Simple construction pedestal for steel pipe painting and using method thereof

A technology of steel pipe brush and pedestal, applied in the direction of spraying device, etc., can solve the problems of damage to the surface coating of steel pipe, difficult manual operation, unqualified anti-corrosion layer, etc., and achieve the effect of reducing the space occupancy rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

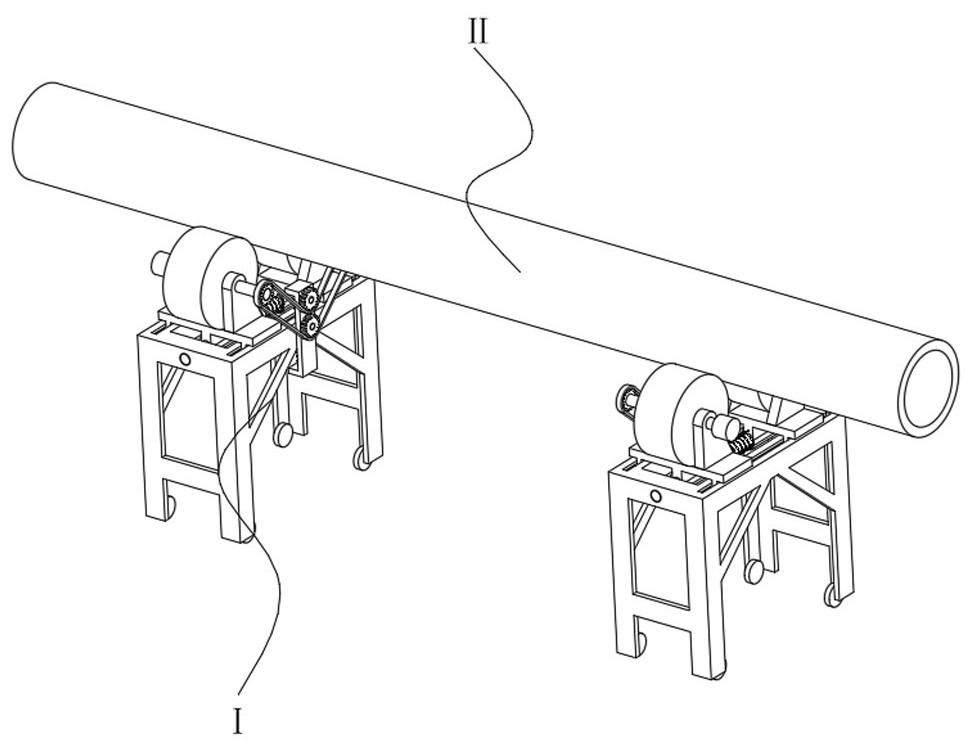

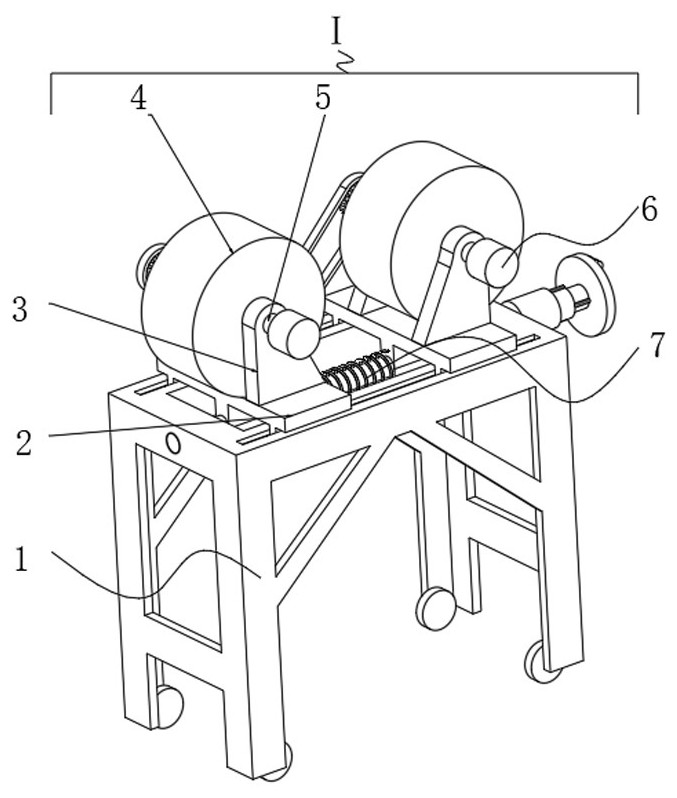

[0047] A simple construction platform for painting steel pipes, such as figure 1 , 2 As shown, it includes two sets of pedestal modules I for supporting the steel pipe II to be coated. The pedestal module I includes a support structure 1 and two supports 2 symmetrically arranged on the top of the support structure 1. The top outer wall of the support 2 is welded with a support plate 3. The inner wall of the support plate 3 is rotatably connected to the rubber roller assembly 4 through the shaft one 5, and the outer wall of one of the shaft one 5 is connected to the crank assembly one 6.

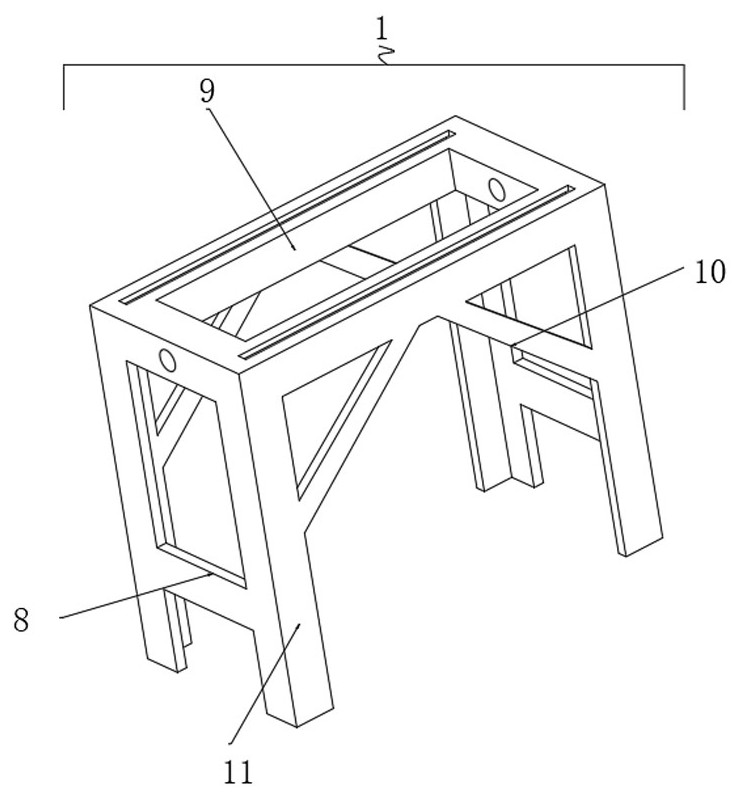

[0048] In order to solve the support problem; such as image 3 As shown, the support structure 1 includes four supporting legs 11 supported on the ground, and the top outer walls of the four supporting legs 11 are welded with the same rectangular seat 9, wherein the opposite sides of every two supporting legs 11 are welded with reinforcing ribs-8 , The opposite side of the leg 11 and the re...

Embodiment 2

[0053] A simple construction platform for painting steel pipes, such as Figure 5 As shown, in order to solve the problem of space occupation; this embodiment makes the following improvements on the basis of embodiment 1: crank assembly one 6 and crank assembly two 16 have the same structure, specifically including an end section one 17, at least one telescopic section 18 and an end section two 21, the outer walls of the expansion joint 18 and the end section two 21 are provided with key-shaped protrusions 20, and the inner walls of the expansion joint 18 and the end section one 17 are provided with key-shaped grooves 19, and the key-shaped grooves 19 and The key-shaped protrusions 20 are connected by a gap fit sliding connection, and the outer wall of the end section 21 is fixed with a turntable 24 by bolts. A crank 25 is fixed by bolts, and two rubber clamps 26 are fixed on the outer wall of the rotating disk 24 by bolts, and the distance between the two rubber clamps 26 is ...

Embodiment 3

[0056] A simple construction platform for painting steel pipes, such as figure 1 , 2 , 6, in order to solve the problem of adjusting the position of the support point; this embodiment makes the following improvements on the basis of embodiment 2: the bottom outer wall of the leg 11 is provided with a universal wheel with brake, and the rubber roller assembly 4 includes a rubber wheel base 27 And two receiving grooves 28 symmetrically opened on the inner wall of the rubber wheel base 27, the inner walls of the receiving grooves 28 are rotationally connected with the reversing rubber wheels 29 arranged linearly through the shaft two 30.

[0057] When this embodiment is in use, since the steel pipe needs to be hoisted into the device, the hoisting rope is easy to swing, and it is difficult to accurately align the device with the planned support point of the steel pipe. However, this device improves the rubber roller assembly 4, Based on the rubber wheel base 27, linearly arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com