Patents

Literature

47results about How to "Avoid surface deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

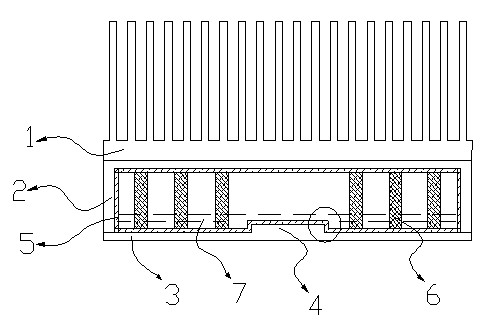

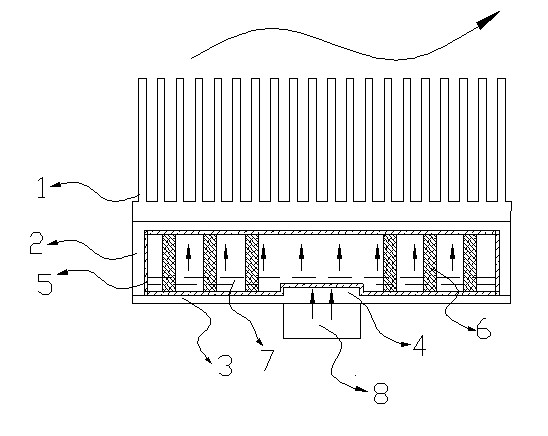

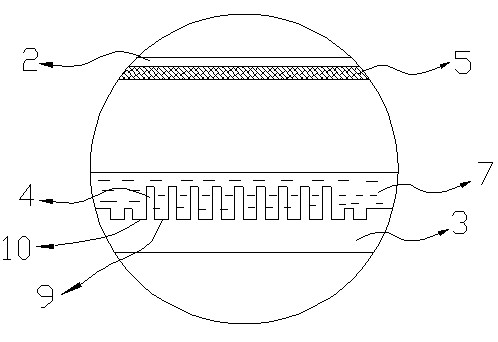

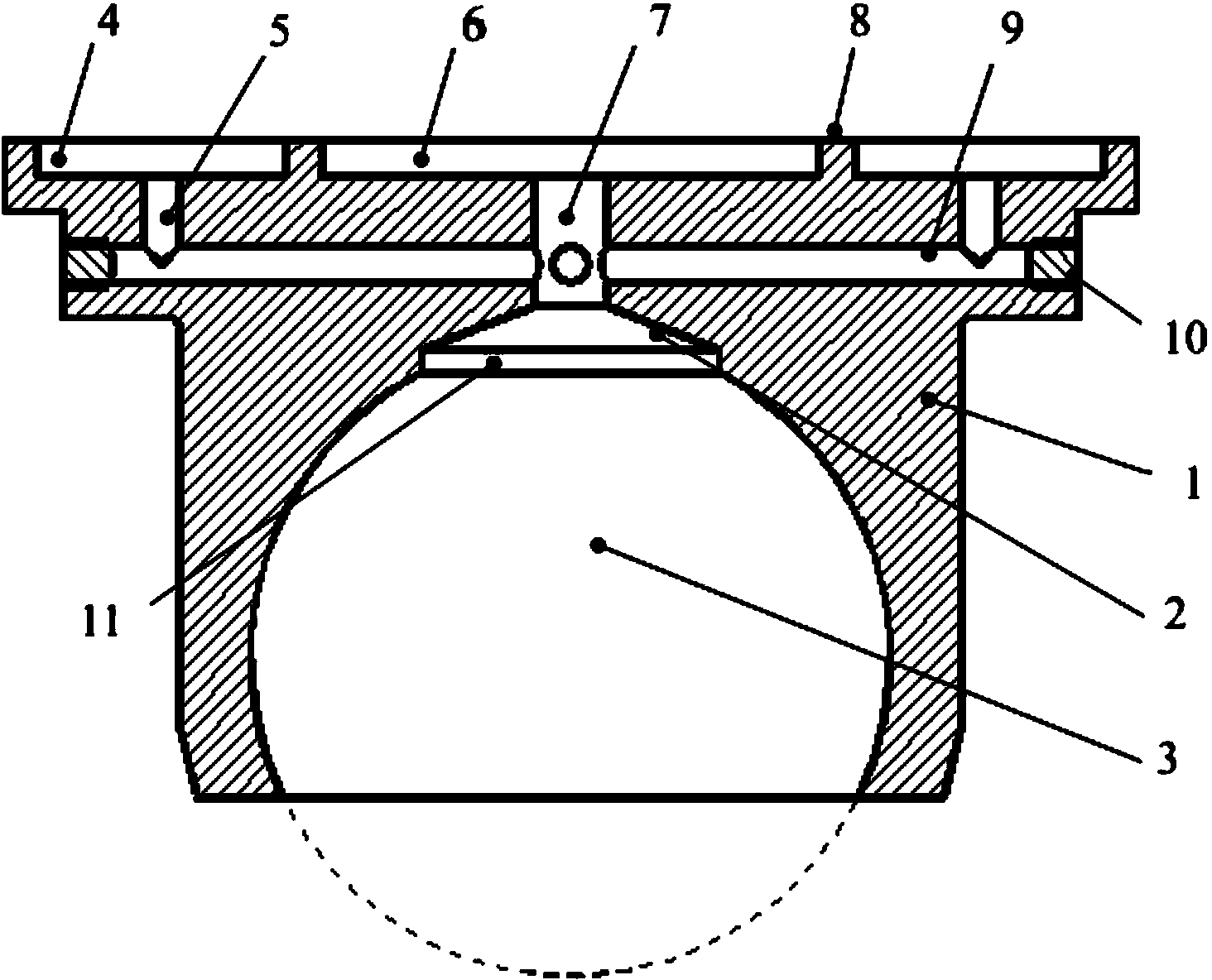

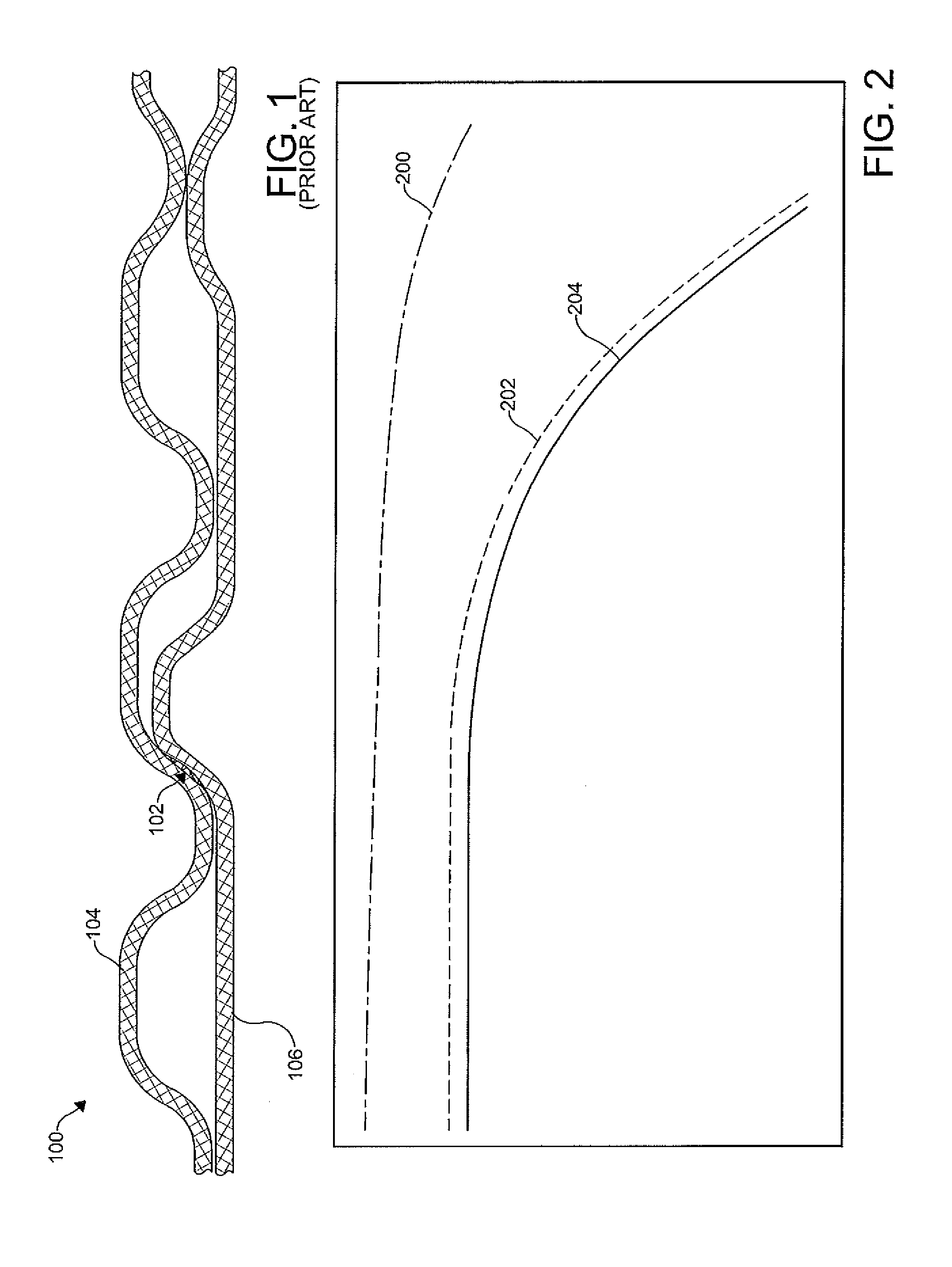

Flat-panel vapor chamber

InactiveCN102095323AHigh mechanical strengthReduce the return pathSemiconductor/solid-state device detailsSolid-state devicesComputer moduleElectron

The invention relates to a flat-panel vapor chamber which belongs to a heat radiating device of a micro electronic device and is used for heat diffusion of a power module and solving the surface deformation problem of the traditional flat-panel vapor chamber and a heat source contact surface so as to further reduce the deformation with the contact surface of a heat source part. The flat-panel vapor chamber comprises heat radiating fins and a metal cavity, wherein the metal cavity consists of a box body and a cover plate; the metal cavity is internally pumped with vacuum and filled with liquid working medium; the box body and the heat radiating fins are tightly contacted or connected into a whole; the inner wall surface of the box body is provided with capillary cores, and supporting bodies are arranged between the box body and the cover plate; the central part of the inner wall surface of the cover plate is provided with a boss, and the thickness of the boss is 0.2-2.0mm; the cross section area of the boss is larger than or equal to the contact area of the heat source; and the inner wall surface of the cover plate including the boss is provided with capillary cores. The flat-panel vapor chamber has the advantages of simple structure and convenience for manufacturing and processing, can be used for effectively reducing the surface deformation and the contact heat resistance, and has high working medium refluxing efficiency and higher working efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

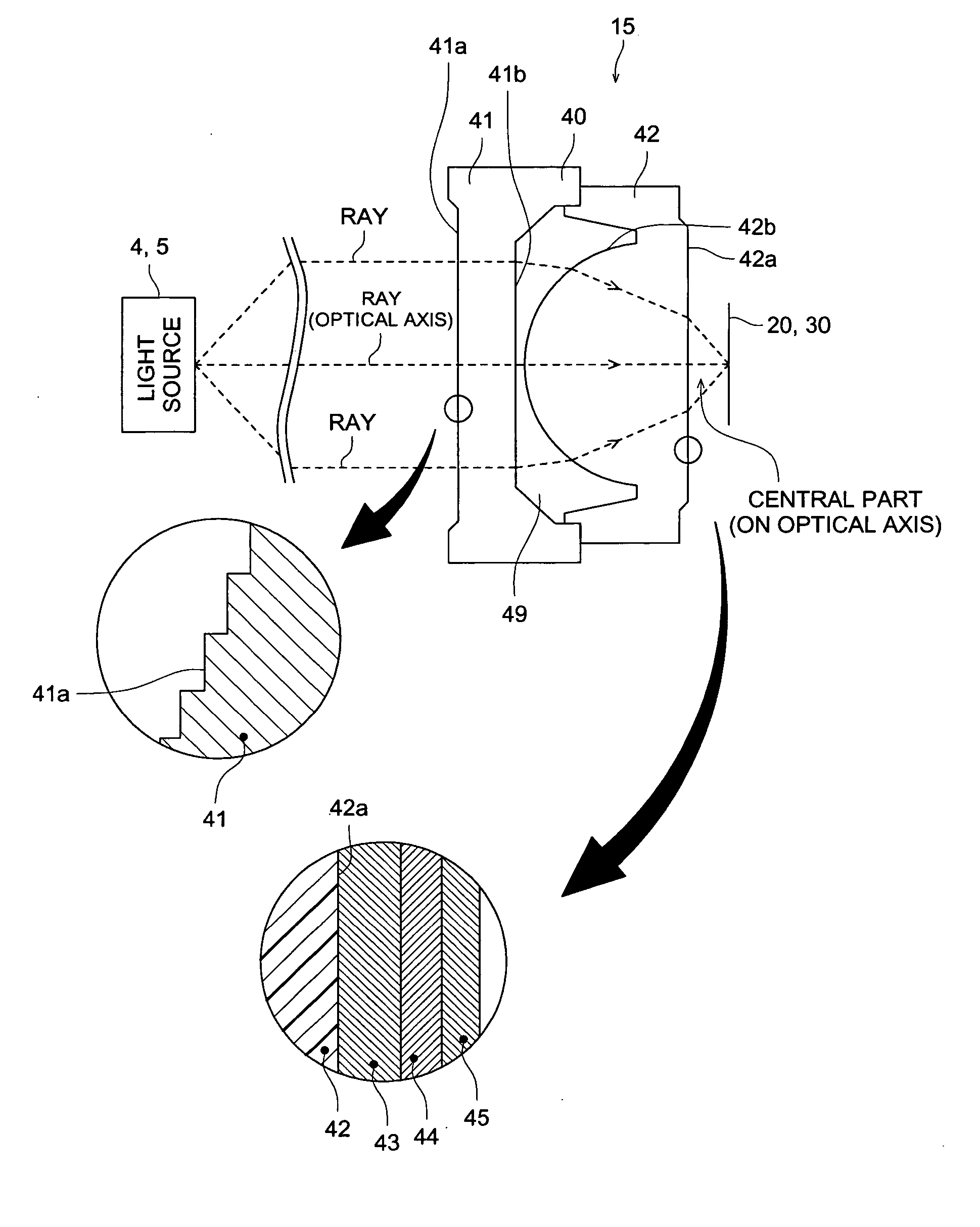

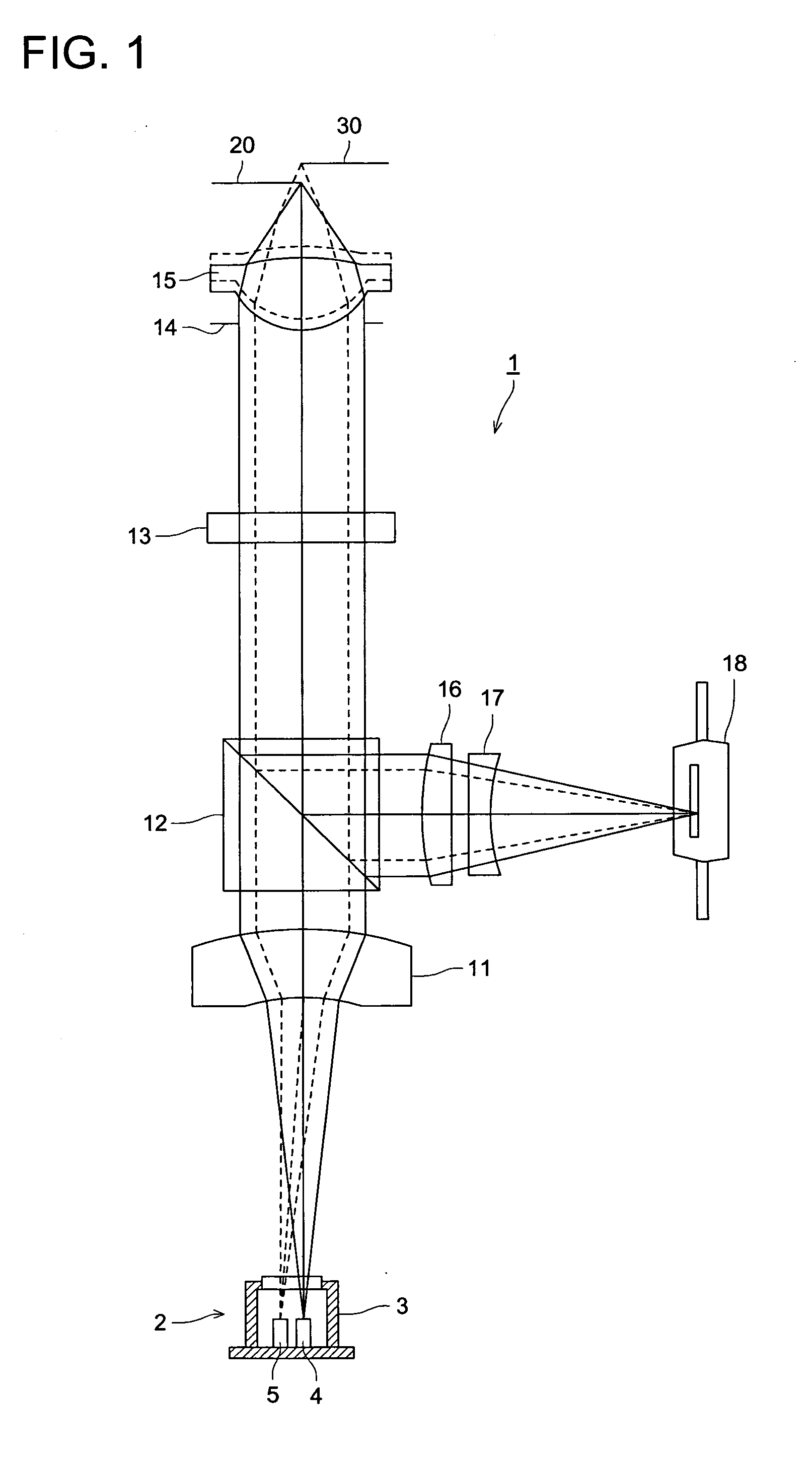

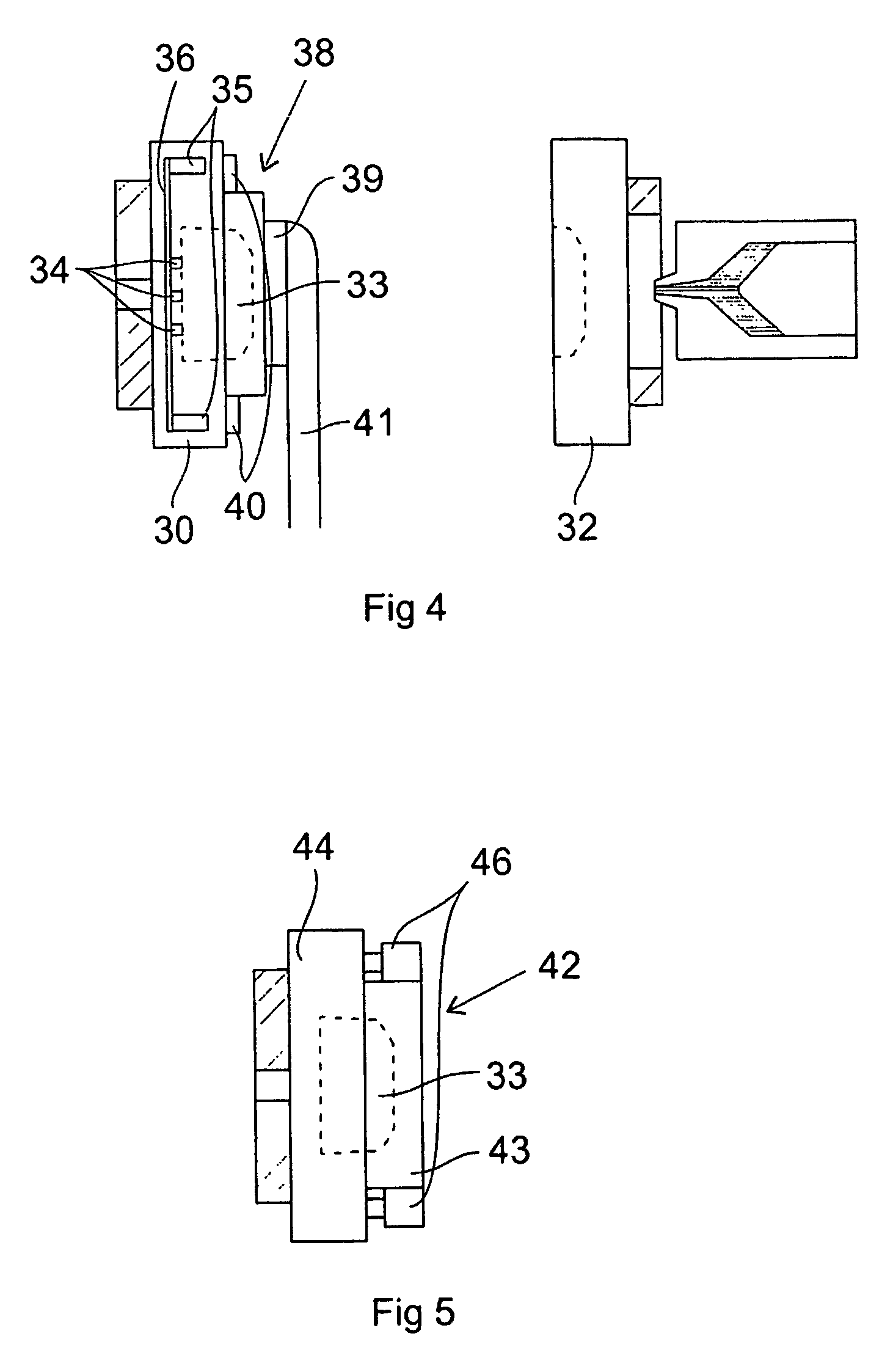

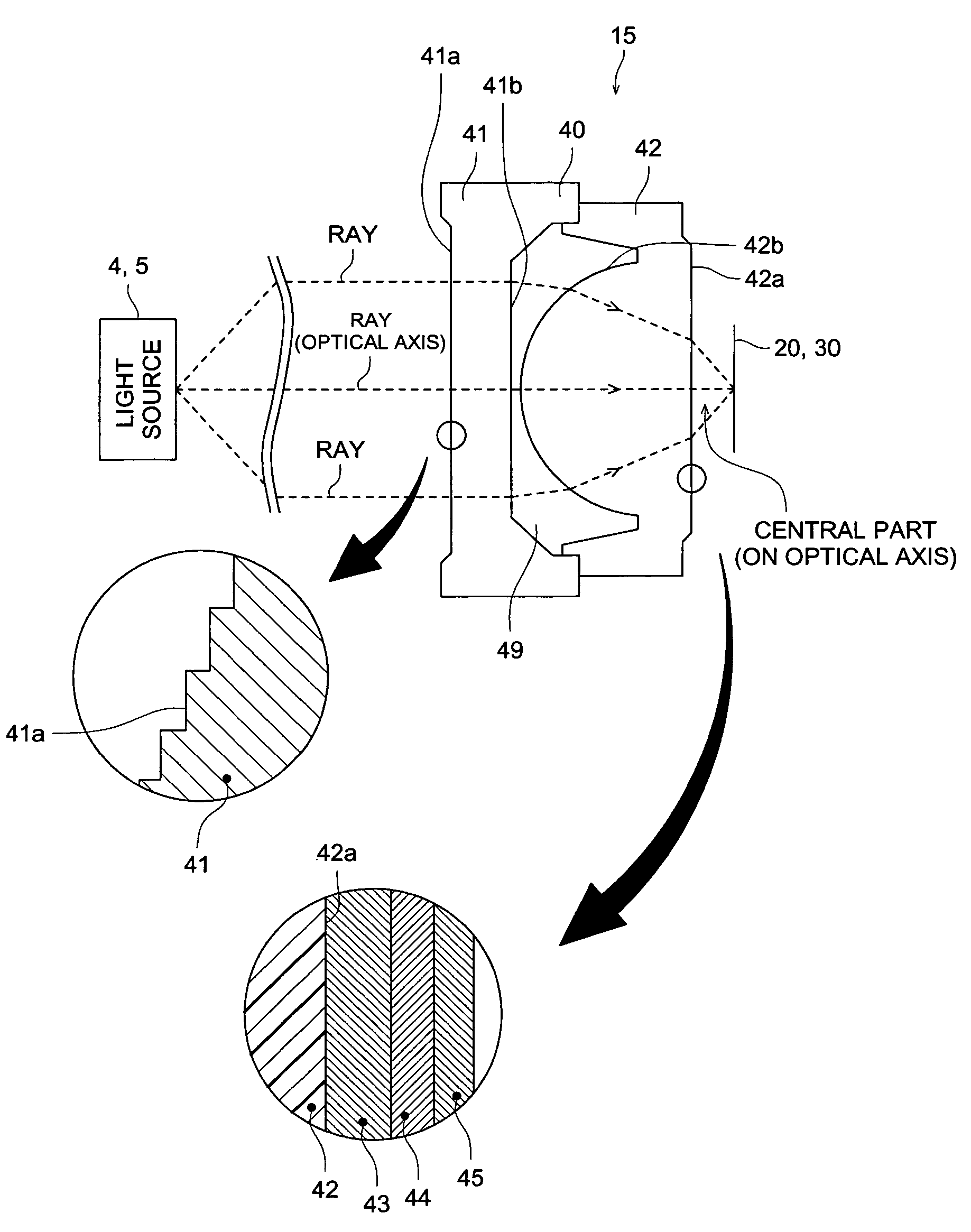

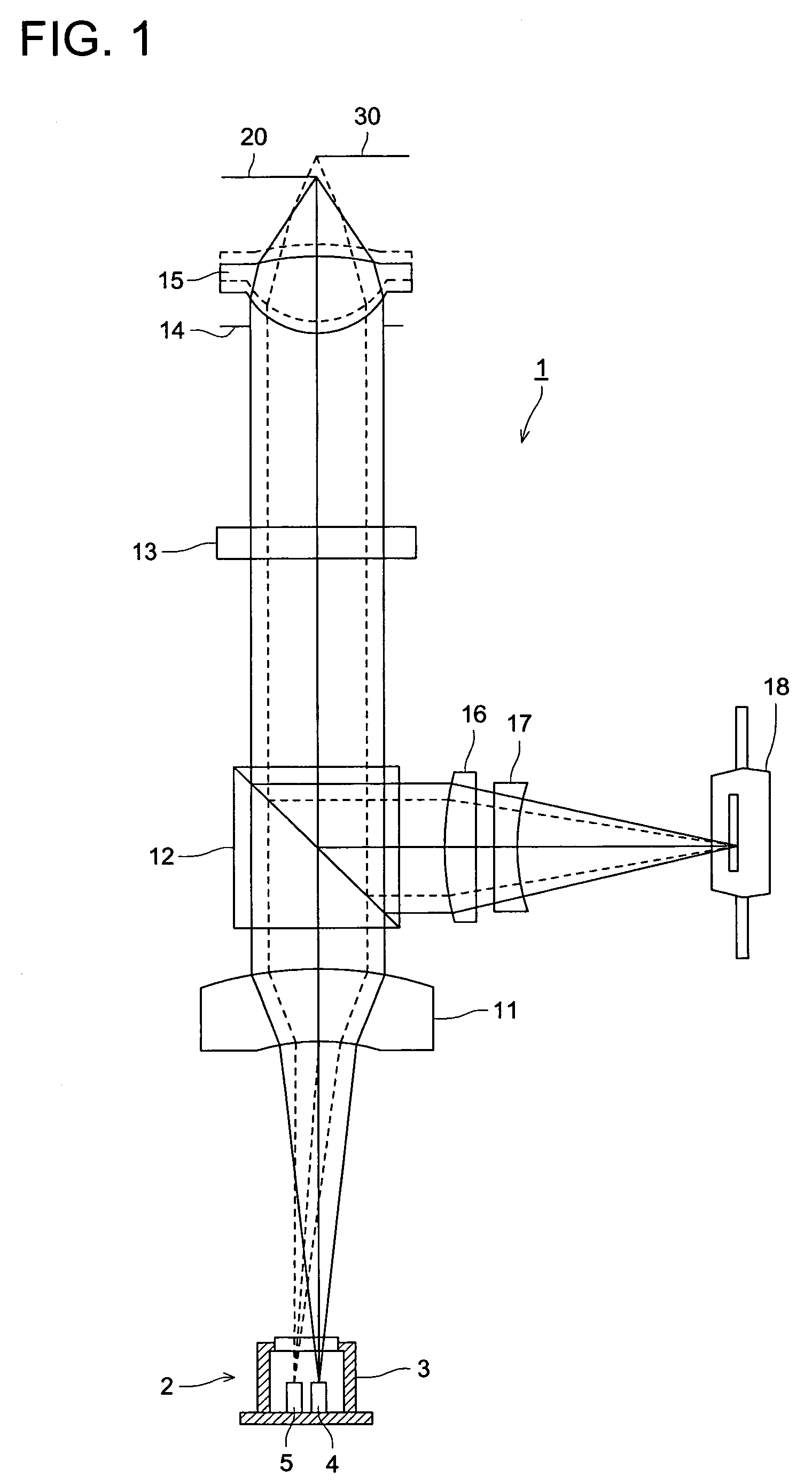

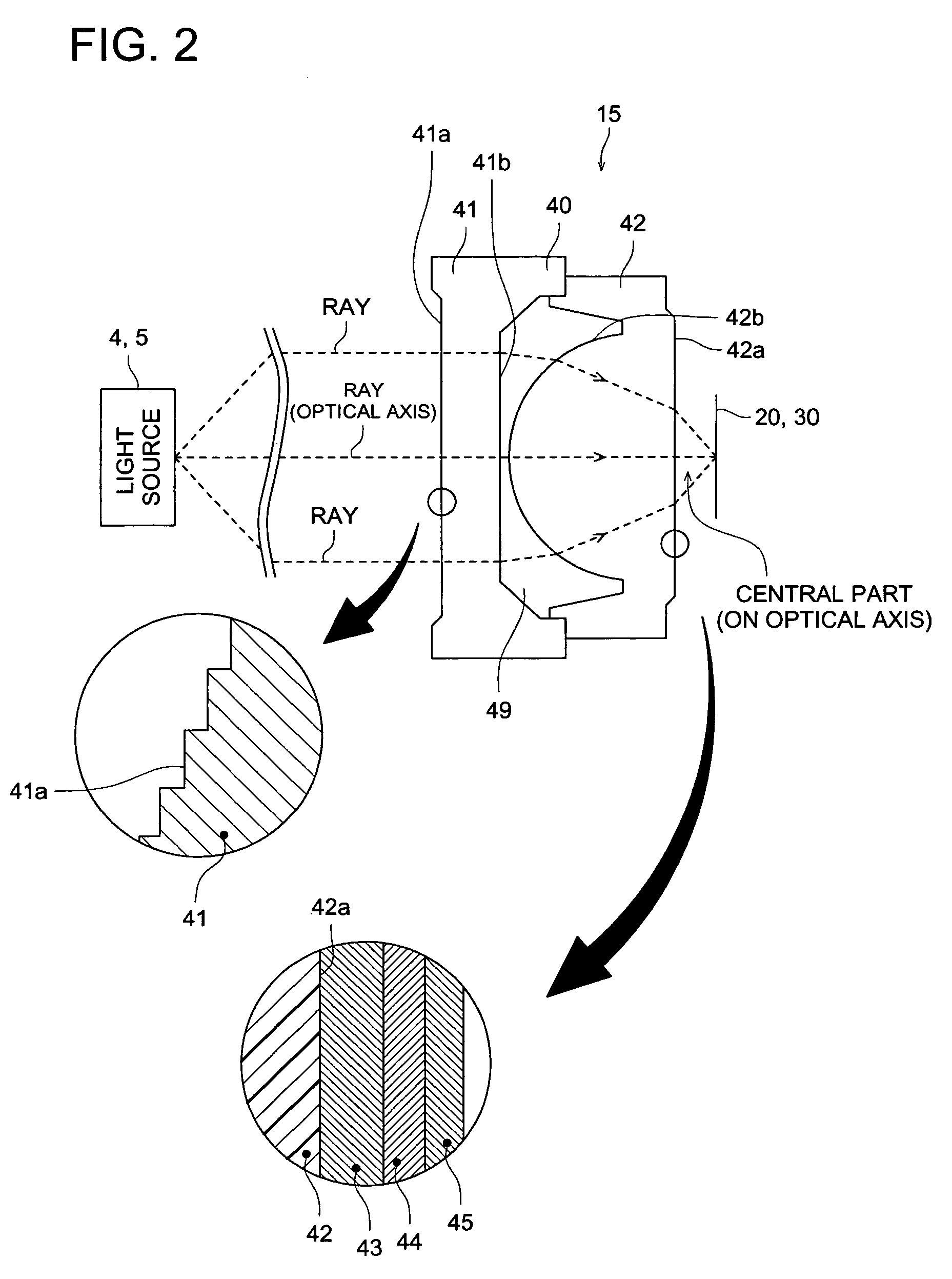

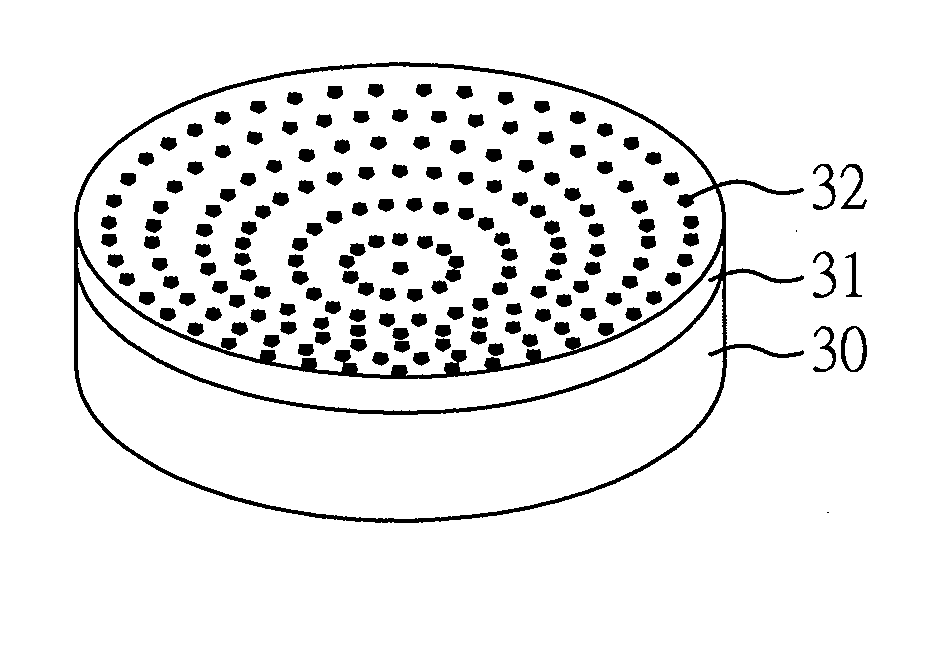

Objective lens and optical pickup apparatus

InactiveUS20050225879A1Excellent abrasion resistanceAvoid surface deformationRecord information storageOptical beam guiding meansOptical pickupPolymer resin

An objective lens for converging a monochromatic light flux having a specific wavelength in a range of 350 to 450 nm on an optical information recording medium while the objective lens is placed facing the optical information recording medium, the objective lens comprising: a lens body containing a polymer resin having an alicyclic structure; a first film having a refractive index of less than 1.7 for light having a wavelength of 405 nm; a second film having a refractive index of 1.7 or more for the light having the wavelength of 405 nm; and a third film having a refractive index of 1.55 or less for the light having the wavelength of 405 nm, wherein: the first film, the second film and the third film are provided on the lens body; the first film is provided between the lens body and the second film; the second film is provided between the first film and the third film; and a thickness of the first film is in a range of 50 to 15000 nm.

Owner:KONICA MINOLTA OPTO

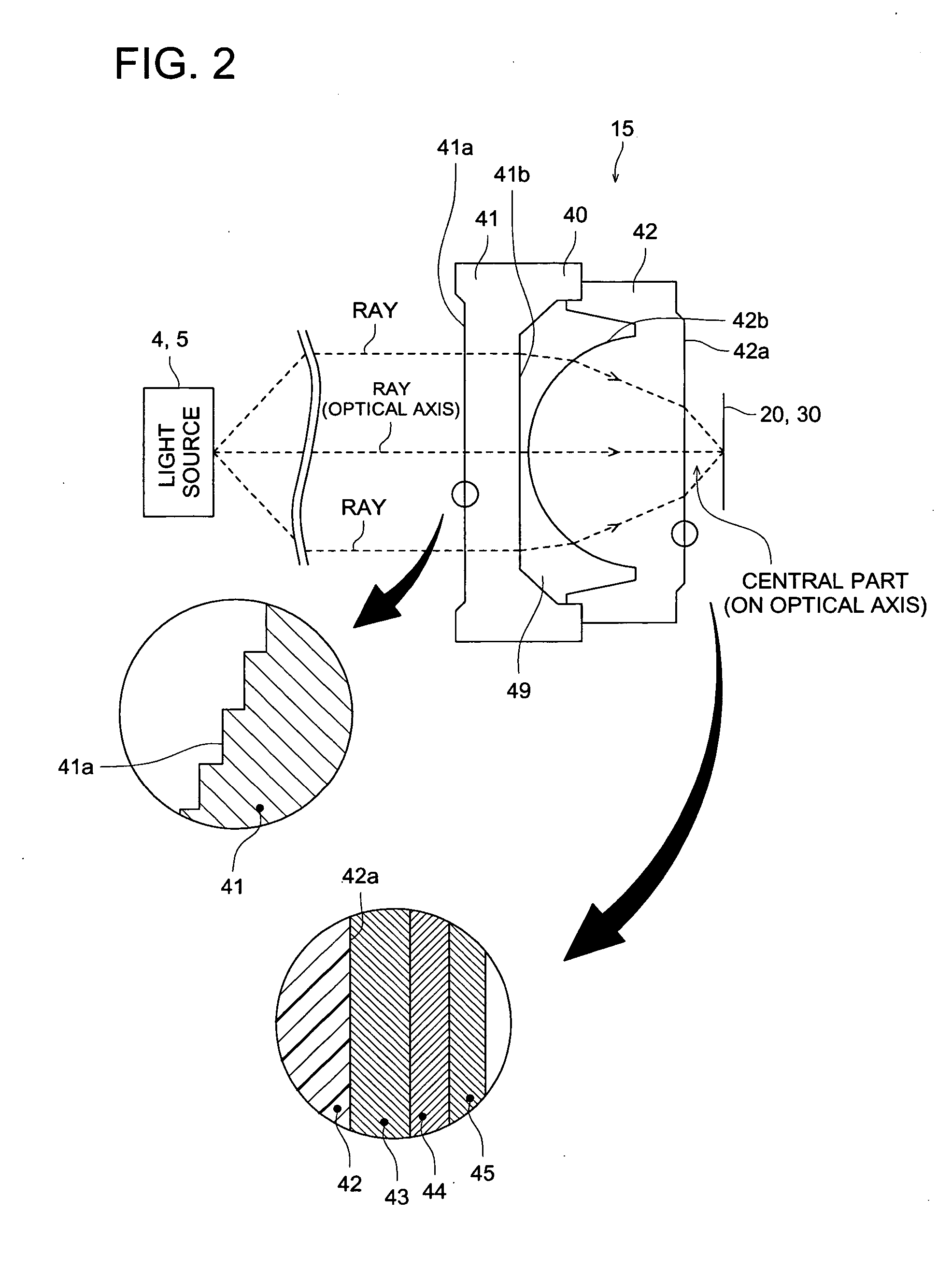

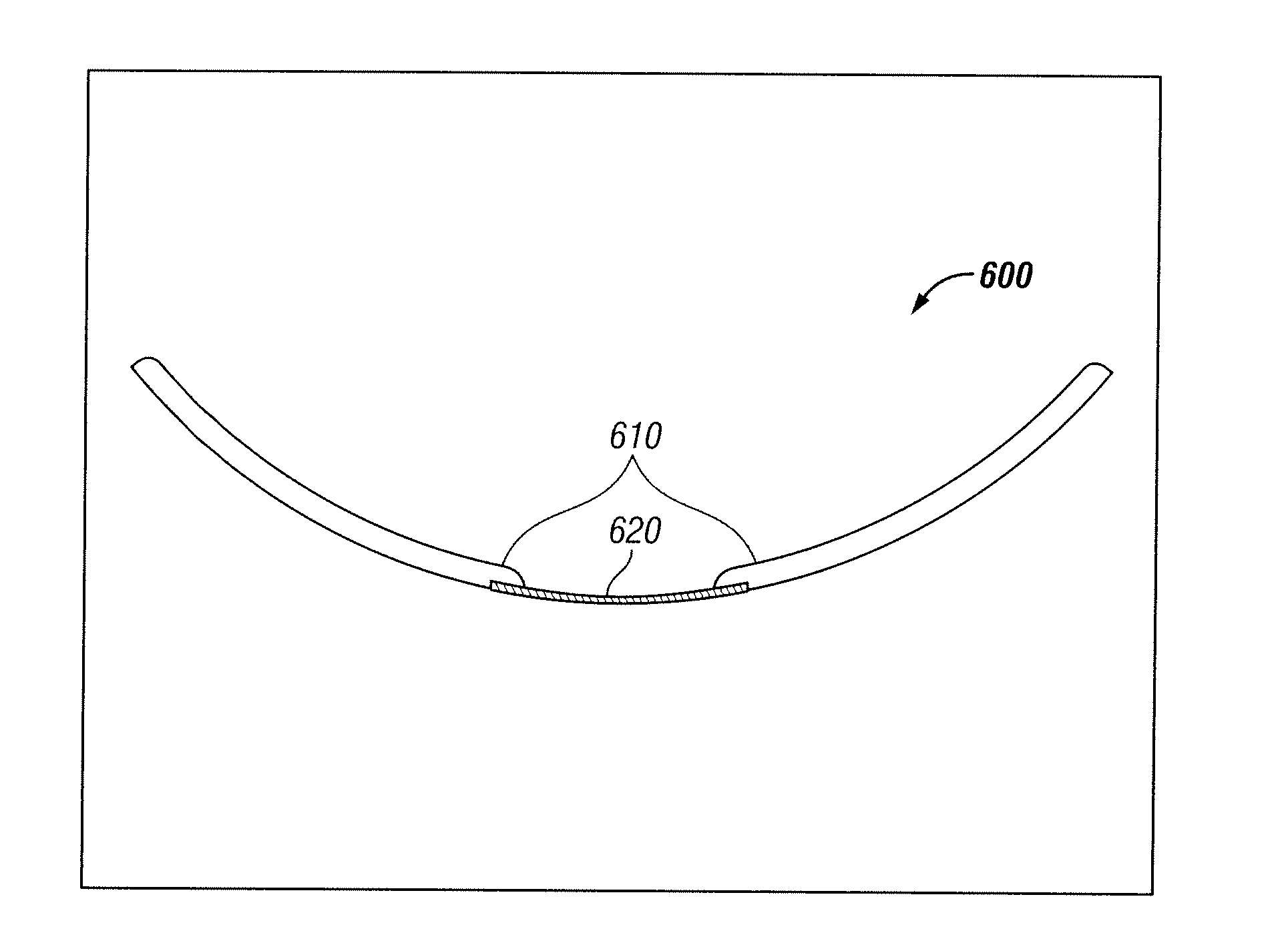

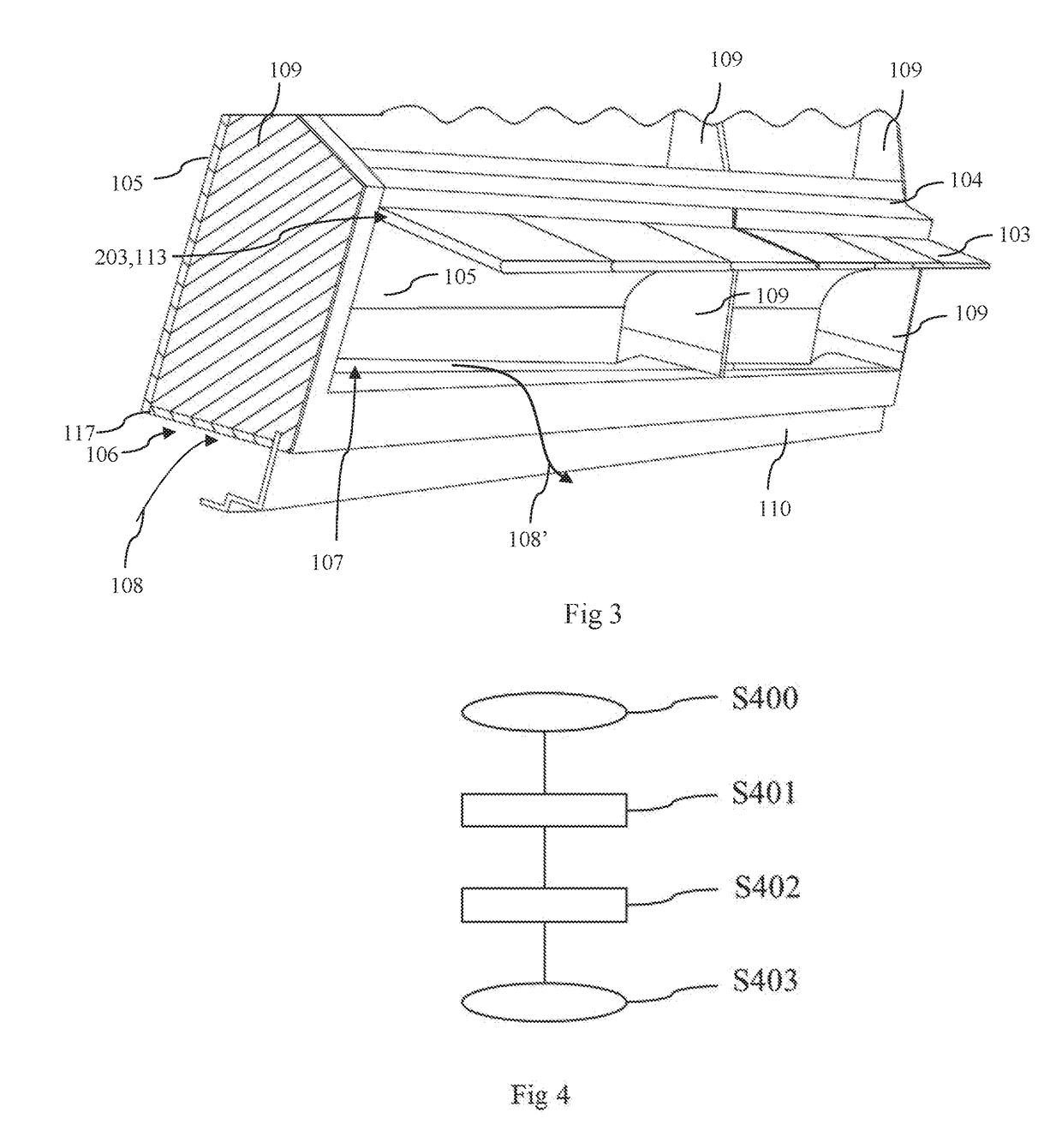

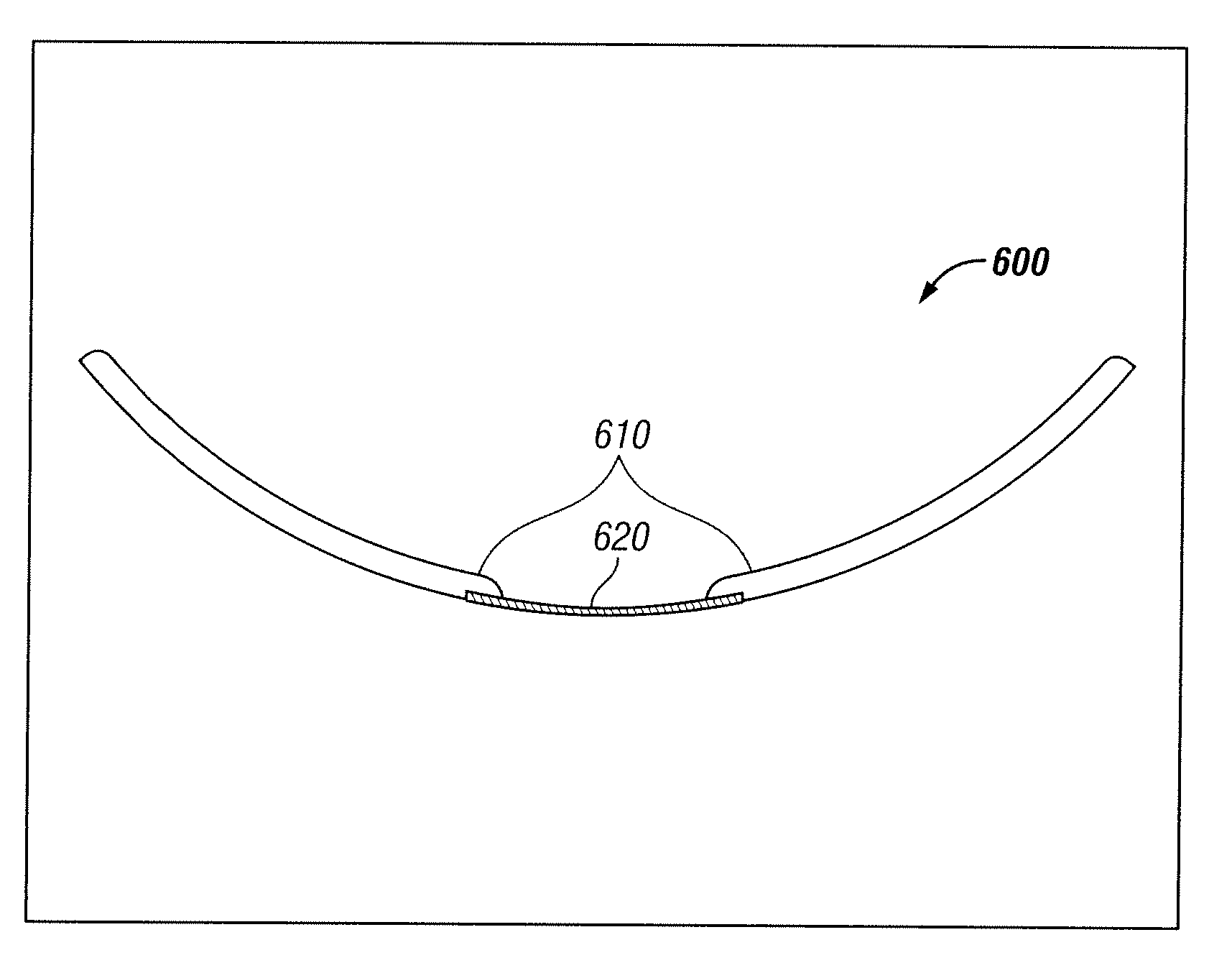

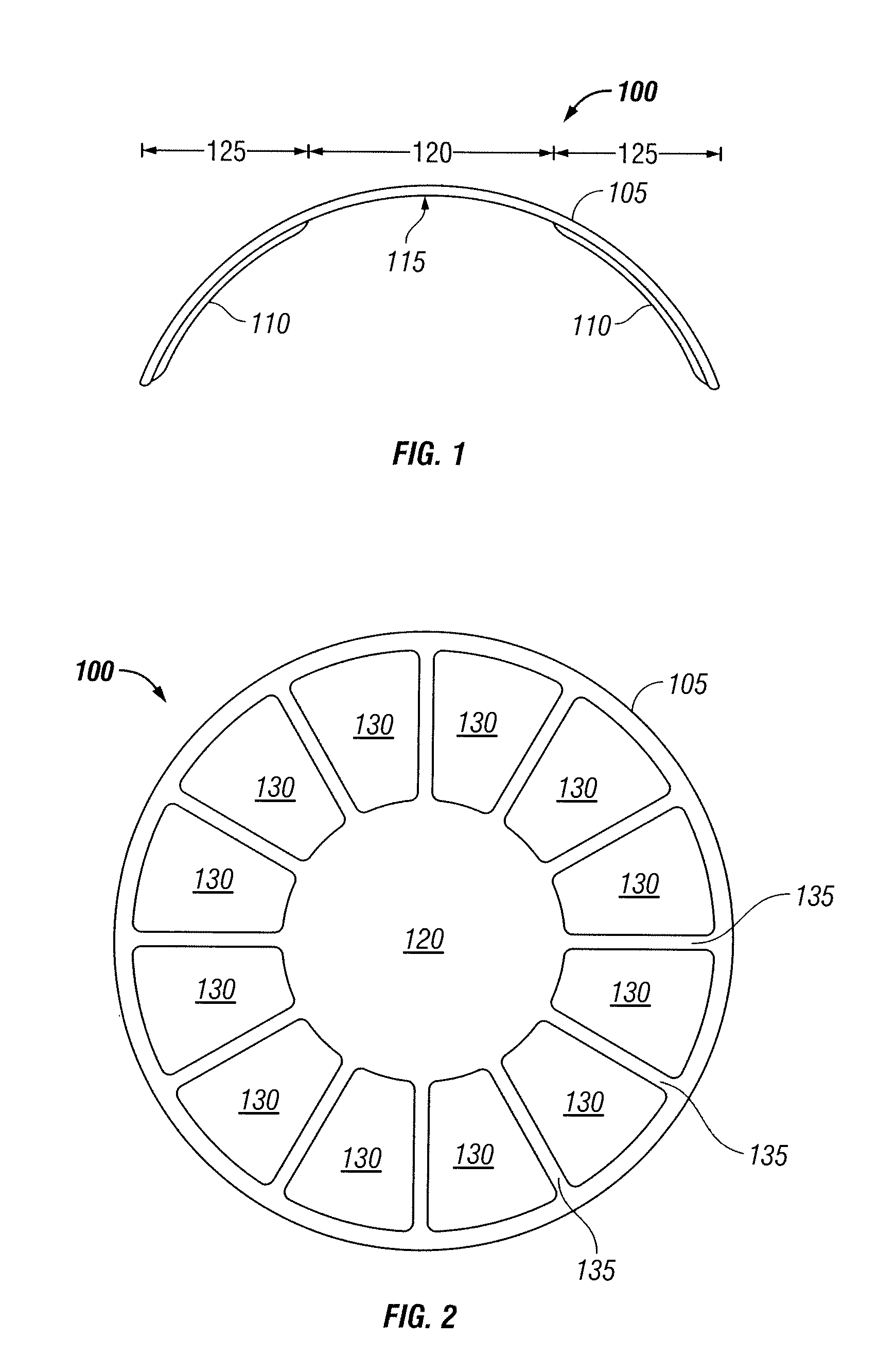

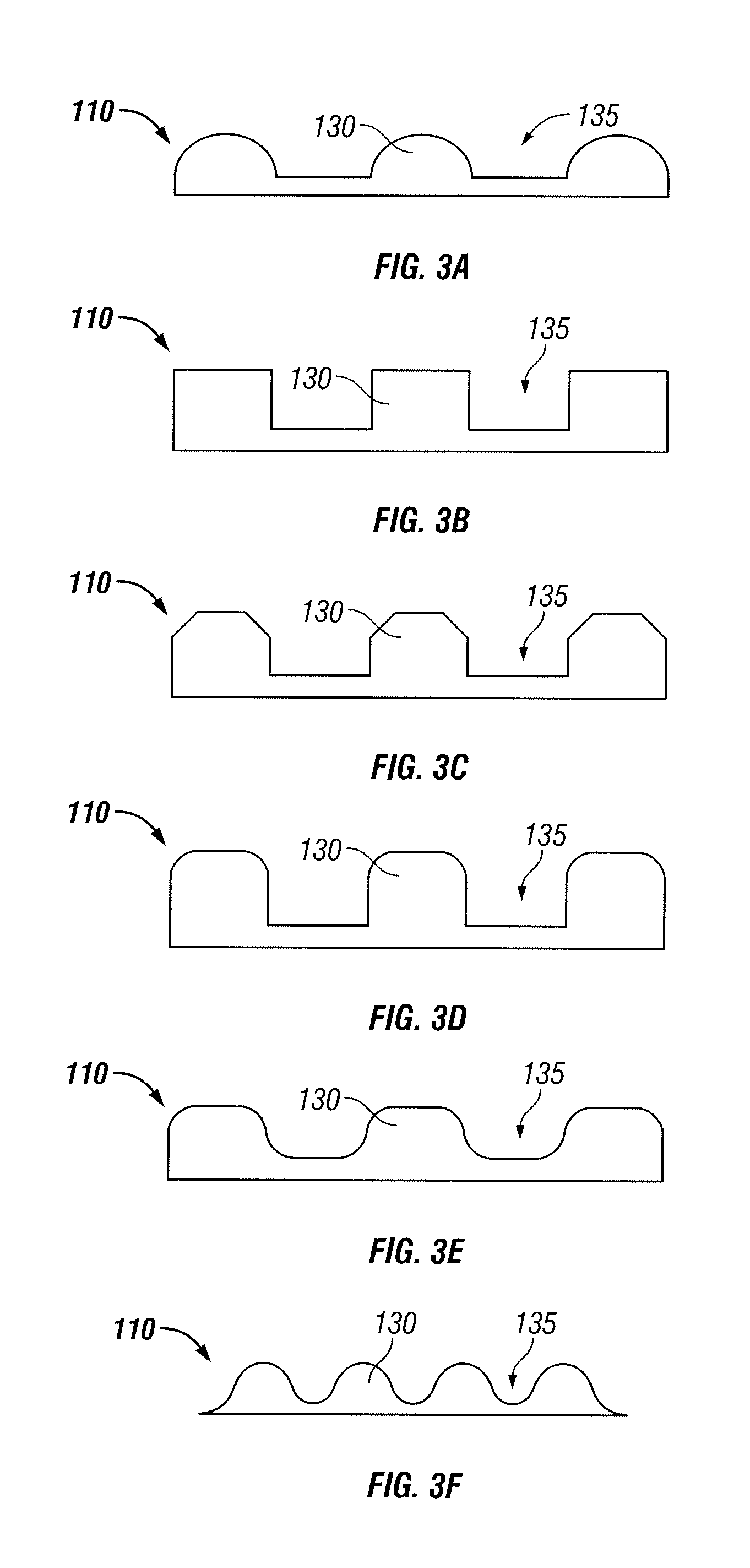

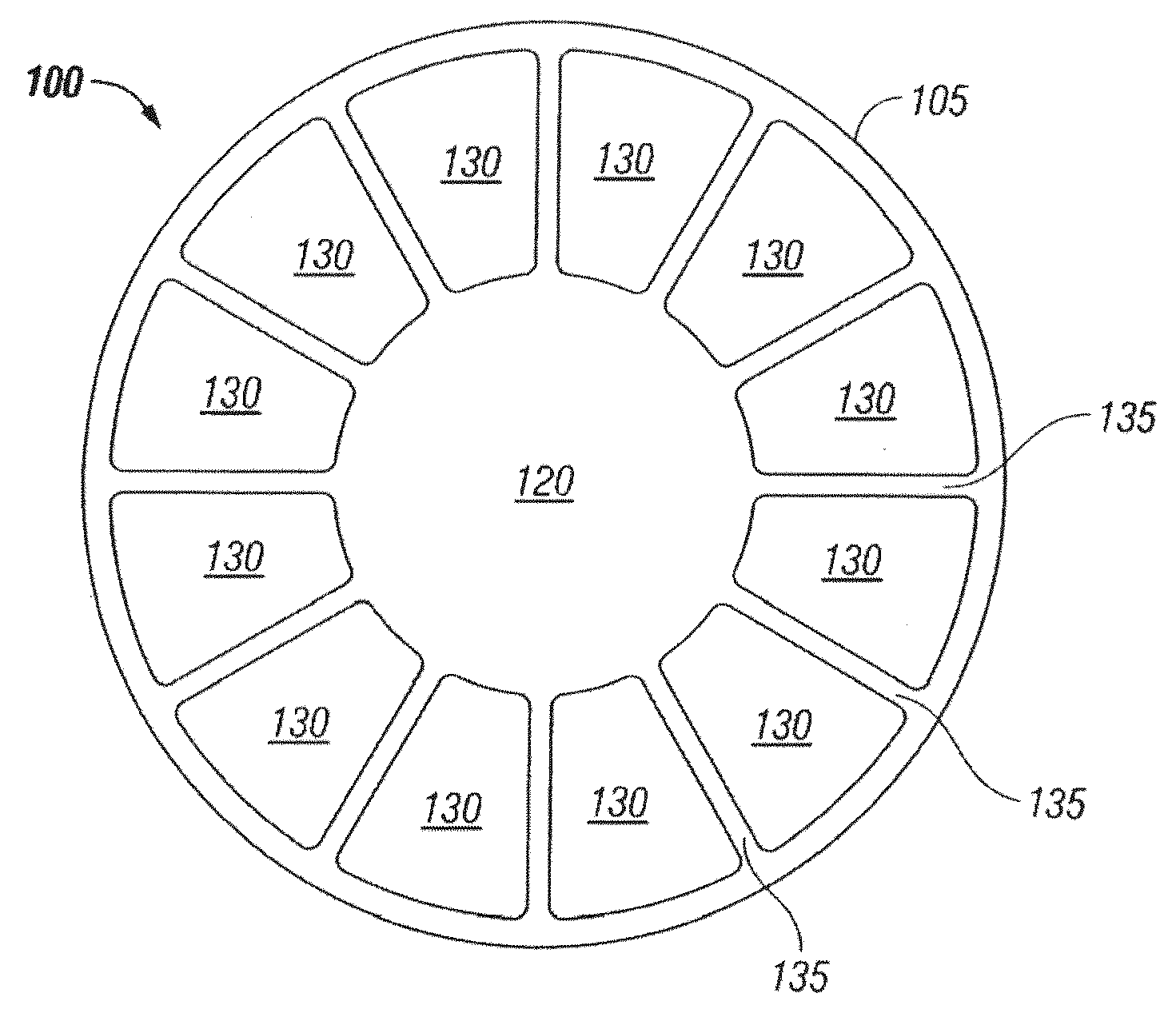

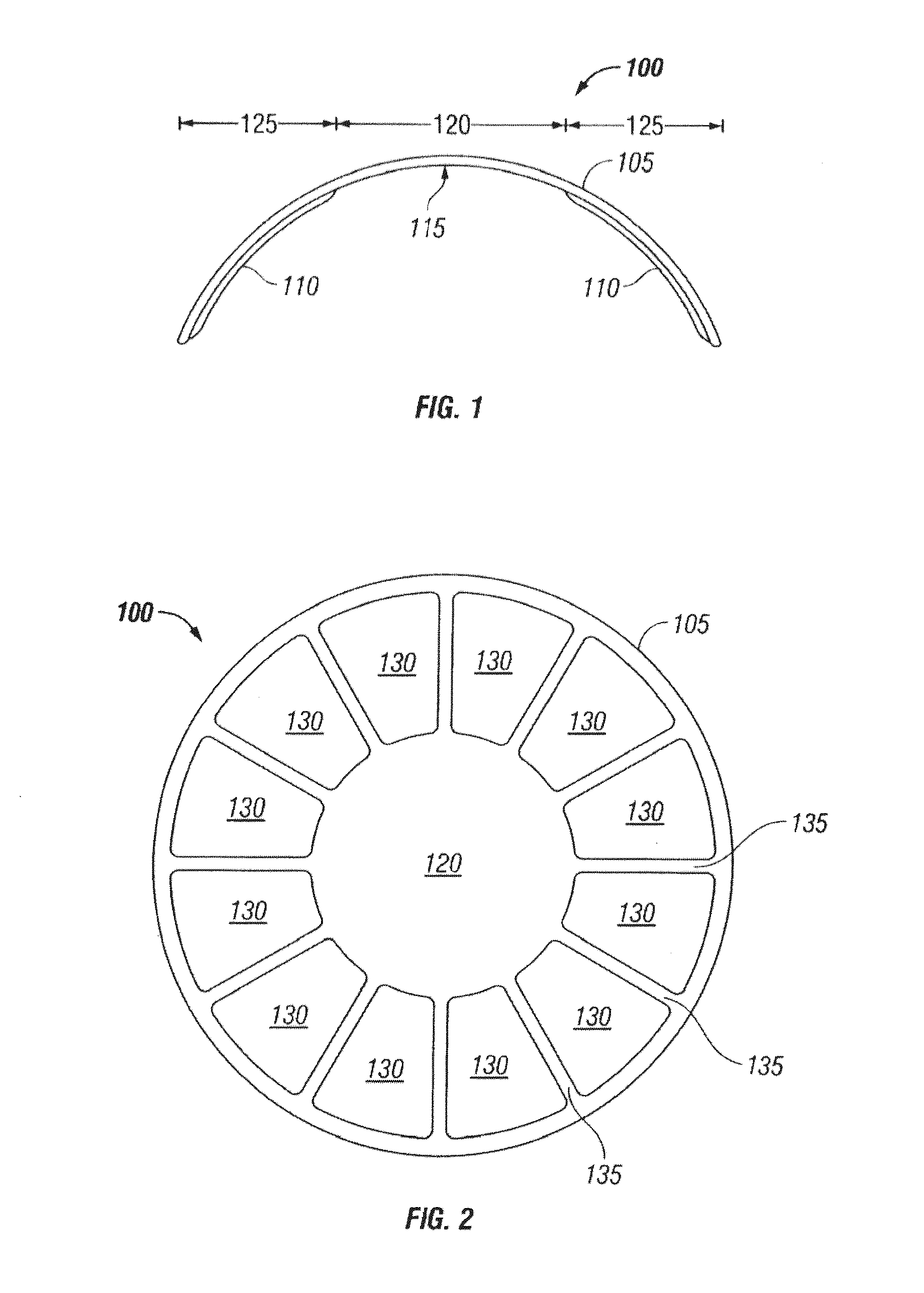

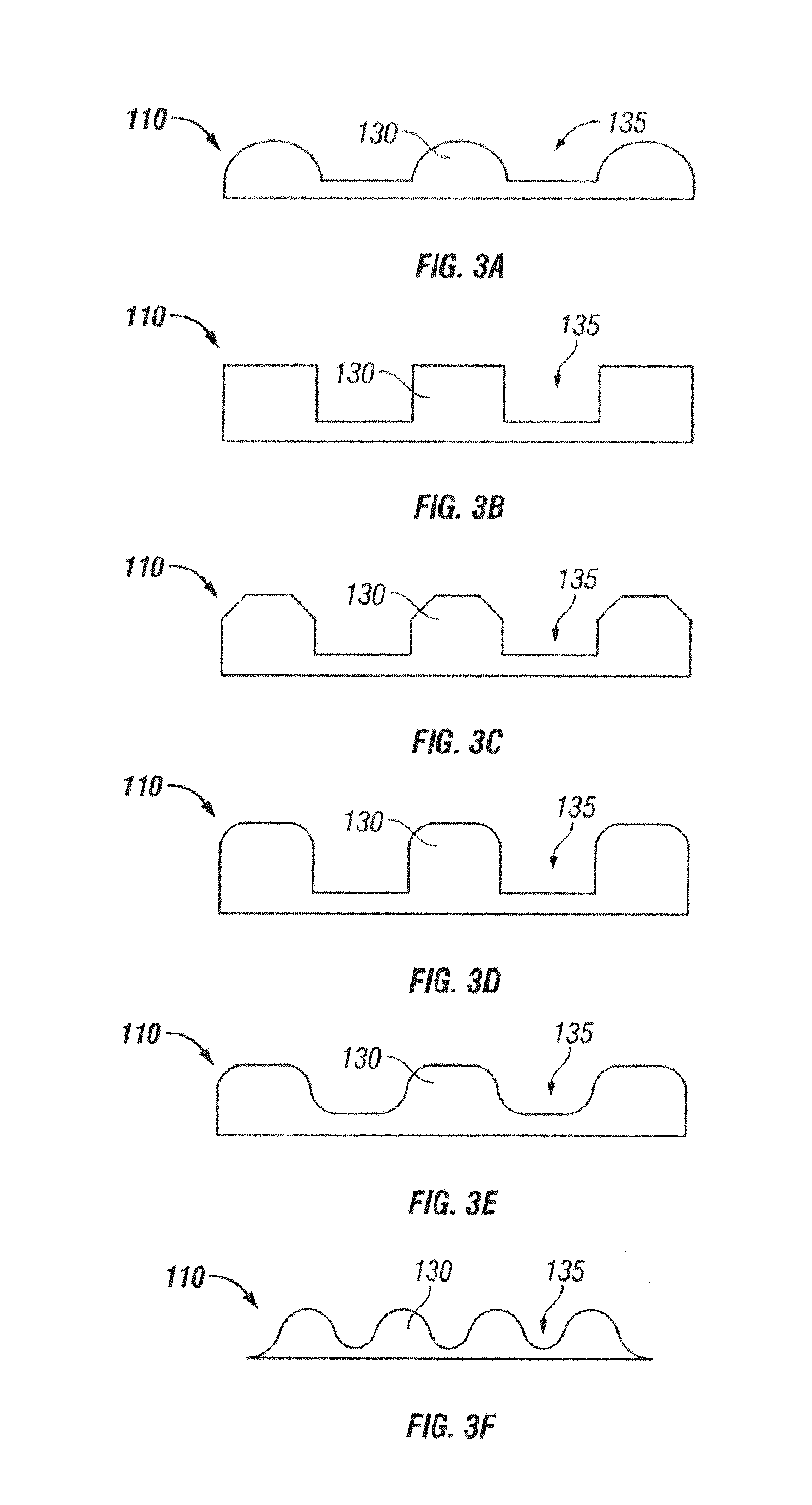

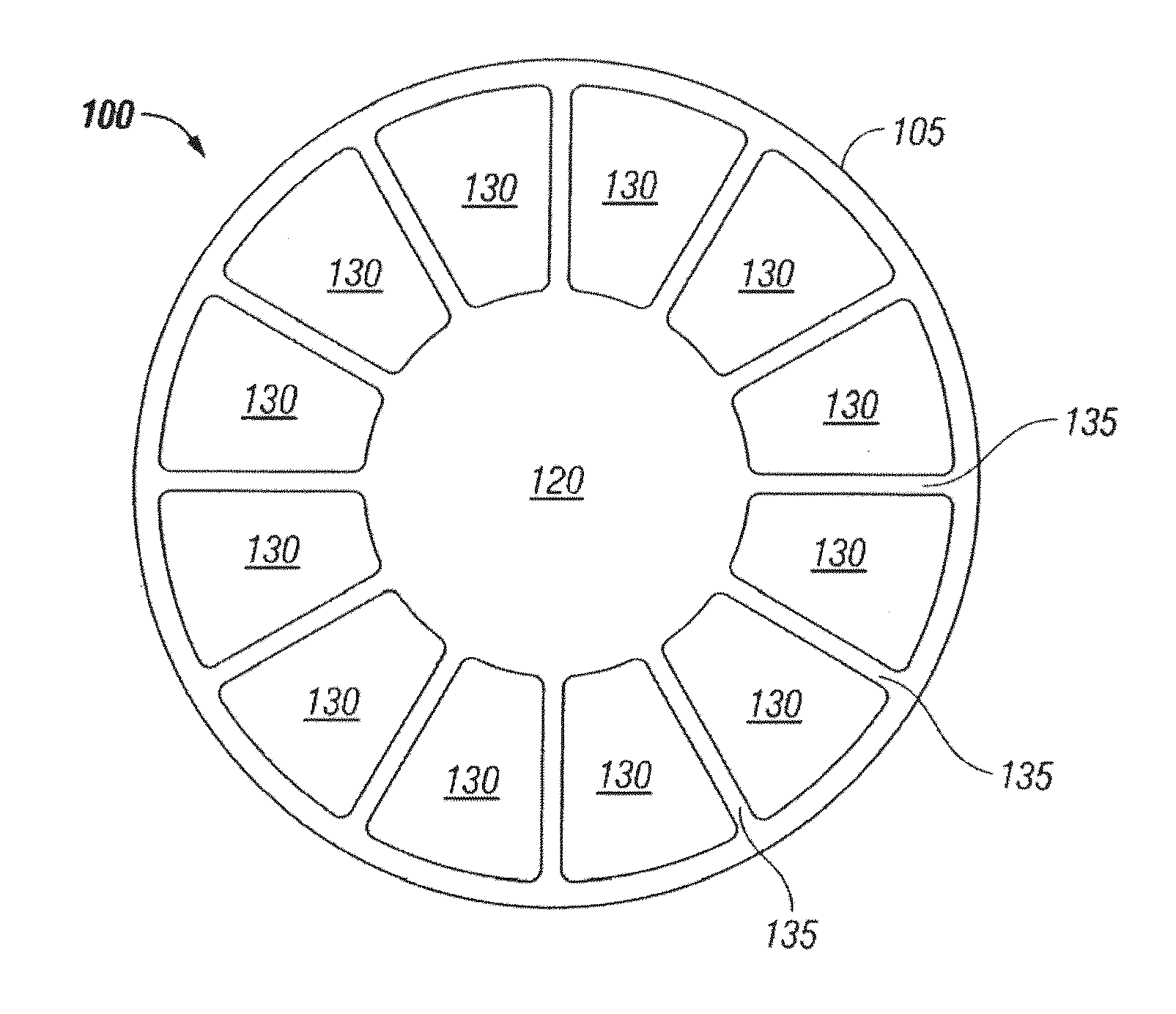

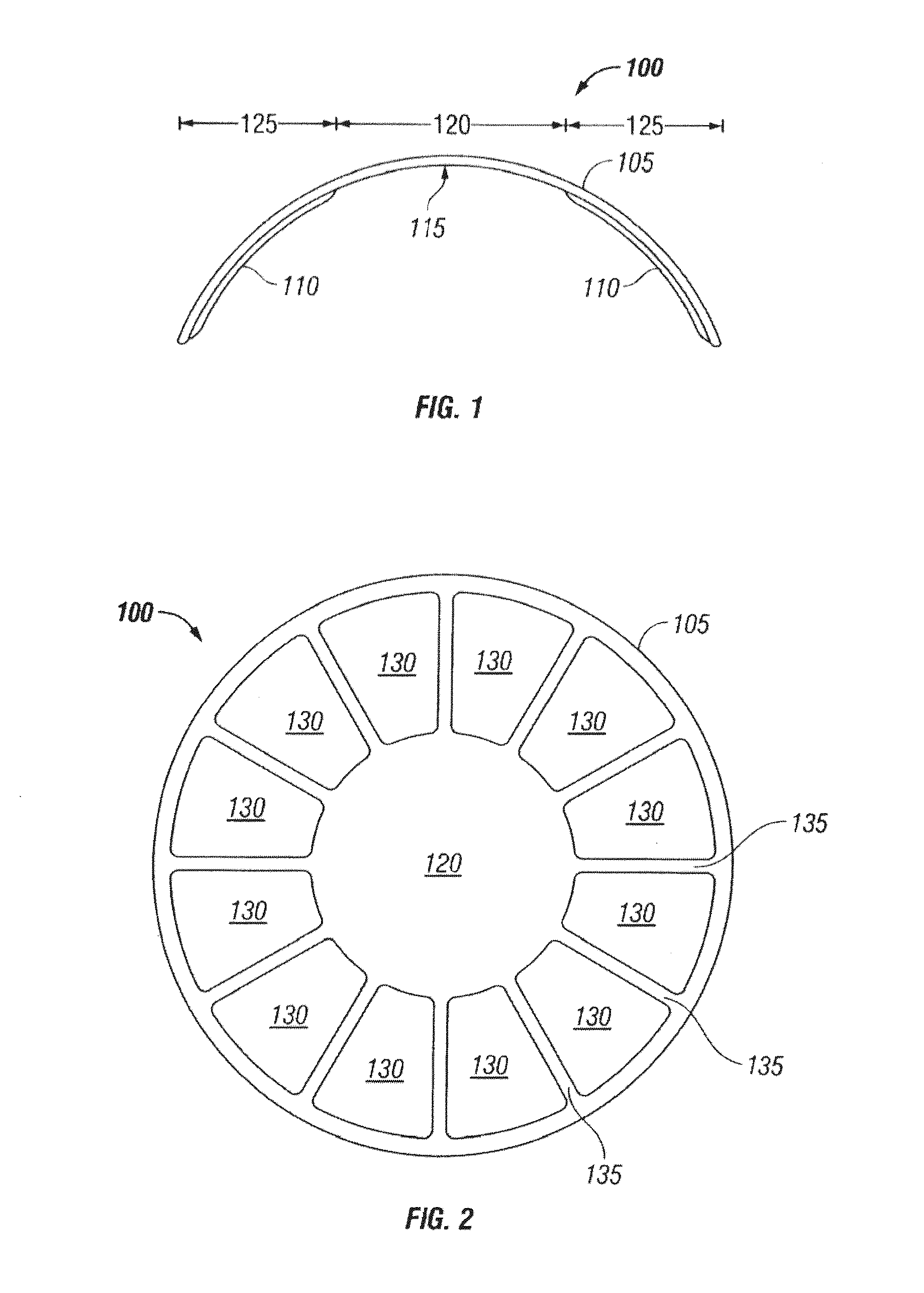

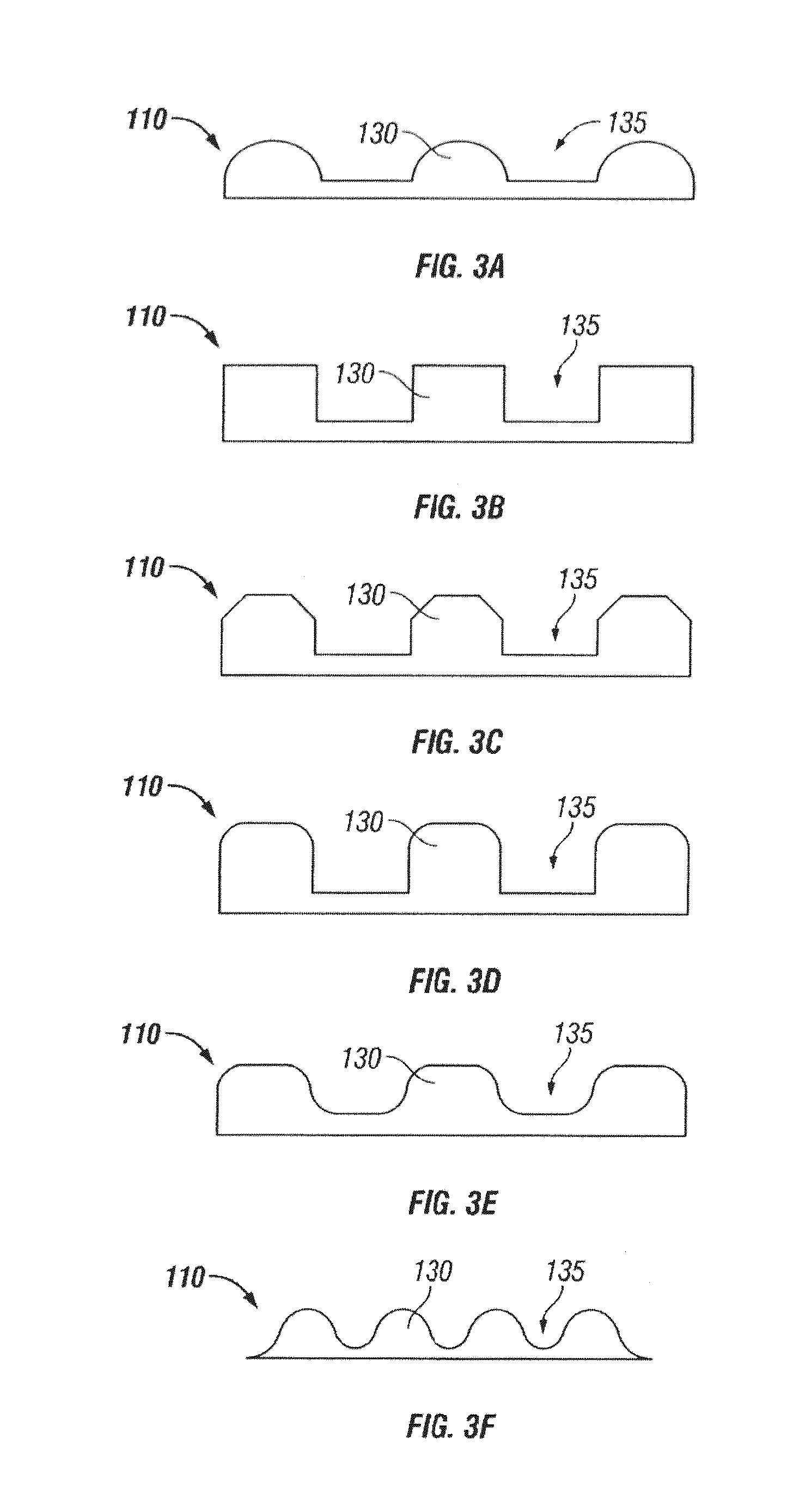

Laminated composite lens

ActiveUS20110228213A1Avoid surface deformationRelieve lens-eye surface attractionSpectales/gogglesOptical articlesSoft layerRigid gas permeable lens

The present invention is directed to a composite lens, comprising an anterior rigid gas permeable layer, and an annulus of soft material bonded to a posterior surface of the anterior rigid gas permeable layer, wherein a central zone of the composite lens is rigid and without a soft layer, wherein a peripheral zone of the composite lens is generally rigid in its anterior aspect and soft in its posterior aspect.

Owner:OCULAR SURFACE INNOVATIONS INC

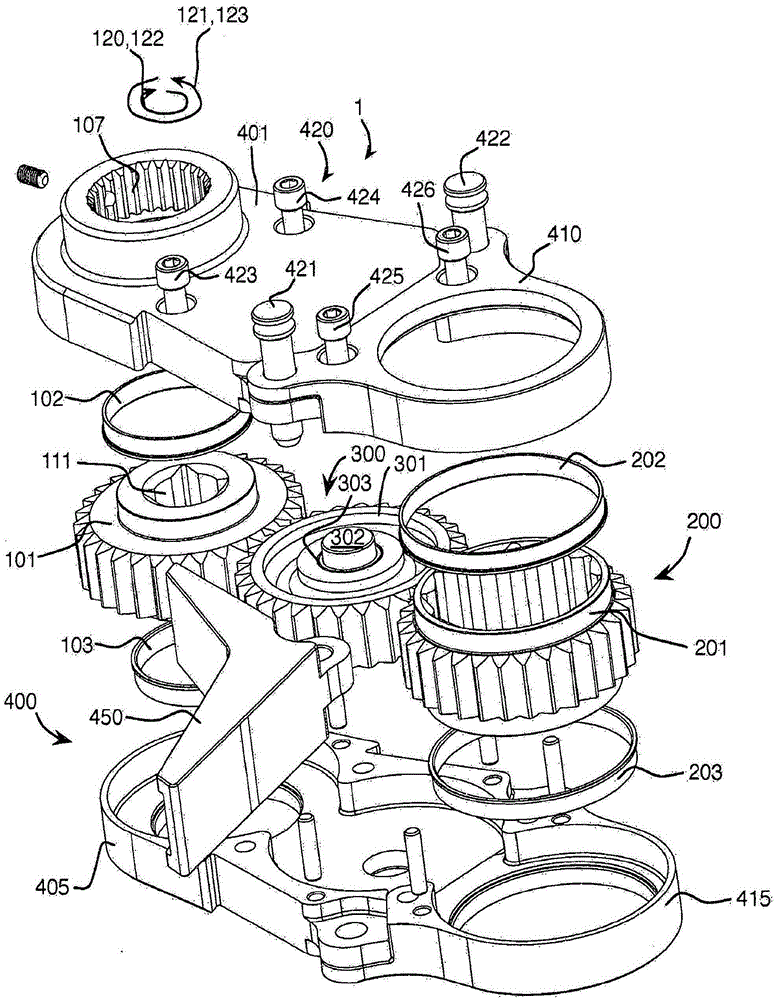

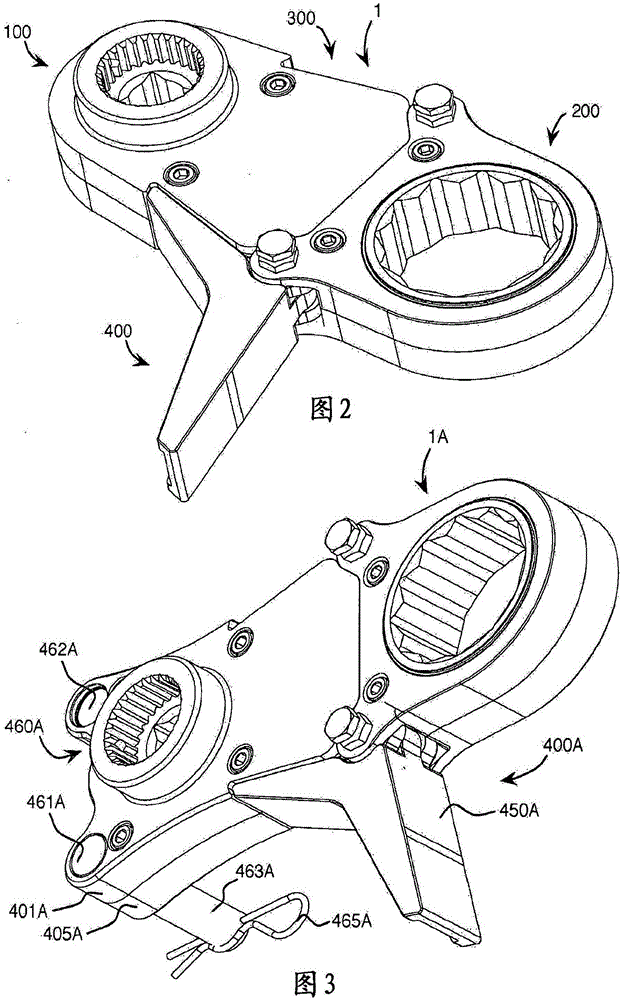

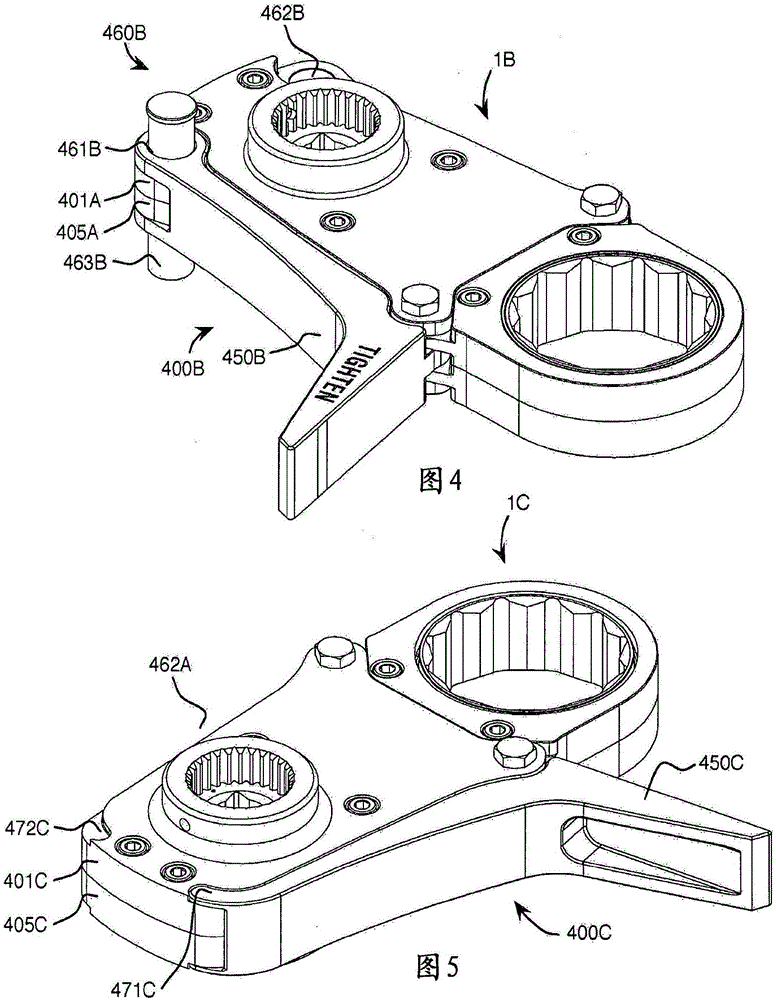

Apparatus for tightening threaded fasteners

ActiveCN105283272ASatisfy connected application characteristicsMeet the application characteristicsPliersSpannersEngineeringPower tool

An offset drive link assembly for transmission and multiplication of torque from a power tool for tightening or loosening a threaded fastener includes: a drive force input assembly; a drive force output assembly; and a reaction force assembly. Advantageously the offset drive link assembly: allows access to previously unreachable fasteners due to, for example protruding threads, limited clearances and obstructions; makes practical previously unusable devices driven either electrically, hydraulically, manually and / or pneumatically; makes feasible previously unusable advanced materials, such as, for example aircraft-grade aluminum; creates modular components, such as, for example hex-reducing and -increasing drive bushings, male to female drive adaptors, to meet bolting application characteristics; yields accurate and customizable torque multiplication; tames drive force and reaction force application; overcomes corrosion, thread and facial deformation; avoids bolt thread galling; nullifies side load; ensures balanced bolt load for symmetrical joint compression; simplifies link and tool use; minimizes risk of operator error; and maximizes bolting safety.

Owner:HYTORC DIV UNEX CORP

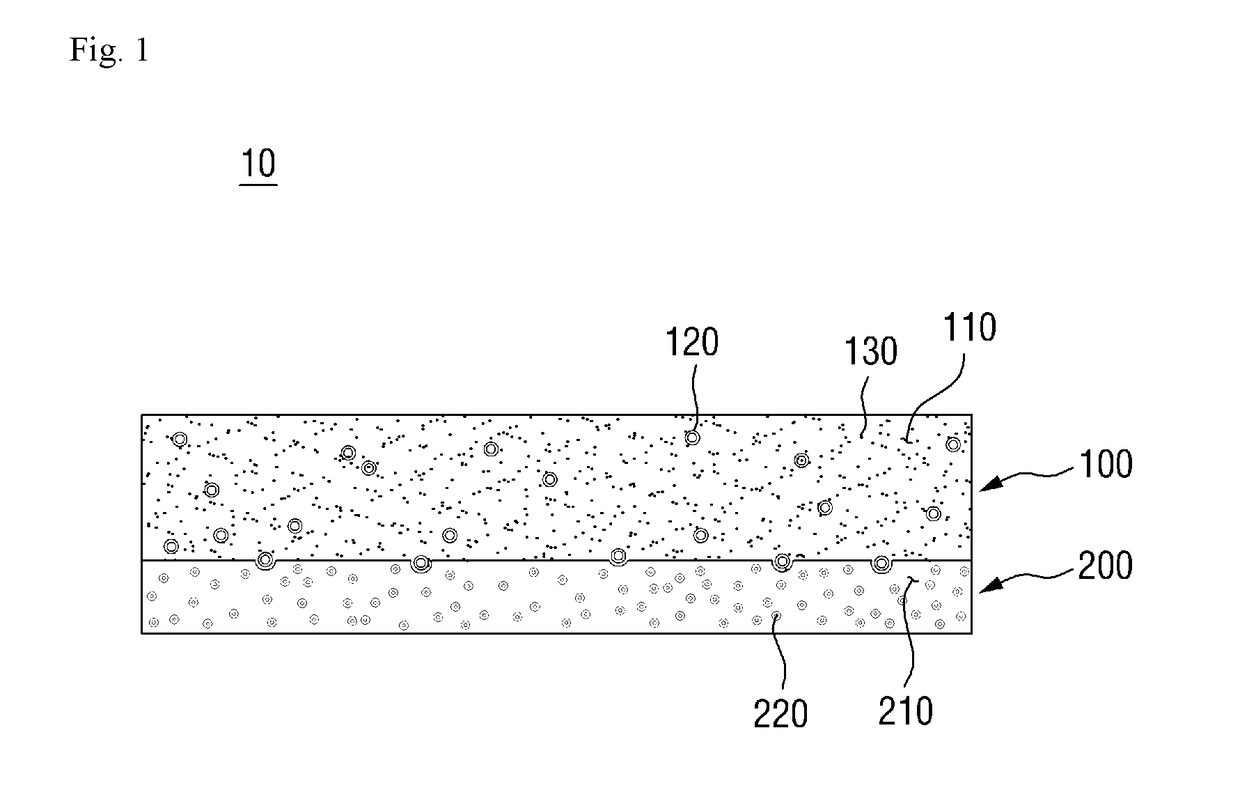

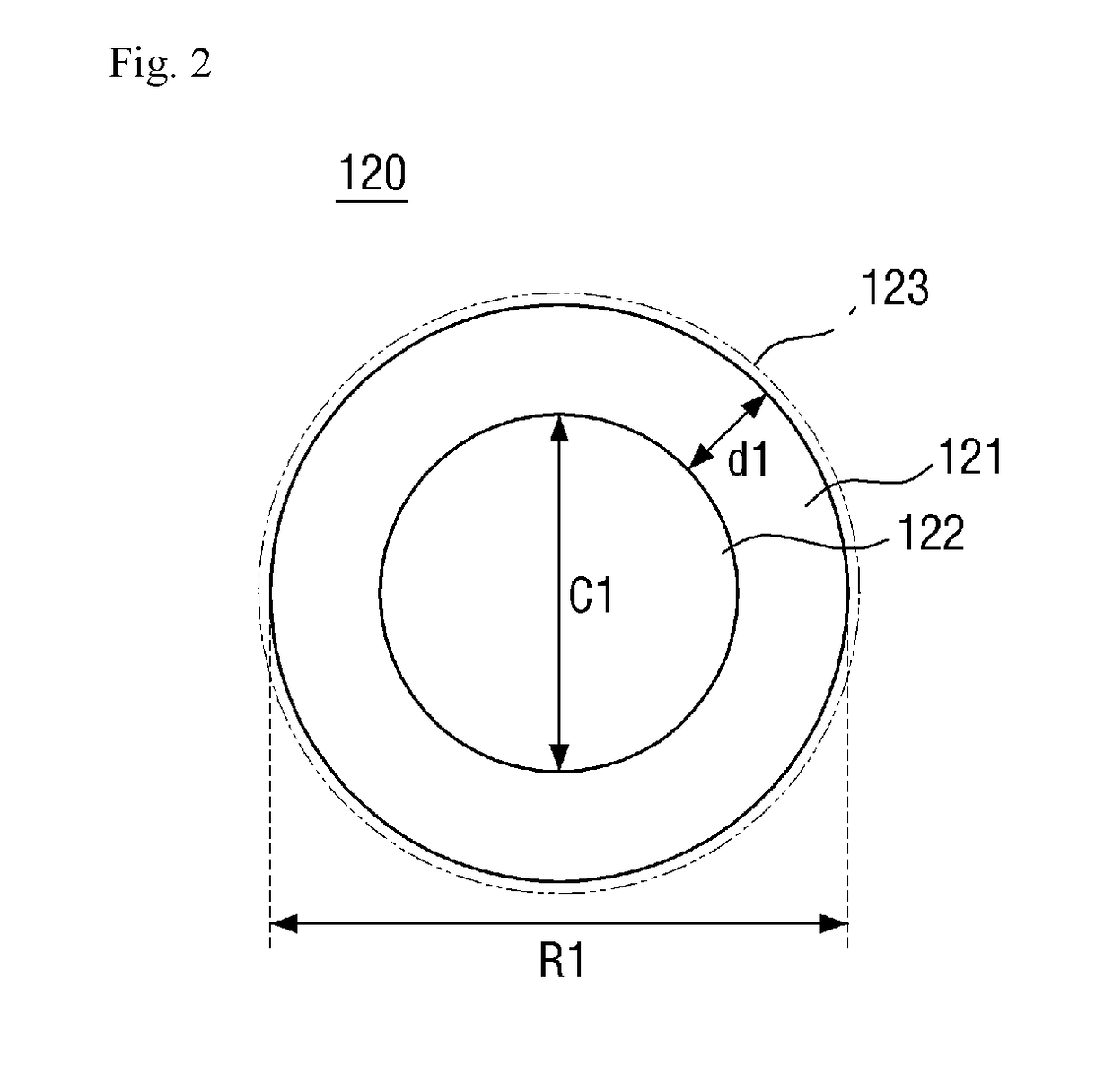

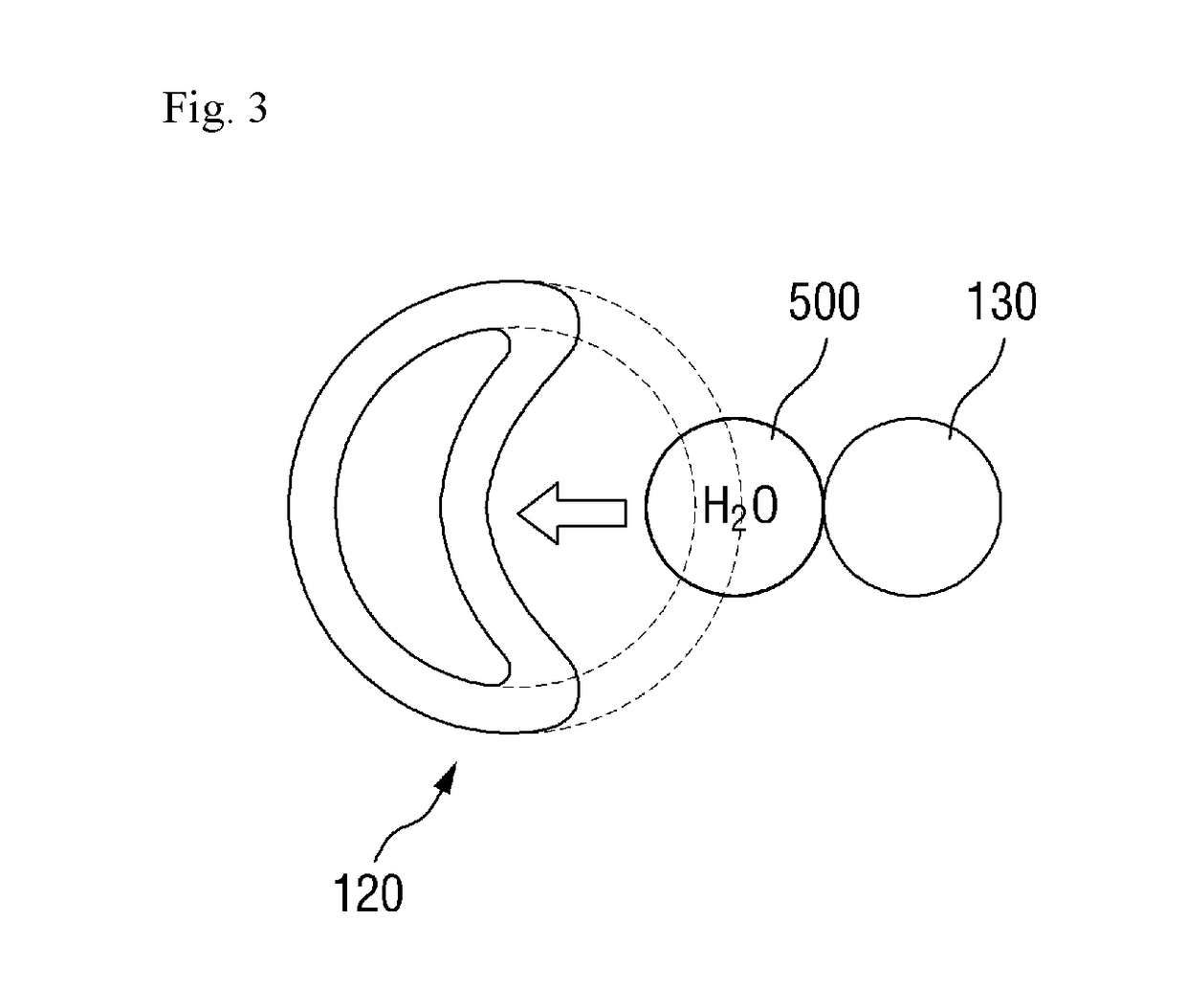

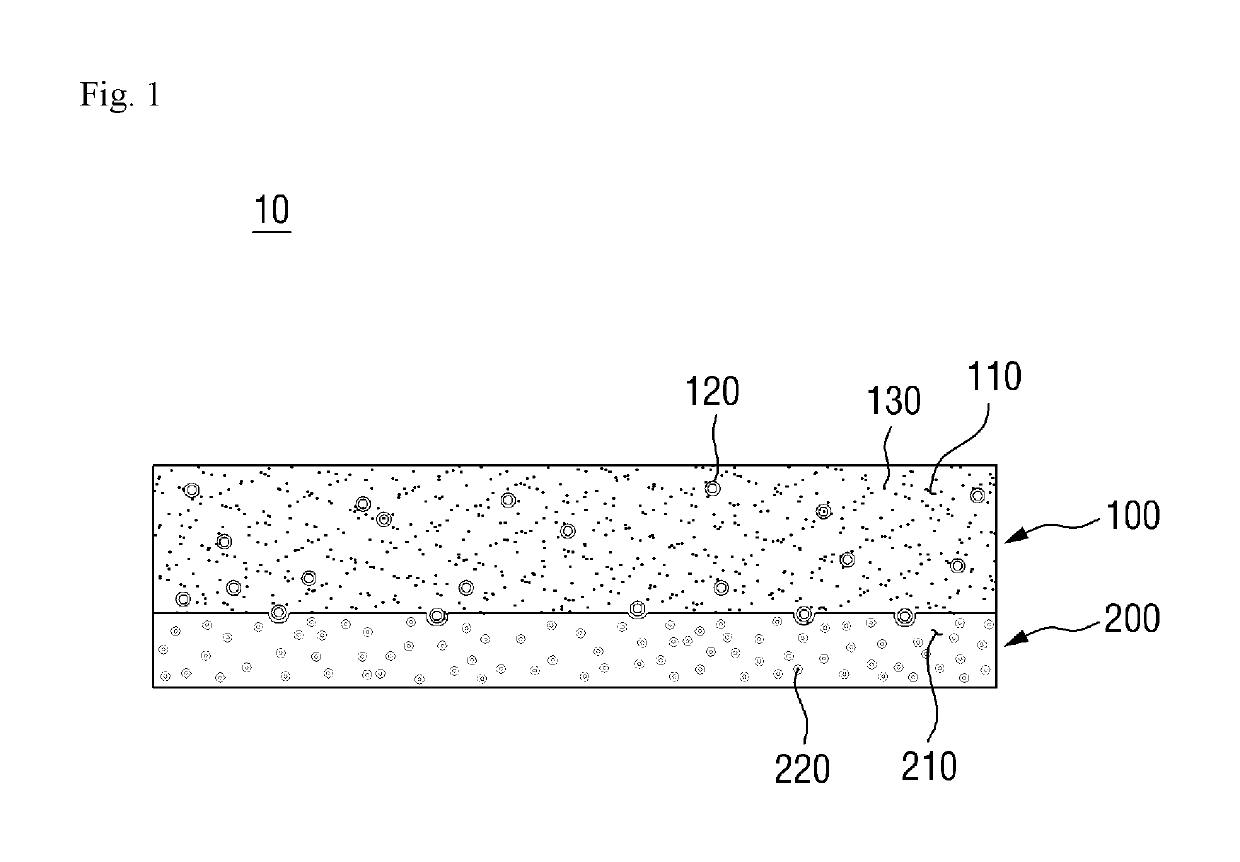

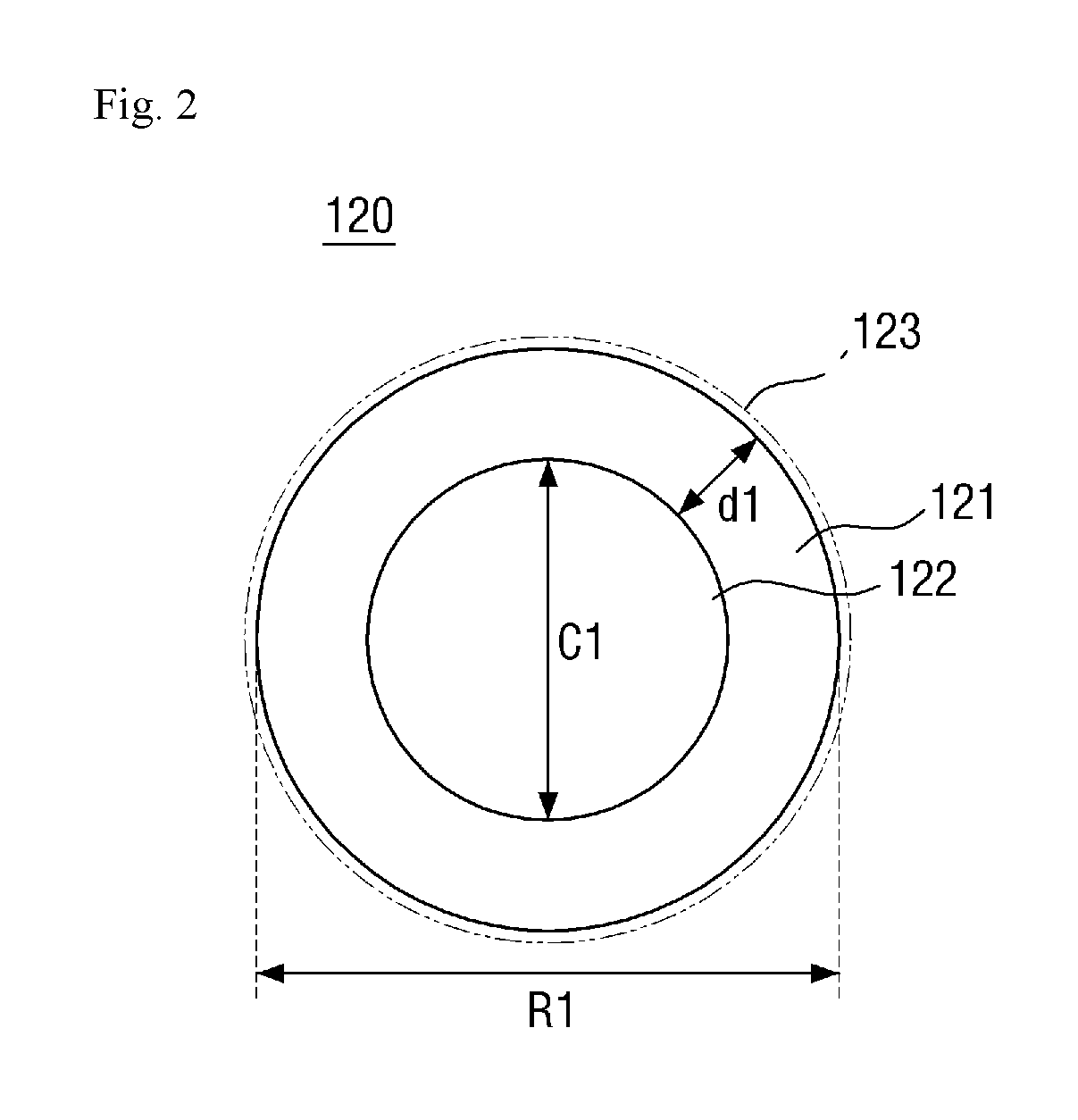

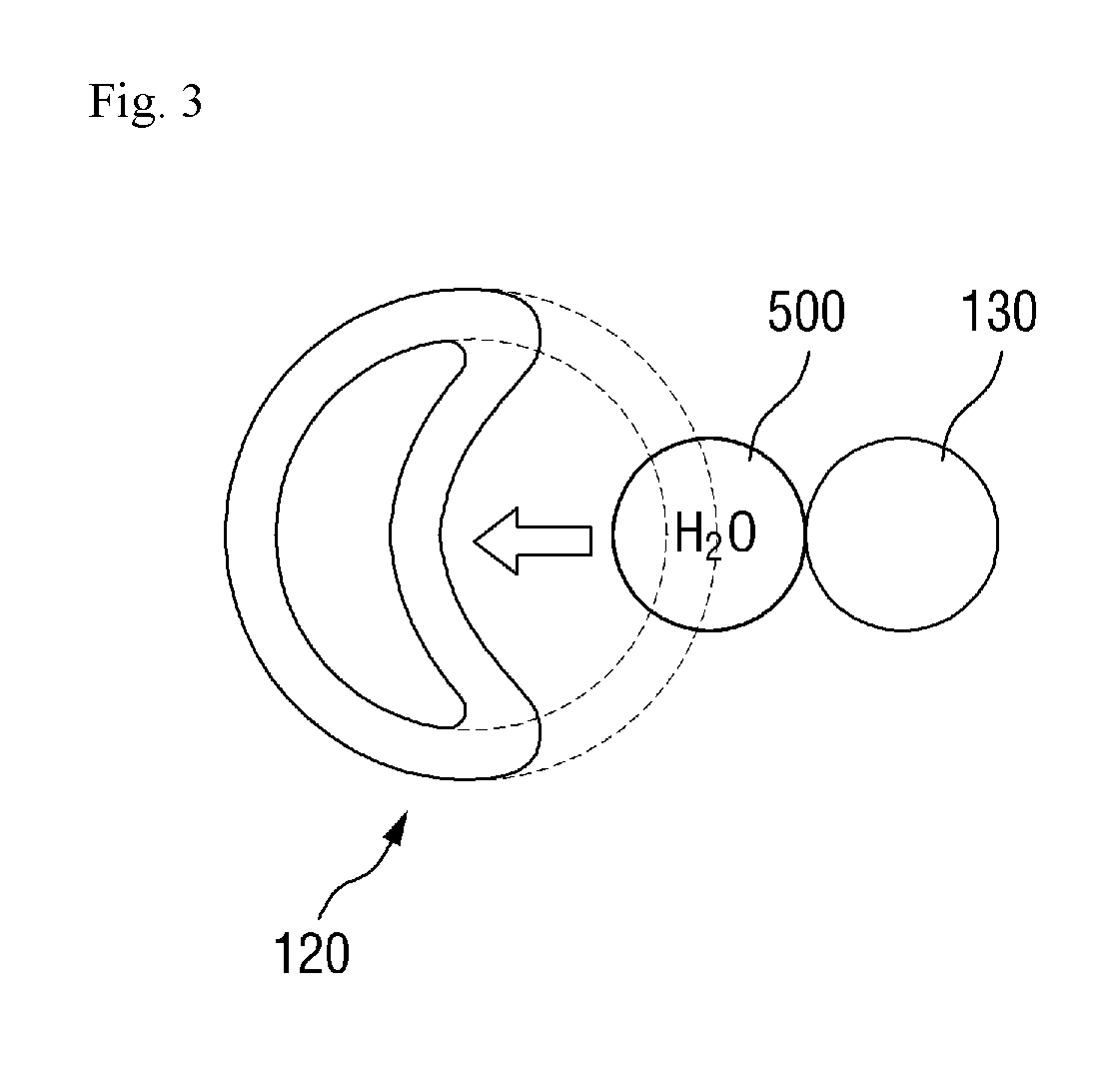

Adhesive film and organic electronic device including the same

ActiveUS20190006624A1Improved water vapor transmission rate (WVTR)Improved WVTR characteristicSolid-state devicesSemiconductor/solid-state device manufacturingCore shellMoisture

An adhesive film and an organic electronic device including the same are provided. The adhesive film includes: a first bonding layer including a first bonding component layer, a moisture absorbent, and first core shell particles; and a second bonding layer disposed below the first bonding layer and including second core shell particles, which are formed of a different material from the first core shell particles, wherein each of the first core shell particles includes a first shell and a first core surrounded by the first shell and each of the second core shell particles includes a second shell and a second core surrounded by the second shell.

Owner:SHINWHA INTERTEK

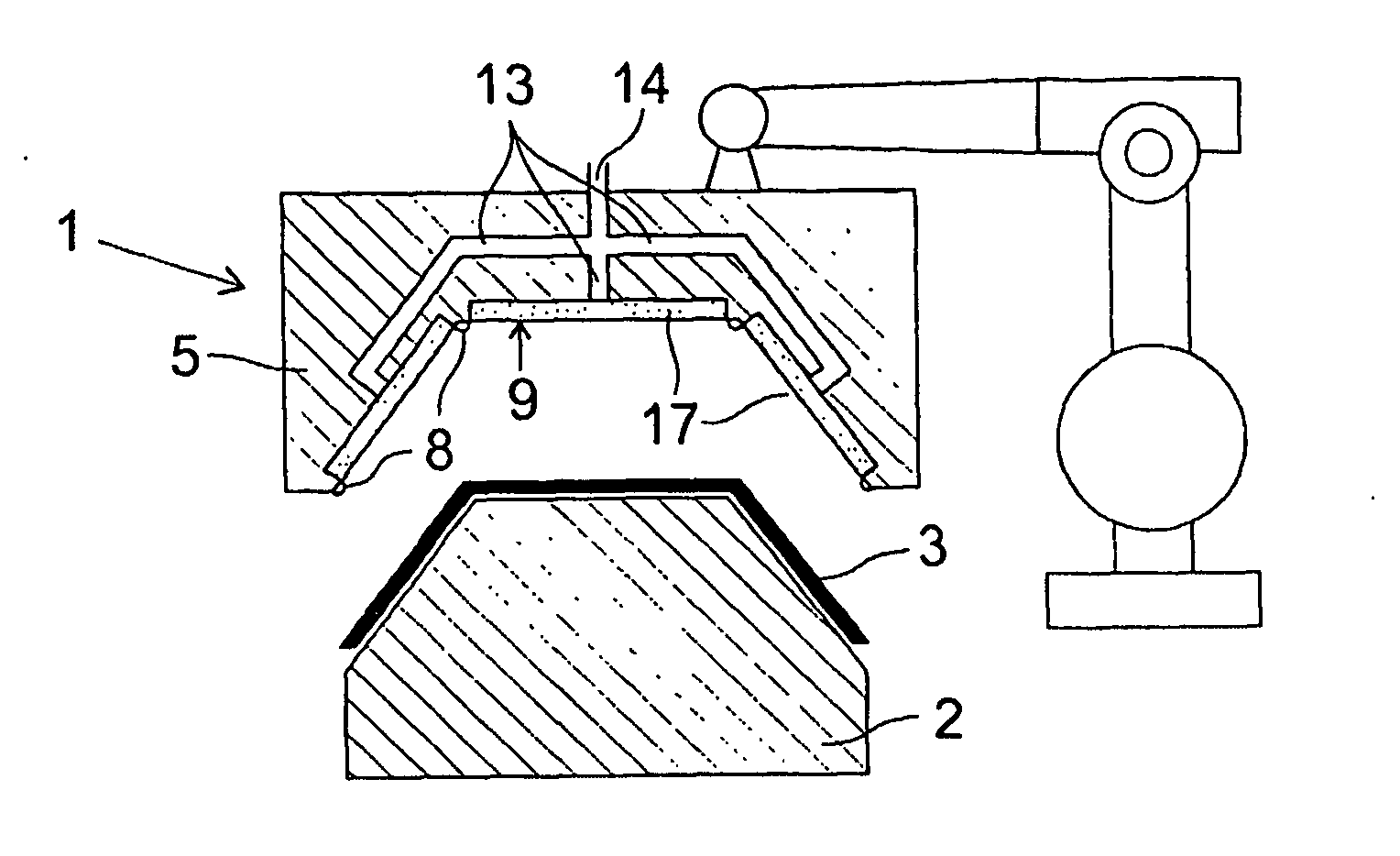

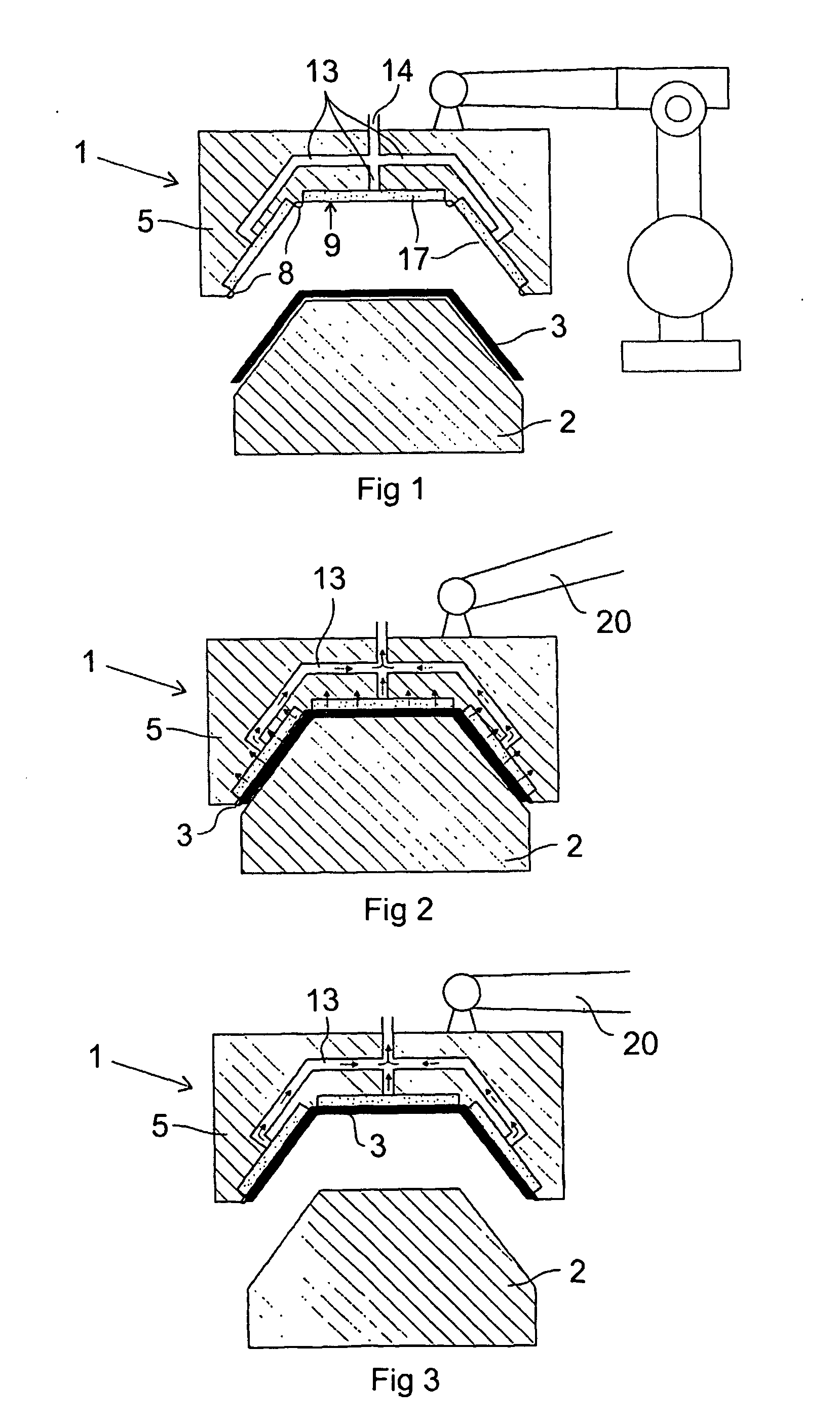

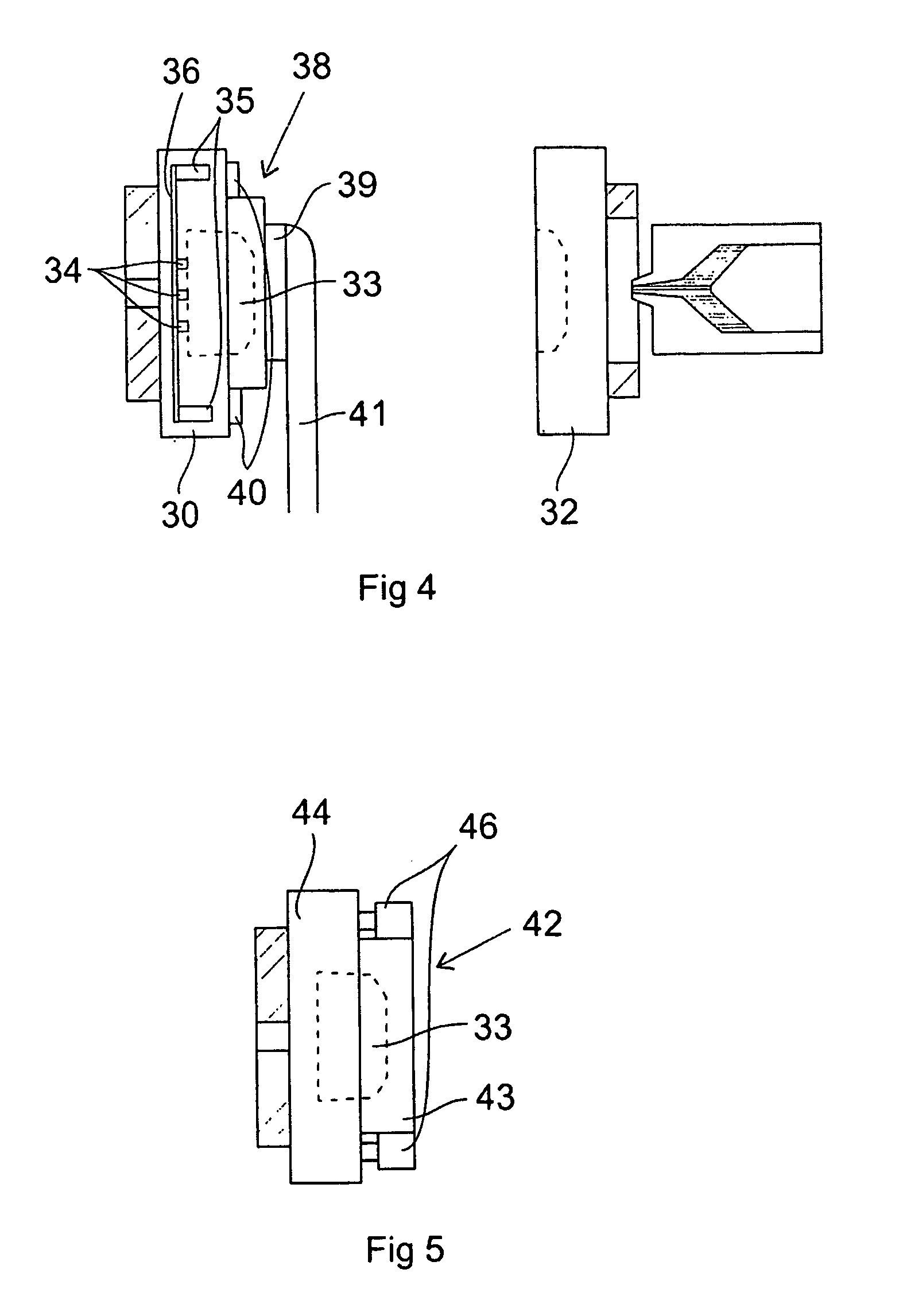

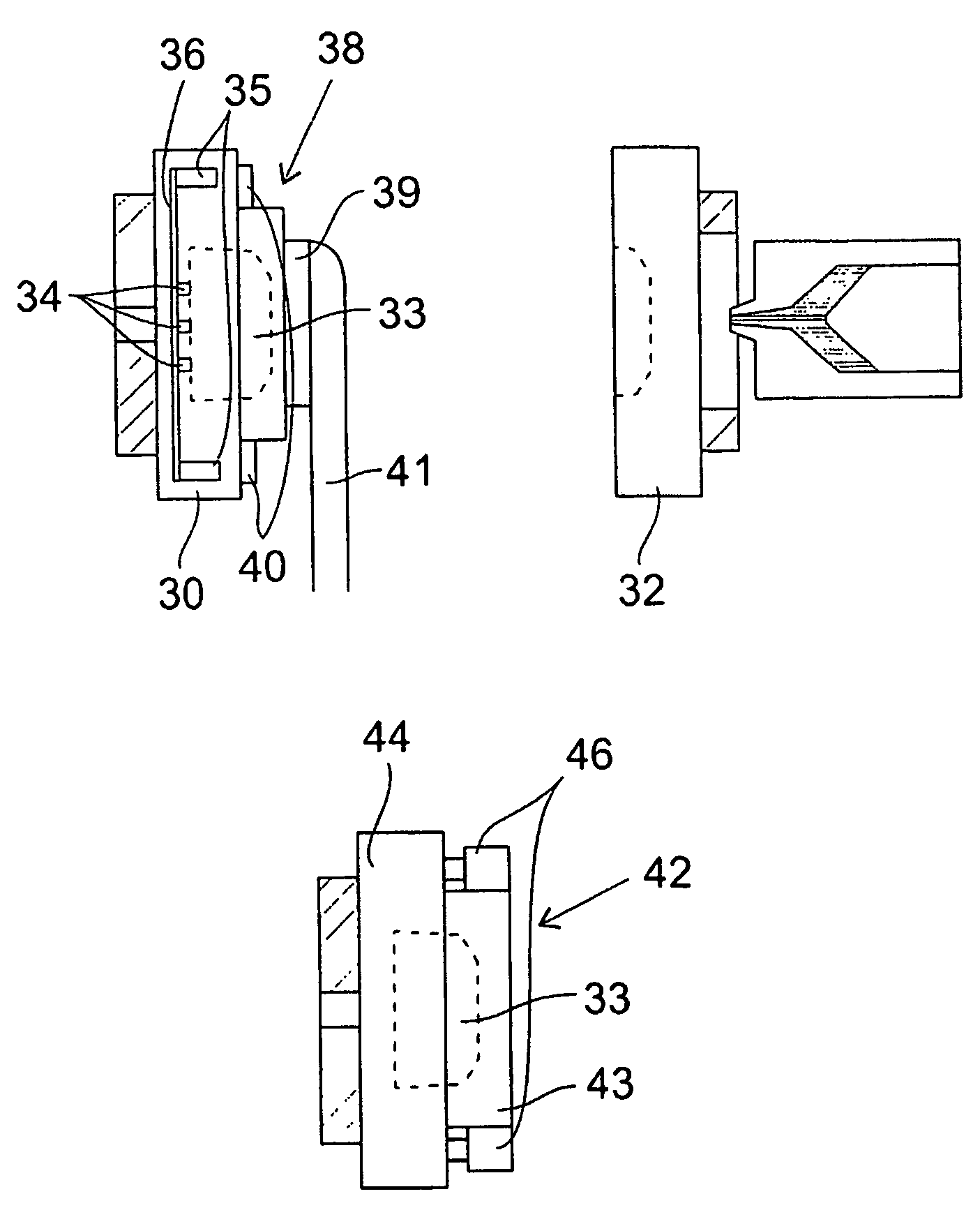

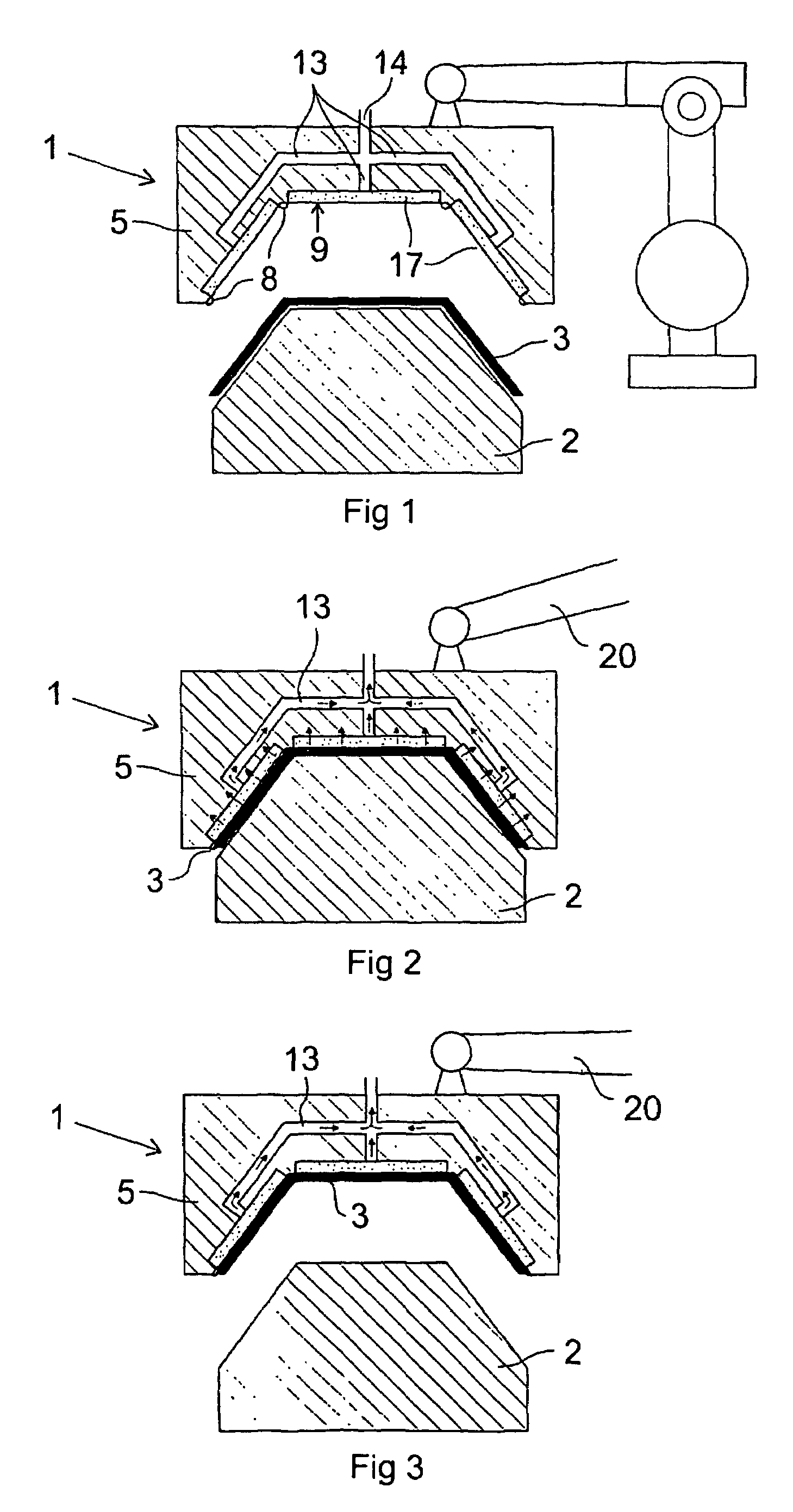

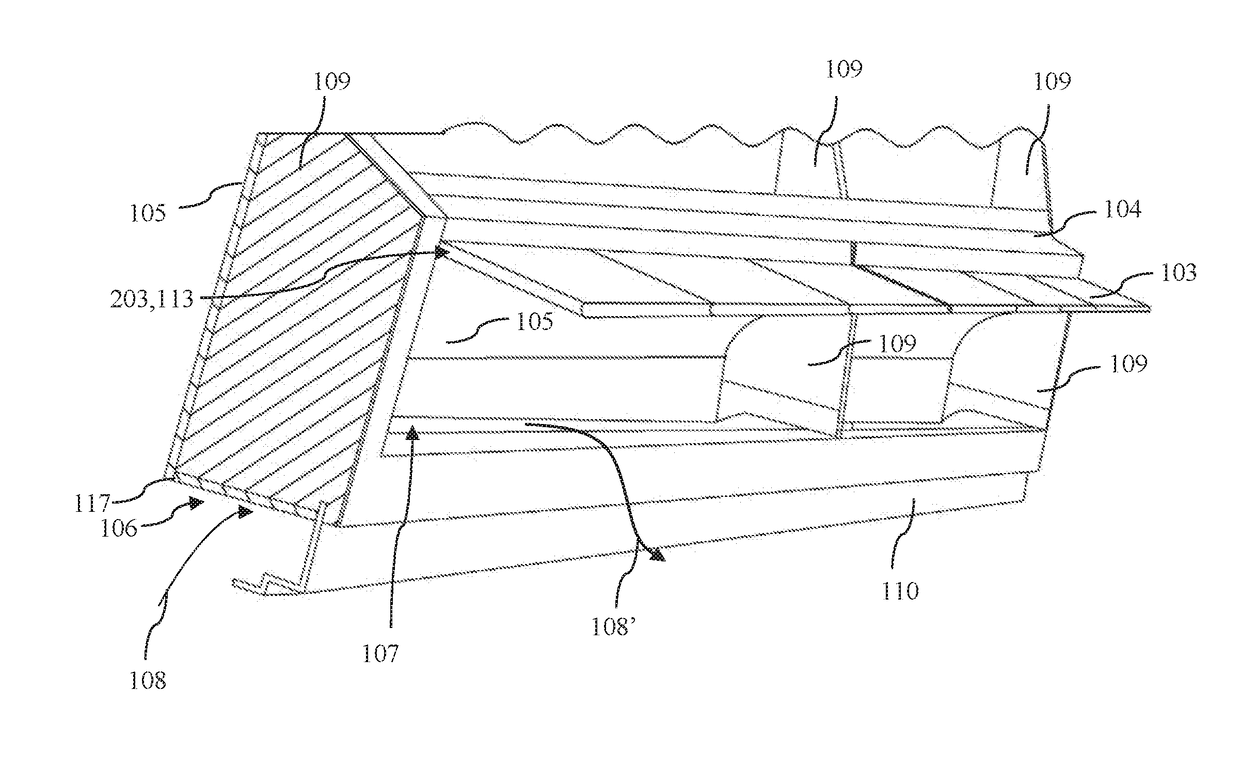

Device and a method for removing an object from a moulding tool

InactiveUS20060034968A1Avoid surface deformationRisk of deformationMouldsGripping headsCouplingEngineering

A device (1) and a method for removing an object from a moulding tool (2) in connection with casting or moulding an object, wherein there is a retaining force between the moulding tool and the object The device comprises a body (5), coupling means (13) arranged for coupling the object to the body and means (20) for applying a traction force on the object, which is substantially opposite to said retaining force, wherein the body is designed with a contact surface adapted for at least partly being in contact with the object, and the coupling means is arranged to couple the object to the contact surfaces such that said traction force becomes substantially uniformly distributed over the part of the surface of the object that is in contact with the contact surface.

Owner:COOL TOOL HLDG

Device and a method for removing an object from a moulding tool

InactiveUS7261549B2Avoid surface deformationRisk of deformationMouldsGripping headsCouplingEngineering

A device (1) and a method for removing an object from a moulding tool (2) in connection with casting or moulding an object, wherein there is a retaining force between the moulding tool and the object. The device comprises a body (5), coupling means (13) arranged for coupling the object to the body and means (20) for applying a traction force on the object, which is substantially opposite to said retaining force, wherein the body is designed with a contact surface adapted for at least partly being in contact with the object, and the coupling means is arranged to couple the object to the contact surfaces such that said traction force becomes substantially uniformly distributed over the part of the surface of the object that is in contact with the contact surface.

Owner:COOL TOOL HLDG

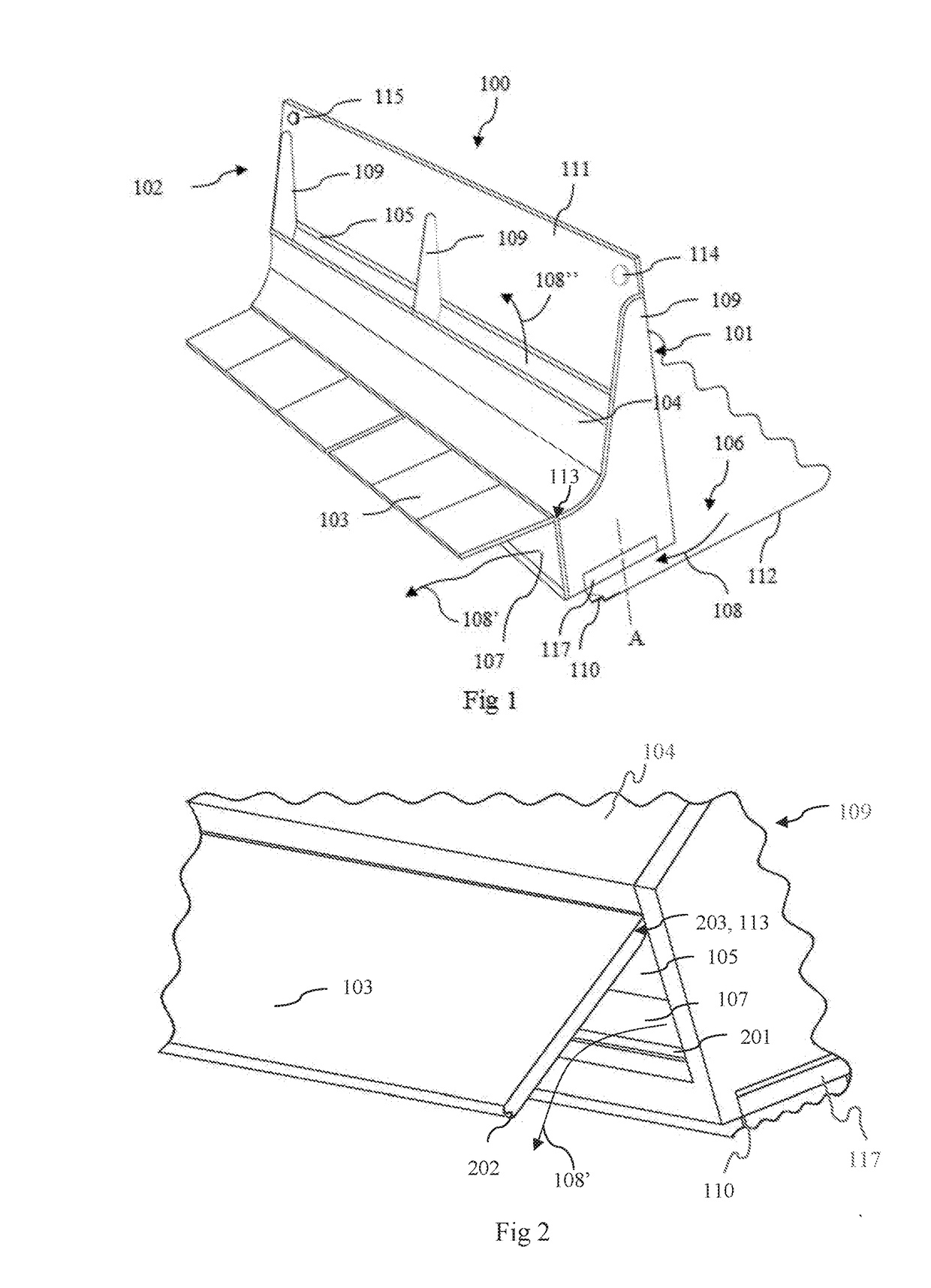

Lining Panel And Method For Manufacturing Lining Panel

InactiveUS20180127100A1Prevent openingSolid surfaceAir-treatment apparatus arrangementsWeight reductionEngineeringFuselage

A lining panel having a panel element, a rectangular through hole and a flap is provided. The lining panel has a flap which is rotatable about a hinge integrated into the panel element in order to open and / or close the rectangular through hole. A fuselage element for an aircraft includes such a lining panel.

Owner:AIRBUS OPERATIONS GMBH

Objective lens and optical pickup apparatus

InactiveUS7161744B2Increase resistanceAvoid surface deformationRecord information storageOptical beam guiding meansOptical pickupPolymer resin

Owner:KONICA MINOLTA OPTO

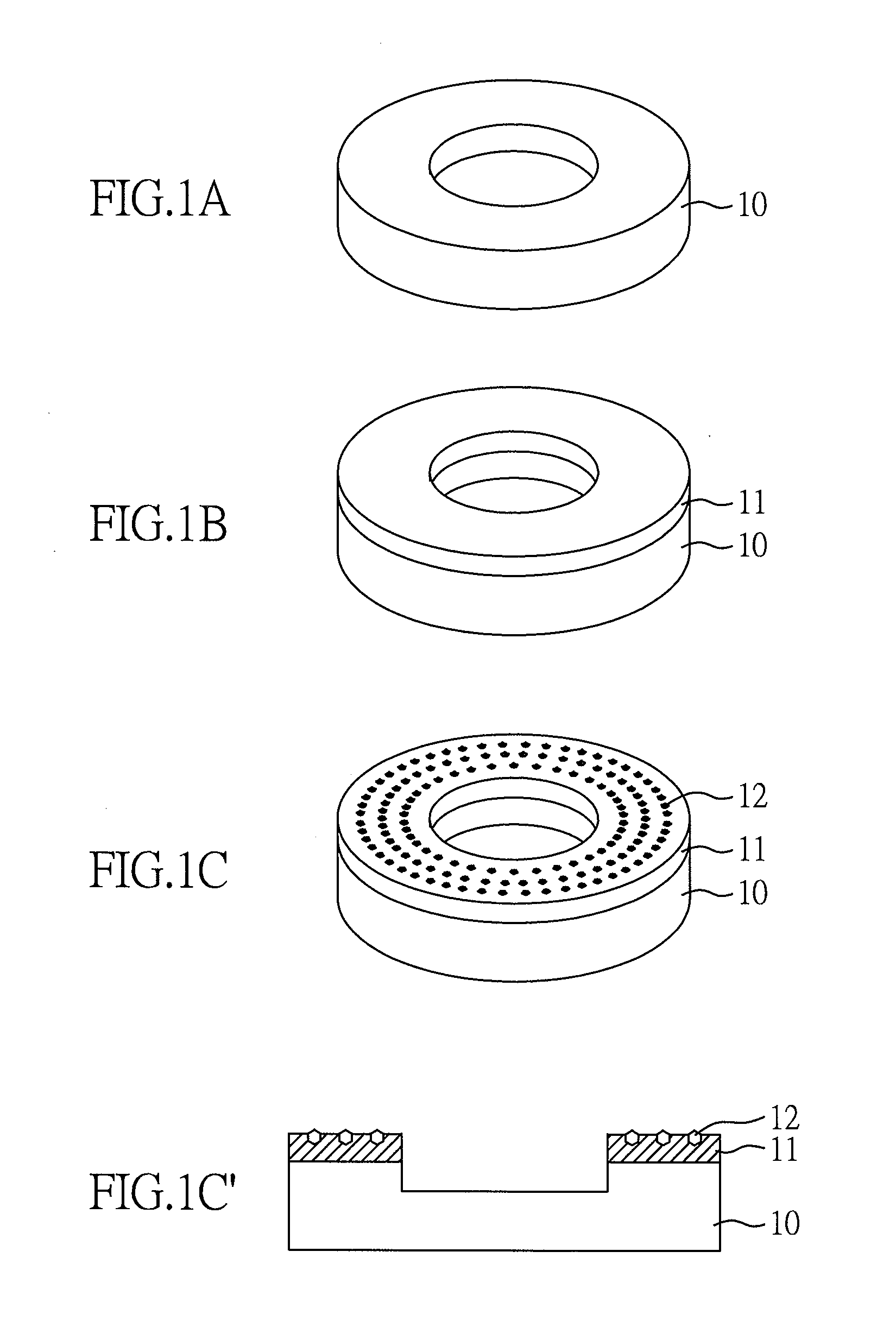

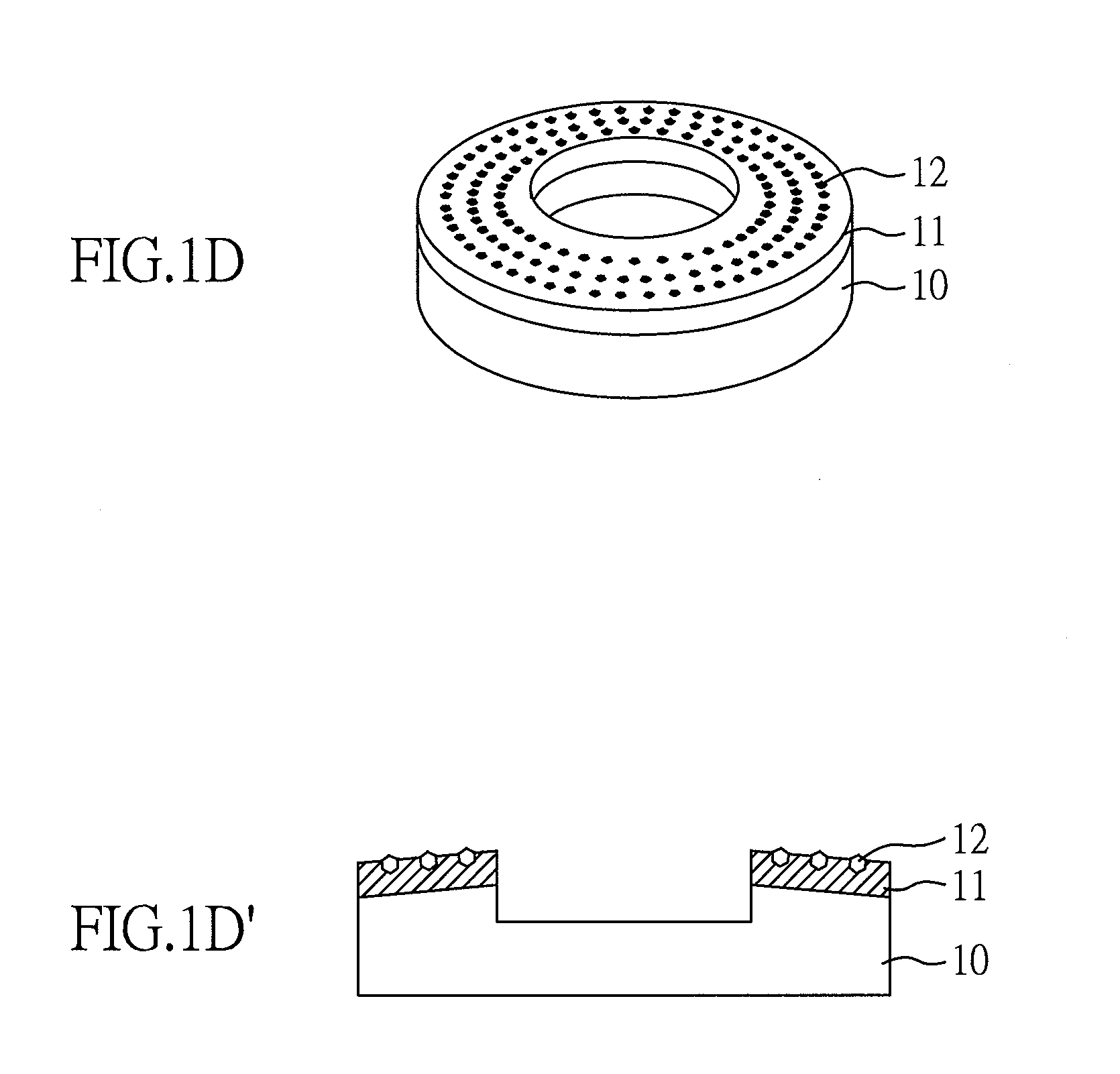

Chemical mechanical polishing conditioner and manufacturing methods thereof

ActiveUS20140273772A1Efficient solutionAchieve flatnessPigmenting treatmentOther chemical processesPlanar substrateThermal deformation

The present invention relates to a chemical mechanical polishing conditioner and manufacturing methods thereof. The chemical mechanical polishing conditioner comprises: a planar substrate having a leveling surface; a bonding layer disposed on the surface of the planar substrate; and a plurality of abrasive particles embedded in the surface of the bonding layer and fixed to the surface of the planar substrate by the binding layer; wherein the planar substrate is formed by a deformation compensation for the non-planar substrate during curing the binding layer, and thus the tips of the abrasive particles have a leveled height. Therefore, the present invention can effectively improve the problem of thermal deformation of the substrate of the chemical mechanical polishing conditioner during heating and curing process, and thereby enhancing the surface flatness of chemical mechanical polishing conditioner.

Owner:KINIK

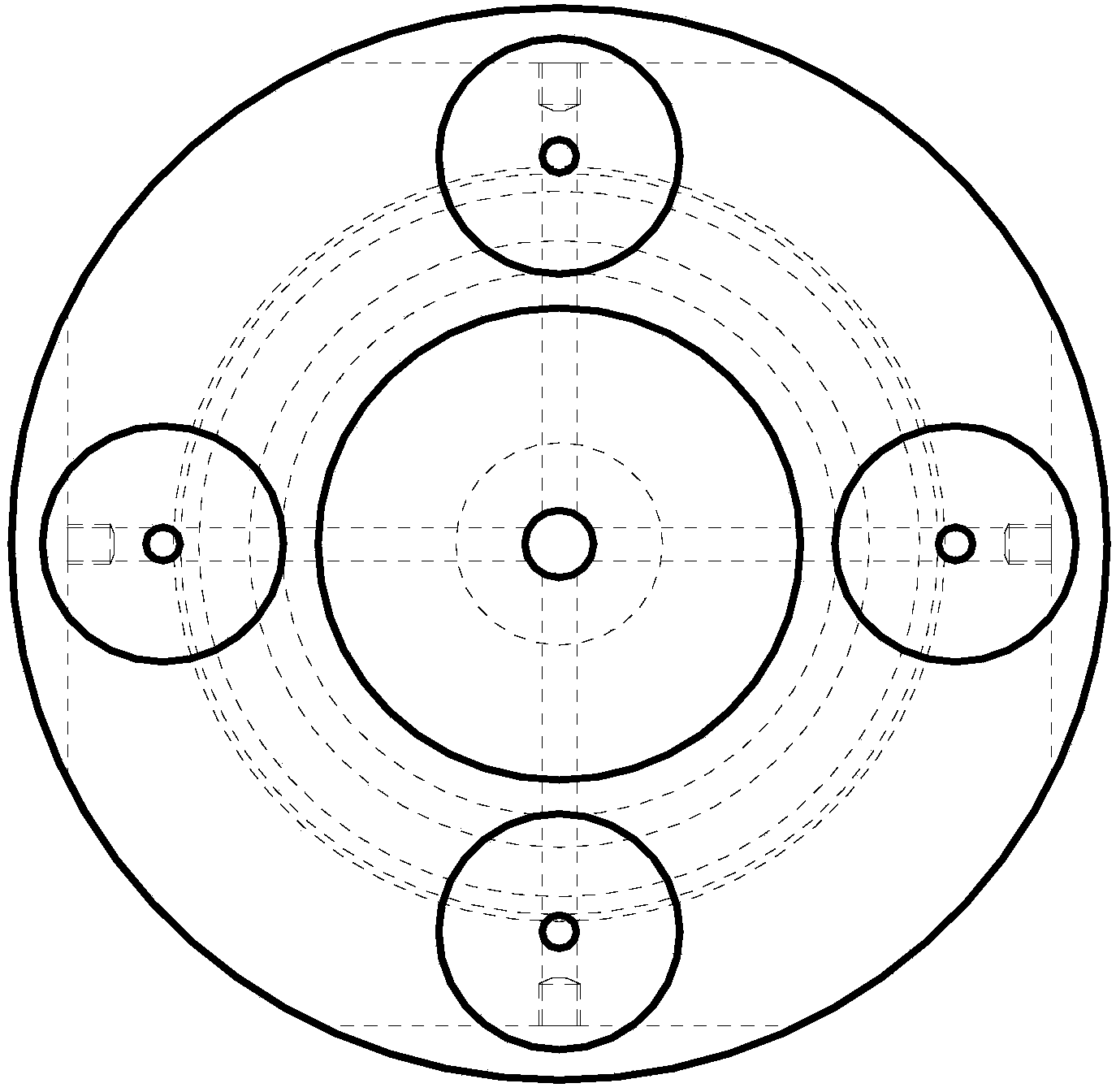

Clearance compensation type annular oil groove sliding shoe for plunger hydraulic pump

ActiveCN103939329AAvoid surface deformationExpand the range of mobilityPositive displacement pump componentsLiquid fuel engine componentsHydraulic pumpFriction force

The invention relates to a clearance compensation type annular oil groove sliding shoe for a plunger hydraulic pump. The clearance compensation type annular oil groove sliding shoe comprises a sliding shoe body, one end of the sliding shoe body is provided with a ball socket trapezoidal groove and a sliding shoe ball socket, and the other end of the sliding shoe body is provided with an end face which is in contact with an oblique plate. A concave annular groove with a damping hole is formed in the middle of the end face, two communicated oil channels which are perpendicular to each other and are crossed are formed in the sliding shoe body, and the communicated oil channels are vertically communicated with the damping hole. Four auxiliary supporting cavities are evenly distributed around the concave annular groove in the end face, each auxiliary supporting cavity is provided with a damping hole which is vertically communicated with the communicated oil channels, one ends of the communicated oil channels are communicated with the auxiliary supporting cavities, and the other ends of the communicated oil channels are matched with screw plugs to form sealing assemblies. In the working process, oil liquid is led into the communicated oil channels through the damping holes, and at last flows into the concave groove and the auxiliary supporting cavities to form auxiliary static pressure bearing. The clearance compensation type annular oil groove sliding shoe can achieve automatic compensation of the sealing clearance between a sliding shoe pair, reduces the friction force of the sliding shoe and the oblique plate, and is convenient to machine and high in practicability.

Owner:TONGJI UNIV

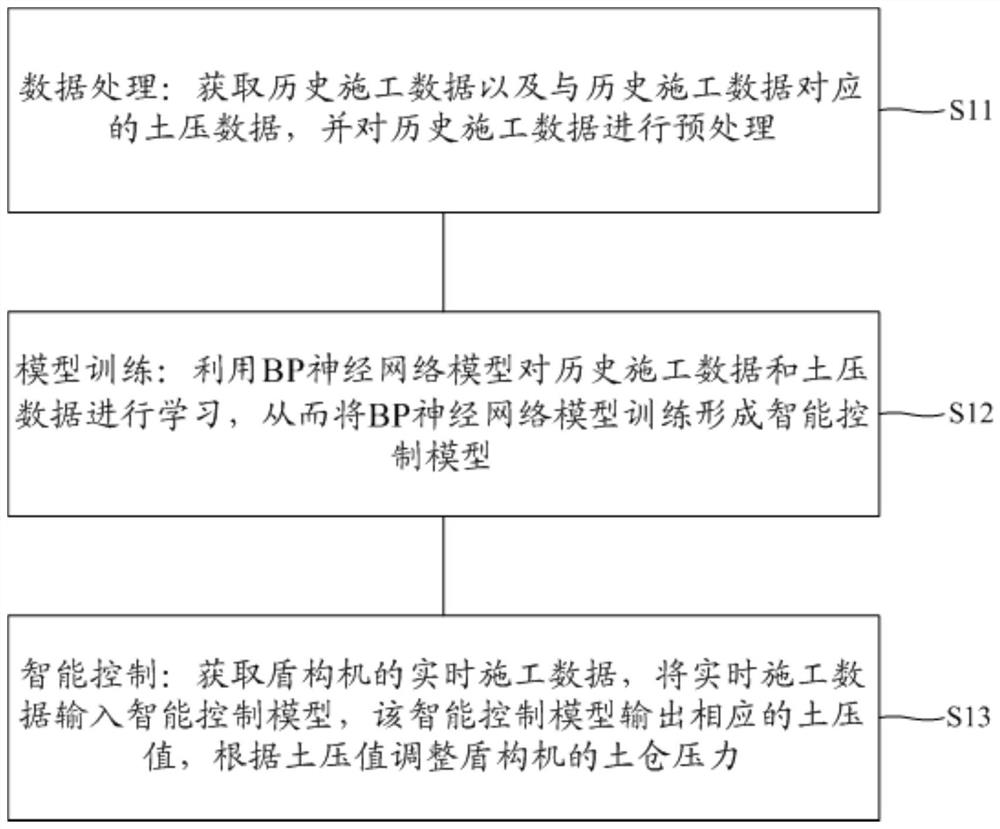

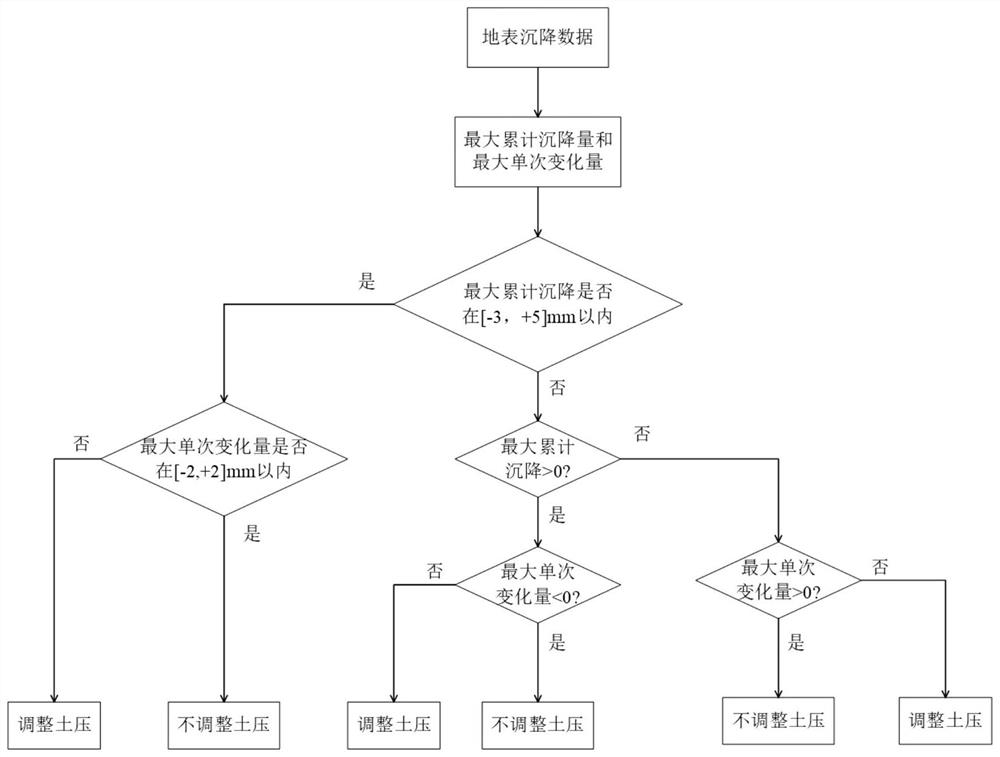

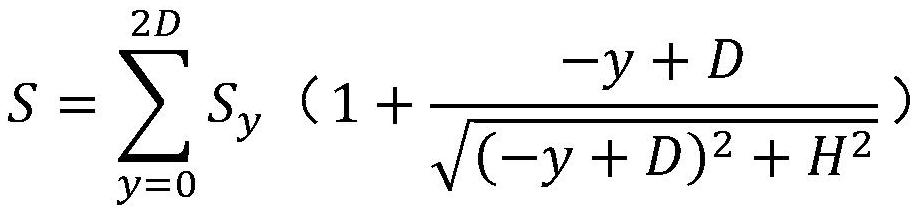

Earth pressure intelligent control method and system of earth pressure balance shield

PendingCN112647957AReduce the impact of constructionGuaranteed settlementMining devicesDesign optimisation/simulationComputational scienceEngineering

The invention relates to an earth pressure intelligent control method and system for an earth pressure balance shield, and the method comprises the following steps: data processing: obtaining historical construction data and earth pressure data corresponding to the historical construction data, and carrying out the preprocessing of the historical construction data; model training: learning the historical construction data and the soil pressure data by using a BP neural network model so as to train the BP neural network model to form an intelligent control model; and intelligent control: acquiring real-time construction data of the shield tunneling machine, inputting the real-time construction data into an intelligent control model, outputting a corresponding soil pressure value by the intelligent control model, and adjusting the soil bin pressure of the shield tunneling machine according to the soil pressure value. According to the method, the problem that the influence of subjective factors is large when the earth pressure is controlled is effectively solved, the influence of the subjective factors on earth pressure control is reduced, it is guaranteed that earth surface settlement is within a reasonable range, and large earth surface deformation and serious safety accidents are avoided.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

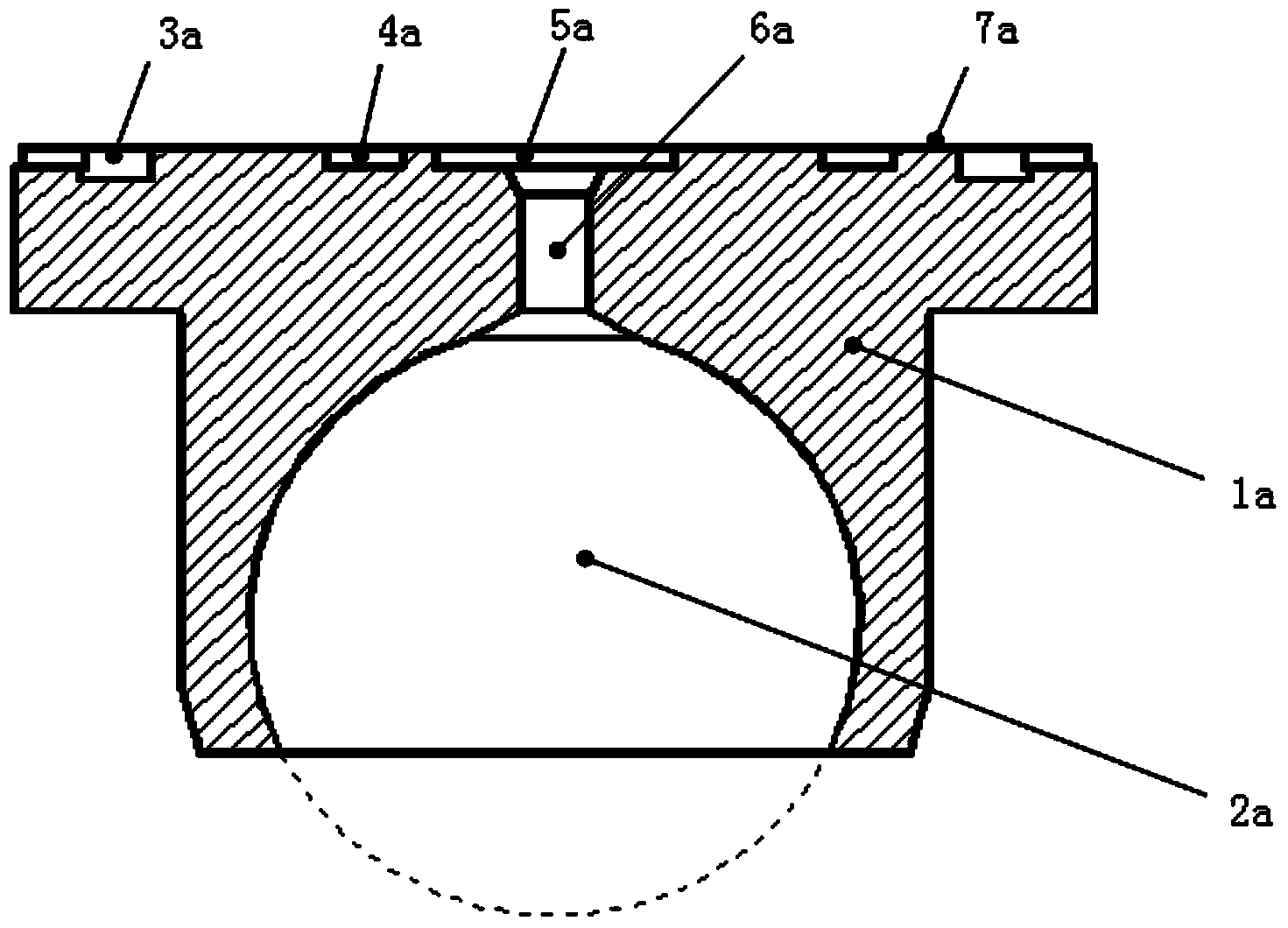

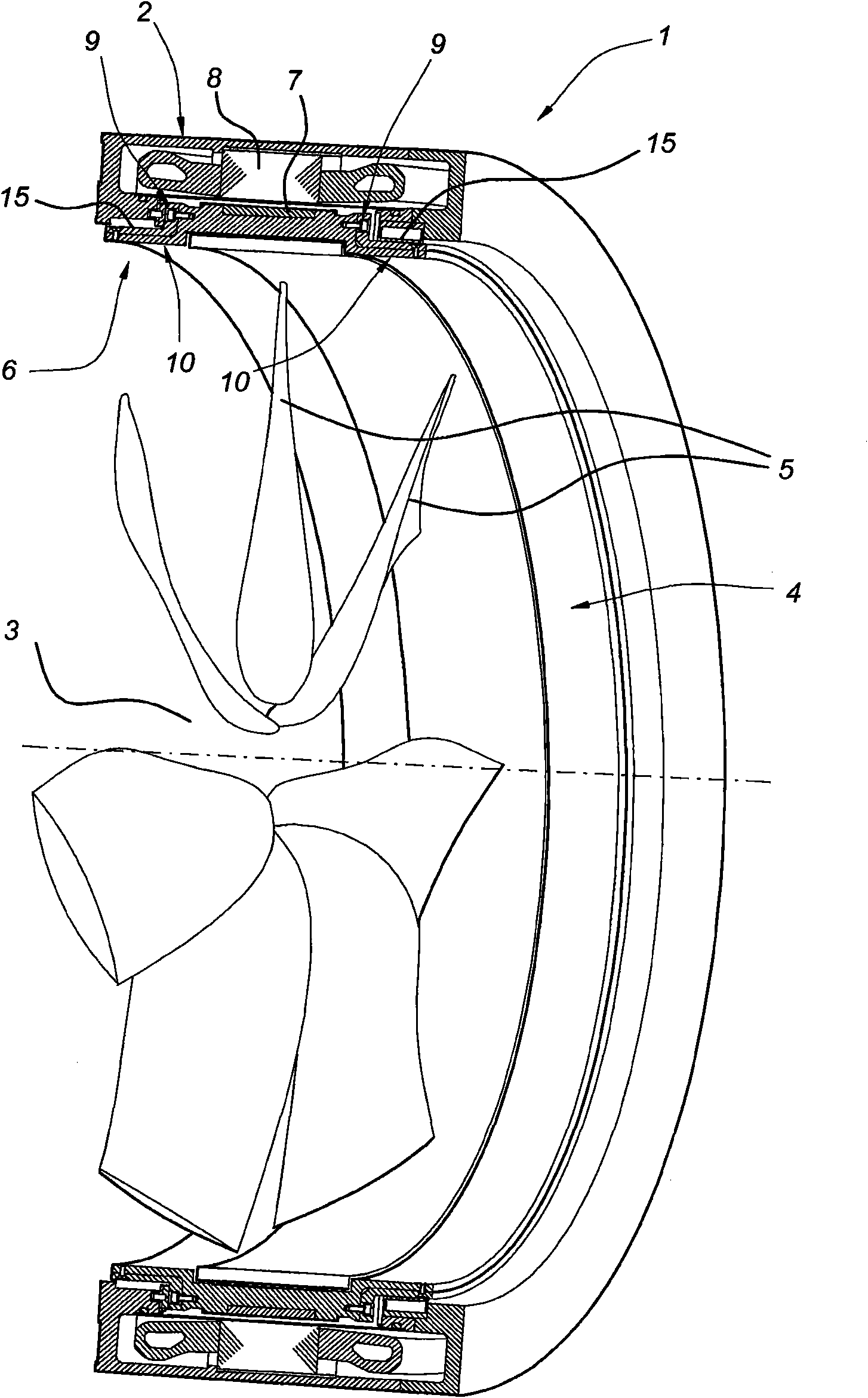

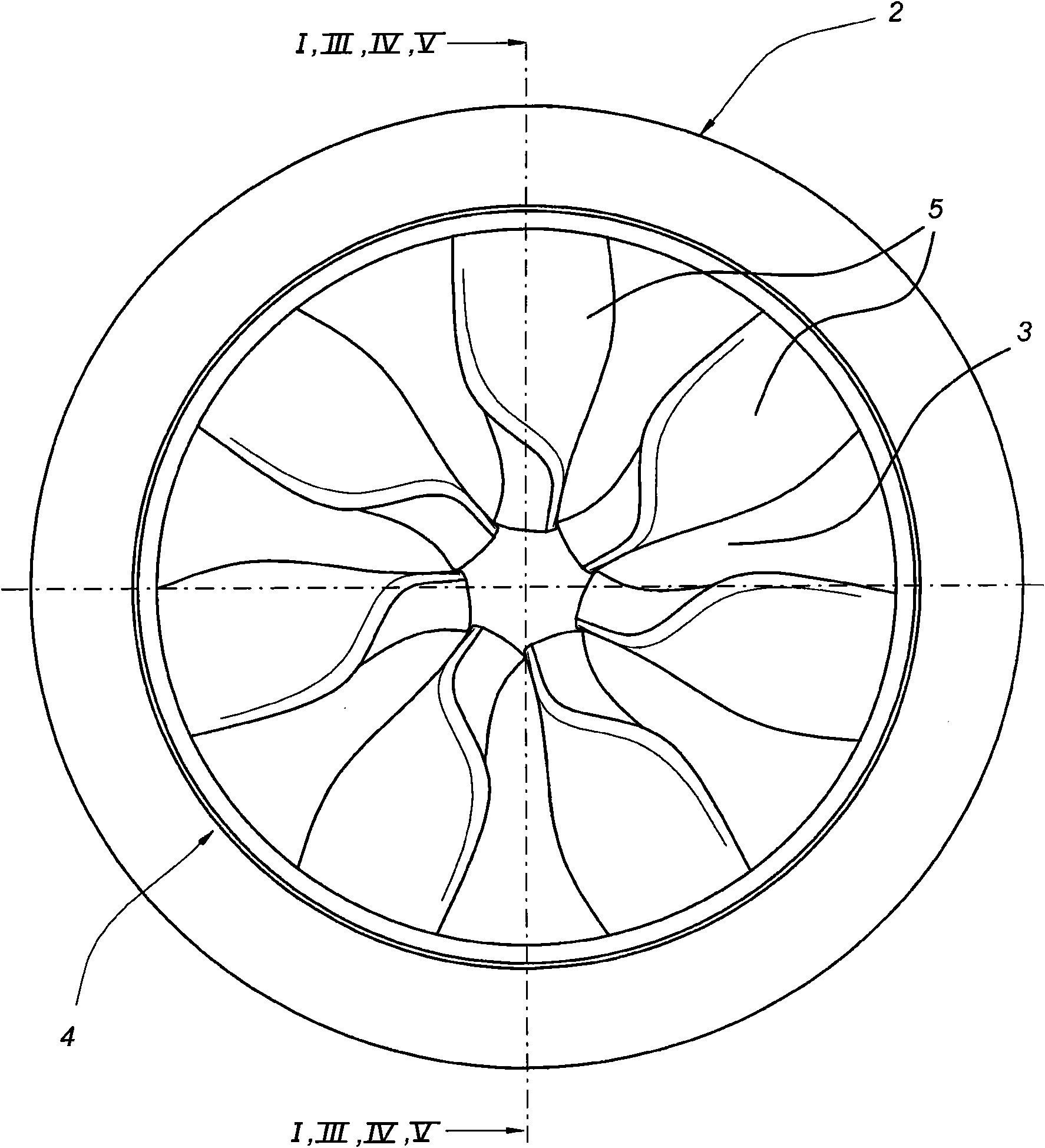

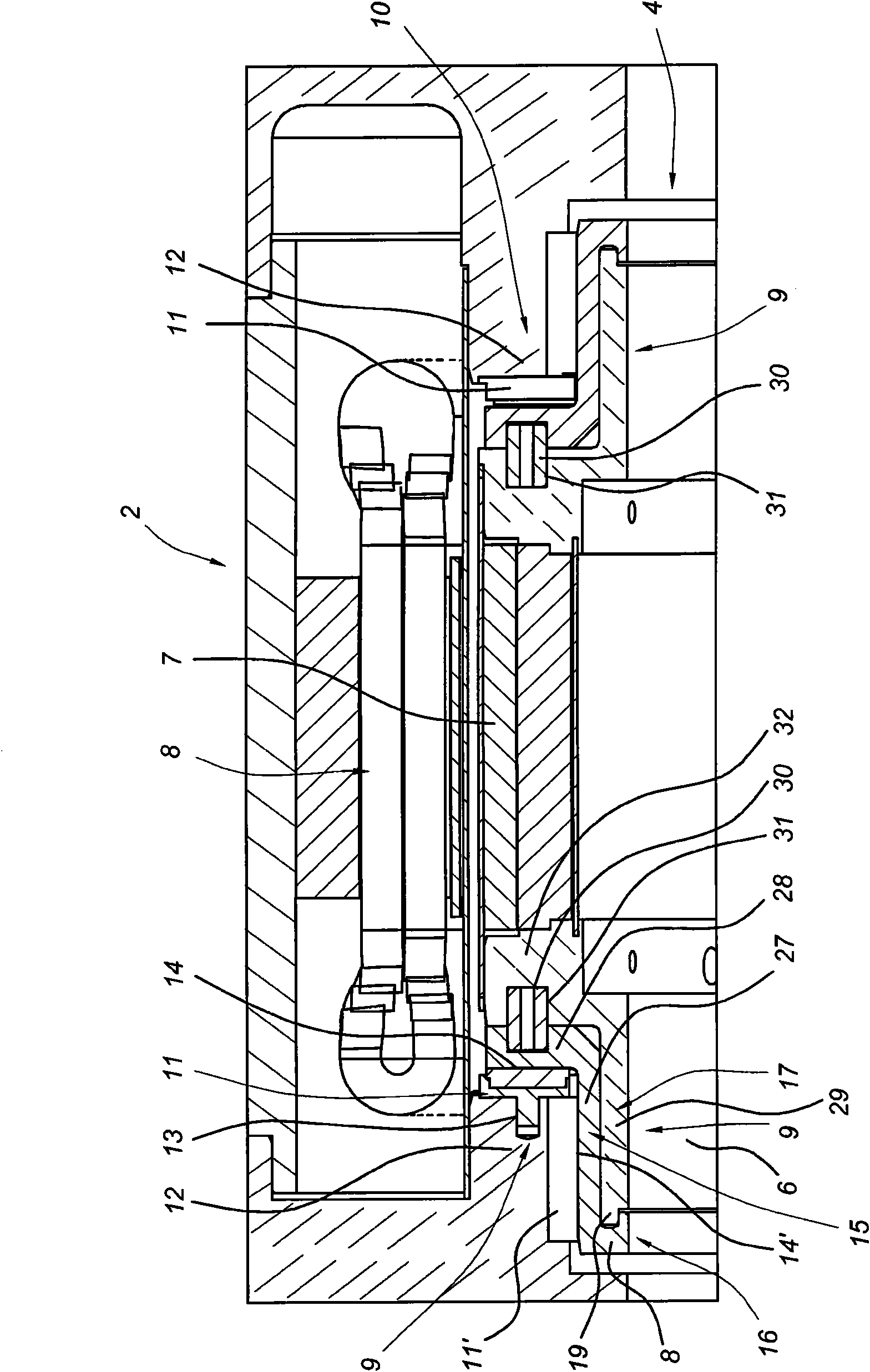

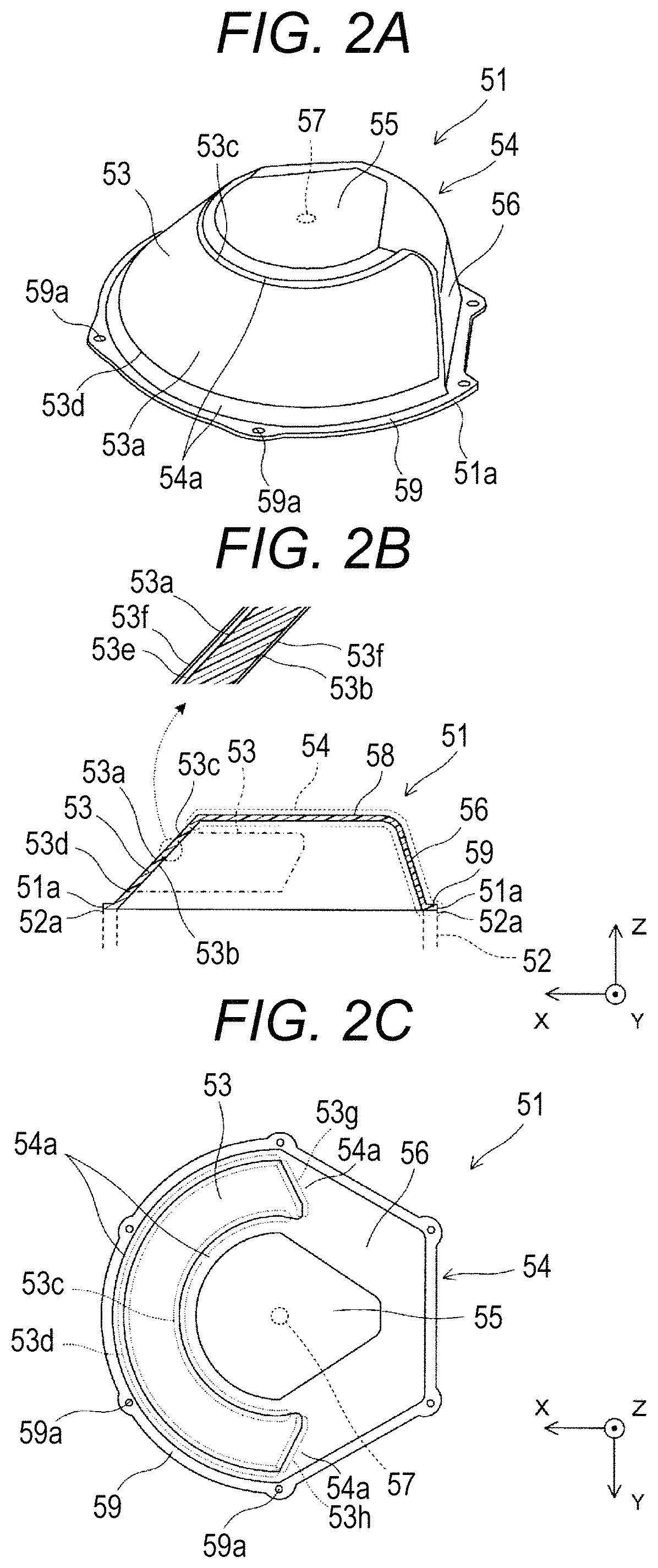

Bearing structure, and propeller device equipped with such bearing structure

InactiveCN102092466AAvoid surface deformationDegree of protection against loss of desired collaborationPropulsive transmission driveRotary propellersBall bearingPropeller

A bearing structure between a rotor (4) and a sleeve (2), such as in a screw device, includes at least one axial bearing (9) and one radial bearing (10). Each bearing including a series of tilting pads (11, 11') extending in the peripheral direction and which are each suspended from a pad suspension area (12) of one of either the rotor (4) or the sleeve (2) by pad fastenings (13) which allow tilting, each tilting pad (11, 11') having a contact surface (14, 14'). Furthermore, each bearing including a bearing ring (15) which is situated opposite the series of tilting pads (11, 11') and cooperates with the contact surfaces thereof. The bearing ring is suspended from a bearing ring suspension area (17) of the other of either the rotor or the sleeve by bearing ring fastenings (16). The bearing ring fastenings allow contraction and expansion movements of the bearing ring.

Owner:MARIFIN BEHEER

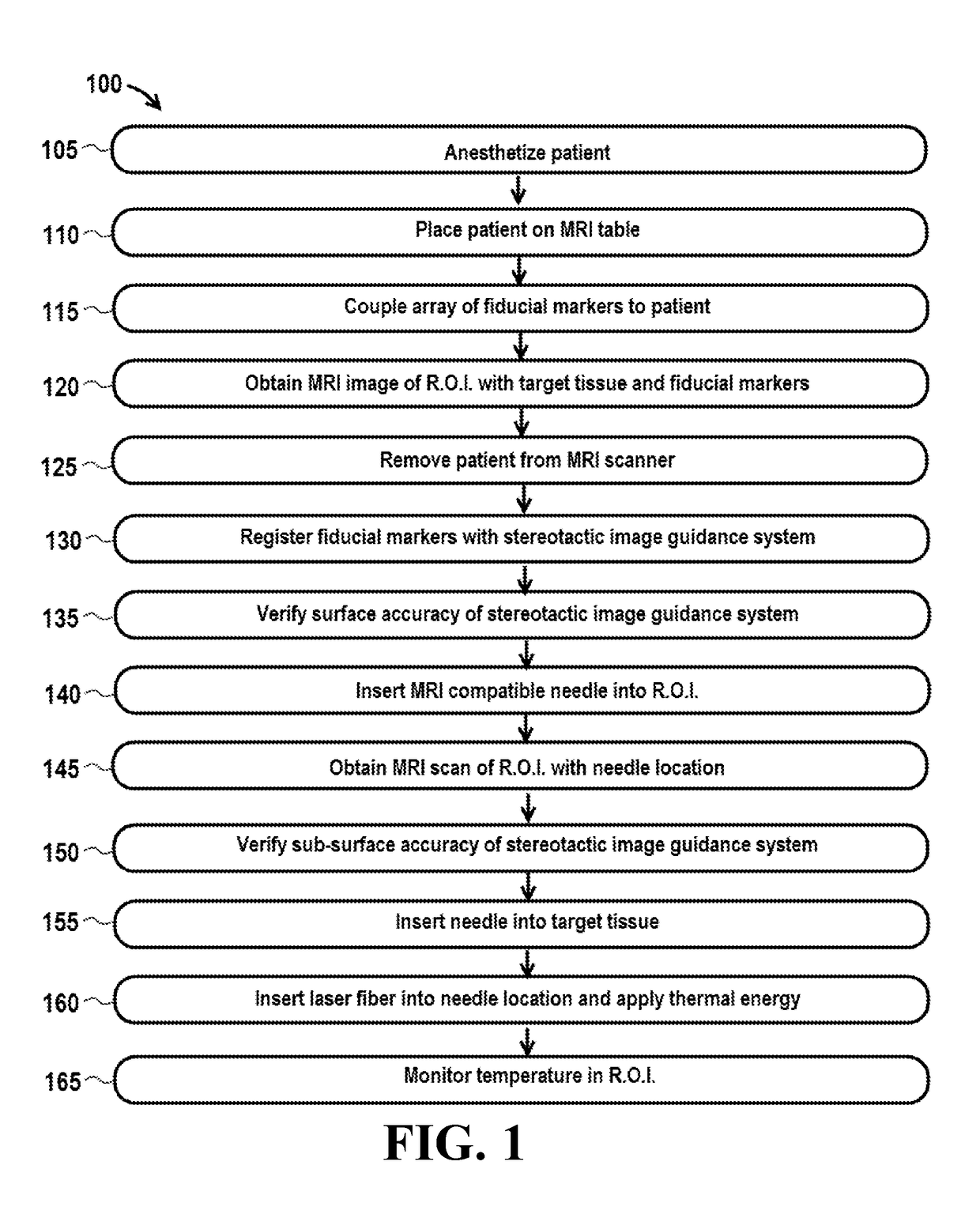

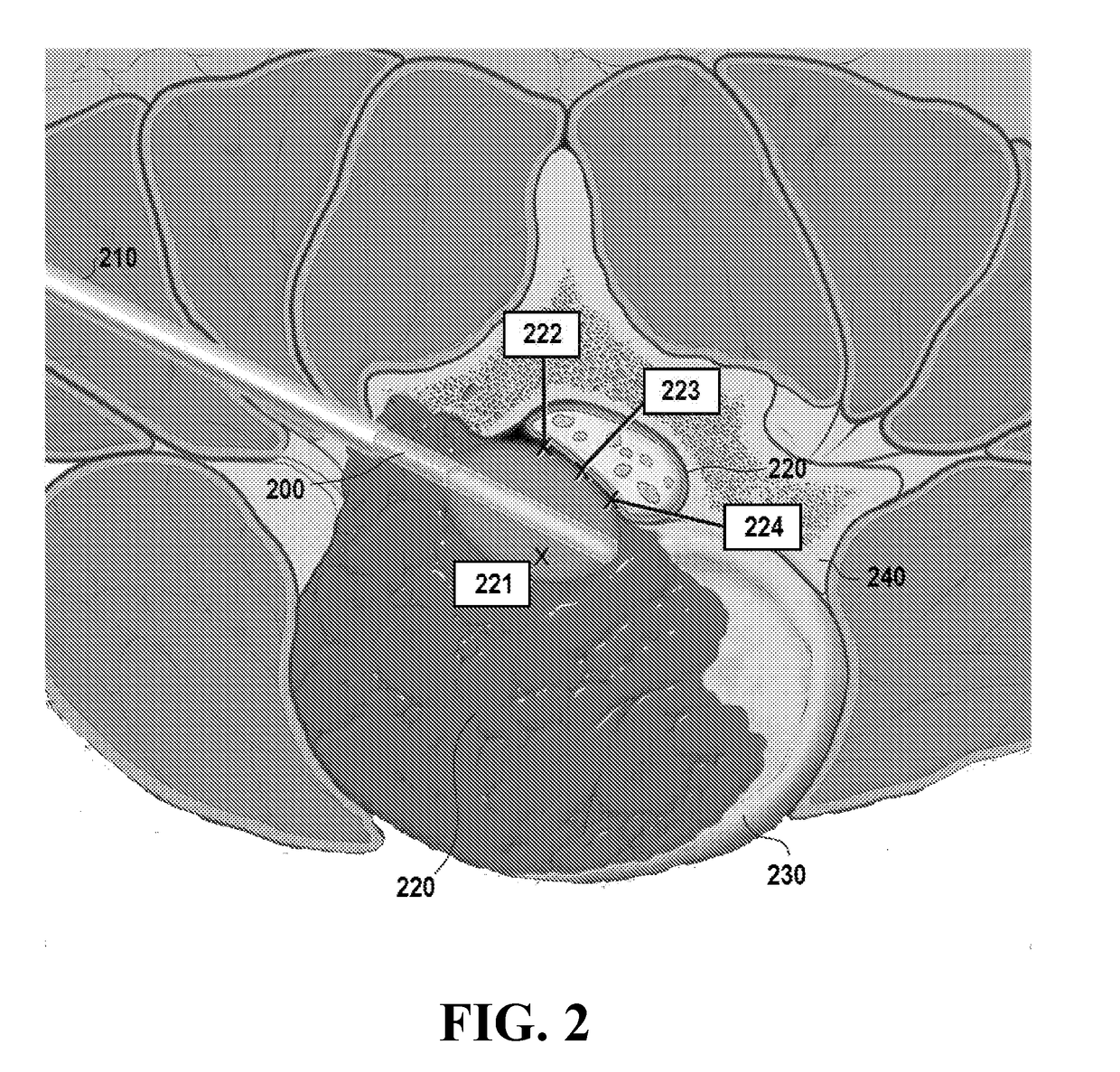

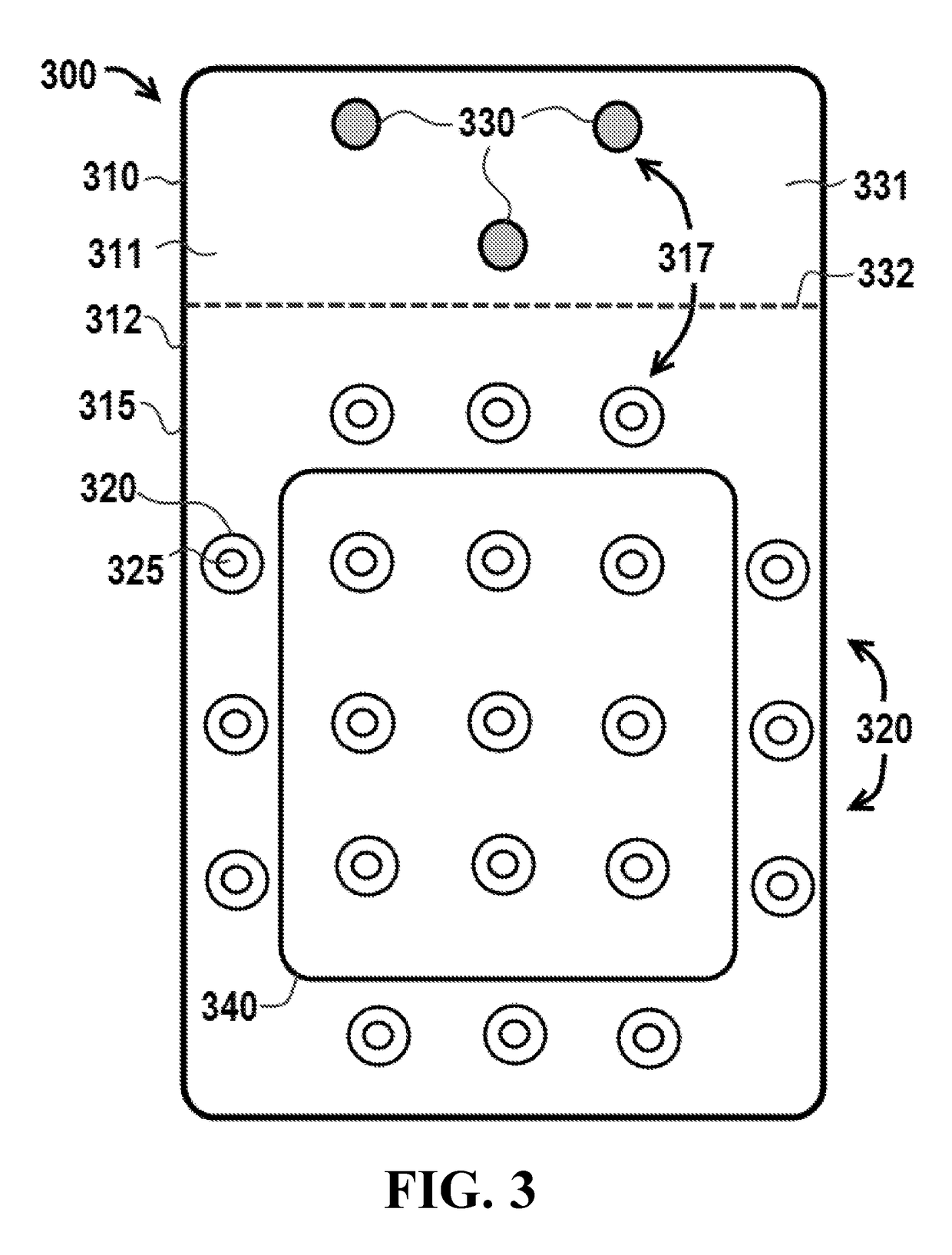

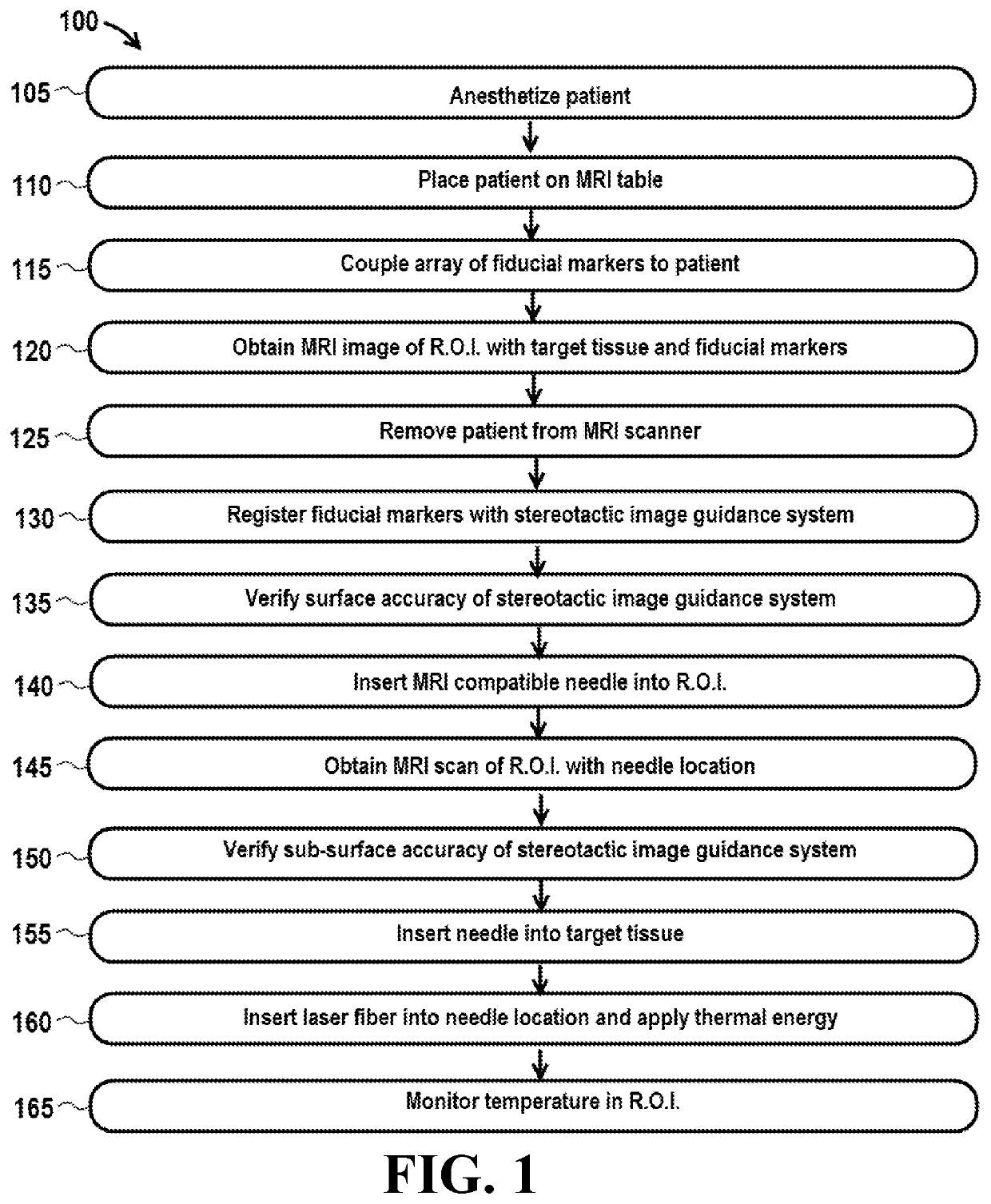

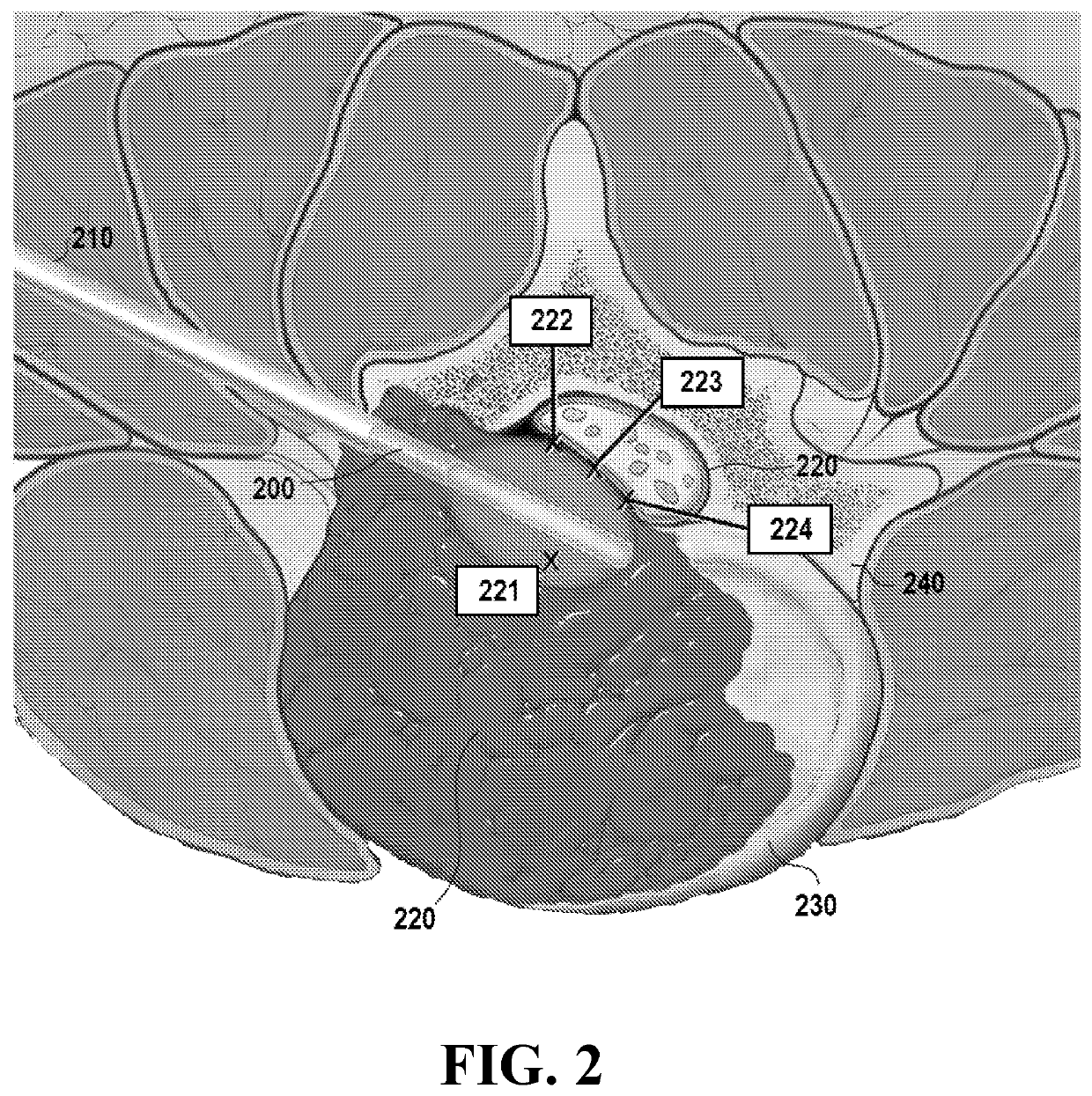

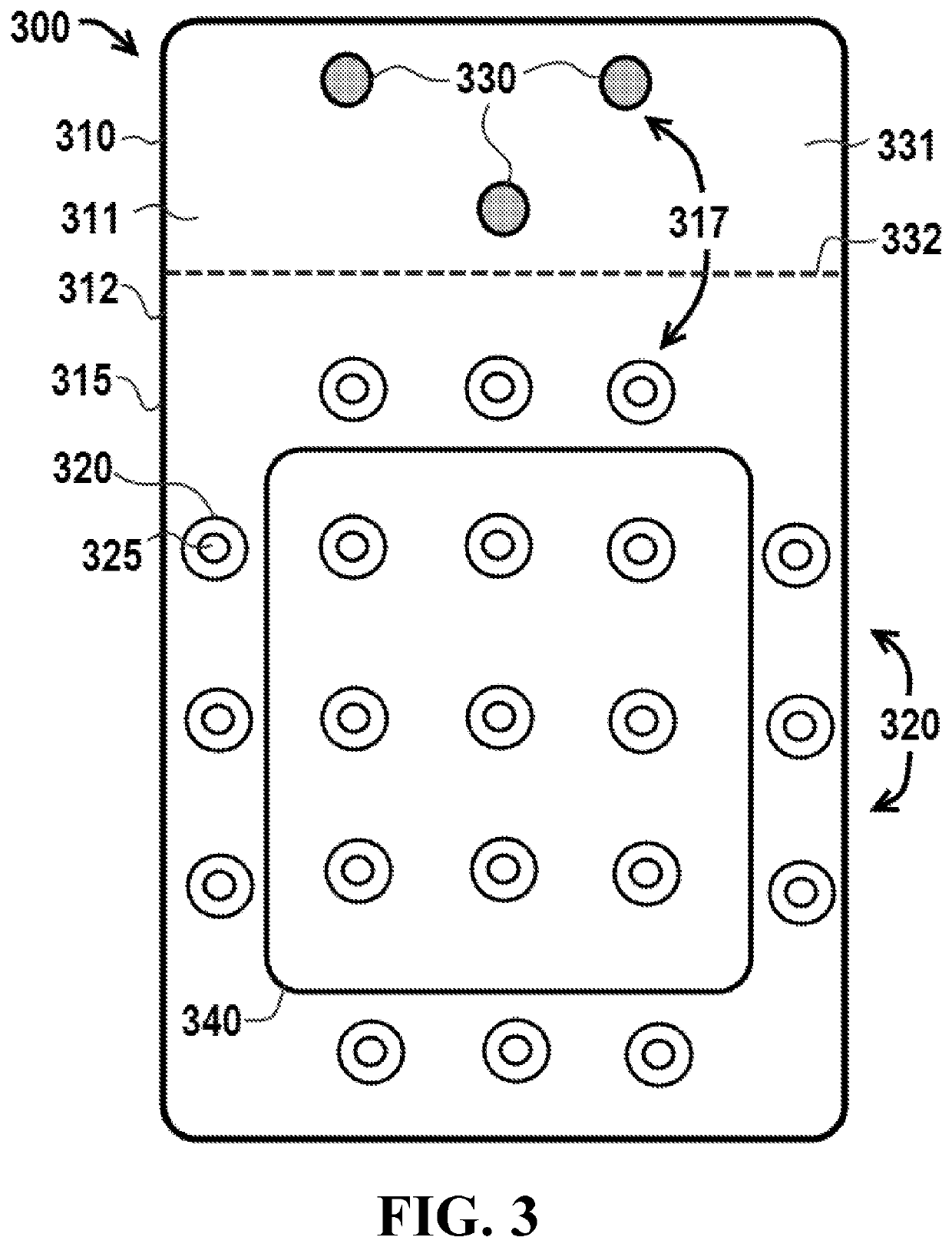

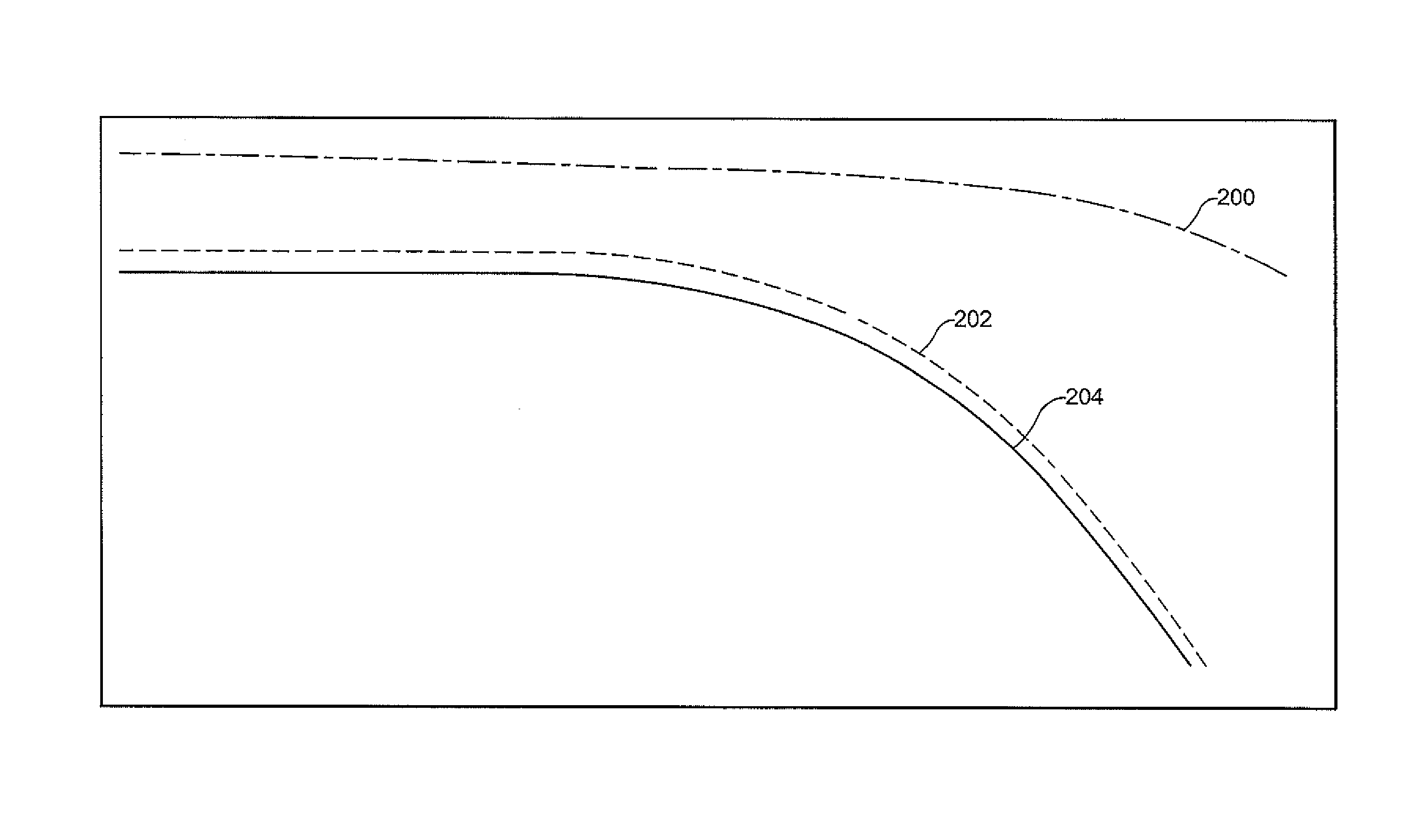

Utilization of laser interstitial thermotherapy guided with real time thermal MRI

ActiveUS20180368918A1Improve securityImprove accuracySurgical navigation systemsSurgical instrument detailsThermal energyTemperature monitoring

Methods, apparatus, and kits for applying thermal energy to tissue in a region of interest. Certain embodiments include registration of fiducial markers with an image guidance system and temperature monitoring via magnetic resonance imaging thermography.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

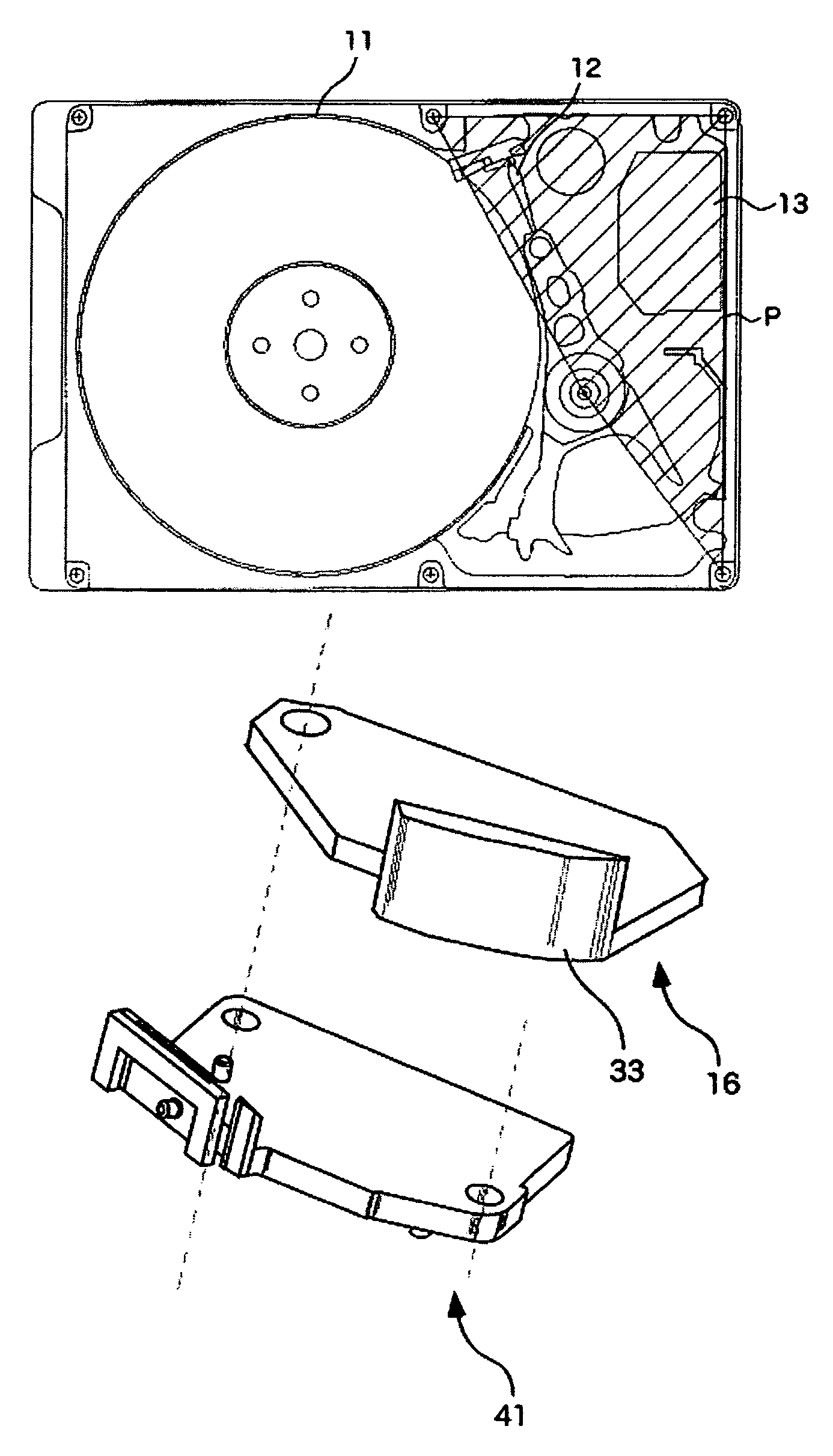

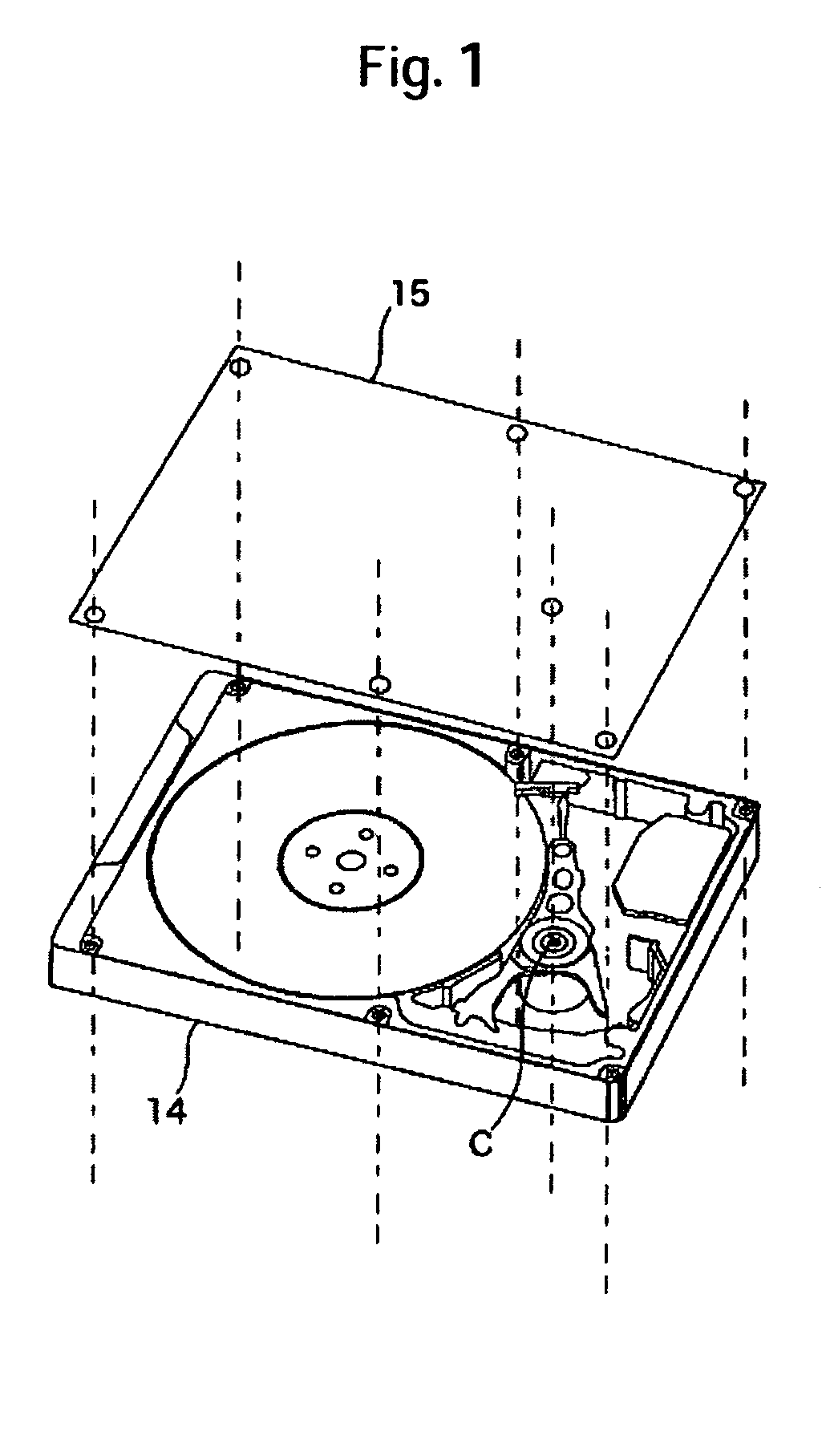

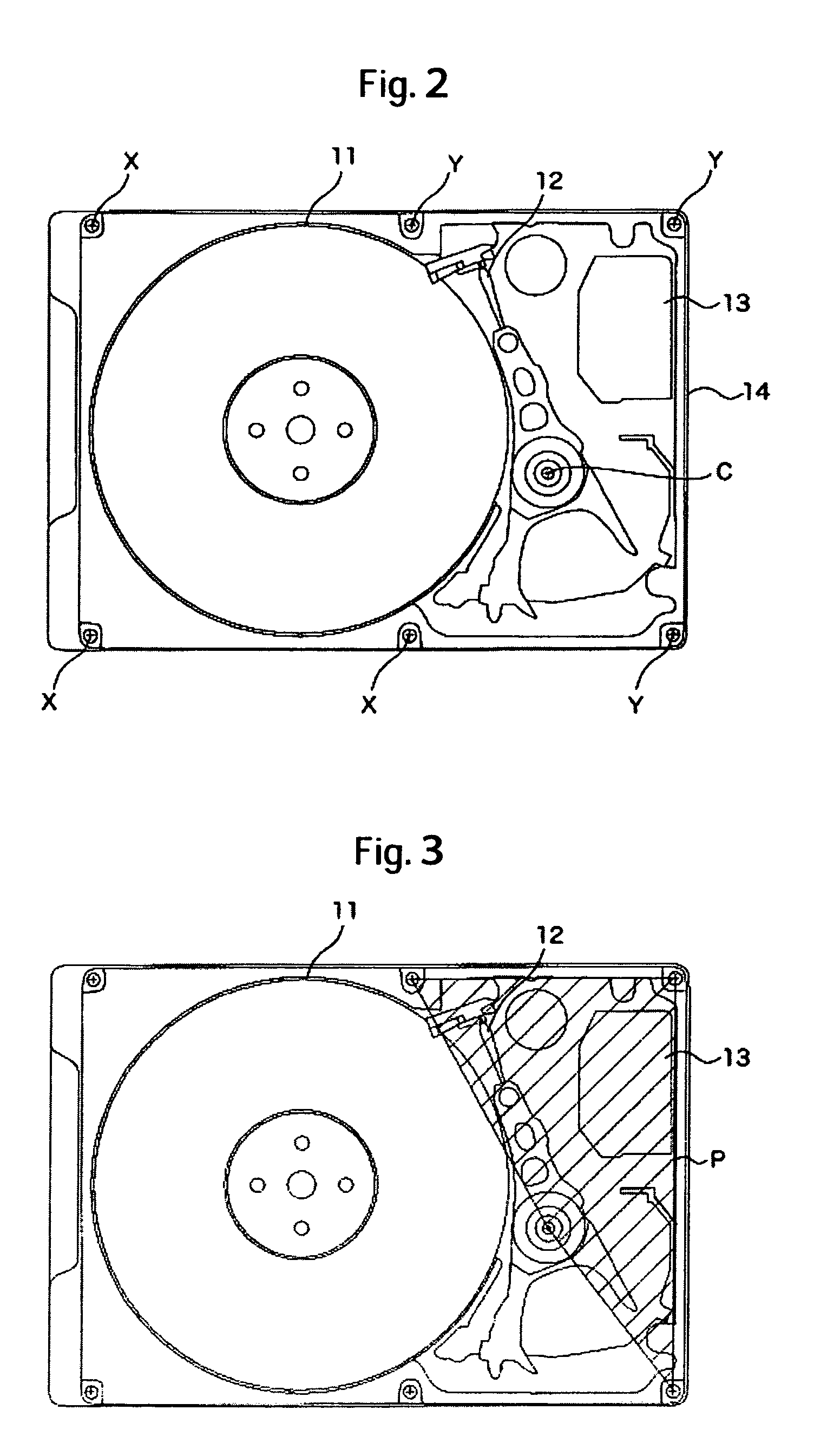

Disk drive with vibration suppression member disposed near head assembly

InactiveUS7545599B2Avoid surface deformationReduce vibrationUndesired vibrations/sounds insulation/absorptionRecord information storageEngineeringMechanical engineering

Embodiments of the invention provide a disk drive suppressing a surface deformation of a top cover. In one embodiment, the disk drive includes a base and a top cover. The base accommodates a head assembly, a circuit unit, and a recording medium. The top cover is supported by the base at a plurality of inner points of support and peripheral edge points of support on a peripheral edge portion near a portion accommodating the head assembly and the circuit unit. The top cover covers the accommodating portion of the base. A vibration suppression member for suppressing vibration of the top cover is disposed in a polygon. The polygon has, as vertices, a plurality of inner points of support and, among the peripheral edge points of support, the peripheral edge points of support near the portion accommodating the head assembly and the circuit unit. The vibration suppression member is disposed at a position in the polygonal portion corresponding to an area near a loop of vibration in a surface of the top cover.

Owner:WESTERN DIGITAL TECH INC

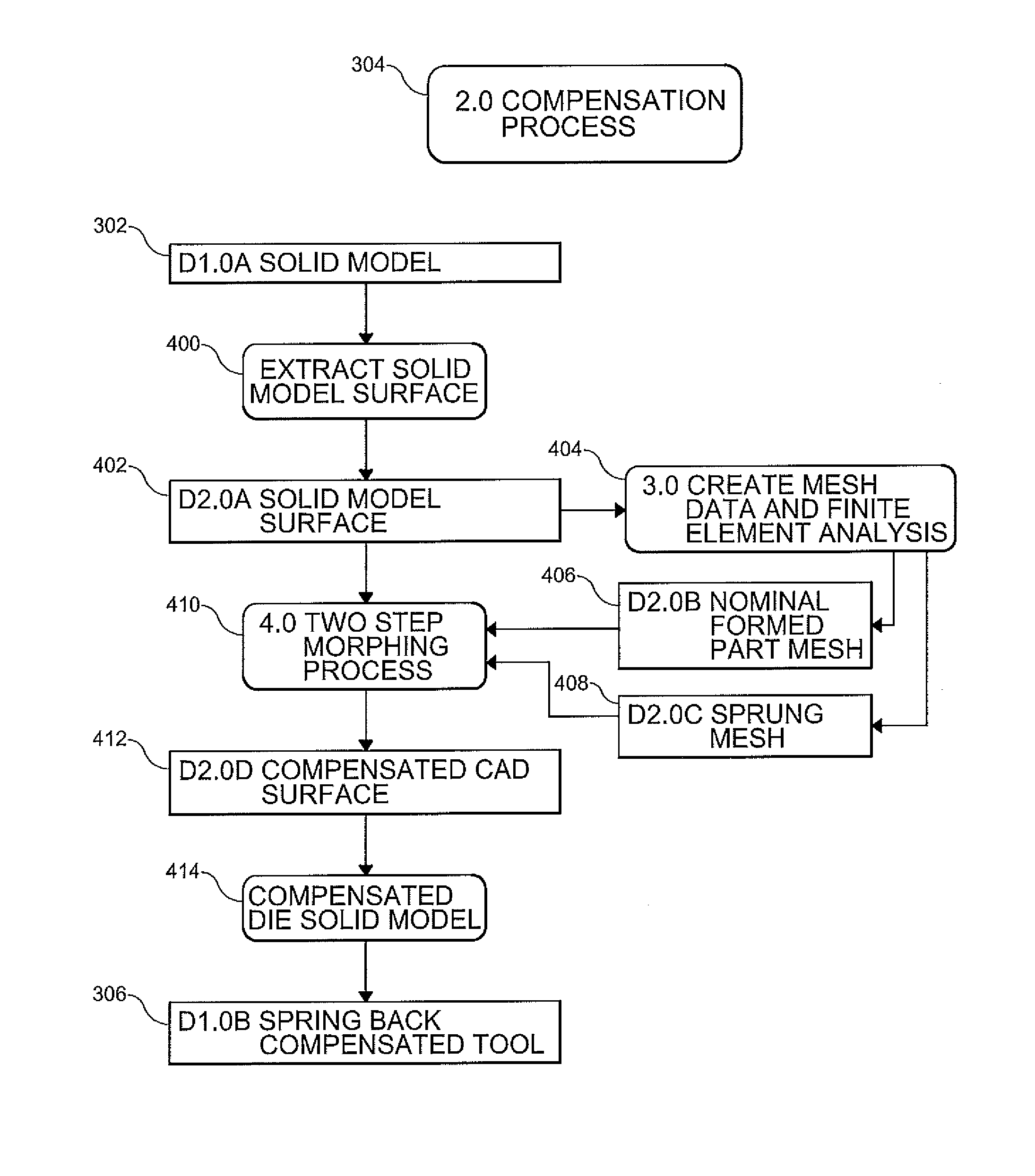

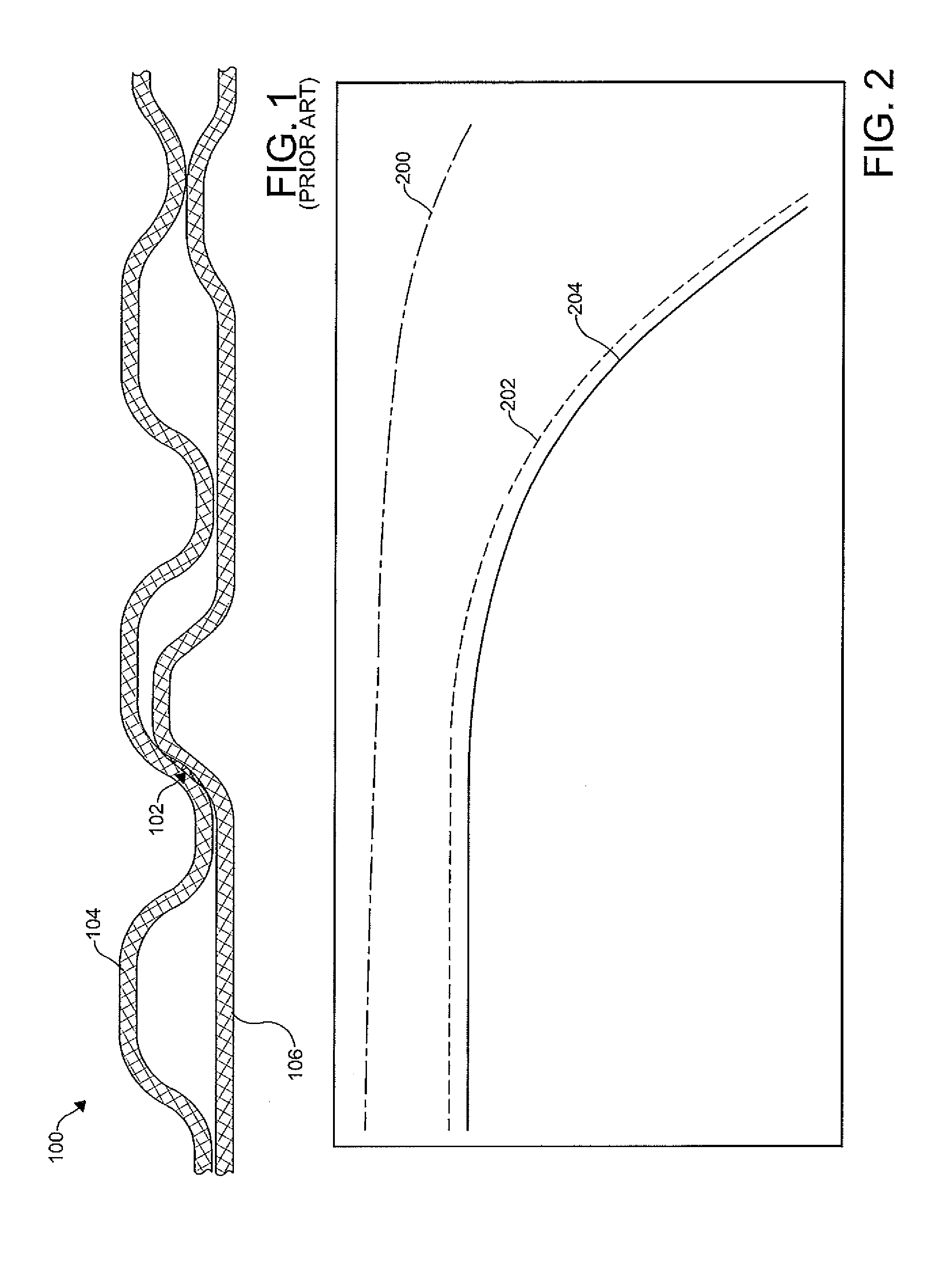

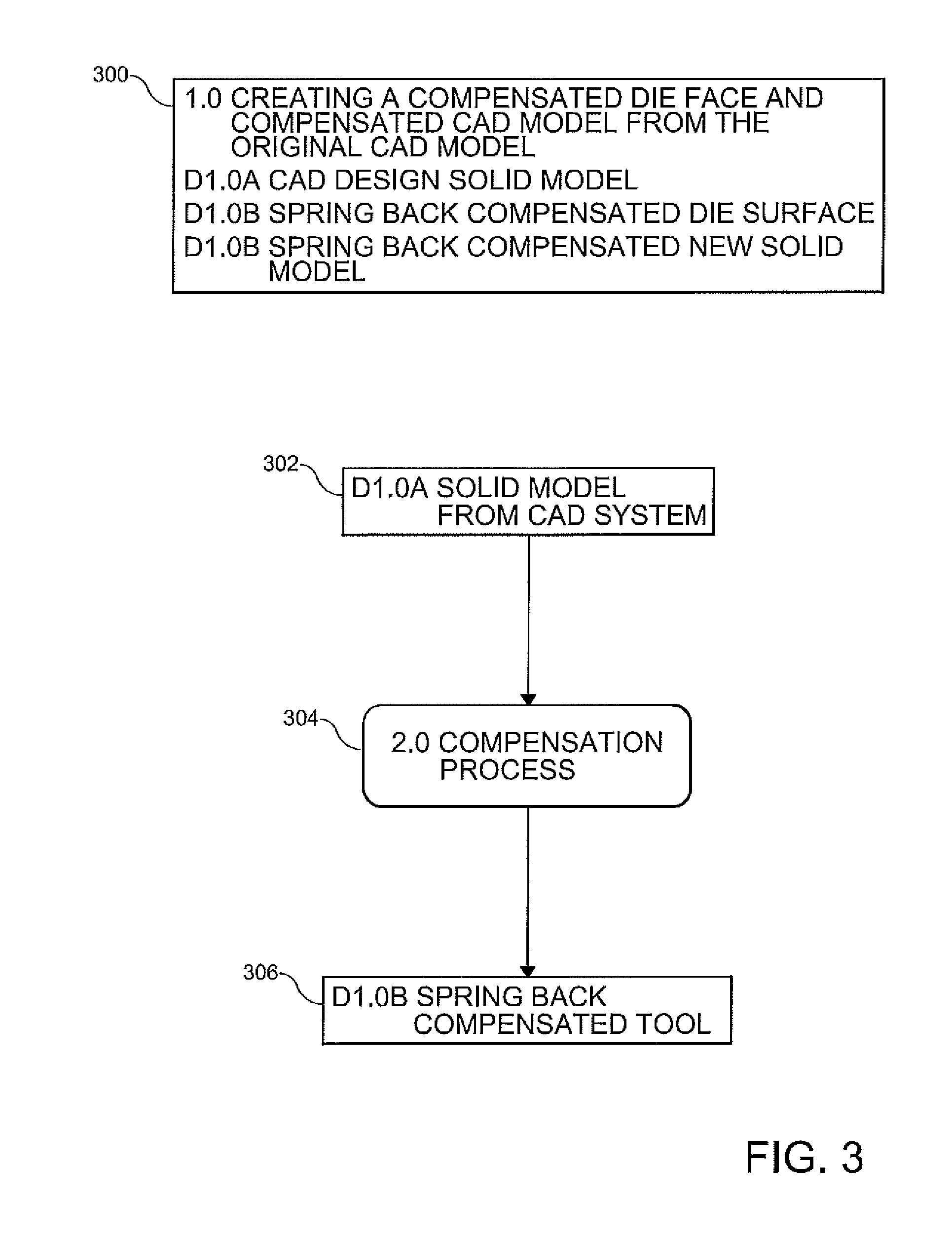

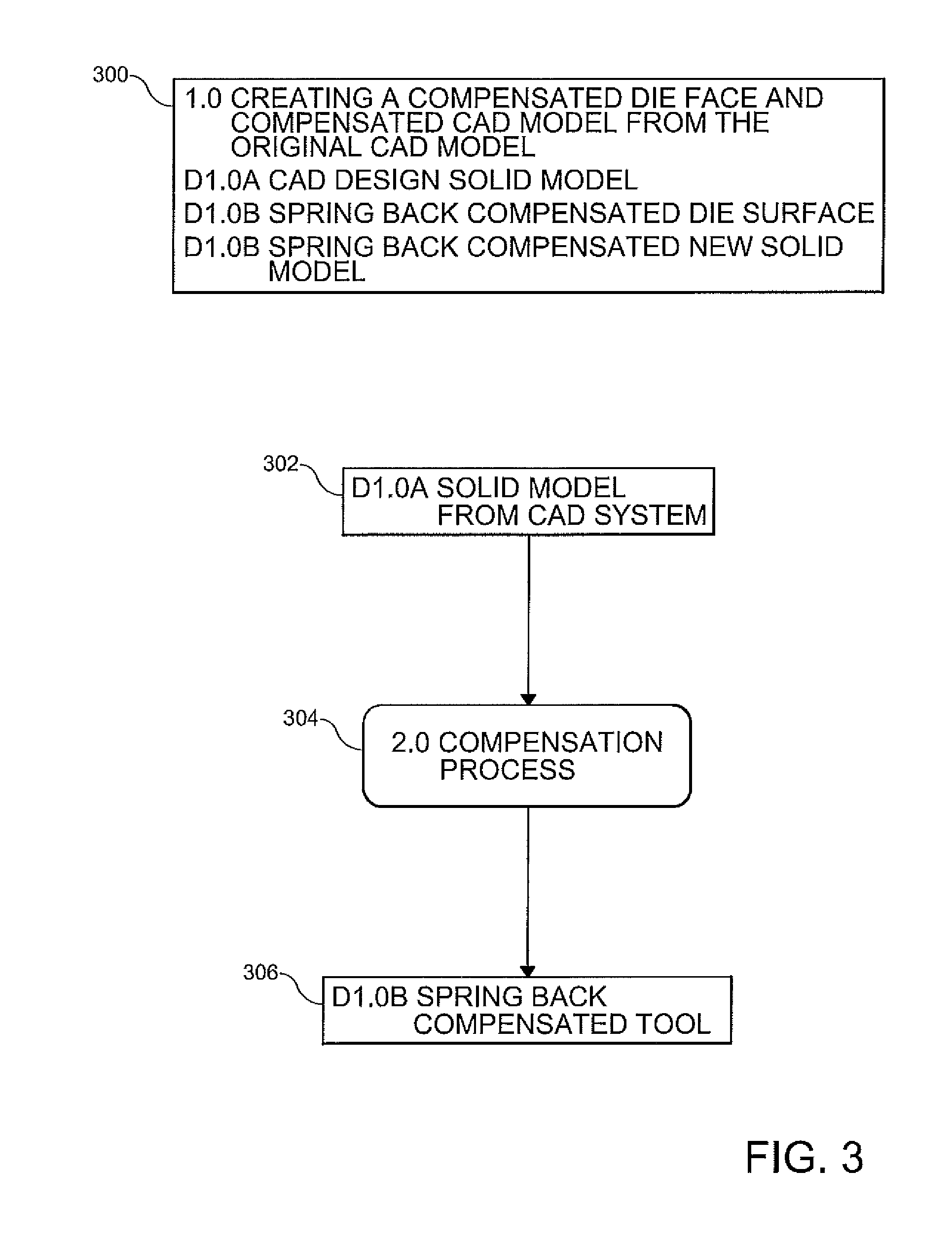

Method to improve the dimensional accuracy and surface quality for large spring back compensation for fuel cell bipolar plate forming

ActiveUS20130074318A1Stable and reliable compensationImprove accuracyFinal product manufactureCollectors/separatorsMorphingFuel cells

A method for manufacturing a stamped part, such as a bipolar plate for a fuel cell, includes the steps of: providing an original model of the bipolar plate; and performing a compensation process on the original model, the compensation process including a two step morphing process based upon a prediction of spring back. The two step morphing process provides a compensated model of the stamped part. A compensated die face may be created based on the compensated model of the stamped part. The stamped part manufactured with the compensated die face has spring back compensation.

Owner:GM GLOBAL TECH OPERATIONS LLC

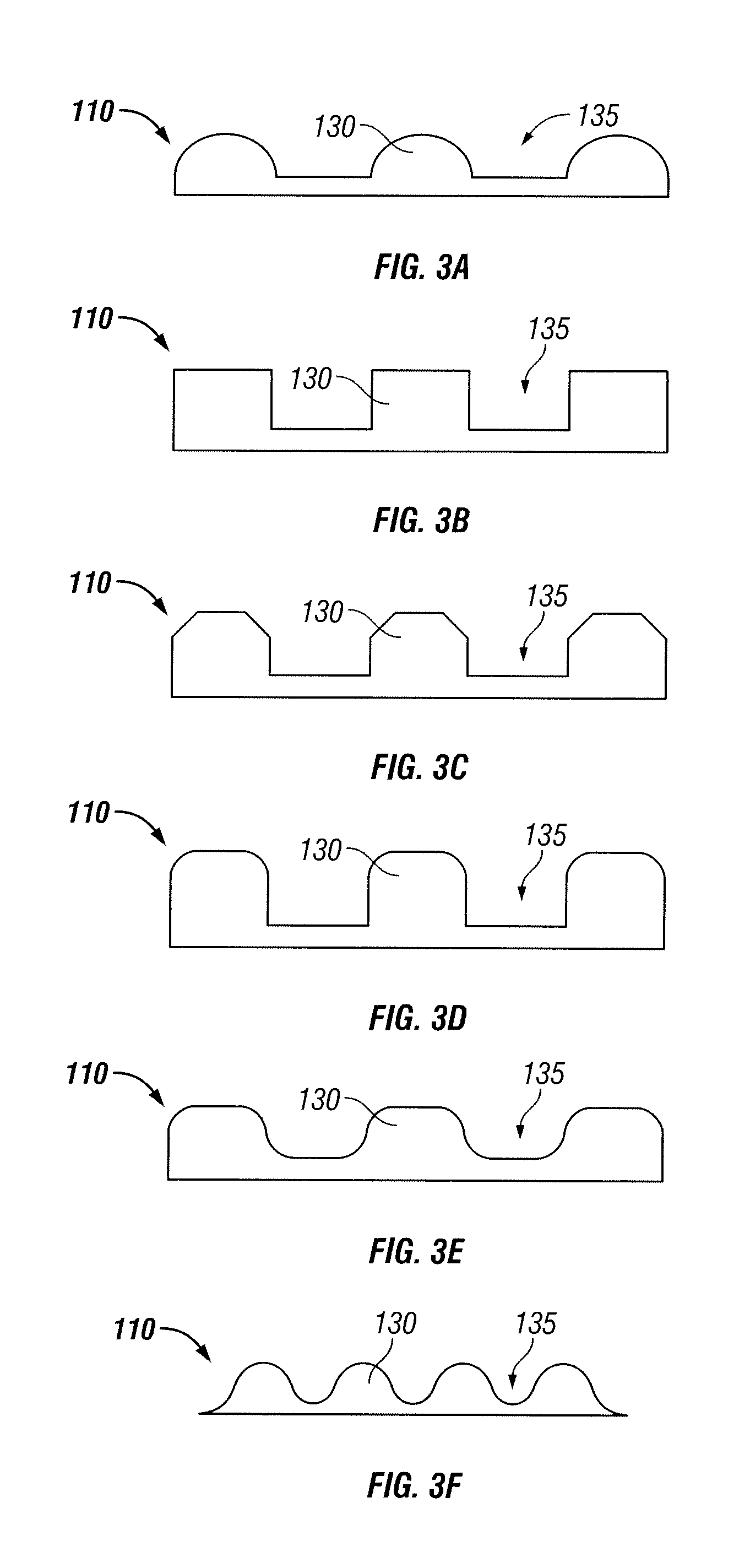

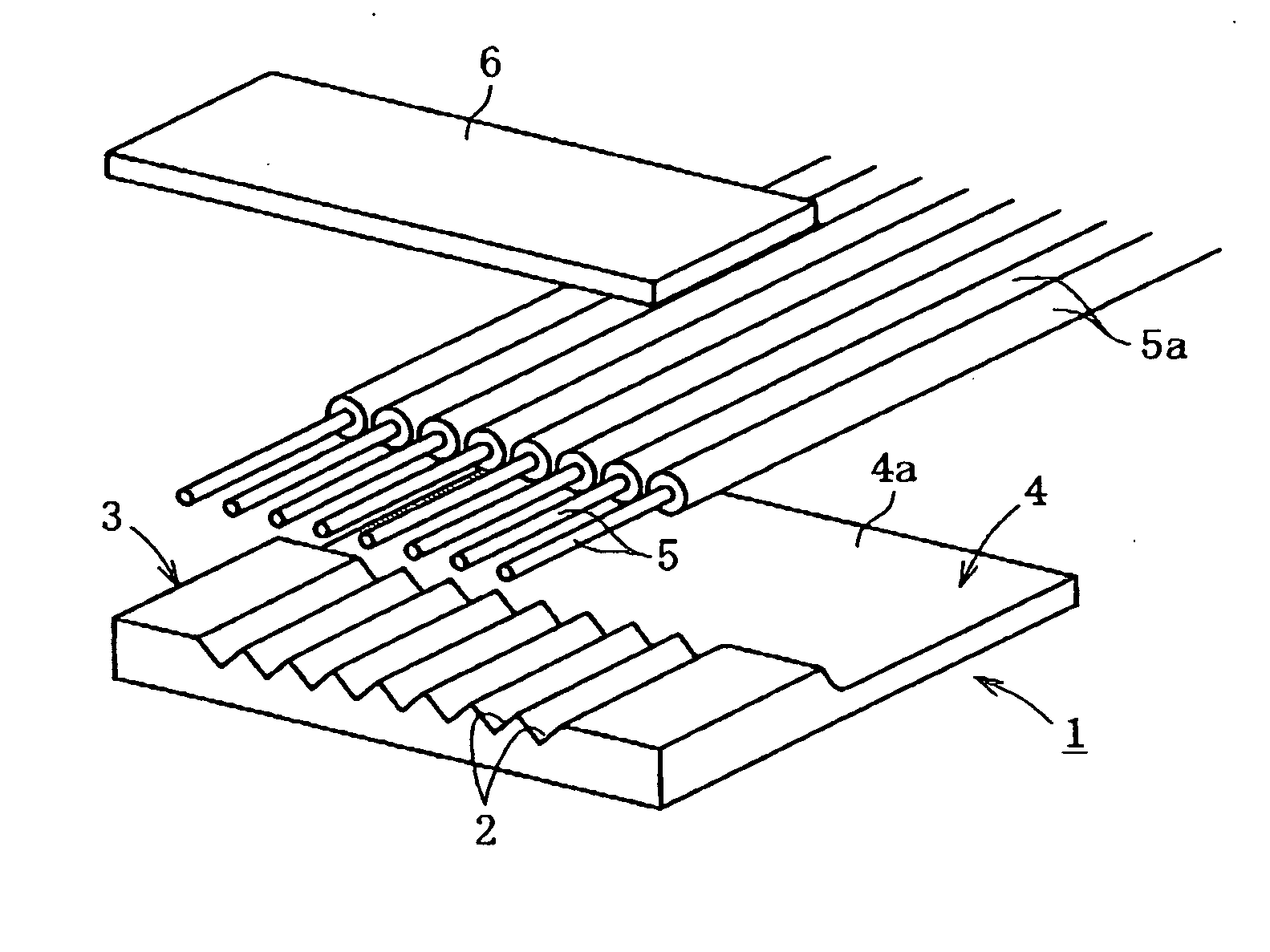

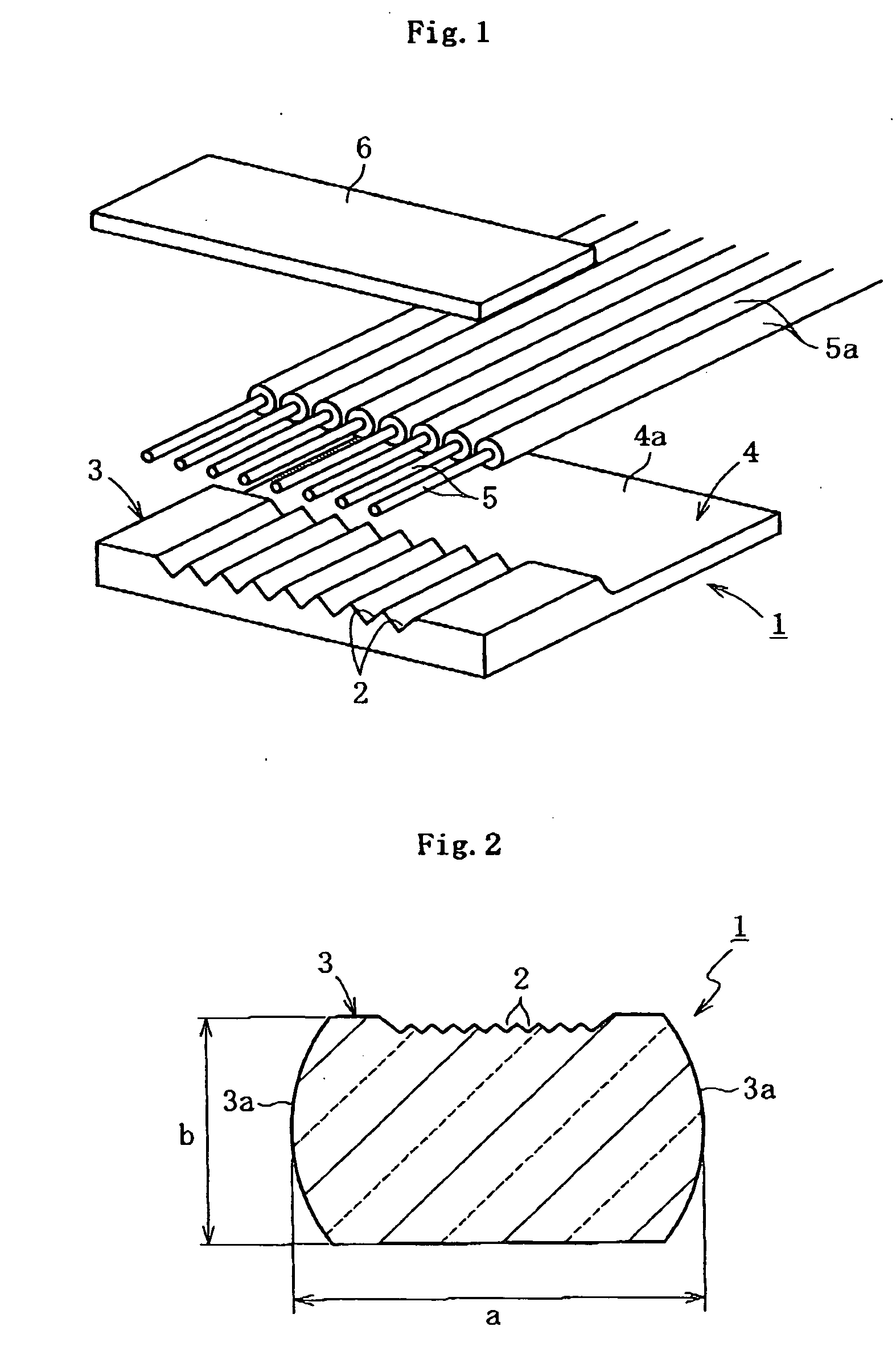

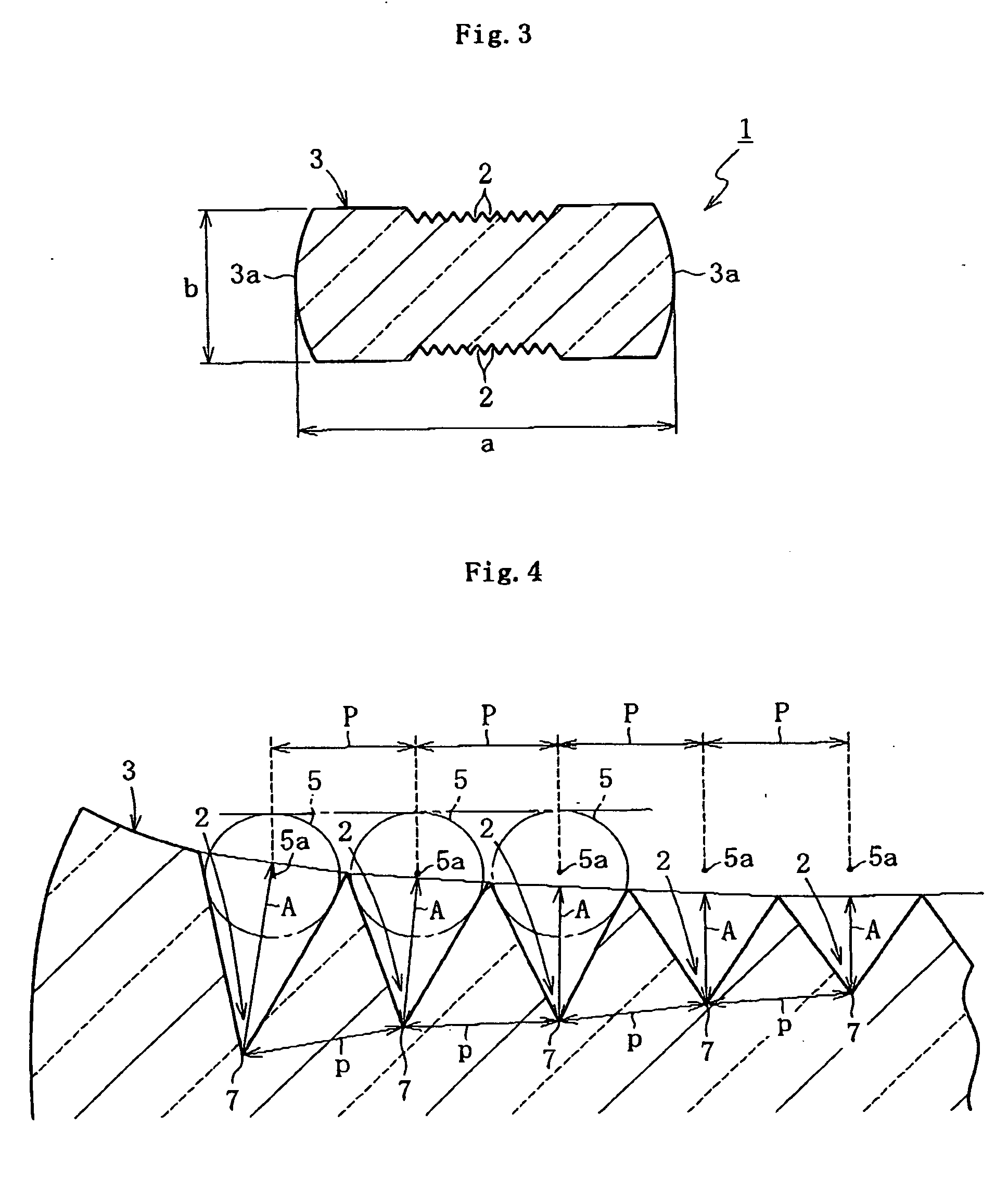

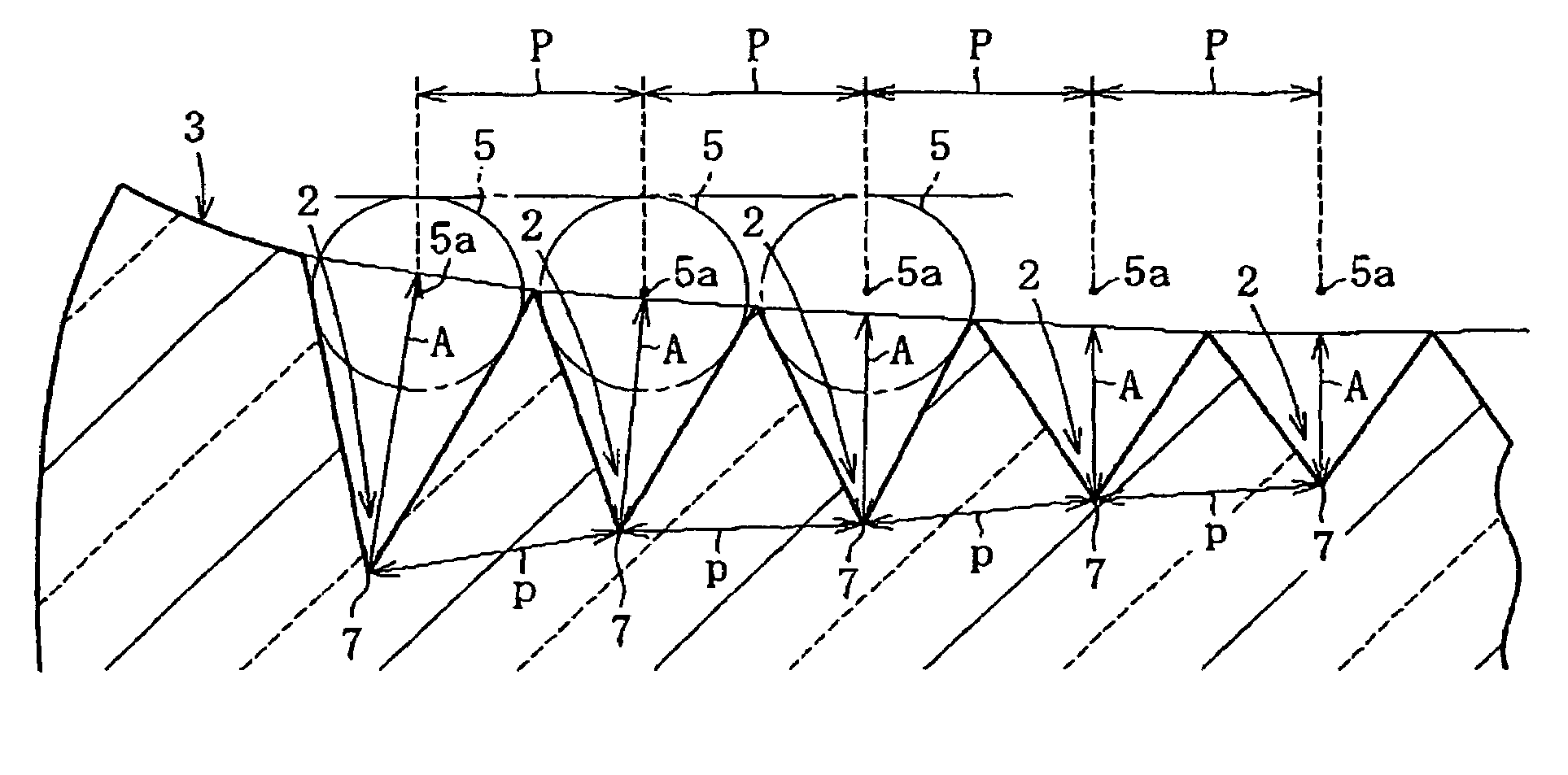

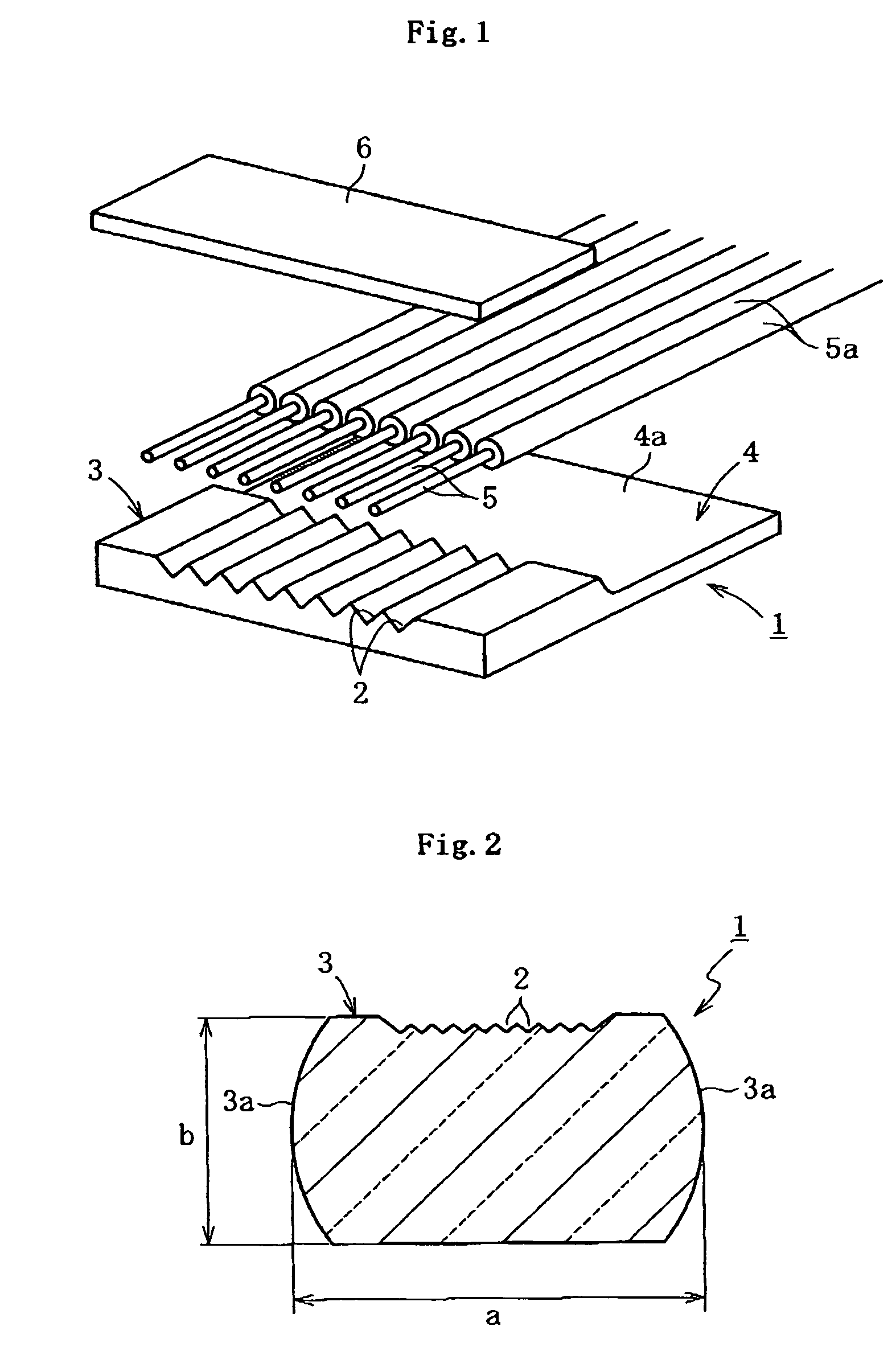

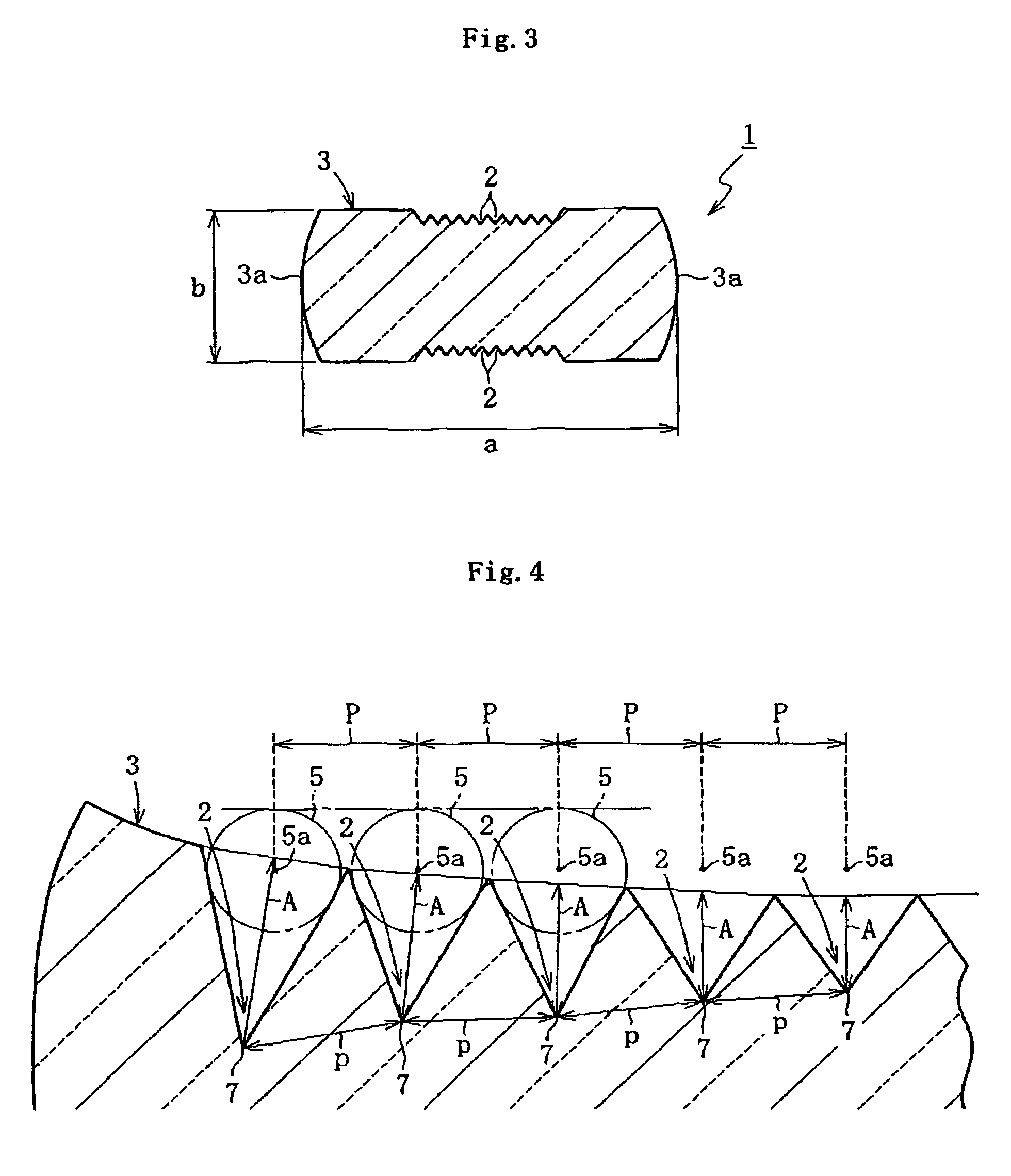

Substrate for optical fiber array and method for fabricating the same

InactiveUS20070104424A1Easily and accurately fabricateGreat fabricationCoupling light guidesFiber arrayEngineering

An object of the present invention is to very accurately position and align a plurality of optical fibers in each groove of a substrate for an optical fiber array, without leading to inappropriate upsizing and complication of an apparatus and increase in cost To achieve the object, an optical-fiber aligning part 3 of a substrate 1 is formed, in parallel, with a plurality of grooves 2 at least on the top thereof, the plurality of grooves retaining and aligning a plurality of optical fibers 5. A cross section perpendicular to a longitudinal direction of the grooves 2 is recessed at a center portion of the top in the widthwise direction, and depths A of the grooves 2 provided at the center portion are shallower than depths A of the grooves 2 provided at both ends in the widthwise direction.

Owner:NIPPON ELECTRIC GLASS CO LTD

Precision assembly method for interference fit part at liquid hydrogen temperature zone

InactiveCN106736239APrevent surface oxidationAvoid surface deformationMetal working apparatusLiquid hydrogenEngineering

The invention discloses a precision assembly method for an interference fit part at the liquid hydrogen temperature zone. The precision assembly method comprises the following steps: a hole part is subjected to vacuumizing heating treatment, a shaft part is subjected to low temperature medium soaking treatment, and during assembly, the shaft part is pressed into the hole part on an electromagnetic vibrating table by using the longitudinal coupling vibrating strengthening principle, thereby completing the assembly. With the adoption of the precision assembly method, the press fitting external force can be reduced effectively, the assembly quality can be improved, and the part damage can be reduced. The precision assembly method is a fine and high-quality assembly method.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

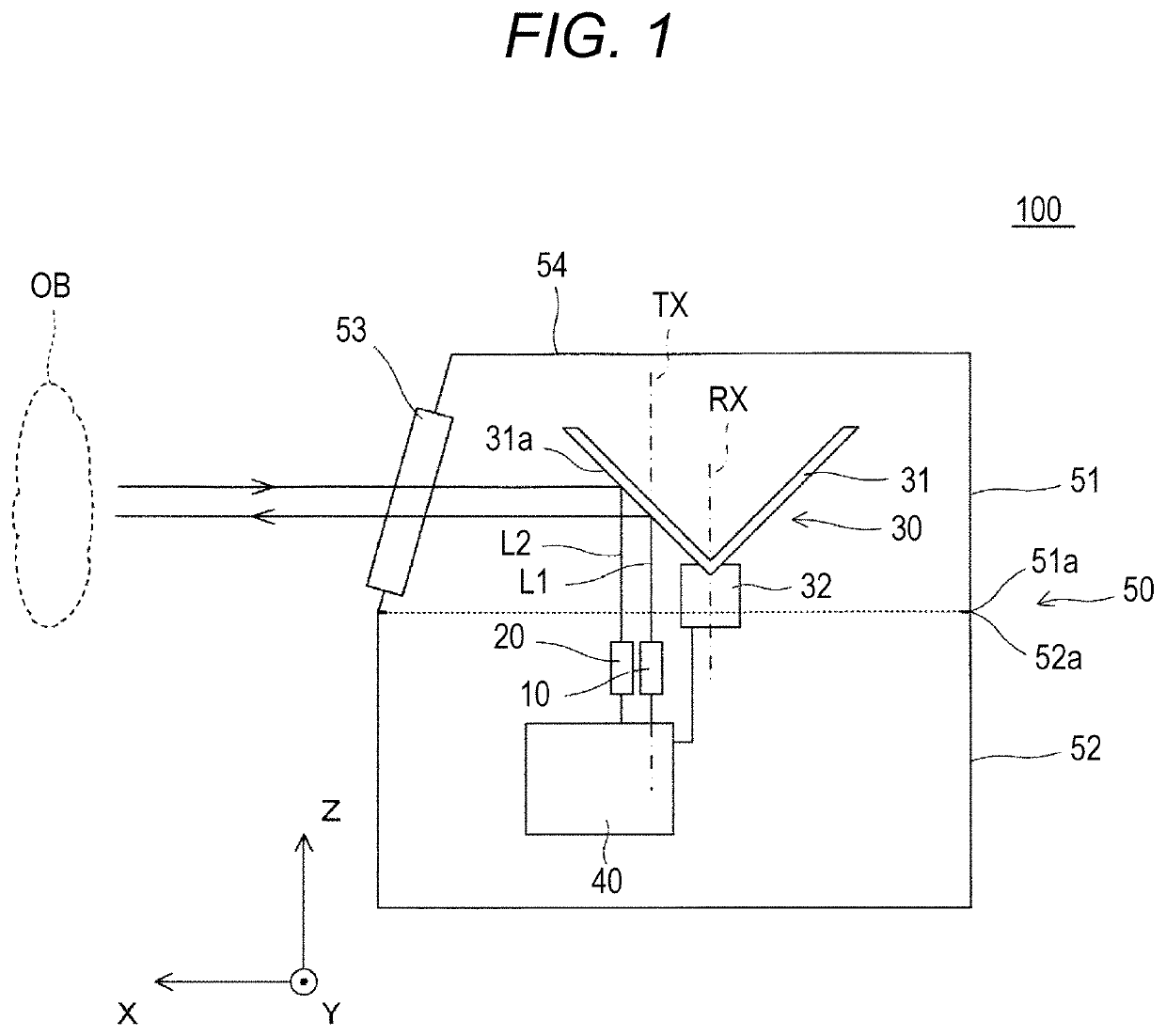

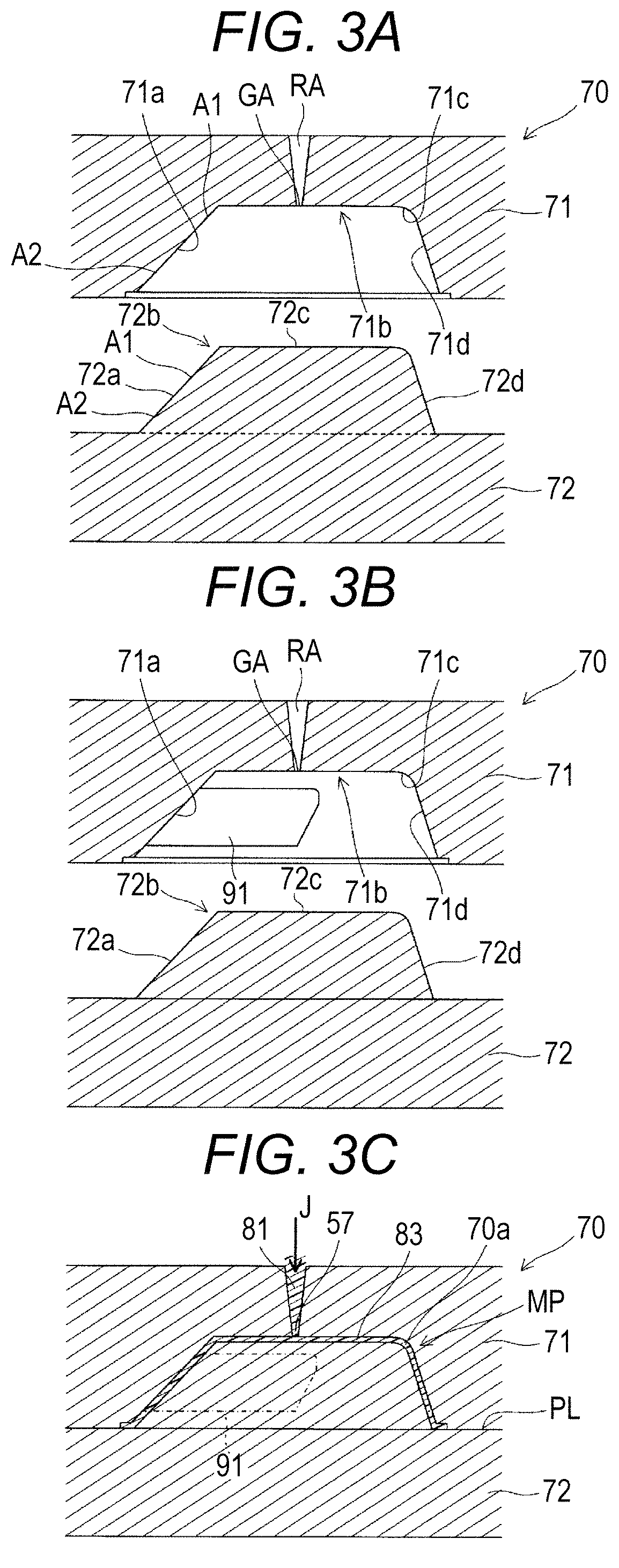

Laser sensor and manufacturing method for exterior component

ActiveUS10704894B2Improve rigidityImprove waterproof and dustproof performanceUsing optical meansElectromagnetic wave reradiationEngineeringLaser sensor

Provided is a laser sensor including an optical window with high accuracy and having excellent dustproof and waterproof properties. The laser sensor includes: a light projector; a light receiver to detect reflection light from a detection object to which laser light is emitted from the light projector; and an exterior component covering the light projector and the light receiver, in which the exterior component includes an optical window that transmits the laser light and the reflection light, and a holder that surrounds an outer periphery of the optical window, the optical window and the holder are formed as an integrally-molded product made of a resin having transmittivity in a wavelength band of the laser light, the optical window includes a pair of curved optical surfaces facing each other, and the holder includes: a gate part at a position relatively distant from the optical window; and a light shielding part that is at least adjacent to the optical window and shields the laser light L1 and ambient light.

Owner:KONICA MINOLTA INC

Substrate for optical fiber array and method for fabricating the same

InactiveUS7435011B2Avoid surface deformationInappropriately large and complicated can be avoidedCoupling light guidesEngineeringOptical fiber

An object of the present invention is to very accurately position and align a plurality of optical fibers in each groove of a substrate for an optical fiber array, without leading to inappropriate upsizing and complication of an apparatus and increase in cost. To achieve the object, an optical-fiber aligning part 3 of a substrate 1 is formed, in parallel, with a plurality of grooves 2 at least on the top thereof, the plurality of grooves retaining and aligning a plurality of optical fibers 5. A cross section perpendicular to a longitudinal direction of the grooves 2 is recessed at a center portion of the top in the widthwise direction, and depths A of the grooves 2 provided at the center portion are shallower than depths A of the grooves 2 provided at both ends in the widthwise direction.

Owner:NIPPON ELECTRIC GLASS CO LTD

Utilization of laser interstitial thermotherapy guided with real time thermal MRI

ActiveUS11065063B2Improve securityImprove accuracySurgical navigation systemsSurgical instrument detailsTemperature monitoringNuclear medicine

Methods, apparatus, and kits for applying thermal energy to tissue in a region of interest. Certain embodiments include registration of fiducial markers with an image guidance system and temperature monitoring via magnetic resonance imaging thermography.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Laminated composite lens

ActiveUS8408698B2Avoid surface deformationRelieve lens-eye surface attractionSpectales/gogglesOptical articlesSoft layerRigid gas permeable lens

The present invention is directed to a composite lens, comprising an anterior rigid gas permeable layer, and an annulus of soft material bonded to a posterior surface of the anterior rigid gas permeable layer, wherein a central zone of the composite lens is rigid and without a soft layer, wherein a peripheral zone of the composite lens is generally rigid in its anterior aspect and soft in its posterior aspect.

Owner:OCULAR SURFACE INNOVATIONS INC

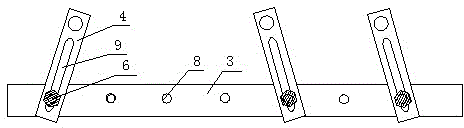

Positioning device for woodworking trepanning machine

The invention provides a positioning device for a woodworking trepanning machine. The positioning device includes a material placement table, a bracket, several positioning blocks, and air cylinders. The bracket is fixed on the material placement table, the material placement table is fixed on a rack, the ends of the positioning blocks are all fixed with the air cylinders, the positioning blocks are provided with strip-shaped holes, the strip-shaped holes pass through bolts for fixing the positioning blocks on the bracket, the piston ends of the air cylinders are provided with press blocks, and the bracket is also provided with a plurality of through holes for selective installation of the bolts. The positioning device provided by the invention can adjust the positioning positions of the press blocks on the material placement table, also can fix the positioning blocks after rotating the angles of the positioning blocks, and realize further adjustment of the positions of the press blocks, thereby ensuring more stable adjustment of the timber on the material placement table, and realizing more stable positioning of timbers with different sizes. The positioning device for the woodworking trepanning machine provided by the invention can realize effective positioning of the timber on the material placement table, is low in cost, and is beneficial to production use.

Owner:朱玉静

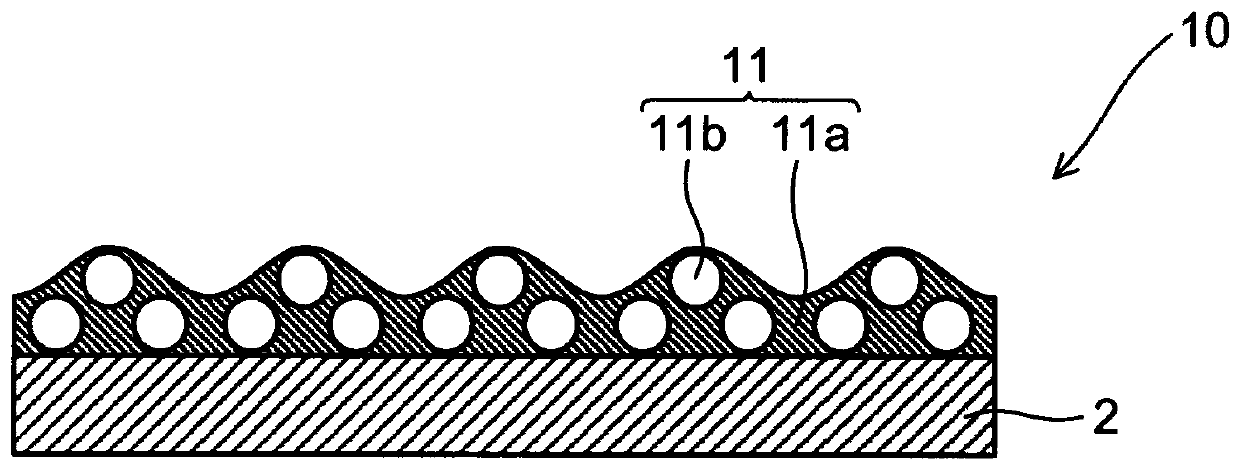

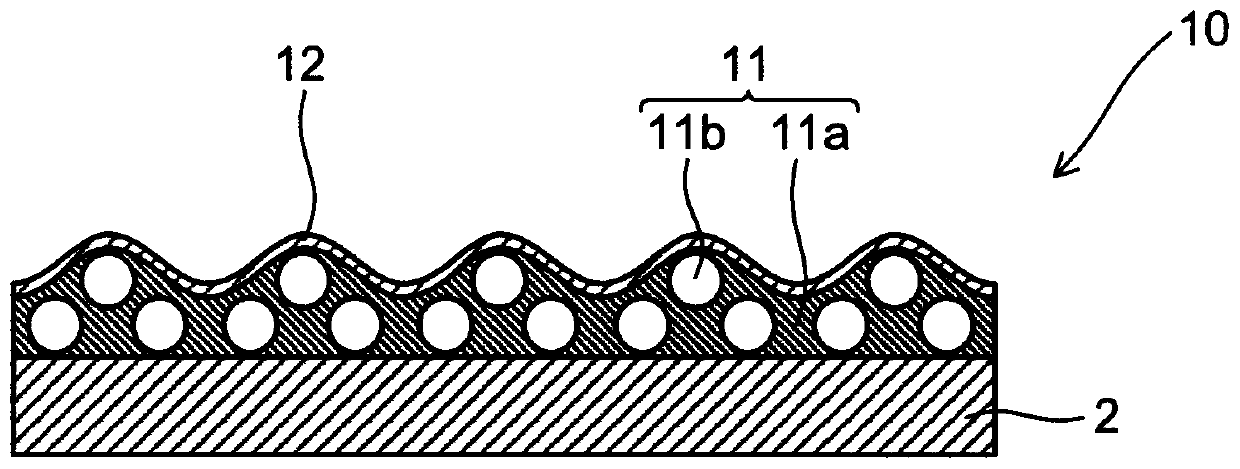

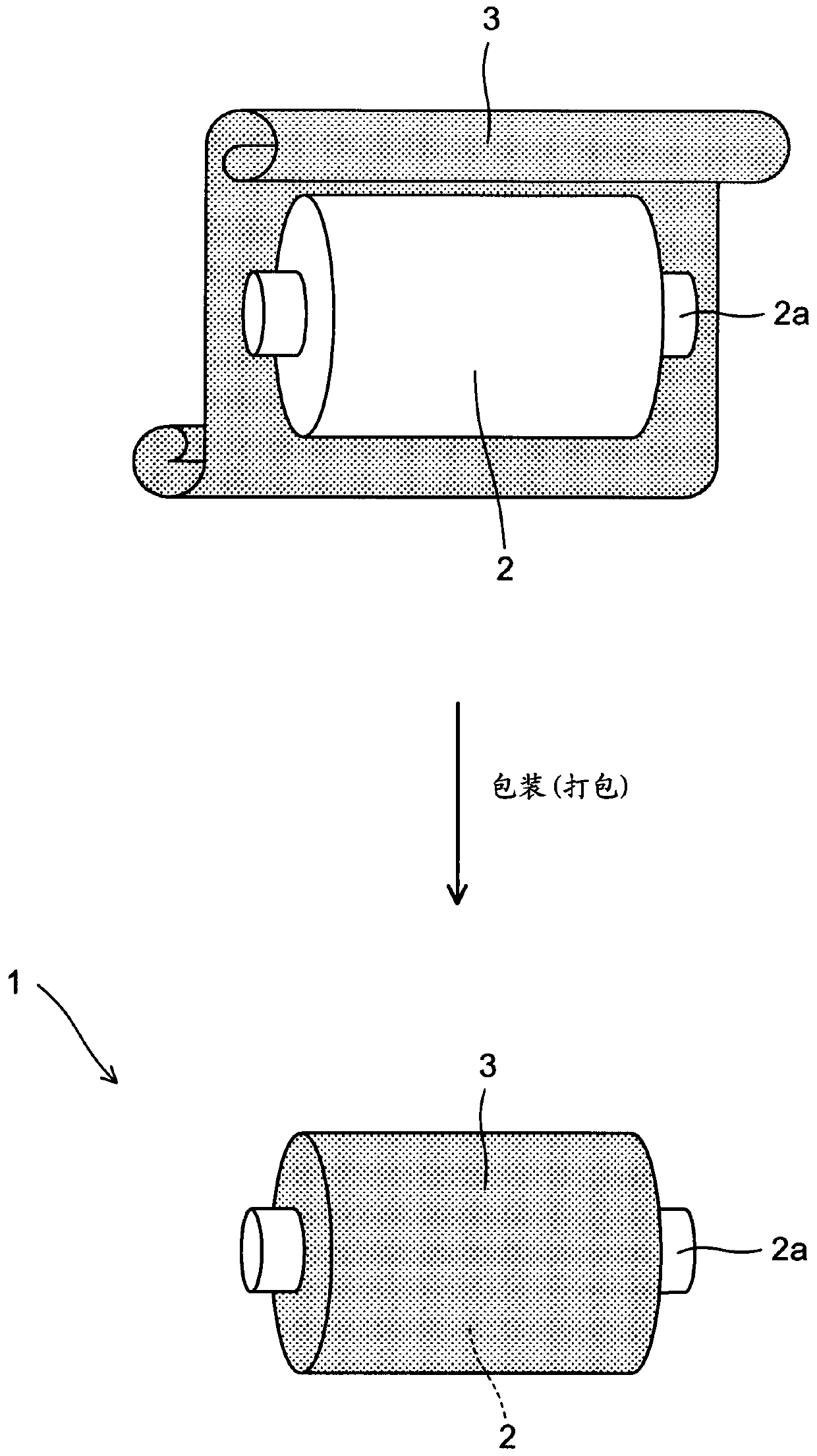

Film roll and method for manufacturing same

ActiveCN110235031ASpeed up productionEasy to produceDiffusing elementsPackagingCellulose ester membranePolymer science

A film roll (1) includes: a cellulose ester film (2) for anti-glare layer coating, the anti-glare layer including particles for forming surface unevenness; and a packaging material that is moisture-resistant and packages the cellulose ester film (2) in a rolled state. In the cellulose ester film (2), the ratio of the actual water content in the rolled state to the saturated water content is 55-85%, and the variation of the actual water content before anti-glare layer coating from the actual water content in the rolled state is in the range of -10% to+10%.

Owner:KONICA MINOLTA INC

Laminated composite lens

ActiveUS9256082B2Avoid surface deformationRelieve lens-eye surface attractionSpectales/gogglesOptical partsSoft layerRigid gas permeable lens

A composite lens comprises an anterior rigid gas permeable layer, and an annulus of soft material bonded to a posterior surface of the anterior rigid gas permeable layer, wherein a central zone of the composite lens is rigid and without a soft layer, wherein a peripheral zone of the composite lens is generally rigid in its anterior aspect and soft in its posterior aspect.

Owner:OCULAR SURFACE INNOVATIONS INC

Method to improve the dimensional accuracy and surface quality for large spring back compensation for fuel cell bipolar plate forming

ActiveUS9008813B2Stable and reliable compensationImprove accuracyFinal product manufactureMeasurement/indication equipmentsMorphingFuel cells

A method for manufacturing a stamped part, such as a bipolar plate for a fuel cell, includes the steps of: providing an original model of the bipolar plate; and performing a compensation process on the original model, the compensation process including a two step morphing process based upon a prediction of spring back. The two step morphing process provides a compensated model of the stamped part. A compensated die face may be created based on the compensated model of the stamped part. The stamped part manufactured with the compensated die face has spring back compensation.

Owner:GM GLOBAL TECH OPERATIONS LLC

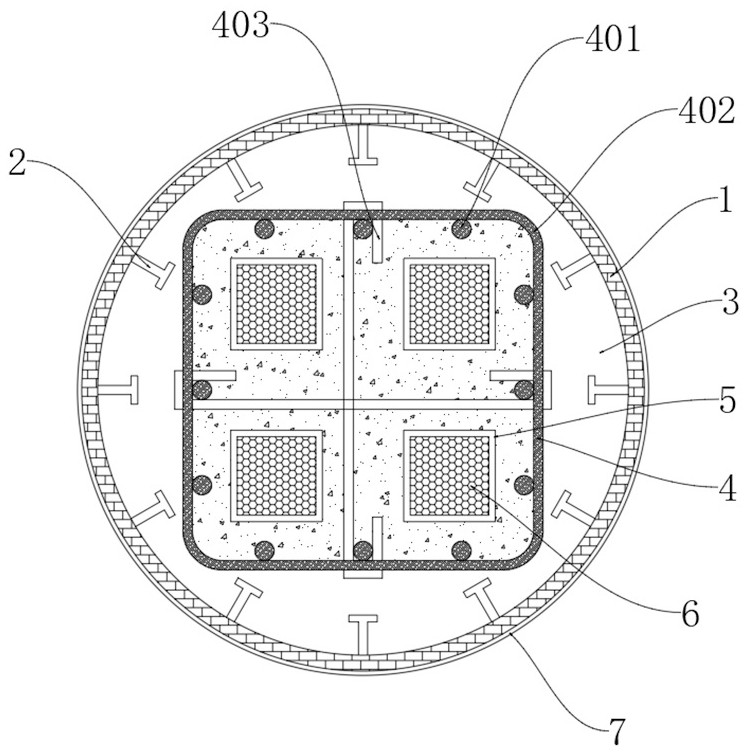

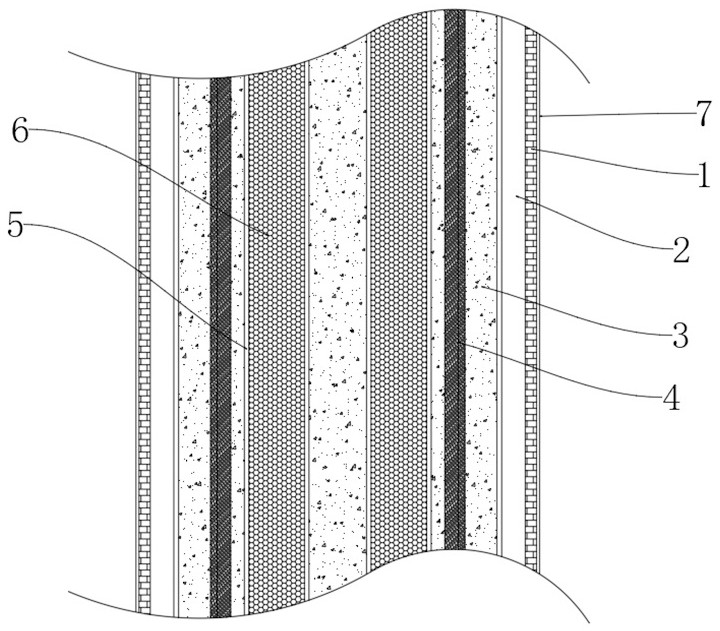

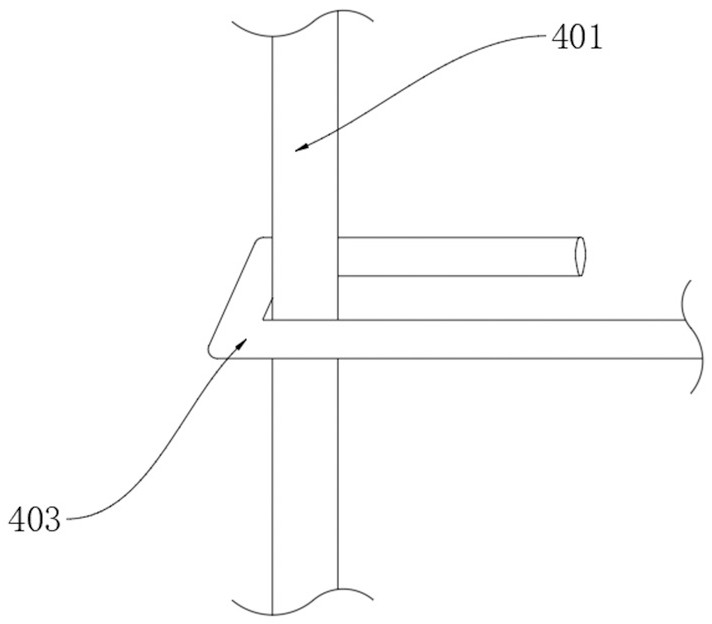

Concrete filled steel tube combination column

PendingCN113445803AImprove connection strengthHigh strengthStrutsProtective buildings/sheltersEarthquake resistanceRebar

The invention relates to the technical field of building structures, and discloses a concrete filled steel tube combination column. The column comprises a steel-encased tube, a connecting steel plate is fixedly connected to the inner side of the steel-encased tube, a concrete structure body is arranged at the position, located at the side of the connecting steel plate, in the steel-encased tube, and a steel bar structural part is arranged in the concrete structure body. According to the concrete filled steel tube combination column, the connecting strength of the steel tube and the concrete is enhanced through the connecting steel plate, the steel tube and the concrete are prevented from being separated after the concrete is solidified, the connecting steel plate provides supporting force for the steel tube, surface deformation of the steel tube is avoided, and the deformation resistance of a steel bar structural part is improved through tie bars, so that the strength of the concrete filled steel tube combination column is greatly improved. The outer surface of the steel tube is protected through a protective coating, the steel tube is prevented from being corroded and damaged, meanwhile, impact force borne by the combination column can be well dissipated through energy dissipation particles, and therefore the good anti-seismic performance is achieved, and the stability of the concrete filled steel tube combination column is guaranteed.

Owner:LIAONING TECHNICAL UNIVERSITY

Laminated composite lens

ActiveUS20140268022A1Avoid surface deformationRelieve lens-eye surface attractionSpectales/gogglesOptical partsSoft layerRigid gas permeable lens

A composite lens comprises an anterior rigid gas permeable layer, and an annulus of soft material bonded to a posterior surface of the anterior rigid gas permeable layer, wherein a central zone of the composite lens is rigid and without a soft layer, wherein a peripheral zone of the composite lens is generally rigid in its anterior aspect and soft in its posterior aspect.

Owner:OCULAR SURFACE INNOVATIONS INC

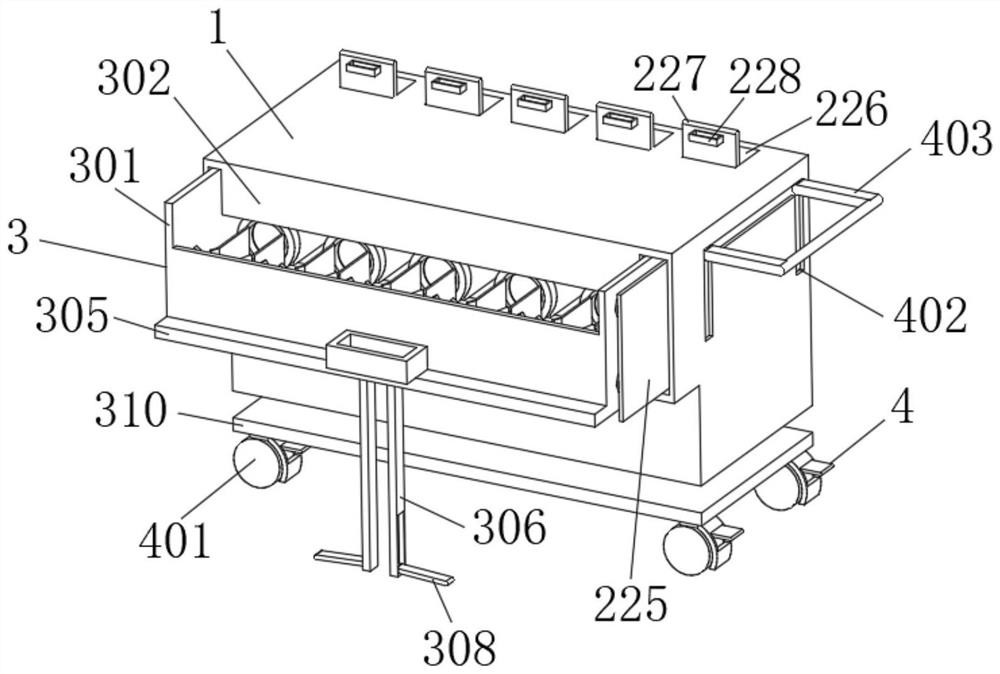

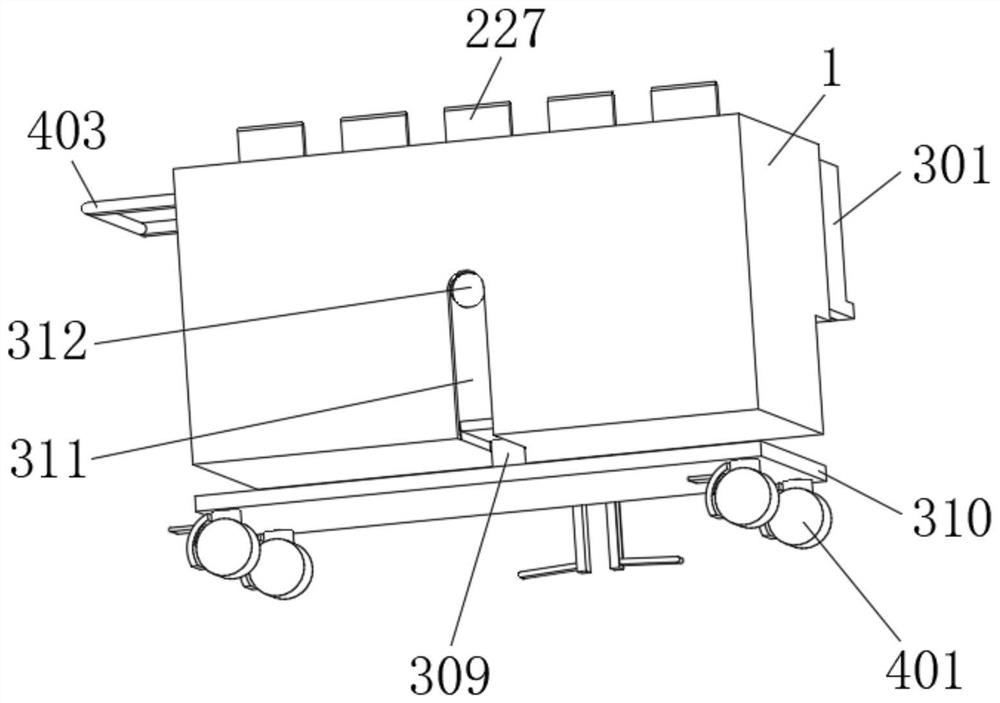

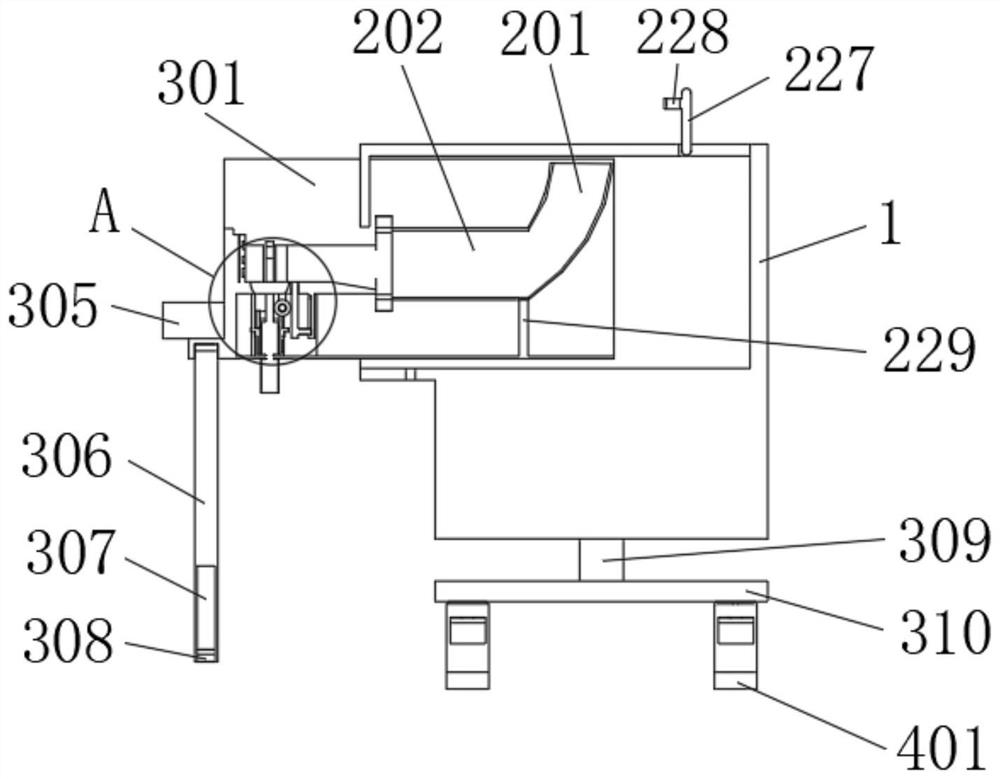

Sports equipment transportation device

InactiveCN113232711AAvoid surface deformationAvoid breakingHand carts with multiple axesHand cart accessoriesSports equipmentEngineering

The invention relates to the technical field of transportation equipment, in particular to a sports equipment transportation device. The device comprises a box body, a positioning protection device is arranged in the box body, the positioning protection device comprises a buffer pipe, one side of the buffer pipe is fixedly connected with a putting-in pipe, the side, away from the buffer pipe, of the putting-in pipe is fixedly connected with a rolling-in base, a placement groove is formed in the upper surface of the rolling-in base, a limiting plate is fixedly connected to the upper surface of the rolling-in base, a driving block is arranged below the rolling-in base, and a sliding column is fixedly connected to the lower surface of the driving block. According to the device, bowling balls cannot be affected by sudden braking in the transportation process, deformation and damage of the surfaces of the bowling balls are avoided, loading and unloading are more convenient, time and labor are saved, the device can be directly used in a venue, all the bowling balls do not need to be completely unloaded, and the device is used for storing and taking at ordinary times.

Owner:山东中医药高等专科学校

Adhesive film and organic electronic device including the same

ActiveUS10374195B2Improved water vapor transmission rate (WVTR)Improved WVTR characteristicSolid-state devicesSemiconductor/solid-state device manufacturingCore shellMoisture

Owner:SHINWHA INTERTEK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com