Automatic loading and unloading sheet screen printing machine

A technology of automatic loading and unloading and screen printing machine, which is applied in the direction of screen printing machine, printing machine, screen printing, etc., can solve the problem that the position cannot be guaranteed accurately, and achieve the effect of improving printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

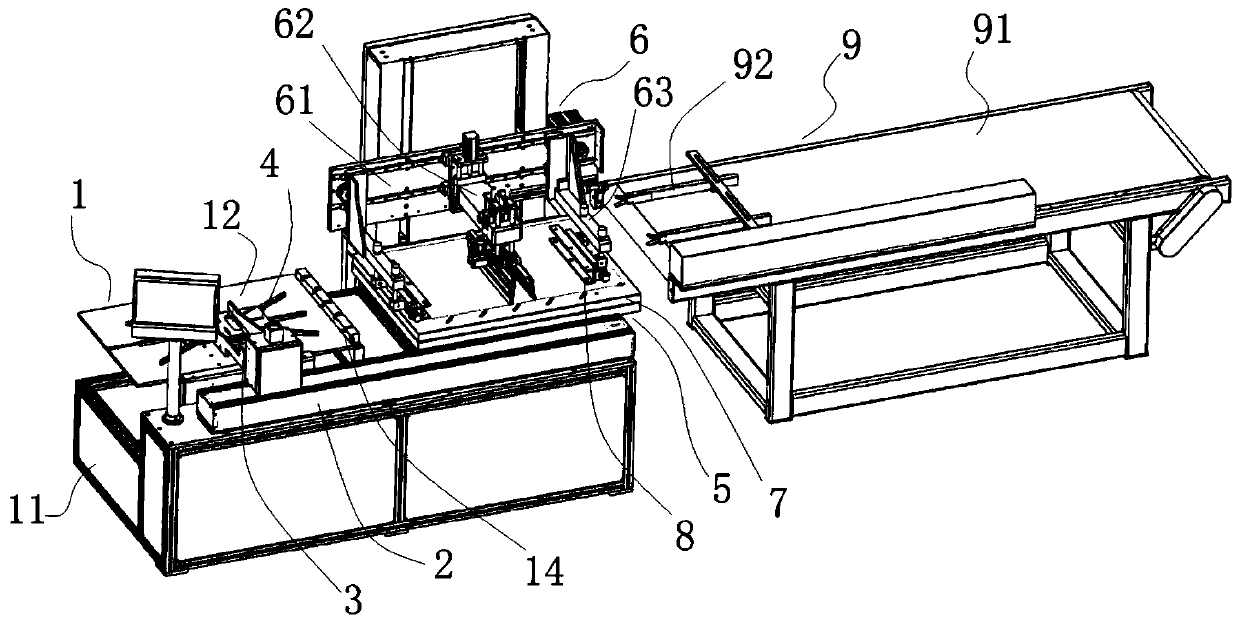

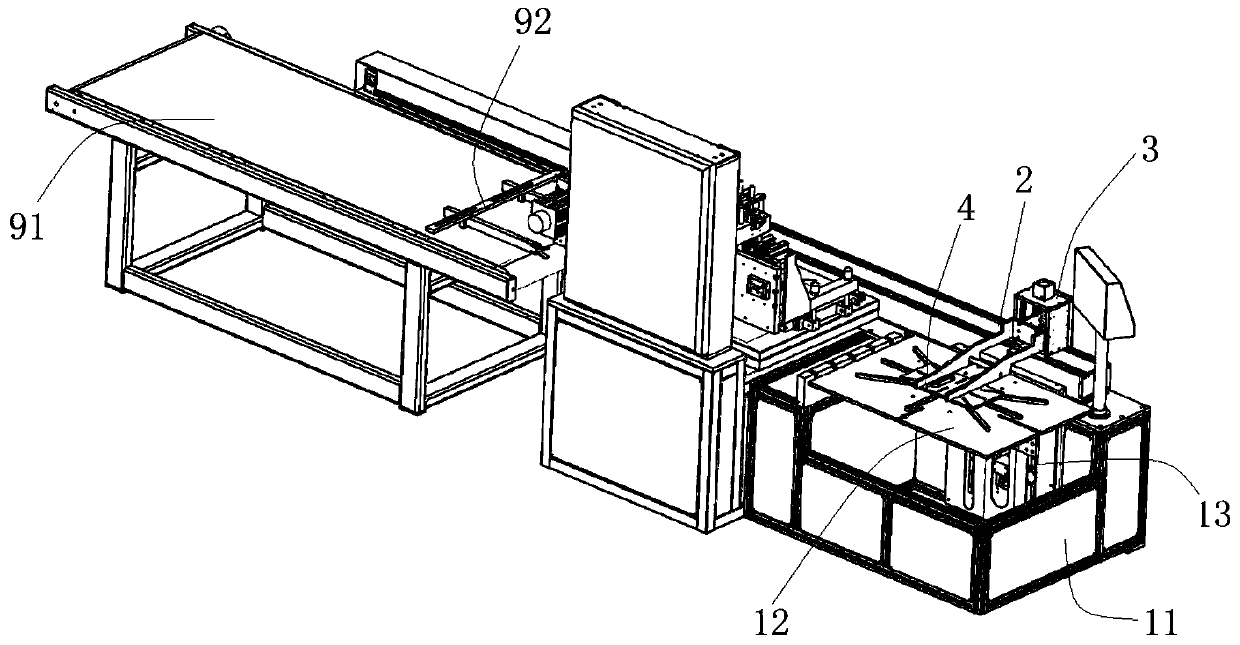

[0040] like Figure 1-Figure 11 As shown, the automatic loading and unloading sheet material screen printing machine includes a feeding device 1 , a printing platform 5 and a feeding device 9 arranged from left to right.

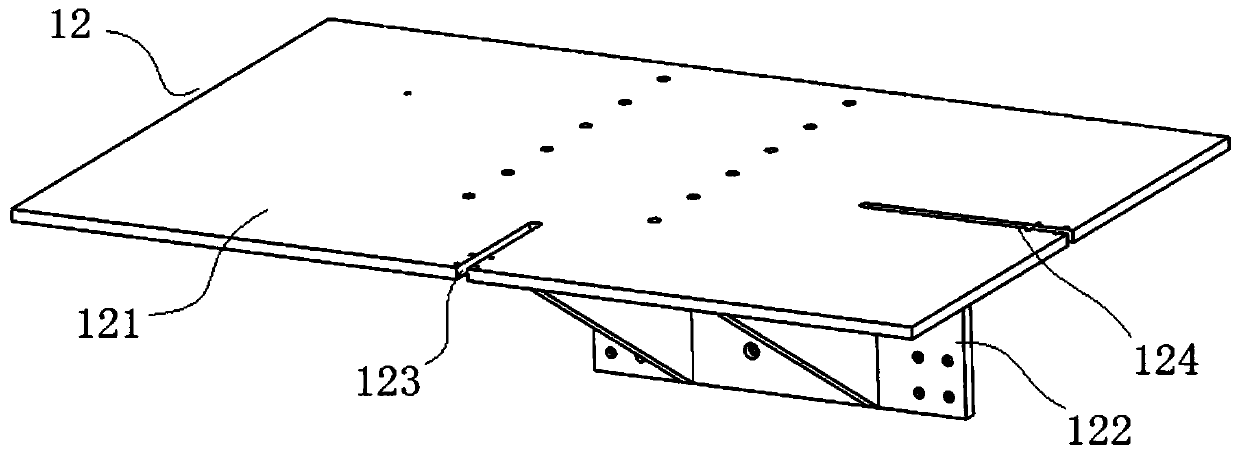

[0041] The feeding device 1 includes a feeding frame 11 and an elevating seat for placing sheets to be printed. The elevating seat is arranged on the feeding frame 11 . The lifting base includes a lifting board 12, and the lifting board 12 includes a horizontal board 121 and a vertical board 122, and the horizontal board 121 is used for placing a stack of sheets. The vertical board body 122 is slidably assembled on the feeding frame 11 along the up and down direction, and the feeding frame 11 is provided with an adapted vertical slide rail 13, and the vertical board body 122 is driven by a feeding screw. The lead screw is driven by a servo motor. The servo motor controls the intermittent fixed-height movement of the lifting seat, that is, when the top shee...

Embodiment 2

[0063] The automatic loading and unloading sheet material screen printing machine of this embodiment is different from Embodiment 1 in that the loading device 1, printing platform, and unloading device are arranged from right to left, that is, the direction of loading and unloading is exactly the same as that of the embodiment 1 instead. The distribution positions of the first positioning component and the second positioning component of the corresponding loading platform are adjusted. like Figure 12 , is a schematic diagram reflecting the position change of the sheet during the positioning process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com