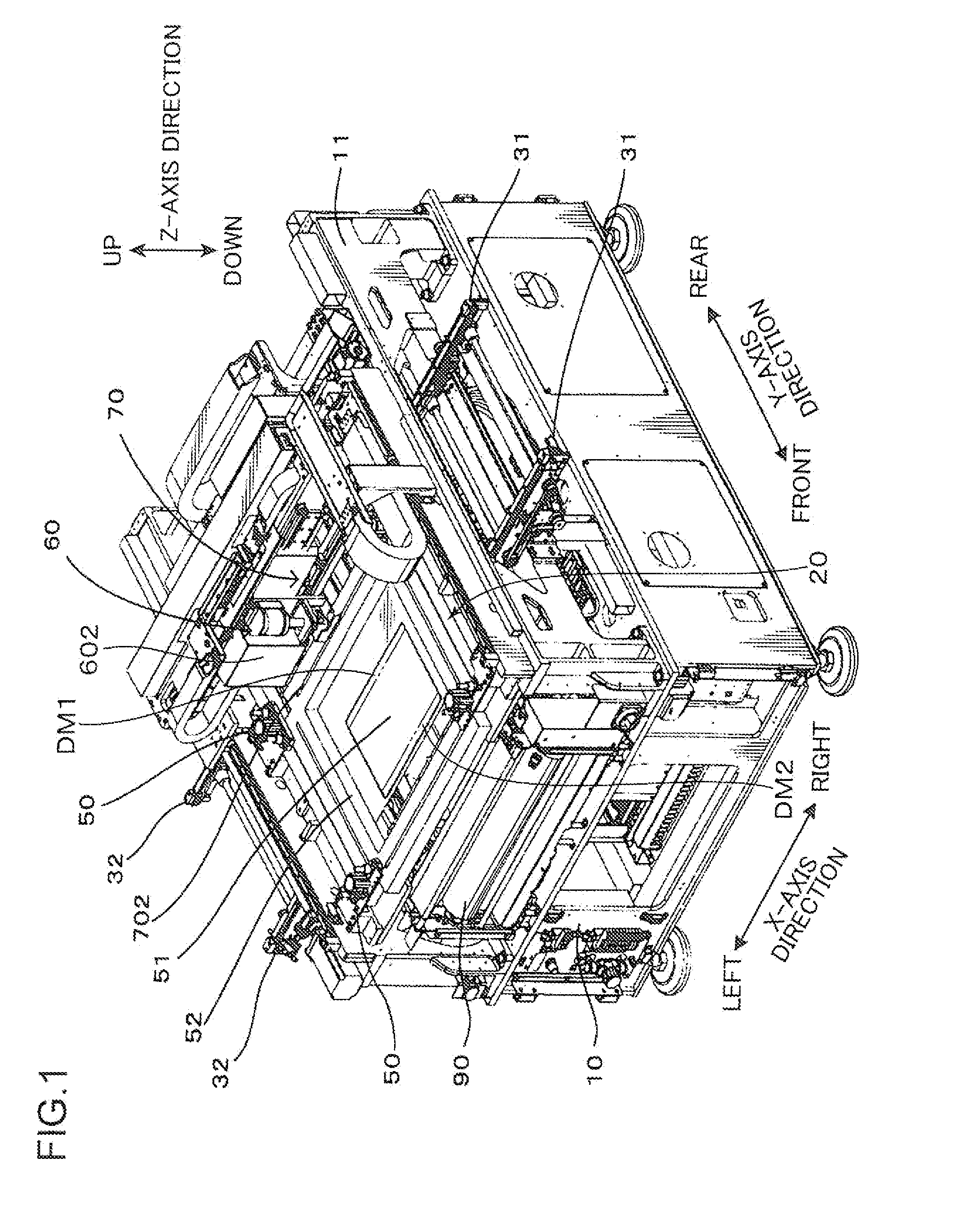

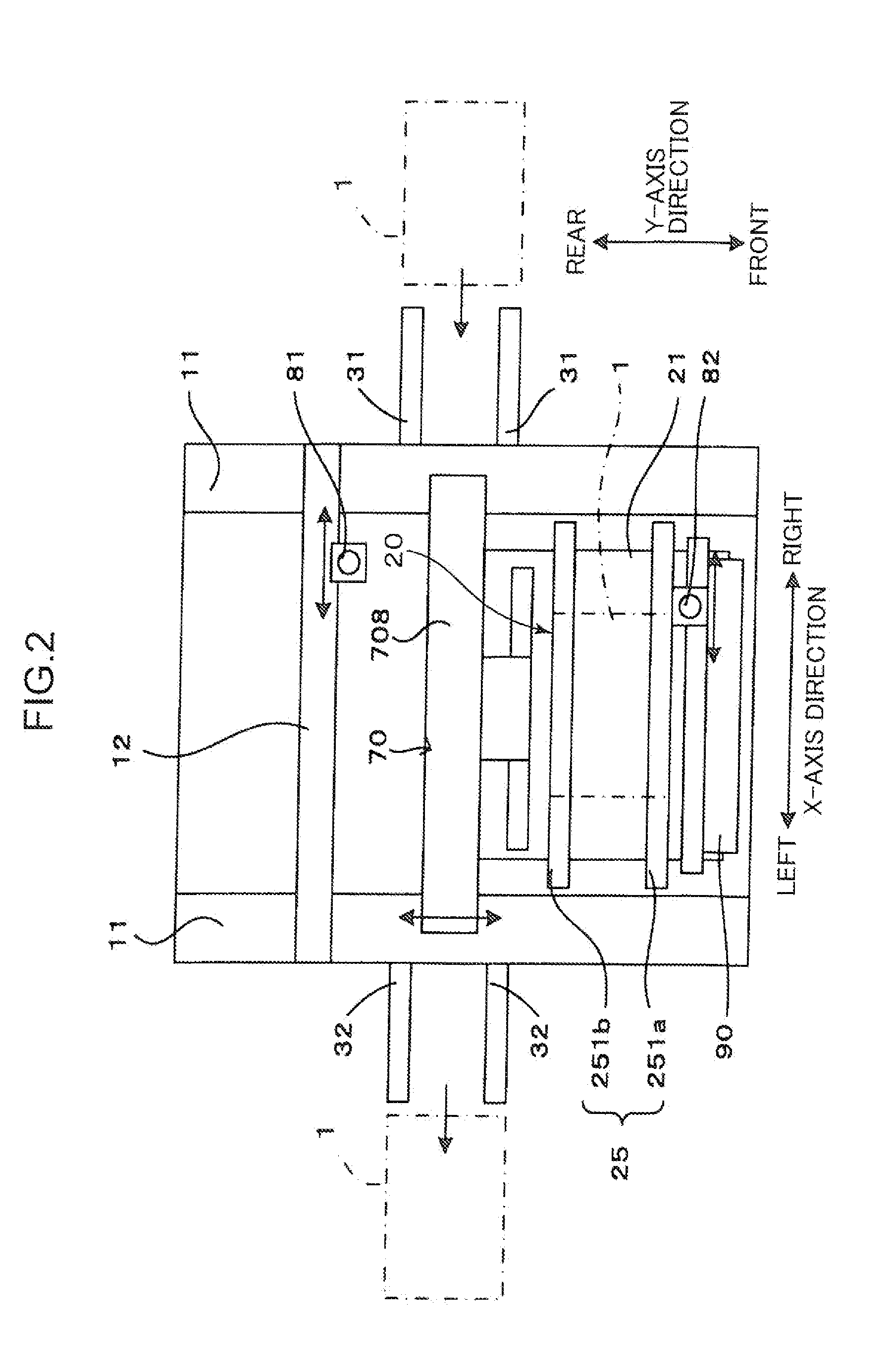

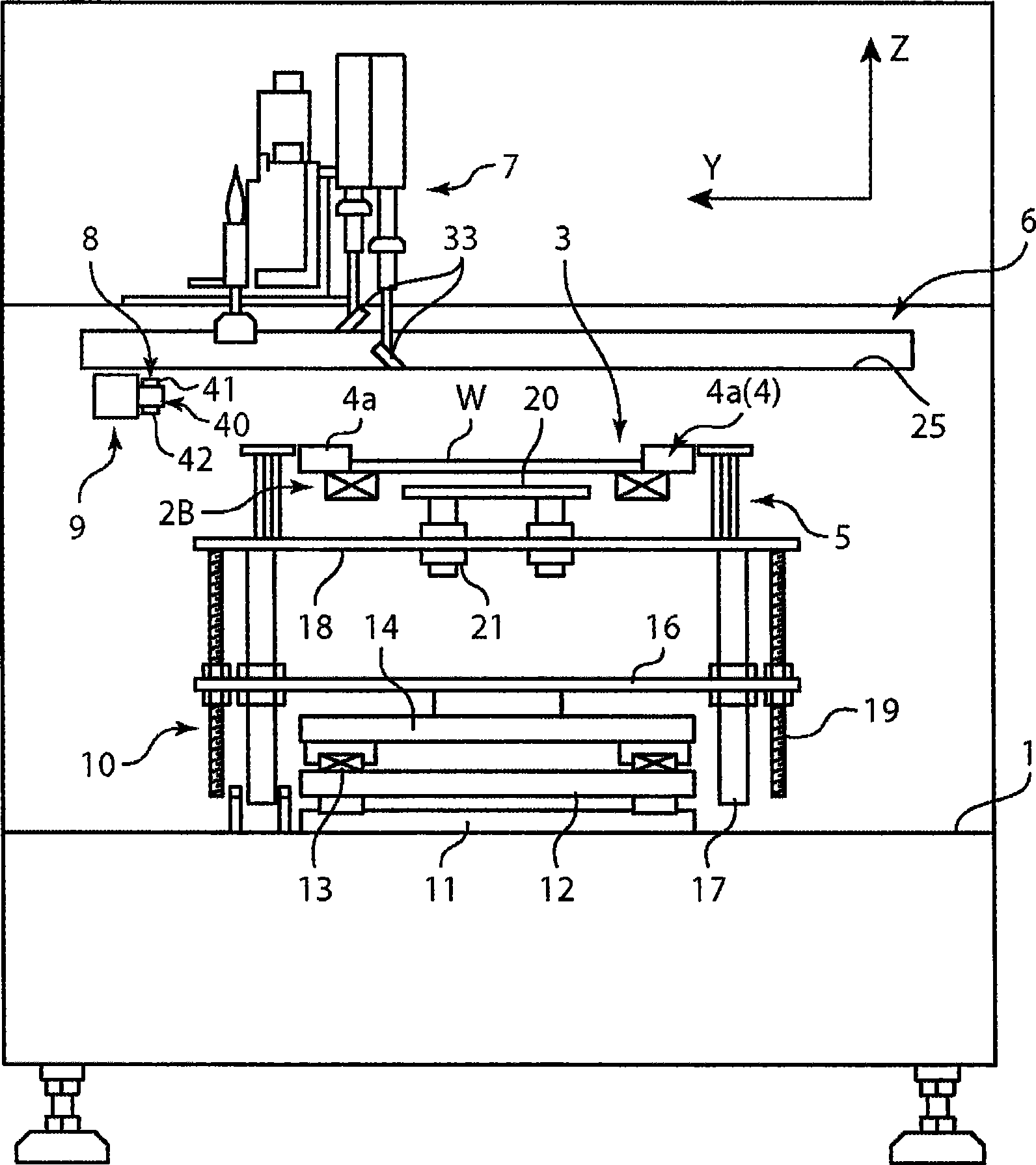

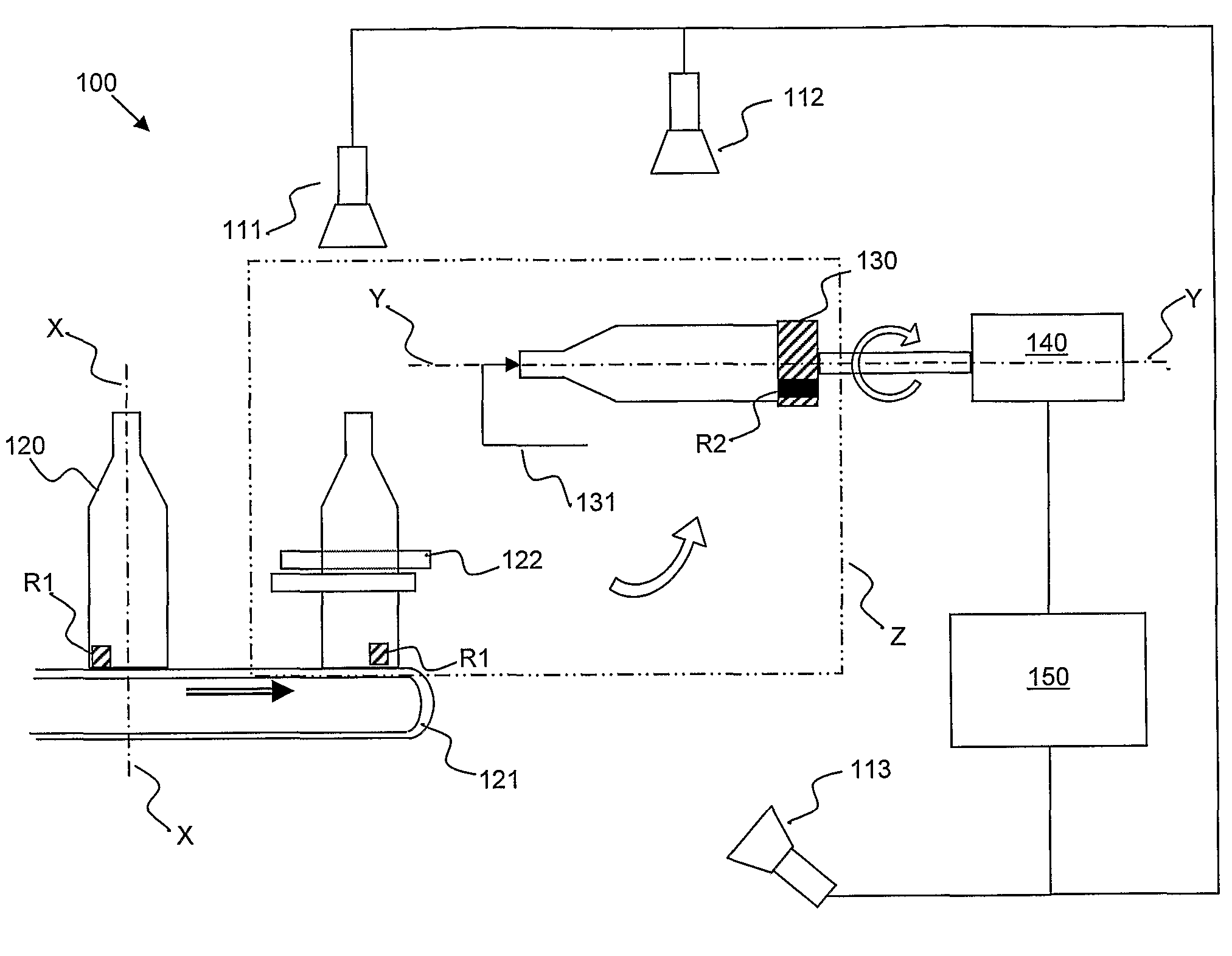

Position matching method and screen printer

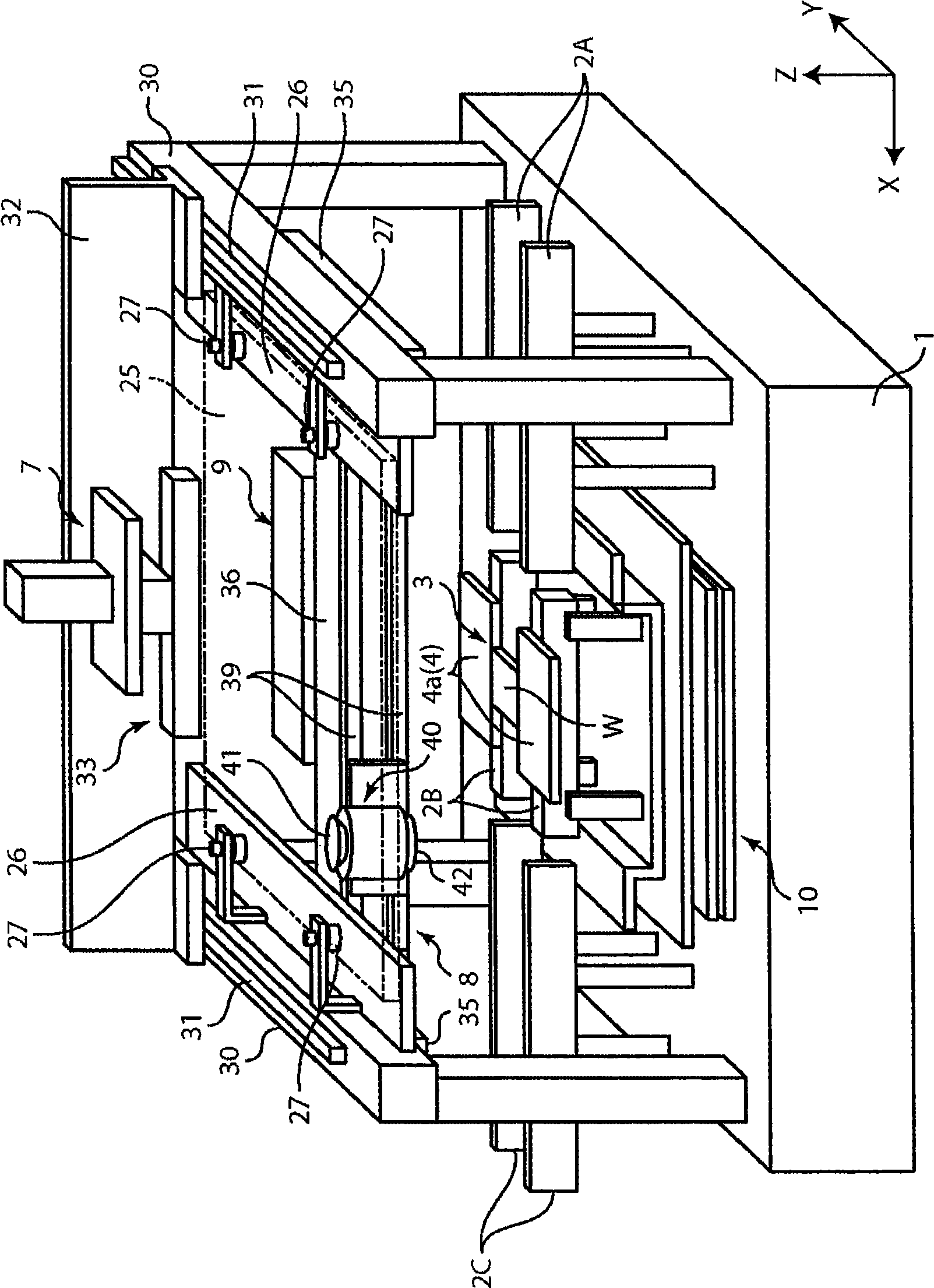

The invention relates to a position matching method for a screen printing device and a screen printing device. The screen pringting device includes a mask sheet (25), a movable printing stage (3), a camera head (40) having a mask recognition camera (41) and a substrate recognition camera (42), and a controller for controlling them. The controller executes mark recognition of the substrate (W) by using the substrate recognition camera (42). The camera head (40) is driven / controlled so as to execute mask recognition of the mask sheet (25) periodically by using the recognition camera (41) while the same mask sheet is used. Moreover, according to the latest mask position information acquired by the mark recognition of the mask sheet (25) and the substrate position information, the controller obtains a correction amount based on the position shift between the mask sheet (25) and the substrate (W) and drives / controls the printing state (3) according to the correction amount so as to mount the substrate (W) on the mask sheet (25).

Owner:YAMAHA MOTOR CO LTD

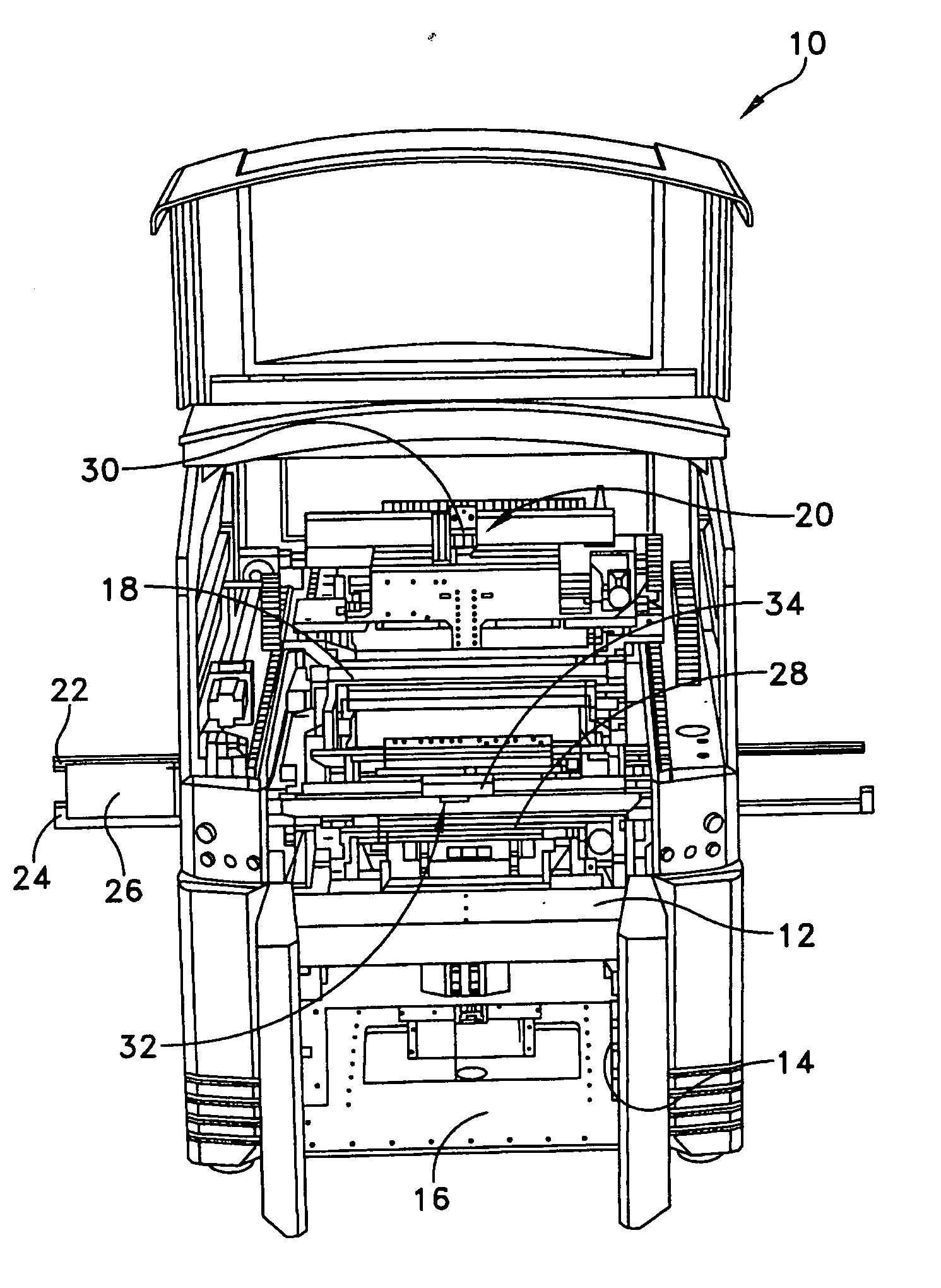

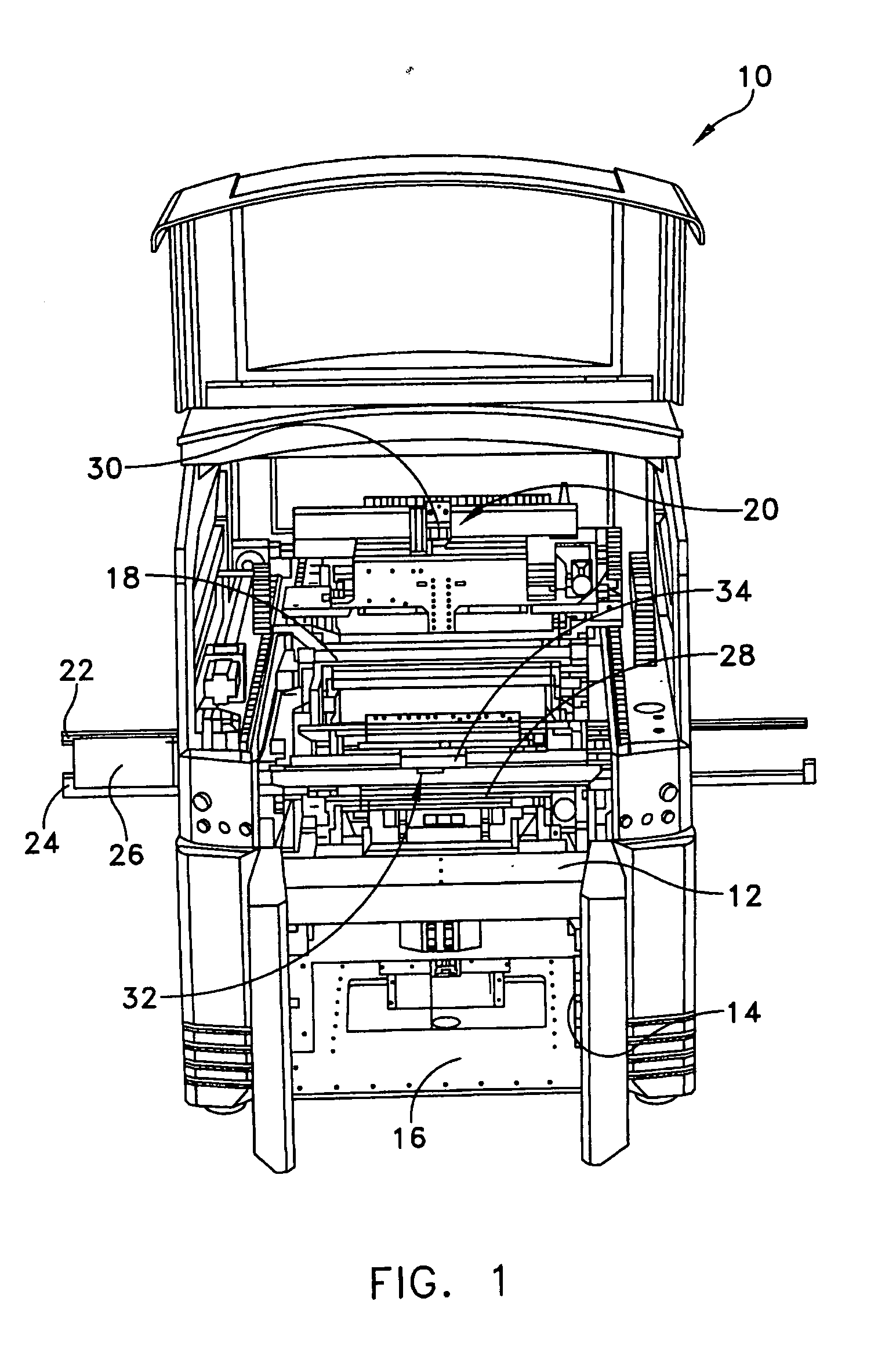

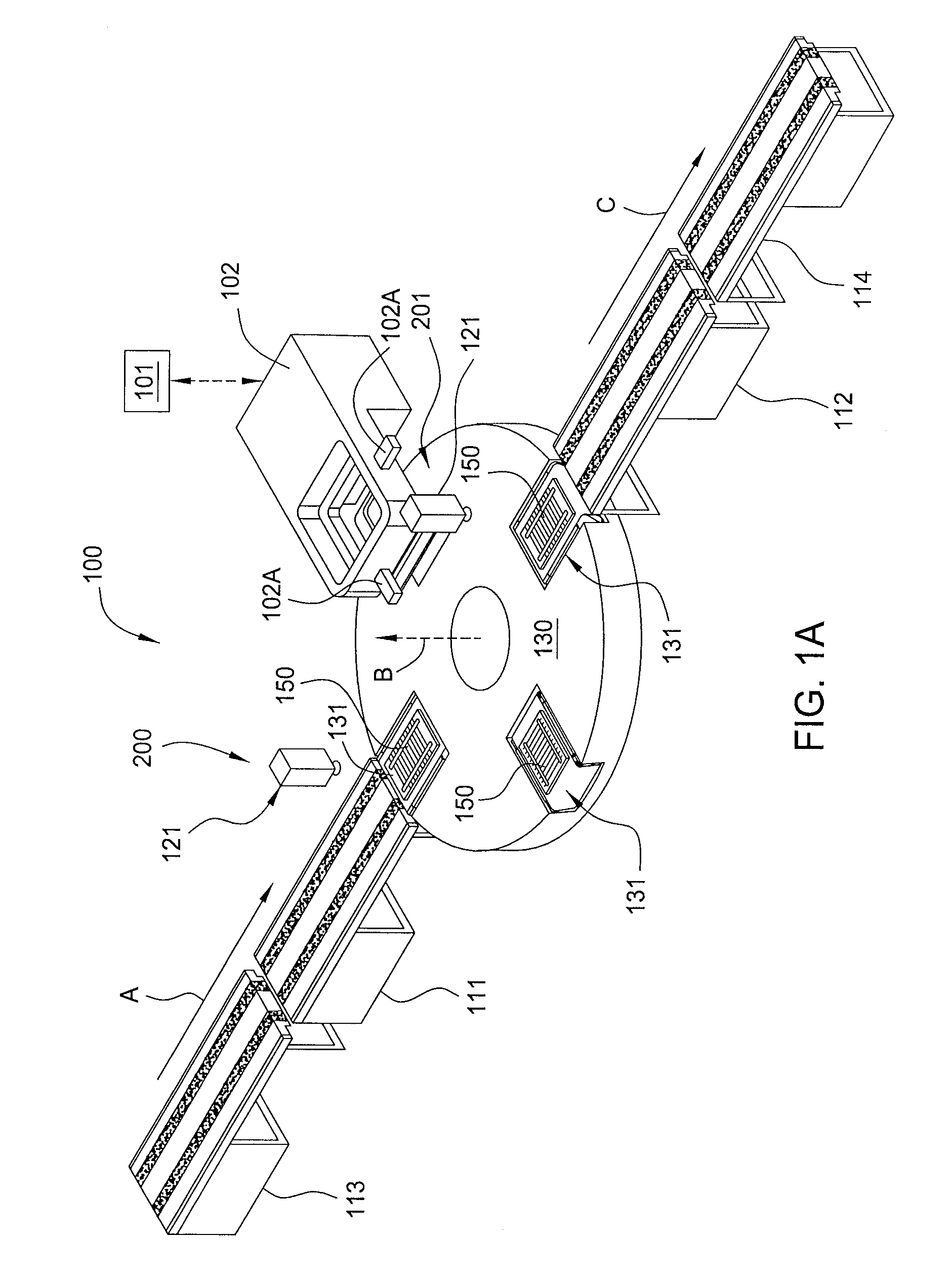

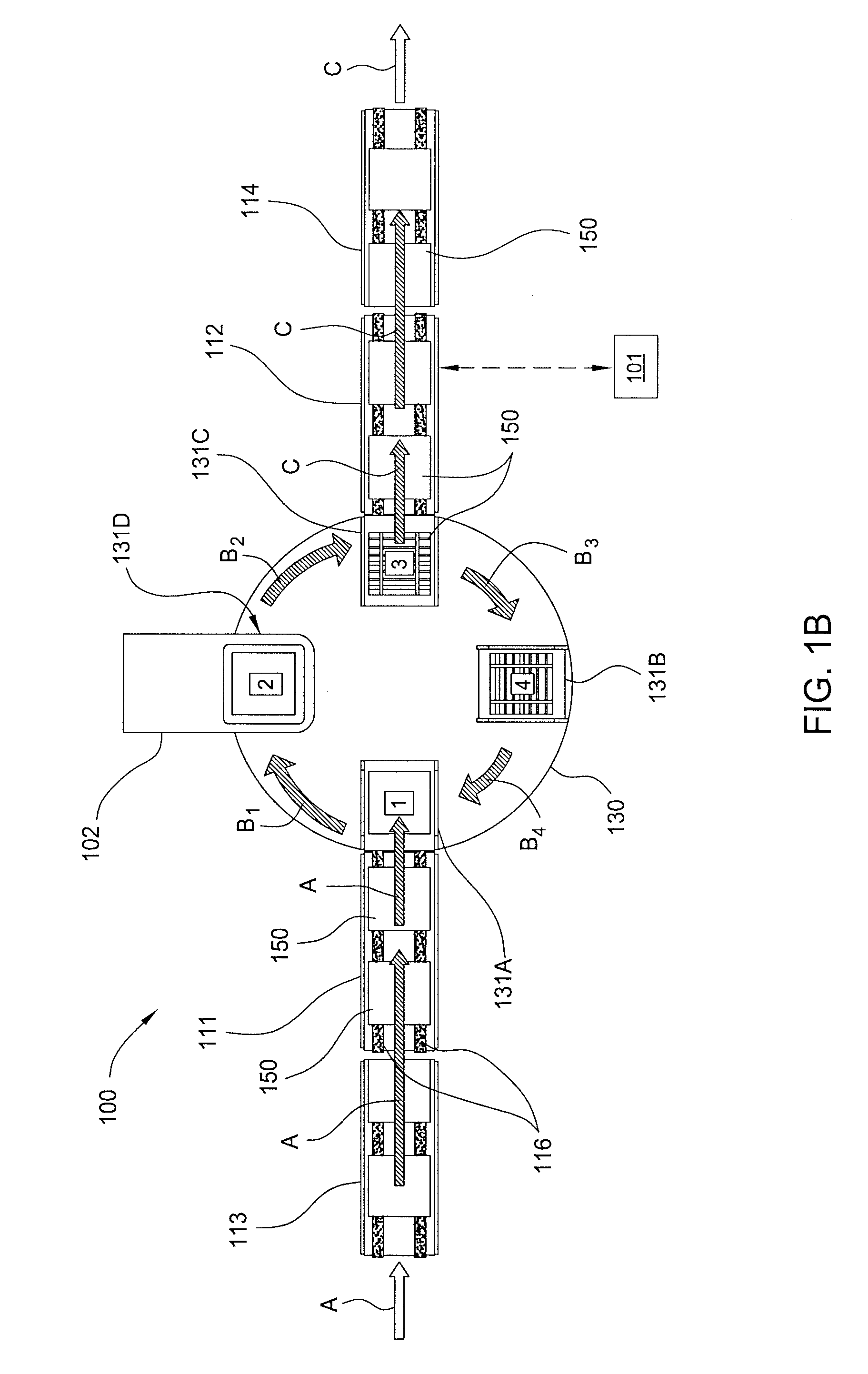

Optimal imaging system and method for a stencil printer

A stencil printer for depositing solder paste onto an electronic substrate includes a frame and a stencil coupled to the frame. A dispenser is coupled to the frame, with the dispenser and the stencil being configured to deposit solder paste onto the plurality of pads of the electronic substrate. An imaging system is configured to capture images of regions of interest of at least one of the electronic substrate and the stencil. The stencil printer further includes a controller coupled to the imaging system, with the controller being configured to control movement of the imaging system to capture images of regions of interest of at least one of the electronic substrate and the stencil extending generally along a first axis before moving the imaging system in another direction. A method for dispensing material on a substrate is further disclosed.

Owner:SPEEDLINE TECH

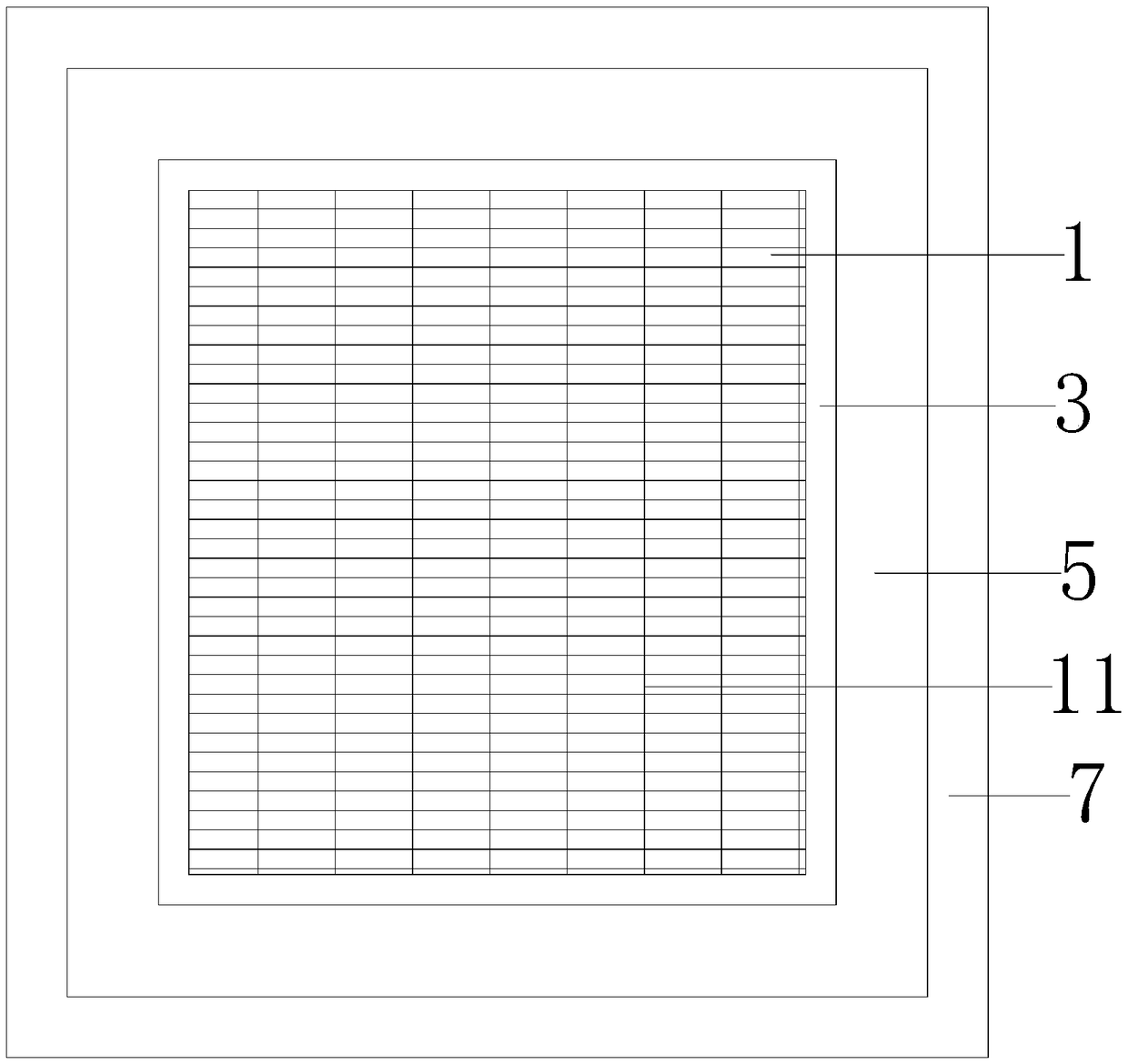

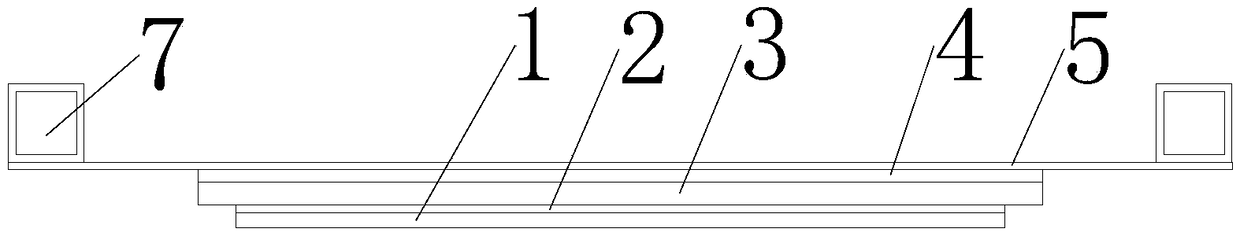

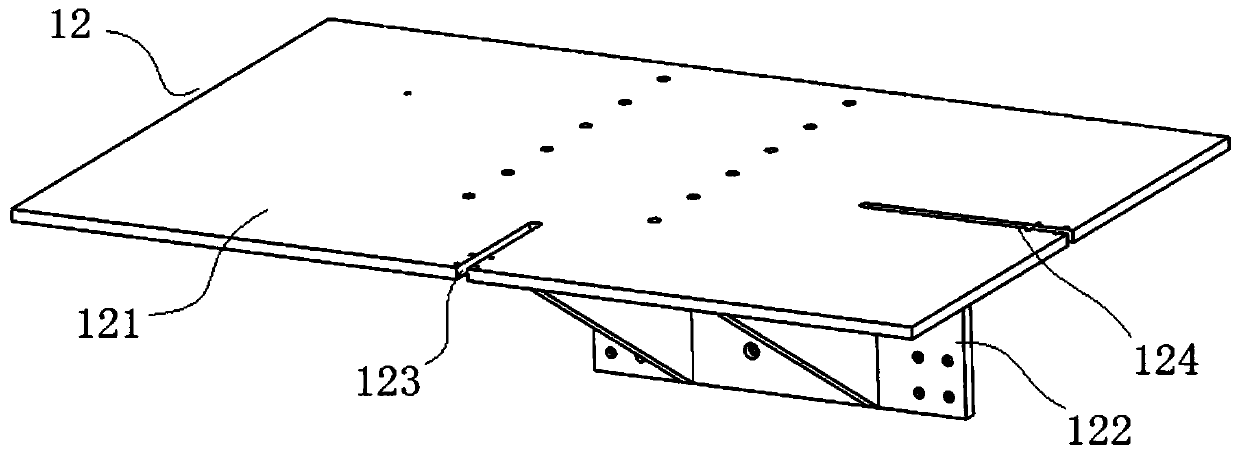

Polyimide solar net plate and manufacturing method

PendingCN108749276ADowngradeReduce manufacturing costScreen printersSynthetic resin layered productsWire gauzeScreen printing

The invention relates to a solar net plate, in particular to a polyimide solar net plate. The polyimide solar net plate comprises a net frame and a polyester wire net. The polyester wire net is tied to the bottom of the net frame. A silk screen printing hole is formed in the center of the polyester wire net, and the polyester wire net is in a concentric square shape. A stainless steel wire net anda polyimide film are further included. The polyimide film is fixed to the bottom face of the stainless steel wire net. A high-temperature glue layer is arranged between the polyimide film and the stainless steel wire net. The polyimide film is provided with a plurality of wire grooves, and a printing pattern is composed of the wire grooves. The top face of the stainless steel wire net is fixed tothe polyester wire net. The stainless steel wire net is larger than the silk screen printing hole and covers the silk screen printing hole, and a hot melt glue layer is arranged between the stainlesssteel wire net and the polyester wire net. The net plate manufacturing technology is simple, the manufacturing cost is low, the yield is high, the service life of the net plate is long, and frictionresistance and cross section sharpness are obviously improved; and the service life reaches 100,000 times or more, and the purchasing cost of printing net plates is reduced for battery piece manufacturers.

Owner:昆山良品丝印器材有限公司

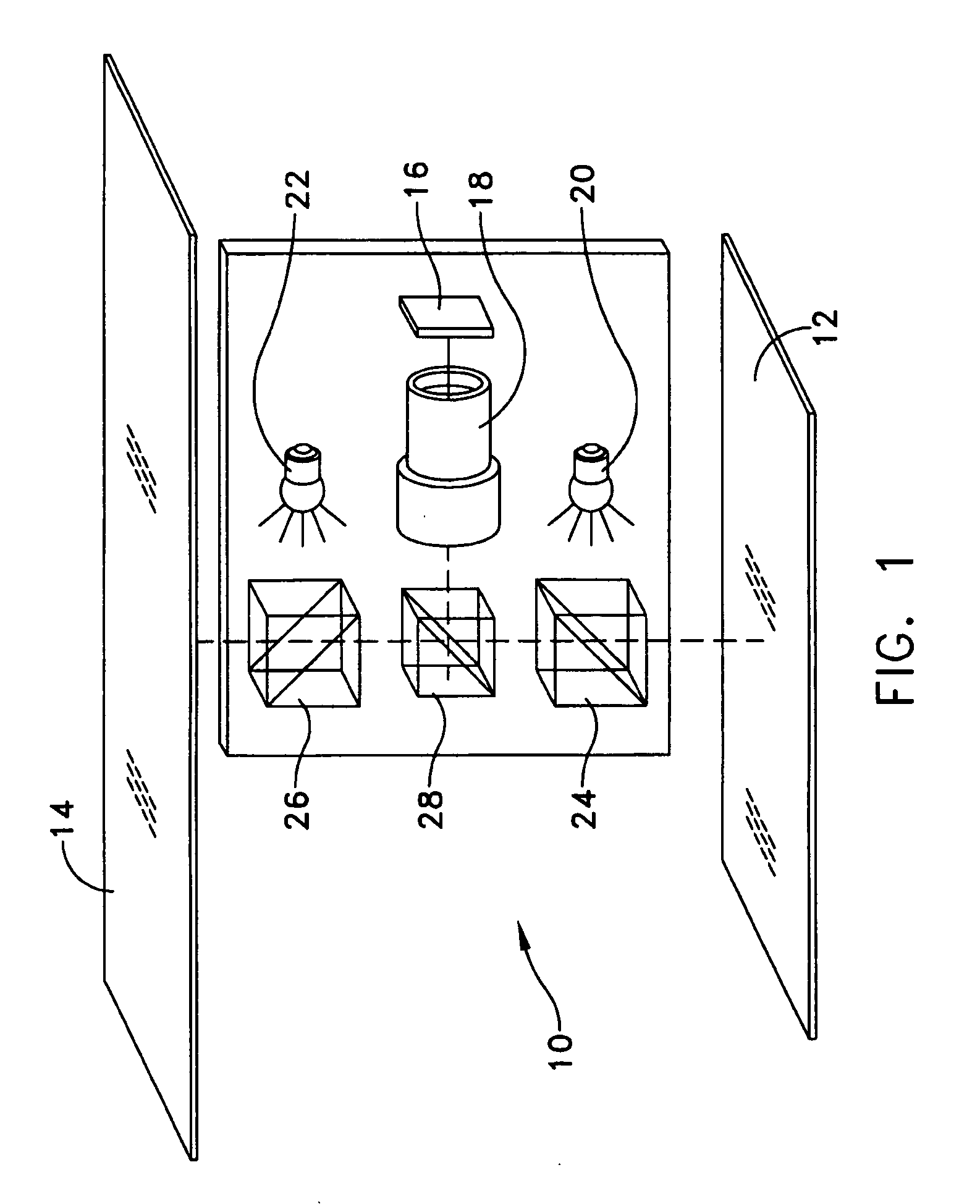

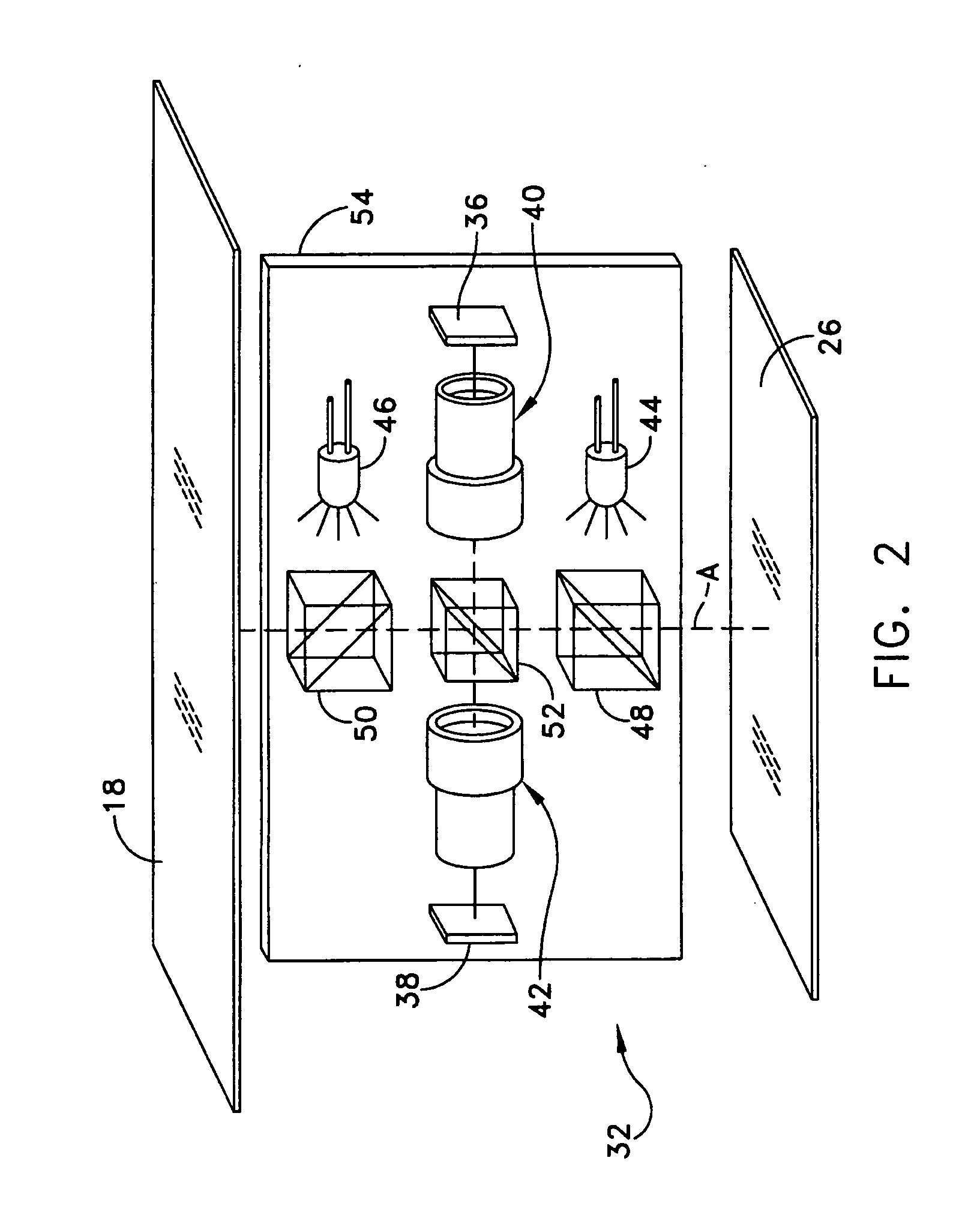

Off-axis illumination assembly and method

ActiveUS20070175343A1Accuracy in determineInking apparatusLiquid surface applicatorsOff-axis illuminationEngineering

A stencil printer is provided for depositing solder paste onto a surface of an electronic substrate. The stencil printer includes a frame and a stencil coupled to the frame. The stencil has a plurality of apertures formed therein. The stencil printer further includes a dispenser coupled to the frame. The stencil and the dispenser are adapted to deposit solder paste onto the electronic substrate. The stencil printer further includes an imaging system constructed and arranged to capture an image of the electronic substrate. The imaging system includes a camera assembly, an on-axis illumination assembly adapted to generate light substantially along a first axis generally perpendicular to the surface of the electronic substrate, and an off-axis illumination assembly adapted to generate rays of light substantially along a second axis extending at an angle with respect to the first axis. A controller is coupled to the imaging system to control movement of the imaging system to capture an image.

Owner:SPEEDLINE TECH

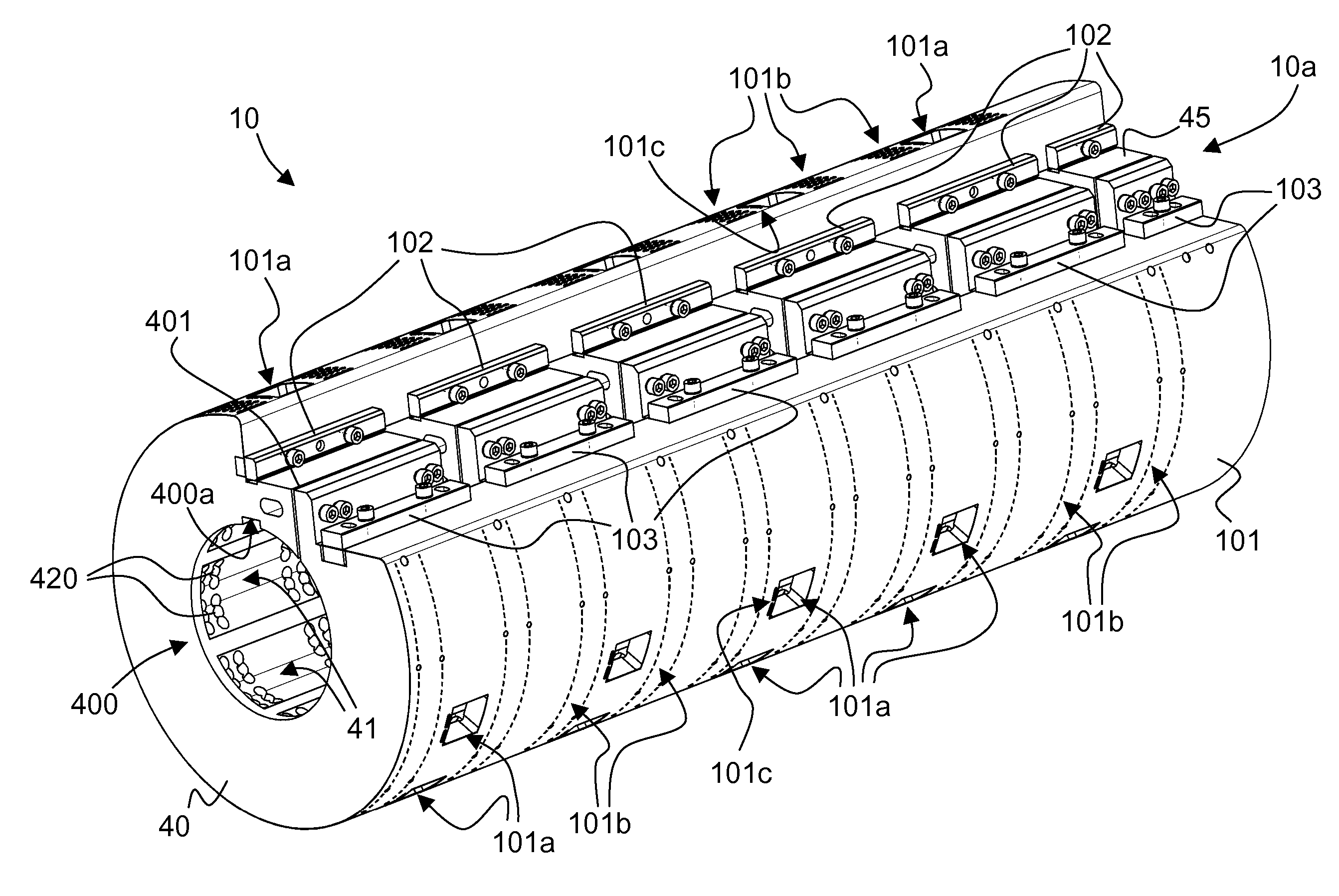

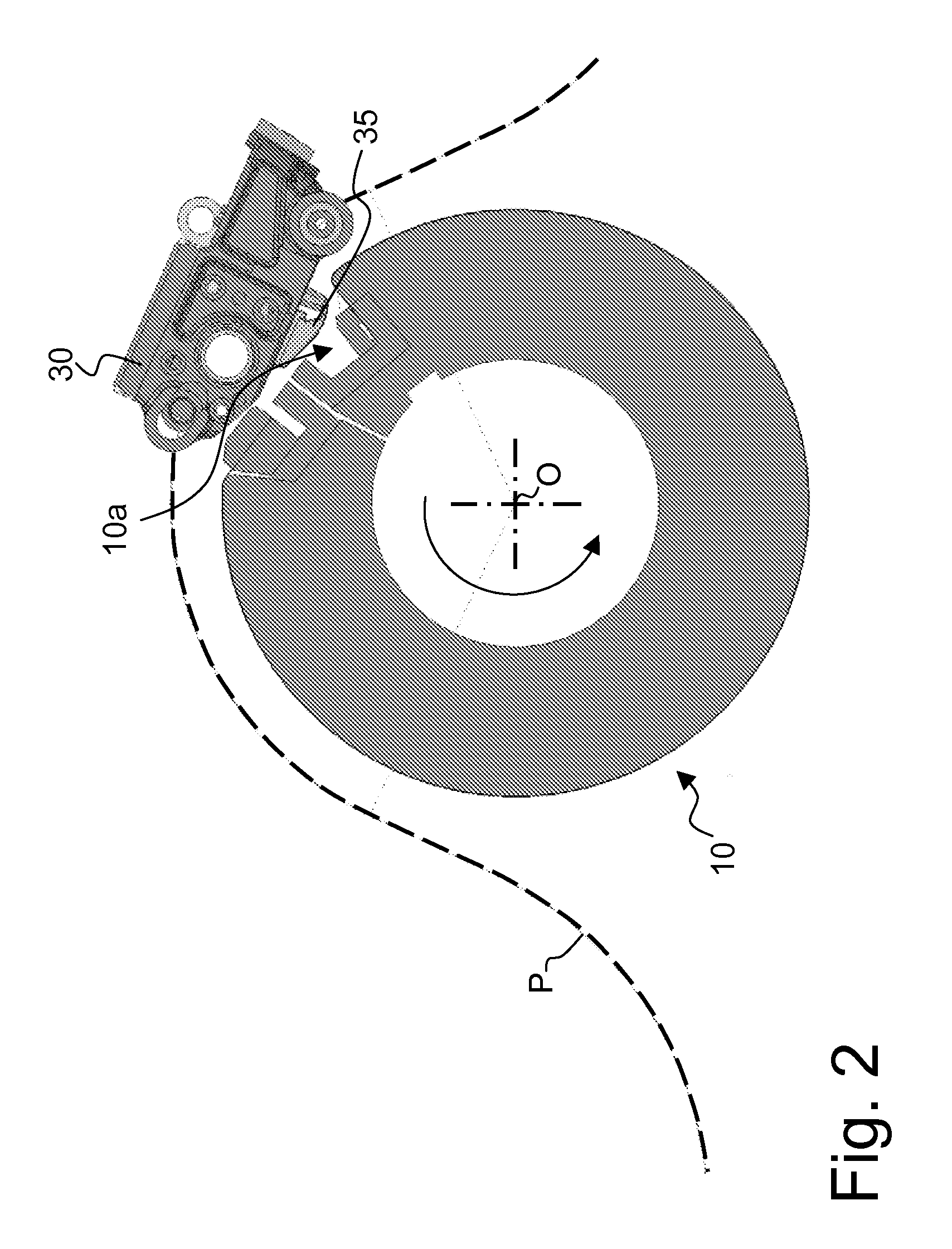

Printing Machine

ActiveUS20110017081A1Improve securityOther printing matterScreen printersTransfer systemPrinting press

The printing machine comprises at least one transfer system for conveying a substrate onto an impression cylinder and at least one screen of cylindrical or flat shape, with a doctor blade, said screen collaborating with the impression cylinder and intended to print the substrate with an ink containing pigments that can be orientated by a magnetic field and an unloading system for carrying the substrate away. The impression cylinder comprises at least one magnetic element on its impression surface, said magnetic element being positioned at a point corresponding to said impression performed by said screen on said substrate.

Owner:KBA NOTASYS SA

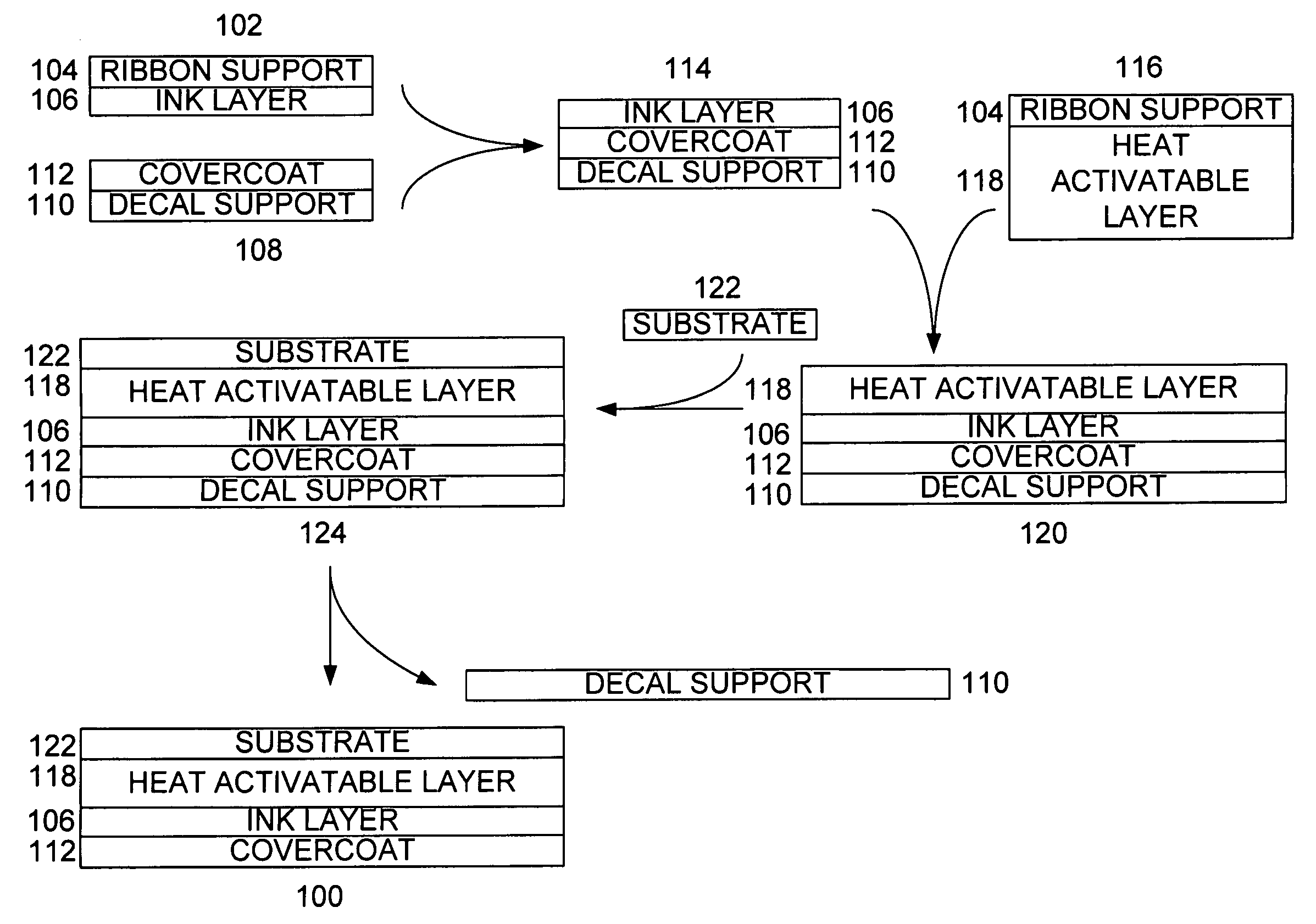

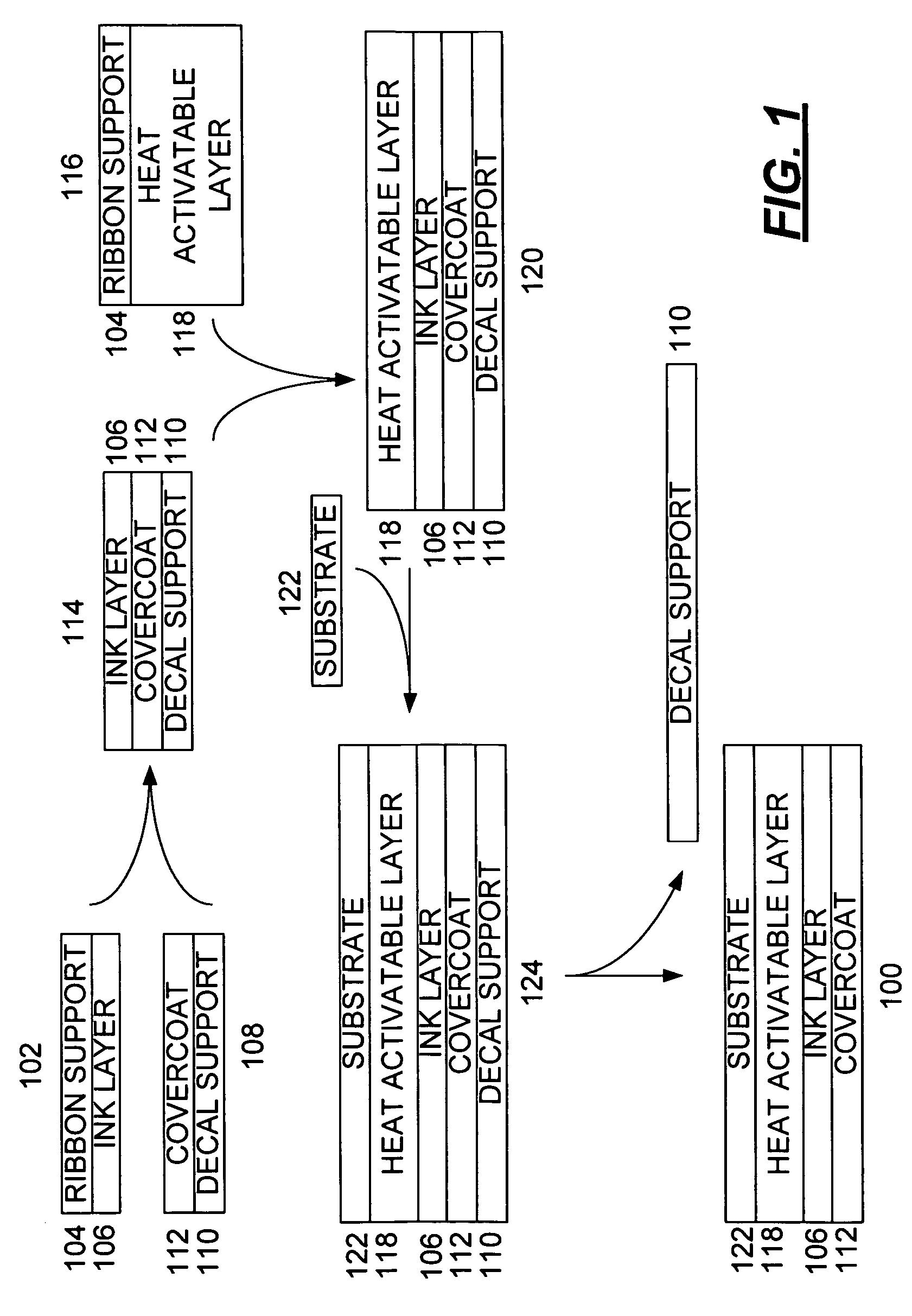

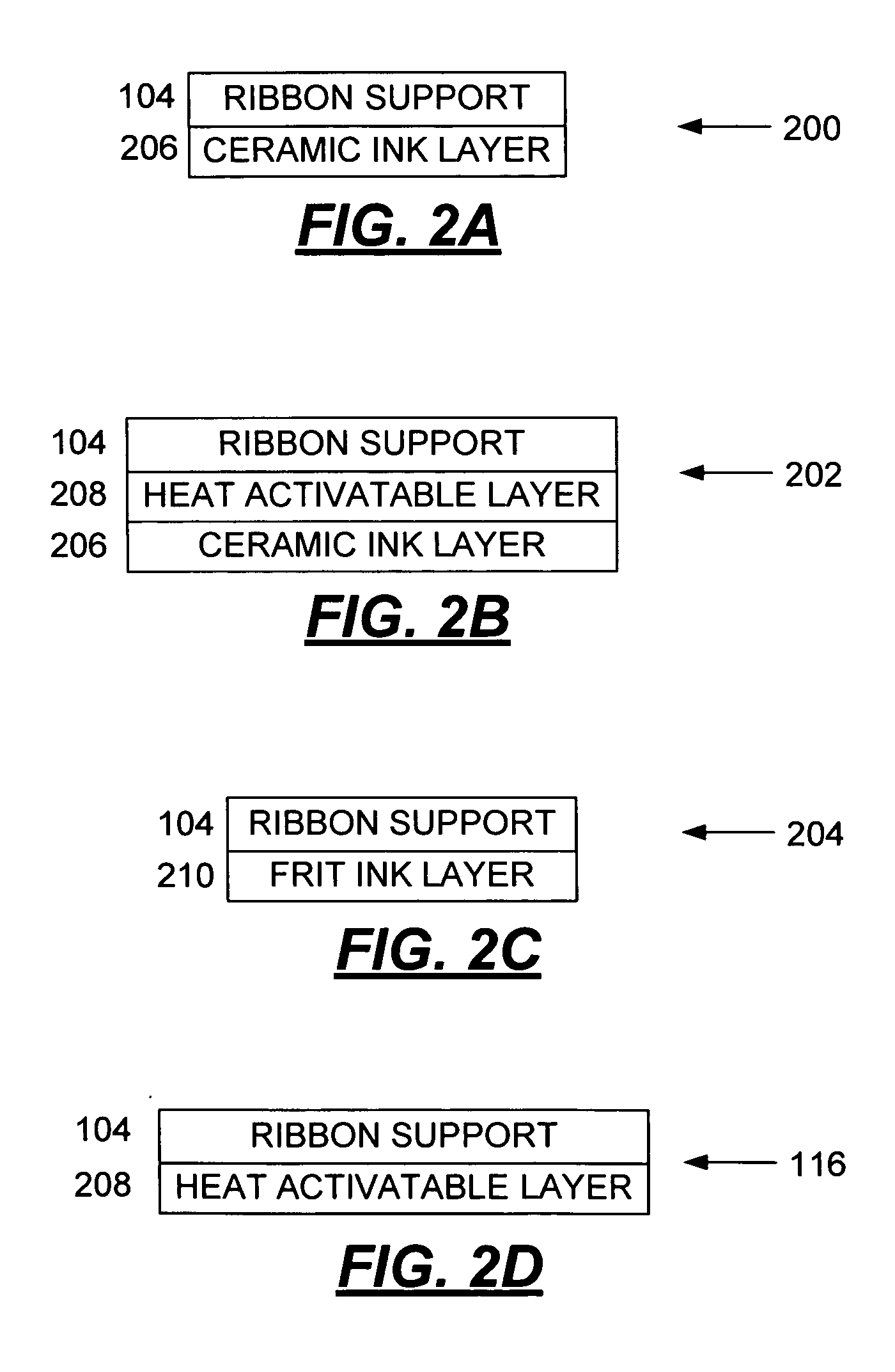

Digital decoration and marking of glass and ceramic substrates

Disclosed in this specification is a decal assembly comprising a decal support, a releasable covercoat, a heat activatable layer, and an ink layer. The ink layer forms a digital image. The heat activatable layer has a high adhesion to a ceramic substrate at high temperatures and a low adhesion to the substrate at lower temperatures. Thus the adhesive properties of the decal are activated by heat. The resulting image has excellent adhesion to the substrate and resists the effects of washing.

Owner:INT IMAGING MATERIALS

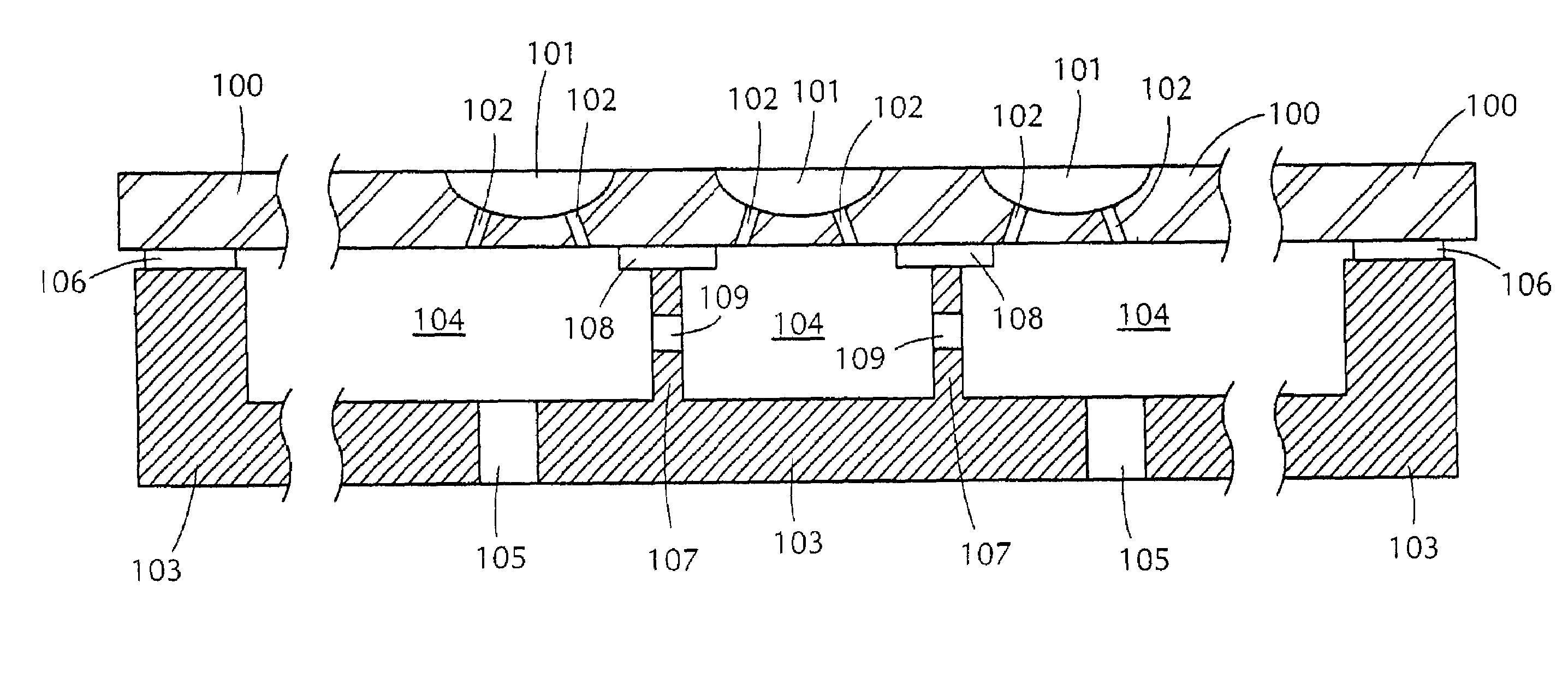

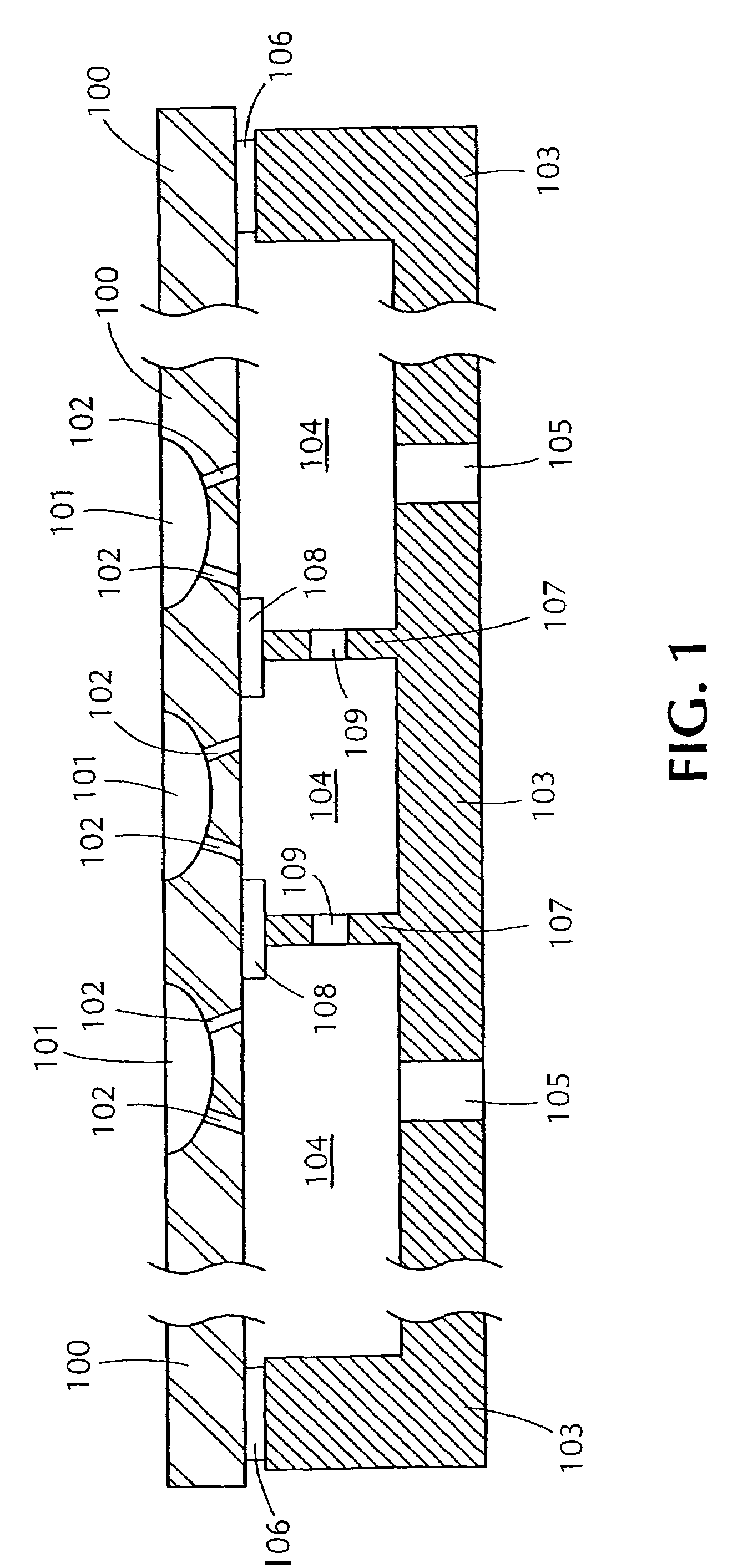

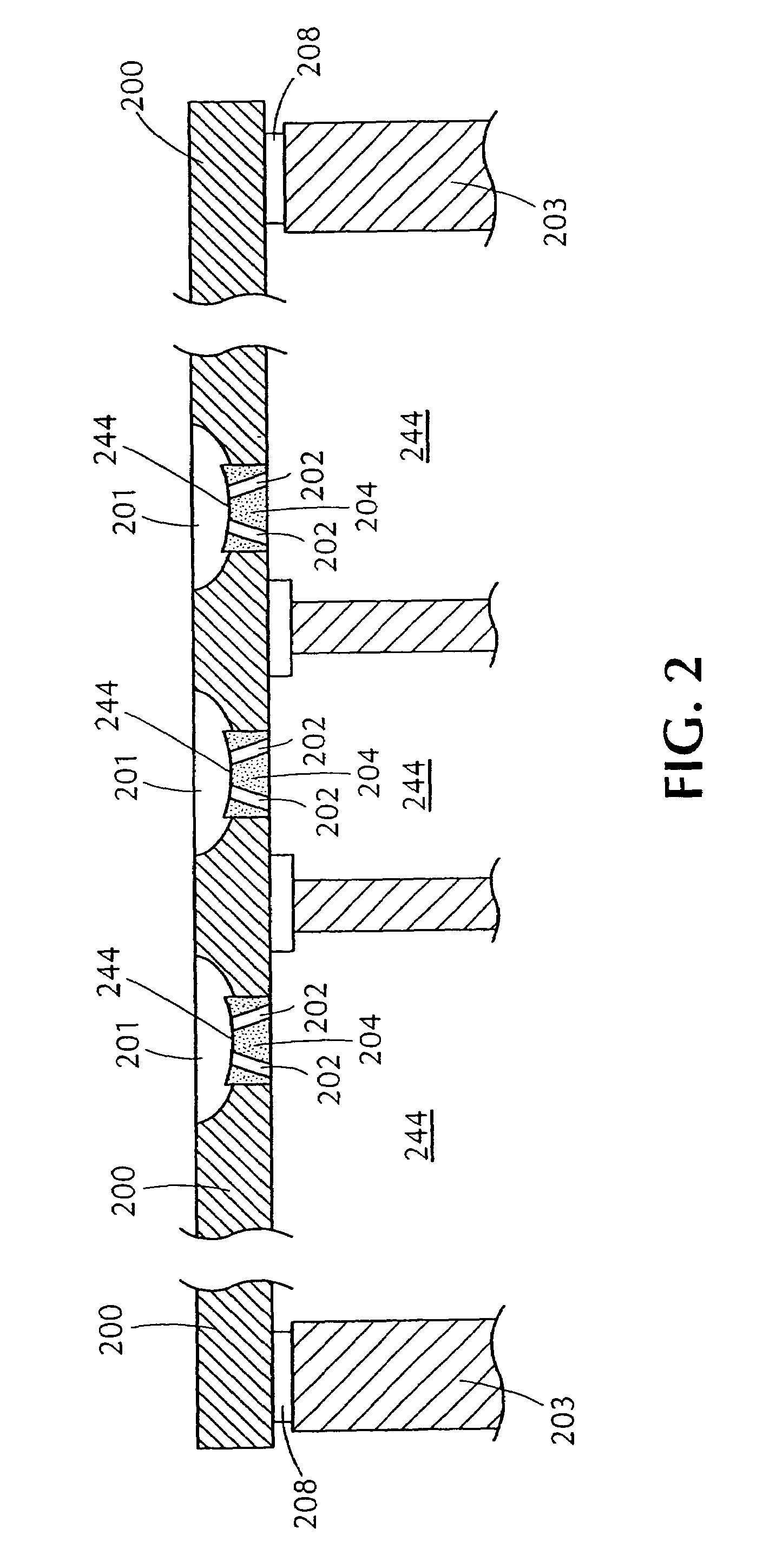

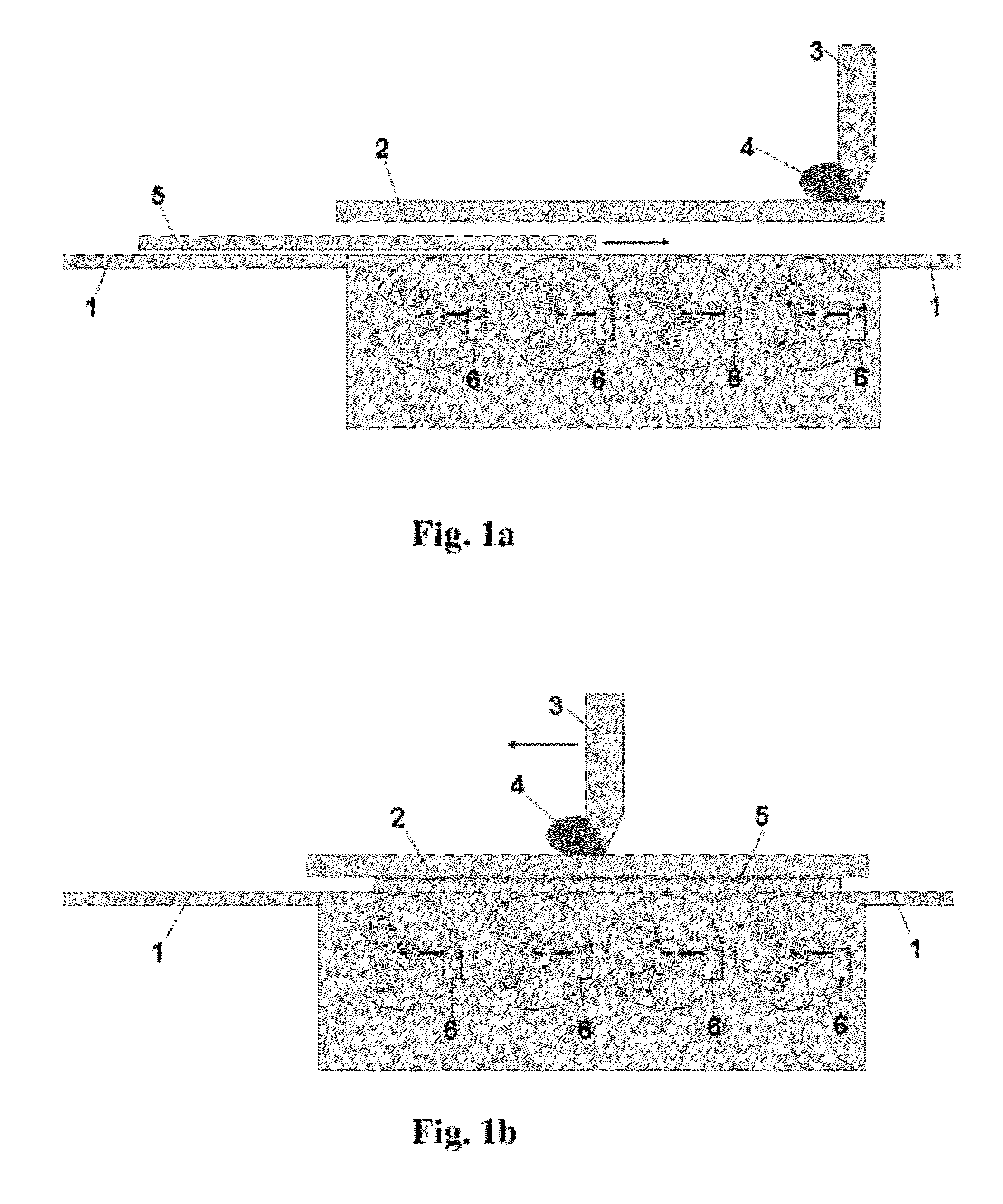

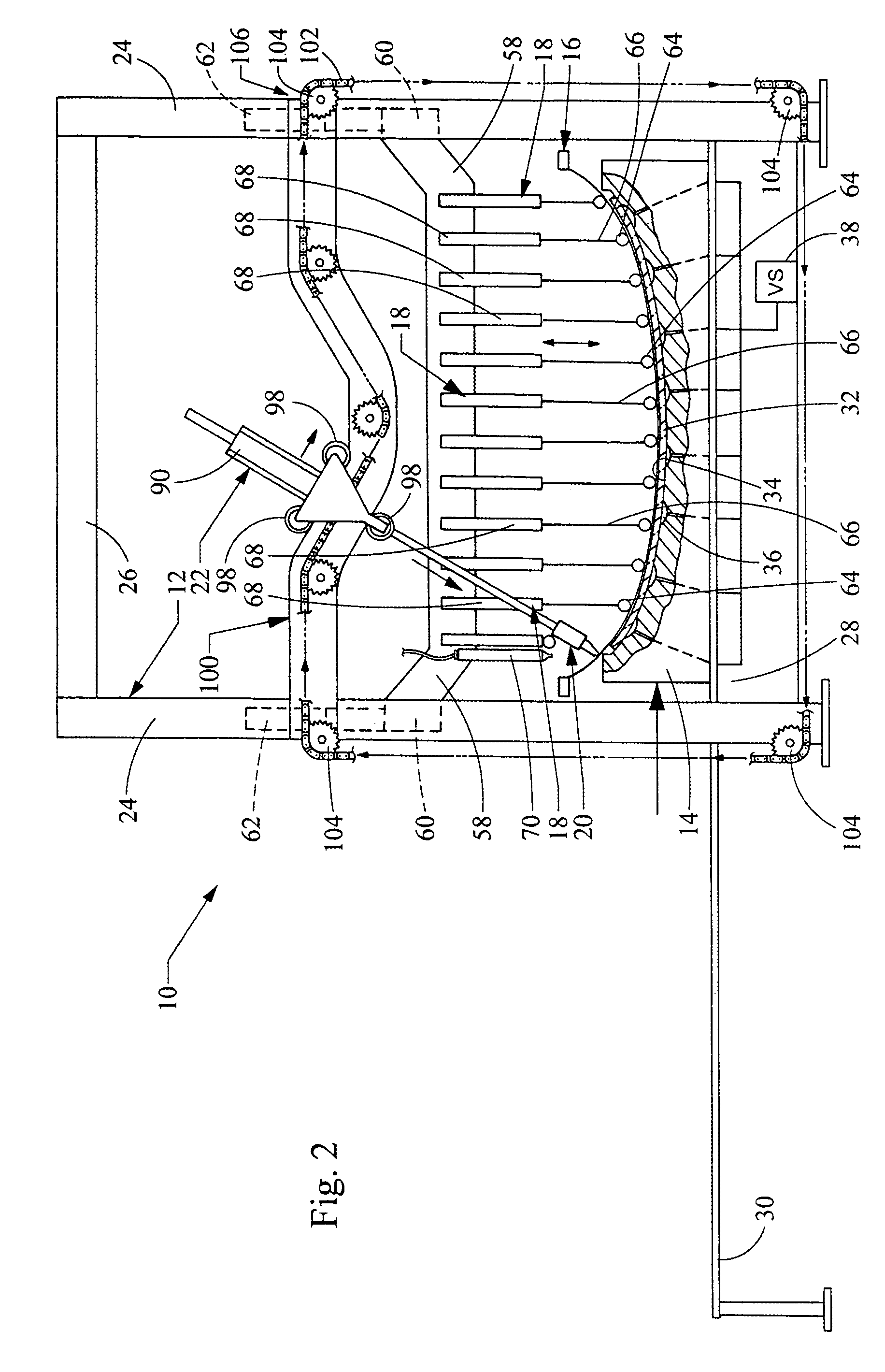

Magnetic orienting and printing

ActiveUS20120055355A1Avoid blurAvoid waiting timeLiquid surface applicatorsInking apparatusScreen printingMagnetization

The invention discloses a device and a process for producing indicia comprising magnetically oriented magnetic or magnetizable particles in an ink or coating composition on a sheet of substrate material. The device comprises a flat-bed screen-printing unit having a flat printing screen and a printing platen for receiving said sheet, the printing platen having an upper surface facing the printing screen and a first direction along its upper surface along which said sheet is unloadable, and a magnetic orienting unit comprising multiple magnet assemblies. The magnetic orienting unit is disposed below the upper surface of the printing platen, said multiple magnet assemblies are disposed along said first direction, and all of said magnet assemblies are concomitantly movable from a first position away from the upper surface of the printing platen to a second position close to the upper surface of the printing platen.The magnetic orienting unit comprising one or more magnet assemblies can also be used as a stand-alone flat-bed magnetization device, subsequent to the printing process, e.g. as an additional process station following a conventional flat-bed or rotary screen printing unit. Processes of producing printed documents using the disclosed devices are shown as well.

Owner:SICPA HLDG SA +1

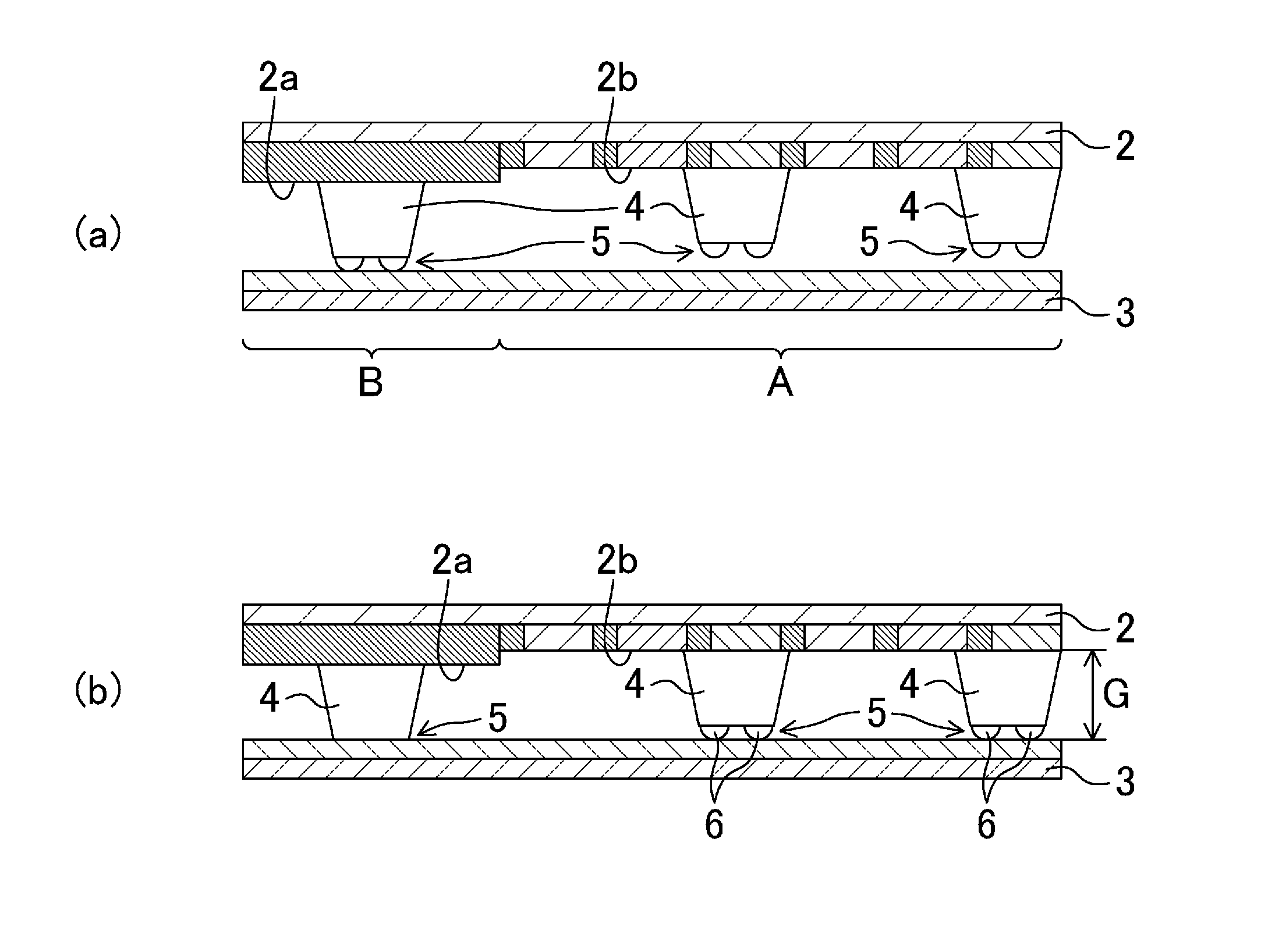

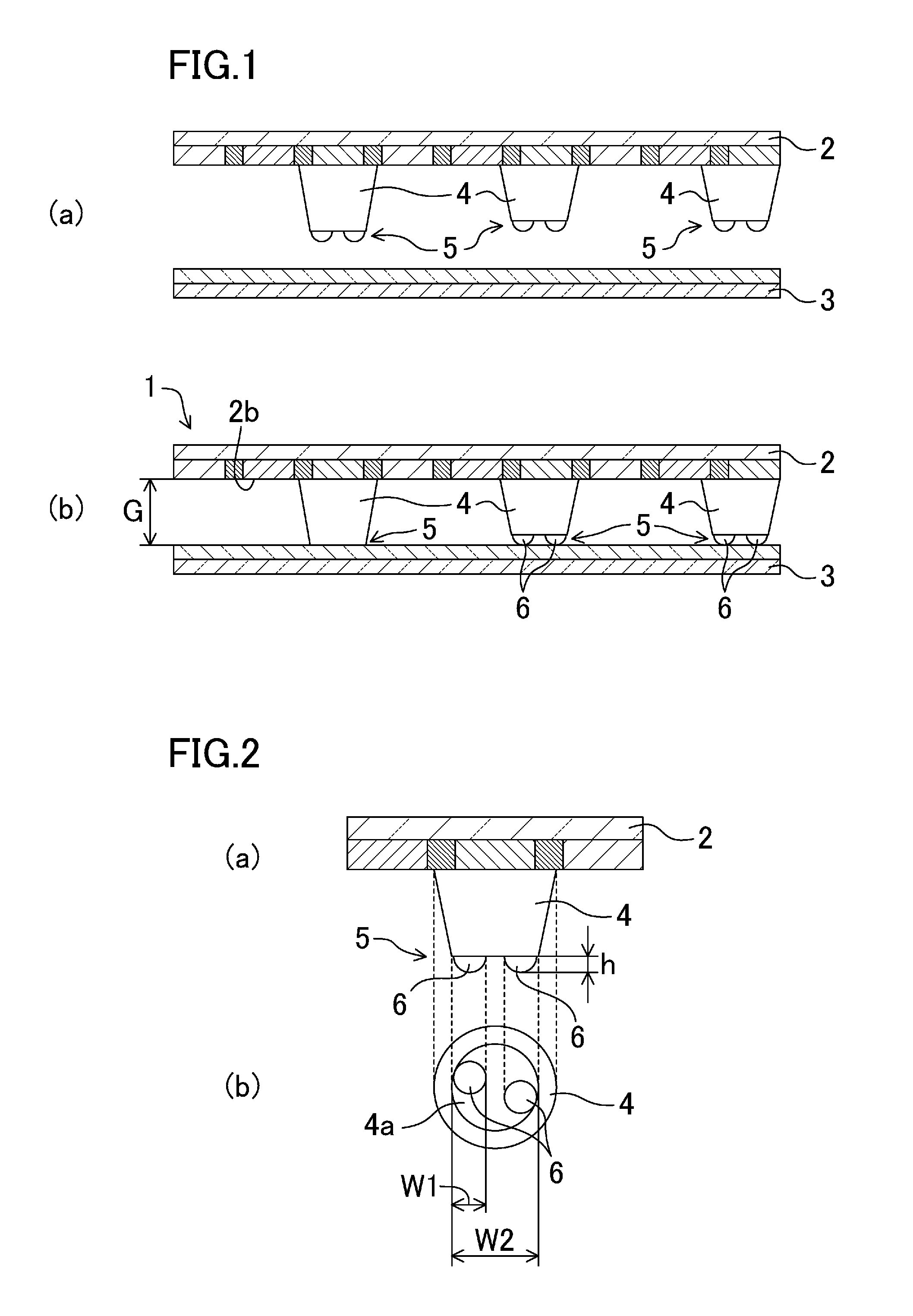

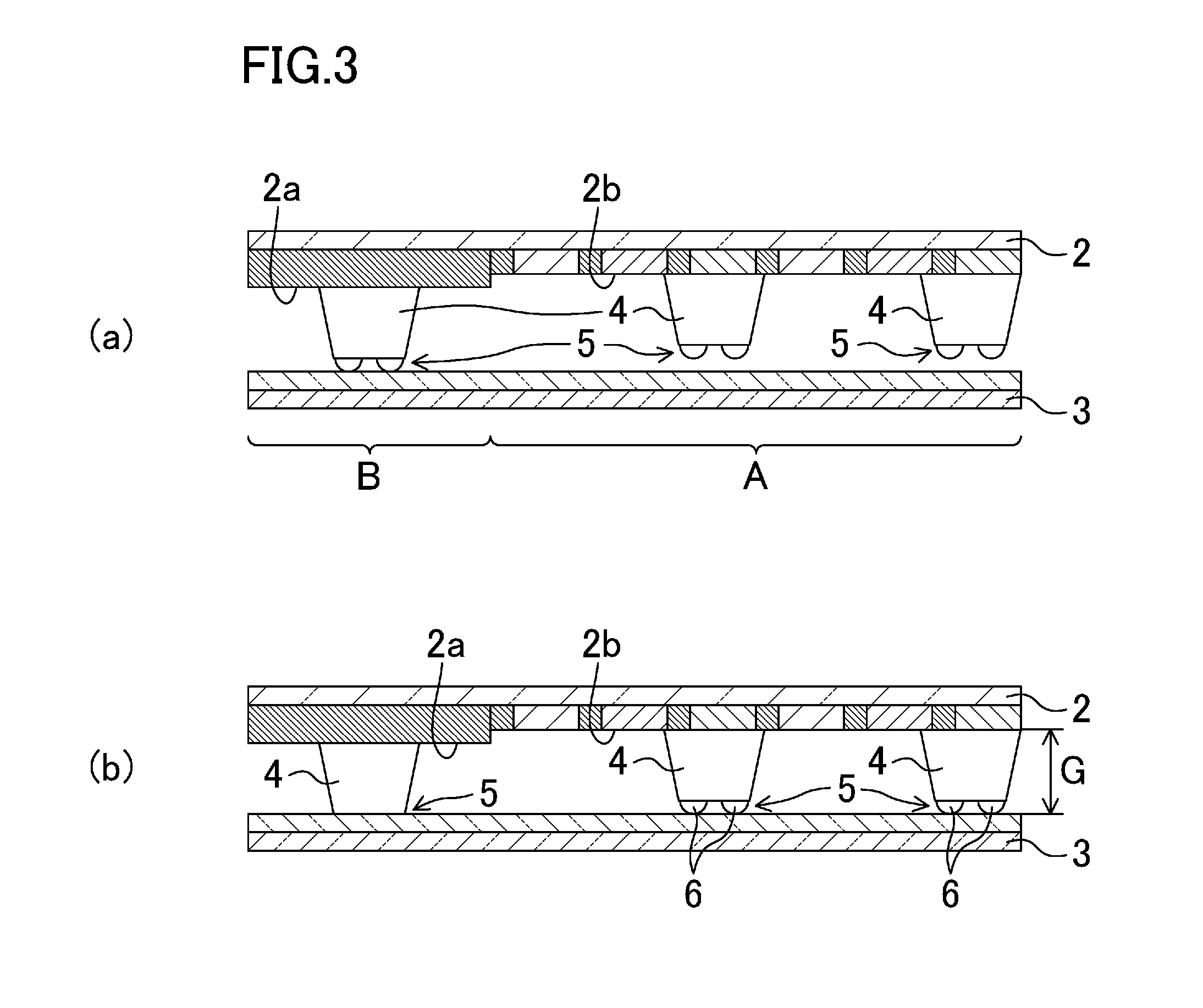

Liquid crystal display device and method for manufacturing the same

InactiveUS20120086901A1Constant gapSimple configurationNon-linear opticsRelief printingLiquid-crystal displayEngineering

A liquid crystal display device includes a plurality of columnar spacers configured to maintain a constant gap between substrates on a color filter substrate of the liquid crystal display device. At a tip end of each of the columnar spacers contacting an array substrate, a height adjusting portion which is easily deformed as compared to a portion of the columnar spacer other than the tip end portion when the pair of substrates are bonded together is provided.

Owner:SHARP KK

PCB circuit board printing process and production line thereof

ActiveCN108738242AImprove protectionExtension of timeScreen printersConductive pattern formationProduction lineEngineering

The invention provides a PCB circuit board printing process and a production line thereof, comprising: the step 1 of printing the side A of a circuit board using a mixed ink; the step 2 of drying theside A by using a UV lamp; the step 3 of flipping the circuit board; the step 4 of printing the side B of the circuit board using the mixed ink; the step 5 of drying the side B using the UV lamp; andthe step 6 of drying the sides A and B using a dryer. The invention includes circuit board printers, a flipper and a dryer, wherein there are two circuit board printers; the flipper is arranged between the two circuit board printers; and the dryer is set on the back end of the second circuit board printer. The printing process is to dry the surface of one side of the printed circuit board, and start the printing on the other side for surface drying then, and both sides are put into the dryer for drying after the surfaces are dried with the surface drying time of only 5-8 seconds. Moreover, theentire printing process costs 30-40 minutes, which is half the original time.

Owner:江西鑫金晖智能科技有限公司

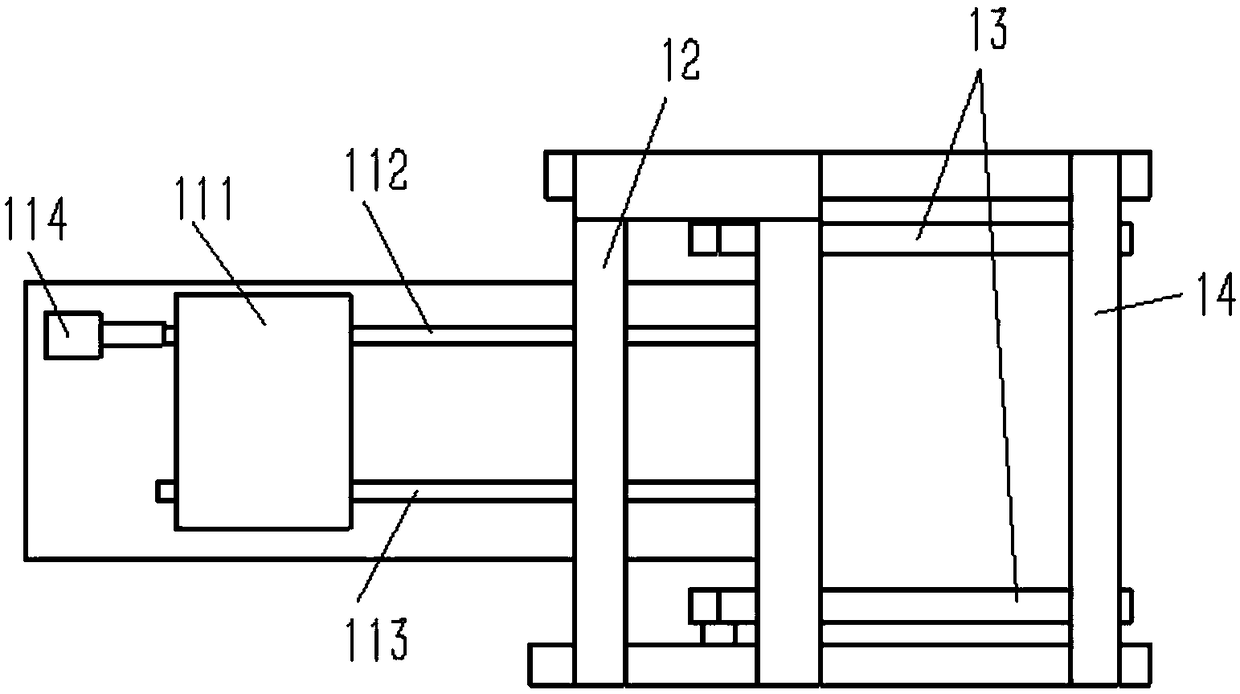

Cylinder Body for Orienting Magnetic Flakes Contained in an Ink or Varnish Vehicle Applied on a Sheet-Like or Web-Like Substrate

ActiveUS20100170408A1Improve the known devicesEasilyMangetographic processShaft and bearingsEngineeringMechanical engineering

There is described a cylinder body (10) for orienting magnetic flakes contained in an ink or varnish vehicle applied on a sheet-like or web-like substrate, which cylinder body (10) has a plurality of magnetic-field-generating devices (50, 60) disposed on an outer circumference of the cylinder body (10). The cylinder body (10) comprises a plurality of distinct annular supporting rings (40) distributed axially along a common shaft member (20), each annular supporting ring (40) carrying a set of magnetic-field-generating devices (50, 60) which are distributed circumferentially on an outer circumference of the annular supporting rings (40).

Owner:KBA NOTASYS SA

Screen printer machine capable of improving printing and dyeing effect

InactiveCN108284664AImprove printing and dyeing effectQuality improvementPrinted circuit assemblingScreen printersComputer engineeringDyeing

The invention discloses a screen printer machine capable of improving printing and dyeing effect. The screen printer machine comprises a box body, the inner wall of the box body is fixedly connected with first hydraulic rods, the top ends of the two first hydraulic rods are fixedly connected with an electricalmotor box and a fixed box correspondingly, and sliding blocks are fixedly connected to one side of the motor box and one side of the fixed box; sliding rails are slidably connected to the surfaces of the sliding blocks, the surfaces of the sliding rails are fixedly connected with the inner wall of the box body, and a sliding rod is fixedly connected between the surface of the electrical motor box and thefixed box; and theelectrical motor is fixedly connected to the inner wall of the electrical motor box. The invention relates to the technical field of screen printer machines. The screen printer machine capable of improving the printing and dyeing effect has the capability of rapidand accurate printing and dyeing, the printing and dyeing screen cleaning capacity is improved, and the printing and dyeing screen is convenient to install and dismount;and the printing and dyeing machine has the capability of automatically sensing and controlling the printing and dyeing pressure in the printing and dyeing process, the condition that printing and dyeing are not sufficient and theprinting and dyeing screen plate is pressed is avoided, and the printing and dyeing quality and effect are greatly improved.

Owner:沈亚红

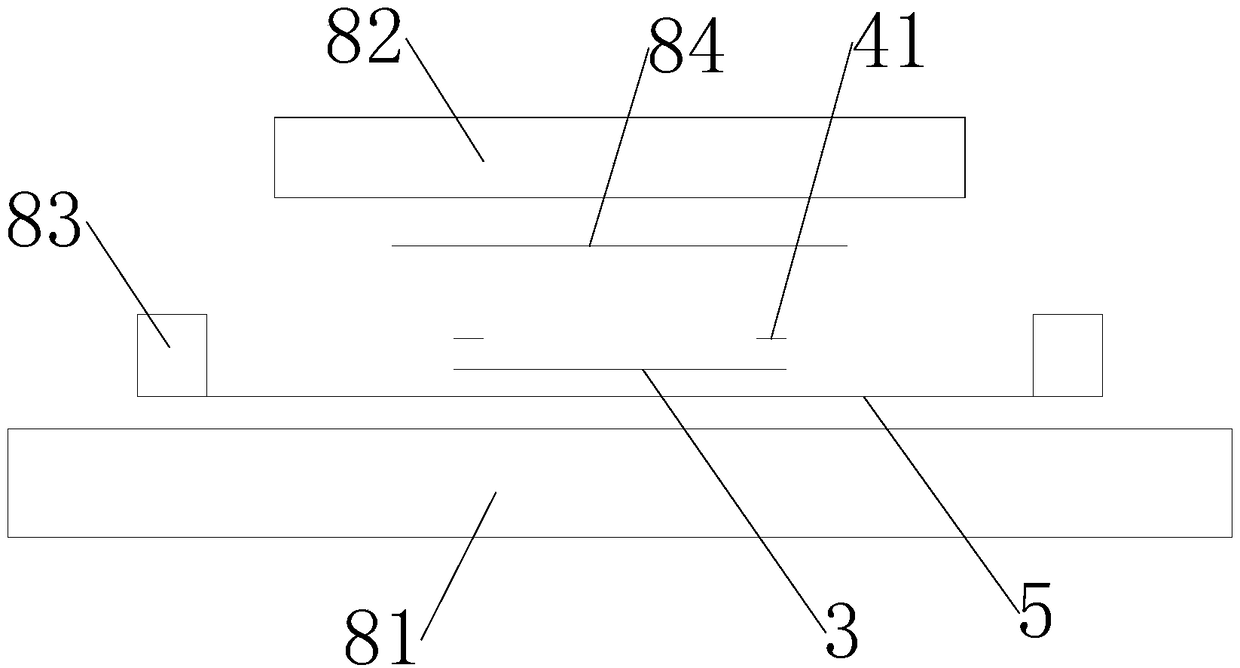

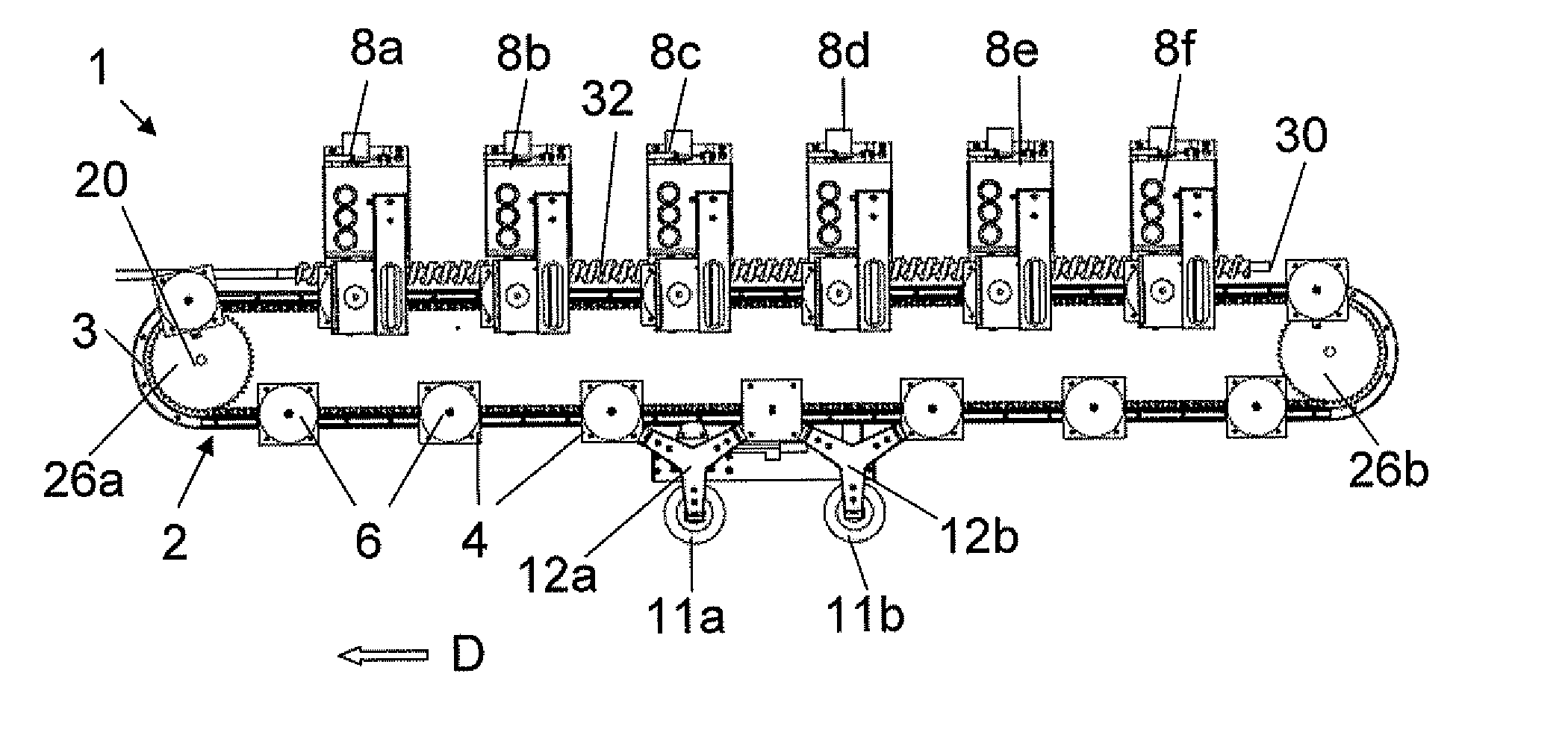

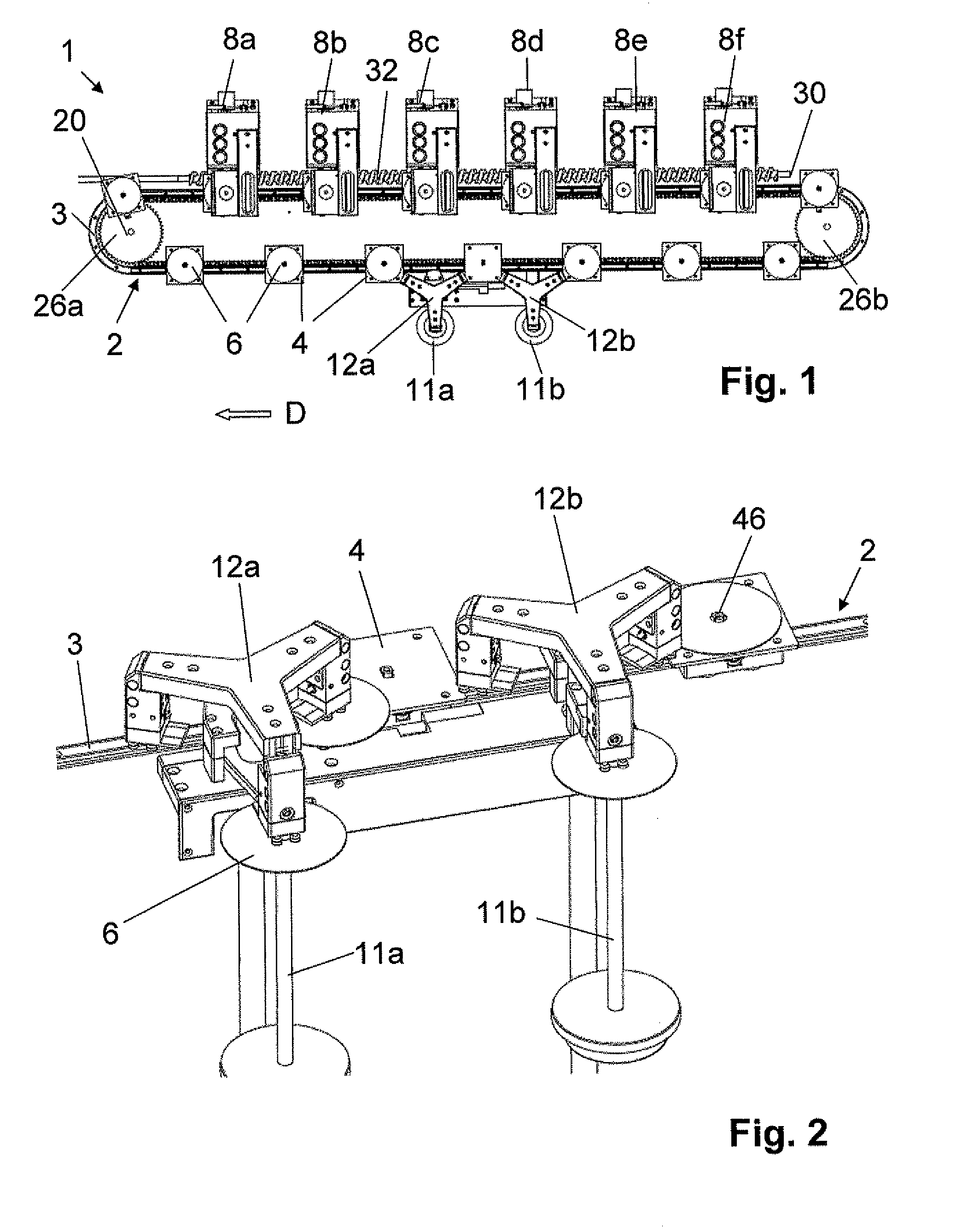

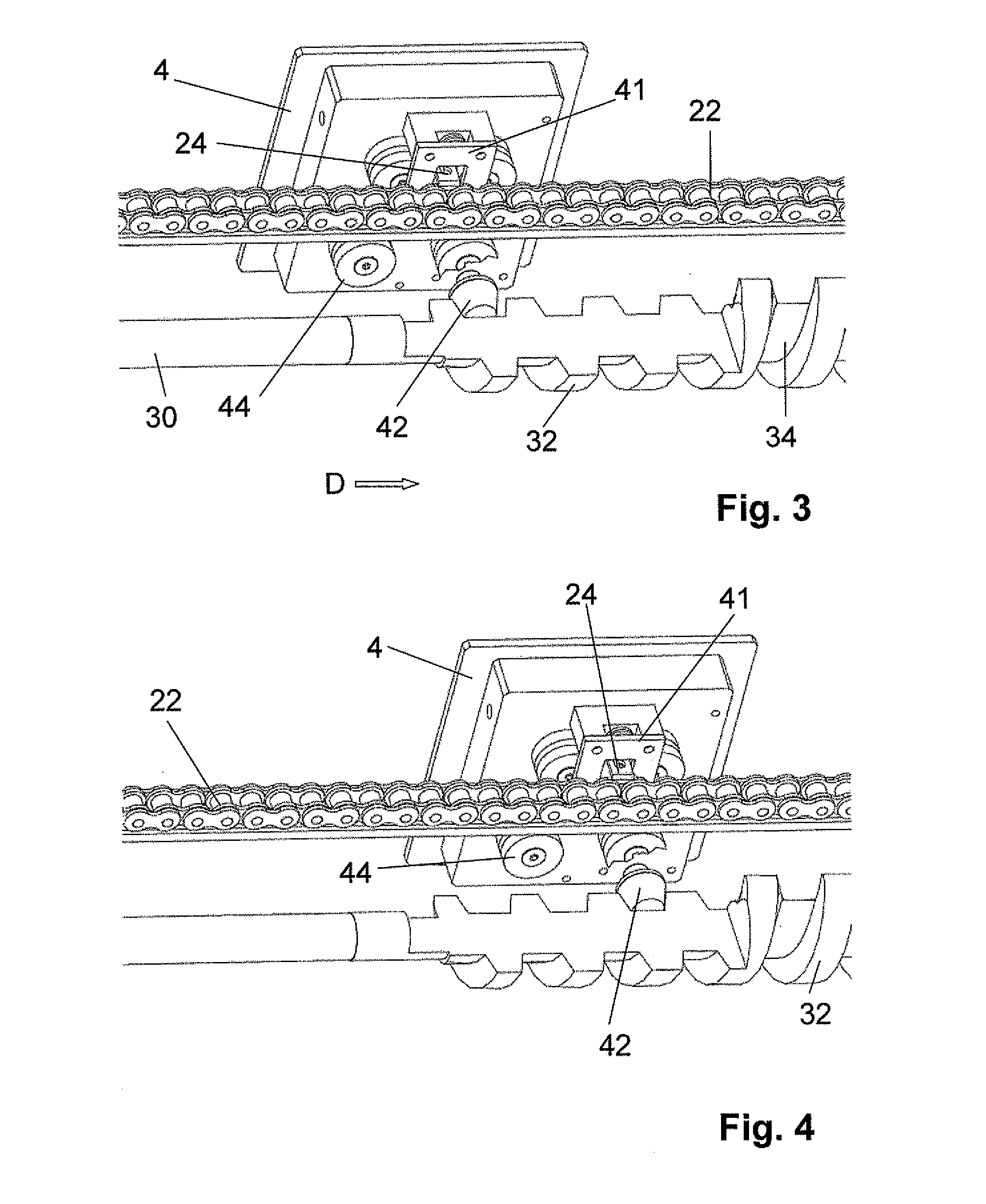

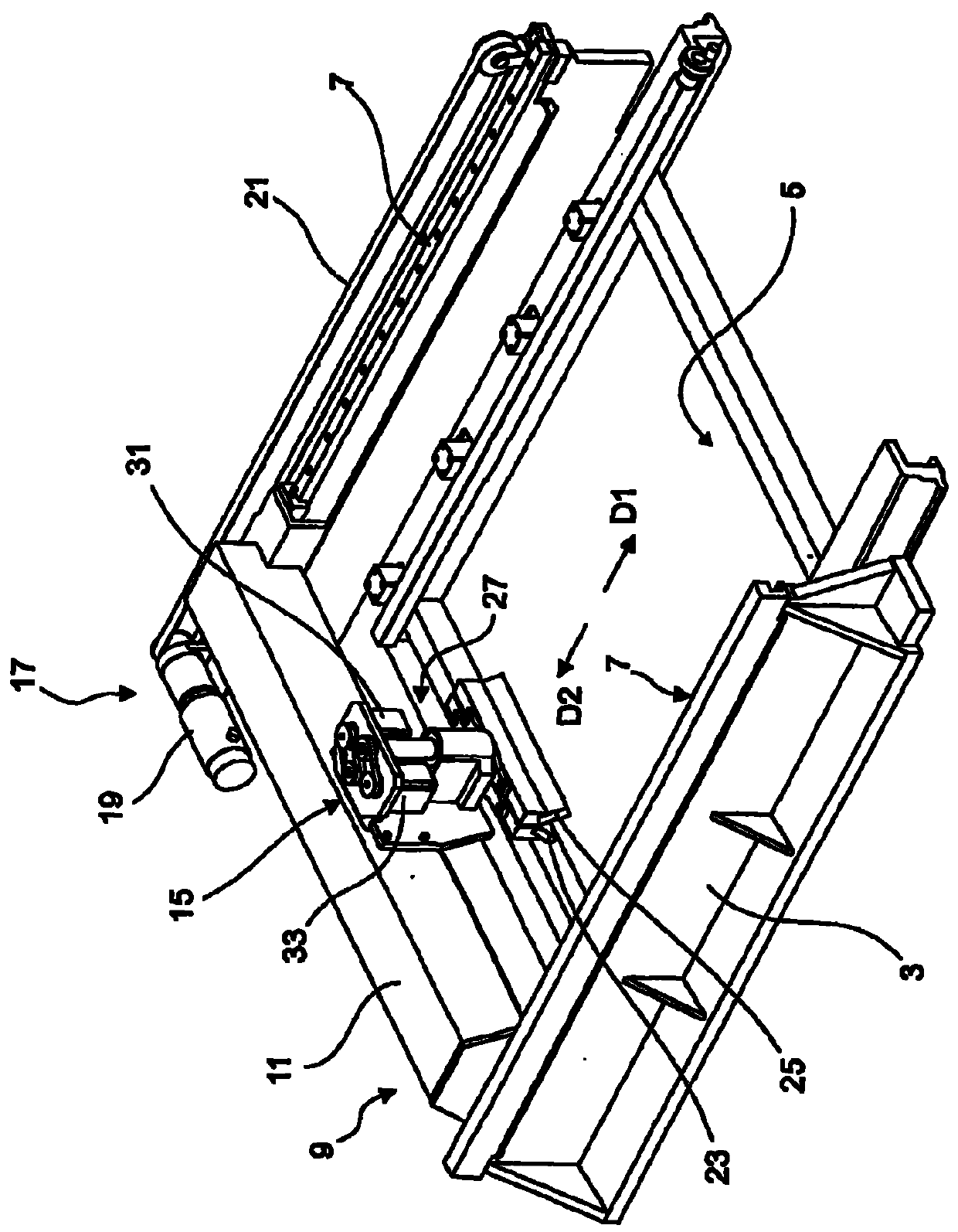

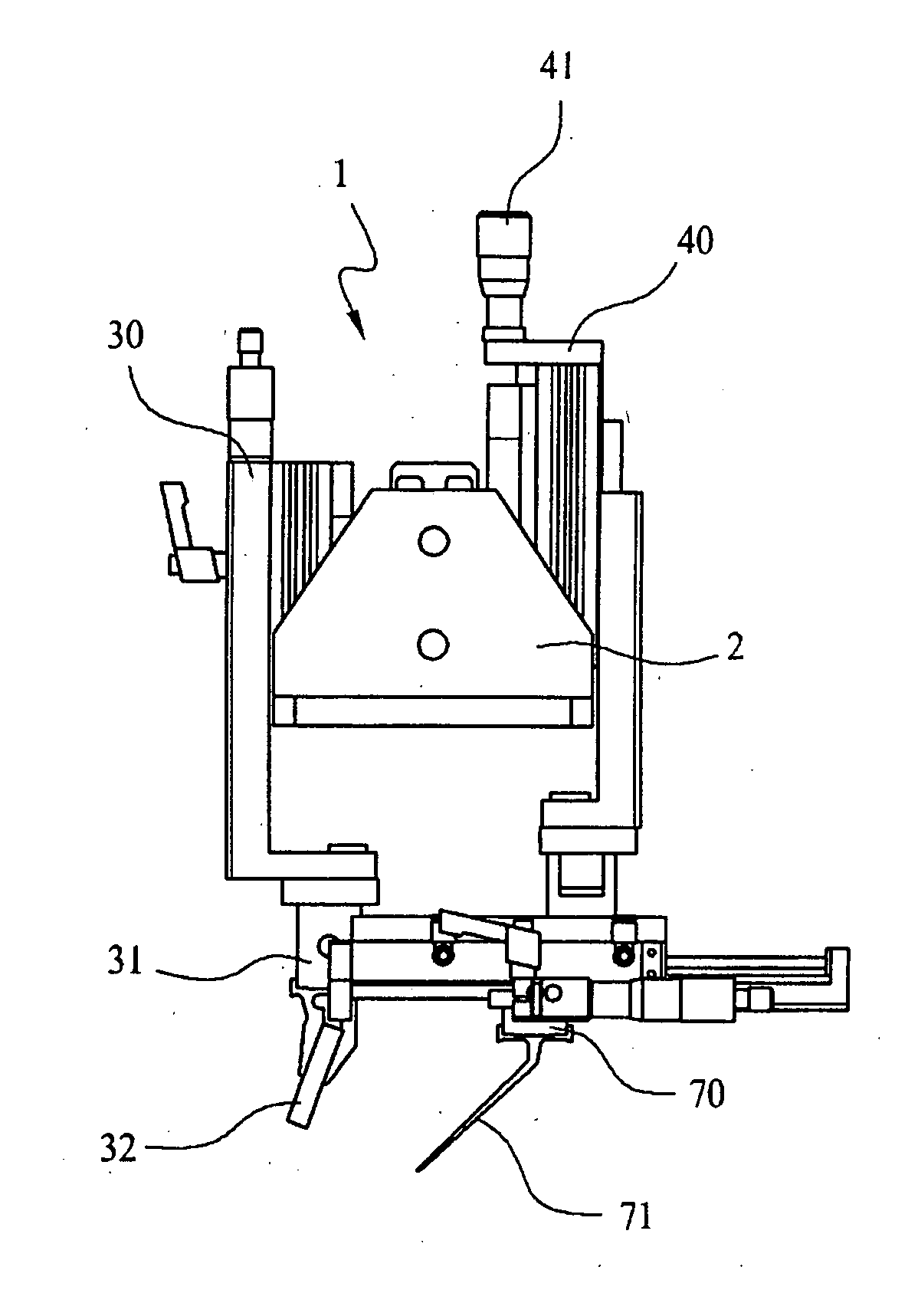

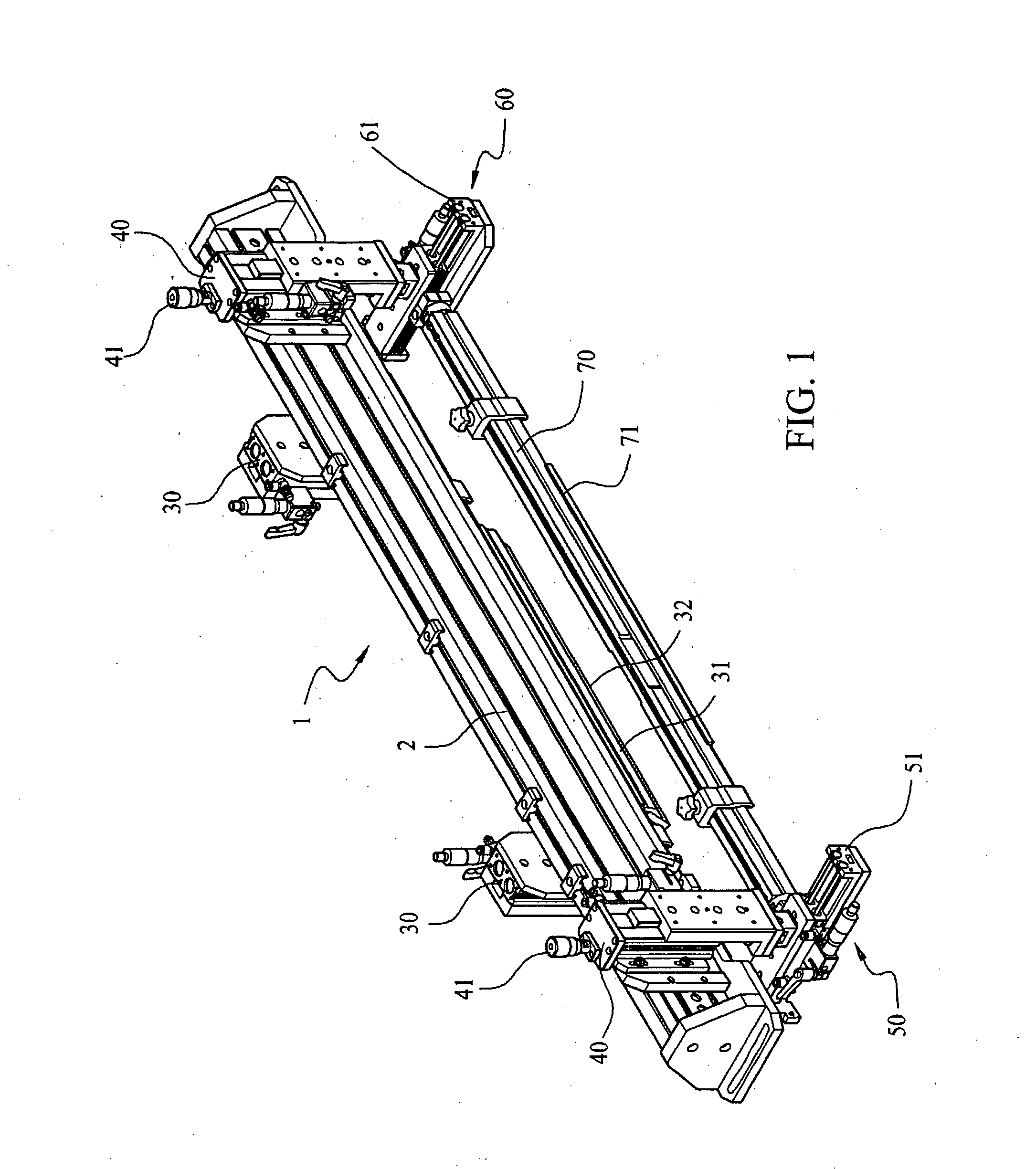

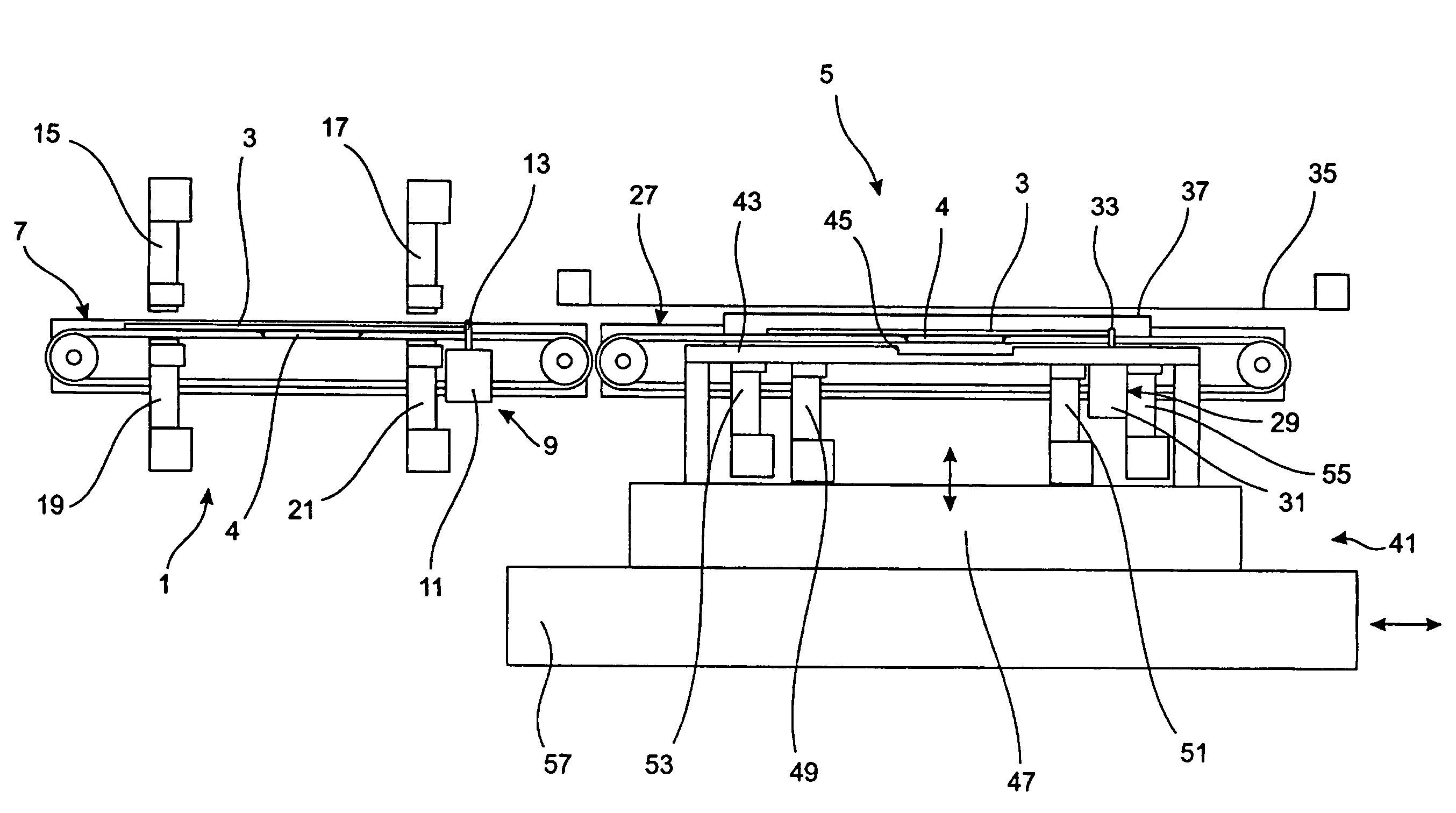

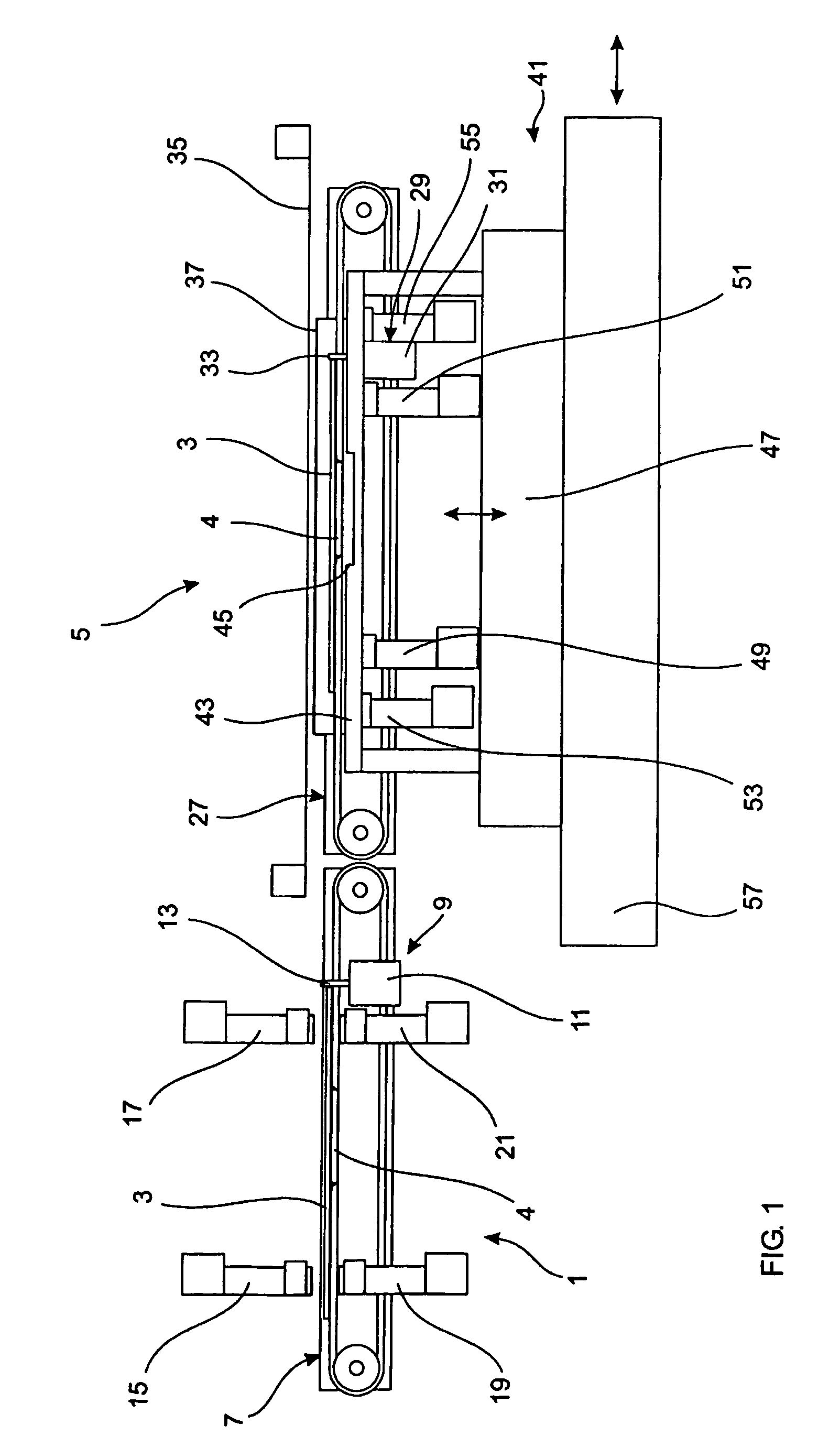

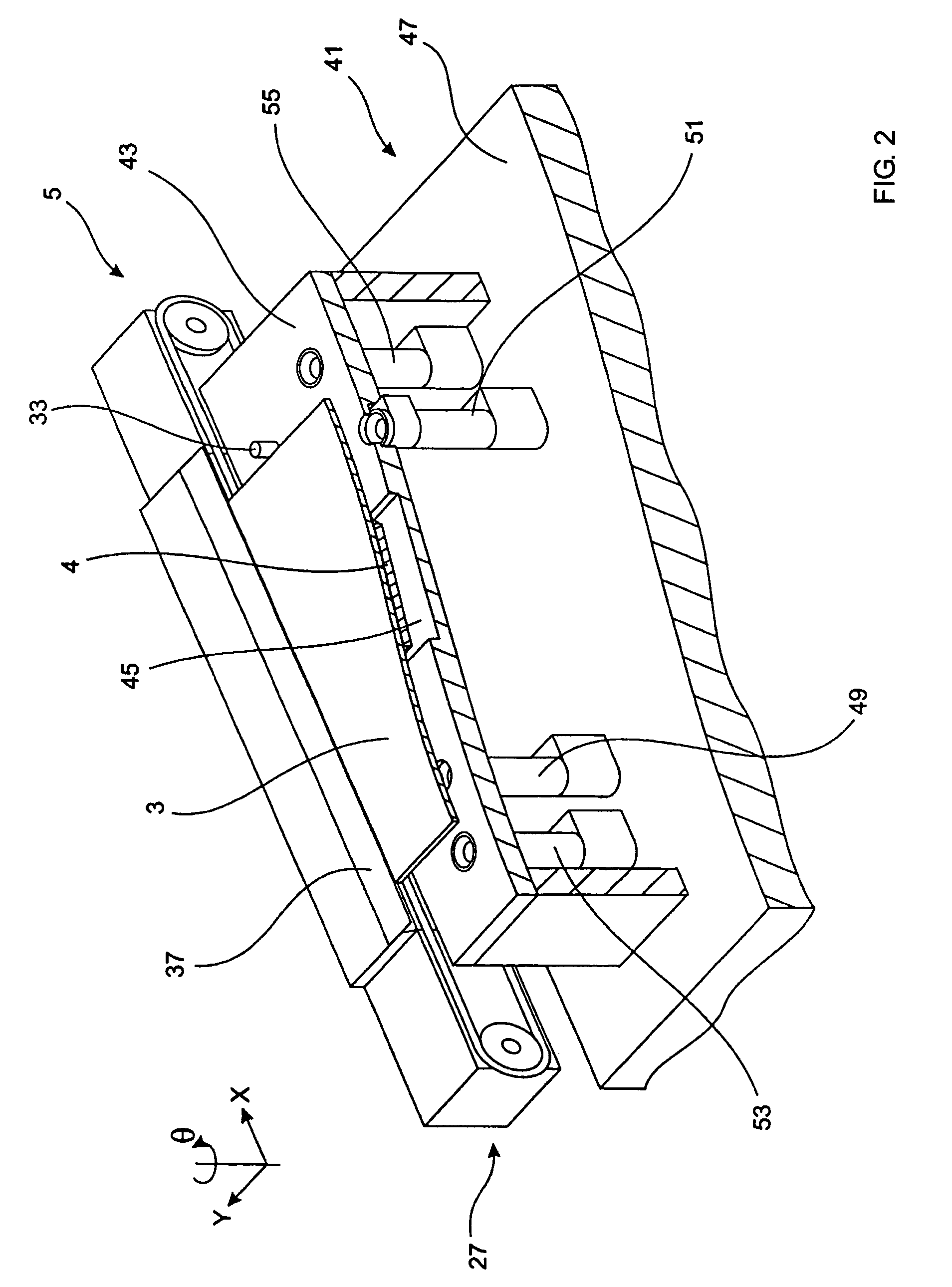

Device for treatment of articles comprising overlapping driving devices

InactiveUS20090321220A1Risk minimizationImprove accuracyScreen printersPackagingEngineeringDriven element

The invention relates to a palette for supporting articles such as CDs, DVDs or the like, which is adapted to be guided forward on a conveyor path (2) on a device according to any of the proceeding claims, which comprises a wheel (44) or the like arranged to interact with a rail (3) along the conveyor path (2); a first pin (41) arranged to engage with a first driving element (22) on a first driving device (20) to drive the palette (4) forward along the rail (3) of the conveyor path (2); a second pin (42, 42′) arranged to engage with a second driving element (32, 32′) on a second driving device (30, 30′). The engagement of the first pin (41) with the first driving element (22) includes an allowance, which by means of the engagement between the second driving element (32, 32′) on the second driving device (30, 30′) allows the palette (4) to be displaced in respect of the first driving element (22), such that the palette may be driven forward by the second driving element (32, 32′) within said allowance. The invention relates also to a device for processing of articles, wherein the articles are guided forward on such a palette.

Owner:GEPRO

Autotuned screen printing process

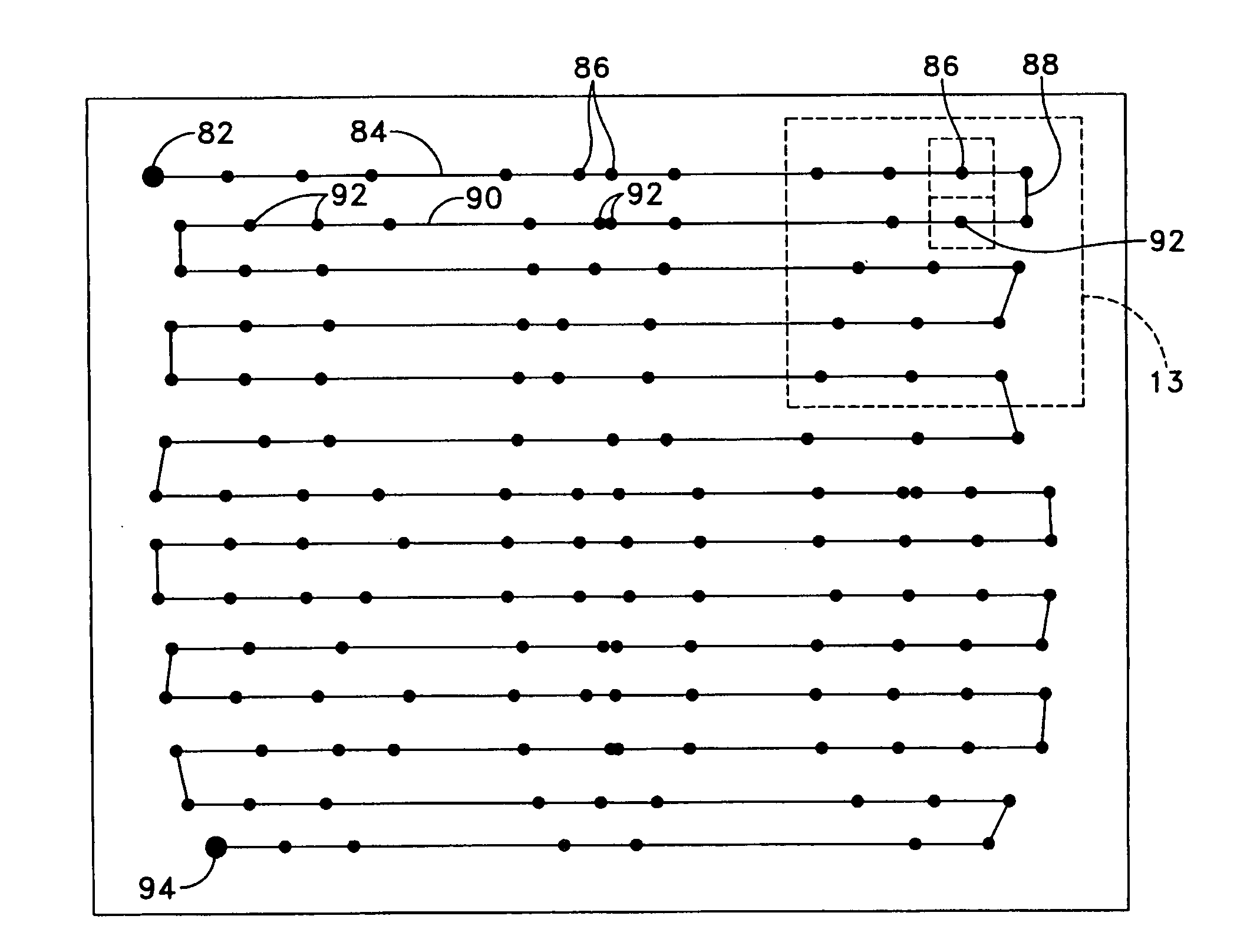

ActiveUS20120045852A1Liquid surface applicatorsSemiconductor/solid-state device testing/measurementScreen printingPosition error

Embodiments of the invention generally provide apparatus and methods of screen printing a pattern on a substrate. In one embodiment, a patterned layer is printed onto a surface of a substrate along with a plurality of alignment marks. The locations of the alignment marks are measured with respect to a feature of the substrate to determine the actual location of the patterned layer. The actual location is compared with the expected location to determine the positional error of the patterned layer placement on the substrate. This information is used to adjust the placement of a patterned layer onto subsequently processed substrates.

Owner:APPLIED MATERIALS INC

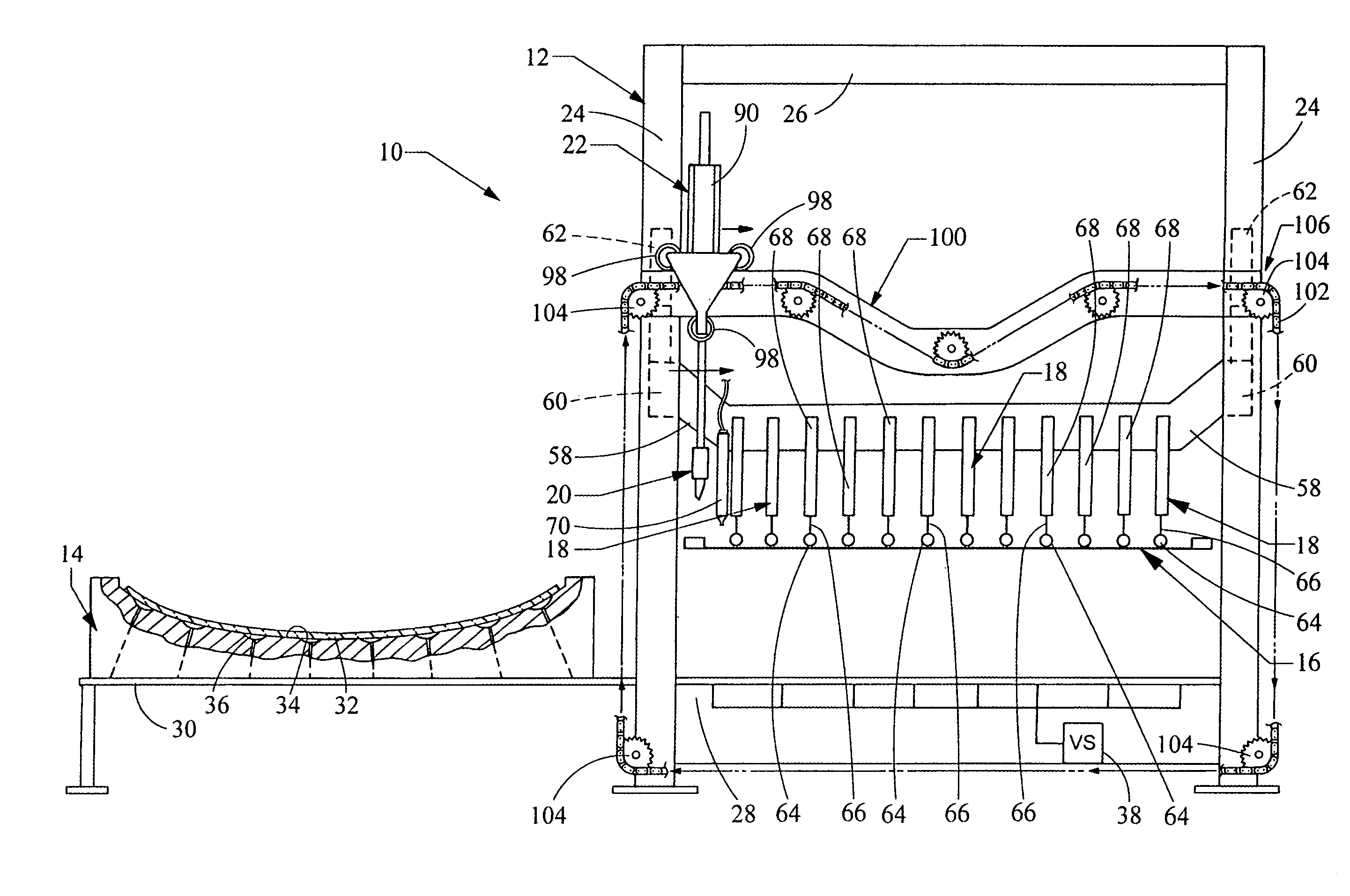

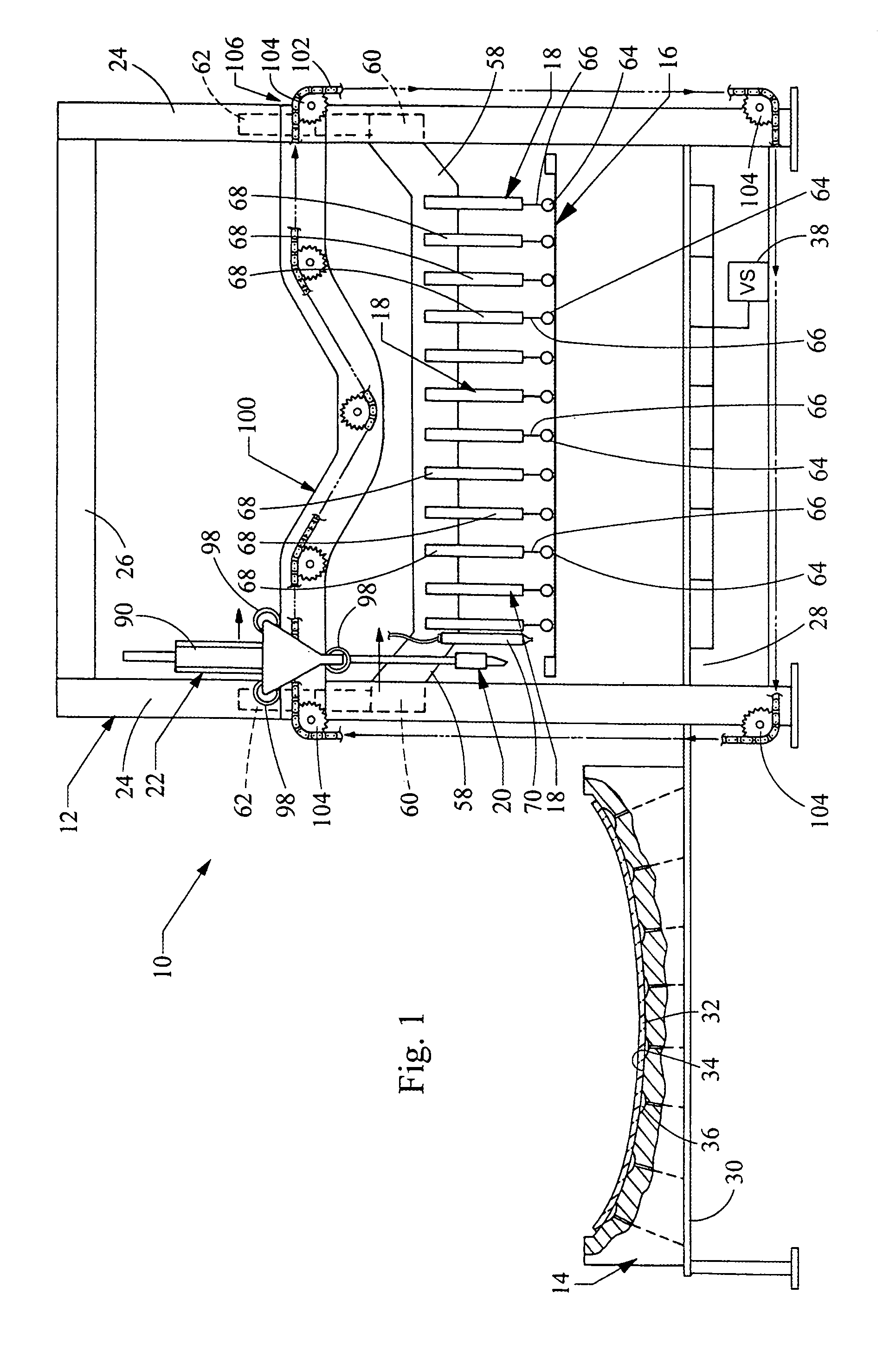

Screen printing apparatus

A screen printing apparatus for printing images onto a three dimensional surface of a substrate. The apparatus includes a screen formed of a flexible mesh material and having porous image portions that allows passage of a printing medium through it. A shaping assembly including a plurality of shapers that are movable between retracted and extended positions. In their extended positions, the shapers are engaged with the screen assembly and generally cause screen to generally conform to the three dimensional surface of the substrate. A squeegee, that is flexible and conformable to the three dimensional surface, is drawn along screen and forces at least some of the printing medium through the porous portion of the screen and onto the three dimensional surface.

Owner:EXATEC LLC

Print head assembly, screen printing system and method

A print head assembly (119) for printing a print medium (PM) onto a workpiece (W) through a printing screen (105) which includes a screen element having a pattern of printing apertures therein, the assembly comprising: first and second carriages (141) which are in use movably supported on respective ones of first and second guides (117); and first and second print head units (143, 145) which are mounted in adjacent, parallel relation to and between the carriages, wherein the print head units each comprise first and second print head actuators which are mounted on respective ones of the carriages, and a support member (151) which extends between the print head actuators, such as to be movable vertically thereby, and in use supports a printing element.

Owner:ASM ASSEMBLY SYST SINGAPORE PTE LTD

Non-contact screen printing method and printing device thereof

InactiveUS20100000428A1Improve evennessImprove stabilityInking apparatusLiquid surface applicatorsScreen printingSilicon

A screen printing method and a printing device thereof are revealed. The printing device consists of a printing table, a screen and a printing head. The printing head includes at least one driving member that moves upward and downward so as to drive at least one squeegee moving upward and downward. By precise control of relative distance between the screen and a printed substrate on a surface of the printing table, the squeegee applies a constant pressure to the screen for printing under the condition that the screen doesn't contact with the printed substrate. As to the printed substrate made from fragile and compact materials such as silicon wafer, the thickness and evenness of the ink are precisely controlled.

Owner:ATMA CHAMP ENTERPRISE

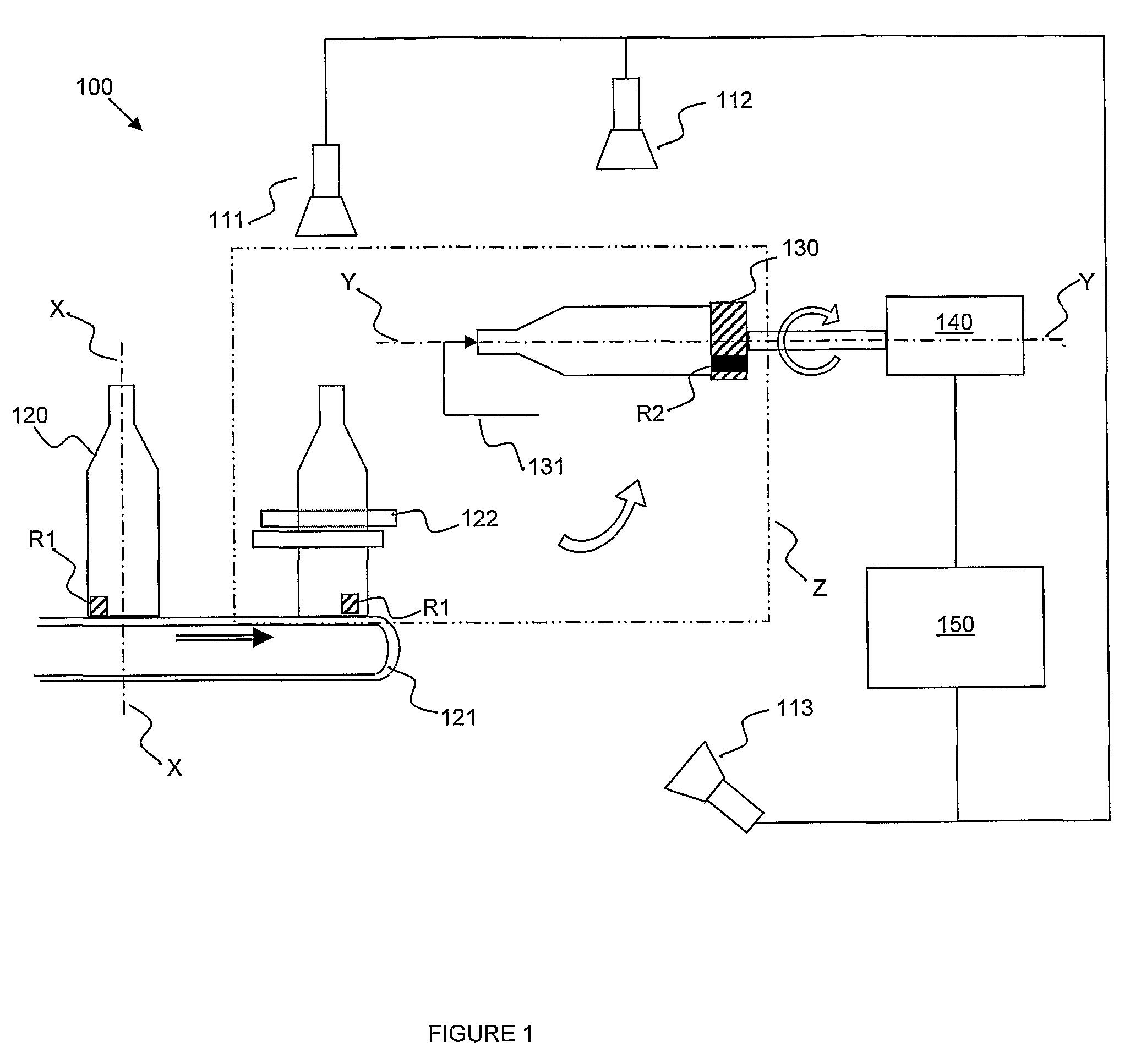

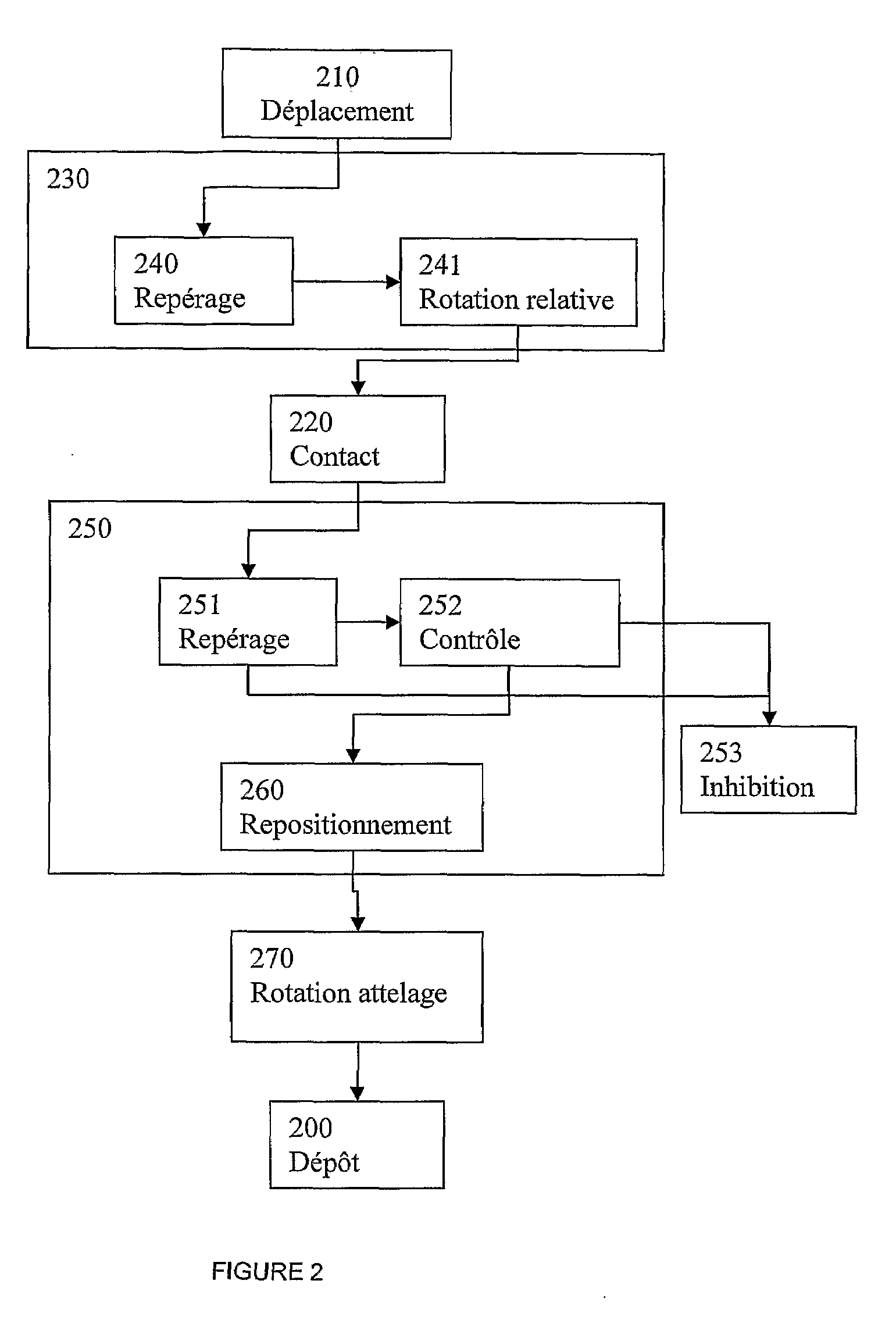

Method for Automatically and Sequentially Loading Objects and Corresponding Equipment

A method is provided for automatically and sequentially loading objects onto a feed system, each having a respective axis of rotation and respective first and second indices of rotation about the respective axes. The loading of each object onto the feed system causes an orientation in a predetermined relative position. The method consists in particular in selectively operating a relative rotation of the object and of the handling device about their axis of rotation to achieve the orientation.

Owner:SAVERGLASS

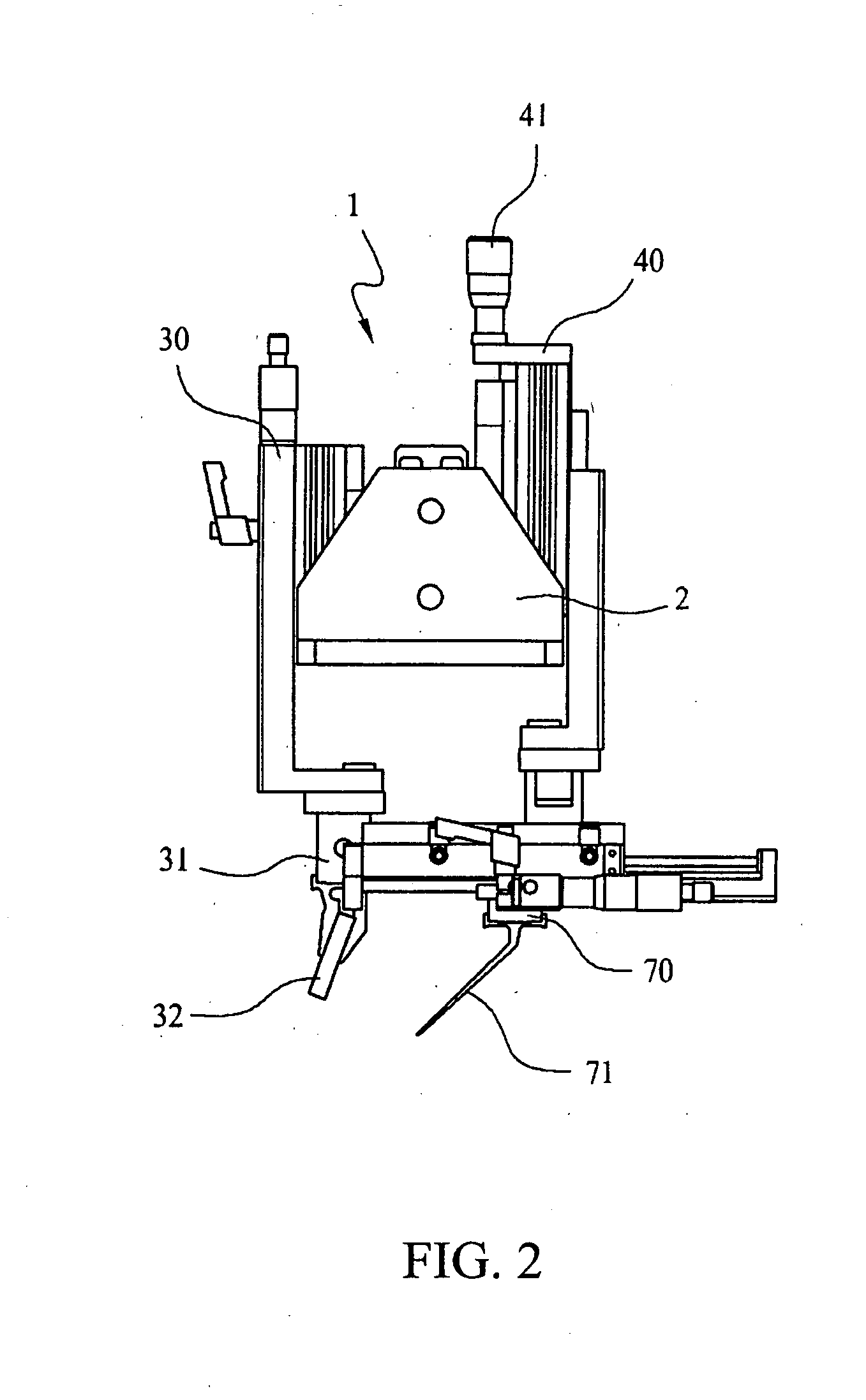

Ink residue lifting and transfer mechanism for screen printing machine

InactiveUS20070272100A1Adversely affect even thicknessReduce printing costsLiquid surface applicatorsInking apparatusTransfer mechanismPrinting press

An ink residue lifting and transfer mechanism is provided on a printing mechanism of a screen printing machine to pneumatically horizontally drive an ink reclaiming blade, so that the ink reclaiming blade is in complete contact with a scraper of the printing mechanism to hold ink residue after one printing in a space contained between the closely contacted scraper and the ink reclaiming blade, preventing the ink residue from dripping off from the scraper to the screen plate to smudge the printed object in the course of ink reclaiming. And, the ink residue is lifted and transferred by the closely contacted scraper and ink reclaiming blade to an initial position for reuse in the next printing without being wasted. Therefore, an improved accuracy of printing can be achieved at reduced cost.

Owner:ATMA CHAMP ENTERPRISE

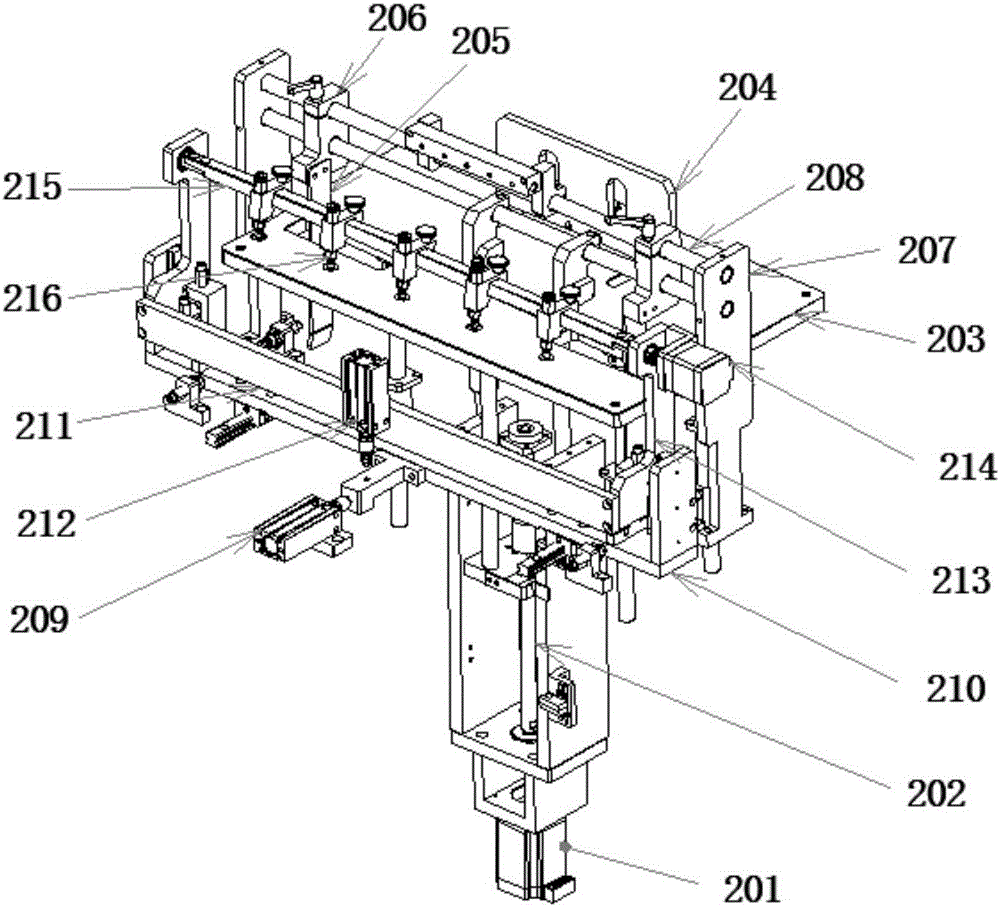

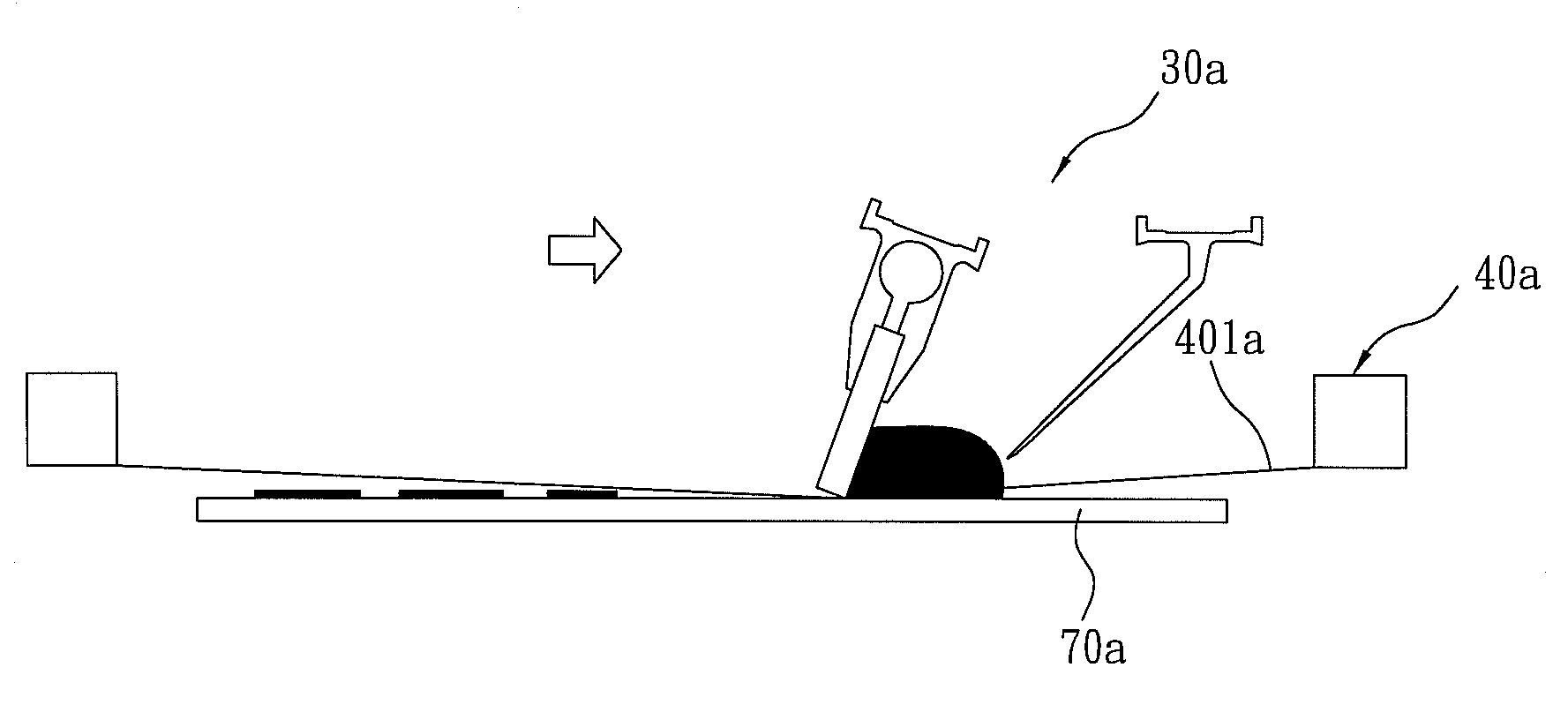

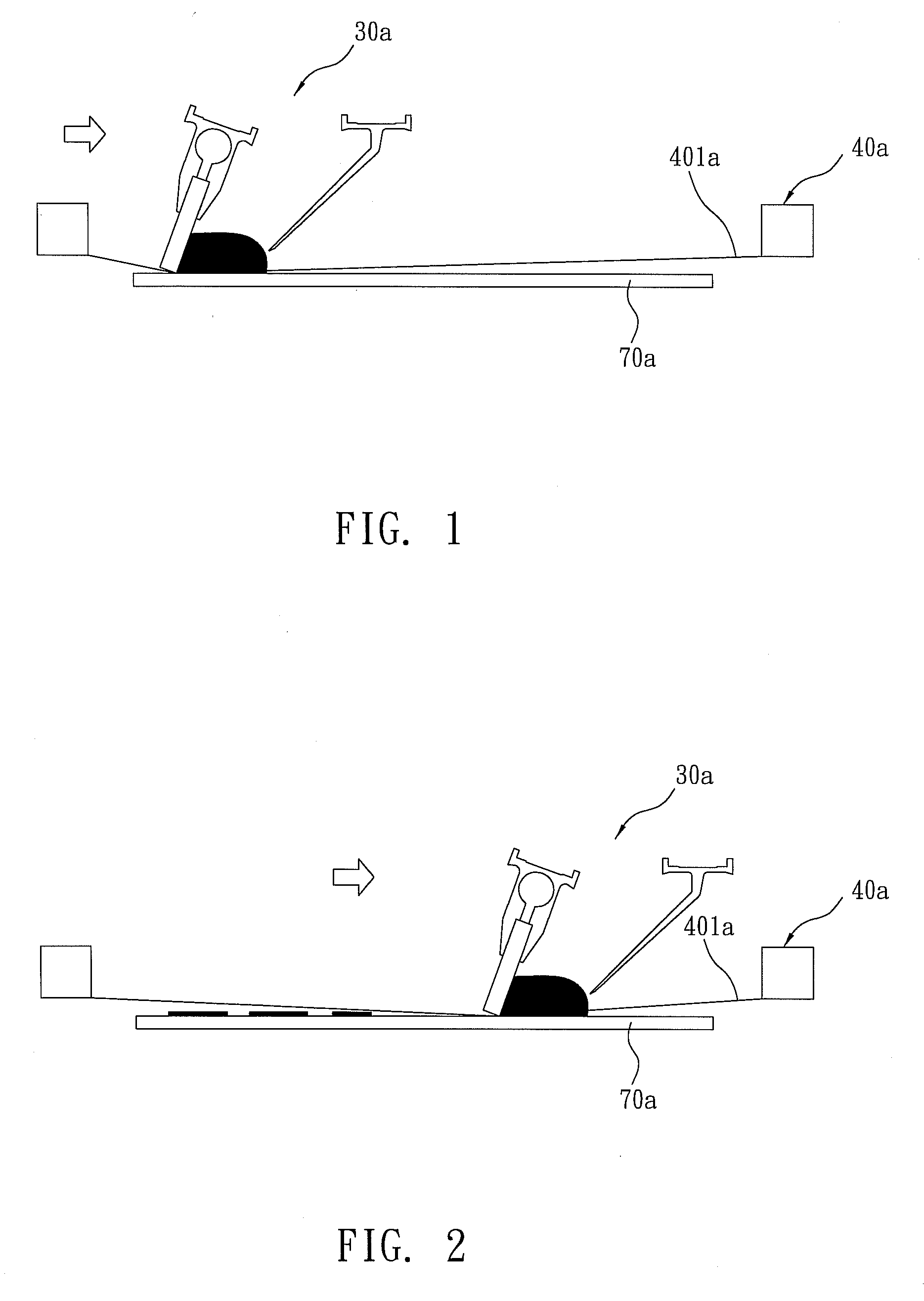

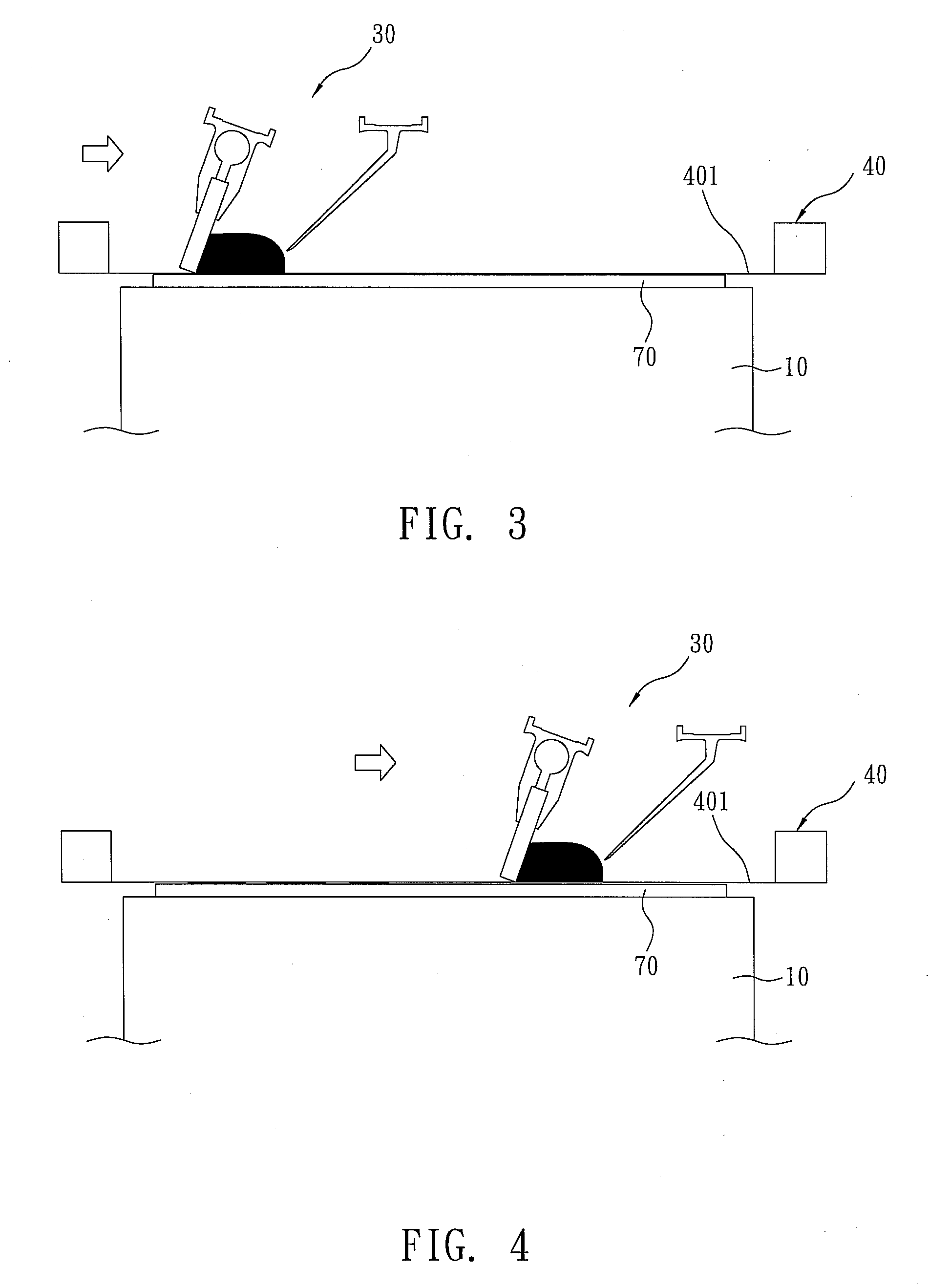

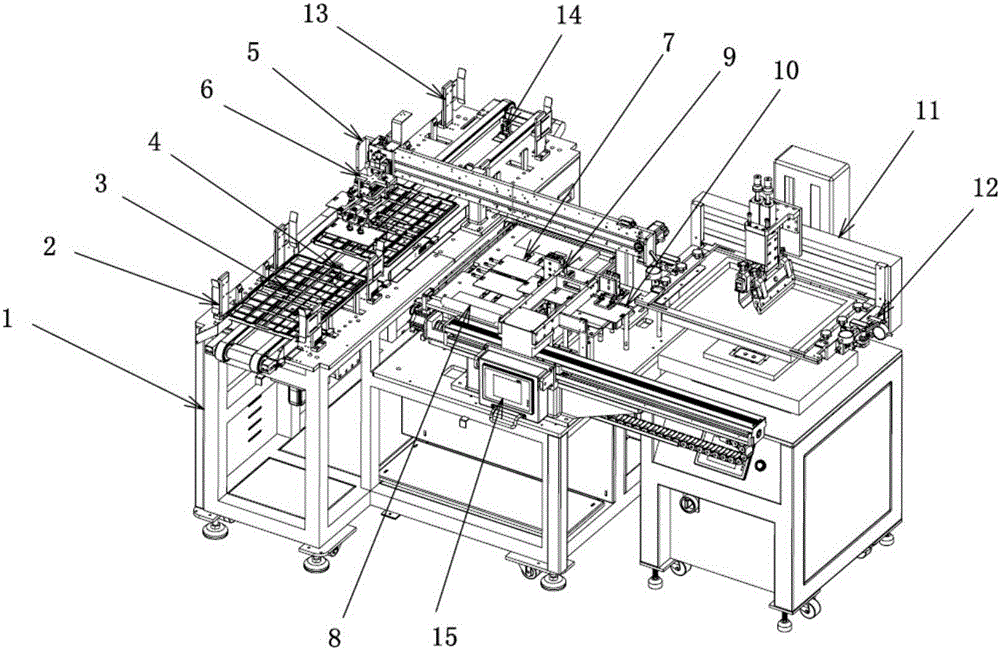

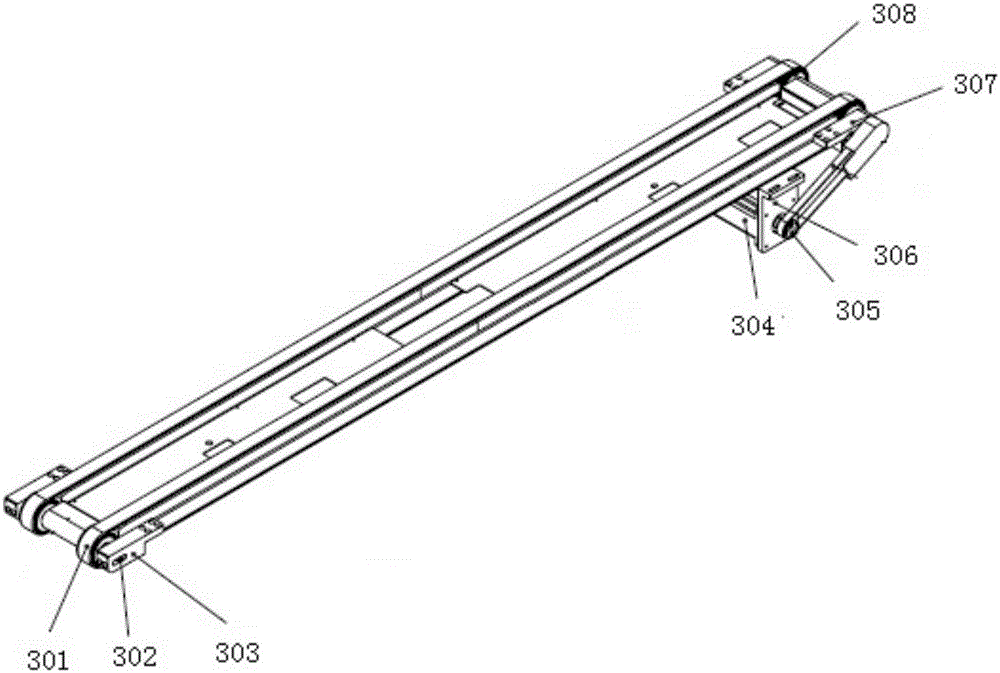

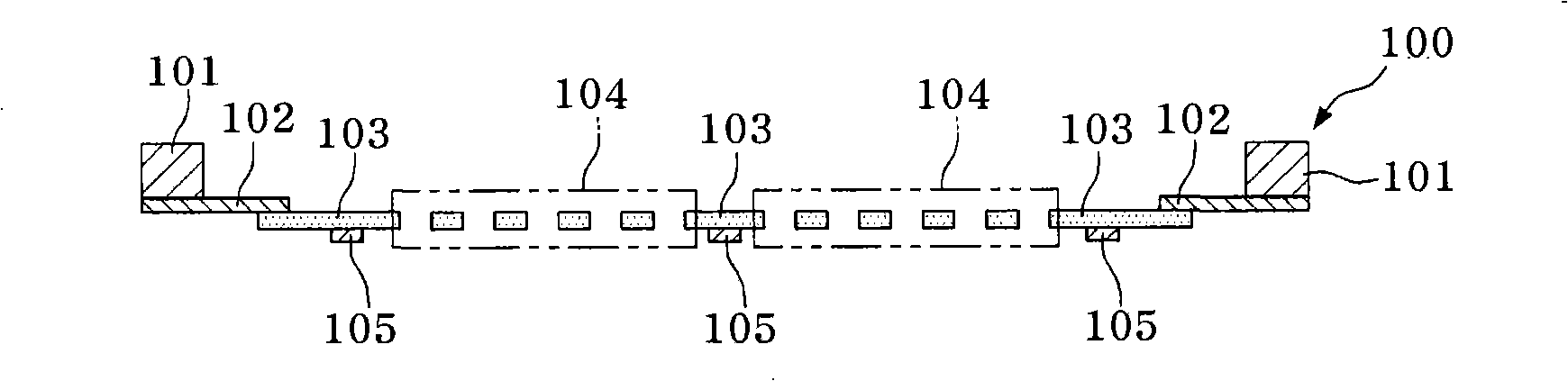

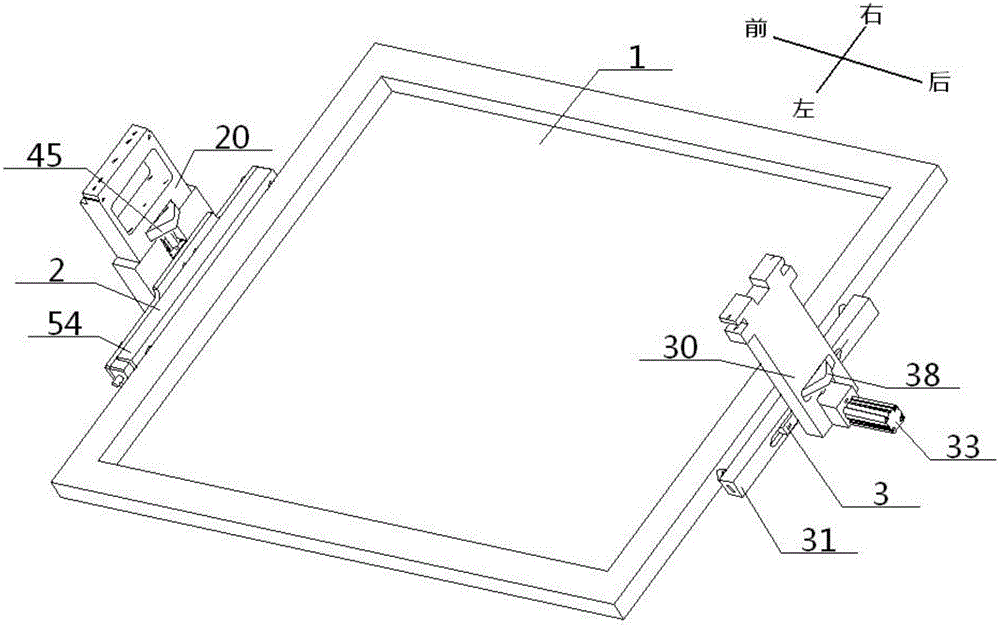

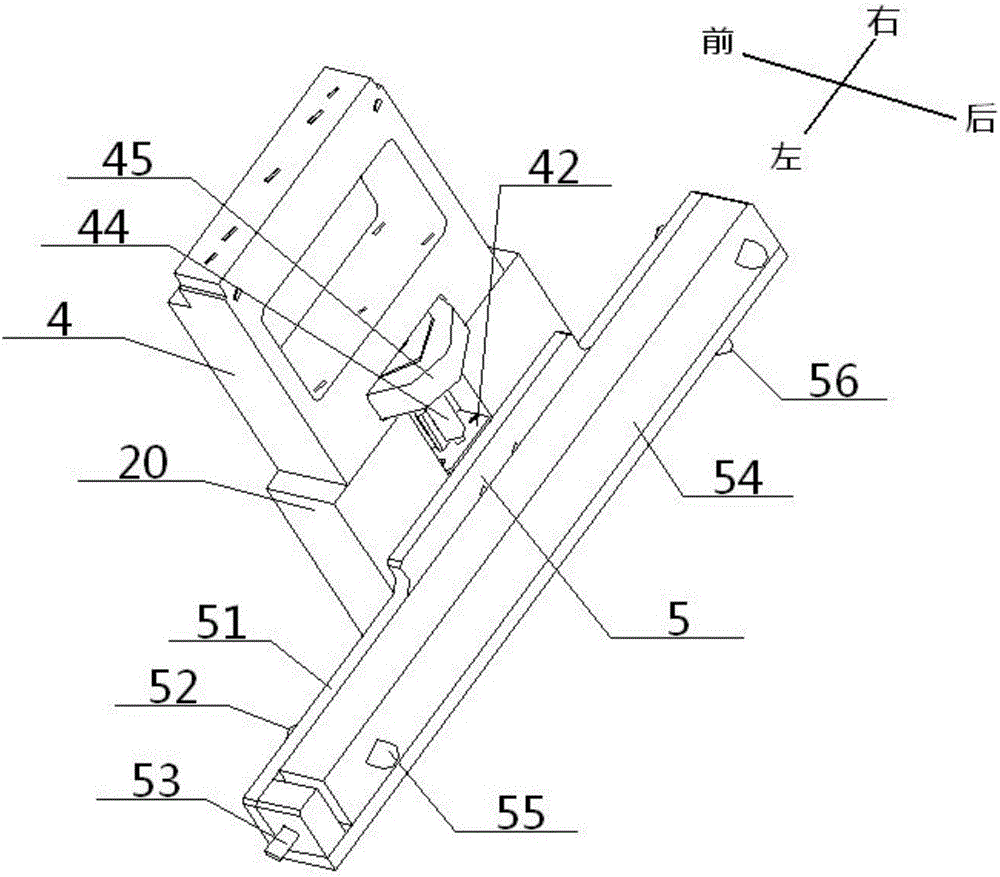

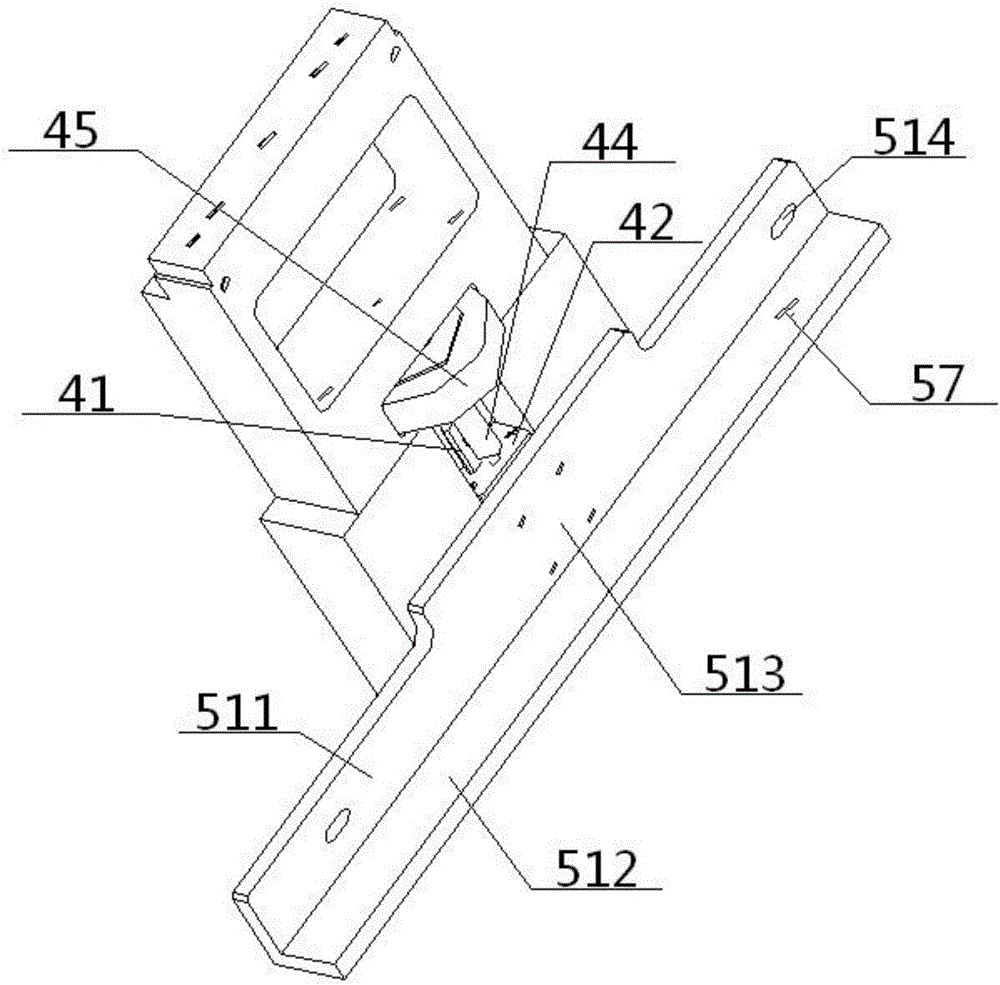

High-precision fully-automatic screen printing machine capable of printing double pieces in one process

InactiveCN106515201ADon't worry about the impactImprove printing accuracyScreen printersScreen printingScreen printingSemi automatic

The invention relates to the technical field of screen printing. A high-precision fully-automatic screen printing machine capable of printing double pieces in one process abuts on a semi-automatic screen printing machine and comprises a rack, a conveying line assembly, a supplying-receiving disc assembly and feeding mechanisms, wherein the conveying line assembly is located on the rack; the supplying-receiving disc assembly is located on a transport surface of the conveying line assembly and capable of being driven to move by the conveying line assembly, and a plurality of printing stocks placed in pairs are arranged in the supplying-receiving disc assembly; and the feeding mechanisms are located between the conveying line assembly and the semi-automatic screen printing machine, grab the printing stocks in the supplying-receiving disc assembly in pairs, and transport the printing stocks to a printing surface of the automatic screen printing machine. According to the high-precision fully-automatic screen printing machine capable of printing double pieces in one process, which is disclosed by the invention, an ingenious double-piece taking mechanism, an accurate one-process double-piece location mechanism and a precise double-piece loading mechanism are designed, so that the printing accuracy can be increased, and the screen printing efficiency can be doubled on the basis of increasing a small amount of cost for a single-piece semi-automatic transformed screen printing machine.

Owner:SHENZHEN TINVICO TECH CO LTD

Screen printing apparatus

ActiveUS7580558B2Tight toleranceAccurate printingScreen printersCharacter and pattern recognitionScreen printingEngineering

A screen printing apparatus and method for printing deposits of material onto a workpiece, the apparatus comprising an inspection station for determining a positional relationship of features on upper and lower surfaces of the workpiece. The inspection station comprises an imaging system for determining a positional relationship of features on upper and lower surfaces of the workpiece. The imaging system comprises at least two spaced imaging units for imaging features on an upper surface of the workpiece and at least two spaced imaging units for imaging features on a lower surface of the workpiece. A processing unit determines a positional relationship of the imaged features on the upper and lower surfaces of the workpiece. A printing station prints deposits of material onto the workpiece. Also described are a transport mechanism and an alignment system.

Owner:ASM ASSEMBLY SYST SINGAPORE PTE LTD

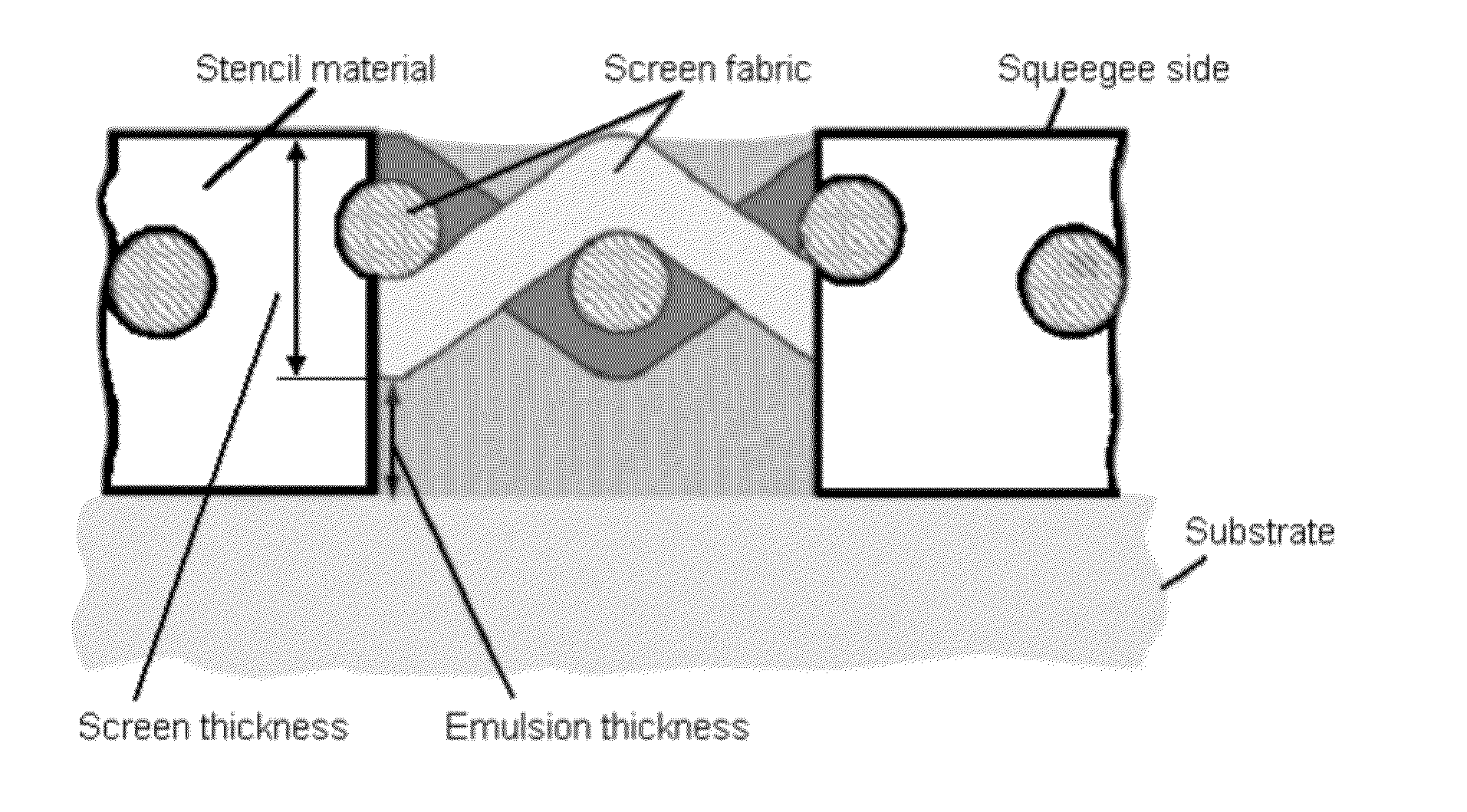

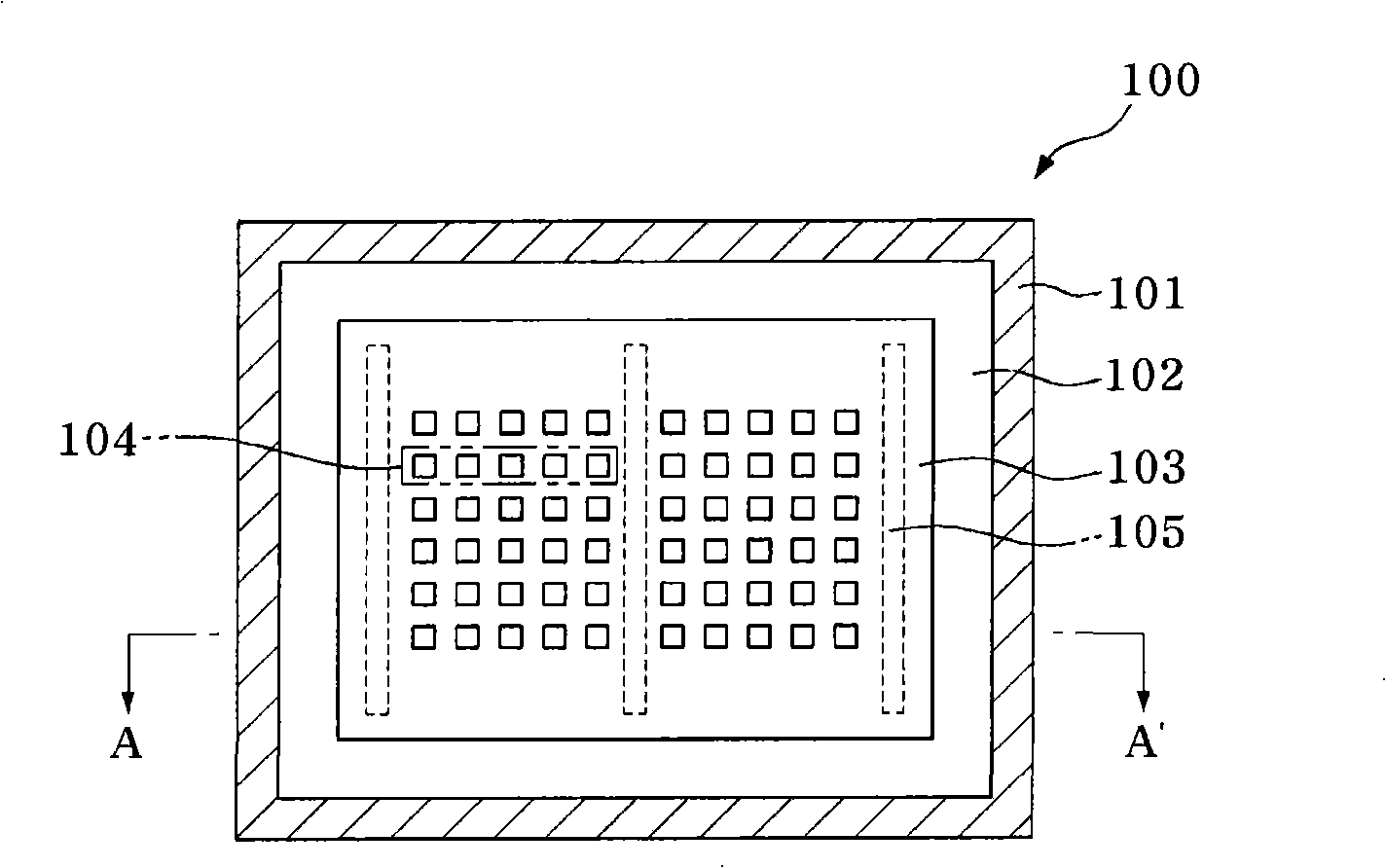

Mask for screen printing and screen printing method using the same

InactiveCN101352954ASolve the problem of low qualityPrinted circuit assemblingScreen printersScreen printingElectrical and Electronics engineering

This invention relates to a mask for screen printing, which includes a mask body composed of a plurality of pattern areas having holes for screen printing and a peripheral area surrounding the outside of the pattern areas; and a protrusion portion formed in the peripheral area of a back surface of the mask body, and to a screen printing method using the same.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

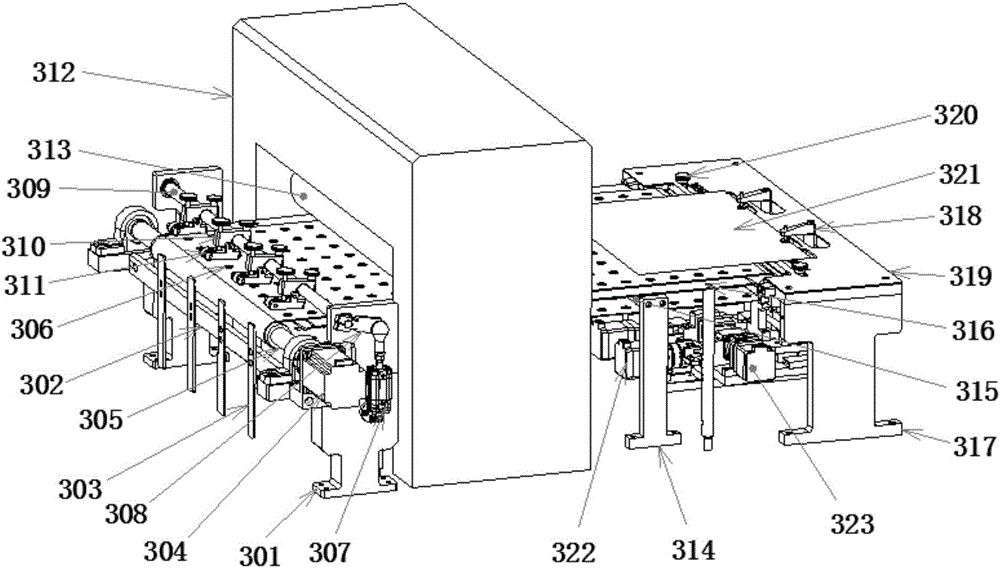

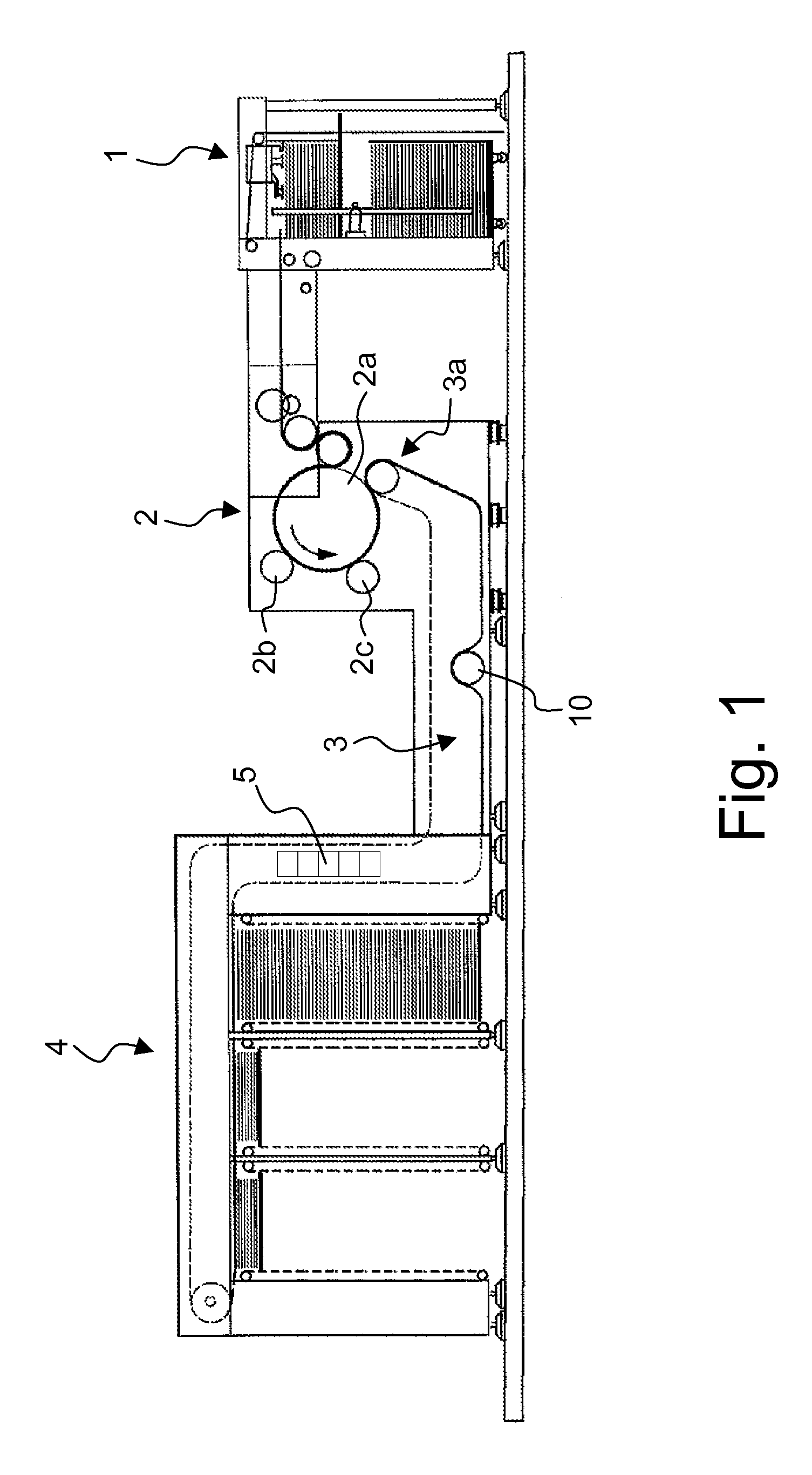

Automatic loading and unloading sheet screen printing machine

PendingCN110014723AThe relative position is the sameImprove printing accuracyScreen printersScreen printingScreen printingEngineering

The invention relates to an automatic loading and unloading sheet screen printing machine which comprises a loading device, wherein the loading device comprises a lifting seat for placing a to-be-printed sheet and further comprises a grabbing and feeding device, a printing platform and an unloading device; the grabbing and feeding device comprises a sucking disc mechanism, a lifting device and a linear driving device; the lifting device comprises a seat body; a lead screw lifting mechanism is arranged on the seat body; the lead screw lifting mechanism and a support arm retainer body are assembled on a linear sliding rail in a sliding manner in the direction of the linear sliding rail; the seat body is driven by a linear driving mechanism; the printing platform comprises a printing rack anda loading platform on the printing rack; and a first positioning component and a second positioning component are arranged on two adjacent sides of the loading platform.

Owner:郑州丝珂瑞科技有限公司

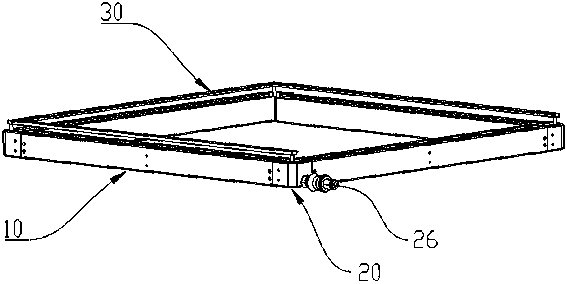

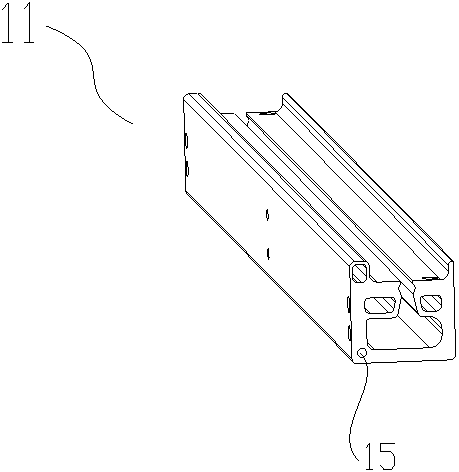

Rapid and simple frame alignment device for silk screen frame

ActiveCN106494075ALarge adjustment rangeEasy to adjustScreen printersScreen printingMechanical engineeringWire mesh

Owner:网都河北科技服务有限公司

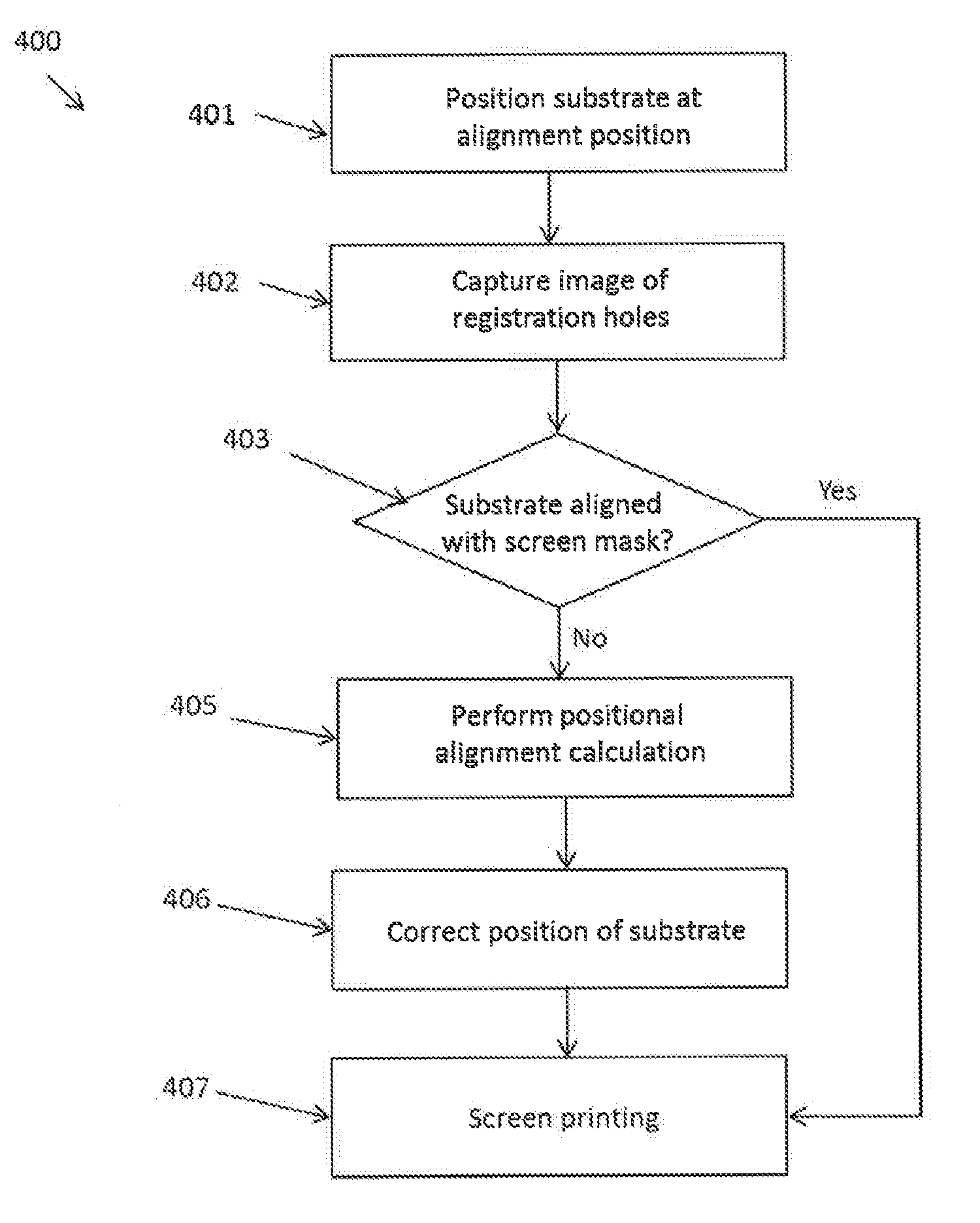

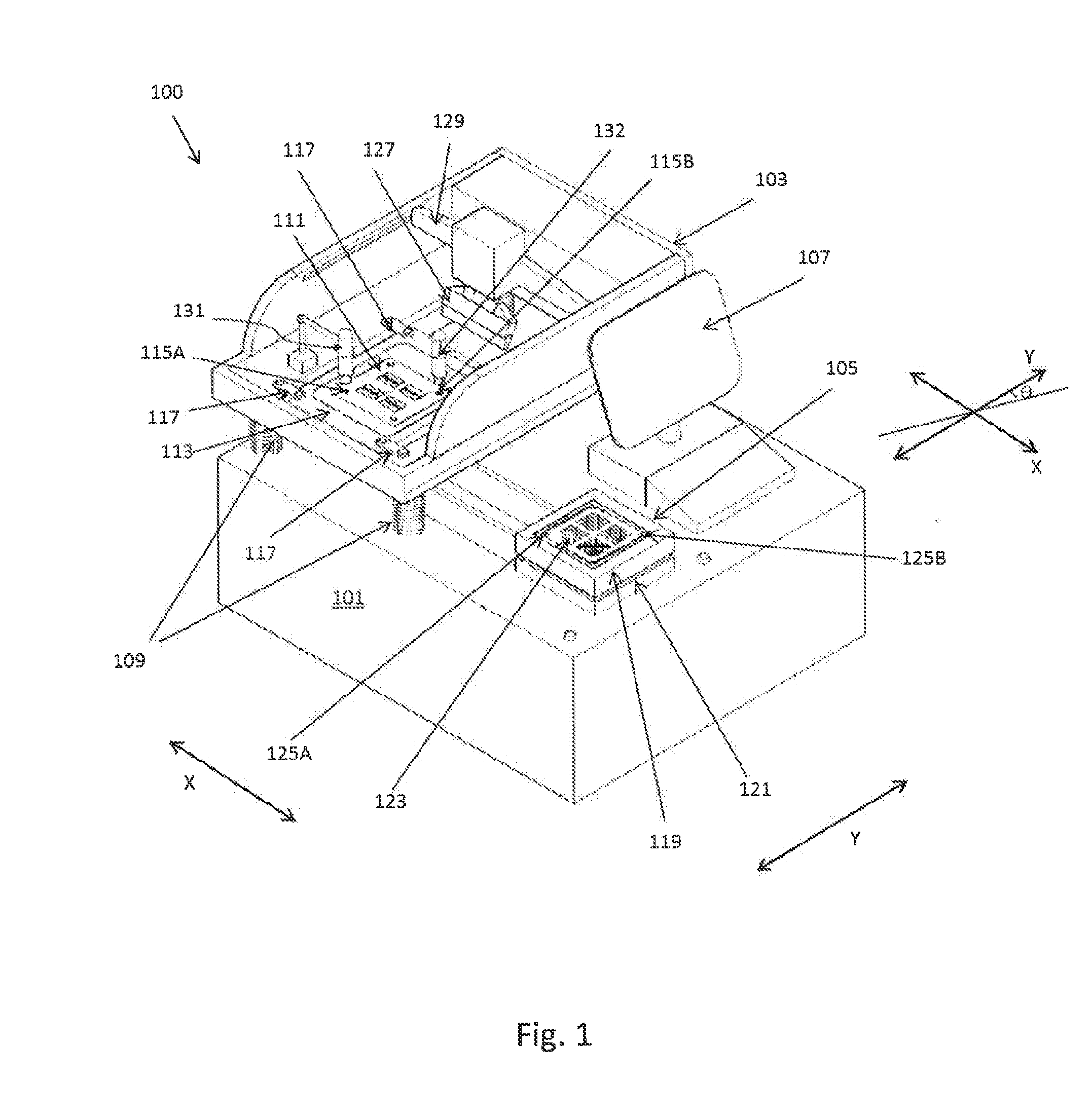

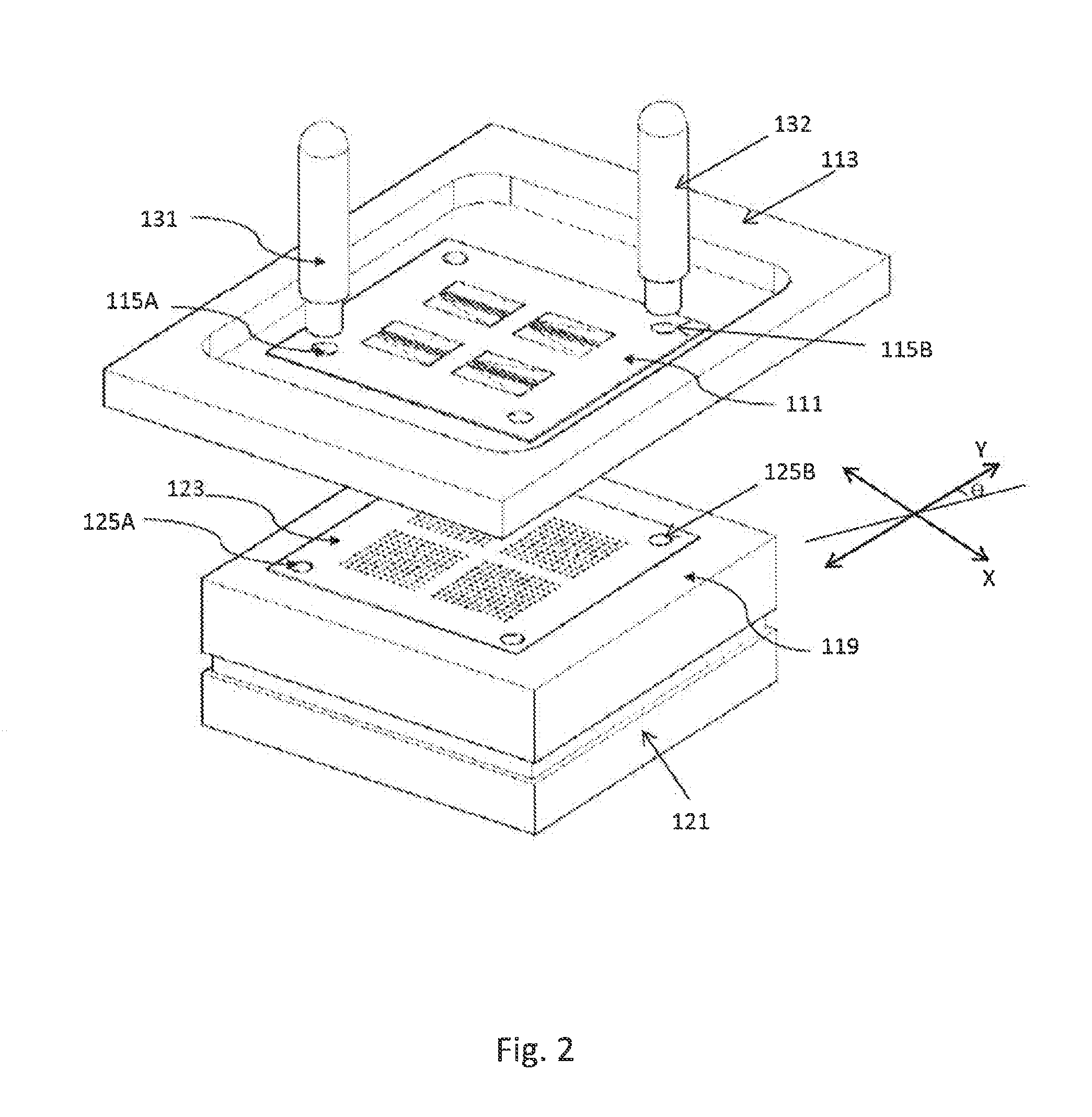

Screen printing system with positional alignment

ActiveUS20140261027A1Reduce setup timeImprove productivity and efficiencyLiquid surface applicatorsScreen printersScreen printingEngineering

Screen printing system with positional alignment for aligning a substrate with a screen mask. The substrate and the screen mask have two registration holes for facilitating the positional alignment. The positional alignment method includes calculating alignment values for correcting the position of the substrate based on the determined offsets between the registration holes of the substrate and the screen mask. The position of the substrate is corrected based on the calculated alignment values so that registration holes of the substrate are vertically aligned with the registration holes of the screen mask.

Owner:TELEKOM MALAYSIA BERHAD

Bearing device of silk screen

PendingCN108437614AEasy to replaceAvoid damageScreen printersScreen printingEngineeringMechanical engineering

Owner:SHENZHEN MENGRUI ELECTRONICS CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com