Heat and sound insulation vacuum glass and manufacturing method thereof

A technology of vacuum glass, heat insulation and sound insulation, applied in the field of glass, can solve the problems of low production efficiency, vacuum glass surface deformation, increase of production cost of enterprises, etc., achieve repeatability and good visual effect, prevent surface deformation, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

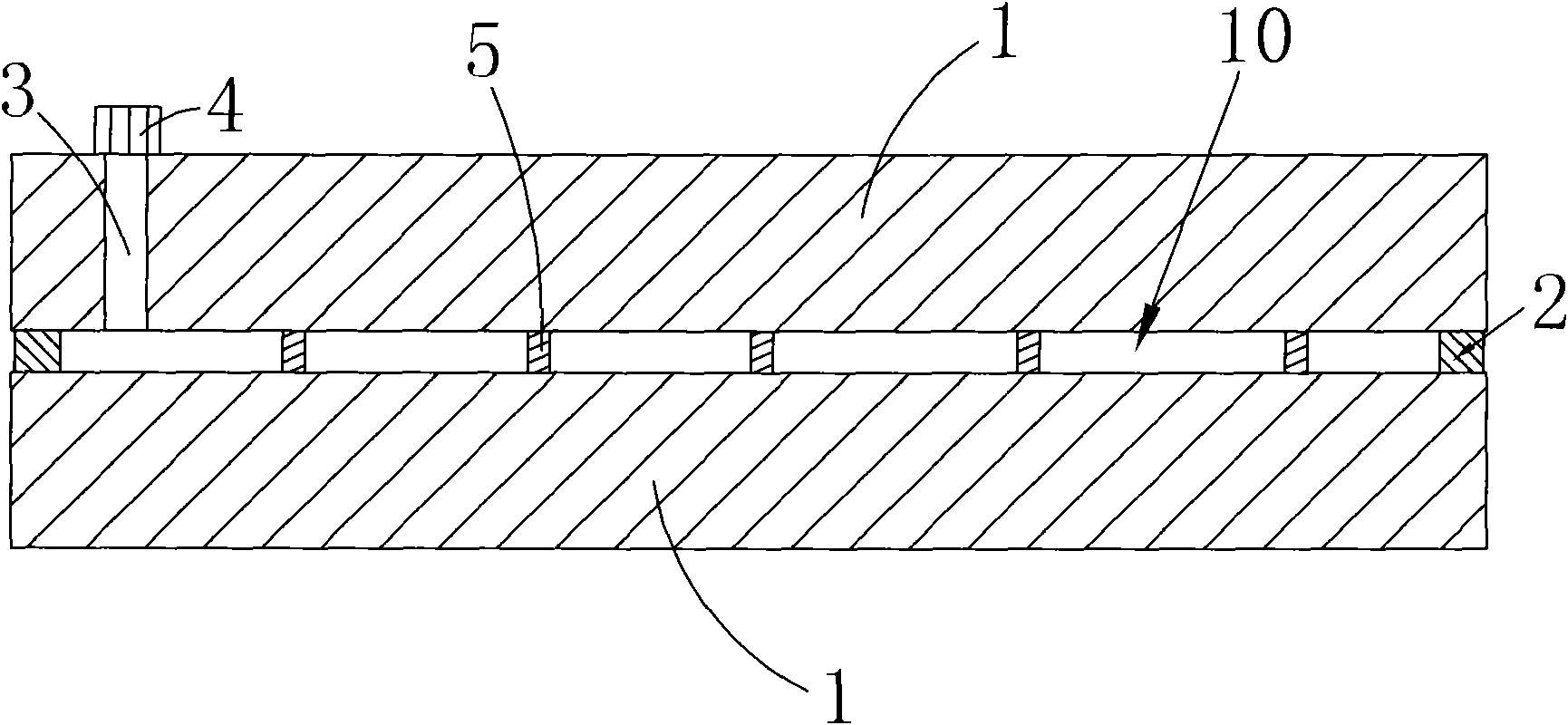

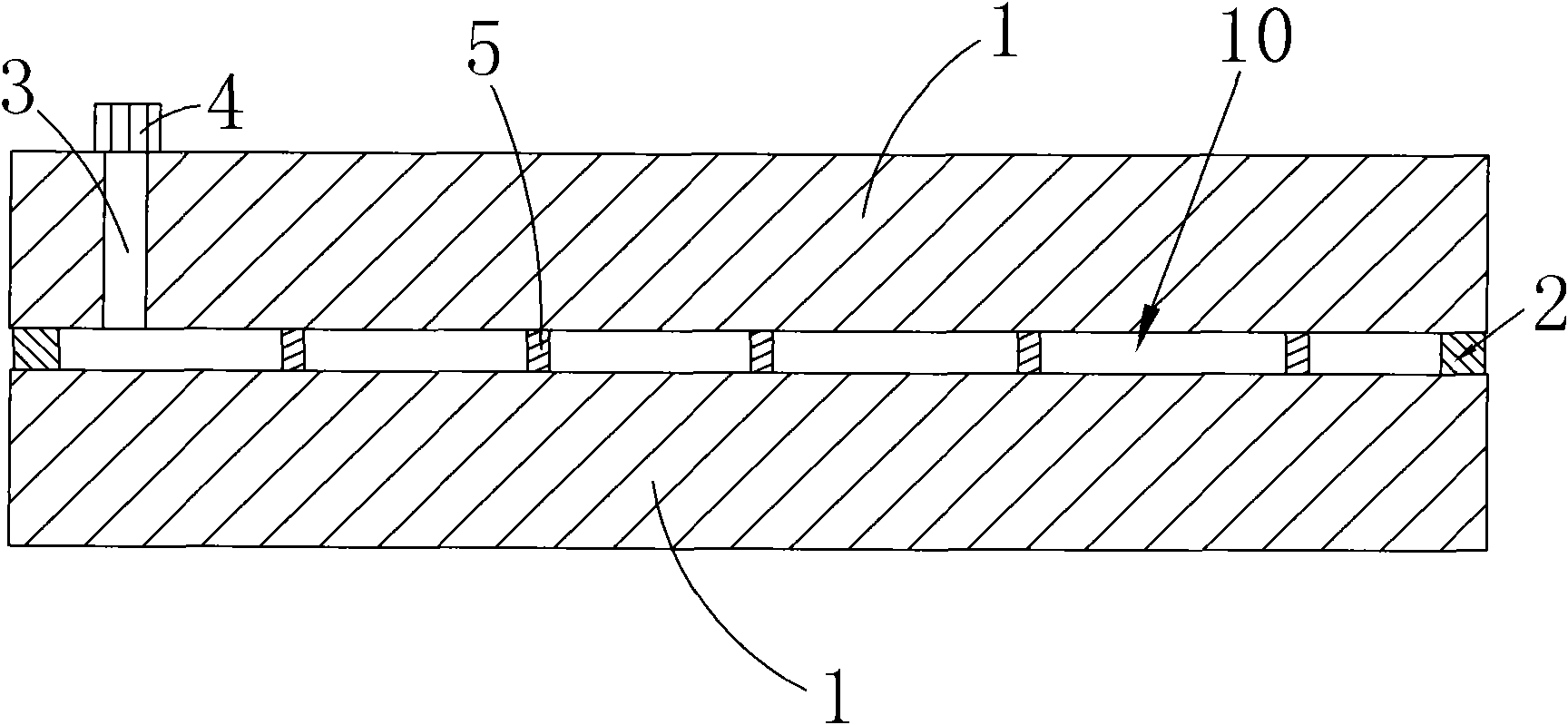

[0027] Embodiment: A heat-insulating and sound-insulating vacuum glass, comprising two glass plates 1 facing each other in parallel, the opposite side of the two glass plates 1 is used as the inner wall of the glass plate 1, and the side of the two glass plates 1 facing away from each other is used as the glass plate 1 The outer wall of the two glass plates 1 is hermetically bonded by a sealant 2 to form a sealed space 10, one of the glass plates 1 is provided with an air extraction port 3, and the air extraction port 3 runs through the inner wall and the outer wall of the glass plate 1, The outer wall of the glass plate 1 at the position of the suction port 3 is provided with a sealing tube 4, the sealing tube 4 seals the suction port 3, and at least one of the inner walls of the glass plate 1 is printed with a plurality of supports 5, and the plurality of supports 5 are supported on two sides. Between the glass plates 1, the inside of the sealed space 10 and the suction port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com