Patents

Literature

72results about How to "The relative position is the same" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

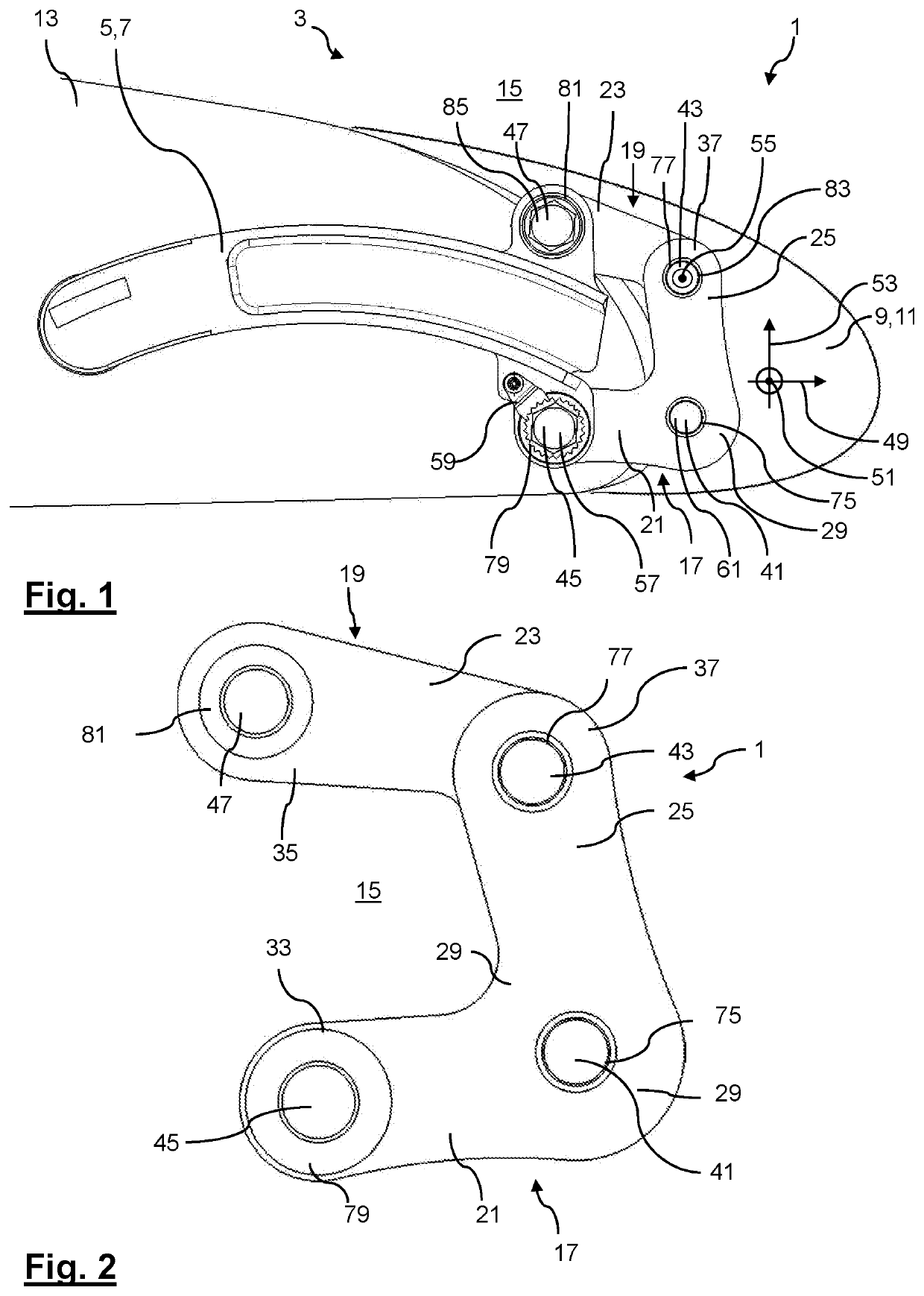

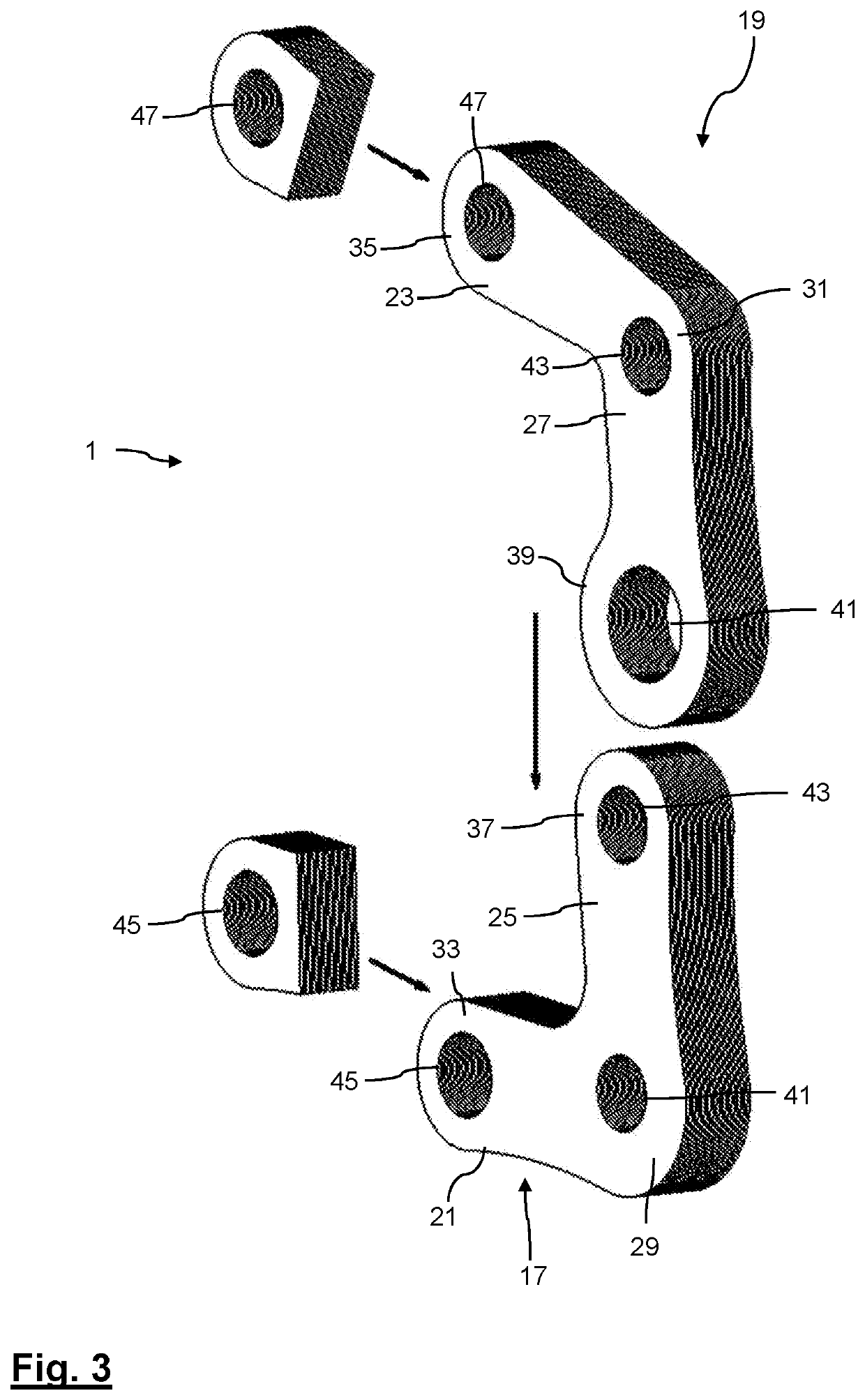

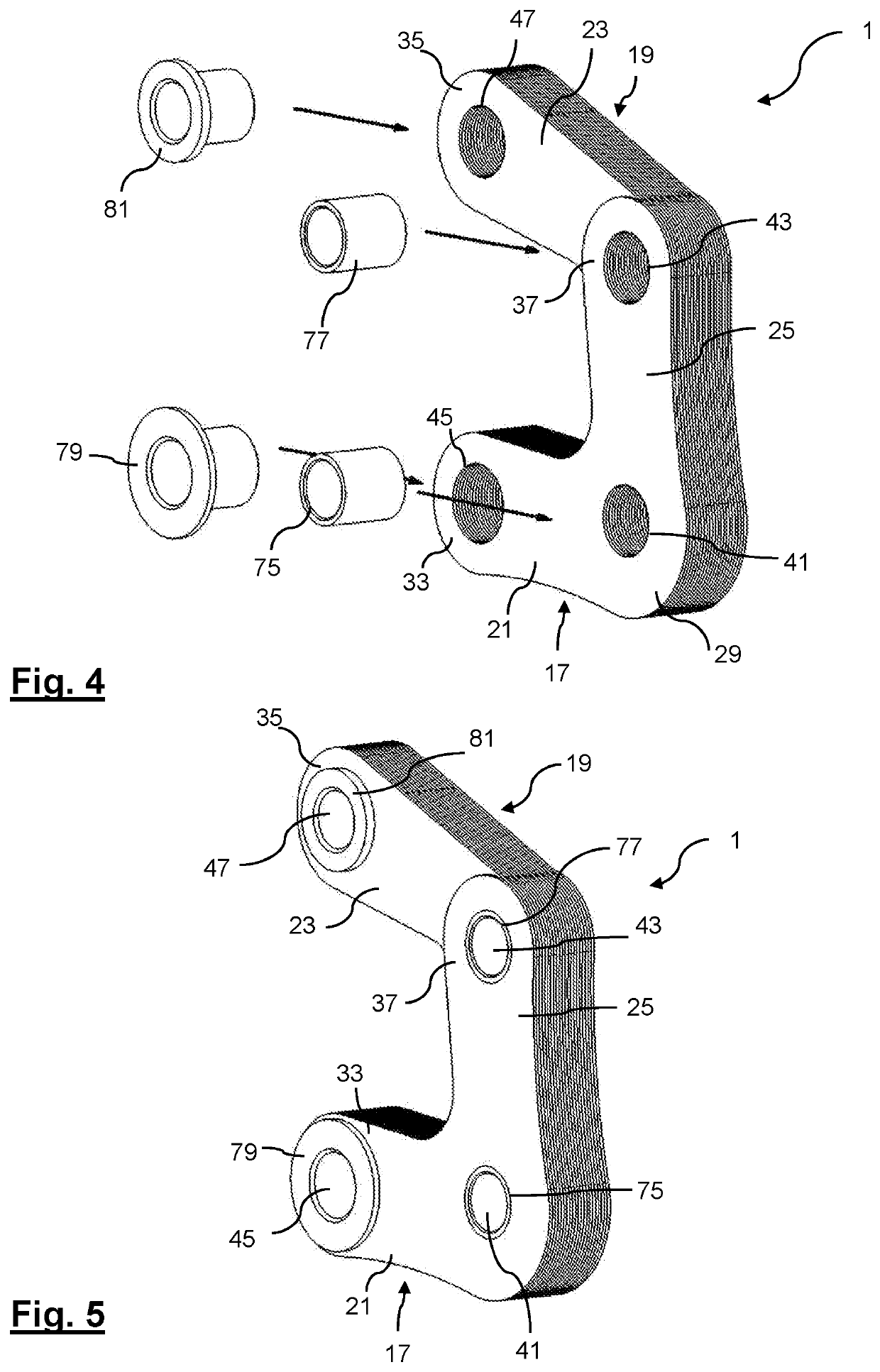

Hearing aid adapted for discrete operation

InactiveUS7221769B1Accidental activation of be prevent and minimisePrecise positioningEar supported setsHearing device specific toolsPotentiometerUser assistance

The present invention relates to a hearing aid, which allows a hearing aid user to discretely operate his / her hearing aid by applying a force to a portion of the ear carrying the hearing aid. A number of different functions of the hearing aid, such as turning a battery supply on / off, adjusting a volume control, selecting a particular pre-programmed listening program, etc., may be provided in a hearing aid according to the present invention—all without directly engaging the hearing aid or switches or potentiometers thereof. Furthermore, if the hearing aid is adapted for use within the ear canal, the present invention may provide user assistance so to allow simple and convenient removal of the aid from the ear canal.

Owner:SONION ROSKILDE

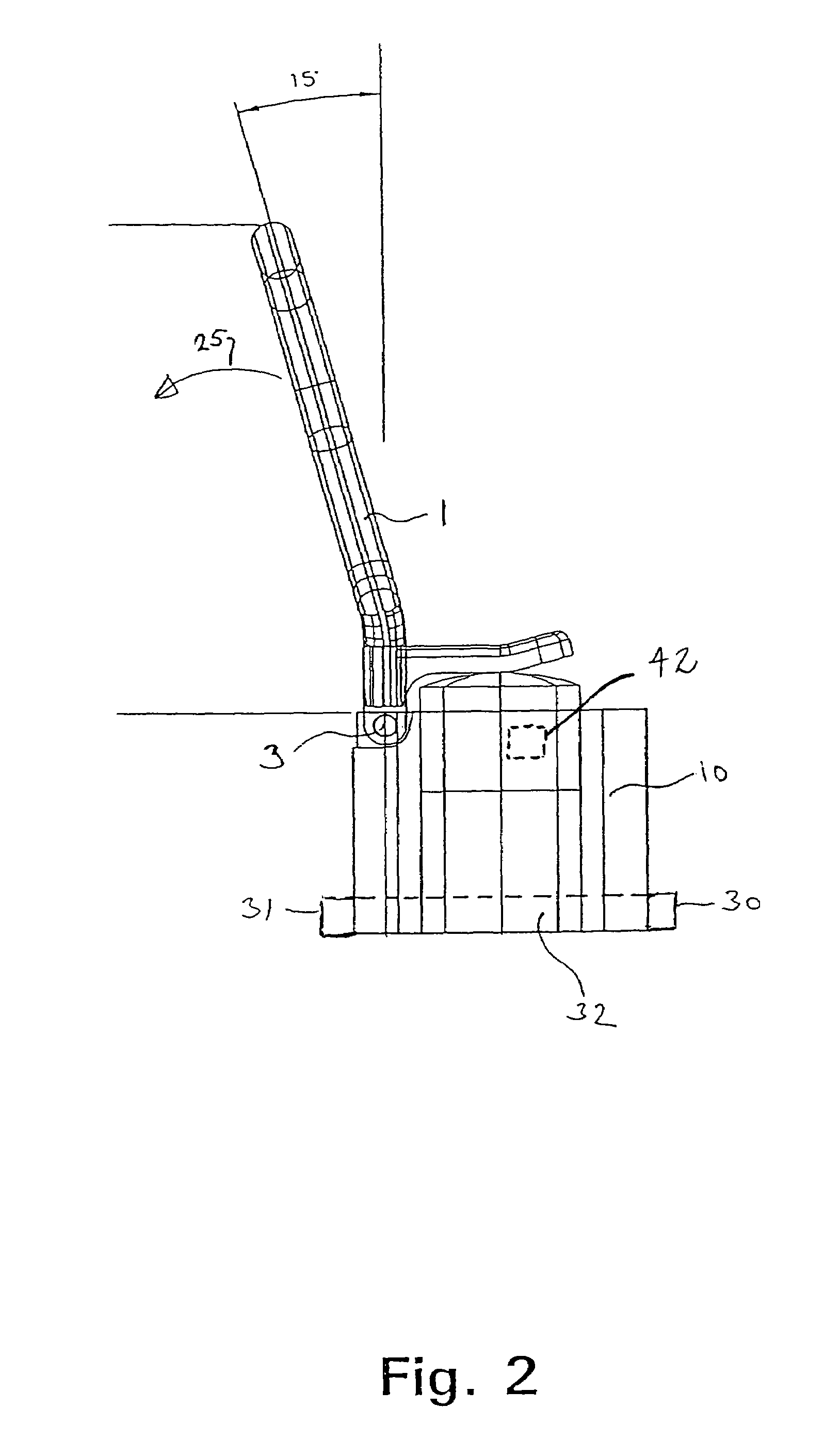

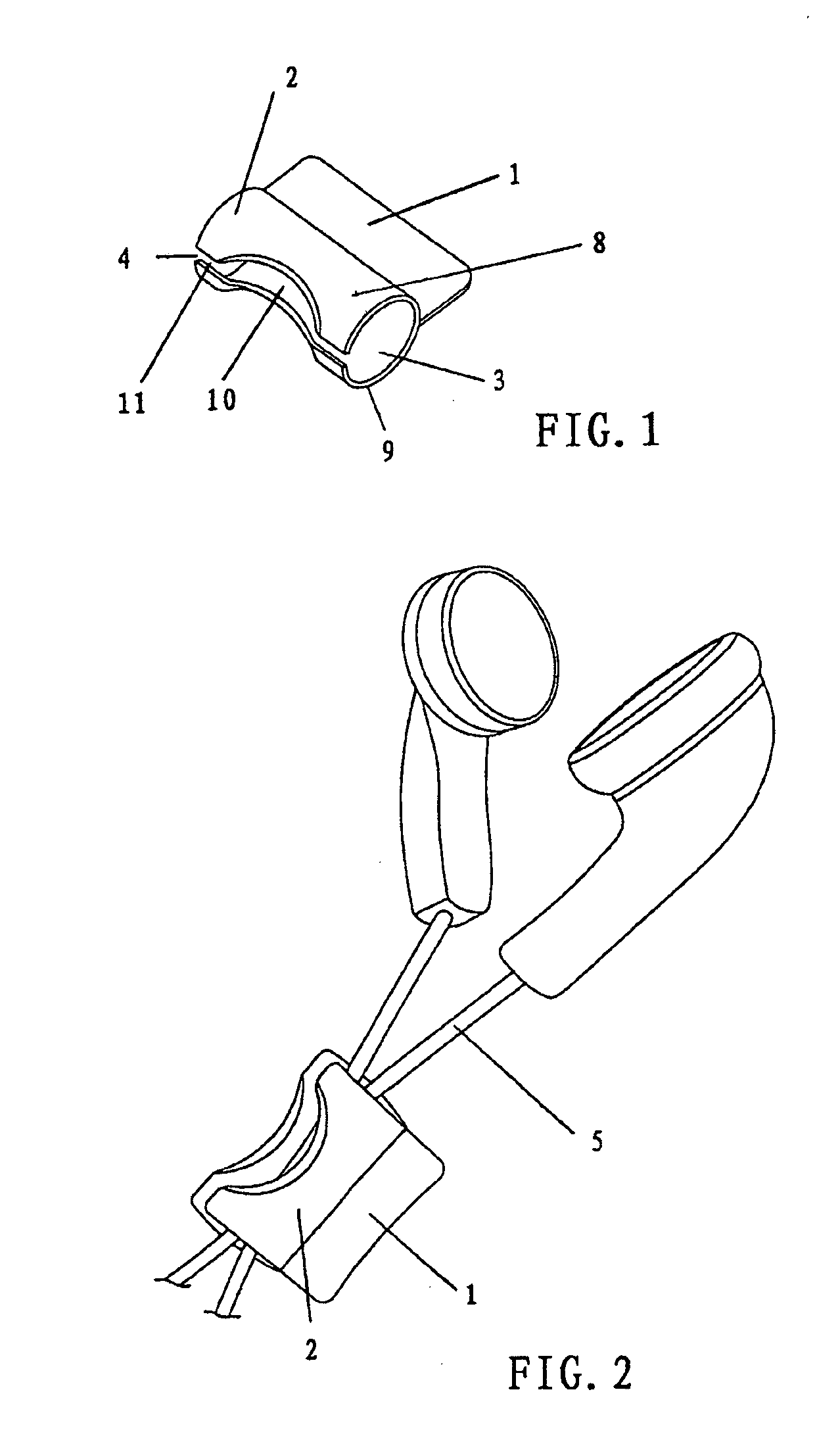

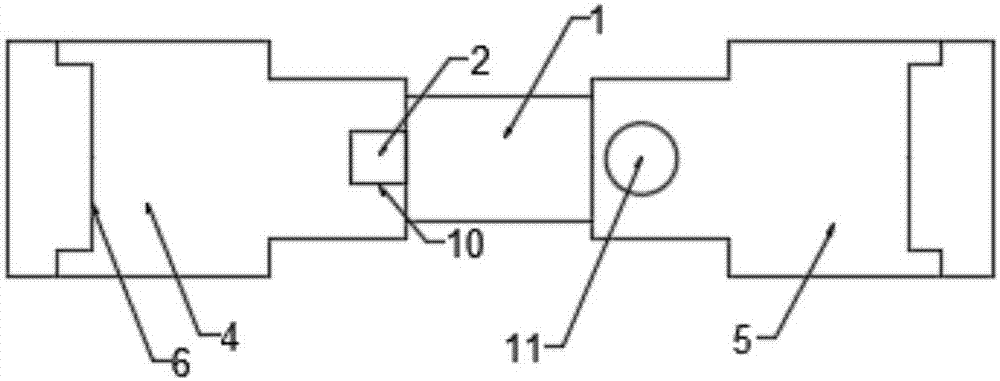

Fastener for cord

InactiveUS20080289151A1Convenient to useEasy to useSnap fastenersTravelling carriersFastenerEngineering

The present utility model relates to a fastener for cord, wherein said fastener comprises a base body 1 and a holding portion 2 connected thereto, the holding portion 2 has a through hole 3 for receiving said cord, a slit 4 is arranged in the side wall of the through hole, and the side wall of the through hole is separated into a first part and a second part by means of said slit. With the fastener, the cord of an article can be fastened so as to retain if in the same position. In this way, even if the cord is relatively long, it can be simply fastened by means of the fastener to retain its stretched state, and it needn't to be rolled up while being out of use. Therefore, it is much more convenient for the users to use the cord again.

Owner:LIFUGAO HONGKONG

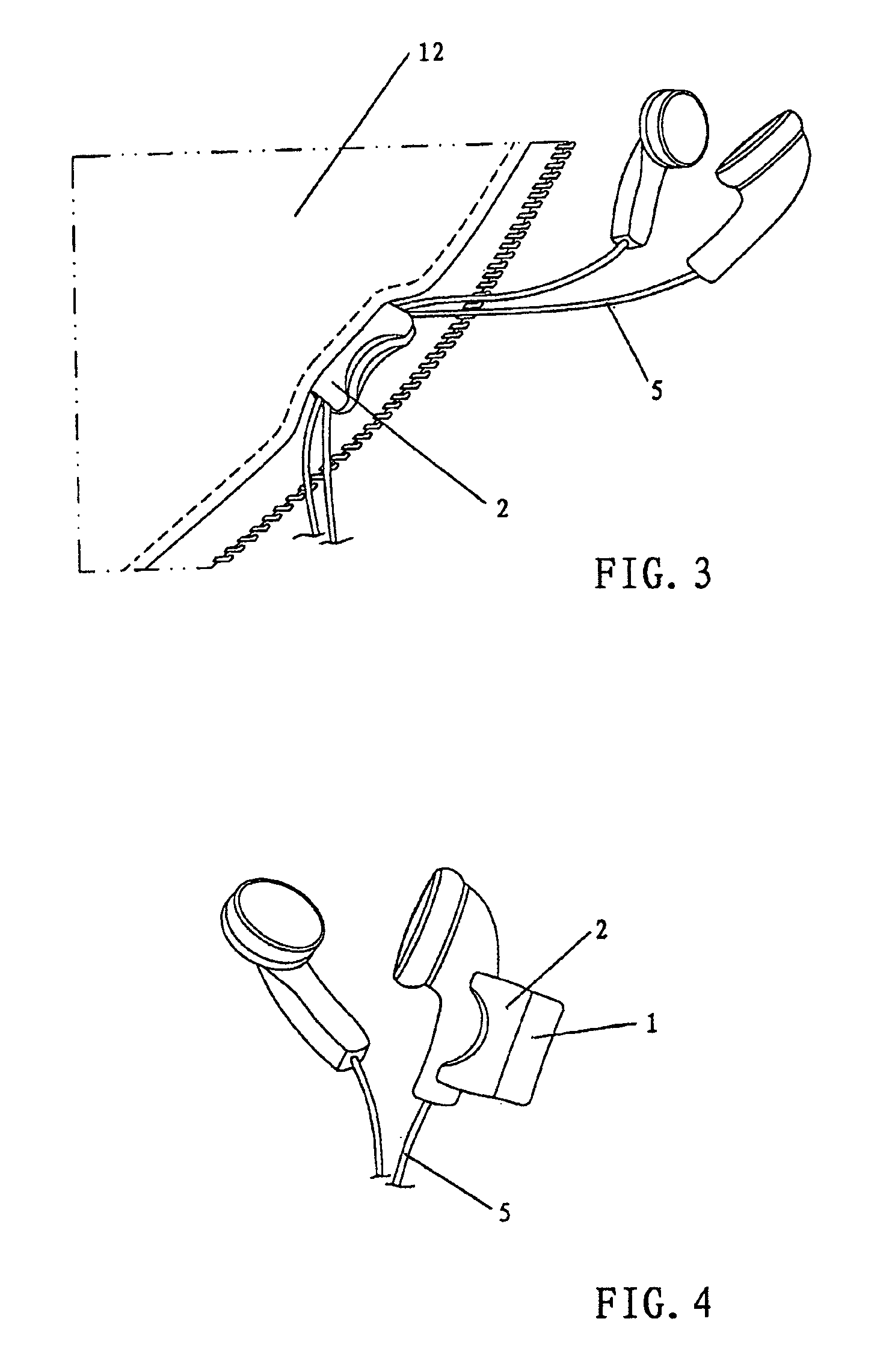

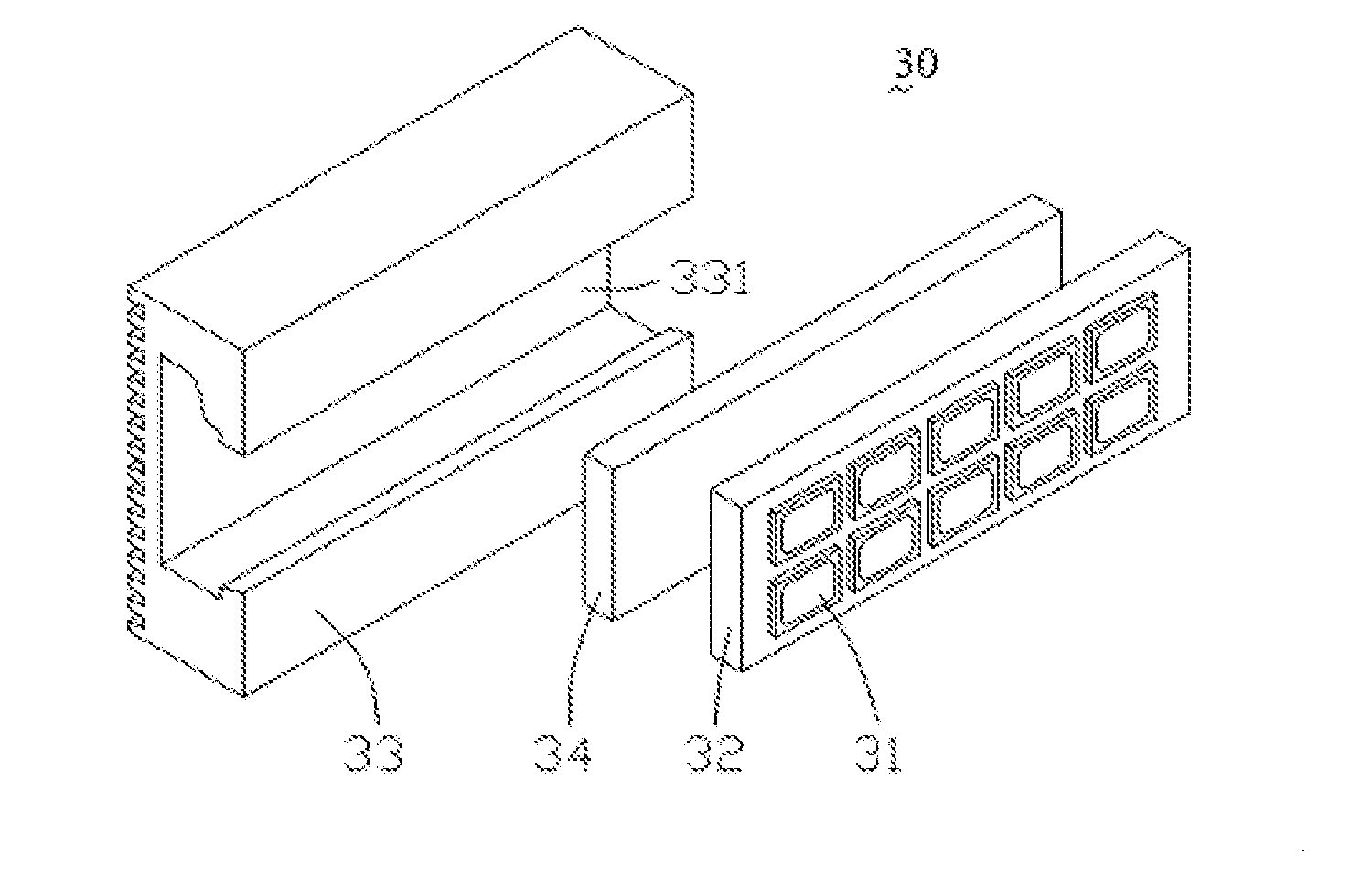

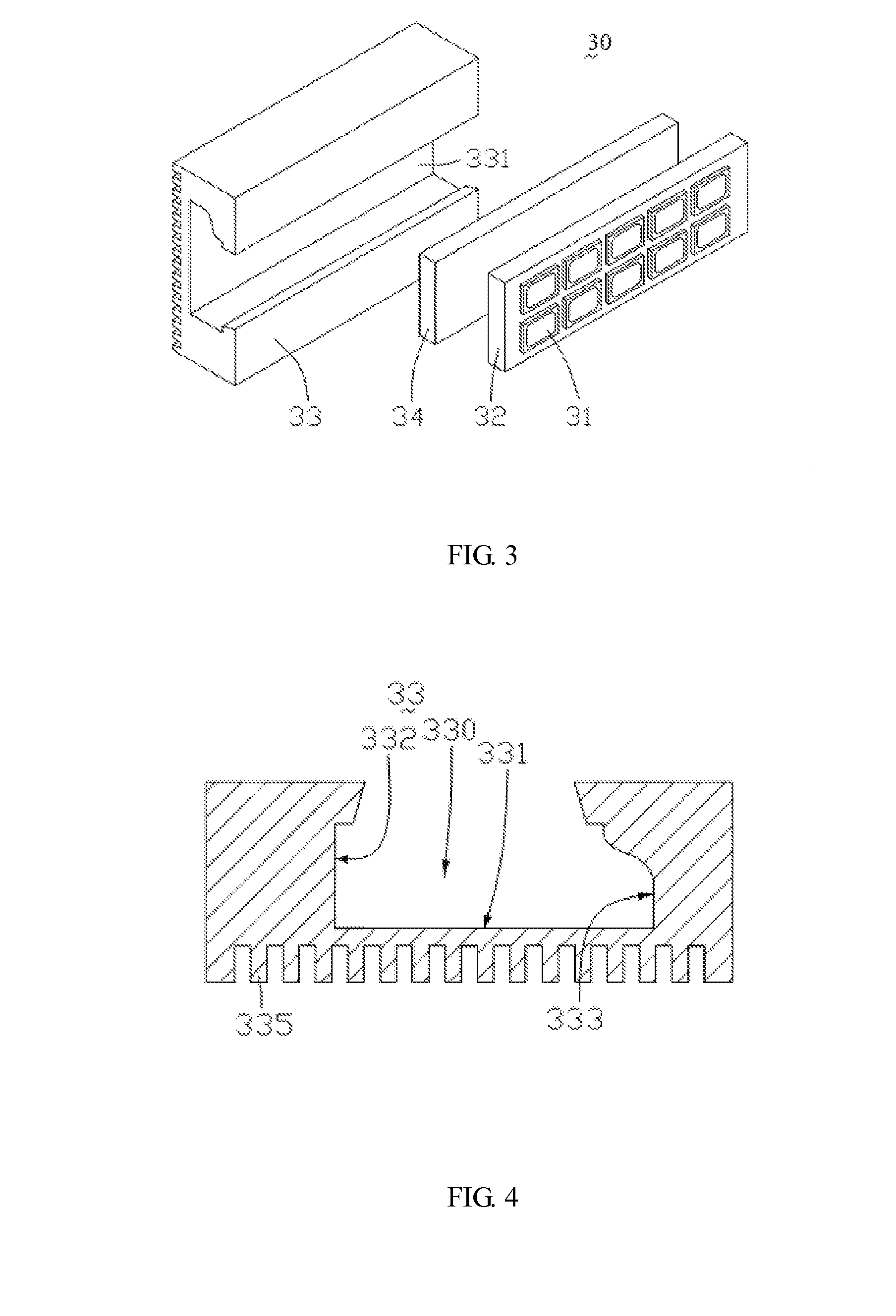

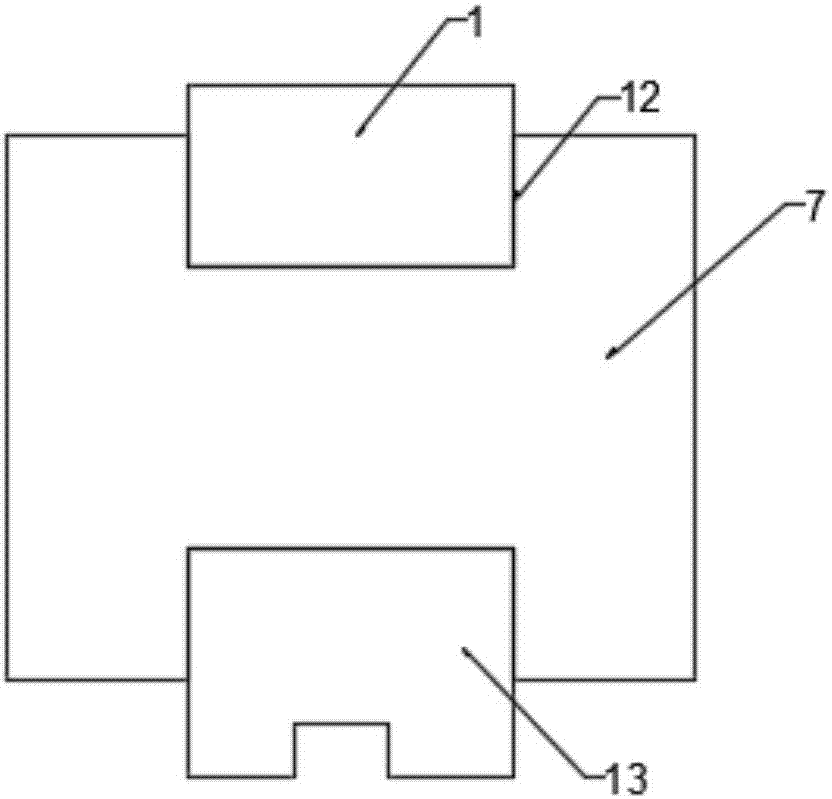

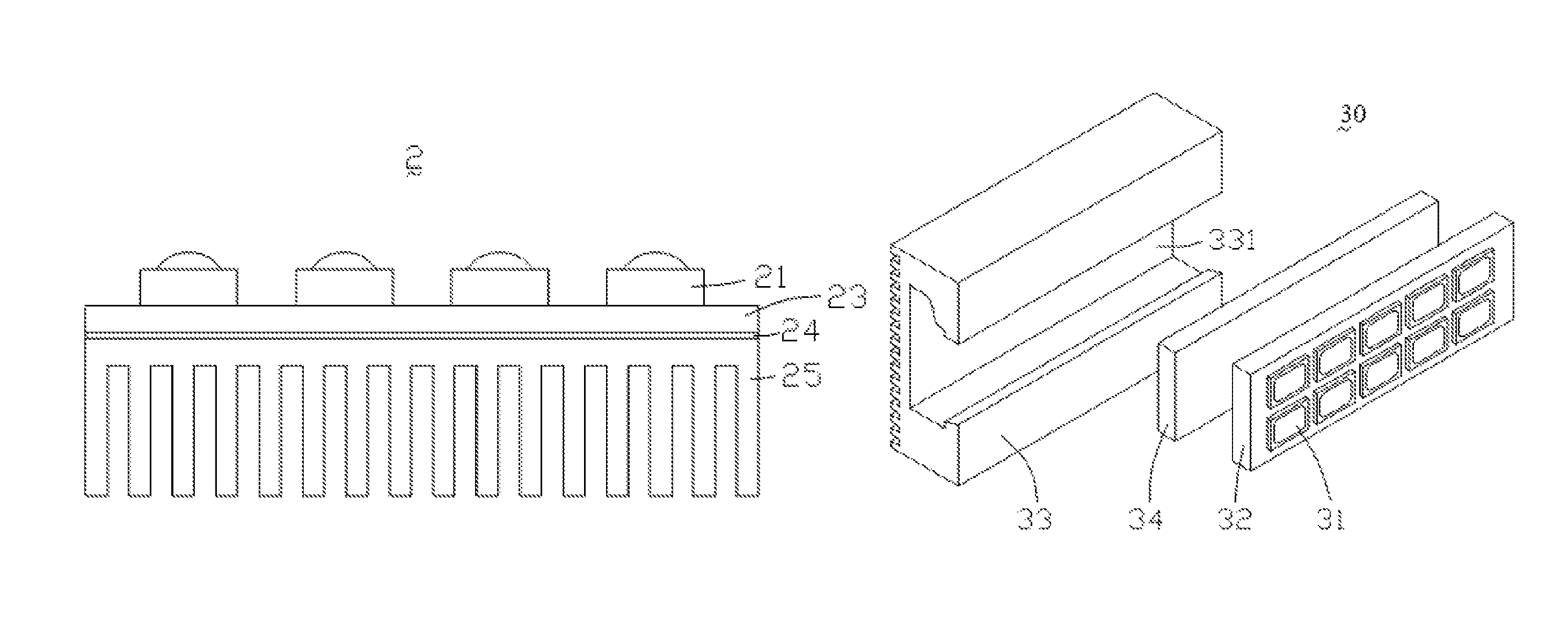

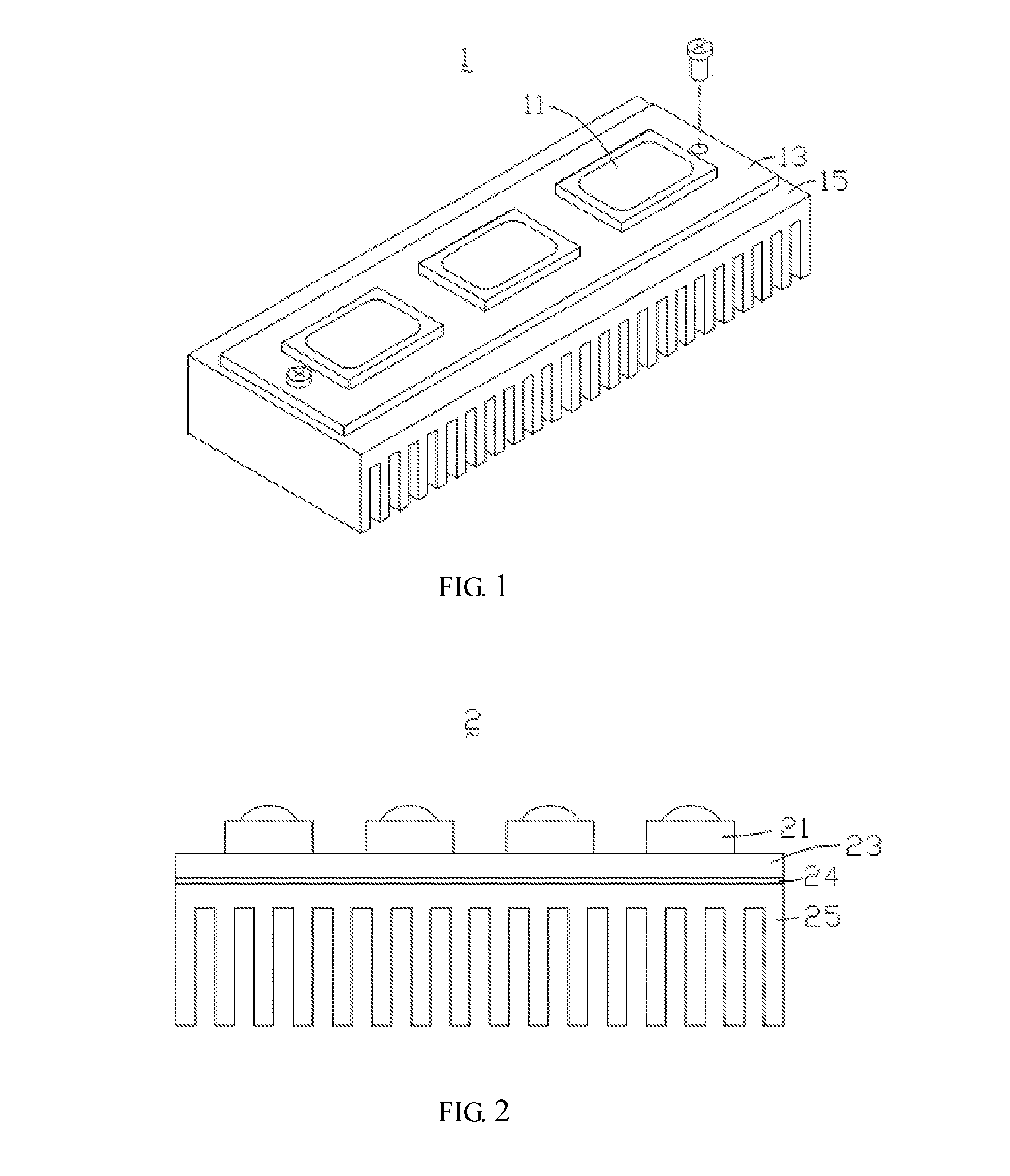

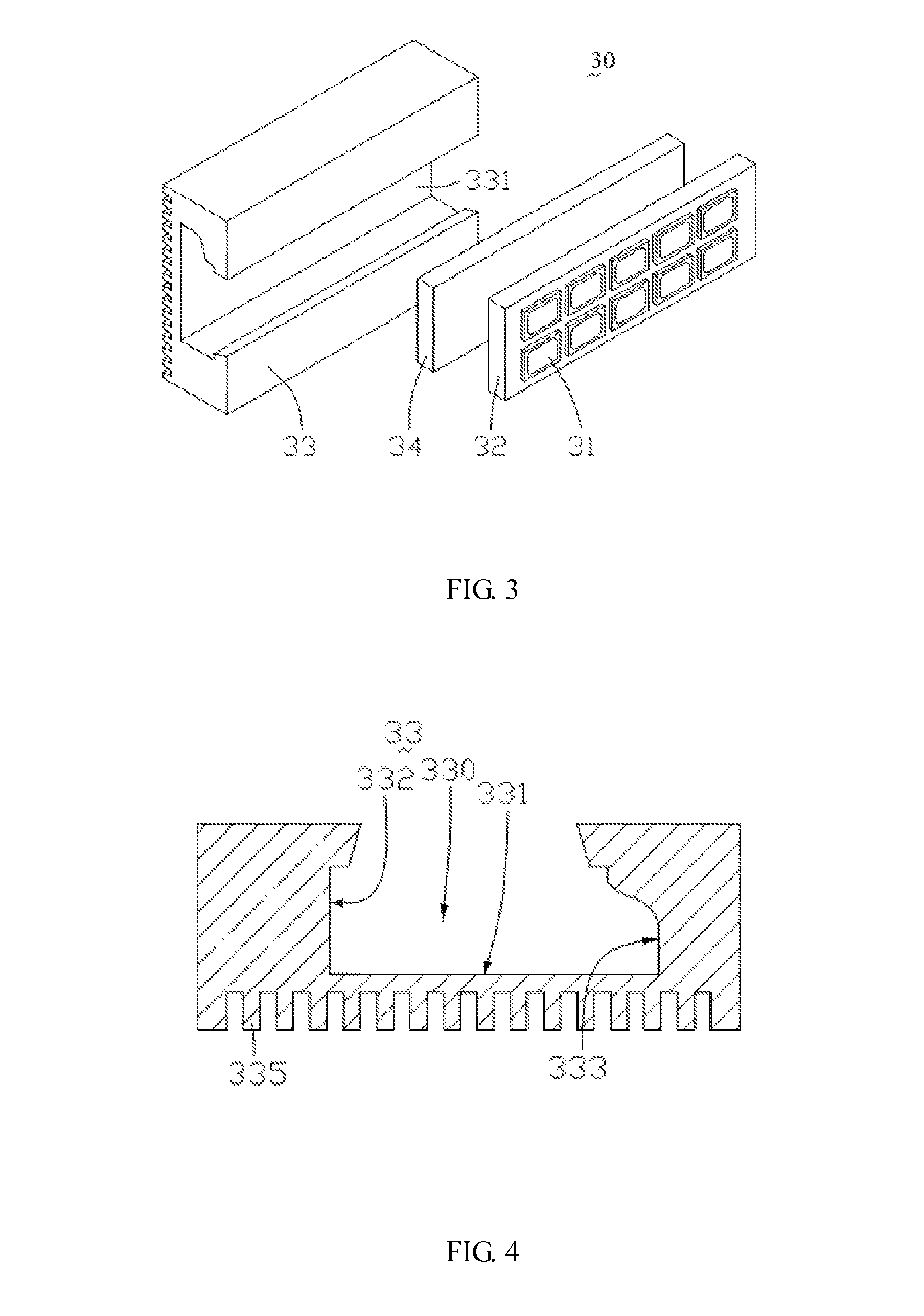

Light Source Fixing Device, Light Source Assembly and Assembling Method Thereof

InactiveUS20120314431A1Simplify the assembly processLow costLighting support devicesLighting heating/cooling arrangementsEngineeringLight source

The present invention provides a light source fixing device for fixing a light emitting element. The light emitting element comprises a light source and a supporting plate for supporting the light source. The light source fixing device comprises a heat dissipating support which comprises a receiving recess. The receiving recess is adapted to receive the supporting plate. The light source fixing device further comprises an elastic element disposed in the receiving recess, and the elastic element is adapted to apply an elastic force on the supporting plate so that the supporting plate is fixed in the receiving recess. The present invention further provides a light source assembly and an assembling method thereof. The light source assembly features a simple assembling process, high reliability and a low cost.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

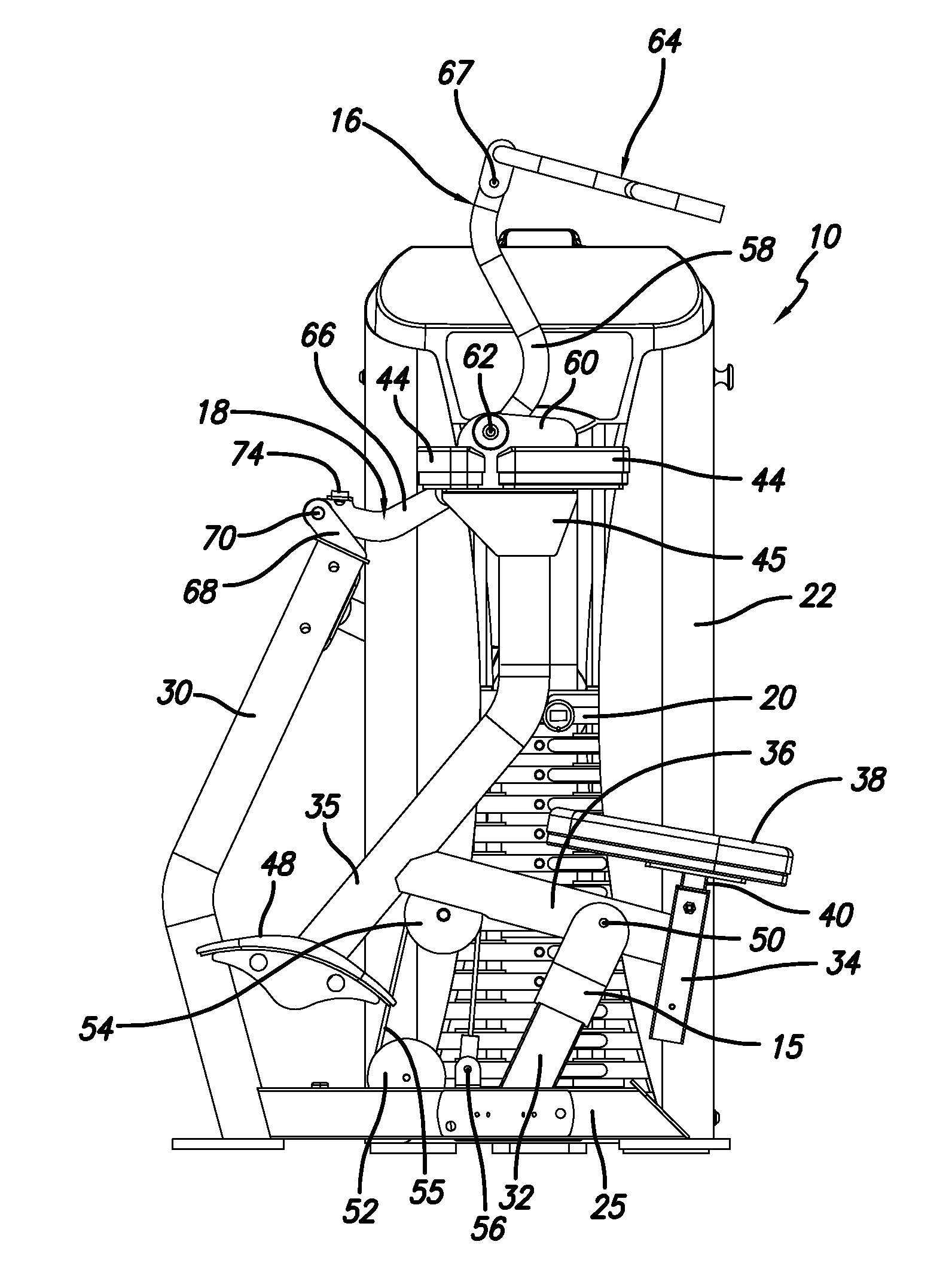

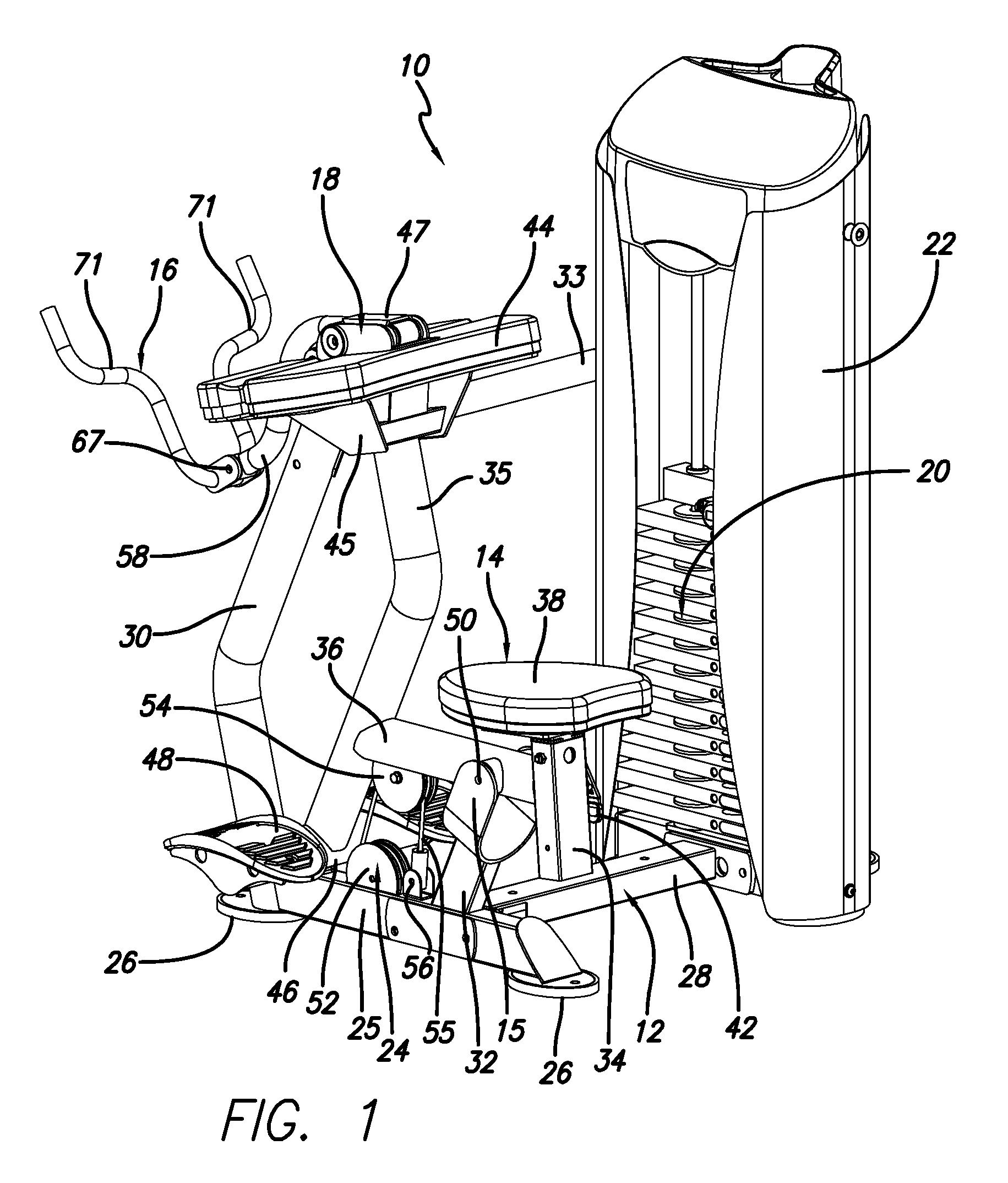

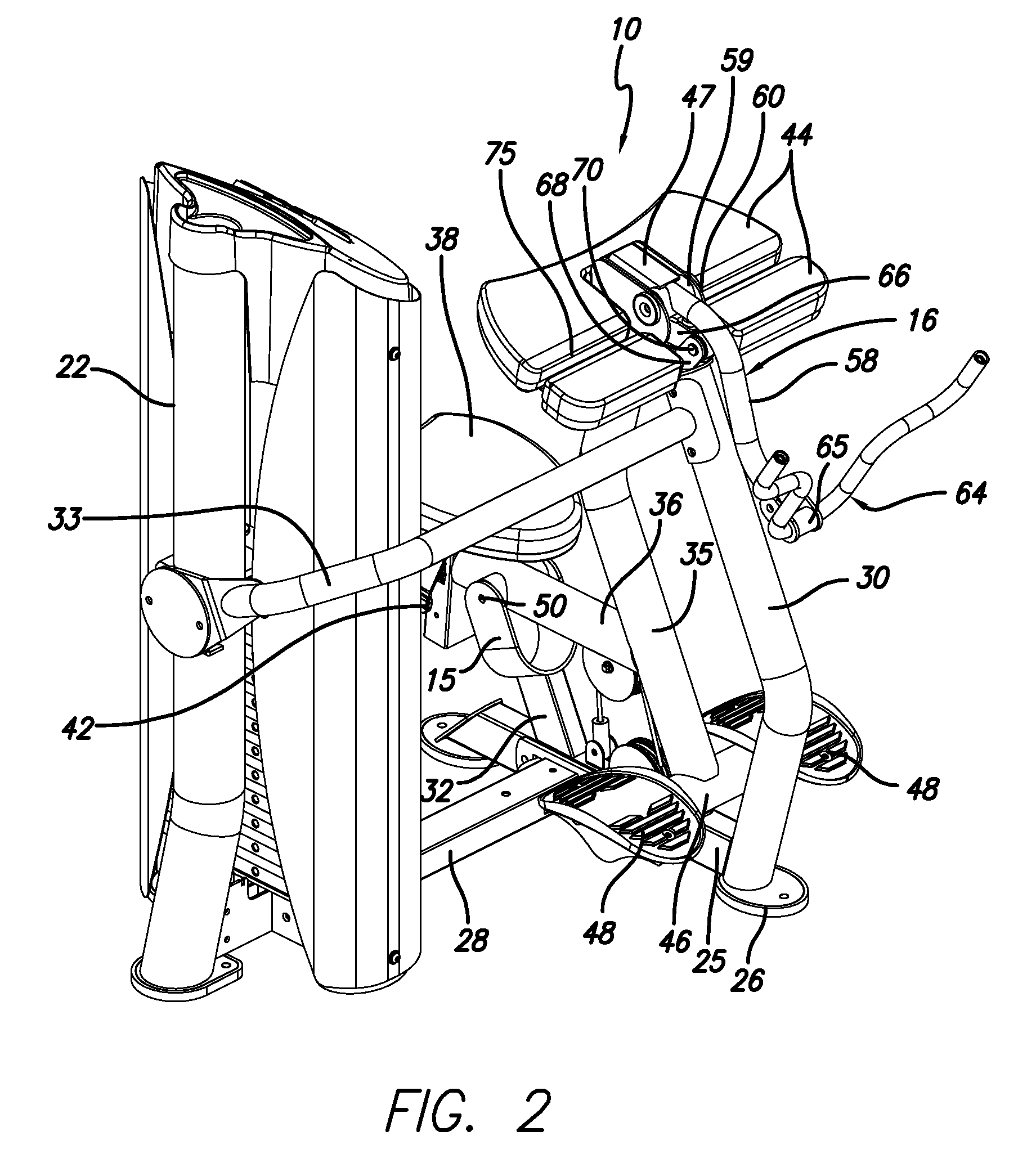

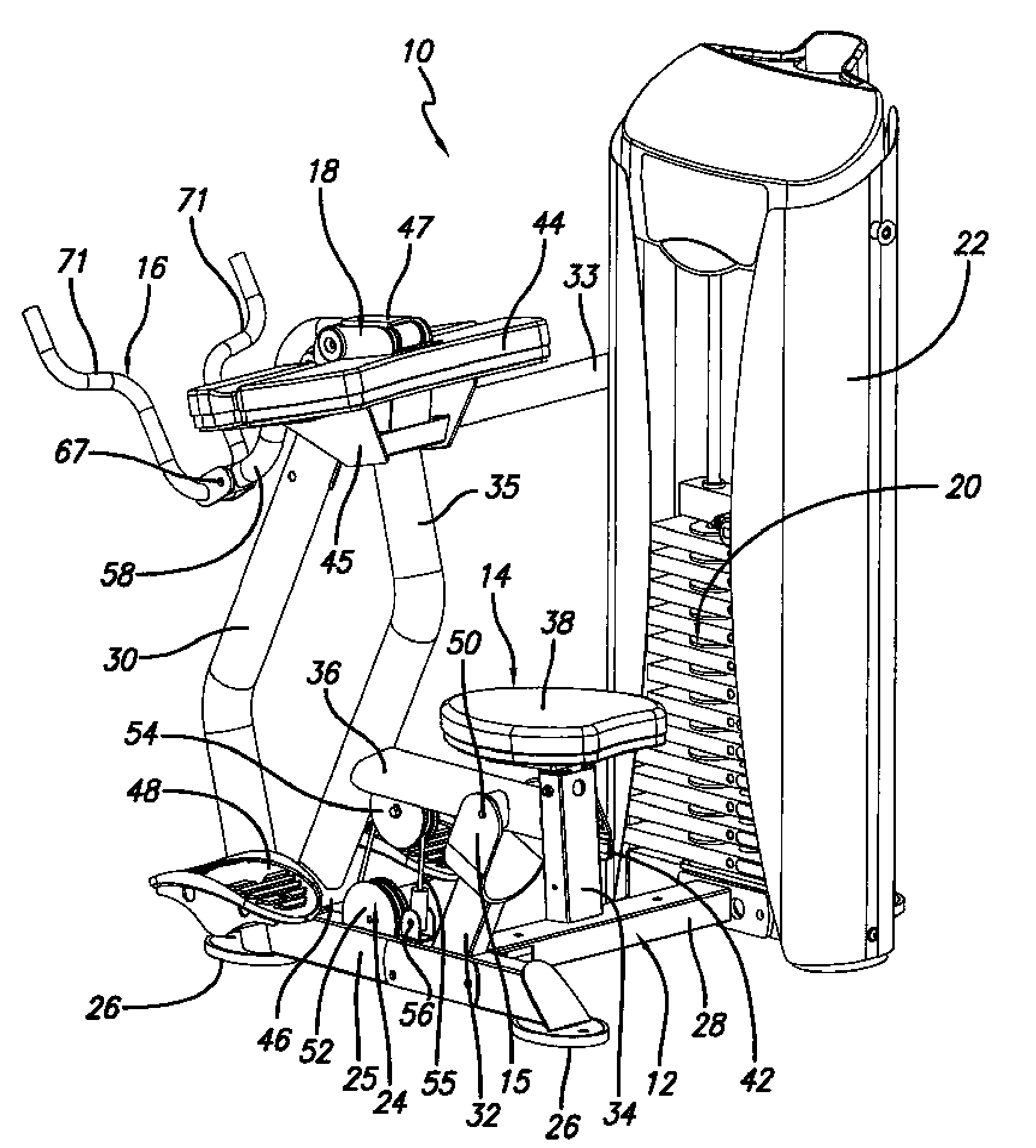

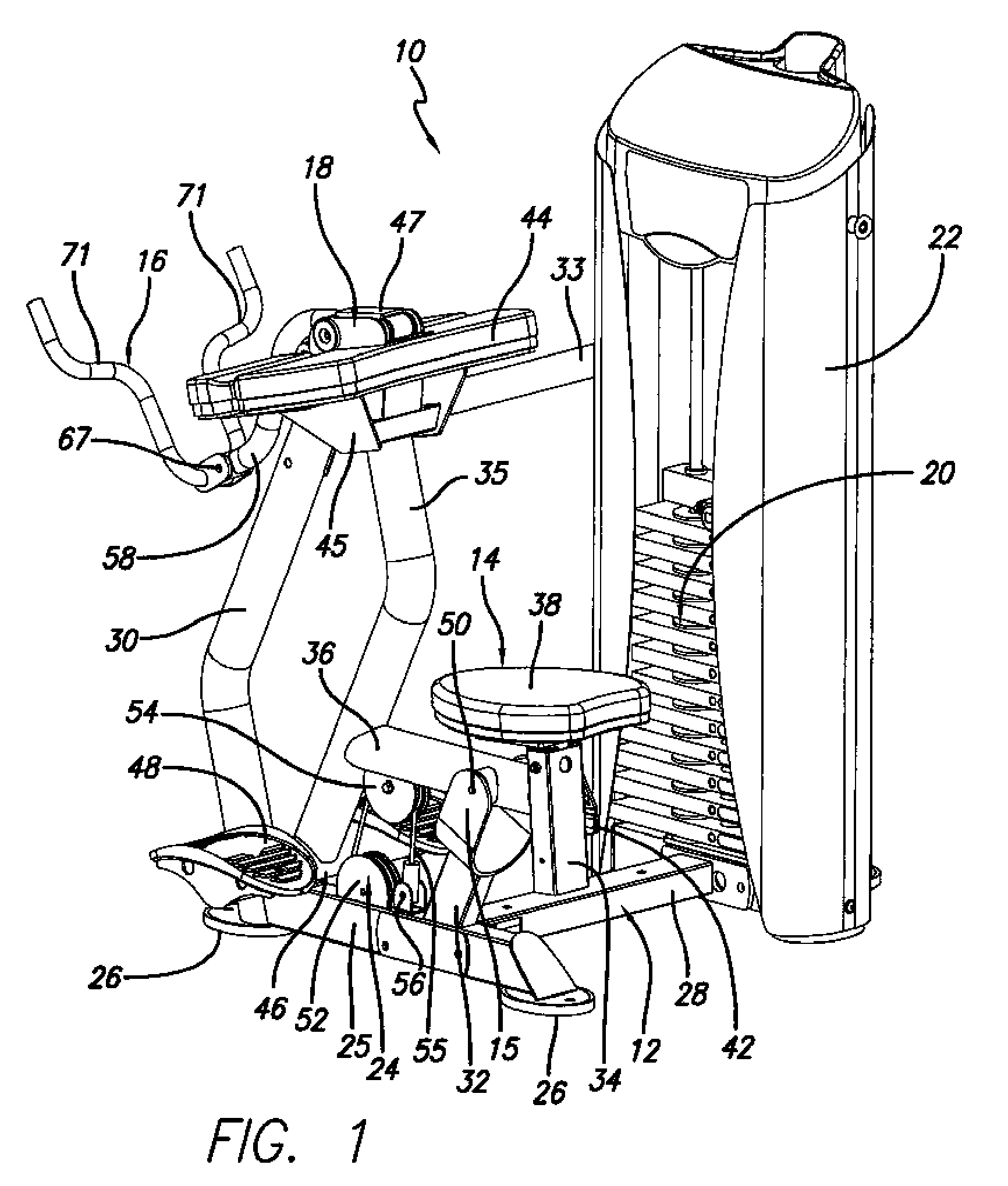

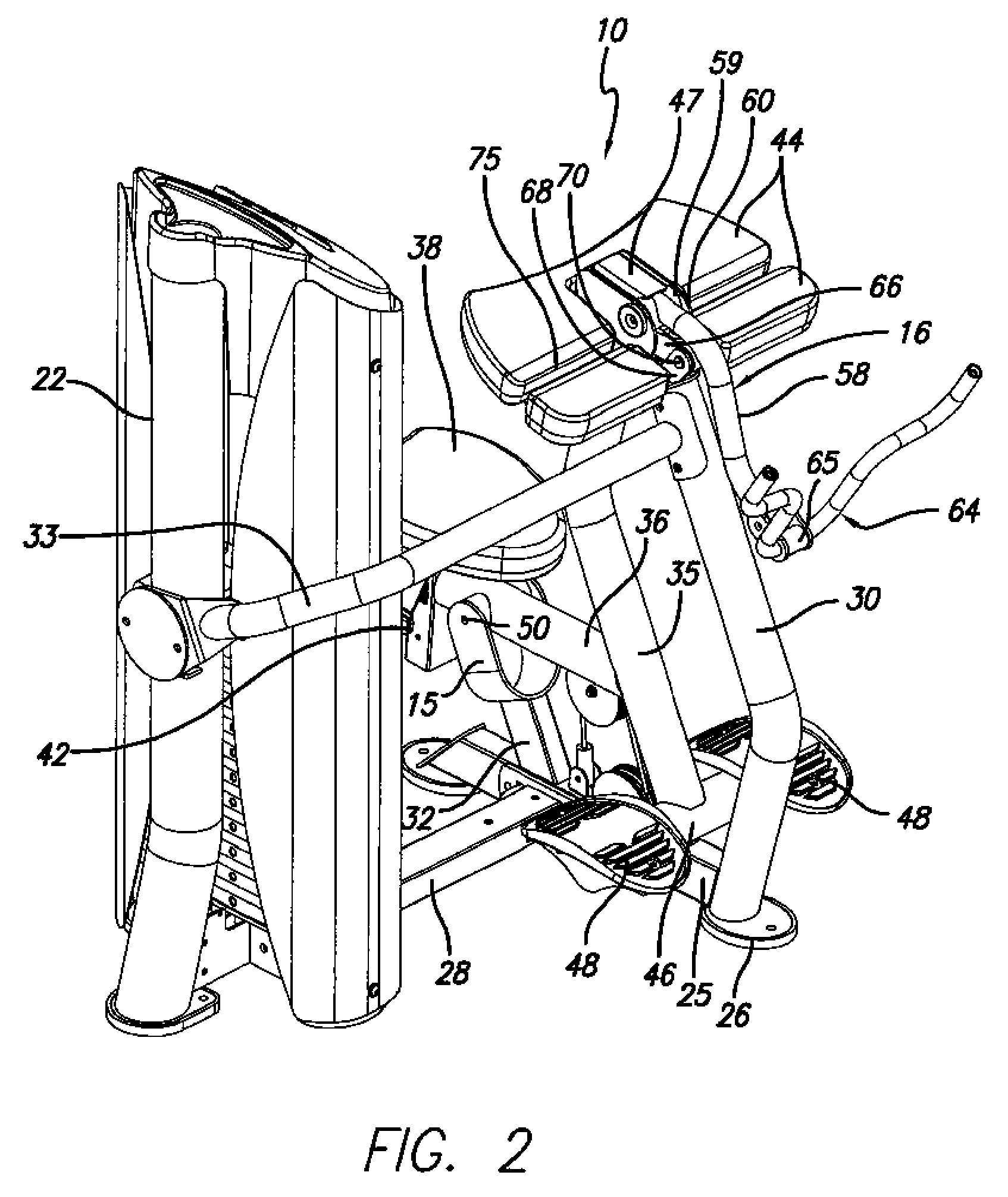

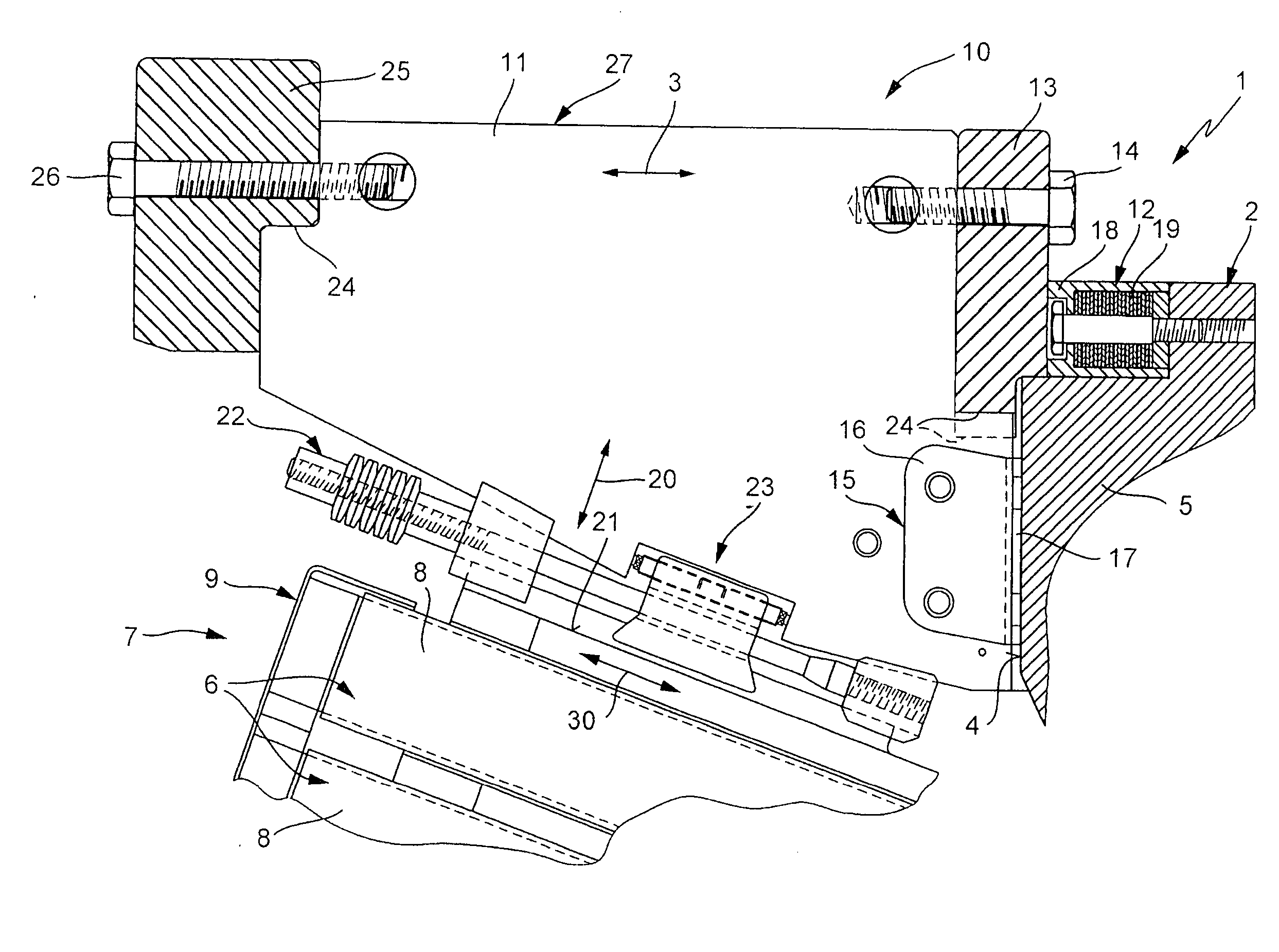

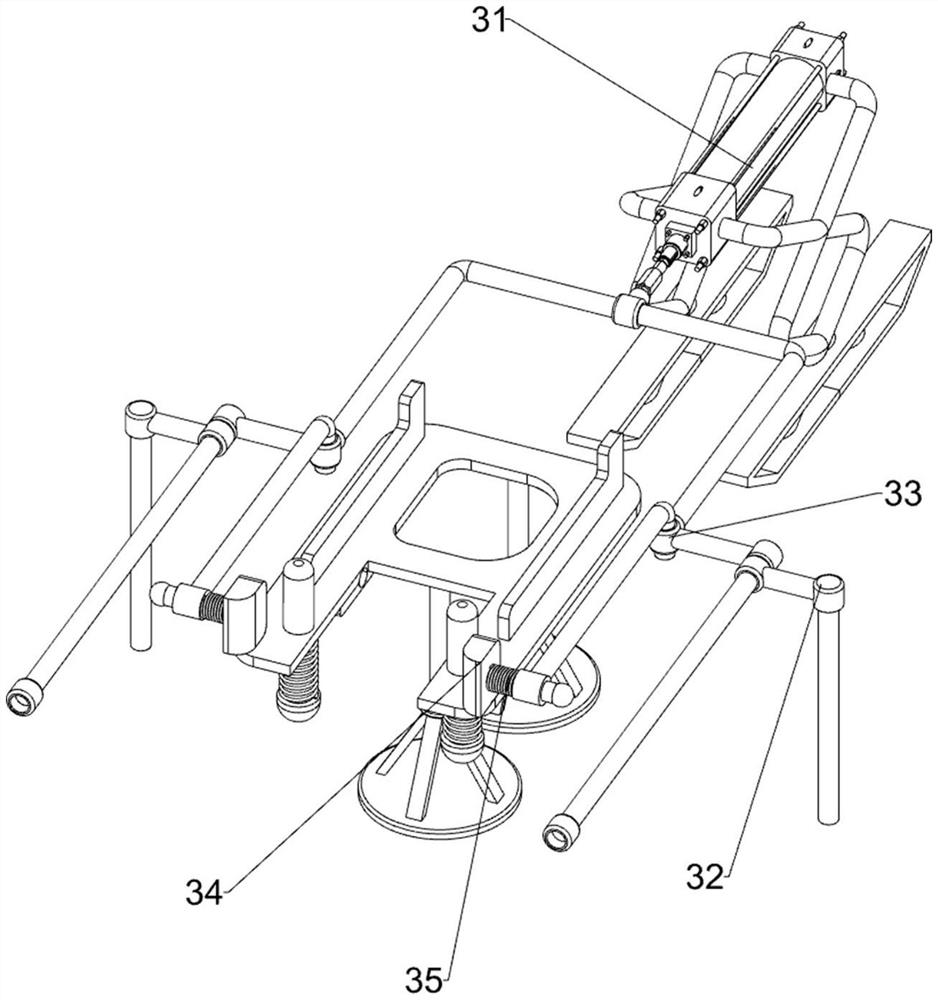

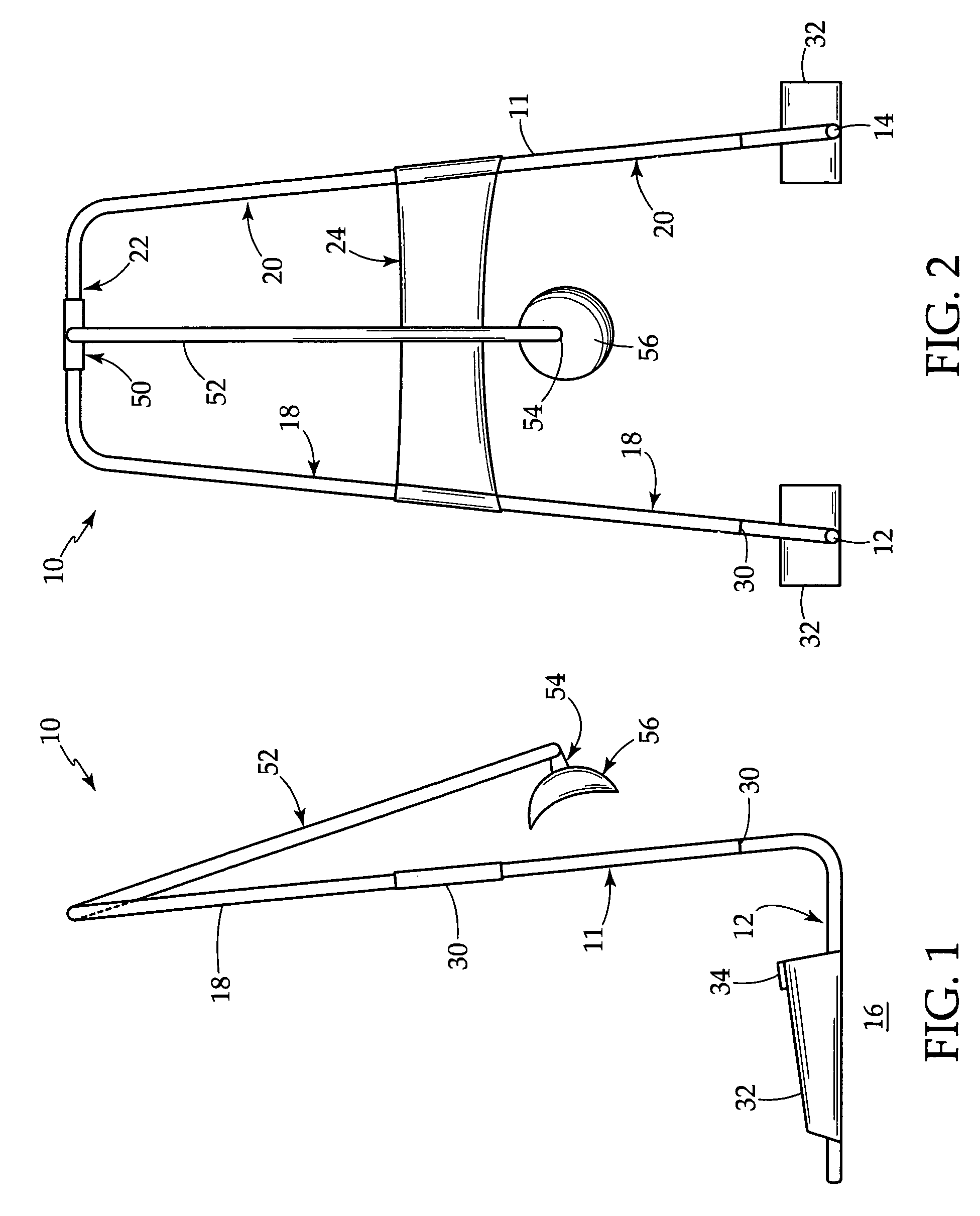

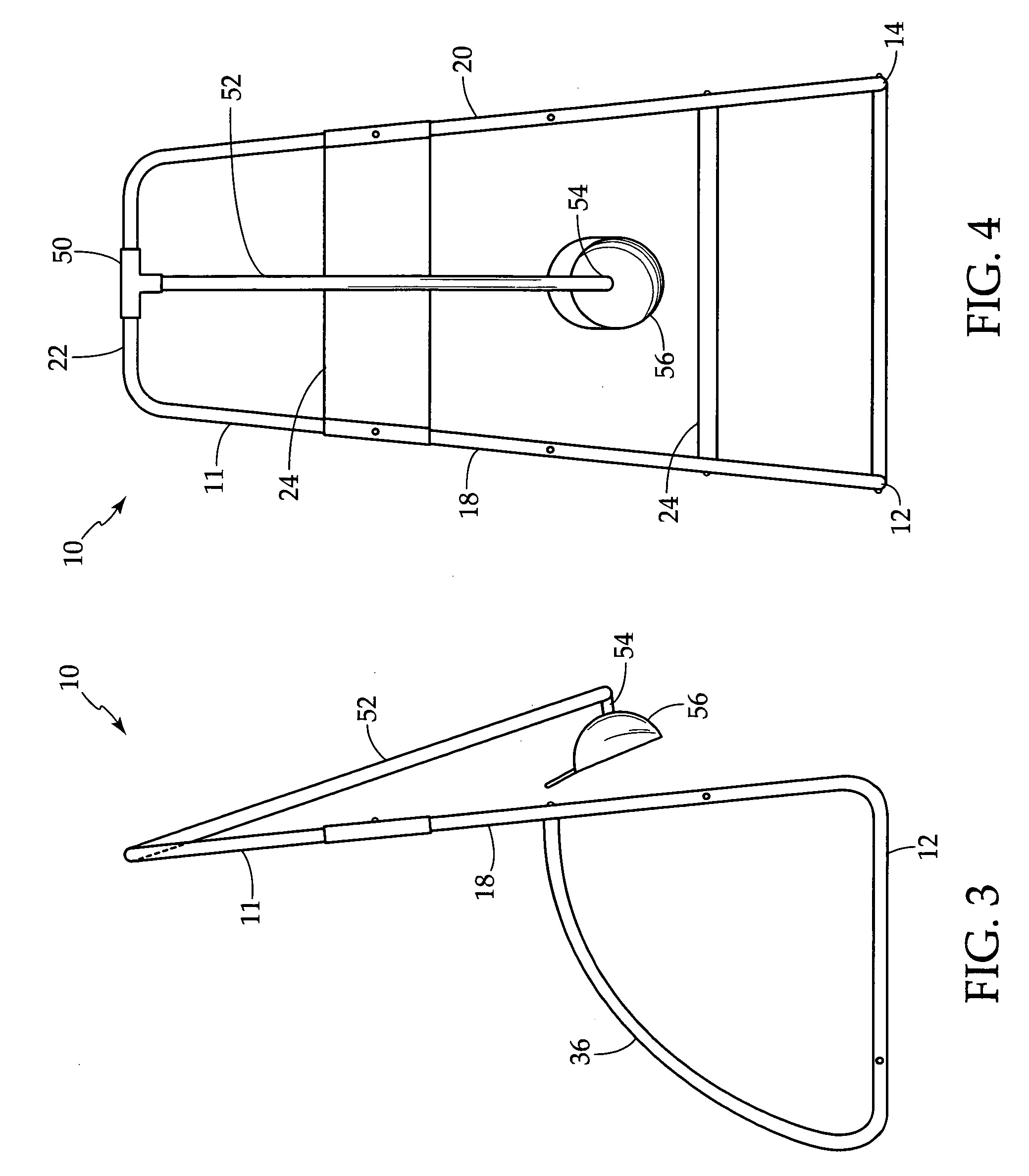

Arm exercise machine with self-aligning pivoting user support

ActiveUS20080058181A1Easy for userThe relative position is the sameStiltsWeightsArm exerciseHand arm

An arm exercise machine for performing isolation arm exercises has a self-aligning pivoting seat or user support on a main frame and an exercise arm for performing biceps curl and / or triceps extension exercises which is linked to the pivoting user support to translate movement of the exercise arm into movement of the user support. The user support is pivotally mounted on the main frame so as to automatically align in order to maintain positioning of the user throughout the exercise motion.

Owner:HOIST FITNESS SYST

Arm Exercise Machine With Self-Aligning Pivoting User Support

An arm exercise machine for performing isolation exercises has a self-aligning pivoting seat or user support on a main frame and an exercise arm for performing biceps curl and / or triceps extension exercises which is linked to the pivoting user support to translate movement of the exercise arm into movement of the user support. The user support is pivotally mounted on the main frame so as to automatically align in order to maintain positioning of the user throughout the exercise motion.

Owner:HOIST FITNESS SYST

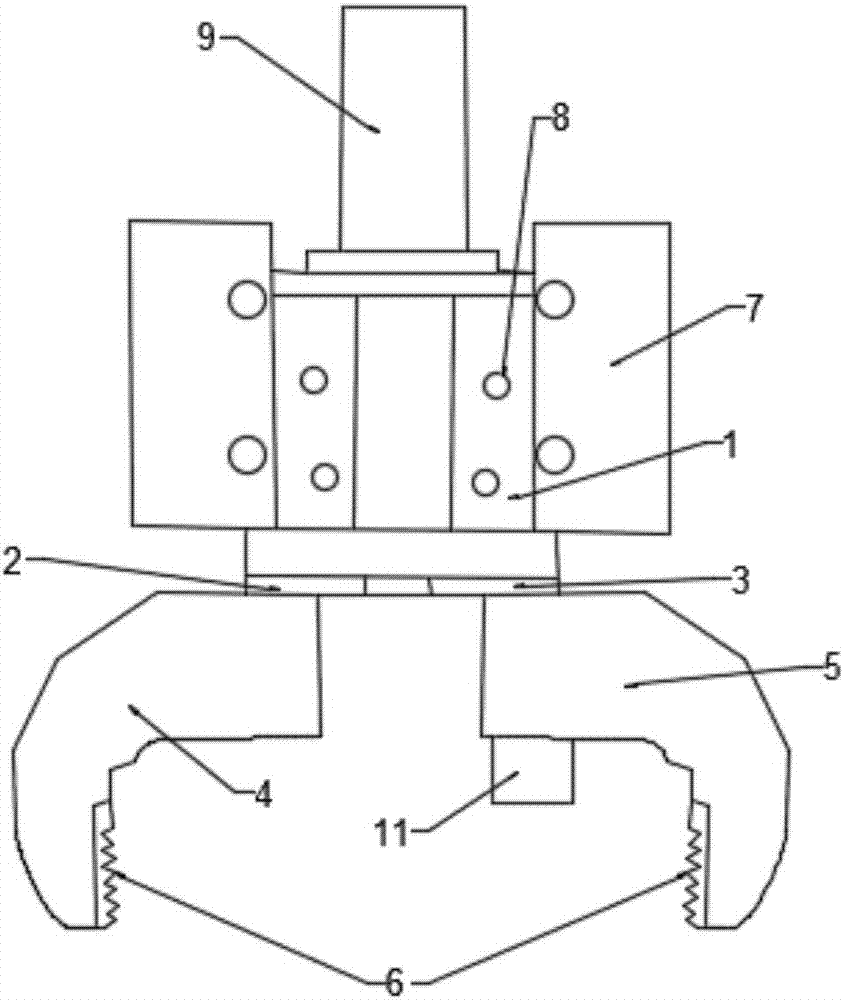

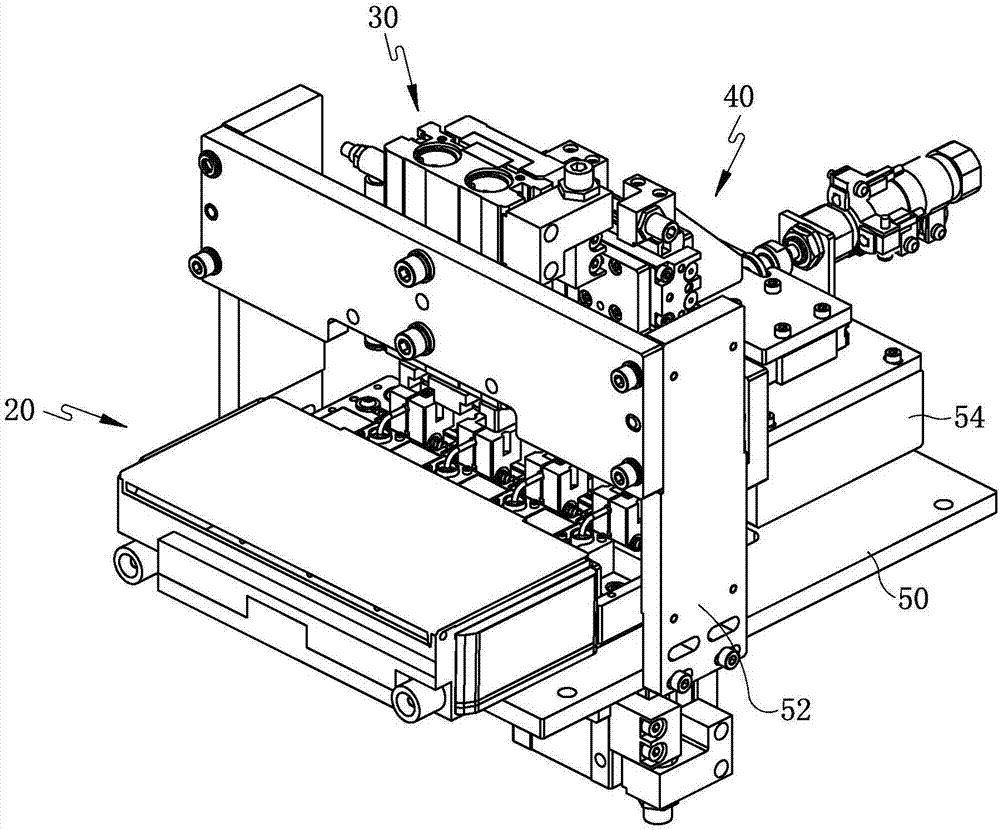

Battery clamping device and replacing device and method applied to autonomous cruising of unmanned aerial vehicle

ActiveCN106864766AAvoid changeReliable cooperationAnchoring installationsRemote controlled aircraftElectrical batteryUncrewed vehicle

The invention discloses a battery clamping device and a replacing device and method applied to autonomous cruising of an unmanned aerial vehicle to clamp and replace an unmanned aerial vehicle battery stably. Saw-toothed blocks are arranged on grippers and can be used for clamping the battery in a fastened mode, downward slipping of the battery during moving is effectively avoided, it can be guaranteed that the clamping depths and positions of the two sides of the battery are the same, and the situation that the clamping depths and positions are different, and consequentially the clamped battery deflects and cannot be mounted in a battery box or the unmanned aerial vehicle is avoided. According to the technical scheme, the battery clamping device comprises a clamping claw mechanism which comprises a clamping claw body; the clamping claw body is connected with a first clamping claw part and a second clamping claw part; the first clamping claw part is fixedly connected with the first gripper, and the second clamping claw part is fixedly connected with the second gripper; and the saw-toothed blocks are arranged on the opposite faces of the first gripper and the second gripper in a matched mode.

Owner:SHANDONG UNIV +1

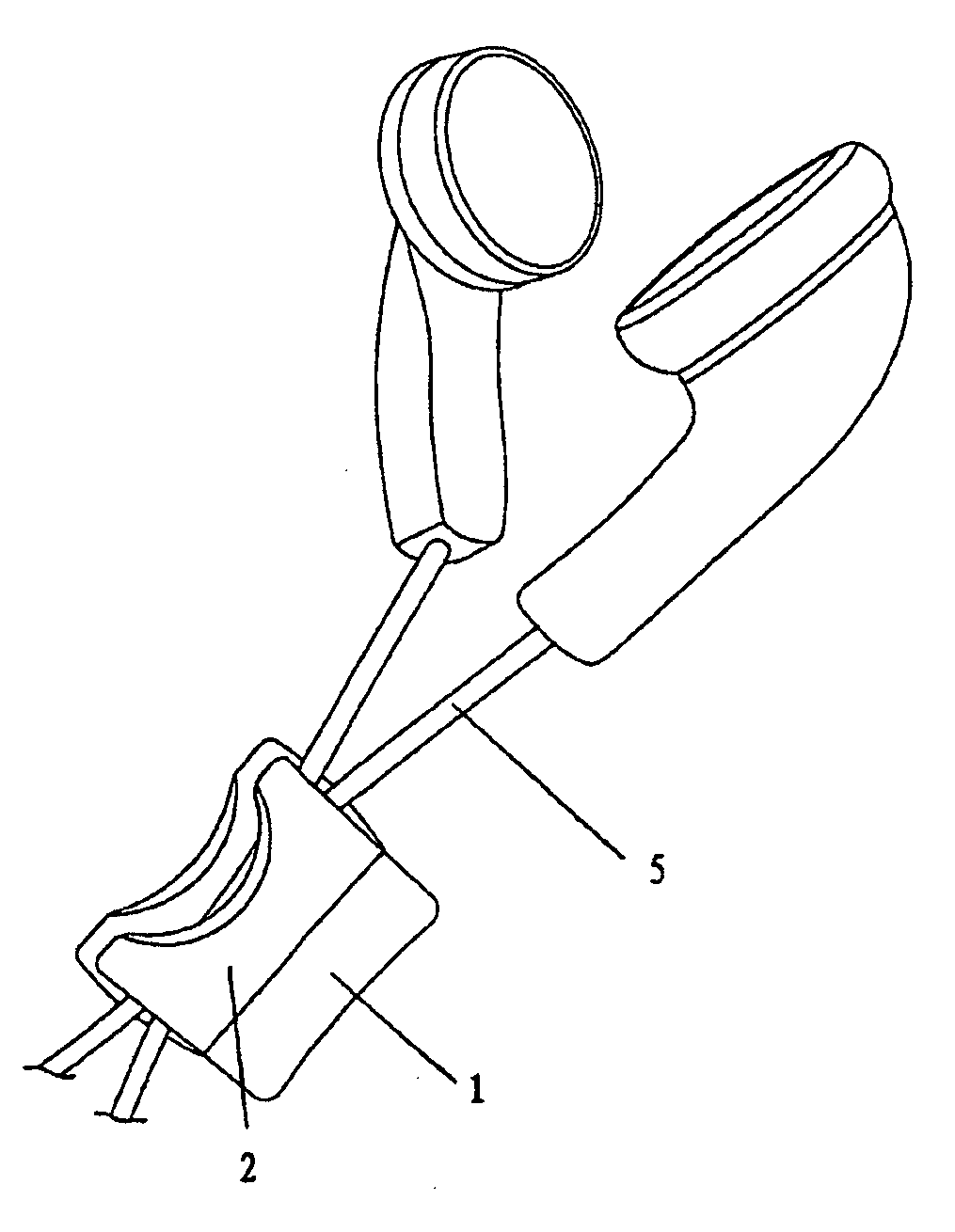

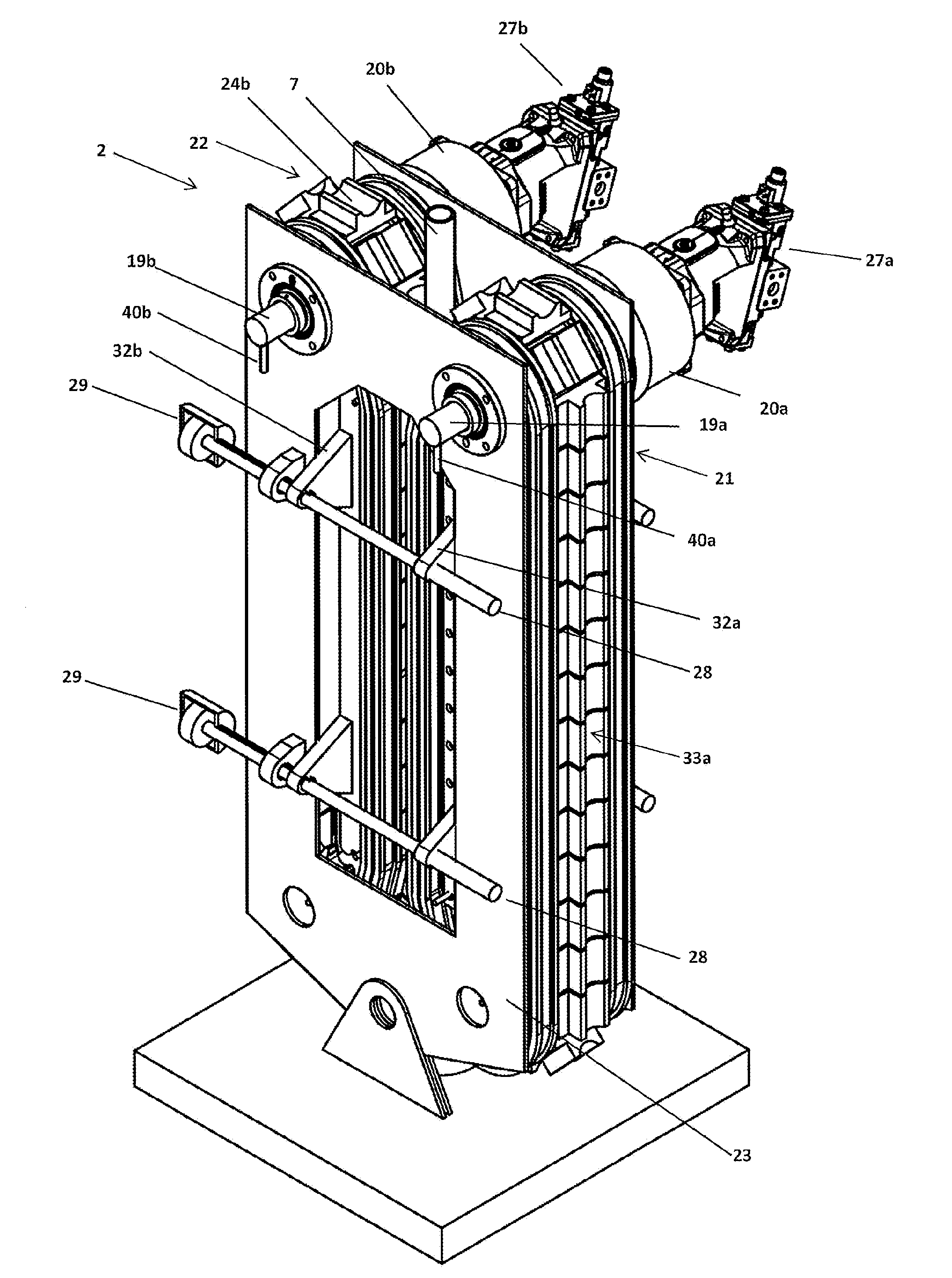

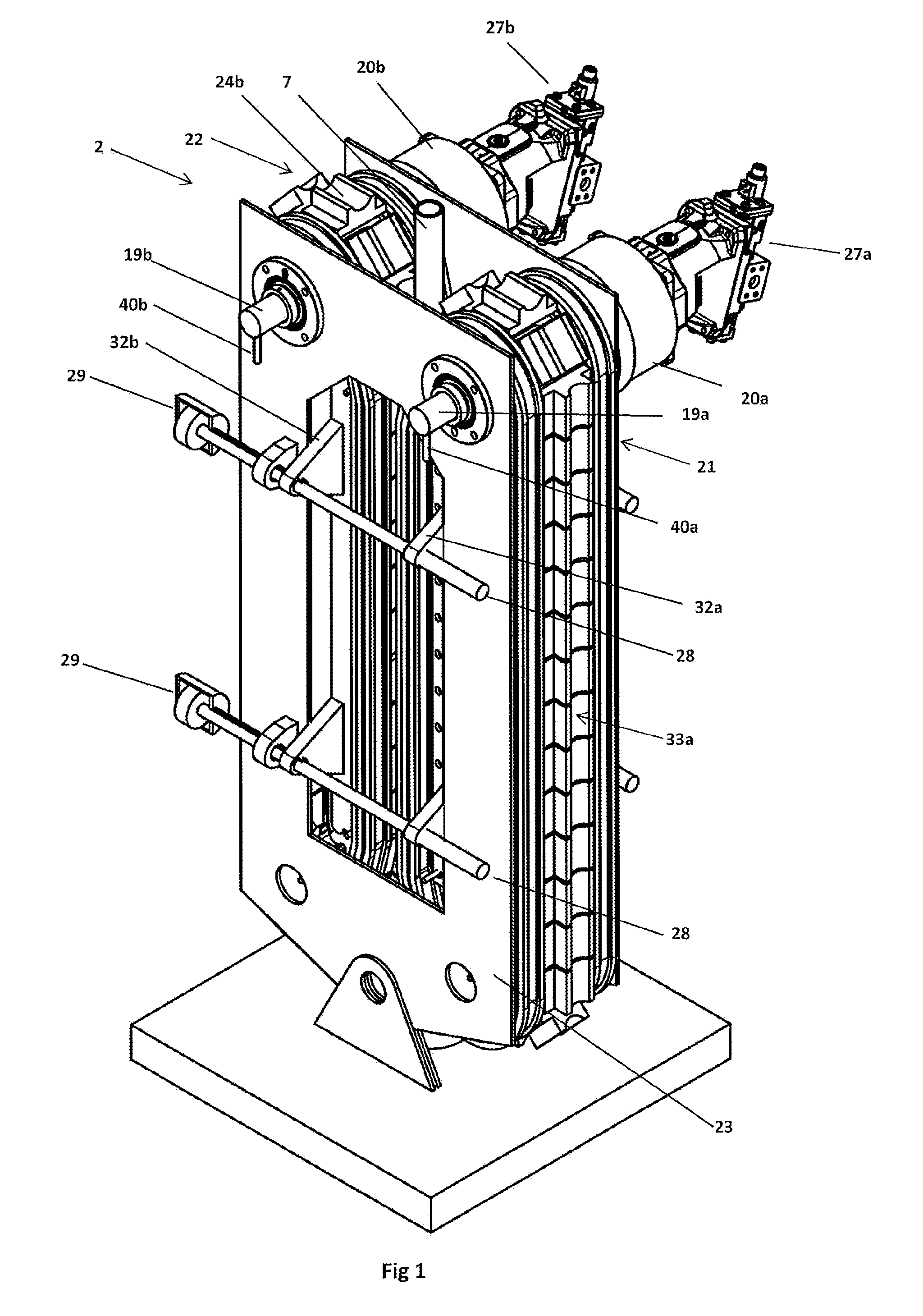

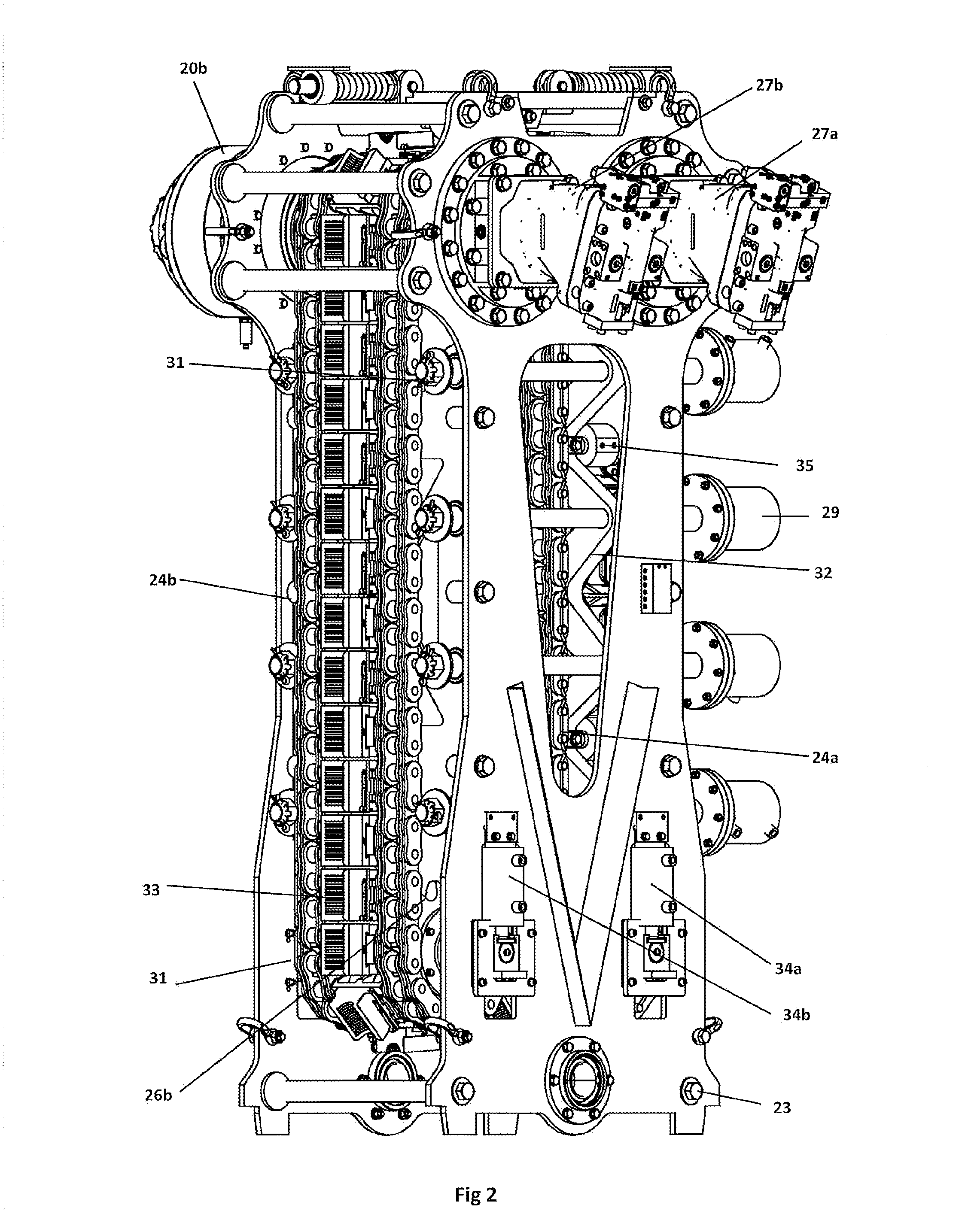

Injector head chain synchronization device

The invention relates to an injector head (2) comprising; a pair of oppositely located, cooperatively movable, segmented continuous belt drive chains (21; 22), said each belt drive chain (21, 22) running over a respective pair of drive sprockets (25a, 25b) and tension sprockets (26a, 26b), wherein a tubing receiving section (7′) is defined between the belt drive chains (21, 22). The tubing receiving section (7′) having a tubing section centerline (46) extending through the center of the tubing receiving section (7′). The injector head (2) having an injector centerline (45) extending through the centerline of the injector head (2), said injector centerline (45) and said tubing section centerline (46) being substantially aligned in the longitudinal direction in an initial position, a pair of elongate counter-force members (32a, 32b) is positioned at each side of the tubing receiving section (7′). The injector head (2) has at least one actuator (35) adapted to move at least one of said elongate counter-force elongate member (32a, 32b) in order to bring the tubing section centerline (46) out of alignment with said injector centerline (45).

Owner:STIMLINE

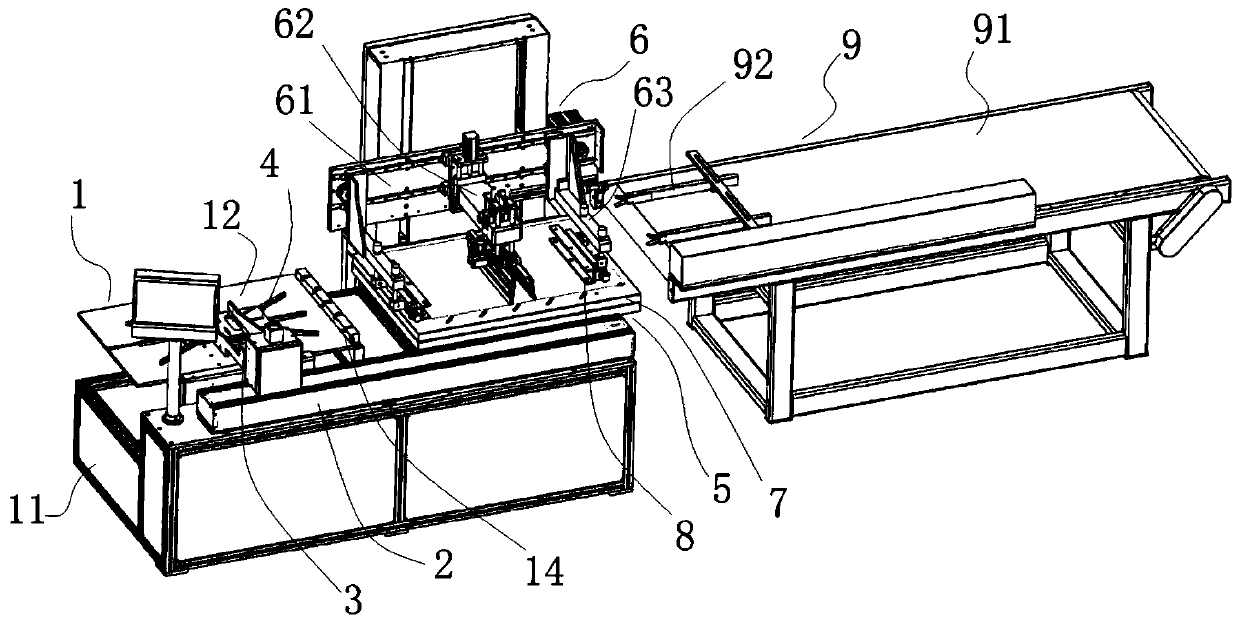

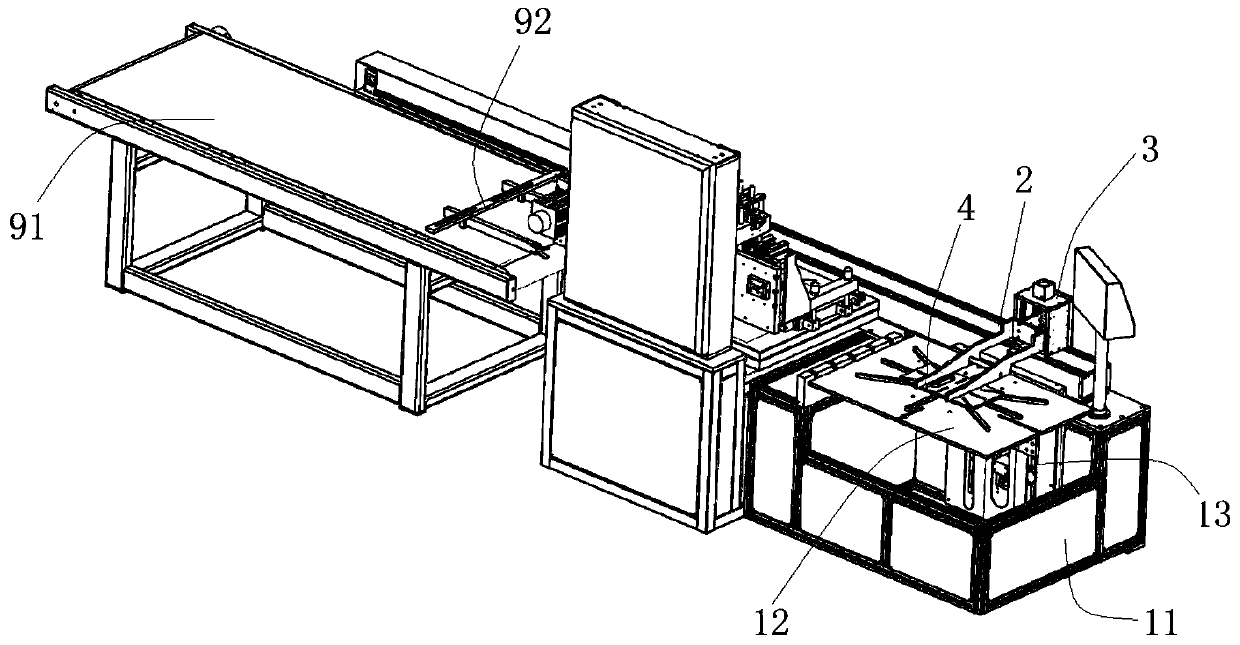

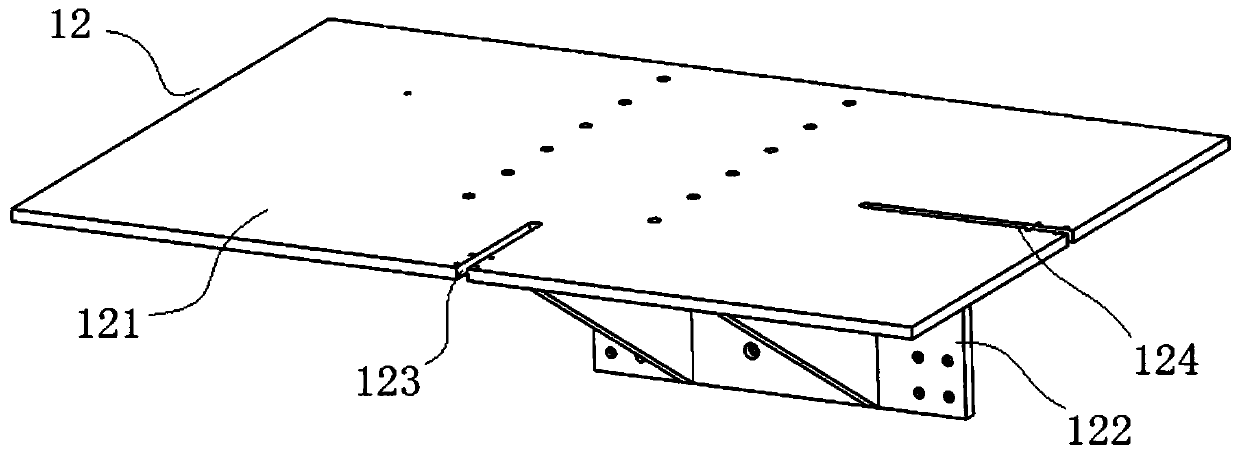

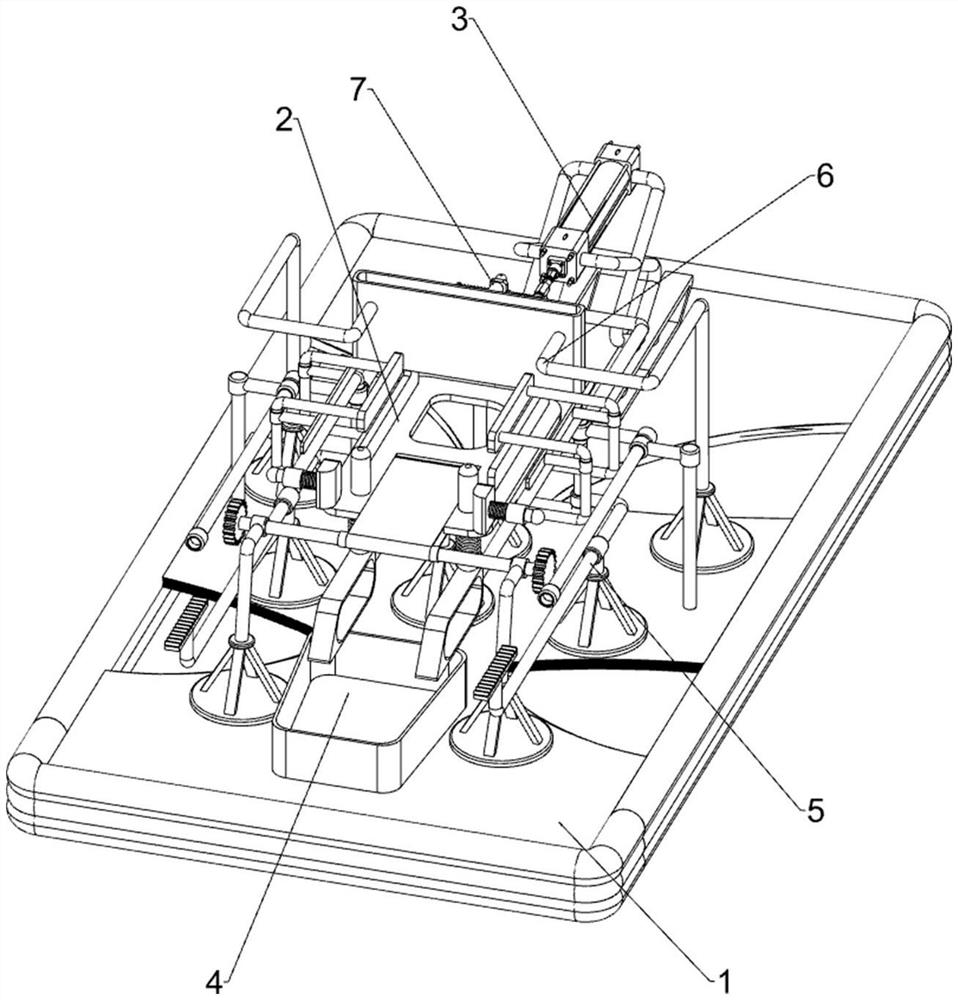

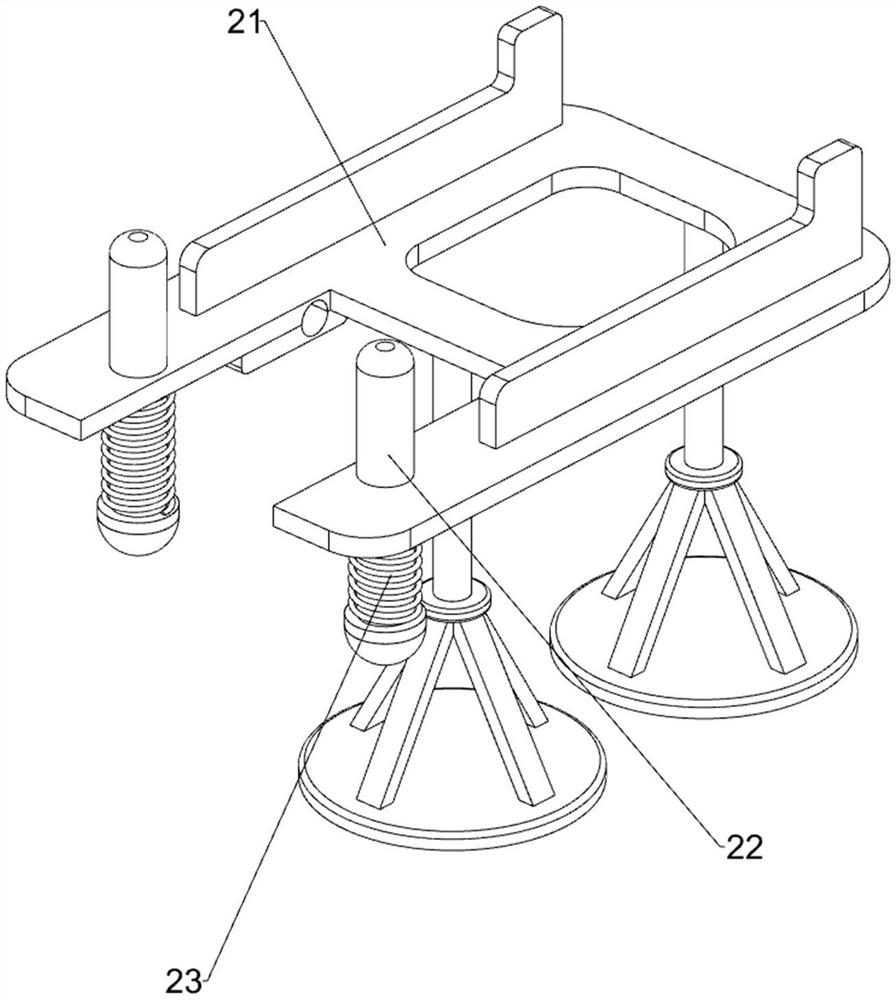

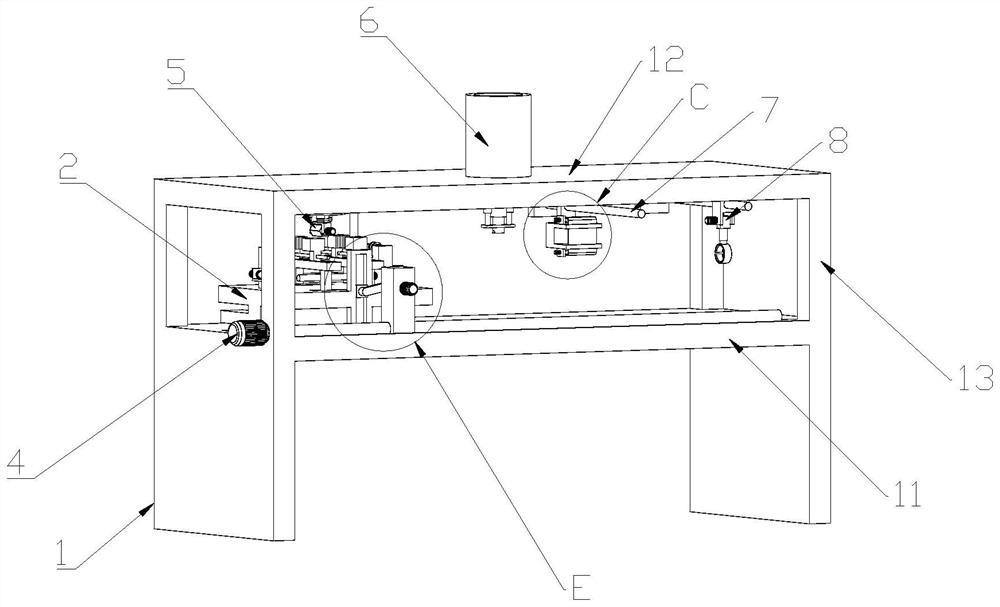

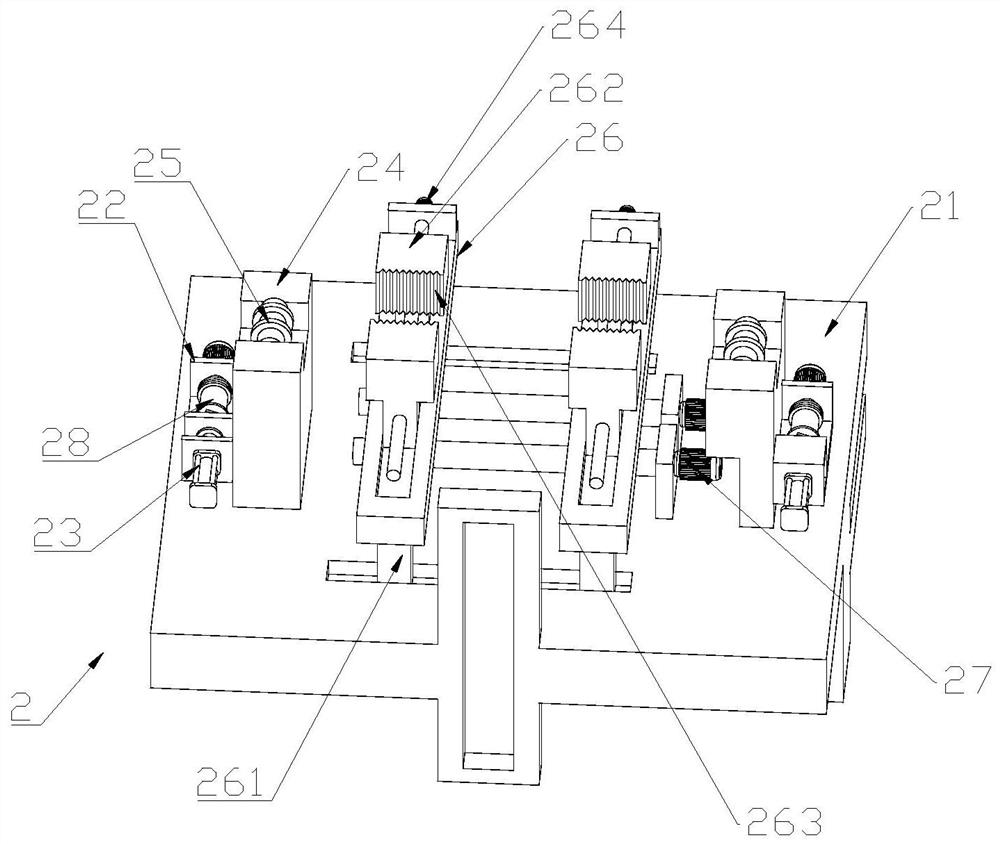

Automatic loading and unloading sheet screen printing machine

PendingCN110014723AThe relative position is the sameImprove printing accuracyScreen printersScreen printingScreen printingEngineering

The invention relates to an automatic loading and unloading sheet screen printing machine which comprises a loading device, wherein the loading device comprises a lifting seat for placing a to-be-printed sheet and further comprises a grabbing and feeding device, a printing platform and an unloading device; the grabbing and feeding device comprises a sucking disc mechanism, a lifting device and a linear driving device; the lifting device comprises a seat body; a lead screw lifting mechanism is arranged on the seat body; the lead screw lifting mechanism and a support arm retainer body are assembled on a linear sliding rail in a sliding manner in the direction of the linear sliding rail; the seat body is driven by a linear driving mechanism; the printing platform comprises a printing rack anda loading platform on the printing rack; and a first positioning component and a second positioning component are arranged on two adjacent sides of the loading platform.

Owner:郑州丝珂瑞科技有限公司

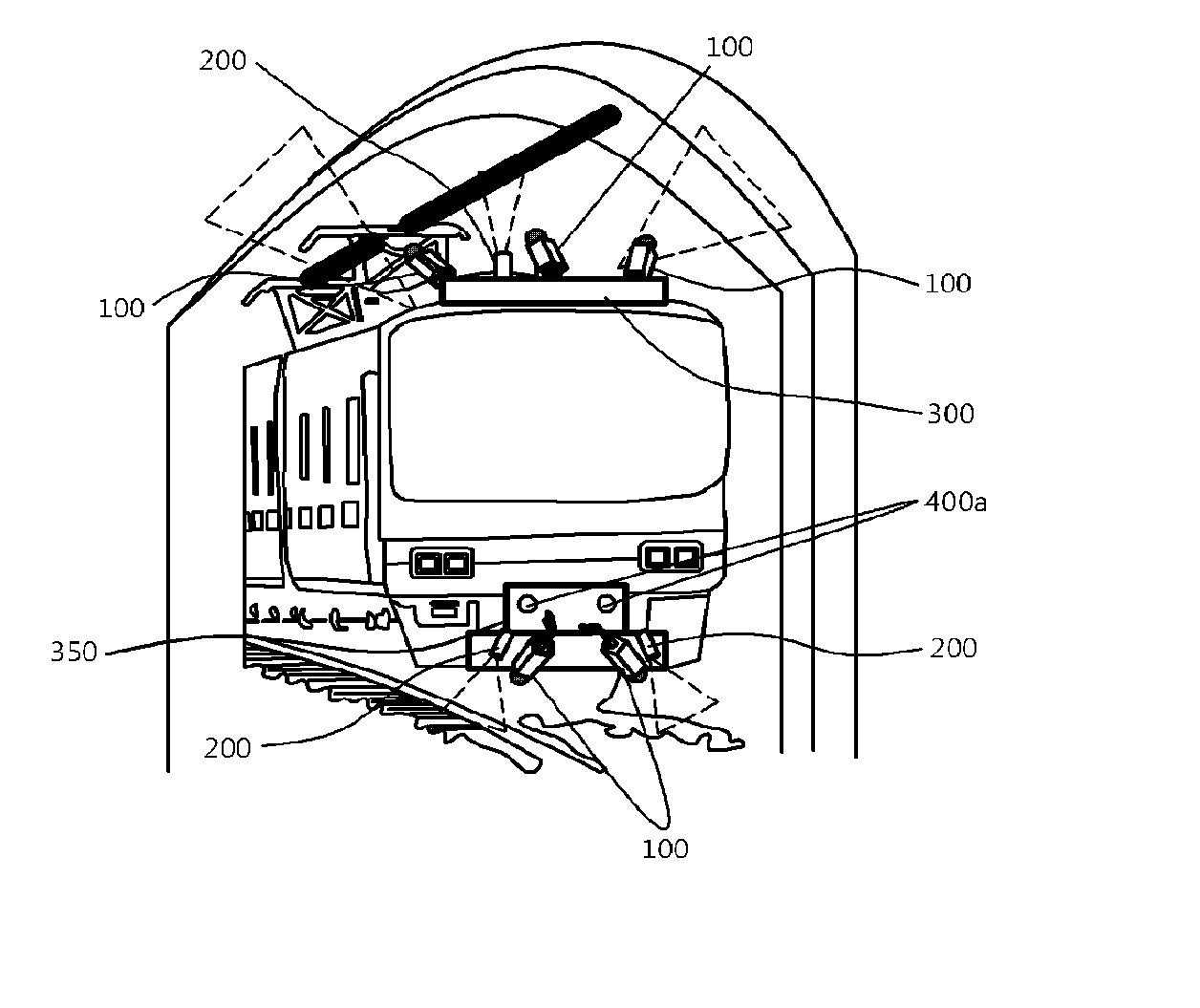

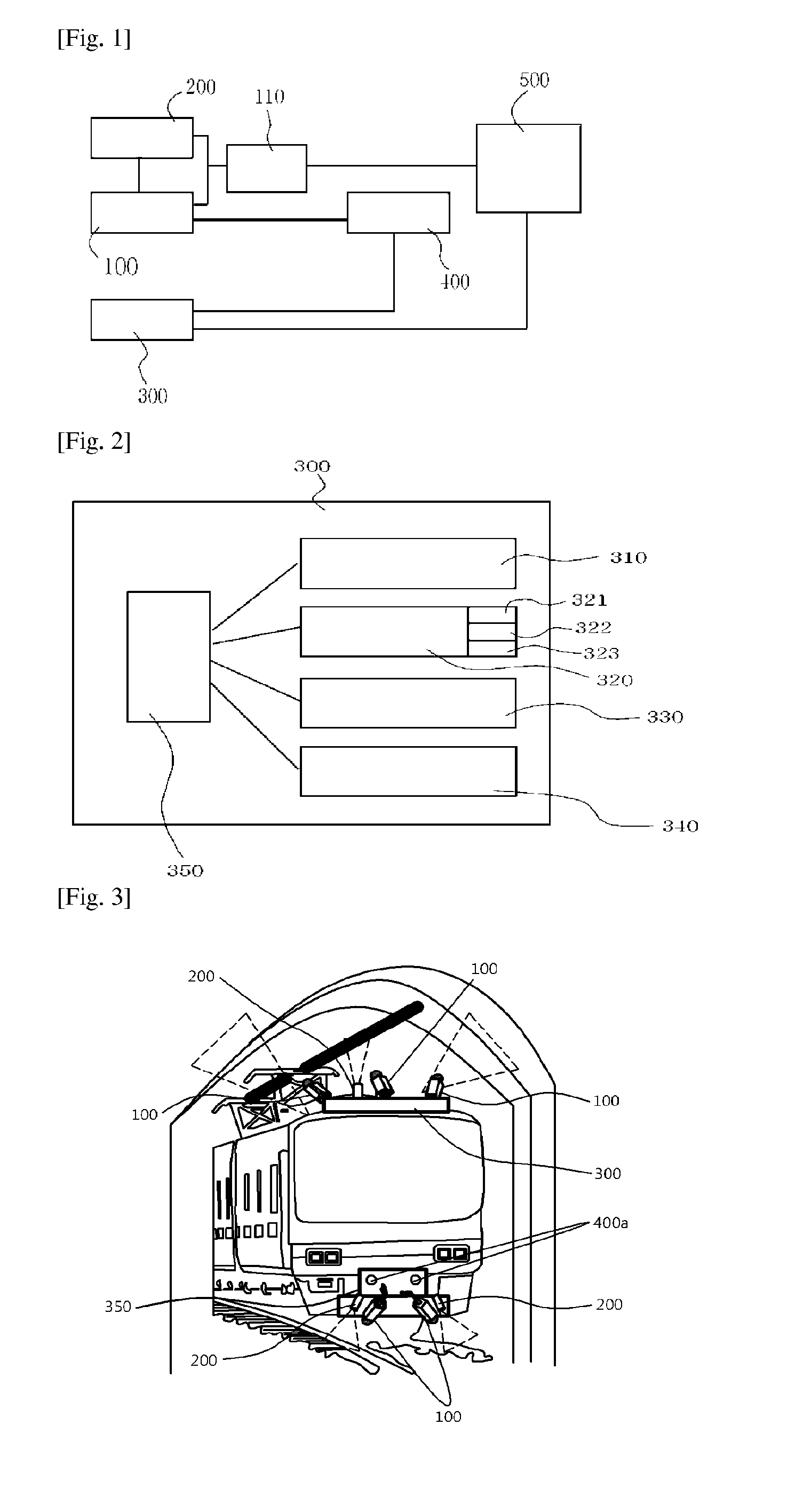

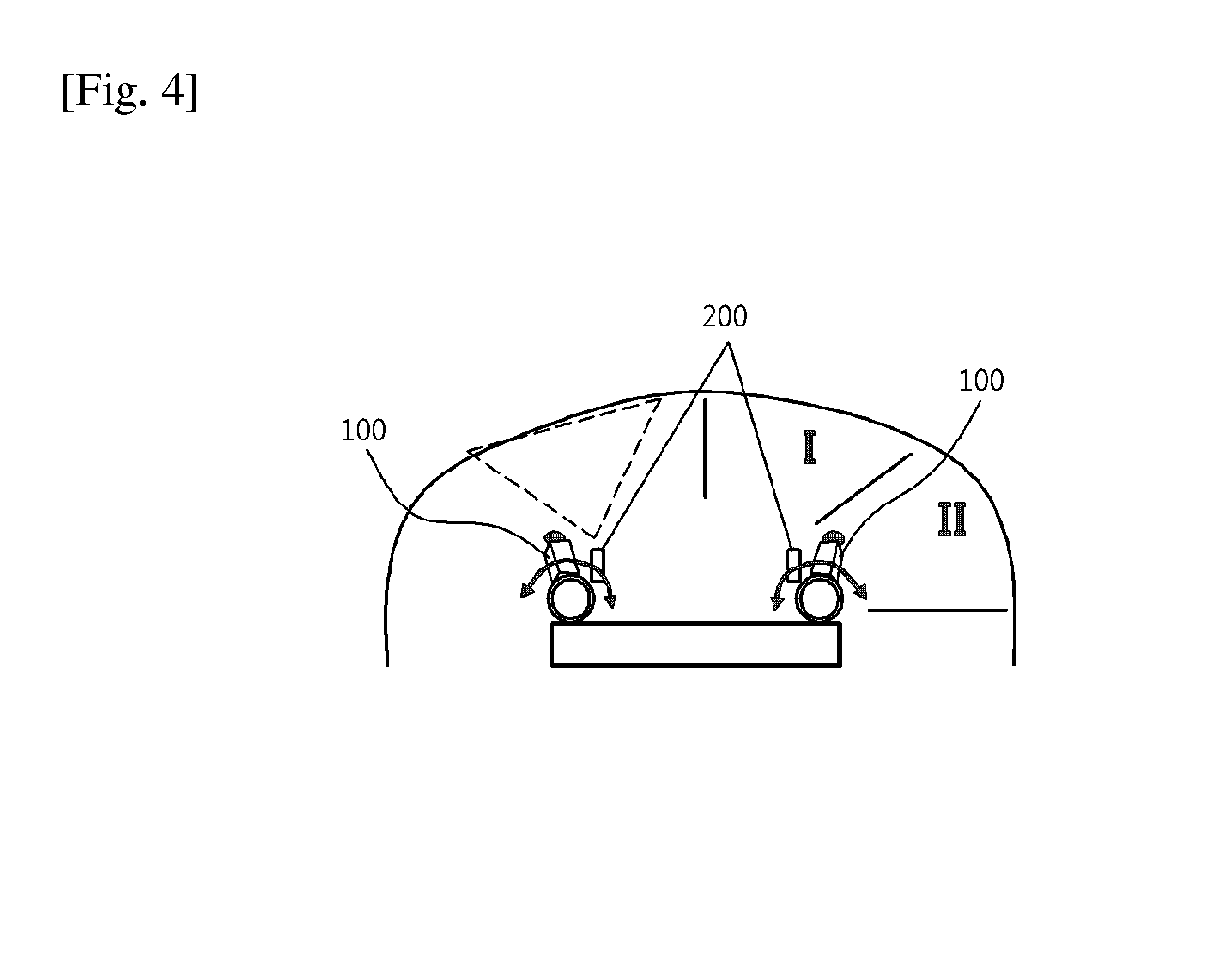

Railway installation synchronization monitoring system

InactiveUS20150145962A1Precision and reliability of dataHigh precisionClosed circuit television systemsRail derailment preventionMonitoring systemEngineering

A railway installation monitoring system may include: a laser generator that is provided on a train; a camera that is operated in connection with the laser generator so as to be capable of monitoring a railway installation and of acquiring image information data that is measured; a three-dimensional image information conversion device that uses the image information data acquired by the laser generator and the camera and converts the data into three-dimensional image information; a position determination unit that determines the position of the railway installation to be measured; a signal processing device that sends an operating command for the laser generator or / and the camera; and an overall data processing device that processes, analyzes, interprets, or stores the image information data, the three-dimensional image information, or the data transmitted from the position determination unit.

Owner:SMARTECH

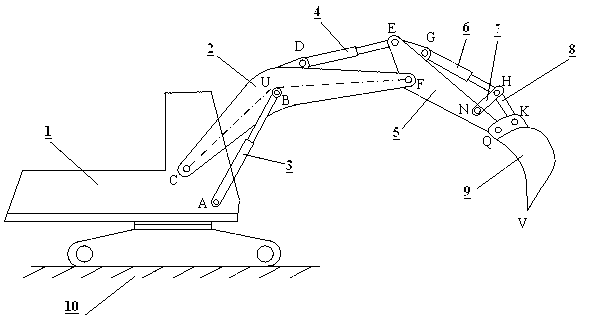

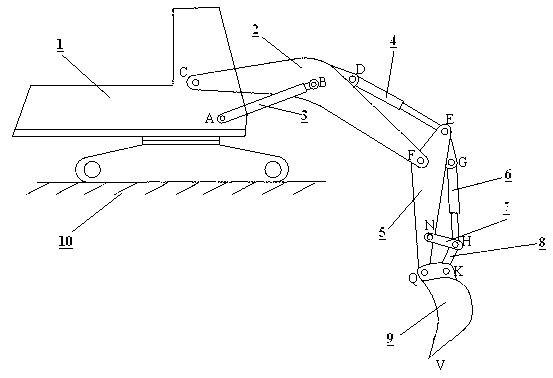

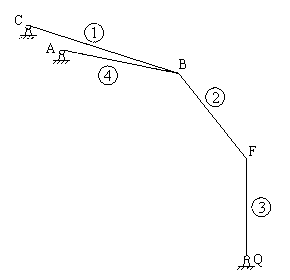

Design method for hinge points of pullshovel working device of monobucket hydraulic excavator

InactiveCN102720231ASimple designThe relative position is the sameMechanical machines/dredgersOptimal designIntelligent algorithms

The invention provides a design method for hinge points of a pullshovel working device of a monobucket hydraulic excavator and belongs to the technical field of monobucket hydraulic excavators. The design method for a hinge point (B) of a movable arm oil cylinder and a movable arm and a hinge point (F) of the movable arm and a bucket rod is characterized by comprising the following steps of: 1, selecting the size and the pose of the working device of an original excavator; 2, establishing a mechanism model; 3, enabling the movable arm oil cylinder to be equivalent to an equal-diameter rod during full shrinkage; 4, establishing a mechanism elastokinetics model; 5, establishing a system quality matrix and a stiffness matrix; 6, establishing constraints; 7, performing optimum design on the hinge point B; and 8, performing optimum design on the hinge point F. According to the method provided by the invention, the hinge points are designed through calculating the maximal hinge point position at natural frequency of the pullshovel working device by utilizing a particle swarm optimization intelligent algorithm, so that the method provided by the invention has the advantages of short design period, high programming degree, systematically improved dynamic characteristic of the pullshovel working device, and the like.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

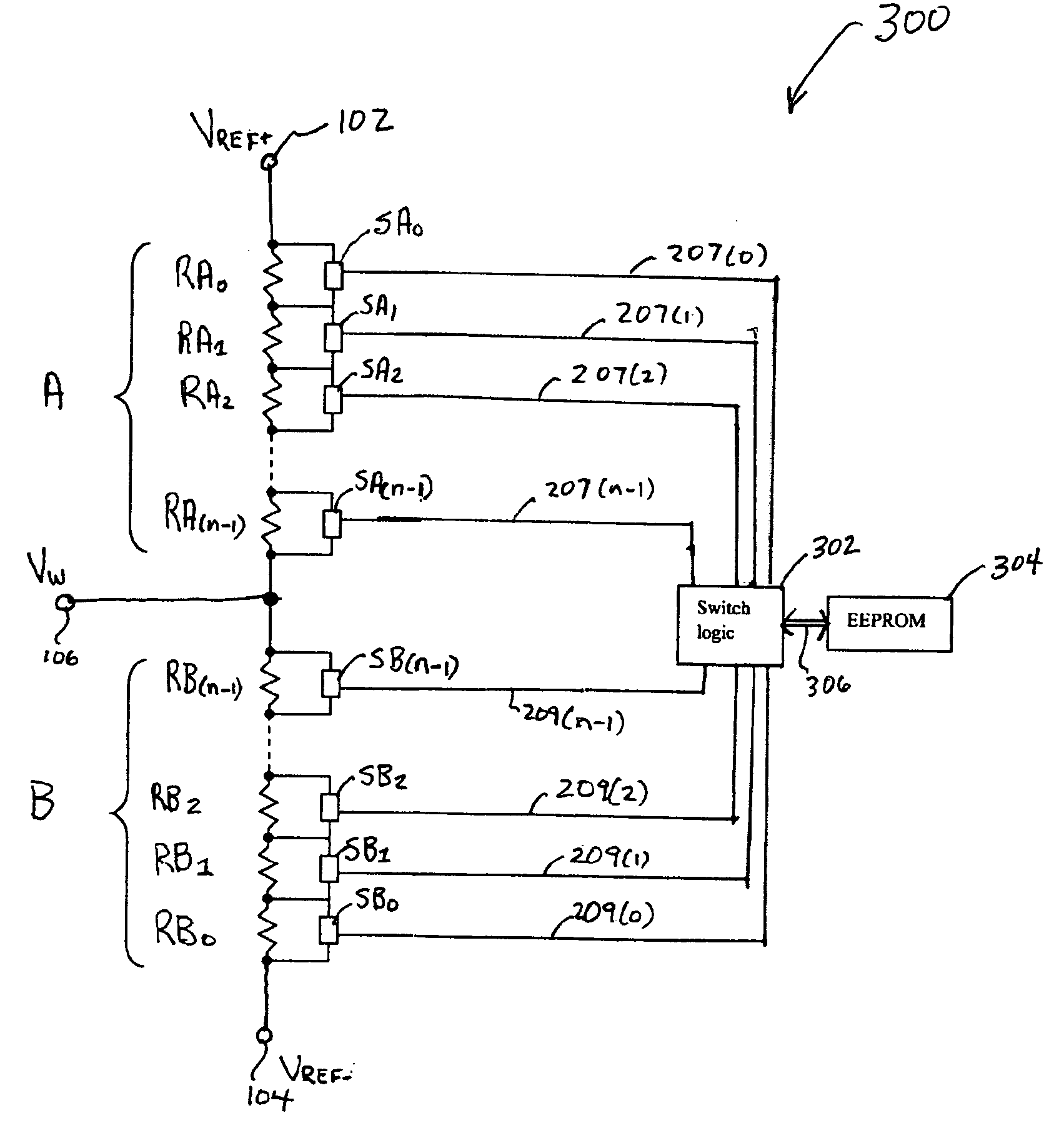

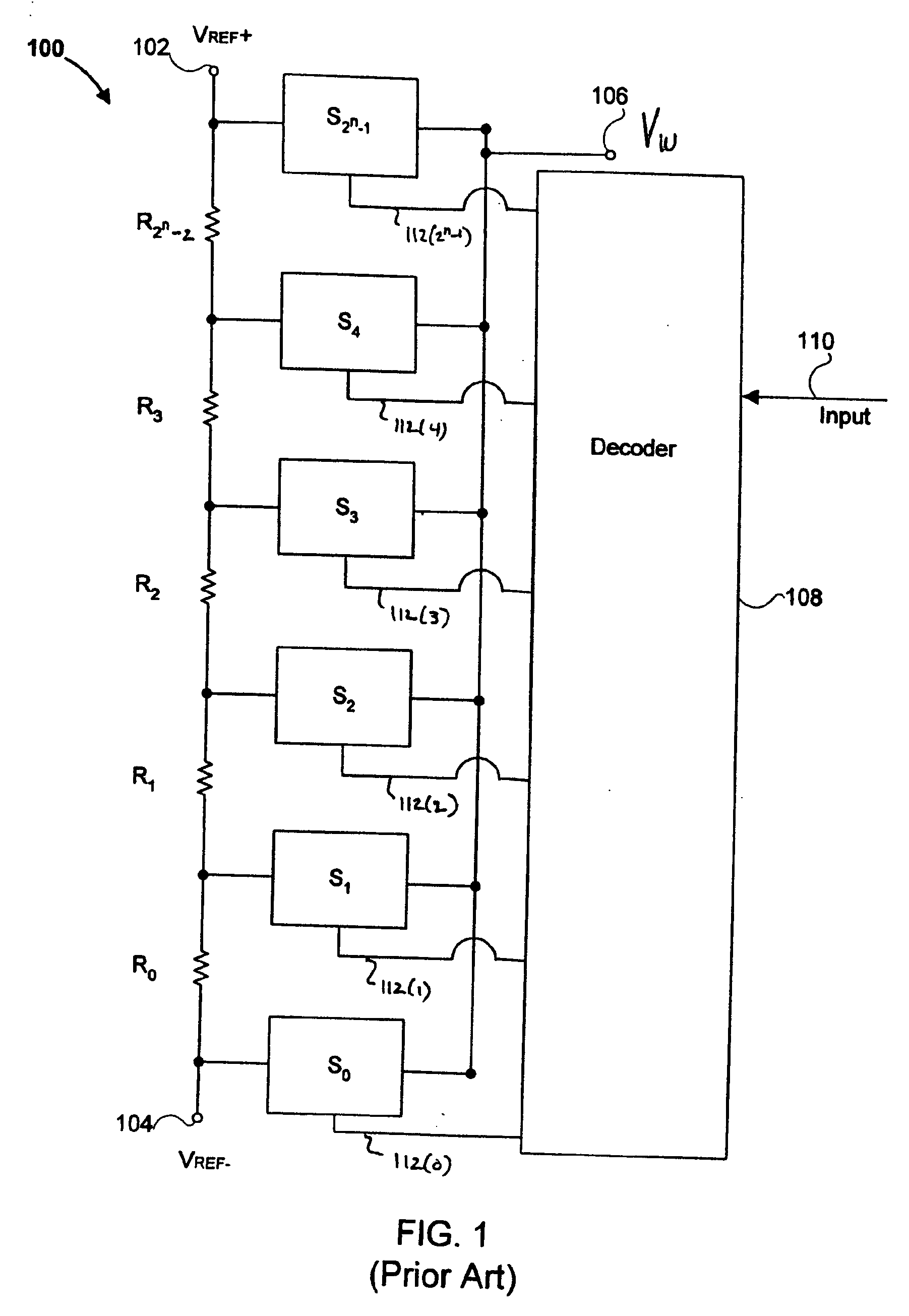

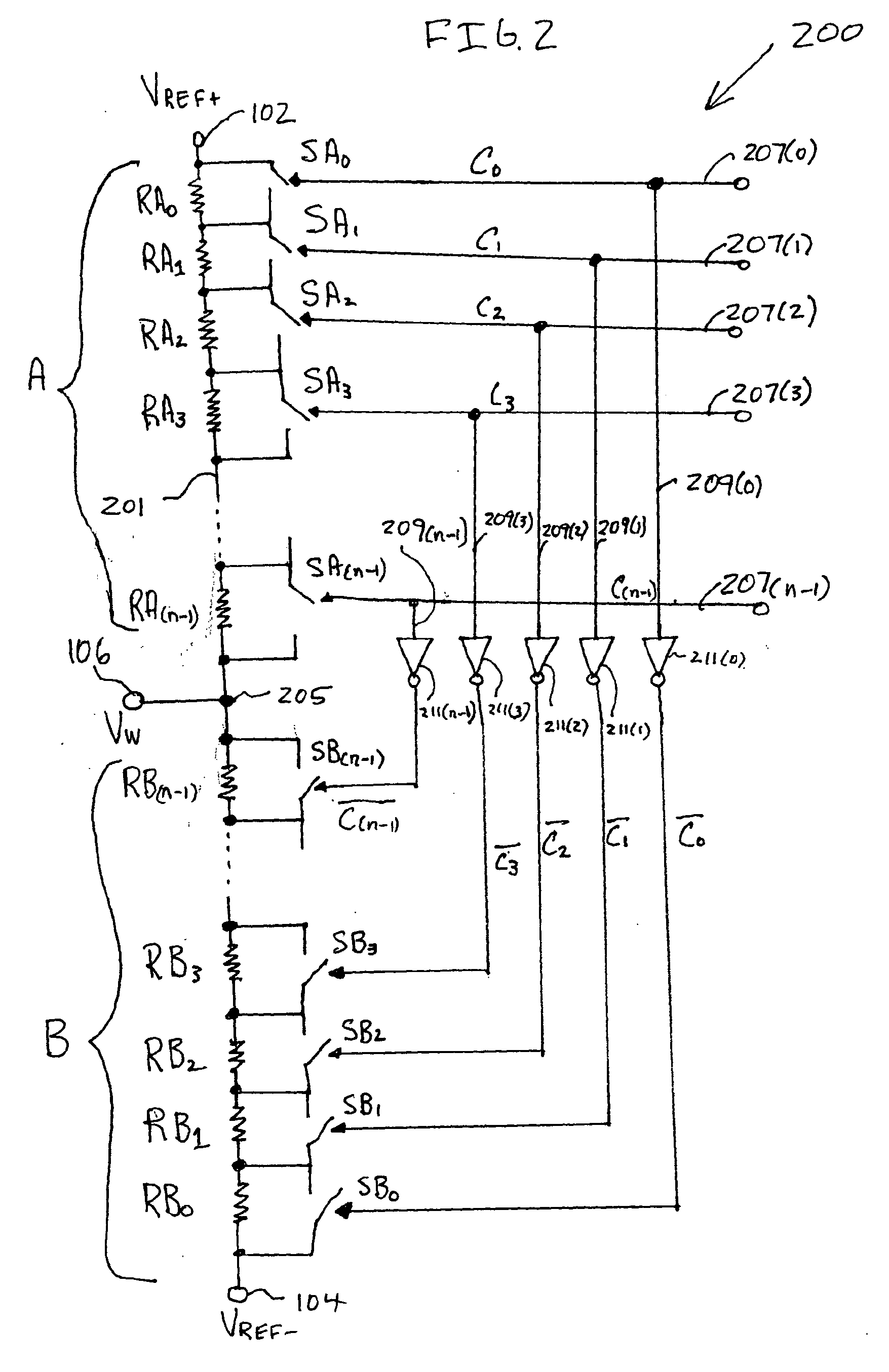

Digital potentiometer with resistor binary weighting decoding

ActiveUS20050270043A1Less componentsThe relative position is the sameMultiple-port networksElectric signal transmission systemsControl signalEngineering

A digital potentiometer includes a string of impedance units in series. The string includes identical first and second sets of impedance units whose individual impedance values increment by a power of two. One of a plurality of switches is coupled in parallel with each respective impedance unit. The switches that are coupled to the first set of impedance units receive logical control signals complementary to logical control signals received by the respective switches coupled to the second set of impedance units, so that for every impedance unit of the first set that is bypassed (not bypassed), the identical impedance unit of the second set is not bypassed (bypassed). The string may include only the first and second sets of impedance units, or may include at least one third impedance unit in series with the first and second sets in a multi-stage design.

Owner:SEMICON COMPONENTS IND LLC

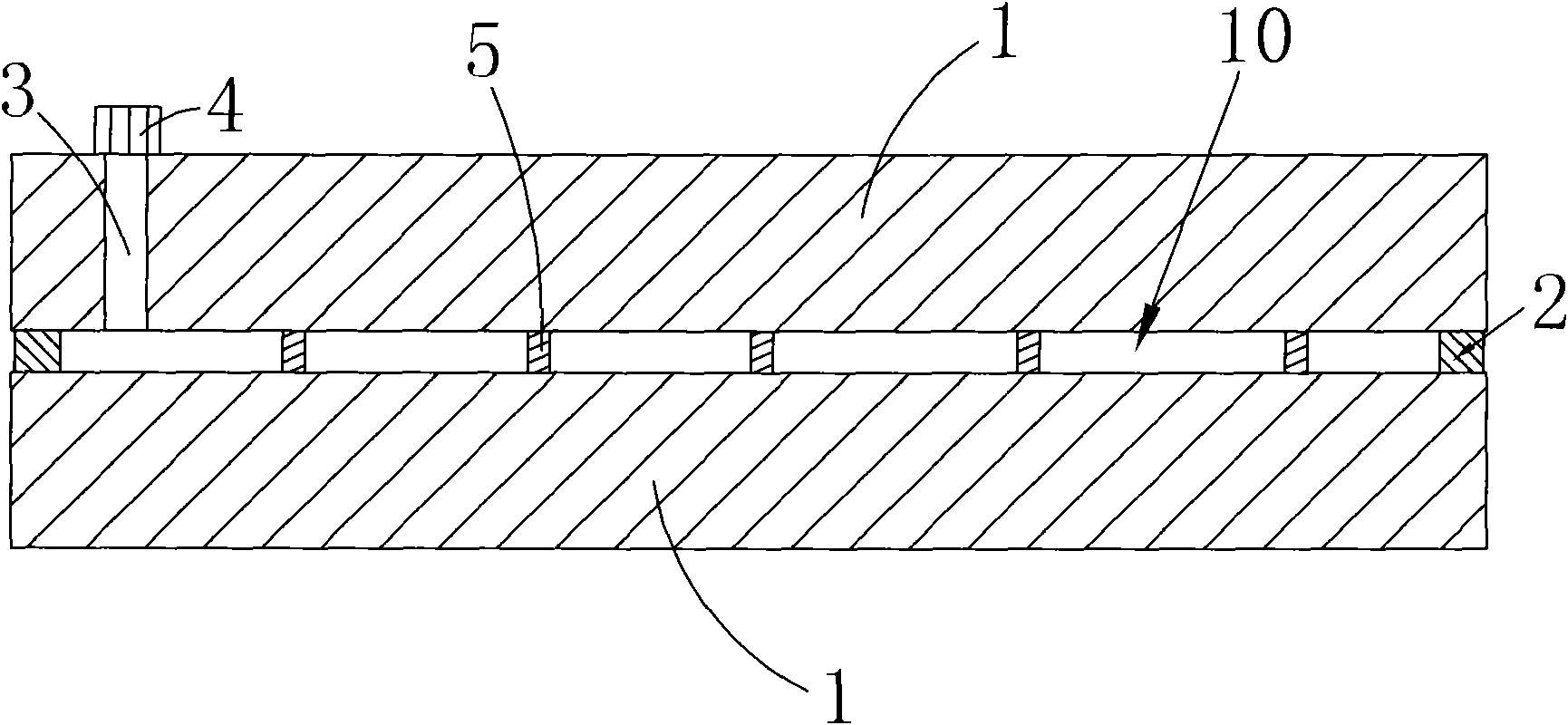

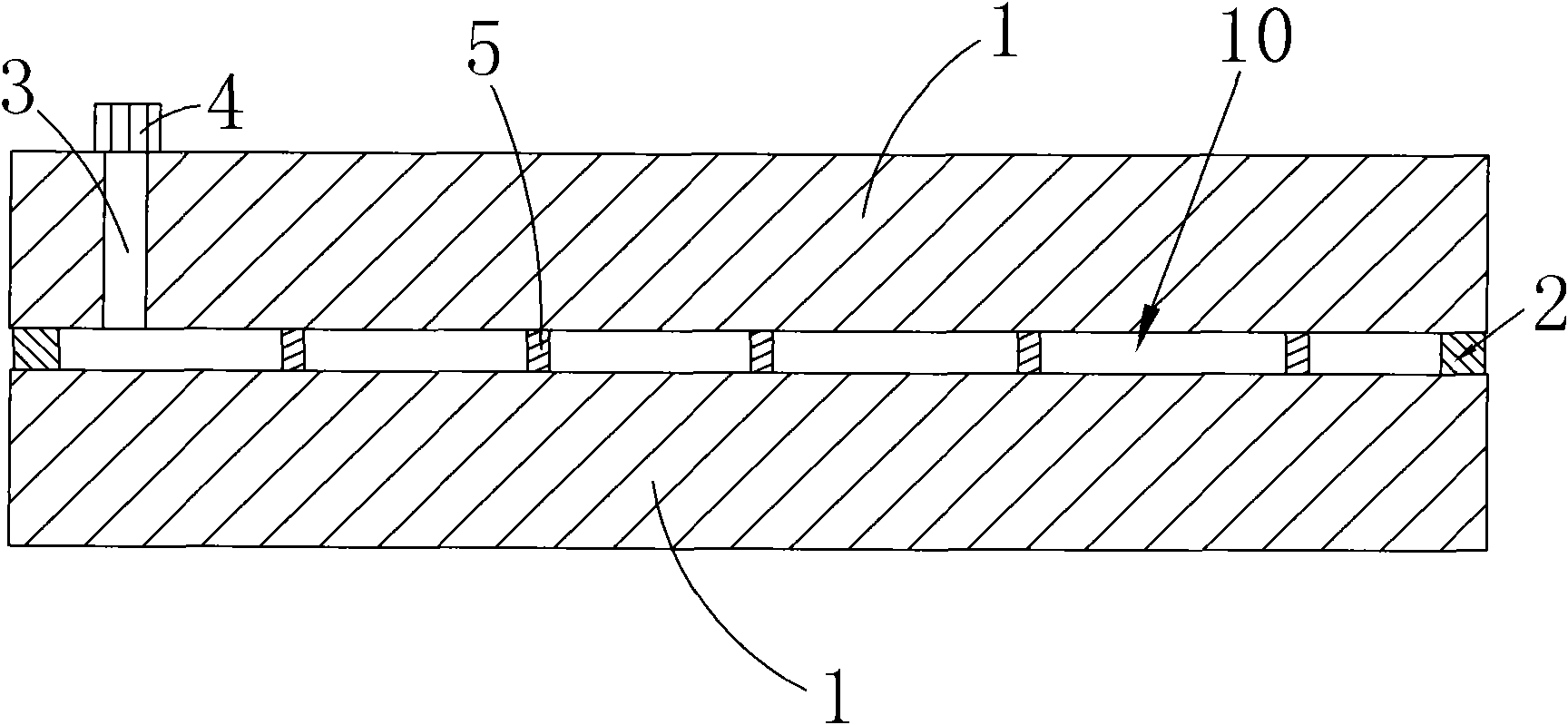

Heat and sound insulation vacuum glass and manufacturing method thereof

InactiveCN101898874AGood repeatability and visual effectIncrease productivityEngineeringElectrical and Electronics engineering

The invention discloses heat and sound insulation vacuum glass and a manufacturing method thereof. The vacuum glass comprises two parallel opposite glass plates; the two glass plates are sealed and bonded by sealing materials to form a sealed space; a suction opening is arranged on one of the glass plates; the space between the two glass plates is vacuumized through the suction opening; the suction opening is sealed by a sealed tube; a plurality of supports are printed and arranged on the inner wall of at least one of the glass plates; and a plurality of supports are supported between the two glass plates. Because the printing technology is very mature at home, the same positions of the supports among all products are effectively ensured; the invention has the characteristics of good repeatability and visual effect, high production efficiency and low production cost; and the supports and the glass plate on which the supports are positioned are sintered, hardened and melted into a whole so that the supports can be positioned permanently, thereby effectively preventing the surface of the vacuum glass from being deformed.

Owner:林嘉宏

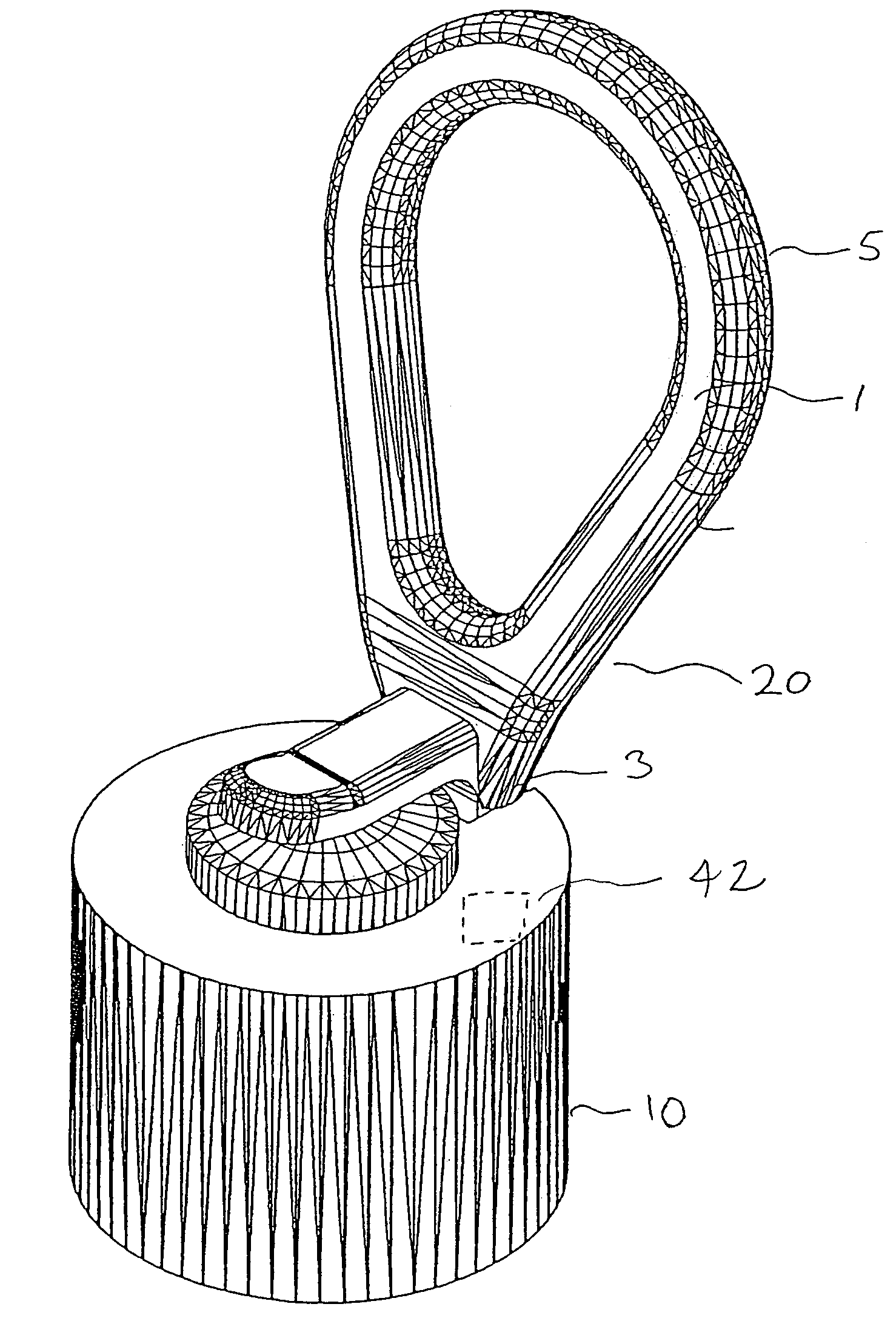

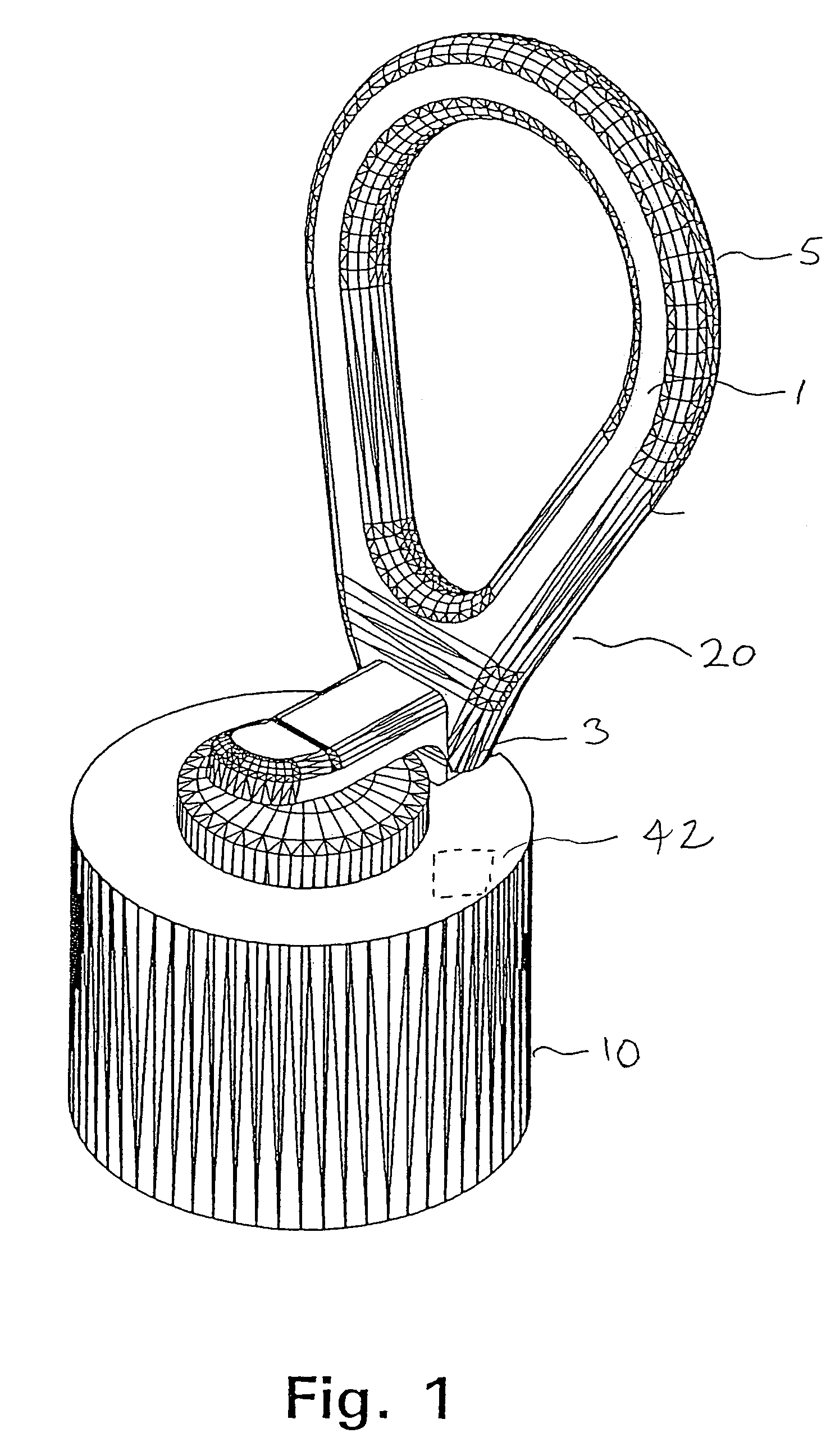

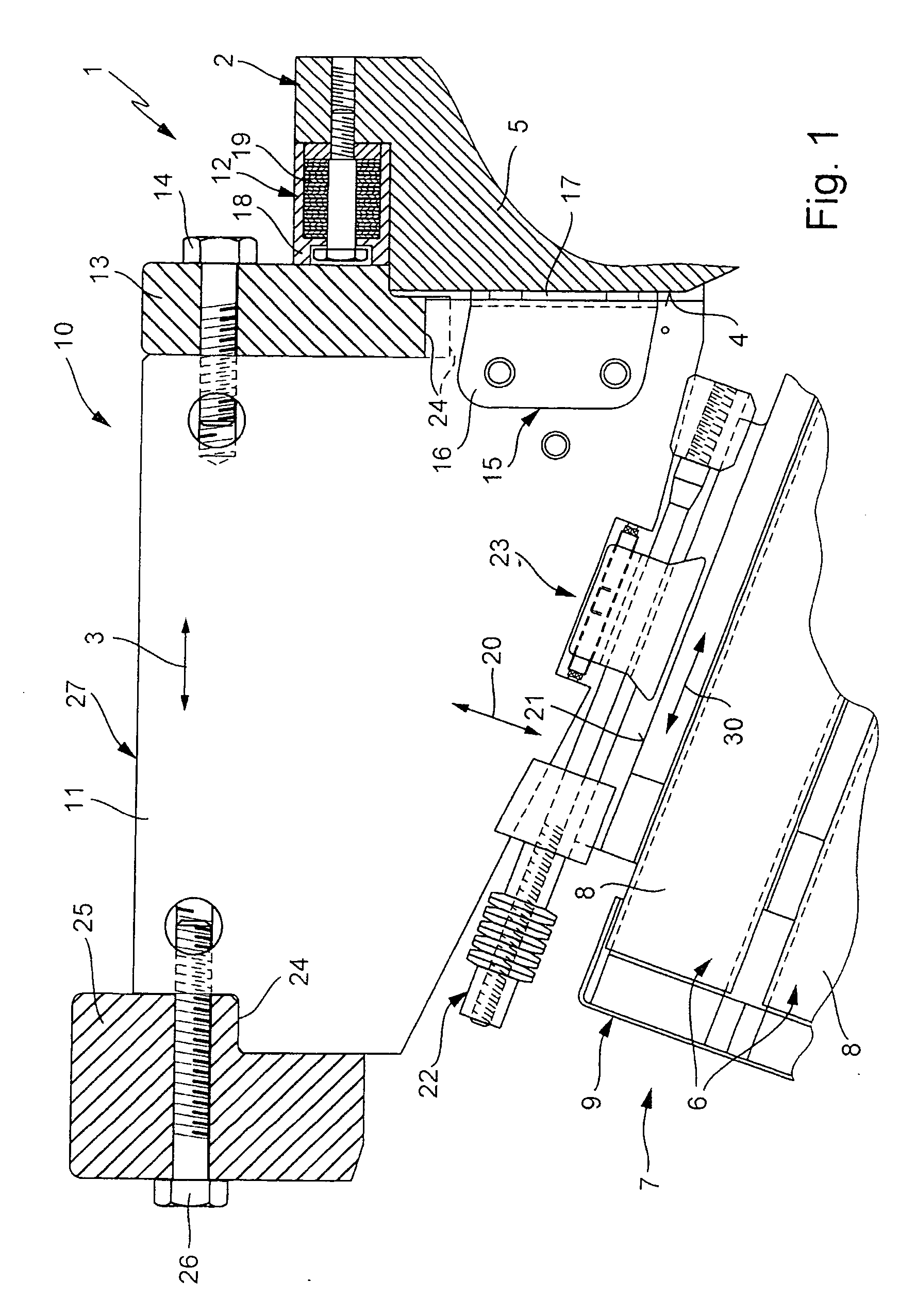

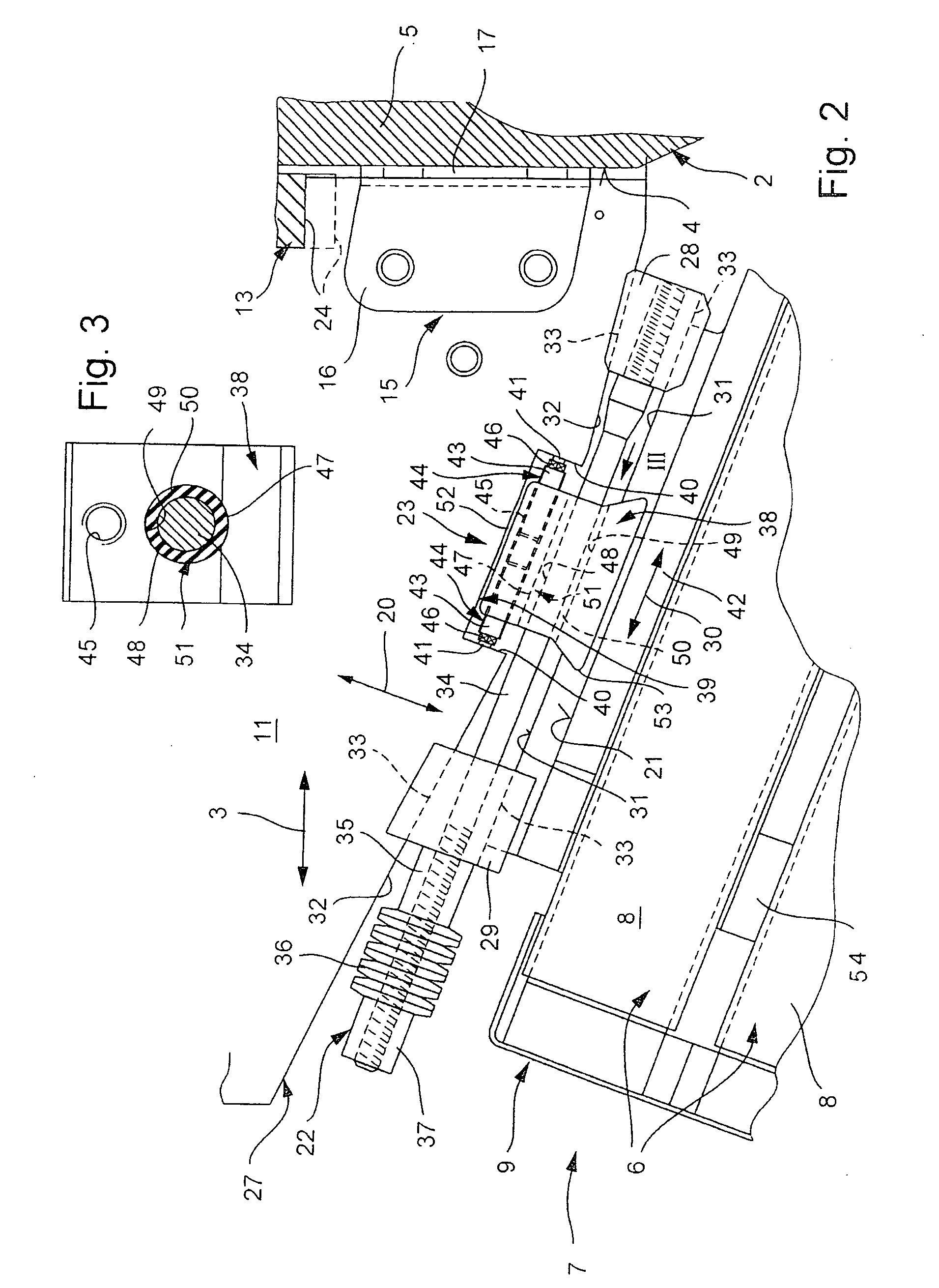

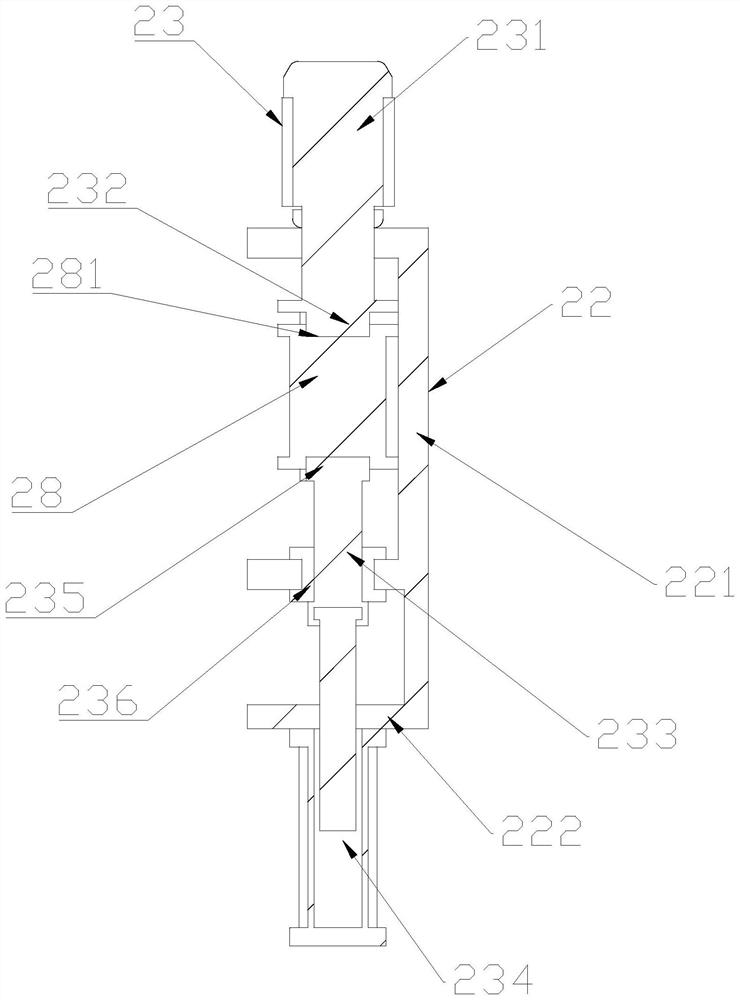

Apparatus for supporting a stator end winding

InactiveUS20050029898A1Improve fatigue lifeAvoids undesirable stressWindingsCooling/ventillation arrangementPower stationEngineering

An apparatus (10) for supporting a winding (7) on a stator (1), in particular on a generator stator in a power station. The winding (7) has an end winding (9) which is supported axially on the core (2) of the stator (1) via winding supports (11) of the supporting apparatus (10). The winding supports (11) are supported on the end winding (9) via a stressing device (22), at right angles to an envelope surface (21). In order to improve the axial position between the winding support (11) and the end winding (9) during operation of the stator (1), a coupling device (23) is provided which allows relative movements between the end winding (9) and the winding support (11) in the circumferential direction and at right angles to the envelope surface (21), and prevents such relative movements in an envelope line direction (30).

Owner:ALSTOM TECH LTD

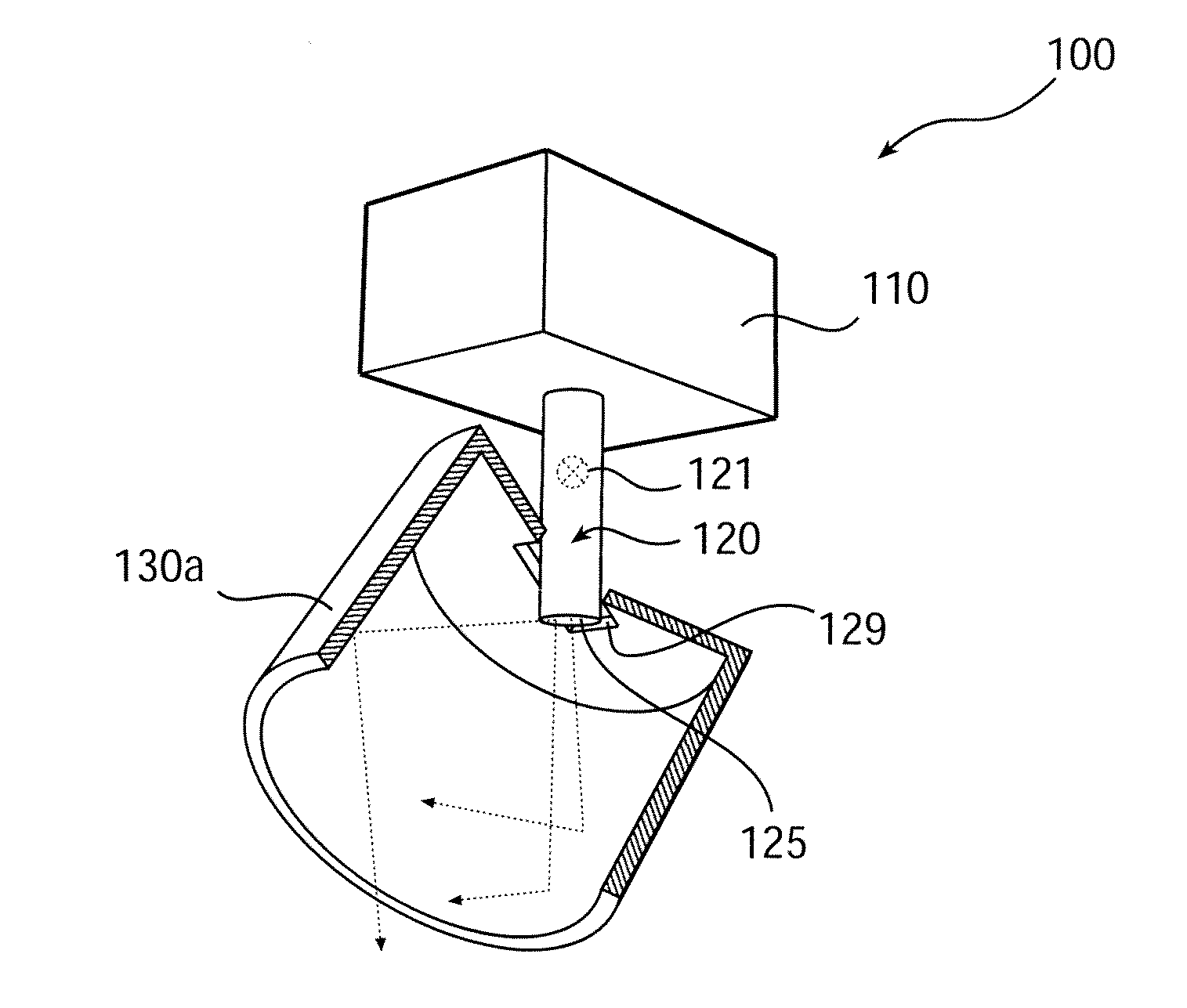

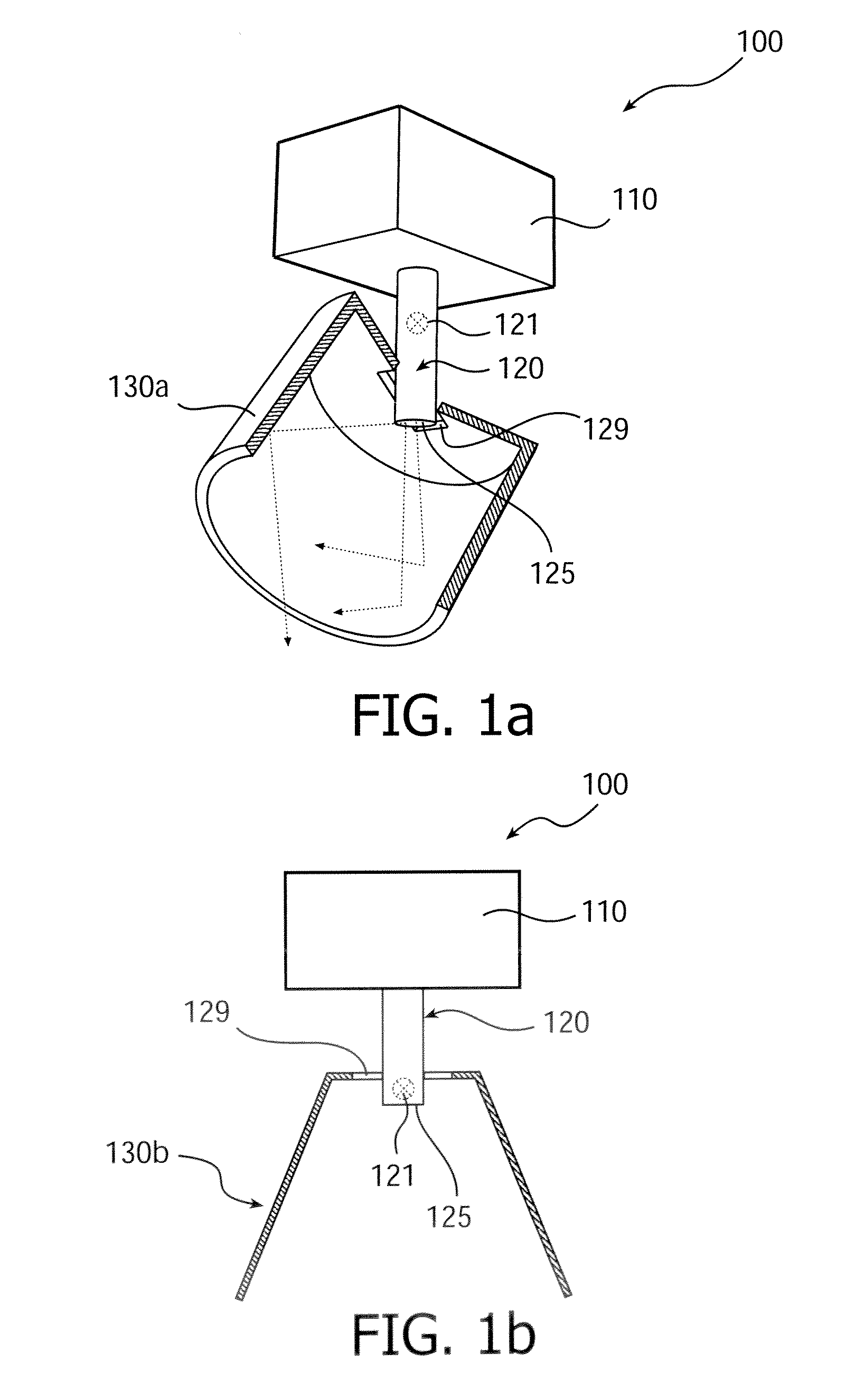

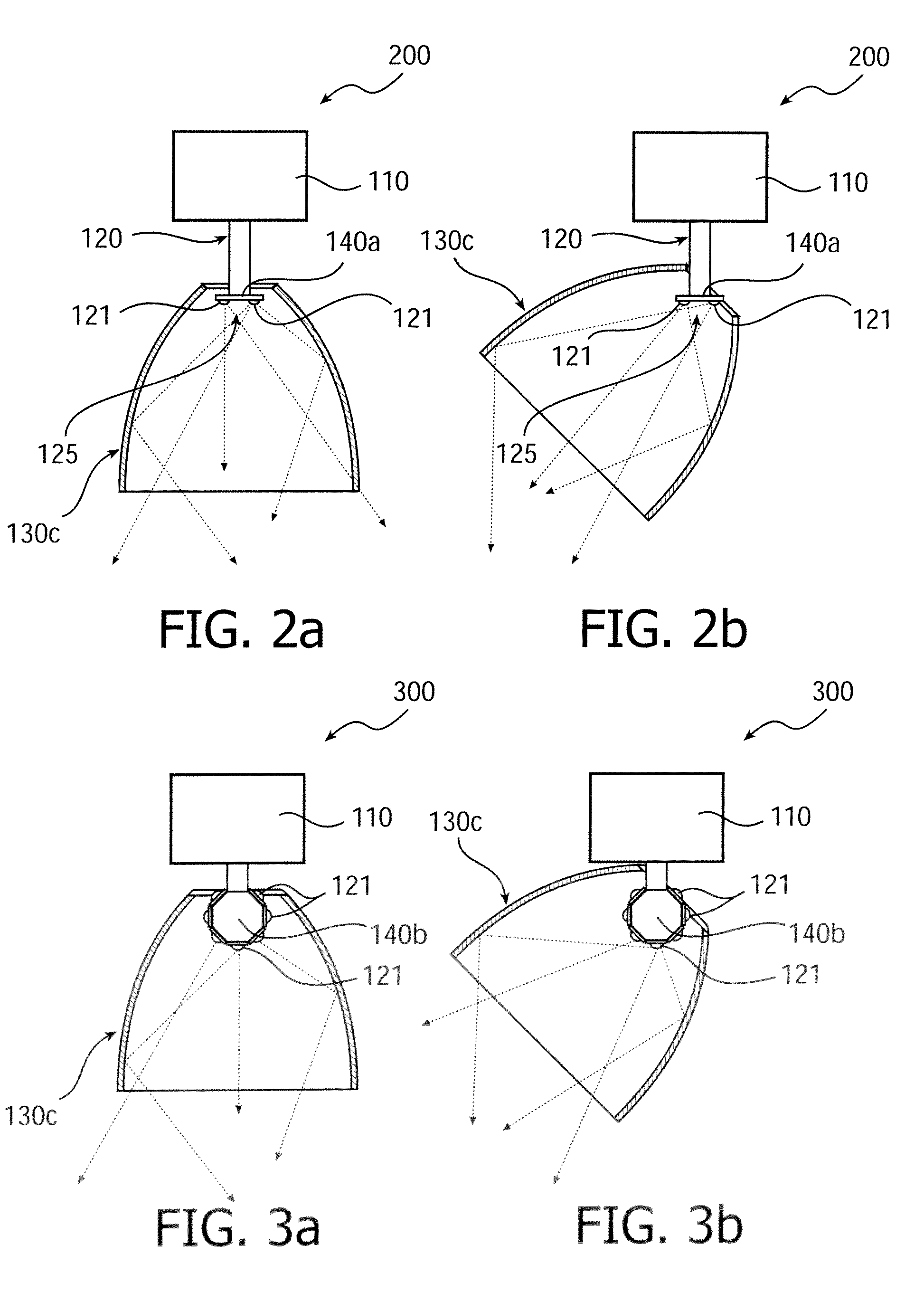

Light emitting device and luminaire

InactiveUS20120002435A1Improve efficiencyReduce riskLighting support devicesPoint-like light sourceLight emitting deviceLight source

This invention relates to a light emitting device (100) having a movable collimating unit for adjusting the output direction of light being emitted from the light emitting device. The light emitting device comprises a base unit (110), and a light output unit (120) which is engaged with the base unit. The light output unit comprises at least one light source (121) for emitting light. The light emitting device further comprises a movably arranged collimating unit (130) for adjusting the direction of the emitted light, which is arranged such that it encompasses a light output portion (125), which is arranged on the light output unit.

Owner:SIGNIFY HLDG BV +1

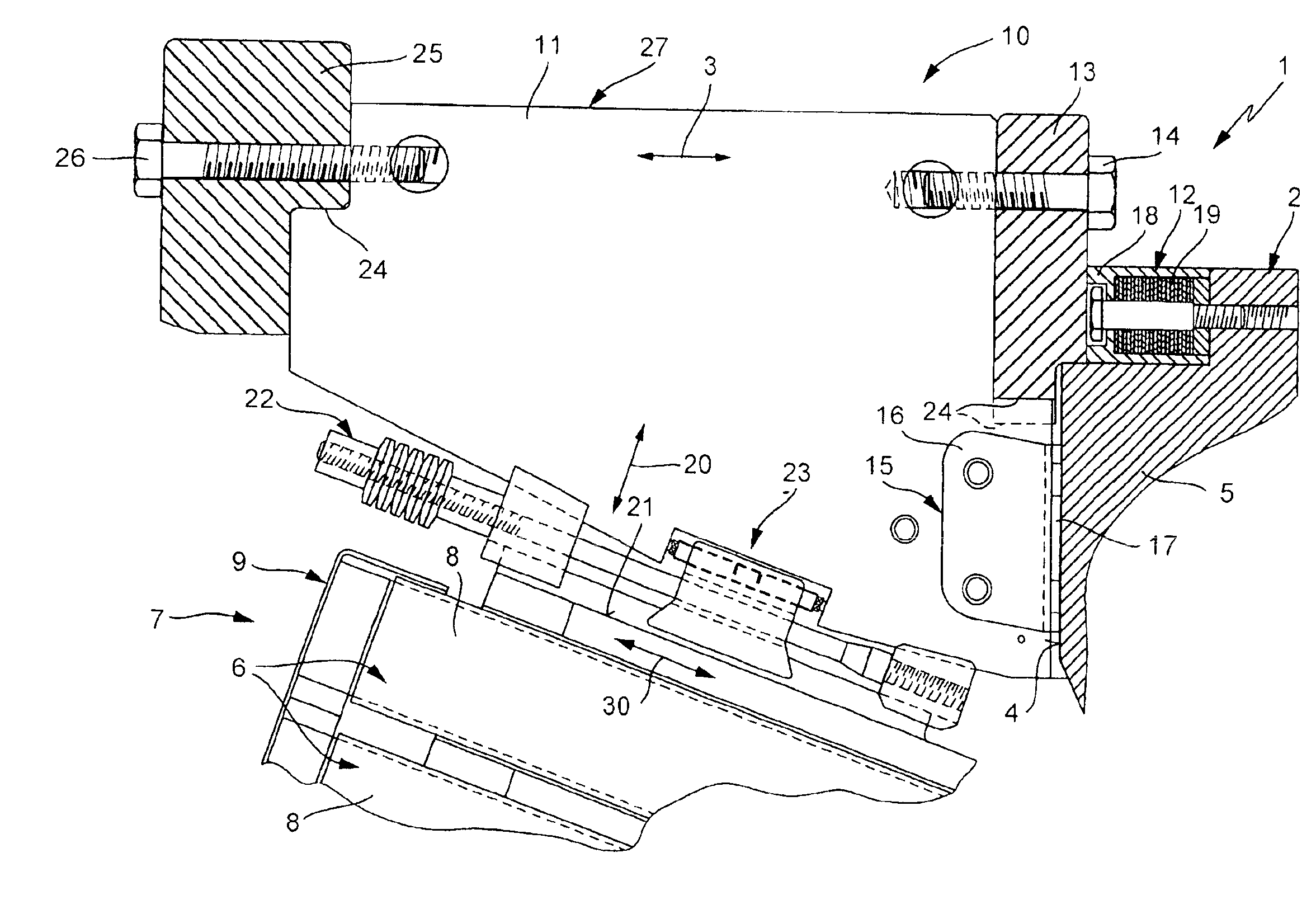

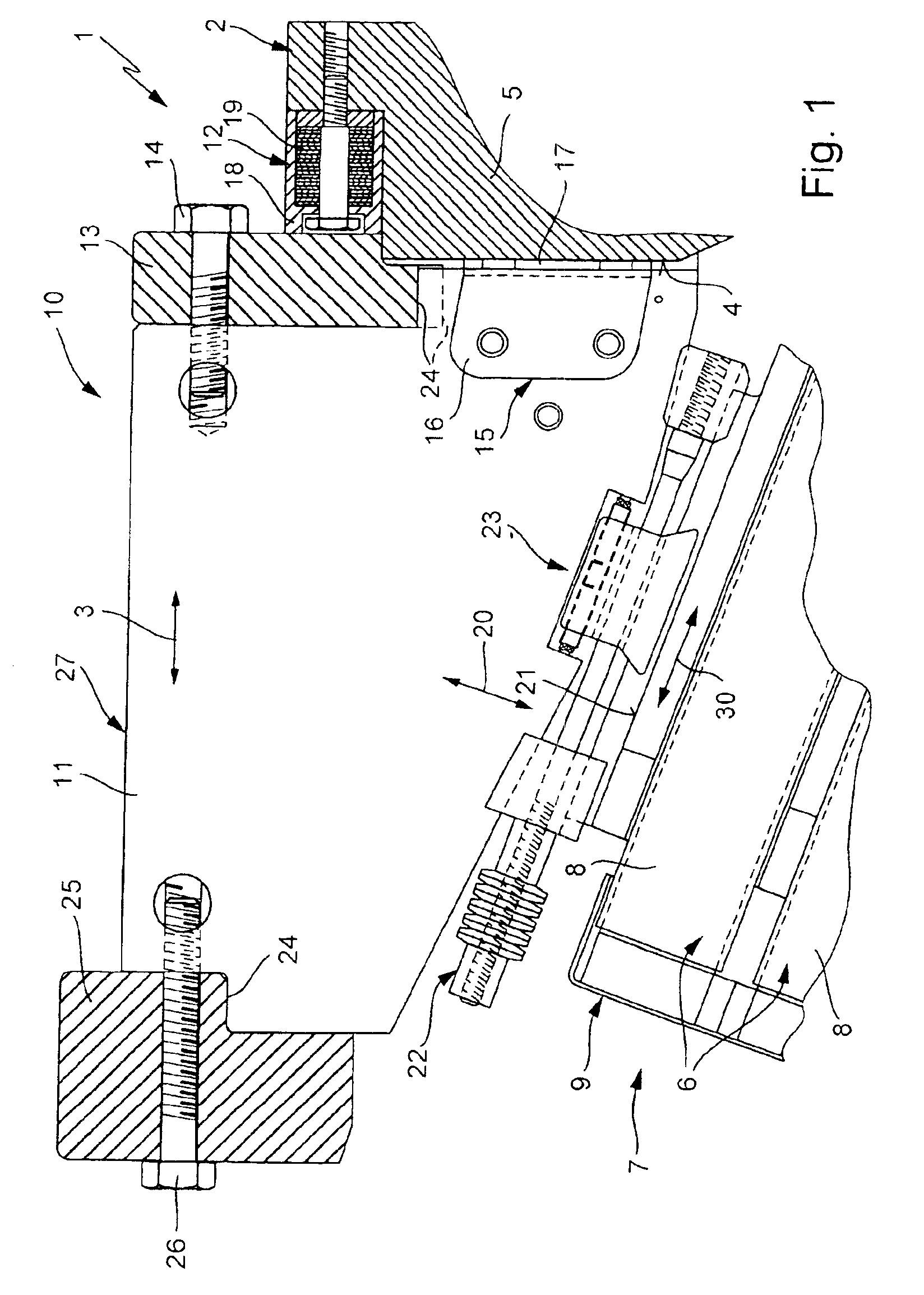

Apparatus for supporting a stator end winding

InactiveUS6965184B2Avoids undesirable stressThe relative position is the sameWindingsPower stationEngineering

An apparatus (10) for supporting a winding (7) on a stator (1), in particular on a generator stator in a power station. The winding (7) has an end winding (9) which is supported axially on the core (2) of the stator (1) via winding supports (11) of the supporting apparatus (10). The winding supports (11) are supported on the end winding (9) via a stressing device (22), at right angles to an envelope surface (21). In order to improve the axial position between the winding support (11) and the end winding (9) during operation of the stator (1), a coupling device (23) is provided which allows relative movements between the end winding (9) and the winding support (11) in the circumferential direction and at right angles to the envelope surface (21), and prevents such relative movements in an envelope line direction (30).

Owner:ALSTOM TECH LTD

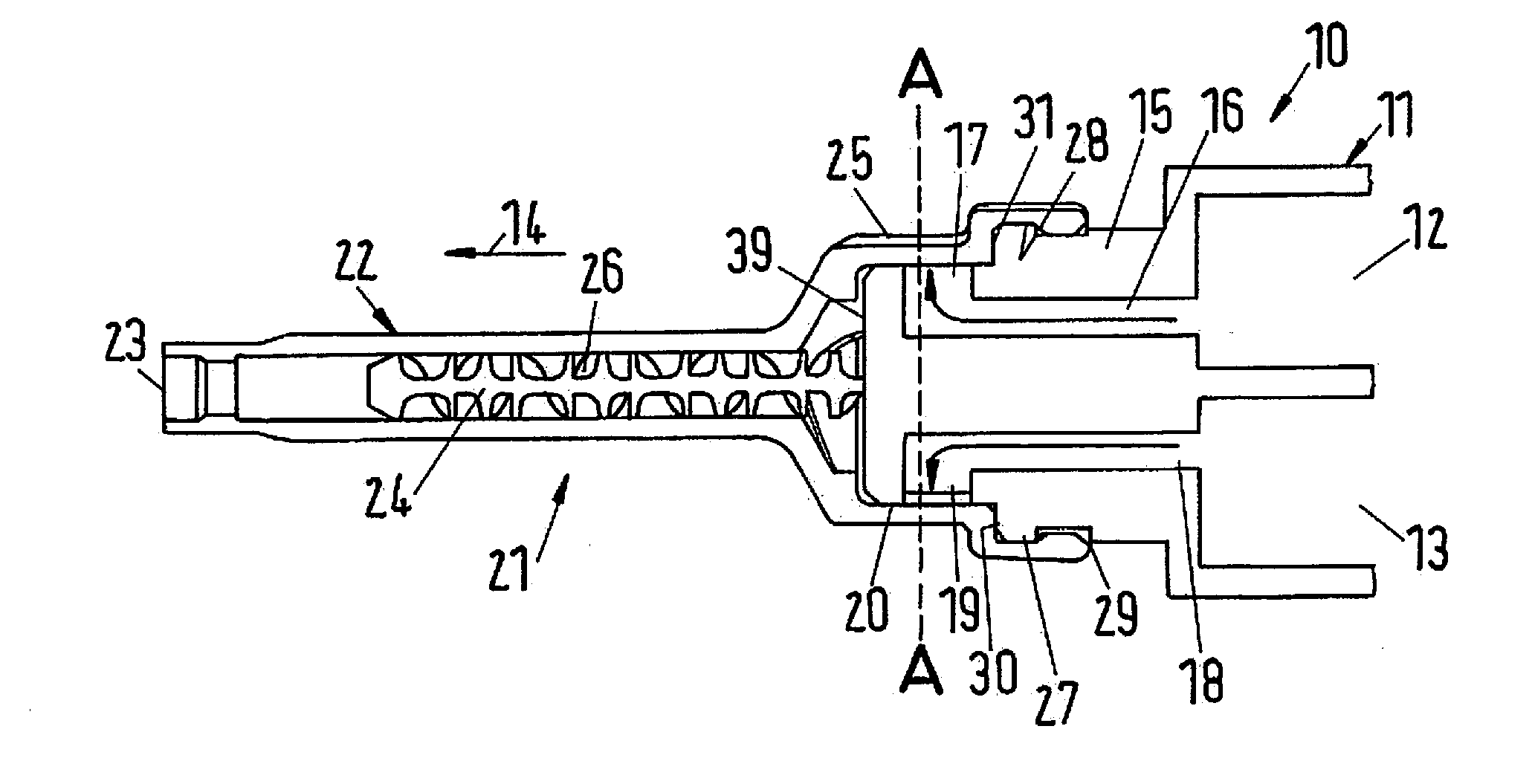

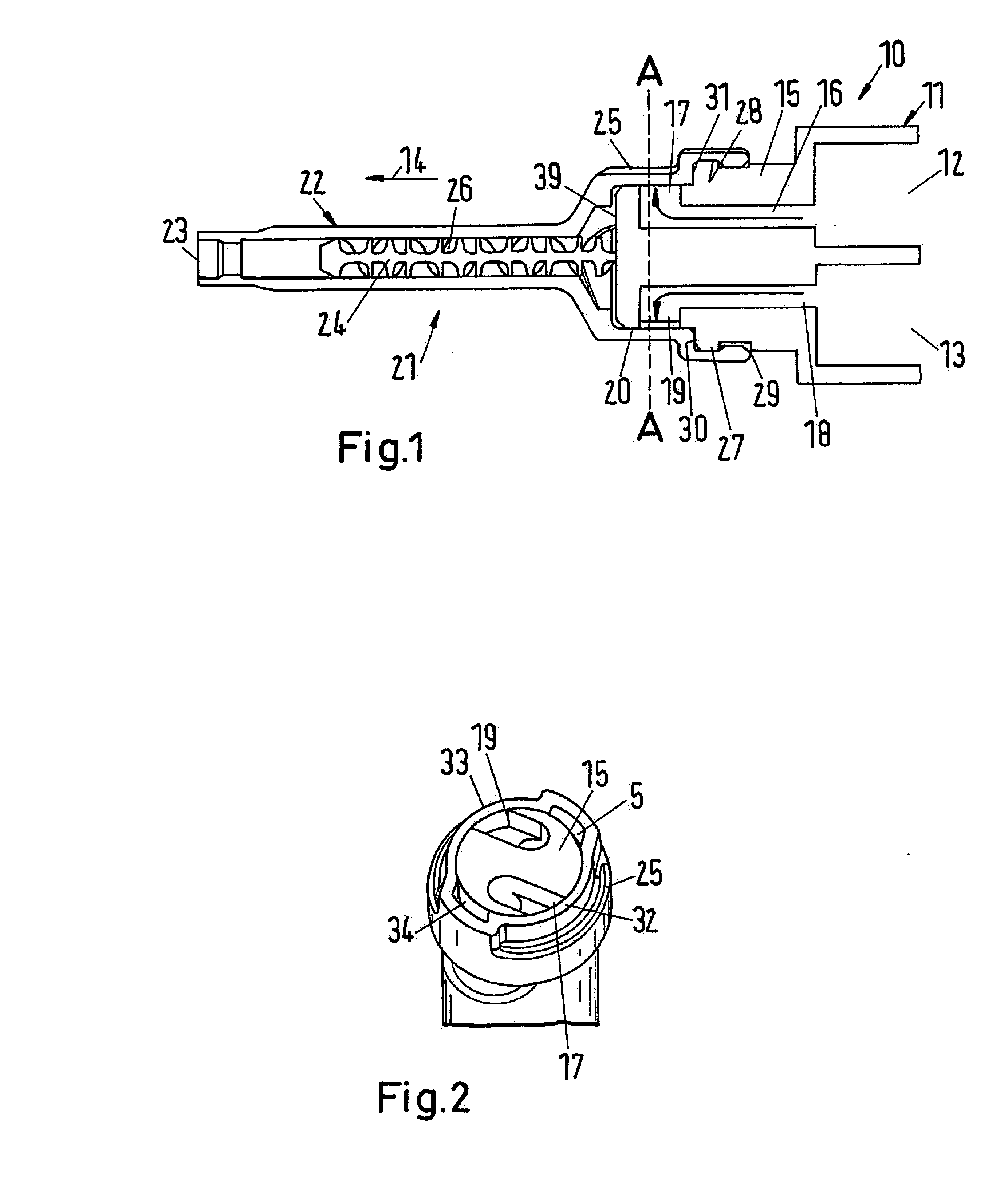

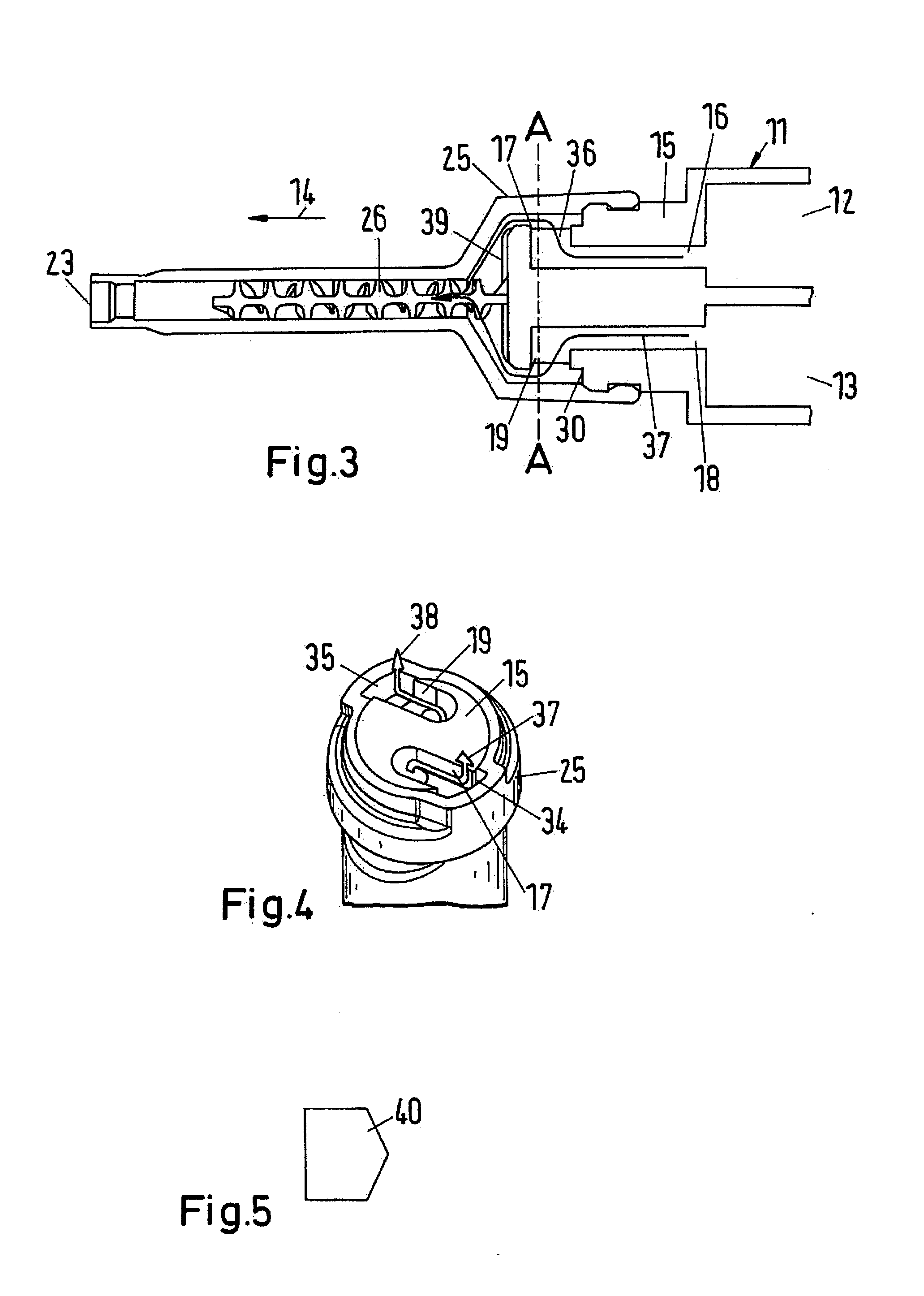

Discharging device

InactiveUS20150291339A1Simply and inexpensively manufacturingEasy to fillLiquid surface applicatorsLiquid transferring devicesIndustrial engineeringFlange

A dispensing apparatus includes a storage container having an outlet flange with a component outlet which is at least partly surrounded by an inlet flange. The inlet flange is configured to adopt a closed position and a dispensing position with respect to the outlet flange. A change from the closed position into the dispensing position is carried out by a rotation of the inlet flange with respect to the outlet flange. The component outlet is arranged at a cylindrical jacket surface of the outlet flange. The first component outlet is closed by the inlet flange in the closed position of the inlet flange. In the dispensing position, a connection is established by a crossover passage between the first component outlet and a dispensing opening.

Owner:SULZER MIXPAC AG

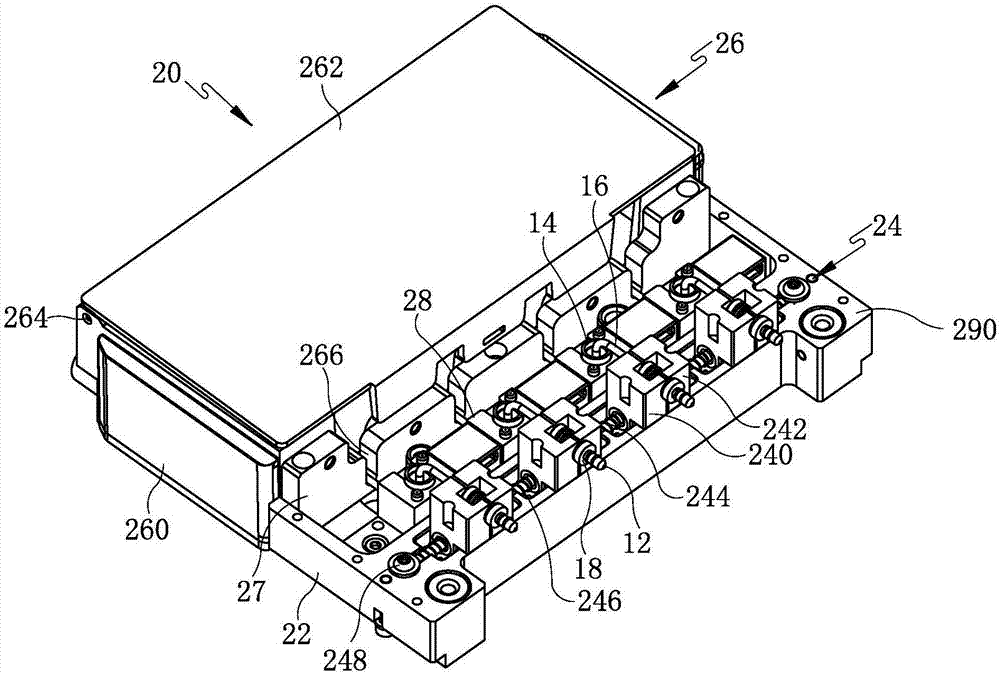

Locating and shaping device

ActiveCN107008773AImprove consistencyAchieve shapingMetal-working feeding devicesPositioning devicesEngineering

The invention discloses a locating and shaping device and relates to the technical field of product shaping equipment. The locating and shaping device comprises an attraction locating device and a shaping device. The attraction locating device comprises an attraction locating assembly capable of longitudinally moving. The attraction locating assembly comprises multiple clamping blocks capable of transversely moving. The clamping blocks can provide transverse clamping force for products. The shaping device comprises an upper shaping device body and a lower shaping device body, wherein the upper shaping device body and the lower shaping device are oppositely arranged on the upper side and the lower side of an installation base plate correspondingly. The portion, corresponding to the shaping device, of the installation base plate is provided with a vertically-through hole. The upper shaping device body and the lower shaping device body each comprise a shaping plate capable of moving up and down. Each shaping plate is provided with shaping grooves adaptable to the structure of components to be shaped. The locating and shaping device can achieve accurate locating of the product, the shaped product components are good in consistency, the shaping efficiency is high, the yield of the products can be improved, automatic product is facilitated, and the production cost of an enterprise is reduced.

Owner:GOERTEK INC

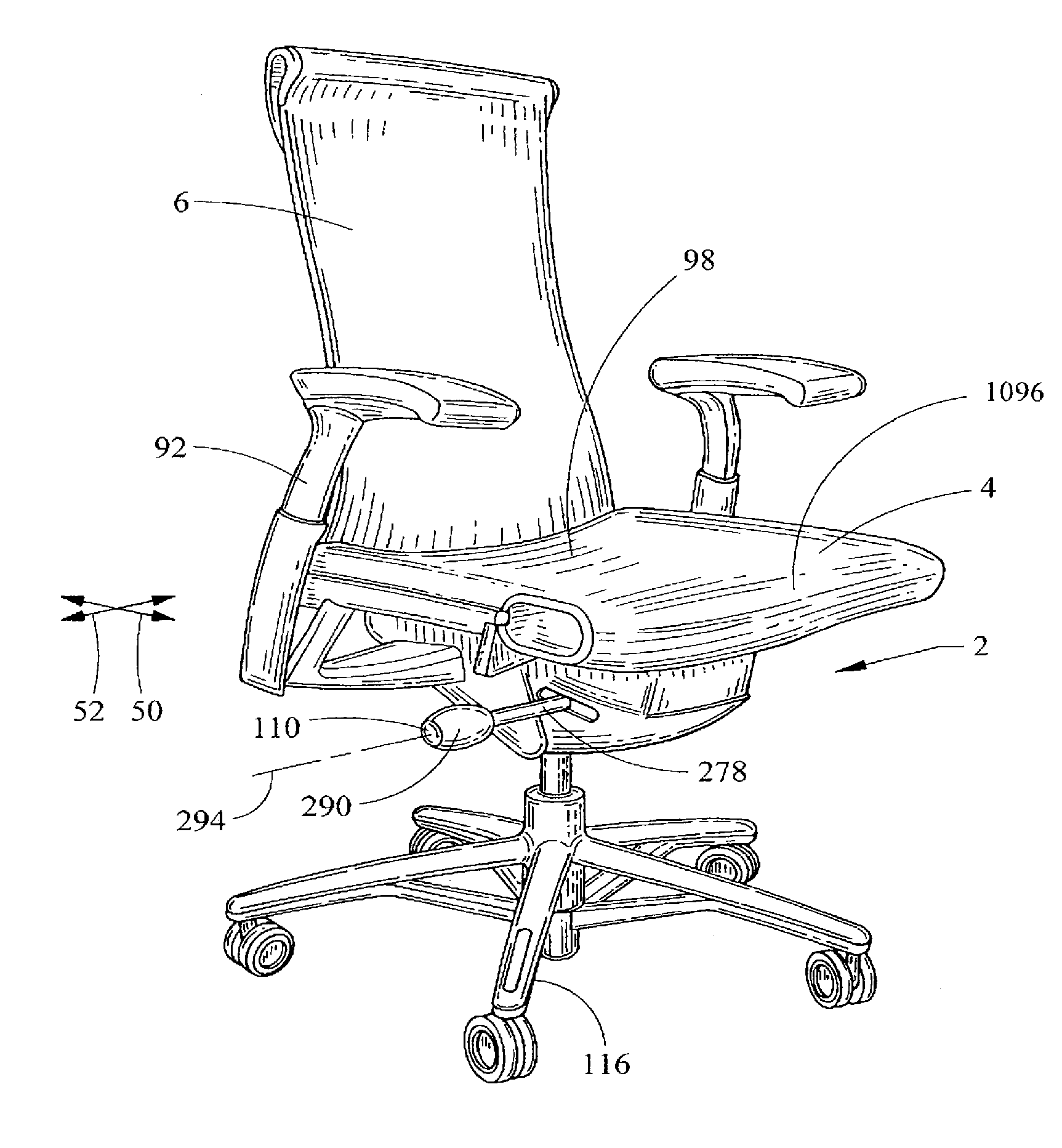

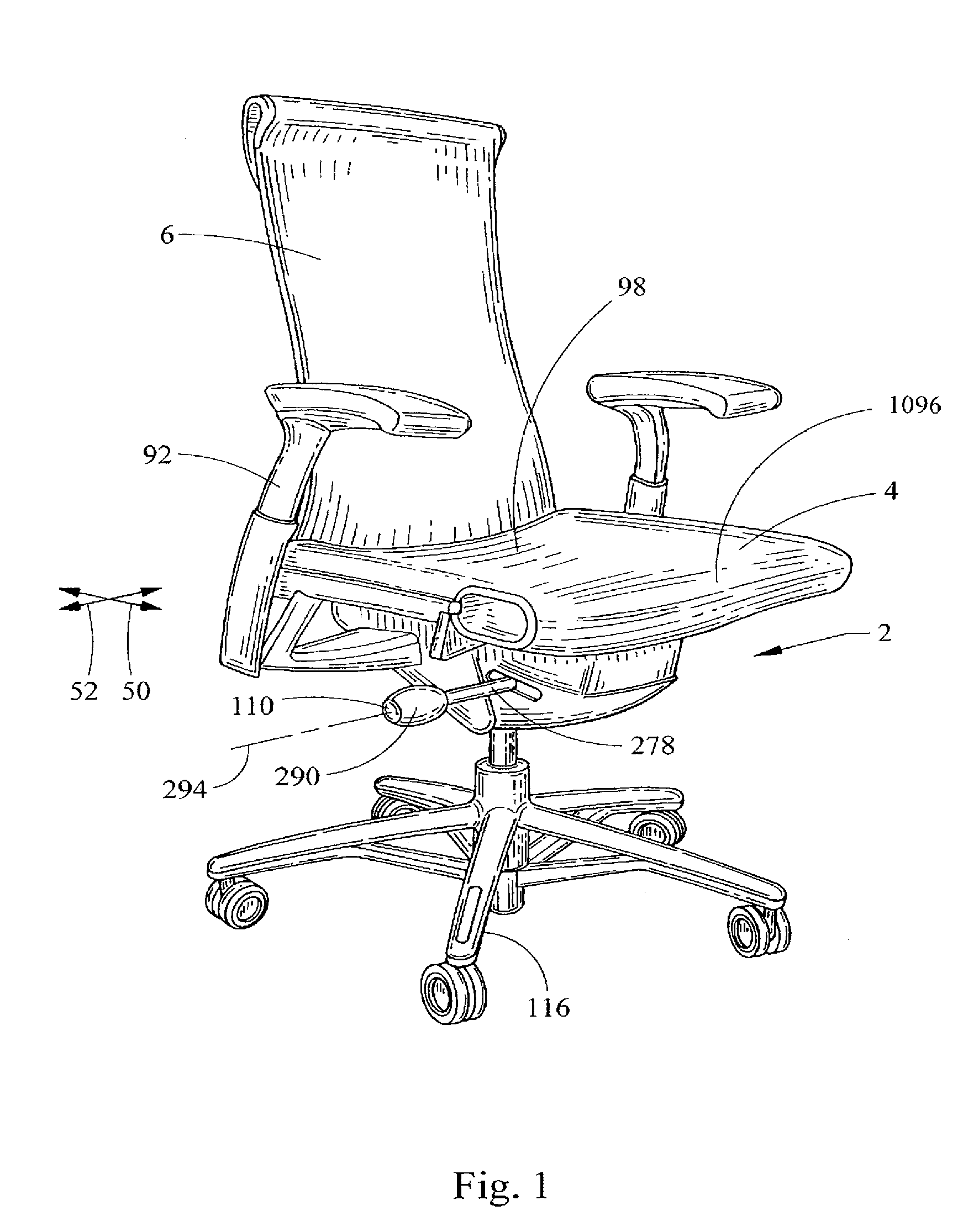

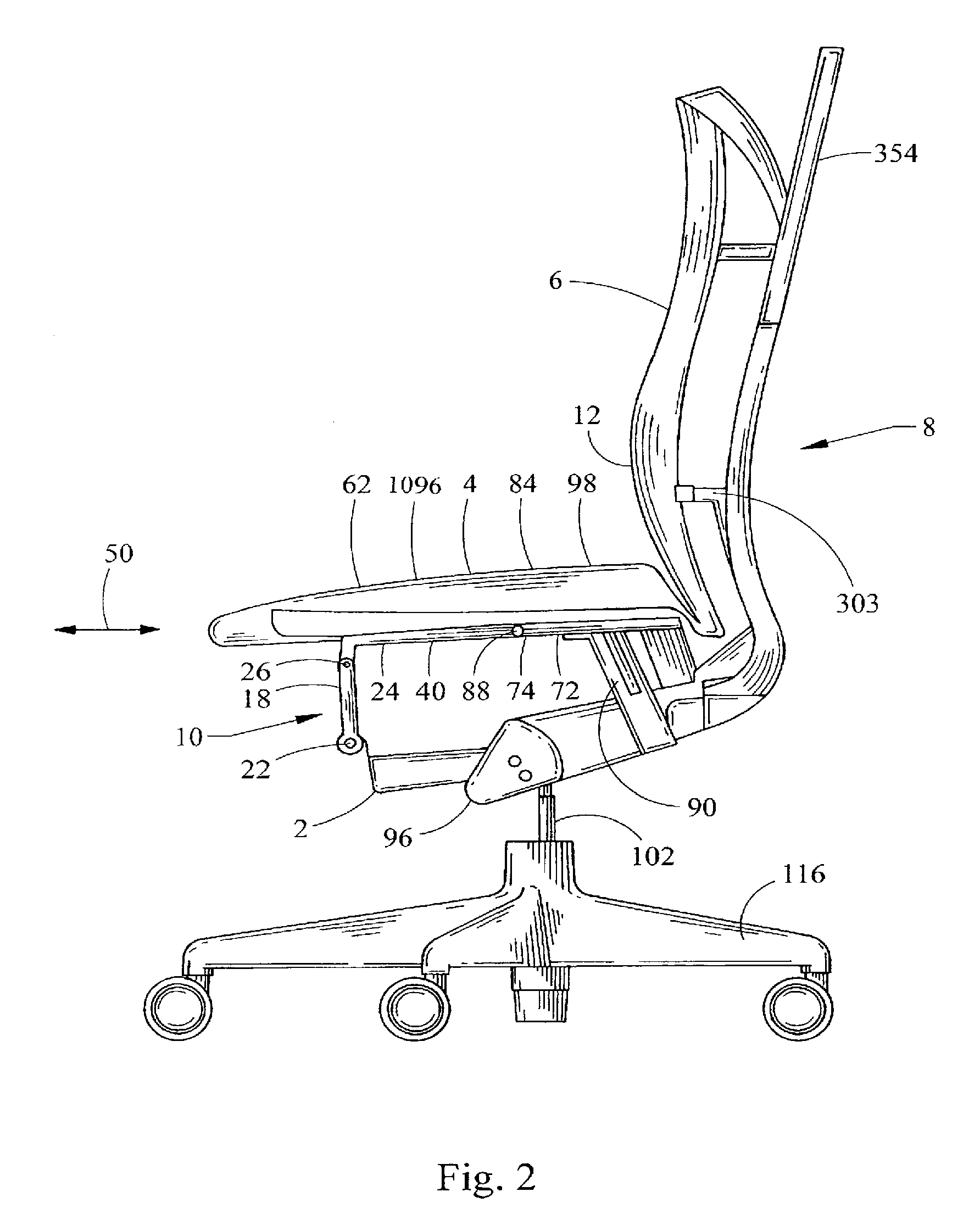

Seating structure and methods for the use thereof

A seat with an adjustable seat depth is also provided, along with various methods for operating the different aspects and embodiments of the seating structure. In one embodiment, a seating structure includes a support structure and a carriage moveably supported by the support structure. The carriage is moveable relative to the support structure in opposite first and second longitudinal directions. A flexible body support member has a first portion coupled to the support structure, a second portion coupled to the carriage, and a third curved portion positioned between the first and second portions. The third portion is moveable toward and away from the support structure as the carriage is moved relative to the support structure in the first and second directions respectively.

Owner:MILLERKNOLL INC

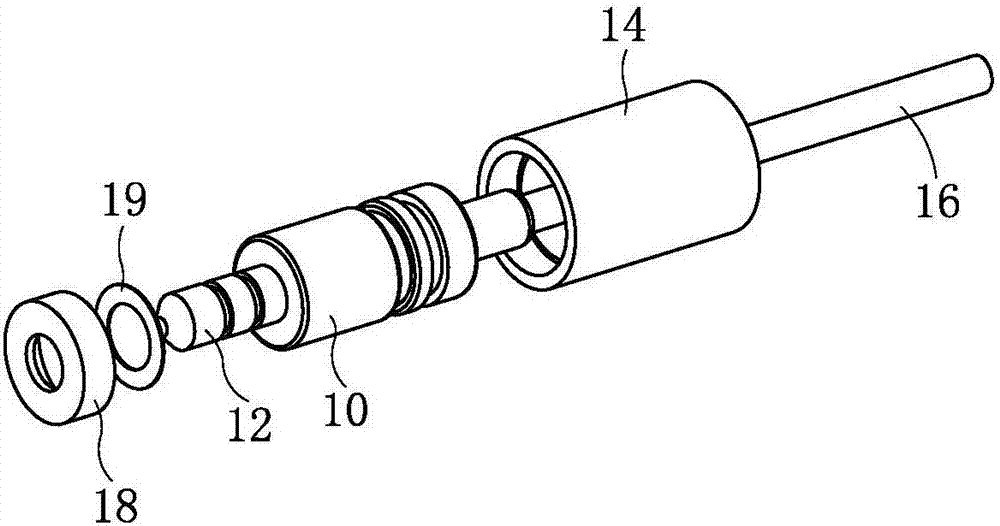

Light source fixing device, light source assembly and assembling method thereof

InactiveUS8899788B2Simplify the assembly processLow costLighting support devicesLighting heating/cooling arrangementsEngineeringLight source

The present invention provides a light source fixing device for fixing a light emitting element. The light emitting element comprises a light source and a supporting plate for supporting the light source. The light source fixing device comprises a heat dissipating support which comprises a receiving recess. The receiving recess is adapted to receive the supporting plate. The light source fixing device further comprises an elastic element disposed in the receiving recess, and the elastic element is adapted to apply an elastic force on the supporting plate so that the supporting plate is fixed in the receiving recess. The present invention further provides a light source assembly and an assembling method thereof. The light source assembly features a simple assembling process, high reliability and a low cost.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

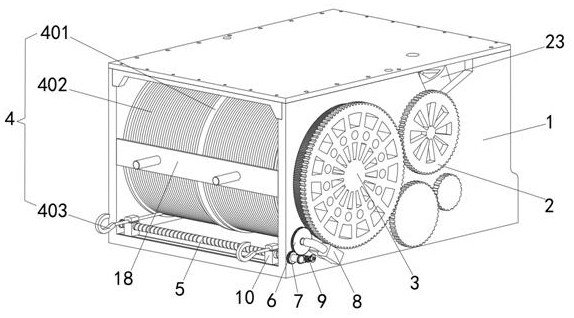

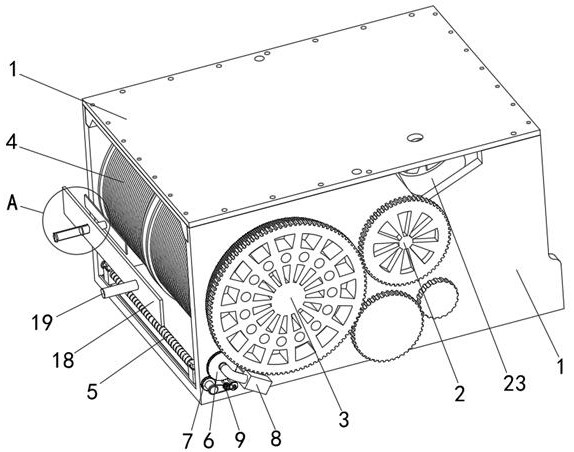

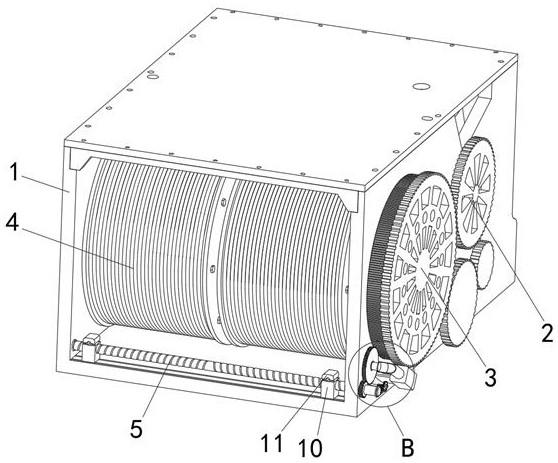

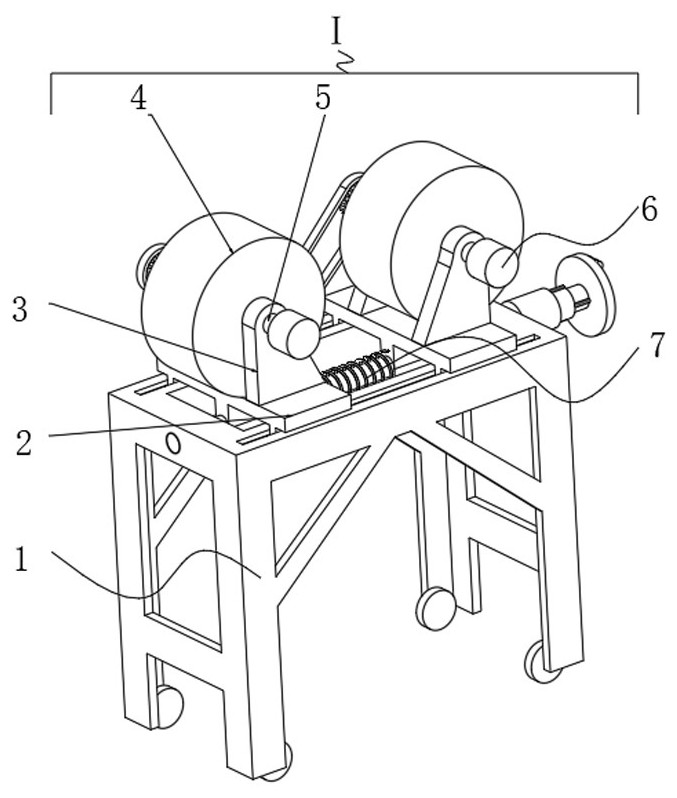

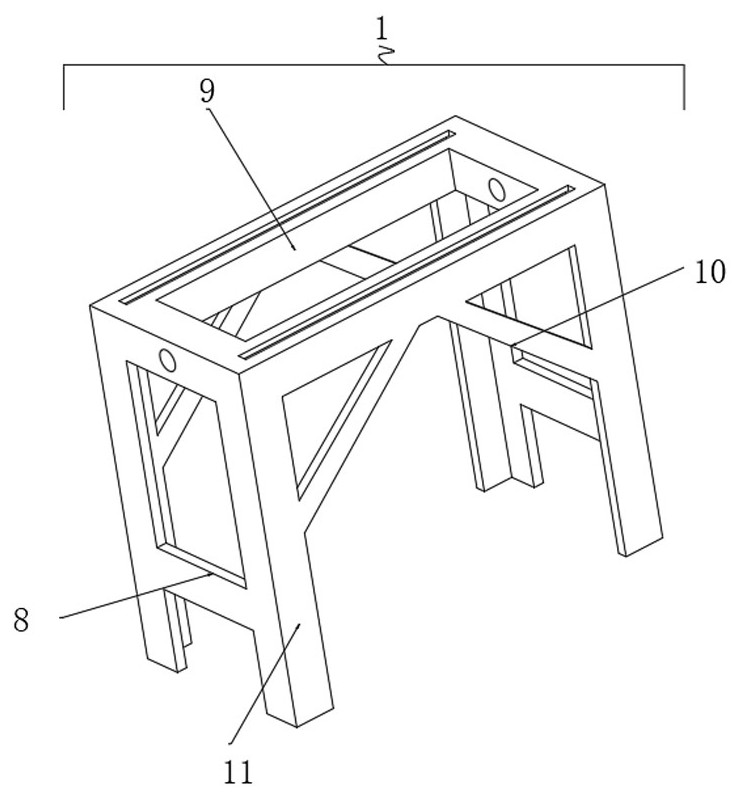

Freight winch structure with good use function

PendingCN113735003AGuaranteed stabilityAvoid personal injuryWinding mechanismsCounter rotationBall screw

The invention belongs to the technical field of winches, and discloses a freight winch structure with a good use function. The freight winch structure comprises a machine shell, a driving device is fixedly arranged at the rear end of the machine shell, a first duplicate gear is movably connected to the front end of the right end of the machine shell, a traction assembly is fixedly arranged at the left end of the first duplicate gear, and the bottom of the front end of the machine shell is movably connected with a double-thread ball screw. According to the freight winch structure, a forward rotation gear drives the double-thread ball screw to rotate, an air cylinder drives a selection gear to move rightwards, the selection gear is separated from the forward rotation gear and meshed with a second duplicate gear, therefore periodic reverse rotation of the double-thread ball screw is achieved, and the double-thread ball screw can drive two meshing blocks to periodically reciprocate left and right, so that traction ropes can be uniformly arranged on the surface of a winding pipe, the winding positions and the winding displacement directions of the two groups of traction ropes are ensured to be completely the same, and the traction and dragging stability of a device is ensured.

Owner:西安高商智能科技有限责任公司

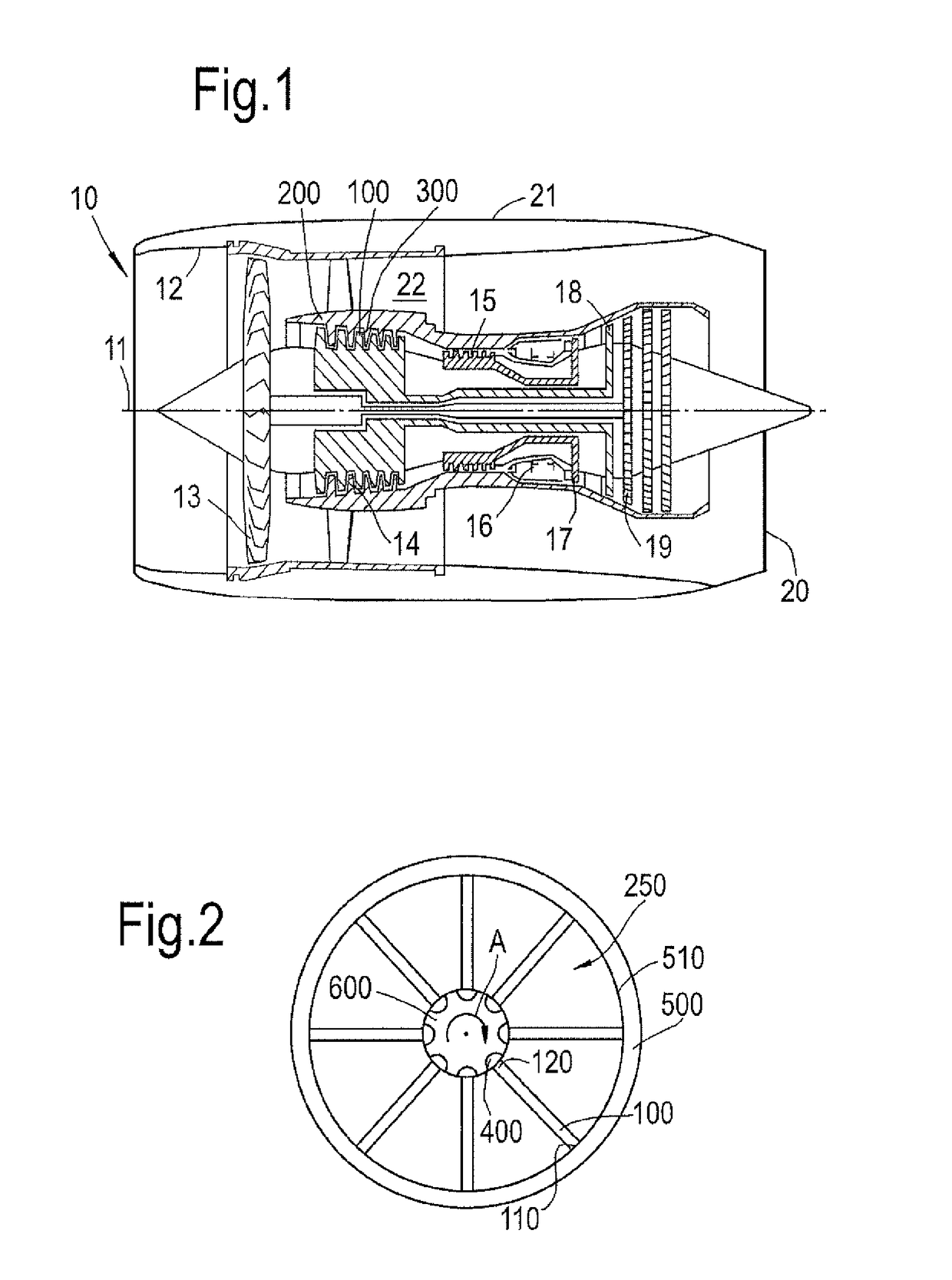

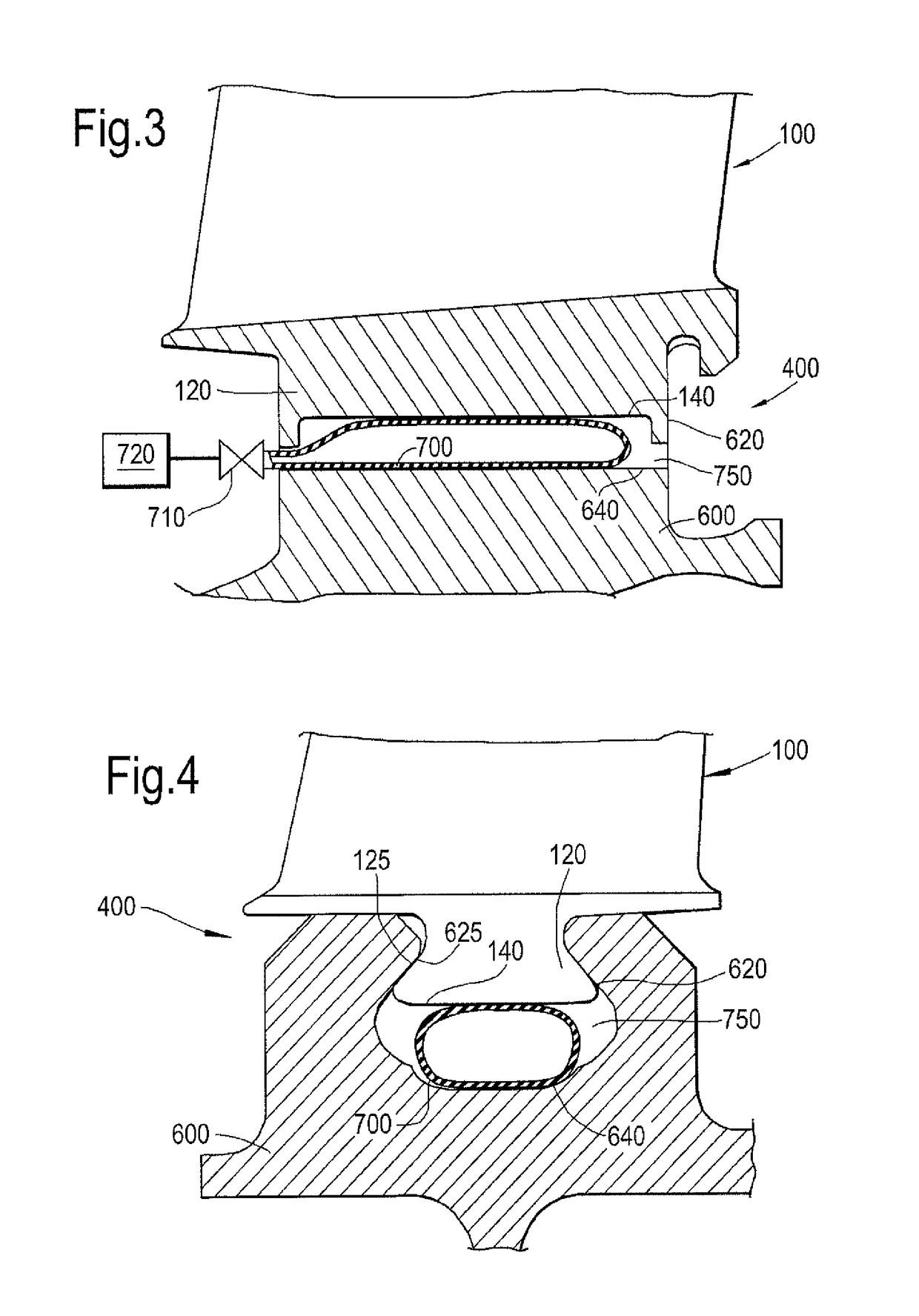

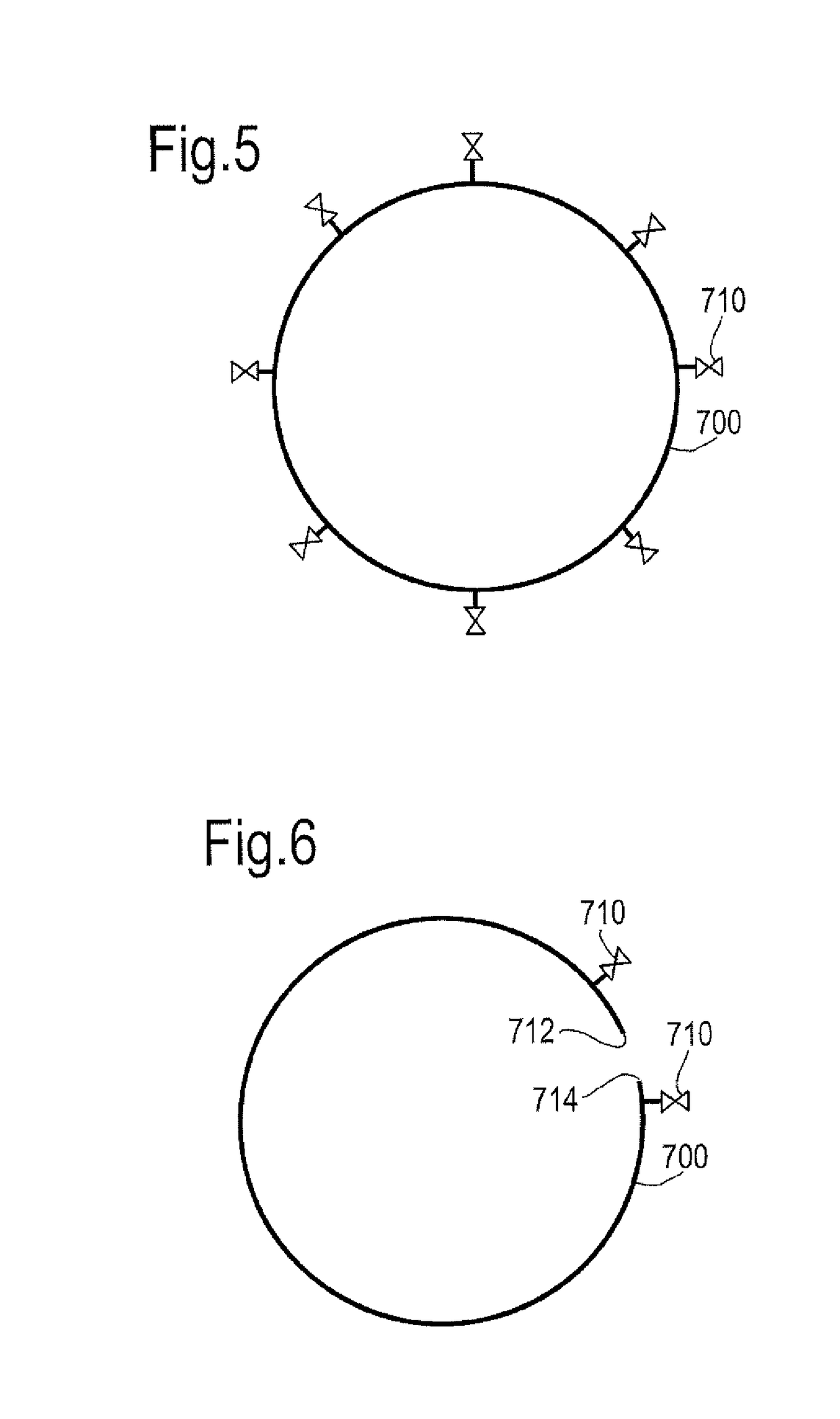

Blade positioning

ActiveUS10160086B2Reduce leakageImprove engine efficiencyPump componentsBlade accessoriesEngineeringTurbine

A method of, and apparatus for, urging blades of a gas turbine engine radially outwardly is disclosed. The method may be used to grind blade tips of blades of a rotor stage of a gas turbine engine. The method comprises locating a fluid-tight bag which is in a radial gap formed between a radially inner surface of a respective blade root and a slot in a disc which the blade root cooperates. The method comprises inflating the fluid-tight bag and rotating the rotor stage relative to a grinding surface so as to grind any blade tips that contact the grinding surface during rotation. This results in more accurate positioning of the blades during the grinding process and / or during operation.

Owner:ROLLS ROYCE PLC

Aluminum alloy fixing and regular forming equipment

ActiveCN112828104ATo achieve the purpose of automatic extrusionTo achieve the purpose of automatic collectionMetal-working feeding devicesPositioning devicesGear wheelMaterials science

The invention relates to forming equipment, in particular to aluminum alloy fixing and regular forming equipment. According to the aluminum alloy fixing and regular forming equipment, automatic and uniform discharging, automatic extrusion and automatic feeding can be achieved. The aluminum alloy fixing and regular forming equipment comprises a bottom plate, a positioning mechanism, an automatic bending mechanism and a feeding mechanism, wherein the positioning mechanism is arranged on the bottom plate; the automatic bending mechanism is arranged on the bottom plate, and the automatic bending mechanism is matched with the positioning mechanism; and the feeding mechanism is arranged on the bottom plate, and the feeding mechanism is connected with the positioning mechanism. According to the aluminum alloy fixing and regular forming equipment, racks are meshed with straight gears, the racks move to enable the straight gears to rotate, a conveying assembly rotates, and the conveying assembly rotates to enable formed aluminum alloy pipes to move forwards, so that the automatic feeding effect is achieved; and the conveying assembly is matched with a collecting frame, so that the formed aluminum alloy pipes can fall into the collecting frame from the front side of the conveying assembly due to gravity, and the purpose of automatic collection is achieved.

Owner:广东杨达鑫科技有限公司

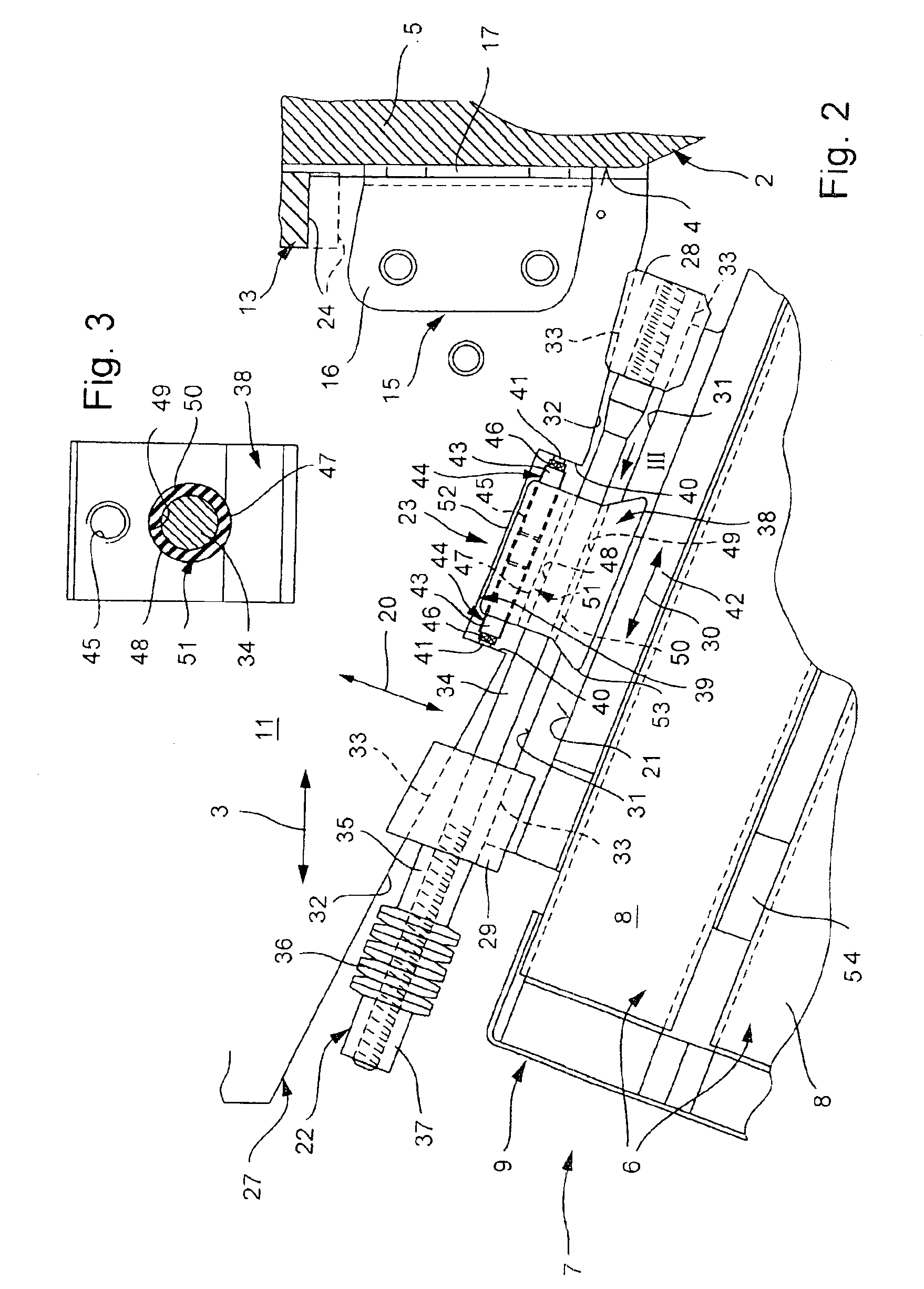

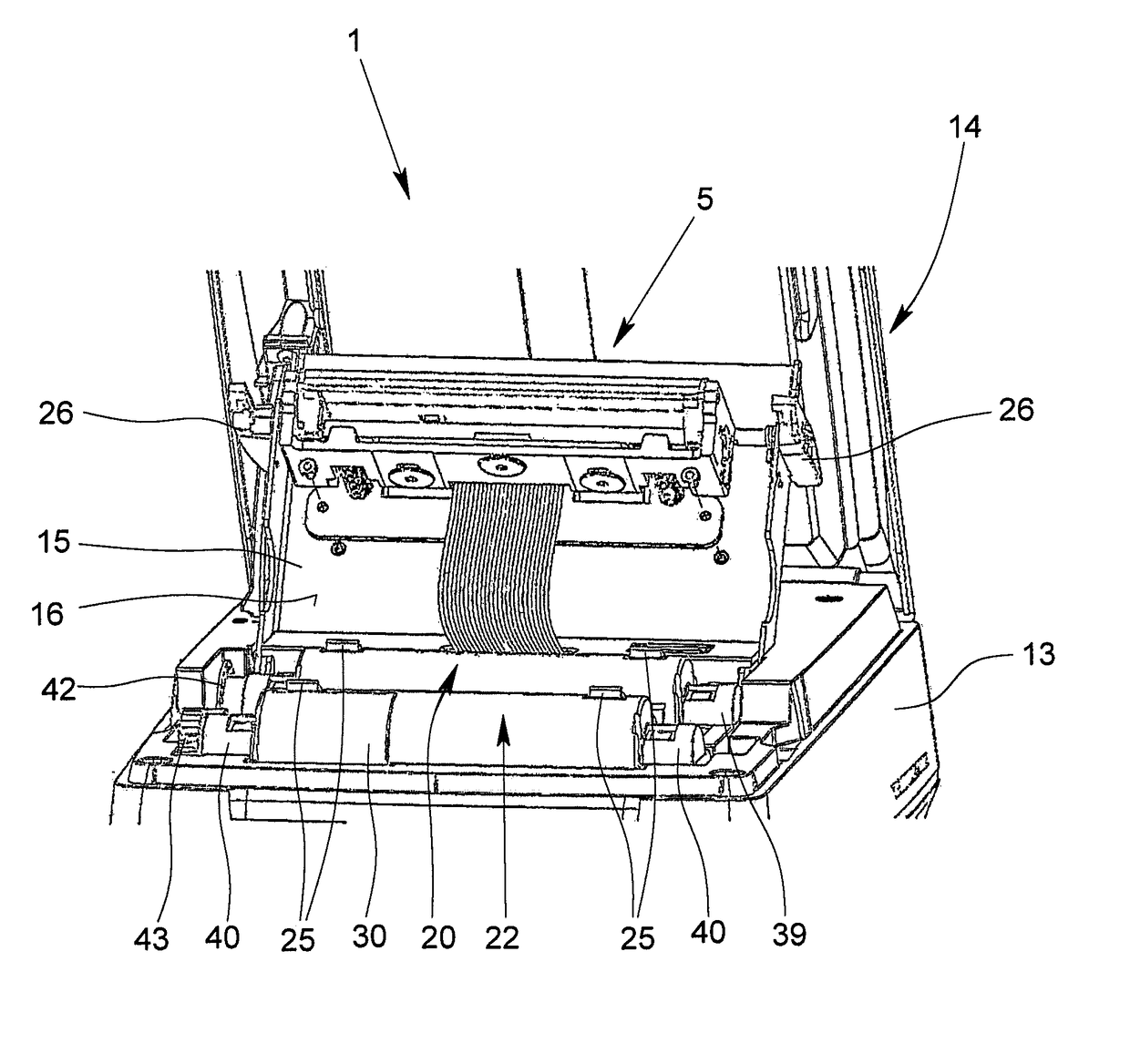

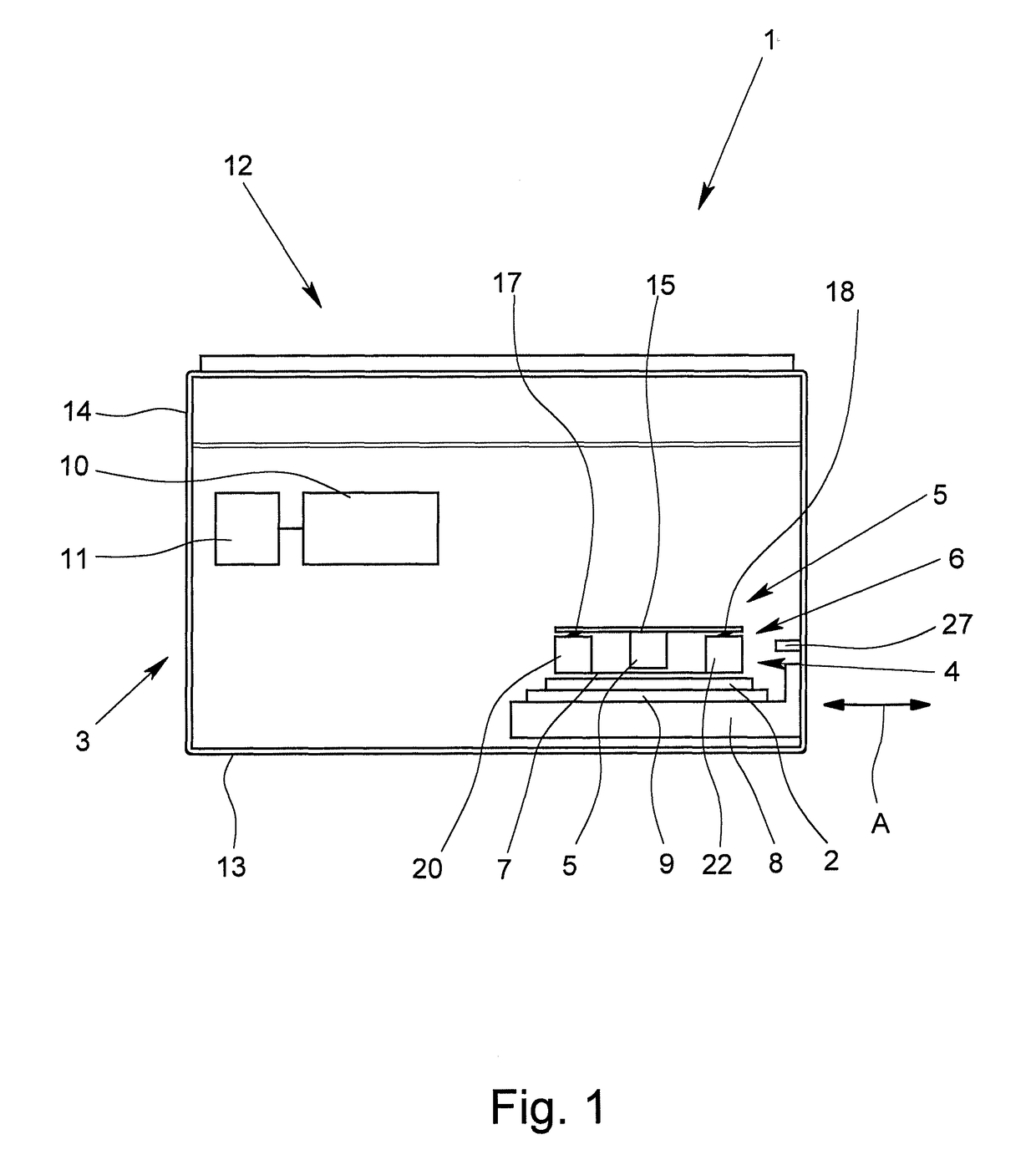

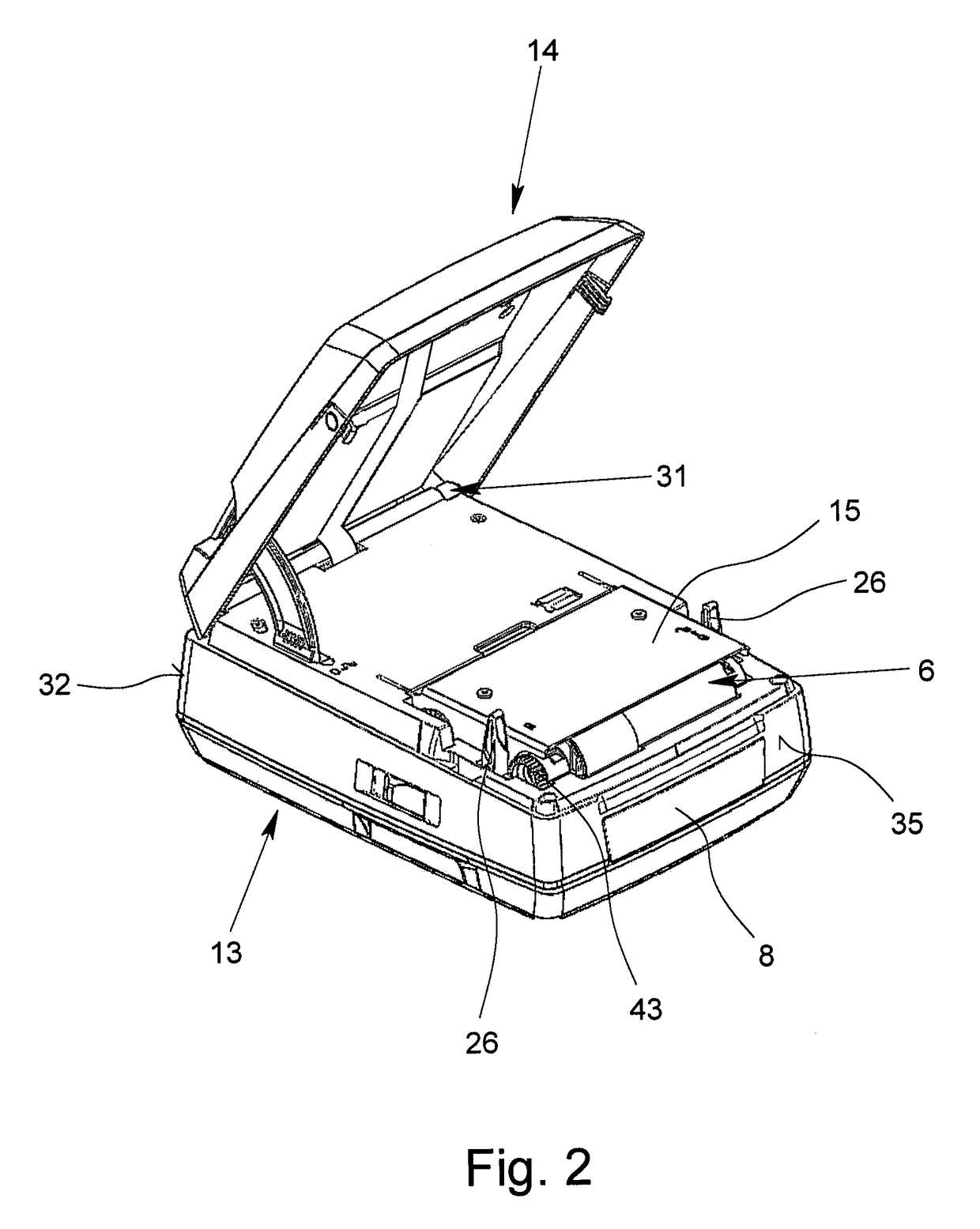

Printer for printing of printable objects and ink ribbon cassette for use in a printer

ActiveUS9802422B2Located reliablyEasy to replaceInk ribbon cartridgesTypewritersEngineeringHead holder

A printer includes: a housing, a print space within the housing, a print head, a replaceable ink ribbon cassette, a receiving device for a printable object which is to be printed, a control and evaluation unit, and an input and display apparatus. The receiving device can travel between a loading and unloading position outside the print space and a print position within the print space.A print head holder on whose bottom the print head is attached is pivotably mounted in the housing. In the closed position of the print head holder the print head is located in a working position above the ink ribbon cassette. In a swung-up position of the print head holder an ink ribbon cassette can be inserted into the housing or can be removed from the housing. At least one spring arm is formed on the top of the ink ribbon cassette or on the bottom of the print head holder.

Owner:PHOENIX CONTACT GMBH & CO KG

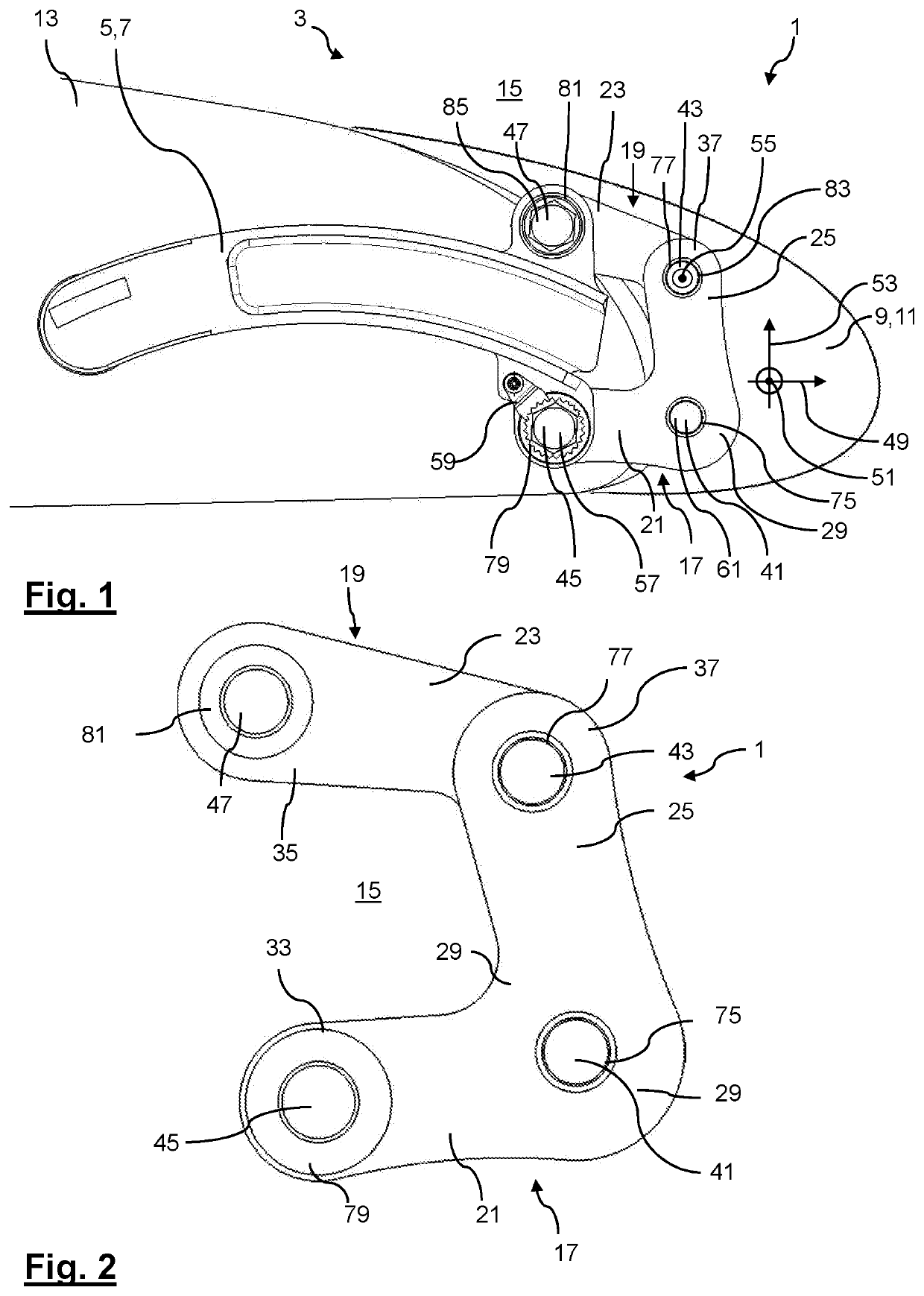

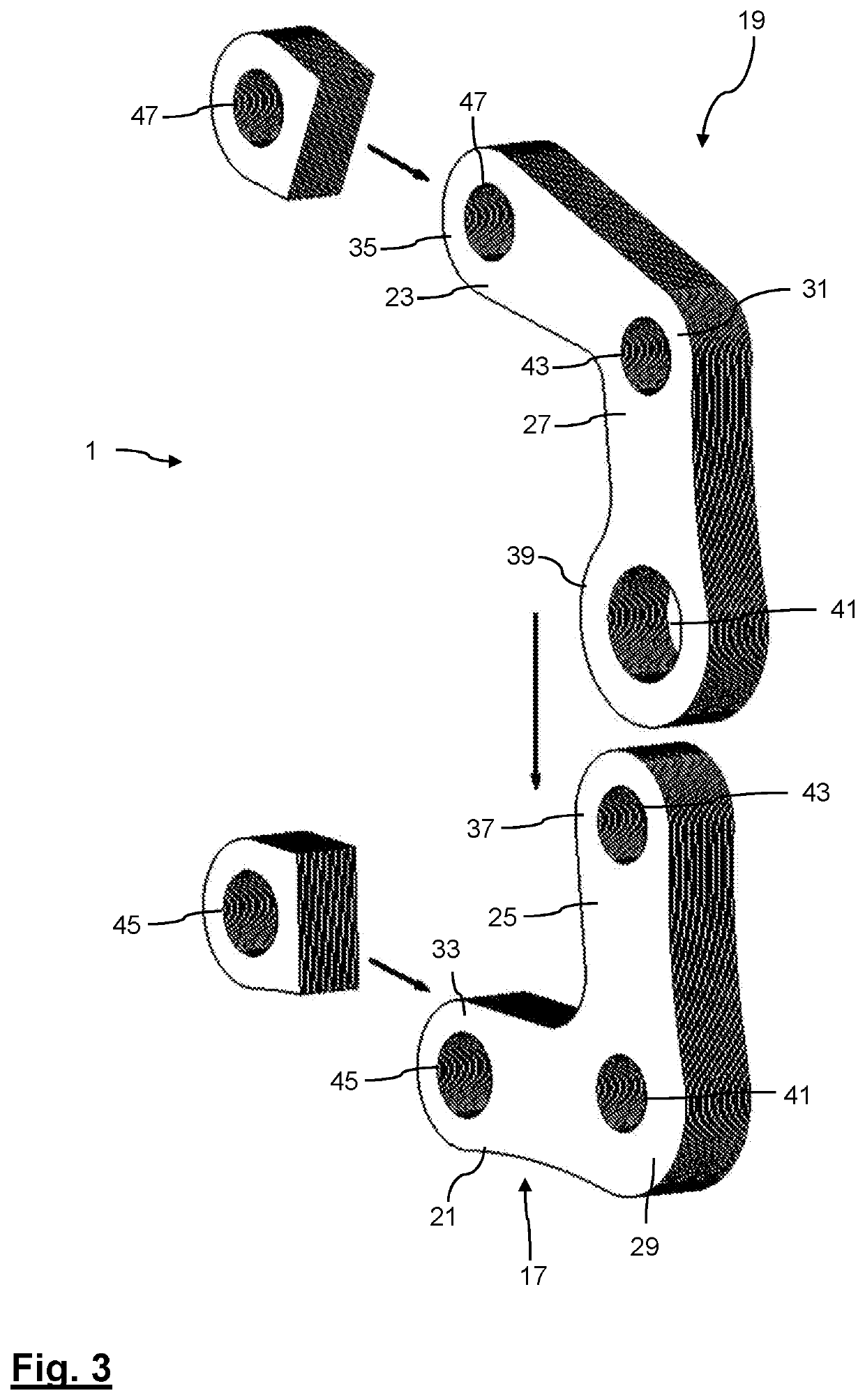

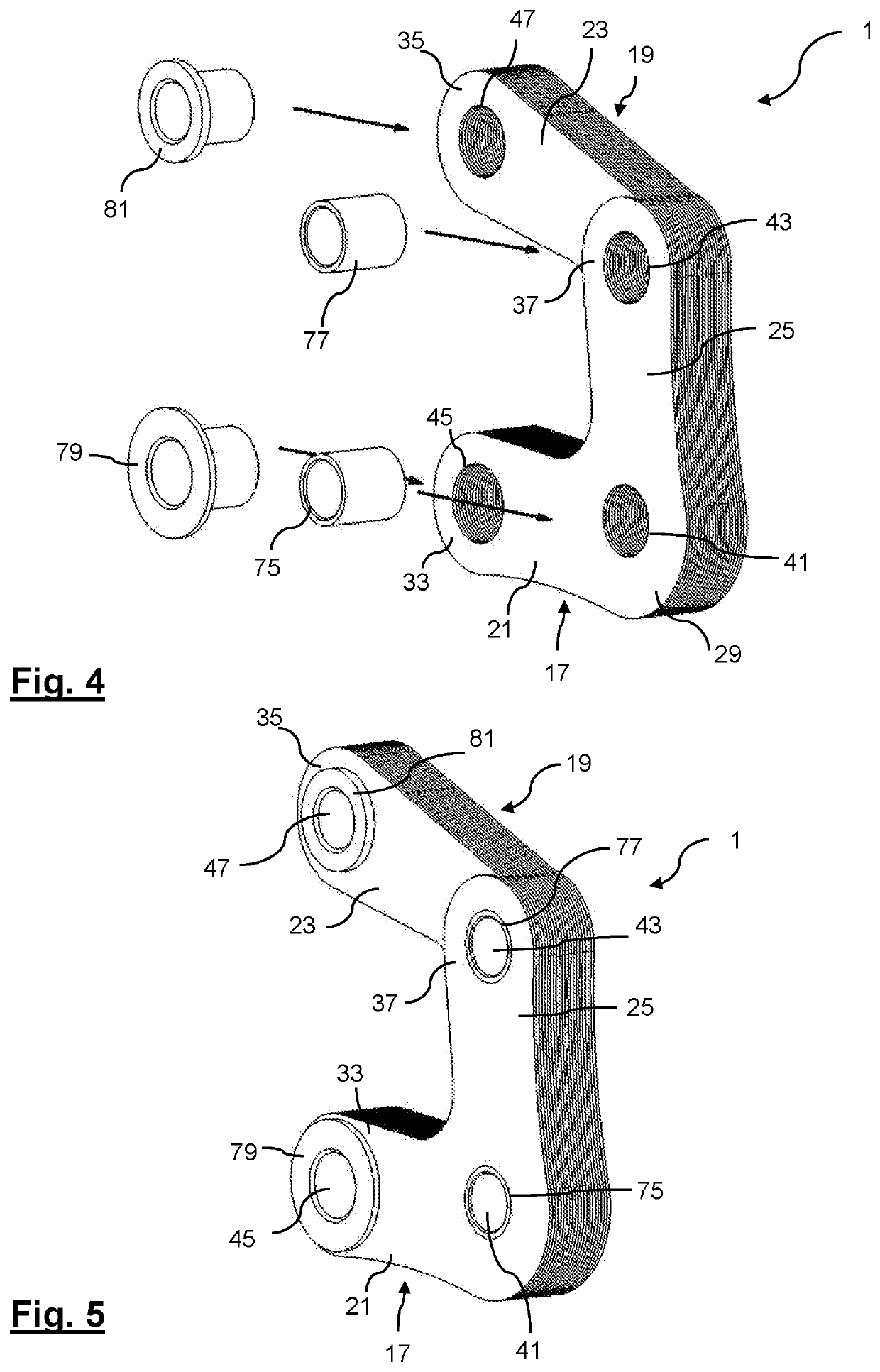

Connection assembly for transmitting loads between two wing elements

ActiveUS20200023939A1Increased bending stiffnessThe relative position is the sameAircraft controlWithout power ampliicationClassical mechanicsMechanical engineering

A C-shaped connection assembly transmits loads in a load plane between a first and a second wing element. The connection assembly comprises a first and a second L-shaped load-bearing device. Each load-bearing device comprises a joint region and two legs extending parallel to the load plane and away from the joint region towards respective end regions. One leg of the first load-bearing device extends parallel to one leg of the second load bearing device. These legs are connected to one another. Two coupling portions which connect the connection assembly to the second wing element are formed in the respective joint regions of the load-bearing devices. Two further coupling portions which connect the connection assembly to the first wing element are formed in respective free end region of the load-bearing device and the joint region of the second load-bearing device.

Owner:AIRBUS OPERATIONS GMBH

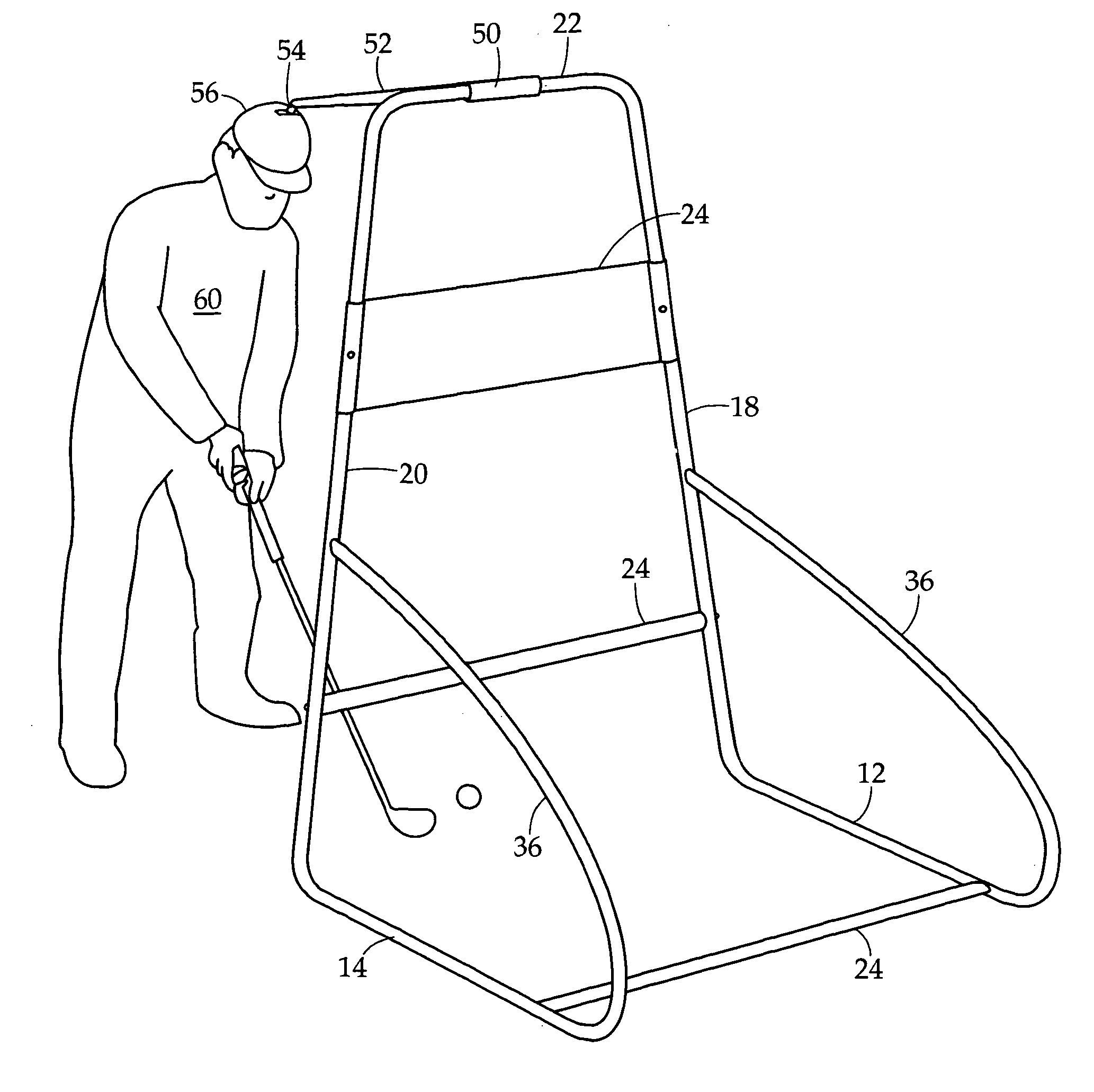

Training apparatus for improving a golf swing

InactiveUS7815518B2The relative position is the sameGolf clubsMuscle exercising devicesEngineeringGolf Ball

In the basic embodiment, the golf training device is a support rod, a first end of which is secured to a hinged mechanism, the hinged mechanism being secured to a support, the opposing end of the support rod having secured thereto a head piece or helmet which is engageable with the upper portion of the head or skull of an individual, the support rod extending a sufficient distance from its support and hinge mechanism to allow an individual to execute a golf swing while the head piece is positioned on the golfer's head.

Owner:DOYLE ROBERT S

Silk yarn detection device and detection method for colored and formed chemical fiber silk yarn

PendingCN114184461AAvoid pullingThe relative position is the sameInvestigating abrasion/wear resistanceYarnFiber

The invention discloses a silk yarn detection device and method after chemical fiber silk yarn coloring and forming, and the device comprises a detection platform, the detection platform is slidably provided with a conveying device used for conveying silk yarns, and the detection platform is slidably provided with a first driving device used for driving the conveying device to do reciprocating motion; the detection platform is provided with a second driving device used for driving the first driving device to slide, and the detection platform is provided with a wear resistance detection device used for detecting the wear resistance of the silk threads. According to the detection device, the first winding device at one end is used for releasing the silk yarn, the first winding device at the other end is used for winding the silk yarn, the silk yarn between the two first winding devices is tensioned, and after tensioning, the silk yarn between the two first winding devices is clamped through the clamping device; therefore, the silk threads on the winding drum can be prevented from being pulled in the silk thread grinding process, and the positions of the silk threads can be the same when the silk threads are clamped every time.

Owner:浙江伊兰文科技股份有限公司

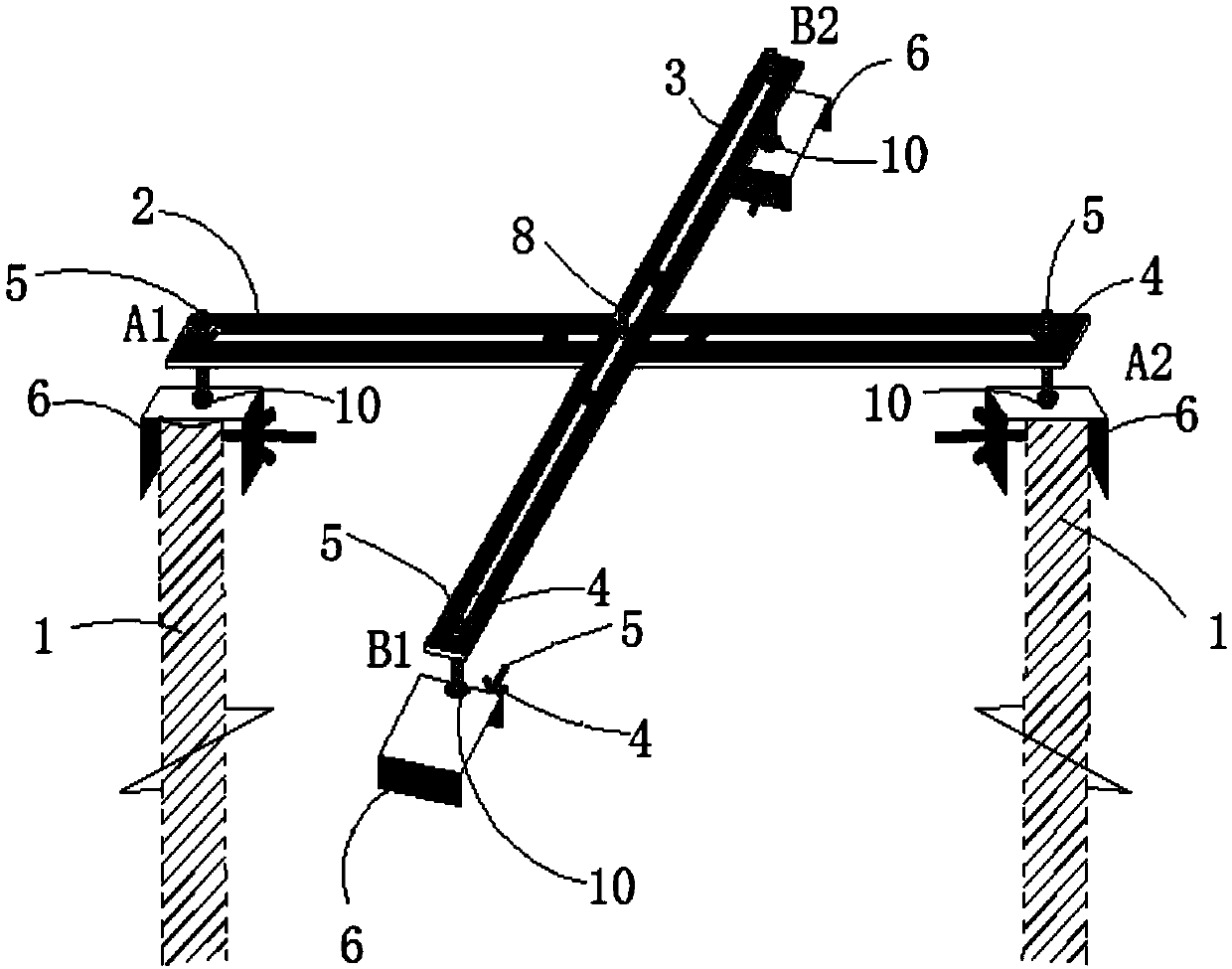

Pore-forming pouring pile inclination detection auxiliary device and inclination detection method

PendingCN109680736AEasy constructionSimple structureFoundation testingEngineeringBuilding construction

The invention discloses a pore-forming pouring pile inclination detection auxiliary device applied to inclination detection of a pore-forming pouring pile under the condition of dry operation. The pore-forming pouring pile inclination detection auxiliary device comprises an upper beam, a lower beam and clamps, wherein the center points of the upper beam and the lower beam are coincided and are rotationally connected with each other; and two end parts of the upper beam and two end parts of the lower beam are fixedly provided with the clamps separately to be used for horizontally fixing the upper beam and the lower beam to a pre-buried protective cylinder during pore-forming pouring pile inclination detection. The pore-forming pouring pile inclination detection auxiliary device is simple instructure, low in manufacturing cost and light in weight by comprising the upper beam, the lower beam and the clamps, only needs to fix the upper beam and the lower beam to the pre-buried protective cylinder by the clamps during detection and is very convenient to mount and disassemble; and a pouring pile is subjected to one pore-forming depth detection when one circulation section is constructedevery time, inclination condition of the pouring pile can be primarily judged through a detection result in each circulation section, and the purpose of guiding construction while performing detectionis realized.

Owner:CCFEB CIVIL ENG

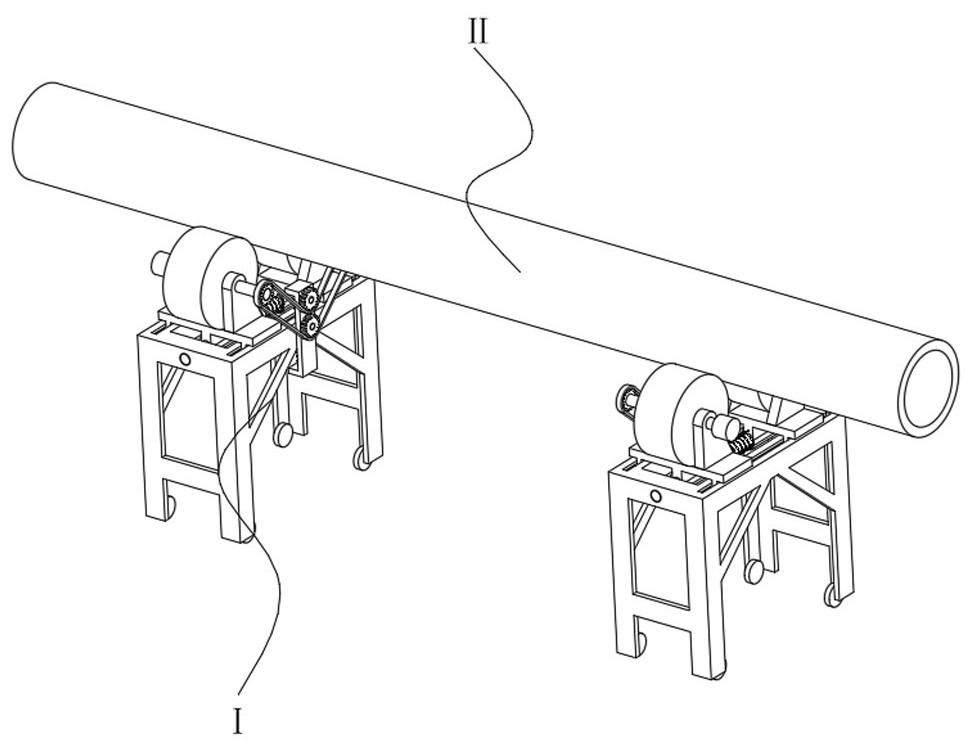

Simple construction pedestal for steel pipe painting and using method thereof

ActiveCN113578586AMeet the convenience of manual brushingChange distanceSpraying apparatusClassical mechanicsEngineering

The invention discloses a simple construction pedestal for steel pipe painting and a using method thereof, and relates to the technical field of pipeline protection. In order to solve the problem that manual painting operation is difficult, the simple construction pedestal comprises two sets of pedestal modules used for supporting a steel pipe to be painted, each pedestal module comprises a support structure and two supports symmetrically arranged at the top of the support structure, and a supporting plate is welded to the outer wall of the top of each support. The using method comprises the steps that the supporting distance between the two sets of pedestal modules is determined according to the length of the steel pipe, and the two sets of pedestal modules are placed at the distance; according to the diameter and the supporting height of the steel pipe, the distance between two rubber roller assemblies is adjusted by rotating a lead screw, and the steel pipe is hoisted to the position between the two sets of rubber roller assemblies; and reversing rubber wheels make contact with the side wall of the steel pipe, and the supporting point positions of the two sets of pedestal modules are finely adjusted. According to the simple construction pedestal for steel pipe painting and the using method thereof, 360-degree dead-angle-free painting can be achieved while the manual painting convenience is met.

Owner:中国建筑土木建设有限公司

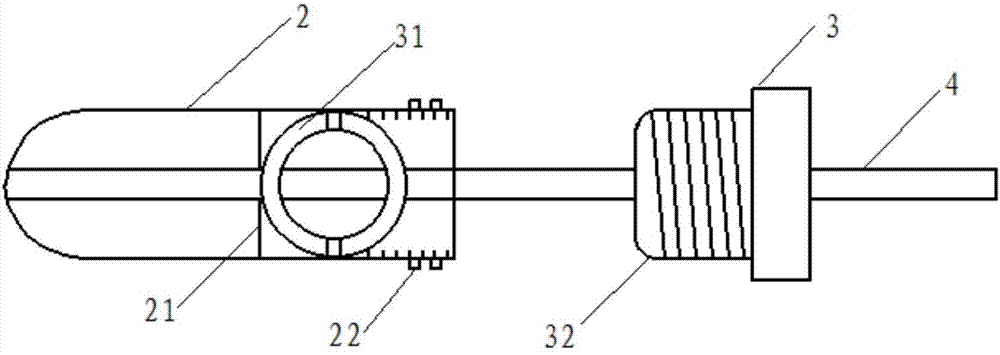

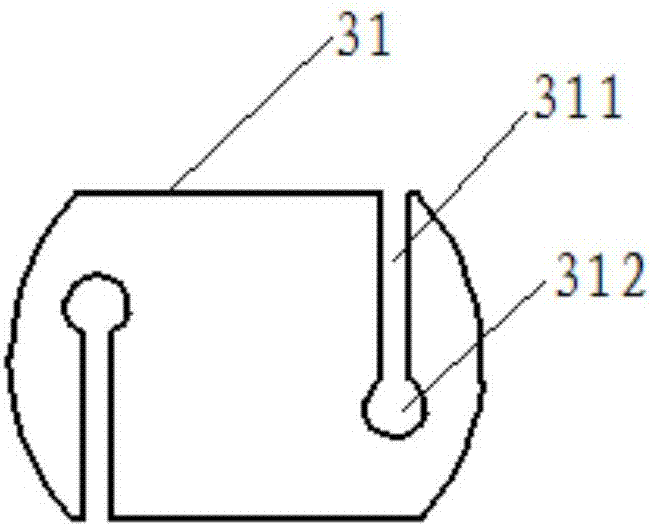

Endoscope sheath tube adaptive to neural navigation

ActiveCN107440796AReduce surgical traumaGood for positioningSurgical navigation systemsSurgical woundBiomedical engineering

The invention discloses an endoscope sheath tube adaptive to neural navigation. The sheath tube comprises an outer sheath (1), an inner sheath (2) and a nerve navigation probe fixing device (3), wherein the nerve navigation probe fixing device (3) fixes a nerve navigation probe (4) in the inner sheath (2), the inner sheath (2) is detachably connected in the outer sheath (1) in a sleeving manner, and the outer sheath (1) of the endoscope sheath tube can serve as a working channel during brain surgery; the sheath tube has a precise positioning function, so that the reliability and efficiency of the surgery are improved, the risk and time of the surgery are reduced, and great surgical wounds can not be caused to patients.

Owner:LISHUI PEOPLES HOSPITAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com